Interline Century User Manual

Displayed below is the user manual for Century by Interline which is a product in the Above Ground Pools category. This manual has pages.

Related Manuals

Building a Century

swimming pool

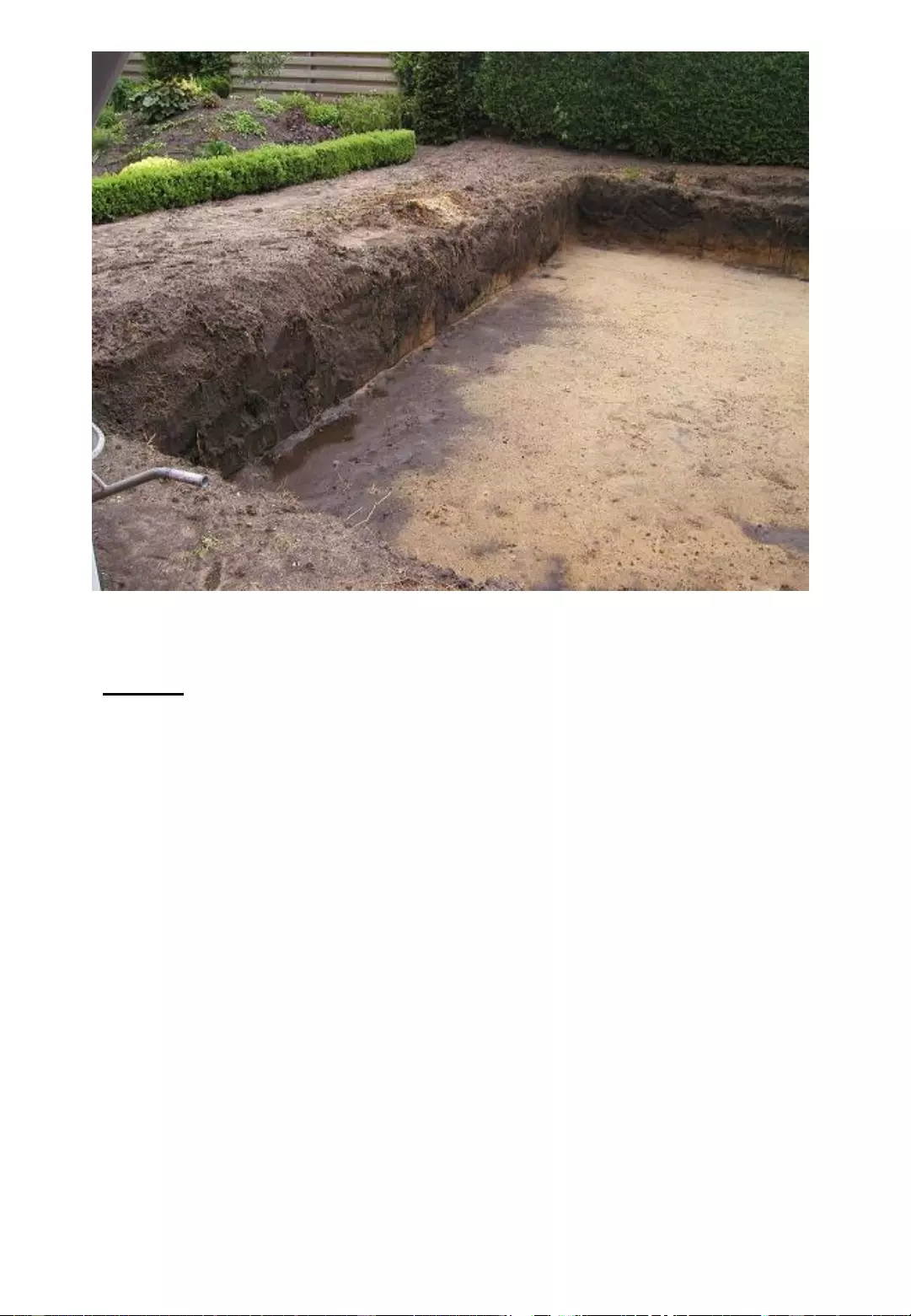

Step 1

It all starts with the digging of a hole with a nice (water)

leveled floor below. Always excavate the hole a bit larger

than the size of your pool. We recommend about 50 cm

larger on all sides (for a pool sized 8.50 x 4.90 m a hole of at

least 9.25 x 5.75 m should be excavated)

The depth of the hole depends on how much you would like

the pool above ground level. We recommend the top of the

pool to be about 15-25 cm above surface level. This is no

obligation, you may choose whatever you like. The picture

shows a rectangular hole, again this is no must, it’s also

possible to make an oval hole.

