Samsung AR12MSWXBWKNEU User Manual

Displayed below is the user manual for AR12MSWXBWKNEU by Samsung which is a product in the Split-System Air Conditioners category. This manual has pages.

Related Manuals

Air conditioner

Installation manual

AR

**

MSPX

***

/ AR

**

MSWX

*** /

AR

**

NSPX

***

/

AR

**

NSWX

***

•Thank you for purchasing this Samsung air conditioner.

•Before operating this unit, please read this user manual carefully and retain it for future reference.

2

English

Contents

Installation 3

Safety Information on Installation 3

Preparation 5

Step 1.1 Choosing the installation location

Step 1.2 Checking and preparing accessories and tools

Step 1.3 Drilling a hole through the wall

Step 1.4 Taping the pipes, cables, and drain hose

Indoor Unit Installation 9

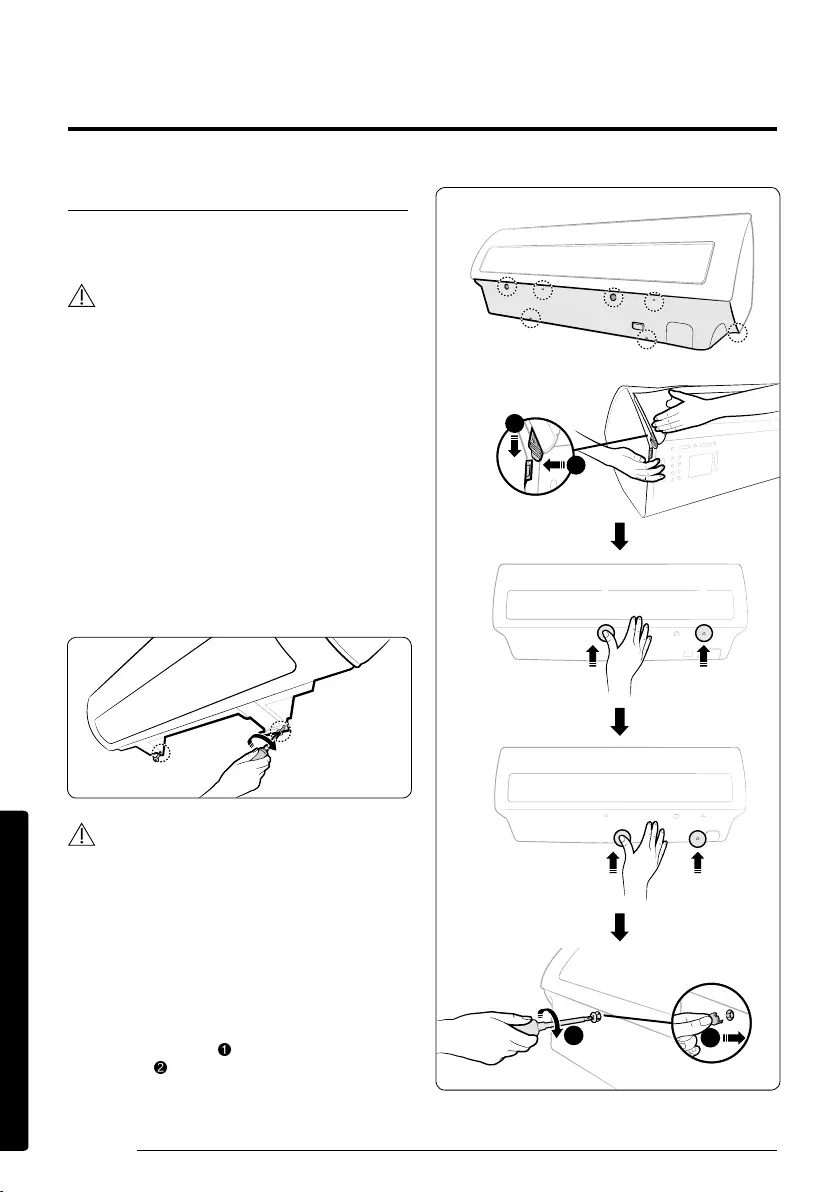

Step 2.1 Disassembling the cover panel

Step 2.2 Disassembling the installation plate

Step 2.3 Connecting the power and communication cables (assembly cable)

Step 2.4 Optional: Extending the power cable

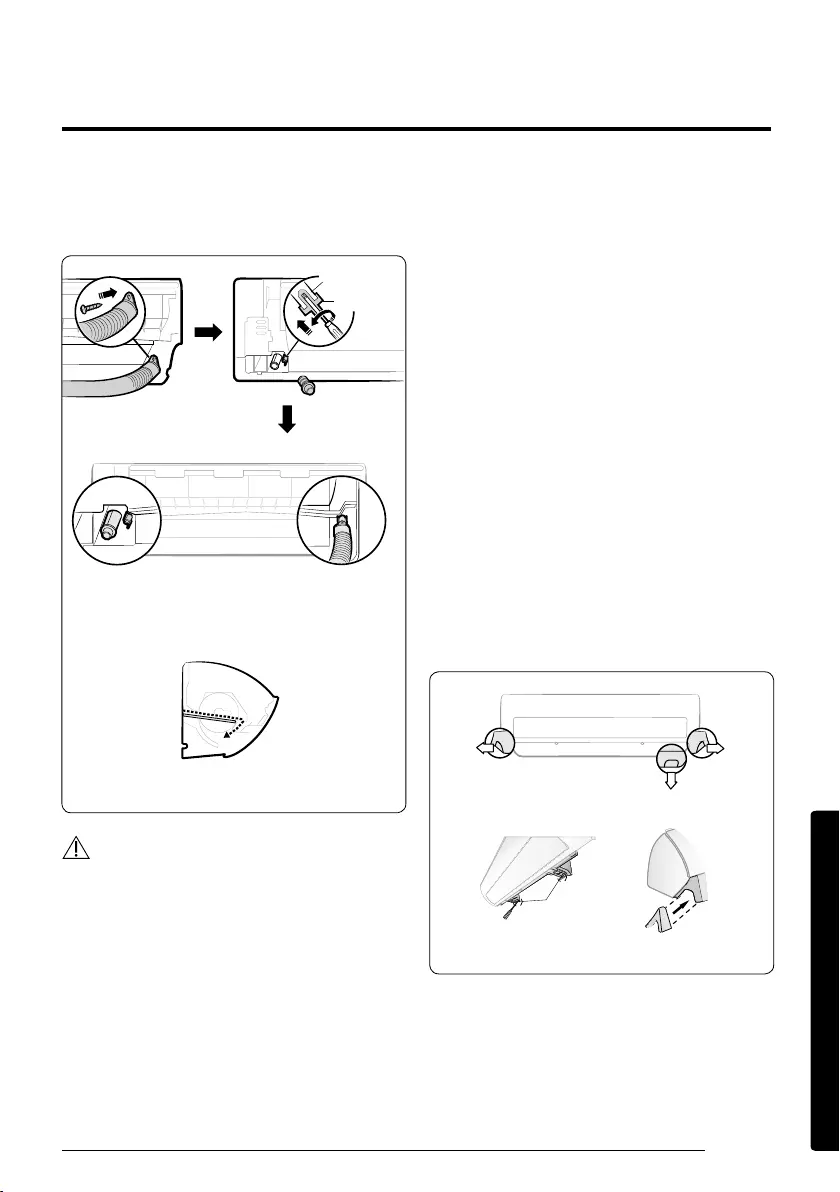

Step 2.5 Installing and connecting the drain hose

Step 2.6 Optional: Extending the drain hose

Step 2.7 Optional: Changing the direction of the drain hose

Step 2.8 Installing and connecting the assembly pipes to the refrigerant pipes (assembly pipe)

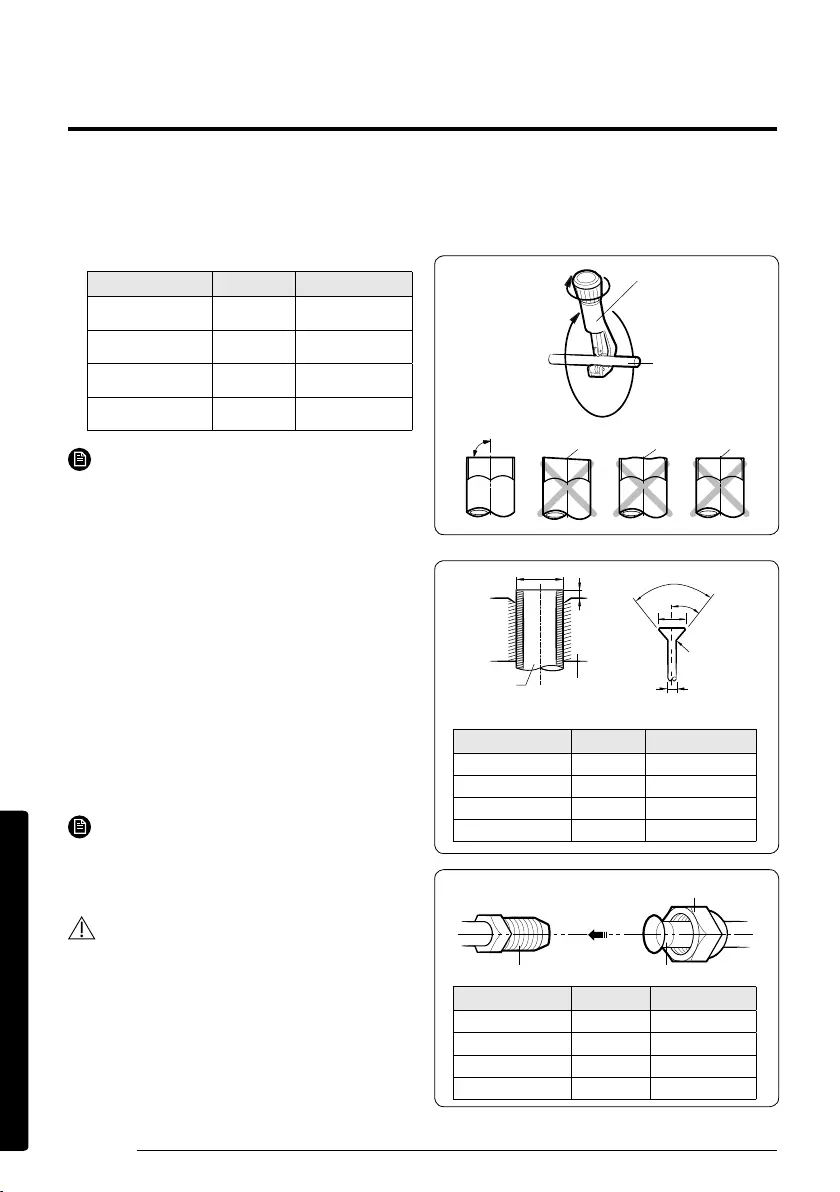

Step 2.9 Shortening or extending the refrigerant pipes (assembly pipe)

Step 2.10 Fixing the installation plate

Step 2.11 Fixing the indoor unit to the installation plate

Step 2.12 Assembling the cover panel

Outdoor Unit Installation 17

Step 3.1 Fixing the outdoor unit in place

Step 3.2 Connecting the power and communication cables and the refrigerant pipes

Step 3.3 Evacuating the air

Step 3.4 Adding refrigerant

Step 3.5 Important information: regulation regarding the refrigerant used

Installation Inspection 21

Step 4.1 Performing the gas leak tests

Step 4.2 Running the Smart Install mode

Step 4.3 Performing final check and trial operation

Sub PCB installation(optional) 24

For information on Samsung’s environmental commitments and product-specific regulatory obligations, e.g.

