Eaton RS User Manual

Displayed below is the user manual for RS by Eaton which is a product in the Rack Cabinets category. This manual has pages.

Related Manuals

RS Enclosure

RS Enclosure instruction manual

SECTION ISECTION I

2

SECTION I

EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

Table of Contents

SECTION I

About this Guide ........................... 2

Contact Information ......................... 2

Before You Begin ........................... 3

Safety Warnings and Precautions .............. 3

Enclosure Capacity ......................... 3

SECTION II

Unpacking, Off-Loading, Moving Enclosures ..... 4

Unlocking, Opening Doors, Grounding & Bonding

Instructions, Main Protective Grounding, ...... 5

Bonding of Doors and Panels, Auto Bonding ..... 6

Removing Doors & Side Panels ............... 6

Leveling, Anchoring, & Stabilizing .............. 7

SECTION III

Baying Adjacent Enclosures .................. 8

Equipment Rail Installation & Removal .......... 8

Cage Nuts ................................ 9

PDU Installation ............................ 9

Horizontal Panels .......................... 10

Reversing Doors .......................... 10

Handle Reversal ............................11

Cable Management ........................ 12

Disclaimer of Warranties and

Limitations of Liability ..................... 12

About this Guide

This document is intended to help provide direction on the

unpacking and moving, basic assembly, and an overview of

configure features on Eaton’s RS Enclosure System.

Intended Audience

This document is intended for personnel experienced at

installing rack and enclosure equipment in a data center

facility.

Technical Support

If you encounter any problems with this installation,

send an email and detailed description of the problem,

as well as contact information, to Technical Support at

www.Eaton.com/RS.

Document Conventions

This document uses the following conventions:

Document names and unfamiliar terms appear in italics, with

a definition as needed.

Acronyms are defined the first time they appear, with the

acronym in parentheses. For example: two rack units (2U).

Document History

The following table shows this document’s revision history:

June, 2016 First Publication – Pub No. IL159003EN

Sales Representative and Contact Information

Contact your Eaton Sales representative using one of the

methods below:

Phone Call us toll free at 800-225-7348 (US Only)

or 508-852-4300

Mail Eaton

160 Gold Star Boulevard

Worcester, MA 01606

Email InfoESWorcesterMA@Eaton.com

Web Visit us at www.eaton.com/wrightline and click on

“Contact Us.” Simply complete and submit the form

as directed on our website.

SECTION I

3EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

• Read and understand the instruction herein before

attempting to unpack, install, operate or service the RS

enclosure.

• Follow all information that is found on safety labels on the

product and packaging.

• Familiarize yourself with the various enclosure

components described within this manual.

• Familiarize yourself with the warning symbols that appear

throughout this manual.

• The use of personal protective equipment such as safety

glasses and work gloves is recommended during the

unpacking and set-up of the enclosure.

• Read, understand and follow the guidelines and

limitations herein for loading your enclosure.

NOTE

Notes point out something of special interest to the reader in

direct context or relationship to the immediate topic or step being

performed.

IMPORTANT

Important notes provide information of interest to the reader of a

more global or general context.

CAUTION

Cautions draw special attention to anything that may cause damage

to equipment.

WARNING

Warnings draw special attention to any situation that may cause

severe injury, physical harm, or death, to the reader and/or person

performing the task at hand.

Safety Warnings and Precautions

WARNING

Installation and assembly must be performed by qualified

personnel.

Ensure that the floor / wall structure is able to withstand the

weight of the enclosure while fully loaded.

Ensure the enclosure is plumb and level for proper operation.

Route all power cords and cabling away from any possible pinch

points or moving parts.

Always fully mount and secure enclosure or rack system before

loading equipment.

Evenly distribute all mounted loads and equipment to ensure

stability within the enclosure system, placing heavier loads towards

the bottom of the enclosure to avoid unstable conditions.

To reduce risk of personal injury and product damage, always

ensure a sufficient amount of personnel are present when loading,

unloading or moving the enclosure or rack system.

Suitable for mounting on concrete or other non-combustible surface

only.

Assembly and installation of certain accessories takes place on

top of an enclosure, at an approximate height of 8-11 feet. If step

ladders are used during installation, installers MUST maintain three

points of contact with the ladder at all times, DO NOT climb to a

point higher than six feet from the ground, unless tethered to a

safety harness, and NEVER stand on the top two steps of a step

ladder, regardless of the ladder’s overall height.

Failure to adhere to these warnings may result

in serious injury or property damage.

Enclosure Capacity

Static load capacity: 3,000 lb. for enclosures that remain

stationary (not relocated after loading).

Dynamic load capacity: 2,000 lb. for enclosures that are rolled

on attached casters, or otherwise relocated, after the application of

the load.

UL 2416, Safety for Audio/Video, Information

and Communication Technology Equipment

Enclosure, Enclosure and Rack Systems

UL60950-1 & CAN/CSA C22.2 No. 60950-01-03, Safety of

Information Technology Equipment, Including Electrical Business

Equipment.

Investigation of the enclosure system or rack equipment or

equipment enclosure, does not include investigation of any

equipment or material contained there in.

WARNING

Do not apply loads that exceed the capacity of the enclosure.

The stated capacities DO NOT include the weight of the

enclosure itself.

The applied load includes any items installed into the enclosure

after receipt of the enclosure from the carrier, including (but not

limited to) electronic equipment, power distribution units, and

cabling. The applied load also includes any item(s) mounted to the

outside of the enclosure or rested on the top of the enclosure,

where the enclosure bears the weight of the items.

It is recommended that you load your heaviest electronic

equipment at the bottom of the enclosure. This will ensure that

the load’s center of gravity (tipping point) is as low as possible.

Failure to follow this warning could result in the possibility of the

enclosure tipping, causing serious injury or property damage.

Before You Begin

Before installing Eaton’s RS Enclosure, it is recommended that you do the following:

SECTION ISECTION II

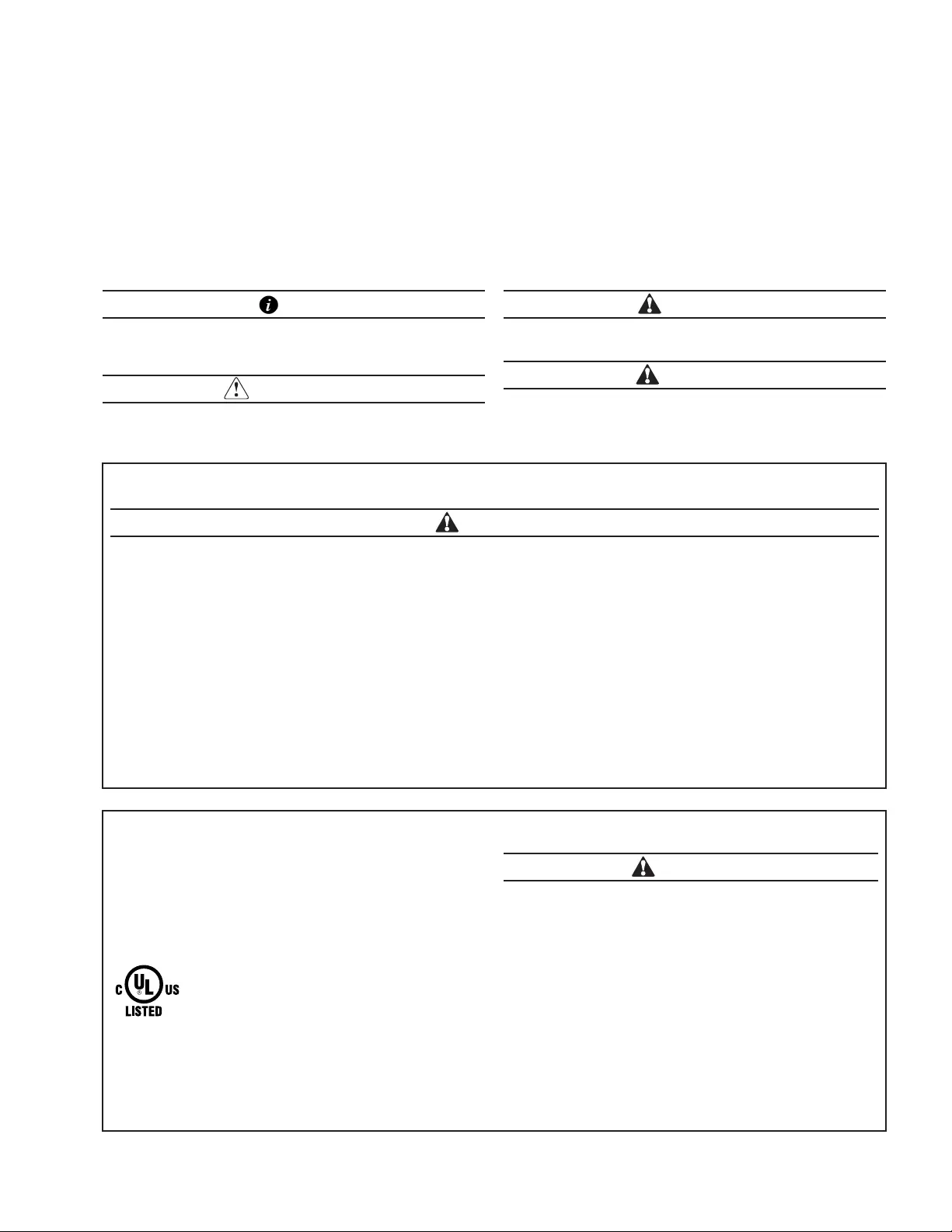

Inspect the enclosure

The packaged enclosure should be

inspected for shipping damage

prior to unpacking. If damage to

the packaging or enclosure is

visible, immediately contact your

Eaton representative and request

the carrier’s agent to be present

when the unit is unpackaged.

Optional Ramp shown

(RSRMPSTD)

Unpack the enclosure

1. Cut the plastic wrap along

the corrugated corner

protectors to avoid damaging

the enclosure.

2. Carefully remove and

properly discard the

packaging material. Remove

all shipping brackets that

anchor the enclosure to the

pallet.

Remove the enclosure from the pallet

Ramps (RSRMPSTD ordered separately) are available to

assist in removing the enclosure from the pallet.

1. Detach the ramp from its shipping position by lifting the

ramp upward.

2. Place the ramp into the open end of the pallet, with the

beveled edge resting on the floor.

Move the enclosure into position.

WARNING

The enclosure can easily be tipped. Use extreme caution

when moving the enclosure.

DO NOT PUSH ON

THE CENTER OF DOORS

OR SIDE PANELS.

DO NOT USE A

“WALKING” METHOD

(PUSHING SIDE TO

SIDE) TO MOVE THE

ENCLOSURE.

Enclosure main components

1

2

3

4

56

7

6

Initial enclosure set-up

For convenience at initial set-up, it may be desirable to

remove doors and side panels to help reduce the enclosure

weight and improve access to the interior of the enclosure.

4EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

Unpacking, off-loading from pallet, and moving enclosures

WARNING

Use two or more people to move the enclosure off the

pallet. Empty enclosures can weigh as much as 500

pounds, depending on size and configuration. Failure

to follow this warning could result in the possibility of

the enclosure tipping, causing serious injury or property

damage.

Tools required

• Utility knife

• Wrench size 7⁄16” (used to remove shipping anchors)

• Site approved moving devices for enclosures without

casters

NOTE

Enclosures with built-in casters may be rolled off of the pallet,

while enclosures without casters need to be slid off.

Use two people to roll and guide a enclosure that is

equipped with casters. Do not attempt to roll the enclosures

sideways. For enclosures that do not have casters installed,

use appropriate material handling and moving devices that

are approved by the installation site.

