Peerless PJF2-UNV-S User Manual

Displayed below is the user manual for PJF2-UNV-S by Peerless which is a product in the Projector Mounts category. This manual has pages.

Related Manuals

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

1 of 9

For customer care call 1-800-865-2112.

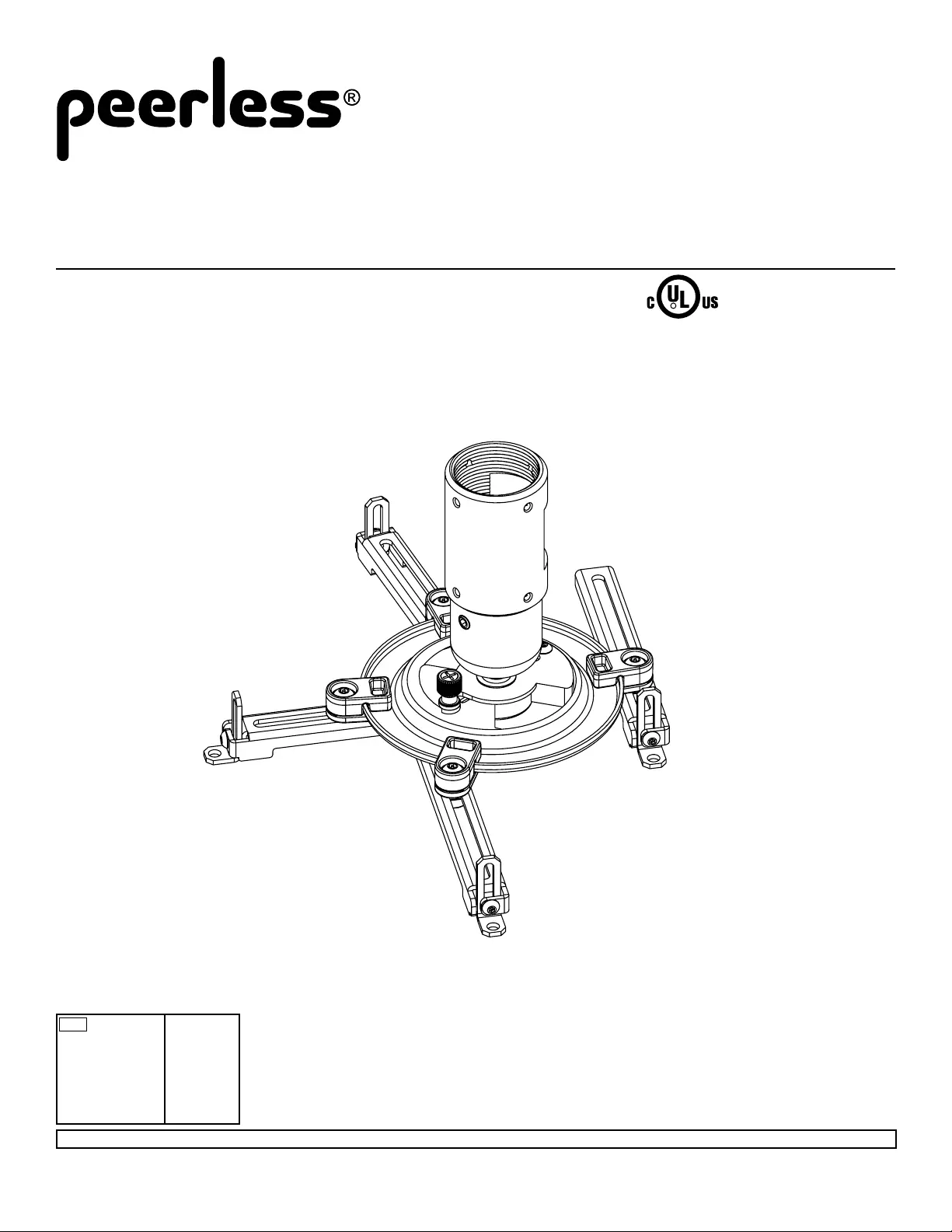

Installation and Assembly Manual:

Vector Pro II™

Models: PJF2-UNV, PJF2-UNV-S

Maximum UL Load Capacity: 50 lb (27 kg)

This product is intended for use with UL

Listed products and must be installed

by a qualied professional installer.

