Belling GTG60C User Manual

Displayed below is the user manual for GTG60C by Belling which is a product in the Hobs category. This manual has pages.

Related Manuals

Belling GTG / GHU 60 & 75 Date: 28/02/19

2

To contact Belling about your appliance, please call:

Calls are charged at the basic rate, please check with your telephone service provider for exact charges

Alternatively general, spares and service information is available from

our website at: www.belling.co.uk

Glen Dimplex Home Appliances, Stoney Lane, Prescot, Merseyside, L35 2XW

Warranty Registration

0800 952 1068

*Please call our Customer Care team for extended

warranty

Spares Store

0344 815 3745

Customer Care Helpline

0344 815 3746

in case of diculty within the UK

To contact us by email:

gdhainfo@gdha.com

To register your appliance by mail:

Please complete the warranty card

and return to the address supplied

To register your appliance online:

www.belling.co.uk

Your new appliance comes with our 12-month guarantee (Uk only), protecting you against

electrical and mechanical breakdown. To register, please complete the registration form included,

register online or by phone. For full terms & conditions of the manufacturer’s guarantee, please

refer to the website above. In addition, you may wish to purchase an extended warranty. A leaet

explaining how to do this is included with your appliance.

Our policy is one of constant development and improvement, therefore we cannot guarantee the

strict accuracy of all of our illustrations and specications. Changes may have been made

subsequent to publishing.

GB - Great Britain þ

IE - Ireland þ

DE - Germany

ES - Spain

FR - French

IT - Italy

PL - Poland

NL - Netherlands

SE - Sweden

CN - China

NZ - New Zealand

AU - Australia

Countries of destination:

3

This user guide book is designed to help you through each step of owning your new product.

Please read it carefully before you start using your appliance, as we have endeavored to answer as

many questions as possible, and provide you with as much support as we can.

General information, spares and service information is available from our website.

If you should nd something missing from your product or have any questions that are not covered in

this user guide, please contact us (see contact information inside the front cover).

European Directives

As a producer and a supplier of cooking appliances we are committed to the protection of the environ-

ment and are in the compliance with the WEEE directive. All our electric products are labelled

accordingly with the crossed out wheeled bin symbol. This indicates, for disposal

purposes at end of life, that these products must be taken to a recognized collection points,

such as local authority sites/local recycling centres.

This appliance Complies with European Community Directives (CE) for household and similar electrical

appliances and Gas appliances where applicable.

This appliance conforms to European Directive regarding Eco design requirements for energy-related

products. Our policy is one of constant development and improvement, therefore we cannot guarantee

the strict accuracy of all of our illustrations and specications - changes may have been made subse-

quent to publishing.

Disposal of Packaging Material

The packaging materials used with this appliance can be recycled. Please dispose of the packaging

materials in the appropriate container at your local waste disposal facilities.

UK ONLY GAS WARNING:

If you smell gas, Do not try to light any appliance. Do not touch any electrical switch.

Call the Gas Emergency Help line at 0800 111999

INTRODUCTION

4

WARNING

• Children less than 8 years of age shall be kept away unless

continuously supervised. This appliance can be used by children

aged from 8 years and above and persons with reduced

physical sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction

concerning the use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

• Do not use harsh abrasive cleaners or sharp metal scrapers to

clean the oven door glass or the hob, since they can scratch the

surface, which may result in shattering of the glass.

• Do not use a steam cleaner on any cooking range, hobs and oven

appliances.

• The appliance is not intended to be operated by means of an

external timer or separate control system.

• Unattended cooking on a hob with fat or oil can be dangerous and

may result in re.

• NEVER try to extinguish a re with water, but switch o the

appliance and then cover the ame with a lid or damp cloth.

• Danger of re: Do not store items on the cooking surfaces.

• Only use hob guards designed by the manufacturer of the cooking

appliance or indicated by the manufacturer of the appliance in

the instructions for use as suitable or hob guards incorporated in

the appliance. The use of inappropriate hob guards can cause

accidents.

• Do not modify this appliance.

• Do not store or use ammable liquids or items in the vicinity of this

appliance.

• Do not spray aerosols in the vicinity of this appliance while it is in

operation.

• Do not modify this appliance.

• Do not place articles on or against the appliance.

• Servicing should be carried out only by authorised personnel.

SAFETY

5

• Always switch o your appliance and allow it to cool down before

you clean any part of it.

• Although every care has been taken to ensure this appliance has

no sharp edges. We recommend that you wear protective gloves

when installing and moving this appliance. This will prevent injury.

• This appliance must be tted to a switch providing all pole

disconnection with a minimum contact separation of 3mm.

• Connection should be made with a suitable exible cable with a

minimum temperature rating of 70°C.

• Only use accessories recommended by the manufacturer.

CAUTION

• The cooking process has to be supervised. A short term cooking

process has to be supervised continuously.

• The use of a gas cooking appliance results in the production of

heat, moisture and products of combustion in the room in which

it is installed. Ensure that the kitchen is well ventilated especially

when the appliance is in use: keep natural ventilation holes open

or install a mechanical ventilation device (mechanical extractor

hood). Prolonged intensive use of the appliance may call for

additional ventilation, for example opening of a window, or more

eective ventilation, for example increasing the level of mechanical

ventilation where present.

• This appliance is for cooking purposes only. It must not be used for

other purposes, for example room heating.

• (Gas through glass models only) In case of hotplate glass

breakage, shut immediately o all burners and any electrical

heating element and isolate the appliance from the power supply,

do not touch the appliance surface, do not use the appliance.

• This appliance must not be installed behind a decorative door in

order to avoid overheating.

Fire Safety Advice

• If you do have a re in the kitchen, don’t take any risks - get everyone out of your home and call the

Fire Brigade.

If you have an electrical re in the kitchen and consider it is safe to do so:

• Pull the plug out, or switch o the power at the fuse box - this may be enough to stop the re

immediately

• Smother the re with a re blanket, or use a dry powder or carbon dioxide extinguisher

6

• Remember: never use water on an electrical or cooking oil re.

Other Safety Advice

• There is a risk of electric shock, so always make sure you have turned o and unplugged your

appliance.

• The appliance must never be disconnected from the mains supply during use, as this will seriously

aect the safety and performance, particularly in relation to surface temperatures becoming hot and

gas operated parts not working eciently.

• GAS WARNING! - If you smell gas: Do not try to light any appliance, Do not touch any electrical

switch. Contact your local gas supplier immediately.

• Any damaged components should be assessed and replaced if necessary.

