Table of Contents

- Contents

- 1 Introduction

- 2 Functional overview

- 3 Installation steps, overview

- 4 Important information

- 5 Hardware installation

- 6 Starting up and operation

- 6.1 Access to the drives

- 6.2 Opening the HDD cover

- 6.3 Controls and indicators

- 6.4 ID card

- 6.5 Switching the server on and off

- 6.6 Configuring the server

- 6.6.1 Configuring the onboard SATA controller

- 6.6.2 Configuring the SAS/SATA RAID controller

- 6.6.3 Configuring the server and installing the operating system with the ServerView Installation Manager

- 6.6.4 Configuring the server and installing the operating system without the ServerView Installation Manager

- 6.7 Cleaning the server

- 7 Property and data protection

- 8 Troubleshooting and tips

- 8.1 Power-on indicator remains unlit

- 8.2 Server switches itself off

- 8.3 Screen remains blank

- 8.4 Flickering stripes on monitor screen

- 8.5 No screen display or display drifts

- 8.6 No mouse pointer displayed on screen

- 8.7 Incorrect date and time

- 8.8 Drives reported as “dead” when starting system

- 8.9 Added drive reported as defective

- 8.10 Error message on screen

Fujitsu TX1320 M3 User Manual

Displayed below is the user manual for TX1320 M3 by Fujitsu which is a product in the Servers category. This manual has pages.

Related Manuals

Operating Manual - English

FUJITSU Server PRIMERGY TX1320 M3

Operating Manual

March 2017

Copyright and Trademarks

Comments…Suggestions…Corrections…

The User Documentation Department would like to

know your opinion of this manual. Your feedback helps

us optimize our documentation to suit your individual

needs.

Feel free to send us your comments by e-mail to

manuals@ts.fujitsu.com.

Certified documentation

according to DIN EN ISO 9001:2008

To ensure a consistently high quality standard and

user-friendliness, this documentation was created to

meet the regulations of a quality management system

which complies with the requirements of the standard

DIN EN ISO 9001:2008.

cognitas. Gesellschaft für Technik-Dokumentation mbH

www.cognitas.de

Copyright 2017 FUJITSU LIMITED

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

– The contents of this manual may be revised without prior notice.

– Fujitsu assumes no liability for damages to third party copyrights or other rights arising from

the use of any information in this manual.

– No part of this manual may be reproduced in any form without the prior written permission

of Fujitsu.

Microsoft, Windows, Windows Server, and Hyper V are trademarks or registered trademarks of

Microsoft Corporation in the USA and other countries.

Intel and Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries

in the USA and other countries.

TX1320 M3 Operating Manual 3

Before reading this manual

For your safety

This manual contains important information for safely and correctly using this

product.

Carefully read the manual before using this product. Pay particular attention to

the accompanying manual "Safety Notes and Regulations" and ensure these

safety notes are understood before using the product. Keep this manual and the

manual "Safety Notes and Regulations" in a safe place for easy reference while

using this product.

Radio interference

This product is a "Class A" ITE (Information Technology Equipment). In a

domestic environment this product may cause radio interference, in which case

the user may be required to take appropriate measures. VCCI-A

Aluminum electrolytic capacitors

The aluminum electrolytic capacitors used in the product's printed circuit board

assemblies and in the mouse and keyboard are limited-life components. Use of

these components beyond their operating life may result in electrolyte leakage

or depletion, potentially causing emission of foul odor or smoke.

As a guideline, in a normal office environment (25°C) operating life is not

expected to be reached within the maintenance support period (5 years).

However, operating life may be reached more quickly if, for example, the

product is used in a hot environment. The customer shall bear the cost of

replacing replaceable components which have exceeded their operating life.

Note that these are only guidelines, and do not constitute a guarantee of

trouble-free operation during the maintenance support period.

High safety use

This product has been designed and manufactured to be used in commercial

and/or industrial areas as a server.

When used as visual display workplace, it must not be placed in the direct field

of view to avoid incommoding reflections (applies only to TX server systems).

The device has not been designed or manufactured for uses which demand an

extremely high level of safety and carry a direct and serious risk of life or body

if such safety cannot be assured.

4 Operating Manual TX1320 M3

These uses include control of nuclear reactions in nuclear power plants,

automatic airplane flight control, air traffic control, traffic control in mass

transport systems, medical devices for life support, and missile guidance

control in weapons systems (hereafter, "high safety use"). Customers should

not use this product for high safety use unless measures are in place for

ensuring the level of safety demanded of such use. Please consult the sales

staff of Fujitsu if intending to use this product for high safety use.

Measures against momentary voltage drop

This product may be affected by a momentary voltage drop in the power supply

caused by lightning. To prevent a momentary voltage drop, use of an AC

uninterruptible power supply is recommended.

(This notice follows the guidelines of Voltage Dip Immunity of Personal

Computer issued by JEITA, the Japan Electronics and Information Technology

Industries Association.)

Technology controlled by the Foreign Exchange and Foreign Trade

Control Law of Japan

Documents produced by Fujitsu may contain technology controlled by the

Foreign Exchange and Foreign Trade Control Law of Japan. Documents which

contain such technology should not be exported from Japan or transferred to

non-residents of Japan without first obtaining authorization in accordance with

the above law.

Harmonic Current Standards

This product conforms to harmonic current standard JIS C 61000-3-2.

Only for Japan: About SATA hard disk drives (HDDs)

The SATA version of this server supports HDDs with SATA / BC-SATA storage

interfaces. Please note that the usage and operation conditions differ

depending on the type of HDD used.

Please refer to the following internet address for further information on the

usage and operation conditions of each available type of HDD:

http://jp.fujitsu.com/platform/server/primergy/harddisk/

Only for Japan:

Shielded LAN cables should be used in this product.

TX1320 M3 Operating Manual

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Concept and target groups for this manual . . . . . . . . . . 9

1.2 Documentation overview . . . . . . . . . . . . . . . . . . . 10

1.3 Notational conventions . . . . . . . . . . . . . . . . . . . . 11

2 Functional overview . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Server specification . . . . . . . . . . . . . . . . . . . . . . 23

3 Installation steps, overview . . . . . . . . . . . . . . . . . . 31

4 Important information . . . . . . . . . . . . . . . . . . . . . 33

4.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 ENERGY STAR . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.3 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4 FCC Class A Compliance Statement . . . . . . . . . . . . . 43

4.5 Environmental protection . . . . . . . . . . . . . . . . . . . 44

5 Hardware installation . . . . . . . . . . . . . . . . . . . . . . 47

5.1 Unpacking the server . . . . . . . . . . . . . . . . . . . . . 48

5.2 Setting up the server . . . . . . . . . . . . . . . . . . . . . . 49

5.2.1 Positioning the server vertically . . . . . . . . . . . . . . . . . 50

5.2.2 Positioning the server horizontally . . . . . . . . . . . . . . . . 53

5.3 Connecting devices to the server . . . . . . . . . . . . . . . 54

5.4 Connecting the server to the mains . . . . . . . . . . . . . . 56

5.4.1 Using cable ties (standard PSU) . . . . . . . . . . . . . . . . . 57

5.4.2 Using the cable clamps (hot-plug PSU) . . . . . . . . . . . . . 58

Operating Manual TX1320 M3

Contents

5.5 Notes on connecting/disconnecting cables . . . . . . . . . . 59

6 Starting up and operation . . . . . . . . . . . . . . . . . . . . 61

6.1 Access to the drives . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Opening the HDD cover . . . . . . . . . . . . . . . . . . . . . 63

6.3 Controls and indicators . . . . . . . . . . . . . . . . . . . . . 64

6.3.1 Server front . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3.1.1 Controls on the front panel . . . . . . . . . . . . . . . . . . 64

6.3.1.2 Indicators on the front panel . . . . . . . . . . . . . . . . . . 65

6.3.1.3 Indicators on the drives . . . . . . . . . . . . . . . . . . . . 68

6.3.2 Server rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.2.1 Indicators on the I/O panel . . . . . . . . . . . . . . . . . . 70

6.3.2.2 Indicator on hot-plug PSUs . . . . . . . . . . . . . . . . . . 74

6.3.2.3 Indicator on Fujitsu battery units (FJBU) . . . . . . . . . . . 75

6.4 ID card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.5 Switching the server on and off . . . . . . . . . . . . . . . . 77

6.6 Configuring the server . . . . . . . . . . . . . . . . . . . . . 80

6.6.1 Configuring the onboard SATA controller . . . . . . . . . . . . . 80

6.6.2 Configuring the SAS/SATA RAID controller . . . . . . . . . . . . 81

6.6.3 Configuring the server and installing the operating system

with the ServerView Installation Manager . . . . . . . . . . . . . 82

6.6.4 Configuring the server and installing the operating system

without the ServerView Installation Manager . . . . . . . . . . . 83

6.7 Cleaning the server . . . . . . . . . . . . . . . . . . . . . . . 84

7 Property and data protection . . . . . . . . . . . . . . . . . . 85

7.1 Mechanical access protection . . . . . . . . . . . . . . . . . 85

7.2 BIOS Setup security functions . . . . . . . . . . . . . . . . . 85

8 Troubleshooting and tips . . . . . . . . . . . . . . . . . . . . 87

8.1 Power-on indicator remains unlit . . . . . . . . . . . . . . . . 87

8.2 Server switches itself off . . . . . . . . . . . . . . . . . . . . 88

8.3 Screen remains blank . . . . . . . . . . . . . . . . . . . . . . 88

TX1320 M3 Operating Manual

Contents

8.4 Flickering stripes on monitor screen . . . . . . . . . . . . . 89

8.5 No screen display or display drifts . . . . . . . . . . . . . . 89

8.6 No mouse pointer displayed on screen . . . . . . . . . . . . 89

8.7 Incorrect date and time . . . . . . . . . . . . . . . . . . . . 90

8.8 Drives reported as “dead” when starting system . . . . . . 90

8.9 Added drive reported as defective . . . . . . . . . . . . . . 90

8.10 Error message on screen . . . . . . . . . . . . . . . . . . . 91

Operating Manual TX1320 M3

Contents

TX1320 M3 Operating Manual 9

1 Introduction

The PRIMERGY TX1320 M3 server is an Intel-based server for small and

medium-sized networks and can be used in the horizontal position or as a

desktop model.

The PRIMERGY TX1320 M3 server features exceptionally low energy

consumption, very quiet running and a compact size. As a result, it is also the

ideal solution for small offices.

Thanks to its highly developed hardware and software components, the

PRIMERGY TX1320 M3 server offers a high level of data security and

availability. This includes hot-plug HDD modules (2.5-inch variant), the

ServerView Operations Manager for server management, Prefailure Detection

and Analysing (PDA), and Automatic Server Reconfiguration and Restart

(ASR&R).

Security functions in the BIOS-setup protect the data on the server against

manipulation. Additional security is provided by the lockable drive cover.

1.1 Concept and target groups for this manual

This operating manual describes how to install, set up and operate your server.

This operating manual is intended for those responsible for installing the

hardware and ensuring that the system runs smoothly. It contains all the

information you need to put your PRIMERGY TX1320 M3 into operation.

To understand the various expansion options, you will need to be familiar with

the fields of hardware and data transmission and you will require a basic

knowledge of the underlying operating system.

10 Operating Manual TX1320 M3

Introduction

1.2 Documentation overview

More information on your PRIMERGY TX1320 M3 can be found in the following

documents:

– "Quick Start Hardware - FUJITSU Server PRIMERGY TX1320 M3"

– "ServerView Quick Start Guide"

– "Safety Notes and Regulations" manual

"安全上のご注意 " for Japan

– "Warranty" manual

"保証書 " for Japan

– "ServerView Suite Local Service Concept - LSC" manual

– "Returning used devices" manual and "Service Desk" leaflet

"サポート&サービス " for Japan

– "FUJITSU Server PRIMERGY TX1320 M3 Upgrade and Maintenance

Manual"

– "D3373 BIOS Setup Utility for FUJITSU Server PRIMERGY TX1320 M3

Reference Manual"

IAll documentation on PRIMERGY hardware and ServerView software is

available online from the Fujitsu manuals server at:

http://manuals.ts.fujitsu.com

For Japan:

http://www.fujitsu.com/jp/products/computing/servers/primergy/manual/

The complete PRIMERGY documentation set can also be downloaded

as a DVD ISO image at:

ftp://ftp.ts.fujitsu.com/images/serverview/manuals

For Japan:

http://www.fujitsu.com/jp/products/computing/servers/primergy/downloads/

Further sources of information:

– ServerView Suite Glossary

– Manual for the monitor

– Documentation for the boards and drives

– Operating system documentation

– Information files in your operating system

TX1320 M3 Operating Manual 11

Introduction

1.3 Notational conventions

The following notational conventions are used in this manual:

Text in italics indicates commands or menu items.

"Quotation marks" indicate names of chapters and terms that are being

emphasized.

Êdescribes activities that must be performed in the order

shown.

VCAUTION! pay particular attention to texts marked with this symbol.

Failure to observe this warning may endanger your life,

destroy the system or lead to the loss of data.

Iindicates additional information, notes and tips.

12 Operating Manual TX1320 M3

Introduction

TX1320 M3 Operating Manual 13

2 Functional overview

This section provides information on the features and technical data of the

PRIMERGY TX1320 M3 server.

2.1 Features

Intel® Xeon®, Pentium®, or Core™ i3 CPU

The server has an Intel® Xeon®, Pentium®, or Core™ i3 CPU for high-speed

data processing.

Customer Self Service (CSS)

The PRIMERGY Customer Self Service (CSS) concept enables you to identify

and replace the affected component yourself in the case of certain error

scenarios.

In the CSS concept, you can replace the following components yourself in the

event of an error:

– Hot-plug HDD/SSD modules

– Hot-plug PSUs

– Memory modules

– System fans

– Expansion cards

For information on replacing these components, see the "FUJITSU Server

PRIMERGY TX1320 M3 Upgrade and Maintenance Manual".

CSS indicators on the control panel and on the back of the PRIMERGY server

provide you with information if a CSS event arises.

In addition, CSS errors are displayed in the ServerView Operations Manager,

the server management software from Fujitsu.

In the event of errors, the ServerView Operations Manager refers you directly

to the affected component and its order information in the Illustrated Spares

catalog of the server in question. (This feature is not available for Japan.)

14 Operating Manual TX1320 M3

Functional overview

IFurther information on the CSS concept is provided in the "PRIMERGY

ServerView Suite Local Service Concept - LSC" manual on the Fujitsu

manuals server.

For the latest information on optional products provided for the

TX1320 M3 see the configurator of the server:

http://ts.fujitsu.com/products/standard_servers/index.html

For Japan:

http://www.fujitsu.com/jp/products/computing/servers/primergy/

System board

The features of the system board are described in the "FUJITSU Server

PRIMERGY TX1320 M3 Upgrade and Maintenance Manual" and in the "D3373

BIOS Setup Utility for FUJITSU Server PRIMERGY TX1320 M3 Reference

Manual" for the firmware.

Trusted Platform Module (TPM)

A Trusted Platform Module (TPM) for safer storage of keys can be implemented

as an option. This module enables programs from third party manufacturers to

store key information (e.g. drive encryption using Windows Bitlocker Drive

Encryption).

The TPM is activated via the BIOS system (for more information, refer to the

“D3373 BIOS Setup Utility for FUJITSU Server PRIMERGY TX1320 M3

Reference Manual").

VCAUTION!

– When using the TPM, note the program descriptions provided by the

third party manufacturers.

– You must also create a backup of the TPM content. To do this, follow

the third party manufacturer's instructions. Without this backup, if the

TPM or the system board is faulty you will not be able to access your

data.

– If a failure occurs, please inform your service about the TPM

activation before it takes any action, and be prepared to provide them

with your backup copies of the TPM content.

