Peerless HP437-C53 User Manual

Displayed below is the user manual for HP437-C53 by Peerless which is a product in the Monitor Mounts & Stands category. This manual has pages.

Related Manuals

2300 White Oak Circle. • Aurora, IL 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerless-av.com

ISSUED: 12-13-2013 SHEET #: 125-9086-9

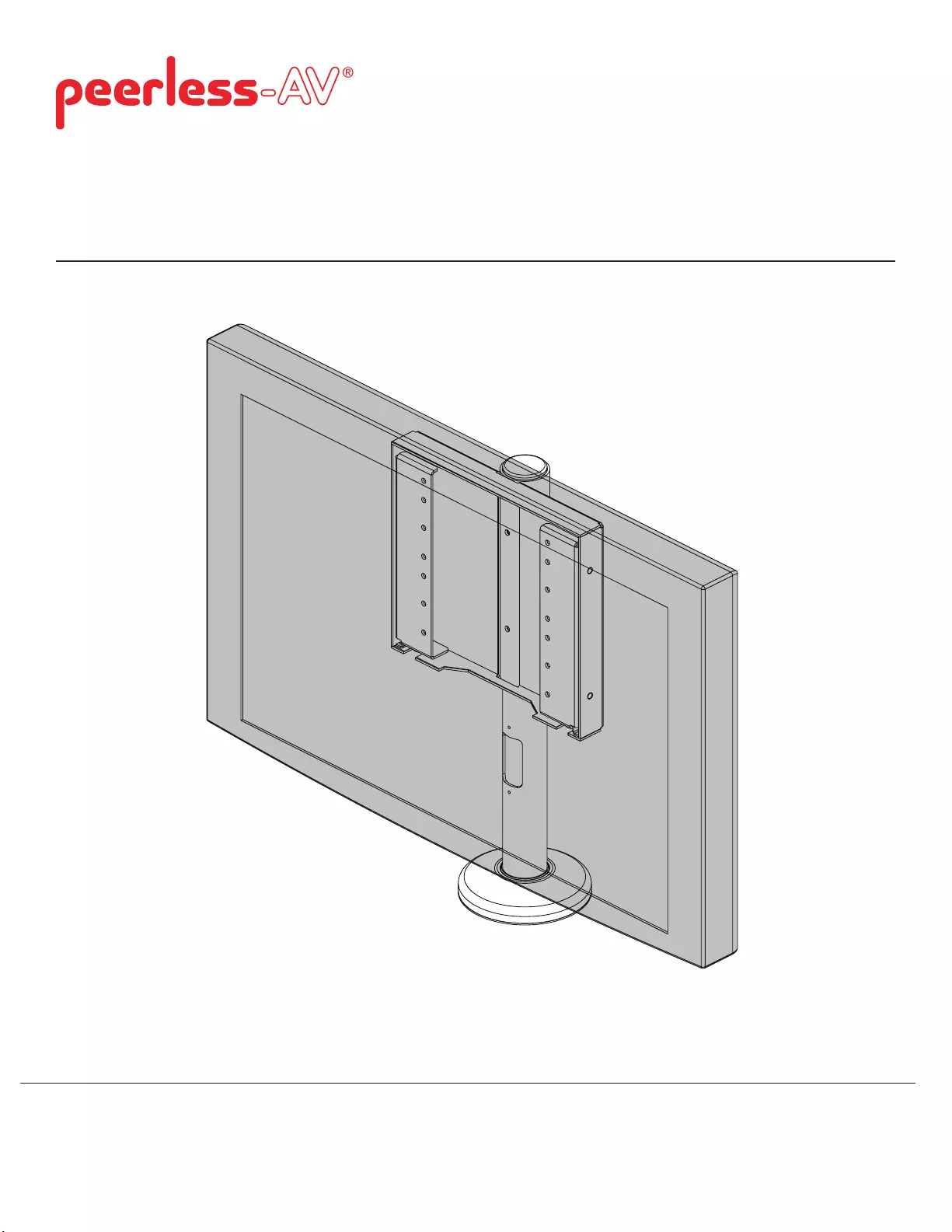

Installation and Assembly:

Desktop Swivel Mount with Cam Locks for VESA 200 x 200

and VESA 200 x 100 Displays

Model: HP437-C# (52-63)

Maximum Load Capacity: 80 lb (36.3 kg)