REACH, WEEE, Batteries, visit : samsung.com/uk/aboutsamsung/samsungelectronics/corporatecitizenship/

data_corner.html

3

English

Installation

Carefully follow the precautions listed below because

they are essential to guarantee the safety of both the

air conditioner and the workers.

• Always disconnect the air conditioner from the

power supply before servicing it or accessing its

internal components.

• Verify that installation and testing operations are

performed by qualified personnel.

• Verify that the air conditioner is not installed in an

easily accessible area.

General information

• Carefully read the content of this manual before

installing the air conditioner and store the manual

in a safe place in order to be able to use it as

reference after installation.

• For maximum safety, installers should always

carefully read the following warnings.

• Store the operation and installation manual in

a safe location and remember to hand it over to

the new owner if the air conditioner is sold or

transferred.

• This manual explains how to install an indoor unit

with a split system with two SAMSUNG units. The

use of other types of units with different control

systems may damage the units and invalidate

the warranty. The manufacturer shall not be

responsible for damages arising from the use of

non compliant units.

• This product has been determined to be in

compliance with the Low Voltage Directive

(2006/95/EC) and the Electromagnetic

Compatibility Directive (2004/108/EC) of the

European Union.

• The manufacturer shall not be responsible for

damage originating from unauthorised changes

or the improper connection of electric and

requirements set forth in the “Operating limits”

table, included in the manual, shall immediately

invalidate the warranty.

• The air conditioner should be used only for the

applications for which it has been designed: the

indoor unit is not suitable to be installed in areas

used for laundry.

• Do not use the units if damaged. If problems

occur, switch the unit off and disconnect it from

the power supply.

• In order to help prevent electric shocks, fires

or injuries, always stop the unit, disable the

protection switch and contact SAMSUNG’s

technical support if the unit produces smoke, if

the power cable is hot or damaged or if the unit is

very noisy.

• Always remember to inspect the unit, electric

connections, refrigerant tubes and protections

regularly. These operations should be performed

by qualified personnel only.

• The unit contains moving parts, which should

always be kept out of the reach of children.

• Do not attempt to repair, move, alter or reinstall

the unit. If performed by unauthorised personnel,

these operations may cause electric shocks or

fires.

• Do not place containers with liquids or other

objects on the unit.

• All the materials used for the manufacture and

packaging of the air conditioner are recyclable.

• The packing material and exhaust batteries of the

remote control (optional) must be disposed of in

accordance with current laws.

• The air conditioner contains a refrigerant that has

to be disposed of as special waste. At the end of

its life cycle, the air conditioner must be disposed

of in authorised centres or returned to the retailer

so that it can be disposed of correctly and safely.

Installation of the unit

• IMPORTANT: When installing the unit, always

remember to connect first the refrigerant tubes,

then the electrical lines. Always disassemble the

electric lines before the refrigerant tubes.

• Upon receipt, inspect the product to verify that

it has not been damaged during transport. If

the product appears damaged, DO NOT INSTALL

it and immediately report the damage to the

carrier or retailer (if the installer or the authorised

technician has collected the material from the

retailer.)

• After completing the installation, always carry out

a functional test and provide the instructions on

how to operate the air conditioner to the user.

• Do not use the air conditioner in environments

with hazardous substances or close to equipment

that release free flames to avoid the occurrence of

Safety Information on Installation

Installation

4

English

Installation

fires, explosions or injuries.

• Our units must be installed in compliance with

the spaces indicated in the installation manual

to ensure either accessibility from both sides

or ability to perform routine maintenance and

repairs. The units’ components must be accessible

and that can be disassembled in conditions of

complete safety either for people or things. For

this reason, where it is not observed as indicated

into the Installation Manual, the cost necessary

to reach and repair the unit (in safety, as required

by current regulations in force) with slings, trucks,

scaffolding or any other means of elevation won’t

be considered in-warranty and will be charged to

end user.

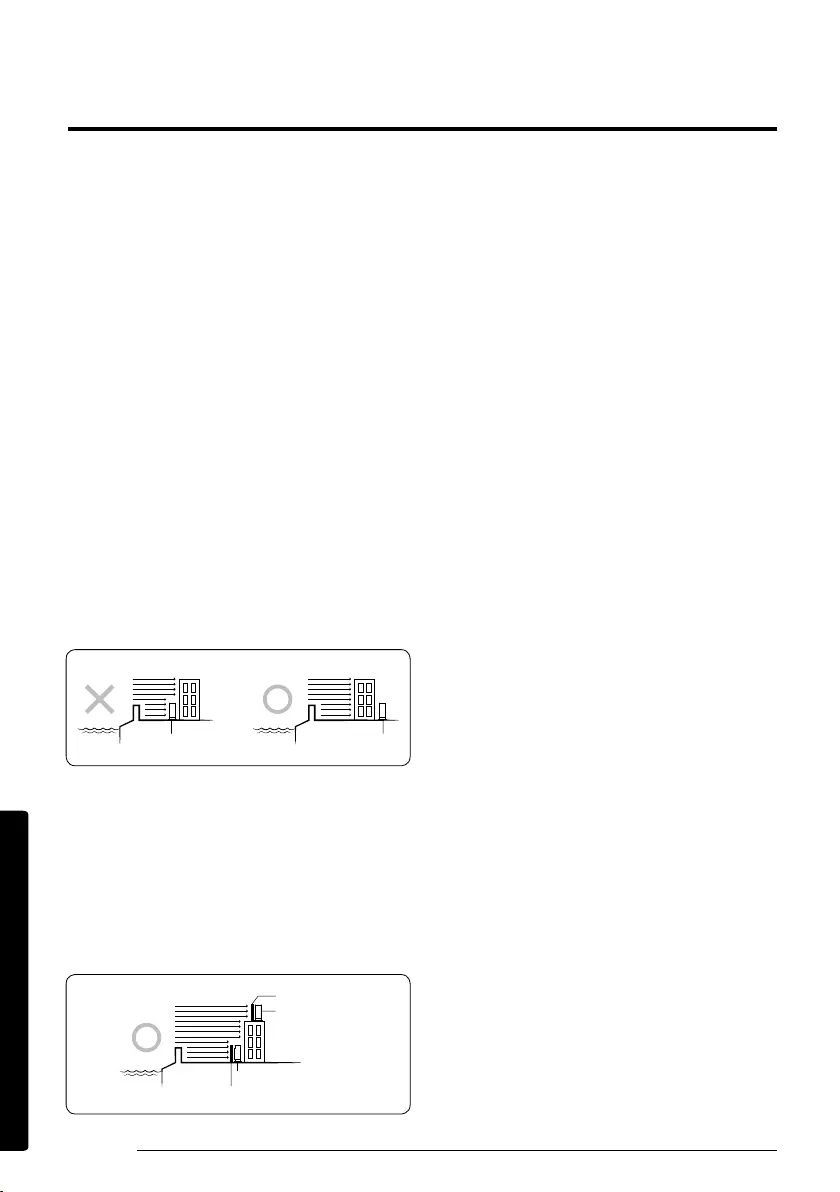

• When installing the outdoor unit at the seaside,

make sure that it is not directly exposed to sea

breeze. If you cannot find an adequate place free

from direct sea breeze, construct a protection wall

or a protective fence.

–Install the outdoor unit in a place (such as

near buildings etc.) where it can be protected

from sea breeze. Failure to do so may cause a

damage to the outdoor unit.

Sea

Sea breeze

Outdoor unit Outdoor unit

Sea breeze

Sea

• If you cannot avoid installing the outdoor unit at

the seaside, construct a protection wall around to

block the sea breeze.

• Construct a protection wall with a solid material

such as concrete to block the sea breeze. Make

sure that the height and the width of the wall are

1.5 times larger than the size of the outdoor unit.

Also, secure a space larger than 600 mm between

the protection wall and the outdoor unit for

exhausted air to ventilate.

Sea

Sea breeze

Outdoor unit

Protection wall

Outdoor unit

Protection wall

• Install the unit in a place where water can drain

smoothly.

• If you have any difficulty finding installation

location as prescribed above, contact your

manufacturer for details.

• Be sure to clean the sea water and the dust on the

heat exchanger of the outdoor unit and apply a

corrosion inhibitor on it. (At least once in a year.)

Power supply line, fuse, or circuit

breaker

• Always make sure that the power supply is

compliant with current safety standards. Always

install the air conditioner in compliance with

current local safety standards.

• Always verify that a suitable grounding connection

is available.

• Verify that the voltage and frequency of the

power supply comply with the specifications and

that the installed power is sufficient to ensure

the operation of any other domestic appliance

connected to the same electric lines.

• Always verify that the cut-off and protection

switches are suitably dimensioned.

• Verify that the air conditioner is connected to the

power supply in accordance with the instructions

provided in the wiring diagram included in the

manual.

• Always verify that electric connections (cable

entry, section of leads, protections…) are

compliant with the electric specifications and with

the instructions provided in the wiring scheme.

Always verify that all connections comply with

the standards applicable to the installation of air

conditioners.

•Be sure not to perform power cable modification,

extension wiring, and multiple wire connection.

–It may cause electric shock or fire due to poor

connection, poor insulation, or current limit

override.

–When extension wiring is required due

to power line damage, refer to "Step 2.4

Optional: Extending the power cable" in the

installation manual.

5

English

Installation

Step 1.1 Choosing the installation

location

If using a multi system, install as described in the

installation manual supplied with the outdoor

unit.

Overview of installation location requirements

CAUTION

CAUTION

• Comply with the length and height limits

described in the figure above.

Minimum clearances for the outdoor unit

Wall

Minimum clearance in mm

300

600

Air flow direction

Side viewTop view

When installing 1 outdoor unit (6 cases)

(Unit: mm)

300

1500

300

150 600

1500

2000

500

300

300 1500

(Unit : m)

Model Pipe length Pipe height

Minimum Maximum Maximum

**07*******

**09*******

**12*******

315 8

**18*******

**24******* 330 15

Preparation

100 mm or more

125 mm

or more

125 mm

or more

Drain hose hole

You can select the direction of

draining (left or right).

Maximum pipe height: 8/15 m

Maximum pipe length: 15/30 m

Make at least one round to

reduce noise and vibration.

The actual units may look different from

the images depicted here.

Make a U-trap (A) on the pipe

(which is connected to the indoor

unit) at outer wall and cut the

bottom part of the insulation

(about 10 mm) to prevent

rainwater from getting inside

through the insulation.

Outdoor

Unit

Outer wall

Indoor

Unit

Cut insulation to have

rainwater drained

6

English

Installation

When installing more than 1 outdoor unit (5 cases)

(Unit: mm)

1500 600 3000 2003000

3001500

600 600

1500

300

300 600 600 600

500

300

500

300

CAUTION

• If the outdoor unit is installed with any insufficient

clearance, it may generate sound and affect the

whole product.

• Be sure to install the outdoor unit in a level place

where its vibration does not affect the whole

product.

