Salicru 699CB000005 User Manual

Displayed below is the user manual for 699CB000005 by Salicru which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

SLC TWIN PRO2

4.. 20 kVA

UNINTERRUPTIBLE POWER SUPPLY (UPS)

USER'S MANUAL

2SALICRU

General index

1. INTRODUCTION.

1.1. ACKNOWLEDGEMENT LETTER.

2. INFORMATION FOR SAFETY.

2.1. USING THIS MANUAL.

2.1.1. Conventions and used symbols.

3. QUALITY AND STANDARD GUARANTEE.

3.1. DECLARATION OF THE MANAGEMENT.

3.2. STANDARD.

3.2.1. First and second environment.

3.2.1.1. First environment.

3.2.1.2. Second environment.

3.3. ENVIRONMENT.

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the equipment.

4.2. PRODUCT DEFINITION.

4.2.1. Nomenclature.

4.3. OPERATING PRINCIPLE.

4.3.1. Main features.

4.4. OPTIONS.

4.4.1. Isolation transformer.

4.4.2. External manual bypass manual.

4.4.3. Communication card.

4.4.3.1. Integration into IT networks by means of the SNMP

adaptor.

4.4.3.2. RS485 Modbus.

4.4.3.3. Dry contacts.

5. INSTALLATION.

5.1. EQUIPMENT RECEPTION.

5.1.1. Reception, unpacking and contents.

5.1.2. Storage.

5.1.3. Unpacking.

5.1.4. Transport till its location.

5.1.5. Location, immobilising and considerations.

5.1.5.1. Location for single units.

5.1.5.2. Location for parallel systems.

5.1.5.3. Immobilising the equipment.

5.1.5.4. Preliminary considerations, before connecting the

equipment.

5.1.5.5. Preliminary considerations for batteries and their

protections before connecting the equipment.

5.1.5.6. Connection parts.

5.2. CONNECTION.

5.2.1. Connection of the input terminals to AC power supply.

5.2.2. Connection of load/s to the output terminals or output 1.

5.2.3. Connection of the load/s to the output terminals 2

(TWIN/3 PRO2 from 8 to 20 kVA only).

5.2.4. Connection with the external battery module and

extended back up times.

5.2.5. AC power supply for the battery charger built in the

battery module.

5.2.6. Connection of the main protective earth and

bonding earth .

5.2.7. EPO terminals (Emergency Power Off).

5.2.8. Terminals for digital Input and Output.

5.2.9. Terminals for the manual bypass auxiliary contact.

5.2.10. Parallel connection.

5.2.10.1. Introduction to the redundancy.

5.2.10.2. Parallel installation and operating.

5.2.11. Communication port.

5.2.11.1. RS232 and USB ports.

5.2.12. Intelligent slot to insert the communication card.

5.2.13. Software.

5.2.14. Considerations before commissioning with the loads.

6. OPERATING.

6.1. COMMISSIONING.

6.1.1. Checking before commissioning.

6.2. START UP AND SHUTDOWN OF THE UPS.

6.2.1. UPS start up with AC mains present.

6.2.2. UPS start up with no AC mains (Cold start).

6.2.3. UPS shutdown with AC mains present.

6.2.4. UPS shutdown with no AC mains.

6.3. MANUAL BYPASS SWITCH (MAINTENANCE).

6.3.1. Shifting to maintenance bypass.

6.3.2. Shifting to normal mode.

6.4. PARALLEL SYSTEM OPERATING

6.5. HOW UPGRADE THE PARALLEL SYSTEM WITH A NEW

UPS OR DOWNGRADE TO SINGLE MODE.

6.6. HOW TO REPLACE A FAULTY UPS FROM THE PARALLEL

SYSTEM.

3

7. CONTROL PANEL WITH LCD.

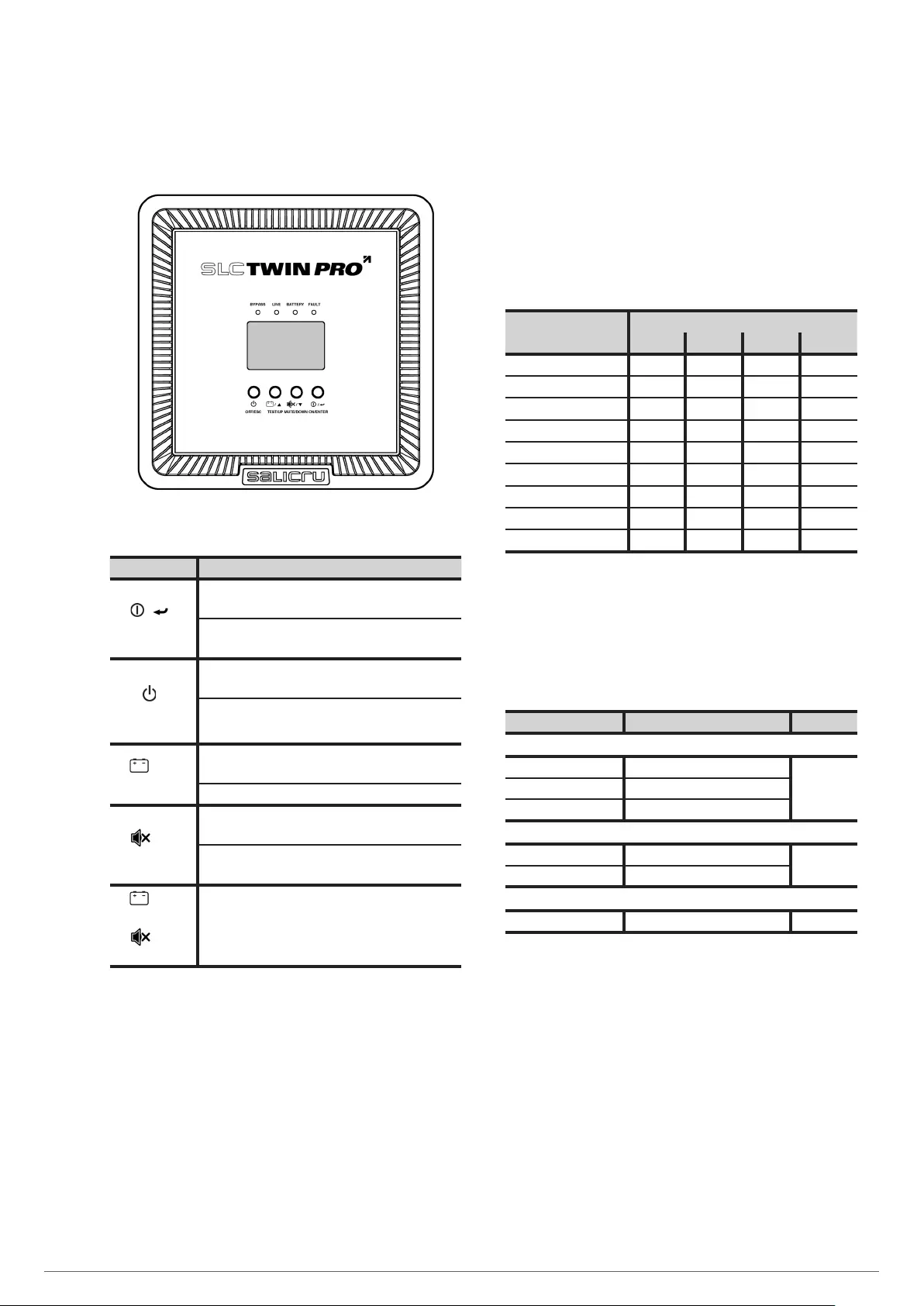

7.1. CONTROL PANEL.

7.2. TABLE 6 SHOWS THE INDIVIDUAL FUNCTION OF EACH

ONE OF THEM OR THEIR INTERACTION WITH OTHERS,

AS REGARDS TO THE UPS STATUS. LED FUNCTIONS.

7.2.1. Acoustic alarms.

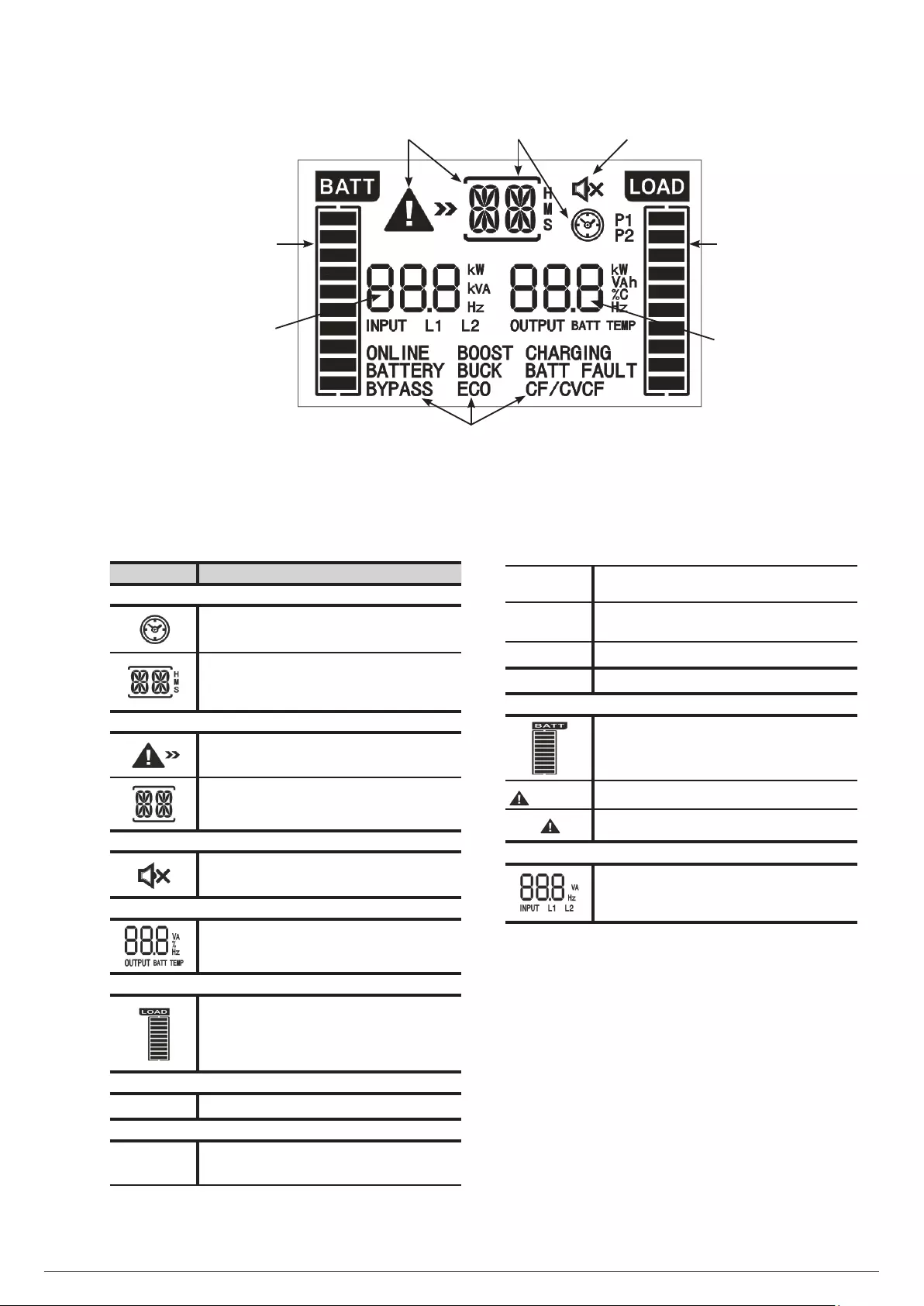

7.2.2. Messages shown in the LCD.

7.3. MEANING OF THE ABBREVIATIONS DISPLAYED IN THE

LCD OF THE CONTROL PANEL.