Compatible

model/series*

ENG AEC*,

EXT*,

ADD*,

ACC500*,

CMJ400*,

DCT100,

DCS200,

CMJ500R1.

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

2 of 9

For customer care call 1-800-865-2112.

Tools Needed for Assembly

• studnder("edgetoedge"studnderisrecommended)

• phillipsscrewdriver

• drill

• 1/4"masonrybitforconcretesurface

• 5/32"bitforwoodstuds

• level

• 3/8"(10mm)socketwrench

• Itistheresponsibilityoftheinstallertoensurethat

theprojectorisproperlyventilated.Feetofchannels

areusedtoraisethemountofftheprojectorsurface.

CAUTION

Note:Readentireinstructionsheetbeforeyoustartinstallationandassembly.

• DonotbegintoinstallyourPeerlessproductuntilyouhavereadandunderstoodtheinstructionsandwarningscon-

tainedinthisInstallationSheet.Ifyouhaveanyquestionsregardinganyoftheinstructionsorwarnings,callPeer-

lesscustomercareat1-800-865-2112.

• Thisproductshouldonlybeinstalledbysomeoneofgoodmechanicalaptitude,hasexperiencewithbasicbuilding

construction,andfullyunderstandstheseinstructions.

• Makesurethatthesupportingsurfacewillsafelysupportthecombinedloadoftheequipmentandallattachedhard-

wareandcomponents.

• NeverexceedtheMaximumULLoadCapacity.

• Alwaysuseanassistantormechanicalliftingequipmenttosafelyliftandpositionequipment.

• Tightenscrewsrmly,butdonotovertighten.Overtighteningcandamagetheitems,greatlyreducingtheirholding

power.Seesuggestedtorquevalueswhereapplicablewithintheseinstructions.

WARNING

Table of Contents

PartsList............................................................................................................................................................................3

InstallationtoWoodJoistorWoodBeamCeilings ............................................................................................................4

InstallationtoConcreteCeilings ........................................................................................................................................ 5

FlushMountApplication .................................................................................................................................................... 6

InstallationtoExtensionColumns ..................................................................................................................................... 7

AttachingAdapterPlatetoProjector.................................................................................................................................. 8

AttachingAdapterPlatetoProjectorMount,ProjectorAlignment ..................................................................................... 9

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

3 of 9

For customer care call 1-800-865-2112.

