Table of Contents

- Important Safety Instructions — SAVE THESE INSTRUCTIONS

- Specifications

- Mechanical Assembly

- Floor Mounting

- Connect Input and PE Cables in Single Systems

- Connect Input and PE Cables in Parallel Systems

- Connect PE Cable in TNC System

- Connect the Communication Cables

- Install an External Battery

- Install a Battery Circuit Breaker Kit for Third Party Battery Cabinets (Option)

- Battery Circuit Breaker Enclosure (Option)

- Install the Battery Temperature Monitor (Option)

- Install the Synchronization Module (Option)

- Install an External Bypass

- Install Marine UPS Adaptation Voltage Transformer

- Install Isolation Transformer (Option)

APC MGE Galaxy 5500 User Manual

Displayed below is the user manual for MGE Galaxy 5500 by APC which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

Galaxy 5500 / Galaxy 5500 Marine

20 - 120 kVA 400 V

Installation

05/2016

www.schneider-electric.com

Legal Information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the owner's

permission, given in writing. This guide and its content are protected, within the

meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications, and designs change from time to time, please ask for

confirmation of the information given in this publication.

20 - 120 kVA 400 V

Table of Contents

Important Safety Instructions — SAVE THESE

INSTRUCTIONS.........................................................................................7

Safety Precautions .....................................................................................8

Electrical Safety..................................................................................10

Periodical Check................................................................................. 11

Battery Safety..................................................................................... 11

Electromagnetic Compatibility..............................................................12

Specifications ............................................................................................13

Input........................................................................................................13

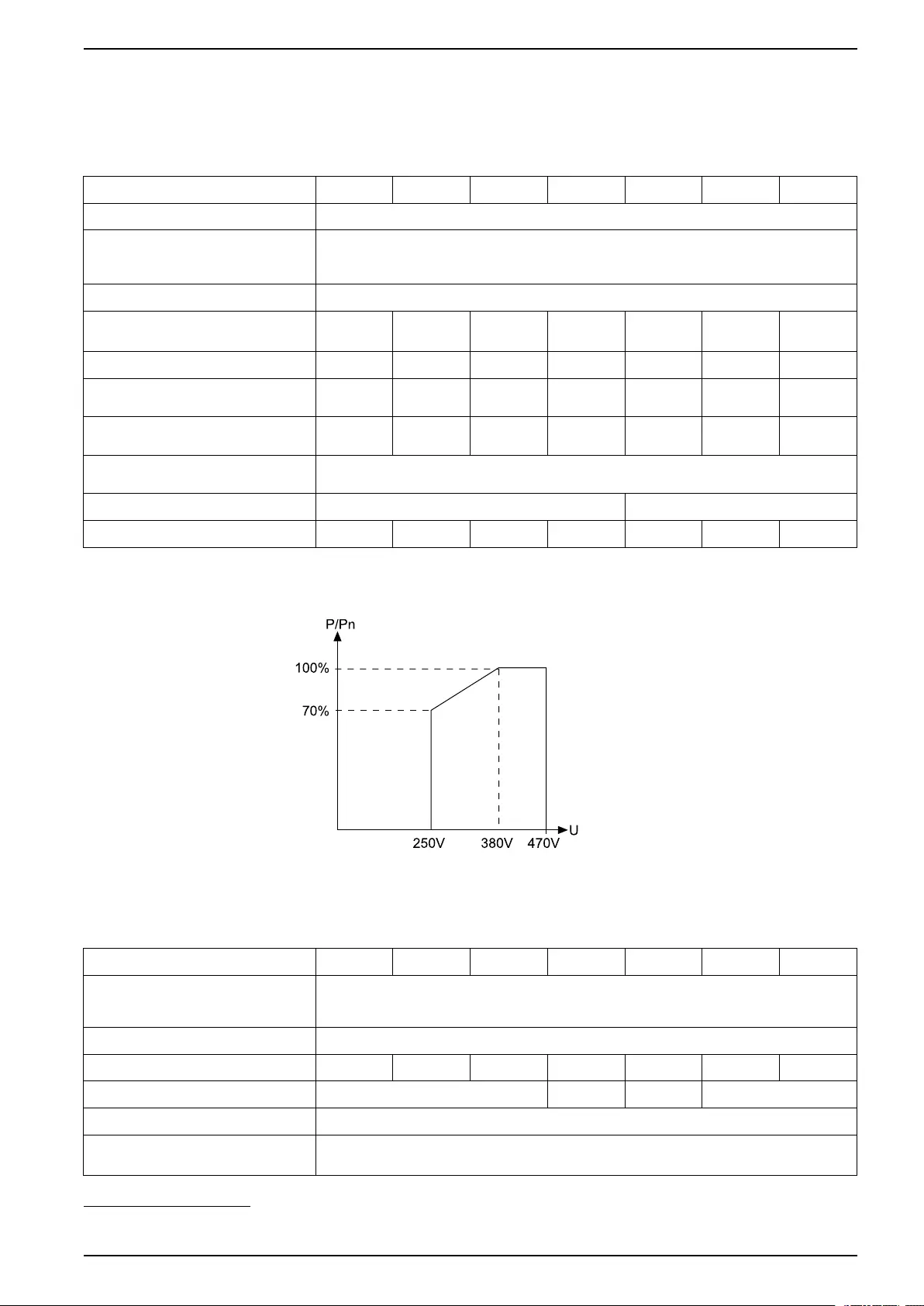

Power Supplied as a Function of Input Voltage......................................13

Output .....................................................................................................13

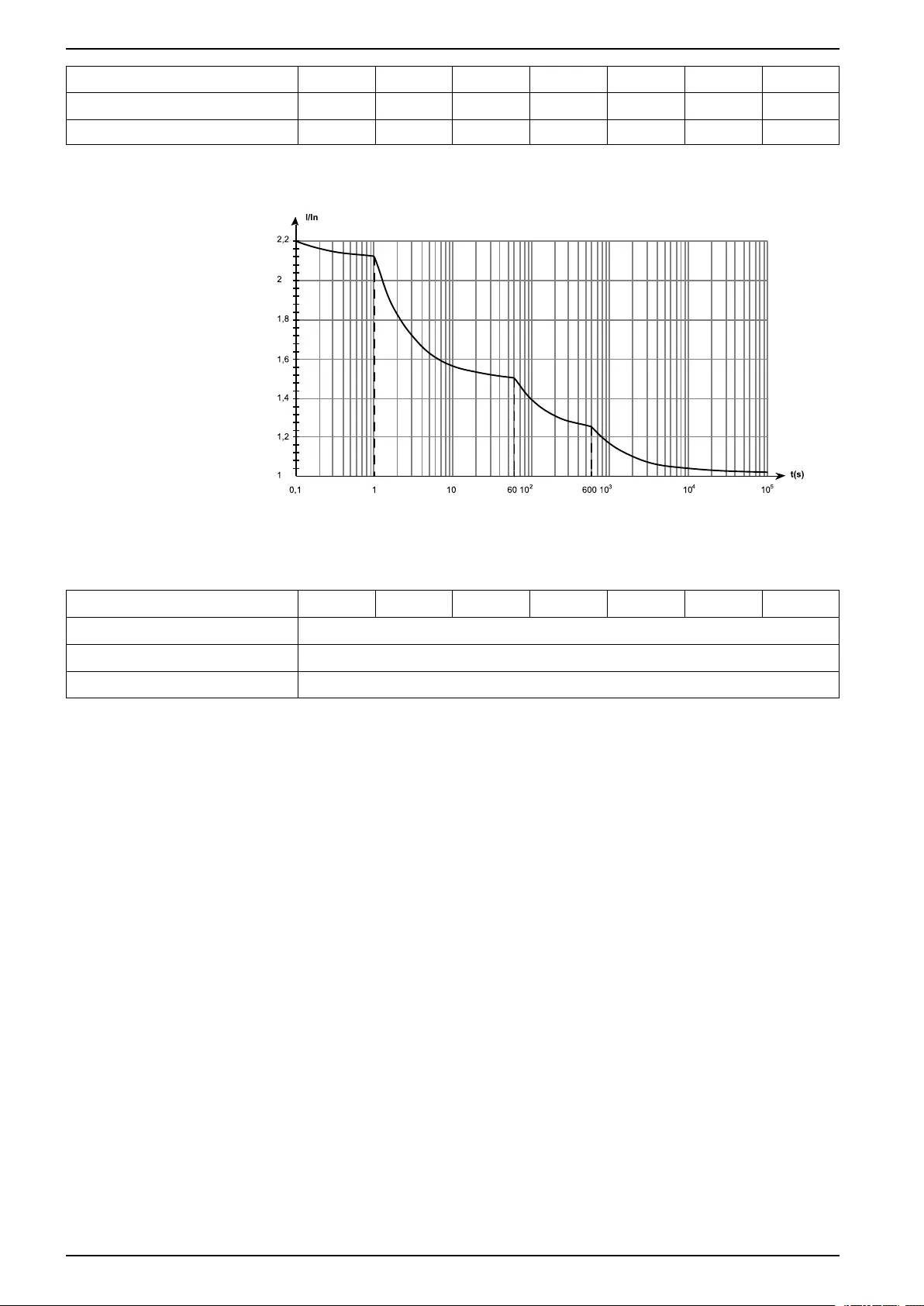

Permissible UPS Overloads as a Function of Time ................................14

Bypass ....................................................................................................14

Environment.......................................................................................15

Batteries ..................................................................................................16

DC Power Levels for Battery Sizing with Output Power Factor =

0.9.....................................................................................................16

DC Power Levels for Battery Sizing with Output Power Factor =

0.8.....................................................................................................16

Maximum Current at End of Discharge .................................................16

Recommended Circuit Breakers and Cable Sizes .......................................17

Selection of Circuit Breakers................................................................17

Recommended Upstream Circuit Breaker ............................................. 18

Recommended Downstream Circuit Breaker.........................................18

Earth-Leakage Current........................................................................18

Fuses.................................................................................................19

Recommended Cable Sizes ................................................................19

Transformers............................................................................................21

Marine UPS Adaptation Voltage Transformer Specifications...................21

Isolation Transformer Specifications .....................................................21

Battery Circuit Breaker Enclosure ..............................................................23

Mechanical Assembly ..............................................................................25

Layout of Cabinets....................................................................................25

Remove Battery Protection........................................................................26

Remove Battery Protection from the UPS .............................................26

Remove Battery Protection from the External Battery Cabinet ................26

Install the Top Entry Option........................................................................27

Install the IP32 Option...............................................................................29

Floor Mounting ..........................................................................................30

Connect Input and PE Cables in Single Systems ................................31

Single Utility/Mains Systems......................................................................31

Dual Utility/Mains Systems ........................................................................31

Frequency Converter ................................................................................32

Connect Input and PE Cables in Parallel Systems..............................34

Overview .................................................................................................34

Single Utility/Mains Systems......................................................................34

Dual Utility/Mains Systems ........................................................................35

990–5233D–001 3

20 - 120 kVA 400 V

Redundant Parallel System .................................................................35

Parallel System with External Bypass ...................................................35

Frequency Converter ................................................................................37

Connect PE Cable in TNC System.........................................................38

Connect the Communication Cables .....................................................39

Overview of the Communication Cables .....................................................39

Overview of Communication Cables in Single Systems..........................39

Overview of Communication Cables in Parallel Systems ........................ 40

Connect Dry Contact Communication Card ................................................41

Connect Network Management Card .........................................................43

Example of Communication Card Connection .............................................43

Add or Change Communication Cards .......................................................43

Connect General Shutdown or Remote Emergency Power Off .....................45

Connect Parallel Communication Cables....................................................45

Redundant Parallel System .................................................................45

Parallel System with External Bypass ...................................................46

Install an External Battery........................................................................48

Lock Battery Cells on Shelves for Marine UPS ............................................48

Connect the Battery Cables.......................................................................49

Install An Empty Battery Cabinet................................................................50

Install Battery Circuit Breaker Kit ..........................................................50

Install Shelves and Battery Cells ..........................................................51

Connect the Battery Remote Control .......................................................... 52

Install a Battery Circuit Breaker Kit for Third Party Battery

Cabinets (Option)......................................................................................54

Battery Circuit Breaker Enclosure (Option)...........................................57

Install Battery Circuit Breaker Enclosure.....................................................59

Install the Battery Temperature Monitor (Option) .................................61

Install the Synchronization Module (Option) .........................................62

Overview of the Synchronization Module ....................................................62

Mount the Synchronization Module to the Wall ............................................62

Recommended Cable Sizes ......................................................................63

Connect Cables to the Synchronization Module for Single UPS....................63

Connect Cables to the Synchronization Module in a Parallel System ............64

Input and Output Contacts.........................................................................66

Characteristics....................................................................................66

Outputs..............................................................................................66

Inputs.................................................................................................66

Install an External Bypass .......................................................................67

Install 150 kVA External Bypass Cabinet ....................................................67

TNS...................................................................................................67

TNC...................................................................................................68

Install 400 kVA External Bypass Cabinet ....................................................69

TNS...................................................................................................69

TNC...................................................................................................70

Install Marine UPS Adaptation Voltage Transformer...........................71

Install Isolation Transformer (Option).....................................................72

Transformer Configuration Options in Single Systems .................................73

Transformer Configuration Options in Parallel UPS System .........................75

4 990–5233D–001

Important Safety Instructions — SAVE

THESE INSTRUCTIONS 20 - 120 kVA 400 V

Important Safety Instructions — SAVE THESE

INSTRUCTIONS

Read these instructions carefully and look at the equipment to become familiar with

it before trying to install, operate, service or maintain it. The following safety

messages may appear throughout this manual or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a “Danger” or “Warning” safety

message indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages with this symbol

to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Failure to follow these instructions can result in injury or equipment

damage.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this type of safety message.

Failure to follow these instructions can result in equipment damage.

Please Note

Electrical equipment should only be installed, operated, serviced, and maintained

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

990–5233D–001 7

20 - 120 kVA 400 V

Important Safety Instructions — SAVE

THESE INSTRUCTIONS

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

Safety Precautions

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

All safety instructions in this document must be read, understood and followed.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read all instructions in the Installation Manual before installing or working on this

UPS system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not install the UPS system until all construction work has been completed

and the installation room has been cleaned.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• The product must be installed according to the specifications and

requirements as defined by Schneider Electric. It concerns in particular the

external and internal protections (upstream breakers, battery breakers,

cabling, etc.) and environmental requirements. No responsibility is assumed

by Schneider Electric if these requirements are not respected.

• After the UPS system has been electrically wired, do not start up the system.

Start-up must only be performed by Schneider Electric.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS system must be installed according to local and national regulations.

Install the UPS according to:

• IEC 60364 (including 60364–4–41- protection against electric shock, 60364–

4–42 - protection against thermal effect, and 60364–4–43 - protection against

overcurrent), or

• NEC NFPA 70, or

• Canadian Electrical Code (C22.1, Part 1)

depending on which one of the standards apply in your local area.

Failure to follow these instructions will result in death or serious injury.

8 990–5233D–001

Important Safety Instructions — SAVE

THESE INSTRUCTIONS 20 - 120 kVA 400 V

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Install the UPS system in a temperature controlled indoor environment free of

conductive contaminants and humidity.

• Install the UPS system on a non-flammable, level and solid surface (e.g.

concrete) that can support the weight of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The UPS is not designed for and must therefore not be installed in the following

unusual operating environments:

• Damaging fumes

• Explosive mixtures of dust or gases, corrosive gases, or conductive or radiant

heat from other sources

• Moisture, abrasive dust, steam or in an excessively damp environment

• Fungus, insects, vermin

• Salt-laden air or contaminated cooling refrigerant

• Pollution degree higher than 2 according to IEC 60664-1

• Exposure to abnormal vibrations, shocks, and tilting

• Exposure to direct sunlight, heat sources, or strong electromagnetic fields

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not drill or cut holes for cables or conduits with the gland plates installed and

do not drill or cut holes in close proximity to the UPS.

Failure to follow these instructions will result in death or serious injury.

WARNING

HAZARD OF ARC FLASH

Do not make mechanical changes to the product (including removal of cabinet

parts or drilling/cutting of holes) that are not described in the Installation Manual.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

RISK OF OVERHEATING

Respect the space requirements around the UPS system and do not cover the

product’s ventilation openings when the UPS system is in operation.

Failure to follow these instructions can result in equipment damage.

NOTICE

RISK OF EQUIPMENT DAMAGE

Do not connect the UPS output to regenerative load systems including

photovoltaic systems and speed drives.

Failure to follow these instructions can result in equipment damage.

990–5233D–001 9

20 - 120 kVA 400 V

Important Safety Instructions — SAVE

THESE INSTRUCTIONS

Electrical Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Electrical equipment must be installed, operated, serviced, and maintained

only by qualified personnel.

• The UPS system must be installed in a room with restricted access (qualified

personnel only).

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• Turn off all power supplying the UPS system before working on or inside the

equipment.

• Before working on the UPS system, check for hazardous voltage between all

terminals including the protective earth.

• The UPS contains an internal energy source. Hazardous voltage can be

present even when disconnected from the utility/mains supply. Before

installing or servicing the UPS system, ensure that the units are OFF and that

utility/mains and batteries are disconnected. Wait five minutes before

opening the UPS to allow the capacitors to discharge.

• A disconnection device (e.g. disconnection circuit breaker or switch) must be

installed to enable isolation of the system from upstream power sources in

accordance with local regulations. This disconnection device must be easily

accessible and visible.

• The UPS must be properly earthed/grounded and due to a high leakage

current, the earthing/grounding conductor must be connected first.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

In systems where backfeed protection is not part of the standard design, an

automatic isolation device (backfeed protection option or other device meeting

the requirements of IEC/EN 62040–1 or UL1778 4th Edition – depending on

which of the two standards apply to your local area) must be installed to prevent

hazardous voltage or energy at the input terminals of the isolation device. The

device must open within 15 seconds after the upstream power supply fails and

must be rated according to the specifications.

Failure to follow these instructions will result in death or serious injury.

When the UPS input is connected through external isolators that, when opened,

isolate the neutral or when the automatic backfeed isolation is provided external to

the equipment or is connected to an IT power distribution system, a label must be

fitted at the UPS input terminals, and on all primary power isolators installed

remote from the UPS area and on external access points between such isolators

and the UPS, by the user, displaying the following text (or equivalent in a language

which is acceptable in the country in which the UPS system is installed):

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Risk of Voltage Backfeed. Before working on this circuit: Isolate the UPS and

check for hazardous voltage between all terminals including the protective earth.

Failure to follow these instructions will result in death or serious injury.

10 990–5233D–001

Important Safety Instructions — SAVE

THESE INSTRUCTIONS 20 - 120 kVA 400 V

Periodical Check

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Limited lifetime components, such as capacitors, fans, electronic boards,

batteries, etc., must be checked periodically by qualified personnel.

• Battery trip control must be done periodically by qualified personnel.

This periodical check is recommended every 6 months and required every

12 months.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Battery Safety

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Battery circuit breakers must be installed according to the specifications and

requirements as defined by Schneider Electric.

• Servicing of batteries must only be performed or supervised by qualified

personnel knowledgeable of batteries and the required precautions. Keep

unqualified personnel away from batteries.

• Disconnect charging source prior to connecting or disconnecting battery

terminals.

• Do not dispose of batteries in a fire as they can explode.

• Do not open, alter, or mutilate batteries. Released electrolyte is harmful to the

skin and eyes. It may be toxic.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Batteries can present a risk of electric shock and high short-circuit current. The

following precautions must be observed when working on batteries

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear protective glasses, gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect the charging source prior to connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently grounded. If inadvertently grounded,

remove source from ground. Contact with any part of a grounded battery can

result in electric shock. The likelihood of such shock can be reduced if such

grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply circuit).

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

When replacing batteries, always replace with the same type and number of

batteries or battery packs.

Failure to follow these instructions will result in death or serious injury.

990–5233D–001 11

20 - 120 kVA 400 V

Important Safety Instructions — SAVE

THESE INSTRUCTIONS

CAUTION

RISK OF EQUIPMENT DAMAGE

Batteries must not be stored more than six months due to the requirement of

recharging. If the UPS system remains de-energized for a long period, we

recommend that you energize the UPS system for a period of 24 hours at least

once every month. This charges the batteries, thus avoiding irreversible

damage.

Failure to follow these instructions can result in injury or equipment

damage.

Electromagnetic Compatibility

NOTICE

RISK OF ELECTROMAGNETIC DISTURBANCE

This is a product Category 3 according to IEC 62040-2 for commercial, industrial

and similar applications in the second environment - installation restrictions or

additional measures may be needed to prevent disturbances. The second

environment includes all commercial, light industry and industrial locations other

than residential, commercial and light industrial premises directly connected

without intermediate transformer to a public low-voltage mains supply. The

installation and cabling must follow the Electromagnetic compatibility rules, e.g.:

• the segregation of cables,

• the use of shielded or special cables when relevant,

• the use of grounded metallic cable tray and supports.

Failure to follow these instructions can result in equipment damage.

12 990–5233D–001

Specifications 20 - 120 kVA 400 V

Specifications

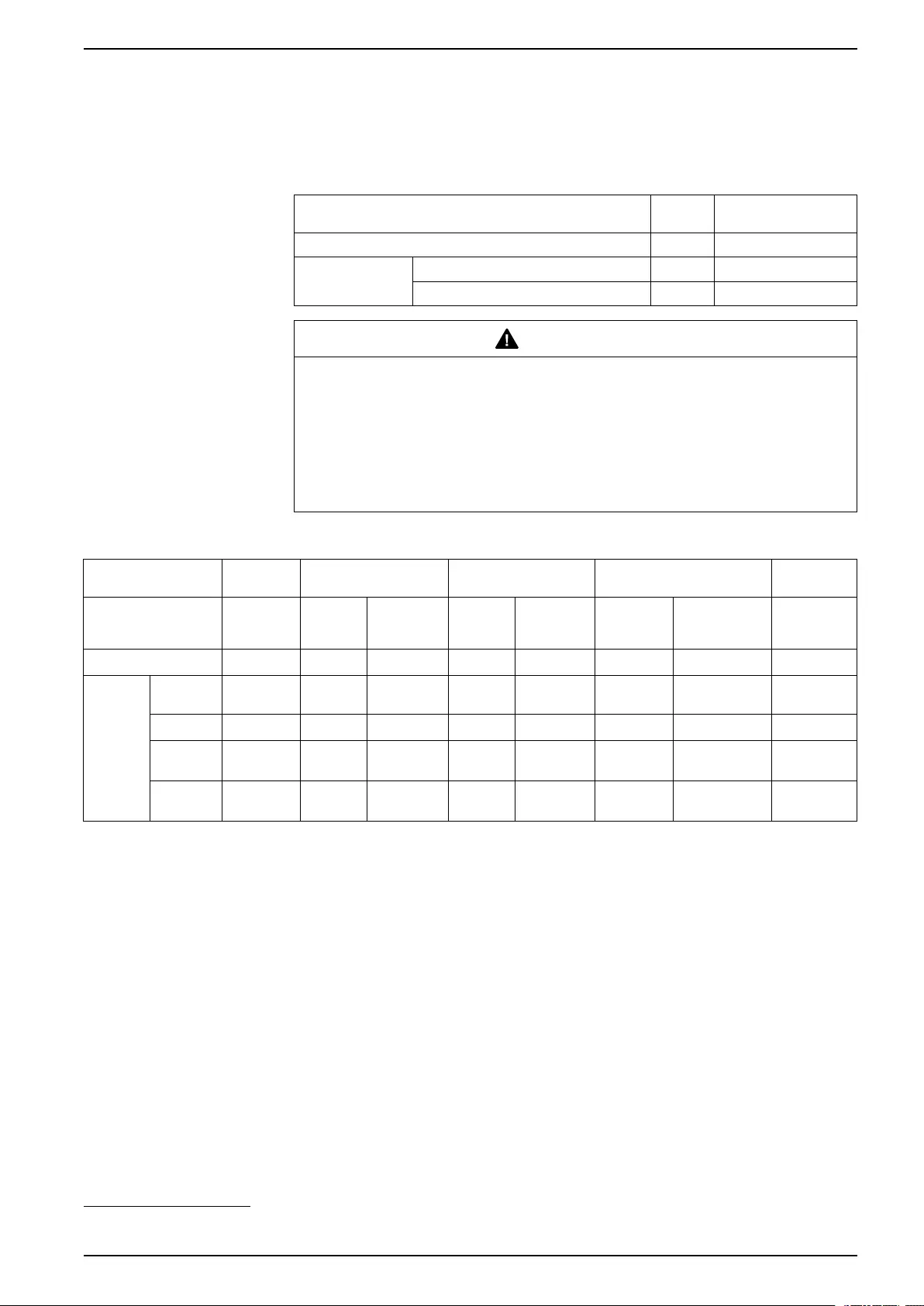

Input

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Input voltage (V) 380 - 400 - 415

Input voltage range permitted by the

standard according to the curve below

(V)

250 to 470 for a standard UPS

342 to 470 for a UPS with backfeed protection

Input frequency (Hz) 45 to 65

Rated current1

Normal AC input (A)

32 45 57 87 115 143 171

Maximum input current (A) for 400 V 33 46 58 88 116 145 173

Input current (A) for 400V, overload=

1.25 In limited to 10 min.

39 56 72 108 145 181 217

Input current (A) for 400V, overload=1.5

In limited to 1 min.

47 68 87 130 174 217 260

THDI < 6% at full load

< 8% at 25–75% load

Maximum short circuit withstand (kA) 20 30

Input fuse ratings (A) 80 80 80 125 160 315 315

Power Supplied as a Function of Input Voltage

Output

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Overload capacity 125% for 10 minutes

150% for 1 minute

220% for 0.1 second

Voltage tolerance (V) 380, 400, 415 ± 3%

Rated output current 29 44 58 87 116 145 174

Output current limitation (A) 190 240 360 480

Output frequency 50 Hz or 60 Hz

THDU ≤ 1% phase to phase, ≤ 1.5% phase to neutral for linear loads

≤ 2.5% phase to phase, ≤ 3.5% phase to neutral for non-linear loads

990–5233D–001 13

1. Rated currents with battery float charging. normal AC input voltage = U, AC bypass input = U, load = 400 V / P

load = PN / load cos phi = 0.9

20 - 120 kVA 400 V Specifications

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Output fuse rating 80 80 80 125 160 315 315

Crest factor 6.55 4.41 3.27 2.75 3.12 3.33 2.77

Permissible UPS Overloads as a Function of Time

Bypass

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Connection type 3PH+N

Input voltage (V) 380 to 443

Input frequency (Hz) 46 to 54

14 990–5233D–001

Specifications 20 - 120 kVA 400 V

Environment

Operating Temperatures

The operating temperature range is 0 to 40 °C, however optimal operation is 20 to

25 °C.

Battery backup time is adversely affected by high and low temperatures. It is

significantly reduced at temperatures under 10 °C.

Above 25 °C, battery service life is reduced by 50% for every 10 °C temperature

increase. Above 40 °C, battery manufacturers no longer guarantee operation due

to the risk of thermal runaway.

Losses calculated with maximum current → V=380 and RL load; cosf: 0.9 @ 100%

load

Heat Dissipation

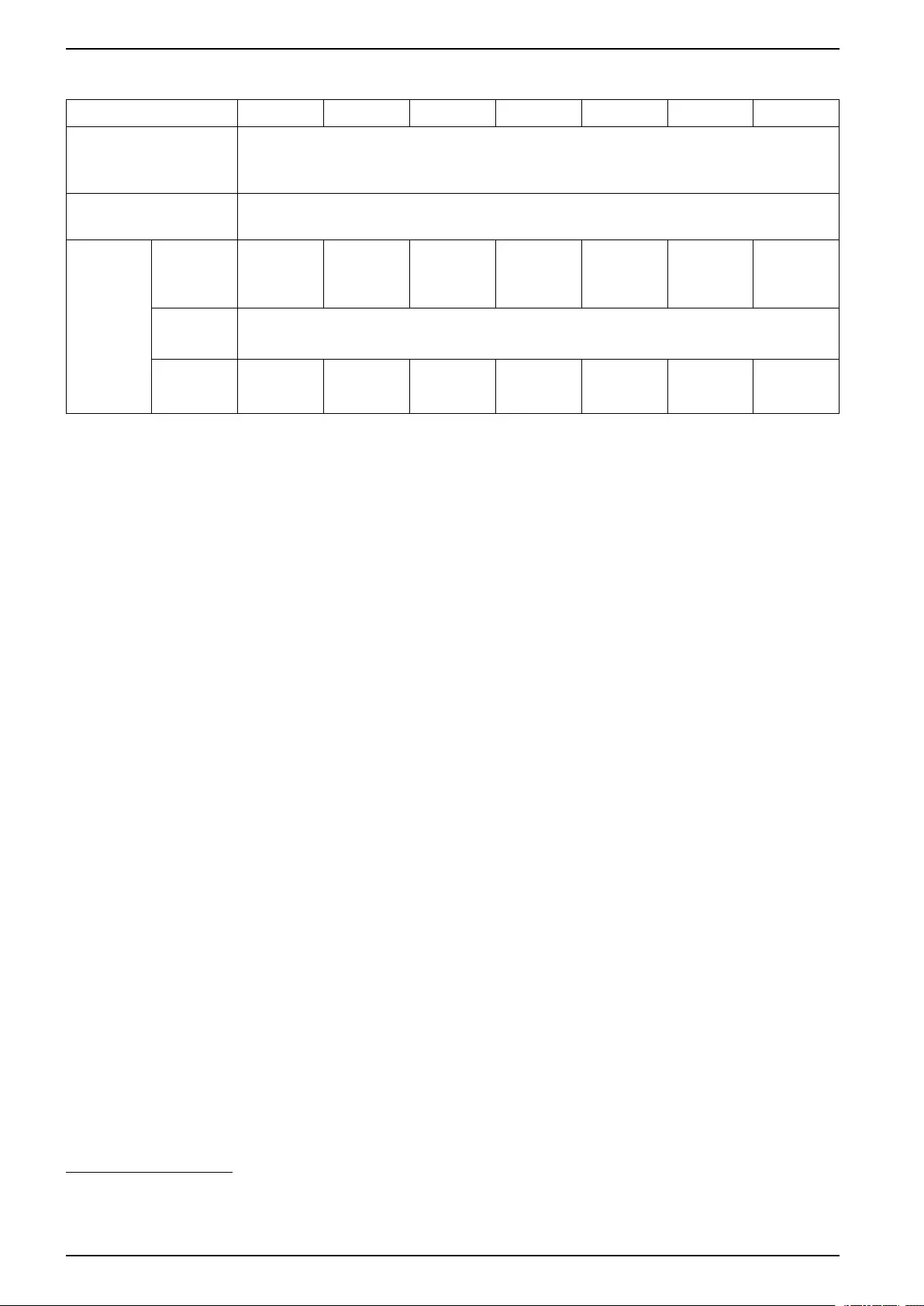

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Losses (kW) 1.61 2.03 2.68 4.26 4.86 6.90 8.41

Heat dissipation

(BTU/hr)

5493 6928 9146 14539 16587 23549 28362

Recommended air throughput (m³/h) 1332 2556

990–5233D–001 15

20 - 120 kVA 400 V Specifications

Batteries

Battery type: Sealed lead-acid or vented lead acid.

DC Power Levels for Battery Sizing with Output Power Factor = 0.9

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

DC power in

KW

Load 25 % 6.3 8.6 10.9 15.6 20.6 25.2 29.8

Load 50 % 10.9 15.6 20.3 29.7 34.9 48.5 58.1

Load 75 % 15.6 22.6 29.7 44.2 58.9 72.5 87.1

Load 100 % 20.3 29.7 39.4 58.6 78.4 97 116.8

DC Power Levels for Battery Sizing with Output Power Factor = 0.8

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

DC power in

KW

Load 25 % 5.8 7.8 9.9 14.1 18.5 22.6 26.8

Load 50 % 9.9 14.1 18.2 26.6 33.1 43.4 51.7

Load 75 % 14.1 20.3 26.6 39.4 52.4 64.5 77.3

Load 100 % 18.2 26.6 35.0 52.2 69.6 86.0 103.5

Maximum Current at End of Discharge

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Battery (A) 68 101 134 201 268 338 402

Load (A) 29 44 58 87 116 145 174

16 990–5233D–001

20 - 120 kVA 400 V Specifications

Recommended Upstream Circuit Breaker

UPS Rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Dual utility/

mains

system –

Input

C60L - 50A C60L - 63A NSX 100F 3P-

TM80D

NSX 160F 3P-

TM125D

NSX 160F 3P-

TM160D

NSX 250F 3P-

TM200D

NSX 250F 3P-

TM250D

Dual utility/

mains

system –

Bypass

NSX 100F 4P-

TM100D

NSX 100F 4P-

TM100D

NSX 100F 4P-

TM100D

NSX 160F 4P-

TM125D

NSX 160F 4P-

TM160D

NSX 250F 4P-

TM250D

NSX 250F 4P-

TM250D

Single utility/

mains

system

NSX 100F 4P-

TM100D

NSX 100F 4P-

TM100D

NSX 100F 4P-

TM100D

NSX 160F 4P-

TM125D

NSX 160F 4P-

TM160D

NSX 250F 4P-

TM250D

NSX 250F 4P-

TM250D

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Place a label with the following text on each upstream circuit breaker: “Isolate

the Uninterruptible Power Supply (UPS) before working on this circuit”.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTICE

RISK OF EXPLOSION, ARC FLASH OR VOLTAGE OUTAGE

For Installation design, consider:

• the above recommended upstream circuit breaker for discrimination with the

UPS internal fuses.

• Icw = 20 kA for 20 to 60 kVA UPS when using the recommended upstream

circuit breaker.

• Icw = 30 kA for 80 to 120 kVA UPS when using the recommended upstream

circuit breaker.

Failure to follow these instructions can result in equipment damage.

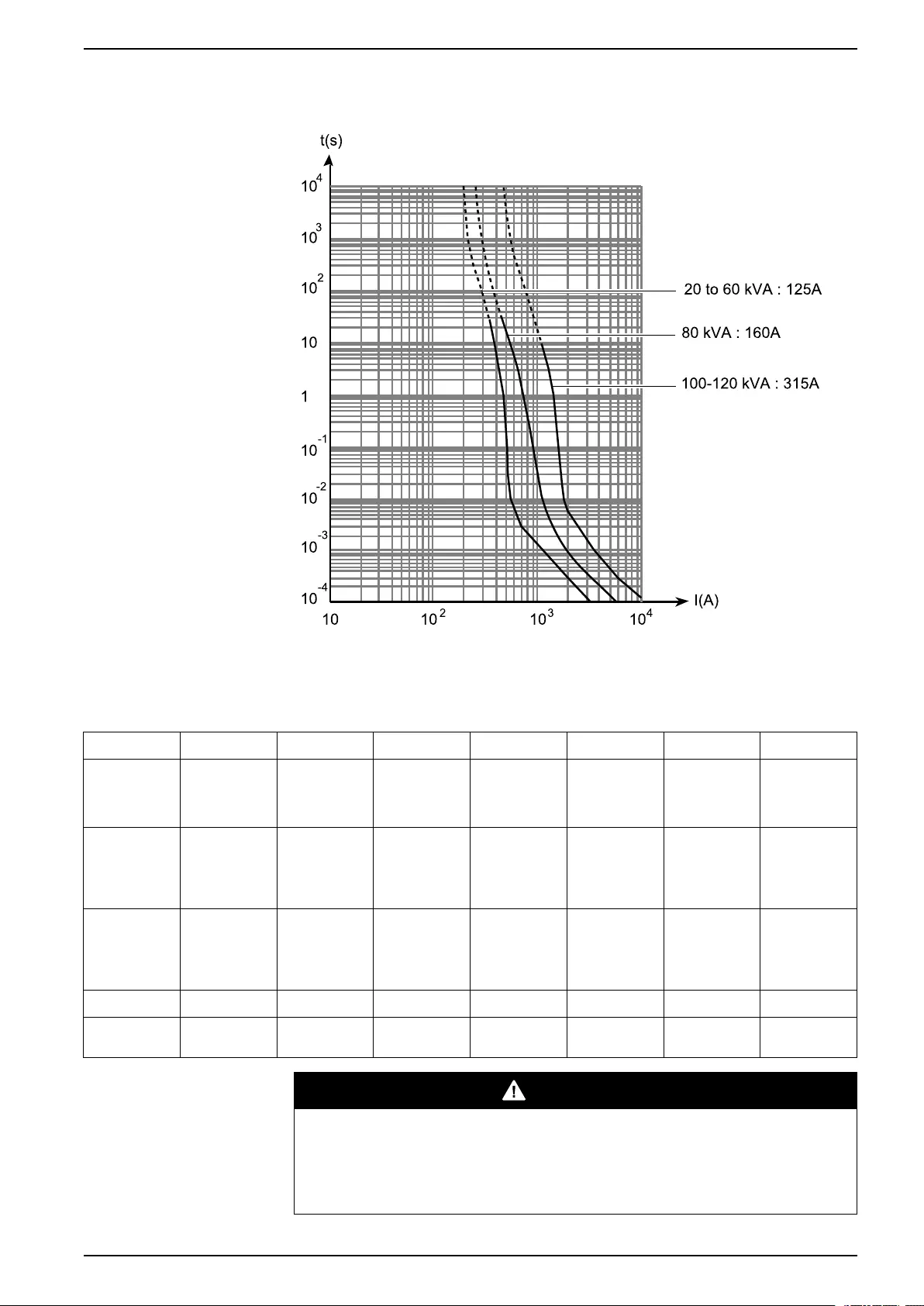

Recommended Downstream Circuit Breaker

UPS rating 20-30-40 kVA 60 kVA 80 kVA 100-120 kVA

Downstream

circuit breaker

C60N C120N NSX100

Trip unit C 16A B 25A C 20A B 32A C 25A B 50A C 32A B 63A TMG 63A

N type curve for the downstream circuit breaker can be replaced by H or L type

curve, depending on the installation. The indicated protection ensures

discrimination for each output circuit downstream of the UPS, whether supplied via

the input or the bypass source.

