Table of Contents

- Contents

- Safety

- Chapter 1. Introduction

- Chapter 2. Server components

- Chapter 3. Hardware replacement procedures

- Installation Guidelines

- Front door replacement

- Foot stands replacement

- Rack latch replacement

- Server cover replacement

- RAID super capacitor module replacement

- Air baffle replacement

- Front fan replacement

- Rear fan replacement

- PCIe adapter holder replacement

- Front bezel replacement

- Front panel replacement

- Optical drive or tape drive replacement

- Simple-swap drive replacement

- Hot-swap drive replacement

- Simple-swap-drive backplate replacement

- Hot-swap-drive backplane replacement

- Remove the backplane for four 2.5-inch hot-swap drives

- Install the backplane for four 2.5-inch hot-swap drives

- Remove the backplane for eight 2.5-inch hot-swap drives

- Install the backplane for eight 2.5-inch hot-swap drives

- Remove the backplane for four 3.5-inch hot-swap drives

- Install the backplane for four 3.5-inch hot-swap drives

- Expansion drive cage replacement

- DIMM replacement

- PCIe adapter retainer replacement

- PCIe adapter replacement

- CMOS battery replacement

- Serial port module replacement

- M.2 backplane and M.2 drive replacement

- TCM/TPM adapter replacement (for Chinese Mainland only)

- Intrusion switch replacement

- Fixed power supply replacement

- Hot-swap power supply replacement

- Power interface board replacement

- Hot-swap power supply cage replacement

- Processor and heat sink replacement

- System board replacement

- Complete the parts replacement

- Chapter 4. Problem determination

- Appendix A. Getting help and technical assistance

- Appendix B. Notices

- Index

Lenovo ST550 User Manual

Displayed below is the user manual for ST550 by Lenovo which is a product in the Servers category. This manual has pages.

Related Manuals

ThinkSystem ST550

Maintenance Manual

Machine Types: 7X09 and 7X10

Note

Before using this information and the product it supports, be sure to read and understand the safety

information and the safety instructions, which are available at:

http://thinksystem.lenovofiles.com/help/topic/safety_documentation/pdf_files.html

In addition, ensure that you are familiar with the terms and conditions of the Lenovo warranty for your server,

which can be found at:

http://datacentersupport.lenovo.com/warrantylookup

Thirteenth Edition (May 2022)

© Copyright Lenovo 2017, 2022.

LIMITED AND RESTRICTED RIGHTS NOTICE: If data or software is delivered pursuant to a General Services

Administration (GSA) contract, use, reproduction, or disclosure is subject to restrictions set forth in Contract No. GS-35F-

05925.

