Legrand RFB-2AB-SS User Manual

Displayed below is the user manual for RFB-2AB-SS by Legrand which is a product in the Brackets & Braces category. This manual has pages.

Related Manuals

Adjusting Screws

RFB Recessed Floor Box

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 002 639 R5 – Updated June 2012

Products Covered: RFB4, RFB4-CI-1, RFB4-CI-NA, RFB4-4DB, RFB4-SS

IMPORTANT: Please read all instructions

before beginning.

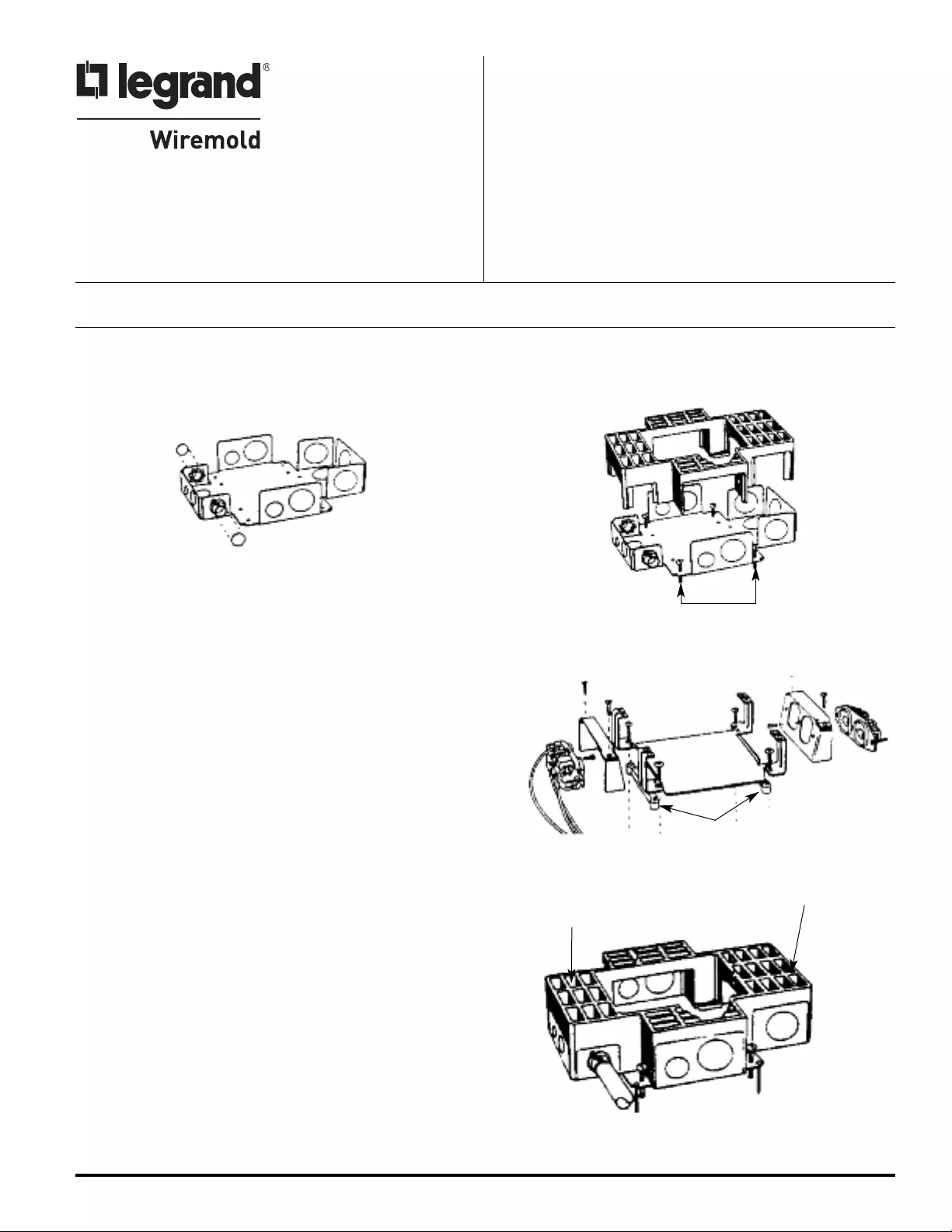

Step 1 Determine box location and conduit layout. Remove

knockouts and attach proper conduit adapters (sold

separately) to steel base.