TX1320 M3 Operating Manual 15

Functional overview

Hard disk drives (HDDs)

The server is shipped with one of the following drive cages:

– For up to two non hot-plug 3.5-inch SATA HDDs:

Up to two 3.5-inch SATA HDD modules can be used in the drive cage. Each

HDD module can accommodate a SATA HDD with a maximum height of 1

inch.

– For up to eight 2.5-inch SAS/SATA HDDs:

Up to four 2.5-inch SAS/SATA HDD modules can be used in each of the two

bays of the drive cage. Each HDD module can accommodate an SAS/SATA

HDD with a 2.5-inch format. The modules are connected to the SAS/SATA

backplane wirelessly. This allows HDD modules to be plugged in or pulled

out easily. If the server has a corresponding RAID configuration, defective

HDD modules can also be replaced during operation.

Onboard SATA controller

A SATA controller is integrated on the system board; up to four SATA HDDs can

be connected to the controller. The LSI Embedded MegaRAID software (SATA

Software RAID) supports RAID levels 0, 1 and 10.

For more information on configuring the controller, see section "Configuring the

onboard SATA controller" on page 80.

16 Operating Manual TX1320 M3

Functional overview

SAS/SATA RAID controller

The server is available with the following SAS/SATA RAID controllers for

operating the internal SAS/SATA HDDs:

– Modular Host Bus Adapter with "Integrated RAID" (IR).

RAID levels 0 and 1 are supported for internal HDD configurations.

– Modular RAID 0/1 controller with "MegaRAID functionality" (integrated

MegaRAID).

RAID levels 0, 1, 10, 5 and 50 are supported for internal HDD configurations.

– Modular RAID 5/6 controller with "MegaRAID functionality" (MegaRAID).

RAID levels 0, 1, 10, 5, 50, 6 and 60 are supported for internal HDD

configurations. As an option, a flash backup unit (FBU) can save the

memory content even if the power fails. Cache memory size of 1GB or 2GB

are available.

IFor more information on configuring the controller, see section

"Configuring the SAS/SATA RAID controller" on page 81.

Further information on SAS/SATA RAID controllers is provided in the

"Modular RAID Controller Installation Guide" (on the Fujitsu manuals

server under x86 Servers - Expansion Cards - Storage Adapters).

Further information on other SAS/SATA RAID controllers (e.g. for

operating external SAS/SATA HDDs or tape drives) is available on the

Fujitsu manuals server under x86 Servers - Expansion Cards - Storage

Adapters - LSI SAS / SCSI Controllers.

Accessible drives

Two mounting locations are available:

– a 3.5-inch bay for a backup drive.

– an ultra slim ODD.

The accessible drives cannot be replaced during operation.

Power supply unit (PSU)

In its basic configuration the server has a standard PSU that adjusts

automatically to any mains voltage in the range 100V - 240V.

In the redundant configuration a hot-plug redundant PSU with two modules

serves as a redundant power supply. If one PSU fails, the second PSU in the

redundant configuration ensures operation can continue uninterrupted.

TX1320 M3 Operating Manual 17

Functional overview

Fujitsu battery unit (FJBU)

FJBU behaves as a modular UPS in the server. When power fail happened, the

server can operate by FJBU battery for a while.

FJBU supports hot-plugging, and can be replaced during operation.

You can download the management software (FJBU management software) for

the following OS:

– Windows Server 2012 R2, Windows Server 2012, Windows Server 2016

– Windows Server 2008 R2 SP1, Windows Server 2008 R2 SP2

IFJBU management software is not available in Red Hat Enterprise Linux

environment. Please use the IPMI function at Linux environment.

Advanced Thermal Design

The Advanced Thermal Design option allows you to operate the system with a

wider temperature range of 5 °C to 40 °C, depending on your system and

configuration.

VCAUTION

In a system that is configured with Advanced Thermal Design, only

certain components which support the respectively increased higher

operating temperature range may be installed and used. For applicable

restrictions, please refer to the official configurator tool.

This option can only be ordered from the manufacturer and is

indicated by the respective logo on the identification rating

plate.

18 Operating Manual TX1320 M3

Functional overview

High level of availability and data security

When memory data is accessed, 1-bit errors are identified in the main memory

and automatically corrected with the error correcting code (ECC) method.

ASR&R (Automatic Server Reconfiguration and Restart) restarts the system in

the event of an error and automatically "hides" the defective system

components.

The PDA (Prefailure Detection and Analysis) technology from Fujitsu analyzes

and monitors all components that are critical for system reliability.

A RAID controller supports different RAID levels and increase the availability

and data security of the system.

The hot-plug HDD modules provide additional availability.

TX1320 M3 Operating Manual 19

Functional overview

iRMC S4 with integrated management LAN connector

The iRMC S4 (integrated Remote Management Controller) is a Baseboard

Management Controller (BMC) with integrated management LAN connector

and expanded functionality that was previously only available with additional

plug-in cards. In this way, the iRMC S4 enables complete control of PRIMERGY

servers, regardless of system status, and thus particularly the control of

PRIMERGY servers that are in the "out-of-band" system status.

Major functions supported by the iRMC S4 include the following:

●Browser access via iRMC S4´s own Web server

●Secure communication (SSH, SSL)

●Power Management for the managed server (depending on its system

status)

●Power Consumption Management

●Connecting virtual drives as remote storage

●Text-based and graphic console bypass (Advanced Video Redirection)

●Remote Storage

●Command Line Interface (CLI)

●Simple, interactive or script-based iRMC S4configuration

●Customer Self Service (CSS)

●iRMC S4´s own user management

●Multi-computer, global iRMC S4 user administration using an LDAP

Directory Service

●Automatic network configuration via DNS / DHCP

●Power supply of the iRMC S4 via the system standby supply

●Full-coverage alarm management

●System Event Log (SEL) reading and processing

●IPMI support

●CIM / WS-MAN support

●Internal Event Log for user login / logout auditing

20 Operating Manual TX1320 M3

Functional overview

More information about the iRMC S4 can be found in the "iRMC S4 - integrated

Remote Management Controller" user guide (on the Fujitsu manuals server

under x86 Servers - Software - ServerView Suite - Out-Of-Band Management).

Server management

Server management is implemented using the ServerView Operations Manager

supplied and the PDA (Prefailure Detection and Analysis) technology from

Fujitsu. PDA reports the threat of a system error or overload at an early stage,

allowing preventive measures to be taken.

The ServerView Operations Manager enables the management of all

PRIMERGY servers in the network via a central console. The ServerView

Operations Manager supports the following functions:

●Round-the-clock monitoring, regardless of server status

●High-performance, graphical console bypass (AVR) protected by

HTTPS/SSL (128 bit)

●Remote storage via USB

●Remote power on

●Intrusion detection in the floorstand model

●Temperature monitoring of the CPU and the surrounding area

●Detailed status and error reports for CPUs and main memory

●Watchdog timer for Automatic Server Reconfiguration and Restart (ASR&R)

in the event that memory modules or CPUs fail

●Power monitoring

●End-of-life monitoring of fans with prompt notification before failure

●Watchdog timer for monitoring the operating system with ASR&R

Further information on the ServerView Operations Manager is provided in the

associated documentation.

TX1320 M3 Operating Manual 21

Functional overview

ServerView Installation Manager

You can configure the PRIMERGY server quickly and precisely with the

ServerView Installation Manager software provided. User-guided menus are

available for installing the server operating system (for further details see

section "Configuring the server" on page 80).

Service and support

PRIMERGY servers are easy to maintain and modular, thus enabling quick and

simple maintenance.

The handles and locks (touch points) used to exchange components are

colored green to ensure simple and immediate recognition.

In order to prevent the components from being damaged by incorrect handling

when they are being installed and removed, the areas of all components that

can be touched without damaging them are also marked green.

PRIMERGY diagnostic LEDs fitted on the system board indicate which

component (memory module, CPU, fan or expansion card) is not functioning

properly.

The Flash EPROM program supplied with the Fujitsu utilities supports a fast

BIOS update.

With the iRMC (integrated Remote Management Controller) on the system

board, the PRIMERGY TX1320 M3 server can also be maintained and serviced

remotely. This enables remote diagnosis for system analysis, remote

configuration and remote restart should the operating system or hardware fail.

22 Operating Manual TX1320 M3

Functional overview

ServerView Remote Management

ServerView Remote Management is the remote management solution from

Fujitsu for PRIMERGY servers. ServerView Remote Management and the

relevant hardware components integrated on the system board allow remote

monitoring and maintenance as well as fast restoration of operation in the event

of errors.

Remote monitoring and maintenance avoids time-consuming and costly on-site

repairs and reduces service costs. This leads to a reduction in the total cost of

ownership and an excellent return on investment for the remote management

solution.

The administrator can access all system information and information from the

sensors such as fan speeds or voltages via the iRMC S4's Web interface (see

section "iRMC S4 with integrated management LAN connector" on page 19).

You can also start the text-based or graphic console bypass (Advanced Video

Redirection, AVR) and connect virtual drives as remote storage.

IMore information about the iRMC S4 can be found in the "iRMC S4 -

integrated Remote Management Controller" user guide (on the Fujitsu

manuals server under x86 Servers - Software - ServerView Suite - Out-Of-

Band Management).

TX1320 M3 Operating Manual 23

Functional overview

2.2 Server specification

This section explains the specifications for the server. The specifications for this

server are liable to be updated without any notice. Please be forewarned.

System Board

CPU

Memory Modules Configuration

System board type D3373

Chipset Intel® E3-1200V6 and Intel® C236

CPU quantity and type 1x Intel® Xeon® E3-1200 v6 (quad-core) / Pentium®

/ Core™ i3

Memory slots 4

Memory slot type UDIMM (DDR4)

Memory capacity

(min. - max.)

4 GB - 64 GB

Memory protection ECC

Memory notes Dual channel support. For dual channel

performance, a minimum of 2 memory modules has

to be ordered. Capacity per channel has to be the

same. Memory modules with 4, 8 or 16 GB and 2400

MHz are available.

24 Operating Manual TX1320 M3

Functional overview

Interfaces

Onboard or integrated controllers

USB connectors 2.0 4x external rear, no USB wake-up supported

USB connectors 3.0 2x external front, no USB wake-up supported

2x external rear, no USB wake-up supported

1x internal for USB backup device

Graphics (15-pin) 1 x VGA

Serial 1 (9-pin) 1 x serial RS-232-C, usable for iRMC or system or

shared

LAN / Ethernet (RJ45) 2 x Intel® i210 Gbit/s Ethernet

Management LAN

(RJ45)

1 x dedicated service LAN port for iRMC S4

(10/100/1000 Mbit/s) Service LAN traffic can be

switched to shared onboard Gbit LAN port

RAID Controller Modular Host Bus Adapter with "Integrated RAID"

(IR). RAID levels 0 and 1 are supported for internal

HDD configurations.

Modular RAID 0/1 controller with “MegaRAID

functionality” (integrated MegaRAID). RAID levels 0,

1, 10, 5 and 50 are supported for internal HDD

configurations.

Modular RAID 5/6 controller with "MegaRAID

functionality" (MegaRAID). RAID levels 0, 1, 10, 5,

50, 6 and 60 are supported for internal HDD

configurations.

SATA Controller A 6-port SATA controller is integrated on the system

board; up to four SATA HDDs can be connected to

the controller. The LSI Embedded MegaRAID

software (SATA Software RAID) supports RAID

levels 0, 1 and 10.

Remote Management

Controller

Integrated Remote Management Controller

(iRMC S4), 256 MB DDR3-800 SRAM for video,

IPMI 2.0 compatible

Trusted Platform

Module (TPM)

Infineon V1.2 / V2.0 compliant (option)

TX1320 M3 Operating Manual 25

Functional overview

Slots

Drive bays

Operating Panel

Slot 1: PCIe Gen3 x1

(mechanical x4)

up to 168 mm length, low profile

Slot 2: PCIe Gen3 x4

(mechanical x4)

notched, up to 168 mm length, low profile

Slots 3, 4: PCIe Gen3 x8

(mechanical x8)

notched, up to 168 mm length, low profile

Slot notes In SAS configuration 1x PCI-Express occupied by

modular RAID controller.

Hard disk bay

configuration

8x 2.5-inch hot-plug SAS/SATA or 2x 3.5-inch non

hot-plug SATA

Accessible drive bays 1x 3.5/1.6-inch for backup devices

Ultra Slim ODD

Notes accessible drives all possible options described in relevant system

configurator

Operating buttons Reset button

NMI button

ID button

On/Off button

Status LEDs ID indicator (blue)

CSS indicator (orange)

Global Error indicator (orange)

HDD/SSD activity indicator (green)

Power-on indicator (green)

AC connected indicator (green)

26 Operating Manual TX1320 M3

Functional overview

Dimensions / Weight

Ventilation clearance

At least 200 mm on the front and rear.

Ambient conditions

Condensation during operation must be avoided!

Upright operating

position (W x D x H)

193 mm x 438 mm x 360 mm (including feet)

Horizontal operating

position (W x D x H)

340 mm x 400 mm x 101 mm

Weight up to 11 kg

Weight notes Weight may vary depending on actual configuration

Environment class 3K2

Environment class 2K2

EN60721 / IEC 721 Part 3-3

EN60721 / IEC 721 Part 3-2

Temperature:

Operation (3K2) 5°C ... 40°C (with ATD)

10°C ... 35°C (without ATD)

Transport (2K2) -25 °C ... 60 °C

Humidity 10% ... 85% (non condensing)

TX1320 M3 Operating Manual 27

Functional overview

Noise level

Noise level (detailed)

SATA systems

(4x 2.5" HDD,

standard PSU)

SAS systems

(8x 2.5" SAS HDD,

standard PSU)

Sound power level LWAd

(ISO 9296)

3.3 B (standby)

3.5 B (operation)

4.3 B (standby)

4.7 B (operation)

Sound pressure level at

adjacent workstation LpAm

(ISO 9296)

20 dB (A) (standby)

21 dB (A) (operation)

29 dB (A) (standby)

33 dB (A) (operation)

Declared noise emission

according to ISO 9296

Standby

Operating (ISO 7779)

ETSI 300 753 Class 3.1

LpAm at

bystander

position

A-weighted

sound

power level

LWAd

Standby (fan control: standard) 20 dB (A) 3.3 B

Standby (fan control: performance), active with

INTEL LAN X540-T2 10 GB

30 dB (A) 4.5 B

Operation (OLTIS 100), depending on the

configuration

22 dB (A) 3.5 B

Standby (fan control: emergency) 26 dB (A) 4.2 B

High fan speed mode (8x 2.5" SAS HDD,

standard PSU)

48 dB (A) 6.2 B

High fan speed mode (8x 2.5" SAS HDD,

redundant PSU)

64 dB (A) 7.6 B

28 Operating Manual TX1320 M3

Functional overview

Electrical values of the PSU

Electrical values of the Fujitsu battery unit (FJBU)

Power supply

configurations

1 x standard PSU or 1x redundant PSU with two

hot-plug PSU modules

Max. output 250 W (standard PSU)

450 W (redundant PSU)

Rated voltage range 100 - 240 V

Rated frequency range 50 - 60 Hz

Rated current 5.0 A - 2.5 A (250 W, AC outlet included)

3 A - 1.5 A (450 W )

Main power fuse 16 A

Protection class I

Battery unit

configuration

1x hot-plug power supply and an FJBU inserted in

slot 2.

Max. output 280 W

Backup duration Max. 2 seconds (380W), 4 minutes (280W) with

FJBU M2

Charge duration 4 hours to 90%,5 hours to 100%

Battery spec. Nickel Metal-Hydrite battery

Battery life time 5 years

Input/Output voltage 12 V DC

Weight 1.2 kg

1x per system maximum

TX1320 M3 Operating Manual 29

Functional overview

Compliance with standards

VCAUTION!

