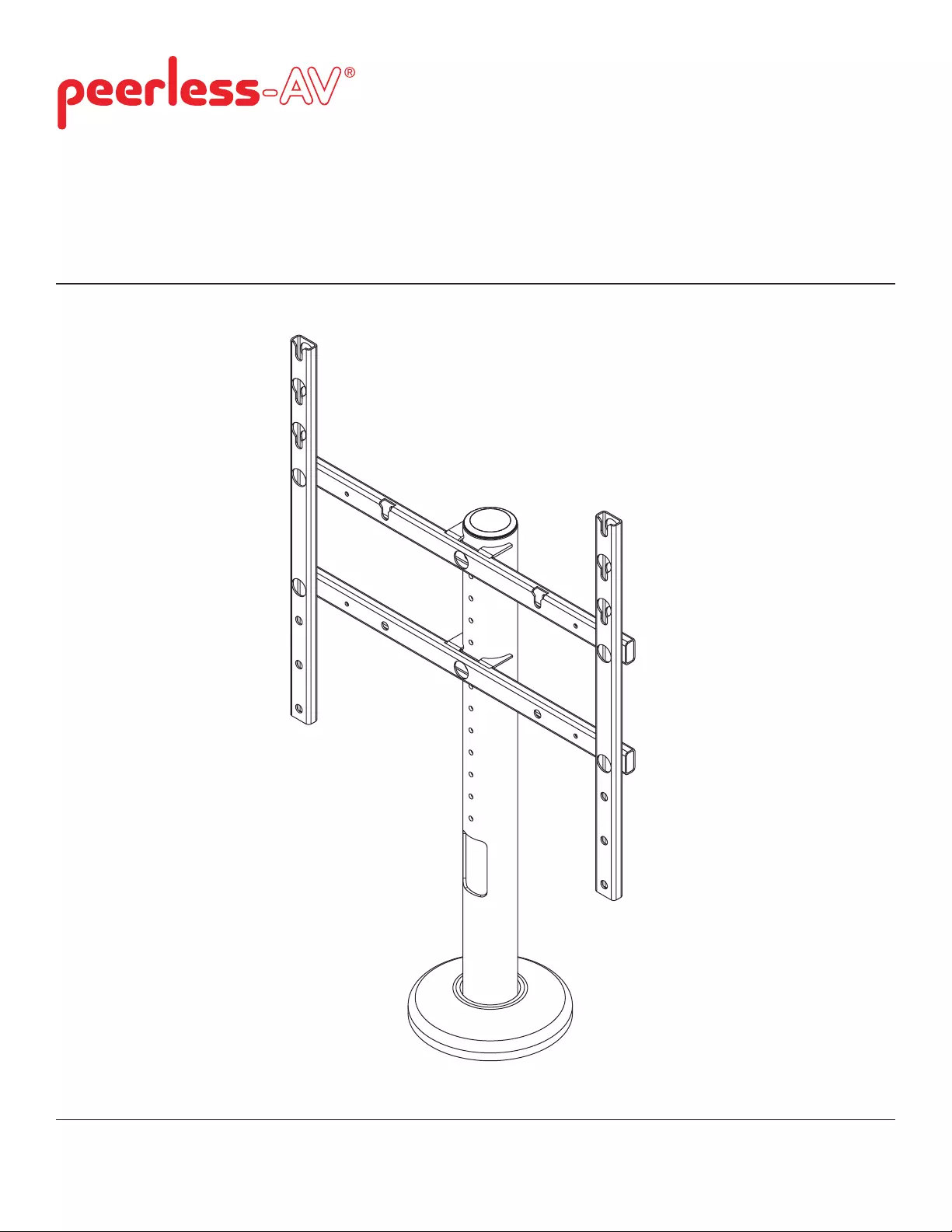

Peerless HP455 User Manual

Displayed below is the user manual for HP455 by Peerless which is a product in the TV Mounts category. This manual has pages.

Related Manuals

ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

Max Load Capacity: 75 lb (34 kg)

