Table of Contents

- Safety

- General Information

- Inventory

- Component Identification

- Dimensions and Weights

- Installation

APC InRow User Manual

Displayed below is the user manual for InRow by APC which is a product in the UPS Accessories category. This manual has pages.

Related Manuals

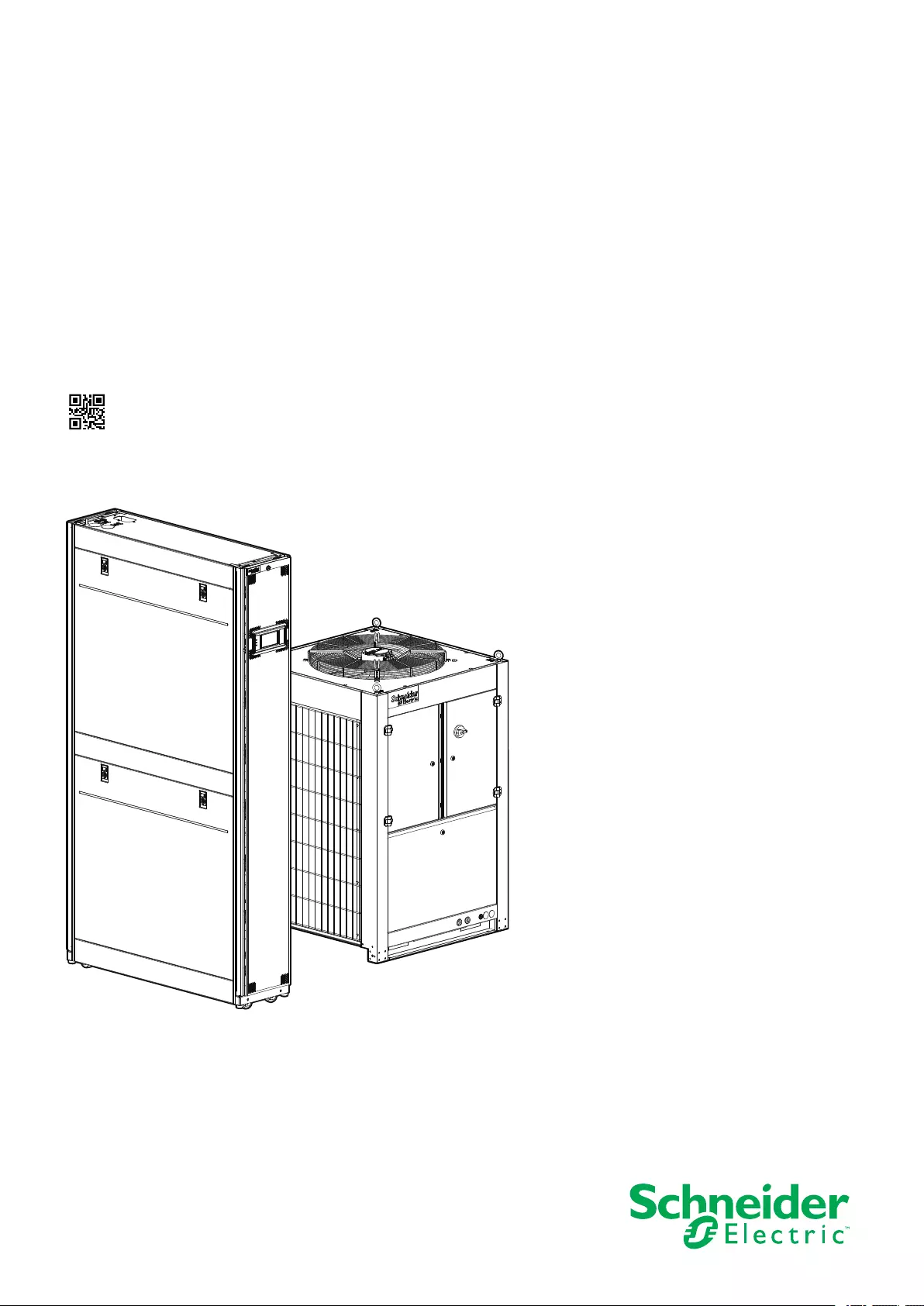

InRow®Direct Expansion Air Conditioners

ACRD300 and ACCU30000 Series

Installation Manual

990–91193A–001

Release date: 11/2018

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric SA

and its subsidiaries. They may not be used for any purpose without the owner's

permission, given in writing. This guide and its content are protected, within the

meaning of the French intellectual property code (Code de la propriété intellectuelle

français, referred to hereafter as "the Code"), under the laws of copyright covering

texts, drawings and models, as well as by trademark law. You agree not to reproduce,

other than for your own personal, noncommercial use as defined in the Code, all or

part of this guide on any medium whatsoever without Schneider Electric's permission,

given in writing. You also agree not to establish any hypertext links to this guide or its

content. Schneider Electric does not grant any right or license for the personal and

noncommercial use of the guide or its content, except for a non-exclusive license to

consult it on an "as is" basis, at your own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications, and designs change from time to time, please ask for

confirmation of the information given in this publication.

ACRD300 and ACCU30000 Series

Table of Contents

Safety...........................................................................................................5

Important Safety Instructions — SAVE THESE INSTRUCTIONS...................5

Safety During Installation ...........................................................................6

General Information...................................................................................7

Document Overview ..................................................................................7

Original Instructions .............................................................................7

Save These Instructions .......................................................................7

Manual Updates ..................................................................................7

Cross-Reference Symbol Used in This Manual.......................................7

Abbreviations ......................................................................................7

Receiving and Inspecting the Equipment .....................................................8

Filing a Claim.......................................................................................8

Radio Frequency Interference ....................................................................8

California Proposition 65—Warning Statement for California

Residents..................................................................................................8

Storing the Cooling Unit Before Installation ..................................................8

Moving the Unit .........................................................................................9

Unit Overview.......................................................................................... 11

Model Identification ............................................................................ 11

Equipment Guidelines ........................................................................13

Unit Compatibility...............................................................................14

Inventory....................................................................................................15

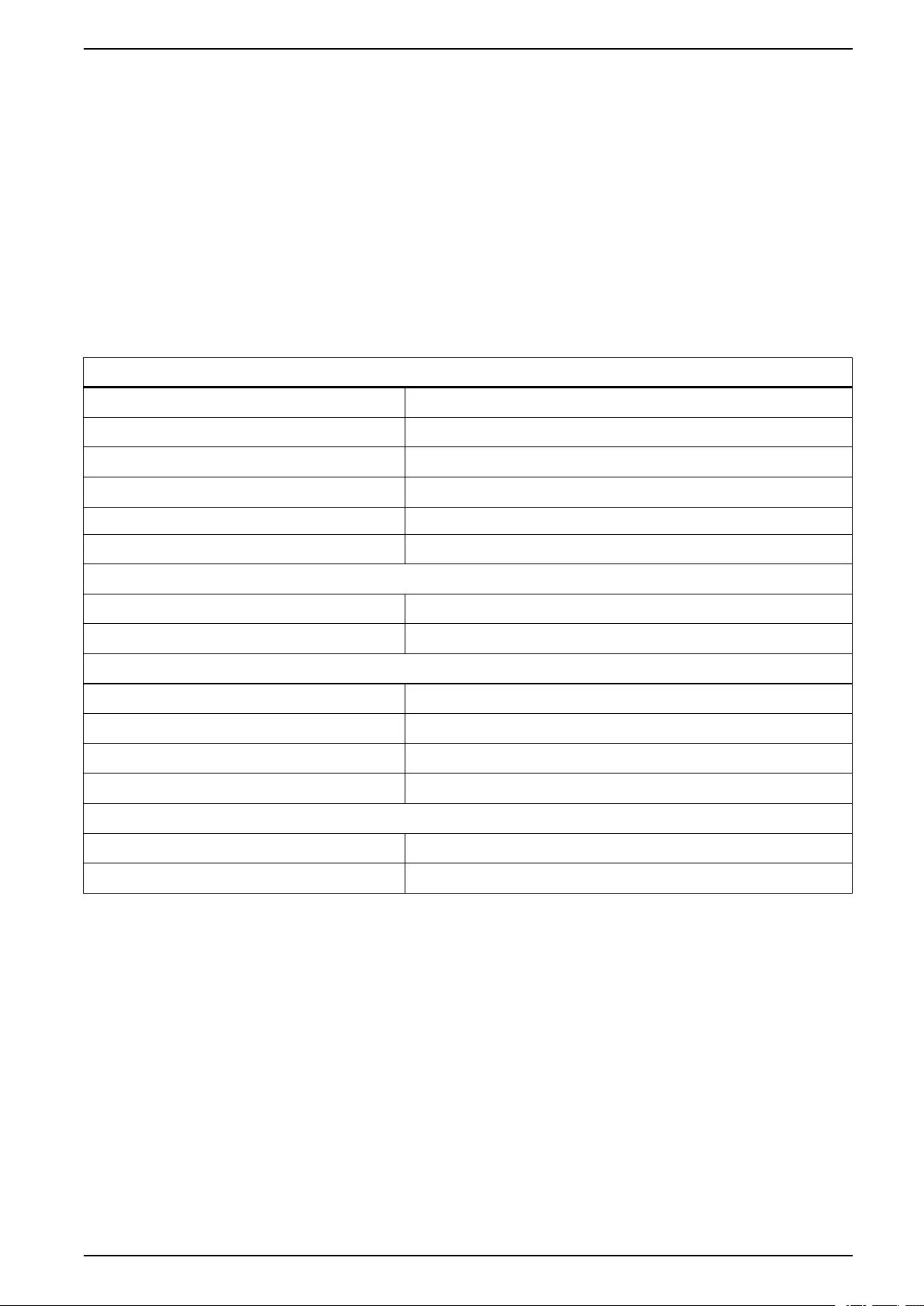

Package Contents—Indoor Unit................................................................15

Package Contents—Outdoor Unit .............................................................16

Component Identification........................................................................18

External Components ..............................................................................18

Indoor Unit—All ACRD30X Units.........................................................18

Outdoor Unit—All ACCU30XXX Units..................................................19

Internal Components ...............................................................................20

Indoor Unit ........................................................................................20

Outdoor Unit......................................................................................21

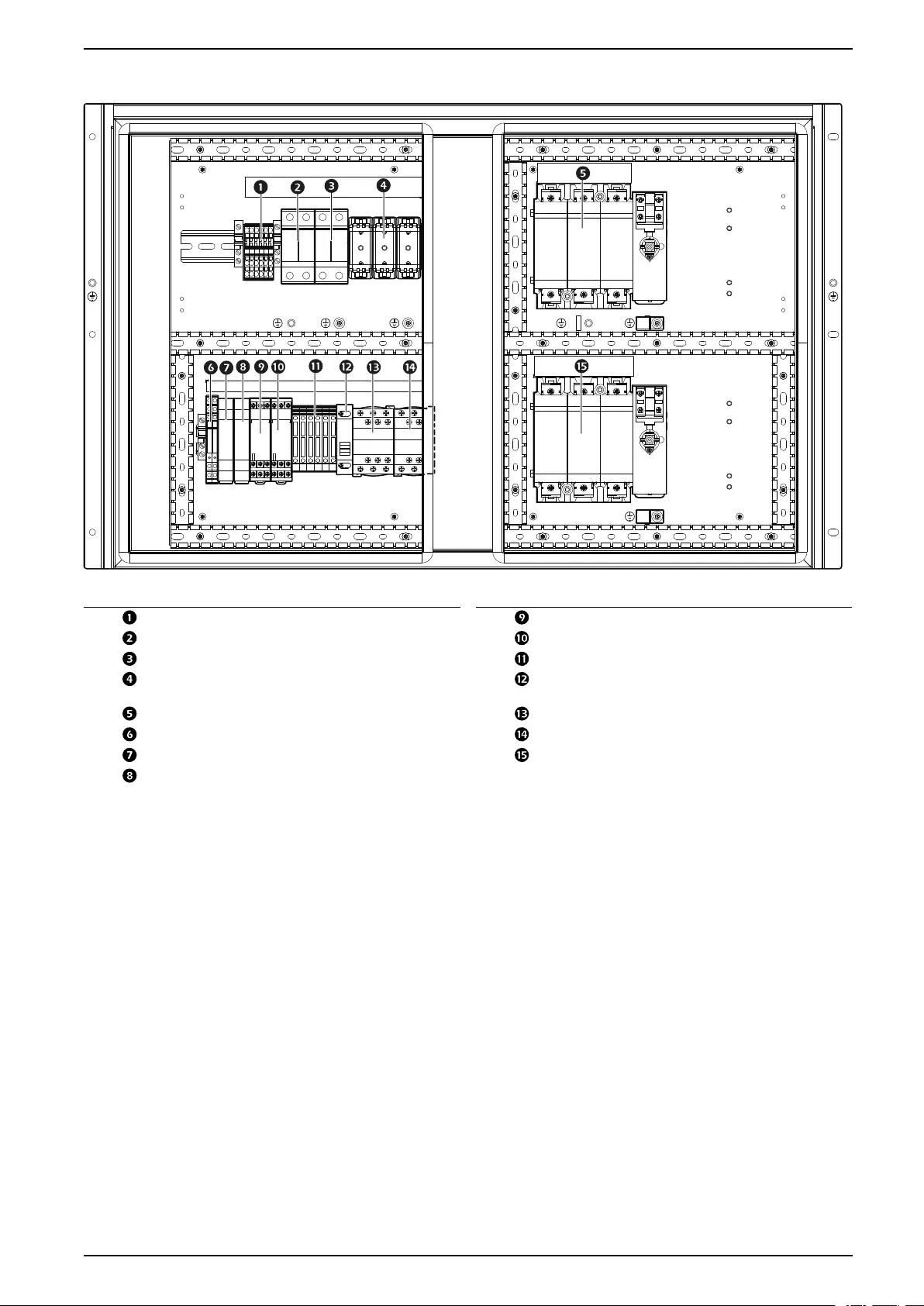

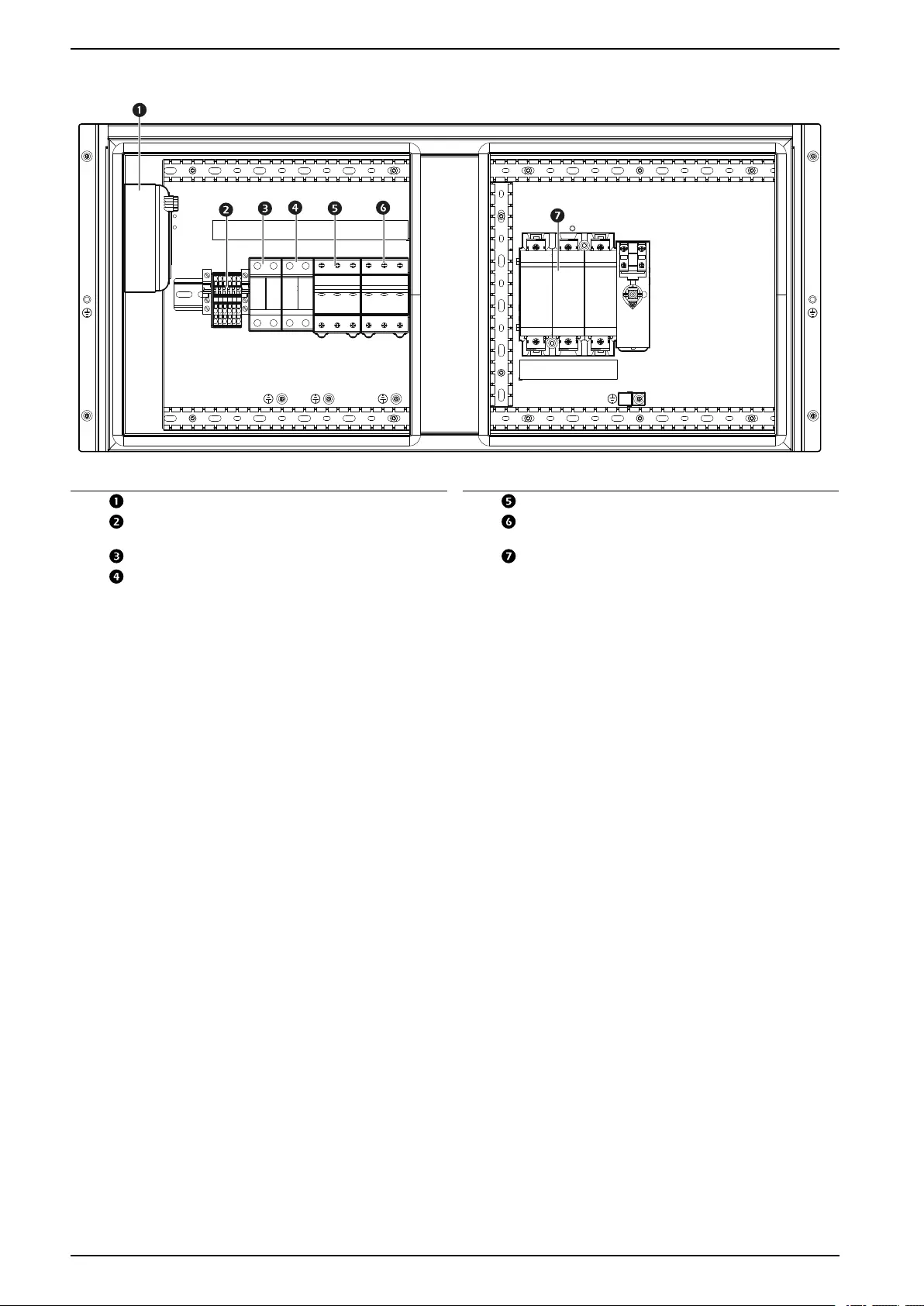

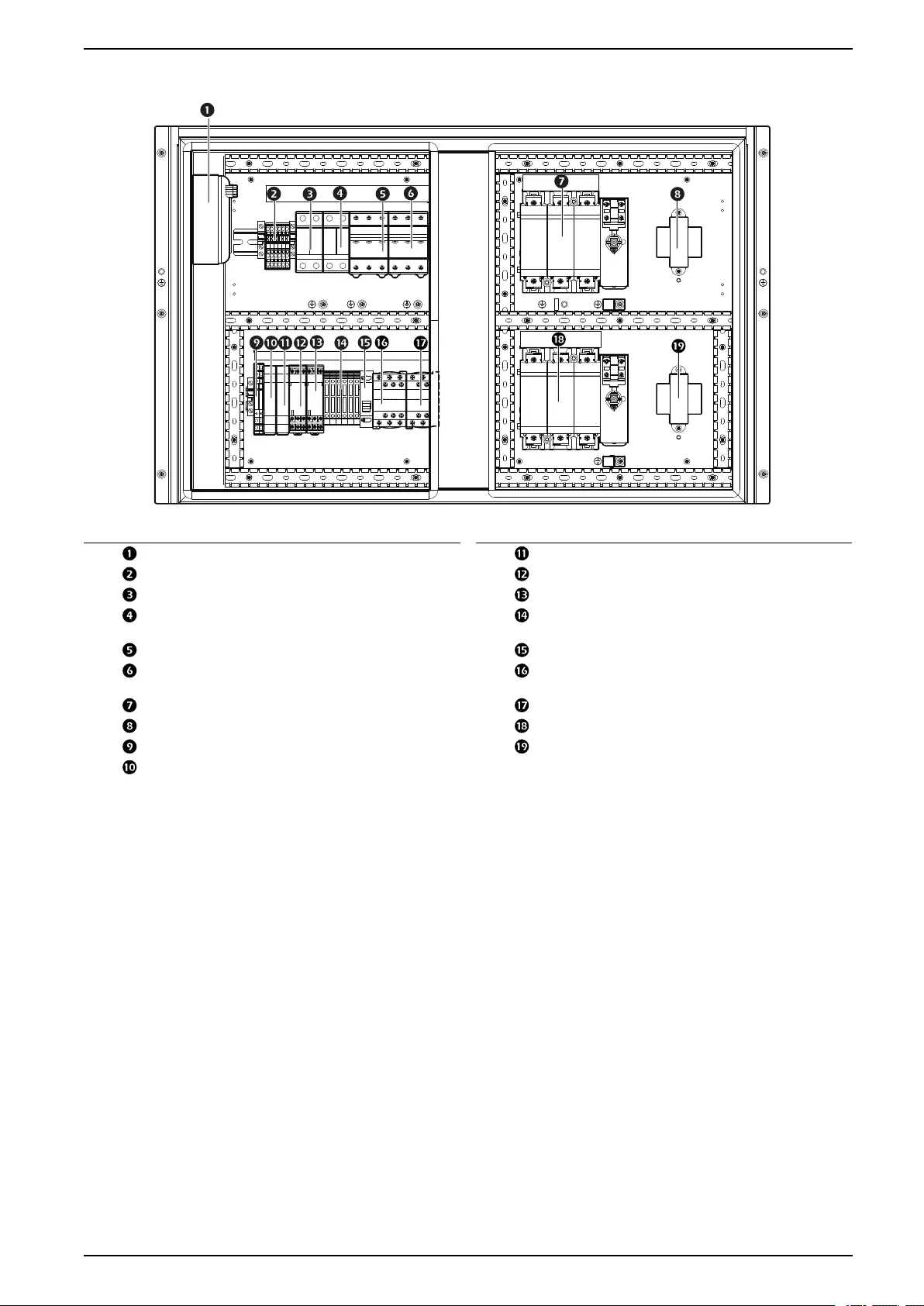

Electrical Panels......................................................................................23

Indoor Unit ........................................................................................23

Outdoor Unit......................................................................................24

Refrigeration Piping Diagram....................................................................30

Display Interface......................................................................................31

Alarm LED.........................................................................................31

Status LED........................................................................................32

Link-RX/TX (10/100) LED ...................................................................32

Dimensions and Weights ........................................................................33

Indoor Unit ..............................................................................................33

Outdoor Unit............................................................................................34

Service Access........................................................................................35

Airflow Clearance ....................................................................................36

Piping and Electrical Access Locations......................................................37

Indoor Unit ........................................................................................37

Outdoor Unit......................................................................................41

990–91193A–001 3

ACRD300 and ACCU30000 Series

Installation.................................................................................................42

Location and Power Considerations ..........................................................42

Room Preparation..............................................................................42

Incoming Power Supply Requirements ................................................42

Indoor Unit Location ...........................................................................43

Outdoor Unit Location ........................................................................43

Removing Doors and Panels ....................................................................44

Indoor Unit ........................................................................................44

Outdoor Unit......................................................................................46

Stabilizing the Cooling Unit.......................................................................48

Joining the Equipment to Enclosures ................................................... 48

Leveling ............................................................................................49

Stabilizing the Outdoor Unit ......................................................................50

Mounting Hole Dimensions .................................................................50

Vibration Damping Pads.....................................................................51

Connections Overview .............................................................................52

Power Connections............................................................................52

Sensor and Communication Connections ............................................53

Mechanical Connections ..........................................................................54

Installing the Main Switch ...................................................................54

Condensate Drain Pan Additions.........................................................56

Condensate Drain Connections...........................................................57

Refrigerant Piping ..............................................................................60

Suction and Liquid Line Piping Connections.........................................62

Electrical Connections .............................................................................70

Power Connections............................................................................71

Communication Connections....................................................................88

Interface Connection ..........................................................................88

A-Link Connections............................................................................89

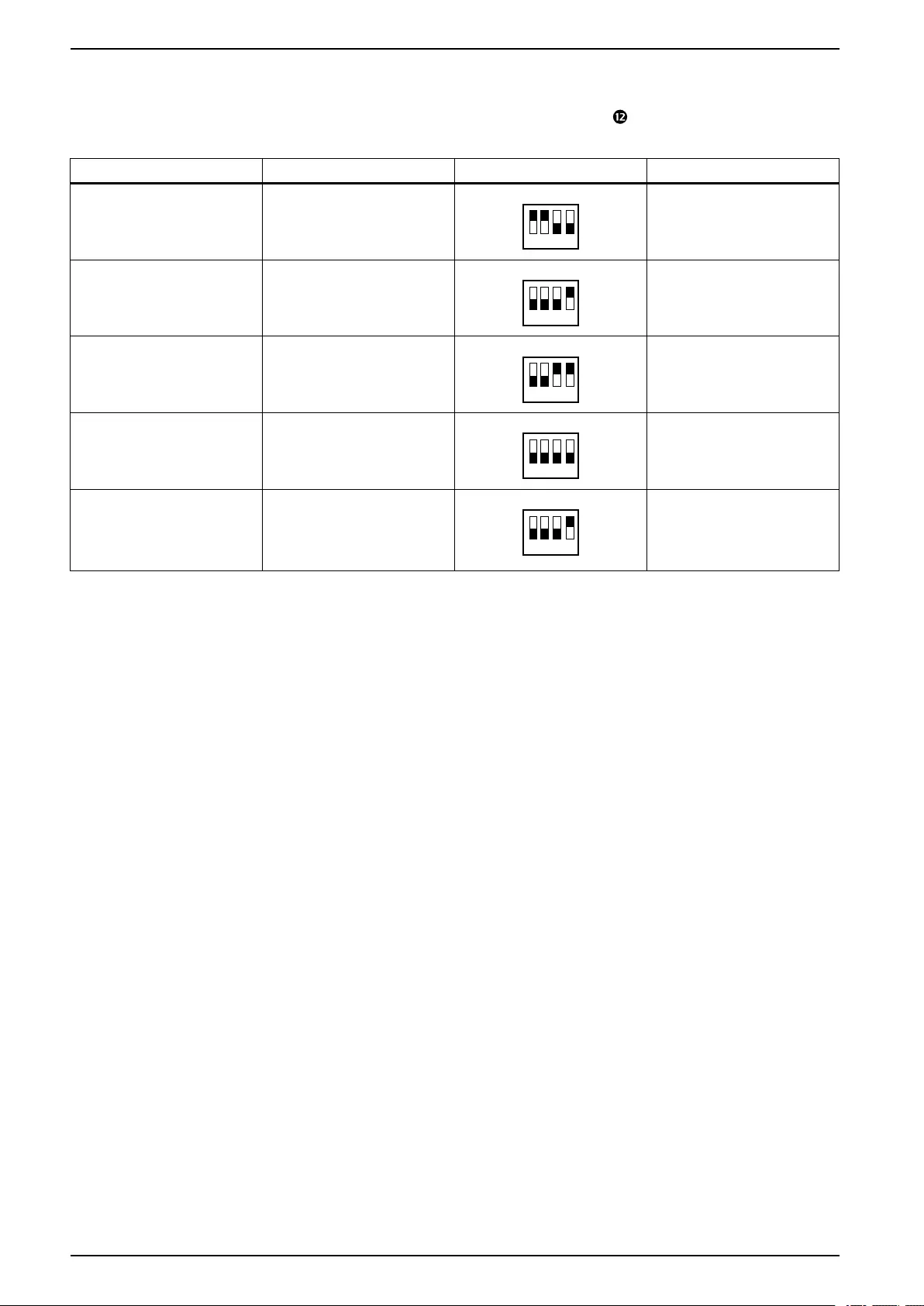

Modbus Switch Configuration .............................................................90

Output Relays and Standby Input ........................................................ 91

Leak Detector—Optional ....................................................................92

Rack Air Temperature Sensors............................................................93

Network Connection...........................................................................94

Outdoor Unit Connection ....................................................................95

Charging the Refrigeration System ...........................................................96

Calculating R410A Refrigerant Charge ................................................96

Refrigerant Charging Process .............................................................96

Compressor Oil Charge............................................................................97

Oil Charging Procedure ......................................................................97

4 990–91193A–001

Safety ACRD300 and ACCU30000 Series

Safety

Important Safety Instructions — SAVE THESE INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar

with it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will

result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

990–91193A–001 5

ACRD300 and ACCU30000 Series Safety

Safety During Installation

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

This equipment is not to be operated or installed by persons with reduced

physical, sensory, or mental capabilities, or persons lacking experience or

knowledge. Children are not to operate or play on or around this equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD OF EQUIPMENT FALLING OVER

• Use two or more persons at all times to move or turn this equipment.

• Always push, pull, or turn while facing the front and rear of this equipment.

Never push, pull, or turn while facing the sides of this equipment.

• Slowly move this equipment across uneven surfaces or door thresholds.

• Lower leveling feet to floor when this equipment is at rest.

• Lower leveling feet and attach joining brackets to adjacent racks when this

equipment is in final position.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD FROM MOVING PARTS

Keep hands, clothing, and jewelry away from moving parts. Check the

equipment for foreign objects before closing the doors and starting the

equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

6 990–91193A–001

General Information ACRD300 and ACCU30000 Series

General Information

Document Overview

Original Instructions

These are the original instructions provided by the manufacturer.

Save These Instructions

This manual contains important instructions that must be followed during the

installation of this equipment.

Manual Updates

Schneider Electric™ policy is one of continuous technological innovation and the

company reserves the right to amend any data herein without prior notice. The

images shown in this manual are for descriptive purposes only and they may differ

from specific models that are selected.

NOTE: Unit images and component identification information are examples

only. The final configuration of the unit may change according to the different

options.

Check for updates to this manual on the Schneider Electric Web site, www.

schneider-electric.com/support. Select the Download Documents and Software

link under the Support tab and enter the manual part number or SKU for your

equipment in the search field. See the back cover of this manual for the part

number.

Cross-Reference Symbol Used in This Manual

See another section of this document or another document for more

information on this subject.

Abbreviations

The following are abbreviations and terms used in this manual:

• EEV: Electronic expansion valve

• VFD/VSD: Variable-frequency drive/variable-speed drive

• DX: Direct expansion

• BMS: Building management system

• ATS: Automatic transfer switch

• HACS: Hot aisle containment system

• CACS: Cold aisle containment system

• RACS: Rack aisle containment system

990–91193A–001 7

ACRD300 and ACCU30000 Series General Information

Receiving and Inspecting the Equipment

Your InRow air conditioner has been tested and inspected for quality assurance

before shipment from Schneider Electric. Carefully inspect both the exterior and

interior of the equipment immediately upon receipt to ensure that the equipment

has not been damaged during transit.

Verify that all parts ordered were received as specified and that the equipment is

the correct type, size, and voltage.

Filing a Claim

If damage is identified on receipt of the equipment, note the damage on the bill of

lading and file a damage claim with the shipping company. Contact Schneider

Electric Worldwide Customer Support at one of the numbers listed on the Web

page on the back page of this manual for information on how to file a claim with

the shipping company. The shipping claim must be filed at the receiving end of the

delivery.

NOTE: In case of shipping damage, do not operate the equipment. Keep all

packaging for inspection by the shipping company and contact Schneider

Electric.

Radio Frequency Interference

The SKUs ACRD301, ACRD301G, ACCU30001, ACCU30002, ACCU30101, and

ACCU30102 comply with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. These devices may not cause harmful interference.

2. These devices must accept any interference received, including interference

that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

California Proposition 65—Warning Statement for California

Residents

WARNING: This product can expose you to chemicals including lead and lead

compounds, that are known to the State of California to cause cancer and birth

defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

Storing the Cooling Unit Before Installation

NOTICE

DAMAGE FROM EXPOSURE

Leaving the equipment uncovered and exposed to possible damage from the

environment will void the factory warranty.

Failure to follow these instructions can result in equipment damage.

If the cooling unit will not be installed immediately, store it in a safe place,

protected from the weather.

8 990–91193A–001

General Information ACRD300 and ACCU30000 Series

Moving the Unit

WARNING

DAMAGE TO EQUIPMENT OR PERSONNEL

• The equipment is heavy. For safety purposes, adequate personnel must be

present when moving this item.

• The load must always be solidly anchored to the bearing element of the

lifting equipment and means of transport.

• No one should be near the suspended load, nor in the working area of the

crane, forklift, truck, or any other lifting equipment or means of transport.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Lifting and transporting the units must be carried out by qualified personnel as

described in this manual.

Use all relevant safety standards to prevent any possible damage to people or

objects.

Indoor Unit

The cooling unit is packaged in a wooden crate or anchored to a pallet and

covered with transparent film. The recommended tools for moving and installing

the equipment include the following:

Forklift Pallet Jack

990–91193A–001 9

ACRD300 and ACCU30000 Series General Information

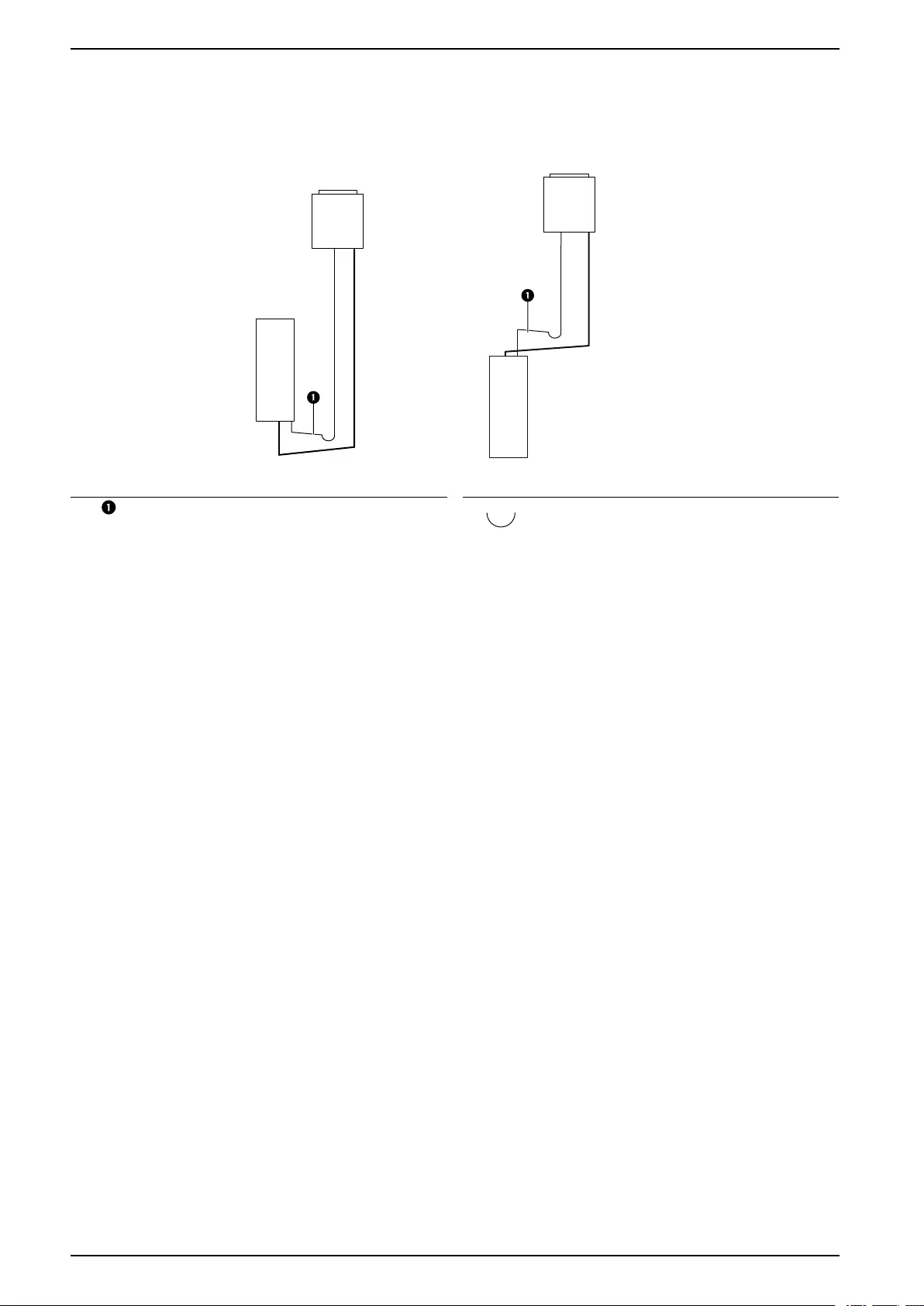

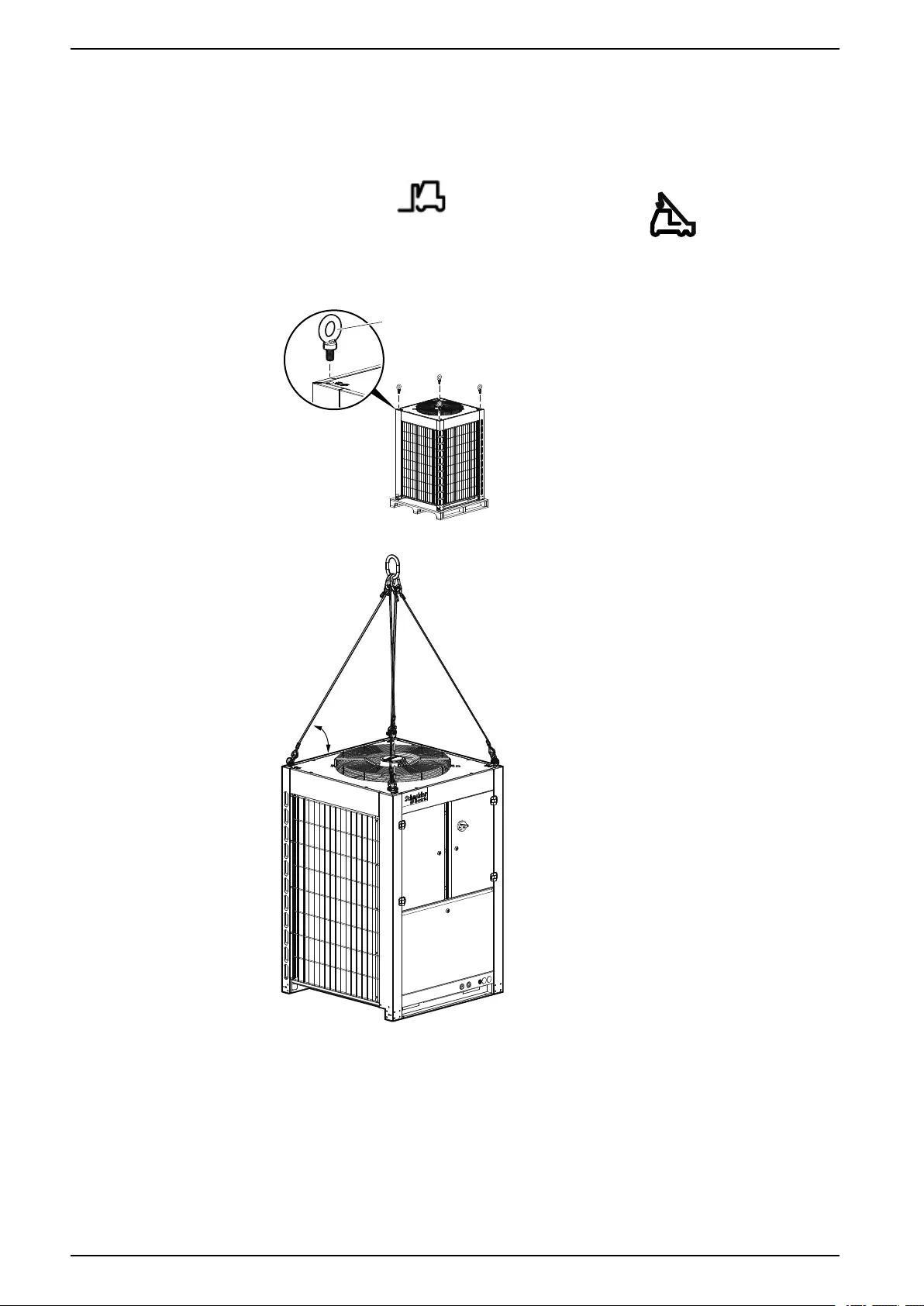

Outdoor Unit

The condensing unit is packaged in a wooden crate. The recommended tools for

moving and installing the equipment include the following:

Forklift Crane

Use field-supplied eyebolts rated for angular lifting with a shoulder similar to the

one shown below. The minimum weight rating for a 90° lift is 726 kg (1600 lb).

M10 EYEBOLT

44.1 N•m

(32.5 ft•lb)

na7012a

The lifting angle for the lifting straps must be greater than or equal to 73°.

≥73°

na7013a

10 990–91193A–001

General Information ACRD300 and ACCU30000 Series

Unit Overview

Model Identification

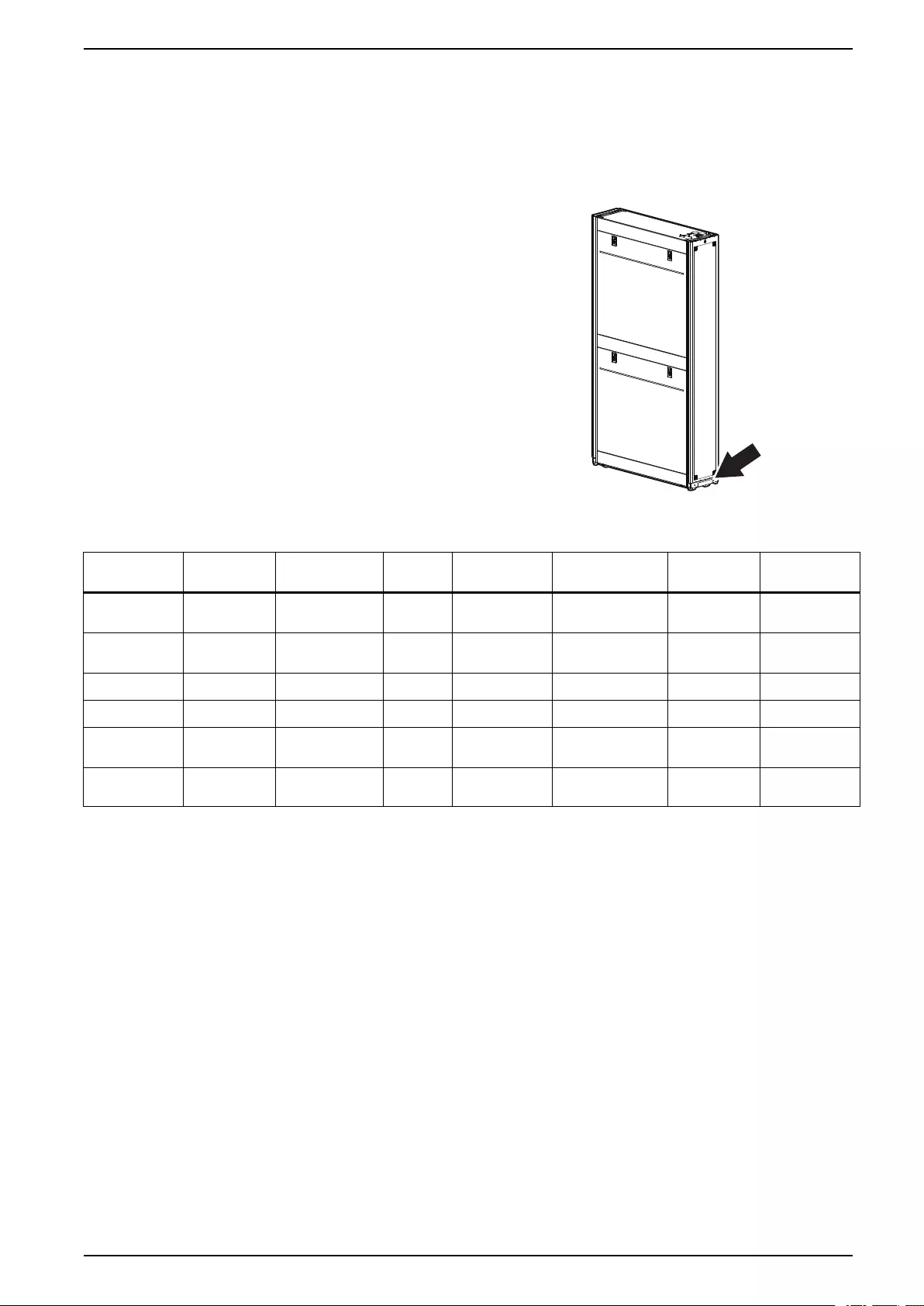

Indoor Unit

The model number can be found on

the outside of the shipping crate and

on the name plate located on the unit

as shown. Use the table below to

verify that the equipment is the right

type and voltage.

REAR

NAME PLATE

na4402b

NOTE: The unit is not to be accessed by the general public.

SKU Voltage Frequency 65 kAIC Power Feed Number of Fan

Power Supplies

Drainage

System

Airflow

Pattern

ACRD300 220 V~ 50 Hz No Dual feed 1 Condensate

pump

Rear to front

ACRD300D 220 V~ 50 Hz No Dual feed 2 Condensate

pump

Rear to front

ACRD300G 220 V~ 50 Hz No Dual feed 1 Gravity drain Rear to front

ACRD300GD 220 V~ 50 Hz No Dual feed 2 Gravity drain Rear to front

ACRD301 100–120 V~*

/ 200–240 V~

50/60 Hz Yes Dual feed 1 Condensate

pump

Rear to front

ACRD301G 100–120 V~*

/ 200–240 V~

50/60 Hz Yes Dual feed 1 Gravity drain Rear to front

*Configure proper voltage before applying power to the cooling unit.