NOTE: If these downstream protection recommendations are not followed, it can

result in a break in power longer than 20 ms in all the output circuits if a short circuit

occurs on an output circuit.

Earth-Leakage Current

UPS earth-leakage current is 1A.

18 990–5233D–001

Specifications 20 - 120 kVA 400 V

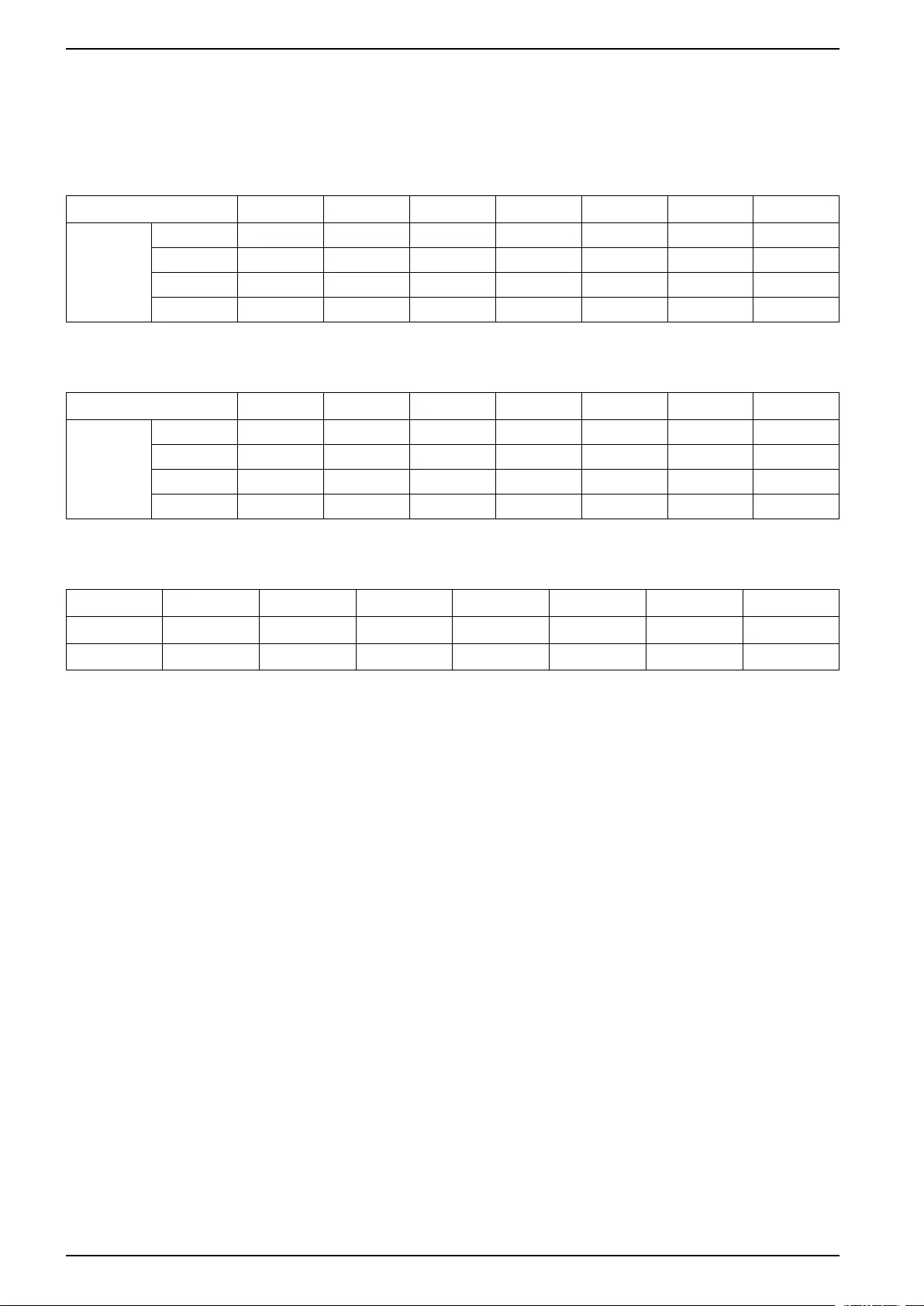

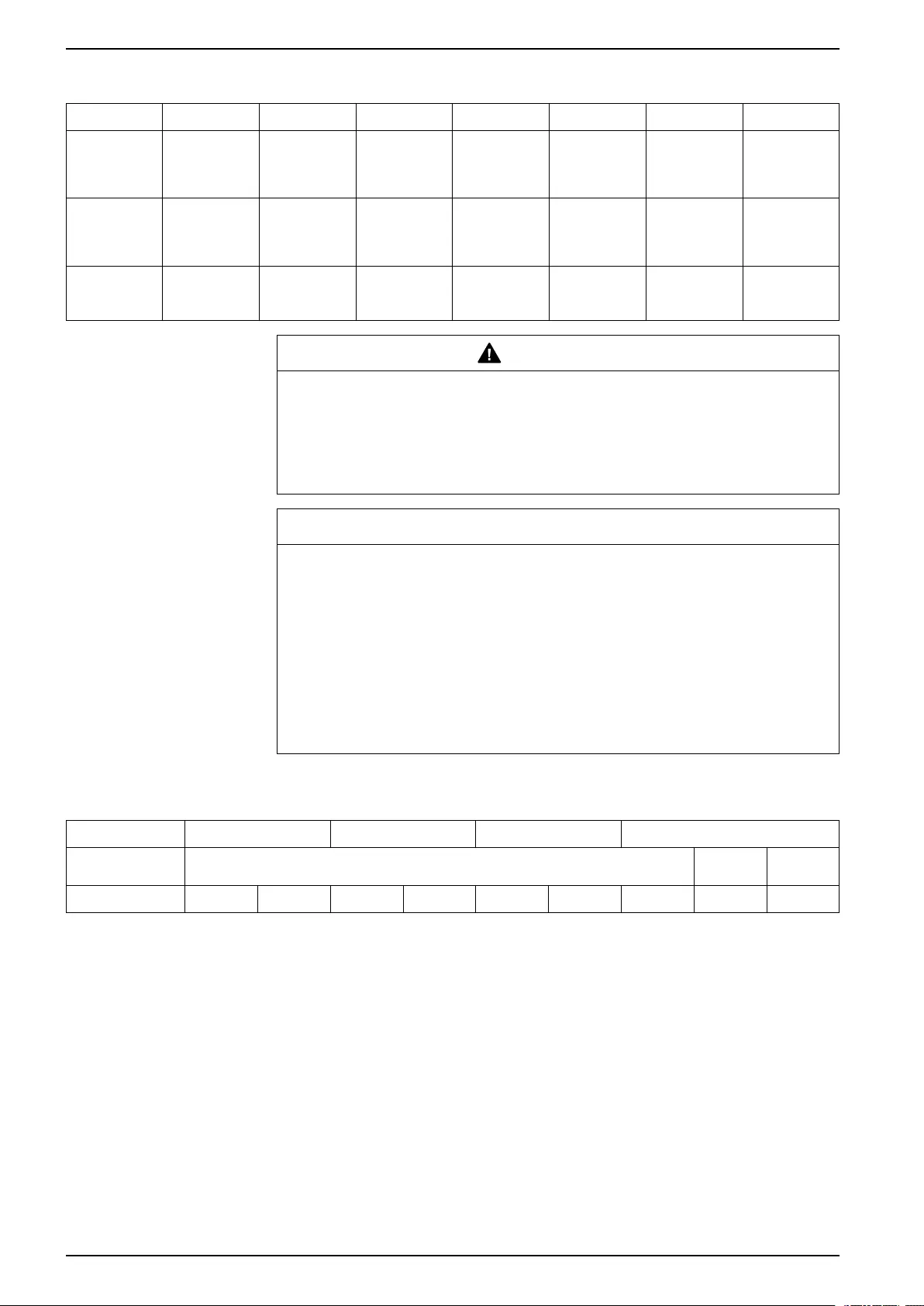

Fuses

Time/Current Curves for UPS Input and Output Fuses

Recommended Cable Sizes

NOTE: Cables length must be less than 100 meters.

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Dual utility/

mains

system –

Input (mm²)

10 16 16 25 50 50 70

Dual utility/

mains

system –

Bypass

(mm²)

16 16 16 25 50 70 70

Single utility/

mains

system –

Input &

bypass (mm²)

16 16 16 25 50 70 70

Output (mm²) 16 16 16 25 50 70 70

Battery (<15

m) (mm²)

16 25 35 70 95 2 x 50 2 x 70

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Use power cables of equal resistance, equal length, and equal size for the same

function.

Failure to follow these instructions will result in death or serious injury.

990–5233D–001 19

20 - 120 kVA 400 V Specifications

NOTE: Cable sizes are determined for copper conductors (for aluminium

conductors, increase the size by 30%). Size calculations also take into account a

voltage of 400 V and grouping of four cables.

Terminal hole diameter: 6.5 mm (8.5 mm for 120 kVA).

PE cables (Protective Earth) cables connect to the earthing terminal. Hole

diameter: 6.5 mm (8.5 mm for 120 kVA).

20 990–5233D–001

Specifications 20 - 120 kVA 400 V

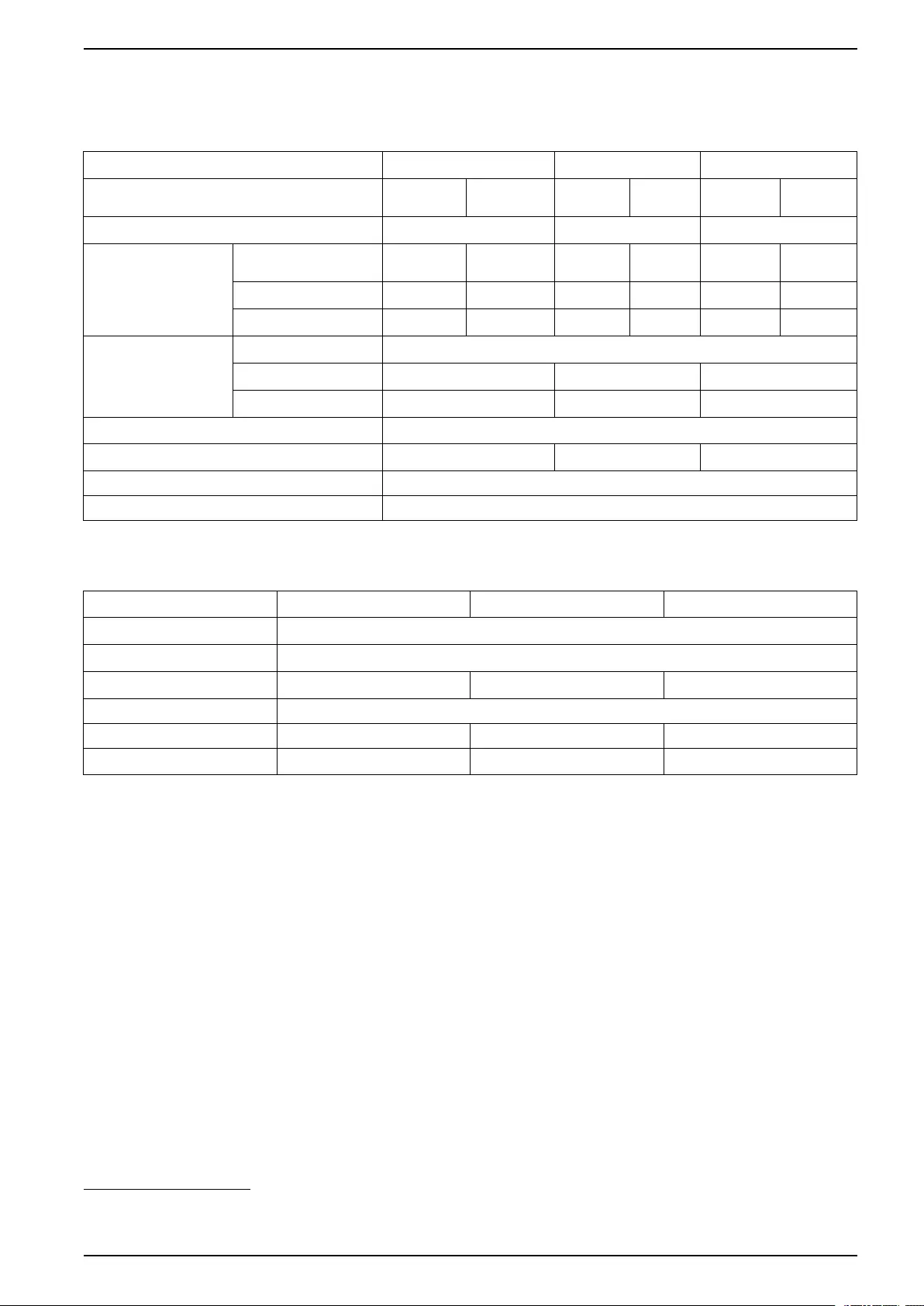

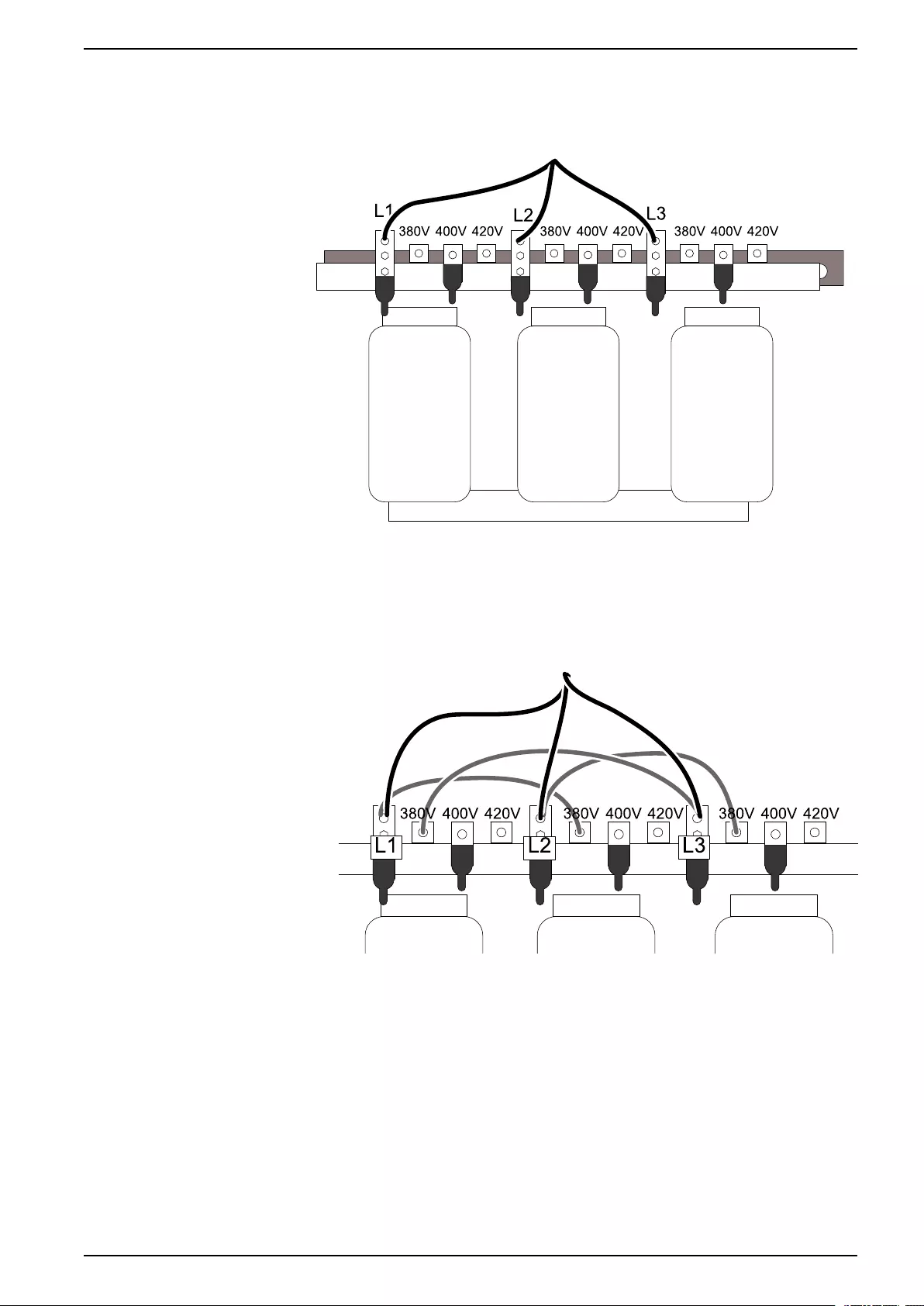

Transformers

Marine UPS Adaptation Voltage Transformer Specifications

UPS Rating 60 kVA 80 kVA 120 kVA

Transformation 440V to

400V

690V to

400V

440V to

400V

690V to

400V

440V to

400V

690V to

400V

Topology Dyn11 Dyn11 Dyn11

Primary Voltage (V) 440 +/- 5% 690 +/- 5% 440 +/- 5% 690 +/-

5%

440 +/- 5% 690 +/- 5%

Current (A) 81 52 108 69 162 103

Cable sizes (mm2)235 35 95 35 95 95

Secondary Voltage (V) 400

Current (A)387 116 174

Cable sizes (mm2)235 35 95

Frequency (Hz) 50/60

Efficiency > 97.3% at 40 °C > 97.7% at 40 °C > 98.5% at 40 °C

Overload 110% for 2 hours

Inrush current < 5 x In

Isolation Transformer Specifications

UPS Rating 40 kVA 60 kVA 120 kVA

Voltage (V) 380–400–415 +/- 5%

Frequency (Hz) 50

Efficiency > 97% at 75 °C > 96% at 75 °C > 97% at 75 °C

Overload 110% for 1 hour

Inrush current < 12 Inom 915 A at 380 V < 12 Inom 1095 A at 380 V < 12 Inom 2005 A at 380 V

Power dissipation 1.88 KW / 450 cal/.s 2.61 KW / 624 cal/.s 4.38 KW / 1047 cal/.s

The isolation transformer is DYN05 type. It can be connected to AC input and AC

bypass sources (upstream) and load output (downstream) of a Galaxy 5500 UPS.

The isolation transformer can setup galvanic isolation from upstream power,

network power supply to downstream power absorber. A 3 meter cable is provided

with the transformer to connect it to the UPS, limiting the installation distance

between the UPS and the transformer to under 3 meters.

990–5233D–001 21

2. The suggested cable sizes are for 1000R02V type copper cables less than 100 meters long and for a voltage

drop of less than 3%.

3. Full load

20 - 120 kVA 400 V Specifications

NOTE: The current values given in the table below are for nominal utility/mains

voltages and rated load.

The transforming ratio is equal to 1.

UPS Rating 40 kVA 60 kVA 120 kVA

Line current for various

utility/mains voltages (A)

380 V 61 91 182

400 V 58 87 173

415 V 56 84 166

Transformer inrush current (max) 12 x Inom 12 x Inom 11 x Inom

Vector group DYN11 DYN5 DYN5

Cable sizes4(mm2)Power cables 35 35 70

PE cables 16 16 35

22 990–5233D–001

4. The suggested cable sizes are for 1000R02V type copper cables less than 100 meters long and for a voltage

drop of less than 3%.

Specifications 20 - 120 kVA 400 V

Battery Circuit Breaker Enclosure

The recommended cable sizes are applicable to U1000R02V type copper cables.

They are calculated in relation to permissible temperature rises and take into

account a maximum line voltage drop of 1 % for a maximum cable length of 25 m.

For greater cable lengths, sizes will be chosen to keep the voltage drop within 1%.

UPS Rating 20 – 120

kVA

100-120 kVA

Runtime ≤ 10 mn > 10 mn

Weight (kg) Enclosure without insulation monitor 15 35

Enclosure with insulation monitor 17 37

WARNING

HAZARD OF FIRE

• Protect the battery circuit with a DC circuit breaker equipped with an

undervoltage coil (MN 24 VDC).

• The DC breaker must be rated. The undervoltage coil must be wired to the

UPS as shown in the connection diagrams below.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Standard Battery Circuit Breaker Offer

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 – 120

kVA

Maximum battery

backup time at full

load5

≤ 30 mn ≤ 15 mn > 15 mn to

≤ 30 mn

≤ 15 mn > 15 mn to

≤ 30 mn

≤ 5 mn > 5 mn to ≤ 30

mn

≤ 30 mn

Enclosure Type AIOB6AIOB6External AIOB6External AIOB6External External

QF1

circuit

breaker

Type NSX160S

DC 3P

NSX160-

S DC 3P

NSX400S

DC 3P

NSX160-

S DC 3P

NSX400S

DC 3P

NSX160S

DC 3P

NSX400S DC

3P

NSX400S

DC 3P

Trip unit TM100D TM100D MP1 TM250D MP1 TM250D MP1 MP1

Magnetic

setting (A)

800 800 800 1250 800 1250 800 800

Thermal

setting

1 1 -1-1- -

990–5233D–001 23

5. For other values, consult the after sales department at Schneider Electric or your local agency.

6. All In One Box – batteries and the circuit breaker are stored in the UPS cabinet.

20 - 120 kVA 400 V Specifications

Circuit Breaker Specifications

UPS rating 20 kVA 30 kVA 40 kVA 60 kVA 80 kVA 100 kVA 120 kVA

Requirements • It must be a DC current circuit breaker (Power pole and tripping).

• DC rating must be higher than 500 VDC.

• Breaking capacity must be higher than maximum battery short circuit current.

Mandatory fitted equipment • 24 VDC Undervoltage coil tripping

• Auxiliary dry contact

Current

setting7

Rated

discharge

battery

current (A)

68 101 134 201 268 338 402

Maximum

magnetic

current

Magnetic current setting (lsd) must be less than 50% of maximum battery short circuit current8

Minimum

magnetic

setting (A)9

95.2 141.1 187.6 281.4 375.2 473.2 562.8

NOTE: Due to discharge time limited to battery backup time, circuit breaker can be

overloaded according to battery supplier specifications.

24 990–5233D–001

7. Rated discharge battery current based on nominal load with a power factor of 0.9

8. According to circuit breaker supplier specifications.

9. Including 20% of circuit breaker trip uncertainty. Magnetic must trip below 40 ms for 50% of maximum battery

short circuit current.

Mechanical Assembly 20 - 120 kVA 400 V

Mechanical Assembly

NOTE: Not applicable for Galaxy 5500 Marine, see Galaxy 5500 Marine receiving

and unpacking manual.

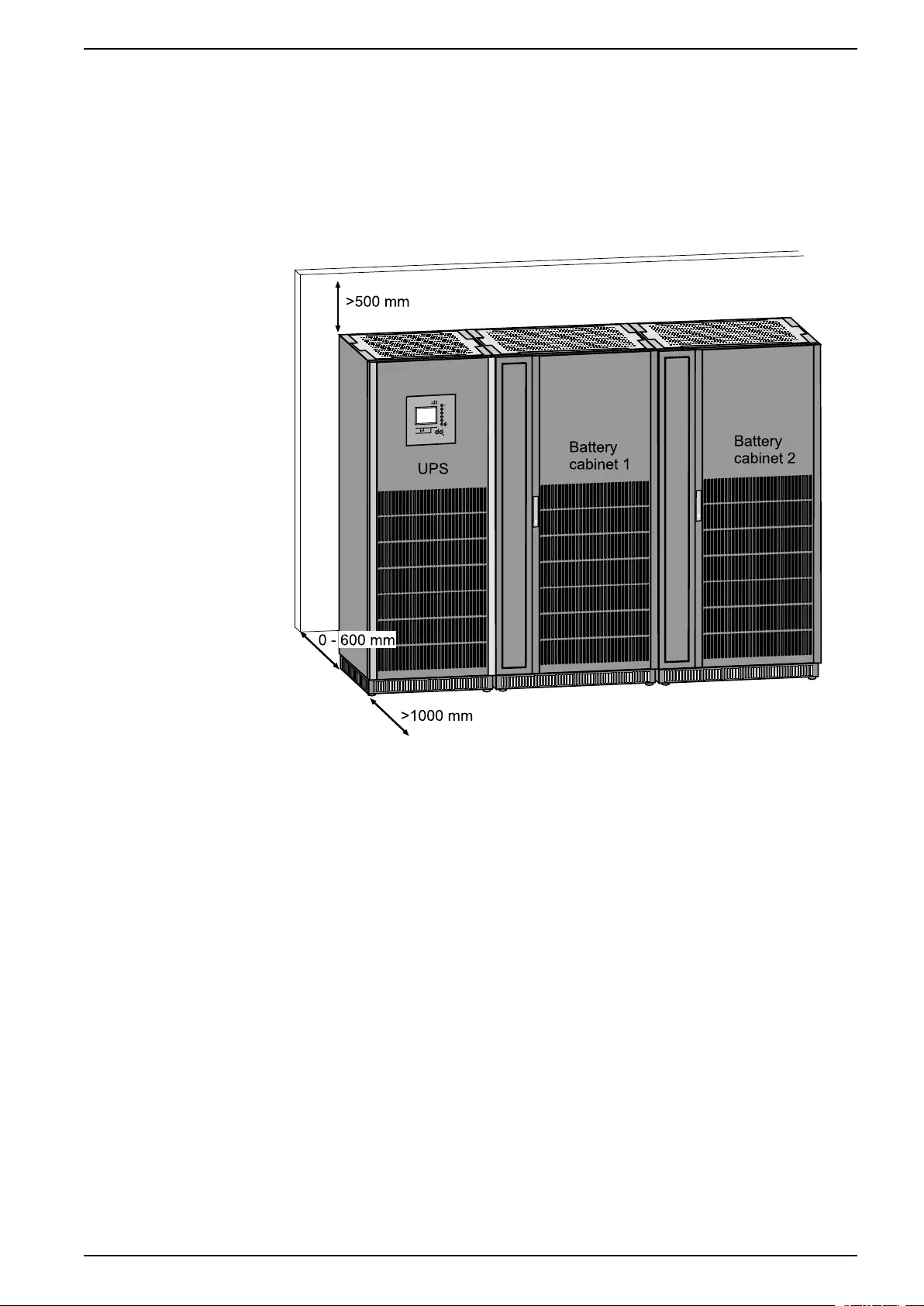

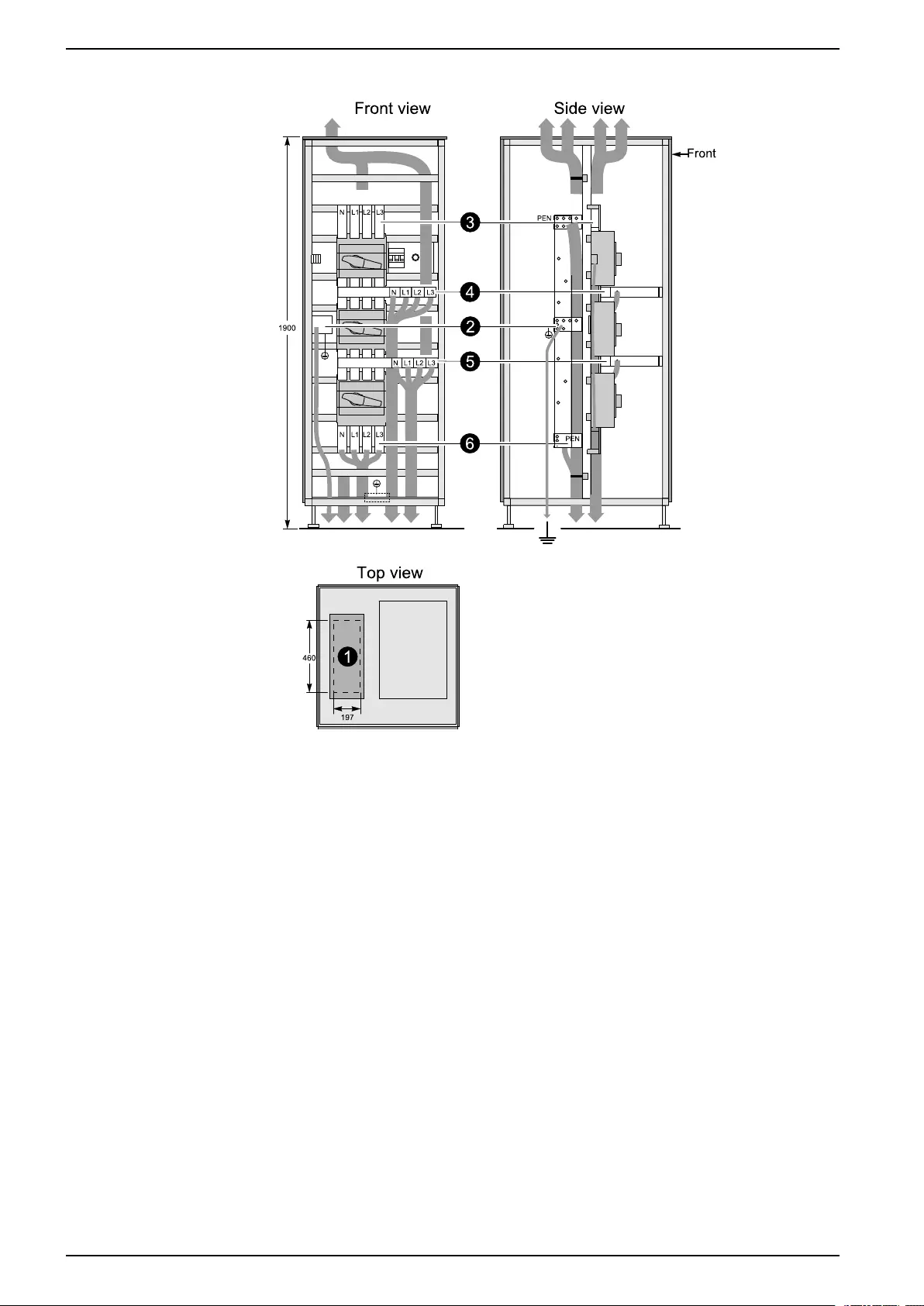

Layout of Cabinets

NOTE: The clearance dimensions given above are published for airflow and

service access only. Consult with the local safety codes and standards for

additional requirements in your local area.

990–5233D–001 25

20 - 120 kVA 400 V Mechanical Assembly

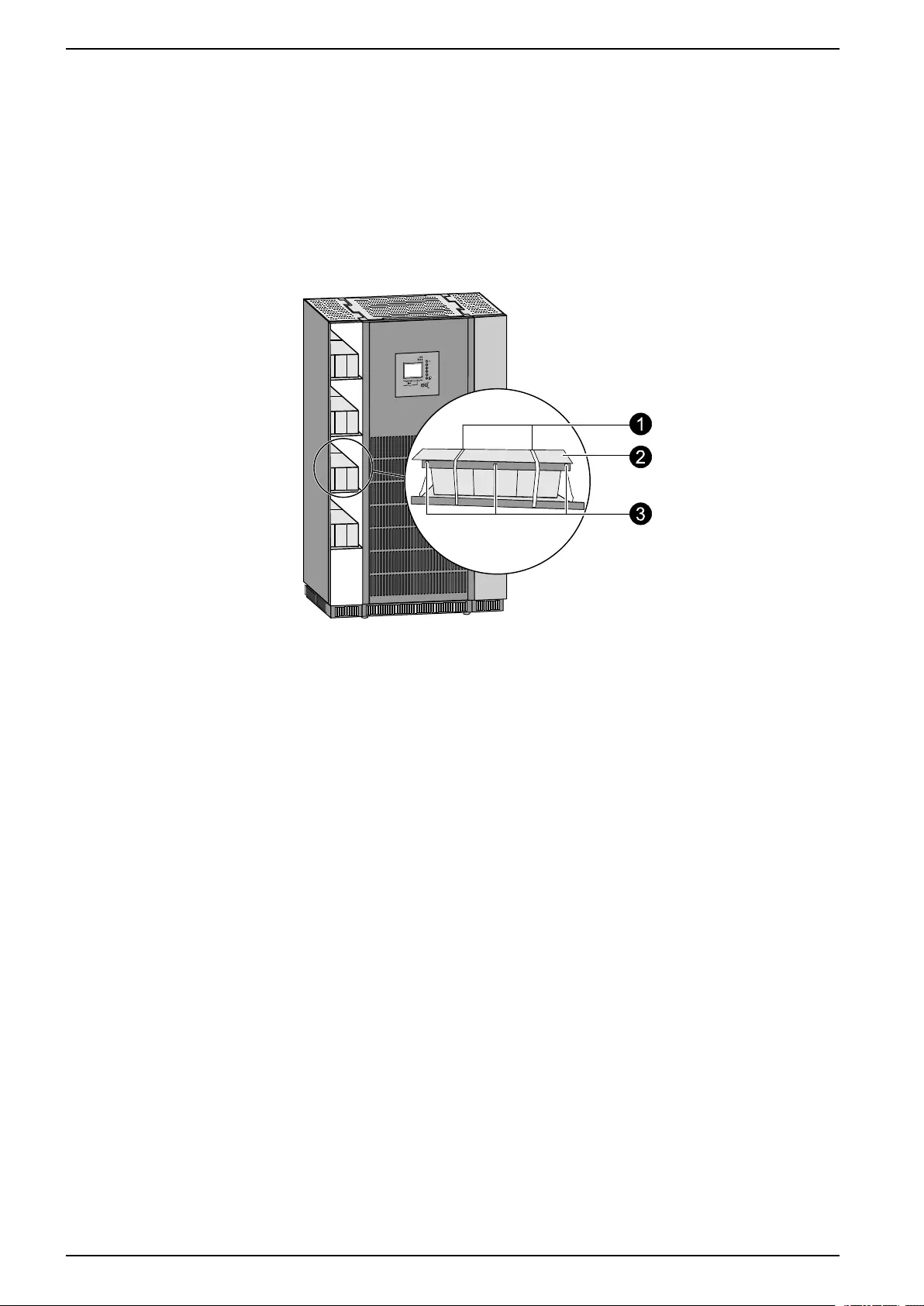

Remove Battery Protection

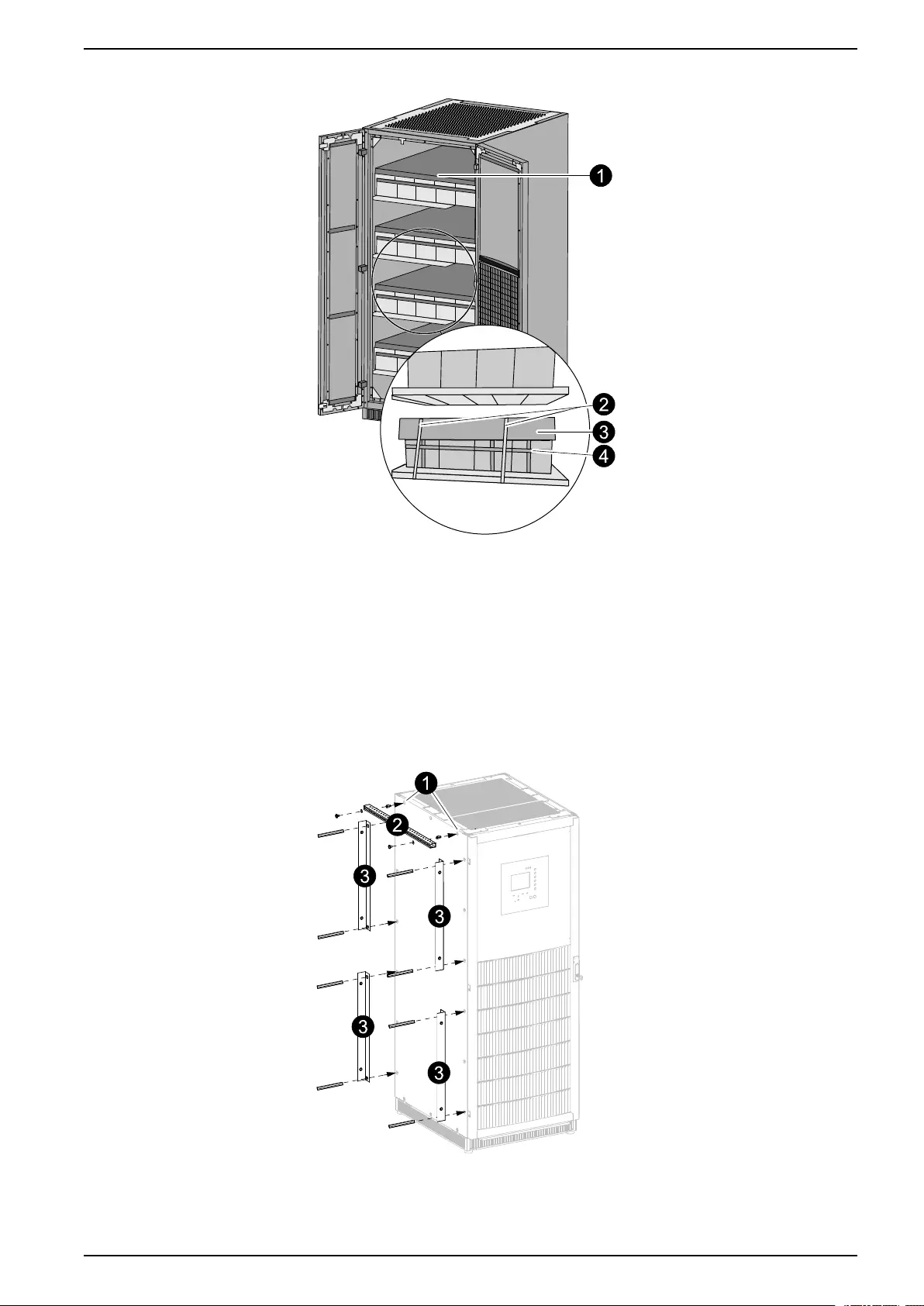

Remove Battery Protection from the UPS

The cardboard protecting the batteries must always be removed once the cabinet

is installed in its final location.