7

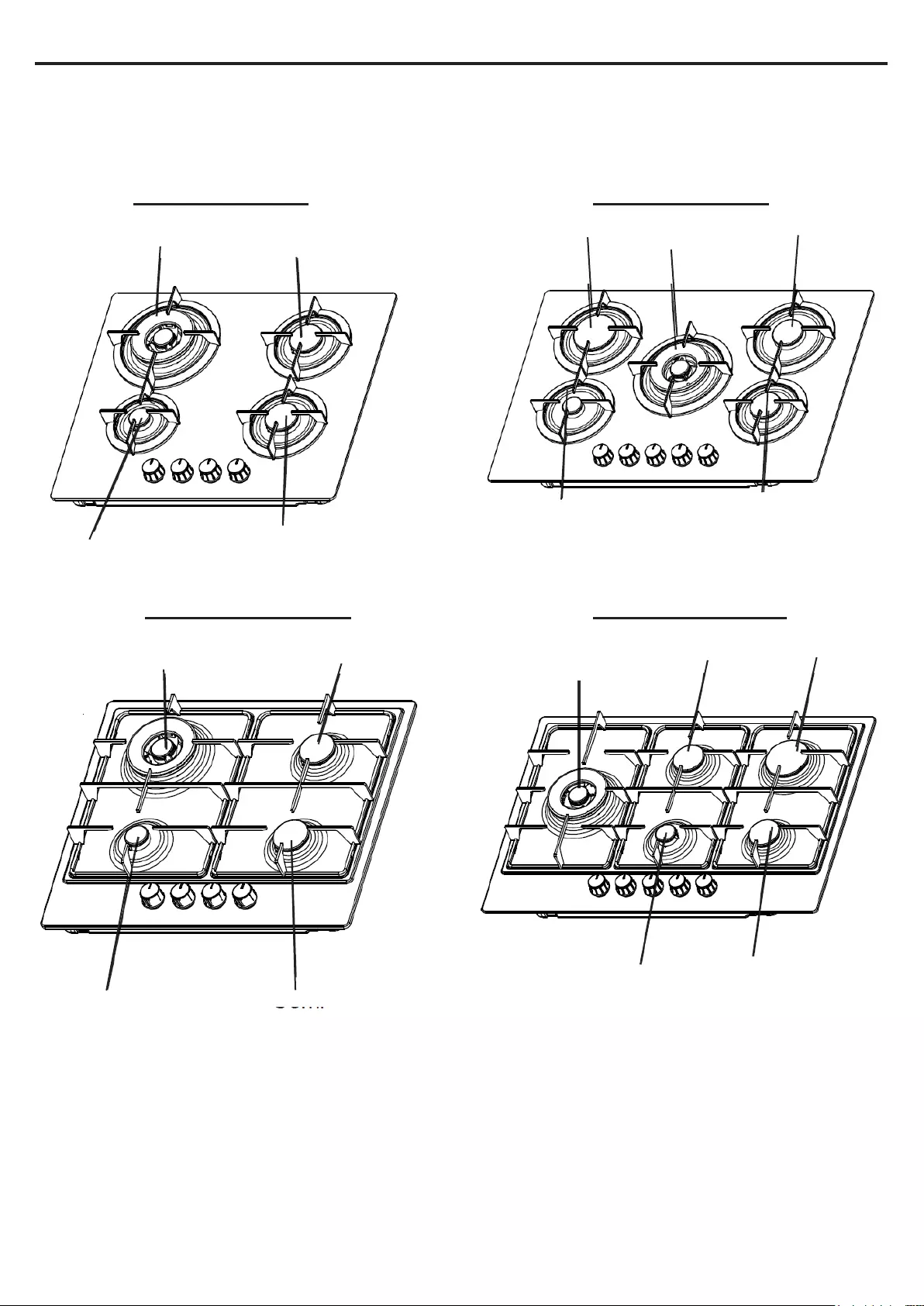

Getting to know your product

Note: Your appliance layout may dier depending on the model.

