Peerless DSX750 User Manual

Displayed below is the user manual for DSX750 by Peerless which is a product in the Signage Display Mounts category. This manual has pages.

Related Manuals

ISSUED: 04-08-10 SHEET #:125-9110-3 02-24-16

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

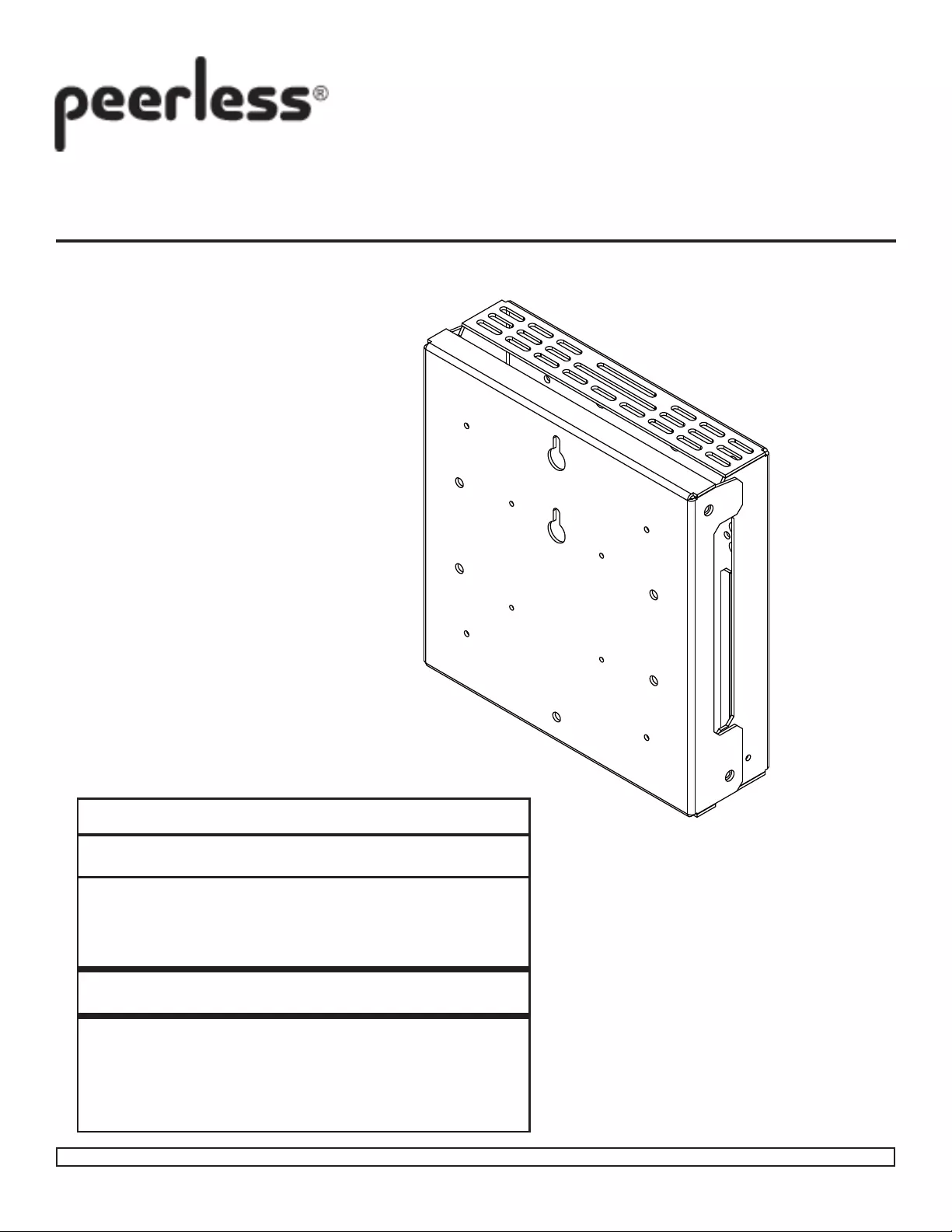

Model: DSX750

Installation and Assembly:

Wall Mount with PC Storage

Maximum Load Capacity

Max. LoadModel

Wall Mounted DSX750+

No Adapter plate 200lb (90kg)

Wall Mounted DSX750+

Dedicated Adapter plate 150lb (68kg)

SP850 150lb (68kg)

FPS-1000 150lb (68kg)

SA740P 70lb (32kg)

SA746PU 70lb (32kg)

SA752PU 80lb (36kg)

SA761PU 130lb (59kg)

SA771PU 160lb (73kg)