990–91193A–001 11

ACRD300 and ACCU30000 Series General Information

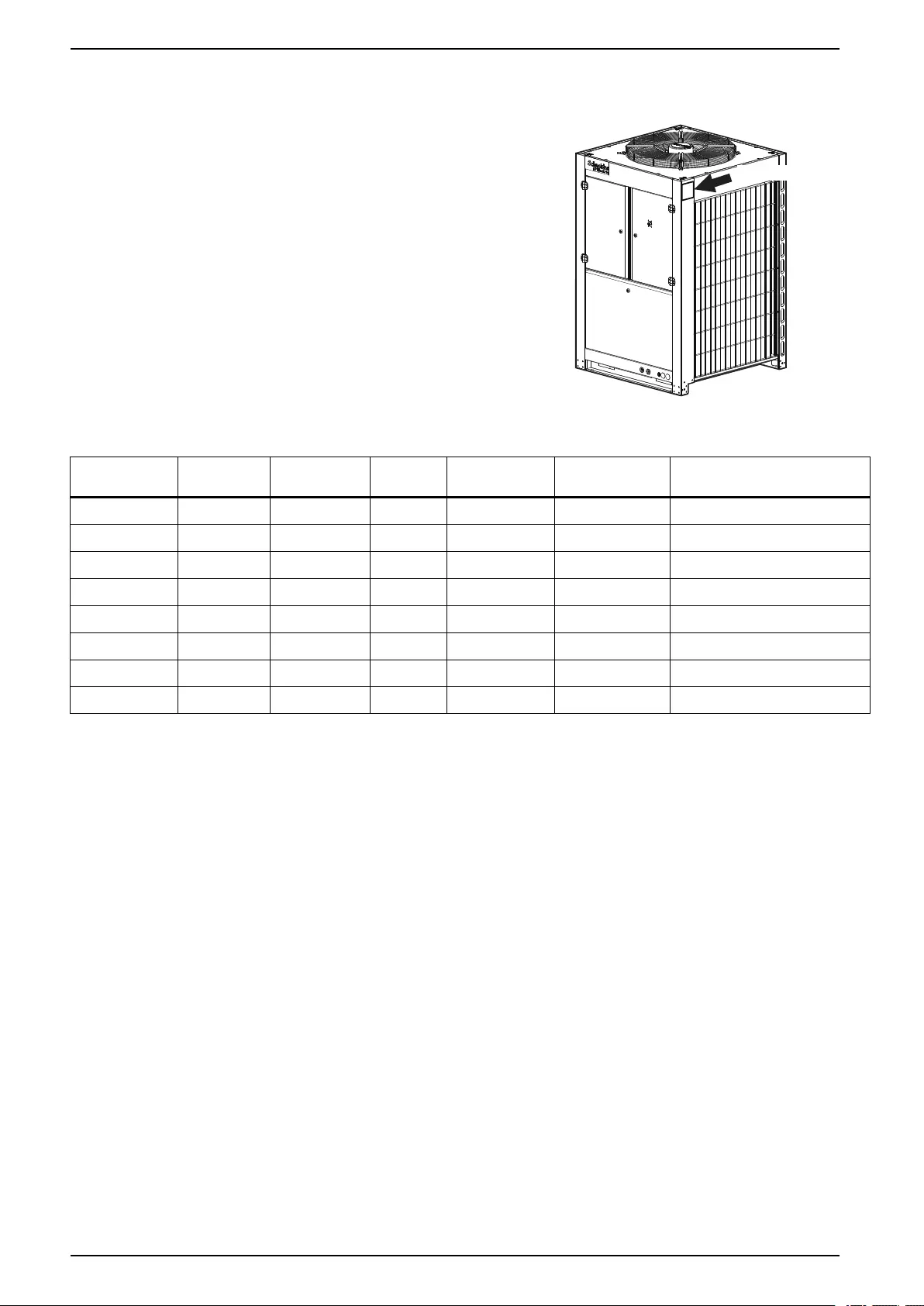

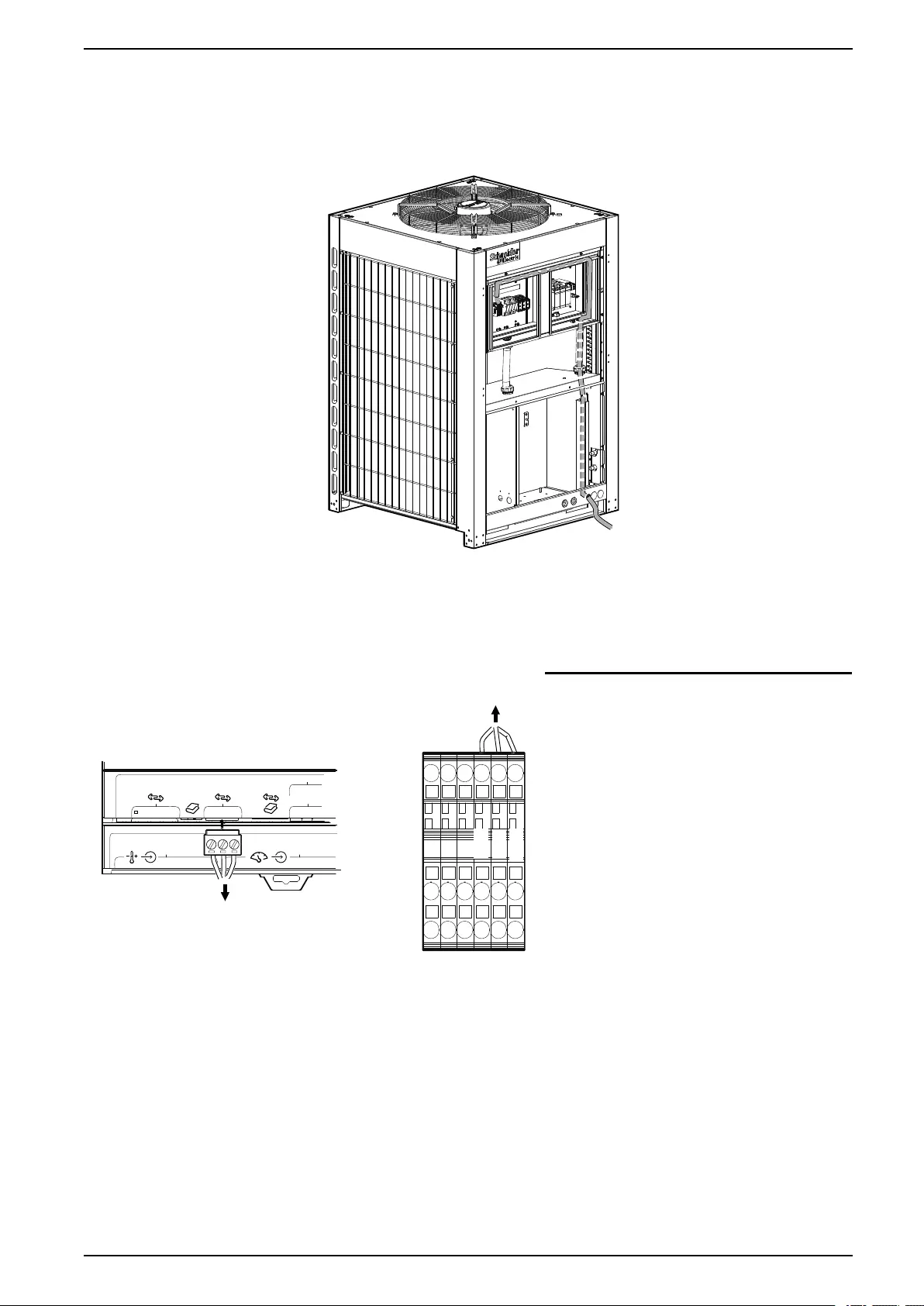

Outdoor Unit

The model number can be found on

the outside of the shipping crate and

on the name plate located on the unit

as shown. Use the table below to

verify that the equipment is the right

type and voltage.

na6990a

NAME PLATE

NOTE: The unit is not to be accessed by the general public.

SKU Voltage Frequency 65 kAIC Power Feed Accumulator Outdoor Temperature Minimum

Operation Temperature

ACCU30301 380 V 3~ 50 Hz No Single feed Yes –20°C (–4°F)

ACCU30302 380 V 3~ 50 Hz No Dual feed Yes –20°C (–4°F)

ACCU30001 200–240 V 3~ 50/60 Hz Yes Single feed Yes (UL) –20°C (–4°F)

ACCU30002 200–240 V 3~ 50/60 Hz Yes Dual feed Yes (UL) –20°C (–4°F)

ACCU30201 380–415 V 3~ 50/60 Hz Yes Single feed Yes (PED) –20°C (–4°F)

ACCU30202 380–415 V 3~ 50/60 Hz Yes Dual feed Yes (PED) –20°C (–4°F)

ACCU30101 460–480 V 3~ 50/60 Hz Yes Single feed Yes (UL) –20°C (–4°F)

ACCU30102 460–480 V 3~ 50/60 Hz Yes Dual feed Yes (UL) –20°C (–4°F)

12 990–91193A–001

General Information ACRD300 and ACCU30000 Series

Equipment Guidelines

Working Conditions and Environmental Limits

InRow DX units have a minimum heat load to ensure proper operation. Failure to

operate the unit with at least the minimum load will result in one or more of the

following conditions:

• Decreased operating efficiency

• Equipment on/off cycling

• Inadequate dehumidification

• Increased wear and tear caused by frequent on/off cycles

• Decreased group control effectiveness

• Potential increase in cost of ownership

Limit Working Conditions—Indoor Unit

Refrigerant type R410A

Voltage input tolerance ±10%

Minimum recommended load 9.5 kW (32,400 BTU/hr)

Ambient temperature +15°C to +45°C (+59°F to +113°F)

Ambient %RH 5 to 80%RH

Altitude 3000 m (9843 ft)

Storage Conditions

Temperature –25°C to +65°C (–13°F to +149°F)

Humidity 5 to 95%RH

Limit Working Conditions—Outdoor Unit

Refrigerant type R410A

Compressor oil type PVE (Daphne Hermetic Oil FVC32D)

Operating Ambient temperature –20°C to +48°C (-4°F to +118°F)

Altitude 3000 m (9843 ft)

Storage Conditions

Temperature –25°C to +65°C (–13°F to +149°F)

Humidity 5 to 95%RH

NOTE: ACRD301, ACRD301G, ACCU30201, ACCU30202 are in accordance with the Electromagnetic

Compatibility Standard (EMC): EN 55032, EN55024, EN61000-3-2, EN61000-3-3, EN61000-6-3,

EN61000-6-1, EN61000-3-11, EN 61000-3-12.

ACRD301, ACRD301G, ACCU30001, ACCU30002, ACCU30101, ACCU30102 are in accordance with

FCC: ANSI C63.4.

NOTE: The SKUs comply with EN61000-3-12 provided that the short-circuit

power SSC is greater than or equal to 350 at the interface point between the

user supply and the public system. It is the responsibility of the installer or user

of the equipment to ensure, by consultation with the distribution network

operator if necessary, that the equipment is connected only to a supply with a

short-circuit power SSC greater than or equal to 350.

990–91193A–001 13

ACRD300 and ACCU30000 Series General Information

Unit Compatibility

SKU ACRD300 ACRD300D ACRD300G ACRD300GD ACRD301 ACRD301G

ACCU30301 Yes Yes Yes Yes No No

ACCU30302 Yes Yes Yes Yes No No

ACCU30001 No No No No Yes Yes

ACCU30002 No No No No Yes Yes

ACCU30201 No No No No Yes Yes

ACCU30202 No No No No Yes Yes

ACCU30101 No No No No Yes Yes

ACCU30102 No No No No Yes Yes

14 990–91193A–001

Inventory ACRD300 and ACCU30000 Series

Inventory

Package Contents—Indoor Unit

na6952a

Item Description Quantity Item Description Quantity

ACRD3xx 1Suction line pipe

insulation

1

Panel keys 2 Suction line pipe

insulation

1

Temperature sensor 1 Liquid line pipe* 1

Wire clip 3 Suction line pipe* 1

Philips screw—M5 x 12** 4Bracket and screw for

ACCS1009

installation****

1

Bolt-down kit*** 1Connector kit —

Gasket (inlet pipe)—1 in. 2RJ-45 terminator 1

Gasket (outlet pipe)—

1 1/4 in.

23–position connector†2

Wire tie 16 9–position connector‡1

Wire tie 3 8–position connector‡1

Documentation —Drain pan supplement 1

Clamp insulation 1

*Shipped inside the unit attached to side braces.

**Use to join the equipment to adjacent enclosures.

***Shipped with ACRD301 and ACRD301G models only.

****Do not throw away. Keep these parts for use with the ACCS1009 extension kit.

†Use for the controller connection (RS485 (1)) for the condensing unit communication cable. (See Outdoor Unit

Connection, page 95.)

‡Use for the output relay and standby input connections. (See Output Relays and Standby Input, page 91.)

990–91193A–001 15

ACRD300 and ACCU30000 Series Inventory

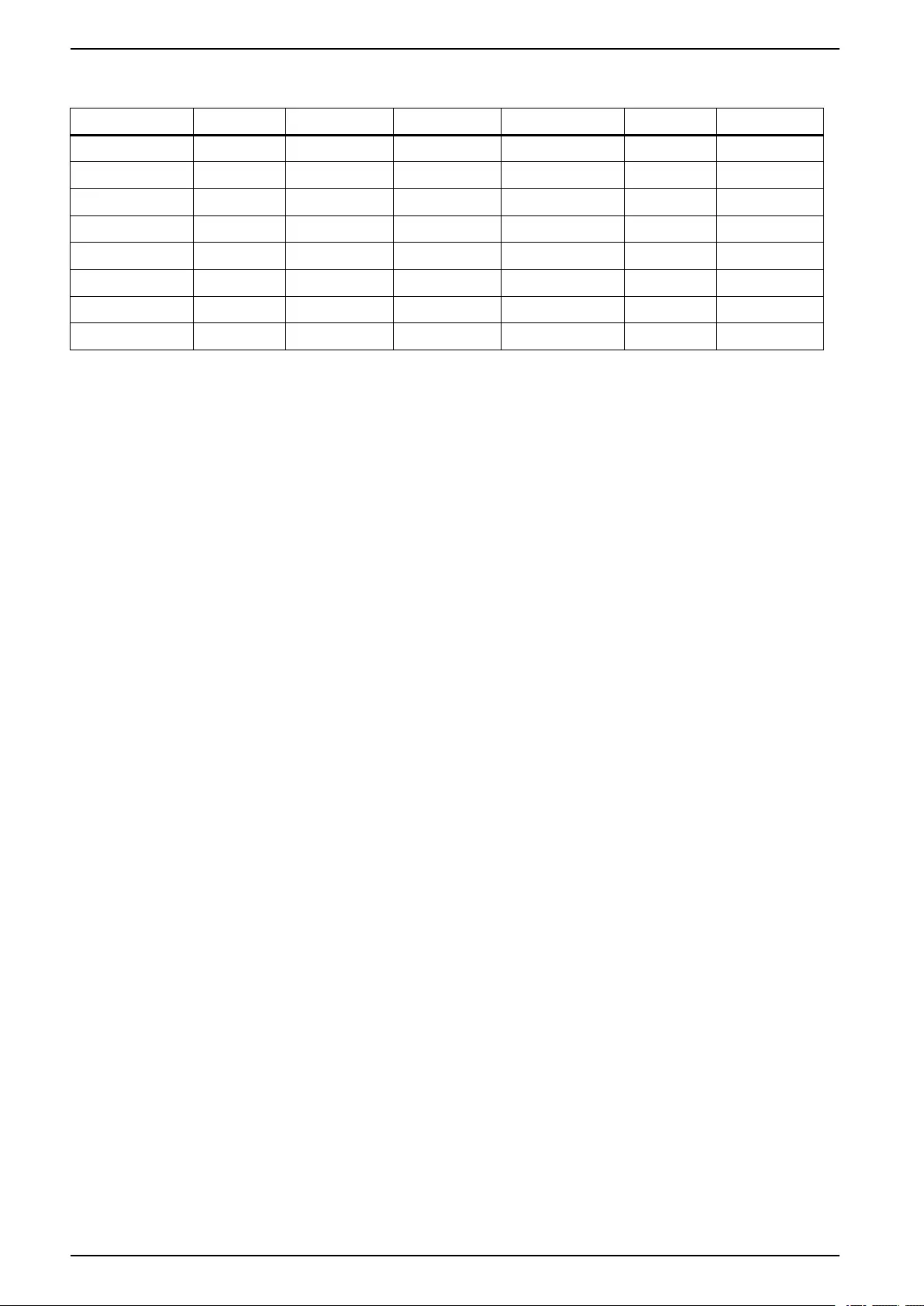

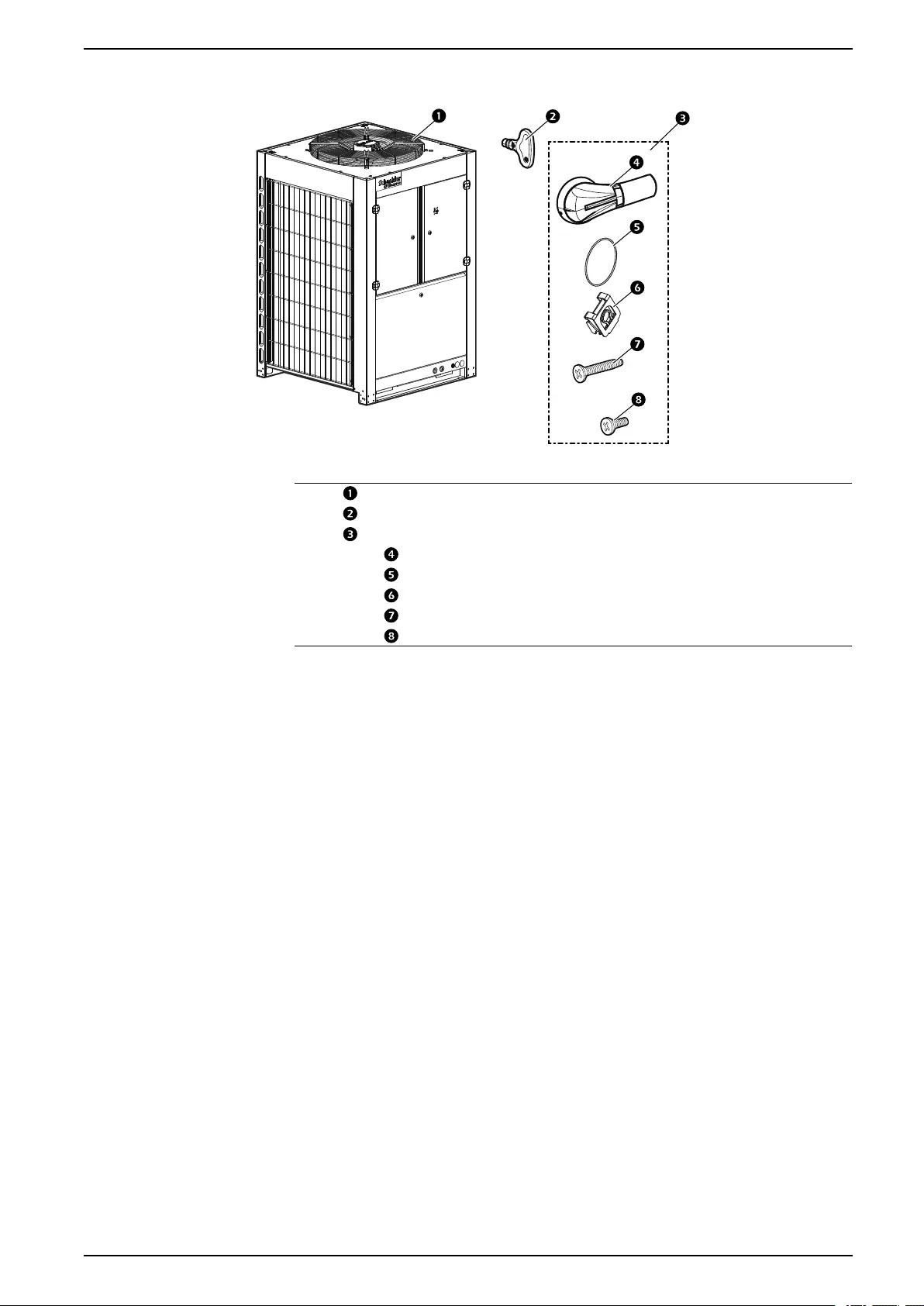

Package Contents—Outdoor Unit

ACCU30301, ACCU30302

na6979a

Item Description Quantity

ACCU30XXX unit 1

Key* 1

Main switch handle installation kit** 1

Main switch handle 1

Main switch gasket 1

Tap screws 4

Grommet 4

Nut*** 1

*Attached to the fan grille with a wire tie.

**Shipped inside the electrical panel.

***Not used. This item can be recycled.

16 990–91193A–001

Inventory ACRD300 and ACCU30000 Series

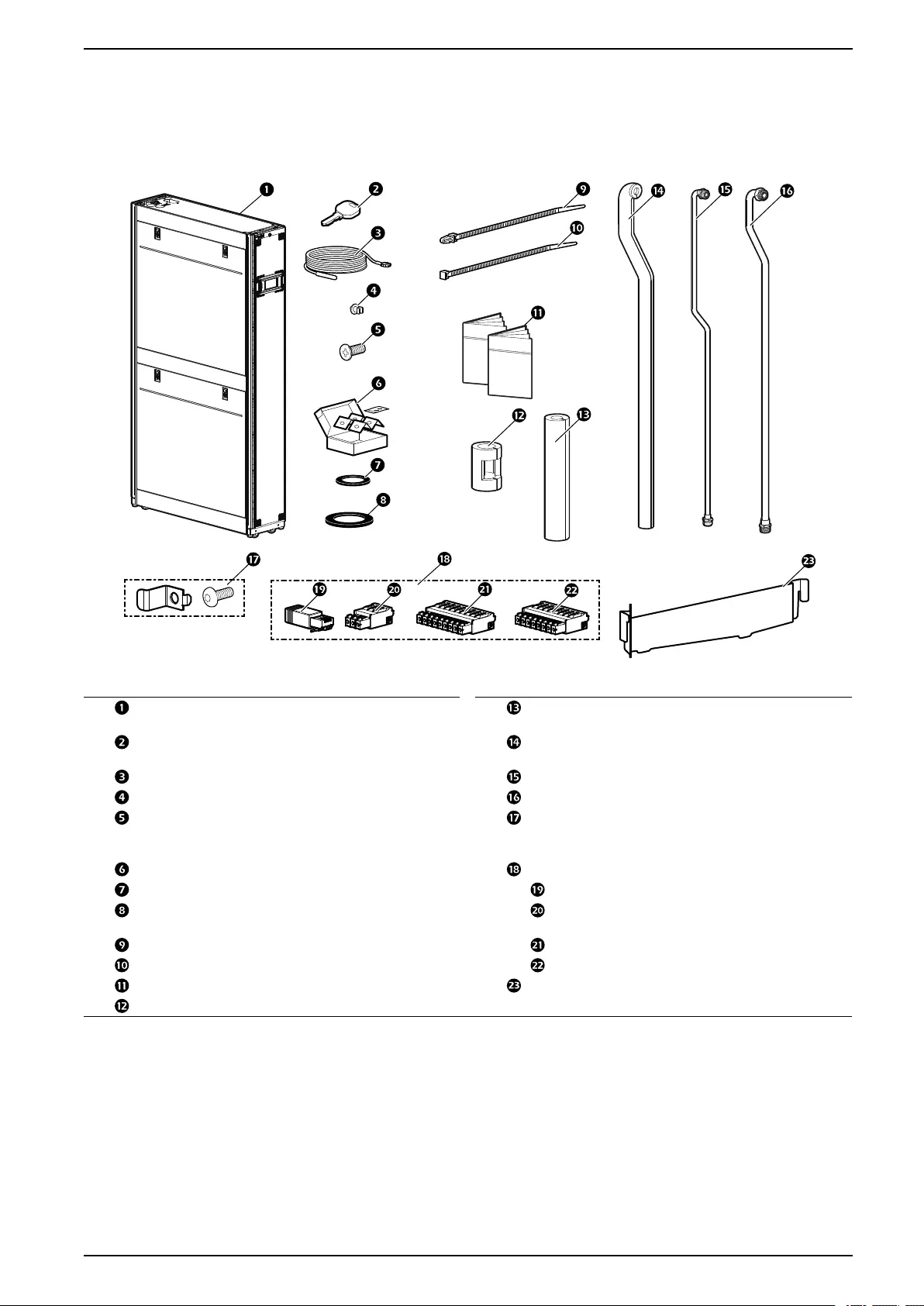

ACCU30001, ACCU30002, ACCU30201, ACCU30202, ACCU30101, ACCU30102

na6979b

Item Description Quantity

ACCU30XXX unit 1

Key* 1

Main switch handle installation kit**

Main switch handle*** 1

Main switch gasket*** 1

Nuts*** 4

Machine screws*** 4

Tap screws**** 4

*Attached to the fan grille with a wire tie.

**Shipped inside the electrical panel.

***Quantity will be doubled for models ACCU30002, ACCU30102, and

ACCU30202.

****Not used. This item can be recycled.

990–91193A–001 17

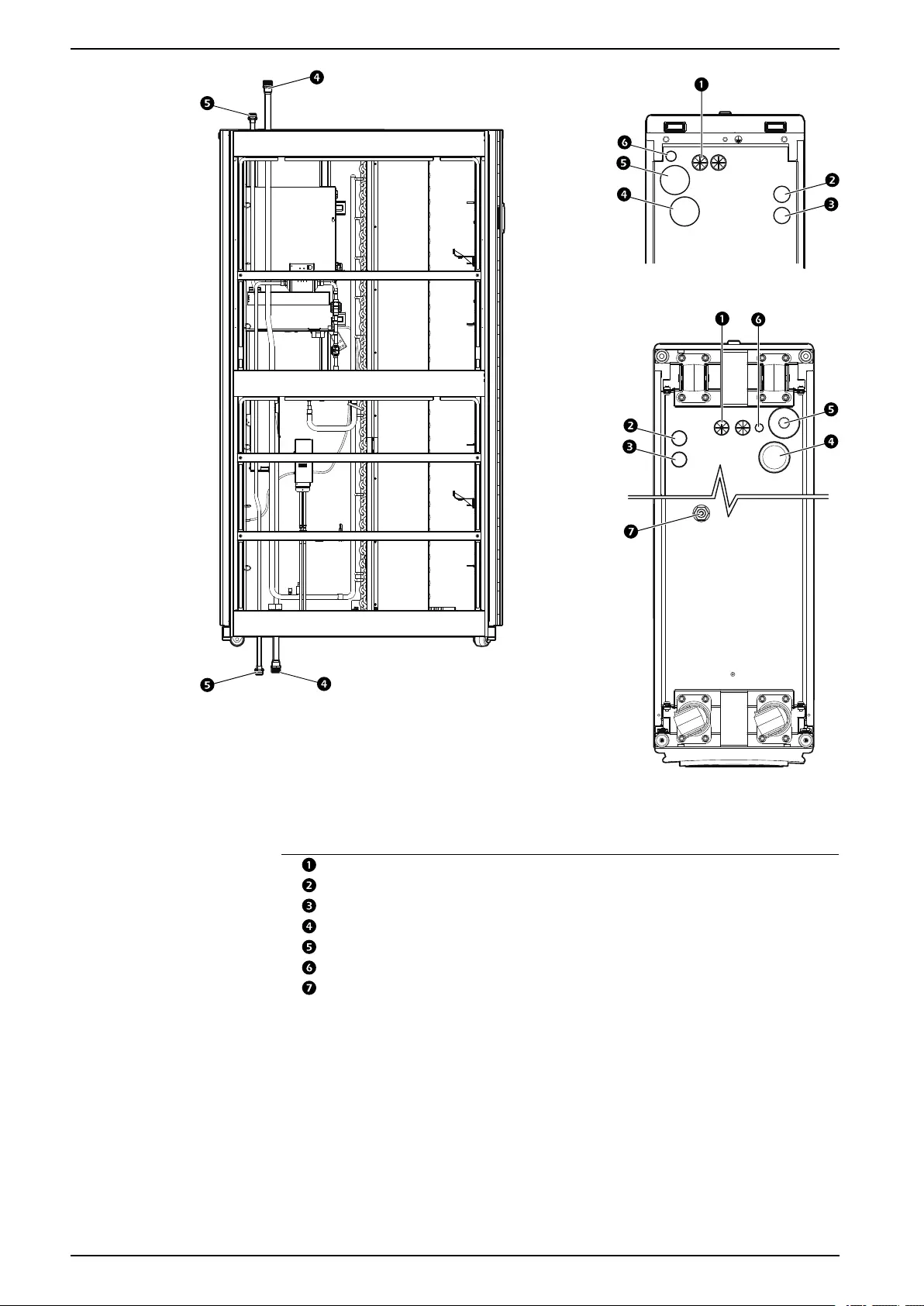

ACRD300 and ACCU30000 Series Component Identification

Component Identification

External Components

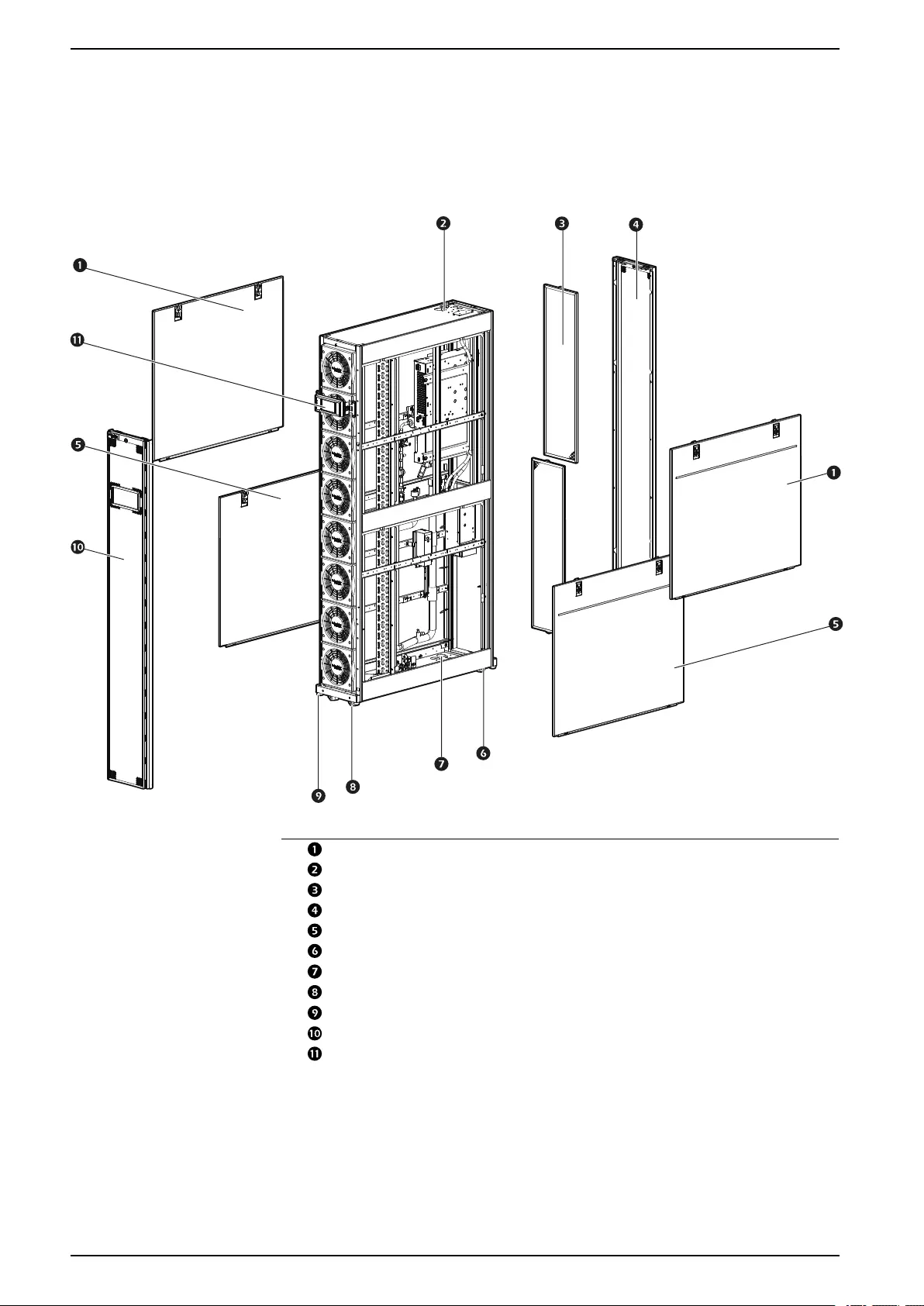

Indoor Unit—All ACRD30X Units

na6950a

Item Description

Upper side panel

Upper piping connection openings

Filters

Rear panel

Lower side panel

Rear casters (non-swiveling)

Lower piping connection openings

Front casters (swiveling)

