DELL SE2416H User Manual

Displayed below is the user manual for SE2416H by DELL which is a product in the Computer Monitors category. This manual has pages.

Related Manuals

23.8" LED Monitor Dell SE2416H

1

Service

Service

Service

Simplified

2

Important Safety Notice

Proper service and repair is important to the safe, reliable operation of all DELL Company Equipment. The service

procedures recommended by DELL and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed for the purpose. The special

tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service methods

may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. DELL could not possibly know, evaluate and advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous consequences of each way. Consequently, DELL has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by DELL must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Hereafter throughout this manual, DELL Company will be referred to as DELL.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock,

fire, or other hazards.

Under no circumstances should the original design be modified or altered without written permission from DELL. DELL

assumes no liability, express or implied, arising out of any unauthorized modification of design.

Servicer assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER-Invisible laser radiation when open. AVOID DIRECT EXPOSURE TO BEAM.

CAUTION-Use of controls or adjustments or performance of procedures other than those specified herein may result

in hazardous radiation exposure.

CAUTION -The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART NUMBERS IN THE PARTS LIST SECTION OF

THIS SERVICE MANUAL.

Take care during handling the LCD module with backlight unit

-Must mount the module using mounting holes arranged in four corners.

-Do not press on the panel, edge of the frame strongly or electric shock as this will result in damage to the screen.

-Do not scratch or press on the panel with any sharp objects, such as pencil or pen as this may result in damage to the

panel.

-Protect the module from the ESD as it may damage the electronic circuit (C-MOS).

-Make certain that treatment person’s body is grounded through wristband.

-Do not leave the module in high temperature and in areas of high humidity for a long time.

-Avoid contact with water as it may a short circuit within the module.

-If the surface of panel becomes dirty, please wipe it off with a soft material. (Cleaning with a dirty or rough cloth may

damage the panel.)