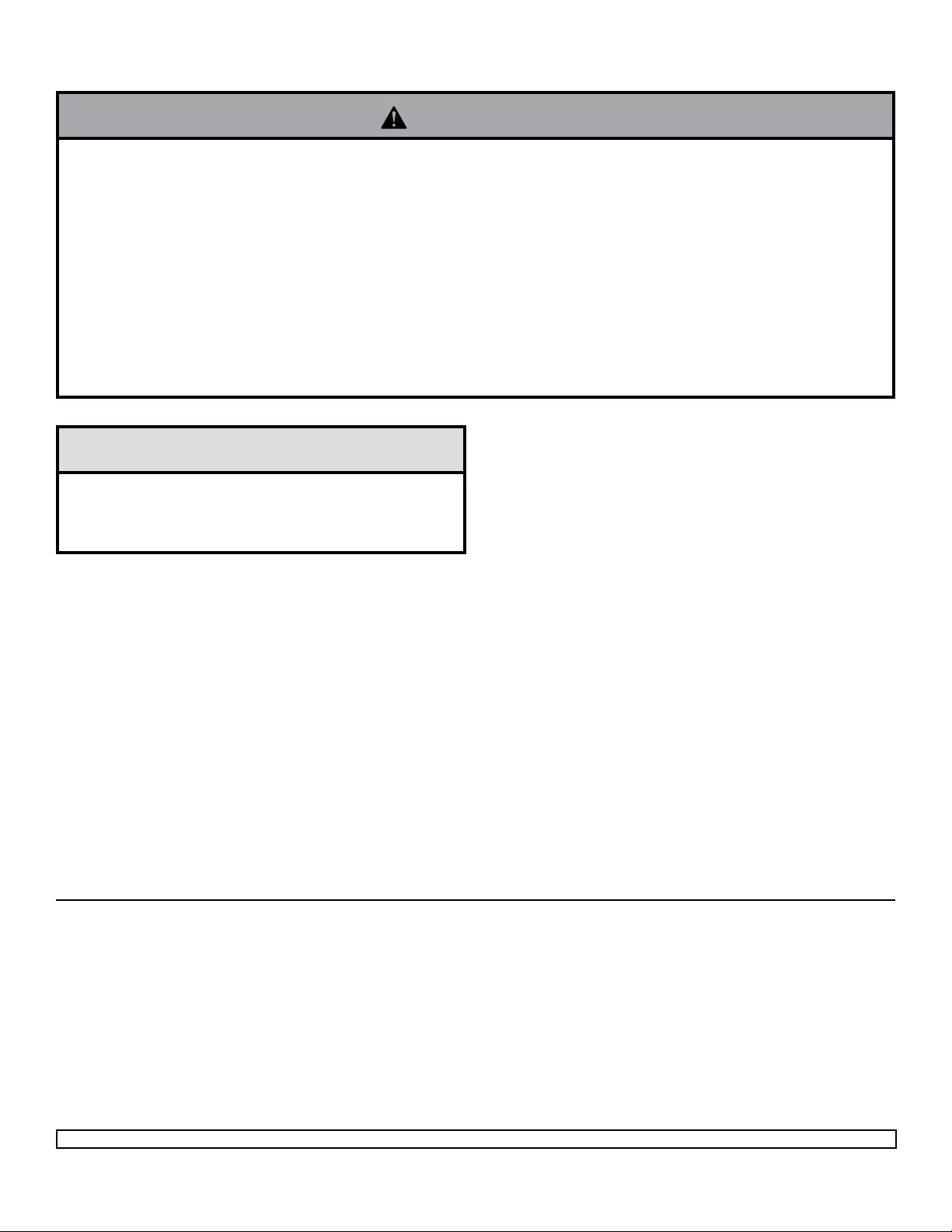

Beforeyoustartcheckthepartslisttoinsureallofthepartsshownareincluded.

ACD

Note: Actual parts may appear slightly different than illustrated.

E GF H J K L

B

OR

N

MP

T

U

Parts List PJF2-UNV

Part #

PJF2-UNV-S

Part #

Description Qty

Aballandsocketmount 1 055-0011 055-0016

Badapter plate 1 055-1867 055-4867

Cceilingplate 1 580-1042 580-4042

Dextensioncolumnconnector 1 580-1025 580-4025

EM5x.8x10mmsocketpintypeFscrew 1520-1164 520-2031

F#10-32x3/8"spadethumbscrew 1560-1107 560-2107

G#10-32x3/8"serratedwasherheadsocketpinscrew 1 520-1151 520-2151

H#14x2.5phillipshexheadwoodscrew 2 5S1-015-C03 5S1-015-C04

J.25"IDx.56"ODx.26spacer 2 590-1050 590-2071

K#10-32x3/8"socketpinscrew 2 520-1084 520-2084

L#10-32x3/16"slottedsetscrew 3 520-1187 520-2187

Mwasher 4 540-1025 540-2025

NM3x8mmserratedwasherheadsocketpinscrew 4 510-1004 510-2004

OM4x10mmserratedwasherheadsocketpinscrew 4510-1060 510-2060

PM5x10mmserratedwasherheadsocketpinscrew 4510-1126 510-2063

RM6x10mmserratedwasherheadsocketpinscrew 4510-1066 510-2066

T2mmsecurityallenwrench 1560-1097 560-1097

U4mmsecurityallenwrench 1560-9646 560-9646

VM5x20mmserratedwasherheadsocketpinscrew 4510-1065 510-2065

V

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

4 of 9

For customer care call 1-800-865-2112.