2 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

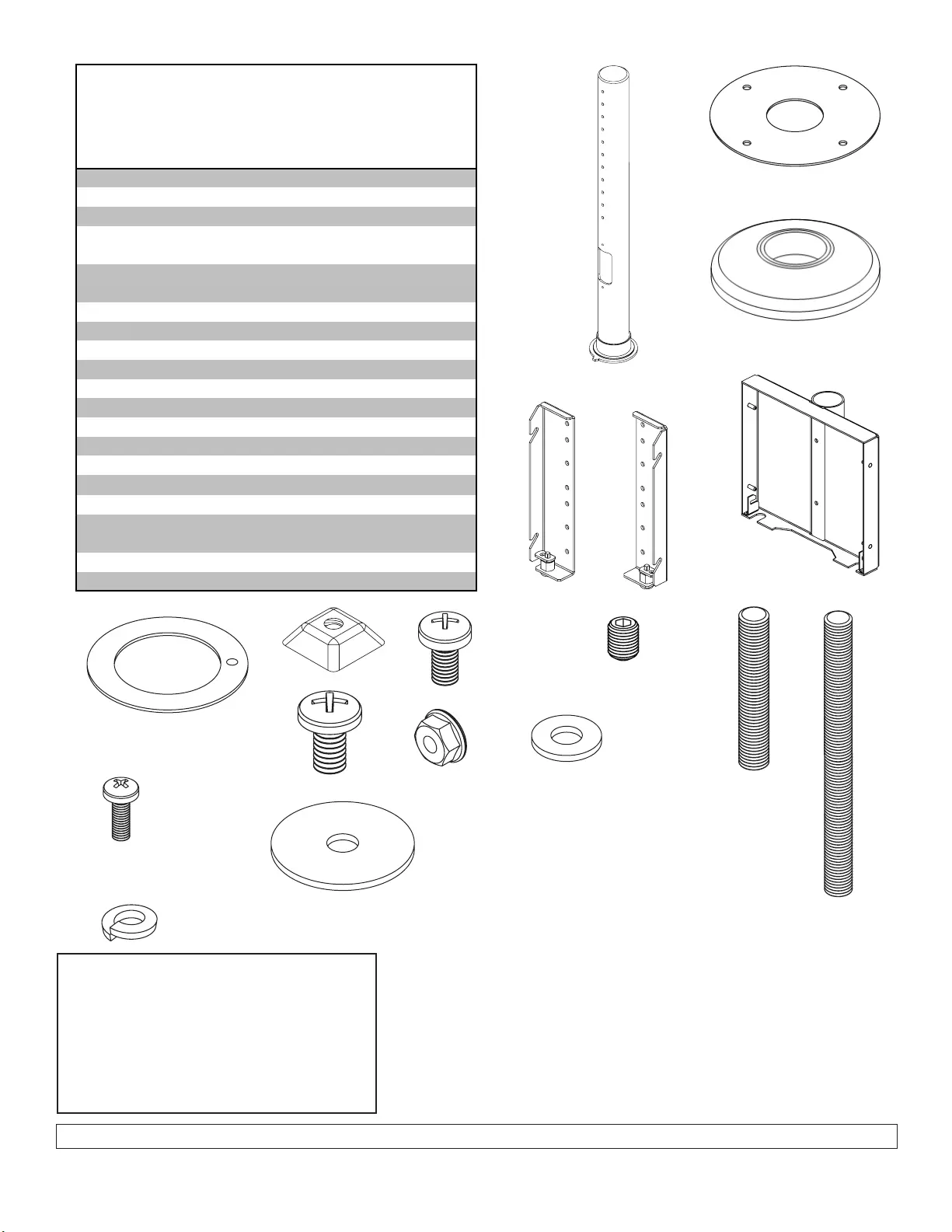

Parts List

Description Qty. Part#

A

support tube 1 090-1783-1

Bbase backer plate 1 090-1544

Cswivel base 1 090-1821

Dright bracket 1 See Chart

on Page 3

Eleft bracket 1 See Chart

on Page 3

Fadapter bracket box 1 090-1913

G#8 washer 4 540-1001

Hthrust washer 1 590-1287

Islope nuts 3 530-0035

J1/4-20 x 1/2" phillips screw 2 510-9108

KM6 x 12 mm phillips screw 4 520-1128

LM4 x 12 mm phillips screw 4 504-9013

M10-32 x 1/2" set screw 2 520-1614

N1/4-20 x 1.5" threaded rod 4 520-2250

O1/4-20 x 3" threaded rod 4 520-2585

Pflanged lock nut 4 530-2021

Rloc-tite 271 thread lock

adhesive (not shown) 1 570-0040

Tfender washer 4 540-1008

U1/4" split washer 2 540-9402

Before you begin, make sure all parts shown are included

with your product.

NOTE: Read instruction sheet before you start installation and assembly.