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

2 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

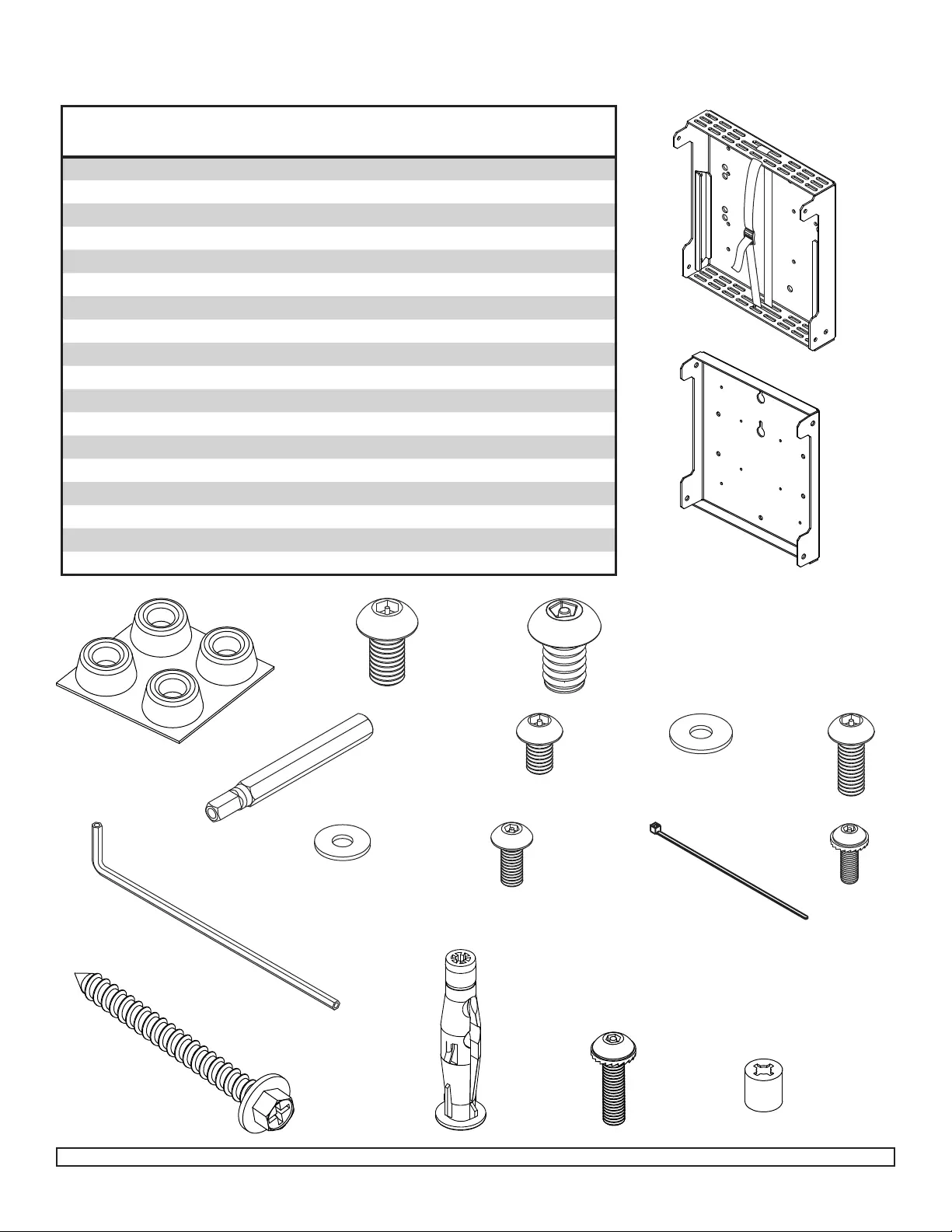

Before you begin, make sure all parts shown are included with your product.