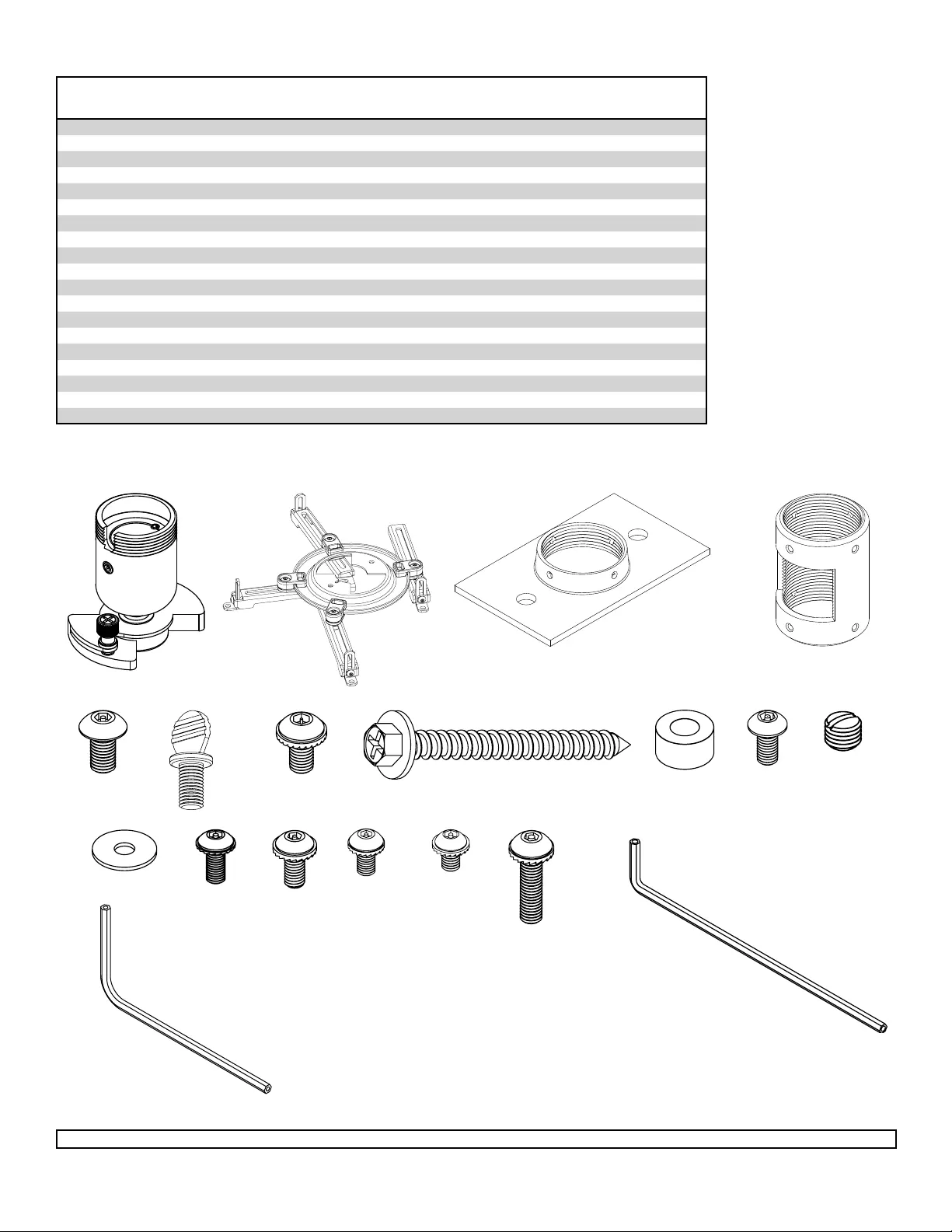

H

C

WOODJOIST

Drilltwo5/32"(4mm)dia.holestoaminimum

depthof2.5"(64mm).Attachceilingplate(C)

withtwo#14x2.5"(6mmx65mm)wood

screws(H)asshownusing3/8"(10mm)socket

wrench.

Skip to step 3 for ush mount installation.

Skip to step 4 for extension column

installation.

For Optional Cord Management,

installtwospacers(J)betweenceiling

plate(C)andceiling.

Installation To Wood Joist Finished Ceilings,

Exposed Wood Joists, or Wood Beam Ceilings

WOODJOIST

CEILING

H

C

J

• Itistheresponsibilityoftheinstallertoverifythatthe

supportingsurfacewillsafelysupportthecombined

loadofallattachedhardwareandcomponents.

WARNING

1

IMPORTANT: Be sure to drill holes into the

joist CENTER!

CEILING

• WheninstallingPeerlessceilingmountsonawoodjoist/beamcoveredwithgypsumboard(drywall),verifythatthe

joistsorbeamsareaminimumof2"x4"nominalsize.Donotinstallovergypsumboardthickerthan5/8".

• Tightenwoodscrews(H)sothatceilingplate(C)isrmlyattached,butdonotovertighten.Overtighteningcandam-

agethescrews,greatlyreducingtheirholdingpower.

