Table of Contents

- 1. Introduction.

- 1.1. Acknowledgement letter.

- 2. Information for safety.

- 2.1. Using this manual.

- 2.1.1. Conventions and used symbols.

- 3. Quality and standard guarantee.

- 3.1. Declaration of the management.

- 3.2. Standard.

- 3.3. Environment.

- 4. Presentation.

- 4.1. Views.

- 4.1.1. Views of the equipment.

- 4.1.2. Frontal UPS panel.

- 4.1.3. Rear panel IEC.

- 4.1.4. Rear panel schuko.

- 4.1.5. Frontal battery panel.

- 4.1.6. Rear battery panel.

- 4.2. Definition of the product.

- 4.2.1. Nomenclature.

- 4.3. Operating principle.

- 4.3.1. Main features.

- 4.4. Options.

- 4.4.1. Isolation transformer.

- 4.4.2. External maintenance manual bypass.

- 4.4.3. Integration in IT networks by means of the SNMP adaptor.

- 4.4.4. MODBUS protocol.

- 5. Installation.

- 5.1. Reception of the equipment.

- 5.1.1. Inspection.

- 5.1.2. Unpacking.

- 5.1.3. Content checking.

- 5.1.4. Storage.

- 5.1.5. Transport to location.

- 5.1.6. Preliminary considerations, before connecting the equipment.

- 5.2. Connection.

- 5.2.1. Connection of input.

- 5.2.2. Connection to output.

- 5.2.3. Connection of external batteries [extended back up times] -B1- or models without batteries -B0-.

- 5.2.4. Terminals for EPO (Emergency Power Off).

- 5.2.5. Communication ports.

- 5.2.5.1. USB interface.

- 5.2.5.2. Smart slot.

- 5.2.6. Software.

- 5.2.7. Considerations before starting up.

- 6. Operating.

- 6.1. UPS commissioning and shutdown.

- 6.1.1. Preliminary controls.

- 6.1.2. Start up the UPS, with AC mains.

- 6.1.3. Start up the UPS, with no AC mains (Battery mode)

- 6.1.4. UPS shutdown with AC mains (on Inverter mode).

- 6.1.5. UPS shutdown with no AC mains [on Battery mode].

- 6.1.6. Battery test function.

- 6.1.7. Alarm silencer.

- 6.1.8. EPO (Emergency Power Output).

- 7. Control panel with LCD.

- 7.1. Control panel.

- 7.2. Setting and configuration of the control panel.

- 7.2.1. Bypass mode -byPA-.

- 7.2.2. No output mode -STby-.

- 7.2.3. Line mode -LINE-.

- 7.2.4. Battery mode / Battery test mode -bATT / TEST-.

- 7.2.5. Economy mode -ECO-.

- 7.2.6. Converter mode -CUF-.

- 7.2.7. Fault code / Alarm code.

- 7.3. Settings through the LCD panel of the LCD PANEL.

- 8. Maintenance, warranty and service.

- 8.1. Battery maintenance.

- 8.1.1. Notes for installing and replacing the batteries.

- 8.2. UPS Trouble Shooting guide.

- 8.2.1. Troubleshooting guide. Warning indications.

- 8.3. WARRANTY CONDITIONS.

- 8.3.1. Warranty terms.

- 8.3.2. Out of scope of supply.

- 8.4. Technical service network.

- 9. Annexes.

- 9.1. General technical specifications.

- 9.2. Glossary.

Salicru 699CA000013 User Manual

Displayed below is the user manual for 699CA000013 by Salicru which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has 28 pages.

Related Manuals

SLC TWIN PRO2

0,7.. 3 kVA

USER'S MANUAL

UNINTERRUPTIBLE POWER SUPPLY (UPS)

SLC TWIN PRO2

0.7.. 3 kVA

3

General index

1. INTRODUCTION.

1.1. ACKNOWLEDGEMENT LETTER.

2. INFORMATION FOR SAFETY.

2.1. USING THIS MANUAL.

2.1.1. Conventions and used symbols.

3. QUALITY AND STANDARD GUARANTEE.

3.1. DECLARATION OF THE MANAGEMENT.

3.2. STANDARD.

3.3. ENVIRONMENT.

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the equipment.

4.1.2. Frontal UPS panel.

4.1.3. Rear panel IEC.

4.1.4. Rear panel schuko.

4.1.5. Frontal battery panel.

4.1.6. Rear battery panel.

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

4.3. OPERATING PRINCIPLE.

4.3.1. Main features.

4.4. OPTIONS.

4.4.1. Isolation transformer.

4.4.2. External maintenance manual bypass.

4.4.3. Integration in IT networks by means of the SNMP adaptor.

4.4.4. MODBUS protocol.

5. INSTALLATION.

5.1. RECEPTION OF THE EQUIPMENT.

5.1.1. Inspection.

5.1.2. Unpacking.

5.1.3. Content checking.

5.1.4. Storage.

5.1.5. Transport to location.

5.1.6. Preliminary considerations, before connecting the equipment.

5.2. CONNECTION.

5.2.1. Connection of input.

5.2.2. Connection to output.

5.2.3. Connection of external batteries [extended back up times] -B1- or

models without batteries -B0-.

5.2.4. Terminals for EPO (Emergency Power Off).

5.2.5. Communication ports.

5.2.5.1. USB interface.

5.2.5.2. Smart slot.

5.2.6. Software.

5.2.7. Considerations before starting up.

6. OPERATING.

6.1. UPS COMMISSIONING AND SHUTDOWN.

6.1.1. Preliminary controls.

6.1.2. Start up the UPS, with AC mains.

6.1.3. Start up the UPS, with no AC mains (Battery mode)

6.1.4. UPS shutdown with AC mains (on Inverter mode).

6.1.5. UPS shutdown with no AC mains [on Battery mode].

6.1.6. Battery test function.

6.1.7. Alarm silencer.

6.1.8. EPO (Emergency Power Output).

7. CONTROL PANEL WITH LCD.

7.1. CONTROL PANEL.

7.2. SETTING AND CONFIGURATION OF THE CONTROL PANEL.

7.2.1. Bypass mode -byPA-.

7.2.2. No output mode -STby-.

7.2.3. Line mode -LINE-.

7.2.4. Battery mode / Battery test mode -bATT / TEST-.

7.2.5. Economy mode -ECO-.

7.2.6. Converter mode -CUF-.

7.2.7. Fault code / Alarm code.

7.3. SETTINGS THROUGH THE LCD PANEL OF THE LCD PANEL.

8. MAINTENANCE, WARRANTY AND SERVICE.

8.1. BATTERY MAINTENANCE.

8.1.1. Notes for installing and replacing the batteries.

8.2. UPS TROUBLE SHOOTING GUIDE.

8.2.1. Troubleshooting guide. Warning indications.

8.3. WARRANTY CONDITIONS.

8.3.1. Warranty terms.

8.3.2. Out of scope of supply.

8.4. TECHNICAL SERVICE NETWORK.

9. ANNEXES.

9.1. GENERAL TECHNICAL SPECIFICATIONS.

9.2. GLOSSARY.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

4SALICRU

SALICRU

1. INTRODUCTION.

1.1. ACKNOWLEDGEMENT LETTER.

We would like to thank you in advance for the trust you have placed in

us by purchasing this product. Read this instruction manual carefully

in order to be familiarized with its contents, because, as much as you

know and understand the equipment the highest will be your satisfac-

tion and safety levels and their features will be optimized too.

We remain at you entire disposal for any further information or any

query you should wish to make.

Yours sincerely.

•The equipment here described can cause important physical

damages due to wrong handling. This is why, the installa-

tion, maintenance and/or fixing of itself must be done by our

staff or qualified personnel exclusively.

•Although we have made every effort to guarantee a complete

and accurate information in this user’s manual, we are not re-

sponsible for any errors or omissions that may exist.

The images included in this document are mere illustrations

and they could not represent the part of the equipment exactly,

therefore they are not contractual. Nevertheless, differences

that could exist will be alleviated or solved with the correct la-

belling of the equipment.

•According to our policy of constant evolution, we reserve the

right to modify the specifications, operating or described

actions in this document without forewarning.

Any reproduction, copy or third party concession,

modification or partial or in whole translations of this manual or

document, in any format or media, is prohibited without the previous

written authorization of our firm, being reserved the full and exclusive

ownership right over it.

5

2. INFORMATION FOR SAFETY.

2.1. USING THIS MANUAL.

The documentation of any standard equipment can be downloaded

from our website by the client (www.salicru.com).

The operation of the device described in this document is

based on the original factory settings and configuration. Sec-

tion 7.3 shows the screens tree, the variables and the original con-

figuration. Take into consideration that any modification of them can

lead to changes in the behaviour of the device.

•Those equipments «supplied by power cord with plug», this is is

the website to get the user’s manual and the «Safety instruc-

tions» EK266*08.

•Those equipments «with permt connection», hardwired, can be

supplied together with a CD-ROM or Pen Drive, which includes

any information needed for its erection and commissioning, in-

cluding the «Safety instructions» EK266*08.

Before doing any action over the equipment regarding installation or

commissioning, change of location, setting or handling, read them

carefully.

This user’s manual is intended to provide information regarding the

safety and to give explanations about the procedures for the instal-

lation and operating of the equipment. Read them carefully and

follow the stated steps in the established order.

Compliance as regards to «Safety instructions» is

mandatory, being the user the legal responsible re-

garding to its observance and application.

The equipments are delivered duly labelled for the correct identi-

fication of any their parts, which combined with the instructions

described in this user’s manual, allows the end-user to make any

operating of both installation and commissioning, in an easy and

ordered way without doubt.

Finally, once the equipment is commissioned and in operation, it

is recommended to keep the downloaded documentation from the

WebSite, or the CD-ROM or Pen Drive in a safe place and with easy

access, for further questions that could arise.

The following terms are used in the document indistinctly to be re-

ferred to:

•«SLC TWIN PRO2, TWIN PRO2, TWIN, PRO2, equipment,

unit o UPS».- Uninterruptible Power Supply.

Depending on the context of the sentence, it can be referred

either to the own equipment or to the equipment with batteries,

although all is assembled in one cabinet or metallic enclosure.

•«Batteries or accumulators».- Group or set of elements that

store the electron flow through electrochemical means.

•«T.S.S.».- Technical Service & Support.

•«client, fitter, operator or end-user».- are used indistinctly

and by extension, to be referred to the fitter and/or operator

which will make the corresponding actions, being responsible

the same person about the actions to take on behalf of himself.

2.1.1. Conventions and used symbols.

Some symbols can be used and shown in the equipment and/or in

the description of this user’s manual.

For more information, see section 1.1.1 of EK266*08 document as

regards to «Safety instructions».

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

6SALICRU

3. QUALITY AND STANDARD GUARANTEE.

3.1. DECLARATION OF THE MANAGEMENT.

Our target is the client’s satisfaction, therefore this Management

has decided to establish a Quality and Environmental policy, by

means of installation a Quality and Environmental Management

System that becomes us capable to comply the requirements de-

manded by the standard ISO 9001 and ISO 14001 and by our Clients

and concerned parts too.

Likewise, the enterprise Management is committed with the devel-

opment and improvement of the Quality and Environmental Man-

agement System, through:

•The communication to all the company about the importance of

satisfaction both in the client’s requirements and in the legal

and regulations.

•The Quality and Environmental Policy diffusion and the fixation

of the Quality and Environment targets.

•To carry out revisions by the Management.

•To provide the needed resources.

3.2. STANDARD.

This product is designed, manufactured and commercialized in accord-

ance with the standard EN ISO 9001 of Quality Management Systems.

The marking shows the conformity to the EEC Directive by means of

the application of the following standards:

•2014/35/EU. - Low Voltage Directive [LVD].

•2014/30/EU. - Electromagnetic Compatibility [EMC].

•2011/65/EU. - Restriction of Hazardous Substances in electrical

and electronic equipment [RoHS).

In accordance with the specifications of the harmonized standards.

Standards as reference:

•EN-IEC 62040-1. Uninterruptible power supply [UPS]. Part 1-1:

General and safety requirements for UPS’s used in accessible

areas by end users..

•EN-IEC 60950-1. IT equipments. Safety. Part 1: General require-

ments.

•EN-IEC 62040-2. Uninterruptible power supply [UPS]. Part 2:

EMC requirements.

The manufacturers responsibility is excluded in the event of any

modification or intervention in the product by the customer’s side.

WARNING!:

SLC TWIN PRO2 0.7.. 3 kVA. This is a category C2 UPS product.

In a residential environment, this product may cause radio

interference, in which case the user may be required to take

additional measures.

The use of this equipment is not suitable for life support

applications, where the failure of it can leave out of service

the life support device or could affect to its safety or efec-

tiveness. Likewise, it is not recommended its use in those

medical applications, commercial transport, nuclear power

stations and other applications or loads, where the failure

of this product can reverse in personal injuries and material

damages.

Declaration of conformity CE of the product is at the client

disposal under previous request to our headquarters offices.

3.3. ENVIRONMENT.

This product has been designed to respect the environment and has

been manufactured in accordance with the standard ISO 14001.

Equipment recycling at the end of its useful life:

Our company commits to use the services of authorised societies

and according to the regulations, in order to treat the recovered

product at the end of its useful life (contact your distributor).

Packaging:

To recycle the packaging, follow the legal regulations in force, de-

pending on the particular standard of the country where the equip-

ment is installed.

Batteries:

The batteries mean a serious danger for health and environment.

The disposal of them must be done in accordance with the stand-

ards in force.

7

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the equipment.

Fig. 1 to 10 show the illustrations of the equipment according to the

case format and depending on the power of the model. Neverthe-

less and due to the constant evolution of the product, some discrep-

ancies or small contradictions can arise. In front of any doubt, the

labelling of the equipment will always prevail.

All the values referring to the main features or specifications

can be checked in the nameplate of the equipment. Keep

them in mind for its installation.