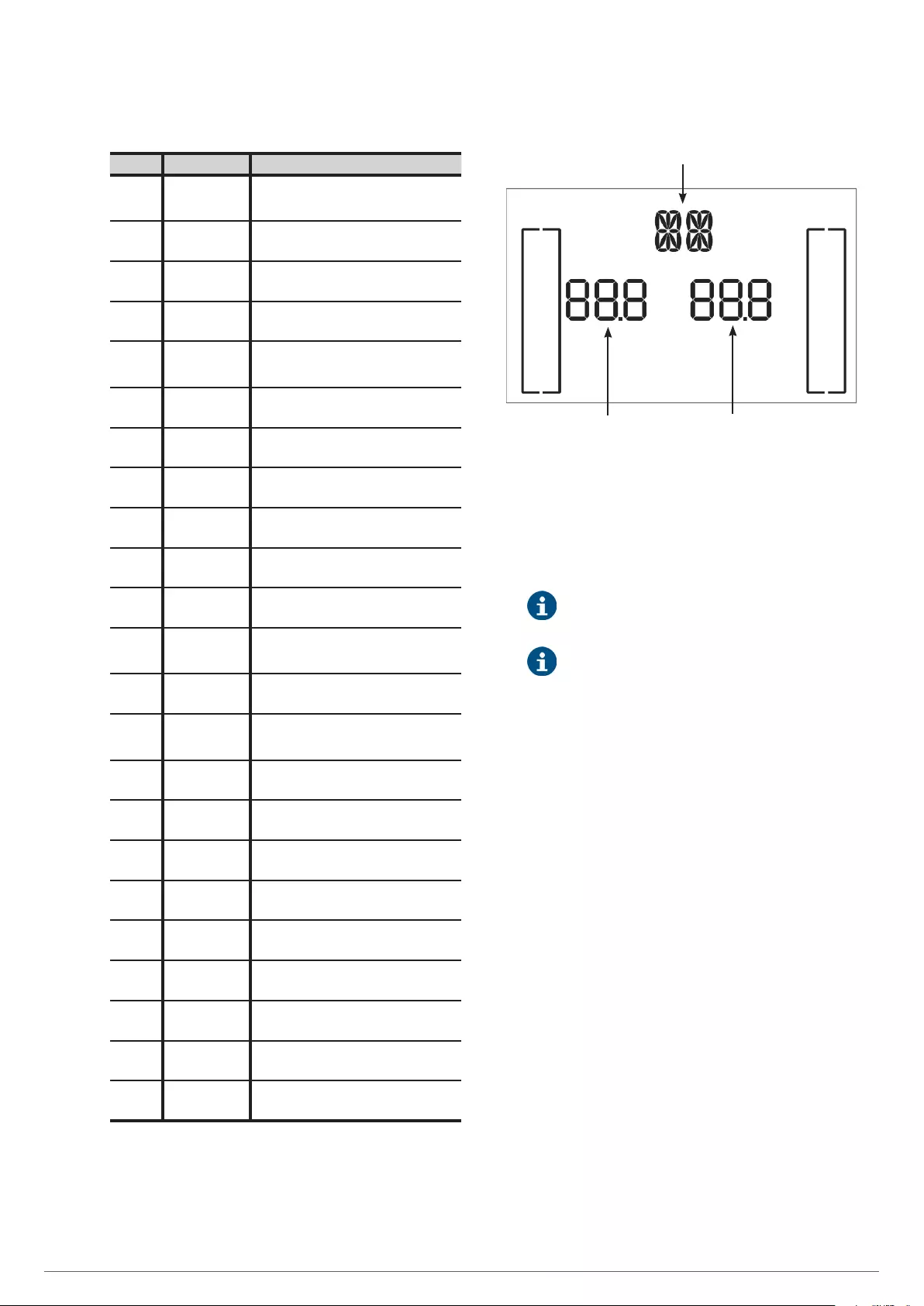

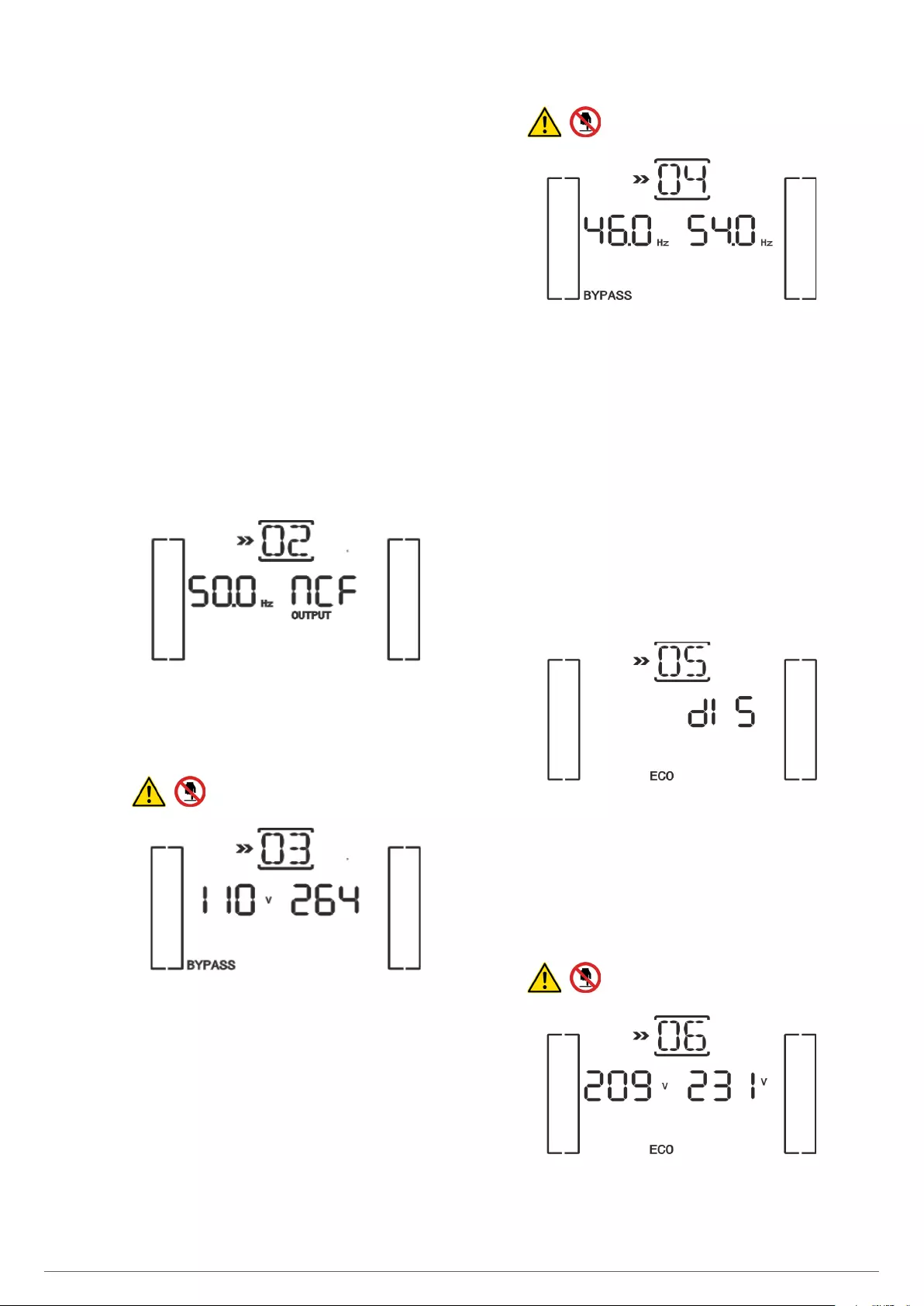

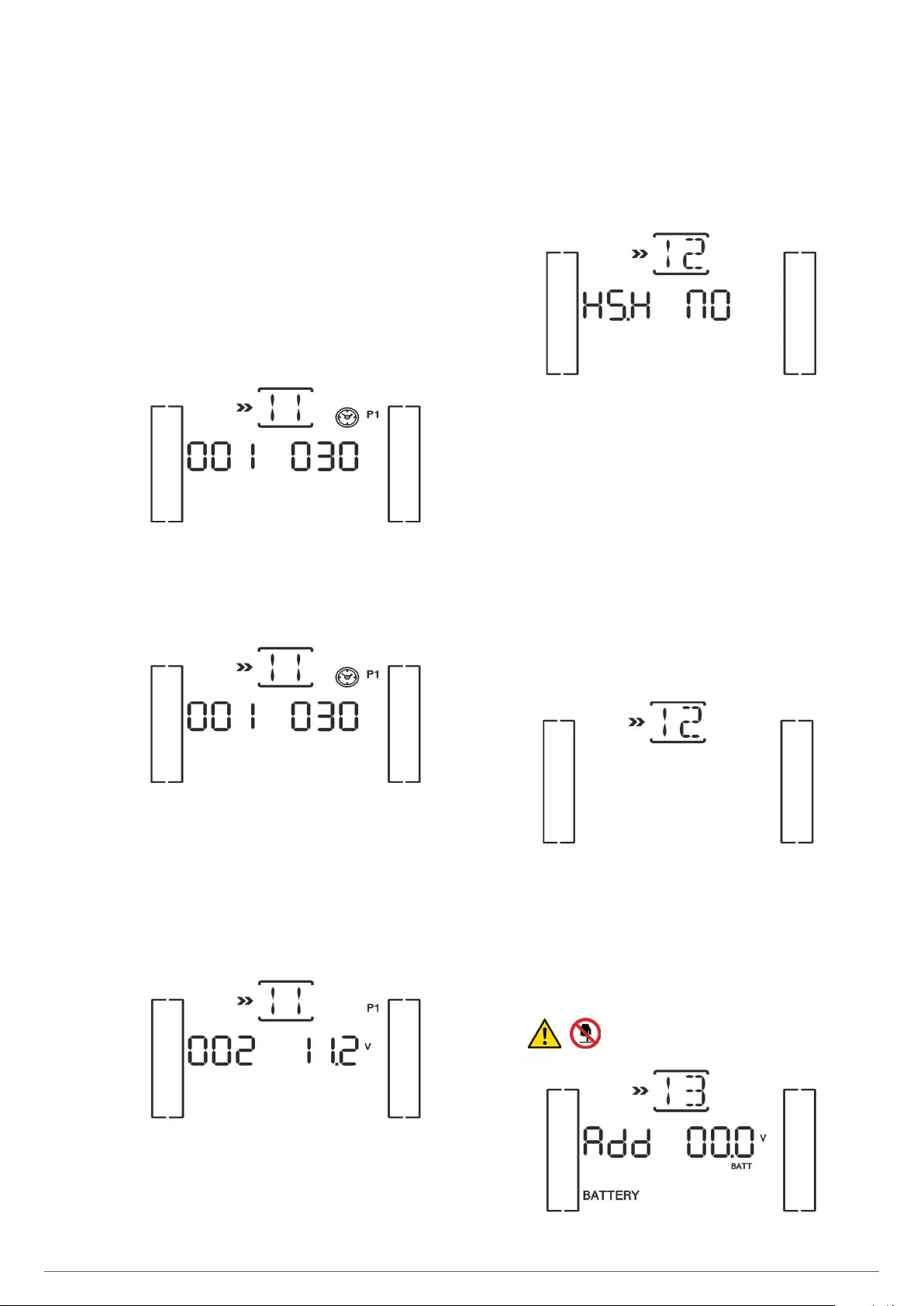

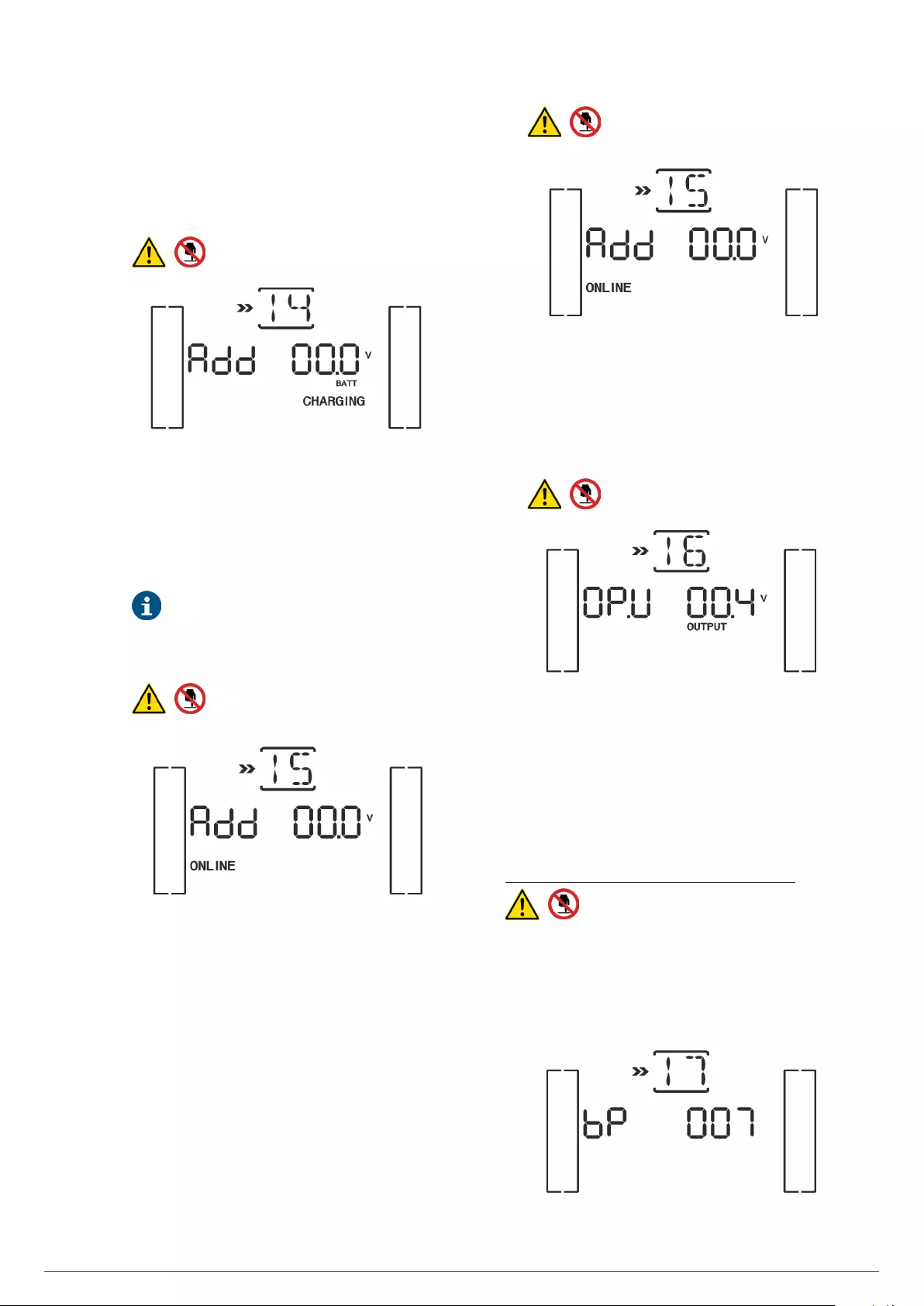

7.4. SETTINGS IN THE LCD CONTROL PANEL.

7.4.1. Setting menu views, depending on the parameter 1

code.

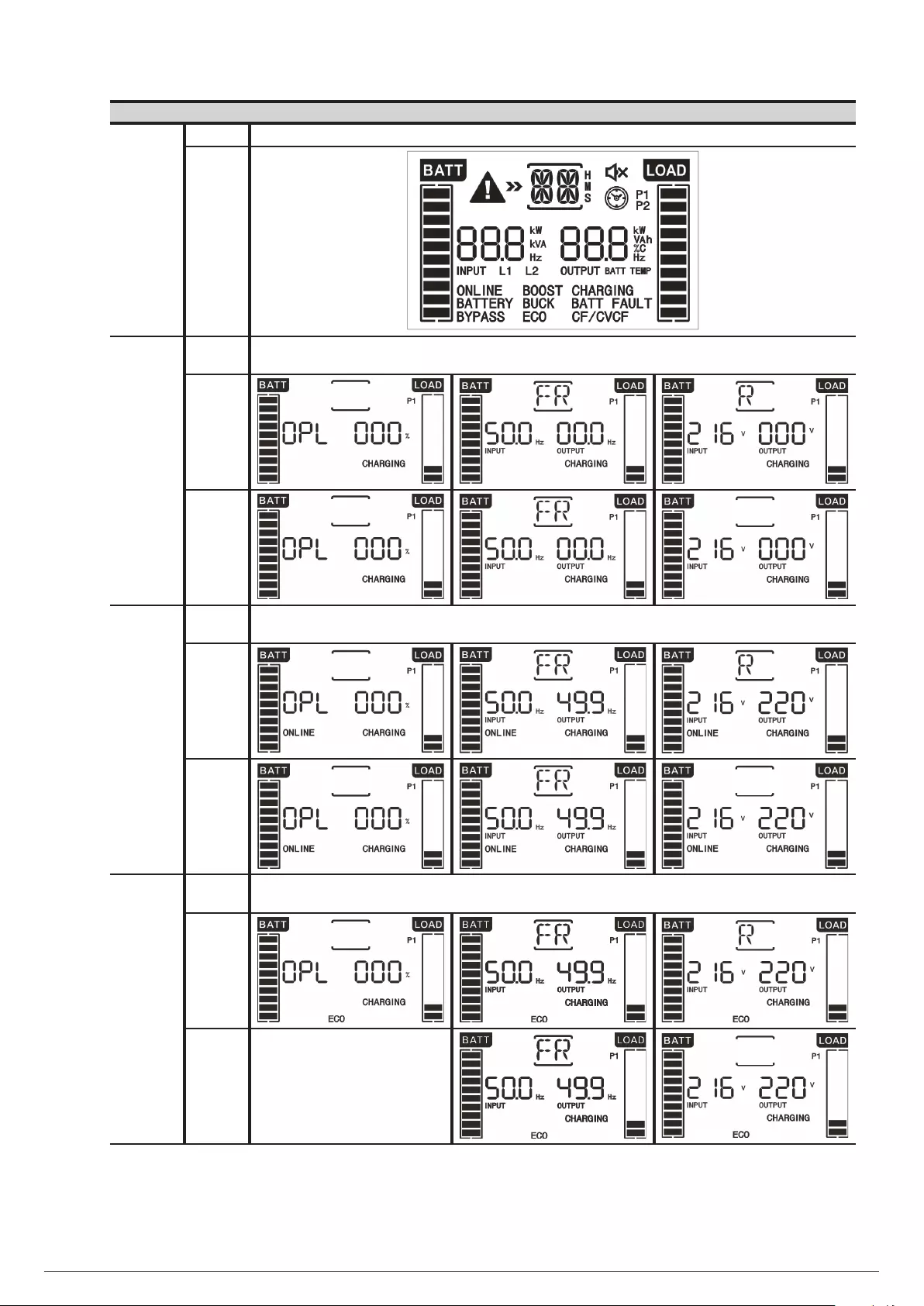

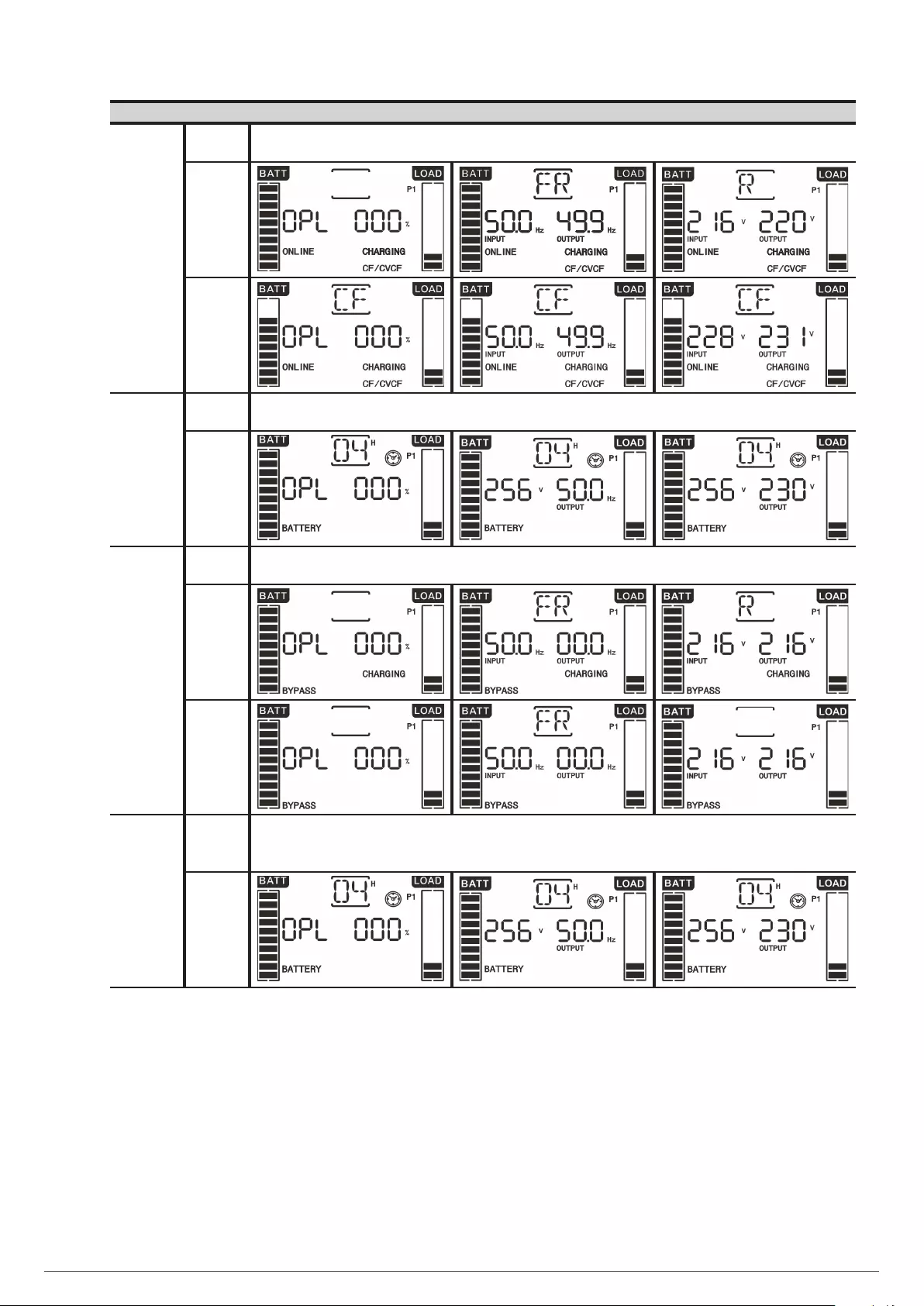

7.5. OPERATING MODES / STATUS DESCRIPTION.

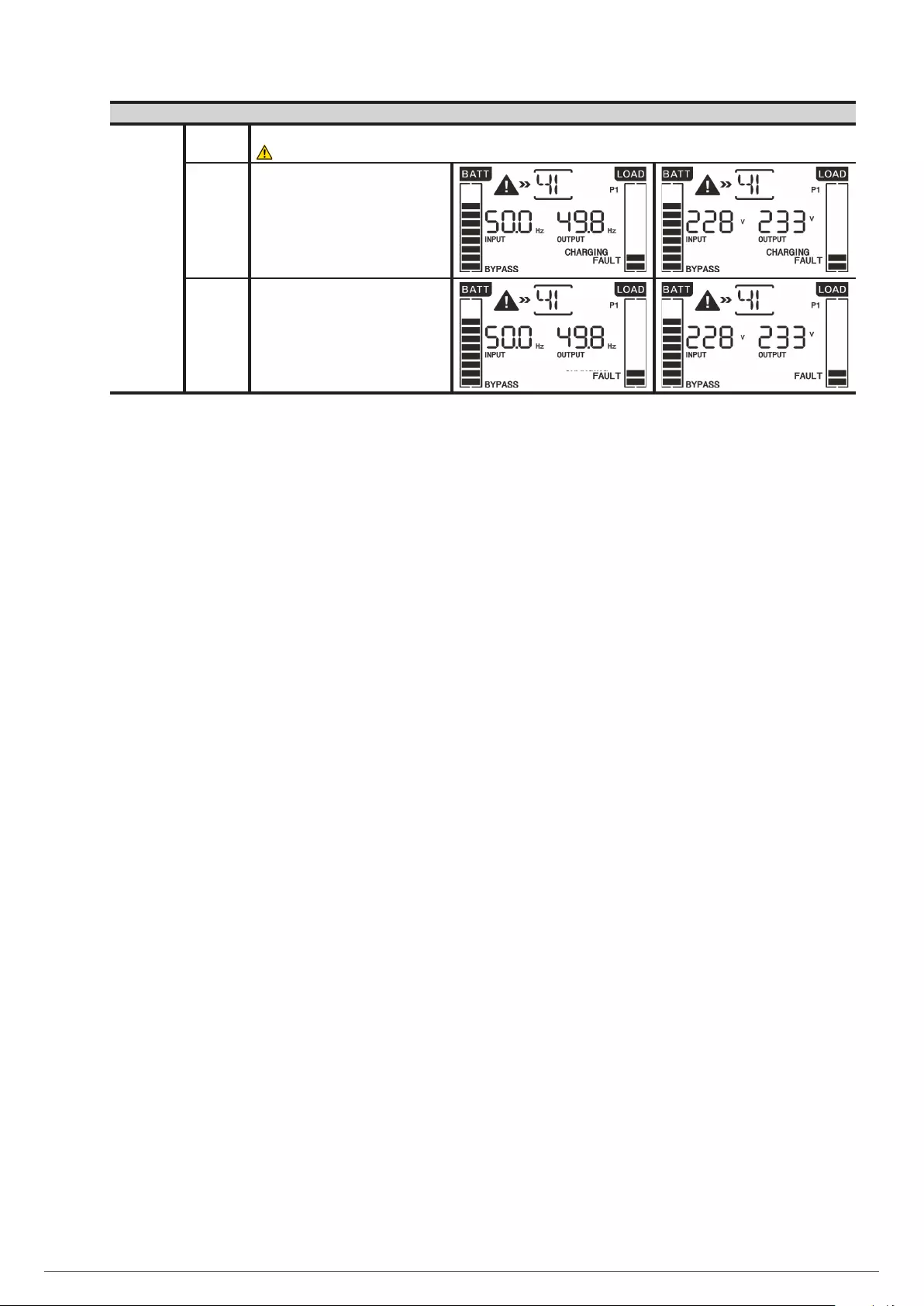

7.6. WARNING CODES.

7.7. ERROR O FAULT CODES.

7.8. WARNING INDICATORS.

8. MAINTENANCE, WARRANTY AND

SERVICE.