1 One frame

2 Two sets of tool-

less rack-mount

rails

3 Caster kit set/4

4 One full

front door

5 One rear

split door

6 Two locking split

side panels

7 One top panel

RSV4262 example shown

SECTION II

5EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

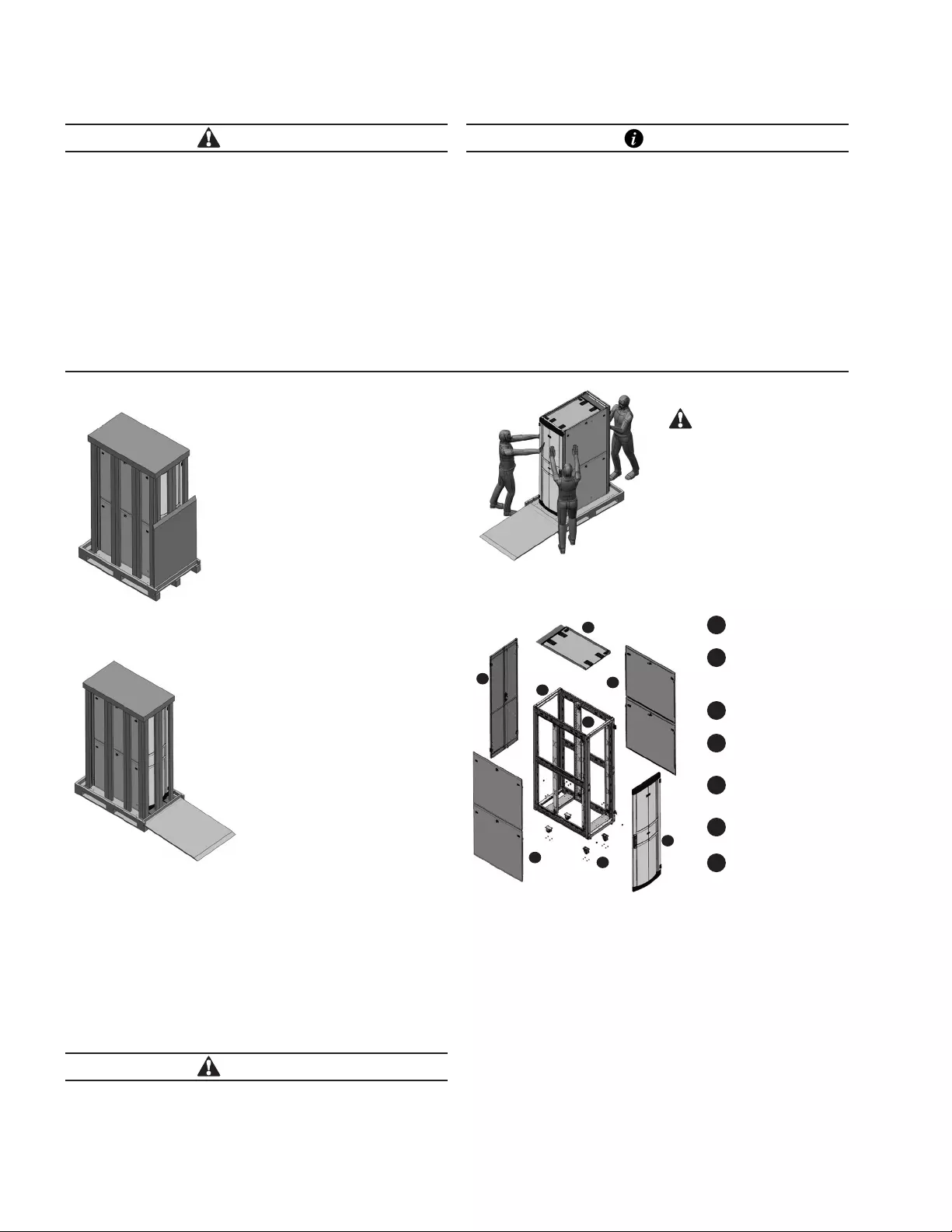

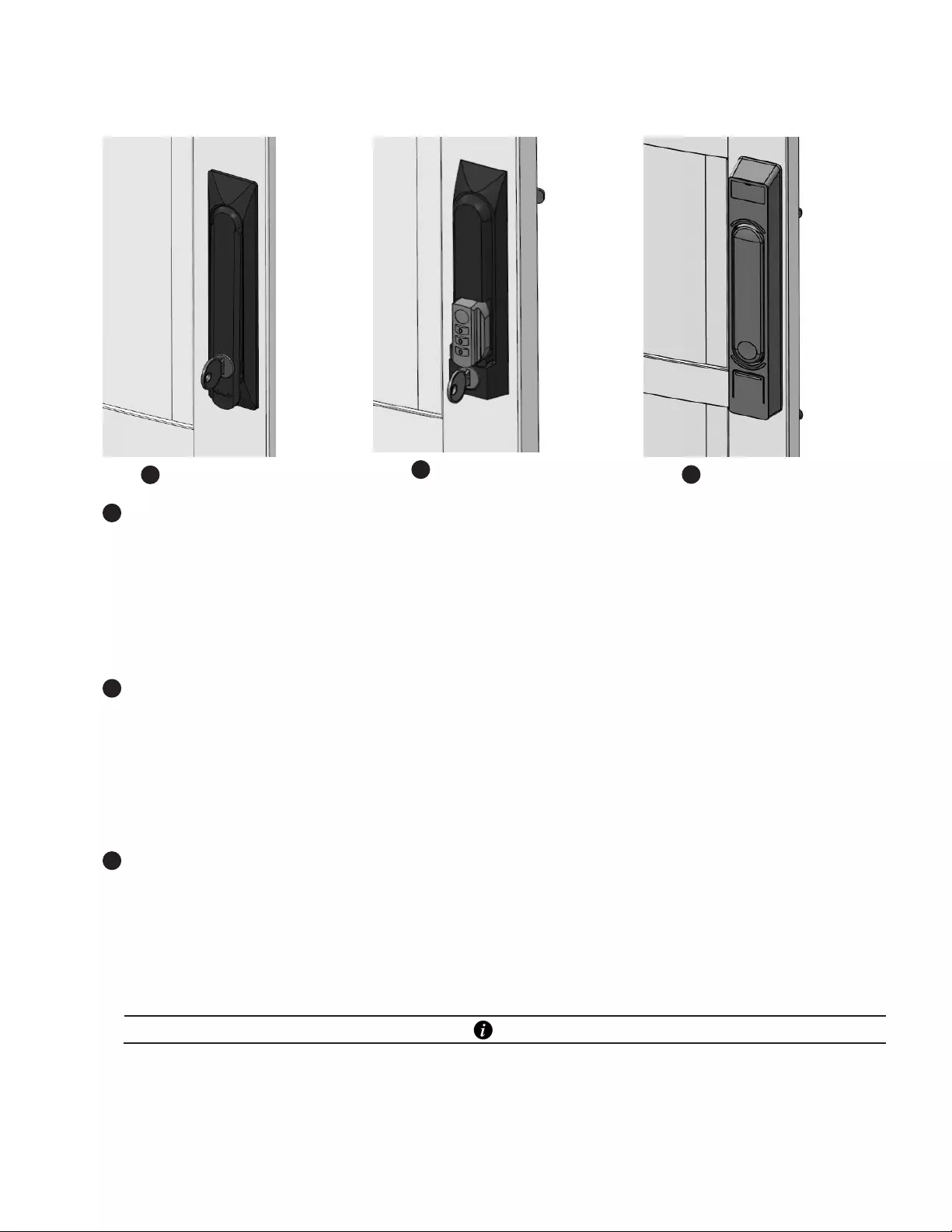

Unlocking and opening the doors

A typical enclosure will have a full width front door and a

split rear door. The doors are available with three styles of

locking handles.

A Key lock handle (standard)

To unlock a key lock handle, insert the key into the

handle and turn the key 180 degrees, counter-clockwise.

Flip the door handle up and then rotate the handle 90

degrees towards the center of the door to allow the

door to open.

B Combination lock handle (optional)

To unlock a combination lock handle, set the (3)

numbered thumb wheels to zero. Flip the door handle

up and then rotate the handle 90 degrees towards the

center of the door to allow the door to open.

C HFID lock handle (optional)

Refer to separate instructions provided with the

enclosure for initial usage and set up.

NOTE

See page 11 for more lock information.