BEL GTG60C Blk BEL GTG75C Blk

BEL GHU602GC Sta BEL GHU75GC Sta

USING YOUR APPLIANCE

Wok Semi

Semi

Auxiliary

Wok

Auxiliary

Rapid

Semi

Semi

Wok

Auxiliary

Semi

Semi

Wok

Auxiliary

Semi - Rapid Rapid

Semi - Rapid

8

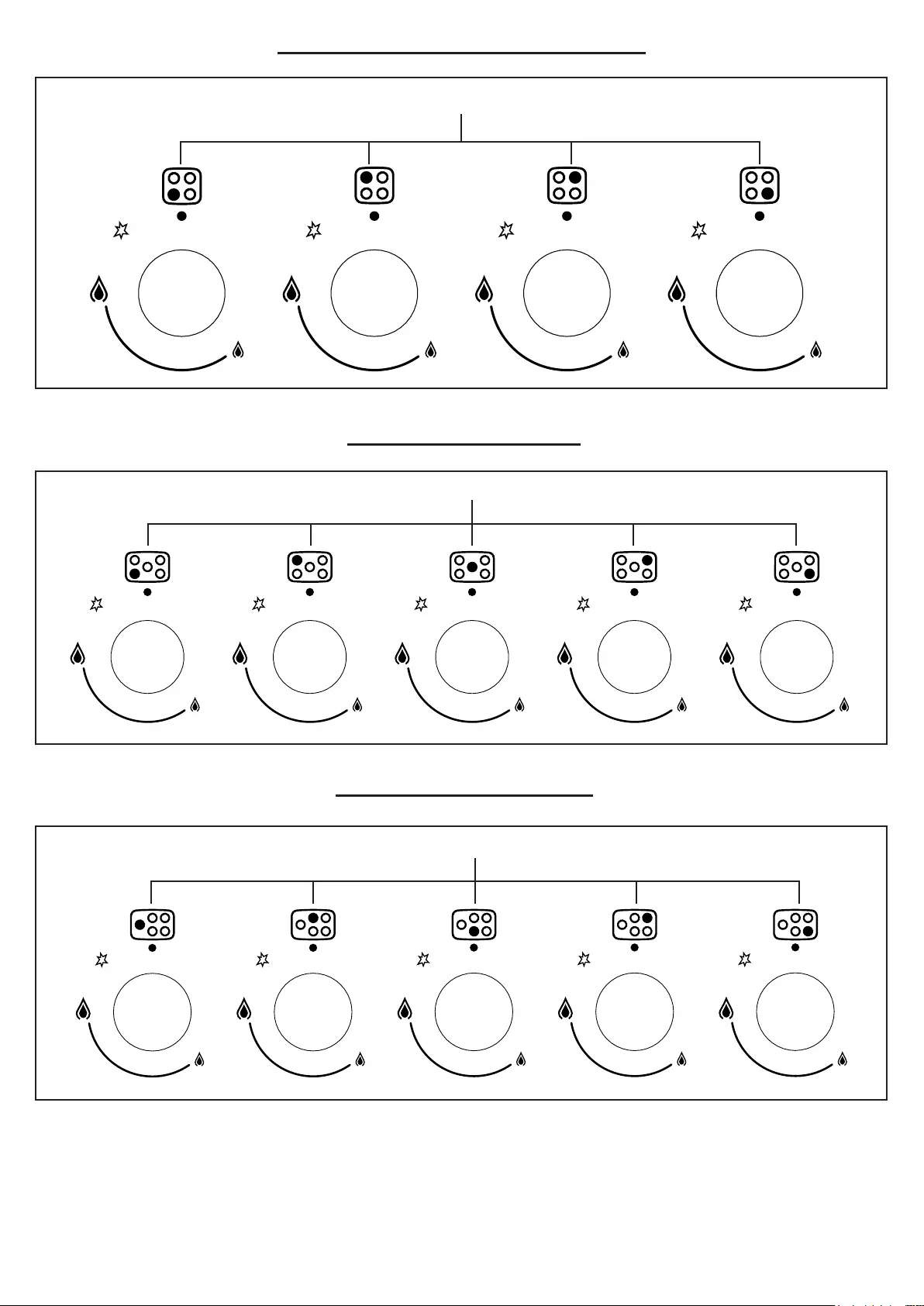

Control panel GTG60C / GHU602GC

Control panel GTG75C

Control panel GHU75GC

Cook zones

Cook zones

Cook zones

9

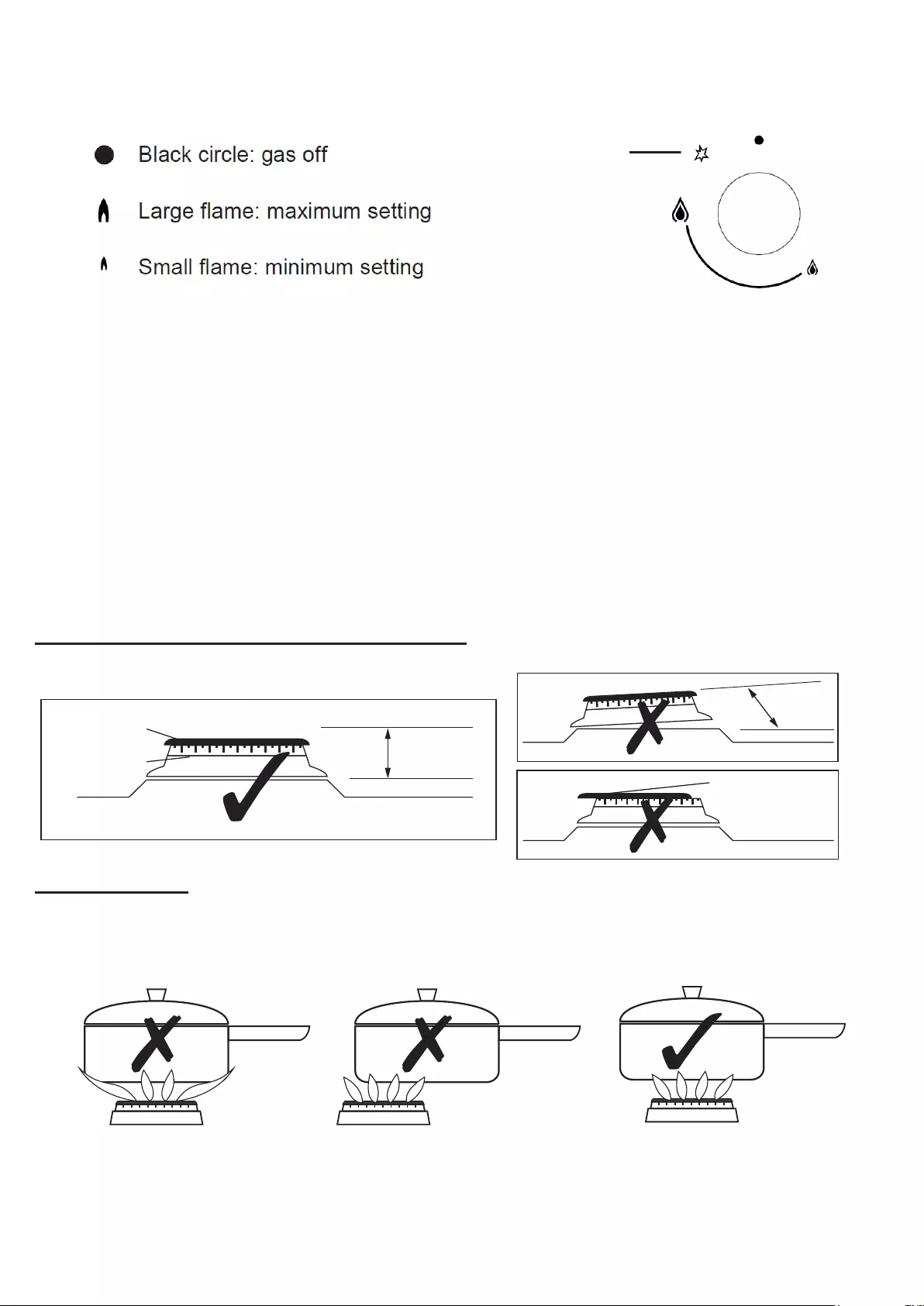

Hob

The following symbols will appear on the control knob, next to each other:

• The minimum setting is at the end of the anti-clockwise rotation of the control handle.

• All operation positions must be selected between the maximum and minimum position.

• The symbol on the control panel,next to the control handle will indicate which burner it operates.

Automatic ignition with ame failure safety device

To light the burner, push the relevant control knob down and turn it anti-clockwise to the large ame

position. Wait for the gas to light and keep the control knob held down for 10 seconds after the ame

has lit, to allow time for the ame failure safety device to warm up, before releasing the control knob.

If the burner fails to light, turn the control knob back (clock-wise) to the o position. Wait for 60 seconds

before attempting to ignite the burner again.

Fitting burner caps and heads (Gas Hobs)

angled

parallel

burner cap

burner head

burner cap not central

Pan placement

Always make sure that your pans are placed centrally on top of the pan support and do not allow the

ame to extend over the base of the pan.

Ignition position

10

Pan sizes required

Burners

Pans

min. max.

Wok 200mm 260mm

Rapid 180mm 220mm

Semi-Rapid 180mm 200mm

Auxiliary 120mm 180mm

Warning: Do not allow cooking vessels to overlap cooking zones.

Not adhering to the maximum recommended pan sizes may result in the control knobs becoming

excessively hot during use and they may become heat damaged over time.

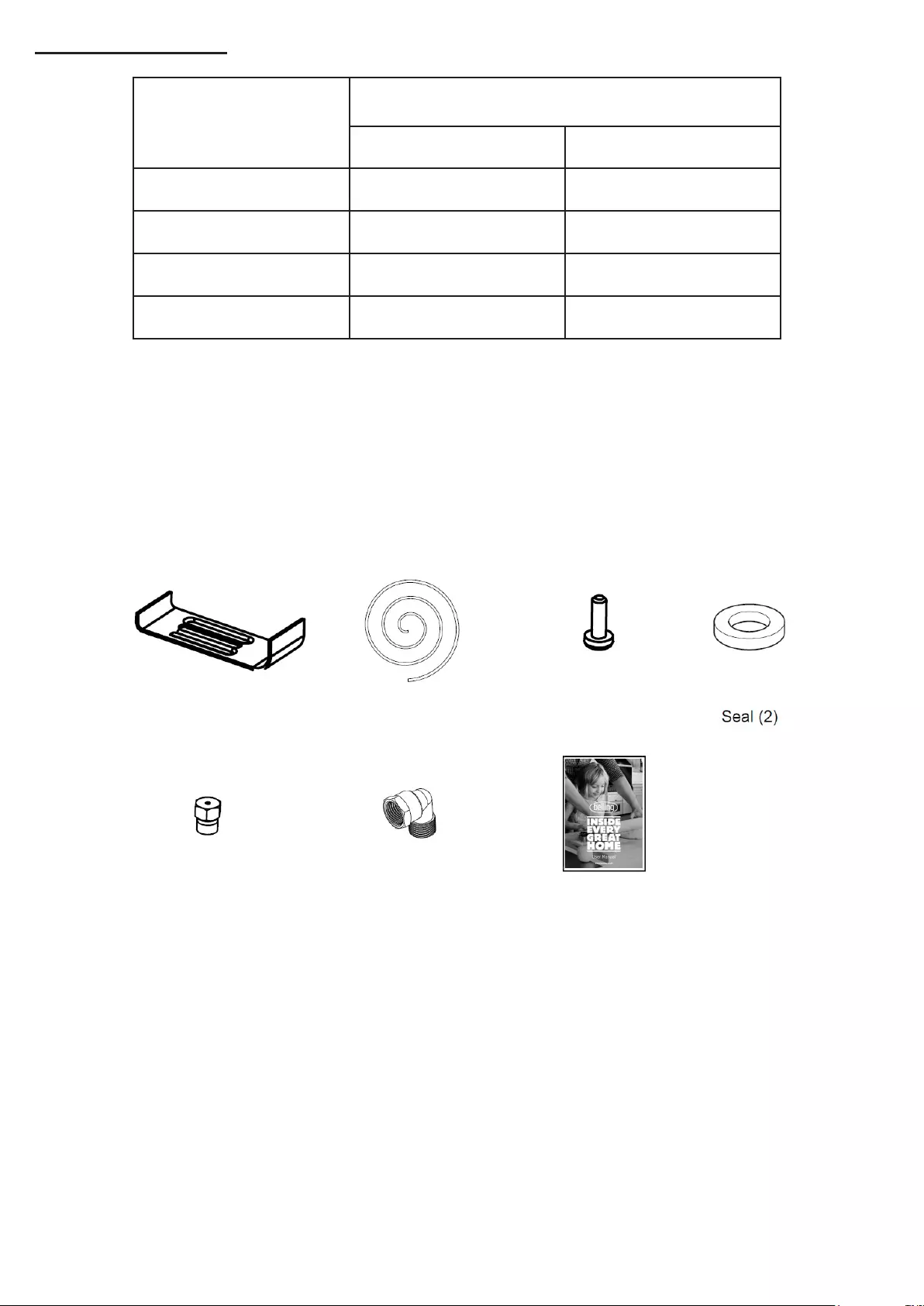

Accessories

Worktop installation

brackets (4)

Instruction Manual (1)

Gas elbow

connection (1)

60G: Injector (4)

75G: Injector (5)

Worktop seal / moisture

control seal (4)

Screws for worktop

brackets (4)

11

Trouble shooting

• Repairs should be performed by a licensed technician only. Improper repair may result in

considerable danger to you and others.

• However, some minor problems can be resolved as follows:

Problem Probable cause Solution

No ignition

No Spark. Check the electricity supply.

The burner caps and skirts are not

correctly assembled. Assemble them correctly.

The gas tap is closed. Open the gas tap completely.

Poor ignition

The gas tap is not completely

open. Open the gas tap completely.

The burner caps and skirts are not

correctly assembled. Assemble them correctly.