4.1.2. Frontal UPS panel.

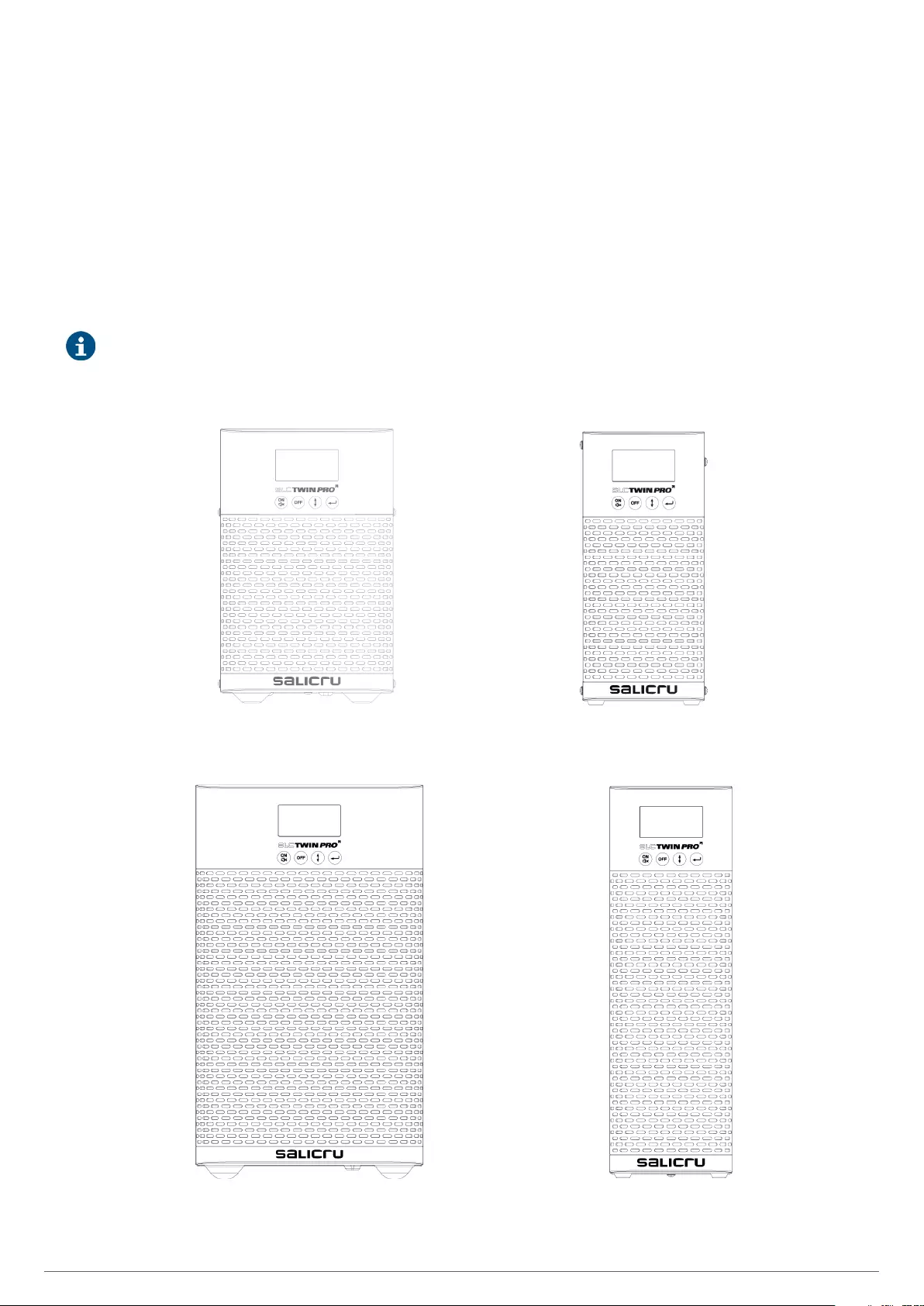

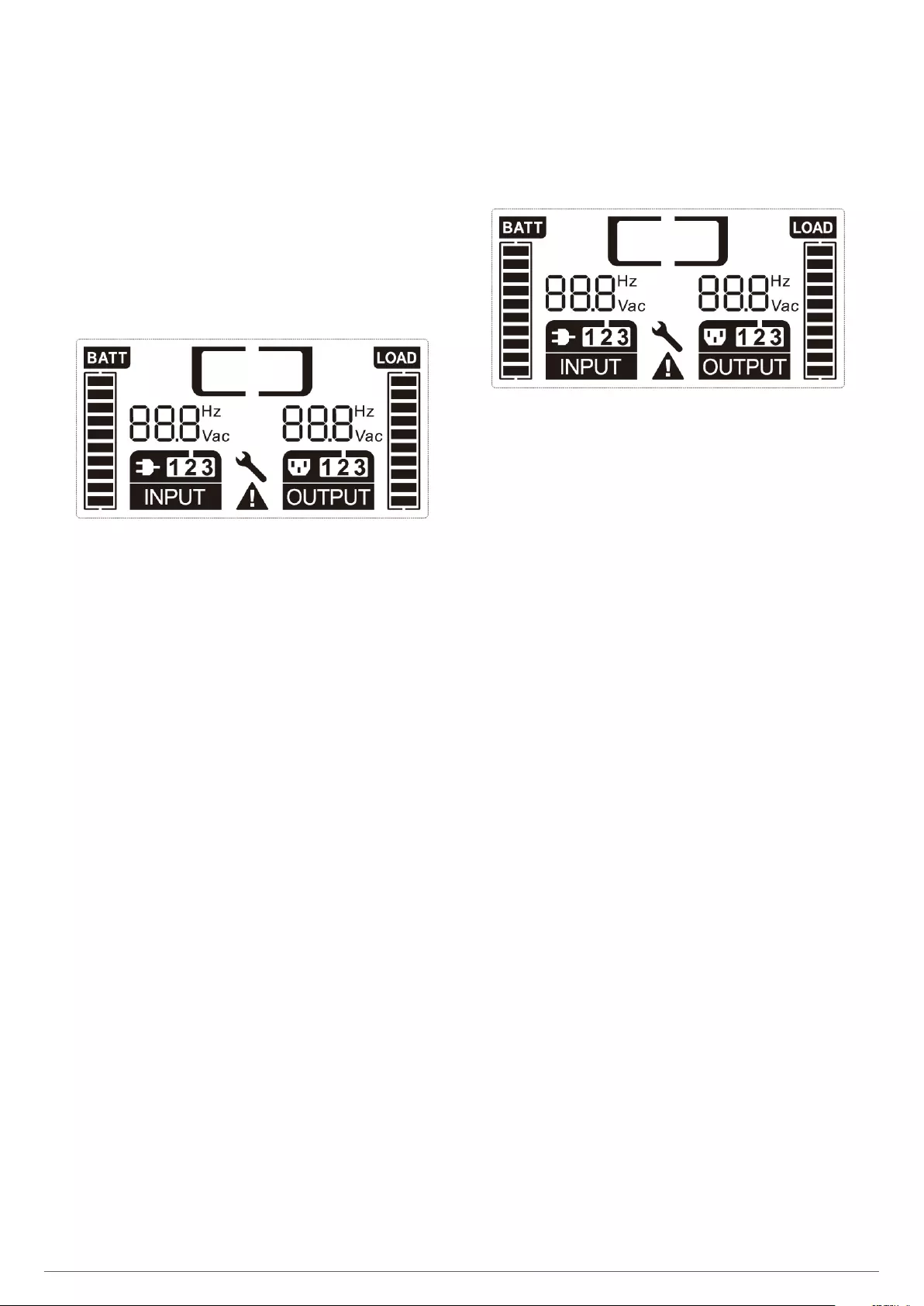

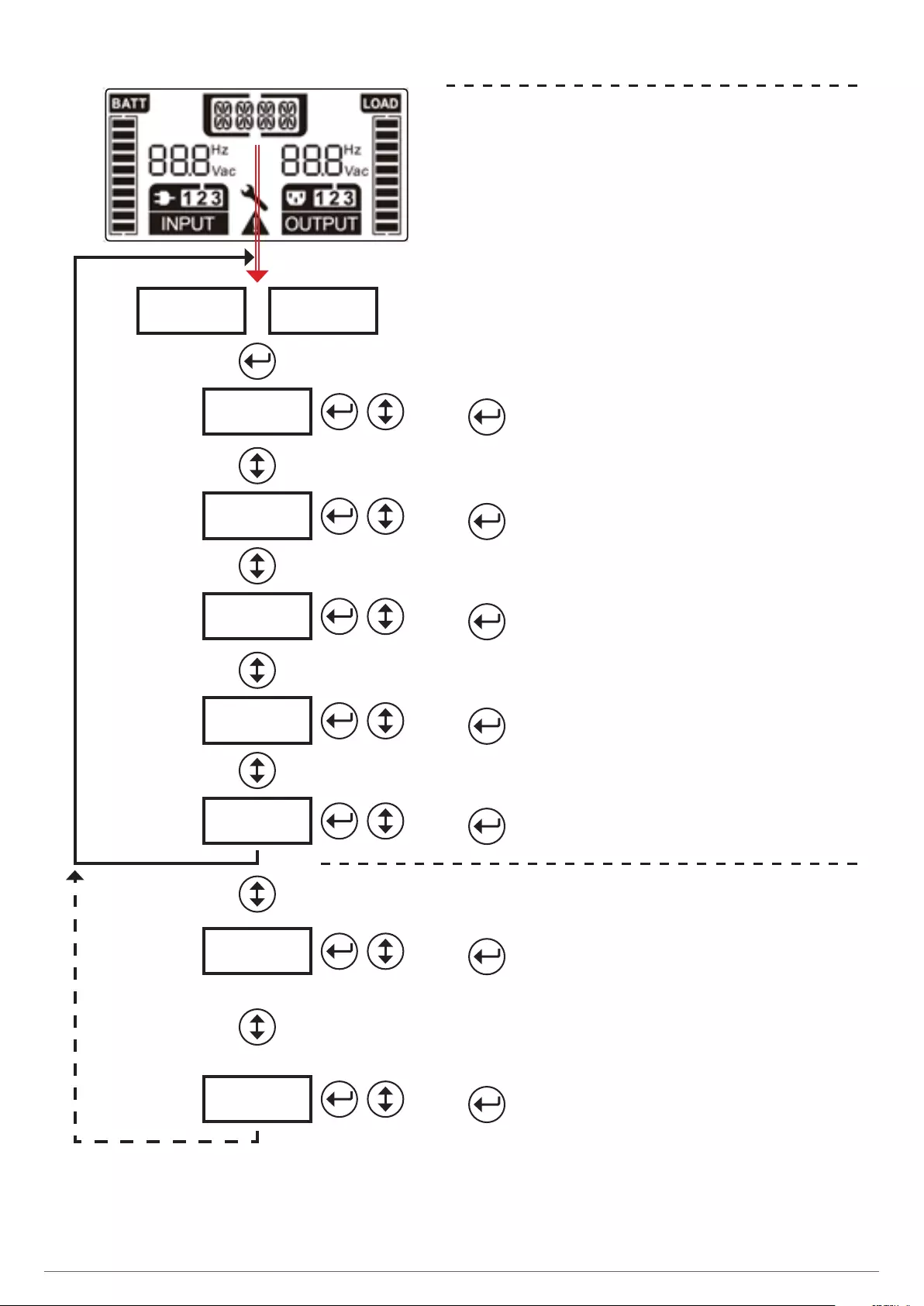

Models from 0.7 and 1 kVA -standard- Models from 0.7 and 1 kVA -B1-

Fig. 1. Front view from 0.7 to 1 kVA models.

Models from 1.5 and 3 kVA -standard- Models from 1.5 and 3 kVA -B1-

Fig. 2. Front view from 1.5 to 3 kVA models.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

8SALICRU

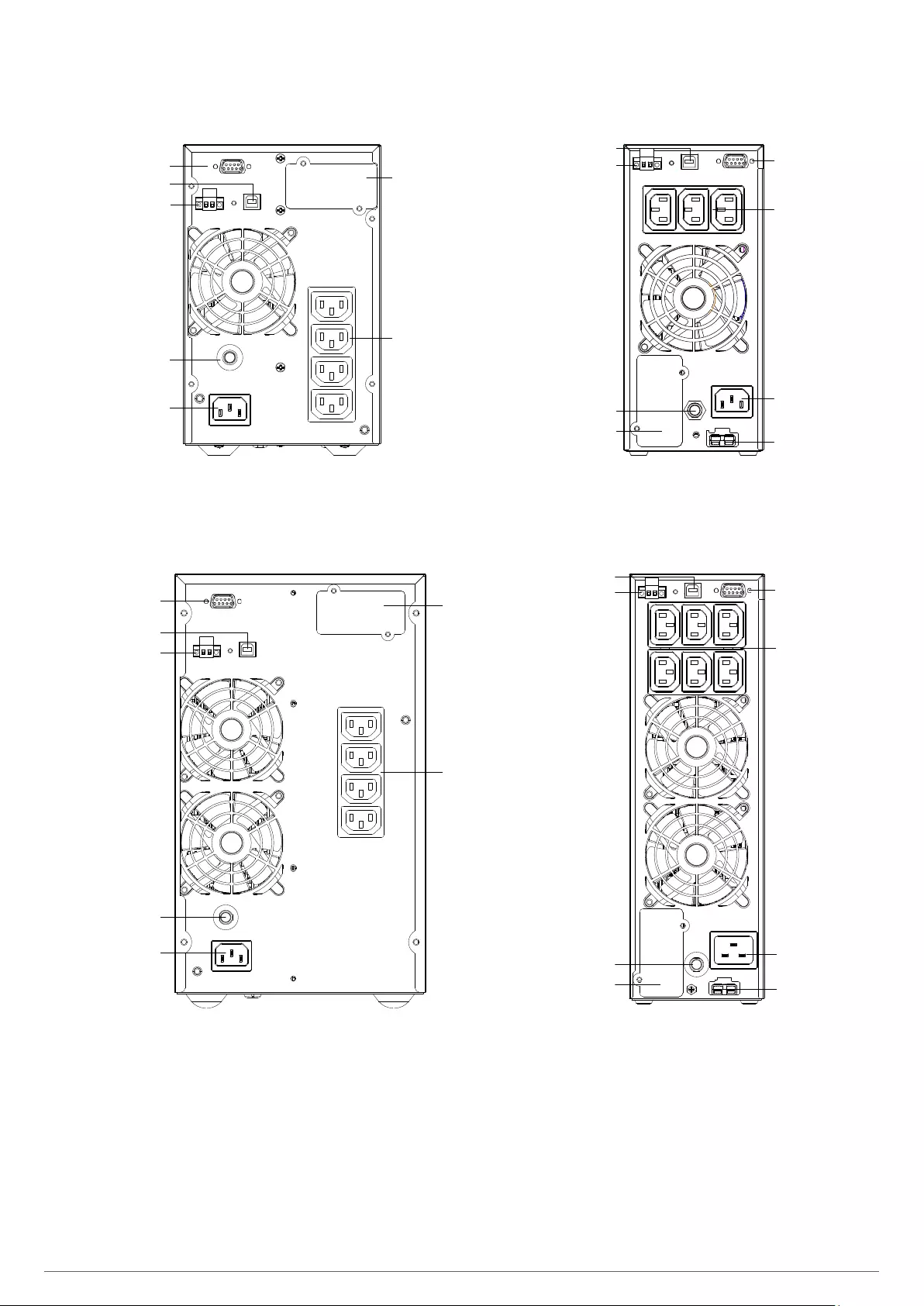

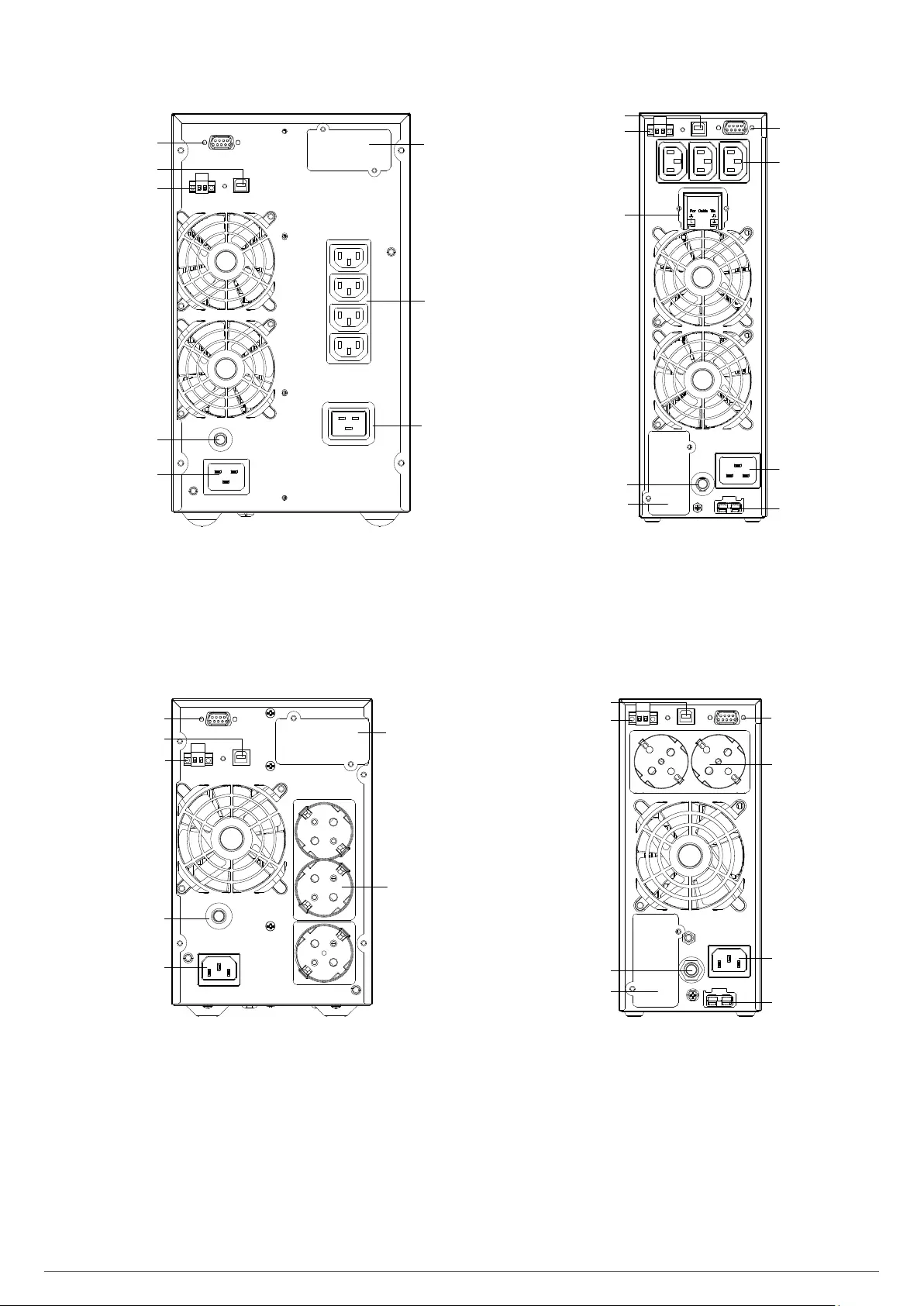

4.1.3. Rear panel IEC.

Protection cover

for smart slot

Output

sockets

Input socket

Input breaker

protection

USB

EPO

Extended

autonomy

connector

Protection cover for

smart slot

Output sockets

Input socket

Input breaker

protection

USB

EPO

RS232

(Optional)

RS232

(Optional)

Models from 0.7 and 1 kVA -standard- Models from 0.7 and 1 kVA -B1-

Fig. 3. Rear views from 0.7 to 1 kVA models with IEC output connectors.

