Peerless DST940 User Manual

Displayed below is the user manual for DST940 by Peerless which is a product in the Signage Display Mounts category. This manual has pages.

Related Manuals

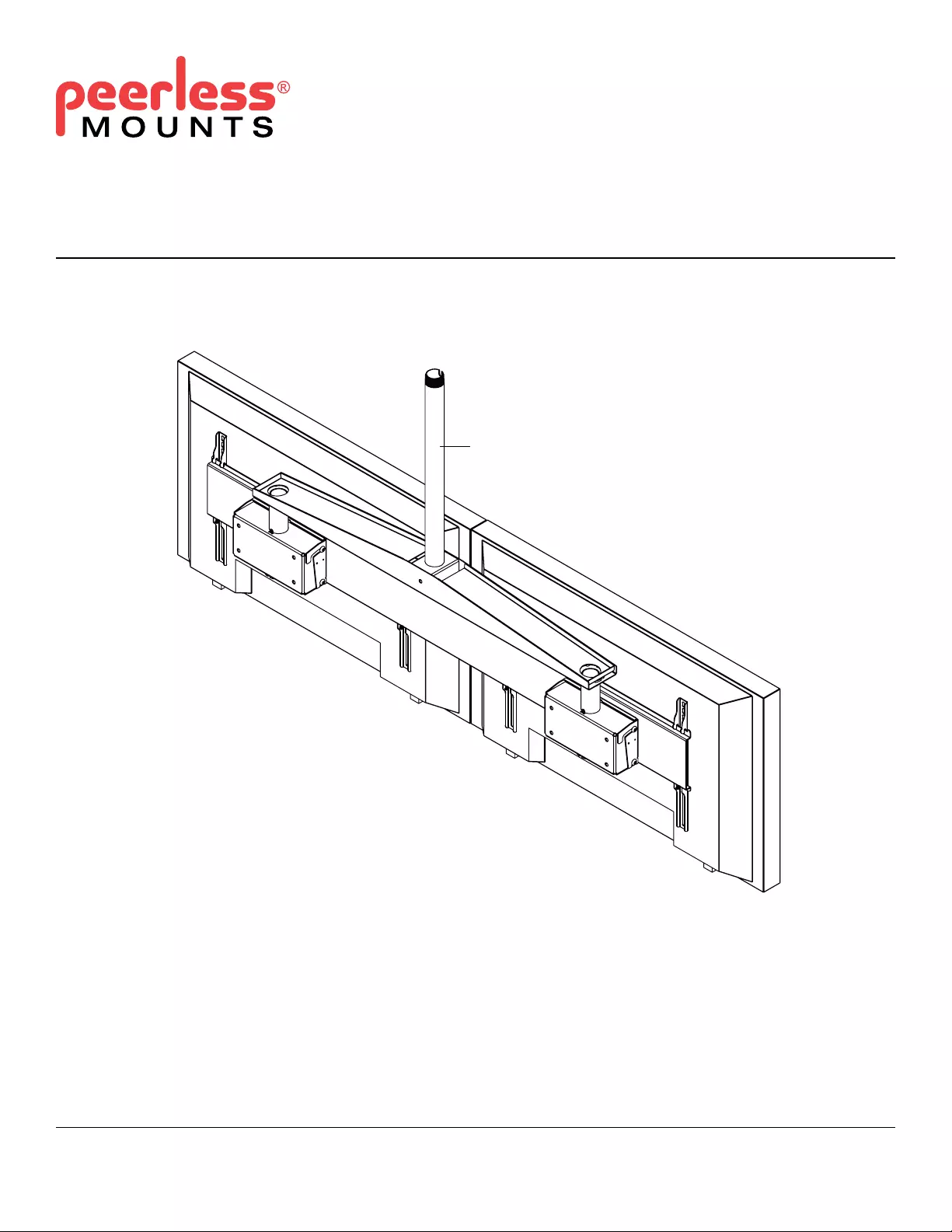

Installation and Assembly:

Dual Display Ceiling Mount System

Models: DST940

ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

Max Load Capacity: 150 lb (68 kg)

Extension pipe

(sold separately)

2 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

NOTE: Read entire instruction sheet before you start installation and assembly.

Tools Needed for Assembly

• phillips screwdriver

• drill

• 3/8" drill bit

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, for US

customers please call Peerless customer care at 1-800-865-2112, for all international customers, please contact

your local distributor.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never exceed the Maximum Load Capacity. See page one.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tightenscrewsrmly,butdonotovertighten.Overtighteningcandamagetheitems,greatlyreducingtheirholding

power.

• This product is intended for indoor use only. Use of this product outdoors could lead to product failure and personal

injury.

WARNING

Table of Contents

Parts List.................................................................................................................................................................................3

Attaching Dual Cross Support to Extension Pipe ...................................................................................................................5

Attaching Extension Columns to Dual Cross Support ............................................................................................................5

Attaching Solid•Point™ Column Mounts to Extension Columns ..............................................................................................6

(Optional)AttachingDSX750toCeilingArmBoxes ...............................................................................................................7

AttachingAdapterPlateandTiltBracketstoCeilingArmBoxes ............................................................................................7

AttachingAdapterBracketstoScreens .............................................................................................................................. 8-9

AttachingAdapterBracketstoAdapterPlate....................................................................................................................... 10