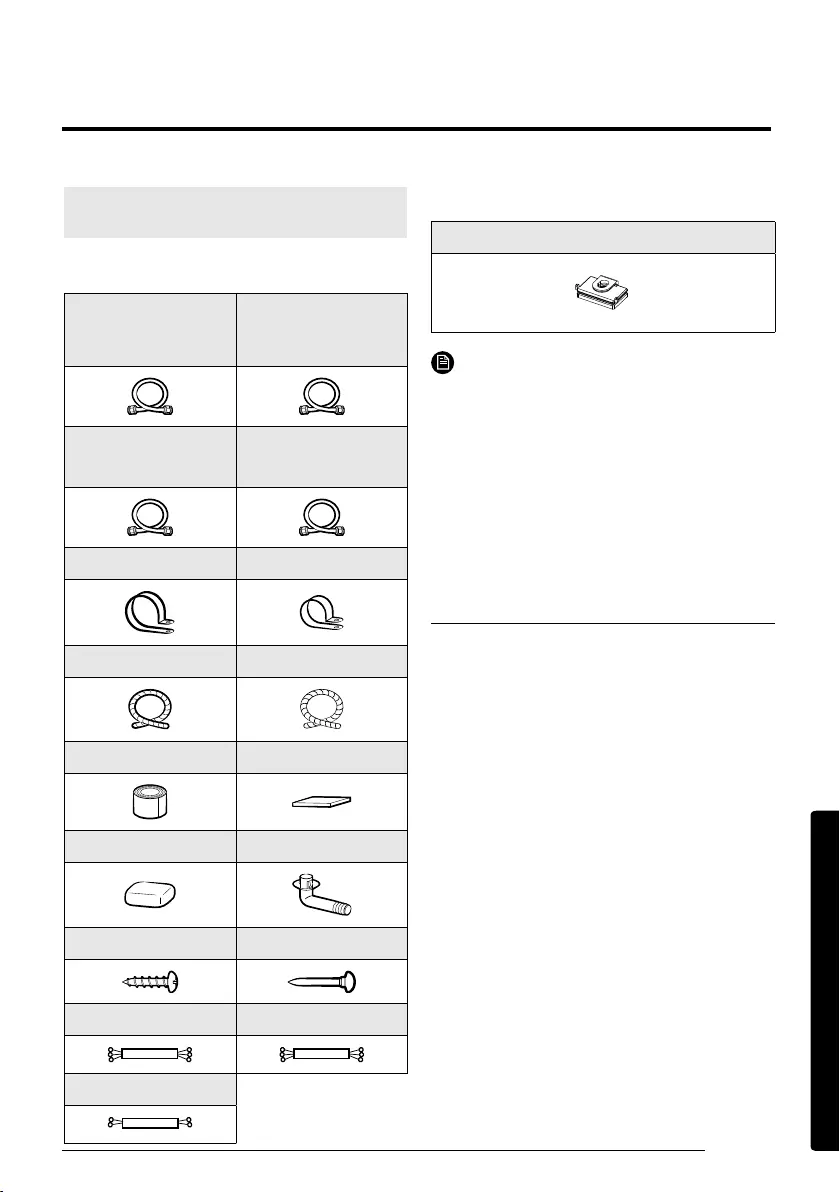

Step 1.2 Checking and preparing

accessories and tools

Accessories

Accessories in the indoor unit package

Installation plate (1)

**07*******

**09*******

**12*******

Installation plate (1)

**18*******

**24*******

Remote control (1) Remote control holder (1)

Remote control battery (2) User Manual (2)

AR**MS*****

User Manual (1)

AR**NS*****

Installation Manual (1)

Cap screw (2) Guide Left (1)

Guide Right (1) Case Sub PCB (1)

M4 x 12 tapping screw (2)

7

English

Installation

If using a multi system, refer to the manual

supplied with the outdoor unit.

Optional accessories

Insulated assembly pipe,

Ø 6.35 mm (1)

Insulated assembly pipe,

Ø 9.52 mm (1)

**09*******

**12*******

Insulated assembly pipe,

Ø 12.70 mm (1)

**18*******

Insulated assembly pipe,

Ø 15.88 mm (1)

**24*******

Pipe clamp B (3) Pipe clamp A (3)

Drain Hose, 2 m long (1) Foam Insulation (1)

Vinyl tape (2) PE T3 foam tube insulation (1)

Putty 100 g (1) Drain plug (1)

M4 x 25 tapped screw (6) Cement nail (6)

3-wire Power Cable (1) 3-wire Assembly Cable (1)

2-wire Assembly Cable (1)

Accessories in the outdoor unit package

Rubber leg (4)

NOTE

• A flare nut is attached to the end of each pipe

of an evaporator or a service port. Use flare nuts

when connecting the pipes.

• Wire assembly cables are optional. If they are not

supplied, use standard cables.

• The drain plug and the rubber legs are included

only when the air conditioner is supplied without

assembly pipes.

• If these accessories are supplied, they are in the

accessory package or outdoor unit package.

Tools

General tools

• Vacuum pump

(Backward flowing prevention)

• Manifold gauge

• Stud finder

• Torque wrench

• Pipe cutter

• Reamer

• Pipe bender

• Spirit level

• Screwdriver

• Spanner

• Drill

• L-wrench

• Measuring tape

Tools for test operation

• Thermometer

• Resistance meter

• Electroscope

8

English

Installation

Step 1.3 Drilling a hole through the

wall

Before fixing the installation plate to a wall and

then fixing the indoor unit to the installation plate,

a window frame, or a gypsum board, you must

determine the position of a hole (with 65 mm inner

diameter) through which the pipe bundle (consisting

of power and communication cables, refrigerant

pipes, and drain hose) will pass and then drill that

hole.

1 Determine the position of a 65 mm hole in

consideration of the possible directions of the pipe

bundle and the minimum distances between the

hole and the installation plate.

RightLeft

Rear right or left

<Possible directions of the pipe bundle>

Bottom right

CAUTION

• If changing the pipe direction from left to right,

do not drastically bent it but slowly turn it in the

opposite direction as shown. Otherwise, the pipe

may be damaged in the process.

2 Drill the hole.

CAUTION

• Be sure to drill only one hole.

• Make sure that the hole slants downwards so that

the drain hose slants downwards to drain water

well.

Wall

Drain hose

Indoor unit

<The hole slants downwards>

Step 1.4 Taping the pipes, cables, and

drain hose

1 Wrap foam insulation on parts without insulation

on the ends of the refrigerant pipes, as shown in

the figure. This wrapping minimises condensation

problem.

Insulation

Refrigerant pipes

2 Wind the refrigerant pipes, power cable,

communication cable and drain hose with vinyl

tape to make a pipe bundle.

Refrigerant pipes

(assembly pipe)

Installation plate

Vinyl tape

Drain hose

Power and communication cables

(assembly cable)

(Unit : mm)

Model A B C D

**07*******

**09*******

**12*******

36 120 81 36

**18*******

**24*******

33 110 110 33

Pipe bundle hole: Ø 65 mm

Pipe bundle hole

<Minimum distances between the hole and the

installation plate>

9

English

Installation

Please scan this QR code for detail

video of indoor unit installation.

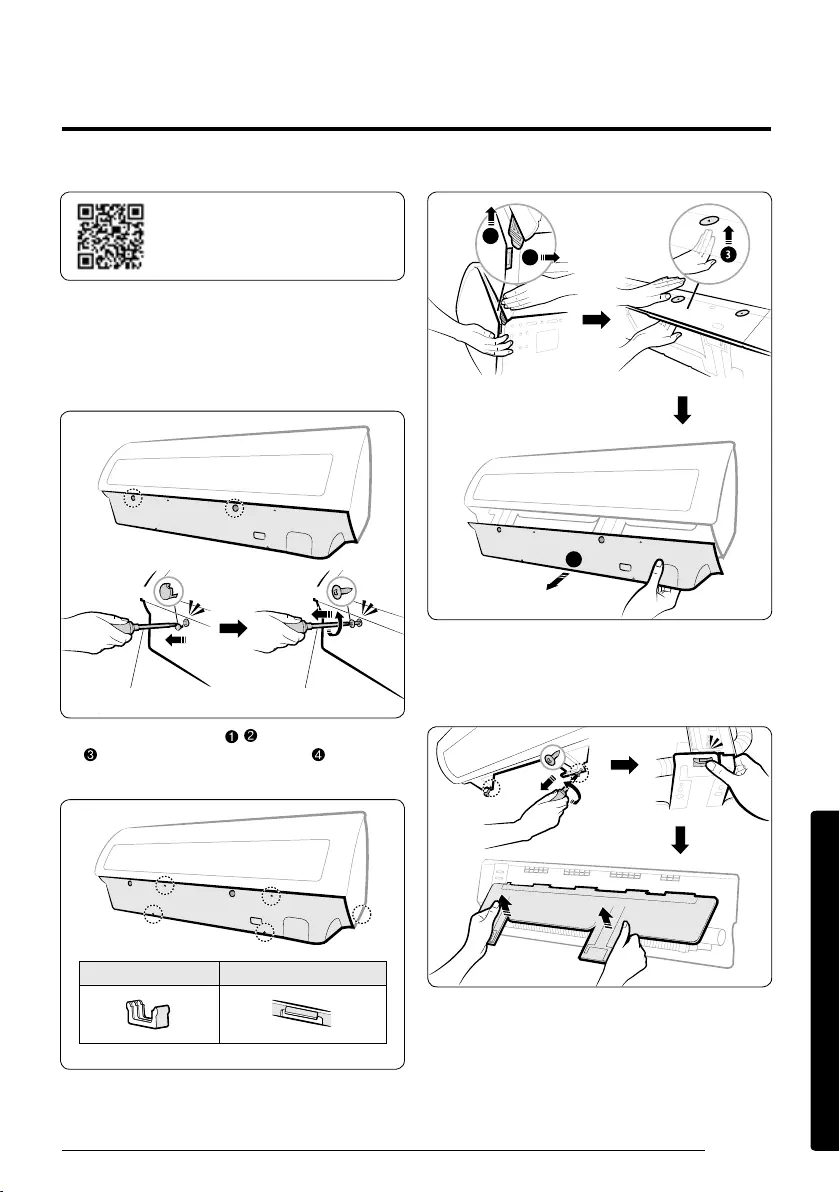

Step 2.1 Disassembling the cover

panel

1 Remove the cap screws, then the screws.

Cap screw Screw

Phillips screwdriver Flat-head screwdriver

2 Unlock the side hooks ( , ), then centre hooks

(). Then unlock the bottom hooks ( ) to pull out

the cover panel.