Leveling feet

Front panel

Display interface

18 990–91193A–001

Component Identification ACRD300 and ACCU30000 Series

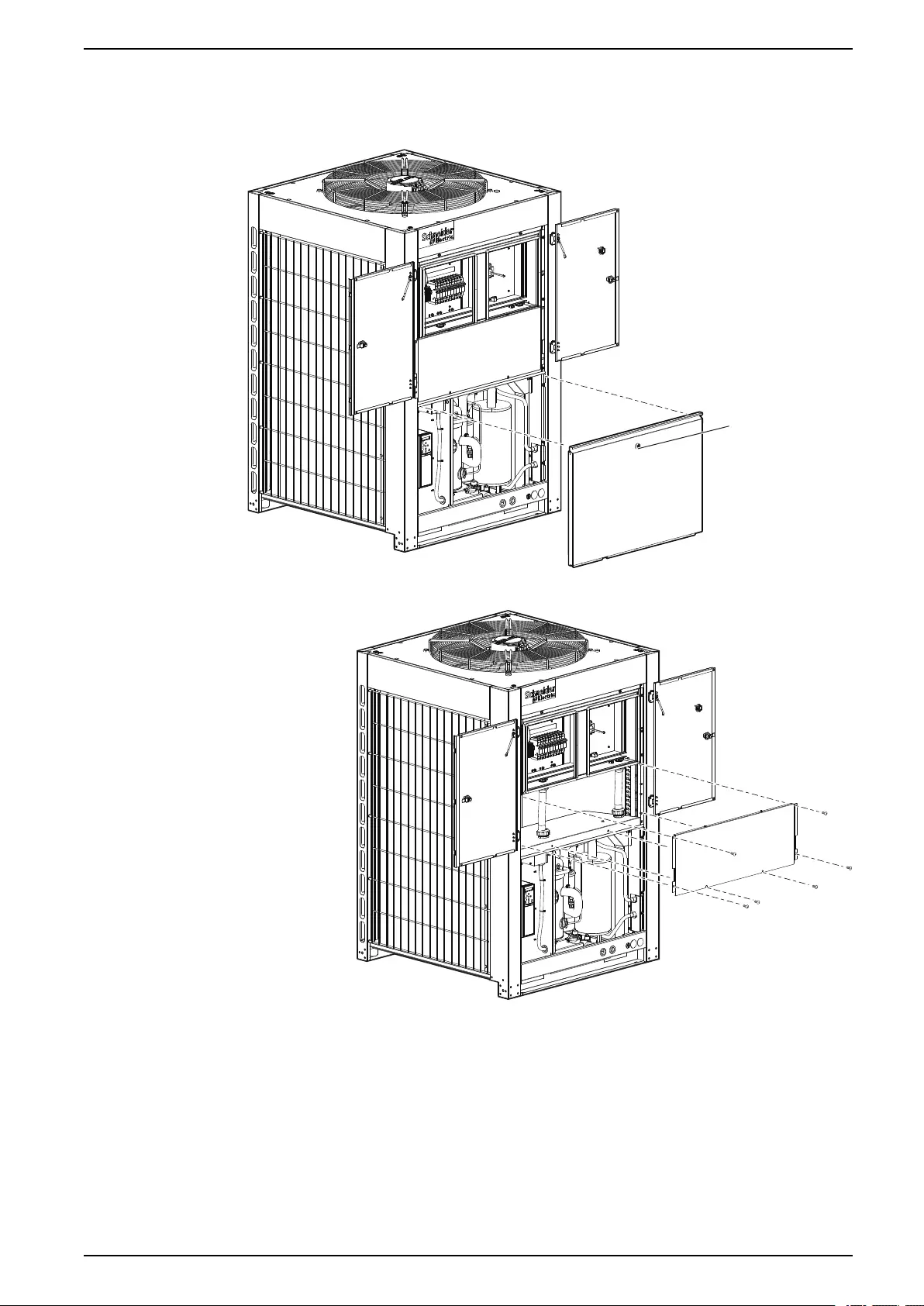

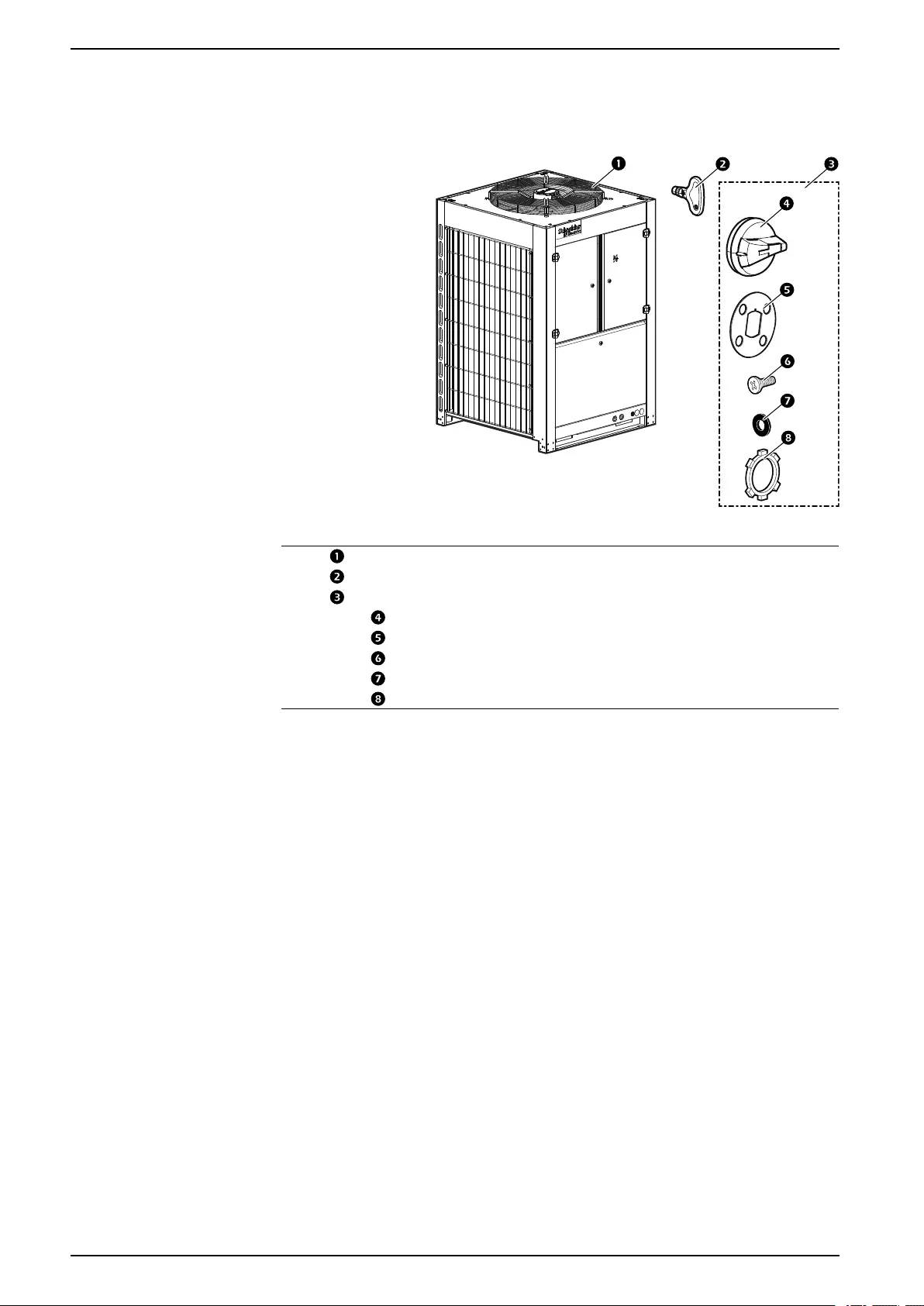

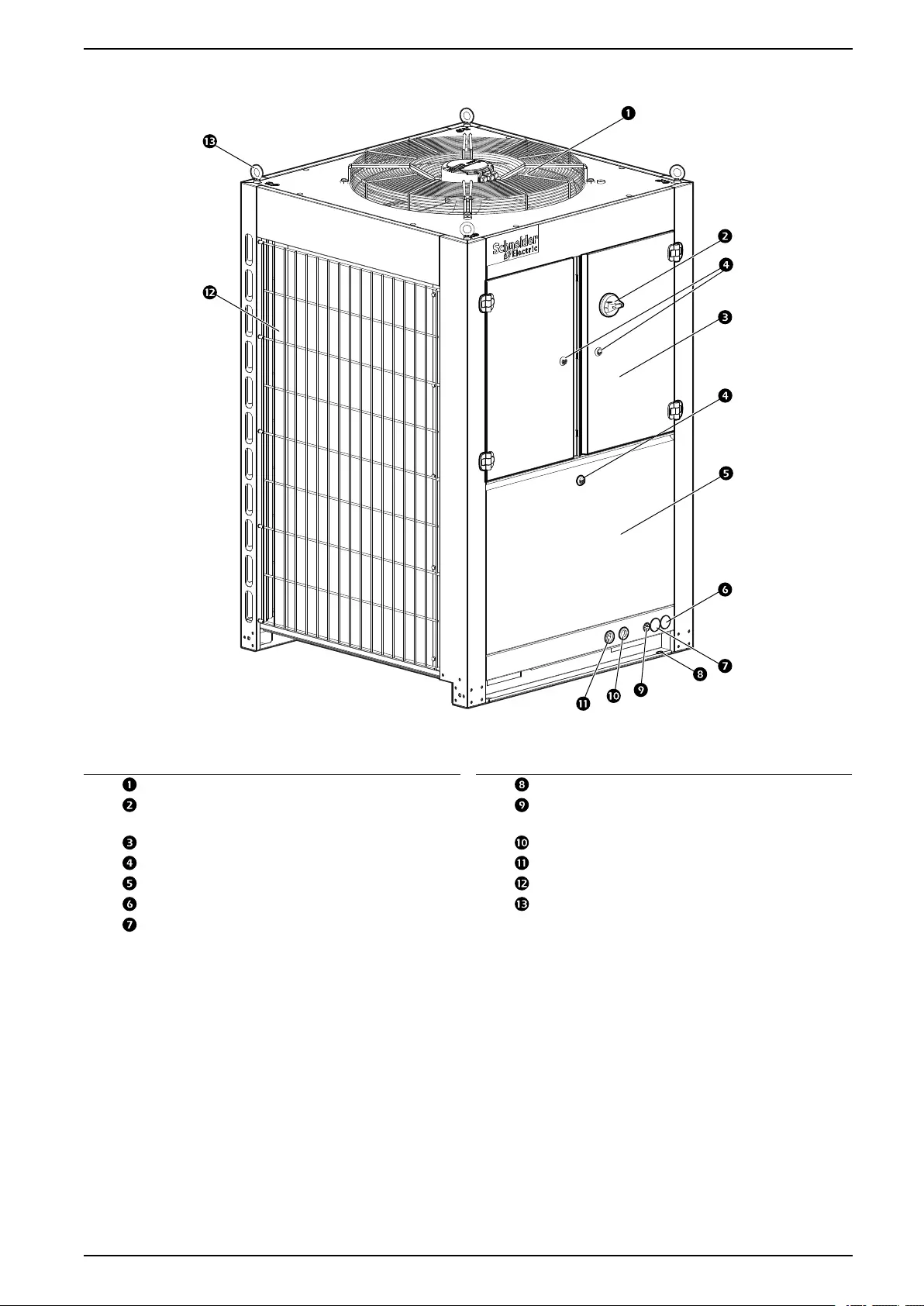

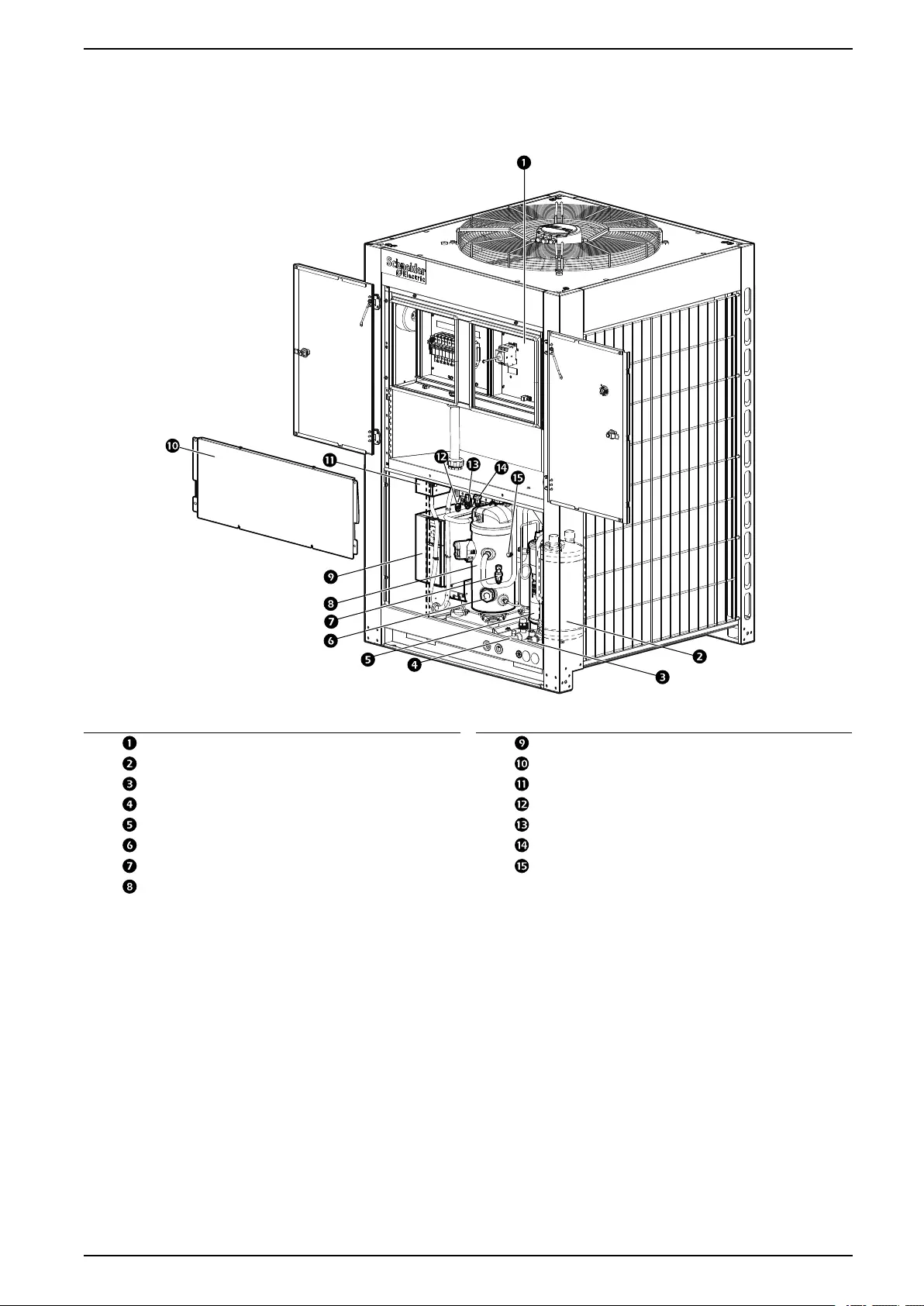

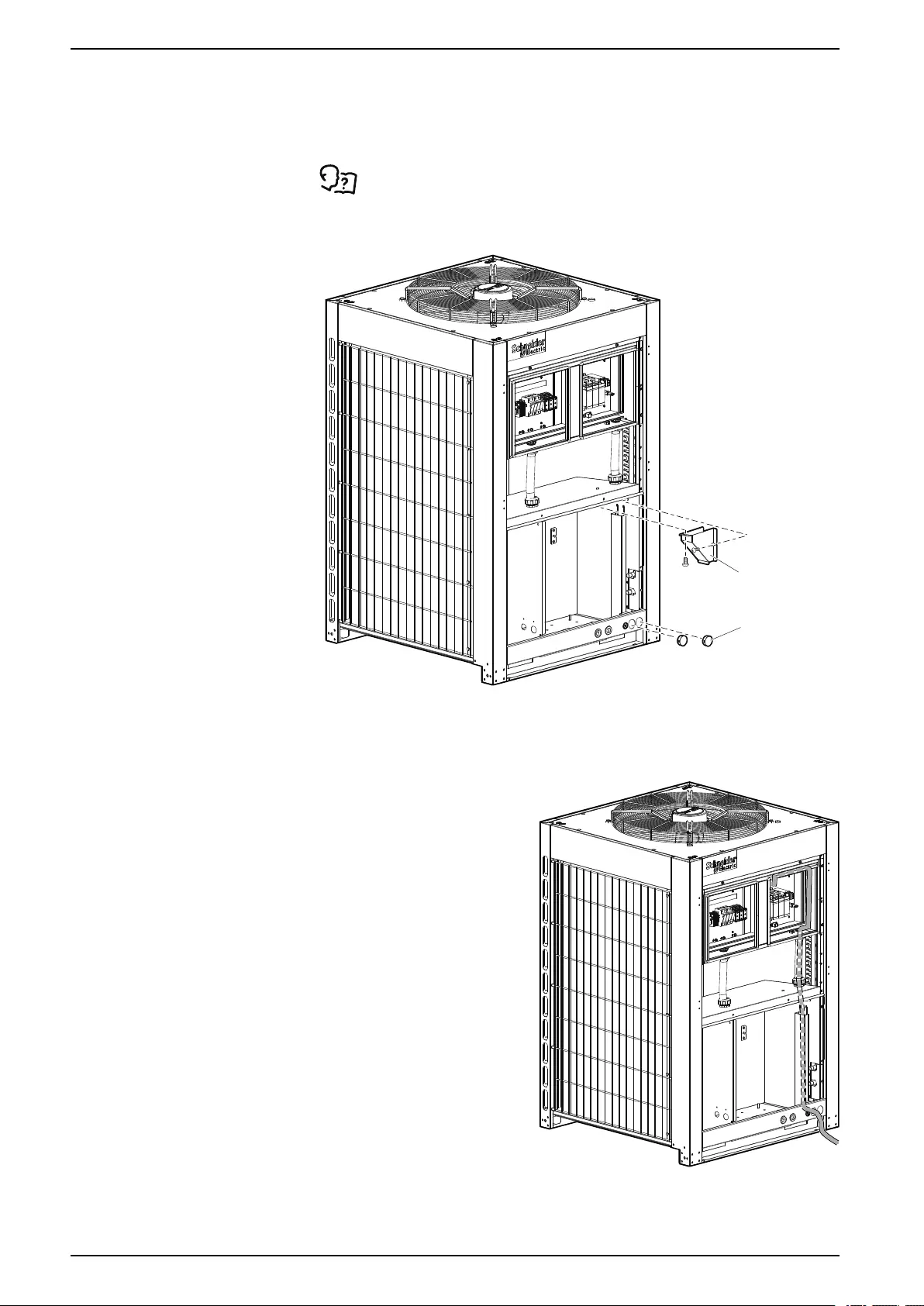

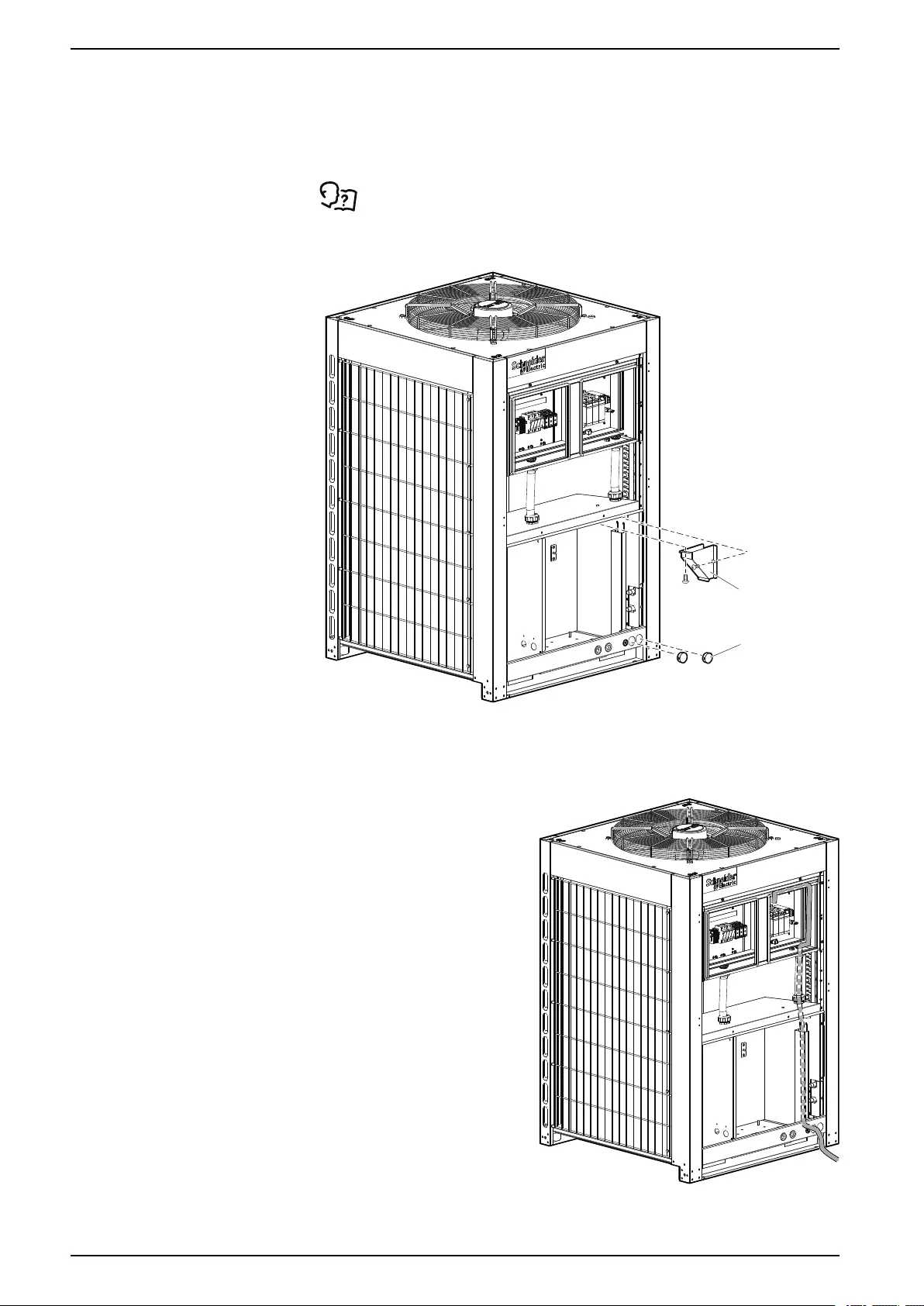

Outdoor Unit—All ACCU30XXX Units

na6953a

NOTE: Model ACCU30301 is shown.

Item Description Item Description

Fan Mounting holes

Main disconnect switch handle (field

installed)

Signal cable inlet

Electrical panel access doors Liquid line inlet

Quarter-turn latches Suction line inlet

Service panel Coil grilles

Power feed A inlet Lifting eyebolts (field supplied)

Power feed B inlet

990–91193A–001 19

ACRD300 and ACCU30000 Series Component Identification

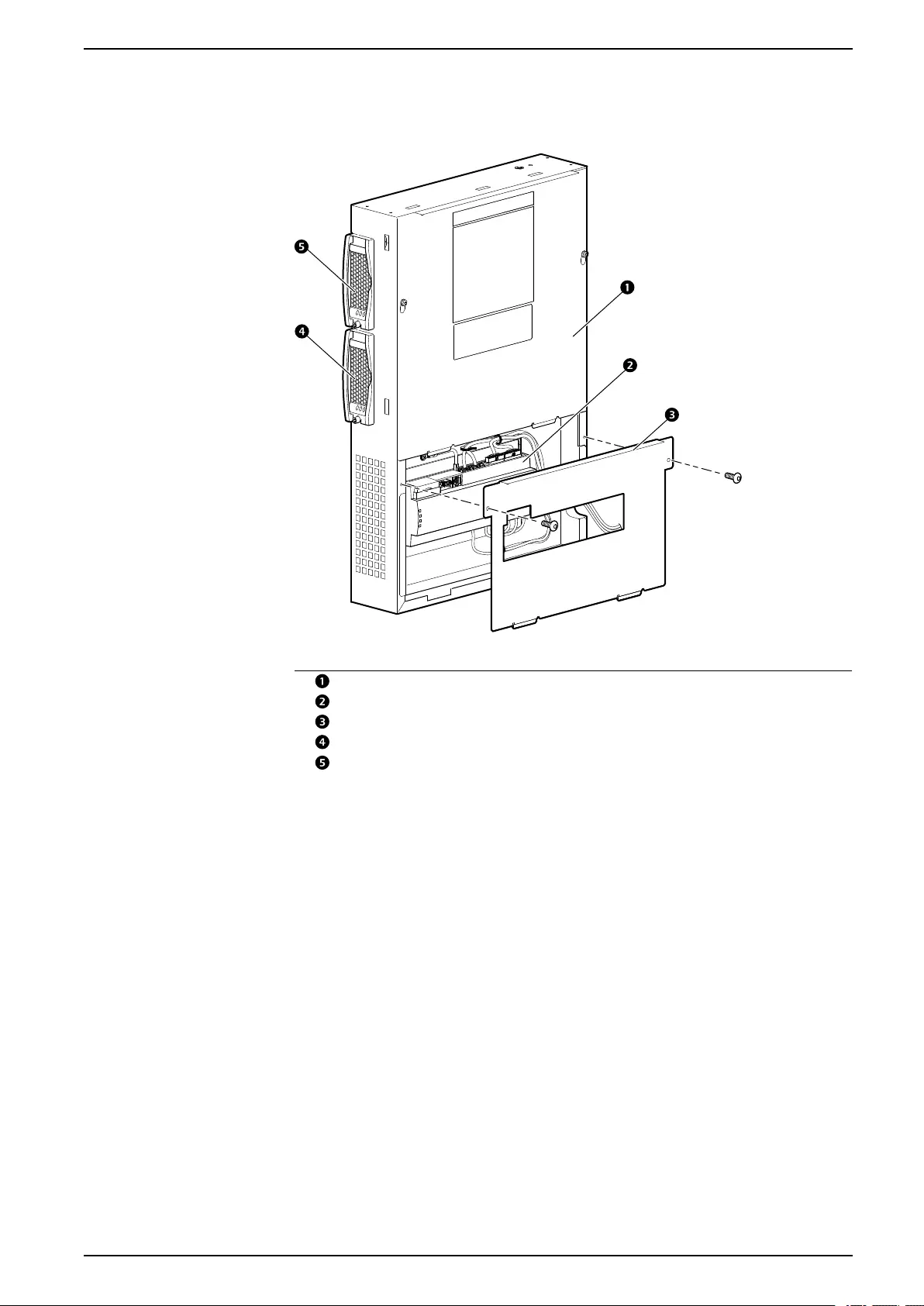

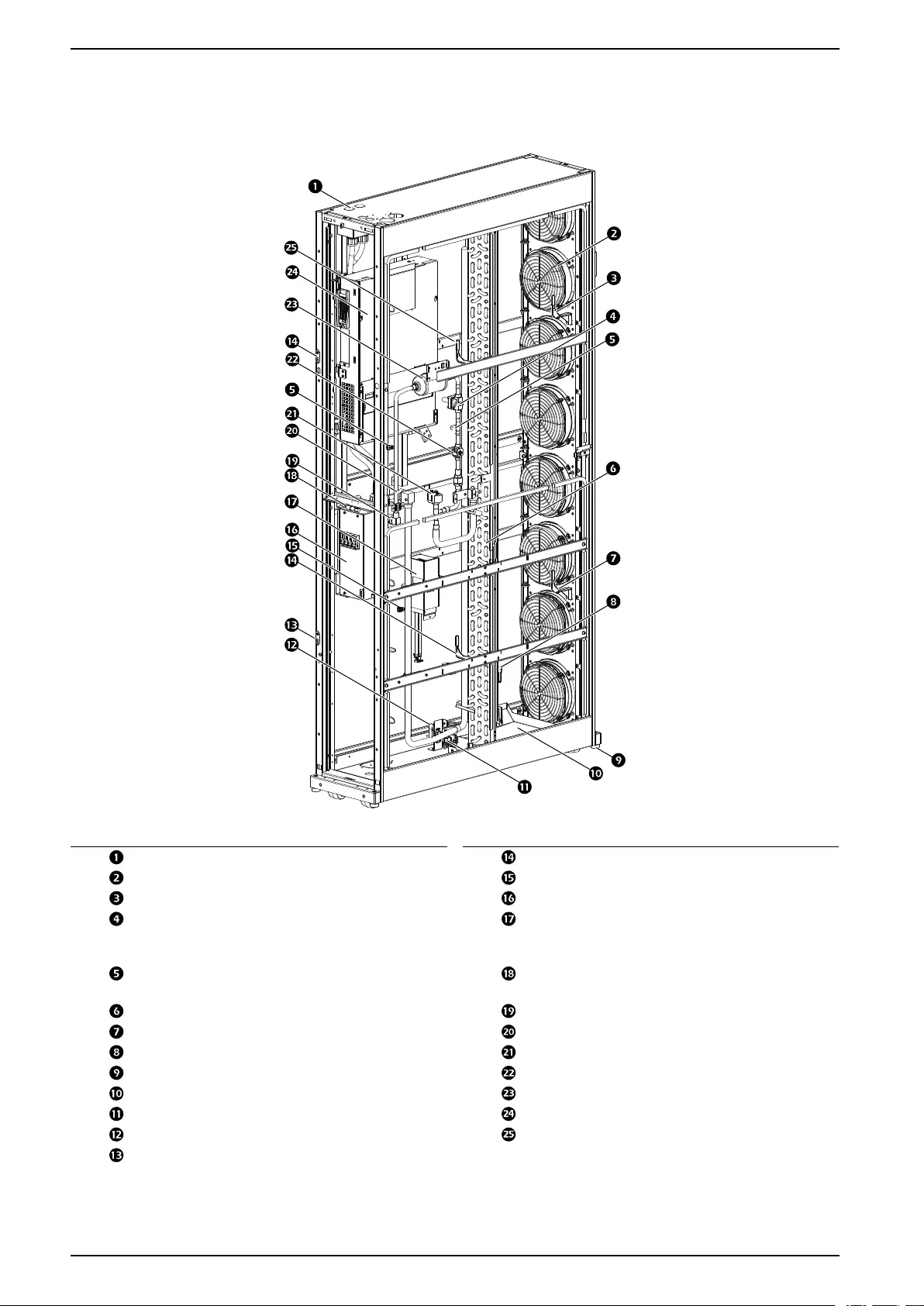

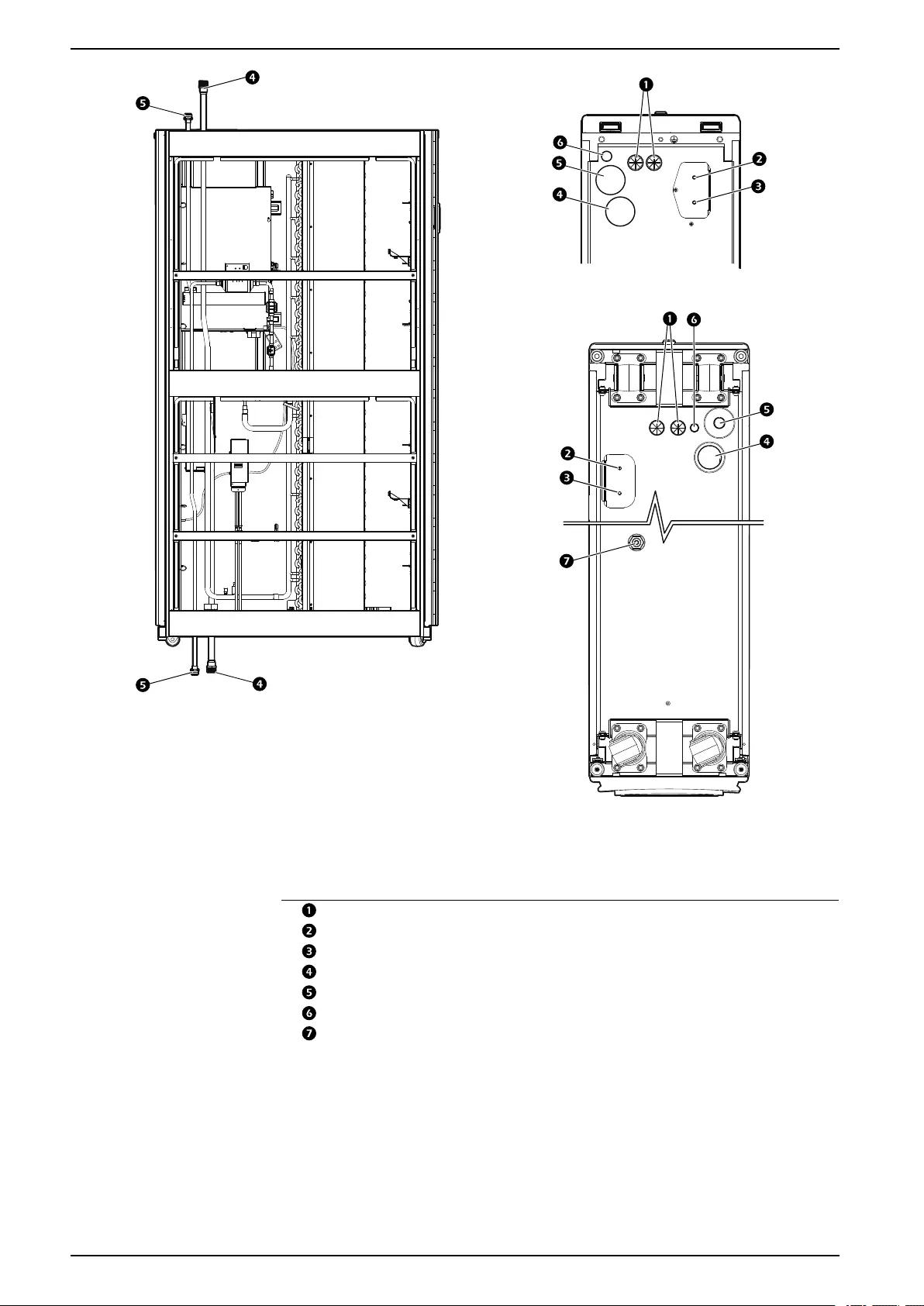

Internal Components

Indoor Unit

na6951a

Item Description Item Description

Power supply connections Lower return air temperature sensor

Fans Service port

Upper supply air temperature sensor Automatic transfer switch (ATS)

Solenoid valve Condensate drain pump

(ACRD300, ACRD300D, and

ACRD301 only)

Service port Temperature and humidity sensor

(optional)

Cooling coil Inlet connection

Lower supply air temperature Outlet connection

Refrigerant temperature sensor Electronic expansion valve (EEV)

Leveling feet Sight glass

Condensate drain pan Filter drier

Drain pan float switch Electrical box

Temperature sensor (suction) Upper return air temperature sensor

Joining bracket

20 990–91193A–001

Component Identification ACRD300 and ACCU30000 Series

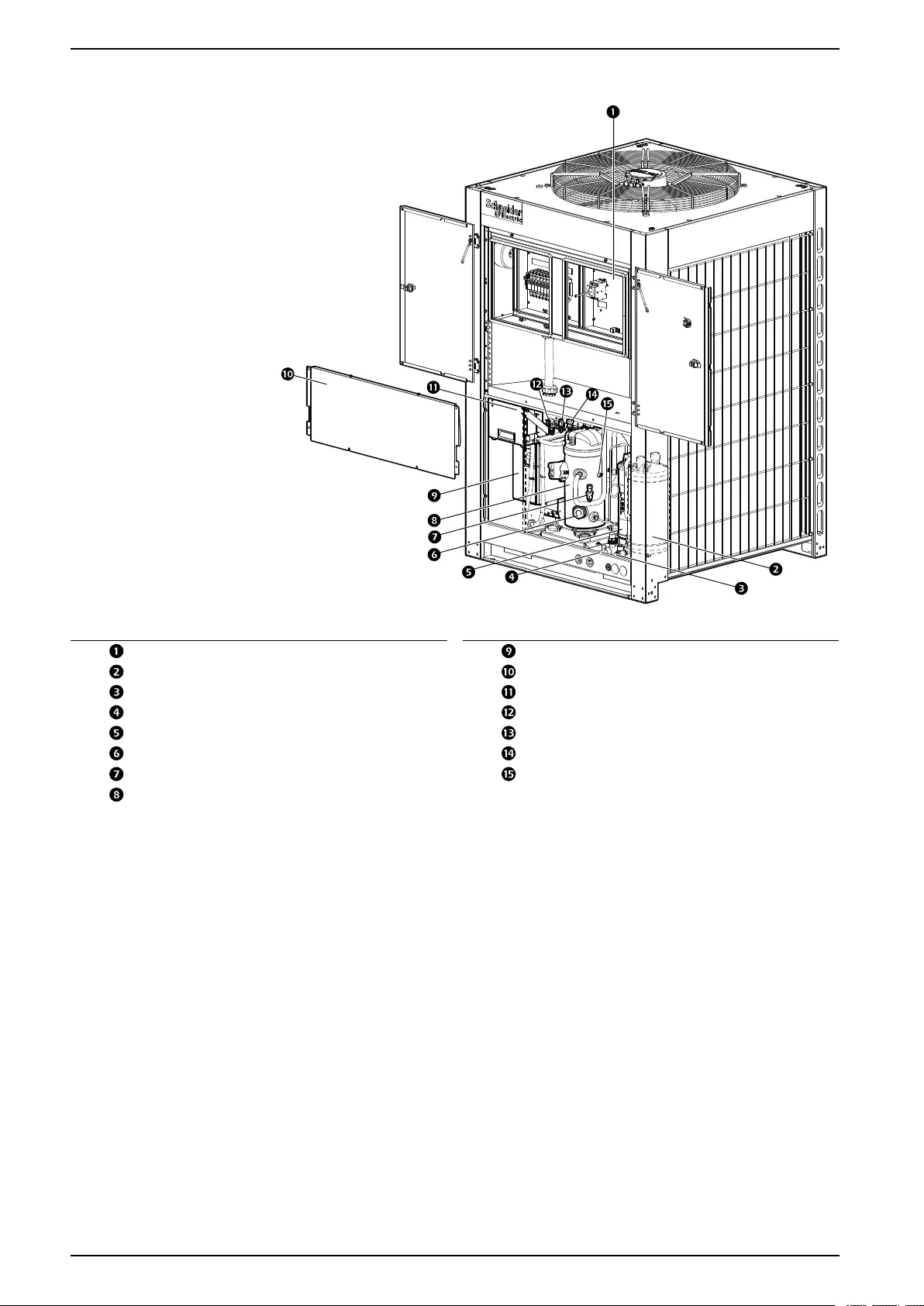

Outdoor Unit

ACCU30301, ACCU30302, ACCU30001, ACCU30002, ACCU30101,

ACCU30102

na6954a

Item Description Item Description

Electrical panel Variable frequency drive (VFD)

Accumulator Interior protection panel

Liquid line connection EMI filter

Suction line connection Service port

Oil separator High pressure switch

Compressor sight glass High (discharge) pressure sensor

Low (suction) pressure sensor Service port

Variable-speed compressor

990–91193A–001 21

ACRD300 and ACCU30000 Series Component Identification

ACCU30201, ACCU30202

na6954b

Item Description Item Description

Electrical panel Variable frequency drive (VFD)

Accumulator Interior protection panel

Liquid line connection Line reactor and EMI filter

Suction line connection Service port

Oil separator High pressure switch

Compressor sight glass High (discharge) pressure sensor

Low (suction) pressure sensor Service port

Variable-speed compressor

22 990–91193A–001

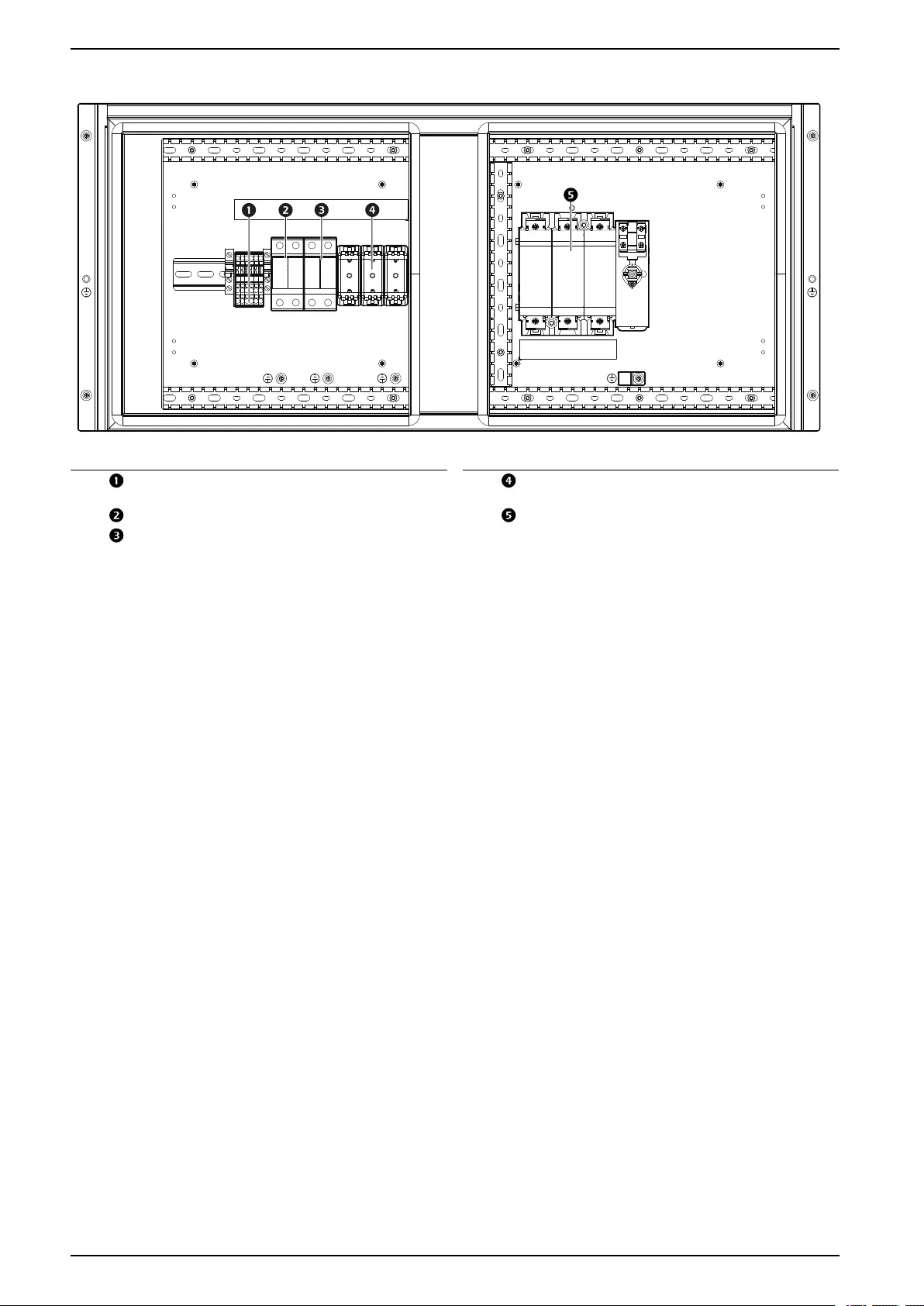

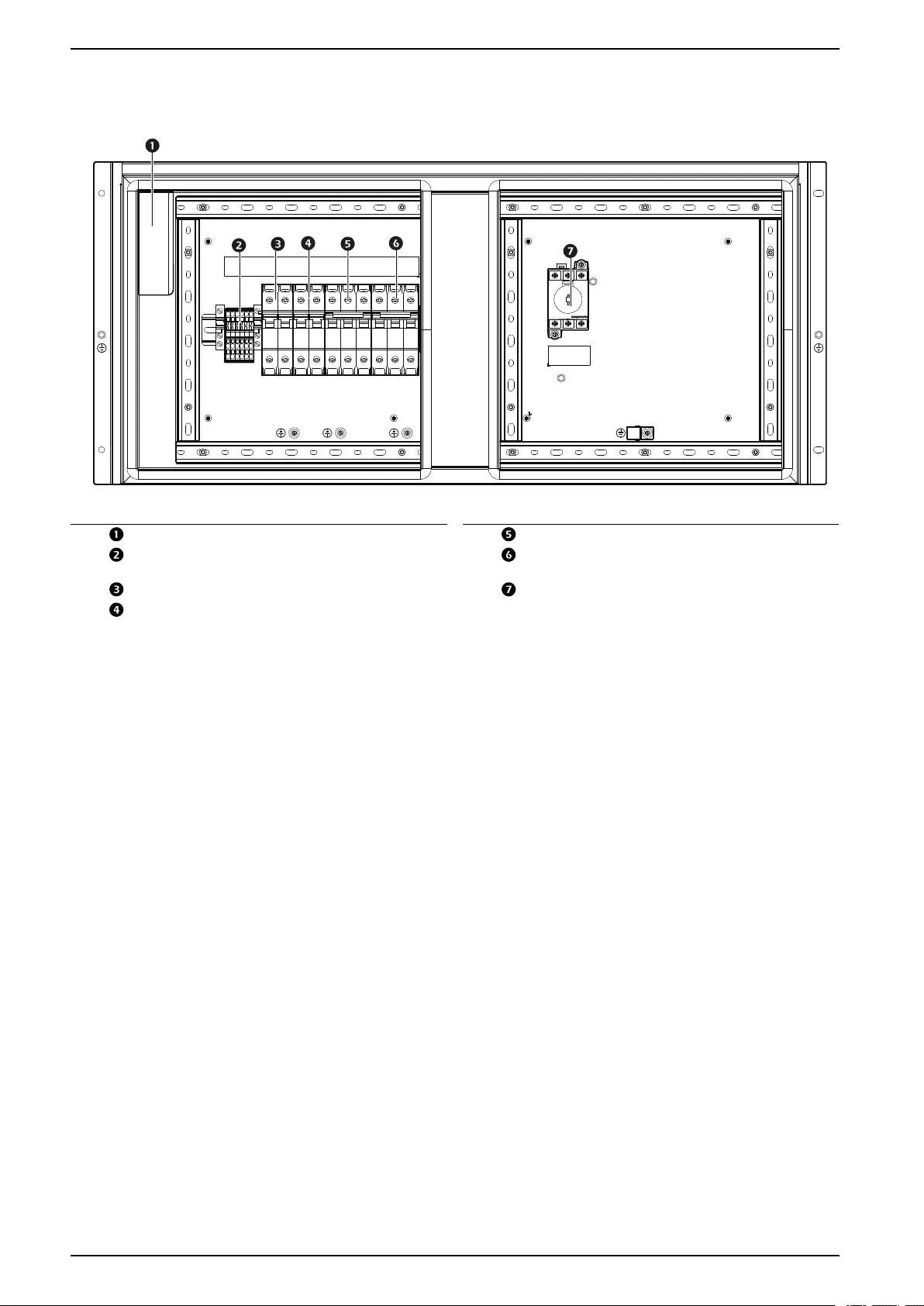

ACRD300 and ACCU30000 Series Component Identification

Outdoor Unit

ACCU30301

na6981a

Item Description Item Description

Crank case heater power transformer Fan motor switch

Terminal block Compressor variable-speed drive

switch

Crank case heater switch Main switch

Crank case heater power transformer

switch

24 990–91193A–001

Component Identification ACRD300 and ACCU30000 Series

ACCU30302

na6980a

Item Description Item Description

Crank case heater power transformer Supply line selector relay

Terminal block Supply A line monitor

Crank case heater switch Supply B line monitor

Crank case heater power transformer

switch

Supply A contactor timer

Fan motor switch Supply B contactor timer

Compressor variable-speed drive

switch

ATS circuit fuse

Main switch Supply line selector A/B

ATS supply A power transformer Supply A contactor

ATS supply B power transformer Supply B contactor

990–91193A–001 25

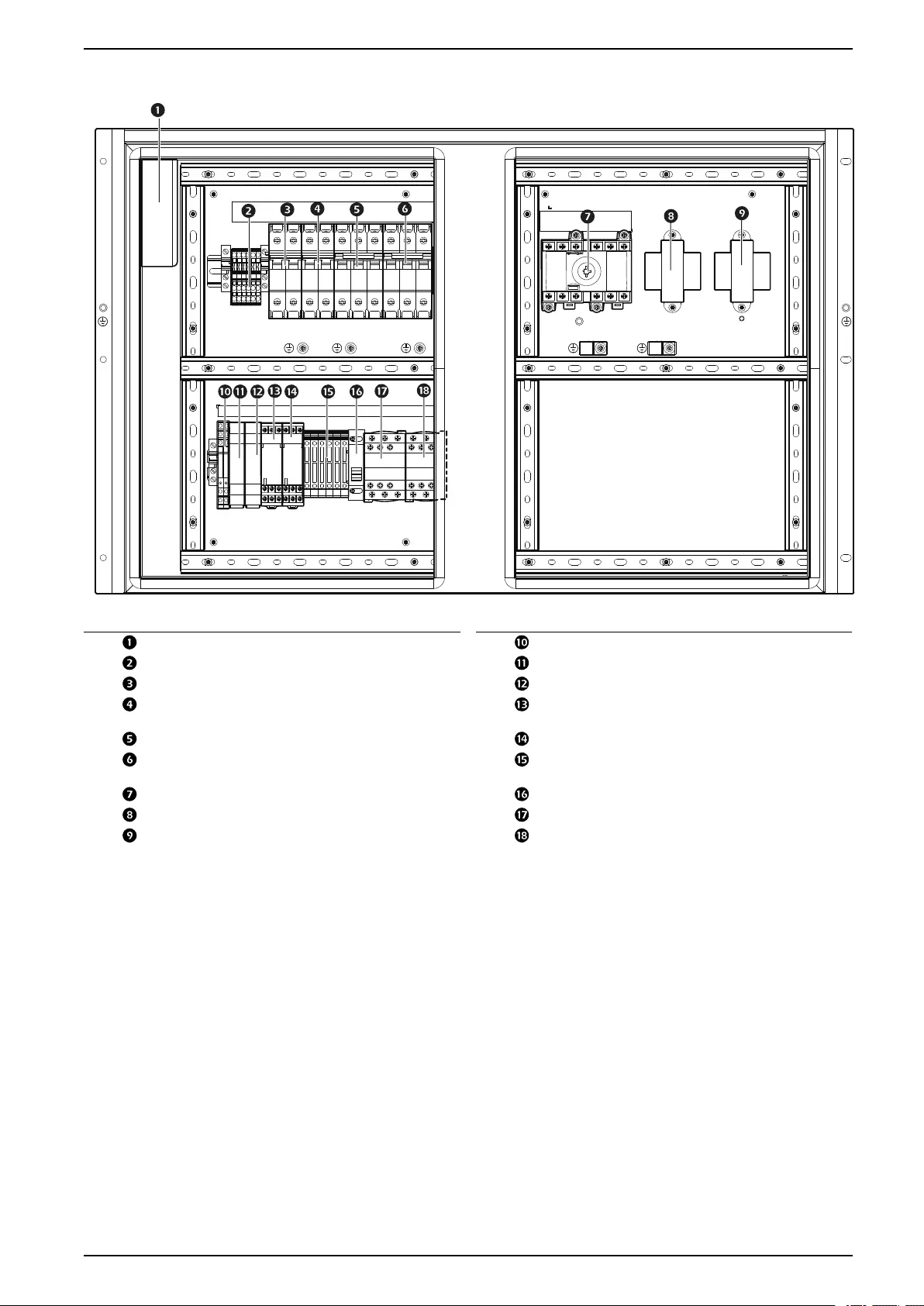

Component Identification ACRD300 and ACCU30000 Series

ACCU30002

na7035a

Item Description Item Description

Terminal block Supply A contactor timer

Crank case heater switch Supply B contactor timer

Fan motor switch ATS circuit fuse

Compressor variable-speed drive

switch

Suppl line selector A/B

Power supply A main switch Supply A contactor

Supply line selector relay Supply B contactor

Supply A line monitor Power supply B main switch

Supply B line monitor

990–91193A–001 27

ACRD300 and ACCU30000 Series Component Identification

ACCU30101 and ACCU30201

na7032a

Item Description Item Description

Crank case heater power transformer Fan motor switch

Terminal block Compressor variable-speed drive

switch

Crank case heater switch Main switch

Crank case heater power transformer

switch

28 990–91193A–001

Component Identification ACRD300 and ACCU30000 Series

ACCU30102 and ACCU30202

na7033a

Item Description Item Description

Crank case heater power transformer Supply B line monitor

Terminal block Supply A contactor timer

Crank case heater switch Supply B contactor timer

Crank case heater power transformer

switch

ATS circuit fuse

Fan motor switch Supply line selector A/B

Compressor variable-speed drive

switch

Supply A contactor

Power supply A main switch Supply B contactor

ATS supply A power transformer Power supply Bmain switch

Supply line selector relay ATS supply B power transformer

Supply A line monitor

990–91193A–001 29

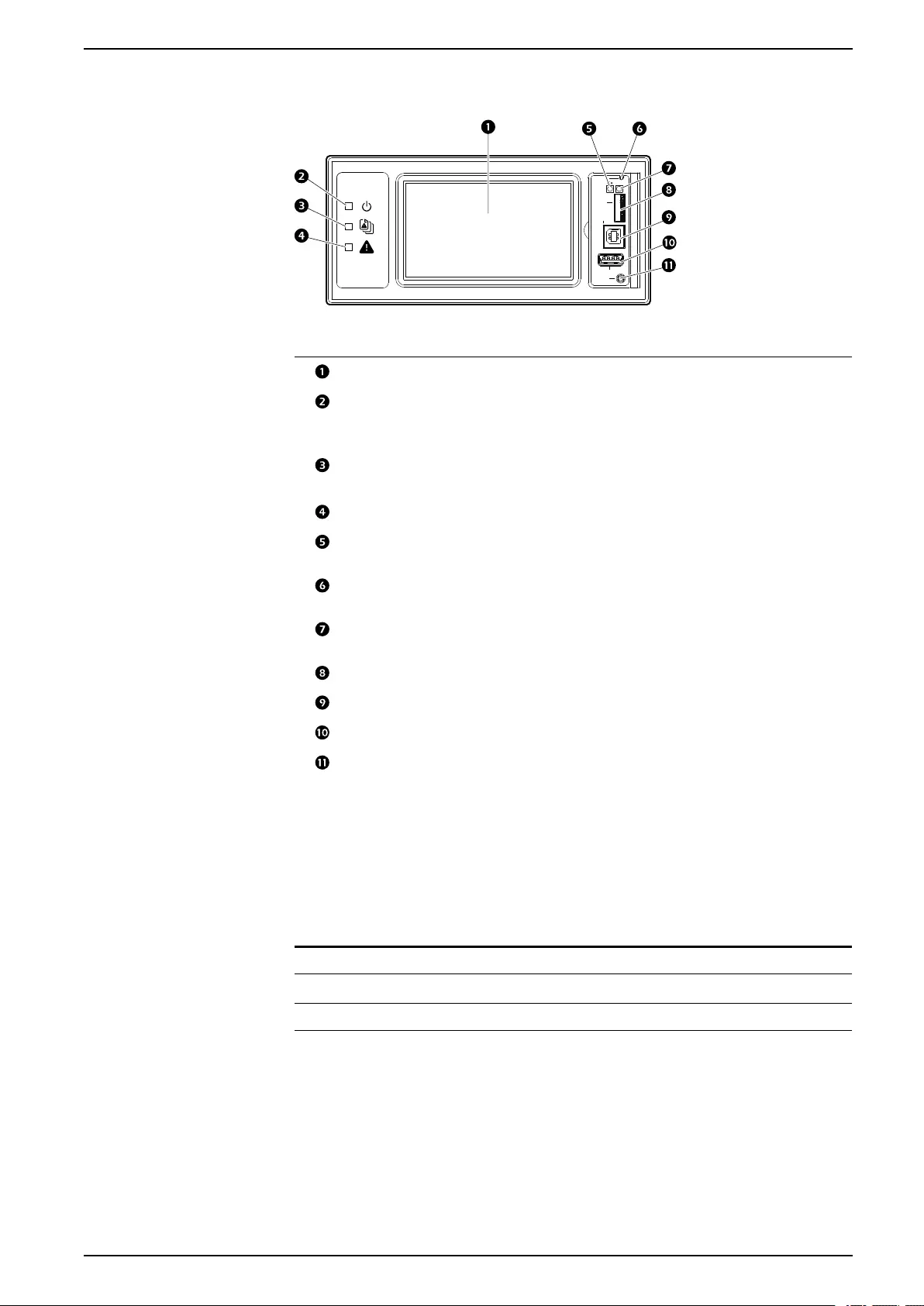

Component Identification ACRD300 and ACCU30000 Series

Display Interface

Display

Reset

Micro

SD

Service

Port

USB

Console

10/100

na4820a

Item Description Function

LCD Display 4.3-inch touch-screen color display

Power LED The cooling unit is powered when the LED is

illuminated. Unit firmware is updating when

LED is blinking.