Step 2 Slip housing over base. Using the adjusting screws provided

and adjust box so that top is 1/16" [1.6mm] below screed line.

RFB4 Recessed Floor Box –

Before Concrete Pour:

Compartment A

Compartment B

Step 4

Step 3

Tunnel Blocks

Step 3 Insert combination bracket inside of housing. Mount to

base with four #10-24 x 5/8" [15.9mm] Phillips drive machine

screws. If compartments (A) and (B) are used for different services,

then one or both tunnel blocks must be pressed into the

combination bracket to block the passage of wires between the two

compartments. If pass-through is required between compartments

(A) and (B), tunnel blocks are not needed. Pass-through is available

only between compartments (A) and (B).

Step 4 Secure box to subfloor using wire or nails through the slot adjacent

to the adjusting screws. Once positioned, connect conduit to

adapters.

Step 5 Leave receptacle brackets in shrink wrapping and inside box until

concrete is set and receptacles are ready to be installed.

Step 6 Insert unused tunnel blocks into fingers of combination bracket.

Place brackets in box and insert mudcap on top of blocks.

WARNING: Pour concrete to 1/16" [1.6mm] above box

housing. Pours of 1/4" [6.4mm] or more over

box housing will make it difficult to breakout

the mudcap and cause excessive spalling.

Legrand/Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Legrand/Wiremold electrical

products may bear the mark of a Nationally Recognized Testing

Laboratory (NRTL) and should be installed in conformance with current

local and/or the National Electrical Code.

AB

Step 7 Locate box and chip away concrete located in

mudcap. Remove mudcap

and device plates. Remove tunnelblocks from the combination bracket fingers.

Clean out any debris. If concrete does not break cleanly around preset, the

activation might not be properly supported. If edges of FloorPort™Series Activations

are not supported by concrete on all sides, repair of excessive concrete spalling is

required.

Step 8 Wire devices (not included) in accordance with the National Electrical Code or any

local code that applies. Make sure that any ground leads are connected to ground

screws. Attach the receptacle to the receptacle mounting bracket using #6-32 screw

provided. Attach the receptacles to the receptacle mounting brackets with two

additional screws and nuts (not provided). Attach the receptacle mounting bracket to

the combination bracket using two #10-24 mounting screws provided.

Step 9 Complete procedure by installing a FloorPort Series Activation (sold separately)

using the installation instructions provided with the unit. instructions provided with

the unit.

This box and activation are UL Listed for use with tile, terrazzo, and

carpet floors.

Use insulator provided with the following catalog numbers:

RFB-GFI, CIHT-GFI, RFB-GFI-SS, RFB-GFI-4DB.

RFB4 Recessed Floor Box –

After Concrete Pour:

Tunnel Block

(See Step Four)