B

B

C

A

A

1

2

4

Step 2.2 Disassembling the

installation plate

Centre hook (A) Bottom/Side hook (B/C)

Indoor Unit Installation

10

English

Installation

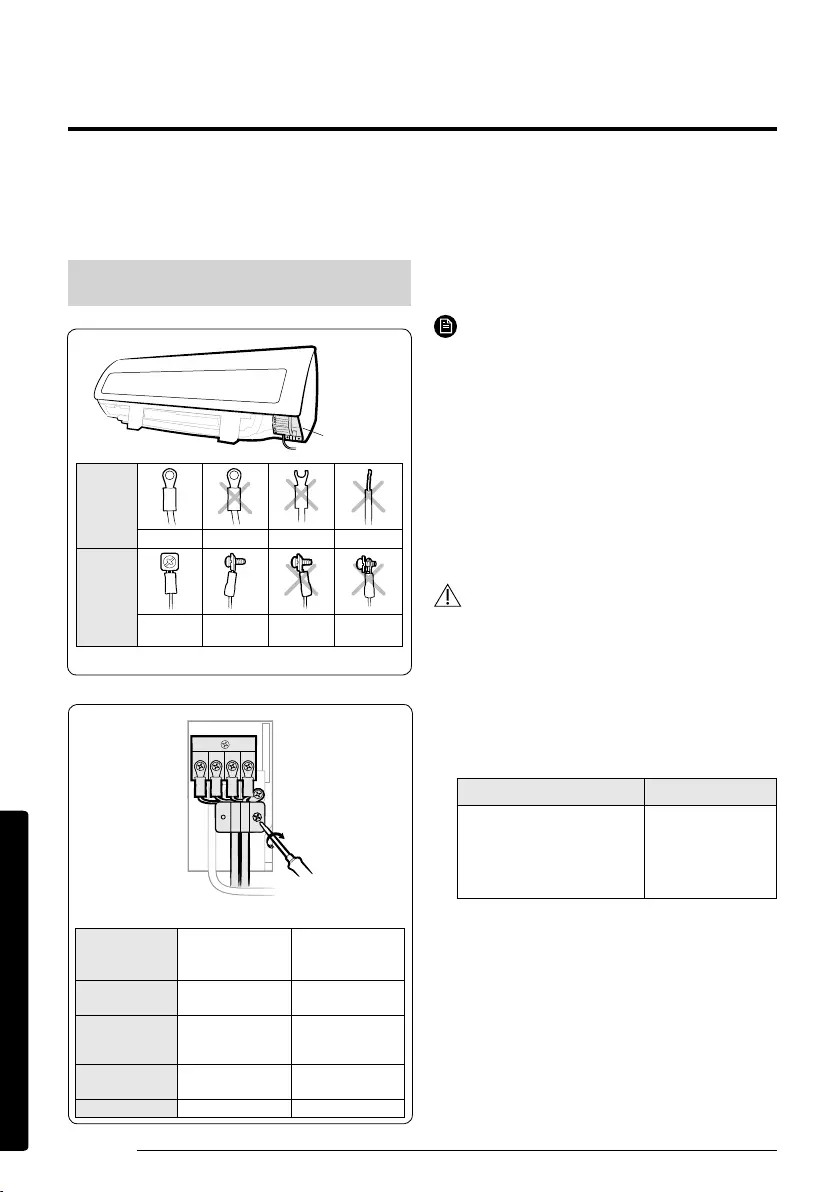

Step 2.3 Connecting the Power and

communication cables (assembly cable)

If using a multi system, install as described in the

installation manual supplied with the outdoor unit.

Control box

1(L)2(N) F1 F2

• When performing electrical and earthing works,

be sure to comply with the 'technical standards of

electrical installations' and the 'wiring regulations'

in the local regulations.

• Tightentheterminalblockscrewto1.2-1.8N•m

(1.2-1.8kgf•cm).

NOTE

• Each wire is labelled with the corresponding

terminal number.

• Use shield cable (Category 5; less than 50pF/m)

for noisy environmental site.

• Power supply cords of parts of appliances

for outdoor use shall not be lighter than

polychloroprene sheathed flexible cord. (Code

designation IEC: 60245 IEC66/CENELEC: H07RN-F,

IEC: 60245 IEC57 CENELEC: H05RN-F, IEC: 60227

IEC53: H05VV-F)

• Power & Communication cable shall not exceed

30m.

CAUTION

• For the terminal block wiring, use a wire with a

ring terminal socket only. Regular wires without

a ring terminal socket may become a hazard due

to overheating of the electrical contact during

installation.

• If you need to extend the pipe, be sure to extend

the cable, too.

(Unit : m)

Model Cable (Maximum)

**07*******

**09*******

**12*******

**18*******

**24*******

30

• Do not connect two or more different cables to

extend the length. This connection may cause fire.

• Each circular terminal must match the size of its

corresponding screw in the terminal block.

• After connecting the cables, make sure that

terminal numbers on the indoor and outdoor units

match.

• Ensure that power and communication cables are

separated, they must not be in the same cable.

Model

**

07

*******

**

09

*******

**

12

*******

**

18

*******

**

24

*******

Power cable

(Outdoor unit)

3G X 2.5 mm²,

H07RN-F

3G X 2.5 mm²,

H07RN-F

Outdoor-to-

indoor power

cable

3G X 1.0 mm²,

H07RN-F

3G X 1.0 mm²,

H07RN-F

Communication

cable

2 X 0.75 mm²,

H05RN-F

2 X 0.75 mm²,

H05RN-F

Type GL 20A 25A

Before

connecting

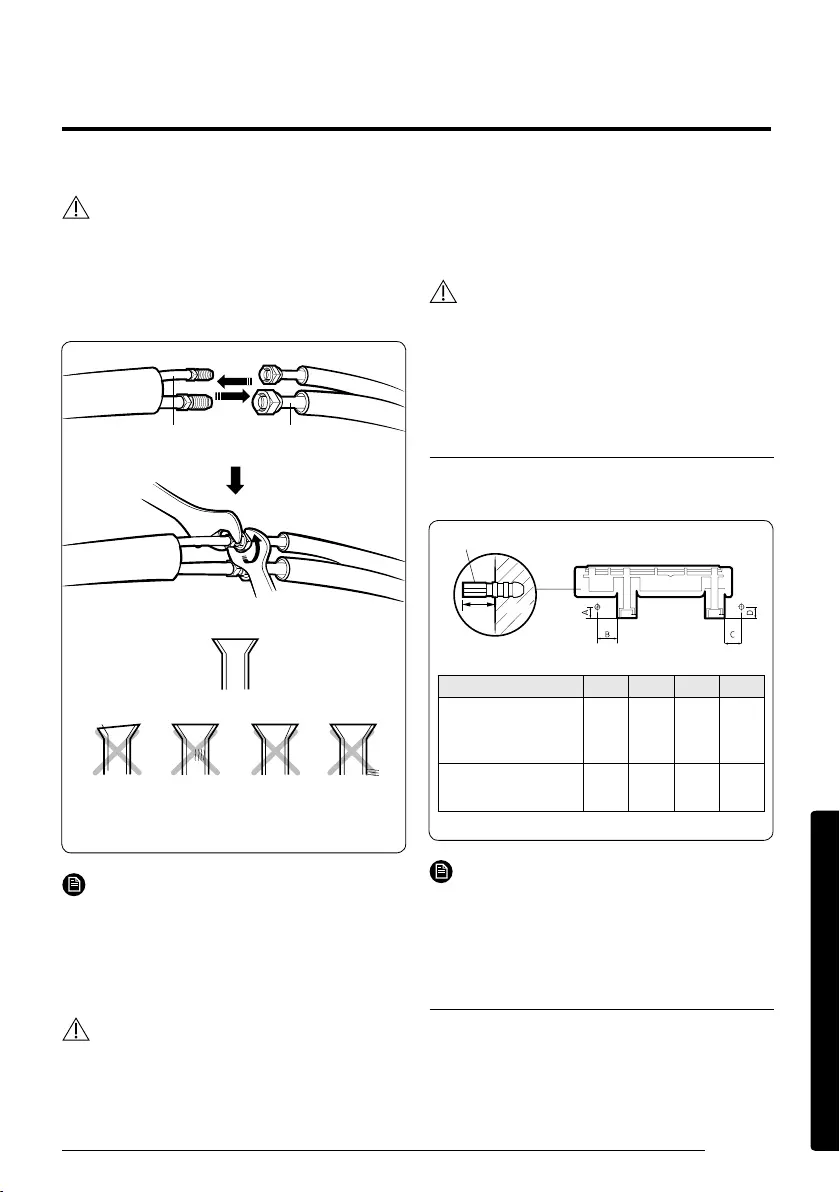

Correct Upside down Damaged Non-circular

After

connecting

Correct Correct Upside down Non-fitted

(Front view) (Side view)

<Circular terminal>

Fasten the screws for the wire holders.

11

English

Installation

WARNING

• Connect the wires firmly so that wires cannot be

pulled out easily. (If they are loose, it could cause

burn-out of the wires.)

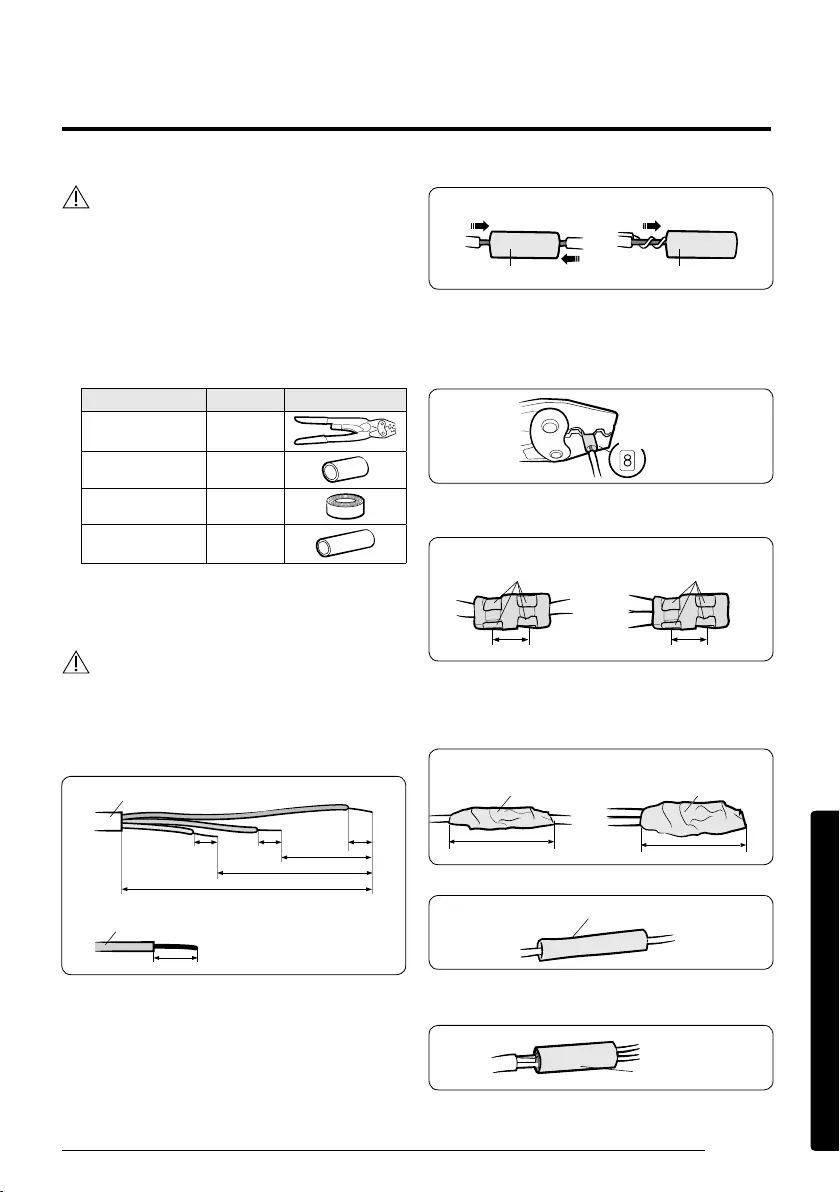

Step 2.4 Optional: Extending the

power cable

1 Prepare the following tools.

Tools Spec Shape

Crimping pliers MH-14

Connection sleeve

(mm)

20xØ7.0

(HxOD)

Insulation tape Width 18

mm

Contraction tube

(mm)

50xØ8.0

(LxOD)

2 As shown in the figure, peel off the shields from the

rubber or wire of the power cable.