• Nevertighteninexcessof80in•lb(9N.M.).

• Makesurethatmountingscrewsareanchoredintothecenterofthestuds.Theuseofan"edgetoedge"studnder

ishighlyrecommended.

WARNING

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

5 of 9

For customer care call 1-800-865-2112.

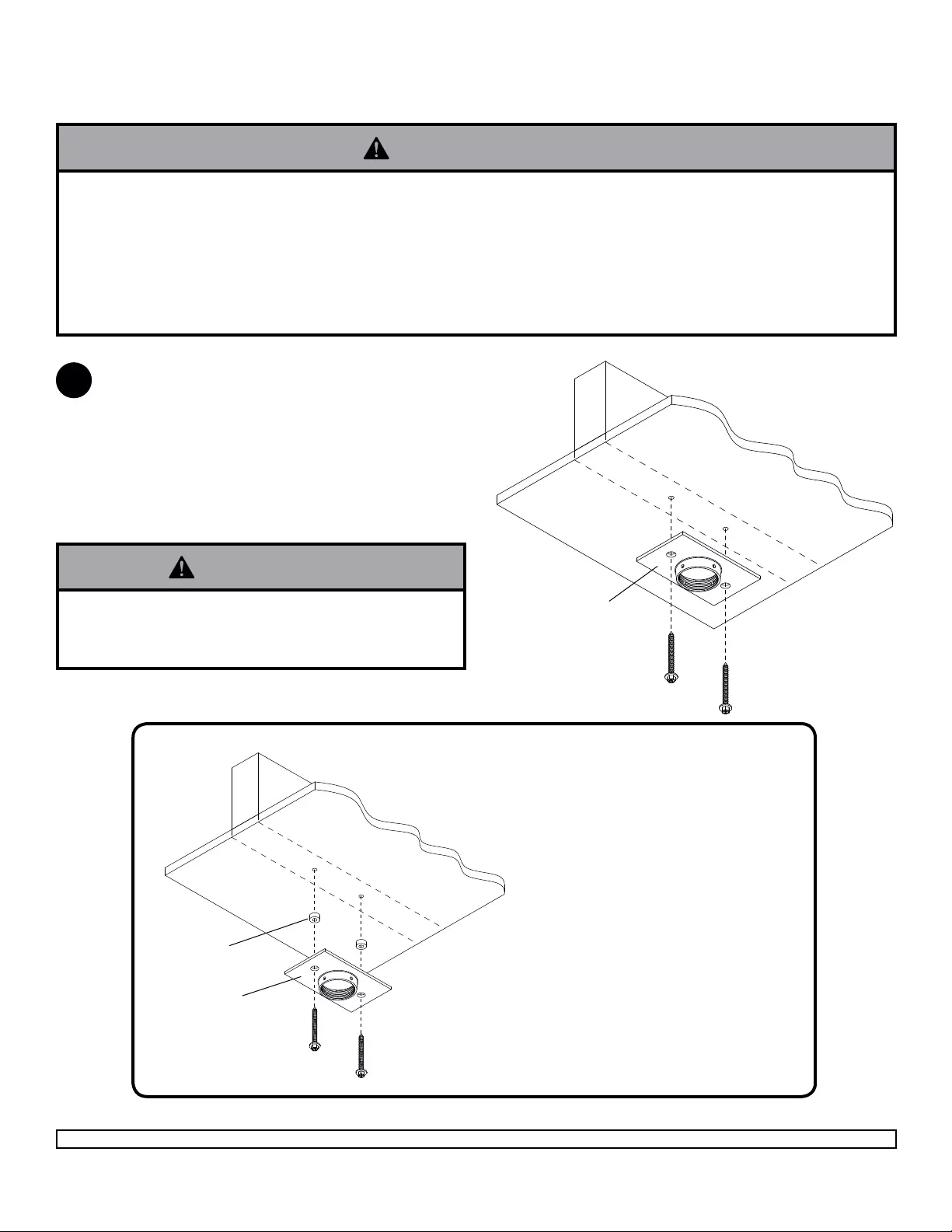

CONCRETECEILING

Drilltwo1/4"(6mm)dia.holestoaminimumdepthof

2.5"(64mm).Attachceilingplate(C)usingtwoconcrete

anchorsand#14x2.5"woodscrews(H)asshownin

Illustration A and 1, 2,and3 (below).Tightenallfasteners.