3

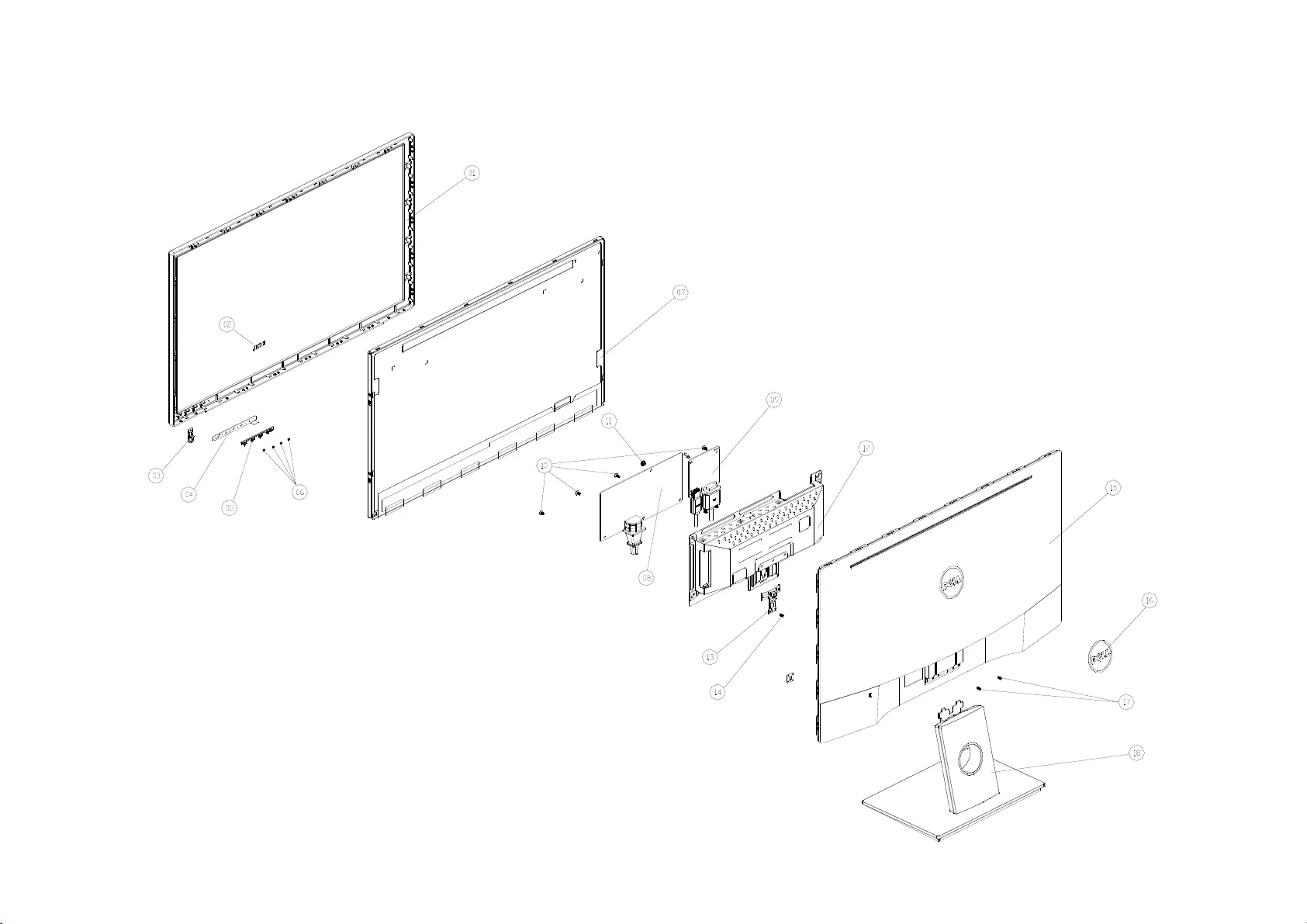

1. Exploded view diagram with list of items

4

SE2416H

No. Description Q'ty

1 BEZEL 1

2 LOGO DELL 1

3 KEY_POWER 1

4 KEY BOARD 1

5 KEY_FUNCTION 1

7 PANEL 1

8 POWER BOARD 1

9 MAIN BOARD 1 No. Part No. Description Q'ty

12 MAINFRAME 1 6 Q01G6019 1 SCREW 4

13 Button 1 10 0D1G1030 6120 SCREW D3 6 4

15 REAR_COVER 1 11 0M1G1140 6120 SCREW M4 6 1

16 REAR LOGO 1 14 0Q1G 130 6120 SCREW (T3X6) 1

18 stand-base ass'y 1 17 0M1G3030 4 47 CR3 SCREW P3 4 2

5

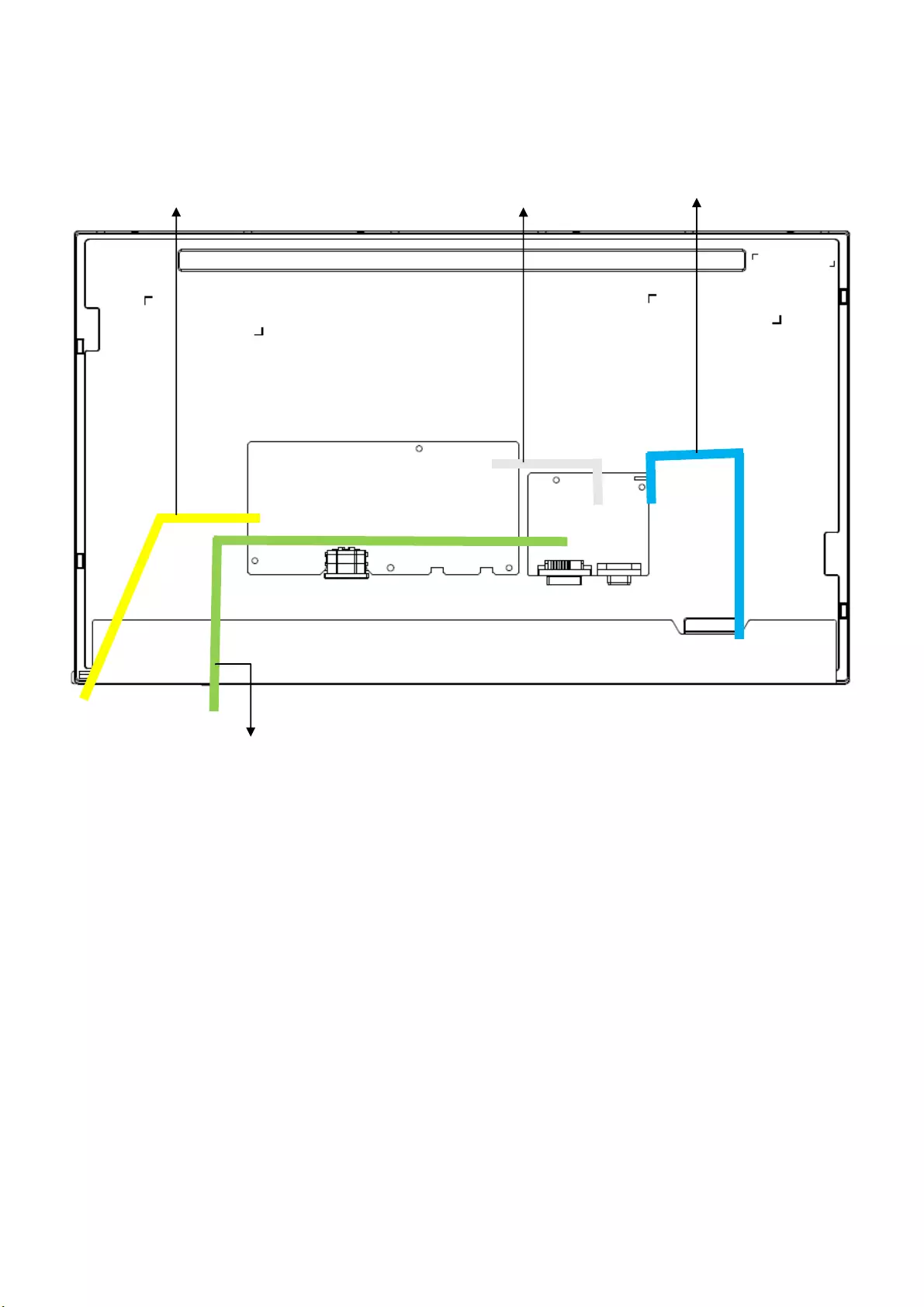