3 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

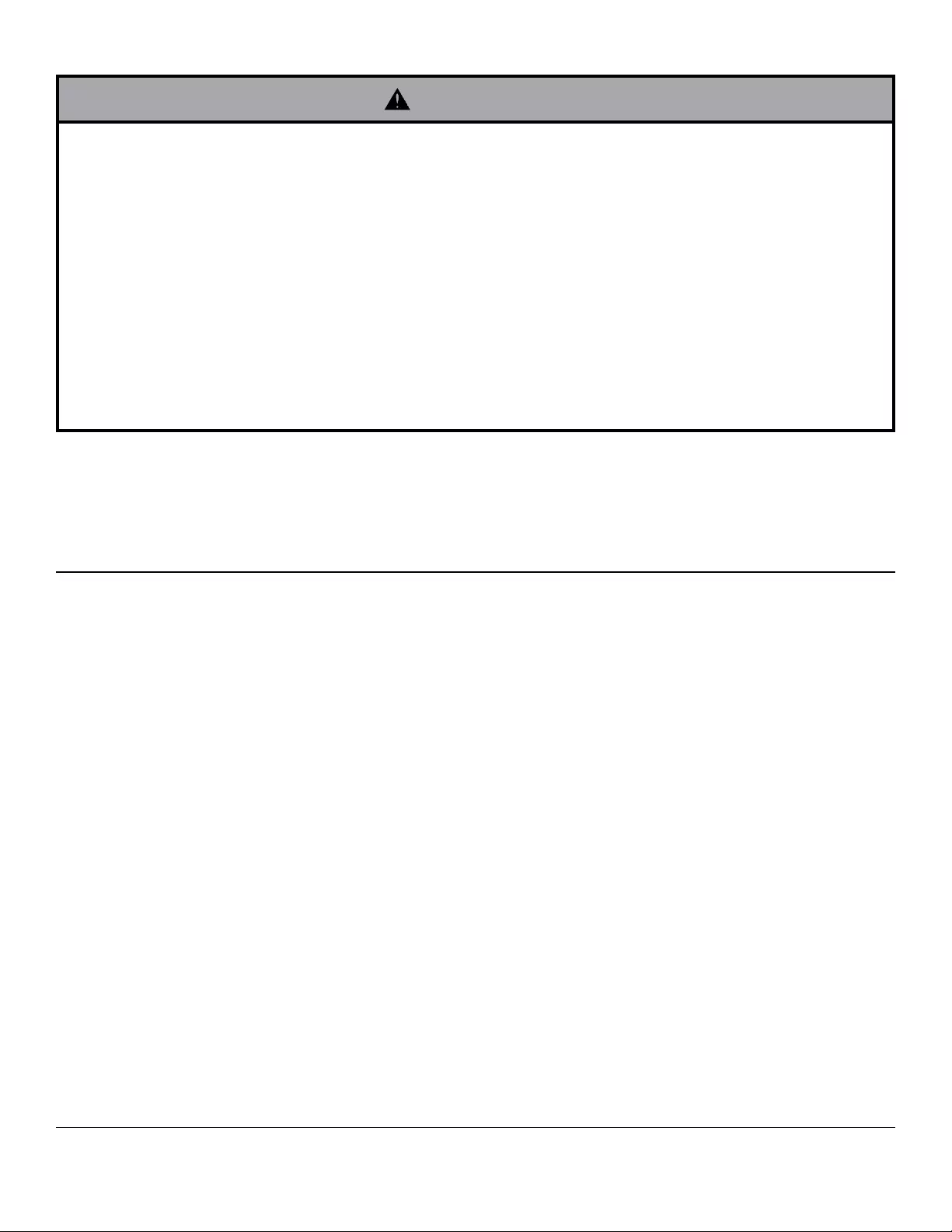

G H

F

E

C

D

A B

Before you begin, make sure all parts shown are included with your product.

Parts may appear slightly different than illustrated.