Check Log LED When this LED is illuminated, a new entry has

been made to the event log.

Alarm LED Displays current alarm condition of unit.

Status LED Displays current network management card

status.

Display Reset button Resets the display microprocessor. This has

no effect on the air conditioner controller.

Link-RX/TX (10/100)

LED

Displays current network link status.

Micro SD card slot Memory card expansion slot.

Service port USB-B port used only by service personnel.

USB-A port Supports firmware upgrades.

Serial Configuration

port

Connects the display to a local computer to

configure initial network settings or access the

command line interface (CLI).

Alarm LED

This LED indicates active alarms on the display.

Condition Description

Off No alarm

Solid yellow Warning alarm

Solid red Critical alarm

990–91193A–001 31

ACRD300 and ACCU30000 Series Component Identification

Status LED

This LED indicates the status of the display.

Condition Description

Off One of the following situations exist:

• The display is not receiving input

power.

• The display is not operating

properly. It may need to be

repaired or replaced. Contact

Schneider Electric Customer

Support.

Solid green The display has valid TCP/IP settings.

Solid orange A hardware malfunction has been

detected in the display. Contact

Schneider Electric Customer Support.

Flashing green The display does not have valid TCP/

IP settings.

Flashing orange The display is making BOOTP

requests.

Alternately flashing green and orange If the LED is flashing slowly, the

display is making DHCP requests. If

the LED is flashing rapidy, the display

is starting up.

Link-RX/TX (10/100) LED

This LED indicates the network status of the display.

Condition Description

Off One or more of the following situations exist:

• The display is not receiving input power.

• The cable or device that connects the cooling unit

to the network is disconnected or not functioning

properly.

• The display itself is not operating properly. It may

need to be repaired or replaced. Contact

Schneider Electric Customer Support.

Solid green The display is connected to a network operating at 10

megabits per second (Mbps).

Solid orange The display is connected to a network operating at 100

Mbps.

Flashing green The display is receiving or transmitting at 10 Mbps.

Flashing orange The display is receiving data packets at 100 Mbps.

32 990–91193A–001

Dimensions and Weights ACRD300 and ACCU30000 Series

Dimensions and Weights

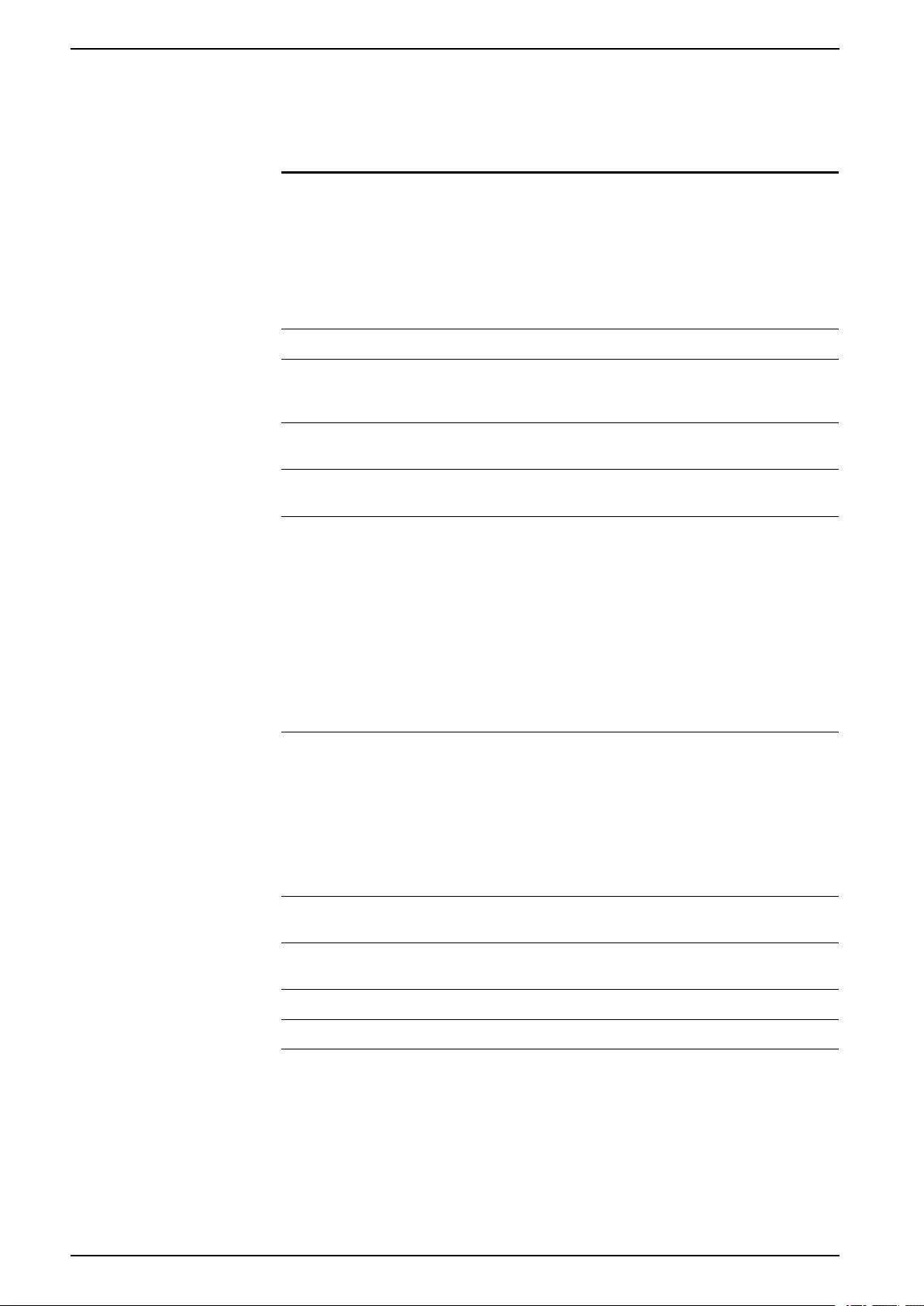

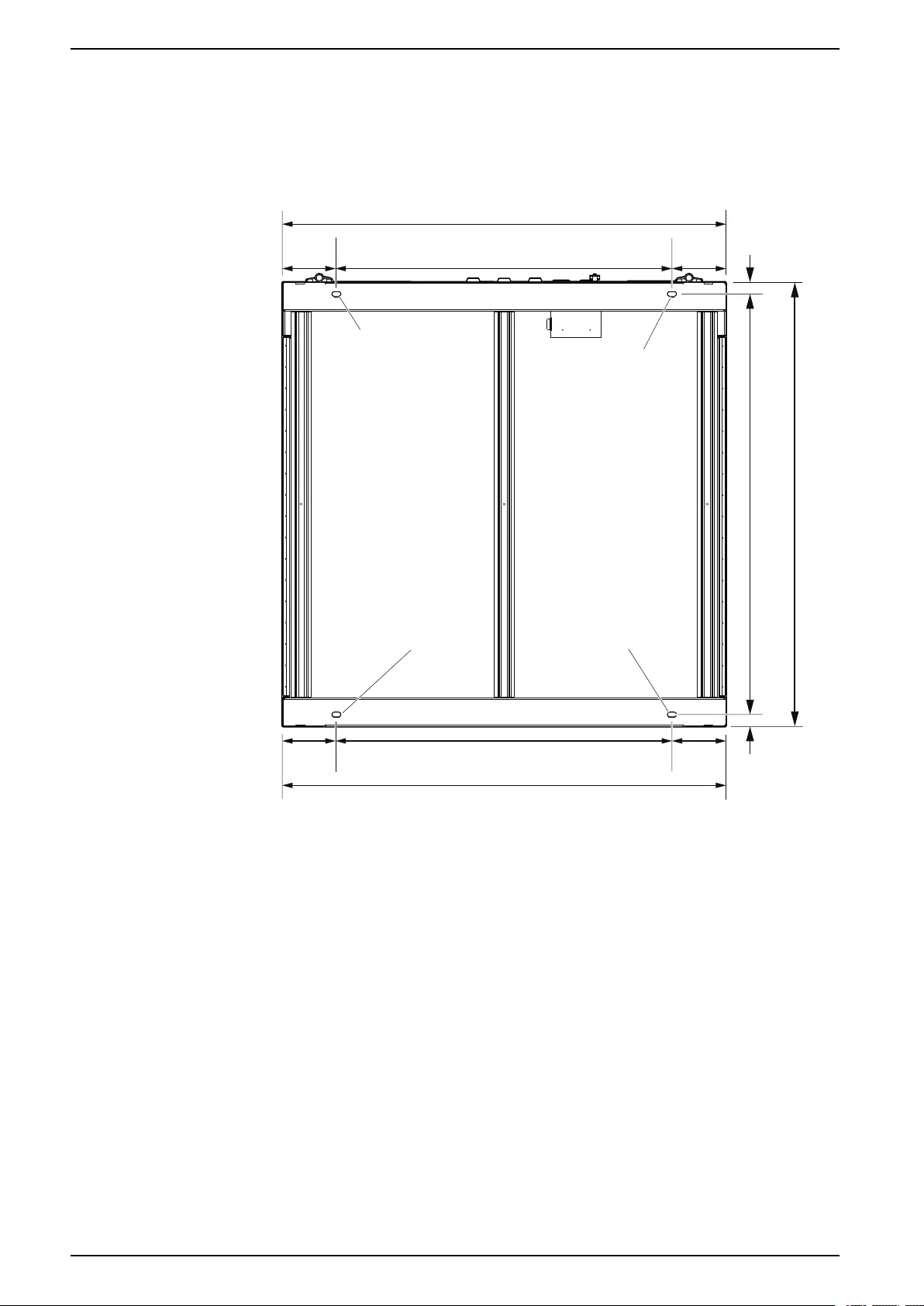

Indoor Unit

na6955b

1095 (43.11)

300 (11.80)

1991 (78.39)

1137 (44.76)

661 (26.02)

2152 (84.72)

NOTE: Image is an example only to show dimensions of unit: your unit may

differ.

Net Weight – kg (lb) Shipping Weight – kg (lb)

160 (352.7) 200 (440.9)

990–91193A–001 33

ACRD300 and ACCU30000 Series Dimensions and Weights

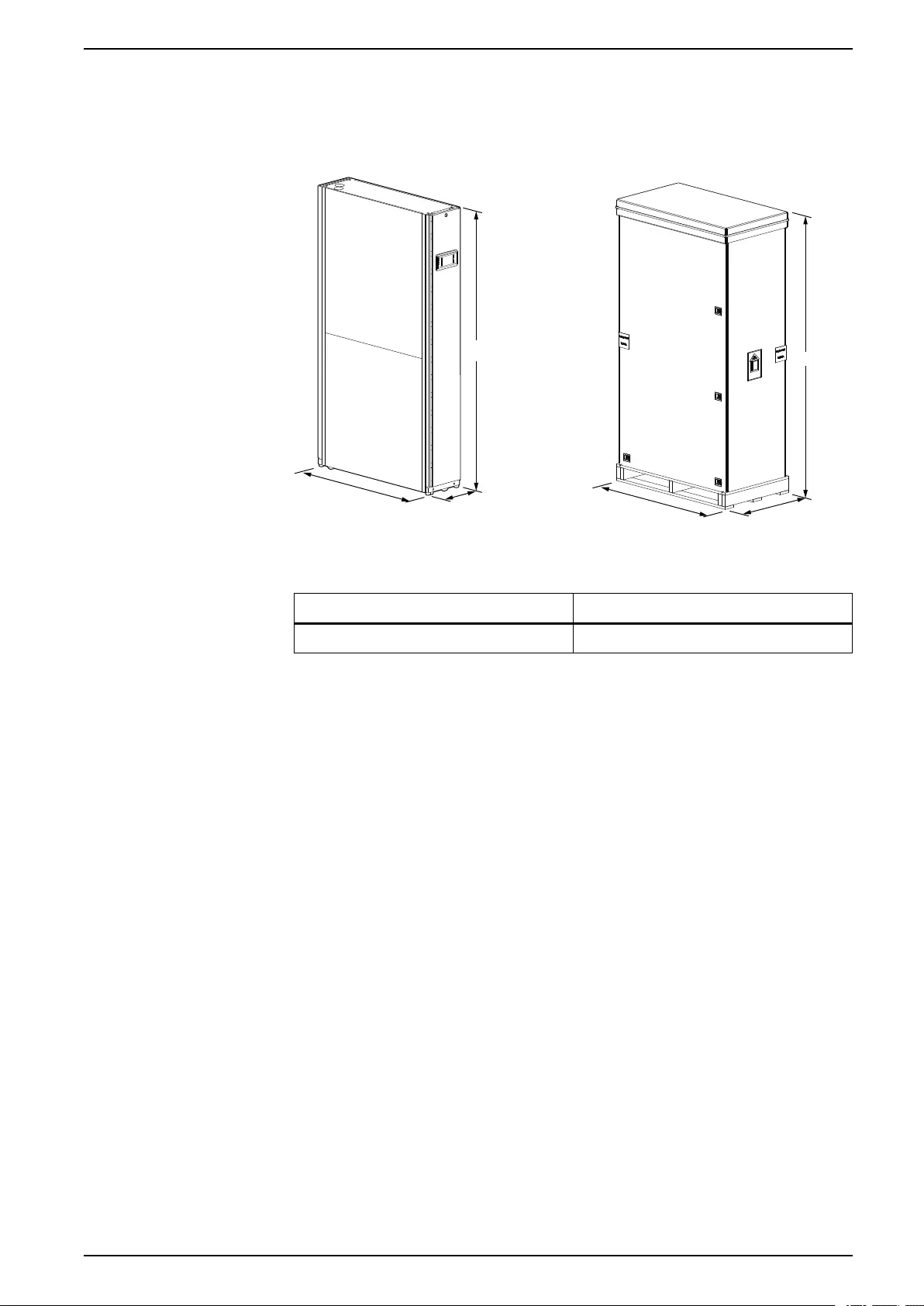

Outdoor Unit

A

B

C

A

B

C

na6956a

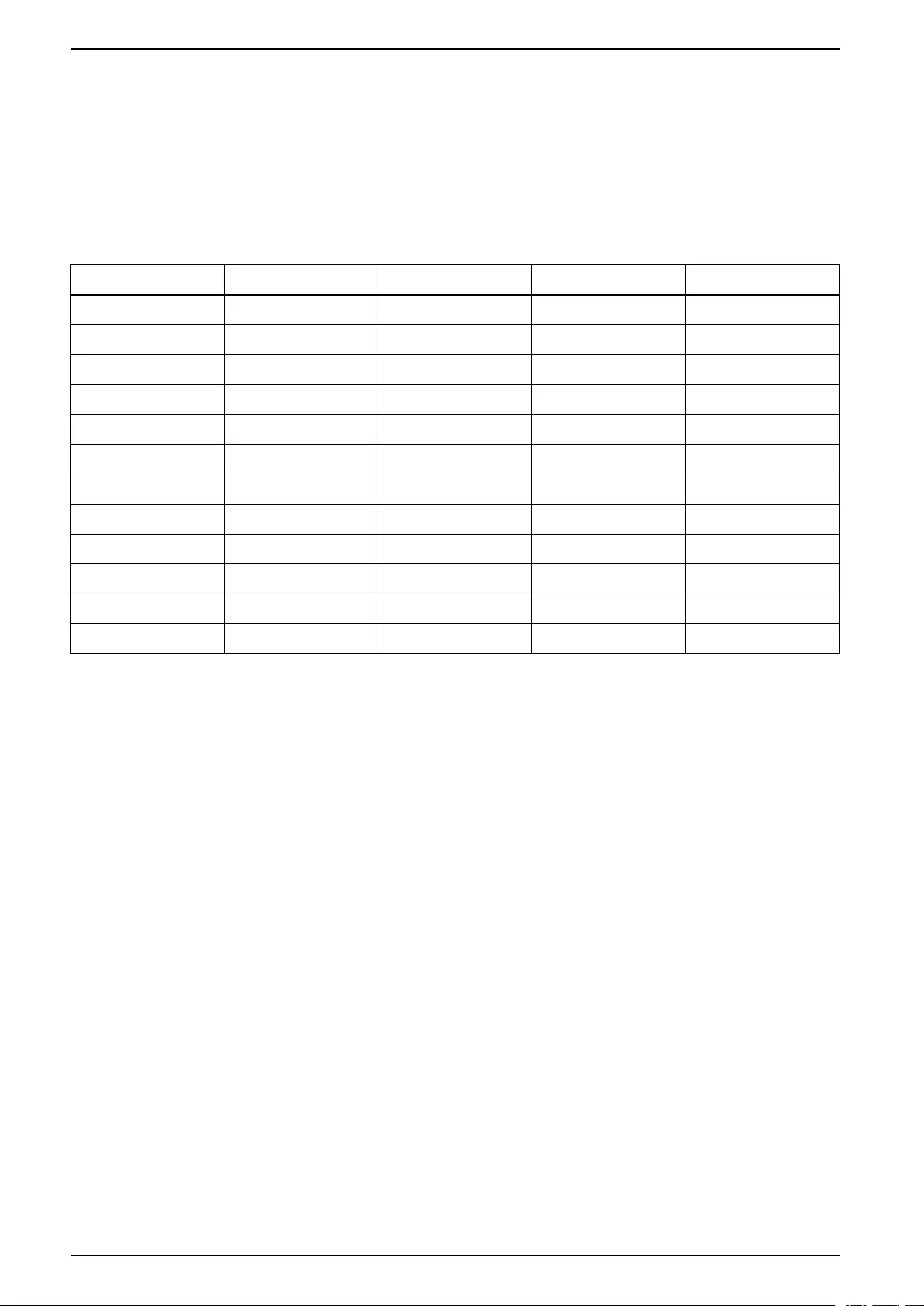

SKU Unit Dimensions – mm (in.) Shipping Dimensions – mm

(in.)

Net

Weight –

kg (lb)

Shipping

Weight –

kg (lb)

A B CA B C

ACCU30301 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

267

(588.6)

297 (654.8)

ACCU30302 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

272

(600.0)

305 (672.4)

ACCU30001 1000

(39.4)

1000

(39.4)

1600

(63.0)

1136

(44.7)

1085

(42.7)

1745

(68.7)

267

(588.6)

297 (654.8)

ACCU30002 1000

(39.4)

1000

(39.4)

1600

(63.0)

1136

(44.7)

1085

(42.7)

1745

(68.7)

272

(600.0)

305 (672.4)

ACCU30201 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

273

(601.9)

303 (668.0)

ACCU30202 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

278

(612.9)

308 (679.0)

ACCU30101 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

267

(588.6)

297 (654.8)

ACCU30102 1000

(39.4)

1000

(39.4)

1555

(61.2)

1136

(44.7)

1085

(42.7)

1745

(68.7)

272

(600.0)

305 (672.4)

34 990–91193A–001

Dimensions and Weights ACRD300 and ACCU30000 Series

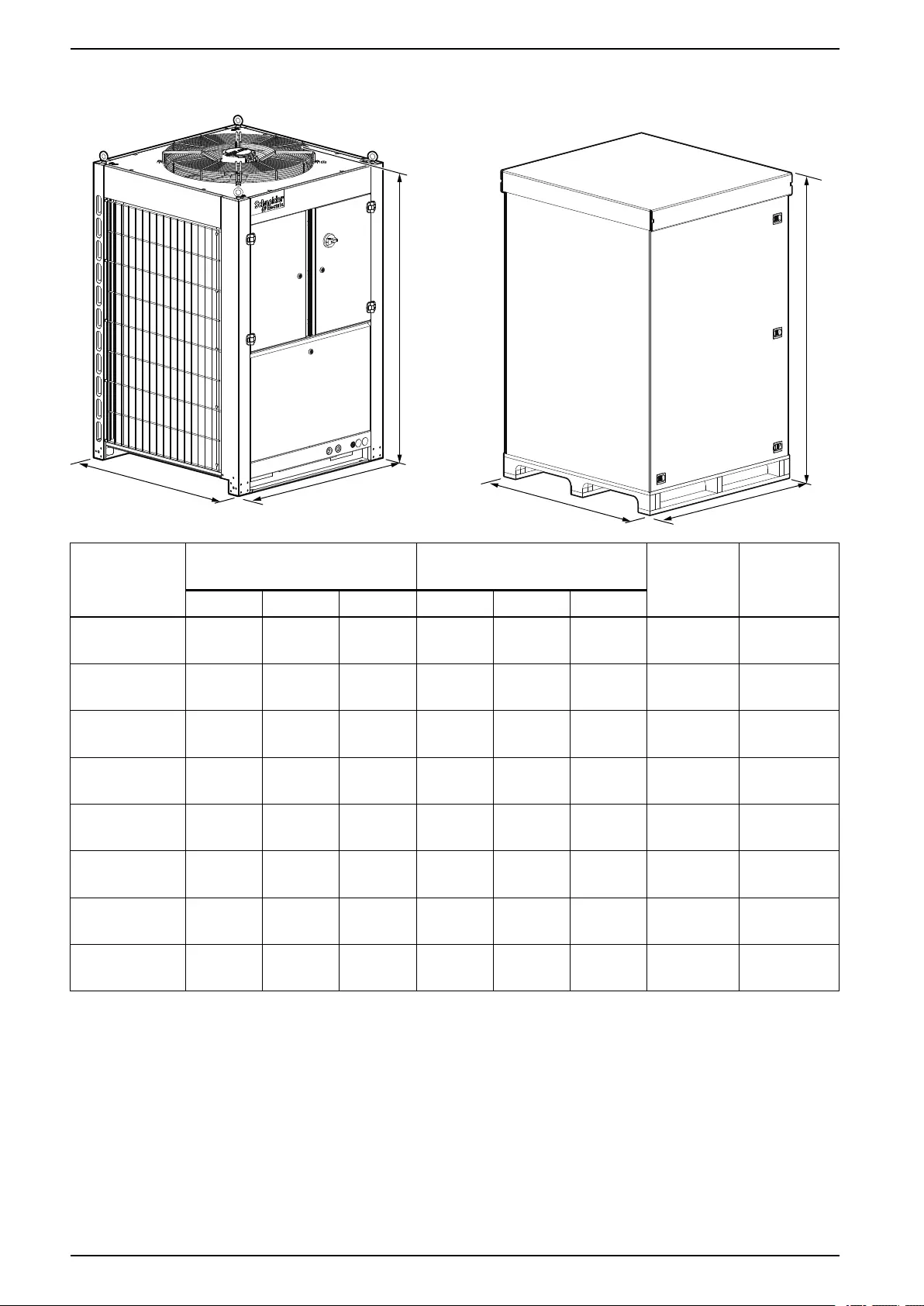

Service Access

Indoor Unit

A minimum of 900 mm (36 in.) of clear floor space in front of and behind the

equipment is recommended for service access. All required normal maintenance

is performed from the front and rear of the equipment.

Most of the cooling components in the equipment can be replaced while the unit is

installed in row and without the use of heavy lift equipment or a welding torch.

However, if it is necessary to remove the unit for repair, use the casters on the

equipment to remove it from the row. An area of minimum 1200 mm (48 in.) of

clear floor space in front of or behind the equipment is recommended to roll out

the equipment.

NOTE: Check local and national codes and regulations for further service

access requirements.

NOTE: Image is an example only: your unit may differ.

na5810a

900 (36.00) 900 (36.00)

1200 (48.00) 1200 (48.00)

SERVICE ACCESS REQUIRED

WHEN EQUIPMENT IS

INSIDE THE ROW

FREE SPACE NEEDED TO

MOVE EQUIPMENT

OUTSIDE THE ROW

NOTE: Dimensions are shown in mm (in.).

990–91193A–001 35

ACRD300 and ACCU30000 Series Dimensions and Weights

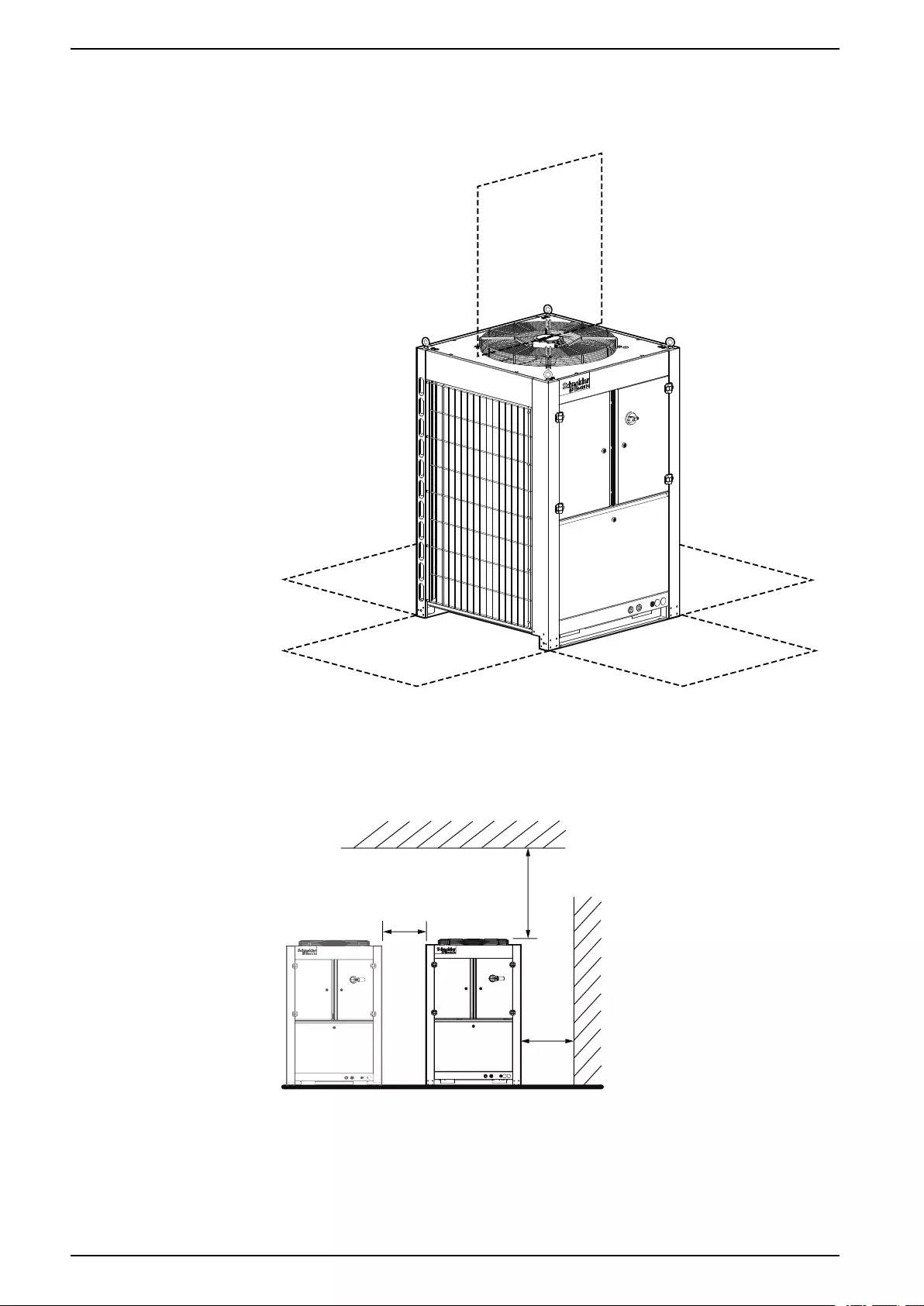

Outdoor Unit

A minimum of 1 m (39 in.) of clear space on all sides of the equipment is

recommended for service access.

1m (39 in.)

1m (39 in.) 1m (39 in.)

1m (39 in.)

1m (39 in.)

na6963a

Airflow Clearance

The following clearances are required for proper airflow around the outdoor unit.

na7029a

> 1 m

(3.3 ft)

> 1 m (3.3 ft)

> 3 m (9.8 ft)

36 990–91193A–001

Dimensions and Weights ACRD300 and ACCU30000 Series

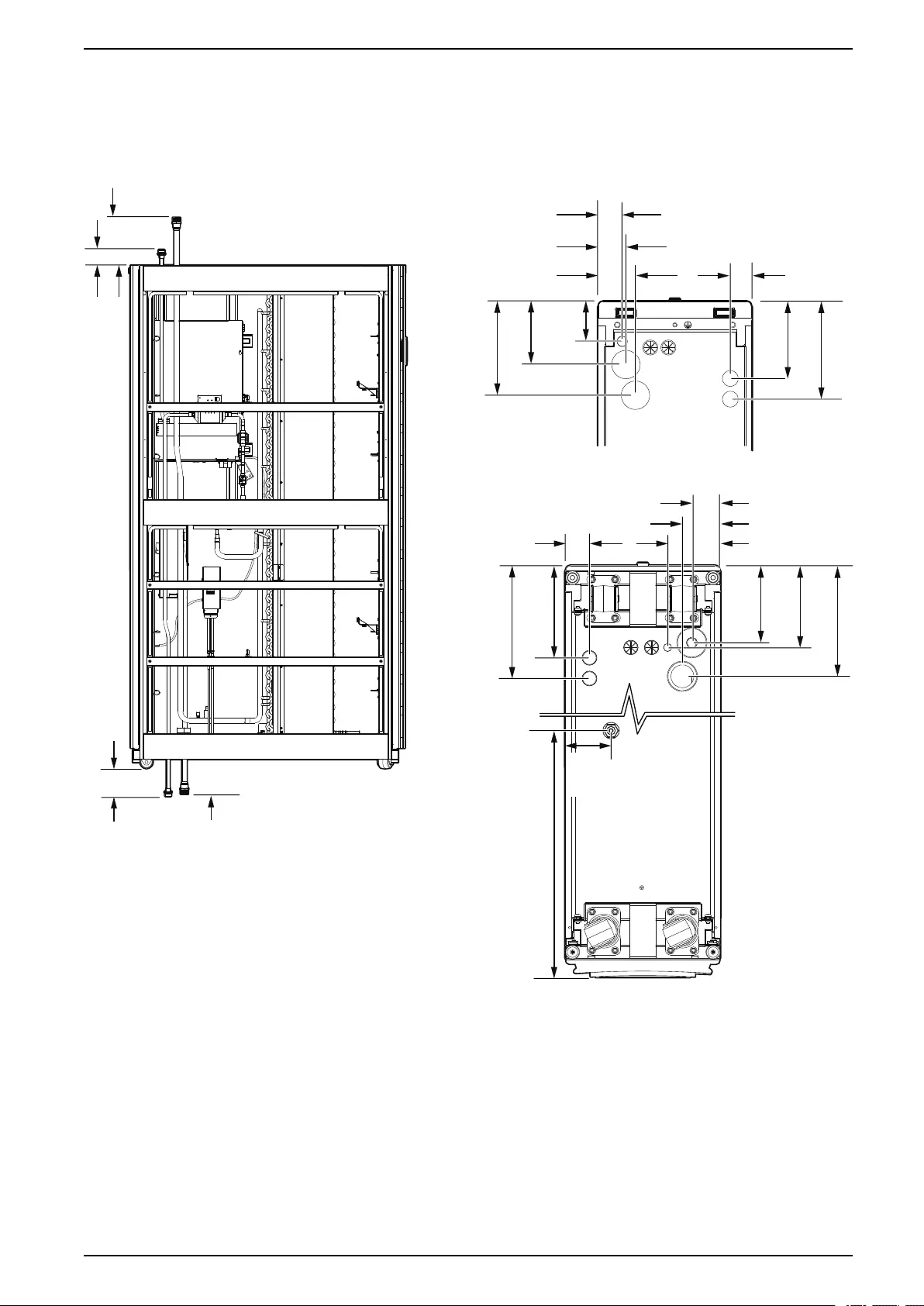

Piping and Electrical Access Locations

Indoor Unit

ACRD300, ACRD300G, ACRD300D, ACRD300GD

TOP VIEW

BOTTOM VIEW

(LOOKING UP)

na6957a

47.0 (1.9)

47.8 (1.9)

55.1 (2.2)

73.5 (2.9) 42.8 (1.7)

78.4

(3.1)

123.4 (4.9)

182.8 (7.2)

150.4 (5.9)

190.4 (7.5)

177.9 (7.0)

217.9 (8.6)

148.8 (5.6)

157.9 (6.2)

213.6 (8.4)

102.0 (4.0)

73.5 (2.9)

55.1 (2.2)

62.8 (2.5)

188.8 (7.4)

111 (4.37)

101.7 (4.0)

437.1 (17.2)

92.66

(3.6)

NOTE: Dimensions are shown in mm (in.).

990–91193A–001 37

ACRD300 and ACCU30000 Series Dimensions and Weights

TOP VIEW

BOTTOM VIEW

(LOOKING UP)

na6958a

Item Description

Low voltage input wiring inlets

Power supply 1 inlet

Power supply 2 inlet

Suction line connection—1 1/4 in. (12 UNF)

Liquid line connection—1 in. (14 UNS)

Condensate drain line outlet

Gravity drain connection

38 990–91193A–001

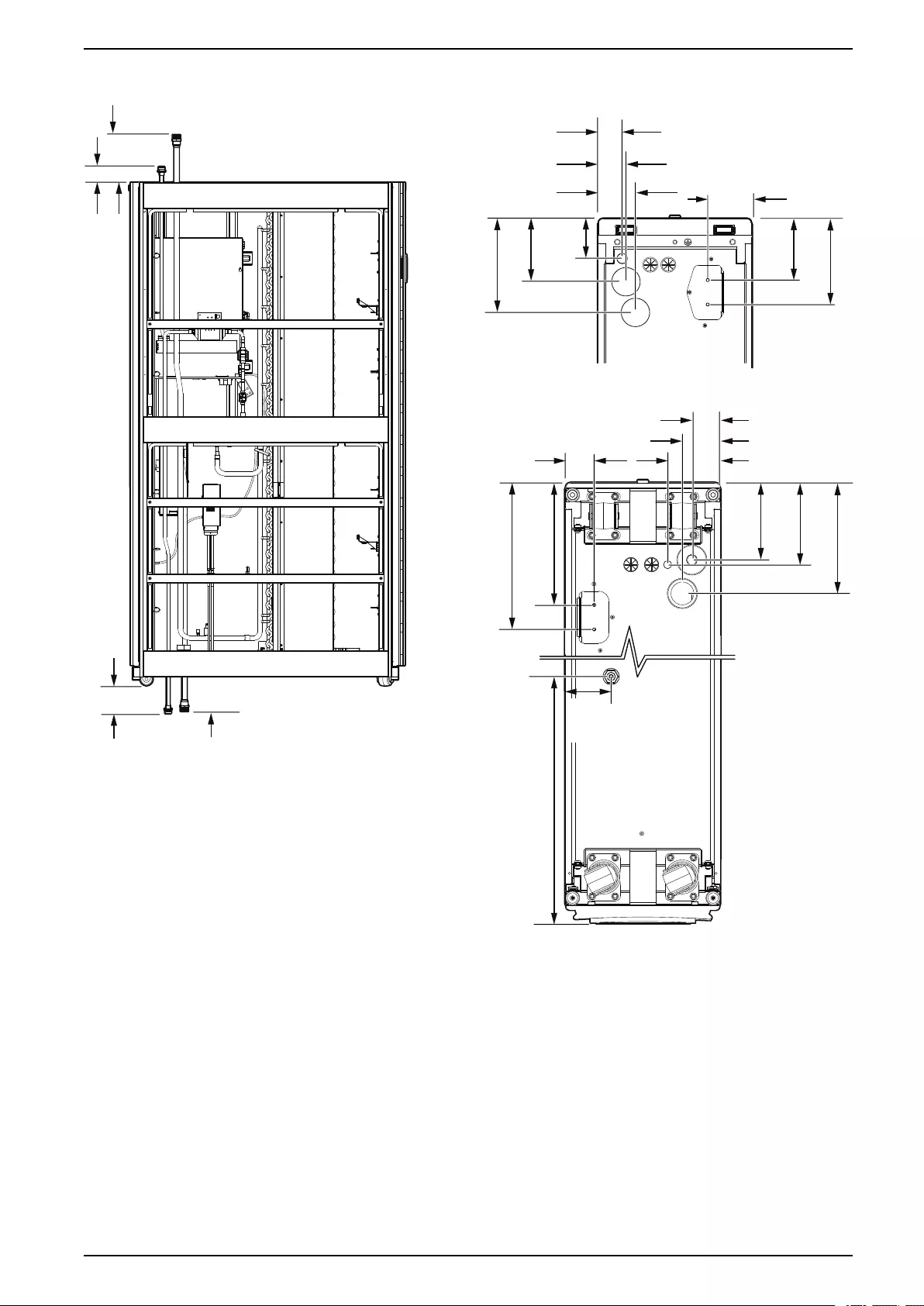

Dimensions and Weights ACRD300 and ACCU30000 Series

ACRD301, ACRD301G

TOP VIEW

BOTTOM VIEW

(LOOKING UP)

na6957a

56.5 (2.2)

47.8 (1.9)

55.1 (2.2)

73.5 (2.9) 87.3 (3.4)

78.4

(3.1)

123.4 (4.9)

182.8 (7.2)

150.4

(5.9)

190.4 (7.5)

227.0 (8.9)

274.0 (10.8)

148.8 (5.6)

157.9 (6.2)

213.6 (8.4)

102.0 (4.0)

73.5 (2.9)

55.1 (2.2)

62.8 (2.5)

188.8 (7.4)

111 (4.37)

101.7 (4.0)

437.1 (17.2)

92.66

(3.6)

990–91193A–001 39

ACRD300 and ACCU30000 Series Dimensions and Weights

TOP VIEW

BOTTOM VIEW

(LOOKING UP)

na6958b

Item Description

Low voltage input wiring inlets

Power supply 1 inlet

Power supply 2 inlet

Suction line connection—1 1/4 in. (12 UNF)

Liquid line connection—1 in. (14 UNS)

Condensate drain line outlet

Gravity drain connection

40 990–91193A–001

Dimensions and Weights ACRD300 and ACCU30000 Series

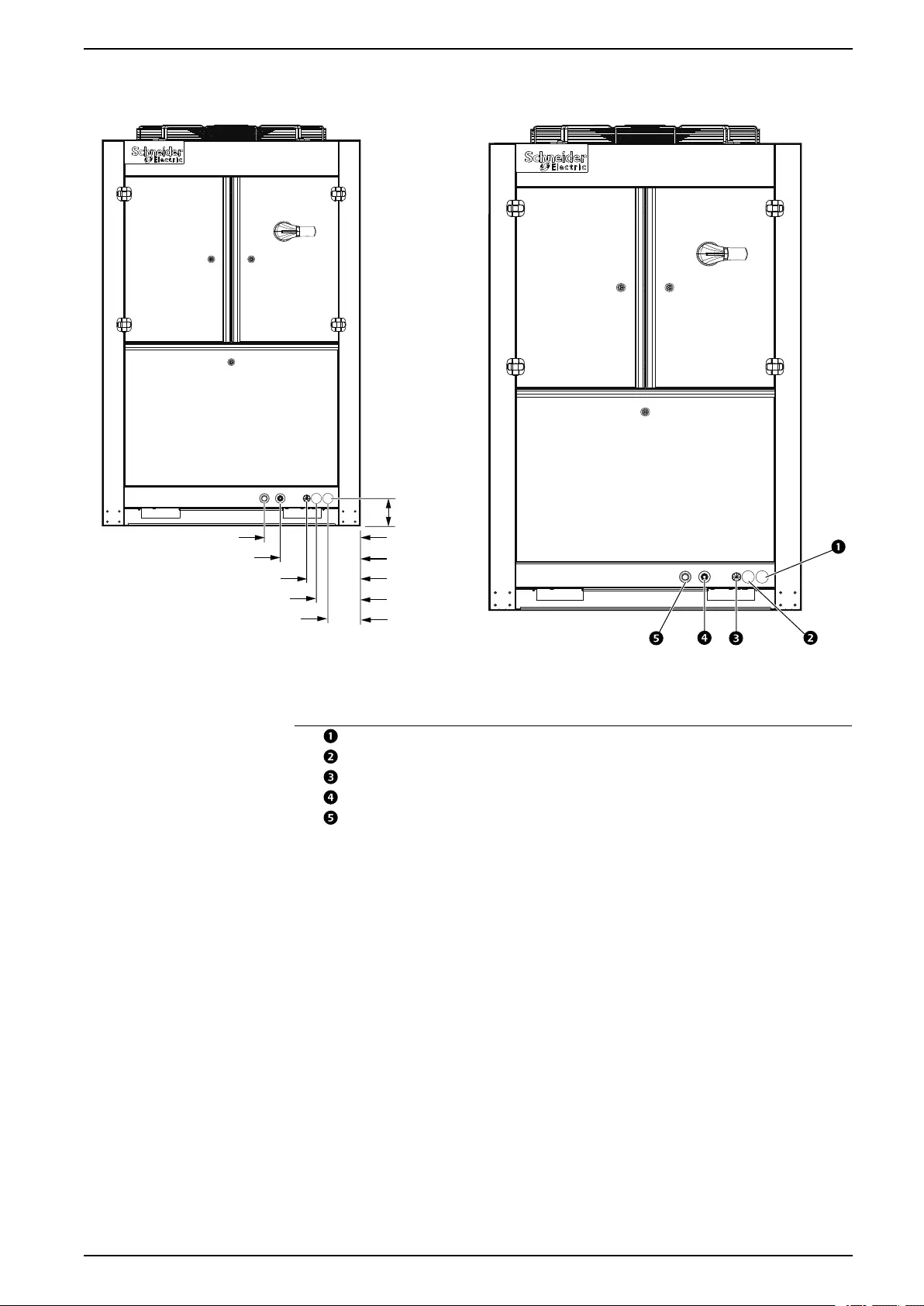

Outdoor Unit

na6961a

309.3 (12.2)

371.0 (14.6)

105.6 (4.2)

121.8 (4.8)

169.0 (6.7)

206.5 (8.1)

na6962a

NOTE: Dimensions are shown in mm (in.).

Item Description

Power supply 1 inlet

Power supply 2 inlet

Communication cable inlet

Liquid line connection inlet

Suction line connection inlet

990–91193A–001 41

ACRD300 and ACCU30000 Series Installation

Installation

Location and Power Considerations

Room Preparation

During the design of the data center, consider ease of entry for the equipment,

floor loading factors, and accessibility to piping and wiring. In addition, the room

temperature and humidity combination should conform to the environmental

operating envelope as defined in the following graphics.

Seal the room with a vapor barrier to minimize moisture infiltration. Polyethylene

film is recommended for ceiling and wall applications. Apply rubber- or plastic-

based paints to concrete walls and floors.

Insulate the room to minimize the influence of exterior heat loads. Reduce fresh

air to the minimum required by local and national codes and regulations. Fresh air

imposes extreme load variation on the cooling equipment from summer to winter

and causes increased system operating costs.

Incoming Power Supply Requirements

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

See the name plate on the unit to determine the maximum possible current draw

of the cooling unit. Provide either a single outlet circuit or a Power Distribution Unit

(PDU) with sufficient capacity to handle all loads. Do not plug two InRow units into

the same branch circuit or PDU.

42 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Indoor Unit Location

Refer to the floor layout drawing for the exact placement of the cooling unit in the

row of IT equipment. This layout drawing can be found in the Configure-to-Order

(CTO) report or the engineering specification drawings provided by the Consulting

Engineer.

Due to potentially high noise levels during peak loads, the InRow cooling unit is

not intended to be used in an occupied office environment. It is recommended that

ear protection be worn if prolonged exposure to the high noise level is expected.