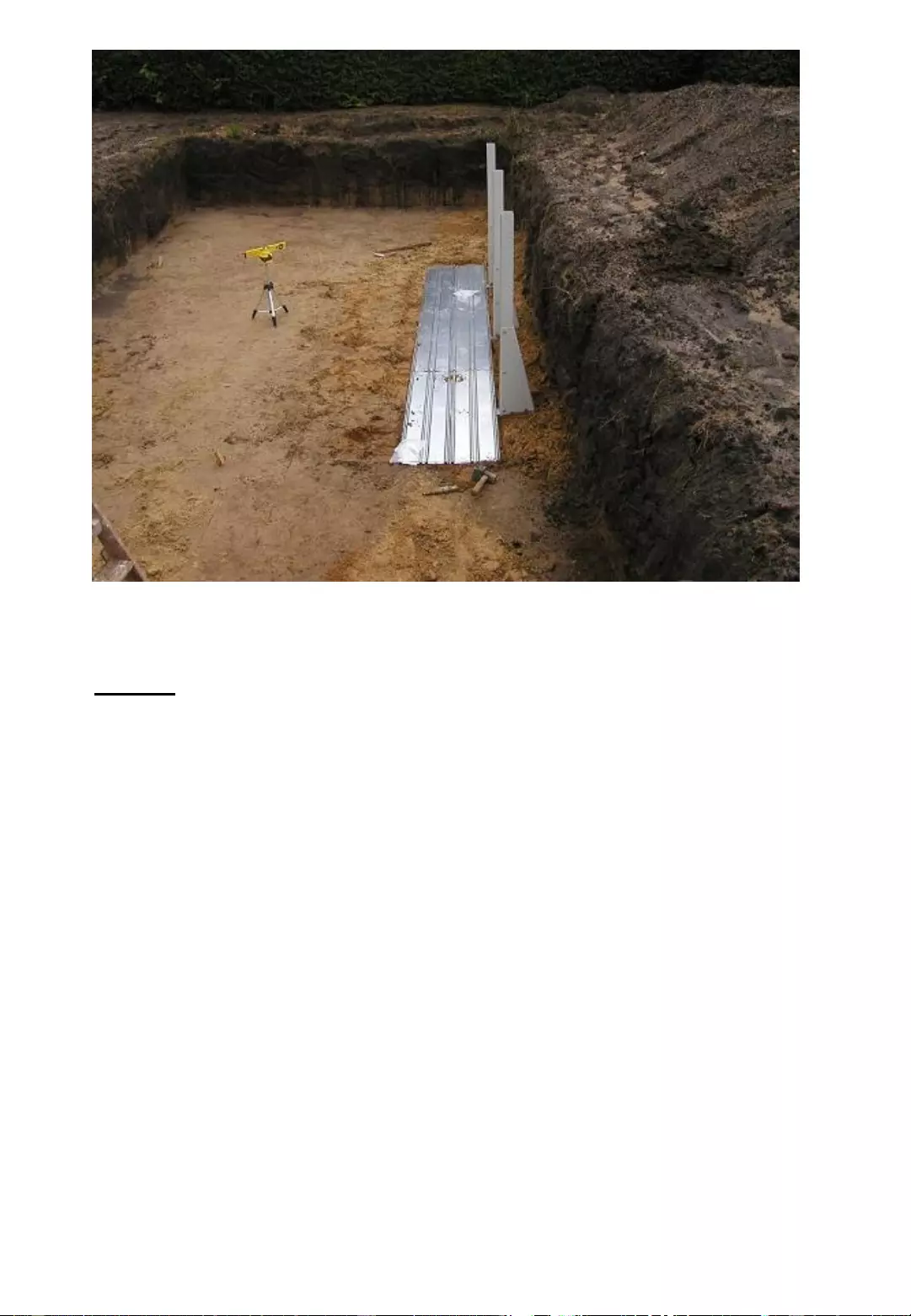

Step 2

After digging the hole as described in step 1, it is now time to

set out the measures of the pool.