This device meets the requirements of Class A CISPR 22/32. This device

can cause radio interference in residential areas.

Product safety and ergonomics

International IEC 60950-1 2ed

Europe

Safety EN 60950-1 2ed

EN 62479

Ergonomics EK1-ITB 2003:2007

USA / Canada CSA-C22.2 No. 60950-1-07 2ed

UL 60950-1 2ed

Taiwan CNS 14336

China GB 4943

Electromagnetic compatibility

International CISPR 22

Europe EN 55032 Class A

EN 55024

EN 61000-3-2

EN 61000-3-3

ETSI 300386

USA / Canada 47CFR part 15 Class A / ICES-003

Taiwan CNS 13438 Class A

China GB 9245 / GB 17625

Japan VCCI Class A / JEITA

Korea KN 32 / KN 35

CE marking to EU directives Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility 2004/108/EC

30 Operating Manual TX1320 M3

Functional overview

TX1320 M3 Operating Manual 31

3 Installation steps, overview

This chapter contains an overview of the steps necessary to install your server.

Links take you to sections where you can find more detailed information about

the respective steps:

ÊFirst of all, it is essential that you familiarize yourself with the safety

information in chapter "Important information" on page 33.

ÊTransport the server to the place where you want to set it up.

ÊUnpack all parts, check the contents of the package for visible transport

damage and check whether the items delivered match the details on the

delivery note (see section "Unpacking the server" on page 48).

ÊMake sure that all necessary manuals (see "Documentation overview" on

page 10) are available; print out the PDF files if required.

ÊSet up the server (see section "Setting up the server" on page 49).

ÊComponents that have been ordered additionally may be delivered loose

with the server. Install these in the server as described in the supplied

documentation.

ÊWire the server. Follow the instructions in sections "Connecting devices to

the server" on page 54 and "Notes on connecting/disconnecting cables" on

page 59.

ÊConnect the server to the mains (see section "Connecting the server to the

mains" on page 56).

ÊFamiliarize yourself with the controls and indicators on the front and rear of

the server (see section "Controls and indicators" on page 64).

32 Operating Manual TX1320 M3

Installation steps, overview

ÊConfigure the server and install the desired operating system and

applications. The following options are available:

– Remote installation with the ServerView Installation Manager:

With the ServerView Suite DVD provided, you can configure the server

and install the operating system in a convenient manner.

Details on how to operate the ServerView Installation Manager, as well

as some additional information, are included in the "ServerView Suite

Installation Manager" user’s guide (on the Fujitsu manuals server under

x86 Servers - Software - ServerView Suite - Server Installation and

Deployment).

Configuration information can also be found in section "Configuring the

server and installing the operating system with the ServerView

Installation Manager" on page 82.

– Local configuration and installation with or without the ServerView

Installation Manager (see section "Configuring the server and installing

the operating system with the ServerView Installation Manager" on

page 82 or section "Configuring the server and installing the operating

system without the ServerView Installation Manager" on page 83).

IYou will find more information on installing the server remotely or

locally in the "ServerView Suite Installation Manager" user’s guide

(on the Fujitsu manuals server under x86 Servers - Software -

ServerView Suite - Server Installation and Deployment).

TX1320 M3 Operating Manual 33

4 Important information

IDepending on your server or the installed options some information is not

valid for your server.

VCAUTION!

Before installing and starting up a server, please observe the safety

instructions listed in the following section. This will help you to avoid

making serious errors that could impair your health, damage the server

and endanger the data base.

4.1 Safety instructions

IThe following safety instructions are also provided in the manual "Safety

Notes and Regulations" or " 安全上のご注意 ".

This server meets the relevant safety regulations for IT equipment. If you have

any questions about whether you can install the server in the intended

environment, please contact your sales outlet or our customer service team.

●The actions described in this manual shall be performed by technical

specialists. A technical specialist is a person who is trained to install the

server including hardware and software.

●Repairs to the server that do not relate to CSS failures shall be performed

by service personnel. Please note that unauthorized interference with the

server will void the warranty and exempt the manufacturer from all liability.

●Any failure to observe the guidelines in this manual, and any improper

repairs could expose the user to risks (electric shock, energy hazards, fire

hazards) or damage the equipment.

●Only valid for non hot-plug components

Before installing/removing internal components to/from the server, turn off

the server, all peripheral devices, and any other connected devices. Also

unplug all power cords from the power outlet. Failure to do so can cause

electric shock or damage.

34 Operating Manual TX1320 M3

Important information

Before starting up

●During installation and before operating the server, observe the instructions

on environmental conditions for your server.

●If the server is brought in from a cold environment, condensation may form

both inside and on the outside of the server.

Wait until the server has acclimatized to room temperature and is absolutely

dry before starting it up. Material damage may be caused to the server if this

requirement is not observed.

●Only transport the server in its original packaging or in packaging that

protects it from impacts and jolts.

In Japan and APAC, transporting the server in its original packaging does

not apply.

Installation and operation

●This server should not be operated in ambient temperatures above 35 °C.

For servers with Advanced Thermal Design the ambient temperature can

increase to 40 °C or 45 °C.

●If the server is integrated into an installation that draws power from an

industrial power supply network with an IEC309 connector, the power

supply's fuse protection must comply with the requirements for non-

industrial power supply networks for type A connectors.

●The server automatically adjusts itself to a mains voltage, see the type label

of your server. Ensure that the local mains voltage lies within these limits.

●This server must only be connected to properly grounded power outlets or

connected to the grounded rack internal power distribution server with

tested and approved power cords.

●Ensure that the server is connected to a properly grounded power outlet

close to the server.

●Ensure that the power sockets on the server and the properly grounded

power outlets are easily accessible.

●The On/Off button or the main power switch (if present) does not isolate the

server from the mains power supply. In case of repair or servicing disconnect

the server completely from the mains power supply, unplug all power plugs

from the properly grounded power outlets.

TX1320 M3 Operating Manual 35

Important information

●Always connect the server and the attached peripheral devices to the same

power circuit. Otherwise you run the risk of losing data if, for example, the

server is still running but a peripheral device (e.g. memory subsystem) fails

during a power outage.

●The adequately shielded data cables must be used.

All data and signal cables must have sufficient shielding. The use of cable

type S/FTP Cat5 or higher is recommended.

Use of unshielded or badly shielded cables may lead to increased emission

of interference and/or reduced fault-tolerance of the device.

●Ethernet cabling has to comply with EN 50173 and EN 50174-1/2 standards

or ISO/IEC 11801 standard respectively. The minimum requirement is a

Category 5 shielded cable for 10/100 Ethernet, or a Category 5e cable for

Gigabit Ethernet.

●Route the cables in such a way that they do not create a potential hazard

(make sure no-one can trip over them) and that they cannot be damaged.

When connecting the server, refer to the relevant instructions in this manual.

●Never connect or disconnect data transmission lines during a storm (risk of

lightning hazard).

●Make sure that no objects (e.g. jewelry, paperclips etc.) or liquids can get

inside the server (risk of electric shock, short circuit).

●In emergencies (e.g. damaged casing, controls or cables, penetration of

liquids or foreign bodies), contact the server administrator or your customer

service team. Only disconnect the server from the mains power supply if

there is no risk of harming yourself.

●Proper operation of the server (in accordance with IEC 60950-1 resp.

EN 60950-1) is only ensured if the server is completely assembled and the

rear covers for the installation slots have been fitted (electric shock, cooling,

fire protection, interference suppression).

●Only install server expansions that satisfy the requirements and rules

governing safety and electromagnetic compatibility and those relating to

telecommunication terminals. If you install other expansions, they may

damage the server or violate the safety regulations. Information on which

server expansions are approved for installation can be obtained from our

customer service center or your sales outlet.

●The components marked with a warning notice (e.g. lightning symbol) may

only be opened, removed or exchanged by authorized, qualified personnel.

Exception: CSS components can be replaced.

36 Operating Manual TX1320 M3

Important information

●The warranty is void if the server is damaged during installation or

replacement of server expansions.

●Only set screen resolutions and refresh rates that are specified in the

operating manual for the monitor. Otherwise, you may damage your monitor.

If you are in any doubt, contact your sales outlet or customer service center.

●Only valid for non hot-plug components

Before installing/removing internal components to/from the server, turn off

the server, all peripheral devices, and any other connected devices. Also

unplug all power cords from the power outlet. Failure to do so can cause

electric shock or damage.

Internal devices remain hot after shutdown. Wait for a while after shutdown

before installing or removing internal options.

●Do not damage or modify internal cables or internal devices. Doing so may

cause a server failure, fire, or electric shock and will void the warranty and

exempt the manufacturer from all liability.

●The circuit boards and soldered parts of internal options are exposed and

can be damaged by static electricity. To ensure reliable protection, you must

wear an earthing band on your wrist when working with this type of module

and connect it to an unpainted, conducting metal part of the server.

●Do not touch the circuitry on boards or soldered parts. Hold the metallic

areas or the edges of the circuit boards.

●Install the screw removed during installation/detaching internal options in

former position. To use a screw of the different kind can cause a breakdown

of equipment.

●The procedure of installation on this notes might change depending on a

configuration of option.

Batteries

●Incorrect replacement of batteries may lead to a risk of explosion. The

batteries may only be replaced with identical batteries or with a type

recommended by the manufacturer.

●Do not throw batteries into the trash can.

Batteries must be disposed of in accordance with local regulations

concerning special waste.

●Make sure that you insert the battery the right way round.

TX1320 M3 Operating Manual 37

Important information

●The battery used in this server may present a fire or chemical burn hazard if

mistreated. Do not disassemble, heat about 100 °C (212F), or incinerate the

battery.

●Replace the lithium battery on the system board in accordance with the

instructions in the corresponding Upgrade and Maintenance Manual,

chapter "System board and components" > "CMOS battery".

●All batteries containing pollutants are marked with a symbol (a crossed-out

garbage can). In addition, the marking is provided with the chemical symbol

of the heavy metal decisive for the classification as a pollutant:

Cd Cadmium

Hg Mercury

Pb Lead

Working with optical disk drives and media

When working with optical disk drives, these instructions must be followed.

VCAUTION!

●Only use CDs/DVDs/BDs that are in perfect condition, in order to

prevent data loss, equipment damage and injury.

●Check each CD/DVD/BD for damage, cracks, breakages etc. before

inserting it in the drive.

Note that any additional labels applied may change the mechanical

properties of a CD/DVD/BD and cause imbalance and vibrations.

Damaged and imbalanced CDs/DVDs/BDs can break at high drive

speeds (data loss).

Under certain circumstances, sharp CD/DVD/BD fragments can

pierce the cover of the optical disk drive (equipment damage) and can

fly out of the drive (danger of injury, particularly to uncovered body

parts such as the face or neck).

●High humidity and airborne dust levels are to be avoided. Electric

shocks and/or server failures may be caused by liquids such as

water, or metallic items, such as paper clips, entering a drive.

●Shocks and vibrations are also to be avoided.

●Do not insert any objects other than the specified CDs/DVDs/BDs.

38 Operating Manual TX1320 M3

Important information

●Do not pull on, press hard, or otherwise handle the CD/DVD/BD tray

roughly.

●Do not disassemble the optical disk drive.

●Before use, clean the optical disk tray using a soft, dry cloth.

●As a precaution, remove disks from the optical disk drive when the

drive is not to be used for a long time. Keep the optical disk tray

closed to prevent foreign matter, such as dust, from entering the

optical disk drive.

●Hold CDs/DVDs/BDs by their edges to avoid contact with the disk

surface.

●Do not contaminate the CD/DVD/BD surface with fingerprints, oil,

dust, etc. If dirty, clean with a soft, dry cloth, wiping from the center to

the edge. Do not use benzene, thinners, water, record sprays,

antistatic agents, or silicone-impregnated cloth.

●Be careful not to damage the CD/DVD/BD surface.

●Keep the CDs/DVDs/BDs away from heat sources.

●Do not bend or place heavy objects on CDs/DVDs/BDs.

●Do not write with ballpoint pen or pencil on the label (printed) side.

●Do not attach stickers or similar to the label side. Doing so may cause

rotational eccentricity and abnormal vibrations.

●When a CD/DVD/BD is moved from a cold place to a warm place,

moisture condensation on the CD/DVD/BD surface can cause data

read errors. In this case, wipe the CD/DVD/BD with a soft, dry cloth

then let it air dry. Do not dry the CD/DVD/BD using devices such as a

hair dryer.

●To avoid dust, damage, and deformation, keep the CD/DVD/BD in its

case whenever it is not in use.

●Do not store CDs/DVDs/BDs at high temperatures. Areas exposed to

prolonged direct sunlight or near heating appliances are to be

avoided.

TX1320 M3 Operating Manual 39

Important information

IYou can prevent damage from the optical disk drive and the

CDs/DVDs/BDs, as well as premature wear of the disks, by observing

the following suggestions:

– Only insert disks in the drive when needed and remove them after

use.

– Store the disks in suitable sleeves.

– Protect the disks from exposure to heat and direct sunlight.

Laser information

The optical disk drive complies with IEC 60825-1 laser class 1.

VCAUTION!

The optical disk drive contains a light-emitting diode (LED), which under

certain circumstances produces a laser beam stronger than laser

class 1. Looking directly at this beam is dangerous.

Never remove parts of the optical disk drive casing!

Modules with Electrostatic-Sensitive Devices (ESD modules)

Modules with electrostatic-sensitive devices are identified by the following

sticker:

Figure 1: ESD label

IThe ESD label can be different.

When you handle ESD modules, you must always observe the following points:

●Switch off the server and remove the power plugs from the power outlets

before installing or removing ESD modules.

40 Operating Manual TX1320 M3

Important information

●The circuit boards and soldered parts of internal options are exposed and

can be damaged by static electricity. To ensure reliable protection, you must

wear an earthing band on your wrist when working with ESD modules and

connect it to an unpainted, conducting metal part of the server.

●Any devices or tools that are used must be free of electrostatic charge.

●Wear a suitable grounding cable that connects you to the external chassis

of the server.

●Always hold ESD modules at the edges or at the points marked green (touch

points).

●Do not touch any connectors or conduction paths on an ESD module.

●Place all the components on a pad which is free of electrostatic charge.

IFor a detailed description of how to handle ESD modules, see the

relevant European or international standards (EN 61340-5-1,

ANSI/ESD S20.20).

Transporting the server

VCAUTION!

Only transport the server in its original packaging or in packaging that

protects it from impacts and jolts.

In Japan and APAC, transporting the server in its original packaging does

not apply.

Do not unpack the server until it is at its installation location.

If you need to lift or transport the server, ask other people to help you.

Never lift or carry the server by the handles or the Quick Release Levers

(QRLs) on the front panel.

Notes on installing the server in the rack

VCAUTION!

●For safety reasons, at least 2 people are required to install the server

in the rack because of its weight and size.

(For the reader in Japan, please refer to " 安全上のご注意 ".)

●Never lift the server into the rack using the QRLs (Quick Release

Levers) on the front panel.

TX1320 M3 Operating Manual 41

Important information

●When connecting and disconnecting cables, observe the relevant

instructions in the "Important Information" chapter of the technical

manual for the corresponding rack. The technical manual is supplied

with the corresponding rack.

●When installing the rack, make sure that the anti-tilt mechanism is

correctly fitted.

●Do not extend more than one server out of the rack simultaneously

even if the tilt protection is in place. If several servers are

simultaneously extended from the rack, there is a risk that the rack

could tip over. See the safety information of the rack and the warning

label.

●If the server/rack is intended for permanent connection to the mains

only an authorized specialist (electrician) is allowed to work.

Please follow the regulation of each country.