M

K

L

JI

Q

P

N

R

Description Qty Part #

A6" extension column 2 026-1014

Bdual cross support 1139-1015

C4.5" hex bolt 1 520-9548

D3/8-16 nylock nut 1530-9310

Eretaining collar 31800-375

Fextension pipe fiber washer 1 540-9431

GM5 x 10 mm screw 1 520-9250

Hceiling arm box 2 124-1974

Itilt bracket 2 200-1552

JM5 x 10 mm penta-pin screw 8 505-9010

Kextension column fiber washer 2 540-9432

LM10 x 15 mm penta-pin screw 16 520-9263

MM10 x 2" penta-pin tool 2 520-9260

NM5 x 1" penta-pin tool 2 520-9249

Padapter bracket 4201-1511

Qadapter plate 1124-1280

R4 mm allen wrench 1 560-9646

Parts List

125-1545

202-1655

4 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

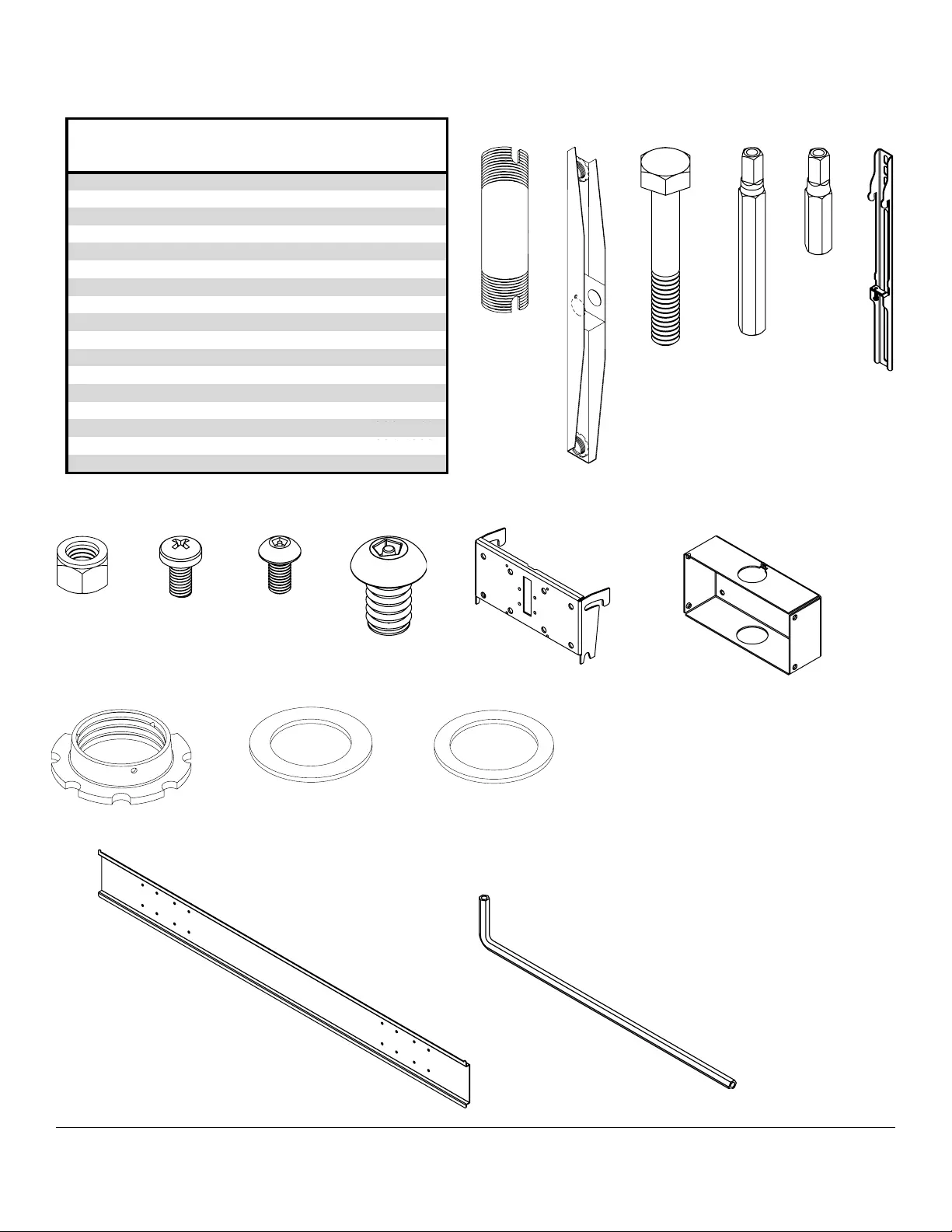

M5 x 25 mm (8)

520-1122

M4 x 12 mm (12)

510-1079

M4 x 25 mm (8)

510-1082

M5 x 12 mm (8)

520-1064

M6 x 12 mm (8)

520-1050

M6 x 25 mm (8)

520-1211

I.D. .22" (5.6 mm) (8)

540-1057

multi-washer (12)

580-1036

I.D..34"(8.7mm)(8)

540-1059

Security Adapter Bracket Fasteners

M6 x 20 mm (8)

520-9554

M6 x 30 mm (8)

520-1067

M8 x 15 mm (12)

520-1068

M8 x 40 mm (8)

520-1152

M8 x 25 mm (8)