Parts may appear slightly different than illustrated. A

B

CDE

FGH

I

J

KL

M

QR

P

N

O

Parts List Part #Description Qty

Aadapter plate 1 201-1724

Bwall plate 1 201-1699

Crubber feet (pack of four) 1 570-1036

DM8 x 15mm socket pin screw 4 520-1068

EM10 x 15mm penta-pin screw 4 520-9263

FM10 penta-pin tool 1 520-9260

GM6 x 12mm socket pin screw 4 510-1050

H#10 fl at washer 4 540-9400

I4mm allen wrench 1 560-9646

JM6 x 16mm socket pin screw 4 520-1132

K#8 fl at washers 4 540-1001

LM5 x 12mm socket pin screw 4 520-1064

Mcable tie 4 560-9711

NM4 x 12mm socket pin screw 4 510-1079

O#14 x 2.5" hex head wood screw 3 5S1-015-C03

Pconcrete anchor 3 590-0320

QM5 x 20mm socket pin screw 4 510-1065

Rretaining spacer 4 590-1150

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

3 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

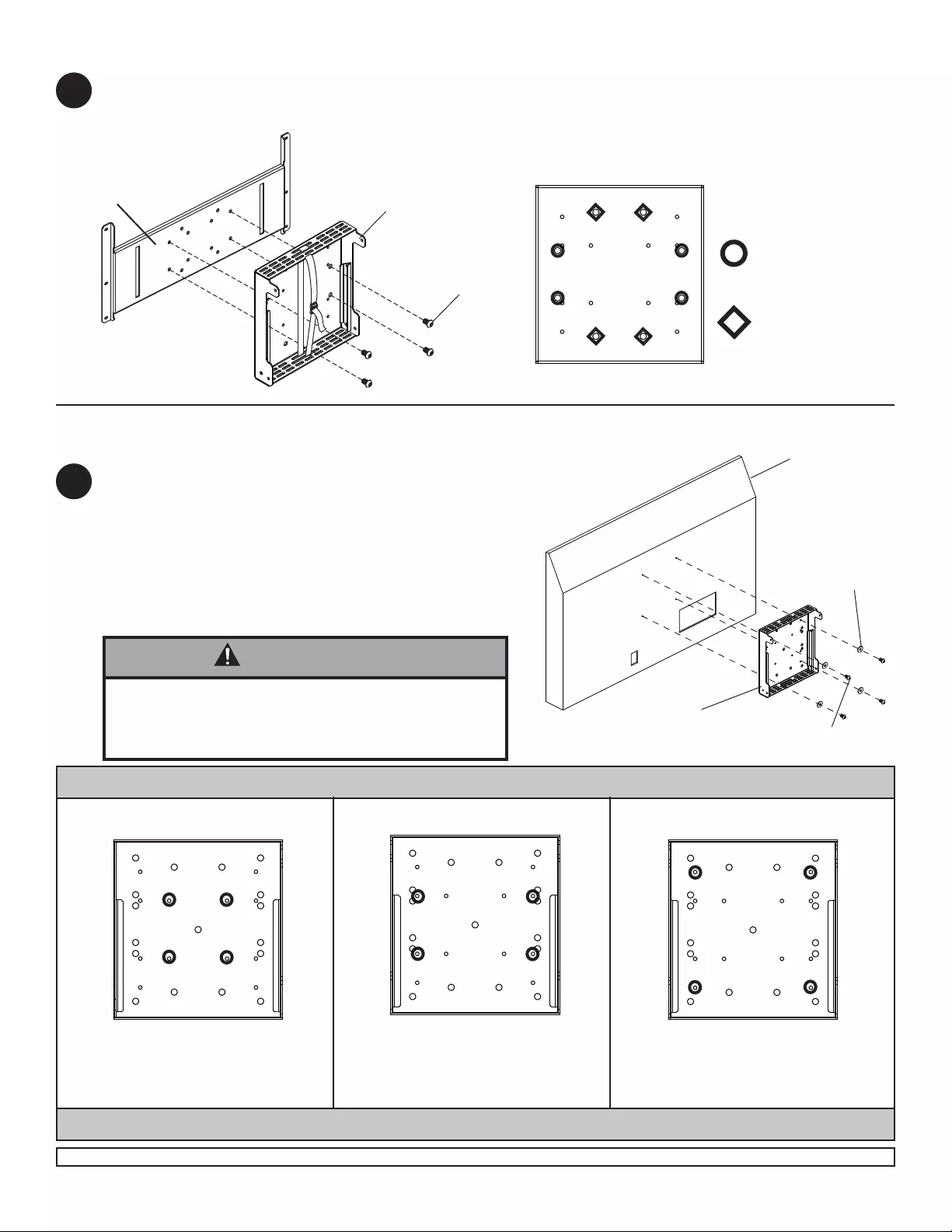

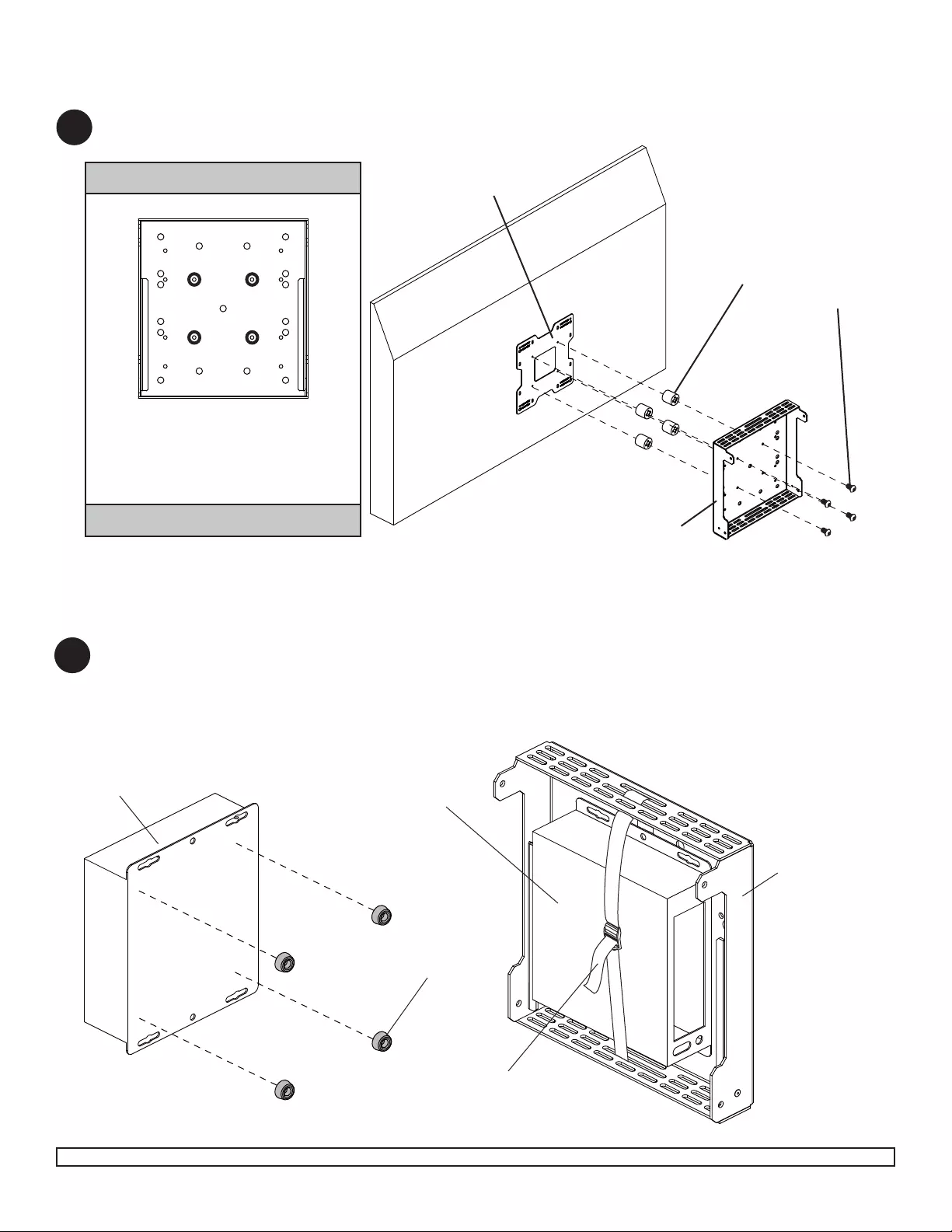

1

Attaching Adapter Plate to Screen

Using SP850, FPS-1000

Attaching adapter plate to screen with

VESA hole pattern:

Choose hole pattern and fasteners shown in detail 2 for

mounting screen with VESA mounting patterns. Hand thread

screws (N, L or G) through washers (K or H) and adapter

plate (A) into screen as shown (right). Screw must make at

least three full turns into the mounting hole and fi t snug into

place. Securely tighten screws using 4 mm allen wrench (I).

• If screws don't get three complete turns in the screen

inserts or if screws bottom out and bracket is still

not tightly secured, damage may occur to screen or

product may fail.