• Peel off 20 mm of cable shields from the

preinstalled tube.

CAUTION

• For information about the power cable

specifications for indoor and outdoor units, refer to

the installation manual.

• After peeling off cable wires from the preinstalled

tube, insert a contraction tube.

Power cable

Pre-installed tube for the power cable

(Unit: mm)

(Unit: mm)

20 20

20

20

60

120

180

3 Insert both sides of core wire of the power cable into

the connection sleeve.

• Method 1: Push the core wire into the sleeve from

both sides.

• Method 2: Twist the wire cores together and push

it into the sleeve.

Connection sleeve Connection sleeve

Method 1 Method 2

4 Using a compressor, compress the two points and flip

it over and compress another two points in the same

location.

• Thecompressiondimensionshouldbe8.0.

Compression

dimension

• After compressing it, pull both sides of the wire to

make sure it is firmly pressed.

Compress it 4 times.

5 mm

Compress it 4 times.

5 mm

Method 1 Method 2

5 Wrap it with the insulation tape twice or more and

position your contraction tube in the middle of the

insulation tape.

Three or more layers of insulation are required.

Method 1 Method 2

Insulation tape

40 mm 35 mm

Insulation tape

6 Apply heat to the contraction tube to contract it.

Contraction tube

7 After tube contraction work is completed, wrap it with

the insulation tape to finish.

Insulation tape

12

English

Installation

CAUTION

• Make sure that the connection parts are not exposed

to outside.

• Be sure to use insulation tape and a contraction tube

made of approved reinforced insulating materials

that have the same level of withstand voltage with

the power cable. (Comply with the local regulations

on extensions.)

WARNING

• In case of extending the electric wire, please

DO NOT use a round-shaped

pressing socket.

–Incomplete wire connections

can cause electric shock or

a fire.

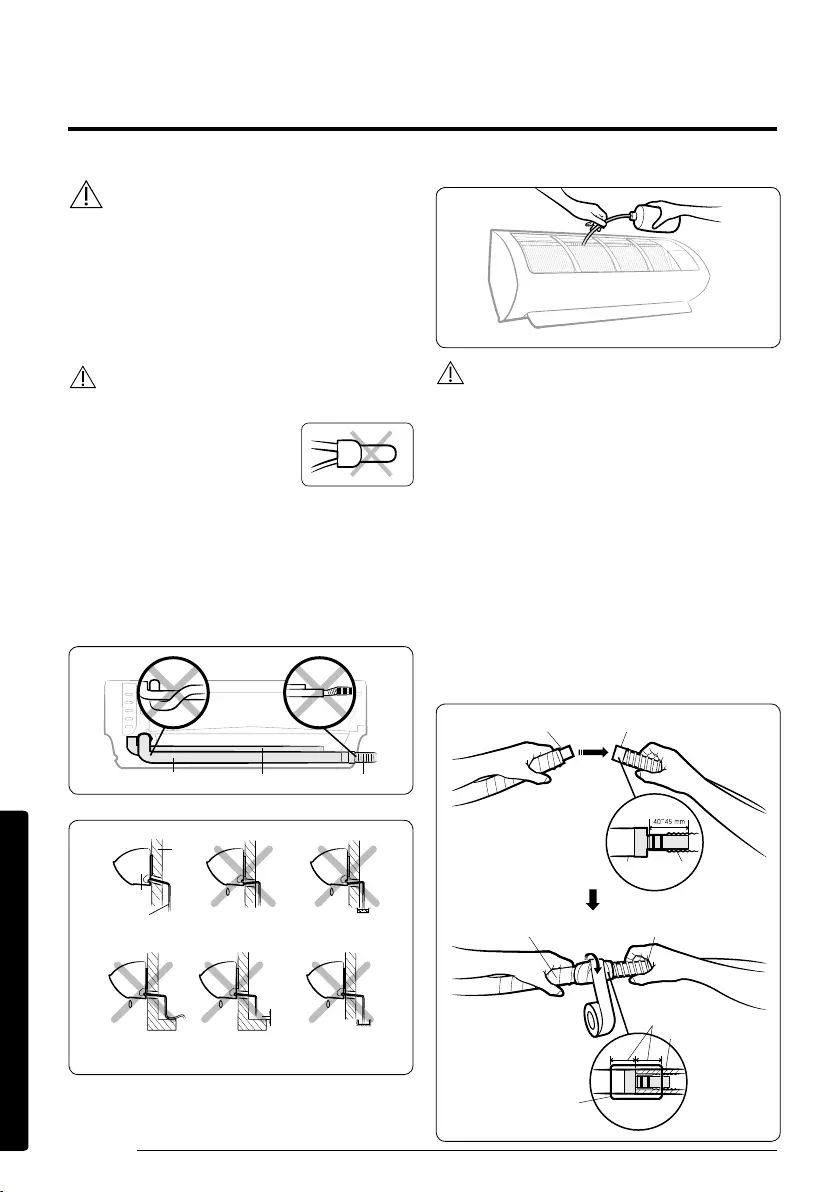

Step 2.5 Installing and connecting

the drain hose

1 Install the drain hose.

Drain hose Assembly pipe Connection hose

Wall

5 cm

less Ditch

Water

Slant downwards Slant upwards Dipped in water

Bent Too small

clearance

Too small

clearance

Indoor unit

Drain hose

2 Pour water into the drain pan. Check whether the

hose is well drained.

CAUTION

• Make sure that the indoor unit is in upright

position when you pour water to check for leakage.

Make sure that the water does not overflow onto

the electrical part.

• If the diameter of the connection hose is smaller

than the product's drain hose, water leakage may

occur.

• Inadequate installation may cause water leakage.

• If the drain hose is routed inside the room,

insulate the hose so that dripping condensation

does not damage the furniture or floors.

• Do not box in or cover the drain hose connection.

Drain hose connection must be easily accessible

and serviceable.

Step 2.6 Optional: Extending the

drain hose

(A) (B)

Drain hose (A) Extension drain hose (B)

Drain hose Extension drain hose

20 mm or more

Foam insulation

Vinyl tape

13

English

Installation

Step 2.7 Optional: Changing the

direction of the drain hose

Pour water in the direction of arrow.

<Front view>

<Side view>

Direction of the drained water

Drain pan outlet

Rubber cap

CAUTION

• Make sure that the indoor unit is in upright

position when you pour water to check for leakage.

Make sure that the water does not overflow onto

the electrical part.

Step 2.8 Installing and connecting

the assembly pipes to the refrigerant

pipes (assembly pipe)

Connect indoor and outdoor units with field-supplied

copper pipes by means of flare connections. Use

insulated seamless refrigeration grade pipe only,

(Cu DHP type according to ISO1337), degreased and

deoxidized, suitable for operating pressures of at

least 4200 kPa and for burst pressure of at least

20700 kPa. Under no circumstances must sanitary

type copper pipe be used.

There are 2 refrigerant pipes of different diameters:

• The smaller one is for the liquid refrigerant

• The larger one is for the gas refrigerant

A short liquid refrigerant pipe and a short gas

refrigerant pipe are already fitted to the air

conditioner. The connection procedure for the

refrigerant pipes varies according to the exit position

of each pipe when facing the wall:

1 <Front view>

3 <Side view>

Left(A)

Underside(C)

Right(B)

Guide right

or left

2 <Assembling the

hanger screw>

Screw

1 Cut out the appropriate knock-out piece (A, B, C)

on the rear of the indoor unit unless you connect

the pipe directly from the rear.

2 Smooth the cut edges.

14

English

Installation

3 Remove the protection caps of the pipes and

connect the assembly pipe to each pipe. Tighten

the nuts first with your hands, and then with a

torque wrench, applying the following torque:

Outer diameter (mm) Torque (N•m) Torque (kgf•cm)

ø 6.35 14 to 18 140 to 180

ø 9.52 34 to 42 350 to 430

ø 12.70 49 to 61 500 to 620

ø 15.88 68 to 82 690 to 830

NOTE

• If you want to shorten or extend the pipes,

see Step 2.9 Shortening or extending the

refrigerant pipes (assembly pipe) on page 14.

4 Cut off the remaining foam insulation.

5 If necessary, bend the pipe to fit along the bottom

of the indoor unit. Then pull it out through the

appropriate hole.

• The pipe should not project from the rear of the

indoor unit.

• The bending radius should be 100 mm or more.

6 Pass the pipe through the hole in the wall.

7 Fix the indoor unit on the wall.Pass the cables,

pipes and hose through the knock-out hole which

would be connected to the outdoor unit .

8 Use 2 screws to fix the indoor unit as shown in the

picture 2.

9 Assemble the Guide into the position of A or B as

shown in the picture 3.

NOTE

• The pipe will be insulated and fixed permanently

into position after finishing the installation and

the gas leak test. For further details. see Step 4.1

Performing the gas leak tests on page 21.

CAUTION

• Tighten the flare nut with a torque wrench

according to specified method. If the flare nut is

over-tightened, the flare may break and cause

refrigerant gas leakage.

• Do not box in or cover the pipe connection.

All refrigerant pipe connection must be easily

accessible and serviceable.

Step 2.9 Shortening or extending the

refrigerant pipes (assembly pipe)

Pipe cutter

Pipe

90° Oblique Rough Burr

R 0.4 to 0.8

90°±2°

45°±2°

L

D

D

A

FlarePipe

Connecting pipe

Flare nut

Indoor outlet pipe

Outer diameter (mm) Torque (N•m) Torque (kgf•cm)

ø 6.35 14 to 18 140 to 180

ø 9.52 34 to 42 350 to 430

ø 12.70 49 to 61 500 to 620

ø 15.88 68 to 82 690 to 830

(Unit: mm)

Outer diameter (D) Depth (A) Flare dimension (L)

ø 6.35 1.3 8.7 to 9.1

ø 9.52 1.8 12.8 to 13.2

ø 12.70 2.0 16.2 to 16.6

ø 15.88 2.2 19.3 to 19.7

15

English

Installation

CAUTION

• If you need a pipe longer than specified in piping

codes and standards, you must add refrigerant to

the pipe. Otherwise, the indoor unit may freeze.

• While removing burrs, put the pipe face down to

make sure that the burrs do not get in to the pipe.

Liquid service port

<High pressure>

Gas service port

<Low pressure>

Correct

<Flare nut>

Inclined Cracked Uneven

thickness

Damaged

surface

NOTE

• Excessive torque may cause gas leakage. When

extending the pipe with welding or brazing,

ensure that nitrogen is used during the welding or

brazing process. The joint must be accessible and

serviceable.

CAUTION

• Tighten the flare nut at the specified torque. If the

flare nut is over-tightened, it may break to cause

leakage of refrigerant gas.

Step 2.10 Fixing the installation plate

You can install the indoor unit on a wall, window

frame, or gypsum board.