Figure A Figure B Figure C

Key lock Combination HFID lock

handle lock handle handle

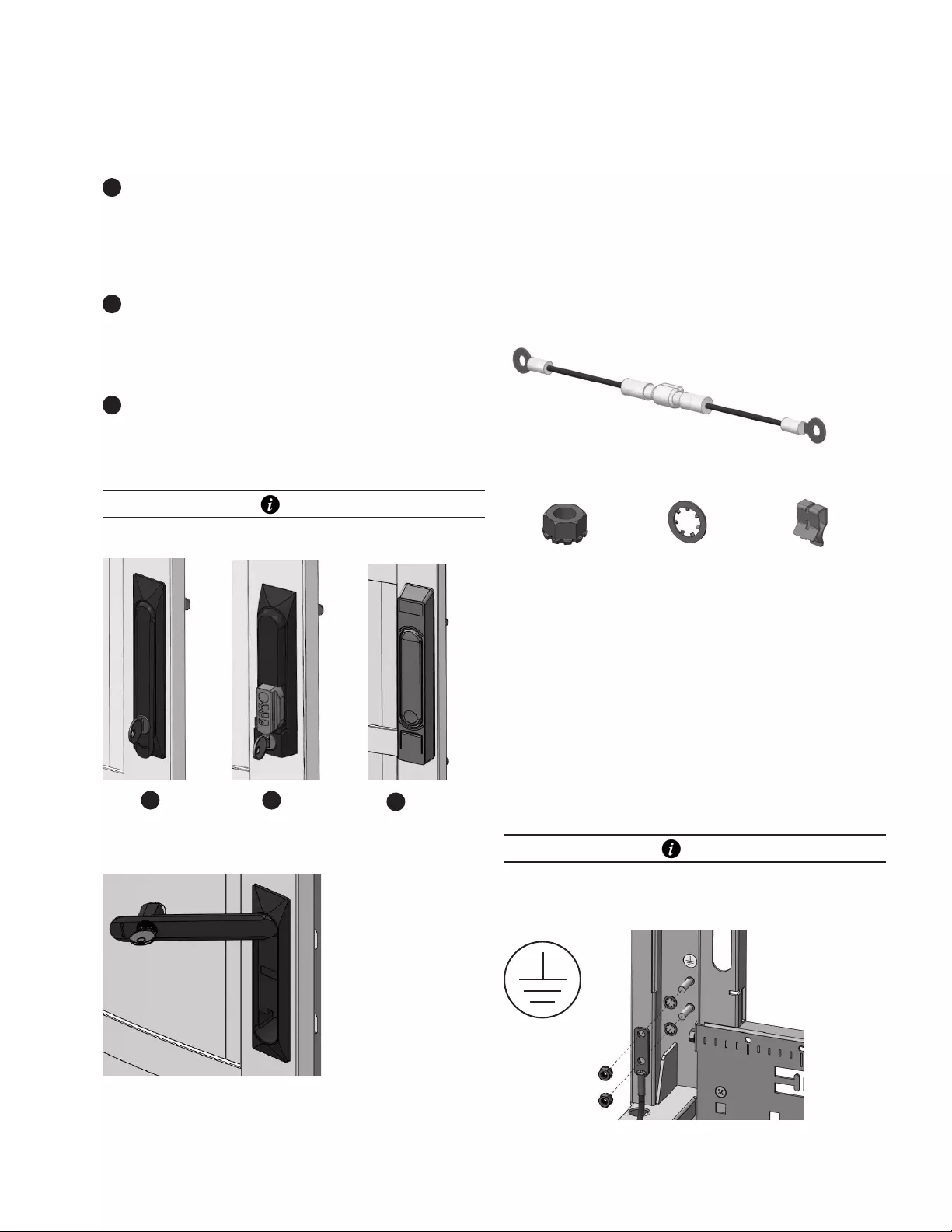

Grounding and bonding

instructions

Grounding hardware

Main ground hardware is NOT included. Use suitable

hardware to help ensure protective earth connections in

accordance with article 250 of the National Electrical Code.

Main ground hardware must include # 10 AWG wire and

hardware to connected to 6mm stud, star tooth washer and

nut.

Bonding cable and hardware

Typical hardware included with enclosure for bonding of

doors and panels.

Bonding Cable Quick Disconnect, 10 AWG,

.265 Dia. Ring Terminal, 12" [300mm]

Lock Nut

M6

Tooth Lock

Washer M6

Bonding Clip for

(14-12 gauge

wire)

Tool required

• 10mm hex wrench or socket.

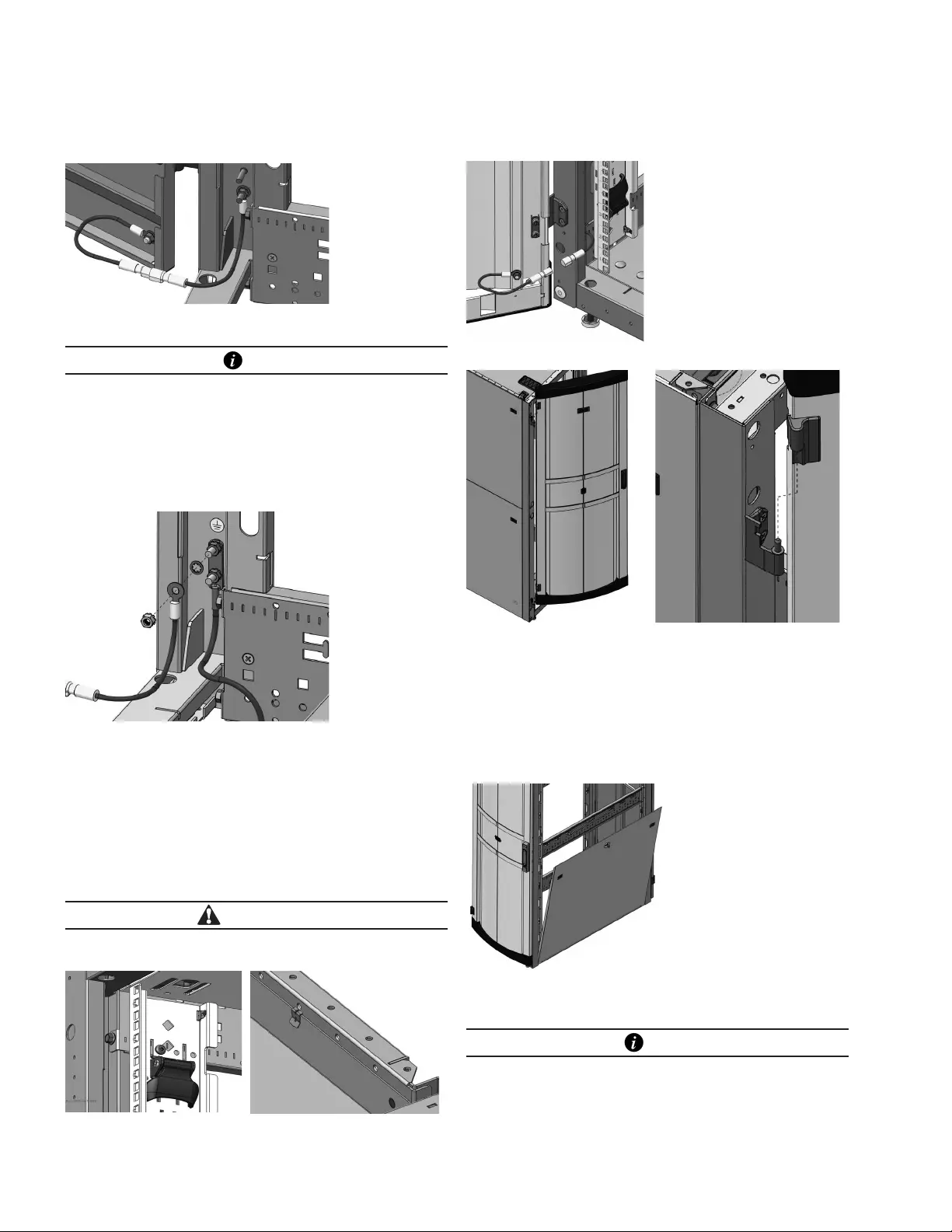

Main protective grounding

Each enclosure must be grounded directly to the building

common grounding system. Grounding is made in accordance

with the CAN/CSA-C22.2 No. 60950-1-03 First Edition, and UL

2416 standards for bonding and grounding guidelines.