●If the server is integrated into an installation that draws power from an

industrial power supply network with an IEC309 type connector, the

power supply's fuse protection must comply with the requirements for

non-industrial power supply networks for the type A connector.

Other important information

●During cleaning, observe the instructions in the corresponding Operating

Manual chapter "Starting up and operation" > "Cleaning the server".

●Keep all manuals close to the server. All documentation must be included if

the equipment is passed on to a third party.

42 Operating Manual TX1320 M3

Important information

4.2 ENERGY STAR

4.3 CE conformity

Products that have been certified compliant with ENERGY STAR

and labelled are in full compliance with the specification at

shipping. Note that energy consumption can be affected by

software that is installed or any changes that are made to the

hardware configuration or BIOS or energy options subsequently.

In such cases, the properties guaranteed by ENERGY STAR can

no longer be assured.

The "ServerView Operations Manager" user guide contains

instructions for reading out measurement values, including those

relating to current energy consumption and air temperatures.

Either the Performance Monitor or the Task Manager can be

used to read out CPU utilization levels.

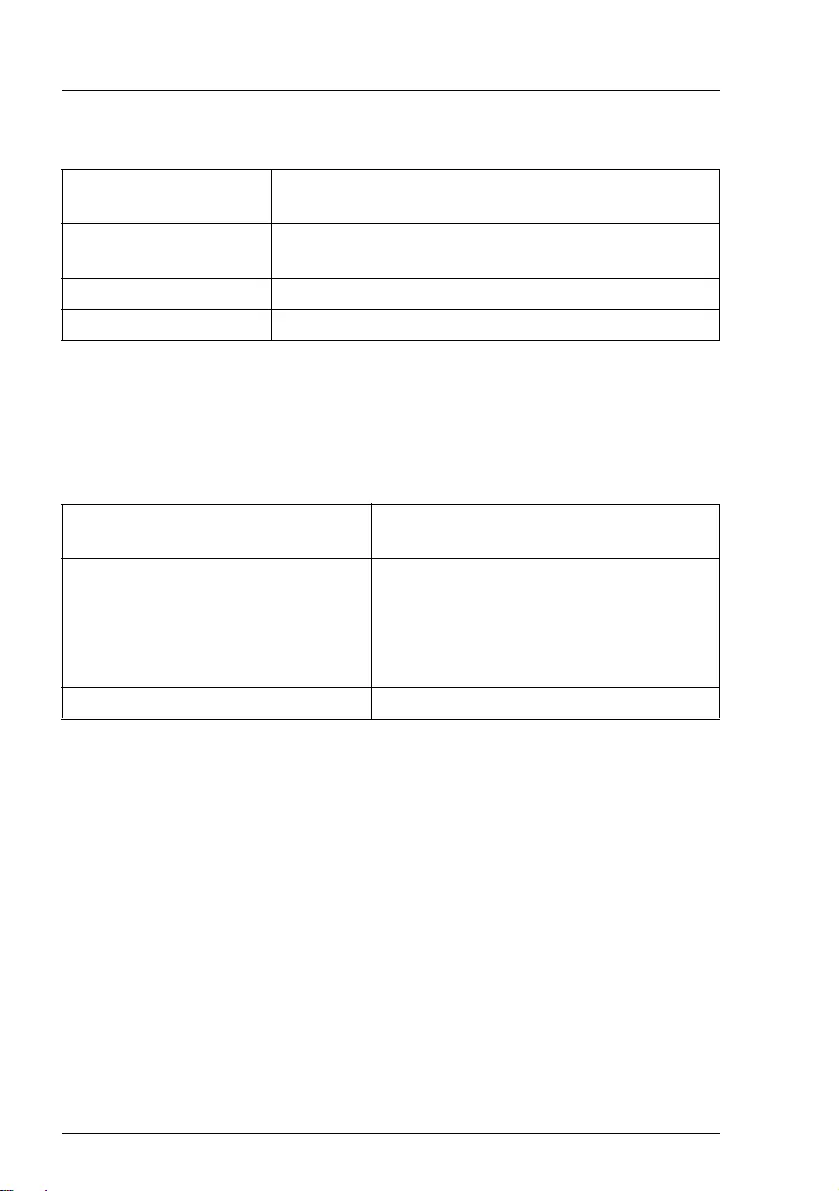

The system complies with the requirements of European

Regulations. Find the CE declaration on certificate portal:

https://sp.ts.fujitsu.com/sites/certificates/default.aspx

To open the CE declaration applicable for your system, proceed

as follows:

ÊSelect Industry Standard Servers.

ÊSelect your model, e.g. Rack server.

ÊSelect your system, e.g. PRIMERGY RX2530 M1.

ÊSelect CE Cert <your system>.

VCAUTION!

This is a Class A product. In a domestic environment this

product may cause RF interference, in which case the

user may be required to take adequate measures.

TX1320 M3 Operating Manual 43

Important information

4.4 FCC Class A Compliance Statement

If there is an FCC statement on the device, it applies to the products covered in

this manual, unless otherwise specified herein. The statement for other

products will appear in the accompanying documentation.

NOTE:

This equipment has been tested and found to comply with the limits for a

"Class A" digital device, pursuant to Part 15 of the FCC rules and meets all

requirements of the Canadian Interference-Causing Equipment Standard

ICES-003 for digital apparatus. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in strict accordance with the instructions, may cause harmful

interference to radio communications. However, there is no warranty that

interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

●Reorient or relocate the receiving antenna.

●Increase the separation between equipment and the receiver.

●Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

●Consult the dealer or an experienced radio/TV technician for help.

Fujitsu is not responsible for any radio or television interference caused by

unauthorized modifications of this equipment or the substitution or attachment

of connecting cables and equipment other than those specified by Fujitsu. The

correction of interferences caused by such unauthorized modification,

substitution or attachment will be the responsibility of the user.

The use of shielded I/O cables is required when connecting this equipment to

any and all optional peripheral or host devices. Failure to do so may violate FCC

and ICES rules.

44 Operating Manual TX1320 M3

Important information

4.5 Environmental protection

Environmentally-friendly product design and development

This product has been designed in accordance with the Fujitsu standard for

"environmentally friendly product design and development". This means that

key factors such as durability, selection and labeling of materials, emissions,

packaging, ease of dismantling and recycling have been taken into account.

This saves resources and thus reduces the harm done to the environment.

Further information can be found at:

http://ts.fujitsu.com/products/standard_servers/index.html

For the reader in Japan:

http://jp.fujitsu.com/platform/server/primergy/concept/

Energy-saving information

Devices that do not need to be constantly switched on should be switched off

until they are needed as well as during long breaks and after completion of work.

Packaging information

This packaging information does not apply in Japan and APAC.

Do not throw away the packaging. You may need it later for transporting the

server. If possible, the equipment should only be transported in its original

packaging.

Information on handling consumables

Please dispose of printer consumables and batteries in accordance with the

applicable national regulations.

In accordance with EU directives, batteries must not be disposed of with

unsorted domestic waste. They can be returned free of charge to the

manufacturer, dealer or an authorized agent for recycling or disposal.

All batteries containing pollutants are marked with a symbol (a crossed-out

garbage can). They are also marked with the chemical symbol for the heavy

metal that causes them to be categorized as containing pollutants:

Cd Cadmium

Hg Mercury

Pb Lead

TX1320 M3 Operating Manual 45

Important information

Labels on plastic casing parts

Please avoid sticking your own labels on plastic parts wherever possible, since

this makes it difficult to recycle them.

Returns, recycling and disposal

Please handle returns, recycling and disposal in accordance with local

regulations.

Details regarding the return and recycling of devices and consumables within

Europe can also be found in the "Returning used devices" manual, via your local

Fujitsu branch, or at:

http://ts.fujitsu.com/recycling

The device must not be disposed of with domestic waste. This

device is labeled in compliance with European directive

2012/19/EU on waste electrical and electronic equipment (WEEE).

This directive sets the framework for returning and recycling used

equipment and is valid across the EU. When returning your used

device, please use the return and collection systems available to

you. Further information can be found at:

http://ts.fujitsu.com/recycling

46 Operating Manual TX1320 M3

Important information

TX1320 M3 Operating Manual 47

5 Hardware installation

VCAUTION!

●Follow the safety instructions in the chapter "Important information"

on page 33.

●Do not expose the server to extreme environmental conditions (see

"Ambient conditions" on page 26). Protect the server from dust,

humidity and heat.

●Make sure that the server is acclimatized for the time indicated in this

table before putting it into operation.

In the table "Acclimatization time", the temperature difference refers

to the difference between the operating environment temperature and

the temperature to which the server was exposed previously (outside,

transport or storage temperature).