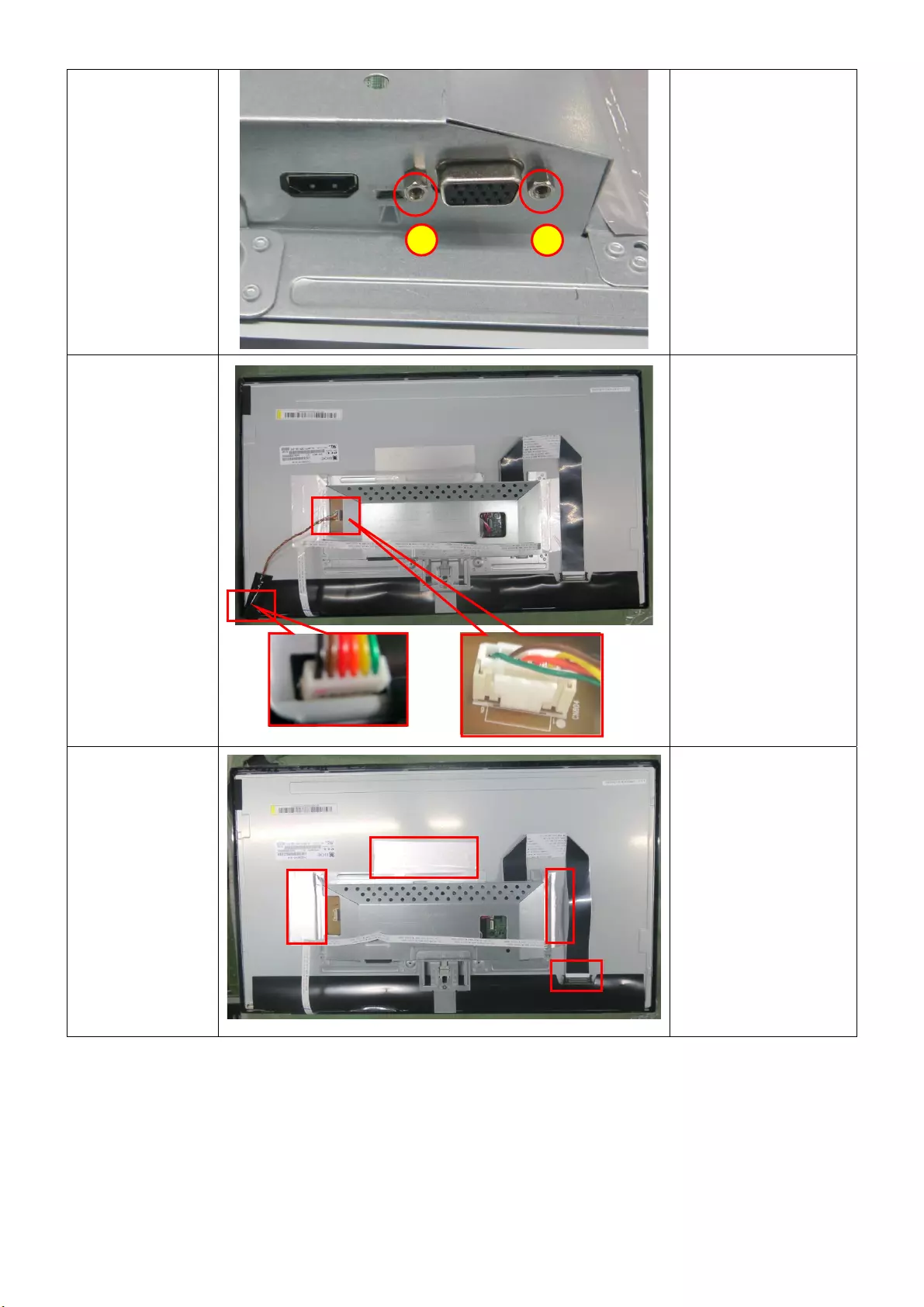

2. Wiring connectivity diagram

Connector Ass’y PN:

395G179W30BS60

Connector Ass’y PN:

395GH25V07DM0090HF

Connector Ass’y PN:

395G801406DF01

This Connector welding

in Key Board

6

3. Mechanical Instruction

Tools Required

Listthetypeandsizeofthetoolsthatwouldtypicallycanbeusedtodisassembletheproducttoapoint

wherecomponentsandmaterialsrequiringselectivetreatmentcanberemoved.

ToolDescription:

- Phillip head Screwdriver

- Hex Screwdriver

- Penknife

7

3.1Disassembly Procedures:

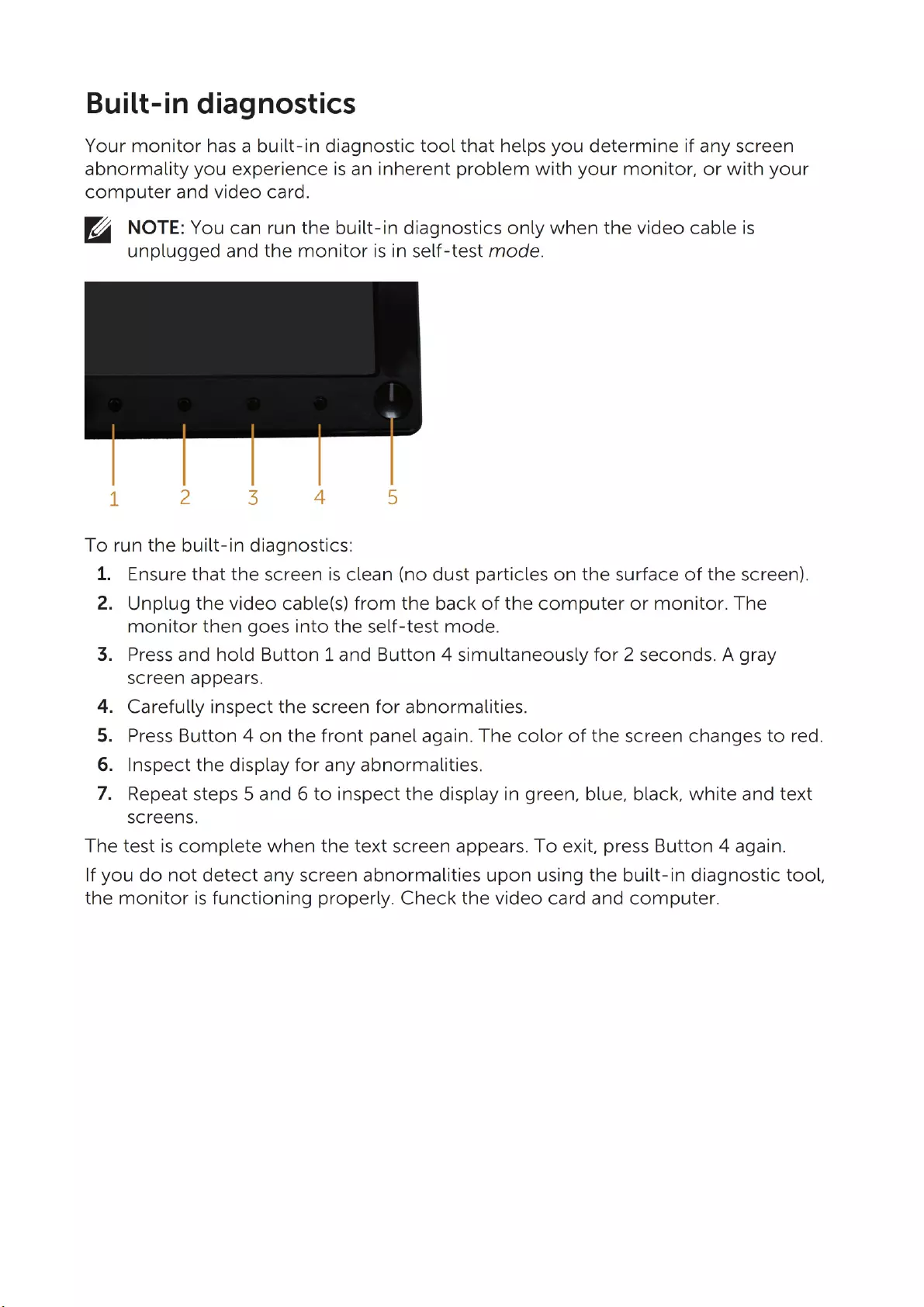

Step Figure Remark

S1.Before

disassemble

Turnoffpower,

Unplugexternalcables

fromproduct

S2.Remove the

STAND-BASE

ASS’Y

To remove the stand:

Press the button on the

red circle then pull out

the stand follow the

arrow, stand will be

remove.

Note:

To prevent scratches on

the LCD screen while

removing the stand,

ensure that the monitor is

placed on a soft, clean

surface.

8

S3.Remove the

REAR COVER

Use a Philips-head

screwdriver to remove 2

screws for unlocking

mechanisms.

(No.1~2 screw

size=M3x4;

Torque=4±1kgf.cm)

Use Penknife to

separate the bezel and

rear cove follow the

arrows in sequence, then

you can take out rear

cover.

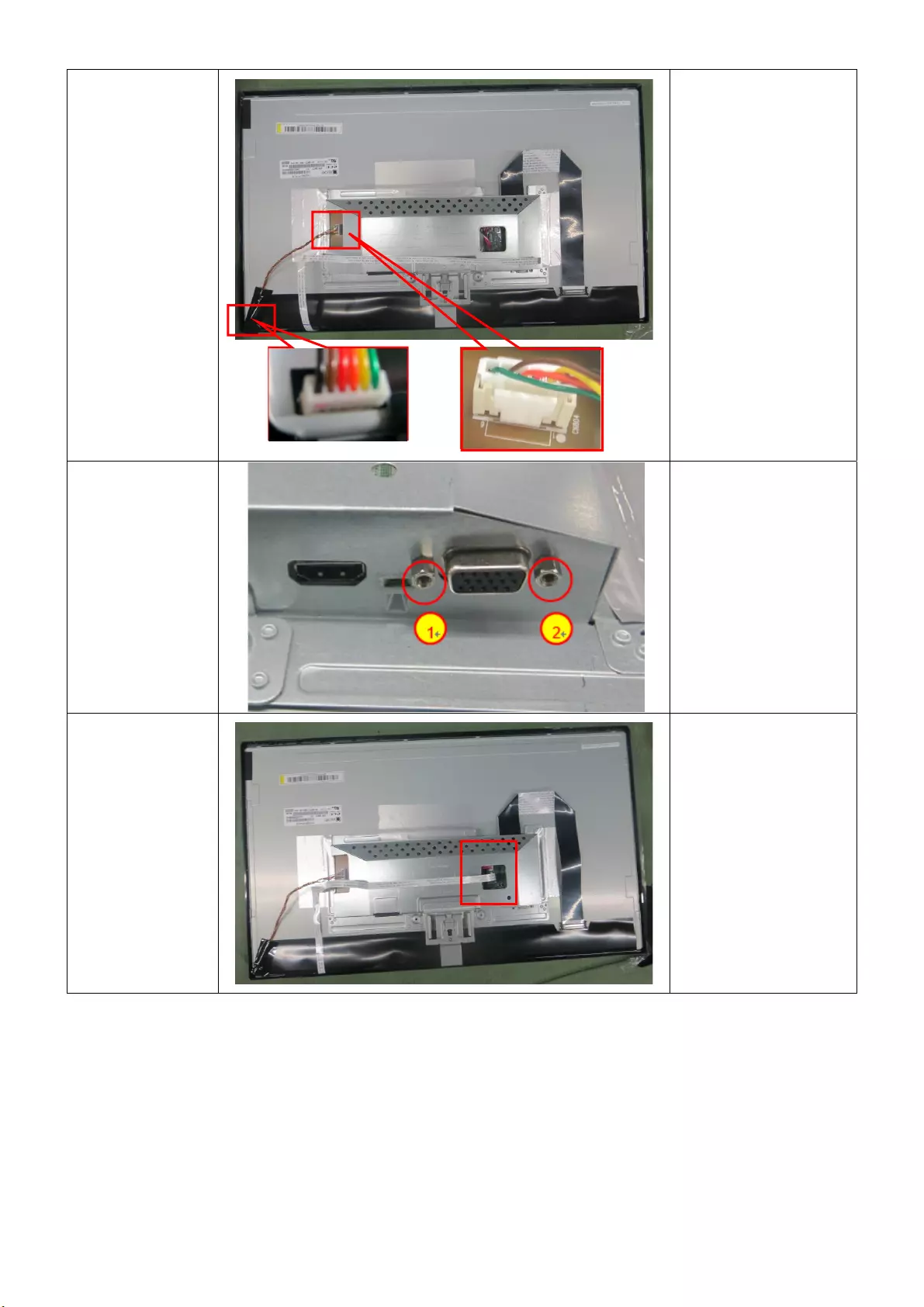

S4.Disconnect the

FFC cable

1 2

9

S5.Remove the

VGA

Use a hex screwdriver to

remove 2 screws for

unlocking mainboard.

