CDA AS1WH User Manual

Displayed below is the user manual for AS1WH by CDA which is a product in the Kitchen Sinks category. This manual has pages.

Related Manuals

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu www.cda.eu

Composite

Sinks

Installation, Use and Maintenance

2

CE Declaration of Conformity:

Having regard to the Council Directive 89/109/EEC of 21st December

1988 on the approximation of the laws of the Member States relating

to materials and articles intended to come into contact with foodstus,

we declare that the materials composing the sink meet the above-

mentioned directives, in particular the EU Food Contact Regulation

(90/128/EEC and 89/109/EEC along with amendments 92/39/ EEC and

93/9/EEC).

Taking Care of Your Sink

Your CDA sink is manufactured using material developed specifically to

withstand the rigours of everyday kitchen use. However, we advise you

to follow these precautions to keep the sink in pristine condition:

• Do not use a plastic washing-up bowl in the sink as grit and other

particles may become embedded in the bowl and scratch

or erode the sink surface. CDA specifically recommend the use of

wire sink-baskets and drainer-racks to help protect your sink. Take

care to not cut the plastic coating on these accessories with sharp

cutlery or the edges of pans, etc.

• Do not use neat bleach or other harsh cleaning agents on the metal

sink waste as this may cause tarnishing. This is especially important

if the waste is either solid brass or brass plated.

• Avoid dropping heavy or sharp objects into the sink as they may

scratch or damage the surface.

• The surface of the sink can be aected by certain chemicals e.g. neat

bleach, nail polish remover, paint stripper, solvents, brush cleaner and

insecticides. If any of these substances come into contact with the

3

sink, wipe o immediately with a dry cloth, wash with mild detergent

and rinse with water.

• Do not use abrasive liquids, powders or steel pads to clean the sink

as they will damage the sink surface and make it more susceptible to

staining. The sink may be cleaned with a dilute bleach solution.

• Do not place very hot objects directly on the sink, place them on a

special surface (board) made from wood or heat-proof plastic, etc.

• If the sink comes into contact with acidic materials, rinse immediately

with plenty of water and wipe with a soft dry cloth.

• In hard-water areas, a limescale deposit may build up on the sink.

The limescale may become stained by coloured foods such as coee

or red wine. If this occurs, we recommend use of a mild limescale

remover.

• Particularly stubborn organic stains can be removed eectively by

soaking the sink in a biological washing-powder solution, dishwasher

powder solution or diluted bleach.

• Do not leave rusty objects in contact with the sink. Rust can cause

staining, cracking or even permanent damage to the sink surface.

• To avoid staining of the surface do not leave food or other materials

with corrosive properties such as juices, salt, vinegar, mustard etc. on

the sink for a long time.

• After using the sink, rinse it clean with warm soapy water and rinse

with clean water before wiping dry.

• During installation, protect from scratches, scus and other damage.

• Do not overtighten or strain plumbing fittings.

• The moulding and edges of the sink must be absolutely level so

water flows o the drainer.

4

Installation

Before Installation

Oer up the sink to the worktop and/or the cabinets to confirm that

the external dimensions of the bowl are compatible with the cabinets

themselves.

Confirm that with the sink in position:

• There is adequate space to install any taps or other required

accessories.

• There is adequate space to install the waste pipework and that any

necessary modification to internal shelves to accommodate the waste

(and trap) is acceptable.

• Access to any water stop-cock or other services will still be adequate

after the installation.

Cutting the tap hole

Only cut the tap hole from the underside of the sink.

• Select the tap hole position based on whether left hand or right hand

drainer is required.

• Locate the centre of the required tap hole and cut it out using a

suitable 35mm diameter hole cutter (available from most plumbers

merchants or DIY stores).

• Caution: Ensure that the sink is safely supported around the hole

to be cut out.