IMPORTANT: It is the responsibility of the installer to

verify that the ceiling will safely support the combined

load of all attached hardware and components.

Skip to step 3 for ush mount installation.

Skip to step 4 for extension column installation.

Illustration A

Installation to Concrete Ceilings

Use only PEERLESS ACC233 concrete anchors (sold separately).

• FOR DIRECT ATTACHMENT TO LOAD BEARING

CONCRETE ONLY! Concreteexpansionanchorsare

not intendedforattachmenttoconcreteceilingscov-

eredwithalayerofplaster,drywall,orothernishing

material.

WARNING

• Tightenwoodscrewssothatceilingplateisrmly

attached,butdonotovertighten.Overtighteningcan

damagethescrews,greatlyreducingtheirholding

power.

• Nevertighteninexcessof80in•lb(9N.M.).

• Makesurethatmountingscrewsareanchoredinto

thecenterofthestuds.Theuseofan"edgetoedge"

studnderishighlyrecommended.

WARNING

• WheninstallingPeerlessceilingmountsonaconcreteceiling,theceilingmustbeatleast8"thickwithaminimum

compressivestrengthof2000psi.

• Makesurethatthesupportingsurfacewillsafelysupportthecombinedloadoftheequipmentandallattachedhard-

wareandcomponents.

• NeverexceedtheMaximumLoadCapacityof50lb(27kg).

WARNING

2

H

C

CONCRETECEILING

concrete

anchor

1

3

2

Drillholesandinsertanchors(H).

Placeplate(B)overanchors(H)andsecurewithscrews(E).

Tightenallfasteners.

C

H

concrete

surface

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

6 of 9

For customer care call 1-800-865-2112.

Screwballandsocketmount(A)intoceilingplate(C)asshowningure 3.1 (minimum5turns).Alignthenotch

withoneofthefourholesoftheceilingplate(C)andsecureballandsocketmount(A)withaM5x10mmsocket

pinscrew(E)usingsecurityallenwrench(U)asshowningure 3.2

NOTE: Slottedsetscrew(L)isusedtojamagainstthethreadsoftheballandsocketmounttopreventanyexcess

movementoftheballandsocketmount(A).Donotovertightenscrew;overtighteningscrewwilldamagethreads

makingitdifculttoseparatetheproducts.

Skip to step 5.

Flush Mount Application

A

C

A

E

WOODJOIST

CEILING

NOTCH

C

L

3

gure 3.1

gure 3.2

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

7 of 9

For customer care call 1-800-865-2112.

Screwextensioncolumntoceilingplate(C).

Alignthenotchwithoneofthefourholesin

theceilingplate(C)andsecureextension

columnwithaM5x10mmsocketpinscrew

(E)usingsecurityallenwrench(U).See

gure 4.1

Screwextensioncolumnconnector(D)to

extensioncolumn.Alignslotinextension

columnwithoneofthetopholesin

extensioncolumnconnector(D).Insertand

tightenone#10-32x3/8"socketpinscrew

(K)throughextensioncolumnconnector(D)

intoslotonextensioncolumnusingsecurity

allenwrench(U).See gure 4.2

Screwballandsocketmount(A)to

extensioncolumnconnector(D).Alignslot

inballandsocketmount(A)tooneofthe

bottomholesinextensioncolumnconnector

(D).Insertandtightenone#10-32x3/8"

socketpinscrew(K)throughextension

columnconnector intoslotinballandsocket

mount(A)usingsecurityallenwrench(U).

See gure 4.3

Allpipethreadconnectionsbetweentheball

andsocketmount(A),columnconnector

(D),ceilingplate(C)mustbethreadeda

minimumof5turns.

Slottedsetscrews(L)areusedtojam

againstthethreadsofeachconnectingjoint

topreventanyexcessmovement.Donot

overtightenscrews;overtighteningscrews

willdamagethreadsmakingitdifcultto

separatetheproducts.

SLOT

SLOT

C

D

gure 4.1

gure 4.3

gure 4.2

EXTENSION

COLUMN

E

C

Installation to

Extension Column

A

L

A

EXTENSION

COLUMN

SLOT

D

K

EXTENSION

COLUMN

SLOT

DK

L

L

4

ULlistedPeerlessmodel

EXT, AEC, or ADD series

extensioncolumn(sold

separately).

