Peerless DS-LEDIF-10X5 User Manual

Displayed below is the user manual for DS-LEDIF-10X5 by Peerless which is a product in the TV Mounts category. This manual has pages.

Related Manuals

12018-03-14 #:146-9020-4 (2019-05-16)

ENG

DS-LEDIF Series

For Samsung IF015H, IF020H, IF025H

*Actual conguration may vary

22018-03-14 #:146-9020-4 (2019-05-16)

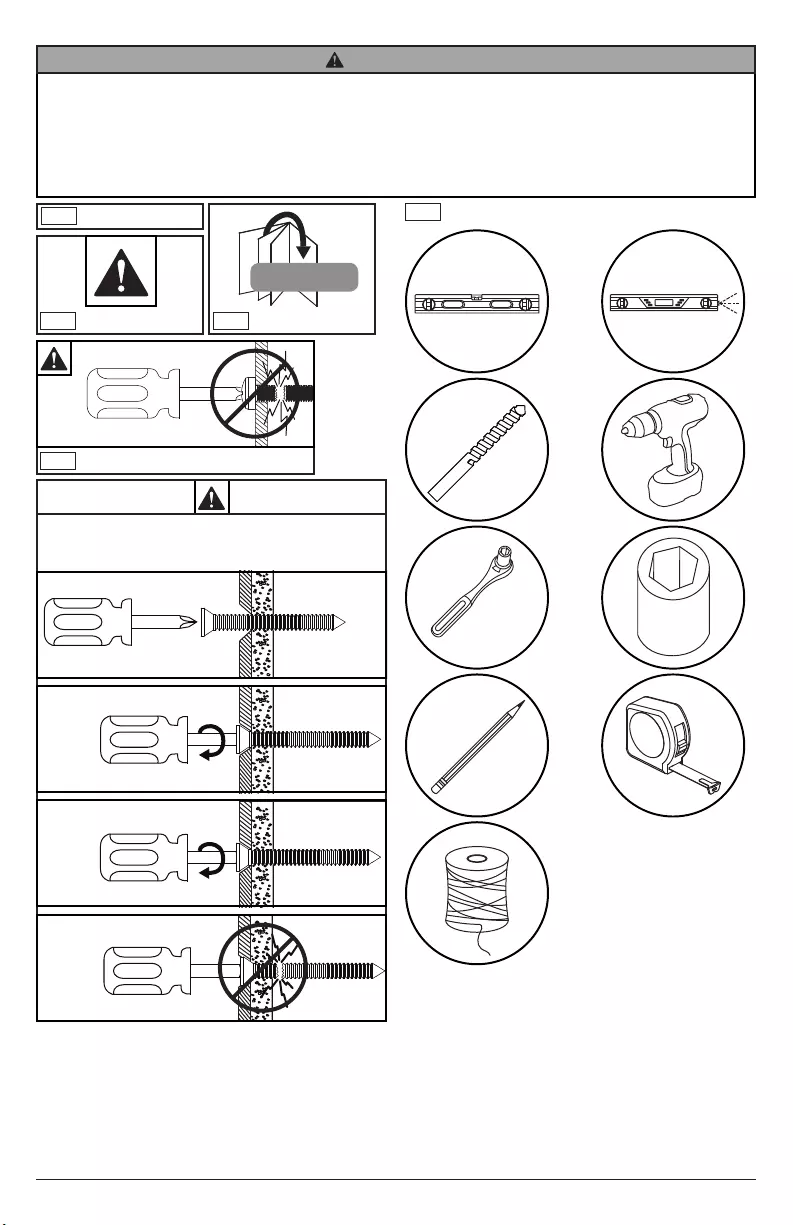

To properly tighten screws: Tighten until screw

head makes contact, then tighten another 1/2

turn. Do not overtighten screws.

1

2

+1/2

4

3

Symbols

ENG

WARNING

ENG

Do not overtighten screws.

ENG

Tools Needed for Assembly.

ENG

5/32"

(4mm)

ENG - This product is designed to be installed on plywood walls. Hardware is included for plywood installation.

Before installing make sure the supporting surface will support the combined load of the equipment and

hardware. Screws must be tightly secured. Do not overtighten screws or damage can occur and product may fail.

Never exceed the Maximum Load Capacity. Always use an assistant or mechanical lifting equipment to safely lift

and position equipment. This product is intended for indoor use only. Use of this product outdoors could lead to

product failure or personal injury. Be careful not to pinch ngers when operating the mount. For support please

call customer care at 1-800-865-2112.

WARNING

3/8"

(10mm)

#

Skip to step.

ENG

32018-03-14 #:146-9020-4 (2019-05-16)

This page intentionally left blank.

ENG

42018-03-14 #:146-9020-4 (2019-05-16)

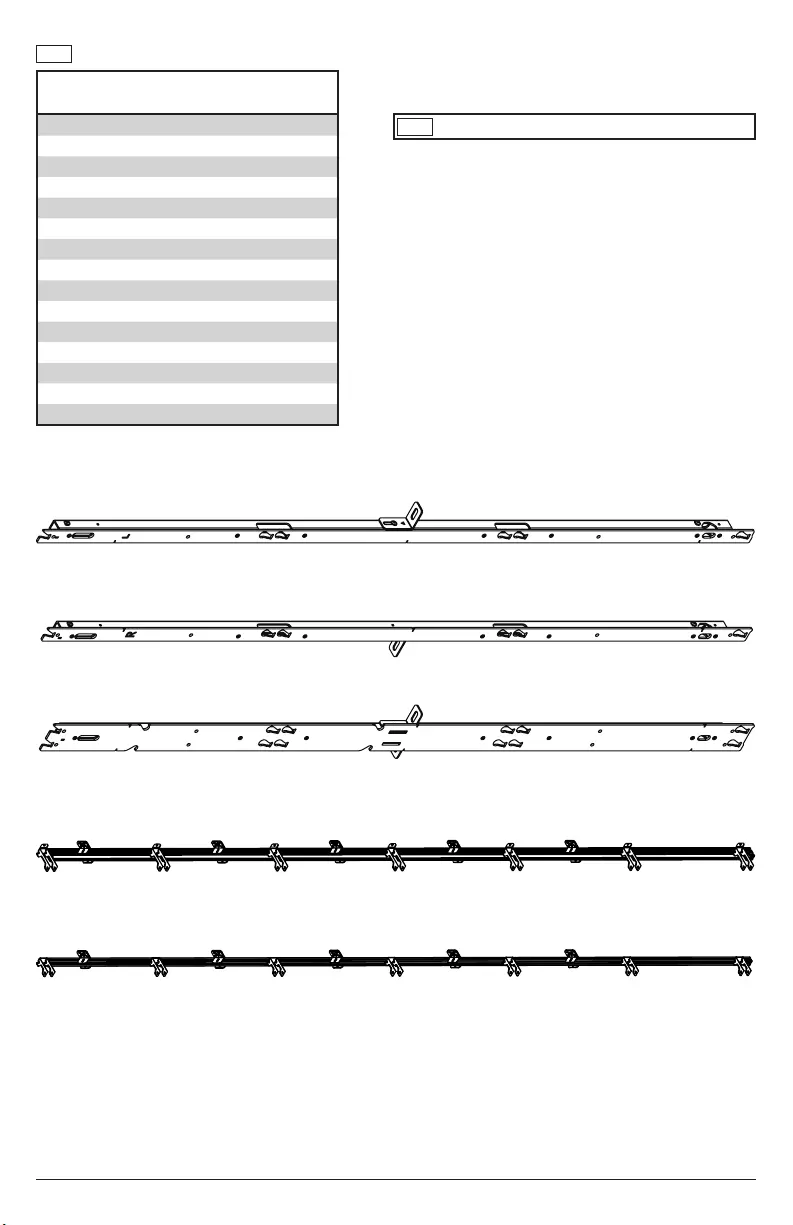

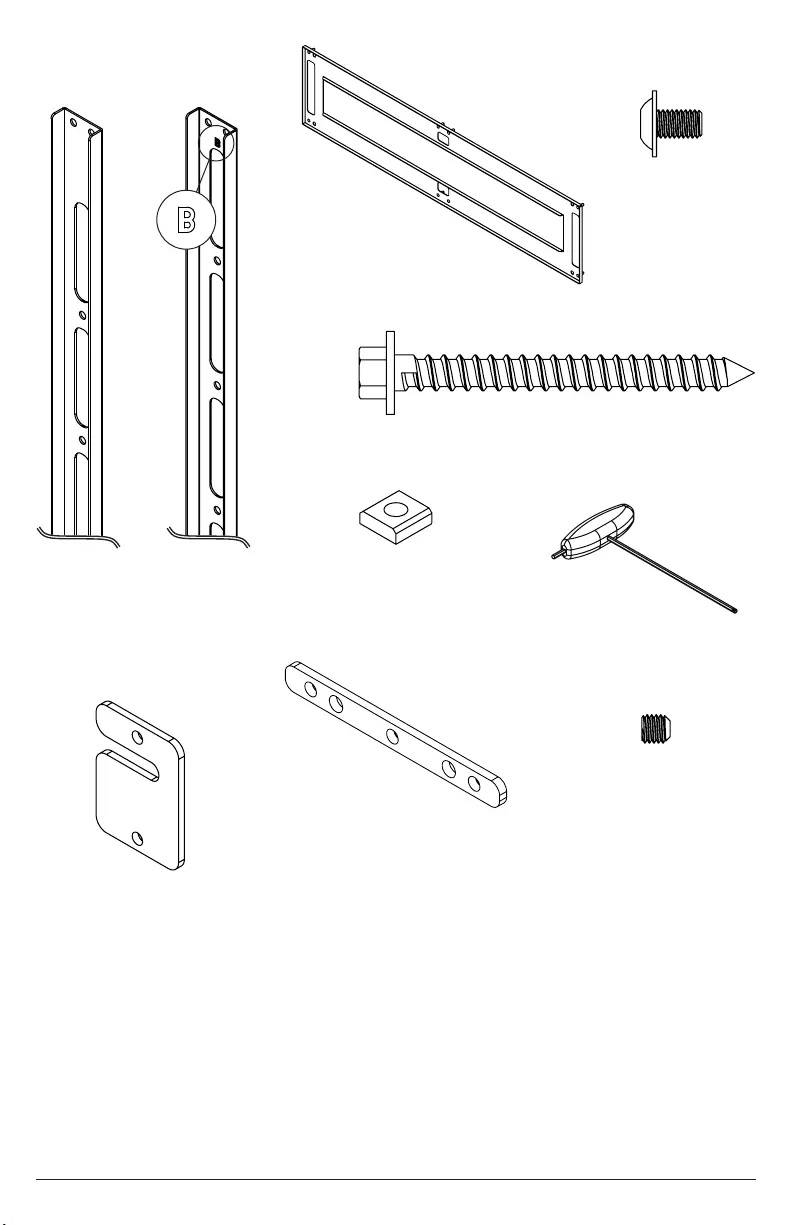

Parts List

Description

Aleft column

Bright column

Cinside vertical column

Dtop horizontal asy

Ebottom horizontal asy

Ftop vertical spacer

Ghorizontal spacer

HM5 x 8mm socket screw

I#14 x 2.5" wood screw

JM5 square nut (spare)

K3mm allen wrench two-tip T-handle

Lwall plate shim

Mconnector plate

NM5 x 5mm set screw

Obottom vertical spacer

Parts (Before beginning, make sure you have all parts shown below).

ENG

A

B

C

left column

right column

inside vertical column

D

E

top horizontal assembly

bottom horizontal assembly

Refer to parts list included for your specic model.

ENG

52018-03-14 #:146-9020-4 (2019-05-16)

N

I

H

J

M5 x 5mm

set screw

#14 x 2.5" wood screw

M5 x 8mm

M5 square nut

O

L

FG

bottom vertical

spacer

wall plate

shim

top vertical

spacer horizontal

spacer

M

connector

plate

K

3mm allen wrench

two-tip T-handle

62018-03-14 #:146-9020-4 (2019-05-16)