Installation and Assembly -

Desktop Swivel Mount

For 32" - 55" Flat Panel Display

Models: HP455

2 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

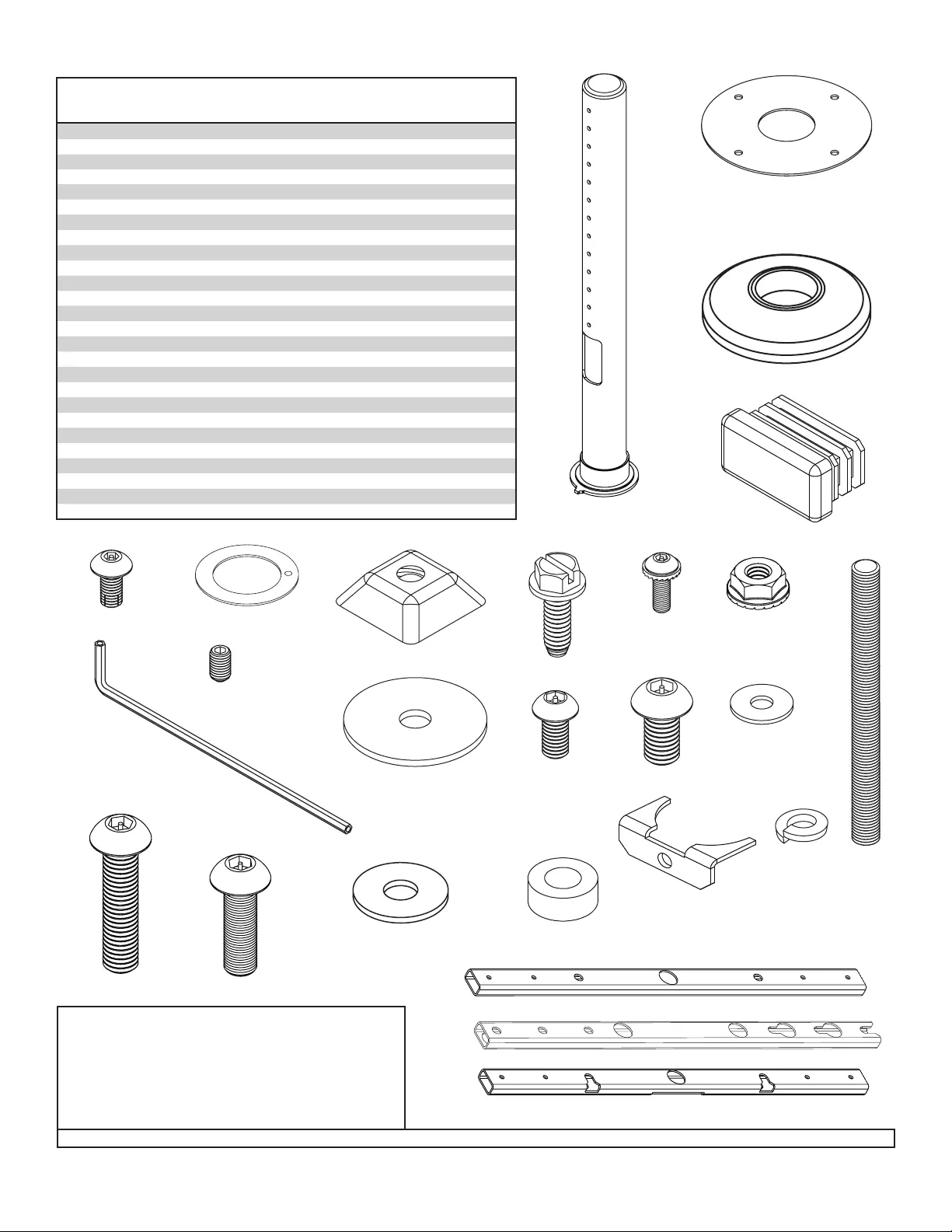

NOTE: Some parts may appear slightly dierent than illustrated.

A B

C

D

FG H I

JKL

M

N

Q

OP

Tools Needed for Assembly

• electric drill

• 5/8" open box wrench

• 17/64" drill bit

• 3/8" socket wrench • 3/32" allen wrench

E

T

V

R

S

U

Parts List

Part #Description Qty

Asupport tube 1 091-1036

Bbase backer plate 1 090-1544

Cdesktop swivel base 1 090-1821

Dtube cap 4 590-0970

EM5 x 10mm socket pin Type-F screw 4 520-1164

Fthrust washer 1 590-1287

Gslope nut 3 530-0035

H1/4-20 x 3/4" hex head screw 2 520-1321

IM4 x 12mm serrated socket pin screw 4 510-1079

J4mm allen wrench 1 560-9646

K10-32 x 1/2" set screw 2 520-1614

Lfender washer 4 540-1008

M1/4-20 x 3" threaded rod 4 520-2585

N1/4-20 lock nut 4 530-1021

OM6 x 12mm socket pin screw 4 510-1050

PM8 x 15mm socket pin screw 4 520-1068

Q#10 SAE at washer 4 540-9400

Rtube gusset 2 091-1032

Slower horizontal rail 1 091-1033

Tvertical rail 2 091-1034

U1/4" split washer 2 540-9402

Vupper horizontal rail 1 091-1041

WM8 x 25mm socket pin screw 4 520-1101

XM8 x 35mm socket pin screw 4 520-1994

Ywasher 8 540-9406

Zspacer 4 600-1215

NOTE: Read instruction sheet before you start installation and assembly.