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

8 of 9

For customer care call 1-800-865-2112.

B

MOUNTINGHOLE

GENERICPROJECTOR

Placeprojectorupsidedown.Locateadapterplate(B)withnotchfacingforwardasclosetoprojectorcenterof

gravityaspossiblewithoutcoveringanymountingholes.Loosenchannels,andifthereareonlythreemount-

ingholesremovefourthchannel.Usingonechannelforeachmountinghole,positionfeetofchannelsover

mountingholesasshownbelow.IMPORTANT:Ifprojectordoesnothaveatleastthreemountingholes,donot

use this adapter plate.

NOTE:Someprojectorshavefeetwhichcanberemovedandthecorrespondingthreadedinsertcanbeused

foramountinghole.

NOTE: Oncechannelsareinpositionretightenfasteners.

NOTE: Theprojectoryouareinstallingmaydifferinappearancefromthesampleillustratedbelow.

Attachadapterplate(B)toprojectorusingonescrew(N, O, P, R, or V)foreachchannelasshownbelow.

Tightenallscrews,whilekeepingthecenterofgravity.Besurethatadapterplate(B)isstraight.Adjustthefeet

ofthechannelstokeeptheadapterplatelevel.Tightenallscrewswith4mmsecurityallenwrench(U)orwrench

providedwithprojectormount,whilekeepingthecenterofgravity.IfM3screwsareused,tightenusing2mm

securityallenwrench(T).

NOTE:Projectorswillrequiredifferentsizescrewsformounting.Useacombinationofscrews(N, O, P, R, or V)

andfootadjustmentthatwillresultinchannelsofadapterplate(B)ttingtightlyagainstprojector.IMPORTANT:

Inordertoproperlyengagethethreadsinthemountingholes,thescrewmustbeturnedatleast3fullturns.

Note:Ifusingscrew(N),placewasher(M)betweenscrew(N)andfootofchannel.

FOOTOFCHANNEL

B

• Itistheresponsibilityoftheinstallertoensurethat

theprojectorisproperlyventilated.Feetofchannels

areusedtoraisethemountofftheprojectorsurface.

CAUTION N, O, P, R, or V

5

6

Attaching Adapter Plate to Projector

NOTCHINDICATES

FRONTOFPROJECTOR

ISSUED: 01-14-09 SHEET #: 056-9018-3 11-10-16

Visit the Peerless Web Site at www.peerless-av.com

9 of 9

For customer care call 1-800-865-2112.

Toadjustroll,pitch,andyawloosenthesetscrew

(shownbelow)usingsecurityallenwrench(U)or

standard4mmallenwrench.Youshouldbeabletojust

slightlyloosenthescrewsothatyouradjustmentscan

besetwithouthavingtoholdtheprojector.Moveprojec-

tortodesiredpositionandslowlytightensetscrew.

NOTE: Be sure not to touch the projector while tight-

ening the set screw. This may cause the image to be

unaligned when you let go.

IMPORTANT: Allen wrench is your key for projector

removal. Store it in a safe place.