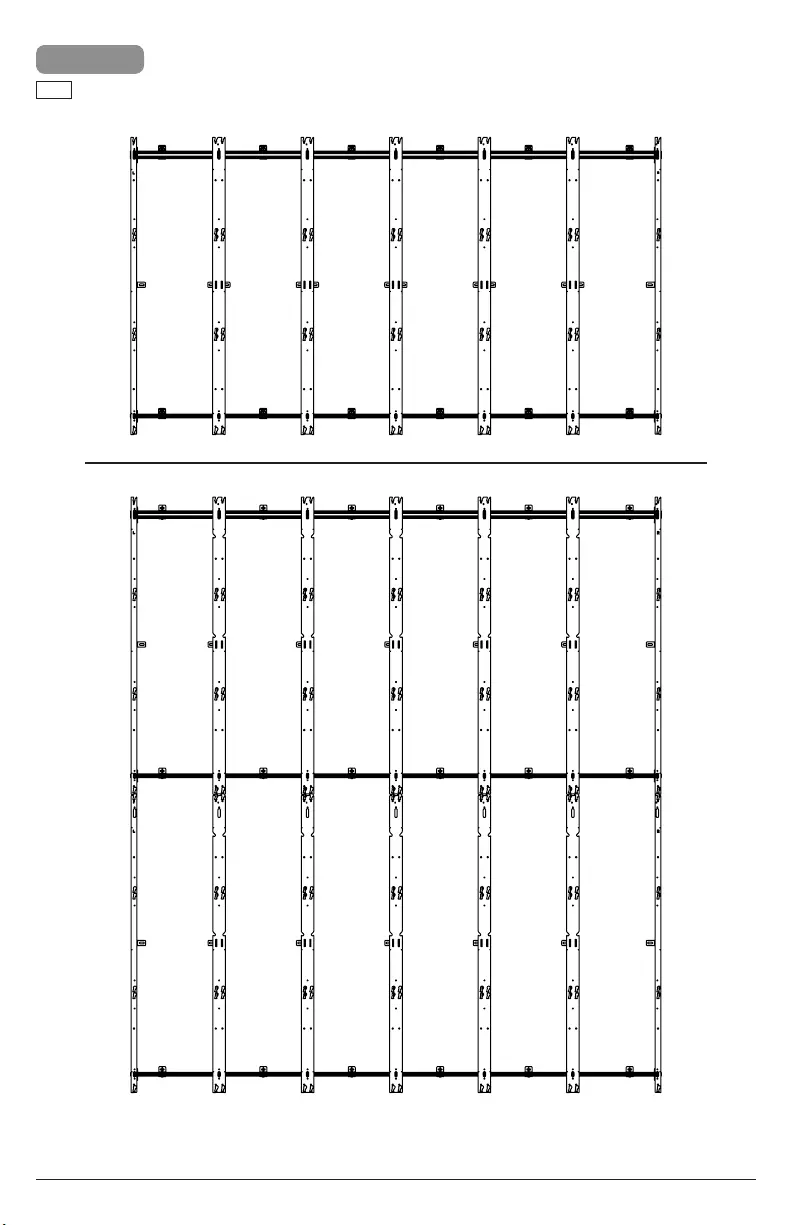

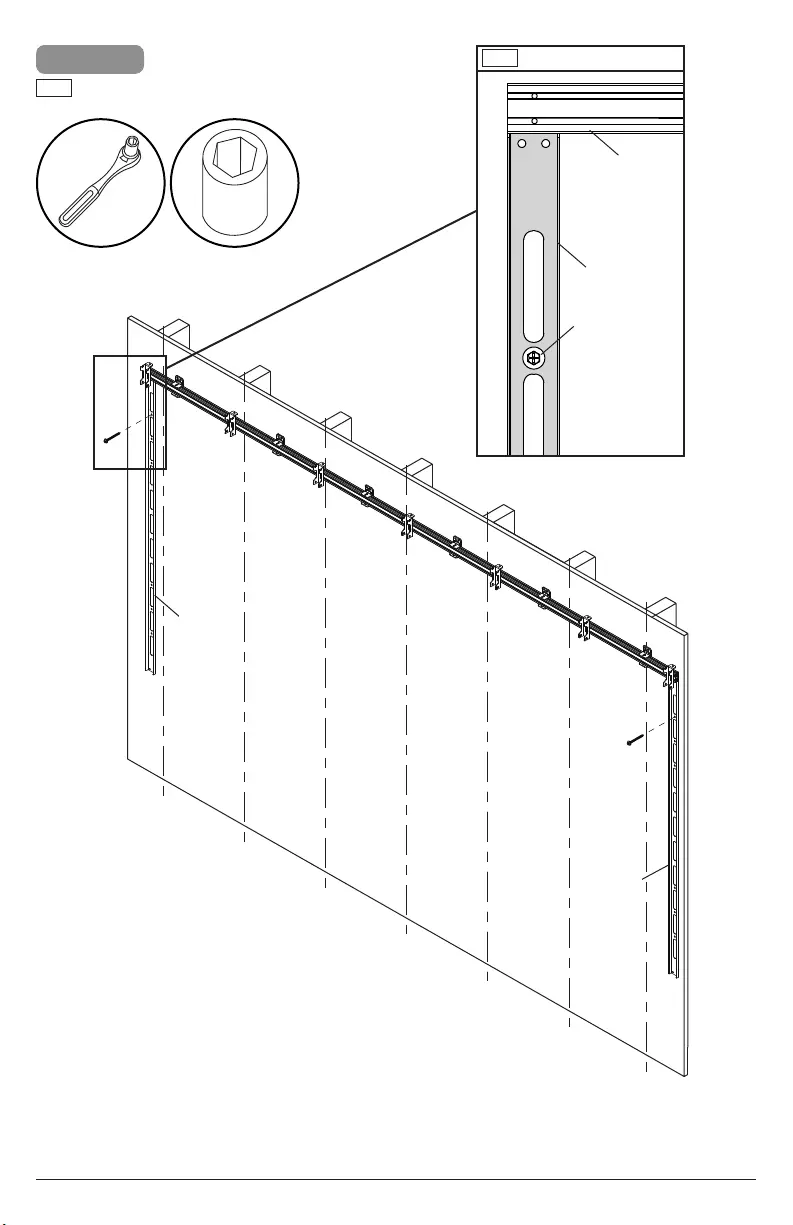

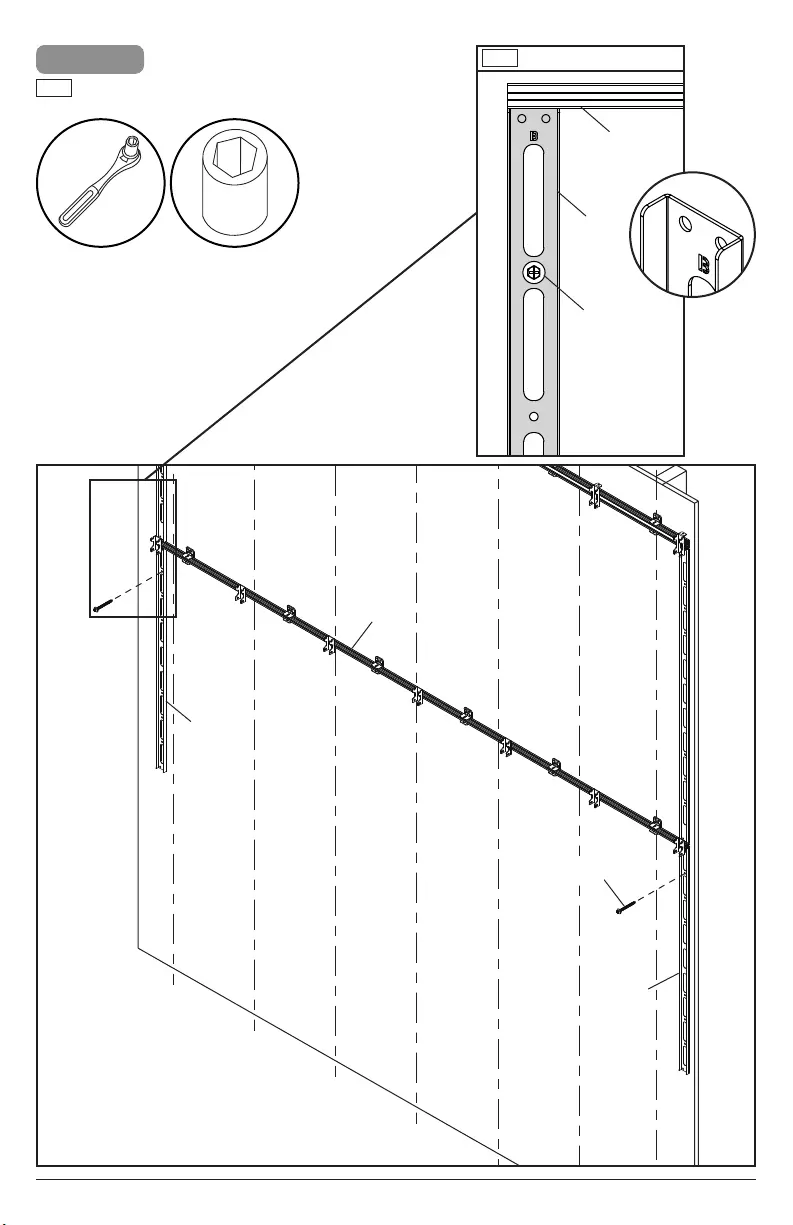

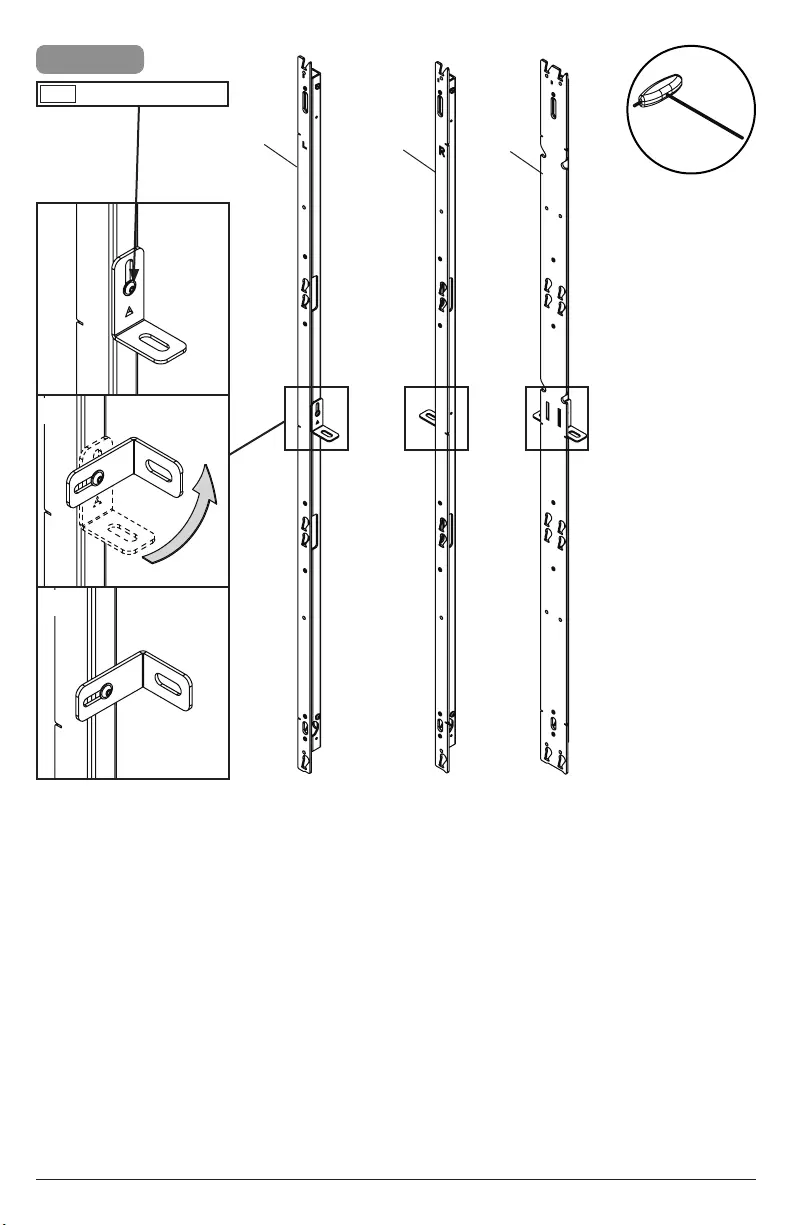

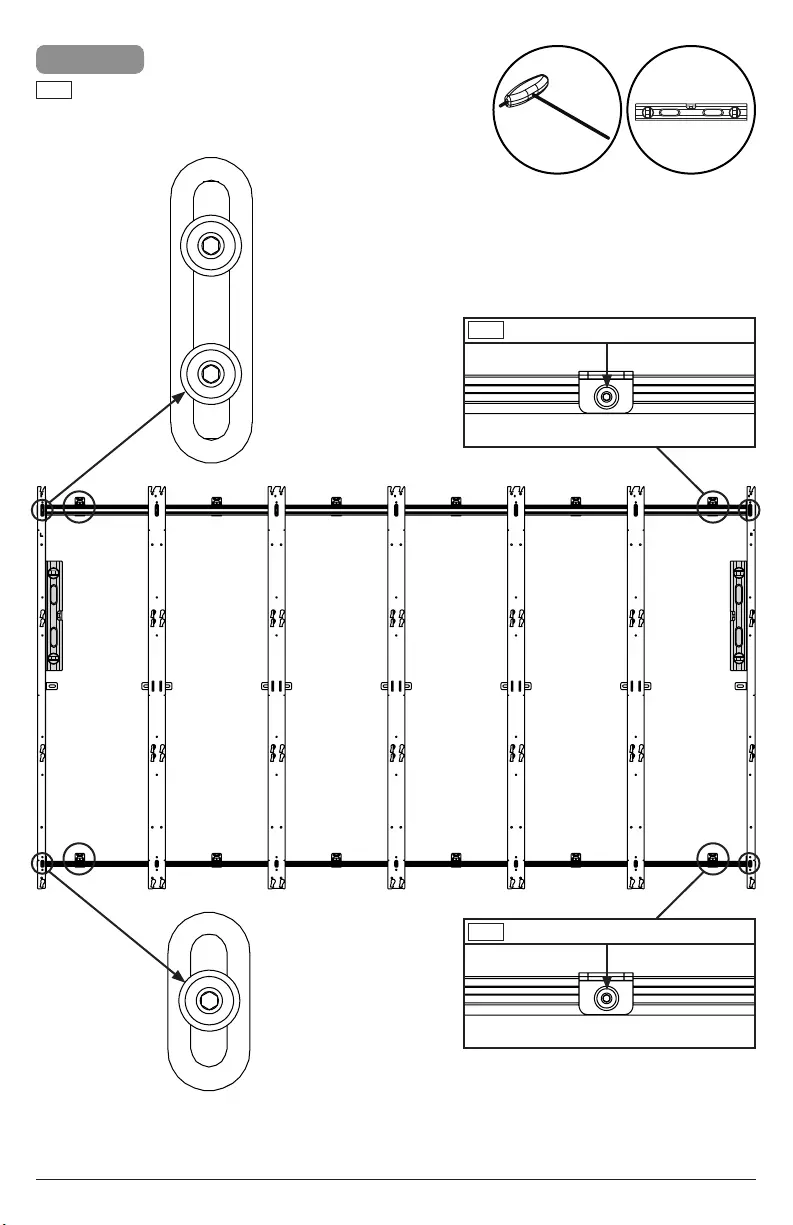

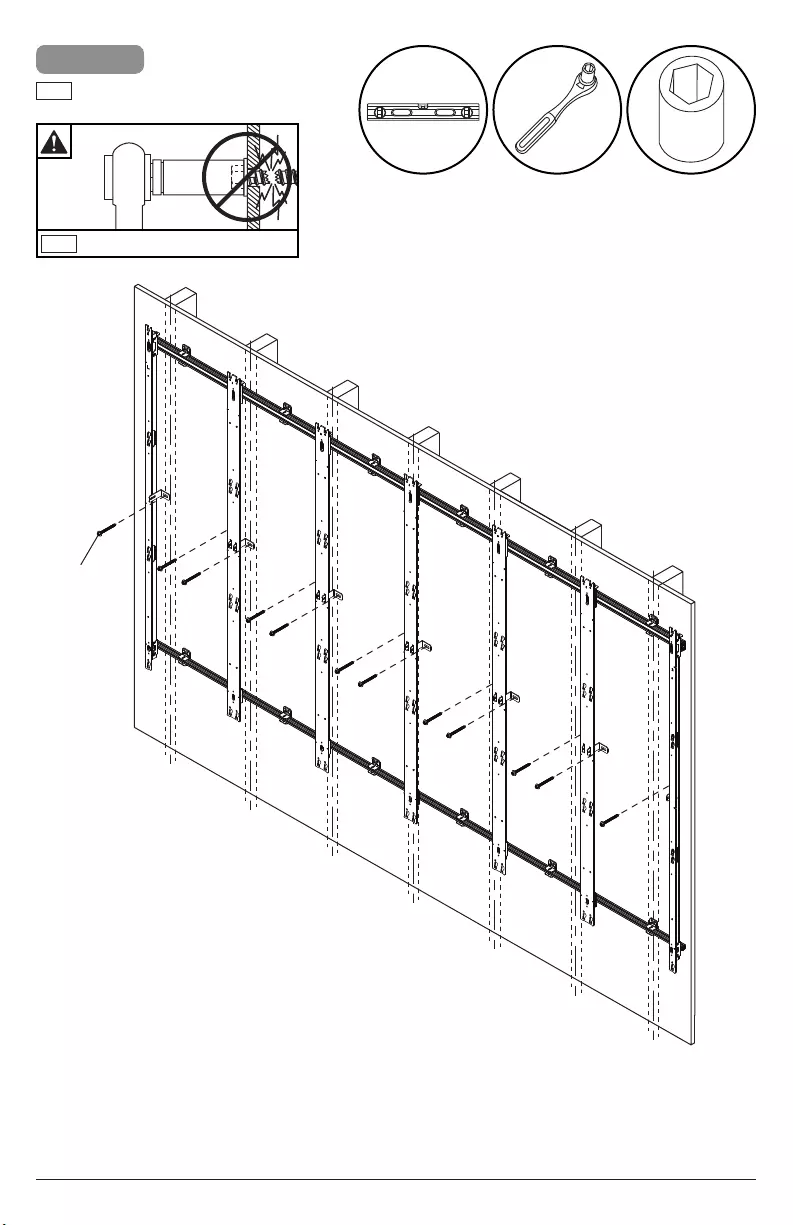

1

Refer to layout drawing included for your

specic model.