WARNING

• Make sure that the wall, window frame, or gypsum

board can withstand the weight of the indoor unit.

If you install the indoor unit in a place where it is

not strong enough to withstand the unit's weight,

the unit could fall and cause injury.

When fixing the indoor unit on a wall

Fix the installation plate to the wall giving attention

to the weight of the indoor unit.

NOTE

• If you mount the plate to a concrete wall using

plastic anchors, make sure that gaps between the

wall and the plate, created by projected anchor, is

less than 20 mm.

When fixing the indoor unit on a window frame

1 Determine the positions of the wooden uprights to

be attached to the window frame.

2 Attach the wooden uprights to the window frame

giving attention to the weight of the indoor unit.

3 Attach the installation plate to the wooden

upright using tapping screws.

(Unit : mm)

Model A B C D

**07*******

**09*******

**12*******

36 120 81 36

**18*******

**24*******

33 110 110 33

Pipe bundle hole: Ø 65 mm

Plastic anchor

20 mm Wall

16

English

Installation

When fixing the indoor unit on a gypsum board

1 Use stud finder to find out locations of the studs.

2 Fix the plate hanger on two studs.

CAUTION

• If you fix the indoor unit on a gypsum board, use

only specified anchor bolts on reference positions.

Otherwise, the gypsum surrounding the joints

may crumble over time and cause the screws

to be loosened and stripped. This may lead to

physical injury or equipment damage.

• Search for other spots if there are less than two

studs, or the distance between the studs are

different from the plate hanger.

• Fix the installation plate without inclining to one

side.

Step 2.11 Fixing the indoor unit to the

installation plate

CAUTION

• Make sure that the pipe bundle does not move

when you install the indoor unit onto the

installation plate.

Step 2.12 Assembling the cover panel

1 Lock the side hooks (D), then centre hooks (B).

Then lock the bottom hooks (C) to engage the

cover panel in place.

2 Fasten the screw (A- ), then assemble the cap

screws (A- ).

B B

CC

A

A

A

B

B

C

C

D

D

1

2

A

2

1

17

English

Installation

If using a multi system, install as described in the

installation manual supplied with the outdoor unit.

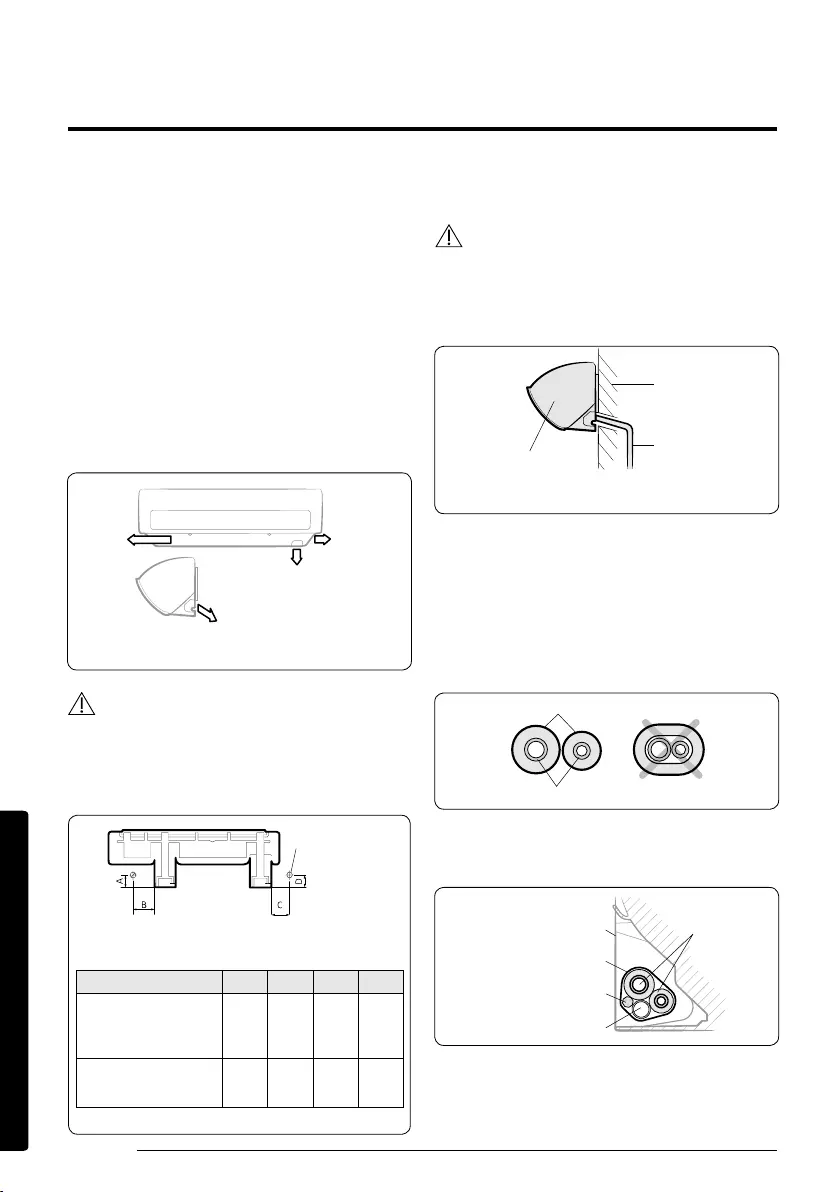

Step 3.1 Fixing the outdoor unit in

place

X

Y

Rubber leg

1 Place the outdoor unit as directed on the top of

the unit to let the discharged air out properly.

2 Fix the outdoor unit in level to an appropriate

support using anchor bolts.

NOTE

• Secure the rubber legs to help prevent the

generation of noise and vibration.

• If the outdoor unit is exposed to strong winds,

install shield plates around the outdoor unit so

that the fan can operate correctly.

Optional: Fixing the outdoor unit to a wall with a

rack

Soft rubber designed to cut off vibration from

rack to wall (not supplied with product)

Soft rubber designed to cut off residual vibration from

outdoor unit to rack (not supplied with product)

NOTE

• Make sure that the wall can support the weights

of the rack and the outdoor unit.

• Install the rack close to the column as much as

possible.

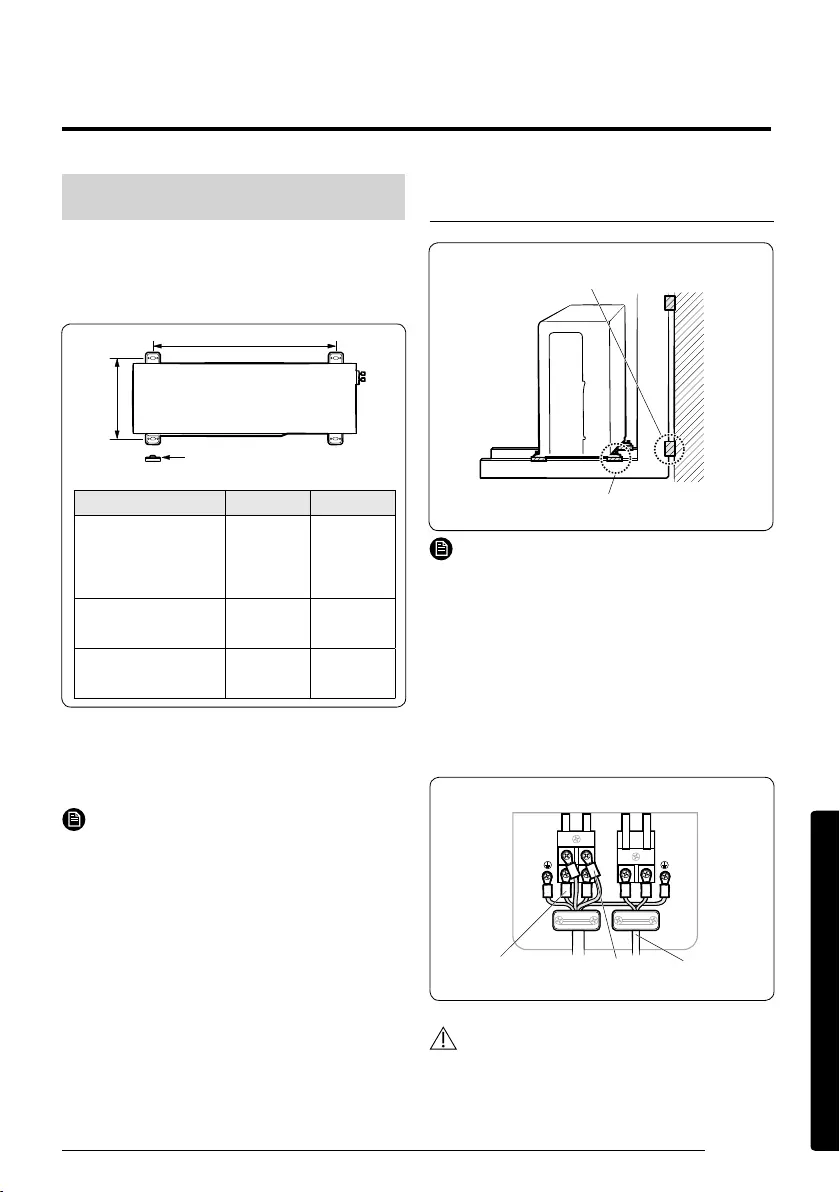

Step 3.2 Connecting the power

and communication cables and the

refrigerant pipes

F1 F2

L N

Outdoor-to-indoor power cable

(three wires)

Power cable

(three wires)

Communication cable

(two wires)

CAUTION

• Be sure to fix the power cables and communication

cable with a cable clamp.

Outdoor Unit Installation

(Unit : mm)

Model X Y

**09MSPXB**

**12MSPXB**

**09MSWX***

**12MSWX***

507 292

**09MSPXA**

**12MSPXA**

602 310

**18NS*****

**24NS*****

660 340

18

English

Installation

Control box

Remove the screw for the

control box cover

Remove the gas and liquid

service port caps

For connecting the

refrigerant pipes

Gas service port

<Low pressure>

Liquid service port

<High pressure>

Connect the gas and liquid

refrigerant pipes

Step 3.3 Evacuating the air

The outdoor unit is loaded with sufficient R-410A

refrigerant. Do not vent R-410A into atmosphere: it

is a fluorinated greenhouse gas, covered by Kyoto

Protocol, with a Global Warming Potential (GWP) =

2088. You should evacuate the air in the indoor unit

and in the pipe. If air remains in the refrigerant pipes,

it affects the compressor. It may cause reduction

of cooling capacity and malfunction. Use a vacuum

pump.

CAUTION

• When installing, make sure there is no leakage.

When recovering the refrigerant, ground the

compressor first before removing the connection

pipe. If the refrigerant pipe is not properly

connected and the compressor works with the

stop valve open, the pipe inhales the air and it

makes the pressure inside of the refrigerant cycle

abnormally high. It may cause explosion and

injury.

1 Leave the system in the standby mode.

WARNING

• Do not turn on the system! This is necessary for

better vacuum operation (full OPEN position of

Electronic Expansion Valve).

2 Connect the charging hose of the low pressure

side of manifold gauge to a gas service port as

seen in the picture.

3

4

15 minutes

Vacuum

Pump

(Backward owing prevention)

Liquid service port <Low pressure>

Liquid service port <High pressure>

Valve

5

19

English

Installation

3 Open the valve of the low pressure side of

manifold gauge anticlockwise.