W

X

YZ

3 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

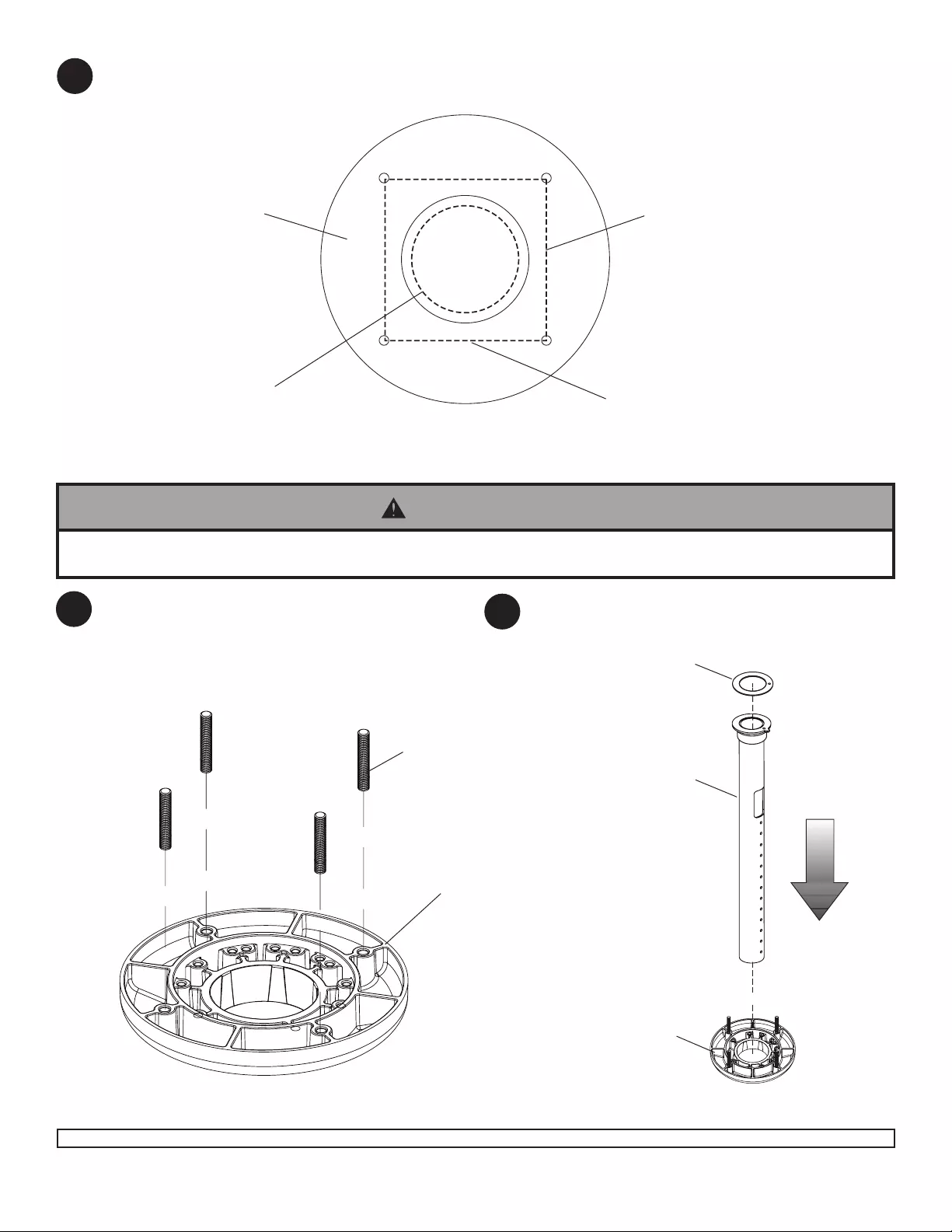

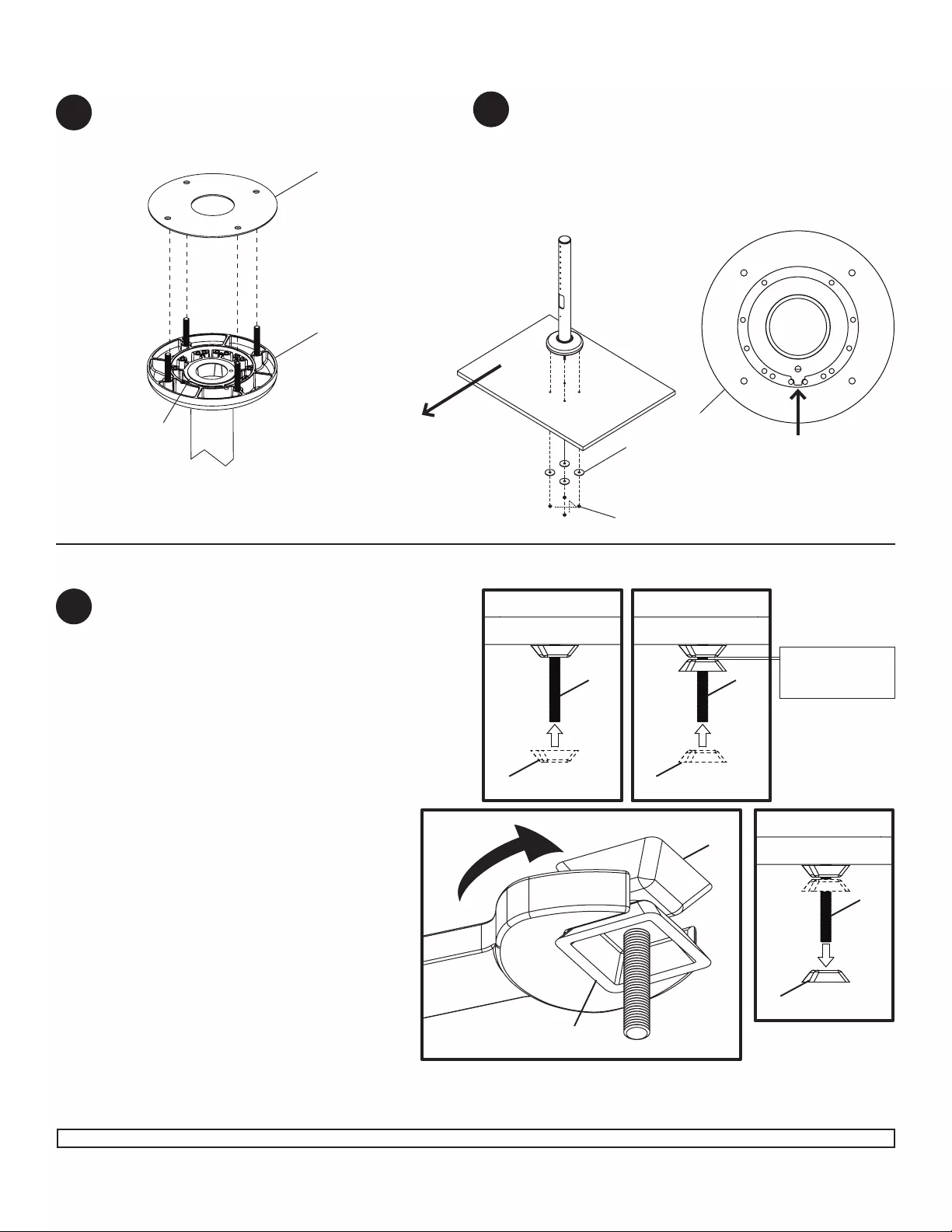

Turn base (C) upside down to insert support tube

(A), and thrust washer (F) as shown below.

A

C

F

g. 3.1

23

Turn base (C) upside down and insert four threaded

rods (M) into base (C), as shown below.

NOTE: Threaded rods must fasten a minimum

of three turns.

M

C

g. 2.1

• Wooden mounting surface requires a minimum of 3/4" thickness to hold screen securely.

WARNING

1Use base backer plate (B) as a template to mark location of holes. Drill four holes using a 17/64'' drill bit in a square

formation. Drill a 2" to 3" cord management hole In the center of the square formation.