WARNING

A

SCREEN

N, L or G

K or H

VESA® 200 x 100 VESA® 200 x 200VESA® 100 x 100

MOUNTING PATTERNS

M4 x 12 mm screws (N) with #8

washers (K) or M5 x 12 mm screws

(L) with #10 washers (H)

M4 x 12 mm screws (N) with #8

washers (K), M5 x 12 mm screws (L) M4 x 12 mm screws (N) with #8

washers (K) or

M6 x 12 mm screws (G) with

#10 washers (H)

DETAIL 2

Using the hole pattern shown in detail 1, attach the adapter plate (A) to dedicated adapter plate with four

M10 x 15 mm screws (E) as shown in fi gure 1.1. Tighten screws using M10 penta-pin tool (F). If attaching to

articulating mount use M10 x 15 mm screws (supplied with mount).

DEDICATED

ADAPTER PLATE

DETAIL 1

MOUNTING PATTERN FOR

DEDICA TED ADAPTER PLA TES

A

E

Figure. 1.1

LANDSCAPE

PORTRAIT

OR

1

Attaching Wall Plate to dedicated adapter Plates:

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

4 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

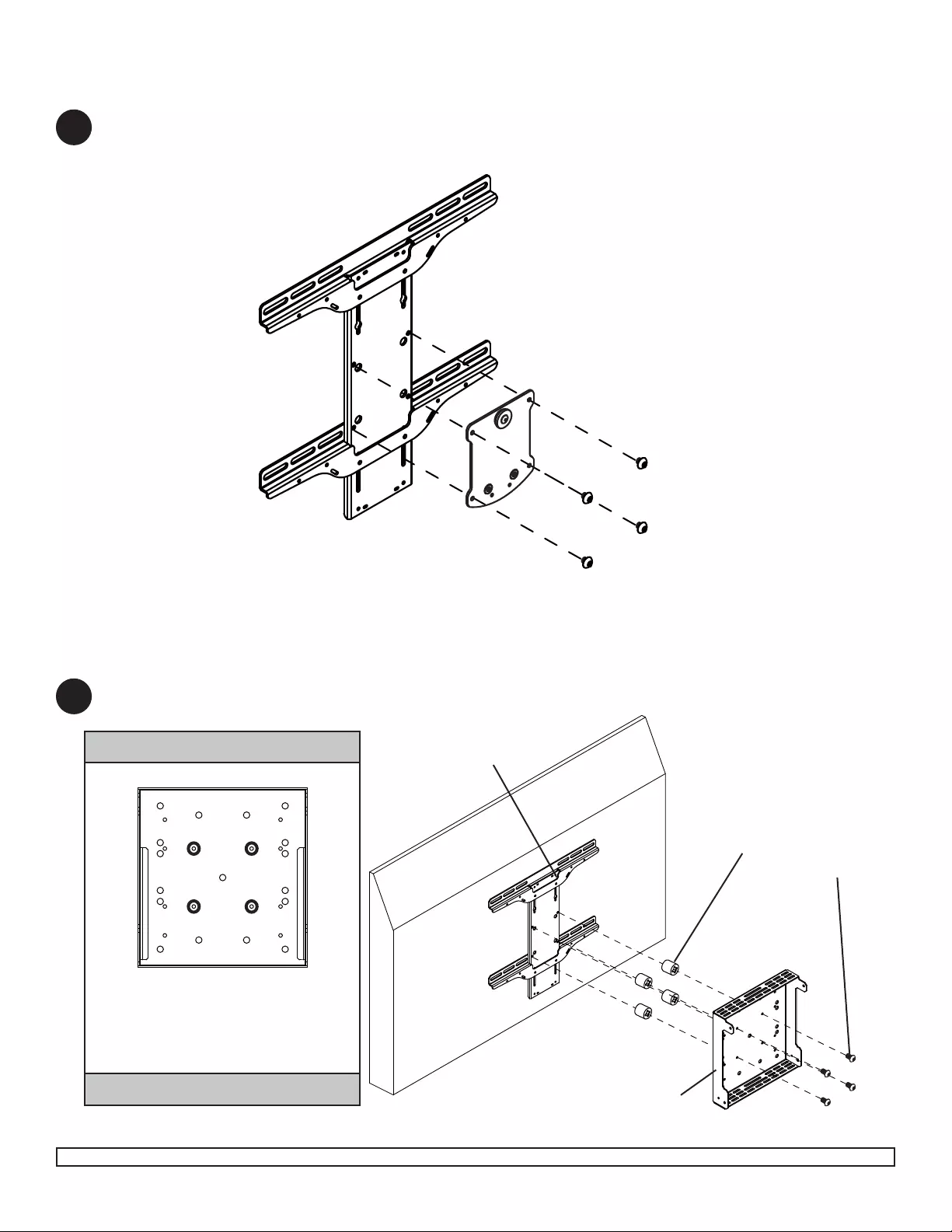

1

1

MOUNTING PATTERN

Attaching adapter Plate to Universal Adapter Bracket

Using SA746PU, SA752PU, SA761PU, SA771PU

Attaching adapter Plate to Universal Adapter Bracket

Using SA740P, SA746PU, SA752PU, SA761PU, SA771PU

Secure adapter plate (A) to universal adapter bracket with four M5 x 20 mm screws and four retaining spacers as

shown in below.

Remove hook brachet from adapter plate if needed.