The bonding connector shall be attached to any one of the

(4) Protective Earth Terminals (PET) connection points in the

enclosure. The bonding connector must be attached to the

enclosure’s ground point as shown in figure 1.

NOTE

Protective Earth Terminals (PET) are labelled with proper

symbol shown in figure 2 , and are the only terminals to

which the protective earth ground connections shall be

attached.

Figure 1 Main Earth Ground (PET)

Figure 2

SECTION ISECTION II

6EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

Bonding of doors and panels

Each enclosure comes with bonding hardware already

installed. Typical installation as shown in figure 3.

Figure 3 Bonding Cable (quick dis-connect)

NOTE

It may be necessary to remove bonding connection for doors

in order to connect main ground connections to enclosure.

When grounding the enclosure to the building common

grounding, it is essential that the main protective ground

is connected and secured first with its own nut before any

bonding connections are made on top as shown in figure 4.

Figure 4 Bonding Cable over PET

Auto bonding features

Side panels, rack rails and horizontal panels all have

integrated features that automatically create a bond

connection to the grounded enclosure frame when properly

attached to the enclosure.

WARNING

Do not remove or tamper with the auto-ground features.

Removing a door from the

enclosure

1. Open the door.

2. De-couple the ground

lanyard center connector.

3. With the door open about

45 degrees, carefully lift

the door off of the hinges.

Reverse the procedure to reinstall the door.

To reverse the swing direction of your full width front door,

see page 10.

Removing side panels

To remove a side panel:

1. Insert key into lock and

turn key 90 degrees

clockwise to unlock.

2. Slide two side panel

latches inward to

release panel.

3. Carefully tilt top of side

panel outward and

then lift to remove.

Reverse the procedure to re-install the panel.

NOTE

The top and bottom side panels are identical and may be

interchanged.

SECTION II

7EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

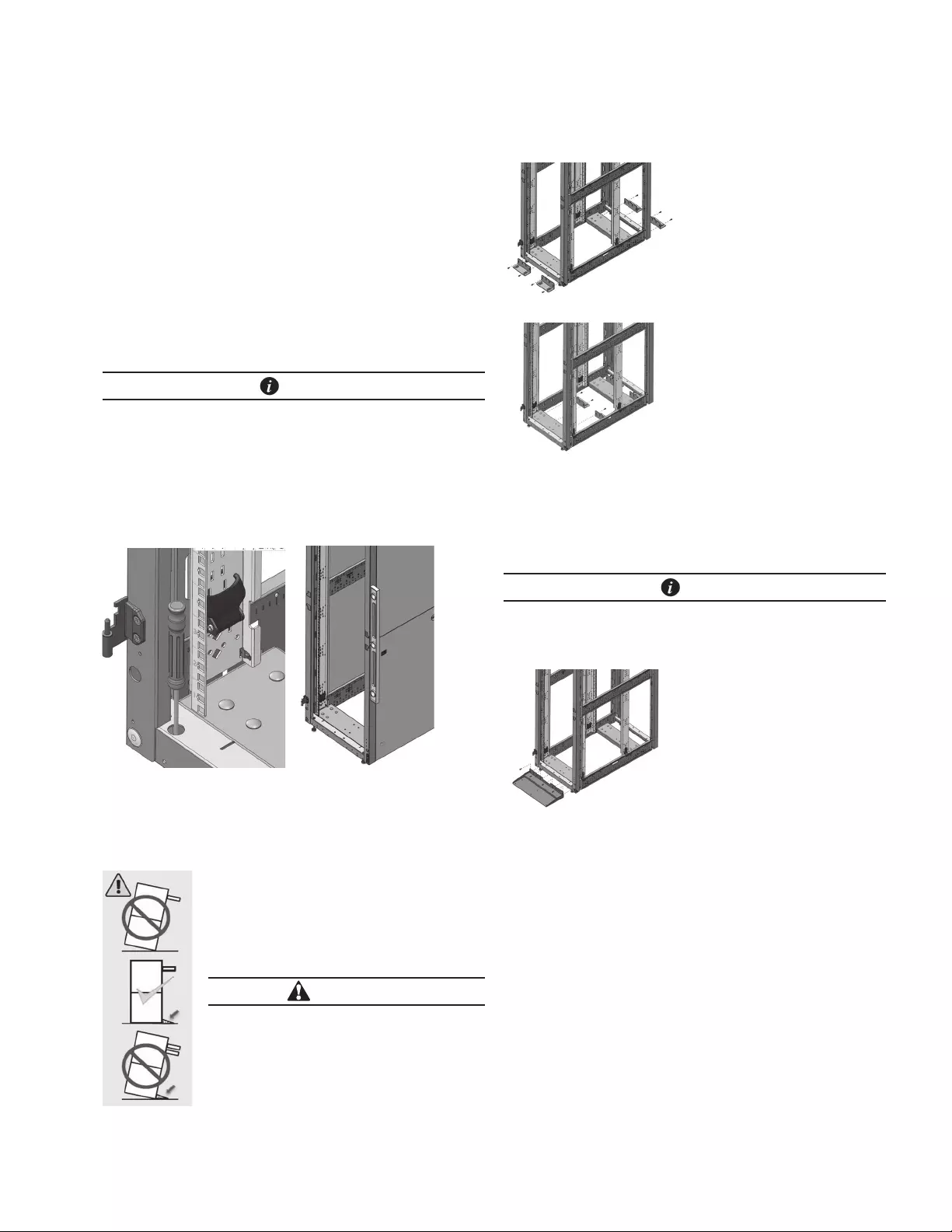

Leveling the enclosure

Tools Required

• Level

• 7mm hex nut driver

• Phillips head screw driver

Ensure that the enclosure is in the proper final position.

Four leveling feet are provided, one at each corner of the

enclosure. The levelers may be adjusted from the top,

using a 7mm nut driver. Access to the top of the levelers is

through the holes in the bottom frame members. Adjust the

levelers as required to level the enclosure both front-to-back

and side-to-side. Remove any shipping tape if required, prior

to adjustment.

NOTE

Isolation pads are included on the leveler feet to provide

protection for the data center floor. The pads are removable

as needed.

If the enclosure is to be bayed to an adjacent enclosure,

ensure that the tops of the enclosures are aligned in height.

See page 8 for baying enclosures.

Anchoring and stabilizing a

enclosure

Tools Required

• Phillips head screw driver or electric drill

with Phillips head bit

WARNING

Never extend more than one shelf or

piece of rollout equipment, even with

stabilizer bracket assembled to the

enclosure.

