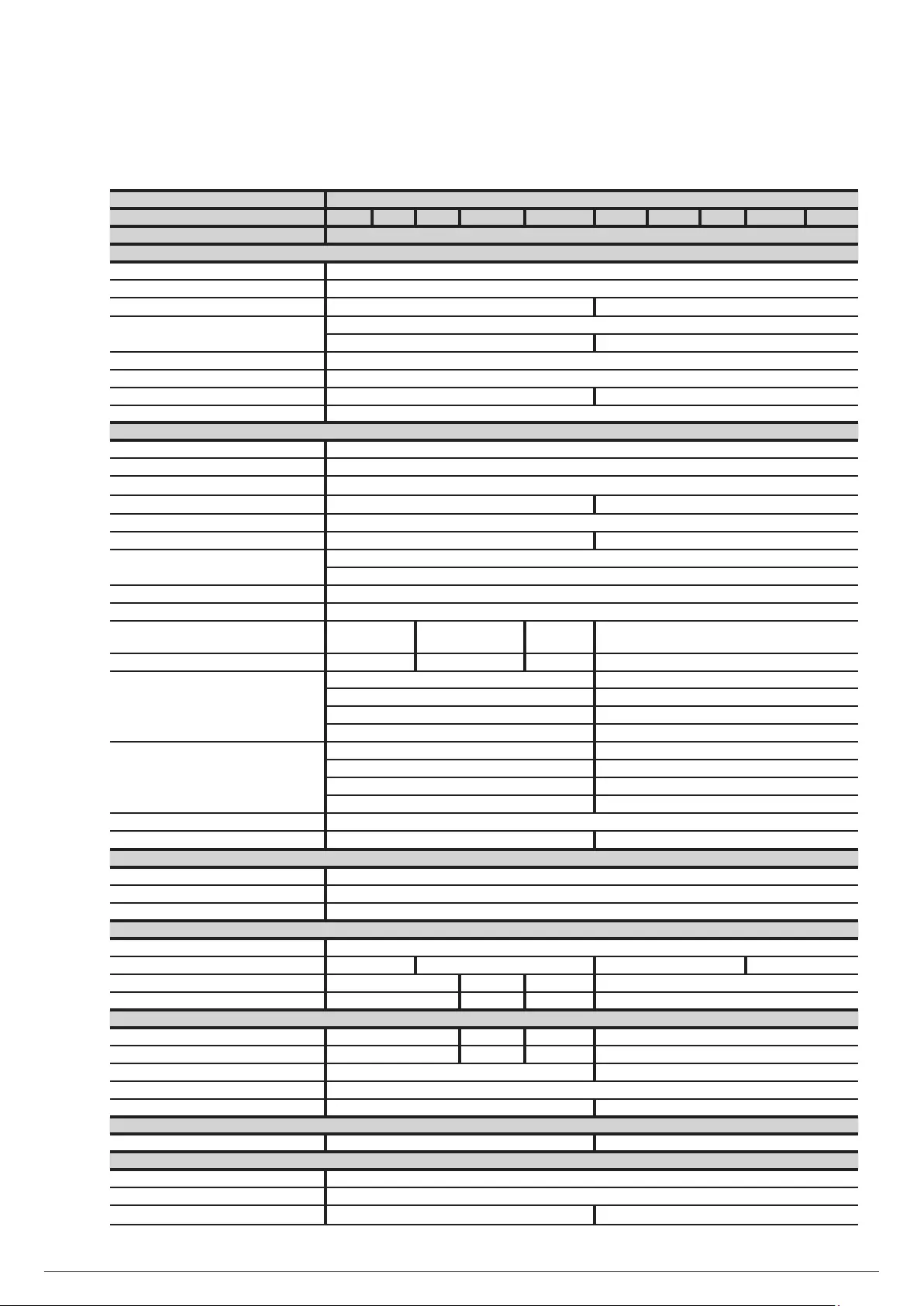

Table of Contents

- 1. Introduction.

- 1.1. Thank you letter.

- 2. Safety information.

- 2.1. Using this manual.

- 2.1.1. Conventions and symbols used.

- 3. Quality assurance and standards.

- 3.1. Statement by the management.

- 3.2. Standards.

- 3.2.1. First and second environment.

- 3.3. Environment.

- 4. Presentation.

- 4.1. Views.

- 4.1.1. Views of the device.

- 4.2. Definition of the product.

- 4.2.1. Nomenclature.

- 4.3. Operating principle.

- 4.4. UPS operating modes.

- 4.4.1. Notable features.

- 4.5. Optional extras.

- 4.5.1. Isolation transformer:

- 4.5.2. Exterior manual maintenance bypass.

- 4.5.3. Communication card.

- 4.5.4. Extendable guide kits for mounting in a rack cabinet.

- 5. Installation.

- 5.1. RECEPTION OF THE DEVICE.

- 5.1.1. Reception, unpacking and contents.

- 5.1.2. Storage.

- 5.1.3. Unpacking.

- 5.1.4. Transport to the site.

- 5.1.5. Siting, immobilising and considerations.

- 5.1.5.1. Rotation of the control panel with LCD display.

- 5.1.5.2. Vertical tower-type mounting.

- 5.1.5.3. Vertical tower-type mounting with backup extension (battery module).

- 5.1.5.4. Mounting as a rack in a 19” cabinet.

- 5.1.5.5. Rack mounting in a 19” cabinet with backup extension (battery module).

- 5.1.5.6. Vertical tower-type mounting with PDU.

- 5.1.5.7. Rack mounting in 19” cabinet with PDU.

- 5.1.5.8. Preliminary considerations before connection.

- 5.1.5.9. Preliminary considerations before connection, regarding the batteries and their protections.

- 5.1.5.10. Connection elements.

- 5.1.5.1. Rotation of the control panel with LCD display.

- 5.2. Connections.

- 5.2.1. Connection of the input.

- 5.2.2. Connection to IEC connectors or output terminals.

- 5.2.3. Connection to external batteries (backup extension).

- 5.2.4. Connection of the input earth terminal () and the earth connection terminal () .

- 5.2.5. Terminals for EPO (emergency power off).

- 5.2.6. Terminals for digital input and output to relay. Only in models with power ratings > 3 kVA.

- 5.2.7. Manual bypass auxiliary contact terminals. Only in models with power ratings > 3 kVA.

- 5.2.8. Connection in parallel, only in models with power ratings > 3 kVA.

- 5.2.9. Communication port.

- 5.2.10. Smart slot for the integration of an electronic communication unit.

- 5.2.11. Protection against voltage spikes for the modem / ADSL / fax, etc., line. .

- 5.2.12. Software.

- 5.2.13. Considerations before start-up with connected loads.

- 6. Operation.

- 6.1. Start-up.

- 6.1.1. Checks before start-up.

- 6.2. UPS start-up and shutdown.

- 6.2.1. UPS start-up with mains voltage.

- 6.2.2. UPS start-up without mains voltage.

- 6.2.3. UPS shutdown with mains voltage.

- 6.2.4. UPS shutdown without mains voltage.

- 6.3. Operating procedure for a parallel system (only in 4 to 10 kVA models).

- 6.4. How to add a UPS to a system in parallel operation or to a functioning single UPS (only in 4 to 10 kVA models).

- 6.5. How to replace a faulty UPS in an operational parallel system.

- 7. Control panel with LCD display.

- 7.1. GENERAL INFORMATION FOR THE SERIES.

- 7.1.1. Information represented by the display.

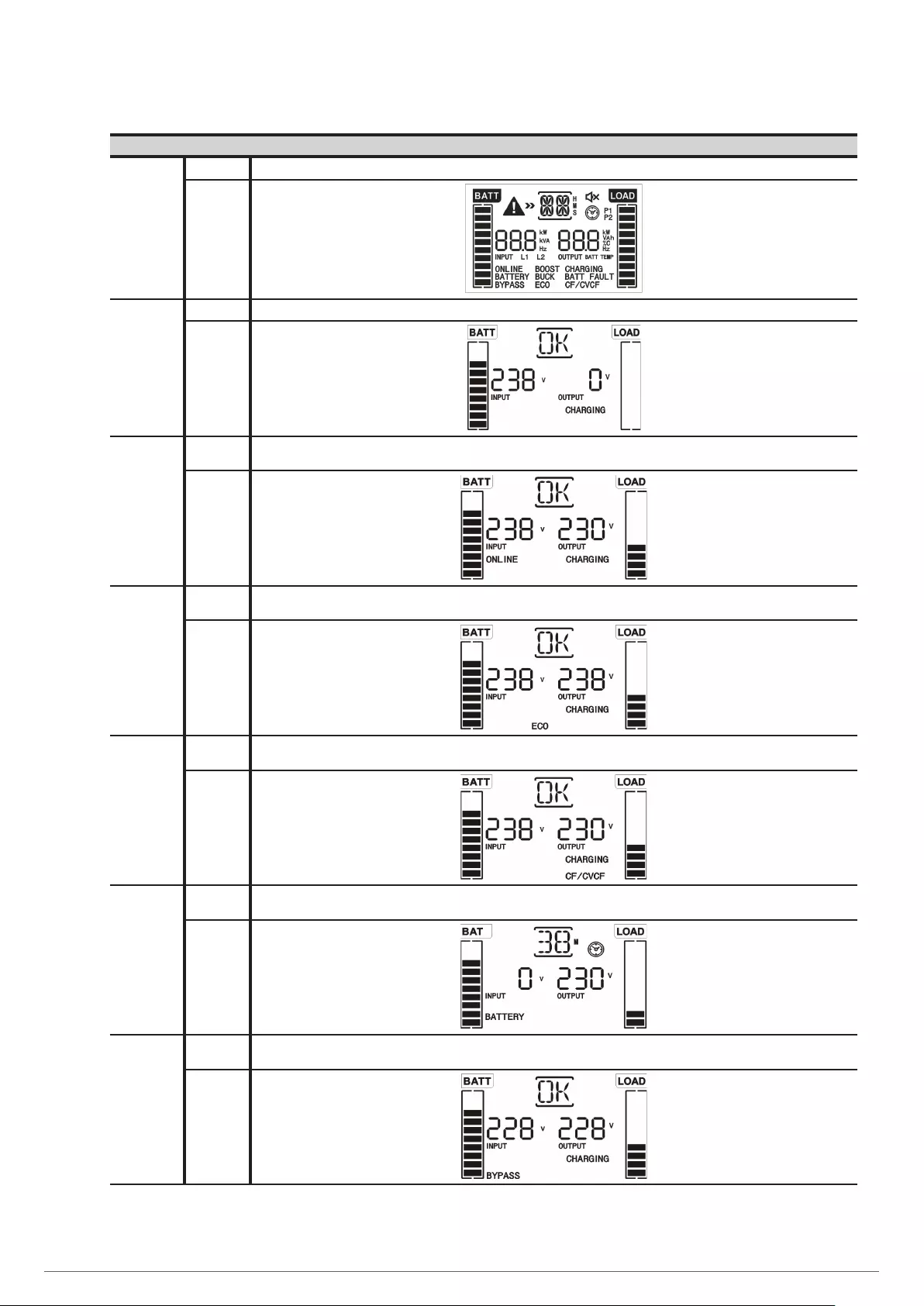

- 7.1.2. Common messages shown on the LCD display.

- 7.1.3. Common abbreviations shown on the display.

- 7.2. Control panel for models up to 3 kVA.

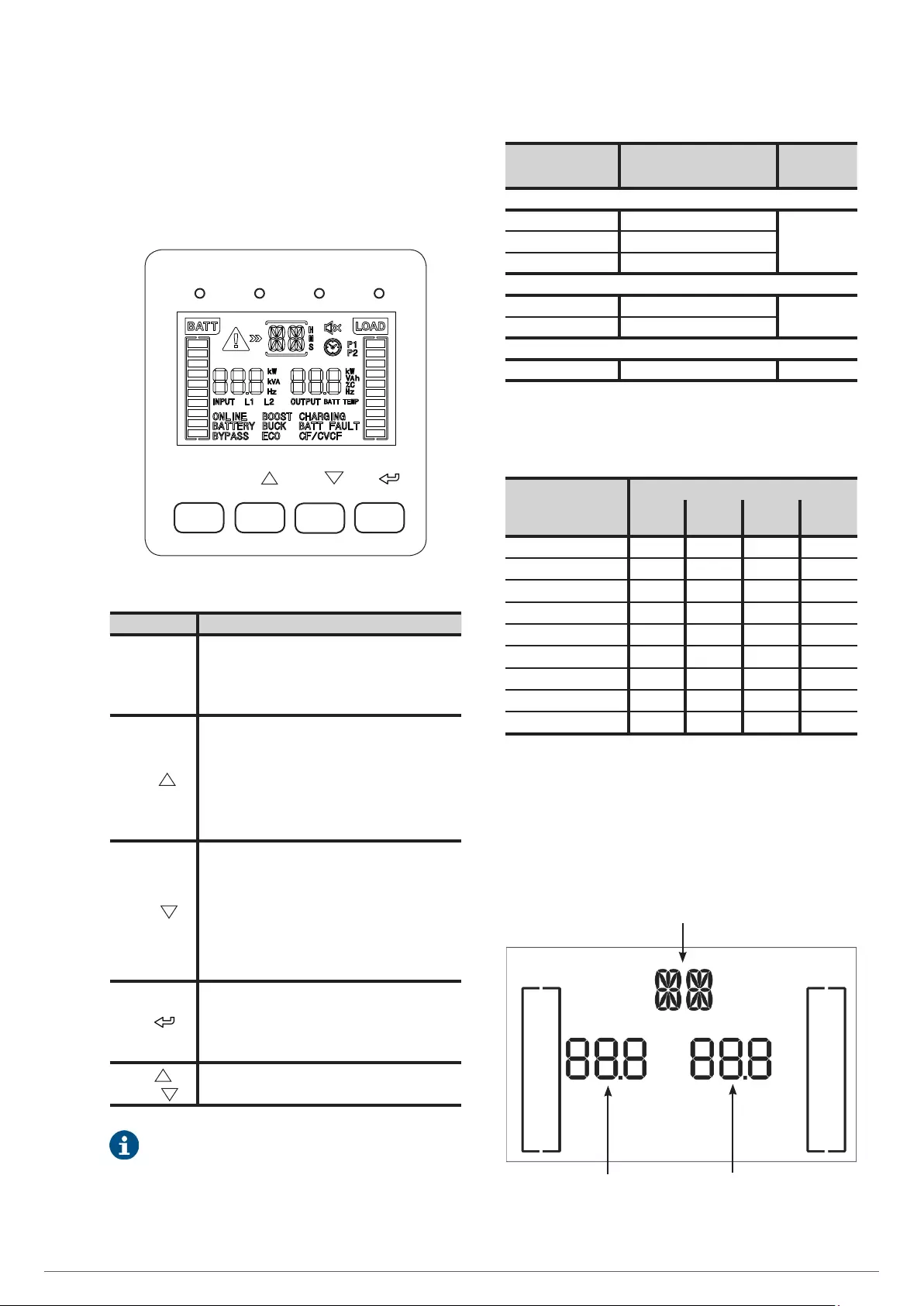

- 7.2.1. Composition of the control panel with LCD display.

- 7.2.2. Audible alarms.

- 7.2.3. Location of the adjustment parameters on the display.

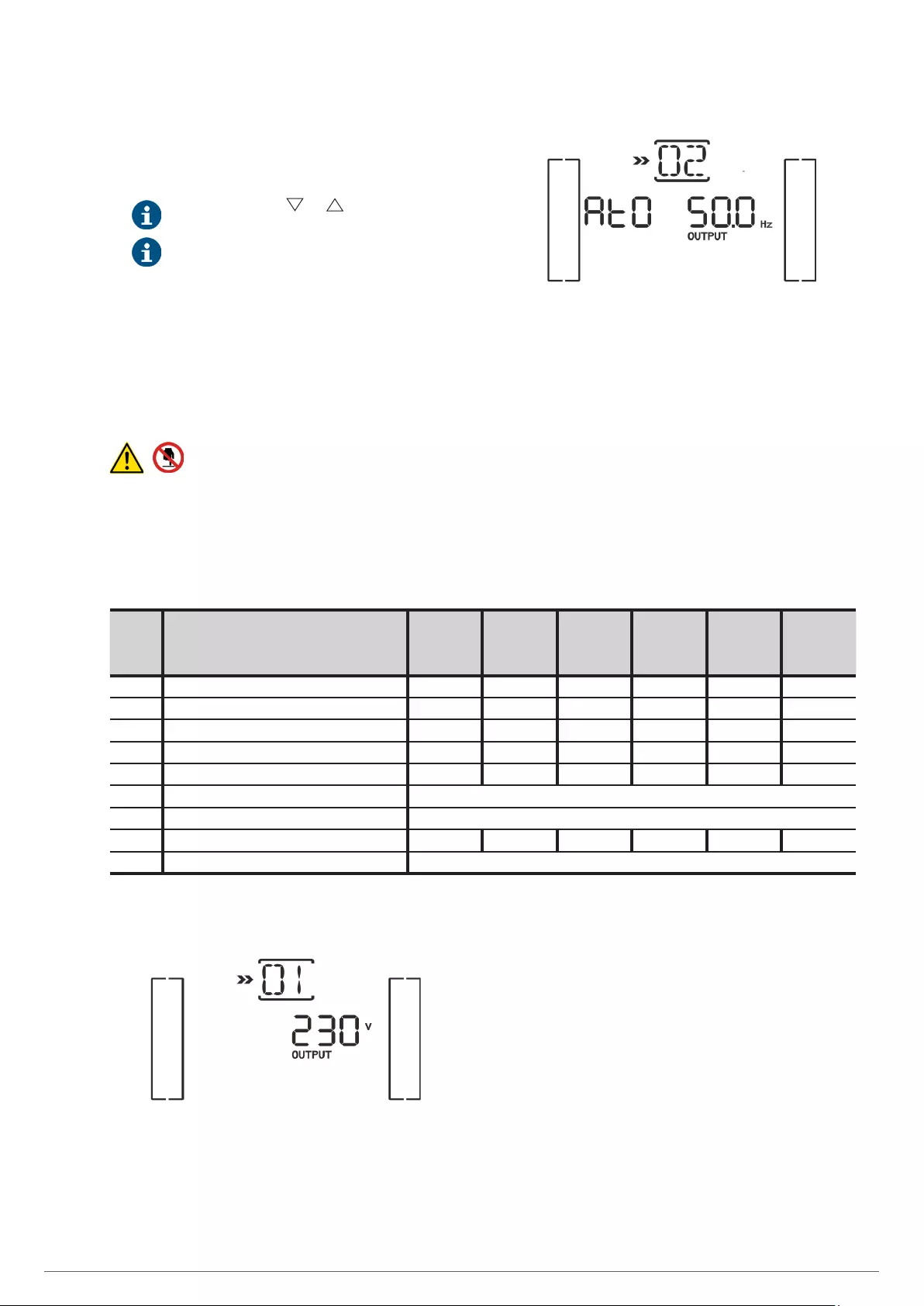

- 7.2.4. Settings.