A

RQ

UNIVERSAL ADAPTER BRACKET

M5 x 20 mm

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

5 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

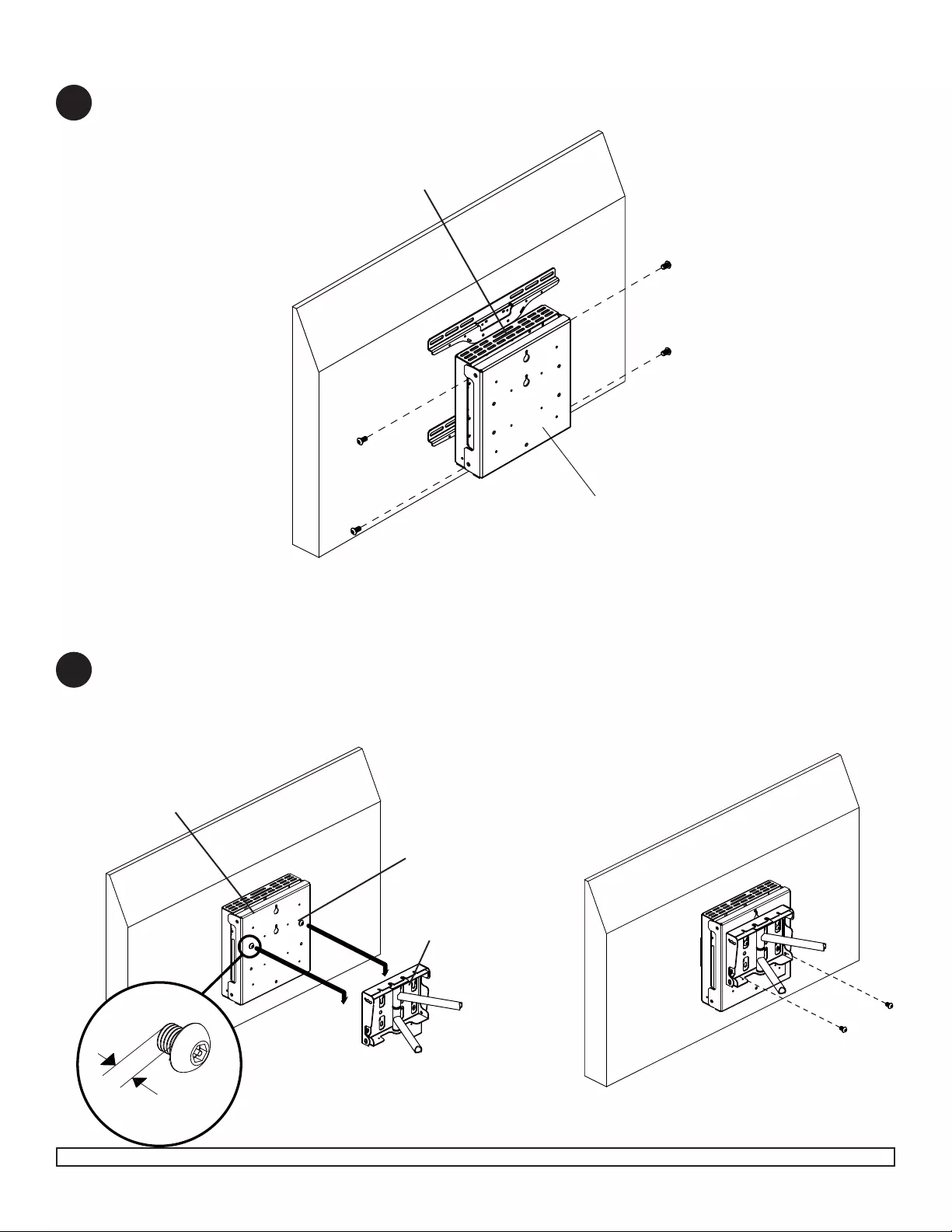

Remove rubber feet from base.

Secure four rubber feet (C) to bottom of CPU

as shown below.

2

CPU

A

SAFETY

STRAP

Attach CPU to Tilt Box

SCREEN NOT SHOWN

FOR CLARITY

CPU

C

NOTE: Safety belt may need to be loosened to attach

CPU to adapter plate (A).

Press CPU against adhesive strips on adapter plate (A)

and tightly secure safety belt against CPU.

CPU MAY APPEAR DIFFERENT

THAN ILLUSTRATED

1

MOUNTING PATTERN

Attaching adapter Plate to Universal Adapter Bracket

Using SA740P

Secure adapter plate (A) to adapter bracket with four M5 x 20 mm screws and four retaining spacers as shown in

below.