520-1101

5 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

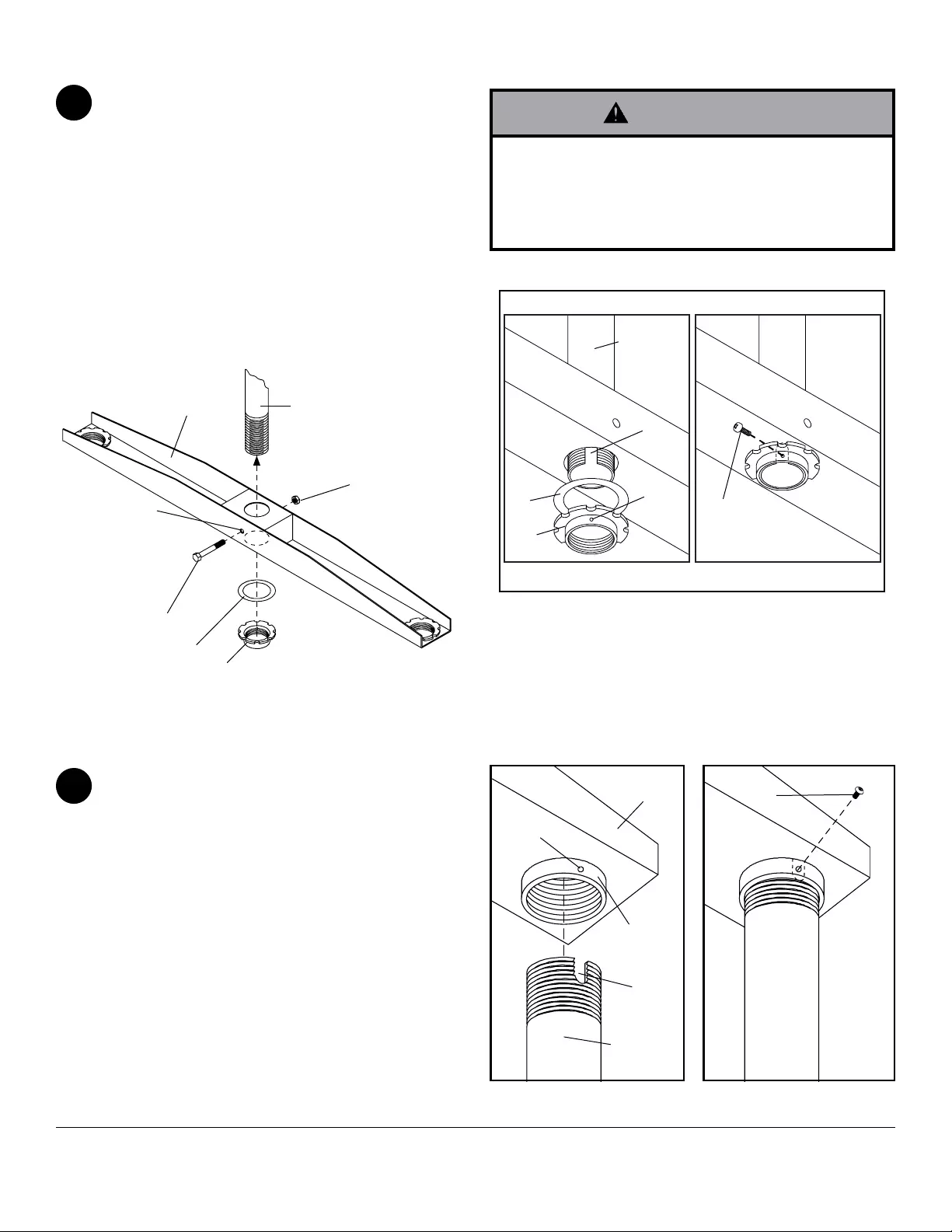

Slide dual cross support (B) onto end of extension

pipe (sold separately) followed by extension pipe

berwasher(F) and retaining collar (E). Tighten

retaining collar so that thread is securely engaged.

Align one small hole of retaining collar (E) with slot

oftheextensionpipeasshowningure1.2.Insert

and tighten one M5 x 10 mm phillips screw (G)

through hole of retaining collar into slot of extension

pipe.

Rotate dual cross support (B) to desired position.

Drill 3/8" dia. hole into extension pipe through hole

of dual cross support (B). Lock into place with 3/8"

bolt (C) and nylock nut (D)asshowningure1.1.

Attaching Dual Cross Support To Extension Pipe

1

• Installer must verify that the supporting surface will

safely support four times the combined weight of all

attached equipment and hardware.

• For safety, retaining collar must be locked to exten-

sion pipe with screw.

WARNING

g. 1.1

Attaching Extension Columns to Dual Cross Support

2Thread extension column (A) into bottom of

threadedttingondualcrosssupport(B) as shown.

Tighten extension column so thread is securely

engaged.

Alignonesmallholeinthethreadedttingofdual

cross support (B) with slot of extension column

(A) as shown. Insert and tighten one M5 x 10 mm

penta-pin screw (J) through the hole of threaded

ttingandslotofextensioncolumn(A).

Use the M5 penta-pin tool (N) to tighten screw.

Repeat step two to attach second extension column

(A) to dual cross support (B).