Protection cover for

smart slot

Output sockets

Input socket

Input breaker

protection

USB

EPO

Protection cover

for smart slot

Output

sockets

Input socket Input breaker

protection

USB

EPO

Extended

autonomy

connector

RS232

(Optional)

RS232

(Optional)

Models from 1.5 and 2 kVA -standard- Models from 1.5 and 2 kVA -B1-

Fig. 4. Rear views from 1.5 to 2 kVA models with IEC output connectors.

9

Input socket

Input breaker

protection

USB

EPO

Protection cover for

smart slot

Output sockets

Output sockets

Protection cover

for smart slot

Input breaker

protection

USB

EPO

Output terminals

Output

sockets

Input socket

Extended

autonomy

connector

RS232

(Optional)

RS232

(Optional)

Models from 3 kVA -standard- Models from 3 kVA -B1-

Fig. 5. Rear views from 3 kVA model with IEC output connectors

4.1.4. Rear panel schuko.

Protection cover

for smart slot

Output

sockets

Input socket

Input breaker

protection

USB

EPO

Extended

autonomy

connector

Protection cover for

smart slot

Output sockets

Input socket

Input breaker

protection

USB

EPO

RS232

(Optional)

RS232

(Optional)

Models from 0.7 and 1 kVA -standard- Models from 0.7 and 1 kVA -B1-

Fig. 6. Rear views from 0.7 to 1 kVA models with schuko output sockets.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

10 SALICRU

Output sockets

Protection cover for

smart slot

Output sockets

Input socket

Input breaker

protection

USB

EPO

Protection cover

for smart slot

Output

sockets

Input socket

Input breaker

protection

USB

EPO

Extended

autonomy

connector

RS232

(Optional)

RS232

(Optional)

Models from 1.5 and 2 kVA -standard- Models from 1.5 and 2 kVA -B1-

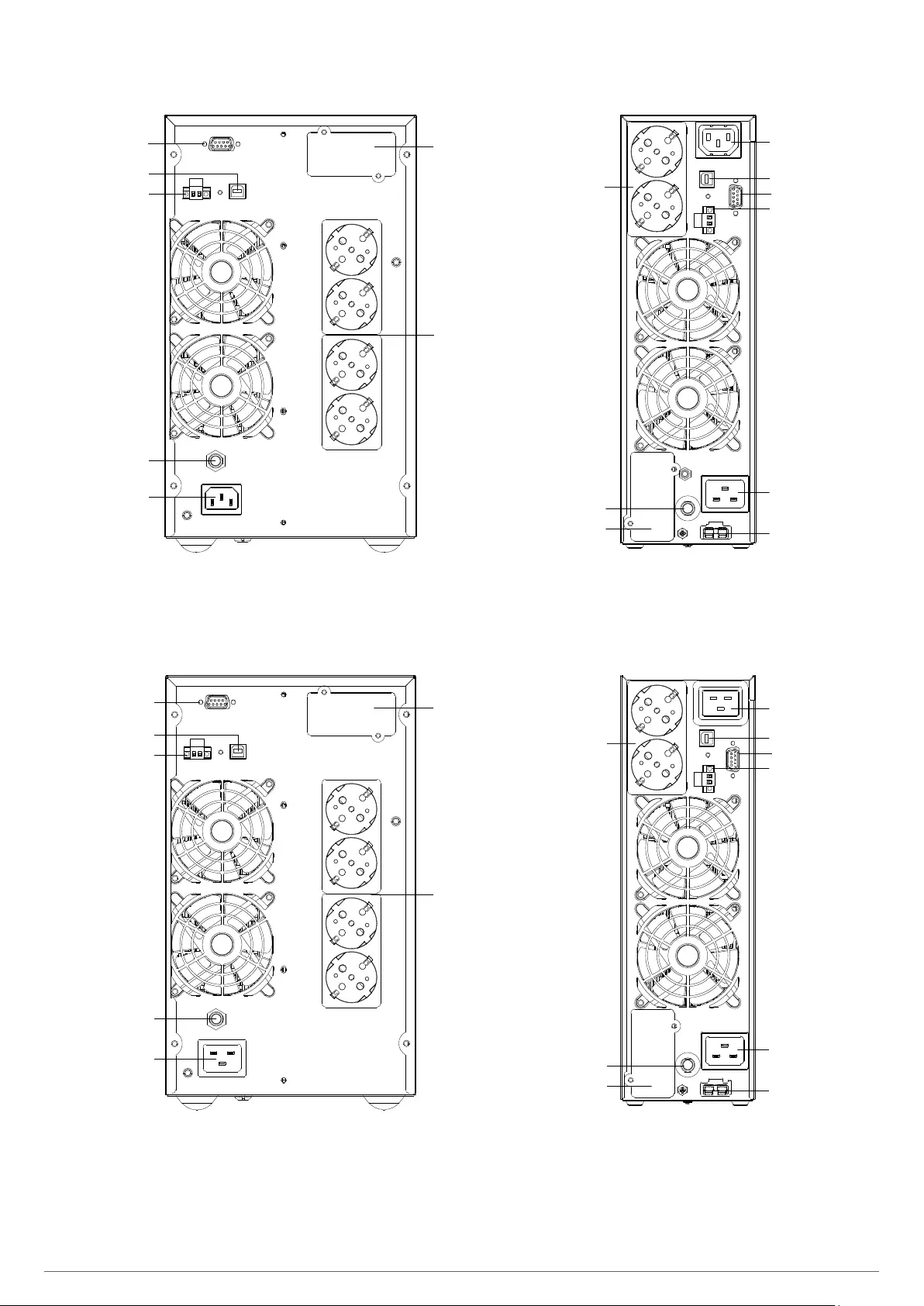

Fig. 7. Rear views from 1.5 to 2 kVA models with schuko output sockets.

RS232

(Optional)

Protection cover for

smart slot

Output sockets

Input socket

Input breaker

protection

USB

EPO

Protection cover

for smart slot

Output

sockets

Input socket

Input breaker

protection

USB

EPO

Extended

autonomy

connector

RS232

(Optional)

Output sockets

Models from 3 kVA -standard- Models from 3 kVA -B1-

Fig. 8. Rear views from 3 kVA model with schuko output sockets.

11

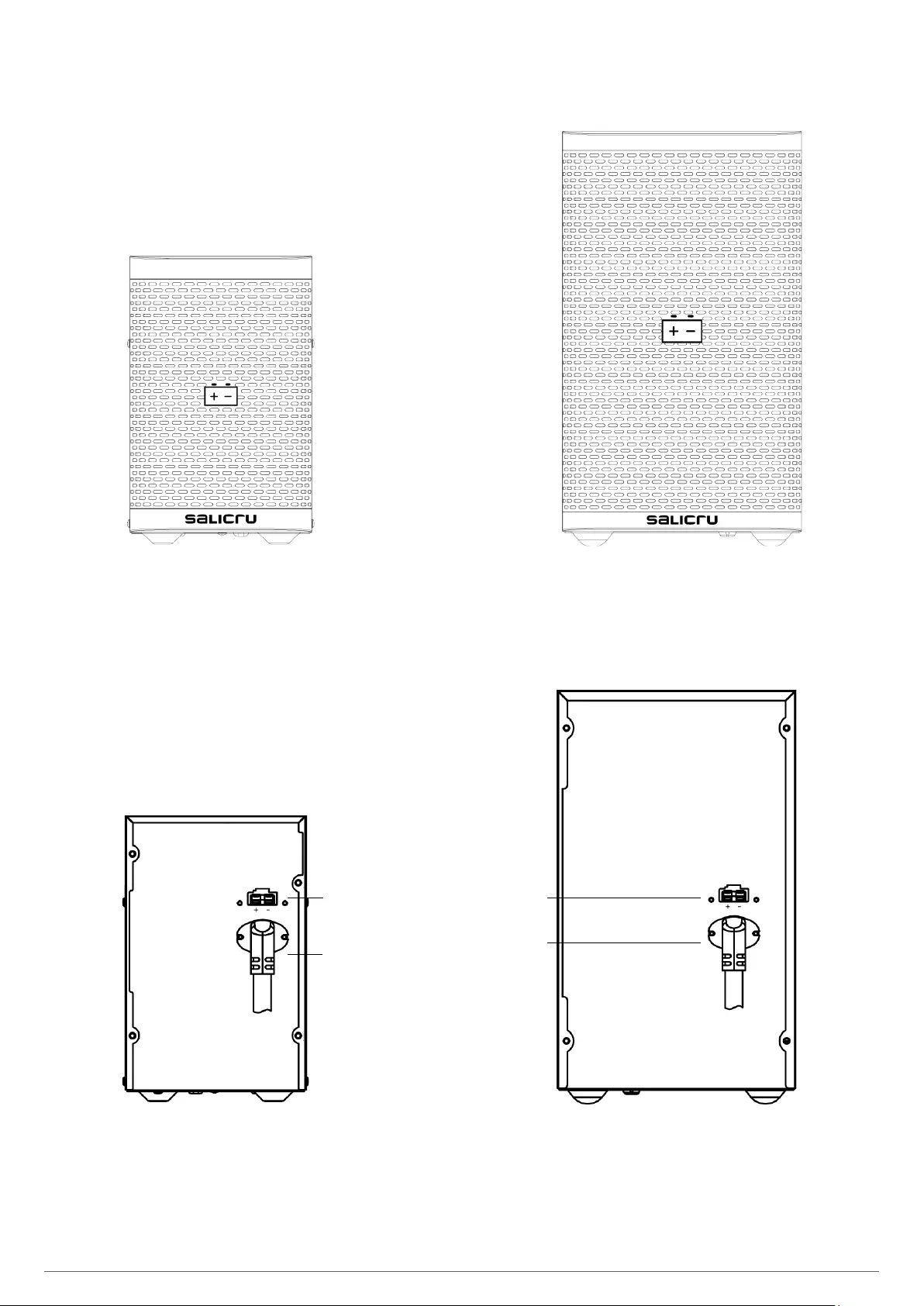

4.1.5. Frontal battery panel.

Battery module for models 0.7 and 1 kVA Battery module for models 1.5 and 3 kVA

Fig. 9. Front view from battery module.

4.1.6. Rear battery panel.

Connector to UPS

(extended

autonomy)

Connector to

parallel with

another module

Connector to UPS

(extended

autonomy)

Connector to

parallel with

another module

Battery module for models 0.7 and 1 kVA Battery module for models 1.5 and 3 kVA

Fig. 10. Rear view battery module for extended autonomy.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

12 SALICRU

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

SLC-2000-TWIN PRO2 IEC B1 CO 0/**AB147 “EE29503”

MOD BAT TWIN PRO2 2x3AB147 3x40A CO EE521925

Note as regards to the batteries:

Acronyms B0 and B1 stated in the nomenclature is related to

the batteries:

B0 Equipment without batteries and with the necessary acces-

sories to install the batteries.

Batteries owned by the client will be installed out from

the case or cabinet of the UPS.

B1 Equipment with extra battery charger. The equip-

ment is supplied without batteries and no accessories

(screws and electrical cables), corresponding to the

specific batteries in the model.

Under request is possible to supply the accessories

(screws and electrical cables), needed to install and

connect the batteries.

For equipments requested with no batteries, the acquisition and

connection of them will always be done by the customer and

under his responsibility.

Data related to batteries about quantity, capacity and voltage

are stated in the battery label sticked beside the nameplate of

the equipment, respect strictly these data and connection po-

larity of the batteries.

4.3. OPERATING PRINCIPLE.

This manual describes the installation and operating of the Uninter-

ruptible Power Supply [UPS] from SLC TWIN PRO2 series as equip-

ments that can run as a complete separate and independent units.

UPSs from SLC TWIN PRO2 series assures an optimal protection for

any critical load, keeping the power supply of the loads between

the stated parameters, with no break, during any blackout, or mains

fluctuations or deteriorations with a wide range of available models

(from 0.7 kVA to 3 kVA), it allows adapting the model to the end-user

needs.

Thanks to the used technology, PWM (Pulse Width Modulation) and

double conversion, the UPSs from SLC TWIN PRO2 series are com-

pact, silent, and with high efficiency.

The double conversion principle cancels all the AC mains pertur-

bations. A rectifier converts the alternating current from AC input

mains into DC direct current, that keeps at the optimal level the bat-

teries and supplies the inverter, which at the same time generates

an AC voltage ready to feed the loads permanently. In case of fault

of the input power supply of the UPS, the batteries supplies clean

energy to the inverter.

EE* Special specifications of the client.

0/**AB147 Equipment without batteries and with the necessary ac-

cessories to install the batteries.

CO “Made in Spain” marking in the UPS and its packaging

(custom issue).

B1 Equipment with extra charger and batteries out from

UPS.

Schuko output connector and schuco cable power supply.

IEC IEC output connector and schuco cable power supply.

UK IEC output connector and UK cable power supply.

TWIN PRO2 Series.

2000 Power in VA.

SLC Acronym of the brand.

CF Frequency converter (without batteries equipment).

EE* Special specifications of the client.

CO “Made in Spain” marking in the UPS and packaging

(custom issue).

40A Size of the protection.

147 Last three characters of the battery code.

AB Initials of the battery family.

3 Quantity of batteries in one string.

2x Quantity of strings in parallel. Omit for only one.

0/ Battery module without them, but with the accessories

to install them.

TWIN PRO2 Series of the battery module.

MOD BAT Battery module.

13

The UPS design and construction from SLC TWIN PRO2 series have

been done in accordance with the international norms.

So, this series has been designed to maximize the availability of the

critical loads and make sure that your business is protected against

fluctuations of voltage, frequency, electrical noises, blackouts and

mains faults, which are present in the energy distribution lines. This

is the main target of the UPSs from SLC TWIN PRO2 series.

This manual is applicable to the standardized models and stated in

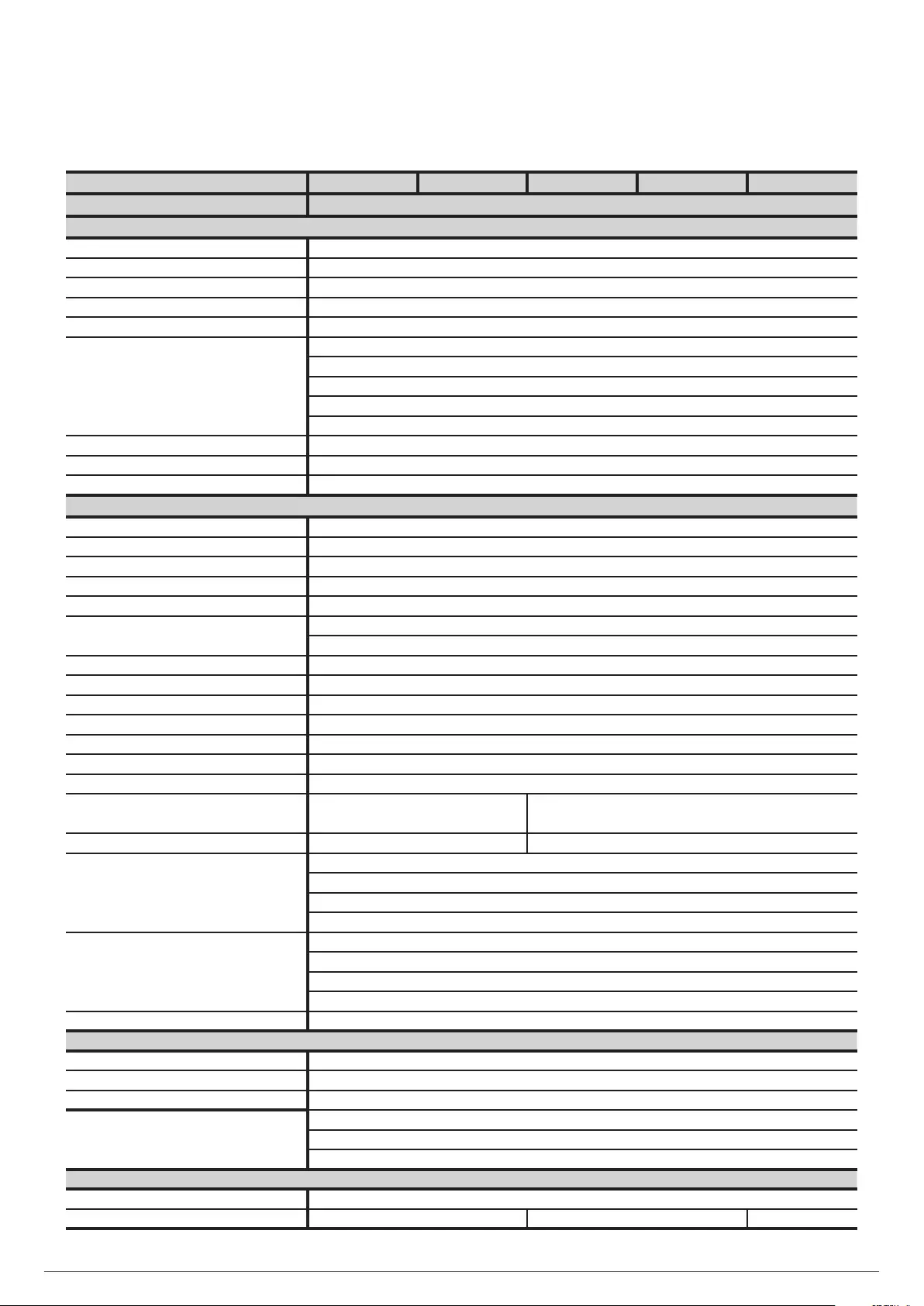

Tab. 1.