BSQUARE FORMATION

CORD MANAGEMENT

CUT-OUT FRONT OF SCREEN

BOTTOM VIEW

4 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

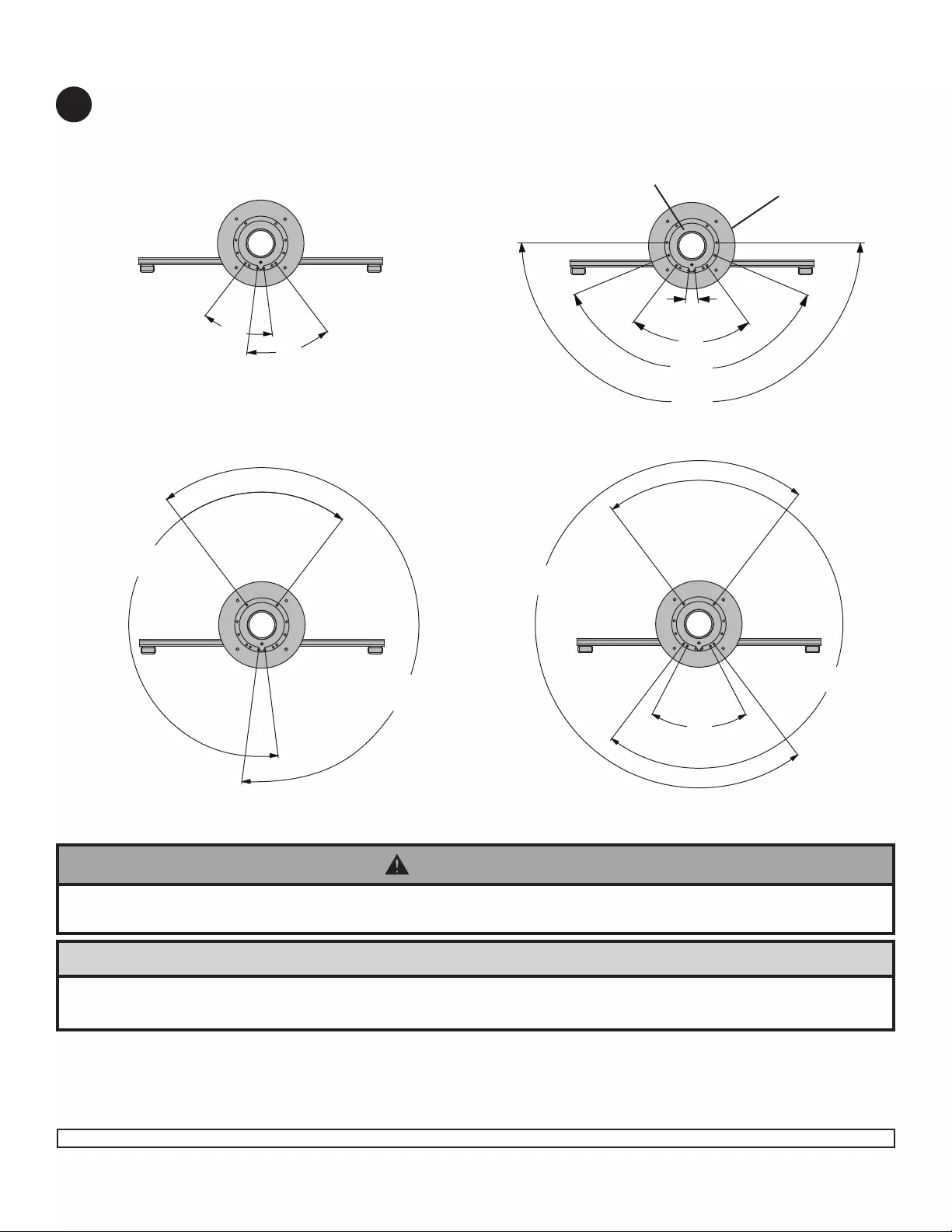

210°

210°

240°

240°

30°

30°

60°

0°

120°

180°

40°

g. 4.1

g. 4.3 g. 4.4

g. 4.2

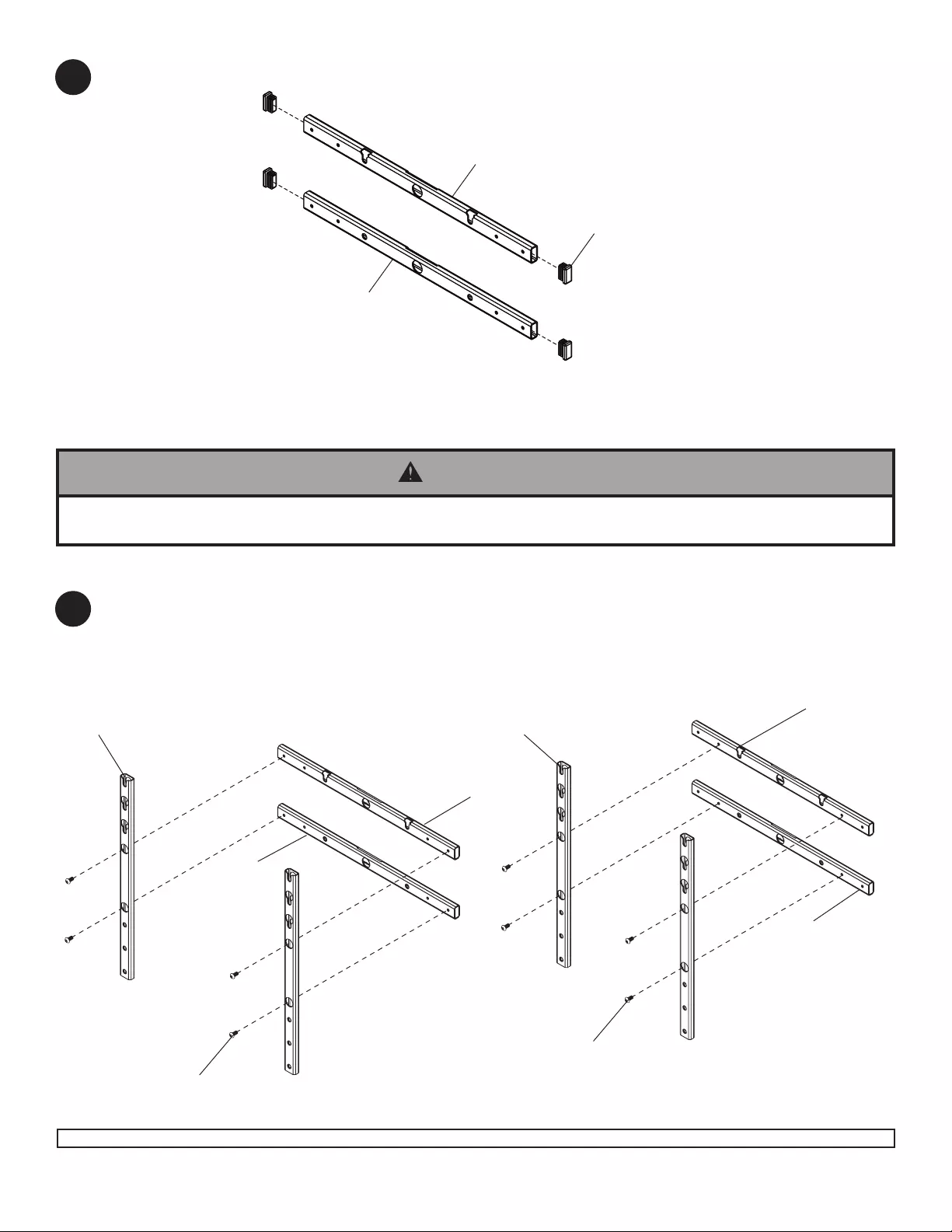

Refer to g. 4.1, 4.2, 4.3, and 4.4, select the desired swivel degree. Using a 3/32" allen wrench, fasten two set

screws (K) where indicated below to the outside of desired angle in steel base (C).

NOTE: Set screws (K) must be bottomed out into base.

Swivel Restriction

4

Mounting using Non-Security........................................................................Step 5 Page 5

CAUTION

• Installations to desktops that have a gap between two supporting boards are not acceptable mounting surfaces

for the HP line of desktop swivel mounts.

Mounting using Security Slop Nuts (Optional) ...........................................Step 7 Page 5

Mounting to Support Surface

FRONT

FRONT FRONT

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components

WARNING

210°

210°

240°

240°

30°

30°

60°

0°

120°

180°

40°

210°

210°

240

°

240°

30°

30°

60°

0°

120°

180°

40°

210°

210°

240°

240°

30°

30°

60°

0°

120°

180°

40°

C

A

5 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

2

3

1

4

5Align backer plate (B) with threaded rods (M).

NOTE: Washer (F) must be centered.

FRONT OF

SCREEN

Detail 1

B

M

g. 5.1

6

C

FRONT OF

SCREEN

F

Align base assembly (step 5) with supporting surface

and base (C) pattern facing the front as shown in

Detail 1. Tighten four fender washers (L) with four lock

nuts (N) in the sequenced pattern shown in Figure

6.1 with the 1/4 - 20 locknuts (N) at minimum ush

with the bottom of the threaded rods (M).

g. 6.1

L

N

Mounting using Non-Security

Mounting using Security Slope Nuts (Optional)

G

M

Detail 3

For added security replace two of

the washers and locknuts with slope nuts.