Drill hole in

extension pipe

through existing

hole in dual

cross support

Extension pipe

VIEW FROM BELOW

g. 1.2

Extension

Pipe

Small

Hole

Slot

Small

Hole

Slot

Threaded

Fitting

C

D

FE

B

F

E

B

G

B

A

J

6 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

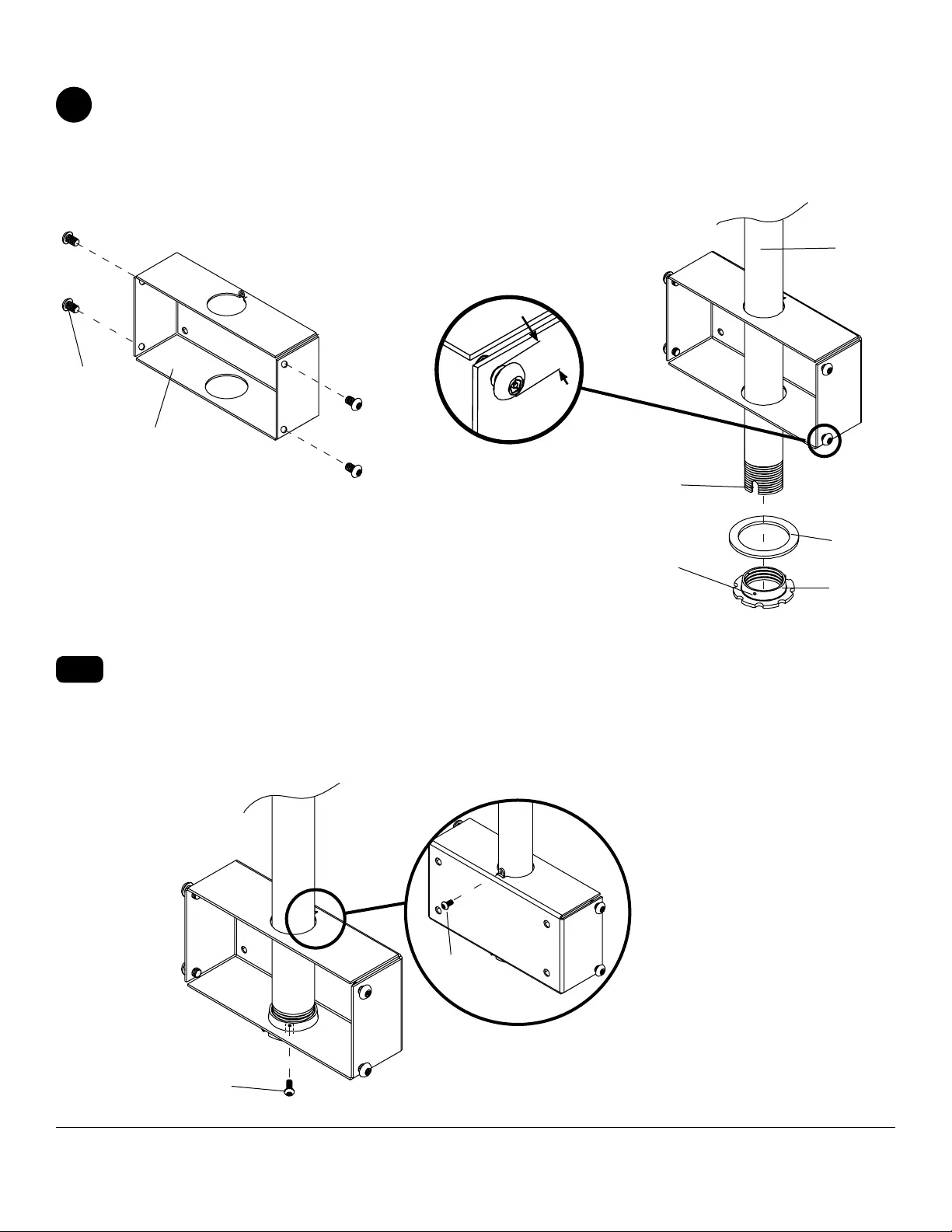

Attaching Solid•Point™ Column Mounts to Extension Columns

Insert four M10 x 15 mm penta-pin screws (L) into threaded holes on the sides of ceiling arm box (H) as shown in

gure3.1.Leaveapproximately1/4"ofexposedthreadasshownindetail1.

Slide ceiling arm box (H) onto end of extension column (A)followedbyextensioncolumnberwasher(K) and

retaining collar (E)asshowningure3.2.Tightenretainingcollarandalignslotofextensioncolumn(A) with hole

of retaining collar (E).

3

Back View

g. 3.1 DETAIL 1 g. 3.2

g. 3.3

DETAIL 2

Slot

Small hole

Insert and tighten one M5 x 10 mm penta-pin screw (J) through the hole of the retaining collar (E) and slot of ex-

tension column (A)asshowningure3.3.

Insert one M5 x 10 mm penta-pin screw (J) through the tab on the back of ceiling arm box (H) as shown in detail 2.

Use the M5 penta-pin tool (N) to tighten screws. Repeat step three to attach second ceiling arm box (H).

NOTE: Bothceilingarmboxes(H) must be at same height to attach adapter plate (Q) properly.

3-2

L

H

A

E

K

J

J

1/4"

7 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

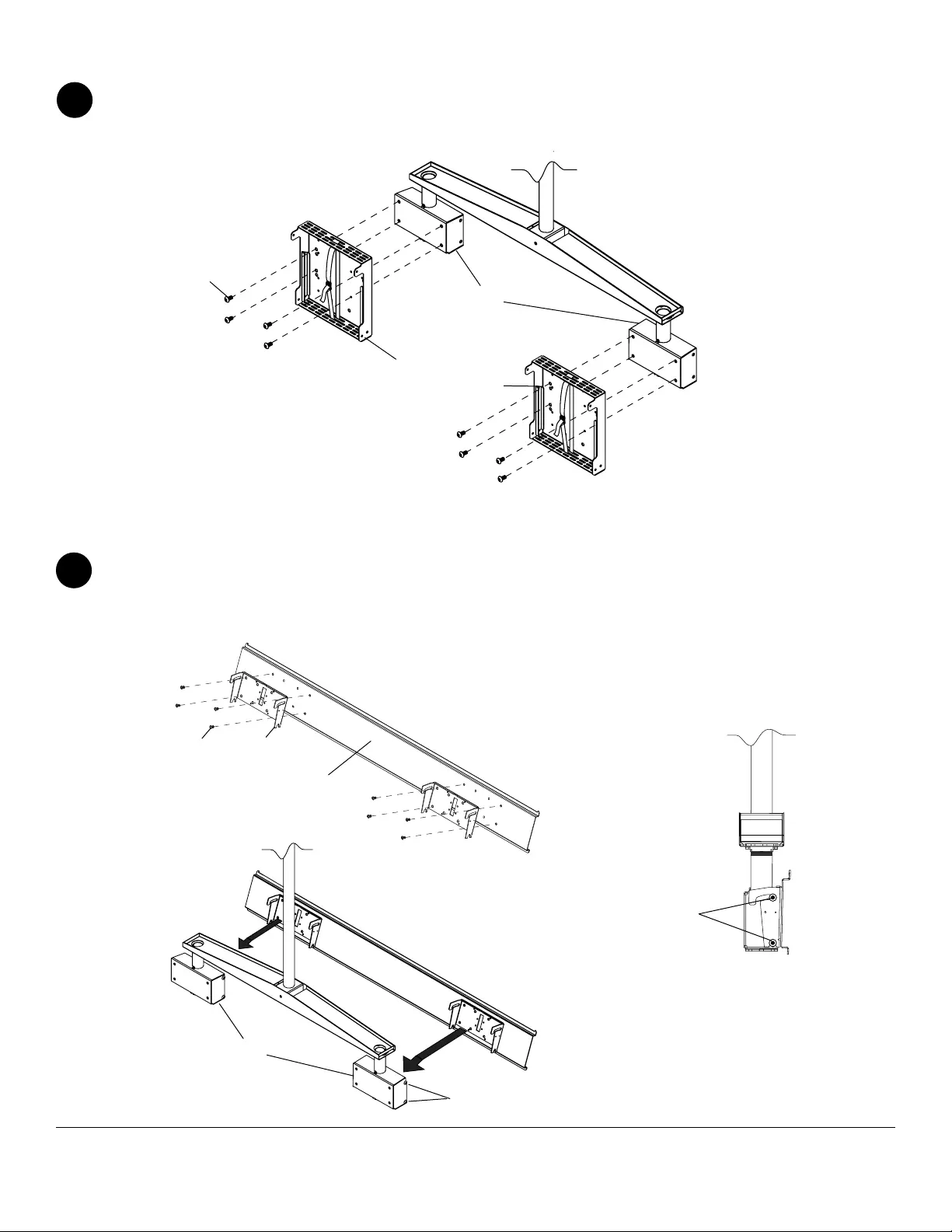

Attachtwoadapterbox(suppliedwithDSX750)toceilingarmbox(H) using four M10 screws

(suppliedwithDSX750)perboxasshownbelow.