4 Evacuate the air in the connected pipes using the

vacuum pump for about 15 minutes.

• Make sure that pressure gauge shows -0.1 MPa

(-76 cmHg, 5 torr) after about 10 minutes. This

procedure is very important to avoid a gas leak.

• Close the valve of the low pressure side of

manifold gauge clockwise.

• Turn off the vacuum pump.

• Check for 2 minutes if there is any pressure

change.

• Remove the hose of the low pressure side of

manifold gauge.

5 Set a valve cork of liquid and gas service port to

the open position.

Step 3.4 Adding refrigerant

If you use a pipe longer than the length specified in

the piping codes and standards, you must add 15g of

refrigerant R-410A for each extra metre. If you use a

pipe shorter than the length specified in the piping

codes and standards, the evacuating time is normal.

Refer to the Service Manual for further details.

CAUTION

• The remaining air in the Refrigeration cycle, which

contains moisture, may cause malfunction of the

compressor.

• Always contact the service centre or a professional

installation agency for product installation.

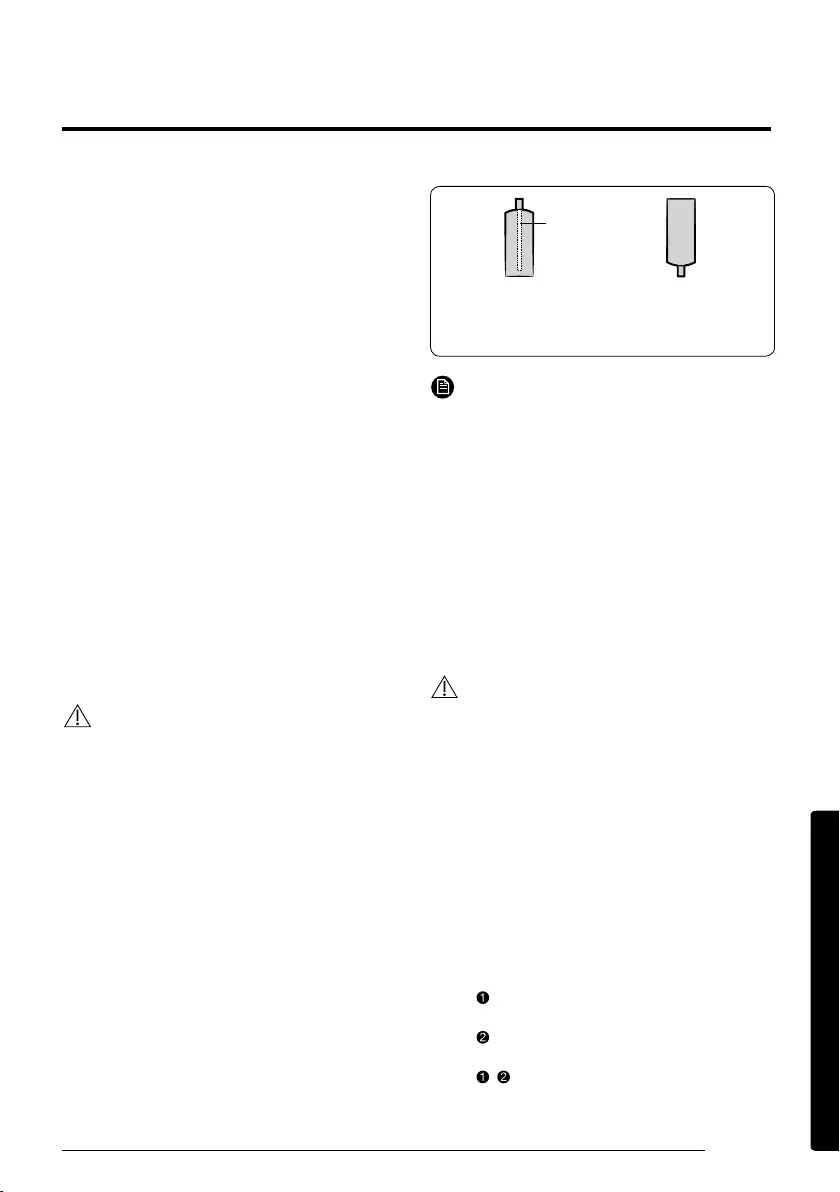

R-410A is a mixed type of refrigerant. It is necessary

for recharging under conditions of liquid. When

recharging refrigerant from the refrigerant cylinder

to the equipment, take the following instructions:

Before recharging, check whether the cylinder has

a siphon or not. There are two ways to recharge the

refrigerant:

Siphon

Charge the refrigerant

standing the cylinder upright.

Charge the refrigerant turning

the cylinder upside down.

<Cylinder with siphon> <Cylinder without siphon>

NOTE

• If R-410A refrigerant is charged with gas, the

composition of the charged refrigerant changes

and the characteristics of the equipment vary.

• During the measuring operation of refrigerant

quantity added, use electronic scales. If cylinder

doesn't have siphon, upset it.

Step 3.5 Important information :

regulation regarding the refrigerant

used

This product contains fluorinated greenhouse gases.

Do not vent gases into the atmosphere.

CAUTION

• Inform user if the system contains 5 tCO2e or

more of fluorinated greenhouse gases. In this

case, it must be checked for leakage at least

once every 12 months, according to regulation

No. 517/2014. This activity must be covered

by qualified personnel only. In the case of the

situation above, the installer (or authorized

person with responsibility for final check)

must provide a maintenance book, with all the

information recorded, according to REGULATION

(EU) No. 517/2014 OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 16 April

2014 on fluorinated greenhouse gases.

1 Please fill in the following with indelible ink on

the refrigerant charge label supplied with this

product and on this manual.

• the factory refrigerant charge of the

product,

• the additional refrigerant amount charged

in the field and

• + the total refrigerant charge. on the

refrigerant charge label supplied with the

product.

20

English

Installation

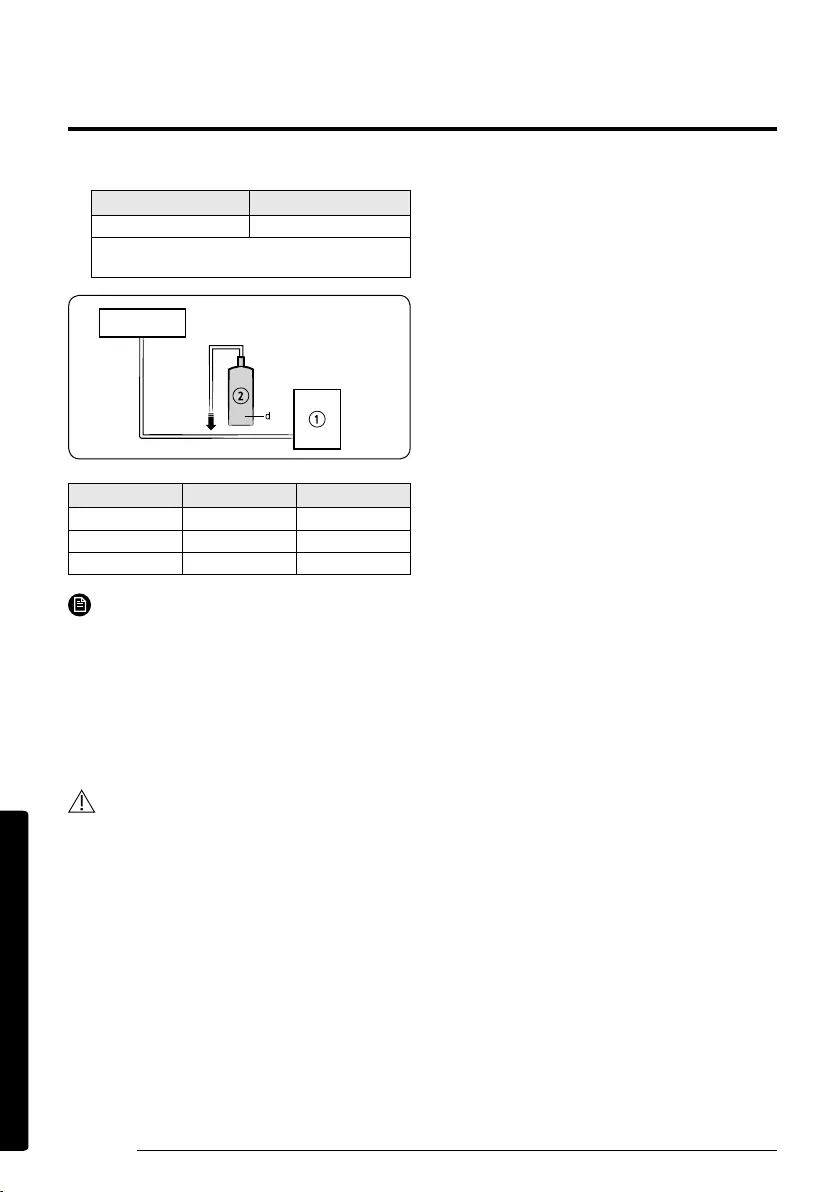

Refrigerant type GWP value

R-410A 2088

•GWP=GlobalWarmingPotential

•CalculatingtCO

2

e : kg x GWP / 1000

Unit Kg tCO

2

e

①, a

②, b

①+②, c

NOTE

a Factory refrigerant charge of the product: see

unit name plate

b Additional refrigerant amount charged in the

field (Refer to the above information for the

quantity of refrigerant replenishment.)

C Total refrigerant charge

d Refrigerant cylinder and manifold for charging

CAUTION

• The filled-out label must be adhered in the

proximity of the product charging port (e.g. onto

the inside of the stop valve cover).

Indoor unit

Outdoor unit

21

English

Installation

Installation Inspection

Step 4.1 Performing the gas leak tests

1 Before inspecting the leakage, use a torque

wrench to close the cap for the stop valve. (Comply

with a tightening torque for each size of the

diameter, and tighten the cap firmly to prevent

any leakage.)

Tightening torque for body cap

(Refer to the table)

Spindle

Charging core

R-22: Thread of the screw - 7/16-2OUNF

R-410A: Thread of the screw -1/2-2OUNF

Tightening torque for charging port cap (Refer to the table)

2 Insert inert gas into the pipes connected to indoor

and outdoor units.

3 Test leakage on the connection parts of the indoor

and outdoor units with soap lather or liquid.