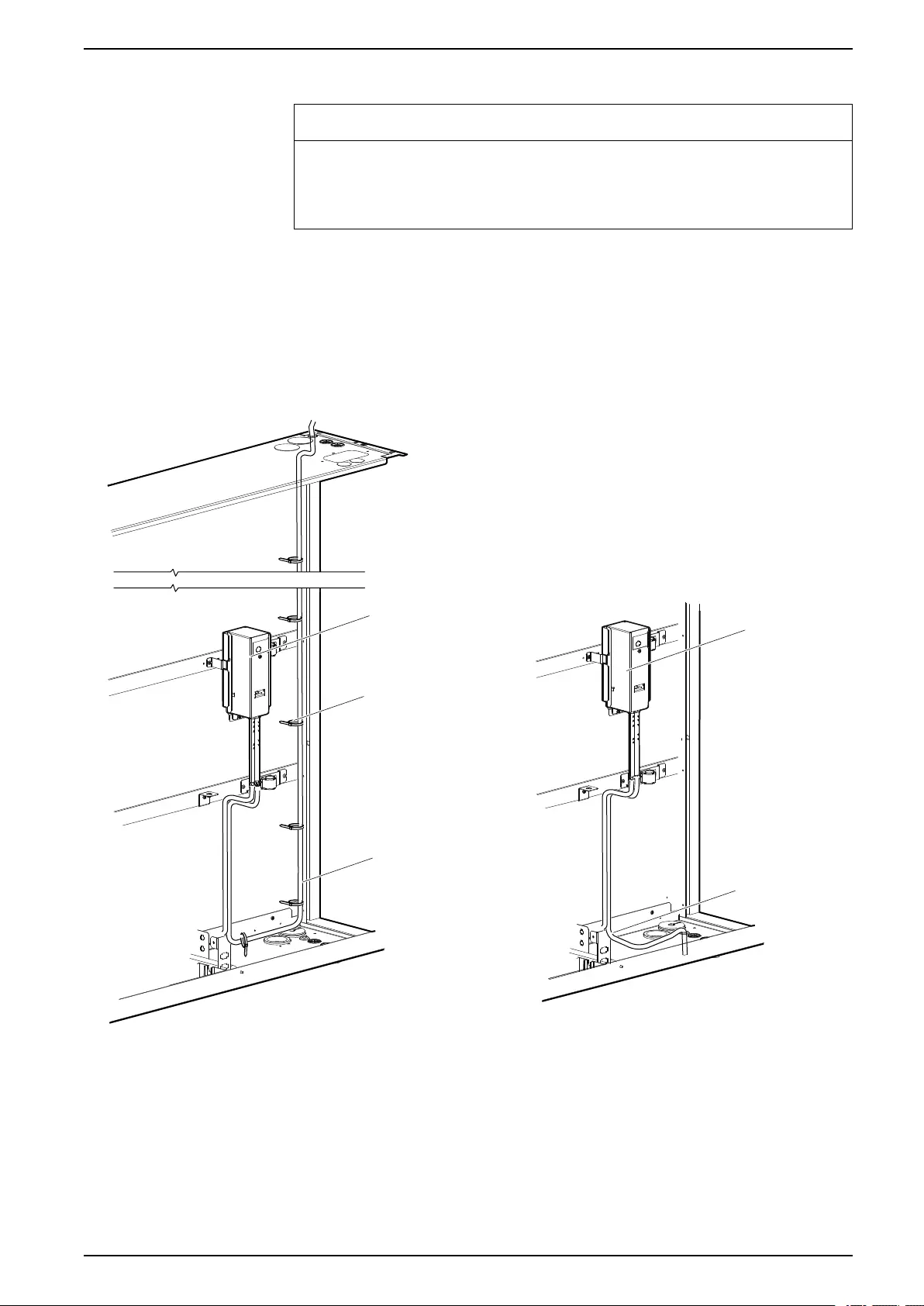

Outdoor Unit Location

The installation area must follow these requirements:

• Installed on a flat, level surface

• Can only be installed at the same level or higher than the indoor unit

• Not exposed to air containing inflammable or greasy substances

• Service clearance of 1 m (39 in.) must be available on all sides

• Clearance of 3 m (10.8 ft) above the unit to allow for proper airflow

• Installing the unit in areas with increased airborne debris may result in more

frequent service intervals

Secure the unit to its foundation using the mounting holes located on the bottom of

the frame.

See Stabilizing the Outdoor Unit, page 50.

990–91193A–001 43

ACRD300 and ACCU30000 Series Installation

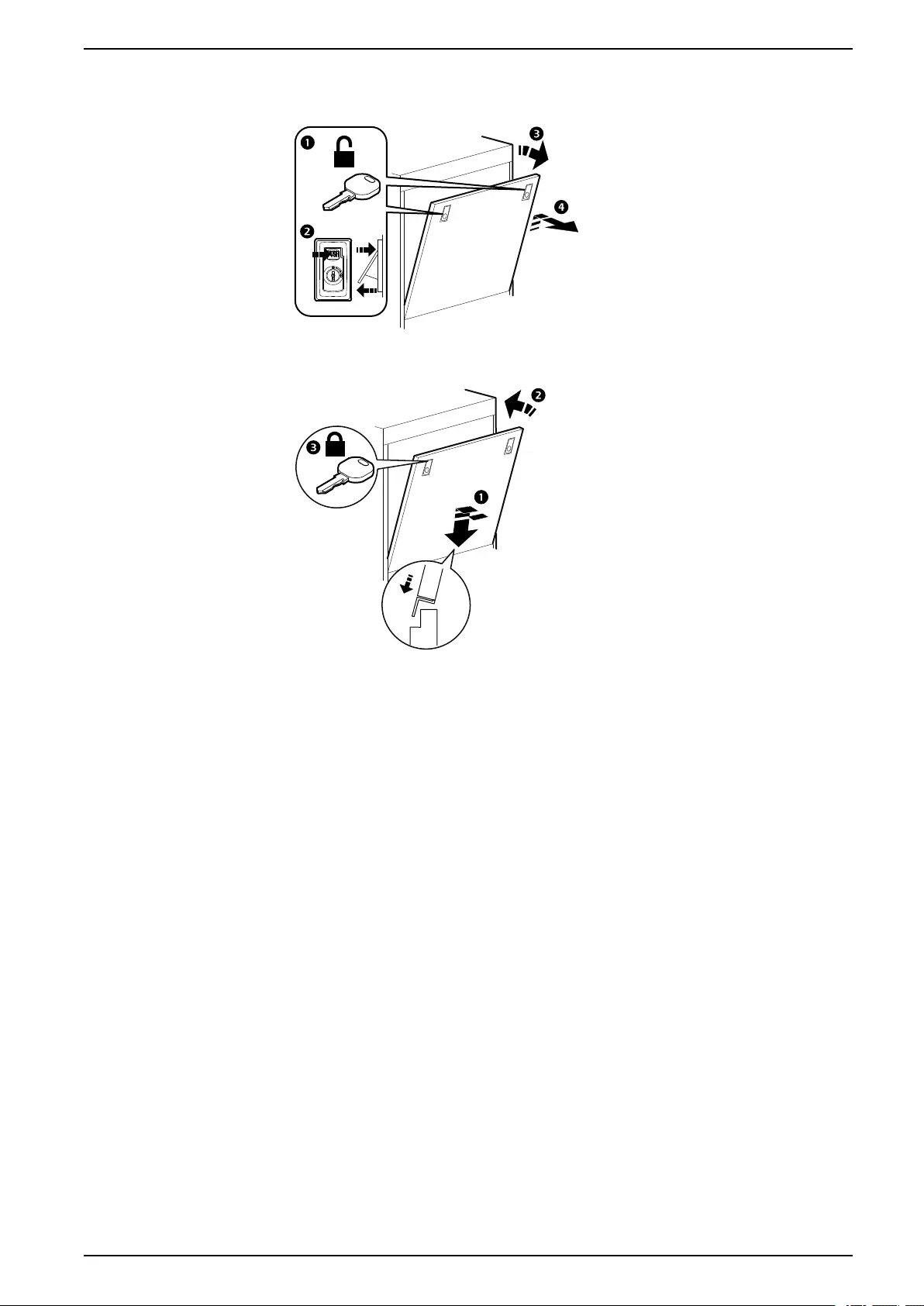

Removing Doors and Panels

WARNING

MOVING PARTS HAZARD

Do not remove rear panels if the equipment is operating.

Failure to follow these instructions can result in death, serious injury, or

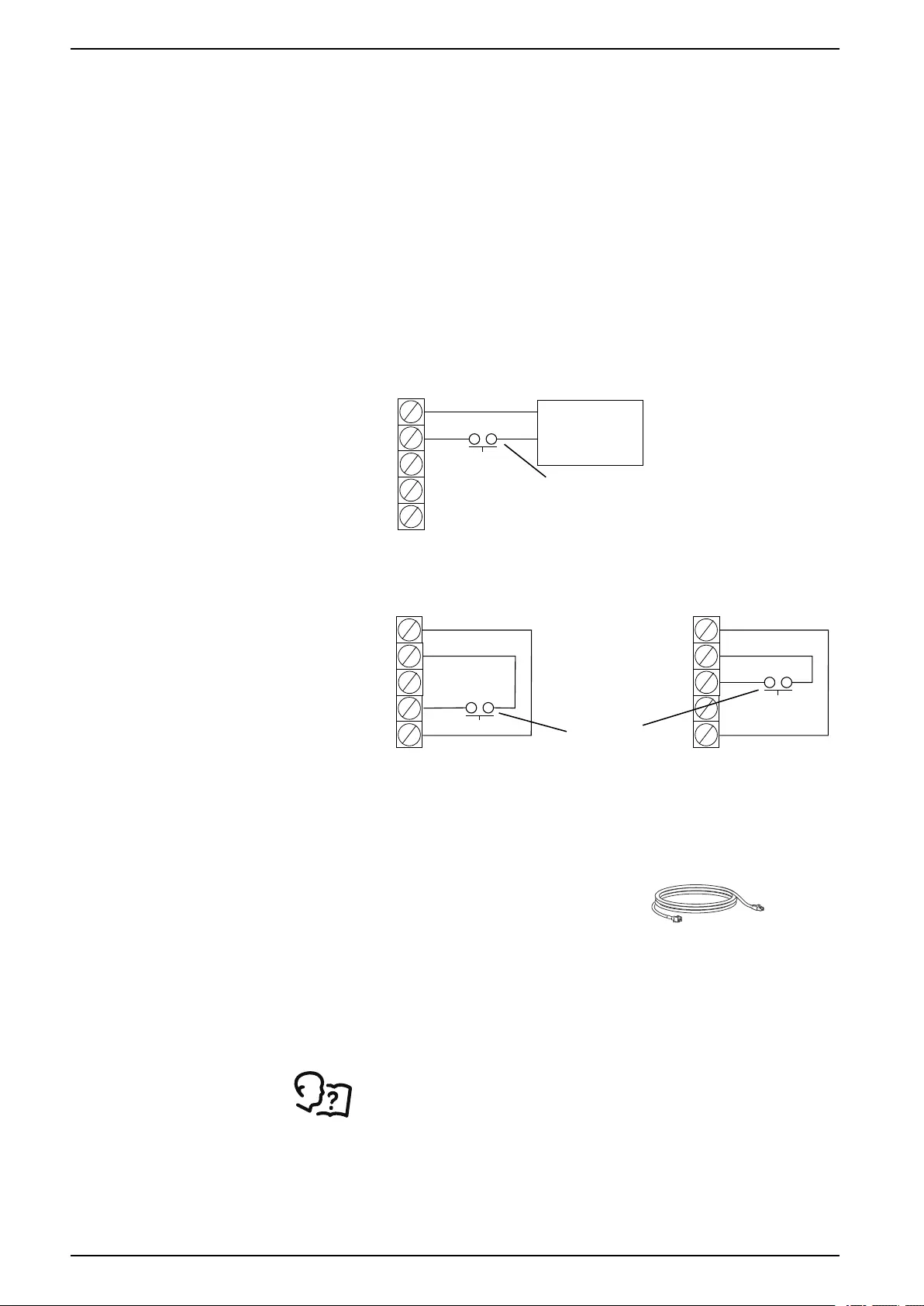

equipment damage.

NOTICE

EQUIPMENT DAMAGE

Do not lean the doors against a wall with the side panel latches facing the wall.

This can deform the latches and prevent them from working properly.

Failure to follow these instructions can result in equipment damage.

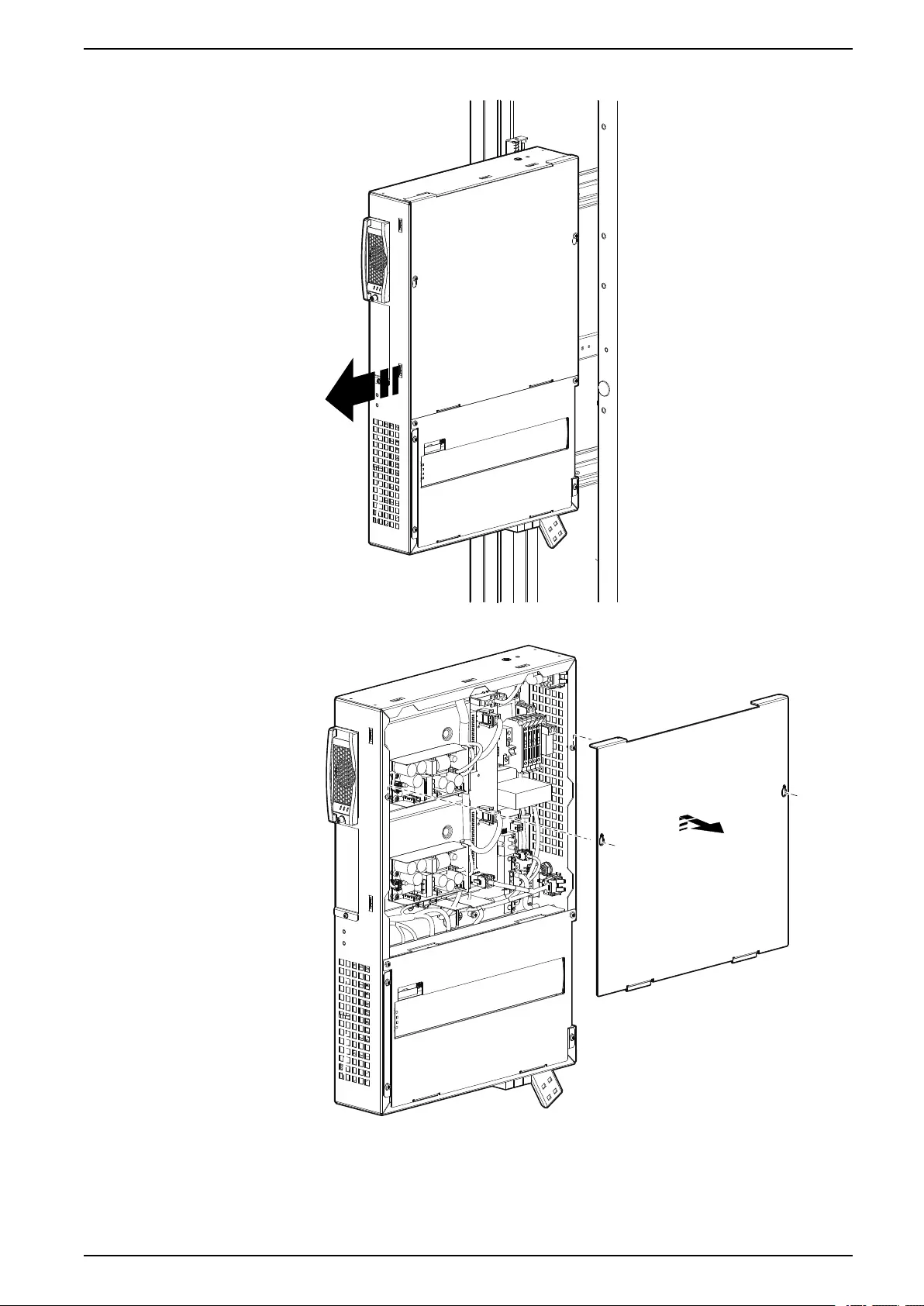

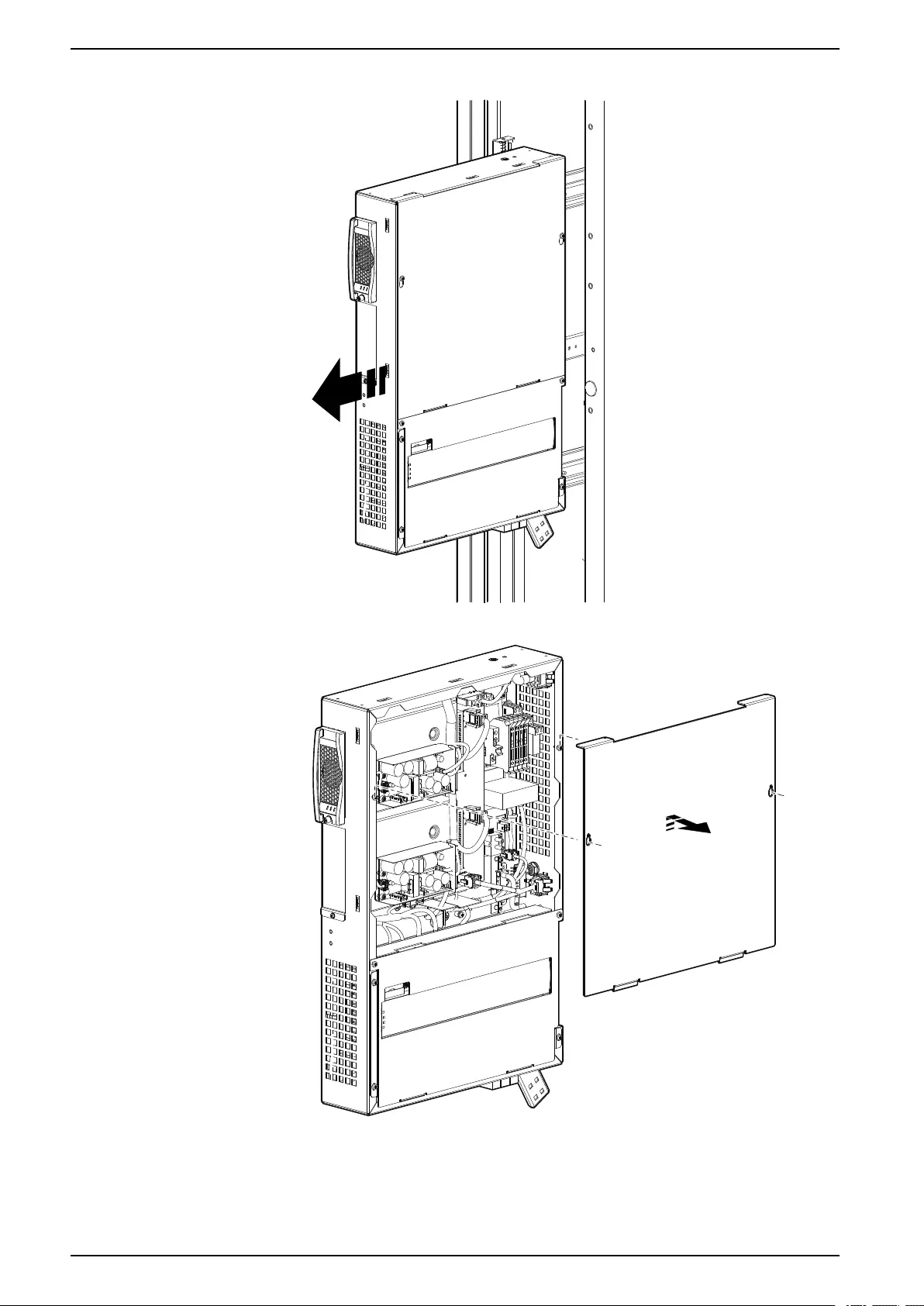

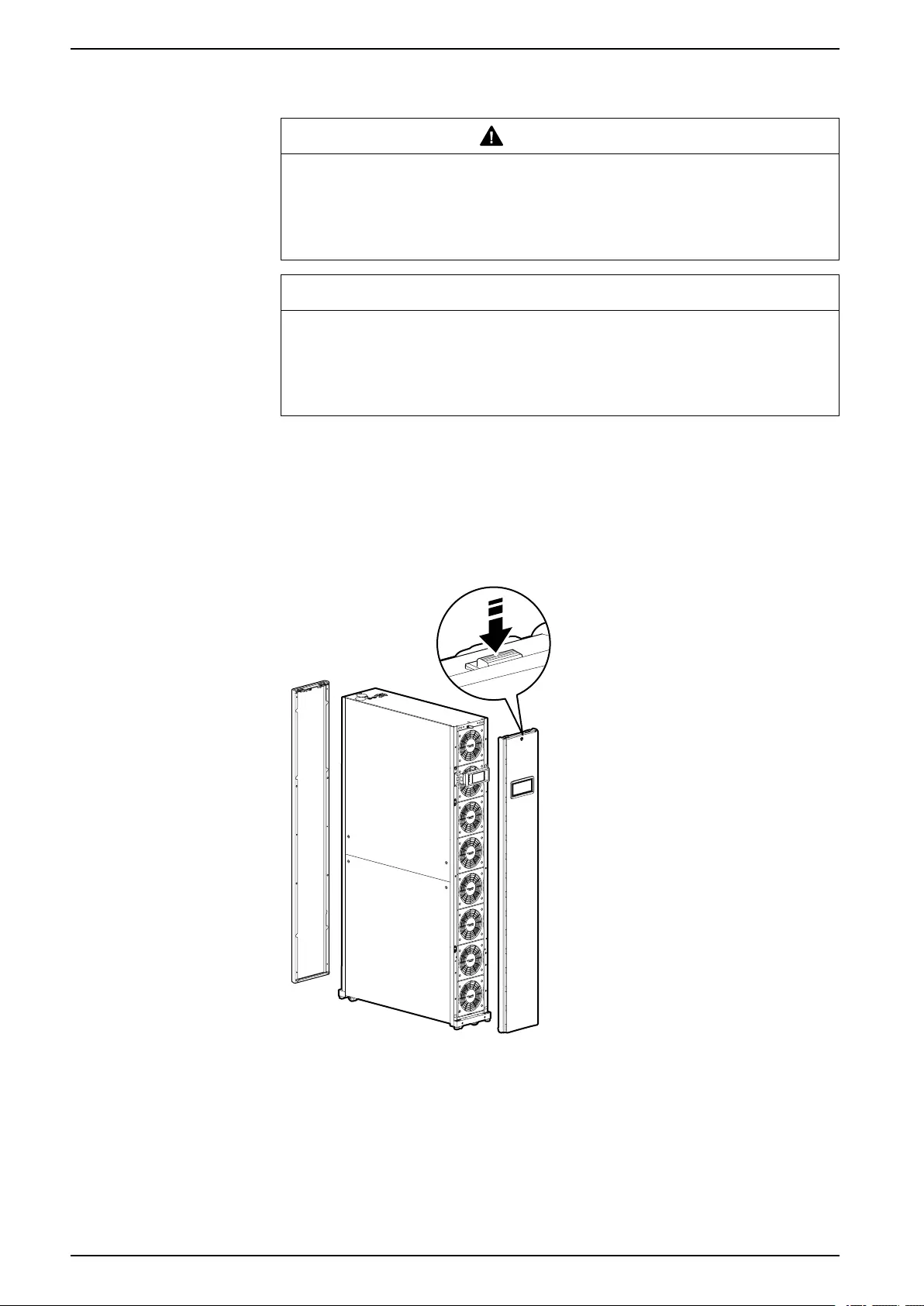

Indoor Unit

Front and Rear Panels

The front and rear panels must first be unlocked before they can be removed. Two

keys are provided with the unit.

NOTE: Image is an example only: your unit may differ.

na4336c

44 990–91193A–001

ACRD300 and ACCU30000 Series Installation

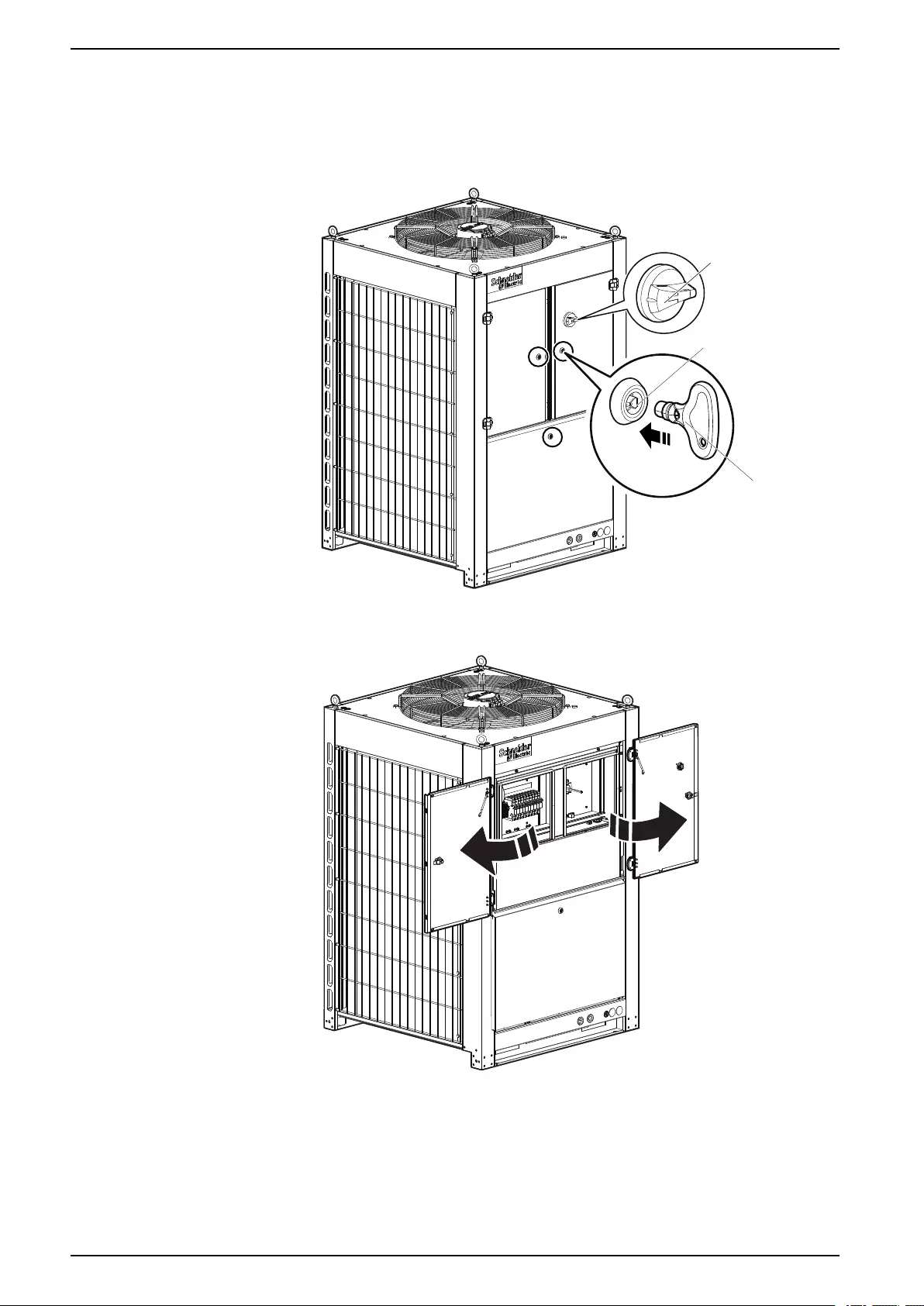

Outdoor Unit

Electrical Panel Access

1. Turn the main switch to the “Off” position and the rotate the quarter-turn

latches to the right.

na6975a

MAIN DISCONNECT

SWITCH

QUARTER-TURN

LATCH

KEY

NOTE: Model ACCU30301 is shown.

2. Open the electrical panel access doors.

na6974a

46 990–91193A–001

ACRD300 and ACCU30000 Series Installation

Stabilizing the Cooling Unit

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Turn off all power supplying this equipment before working on the equipment.

All electrical work must be performed by qualified personnel. Practice Lockout/

Tagout procedures. Do not wear jewelry when working with electrical

equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF EQUIPMENT FALLING OVER

• Use two or more persons at all times to move or turn this equipment.

• Always push, pull, or turn while facing the front and rear of this equipment.

Never push, pull, or turn while facing the sides of this equipment.

• Slowly move this equipment across uneven surfaces or door thresholds.

• Lower leveling feet to floor when this equipment is at rest.

• Lower leveling feet and attach joining brackets to adjacent racks when this

equipment is in final position.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

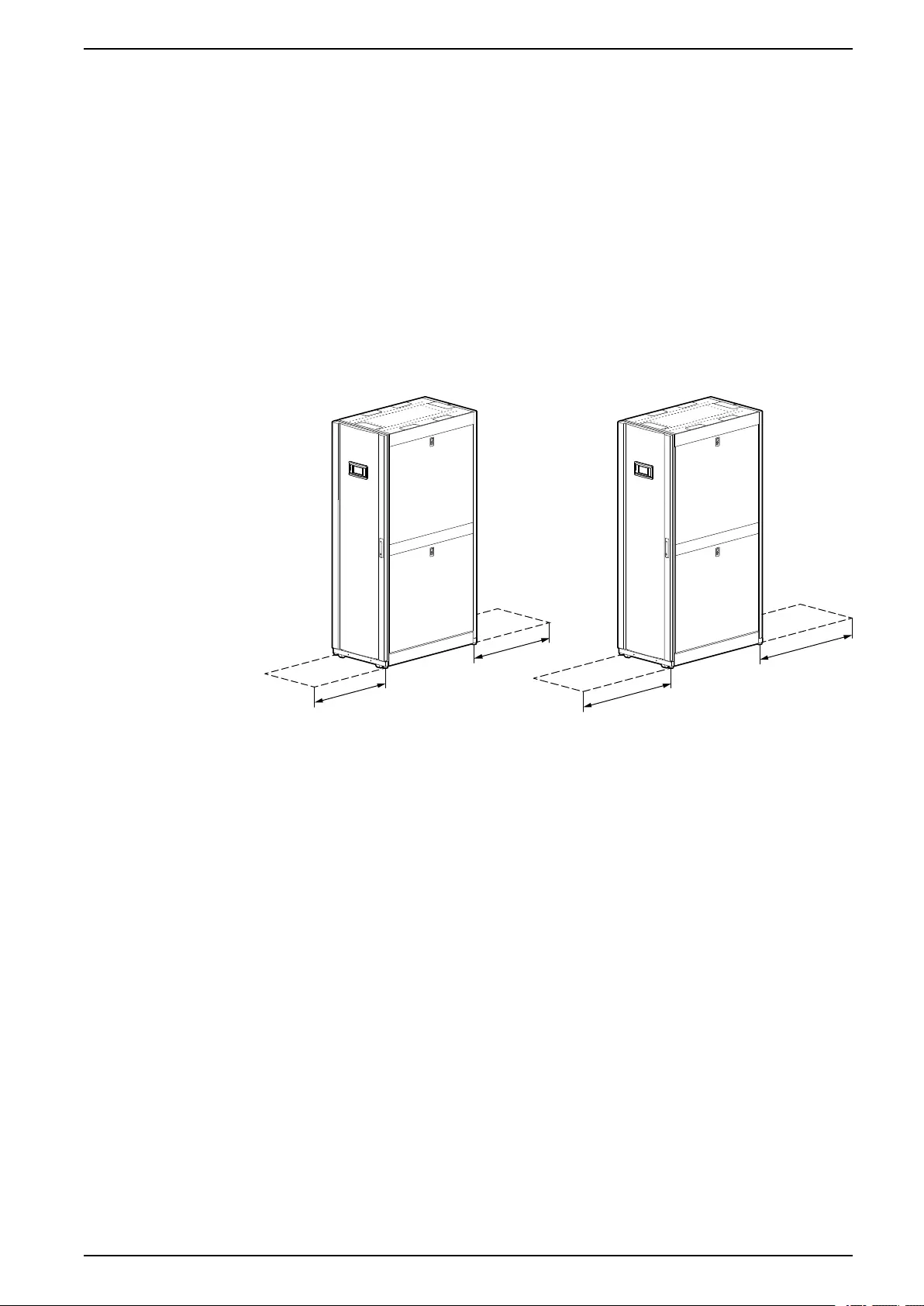

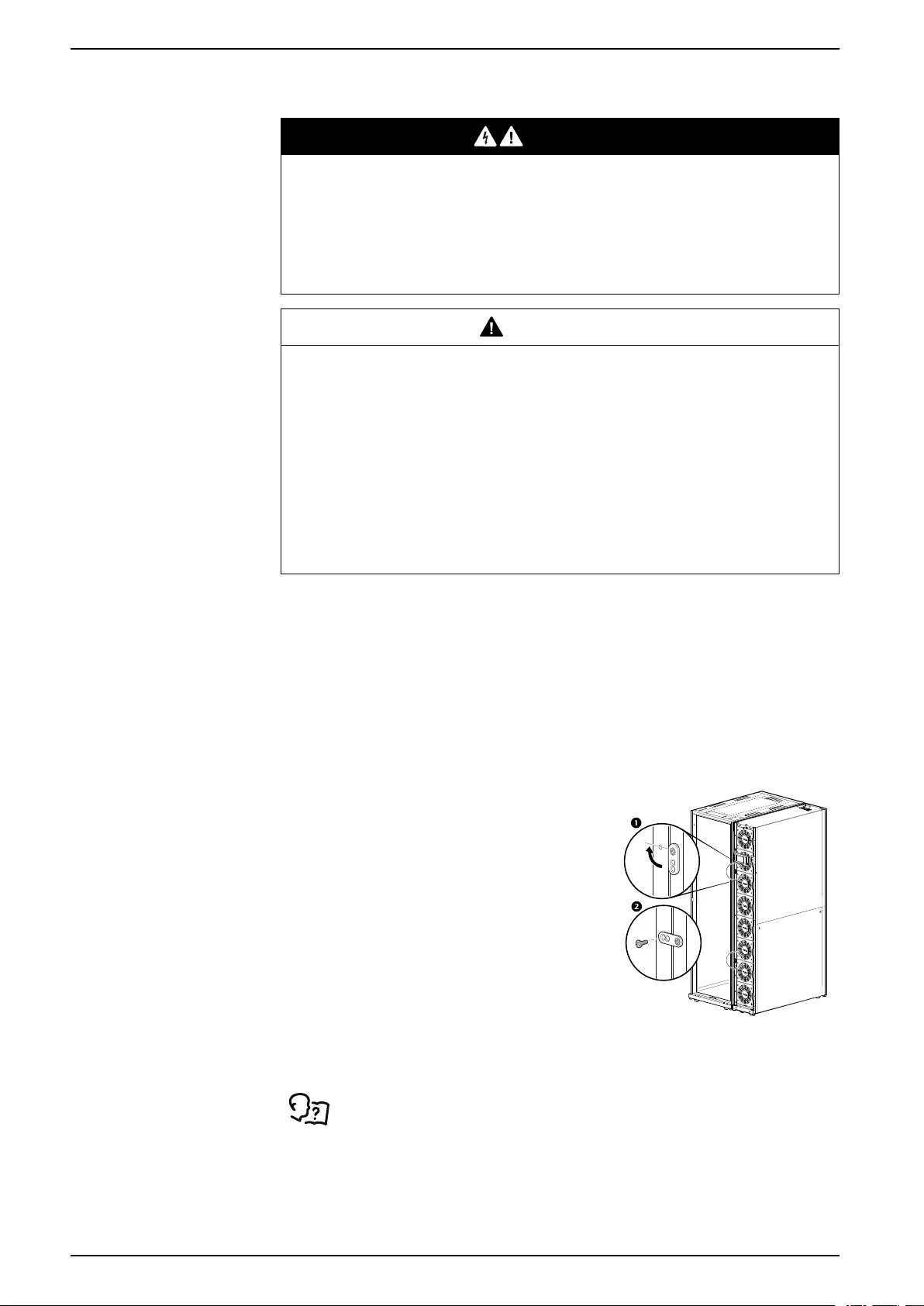

Joining the Equipment to Enclosures

Joining to NetShelter™SX Enclosures

Joining brackets are installed on the unit, two in the front and two on the rear.

Each bracket is designed to accommodate both 24-in. or 600- mm enclosure

spacing.

NOTE: Image is an example only: your unit may differ.

1. Loosen the attachment screw.

2. Rotate the brackets 90°.

3. Install a provided Phillips M5 screw

through the bracket and into the adjoining

enclosure.

4. Re-tighten the attachment screw.

na4354a

90°

Joining to NetShelter VX and VS Enclosures

For information on joining the equipment to NetShelter VX and VS

enclosures, see the installation sheet NetShelter SX to VX or VS

External Joining Kit—AR7601, AR7602.

48 990–91193A–001

Installation ACRD300 and ACCU30000 Series

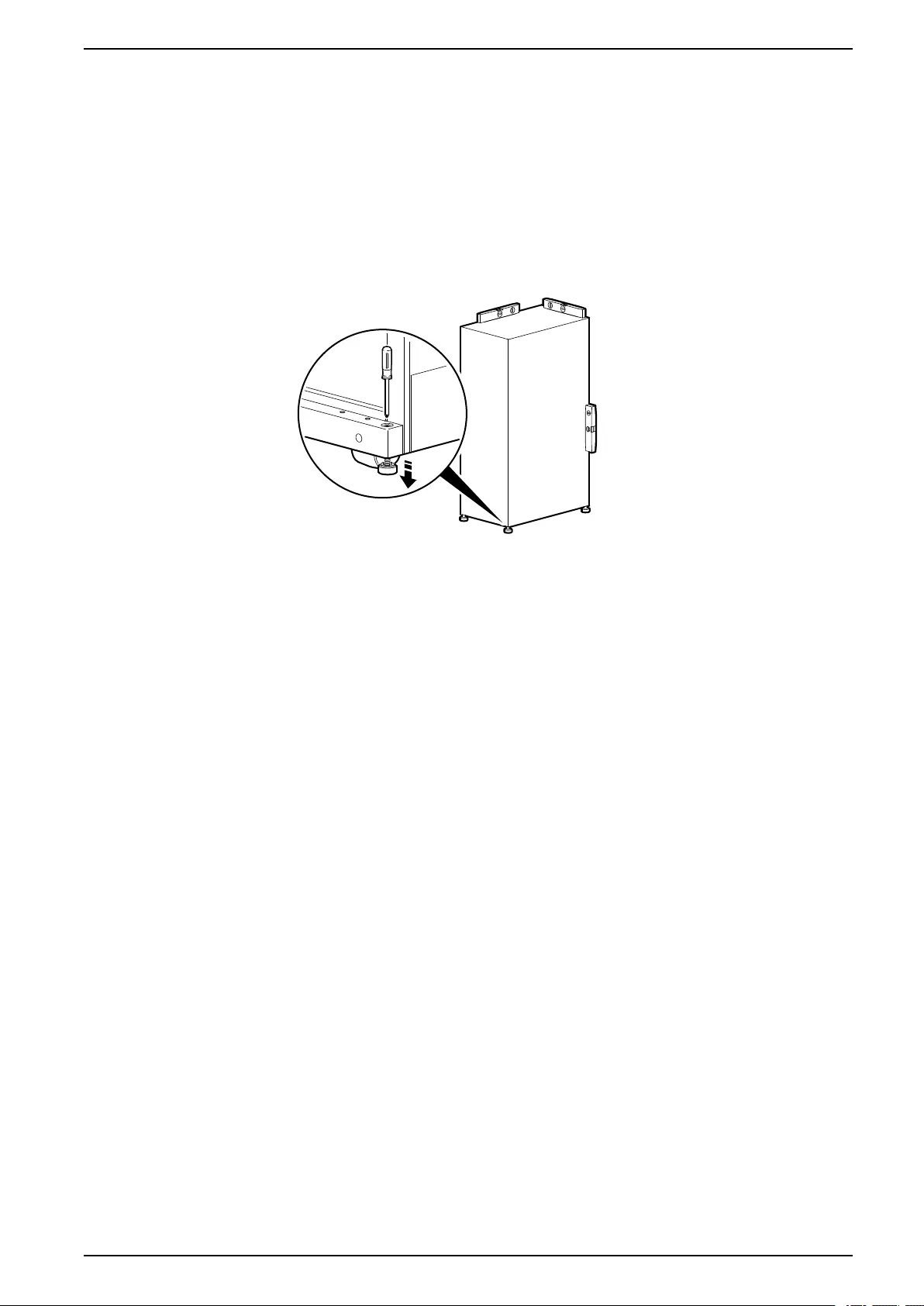

Leveling

The leveling feet provide a stable base if the floor is uneven but cannot

compensate for a badly sloped surface.

Once the cooling unit is in its intended location, use a screwdriver to turn each

leveling foot until it makes contact with the floor. Adjust each foot until the cooling

unit is level and plumb. The casters and leveling feet can be removed to allow the

cooling unit to rest directly on the floor.

NOTE: Front and rear panels will need to be removed to access the leveling

screw.

NOTE: Image is an example only: your unit may differ.

na1572b

NOTE: Use a 13-mm open-ended wrench to level the equipment without

removing the doors.