NOTE:UseDSX750instructionstocompleteinstallationofadapterbox(suppliedwithDSX750).

Attaching DSX750 To Ceiling Arm Boxes (Optional)

4

Attach two tilt brackets (I) to adapter plate (Q) using eight M10 x 15 mm penta-pin screws (L) and tighten with

M10 penta-pin tool (M)asshowningure5.1.Hooktiltbracketsontoscrewsofceilingarmboxes(H) as shown in

gure5.2.Adjusttilttothezerodegreetiltpositionasshowningure5.3andtighteneightM10x15mmpenta-pin

screws (L) with M10 penta-pin tool (M).

Attaching Adapter Plate And Tilt Brackets To Ceiling Arm Boxes

5

g. 5.1

g. 5.2

LI

Q

H

L

g. 5.3

L

H

M10 SCREWS

(SUPPLIEDWITHDSX750)

ADAPTERBOX

(SUPPLIEDWITHDSX750)

8 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

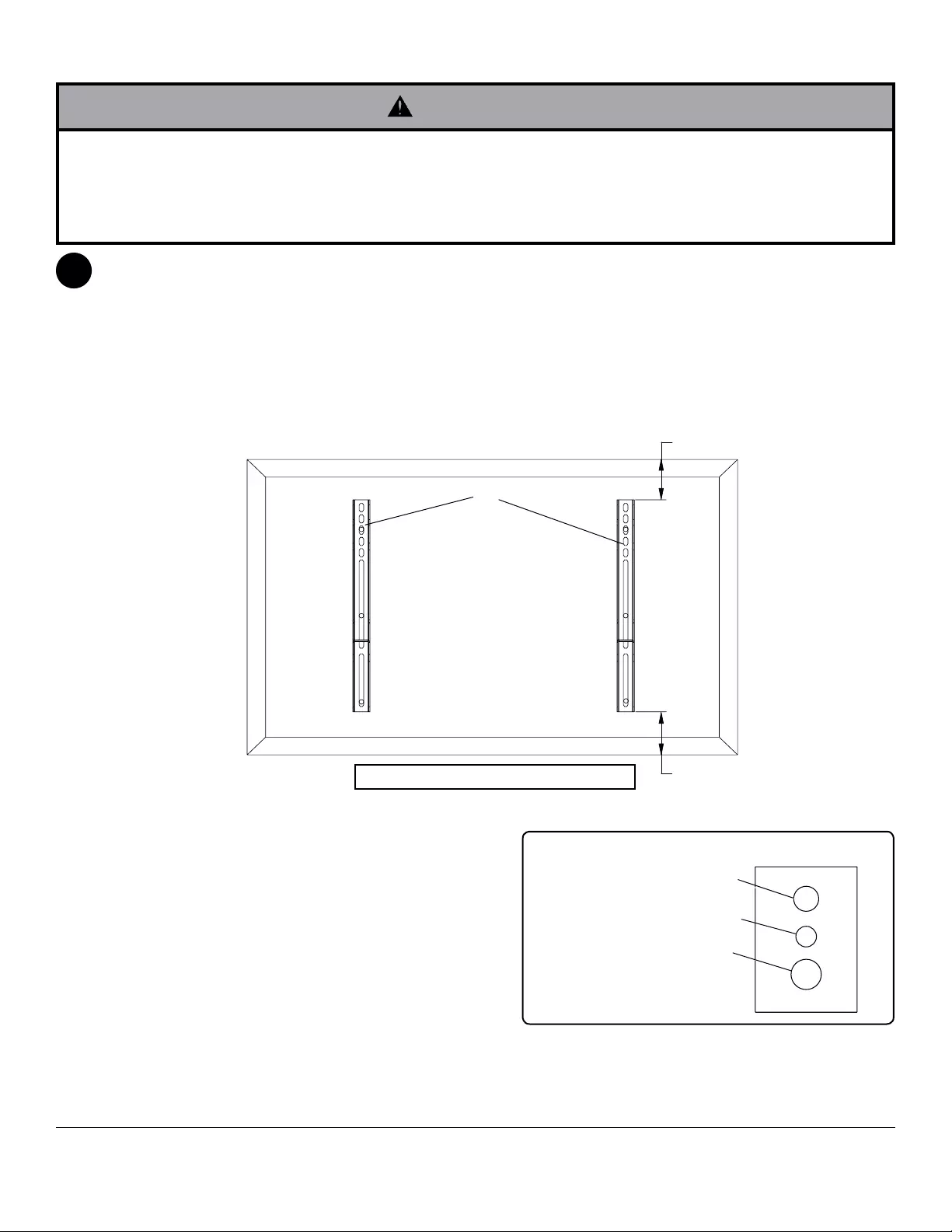

Note:"X"dimensionsshouldbeequal.

Installing Adapter Brackets

Topreventscratchingthescreen,setaclothonaat,levelsurfacethatwillsupporttheweightofthescreen.Place

screen face side down. If screen has knobs on the back, remove them to allow the adapter brackets to be attached.

Place adapter brackets (P) on back of screen, align to holes, and center on back of screen as shown below. Attach

the adapter brackets to the back of the screen using the appropriate combination of screws, multi-washers and

spacers.