Debris on the spark plug ceramic sleeve. Wipe the spark plug ceramic

sleeve with a dry cloth.

The burners are wet. Dry the burner parts carefully.

The holes in the burner skirt are clogged. Clean the burner skirt.

Strange noises when

gas is burning

The burner caps and skirts are not

correctly assembled.

If there is continuous clicking, check

whether the burner parts and spark plugs

have got wet - let them dry out. Check that

control knobs are not stuck down. Do not

touch a spark plug while it is sparking.

Assemble them correctly.

Flame cuts out

The ame supervision device is

contaminated with alien substance.

Clean the ame supervisory

device probe

A pan has boiled over and extinguished the

ame.

Turn the burner control knob to

the o position. Wait at least 1

minute before attempting to

reignite the burner.

A strong draught may have blown

the ame out.

Please turn o zone and check

cooking area for draught such

as open windows. Wait one

minute and reignite zone.

Yellow ame (on

natural gas)

The holes in the burner skirt are clogged. Clean the burner skirt.

The hob has not been converted to the

type of gas available. Check the type of gas available.

Unstable Flame The burner caps and skirts are not

correctly assembled. Assemble them correctly.

Smell of unburnt gas,

even when the knobs

are returned to the o

position.

Gas leakage

Turn the gas o at the isolation

valve at the gas meter. Do not

turn any electrical switches on

or o. Do not use any sources of

ignition. Open doors and

windows to ventilate the

property. Call the gas

emergency service on 0800 111

999 from outside the property.

12

CLEANING YOUR APPLIANCE

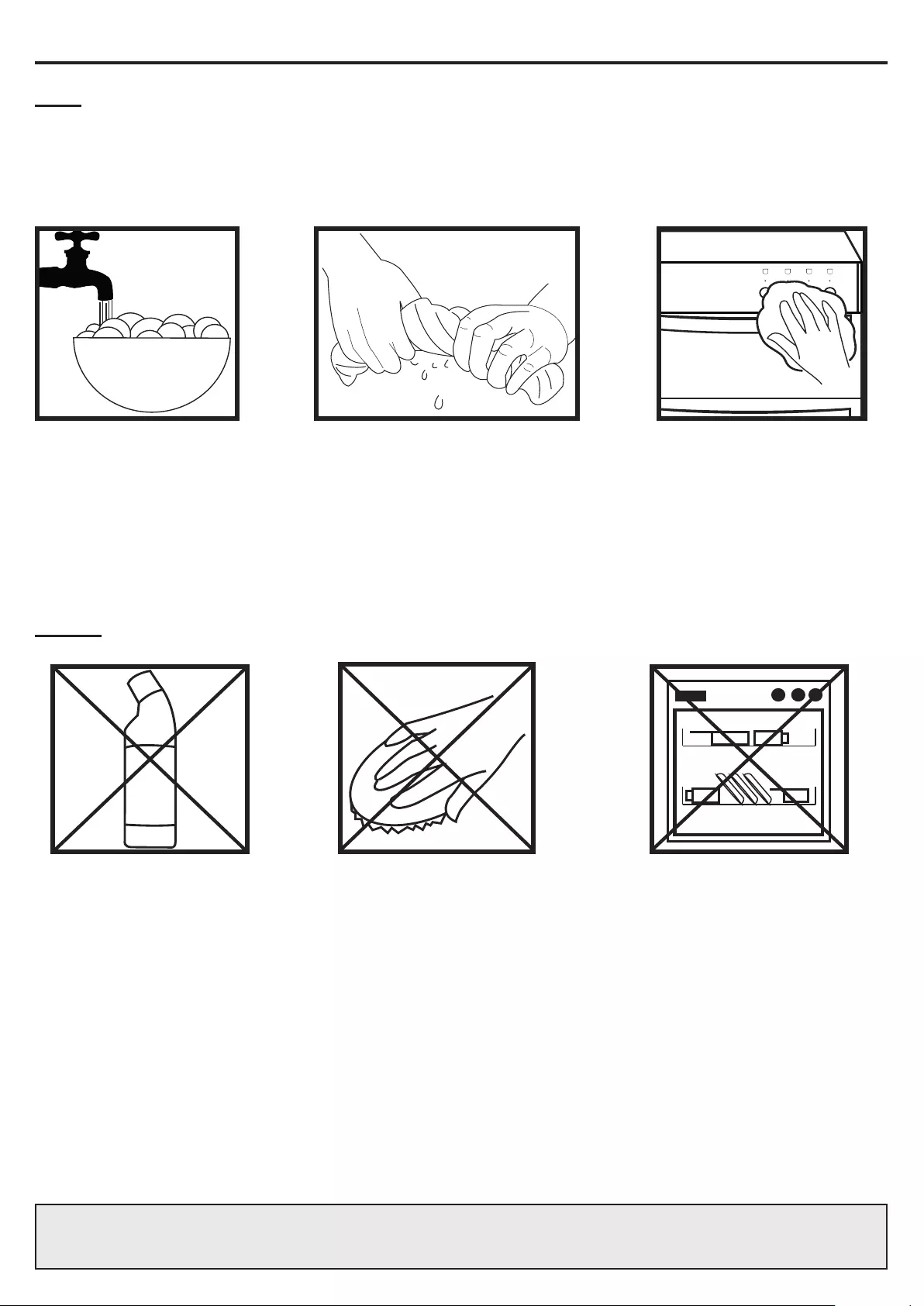

Do’s

Note: Always switch o your appliance and allow it to cool down before you clean any part of it.

Note: Please take extra care when cleaning over the symbols on the control panel, as this can lead to

them fading.

H

Tips: Some foods can mark or damage the metal or paint work e.g.; Vinegar, fruit juices and salt.

Always clean food spillages as soon as possible.

Dont’s

IT IS IMPORTANT TO CLEAN YOUR APPLIANCE REGULARLY AS A BUILD UP OF FAT CAN

AFFECT IT’S PERFORMANCE OR DAMAGE IT AND MAY INVALIDATE YOUR GUARANTEE.

• Undiluted bleaches

• Chloride products

• Warm, soapy water • Wipe with damp cloth

• Dry with a soft cloth

• Clean, wring out cloth

• Wire Wool

• Abrasive cleaners

• Nylon pads

• Steam cleaners

Do not place in the

dishwasher:

• Cast iron griddle

• Pan supports

We oer a great range of cleaning products and accessories for your appliance.

To shop, please visit www.gdhaonline.co.uk

13

Gas Installation

• It is the law that all gas appliances are installed by competent persons in accordance with the

current edition of the Gas Safety Installation and Use Regulations.

• It is in your interest and that of safety to ensure compliance with the law.

• In the UK, GAS SAFE registered installers work to safe standards of practice. The hob must also be

installed in accordance with the current edition of BS 6172. Failure to install the hob correctly could

invalidate the warranty, liability claims and lead to prosecution.

This appliance must be installed in accordance with the regulations in force, and only in a well

ventilated space. Read the instructions before using or installing this appliance. This appliance will be

factory set for use on either natural gas only, or LPG only.

Regulations & Standards

Prior to installation, ensure that the local distribution conditions (nature of the gas and gas pressure)

and the adjustment of the appliance are compatible. The adjustment conditions are stated on the data

badge.

This appliance is not connected to a combustion evacuation device. It shall be installed and

connected in accordance with current installation regulation. Particular attention shall be given to the

relevant requirements regarding ventilation.

The appliance must be installed, converted (where necessary) and serviced by a competent person to

ensure that the installation is in accordance with “The Gas Safety (Installation & Use) Regulations”, &

the “The Gas Safety (Installation & Use) (Amendment) Regulations ”.

Failure to comply with these Regulations is a criminal oence.

Where regulations or standards have been revised since this handbook was printed, always use the

latest edition. All gas installation, servicing and repair work must be in accordance with local standards

and regulations.

For installation in countries other than the UK, the appliance must be connected in accordance with all

local gas and electrical regulations. In the Republic of Ireland, Installers should refer to IS813 Domestic

Gas Appliances.