990–91193A–001 49

ACRD300 and ACCU30000 Series Installation

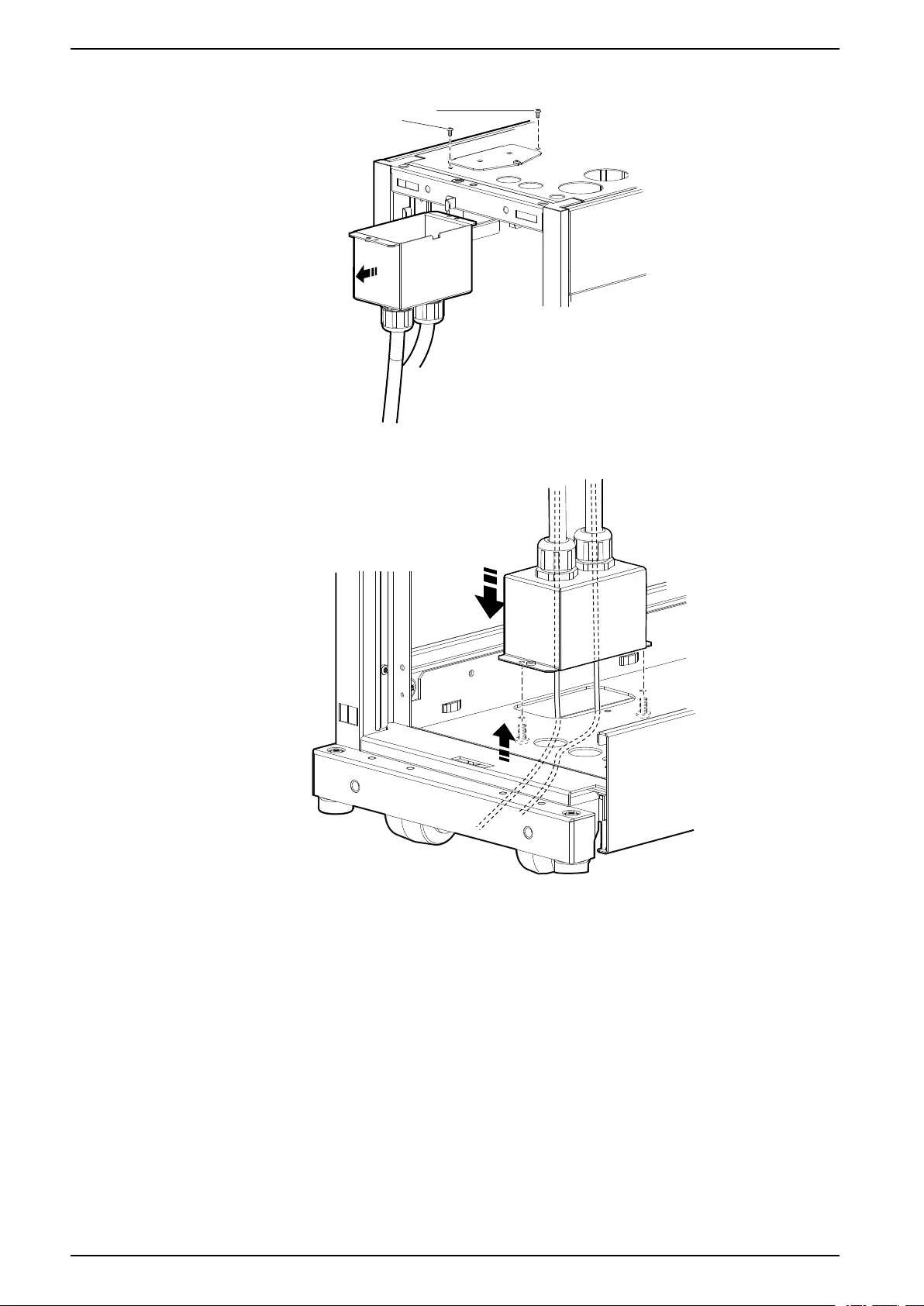

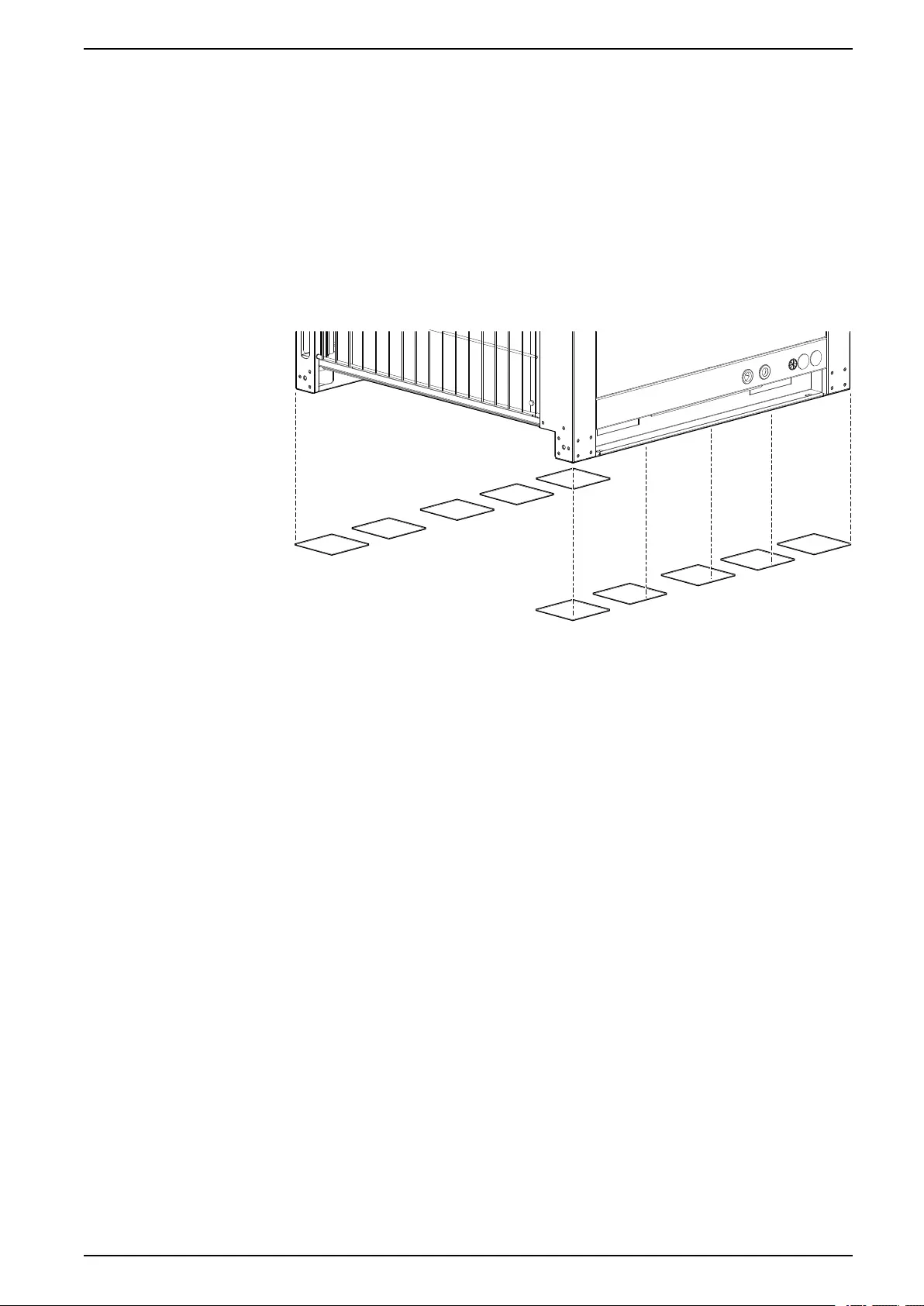

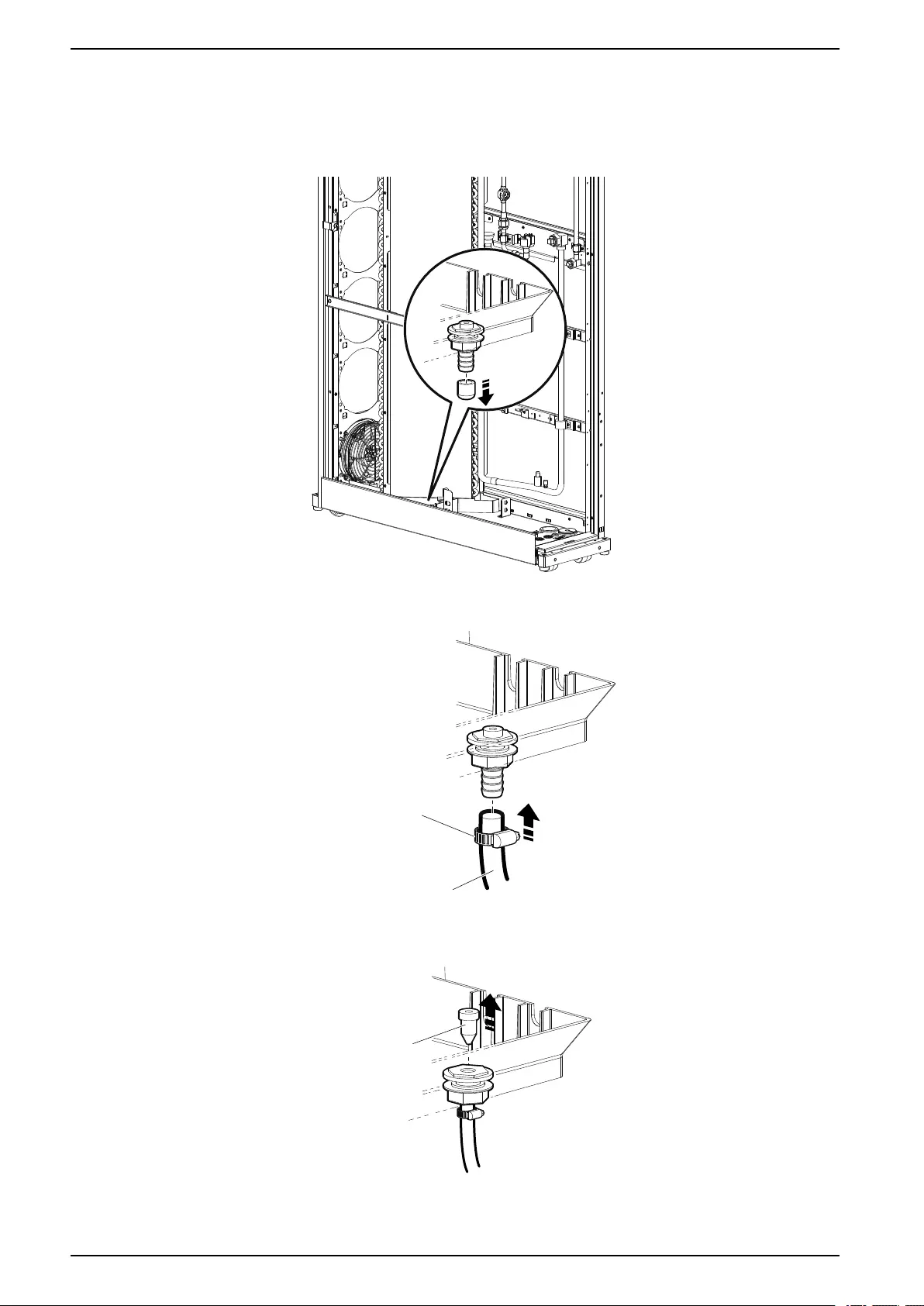

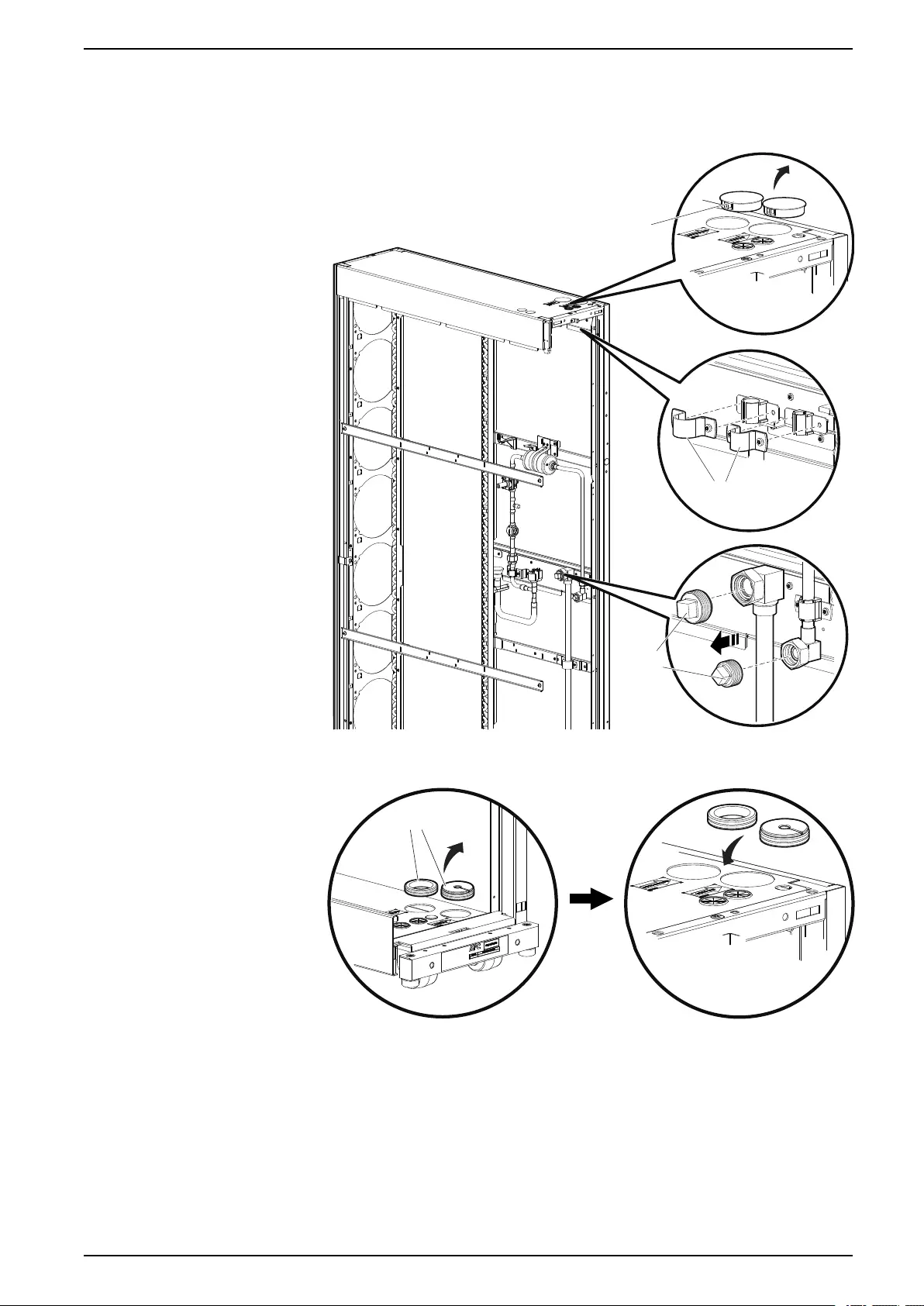

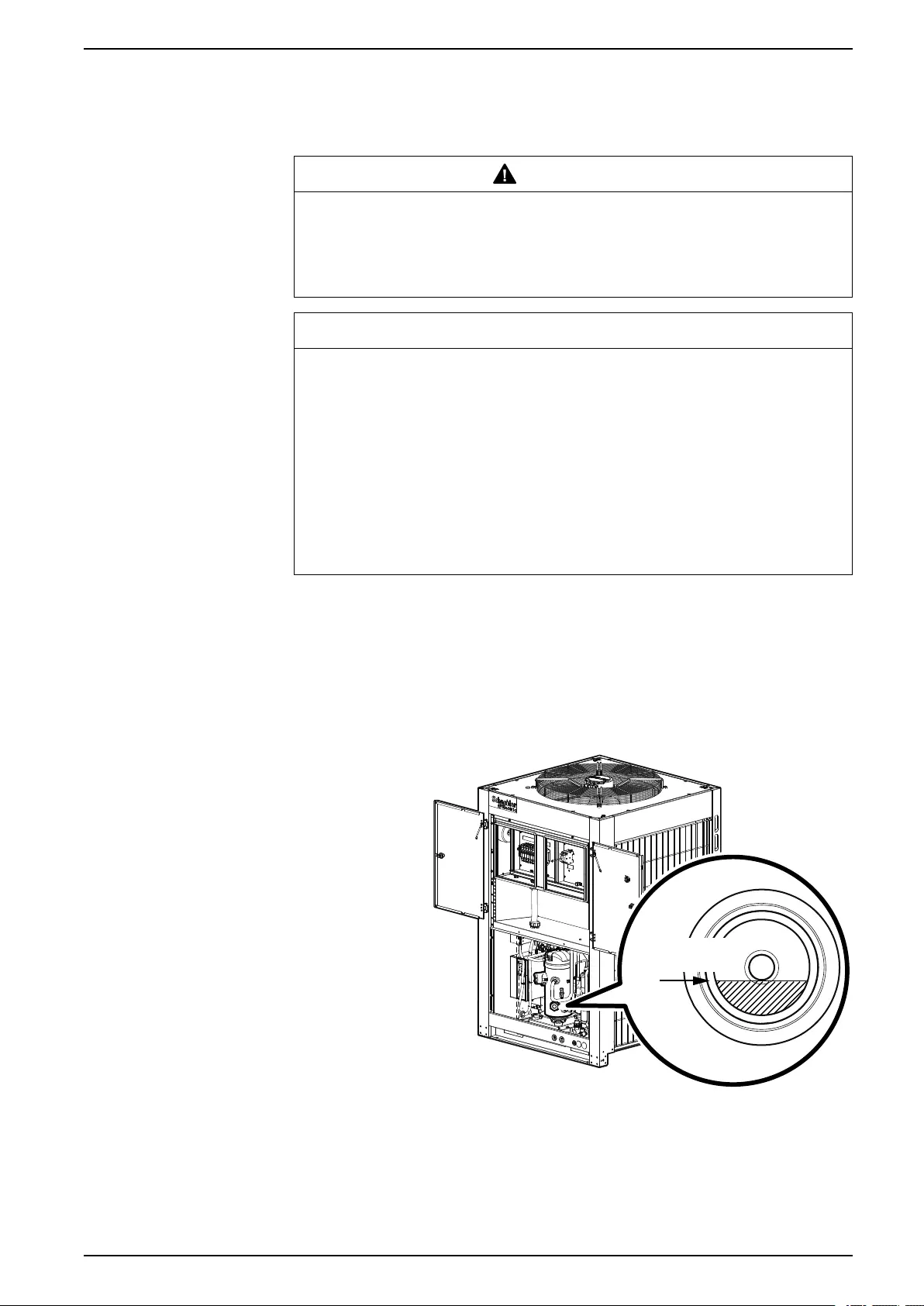

Stabilizing the Outdoor Unit

Mounting Hole Dimensions

The following image shows the dimensions for the mounting holes located on the

frame of the outdoor unit.

FRONT OF UNIT

REAR OF UNIT

MOUNTING HOLE

MOUNTING HOLE

MOUNTING HOLE

MOUNTING HOLE

na7028a

+ +

27 (1.1)

27 (1.1)

946

(37.2)

1000.0 (39.4)

122

(4.8)

122

(4.8)

756 (29.8)

1000.0 (39.4)

122

(4.8)

122

(4.8)

756 (29.8)

1000.0

(39.4)

NOTE: Dimensions are shown in mm (in.).

NOTE: View is bottom view looking up.

50 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Vibration Damping Pads

It is recommended to place field-supplied vibration damping pads under the

outdoor unit to minimize vibration and noise. The following specs are

recommended for the vibration pads:

• Hardness: Durometer 90A

• Material: Green neoprene rubber

• Dimensions: 152 mm x 152 mm (6 in. x 6 in.)

• Thickness: 9.5 mm (3/8 in.)

Place the vibration damping pads flush with the edges of the unit so they are not

visible. The following is the recommended placement of the vibration damping

pads:

na7044a

NOTE: Do not block the mounting holes with vibration damping pads.

Vibration damping pads may need to be cut to size.

990–91193A–001 51

ACRD300 and ACCU30000 Series Installation

Connections Overview

All connections to and from the indoor unit can be made through either the top or

the bottom of the unit. Once the corresponding connectors are sweated or

soldered into place, the equipment can be disconnected without soldering,

welding, or gluing. See the following tables for information about the sizes and

types of connectors.

Power Connections

Model Type Minimum Maximum Torque

ACRD300 Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACRD300D Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACRD300G Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACRD300GD Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACRD301 Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACRD302 Screw connector AWG 14 (2.5 mm2) —1.0 Nm (0.74 ft-lb)

ACCU30301 Screw connector AWG 14 (2.5 mm2) —1.5 Nm (1.1 ft-lb)

ACCU30302 Screw connector AWG 14 (2.5 mm2) —1.5 Nm (1.1 ft-lb)

ACCU30001 Screw connector AWG 10 (6 mm2) —1.5 Nm (1.1 ft-lb)

ACCU30002 Screw connector AWG 10 (6 mm2) —1.5 Nm (1.1 ft-lb)

ACCU30201 Screw connector AWG 14 (2.5 mm2) —1.5 Nm (1.1 ft-lb)

ACCU30202 Screw connector AWG 14 (2.5 mm2) —1.5 Nm (1.1 ft-lb)

52 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Sensor and Communication Connections

Wire Size

Connection Type Minimum Maximum

Rack temperature RJ-45 — —

Leak Rope RJ-45 — —

A-Link IN RJ-45 — —

A-Link OUT RJ-45 — —

Network port RJ-45 — —

Console port USB (Type B) — —

Customer output,

Normally Closed (NC)

Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Customer output,

Common (COM)

Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Customer output,

Normally Open (NO)

Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Supply GND Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Supply 12 Vdc Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Supply 24 Vdc Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Customer input + Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Customer input - Push-in spring

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Modbus D1 Push-in spring

connection/ Spring-cage

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Modbus D0 Push-in spring

connection/ Spring-cage

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Modbus GND Push-in spring

connection/ Spring-cage

connection

AWG 24 (0.2 mm2) AWG 18 (0.75 mm2)

Temperature sensor 2P Molex Mini-Fit Jr.™— —

Humidity sensor 6P Molex Mini-Fit Jr.™— —

Display interface HDMI — —

990–91193A–001 53

ACRD300 and ACCU30000 Series Installation

Mechanical Connections

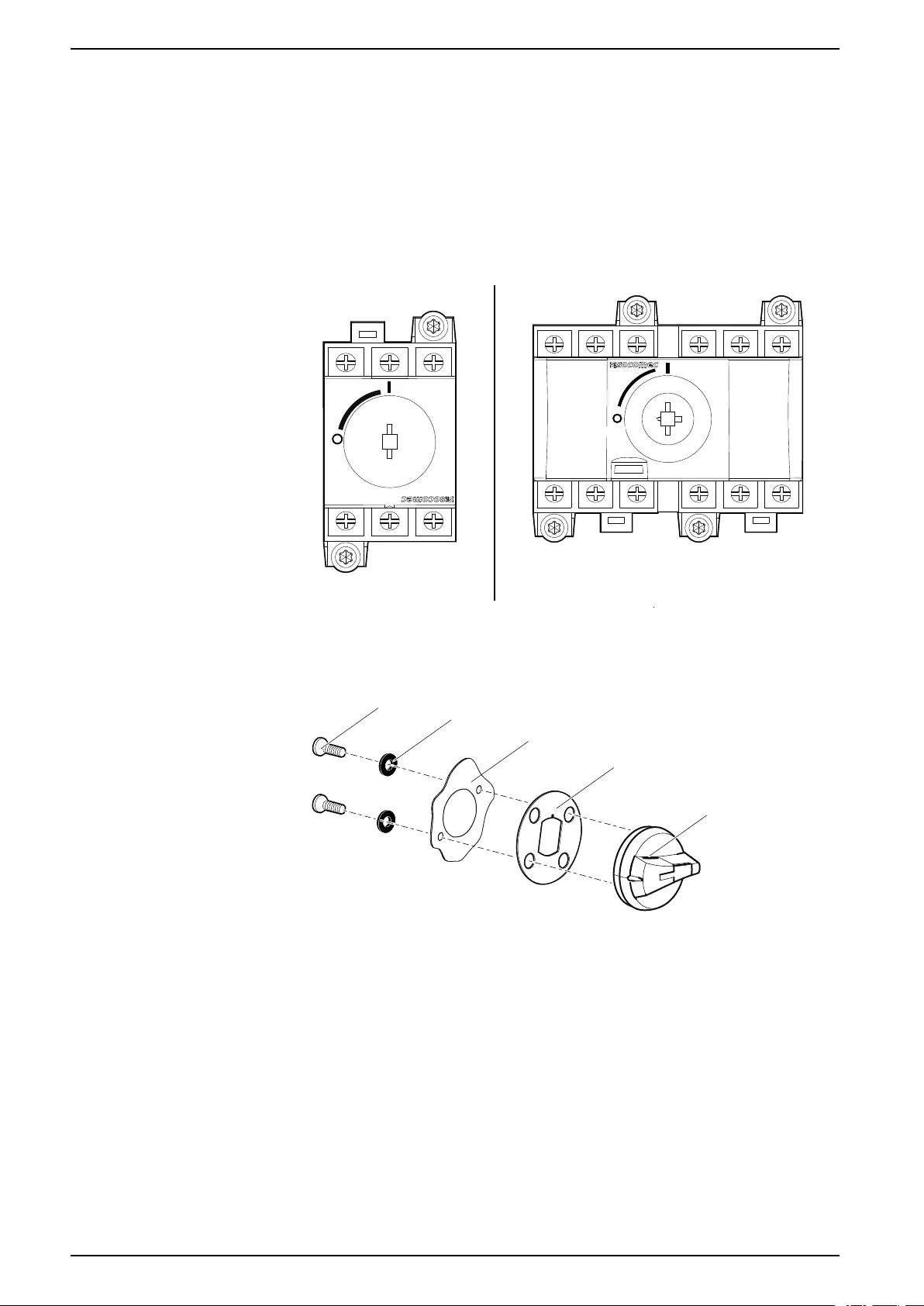

Installing the Main Switch

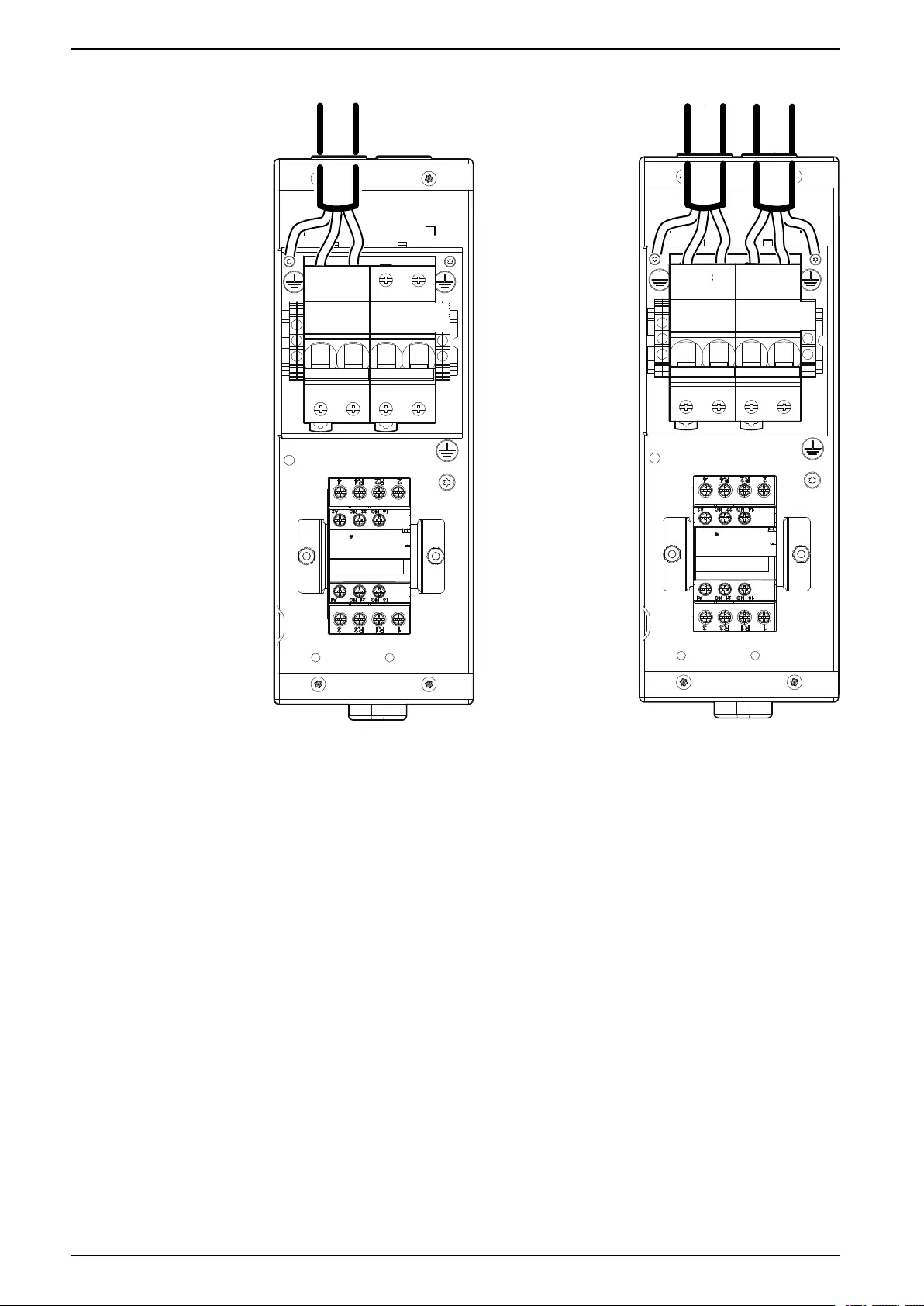

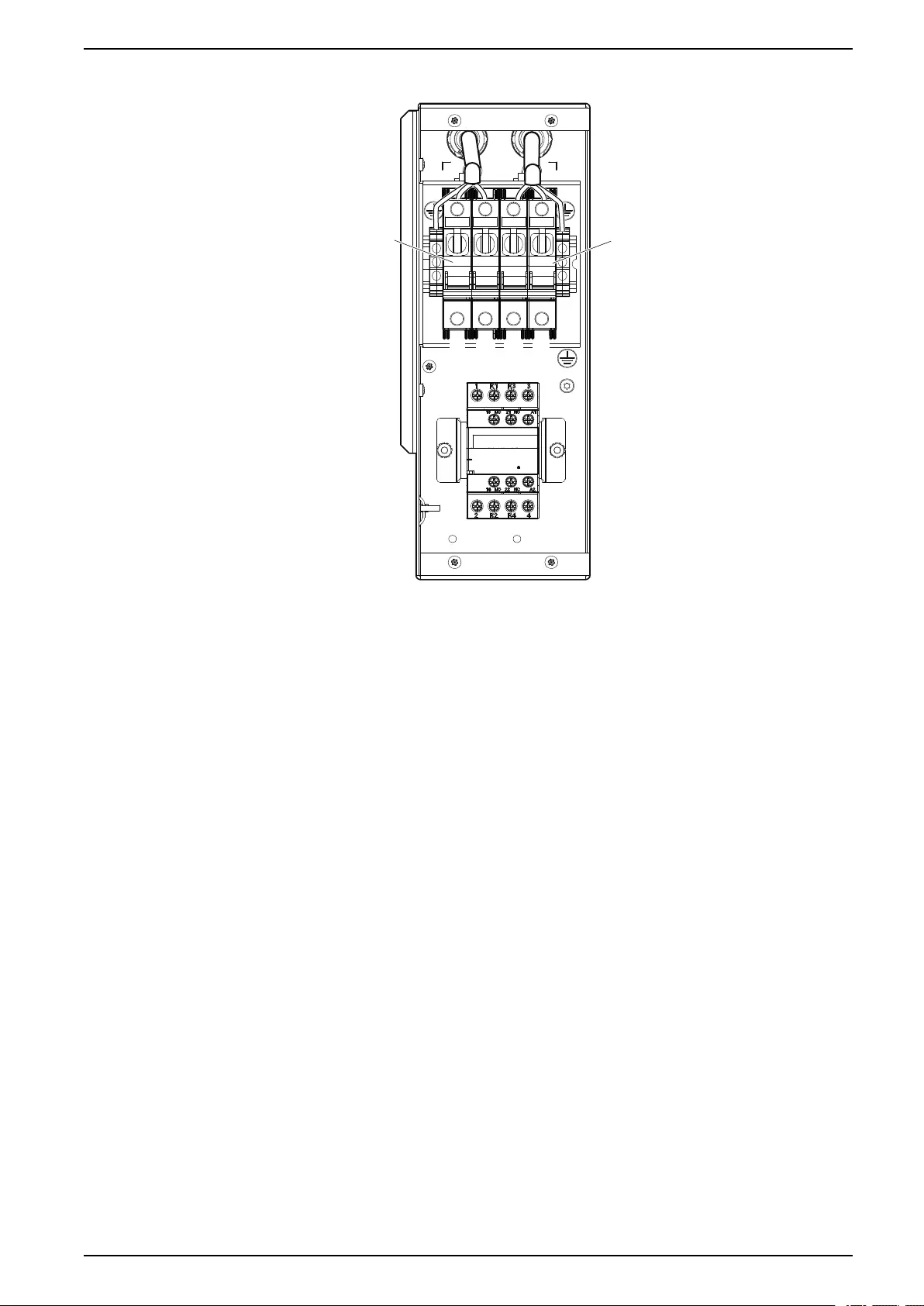

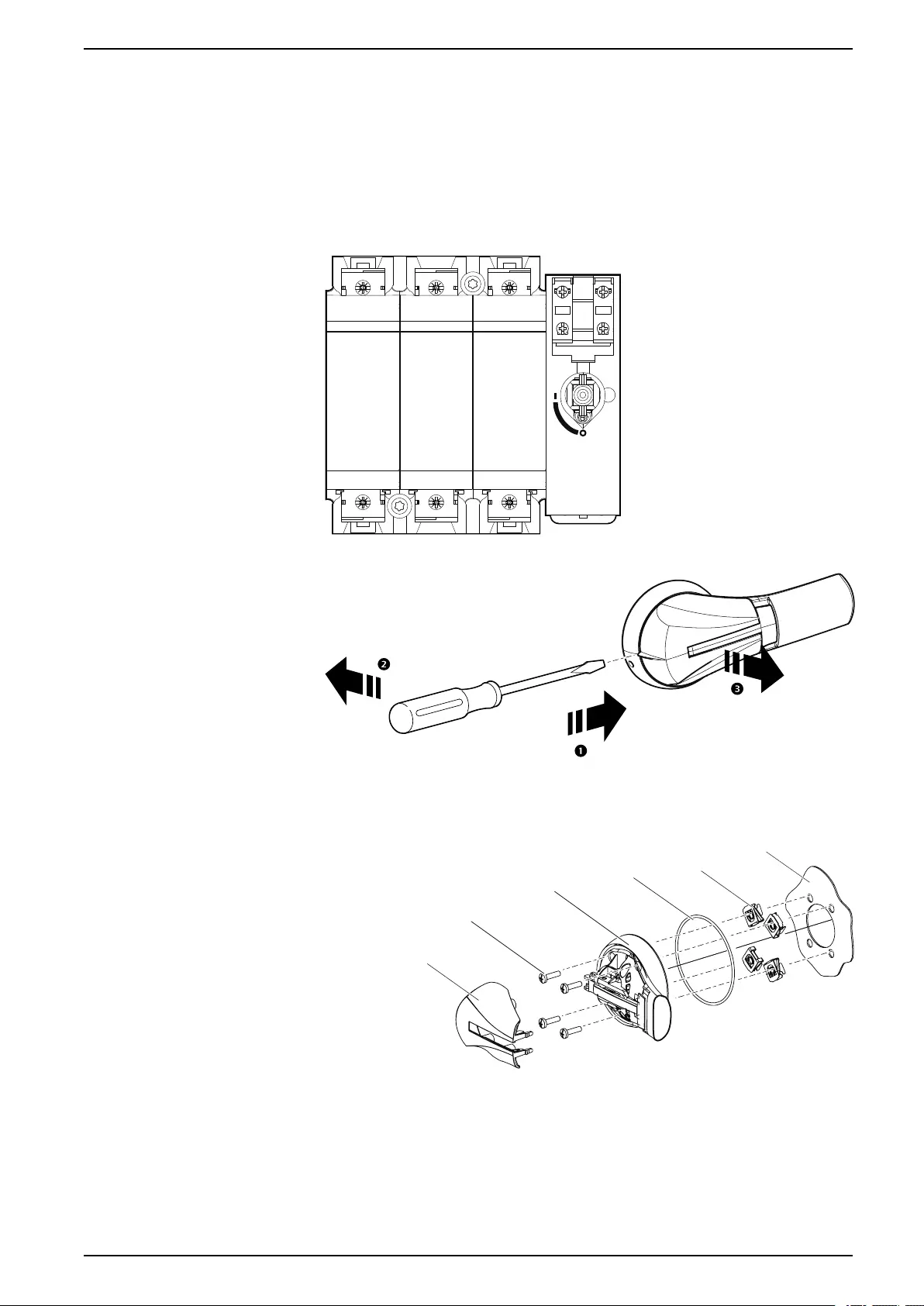

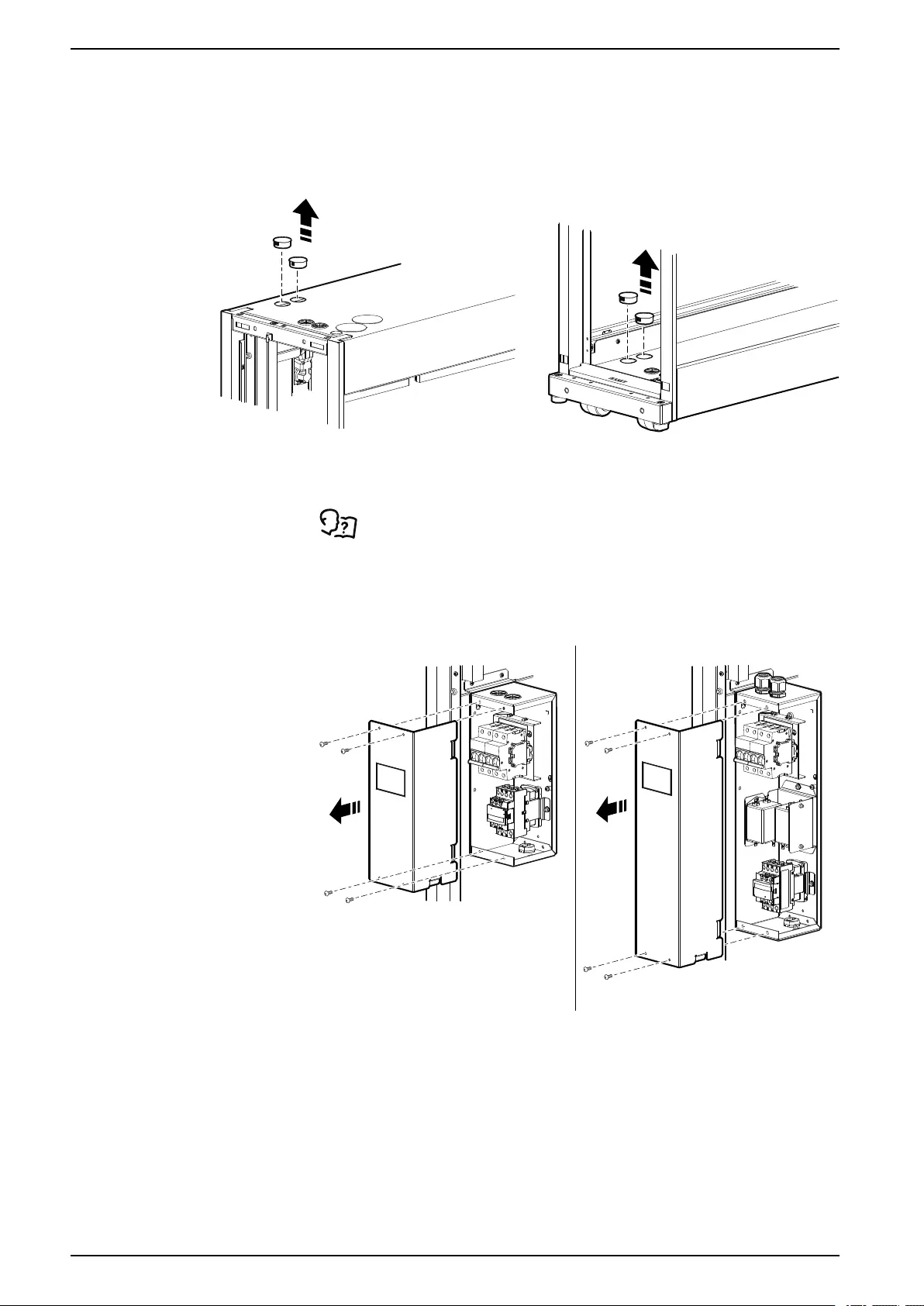

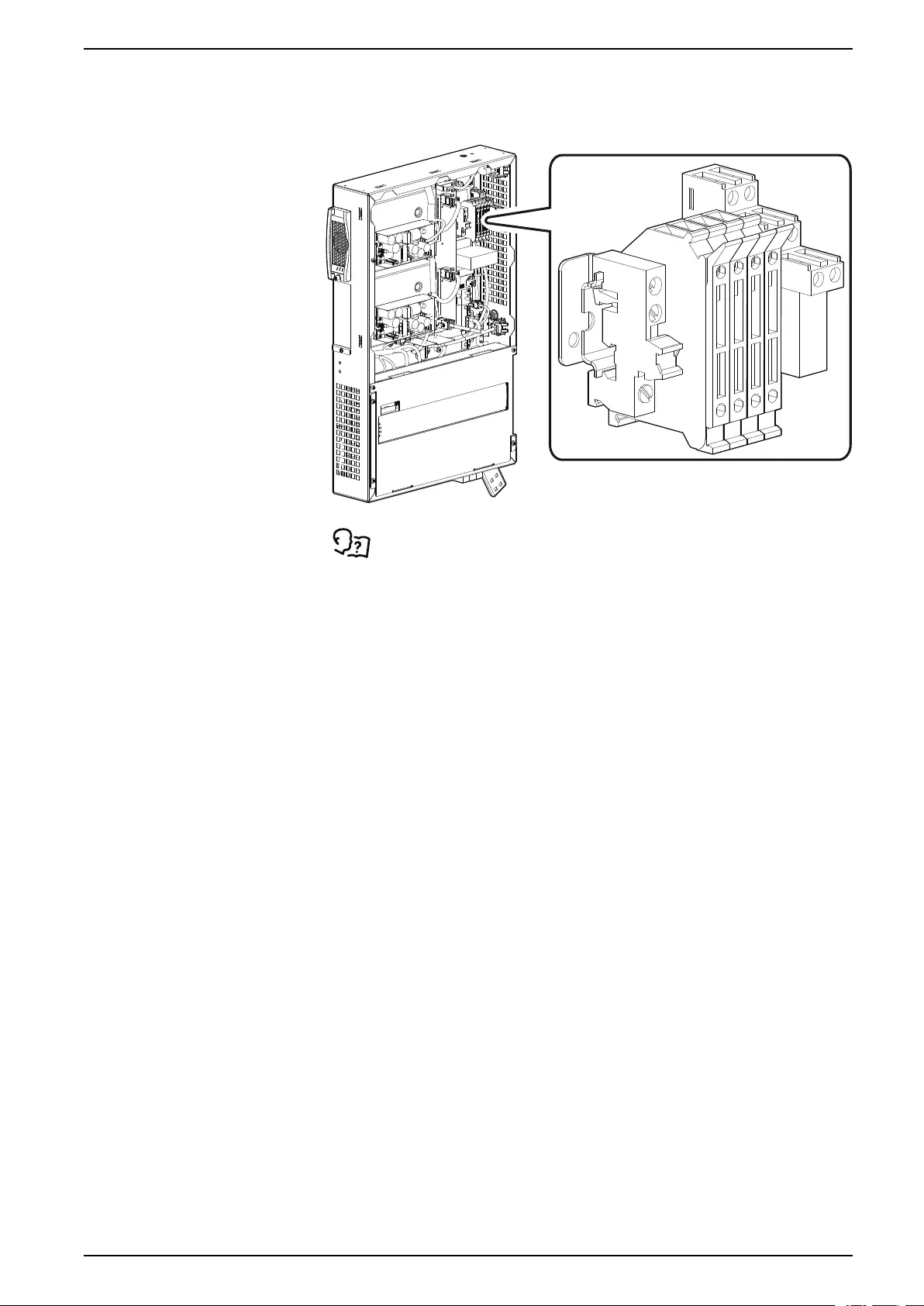

ACCU30301 and ACCU30302

The main switch handle of the condensing unit is shipped inside the electrical

panel of the unit and must be installed in the field.

1. Open the electrical panel access door.

2. Make sure the power supply is in the “OFF” position.

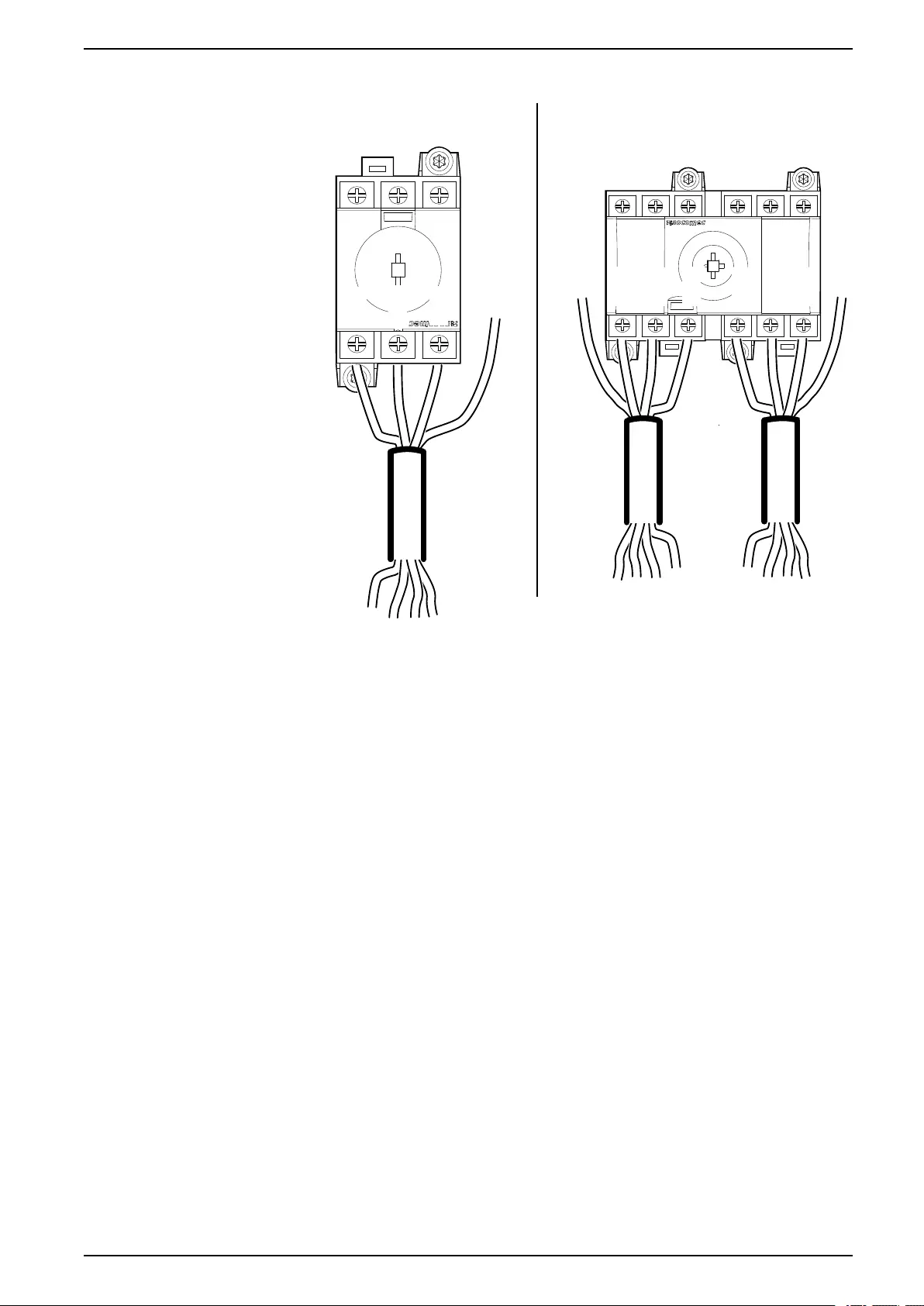

SINGLE FEED DUAL FEED

PRIMARY

(FEED A)

SECONDARY

(FEED B)

OFF

ON

OFF

ON

na7010a

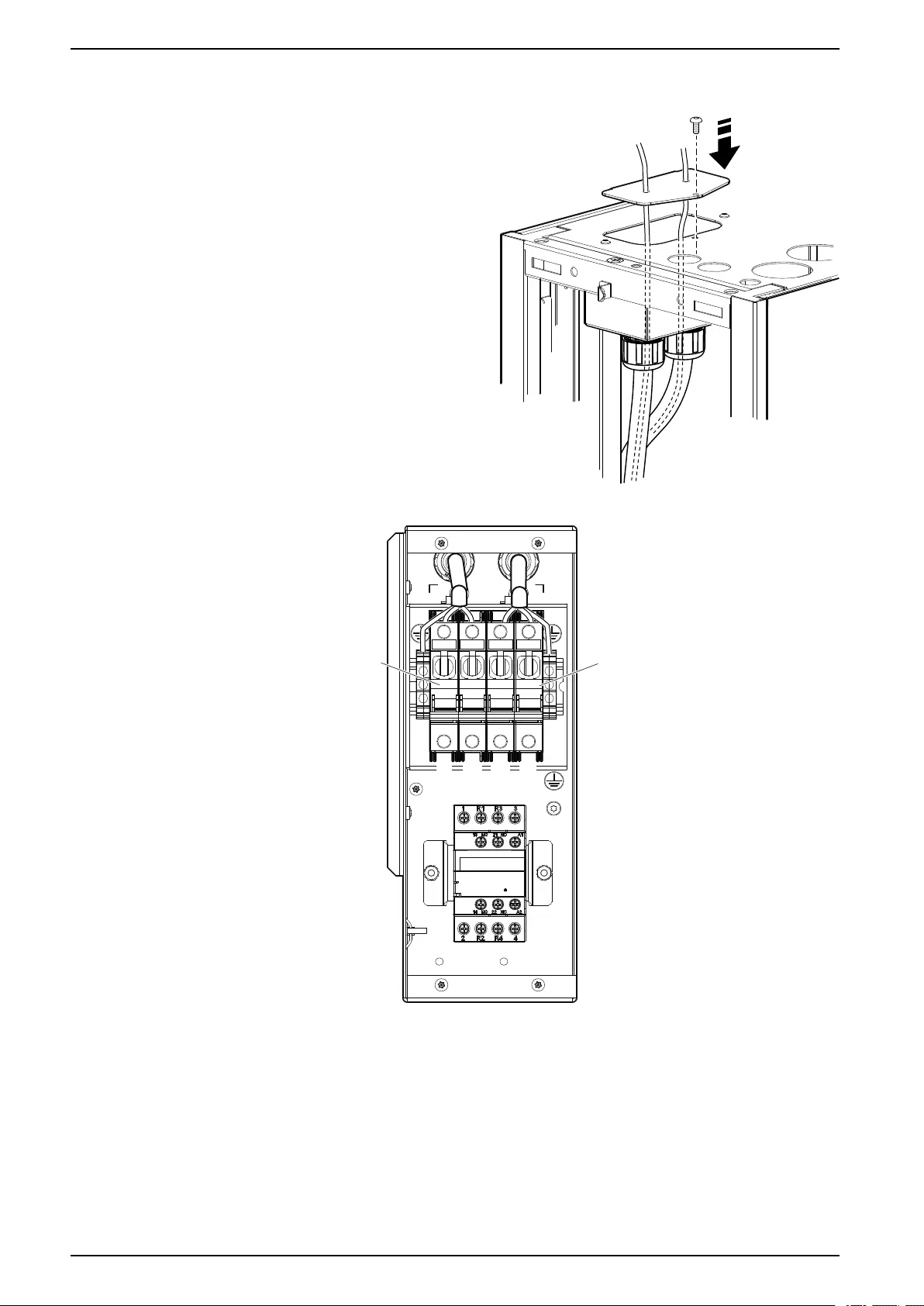

3. Install the main switch handle on the outside of the door using the gasket, 2

tap screws, and 2 grommets.