NOTE: Top and bottom holes on screen must always be used.

Verify that all holes are properly aligned, and then tighten screws using 4 mm allen wrench (R).Repeatstepveto

attach adapter brackets to second screen.

MEDIUMHOLEFORM5SCREWS

SMALLHOLEFORM4SCREWS

LARGEHOLEFORM6SCREWS

P

CENTERBRACKETS

VERTICALLYONBACKOF

SCREEN

X

X

Notes:

• The number of fasteners used will vary,

depending upon the type of screen.

• Multi-washers and spacers may not be

used, depending upon the type of screen.

• Use the corresponding hole in the multi-

washerthatmatchesyourscrewsizeas

shown.

MULTI-WASHER

6

• Tightenscrewssoadapterbracketsarermlyattached.Donottightenwithexcessiveforce.Overtighteningcan

cause stress damage to screws, greatly reducing their holding power and possibly causing screw heads to become

detached. Tighten to 40 in. • lb (4.5 N.M.) maximum torque.

• If screws don't get three complete turns in the screen inserts or if screws bottom out and bracket is still not tightly

secured, damage may occur to screen or product may fail.

WARNING

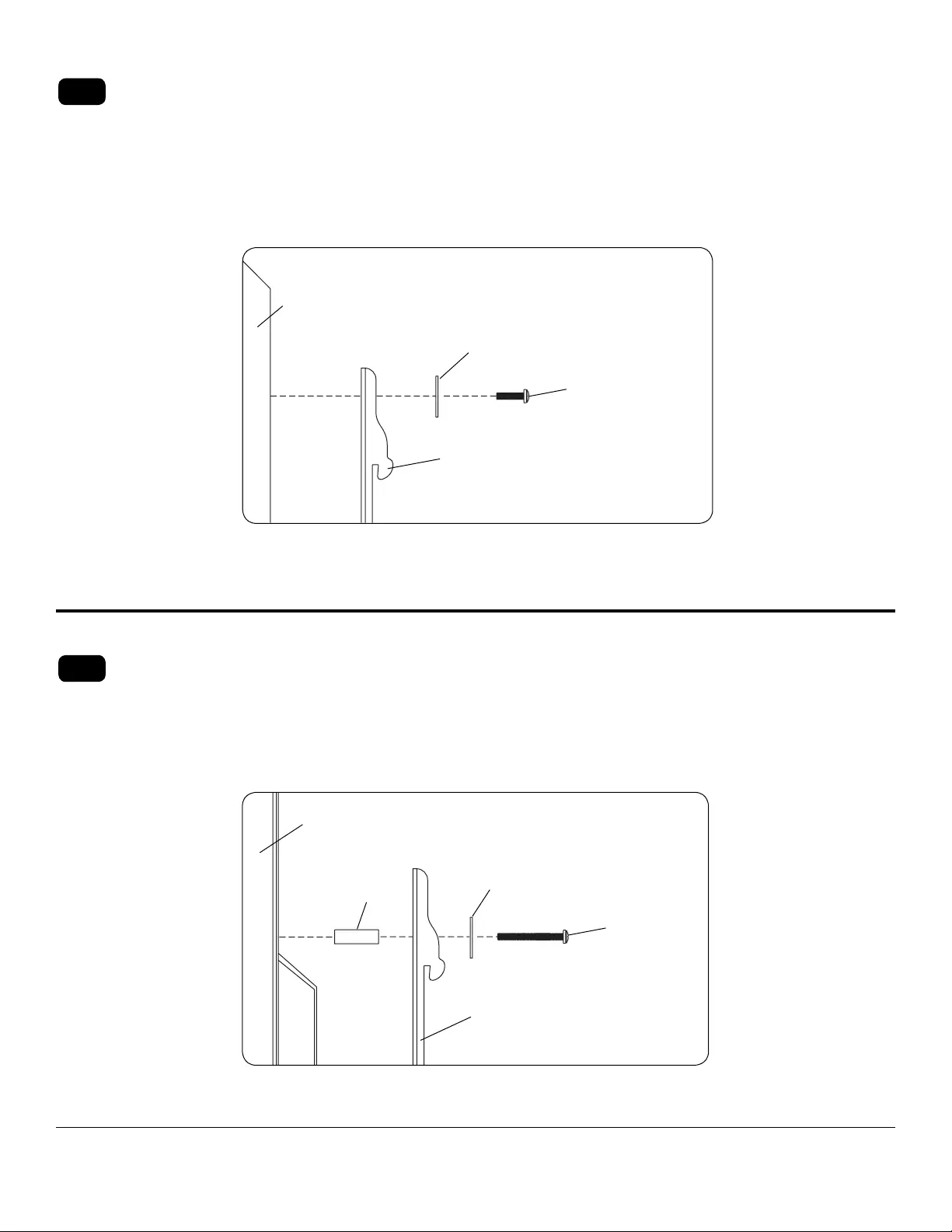

NOTE: For at back screens proceed to step 6-1. For bump-out or recessed back screen skip to step 6-2

9 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

Refer to Screen Compatibility Chart to determine the proper fastener to use. Visit www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

Beginwiththeshortestlengthscrew,handthreadthroughmulti-washerandadapterbracketintoscreenasshown

below.Screwmustmakeatleastthreefullturnsintothemountingholeandtsnugintoplace.Donotovertighten.

Ifscrewcannotmakethreefullturnsintothescreen,selectalongerlengthscrewfromthebafedfastenerpack.

Repeat for remaining mounting holes, level brackets and tighten screws.

NOTE: Spacers may not be used, depending upon the type of screen.