(No.1~2 is Hex-screw,

Torque= 4.5±0.5kgf.cm)

S6.Remove the

FFC cable

S7.Remove the

PAPER TAPE

and panel FFC

cable

1 2

10

S8. Remove the

MAIN FRAME

Remove and turn over it.

11

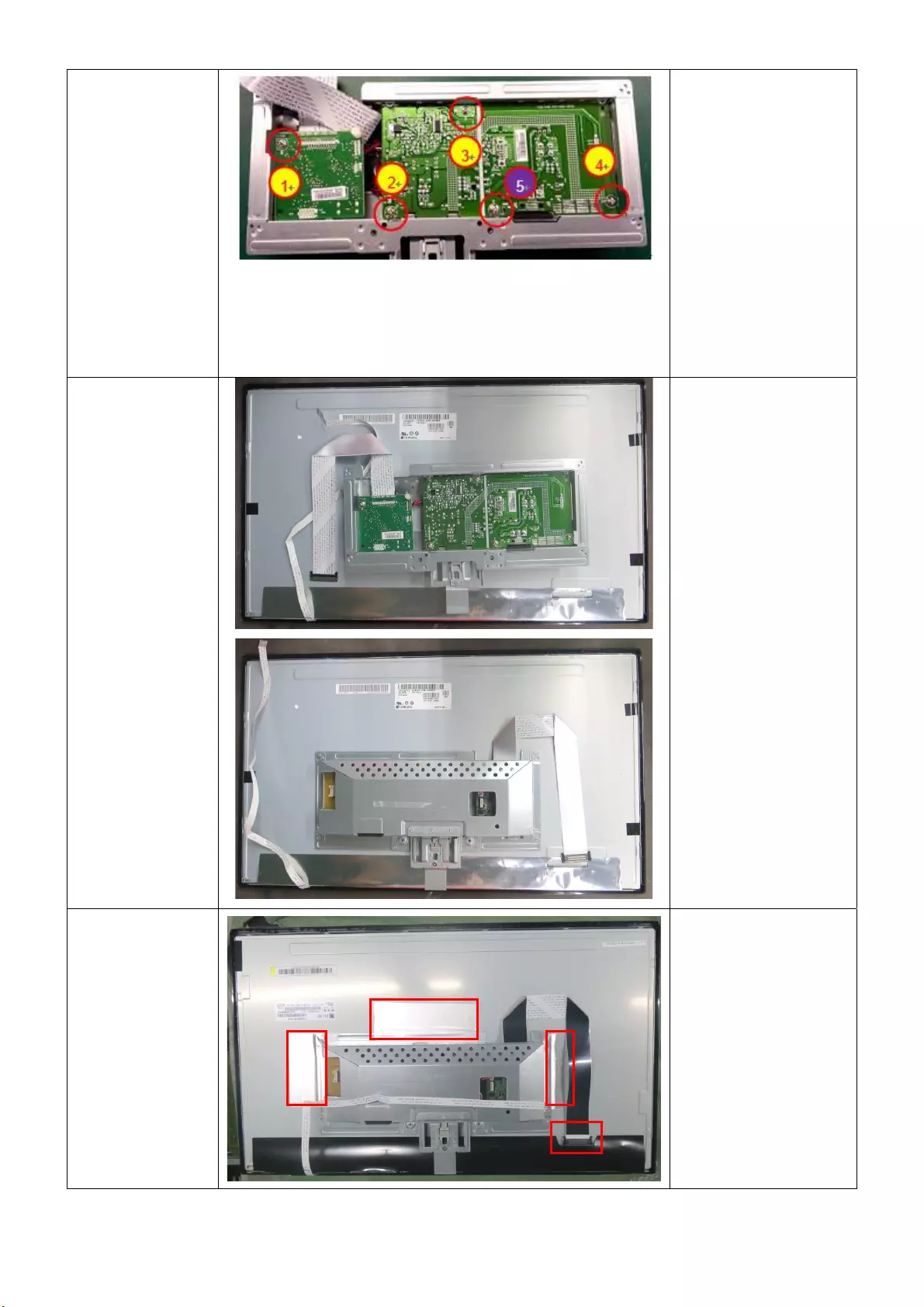

S9.Remove the

MAIN &POWER

BOARD

Use a Philips-head

screwdriver to remove 5

screws for unlocking

mainboard and power

board

(No.1~4 screw

size=M4x8;

Torque= 6±1kgf.cm;

No.5 screw size=D3x6;

Torque= 6±1kgf.cm)

disconnect the cables

S10.Remove the

KEY BOARD

Use a Philips-head

screwdriver to remove 4

screws for unlocking Key

board.