NOTE: Make sure the main switch handle is in the “OFF” position.

na7011a

MAIN SWITCH

HANDLE

TAP SCREW

GASKET

GROMMET

DOOR

4. Close the door and make sure the shaft of the switch and main switch handle

align properly.

54 990–91193A–001

Installation ACRD300 and ACCU30000 Series

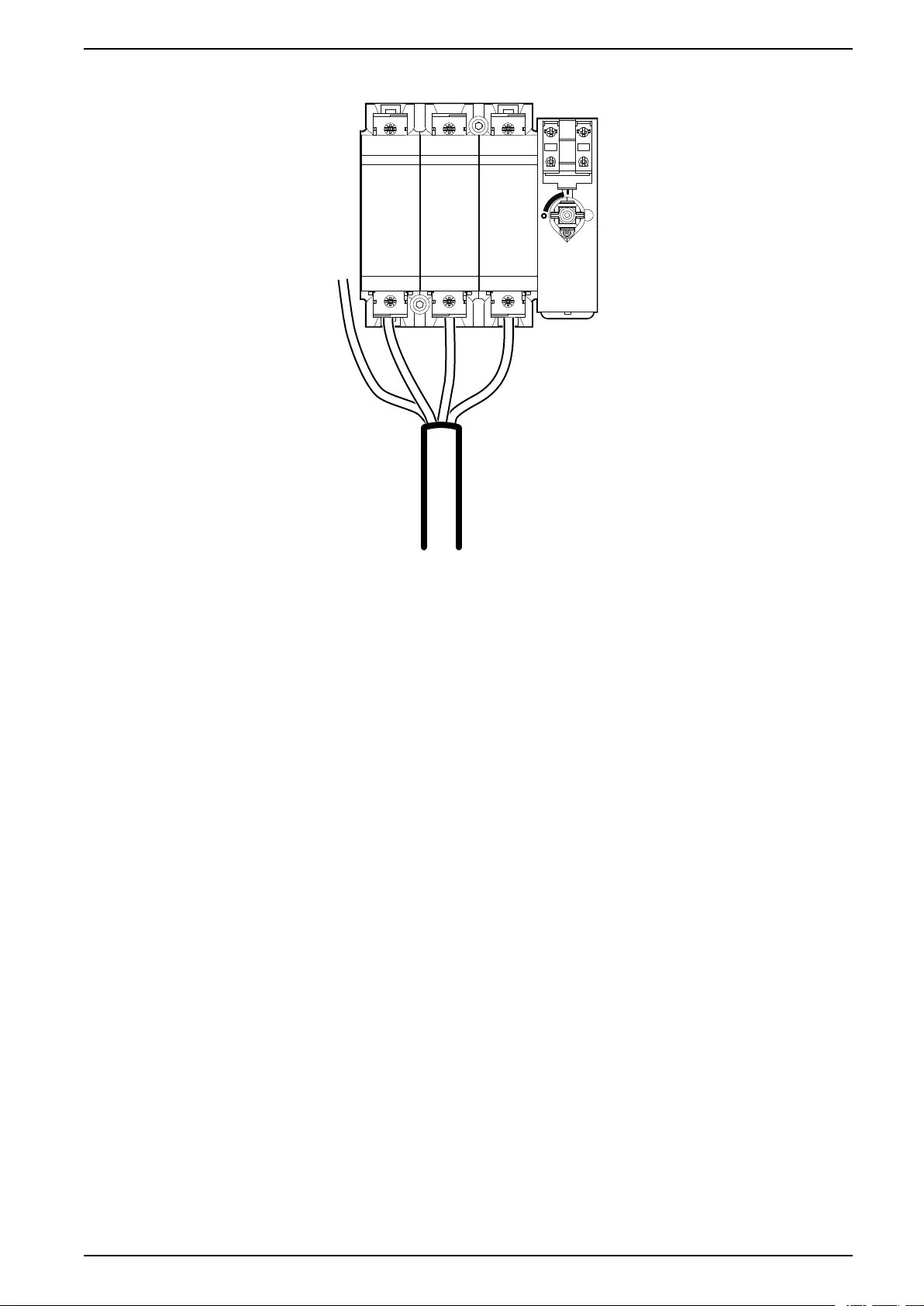

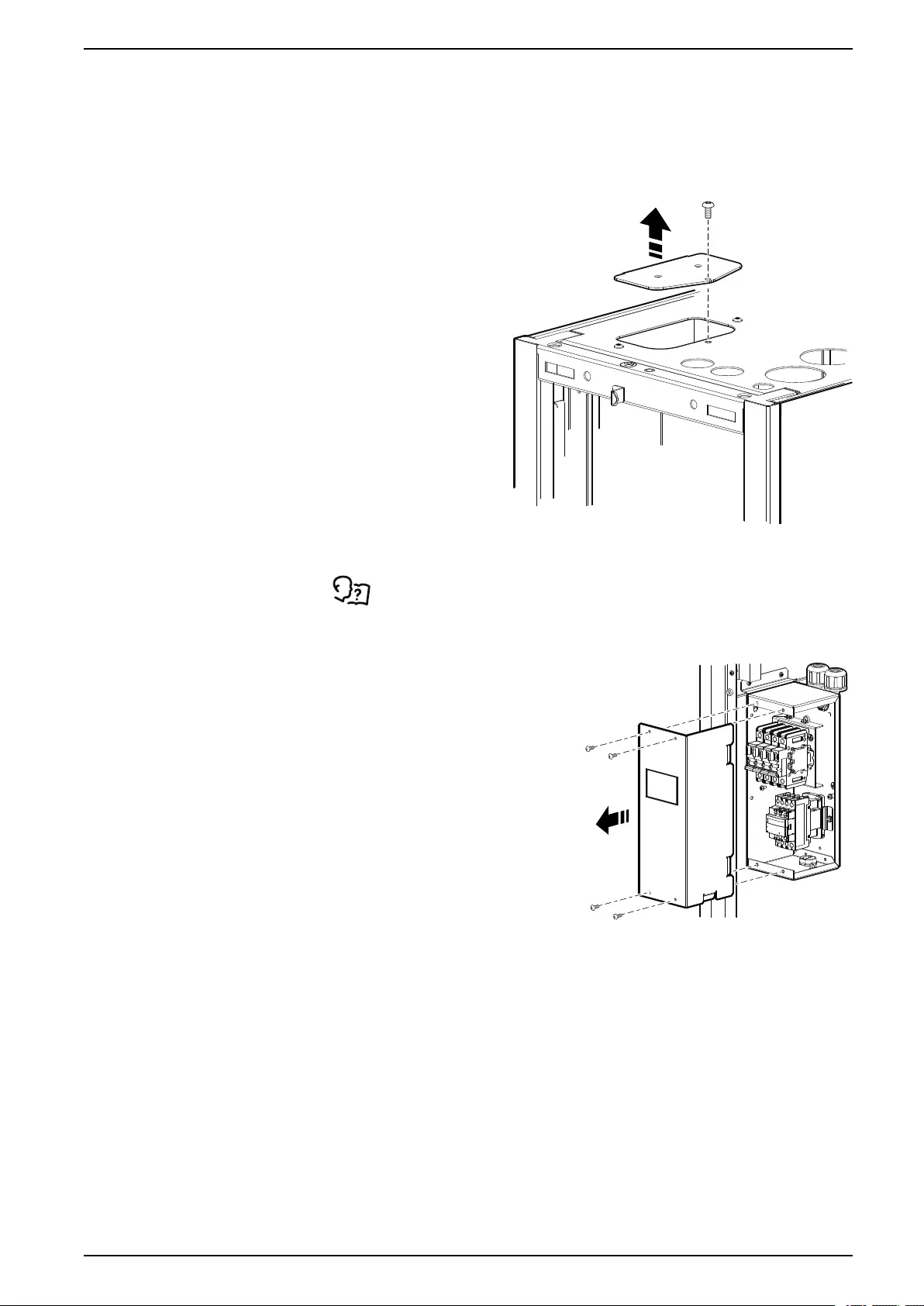

ACCU30001, ACCU30002, ACCU30201, ACCU30202, ACCU30101, and

ACCU30102

The main switch handle of the condensing unit is shipped inside the electrical

panel of the unit and must be installed in the field.

1. Open the electrical panel access door.

2. Make sure the power supply is in the “OFF” position.

NOTE: Make sure both power supplies are in the “OFF” position if two are

present.

OFF

ON

na7030a

3. Remove the cover from the main switch handle.

na7031a

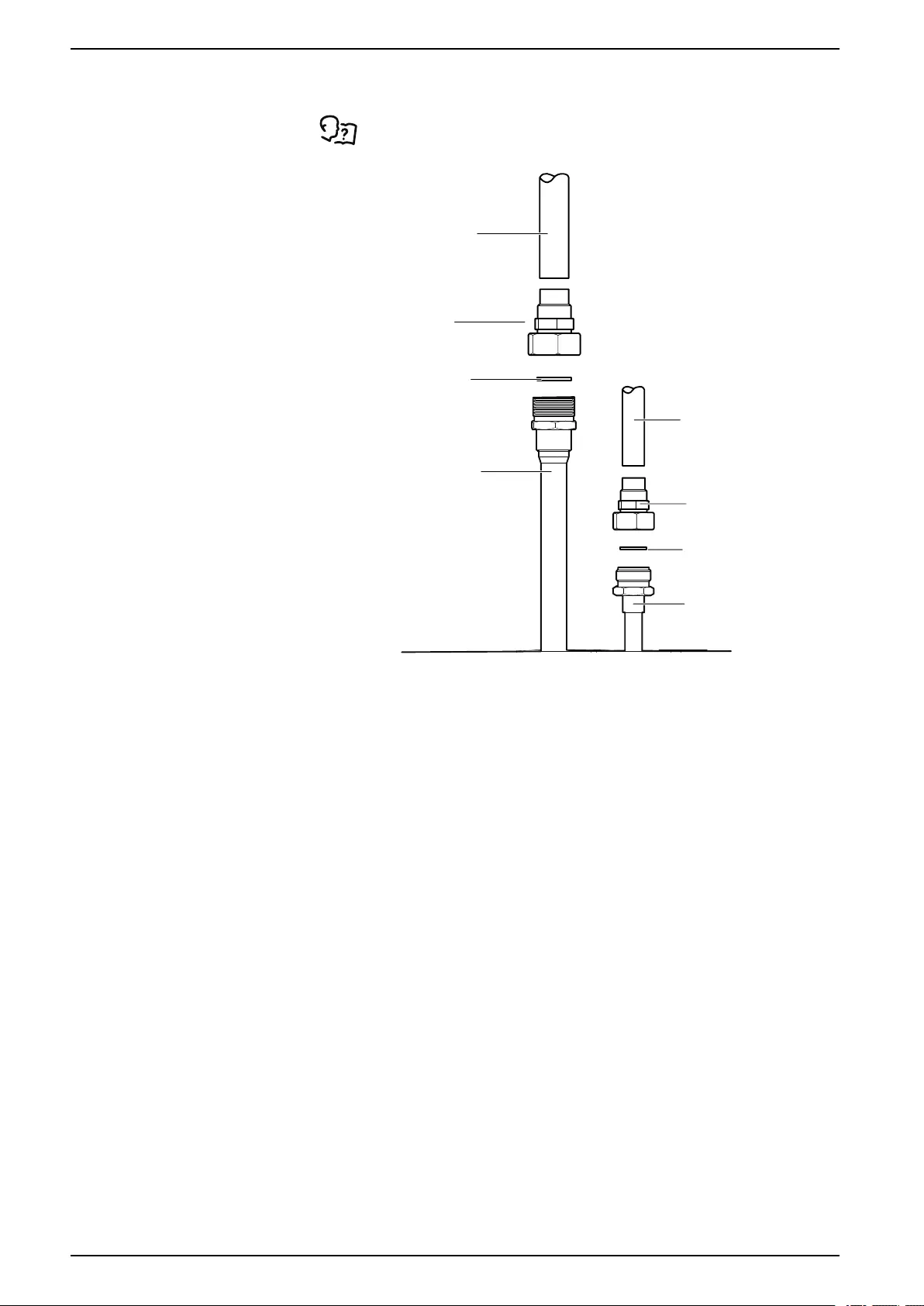

4. Install the main switch handle on the outside of the door using the gasket, 4

machine screws, and 4 nuts.

NOTE: Place the flat side of the nuts against the main switch handle.

MAIN SWITCH

HANDLE

MACHINE

SCREWS

GASKET NUTS

DOOR

MAIN SWITCH

HANDLE COVER

na7027a

990–91193A–001 55

ACRD300 and ACCU30000 Series Installation

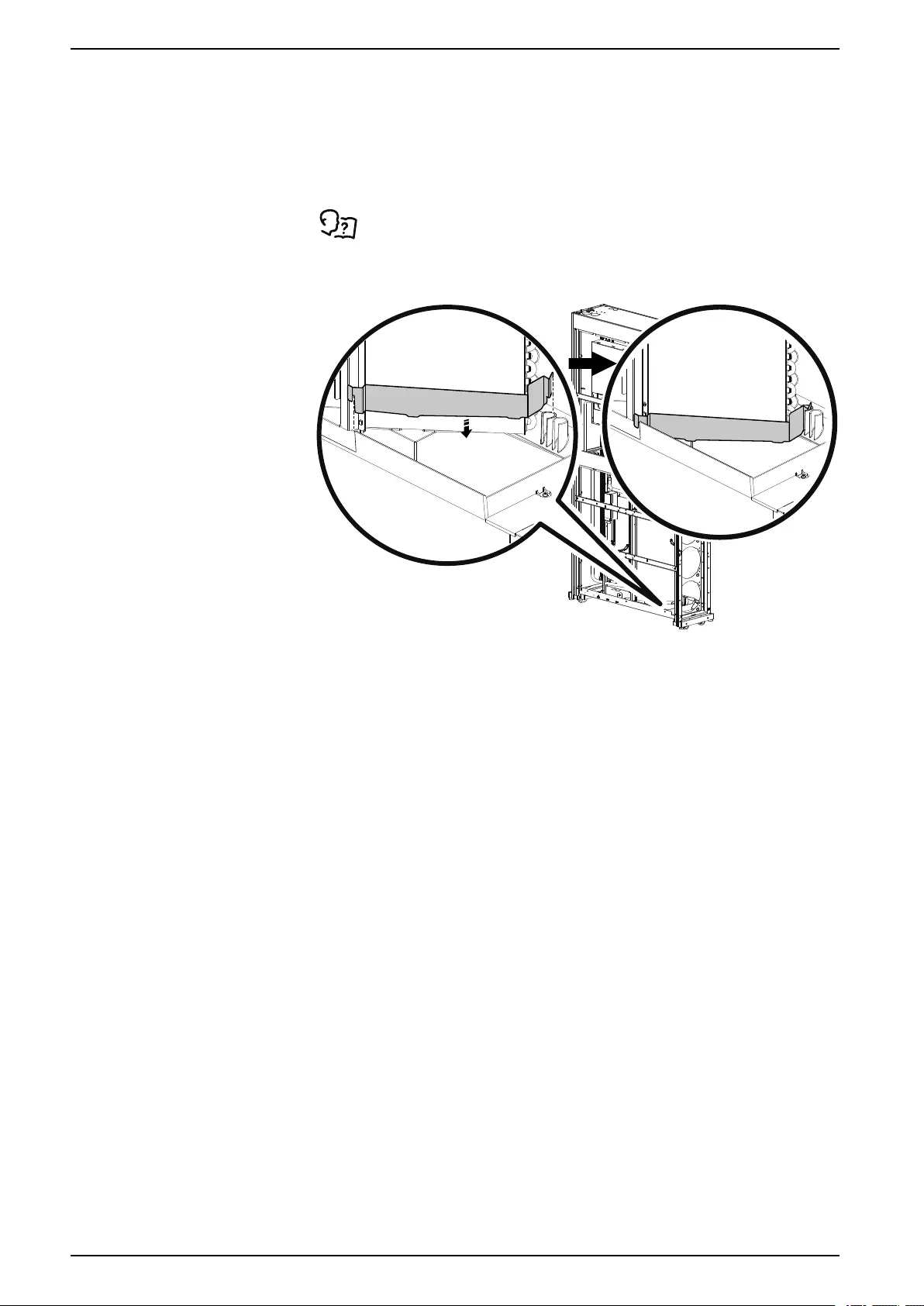

Condensate Drain Pan Additions

The condensate drain pan requires a strip of insulation and a supplemental

bracket around the cooling coil to prevent water from overflowing when the fans

are operating at high speed.

1. Remove the lower side panels.

See Side Panels, page 45 for panel removal instructions.

2. Place the supplemental bracket in front of the cooling coil (fan side).

na7193a

56 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Condensate Drain Connections

NOTICE

COMPLIANCE REQUIREMENT

The installation must comply with local plumbing codes.

Failure to follow these instructions can result in equipment damage.

With Condensate Pump

The pump is factory-wired and piped internally to the condensate drain pan. The

pump uses an on-board, condensate-high-level float switch wired into the

equipment for alarm capabilities.

The condensate drain line can be connected through either the top or the bottom

of the equipment using factory-installed male quick connectors and tubing.

The following image shows routing options for the condensate drain line:

na6964a

CONDENSATE

PUMP CONDENSATE

PUMP

WIRE TIE

(SQUARE-HEAD)

TUBING

TUBING

BOTTOM ROUTING

TOP ROUTING

990–91193A–001 57

ACRD300 and ACCU30000 Series Installation

With Gravity Drain

NOTE: A hole at least 102 mm (4 in.) in diameter is required in the raised floor

to access the gravity drain connection.

1. Remove the rubber seal cap from the drain connection.

na7002a

2. Attach tubing with a 136-mm (0.5-in.) internal diameter (field supplied) to the

barbed connection with a tube clamp (field supplied).

CLAMP

(FIELD SUPPLIED)

TUBING

(FIELD SUPPLIED)

na7003a

3. Remove the silicon plug.

NOTE: Water will not drain if the plug is not removed.

SILICON PLUG

na7004a

4. Route the tubing through the hole in the raised floor.

58 990–91193A–001

Installation ACRD300 and ACCU30000 Series

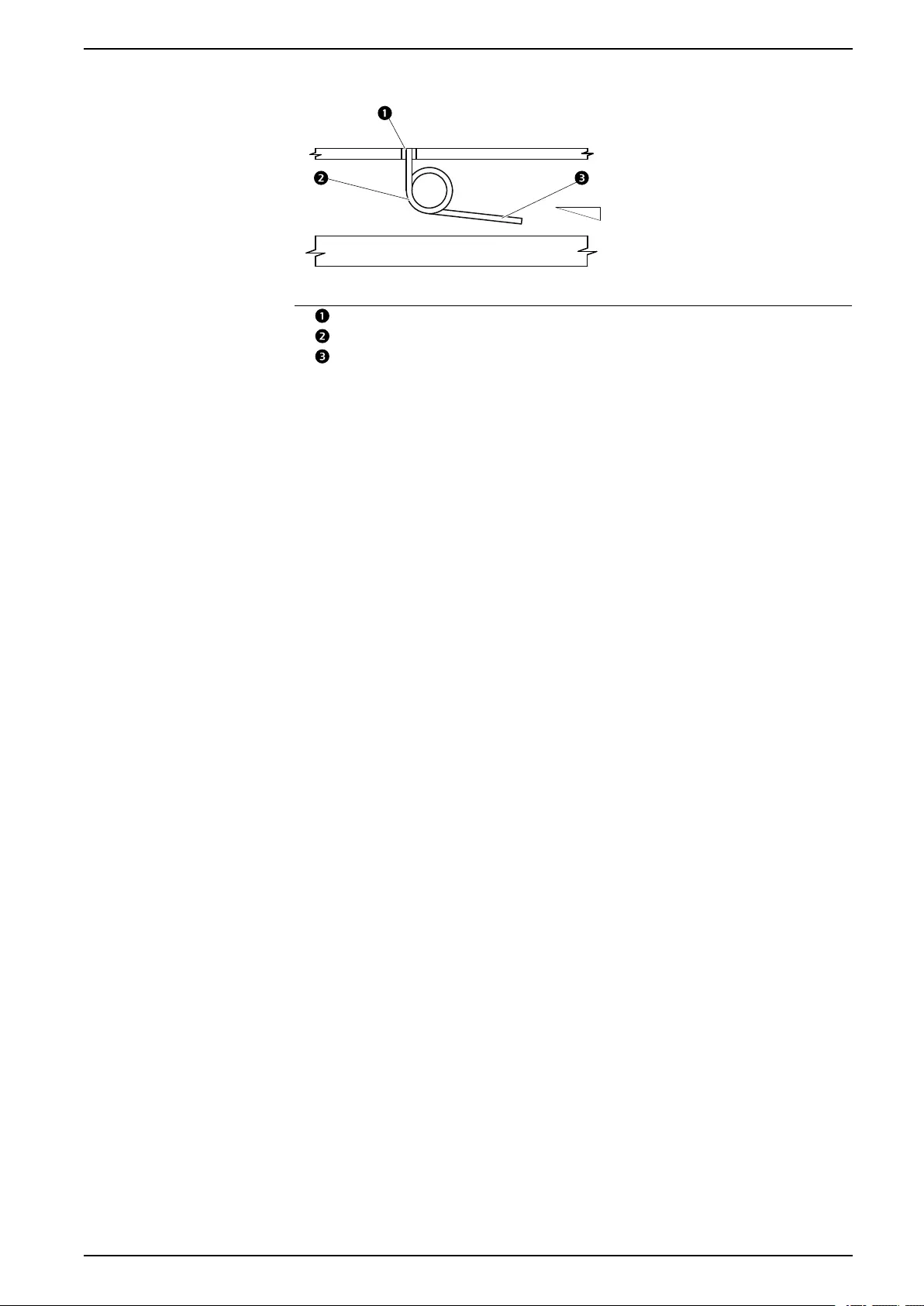

Connection to Building Drain

na4737a

2.5 cm PER 2.1 m

(1 in PER 10 ft)

Item Description

Drain

Trap

Minimum slope

1. Connect the unit drainage tube to the building drains using a rubber or plastic

tube with a 25-mm (1-in.) internal diameter.

2. Use a trap on the external drainage tube in order to avoid unpleasant odors

and to allow the condensate pan to drain properly. Consult local building

codes for drain requirements.

3. Once the connections have been made, pour water into the condensate drain

until the trap inside the unit is full.

990–91193A–001 59

ACRD300 and ACCU30000 Series Installation

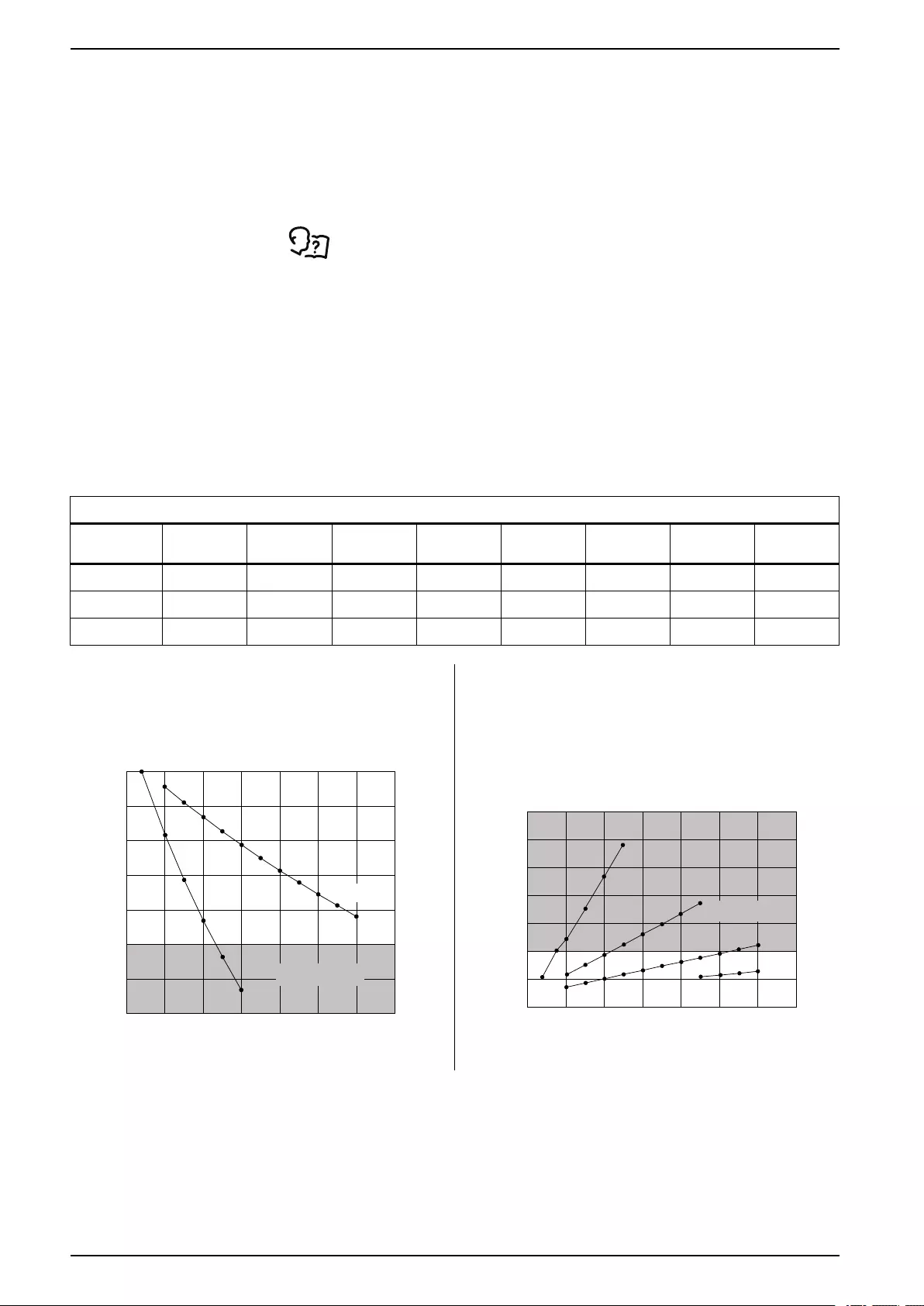

Refrigerant Piping

The indoor unit connects to an external condensing unit. Install all refrigerant lines

in accordance with applicable industry guidelines as well as local and national

codes and regulations. Calculate an equivalent length based on the actual linear

length of the run, including valves and fittings.

NOTE: All fittings should be long-radius to minimize pressure drop.

See Refrigeration Piping Diagram, page 30.

Make all refrigerant lines as short and direct as possible. Horizontal suction lines

must be pitched downward at a minimum of 4 mm per m (1/2 in. per 10 ft) in the

direction of flow to aid in oil return. Install a trap in the suction line at the bottom of

the riser and additional traps approximately every 6 m (20 ft) of rise to ensure

proper oil return. Isolate piping from structural surfaces using vibration clamps.

NOTE: Field-installed gas lines must be insulated.

NOTE: Install all piping in accordance with applicable industry guidelines as

well as local and national codes and regulations.

The following table provides ASHRAE standards for equivalent piping lengths of

fittings and valves.

Type of Fitting or Valve—Equivalent Length of Pipe in m (ft)

Nominal

Pipe Size

ACR

Tubing Size

Gate Valve Angle Valve Globe

Valve

Standard

Elbow 90°

Contraction

1/2

Tee Branch Tee

Straight

3/4 in. 7/8 in. 0.27 (0.9) 2.74 (9.0) 6.71 (22.0) 0.61 (2.0) 0.30 (1.0) 1.22 (4.0) 0.43 (1.4)

1 in. 1 1.8 in. 0.30 (1.0) 3.66 (12.0) 8.84 (29.0) 0.79 (2.6) 0.37 (1.2) 1.52 (5.0) 0.52 (1.7)

1 1/4 in. 1 3.8 in. 0.46 (1.5) 4.57 (15.0) 11.58 (38.0) 1.01 (3.3) 0.55 (1.8) 2.13 (7.0) 0.70 (2.3)

Size the suction line piping based on the equivalent

length to provide a capacity greater than 90% of the

rated capacity.

Size the liquid line piping based on the equivalent

length to provide a sub-cooling loss of less than 2°C

(3.6°F).

0

(0)

86%

88%

90%

92%

94%

96%

98%

100%

SUCTION LINE EQUIVALENT PIPING LINE LENGTH – m (ft)

PERCENT OF RATED CAPACITY

RECOMMENDED PIPE SIZES

20.0

(65.6)

40.0

(131.2)

60.0

(196.9)

80.0

(262.5)

100.0

(328.1)

120.0

(393.7)

140.0

(459.3)

1 1/8 in.

7/8 in.

UNACCEPTABLE

RANGE

na7005a

1 (1.8)

2 (3.6)

3 (5.4)

4 (7.2)

0 (0) 0

(0)

20.0

(65.6)

40.0

(131.2)

60.0

(196.9)

80.0

(262.5)

100.0

(328.1)

120.0

(393.7)

140.0

(459.3)

5 (9.0)

6 (10.8)

7 (12.6)

1/2 in. 5/8 in. 3/4 in.

7/8 in.

SUB-COOLING LOSS – °C (°F)

LIQUID LINE EQUIVALENT LINE LENGTH – m (ft)

UNACCEPTABLE

RANGE

na7006a

NOTE: The maximum vertical height of the condensing unit above the indoor unit is 30 m (98 ft).

60 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Unit Connections

Be sure to use only clean, air conditioning/refrigeration (ACR) pipe and follow

standard procedures for pipe size selection for air-cooled equipment. All

refrigerant piping must be Type L ACR hard-drawn copper pipes (soft/annealed

copper is unacceptable) and must be 700 psig UL rated or equivalent. The

maximum allowable equivalent length between the evaporator and condenser is

120 equivalent m (394 equivalent ft). Vertical runs require a trap every 6 m (20 ft)

of rise.

IMPORTANT: The outdoor condensing unit can only be installed at the same

level or higher than the indoor unit. The maximum vertical height above the

indoor unit is 30 m (98 ft).

NOTE: When brazing field-installed copper refrigeration lines, use a nitrogen

purge to minimize contamination of the refrigeration system during the brazing

process.

The air-cooled equipment has been dehydrated at the factory and is shipped with

a holding charge of nitrogen. Test refrigerant connections for leaks before

replacing the holding charge.

NOTE: Remove the nitrogen holding charge tag from the lines after nitrogen

removal and product startup.

990–91193A–001 61

ACRD300 and ACCU30000 Series Installation

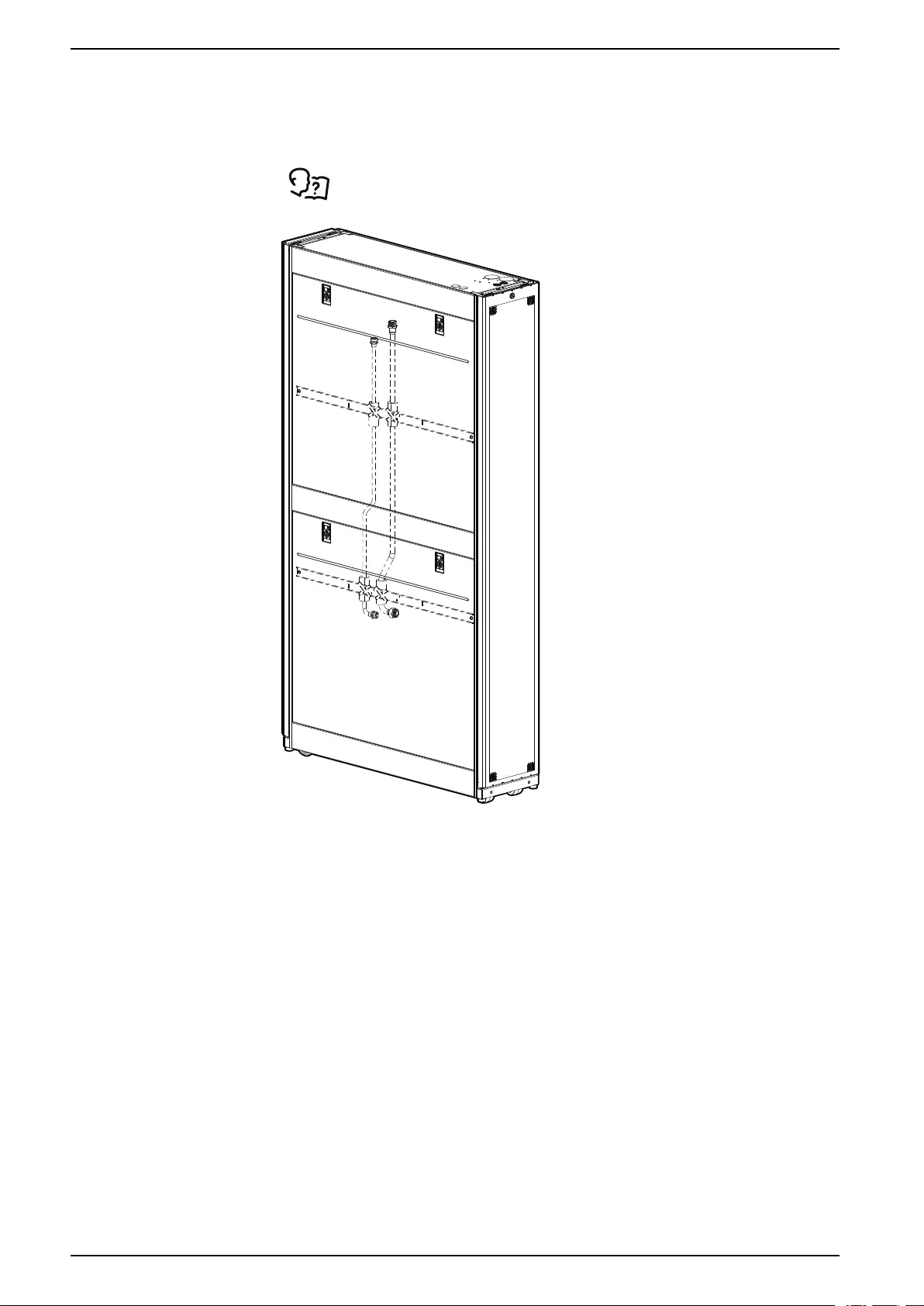

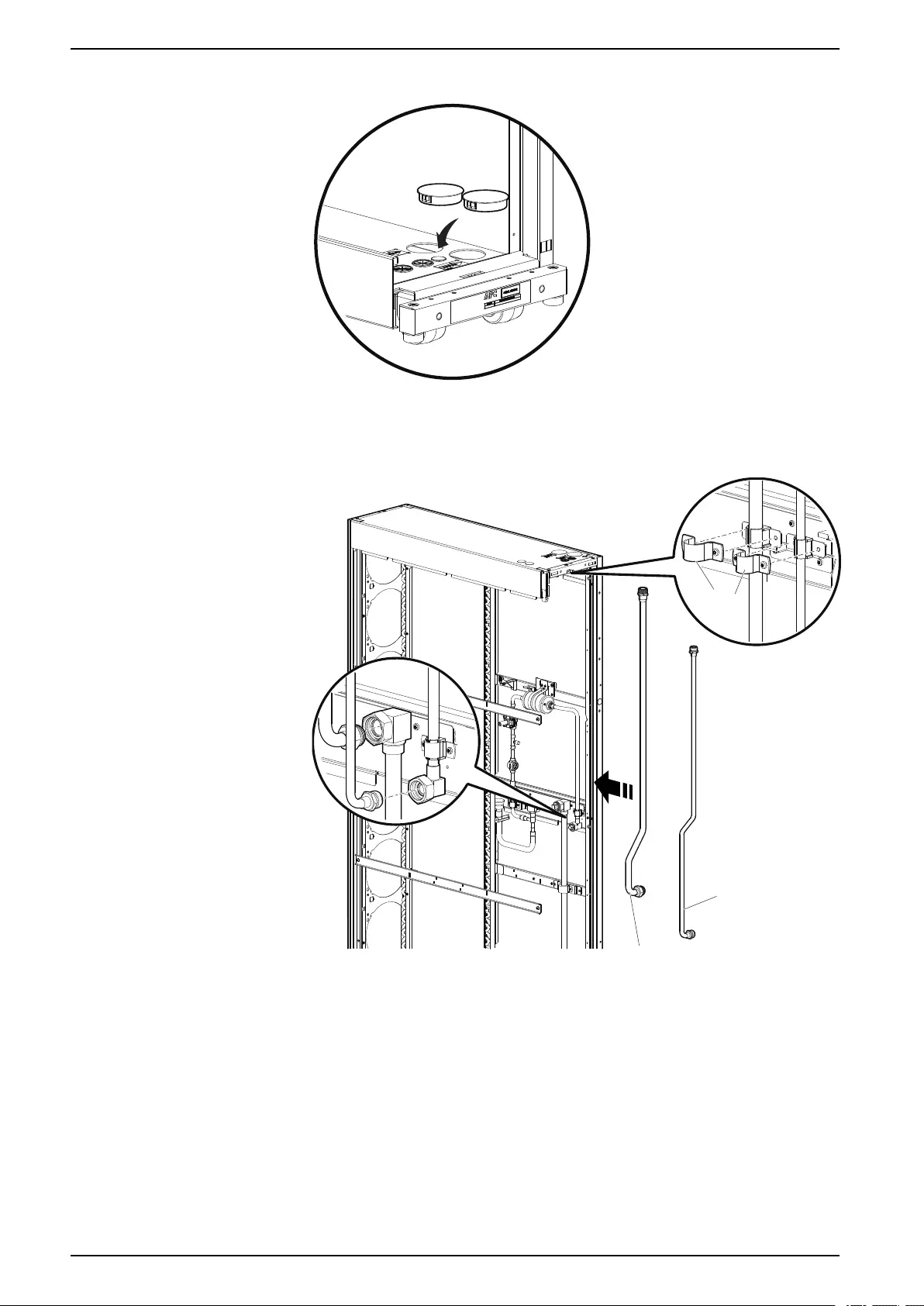

Suction and Liquid Line Piping Connections

The suction and liquid line pipes are shipped inside the unit attached to the side

braces. Remove the piping from inside the unit.

See Removing Doors and Panels, page 44.

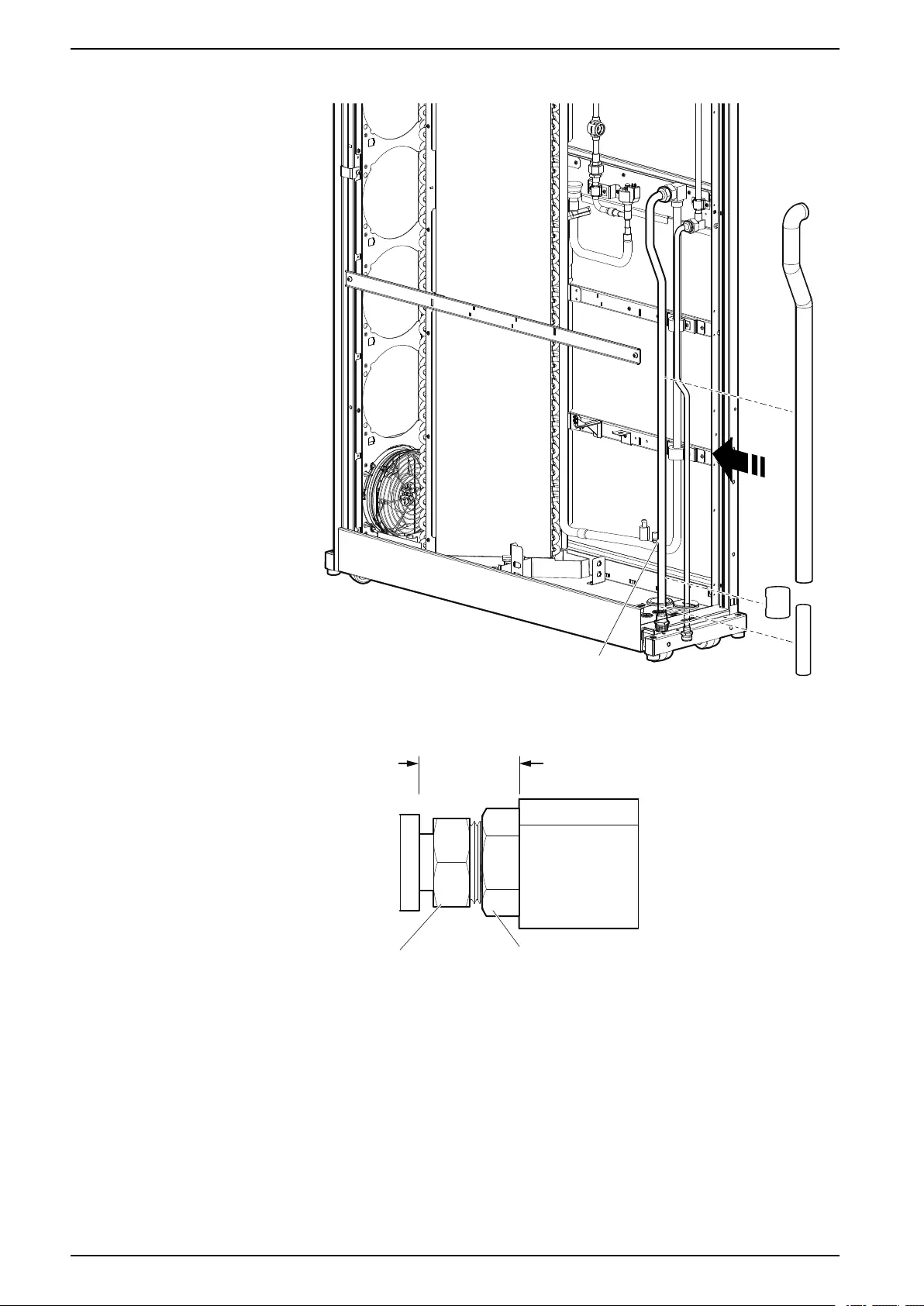

na6983b

NOTE: Some components not shown for clarity.