ENG

72018-03-14 #:146-9020-4 (2019-05-16)

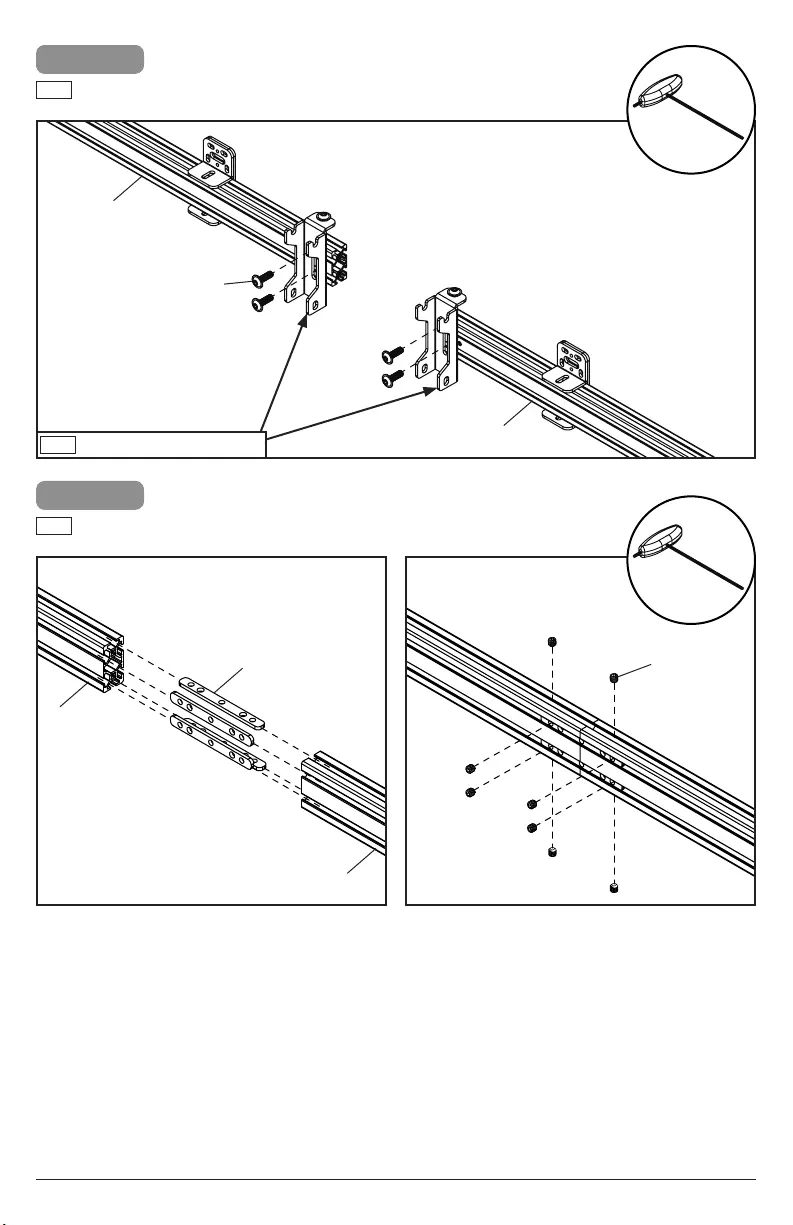

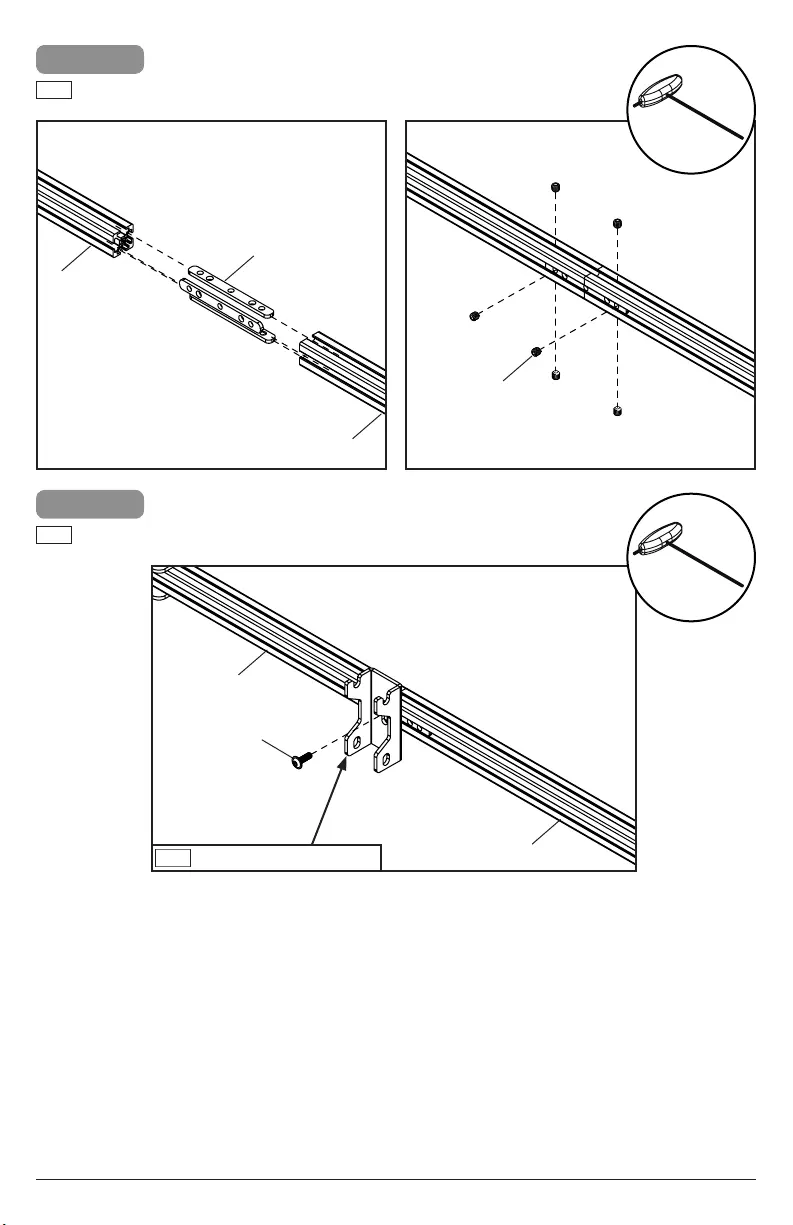

2-1

Optional: If connecting two top horizontal extrusions,

rst remove inner hook-on brackets.

ENG

Remove and save hardware.

ENG

M5 x 16mm

D

D

2-2

Use extrusion connectors to connect top horizontal

extrusions.

ENG

M (4) N (8)

D

K

K

D

82018-03-14 #:146-9020-4 (2019-05-16)

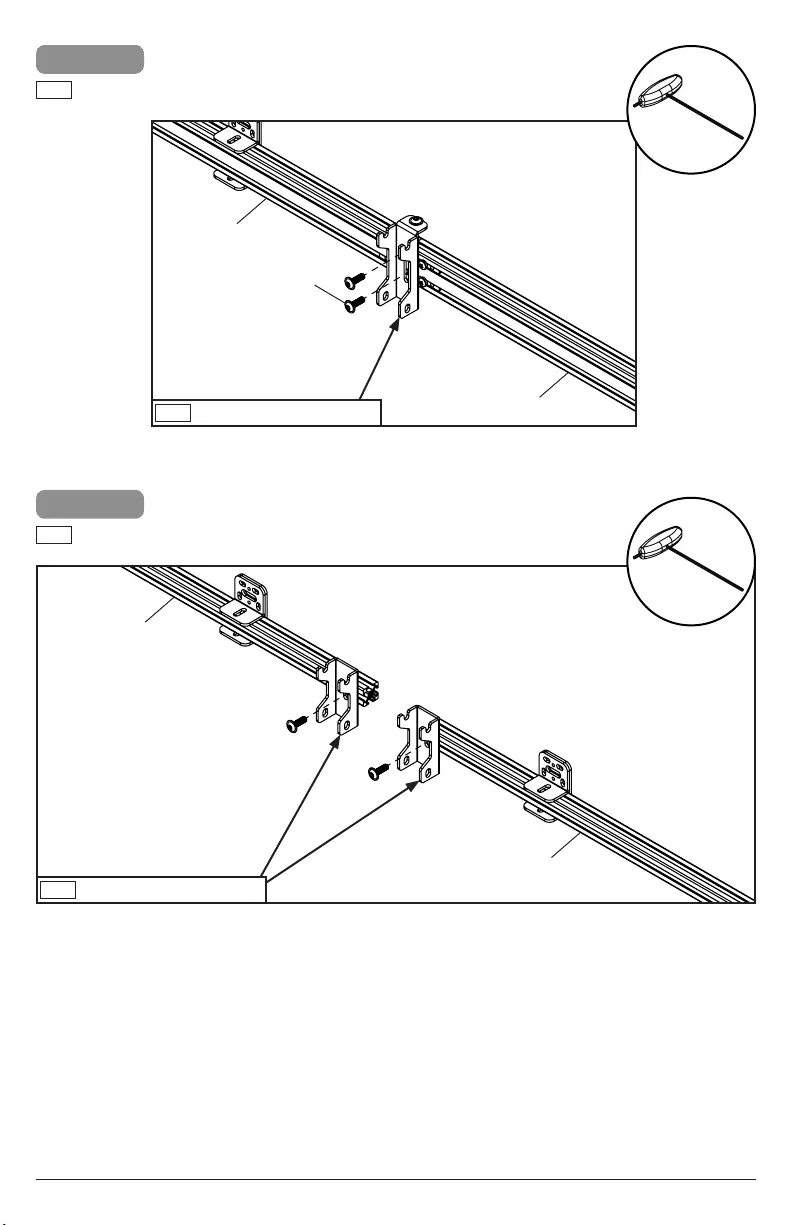

2-4

Optional: If connecting two bottom horizontal

extrusions, rst remove inner hook-on brackets

ENG

Remove and save hardware.

ENG

E

E

2-3

Replace one hook-on bracket in between connected

extrusions.

ENG

Use saved hardware.

ENG

D

H (2)

D

K

K

92018-03-14 #:146-9020-4 (2019-05-16)

H

2-5

Use extrusion connectors to connect bottom

horizontal extrusions.

ENG

N (6)

M (3)

E

E

E

E

2-6

Replace one hook-on bracket in between connected

extrusions.

ENG

Use saved hardware.

ENG

K

K

10 2018-03-14 #:146-9020-4 (2019-05-16)

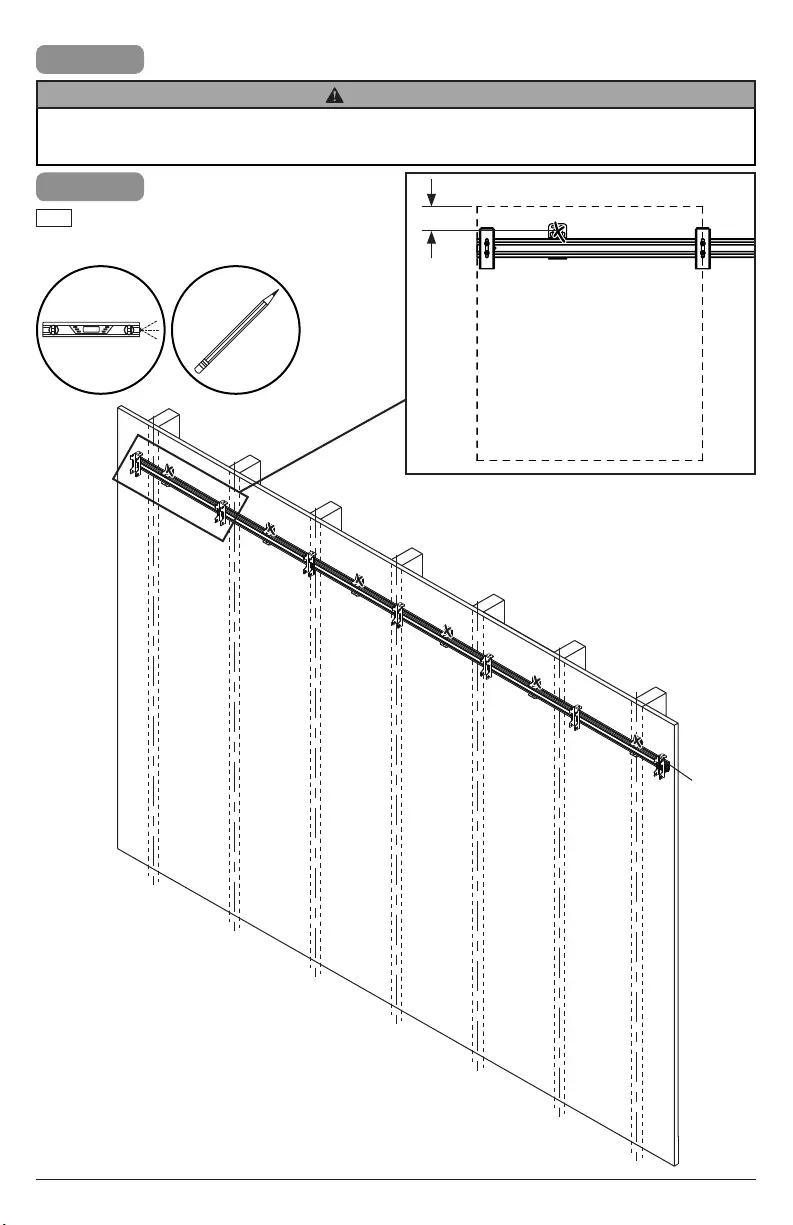

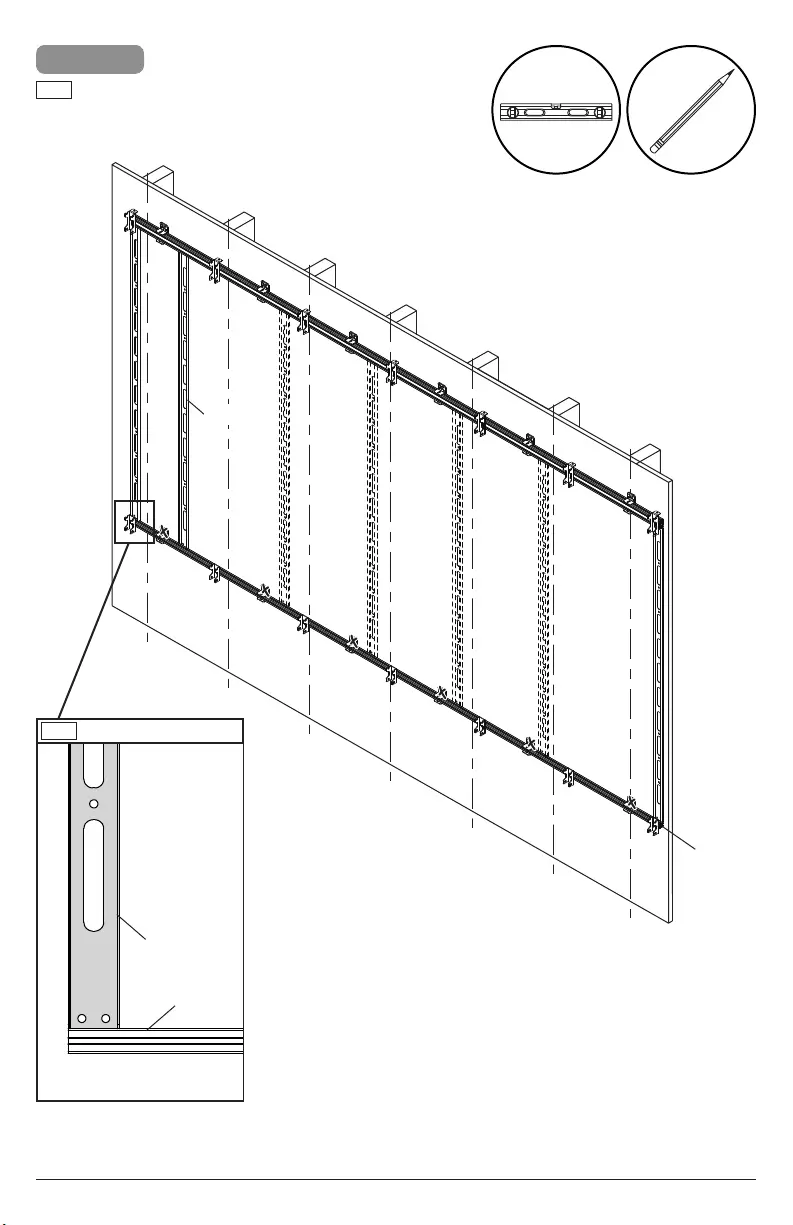

3-1

3

ENG - When installing Peerless wall mounts on a wood stud wall covered with plywood, verify that the wood

studs are a minimum of 2" x 4" nominal size and plywood is a minimum Grade BC, 1/2" (13 mm) thick. Plywood

may be covered by gypsum board (drywall) up to 5/8" thick.