B

C

D E

L

G

HIM

A

P

J

K

F

O

N

T

U

Tools Needed for Assembly

• drill • 5 mm allen wrench

• 17/64" drill bit

• phillips screwdriver

• 3/32" allen wrench

• 5/16" box wrench

• hole saw

3 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

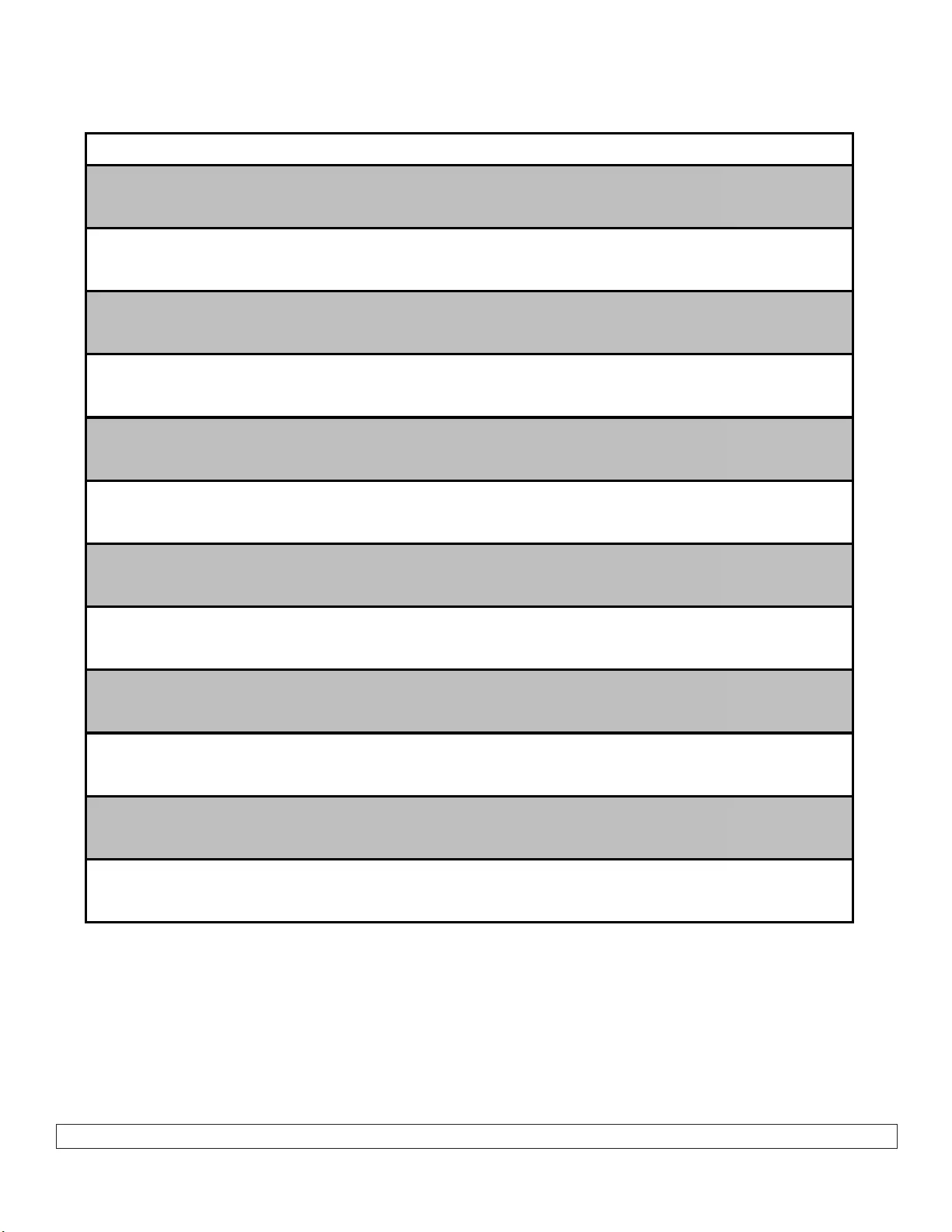

Chart

Description Qty. Part#

HP437-C52 Dright vertical bracket 1 091-1111

Eleft vertical bracket 1 091-1112

HP437-C53 Dright vertical bracket 1 091-1113

Eleft vertical bracket 1 091-1114

HP437-C54 Dright vertical bracket 1 091-1115

Eleft vertical bracket 1 091-1116

HP437-C55 Dright vertical bracket 1 091-1117

Eleft vertical bracket 1 091-1118

HP437-C56 Dright vertical bracket 1 091-1119

Eleft vertical bracket 1 091-1120

HP437-C57 Dright vertical bracket 1 091-1121

Eleft vertical bracket 1 091-1122