- 7.3. Control panel for 4 kVA to 10 kVA models.

- 7.3.1. Audible alarms.

- 7.3.2. Optical indications.

- 7.3.3. Location of the adjustment parameters on the display.

- 7.3.4. Settings.

- 8. Maintenance, warranty and service.

- 8.1. Battery maintenance.

- 8.1.1. Notes for the installation and replacement of the battery.

- 8.2. UPS troubleshooting guide.

- 8.2.1. Troubleshooting guide for devices up to 3 kVA.

- 8.2.2. Troubleshooting guide for 4 kVA to 10kVA devices.

- 8.3. Warranty conditions.

- 8.3.1. Terms of the warranty.

- 8.3.2. Exclusions.

- 8.4. Technical services network.

- 9. Annexes.

- 9.1. General technical specifications.

- 9.2. Glossary.

Salicru 698CC000003 User Manual

Displayed below is the user manual for 698CC000003 by Salicru which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

SLC TWIN RT2

0,7.. 10 kVA

UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)

USER MANUAL

2SALICRU

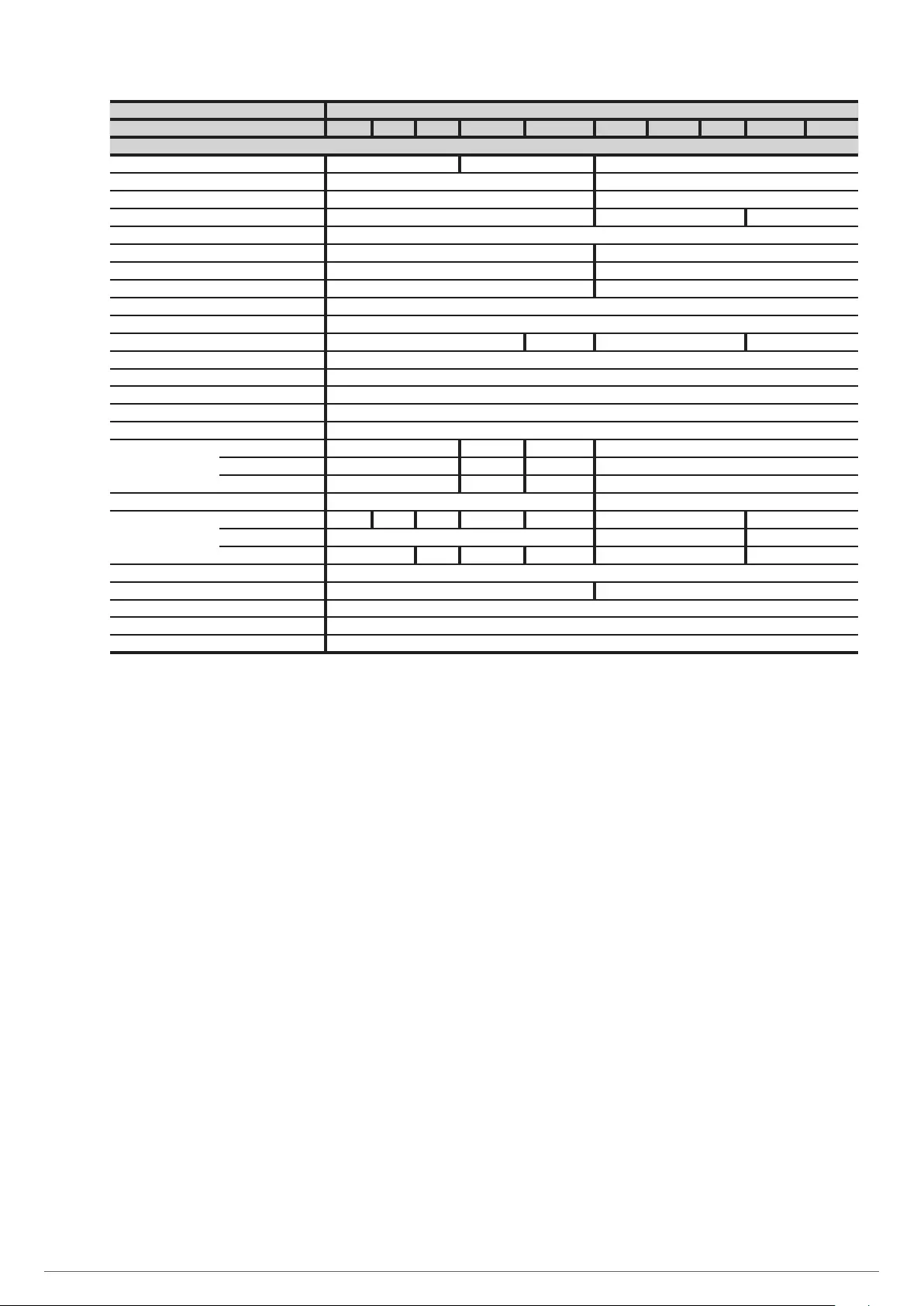

General index

1. INTRODUCTION.

1.1. THANK YOU LETTER.

2. SAFETY INFORMATION.

2.1. USING THIS MANUAL.

2.1.1. Conventions and symbols used.

3. QUALITY ASSURANCE AND STANDARDS.

3.1. STATEMENT BY THE MANAGEMENT.

3.2. STANDARDS.

3.2.1. First and second environment.

3.2.1.1. First environment.

3.2.1.2. Second environment.

3.3. ENVIRONMENT.

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the device.

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

4.3. OPERATING PRINCIPLE.

4.4. UPS OPERATING MODES.

4.4.1. Notable features.

4.5. OPTIONAL EXTRAS.

4.5.1. Isolation transformer:

4.5.2. Exterior manual maintenance bypass.

4.5.3. Communication card.

4.5.3.1. Integration into computer networks using an SNMP adapter.

4.5.3.2. Modbus RS485.

4.5.3.3. Interface to relays.

4.5.4. Extendable guide kits for mounting in a rack cabinet.

5. INSTALLATION.

5.1. RECEPTION OF THE DEVICE.

5.1.1. Reception, unpacking and contents.

5.1.2. Storage.

5.1.3. Unpacking.

5.1.4. Transport to the site.

5.1.5. Siting, immobilising and considerations.

5.1.5.1. Rotation of the control panel with LCD display.

5.1.5.2. Vertical tower-type mounting.

5.1.5.3. Vertical tower-type mounting with backup extension (battery

module).

5.1.5.4. Mounting as a rack in a 19” cabinet.

5.1.5.5. Rack mounting in a 19” cabinet with backup extension

(battery module).

5.1.5.6. Vertical tower-type mounting with PDU.

5.1.5.7. Rack mounting in 19” cabinet with PDU.

5.1.5.8. Preliminary considerations before connection.

5.1.5.9. Preliminary considerations before connection, regarding the

batteries and their protections.

5.1.5.10. Connection elements.

5.2. CONNECTIONS.

5.2.1. Connection of the input.

5.2.2. Connection to IEC connectors or output terminals.

5.2.2.1. Connection of loads in models up to 3 kVA.

5.2.2.2. Connection of loads in 4 to 10 kVA 10 kVA.

5.2.3. Connection to external batteries (backup extension).

5.2.4. Connection of the input earth terminal ( ) and the earth

connection terminal ( ) .

5.2.5. Terminals for EPO (emergency power off).

5.2.6. Terminals for digital input and output to relay. Only in models

with power ratings > 3 kVA.

5.2.7. Manual bypass auxiliary contact terminals. Only in models with

power ratings > 3 kVA.

5.2.8. Connection in parallel, only in models with power ratings > 3

kVA.

5.2.8.1. Introduction in redundancy.

5.2.8.2. Installation and operation in parallel.

5.2.9. Communication port.

5.2.9.1. RS232 and USB port.

5.2.10. Smart slot for the integration of an electronic communication

unit.

5.2.11. Protection against voltage spikes for the modem / ADSL / fax,

etc., line. .

5.2.12. Software.

5.2.13. Considerations before start-up with connected loads.

6. OPERATION.

6.1. STAR T-UP.

6.1.1. Checks before start-up.

6.2. UPS START-UP AND SHUTDOWN.

6.2.1. UPS start-up with mains voltage.

6.2.2. UPS start-up without mains voltage.

6.2.3. UPS shutdown with mains voltage.

6.2.4. UPS shutdown without mains voltage.

3

6.3. OPERATING PROCEDURE FOR A PARALLEL SYSTEM (ONLY

IN 4 TO 10 KVA MODELS).

6.4. HOW TO ADD A UPS TO A SYSTEM IN PARALLEL

OPERATION OR TO A FUNCTIONING SINGLE UPS (ONLY IN 4

TO 10 KVA MODELS).

6.5. HOW TO REPLACE A FAULTY UPS IN AN OPERATIONAL

PARALLEL SYSTEM.