WARNING

D

Level top horizontal extrusion and mark

mounting holes on plywood (must be

minimum Grade BC, 1/2" (13mm) thick.)

ENG

2.24"

(57mm)

display tile

11 2018-03-14 #:146-9020-4 (2019-05-16)

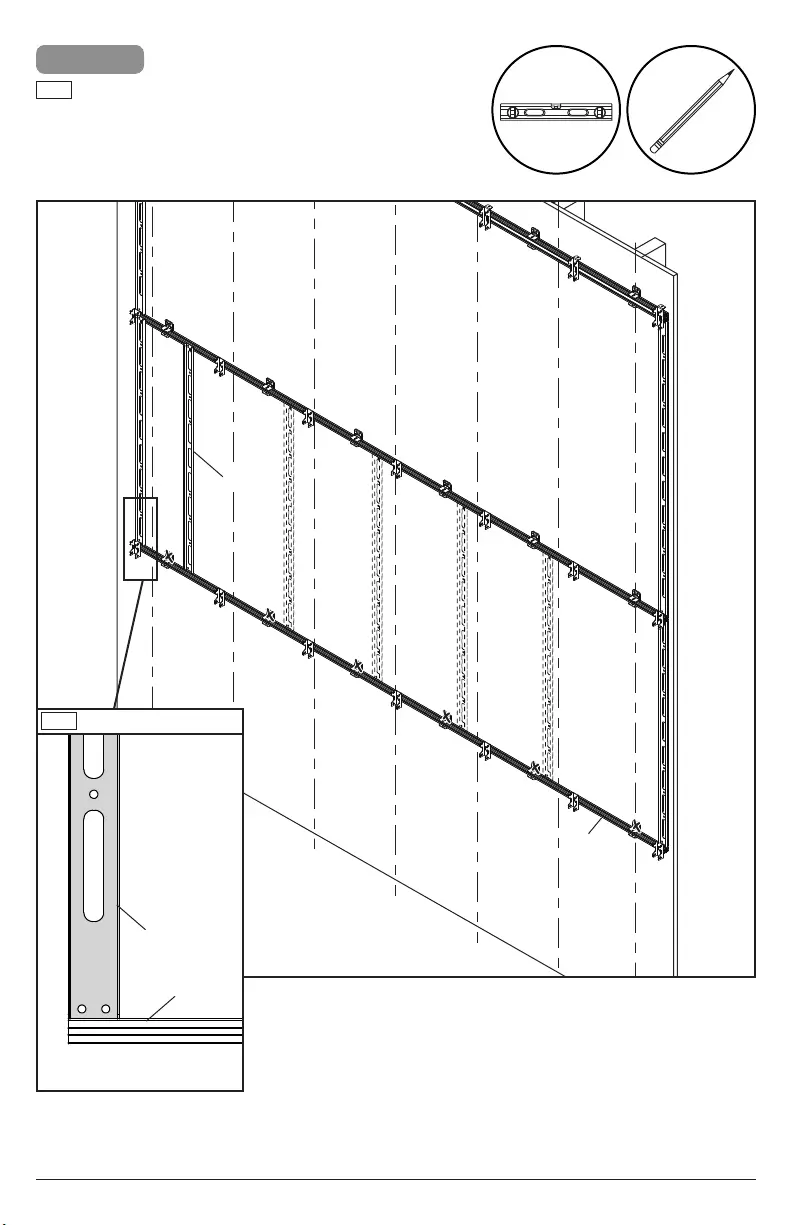

Use a laser level to keep mounting holes

level.

ENG

3-2

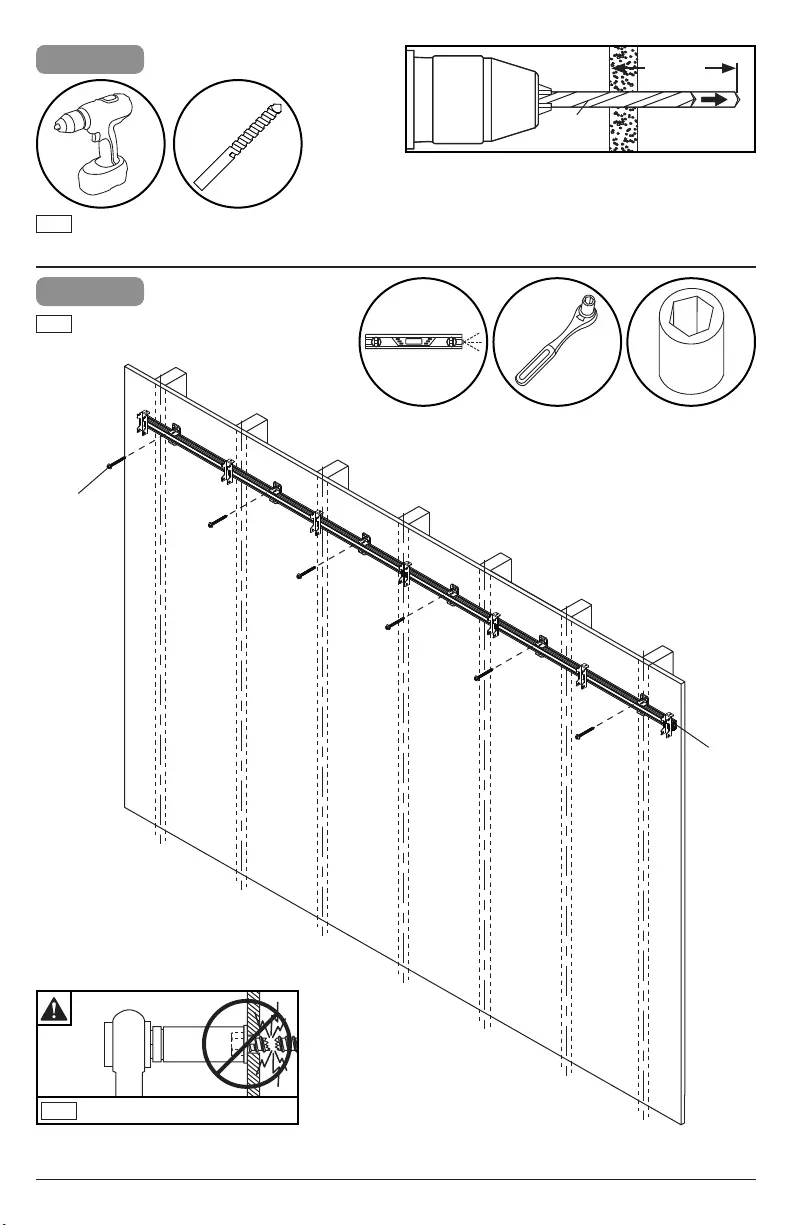

12 2018-03-14 #:146-9020-4 (2019-05-16)

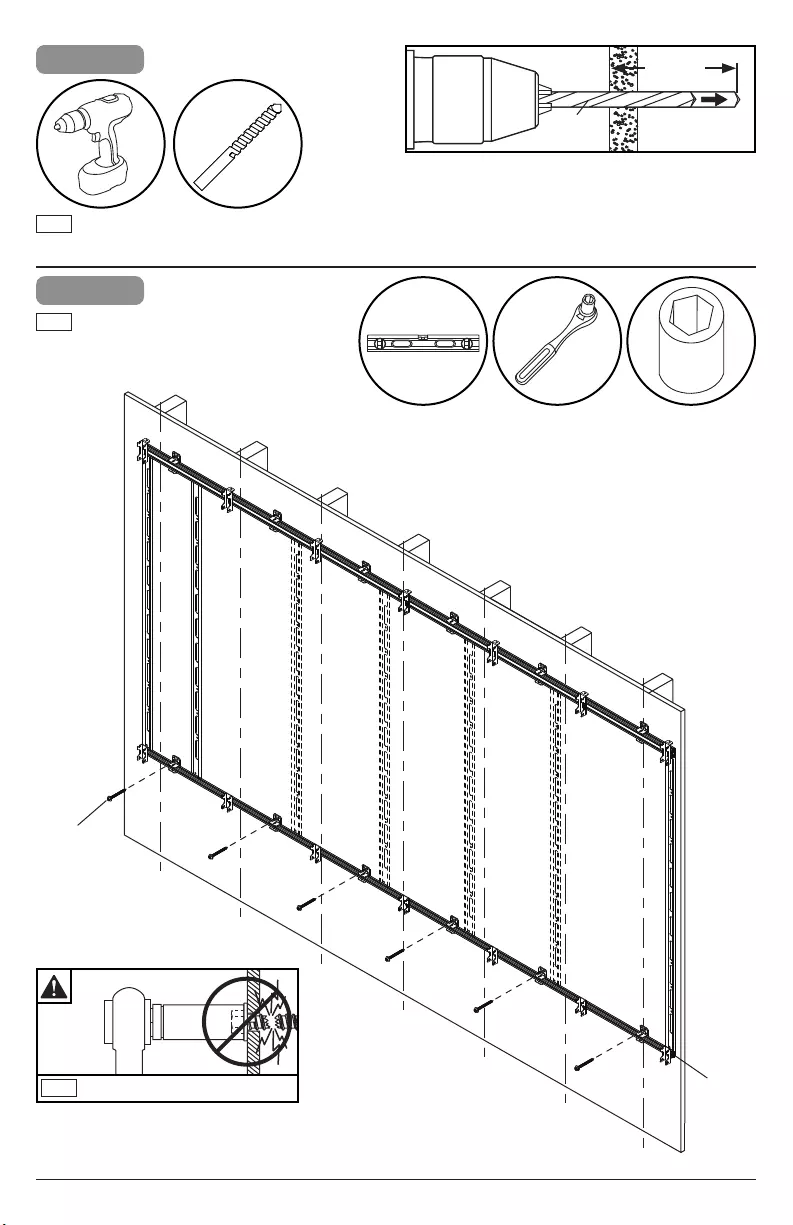

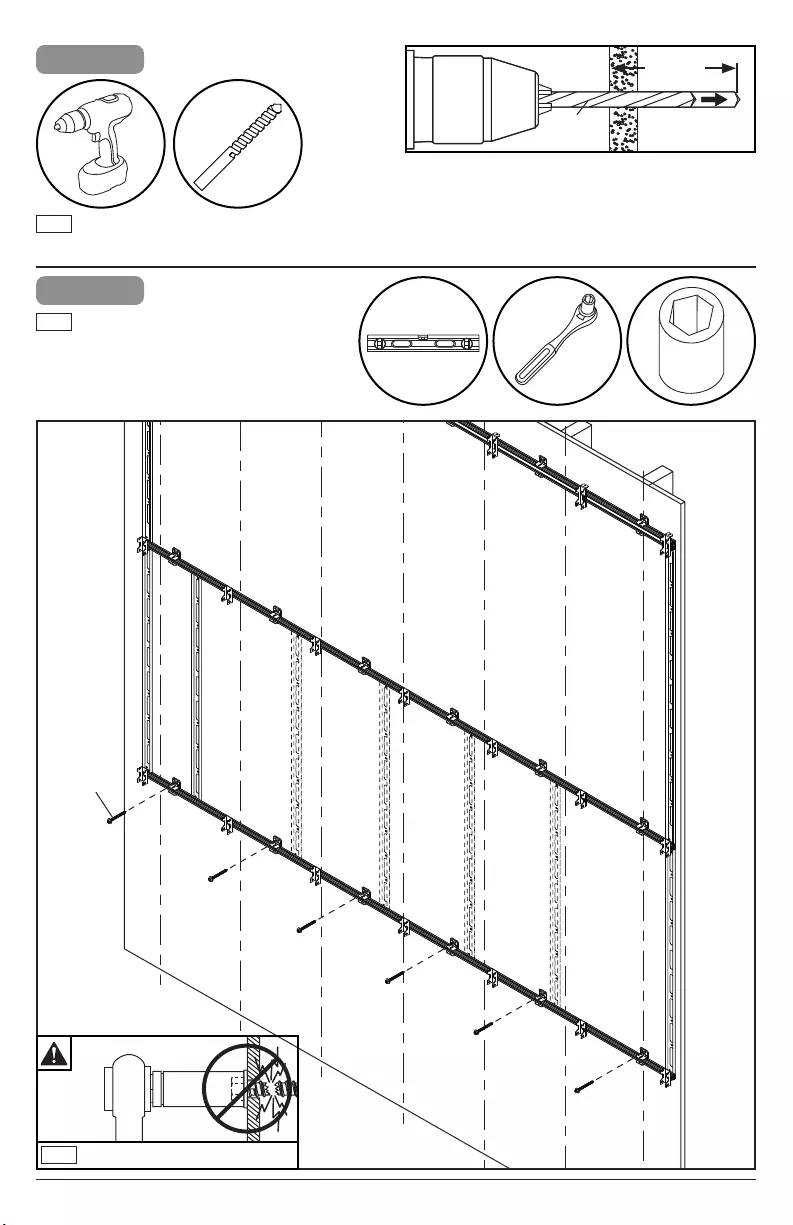

3-3

Drill mounting holes into supporting surface

(2.5" (64mm) minimum depth required).

ENG

5/32"

(4mm)

2.5"

(64mm)

5/32"

(4mm)

3-4

Level extrusion. Install using wood screws

provided.

ENG

3/8"

(10mm)

Maximum 80 in. • lb (9 N.M.).