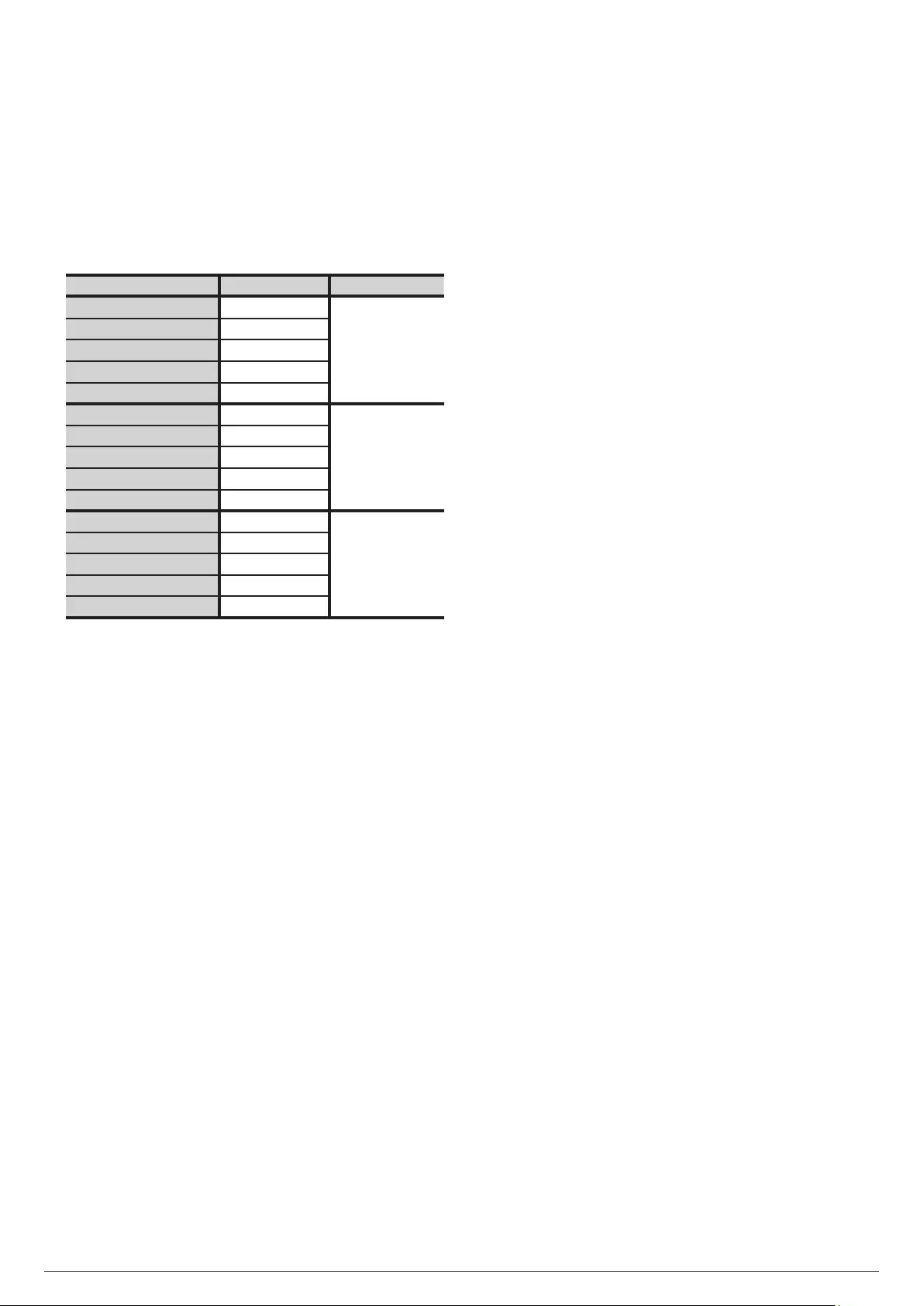

Model Power (VA) Type

SLC-700-TWIN PRO2 700

Standard

SLC-1000-TWIN PRO2 1000

SLC-1500-TWIN PRO2 1500

SLC-2000-TWIN PRO2 2000

SLC-3000-TWIN PRO2 3000

SLC-700-TWIN PRO2 B0 700

Without batteries

SLC-1000-TWIN PRO2 B0 1000

SLC-1500-TWIN PRO2 B0 1500

SLC-2000-TWIN PRO2 B0 2000

SLC-3000-TWIN PRO2 B0 3000

SLC-700-TWIN PRO2 B1 700

Standard with

extended autonomy

SLC-1000-TWIN PRO2 B1 1000

SLC-1500-TWIN PRO2 B1 1500

SLC-2000-TWIN PRO2 B1 2000

SLC-3000-TWIN PRO2 B1 3000

Tab. 1. Standardized basic models.

4.3.1. Main features.

•True on-line double conversion and independent output fre-

quency from mains.

•Output power factor of 0,9 and pure sinewave, suitable for al-

most any kind of loads.

•Input power factor > 0,99.

•Great adaptability to the worst conditions of the input mains.

Wide margins of the input voltage, frequency range and wave

shape, so it is avoided the excessive dependence on the limited

energy of the battery.

•Availability of battery chargers up to 6 A in order to decrease

the battery recharging time.

•High efficiency mode can be selected > 0,97 [ECO-MODE]. En-

ergy saving, which reverts to the user in an economy way.

•It is possible to start up the equipment without mains or the battery

discharged. Watch this last aspect, because the back up time will be

decreased as much discharged the batteries are.

•The technology of the smart management of the battery is very

useful for making longer the accumulator lifetime and to opti-

mise the recharging time.

•Standard communications options by means of USB port.

•Control of the remote emergency power off [EPO].

•Control signal of the remote emergency power off [EPO].

•Interface between the user and the equipment through the con-

trol panel LCD, user friendly.

•Option cards are available to improve the communication ca-

pacity of connectivity.

4.4. OPTIONS.

Depending on the selected configuration, the equipment can include

any of the following options:

4.4.1. Isolation transformer.

The isolation transformer, provides a galvanic isolation that allows

isolating the output from the input completely.

The installation of an electrostatic shield between the primary and

secondary windings of the transformer provides a high level of at-

tenuation of the electrical noises.

The isolation transformer can be installed at the input or output of

the UPS from SLC TWIN PRO2 series and it will always be located

out from the equipment enclosure.

4.4.2. External maintenance manual bypass.

The purpose of this option is to isolate electrically the equipment

from mains and critical loads, without breaking the power supply to

the loads. Therefore, in this way the maintenance or fixing tasks can

be done in the equipment with no interruption on the power supply

energy to the protected system, at the same time that unnecessary

risks are avoided to the technical staff, because it allows a complete

disconnection of the UPS from the installation.

4.4.3. Integration in IT networks by means of the SNMP

adaptor.

The big IT systems based on LANs and WANs that integrate servers

with different platforms, they have to include an easy way of con-

trolling and managemet at the manager system disposal. This fa-

cility is got through the SNMP adaptor, which is well-known by the

main software and hardware manufacturers.

The available SNMP option for SLC TWIN PRO2 series is a card to be

inserted into the slot that the UPS has in its rear side.

The connection of the UPS with the SNMP is internal meanwhile the

connection between the SNMP and the IT network is done through a

RJ45 connector 10 base.

4.4.4. MODBUS protocol.

The big IT systems based on LANs and WANs, many times they re-

quire that the communication with any device to be integrated in

the IT network has to be done by means of an industrial standard

protocol.

One of the most used industrial standard protocols in the market is

the MODBUS protocol. SLC TWIN PRO2 series is also ready to be

integrated in this type of environments through the external SNMP

device with MODBUS protocol.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

14 SALICRU

5. INSTALLATION.

•Read and respect the Safety Information, described in

section 2 of this document. The fact of ignoring any of

the indications described in it, can cause serious accidents or

very serious injuries to the persons in the vicinities in direct con-

tact, as well as damages to the equipment and/or loads con-

nected to itself.

•All connections of the equipment including the control

(interface, remote panel, ...), will be done with the

switches at rest and no voltage present (UPS power supply

switch to «Off»).

•Never forget that the UPS is an electrical energy gener-

ator, so the user has to take the needed cautions against

direct and indirect contacts.

•Battery circuit is not isolated from input voltage. Haz-

ardous voltages can be found out between the battery

terminals and earth. Check that there is not input voltage before

doing any intervention on them.

•Any protection earth ( ) contact or terminal of the

plugs, outlets and/or connectors, at the input or output of

the equipment are electrically joined among them, which is ex-

tended till the loads connected to the output of the UPS.

•As this is a device with class I protection against electric

shocks, it is essential to install a protective earth con-

ductor (connect earth ).

It is compulsory that the power supply that feeds the equipment

has this protection earth ( ) cable duly connected.

5.1. RECEPTION OF THE EQUIPMENT.

•Any equipment handling will be done keeping in mind the

weights and technical features of the model, stated in sec-

tion «9. Annexes». Pay attention to section 1.2.1. from «Safety

intructions» EK266*08 regarding handling, moving and loca-

tion of the equipment.

5.1.1. Inspection.

•On receiving the device, make sure that it has not suffered any

damage in transport (impact, drop, ...) and its features corre-

spond with the ones in the order, so it is recommended to un-

pack the UPS and make a first visual inspection.

•In case of observing damages, make all pertinent claims to the

transport agency or in their lack to our company.

Never start up an equipment when external damages

can be observed.

•Also check that the data in the nameplate sticked in the pack-

aging and in the equipment, correspond to the ones stated in the

order, so it is required to unpack it (see section 5.1.2). Otherwise,

make a nonconformity as soon as possible, by quoting the serial

number of the equipment and references in the delivery note.

5.1.2. Unpacking.

•The packaging of the equipment has a cardboard enclosure, ex-

panded polystyrene [EPS] or polyethylene foam [EPE] corners,

plastic bag and polyethylene strip, all materials a re recyclable;

so if you are going to dispose them, do it in accordance with the

regulations in force. It is recommended to keep the packaging in

case it were needed in future.

•Proceed as follows:

Cut the strips of the cardboard enclosure, in those models

with strips.

Take out the accessories (cables, documentation, ... )

Take out the equipment or battery module from the pack-

aging, considering the help of a second person depending

on the weight of the model.

Remove the protection corners of the packaging and the

plastic bag.

Keep out of reach of children the plastic bag, due to

the risks that it involves.

Inspect the equipment before continuing and in case dam-

ages are confirmed, contact with the supplier or in lack of

him with out firm.

5.1.3. Content checking.

•Check the contents of the packaging. Depending on what we

are checking, an equipment or battery module, the contents

will vary.

UPS:

–The own equipment.

–Hardcopy quick guide.

–Information for the registration of the guarantee.

–1 USB communication cable.

–1 connection cable for input - plug and IEC connector -.

–2 output cables (only on models with IEC connectors).

Battery module:

–The own module.

–Information for the registration of the guarantee.

–1 cable for connection between equipment and battery

module or between modules.

•Once the reception is finished, it is advisable to pack the UPS

again till its commissioning in order to protect it against me-

chanical shocks, dust, dirt, etc...

5.1.4. Storage.

•Storage of the equipment will be done in a dry place, safeguard

from rain, protected from dust, water jets or chemical agents,

never outdoors. It is advisable to keep the equipment and the

battery pack/s, into their original packages, which have been

designed to assure the maximum protection during the transport

and storage.

•In equipments that include Pb-Ca batteries, the figures,

stated in Tab. 2 of the EK266*08 document, of charge

period time depending on the temperature that they are ex-

posed, must be respected, otherwise the warranty will be in-

validated.

•After this time, connect the equipment to mains and together

with battery unit, if any, start it up according to the instructions

described in this manual and charge them for 12 hours.

•Finally, shutdown the equipment, disconnect it and fit the UPS

and batteries in their original packaging, noting the new battery

charge date on each respective label.

•Do not store the devices where the ambient temperature ex-

ceeds above 50ºC or below –15ºC, otherwise it may degrade the

electrical characteristics of the batteries.

15

5.1.5. Transport to location.

•Although the weight of the equipments is not so high, it is rec-

ommended to move the UPS by the use of a forklift, pallet truck

or by means of the most suitable means of transport by evalu-

ating the remoteness of the location point.

If the distance is high, it is recommended to move the equipment

still packaged till the installation place and unpack it later.

5.1.6. Preliminary considerations, before connecting the

equipment.

•Check that the data in the nameplate are the required by the

installation.

•A wrong connection or manoeuvring, can make faults in the UPS

and/or loads connected to itself. Read carefully the instructions of

this manual and follow the stated steps in the established order.

•All the equipments have power cord with plug to be connected

to the AC mains.

In the same way, “N” output outlets or IEC connectors de-

pending on the model are supplied, for its connection with the

loads [output].

For the rest of connections is used an connector for the battery

connection [B1 version] and ports for communications.

•Cross cable section of the input and output lines, will be calculated

from the currents stated in the nameplate of each equipment, and

respecting the Local and/or National Low Voltage Electrotechnical

Regulations.

•Protections of the switchgear panel, will have the following fea-

tures:

For input line, type B for RCD devices and C characteristic

for circuit breakers.

For the output (load feeding), C characteristic for circuit breaker.

Regarding the size, they will be as minimum to the currents

stated in the nameplate of each UPS.

•In the nameplate of the equipment there are only printed the

nominal currents as it is stated in the safety standard EN-IEC

62040-1. To calculate the input current, the power factor and the

efficiency of the equipment have been considered.

Overload conditions are considered as nonpermanent and ex-

ceptional operating mode.

•If it is added peripherals to the input or output like transformers

or autotransformers to the UPS, the currents stated in the own

nameplates of those elements has to be considered in order to

use the suitable cross sections, by respecting the Local and/or

National Low Voltage Regulation.

•When an equipment incorporates a galvanic isolation

transformer, as standard, as an option or either installed

by yourself, either at the UPS input line, output or in both, pro-

tections against indirect contact has to be fitted in (residual cur-

rent device) at the output of each transformer, because due to its

specification of isolation it will prevent the triggering of the

protections fitted in the primary of the transformer in case of

electrical shock in the secondary (output of the isolation trans-

former)

•Remind you that all external isolation transformers already in-

stalled or supplied from factory, has the neutral of the secondary

connected to earth by means of a cable bridge between both

terminals. If it were required an isolated output neutral, remove

this cable bridge, keeping the precautions stated in the respec-

tive local and/or national low voltage regulations.

•All standard UPSs have batteries in the same enclosure of the

equipment , less those ones as B1. In the first ones, the battery

protection is by internal fuses and there is no access to the end-

user.

Also the battery modules have internal protections by fuses and

in the same way as it is done in the own equipments, they are

not accessible by the end-user.