In the instruction you will find the schedule with the different

measurements and sizes of pools. It is best to start by

placing the supports according the instruction. When finished,

it will look like this picture.

The (side) supports are well packed in the support pack(s) of

your pool.

Step 3

When all side supports are adjusted according the

instruction, it is time to equalize/fill up the floor with sand

and Styrodur isolation plates and/or make the final concrete

floor.

Remember that you don’t use isolation plates if there is

ground/level water.

You will notice that the pressure pads will stay about 5 cm

under the final floor. When the concrete is pored in, please

dig a little extra in the middle of the floor and around the

pressure plates to get a thick enough floor.

Thickness of the floor needs to be at least 12 cm or more,

depending the sort of soil it is put on.

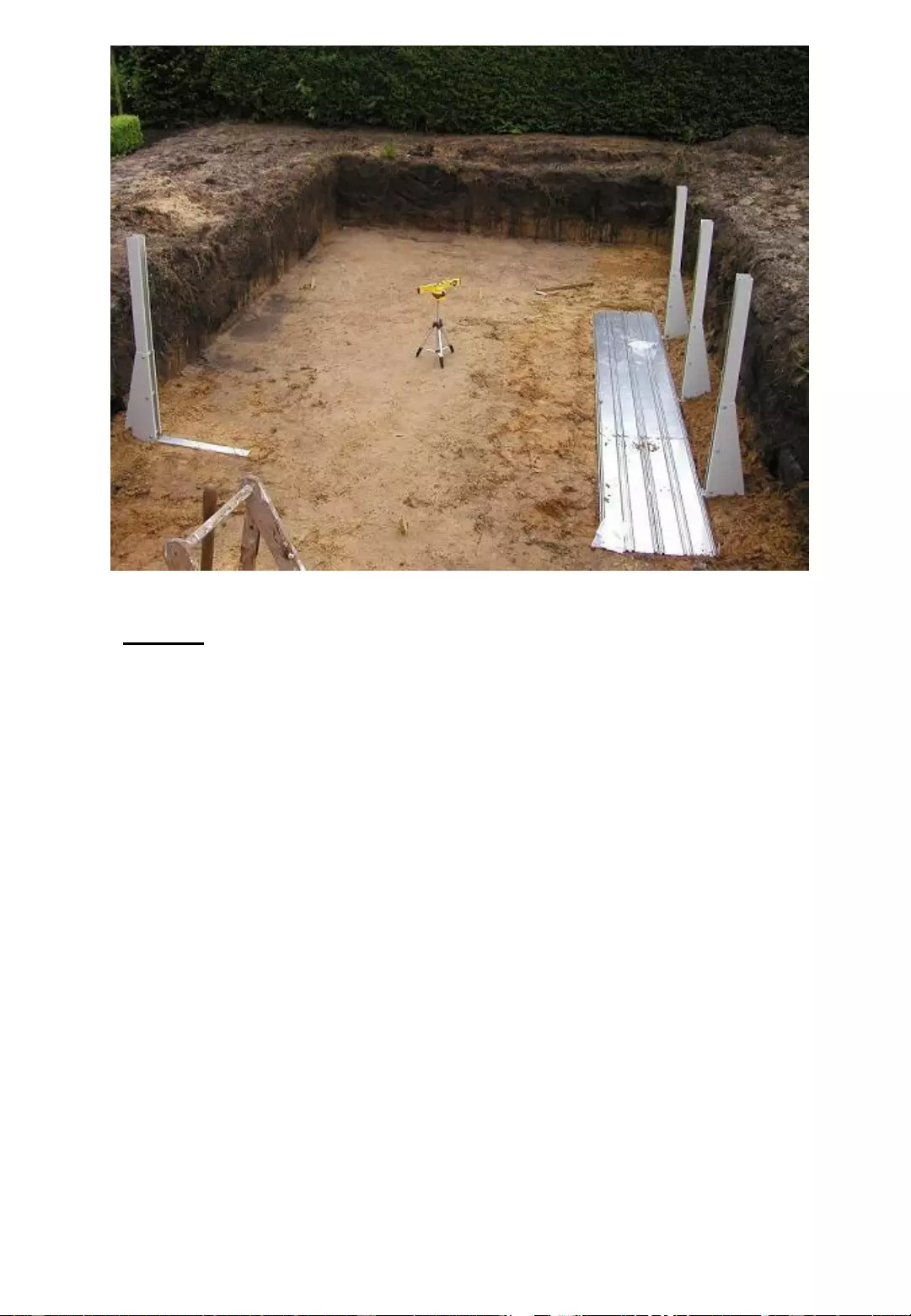

Step 4

The picture below shows a floor of sand. This could also

have been a concrete or a stabilized sand floor.