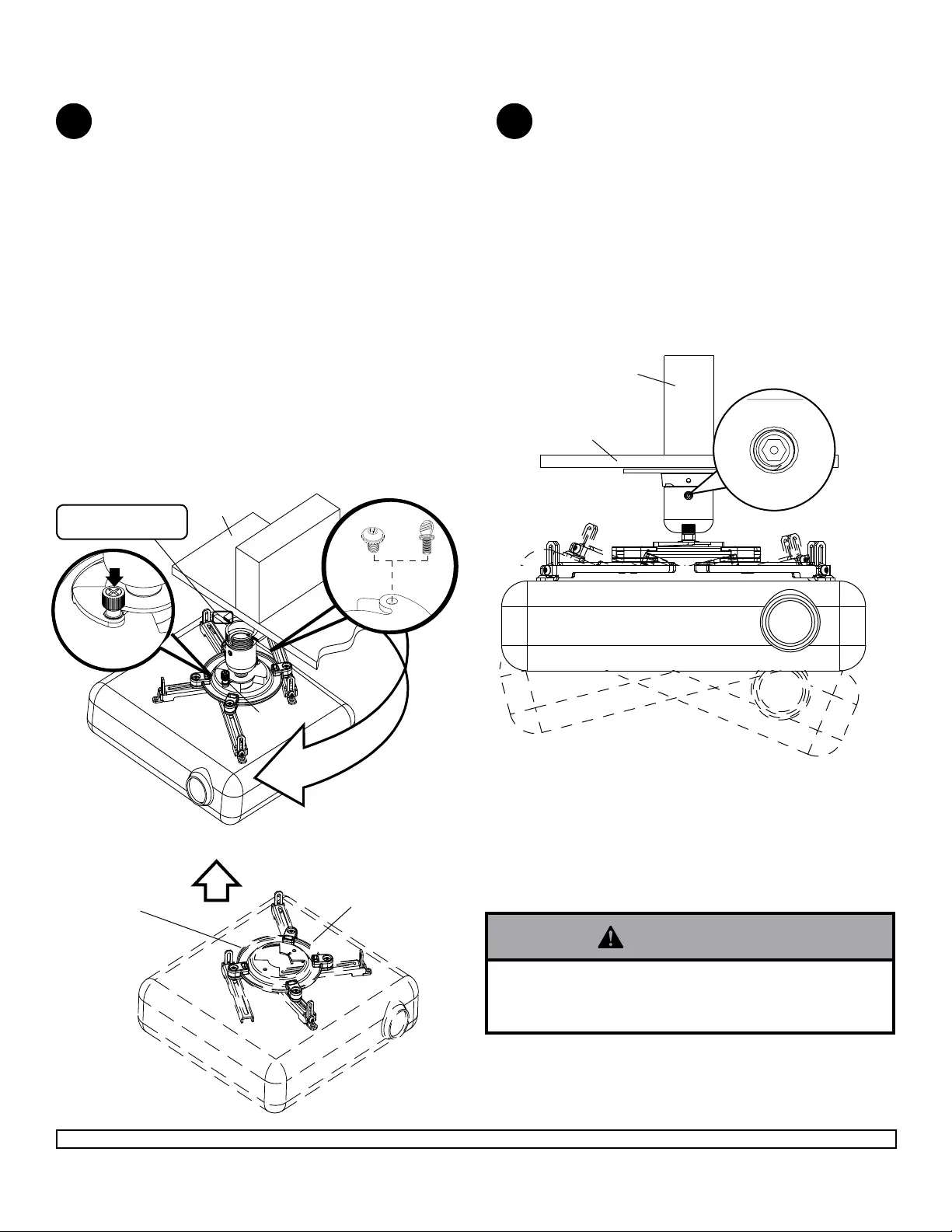

Attachprojector,withadapterplate(B)alreadyonit,to

theballandsocketmount(A)byinsertingtheballand

socketmountintotheadapterplateconnectionand

twistinguntiltheadapterplatewillnolongerturn(about

75°).Thespringloadedcaptivescrewshouldlineup

withacorrespondingholeontheadapterplate(this

shouldlineupautomaticallywhenthetwoareconnect-

ed).Pushdownandtightenthespringloadedcaptive

screwtosecuretheadapterplatetothemount.Ifnot

usingtheoptionalsecurityfeature,fastenthumbscrew

(F)intheholeoppositethespringloadedcaptivescrew.

OPTIONAL:ForArmorLock™security,insertserrated

washerheadsocketpinsecurityscrew(G)inthehole

oppositethespringloadedcaptivescrew.Tightenwith

securityallenwrench(U).Thiswillpreventtheprojector

frombeingremoved.

NOTE: Be sure to only use the #10-32 x 3/8"

screw (G) (or the thumb screw (F)) opposite the

spring loaded captive screw.

A

WOOD

JOIST

CEILING

PROJECTOR

ADAPTERPLATE

PROJECTOR

WOODJOIST

CEILING

PROJECTOR

CUTAWAYVIEWOF

CEILINGPLATE(C)

G

2

1

F

• Donotliftmoreweightthanyoucanhandle!Usead-

ditionalmanpowerormechanicalliftingequipmentto

safelyhandleplacementoftheprojector!

WARNING

7 8

©2009PeerlessIndustries,Inc.Allrightsreserved.

Allotherbrandandproductnamesaretrademarksorregisteredtrademarksoftheirrespectiveowners.

Attaching Adapter Plate to Projector Mount

B

SETSCREW

CAPTIVE

SCREW