7. CONTROL PANEL WITH LCD DISPLAY.

7.1. GENERAL INFORMATION FOR THE SERIES.

7.1.1. Information represented by the display.

7.1.2. Common messages shown on the LCD display.

7.1.3. Common abbreviations shown on the display.

7.2. CONTROL PANEL FOR MODELS UP TO 3 KVA.

7.2.1. Composition of the control panel with LCD display.

7.2.2. Audible alarms.

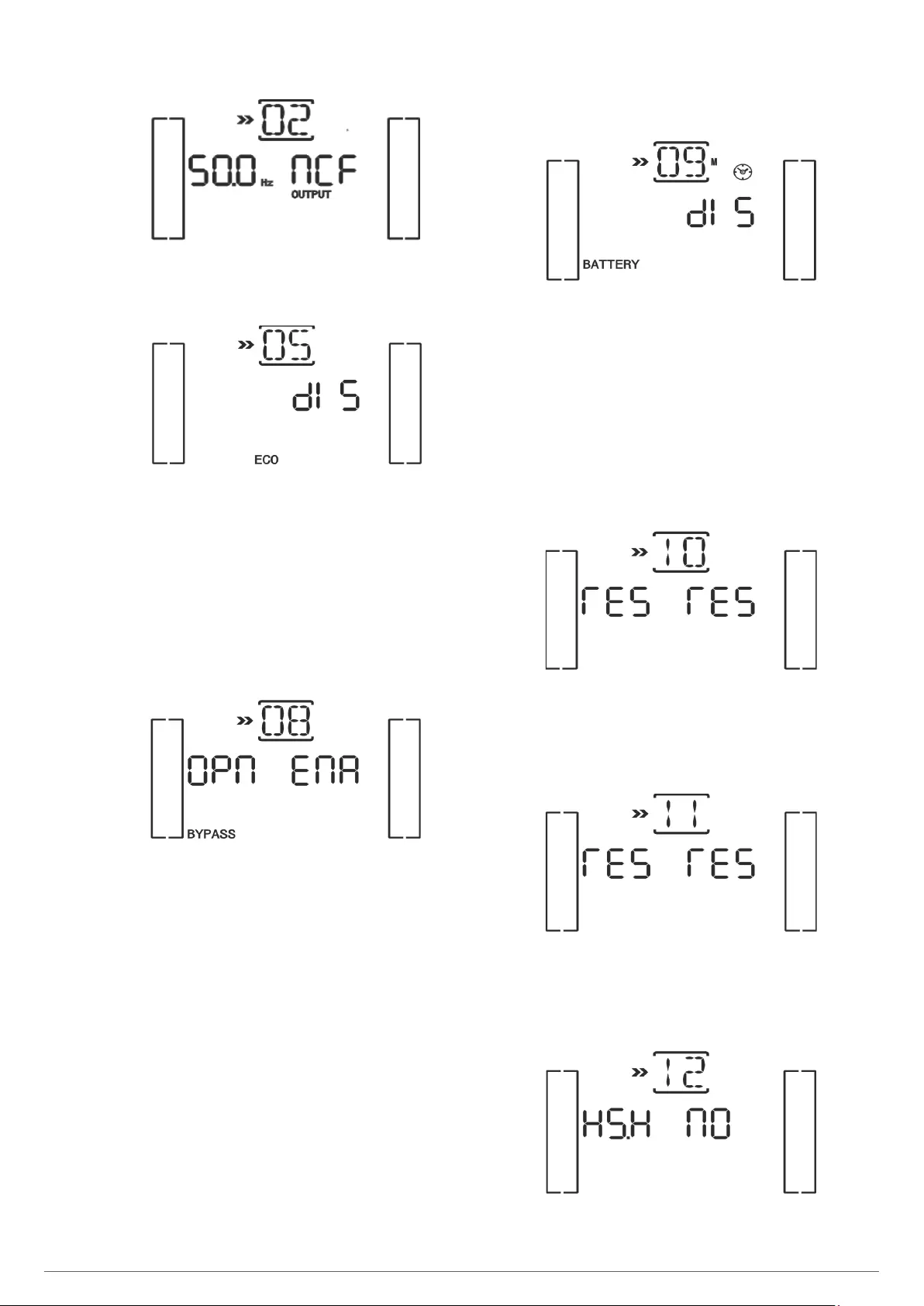

7.2.3. Location of the adjustment parameters on the display.

7.2.4. Settings.

7.2.4.1. Ah configuration of parameter ‘12’.

7.2.4.2. Operating mode / Description of state.

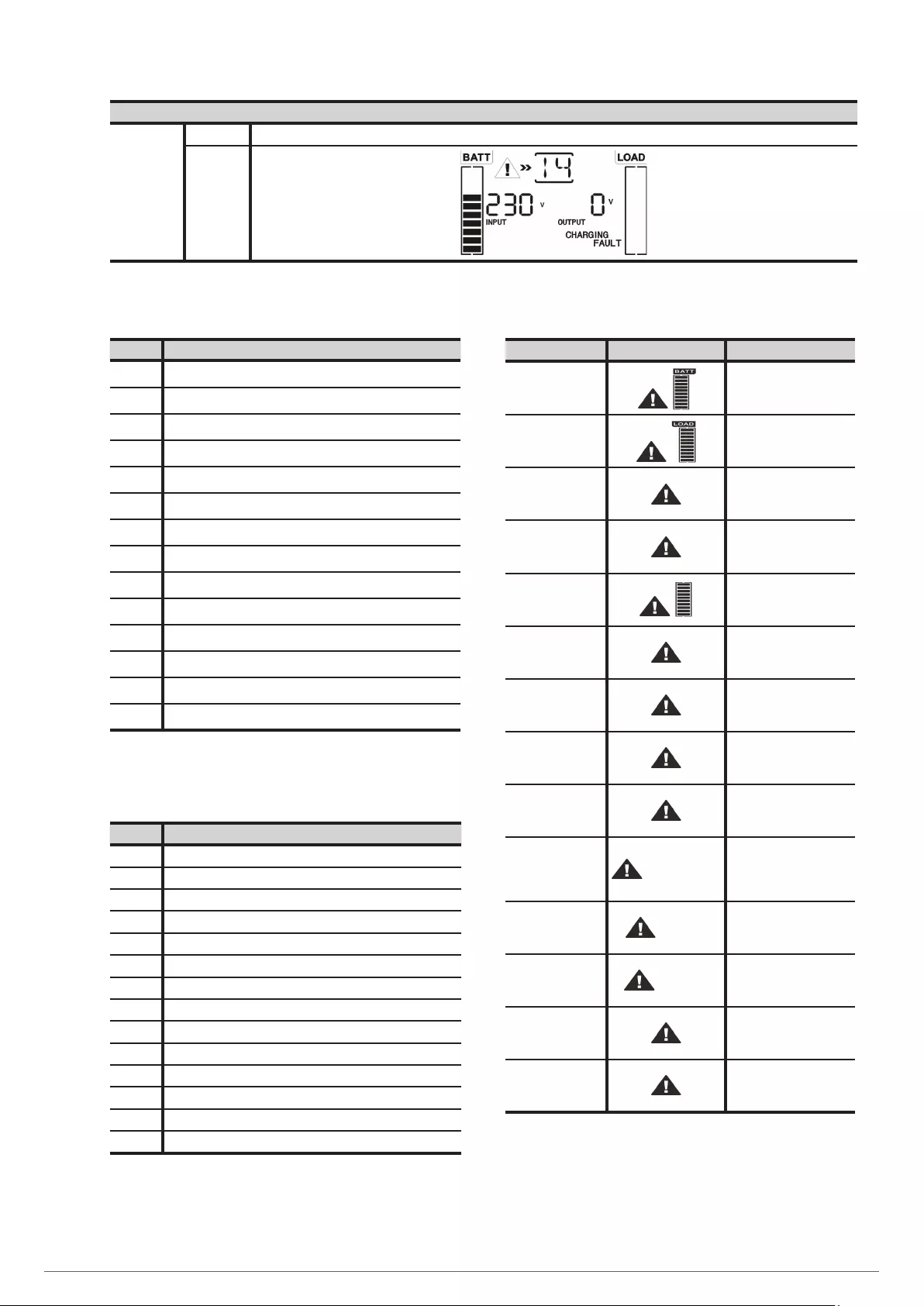

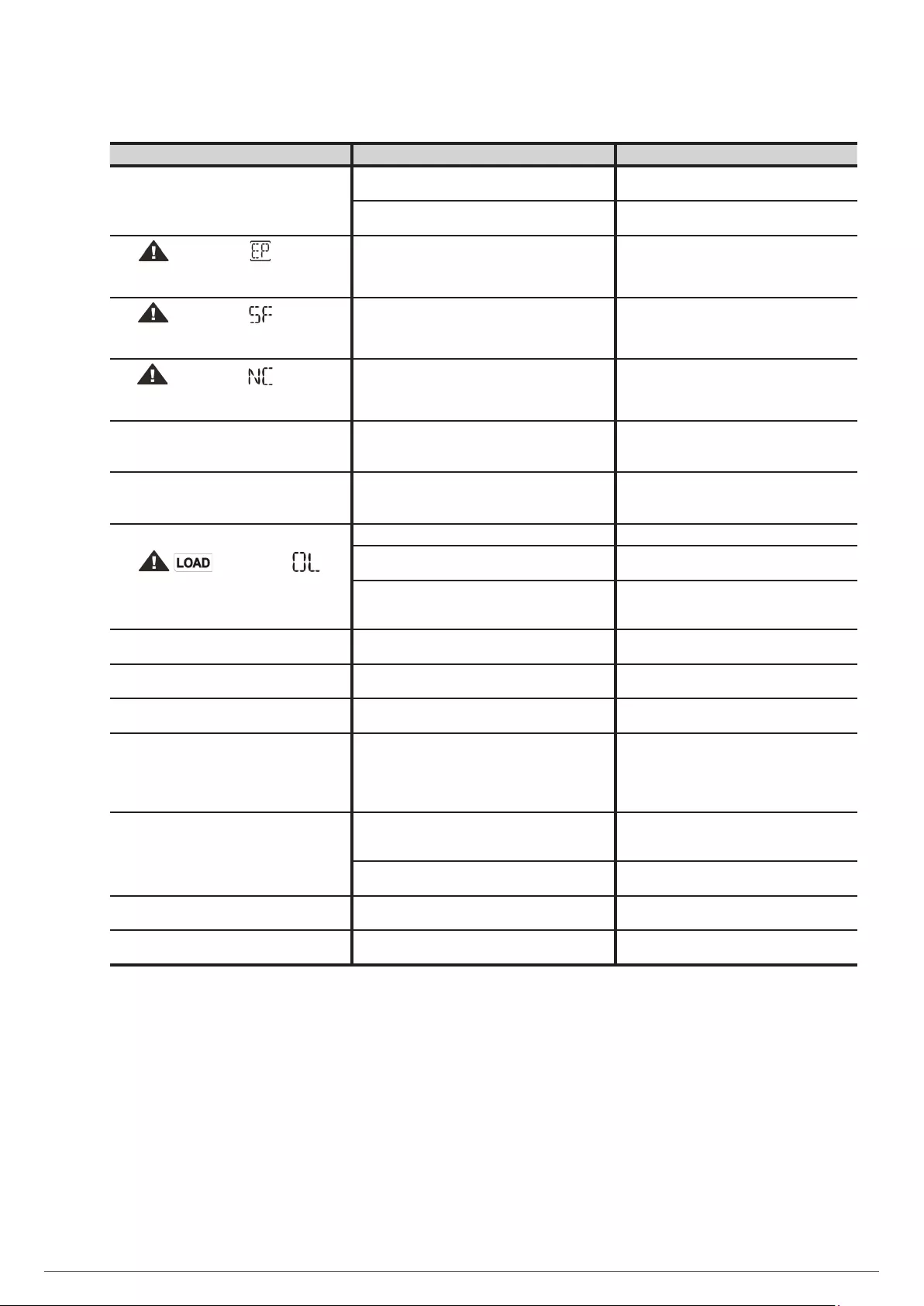

7.2.4.3. Warning or alert codes.

7.2.4.4. Error or fault codes.

7.2.4.5. Warning or alert indicators.

7.3. CONTROL PANEL FOR 4 KVA TO 10 KVA MODELS.

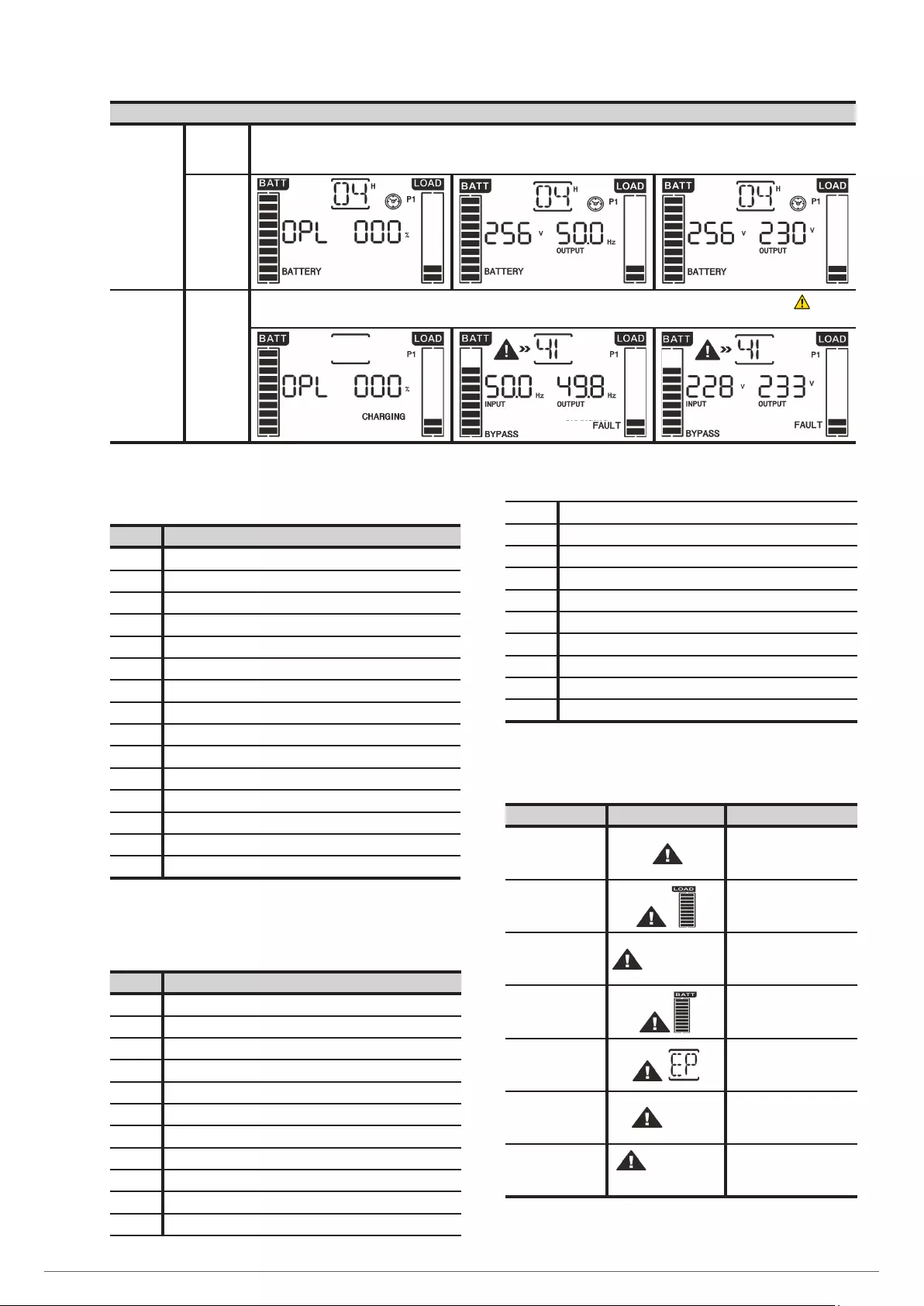

7.3.1. Audible alarms.

7.3.2. Optical indications.

7.3.3. Location of the adjustment parameters on the display.

7.3.4. Settings.

7.3.4.1. Operating mode / Description of state.

7.3.4.2. Operating mode / Description of state.

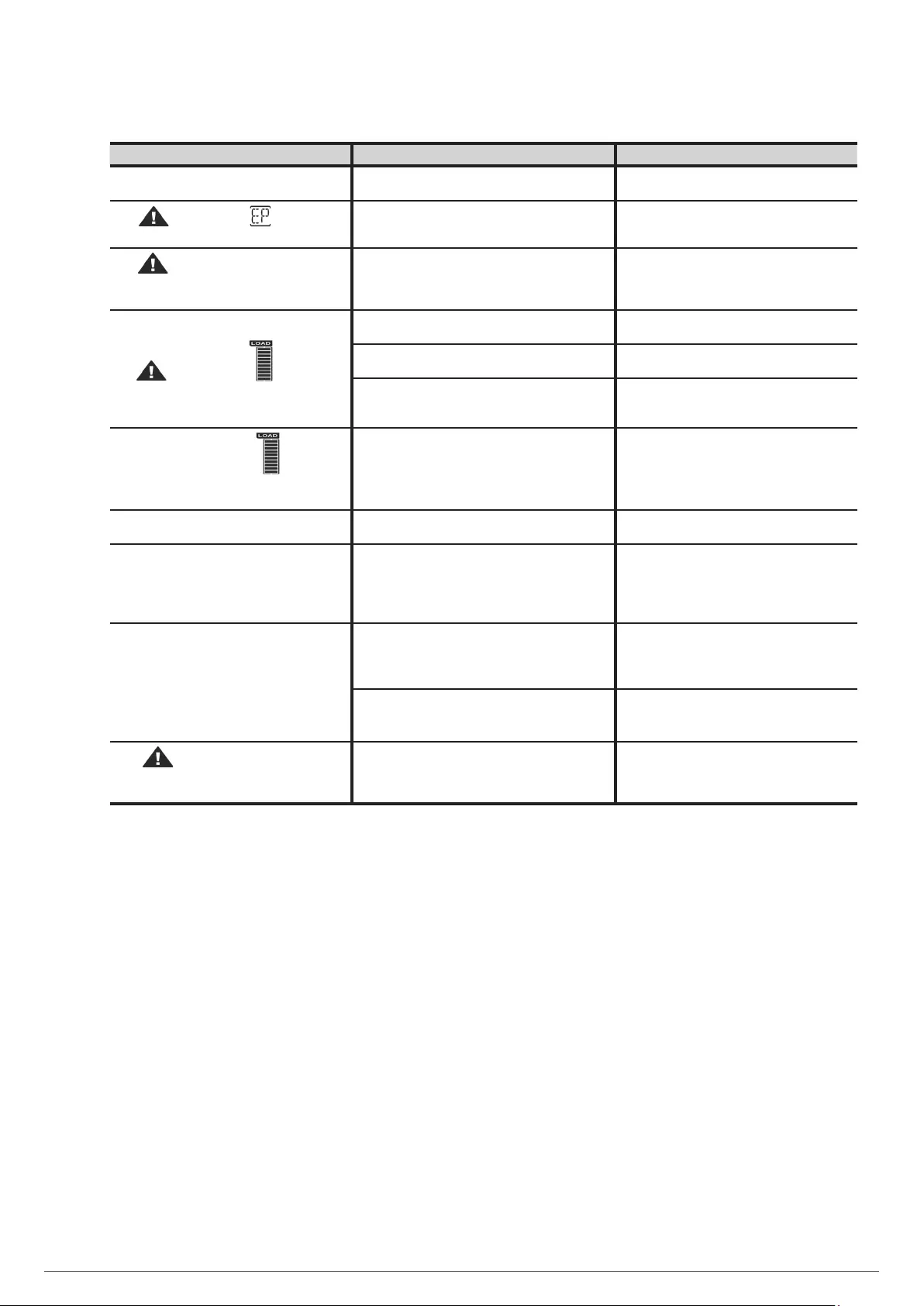

7.3.4.3. Warning or alert codes.

7.3.4.4. Error or fault codes.

7.3.4.5. Warning or alert indicators.

8. MAINTENANCE, WARRANTY AND SERVICE.

8.1. BATTERY MAINTENANCE.

8.1.1. Notes for the installation and replacement of the battery.

8.2. UPS TROUBLESHOOTING GUIDE.

8.2.1. Troubleshooting guide for devices up to 3 kVA.

8.2.2. Troubleshooting guide for 4 kVA to 10kVA devices.

8.3. WARRANTY CONDITIONS.

8.3.1. Terms of the warranty.

8.3.2. Exclusions.

8.4. TECHNICAL SERVICES NETWORK.

9. ANNEXES.

9.1. GENERAL TECHNICAL SPECIFICATIONS.

9.2. GLOSSARY.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

4SALICRU

SALICRU

1. INTRODUCTION.

1.1. THANK YOU LETTER.

We thank you in advance for the trust placed in us in the

purchasing of this product. Read this instruction manual

carefully in order to familiarize yourself with its content,

since the more you know and understand the equipment the

greater your satisfaction, level of safety and optimization of its

functionalities will be.

We remain at your disposal for any additional information or

queries that you may wish to make.

Yours sincerely.

•The equipment described herein is capable of causing

significant physical damage in the event of improper

handling. For this reason its installation, maintenance and/

or repair must be carried out exclusively by our personnel or

by qualified personnel.

•Although no effort has been spared to ensure that the

information in this user manual is complete and accurate, we

are not responsible for any errors or omissions that may exist.

The images included in this document are for illustrative

purposes and may not represent exactly the parts of the

equipment shown, therefore they are not contractual.

However, any divergence that may arise will be remedied or

solved with the correct labelling on the unit.

•Following our policy of constant evolution, we reserve

the right to modify the characteristics, operations

or actions described in this document without prior

notice.

•Reproduction, copying, assignment to third parties,

modification or total or partial translation of this manual

or document, in any form or by any means, without previous

written authorization by our firm is prohibited, with

the full and exclusive property rights over the same being

reserved by our firm.

5

2. SAFETY INFORMATION.

2.1. USING THIS MANUAL.

The documentation of any standard equipment is available to the

customer on our website for download (www.salicru.com).

•For devices “powered by socket”, this is the website for

obtaining the user manual and “Safety Instructions”

EK266*08.

•For devices with “permanent connection” via terminals, a

CD-ROM or pen drive containing all necessary information for

connection and start-up, including “Safety Instructions”

EK266*08, may be supplied with it.

Before carrying out any action on the device relating to its

installation or start-up, change of location, configuration or

handling of any kind, carefully read the safety instructions.

The purpose of the user manual is to provide information

regarding safety and explanations of the procedures for

installation and operation of the equipment. Read them carefully

and follow the steps indicated in the order established.

Compliance with the "Safety Instructions" is

mandatory and the user is legally responsible for

compliance and enforcement.

The equipment is delivered properly labelled for the correct

identification of each of the parts, which together with the

instructions described in this user manual allows the operations

of installation and commissioning to be performed in a simple

and orderly manner without having any doubts whatsoever.

Finally, once the equipment is installed and operating, it is

recommended to save the documentation downloaded from the

website, CD-ROM or Pen Drive in a safe and easy-to-access

place, for any future queries or doubts that may arise.

The following terms are used interchangeably in the document

to refer to:

•‘SLC TWIN RT2’, ‘TWIN RT2’, ‘TWIN’, ‘RT2’, ‘device’,

‘unit’ and ‘UPS’ - Uninterruptible power supply.

Depending on the context of the phrase, it can refer either

to the actual UPS itself or to the the UPS and the batteries,

regardless of whether it is all assembled in the same metal

casing - box - or not.

•“Batteries or accumulators”.- Group or set of elements

that stores the flow of electrons by electrochemical means.

•‘T.S.S.’ - Technical Service and Support.

•‘Client, installer, operator or user’ - These are used

interchangeably and by extension to refer to the installer

and/or operator who will carry out the corresponding

actions, and the same person may be responsible for

carrying out the respective actions when acting on behalf

of, or in representation of, same.

2.1.1. Conventions and symbols used.

Some symbols may be used and appear on the equipment,

batteries and/or in the context of the user manual.

For more information, see section 1.1.1 of document EK266*08

on "Safety instructions".

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

6SALICRU

3. QUALITY ASSURANCE AND STANDARDS.

3.1. STATEMENT BY THE MANAGEMENT.

Our goal is customer satisfaction, therefore this Management

has decided to establish a Quality and Environment Policy,

through the implementation of a Quality and Environmental

Management System that will enable us to comply with the

requirements demanded in the ISO 9001 and ISO 14001 and

also by our Customers and Stakeholders.

Likewise, the management of the company is committed to the

development and improvement of the Quality and Environmental

Management System, through:

•Communication to the entire company of the importance of

satisfying both the client's requirements as well as legal

and regulatory requirements.

•The dissemination of the Quality and Environment Policy

and the setting of the Quality and Environment objectives.

•Conducting reviews by the Management.

•Providing the necessary resources.

3.2. STANDARDS.

The SLC TWIN RT2 is designed, manufactured and sold in

accordance with Quality Management Standard EN ISO 9001.

The marking indicates conformity with EC Directives

through the application of the following standards:

•2014/35/EU. - Low voltage safety.

•2014/30/EU. - Electromagnetic Compatibility - EMC-.

•2011/65/EU. - Restriction of the use of hazardous

substances in electrical and electronic equipment (RoHS).

According to the specifications of the harmonized standards.

Reference standards:

•EN-IEC 62040-1. Uninterruptible Power Supplies -UPS-. Part

1-1: General and safety requirements for UPS used in user

access areas.

•EN-IEC 60950-1. Information technology equipment. Safety.

Part 1: General requirements.

•EN-IEC 62040-2. Uninterruptible Power Supplies -UPS-.

Part 2: EMC requirements.

The manufacturer accepts no liability in the event of

modification of or intervention on the device by the

user.

WARNING!:

SLC TWIN RT2 0.7.. 3 kVA. This is a category C2 UPS.

In a residential environment, this product may cause

radio interference, in which case the user must take

additional measures.

SLC TWIN RT2 4.. 10 kVA. This is a category C3 UPS. This

is a product for commercial and industrial application

in the second environment; Installation restrictions

or additional measures may be necessary to avoid

disturbances.

It is not appropriate to use this equipment in basic

life support applications (BLS), where a failure of the

former can render vital equipment out of service or

significantly affect its safety or effectiveness. It is also

not recommended in medical applications, commercial

transport, nuclear installations, or other applications

or loads, where a failure of the product can lead to

personal or material damages.

The EC declaration of conformity of the product is

available to the customer upon express request to our

headquarters.

3.2.1. First and second environment.

The environment examples that follow cover most UPS

installations.

3.2.1.1. First environment.

Environment including residential, commercial and light

industry installations, directly connected, without intermediate

transformers, to a low voltage public power grid.

3.2.1.2. Second environment.

An environment that includes all commercial, light industrial

and industrial establishments that are not directly connected

to a low voltage power grid supplying buildings used for

residential purposes.

3.3. ENVIRONMENT.

This product has been designed to respect the environment and

manufactured according to ISO 14001.

Recycling of the equipment at the end of its useful life:

Our company undertakes to use the services of authorized and

regulatory companies to treat the set of products recovered at

the end of their useful life (contact your distributor).

Packaging:

For the recycling of the packaging there must be compliance

with the legal requirements in force, according to the specific

regulations of the country where the equipment is installed.

Batteries:

Batteries pose a serious danger to health and the environment.

The disposal of them shall be carried out in accordance with

the laws in force.

7

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the device.