Contents

Contents . . . . . . . . . . . . . . . . . i

Safety . . . . . . . . . . . . . . . . . . iii

Safety inspection checklist . . . . . . . . . . . iv

Chapter 1. Introduction . . . . . . . . . 1

Server form factor . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . 3

Particulate contamination . . . . . . . . . 10

Firmware updates . . . . . . . . . . . . . . 11

Tech Tips . . . . . . . . . . . . . . . . . 15

Security advisories . . . . . . . . . . . . . 15

Power on the server . . . . . . . . . . . . . 15

Power off the server . . . . . . . . . . . . . 15

Chapter 2. Server components . . . . 17

Front view . . . . . . . . . . . . . . . . . 17

Front panel . . . . . . . . . . . . . . . . 20

Rear view . . . . . . . . . . . . . . . . . 23

Rear view LEDs . . . . . . . . . . . . . . . 26

System board components . . . . . . . . . . 28

System board jumpers . . . . . . . . . . . . 29

Internal cable routing. . . . . . . . . . . . . 31

Front panel . . . . . . . . . . . . . . . 32

Optical drive . . . . . . . . . . . . . . 33

Tape drive . . . . . . . . . . . . . . . 34

Power interface board . . . . . . . . . . 36

Fixed power supply . . . . . . . . . . . 37

Graphics adapter . . . . . . . . . . . . 38

Simple-swap-drive backplate . . . . . . . 39

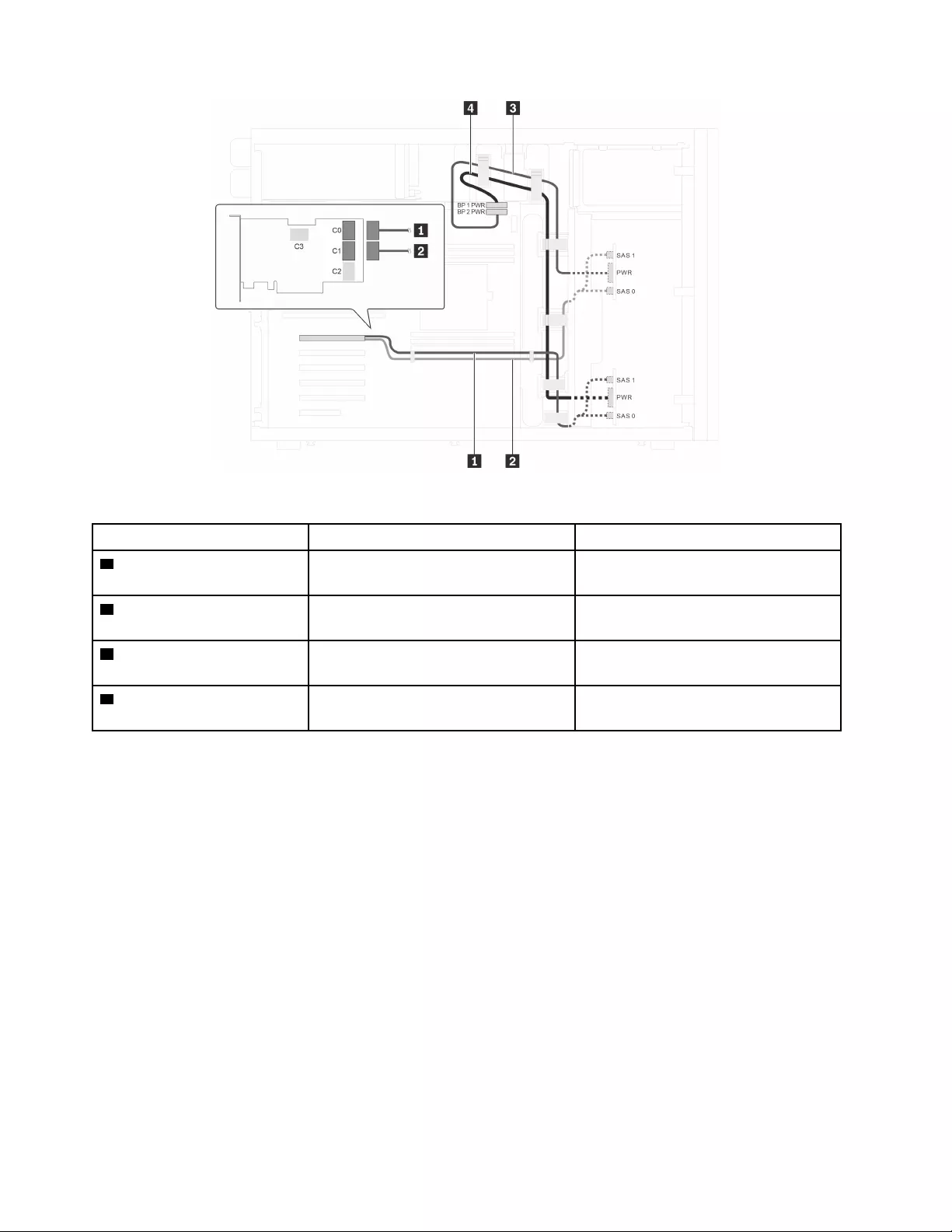

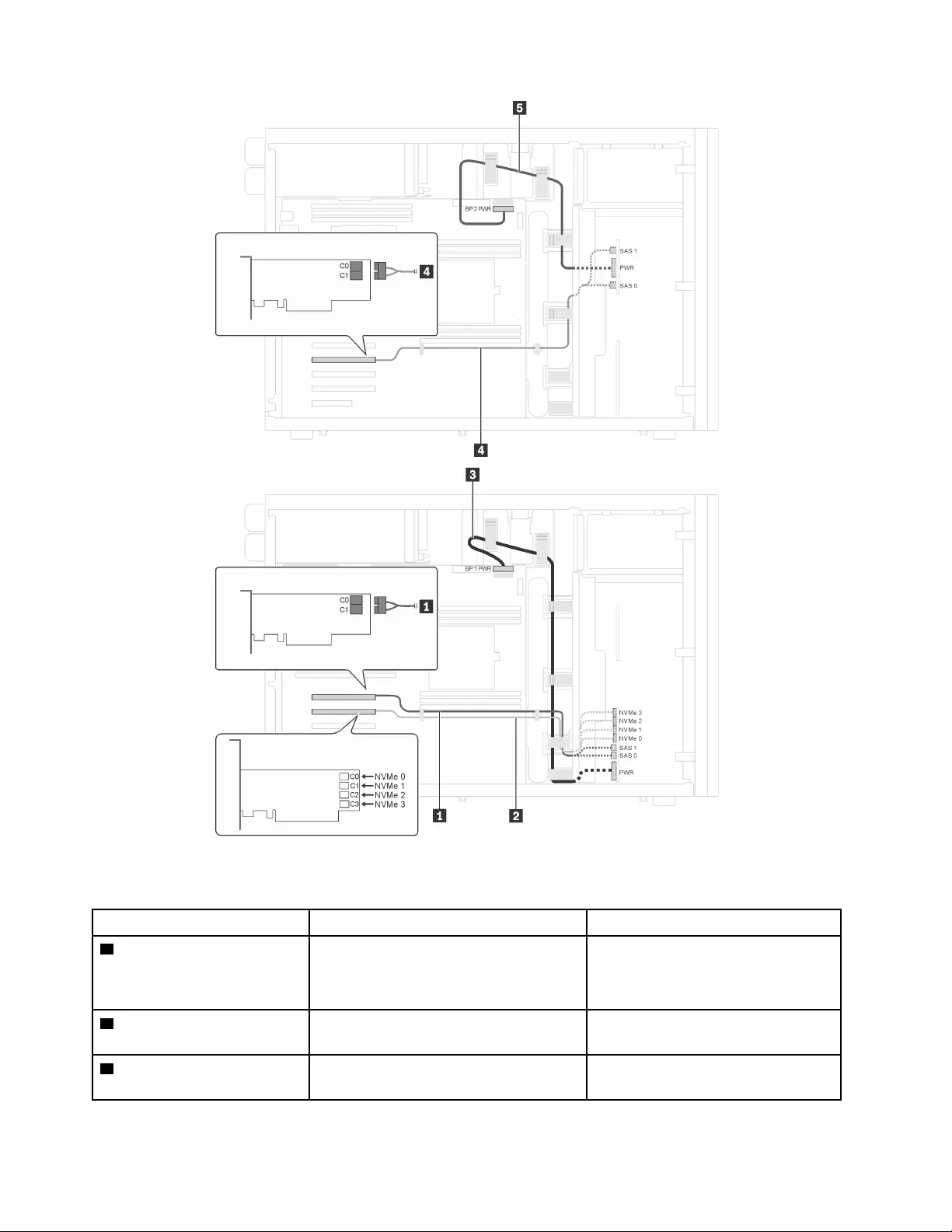

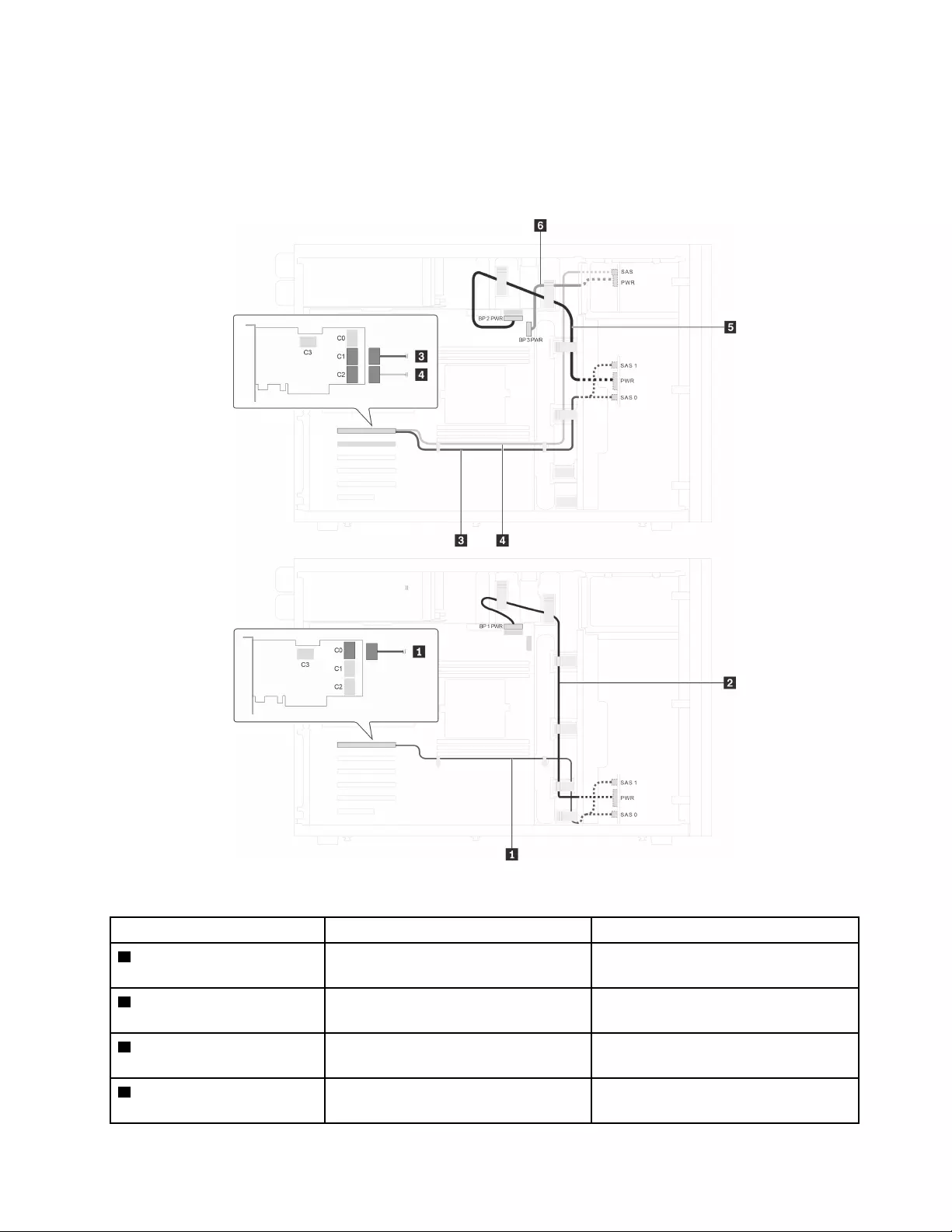

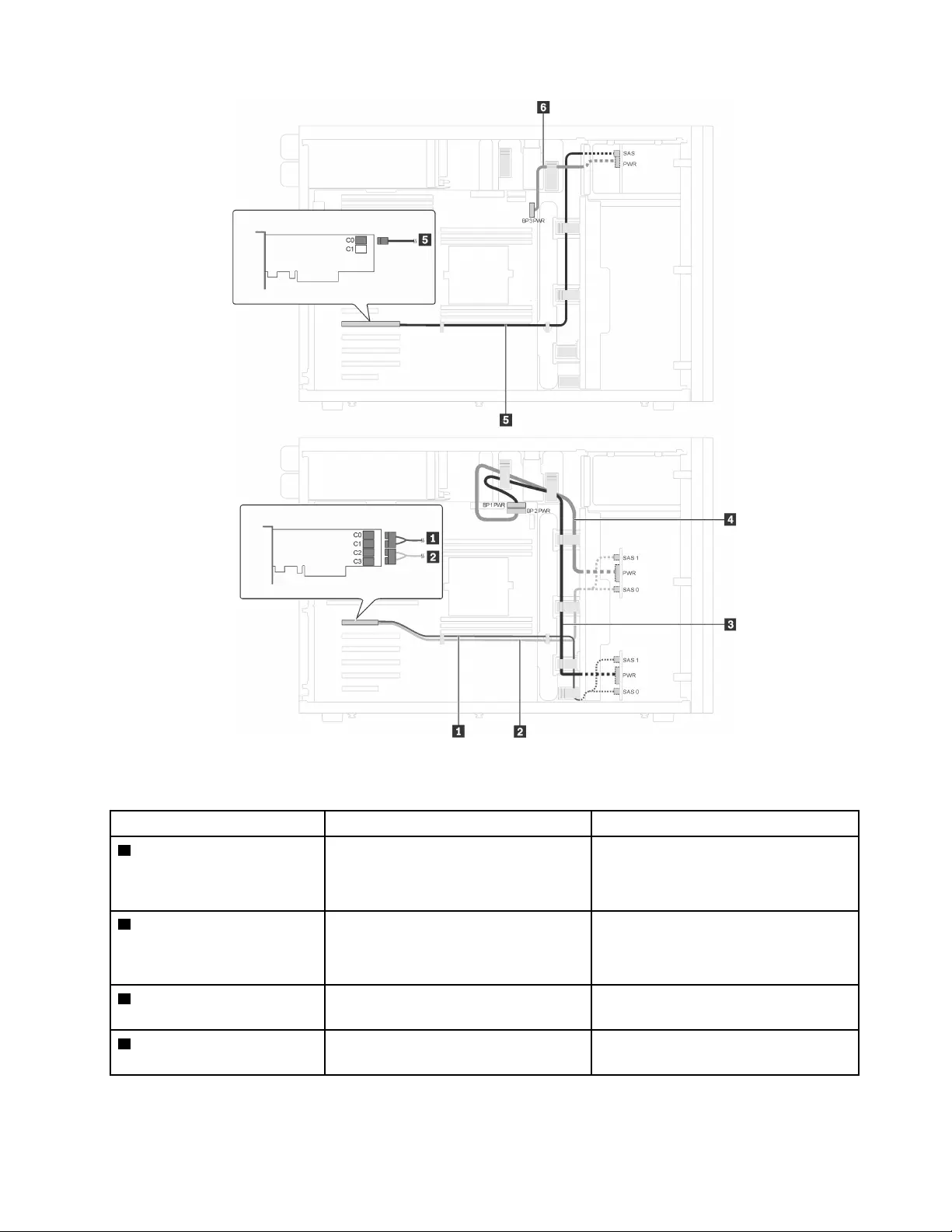

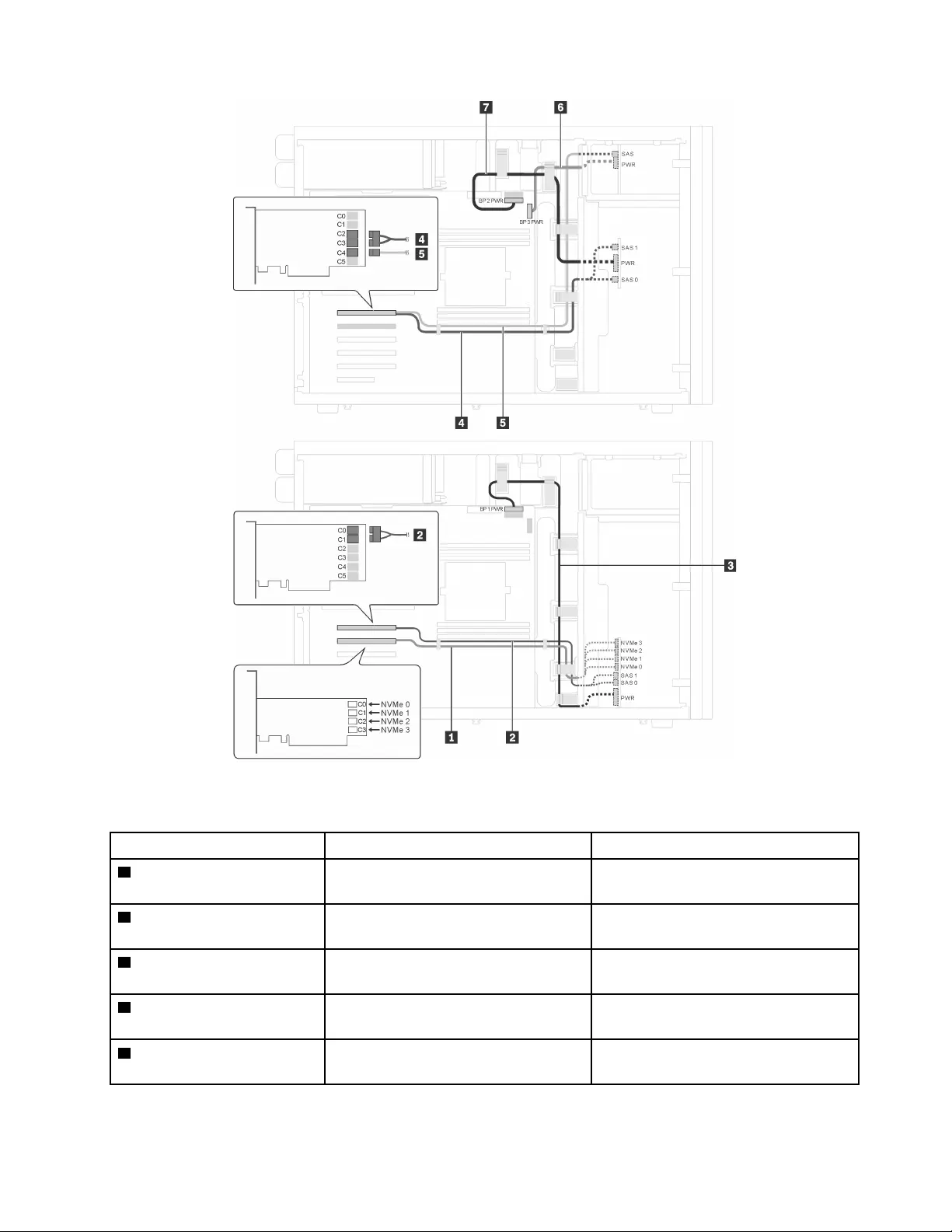

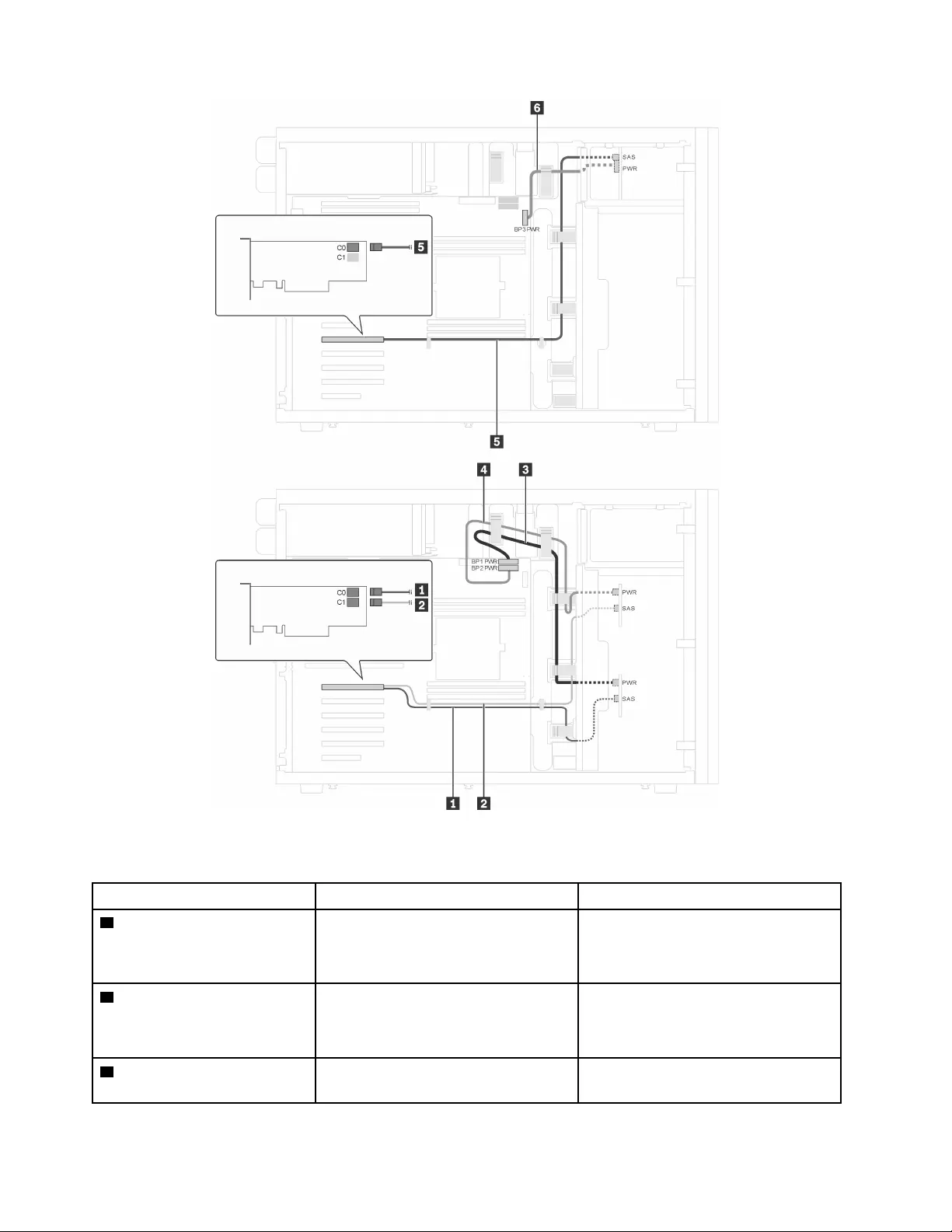

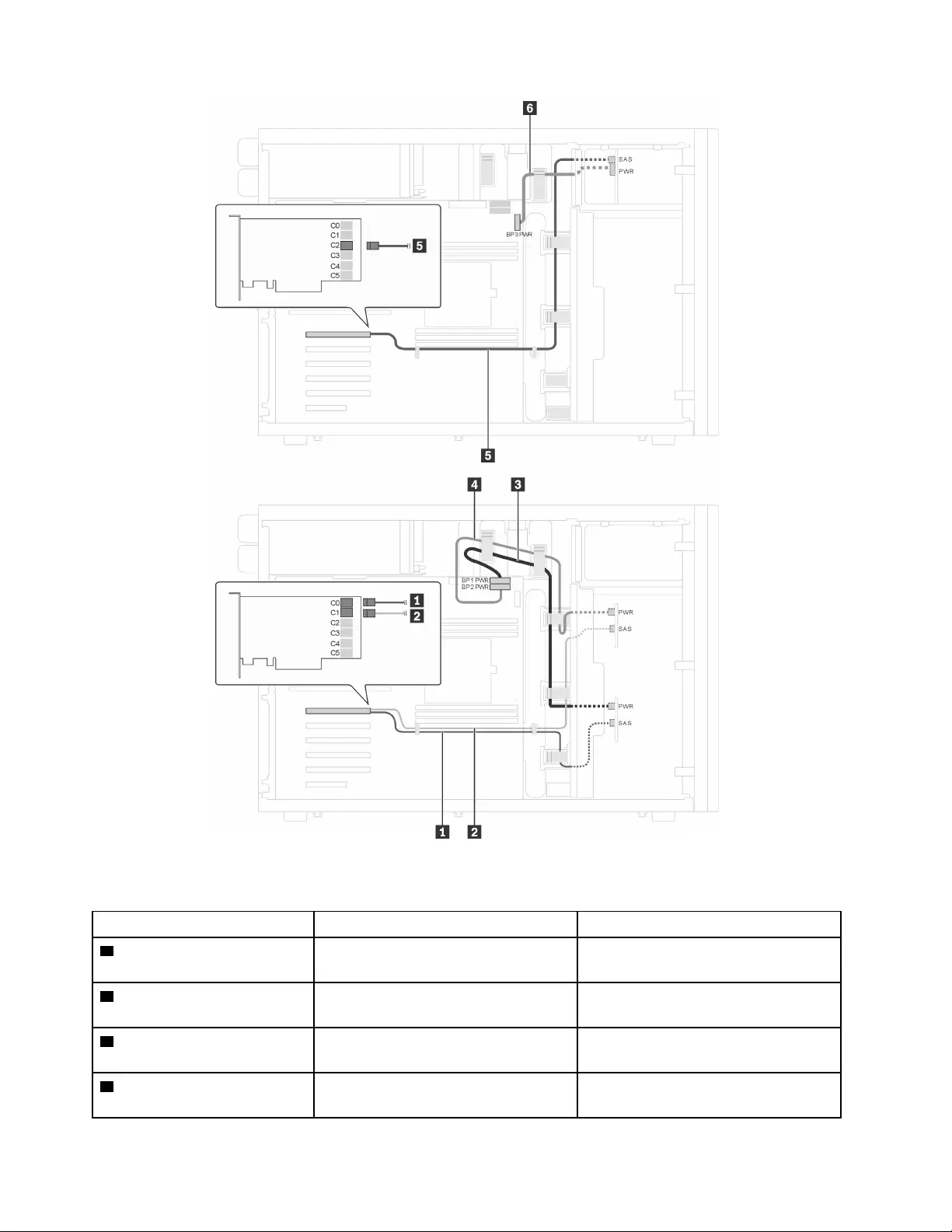

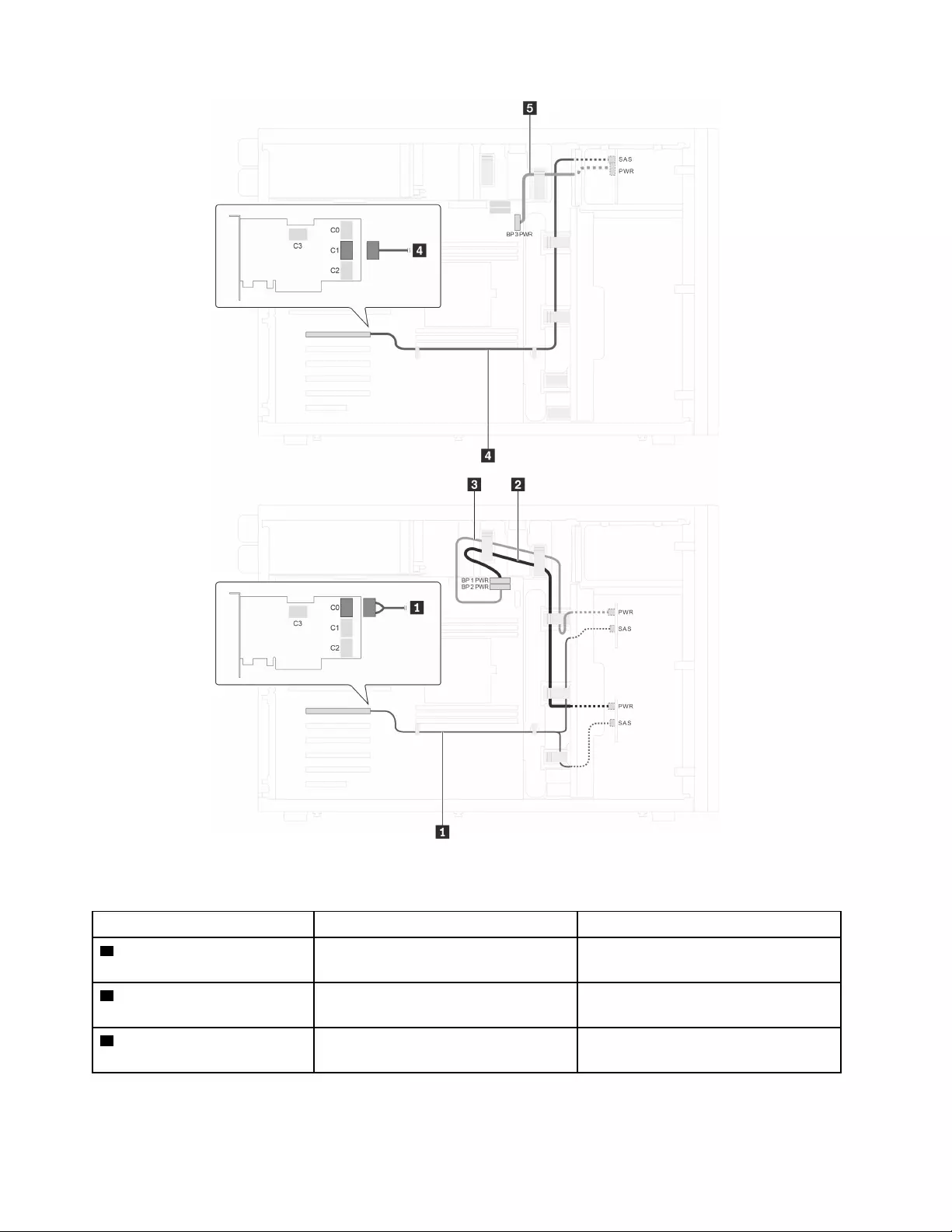

Hot-swap-drive backplane. . . . . . . . . 40

Parts list. . . . . . . . . . . . . . . . . . 65

Power cords . . . . . . . . . . . . . . 69

Chapter 3. Hardware replacement

procedures . . . . . . . . . . . . . . . 71

Installation Guidelines . . . . . . . . . . . . 71

Safety inspection checklist. . . . . . . . . 72

System reliability guidelines . . . . . . . . 73

Working inside the server with the power on . . 73

Handling static-sensitive devices . . . . . . 74

Front door replacement. . . . . . . . . . . . 74

Remove the front door . . . . . . . . . . 74

Install the front door . . . . . . . . . . . 75

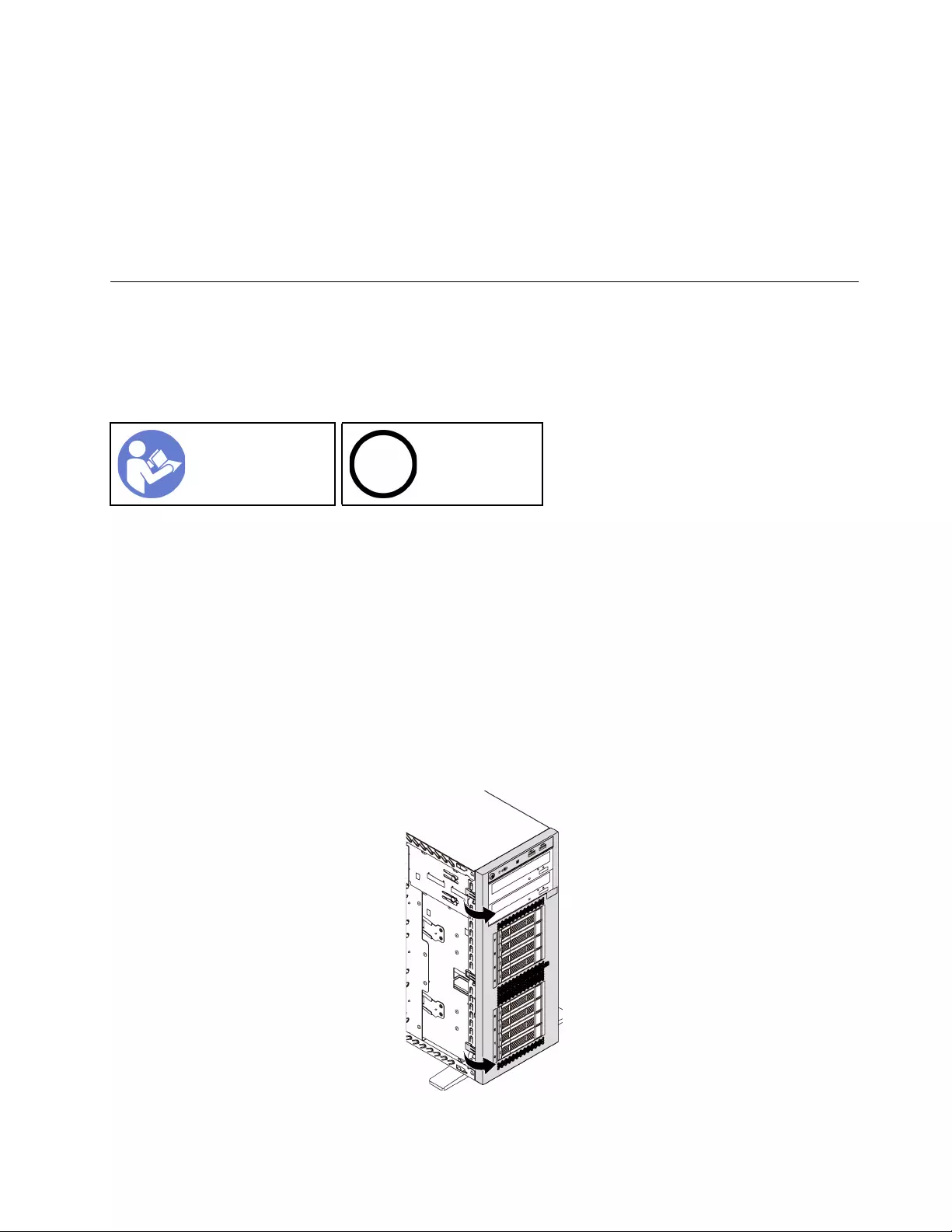

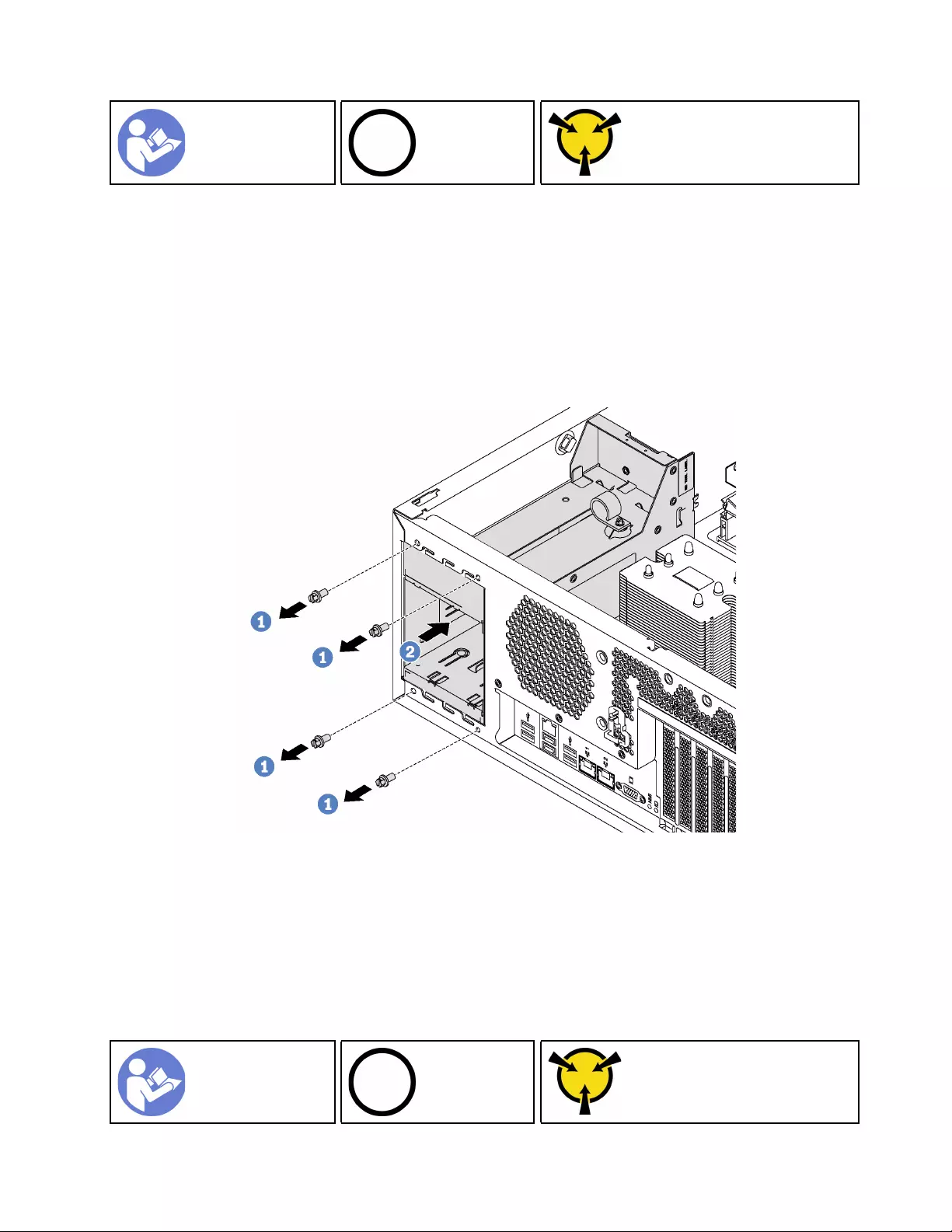

Foot stands replacement . . . . . . . . . . . 76

Remove the foot stands . . . . . . . . . . 76

Install the foot stands . . . . . . . . . . . 77

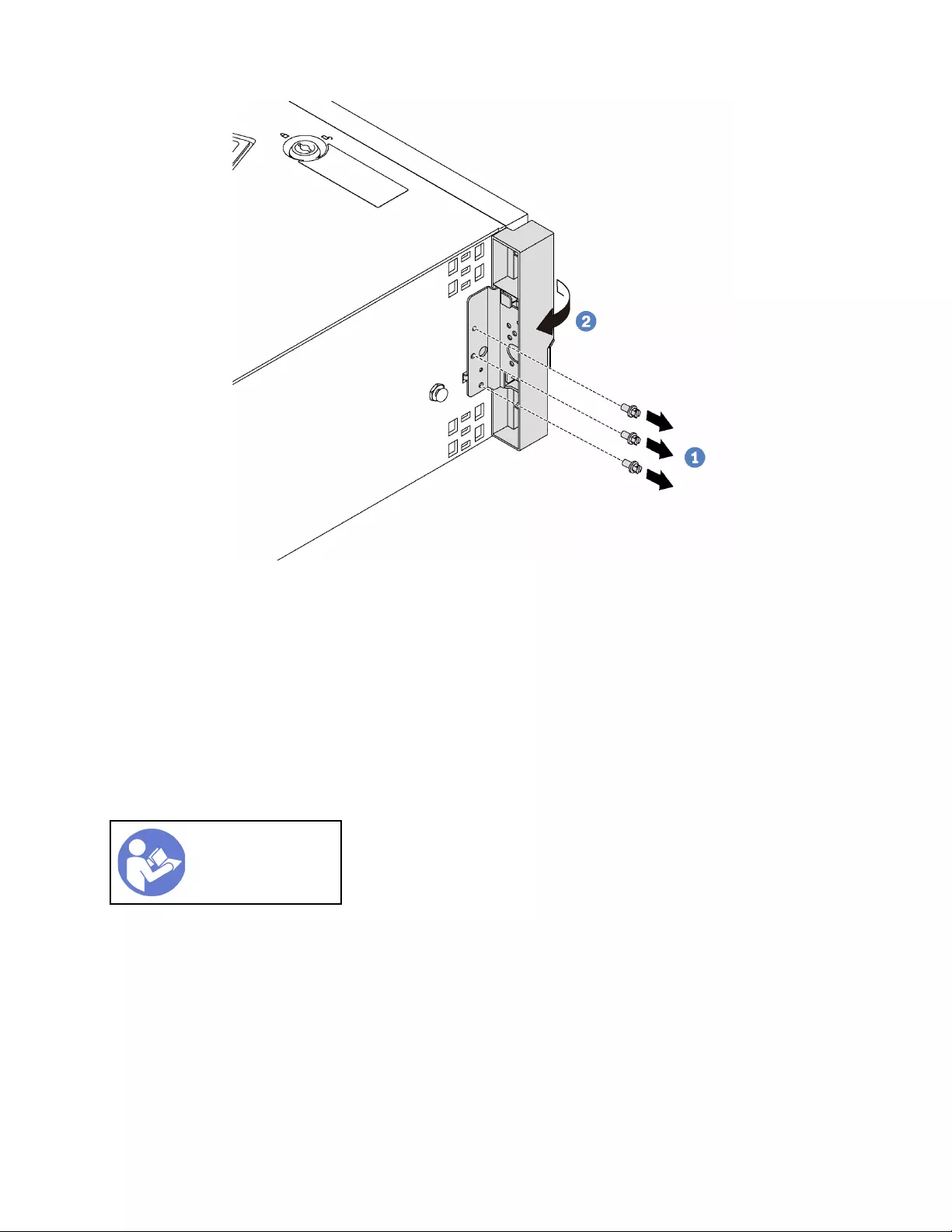

Rack latch replacement. . . . . . . . . . . . 78

Remove a rack latch . . . . . . . . . . . 78

Install a rack latch . . . . . . . . . . . . 79

Server cover replacement . . . . . . . . . . . 80

Remove the server cover . . . . . . . . . 81

Install the server cover . . . . . . . . . . 82

RAID super capacitor module replacement . . . . 83

Remove a RAID super capacitor module . . . 83

Install a RAID super capacitor module . . . . 84

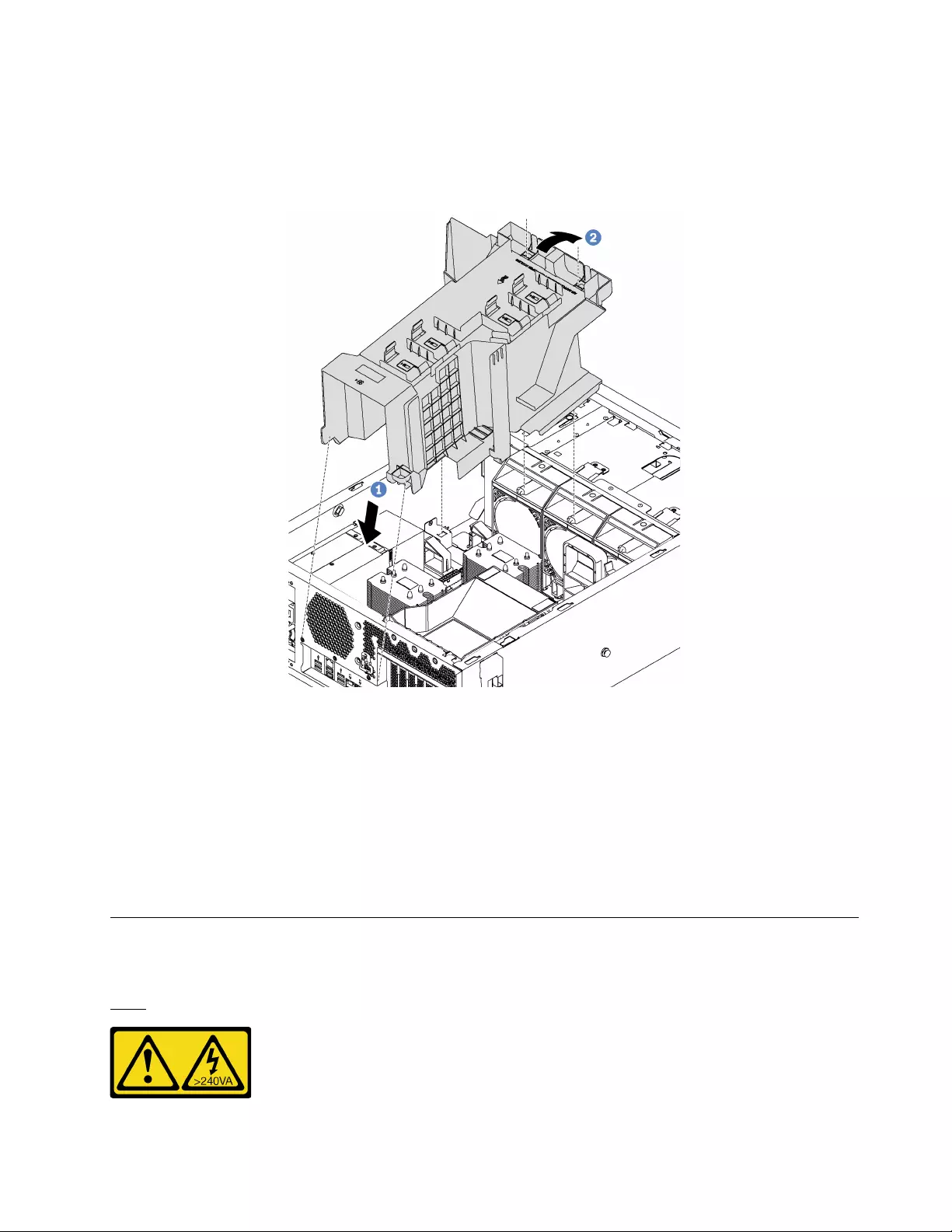

Air baffle replacement . . . . . . . . . . . . 85

Remove the air baffle . . . . . . . . . . . 85

Install the air baffle . . . . . . . . . . . . 86

Front fan replacement . . . . . . . . . . . . 87

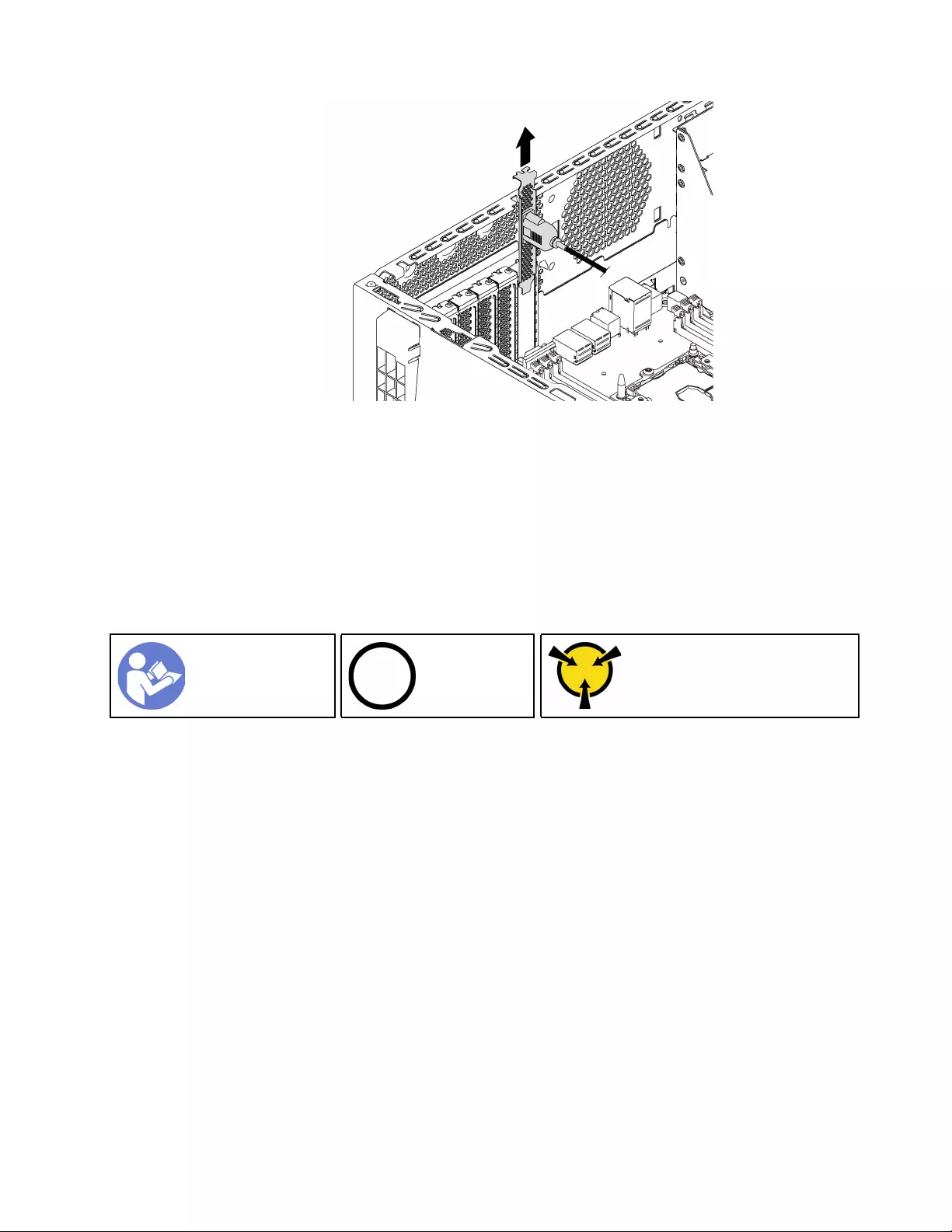

Remove a front fan . . . . . . . . . . . . 88

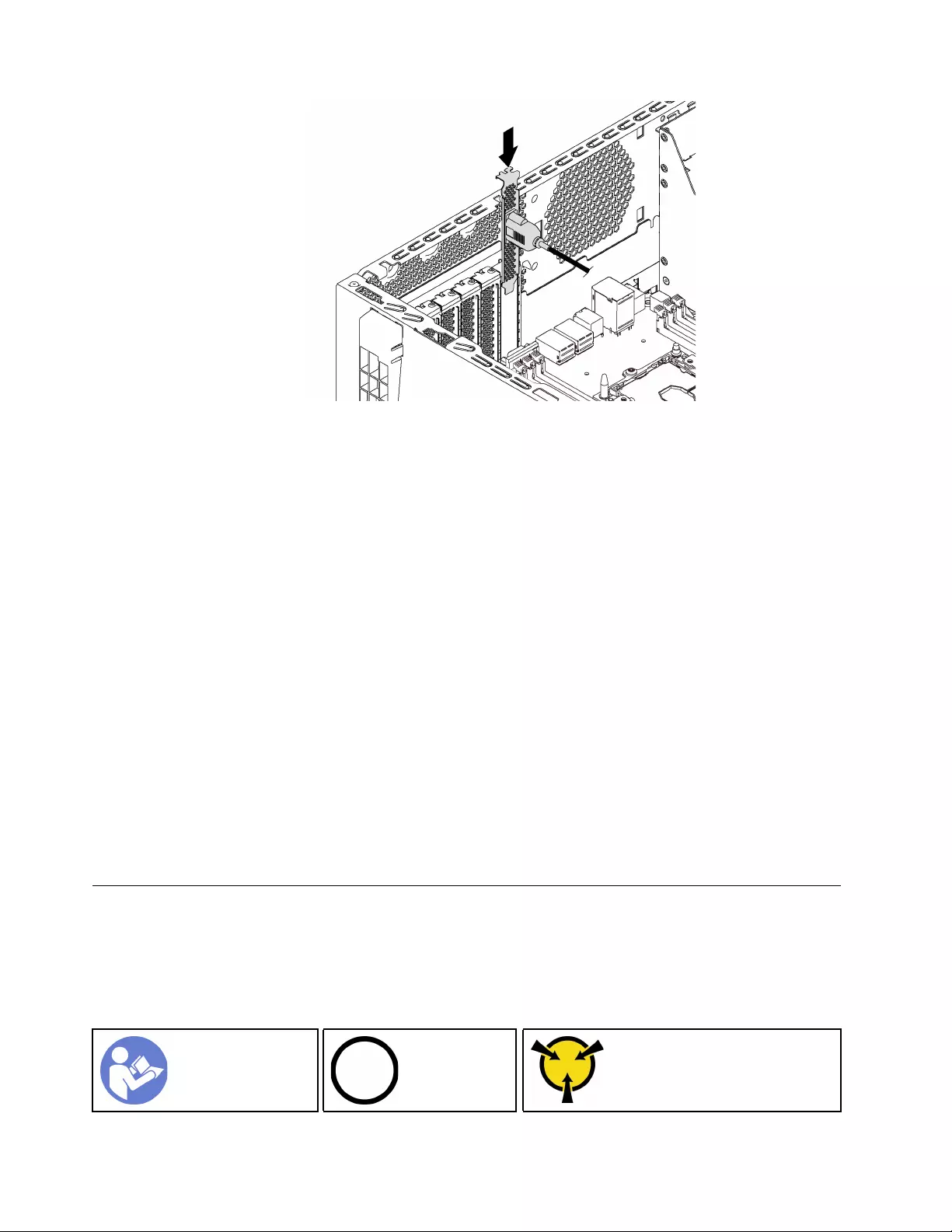

Install a front fan. . . . . . . . . . . . . 89

Rear fan replacement . . . . . . . . . . . . 90

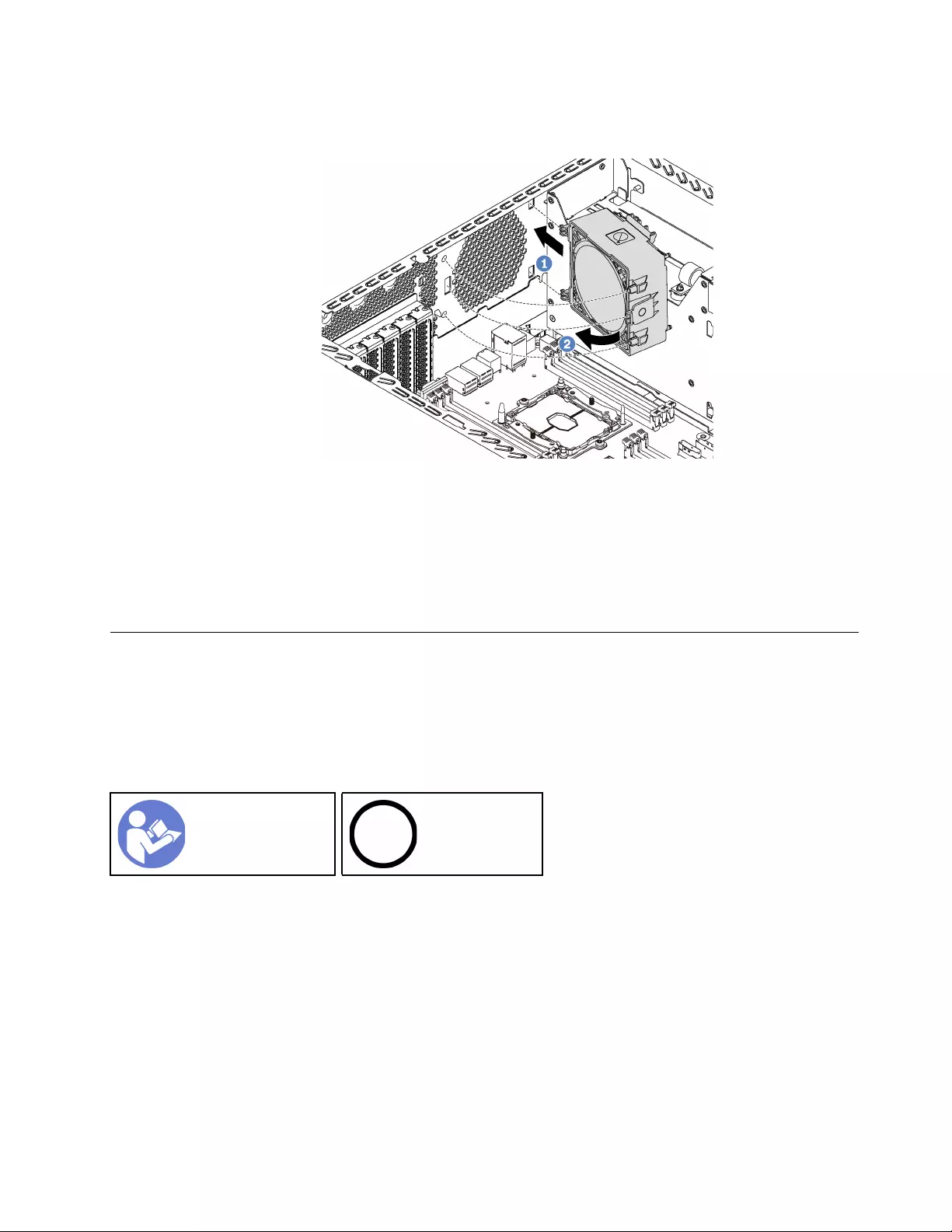

Remove the rear fan . . . . . . . . . . . 91

Install the rear fan . . . . . . . . . . . . 92

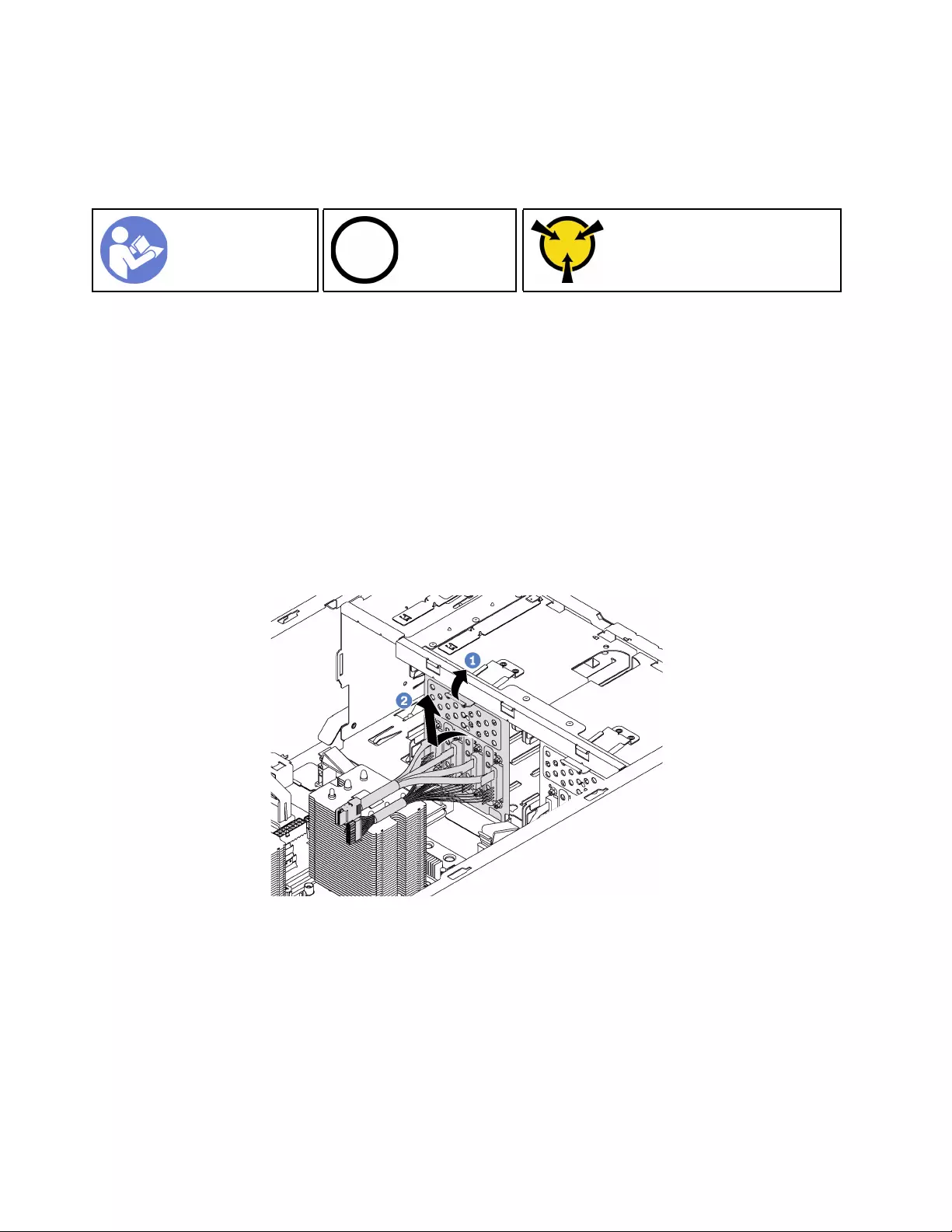

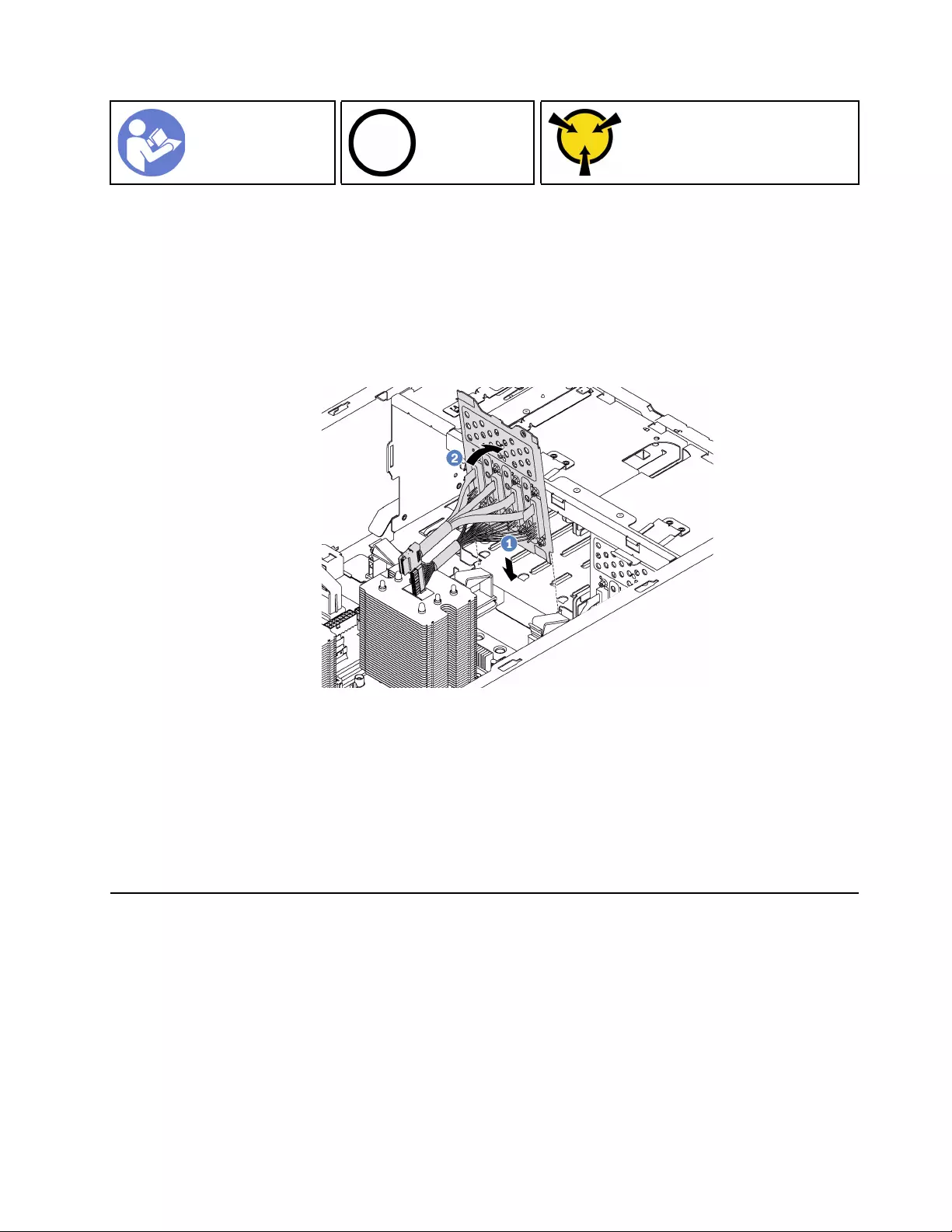

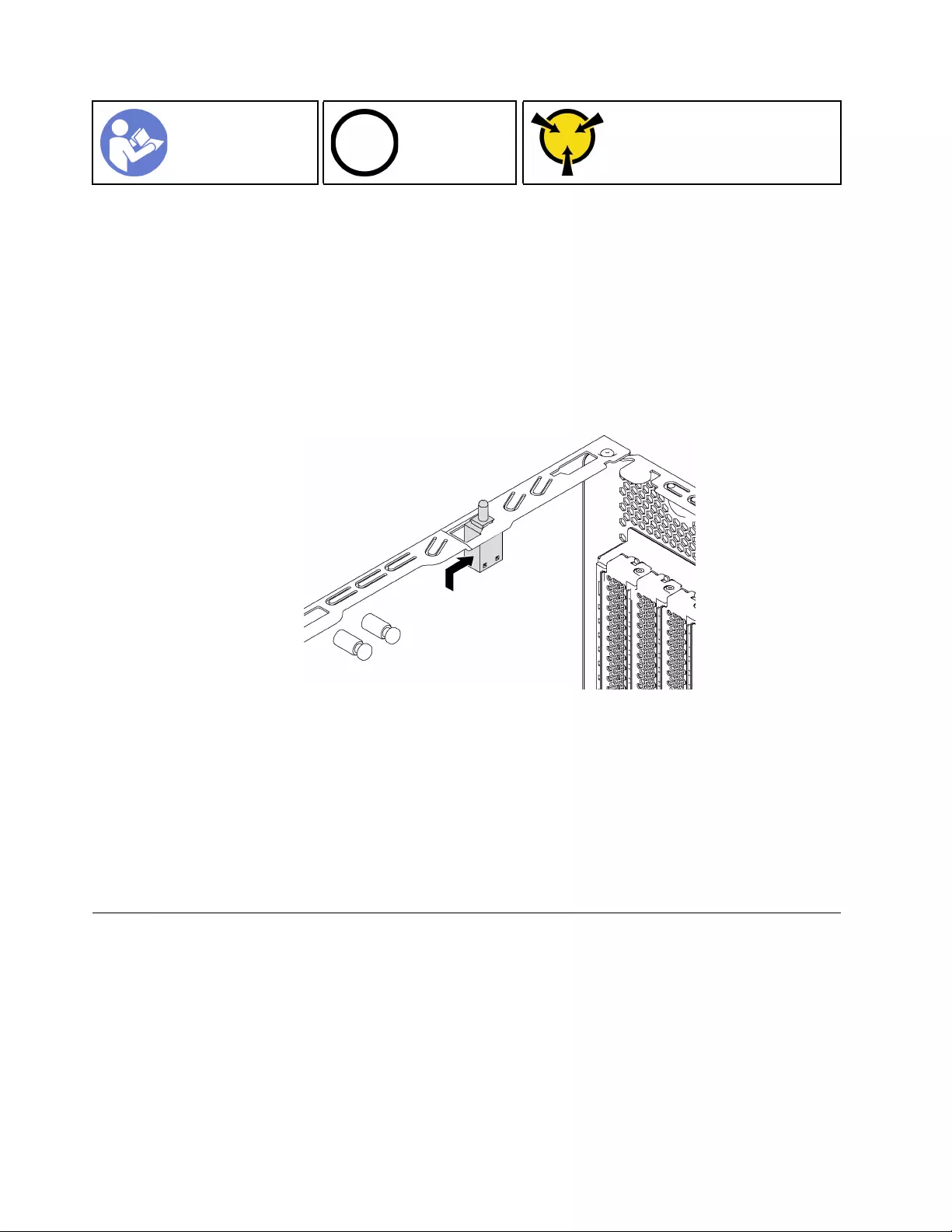

PCIe adapter holder replacement . . . . . . . . 93

Remove the PCIe adapter holder . . . . . . 93

Install the PCIe adapter holder . . . . . . . 94

Front bezel replacement . . . . . . . . . . . 95

Remove the front bezel . . . . . . . . . . 95

Install the front bezel . . . . . . . . . . . 96

Front panel replacement . . . . . . . . . . . 96

Remove the front panel . . . . . . . . . . 96

Install the front panel . . . . . . . . . . . 97

Optical drive or tape drive replacement . . . . . 98

Remove an optical drive or a tape drive. . . . 99

Install an optical drive or a tape drive. . . . . 101

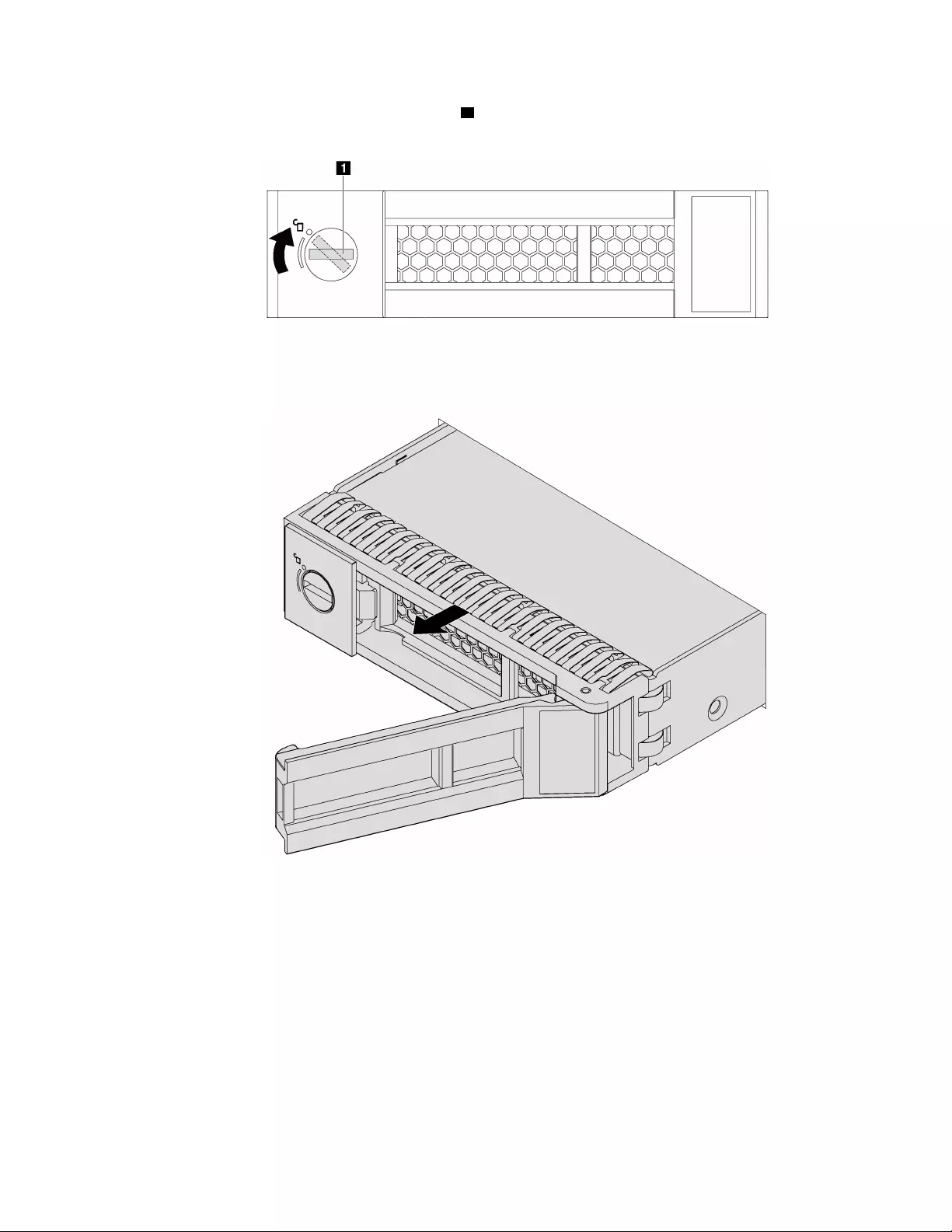

Simple-swap drive replacement . . . . . . . . 104

Remove a simple-swap drive . . . . . . . . 104

Install a simple-swap drive. . . . . . . . . 106

Hot-swap drive replacement . . . . . . . . . . 108

Remove a hot-swap drive . . . . . . . . . 108

Install a hot-swap drive . . . . . . . . . . 109

Simple-swap-drive backplate replacement . . . . 111

Remove a simple-swap-drive backplate . . . 112

Install a simple-swap-drive backplate . . . . 112

Hot-swap-drive backplane replacement . . . . . 113

Remove the backplane for four 2.5-inch hot-

swap drives . . . . . . . . . . . . . . 114

Install the backplane for four 2.5-inch hot-

swap drives . . . . . . . . . . . . . . 115

Remove the backplane for eight 2.5-inch hot-

swap drives . . . . . . . . . . . . . . 115

© Copyright Lenovo 2017, 2022 i

Install the backplane for eight 2.5-inch hot-swap

drives . . . . . . . . . . . . . . . . . 116

Remove the backplane for four 3.5-inch hot-

swap drives . . . . . . . . . . . . . . 117

Install the backplane for four 3.5-inch hot-

swap drives . . . . . . . . . . . . . . 118

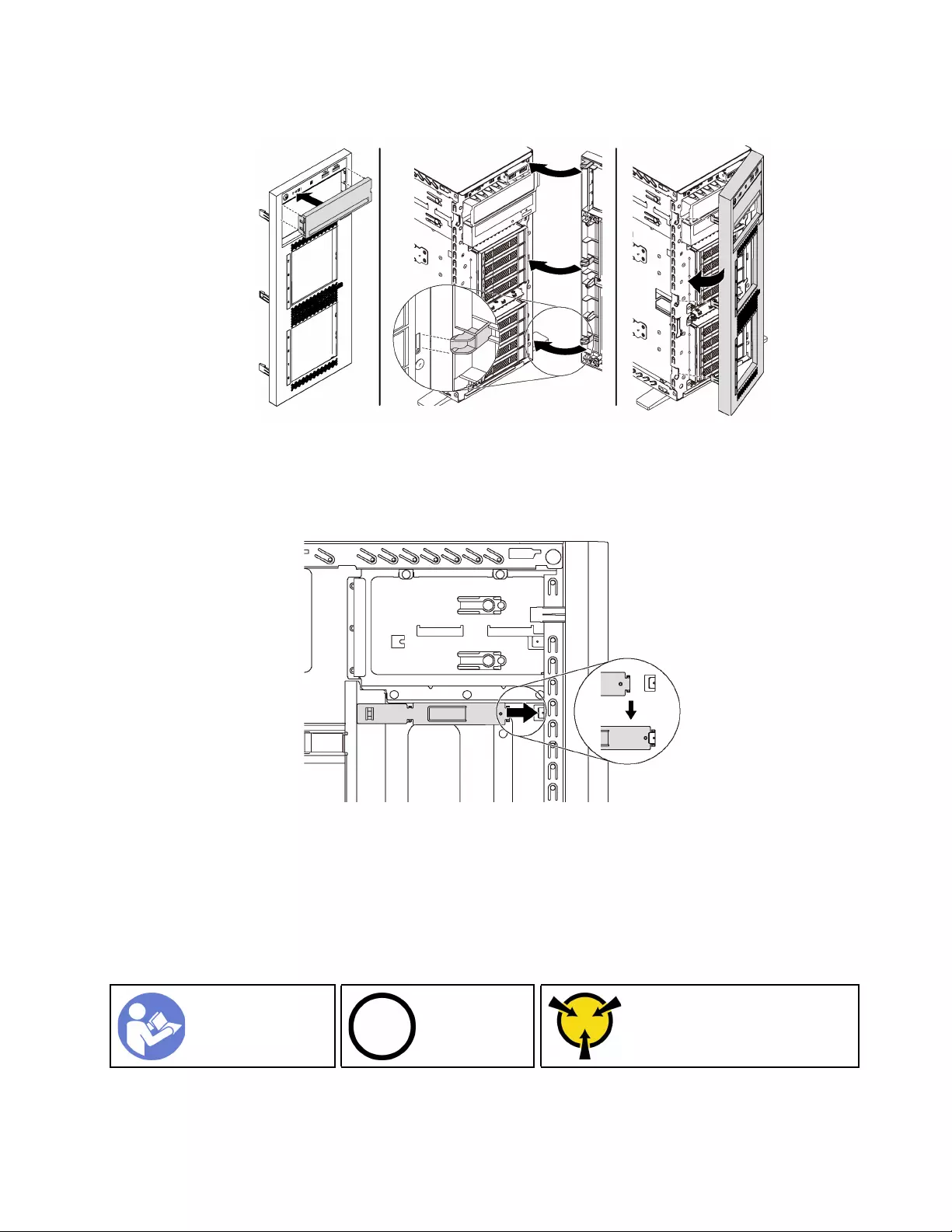

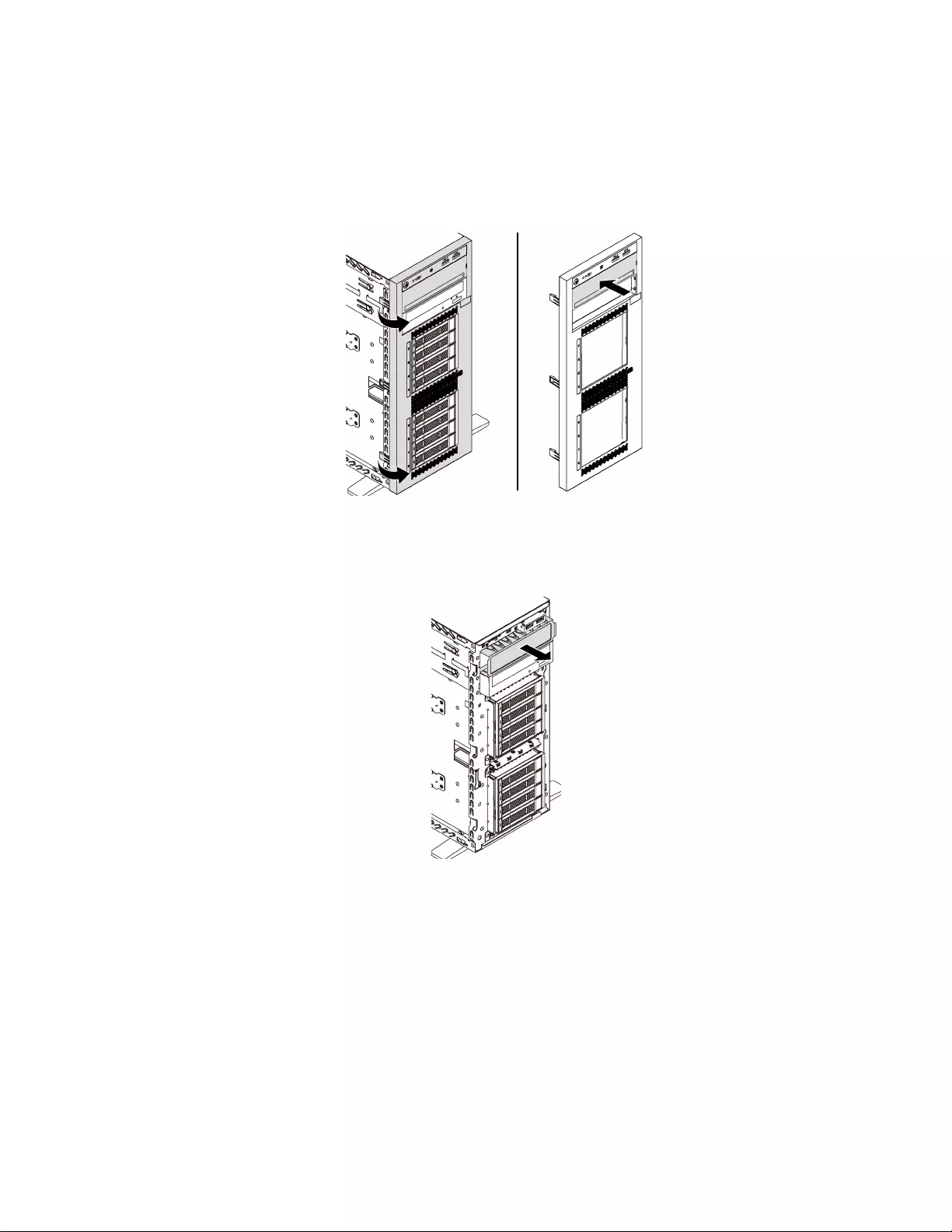

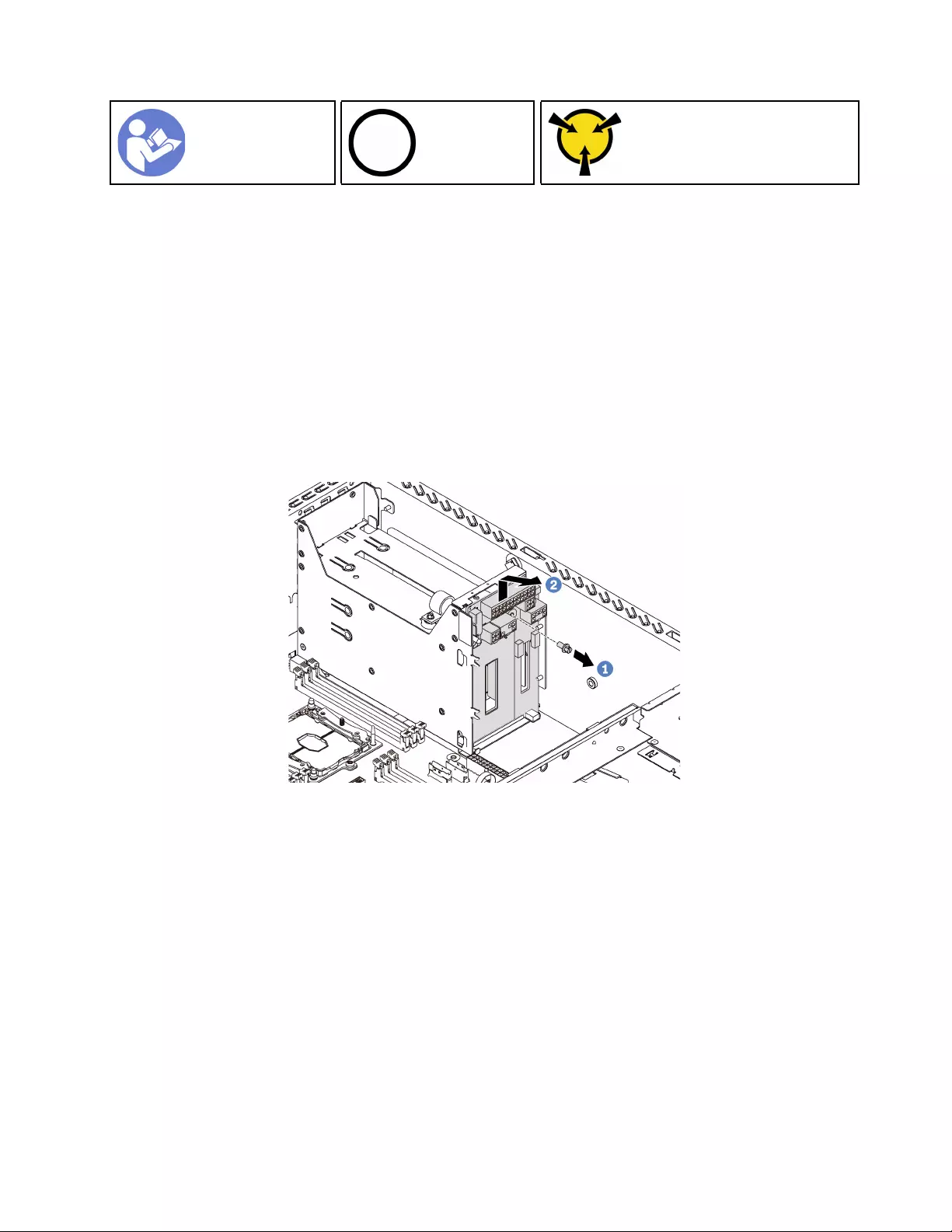

Expansion drive cage replacement . . . . . . . 119

Remove the expansion drive cage . . . . . . 120

Install the expansion drive cage. . . . . . . 121

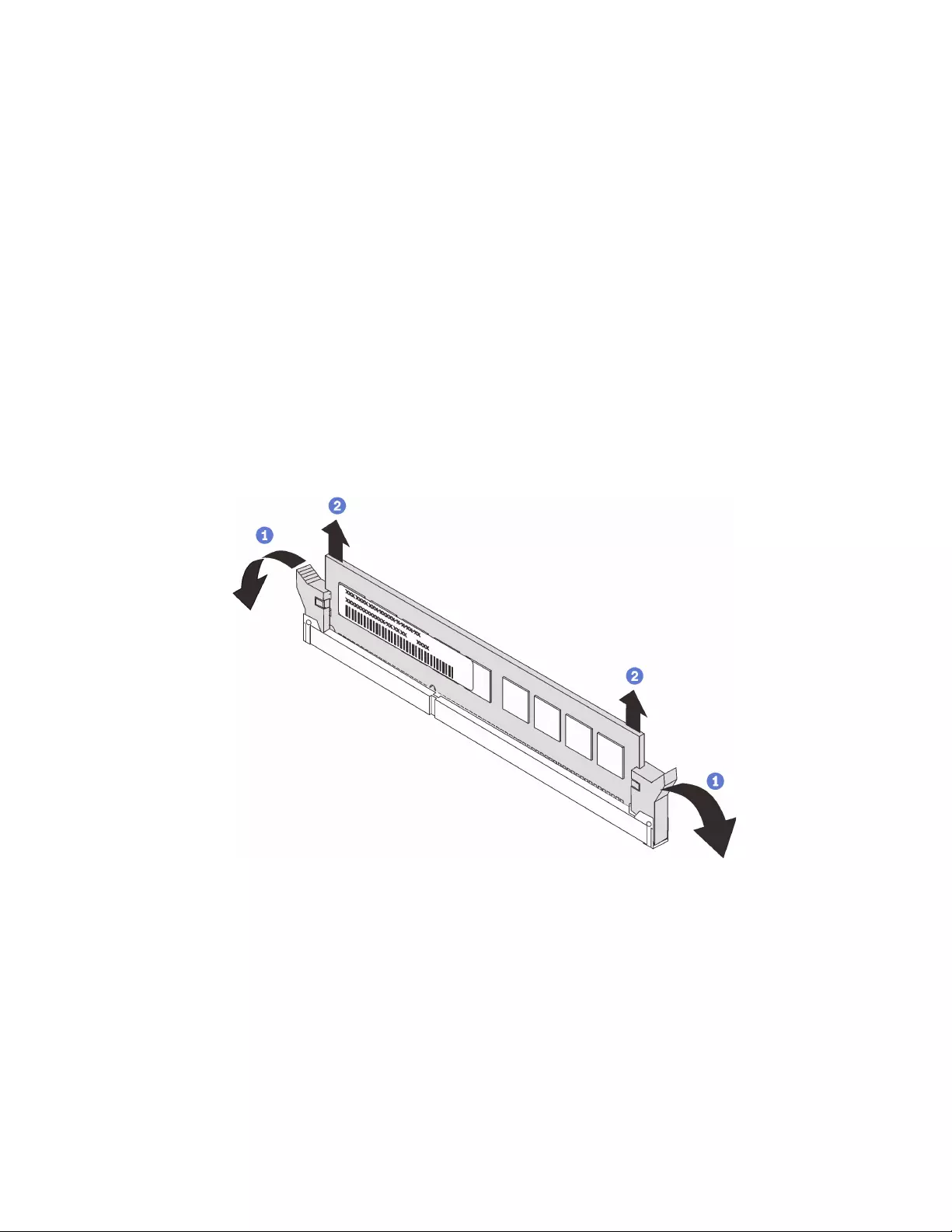

DIMM replacement . . . . . . . . . . . . . 122

Remove a DIMM. . . . . . . . . . . . . 122

DIMM installation rules . . . . . . . . . . 124

Install a DIMM . . . . . . . . . . . . . 128

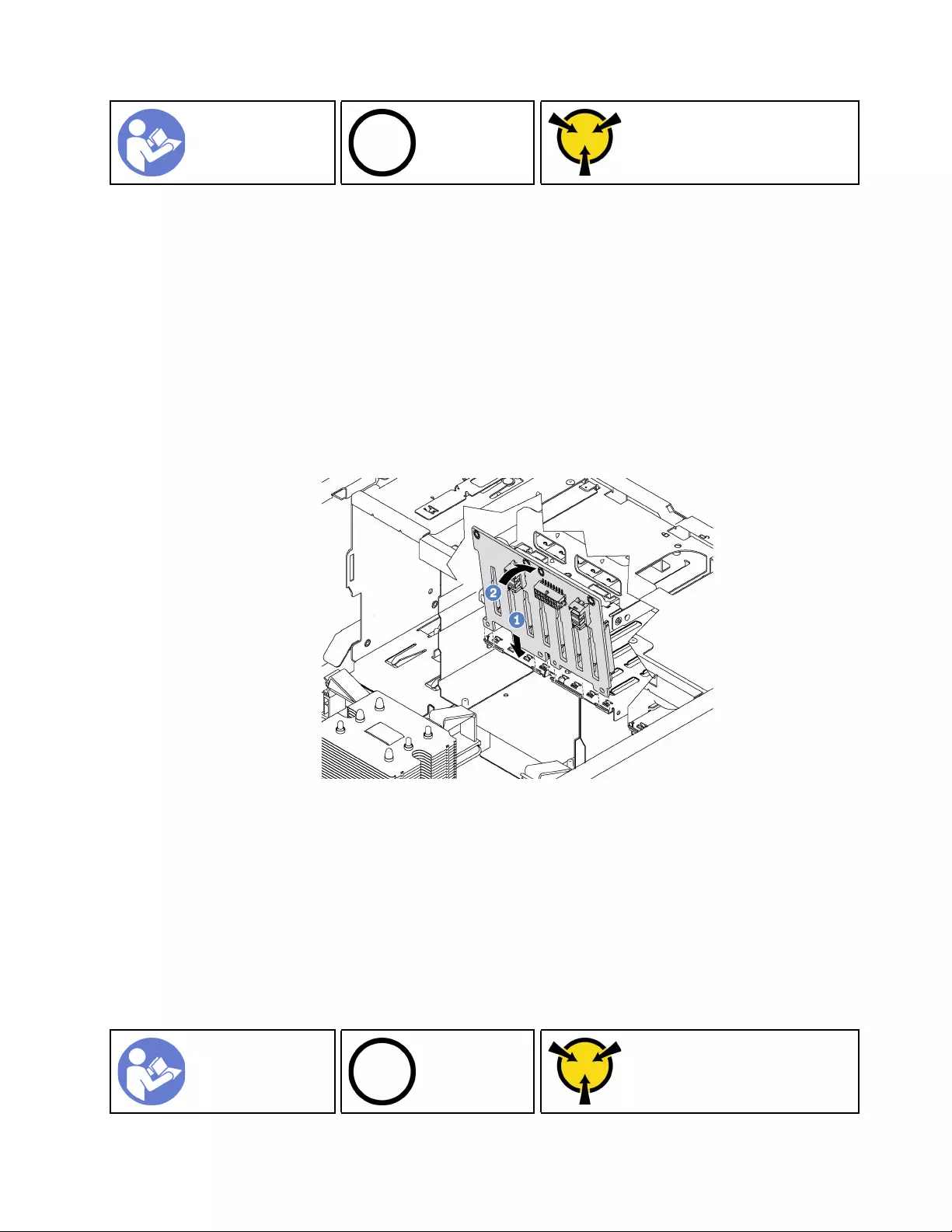

PCIe adapter retainer replacement . . . . . . . 129

Remove the PCIe adapter retainer . . . . . . 129

Install the PCIe adapter retainer. . . . . . . 130

PCIe adapter replacement. . . . . . . . . . . 131

Remove a PCIe adapter . . . . . . . . . . 131

Install a PCIe adapter . . . . . . . . . . . 132

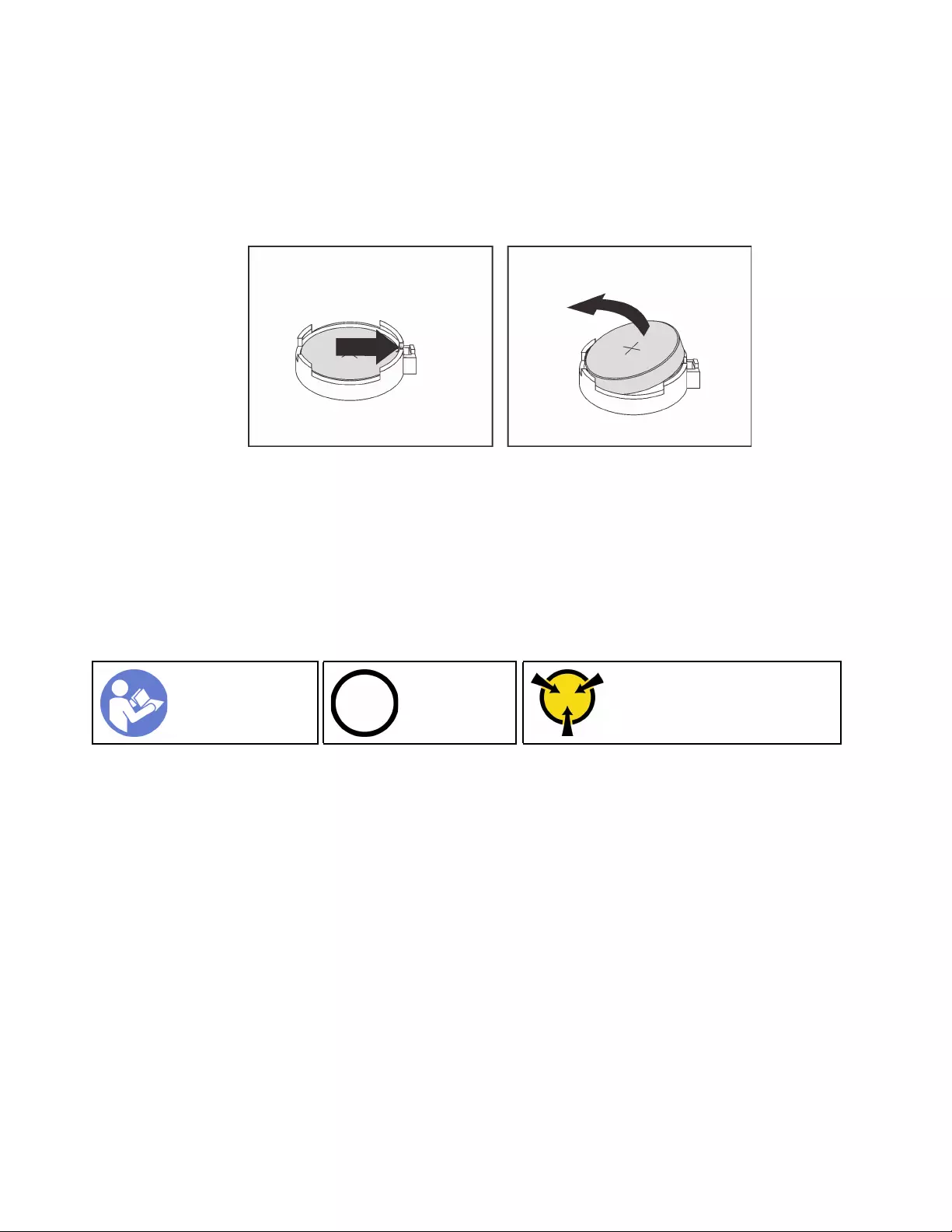

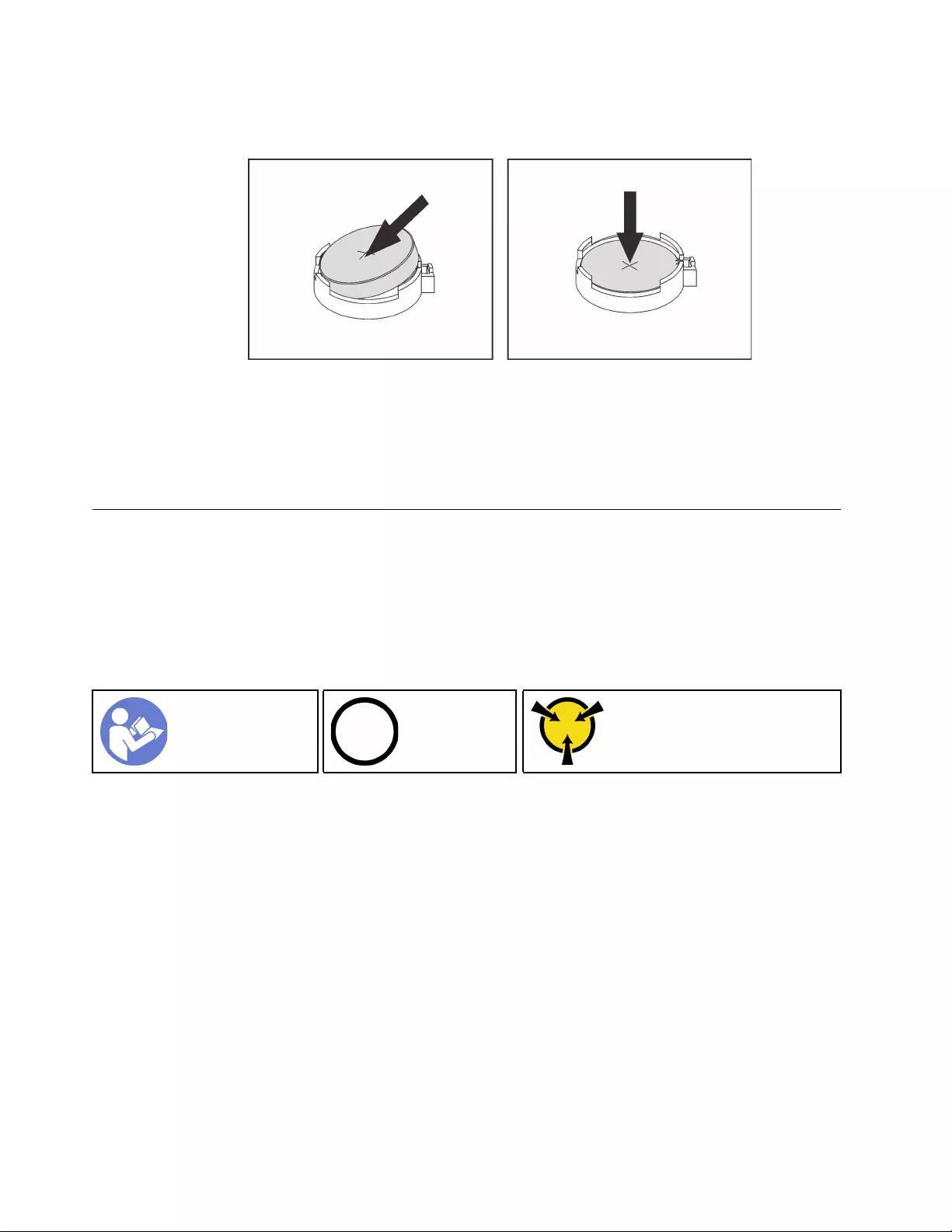