HP437-C58 Dright vertical bracket 1 091-1123

Eleft vertical bracket 1 091-1124

HP437-C59 Dright vertical bracket 1 091-1125

Eleft vertical bracket 1 091-1126

HP437-C60 Dright vertical bracket 1 091-1127

Eleft vertical bracket 1 091-1128

HP437-C61 Dright vertical bracket 1 091-1129

Eleft vertical bracket 1 091-1130

HP437-C62 Dright vertical bracket 1 091-1131

Eleft vertical bracket 1 091-1132

HP437-C63 Dright vertical bracket 1 091-1133

Eleft vertical bracket 1 091-1134

4 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

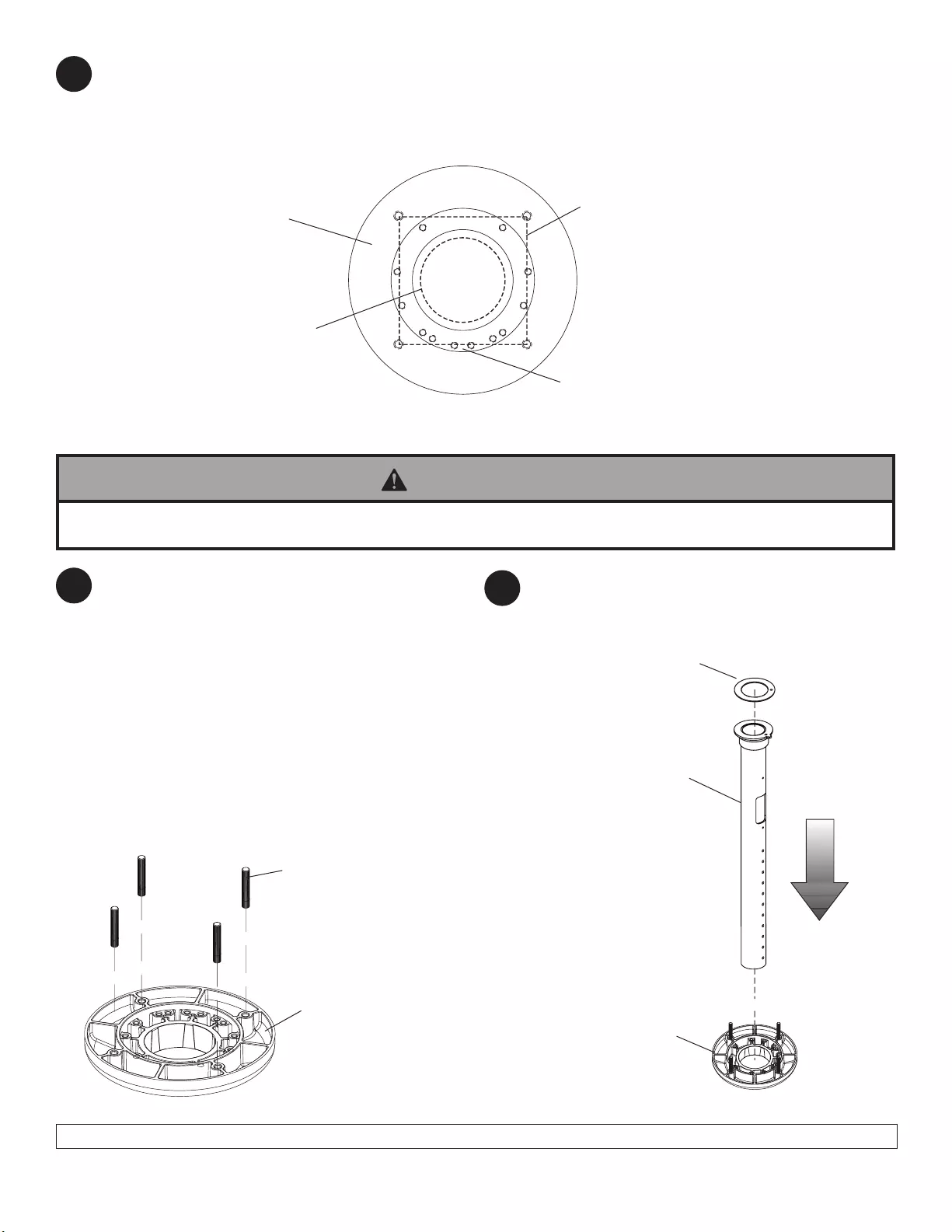

1

BOTTOM VIEW

FRONT OF DISPLAY

SQUARE FORMATION

B

CABLE MANAGEMENT

CUT-OUT

g. 1.1

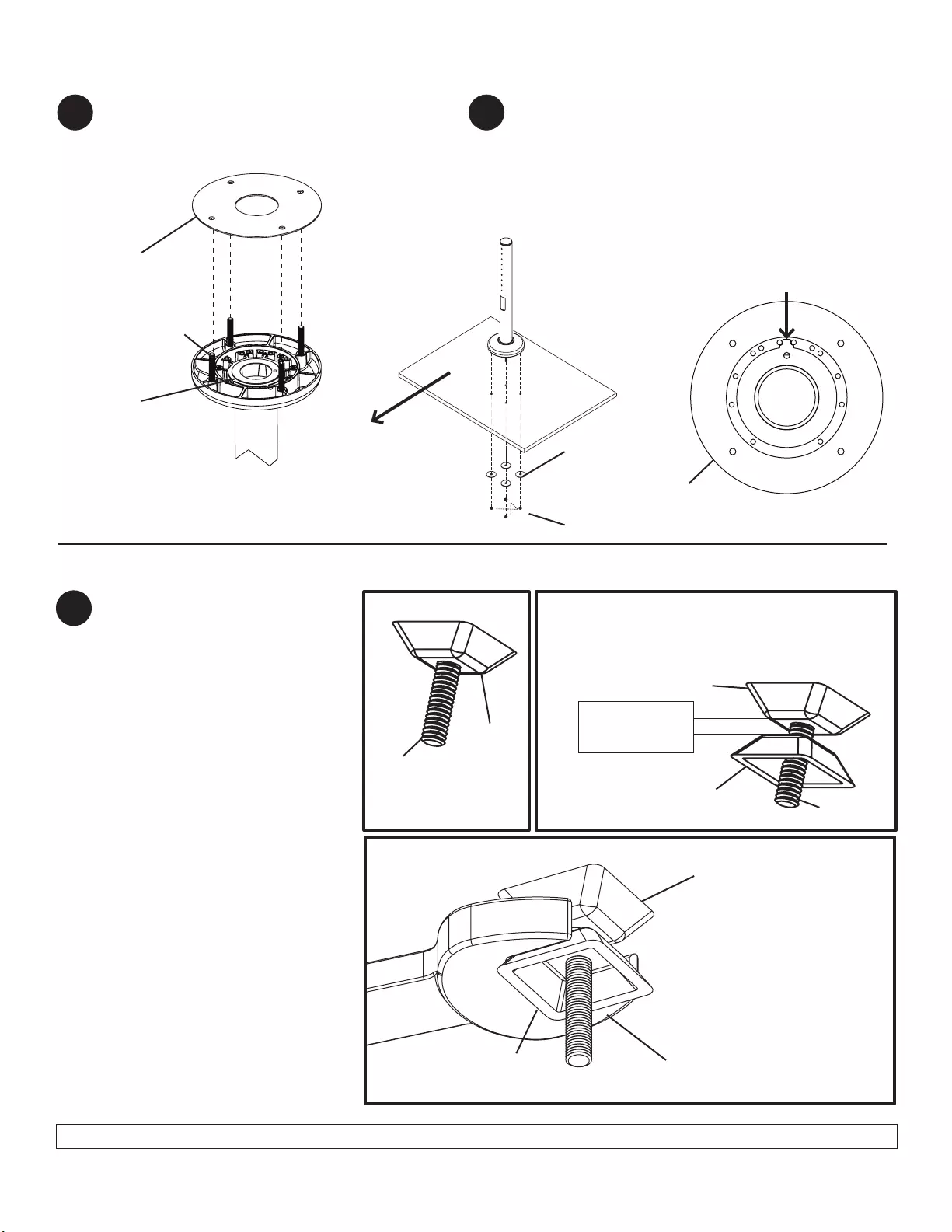

Turn base (C) upside down insert support tube (A),

and thrust washer (H) as shown below.