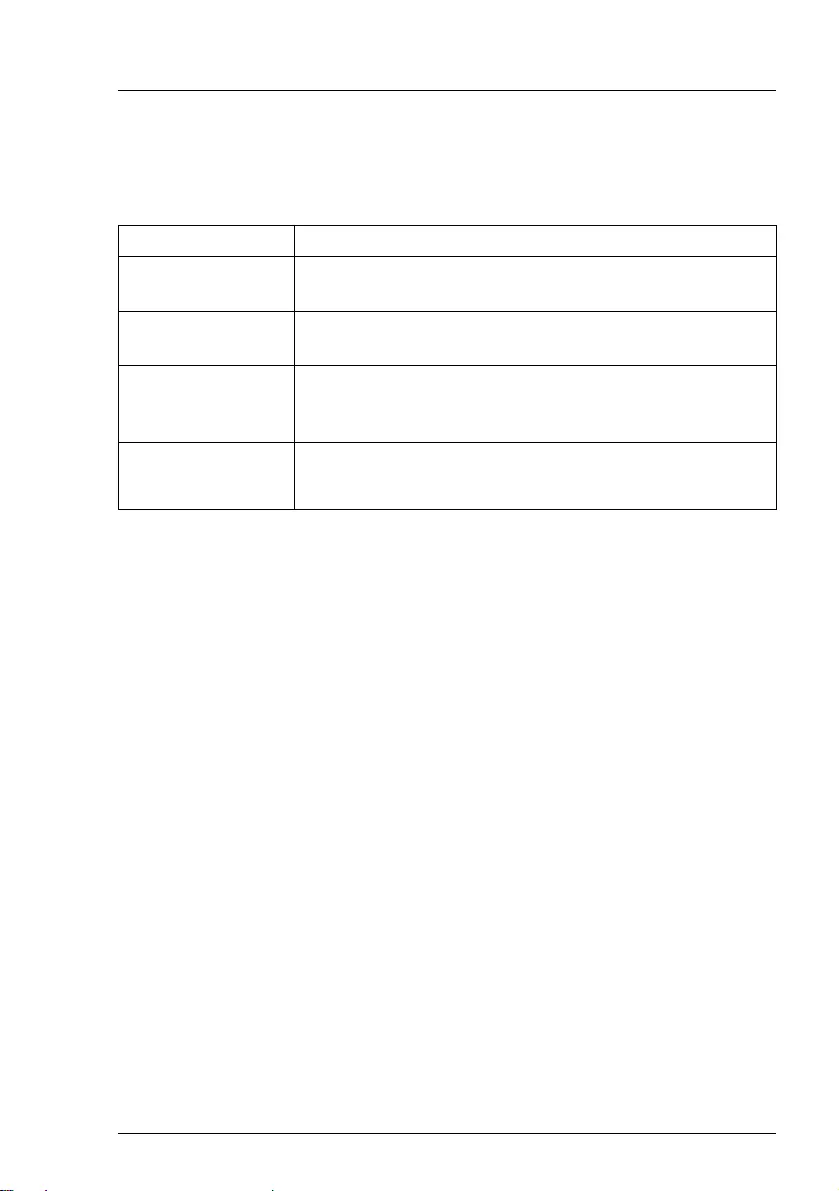

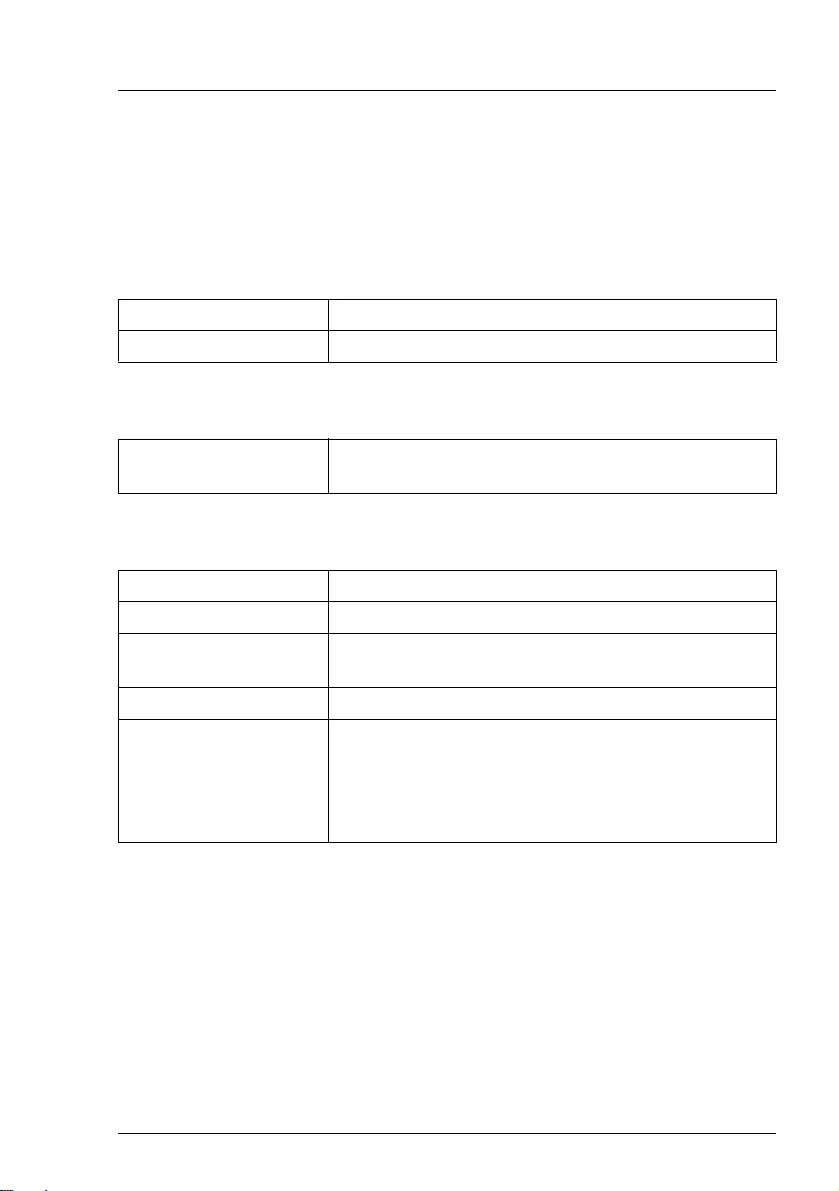

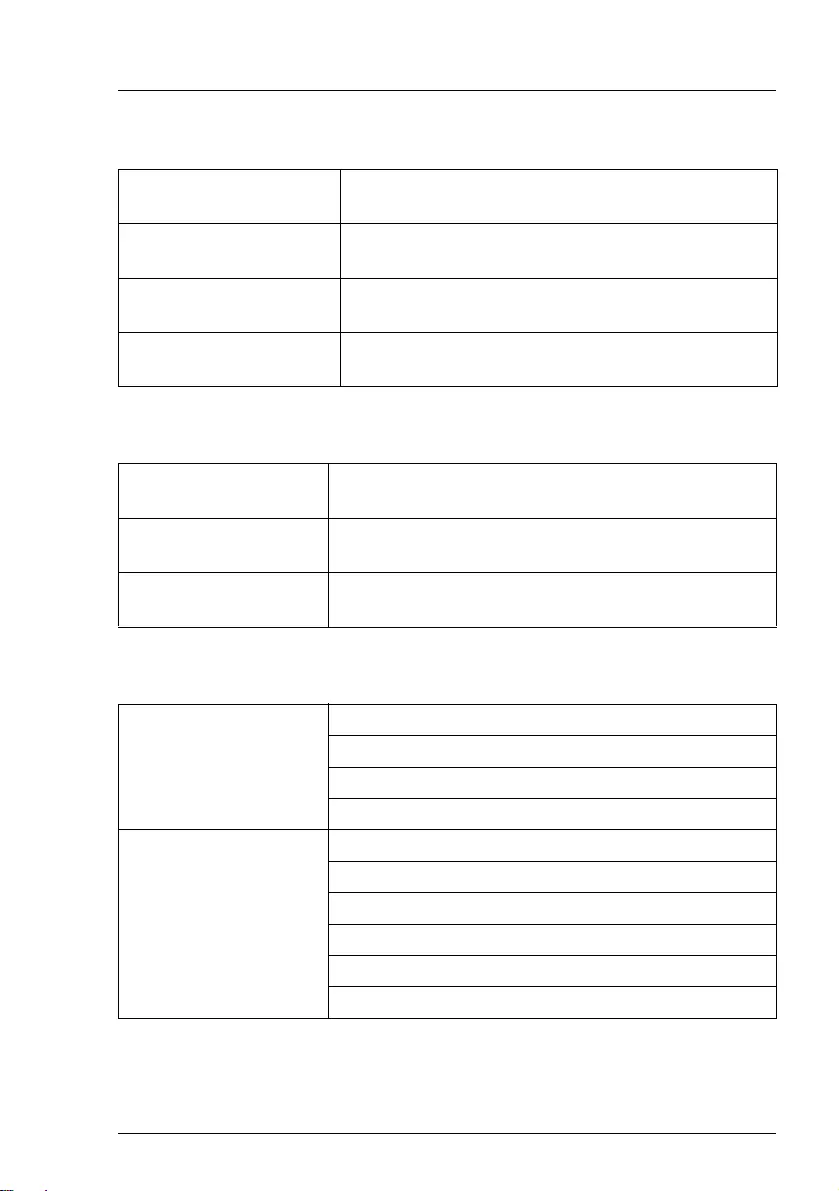

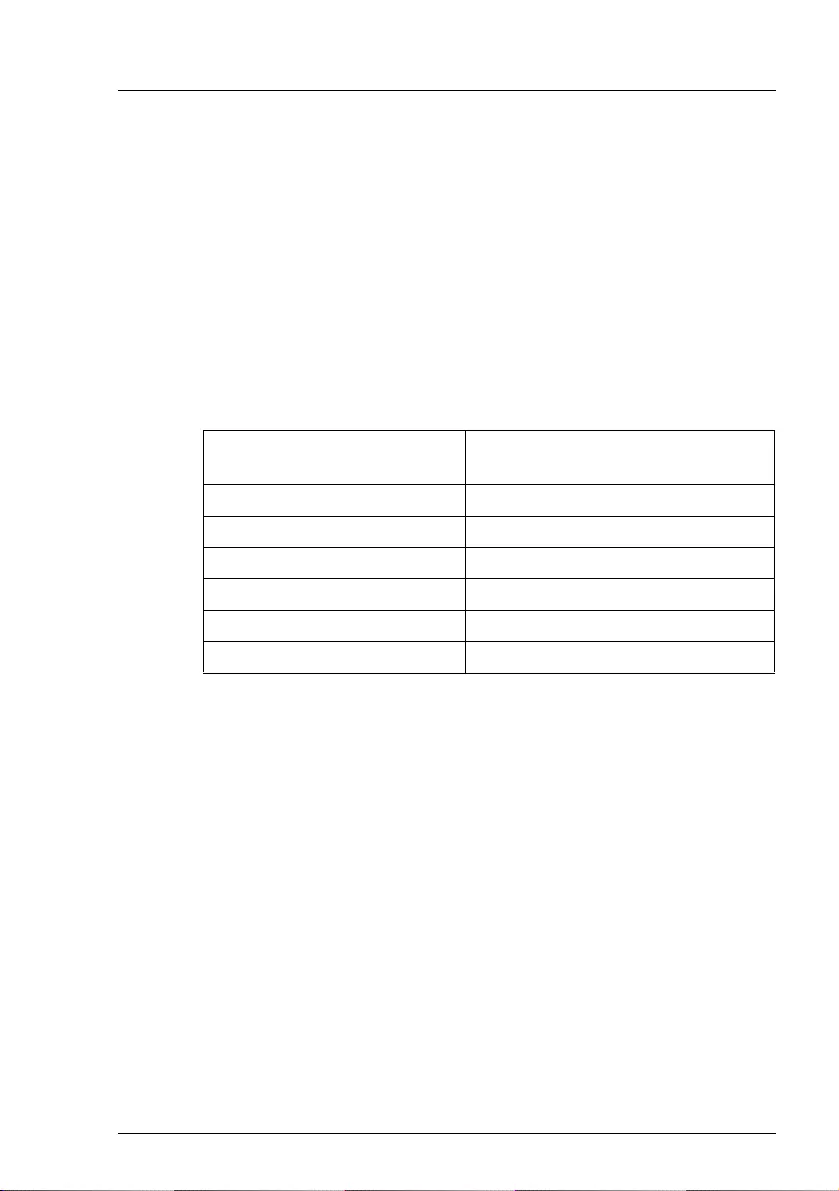

Temperature difference (°C) Minimum acclimatization time

(hours)

53

10 5

15 7

20 8

25 9

30 10

Table 1: Acclimatization time

48 Operating Manual TX1320 M3

Hardware installation

5.1 Unpacking the server

VCAUTION!

Follow the safety instructions in "Important information" on page 33.

The server must always be lifted or carried by at least two people.

For Japan:

Please refer to " 安全上のご注意 ".

Do not unpack the server until it is at its installation location.

ÊTransport the server to the place where you want to set it up.

ÊUnpack all individual parts.

Keep the original packaging in case you want to transport the server again

(does not apply to Japan).

ÊCheck the delivery for any damage during transport.

ÊCheck whether the items delivered match the details on the delivery note.

The product name and serial number of the product can be found on the ID card

(see section "ID card" on page 76).

ÊNotify your supplier immediately should you discover that the items

delivered do not correspond to the delivery note.

TX1320 M3 Operating Manual 49

Hardware installation

5.2 Setting up the server

ÊSet up the server.

INote that the server may be operated in the vertical (see section

"Positioning the server vertically" on page 50) or horizontal position

(see section "Positioning the server horizontally" on page 53).

VCAUTION!

– The device must be protected from direct sunlight.

– The required minimum distances for operation and maintenance

areas must be adhered to.

– The server must be accessible at the rear for connection to other

devices (e.g. memory subsystem).

– The mains plug must be accessible easily and safely.

– There must be a clearance of at least 200 mm in front of and

behind the server to ensure adequate ventilation of the system.

ÊWire the server. Follow the instructions in sections "Connecting devices to

the server" on page 54 and "Notes on connecting/disconnecting cables" on

page 59.

ÊConnect the server to the mains (see section "Connecting the server to the

mains" on page 56).

50 Operating Manual TX1320 M3

Hardware installation

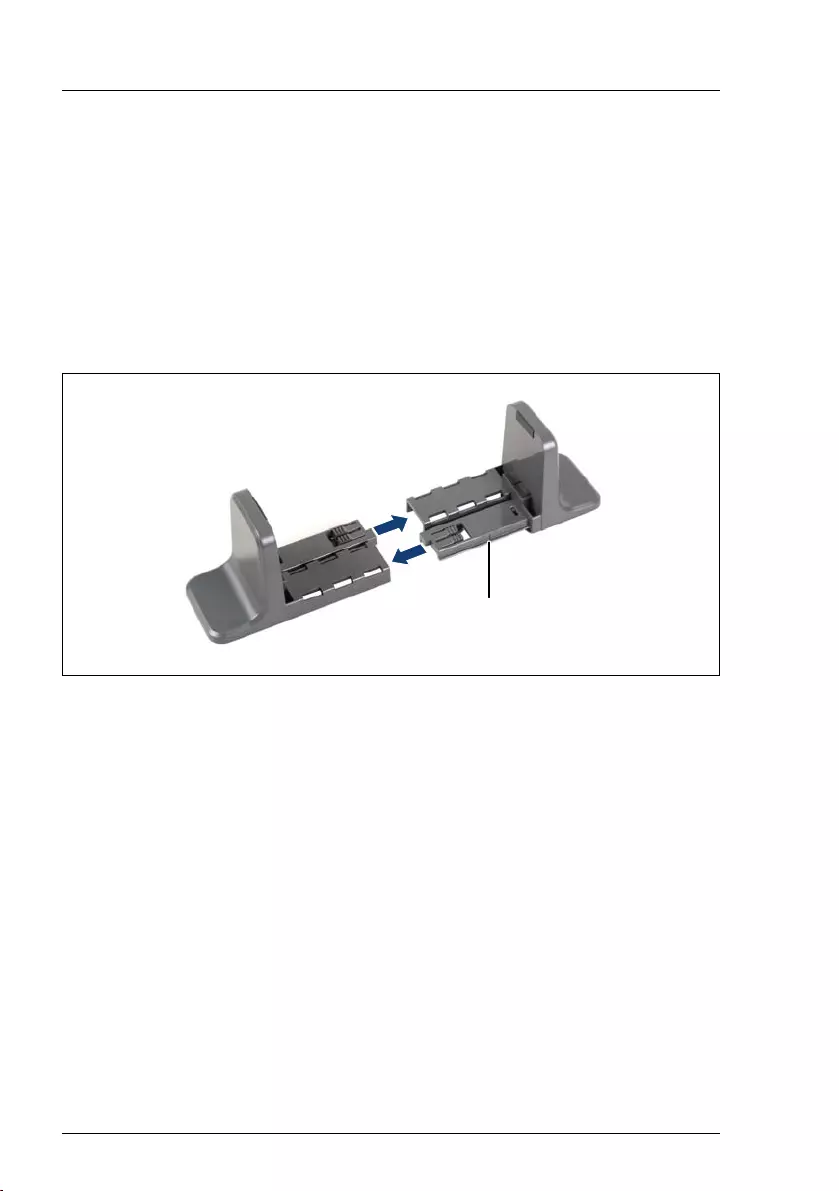

5.2.1 Positioning the server vertically

VCAUTION!

If the server is positioned vertically, the stabilizers must be attached!

The stabilizers must be attached in the correct direction (see figure 4 on

page 52).

Clipping the stabilizers together

Figure 2: Clipping the stabilizer together

ÊClip the stabilizers together in the direction of the arrow as far as the marking

line (a).

a

TX1320 M3 Operating Manual 51

Hardware installation

Adjusting the width of the stabilizers

Figure 3: Adjusting the width of a stabilizer

You may have to adjust the width of the stabilizers.

ÊPress the two locking levers (1) and keep them pressed.

ÊPull the stabilizer apart (2).

/

/

0

0

52 Operating Manual TX1320 M3

Hardware installation

Placing the server on the stabilizers

Figure 4: Placing the server on stabilizers

ÊPlace the server on the stabilizers (1).

Position the stabilizers between the rubber feet (2).

ÊPress the stabilizers together (3).

TX1320 M3 Operating Manual 53

Hardware installation

5.2.2 Positioning the server horizontally

VCAUTION!

If the server is positioned horizontally, ensure that the rubber feet are

pointing downward.

Figure 5: Positioning the server horizontally

ÊPlace the server on its four rubber feet.

54 Operating Manual TX1320 M3

Hardware installation

5.3 Connecting devices to the server

The connectors for external devices are on the front and rear of the server. The

additional connectors available on your server depend on the expansion cards

installed.

Two color-coded USB connectors are located on the front of the server.

Figure 6: Connectors on the front

1 2 x USB 3.0 connectors (blue)