CMOS battery replacement . . . . . . . . . . 134

Remove the CMOS battery . . . . . . . . 134

Install the CMOS battery . . . . . . . . . 136

Serial port module replacement . . . . . . . . 138

Remove the serial port module . . . . . . . 138

Install the serial port module . . . . . . . . 139

M.2 backplane and M.2 drive replacement . . . . 140

Remove the M.2 backplane and M.2 drive. . . 140

Adjust the retainer on the M.2 backplane . . . 142

Install the M.2 backplane and M.2 drive. . . . 143

TCM/TPM adapter replacement (for Chinese

Mainland only) . . . . . . . . . . . . . . . 146

Remove the TCM/TPM adapter (for Chinese

Mainland only) . . . . . . . . . . . . . 146

Install the TCM/TPM adapter (for Chinese

Mainland only) . . . . . . . . . . . . . 147

Intrusion switch replacement . . . . . . . . . 149

Remove the intrusion switch . . . . . . . . 149

Install the intrusion switch . . . . . . . . . 149

Fixed power supply replacement . . . . . . . . 150

Remove the fixed power supply. . . . . . . 150

Install the fixed power supply. . . . . . . . 154

Hot-swap power supply replacement . . . . . . 157

Remove a hot-swap power supply. . . . . . 157

Install a hot-swap power supply . . . . . . 160

Power interface board replacement . . . . . . . 164

Remove the power interface board . . . . . 164

Install the power interface board . . . . . . 165

Hot-swap power supply cage replacement . . . . 166

Remove the hot-swap power supply cage. . . 166

Install the hot-swap power supply cage. . . . 167

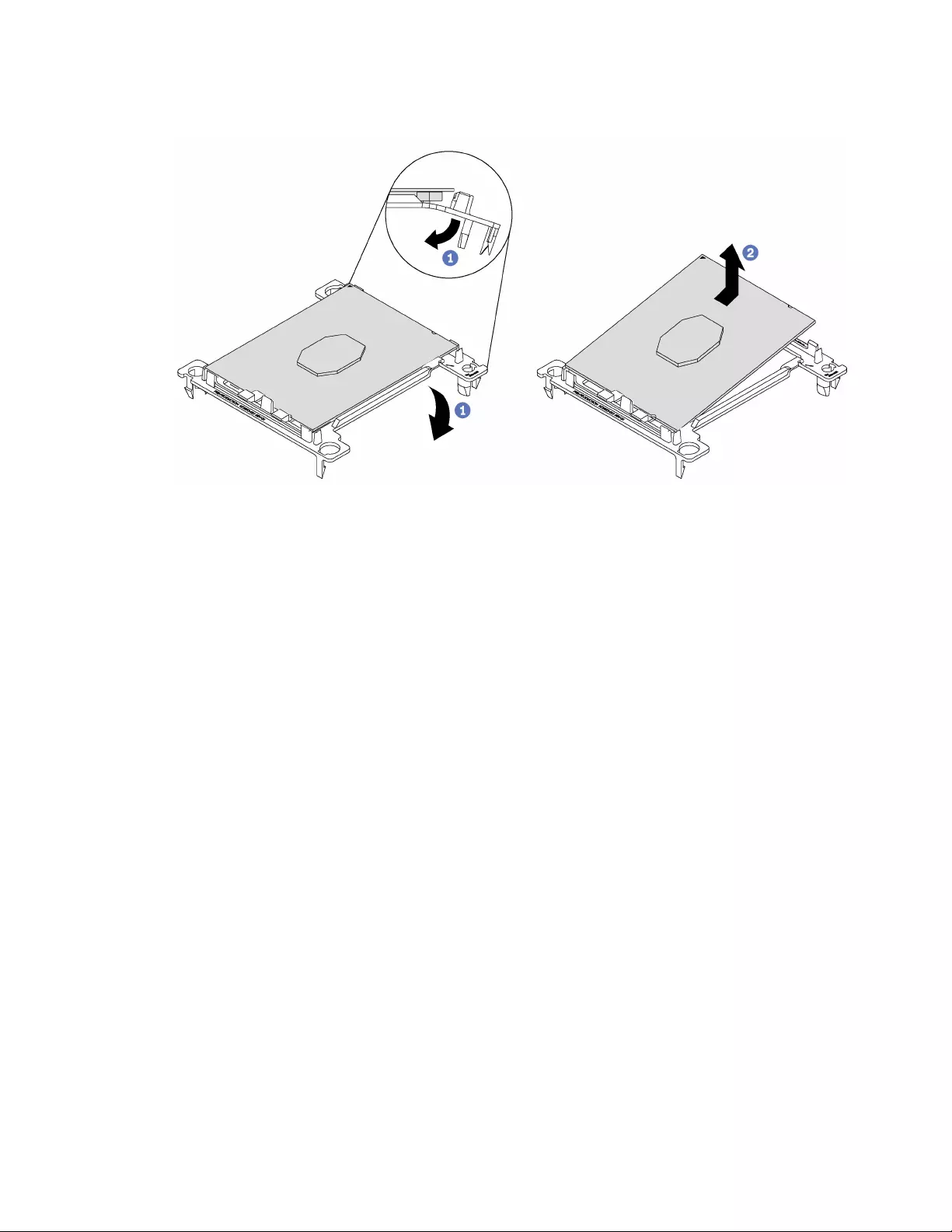

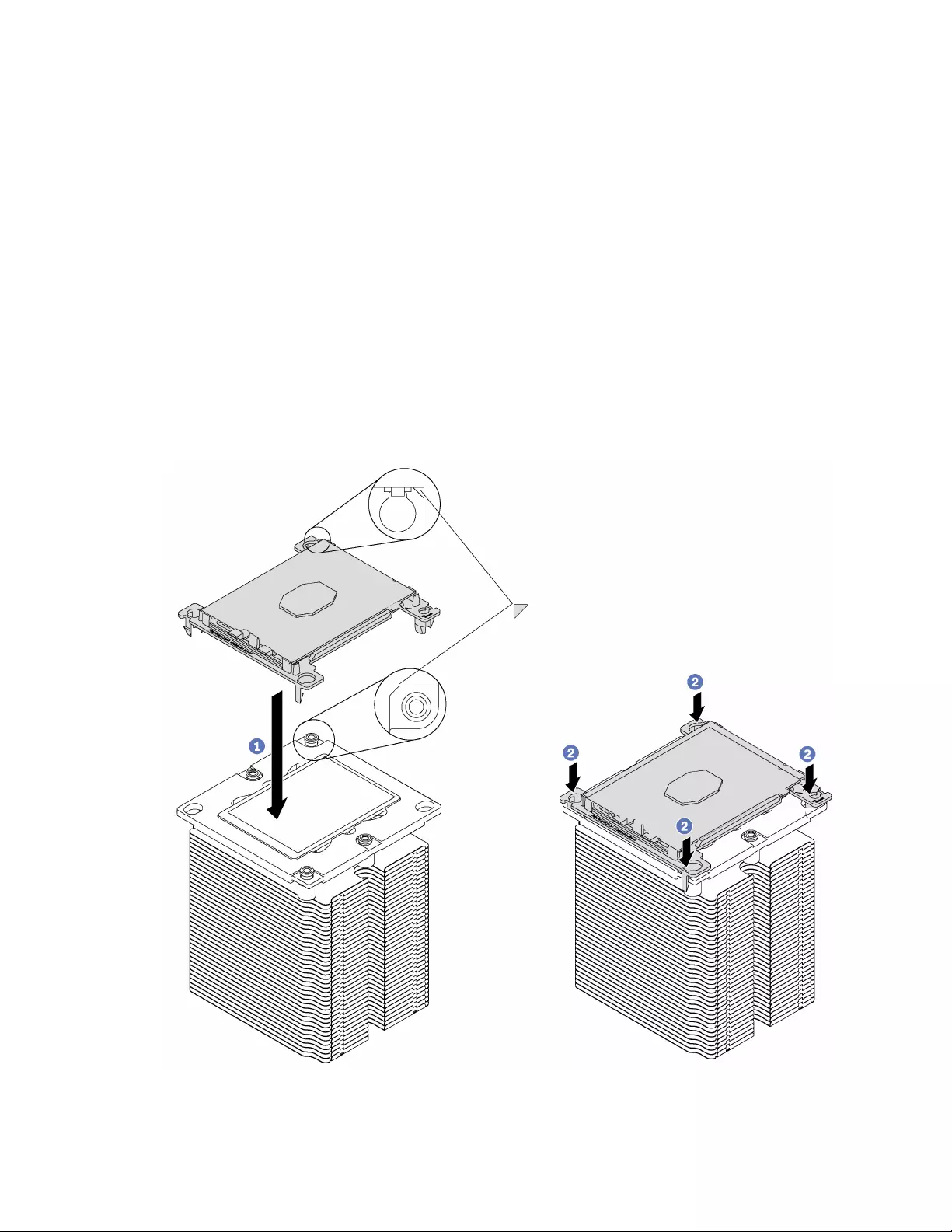

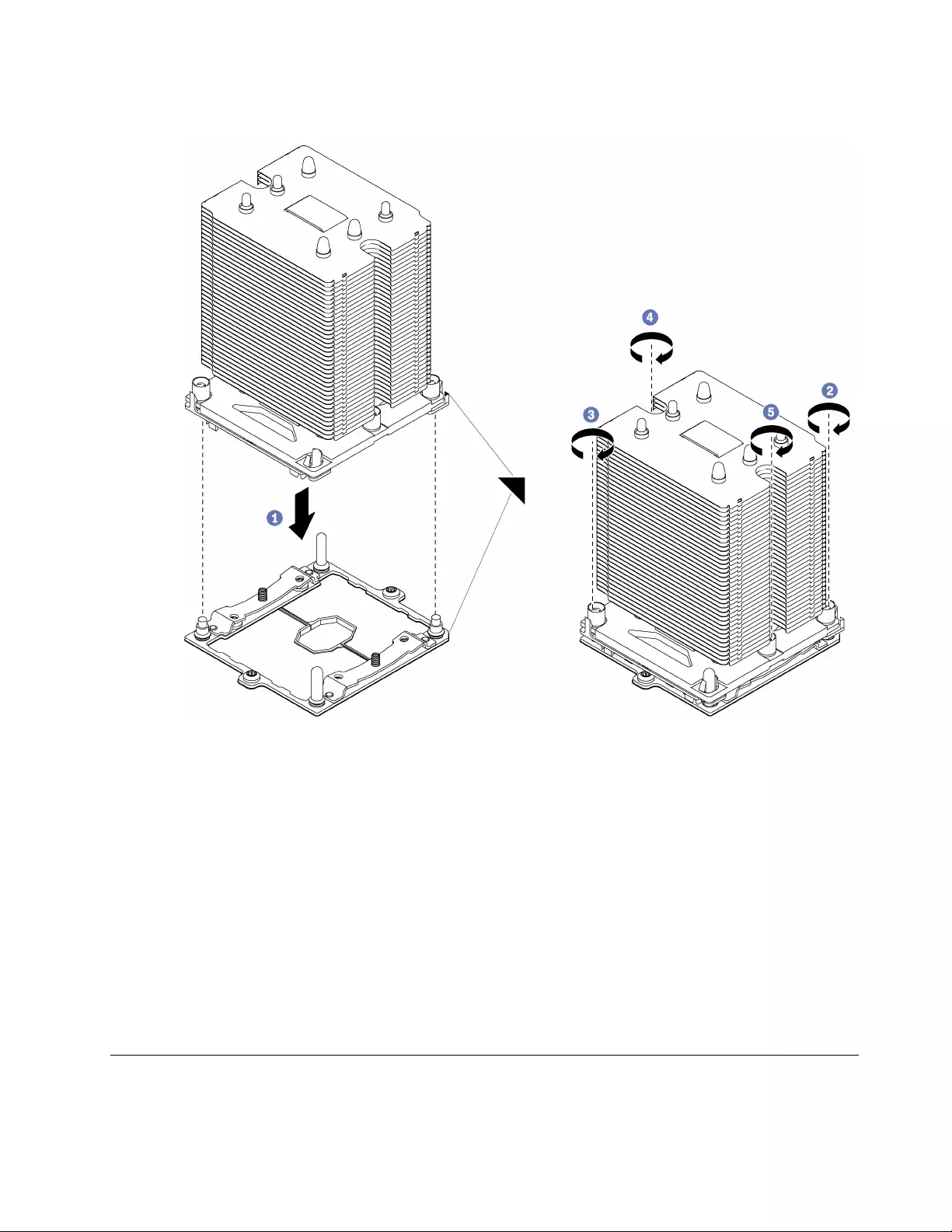

Processor and heat sink replacement . . . . . . 169

Remove a processor and heat sink . . . . . 169

Install a processor and heat sink . . . . . . 172

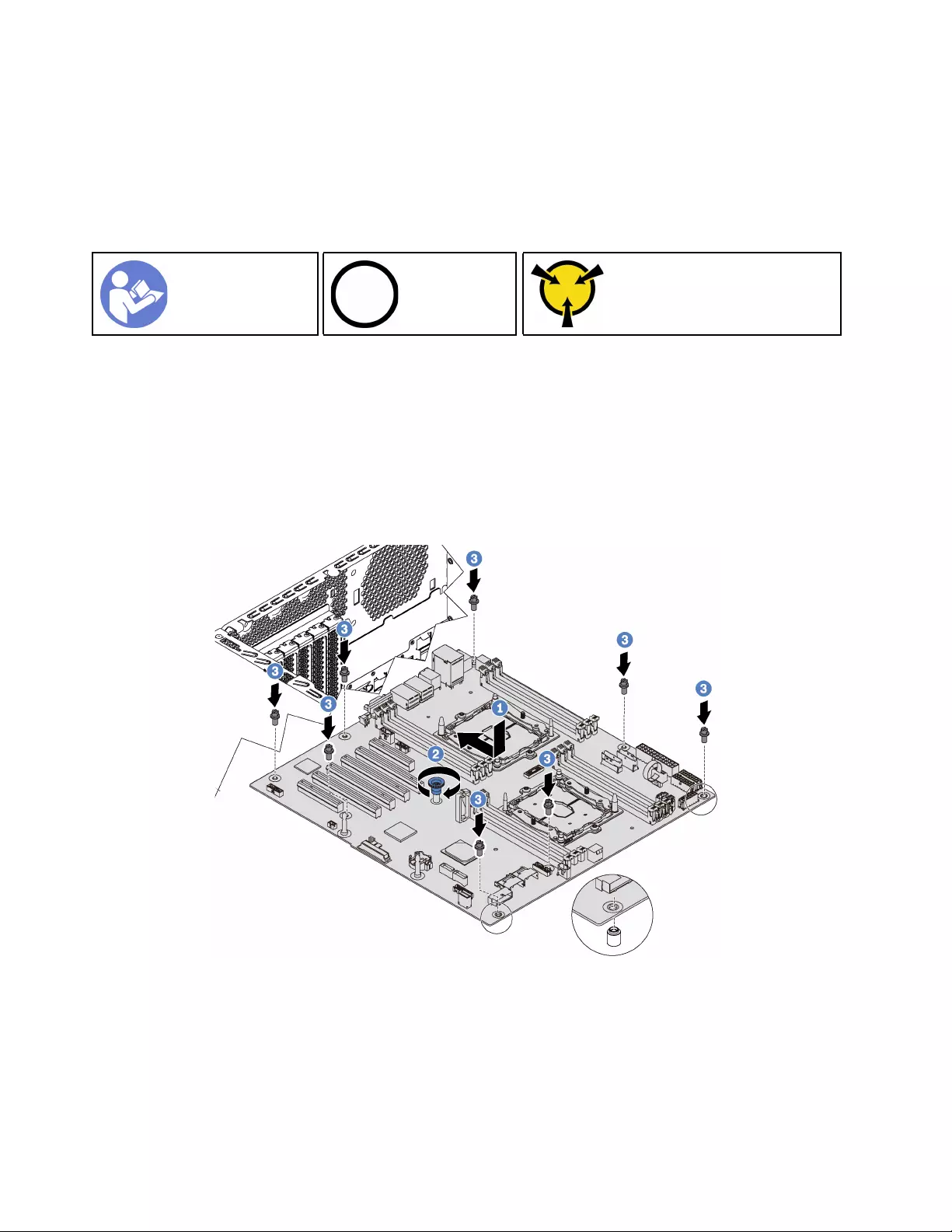

System board replacement . . . . . . . . . . 177

Remove the system board . . . . . . . . . 178

Install the system board . . . . . . . . . . 180

Update the machine type and serial

number . . . . . . . . . . . . . . . . 181

Enable TPM/TCM . . . . . . . . . . . . 182

Enable UEFI Secure Boot . . . . . . . . . 186

Complete the parts replacement . . . . . . . . 186

Chapter 4. Problem

determination . . . . . . . . . . . . . 189

Event logs . . . . . . . . . . . . . . . . . 189

General problem determination procedures . . . . 191

Resolving suspected power problems . . . . 191

Resolving suspected Ethernet controller

problems . . . . . . . . . . . . . . . 192

Troubleshooting by symptom . . . . . . . . . 192

Power on and power off problems . . . . . . 193

Memory problems . . . . . . . . . . . . 194

Hard disk drive problems . . . . . . . . . 195

Monitor and video problems . . . . . . . . 197

Keyboard, mouse, or USB-device

problems . . . . . . . . . . . . . . . 198

Optional-device problems . . . . . . . . . 199

Serial-device problems . . . . . . . . . . 201

Intermittent problems. . . . . . . . . . . 201

Power problems . . . . . . . . . . . . . 202

Network problems . . . . . . . . . . . . 202

Observable problems. . . . . . . . . . . 203

Software problems. . . . . . . . . . . . 205

Appendix A. Getting help and

technical assistance . . . . . . . . . . 207

Before you call . . . . . . . . . . . . . . . 207

Collecting service data . . . . . . . . . . . . 208

Contacting Support . . . . . . . . . . . . . 209

Appendix B. Notices. . . . . . . . . . 211

Trademarks . . . . . . . . . . . . . . . . 212

Important notes . . . . . . . . . . . . . . . 212

Telecommunication regulatory statement. . . . . 212

Electronic emission notices . . . . . . . . . . 213

Taiwan BSMI RoHS declaration . . . . . . . 213

Taiwan import and export contact information . . . 213

Index . . . . . . . . . . . . . . . . . . 215

ii ThinkSystem ST550 Maintenance Manual

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

在安装本产品之前,请仔细阅读 Safety Information (安全信息)。

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright Lenovo 2017, 2022 iii

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Safety inspection checklist

Use the information in this section to identify potentially unsafe conditions with your server. As each machine

was designed and built, required safety items were installed to protect users and service technicians from

injury.

Notes:

1. The product is not suitable for use at visual display workplaces according to §2 of the Workplace

Regulations.

2. The set-up of the server is made in the server room only.

CAUTION:

This equipment must be installed or serviced by trained personnel, as defined by the NEC, IEC 62368-

1 & IEC 60950-1, the standard for Safety of Electronic Equipment within the Field of Audio/Video,

Information Technology and Communication Technology. Lenovo assumes you are qualified in the

servicing of equipment and trained in recognizing hazards energy levels in products. Access to the

equipment is by the use of a tool, lock and key, or other means of security, and is controlled by the

authority responsible for the location.

Important: Electrical grounding of the server is required for operator safety and correct system function.

Proper grounding of the electrical outlet can be verified by a certified electrician.

Use the following checklist to verify that there are no potentially unsafe conditions:

1. Make sure that the power is off and the power cord is disconnected.

2. Check the power cord.

• Make sure that the third-wire ground connector is in good condition. Use a meter to measure third-

wire ground continuity for 0.1 ohm or less between the external ground pin and the frame ground.

• Make sure that the power cord is the correct type.

To view the power cords that are available for the server:

a. Go to:

http://dcsc.lenovo.com/#/

b. In the Customize a Model pane:

iv ThinkSystem ST550 Maintenance Manual

1) Click Select Options/Parts for a Model.

2) Enter the machine type and model for your server.

c. Click the Power tab to see all line cords.

• Make sure that the insulation is not frayed or worn.

3. Check for any obvious non-Lenovo alterations. Use good judgment as to the safety of any non-Lenovo

alterations.

4. Check inside the server for any obvious unsafe conditions, such as metal filings, contamination, water or

other liquid, or signs of fire or smoke damage.

5. Check for worn, frayed, or pinched cables.