8.1. BATTERY MAINTENANCE.

8.1.1. Notes to replace and install the batteries.

8.2. UPS TROUBLE SHOOTING GUIDE.

8.2.1. Troubleshooting guide.

8.3. WARRANTY CONDITIONS.

8.3.1. Warranty terms.

8.3.2. Out of scope of supply.

8.4. TECHNICAL SERVICE NETWORK.

9. ANNEXES.

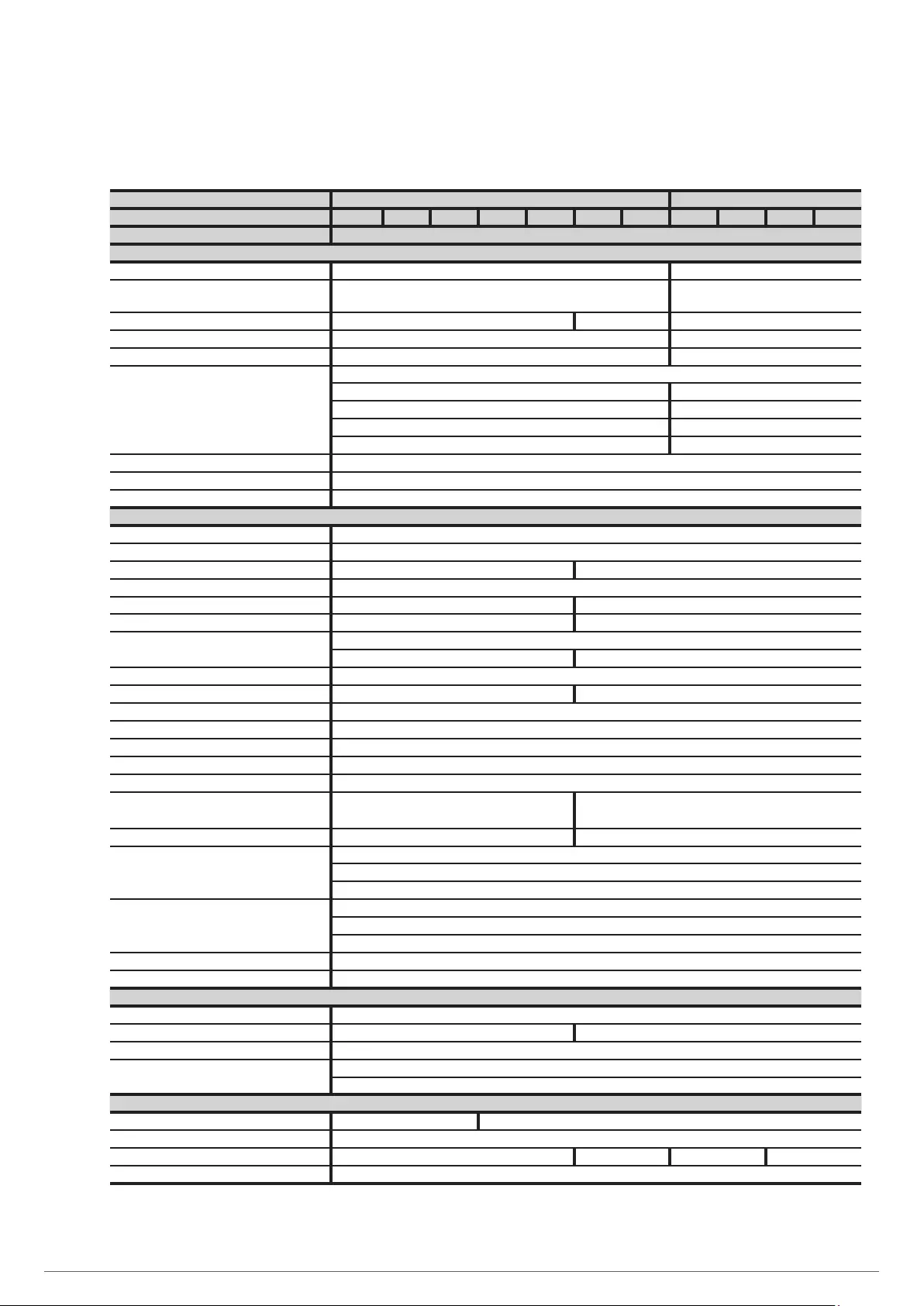

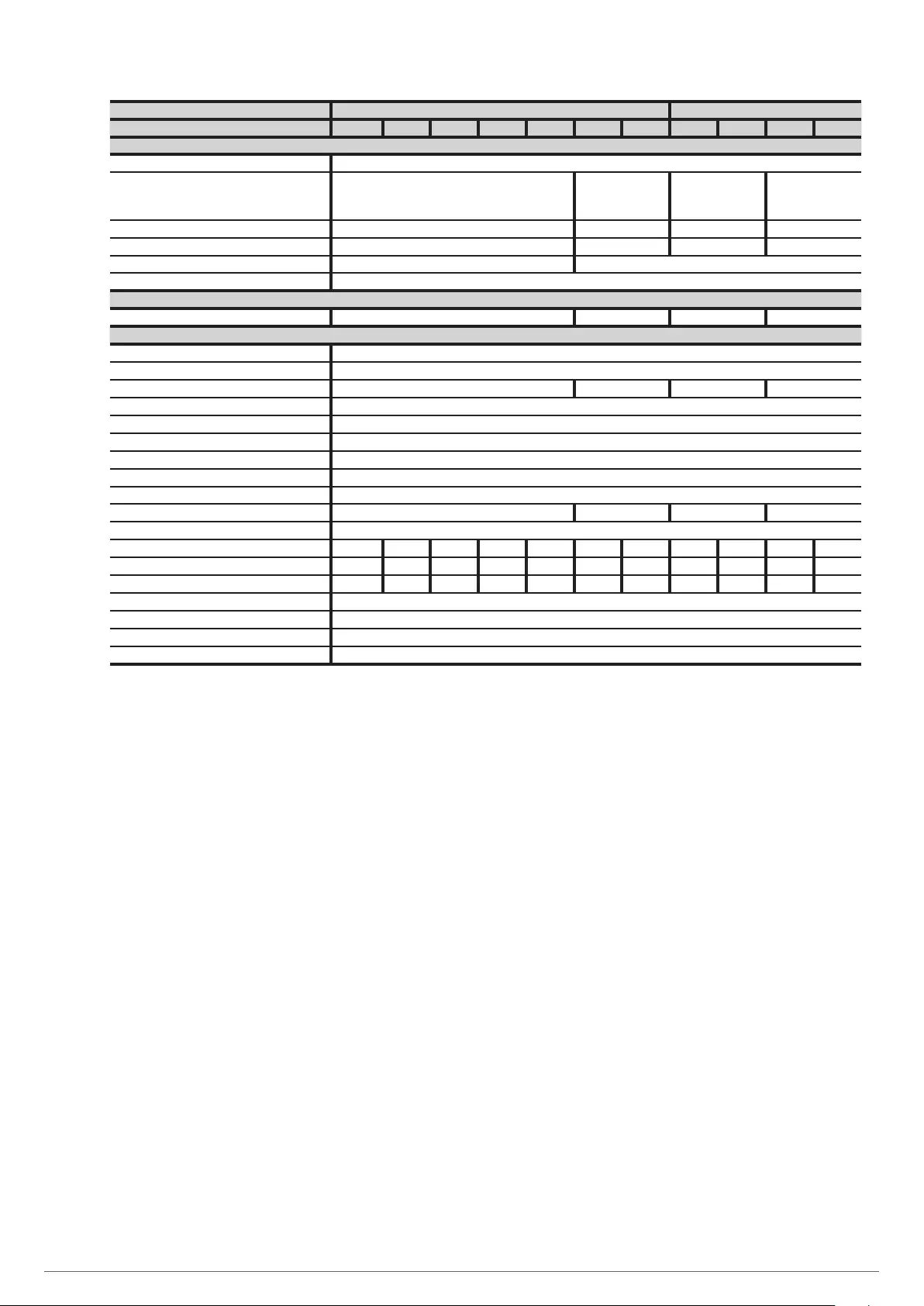

9.1. GENERAL TECHNICAL FEATURES.

9.2. GLOSARIO.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

4SALICRU

SALICRU

1. INTRODUCTION.

1.1. ACKNOWLEDGEMENT LETTER.

We would like to thank you in advance for the trust you have

placed in us by purchasing this product. Read this instruction

manual carefully in order to be familiarized with its contents,

because, as much as you know and understand the equipment

the highest will be your satisfaction and safety levels and their

features will be optimized too.

We remain at you entire disposal for any further information or

any query you should wish to make.

Yours sincerely.

•The equipment here described can cause important

physical damages due to wrong handling. This is why,

the installation, maintenance and/or fixing of itself must

be done by our staff or qualified personnel exclusively.

•Although we have made every effort to guarantee a com-

plete and accurate information in this user’s manual, we

are not responsible for any errors or omissions that may

exist.

The images included in this document are mere illustrations

and they could not represent the part of the equipment ex-

actly, therefore they are not contractual. Nevertheless, dif-

ferences that could exist will be alleviated or solved with

the correct labelling of the equipment.

•According to our policy of constant evolution, we reserve

the right to modify the specifications, operating or

described actions in this document without fore-

warning.

Any reproduction, copy or third party concession,

modification or partial or in whole translations of this

manual or document, in any format or media, is prohibited without

the previous written authorization of our firm, being reserved

the full and exclusive ownership right over it.

5

2. INFORMATION FOR SAFETY.

2.1. USING THIS MANUAL.

The documentation of any standard equipment can be down-

loaded from our website by the client (www.salicru.com).

•Those equipments «supplied by power cord with plug», this

is is the website to get the user’s manual and the «Safety

instructions» EK266*08.

•Those equipments «with permt connection», hardwired,

can be supplied together with a CD-ROM or Pen Drive,

which includes any information needed for its erection

and commissioning, including the «Safety instructions»

EK266*08.

Before doing any action over the equipment regarding installa-

tion or commissioning, change of location, setting or handling,

read them carefully.

This user’s manual is intended to provide information regarding

the safety and to give explanations about the procedures for

the installation and operating of the equipment. Read them

carefully and follow the stated steps in the established order.

Compliance as regards to «Safety instructions» is

mandatory, being the user the legal responsible

regarding to its observance and application.

The equipments are delivered duly labelled for the correct iden-

tification of any their parts, which combined with the instruc-

tions described in this user’s manual, allows the end-user to

make any operating of both installation and commissioning, in

an easy and ordered way without doubt.

Finally, once the equipment is commissioned and in operation,

it is recommended to keep the downloaded documentation

from the WebSite, or the CD-ROM or Pen Drive in a safe place

and with easy access, for further questions that could arise.

The following terms are used in the document indistinctly to

be referred to:

•«SLC TWIN PRO2, TWIN PRO2, TWIN, PRO2, equip-

ment, unit o UPS».- Uninterruptible Power Supply.

Depending on the context of the sentence, it can be re-

ferred either to the own equipment or to the equipment

with batteries, although all is assembled in one cabinet or

metallic enclosure.

•«Batteries or accumulators».- Group or set of elements

that store the electron flow through electrochemical means.

•«T.S.S.».- Technical Service & Support.

•«client, fitter, operator or end-user».- are used indis-

tinctly and by extension, to be referred to the fitter and/or

operator which will make the corresponding actions, being

responsible the same person about the actions to take on

behalf of himself.

2.1.1. Conventions and used symbols.

Some symbols can be used and shown in the equipment and/or

in the description of this user’s manual.

For more information, see section 1.1.1 of EK266*08 document

as regards to «Safety instructions».

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

6SALICRU

3. QUALITY AND STANDARD GUARANTEE.

3.1. DECLARATION OF THE MANAGEMENT.

Our target is the client’s satisfaction, therefore this Manage-

ment has decided to establish a Quality and Environmental

policy, by means of installation a Quality and Environmental

Management System that becomes us capable to comply the

requirements demanded by the standard ISO 9001 and ISO

14001 and by our Clients and concerned parts too.

Likewise, the enterprise Management is committed with the

development and improvement of the Quality and Environ-

mental Management System, through:

•The communication to all the company about the impor-

tance of satisfaction both in the client’s requirements and

in the legal and regulations.

•The Quality and Environmental Policy diffusion and the fixa-

tion of the Quality and Environment targets.

•To carry out revisions by the Management.

•To provide the needed resources.

3.2. STANDARD.

The SLC TWIN PRO2 product is designed, manufactured and com-

mercialized in accordance with the standard EN ISO 9001 of

Quality Management Systems. The marking shows the con-

formity to the EEC Directive by means of the application of the fol-

lowing standards:

•2014/35/EU. - Low Voltage Directive [LVD].

•2014/30/EU. - Electromagnetic Compatibility [EMC].

•2011/65/EU. - Restriction of Hazardous Substances in elec-

trical and electronic equipment [RoHS).

In accordance with the specifications of the harmonized stand-

ards. Standards as reference:

•EN-IEC 62040-1. Uninterruptible power supply [UPS]. Part

1-1: General and safety requirements for UPS’s used in ac-

cessible areas by end users..

•EN-IEC 60950-1. IT equipments. Safety. Part 1: General

requirements.

•EN-IEC 62040-2. Uninterruptible power supply [UPS]. Part

2: EMC requirements.

The manufacturers responsibility is excluded in the event of

any modification or intervention in the product by the cus-

tomer’s side.

ADVERTENCIA!:

SLC TWIN PRO2 4.. 20 kVA. This is a category C3 UPS

product. This is a product for commercial and industrial

application in the second environment; installation re-

strictions or additional measures may be needed to pre-

vent disturbances

The use of this equipment is not suitable for life sup-

port applications, where the failure of it can leave out

of service the life support device or could affect to its

safety or efectiveness. Likewise, it is not recommended

its use in those medical applications, commercial trans-

port, nuclear power stations and other applications or

loads, where the failure of this product can reverse in

personal injuries and material damages.

Declaration of conformity CE of the product is at the

client disposal under previous request to our headquar-

ters offices.

3.2.1. First and second environment.

The following examples of environment cover the majority of

UPS installations.

3.2.1.1. First environment.

Environment that includes residential, commercial and light

industrial premises directly connected without intermediate

transformers to a public low-voltage mains supply.

3.2.1.2. Second environment.

Environment that includes all commercial, light industry and in-

dustrial establishments other than those directly connected to

a low-voltage mains that supplies buildings used for residential

purposes.

3.3. ENVIRONMENT.

This product has been designed to respect the environment and

has been manufactured in accordance with the standard ISO

14001.

Equipment recycling at the end of its useful life:

Our company commits to use the services of authorised so-

cieties and according to the regulations, in order to treat the

recovered product at the end of its useful life (contact your dis-

tributor).

Packaging:

To recycle the packaging, follow the legal regulations in force,

depending on the particular standard of the country where the

equipment is installed.

Batteries:

The batteries mean a serious danger for health and environ-

ment. The disposal of them must be done in accordance with

the standards in force.

7

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the equipment.