The supports are in place, the bottom rails in model waiting

for the mounting of the sidewall and verticals.

The Styrofoam plates in this example will be put in at a

later stadium (Step 6).

It is also possible to lay the plates first and put the bottom

rails on top of them. This way the depth of the pool will stay

about 5 cm deeper and chances of sinking will be less.

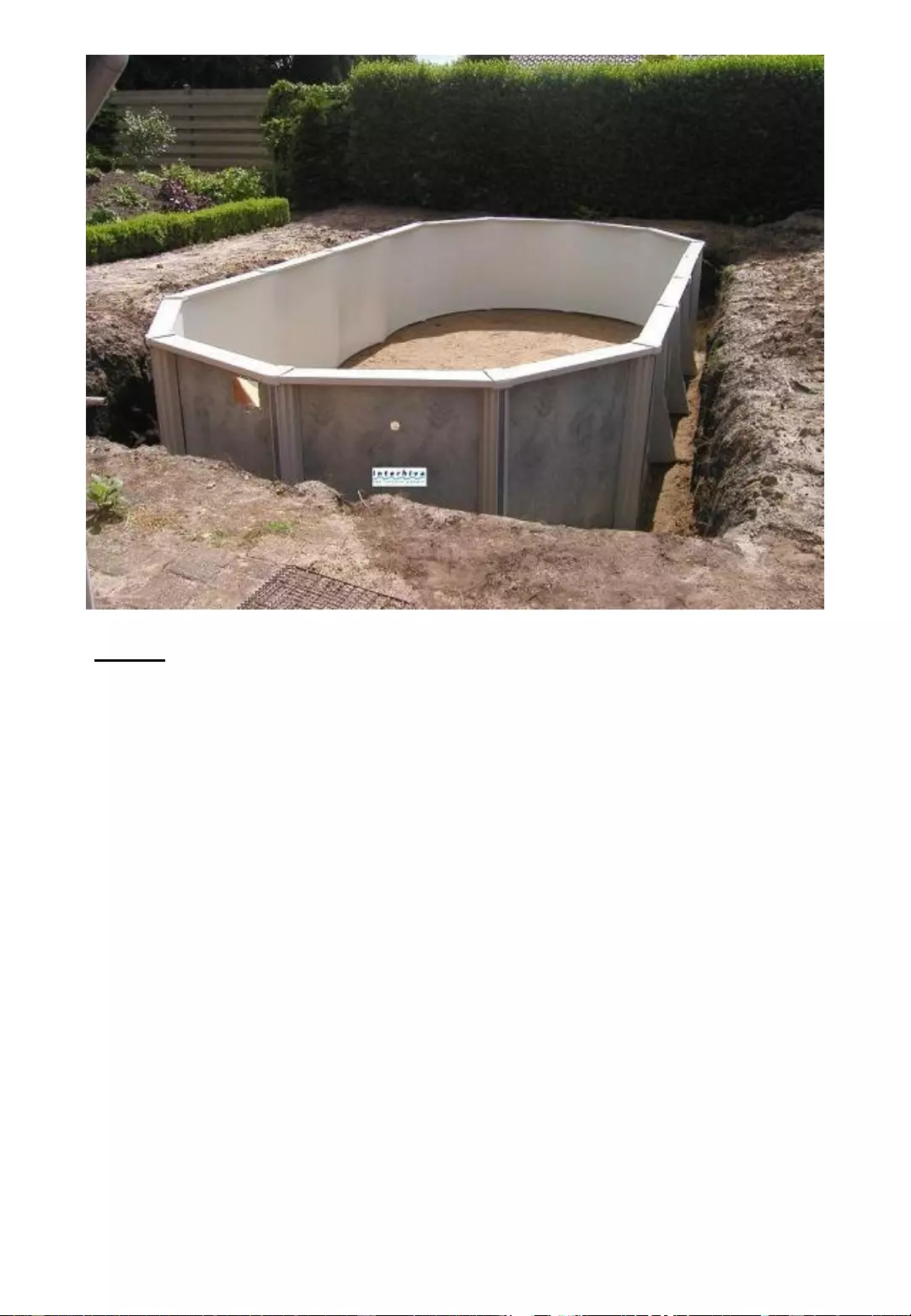

Stap 5

Sidewall, verticals and toprail are mounted.