Adjusting Screw

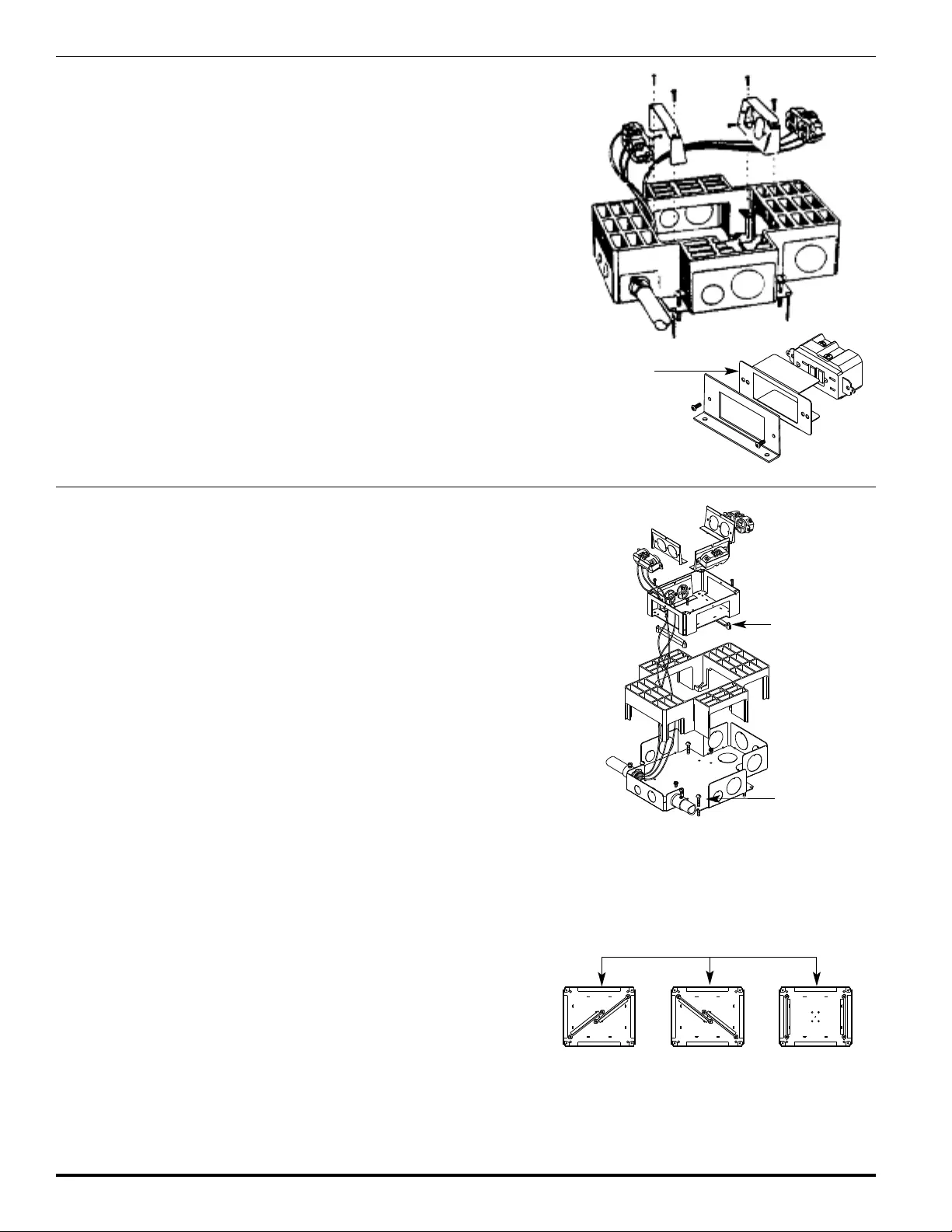

Step 1 Remove knockouts and attach conduit to base using proper conduit adapters

(not supplied).

Step 2 Slip housing over base. Using the adjusting screws provided adjust box so that

top is 1/16" [1.6mm] below screed line.

Step 3 Once positioned, connect conduit to adapters and anchor box to the subfloor by

wire or nails through the slot adjacent to the adjusting screws.

Step 4 If all four compartments are not being used for single service, tunnel blocks may

be installed to provide service isolation when feedback through wiring is not

required (see Tunnel Block Arrangements Illustration).

Step 5 Insert combination bracket inside of housing and mount to base with four #10-24

x 5/8" [15.9mm] machine screws.

Step 6 Leave receptacle brackets in shrink wrapping until concrete is set and receptacles

are ready to be installed.

Step 7 Insert unused tunnel blocks inside of box and insert mudcap.

WARNING: Pour concrete to 1/16" [1.6mm] above box housing. Pours of

1/4" [6.4mm] or more over box housing will make it difficult to

breakout the mudcap and cause excessive spalling.

WARNING: Compartments for power applications must be configured to

allow either direct access or via tunneling to one of the two

grounding screws in either compartment.

RFB4-4DB Recessed Floor Box –

Before Concrete Pour:

Step 1 Locate box and chip away concrete located in mudcap. Remove

mudcap and unused tunnel blocks. Clean out any debris.

tep 2 Attach receptacles (not supplied) to the receptacle brackets, using

#6-32 screw provided. Attach the receptacles to the receptacle

mounting brackets with two additional screws and nuts (not

provided). Wire devices (not included) in accordance with the

National Electrical Code or any local code that applies. Make sure

that any ground leads are connected to ground screws before

securing receptacle brackets using #6-32 x 3/8" [9.5mm] R.H.M.S.