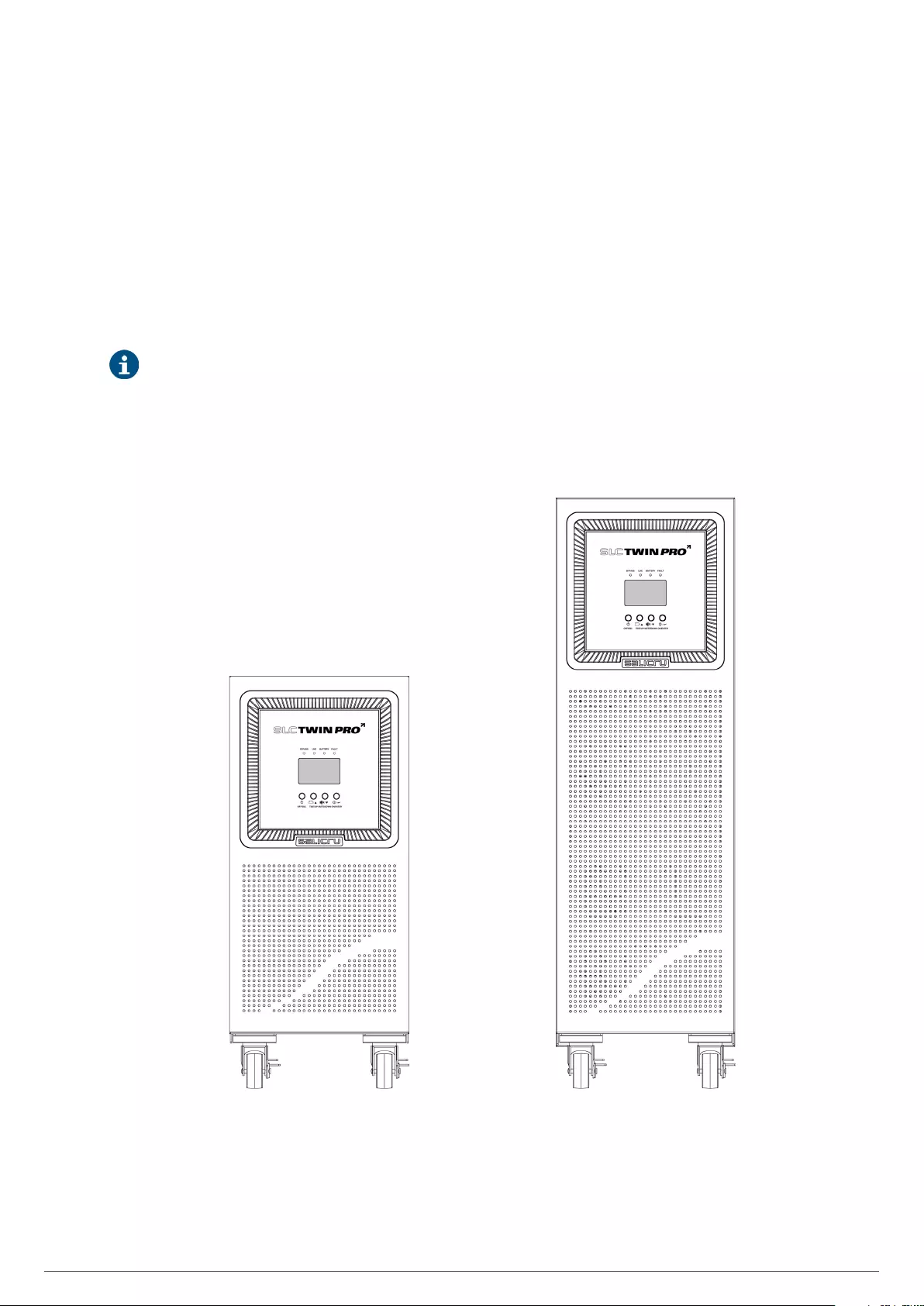

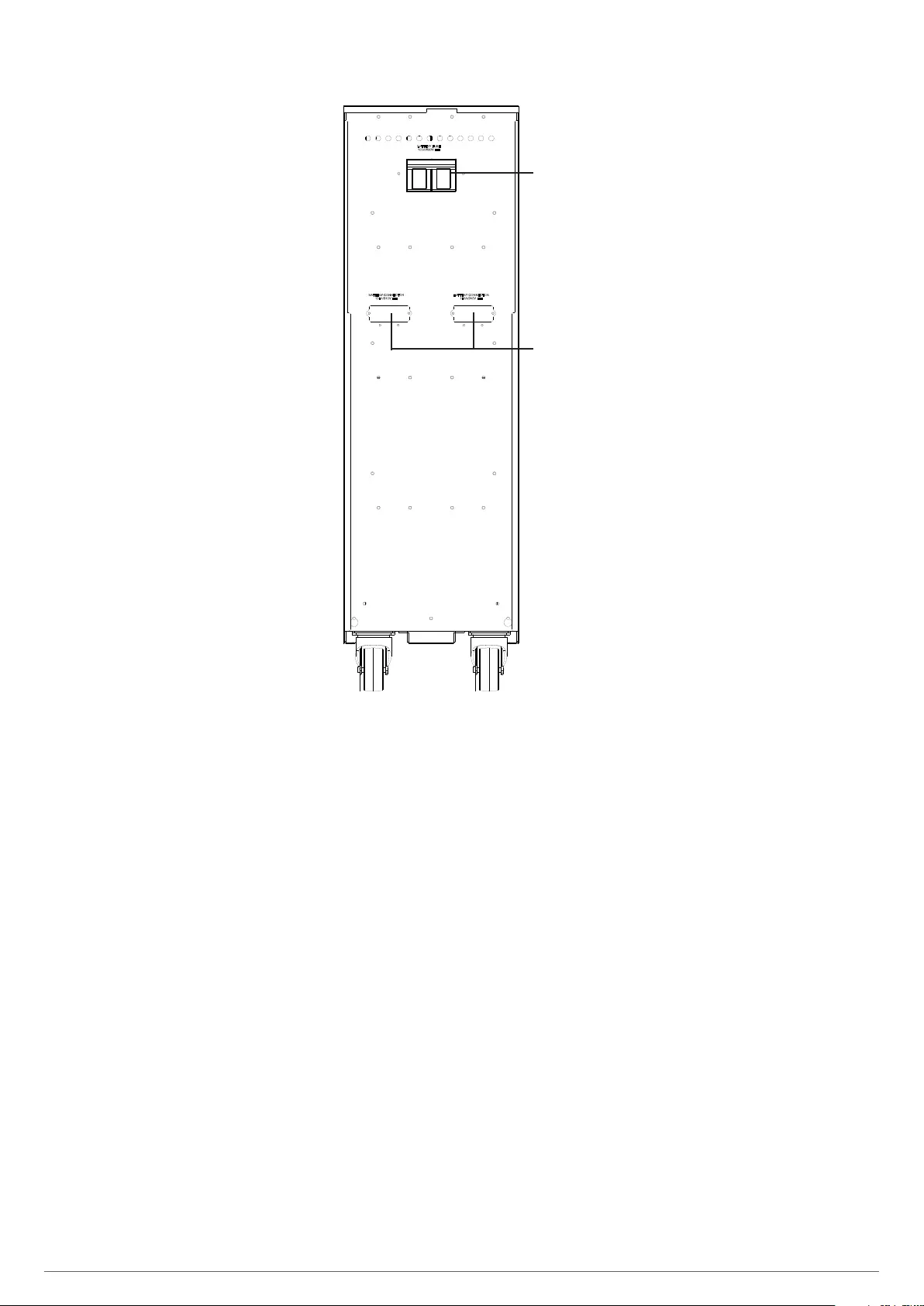

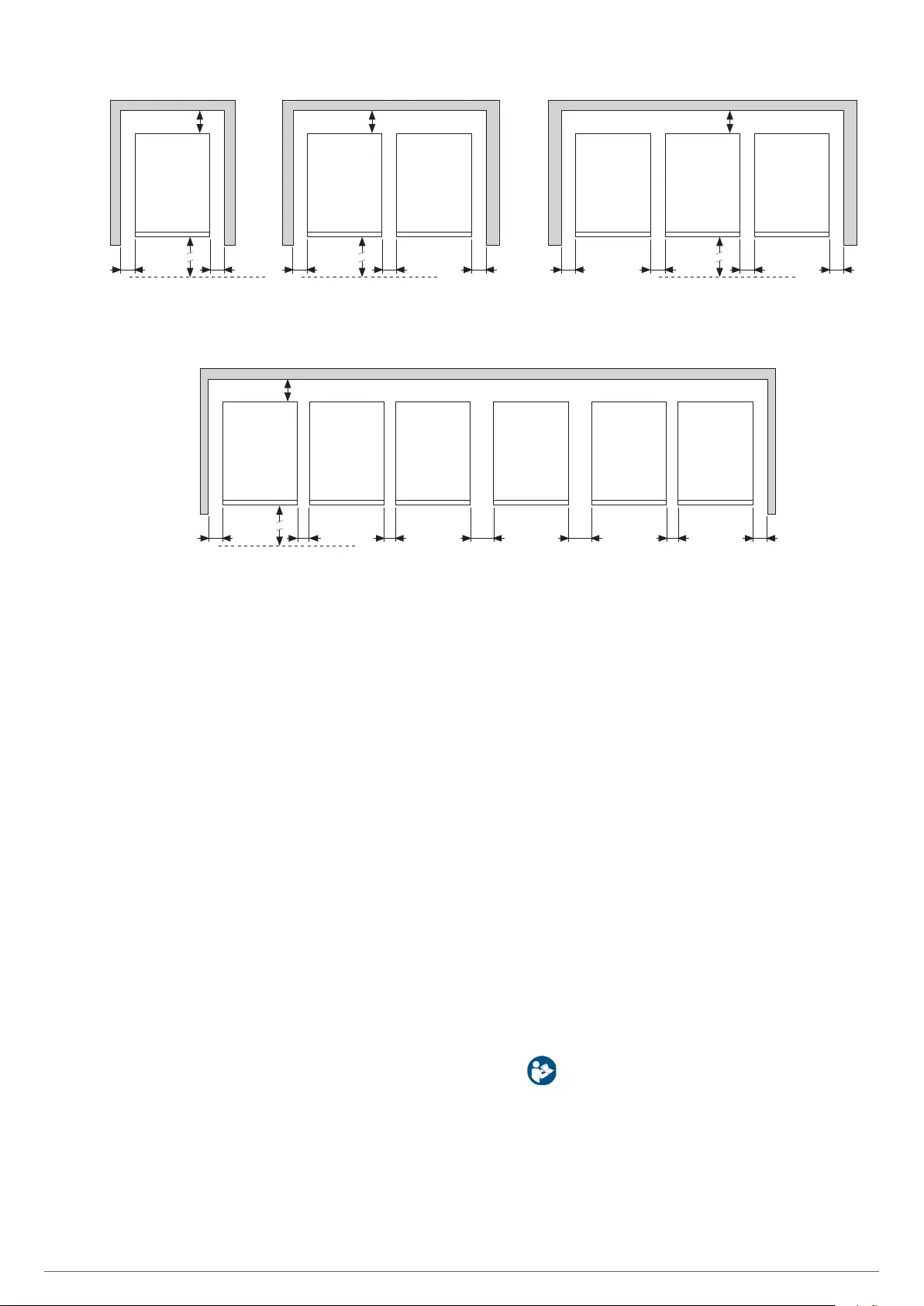

Figures from 1 to 3 show the equipment illustrations according

to the format of the case and its power rate. Nevertheless, as

the product is in constant evolution, some discrepancies or

slight contradictions can arise. In case of any doubt, the label-

ling in the own equipment will always prevail

In the nameplate of the equipment, the most important

parameters and features can be checked. Proceed with

the installation accordingly.

Standard and B1, from 4 to 10 kVA. Single phase input and output.

Standard and B1, from 8 to 10 kVA. Three phase input and single

phase output.

B1, from 15 and 20 kVA. Three phase input and single phase output.

Standard, 15 and 20 kVA. Three phase input and single phase

output.

Size 2

Size 1

Fig. 1. Front view for 4 to 20 kVA equipments.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

8SALICRU

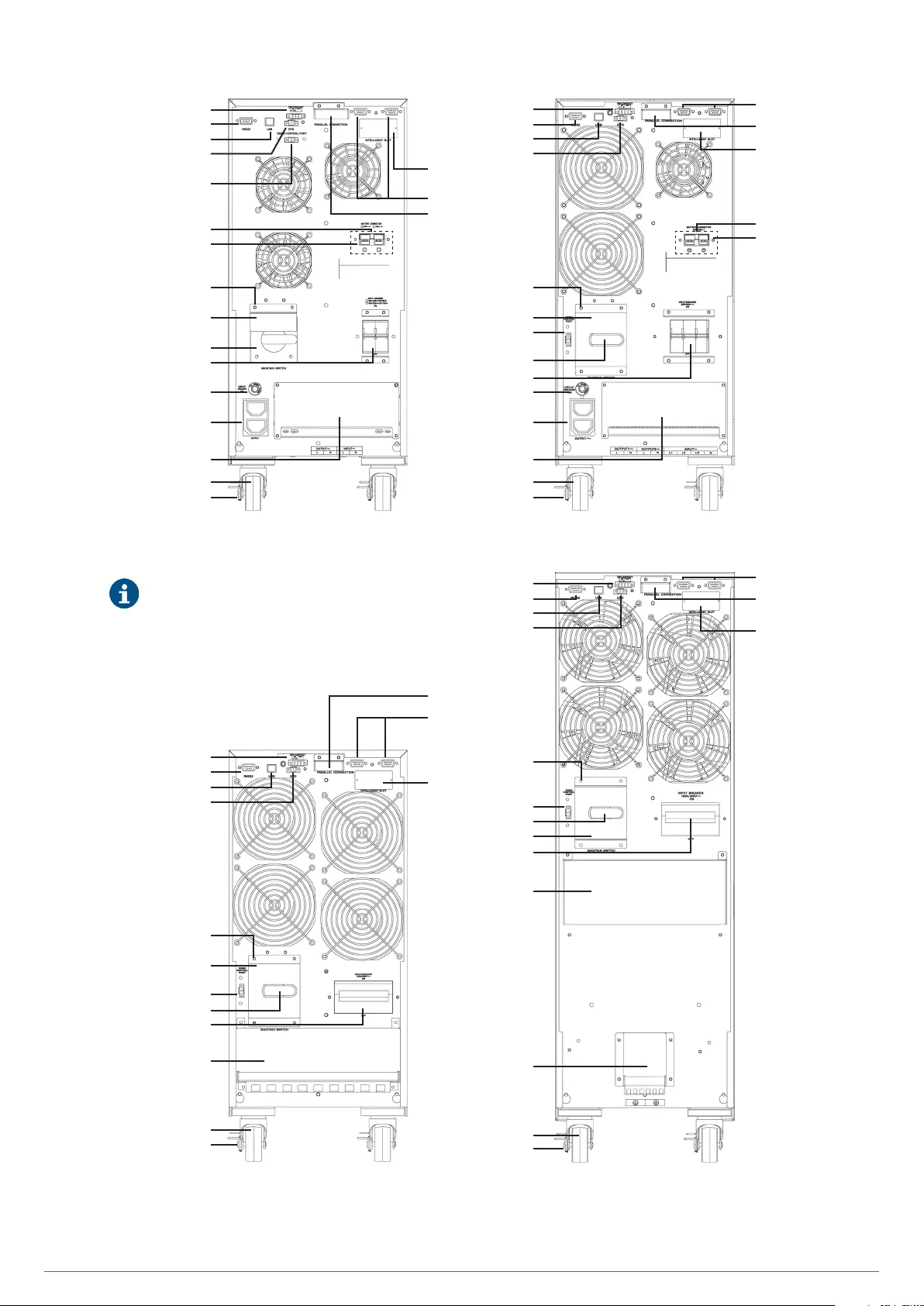

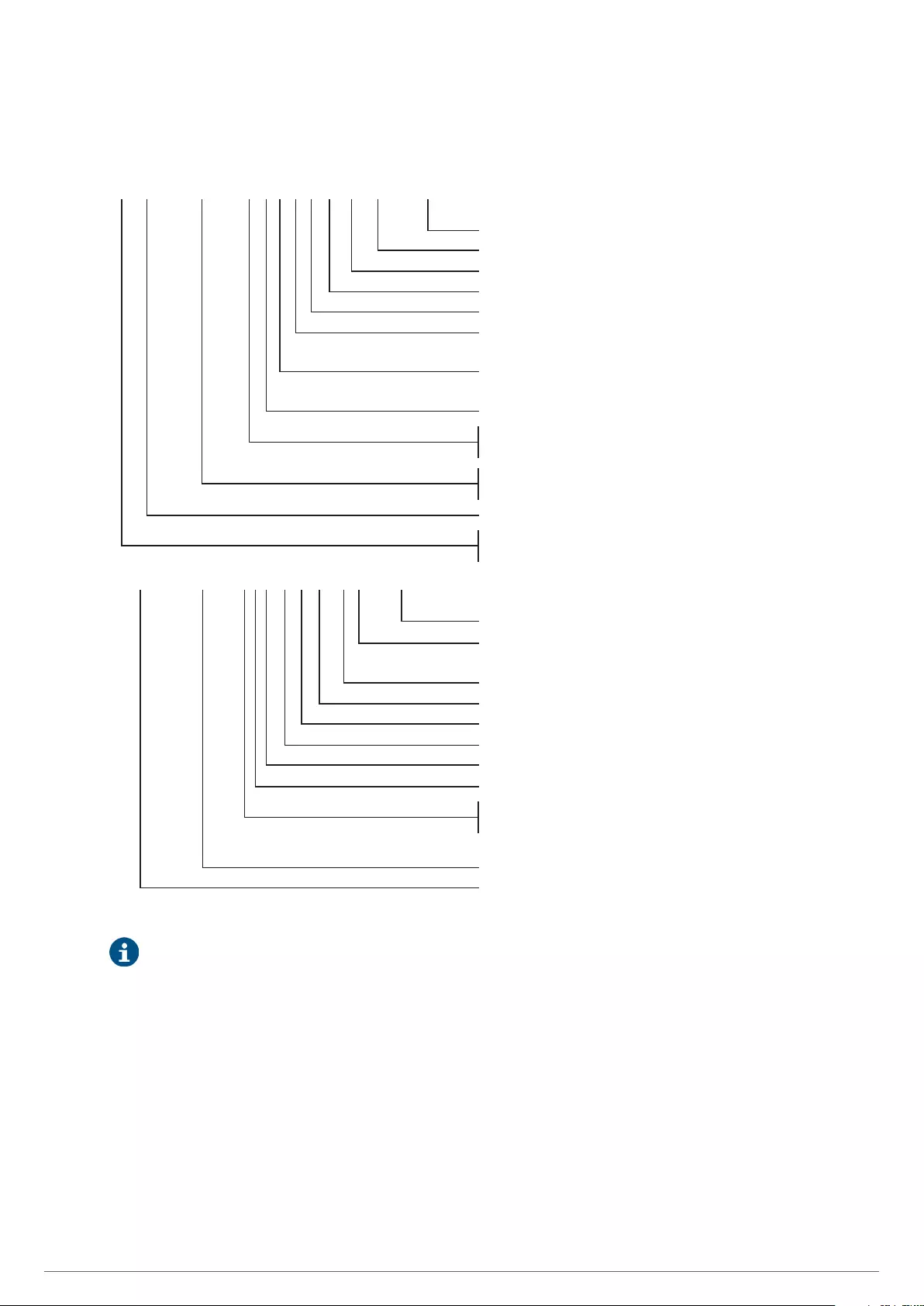

Standard and B1, from 4 to 10 kVA. Single phase input and output.

Digital input-output

RS232

USB

EPO

Manual Byp aux.

contact

Bat. connector cover

Battery connector

Manual bypass screw

locking

Manual bypass lock

Manual Bypass -BM-

Input protection

Output 1 breaker

Output 1, connected to

critical loads

Terminal cover, see

Fig. 17

Swivel casters

Caster brake

Digital input-output

RS232

USB

EPO

Smart Slot

Communication bus

Current sharing signal,

under the cover

Manual bypass screw

locking

Manual bypass lock

Manual byp. aux.

contact

Manual Bypass -BM-

Input protection

Output 1 breaker

Output 1, connected to

critical loads

Terminal cover, see

Fig. 17

Swivel casters

Caster brake

Communication bus

Current sharing signal,

under the cover

Smart Slot

Bat. connector cover

Battery connector

Standard and B1, from 8 to 10 kVA. Three phase input and single phase output.

Digital input-output

RS232

USB

EPO

Manual bypass screw

locking

Manual bypass lock

Contacto auxiliar BM

Manual Bypass -BM-

Input protection

Terminal cover, see

Fig. 17

Swivel casters

Caster brake

Digital input-output

RS232

USB

EPO

Current sharing signal,

under the cover

Communication bus

Manual bypass screw

locking

Smart slot

Manual byp. aux.

contact

Manual Bypass -BM-

Manual bypass lock

Input protection

Terminal cover, see

Fig. 17

Terminal cover, PE

terminals

Swivel casters

Caster brake

Communication Bus

Current sharing signal

under the cover

Smart slot

B1, from 15 and 20 kVA. Three phase input and single phase output. Standrd from 15 and 20 kVA. Three phase input and single phase output.

-BM- letters means Manual Bypass.

Fig. 2. Rear view for 4 to 20 kVA models.

9

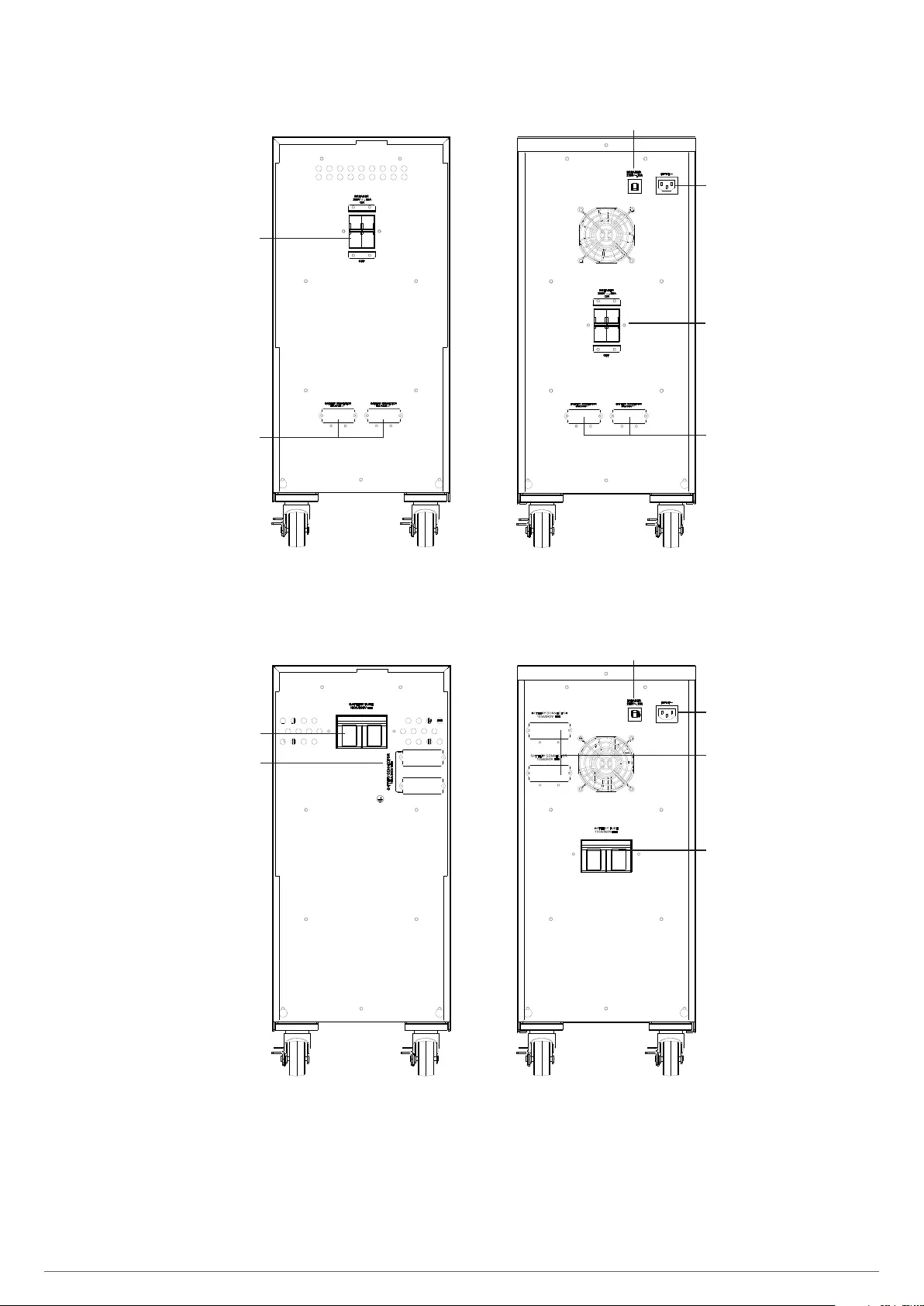

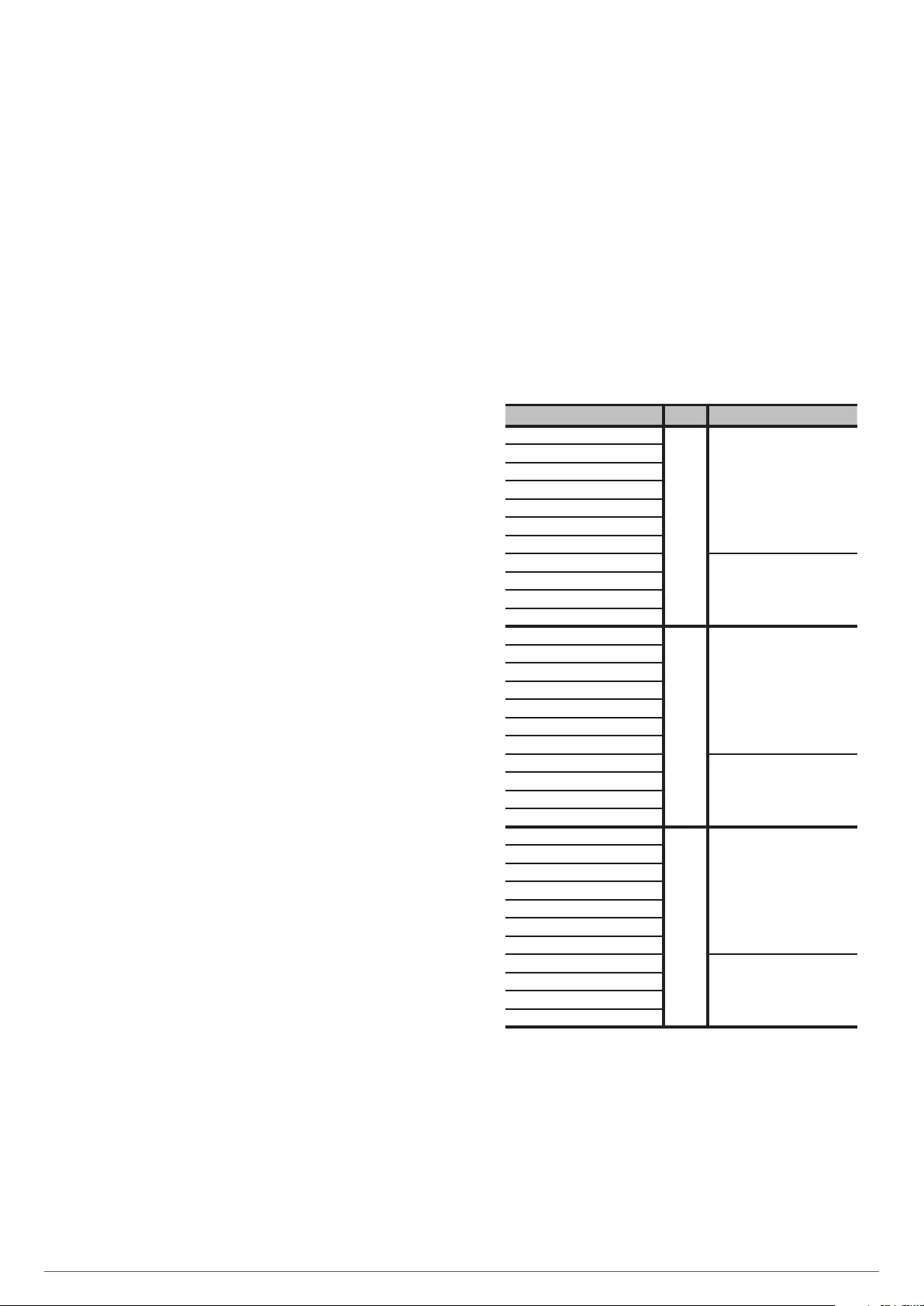

Battery switch

Terminal cover

Conector IEC para alimen-

tación AC

Batery switch

Terminal cover

Térmico de protección

Battery module, size 1, with 2x20 batteries

and 50 A protection.