The wall is rolled in a heavy carton en needs to be placed

vertically. Unfold it now step by step and place it, one section at

a time, in the bottom rails. Place the verticals at the same time

and see to it that the vertical end cap is ready for assembly.

Determine where you want the skimmer to be placed, to start

unfolding the wall at the right place. Always start with the wall-

end behind a vertical, so that the joint piece will not be visible

after completion. Going round the pool while mounting the wall,

assemble directly the verticals, and put the end caps on top of

them, so that the wall keeps standing.

When wall, verticals and end caps are standing, the top rails

can be put on the end caps. It is not necessary to mount coping

(plastic strips) and stabilizers in this stadium. This will be done

during the finishing of the liner/top rails.

Step 6

The Styrofoam plates and pool cove are in place. As mentioned

earlier, it’s also possible to lay these plates entirely underneath

the pool.

TIP: When the temperature rises to a high level, it is better to lay

the plates in the early morning or late evening. Put the plates

tightly together and hold them tight by placing a picket on the

sides, before taping the seams. (Keep in mind, that when the

temperature falls, the plates may shrink a little and the seams will

be more visible when the pool is finished).

We are now ready for the next step.

Note: Do not use foam plates or a foam pool cove in case of a

high groundwater level. In this case we advise you to make the

cove out of concrete or stabilized sand. You can also find this

description in your pool instruction

Step 7

Whether there are isolation (foam)plates, a sand or concrete

floor under the pool, it is always best to use an underlayment

(sort of carpet) before mounting the liner. It is protective and

takes away any (left behind) little unevenness.

Available at your pool supplier in ready-made sizes or perhaps

per meter.

Especially with a concrete floor this is really a must in order to

protect your liner.

Step 8

The casing of the pool liner can now begin. Carefully read the

instructions on how to do this. We see here that the liner is first

hung over the pool all around until the bottom seam is around 30

cm under the edge.

Only then filling with clean tap water can begin. Keep the liner from

dropping in by using clamps on the top rails or through a number

of people holding it until the middle of the liner touches the ground.

Provide adequate protection of the liner when using clamps!

After this, the liner can be added gradually. With a bit thinner and

sharper top rail, make sure the liner is shielded. Make sure the

bottom seam fits exactly in the corner of the pool on the cove.

Note; Assembling the liner is best done when the outside

temperature is above 17°C and / or the sun is shining. The liner

will be much more flexible when it is warmer and when the sun

shines on it.