TX1320 M3 Operating Manual 55

Hardware installation

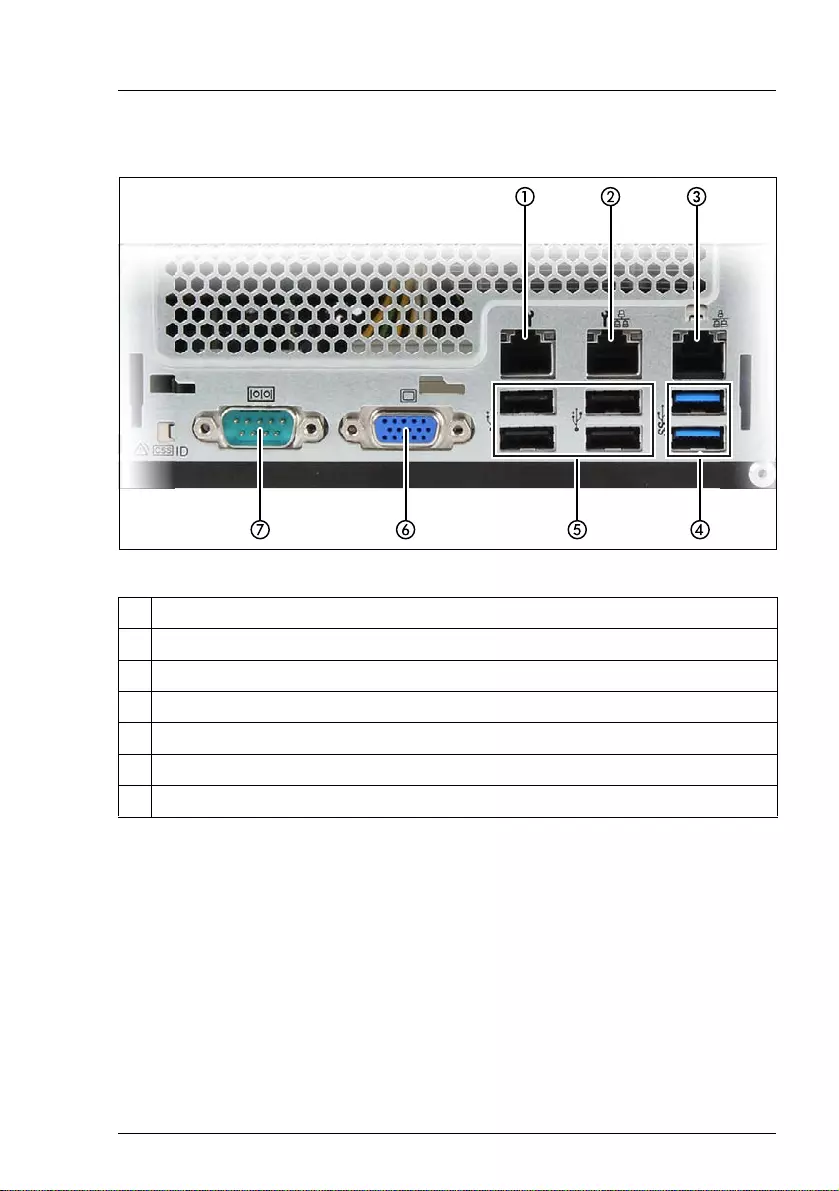

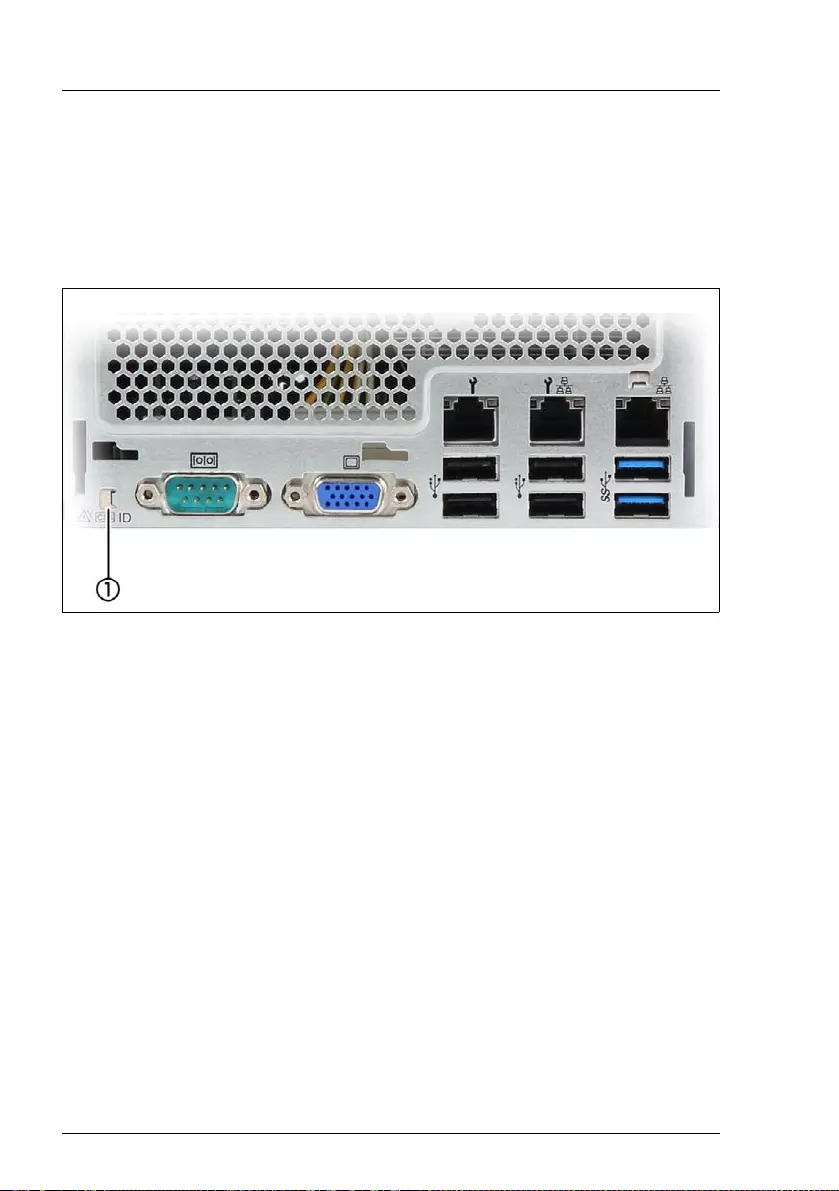

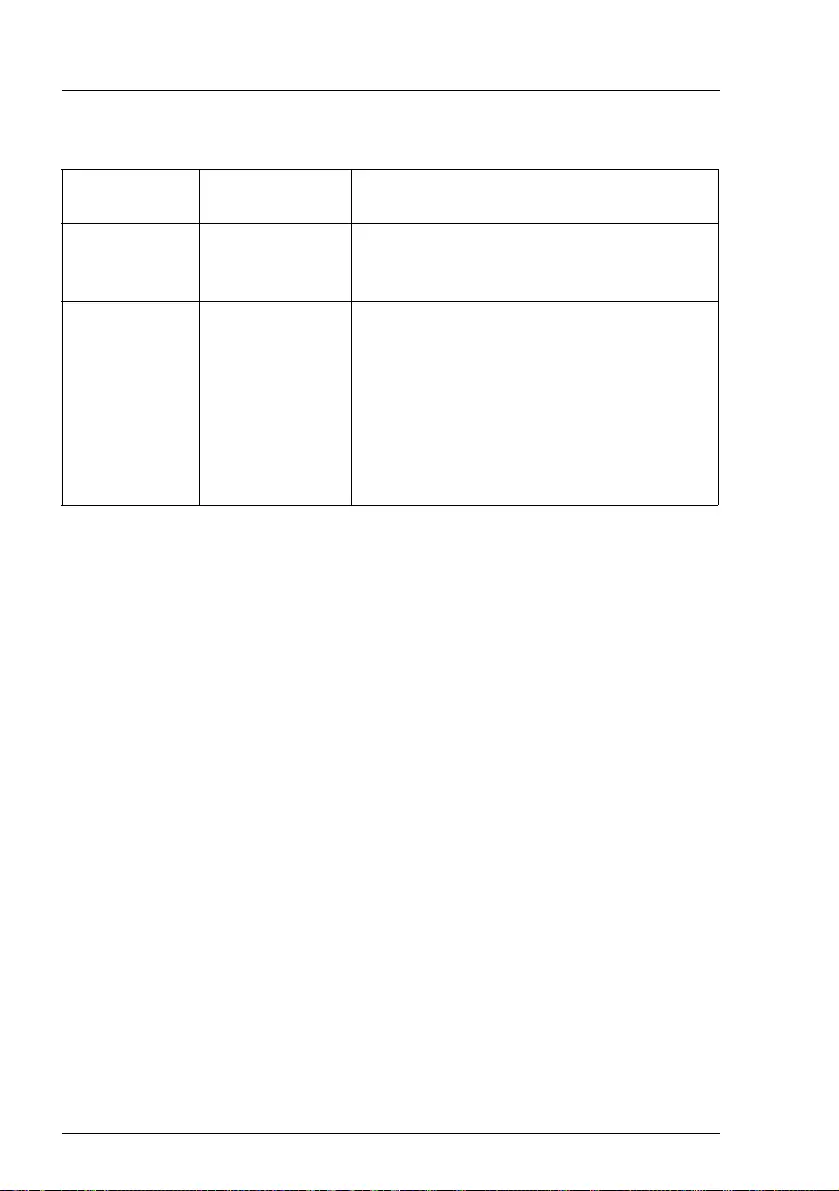

The standard connectors on the rear are indicated by symbols and color-coding.

Figure 7: Connector panel on the rear side

ISome of the devices that can be connected may require special drivers

(see the documentation for the connected device).

ÊConnect the data cables to the server and peripherals.

1 Management LAN connector, for iRMC S4 server management function

2 Shared LAN connector (LAN1)

3 Standard LAN connector (LAN2)

4 2x USB 3.0 connectors (blue)

5 4x USB 2.0 connectors (black)

6 Video connector (blue)

7 Serial connector COM1 (turquoise)

56 Operating Manual TX1320 M3

Hardware installation

5.4 Connecting the server to the mains

In its basic configuration the server has a permanently installed PSU or a hot-

plug PSU. Besides the hot-plug PSU, a second hot-plug PSU can be installed

optionally to serve as a redundant power supply. If one PSU fails, the second

PSU in the redundant configuration ensures operation can continue

uninterrupted.

VCAUTION!

The server is automatically set to a mains voltage in the range 100V -

240V. You may only operate the server if its rated voltage range

corresponds to the local mains voltage.

ÊConnect the power cord to the server PSU.

TX1320 M3 Operating Manual 57

Hardware installation

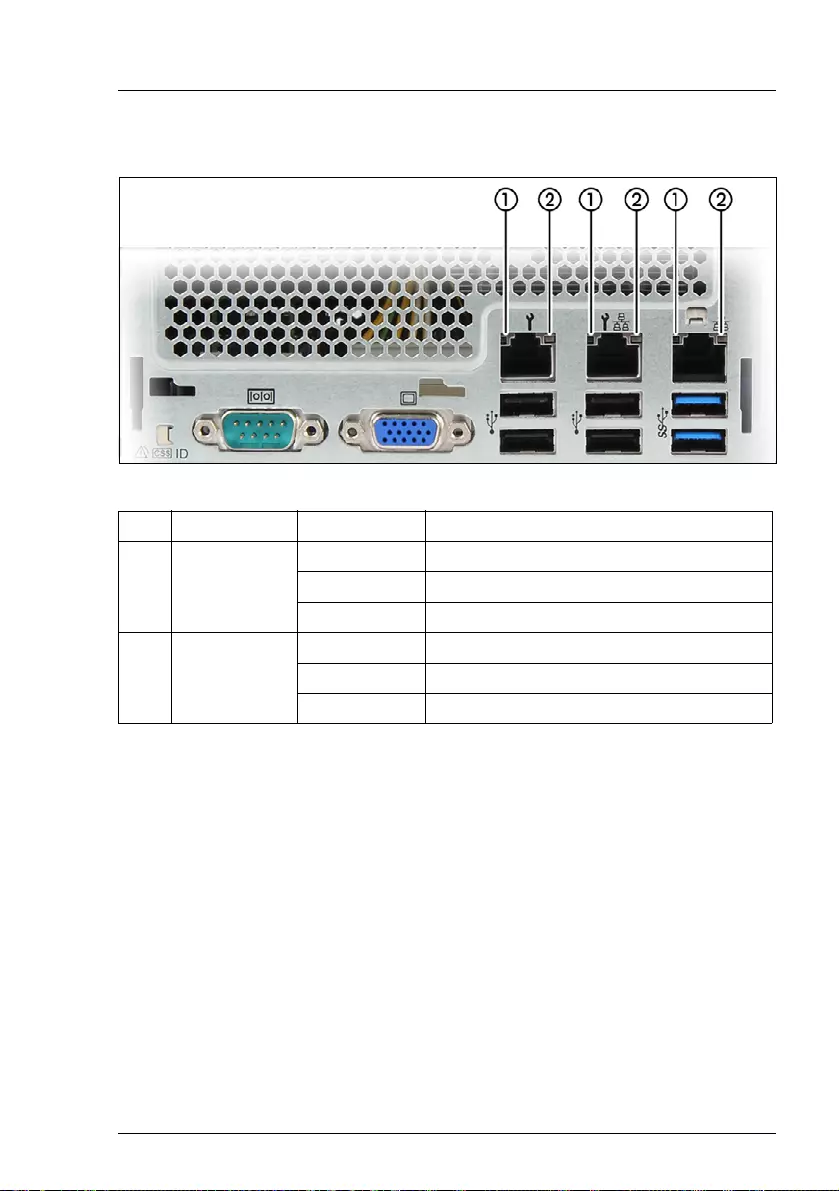

5.4.1 Using cable ties (standard PSU)

You can secure the power cable using a cable tie to ensure that the insulated

connector cannot be disconnected from the PSU accidentally. The cable tie is

included in the accessories pack that is delivered together with the server.

Figure 8: Using cable ties

ÊThread the cable tie through the eye (1).

ÊPull the cable tie tight to secure the power cable.

The insulated connector cannot now be disconnected from the server

accidentally.

IYou can loosen the cable tie by opening the small locking lever (2).

0

1

58 Operating Manual TX1320 M3

Hardware installation

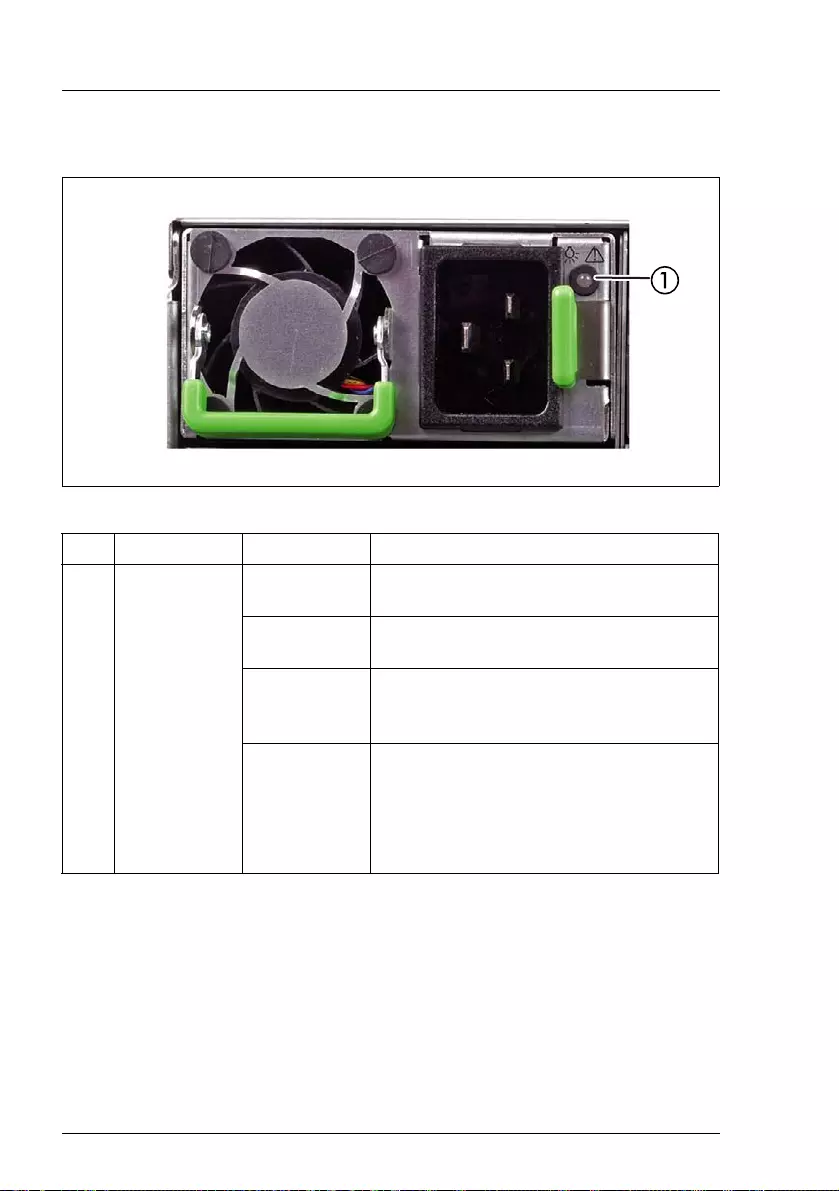

5.4.2 Using the cable clamps (hot-plug PSU)

You can secure the power cords in cable clamps to ensure that the insulated

connectors cannot be disconnected from the server accidentally.

Figure 9: Using cable clamps

ÊPull the cable clamp up (1).

ÊThread the power cord through the cable clamp (2).

ÊPress the cable clamp down until it engages to secure the cable (3).

TX1320 M3 Operating Manual 59

Hardware installation

5.5 Notes on connecting/disconnecting cables

VCAUTION!

Always read the documentation supplied with the device you wish to

connect.

Never connect, or disconnect cables during a thunderstorm.

Never pull on a cable when disconnecting it. Always take hold of the

cable by the plug.

Follow the sequence described below to connect or disconnect external

devices to or from the server:

Be sure to wait for 10 seconds or more after shutdown before turning the

server on.

Connecting cables

ÊTurn off all power and equipment switches.

ÊDisconnect all power plugs from the properly grounded power outlets.

ÊConnect all cables to the server and peripherals.

ÊPlug all data communication cables into the utility sockets.

ÊPlug all power cords into the properly grounded power outlets.

Disconnecting cables

ÊTurn off all power and equipment switches.

ÊDisconnect all power plugs from the properly grounded power outlets.

ÊUnplug all data communication cables from the utility sockets.

ÊDisconnect the relevant cables from the server and all the peripherals.

IFor connecting or disconnecting LAN cables, the server does not need

to be powered off. To avoid loss of data teaming function has to be

enabled.

60 Operating Manual TX1320 M3

Hardware installation

Information for ensuring electromagnetic compatibility

All data and signal cables must have sufficient shielding. The use of cable type

S/FTP Cat5 or higher is recommended.

Use of unshielded or badly shielded cables may lead to increased emission of

interference and/or reduced fault-tolerance of the device.

TX1320 M3 Operating Manual 61

6 Starting up and operation

VCAUTION!

Follow the safety instructions in chapter "Important information" on

page 33.