(No.1~4 screw

size= M2x2.5

Torque=0.9±0.4kgf.cm)

S11.The PANEL

1 2

3 4

5

1 2 3 4

12

S12.Remove the

screw

Use a Philips-head

screwdriver to remove

1screws for unlocking

main frame

(No.1 screw size= Q3x6

Torque=4±1kgf.cm)

S13. The MAIN

FRAME

S14.The BEZEL

1

13

3.2 Assembly Procedures:

Step Figure Remark

S1.Assembly the

main fraim

Use a Philips-head

screwdriver to tighten

1screws for locking main

frame

(No.1 screw size= Q3x6

Torque=4±1kgf.cm)

S2.Assembly the

KEY BOARD

Use a Philips-head

screwdriver to tighten 4

screws for locking Key

board.

(No.1~4 screw

size= M2x2.5

Torque=0.9±0.4kgf.cm)

S3.Assembly the

MAIN BOARD,

POWER BOARD

Connect the cables

14

Use a Philips-head

screwdriver to tighten 5

screws for locking

mainboard and power

board

(No.1~4 screw

size=M4x8;

Torque= 6±1kgf.cm;

No.5 screw size=D3x6;

Torque= 6±1kgf.cm)

S4. Assembly the

MAIN FRAME

Assembly the

MAIN FRAME

S5. Pasted the

TAPEs

and connect the

panel FFC cable

15

S6.Connect the

cables

S7.Tighten he

VGA port

Use a hex screwdriver to

tighten 2 screws for

locking mainboard.

(No.1~2 is Hex-screw,

Torque= 4.5±0.5kgf.cm)

S8.Connect the

FFC cable

16

S9.Assembly the

REAR COVER

Assembly the Rear

cover.

Use a Philips-head

screwdriver to tighten 2

screws for locking

mechanisms.

(No.1~2 screw

size=M3x4;

Torque=4±1kgf.cm)