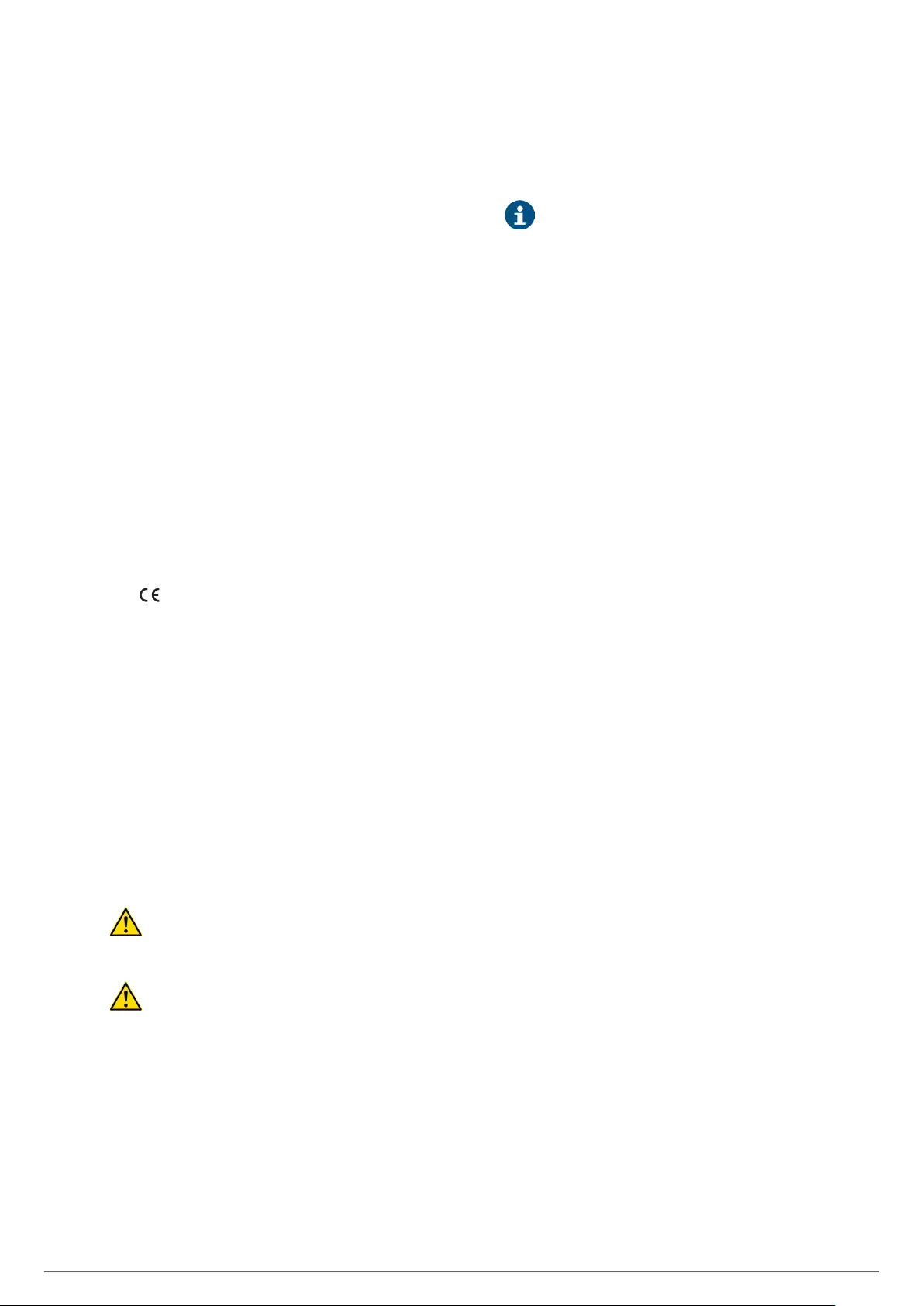

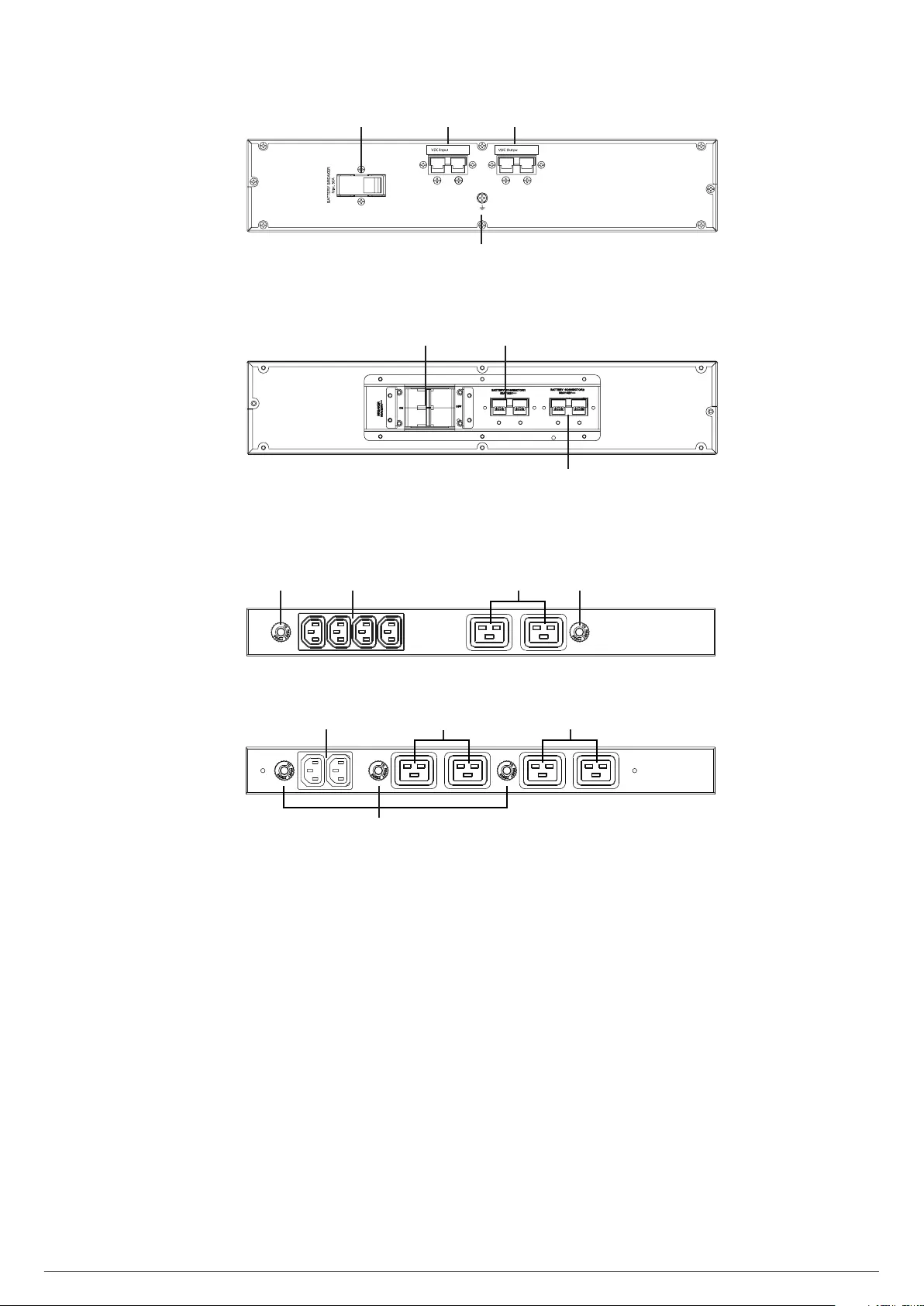

In Fig. 1 to Fig. 4, illustrations of the device are shown according

to box size in relation to the power rating of the model. However,

because the product is constantly evolving, discrepancies or

slight contradictions may arise. If in any doubt, the labelling on

the equipment itself will always prevail.

The nameplate of the device shows all of the values

relating to its main properties and characteristics. Act

accordingly for its installation.

0.7 to 3 kVA models

4 to 10 kVA models

Battery module for

0.7 to 10 kVA models

Control panel with

LCD display

Plastic front trim

Control panel with

LCD display

Plastic front trim

BATTERY LINEBYPASS FAULT

Fig. 1. Front view of 0.7 to 10 kVA models and their

battery modules for extended backups.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

8SALICRU

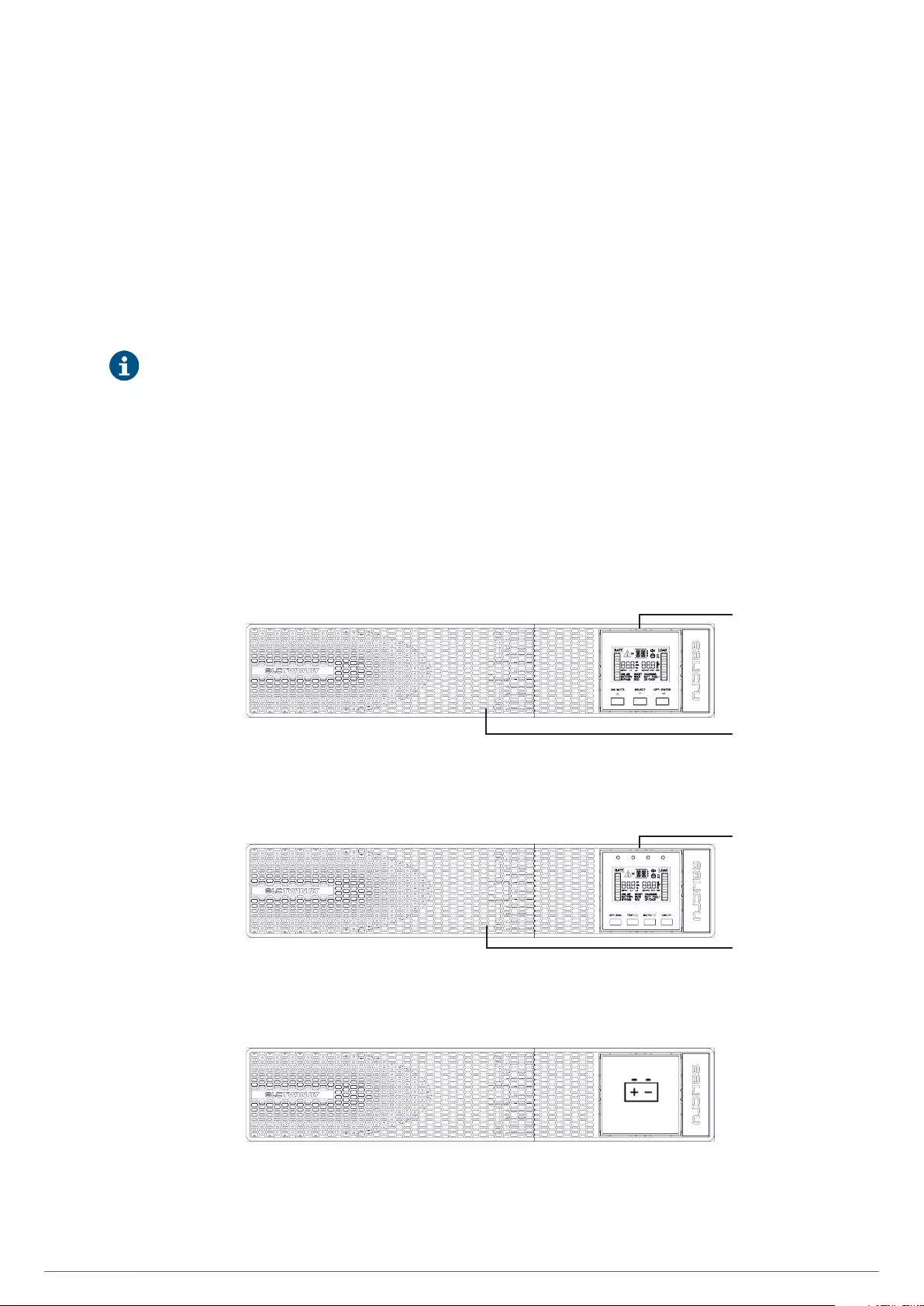

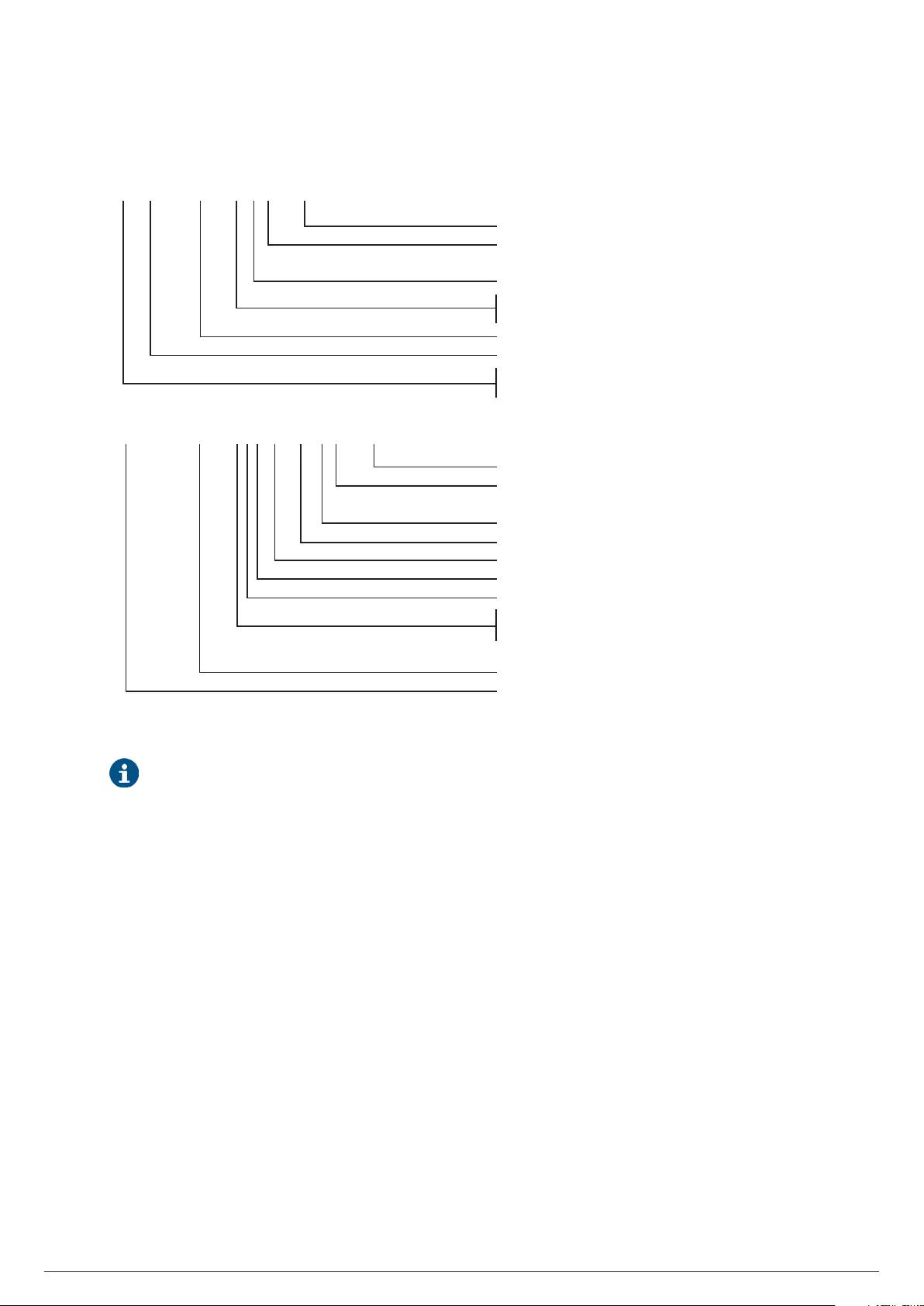

IEC output connectors programmable

at disconnection, for non-critical loads

Standard and B1 0.7

to 1.5 kVA models

COM port

USB

RS232

COM port

AC power IEC connector

Smart slot

protective cover

Fan

Input connector for modem/

ADSL/fax, etc., lines

Connector for

external EPO

Output connector, with protection

for modem/ADSL/fax, etc.

Connector for connection to

external battery module.

Earth

connection

Non-programmable IEC output

connectors, for critical loads

Standard and B1

2 kVA models

COM port

USB

RS232 COM

port

AC power IEC connector

Smart slot

protective cover

Fan

Input connector for modem/

ADSL/fax, etc., lines

Connector for

external EPO

Output connector, with protection

for modem/ADSL/fax, etc.

Non-programmable IEC output

connectors, for critical loads

Earth

connection

IEC output connectors programmable

at disconnection, for non-critical loads

Connector for connection to

external battery module.

Standard and B1

3 kVA models

COM port

USB

RS232 COM

port

AC power IEC connector

Smart slot

protective cover

Input connector for modem/

ADSL/fax, etc., lines

Connector for

external EPO

Fans

Output connector, with protection

for modem/ADSL/fax, etc.

16 A IEC output connector

Earth

connection

Non-programmable IEC output

connectors, for critical loads

IEC output connectors programmable

at disconnection, for non-critical loads

Connector for connection to

external battery module.

Communication bus for

parallel systems

4 to 10 kVA models

COM port

USB

RS232 COM

port

Connector for

external EPO

Smart slot

protective cover

Connector for connection to

external battery module.

Output, earth,

input terminals

Manual Bypass

auxiliary contact.

Current signal bus for

parallel systems

Input

switch

Digital

input/output

Fans

Standard 4 to 10 kVA

models, represented

with battery module

Fig. 2. Rear view of 4 to 10 kVA models.