ENG

D

I (6)

13 2018-03-14 #:146-9020-4 (2019-05-16)

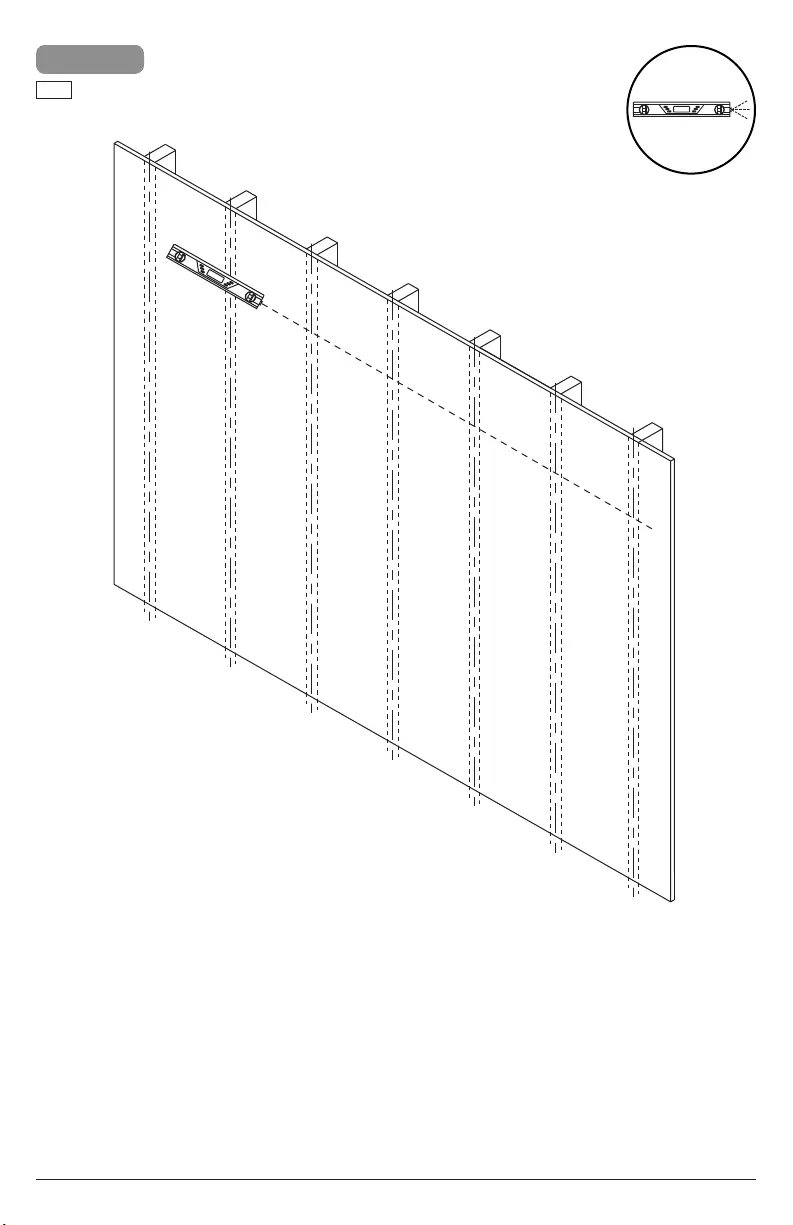

3-5

Secure vertical spacers to the wall ush with the

horizontal extrusion.

ENG

3/8"

(10mm)

Edges must be ush.

ENG

I

F

F

F

D

14 2018-03-14 #:146-9020-4 (2019-05-16)

3-6

Use third vertical spacer to align bottom

horizontal extrusion ush with vertical spacer,

then mark mounting holes on plywood (must be

minimum Grade BC, 1/2" (13mm) thick.)

ENG

E

F

Edges must be ush.

ENG

F

E

15 2018-03-14 #:146-9020-4 (2019-05-16)

3-8

Use third vertical spacer to align bottom

horizontal extrusion ush with vertical

spacer, then install using wood screws

provided.

ENG

3/8"

(10mm)

Maximum 80 in. • lb (9 N.M.).

ENG

3-7

Drill mounting holes into supporting surface

(2.5" (64mm) minimum depth required).

ENG

5/32"

(4mm)

2.5"

(64mm)

5/32"

(4mm)

E

I (6)

16 2018-03-14 #:146-9020-4 (2019-05-16)

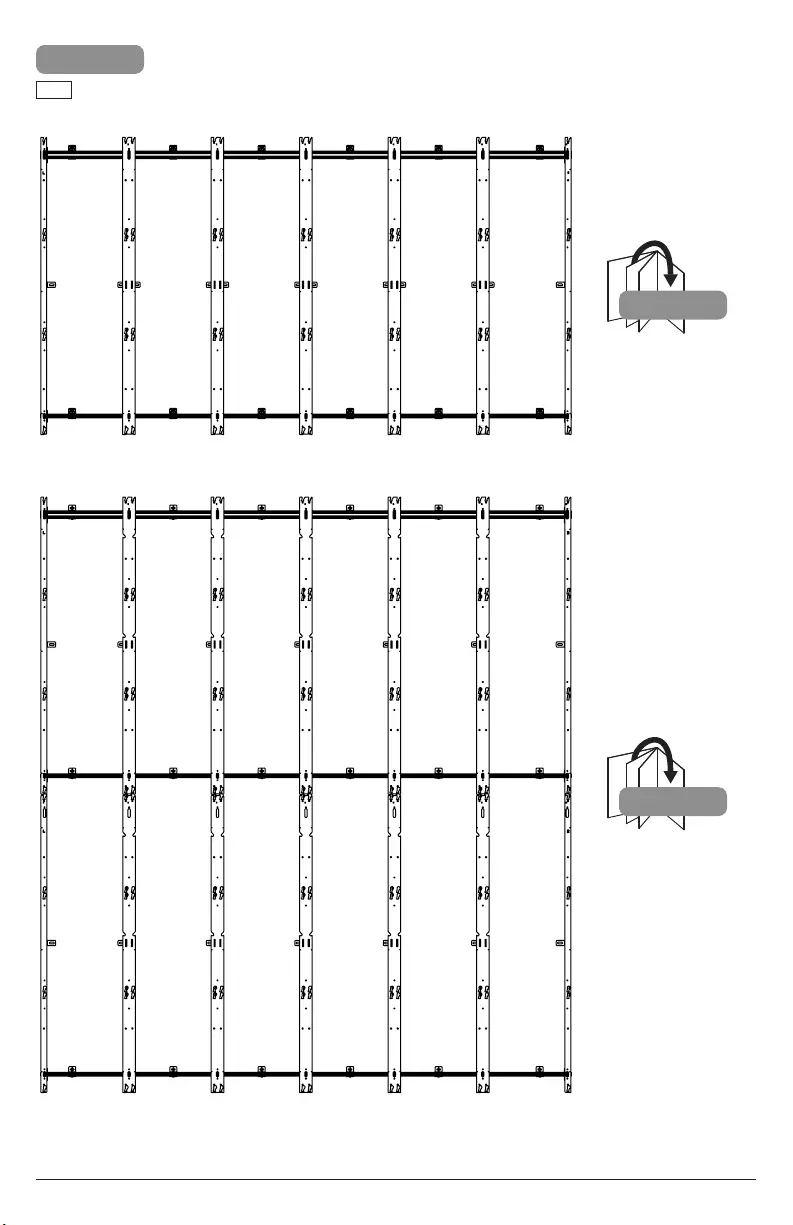

4

Refer to layout drawing included for your

specic model.

ENG

5

4-1

17 2018-03-14 #:146-9020-4 (2019-05-16)

4-1

For larger congurations only; Secure vertical spacer

to the wall ush with the horizontal extrusion.

ENG

3/8"

(10mm)

Edges must be ush.

ENG

I

I (2)

O

E

O

O

E

18 2018-03-14 #:146-9020-4 (2019-05-16)

4-2

Use third vertical spacer to align bottom

horizontal extrusion ush with vertical spacer,

then mark mounting holes on plywood (must be

minimum Grade BC, 1/2" (13mm) thick.)

ENG

Edges must be ush.

ENG

O

E

E

O

19 2018-03-14 #:146-9020-4 (2019-05-16)

4-4

Use third vertical spacer to align bottom

horizontal extrusion ush with vertical

spacer, then install using wood screws

provided.

ENG

3/8"

(10mm)

Maximum 80 in. • lb (9 N.M.).

ENG

4-3

Drill mounting holes into supporting surface

(2.5" (64mm) minimum depth required).

ENG

5/32"

(4mm)

2.5"

(64mm)

5/32"

(4mm)

I (6)

20 2018-03-14 #:146-9020-4 (2019-05-16)

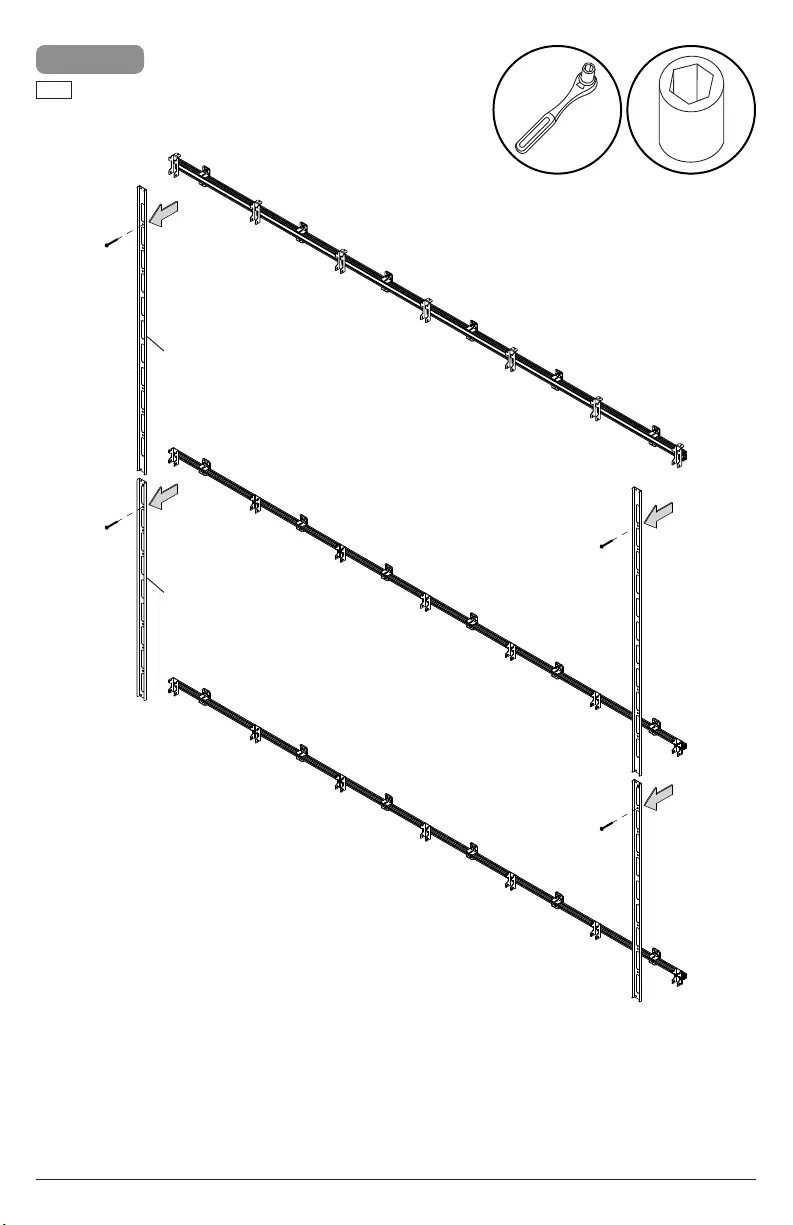

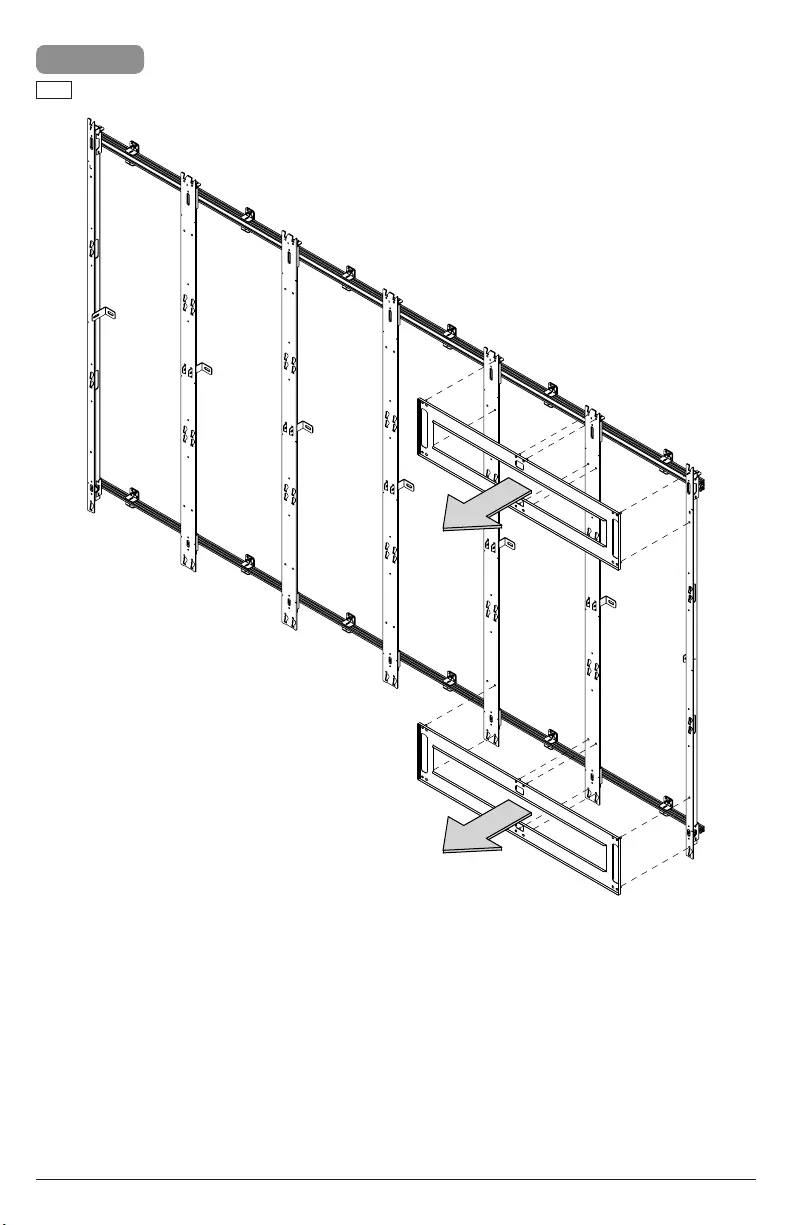

5

Remove vertical spacers.

ENG

3/8"

(10mm)

F (2)

O (2)

21 2018-03-14 #:146-9020-4 (2019-05-16)

6

AB

Loosen, adjust, tighten.