A

C

H

g. 3.1

23

N or O

C

g. 2.1

• Wooden mounting surface requires a minimum of 3/4" thickness to hold display securely

WARNING

If the desk thickness is 3/4" use 1/4-20 x 1.5"

threaded rods (N). If the desk thickness is between

3/4" to 2-1/4" use 1/4-20 x 3" threaded rods (O). Turn

base (C) upside down and insert four threaded rods

(N or O) into base (C), as shown below.

NOTE: Threaded rods must fasten a minimum of

three turns.

NOTE: If enhanced security is desired, use three

drops of loc-tite 271 thread lock adhesive (R) along

1/4" at the end of each threaded rod. Insert adhesive

end of threaded rods (N or O) into bottom of base

(C).

Use base backer plate (B) as a template to mark location of holes. Drill four holes using a 17/64'' drill bit in a

square formation. In the center of the square formation drill a 2" to 3" cable management hole.

5 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components

WARNING

Mounting using Non-Security....................................................................Step 5 Page 5

CAUTION

• Installations to desktops that have a gap between two supporting boards are not acceptable mounting surfaces

for the HP line of desktop swivel mounts.

Mounting using Security Slop Nuts (Optional) .......................................Step 7 Page 5

Mounting to Support Surface

g. 4.1 g. 4.2

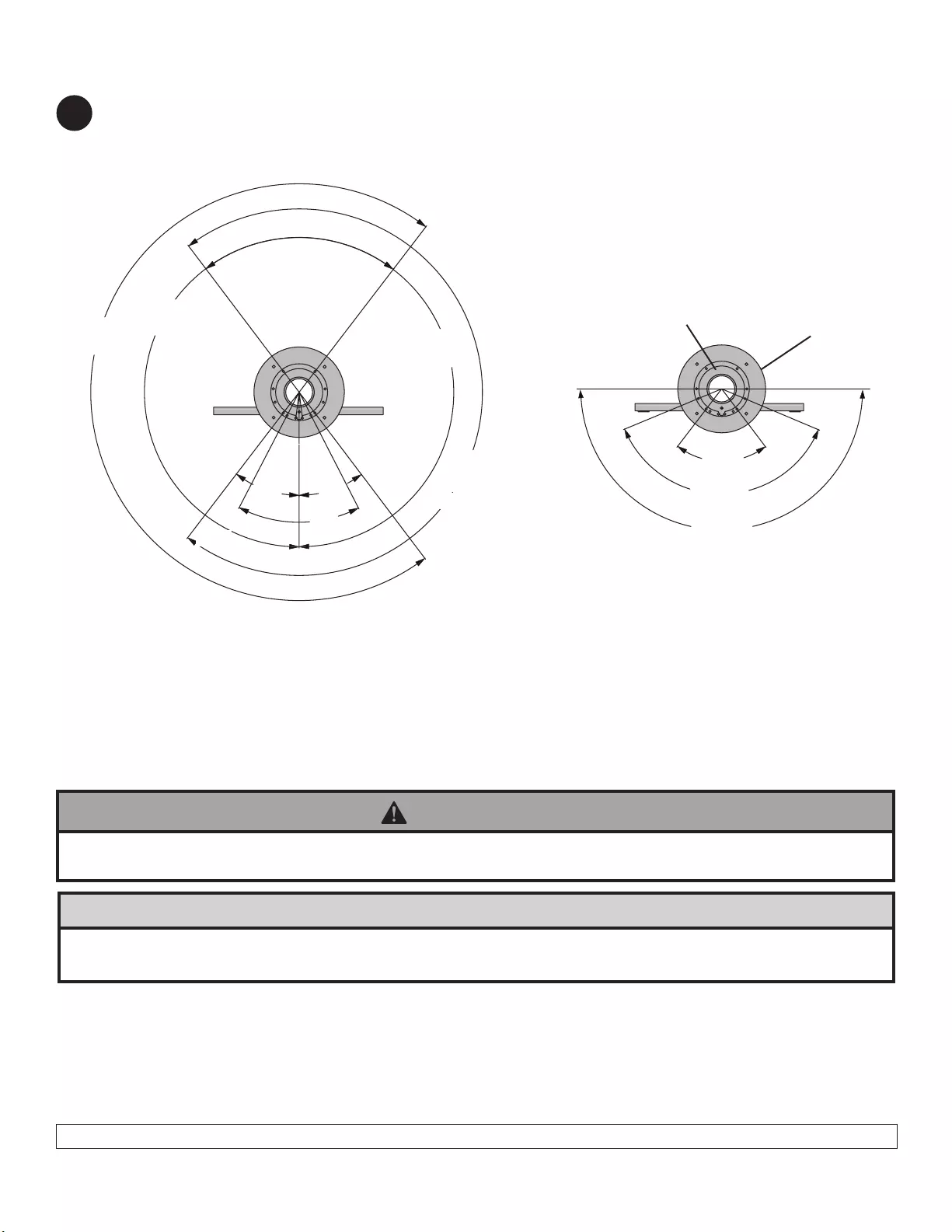

60°

120°

LOCK AT 0°

Refer to g. 4.1 and 4.2, select the desired swivel degree. Using a 3/32" allen wrench, fasten two set screws (M)

where indicated below to the outside of desired angle in steel base (C).