Hand tighten slope nuts (G) onto

two of the thread rods (M) until snug against

bottom of table as shown in Detail 2.

Thread another slope nut (G)

upside-down, about two turns from

rst slope nut (G) as shown in Detail 3.

NOTE: Avoid jamming both slope nuts (G)

together, doing so may make it dicult to

remove slope nut used for tightening.

Insert a 5/8" open box wrench

between both slope nuts (G) and tighten as

shown in Detail 4.

After top slope nut is secure remove bottom

slope nut as shown in Detail 5.

7

G

M

Detail 2

BOTTOM OF DESK

G

M

Detail 5

BOTTOM OF DESK

BOTTOM OF DESK

LEAVE SPACE

IN BETWEEN

SLOPE NUTS

Detail 4

TIGHTENING SLOPE NUT (G)

G

BOTTOM OF DESK

6 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

Mounting using Large Hole Pattern (300 mm x 300 mm or greater)....................Start page 6

Mounting using Small Hole Pattern (200 mm x 200 mm or less) .....................Skip to page 8

Mounting using Large Hole Pattern (300 mm x 300 mm or greater)

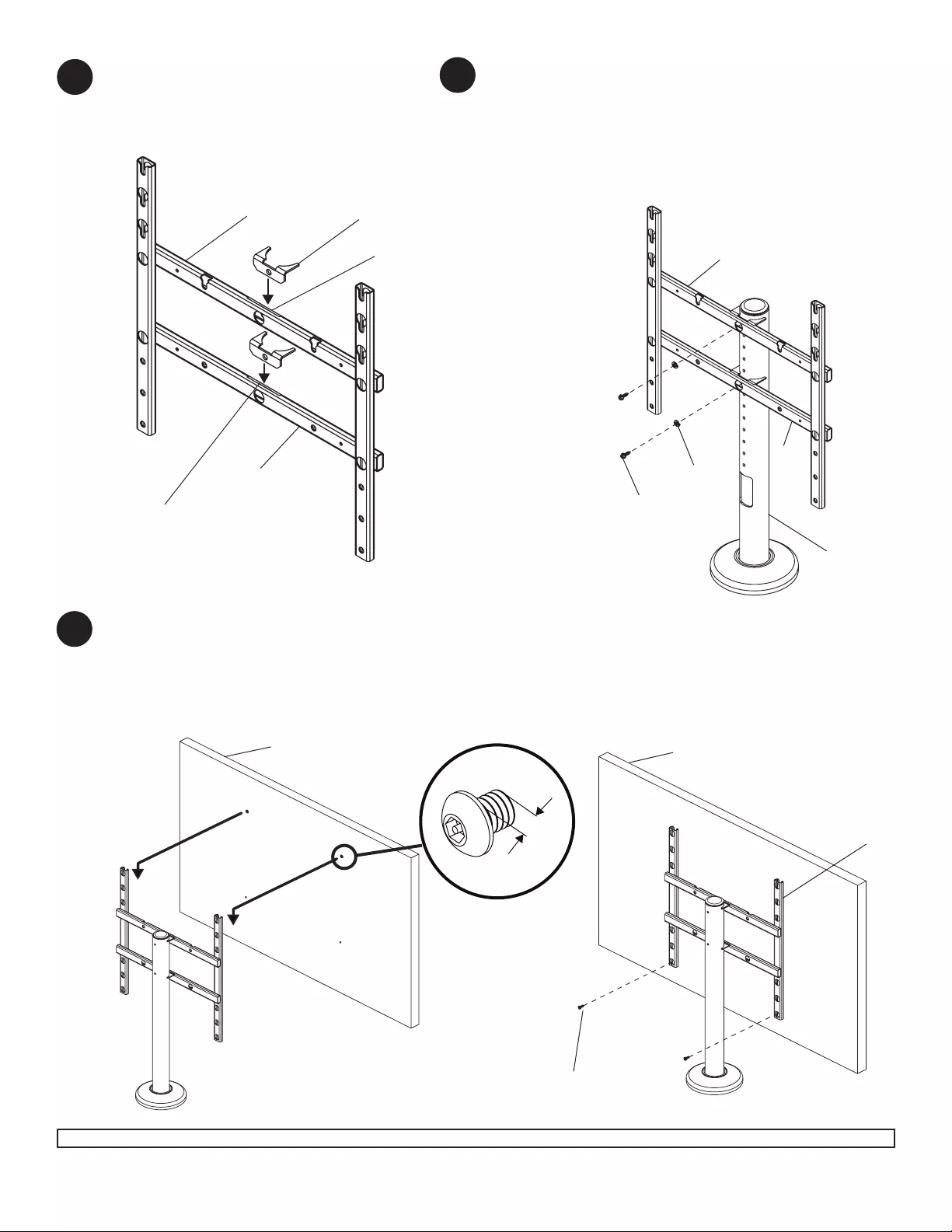

9Fasten two vertical rails (T) to lower horizontal rail (S) and upper horizontal rail (V) in 300 mm x 300 mm or 400 mm

x 400 mm hole patterns using four M5 x 10 mm socket pin Type-F screws (E) as shown below.