Battery module, size 1, with 3x20 batteries

and 50 A protection.

Battery fuses

Terminal cover

IEC inlet for AC power

supply

Terminal cover

Battery switch

Protection breaker

Battery module, size 1, with 2x20 batteries

and 100 A protection.

Battery module, size 1, with 3x20 batteries

and 100 A protection.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

10 SALICRU

Battery switch

Terminal cover

Battery module, size 2 with 4x20 batteries

and 100 A protection

Fig. 3. Rear view of the battery module.

11

4.2. PRODUCT DEFINITION.

4.2.1. Nomenclature.

SLC-8000-TWIN/3 PRO2 B1 WCO 0/AB147 208/208V EE521925

MOD BAT TWIN PRO2 2x3AB147 3x40A WCO EE521925

EE521925 Particular specifications of the client.

208V Output voltage if it is not 220/230/240V AC.

208V Input voltage if it is not 220/230/240V AC.

147 Last three characters of the battery code.

AB Family of the battery according to Salicru's code.

0/ Equipment with no batteries but with the needed

accessories to fit them in.

CO “Made in Spain” marking in the UPS and packaging

(custom issues).

W Neutral equipment brand.

B0 No batteries and no space to install them.

B1 External batteries to the UPS enclosure and extra charger.

TWIN PRO2 Single phase input - output configuration.

TWIN/3 PRO2 Three phase input / single phase output equipment.

8000 Power in VA.

SLC Brand acronym.

CF Frequency converter (equipment with no batteries).

EE* Particular specifications of the client.

CO “Made in Spain” marking in the UPS and packaging

(custom issue).

W Neutral equipment brand.

40A Protection size.

3x Quantity of fuses in parallel. Omitted for only one.

147 Last three characters of the battery code.

AB Family of the battery according to Salicru's code..

3 Quantity of batteries in one string.

2x Quantity of strings in parallel. Omitted for only one.

0/ Battery module with no batteries, but with the needed

accessories to fit them in.

TWIN PRO2 Battery module series.

MOD BAT Battery module.

Note concerning batteries:

B0 and B1 acronyms, stated in the nomenclature are re-

lated with the batteries:

B0 The equipment is supplied with no batteries and no

accessories (screws and electrical cables). Batteries

belong to the client and they will be installed externally

to the UPS enclosure. Under request, it is possible to

supply these accessories, which are needed to inter-

connect them with the own the equipment.

B1 Equipment with extra battery charger. The UPS

is supplied with no batteries and no accessories

(screws and electrical cables).Under request, it is pos-

sible to supply these accessories, which are needed to

interconnect them with the own the equipment.

Those equipments requested with no batteries, their pur-

chasing, installation and connection will be borne by the

client and under his responsibility.

Data concerning batteries in respect of quantity, capacity

and voltage are stated in the battery label sticked beside

the nameplate of the equipment, respect this data and

their polarity strictly when connecting them.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

12 SALICRU

4.3. OPERATING PRINCIPLE.

This manual describes the commissioning and operating of

the Uninterruptible Power Supplies -UPS- from SLC TWIN

PRO2 series as equipments that can operate in parallel or

single configurations, without needing a centralised bypass.

The UPS's from SLC TWIN PRO2 series assure an optimal

protection for any critical load, keeping the power supply to

the loads inside the stated parameters, with either no break

in case of mains failure nor fluctuations. The wide range of

available models (from 4kVA up to 20kVA), allows adapting

the model to the end-user needs.

Thanks to the used technology, PWM (Pulse Width Modula-

tion) and the double conversion, the UPS's from SLC TWIN

PRO2 series are compact, cold, silent and with high efficiency.

The double conversion principle cancels any fluctuations from

the electrical mains. A rectifier converts the alternating cur-

rent from mains in to direct current, and it keeps the optimal

charge level to the batteries and at the same time feeds the

inverter; the inverter generates a alternating current sin-

ewave, which is ready to feed the loads constantly. In case

of power outage at the UPS input, the batteries supply the

energy to the inverter.

The UPS design and manufacturing from SLC TWIN PRO2

series has been done in accordance with the international

standards.

These equipments allow their upgrading by connecting addi-

tional equipments of the same power rate in parallel, in order

to get redundancy -i.e.: N+1- or increasing the power of the

system.

Therefore, this series has been designed to maximize the

availability of the critical loads in order to protect them

against voltage fluctuations, power outages and blackouts,

which are present in the energy distribution lines. This is the

main aim of the UPS's from de SLC TWIN PRO2 series.

This manual applies to the standardised models stated in Tab. 1.

4.3.1. Main features.

•True on-line technology of double conversion and inde-

pendent output frequency from mains.

•Output power factor 1 in single phase input equipments and

0.9 in three phase input ones. Pure sinewave shape, suit-

able for almost all type of loads.

•Input power factor > 0.99 and high efficiency (> 0.94 for

single phase input or > 0.92 for three phase input). So, it

is got a high economy saving and lower installation cost

-wiring-, as well as low input current distortion, so the per-

turbances to mains are reduced.

•Great adaptability to the worst conditions of input mains.

Wide input voltage range, frequency range and wave

shape, so it is avoided the excessive use of the battery,

which has limited energy.

•Available battery charger up to 8 A in order to decrease the

battery recharge time.

•Parallel redundant N+X connection, in order to increase

the reliability and flexibility. 3 equipments in parallel as

maximum.

•Selectable of the High Efficiency Mode > 0.97 -ECO-MODE-.

Energy saving, which means economic saving for the end-

user.

•Possibility to start it up with no mains or discharged bat-

teries. Be careful, with this last point, because the back up

time will be reduced, as much as they are more discharged.

•The smart battery management technology is very useful

to extend the lifetime of the batteries and to optimise their

recharging time.

•RS232 or USB communication ports as standard.

•Digital input to start up-shutdown the equipment.

•Digital output for «Error or fault».

•Remote emergency power off -EPO-.

•User-friendly interface between user and equipment by

means of the control panel with LCD and LED.

•Optional available cards to improve the communication ca-

pabilities.

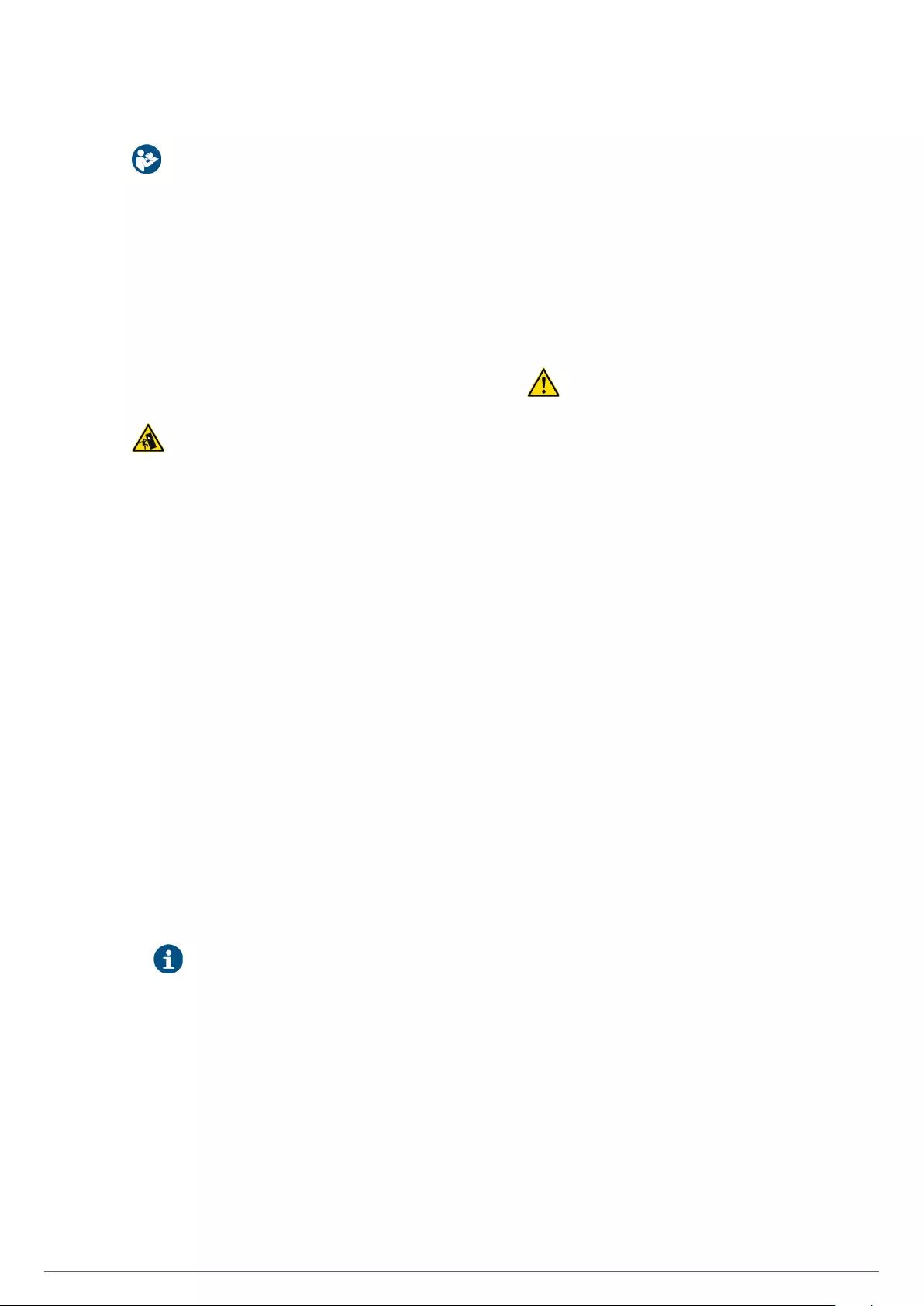

Model Type Input/output topology

SLC-4000-TWIN PRO2

Standard

Single phase in/out

SLC-5000-TWIN PRO2

SLC-6000-TWIN PRO2

SLC-8000-TWIN PRO2

SLC-10000-TWIN PRO2

SLC-15000-TWIN PRO2

SLC-20000-TWIN PRO2

SLC-8000-TWIN/3 PRO2

Three phase in / Single

phase out

SLC-10000-TWIN/3 PRO2

SLC-15000-TWIN/3 PRO2

SLC-20000-TWIN/3 PRO2

SLC-4000-TWIN PRO2 (B0)

No batteries

Single phase in/out

SLC-5000-TWIN PRO2 (B0)

SLC-6000-TWIN PRO2 (B0)

SLC-8000-TWIN PRO2 (B0)

SLC-10000-TWIN PRO2 (B0)

SLC-15000-TWIN PRO2 (B0)

SLC-20000-TWIN PRO2 (B0)

SLC-8000-TWIN/3 PRO2 (B0)

Three phase in / Single

phase out

SLC-10000-TWIN/3 PRO2 (B0)

SLC-15000-TWIN/3 PRO2 (B0)

SLC-20000-TWIN/3 PRO2 (B0)

SLC-4000-TWIN PRO2 (B1)

Extended back up time

Single phase in / out

SLC-5000-TWIN PRO2 (B1)

SLC-6000-TWIN PRO2 (B1)

SLC-8000-TWIN PRO2 (B1)

SLC-10000-TWIN PRO2 (B1)

SLC-15000-TWIN PRO2 (B1)

SLC-20000-TWIN PRO2 (B1)

SLC-8000-TWIN/3 PRO2 (B1)

Three phase in / Single

phase out

SLC-10000-TWIN/3 PRO2 (B1)

SLC-15000-TWIN/3 PRO2 (B1)

SLC-20000-TWIN/3 PRO2 (B1)

Tab. 1. Standardized models.

13

4.4. OPTIONS.

Depending on the selected configuration, the equipment can

include any of the following options:

4.4.1. Isolation transformer.

The isolation transformer, provides a galvanic isolation that al-

lows isolating the output from input completely and/or even

change the neutral regime.

The fact of having an electrostatic shield between the primary

and secondary windings of the transformer provides a high at-

tenuation level of the electrical noise.

Physically, the isolation transformer can be located at the input

or output of the UPS, depending on the particular specifications

of the installation (equipment power supply and/or loads, type

of loads,...).

In parallel systems, it is not possible to operate with separate

isolation transformers for each UPS. So it is necessary to have

only one transformer for the complete parallel system of the

suitable power rate.

In any case, it will always be supplied as a separate item to the

own UPS enclosure.

4.4.2. External manual bypass manual.

The purpose of this option is to isolate electrically the equip-

ment from mains and critical loads with no break. Therefore the

maintenance or reparation tasks can be done in the equipment

with no breaks in the power supply of the protected system and

at the same time undue risks to the technical staff are avoided.

The basic difference, between this option and the integrated manual by-

pass in the own UPS enclosure is its better operability, because it allows

the total disconnection of the UPS from the installation.

4.4.3. Communication card.

In the rear side of the UPS there is a slot, which allows in-

serting any of the following communication cards.

4.4.3.1. Integration into IT networks by means of the SNMP

adaptor.

The large-scale IT systems based in LANs and WANs, which

integrates servers with different operating systems, must in-

clude an easy control by the management of the system. This

feature is get by the use of the SNMP adaptor, which is ac-

cepted by the main manufacturers of software and hardware.

The connection of the UPS with the SNMP is internal, mean-

while the connection between the SNMP and the IT network is

done by means of a RJ45 10 base connector.

4.4.3.2. RS485 Modbus.

Many times, the large-scale IT systems based in LANs and

WANs require communication by means of a industrial standard

protocol with any part or component integrated inside the IT

network.

One of the most used industrial protocols in the market is the

MODBUS protocol. The SLC TWIN PRO2 series is ready to be

integrated in this kind of environments either by means of the

“SNMP mini card” adaptor or the RS485 Modbus card which is

described in the documentation of the optional.

4.4.3.3. Dry contacts.

•As an option, the UPS has a dry contact card, which pro-

vides digital signals, with maximum applicable voltage and

current of 240 V AC or 30 V DC and 1A.

•This port provides a dialogue between the equipment and

other machines or devices, thanks to the supplied dry con-

tacts, which includeds a terminal strip located in the own

card, with only one common terminal for all of them.

All the dry contacts are normally opened, preset from fac-

tory, being able to set them independently, according to the

information supplied with the option.

•The most common use of these type of ports is to provide

the needed information to the closing file software.

•For information, contact with our T.S.S. or our closest dis-

tributor.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

14 SALICRU

5. INSTALLATION.

•Read and respect the Safety Information, described

in section 2 of this document. The fact of ignoring

any of the indications described in it, can cause serious ac-

cidents or very serious injuries to the persons in the vicini-

ties in direct contact, as well as damages to the equipment

and/or loads connected to itself.

•A part from the own user's manual of the equipment, the

CD-ROM or Pen Drive contents other documents, which

have to consulted and followed strictly.

•Unless otherwise indicated, any action, indications, notes

and other ones are applicable to the equipments, never

mind if they belong to a parallel system or not.

5.1. EQUIPMENT RECEPTION.

•It is dangerous to handle the equipment over the pallet

with no caution, because it could tip over or cause se-

rious injuries to the operators due to the impact of the fall and/or

entrapment. Pay attention to section 1.2.1. from Safety Intruc-

tions -EK266*08- regarding handling, moving and location of the

equipment.

•Use the most suitable medium to move the UPS meanwhile

it is still packaged, by means of pallet jack or forklift.

•Any equipment handling will be done keeping in mind the

weights and technical features of the model, stated in sec-

tion «9. Annexes».

5.1.1. Reception, unpacking and contents.

•Reception. Check the following:

Data in the labelling of the packaging are the same as

the stated in the purchase order. Once the UPS is un-

packed, check previous data with the nameplate of the

equipment.

In case of discrepancies, make the non-conformity as

soon as possible by quoting the serial number of the

equipment and the delivery note reference.

No damage during transport (packaging and impact in-

dicator correct).

Otherwise, follow the stated protocol in the labelling

beside the impact indicator, located in the packaging.

•Unpacking.

To check the contents, the packaging must be removed.

Complete the unpacking procedure according to

section 5.1.3.

•Contents.

The own equipment.

User's manual in IT support: [CD-ROM] or [Pen Drive].

1 communication cable.

2 cables for parallel connection, current bus and control

signal.

1 female connector to connect into the external EPO. It in-

cludes an isolated cable as a «bridge» mode to close the

circuit (already fitted in).

•Once the reception is finalised, it is better to pack the UPS

again till its commissioning in order to protect it against pos-

sible mechanical impacts, dust, dirt, etc...

•The equipment packaging has wooden pallet, cardboard

or wooden enclosure depending on the requirements, ex-

panded polystyrene corners, plastic bag and polyethylene

wrap, all of them are recyclable materials. When they has

to be disposed proceed in accordance with the laws in

force.

It is advised to keep the packaging, for 1 year at least.

5.1.2. Storage.

•The storage of the equipment will be done in a dry and

cool room, protected from rain, dust, water jets or chemical

agents. It is advisable to keep each equipment and battery

unit inside their original packaging, because they have

been designed to assure the maximum protection during

transport and storage.

•Those equipments, which include Pb-Ca batteries,

the recharging period of time according to the storage

temperature, stated in Tab. 2 from EK266*08 document, must

be respected. Otherwise the warranty will be cancelled.

•After this period of time, connect the equipment with the

batteries unit,if any, and start it up according to the instruc-

tions described in this user's manual and charge them for

12 hours.

In parallel systems, to charge only the batteries, it is not needed

to make the connection among the equipments. Proceed as com-

plete single equipments to charge them.