62 990–91193A–001

Installation ACRD300 and ACCU30000 Series

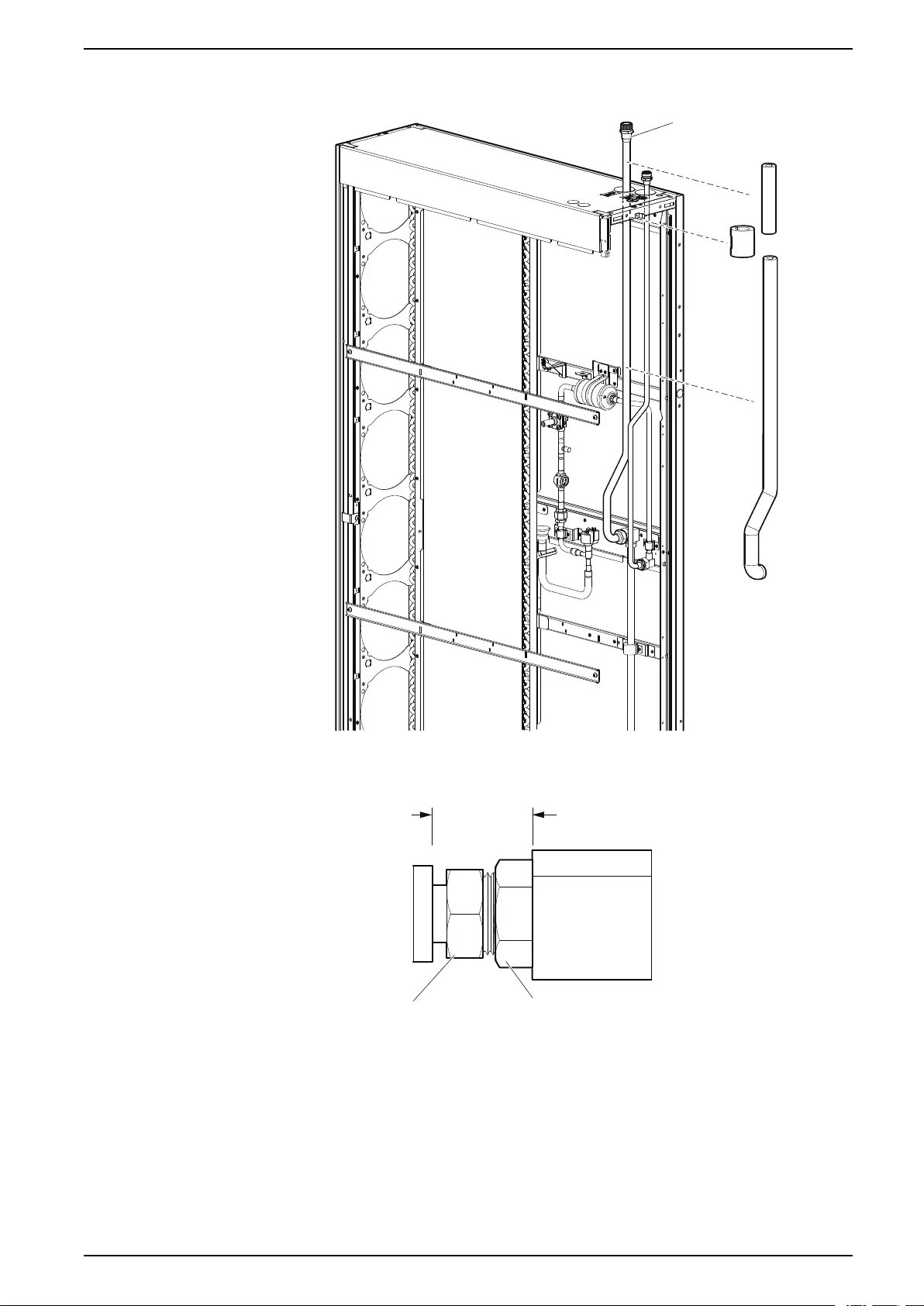

Top Routing

1. Remove the pipe connection caps from the unit piping, the caps from the

inlets, and the pipe clamps from the side of the unit.

PLUGS

PIPE

CLAMPS

CAPS

na6982a

2. Remove the grommets from the bottom piping inlets and move them to the

top piping inlets.

GROMMETS

na7007a

990–91193A–001 63

ACRD300 and ACCU30000 Series Installation

3. Place the plugs from the top piping inlets in the bottom piping inlets.

na7008a

4. Hold the pipes in position by replacing the pipe clamps. Tighten connections

to 50 Nm (37 lb-ft).

NOTE: Use caution when routing the pipes through the top of the unit to

avoid damaging sensors.

PIPE

CLAMPS

LIQUID LINE

PIPE

SUCTION LINE

PIPE

na6984a

64 990–91193A–001

Installation ACRD300 and ACCU30000 Series

5. Place insulation on the suction line unit piping.

SUCTION LINE PIPE

na6986a

NOTE: There is a gap between the provided insulation around the union.

Insulation needs to be field supplied for the suction line union.

na7051a

GAP

SUCTION LINE

PIPE

UNION

990–91193A–001 65

ACRD300 and ACCU30000 Series Installation

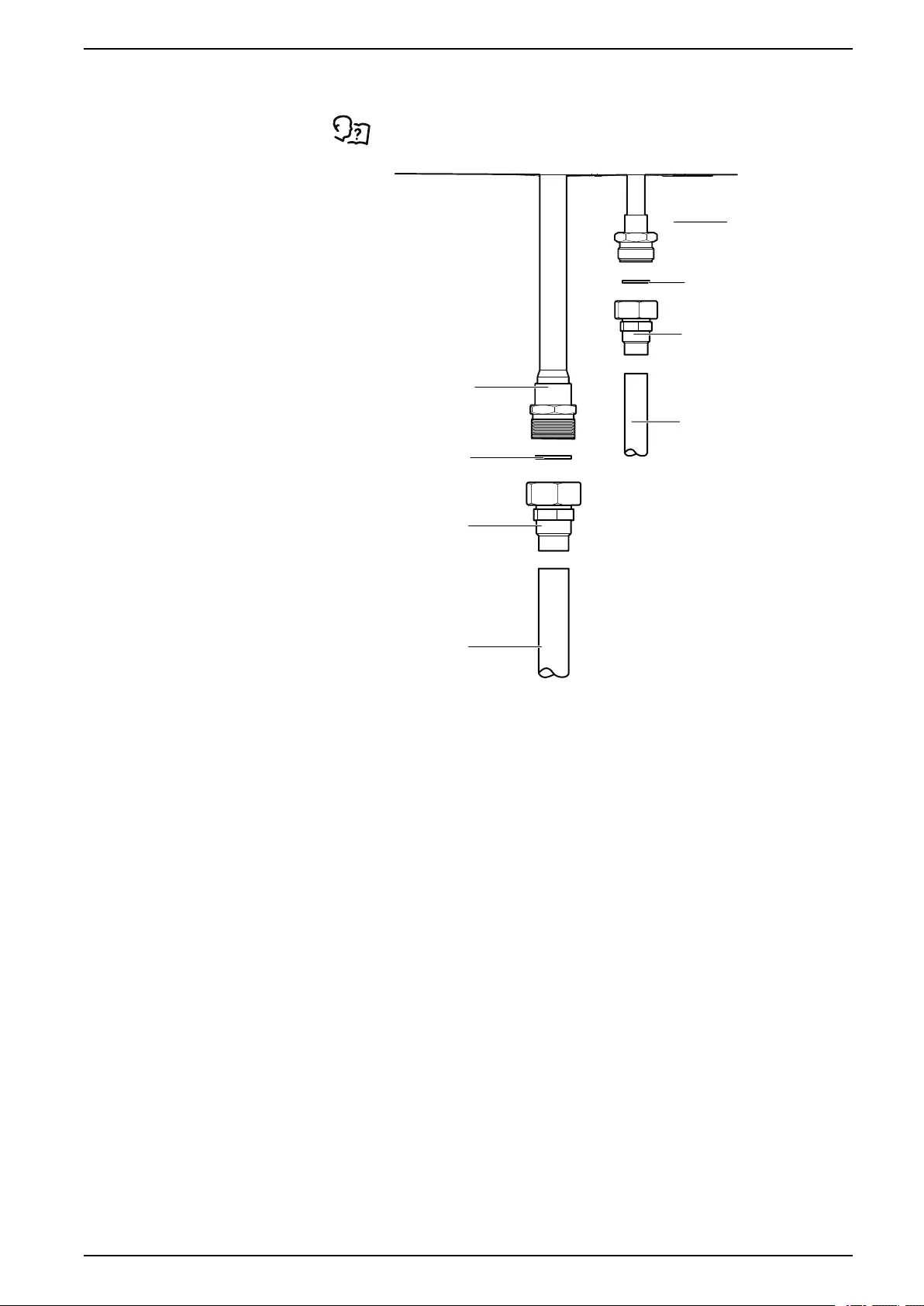

6. Make customer piping connections.

If the ball valve and union kit (ACAC10037) will be installed, see the

sheet included with the kit for installation instructions.

SUCTION LINE

LIQUID LINE

1 IN. GASKET

CUSTOMER PIPING

(FIELD SUPPLIED)

CUSTOMER PIPING

(FIELD SUPPLIED)

CUSTOMER PIPING

(FIELD SUPPLIED)

1 1/4 IN. GASKET

BALL VALVE AND UNION

(ACAC10037

OR FIELD SUPPLIED)

na7009a

BALL VALVE AND UNION

(ACAC10037

OR FIELD SUPPLIED)

66 990–91193A–001

Installation ACRD300 and ACCU30000 Series

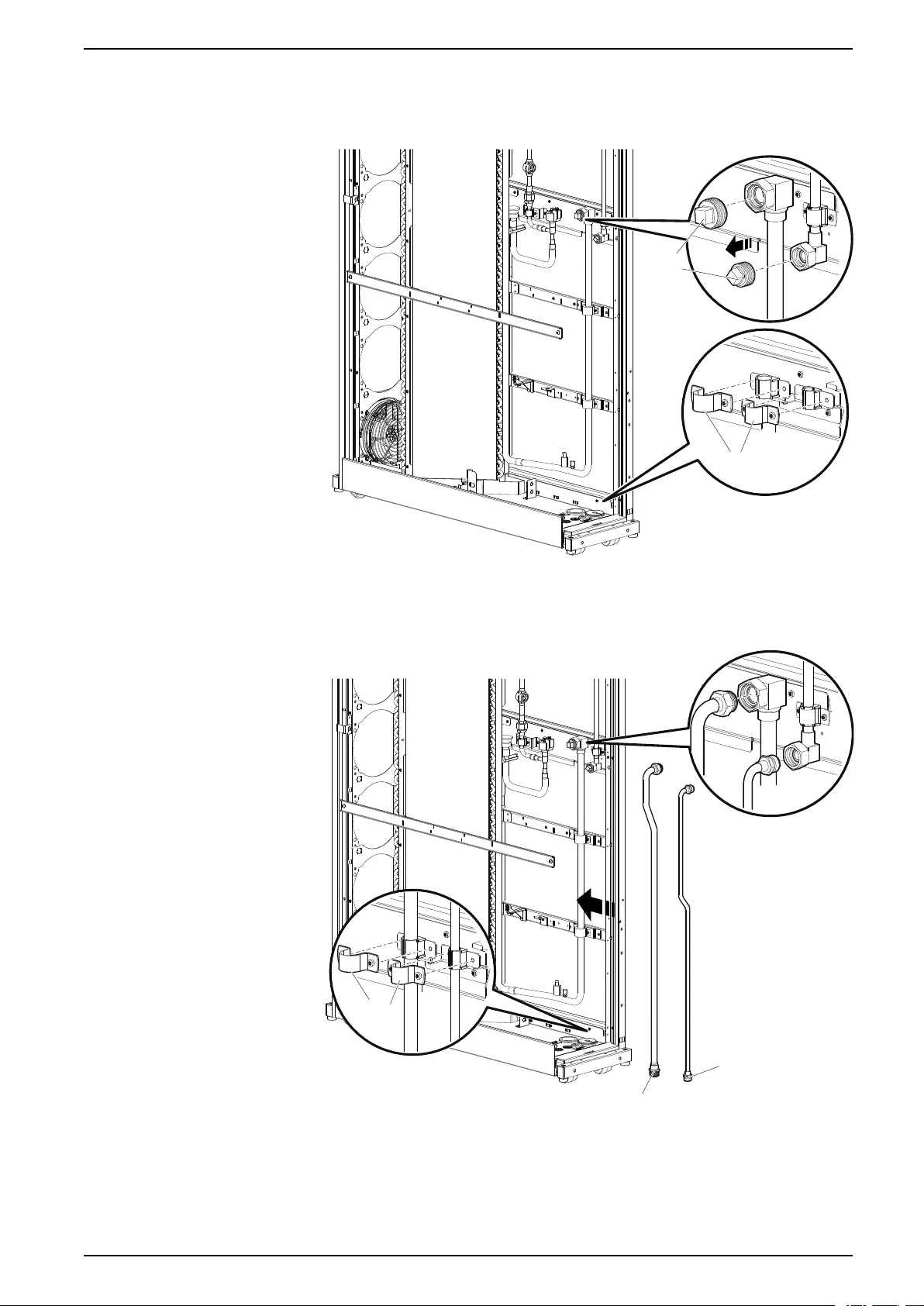

Bottom Routing

1. Remove the pipe connection caps from the unit piping and the pipe clamps

from the side of the unit.

PIPE

CLAMPS

CAPS

na6987a

2. Hold the pipes in position by replacing the pipe clamps. Tighten connections

to 50 Nm (37 lb-ft).

NOTE: Use caution when routing the pipes through the bottom of the unit

to avoid damaging sensors.

PIPE

CLAMPS

LIQUID LINE

PIPE

SUCTION LINE PIPE

na6988a

990–91193A–001 67

ACRD300 and ACCU30000 Series Installation

3. Place insulation on the suction line unit piping.

SUCTION LINE PIPE

na6989a

NOTE: There is a gap between the provided insulation around the union.

Insulation needs to be field supplied for the suction line union.

na7051a

GAP

SUCTION LINE

PIPE

UNION

68 990–91193A–001

Installation ACRD300 and ACCU30000 Series

4. Make customer piping connections.

If the ball valve and union kit (ACAC10037) will be installed, see the

sheet included with the kit for installation instructions.

SUCTION LINE

LIQUID LINE

1 IN. GASKET

1 1/4 IN. GASKET

BALL VALVE AND UNION

(ACAC10037

OR FIELD SUPPLIED)

BALL VALVE AND UNION

(ACAC10037

OR FIELD SUPPLIED)

na7009b

CUSTOMER PIPING

(FIELD SUPPLIED)

CUSTOMER PIPING

(FIELD SUPPLIED)

CUSTOMER PIPING

(FIELD SUPPLIED)

990–91193A–001 69

ACRD300 and ACCU30000 Series Installation

Electrical Connections

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must be installed and serviced by qualified personnel only.

• Turn off all power supplying this equipment before working on or inside the

equipment.

• Replace all devices, doors, and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Potentially dangerous and lethal voltages exist within this unit. More than one

disconnect switch may be required to energize or de-energize this equipment.

Observe all cautions and warnings. Failure to do so could result in serious injury

or death. Only qualified service and maintenance personnel may work on this

equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

The following electrical connections are required in the field:

• Power to the indoor unit (single-phase plus ground)

• Power to the outdoor unit (three-phase plus ground)

• Communication (A-Link, Building Management System, Modbus)

• Outdoor unit RS-485 connection

• Sensors

See the electrical schematic (located on the electrical box) for all

electrical connections.

See the equipment name plate for voltage and current requirements.

All low-voltage connections, including data and control connections, must be

made with properly insulated wires. Low-voltage wiring must be insulated based

on the wiring with which it is routed. The low-voltage connections must have 300-

V minimum insulation.

NOTE: A power disconnect is required to isolate each unit for maintenance

and servicing.

70 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Power Connections

WARNING

ELECTRICAL HAZARD

• Electrical service must conform to local and national electrical codes and

regulations.

• The equipment must be grounded.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

HAZARD TO EQUIPMENT OR PERSONNEL

All work must be performed by Schneider Electric qualified personnel.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Primary and Secondary Power Feeds

All indoor unit models and some of the outdoor units (ACCU30302, ACCU3002,

ACCU30202, and ACCU30102) are capable of receiving power through one of

two separate feeds: primary feed or secondary feed. Use the display interface to

configure the unit to receive power through the primary feed, the secondary feed,

or both). The equipment receives power through the primary feed regardless of

whether the secondary feed is receiving power. If power is removed from the

primary feed, the secondary feed takes over and supplies power to the equipment

(if a secondary feed is connected).

Connect the primary feed and secondary feed input cables to individual, breaker-

controlled branch circuits or to PDUs backed by separate Uninterruptible Power

Supplies (UPS).

NOTE: The primary and secondary feeds must not use the same branch

circuit, PDU, or UPS.

990–91193A–001 71

ACRD300 and ACCU30000 Series Installation

Indoor Unit—ACRD300, ACRD300D, ACRD300G, ACRD300GD

Power connections can be routed through the top or bottom of the unit.

NOTE: Some components not shown for easier viewing.

1. Remove the plugs from the power supply inlets that will be used on top of the

unit or bottom of the unit.

na6969a

TOP CONNECTION BOTTOM CONNECTION

2. Remove the rear door and filters.

See Removing Doors and Panels, page 44.

3. Remove the cover from the ATS.

NOTE: The ATS in ACRD300 units is different from other units and

includes an EMI filter; power connections are made the same.

na6970a

na7203a

ACRD300 ONLY

72 990–91193A–001

Installation ACRD300 and ACCU30000 Series

Indoor Unit (Top Routing)—ACRD301, ACRD301G

Power connections can be routed through the top or bottom of the unit: this

section covers a top routing.

NOTE: Some components not shown for easier viewing.

1. Remove the cover plate from the top of the unit.

na7036a

2. Remove the rear door and filters.

See Removing Doors and Panels, page 44.

3. Remove the cover from the ATS.

na6970b

990–91193A–001 75

ACRD300 and ACCU30000 Series Installation

8. Configure the voltage.

• 200–240 V: Connect the wire labeled F2-1 to the 240–V fuse.

• 100–120 V: Connect the wire labeled F2-1 to the 120–V fuse.

na7050a

F1

F2

F3

F4

120 V

240 V

24 AC

24 DC

See the ladder diagram included with the unit for more information.

9. Replace the ATS cover, filters, and rear door.

78 990–91193A–001

Installation ACRD300 and ACCU30000 Series

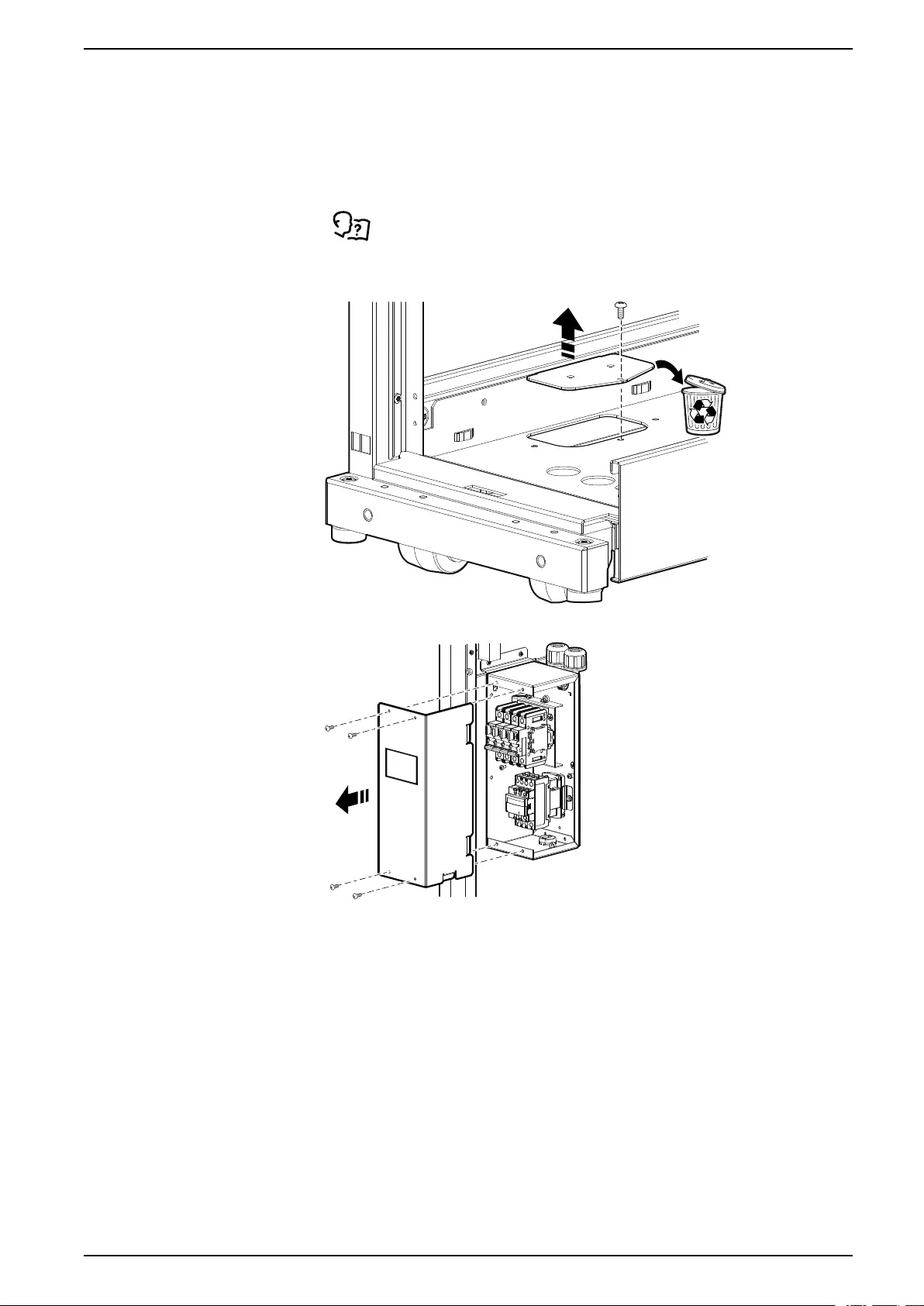

Indoor Unit (Bottom Routing)—ACRD301, ACRD301G

Power connections can be routed through the top or bottom of the unit: this

section covers a bottom routing.

NOTE: Some components not shown for easier viewing.

1. Remove the rear door and filters.

See Removing Doors and Panels, page 44.

2. Remove the cover plate from the bottom of the unit and recycle the plate.

na7039a

3. Remove the cover from the ATS.

na6970b

990–91193A–001 79

Installation ACRD300 and ACCU30000 Series

9. Configure the voltage.

• 200–240 V: Connect the wire labeled F2-1 to the 240–V fuse.

• 100–120 V: Connect the wire labeled F2-1 to the 120–V fuse.

na7050a

F1

F2

F3

F4

120 V

240 V

24 AC

24 DC

See the ladder diagram included with the unit for more information.

10. Replace the ATS cover, filters, and rear door.

990–91193A–001 83

ACRD300 and ACCU30000 Series Installation

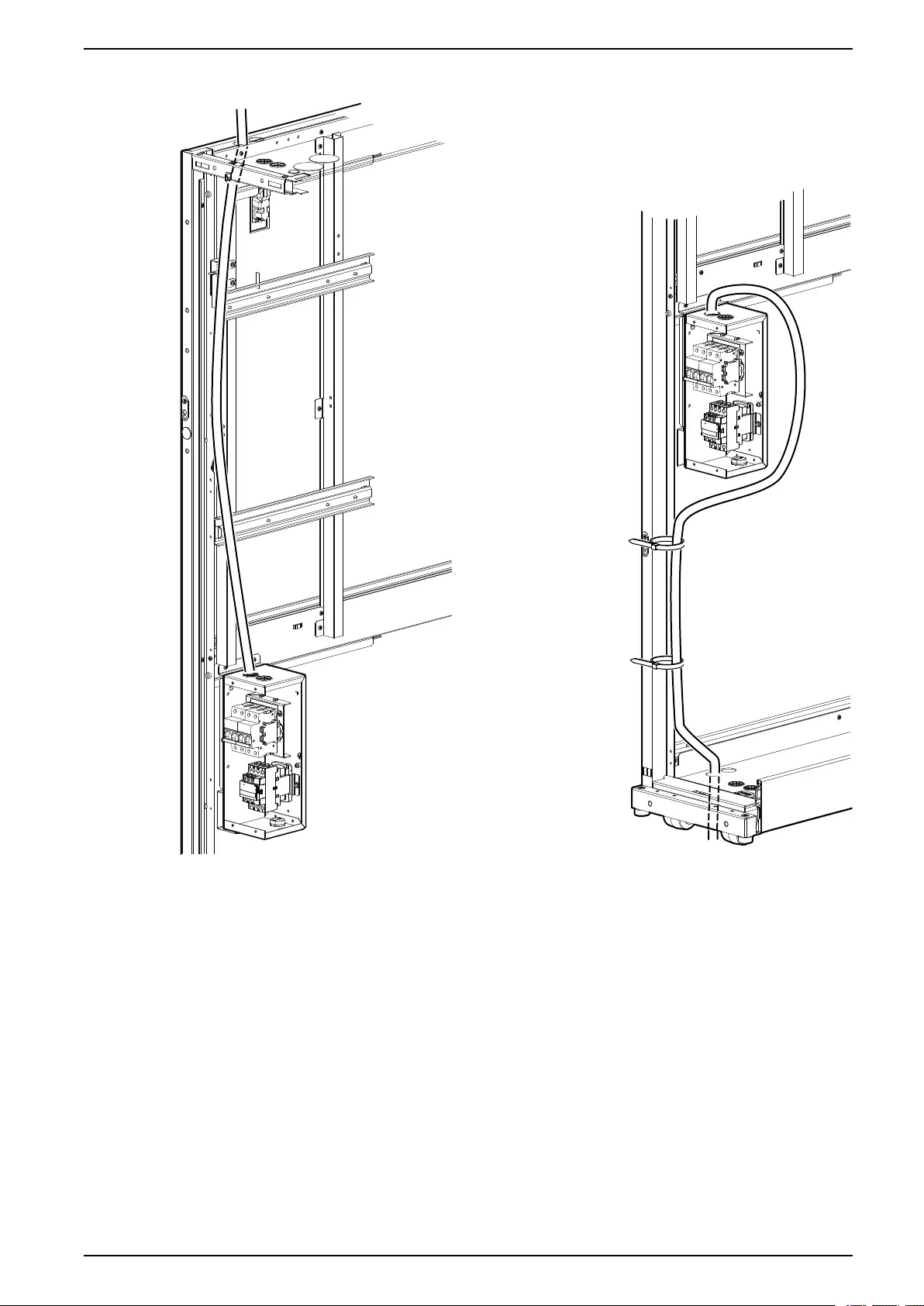

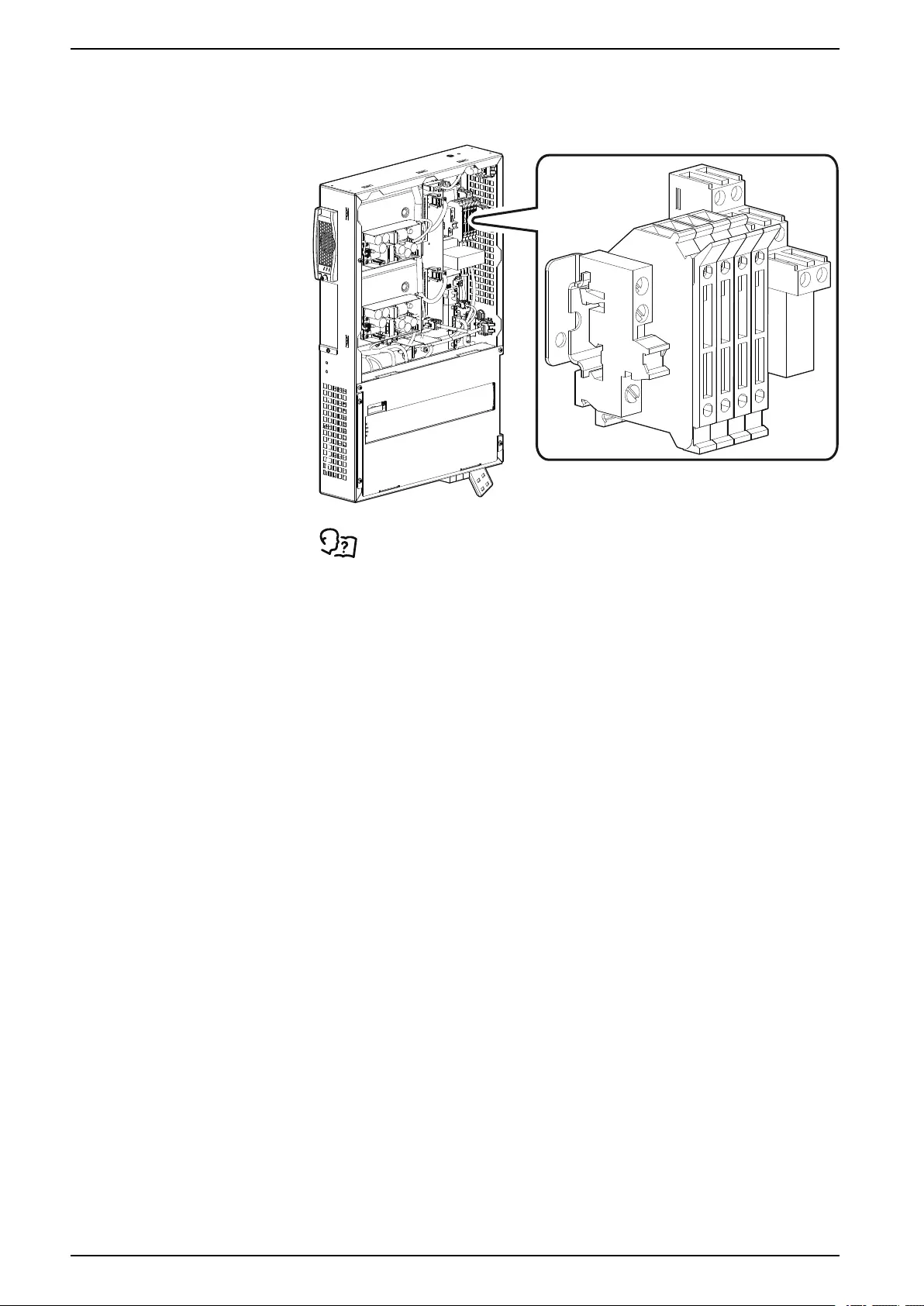

Outdoor Unit—ACCU30301, ACCU30302

1. Remove the service and internal protection panels, and open the electrical

panel.

See Removing Doors and Panels, page 44.

2. Remove the cover plate and plugs from the power supply inlets.

na6968c

COVER PLATE

PLUGS

3. Route the cable or cables through the unit to the electrical panel.

NOTE: Use a conduit at least 25 mm (1 in.) ID to protect the exposed

portion of the power cable between the unit and the building. The conduit

must conform to any applicable local and national codes.

na6968b

84 990–91193A–001

ACRD300 and ACCU30000 Series Installation

Outdoor Unit—ACCU30001, ACCU30002, ACCU30201, ACCU30202,

ACCU30101, ACCU30102

1. Remove the service and internal protection panels, and open the electrical

panel.

See Removing Doors and Panels, page 44.

2. Remove the cover plate and plugs from the power supply inlets.

na6968c

COVER PLATE

PLUGS

3. Route the cable or cables through the unit to the electrical panel.

NOTE: Use a conduit at least 25 mm (1 in.) ID to protect the exposed

portion of the power cable between the unit and the building. The conduit

must conform to any applicable local and national codes.

na6968b

86 990–91193A–001

ACRD300 and ACCU30000 Series Installation

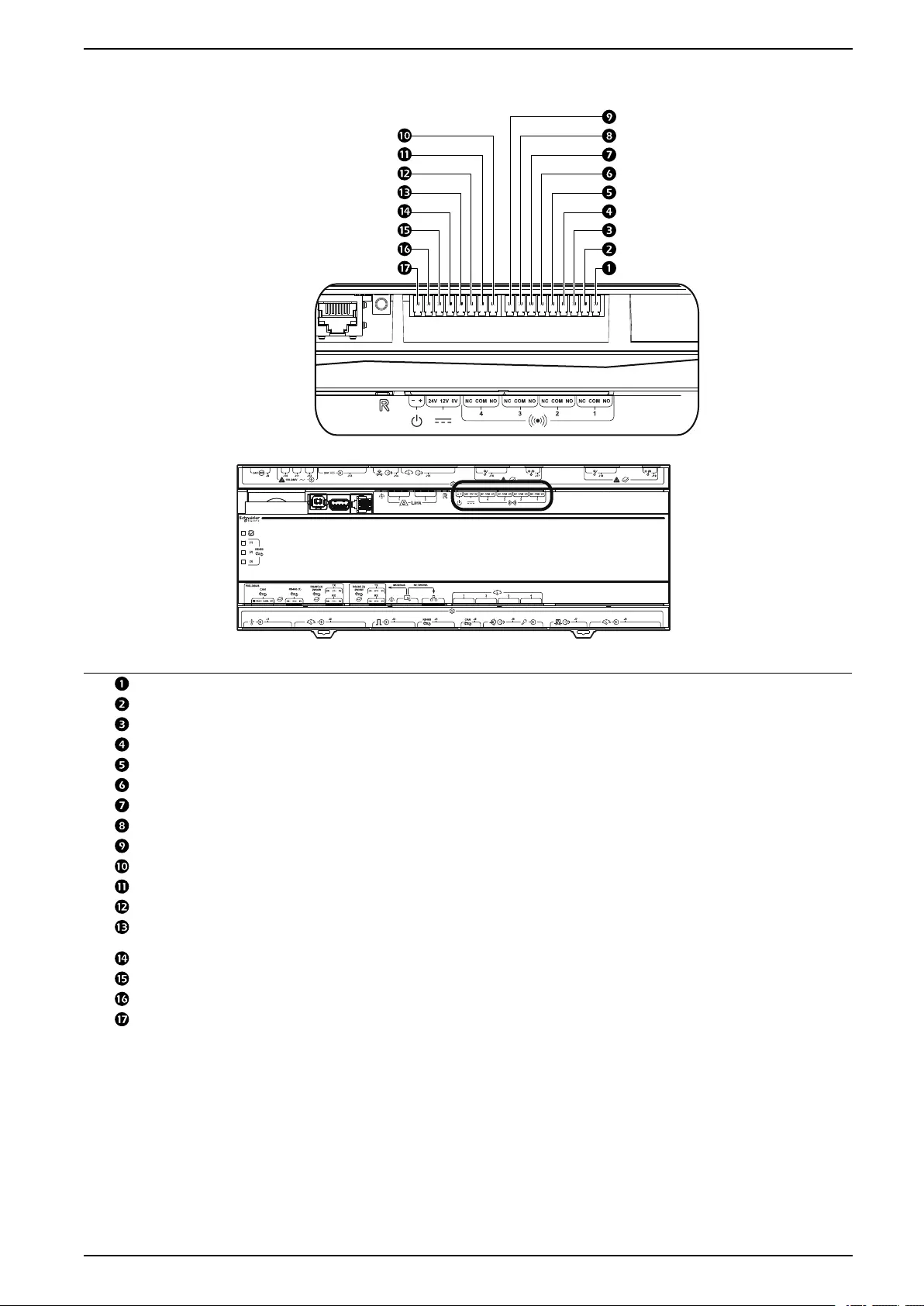

Communication Connections

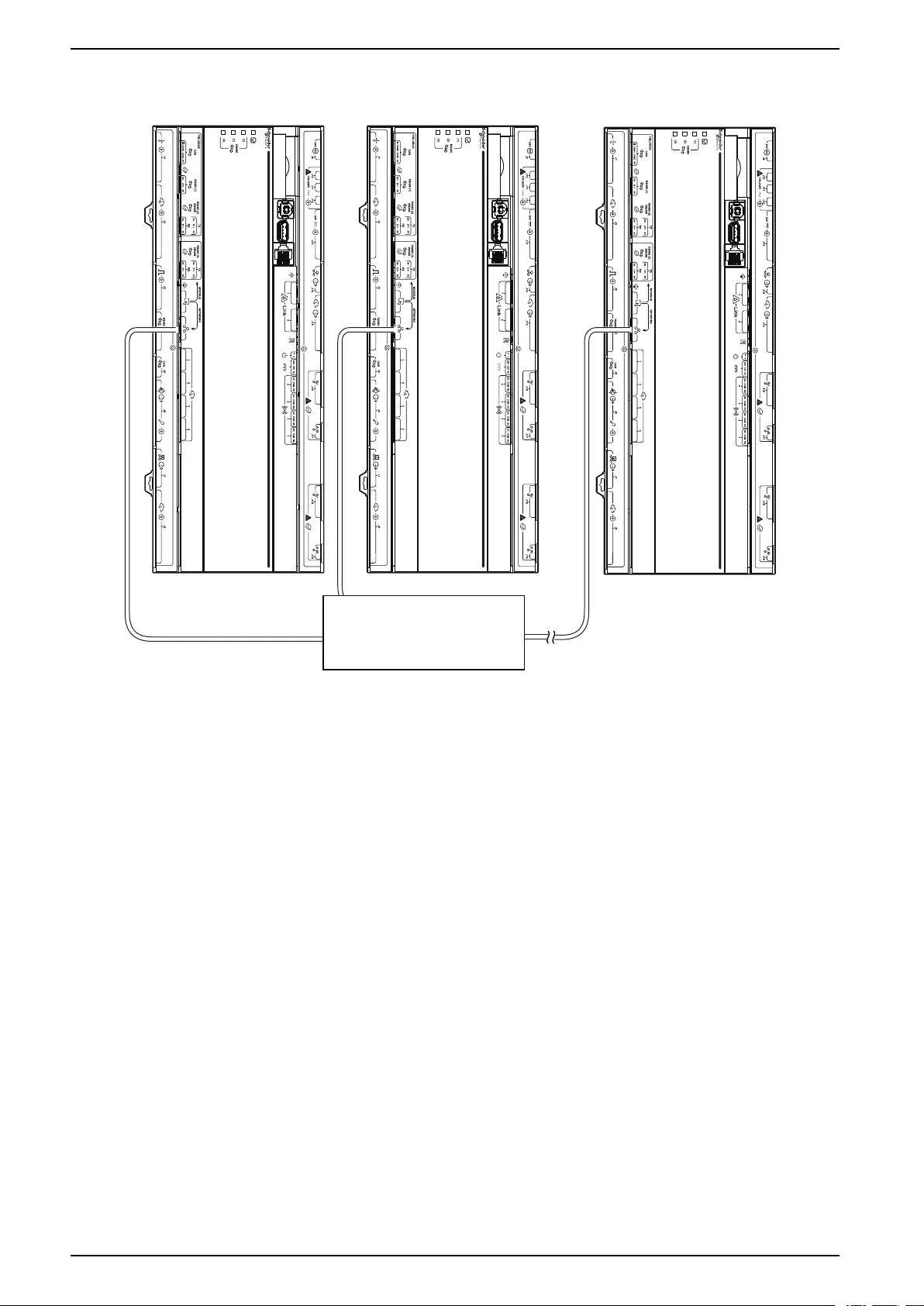

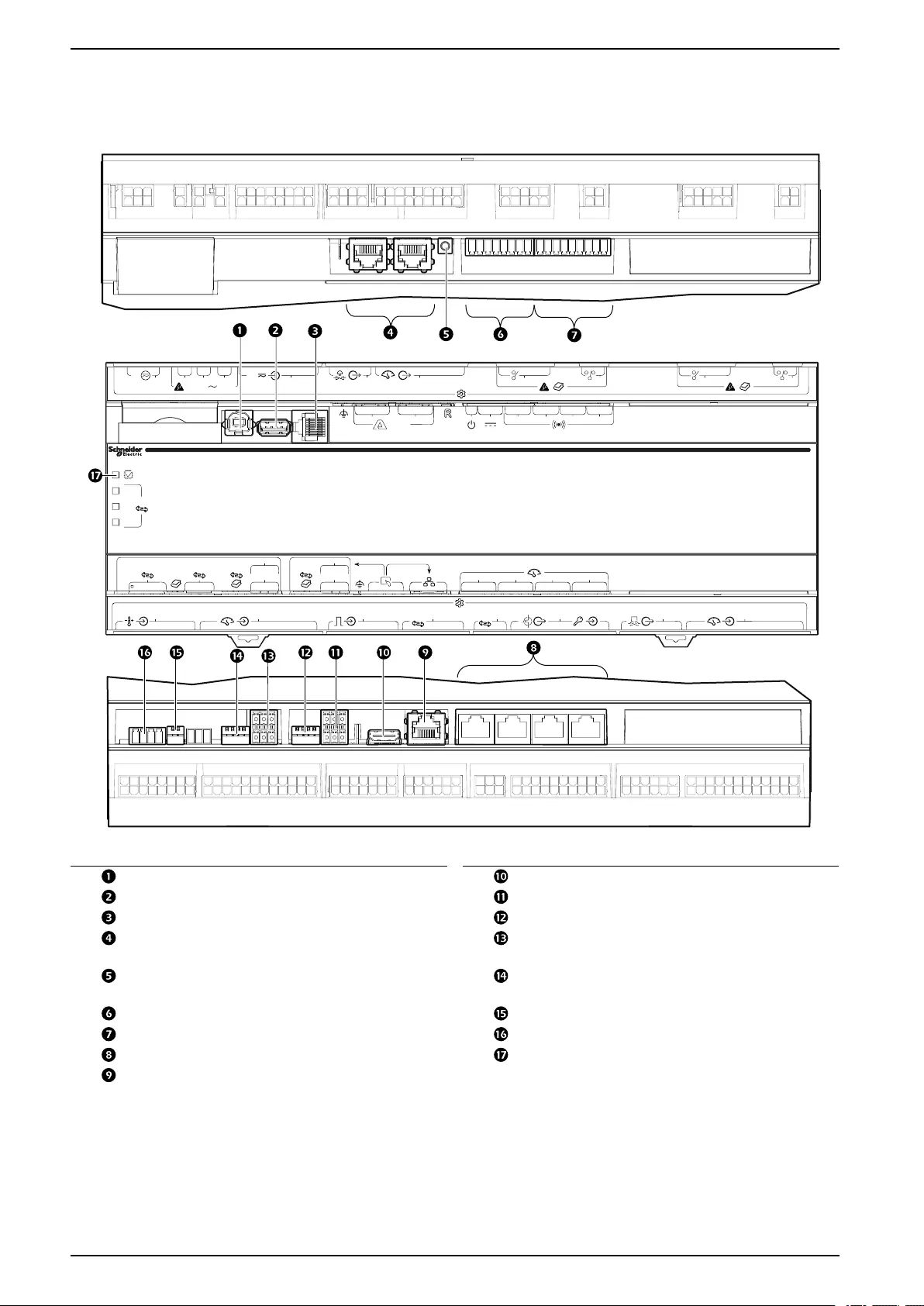

Interface Connection

J15

J9

24V

J10 J11 J12

100-240V

J13

24V

J14 J16 J17 J18 J19

123

NC COM NONC COM NONC COM NO

4

24V 12V 0V

– +

21 – Link

21

3 4

(1)

(2)

(3)

RS485

RS485 (1)

FIELDBUS

CAN

CANH CANL 0V D0- D1+ 0V

RS485 (2)

2W/4W D0- D1+ 0V

D0- D1+ 0V

TX

RX

RS485 (3)

2W/4W D0- D1+ 0V

D0- D1+ 0V

TX

RX

MODBUS NETWORK

12 3 4

J8J7

M

J6

J5J4 CAN

RS485

J3J2J1

na6256a

Item Description Item Description

USB device port Touch screen display connection

USB host port (Not available) Modbus connection

Serial port (Not available) Modbus configuration switches

A-Link ports Fieldbus Modbus connection (Not

available)

Reset button Fieldbus Modbus configuration switches

(Not available)

Output relay 4/standby input Fieldbus CANbus configuration switches