400 mm x 400 mm Hole Pattern

T T

E

V

V

E300 mm x 300 mm Hole Pattern

8Press-in four tube caps (D) into lower horizontal rail (S) and upper horizontal rail (V) as shown below.

S

V

D

S

S

NOTE: Vertical rails (T) must be perpendicular to lower horizontal rail (S) and upper horizontal rail (V). Use a at

surface as guide while tightening.

• If screws don't get three complete turns in the screen inserts or if screws bottom out and bracket is still not

tightly secured, damage may occur to screen or product may fail.

WARNING

7 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

V

H

NOTE: Determine desired height of display prior to

attaching lower horizontal rail (S) and upper horizontal rail

(V) to support tube (A).

Attach tube gussets (R), lower adapter rail (S), and upper

horizontal tube (V) onto support tube (A) using

two 1/4-20 x 3/4" hex head screws (H) with two 1/4" split

washers (U) as shown below.

10 11

Position tube gussets (R) inside slots of lower

horizontal rail (S) and upper horizontal rail (V)

as shown below.

R

SS

SLOT

SLOT

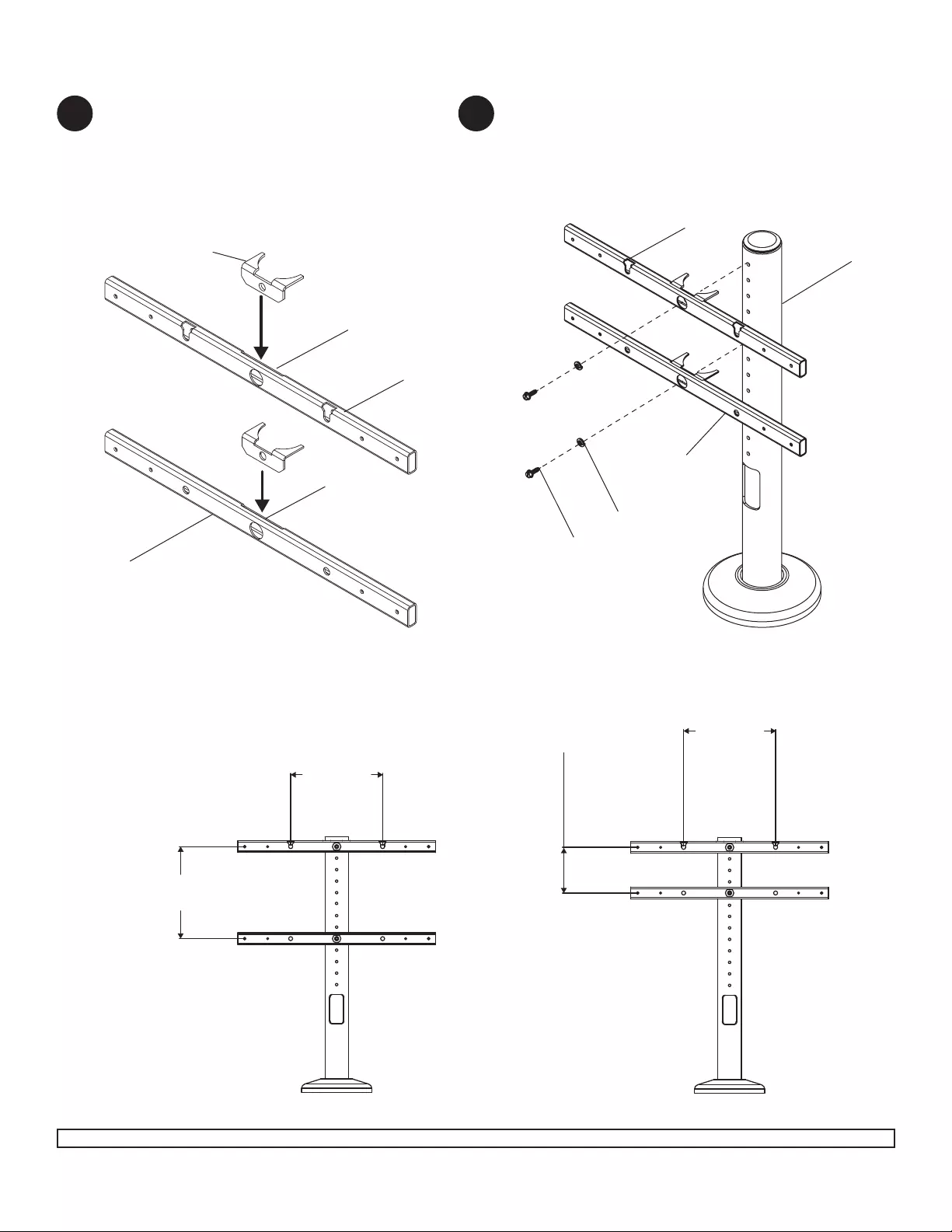

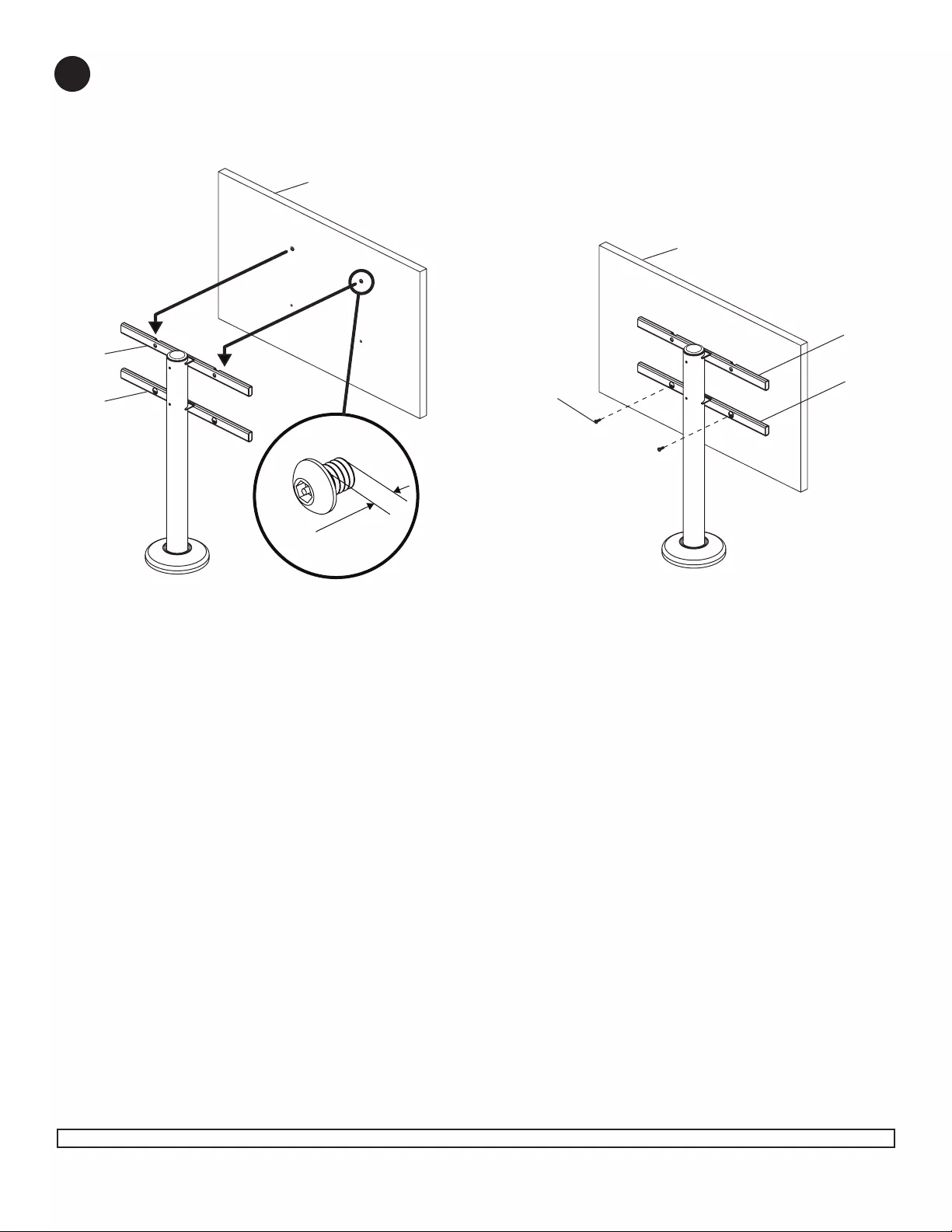

Fasten two socket pin screws (I, O, P, W, or X) into the top mounting holes behind the screen leaving 1/8" of

exposed threads as shown below. Use of washer (Y) and spacer (Z) is optional.

Hook exposed threads onto the top of vertical rails (T) and secure lower horizontal rail (S) using two socket pin

screws (I, O, P, W, or X).

1/8"

SCREEN SCREEN

12

T

Mounting using Large Hole Pattern (300 mm x 300 mm or greater)