Step 3 Complete procedure by installing a FloorPort Series Activation

using the instructions provided with the unit.

Possible Tunnel Block Arrangements

WARNING: If concrete does not break cleanly around preset,

the activation might not be properly supported. If

edges of FloorPort Activations are not supported

by concrete on all sides, repair of excessive

concrete spalling is required.

RFB4-4DB Recessed Floor Box –

After Concrete Pour:

Insulator

Adjusting Screws

Cover Plate

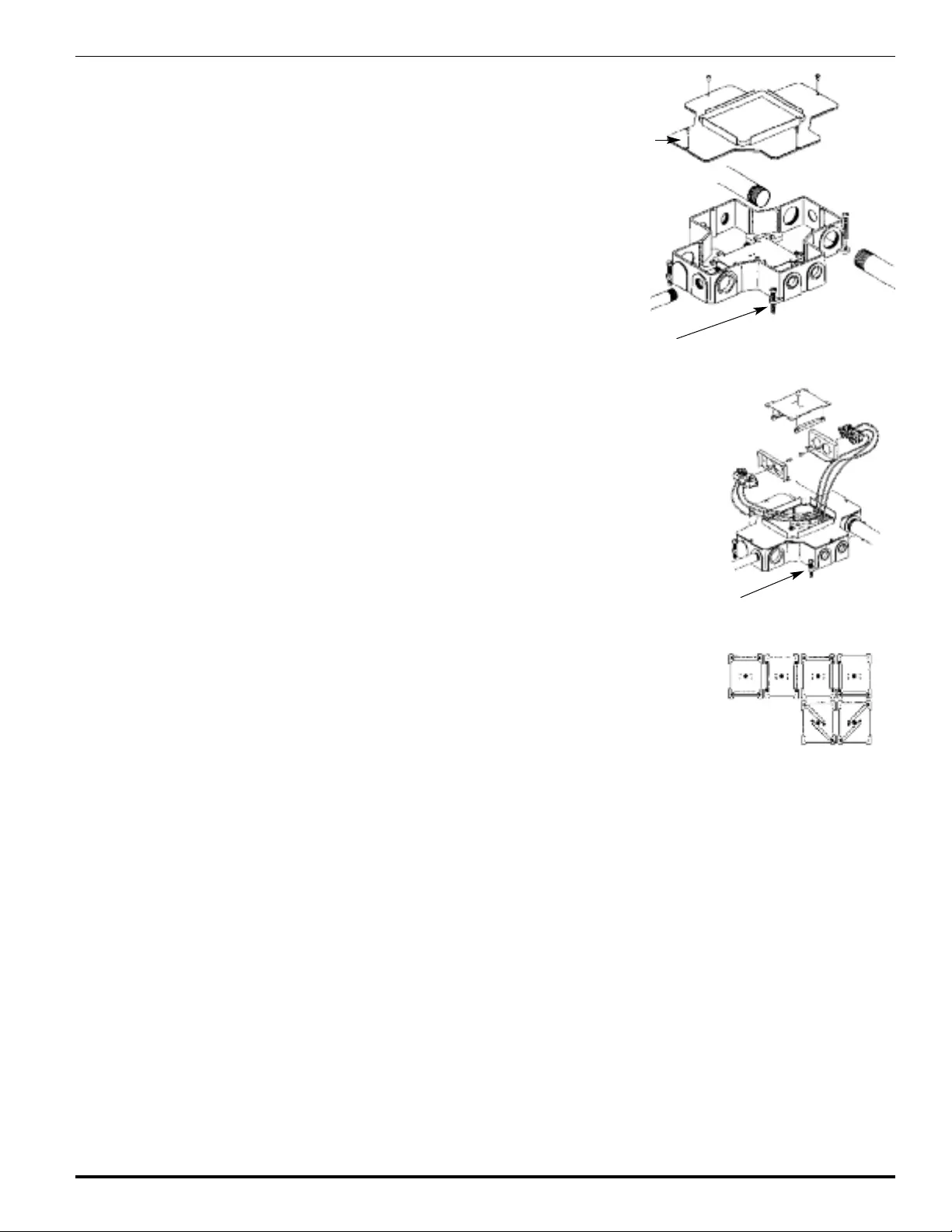

Step 1 Remove conduit opening hole plugs and attach conduit to housing in accordance

with local codes.