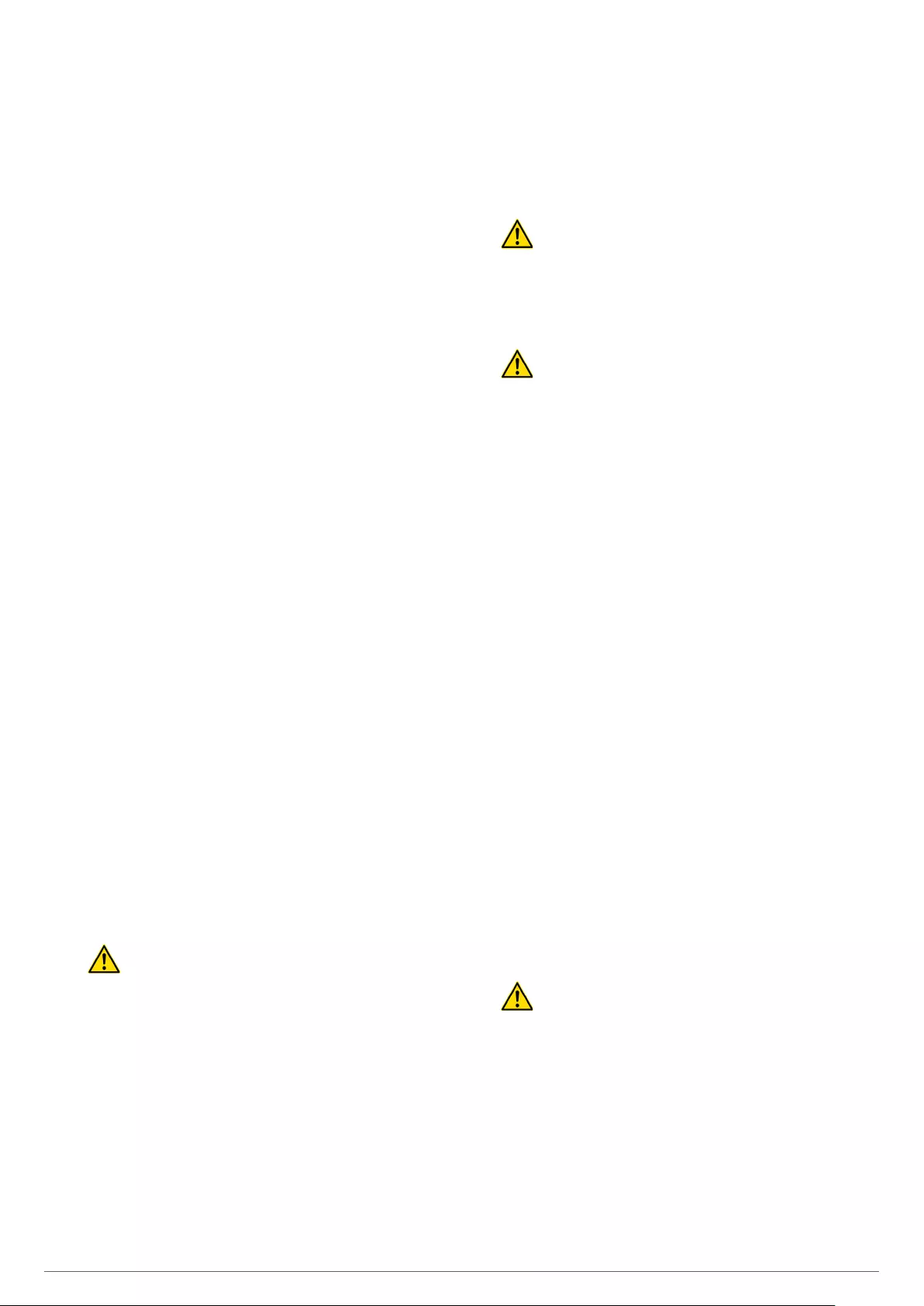

•IMPORTANT FOR SAFETY: In case of installing the bat-

teries by yourself, the accumulators have to be provided

with a two pole circuit breaker protection sized to the features

stated in Tab. 2.

5.2. CONNECTION.

•Cross cable section used in the power supply of the

equipment and loads to feed, will be sized according to

the nominal current stated in the nameplate sticked on the

equipment, by respecting the Low Voltage Electrotechnical Reg-

ulations or norms of the corresponding country.

•Installation will have the suitable input protections sized to the

current of the equipment and stated in the nameplate of the

equipment (residual current devices type B and circuit breaker

with C characteristic or any other equivalent one).

Overload conditions are considered as a nonpermanent an ex-

ceptional operating mode, so these currents will not be kept in

mind when sizing the protections.

•To insert the option cards, it is needed to remove the fixing

screws of the smart slot and the own cover.

5.2.1. Connection of input.

•Toke the input power cord with plug and IEC connector.

•Insert the IEC connector to the UPS inlet.

•Insert the plug in to the wall AC outlet.

5.2.2. Connection to output.

•All the equipments have «N» output outlets or IEC connectors

depending on the model.

•Connect the loads to the outlets or IEC connectors.

•The 3 kVA B1 models with IEC output connectors also feature

output terminals. To access them, it is necessary to remove the

corresponding terminal protection cover, which will be replaced at

the end of the connection tasks.

Connect the loads to the output terminals, observing the order

of the phase, the neutral and the earth cable indicated on

the labelling of the device, otherwise faults and/or defects may

occur in the UPS and/or load or connected loads.

The sum of the loads connected to the different sockets,

IEC connectors and/or terminals must not under any cir-

cumstances exceed the rated power of the device.

•If besides of the critical loads, it is required to connect lagging

loads of high consumption, like laser printers or CRT monitors,

the inrush currents of these peripherals will be kept in mind in

order to avoid blocking the equipment under the worst condi-

tions.

It is better to not connect the loads of this kind, due to the high

quantity of energy resources that take from the UPS.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

16 SALICRU

UPS Module 1 Module “n”

Fig. 11. Connection among the equipment and "n" battery modules.

•Each battery module is independent for each equipment.

It is strictly prohibited to connect two equipments

to one battery module.

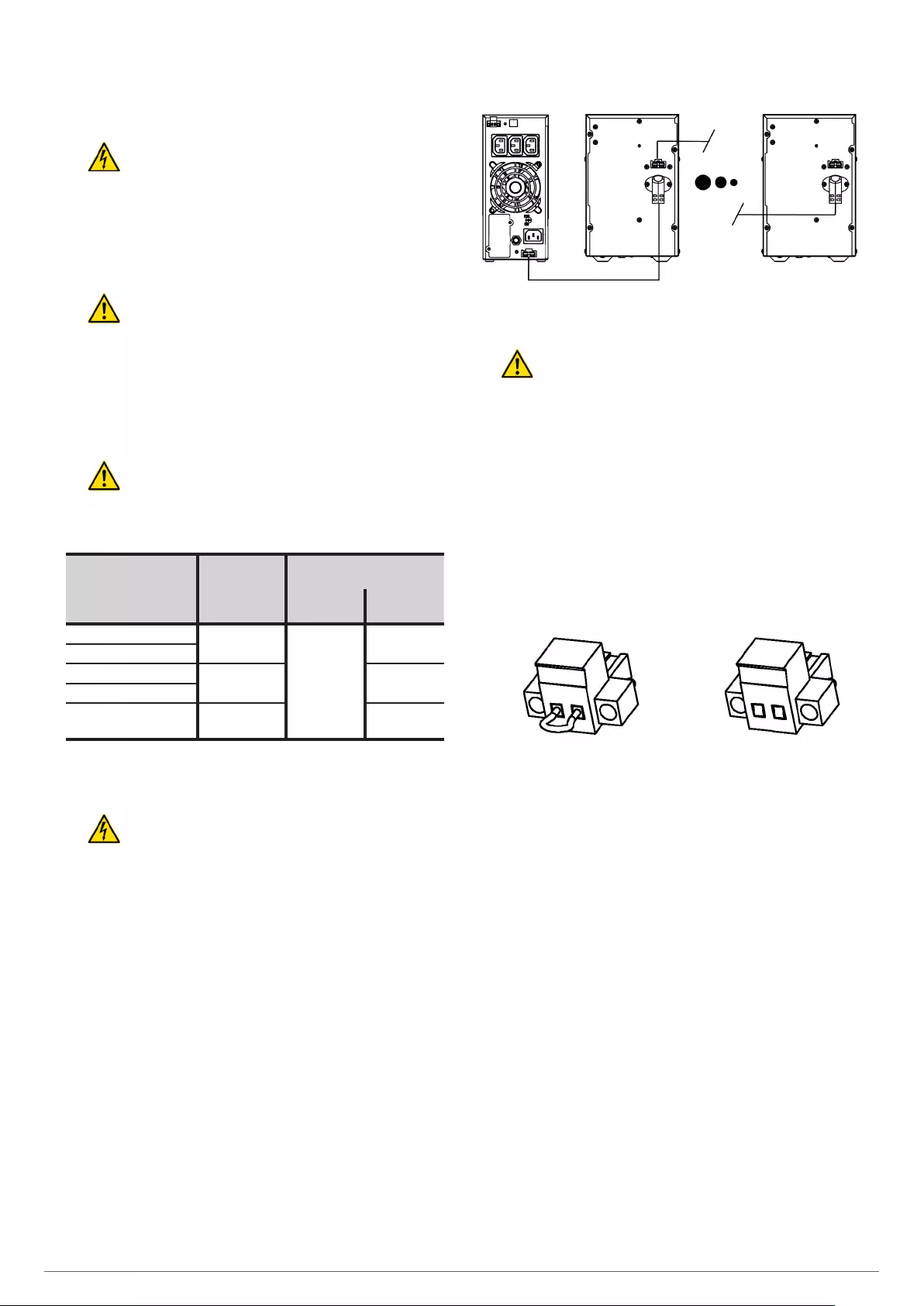

5.2.4. Terminals for EPO (Emergency Power Off).

•All UPSs have a terminal strip to install an external button, for

Emergency Power Off [EPO].

•The equipment is preset from factory with the EPO as normally

closed contact [NC]. So, the UPS will break the output power

supply when the circuit is open:

Either by removing the female connector inserted in the plinth.

This connector has a cable bridge to close the circuit [Fig. A].

Fig. A Fig. B

Or by turning on the external button installed and belonging

to the end-user. The connection in the button has to be

in normally closed because it will open the circuit when

turning it on.

•The reverse operating of the opened circuit [NO], can be set at

factory or later on by our T.S.S. at site.

Less punctual cases, it is not recommended to use this type of

connection due to the function of the EPO button, because it

would not work in case of any of the two cables that goes from

the button to the UPS were cut [damaged].

On the other hand this failure would be immediately detected

in the normally closed EPO type, with the inconvenience of the

sudden break in the power supply to the loads, but with a com-

plete guarantee of the functioning of the emergency power off.

•To restore the normal operating mode of the UPS, the connector

with the cable bridge has to be fitted back in the terminal strip

or to deactivate the EPO button and later on to cancel the EPO

status in the control panel . The equipment will be operative.

5.2.3. Connection of external batteries [extended back up

times] -B1- or models without batteries -B0-.

•To not respect the stated indications in the safety

instructions EK266*08 means a high risk of elec-

trical discharge and even the death.

•All the standard UPS’s have batteries in the same enclosure,

less the B0 and B1 models. Battery protection is done by internal

fuses and not accessible for the end-user.

Battery modules have internal protections for the batteries too

and they are not accessible for the end-user.

•

NECESSARY ADJUSTMENTS WHEN ADDING BAT-

TERY MODULES TO SERIAL MODULES IN B1 MODELS.

B0 and B1 models have factory default settings for connection

to a single battery module. Whether battery modules are added

to an already available device or if the acquired device has more

than one module, it is necessary to change the parameter to the

corresponding value.

Section 7.3 of this document indicates the steps to follow to

adjust this setting and that of the load current.

•IMPORTANT FOR SAFETY: In case of installing the bat-

teries by yourself -B0-, the accumulators has to be pro-

vided with a two pole circuit breaker protection sized to the

features stated in Tab. 2.

Model

Batteries

(U element x Nº) =

U nominal / U floating

Characteristics of the

protection

Voltage

DC (V)

Current

(A)

SLC-700- TWIN PRO2 B1 (12 V x 2 ) =

24 V / 27,3 V

125

40

SLC-1000- TWIN PRO2 B1

SLC-1500- TWIN PRO2 B1 (12 V x 4 ) =

48 V / 54,6 V 40

SLC-2000- TWIN PRO2 B1

SLC-3000- TWIN PRO2 B1 (12 V x 6 ) =

72 V / 81,9 V 50

Tab. 2. Features of protection between the UPS and battery module.

•Before starting the connection between the bat-

tery module/s and the equipment, check that the

equipment switch/es and the one in the battery cabinet

are in “Off” position.

Likewise when batteries are installed by own self, the

fuse or switch has to be turned off.

•Connection terminals of external batteries with the equipment

are done with a polarised connector in B0 and B1 models. This

connector is not available on standard models.

•To connect the equipment with the battery module, use the

cable trunk supplied with the module and connect it between

both units and through the connectors.

When more than one battery module is supplied for one equip-

ment, the connection among the modules will be done through

the cable trunk supplied in the second battery module.

Fig. 11 shows as an example, the connection of a SLC-TWIN

PRO2 B1 with «N» battery modules. Less the rear view of the

model, it is applicable to all the range stated in this manual.

Connect the available modules depending on each case.

•If for any reason the end-user manufactures the battery cable

trunk, the colour code of the cables has to be respected, red for

positive, black for negative and green-yellow for earth, as well

as the correlation of the connection (+ with + and – with –).

17

5.2.5. Communication ports.

5.2.5.1. USB interface.

•The USB interface provides the “smart battery” feature which

supports the HID (Human Interface Device) Power Device Class,

no software installation is required. Windows/Linux/Mac Op-

erating Systems come with an embedded power management

and monitoring function. When that computer is connected to

the UPS via the USB interface, the UPS will be automatically

acknowledged by the OS as a “HID UPS Battery”, and the user

will be able to set action to make when the low battery alarm

is triggered, like shutdown the computer automatically. Also,

the UPS with this feature is the ideal back-up power for NAS

(Network-Attached Storage).

•Communication line (COM) is a very low voltage circuit

of safety. To preserve the quality, it has to be installed

separate from other lines that have dangerous voltages (energy

distribution line).

•USB interface is used by the monitoring software and firmware

updating.

USB communication port is compatible with the USB 1.1 pro-

tocol for communication software.

5.2.5.2. Smart slot.

•UPSs have a unique slot, hidden rear the cover stated in the

views of the equipment as “Smart slot”, and allows inserting

any of the following options cards:

Relay interface to terminals -dry contacts-.

SNMP adaptor.

•Each option card is supplied with its own particular documenta-

tion. Read it before installing them.

5.2.6. Software.

•Free software download - VinPower.

VinPower is a UPS monitoring software, which makes a user-

friendly interface of monitoring and management. This software

supplies an auto Shutdown for a system based on several PCs

in case of an electrical blackout. With this software, the end-

users can monitor and manage any UPS in the same IT network,

through the RS232 or USB communication port, never mind the

distance between them.

•Installation procedure:

Go to website:

http://support.salicru.com

Choose the operating platform that you need and follow the

instructions described in the web site to download the soft-

ware.

When downloading the needed files from Internet, enter the

following licence to install the software:

511C1-01220-0100-478DF2A .

When the computer is rebooted, VinPower software will be

shown as an icon with plug shape and green colour in the

system tray, near the clock.