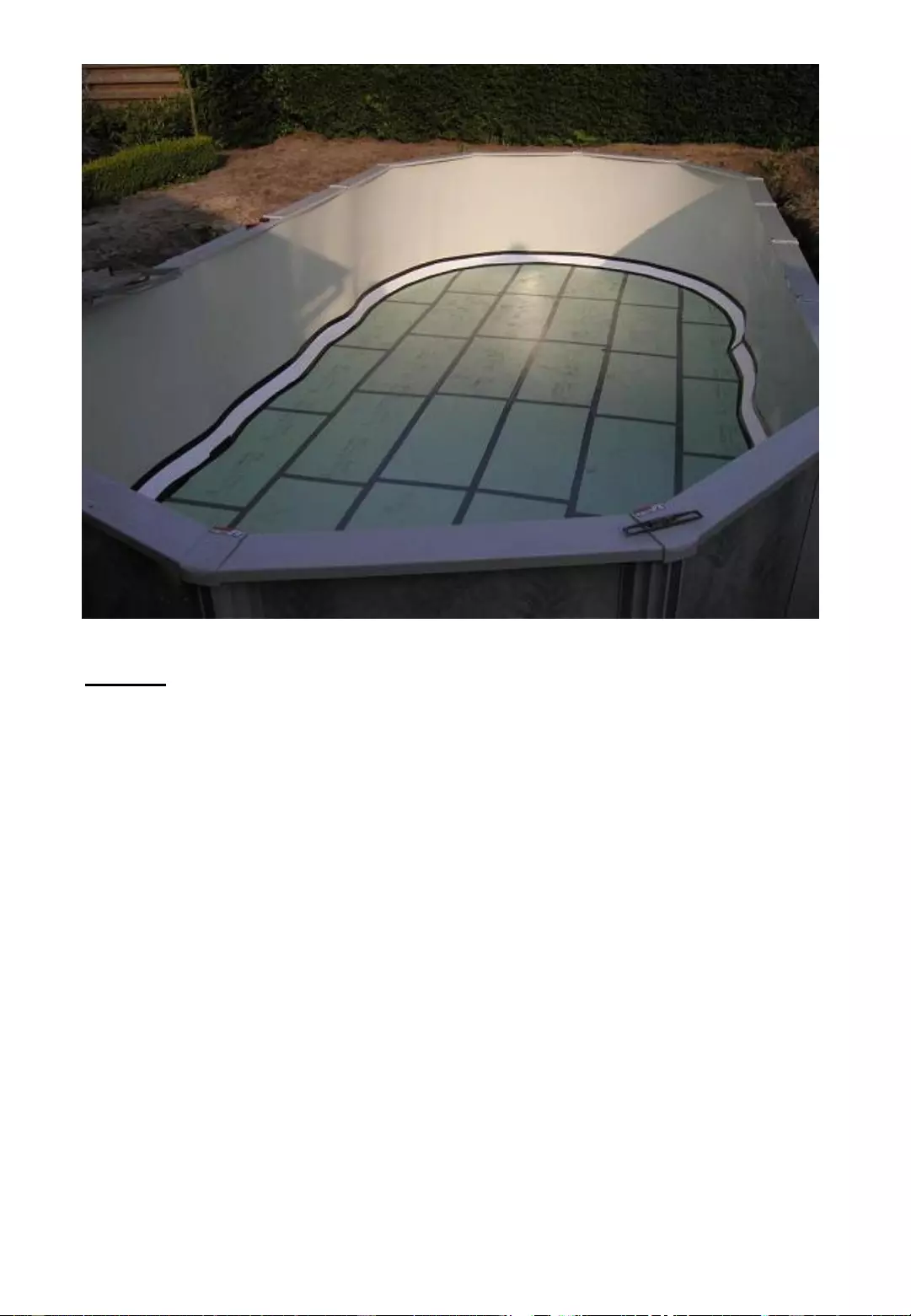

Step 9

On this picture mounting the liner has been finished. But you

can only start finishing the liner when there is about 60–70 cm

of water in the pool. Not sooner, because the liner may shift a

little during the filling process.

Remove 2 or 3 top rails and put the liner over the wall according

your pool instruction. Be sure that the loose part of the liner

doesn’t fall in the water. Pull the liner tight over the wall and

secure the coping (white plastic strips) and later on the

stabilizers. Mount the 2 or 3 top rails and top connectors and

proceed.

The over flap of the liner can be cut away if you want (don’t

throw it away, but keep it for emergency). Be sure that you do

not scratch the wall coating! Go round your pool this way and it

will look like the pool in this picture.

Step 10

The pool is nearly finished. Fill the water just under (5–10 cm)

the inlet and skimmer edge.

Now the skimmer and return fitting can be mounted.

Warning; do not yet cut the square hole out of the liner. First

mount the gaskets on the pool wall by folding them over the

edges. Than mount the skimmer flap (floating weir) in the

skimmer. Hold the skimmer on the outside of the pool against

the wall and the faceplate on the inside against the liner.

Puncture the screws through the faceplate and liner and screw

down the parts. The liner is still not cut out. Later when all

screws are tightened, the liner cannot shift anymore and the

hole may be cut out. Don’t forget the little hole for the vacuum

cleaner.

Read the pool manual for further instructions.