6. Make sure that the power-supply cover fasteners (screws or rivets) have not been removed or tampered

with.

© Copyright Lenovo 2017, 2022 v

vi ThinkSystem ST550 Maintenance Manual

Chapter 1. Introduction

The ThinkSystem ST550 server is a 4U tower server designed for performance and expansion for various IT

workloads. With the modular design, the server is flexible to be customized for maximum storage capacity or

high storage density with selectable input/output options and tiered system management.

Performance, ease of use, reliability, and expansion capabilities were key considerations in the design of the

server. These design features make it possible for you to customize the system hardware to meet your needs

today and provide flexible expansion capabilities for the future.

The server comes with a limited warranty. For details about the warranty, see:

https://support.lenovo.com/us/en/solutions/ht503310

For details about your specific warranty, see:

http://datacentersupport.lenovo.com/warrantylookup

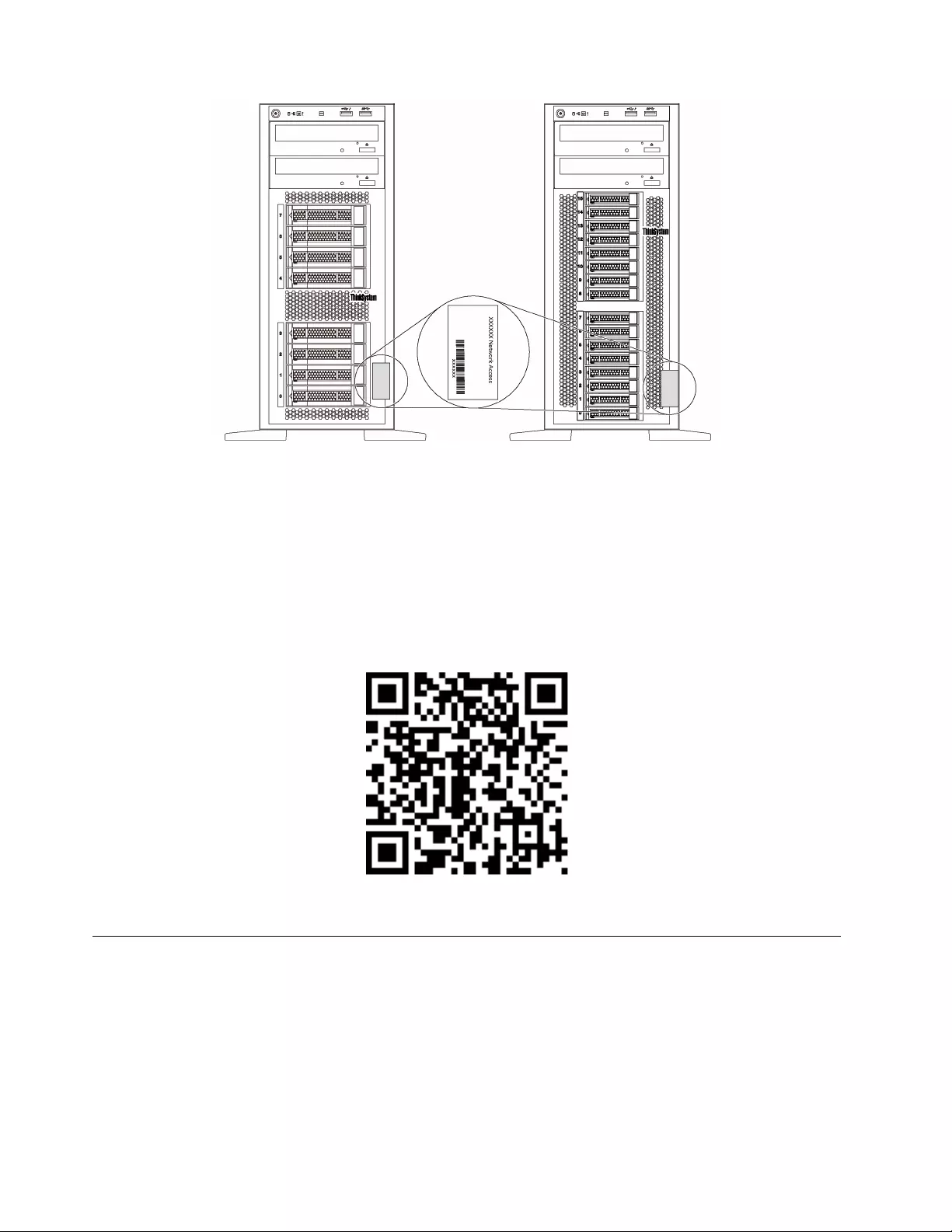

Identifying your server

When you contact Lenovo for help, the machine type and serial number information helps support

technicians to identify your server and provide faster service.

The machine type and serial number are on the ID label on the front of the server.

The following illustration shows the location of the ID label.

Note: The illustrations in this document might differ slightly from your server.

Figure 1. Location of the ID label

XClarity Controller network access label

The XClarity® Controller network access label is attached on the front bezel as shown. After you get the

server, peel the XClarity Controller network access label away and store it in a safe place for future use.

© Copyright Lenovo 2017, 2022 1

Figure 2. Location of the XClarity Controller network access label

Quick response code

The system service label, which is on the inside of the server cover, provides a quick response (QR) code for

mobile access to service information. Scan the QR code with a mobile device and a QR code reader

application to get quick access to the Lenovo Service web site for this server. The Lenovo Service web site

provides additional information for parts installation and replacement videos, and error codes for server

support.

The following illustration shows the QR code: https://support.lenovo.com/p/servers/st550

Figure 3. QR code

Server form factor

The ThinkSystem ST550 server is designed to support both tower and rack form factors.

You can change the server from tower form factor to rack form factor by installing the tower-to-rack

conversion kit. For instructions on how to install the tower-to-rack conversion kit, refer to the documentation

that comes with the conversion kit.

2ThinkSystem ST550 Maintenance Manual

Specifications

The following information is a summary of the features and specifications of the server. Depending on the

model, some features might not be available, or some specifications might not apply.

Dimensions for tower form factor

• a Height:

– With foot stands: 437.7 mm (17.3 inches)

– Without foot stands: 425.5 mm (16.8 inches)

• b Depth: 666.4 mm (26.3 inches)

• c Width:

– With foot stands: 272.0 mm (10.7 inches)

– Without foot stands: 175.8 mm (7.0 inches)

Note: The depth is measured with power supplies

installed, but without the front door installed.

Dimensions for rack form factor

• a Width:

– With rack latches: 482.0 mm (19.0 inches)

– Without rack latches: 427.7 mm (16.9 inches)

• b Depth: 670.2 mm (26.4 inches)

• c Height: 175.8 mm (7.0 inches)

Note: The depth is measured with rack latches and

power supplies installed.

Weight

Up to 36.9 kg (79.4 lb), depending on the server configuration

Processor

• Up to two Intel® Xeon® scalable processors

– Scalable up to 22 cores

– Designed for Land Grid Array (LGA) 3647 socket

• Up to two Jintide® processors for Chinese Mainland only

Note: For Jintide processors, only C08101, C10201, C12301, C14501, and C16401 models are supported

for Chinese Mainland.

For a list of supported processors, see:

https://static.lenovo.com/us/en/serverproven/index.shtml

Memory

For 1st Generation Intel Xeon Scalable Processors (Intel Xeon SP Gen 1) or Jintide processors

• Minimum: 8 GB

• Maximum:

– 384 GB using registered DIMMs (RDIMMs)

– 768 GB using load-reduced DIMMs (LRDIMMs)

Chapter 1.Introduction 3

• Type:

– TruDDR4 2666, single-rank/dual-rank, 8 GB/16 GB/32 GB registered DIMMs (RDIMMs)

– TruDDR4 2666, quad-rank, 64 GB load-reduced DIMMs (LRDIMMs)

• Slots: 12 DIMM slots

For 2nd Generation Intel Xeon Scalable Processors (Intel Xeon SP Gen 2)

• Minimum: 8 GB

• Maximum: 768 GB

• Type:

– TruDDR4 2666, single-rank/dual-rank, 16 GB/32 GB registered DIMMs (RDIMMs)

– TruDDR4 2933, single-rank/dual-rank, 8 GB/16 GB/32 GB/64 GB registered DIMMs (RDIMMs)

• Slots: 12 DIMM slots

Note: The actual operating speed depends on the processor model and UEFI Operating Mode selection. For

a list of supported DIMMs, see:

https://static.lenovo.com/us/en/serverproven/index.shtml

Supported operating systems

Below lists all supported and certified operating systems:

• Microsoft Windows Server

• VMware ESXi

• Red Hat Enterprise Linux

• SUSE Linux Enterprise Server

For a complete list of operating systems, see:

https://lenovopress.com/osig

For OS deployment instructions, see: “Deploy the operating system” in Setup Guide.

Supported drives

The drives supported by your server vary by model.

• Storage drive

Drive bay Supported drive type

Eight 2.5-inch drive bays Hot-swap SAS/SATA/NVMe HDD or SSD (NVMe drives are

supported only in bays 4–7 if an AnyBay backplane is installed)

Sixteen 2.5-inch drive bays Hot-swap SAS/SATA/NVMe HDD or SSD (NVMe drives are

supported only in bays 4–7 if an AnyBay backplane is installed)

Twenty 2.5-inch drive bays Hot-swap SAS/SATA/NVMe HDD or SSD (NVMe drives are

supported only in bays 4–7 if an AnyBay backplane is installed)

Four 3.5-inch drive bays – Simple-swap SATA HDD

– Hot-swap SAS/SATA HDD or SSD

Eight 3.5-inch drive bays – Simple-swap SATA HDD

– Hot-swap SAS/SATA HDD or SSD

Eight 3.5-inch drive bays and four 2.5-inch drive

bays Hot-swap SAS/SATA HDD or SSD

4ThinkSystem ST550 Maintenance Manual