9

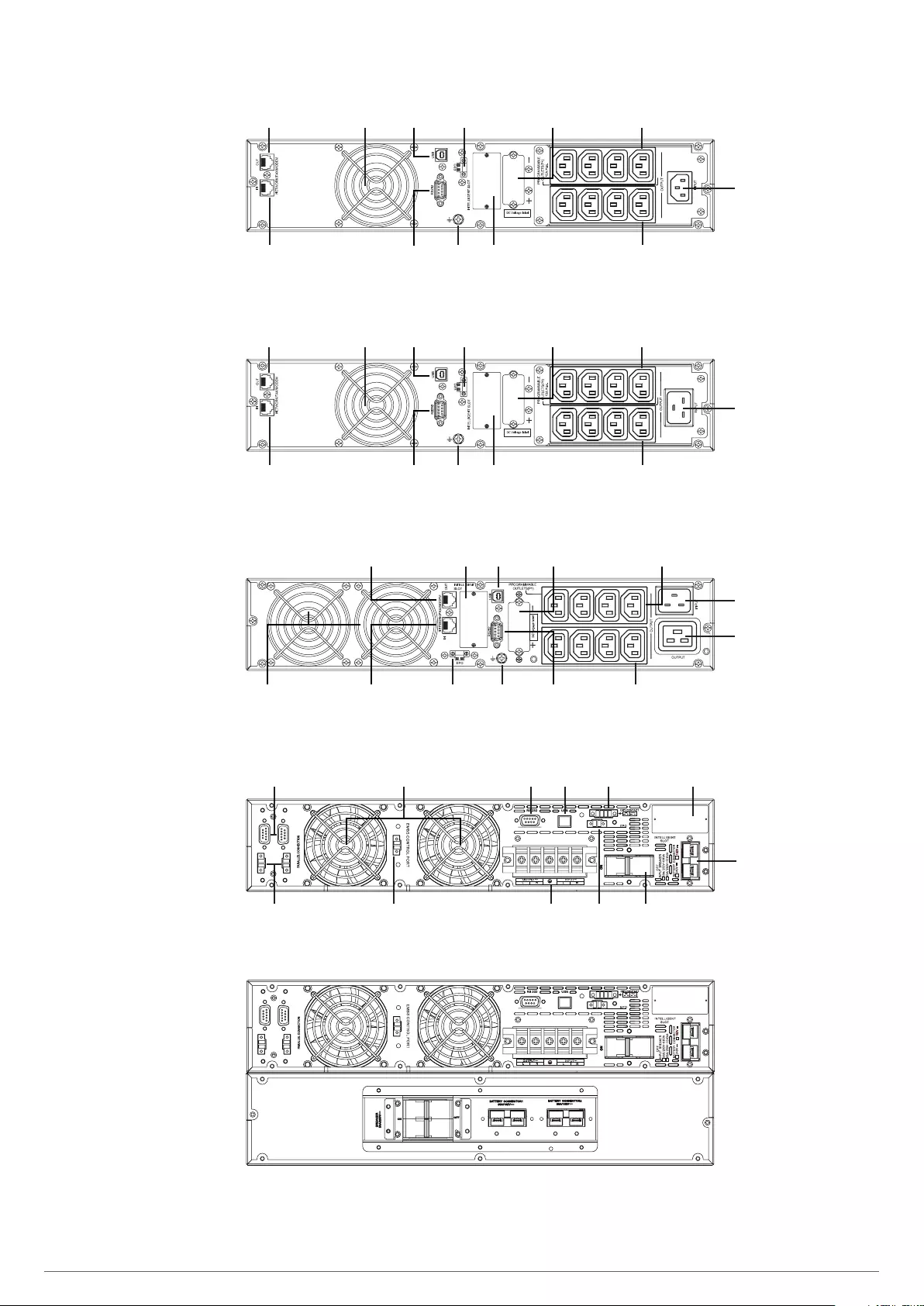

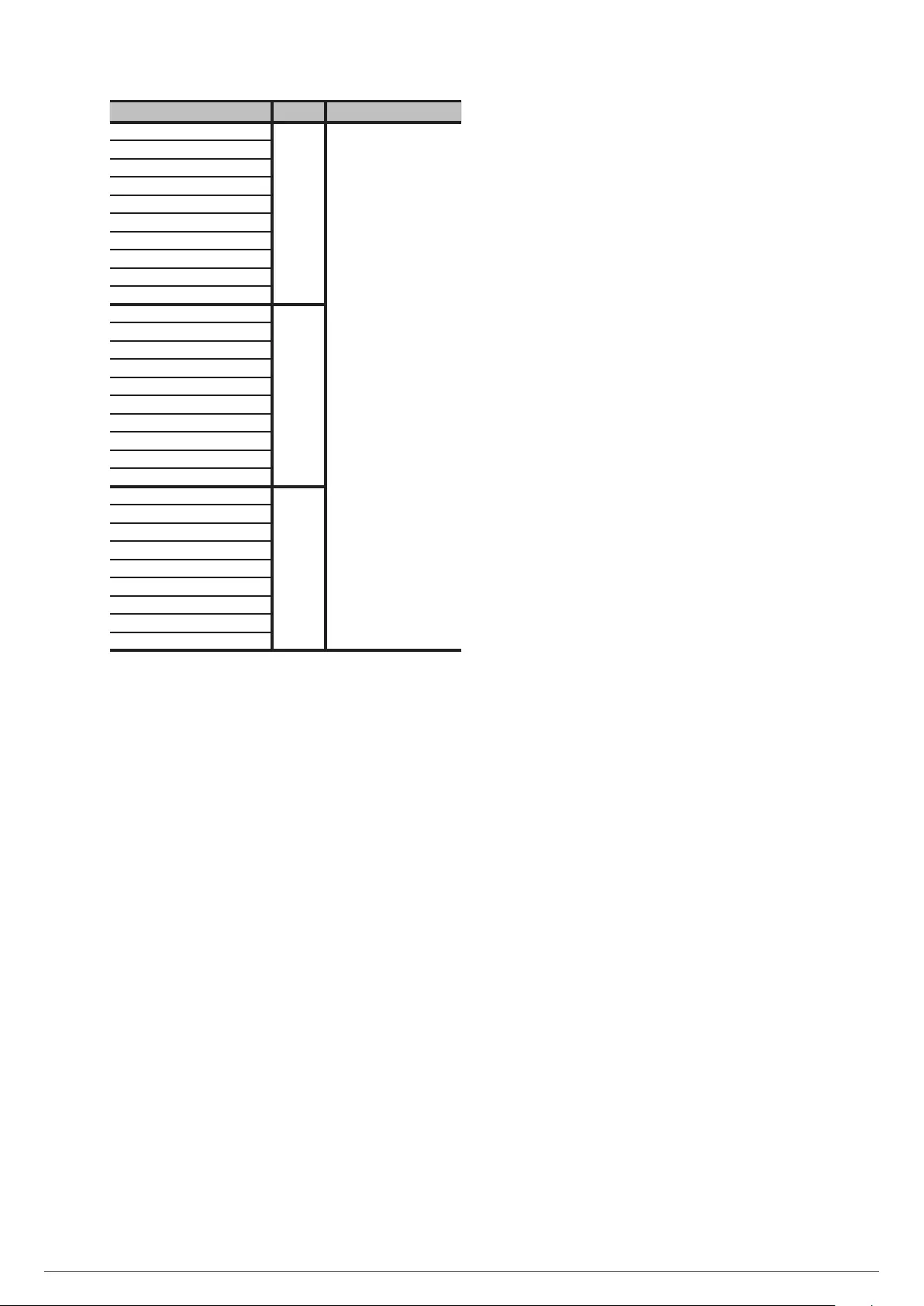

Battery module input

connector

VDC protection

Battery module for

0.7 to 3 kVA devices

Output connector for

battery module

Earth connection

Battery module for 4

to 10 kVA devices

Battery module

connector

VDC protection

Battery module

connector

Fig. 3. Rear view of battery modules for extended backups.

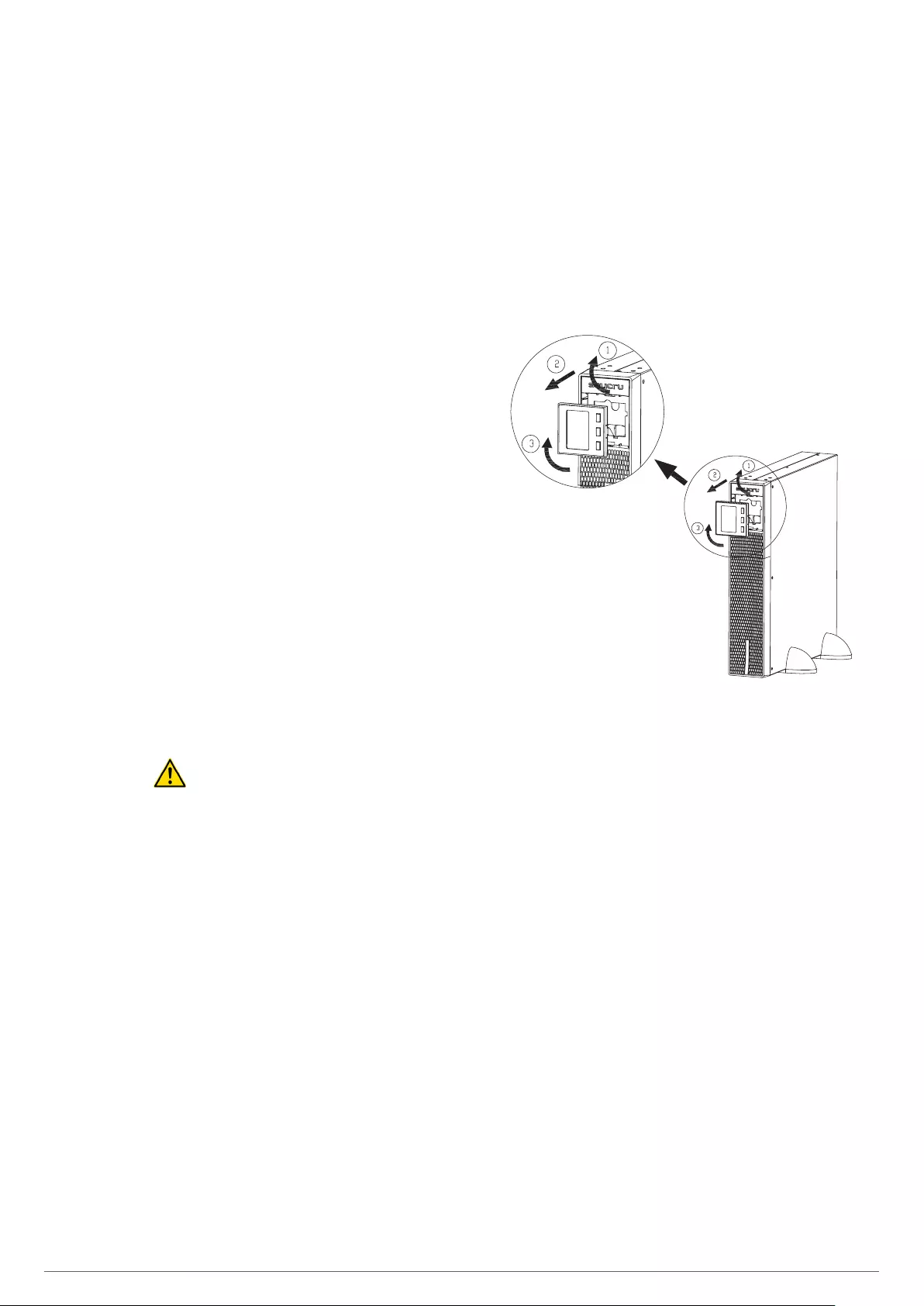

PDU for 4 to 6 kVA

devices

Output circuit

breaker

Output IEC

connectors

Output circuit

breaker

Output IEC

connectors

PDU for 8 to 10 kVA

devices

Output circuit

breaker

Output IEC

connectors

Output IEC

connectors

Output IEC

connectors

Fig. 4. Front view of PDU (power distribution unit).

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

10 SALICRU

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

SLC-8000-TWIN RT2 B1 WCO EE29503

MOD BAT TWIN RT2 2x6AB003 40A WCO EE29503

EE* Special customer specifications.

CO 'Made in Spain' marking on UPS and packaging

(for customs purposes).

W Private-label device.

B0 Without batteries.

B1 Device with extra charger and without batteries.

TWIN RT2 Device series.

8000 Power in VA.

SLC Brand acronym (for UPS).

CF Frequency converter (device without batteries).

EE* Special customer specifications.

CO ‘Made in Spain’ marking on UPS and packaging

(for customs purposes).

W Private-label device.

40A Protection size.

003 Last three digits of the battery code.

AB Initials of the battery family.

6 Number of batteries in one branch.

2x Number of branches in parallel. Omit for one.

0/ Battery module without them, but with the

necessary accessories to install them.

TWIN RT2 Battery module series.

MOD BAT Battery module.

Note related to B0 and B1 batteries:

(B0) The device is supplied without batteries, but with

a space reserved for installation in the same box

for models whose standard version specifies this.

For other models, the battery pack will be installed

in the manner considered most appropriate (box,

cabinet, rack, etc.).

For B0 devices ordered, the cost of acquisition,

installation and connection of the batteries shall

always be borne by the customer or distributor

and under their responsibility.

Accessories such as screws, cables and battery

connection plates are considered optional and

can be supplied upon request.

(B1) Device with a more powerful charger, which does

not have a battery pack, nor the possibility of

installing them in the same box.

If an accumulator module is required, it will need

to be ordered as a separate item, which will be

connected to the UPS using the supplied cable.

Before connecting a module or group of batteries to the

device or another available module, it is necessary

to check that the voltage value printed on the back of

the device next to the battery connector is appropriate

and that the polarity between the means of connection

corresponds.

For more information, see Chapter 9 of this document.

11

4.3. OPERATING PRINCIPLE.

This manual describes the installation and operation of SLC

TWIN RT2 series UPSs as devices that can be independently

operated or connected in parallel (for models > 3 kVA). SLC

TWIN RT2 series UPSs ensure optimum protection of any

critical load, maintaining the supply voltage of the loads

between the specified parameters without interruption during

failure, deterioration or fluctuation of mains power, and come

in a wide range of models (from 0.7 kVA to 10 kVA), enabling

the end user to select the model that best suits his needs.

Thanks to their PWM (pulse width modulation) and double-

conversion technology, SLC TWIN RT2 series UPSs are compact,

cool, silent and high performance.

The double converter principle eliminates all mains power

disturbances. A rectifier converts the AC current of the mains

into DC current, thereby maintaining optimum battery charge

level and powering the inverter, which, in turn, generates a

suitable AC sine-wave voltage for continuously powering the

loads. In the event of failure of the UPS’s mains power, the

batteries supply clean power to the inverter.

The design and construction of the SLC TWIN RT2 series UPS

has been carried out in accordance with international standards.

In addition, models with power ratings greater than 3 kVA can

be expanded with the connection of additional modules with

the same power in parallel to obtain N+X redundancy or an

increase in the system’s power.

Thus, this series has been designed to maximise the availability

of critical loads and to ensure that your business is protected

from variations in power distribution line voltage, frequency,

electrical noise, cuts and micro-cuts. This is the primary goal of

SLC TWIN RT2 series UPSs.

This manual applies to the standardised models shown in Tab. 1.

4.4. UPS OPERATING MODES.

•Normal mode.

Device running supplying output voltage from the inverter.

Mains power present with correct input voltage and

frequency.

•Battery mode.

Device running with mains voltage or frequency out of

range or without AC input power, either due to mains

failure or absence of cable connection, supplying output

voltage from the batteries.

•Bypass mode.

Device running or not, supplying output voltage directly

from the AC mains.

With the inverter running, this operating mode may be

due to an overload, blockage or inverter fault.

The actions for each incident will be as follows: Reduce

the load connected to the output, unblock the device by

resetting it – stop it and start it up again – and, if the

blockage or fault remains, contact T.S.S.

With the inverter shut down, the output supplies mains

power directly through the static bypass of the device

provided that it has AC input power.

•Frequency converter (CF) mode.

Operating mode of the UPS as a frequency converter. In

this mode, the static bypass is disabled by the condition of

disparate input and output frequencies.

Even if the LCD display on the backlit control panel

shows messages, it does not mean that the inverter is

operational. It is switched on by pressing the ‘ON’

button on the control panel, see Chapter 6.

4.4.1. Notable features.

•True on-line with double-conversion technology and output

frequency separate from the mains.

•Output power factor 1, except for B1 models where it is 0.8.

Pure sine waveform, suitable for almost all kinds of loads.

•Input power factor > 0.99 and high overall performance

(between 0.89 and 0.91 for 0.7 to 3 kVA models and > 0.93

for higher power ratings). Greater energy savings and lower

user installation costs (wiring), as well as low distortion

of the input current, which reduces pollution in the power

supply network.

•Great adaptability to the worst conditions of the mains.

Wide input voltage, frequency and waveform ranges, thus

avoiding excessive dependence on limited battery power.

•Possibility of fast and easy backup extension by adding

modules in rack format. Each battery module has two

connectors for easy connection to the device and other

identical modules.

•Availability of battery chargers of up to 6 A to reduce bat-

tery recharge times.

•N+X redundant parallel connection to increase reliability

and flexibility in power models > 3 kVA, with a maximum

of 3 devices in parallel.

•Selectable high-performance mode (ECO MODE) > 0.95 to

0.99 depending on model. Energy savings, economically

beneficial for the user.

•Possibility of starting the device without mains power

supply or discharged battery. Be careful with this aspect

because the greater the batteries are discharged, the more

the backup will be reduced.

•Intelligent battery management technology is very useful

for extending the life of accumulators and optimising

recharge times.

•Standard communication options via the RS232 serial port

or USB port.

•Digital input for device Start/Stop and ‘Error or fault’ digital

output in models with power ratings > 3 kVA.

•Remote emergency power off control (EPO).

•Control panel with LCD display available on all models and

LED indicators on devices with power ratings > 3 kVA.

•Availability of optional connectability cards to improve

communication capabilities.

•Device that can be installed as a tower or rack using the

accessories supplied. The control panel can be rotated to

adapt to either format.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

12 SALICRU

Model Type Input/output type

SLC-700-TWIN RT2

Standard

Single-phase / Single-phase.

SLC-1000-TWIN RT2

SLC-1500-TWIN RT2

SLC-2000-TWIN RT2

SLC-3000-TWIN RT2

SLC-4000-TWIN RT2

SLC-5000-TWIN RT2

SLC-6000-TWIN RT2

SLC-8000-TWIN RT2

SLC-10000-TWIN RT2

SLC-700-TWIN RT2 (B0)

Without batteries

SLC-1000-TWIN RT2 (B0)

SLC-1500-TWIN RT2 (B0)

SLC-2000-TWIN RT2 (B0)

SLC-3000-TWIN RT2 (B0)

SLC-4000-TWIN RT2 (B0)

SLC-5000-TWIN RT2 (B0)

SLC-6000-TWIN RT2 (B0)

SLC-8000-TWIN RT2 (B0)

SLC-10000-TWIN RT2 (B0)

SLC-700-TWIN RT2 (B1)

Long backup with additional charger

SLC-1000-TWIN RT2 (B1)

SLC-1500-TWIN RT2 (B1)

SLC-2000-TWIN RT2 (B1)

SLC-3000-TWIN RT2 (B1)

SLC-4000-TWIN RT2 (B1)

SLC-6000-TWIN RT2 (B1)

SLC-8000-TWIN RT2 (B1)

SLC-10000-TWIN RT2 (B1)

Tab. 1. Standardised models.

4.5. OPTIONAL EXTRAS.

Depending on the configuration chosen, the device may include

any of the following options:

4.5.1. Isolation transformer:

The isolation transformer provides galvanic isolation in order

to completely isolate the output from the input and/or change

neutral mode.

The placement of an electrostatic screen between the primary

and secondary windings of the transformer provides a high

level of electrical noise attenuation.

The isolation transformer can be physically placed at the input

or output of the UPS depending on the technical conditions of

the whole system (device supply voltage and/or load voltage,

characteristics or their type, etc.).

In parallel systems, it is not possible to operate with independent

transformers for each UPS; on the contrary, it is necessary to

have a single common element for the total adequate power.

In any event, it will always be supplied as a peripheral

component external to the device itself in a separate box.

4.5.2. Exterior manual maintenance bypass.

The purpose of this option is to electrically isolate the device

from the mains and the critical loads without cutting the power

to the latter. In this way, maintenance or repair operations on

the device can be carried out without interruptions to the power

supply of the protected system, while preventing unnecessary

hazards for the technical personnel.

4.5.3. Communication card.

The UPS features a slot at the rear for inserting one of the

following communication cards.

4.5.3.1. Integration into computer networks using an SNMP

adapter.

Large computer systems based on LANs and WANs that

integrate servers in different operating systems must provide

the system manager with ease of control and administration.

This facility is obtained through an SNMP adapter, which

is universally supported by the main software and hardware

manufacturers.

Connection of the UPS to the SNMP is internal while that of

the SNMP to the computer network is made through a RJ45 10

base connector.

4.5.3.2. Modbus RS485.

Large computer systems based on LANs and WANs often

require that communication with any element that is integrated

into the computer network be made through a standard

industrial protocol.

One of the most used standard industrial protocols on the

market is the MODBUS protocol.

4.5.3.3. Interface to relays.

•The UPS has, as an option, an interface to relays card

that provides digital signals in the form of potential-free

contacts, with a maximum applicable voltage and current

of 240 V AC or 30 V DC and 1A.

•This communication port enables dialogue between the

device and other machines or devices through the relays

supplied in the terminal block arranged on the same card,

with a single common terminal for all of them.

From the factory, all contacts are normally open and can

be changed one by one, as indicated in the information

supplied with the optional extra.

•The most common use of these types of ports is to provide

the necessary information to the file-closing software.

•For more information, contact our T.S.S. or our nearest

distributor.

4.5.4. Extendable guide kits for mounting in a rack cabinet.

An extendable and unique guide kit is available for all device

models, valid for any kind of rack-type cabinet.

These guides allow the installation of any TWIN RT2 device

unit and possible battery modules in the case of extended

backups, as if it were a rack in its respective cabinet.