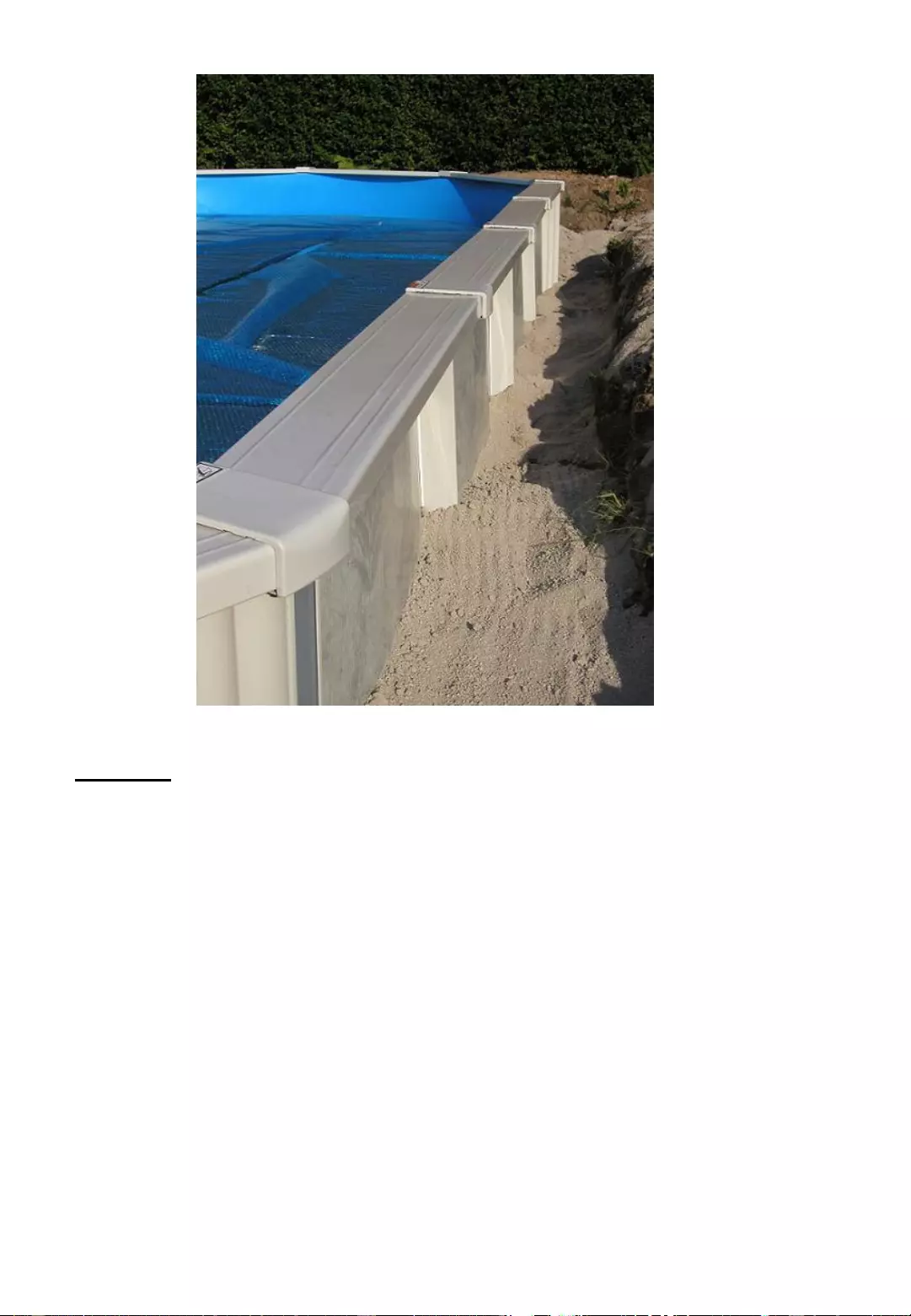

Step 11

When skimmer and return fitting are mounted, fill your pool till 5

cm below the top edge. After this you can start re-filling the hole in

which the pool is built. (Also look at step 3, excavation drawing.)

Filling the hole has to be done with stabilized sand from top to

bottom. Stabilized sand is clean sand used in building, river sand,

mixed with dry cement powder in the proportion 1:8 (1 m³ river

sand on 150 kg cement.) In the pool instruction you’ll find the

directions for use.

Note: Do not use stabilized sand round the skimmer and return

fitting, but use clean building sand instead. (This can be removed

easily, if there’s a problem.)