1. Remove the ties holding the cardboard.

2. Remove the cardboard.

3. Remove the struts.

Remove Battery Protection from the External Battery Cabinet

The cardboard protecting the batteries must always be removed once the cabinet

is installed in its final location.

1. Remove the battery support upright.

2. Remove the ties holding the cardboard (1000 mm external battery cabinet).

3. Remove the cardboard protecting the batteries.

26 990–5233D–001

Mechanical Assembly 20 - 120 kVA 400 V

4. Remove the ties holding the batteries.

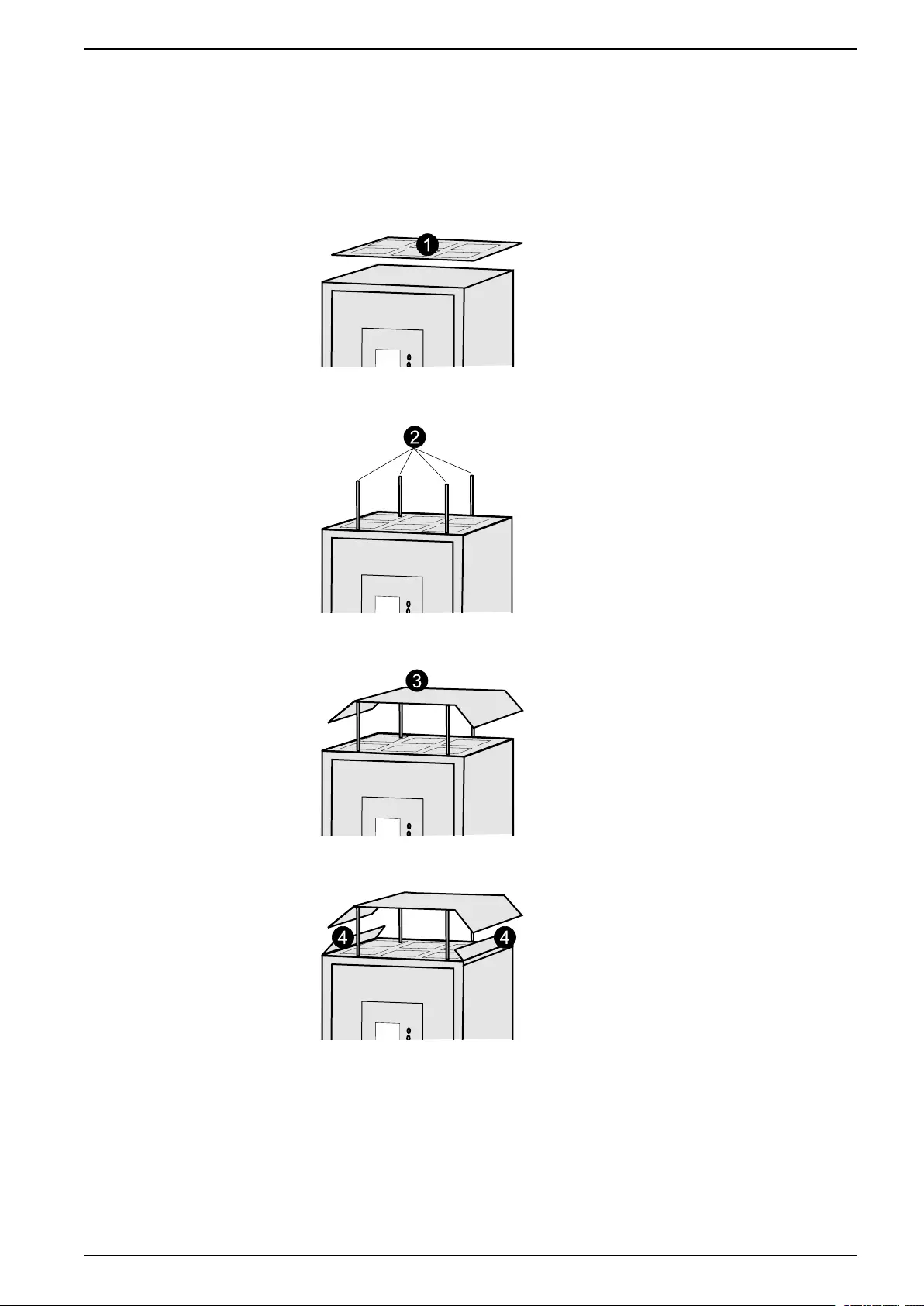

Install the Top Entry Option

NOTE: Tightening torque for all operations is 6.5 Nm.

1. Remove the two screws on the top edges of the UPS left side panel.

2. Install the cable fastening bar using the M5 spacers, the washers, and the M5

screws.

3. Install the panel brackets and spacers.

990–5233D–001 27

Mechanical Assembly 20 - 120 kVA 400 V

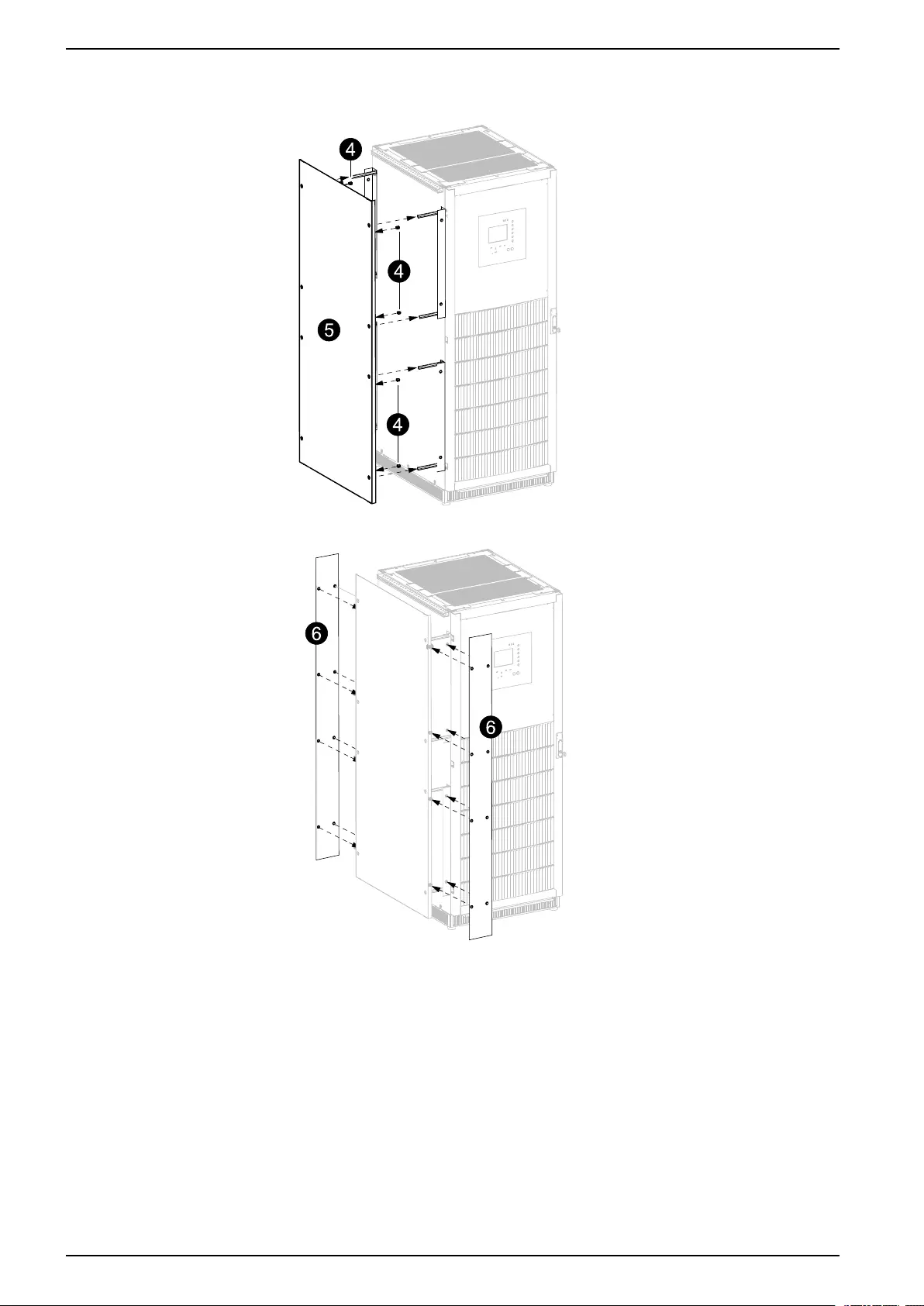

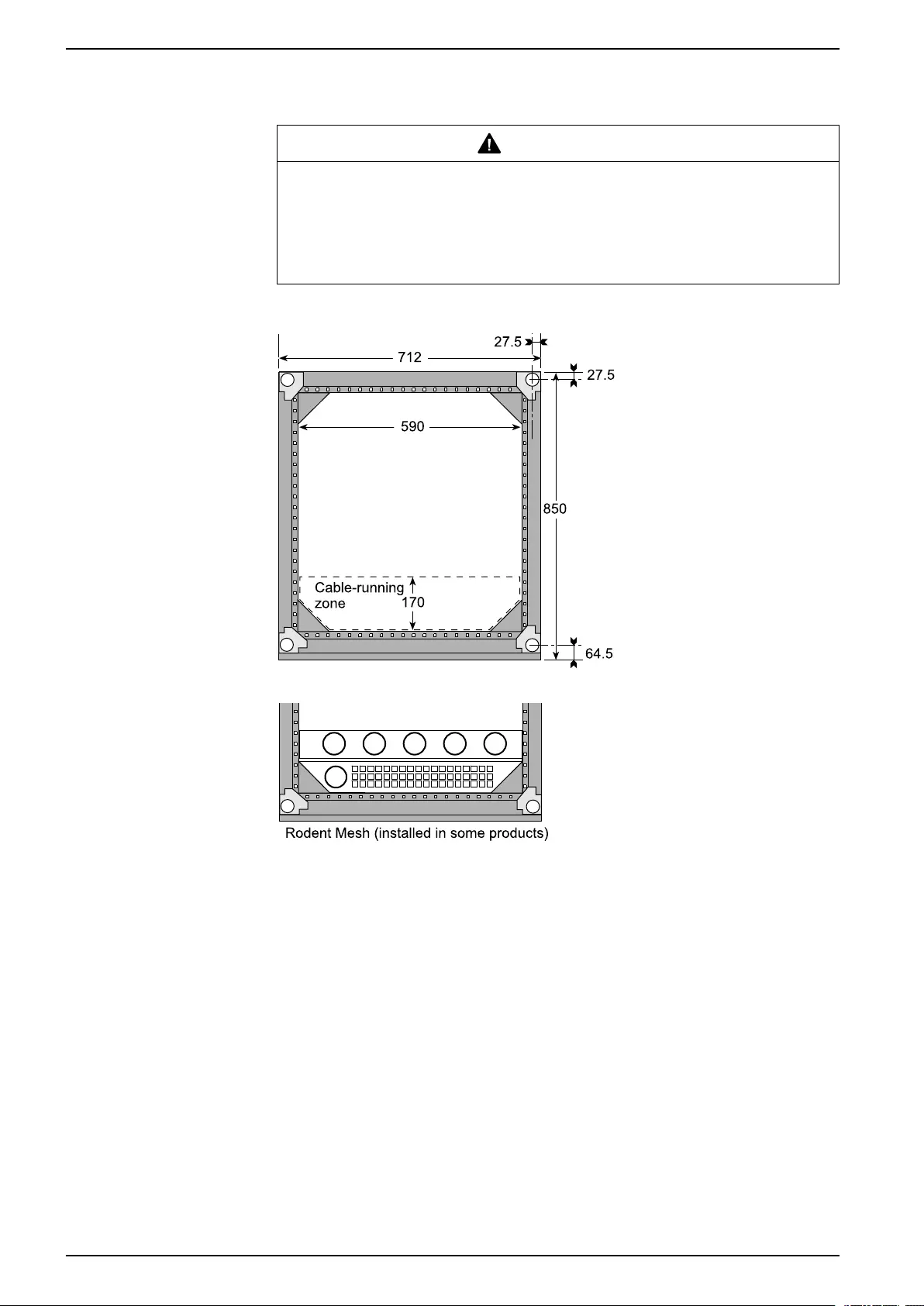

Install the IP32 Option

NOTE: Not applicable for Galaxy 5500 Marine, see Galaxy 5500 Marine receiving

and unpacking manual.

NOTE: The IP32 option will add 200 mm to the height of the cabinet.

1. Install the protection cover on top of the UPS.

2. Install the posts. The longer posts must be positioned in the front.

3. Install the roof.

4. Install the side deflectors.

990–5233D–001 29

20 - 120 kVA 400 V Floor Mounting

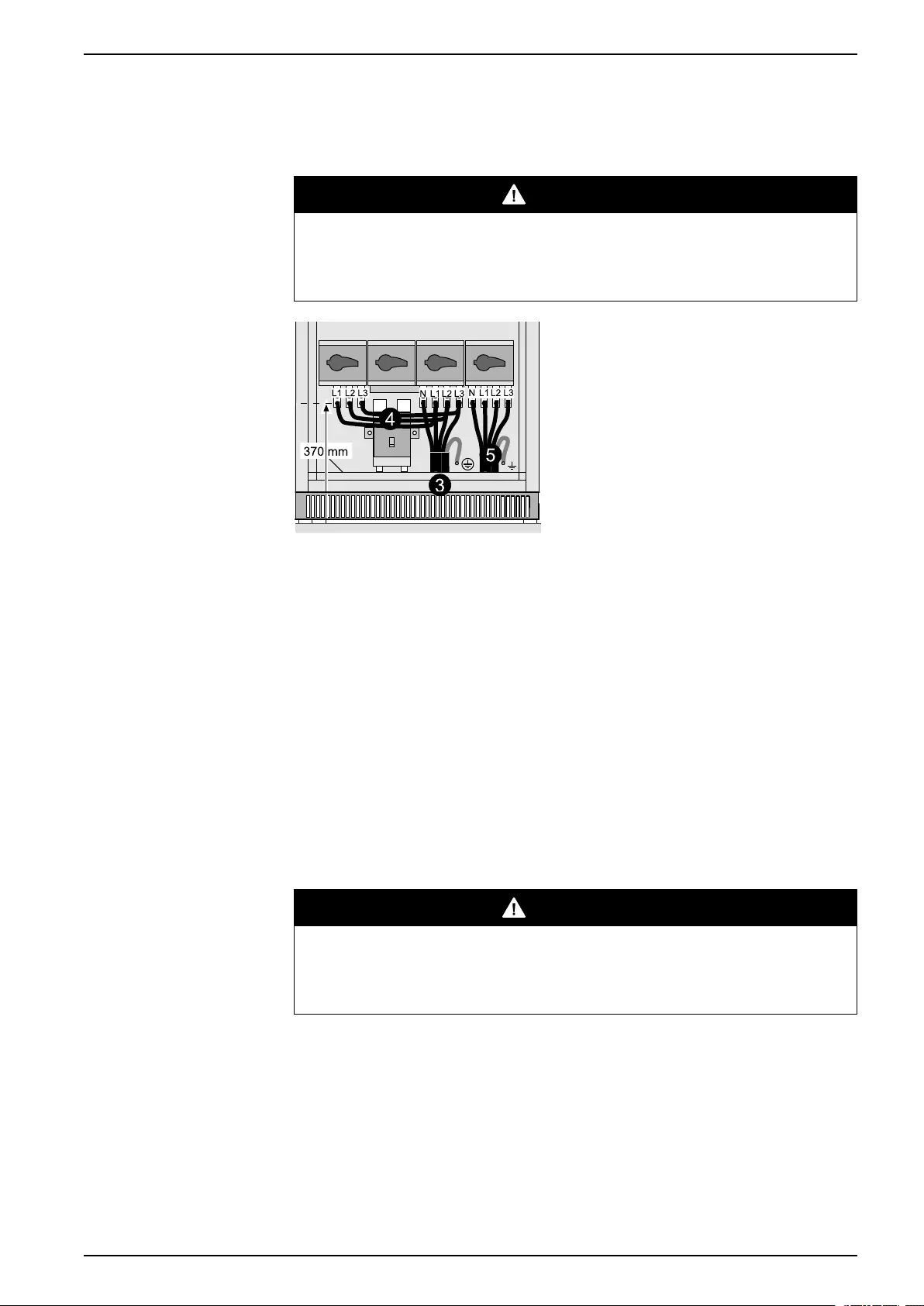

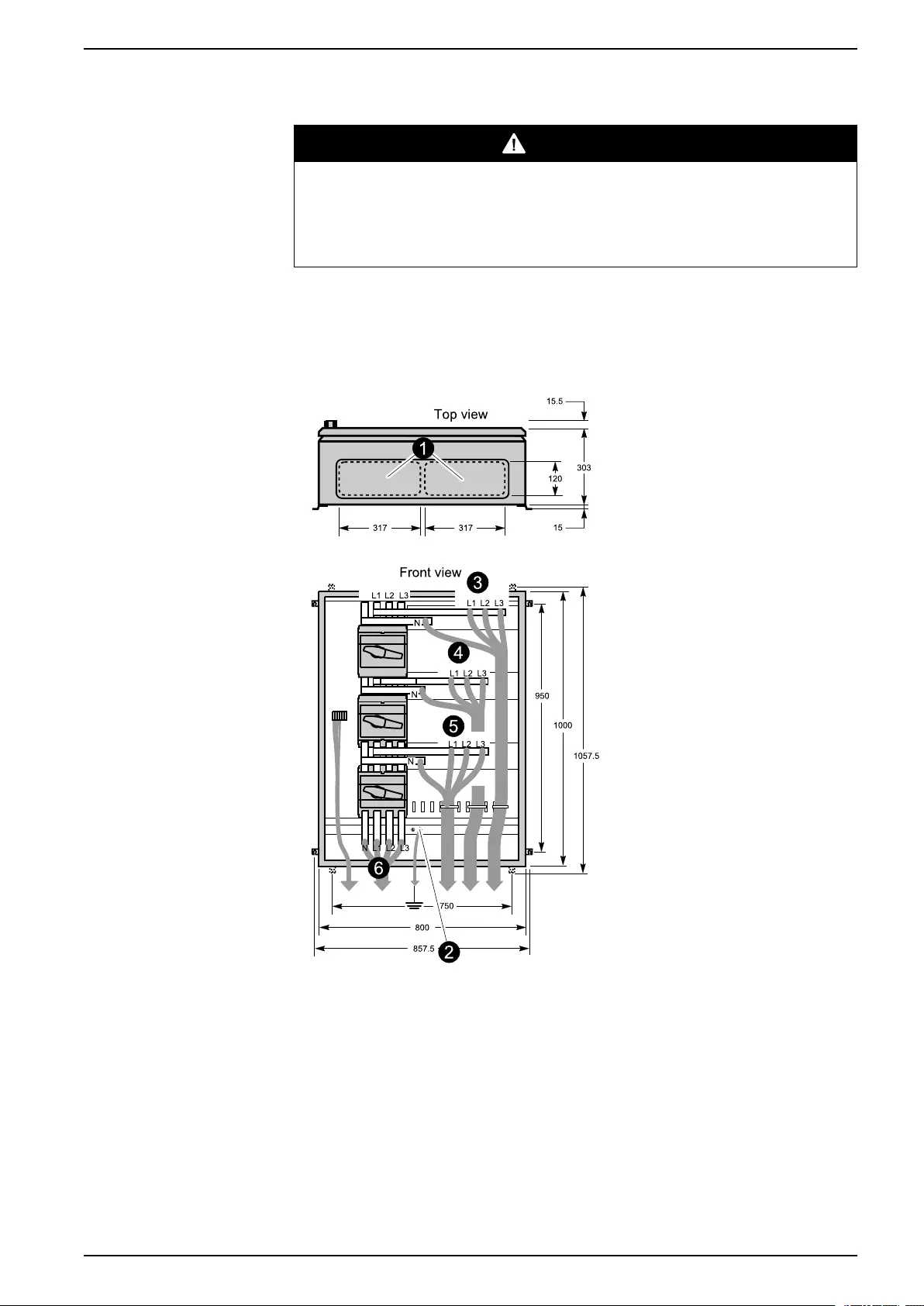

Floor Mounting

WARNING

HAZARD OF OVERHEATING

Do not remove the cabinet feet as they are required to ensure sufficient

ventilation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

The measurements include the cabinet side (panels and door).

30 990–5233D–001

Connect Input and PE Cables in Single

Systems 20 - 120 kVA 400 V

Connect Input and PE Cables in Single Systems

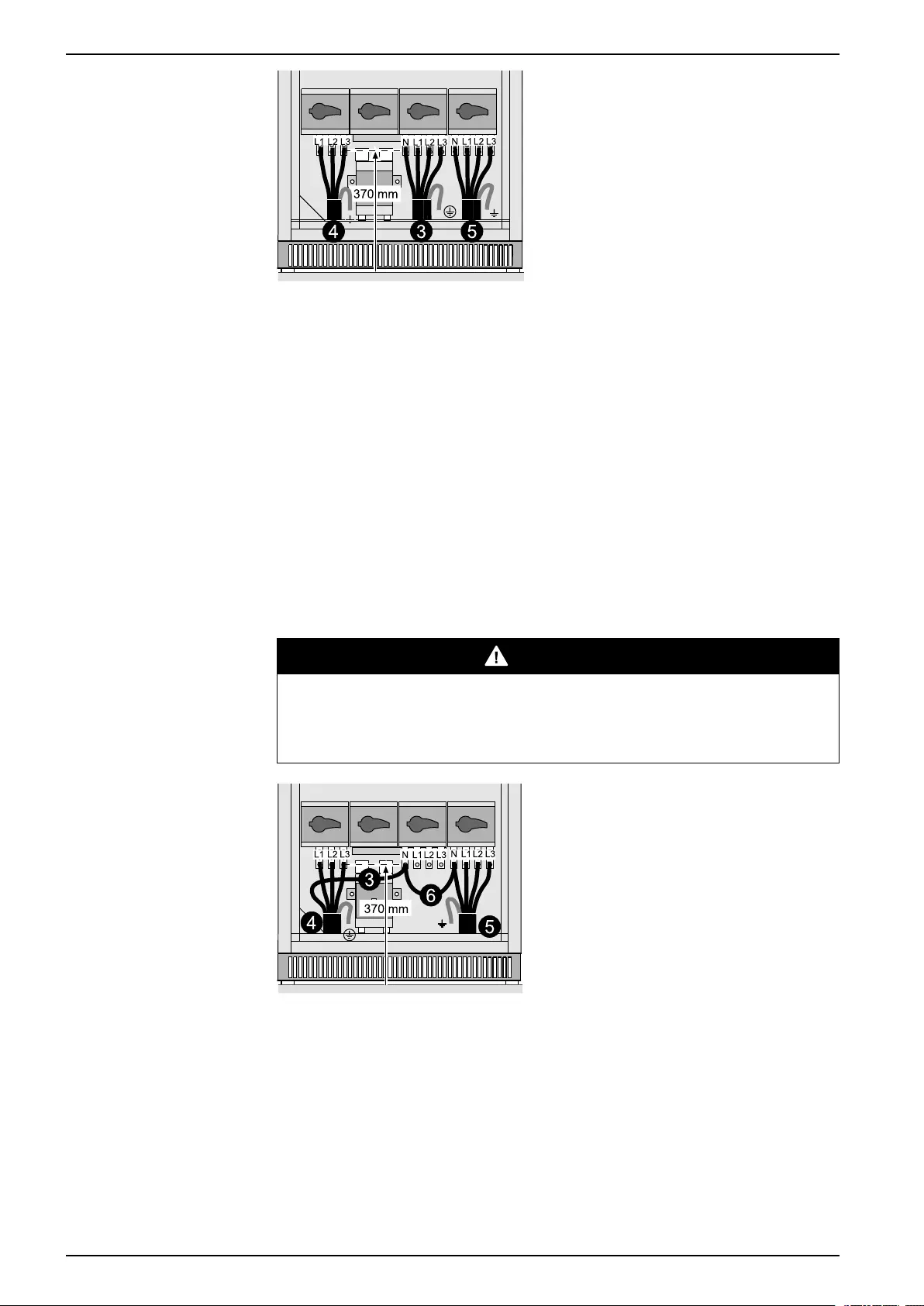

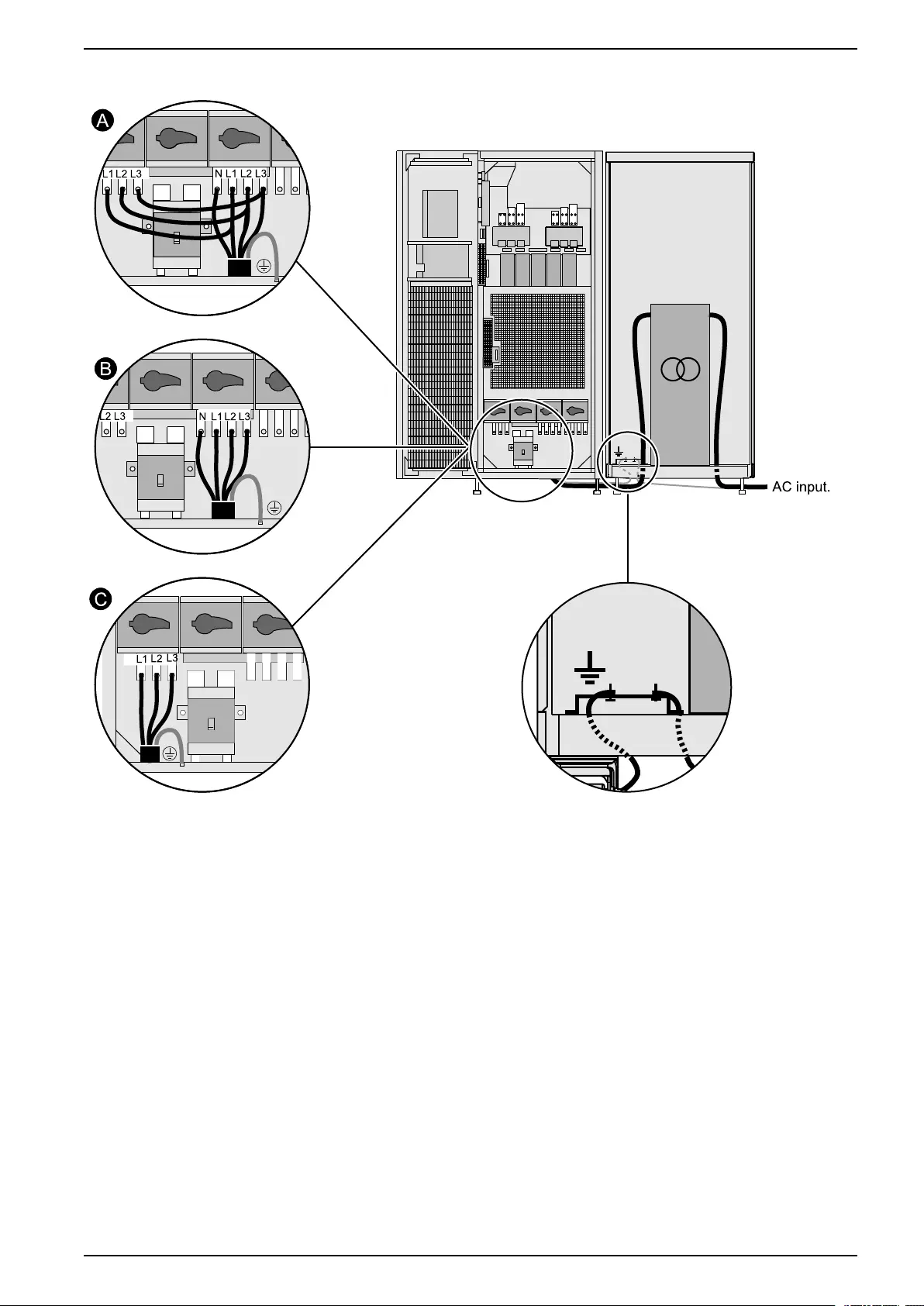

Single Utility/Mains Systems

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the AC input cables to the bypass terminals and to the UPS earthing

terminal.

4. Connect cables from the input terminals to the bypass terminals.

5. Connect the AC output cables to the output terminals and to the UPS earthing

terminal.

6. Fasten the cables to the cabinet.

7. Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

8. Unfold the dust protection cover.

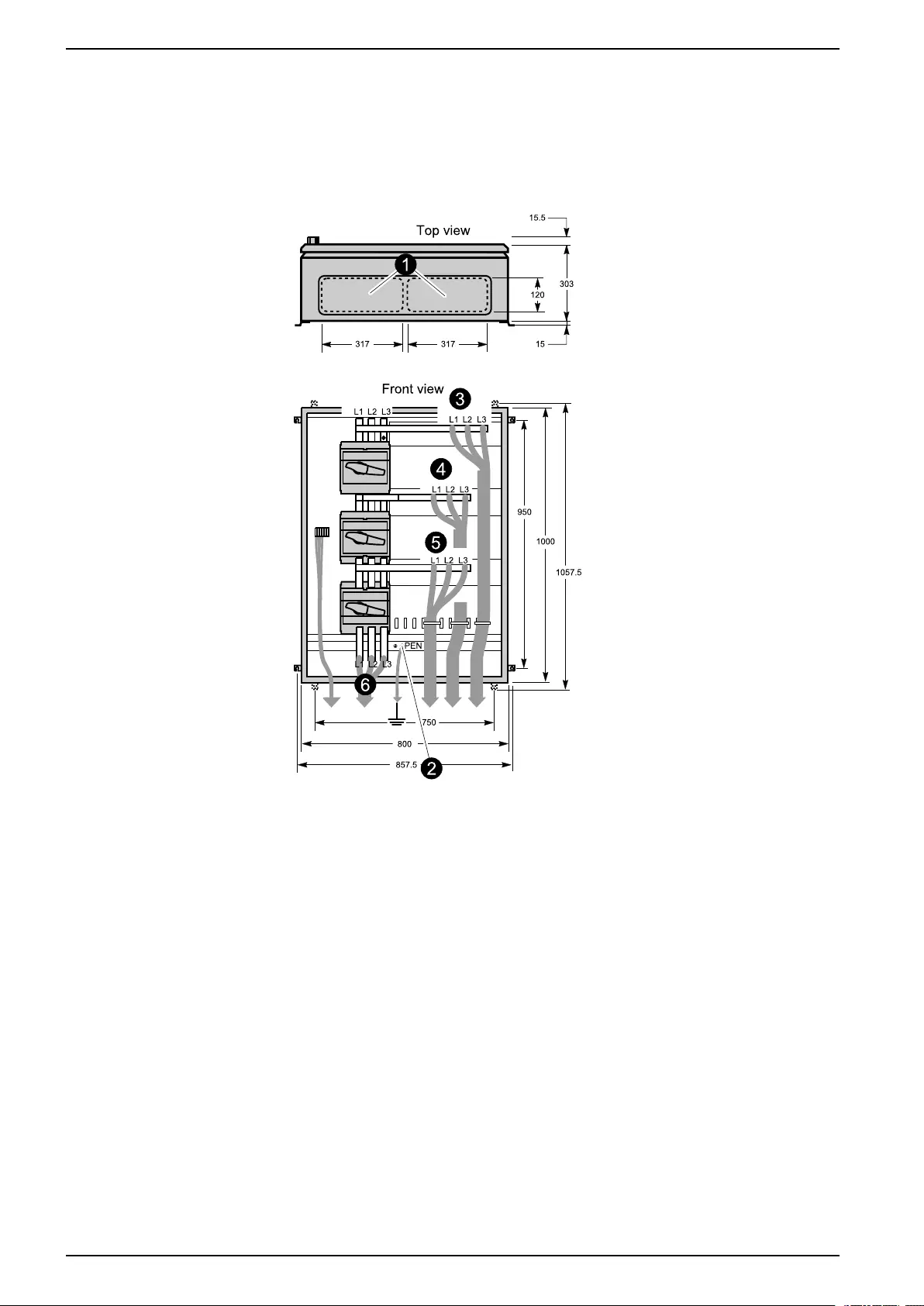

Dual Utility/Mains Systems

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

990–5233D–001 31

20 - 120 kVA 400 V

Connect Input and PE Cables in Single

Systems

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the AC bypass cables to the bypass terminals and to the UPS earthing

terminal.

4. Connect the AC input cables to the input terminals.

5. Connect the AC output cables to the output terminals and to the UPS earthing

terminal.

6. Fasten the cables to the cabinet.

7. Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

8. Unfold the dust protection cover.

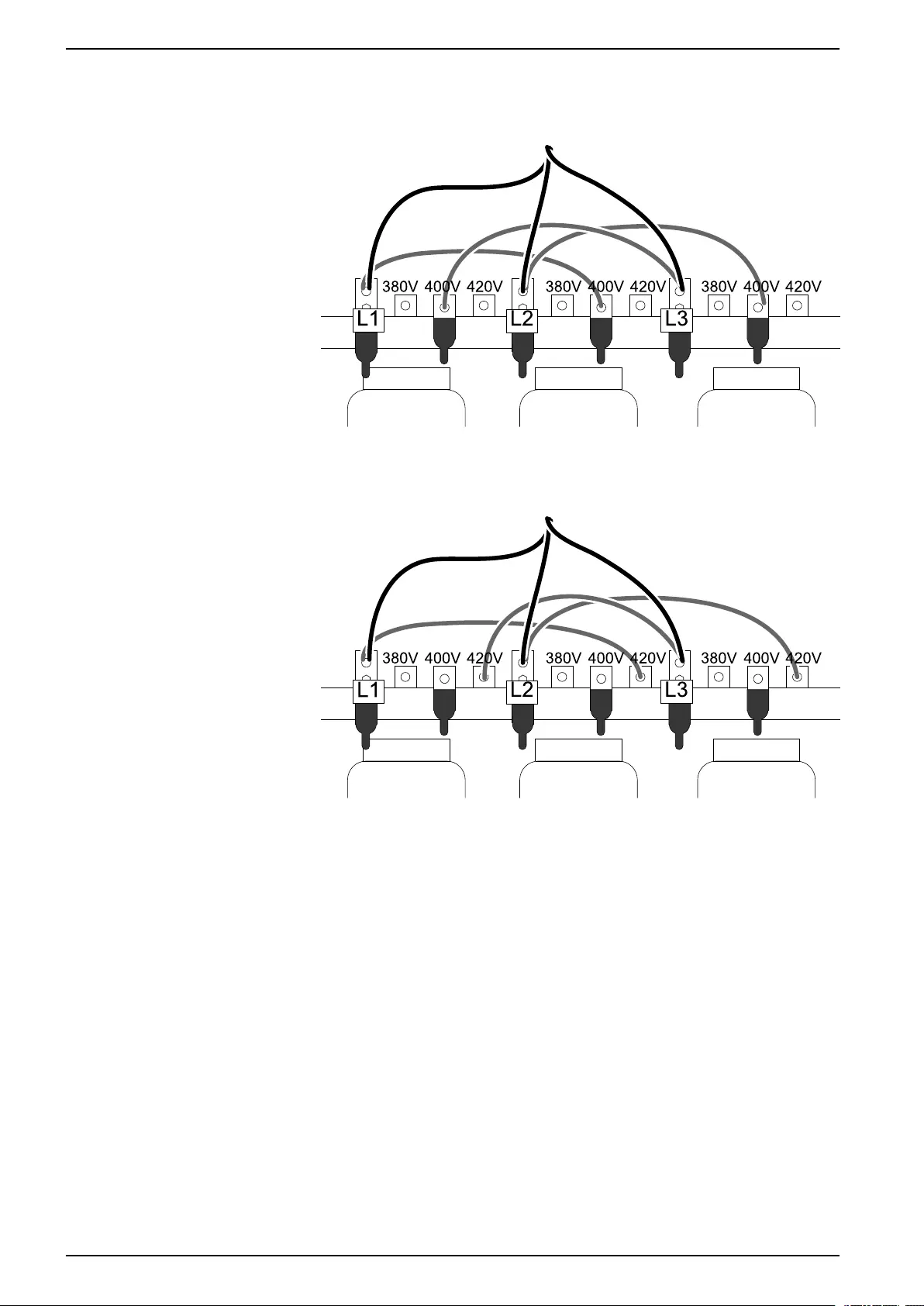

Frequency Converter

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the AC input neutral cable to the AC bypass neutral terminal.