LP Gas only - Do not install this appliance in a room below ground level. This does not preclude

installation into rooms which are basements with respect to one side of the building but open to ground

level on the opposite side. For installation into environments other than domestic dwellings,

e.g. caravans, boats and similar - refer to the relevant standards on ventilation and gas supply.

Failure to install appliances correctly is dangerous & could lead to prosecution.

14

The room containing the appliance should have an air supply in accordance with BS5440: Part 2

• All rooms require an openable window, or equivalent, and some rooms will require a permanent vent

as well.

• For room volumes up to 5m3 an air vent of 100cm2 is required.

• If the room has a door that opens directly to the outside, or the room exceeds 10m3 NO AIR VENT is

required.

• For room volumes between 5m3 and 10m3 an air vent of 50cm2 is required.

• If there are other fuel burning appliances in the same room, BS 5440: Part 2: (or equivalent) should

be consulted to determine the air vent requirements.

• This appliance must not be installed in a bed sitting room of less than 20m3 or in a bathroom or

shower room.

• Windows and permanent vents should therefore not be blocked or removed without rst consulting a

competent engineer.

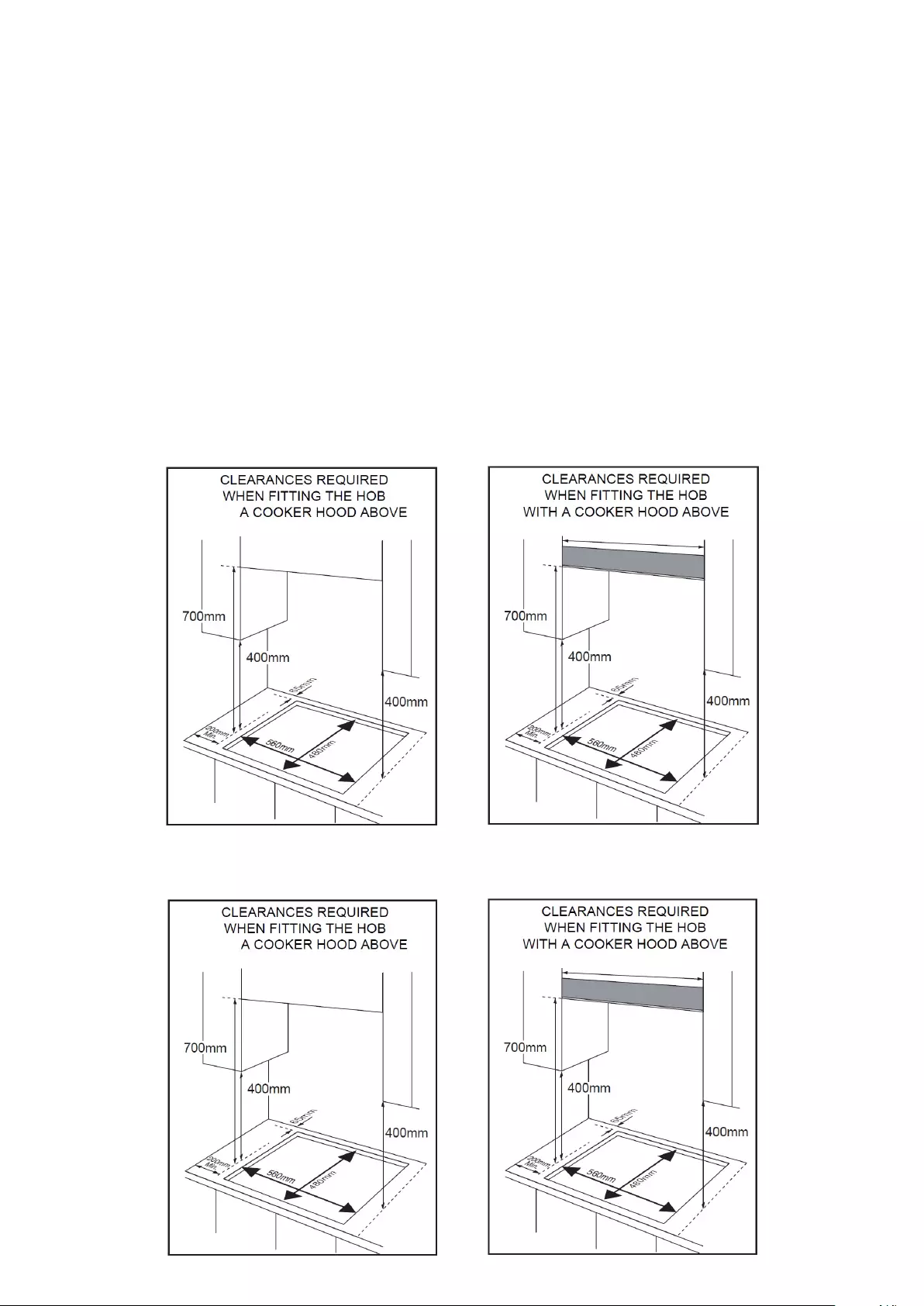

Positioning

60cm

WITHOUT

75cm

WITHOUT

750mm

750mm

15

Installing the appliance

This appliance is to be built into a worktop cutout, 600mm deep, providing the following

minimum distances are allowed;

• The edges of the hob must be a minimum distance of 65mm from rear wall and 200mm from side

wall.

• 700 mm between the highest point of the hob surface (including the pan supports) and the

underside of any horizontal surface directly above it.

• 400mm between the level of the hob and the underside of the wall units adjacent to the hob. The

area above the hob must be kept free of combustible materials for a distance of 50mm behind and

either side of the hob in the horizontal orientation up to a height of 400mm in the vertical orientation.

• 50 mm clearance around the appliance and between the hob surface and any combustible

materials.