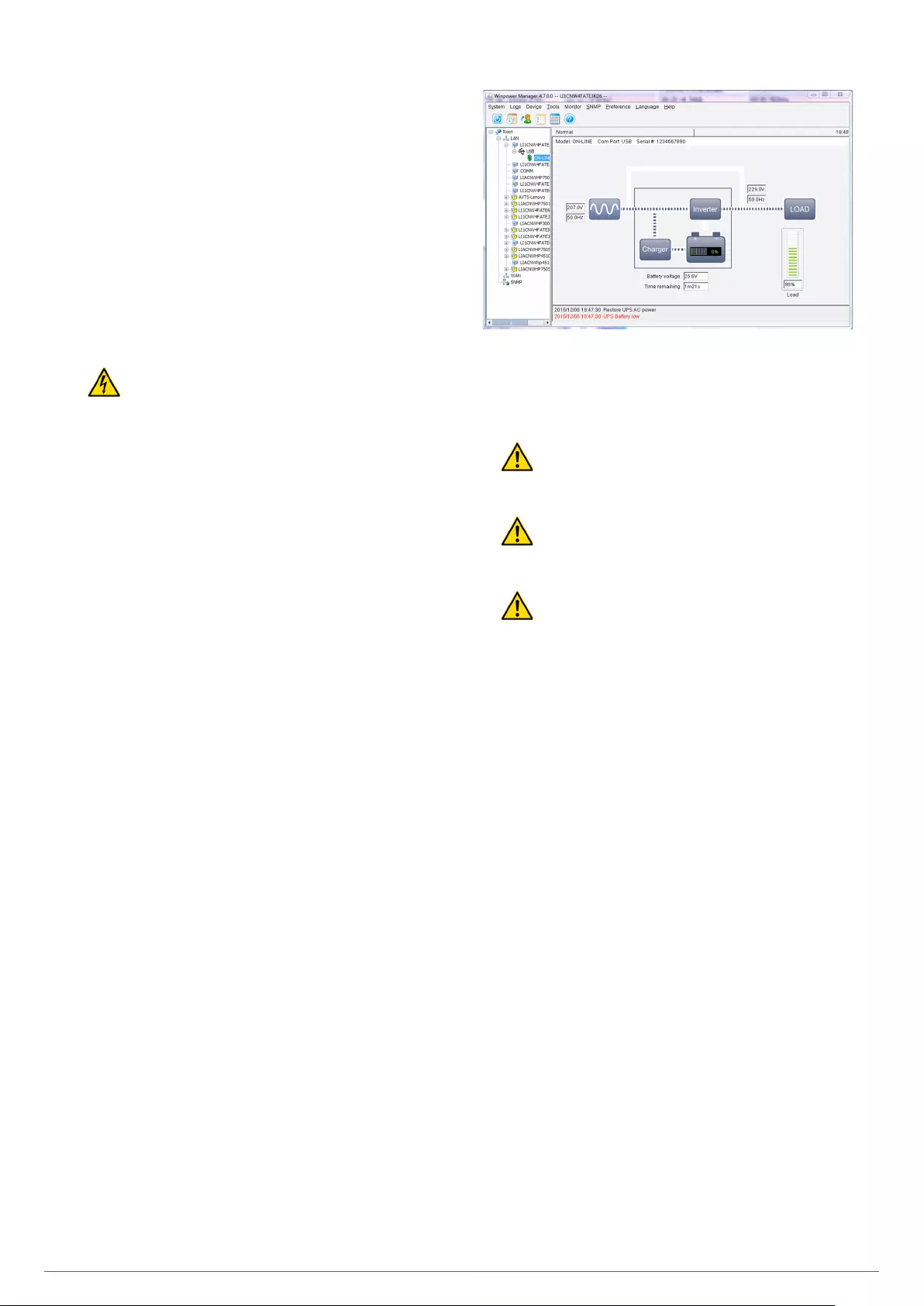

Fig. 12. Main screen of the monitoring software.

5.2.7. Considerations before starting up.

•It is recommended to charge the batteries for 12 hours as

minimum before using the UPS for first time. When sup-

plying voltage to the equipment, the battery charger will auto-

matically work.

•[B1] equipments with extended back up time has a bat-

tery charger with higher quality performances. It is rec-

ommended to charge the batteries for 12 hours as minimum

before using the UPS for first time.

•Nevertheless, those equipments with extended back up

time and with no additional battery charger, it is recom-

mended to charge the batteries of each battery module for 12

hours.

•Although the equipment can work without charging the bat-

teries during the stated time without any problem, the risk of a

long blackout has to be valued during the first operating hours

and the available autonomy time in the UPS.

•Do not start up the equipment and loads completely till chapter

6 states it.

Nevertheless, when it is done, it will be done gradually to avoid

any problem, as minimum in the first commissioning.

•If inductive loads with big inrush current apart from sensitive

ones are required to be connected like laser printers or CRT

monitors, keep in mind the start inrush currents of these pe-

ripherals in order to avoid that the equipment becomes blocked

under the worst conditions.

It is better to not connect the loads of this kind, due to the high

quantity of energy resources that take from the UPS.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

18 SALICRU

6. OPERATING.

6.1. UPS COMMISSIONING AND SHUTDOWN.

6.1.1. Preliminary controls.

•Make sure that all connections have been done properly, and

respecting the labelling of the equipment and the instructions

of chapter 5.

•Check that the power supply is correct.

•Check that the UPS is «OFF» [shutdown].

•Make sure that all loads are shutdown «OFF».

•Check that the thermal protection of the equipment is not tripped.

•It is very important to proceed in the established order.

•For UPS views, see Fig. 1 to 10.

•Turn «ON» the protection of the distribution panel.

The operation of the device described in this document is

based on the original factory settings and configuration. Sec-

tion 7.3 shows the screens tree, the variables and the original con-

figuration. Take into consideration that any modification of them can

lead to changes in the behaviour of the device.

6.1.2. Start up the UPS, with AC mains.

•When applying input voltage to the UPS, the sockets,

connectors and/or output terminals supply power

through the static bypass without the device running.

•The UPS can’t supply voltage to the loads because the bypass

mode is deactivated, code «STbY».

•To start up the UPS, press over the key «ON» of front panel for

more than 1 second, the inverter will start up and at the same

time the status of the UPS will be displayed in the LCD of the

front panel.

•Start up the load/s.

6.1.3. Start up the UPS, with no AC mains (Battery mode)

•To start the device without mains voltage, i.e. cold start, press

the «ON» key on the front panel for more than 1 second. The in-

verter will start up while the status of the UPS will be displayed

on the front panel LCD display.

The time that the UPS will be working, will depend on the bat-

tery charge level and the consumption of the own loads con-

nected to the output.

•Start up the load/s.

6.1.4. UPS shutdown with AC mains (on Inverter mode).

•To shutdown the inverter of UPS, press over the key «OFF» of

front panel for more than 1 second.

•Even if the inverter is «OFF», the device will supply

output voltage through its static bypass.

•To carry out a complete shutdown, it is necessary to set the distri-

bution board protection to «OFF».

6.1.5. UPS shutdown with no AC mains [on Battery mode].

•Shutdown the UPS inverter by a simple pulsation of more than 1

second over the key «OFF». The UPS will be shutdown.

•With no mains power present, no output voltage will be

available; however, take into consideration that, when it is

restored, the device will immediately supply output voltage

through its static bypass.

•To carry out a complete shutdown, it is necessary to set the distri-

bution board protection to «OFF».

6.1.6. Battery test function.

•To make a battery test with the equipment started up and mains present,

press over the button «ON» of the front panel for more than 1 second, the

test will start automatically.

•With this test, it is able to detect if the batteries are low, open

or not connected.

6.1.7. Alarm silencer.

•The acoustic alarm is activated when the equipment works on battery

mode. If it disturbs, it can be silenced by pressing for more than 1 second

the key «ON»/«MUTE».

The alarm will be automatically activated again due to low bat-

tery (end of back up time). When it happens, loads and UPS have

to de shutdown, because the equipment will break the output

voltage in short.

•If the alarm on bypass mode disturbs, press the key «OFF» for

more than 1 second to deactivate it. This action will not affect to

the warning and/or alarm fault.

6.1.8. EPO (Emergency Power Output).

•Also it is know as RPO (Remote Power Output).

Check that the connector of Fig. A is inserted, before pro-

ceeding with the start up.

When it is activated, the output of the equipment doesn’t supply

voltage and the screen of the LCD panel shows the «EPO».

It is a special situation, where it is done an immediate break of

the UPS output voltage, as a preventive or emergency measures.

The EPO condition leaves the loads with no power supply, but

the UPS is not shutdown. To do it, the EPO condition has to be

released previously and then shutdown the equipment through

the key «OFF», see Tab. 3. To start up the UPS press over the key

«ON», see Tab. 3.

19

7. CONTROL PANEL WITH LCD.

7.1. CONTROL PANEL.

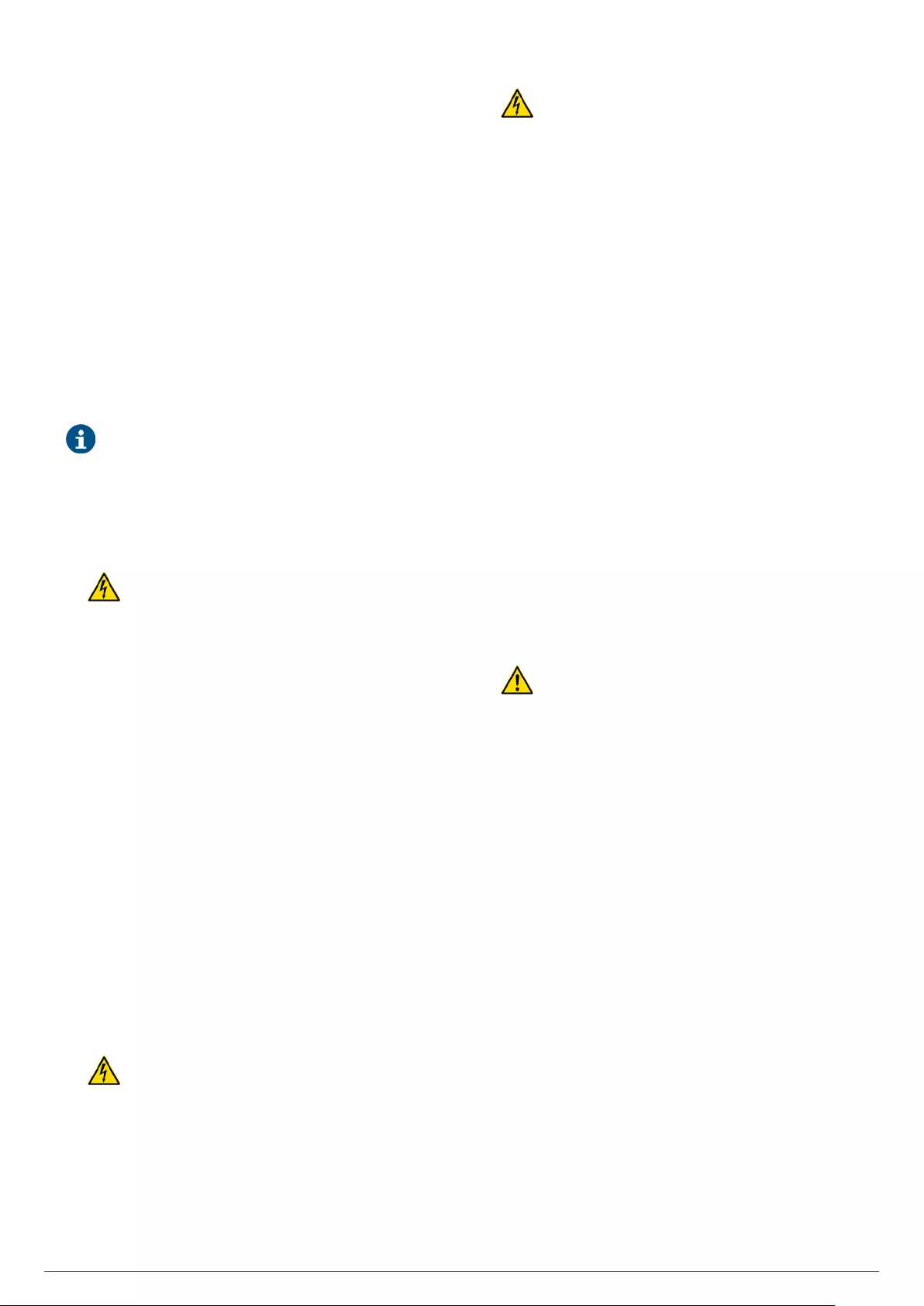

•The UPS has a control panel, which includes the following parts:

Four buttons or keys, see Tab. 3.

A LCD panel.

OFF

ON

Fig. 13. Control panel view.

Key Function Description

ENTER key The ENTER key has three utilities: entry to the

main settings menu, entry to a submenu and

validation of the new selected value.

The SELECT key enables scrolling through the

different menus and submenu variables.

SELECT key

OFF UPS shutdown

When mains power is normal, the UPS system shifts

to Bypass mode or No output by pressing the OFF-

Button “ “, the inverter is shutdown. The outlets are

fed by the bypass, in case the Bypass mode option is

enabled.

Deactivating the acoustic alarm:

With the UPS on Bypass mode, press this button

and the acoustic alarm will be silenced.

Re-start up the UPS from fault mode and EPO

status.

ON

MUTE

UPS start up By pressing the ON-Button for more than 1 second

the UPS system is turned on.

Acoustic alarm

silencer

By pressing this Button the acoustic alarm can be

silenced when the UPS is on battery mode.

By a short pressing on this Button, all the acoustic

alarms can be silenced at any operating mode.

Battery test

By pressing on this button, the device performs a

battery test provided that the UPS is running. It

is not possible to perform the test in Bypass, No

Output or Battery modes.

Tab. 3. Functionality of the buttons or keypad from control panel.

Display Function

Input information

It displays the input voltage/frequency figure alternately.

It shows the input is connected to mains (input power is

single phase).

Output information

It displays the output voltage/frequency figure alternately.

Load information

It displays the load level. Every two bars means 20% load

level. Two bars will always be displayed in case the load is

below 20%.

Battery information

It displays the battery capacity. Every two bars means 20%

capacity. If the battery low alarm is triggered, the lowest

bar will blink.

Information of Mode/Fault/Warning codes

It displays the operating mode, fault type, alarm or battery

remaining time. In case of having several warning, they will

be displayed alternately.

Else

It shows that the UPS is on setting mode.

It shows that the UPS is on Fault mode or it has any alarm.

Tab. 4. LCD panel messages and their functions.

bYPA

Input

information

Operating Mode / Fault /

Alarm

Output

information

Setting mode

Battery

information

Load

information

Fig. 14. Display LCD panel control description.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

20 SALICRU

7.2. SETTING AND CONFIGURATION OF THE CONTROL PANEL.

Description Code

Operating codes

Bypass mode bYPA

No output mode STbY

Line mode LINE

Battery mode bATT

Battery test mode TEST

ECO mode ECO

Converter mode CUF

Fault codes

Inverter short SHOR

Overload fault OVLD

Inverter soft start failure ISFT

DC Bus soft start failure bSFT

Over temperature fault OVTP

Inverter Volt Low INVL

Inverter Volt High INVH

DC Bus volt High bUSH

DC Bus volt Low bUSL

DC Bus short bUSS

Inverter NTC open NTCO

Emergency Power Off EPO

Alarm codes

Fan faulty FANF

Battery over voltage (over charged) HIGH

Battery low bLOW

Charge failure CHGF

Inverter temperature high TEPH

Battery open bOPN

Overload OVLD

Extra-charger failure dCHF

Internal temperature high ITPH

Tab. 5. Code list and their meaning.

The codes displayed in the LCD panel as regards to operating, fault

or alarm are listed in Tab. 5. Several codes can be activated or dis-

played at the same time, and they can correspond to operating, fault

or alarm. Each one of these codes will be displayed cyclically in the

LCD panel, less when one or several alarms are triggered. In case

of several alarms are triggered, they will be displayed cyclically, but

the operating mode or fault will not be shown.