4. Connect the AC input cables to the input terminals and to the UPS earthing

terminal.

5. Connect the AC output cables to the output terminals and to the UPS earthing

terminal.

6. Connect the bypass neutral terminal to the output neutral terminal.

7. Fasten the cables to the cabinet.

32 990–5233D–001

20 - 120 kVA 400 V

Connect Input and PE Cables in Parallel

Systems

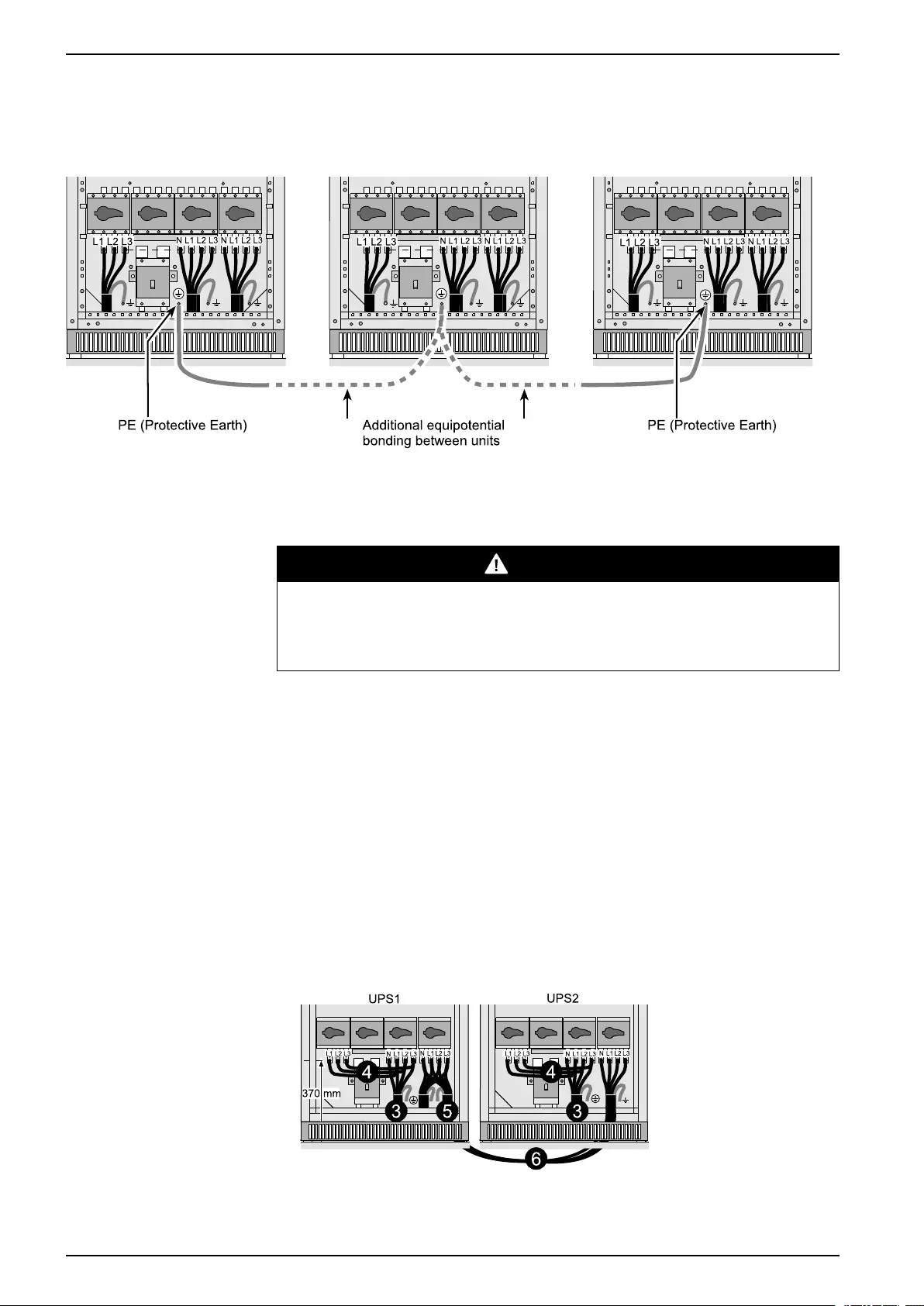

Connect Input and PE Cables in Parallel Systems

Overview

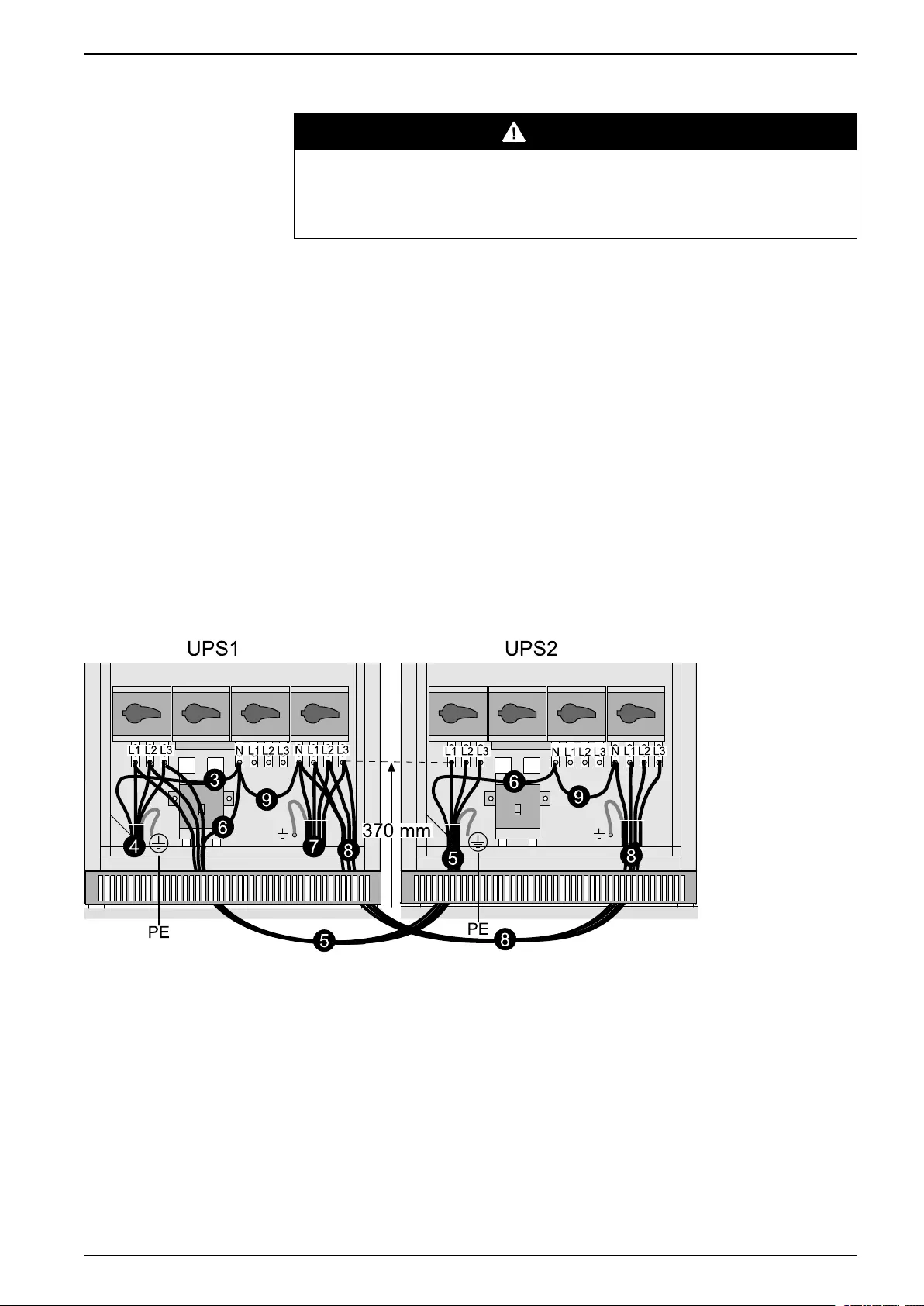

Single Utility/Mains Systems

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the AC input cables to the bypass terminals and to the UPS earthing

terminal for each UPS.

4. Connect cables from the input terminals to the bypass terminals for each UPS.

5. Connect the AC output cables to the output terminals and to the UPS earthing

terminal of UPS1.

6. Connect cables from the output terminals of UPS1 to the output terminals of

UPS2.

7. Fasten the cables to the cabinet.

8. Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

9. Unfold the dust protection cover.

34 990–5233D–001

Connect Input and PE Cables in Parallel

Systems 20 - 120 kVA 400 V

Dual Utility/Mains Systems

Redundant Parallel System

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the terminal protection cover in the bottom of the cabinet.

3. Connect the AC input cables to the input terminals and to the UPS earthing

terminal for each UPS.

4. Connect the AC bypass cables to the bypass terminals and to the UPS earthing

terminal for each UPS.

5. Connect the AC output cables to the output terminals and to the UPS earthing

terminal for UPS1.

6. Connect cables from output terminals of UPS1 to output terminals of UPS2.

7. Fasten the cables to the cabinet.

8. Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

9. Unfold the dust protection cover.

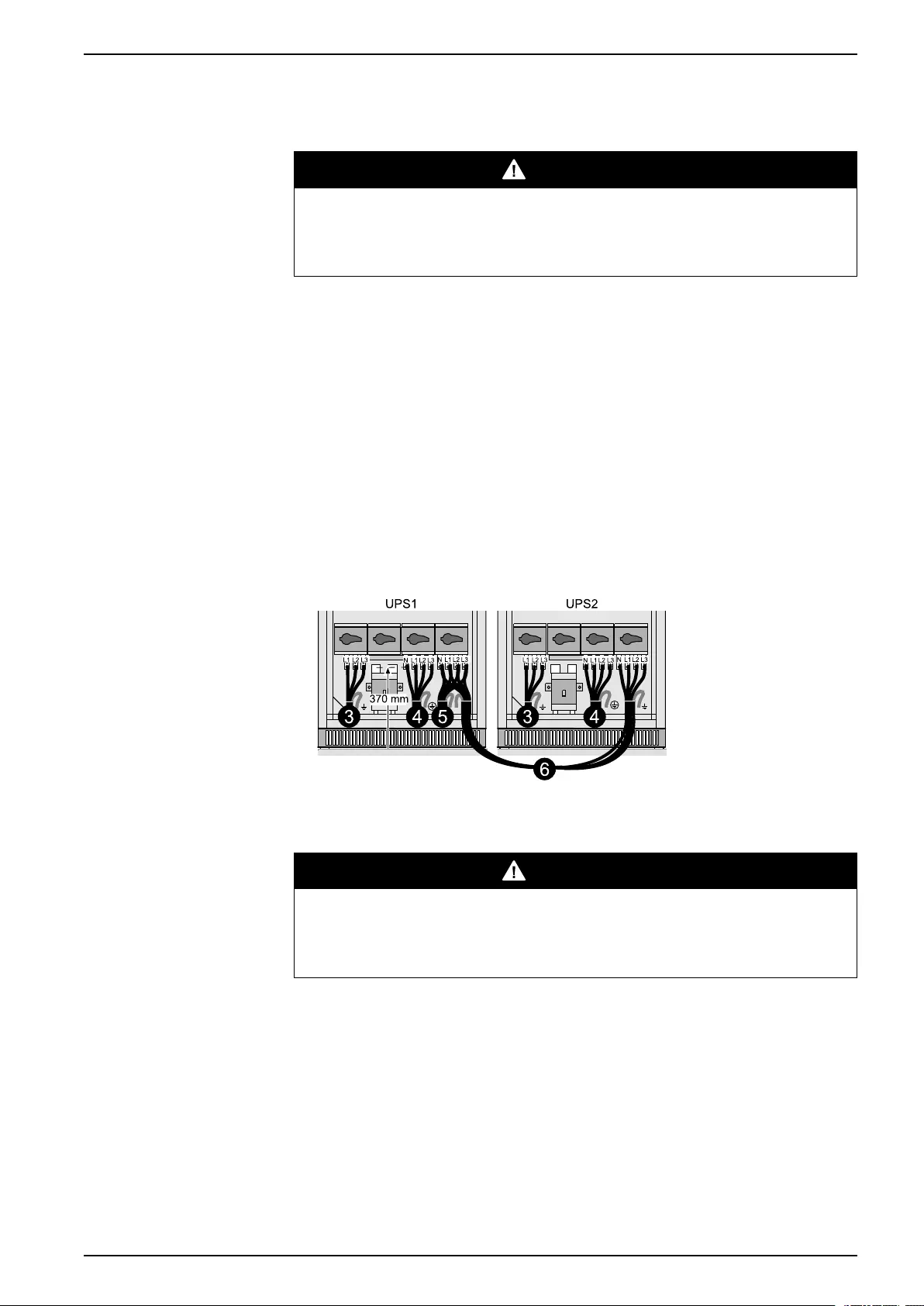

Parallel System with External Bypass

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection covers in the bottom of the cabinets.

3. Connect the AC input cables to the input terminals and to the UPS earthing

terminal of each UPS.

4. Connect the AC bypass input cables to the bypass terminals and to the UPS

earthing terminal of the external bypass.

5. Connect the bypass terminals of the UPSs to the bypass terminals of the

external bypass using cables with equal lengths and sizes.

6. Connect the AC output cables to the output terminals and to the earthing

terminal of the external bypass.

990–5233D–001 35

20 - 120 kVA 400 V

Connect Input and PE Cables in Parallel

Systems

7. Connect the output terminals of the UPSs to the output terminals of the external

bypass using cables with equal lengths and sizes.

8. Fasten the cables to the cabinet.

9. Reinstall the protection covers for power terminals. Tightening torque is 2 Nm.

10.Unfold the dust protection cover.

36 990–5233D–001

Connect Input and PE Cables in Parallel

Systems 20 - 120 kVA 400 V

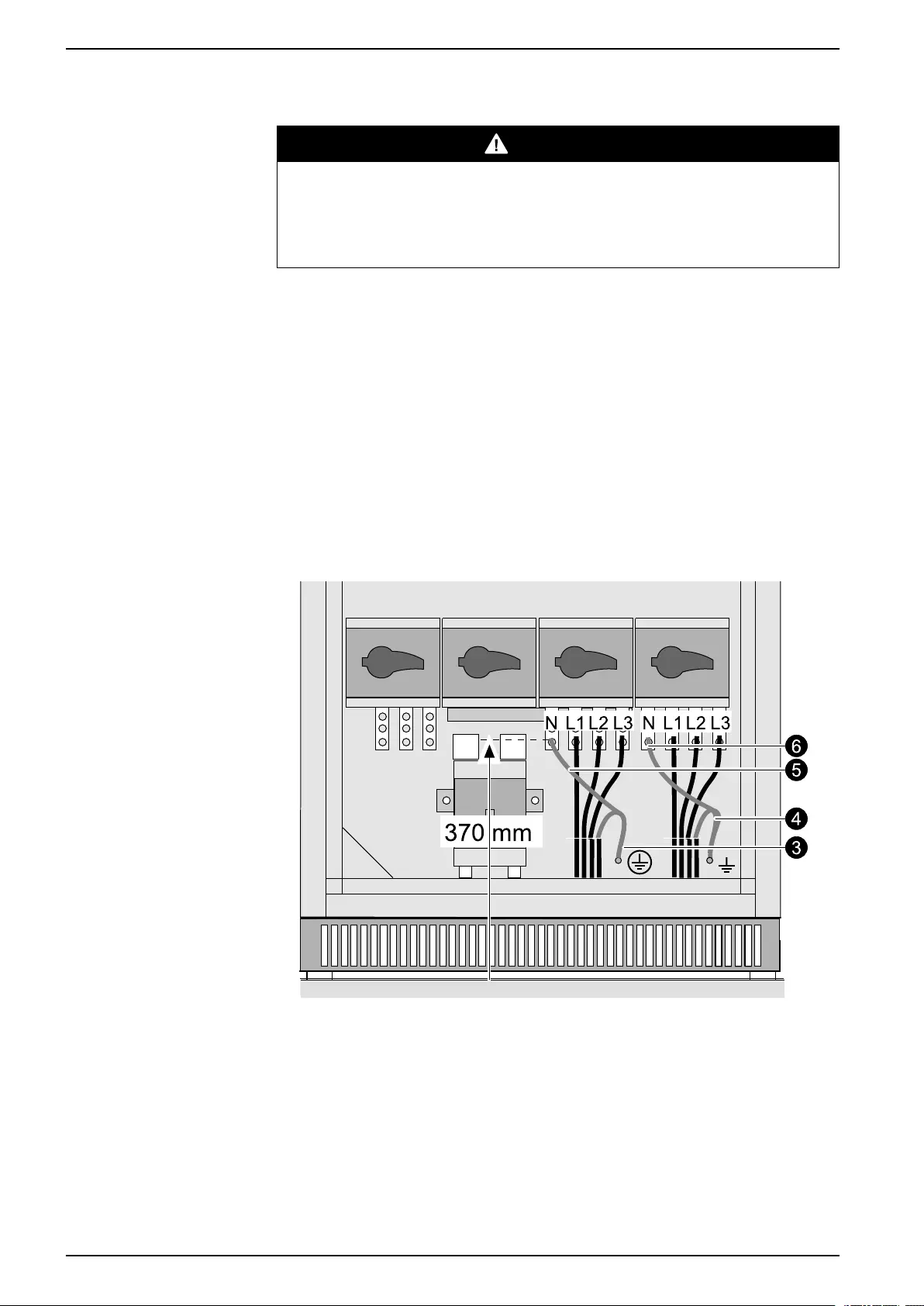

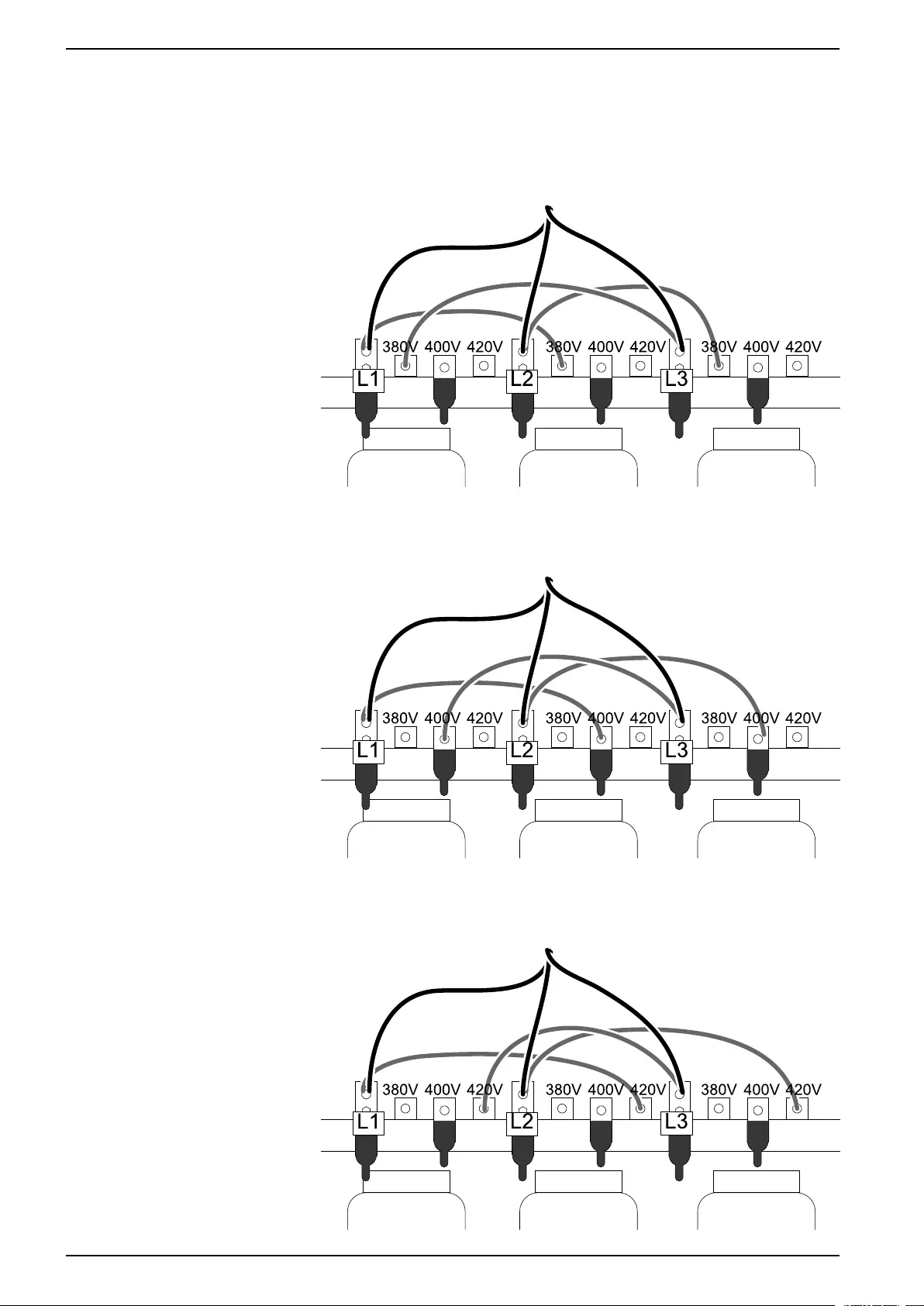

Frequency Converter

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected first.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the neutral cable of AC input to the neutral terminal on the bypass

terminals.

4. Connect the AC input cables to the input terminals and to the UPS earthing

terminal.

5. Connect the input terminal of UPS1 to the input terminal of UPS2.

6. Connect the bypass neutral terminal of UPS1 to the bypass neutral terminal of

UPS2.

7. Connect the AC output cables to the output terminals of UPS1.

8. Connect the output terminals of UPS1 to the output terminals of UPS2.

9. Connect bypass neutral terminal to output neutral terminal on both UPSs.

10.Fasten the cables to the cabinet.

11.Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

12.Unfold the dust protection cover.

990–5233D–001 37

20 - 120 kVA 400 V Connect PE Cable in TNC System

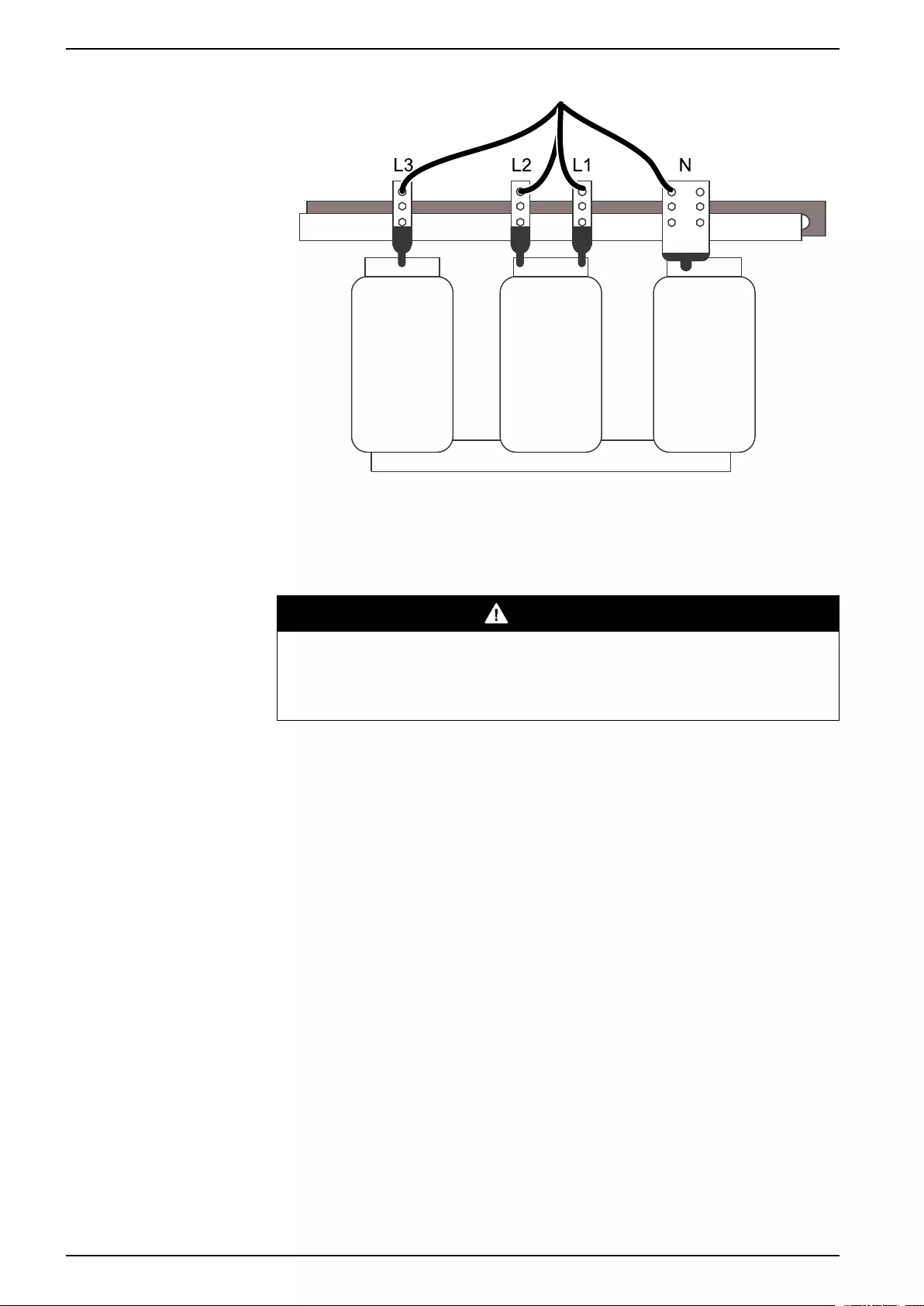

Connect PE Cable in TNC System

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

PE cables must be connected for single UPSs, parallel UPSs and external

bypasses.

Failure to follow these instructions will result in death or serious injury.

1. Fold the dust protection cover as shown on the cover.

2. Remove the protection cover in the bottom of the cabinet.

3. Connect the AC input PEN cable to the UPS bypass earthing terminal.

4. Connect the AC output PEN cable to the UPS output earthing terminal.

5. Connect the UPS bypass earthing terminal to the bypass neutral terminal with

the supplied cable.

6. Connect the UPS output earthing terminal to the output neutral terminal with the

supplied cable.

7. Fasten the cables to the cabinet.

8. Reinstall the protection cover for power terminals. Tightening torque is 2 Nm.

9. Unfold the dust protection cover.

38 990–5233D–001

Connect the Communication Cables 20 - 120 kVA 400 V

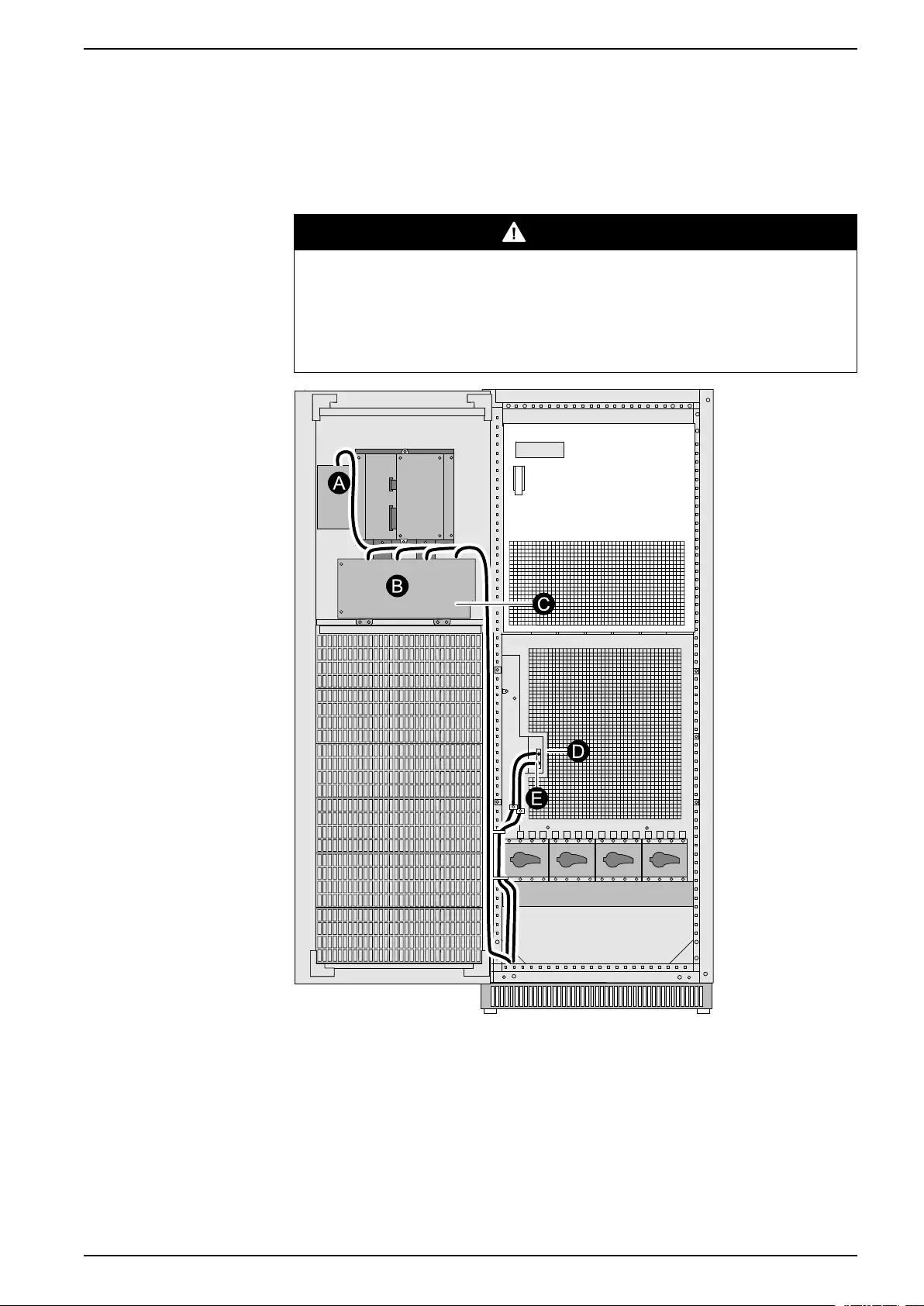

Connect the Communication Cables

Overview of the Communication Cables

Overview of Communication Cables in Single Systems

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Run the communication cables separately from the power cables to ensure

sufficient isolation. If any risk of contact with the power cables exists, reinforce

the insulation of the communication cables.

Failure to follow these instructions will result in death or serious injury.

A. Network management card (SELV)

B. Optional communication cards (SELV or LV)

C. Dry contact communication card (SELV)

D. External battery circuit breaker cables (SELV)

E. General shutdown cable (SELV)

990–5233D–001 39

20 - 120 kVA 400 V Connect the Communication Cables

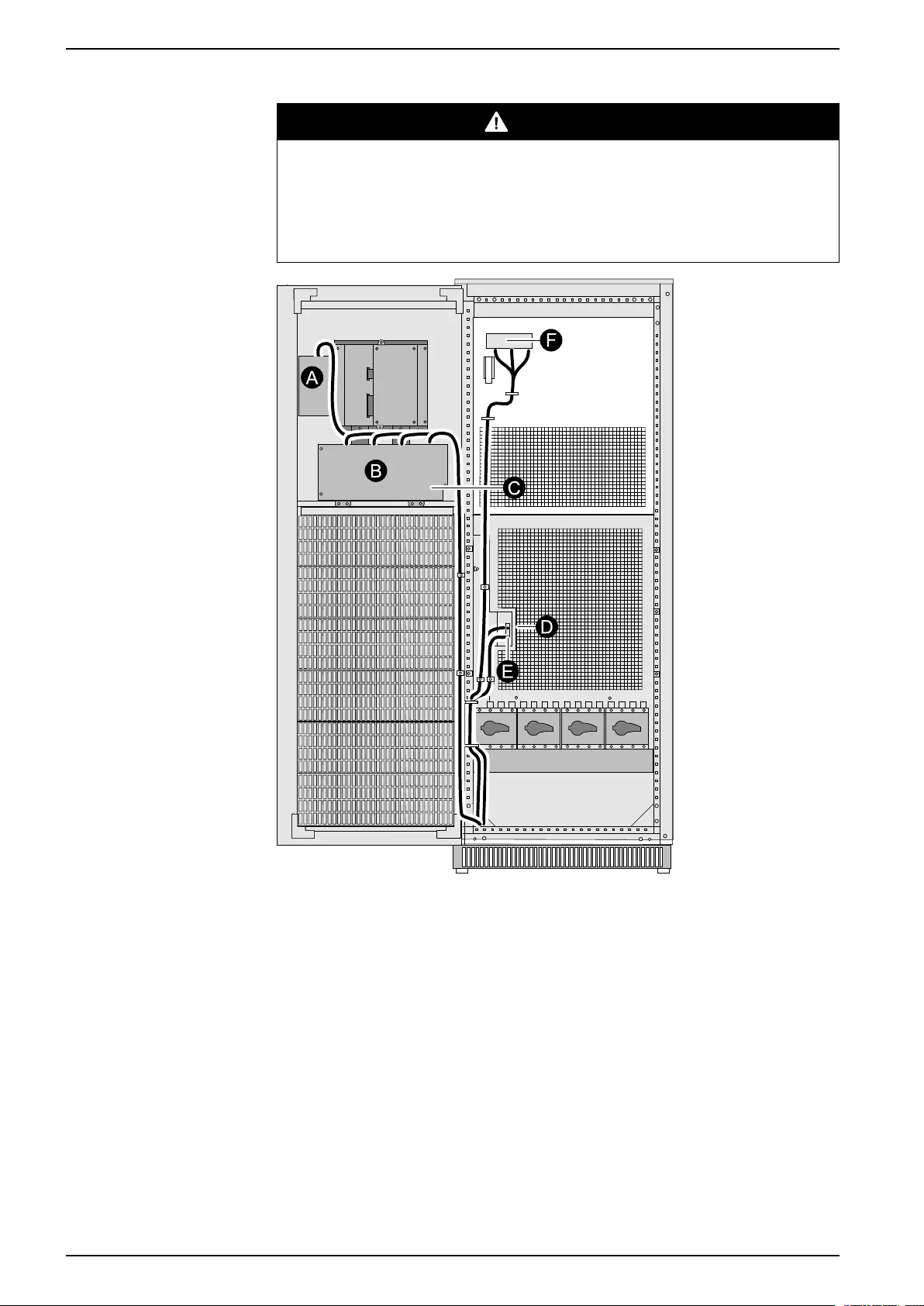

Overview of Communication Cables in Parallel Systems

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Run the communication cables separately from the power cables to ensure

sufficient isolation. If any risk of contact with the power cables exists, reinforce

the insulation of the communication cables.

Failure to follow these instructions will result in death or serious injury.

A. Network management card (SELV)

B. Optional communication cards (SELV or LV)

C. Dry contact communication card (SELV)

D. External battery circuit breaker cables (SELV)

E. General shutdown cable (SELV)

F. External bypass cable (ELV), CAN cables (SELV) and exchange-current cables

(SELV)

40 990–5233D–001

Connect the Communication Cables 20 - 120 kVA 400 V

Connect Dry Contact Communication Card

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Isolate and tagout/lockout all power sources for the dry contact communication

card (also known as SECI) before making connections. Never connect SELV

(safety extra low voltage) and non-SELV circuits to the different outputs of the

same card.

Failure to follow these instructions will result in death or serious injury.

NOTE: Only one dry contact communication card can be installed in a UPS.