Failure to follow this warning could

result in the possibility of the enclosure

tipping, causing serious injury or

property damage.

Anchor brackets

Anchor brackets (RSANX) may be attached to the enclosure

in three ways:

1. Attach to enclosure lower

frame, with floor flange

oriented outward

2. Attach to enclosure lower

frame, with floor flange

oriented inward

Stabilizer brackets

Stabilizer brackets are attached to the outside of the

enclosure lower cross member. The extended depth of the

stabilizer brackets add stability to the enclosure.

NOTE

The enclosure will NOT meet anchorage requirements

unless it is also attached to the floor with appropriate anchor

brackets (see above).

3. Attach to the caster channel

inside enclosure

Anchor brackets must be attached to the site floor with

appropriate hardware in order to meet the appropriate

seismic design categories as described in the IBC

(International Building Code).

Please refer to Eaton Support for more information.

SECTION ISECTION III

8EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

Congurable enclosure features

The following covers the methods required to move, adjust

and operate user configurable features in the enclosure,

including equipment rails, PDU brackets, horizontal

panels and full width door swing reversal. For additional

accessories, see www.Eaton.com/RS.

Equipment rails

The position of the front equipment rail’s mounting flange

is factory pre-set at 50mm (~2”) from the face of the

enclosure frame. The front-to-back rail-to-rail spacing is

pre-set to 700mm (~27.5”).

Rail position adjustment

To reposition an equipment rail:

1. Flip open the (2) blue cam levers.

2. Slide the equipment rail forward or back to the desired

position.

3. Align face of rail with desired hash marks on enclosure

side members, (the spacing of hash marks is 10mm, or

approximately 3⁄8").

4. Ensure rail is aligned vertically, then flip cam levers to

locked position.

NOTE

Pre-configured networking enclosure rails are recessed

150mm (5.9") due to the space required for the vertical cable

manager fingers.

The face of the rail must be aligned with a hash mark to

ensure that the clamping mechanism’s ball detent will align

into a locking hole.

Removing an equipment rail

1. Flip open the (2) blue cam levers.

2. Tilt the top of the rail forward or back to unseat the rail’s

hanger brackets.

3. Lift and remove the rail from the enclosure side

members.

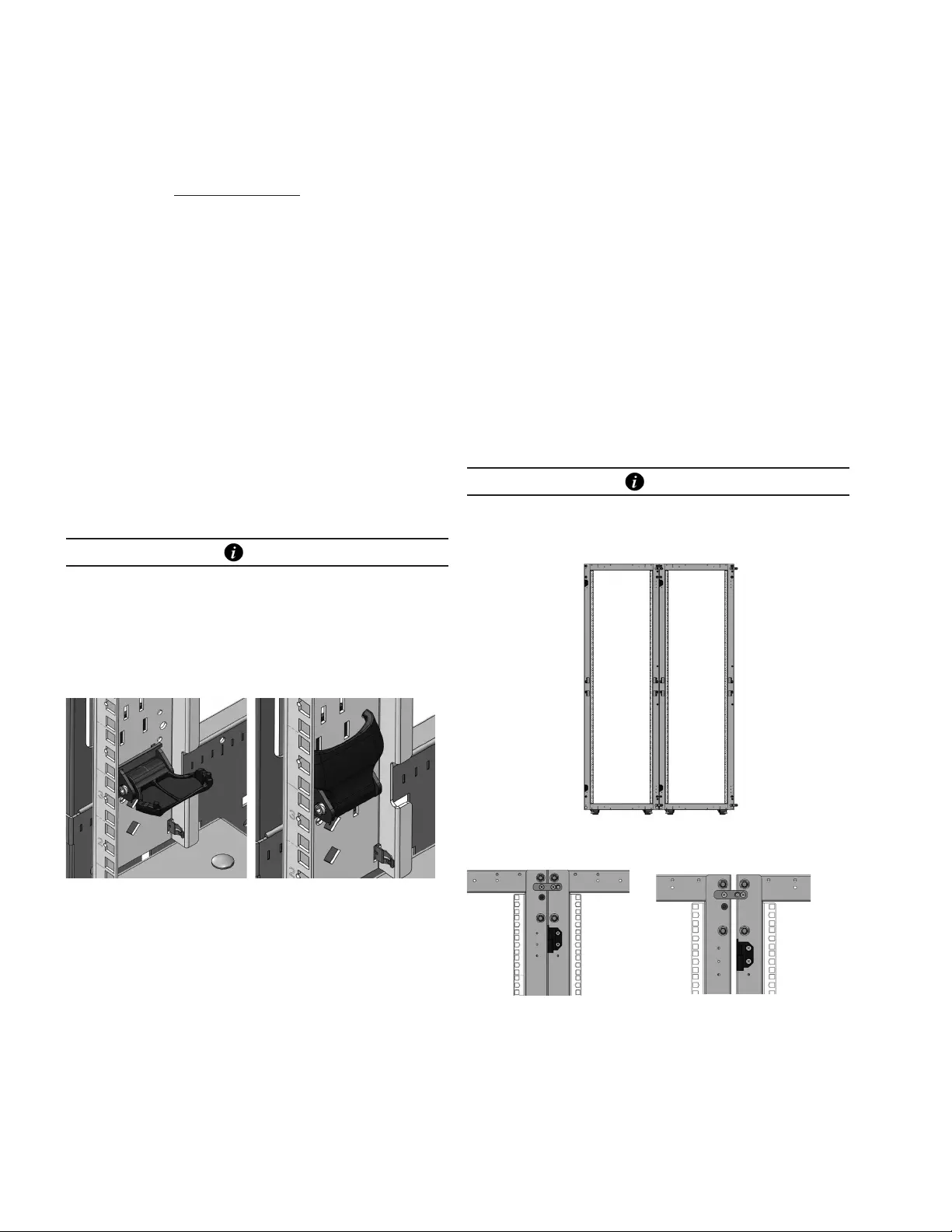

Baying adjacent enclosures

Tool Required

•Phillips head screw driver

Four baying brackets are provided with each enclosure.

Using the supplied hardware, attach two brackets to the

front, and two to the rear of the adjacent enclosures to join

them together.

Using the 24" baying position will result in a 3⁄8" (9.5mm) gap

between the enclosures. Use plastic filler strip included in

RSBAYKIT to fill gap. Trim as needed.

Anchoring brackets and stabilizing plates are available to

increase the stability of the enclosure. See page 7 for more

information.

There are two alternate attachment positions on the baying

brackets. The alternate positions may be used when baying

600mm wide enclosures together. One bracket position spaces

the enclosures on a 24" (609.5mm) module, allowing alignment

with 24" floor tiles. The second position will join the enclosures

directly on a 600mm (23 5/8") module (see figure 5).

NOTE

If side panels are desired on the enclosures, they must

be installed onto the enclosures prior to positioning the

enclosures next to one another.