ENG K

1

2

3

C

22 2018-03-14 #:146-9020-4 (2019-05-16)

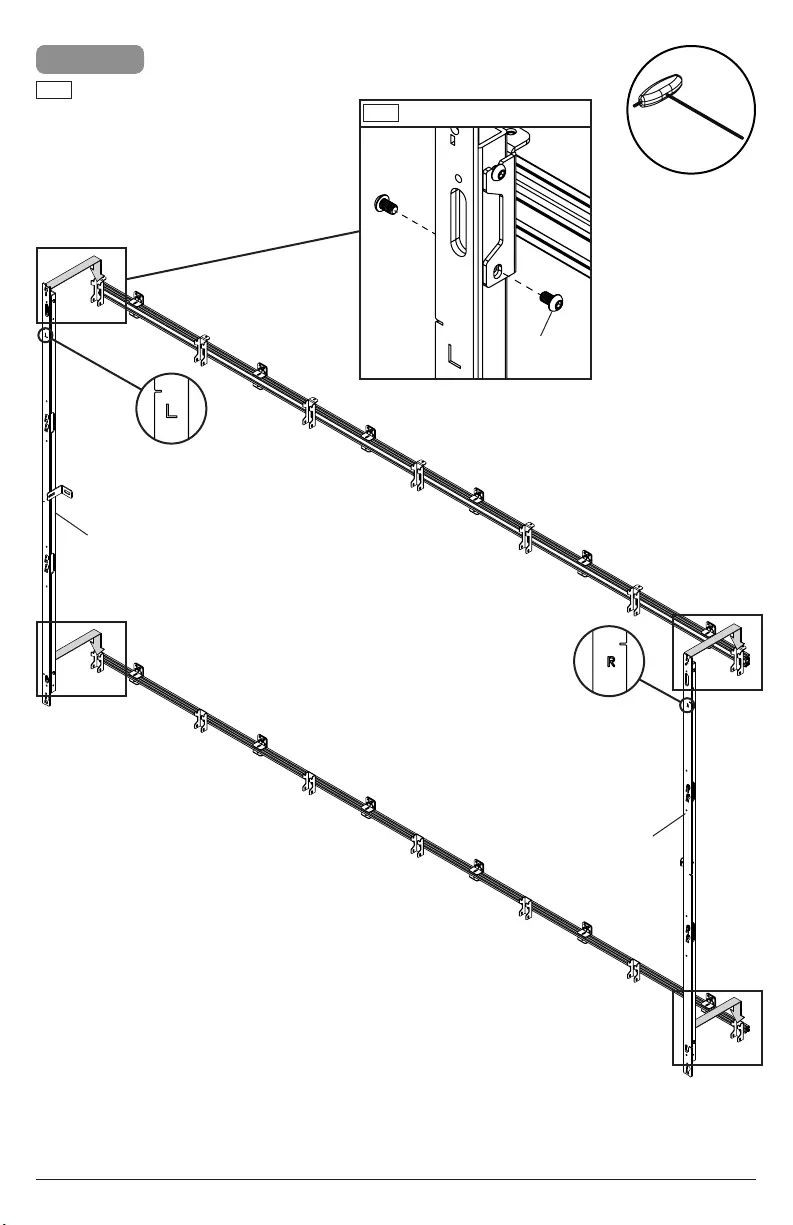

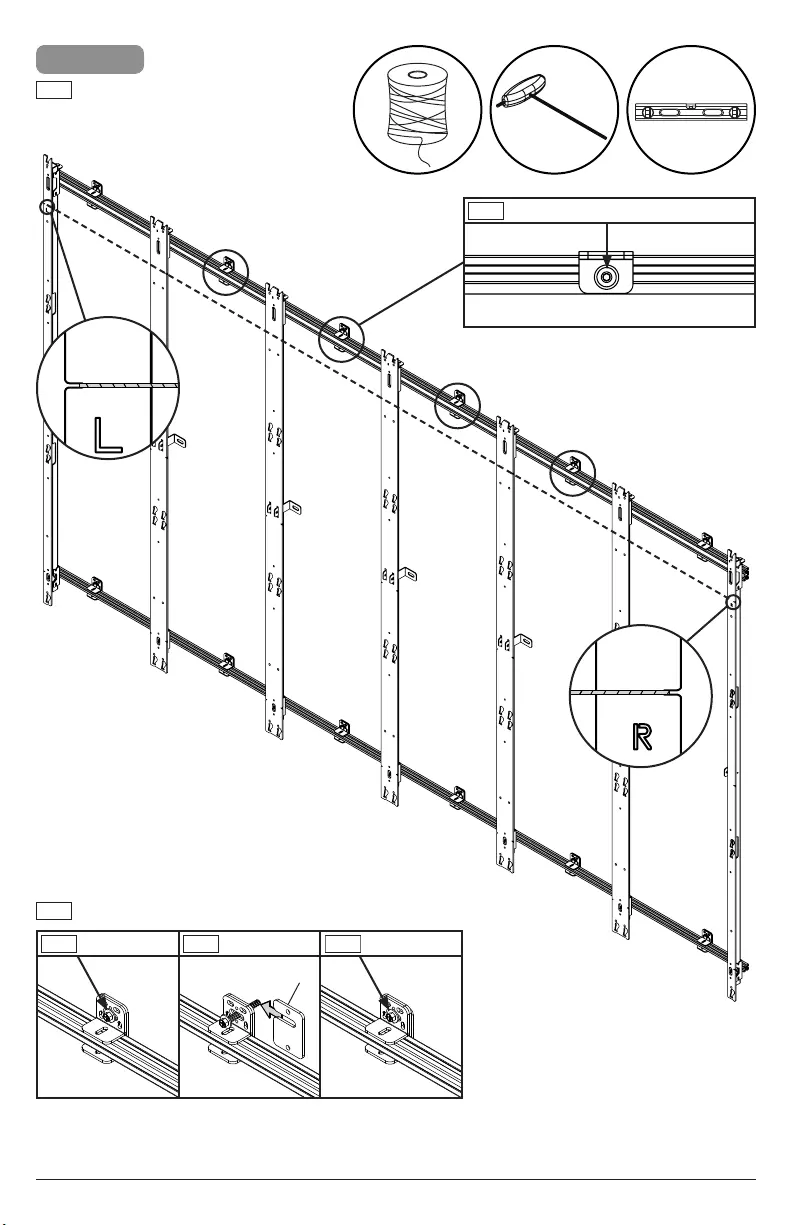

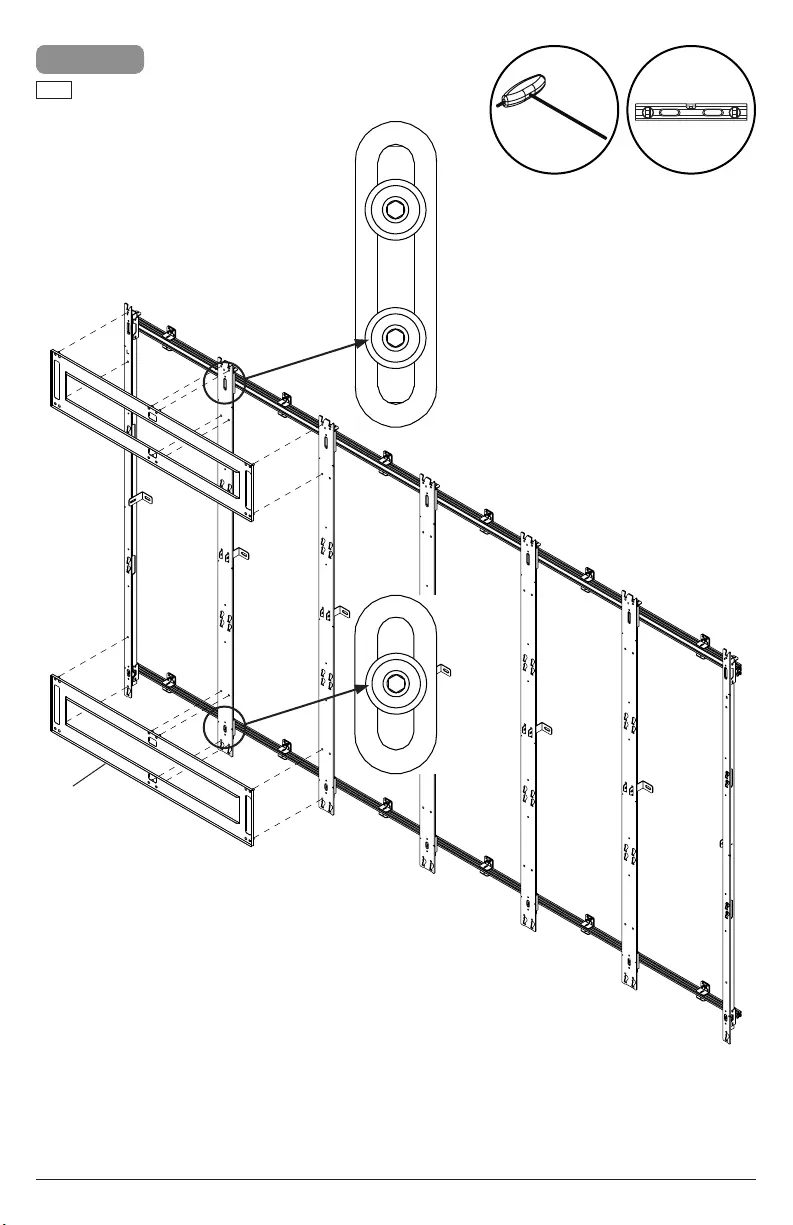

7-1

Hook on and secure outer vertical columns.

"L" and "R" markings designate left and right

column.

ENG

B

A

H (8)

Tighten hardware.

ENG

K

23 2018-03-14 #:146-9020-4 (2019-05-16)

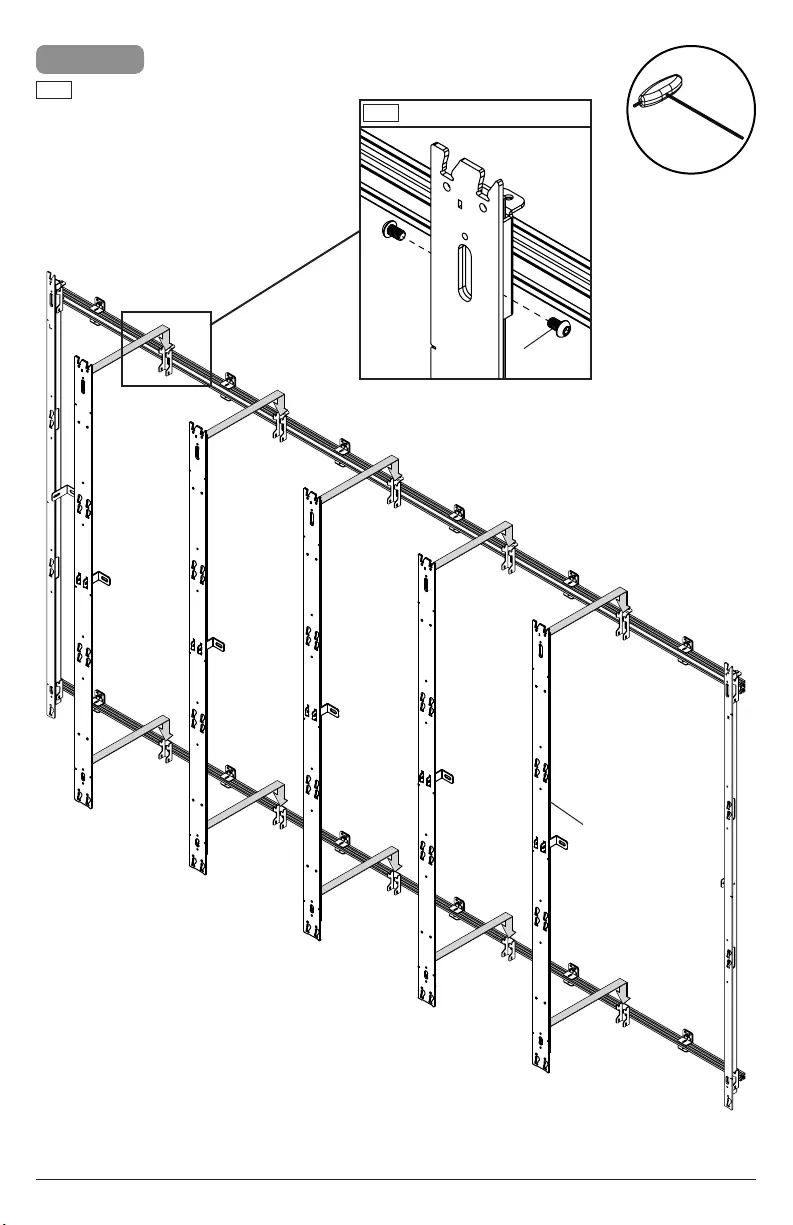

7-2

Hook on and secure all inside vertical

columns.

ENG

C (5)

H (20)

Tighten hardware.

ENG

K

24 2018-03-14 #:146-9020-4 (2019-05-16)