Characteristics of output contacts:

• Permissible voltage: 250 V AC, 30 V DC

• Permissible current: 2 A

• Cable: 4 x 0.93 mm², Ø 6.6 mm +/- 0.3 mm

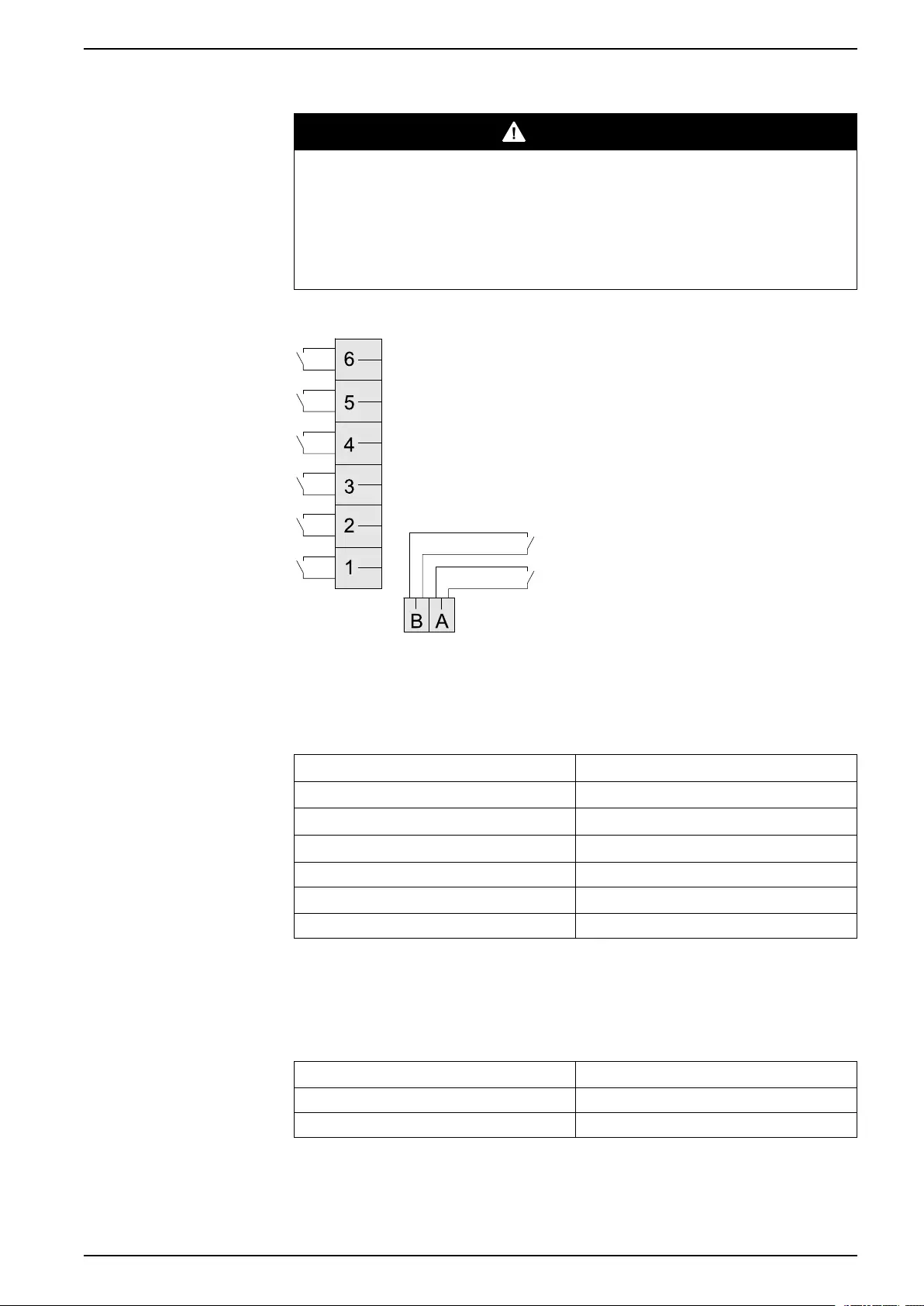

Pin Description

6 Low battery warning

5 Load on battery power

4 Load on automatic bypass

3 Load on UPS

2 Battery inoperable

1 General alarm

Characteristics of input contacts:

• Switched voltage: 5 V DC

• Consumption: 10 mA

• Cable: 4 x 0.34 mm², Ø 5 mm +/- 0.5 mm

Pin Description

A UPS OFF

B UPS ON

1. Remove the cover fastened by the screws.

2. Run the communication cables through the cable entry holes.

3. Connect the communication cables to the input contacts.

990–5233D–001 41

20 - 120 kVA 400 V Connect the Communication Cables

4. Connect the communication cables to the output contacts.

5. Reinstall the cover and fasten it with the screws.

6. Tighten the screws to lock the cables.

7. Indicate the location of the power sources on the labels.

8. Install the card in its slot.

9. Fasten the card with two screws.

42 990–5233D–001

Connect the Communication Cables 20 - 120 kVA 400 V

Connect Network Management Card

Follow the instructions in the network management card installation manual 990-

3194.

Example of Communication Card Connection

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

If a SELV source is used, isolate the communication card from the power source

to ensure the safety of personnel working on the installation.

Failure to follow these instructions will result in death or serious injury.

Add or Change Communication Cards

1. Open the UPS door. The cardholder for optional communication cards is placed

on the inside of the door.

2. Remove the four screws from the cardholder.

990–5233D–001 43

Connect the Communication Cables 20 - 120 kVA 400 V

Connect General Shutdown or Remote Emergency Power Off

Pressing the general shutdown button causes UPS shutdown and opening of the

battery circuit breaker (When the opening of the bypass static switch is disabled

through customization settings, then the installer must make sure that the source

disconnection will be managed at upstream level). A Remote Emergency Power

Off (REPO) is applicable to installations where pressing the button also causes the

AC input source and AC bypass source circuit breakers to open. In parallel

systems, there must be a single general shutdown button with a separate contact

for each UPS unit.

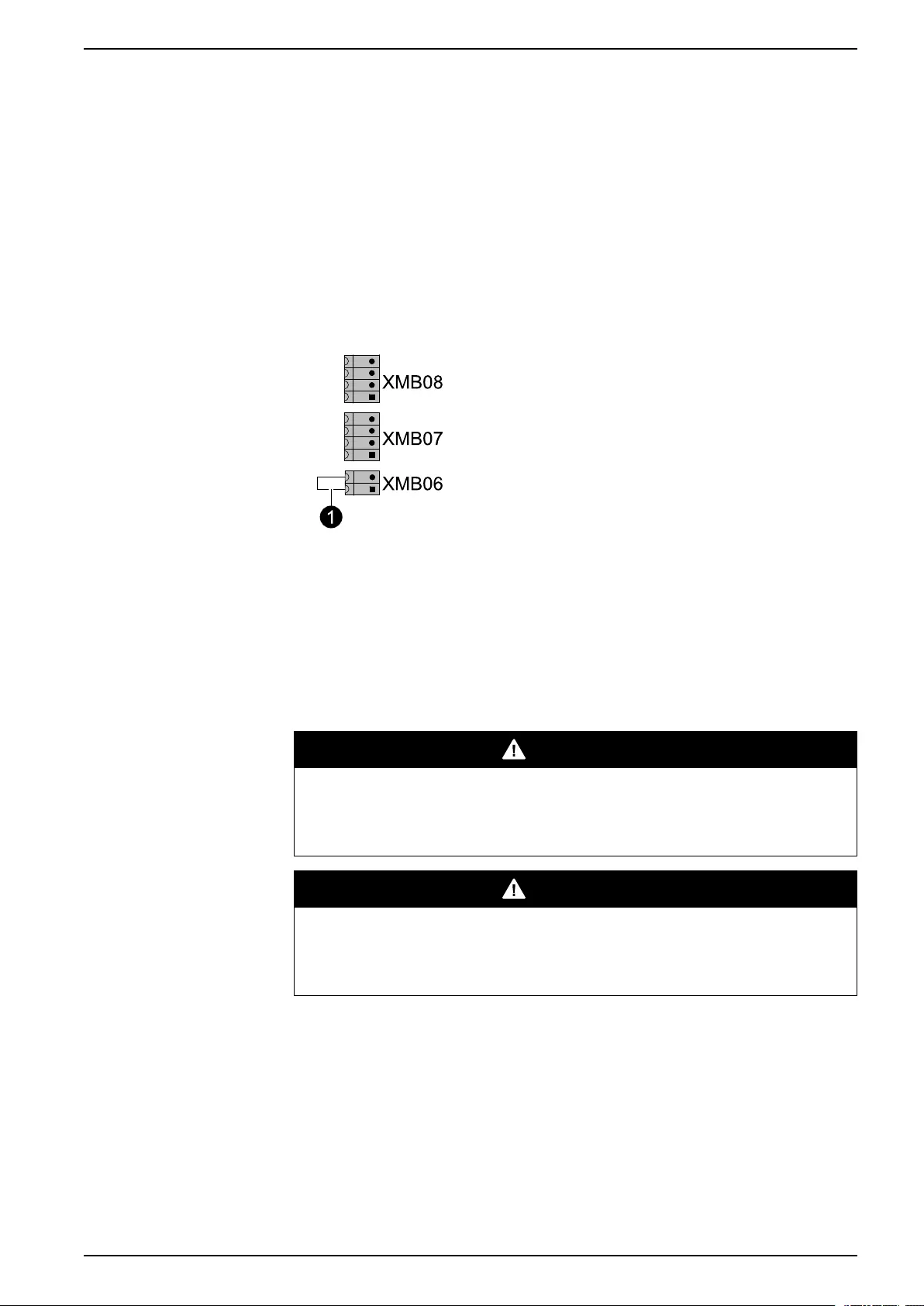

To locate the terminals in the cabinet, see Overview of the Communication Cables,

page 39

1. Remove the wire jumper from the terminal block.

2. Connect the general shutdown (Normally Closed) contact to XMB06 terminals 1

and 2 (SELV).

3. Fasten the cable.

Connect Parallel Communication Cables

Redundant Parallel System

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

De-energize the UPSs before connecting the cables.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

A maximum of two UPSs can be installed in parallel.

Failure to follow these instructions will result in death or serious injury.

NOTE: The supplied cables (10 m) limit the distance between the two UPSs to

approximately six meters.

To locate the terminals in the cabinet, see Overview of the Communication Cables,

page 39

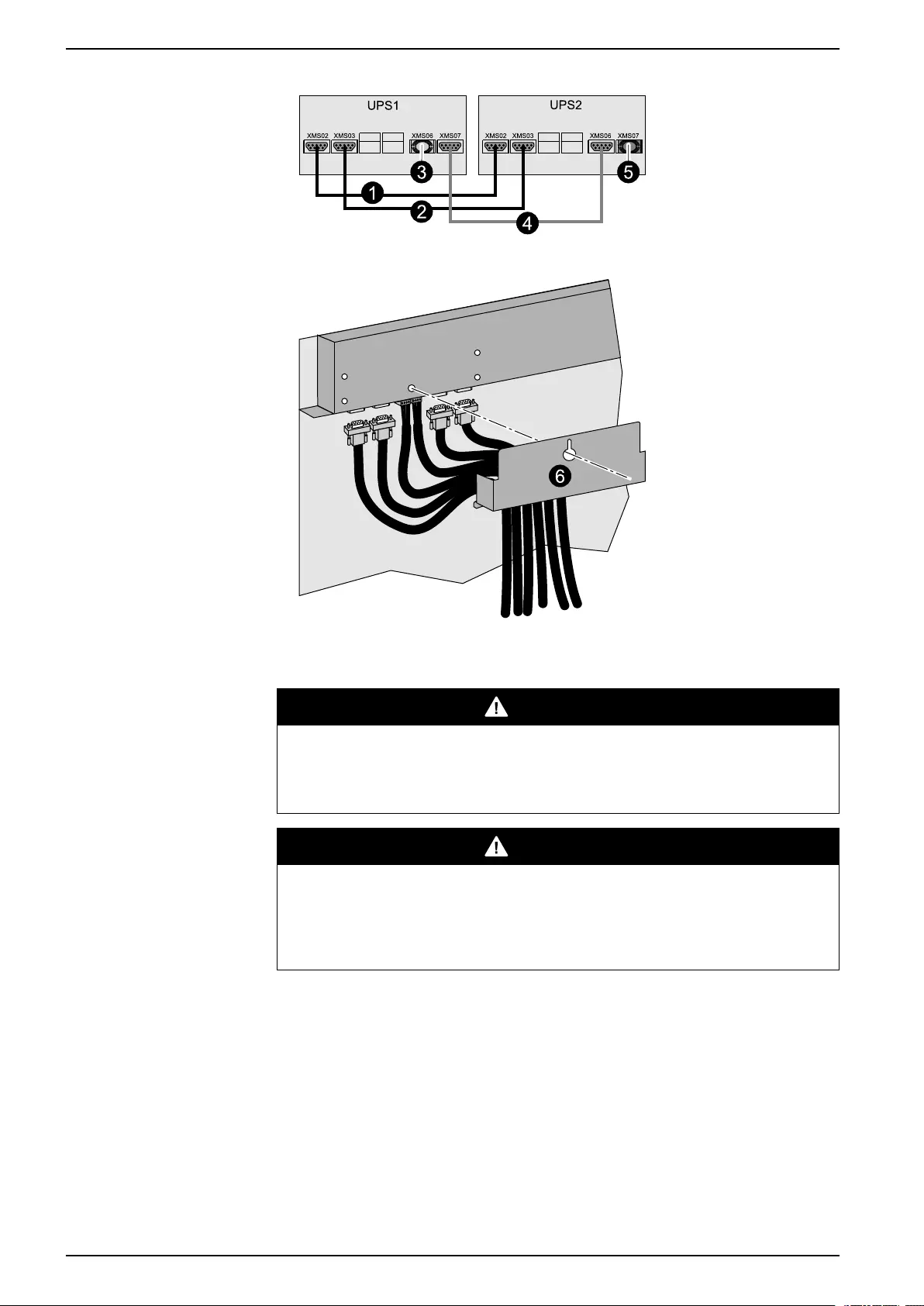

1. Connect a communication cable from XMS02 of UPS1 to XMS02 of UPS2.

2. Connect a communication cable from XMS03 of UPS1 to XMS03 of UPS2.

3. Install a blue terminator in connector XMS06 of UPS1.

4. Connect a communication cable from XMS07 of UPS1 to XMS06 of UPS2.

990–5233D–001 45

20 - 120 kVA 400 V Connect the Communication Cables

5. Install a red terminator in connector XMS07 of UPS2.

6. Install the supplied protection cover over the communication cables.

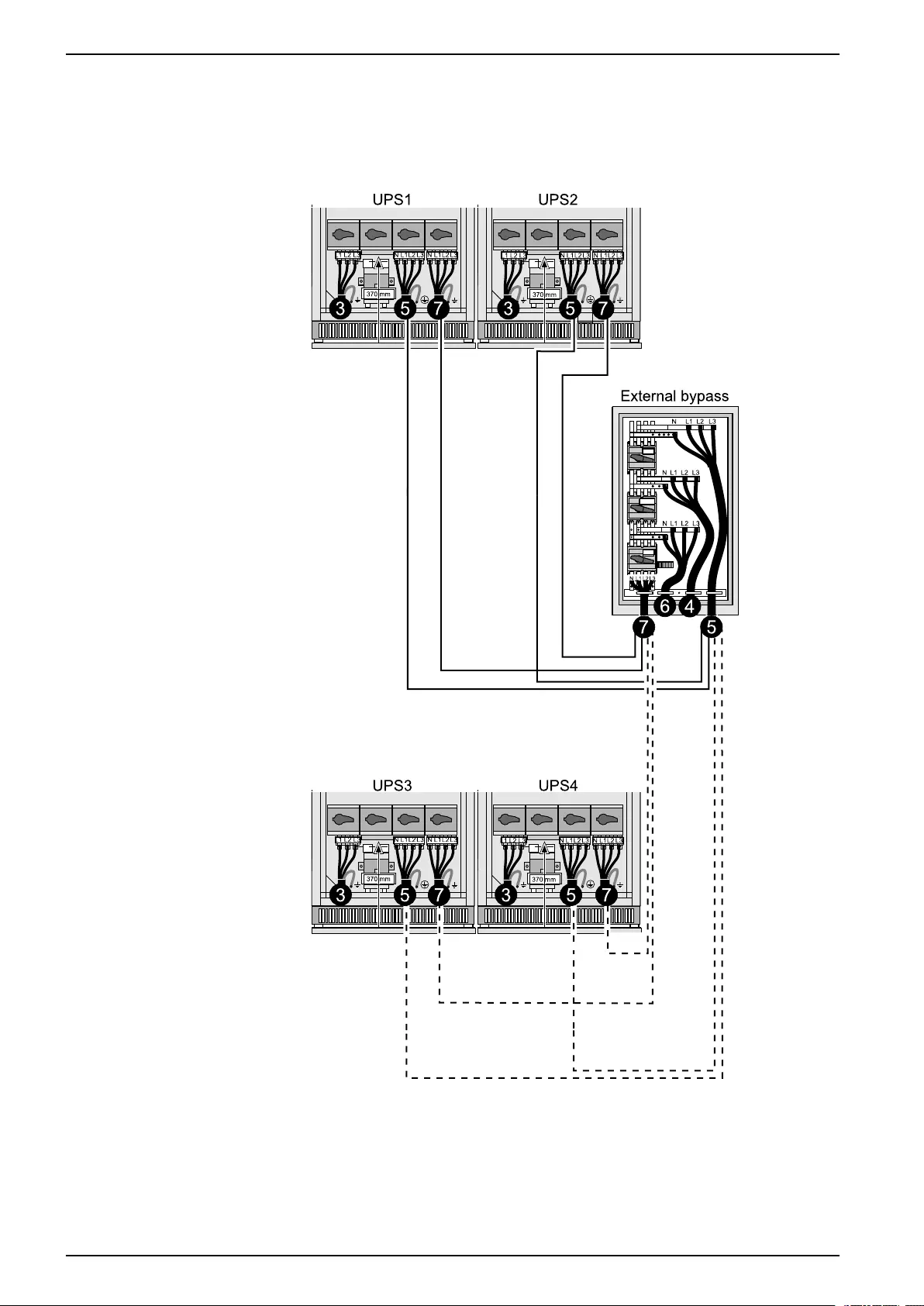

Parallel System with External Bypass

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

De-energize the UPSs before connecting the cables.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

A maximum of two UPSs can be installed in parallel. (Four UPSs can be present

in redundancy parallel system).

Failure to follow these instructions will result in death or serious injury.

NOTE: The supplied cables (10 m) limit the distance between the two UPSs to

approximately six meters.

To locate the terminals in the cabinet, see Overview of the Communication Cables,

page 39

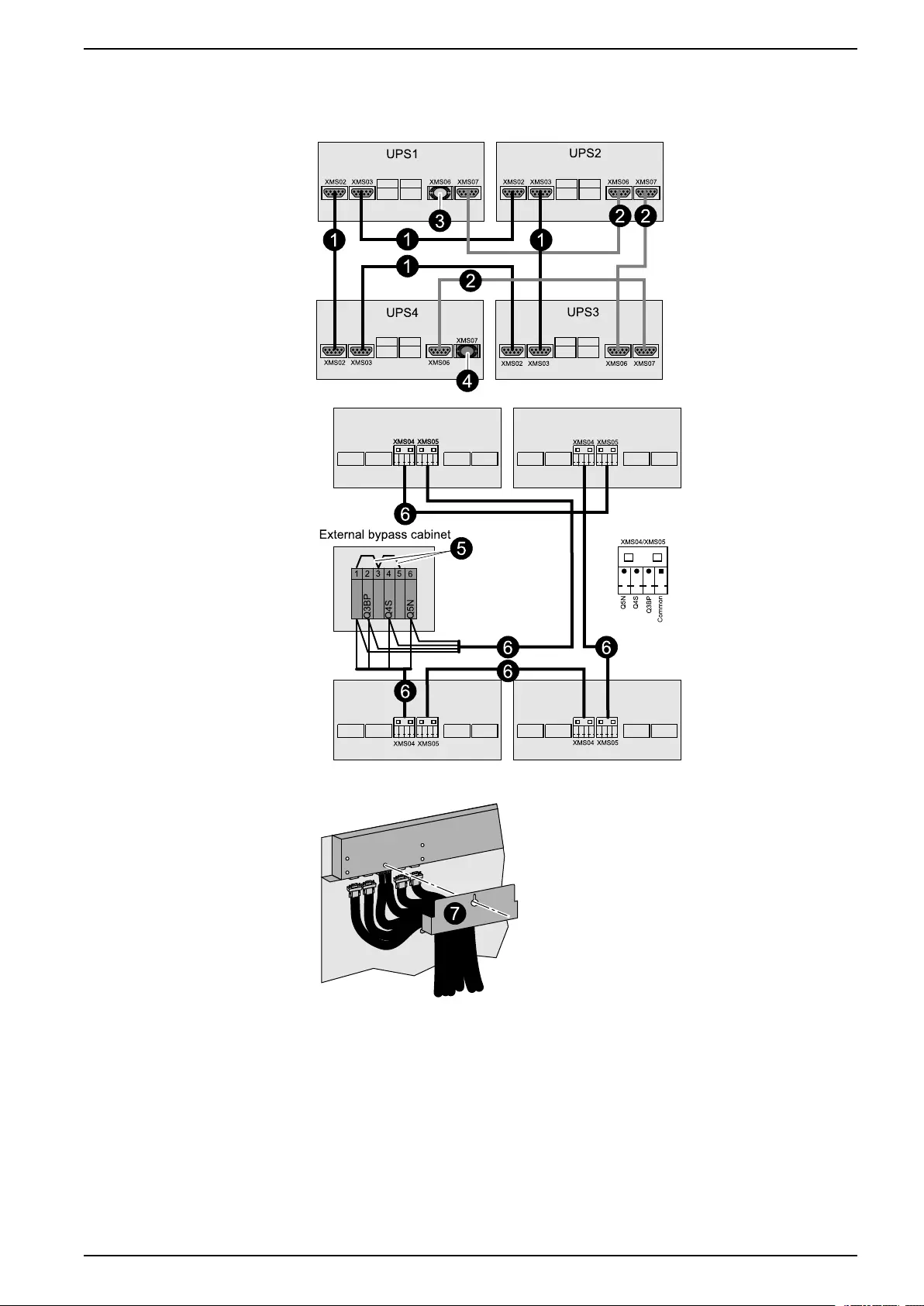

1. Connect the communication cables to XMS02 and XMS03 terminals as shown,

creating a loop between all the UPSs.

2. Connect the communication cables to XMS06 and XMS07 terminals as shown,

creating a loop between all the UPSs.

3. Install a blue terminator in connector XMS06 of UPS1.

4. Install a red terminator in connector XMS07 of UPS4.

46 990–5233D–001

Connect the Communication Cables 20 - 120 kVA 400 V

5. Connect the external bypass terminals 1,3,5 as shown.

6. Connect the external bypass terminals 1,2,4,6 to XMS04 and XMS05 terminals

of the UPSs as shown, using maximum size 2.5 mm² cables.

7. Install the supplied protection cover over the communication cables.

990–5233D–001 47

20 - 120 kVA 400 V Install an External Battery

Install an External Battery

Lock Battery Cells on Shelves for Marine UPS

CAUTION

FOR INSTALLATION ON SHIP – RISK OF ELECTRICAL DISCONNECTION

Install wedges as shown below.

Failure to follow these instructions can result in injury or equipment

damage.

Rear wedges are already mounted on the shelves.

Depending on battery cells configuration, some provided wedges remain unused.

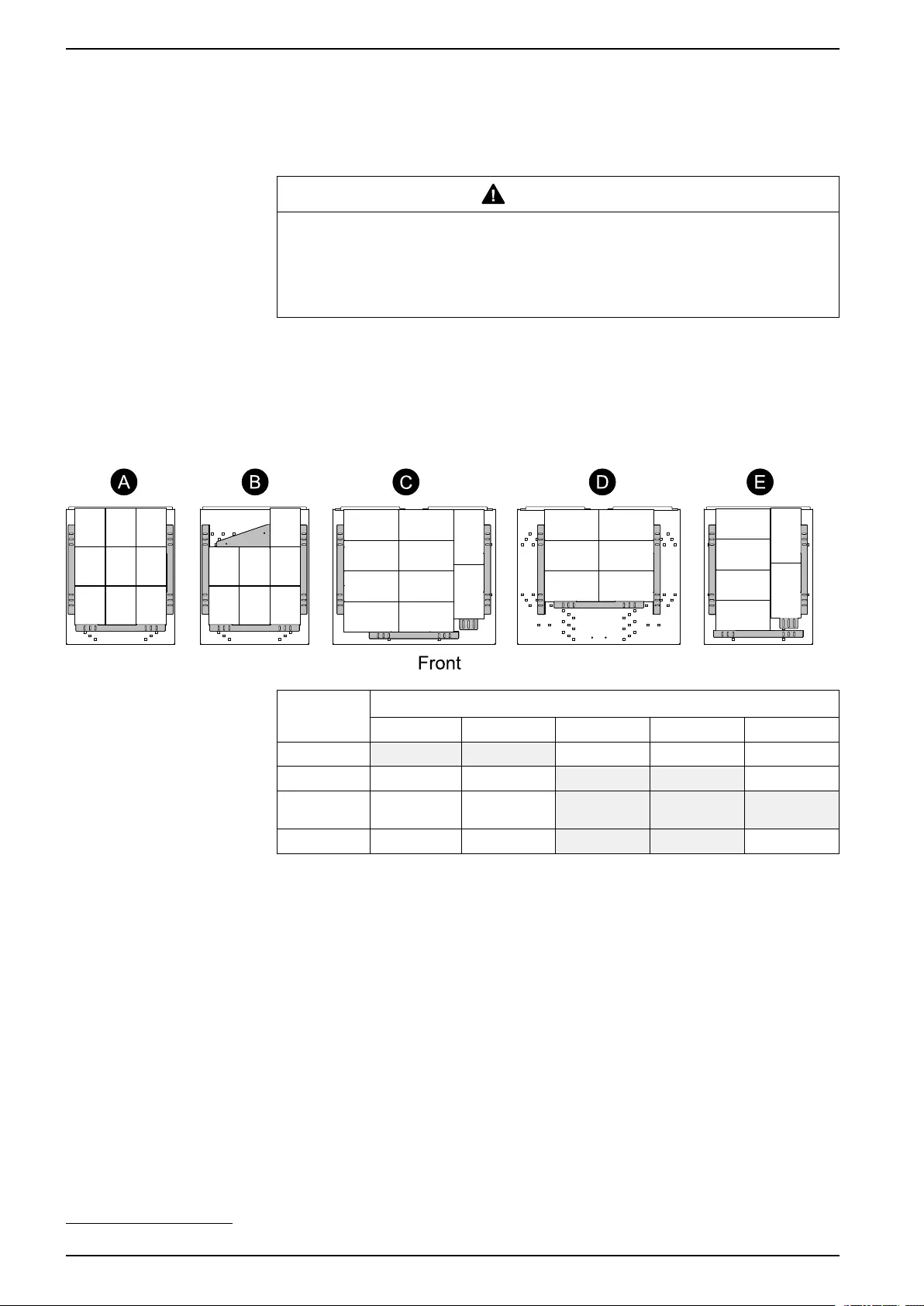

Shelf types

Top View, Wedges Filled in Grey Color

UPS power

rating

Number of shelves to mount by shelf type

A B C D E

20 - 30 kVA 3 1 0 0 0

40 – 60 kVA 0 0 3 1 0

80 – 100

kVA10

0 0 3 1 4

120 kVA10 0 0 6 2 0

1. Install the battery cells on the shelves according to the documentation supplied

by the battery vendor.

2. Mount the back wedge (20 - 30 kVA only).

3. Mount the sides wedges.

4. Mount the front wedges.

48 990–5233D–001

10. Two battery cabinets.

Install an External Battery 20 - 120 kVA 400 V

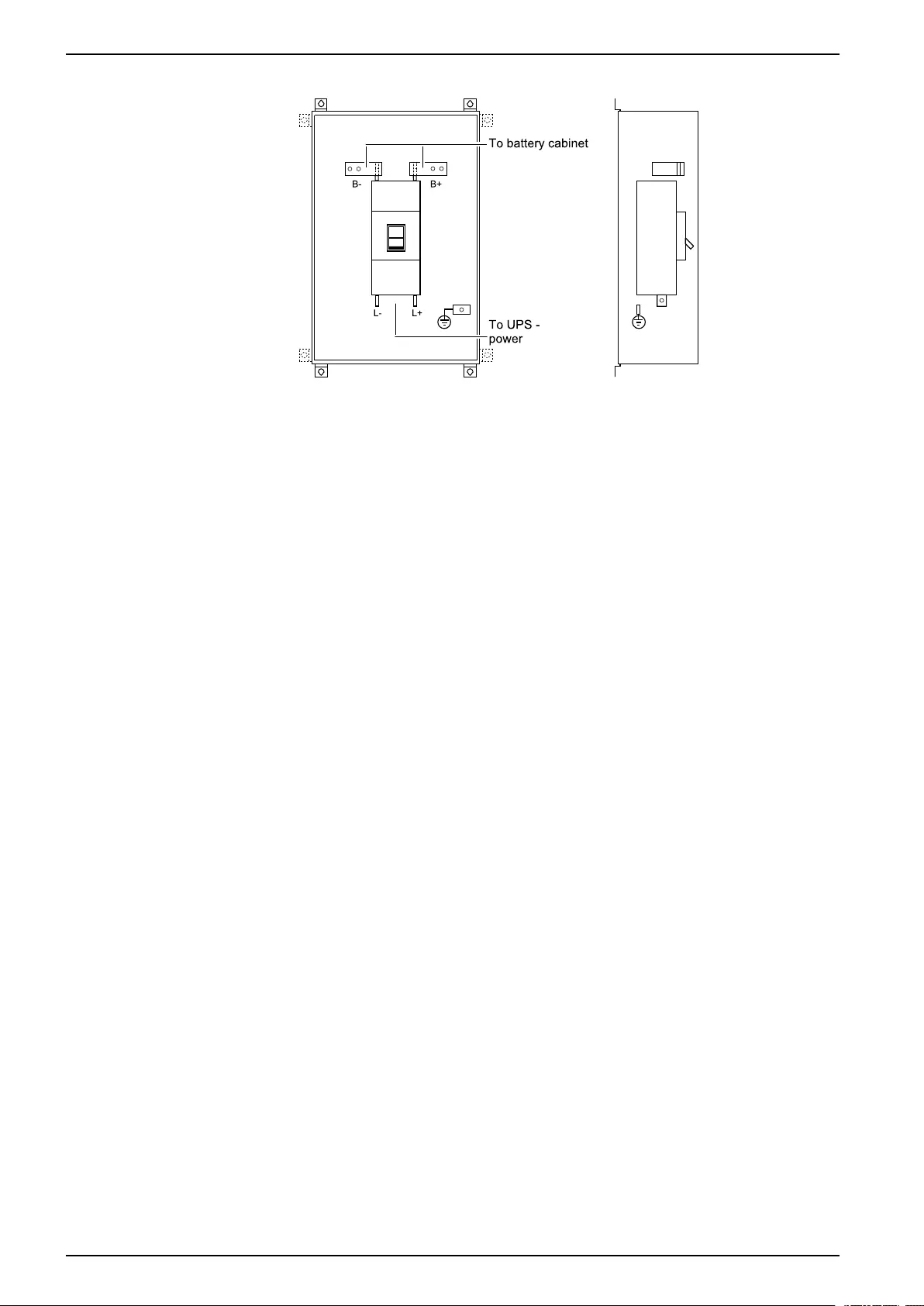

Connect the Battery Cables

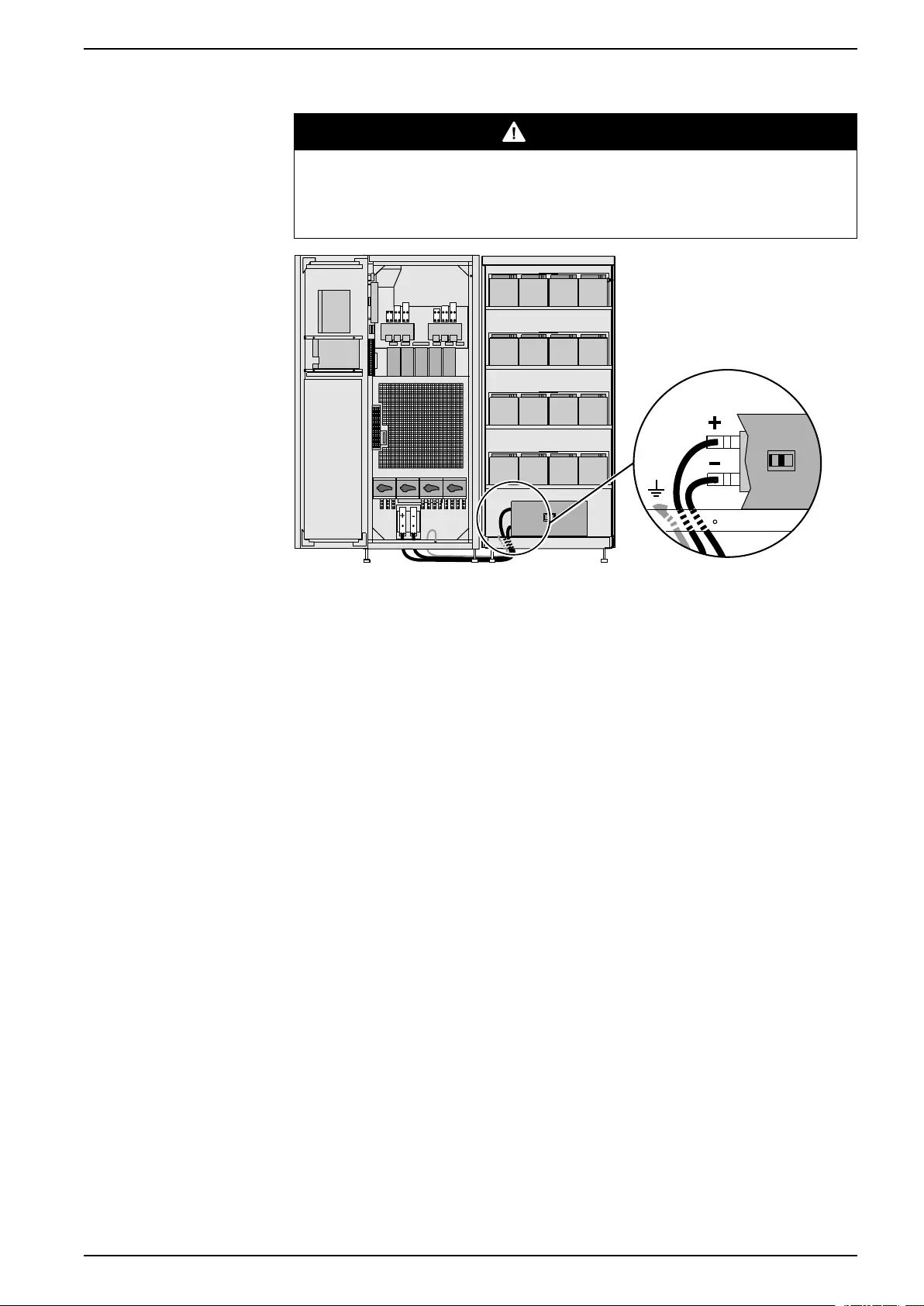

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Connect PE cables to the battery cabinet and the UPS first.

Failure to follow these instructions will result in death or serious injury.

1. Connect a PE cable from the battery cabinet to earth.

2. Connect the battery cables from the BAT- and BAT+ terminals of the battery

breaker in the UPS to the BAT- and BAT+ terminals of the battery breaker in the

battery cabinet.