Step 2 Align cover plate over top of housing and secure in place with four #8-32 x 3/8"

[9.5mm] machine screws.

Step 3 Using the adjusting screws supplied, adjust box so that the flat surface of the cover

plate is 3/4" [19.1mm] below the screed line.

RFB4-CI-1, RFB4-CI-NA Recessed Floor Box –

Before Concrete Pour:

RFB4-CI-1, RFB4-CI-NA Recessed Floor Box –

After Concrete Pour:

Possible Tunnel Block Arrangements

Mounting Screws

Step 4 Locate box and chip away concrete located in mudcap. Remove mudcap and device plates.

Clean out any debris.

Step 5 Remove wiring compartment cover by first removing the #8-32 x 3/8" [9.5mm] machine

screw and then lifting the cover out of box (a small tip screwdriver used as a lever will help

in removing cover).

Step 6 Wire devices (not included) in accordance to the National Electrical Code or any local code

that applies. Make sure that any required ground leads are connected to the ground screws

before securing receptacle brackets in place. Connect receptacles to the receptacle brackets

using the #6-32 screw provided. Attach the receptacle to the receptacle mounting bracket

with two additional screws and nuts (not included).

Step 7 Secure receptacle brackets to box by first loosening the mounting screws a few turns. Next,

position top of bracket in place and pivot the forked ends under mounting screws. Tighten

mounting screws.

Step 8 Make sure that wires in tunnel area are not kinked or pinched. Attach tunnel blocks to wiring

compartment cover to isolate one compartment from the other as required (see Tunnel

Block Arrangement Illustration). Secure wiring compartment cover to box with #8-32 x 3/8"

[9.5mm] screws.

Step 9 Complete installation by installing a FloorPort Series Activation using the instructions

provided with the unit.

This box and activation are UL Listed for use with tile, terrazzo, and carpet floors.

WARNING: If concrete does not break cleanly around preset,the activation might

not be properly supported. If edges of FloorPort Activations are not

supported by concrete on all sides, repair of excessive concrete

spalling is required.