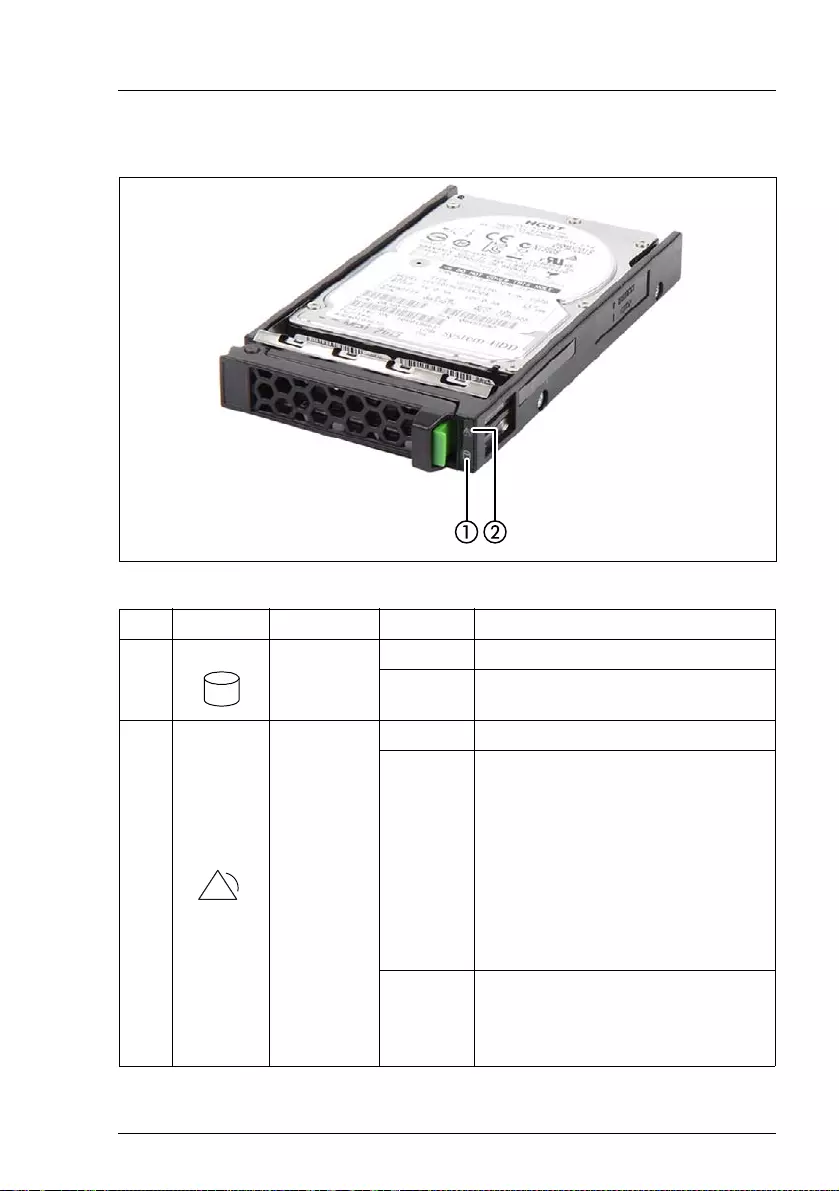

6.1 Access to the drives

Opening the drive cover

Figure 10: Opening the drive cover

ÊTurn the key counterclockwise (1) to unlock the front cover and remove the

key.

ÊOpen the drive cover carefully in the direction of the arrow (2) until the

ratches of the cover are released, and pull it downward to remove it (3).

VCAUTION!

Do not pull too hard to avoid damage to the locking mechanism.

62 Operating Manual TX1320 M3

Starting up and operation

ÊAttach the drive cover to the recesses on the HDD cover (4).

ÊPush down the HDD cover in the direction of the arrow (5).

IPlease note the following when operating with tape drives:

If the system is programmed to eject the media automatically, the

accessible drives must not be obstructed.

The drive cover is replaced and the server locked in the reverse order.

Figure 11: Removing the drive cover from the HDD cover

ÊCarefully pull out on the green release lever (1) and lift off the drive cover (2).

TX1320 M3 Operating Manual 63

Starting up and operation

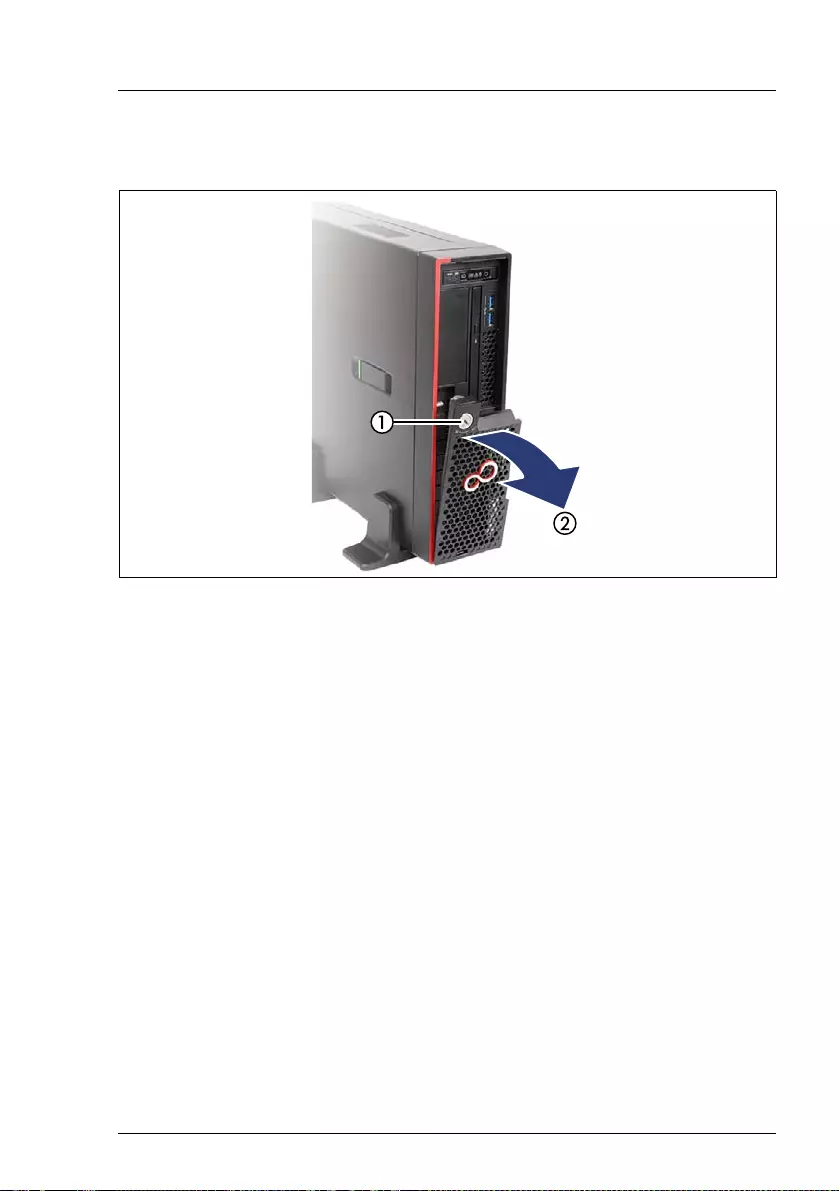

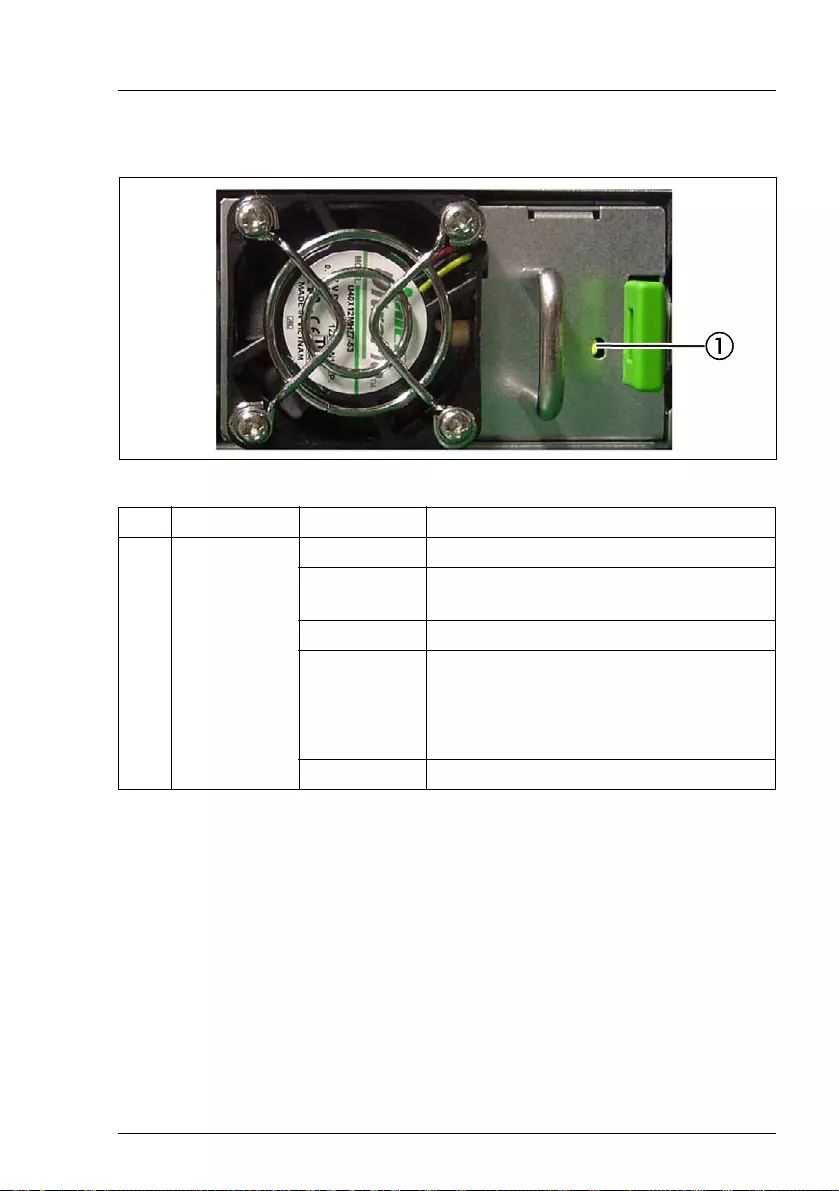

6.2 Opening the HDD cover

Figure 12: Removing the HDD cover

ÊUnlock the server (1).

ÊRemove the HDD cover (2).

The HDD cover is replaced and the server locked in the reverse order.