To locate the storage drives or drive bays, see “Front view” on page 17.

• Optical drive

Some server models have two optical drive bays. For more information, see “Front view” on page 17.

• Tape drive

A tape drive enables you to store data on tape media. For server models with two optical drive bays, you

can install an internal tape drive in the optical-drive bay 2.

• M.2 drive

Your server supports one M.2 backplane which provides an easy way for data storage. You can install up

to two M.2 drives into the M.2 backplane. For more information, see “Install the M.2 backplane and M.2

drive” on page 143.

Expansion slots

The server has six expansion slots on the system board for installing appropriate Peripheral Component

Interconnect Express (PCIe) adapters.

• For processor 1

– PCIe slot 1: PCIe x8 (x8, x4, x1), full-height, half-length

– PCIe slot 2: PCIe x16 (x16, x8, x4, x1), full-height, half-length

– PCIe slot 3: PCIe x16 (x16, x8, x4, x1), full-height, full-length, double-width

– PCIe slot 6: PCIe x8 (x4, x1), full-height, full-length

• For processor 2

– PCIe slot 4: PCIe x16 (x8, x4, x1), full-height, full-length

– PCIe slot 5: PCIe x16 (x16, x8, x4, x1), full-height, full-length, double-width

The following HBA/RAID adapters can be installed in an appropriate PCIe slot.

• SAS/SATA HBA adapters

– ThinkSystem 430-8i SAS/SATA 12Gb HBA

– ThinkSystem 430-16i SAS/SATA 12Gb HBA

– ThinkSystem 430-8e SAS/SATA 12Gb HBA

– ThinkSystem 440-8i SAS/SATA PCIe Gen4 12Gb HBA

– ThinkSystem 440-16i SAS/SATA PCIe Gen4 12Gb HBA

– ThinkSystem 4350-8i SAS/SATA 12Gb HBA

• SAS/SATA RAID adapters

– ThinkSystem RAID 530-8i PCIe 12Gb Adapter

– ThinkSystem RAID 540-8i PCIe 12Gb Adapter

– ThinkSystem RAID 730-8i 1GB Adapter

– ThinkSystem RAID 730-8i 2GB PCIe Adapter

– ThinkSystem RAID 930-8e 4GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 930-8i 2GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 930-16i 4GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 930-16i 8GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 930-24i 4GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 940-8i 4GB Flash PCIe Gen4 12Gb Adapter

Chapter 1.Introduction 5

– ThinkSystem RAID 940-8e 4GB Flash PCIe 12Gb Adapter

– ThinkSystem RAID 940-16i 4GB Flash PCIe Gen4 12Gb Adapter

– ThinkSystem RAID 940-16i 8GB Flash PCIe Gen4 12Gb Adapter

– ThinkSystem RAID 940-32i 8GB Flash PCIe Gen4 12Gb Adapter

– ThinkSystem RAID 5350-8i PCIe 12Gb Adapter

– ThinkSystem RAID 9350-8i 2GB Flash PCIe 12Gb Adapter

Notes:

• RAID 730–8i 1G Cache SAS/SATA adapter is not available for North America.

• RAID 530–8i SAS/SATA adapter cannot be mixed with RAID 730–8i 1G Cache SAS/SATA adapter.

• RAID 730–8i 2G Flash SAS/SATA adapter cannot be mixed with RAID 730-8i 1G Cache SAS/SATA

adapter or RAID 930–8i SAS/SATA adapter.

• The RAID 940 adapters can be mixed with the ThinkSystem 440-8i SAS/SATA PCIe Gen4 12Gb HBA and

the ThinkSystem 440-16i SAS/SATA PCIe Gen4 12Gb HBA.

• Mixing of RAID/HBA 430/530/730/930 adapters (Gen 3) and RAID/HBA 440/540/940 adapters (Gen 4) in

the same system is not allowed.

• RAID 930/940 series or 9350 series adapters require a RAID flash power module.

• RAID 4350/5350/9350 series adapters cannot be mixed with HBA/RAID 430/440/530/540/730/930/940

series SAS/SATA adapters.

• For server models that support NVMe drives, the NVMe adapter (also known as the NVMe switch adapter)

can be installed only in PCIe slot 2.

• For RAID adapters or host bus adapters, you can install them in either PCIe slot 1 or PCIe slot 2.

• For server models with one processor, you can install a double-width graphics adapter only in PCIe slot 3.

For server models with two processors, you can install up to two double-width graphics adapters in PCIe

slot 3 and PCIe slot 5. After any double-width graphics adapter is installed, PCIe slot 4 or PCIe slot 6

becomes unavailable because the space is occupied by the double-width adapter.

Graphics adapters

• Your server supports the following GPUs:

– Full-height, full-length, double-slot GPUs: NVIDIA P6000

– Full-height, full-length, single-slot GPU: NVIDIA P4000, NVIDIA RTX4000.

– Full-height, 3/4-length, single-slot GPU: NVIDIA P2000, NVIDIA P2200.

– Low-profile, half-height, half-length, single-slot GPUs: NVIDIA P600, NVIDIA P620

• Thermal Design Power (TDP): up to 250 watts

Notes:

• NVIDIA P4000 and NVIDIA RTX4000 are supported only in the new chassis. See “Differences between the

original chassis and new chassis” on page 7

• Your server supports up to two graphics adapters installed.

• Graphics adapter is supported only when the following configuration requirements are met:

– Fan 4 is installed.

– Two 1100-watt power supplies are installed.

– For NVIDIA P6000 graphics adapter, operating temperature is lower than 35°C (95°F) when one P6000

is installed, and operating temperature is lower than 30°C (86°F) when two are installed. For other

6ThinkSystem ST550 Maintenance Manual

supported graphics adapters, operating temperature is lower than 35°C (95°F) when one or two graphic

adapters are installed.

• Fan redundancy function is supported when:

– One NVIDIA P600, P620, P2000, P2200, P4000, or RTX4000 graphics adapter is installed

– Two NVIDIA P600 or P620 graphics adapters are installed

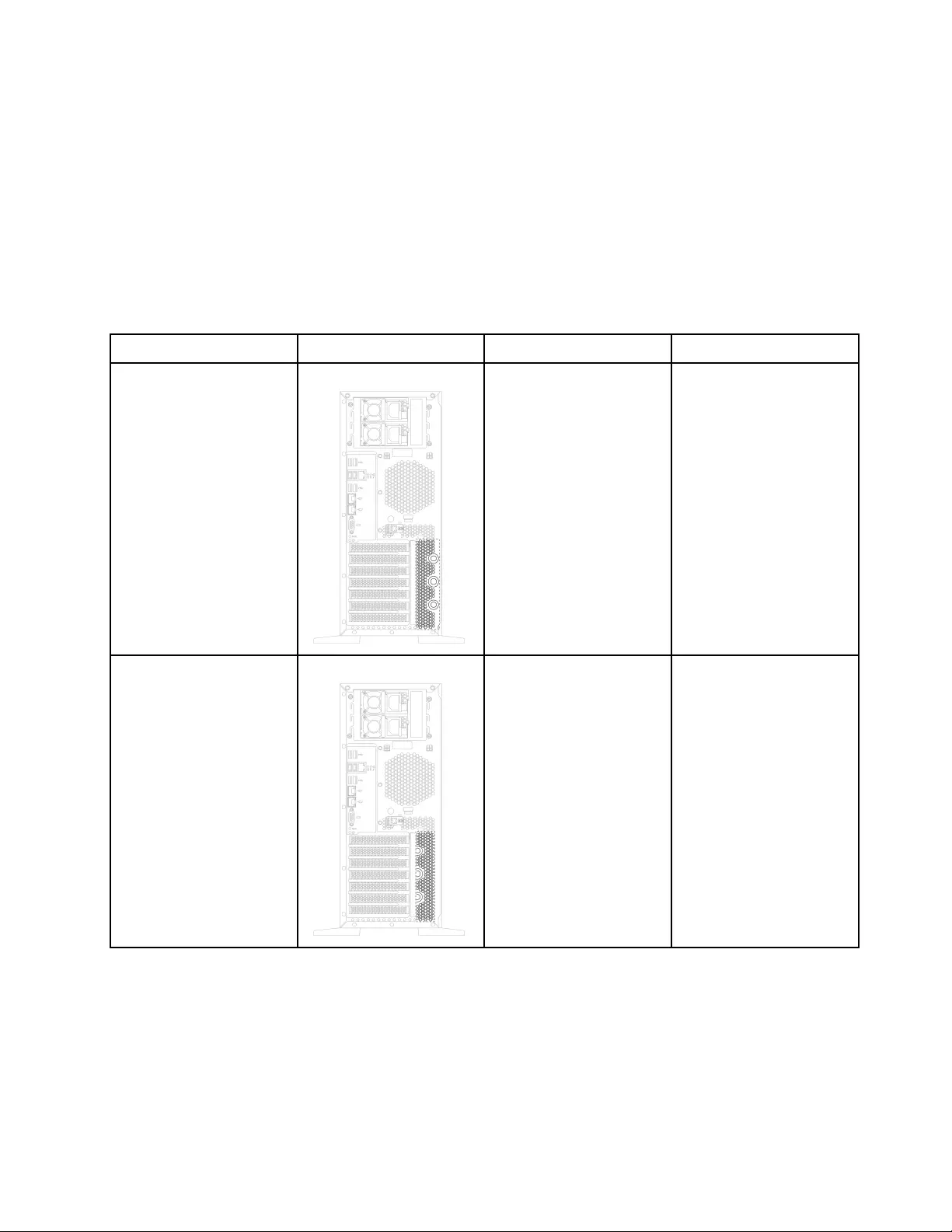

Differences between the original chassis and new chassis

Two types of chassis are available for your server, and different chassis type supports different GPU models.

You can identify the chassis type of your server by the rear view of your server or the part number label

affixed on the bottom of your server.

Chassis type Rear view Part number Supported GPU model

Original chassis • SC87A02105 (eight 3.5-

inch-drive-bay chassis)

• SC87A02106 (sixteen

2.5-inch-drive-bay

chassis)

• NVIDIA P2000

• NVIDIA P2200

• NVIDIA P6000

• NVIDIA P600

• NVIDIA P620

New chassis • SC87A19892 (eight 3.5-

inch-drive-bay chassis)

• SC87A19894 (sixteen

2.5-inch-drive-bay

chassis)

• NVIDIA P2000

• NVIDIA P2200

• NVIDIA P4000, NVIDIA

RTX4000 and other

NVIDIA form factor V3.0

GPUs

• NVIDIA P6000

• NVIDIA P600

• NVIDIA P620

Notes:

• The new chassis is the updated version of the original chassis to support NVIDIA form factor V3.0 GPUs,

such as NVIDIA P4000 and NVIDIA RTX4000.