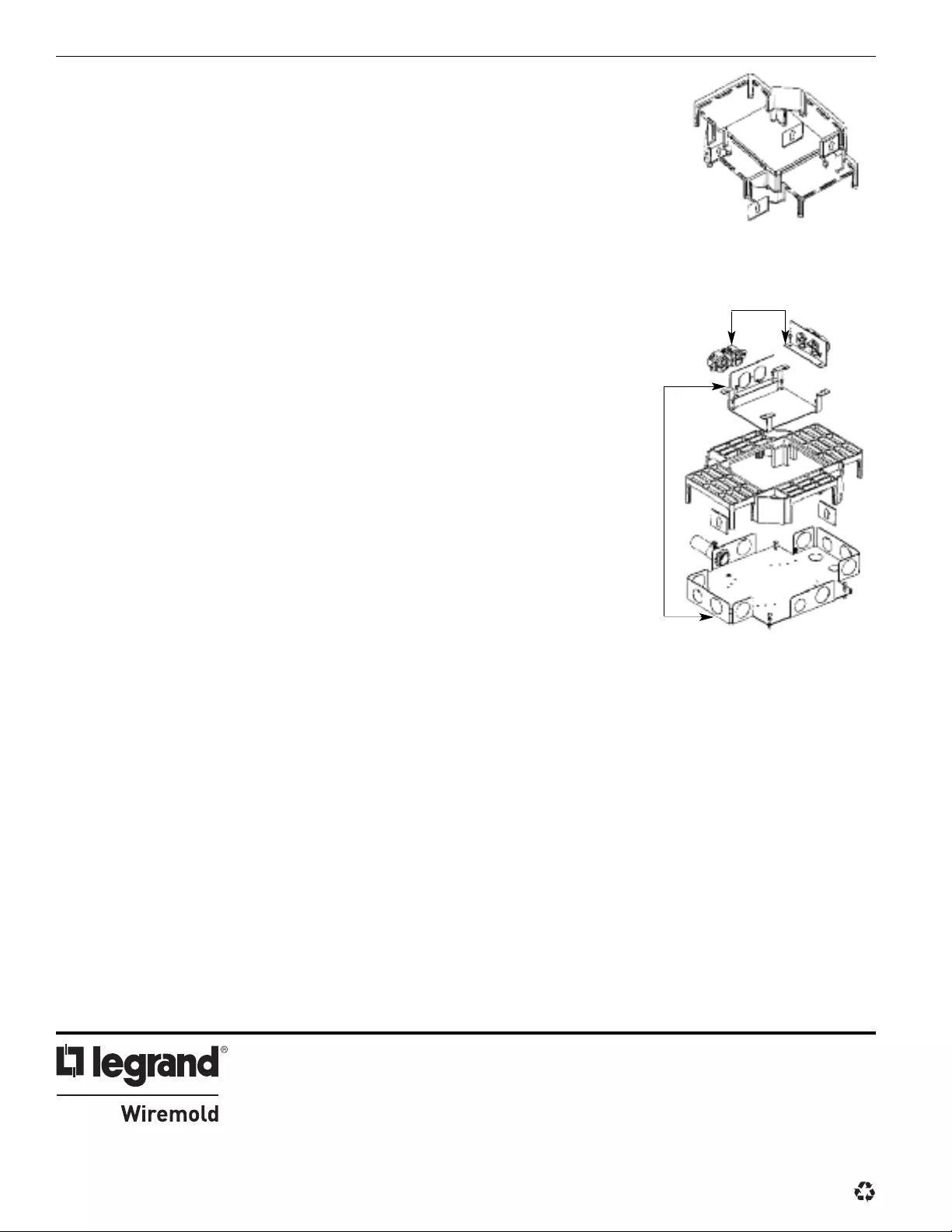

Figure 1

Figure 2

Step 3

Step 1 Determine box location and conduit layout. Remove knockouts and attach proper

conduit adapters (not included) to steel base.

Step 2 Select internal compartments of box which are to be used for power. Service

isolation may be acquired by plastic housing. Power compartments must be

arranged adjacent to one another to utilize the “pass-around” tunneling system (see

Figure 1).

Step 3 Slip housing over base. Insert retaining bracket inside housing and secure to base

using four #10-24 x 3/16" [4.8mm] screws provided (see Figure 2).

Step 4 Adjust box so that top of housing is 1/16" [1.6mm] below screed line using the

leveling screws provided. Secure box to subfloor using wire or nails through the

slots adjacent to the adjusting screws. Once positioned, connect conduit to fittings.

Step 5 Leave receptacle brackets in plastic bags until concrete is set and receptacles are

ready to be installed. Place brackets in box and insert mudcap.

NOTE: Make sure proper compartments are isolated before concrete

placement as barriers must be broken out rendering the barrier

useless and possibly breaking the plastic housing

.

RFB4-SS Shallow Steel Recessed Floor Box –

Before Concrete Pour:

Step 6 Locate box and chip away concrete located in mudcap. Remove mudcap and

device plates from the box. Clean out any debris.

Step 7 Wire devices (not included) in accordance with the National Electrical Code or any

local code that applies. Make sure that any ground leads are connected to ground

screws. Connect receptacles to receptacle brackets using #6-32 x 3/8" [9.5mm]

screws (see Figure 2).Attach the receptacle to the receptacle mounting bracket with

two additional screws and nuts (not provided). Secure receptacle brackets to base

using remaining #10-24 x 3/16" [4.8mm] screws.

Step 8 Complete procedure by installing a FloorPort Series Activation (sold separately)

using the installation instructions provided with the unit.

This box and activation are UL Listed for use with tile, terrazzo, and carpet

floors.

WARNING: If concrete does not break clearly around preset, the

activation might not be properly supported. If edges of

FloorPort Activations are not supported by concrete on all

sides, repair of excessive concrete spalling is required.

Step 7

© Copyright 2012 Legrand/Wiremold All Rights Reserved 1 002 639 R5 0612

RFB4-SS Shallow Steel Recessed Floor Box –

After Concrete Pour:

WIREMOLD

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721