Figure 5 Baying adjacent enclosures

600mm Module 24" Module

SECTION III

9EATON RS ENCLOSURE www.eaton.com

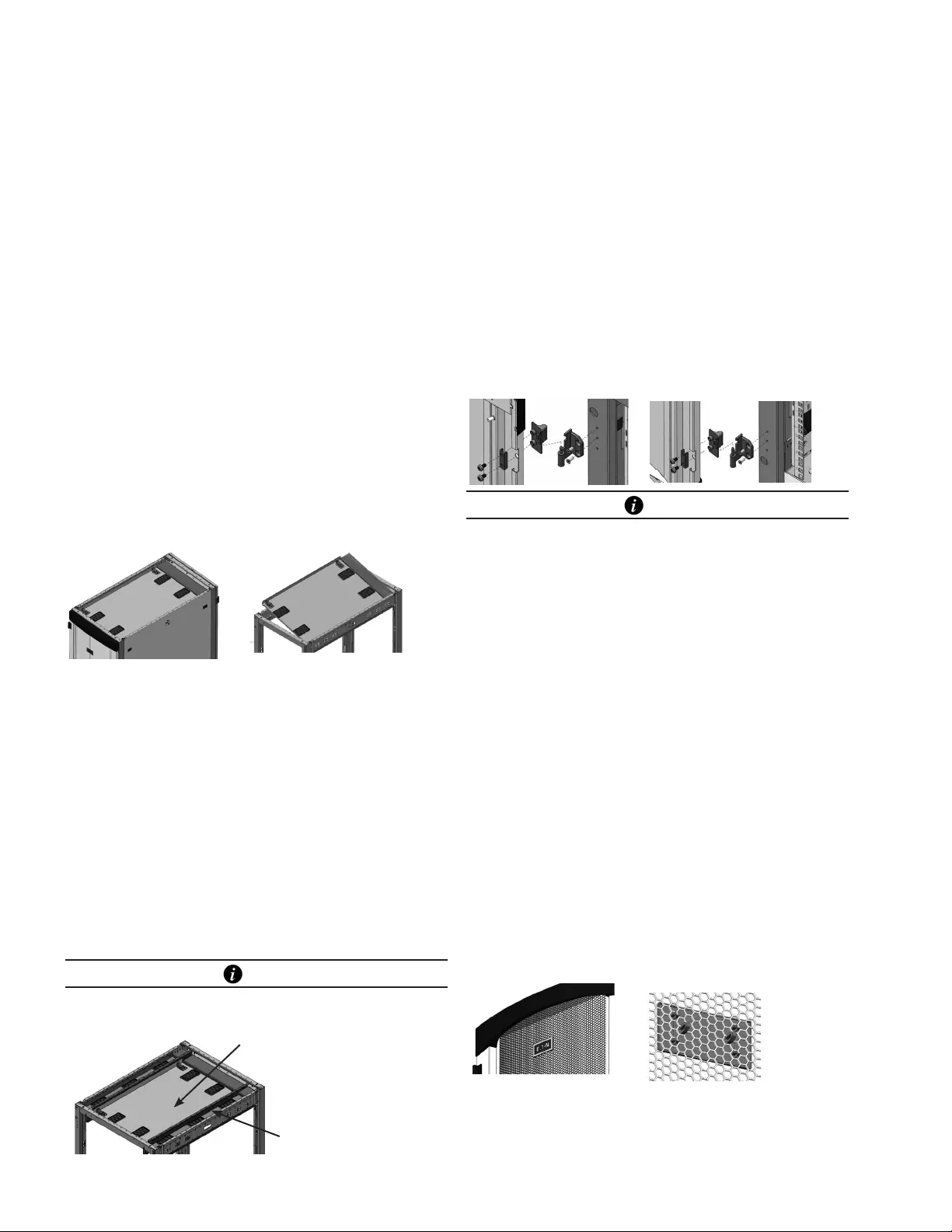

Installing cage nuts

Cage nuts must be installed horizontally into the equipment

rail square holes with the retention ears engaging the

vertical sides of the square holes.

The cage nuts must be installed into the rear face of the

equipment rail, opposite the equipment mounting face.

1. Angle the cage nut into the square hole, engaging one

of its retention ears.

2. Use a cage nut installation tool to grab the remaining

retention ear, pulling the cage nut fully into the square

hole (see figure 6).

Figure 6

NOTE

A clip nut that is installed vertically will not engage properly

and is in danger of falling out of the square hole.

For tool-less cage nuts, Eaton offers kits of rack studs for

ease of equipment installation.

PDU cable management brackets

PDU Standard

RSPDUMTG

PDU Extended

RSPDULMTGX

PDU 90º

RSPDU9MTGX

The PDU brackets are multi-purpose brackets that can be

used to:

1. Mount power distribution units.

2. Act as lacing brackets to retain cable bundles when

used with Velcro™ Straps (see page 12).

3. Mount Eaton’s B-Line series Flextray™ vertical cable

managers. Visit www.Eaton.com/RS, for more

information.

PDU brackets can be installed at several predetermined

locations on enclosure corner posts. Predefined positions

are vertically spaced at 7U (12.25"). This spacing enables

brackets to be aligned to typical spacing found on most

tool-less mounted power distribution units. The factory

pre-set spacing is 35U (61.25").

How to remove and install a PDU

bracket

To remove a PDU bracket:

1. Depress the blue

retention tab.

2. Pull bracket away from

enclosure corner post.

To install a PDU bracket:

1. Engage bracket ears into

slots of enclosure corner

post.

2. Push on bracket to engage blue retention tab.

3. Ensure blue retention tab is flush and fully engaged to

secure bracket.

Attaching a PDU

Ensure that the vertical PDU bracket spacing matches the

requirements of your tool-less mounted PDU.

1. Engage the PDU

mounting buttons

into the teardrop

holes in the

bracket

2. Lower the buttons

into the narrow

end of the

teardrop holes.

PDU retainer

A tool-less retainer (RSPDURTNKITB) is available to lock

Eaton’s ePDUs into the installed position.

1. Engage the small

tab on the retainer

into the slot in

the PDU bracket,

adjacent to the

ePDU bracket.

2. Press the

retractable plastic

buttons into the

two holes in the

ePDU.

SECTION ISECTION III

10 EATON RS ENCLOSURE INSTRUCTION MANUAL www.eaton.com

Horizontal panel modularity

Our preconfigured enclosures all come equipped with single

piece, full depth panels installed in the top of the enclosure.

The family of horizontal panels may be used interchangeably

as enclosure top or bottom panels.

The front-to-back depths of the enclosure top and bottom

openings are evenly divisible by 100mm. Modular horizontal

panels are available in depths that are multiples of 100mm.

This allows many panel styles and sizes to be mixed and

matched to the function and requirements of the enclosure.

These modular panel options are available in Configure-To-

Order Enclosures or as accessory items.

Horizontal panel “flip-over” feature

When used as top panels, the horizontal panels may be

installed with the “smooth side” up or down. Installing

the panel with the “smooth side” down is useful to help

minimize cold air bypass over the top of the electronic

equipment zone. This “smooth side down” mode of

installation is also useful to create a front-to-back cable chase

over the top exterior of the enclosure (see page 12, Cable

management).