• The original chassis will phase out and be replaced by the new chassis.

Input/Output (I/O) features

• Front panel:

Chapter 1.Introduction 7

– One XClarity Controller USB connector

– One USB 3.0 connector

• Rear panel:

– One VGA connector

– One XClarity Controller network connector

– Two Ethernet connectors

– Two USB 3.0 connectors

– Four USB 2.0 connectors

System fans

• One processor: two fans (fan 1 and 2) or three fans (fan 1, 2, and 4)

• Two processors: three fans (fan 1, 2, and 3) or four fans (fan 1, 2, 3, and 4)

Notes:

• Fan 3 is required if the expansion drive cage is installed.

• Fan 4 is optional and is the redundant fan.

• If your server comes with only one processor, two or three system fans are adequate to provide proper

cooling. However, you must keep the location for fan 3 occupied by a fan filler to ensure proper airflow.

Power supplies

• One fixed 450-watt power supply

• One or two hot-swap power supplies for redundancy support

– 550-watt ac 80 PLUS Platinum

– 750-watt ac 80 PLUS Platinum

– 750-watt ac 80 PLUS Titanium

– 1100-watt ac 80 PLUS Platinum

Electrical input

• ac input (50 Hz to 60 Hz) required

– Input voltage low range:

– Minimum: 100 V ac

– Maximum: 127 V ac

– Input voltage high range:

– Minimum: 200 V ac

– Maximum: 240 V ac

Note: For server models with 750-watt ac 80 PLUS Titanium power supplies, the 100 V –127 V ac input

voltage is not supported.

CAUTION:

240 V dc input (input range: 180-300 V dc) is supported in Chinese Mainland ONLY. Power supply with

240 V dc input cannot support hot plugging power cord function. Before removing the power supply

with dc input, please turn off server or disconnect dc power sources at the breaker panel or by turning

off the power source. Then, remove the power cord.

8ThinkSystem ST550 Maintenance Manual

Minimal configuration for debugging

• One processor in processor socket 1

• One memory DIMM on slot 3

• One power supply

• Two system fans (fan 1 and 2)

Acoustical noise

• Sound power levels, idle

– 4.0 bels, minimum

– 4.7 bels, typical

– 5.3 bels, maximum

• Sound power levels, operating

– 4.1 bels, minimum

– 4.7 bels, typical

– 5.3 bels, maximum

Notes:

• These sound power levels are measured in controlled acoustical environments according to procedures

specified by ISO 7779 and are reported in accordance with ISO 9296.

• The declared acoustic noise levels are based on specified configurations, which may change depending

on configurations/conditions.

Environment

The server is supported in the following environment:

Note: This server is designed for standard data center environment and recommended to be placed in

industrial data center.

• Air temperature:

– Operating:

– ASHRAE class A2: 10–35°C (50–95°F); when the altitude exceeds 900 m (2953 ft), the maximum

ambient temperature value decreases by 1°C (1.8°F) with every 300 m (984 ft) of altitude increase.

– ASHRAE class A3: 5–40°C (41–104°F); when the altitude exceeds 900 m (2953 ft), the maximum

ambient temperature value decreases by 1°C (1.8°F) with every 175 m (574 ft) of altitude increase.

– ASHRAE class A4: 5–45°C (41–113°F); when the altitude exceeds 900 m (2953 ft), the maximum

ambient temperature value decreases by 1°C (1.8°F) with every 125 m (410 ft) of altitude increase.

– Server off: 5–45°C (41–113°F)

– Shipping or storage: -40–60°C (-40–140°F)

• Maximum altitude: 3050 m (10 000 ft)

• Relative humidity (non-condensing):

– Operating:

– ASHRAE class A2: 8%–80%; maximum dew point: 21°C (70°F)

– ASHRAE class A3: 8%–85%; maximum dew point: 24°C (75°F)

– ASHRAE class A4: 8%–90%; maximum dew point: 24°C (75°F)

– Shipping or storage: 8%–90%

Chapter 1.Introduction 9

• Particulate contamination

Attention: Airborne particulates and reactive gases acting alone or in combination with other

environmental factors such as humidity or temperature might pose a risk to the server. For information

about the limits for particulates and gases, see “Particulate contamination” on page 10.

Note: Your server complies with ASHRAE class A2 specifications. The server performance might be

impacted when the operating temperature is outside the ASHRAE A2 specifications. Depending on the

hardware configuration, some server models comply with ASHRAE class A3 and class A4 specifications. To

comply with ASHRAE class A3 and class A4 specifications, the server models must meet the following

hardware configuration requirements at the same time:

• Fan 4 is installed.

• Two hot-swap power supplies are installed.

• NVMe SSD is not installed.

• Graphics adapters are not installed.

• SAS drives with capacity larger than or equal to 2 TB are not installed in the expansion drive cage.

• Processors with TDP more than 125 watts are not installed.

Important information about EU ecodesign requirements

The following are EU ecodesign requirements for ErP Lot 9 products:

• Minimum memory should be 16 GB.

• Delta or Acbel 450-watt power supplies should not be picked.

• Processors should not picked for one-processor configurations: Intel Xeon 3104, 3106, 3204, 4108, 4112,

5122, 5222, 8156, and 8256

Particulate contamination

Attention: Airborne particulates (including metal flakes or particles) and reactive gases acting alone or in

combination with other environmental factors such as humidity or temperature might pose a risk to the

device that is described in this document.

Risks that are posed by the presence of excessive particulate levels or concentrations of harmful gases

include damage that might cause the device to malfunction or cease functioning altogether. This

specification sets forth limits for particulates and gases that are intended to avoid such damage. The limits

must not be viewed or used as definitive limits, because numerous other factors, such as temperature or

moisture content of the air, can influence the impact of particulates or environmental corrosives and gaseous

contaminant transfer. In the absence of specific limits that are set forth in this document, you must

implement practices that maintain particulate and gas levels that are consistent with the protection of human

health and safety. If Lenovo determines that the levels of particulates or gases in your environment have

caused damage to the device, Lenovo may condition provision of repair or replacement of devices or parts

on implementation of appropriate remedial measures to mitigate such environmental contamination.

Implementation of such remedial measures is a customer responsibility.

10 ThinkSystem ST550 Maintenance Manual

Table 1. Limits for particulates and gases

Contaminant Limits

Gaseous Severity level G1 as per ANSI/ISA 71.04-19851, which states that the reactivity rate of copper

coupons shall be less than 300 Angstroms per month (Å/month, ≈ 0.0039 μg/cm2-hour weight

gain).2 In addition, the reactivity rate of silver coupons shall be less than 200Å/month (≈ 0.0035

μg/cm2-hour weight gain).3 The reactive monitoring of gaseous corrosivity must be conducted

approximately 5 cm (2 in.) in front of the rack on the air inlet side at one-quarter and three-quarter

frame height off the floor or where the air velocity is much higher.

Particulate Data centers must meet the cleanliness level of ISO 14644-1 class 8. For data centers without

airside economizer, the ISO 14644-1 class 8 cleanliness might be met by choosing one of the

following filtration methods:

• The room air might be continuously filtered with MERV 8 filters.

• Air entering a data center might be filtered with MERV 11 or preferably MERV 13 filters.

For data centers with airside economizers, the choice of filters to achieve ISO class 8 cleanliness

depends on the specific conditions present at that data center.

The deliquescent relative humidity of the particulate contamination should be more than 60%

RH.4

Data centers must be free of zinc whiskers.5

1 ANSI/ISA-71.04-1985. Environmental conditions for process measurement and control systems: Airborne

contaminants. Instrument Society of America, Research Triangle Park, North Carolina, U.S.A.

2 The derivation of the equivalence between the rate of copper corrosion growth in the thickness of the corrosion

product in Å/month and the rate of weight gain assumes that Cu2S and Cu2O grow in equal proportions.

3 The derivation of the equivalence between the rate of silver corrosion growth in the thickness of the corrosion

product in Å/month and the rate of weight gain assumes that Ag2S is the only corrosion product.

4 The deliquescent relative humidity of particulate contamination is the relative humidity at which the dust absorbs

enough water to become wet and promote ionic conduction.

5 Surface debris is randomly collected from 10 areas of the data center on a 1.5 cm diameter disk of sticky

electrically conductive tape on a metal stub. If examination of the sticky tape in a scanning electron microscope

reveals no zinc whiskers, the data center is considered free of zinc whiskers.

Firmware updates

Several options are available to update the firmware for the server.

You can use the tools listed here to update the most current firmware for your server and the devices that are

installed in the server.

Note: Lenovo typically releases firmware in bundles called UpdateXpress System Packs (UXSPs). To ensure

that all of the firmware updates are compatible, you should update all firmware at the same time. If you are

updating firmware for both the Lenovo XClarity Controller and UEFI, update the firmware for Lenovo XClarity

Controller first.

Best practices related to updating firmware is available at the following location:

http://lenovopress.com/LP0656

Important terminology

• In-band update. The installation or update is performed using a tool or application within an operating

system that is executing on the server’s core CPU.

Chapter 1.Introduction 11

• Out-of-band update. The installation or update is performed by the Lenovo XClarity Controller collecting

the update and then directing the update to the target subsystem or device. Out-of-band updates have no

dependency on an operating system executing on the core CPU. However, most out-of-band operations

do require the server to be in the S0 (Working) power state.

• On-Target update. The installation or update is initiated from an Operating System executing on the

server’s operating system.

• Off-Target update. The installation or update is initiated from a computing device interacting directly with

the server’s Lenovo XClarity Controller.

• UpdateXpress System Packs (UXSPs). UXSPs are bundled updates designed and tested to provide the

interdependent level of functionality, performance, and compatibility. UXSPs are server machine-type

specific and are built (with firmware and device driver updates) to support specific Windows Server, Red

Hat Enterprise Linux (RHEL) and SUSE Linux Enterprise Server (SLES) operating system distributions.

Machine-type-specific firmware-only UXSPs are also available.

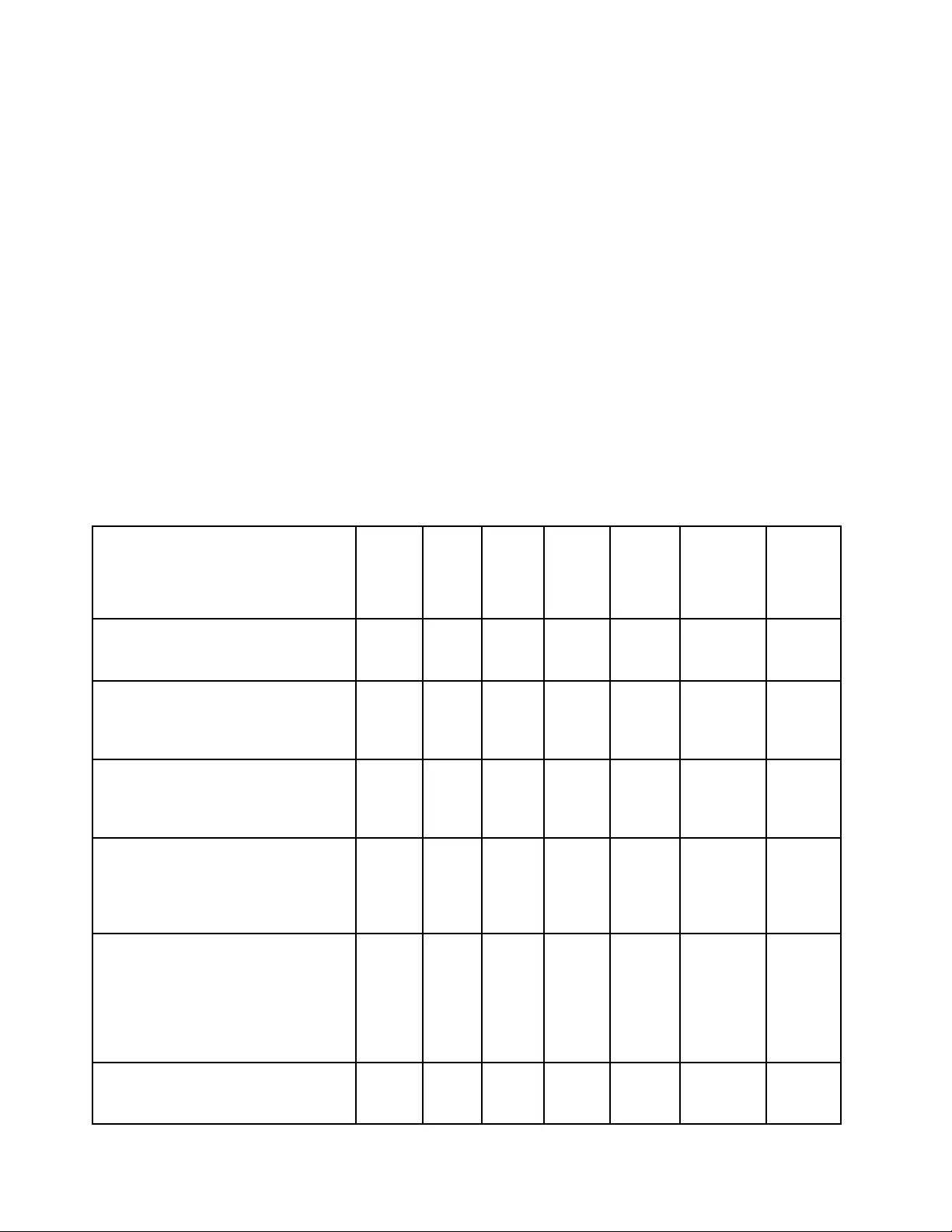

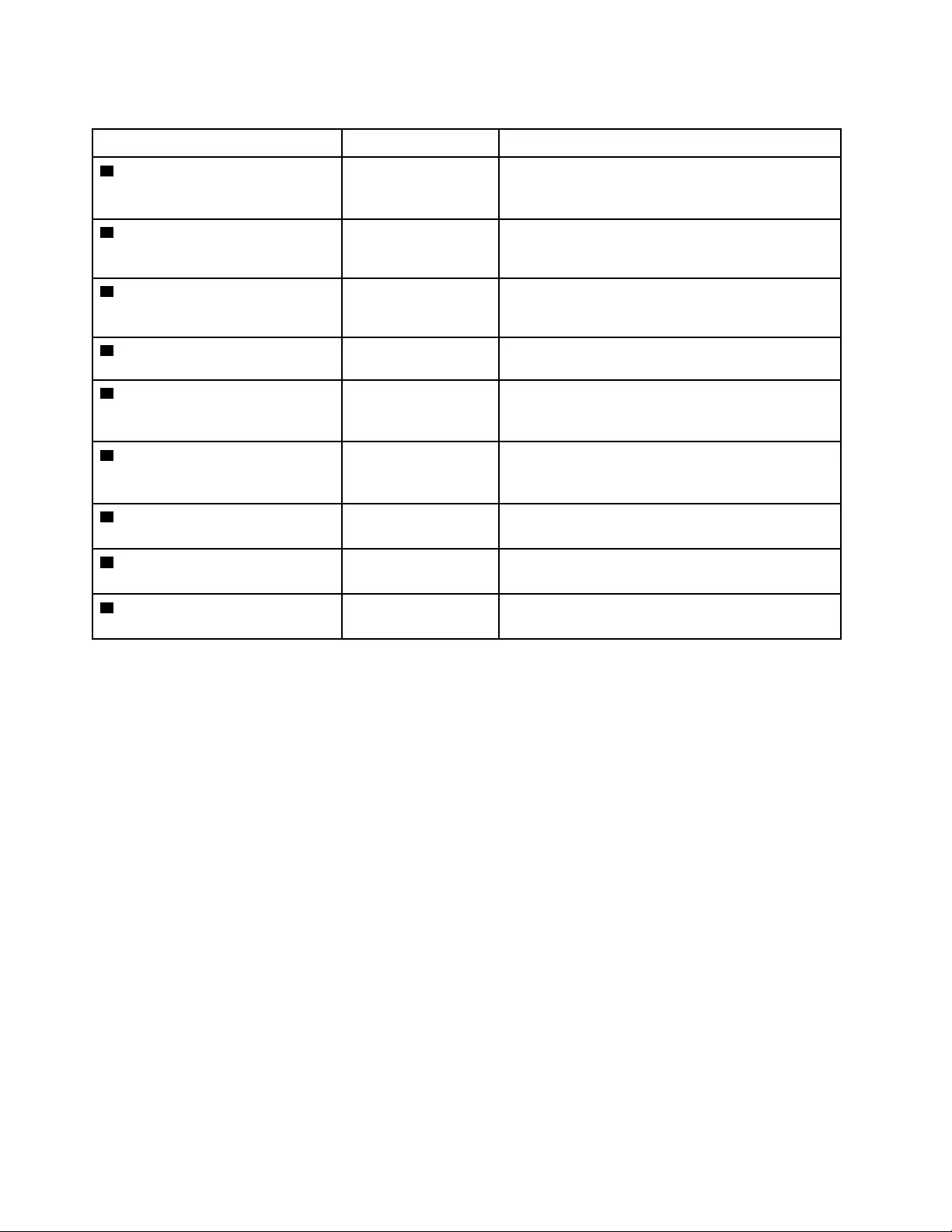

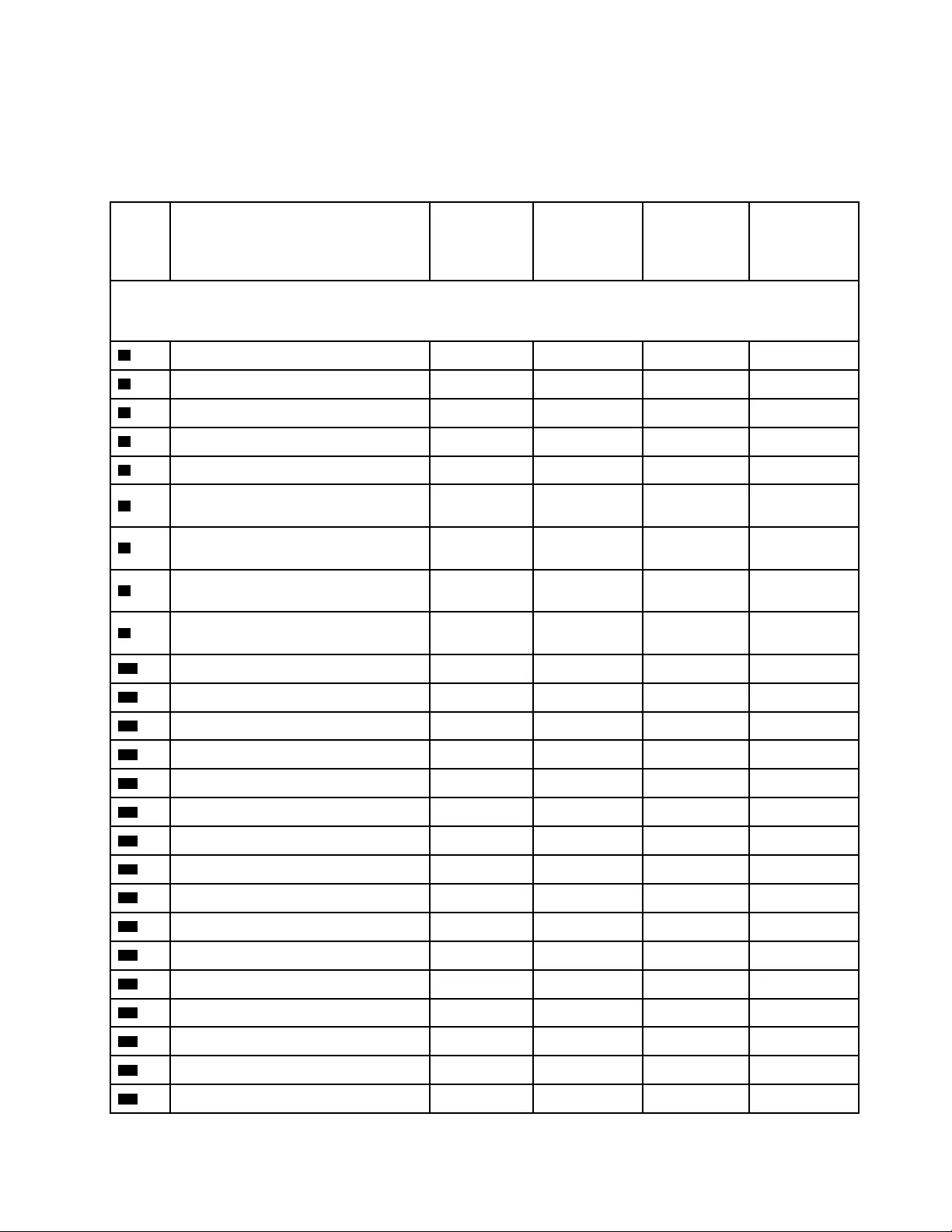

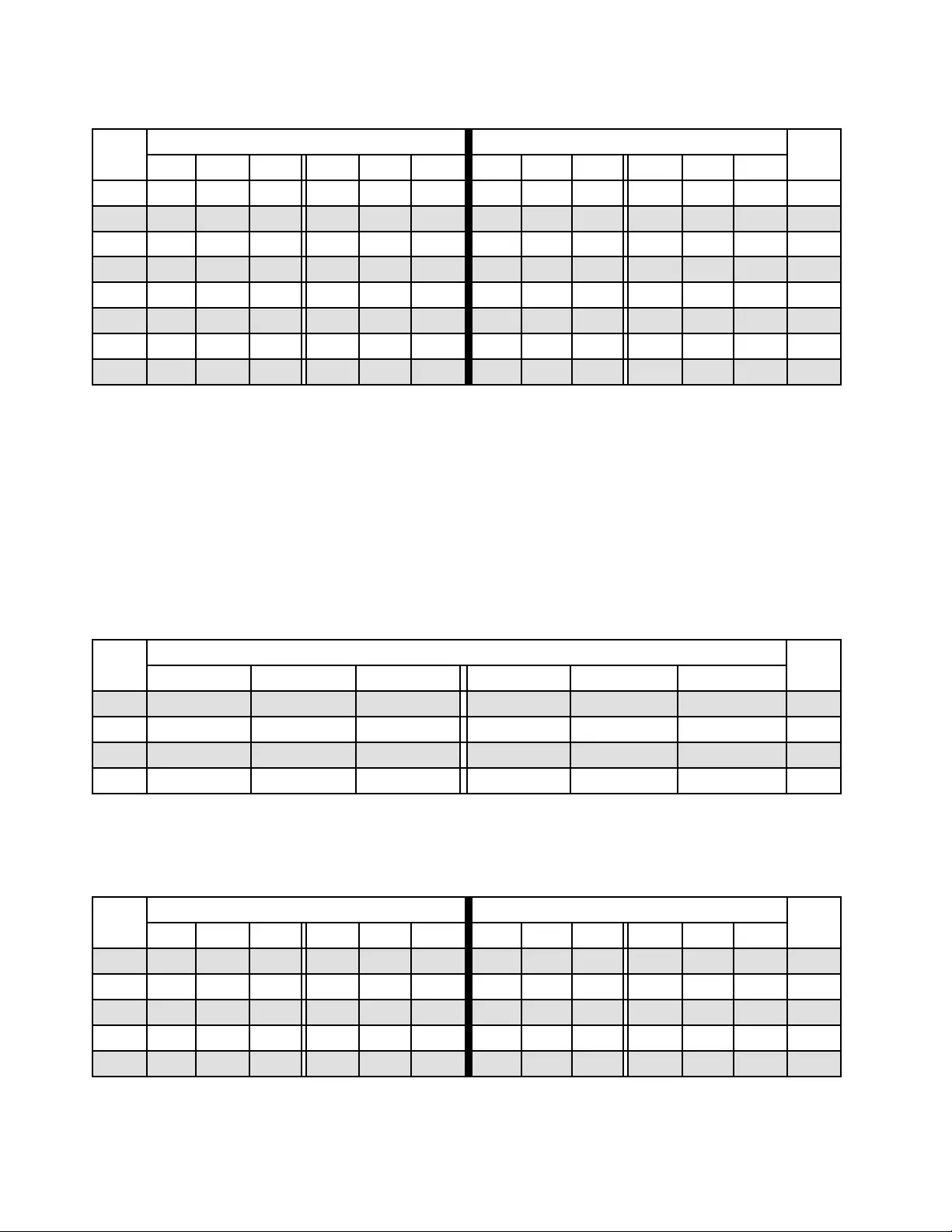

See the following table to determine the best Lenovo tool to use for installing and setting up the firmware:

Note: The server UEFI settings for option ROM must be set to Auto or UEFI to update firmware using

Lenovo XClarity Administrator or Lenovo XClarity Essentials. For more information, see the following Tech

Tip:

https://datacentersupport.lenovo.com/us/en/solutions/ht506118

Tool

In-

band

update

Out-

of-

band

up-

date

On-

target

update

Off-

target

update

Graphi-

cal user

inter-

face

Com-

mand- line

interface

Sup-

ports

UXSPs

Lenovo XClarity Provisioning

Manager

Limited to core system firmware only.

√2√ √ √

Lenovo XClarity Controller

Supports core system firmware and

most advanced I/O option firmware

updates

√ √ √ √

Lenovo XClarity Essentials OneCLI

Supports all core system firmware, I/O

firmware, and installed operating

system driver updates

√ √ √ √

Lenovo XClarity Essentials

UpdateXpress

Supports all core system firmware, I/O

firmware, and installed operating

system driver updates

√ √ √ √

Lenovo XClarity Essentials Bootable

Media Creator

Supports core system firmware and I/O

firmware updates. You can update the

Microsoft Windows operating system,

but device drivers are not included on

the bootable image

√ √ √ √

Lenovo XClarity Administrator

Supports core system firmware and I/O

firmware updates

√ √ √ √

12 ThinkSystem ST550 Maintenance Manual

Tool

In-

band

update

Out-

of-

band

up-

date

On-

target

update

Off-

target

update

Graphi-

cal user

inter-

face

Com-

mand- line

interface

Sup-

ports

UXSPs

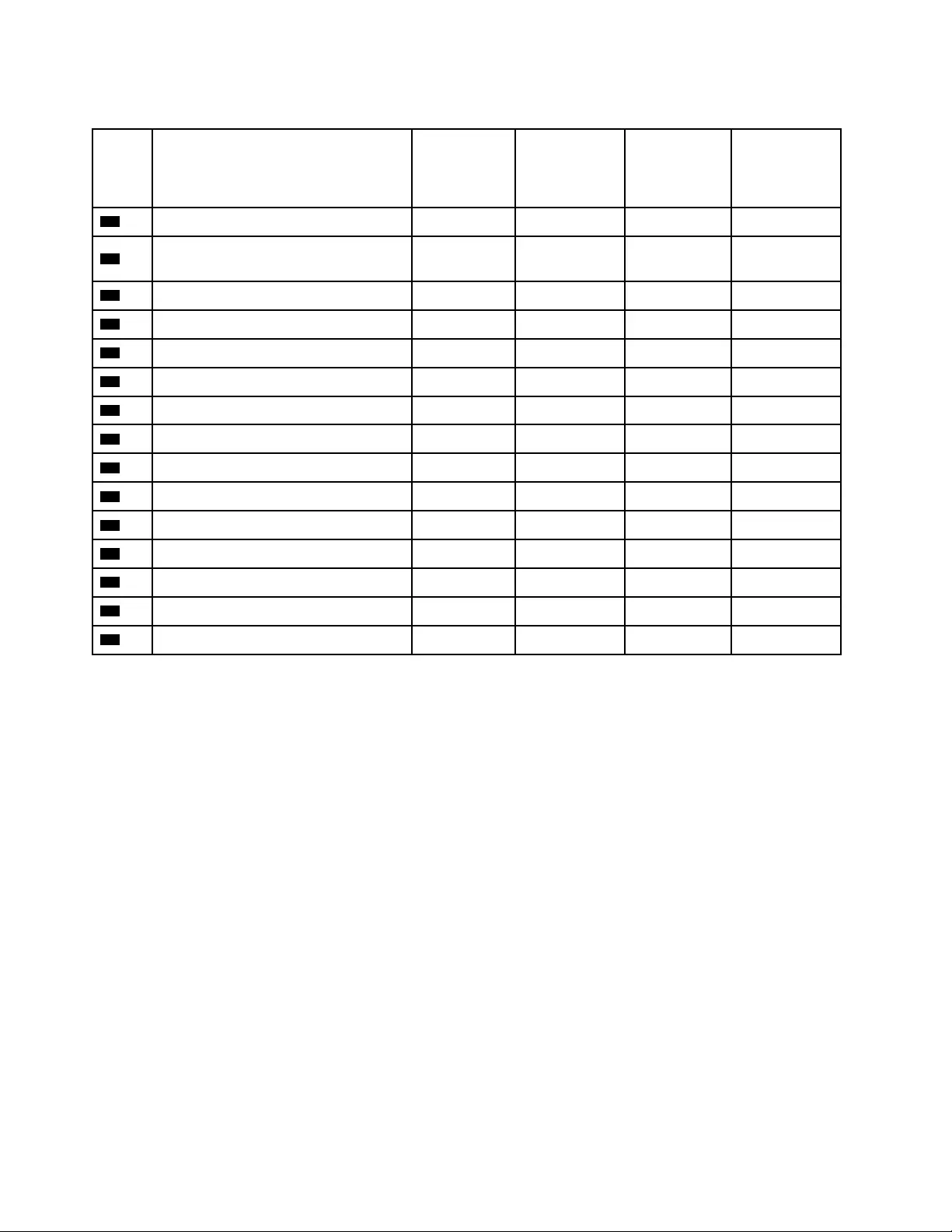

Lenovo XClarity

Integrator

offerings

Lenovo XClarity

Integrator for

VMware vCenter

Supports all core

system firmware,

I/O firmware, and

installed operating

system driver

updates

√ √ √

Lenovo XClarity

Integrator for

Microsoft

Windows Admin

Center

Supports all core

system firmware,

I/O firmware, and

installed operating

system driver

updates

√ √ √ √ √

Lenovo XClarity

Integrator for

Microsoft

System Center

Configuration

Manager

Supports all core

system firmware,

I/O firmware, and

installed operating

system driver

updates

√ √ √ √

The latest firmware can be found at the following site:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/st550/7X09/downloads

• Lenovo XClarity Provisioning Manager

From Lenovo XClarity Provisioning Manager, you can update the Lenovo XClarity Controller firmware, the

UEFI firmware, and the Lenovo XClarity Provisioning Manager software.