•Later on, shutdown the equipment, disconnect it and pack

the UPS and batteries in their original packaging again, by

writing down the new recharging battery date in any docu-

ment or over the own packaging as a record mode.

•Do not store the devices, where the temperature exceeds

over 50º C or below –15º C, because the electrical features

of the batteries can be affected.

5.1.3. Unpacking.

•The equipment packaging has wooden pallet, cardboard

or wooden enclosure depending on the requirements, ex-

panded polystyrene corners [EPS] or polyethylene foam

[EPE], plastic bag and polyethylene wrap, all of them are

recyclable materials. When they has to be disposed pro-

ceed in accordance with the laws in force.

It is advised to keep the packaging, in case it was to be

used in future.

•Equipments with single phase input TWIN PRO2 or three

phase input TWIN/3 PRO2 up to 10 kVA.

To unpack the equipment follow the sequence from

figure 4 to 7 (cut the wraps of the cardboard enclosure

and remove it from the top as it was a cover or in case

of wooden packaging, dismantle it with the needed

tools; remove the corners and plastic bag. The UPS will

be naked over the pallet.

With the help of one or two people in each side of the

UPS, download it from the wooden pallet.

15

Fig. 4. Fig. 5. Fig. 6. Fig. 7.

Fig. 8. Fig. 9. Fig. 10. Fig. 11.

5.1.4. Transport till its location.

•All the equipments have four casters (with mechanical

lock), so it is easy to move it till its right location once it

is unpacked.

Nevertheless, if the reception area is far from the installa-

tion location, it is recommended to move the UPS by means

of a pallet jack or the most suitable transport medium,

keeping in mind the distance between both points.

In case of long distances, it is recommended to move the

equipment with its packaging till the installation location

and finally unpack it there.

5.1.5. Location, immobilising and considerations.

5.1.5.1. Location for single units.

•As an example, Fig. 14 shows the typical case depending

on the model. The equipment based on one single phase

(UPS with batteries fitted in) and UPS with the batteries in

a separate case or extended back up times.

For a correct cooling, the space around the equipment

must be free of obstacles. Respect the minimum dis-

tances stated in Tab. 1 from section 1.2.1 of the docu-

ment EK266*08 (Safety Instructions), where the figures

of each dimension A, B, C and D are stated according to

the power rate of each equipment.

For the battery cases, keep the same distances as the

same UPS enclosure.

It is recommended to leave 75 cm additional free in each

side, for the possible tasks of the (T.S.S.) or the needed

power cable length to facilitate the movement of the

equipment to the front.

For extended back up times, with more than one case, it

is recommended to put one at each side of the equipment

and in case of a higher quantity proceed in the same way

alternately.

•Equipments with three phase input TWIN/3 PRO2

To unpack the equipment, follow the sequence of figures

8 to 10 (cut the wraps of the cardboard enclosure and

remove it from the top as it was a cover or in case of

wooden packaging use the needed tools; remove the

corners and plastic bag. The UPS will be naked over the

pallet.

The equipment is fixed to the wooden pallet by means

of metallic support with «L» shape (stabilising support),

fixed at each side of the equipment.

Remove the screws that fix the equipment to the pallet

by means of the support [see Fig. 12 and 13].

Before downloading the equipment from the

pallet, the stabilising supports have to be removed

first, otherwise they will make difficult the downloading

procedure and they will be bent when impacting with

the wooden ramp, being able to cause damages to the

own structure of the equipment.

Put the ramp as figure 11 shows and download the

equipment from the pallet.

Fig. 12.

Fig. 13.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

16 SALICRU

B

AA

UPS cabinet

with

batteries

D

B

AA A

UPS cabinet Battery UPS

cabinet

D

B

AA A

Battery

cabinet UPS

nr 1

Battery

cabinet UPS

nr 2

A

UPS cabinet

D

Fig. 14. Minimum distances for a correct UPS cooling.

D

B

AA A Ax2Ax2 A A

Battery

cabinet UPS

nr 1

Battery

cabinet UPS

nr 2

UPS cabinet

nr 1

UPS cabinet

nr 2

UPS cabinet

nr 3

Battery

cabinet UPS

nr 3

Fig. 15. Minimum distances for a correct UPS system

cooling.

5.1.5.2. Location for parallel systems.

•As an example of three equipments in parallel, Fig. 15

shows them with their battery case. For systems with two

equipments in parallel and/or more battery modules pro-

ceed accordingly in the same way.

Likewise, obviate the illustration of the battery modules

when they are not available.

The numbering of the equipments in Fig. 15 doesn't have

any purpose less than number each unit in the illustration.

•For a correct cooling, the space around equipment must be

free of obstacles. Respect the minimum distances stated in

Tab. 1 from section 1.2.1 of the document EK266*08 (Safety

Instructions), where the figures of each dimension A, B, C

and D are stated according to the power rate of each equip-

ment.

For the battery cases, keep the same distances as the UPS

enclosure.

5.1.5.3. Immobilising the equipment.

•The equipment has casters with brakes. Once the equip-

ment is placed in its final location, to immobilise the equip-

ment is recommended to lock them.

5.1.5.4. Preliminary considerations, before connecting the

equipment.

•In the description of this manual, there is reference to con-

nect terminals and manoeuvring switches, which are only

available in some models or equipments with extended

back up times. Ignore those operations related with your

unit in case it does not have them.

•Regarding the installation instructions of a single equip-

ment or parallel system, follow and respect them.

•The switchgear or external manual bypass panel:

At least, the installation will have one protection for

the short-circuit in the power supply line of the UPS.

For single equipments, it is recommended to install an

external manual bypass panel, equipped with input,

output and manual bypass protections.

For parallel systems, it is essential to install a switch-

gear or manual bypass panel. The switches of the panel

must allow isolating one UPS from the system, in case

of any failure and allow feeding the loads with the rest

ones, either during the preventive maintenance tasks or

during the failure and its reparation.

•An external manual bypass panel for a single unit or parallel

system can be purchased under request.

Also, it can be manufactured by yourself by keeping in mind

the version and configuration of the available equipment

or system and the attached documentation in the CD-ROM

or el Pen Drive as regards to «Recommended installation

diagram».

•The documentation delivered together with this us-

er's manual and/or CD-ROM or Pen Drive, includes

information regarding the «Recommended installation dia-

gram» for each input and output configuration. This docu-

mentation shows the wiring circuit diagrams, as well as the

protection and cross cable sizes that are connected to the

equipment, considering the nominal voltage. All the figures

are calculated for a total maximum cable length of 30 m

between the switchgear panel, equipment and loads.

For longer lengths, correct the cross cable sections in

17

accordance with the Regulations or standards of the

country, in order to avoid dropping voltages.

In the own documentation and for each configuration,

it is available the information for «N» equipments in

parallel, as well as the features of the «Backfeed pro-

tection».

•In parallel systems, the length and cross cable sec-

tion that connect the switchgear or manual bypass

panel with each UPS must be the same for all of them, with

no exception.

•The cross cable section must be always according to the size

of the own terminals of the switches, in such way that the

wire is embraced properly, in order to guarantee an optimal

contact between both parts.

•The data in the nameplate of the equipment states the

nominal current only, as the safety standard EN-IEC

62040-1 states. To calculate the input current, it has been

considered the power factor and the own efficiency of the

equipment.

The overload conditions are considered as a non-perma-

nent and exceptional operating mode, so it will not be kept

in mind when sizing the protections. Do not connect devices

to the UPS terminals or outlets that could overload it, like

motors.

•TWIN/3 PRO2 models (three phase input and single

phase output), the input current of R phase and Neutral

is higher than the other two lines/phases when the UPS

works on bypass mode (loads supplied from mains directly). Pay

attention to the nameplate data to size the two corresponding

cables.

•In case of adding peripheral parts at the UPS or parallel

system input or output, like transformers or autotrans-

formers, the stated currents in their own nameplates

must be also considered, in order to use the suitable cross

cable section, by respecting the Local and/or National Low

Voltage Electrotechnical Regulation.

•When a UPS or parallel system, as standard, as an option

or installed by yourself, at the input line or at the output or

in both, include a galvanic isolation transformer, a Residual

Current Device must be installed at its output, in order to

protect against electrical shocks and indirect contacts, be-

cause its intrinsic feature of isolation will prevent the trip-

ping of the protections fitted in the primary winding of the

transformer.

•As a reminder, all the isolation transformers installed or

supplied from factory has the output neutral connected to

the protective earth by means of a cable bridge between

the neutral and PE terminals. In case of requiring an iso-

lated output neutral, remove this cable bridge, by taking

the stated cautions in the local and/or national low voltage

regulations.

•This equipment is ready to be installed in grids with

power distribution systems TT, TN-S, TN-C or IT,

keeping in mind the particular features of each neutral re-

gime and the electrical regulations of the destination

country.

•The switches, RCD and circuit breaker of a three phase input

equipment connected to an IT power distribution system

must break the NEUTRAL apart from the three phases.

•TWIN PRO2 has a terminal strip to install an external emer-

gency power off button -EPO-. Only one device has to be

fitted in, in order to break the energy to the loads in any

operating mode.

5.1.5.5. Preliminary considerations for batteries and their

protections before connecting the equipment.

•All the standard UPSs include batteries in the same enclo-

sure, less those models called B0 and B1. For the standard

UPSs, the battery protection is done by internal fuses and

they are not accessible by the end-user.

Also, the battery modules have protection and in this case they

are doubled. Once are internal by means of fuses and not ac-

cessible by the end-user and the second ones by means of a

two poles circuit breaker or fuses.

•IMPORTANT FOR THE SAFETY: In case of installing the

batteries by yourself, the battery set must have a two

poles circuit breaker or fuses switch, with the size stated in

Tab. 2.

•Inside the battery module there are DANGEROUS VOLT-

AGES with the risk of electrical shock it involves, so it is

classified as RESTRICTED ACCESS AREA.

•Do not handle the battery fuse holder or circuit breaker

switch when the equipment is turned ON. These

switches cannot be turned ON/OFF with load.

•When the power supply to the equipment or parallel

system is broken and it is foreseen an out of service of

the equipment for long time, the equipment must be shutdown

completely.

•The battery circuit is not isolated from the input

voltage. So, dangerous voltages can be found be-

tween the battery terminals and the earth. Check that there

is not any kind of voltage, before doing any action over the

terminals.

5.1.5.6. Connection parts.

•Any electrical connection of the equipment is done through

the rear side of the equipment:

Input and output connection terminals. Remove the

fixing screws of the protection cover and the own cover,

to have access to the terminals.

Connect the UPS with the battery modules. Depending

on the power rate of the UPS, it has a connector or ter-

minals.

–Equipment and battery module with connector. Re-

move the screws and the «BATTERY CONNECTOR»

cover. These covers will not be put back again,

keep them.

–Equipment with battery terminals. They are beside

the AC power terminals.

–Battery module with terminals. Remove the screws

and protection cover.

Communication connectors:

–DB9 type for RS232.

–USB type for communication as a peripheral.

–Digital input and output.

–Terminal strip for external EPO button.

–Auxiliary contact for manual bypass switch.

Control connections for parallel systems, by DB15 connec-

tors and analogical signal for current sharing. Remove the

screws and the protection cover to have access to them.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

18 SALICRU

Slot to insert one of the optional communication cards.

Remove the fixing screws and the plastic cover to allow its

inserting.

•When finalising the connection tasks, the cover or

covers and their fixing screws will be put back be-

fore commissioning the equipment, in order to avoid acci-

dents due to direct contacts.

•It is recommended the use of crimping pin terminal in all

the cable ends connected to terminals, in particular the

power ones (input, output and batteries).

•Check the correct torque in the screws of the terminals.

5.2. CONNECTION.

•The terminal protection cover leaves a slot for the cable

entering to the power terminal strip. The cover and/or en-

closure frame has drills that allows fixing the connection

cables in order to avoid unexpected cable pulling due to the

consequences that it could have.

5.2.1. Connection of the input terminals to AC power

supply.

•As this is an equipment with protection against elec-

trical shocks of class I, it is essential to connect the

main protective earth cable [ ]. Connect this cable to the

terminal before supplying voltage to the input terminals.

•Pay attention to the «Recommended installation» document

in section 5.1.5.4., which states the cross cable section,

protection size and features, etc, ...

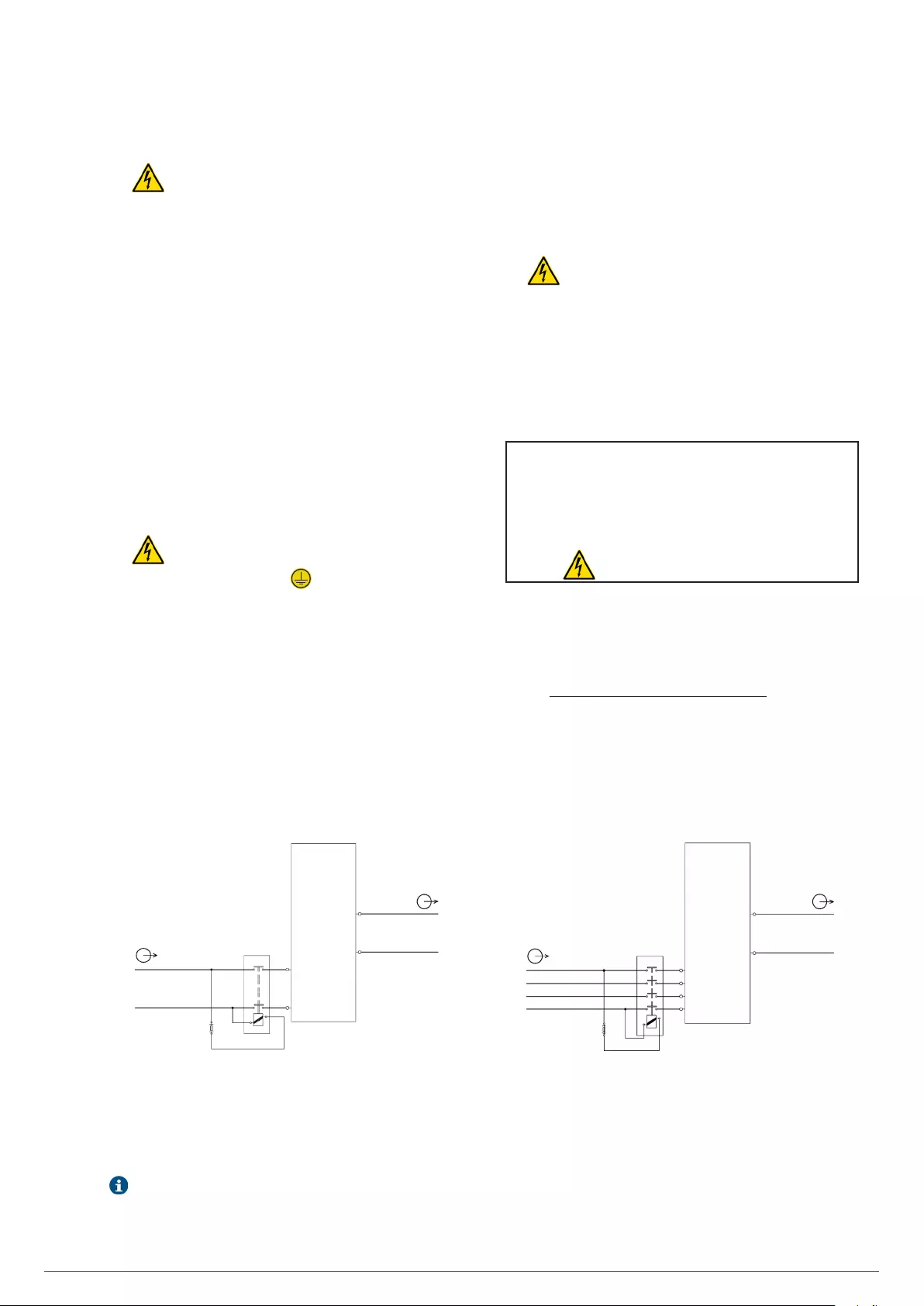

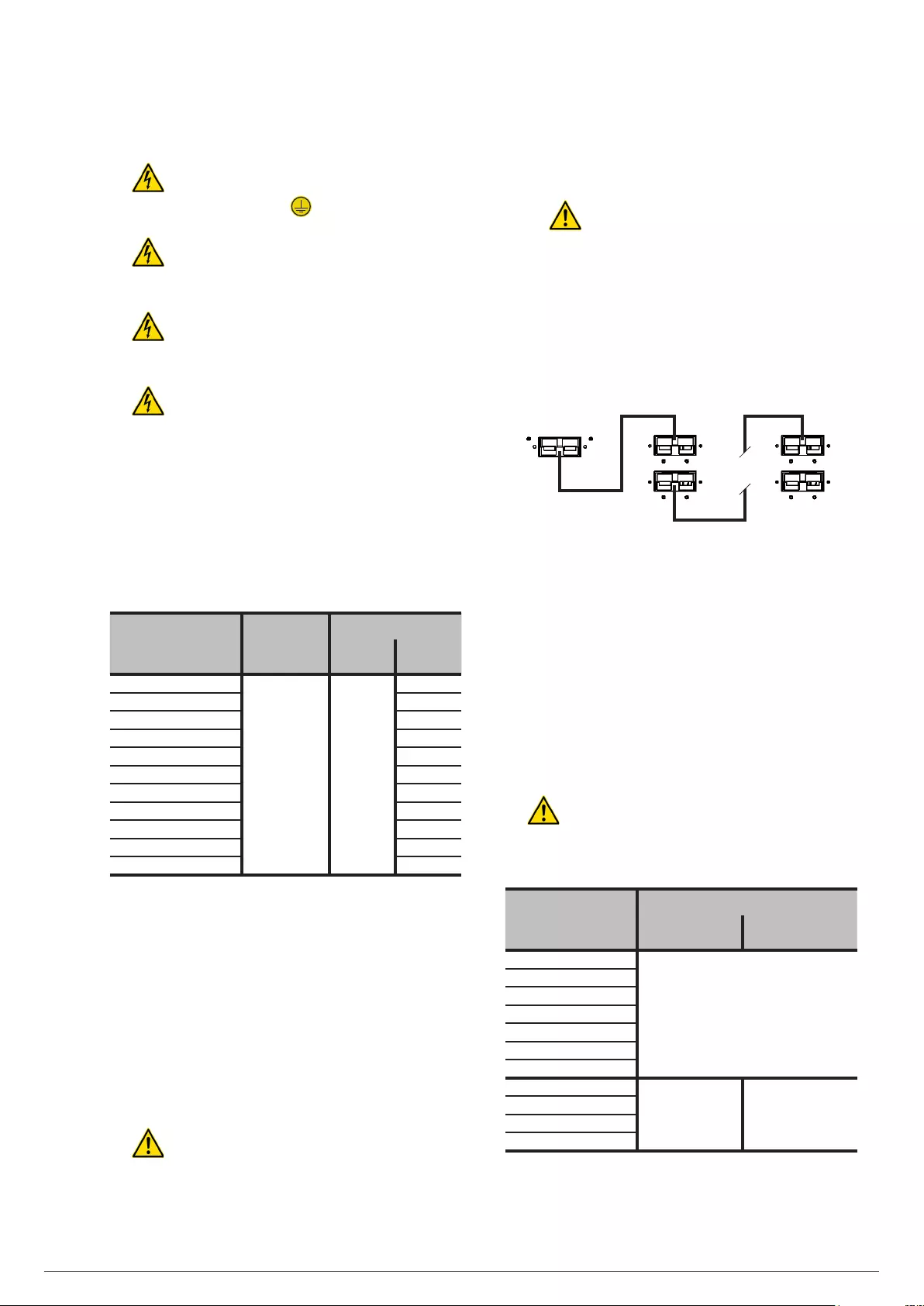

«Backfeed protection» connection for TWIN PRO2.

(BP) Automatic «Backfeed protection» system, external to the UPS (EN-IEC 62040-1).

(1) General purpose fuse or fuses with size 600V AC and 1A of type F.

(2) Two or four poles contactor of 400V AC with minimum distance among the contacts of 1.4 mm and230V ACcoil, with minimum current size of the stated one in

the UPS namopete .