S10.Assembly the

Stand

Insert the Stand

17

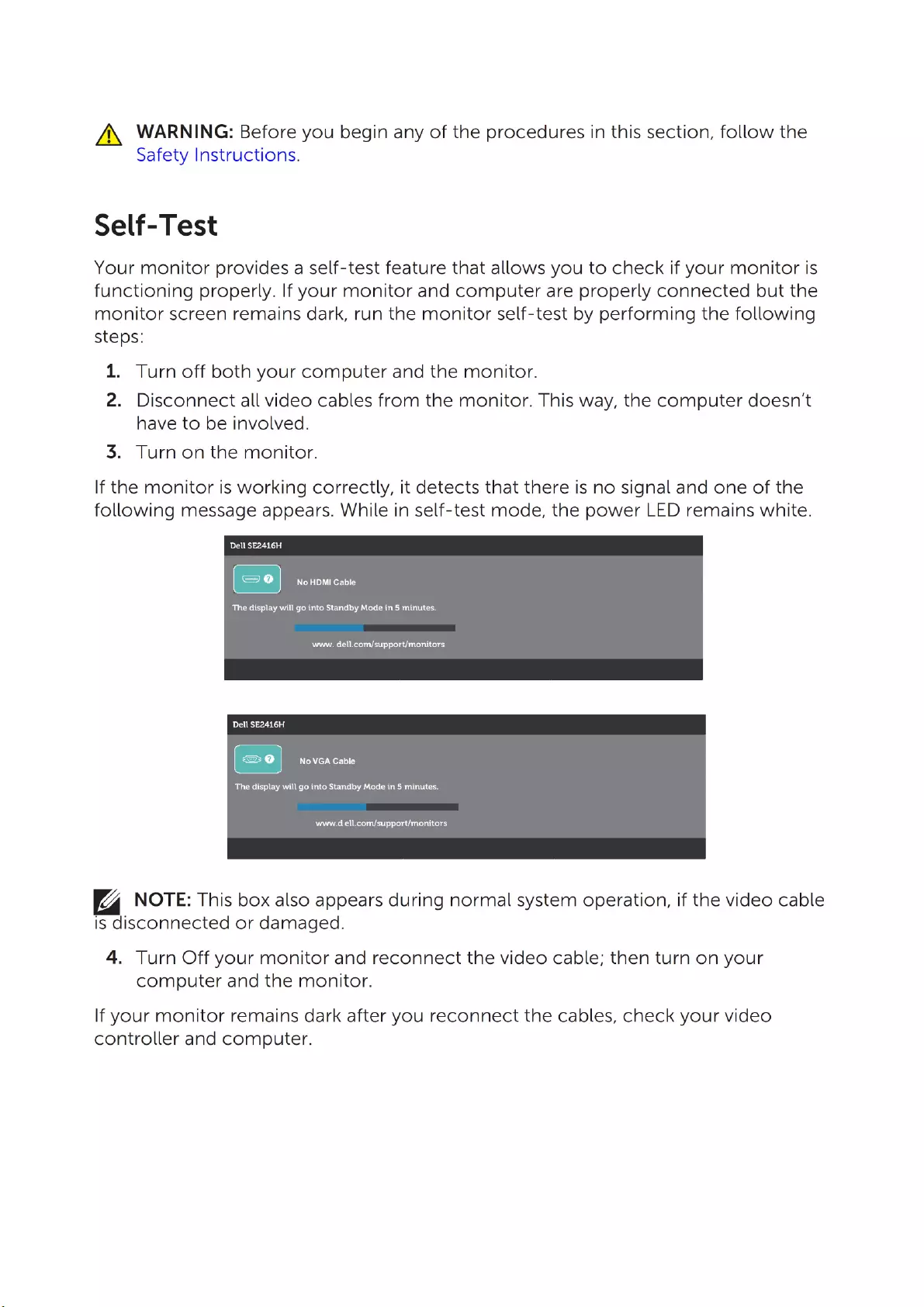

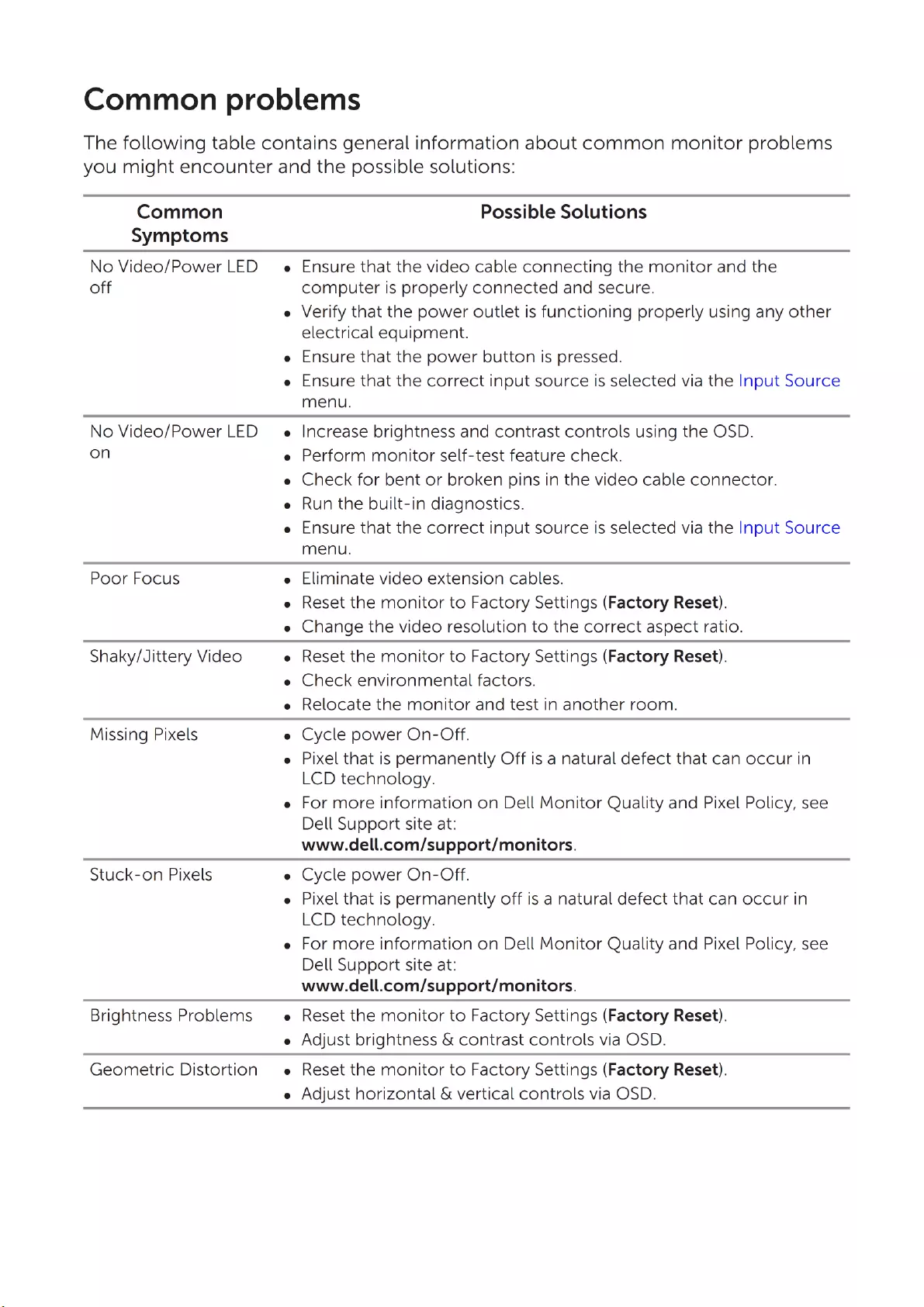