990–5233D–001 49

20 - 120 kVA 400 V Install an External Battery

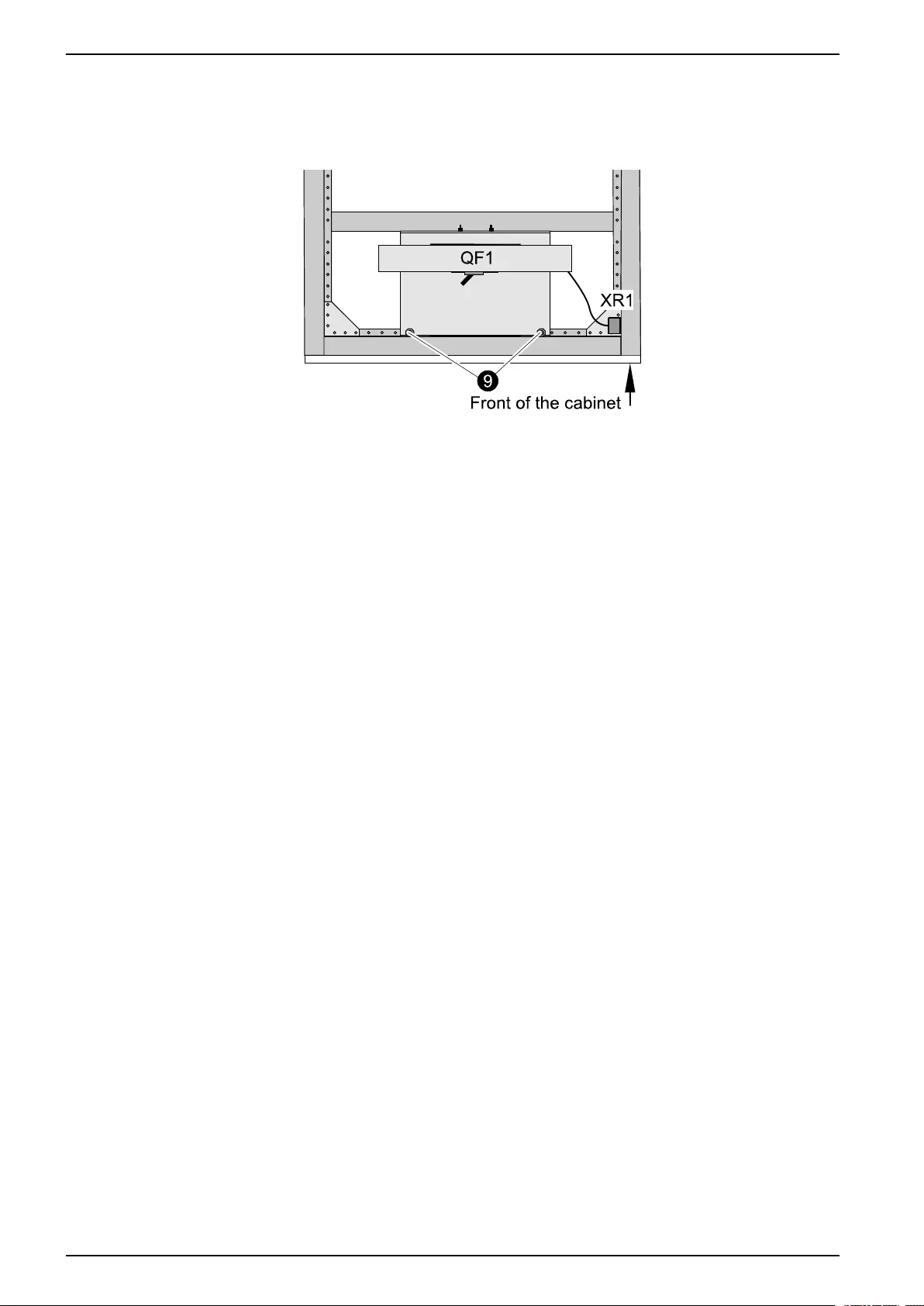

Install An Empty Battery Cabinet

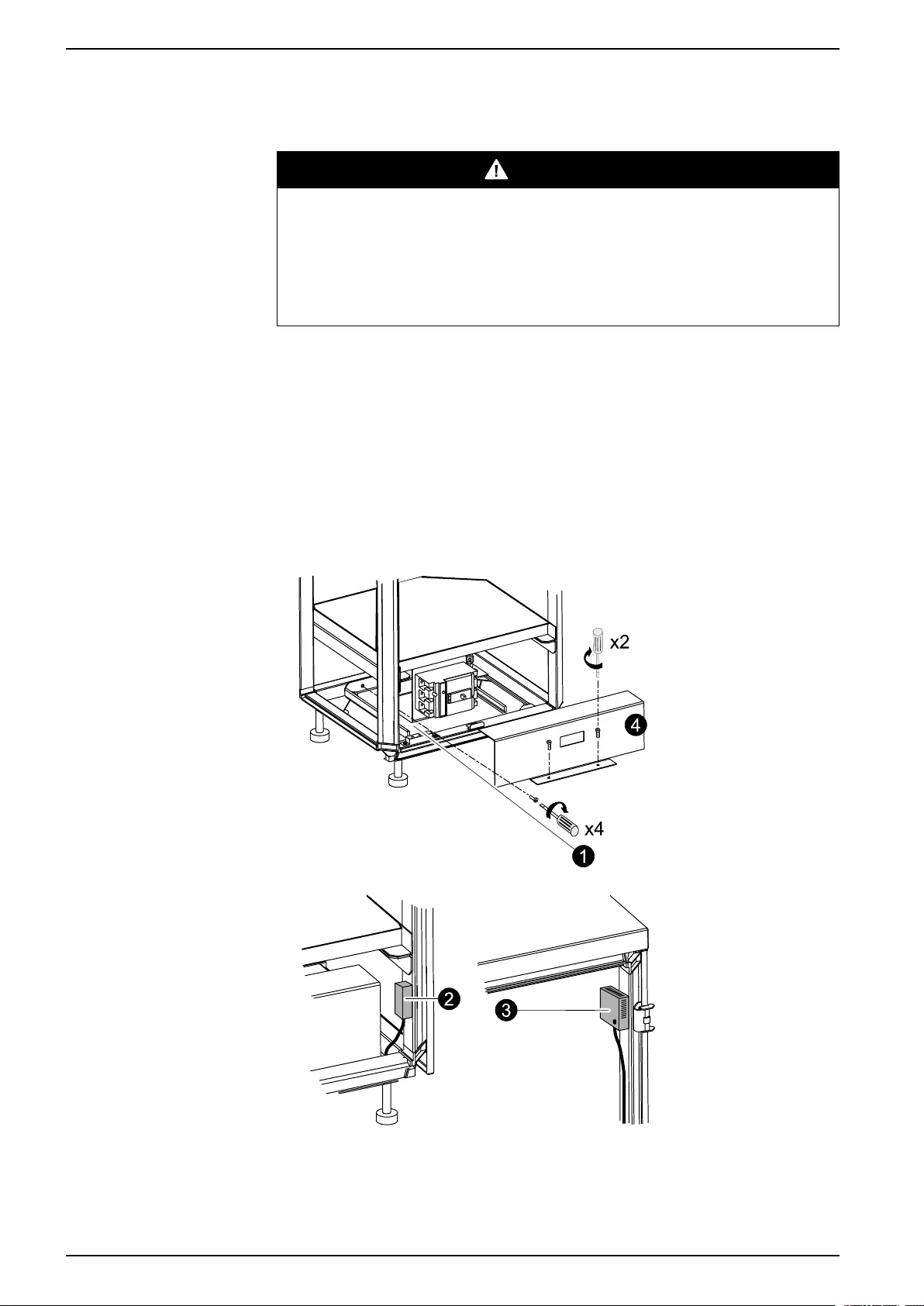

Install Battery Circuit Breaker Kit

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• It is mandatory to protect the battery circuit with a circuit breaker equipped

with an undervoltage coil (MN 24V DC).

• Circuit breaker type and rated must be compliant with specifications given.

See Battery Circuit Breaker Enclosure, page 23

Failure to follow these instructions will result in death or serious injury.

NOTE: Please contact Schneider Electric when selecting the battery circuit

breaker. In systems with several battery cabinets, only one circuit breaker is

necessary. Temperature sensors must be installed to obtain the battery warranty

and to optimize battery lifetime.

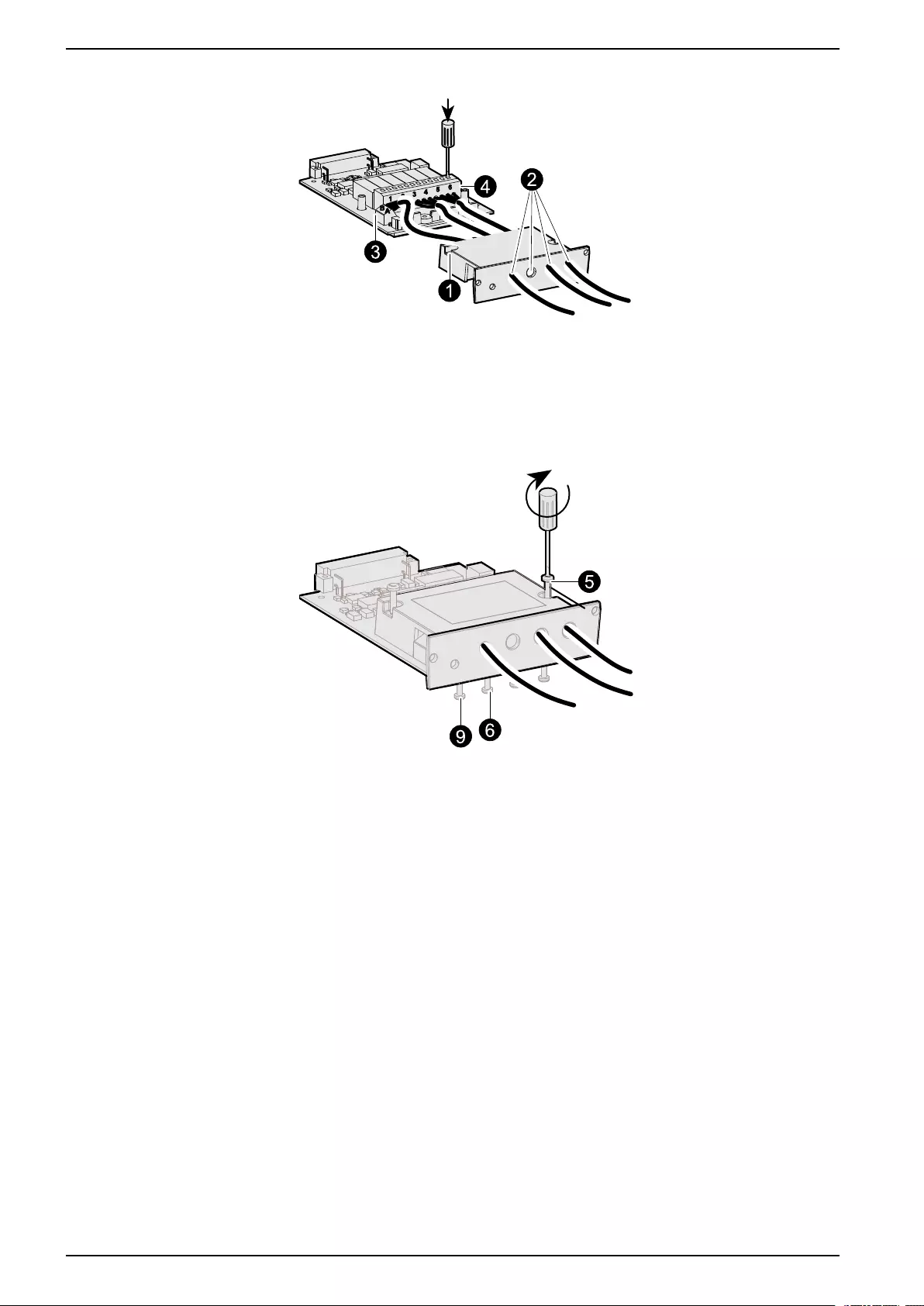

1. Fasten the circuit breaker plate (four screws).

2. Fasten the XR1 terminals.

3. Fasten the temperature sensor.

4. Fasten the protection cover after connecting the batteries to the battery circuit

breaker. Tightening torque is 6.5 Nm.

50 990–5233D–001

Install an External Battery 20 - 120 kVA 400 V

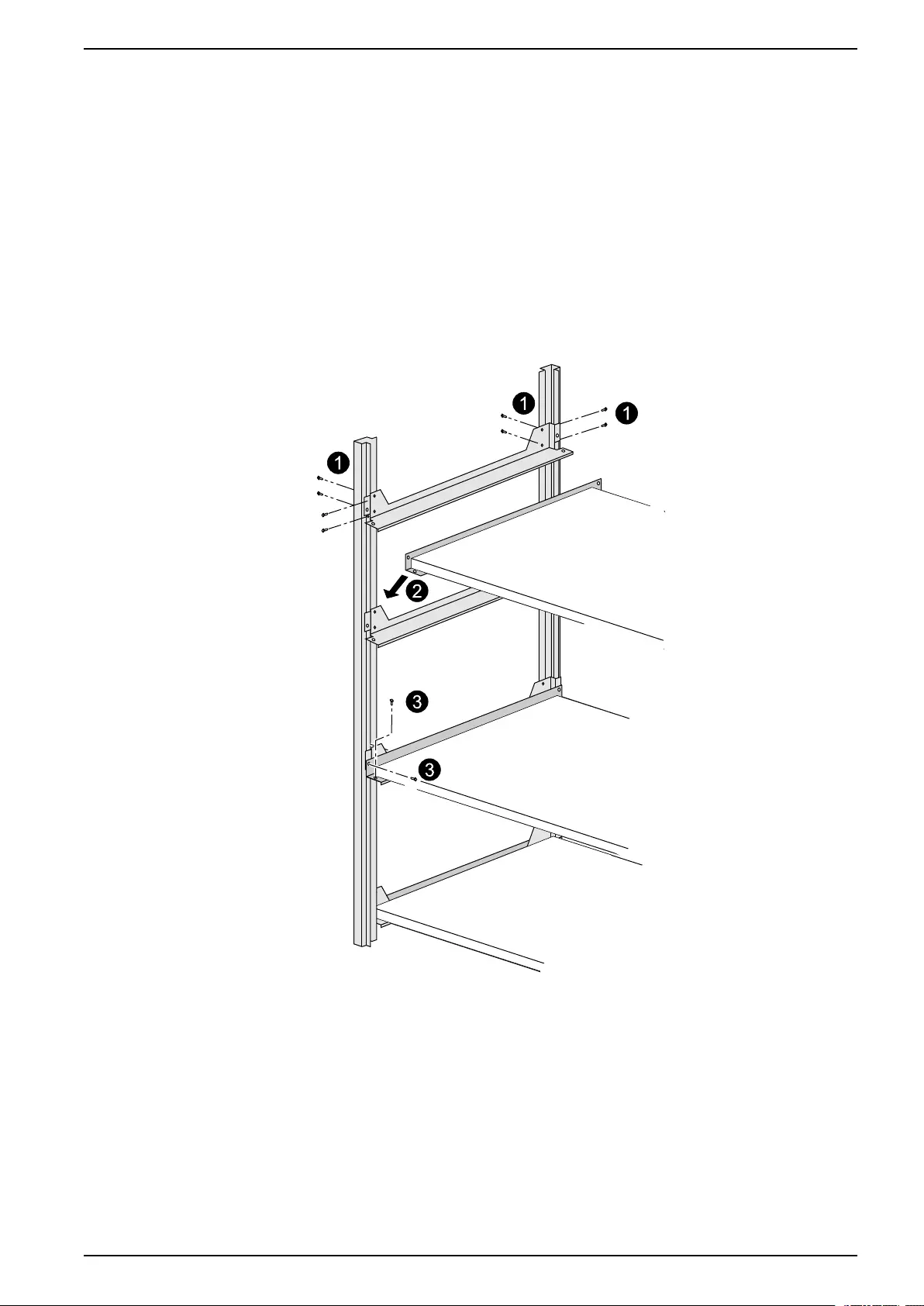

Install Shelves and Battery Cells

NOTE: Assembly of the battery cabinet must be carried out by certified personnel

(standard EN 62040-1).

NOTE: The minimum clearance between the top of the battery cells and the next

shelf above them is 150 mm.

1. Fasten the angle supports (six screws per support).

2. Position the shelves individually.

3. Fasten the shelves individually with two screws in each angle.

4. Install the battery cells on each shelf, fasten and interconnect them per shelf.

5. Interconnect all the battery assemblies from the different shelves and then

connect the overall battery assembly to the battery circuit breaker.

990–5233D–001 51

20 - 120 kVA 400 V Install an External Battery

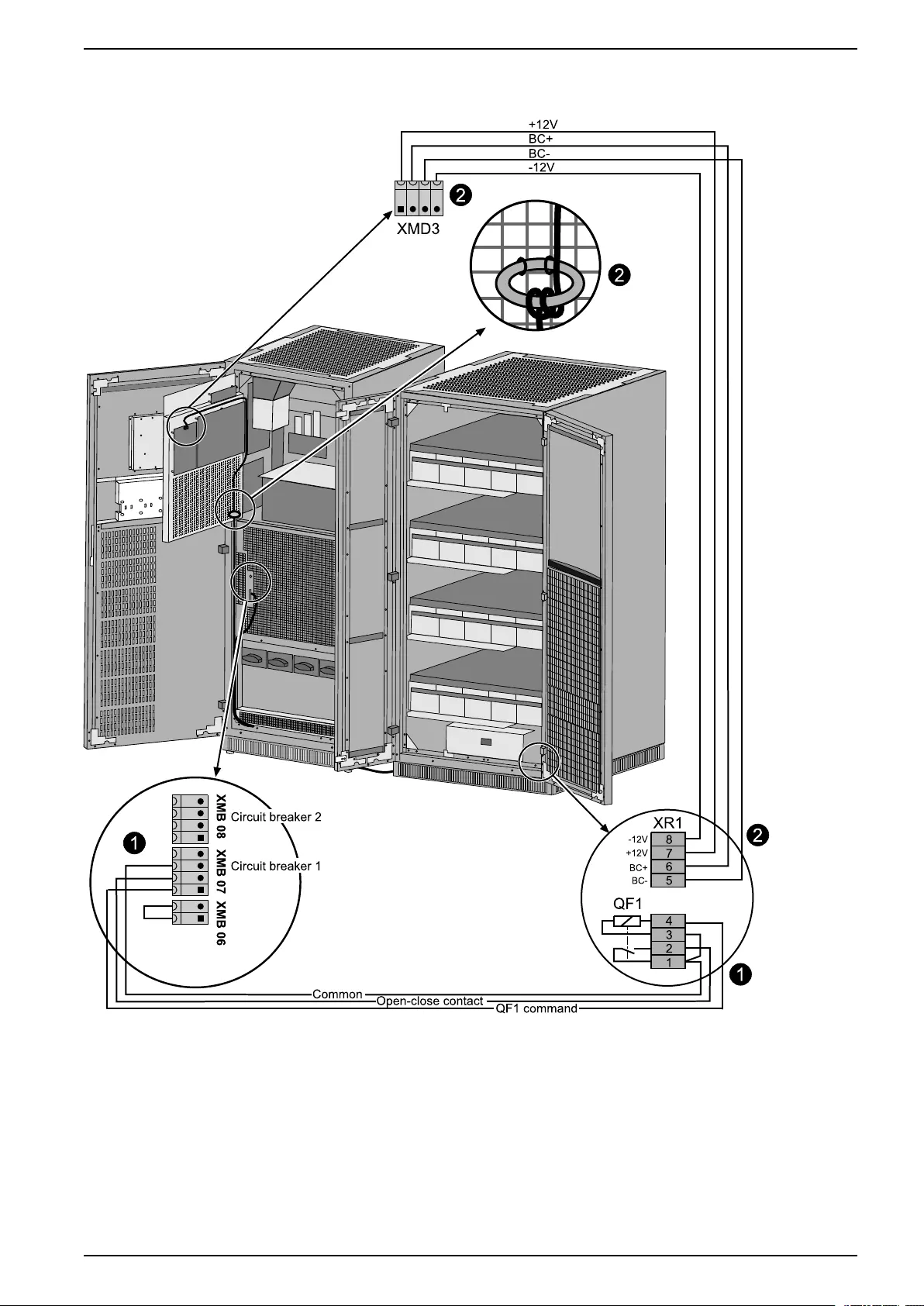

Connect the Battery Remote Control

WARNING

RISK OF EQUIPMENT DAMAGE

The maximum size for the communication cables (SELV) is 2.5 mm² and the

total length must be less than 100 meters.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

1. Connect the external battery cabinet connector XR1 to UPS connector XMB07,

as shown.

52 990–5233D–001

20 - 120 kVA 400 V

Install a Battery Circuit Breaker Kit for

Third Party Battery Cabinets (Option)

Install a Battery Circuit Breaker Kit for Third Party

Battery Cabinets (Option)

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

This battery circuit breaker kit contains an undervoltage coil (MN 24 VDC) which

is mandatory for all external battery cabinets. This battery circuit breaker is for

installations with third party batteries.

Failure to follow these instructions will result in death or serious injury.

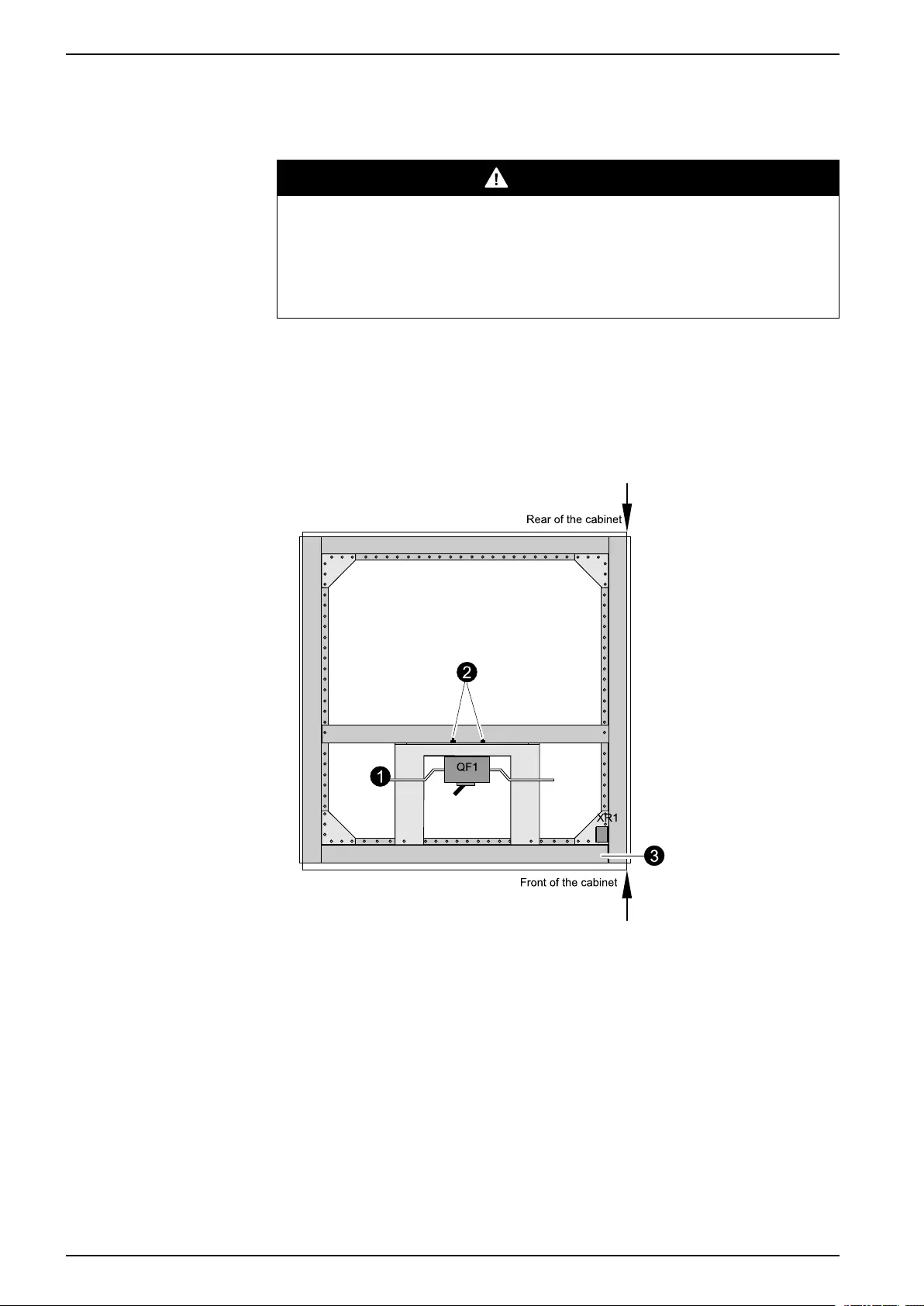

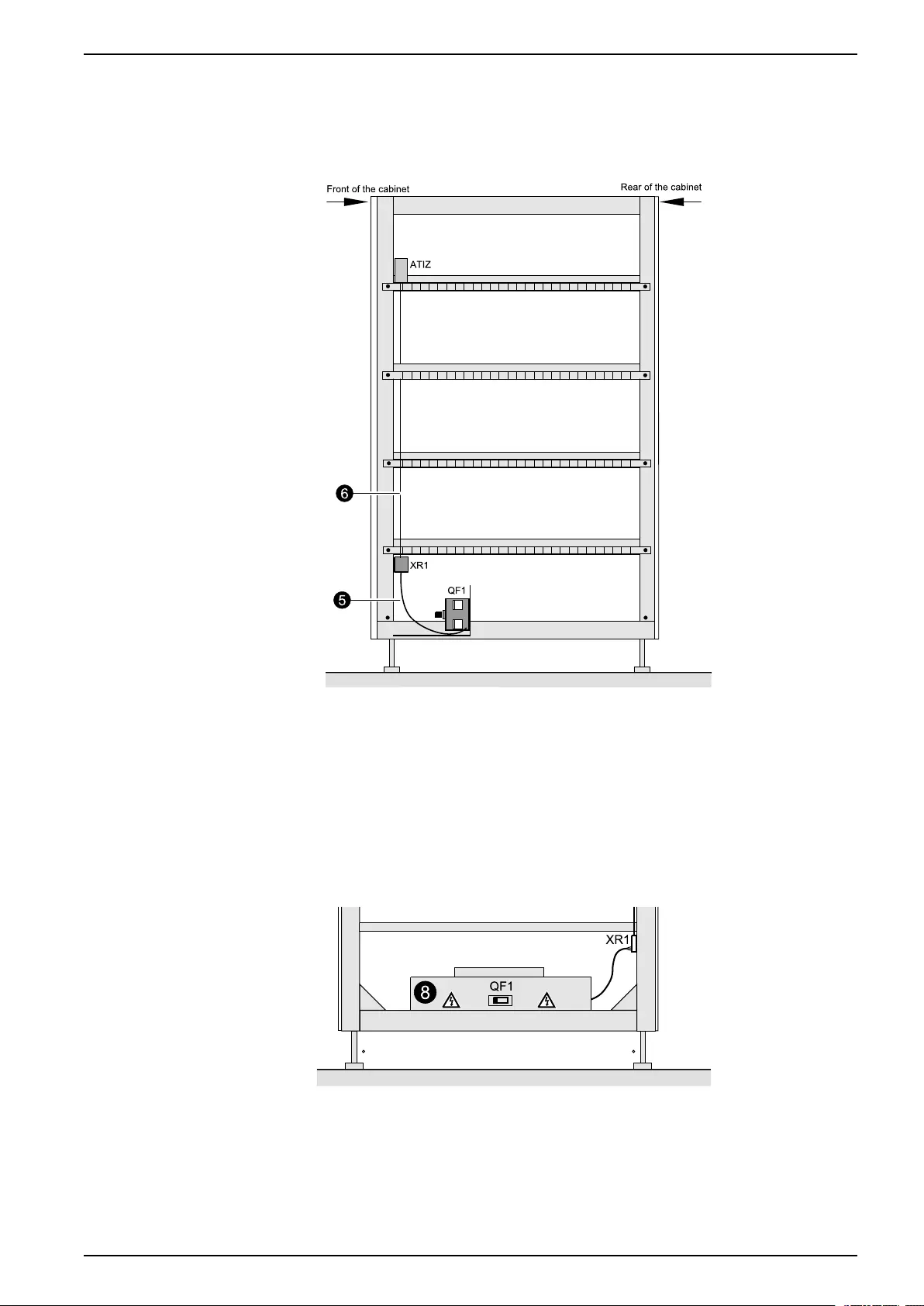

1. Mount the fixing bar onto the battery cabinet.

2. Position the battery circuit breaker on the fixing bar and fasten with 2 screws.

3. Bolt the support plate for the connector XR1 to the front upright of the cabinet.

Bottom View of the Battery Cabinet

4. Attach XR1 to the support plate.

54 990–5233D–001

Install a Battery Circuit Breaker Kit for

Third Party Battery Cabinets (Option) 20 - 120 kVA 400 V

5. Connect the battery circuit breaker to XR1. The connecting cables (2.5 m) are

supplied (N° 51031630).

6. Connect XR1 to the ATIZ board.

Side View of the Battery Cabinet

7. The terminals 1 to 4 of the XR1 terminal block must be connected to the UPS to

provide the functions for automatic opening of battery circuit breaker QF1 (in

case of emergency shutdown) and detection of the battery circuit breaker

position for the UPS. Details of these connections are given in the installation

manuals of these units.

8. Place the QF1 protection cover over the circuit breaker and its connections.

Side View of the Battery Cabinet

990–5233D–001 55

Battery Circuit Breaker Enclosure

(Option) 20 - 120 kVA 400 V

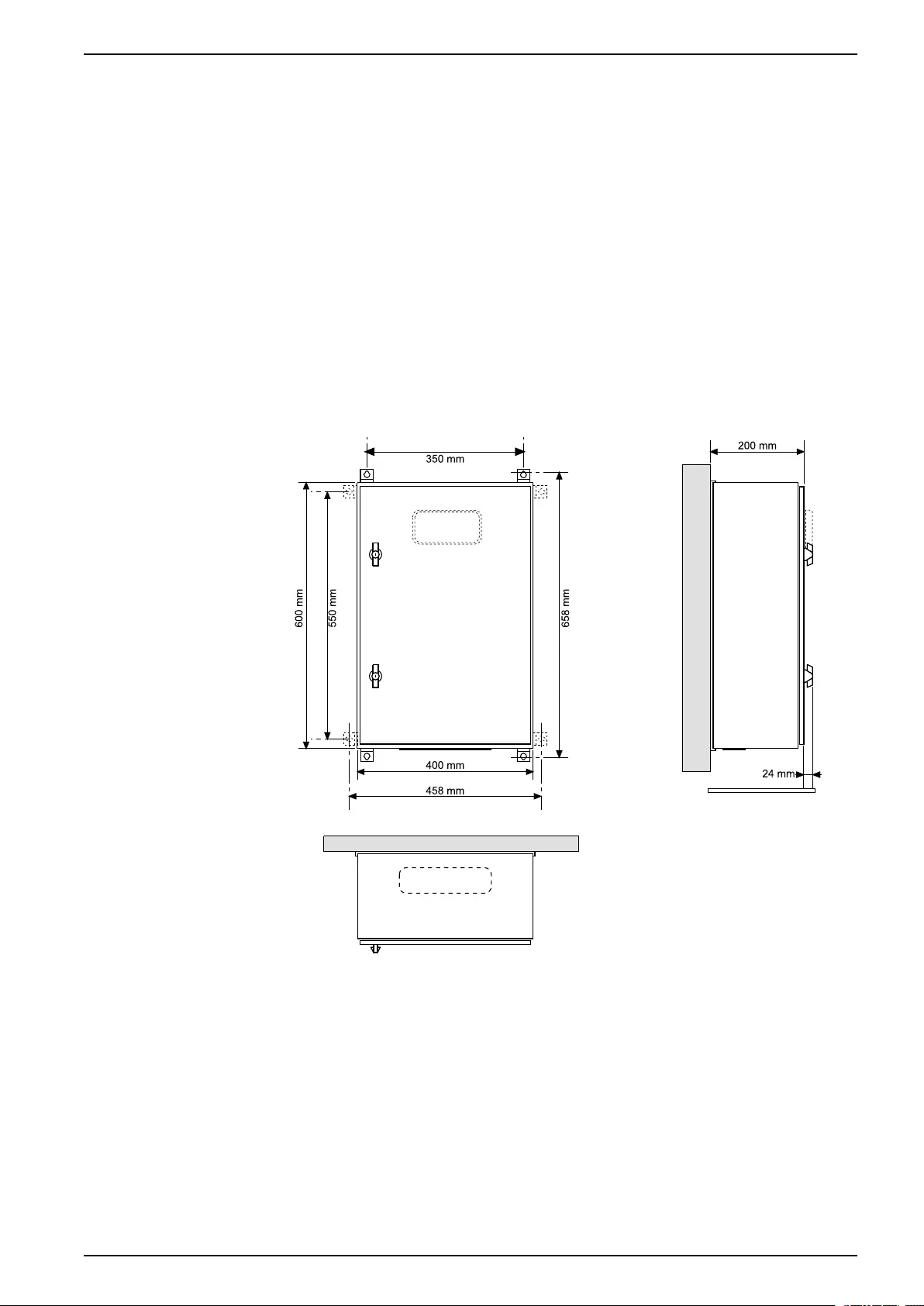

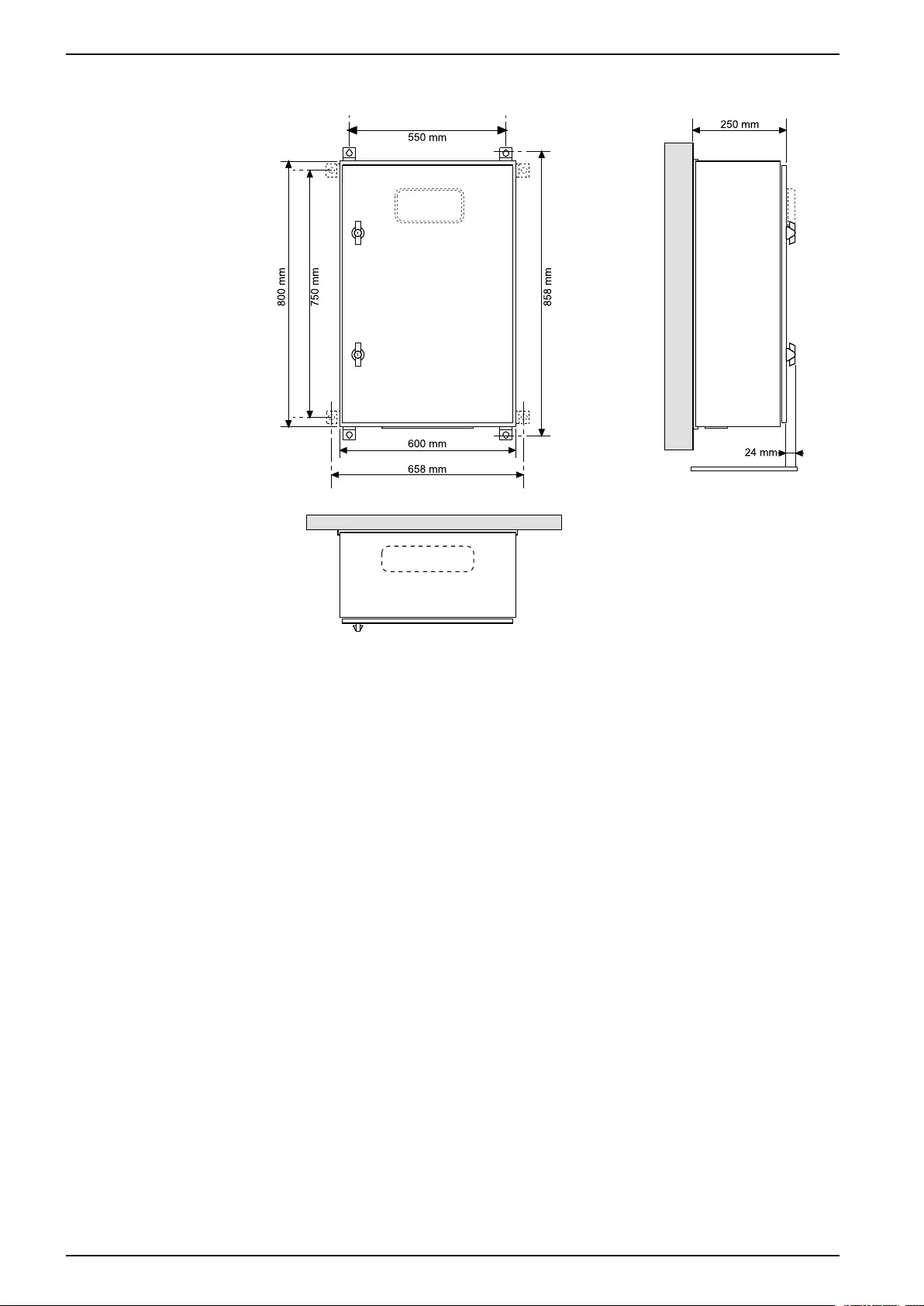

Battery Circuit Breaker Enclosure (Option)

Overview

The circuit breaker enclosure must be located as close to the batteries as possible.

The enclosure is mounted to a vertical wall by means of four M8 screws using the

fastening lugs placed in the vertical or horizontal position.

The enclosure door is closed by two lock knobs with a key (405 type) on one of the

knobs.

The enclosure with insulation controller has the same characteristics as the

standard version (except for dimensions), with the insulation controller being

located in the upper part of the enclosure door.

Cables are fed through the bottom of the enclosure via a 315 x 90 mm opening.