For parallel systems, each equipment must have its own "Backfeed protection" separately.

Conexión «Backfeed protection» para TWIN/3 PRO2.

R

N

(2)

Input

Output

UPS

U

N

(1)

(BP) R

S

T

N

U

N

(BP)

(2)

Salida

Entrada

(1)

SAI

Fig. 16. «Backfeed protection» circuit diagram.

•In accordance with the EN-IEC 62040-1 safety standard the

installation must have an automatic «Backfeed protection»

system, i.e.: a contactor, which prevents power supply or

dangerous energy at the UPS input during a power outage

[seer Fig. 16].

The standard applies to single or three phase input equip-

ments as well as both single units and UPSs in a parallel

systems.

•Do not connect any line between the «Backfeed pro-

tection» and UPS, because the safety standard

would not be met.

•Warning labelling must be placed in all the primary power

switches, installed far from the equipment, in order to warn

the electrical maintenance staff about the presence of a

UPS in the electrical circuit.

The labelling will include the following text or an equiva-

lent one:

Before operating in the circuit.

•Isolate the Uninterruptible Power Supply (UPS).

•Check that the voltage among the terminals, PE

included.

Risk of UPS voltage backfeed.

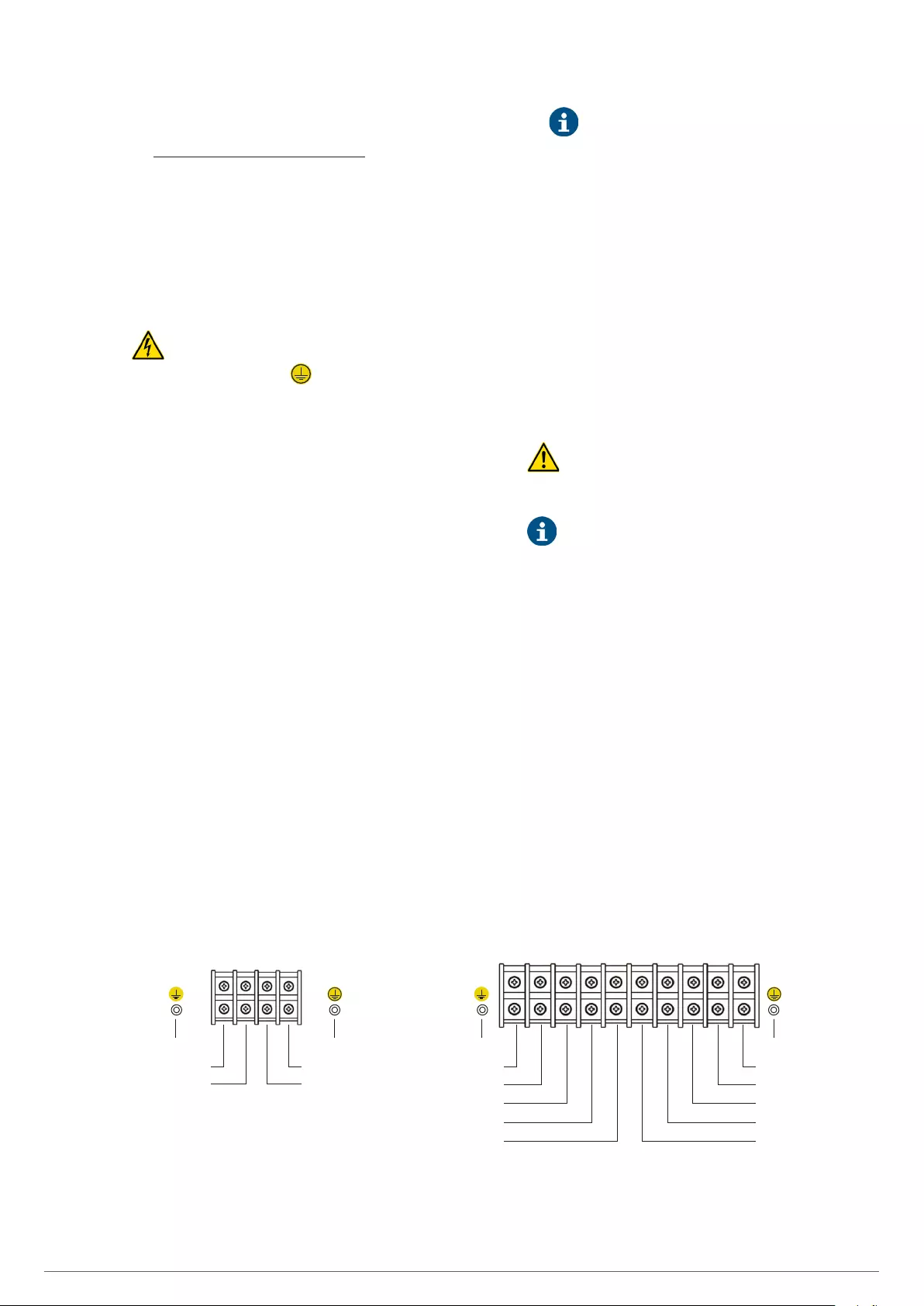

•Connect the input cables to the respective power terminal

strip depending on the available equipment [see Fig. 17].

For parallel systems, it will be needed to repeat the connec-

tions that go from the switchgear panel to each equipment.

Connection to a single phase input:

Connect the power supply cables to the R and N input ter-

minals, by respecting the phase rotation of the neu-

tral and phase stated in the labelling of the equipment

and this manual. Otherwise it can be damaged.

19

In 15 and 20 kVA equipment, the R phase cable will be

connected to the plate and the neutral cable to terminal N.

Connection to a three phase input:

Connect the power supply cables to the R, S T and N input

terminals, by respecting the phase rotation of the

phases and neutral stated in the labelling of the equip-

ment and this manual. Otherwise it can be damaged.

In case of discrepancies between the labelling and the in-

structions of this manual, the first ones will always prevail.

5.2.2. Connection of load/s to the output terminals or output 1.

•As this is an equipment with protection against elec-

trical shocks of class I, it is essential to connect the

main protective earth cable [ ]. Connect this cable to the

terminal before supplying voltage to the input terminals.

•Pay attention to the «Recommended installation» document

in section 5.1.5.4., which states the cross cable section,

protection size and features, etc, ...

•Connect the loads to the output power terminals or output

1, U and N, by respecting the rotation of the phase and

neutral stated in the labelling of the equipment and this

manual [see Fig. 17]. Otherwise the UPS and/or load/s can

be damaged.

•For parallel systems, it will be needed to repeat the connec-

tions that go from the switchgear panel to each equipment.

In case of discrepancies between the labelling and the in-

structions of this manual, the first ones will always prevail.

•As regards to the output protection to be fitted in the

switchgear or manual bypass panel, it is recommended to

split the output power into four different lines. Each one of

them will have a circuit breaker sized to the suitable figure.

This type of energy distribution at the output will allow that

in case of tripping one of them due to a problem in one of the

connected loads in that line, will not affect to the other ones.

Because the rest of loads will have their power supply con-

tinuously, because the only protection that will trip will be

the affected one by the short-circuit in their loads.

•The single phase input equipments up to 10 kVA, apart from

the power terminal strip, also has two IEC outlets protected

by a 10 A breaker.

These outlets are connected in parallel with the output ter-

minals, so it is important to pay attention to the following

consideration:

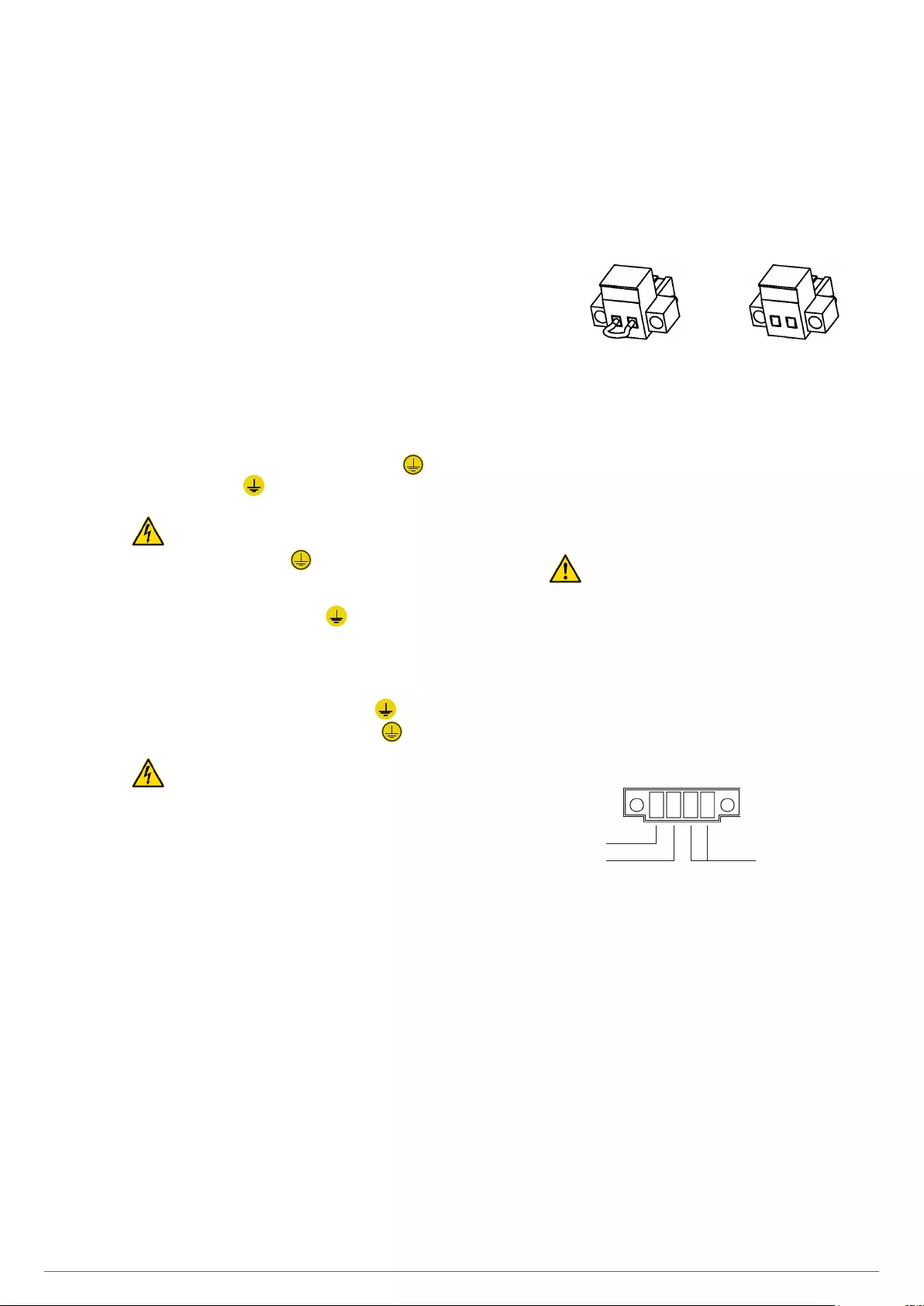

Bonding PE stud

U output phase

Output neutral

Main PE stud

Input neutral

R phase input

Bonding PE stud

U phase output 1

Output neutral 1

U phase output 2

Output neutral 2

(*) + Battery

Main PE stud

Input neutral

T input phase

S input phase

R input phase

– Battery (*)

TWIN/3 PRO2 8.. 20 kVA power terminal stripTWIN PRO2 4.. 10 kVA power terminal strip

(*) Special features of these terminals according to models:

Not available in models of up to 10 kVA.

Not useful in models of 15 and 20 kVA III / II standard.

Implied connection in models of 15 and 20 kVA III / II B1.

Fig. 17. Power terminal strip.

The size of the output protection stated in the rec-

ommended installation document, is done for

the loads connected at the output power terminals.

This protection will be adapted by the fitter or end-user

to the installation in case part of the power is con-

nected to the IEC outlets, otherwise it is possible that

the input of the UPS will not trip, although the overload

alarm in the UPS is triggered.

5.2.3. Connection of the load/s to the output terminals 2

(TWIN/3 PRO2 from 8 to 20 kVA only).

•Models from 8 to 20 kVA with three phase input has a

second set of output power terminals labelled as output

2, which supply voltage from the same source of output 1,

from the inverter or static bypass.

By means of the control panel the output 2 can be set as

Non-critical loads (set to «On»).

•When setting the output 2 to Non-critical loads, the

back up time is reserved for the most critical loads,

which are connected to output 1, by breaking the power

supply of the output 2 during power outages.

• The size of the output protection stated in the recom-

mended installation document, is the sum of both

output 1 and 2, which does not exceed the power rate of

the UPS in any case.

In case of using both terminal strips, the installer or

end-user will fit the suitable protection at each output,

otherwise the input protection of the equipment could

trip, apart from triggering the overload alarm.

•In parallel systems check that the Output 2 is set to the

same figure in all of them, in order to avoid problems.

•Connect the loads to the output power terminals 2, U and

N, by respecting the rotation of the phase and neutral

stated in the labelling of the equipment and this manual [see

Fig. 17]. Otherwise the UPS and/or load/s can be damaged.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

20 SALICRU

5.2.4. Connection with the external battery module and

extended back up times.

•As this is an equipment with protection against elec-

trical shocks of class I, it is essential to connect the

main protective earth cable [ ]. Connect this cable to the

terminal before supplying voltage to the input terminals.

•Respect the instructions stated in this section and

those ones referred to the batteries in the EK266*08

safety instructions, section 1.2.3, because risk of electrical

shock exists, which can cause even the death.

•Before starting the connection procedure between

the battery module or modules and the equipment,

check that the UPS input switch and the battery protection in

the module or modules are turned « Off».

•The battery module has been designed for its equip-

ment. Do not modify the battery capacity or quantity

that makes it.

Also, it exists risk of electrical or electrocution shock due to

the high internal DC voltage, which can cause serious inju-

ries for the health and life.

•Do not connect the battery modules between them or with

UPSs with different DC voltage (figure stated in the rear side

of each equipment).

•Tab. 3 states the physical connection between the UPS and

the battery module or modules.

Model

Batteries

(U bat. block x Nº) =

U nominal / U floating

Two poles switch

DC

voltage(V) Current (A)

SLC-4000-TWIN PRO2

(12 V x 20) =

240 V / 275 V 440

20

SLC-5000-TWIN PRO2 25

SLC-6000-TWIN PRO2 32

SLC-8000-TWIN PRO2 40

SLC-10000-TWIN PRO2 50

SLC-15000-TWIN PRO2 63

SLC-20000-TWIN PRO2 100

SLC-8000-TWIN/3 PRO2 40

SLC-10000-TWIN/3 PRO2 50

SLC-15000-TWIN/3 PRO2 63

SLC-20000-TWIN/3 PRO2 100

Tab. 2. Features of the protection to install in the battery

set belonging to the end-user.

•All the standard UPSs include batteries in the same enclo-

sure, less those models called B0 and B1. For the standard

UPSs, the battery protection is done by internal fuses and

they are not accessible by the end-user.

Also, the battery modules have protection and in this case they

are doubled. Once are internal by means of fuses and not ac-

cessible by the end-user and the second ones by means of a

two poles circuit breaker or fuses

•IMPORTANT FOR THE SAFETY: In case of installing the

batteries by yourself, the battery set must have a two

poles circuit breaker or fuses switch, with the size stated in

Tab. 2.

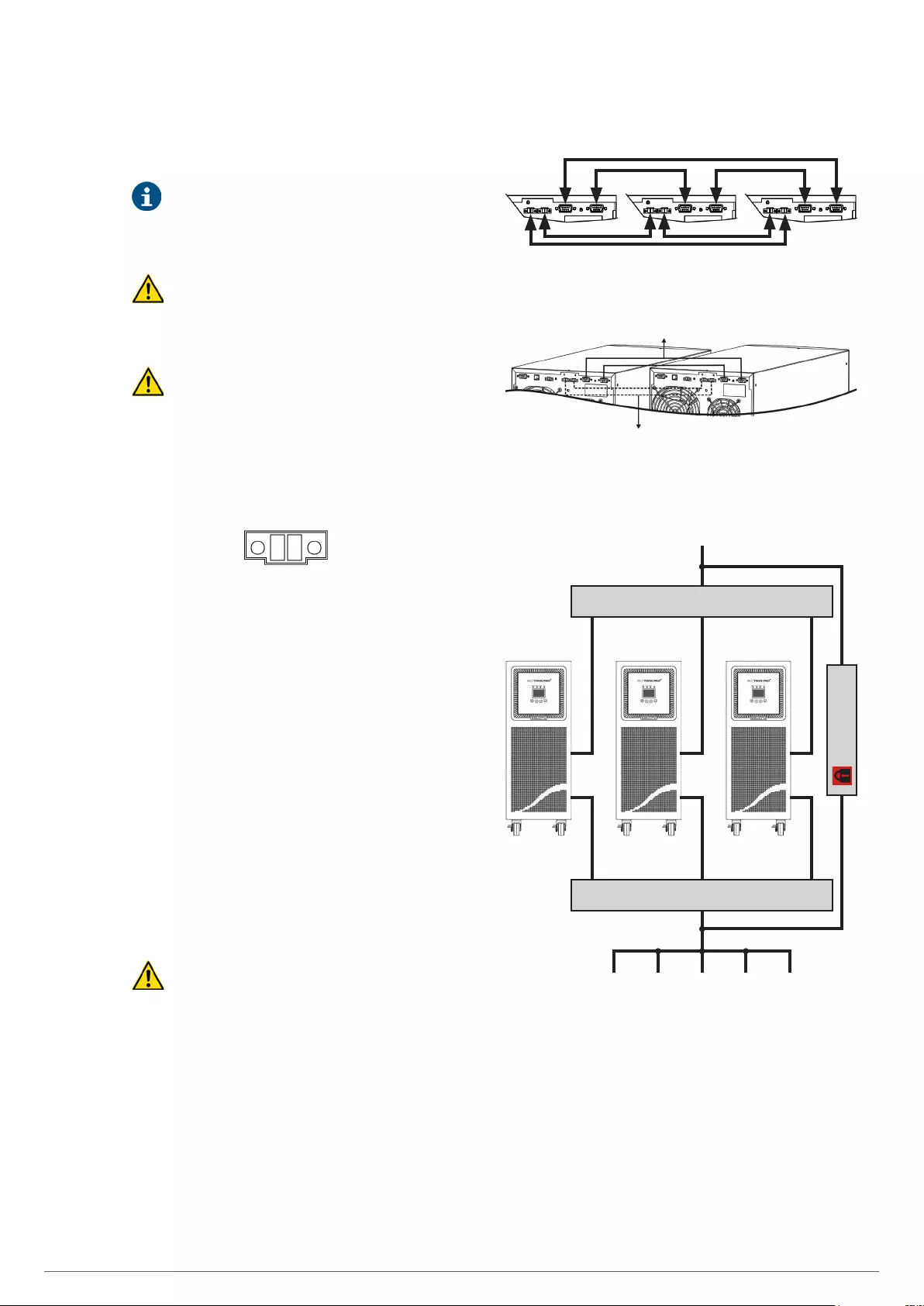

•The connection of the UPS with the battery module will

be done with the supplied cable bundle. First connect one

cable end to the UPS terminals or connector and then the

other cable end to the battery module terminal or con-

nector. See Fig. 18, as an example.

Equipments with connectors, there is not any possi-

bility of wrong polarity connection.

For the equipments with terminals, respect the

polarity and the colour of the cables (red for

positive, black for negative and green-yellow for PE)

stated in the labelling of each module and this

manual.

•When more than one battery module for the UPS is sup-

plied, the connection among them will be in parallel.

• • •

Connector at the

rear side of the UPS

Connectors at the rear side of the

battery modules

Battery

module 1

Battery

module «n»

Fig. 18. Example of connection between a UPS and bat-

teyr modules with connectors.

•In extended back up times, to make easier the connection

between the UPS and the battery modules in parallel, all

the battery modules have two connectors or terminal strips.

•Models with terminals, the polarity and colour of the cables

(red for positive and black for negative) must always be

respected.