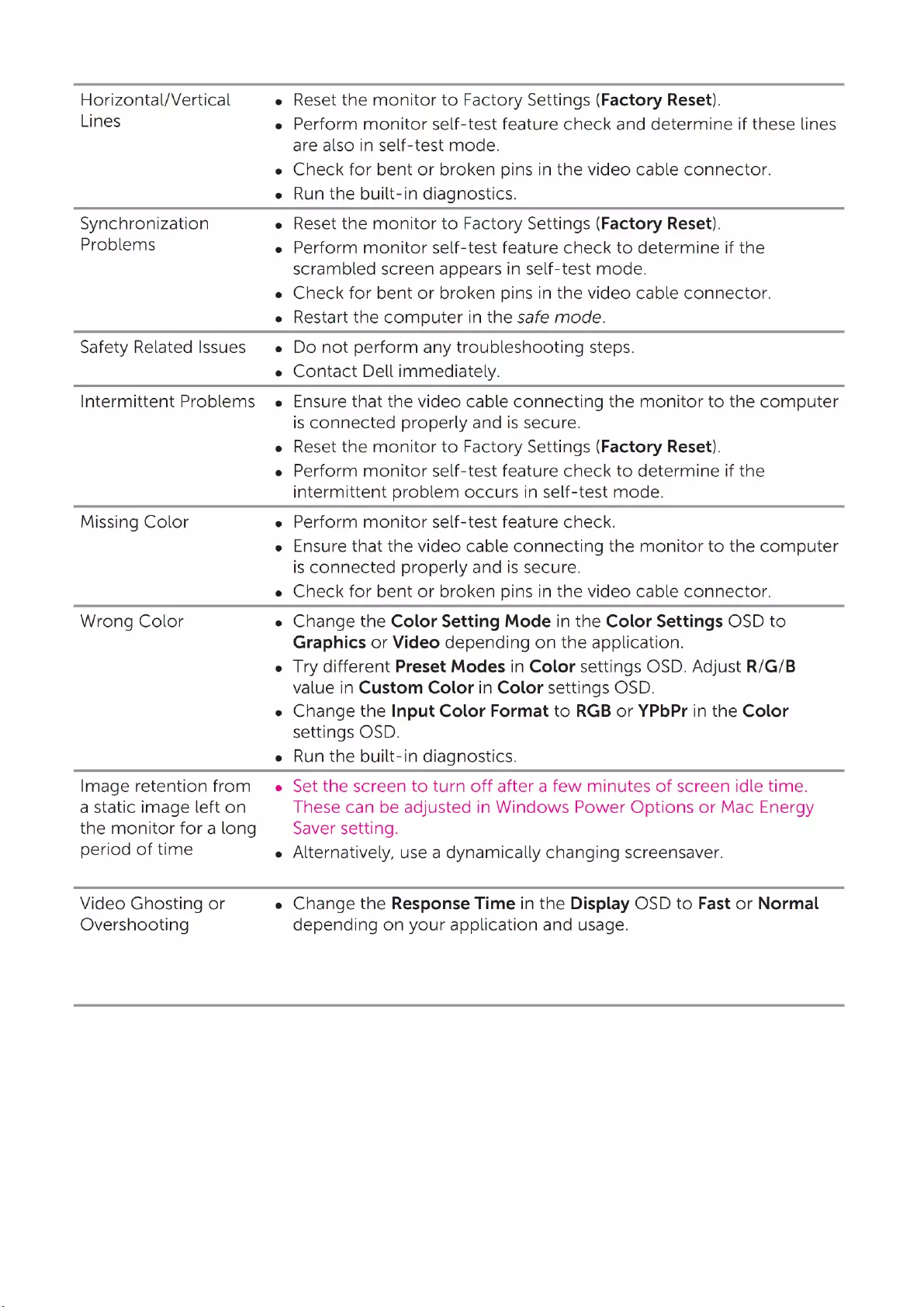

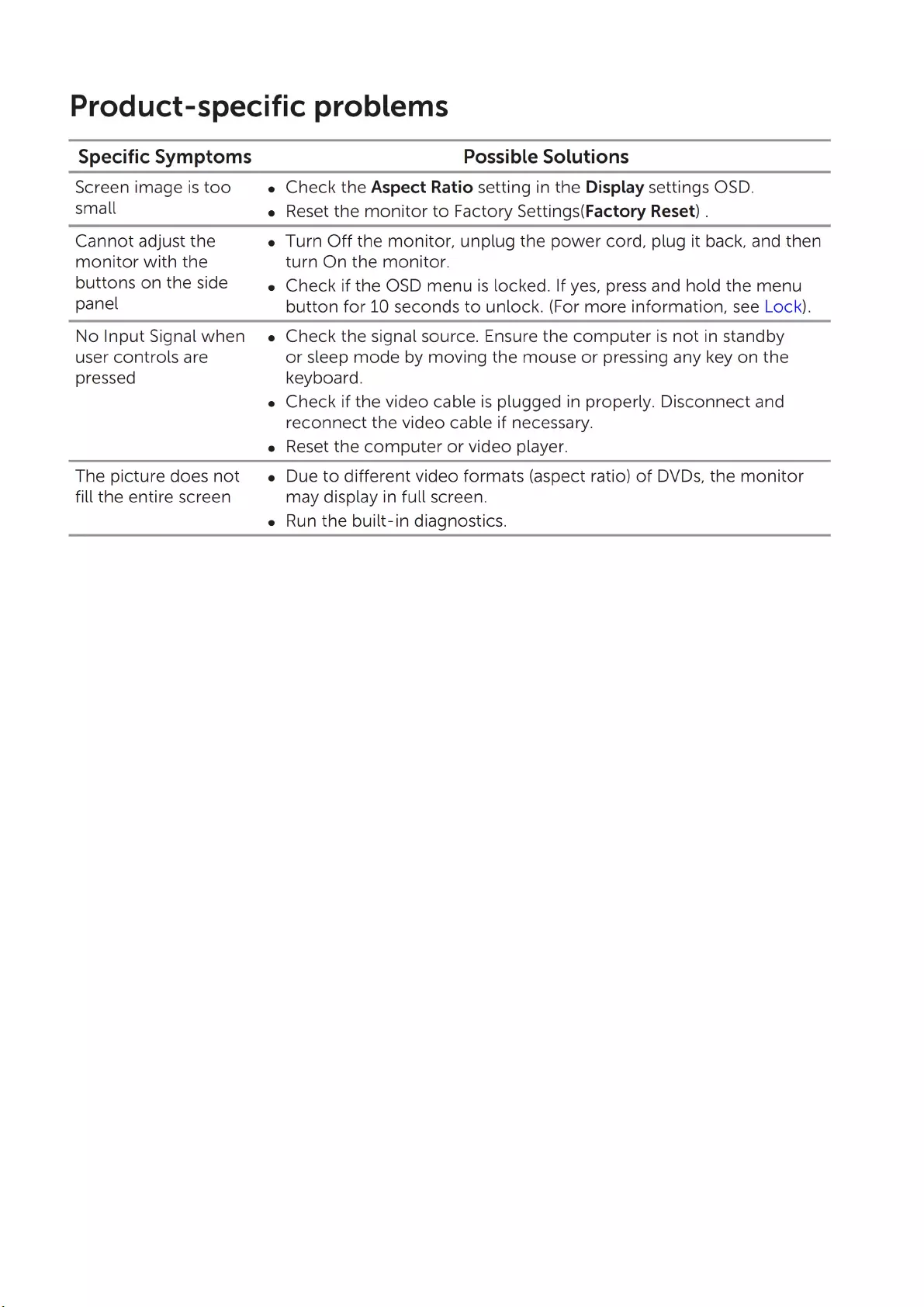

4. Trouble shooting instructions

18

19

20

21