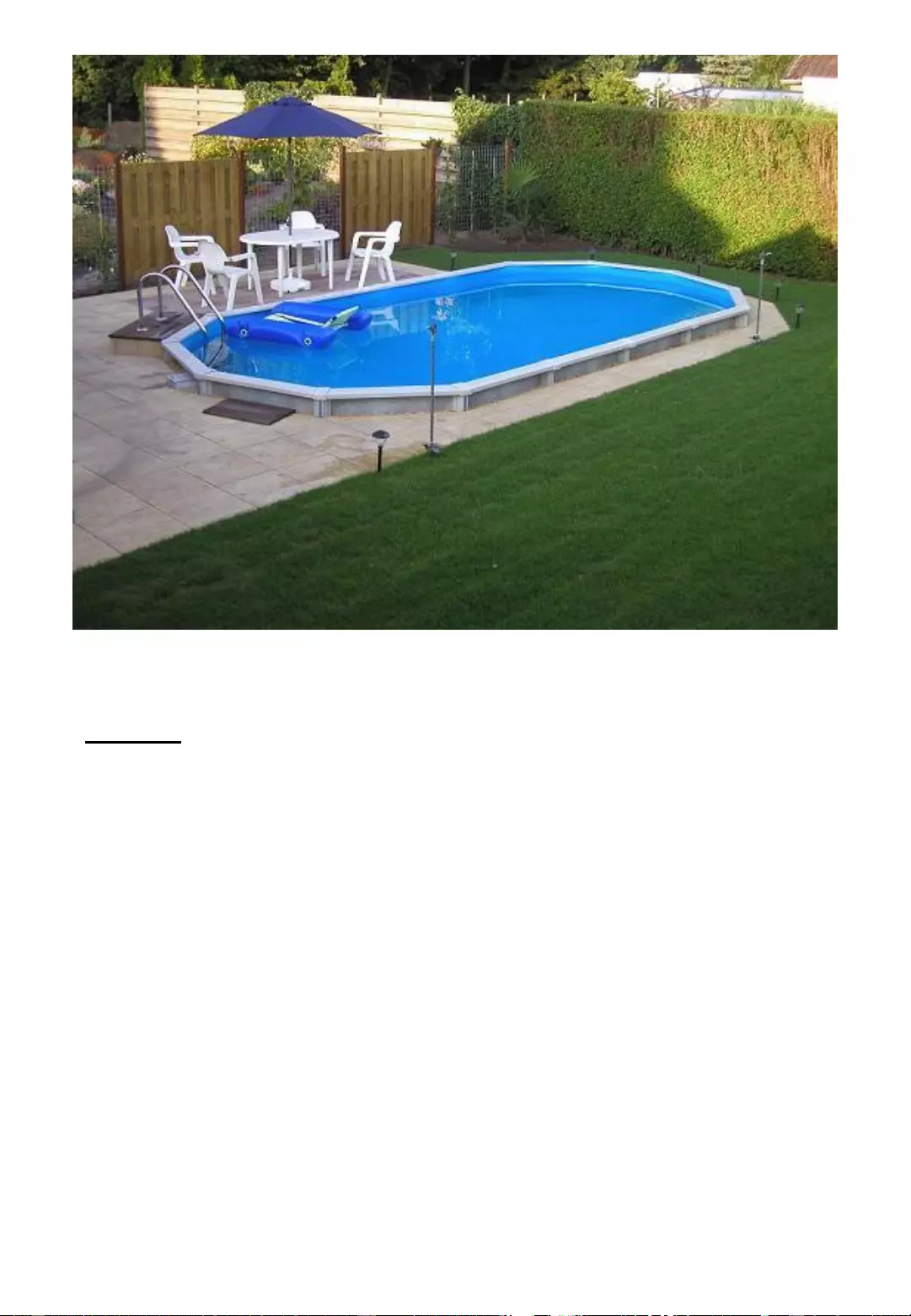

Step 12

Because you built the pool a little above ground surface level,

the skimmer lid fits perfectly in the pavement.

After completion with random materials the pool looks

respectable.

Step 13

The rest of the garden can be arranged. Tiles, pavement, a

lawn, a wooden platform or plank bridges…, everything is

possible.

Good luck building your swimming pool and enjoy it

afterwards!