20–120 kVA Battery Circuit Breaker Enclosure with up to 10 Minutes Runtime

990–5233D–001 57

20 - 120 kVA 400 V

Battery Circuit Breaker Enclosure

(Option)

100–120 kVA Battery Circuit Breaker Enclosure with More Than 10 Minutes

Runtime

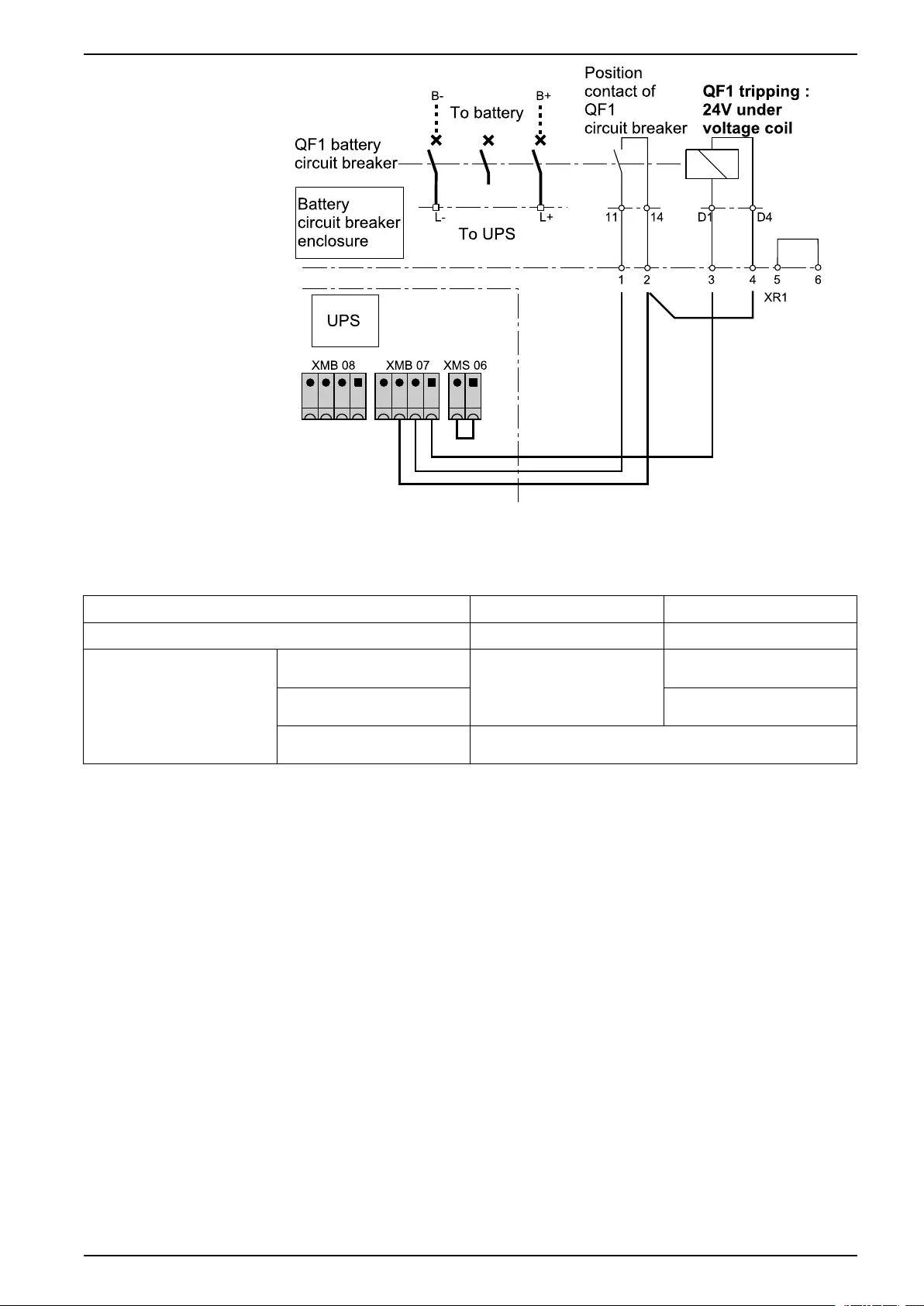

Connection Diagrams

• The size of the power cables is given in the tables above.

• The recommended size of auxiliary cables is 1 mm2(terminal acceptance

capacity: 2.5 mm2).

• Make sure that the auxiliary cables and power cables do not follow the same

path.

• Power cables and auxiliary cables are not supplied.

58 990–5233D–001

Battery Circuit Breaker Enclosure

(Option) 20 - 120 kVA 400 V

Connection Points

UPS rating 20 – 120 kVA 100 – 120 kVA

Battery backup time ≤ 10 min > 10 min

connection to UPS 25 x 5 mm copper terminal

8.2 mm diameter holes

32 x 8 mm copper terminal

12.2 mm diameter holes

battery 32 x 10 mm copper terminal

12.2 mm diameter holes

earth 50 x 5 mm copper terminal, or

8 mm threaded rod

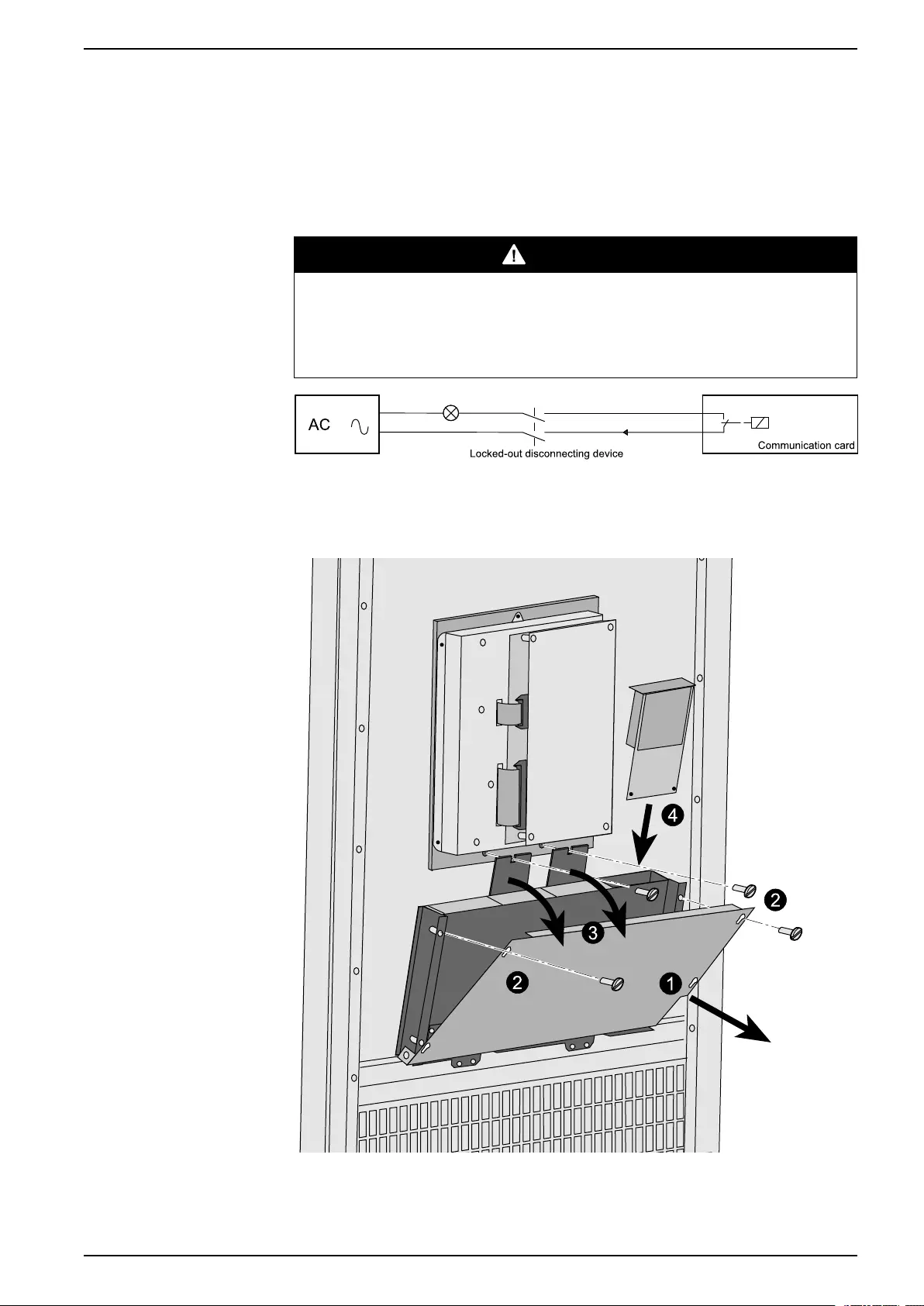

Install Battery Circuit Breaker Enclosure

1. Drill appropriate holes in a wall and mount the battery circuit breaker enclosure

to the wall as close to the batteries/battery cabinet(s) as possible.

2. Open the door of the battery circuit breaker enclosure.

3. Connect the PE terminal to PE.

4. Connect B- and B+ terminals to the battery B- and B+ terminals.

990–5233D–001 59

Install the Battery Temperature Monitor

(Option) 20 - 120 kVA 400 V

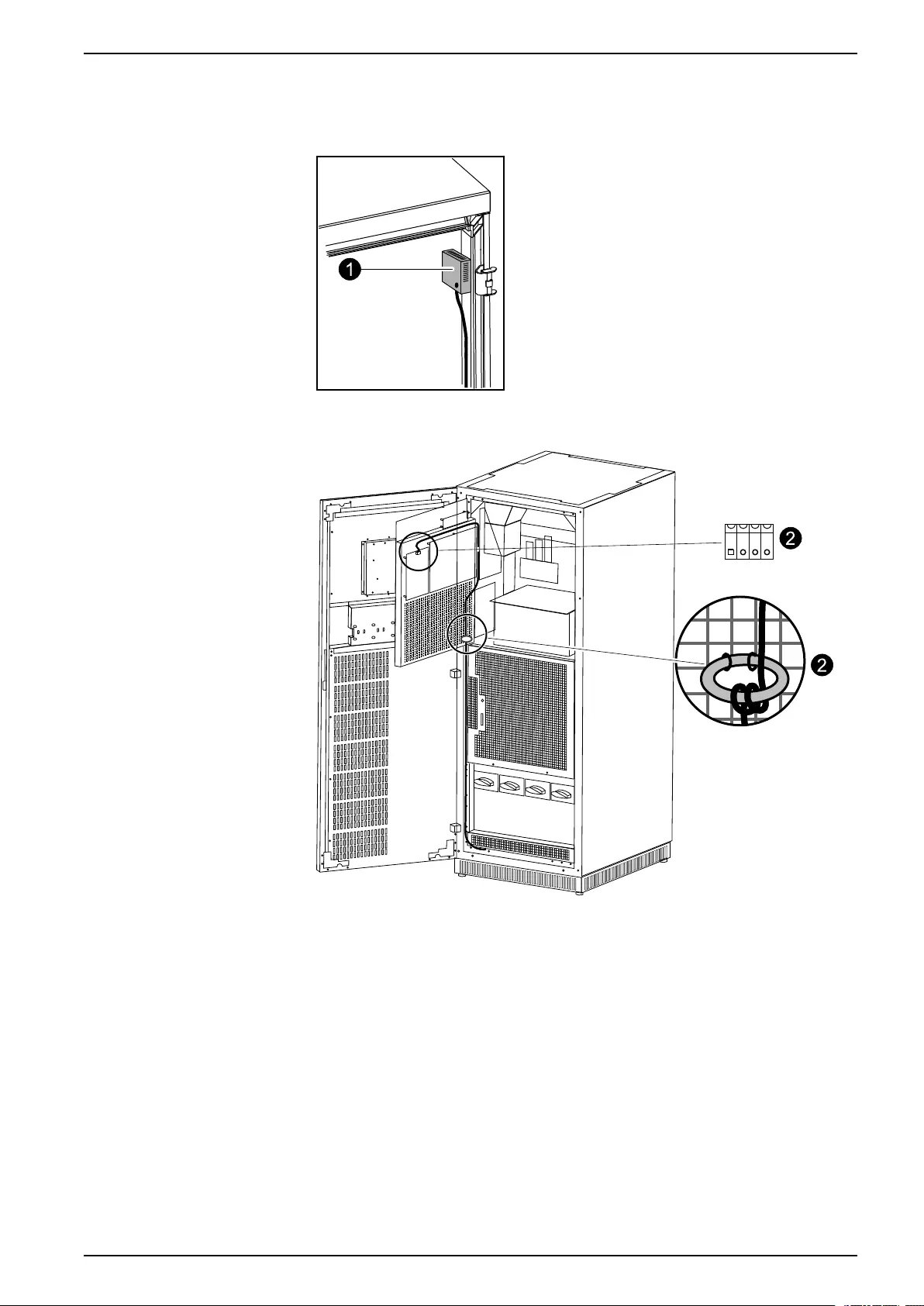

Install the Battery Temperature Monitor (Option)

1. Install the temperature monitor in the battery cabinet.

2. Connect the temperature monitor to the XMD3 connector in the UPS, and pass

the cable through the ferrite three times.

990–5233D–001 61

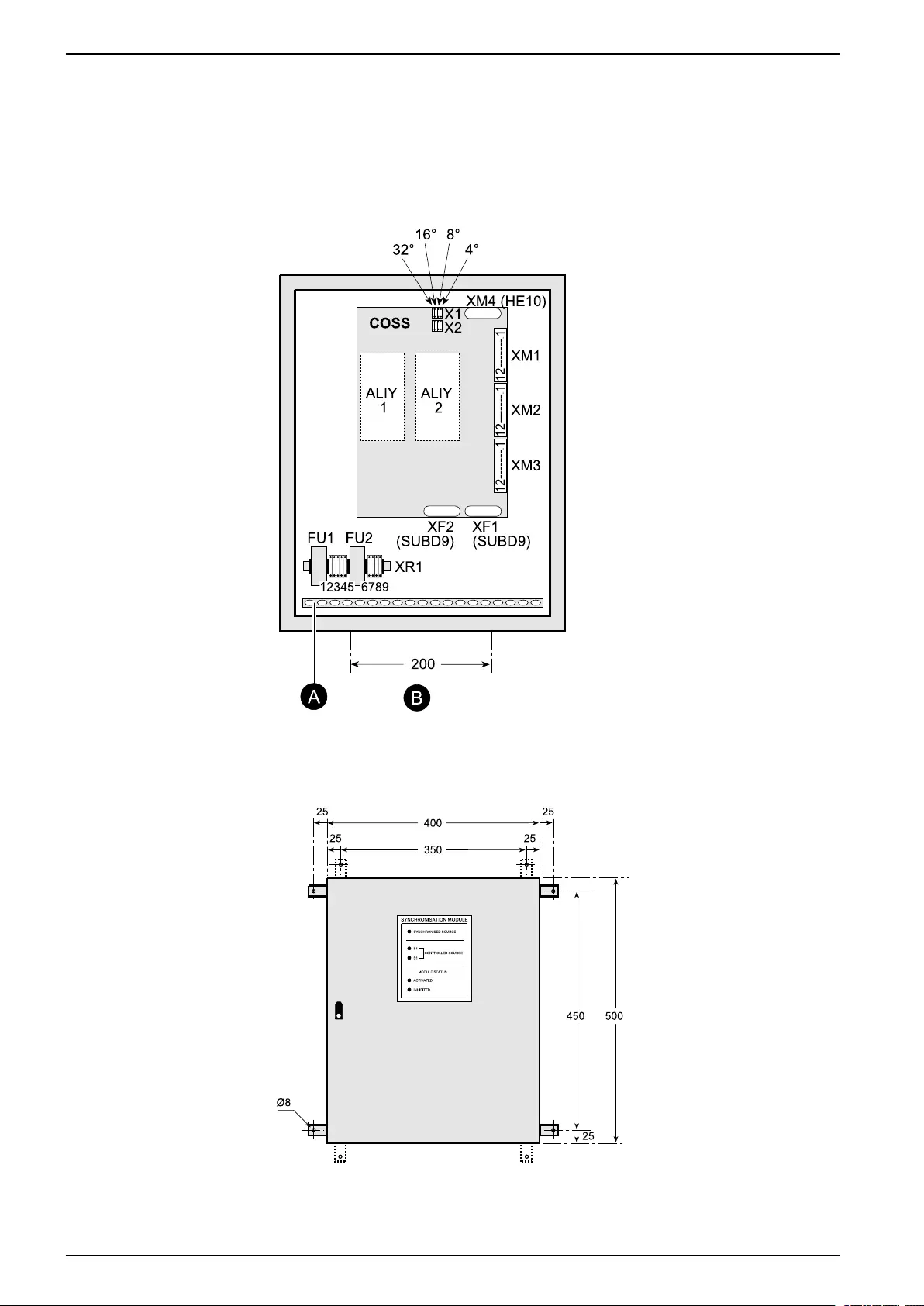

Install the Synchronization Module

(Option) 20 - 120 kVA 400 V

1. Mark the four mounting hole locations on the wall. You can either use the

horizontal or the vertical mounting brackets. Drill holes in each of the four

marked locations and install plugs.

2. Place the synchronization module enclosure against the wall lining up with the

holes and fasten the synchronization module enclosure to the wall with four

screws.

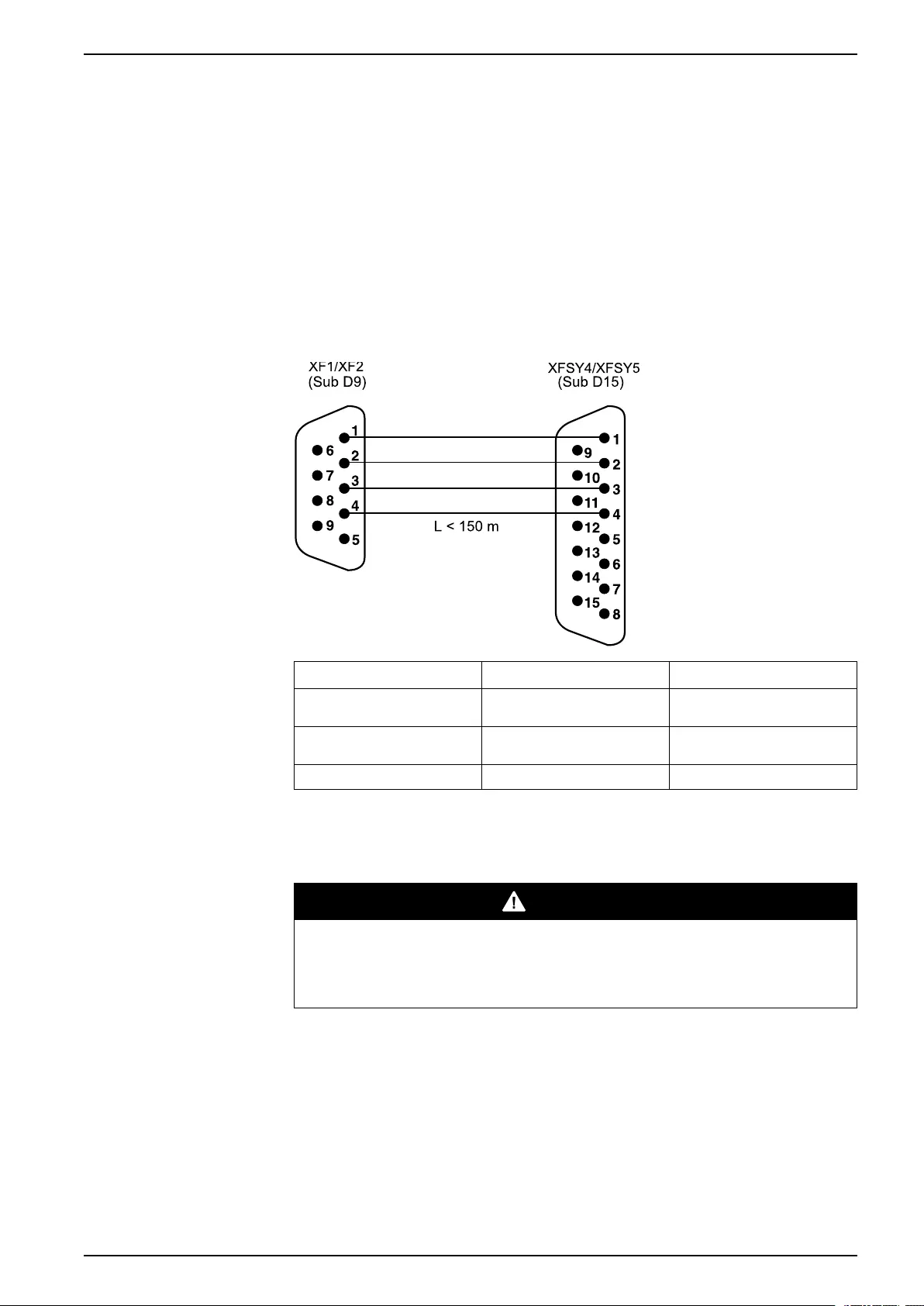

Recommended Cable Sizes

A 12m long Sub D9/Sub D15 (XF1/XF2 to XFSY4/XFSY5) cable is supplied for

each UPS.

You can make a longer cable (maximum length is 150 m) using the pinout diagram

below connecting only the 4 twisted wires shown.

Connection Cable length Recommended cable

XF1/XF2 to XFSY4/XFSY5 < 20 m Unshielded twisted pair cable

AWG24

XF1/XF2 to XFSY4/XFSY5 > 20 m Unshielded twisted pair cable

AWG18

XR1 – XR3 All Unshielded cable 1.5 mm²

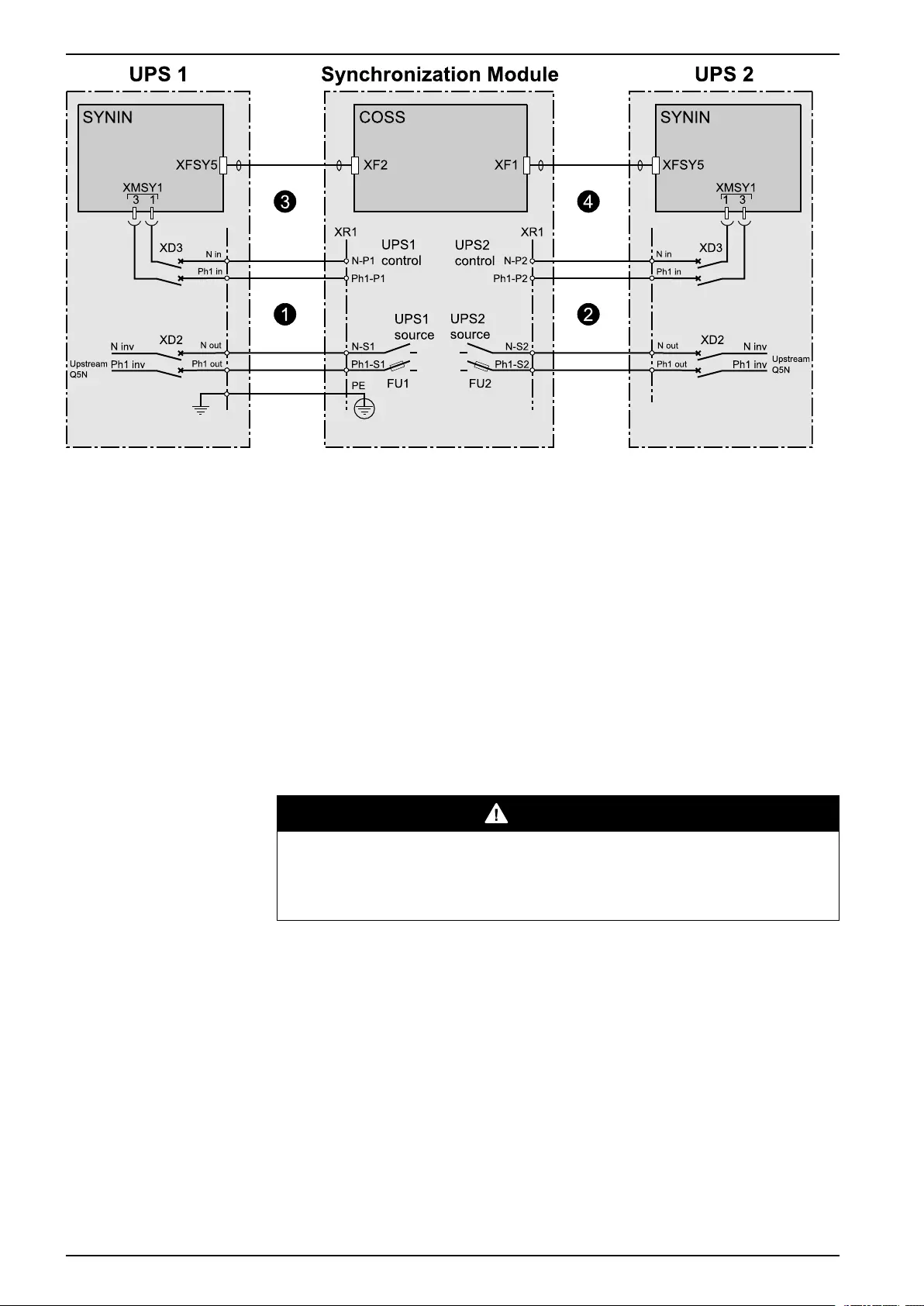

Connect Cables to the Synchronization Module for Single UPS

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The synchronization module must be earthed at one point only.

Failure to follow these instructions will result in death or serious injury.

990–5233D–001 63

20 - 120 kVA 400 V

Install the Synchronization Module

(Option)

1. Connect power cables from UPS 1 to the synchronization module according to

the illustration above.

2. Connect power cables from UPS 2 to the synchronization module according to

the illustration above.

3. Connect the supplied 12 m Sub D9/Sub D15 cable from terminal XFSY5 on the

SYNIN board in UPS 1 to XF2 on the COSS board in the synchronization

module.

4. Connect the supplied 12 m Sub D9/Sub D15 cable from terminal XFSY5 on the

SYNIN board in UPS 2 to XF1 on the COSS board in the synchronization

module.

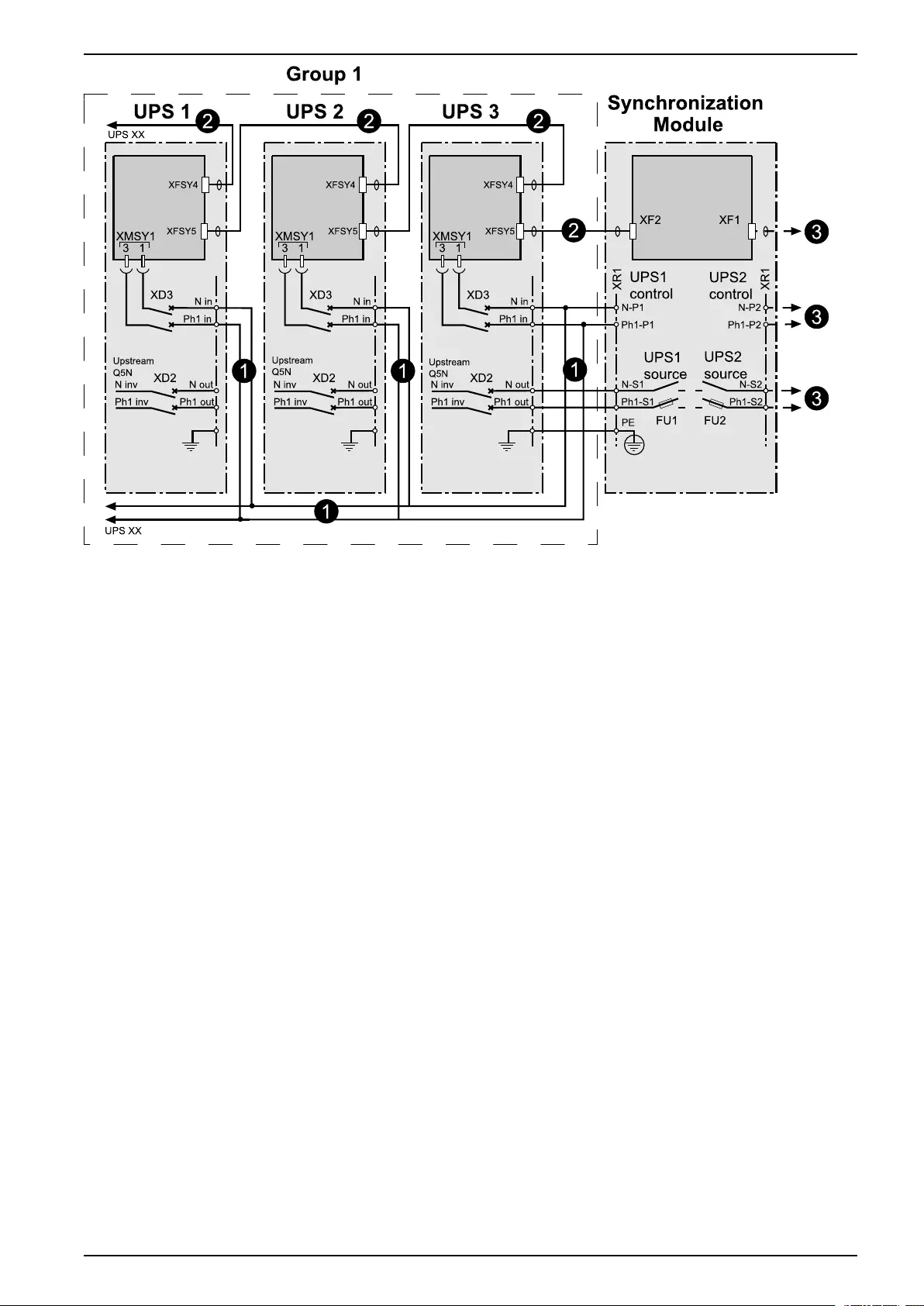

Connect Cables to the Synchronization Module in a Parallel

System

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The synchronization module must be earthed at one point only.

Failure to follow these instructions will result in death or serious injury.

64 990–5233D–001

Install the Synchronization Module

(Option) 20 - 120 kVA 400 V

1. Connect power cables between all UPS units in Group 1 and connect them to

the synchronization module.

2. Connect the supplied 12 m Sub D9/Sub D15 cables between the SYNIN boards

in the UPS units, and connect Sub D9/Sub D15 cable from the last UPS in the

row to the COSS board in the synchronization module.

3. Connect Group 2 to the synchronization module according to the procedures in

step 1 and 2 above.

990–5233D–001 65

20 - 120 kVA 400 V

Install the Synchronization Module

(Option)

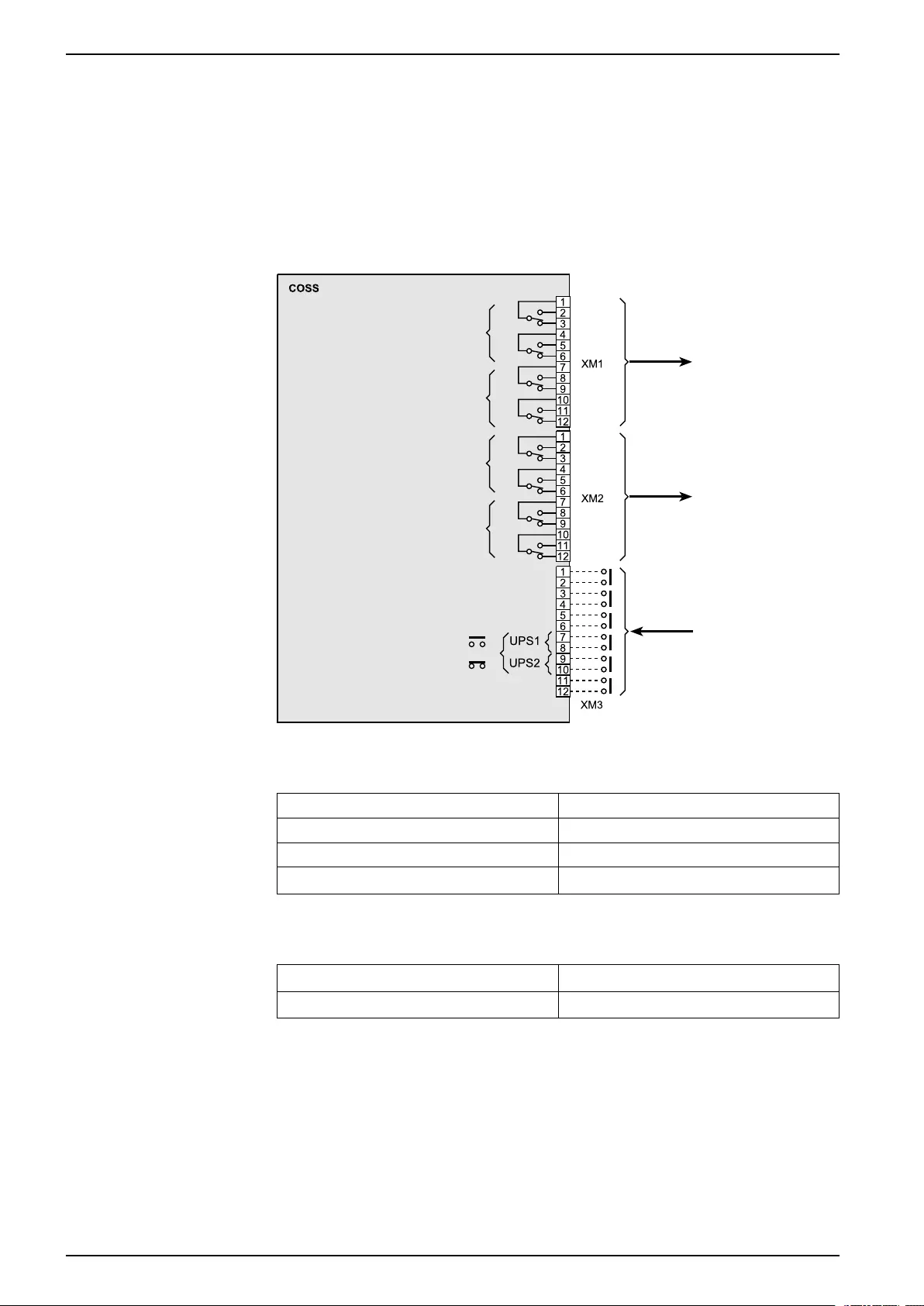

Input and Output Contacts

Characteristics

The Phase in tolerance,Major malfunction,UPS 1 controlled, and UPS 2

controlled relay contacts have a breaking capacity of 30 W maximum (on resistive

load) for 2 A maximum current.

Permissible voltage: SELV only.

The contacts are represented in unactuated state.

Outputs

XM1 terminals 1–6 UPS 1 controlled

XM1 terminals 7–12 UPS 2 controlled

XM2 terminals 1–6 Phase within tolerance

XM2 terminals 7–12 Major alarm

Inputs

XM3 terminals 7–8 UPS supplied by utility/mains

XM3 terminals 9–10 UPS supplied by generator set

66 990–5233D–001

Install an External Bypass 20 - 120 kVA 400 V

Install an External Bypass

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

The combined UPS power of all the installed UPS cabinets must not exceed the

available bypass power.

Failure to follow these instructions will result in death or serious injury.