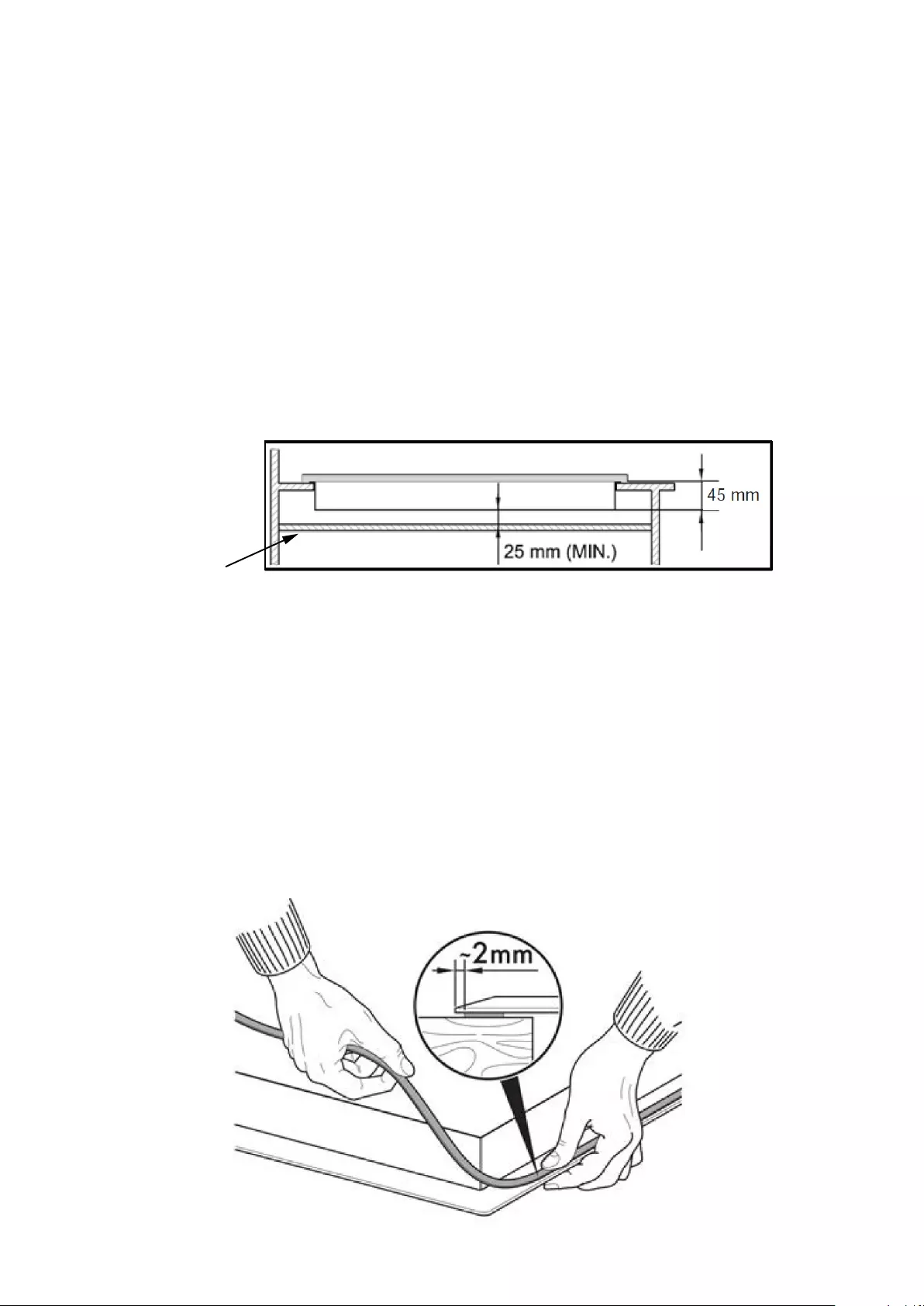

• 45 mm You must have a gap (in the horizontal orientation) of at least 25 mm and at most 74 mm

between the underneath of the appliance and any surface that is below it (such as an isolation plate

or an oven).

Partition

Installation above a unit with a drawer or door

The underside of the hob will become hot during prolonged use, the user must be protected from hot

surfaces on the underside of the hob.

If tting the hob above drawers or cupboards, a partition panel (isolation plate) must be tted under-

neath the hob to the minimum dimensions as shown above.

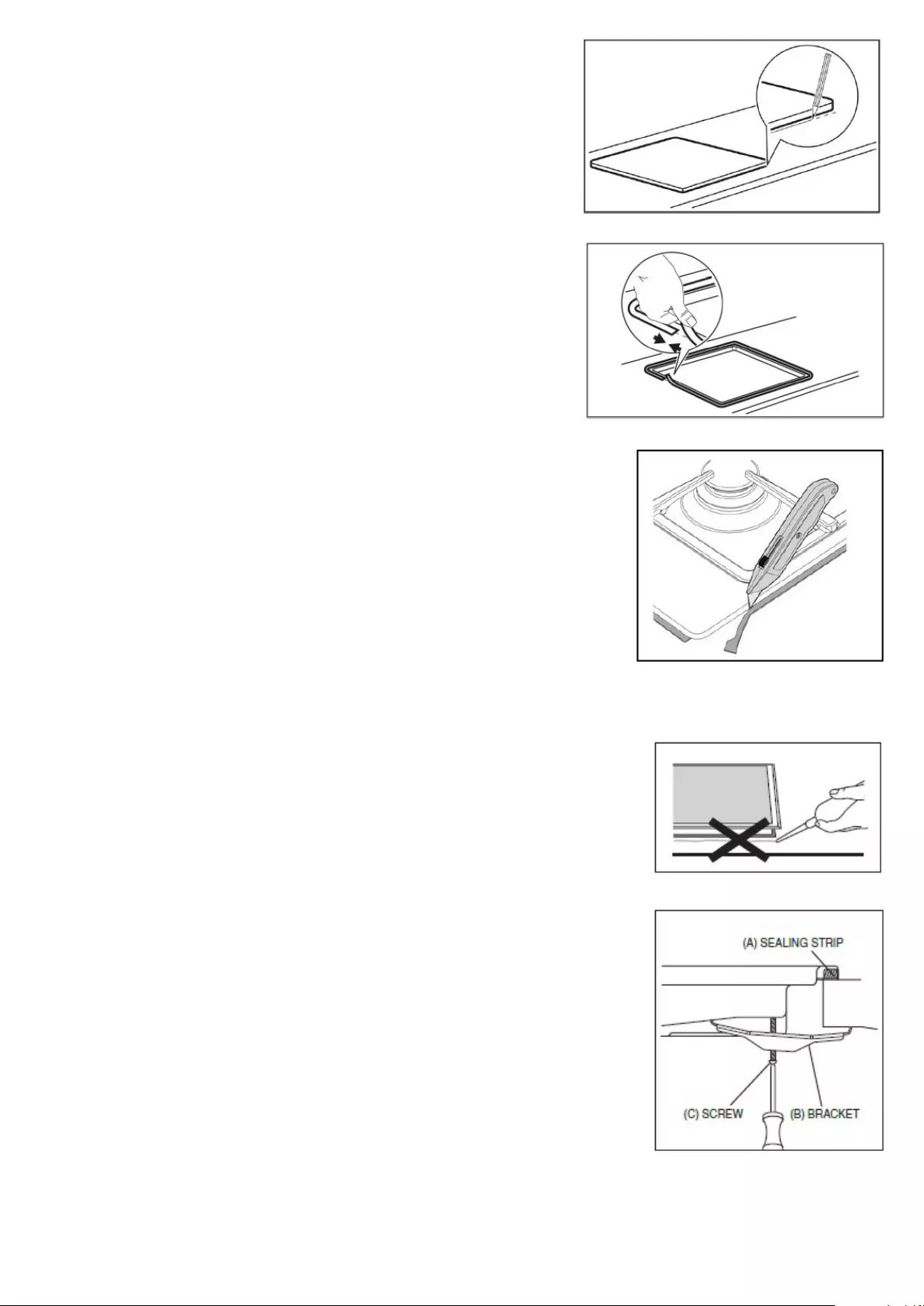

With Glass hob

To prevent leakage of liquid between the frame of the hob and the worktop, place the adhesive seal

provided along the entire outer edge of the underside of the hob before assembly.

16

With Steel hob

To prevent leakage of liquid between the frame of the hob and

the worktop, put the insulating seal provided in position before

assembly.

1. Install the product into the worktop cut-out and use a pencil to

draw a line along the product outer edges.

2. Take out the product and place the adhesive seal provided

along the line you drew in step 1. Use light pressure to make

the seal stick to the worktop.

3. Install the product again, Use light pressure to make the seal

stick to product edge.

4. Carefully trim the surplus edge away from the seal.

5. Clean the edge of the hotplate and the area of the worktop

immediately adjacent to the appliance.

Do not use a silicon sealant to seal the appliance against the aperture.

This will make it dicult to remove the appliance from the aperture in

future, particularly if it needs to be serviced.

1. Remove the pan supports, burner caps and burner skirts, and turn the

hob upside down. Place the bracket (B) over the holes that match the

size of the screws. There are one set of screw holes in each corner

of the hob (H). Slightly tighten a screw (C) through the bracket (B) so

that the bracket is attached to the hob, but so that you can still rotate

the bracket.

2. Carefully turn the hob back over and then gently lower it into the

aperture hole that you have cut out.

3. On the underneath of the hob, rotate the brackets into a position that

is suitable for your worktop. Then fully tighten the screws (C) to

secure the hob in the worktop. Leave a small gap between the work-

top bracket and the underside of the worktop to allow space for heat

expansion.