NOTE: Set screws (M) must be bottomed out into base.

C

A

Swivel Restriction

4

180°

240°

240°

210°

40°

30°30°

210°

FRONT

FRONT

6 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

5 6

Line up backer plate (B) with threaded rods

(N or O).

NOTE: Washer (H) must be centered.

FRONT OF

SCREEN

Detail 1

B

N or O

g. 5.1 C

C

Using four fender washers (T) and four lock nuts (P)

tighten in numbered pattern as shown in Figure 6.1.

At minimum 1/4 - 20 locknuts (P) should be ush with

bottom of threaded rods (N or ).

Line up base assembly (step 5), through supporting

surface with pattern of base (C) facing the front as

shown in Detail 1.

2

3

1

4

FRONT OF

SCREEN

g. 6.1

T

N or O

Mounting using Non-Security

Mounting using Security Slope Nuts (Optional)

Detail 4

TIGHTENING

SLOPE NUT (I)

I

5/8" OPEN BOX WRENCH

TIGHTENING

SLOPE NUT (I)

N or O

N or O

I

Detail 2 Detail 3

I

For added security replace two of

the washers and locknuts with slope

nuts.

Hand tighten slope nuts (I) onto

two of the thread rods (M) till snug

against bottom of table as shown in

Detail 2.

Thread another slope nut (I) upside-

down, about two turns from rst

slope nut (I) as shown in Detail 3.

Insert a 5/8" open box wrench

between both slope nuts (I) and

tighten

as shown in detail 4.

7BOTTOM OF DESK

BOTTOM OF DESK

NOTE: Avoid jamming both slope nuts (I) together,

doing so may make it difcult to remove slope nut

used for tightening.

After slope nut is secure remove bottom slope nut.