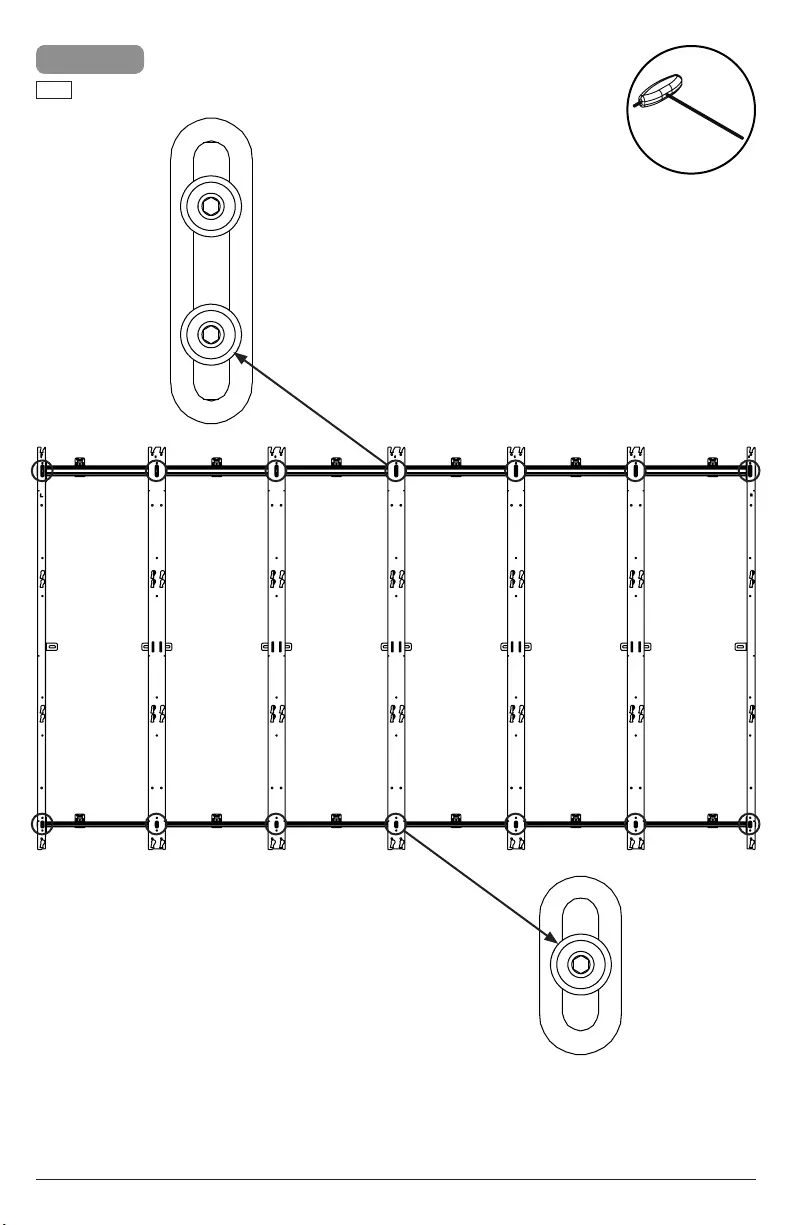

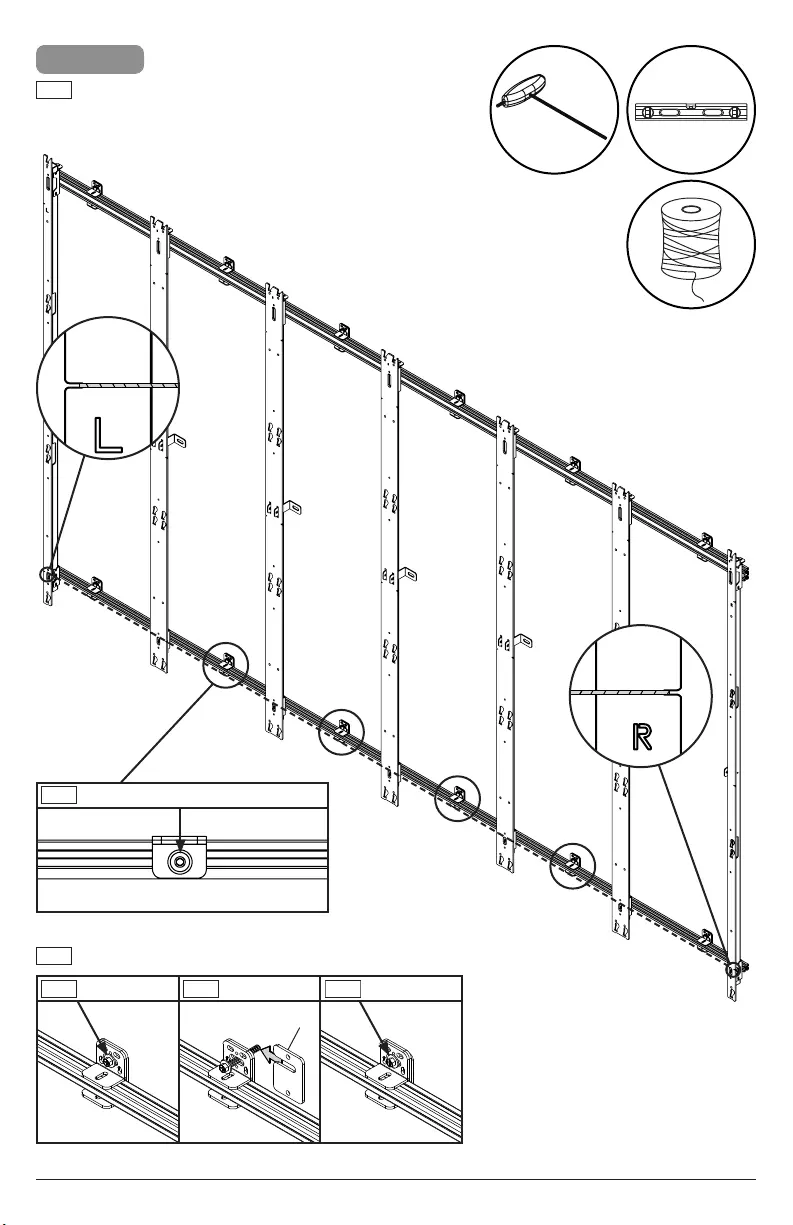

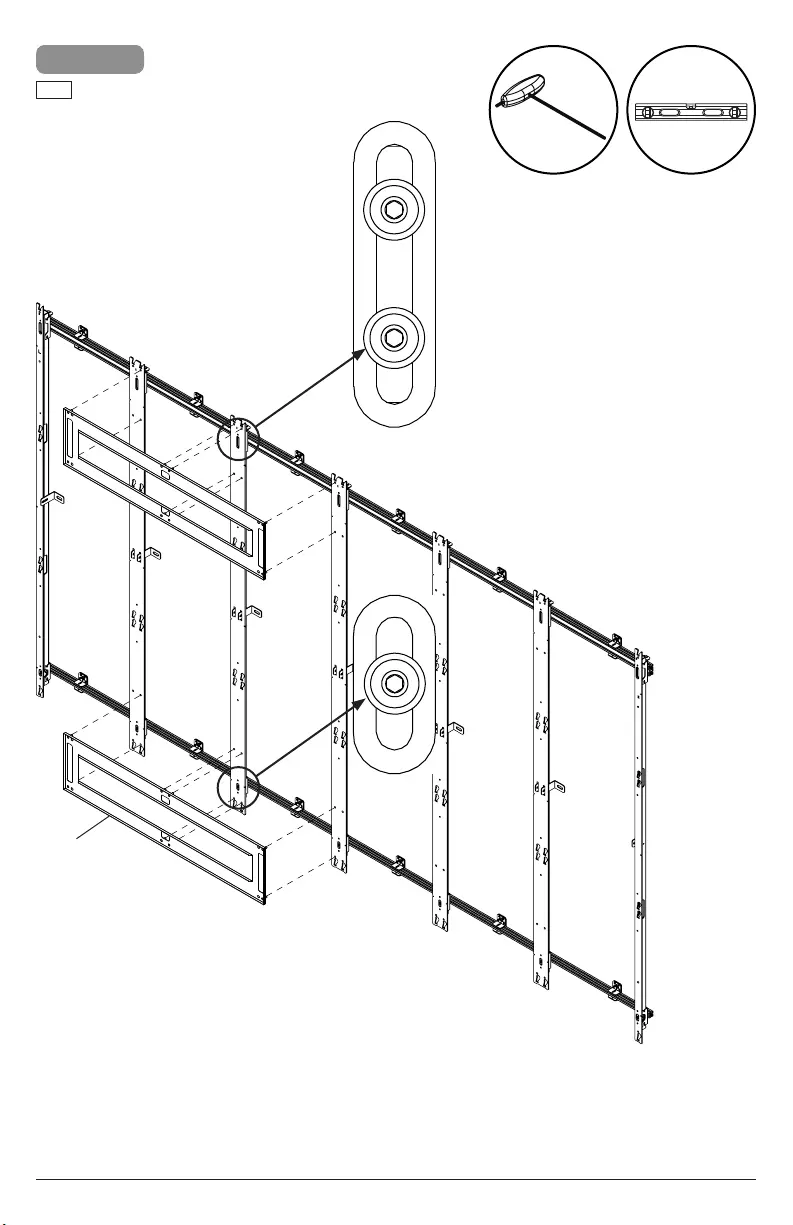

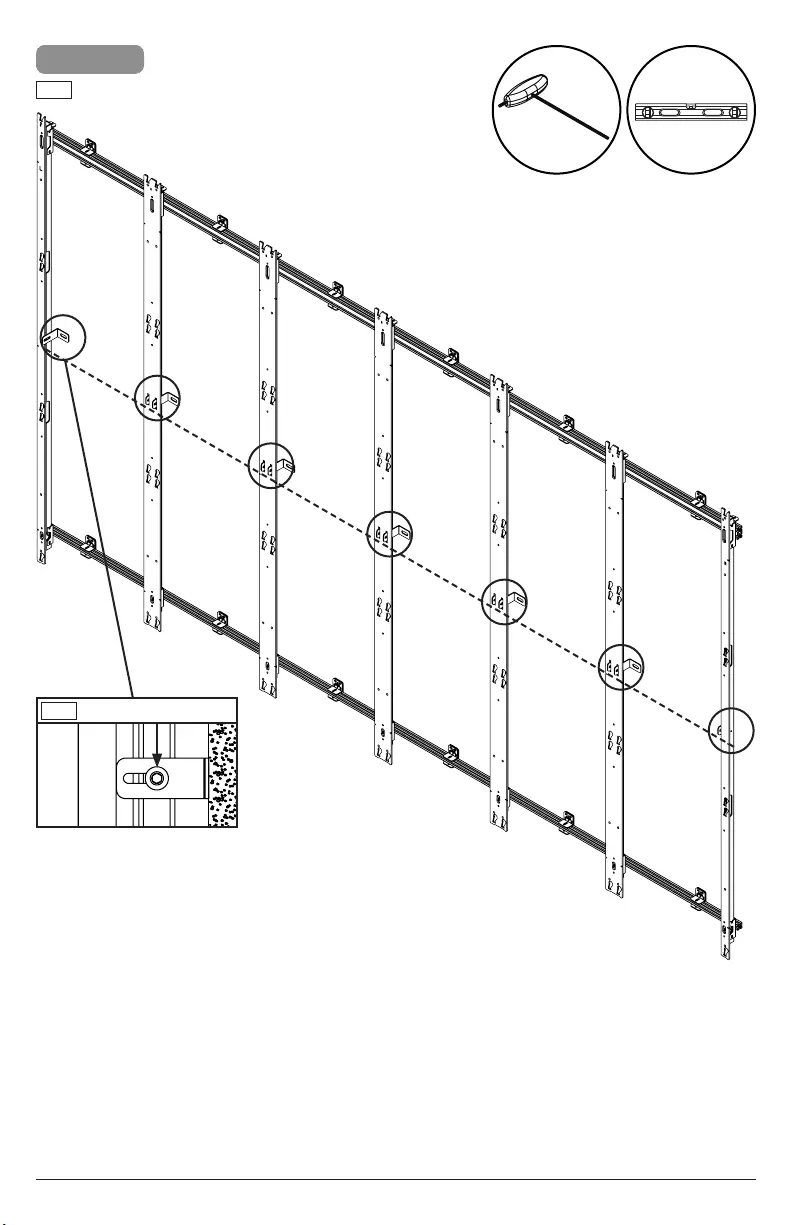

8-1

Loosen hardware on vertical columns.

ENG K

25 2018-03-14 #:146-9020-4 (2019-05-16)

8-2

Plumb and level outer columns, then tighten

hardware. Tighten hardware on four corner wall

plates

ENG

Tighten.

ENG

Tighten.

ENG

K

26 2018-03-14 #:146-9020-4 (2019-05-16)

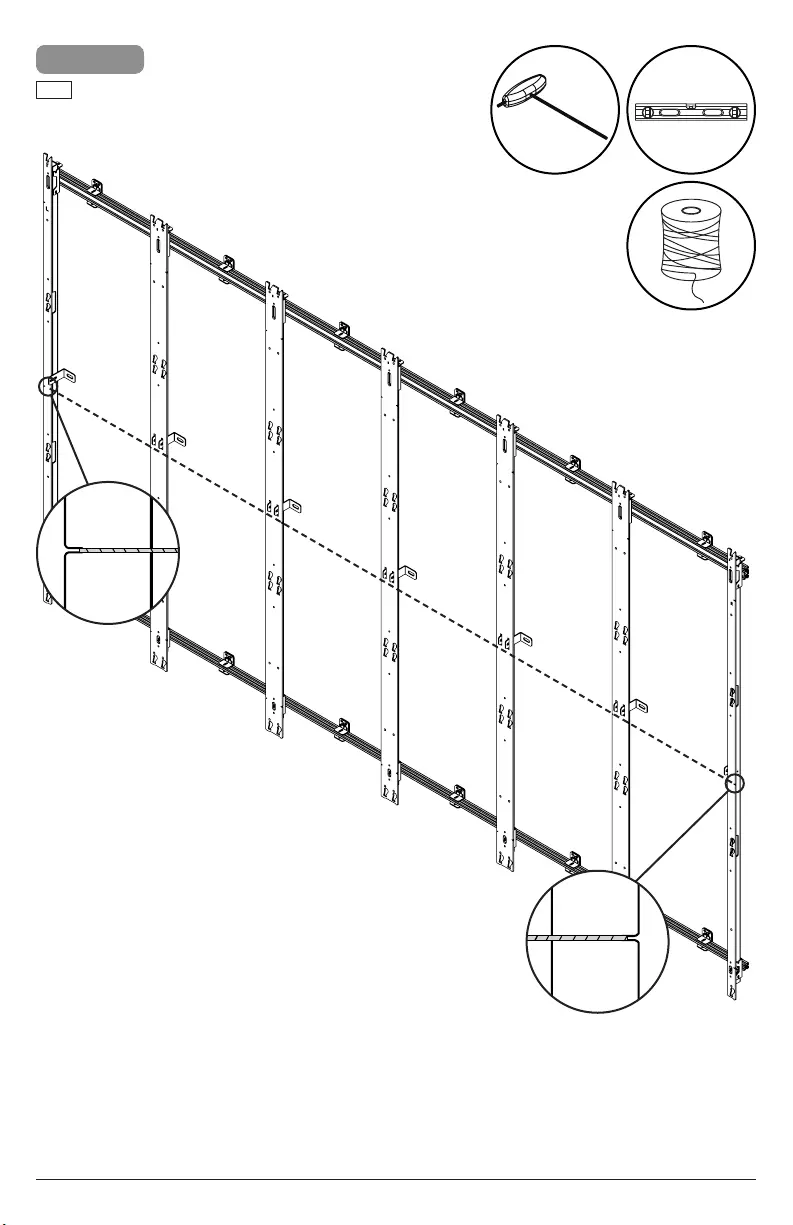

8-3

Tie a string between top slots on outer

columns in order to level the depth of each

vertical column.

ENG

Loosen, adjust, tighten.

ENG

Tighten.

ENG

Loosen.

ENG

Optional leveling for bowed walls

ENG

Insert.

ENG

L

K

27 2018-03-14 #:146-9020-4 (2019-05-16)

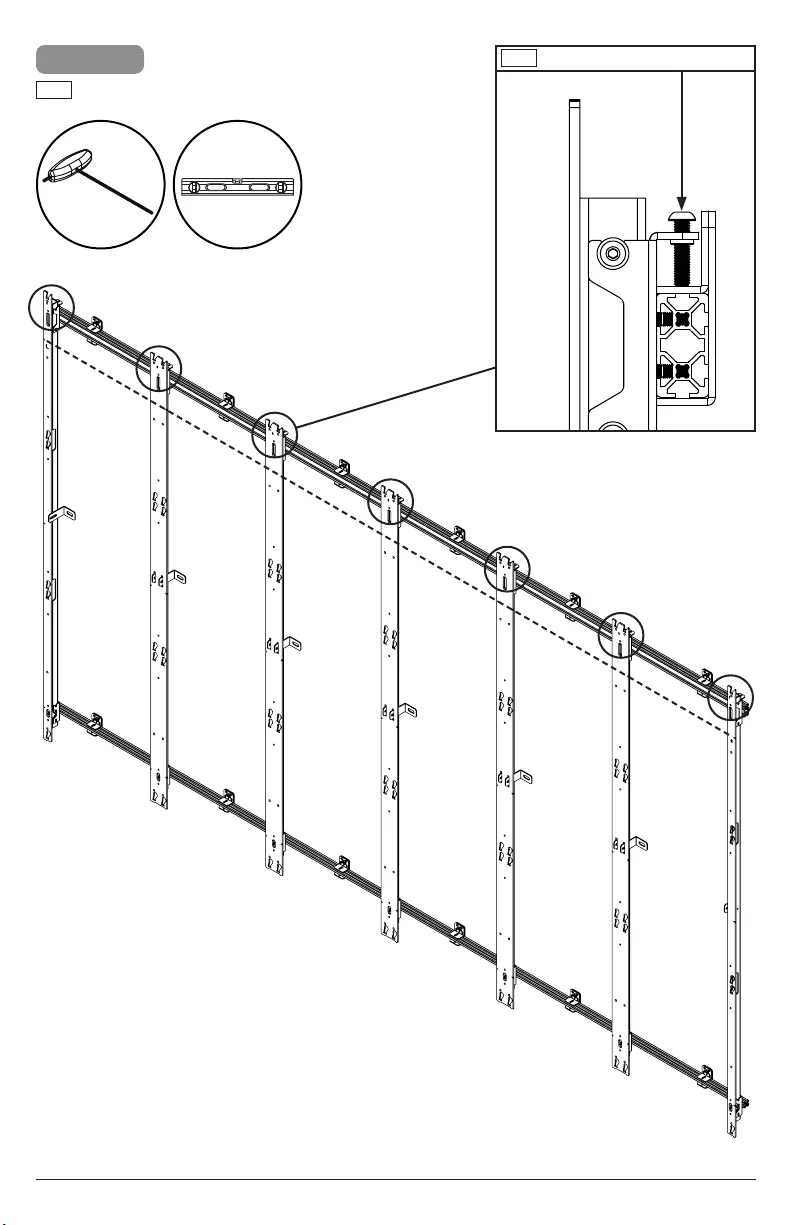

8-4

Tie a string between bottom slots on outer columns

in order to level the depth of each vertical column.

ENG

Loosen, adjust, tighten.

ENG

Tighten.

ENG

Loosen.

ENG

Optional leveling for bowed walls

ENG

Insert.

ENG

L

K

28 2018-03-14 #:146-9020-4 (2019-05-16)

8-5

With the string still attached, level the height of

each column

ENG

Tighten or loosen to adjust height.

ENG

K

29 2018-03-14 #:146-9020-4 (2019-05-16)

8-6

Adjust inner columns to t horizontal spacers.

Tighten column hardware after spacing. Start

from the left column.

ENG

G

K

30 2018-03-14 #:146-9020-4 (2019-05-16)

8-7

Continue adjusting inner columns to t horizontal

spacers until all are level. Tighten column hardware

after spacing

ENG

G

K

31 2018-03-14 #:146-9020-4 (2019-05-16)

8-8

Remove all spacers.