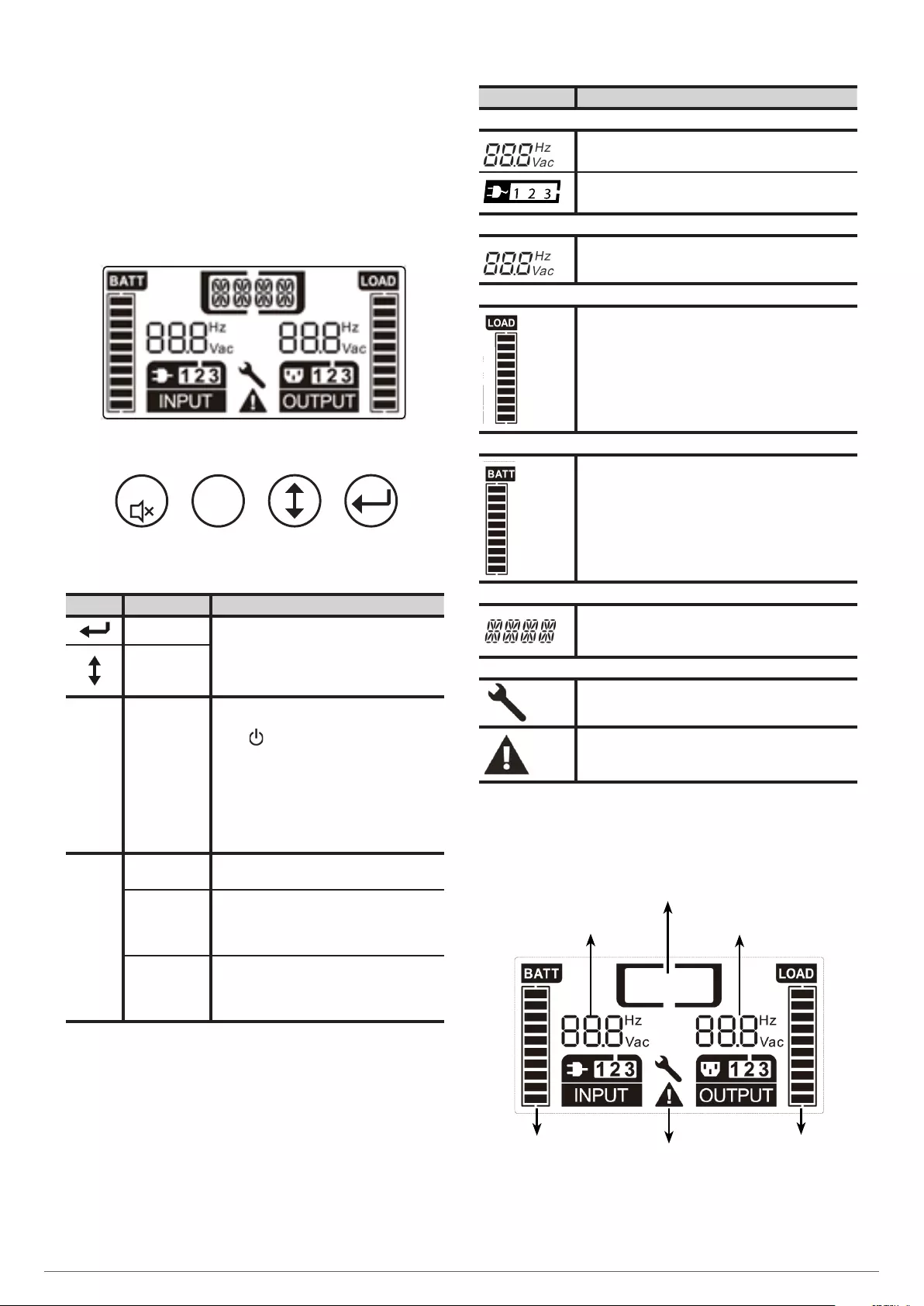

7.2.1. Bypass mode -byPA-.

The LCD panel on bypass mode is shown in Fig. 16. And it displays

the following information: mains, battery, UPS output and load. The

UPS operating code is «byPA».

Fig. 15 shows the «byPA» stage is activated (frame with BYPA in-

scription inside), and it means that the bypass is supplying the en-

ergy to the load/s from mains directly, through the internal filter and

at the same time the batteries are being charged.

The UPS acoustic alarm will beep every two minutes.

On this operating mode, the UPS doesn’t have back up time function,

so in case of mains failure, the loads will be shutdown.

bYPA

Fig. 15. Bypass mode screen.

7.2.2. No output mode -STby-.

The LCD panel on no output mode is shown in Fig. 16. And it displays

the following information: mains, battery, UPS output and load. The

UPS operating code is «STby».

On this mode, the UPS doesn’t supply output voltage, but it is still

charging the batteries.

STbY

Fig. 16. No output mode screen.

7.2.3. Line mode -LINE-.

The LCD panel on line mode is shown in Fig. 17. And it displays the

following information: mains, battery, UPS output and load. The UPS

operating code is «LINE».

In the event of output overload, the fault code «OVLD» will be dis-

played and an audible alarm modulated at two beeps per second will

be activated. It is necessary to stop the non-critical loads to reduce the

load percentage to below 90% of the rated power of the UPS.

.

LINE

Fig. 17. Line mode screen.

21

7.2.4. Battery mode / Battery test mode -bATT / TEST-.

The LCD display in battery mode is shown as Fig. 18. And it dis-

plays the following information: battery voltage, battery capacity,

UPS output and the load level. The «bATT» bar indicates the UPS is

working on the battery mode. If the remaining back up time function

is enabled, the «bATT» bar and the remaining back up time (dis-

played in Min or Sec) will be displayed alternately every 2s.

When the UPS is running on battery mode, the buzzer beeps once every

4 seconds. If the «ON» button of the front panel is pressed for more than

1 second, the buzzer will stop beeping (silence mode). Press the «ON»

button once again for more than 1 second to resume the alarm function.

bATT

Fig. 18. Battery mode screen.

7.2.5. Economy mode -ECO-.

It is also known as high efficiency mode [HE]. The UPS operating

code of the ECO mode is «ECO».

When the UPS is on ECO mode and meanwhile the voltage and fre-

quency are inside the preset range, the load is supplied from mains

directly through the internal filter. So, a high efficiency is achieved.

When mains is out of the preset limits, the UPS shifts to battery

mode and the load will be supplied from batteries, till the normal

conditions of mains are restored.

The ECO mode can be activated by means of the LCD panel, or soft-

ware (VinPower, ...).

Notice that when running on ECO mode, there is a transfer tome of

less than 10 ms when shifting to battery mode and some loads could

not support it, act in consequence for those each particular cases.

7.2.6. Converter mode -CUF-.

The UPS operating code on Converter mode is «CUF». On this oper-

ating mode, the UPS works as a frequency converter (50 Hz or 60 Hz).

When mains is wrong or in case of blackout, the UPS will shift to

battery mode and the load will be supplied from batteries, till the

normal conditions of mains are restored.

The Converter mode can be activated by means of the setting screen

in the LCD panel, or software (VinPower, ...).

It has to be considered that on this operating mode, the power rate

of the equipment is derated up to 60 % of the nominal.

7.2.7. Fault code / Alarm code.

Fault and alarm codes are shown in Tab. 5.

Fig. 19 shows the fault code «SHOR» as an example.

SHOR

Fig. 19. «SHOR» fault code screen.