LEAVE SPACE

IN BETWEEN

SLOPE NUTS

7 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

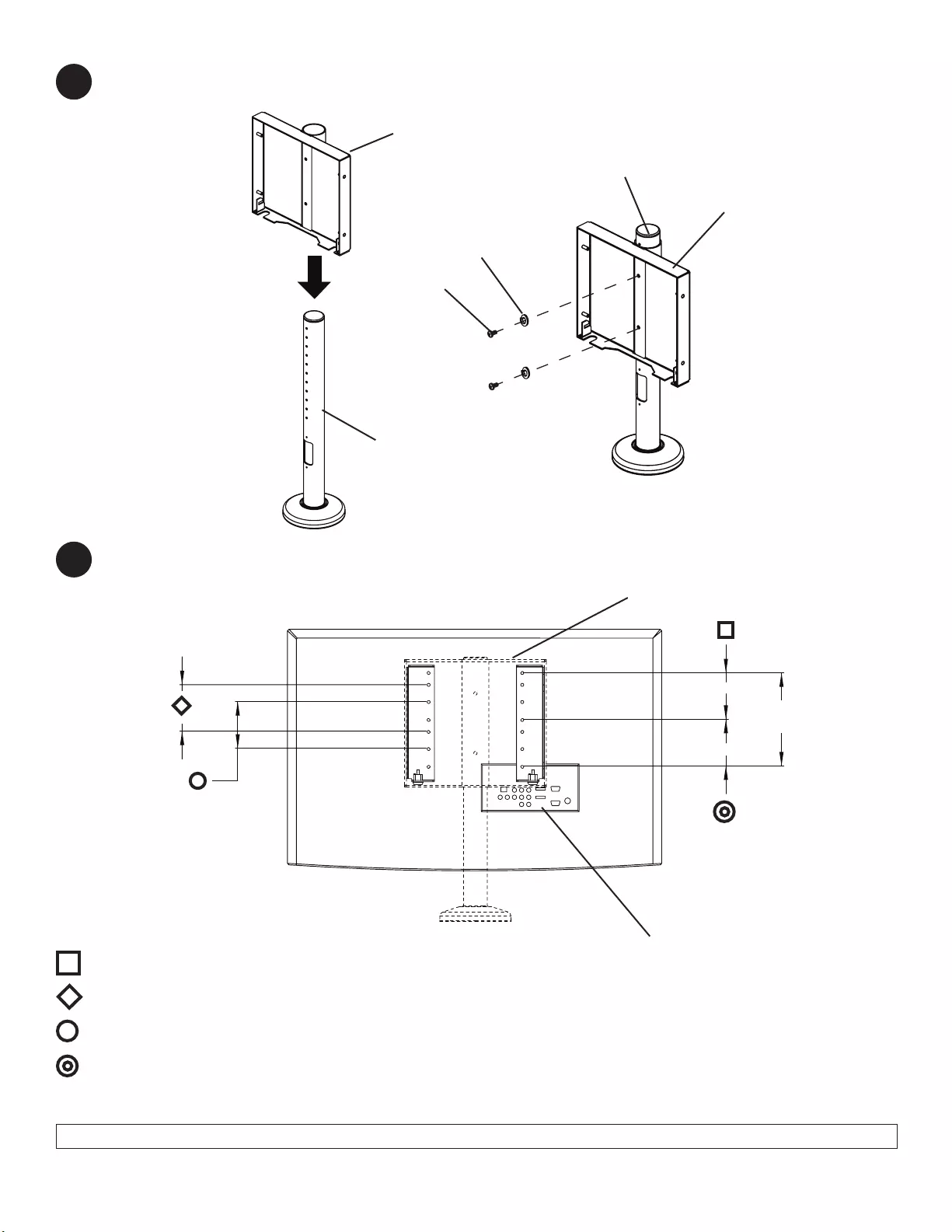

200 x 100 mounting pattern. Use four M4 x 12 mm phillips screws

200 x 200 mounting pattern. Use four M6 x 12 mm phillips screws

200 x 100 mounting pattern. Use four M4 x 12 mm phillips screws

200 x 100 mounting pattern. Use four M4 x 12 mm phillips screws

200 x 100 mounting pattern. Use four M4 x 12 mm phillips screws

Mounting Hole Patterns

9Select desired mounting pattern from list below.

NOTE: Make sure that jack inputs on the back of the display are not covered by the adapter bracket box. Move the

vertical adapter brackets up or down accordingly to ensure accessibility.

X

X

DISPLAY JACK INPUTS

ADAPTER BRACKET BOX

Attach adapter bracket box (F) to support tube (A) with two 1/4-20 x 1/2" phillips screw (J) and 1/4" split

washer (U) as shown in g 7.1.