13

5. INSTALLATION.

•Read and respect the Safety Information, described

in chapter 2 of this document. Failure to obey some

of the instructions described in this manual can result in a

serious or very serious accident to persons in direct contact

or in the vicinity, as well as faults in the equipment and/or

loads connected to it.

•In addition to the device’s own user manual, other

documents are supplied on the CD-ROM or documentation

pen drive. Consult them and strictly follow the indicated

procedure.

•Unless otherwise indicated, all actions, instructions,

guidelines and notes are applicable to the devices, whether

or not they form part of a parallel system.

5.1. RECEPTION OF THE DEVICE.

•Pay attention to section 1.2.1. of the safety instructions

-EK266 * 08- in all matters relating to the handling, move-

ment and location of the unit.

•Use the most suitable means to move the UPS while it is

packed, with a transpalet or forklift.

•Any handling of the device must be carried out in accordance

with the weights shown in the technical specifications

according to the model, indicated in chapter ‘9. Annexes’.

5.1.1. Reception, unpacking and contents.

•Reception. Check that:

The data on the label affixed to the packaging

correspond to those specified in the order. Once the

UPS is unpacked, check the previous data with those of

the equipment nameplate.

If there are discrepancies, file the disagreement as

soon as possible, citing the equipment manufacture

number and the delivery note references.

It has not suffered any mishaps during transportation

(packaging and impact indicator in perfect condition).

Otherwise, follow the protocol indicated on the label

attached to the impact indicator, located on the

packaging.

•Unpacking.

To check the contents, it will be necessary to remove

the packaging.

Complete the unpacking according to the

procedure of section 5.1.3. Content.

•Content

0.7 to 3 kVA device:

–1 UPS.

–Quick guide on paper.

–Information for warranty registration.

–1 USB cable.

–3 cables with IEC connectors for loads.

–1 cable for the device’s AC power supply.

–2 metal pieces for use as handles and screws for

installing the unit in a rack cabinet.

–4 plastic pieces for use as a base to facilitate

the arrangement of the UPS as a tower (vertical

position).

Optional battery module for 0.7 to 3 kVA UPS:

–1 battery module.

–Information for warranty registration.

–2 metal pieces for use as handles and screws for

installing the unit in a rack cabinet.

–2 plastic pieces to extend the base of the UPS and

enable the arrangement of the attached battery

module in its mounting as a tower.

–1 cable for interconnecting the battery module and

UPS or other module.

4 to 10 kVA device:

–1 UPS.

–1 PDU module (power distribution unit).

–Information for warranty registration.

–2 metal pieces for use as handles and screws for

installing the UPS in a rack cabinet.

–2 metal pieces for use as handles and screws for

installing the PDU in a rack cabinet.

–1 metal piece and screws for mounting the PDU

attached to the UPS arranged as a tower.

–1 USB cable.

–4 plastic pieces for use as a base to facilitate

the arrangement of the UPS as a tower (vertical

position).

–1 cable for connecting the communication bus.

Useful only for connection to a parallel device.

–1 cable for connecting the current bus. Useful only

for connection to a parallel device.

–1 cable for interconnecting the battery module and

UPS.

4 to 10 kVA battery module:

–1 battery module.

–Information for warranty registration.

–2 metal pieces for use as handles and screws for

installing the unit in a rack cabinet.

–2 plastic pieces to extend the base of the UPS and

enable the arrangement of the attached battery

module in its mounting as a tower.

–1 cable for interconnecting the battery module and

another module.

•Once the reception is completed, it is advisable to re-pack

the UPS until it is put into service in order to protect it

against mechanical shock, dust, dirt, etc.

•The packaging of the device consists of a wooden pallet,

cardboard or wooden box, depending on the item, expanded

polystyrene corners, polyethylene cover and strapping, all

of which are recyclable materials. When the packaging

requires disposal, it must be carried out in accordance with

current laws.

We recommend keeping it for at least 1 year.

5.1.2. Storage.

•The device should be stored in a dry, ventilated room and

protected from rain, dust, and water or chemical splashes. It

is advisable to keep each device and battery unit in its orig-

inal packaging, as it has been specifically designed to en-

sure maximum protection during transportation and storage.

•For devices that contain Pb-Ca batteries, the

charging times indicated in Tab. 2 of document

EK266*08, determined by the temperature to which they

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

14 SALICRU

are exposed, must be respected, otherwise the warranty

may be invalidated.

•After this period, connect the device to the mains together

with the battery unit if applicable, start it according to the

instructions described in this manual and charge for 12

hours.

In parallel systems, it is not necessary to interconnect

devices before battery charging. Each of them can be

treated independently to charge them.

•Then shut down the device, disconnect it and store the UPS

and batteries in their original packaging, noting the new

date for recharging the batteries on a document as a record

or even on the packaging itself.

•Do not store the devices where the ambient temperature

exceeds 50ºC or drops below -15ºC, as this may cause

degradation of the electrical characteristics of the batteries.

5.1.3. Unpacking.

•The packaging of the device consists of a cardboard box,

expanded polystyrene (EPS) or polyethylene foam (EPE)

corners, polyethylene cover and strapping, all of which are

recyclable materials; consequently, if it requires disposal,

it must be carried out in accordance with current laws. We

recommend keeping the packaging in case it needs to be

used in the future.

•Proceed as follows:

Cut the straps around the cardboard box.

Remove the accessories (cables, brackets, etc. )

Remove the device or battery module from the box with

the help, if necessary, of a second person depending

on the weight of the model or using appropriate

mechanical means.

Remove the protective corners from the device and the

plastic bag.

Do not leave the plastic bag within the reach of

children to avoid danger of suffocation.

Inspect the device before proceeding and, in the event

of finding damage, contact the supplier or, failing that,

our firm.

5.1.4. Transport to the site.

It is recommended to transport the UPS by means of a

pallet jack or the most appropriate method considering the

distance between the two points.

If the distance is considerable, it is recommended to

transport the device in its packaging to the installation site

and then unpack it.

5.1.5. Siting, immobilising and considerations.

•All TWIN RT2 series UPSs are designed to be mounted as

a tower model -vertical arrangement of the device- or rack

-horizontal arrangement- for installation in 19” cabinets,

regardless of whether they operate independently or as

parallel systems, whether or not they have a battery module

or whether the available backup is standard or extended

(greater number of battery modules).

Follow the instructions indicated in the sections relating to

either of the two possibilities, according to the particular

configuration of your device.

•Figs. 5 to 11 show, by way of example, illustrations of a

device with or without battery module. These illustrations

provide help and guidance in the steps to follow, but the

instructions are not intended to refer to a single model,

although, in practice, the actions to be carried out are

always the same for all of them.

•For all instructions regarding connections, refer to section 5.2.

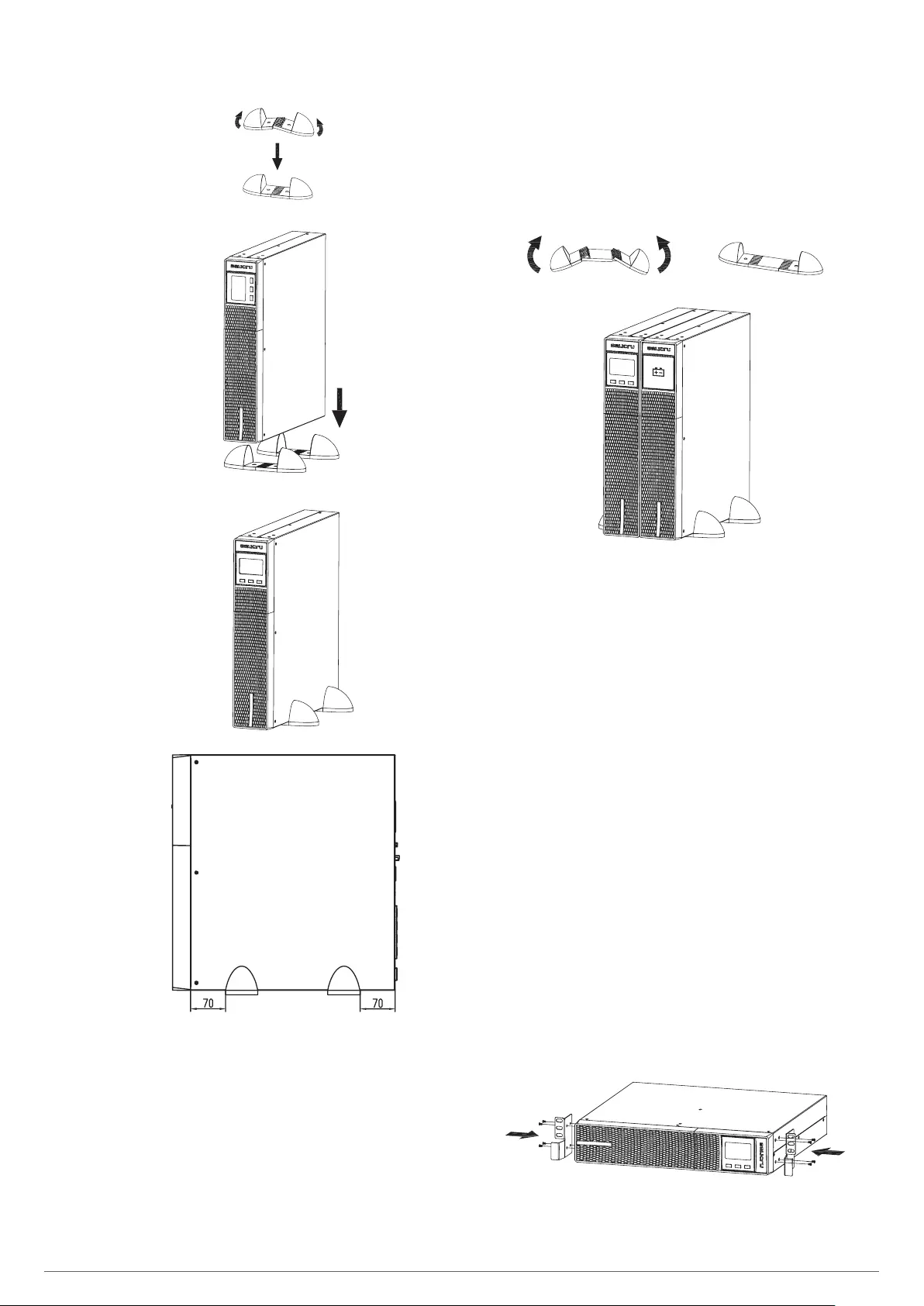

5.1.5.1. Rotation of the control panel with LCD display.

Fig. 5. Rotation of the control panel with LCD display on

the plastic front trim.

•To facilitate the reading of messages on the display when

the device is installed vertically, it is possible to rotate the

control panel clockwise by 90º (see Fig. 5).

•Likewise, reverse the rotation of the control panel if a

device arranged as a tower needs to be installed as a rack.

In this case, the rotation of the control panel will be anti-

clockwise.

•Proceed as follows:

Insert fingertips into the recesses of the plastic trim

around the display and pull outwards.

Rotate the control panel with LCD display 90º to the

right with respect to its initial position and insert it back

into the front.

5.1.5.2. Vertical tower-type mounting.

•Rotate the control panel according to section 5.1.5.1.

•Take the 4 pieces of plastic supplied with the device and

join them together in twos to obtain two bases.

•Place the UPS upright between the two bases at a distance

of 70 mm from each end (see Fig. 6).

15

and install them to obtain two bases to hold the device and

the battery module.

•Place the UPS and battery module upright between the two

bases (see Fig. 7) and at a distance of 70 mm from each

end, similar to as shown in Fig. 7.

Fig. 7. Vertically mounted tower-type model with backup

extension (battery module).

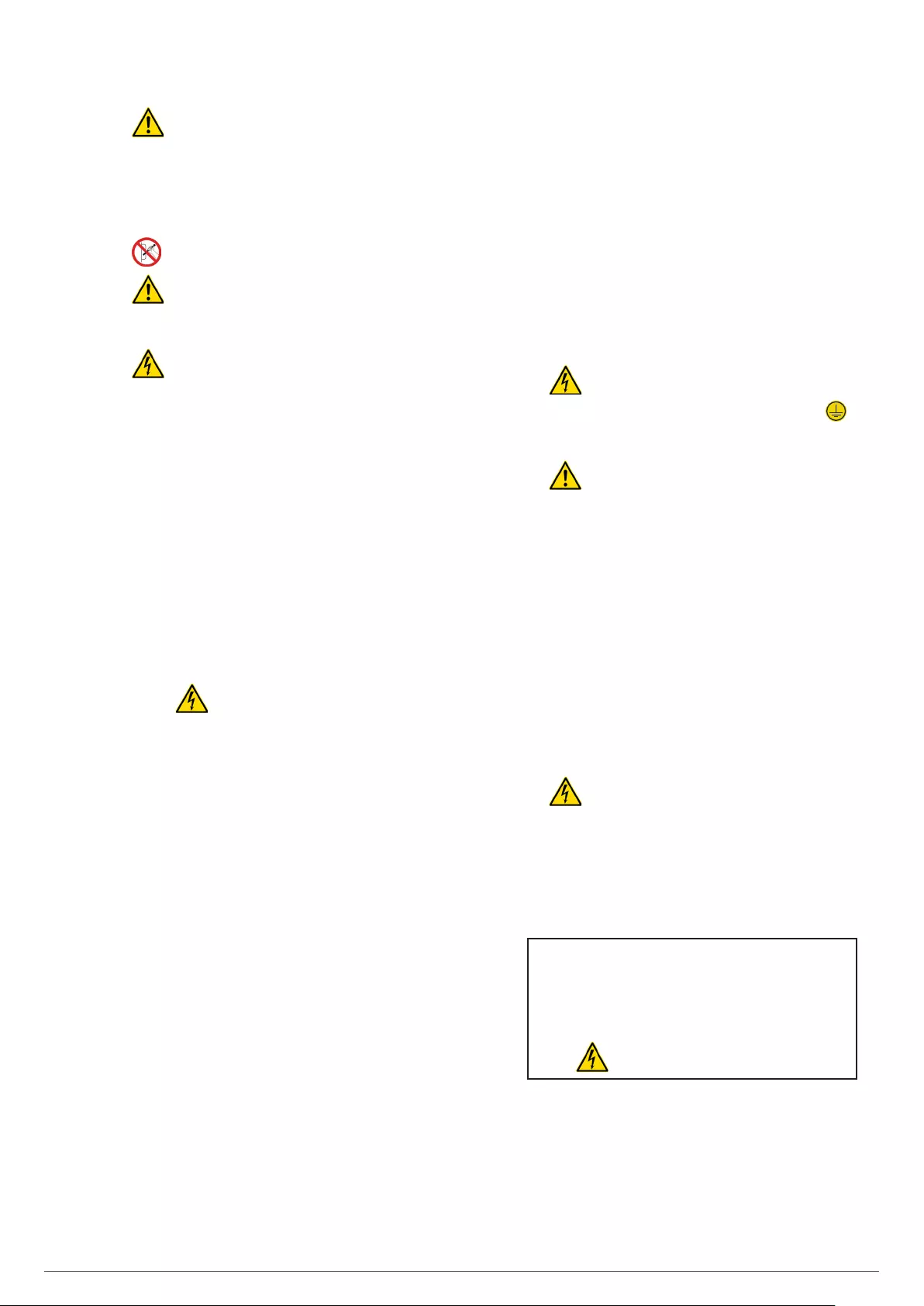

5.1.5.4. Mounting as a rack in a 19” cabinet.

•To mount a device in a 19” rack cabinet, proceed as follows

(see Fig. 8):

Using the supplied screws, fix the two adapter angles

for use as handles on each side of the UPS, respecting

your hand.

To install the device in a rack cabinet, it is necessary

to have internal lateral guides for use as supports.

Alternatively, and upon request, we can supply

universal slides for use as guides, for installation by

the user.

Mount the guides at the required height, ensuring

correct tightening of the fixing screws and appropriate

fitting in the machining, according to each case.

Place the device onto the guides and insert it all the

way to the back.

Depending on the device model and weight, and/or

whether it is installed in the upper or lower part of the

cabinet, it is recommended that two people carry out

the installation operations.

Fix the UPS to the cabinet frame using the screws

supplied with the handles.Fig. 6. Vertical tower-type mounting.

5.1.5.3. Vertical tower-type mounting with backup extension

(battery module).

•The description in this section refers to a device with a

single battery module. For a greater number, proceed in a

similar way.

•Rotate the control panel according to section 5.1.5.1.

•Take the 4 plastic pieces in the form of an angle supplied

with the UPS and the two supplied with the battery module,

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

16 SALICRU

Fig. 8. Rack-type mounting in a 19” cabinet.

5.1.5.5. Rack mounting in a 19” cabinet with backup extension

(battery module).

•This section describes a device with one battery module.

For more battery modules, repeat the same procedure for

each of them.

•To install a device and its battery module in a 19” rack

cabinet, proceed as follows (see Fig. 9):

Using the supplied screws, fix the two adapter angles

for use as handles on each side of the UPS, respecting

your hand. Repeat the same procedure for the battery

module.

To install each unit, UPS and battery module in a rack

cabinet, it is necessary to have internal lateral guides

for use as supports. Alternatively, and upon request,

we can supply universal slides for use as guides, for

installation by the user.

Mount the guides at the required height, ensuring

correct tightening of the fixing screws and appropriate

fitting in the machining, according to each case.

Place the device onto the guides and insert it all the

way to the back. Proceed in the same way for the

battery module.

Depending on the weight of each unit according to the

type of device and battery module, and/or whether it is

installed in the upper or lower part of the cabinet, it is

recommended that two people carry out the installation

operations.

Fix the UPS and the battery module to the cabinet frame

by means of the screws supplied with the respective

handles.

Fig. 9. Rack-mounted model in a 19” cabinet with

backup extension (battery module).

5.1.5.6. Vertical tower-type mounting with PDU.

4 to 10 kVA models are supplied as standard with a PDU

module, designed to be attached to the side of the device.

Fix it to the UPS using the plate supplied as a support as shown

in Fig. 10.

Fig. 10. Vertically mounted tower-type model with PDU.

5.1.5.7. Rack mounting in 19” cabinet with PDU.

Similar to the UPS, the PDU module has angles for use as

handles for mounting in a rack cabinet.

•Proceed as follows (see Fig. 11):

Using the supplied screws, fix the two adapter angles

for use as handles on each side of the PDU, respecting

your hand.

According to each case, perform the steps indicated in

section 5.1.5.4 or 5.1.5.5.

To install the PDU in a rack cabinet, it is necessary to

have internal lateral guides for use as supports, just

like for the UPS and/or battery module. Follow the

guidelines described in section 5.1.5.4 or 5.1.5.5 for

everything related to the guides.

Place the PDU onto the guides and insert it all the way

to the back.

Fix it to the cabinet frame using the screws supplied

with the handles.

17

Fig. 11. Rack-type mounting in a 19” cabinet with PDU.

5.1.5.8. Preliminary considerations before connection.

•In the description of this manual, reference is made to the

connection of terminals and switch operations that are

only available in some versions or devices with extended

backup. Ignore the related operations if your unit does not

feature them.