A

RQ

ADAPTER BRACKET

M5 x 20 mm

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

6 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

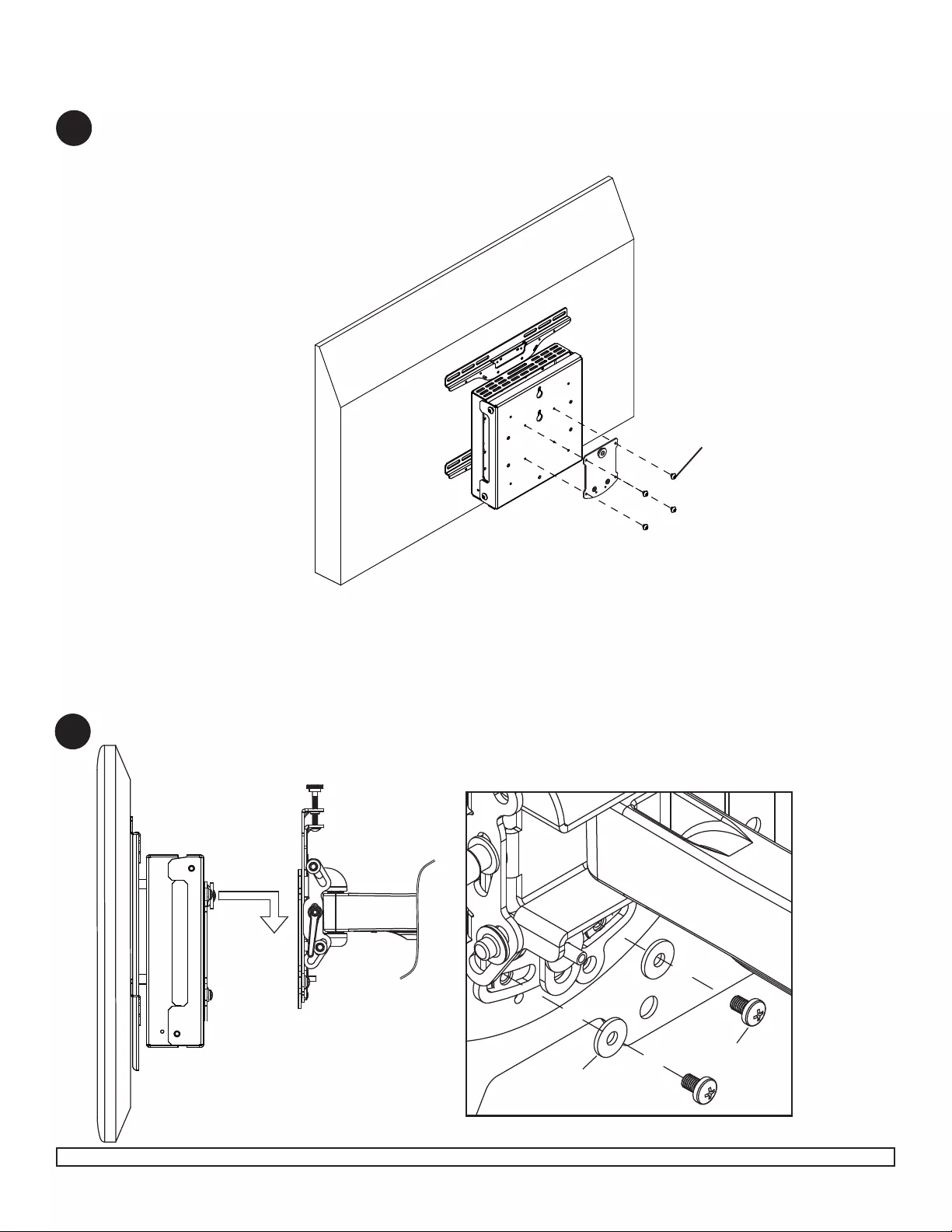

Thread two M10 x 15 mm penta-pin screws (E) into top

holes of wall plate (B) leaving 1/8" space between head

of screw and wall plate as shown below.

Hook wall plate (B) and two exposed M10 x 15 mm

penta-pin screws (E) into keyhole slots on mount.

4Secure with two M10 x 15 mm penta-pin screws (E)

using M10 penta-pin tool (F) as shown below.

KEYHOLE SLOT

Attaching Wall Plate to Wall Arm Mount

Using SP850, FPS-1000

1/8"

B

E

E

E

A

Skip to Step 5 Page 8 if mounting wall plate (B) to wall.

Secure wall plate (B) to adapter plate (A) with four M8 x 15 mm screws (D) using 4 mm allen wrench (I)

as shown below.

3

Attaching Adapter Plate to Wall Plate

B

D

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

7 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

Attaching Adapter Plate to Wall Arm Mount

Using SA745PU, SA750PU, SA760PU, SA770PU

4

M5 X 8MM SCREW

M5 X 1.5MM WASHER

4Secure with four M10 x 15 mm penta-pin screws (E)

using M10 penta-pin tool (F) as shown below.