Note: By default, the Lenovo XClarity Provisioning Manager Graphical User Interface is displayed when

you press F1. If you have changed that default to be the text-based system setup, you can bring up the

Graphical User Interface from the text-based system setup interface.

Additional information about using Lenovo XClarity Provisioning Manager to update firmware is available

at:

http://sysmgt.lenovofiles.com/help/topic/LXPM/platform_update.html

• Lenovo XClarity Controller

Chapter 1.Introduction 13

If you need to install a specific update, you can use the Lenovo XClarity Controller interface for a specific

server.

Notes:

– To perform an in-band update through Windows or Linux, the operating system driver must be installed

and the Ethernet-over-USB (sometimes called LAN over USB) interface must be enabled.

Additional information about configuring Ethernet over USB is available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

configuringUSB.html

– If you update firmware through the Lenovo XClarity Controller, make sure that you have downloaded

and installed the latest device drivers for the operating system that is running on the server.

Specific details about updating firmware using Lenovo XClarity Controller are available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

manageserverfirmware.html

• Lenovo XClarity Essentials OneCLI

Lenovo XClarity Essentials OneCLI is a collection of command line applications that can be used to

manage Lenovo servers. Its update application can be used to update firmware and device drivers for

your servers. The update can be performed within the host operating system of the server (in-band) or

remotely through the BMC of the server (out-of-band).

Specific details about updating firmware using Lenovo XClarity Essentials OneCLI is available at:

http://sysmgt.lenovofiles.com/help/topic/toolsctr_cli_lenovo/onecli_c_update.html

• Lenovo XClarity Essentials UpdateXpress

Lenovo XClarity Essentials UpdateXpress provides most of OneCLI update functions through a graphical

user interface (GUI). It can be used to acquire and deploy UpdateXpress System Pack (UXSP) update

packages and individual updates. UpdateXpress System Packs contain firmware and device driver

updates for Microsoft Windows and for Linux.

You can obtain Lenovo XClarity Essentials UpdateXpress from the following location:

https://datacentersupport.lenovo.com/solutions/lnvo-xpress

• Lenovo XClarity Essentials Bootable Media Creator

You can use Lenovo XClarity Essentials Bootable Media Creator to create bootable media that is suitable

for applying firmware updates, running preboot diagnostics, and deploying Microsoft Windows operating

systems.

You can obtain Lenovo XClarity Essentials BoMC from the following location:

https://datacentersupport.lenovo.com/solutions/lnvo-bomc

• Lenovo XClarity Administrator

If you are managing multiple servers using the Lenovo XClarity Administrator, you can update firmware for

all managed servers through that interface. Firmware management is simplified by assigning firmware-

compliance policies to managed endpoints. When you create and assign a compliance policy to managed

endpoints, Lenovo XClarity Administrator monitors changes to the inventory for those endpoints and flags

any endpoints that are out of compliance.

Specific details about updating firmware using Lenovo XClarity Administrator are available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.lxca.doc/update_fw.html

• Lenovo XClarity Integrator offerings

14 ThinkSystem ST550 Maintenance Manual

Lenovo XClarity Integrator offerings can integrate management features of Lenovo XClarity Administrator

and your server with software used in a certain deployment infrastructure, such as VMware vCenter,

Microsoft Admin Center, or Microsoft System Center.

Specific details about updating firmware using Lenovo XClarity Integrator offerings are available at:

https://sysmgt.lenovofiles.com/help/topic/lxci/lxci_product_page.html

Tech Tips

Lenovo continually updates the support website with the latest tips and techniques that you can use to solve

issues that you might have with your server. These Tech Tips (also called retain tips or service bulletins)

provide procedures to work around issues related to the operation of your server.

To find the Tech Tips available for your server:

1. Go to http://datacentersupport.lenovo.com and navigate to the support page for your server.

2. Click Documentation from the navigation pane.

Follow the on-screen instructions to choose the category for the problem that you are having.

Security advisories

Lenovo is committed to developing products and services that adhere to the highest security standards in

order to protect our customers and their data. When potential vulnerabilities are reported, it is the

responsibility of the Lenovo Product Security Incident Response Team (PSIRT) to investigate and provide

information to our customers so they may put mitigation plans in place as we work toward providing

solutions.

The list of current advisories is available at the following location:

https://datacentersupport.lenovo.com/product_security/home

Power on the server

After the server performs a short self-test (power status LED flashes quickly) when connected to input power,

it enters a standby state (power status LED flashes once per second).

The server can be turned on (power LED on) in any of the following ways:

• You can press the power button.

• The server can restart automatically after a power interruption.

• The server can respond to remote power-on requests sent to the Lenovo XClarity Controller.

For information about powering off the server, see “Power off the server” on page 15.

Power off the server

The server remains in a standby state when it is connected to a power source, allowing the Lenovo XClarity

Controller to respond to remote power-on requests. To remove all power from the server (power-on LED off),

you must disconnect all power cables.

To place the server in a standby state (power-on LED flashes once per second):

Note: The Lenovo XClarity Controller can place the server in a standby state as an automatic response to a

critical system failure.

• Start an orderly shutdown using the operating system (if supported by your operating system).

Chapter 1.Introduction 15

• Press the power-on button to start an orderly shutdown (if supported by your operating system).

• Press and hold the power button for more than 4 seconds to force a shutdown.

When in a standby state, the server can respond to remote power-on requests sent to the Lenovo XClarity

Controller. For information about powering on the server, see “Power on the server” on page 15.

16 ThinkSystem ST550 Maintenance Manual

Chapter 2. Server components

This section provides information to help you locate your server components.

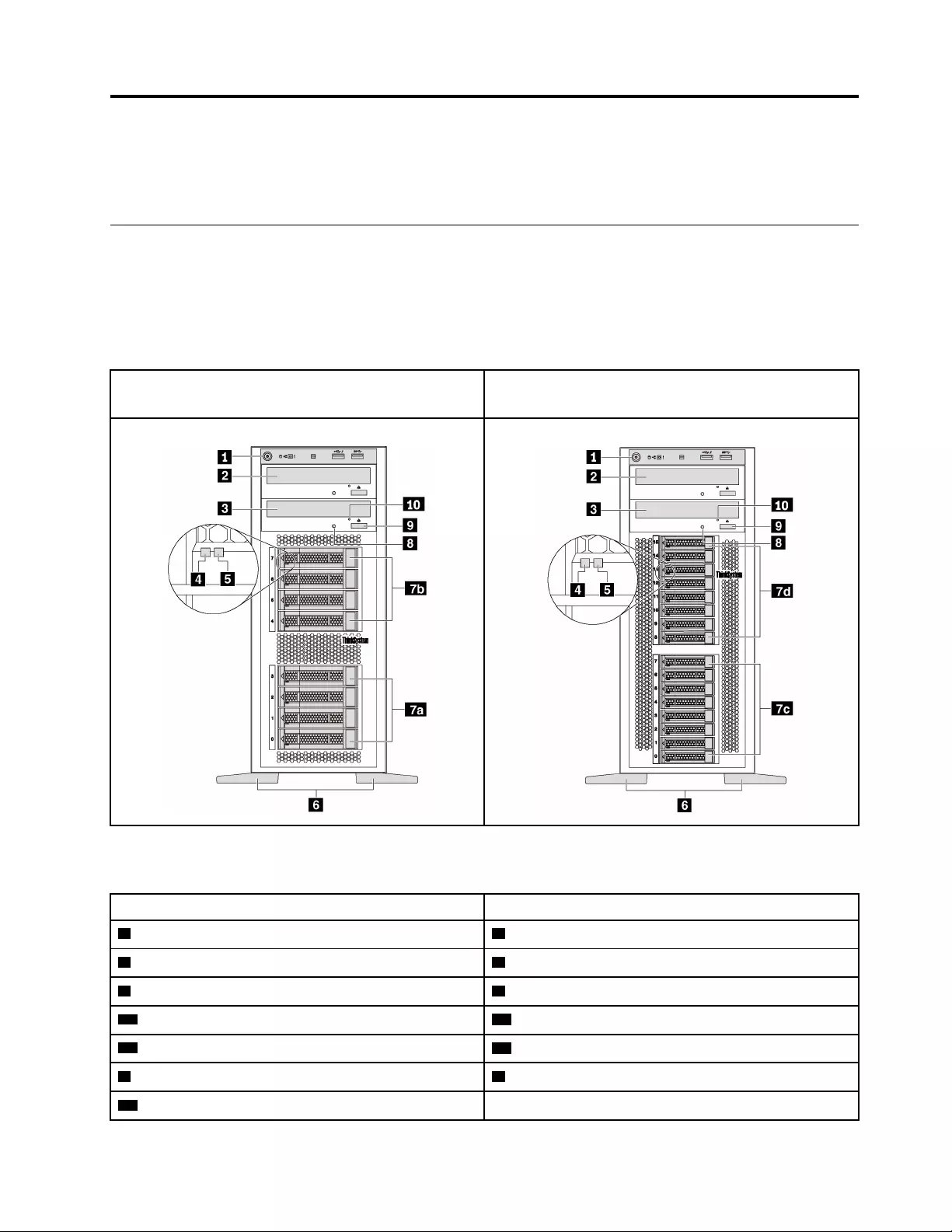

Front view

The front view of the server varies by model.

The illustrations in this topic show the server front views based on the supported drive bays.

Note: Your server might look different from the illustrations in this topic.

Front view of server models with two optical

drive bays and eight 3.5-inch-drive bays

Front view of server models with two optical

drive bays and sixteen 2.5-inch-drive bays

Figure 4. Front view of server models with optical drive bays

Table 2. Components on the front of server models with optical drive bays

Callout Callout

1 Front panel 2 Optical-drive bay 2

3 Optical-drive bay 1 4 Drive activity LED (green)

5 Drive status LED (yellow) 6 Foot stands

7a 3.5-inch drive bays 0–3 7b 3.5-inch drive bays 4–7

7c 2.5-inch drive bays 0–7 7d 2.5-inch drive bays 8–15

8 Optical-drive status LED 9 Optical-drive eject/close button

10 Optical-drive manual-eject hole

© Copyright Lenovo 2017, 2022 17

1 Front panel

For information about the controls, connectors, and status LEDs on the front panel, see “Front panel” on

page 20.

2 Optical-drive bay 2

The 5.25-inch optical-drive bay 2 is for a secondary optical drive or a tape drive. Some models have a

secondary optical drive or a tape drive installed.

3 Optical-drive bay 1

Depending on the model, your server might come with an optical drive installed in the 5.25-inch optical-drive

bay 1.

4 Drive activity LED

5 Drive status LED

Each hot-swap drive has two LEDs.

Drive LED Status Description

4 Drive activity LED (left) Solid green The drive is powered but not active.

Blinking green The drive is active.

5 Drive status LED (right) Solid yellow The drive has an error.

Blinking yellow (blinking slowly, about one

flash per second)

The drive is being rebuilt.

Blinking yellow (blinking rapidly, about four

flashes per second)

The RAID adapter is locating the drive.

6 Foot stands

For tower-form-factor models, your server comes with four foot stands. To help the server stand steadily,

ensure that you install the foot stands correctly as shown. See “Install the foot stands” on page 77.

7a 7b 7c 7d Drive bays

The drive bays are used to install 3.5-inch or 2.5-inch storage drives. When you install drives, follow the order

of the drive bay numbers. The EMI integrity and cooling of the server are protected by having all drive bays

occupied. The vacant drive bays must be occupied by drive bay fillers or drive fillers. Depending on the

model, your server supports one of the following drive bay configurations:

• Four 3.5-inch-drive bays

• Eight 3.5-inch-drive bays

• Eight 2.5-inch-drive bays

• Sixteen 2.5-inch-drive bays

Note: For the 2.5-inch-drive-bay models that support NVMe drives, you can install up to four NVMe drives in

bays 4–7.

8 Optical-drive status LED

The optical-drive status LED is blinking in green when the optical drive is working or in the POST process.

18 ThinkSystem ST550 Maintenance Manual

9 Optical-drive eject/close button

Press this button to eject or close the optical drive when the server power is on.

10 Optical-drive manual-eject hole

Insert a straightened paper clip into the optical-drive manual-eject hole to eject the disc tray when the eject/

close button does not work.

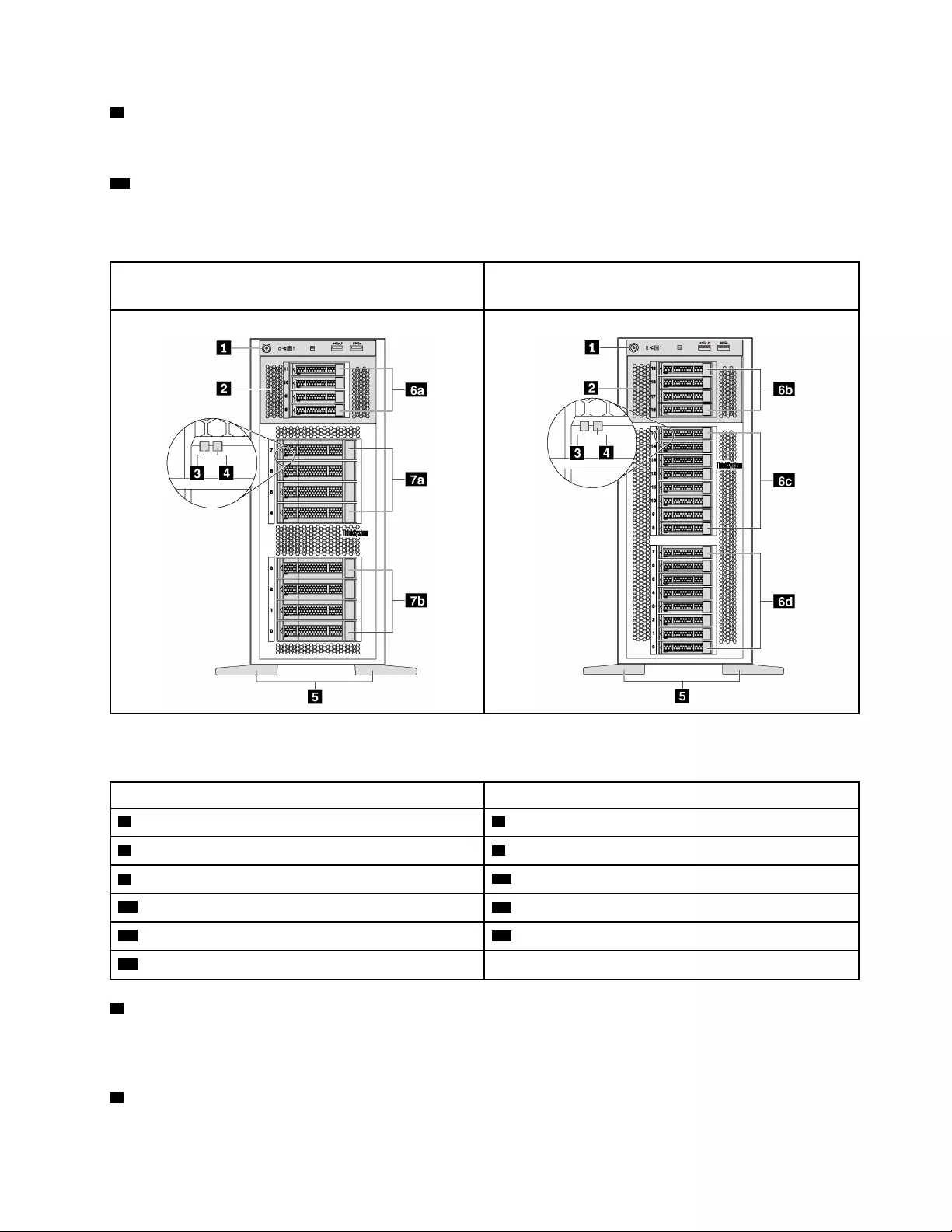

Front view of server models with eight 3.5-inch-

drive bays and four 2.5-inch-drive bays

Front view of server models with twenty 2.5-

inch-drive bays

Figure 5. Front view of server models without optical drive bays

Table 3. Components on the front of server models without optical drive bays

Callout Callout

1 Front panel 2 Expansion drive cage

3 Drive activity LED (green) 4 Drive status LED (yellow)

5 Foot stands 6a 2.5-inch drive bays 8–11

6b 2.5-inch drive bays 16–19 6c 2.5-inch drive bays 8–15

6d 2.5-inch drive bays 0–7 7a 3.5-inch drive bays 4–7

7b 3.5-inch drive bays 0–3

1 Front panel

For information about the controls, connectors, and status LEDs on the front panel, see “Front panel” on

page 20.

2 Expansion drive cage

Chapter 2.Server components 19

For some server models, your server comes with an expansion drive cage. You can install up to four 2.5-inch

SAS/SATA drives to the cage.

3 Drive activity LED

4 Drive status LED

Each hot-swap drive has two LEDs.

Drive LED Status Description

3 Drive activity LED (left) Solid green The drive is powered but not active.

Blinking green The drive is active.

4 Drive status LED (right) Solid yellow The drive has an error.

Blinking yellow (blinking slowly, about one

flash per second)

The drive is being rebuilt.

Blinking yellow (blinking rapidly, about four

flashes per second)

The RAID controller is locating the drive.

5 Foot stands

For tower-form-factor models, your server comes with four foot stands. To help the server stand steadily,

ensure that you install the foot stands correctly as shown. See “Install the foot stands” on page 77.

6a 6b 6c 6d 7a 7b Drive bays

The drive bays are used to install 3.5-inch or 2.5-inch storage drives. The EMI integrity and cooling of the

server are protected by having all drive bays occupied. The vacant drive bays must be occupied by drive bay

fillers or drive fillers. When you install drives, follow the order of the drive bay numbers.

Note: For the 2.5-inch-drive-bay models that support NVMe drives, you can install up to four NVMe drives in

bays 4–7.

Front panel

The front panel of the server provides controls, connectors, and LEDs.

The following illustration shows the control, connectors, and LEDs on the front panel of the server.

Figure 6. Front panel

20 ThinkSystem ST550 Maintenance Manual

Table 4. Components on the front panel

Callout Callout

1 Power button with power status LED (green) 2 Simple-swap-drive activity LED (green)

3 Network activity LED (green) 4 System ID button with system ID LED (blue)

5 System error LED (yellow) 6 Opening for temperature sensor

7 XClarity Controller USB connector 8 USB 3.0 connector

1 Power button with power status LED

You can press the power button to turn on the server when you finish setting up the server. You also can hold

the power button for several seconds to turn off the server if you cannot turn off the server from the operating

system. The power status LED helps you to determine the current power status.

Status Color Description

Solid on Green The server is on and running.

Slow blinking

(about one flash

per second)

Green The server is off and is ready to be powered on (standby state).

Fast blinking

(about four

flashes per

second)

Green The server is off, but the XClarity Controller is initializing, and the server is not ready

to be powered on.

Off None There is no ac power applied to the server.

2 Simple-swap-drive activity LED

The simple-swap-drive activity LED is only for server models with simple-swap storage drives.

Status Color Description

Solid on Green The simple-swap drive is active.

Off None The simple-swap drive is not active.

3 Network activity LED

Compatibility of the NIC adapter and the network activity LED.

NIC adapter NIC adapter

LOM adapter Support

ML2 NIC adapter Support

PCIe NIC adapter Not support

The network activity LED on the front panel helps you identify the network connectivity and activity.

Chapter 2.Server components 21

Status Color Description

On Green The server is connected to a network.

Blinking Green The network is connected and active.

Off None The server is disconnected from the network.

4 System ID button with system ID LED

Use this system ID button and the blue system ID LED to visually locate the server. A system ID LED is also

located on the rear of the server. Each time you press the system ID button, the state of both the system ID

LEDs changes. The LEDs can be changed to on, blinking, or off. You can also use the Lenovo XClarity

Controller or a remote management program to change the state of the system ID LEDs to assist in visually

locating the server among other servers.

If the XClarity Controller USB connector is set to have both the USB 2.0 function and XClarity Controller

management function, you can press the system ID button for three seconds to switch between the two

functions.

5 System error LED

The system error LED provides basic diagnostic functions for your server.

Status Color Description Action

On Yellow An error has been detected on the server.

Causes might include one or more of the

following errors:

• The temperature of the server reached

the non-critical temperature threshold.

• The voltage of the server reached the

non-critical voltage threshold.

• A fan has been detected to be running at

low speed.

• A fan has been removed.

• The power supply has a critical error.

• The power supply is not connected to

the power.

Check the event log to determine the exact

cause of the error.

Off None The server is off or the server is on and is

working correctly.

None.

6 Opening for temperature sensor

Used to detect the surrounding temperature.

7 XClarity Controller USB connector

Depending on the setting, this connector supports USB 2.0 function, XClarity Controller management

function, or both.

• If the connector is set for USB 2.0 function, you can attach a device that requires a USB 2.0 connection,

such as a keyboard, a mouse, or a USB storage device.

• If the connector is set for XClarity Controller management function, you can attach a mobile device

installed with the application to run XClarity Controller event logs.

22 ThinkSystem ST550 Maintenance Manual

• If the connector is set to have both functions, you can press the system ID button for three seconds to

switch between the two functions.

8 USB 3.0 connector

Used to attach a device that requires a USB 2.0 or 3.0 connection, such as a keyboard, a mouse, or a USB

flash drive.

Rear view

The rear of the server provides access to several connectors and components.

Rear view of server models with a fixed power supply

Figure 7. Rear view of server models with a fixed power supply

Table 5. Components on the rear of server models with a fixed power supply

Callout Callout

1 Fixed power supply 2 USB 2.0 connectors (2)

3 USB 3.0 connectors (2) 4 XClarity Controller network connector

5 USB 2.0 connectors (2) 6 Ethernet connectors (2)

7 VGA connector 8 NMI button

9 Serial-port-module slot 10 PCIe slot 1

11 PCIe slot 2 12 PCIe slot 3

13 PCIe slot 4 14 PCIe slot 5

15 PCIe slot 6

1 Fixed power supply

Used to connect the power cord.

2 3 5 USB connectors

Chapter 2.Server components 23

Used to attach a device that requires a USB 2.0 or 3.0 connection, such as a keyboard, a mouse, or a USB

flash drive.

4 XClarity Controller network connector

Used to attach an Ethernet cable to manage the system using XClarity Controller.

6 Ethernet connectors

Used to attach an Ethernet cable for a LAN. Each Ethernet connector has two status LEDs to help you

identify the Ethernet connectivity and activity. For more information, see “Rear view LEDs” on page 26.

7 VGA connector

Used to attach a VGA-compatible video device, such as a VGA monitor.

8 NMI button

Press this button to force a nonmaskable interrupt (NMI) to the processor. By this way, you can blue screen

the server and take a memory dump. You might have to use a pen or the end of a straightened paper clip to

press the button.

9 Serial-port-module slot

Used to install a serial port module. The serial port module is available on some models. For instructions on

how to install the serial port module, see “Install the serial port module” on page 139.

10 11 12 13 14 15 PCIe slots

Your server has six PCIe slots on the system board for you to install appropriate PCIe adapters. For

information about the PCIe slots, see “Specifications” on page 3.

Rear view of server models with two hot-swap power supplies

Figure 8. Rear view of server models with two hot-swap power supplies

24 ThinkSystem ST550 Maintenance Manual

Table 6. Components on the rear of server models with two hot-swap power supplies

Callout Callout

1 Power supply 1 2 Power supply 2 (available on some models or available

as an option)

3 USB 2.0 connectors (2) 4 USB 3.0 connectors (2)

5 XClarity Controller network connector 6 USB 2.0 connectors (2)

7 Ethernet connectors (2) 8 VGA connector

9 NMI button 10 Serial-port-module slot

11 PCIe slot 1 12 PCIe slot 2

13 PCIe slot 3 14 PCIe slot 4

15 PCIe slot 5 16 PCIe slot 6

1 Power supply 1

2 Power supply 2 (available on some models or available as an option)

The hot-swap redundant power supplies help you avoid significant interruption to the operation of the

system when a power supply fails. You can purchase a power supply option from Lenovo and install the

power supply to provide power redundancy without turning off the server.

On each power supply, there are three status LEDs near the power cord connector. For information about the

status LEDs, see “Rear view LEDs” on page 26.

3 4 6 USB connectors

Used to attach a device that requires a USB 2.0 or 3.0 connection, such as a keyboard, a mouse, or a USB

flash drive.

5 XClarity Controller network connector

Used to attach an Ethernet cable to manage the system using XClarity Controller.

7 Ethernet connectors

Used to attach an Ethernet cable for a LAN. Each Ethernet connector has two status LEDs to help you

identify the Ethernet connectivity and activity. For more information, see “Rear view LEDs” on page 26.

8 VGA connector

Used to attach a VGA-compatible video device, such as a VGA monitor.

9 NMI button

Press this button to force a nonmaskable interrupt (NMI) to the processor. By this way, you can blue screen

the server and take a memory dump. You might have to use a pen or the end of a straightened paper clip to

press the button.

10 Serial-port-module slot

Used to install a serial port module. The serial port module is available on some models. For instructions on

how to install the serial port module, see “Install the serial port module” on page 139.

Chapter 2.Server components 25

11 12 13 14 15 16 PCIe slots

Your server has six PCIe slots on the system board for you to install appropriate PCIe adapters. For

information about the PCIe slots, see “Specifications” on page 3.

Rear view LEDs

The illustration in this section shows the LEDs on the rear the server.

Figure 9. Rear view LEDs of the server

Table 7. LEDs on the rear of the server

Callout Callout

1 Ethernet link LED (green) 2 Ethernet activity LED (green)

3 System ID LED (blue) 4 Power input LED (green)

5 Power output LED (green) 6 Power supply error LED (yellow)

1 2 Ethernet status LEDs

Each network connector has two status LEDs.

Ethernet status LED Color Status Description

1 Ethernet link LED Green On Network link is established.

None Off Network link is disconnected.

2 Ethernet activity LED Green Blinking Network link is connected and active.

None Off The server is disconnected from a LAN.

3 System ID LED

The blue system ID LED helps you to visually locate the server. A system ID LED is also located on the front

of the server. Each time you press the system ID button, the state of both the system ID LEDs changes. The

26 ThinkSystem ST550 Maintenance Manual

LEDs can be changed to on, blinking, or off. You can also use the Lenovo XClarity Controller or a remote

management program to change the state of the system ID LEDs to assist in visually locating the server

among other servers.

4 Power input LED

5 Power output LED

6 Power supply error LED

Each hot-swap power supply has three status LEDs.

LED Description

4 Power input LED • Off: The power supply is disconnected from the ac power source or a power problem

occurs.

• Green: The power supply is connected to the ac power source.

5 Power output LED • Green: The server is on and the power supply is working normally.

• Blinking green: The power supply is in zero-output mode (standby). When the server

power load is low, one of the installed power supplies enters into the standby state

while the other one delivers entire load. When the power load increases, the standby

power supply will switch to active state to provide sufficient power to the server.