•Thermal control of these devices is carried out with the

passage of forced air from the front to the rear.

The front surface and about 15 cm on the rear side should

be left free of obstructions to facilitate the free circulation

of air for ventilation.

•Follow and respect the instructions described in this section

referring to the installation of a single device or a system

in parallel.

•Protection or external manual bypass board:

The system will have at least one short-circuit

protection on the UPS’s power supply line.

It is advisable to have an external manual bypass board

fitted with input, output and manual bypass protections

in single systems.

For parallel systems, it is essential to have a

distribution or manual bypass board. The board’s

circuit breakers must be able to isolate a UPS from

the system in the event of a fault and power the loads

with the others, either during periods of preventative

maintenance or during breakdown and repair.

•Upon request, we can supply an external manual bypass

board for a single device or parallel system.

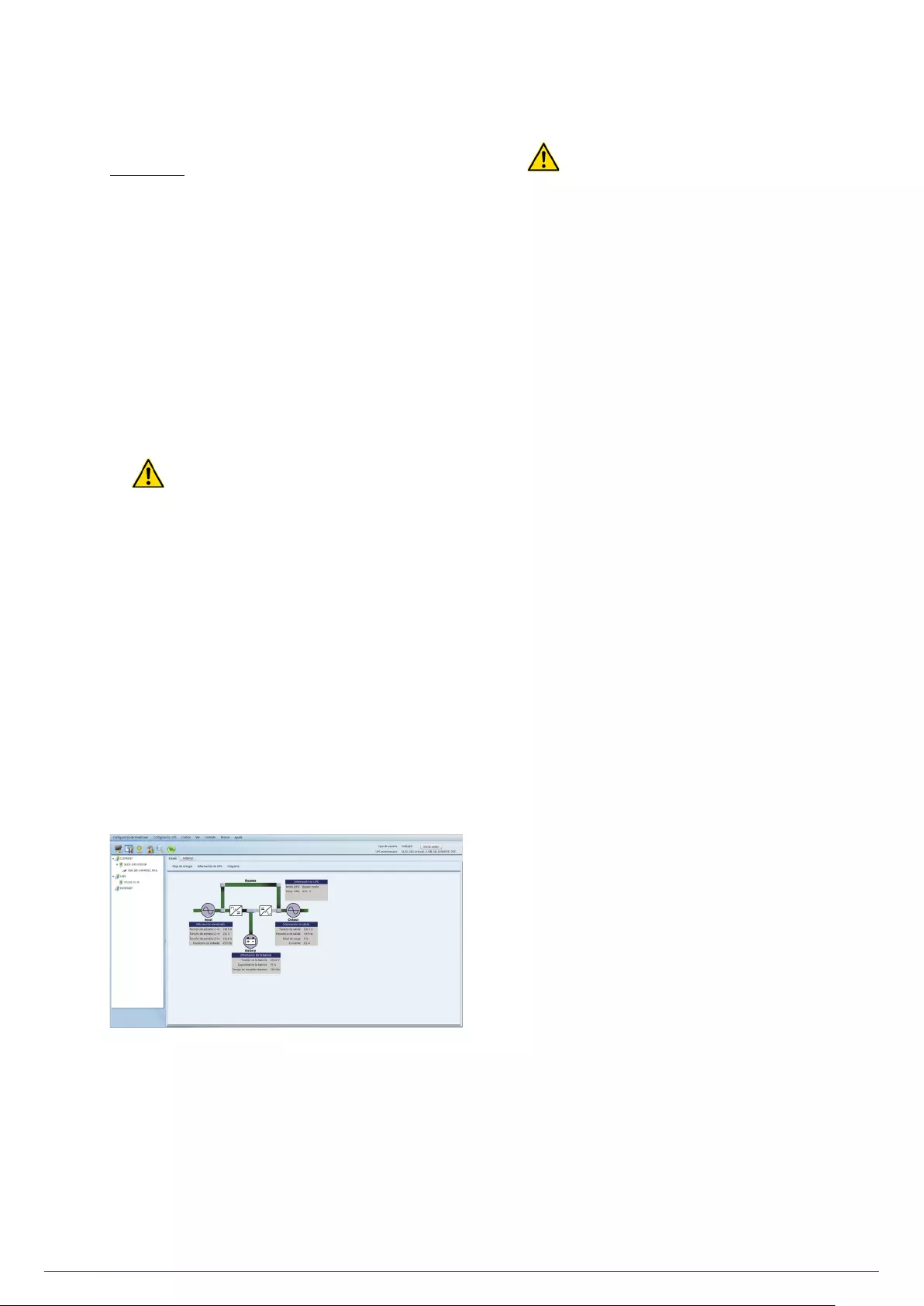

You can also choose to manufacture it, taking into account

the version and configuration of the device or system

available and the documentation contained in the CD-ROM

or pen drive relating to ‘Recommended installation’.

•In the documentation supplied with this user manual

and/or on the CD-ROM or pen drive, information is

available on ‘Recommended installation’ for each input and

output configuration. This documentation includes wiring

diagrams and information about the sizes of the protections

and the minimum cross sections of cables connected to the

device according to their rated working voltage. All values

are calculated for a maximum total cable length of 30 m

between the distribution board, equipment and loads.

For longer lengths correct the cross sections to avoid

voltage drops, respecting the regulations or standards

corresponding to the country.

In the same documentation and for each configuration,

information for ‘N’ units in parallel, as well as backfeed

protection characteristics, is available.

•In parallel systems, the length and cross section of

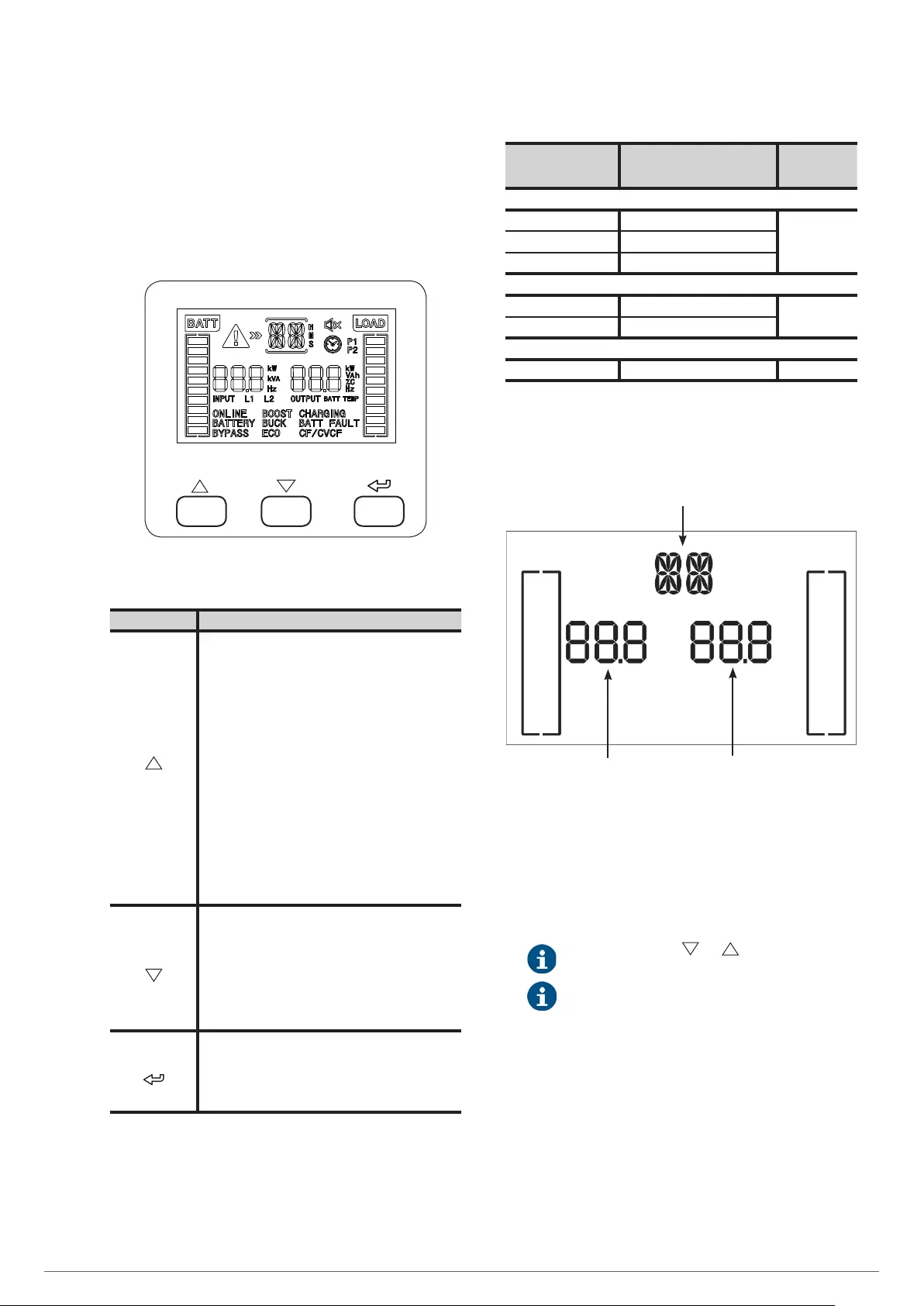

the cables that run from the distribution or manual

bypass board to each UPS and from these to the board will

be the same for all of them without exception.

•The cross section of the cables must always be considered

in relation to the size of the terminals of the switches, so

that they are correctly fastened across their entire cross

section for optimum contact between the two elements.

•Only rated currents are printed on the nameplate of the

equipment as indicated by the EN-IEC 62040-1 safety

standard. For the calculation of the input current, the power

factor and the equipment's own performance have been

considered.

Overload conditions are considered a non-permanent

and exceptional working mode, and will not be taken

into account in the application of the protections. Do not

connect appliances or devices which may overload the UPS

to the terminals and/or outlets, such as motors.

•If peripheral input, output or bypass elements such as

transformers or autotransformers are added to the UPS or

parallel system, the currents indicated on the nameplates of

these elements must be taken into consideration in order to

use the appropriate cross sections, in compliance with local

and/or national Low Voltage Electrotechnical Regulations.

•When a galvanic isolation transformer is added to a UPS

or parallel system as an optional extra, as standard or

independently, either on the input line, at the output or

both, it must be fitted with protection against indirect

contact (differential circuit breaker) at the output of each

transformer, since, due to its own insulation properties, it

will prevent the tripping of the protections placed on the

primary of the isolation transformer in case of electric shock

on the secondary (output of the isolation transformer).

•We remind you that all the isolation transformers installed

or factory supplied, have the output neutral grounded

through a bridge between the neutral terminal and ground.

If the isolated output neutral is required, this bridge must be

removed, taking the precautions indicated in the respective

local and/or national low voltage regulations.

•This device is suitable for installation in networks

with TT, TN-S, TN-C or IT power distribution

systems, taking into account at the time of installation the

particularities of the system used and the national electrical

regulations of the destination country.

•The SLC TWIN RT2 features terminals for the installation

of an external emergency power off button (EPO) or, failing

that, a single device must be installed to cut the power

supply to the loads in any operating mode.

5.1.5.9. Preliminary considerations before connection, regarding

the batteries and their protections.

•SLC TWIN RT2 devices from 0.7 to 3 kVA incorporate the

batteries in the same box as the device, except for B0, B1

and higher power models.

•The battery protection of the device and of any accumulator

module is always by means of internal fuses that are not

accessible to the user.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

18 SALICRU

•IMPORTANT FOR SAFETY: If batteries are installed

independently, the accumulator group must be fitted

with a bipolar circuit breaker or disconnect fuse of the size

indicated in Tab. 2.

•Inside the battery module, there are HAZARDOUS

VOLTAGES with risk of electric shock, so it is classified as a

RESTRICTED ACCESS AREA.

•Do not handle the fuse holder or battery circuit

breaker when the device is running.

•If the mains power of the device or parallel system

is cut for longer than a simple intervention and it is

expected that it will be out of service for a prolonged period

time, the system must be shut down completely.

•The battery circuit is not isolated from the input

voltage. Dangerous voltages can occur between the

terminals of the battery group and the earth. Check that

there is no input voltage before intervening on the terminals.

5.1.5.10. Connection elements.

•All of the device’s electrical connections are made from the

back of each unit:

Input and output connection.

–For models up to 3 kVA.

Input by means of a cable with plug, connectable to

the UPS through an IEC connector.

Outputs through IEC connectors.

–For models with power ratings greater than 3 kVA.

Terminals for powering the device and loads.

It is necessary to remove the transparent protective

cover to access the terminals.

Replace the cover after making the

connections to prevent possible accidents

due to direct contact, especially in tower mountings

as there is a greater risk.

Connection to batteries.

–The device and battery module have a polarised

connector.

Remove the screws and protective cover of the

connector before interconnecting it.

–All battery modules have two connectors that

enable backup extension.

Communication connectors available:

–DB9 for RS232. In models up to 3 kVA, the interface

to relays signals are supplied with the same

connector.

–USB to operate the UPS as a PC peripheral.

–Digital input and output (only in models > 3 kVA).

–For connection to external EPO button.

–Auxiliary contact for the manual bypass switch

(only in models > 3 kVA).

DB15 communication bus connectors and analogue

current signal block for connecting systems in parallel

(only in models > 3 kVA).

To access the signal block, it is necessary to remove its

protective cover.

Slot for the integration of one of the optional electronic

communication units. Remove the fixing screws and

plastic cover to enable it to be inserted.

•It is recommended to use terminals on all of the ends of

the cables connected to power terminals (input and output).

•Check that the terminal screws are correctly tightened.

5.2. CONNECTIONS.

5.2.1. Connection of the input.

•0.7 to 3 kVA models:

Take the power cable with plug and IEC connector on

the end and insert the latter into the input connector

of the UPS.

Plug the power cable into an AC power socket.

•4 to 10 kVA models:

As the device has Class I protection against

electric shock, it is essential to install a

protective earth conductor (connect earth ( )).

Connect this conductor before supplying voltage to the

input terminals.

Connect the power cables to the input terminals

respecting the order of the phase (R) and the

neutral (N) indicated on the labelling of the device and in

this manual. Pay particular attention when connecting

the power cables to the input terminals and do not

reverse the connection to the output terminals or vice

versa. Failure to respect the order will result in faults.

Where there are discrepancies between the labelling

and the instructions in this manual, labelling shall

always prevail.

In accordance with safety standard EN-IEC 62040-1, the

facility must be equipped with an automatic backfeed

protection system, such as a contactor, which prevents

the appearance of hazardous voltage or power on the

UPS input line during a mains failure (see Fig. 12).

The standard applies to both individual units and all

UPSs in parallel systems.

There can be no derivation of the line that goes

from the backfeed protection to the UPS, as this

would breach the safety standard.

Warning labels shall be affixed to all primary power

switches installed in areas remote from the equipment

to alert electrical maintenance personnel of the

presence of a UPS in the circuit.

The label shall bear the following text or an equivalent:

Before working on the circuit.

•Isolate the uninterruptible power supply system

(UPS).

•Check the voltage between all terminals, including

the protective earth.

Return voltage risk of the UPS.

19

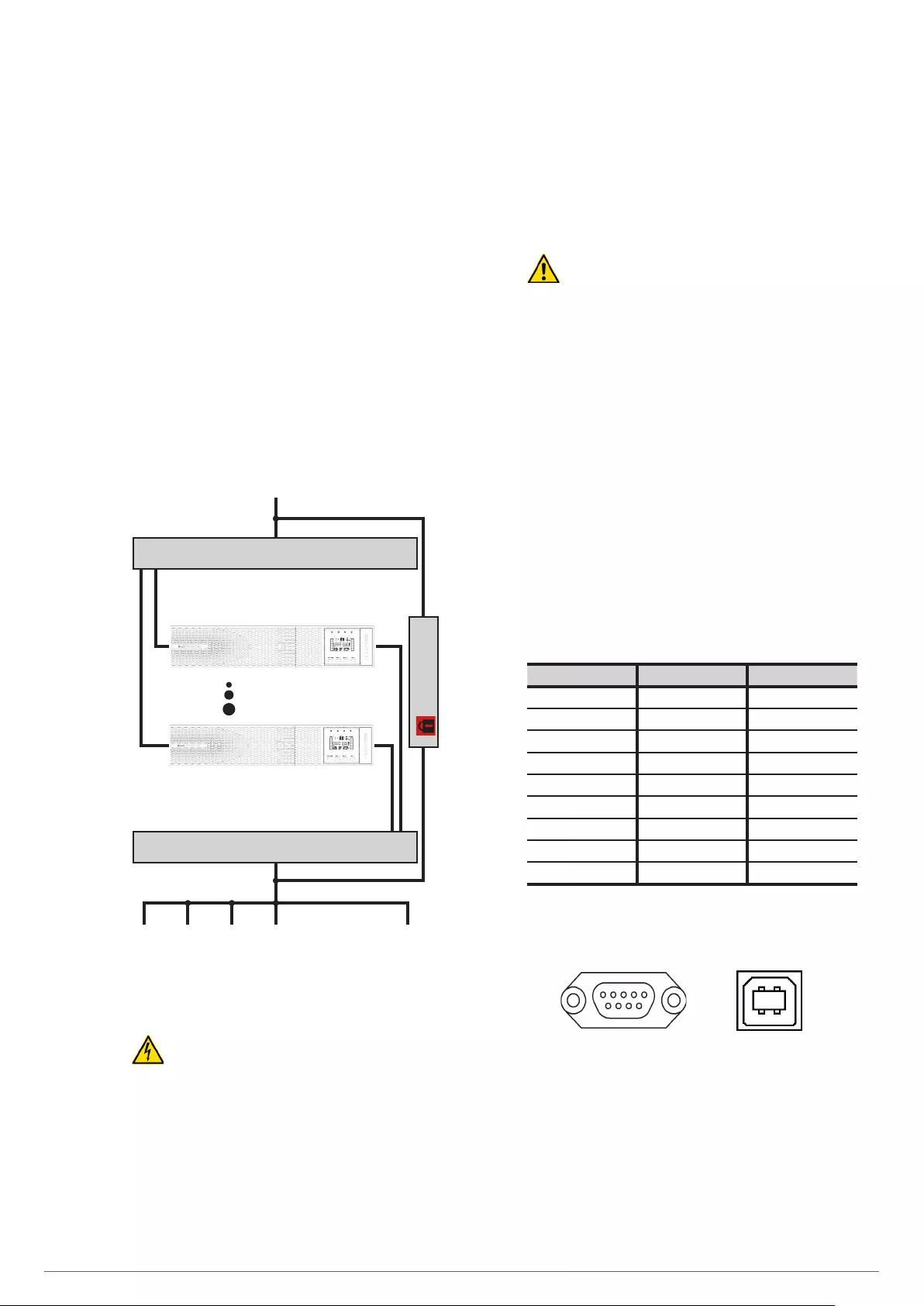

(3)

(2)

(1)

UPS

Input

Output

R (L)

U (L)

N

N

(1) Automatic backfeed protection system external to the UPS (EN-IEC 62040-1).