17

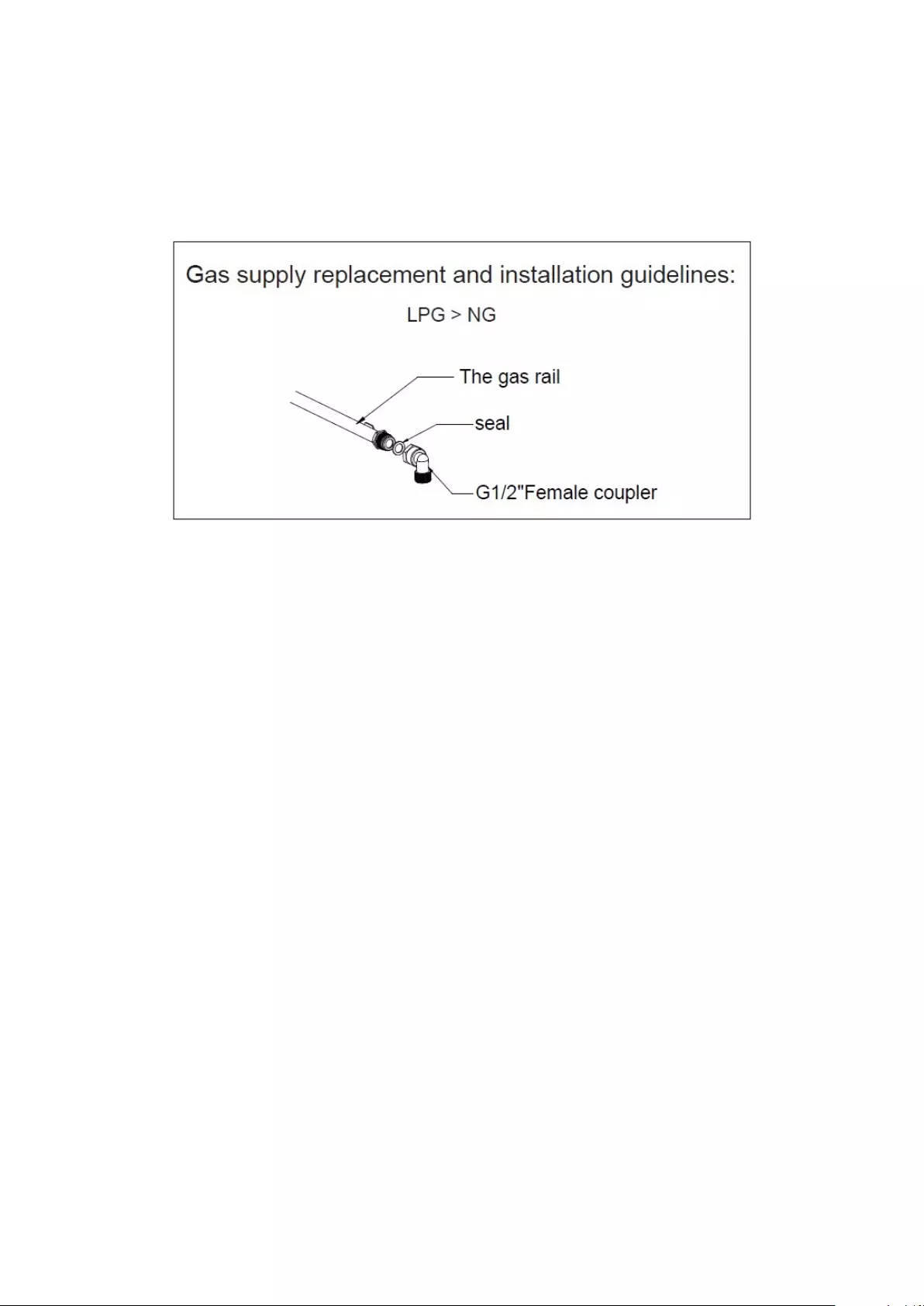

Gas Connection

• This appliance must be installed and connected in accordance with installation regulations

in force in the country in which the appliance is to be used.

• This appliance is supplied to run on LPG and natural gas. Conversion for use on LPG and

natural gases must only be undertaken by a qualied person.

• The gas inlet is at the rear RH side of the hob. The hob should be connected to the gas

supply by rigid pipework as per the regulations in force.

Connect to the electricity supply

• This appliance must be earthed.

• This appliance is designed to be connected to a 220-240V, 50Hz-60Hz AC electricity supply.

• The wires in the mains lead are coloured in accordance with the following code;

Green/yellow = Earth

Blue = Neutral

Brown = Live

• The wire which is coloured green and yellow must be connected to the terminal which is marked

with the letter E or by the earth symbol.

The exible mains lead is supplied connected to a BS 1363 fused plug, the plug is tted with the correct

fuse. Replace only with a fuse of the same rating and type.

The plug and socket must be accessible after installation. Should the mains lead of the appliance ever

require replacing, we recommend that this is carried out by a qualied electrician who will replace it with

a lead of the same size and temperature rating.

Important: - Ensure that you route all mains and electrical cables and exible tubing well clear of any

adjacent heat source.

Under no circumstances should the mains electric cable be allowed to come into contact with hot oven

ues or similar surfaces and keep well clear of any moving parts that may be in the vicinity of the instal-

lation, such as cooling fans on adjacent appliances.

18

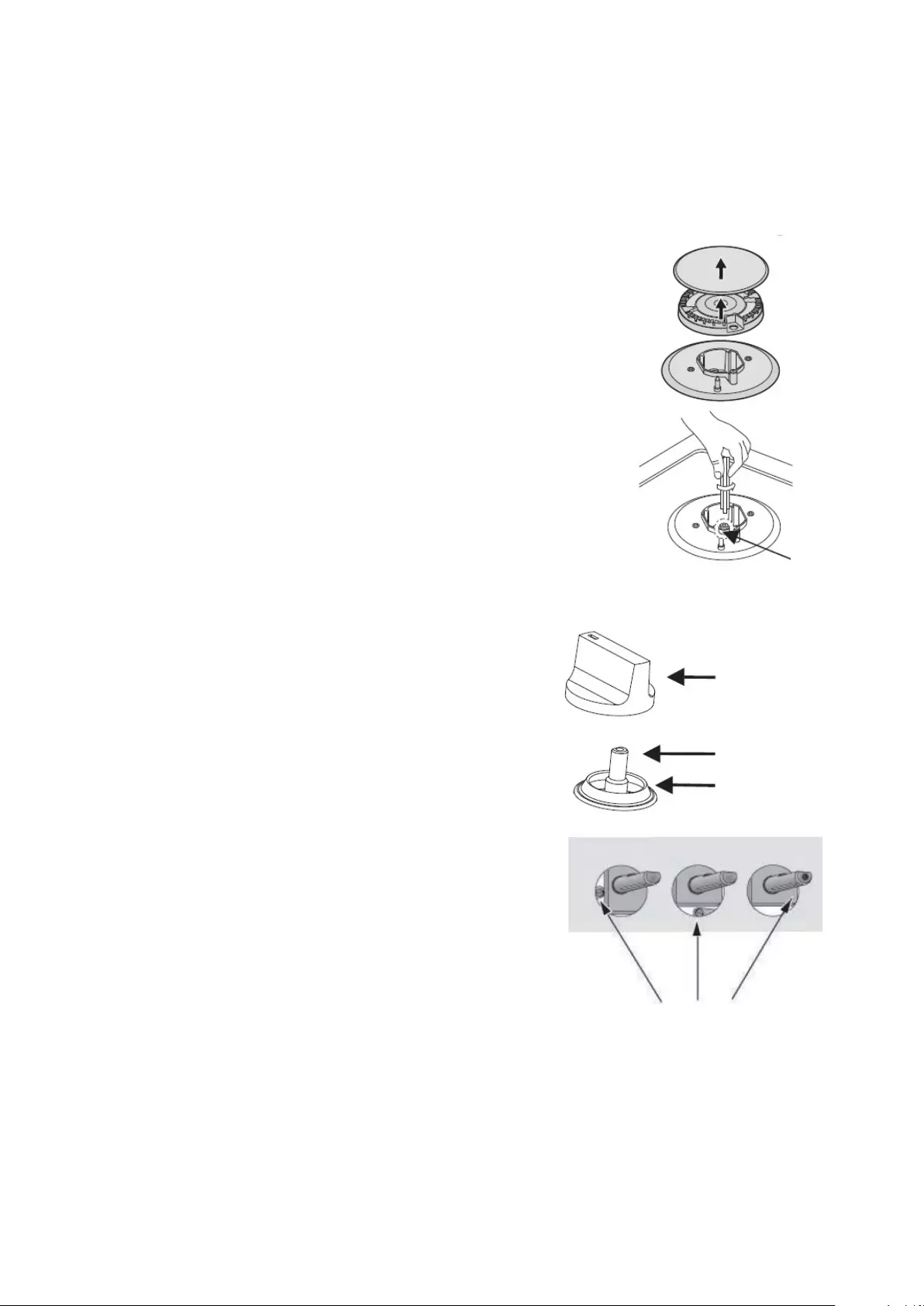

LPG conversion

• Take the precautions on the operations and adjustment to be carried out when converting from one

gas to another.

• All work must be carried out by a qualied technician.