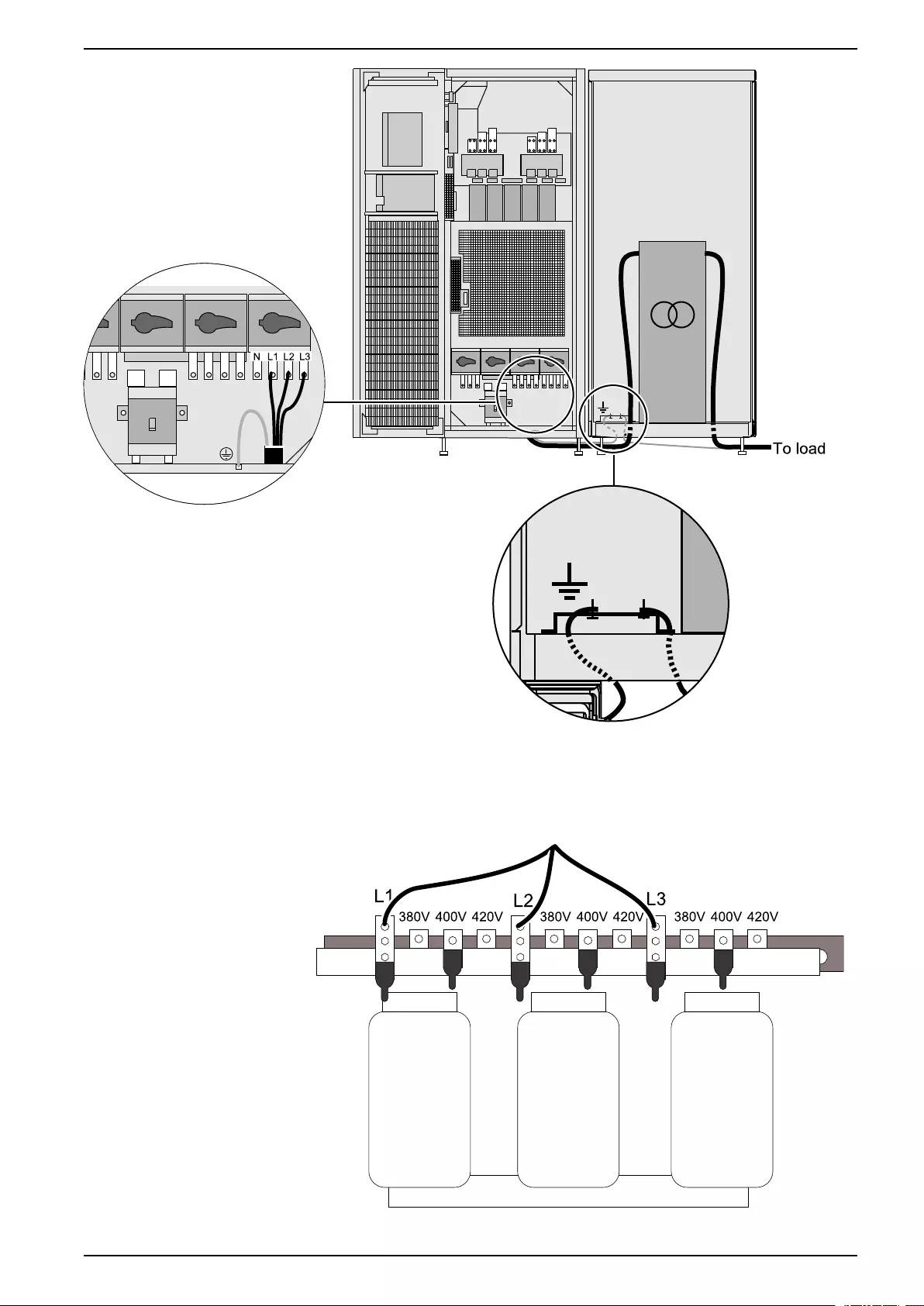

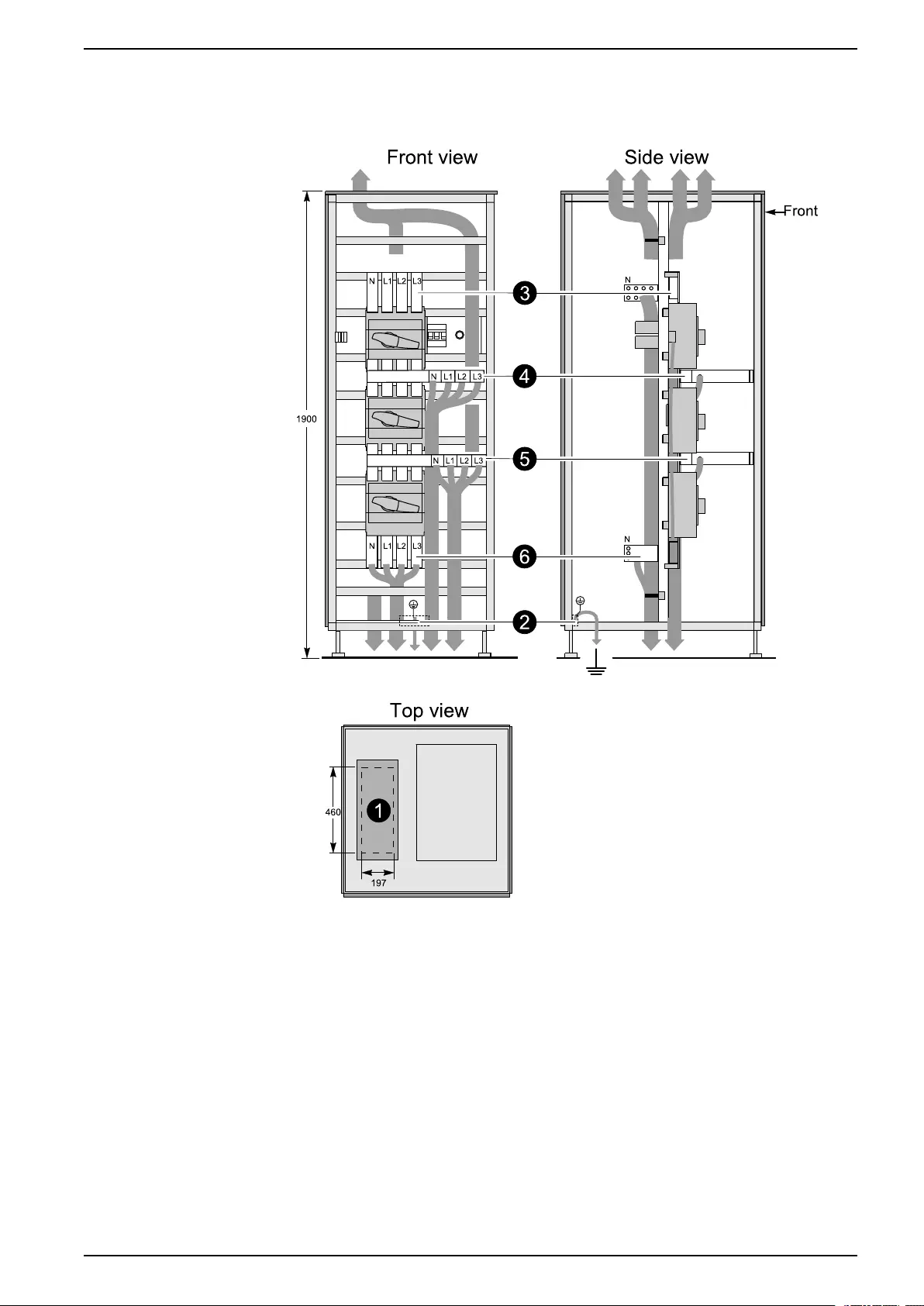

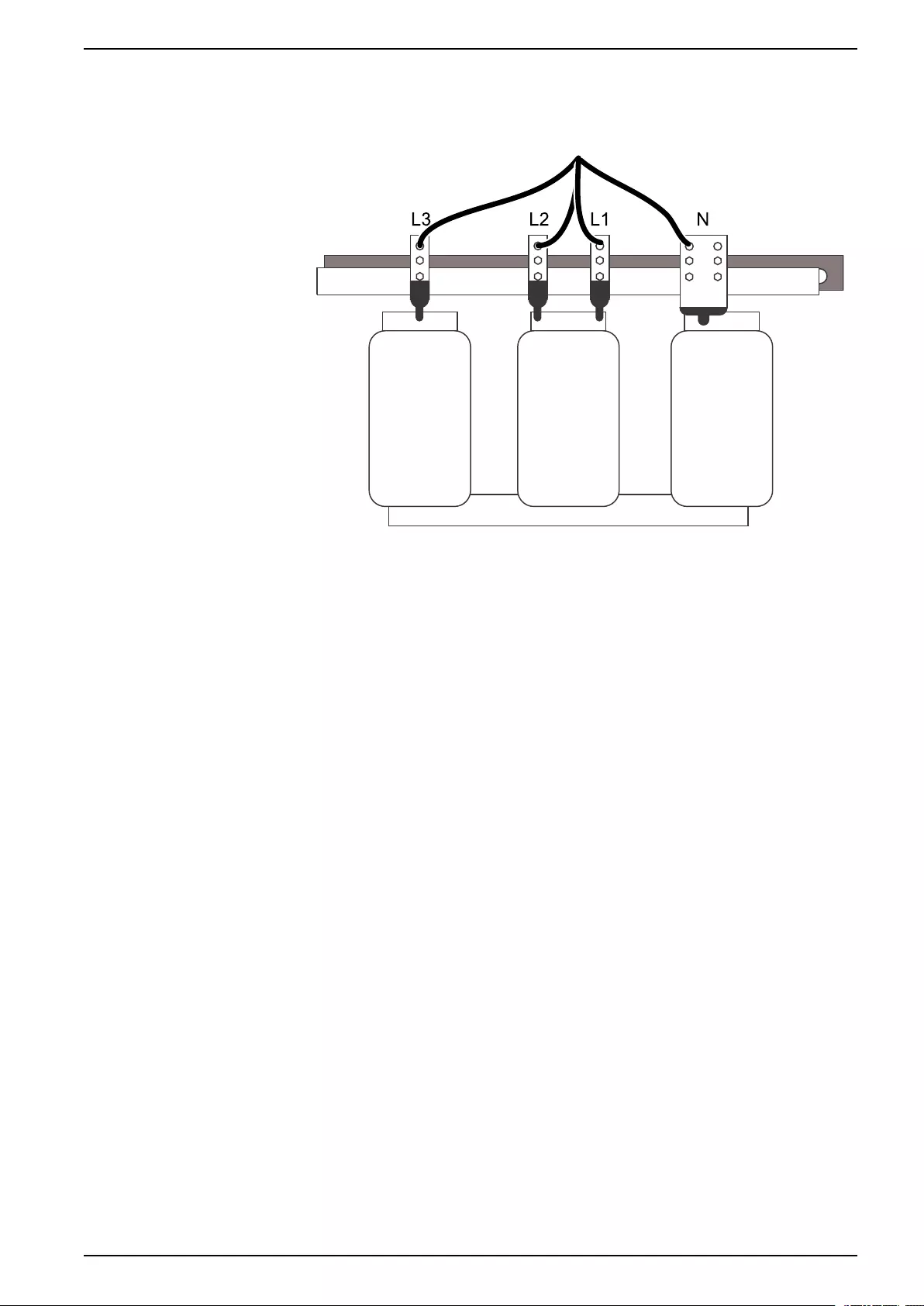

Install 150 kVA External Bypass Cabinet

TNS

1. Prepare the external bypass cabinet for cables by clearing the cable running

entries.

2. Connect the external bypass cabinet to earth.

3. Connect the bypass cables from the terminals (N, L1, L2, L3) in the external

bypass cabinet to the bypass terminals (N, L1, L2, L3) on the UPSs.

4. Connect the bypass cables from the AC bypass source to the terminals (N, L1,

L2, L3) in the external bypass cabinet.

5. Connect the load cables from the load to the terminals (N, L1, L2, L3) in the

external bypass cabinet.

990–5233D–001 67

20 - 120 kVA 400 V Install an External Bypass

6. Connect the AC output cables from output terminals (N, L1, L2, L3) in the UPSs

to the terminals (N, L1, L2, L3) in the external bypass cabinet.

NOTE: Connection of the communication cables is shown in Parallel System

with External Bypass, page 35.

TNC

1. Prepare the external bypass cabinet for cables by clearing the cable running

entries.

2. Connect the external bypass cabinet to earth and neutral (PEN).

3. Connect the bypass cables from the terminals (L1, L2, L3) in the external

bypass cabinet to the bypass terminals (L1, L2, L3) on the UPSs.

4. Connect the bypass cables from the AC bypass source to the terminals (L1, L2,

L3) in the external bypass cabinet.

5. Connect the load cables from the load to the terminals (L1, L2, L3) in the

external bypass cabinet.

6. Connect the AC output cables from the output terminals (L1, L2, L3) in the

UPSs to the terminals (L1, L2, L3) in the external bypass cabinet.

NOTE: Connection of the communication cables is shown in Parallel System

with External Bypass, page 35.

68 990–5233D–001

Install an External Bypass 20 - 120 kVA 400 V

Install 400 kVA External Bypass Cabinet

TNS

1. Prepare the external bypass cabinet for cables by clearing the cable running

entries.

2. Connect the external bypass to earth.

3. Connect the bypass cables from the terminals (N, L1, L2, L3) in the external

bypass cabinet to the bypass terminals (N, L1, L2, L3) on the UPSs through the

top cable entry.

4. Connect the bypass cables from the AC bypass source to the terminals (N, L1,

L2, L3) in the external bypass cabinet.

5. Connect the load cables from the load to the terminals (N, L1, L2, L3) in the

external bypass cabinet.

6. Connect the AC output cable from output terminals (N, L1, L2, L3) in the UPSs

to the terminals (N, L1, L2, L3) in the external bypass cabinet.

NOTE: Connection of the communication cables is shown in Parallel System

with External Bypass, page 35.

990–5233D–001 69

20 - 120 kVA 400 V Install an External Bypass

TNC

1. Prepare the external bypass cabinet for cables by clearing the cable running

entries.

2. Connect the external bypass cabinet to earth.

3. Connect the bypass cables from the terminals (PEN, L1, L2, L3) in the external

bypass cabinet to the bypass terminals (PEN, L1, L2, L3) on the UPSs through

the top cable entry.

4. Connect the bypass cables from the AC bypass source to the terminals (PEN,

L1, L2, L3) in the external bypass cabinet.

5. Connect the load cables from the load to the terminals (PEN, L1, L2, L3) in the

external bypass cabinet.

6. Connect the AC output cables from output terminals (PEN, L1, L2, L3) in the

UPSs to the terminals (N, L1, L2, L3) in the external bypass cabinet.

NOTE: Connection of the communication cables is shown in Parallel System

with External Bypass, page 35.

70 990–5233D–001

Install Marine UPS Adaptation Voltage

Transformer 20 - 120 kVA 400 V

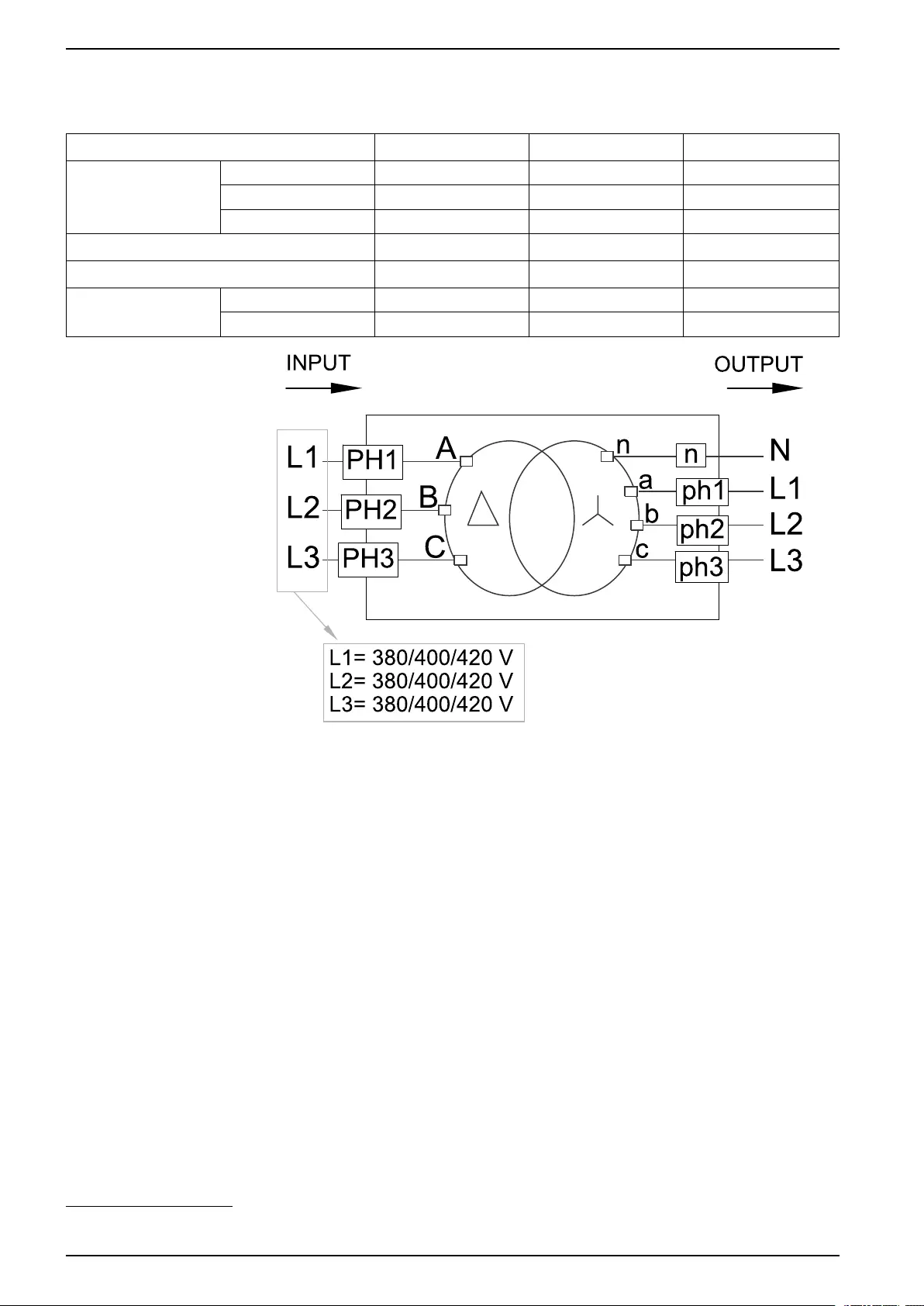

Install Marine UPS Adaptation Voltage Transformer

For transformer specifications, see Transformers, page 21.

WARNING

HAZARD OF OVERHEATING

• Do not cover the transformer ventilation openings when the transformer is in

operation.

• Do not remove the transformer feet.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Install the transformer according to the documentation supplied by the transformer

vendor.

990–5233D–001 71

20 - 120 kVA 400 V Install Isolation Transformer (Option)

Install Isolation Transformer (Option)

For transformer specifications, see Transformers, page 21.

NOTE: A transformer cabinet can only be placed to the right of the UPS cabinet.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Do not install different transformer sizes that belong to different vector groups in

the same UPS installation.

Failure to follow these instructions will result in death or serious injury.

72 990–5233D–001

Install Isolation Transformer (Option) 20 - 120 kVA 400 V

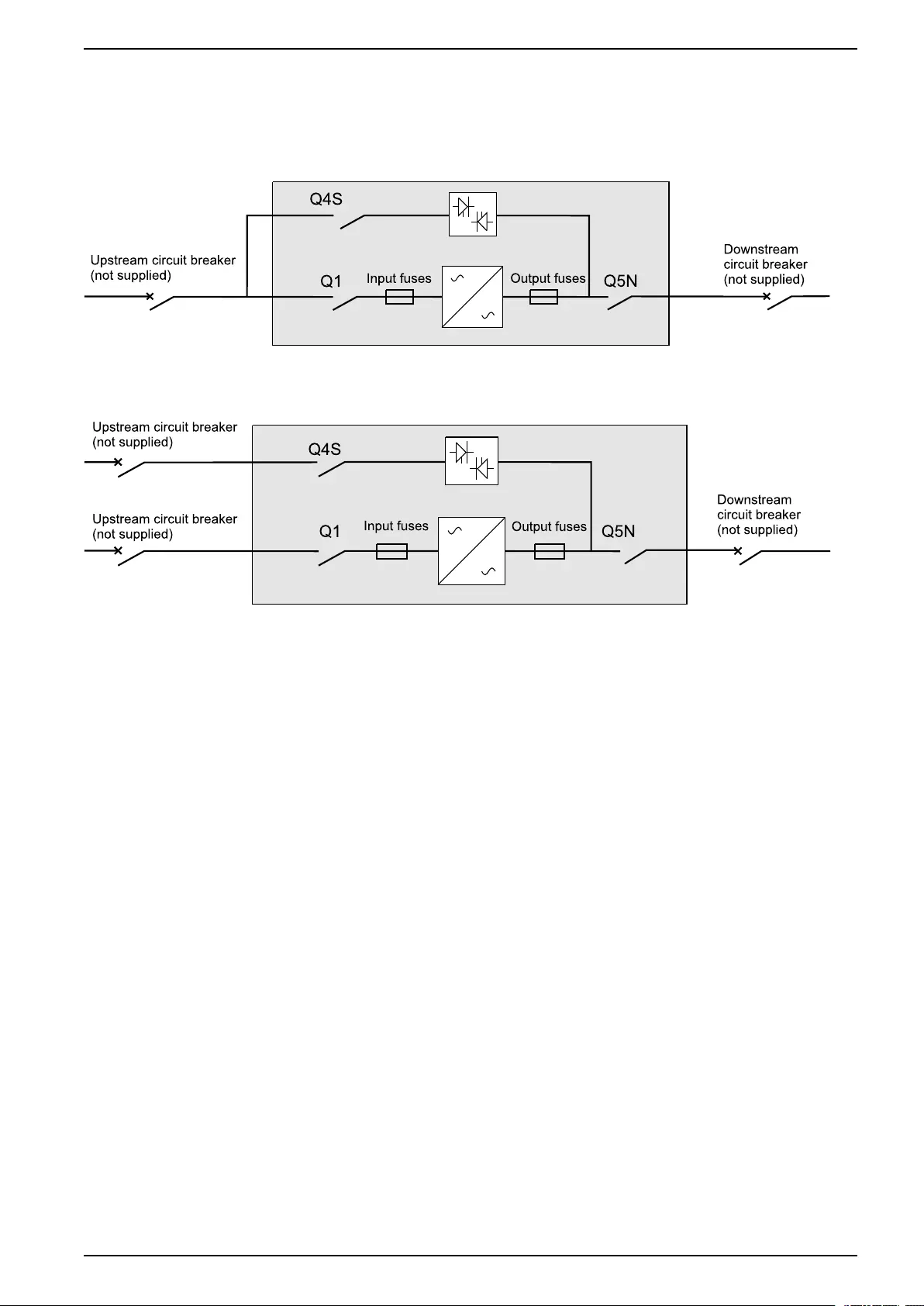

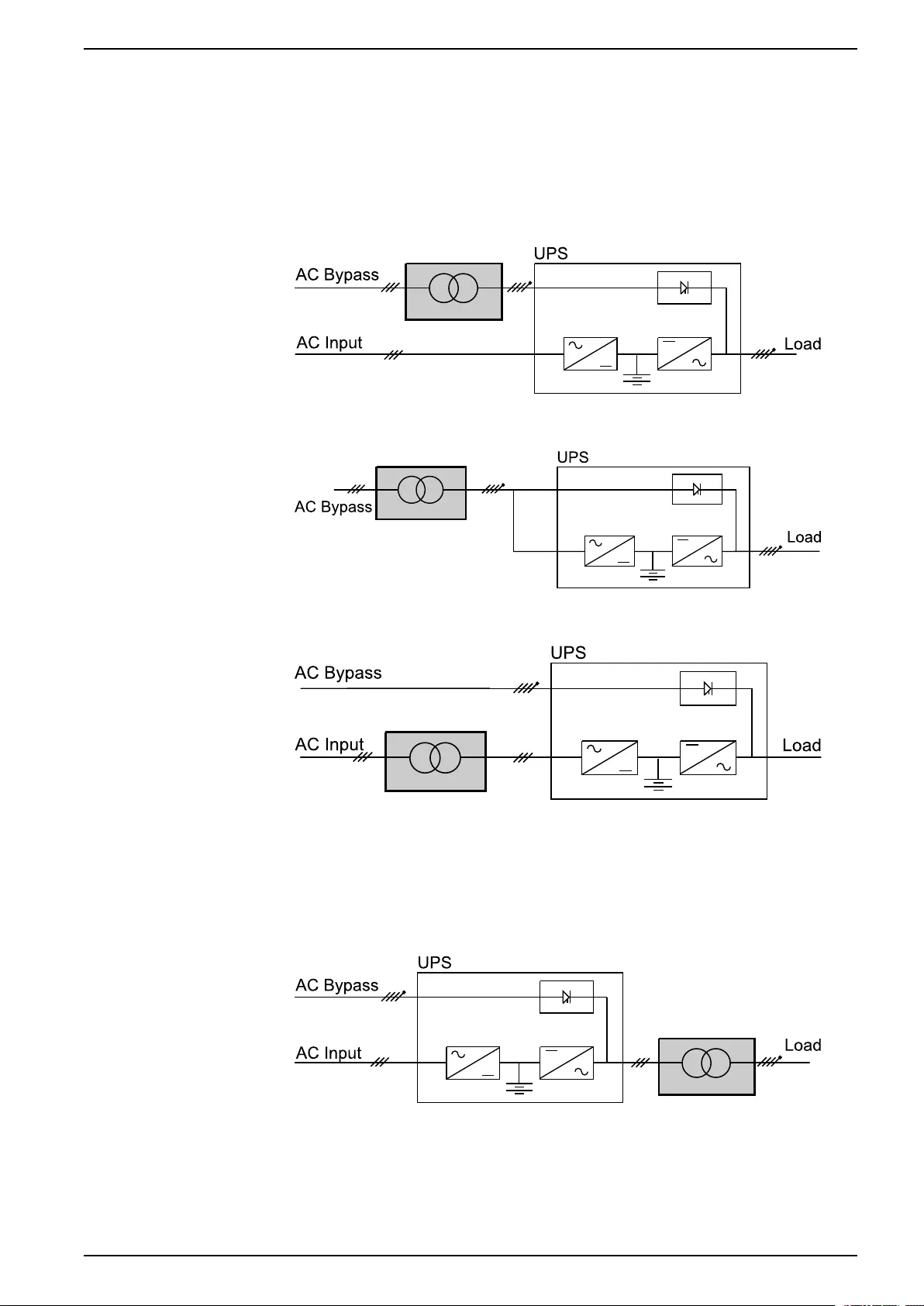

Transformer Configuration Options in Single Systems

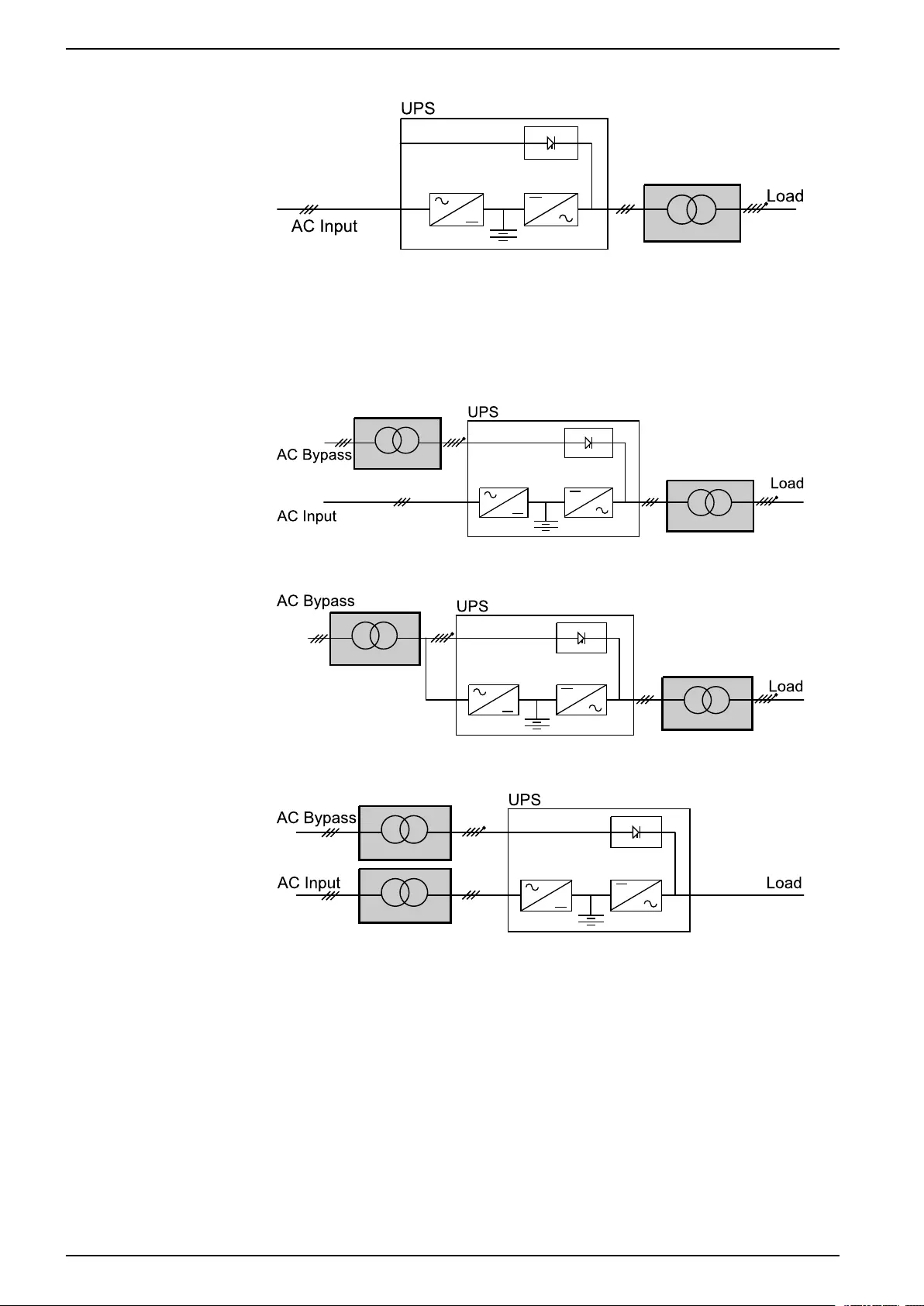

For Single Transformer Connected to Input

Upstream: TT, TN or IT system

Downstream: with neutral distributed

Dual Utility/Mains System

Single Utility/Mains System

Dual Utility/Mains System

For Single Transformer Connected to Output

Upstream: TT, TN system

Downstream: with neutral distributed

Dual Utility/Mains System

990–5233D–001 73

20 - 120 kVA 400 V Install Isolation Transformer (Option)

Single Utility/Mains System

For Transformers Connected to Output and/or One or Two Sources

Upstream: TT, TN or IT system

Downstream: with neutral distributed

Dual Utility/Mains System

Single Utility/Mains System

Dual Utility/Mains System

74 990–5233D–001

Install Isolation Transformer (Option) 20 - 120 kVA 400 V

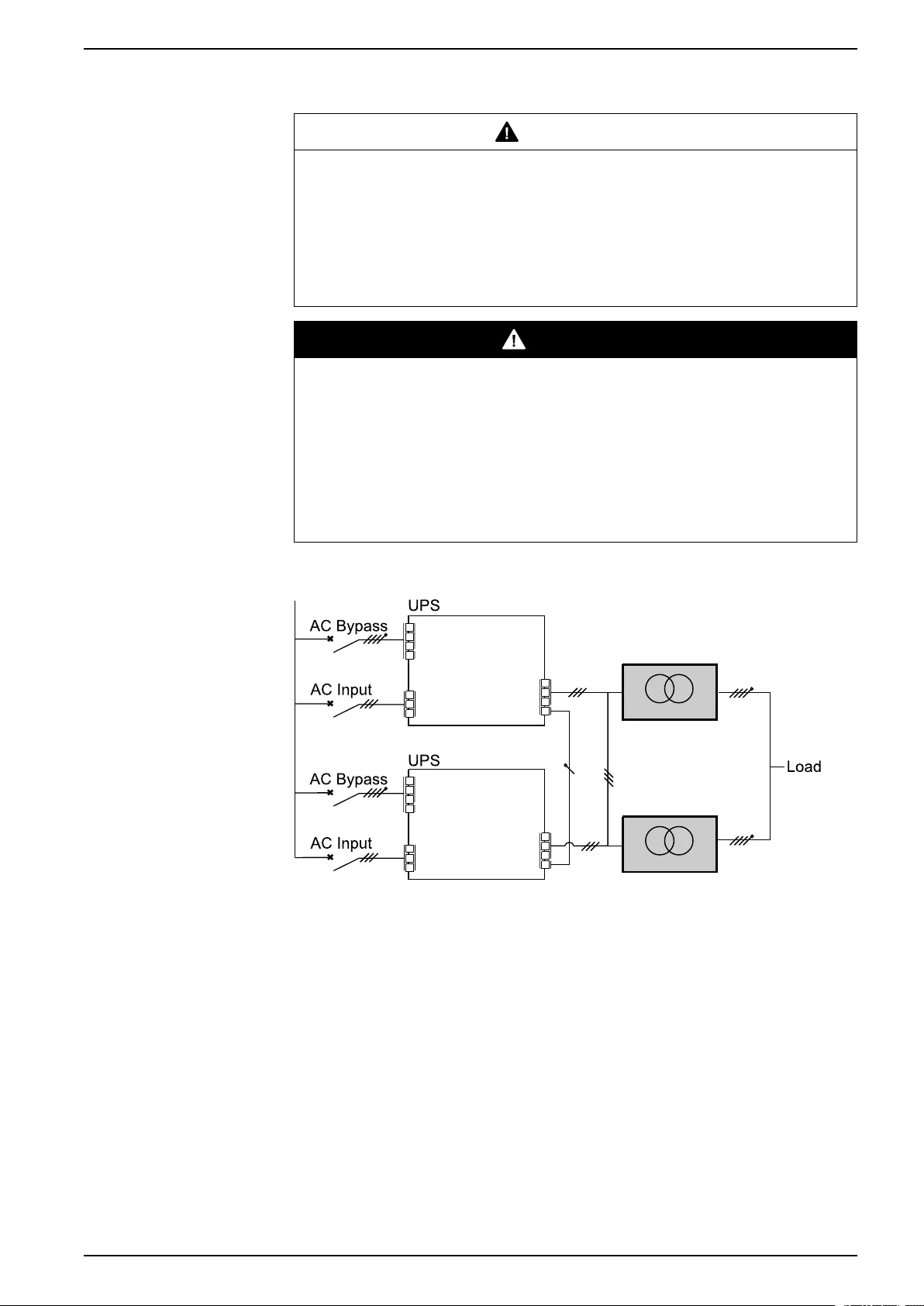

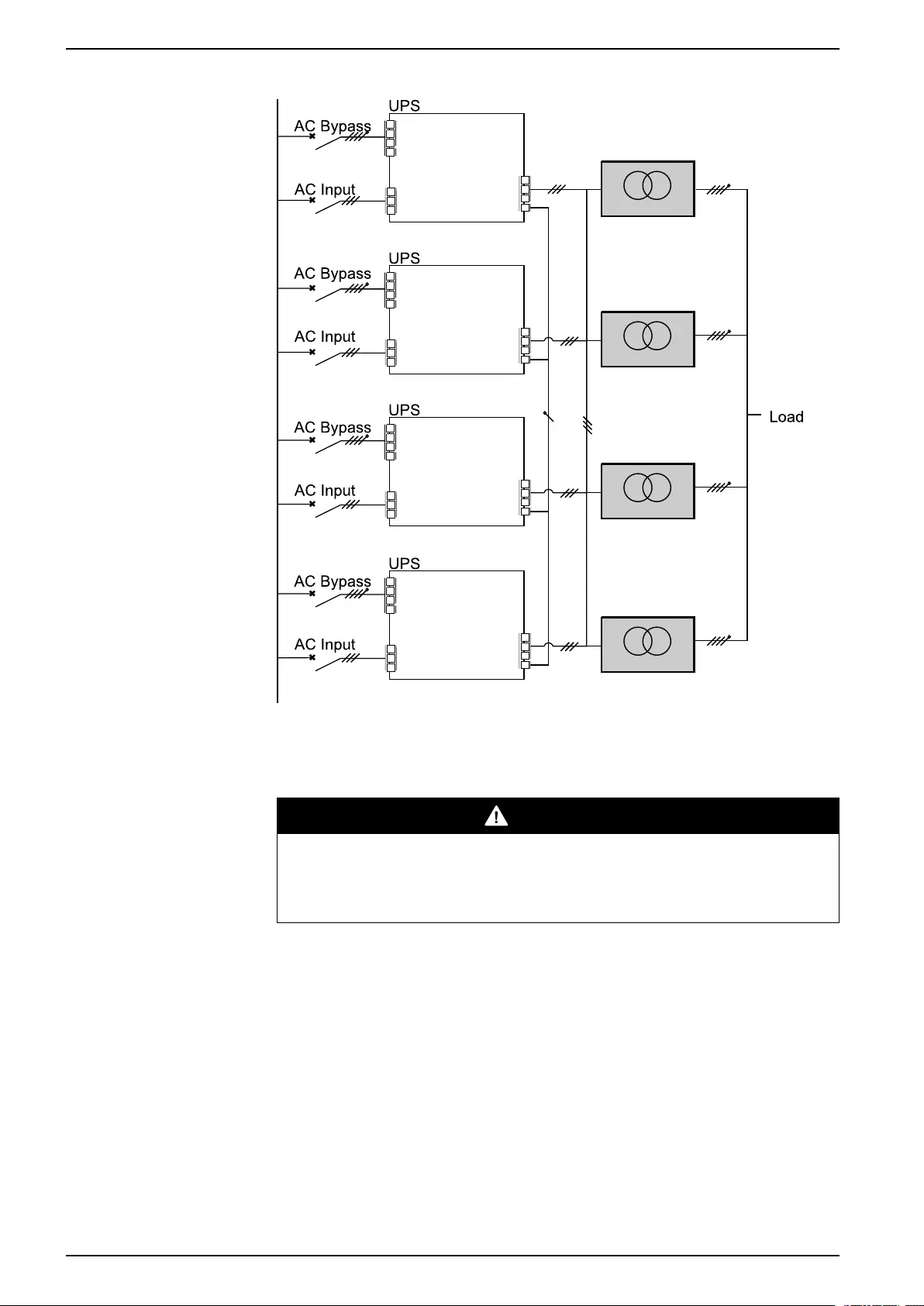

Transformer Configuration Options in Parallel UPS System

WARNING

RISK OF EQUIPMENT DAMAGE

Before turning on the UPS system, make sure that N on the UPSs are parallel

connected and that the output of the UPSs are parallel connected as shown in

the diagram below. This requires extra cables which are not provided by

Schneider Electric.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

A maximum of four UPSs plus transformers can be connected in parallel.

Transformers must be earthed correctly.

• Use power cables of equal resistance, equal length and equal size for the

same function.

• To choose the correct upstream circuit breaker, see the table in Install

Isolation Transformer (Option), page 72.

Failure to follow these instructions will result in death or serious injury.

Two UPSs in Parallel

990–5233D–001 75

20 - 120 kVA 400 V Install Isolation Transformer (Option)

Four UPSs in Parallel

Install Input Isolation Transformer

DANGER