(2) Fuse holder and general purpose fuse 250V AC / 3A type F.

(3) 230V AC bipolar contactor with minimum contact spacing of 1.4 mm and coil

with same voltage and the minimum current indicated on the nameplate of

the UPS (input or bypass as appropriate).

For parallel systems, each device must have its own separate backfeed

protection.

Fig. 12. Backfeed protection wiring diagrams.

5.2.2. Connection to IEC connectors or output terminals.

•SLC TWIN RT2 devices feature female IEC output connectors

or terminals depending on the power of the model:

Models up to 2 kVA: 2 groups of 4 x 10A IEC

connectors identified as «OUTPUT» and «OUTPUT

PROGRAMMABLE (P1)», configurable through the

control panel and/or ViewPower.

3 kVA models: same connectors as models up to 2 kVA

and an additional 16A IEC connector.

4 to 10 kVA models: 1 group of output terminals.

In these models, a PDU (power distribution unit) is

supplied to connect to the output terminals of the

UPS. Through it, loads can be powered directly through

the two or three groups of 10 or 16 A IEC connectors

protected by a selective circuit breaker.

•Do not connect loads that in their entirety exceed

the specifications of the device, as this would cause

inconvenient cuts in the power supply of the loads

connected to the output.

•If, in addition to the more sensitive ‘critical loads’, it is

necessary to connect high-consumption inductive loads,

such as for laser printers or CRT monitors, the starting up

of these peripherals will need to be taken into account to

prevent the device from crashing.

We do not recommend connecting loads of this type due to

the amount of power they absorb from the UPS.

5.2.2.1. Connection of loads in models up to 3 kVA.

•Connect the loads to the 10 A IEC connectors.

It is important to consider the two groups of IEC

connectors available, those for ‘critical loads’ and

those for ‘non-critical loads’.

By definition, ‘critical loads’ are considered to be those

that can cause economic damage if they stop functioning

or function incorrectly.

The IEC connectors indicated in Fig. 2 as ‘non-critical

loads’ can be programmed as such through the control

panel. In this case, the backup of the batteries for the

loads connected to the IEC connectors indicated in Fig. 2 as

‘critical loads’ will be reserved. Take into account that they

are set by default as ‘critical loads’.

•The 3 kVA models also have a 16A IEC connector

that enables the connection of a load of the total

power of the device.

5.2.2.2. Connection of loads in 4 to 10 kVA 10 kVA.

•As the device has Class I protection against electric

shock, it is essential to install a protective earth

conductor (connect earth ( )). Connect this conductor

before supplying voltage to the input terminals.

•Connect the loads to output terminals U (L) and N,

respecting the order of the phase and the neutral

indicated on the labelling of the device and in this manual

(see Fig. 2). Where there are discrepancies between the

labelling and the instructions in this manual, labelling shall

always prevail.

•Together with the device, a PDU with several 10 and 16A

IEC output connectors with their respective circuit breaker

is supplied.

When the utility of the PDU is required to power the loads,

it will be necessary to connect its input cables to the output

of the UPS, respecting the following assignment:

Black or brown cable to phase U (L).

Red or blue cable to neutral (N).

Green-yellow cable to earth terminal ( ).

•With regard to the protection that must be placed at the

output of the UPS when the PDU is not used, we recommend

distributing the output power over at least four lines. Each of

them will have a circuit breaker with a value of one quarter

of the rated power. This type of output power distribution

will allow that in the event of a fault in any of the machines

connected to the equipment, which provokes a short circuit,

does not affect more than the line that is broken.

The remaining connected loads will have continuity

assured due to the tripping of the protection, only in the

line affected by the short circuit.

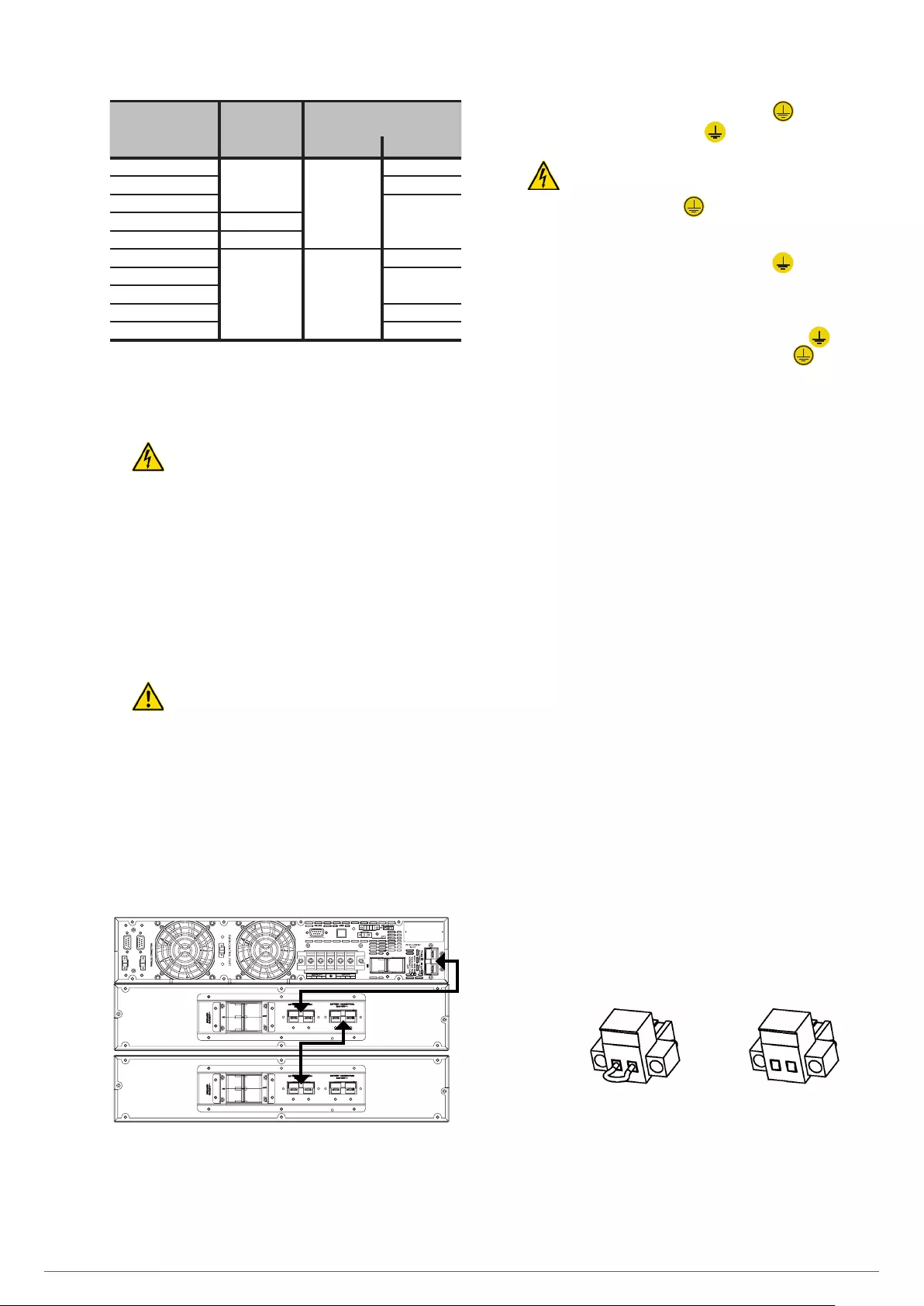

5.2.3. Connection to external batteries (backup extension).

•Failure to comply with the instructions in this

section and Safety Instructions EK266*08 car-

ries a high risk of electric shock and even death.

•SLC TWIN RT2 devices from 0.7 to 3 kVA incorporate the

batteries in the same box as the device, except for B0, B1

and higher power models.

•The battery protection of the device and of any accumulator

module is always by means of internal fuses that are not

accessible to the user.

•IMPORTANT FOR SAFETY: If batteries are installed

independently, the accumulator group must be fitted

with a bipolar circuit breaker or disconnect fuse of the size

indicated in Tab. 2.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

20 SALICRU

Model Rated voltage

of batteries

Minimum values,

fast type fuses

DC voltage (V) Current (A)

SLC-700-TWIN RT2

(12 V x 3) = 36 V

125

20

SLC-1000-TWIN RT2 32

SLC-1500-TWIN RT2

50

SLC-2000-TWIN RT2 (12 V x 4) = 48 V

SLC-3000-TWIN RT2 (12 V x 6) = 72 V

SLC-4000-TWIN RT2

(12 V x 16) = 192V 400

20

SLC-5000-TWIN RT2 32

SLC-6000-TWIN RT2

SLC-8000-TWIN RT2 40

SLC-10000-TWIN RT2 50

Tab. 2. Protection features between device and battery

module.

•Before starting the connection process between

battery module or modules and device, check that

the device and loads are ‘Off’.

Also, when the batteries are installed by the user

independently, the protection fuse or isolator must be

deactivated.

•Connection of the battery module to the device is made by

means of a cable featuring polarised connectors at both

ends, which is supplied with the first one. Two connectors

are available for this purpose on the device and battery

module.

Similarly, the battery modules feature two connectors that

allow the linking of modules in parallel.

•Each battery module is independent for each device.

Two devices must not be connected to the

same battery module.

Likewise, in parallel systems (4 to 10 kVA models), with

each device connected to its battery module or modules,

they should be considered as single devices that are

independent of each other.

•Fig. 13 shows the connection of a 10 kVA device in a

rack arrangement with two battery modules. For a larger

number, proceed in a manner similar to those shown in the

illustration.

Fig. 13. Connection to battery modules.

5.2.4. Connection of the input earth terminal ( ) and the

earth connection terminal ( ) .

•As the device has Class I protection against electric

shock, it is essential to install a protective earth

conductor (connect earth ( )). Connect this conductor

before supplying voltage to the input terminals.

•Make sure that all of the loads connected to the UPS are only

connected to its earth connection terminal ( ). Failure to

limit the earthing of the load or loads and battery module or

modules to this single point will create earth return loops

that will degrade the quality of the power supplied.

•All terminals identified as an earth connection ( ) are

connected to each other, to the earth terminal ( ) and to

the device’s earth.

5.2.5. Terminals for EPO (emergency power off).

•The UPSs have two terminals for the installation of an

external emergency power off (EPO) output button.

•The device is dispatched from the factory with its EPO

circuit set to closed (NC) by default. In other words, the

UPS will cut the output power supply, emergency power

off, when the circuit is opened:

Either by removing the female connector from the socket

where it is inserted. This connector has a cable connected

as a jumper that closes the circuit (see Fig. 14-A).

Or by pressing the button external to the device

belonging to the user installed between the terminals

of the connector (see Fig. 14-B). The connection on the

button must be in the normally closed contact (NC), so

it will open the circuit when activated.

The reverse functionality can be selected through the

communications software and control panel.

Except for specific cases, we advise against this type

of connection in view of the purpose of the EPO button,

since it will not act upon an emergency request if either

of the two cables that run from the button to the UPS is

accidentally cut.

By contrast, this anomaly would immediately be detected

in a closed EPO circuit, with the inconvenience of an

unexpected cut in the powering of the loads, but a

guarantee of effective emergency functionality.

•To recover the normal operating state of the UPS, it is

necessary to insert the connector with the jumper in its

receptacle or deactivate the EPO button. The device will

be operational.

A B

Fig. 14. Connector for external EPO.

21

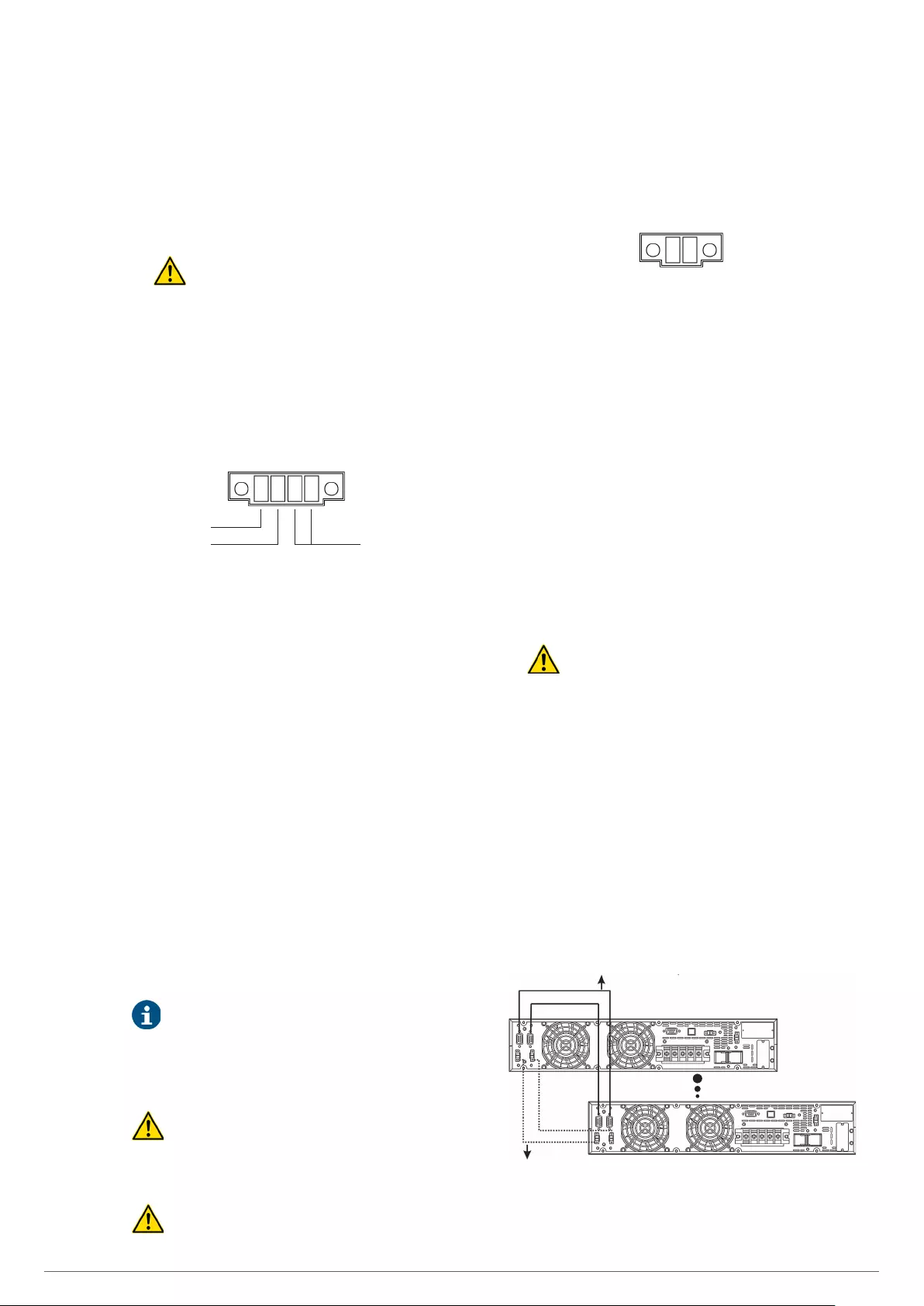

5.2.6. Terminals for digital input and output to relay. Only in

models with power ratings > 3 kVA.

•The device has a four-terminal connector for a digital input

and output to relay (see Fig. 15).

‘Start/Stop’ digital input. With the device running,

apply a sequential voltage of between 5 and 12 V DC to

reverse its state.

The static bypass function of the UPS is enabled

by default. In this condition, when the inverter

shuts down, the output terminals will supply voltage

through the internal static bypass.

Disable the bypass function through the control panel if

the output supply needs to be cut when giving the shut

down command.

Error or fault dry contact. Any error or fault will modify

the state of the normally open (NO) 24V DC 1A contact.

(PAY ATTENTION to the voltage and current applied).

– Digital input

+ Digital input

Output to relay,

error or fault

Fig. 15. Digital input/output to relay connector.

5.2.7. Manual bypass auxiliary contact terminals. Only in

models with power ratings > 3 kVA.

•The SLC TWIN has a signal block through which it is

possible to activate the shut down command for the UPS’s

inverter when closing the circuit. This normally open

contact is intended for connection to an external manual

bypass switch or disconnector. (see Fig. 16).

•On the distribution boards with manual bypass that

we supply upon request, there is a two-terminal block

connected in parallel to the normally open auxiliary contact

of the board’s manual bypass switch or disconnector. The

manual bypass auxiliary contacts are of the advanced type

when closing.

•The connection between the auxiliary contact of the board

and the UPS or UPSs is in parallel. This way, any of the

auxiliary contacts that close the circuit will activate the

shut down command of the inverter, transferring the

powering of the loads to the internal static bypass, unless

this is disabled through the control panel, in which it will

cut the powering of the loads.

•In parallel systems, the distribution board’s manual

bypass switch or disconnector will have an auxiliary

contact block for each device. Under no circumstances

should the different contacts be joined together as this

would connect the different earths of the control of each

UPS.

•In the event of acquiring a manual bypass board

through another conduit, check that it has this

auxiliary contact and connect it to the terminal block of the

UPS or each device in parallel systems. The type of auxiliary

contact has to necessarily be advanced when closing.

•It is ESSENTIAL, as a safety measure for the

assembly, including the loads, to connect the UPS’s

auxiliary bypass contact to the block of the same

functionality on the manual bypass board. This will prevent

any incorrect action on the manual bypass disconnector

when the UPS is running from causing total or partial failure

of the system.

This is also applicable for systems in parallel.

Fig. 16. Terminal block for connection to the inverter shut-

down auxiliary contact of the manual bypass board.

5.2.8. Connection in parallel, only in models with power

ratings > 3 kVA.

5.2.8.1. Introduction in redundancy.

N+X is usually the most reliable power structure. N represents

the minimum number of devices that the total load needs; X re-

presents the number of redundant devices, that is, the number of

faulty UPSs that the system can simultaneously allow. The higher

X is, the greater the reliability of the system. For occasions where

reliability is essential, N+X will be the optimum mode.

Up to 3 devices can be connected in parallel to configure a

shared output or power redundancy.

5.2.8.2. Installation and operation in parallel.

•The communications line -COM- constitutes a very

low voltage safety circuit. To preserve the quality

must be installed separately from other lines carrying

dangerous voltages (power distribution line).

•Parallel connections and current signal bus.

Use the 15-wire signal cable with mesh and DB15

connectors at the ends to connect a maximum of 3 devices.

Each cable has a male and a female connector at the ends

which must be connected to link two devices. It is essential

to close the communications loop of the parallel bus and

the current signal bus through the cable with connectors

(see Fig. 17).

The length of the cables related to the parallel bus is ap-

prox. 1.5 metres and must not be prolonged under any

circumstances due to the risk of interference and communi-

cation failures that this would entail.

Communication bus.

Current signal bus

Fig. 17. Communication and current signal connections

for system in parallel.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY SYSTEMS (UPS)USER MANUAL

22 SALICRU

•When installing systems in parallel, it is necessary to

provide them with a board equipped with individual input