5

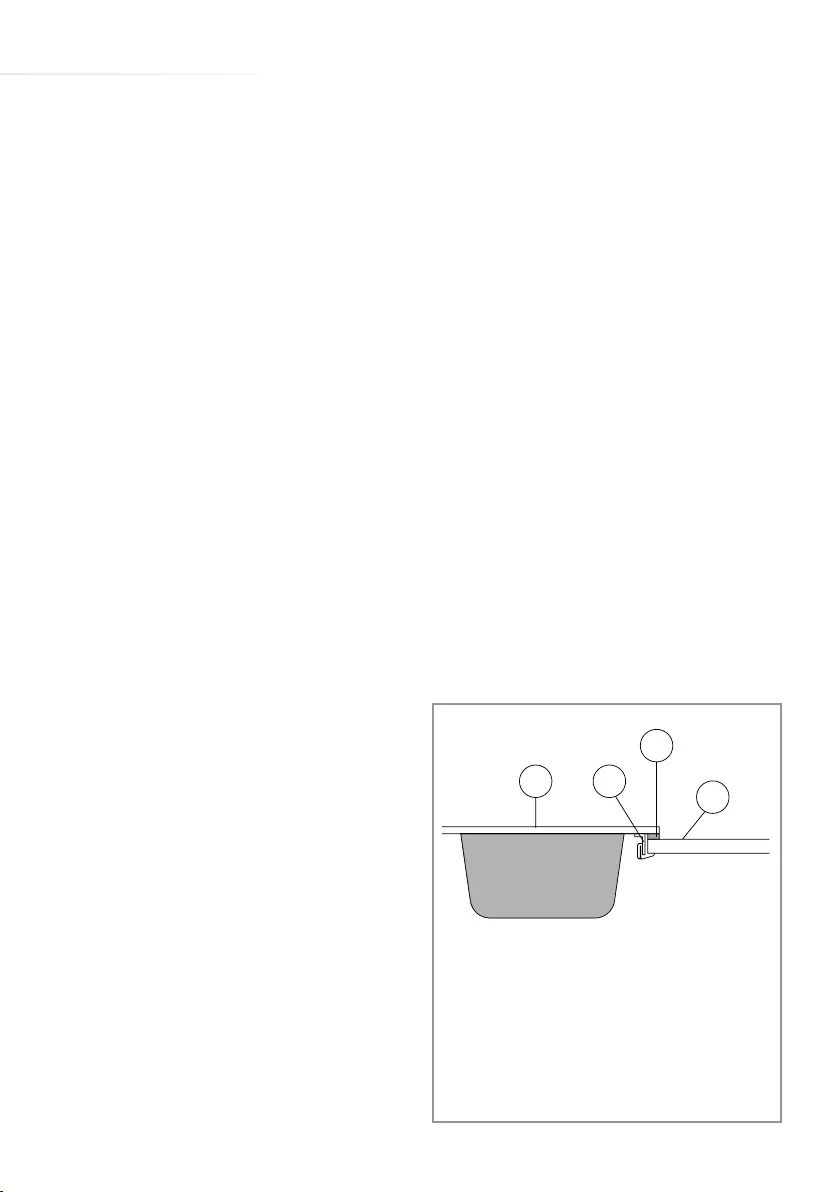

24

1

3

Fig. 1

1: Seal

2: Sink

3: Worktop

4: Fitting bracket supplied (suitable

for 30mm or 40mm worktop)

Installation

• Place the sink upside-down on the worktop where it will be mounted.

• Draw the perimeter of the sink on the worktop with a pencil.

• Remove the sink and draw a dotted line, 1cm inside the perimeter.

• Double check the marking out and positioning before starting to cut

the worktop.

• Make the cutout with suitable tools along the dotted line.

• After cutting out the worktop aperture, we recommend you seal the

cut edges with silicone (or similar) sealant to help prevent ingress of

water.

• It is often easier to mount the taps, waste-fitting and overflow onto the

sink prior to fitting the sink to the worktop (see next page for assembly

of supplied waste system).

• Position the sink on the worktop, bedding it onto the supplied seal

strip (Fig. 1).

• The taps, waste-fitting and overflow can now be mounted onto

the sink (if not already done)

and fully connected to their

respective services.