How to remove and install a horizontal panel

Horizontal panels are retained by two fixed pins on one side

and two blue pin latches on the other side.

To remove a top panel:

1. Pull blue latches toward center of panel.

2. Angle panel upwards to disengage fixed pins.

Reverse the procedure to install the top panel.

How to remove and install a horizontal panel –

800mm wide enclosures

Horizontal panels for 800mm wide enclosure consist of

additional side panels that fill the roughly 100mm gap on

either side of the enclosure.

To remove these panels:

1. Remove plastic retaining pins along inside of inner

front-to-back channel.

2. Angle panel upwards to disengage fixed pins.

NOTE

Remove inner panel(s) as noted previously.

Reverse procedure to reinstall panels or flip inner panel(s).

Middle panel

Side panel(s)

Reversing swing direction of a

full width door

Hinge kits are available to change the swing of a door. Kit

includes hinges, mounting hardware and Eaton badge.

Available hinge kits:

•

Left Hand Swing Kit #RSHINGEKITL

•

Right Hand Swing Kit # RSHINGEKITR

Contact your Eaton sales representative for more information

on accessories and options.

Tools required

• Phillips head screw driver

• 10mm hex wrench (required for combination and HFID

style swing handles only)

NOTE

For doors having HFID locks, you must also detach HFID

connector wire from control box.

1. Open door and then disconnect ground lanyard’s center

connector.

2. With door open to 45 degrees, carefully lift door off

hinges.

3. Disconnect enclosure portion of ground lanyard from

enclosure and re-attach to opposite side of enclosure.

4. Remove snap-on Eaton logo plate and relocate to

opposite end of door. Refer to “Door Reversal Hinge Kit”

installation manual sheet for proper location.

5. Remove and discard existing hinge components from

enclosure frame and door.

6. install new hinge components from the reversal kit onto

enclosure and door.

7. Reverse swing handle orientation (see page 11 for

detailed handle reversal instructions).

8. Carefully lift and hang door onto new hinges.

9. Reconnect ground lanyard’s center connector.

10.

For HFID doors, reroute HFID connector wire to control box.

Remove existing logo badge

Pinch center barbs to remove. A replacement badge is

provided in the event existing gets damaged during removal.

1. Locate badge on opposite end of newly oriented door.

2. Center on door and align with top of hinge.

3. Push plastic barbs through hex perf until fully engaged.

SECTION III

11EATON RS ENCLOSURE www.eaton.com

Figure A Figure B Figure C

A Key lock handle (standard)

1. Ensure swing handle is LOCKED.

2. Unscrew and remove lock pawl and rotation control washer from swing handle.

3. Compress two retention tabs on back of swing handle; then rotate handle out of door.

4. Rotate handle 180 degrees and then reinstall it into door.

5. Reattach lock pawl and rotation control washer onto swing handle.

6. Unlock and rotate swing handle to ensure that assembly rotates properly.

B Combination lock handle (optional)

1. Ensure combination swing handle is LOCKED.

2. Unscrew and remove lock pawl from swing handle.

3. Remove swing handle from door by unscrewing two retention plates.

4. Rotate swing handle 180 degrees; reinstall it into door with two retention plates.

5. Reattach lock pawl onto swing handle.

6. Unlock and rotate swing handle to ensure assembly rotates properly.

C HFID lock handle (optional)

1. Ensure HFID swing handle is LOCKED.

2. Unthread HFID connector wire, taking note of appropriate wire path through door structure. The wire will be

threaded through door’s opposite end following the same path.

3. Unscrew and remove lock pawl from swing handle.

4. Remove swing handle from door by unscrewing retention plate and HFID connector wire cover.

5. Rotate swing handle 180 degrees; reinstall it into door with retention plate and HFID connector wire cover.

NOTE

Take care to ensure that HFID connector wire is properly seated under connector wire cover.

1. Reattach lock pawl onto swing handle.

2. Unlock and rotate swing handle to ensure assembly rotates properly.

3. Reroute the HFID connector wire through the door’s structure.

Handle reversal instructions

SECTION ISECTION III

Cable management

The RS Enclosure has many protected openings to allow convenient ingress and egress of cabling. There are also many

standard features inside of the enclosure that enable retention and routing of bundled cables both vertically and horizontally

within the enclosure.

Bottom ingress/egress

The standard position of

the rear caster channel

provides a 100mm (~4")

opening between the

channel and the

enclosures rear bottom

member. This allows for

direct passage of cables

without the need to

bend cables around the

enclosure structure.

Top ingress/egress

Standard configurations

come with single panels

that have 100mm (~4")

cable opening with

integrated brush strip.

This opening is located

to the rear of the

enclosure and allows

direct access to internal

vertical cable managers

without the need to

bend cables around the

enclosure structure.

Cable opening brushes

The 800mm wide

enclosures also have

removable top covers

along each side of the

enclosure. These covers

have integrated cable

grommets and brushed

openings for cable

passage. The covers can also be completely removed

to allow total access to the “zero U” space on each

side of the EIA equipment zone. To remove the cover,

pull outward on the tool-less plastic retention pins.

The 100mm brush strips are available to help minimize

air loss through top panel cable openings. Use one brush

for 100mm openings. The brush strips simply clip onto

the lateral edges of the modular top panels.

Cable grommets

Some top and side panels

are equipped with soft

durometer perforated cable

grommets. The grommets

may be torn on the

perforations, as required, to

help minimize air bypass.

RS Velcro™ strap installation

RS Enclosures have

numerous cutouts

throughout that support

attachment of Velcro straps,

offering convenient built in

cable management.

Velcro kits are available in

two styles, standard and

buckle straps, and range in

length from 8"-12" Standard

kit contains 50 straps and

buckle kit contains 10 straps.

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

© 2016 Eaton

All Rights Reserved

Printed in USA

Publication No. IL159003EN

June 2016

Eaton is a registered trademark.

All trademarks are property

of their respective owners.

Follow us on social media to get the

latest product and support information.

Follow us on social media to get the

latest product and support information.

Disclaimer of warranties

and limitation of liability

The information, recommendations, descriptions and safety notations in this

document are based on Eaton Corporation’s (“Eaton”) experience and judgment and

may not cover all contingencies. If further information is required, an Eaton sales

office should be consulted. Sale of the product shown in this literature is subject

to the terms and conditions outlined in appropriate Eaton selling policies or other

contractual agreement between Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY EXISTING

CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE

OBLIGATION OF EATON. THE CONTENTS OF THIS DOCUMENT SHALL NOT BECOME

PART OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort

(including negligence), strict liability or otherwise for any special, indirect, incidental

or consequential damage or loss whatsoever, including but not limited to damage

or loss of use of equipment, plant or power system, cost of capital, loss of power,

additional expenses in the use of existing power facilities, or claims against the

purchaser or user by its customers resulting from the use of the information,

recommendations and descriptions contained herein. The information contained in

this manual is subject to change without notice.