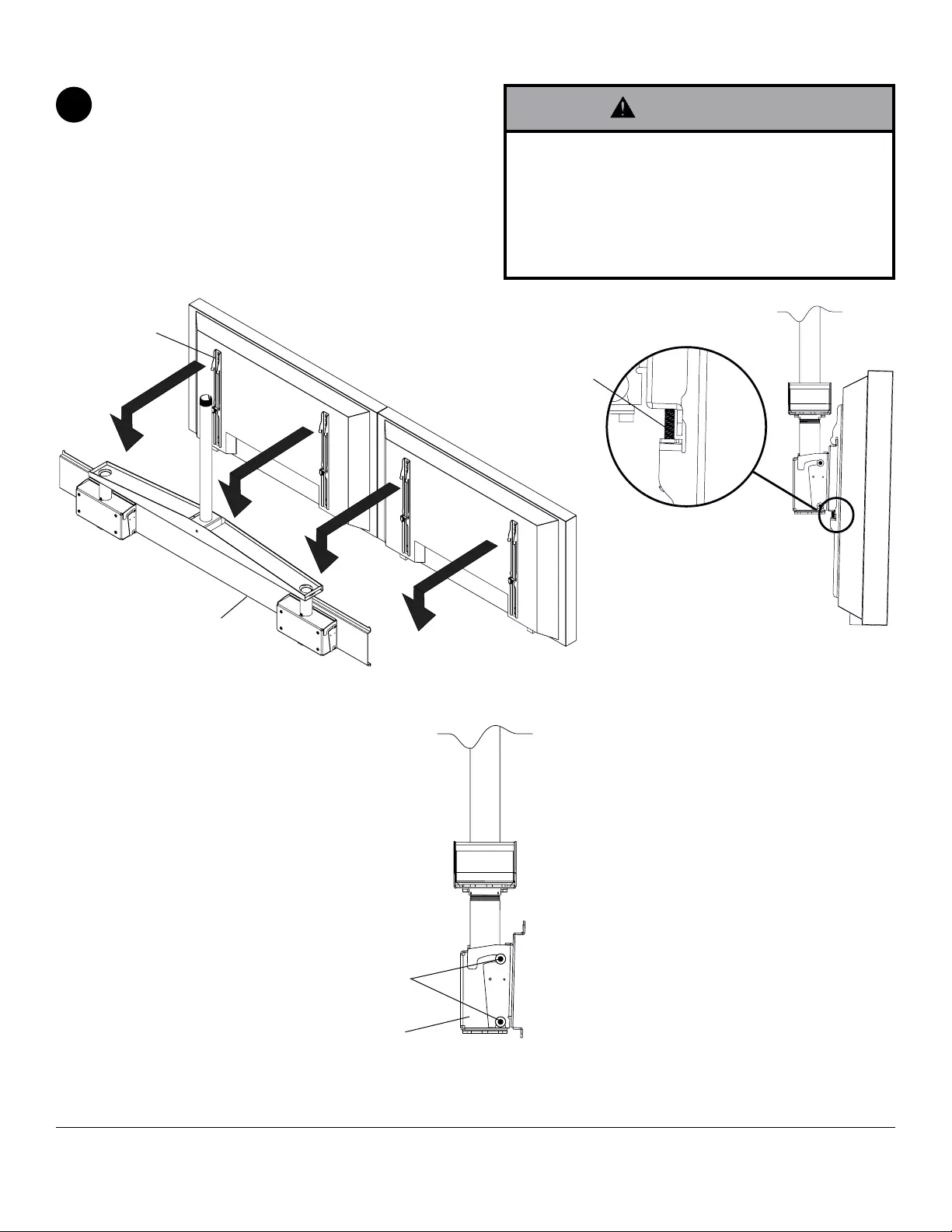

Refer to Screen Compatibility Chart to determine the proper fastener to use. Visit www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

Beginwithlongerlengthscrew,handthreadthroughmulti-washer,adapterbracketandspacerinthatorderinto

screenasshownbelow.Screwmustmakeatleastthreefullturnsintothemountingholeandtsnugintoplace.

Do not over tighten. If screw cannot make three full turns into the screen, select a longer length screw from the

bafedfastenerpack.Repeatforremainingmountingholes,levelbracketsandtightenscrews.

For Flat Back Screen

For Bump-out or Recessed Back Screen

6-1

6-2

If you have any questions, please call Peerless customer care at 1-800-865-2112.

If you have any questions, please call Peerless customer care at 1-800-865-2112.

ADAPTERBRACKET(P)

SCREEN

g 6.1

MULTI-WASHER

SCREW

SCREEN

MULTI-WASHER

SCREW

ADAPTERBRACKET(P)

g 6.2

SPACER

10 of 10 ISSUED: 08-10-09 SHEET #: 139-9011-5 02-18-2016

Hook adapter brackets (P) to adapter plate (Q) as

showningure7.1.Tightensafety/securityscrews

using allen wrench (R) until safety/security screw

touches bottom of wall plate as shown in detail 4. To

adjust tilt of screens, loosen M10 x 15 mm penta-pin

screws (L) of ceiling arm box (H) using M10 penta-

pin tool (M)asshowningure7.2.Oncedesiredtilt

is acquired retighten the screws.

Attaching Adapter Brackets To Adapter Plate

7

g. 7.1

DETAIL 4

g. 7.2

Security/Safety

Screws

L

P

Q

H

© 2010, Peerless Industries, Inc. All rights reserved.

All other brand and product names are trademarks or registered trademarks of their respective owners.

• Always use an assistant or mechanical lifting

equipmenttosafelyliftandpositiontheatpanel

screen.

• Do not tighten screws with excessive force.

Overtighteningcancausedamagetomount.

Tighten screws to 40 in. • lb (4.5 N.M.) maximum

torque.

WARNING