•Each battery module is totally independent for

each equipment. It is completely prohibited to

connect two equipments to the same battery

module.

Model

Connection mode with the batteries

In the UPS In the external

battery module

SLC-4000-TWIN PRO2

Connector

SLC-5000-TWIN PRO2

SLC-6000-TWIN PRO2

SLC-8000-TWIN PRO2

SLC-10000-TWIN PRO2

SLC-8000-TWIN/3 PRO2

SLC-10000-TWIN/3 PRO2

SLC-15000-TWIN PRO2

Terminal strip Connector

SLC-20000-TWIN PRO2

SLC-15000-TWIN/3 PRO2

SLC-20000-TWIN/3 PRO2

Tab. 3. Connection between the UPS and battery module

or modules.

21

5.2.5. AC power supply for the battery charger built in

the battery module.

•Some battery modules have an additional charger, which

means making some additional work.

They can be identified, because they include an IEC male

connector, circuit breaker and cooling grid

•Together with the module, it is supplied a power cord with

an IEC female connector in one end and Schuko plug in the

other end.

•The installation must have a wall outlet, schuko type, pro-

tected by a circuit breaker of 6 A, in order to feed the charger

with 230 V AC.

•Those equipments with more than one battery module of

this type, each one of them must have the Schuko wall

output with its corresponding protection.

•Insert the cable into the IEC connector of the battery module

and the schuko plug into the wall outlet of 230 V AC.

5.2.6. Connection of the main protective earth and

bonding earth .

•As this is an equipment with protection against elec-

trical shocks of class I, it is essential to connect the

main protective earth cable [ ]. Connect this cable to the

terminal before supplying voltage to the input terminals.

•Make sure that all the loads connected to the UPS are only

connected to its bonding earth stud . The fact of not lim-

iting the connection this bonding earth of the load or loads

and battery module or modules to this single point, will

break backfeed loops of earth that will decrease the quality

of the energy supplied.

•Those terminals labelled as bonding earth , are joined

among them to the main protective earth stud and to the

ground of the equipment.

•Never and under no circumstances disconnect the

protective earth cable from the building and/or UPS.

5.2.7. EPO terminals (Emergency Power Off).

•The UPSs has two terminals to install a remote Emergency

Power Off button -EPO-.

•The equipment is delivered from factory with the EPO circuit

closed -NC-. So, the UPS will break the output when the

emergency power off button opens the circuit:

Or by removing the own female connector from the

equipment, because this connector includes a cable as

a bridge mode, which closes the electrical circuit [see

Fig. 19-A].

Or when pressing the external button, which belongs to

the end-user and it is installed between the terminals

of the connector [see Fig. 19-B]. The connection of the

button will be normally closed -NC-, so it will open the

electrical circuit when pressing it.

•By means of the communication software, the inverse func-

tion can be set.

Less particular cases, it is better to not use this type of con-

nection, because in case of one of the cables were cut, the

EPO will not break the output voltage.

On the other hand, the use of the normally closed contact ,

the cut cable would be detected immediately, because the

power supply to the loads would be broken.

•To restore the normal operating of the UPS, it is needed to in-

sert the connector with the cable as a bridge mode again in the

equipment or deactivate the EPO button. The equipment will

be turned ON automatically.

A B

Fig. 19. Connector for the external EPO.

5.2.8. Terminals for digital Input and Output.

•The equipment has a terminal strip of four terminals for a

digital input and output [see Fig. 20].

The «Start up-Shutdown» digital input. When the equipment

is turned ON, when applying a voltage between 5 and 12 V

DC, it is shutdown.

The static bypass is enabled from factory. In this

situation, when the inverter is shutdown the

output terminals will supply voltage through the in-

ternal static bypass.

Disable the bypass function through the control panel,

when it is required to break the output when the shut-

down order has been triggered.

Error or fault dry contact. Any error or fault of the UPS

will trigger the digital output (-NO- dry contact of 24V

DC 1A). (ATTENTION to the applied voltage and current

to the contact).

– Digital input

+ Digital input

Error or fault dry

contact output

Fig. 20. Digital input and output connector.

5.2.9. Terminals for the manual bypass auxiliary

contact.

•The manual bypass switch of the equipment has a micros-

witch located under its mechanical lock. This contact is nor-

mally opened and it is extended till a terminal strip located

in the rear side of the equipment [see Fig. 21] and internally

connected with the own UPS control.

•The manual bypass panels supplied under request, they

include a terminal strip with two terminals connected in

parallel with the normally opened auxiliary contact of the

manual bypass switch of the own panel. The auxiliary con-

tacts of the manual bypass are advanced to its closing.

•The connection between the auxiliary contact of the panel

and the UPS or UPSs must be in parallel. Therefore, in case

any of the auxiliary contacts closes the circuit will trigger

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

22 SALICRU

the command to shutdown the inverter, so the equipment

will supply output voltage through the static bypass, unless

it is disabled by means of the control panel, which in that

case would break the load feeding.

•In parallel systems, the manual bypass switch of the

switchgear panel will have a terminal strip for each

equipment. Under no circumstances joint the contacts

of the different UPSs among them, because the ground of

the UPS control would be joined.

•In case of buying the manual bypass panel from

other sources, check that it has the stated auxiliary

contact and connect it to the terminal strip of the UPS or

UPSs in parallel systems. The auxiliary contact type must

be advanced to its closing.

•As safety measures, it is ESSENTIAL, to connect

the terminals strips of the UPS, and even for the

loads, with the ones of the manual bypass panel with the

same function. Therefore, it will be avoided any wrong han-

dling of the manual bypass switch/es when the UPS or

UPSs are turned ON, which could cause a total or partial

failure of the installation and/or loads.

Fig. 21. Auxiliary contact connector of the UPS manual

bypass.

5.2.10. Parallel connection.

5.2.10.1. Introduction to the redundancy.

N+X is usually the most reliable power structure. N means the

minimum quantity of equipments that the total load needs; X

means the quantity of redundant equipments, that is to say, the

quantity of faulty UPSs that the system can allow at the same

time. As higher is the X, the more reliable will be the system.

For those situations, where the reliability is the most important,

N+X will the optimal mode.

Up to 3 equipments can be connected in parallel to set a shared

output and redundant in power.

5.2.10.2. Parallel installation and operating.

•The communication line -COM- means a low safety

voltage circuit.

To preserve the quality of them, they must be installed

separate from other lines with dangerous voltages (energy

distribution line).

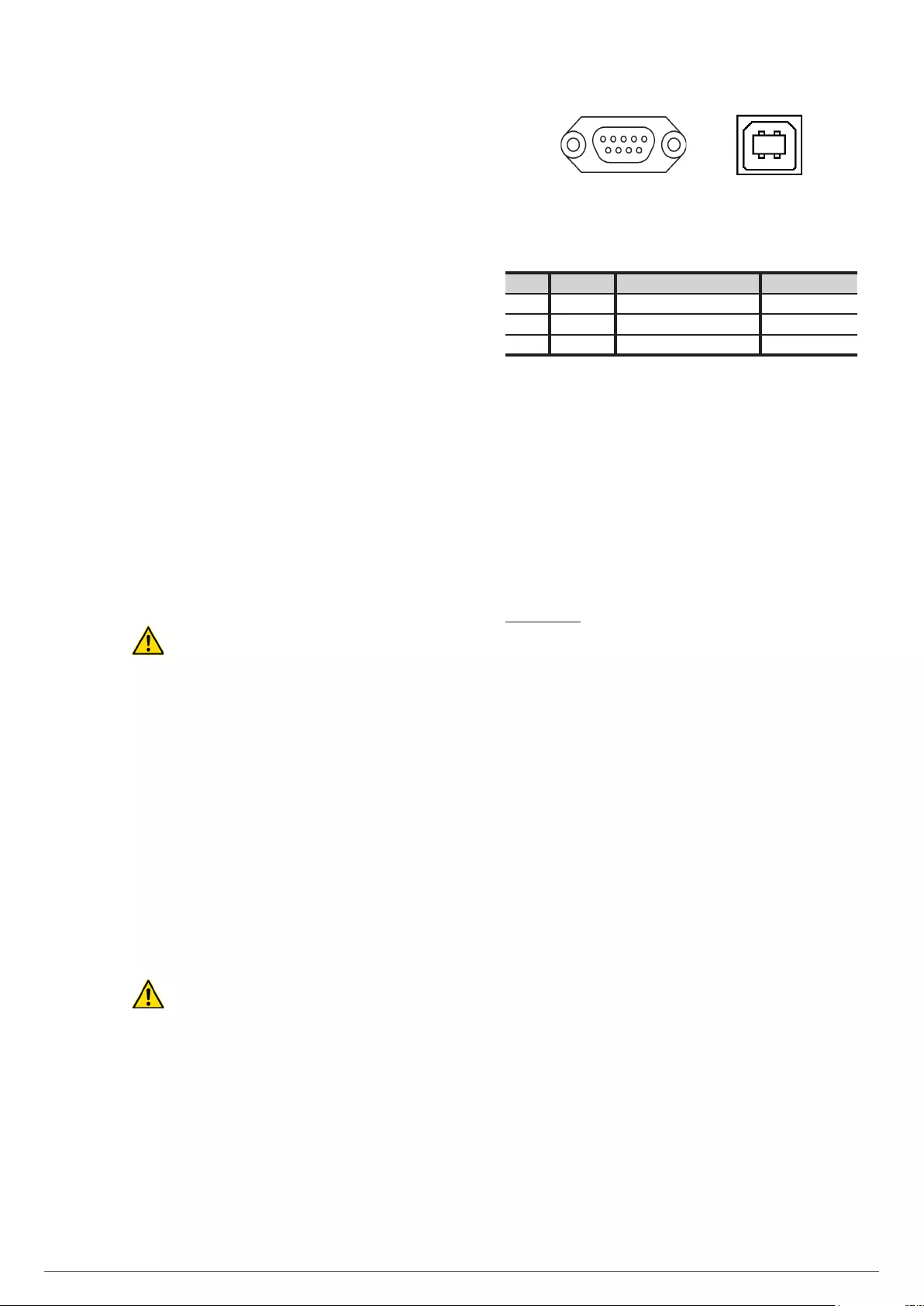

Parallel connection bus

Current sharing signal bus

UPS nr 1 UPS nr 3UPS nr 2

Communication bus

Current sharing signal bus

Fig. 22. Connection of the communication bus and current

sharing signal.

Input circuit breaker switches

Output circuit breaker switches

Man ual Bypass

SAI nº 1 SAI nº 2 SAI nº "3"

Input

To loads

Fig. 23. Parallel UPS installation with a switchgear panel

with manual bypass.

•Parallel connection bus. Use the 15 pins DB15 connectors

and shielded cable bundle to joint 3 equipments maximum.

Each bundle has a male and female connectors at its end,

which have to be connected between two correlative equip-

ments. It is essential to close the loop of the parallel bus

among the equipments.

23

The length of the parallel cable is 1.5 metres and it can't be

extended under no circumstances, due to the risk of interfer-

ences that it would mean.

Fig. 22 shows an installation of two equipments in parallel.

For three UPSs proceed in the same way to close the com-

munication bus and current sharing circuits.

•Bus connection of the signal of current. Joint the equip-

ments, by using the cable bundle with connectors in both

ends and connecting them in the connectors of both correla-

tive equipments as Fig. 22 shows. Finally, close the bus loop

between the last and first equipment.

The length of the cable is 1.5 metres and it can't be extended

under no circumstances, due to the risk of interferences that

it would mean.

Fig. 22 shows an installation of two equipments in parallel.

For three UPSs proceed in the same way to close the com-

munication bus and current sharing circuits.

•Parallel installations must have a switchgear panel with sep-

arate input and output protections for each UPS, apart from

a manual bypass switch with mechanical lock, see Fig. 23.

For more information, about the descriptions referred to the

manual bypass and the indications of the «Recommended

installation» see section 5.1.5.4.

•Respect the stated procedures in the previous sections, for

the input and output connections of each equipment.

•For those equipments with extended back up time, respect

the stated procedures for the battery modules, which are de-

scribed in the previous sections.

•In parallel systems, where the length and cross sec-

tion of the cables that go from the switchgear panel

to each UPS and from the UPS to the switchgear panel will

be the same for all them, with no exception.

In the worst conditions, the following deviations must be

strictly respected:

When the distance between the parallel UPSs and the

switchgear panel is less than 20 metres, the length

difference among the input and output cables of each

equipment must be lower than 20%.

When the distance between the parallel UPSs and the

switchgear panel is over 20 metres, the length difference

among the input and output cables of each equipment

must be lower than 10%.

5.2.11. Communication port.

5.2.11.1. RS232 and USB ports.

• The communication line -COM- means a low safety

voltage circuit. To preserve the quality of them, they

must be installed separate from other lines with dangerous

voltages (energy distribution line).

•The RS232 and USB interface are used by the monitoring

software and firmware updating.

•It is not possible to use both ports (RS232 and USB) at the

same time.

•Tab. 4 shows the pin-out of the RS232 signal in the DB9

female connector. The RS232 is a serial data port, so an

important amount of information can be sent through a

communication cable of 3 wires.

•The USB communication port is compatible with the USB

1.1 protocol for the monitoring software.

5 1

9 6

2 1

3 4

Fig. 24. DB9 connectors for RS232 and USB.

Pin # Ref. Description Input / Output

2 RS232 TXD (serial data transmission) Output

3 RS232 RXD (serial data reception) Input

5 RS232 RS232 ground signal GND

Tab. 4. DB9 connector pinout, RS232.

5.2.12. Intelligent slot to insert the communication card.

•Different communication cards can be inserted into the slot:

Programmable dry contacts.

SNMP adaptor.

RS485 Modbus adaptor.

•Each option card is supplied with its own particular docu-

mentation. Read it before installing them.

Installation.

•Remove the protection cover from the slot of the equip-

ment.

•Take the corresponding card and insert it into the reserved

slot. Make sure that it is well connected, to do it the resist-

ance that own connector faces when it inserted into the

slot has to be overcome.

•Make the needed connections of the terminal strips or con-

nectors depending on each case.

•Put the new protection cover supplied with the option cards

and fix it by means of the same screws that previously fixed

the original one.

•For more information, contact with our T.S.S. or our nearest

distributor.

5.2.13. Software.

•Download the free software - Viewpower.

Viewpower is a UPS monitoring software, which has a user

friendly interface for monitoring and control. This software,

in case of power outage provides an auto Shutdown for a

system based on several computers. With this software,

the end-users can monitor and control any UPS hosted in

the same IT network, by means of the communication port

(RS232 or USB), no matter the distance among them.

•Installation procedure:

Go to the website:

http://support.salicru.com

Choose the operating system that you need and follow

the instructions described in the website to download

the software.

SLC TWIN PRO2 UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

24 SALICRU

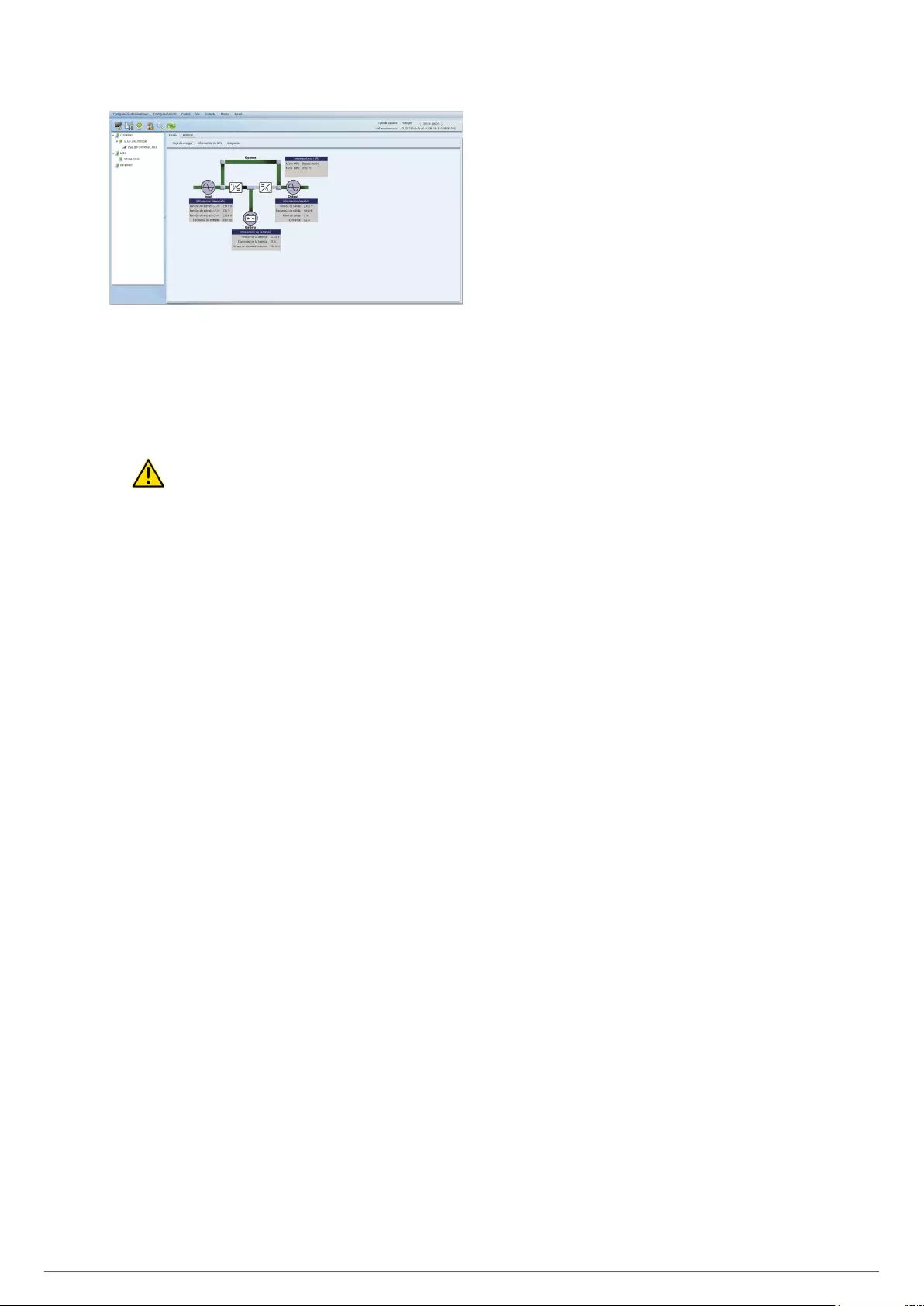

Fig. 25. Screen shot of the main screen of ViewPower

monitoring software.

5.2.14. Considerations before commissioning with the

loads.

•It is recommended to charge the batteries for 12

hours at least before using the UPS for first time.

To do it, supply the input of the equipment and turn the

input switch «On». The battery charger will be auto-

matically started up.

For battery modules.

Those models with extended back up times with one or

more battery modules, the fuse or battery switch has to

be turned «On» too.

•Although the equipment can work without charging the bat-

teries for stated 12 h, the risk of a long power outage for

the first operating hours must be evaluated, because the

back up time of the UPS will be lower.

•Do not start up the equipment and loads before section 6

states it.

Nevertheless, when it is started up, it will be done gradu-

ally, in order to avoid possible issues, at least in the first

UPS start up.

•In case of connecting inductive loads with high consump-

tion, apart from the sensitive loads, like laser printers or

CRT monitors; their worst inrush current will be kept in

mind in order to avoid blocking the equipment.

Depending on the equipment, for this type of loads, which

are considered NON-CRITICAL, the equipment has a pro-

grammable terminal strip. Depending on the setting of that

terminal strip, the power supply will be broken or not in

case of power outage.

25

6. OPERATING.

6.1. COMMISSIONING.

6.1.1. Checking before commissioning.

•Make sure that all connections have done properly with the

correct torque, by respecting the labelling of the equipment

and the instructions of section 5.

•Check that the UPS switch and battery module or modules

are turned -«Off»-.

•Make sure that all the loads are turned «Off».

Shutdown the loads before starting up the UPS and