To disable zero-output mode, start the Setup utility, go to System Settings ➙ Power

➙ Zero Output and select Disable. If you disable zero-output mode, both power

supplies will be in the active state.

• Off: The server is powered off, or the power supply is not working properly. If the

server is powered on but the power output LED is off, replace the power supply.

6 Power supply error LED • Off: The power supply is working normally.

• Yellow: The power supply has failed. To resolve the issue, replace the power supply.

Chapter 2.Server components 27

System board components

The illustration in this section shows the component locations on the system board.

Figure 10. System board components

Table 8. Components on the system board

Callout Callout

1 CPU 2 power connector 2 Processor 2 socket

3 DIMM slots (12) 4 Main power connector

5 Backplane 1 power connector 6 Backplane 2 power connector

7 Backplane 3 power connector 8 System fan 2 connector

9 System fan 3 connector 10 Processor 1 socket

11 CPU 1 power connector 12 System fan 1 connector

13 Power-interface-board signal connector 14 SAS 4–7 connector

15 SAS 0–3 connector 16 Front-panel-USB connector

17 Internal USB 3.0 connector 18 Operator-information-panel connector

19 Optical-drive-2 signal connector 20 Optical-drive-1 signal connector

21 CMOS battery connector 22 M.2 module slot

28 ThinkSystem ST550 Maintenance Manual

Table 8. Components on the system board (continued)

Callout Callout

23 Intrusion switch connector 24 TCM1/TPM2 connector (for only)

25 PCIe slot 6 (for processor 1) 26 PCIe slot 5 (for processor 2)

27 PCIe slot 4 (for processor 2) 28 PCIe slot 3 (for processor 1)

29 PCIe slot 2 (for processor 1) 30 PCIe slot 1 (for processor 1)

31 System fan 4 connector 32 Serial-port-module connector

Notes:

• 1 Trusted Cryptography Module

• 2 Trusted Platform Module

System board jumpers

The following illustration shows the location of the jumpers on the server.

Figure 11. System board jumpers

Chapter 2.Server components 29

Table 9. Jumper description

Jumper name Jumper number Jumper setting

1 Force XCC update jumper JP16 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Force the Lenovo XClarity Controller

to update to the latest version.

2 Force XCC reset jumper JP19 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Reset the Lenovo XClarity

Controller.

3 TPM/TCM physical presence

jumper

JP23 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: TPM/TCM physical presence is

asserted.

4 Power permission JP72 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Enable Power On.

5 Boot backup XClarity Controller JP71 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: The tower server will boot by using

a backup of the XClarity Controller firmware.

6 Clear CMOS jumper JP76 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Clear the real-time clock (RTC)

registry.

7 ME recovery JP59 • The jumper is in default setting.

• ME boots to recovery.

8 ME firmware security override JP38 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Enable Flash security override.

9 Override power-on password

jumper

JP61 • Pins 1 and 2: The jumper is in default setting.

• Pins 2 and 3: Override the power-on password.

Important:

• Before you move the jumpers, turn off the server. Then, disconnect all power cords and external cables.

Do not open your server or attempt any repair before reading and understanding the following information:

– http://thinksystem.lenovofiles.com/help/topic/safety_documentation/pdf_files.html

– “Handling static-sensitive devices” on page 74

• Any system-board switch or jumper block that is not shown in the illustrations in this document are

reserved.

30 ThinkSystem ST550 Maintenance Manual

Internal cable routing

Some of the components in the server have internal cables and cable connectors.

To connect cables, observe the following guidelines:

• Turn off the server before you connect or disconnect any internal cables.

• See the documentation that comes with any external devices for additional cabling instructions. It might

be easier for you to route cables before you connect the devices to the server.

• Cable identifiers of some cables are printed on the cables that come with the server and optional devices.

Use these identifiers to connect the cables to the correct connectors.

• Ensure that the cable is not pinched and does not cover any connectors or obstruct any components on

the system board.

• Ensure that the relevant cables pass through the cable clips.

Note: Disengage all latches, release tabs, or locks on cable connectors when you disconnect cables from

the system board. Failing to release them before removing the cables will damage the cable sockets on the

system board, which are fragile. Any damage to the cable sockets might require replacing the system board.

Chapter 2.Server components 31

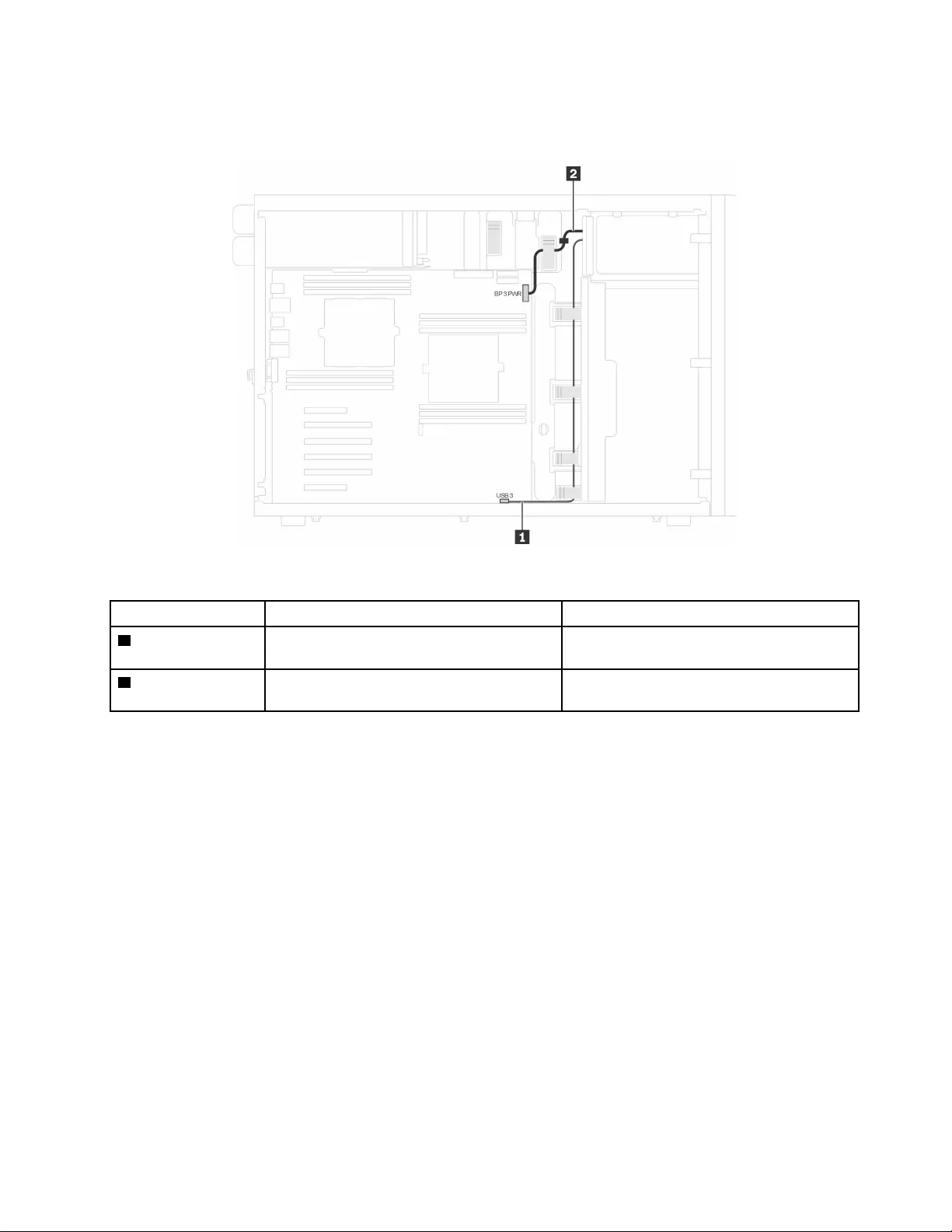

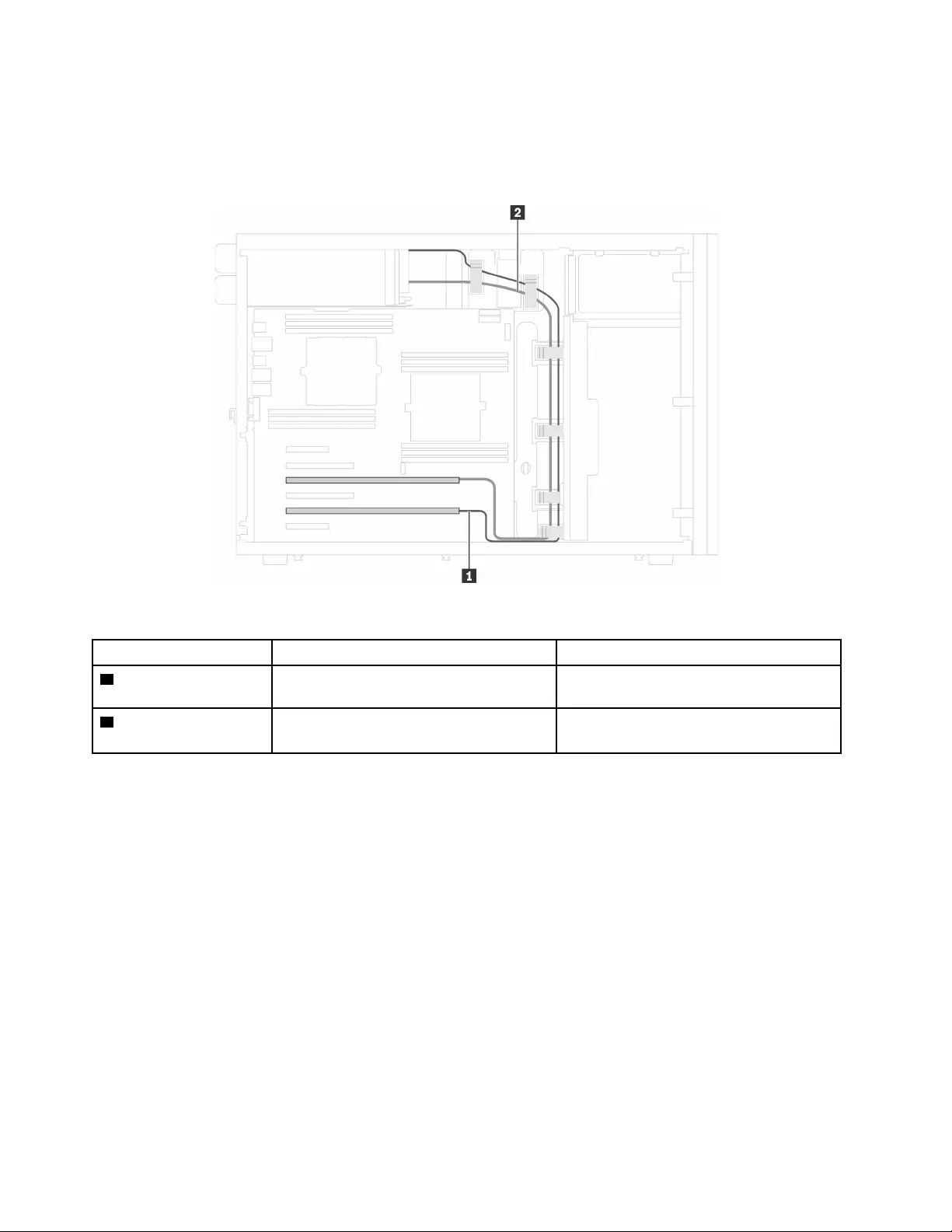

Front panel

Use the section to understand the cable routing for the front panel.

Note: Ensure that all cables are routed through the correct cable clips.

Figure 12. Cable routing for the front panel

Cable To

1 Operator-information-panel cable Operator-information-panel connector on the system

board

2 USB cable Front-panel-USB connector on the system board

32 ThinkSystem ST550 Maintenance Manual

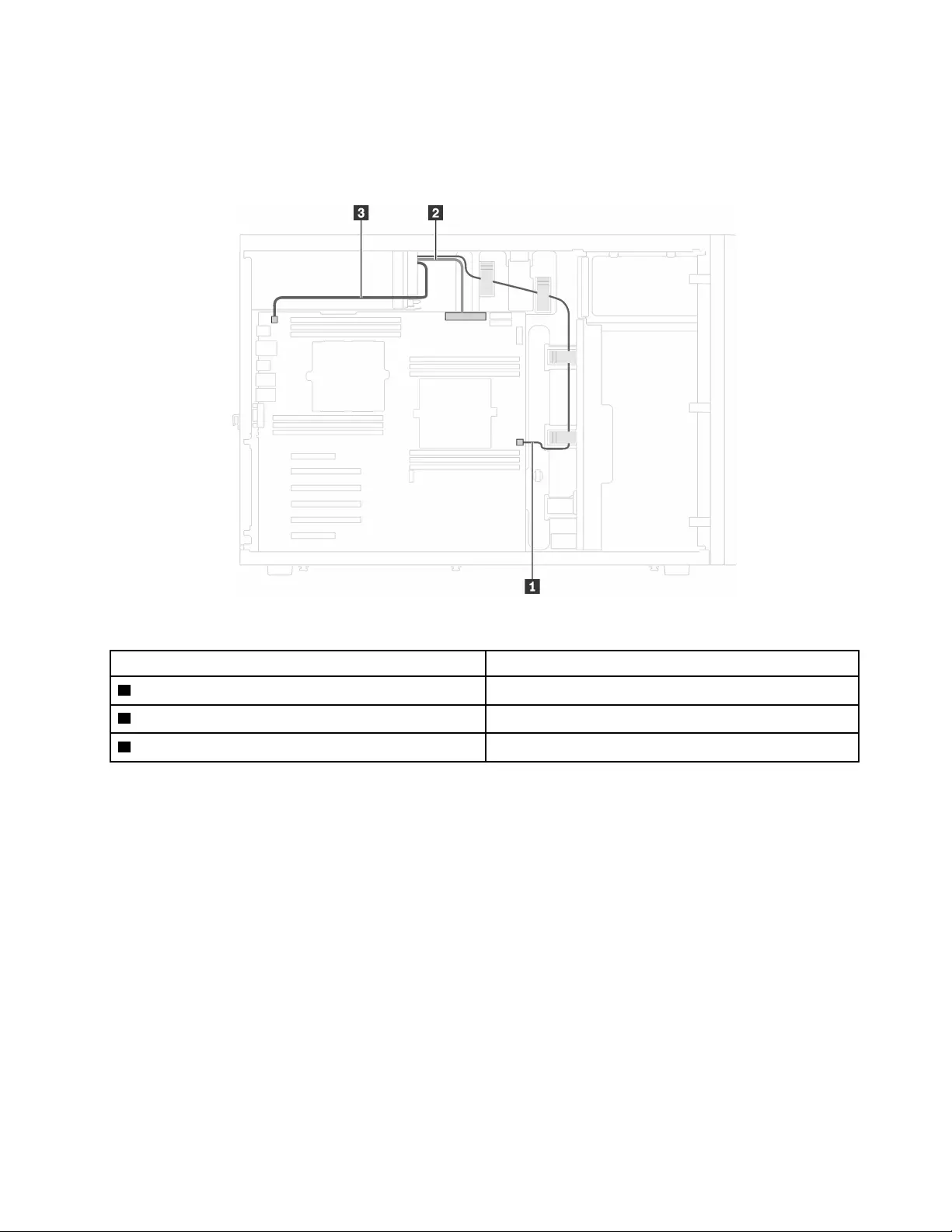

Optical drive

Use the section to understand the cable routing for the optical drives.

Note: Ensure that all cables are routed through the correct cable clips.

Figure 13. Cable routing for the optical drives

Cable From To

1 Signal cable Signal connector on the optical drive 1 Optical-drive-1 signal connector on the

system board

2 Signal cable Signal connector on the optical drive 2 Optical-drive-2 signal connector on the

system board

3 Power cable Power connector on each optical drive Backplane 3 power connector on the system

board

Chapter 2.Server components 33

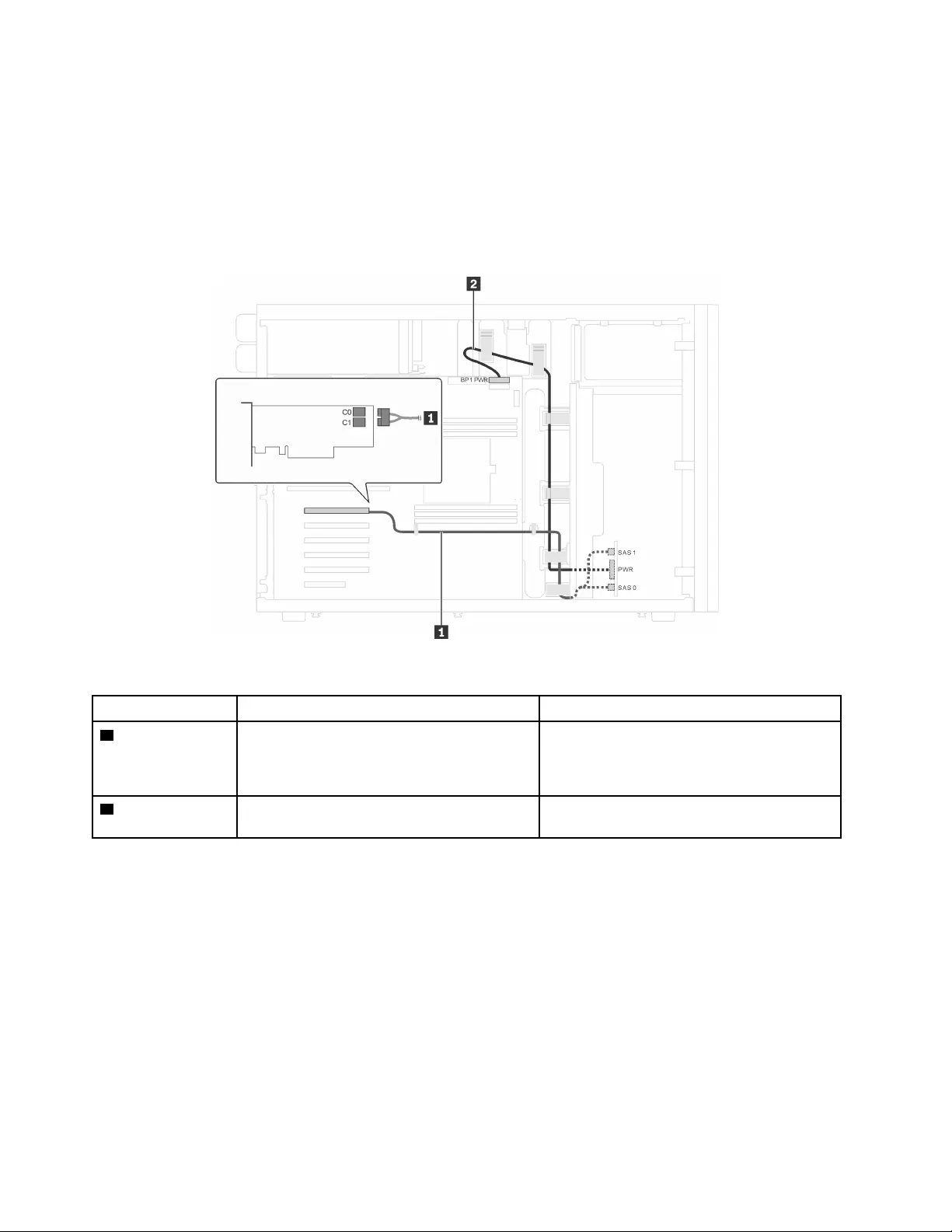

Tape drive

Use the section to understand the cable routing for the tape drive.

SAS tape drive

Note: Ensure that all cables are routed through the correct cable clips.

Figure 14. Cable routing for the SAS tape drive

Cable From To

1 Signal cable Signal connector on the tape drive An available connector on the RAID adapter

2 Power cable Power connector on the tape drive Backplane 3 power connector on the system

board

34 ThinkSystem ST550 Maintenance Manual

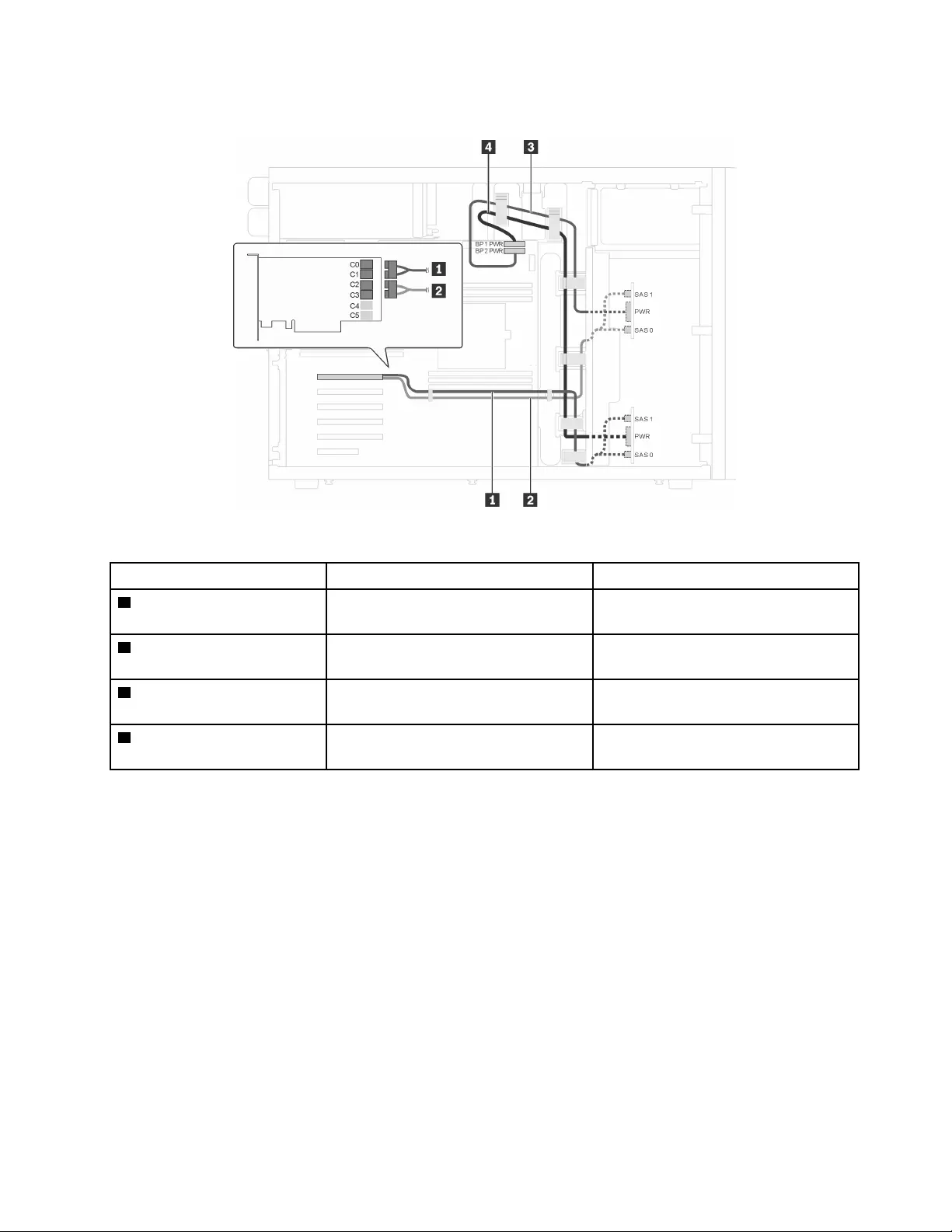

USB tape drive

Note: Ensure that all cables are routed through the correct cable clips.

Figure 15. Cable routing for the USB tape drive

Cable From To

1 Signal cable Signal connector on the tape drive Internal USB 3.0 connector on the system

board

2 Power cable Power connector on the tape drive Backplane 3 power connector on the system

board

Chapter 2.Server components 35

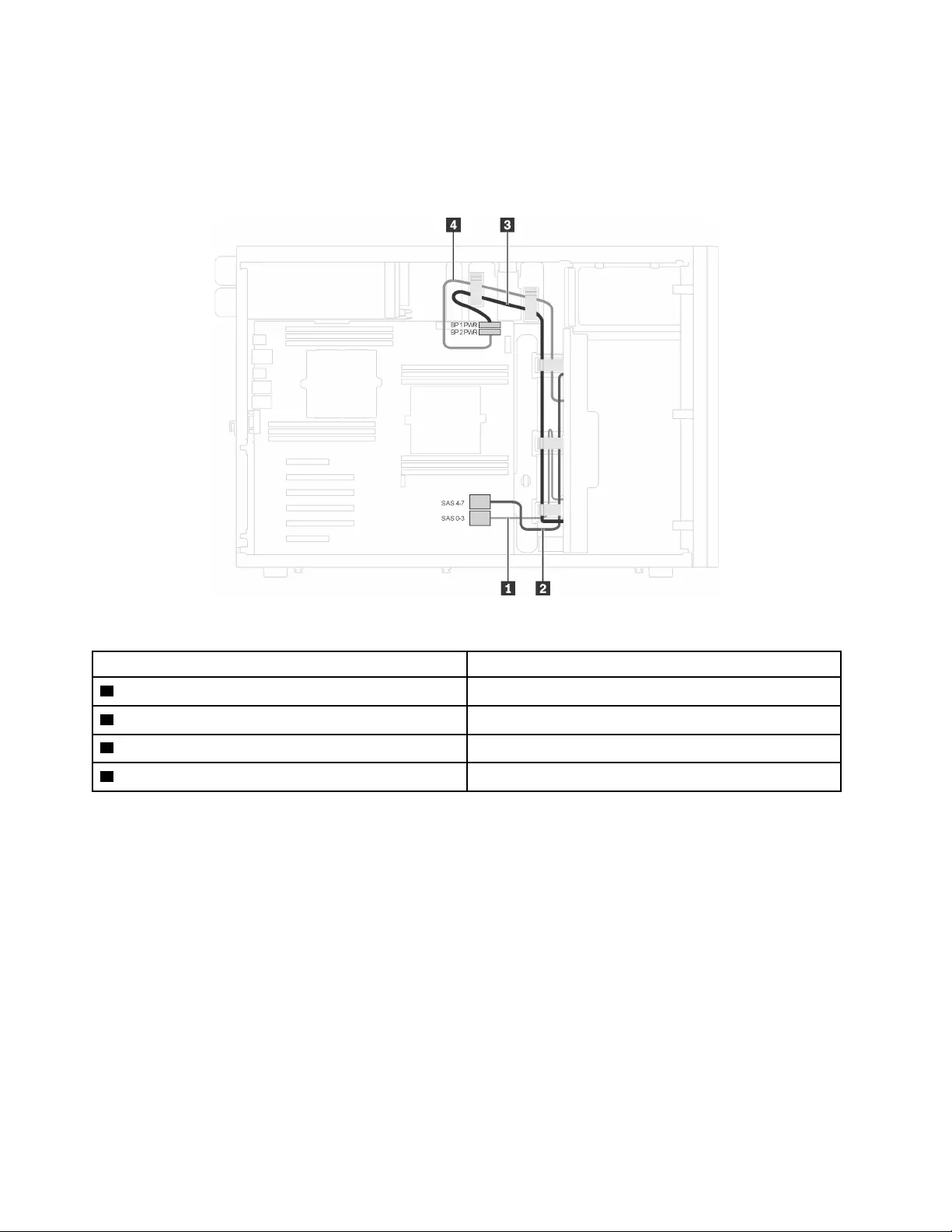

Power interface board

Use the section to understand the cable routing for the power interface board.

Note: Ensure that all cables are routed through the correct cable clips.

Figure 16. Cable routing for the power interface board

Cable From To

1 Signal cable Signal connector on the power interface

board

Power-interface-board signal connector on

the system board

2 CPU 1 power cable CPU 1 connector on the power interface

board

CPU 1 power connector on the system

board

3 Power cable Main power connector on the power

interface board

Main power connector on the system board

4 CPU 2 power cable CPU 2 connector on the power interface

board

CPU 2 power connector on the system

board

36 ThinkSystem ST550 Maintenance Manual

Fixed power supply

Use the section to understand the cable routing for the fixed power supply.

Note: Ensure that all cables are routed through the correct cable clips.

Figure 17. Cable routing for the fixed power supply

Cable To

1 CPU 1 power cable CPU 1 power connector on the system board

2 Main power cable Main power connector on the system board

3 CPU 2 power cable CPU 2 power connector on the system board

Chapter 2.Server components 37

Graphics adapter

Use the section to understand the cable routing for the graphics adapters.

Note: Ensure that all cables are routed through the correct cable clips.