A

U

V

NOTE: When using socket pin screw (I), #10 at washers (Q) are required.

I, O, P, W, or X

I, O, P, W, or X

TIP: Grip tube rmly while

fastening screws using 3/8"

socket drive. Drive screws

into center of pole.

8 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

7.87"

(200 mm)

7.87"

(200 mm)

7.87"

(200 mm)

3.93"

(100 mm)

Mounting using Small Hole Pattern (200 mm x 200 mm or less)

Detail 5 Detail 6

Attach tube gussets (R), lower horizontal rail (S), and

upper horizontal rail (V) onto support tube (A) using

two 1/4-20 x 3/4" hex head screws (H) with two 1/4" split

washers (U) as shown below. NOTE: Use details 5 and

6 when determining the placement of adapter rail (S)

and upper horizontal tube (V).

910

Position tube gussets (R) inside slots in lower

horizontal rail (S) and upper horizontal rail (V) as

shown below.

A

R

S

V

V

SLOT

SLOT

H

U

TIP: Grip tube rmly while

fastening screws using 3/8"

socket drive. Drive screws

into center of pole.

S

9 of 9 ISSUED: 2012-06-28 SHEET #: 125-9328-6 (2020-08-17)

Fasten two socket pin screws (I, O, P, W, or X) into the top mounting holes behind the screen leaving 1/8" of

exposed thread as shown below. Use of washer (Y) and spacer (Z) is optional. Hook the exposed threads onto the

top of upper horizontal rail (V). Fasten lower horizontal rail (S) using two socket pin screws (I, O, P, W, or X).

1/8"

SCREEN

SCREEN

11

S

V

I, O, P, W, or X S

V

NOTE: When using socket pin screw (I), #10 at washers (Q) are required.

I, O, P, W, or X