Test parts for the

indoor unit

Test parts for the

indoor unit

Test parts for the

indoor unit

Test parts for the

indoor unit

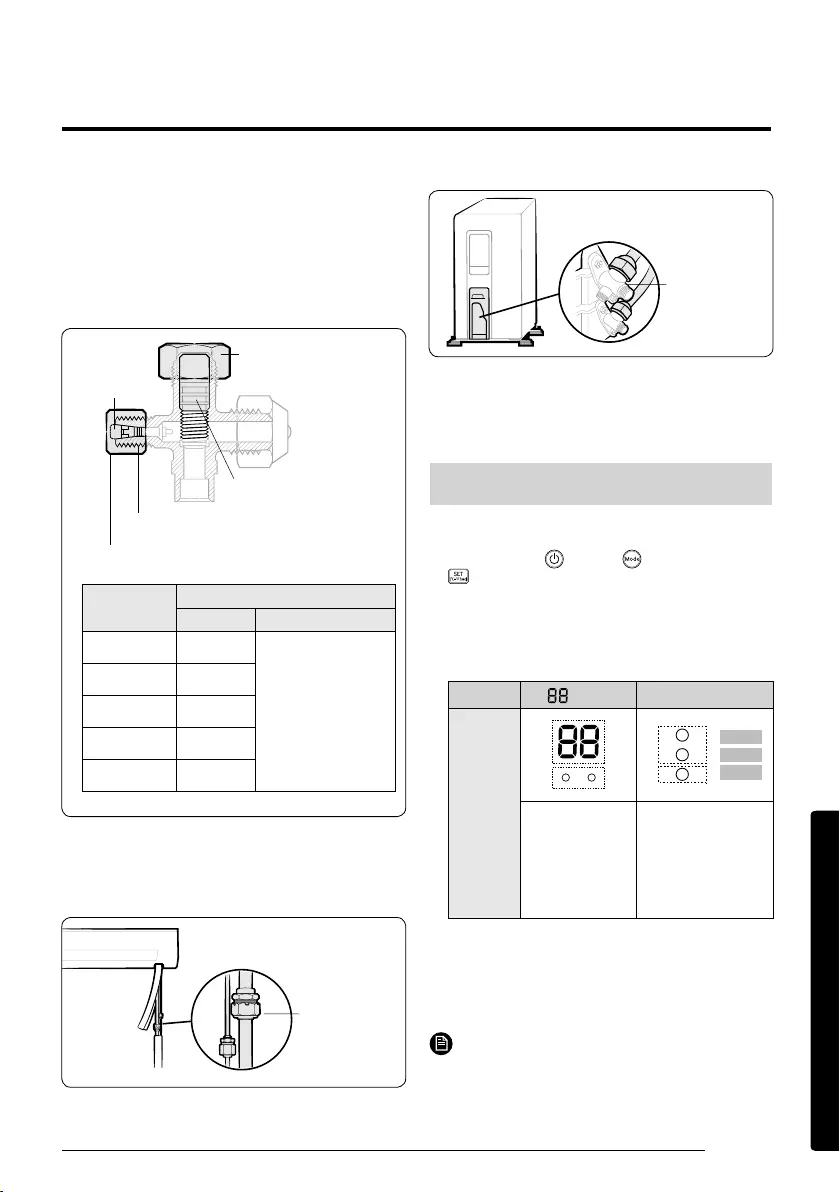

Step 4.2 Running the Smart Install

mode

If using a multi system, this function is not

supported.

1 Make sure that the air conditioner is in the standby

status.

2 Hold down the (Power), (Mode) and

(SET/Temperaturetype(℃↔℉))buttonson

the remote control simultaneously for 4 seconds.

3 Wait until Smart Install mode succeeds or fails. It

takes approximately 7 to 13 minutes.

• While Smart Install mode is proceeding:

Type Display LED Display

Indoor

unit

indicator

LED1

LED2

LED3

The progress is

displayed as a

number between

0 and 99 on

the indoor unit

display.

The LEDs on the

indoor unit display

blink in sequence,

then all of them

blink simultaneously.

These operations

repeat.

• When Smart Install mode succeeds: Smart

Install mode ends with ringing sound, and the

air conditioner is in standby status.

• When Smart Install mode fails: An error

message is displayed on the indoor unit display,

and Smart Install mode ends.

NOTE

• Smart Install mode can be operated only with the

supplied remote control.

• During the Smart install mode procedure, remote

control cannot be operated.

Outer diameter

(mm)

Tightening torque

Bodycap(N•m) Chargingportcap(N•m)

ø 6.35 20 to 25

10 to 12

ø 9.52 20 to 25

ø 12.70 25 to 30

ø 15.88 30 to 35

Over ø 19.05 35 to 40

(1N•m=10kgf•cm)

22

English

Installation

When error occurs, take necessary measures by referring to the following table. For more information on

necessary measures for errors, refer to the service manual.

Error indicator

Error Measures for the installer to take

Display

LED Display

LED 1 LED 2 LED 3

/ /

Communication

error between

indoor and outdoor

units

• Check the connection wire between

the indoor and outdoor units (whether

the power cable or communication

cable is crossed or not).

Error on indoor

temperature

sensor

• Check the connection of the

connector.

, Error on indoor

heat exchanger

• Check the connection of the

connector.

Error on indoor fan

motor

• Check the connection of the

connector.

• Remove foreign substance. (Check

for the cause that restrains motor.)

display

and all LEDs

blink.

EEPROM/Option

error

• Re-set options.

,

Refrigerant flow

blocking error

• Check if the stop valve is completely

open.

• Check if there is any blockage in the

refrigerant pipe which connects the

indoor and outdoor units.

• Check for refrigerant leak.

Lack of refrigerant

(for inverter

models only)

• Check if a sufficient amount of

refrigerant is additionally charged

for the pipe longer than specified in

piping codes and standards.

• Check for refrigerant leak between

valve and pipe connection.

❈ This LED pattern

appears when an

error occurs on the

outdoor unit.

❈ : Off, : Blinking, : On

23

English

Installation

Step 4.3 Performing final check and trial

operation

1 Check the following:

• Strength of the installation site

• Tightness of pipe connection to detect gas leak

• Electric wiring connection

• Heat-resistant insulation of the pipe

• Drainage

• Grounding conductor connection

• Correct operation (Take the following steps.)

2 Press the (Power) button on the remote control to

check the following:

• The indicator on the indoor unit lights up.

• The airflow blade opens and the fan gears up for

operation.

3 Press the (Mode) button to select Cool or Heat mode.

Then take the following sub-steps:

• In Cool mode, use the Temperature button to set the

set temperature to 16 °C.

• In Heat mode, use the Temperature button to set the

set temperature to 30 °C.

• Check whether, approximately 3 to 5 minutes later,

the outdoor unit starts, and a cool air blows out.

• After 12 minutes of stationary condition, check the

indoor unit air treatment.

4 Press the (Air swing) button to check whether the

airflow blades work properly.

5 Press the (Power) button to stop the trial operation.

Pumping down for removing the product

Pump-down is an operation intended to collect all the

system refrigerant in the outdoor unit. This operation must

be carried out before disconnecting the refrigerant tubing

in order to avoid refrigerant loss to the atmosphere.

WARNING

• After installing the product, be sure to perform leak

tests on the piping connections. After pumping down

refrigerant to inspect or relocate the outdoor unit,

be sure to stop the compressor and then remove the

connected pipes.

–Do not operate the compressor while a valve is

open due to refrigerant leakage from a pipe or an

unconnected or incorrectly connected pipe. Failure

to do so may cause air to flow into the compressor

and too a high pressure to develop inside the

refrigerant circuit, leading to an explosion or

product malfunction.

1 Hold down the (Power) button on the indoor unit for

5 seconds. Beep sounds immediately to indicate that the

product is ready for pump down procedure.

2 Let the compressor run for more than 5 minutes.

3 Release the valve caps on High and Low pressure side.

4 Use L-wrench to close the valve on the high pressure

side.

5 After approximately 1 minute, close the valve on the low

pressure side.

6 Stop operation of the air conditioner by pressing the

(Power) button on the indoor unit or remote control.

7 Disconnect the pipes.

CAUTION

• Compressor damage may occur if the compressor is run

at a negative suction pressure.

1

2

Gas service port

<Low pressure>

Liquid service port

<High pressure>

1 minute

Off

24

English

Installation

Only for multi system

(Wried remote controller, central remote controller

etc.)

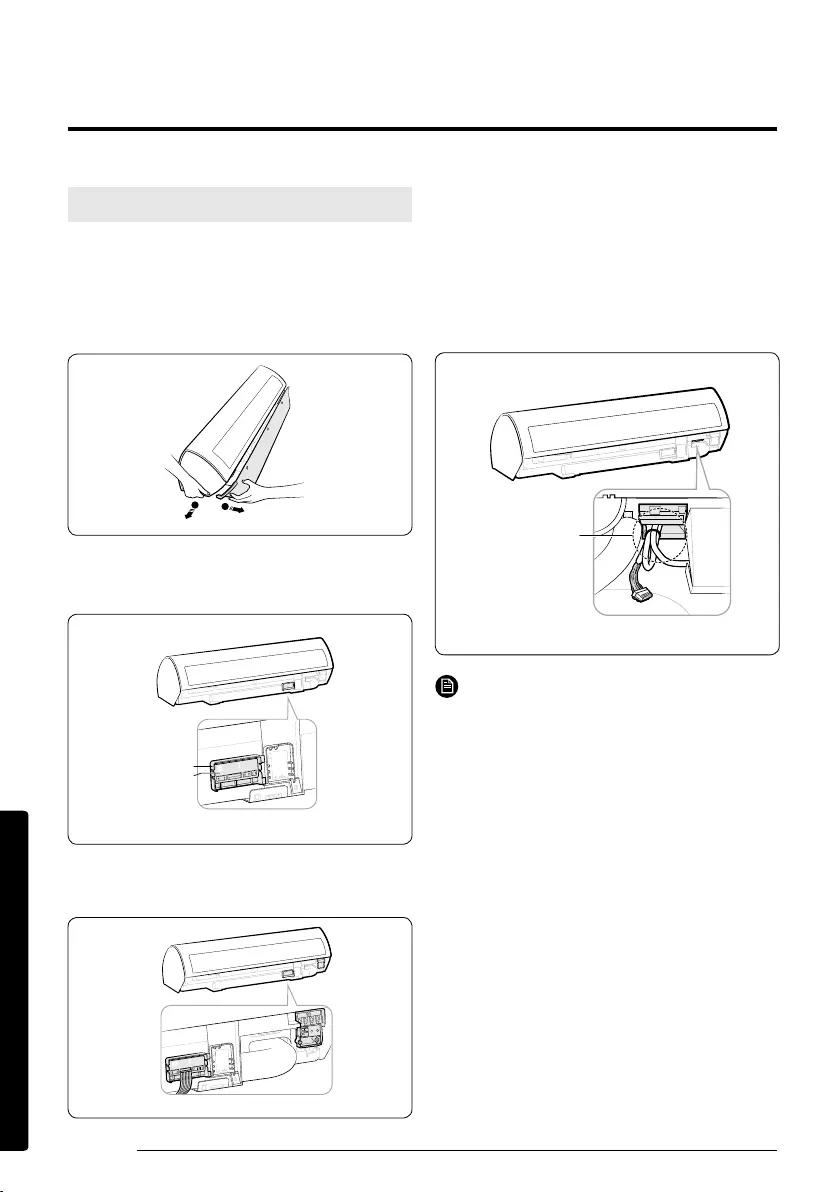

1 Turn the power off and take off the cover panel of

the indoor unit.

12

2 Attach the Sub PCB to the Case Sub PCB.

3 Assemble the Case Sub PCB to the indoor unit.

Sub PCB

Case Sub PCB

4 Find the PCB wire, and connect the wire to the

Sub PCB as seen in the picture.

5 Connect the wire(remote controller, central

remote controller etc) to the Sub PCB.

6 Assemble the Cover PCB and the front panel.

❈

If the Sub PCB is not installed, arrange

the wire for multi system (connection) as

shown in the illustration.

Wire for multi

system connection

NOTE

• The Sub PCB is attached to be controlled by the

wired remote controller and central controller.

Sub PCB installation(optional)

DB68-06732A-03