8

A

F

U

J

A

F

8 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

G:\125\EPS_les\126631.eps

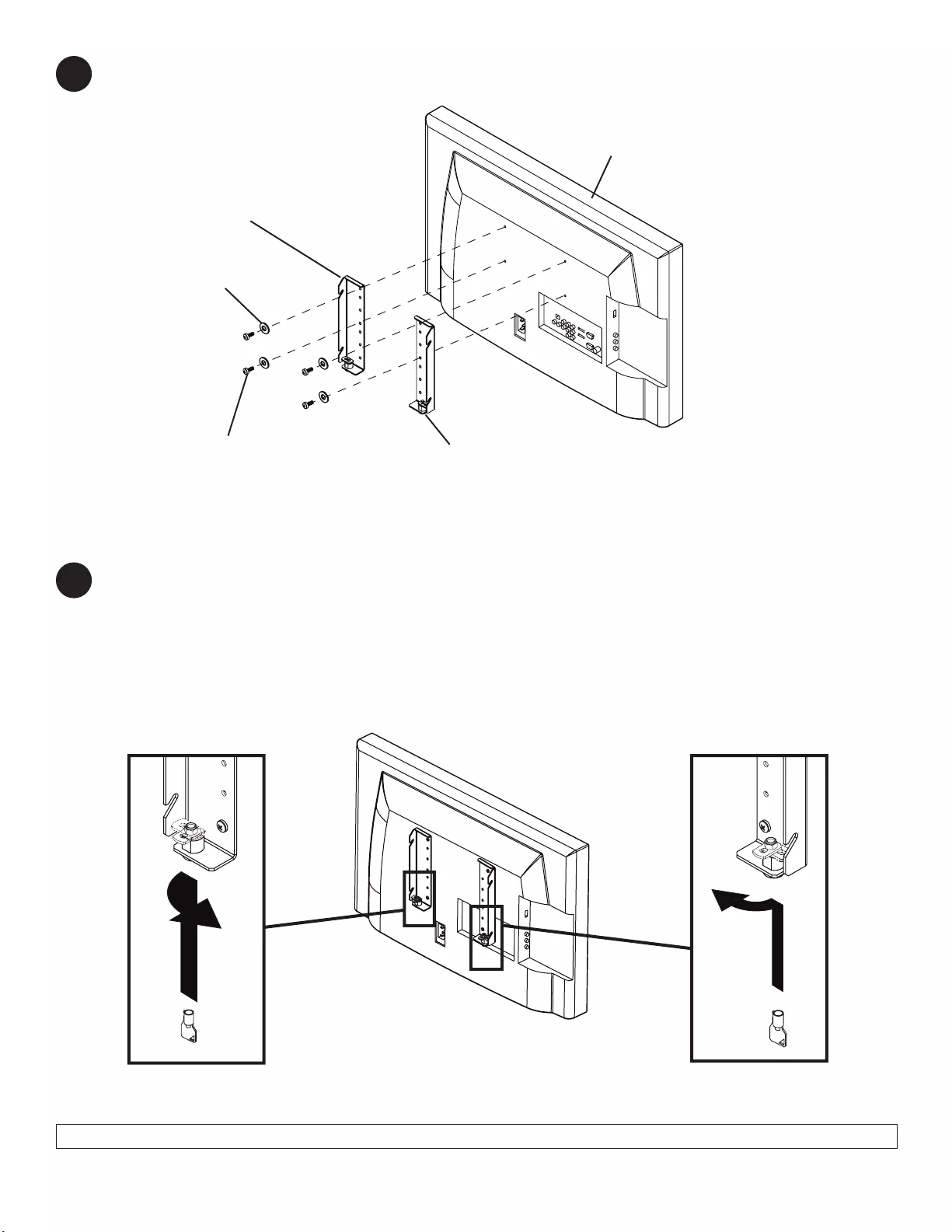

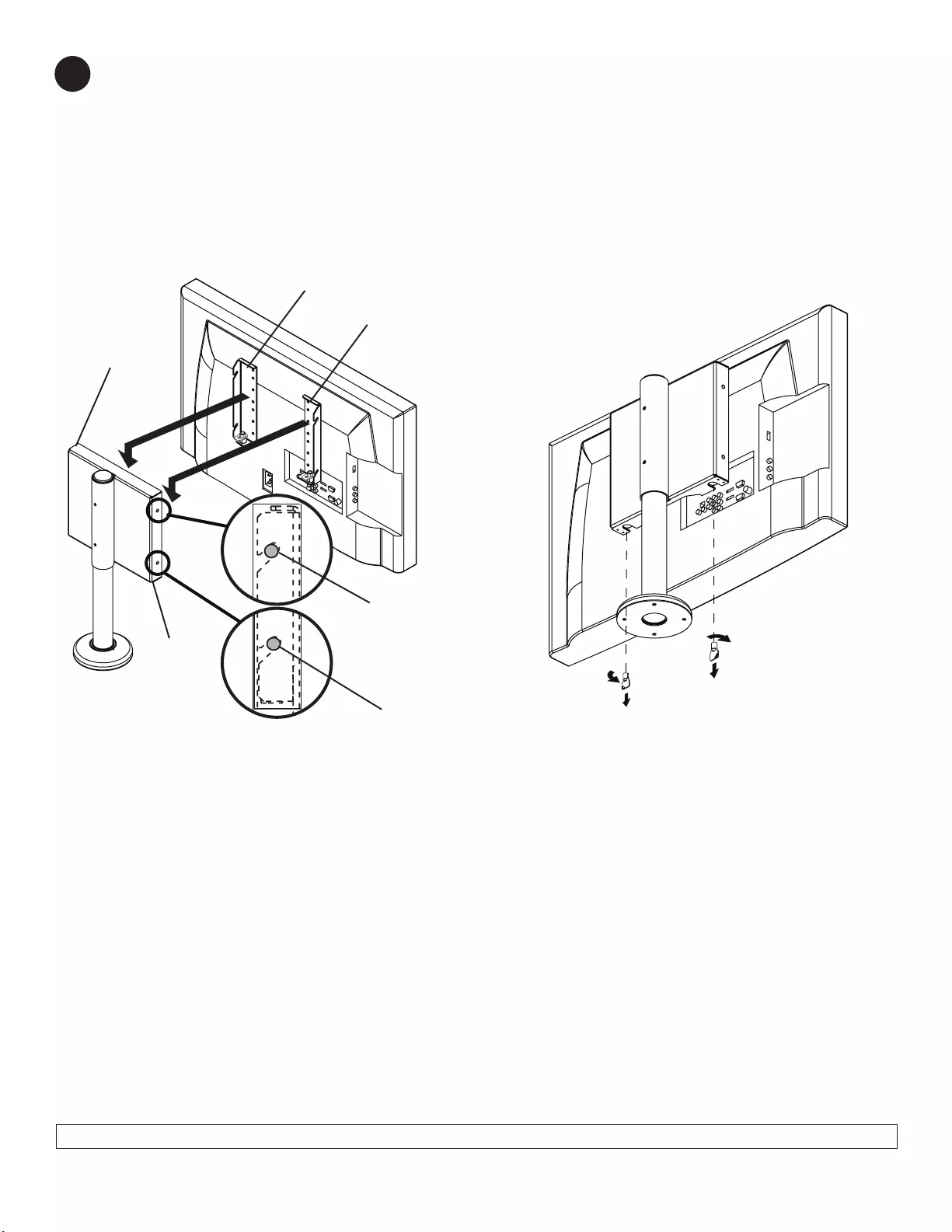

10

D

E

K or L

DISPLAY

Secure right and left vertical brackets (D and E) to display using four M4 x 12 mm phillips screws (K) and

#8 washers (G) or four M6 x 12 mm phillips screws (L).

G

NOTE: To complete the installation, two keys for the cam locks must be obtained from the General Man-

ager or Purchaser/Receiver of the mounting product. The display and mount installation cannot be com-

pleted without these two keys. Be sure to return the keys to the General Manager or responsible party upon

completion of the installation. Only a limited number of keys is supplied per installation location.

Insert the keys into the bottom of the locks and rotate to the unlocked position as shown in Detail 4 and 5.

Note that the keys are NOT removable in the open position.

11

Detail 4 Detail 5

9 of 9 ISSUED: 12-13-2013 SHEET #: 125-9086-9

Visit the Peerless Web Site at www.peerless-av.com For customer care call 1-800 865-2112

MOUNTING SURFACE

NOT SHOWN FOR CLARITY

NOTE: Locks must be in the open or unlocked position to continue installation.

Hook vertical brackets (D and E) into adapter bracket box (A) engaging adapter pins as shown in g. 5.1 and detail 6.

Rotate keys to locked position and remove keys as shown in gure 5.2. Return the keys to the General Manager or

responsible party immediately after installation is complete.

NOTE: Run cables from the jack inputs and power location through the cable management hole in the support tube

and down through the desktop surface.

ADAPTER PIN

ADAPTER PIN

12

D

E

A

g. 12.2

g. 12.1

Detail 6

A