Hook bracket into slot and secure with two M5 x

8mm screws and two M5 x 1.5 mm washers

Attaching Wall Plate to Wall Arm Mount

Using SA740P, SA746PU, SA752PU, SA761PU, SA771PU

E

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

8 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

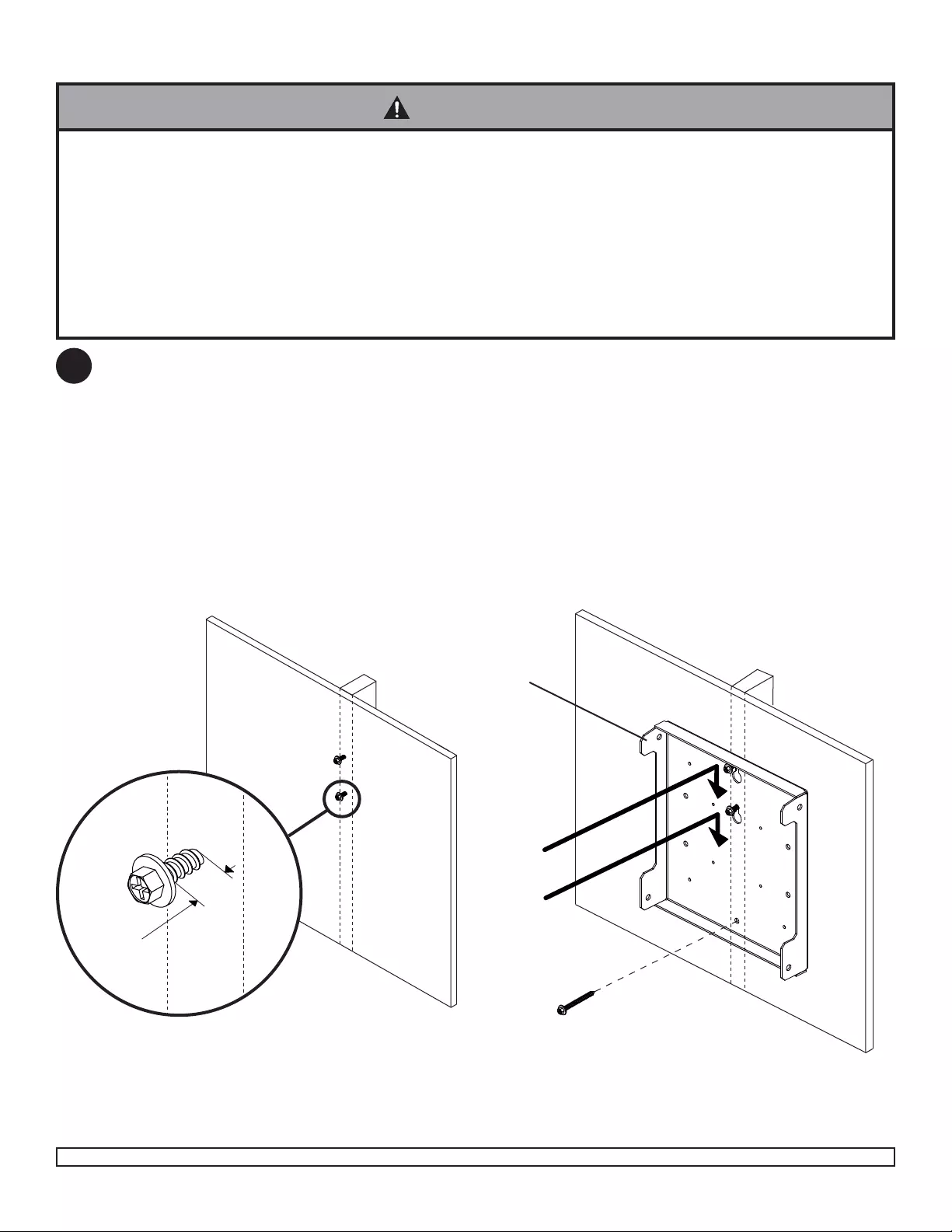

Installation to Wood Stud Wall

Use a stud fi nder to locate the edges of the stud. Use of an edge-to-edge stud fi nder is highly recommended.

Based on their edges, draw a vertical line down each stud center. Place wall plate (B) on wall as a template. Level,

and mark the center of the three mounting holes. Make sure that the mounting holes are on the stud centerlines.

Drill three 5/32" (4 mm) dia. holes 2.5" (64 mm) deep. Fasten two #14 x 2.5" wood screws (O) leaving 1/4" of

thread exposed as shown in Figure 5.1.

Hook wall plate (A) onto exposed #14 x 2.5" wood screws (O). Secure using one #14 x 2.5" wood screws (O) as

shown in fi gure 5.2

Skip to Step 6.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Install-

ers are responsible to provide hardware for other types of mounting situations

WARNING

5

1/4"

Figure 5.1 Figure 5.2

B

O

O

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

9 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

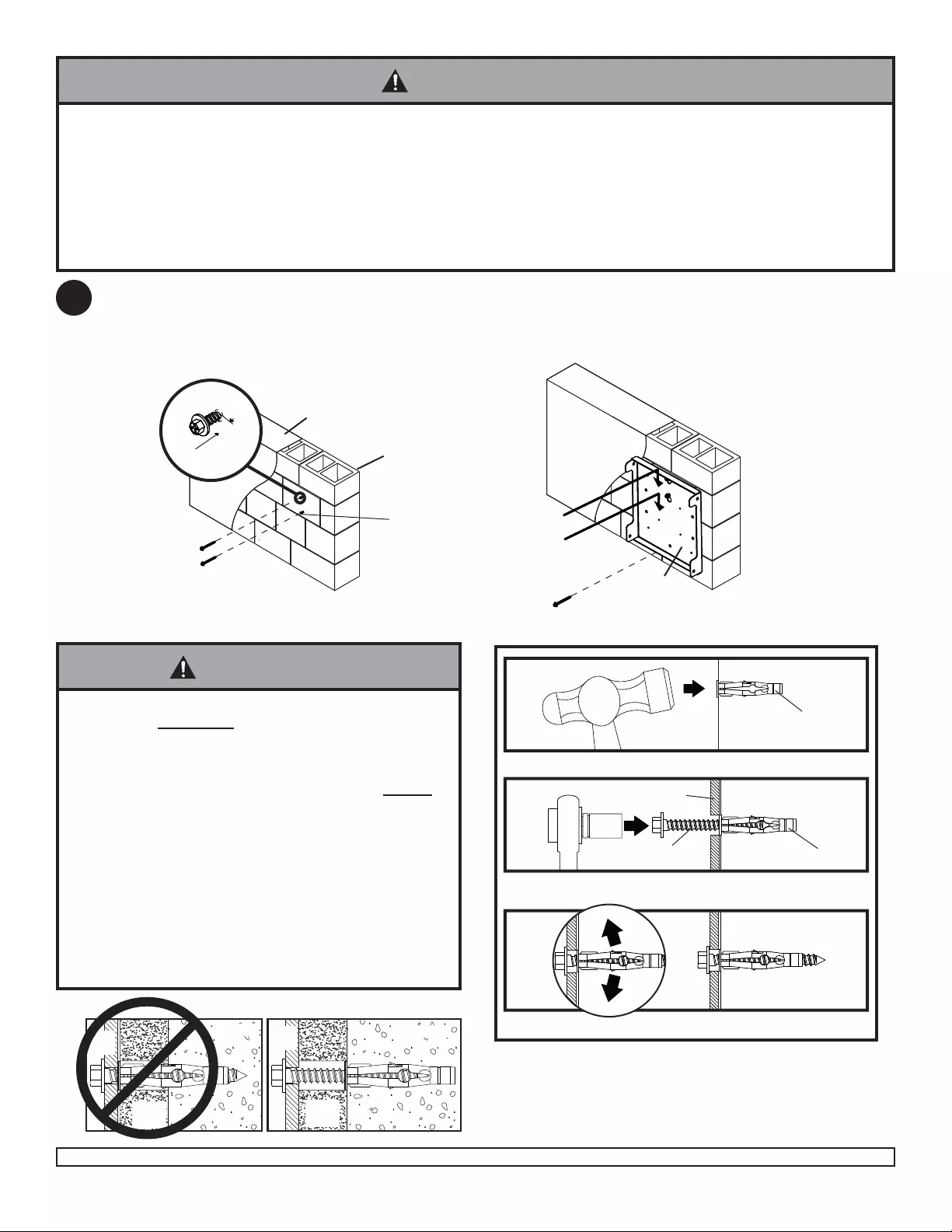

SOLID CONCRETE

CINDER BLOCK

1/4"

Installation to Solid Concrete or Cinder Block

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" (35 mm) of actual con-

crete thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" (25 mm) minimum from the side of the block. Cinder block must meet ASTM C-90 specifi ca-

tions. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to avoid

breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hardware and

components.