ENG

32 2018-03-14 #:146-9020-4 (2019-05-16)

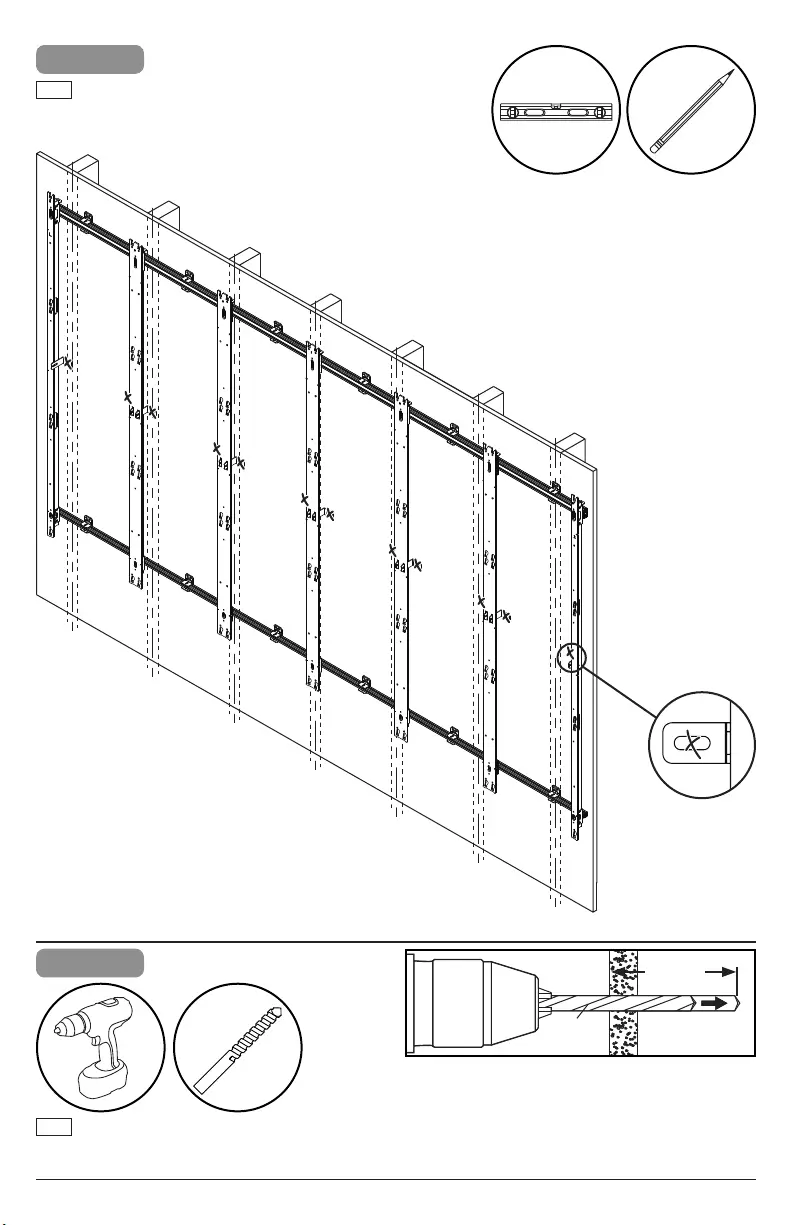

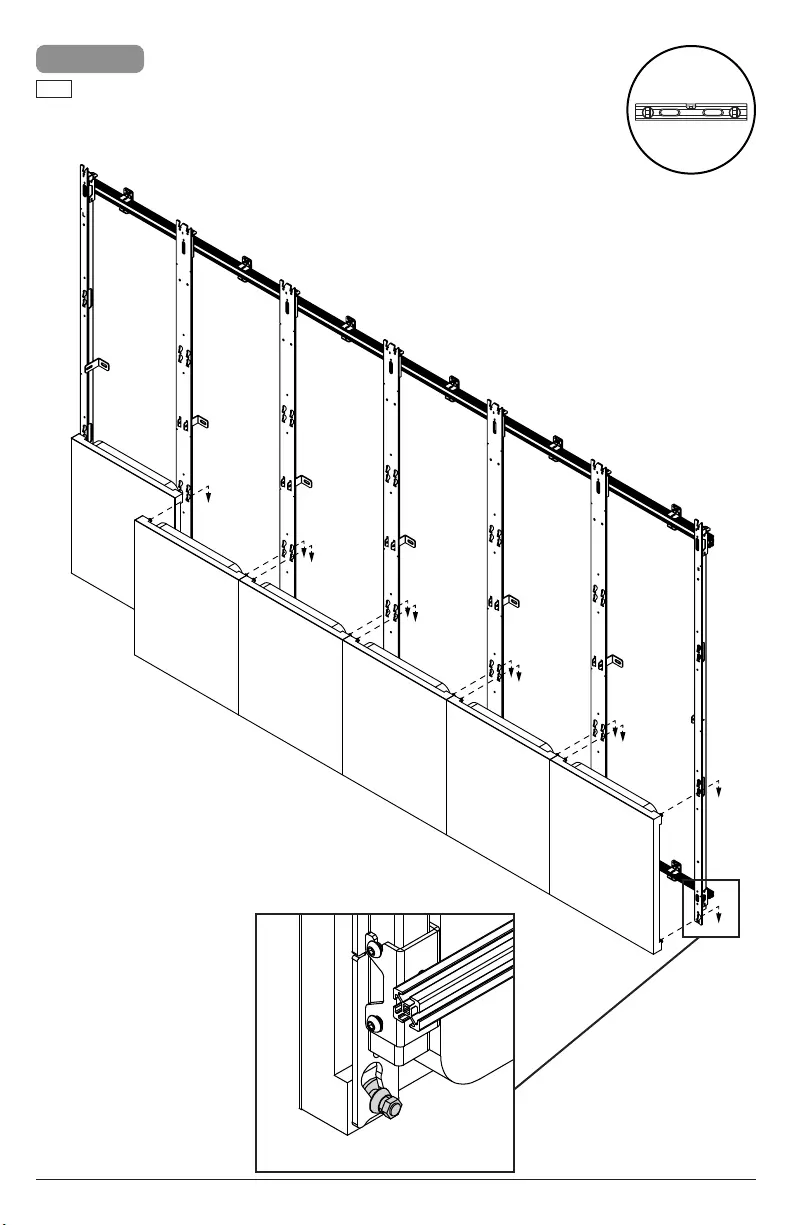

9-1

Level L brackets and mark mounting holes

on plywood (must be minimum Grade BC,

1/2" (13mm) thick.)

ENG

9-2

Drill mounting holes into supporting surface

(2.5" (64mm) minimum depth required).

ENG

5/32"

(4mm)

2.5"

(64mm)

5/32"

(4mm)

33 2018-03-14 #:146-9020-4 (2019-05-16)

9-3

Level L brackets. Install using wood

screws provided.

ENG

3/8"

(10mm)

Maximum 80 in. • lb (9 N.M.).

ENG

I (12)

34 2018-03-14 #:146-9020-4 (2019-05-16)

9-4

Tie a string between center slots on outer column

in order to level the depth of each vertical column.

ENG K

35 2018-03-14 #:146-9020-4 (2019-05-16)

9-5

Adjust depth, then remove string.

ENG

Loosen, adjust, tighten.

ENG

K

36 2018-03-14 #:146-9020-4 (2019-05-16)

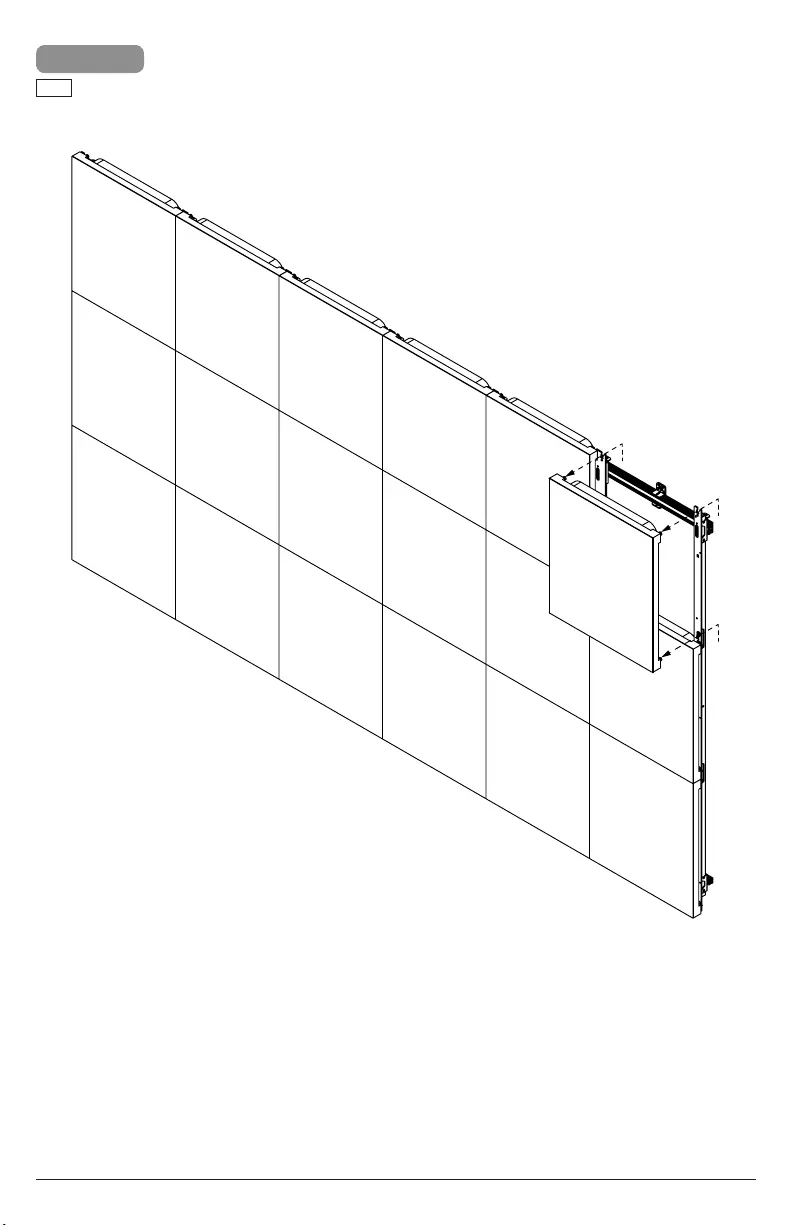

10-1

ENG Attach display, tighten connecting hardware, and run

cables one at a time starting from the bottom left.

1

23456

37 2018-03-14 #:146-9020-4 (2019-05-16)

10-2

7

13

8

14

9

15

10

16

11

17

12

18

38 2018-03-14 #:146-9020-4 (2019-05-16)

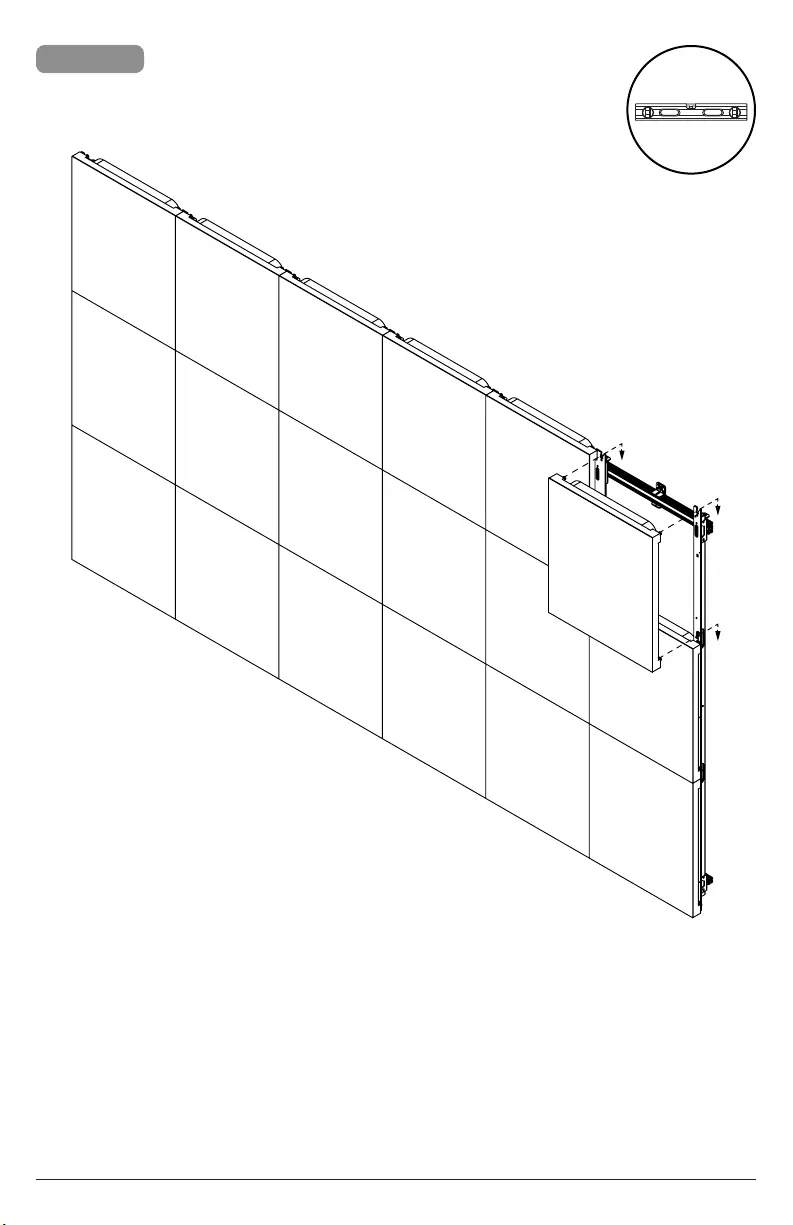

11

ENG To remove, start from the top right.

65432

7

1

39 2018-03-14 #:146-9020-4 (2019-05-16)

This page intentionally left blank.

ENG

Peerless Industries, Inc. (“Peerless-AV”) warrants to original end-users that each Peerless-AV® mounting product will be free from defects

in material and workmanship, under normal use, for the applicable warranty period (from date of the original installation of the product).

At its option, Peerless-AV will repair or replace, or refund the purchase price of, any product which fails to conform with this warranty.

Any implied warranty of merchantability or tness for a particular purpose shall be limited to the period of the

express warranty set forth below.

In no event shall Peerless-AV be liable for incidental or consequential damages, whether or not secured by a

security device which may be included with the product.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion of incidental or consequential damages, so

the above limitation and/or the above exclusion may not apply to you.

This warranty does not cover damage caused by incorrect selection, installation or the failure to follow Peerless-AV instructions or

warnings when installing, using or storing the product.

This warranty gives specic legal rights, and you may also have other rights which vary from state to state. To make a warranty claim in

North America, contact Peerless-AV customer care at 1-800-865-2112. See complete global warranty information for regions outside North

America at www.peerless-av.com/en-uk/customer-care/warranties-returns.

LIMITED FIVE-YEAR WARRANTY

Peerless-AV Europe

Unit 3 Watford Interchange,

Colonial Way, Watford, Herts,

WD24 4WP, United Kingdom

Customer Care

44 (0) 1923 200 100

www.peerless-av.com

© 2019, Peerless Industries, Inc.

Peerless-AV de Mexico

Ave de las Industrias 413

Parque Industrial Escobedo

Escobedo N.L Mexico 66062

Servicio al Cliente

01-800-849-65-77

www.peerless-av.com

© 2019, Peerless Industries, Inc.

Peerless-AV

2300 White Oak Circle

Aurora, IL 60502

Email: tech@peerlessmounts.com

Ph: (800) 865-2112

Fax: (800) 359-6500

www.peerless-av.com

© 2019, Peerless Industries, Inc.