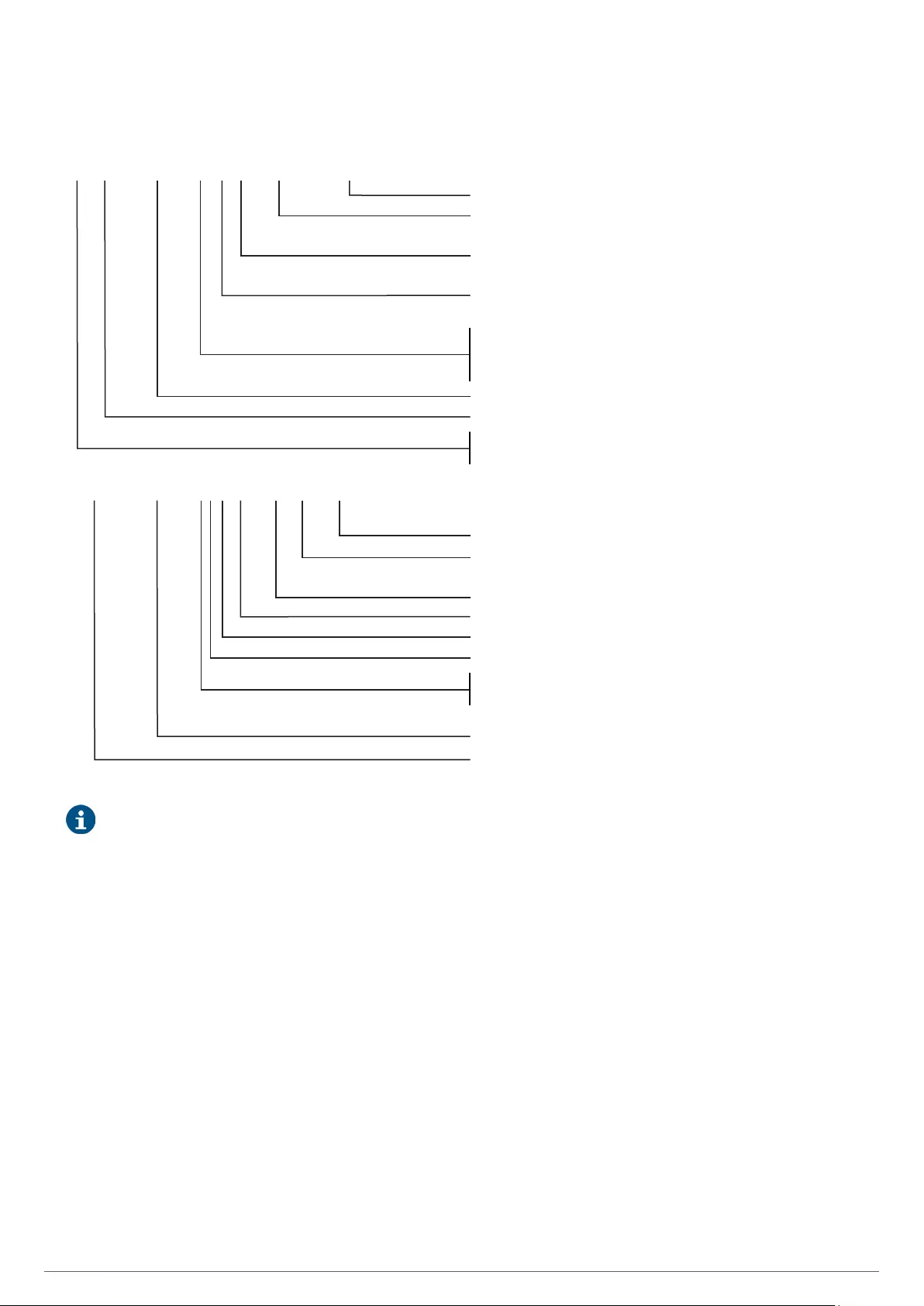

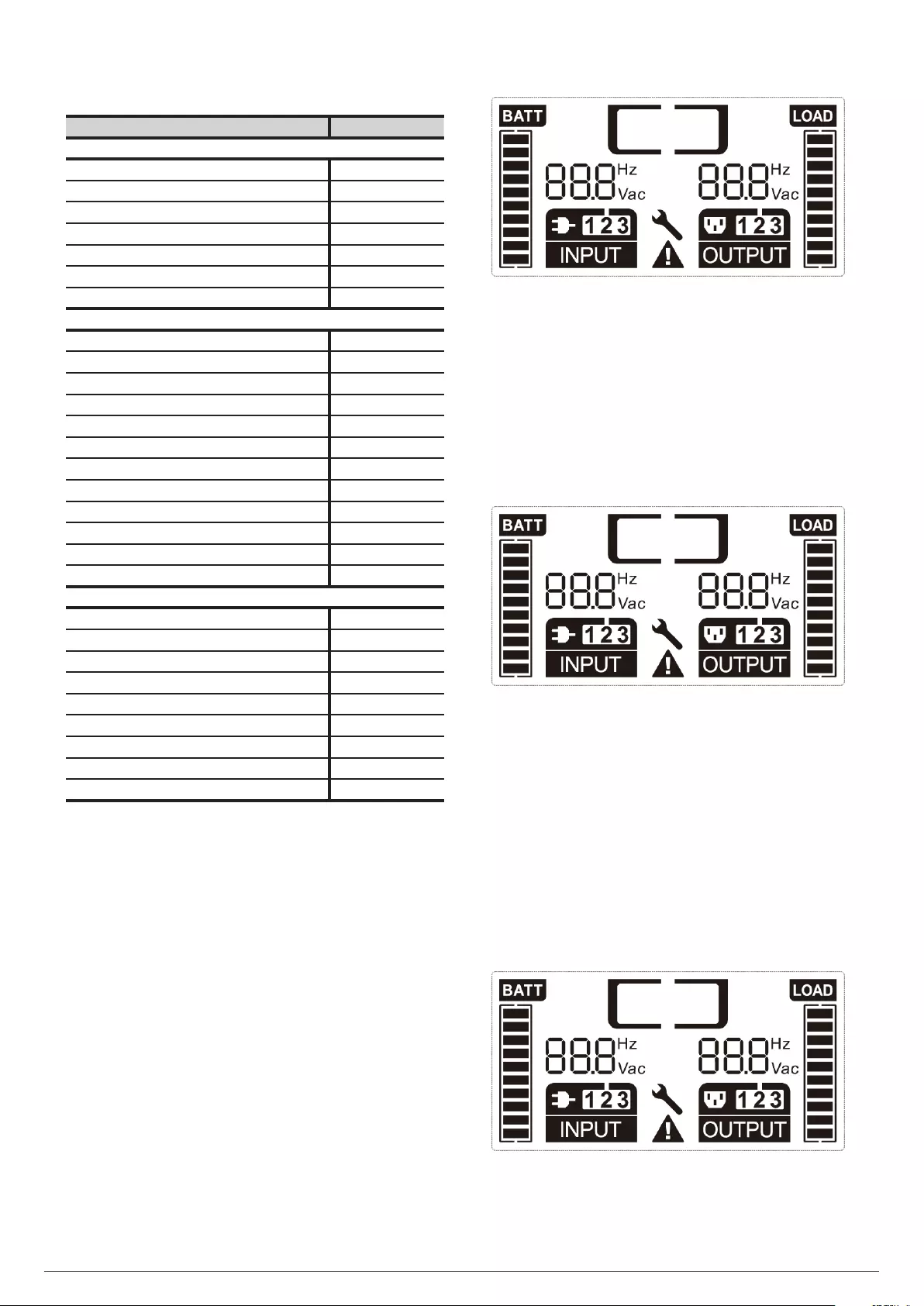

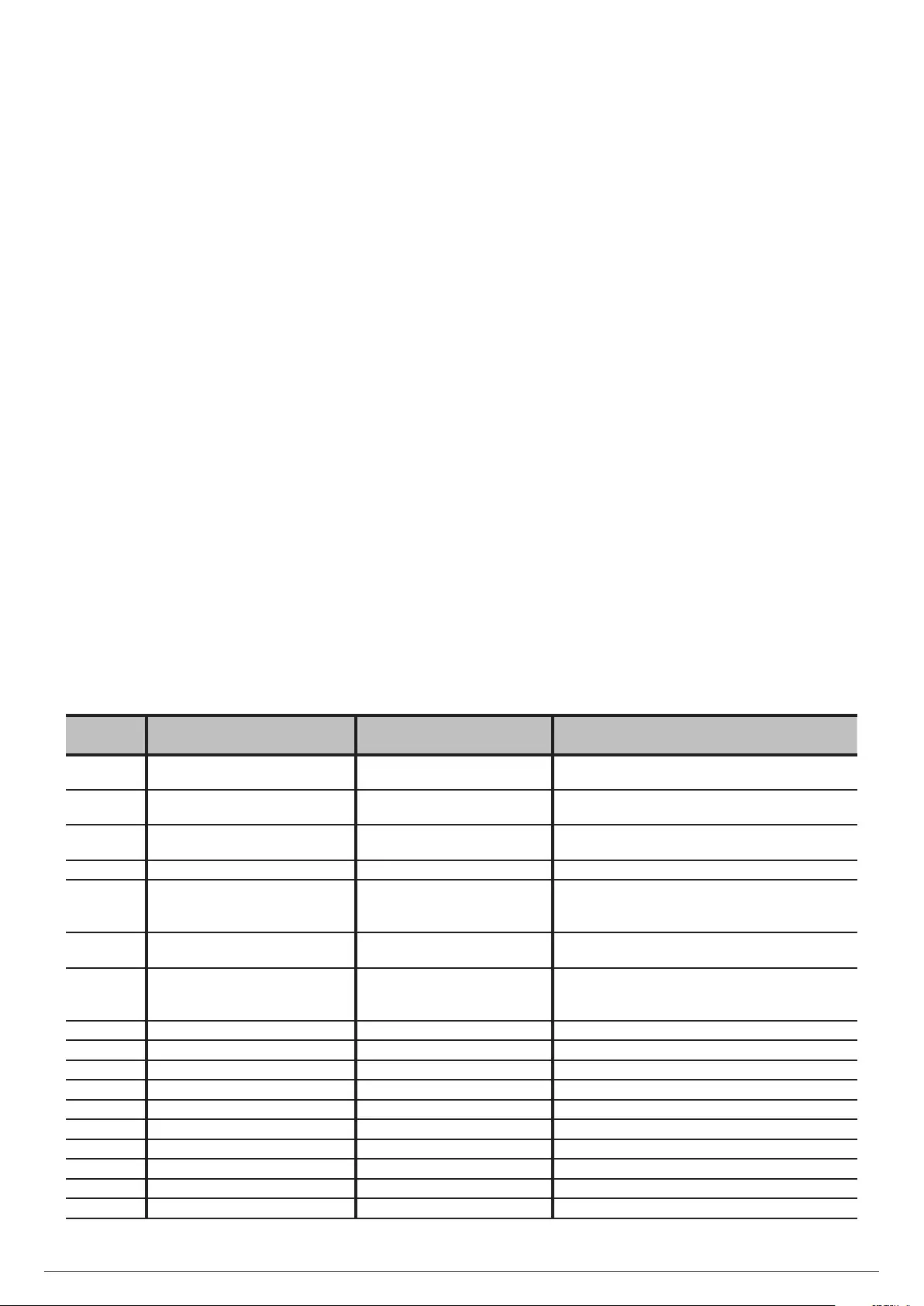

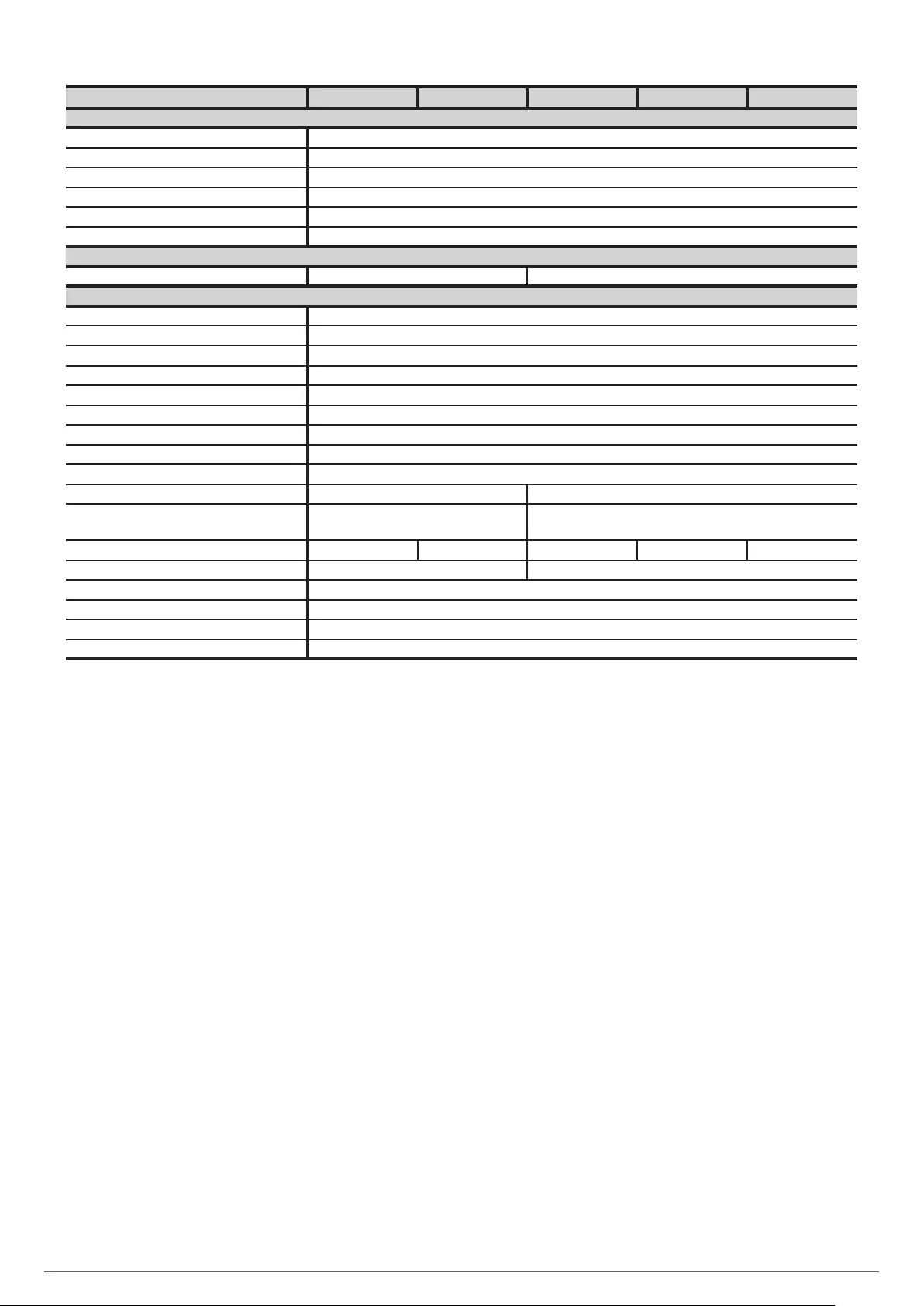

7.3. SETTINGS THROUGH THE LCD PANEL OF THE LCD PANEL.

The user can change some of the factory default settings very easily.

It is however important to take into consideration that changes to

the settings can affect the loads.

The Fig. 20 screens map shows the chronological and cyclical order

in which the parameters are displayed and their default value indi-

cated with an asterisk in brackets (*), as well as the procedure for

making the changes using the buttons of the control panel. Observe

the sequence and minimum pulse times.

To change the configuration of the device, it needs be connected

to the mains in Bypass or No Output mode, i.e. with the inverter

stopped. This operation will always be carried out with no load con-

nected to its output.

Fig. 20 just shows the fields that relate to the modifiable parameters

and not a full view of the screen, except the first, which is used for

reference.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

22 SALICRU

bYPA STbY

or

2 sec.

OPV

Output voltage

230 (*)

240

220

1 sec.

OPF

Output frequency ASF

50 (*)

60

1 sec. ASF (Automatic input frequency detection).

bYPA

Bypass operation

00

01 (*)

1 sec. 00 (No Output mode value «STby»).

01 (Bypass mode value «byPA»).

STANDARD DEVICES

MOdE

Device operating

mode

UPS (*)

ECO

CUF

1 sec. UPS (Normal operating mode, UPS On-Line).

ECO (High-performance economical operating mode).

CUF (Operating mode as frequency converter).

BAT

Backup display

00

01 (*)

1 sec. 00 (In battery mode, shows remaining time as %).

01 (In battery mode, shows remaining time in min).

Notes: The values indicated with (*) are those established

at the factory.

All settings can be made in «byPA» or «STby» operation.

ONLY IN B1 DEVICES

EbPN

Number of battery

modules

00

01 (*)

...

09

1 sec. 00 (Without battery module).

01 (Device configured for a battery module).

...

01 (Device configured for nine battery modules).

Note: Adjust this value to the number of modules acquired,

otherwise the backup shown as a % or in minutes will be

wrong.

CHG

Battery charging

current

6 A (*)

1,5 A

3 A

4,5 A

1 sec. 6 A (Default, battery charging current in B1 models).

Other battery charging current optional. For B1 models up to

1 kVA, only options 3 and 6 A are available.

Fig. 20. Settings screens map.

23

8. MAINTENANCE, WARRANTY AND SERVICE.

8.1. BATTERY MAINTENANCE.

•Pay attention to any safety instructions stated in EK266*08

manual section 1.2.3 referred to batteries.

•The useful lifetime of the batteries depends on the ambient

temperature and other factors like the quantity of charging and

discharging cycles and the deep discharges done.

Its design lifetime is between 3 and 5 years if the ambient tem-

perature is between 10 and 20 ºC. Under request, other typology

and/or design lifetime batteries can be supplied.

•The UPS from SLC TWIN PRO2 series only needs a minimum

maintenance. The used batteries in standard models are lead

acid, sealed, VRLA and maintenance free. The only requirement

is to charge them regularly in order to extend their lifetime.

Meanwhile, the UPS is connected to mains, started up or not, it

will keep the batteries charged and will guarantee a protection

against overcharge and deep discharge.

8.1.1. Notes for installing and replacing the batteries.

•If it is needed to replace the connection of any wire, purchase

original parts through authorised distributors or service centres

in order to avoid overheating and sparks with fire risk because

the size is not enough.

•Do not short the + and - poles of the batteries, there is risk of

fire or electrocution.

•Be sure that there is no voltage before touching the batteries.

Battery circuit is not isolated from the input. Hazardous voltages

can be found between the battery and earth terminals

•Although the input circuit breaker the switchgear panel is turned

off, the internal parts of the UPS are still connected to the bat-

teries, so there are hazardous voltages inside.

Therefore, before doing any reparation or maintenance task, the

internal battery fuses have to be removed and/or the interlink

connections between them and the UPS.

•Batteries have hazardous voltages. The battery maintenance

and replacement have to be done by qualified personnel and

familiarised with them. Nobody else can manipulate them.

8.2. UPS TROUBLE SHOOTING GUIDE.

If the UPS doesn’t work properly, check the information given by the

LCD of the control panel. Try to solve the problem by means of the

established steps in the Tab. 6. In case the problem persists, consult

with our Technical Service & Support T.S.S..

When it is needed to contact with our Technical Service & Support

T.S.S. , provide the following information:

•UPS model and serial number.

•Date when the problem occurred.

•Complete description of the problem, including the information

given by the LCD panel and the status of the alarms.

•Power supply condition, type of load and the level connected to

the UPS, ambient temperature, cooling conditions.

•Information of the batteries (capacity and battery quantity), if

the equipment is B0 or B1 -with external batteries-.

•Other informations that you may think that they are important.

8.2.1. Troubleshooting guide. Warning indications.

If the UPS doesn’t work properly, before calling S.S.T. try to resolve

the problem using the information in the following table:

Warning &

fault code Problem Possible cause Solution

/No indication, no warning tone even though

system is connected to mains power supply.

1) No input voltage.

2) Input switch is opened.

1) Check building wiring socket outlet and input cable.

2) Check the Breaker.

/ No Communication data. 1) RS232 wire is not matched.

2) USB wire is not matched.

1) check or change the RS232 wire.

2) check or change the USB wire.

/Emergency supply period shorter than

nominal value.

1) Batteries not fully charged

2) Batteries defect.

1) Charge the batteries until the Batteries are fully charged.

2) Change the batteries or consult your dealer.

FANF Fan fail. Fan abnormal. Check if the fan is running.

HIGH Battery over voltage. Battery is over charged.

Switching to battery mode automatically, and after the battery

voltage is normal and the mains is normal, the UPS would Switch

to line mode automatically again.

bLOW Battery low. Battery voltage is low. When acoustic alarm sounding every second, battery is almost

empty.

bOPN Battery open. Battery pack is not connected correctly.

Do the battery test to confirm.

Check the battery bank is connected to the UPS.

Check the battery breaker is turn on.

CHGF Charger is faulty. The charge is broken. Call the Technical Service and Support.

dCHF Extra-charger is faulty. The charge is broken. Call the Technical Service and Support.

bUSH DC Bus is too high. UPS internal fault. Call the Technical Service and Support.

bUSL DC Bus is too low. UPS internal fault. Call the Technical Service and Support.

bSFT DC Bus soft start fails. UPS internal fault. Call the Technical Service and Support.

bUSS DC Bus short. UPS internal fault. Call the Technical Service and Support.

TEPH Inverter temperature high. Inside temperature of the UPS is too high. Check the ventilation of the UPS, check the ambient temperature.

ITPH Internal ambient temperature is too high. The ambient temperature is too high. Check the environment ventilation.

INVH Inverter voltage is too high. UPS internal fault. Call the Technical Service and Support.

INVL Inverter voltage is too low. UPS internal fault. Call the Technical Service and Support.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

24 SALICRU

ISFT Inverter soft start fail. UPS internal fault Call the Technical Service and Support.

NTCO Inverter NTC open. UPS internal fault. Call the Technical Service and Support.

SHOR Inverter short. Output short circuit.

Remove all the loads. Turn off the UPS. Check whether the output of

UPS and loads is short circuit. Make sure the short circuit is removed,

and the UPS has no internal faults before turning on again.

OVTP Over temperature fault. Over temperature. Check the ventilation of the UPS, check the ambient temperature

and ventilation.

OVLD Overload. Overload. Check the loads and remove some non-critical loads.

Check whether some loads are failed.

EPO EPO active. EPO function is enabled. Plug into the EPO switch.

Tab. 6. Troubleshooting guide. Other circumstances or condi-

tions.

8.3. WARRANTY CONDITIONS.

8.3.1. Warranty terms.

The warranty conditions for the acquired product can be found in our

website and in that you will be able to register it. It is recommended

to do it as soon as possible in order to include it in the Technical

Service & Support (T.S.S.) database. Among other advantages, it

will be easier to make any regulatory process to allow the T.S.S.

action in case of any hypothetical fault.

8.3.2. Out of scope of supply.

Our company is not forced by the warranty if it appreciates that

the defect in the product doesn’t exist or it was caused by a wrong

use, negligence, installation and/or inadequate testing, tentative of

non-authorised repairing or modification, or any other cause beyond

the foreseen use, or by accident, fire, lightnings or other dangers.

Neither it will cover, in any case, compensations for damages or

injuries.

8.4. TECHNICAL SERVICE NETWORK.

Coverage, both national and international, from our Technical Ser-

vice & Support (T.S.S.), can be found in our Website.

25

9. ANNEXES.

9.1. GENERAL TECHNICAL SPECIFICATIONS.

Available powers (kVA / kW) (**) 0,7 / 0,63 1 / 0,9 1,5/ 1,35 2 / 1,8 3 / 2,7

Technology On-line double conversion, PFC, double DC bus

Rectifier

Tipology of the input Single phase

Quantity of wires 3 wires - Phase R (L) + Neutral (N) and earth

Nominal voltage 220 / 230 / 240 V AC

Input voltage range with 100 % load 176÷300 V AC

Input voltage range with 40 % load 100÷300 V AC

Voltage range of transference: Depending on the load percentage between 100 and 50 %

- Low mains voltage 176 V AC (±3 %)

- Restore from low mains 186 V AC (±3 %)

- High mains voltage 300 V AC (±3 %)

- Restore from mains high 290 V AC (±3 %)

Frequency 50 / 60 Hz (autosensing)

Input frequency range ± 10 % (45-55 / 54-66 Hz)

Power factor > 0.99 (at full load)

Inverter

Technology PWM

Wave shape Pure sinewave

Nominal voltage 220 / 230 / 240 V AC

Output voltage accuracy ± 1 %

Voltage THD with linear load < 2 %

Frequency With mains present, synchronised at nominal input (45-55 / 54-66 Hz)

Free running, back up time mode 50 / 60 ±0.05 Hz

Slew rate 1 Hz/sec.

Power factor 0.9 (by default)

Permissible load power factor 0.3 inductive to 1

Transfer time, inverter to battery 0 ms

Transfer time, inverter to bypass < 4 ms

Transfer time, inverter to ECO < 4 ms

Transfer time, ECO to inverter < 10 ms

Efficiency at full load, line mode with 100% charged

battery > 89% > 91%

Efficiency at full load, on ECO mode > 97.2 % > 98 %

Overload, line mode

100-105 %, constant

> 105-130 %, 60 sec

> 130-150 %, 10 sec

> 150 %, 300 ms

Overload, battery mode

100-105 %, constant

105-130 %, 10 sec

130-150 %, 1 sec

>150 %, 300 ms

Crest factor 3:1

Static bypass

Type Hybrid (thyristors in antiparallel + relay)

Nominal voltage 220 / 230 / 240 V

Nominal frequency 50 / 60 Hz ±4 Hz

Overload

< 130 %, constant

> 130-180 %, 60 sec.

> 180 %, 300 ms.

Batteries

Voltage / capacity 12 V DC / 9 Ah

Quantity of batteries in serial / set voltage 2 / 24 V DC 4/ 48 V DC 6/72 V DC

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

26 SALICRU

Available powers (kVA / kW) (**) 0,7 / 0,63 1 / 0,9 1,5/ 1,35 2 / 1,8 3 / 2,7

Internal battery charger

Type of charge I / U (Constant current / constant voltage)

Constant current / constant voltage 1.5 A / 13.65 V DC batterie

Floating voltage, block / set 13.65 V DC

Maximum charging current 1.5 A

Recharging time 4 hours at 90%

Voltage / temperature compensation -20 mV / ºC per battery and above 25 °C (***)

Internal battery charger option (B1)

Maximum charging current 3 A or 6 A 1.5 / 3 / 4.5 / 6 A

Generals

Communication ports USB

Monitoring software VinPower (free download)

Noise level at 1 m, < 49 dB (100 % load) / < 41 dB (60 % load)

Operating temperature 0.. 40 ºC

Storage temperature – 15.. + 50 ºC

Storage temperature without batteries – 20.. + 70 ºC

Operating altitude 2,400 m a.s.l.

Relative humidity 0-95 % non-condensing

Protection degree IP20

Dimensions -Depth x Width x Height- (mm) - UPS 356 x 144 x 228 399 x 190 x 327

Dimensions -Depth x Width x Height- (mm) - UPS

- B1 346 x 102 x 228 390 x 102 x 327

Weight (kg) -Standard UPS 9.2 10.2 17.4 18.4 22.7

Weight (kg) -B1 version UPS 3.9 6.4

Safety EN-IEC 62040-1; EN-IEC 60950-1

Electromagnetic compatibility (EMC) EN-IEC 62040-2

Marking CE

Quality system ISO 9001 e ISO 140001

(**) As frequency converter mode, the supplied power is a 60 % of