• Before you begin, turn o the gas and electricity supply to the appliance.

1. Change the injector of the burners.

• Remove the pan supports, burner caps and burner skirts.

• Unscrew the injector using a 7mm box spanner and replace it with

the stipulated injector for new gas supply referring to the table on

page 20. Carefully reassemble all of the components. After

injectors are replaced, it is advisable to strongly tighten the injector in

place.

2. Simmer rate adjustment.

• Turn the taps down to minimum.

• Remove the knob from the tap and place a small bladed

screwdriver into the adjustment screw as shown on the

diagram.

• The correct adjustment is obtained when the ame has a

length of about 3-4 mm.

- For butane / propane gas, the adjusting screw must be

tightly screwed in.

- Ret the control knob.

Make sure that the ame does not go out by quickly turning

from maximum ow to minimum ow. If it does then remove

the control knob and make further adjustments to the gas

ow, testing it again once the adjustment has been made.

• Do not dismantle the tap shaft in the event of a malfunction, change the whole tap.

• Before placing the burner skirts and burner caps back on top of the hotplate, make sure the injector

is not blocked.

• A full operational test and a test for possible leakages must be carried out after gas conversion

(such as leak detection uid or gas detector).

• After converting the hob to LPG, or back to NG, ensure that the relevant label is placed on the data

badge to indicate the correct gas category that the appliance has been converted to.

• Ensure the correct gas hose is used for connection to a Nat Gas or LPG supply.

Control knob

Tap

Sealing ring

Adjustment

screw

Injector

19

&XVWRPHU&DUH

3OHDVHNHHSWKLVKDQGERRNLQDVDIHSODFHDVWKHLQIRUPDWLRQLQVLGHPD\

EHRIXVHVKRXOG\RXVHOORUSDVVRQWKHDSSOLDQFH3OHDVHILOOLQWKH

PRGHOQXPEHUDQGVHULDOQXPEHULQWKHVSDFHVSURYLGHG EHORZDVWKH\

ZLOODVVLVWXVVKRXOG\RXQHHGWRFDOO

:KHQ\RXGLDOWKLVQXPEHU\RXZLOOKHDUDUHFRUGHGPHVVDJHDQGEH

JLYHQVHYHUDORSWLRQV7KLVLQGLFDWHVWKDW\RXUFDOOKDVEHHQDFFHSWHG

DQGLVEHLQJKHOGLQDTXHXH&DOOVDUHDQVZHUHGLQVWULFWURWDWLRQDVRXU

&XVWRPHU&DUHUHSUHVHQWDWLYHVEHFRPHDYDLODEOH

(QWHUDSSOLDQFHQXPEHUVKHUHIRUIXWXUHUHIHUHQFH

7KHVHQXPEHUVFDQEHIRXQGRQ\RXUDSSOLDQFHVGDWD

EDGJH2XWVLGH WKH 8. DQG1RUWKHUQ,UHODQG UHIHU WR \RXU

ORFDOVXSSOLHU

6WRQH\/DQH3UHVFRW0HUVH\VLGH/;:

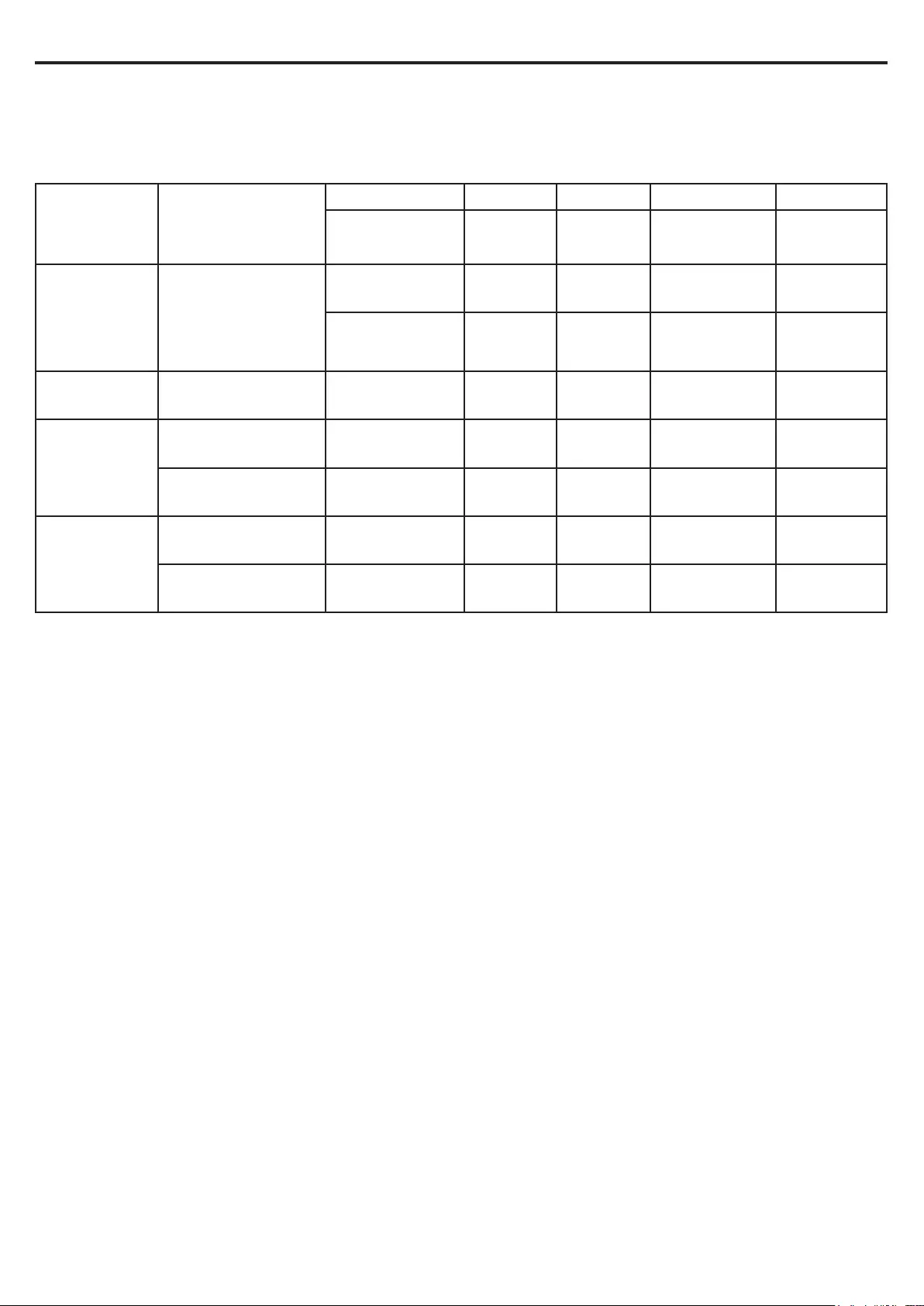

Category Gas Type

Burner Wok Rapid Semi-Rapid Auxiliary

Rated Power

(kW) 3.6 3.0 1.75 1.0

I3+ G30/G31

28-30/37 mbar

Rated Flow

(g/h) 263 219 127 73

Injector

Diameter(mm) 0.96 0.87 0.66 0.50

I2H/I2E/I2E+ Natural Gas

20 mbar

Injector

Diameter(mm) 1.44 1.30 1.00 0.78

II2H3+

G30/G31

28-30/37 mbar

Injector

Diameter(mm) 0.96 0.87 0.66 0.50

Natural Gas

20 mbar

Injector

Diameter(mm) 1.44 1.30 1.00 0.78

II2E3B/P,

II2H3B/P

L.P.G (G30, G31

(28-30)mbar

Injector

Diameter(mm) 0.96 0.87 0.66 0.50

Natural Gas

20 mbar

Injector

Diameter(mm) 1.44 1.30 1.00 0.78

• If you want to process gas conversion, all work must be carried out by a qualied technician.

• When converting to LPG, use the injector sizes shown in the table above.

• After gas conversion, it is strongly suggested to place new label on the product for clarcation.

• For operation detail, please refer to the LPG Conversion section.

• Appliance Class - Class 3 Built-In Hotplate

Gas hob

TECHNICAL DATA

20