64 Operating Manual TX1320 M3

Starting up and operation

6.3 Controls and indicators

6.3.1 Server front

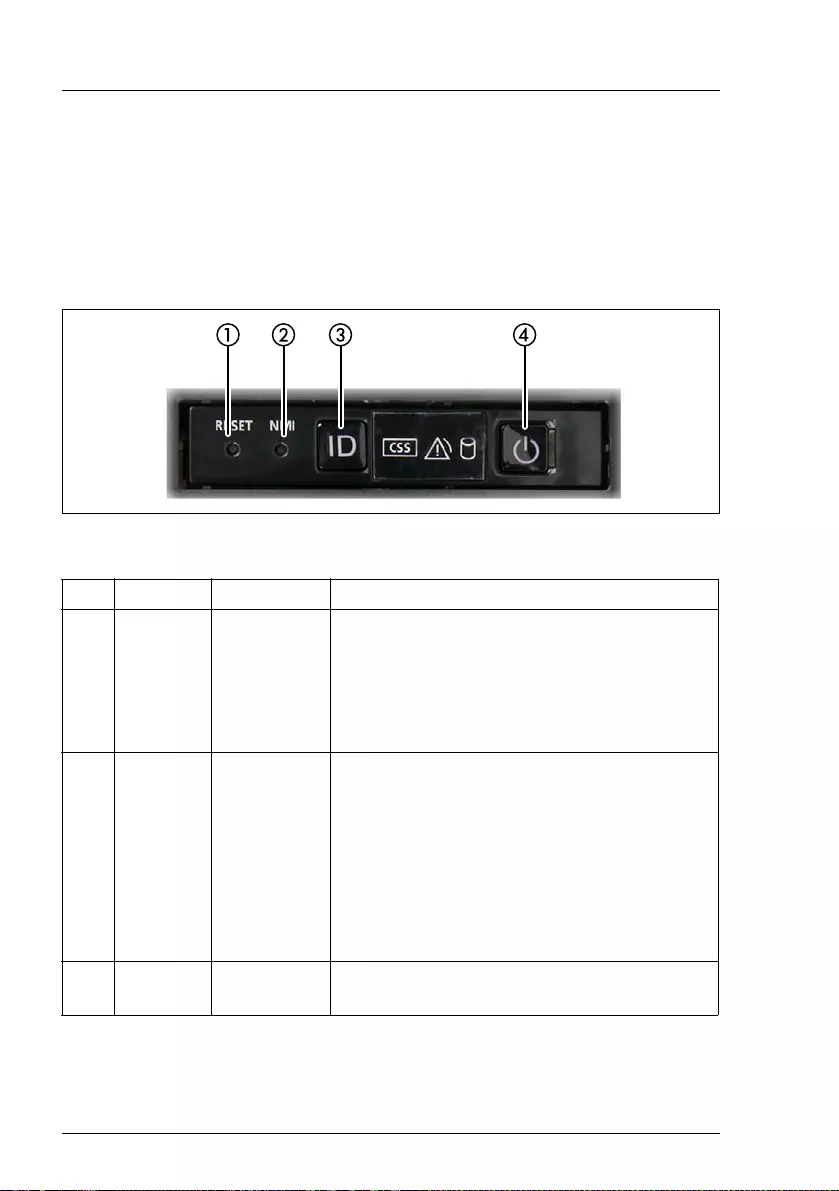

6.3.1.1 Controls on the front panel

Figure 13: Controls on the front panel

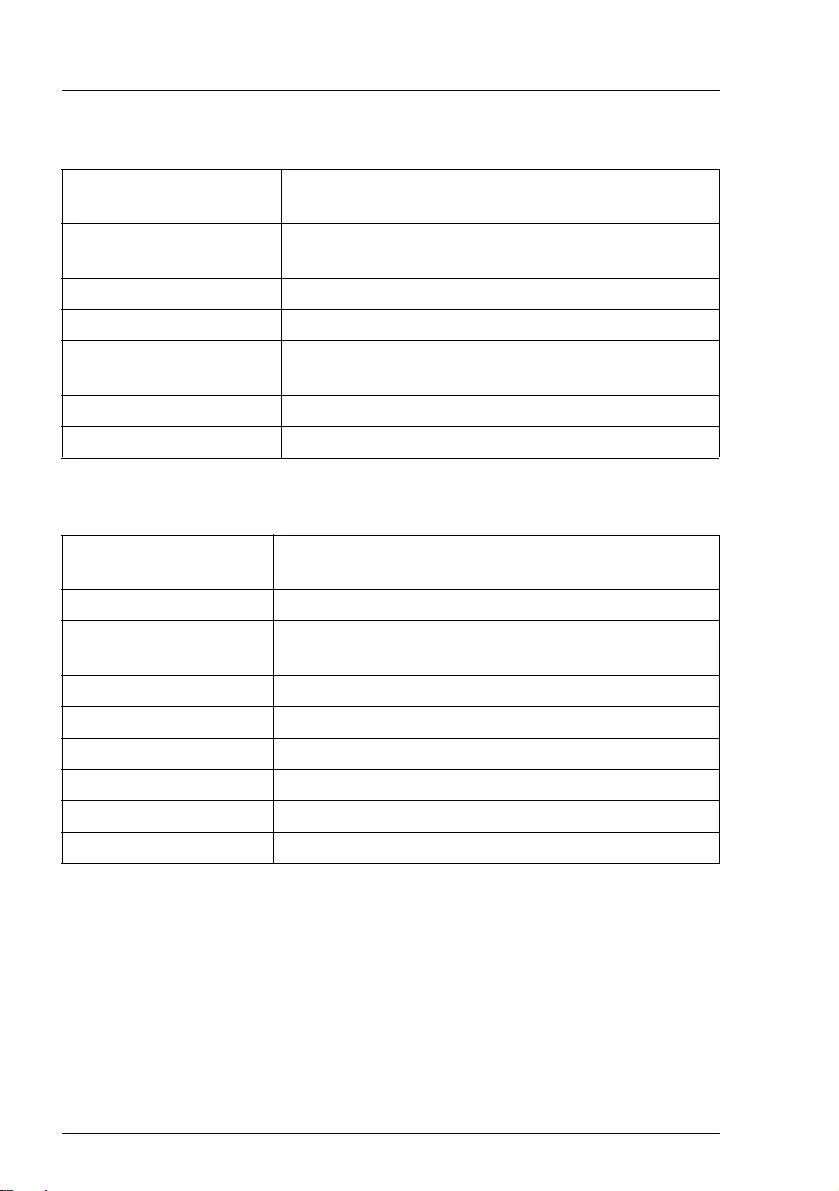

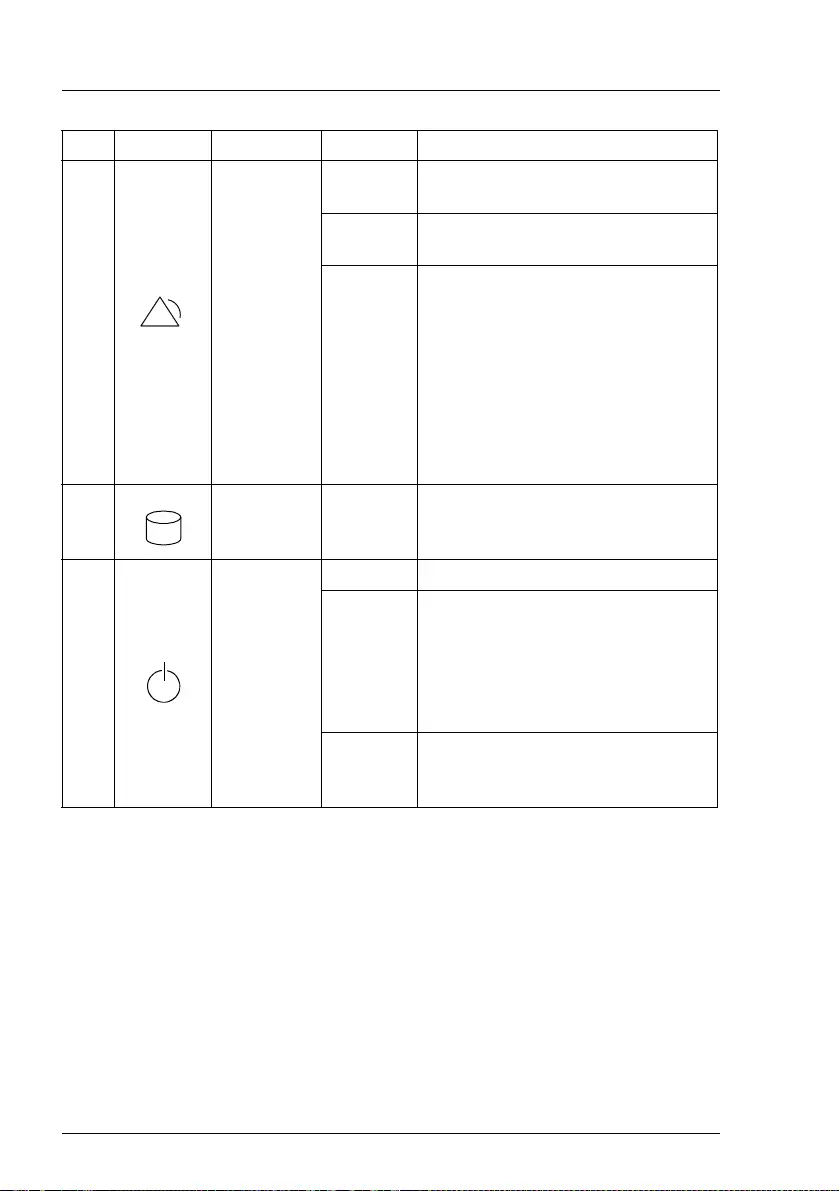

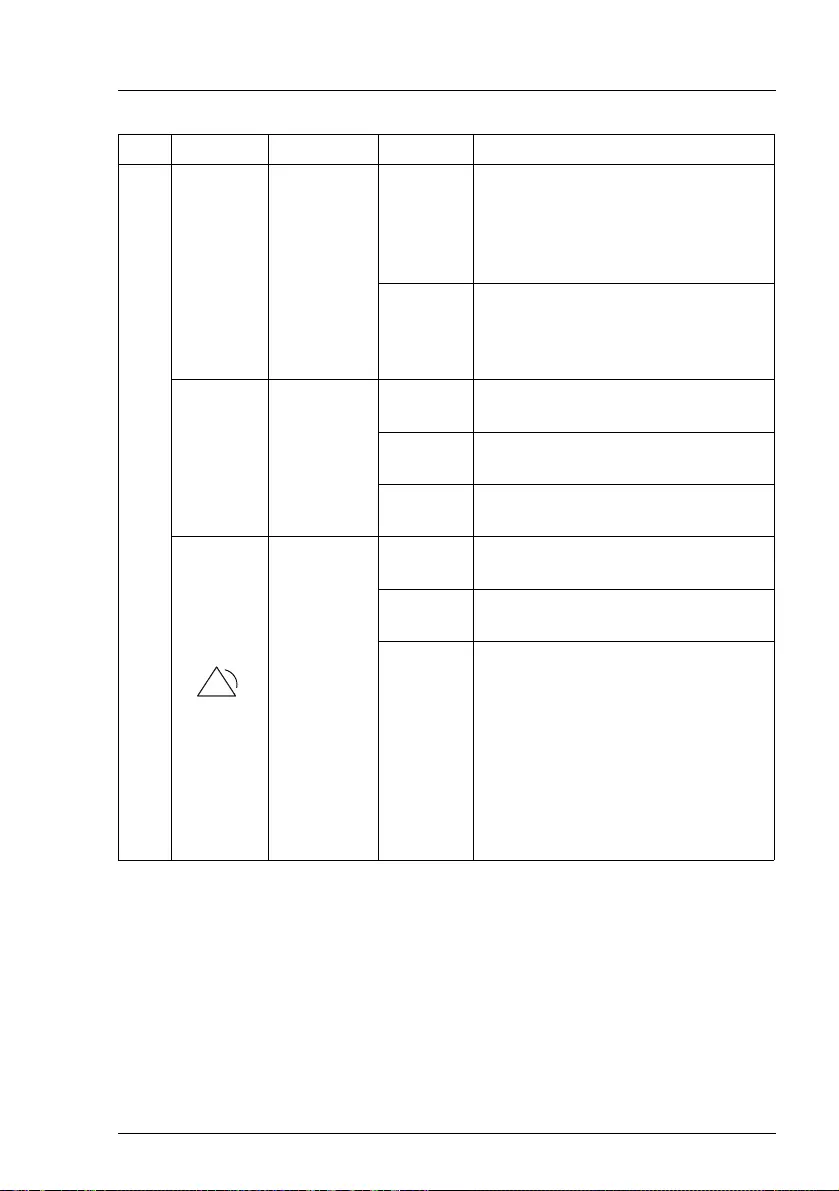

Pos. Label Button Function

1RESET Reset button

Reboots the system.

Press the reset button with a straightened end

of a paper clip.

VCAUTION!

Risk of data loss!

2NMI NMI button

Used to troubleshoot software and device driver

errors.

Press the NMI button with a straightened end of

a paper clip.

VCAUTION!

Use this button only if directed to do so

by qualified certified maintenance

personnel!

3ID ID button Highlights the ID indicator on the front panel and

the rear panel for easy server identification.

TX1320 M3 Operating Manual 65

Starting up and operation

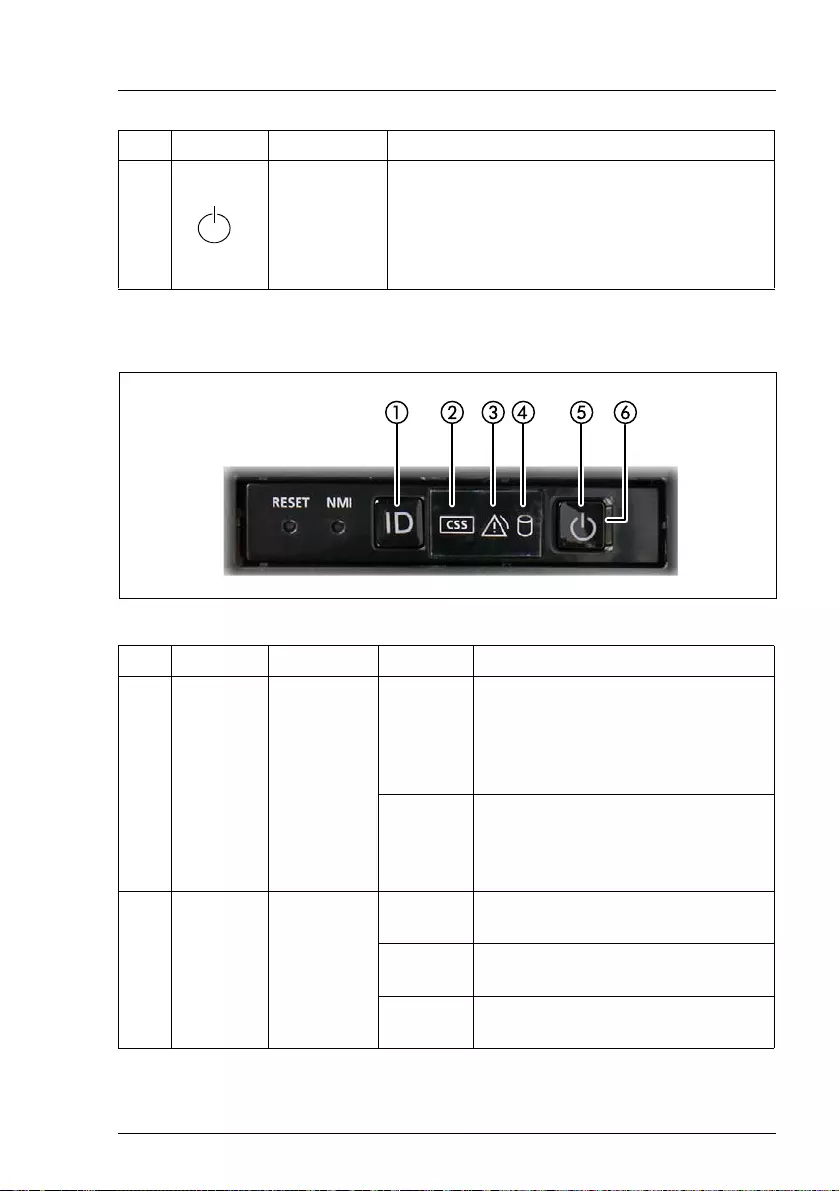

6.3.1.2 Indicators on the front panel

Figure 14: Indicators on the front panel

4 On/Off button

Used to switch the server on or off.

IIf the system is running an ACPI-

compliant operating system, pressing

the On/Off button will perform a graceful

shutdown.

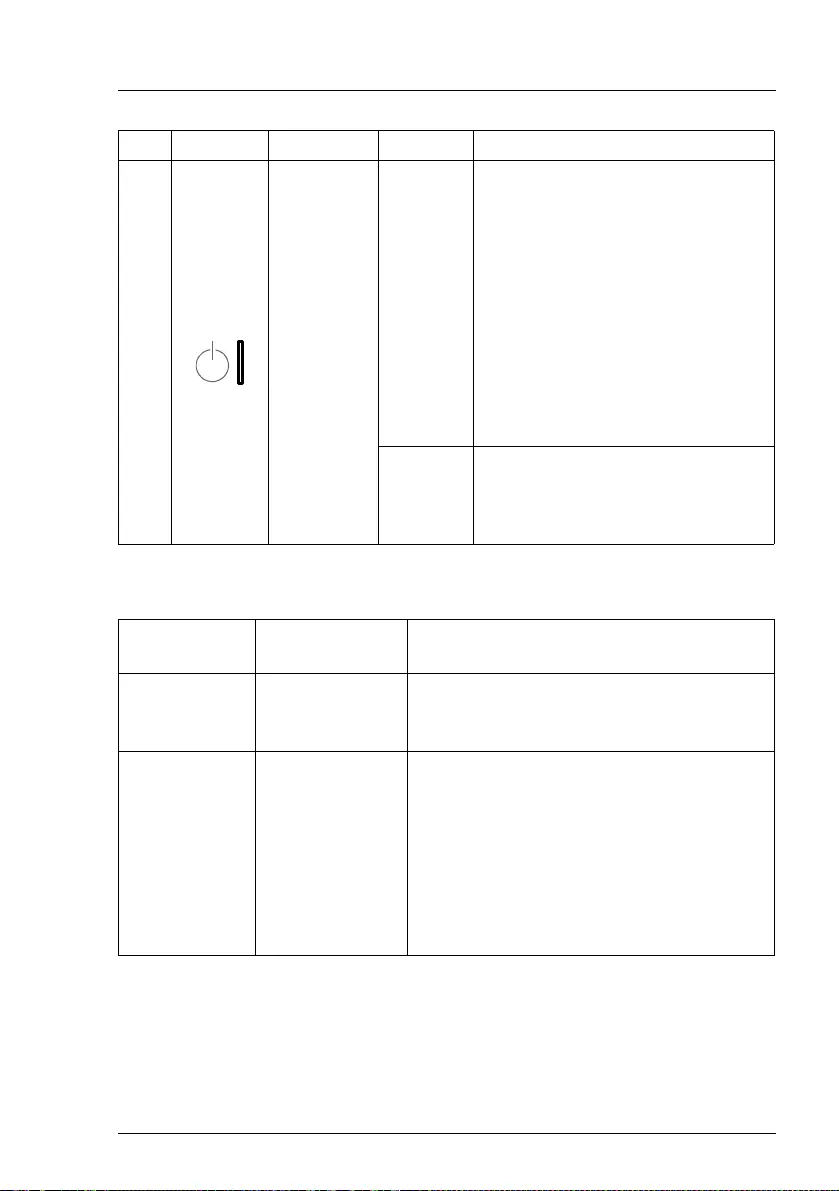

Pos. Label Indicator Status Description

1ID

ID indicator,

see also

"iRMC-

related

status

signals" on

page 67

blue on

The server has been highlighted

using ServerView Operations

Manager, iRMC web frontend or the

ID button on the front panel for easy

identification.

blue

flashing

The server has been highlighted for

easy identification using the iRMC

(AVR) with disabled local VGA

output.

2[CSS] CSS

indicator

off No critical event detected (CSS

component).

orange on Prefailure event detected (CSS

component).

orange

flashing CSS component failure detected.

Pos. Label Button Function

66 Operating Manual TX1320 M3

Starting up and operation

3

Global Error

indicator,

see also

"iRMC-

related

status

signals" on

page 67

off No critical event detected (non CSS

component).

orange on Prefailure event detected (non CSS

component).

orange

flashing

Non CSS component failure

detected.

Possible causes:

– System is out of the temperature

specified range

– Defective sensor