WARNING

5

CUTAWAY VIEW

INCORRECT CORRECT

wall

plate

wall

plate

plaster/

dry wall plaster/

dry wall

concrete concrete

1

3

2

P

Drill holes and insert anchors (P).

Place plate (B) over anchors (P) and secure with screws (O).

Tighten all fasteners.

B

P

O

concrete

surface

• Tighten screws so that wall plate is fi rmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Always attach concrete expansion anchors directly

to load-bearing concrete.

• Never attach concrete expansion anchors to

concrete covered with plaster, drywall, or other

fi nishing material. If mounting to concrete surfaces

covered with a fi nishing surface is unavoidable,

the fi nishing surface must be counterbored as

shown below. Be sure concrete anchors do not

pull away from concrete when tightening screws. If

plaster/drywall is thicker than 5/8" (16 mm), custom

fasteners must be supplied by installer.

WARNING

Place wall plate (B) on wall as a template. Level, and mark the center of the three mounting holes. Drill three 5/16"

(8 mm) dia. holes to a minimum depth of 2.5" (64 mm). Insert anchors (P) in holes fl ush with wall as shown. Fasten

two #14 x 2.5" wood screws (O) leaving 1/4" of thread exposed as shown in Figure 5.3.

Hook wall plate (A) onto exposed #14 x 2.5" wood screws (O). Secure using one #14 x 2.5" wood screws (O) as

shown in fi gure 5.4.

B

OO

P

Figure. 5.3 Figure. 5.4

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

10 of 10 ISSUED: 04-08-10 SHEET #:125-9110-3 02-03-16

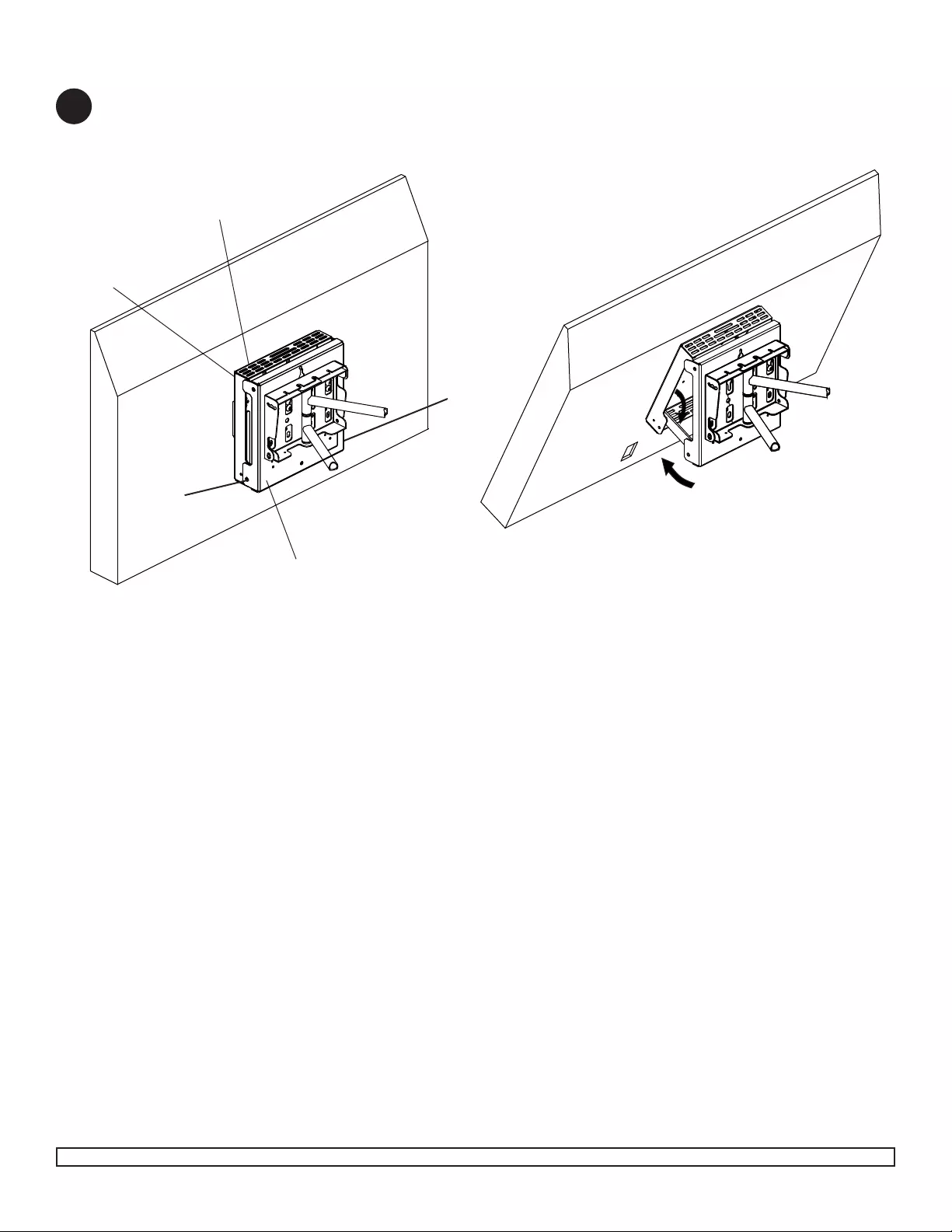

Loosen top two M8 x 15 mm screws (E) 1/4 turn and temporarily remove bottom two M8 x 15 mm screws (D) on

adapter plate (A) as shown in fi gure 6.1. Swing screen forward and swing support brackets downward into adapter

plate (B) to brace screen in open position as shown in fi gure 6.2.

6

Accessing CPU

LOOSEN 1/4 TURN ON

BOTH SIDES

A

Figure 6.1

REMOVE Figure 6.2

REMOVE

B

© 2010, Peerless Industries, Inc. All rights reserved.

All other brand and product names are trademarks or

registered trademarks of their respective owners.