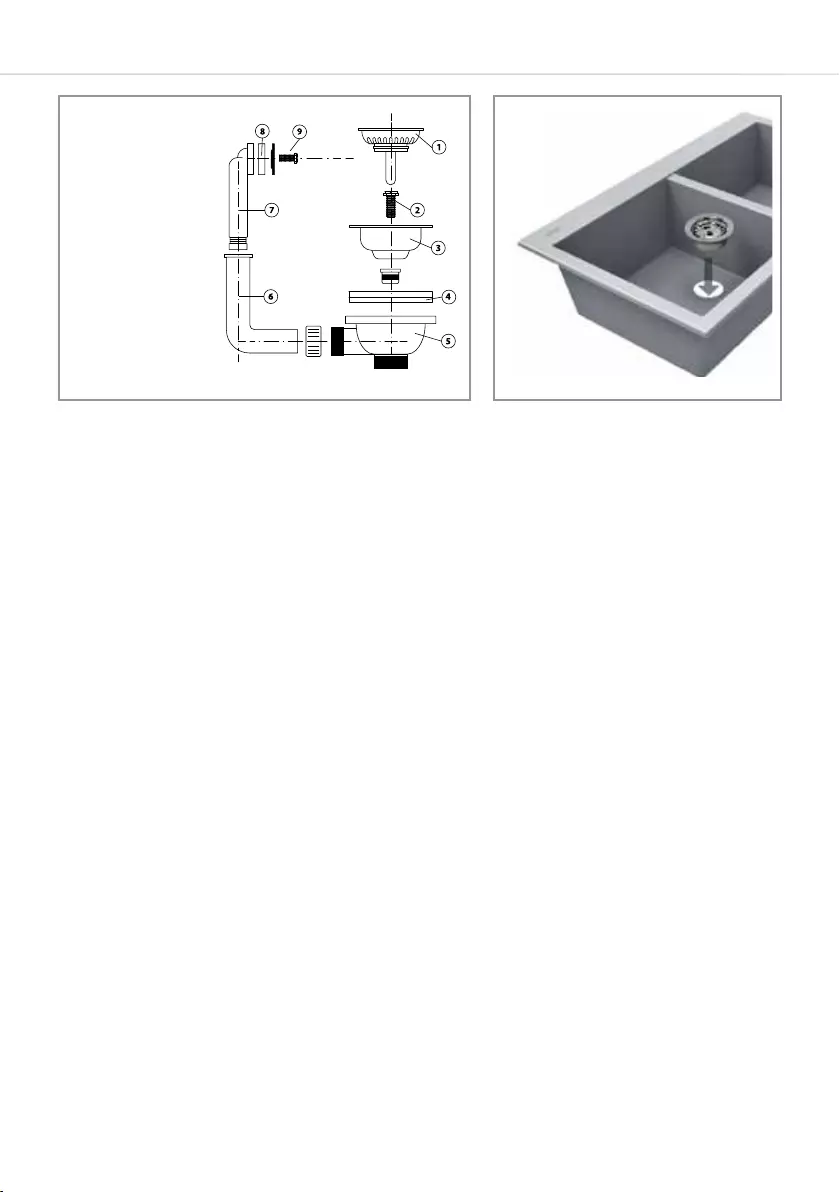

• Assemble the supplied waste

and overflow fittings as shown

(Fig. 2) and insert into the sink

from above (Fig. 3). NOTE: do

not use silicone sealant.

6

• To check the waste for leaks, close the plug/basket of the waste

fitting, open the tap and fill the sink to the level of the overflow; turn

o the tap and wait several minutes to verify that the water doesn’t

drain away.

• Empty the sink.

If a washing machine or dishwasher is going to be installed beneath

the sink top:

• Before installing the washing machine or dishwasher, make sure

that all of the fastening brackets for the sink top have been fastened

securely.

• To prevent overheating, which may result in the deformation and

consequent detachment of the sink from the top, adjust the feet on

the washing machine/dishwasher so that there is sucient ventilation

between the top of the appliance and the sink. To aid the circulation

and cooling of the air, it is recommended that ventilation slots be made

in the cabinet base.

)asket

:cre^

:trainer

:eal

+rain

+rain pipe

6]erÅo^ pipe

:eal

:cre^

Fig. 2

the

hen

n

der

6

(

(

Fig. 3

7

E & O E. All instructions, dimensions and illustrations are provided for guidance only. CDA reserve the

right to change specifications without prior notice.

The Guarantee is Valid Providing That

• The product has been installed by a suitably qualified person.

• Installation has been carried out in accordance with instructions and

current legislation.

• Proof of purchase can be produced.

• The product has been used for domestic purposes only.

• The product has not been tampered with or repair attempted or

modified by any unauthorised person.

• All products have been installed in accordance with WRAS regulations

and local water bye-laws

The Guarantee Does Not Cover

• Damage by misuse, neglect or transit.

• Use of parts not used or recommended by CDA.

• Routine maintenance, general wear & tear and installation faults.

• Products used for commercial or professional purposes.

Your sink is guaranteed against defects in materials and/or workmanship

for 5 years. At the discretion of CDA, should a fault arise the sink may be

repaired or replaced and agreed refitting may be reimbursed on receipt

on a faulty sink/part, once they have been inspected and deemed faulty.

Customer Care Department • The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu W : www.cda.eu www.cda.eu

Please contact our Customer Care Department for Service on the details below

Customer Care Department

The Group Ltd. • Harby Road • Langar • Nottinghamshire • NG13 9HY

T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu