Table of Contents

- LED Display Installation Manual Ver. 4.2 IER / IER-F / IFR /IFR-F Series LH0**IER*LS , LH0**IER*FS LH0**IFR*LS , LH0**IFR*FS

- Revision History

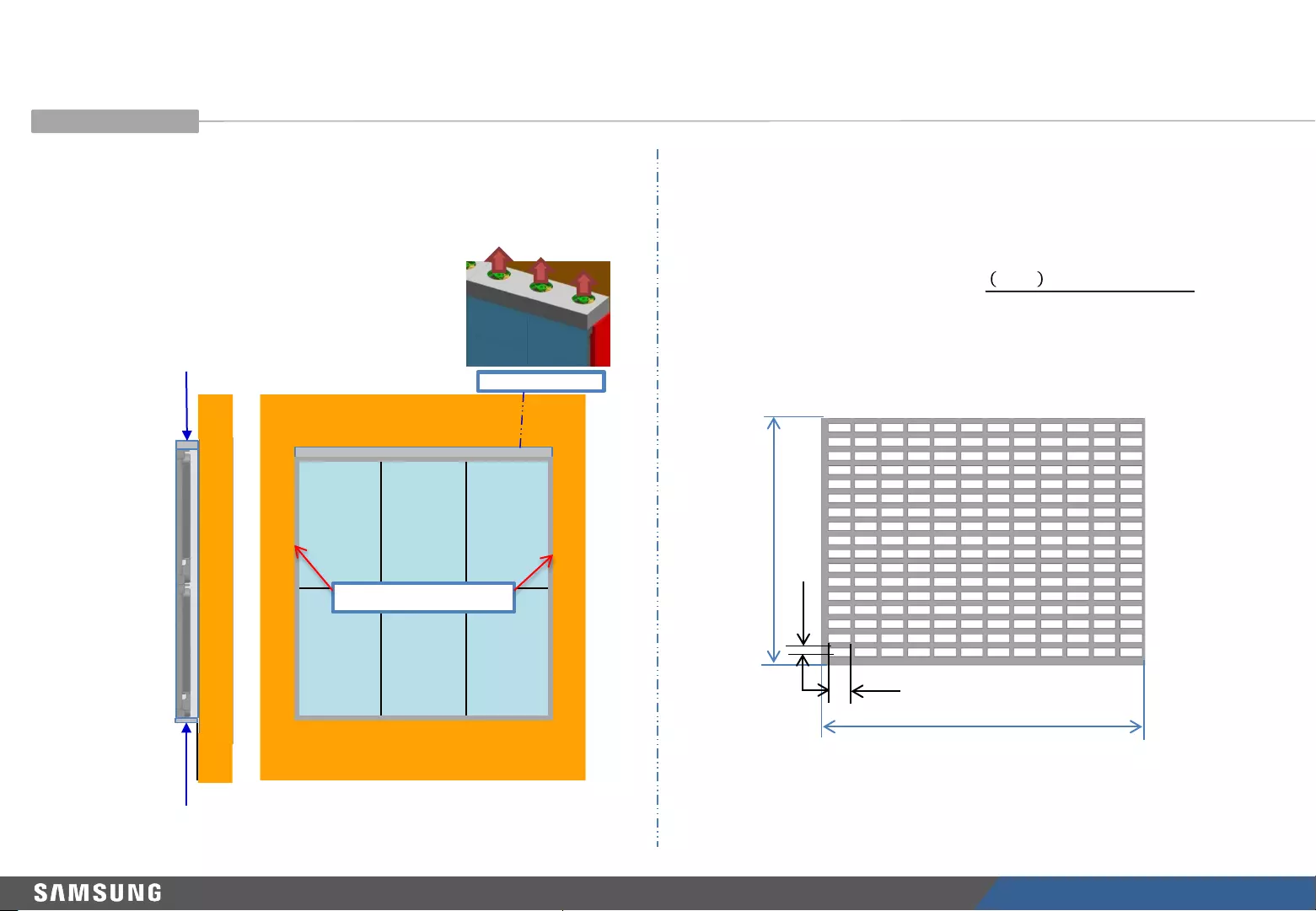

- Dehumidification guidance – during installation

- Dehumidification guidance – during installation

- Dehumidification guidance – during installation

- Dehumidification guidance – during operation

- 슬라이드 번호 7

- 슬라이드 번호 8

- Guidance of latest firmware

- Table of Contents

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

- 1. Product Information and Installation Precautions

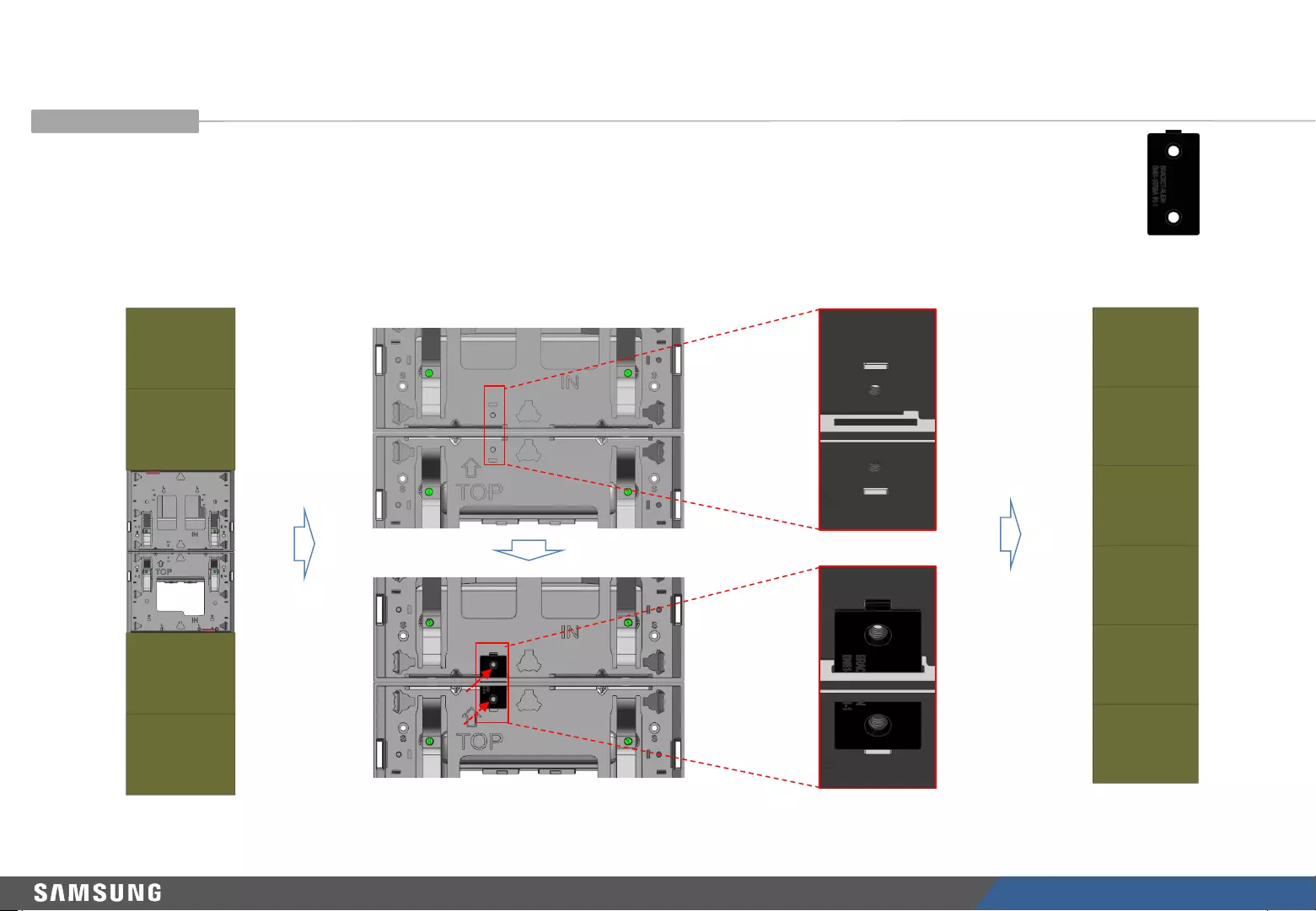

- 2. Preparation for Cabinet Installation

- 2. Preparation for Cabinet Installation

- 2. Preparation for Cabinet Installation

- 2. Preparation for Cabinet Installation

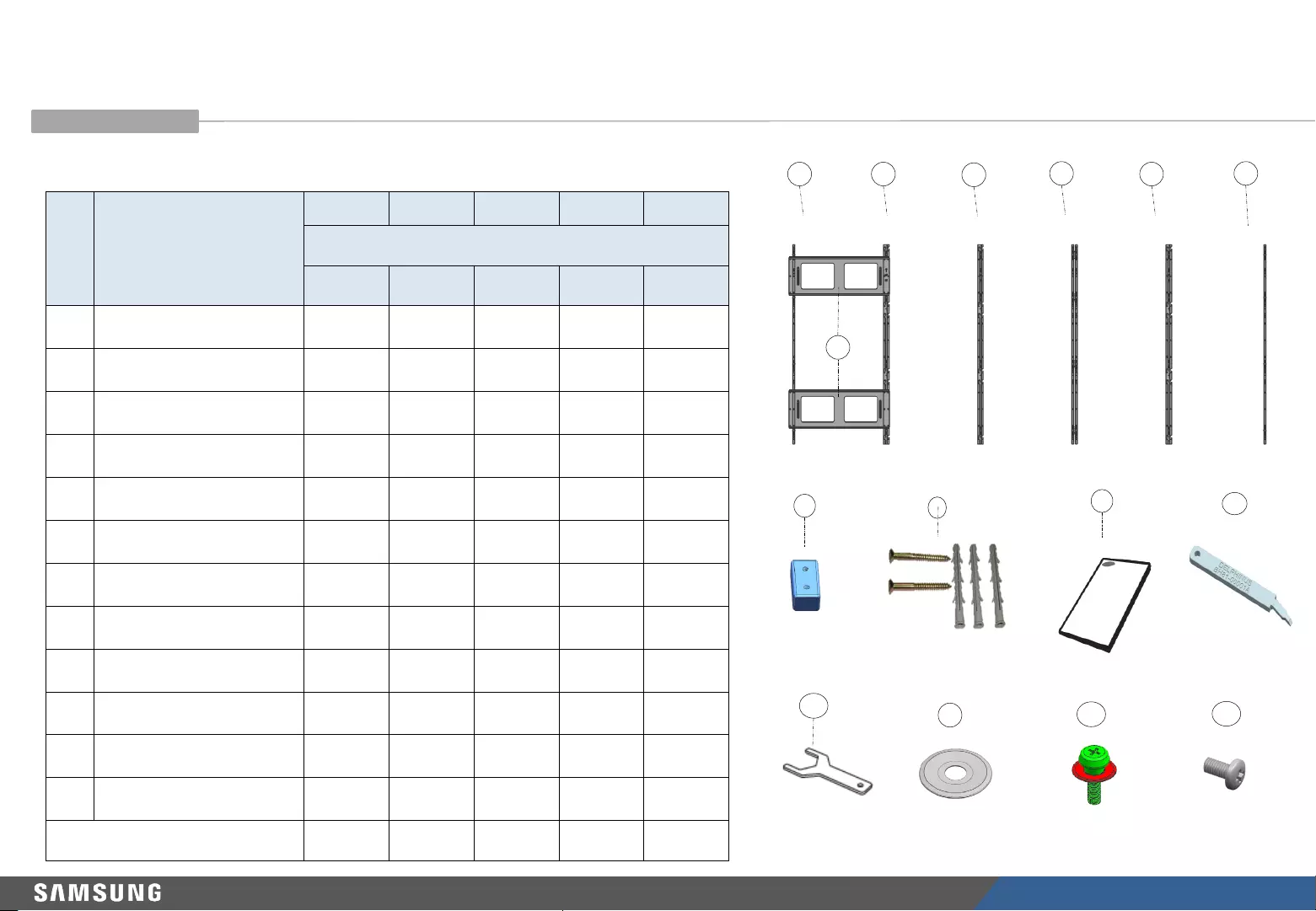

- 3. Frame kit Components

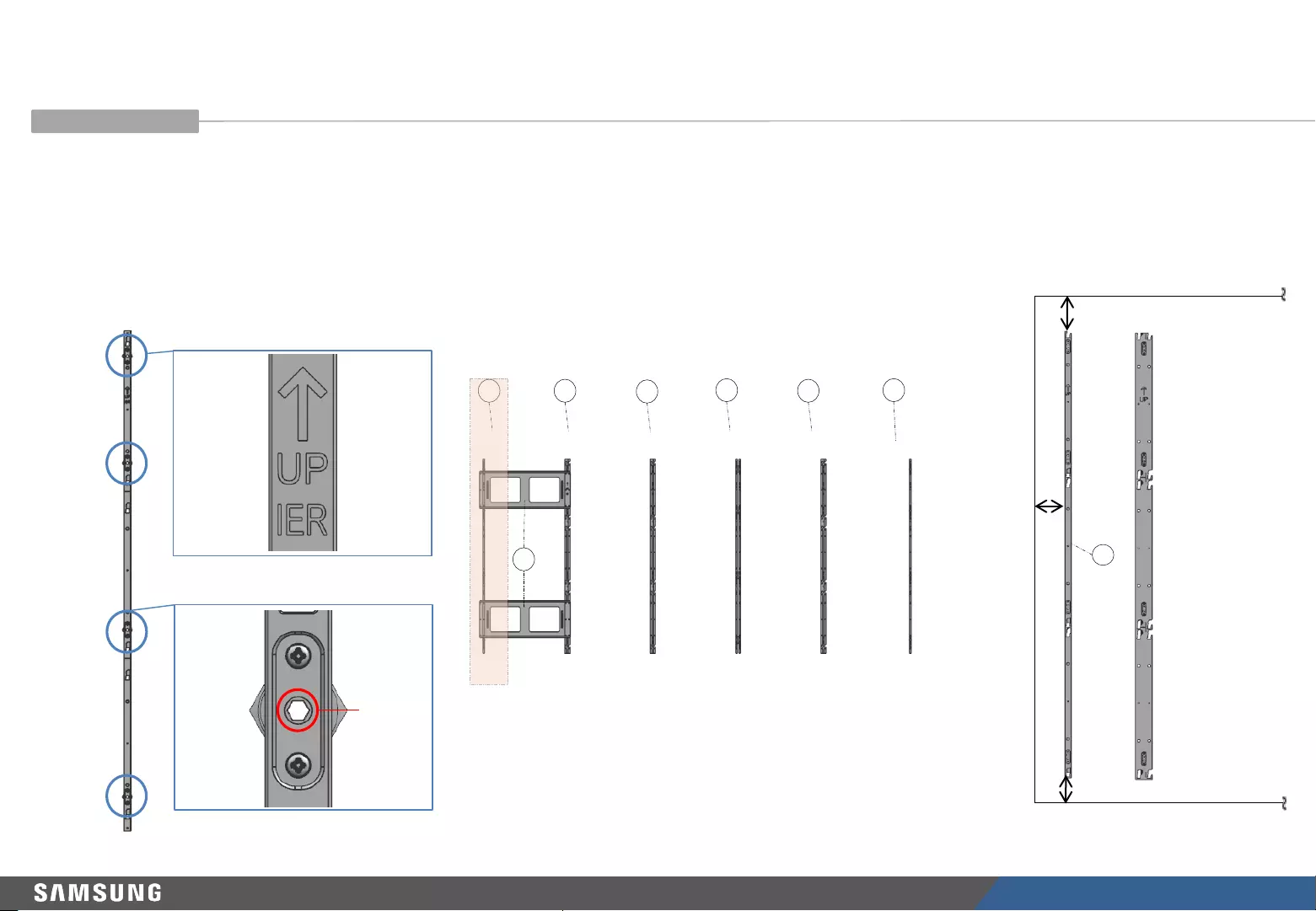

- 4. Frame Installation

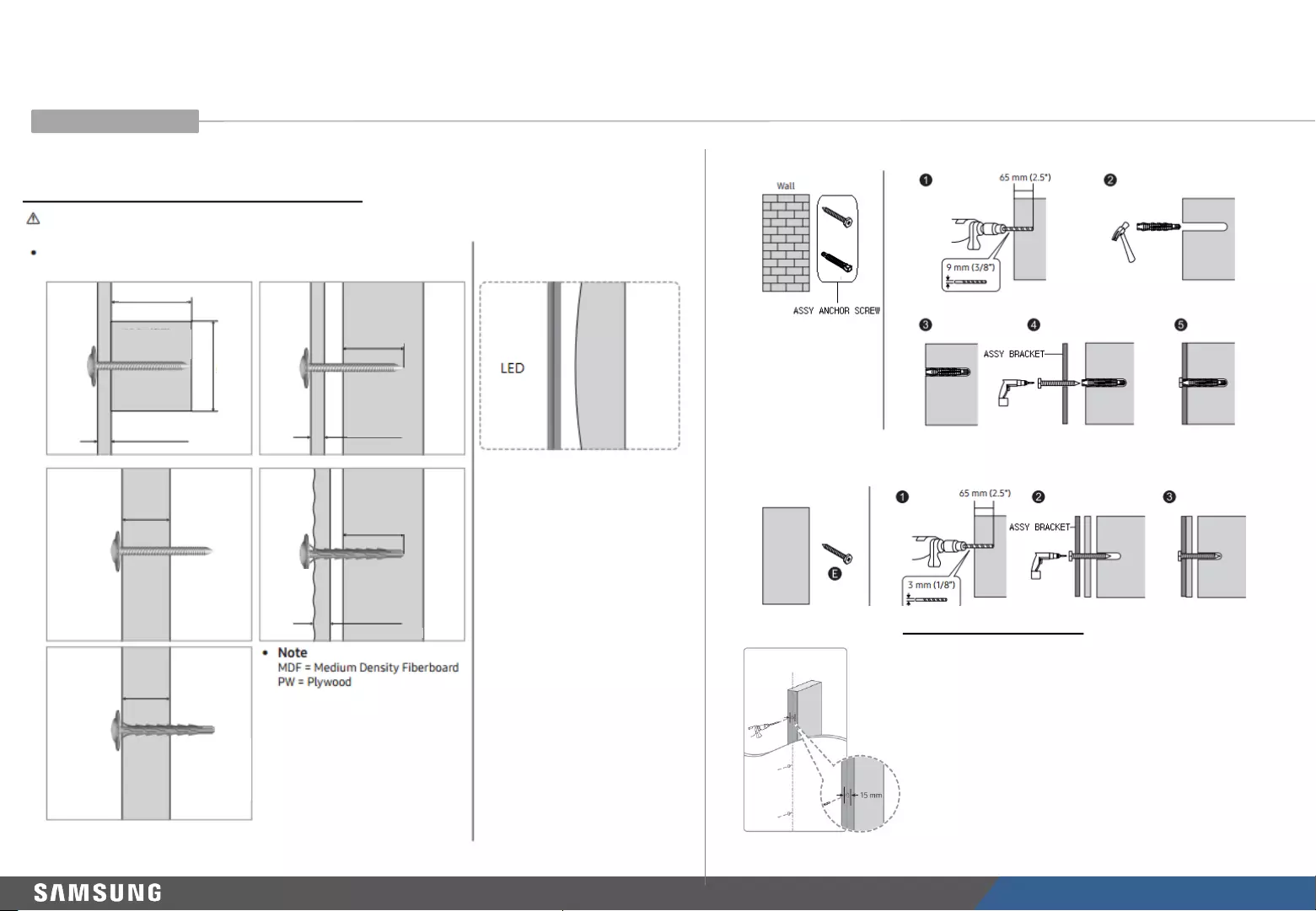

- 4. Frame Installation

- 4. Frame Installation

- 4. Frame Installation

- 슬라이드 번호 34

- 4. Frame Installation

- 4. Frame Installation

- 4. Frame Installation

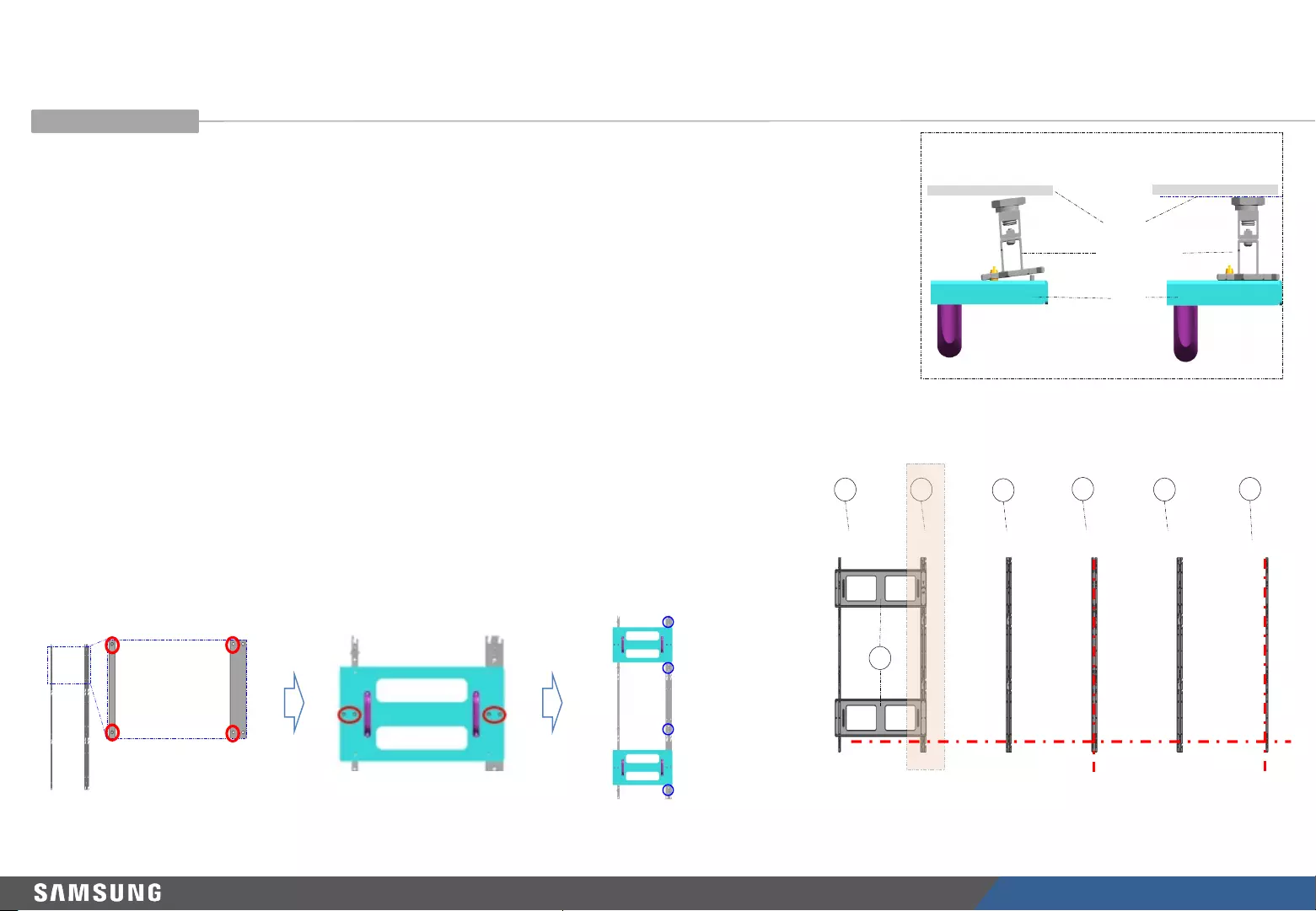

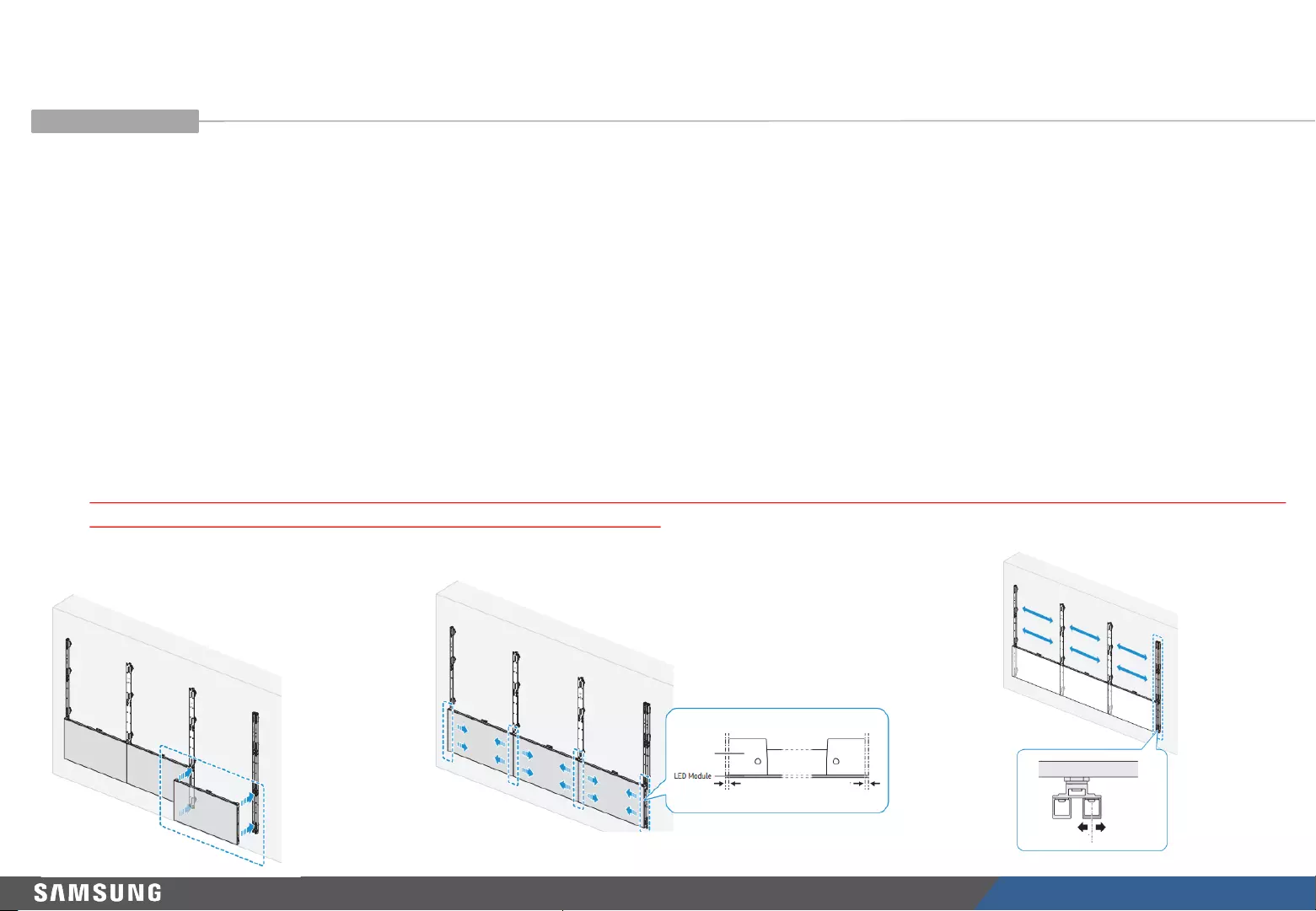

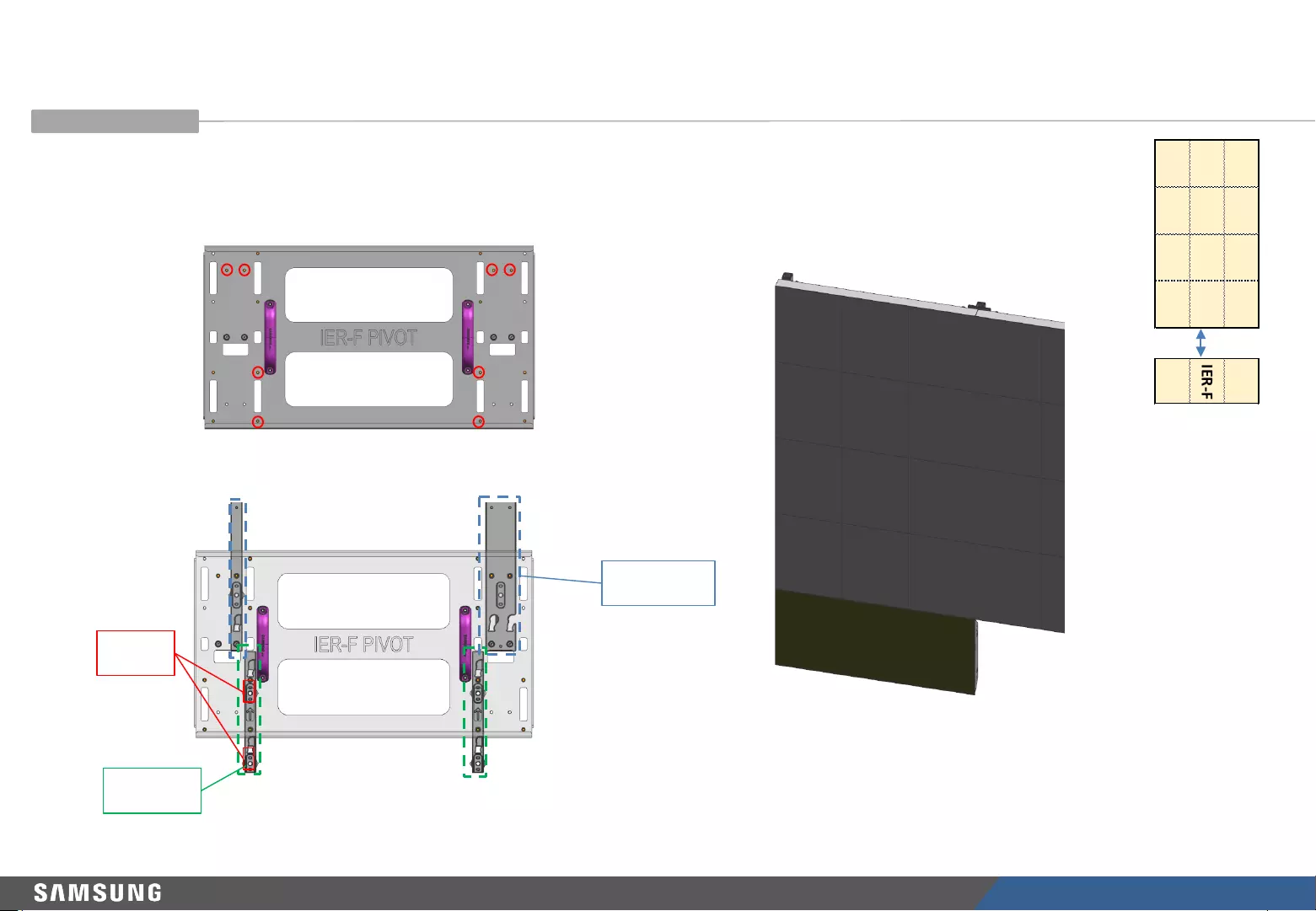

- 5. Cabinet + Frame Installation

- 5. Cabinet + Frame Installation

- 5. Cabinet + Frame Installation

- 5. Cabinet + Frame Installation

- 슬라이드 번호 42

- 슬라이드 번호 43

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 6. S-Box Installation and Connection

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 7. Settings / How to Use

- 슬라이드 번호 87

- 슬라이드 번호 88

- 슬라이드 번호 89

- 슬라이드 번호 90

- 슬라이드 번호 91

- 슬라이드 번호 92

- 슬라이드 번호 93

- 슬라이드 번호 94

- 슬라이드 번호 95

- Table of Contents

- 0. Product Information

- 0. Product Information

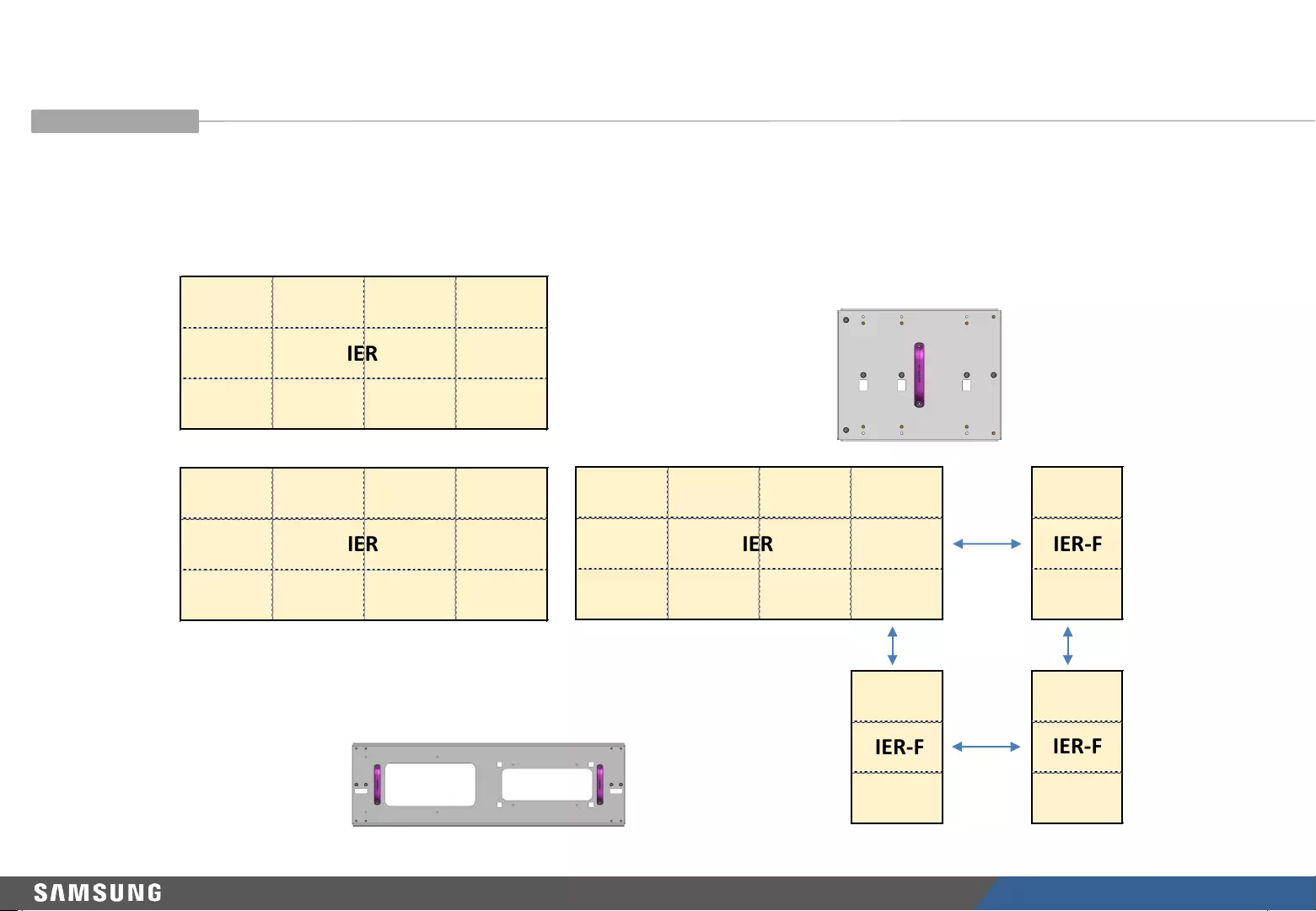

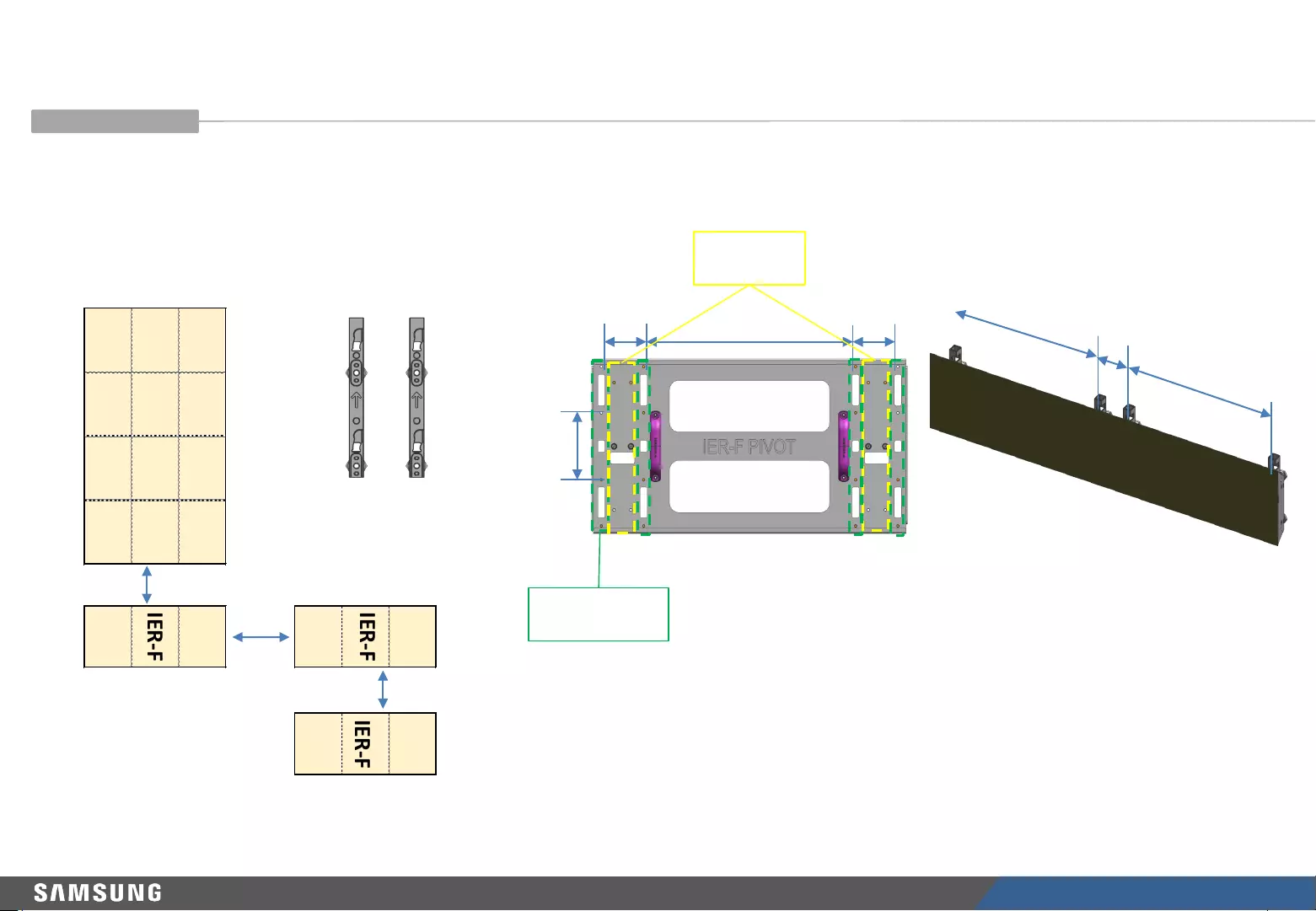

- 1. Frame Kit & JIG Configuration

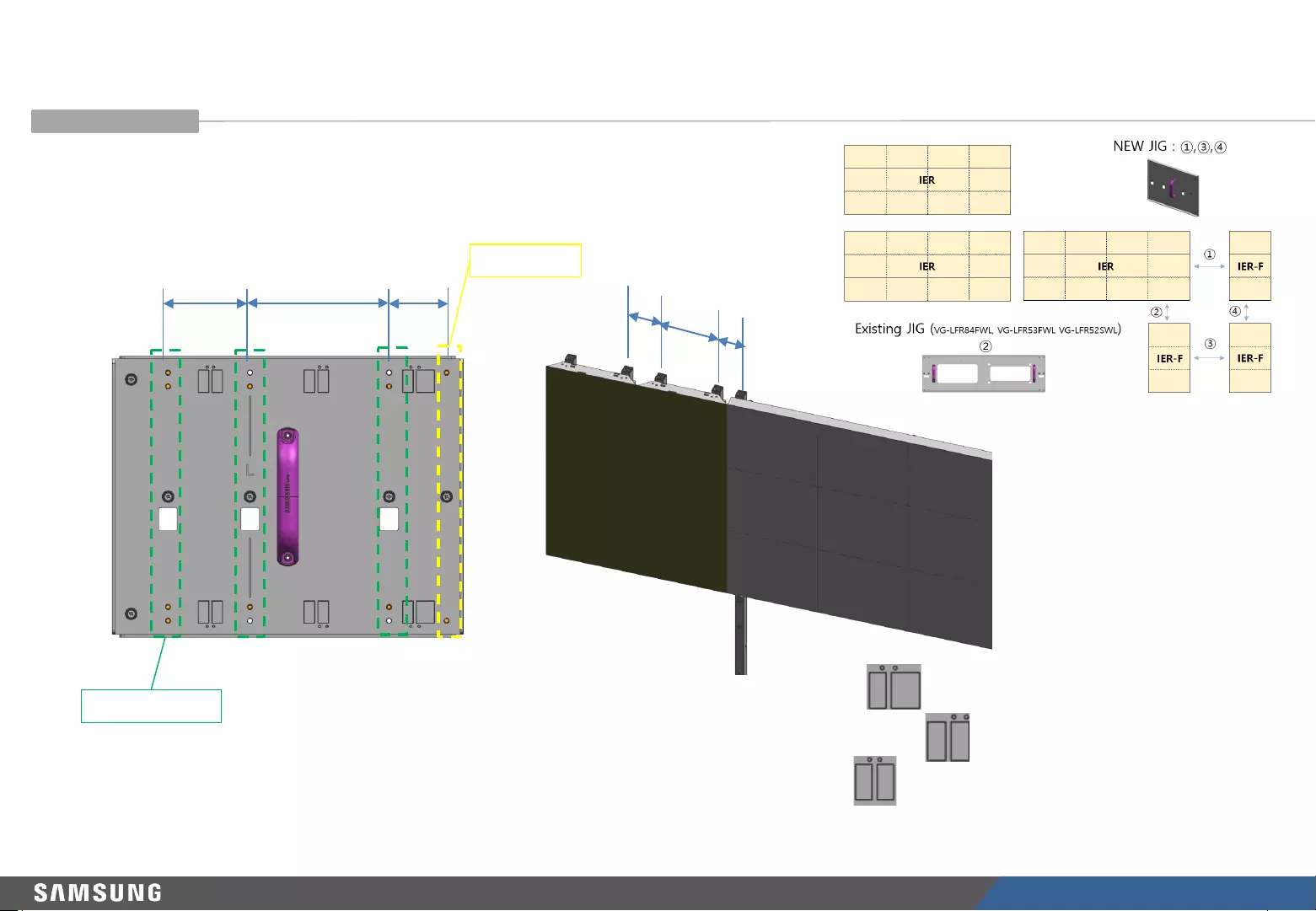

- 1. Frame Kit & JIG Configuration

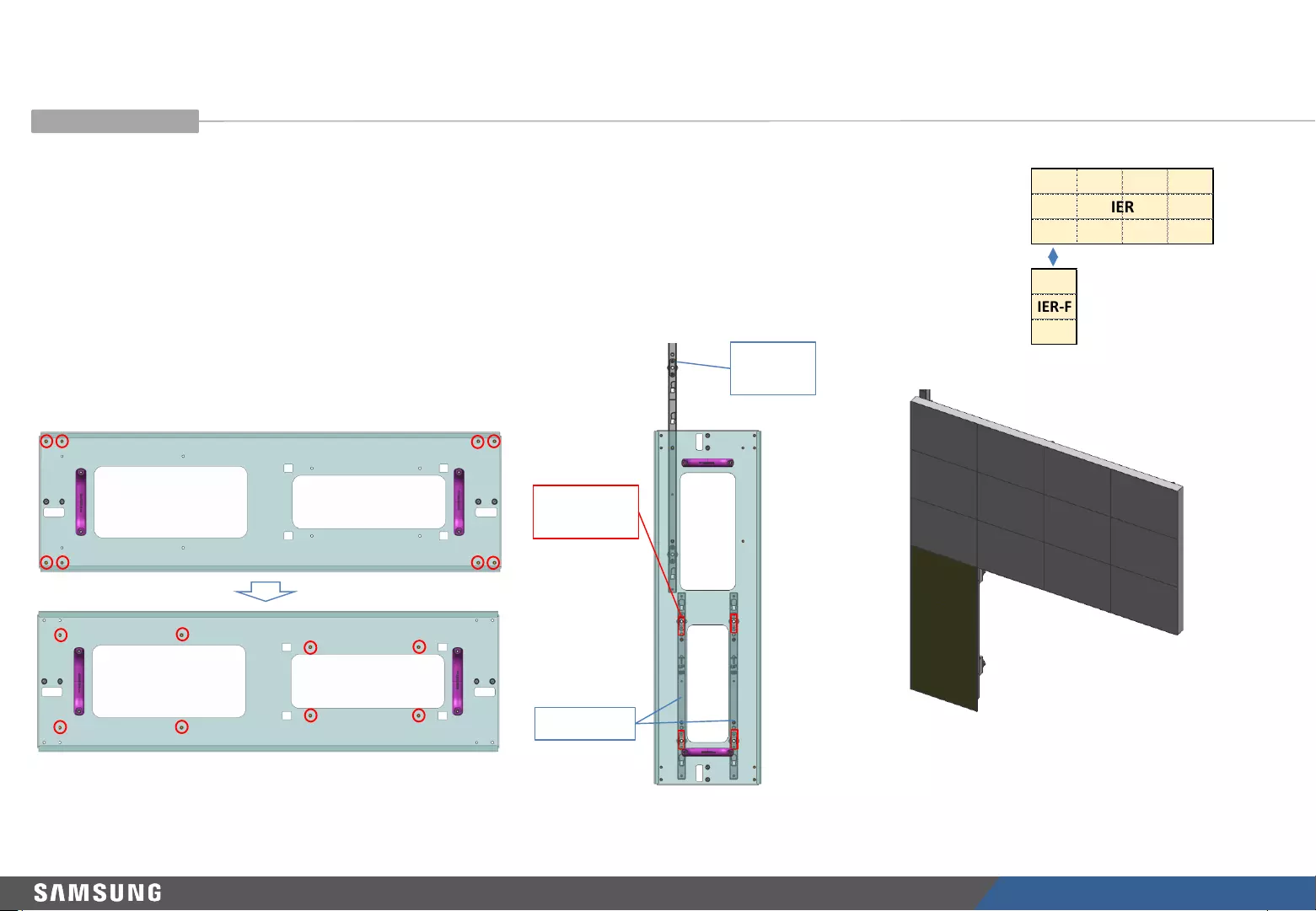

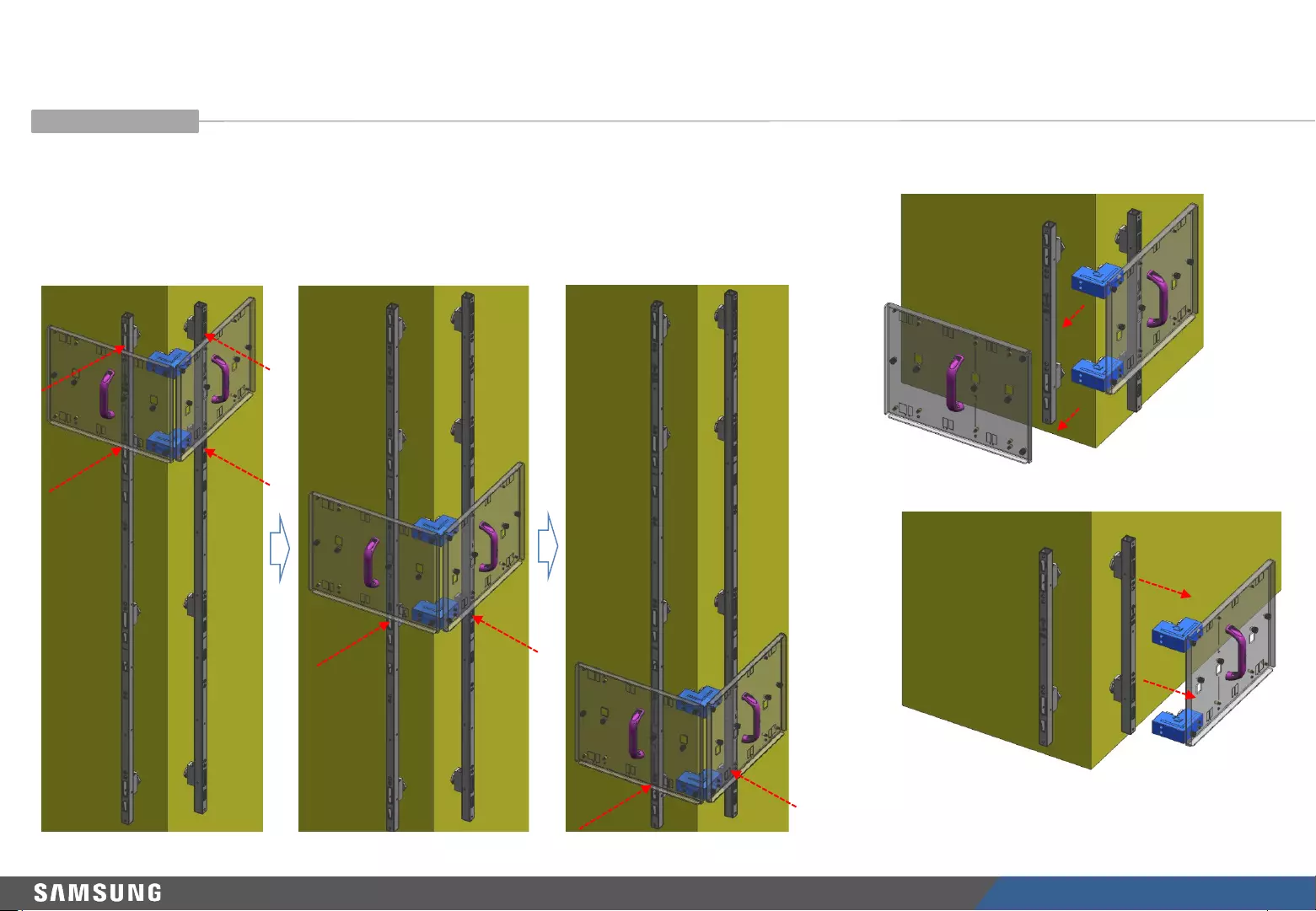

- 2. IER Landscape Installation + IER-F Extension

- 2. IER Landscape Installation + IER-F Extension

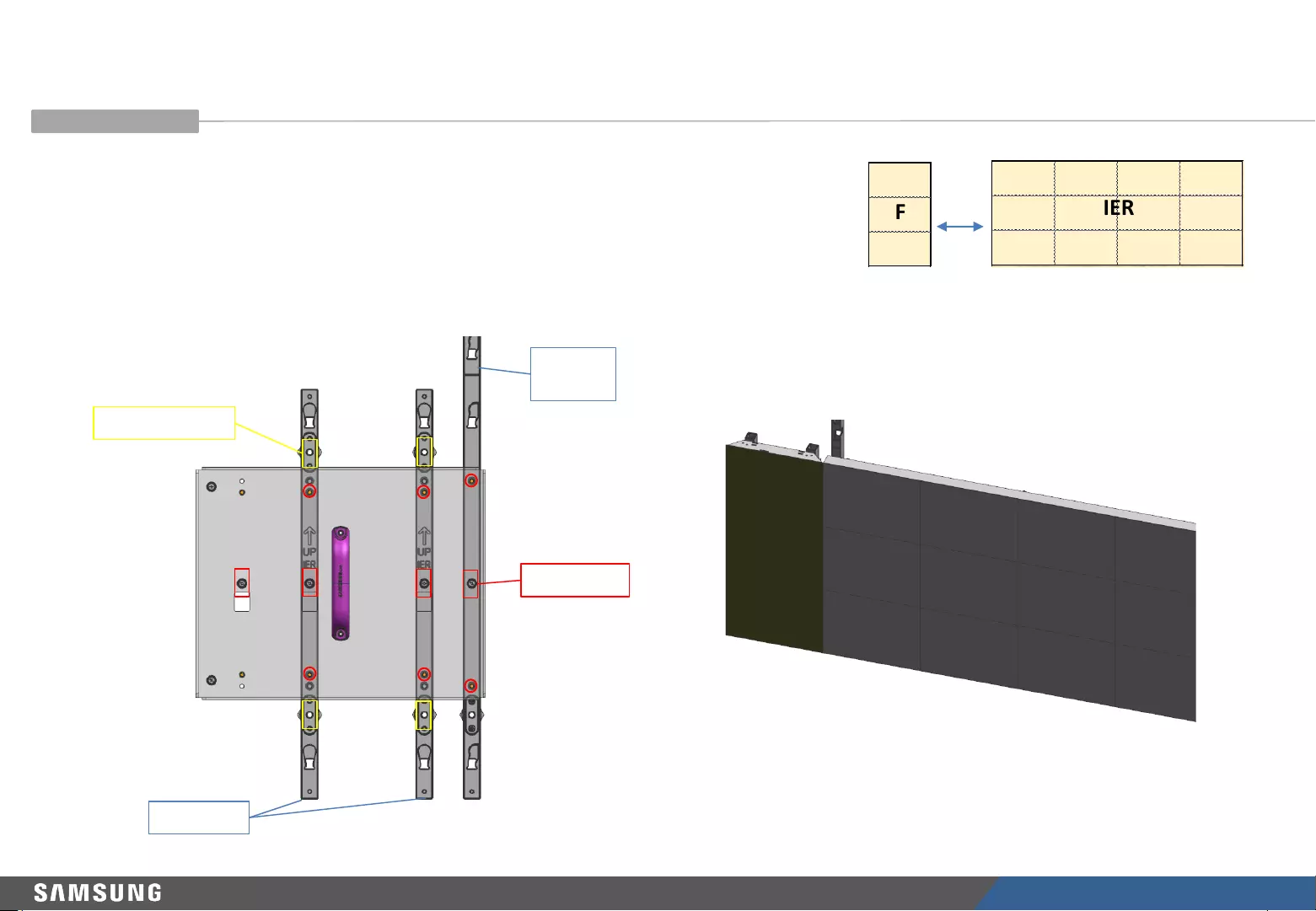

- 2. General Installation of IER + IER-F Extension Frame F

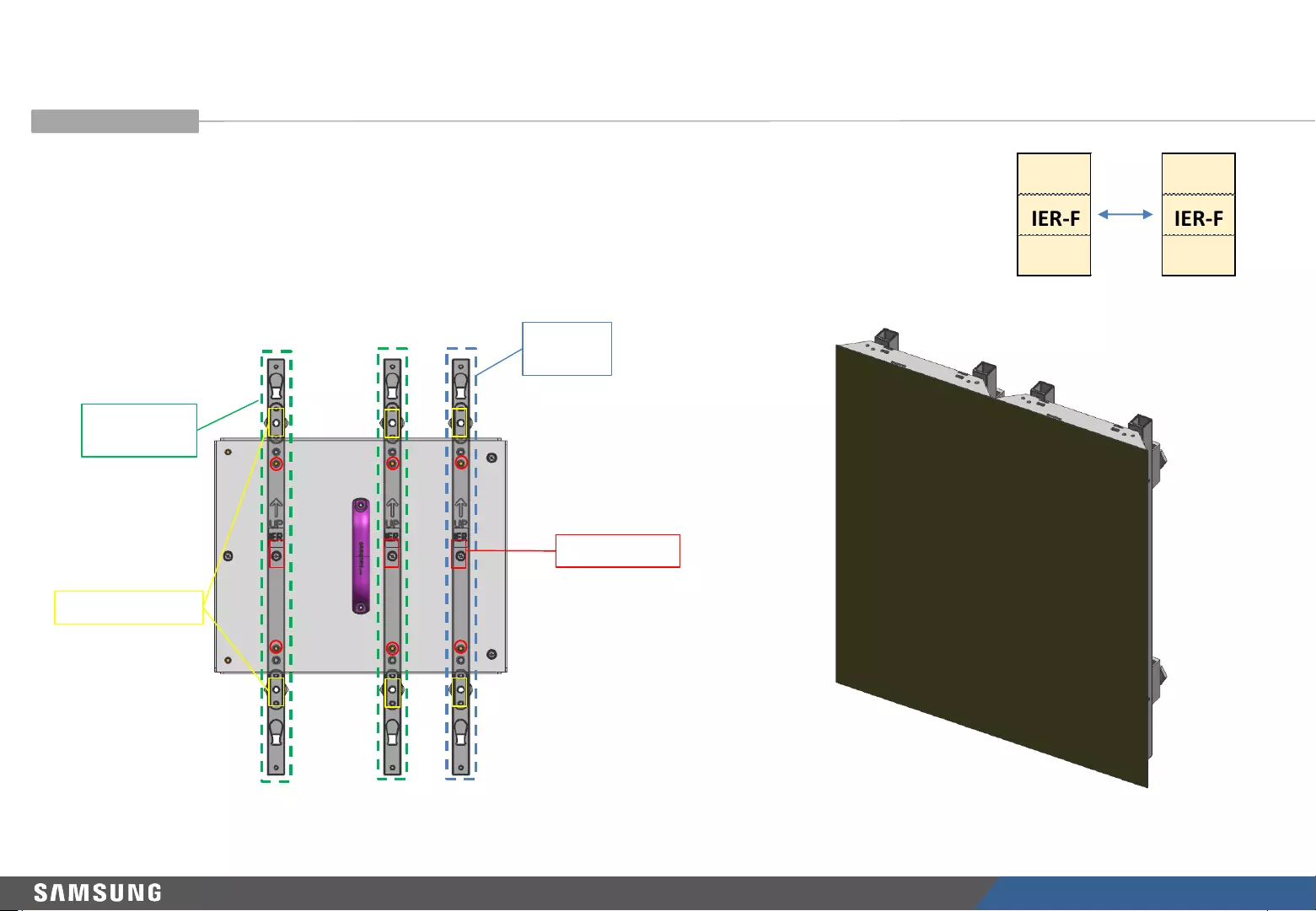

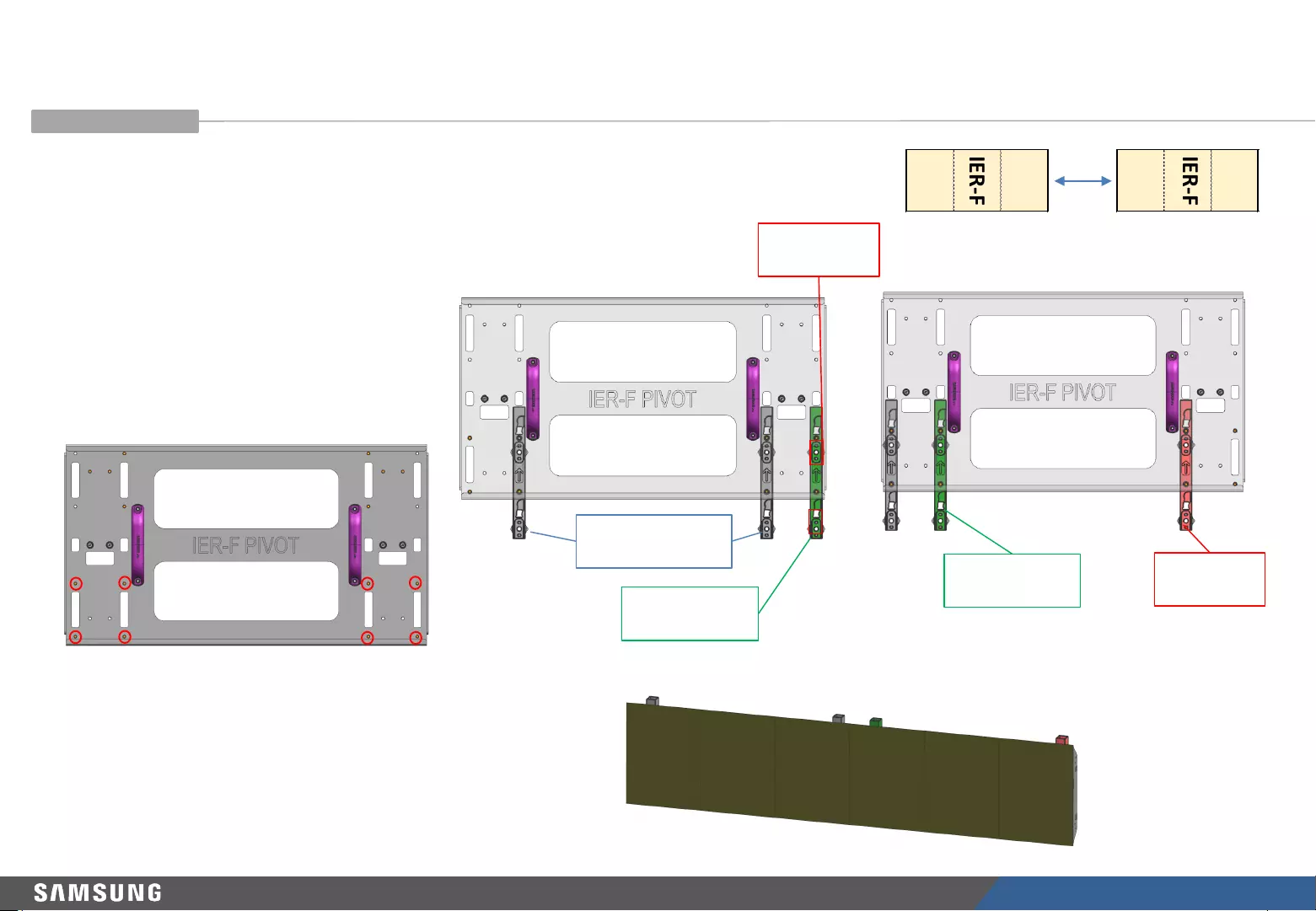

- 2-1. IER + IER-F Extension (Left to Right)

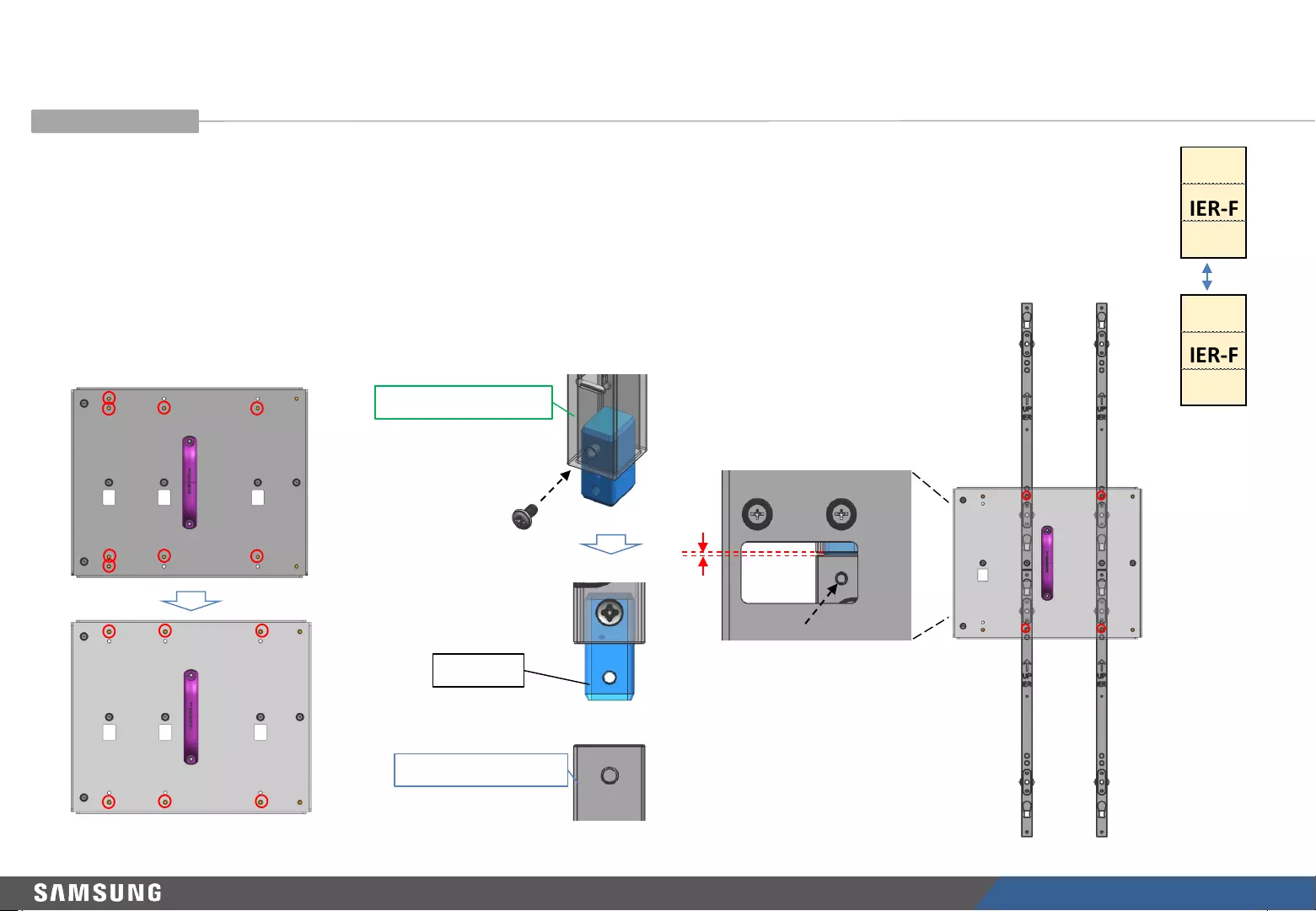

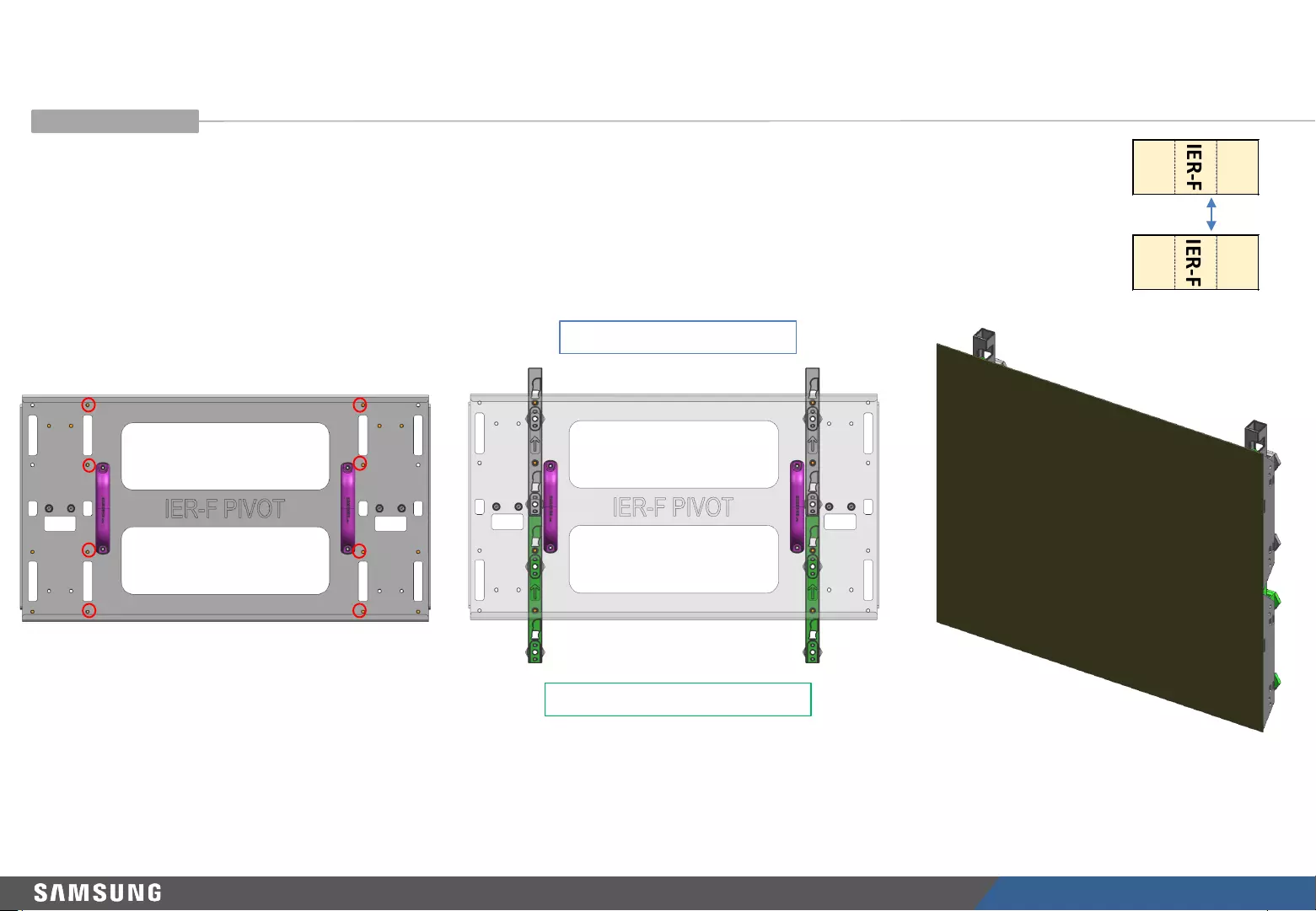

- 2-2. IER + IER-F Extension (Up to Down)

- 2-3. IER-F + IER-F Extension (Left to Right)

- 2-4. IER + IER-F Extension (Up to Down)

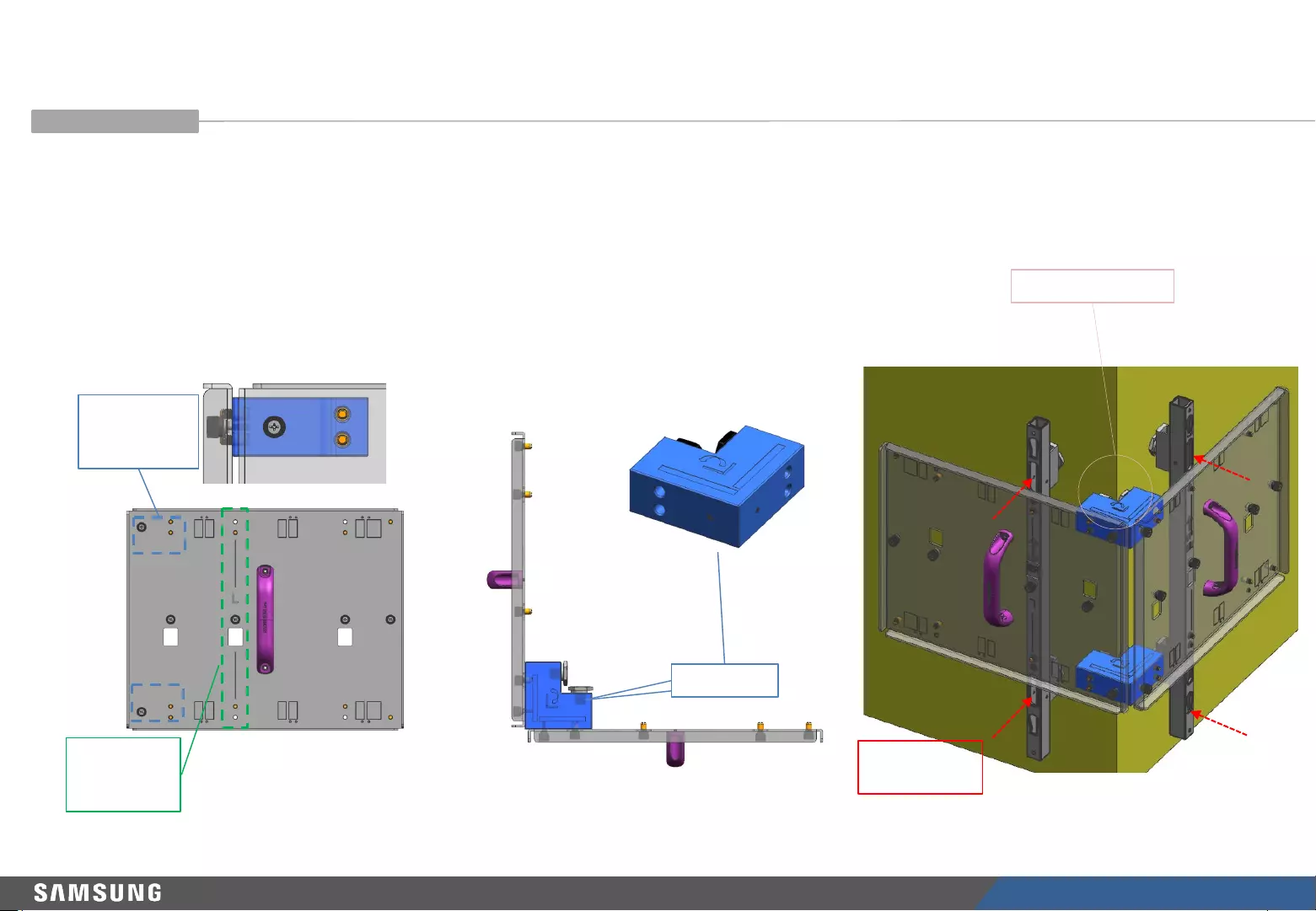

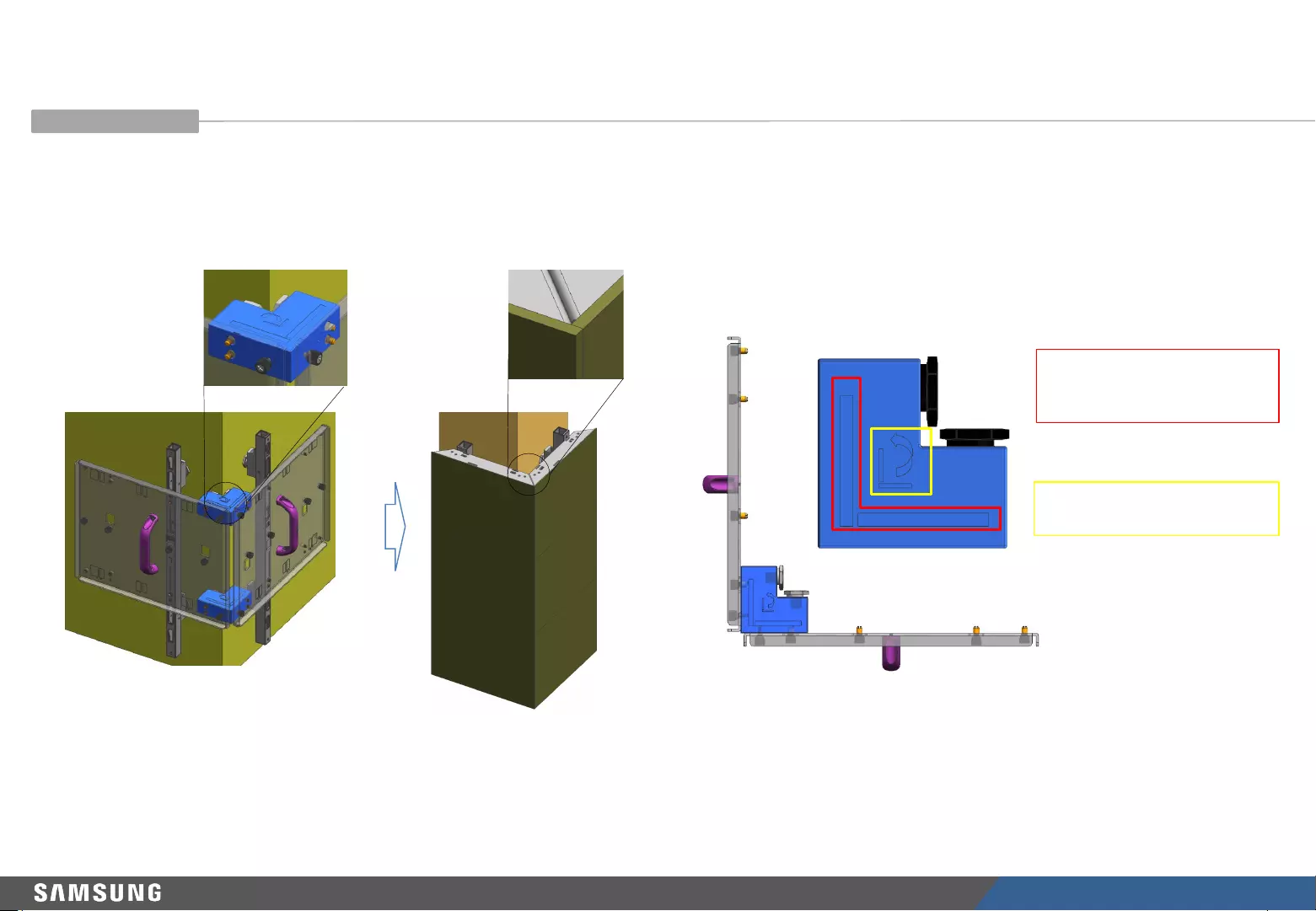

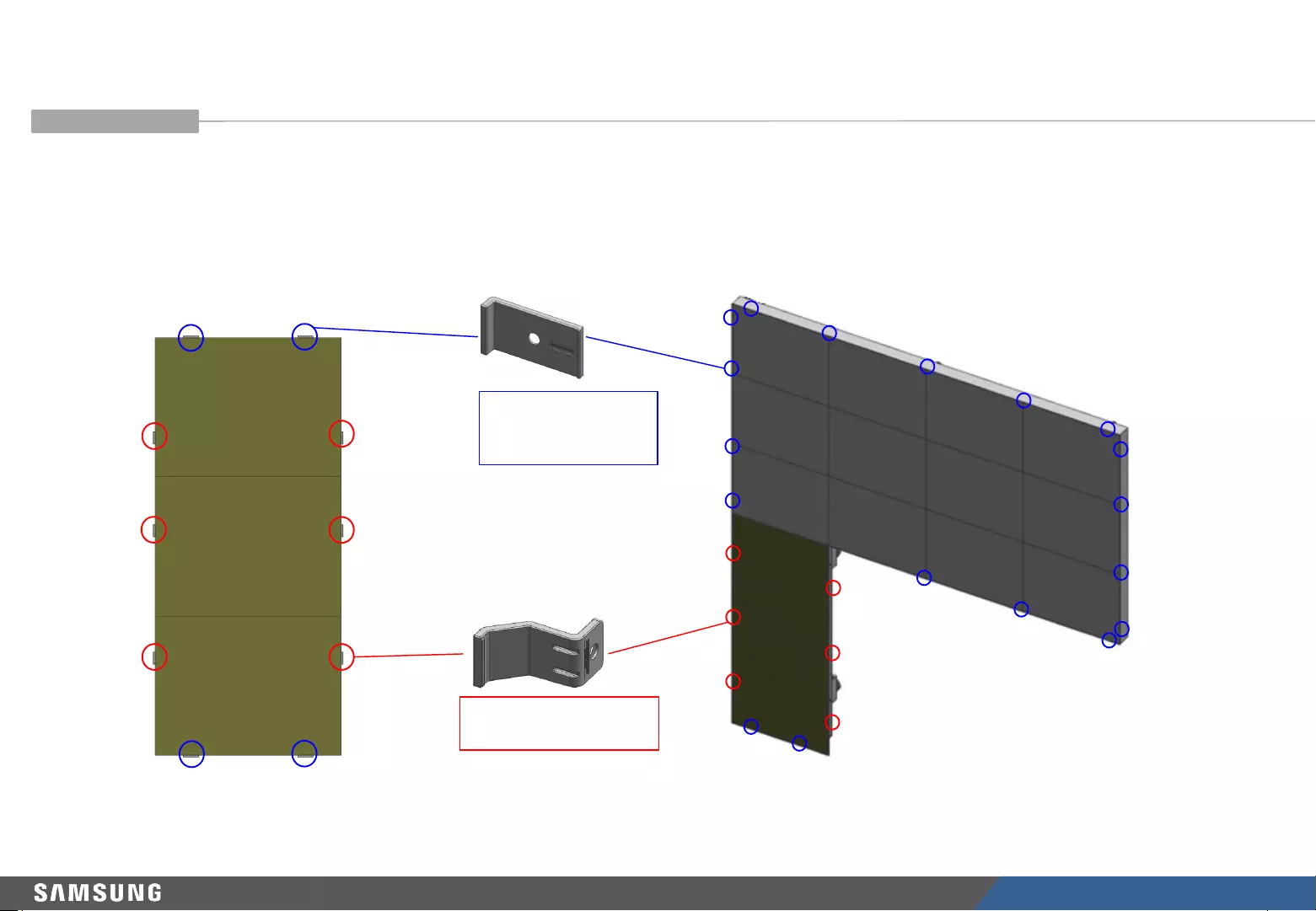

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

- 2-5. IER-F + IER-F L-Type Installation

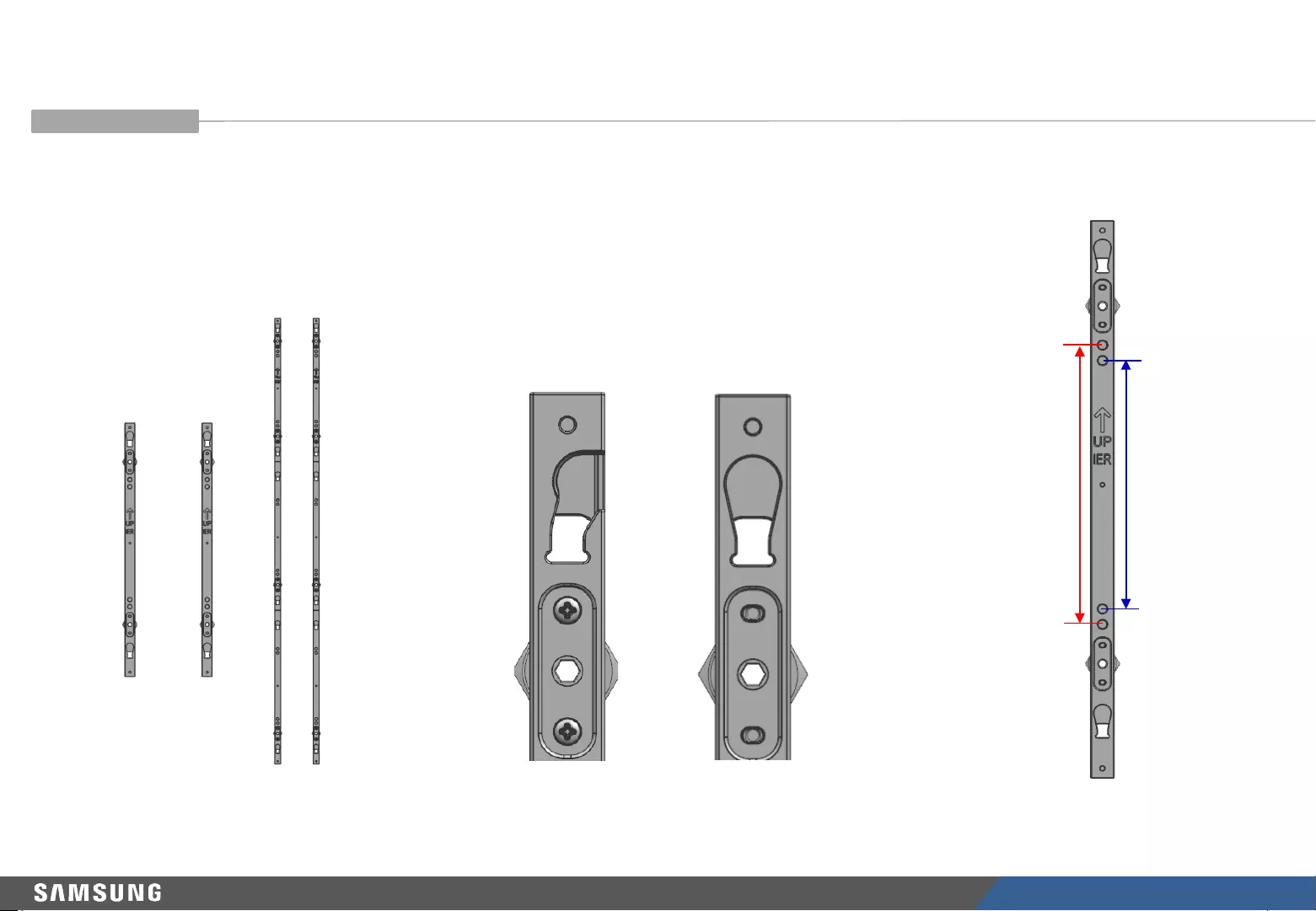

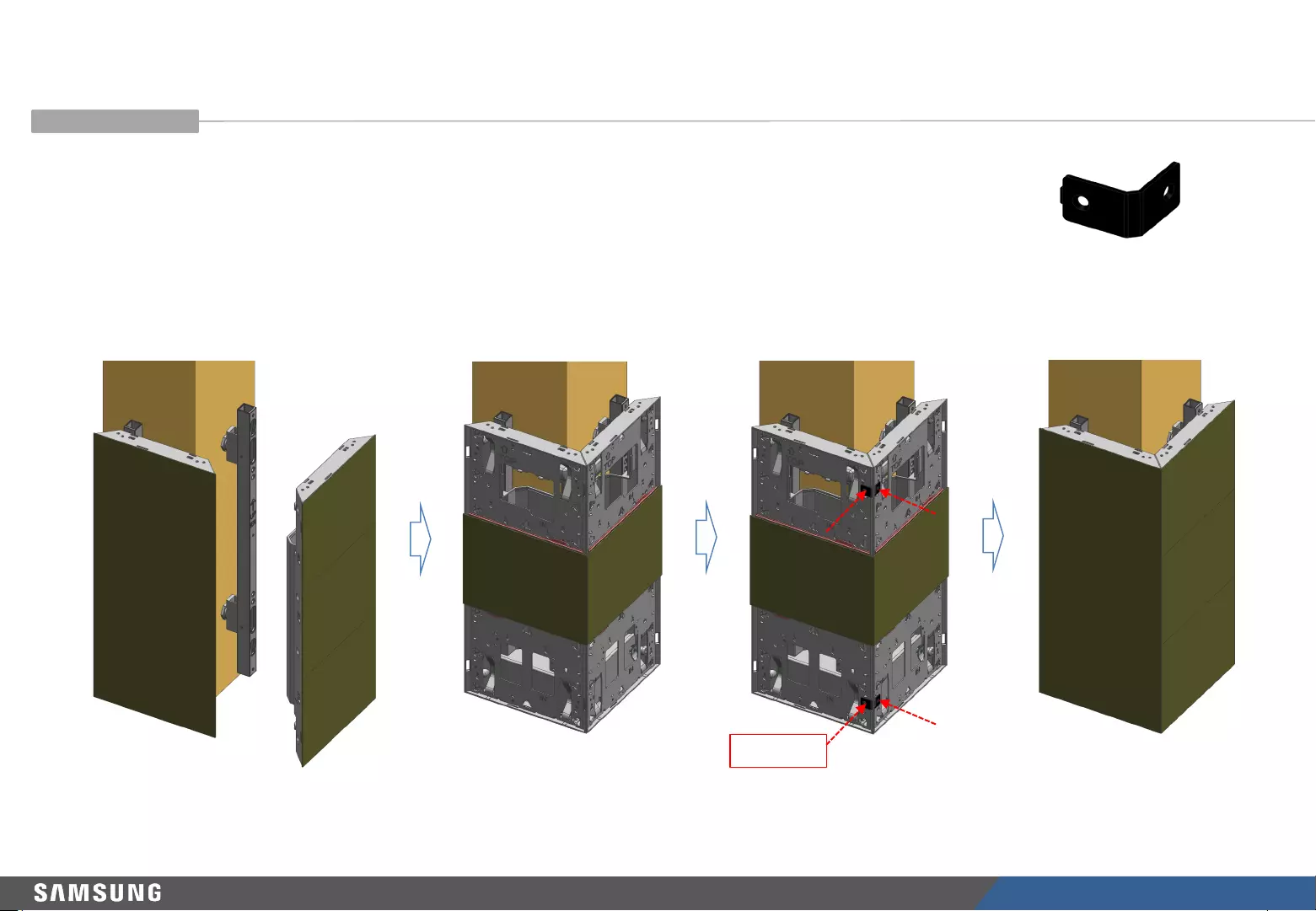

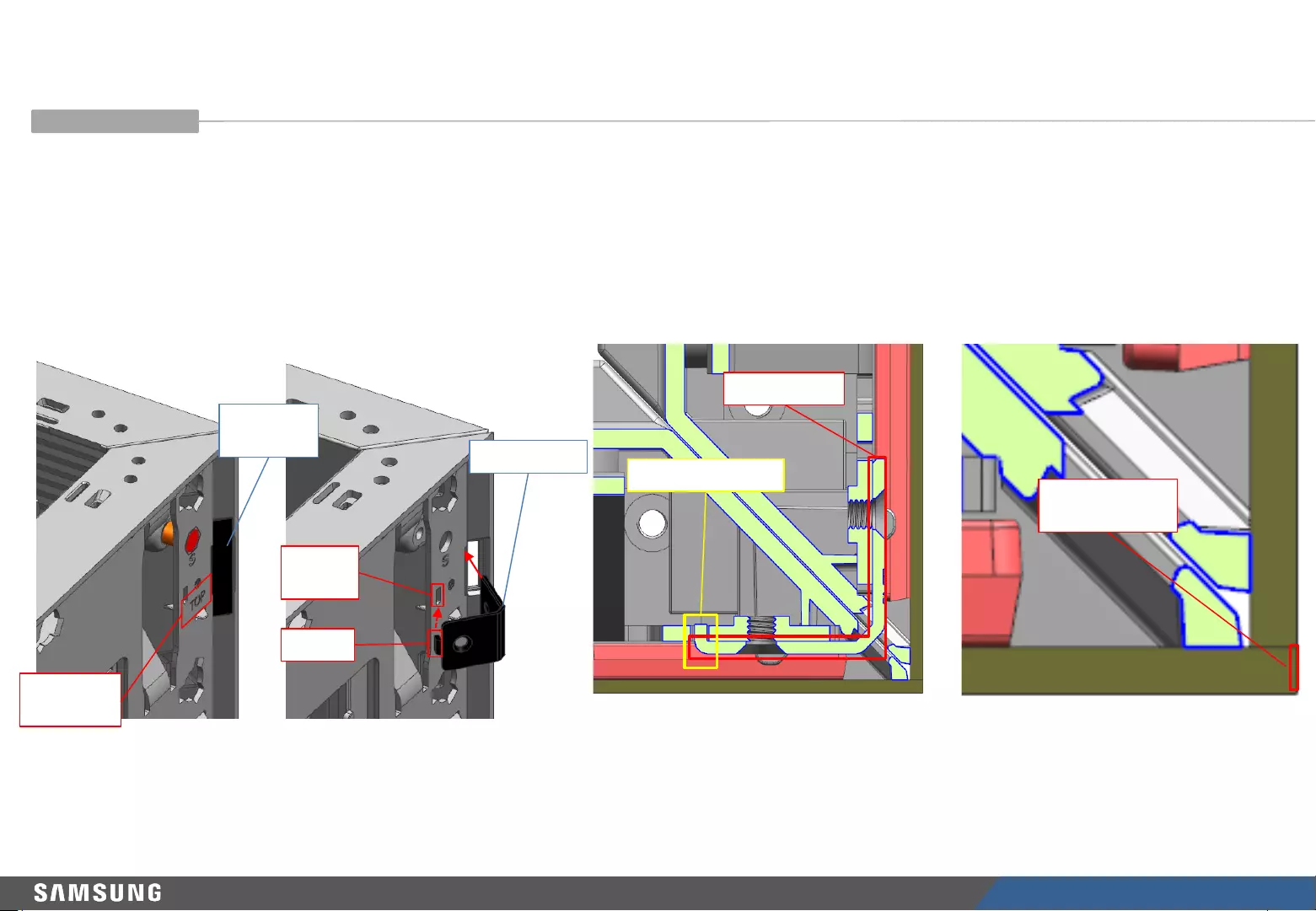

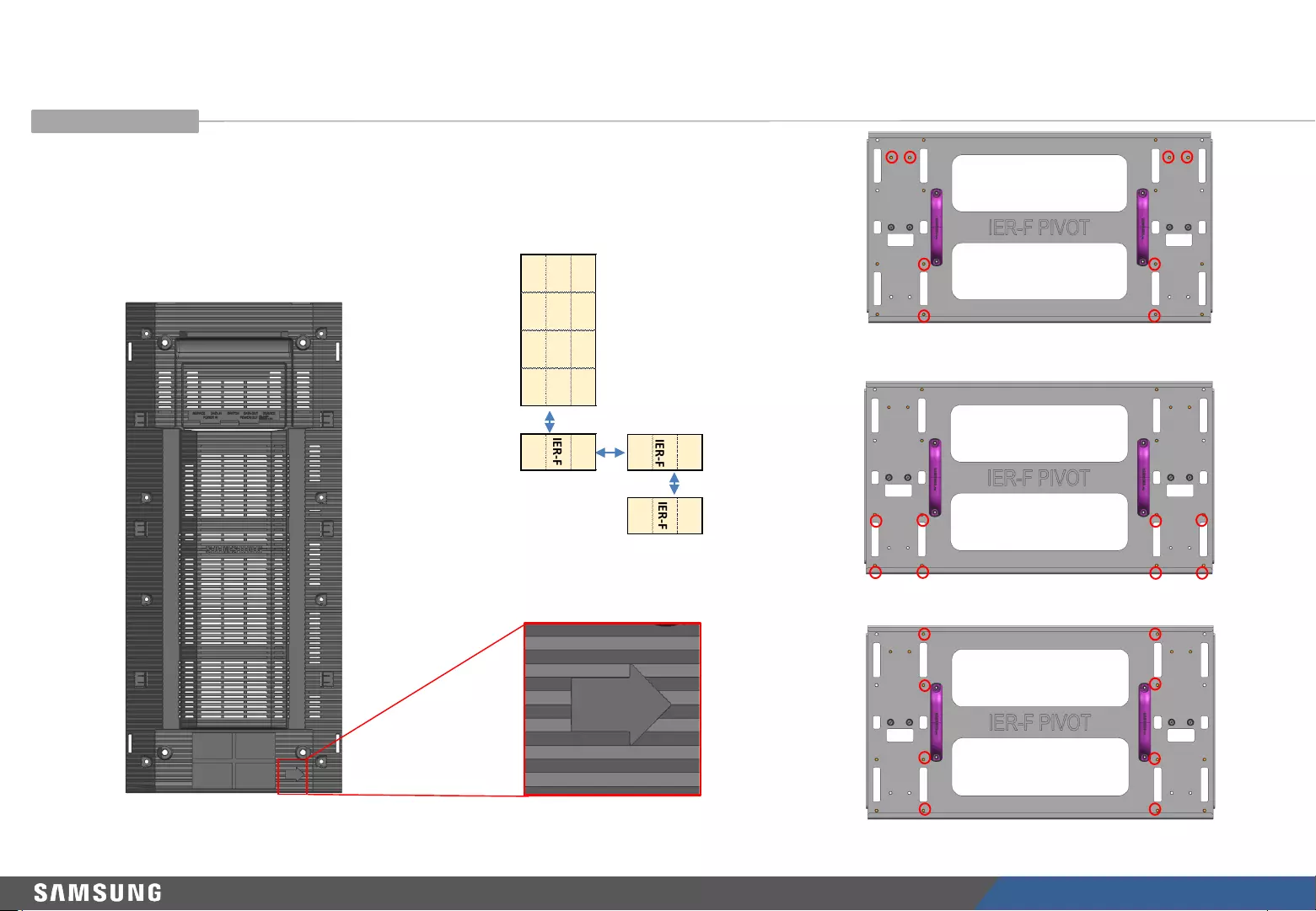

- 3. [PIVOT] IER + IER-F Extension

- 3. [PIVOT] IER + IER-F Extension

- 3-1. [Pivot] IER + IER-F Extension (Up to Down)

- 3-2. [Pivot] IER-F + IER-F Extension (Left to Right)

- 3-3. [Pivot] IER-F + IER-F Extension (Up to Down)

- 슬라이드 번호 120

- 슬라이드 번호 121

- Appendix 1 – S-BOX Network IP Set

- Appendix 2 – IFR P1.5 Screen FAN guide

Samsung VG-LFR13SWL User Manual

Displayed below is the user manual for VG-LFR13SWL by Samsung which is a product in the Mounting Kits category. This manual has pages.

Related Manuals

LED R&D Lab(VD)

LED Display

Installation Manual

Ver. 4.2

IER / IER-F / IFR /IFR-F Series

LH0**IER*LS , LH0**IER*FS

LH0**IFR*LS , LH0**IFR*FS

LED R&D Lab(VD)

1

Revision History

Version Date (Y/M/D) Description

2.0 2020/03/20 New Release

3.2 2020/06/22 Add SNOW-1810U installation and picture setting

3.3 2020/08/07 Add test pattern function

3.4 2020/08/21 Adjust Power consumption info and Table of contents + Appendix

3.5 2020/09/04 Add the luminance function of the operation for the mixed connections

3.6 2020/11/02 Modify dehumidification mode

3.7 2020/11/16 Add Network IP Setting by USB

3.8 2020/11/27 Update LSM guide

3.9 2020/12/01 Update Picture Option

4.0 2020/12/02 Update Dehumidification Guide

4.1 2020/12/14 Update Ventilation Guide

4.2 2020/12/28 AC placement guide to prevent condensation

Dehumidification guidance –during installation

When moist gets into LED package because of high humidity, ‘Line defect’ can

be caused by electrical short inside of LED Package.

For keeping the best quality of products during installation, please refer to the

below cautions.

-If the condition meets one of the below cases at least, dehumidification MUST be

processed. Do not play any contents on the screen before dehumidification finishes.

∙Case when vacuum packaging is already unsealed before unpacking products.

∙Case when environment condition is worse than Samsung working condition (0°C~40°C/10~80%RH).

∙Case when it elapses longer than 7 days after unpacking them, even though the environment condition

satisfies Samsung working condition (0°C~40°C/10~80%RH).

∙Case when production date on the label elapses more than 6 months, even though vacuum packaging is

sealed.

∙Case when volatile chemicals such as oil paint, solvent are used in same place of installation.

(You can refer to Product Information and Precautions for Installation part in detail.)

-If the screen needs dehumidification on installation, MUST follow the directions of next page.

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance –during installation

How to install the screen in the case that dehumidification is necessary

※ Before finishing the directions explained in next pages, never play other contents or use them.

※ If the installation site has higher humidity, it is highly recommended to use dehumidifier.

(If A/C turned off after working hour, it may make humidity higher and cause line defects.)

※ Chilled air from A/C should never touch LED surface directly.

※ If thermo-hygrometer is equipped on the site while the screen is installed, it is useful to analyze

the cause of line defects.

1. Play a specific pattern of LSM program without any cabinets.

(This pattern should be used. If other pattern is used, it can cause line defects.)

2. Inspect cabinets with darker solid patterns(W/R/G/B) and turn off cabinets.

(It should take less than 30 seconds to show each solid patter and you can refer to ‘Process of

Screen check’ category in detail.)

This contents must be noticed to customer.

Please print this page and hand it to user.

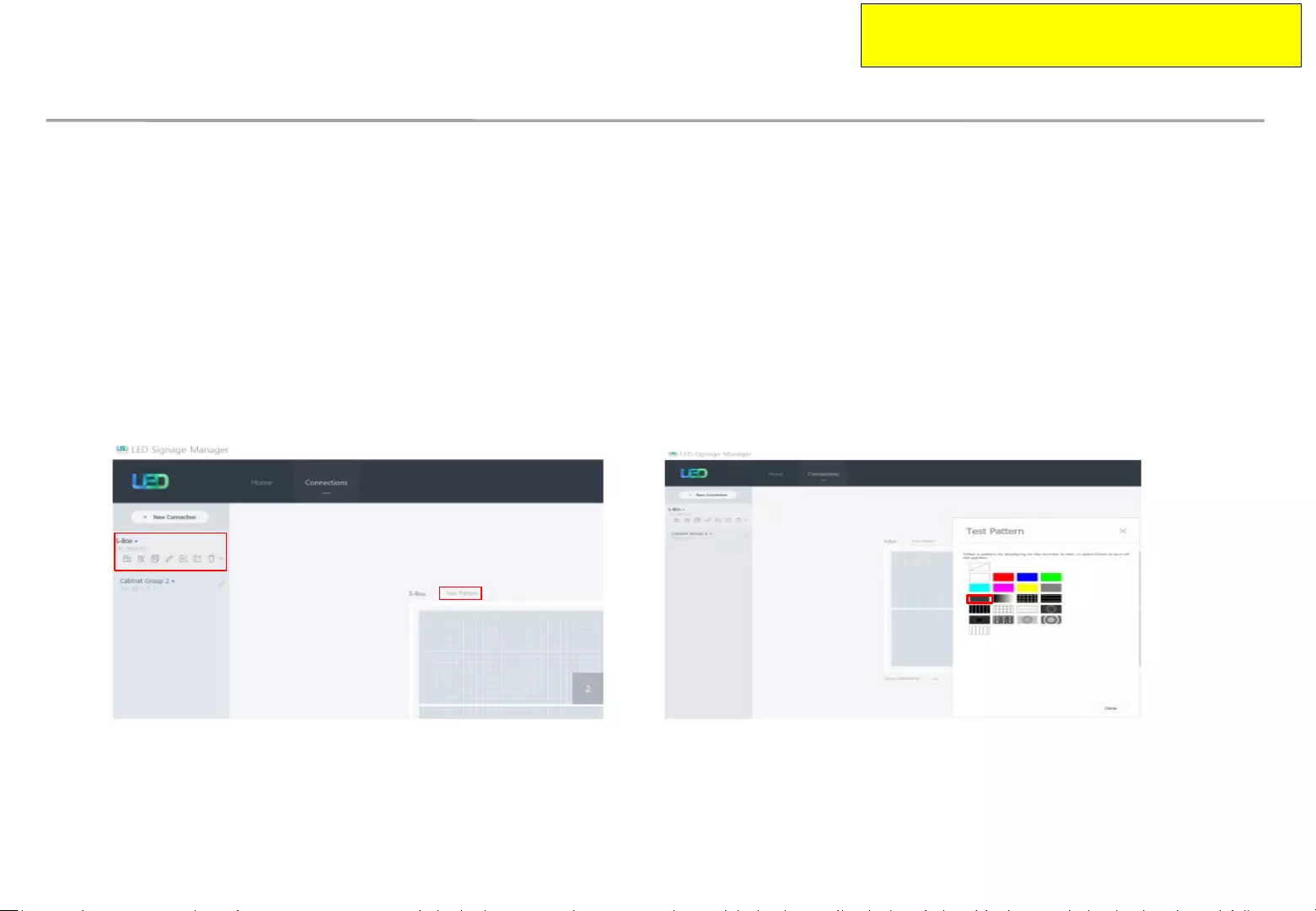

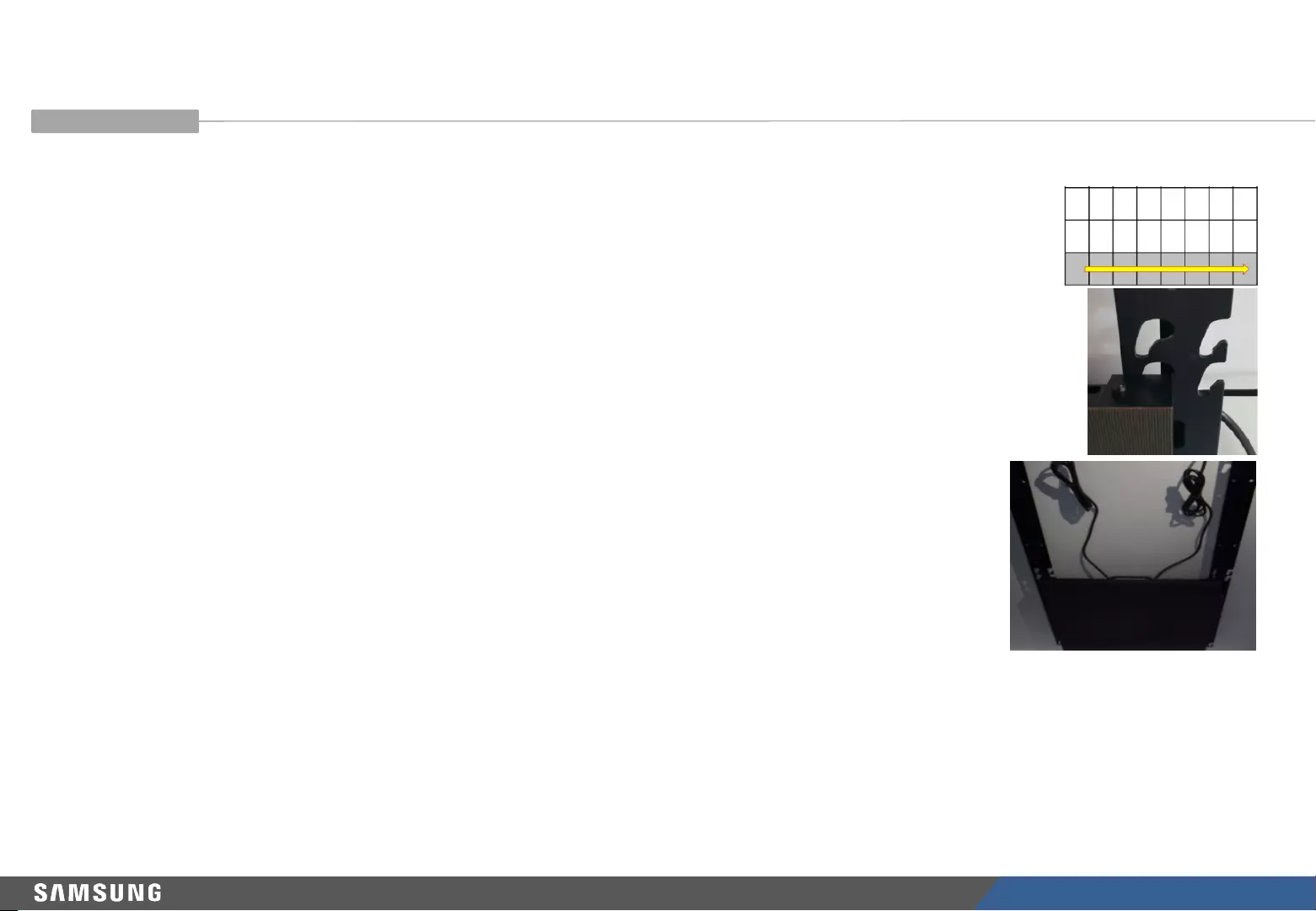

①Select S-Box and Test Pattern ②Set darker gray pattern among various patterns.

Dehumidification guidance –during installation

How to install the screen in the case that dehumidification is necessary.

3. While installing cabinets, S-Box should play only this pattern.

•Check S-Box shows the pattern through monitor connected to S-Box service port.

•After installing each cabinet, check whether the pattern is shown in it.

•OCM cable connection can be checked through this.

•Before turning off S-Box, turn off the cabinets, first.

•After being sure S-Box plays this pattern, turn on the cabinets.

4. After completing installation of cabinets, start 24hr dehumidification process.

5. After finishing 24hr dehumidification process, do edge correction and module calibration.

This contents must be noticed to customer.

Please print this page and hand it to user.

•Electrical short in package is possible to happen during products are working.

•For keeping quality of products during installation, please refer below cautions.

–If one of below case meet during operation, MUST do dehumidification process.

Case when environment condition is exceed operation condition.

Case when products are not working more than 1 month, even though environment condition is under

operation condition.

–When environment condition is exceed operation condition, products are out of warranty.

Please check environment condition.

–Even products are operating, if the installed place have extra construction such as interior

modification, MUST do dehumidification following installation condition.

–It is possible to happen dew condensation on surface of products, even though working on

operating condition. When happening dew condensation, MUST operate after cleaning the dew

condensation & dehumidification.

Dehumidification guidance –during operation

This information should be noticed to customer.

Please print this page and hand it to user.

Dew condensation due to overcooling

Even though meet with Samsung recommended operation

condition, dew condensation is possible to happen when

surface of products is colder than environment temperature or

hot & humid air blow to cooled surface of products.

(cf : Principle of happening dew on surface of glass which have ice)

Case when dew condensation is happen on products, it is

possible to be the root of defect. In this case, it is possible to

be out of warranty.

This information should be noticed to customer.

Please print this page and hand it to user.

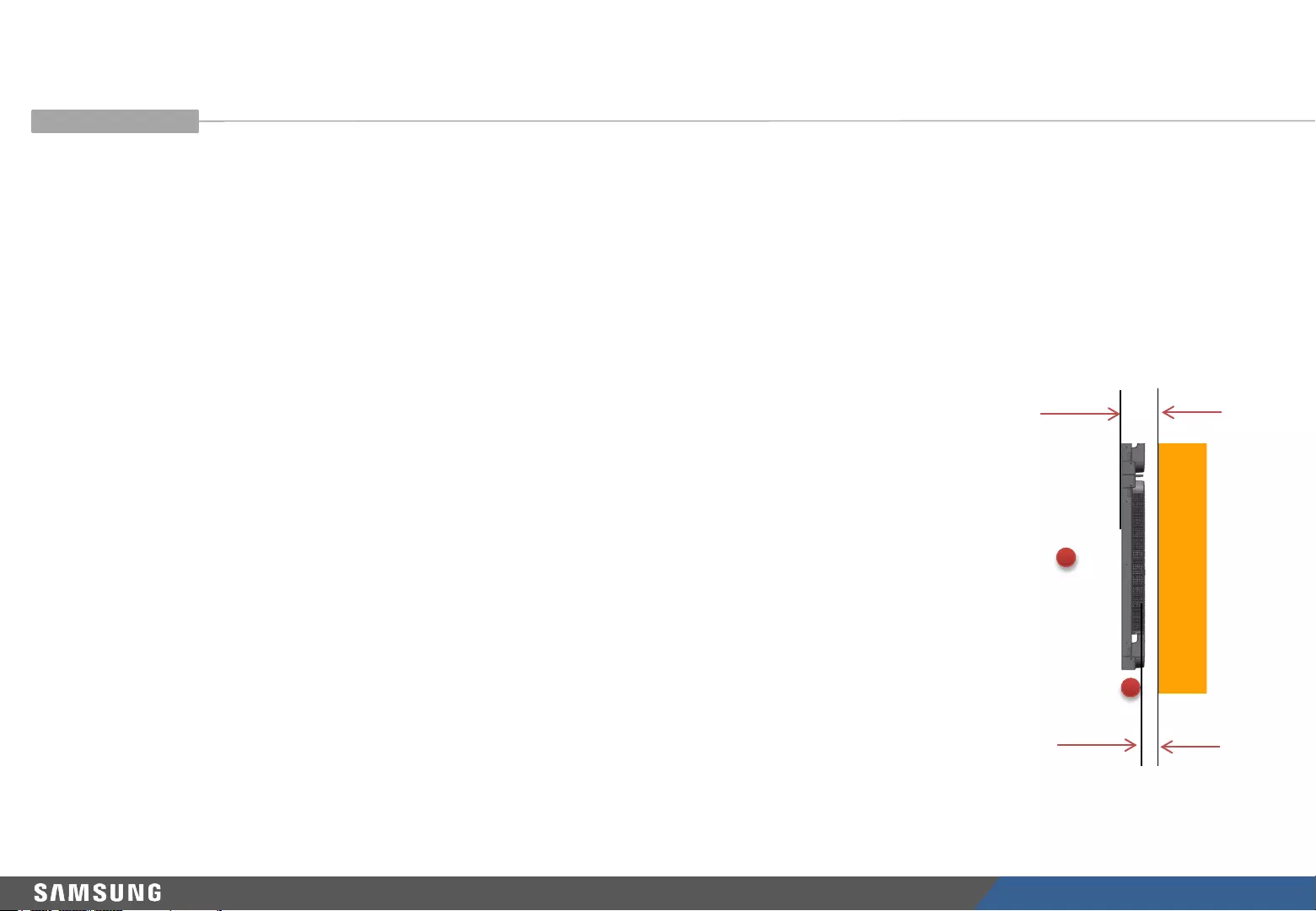

Prevent condensation due to A/C

Make sure that the cold air does not blow directly on the screen.

–When the cold air from A/C (air conditioner) blows directly onto the screen surface,

condensation may occur depending on the ambient humidity and temperature of

screen surface.

–If the A/C and screen are close, install a wind deflector as shown in the figure

below to prevent condensation.

This information should be noticed to customer.

Please print this page and hand it to user.

Install the wind deflector toward the screen.

•When install products, please update latest firmware on online

-You can download latest firmware from SLM site.

URL of SLM Page : https://www.secslm.com

After login Help Download Center에서 Download

Before you download firmware, you MUST check same firmware of model

(marked red letter in below) & upper number of version (marked blue in below).

-You can update firmware through LSM.

Please refer ‘7-1 PC control program’ for the way to update firmware.

8

Guidance of latest firmware

Cabinet : Main -L-xxxMWWAC-nnnn.n xxx = Pan name, nnnn.n = version

FPGA -aabbd_ddddd aa = pixel pitch, bb = LED package type, d_ddddd= version

Example : IER P2.5 Cabinet : L-IERMWWAC-1003.1, FPGA : 25252-31046

S-box : TB-KTM2SBMDWWC_100x.x

LED R&D Lab(VD)

9

Table of Contents

1. Product Information and Installation Precautions (P.7)

2. Preparation for Cabinet Installation (P.18)

3. Frame Kit (P.22)

4. Frame Installation (P.23)

5. Cabinet + Frame Installation (P.31)

6. S-Box Installation and Connection (P.35)

7. Settings / How to Use (P.54)

8. Power and Cable Connection (P.73)

9. Seam Adjustment (P.79)

Appendix. IER-F/IFR-F series Installation Manual (P.81)

Appendix 1. S-BOX Network IP Set (P.108)

Appendix 2. IFR P1.5 Screen FAN guide (P.109)

LED R&D Lab(VD)

10

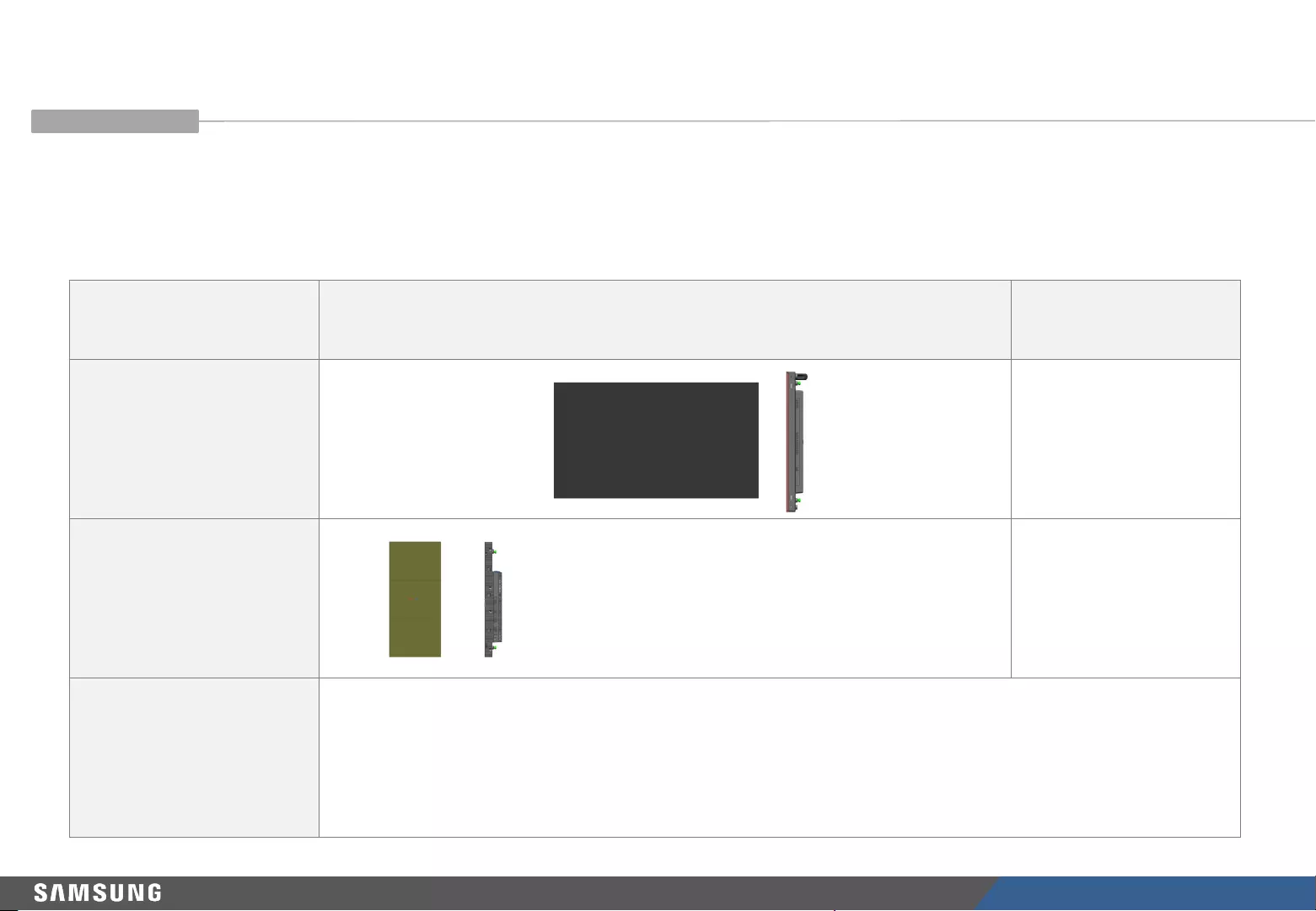

Models Product Appearance and Information

Installation Table

of Contents

IER/IFR series See pages 2 to 76

IER-F/IFR-F series See 77 to 96 pages

remarks IER/IER-F Series : Using Copper Wire LEDs

IFR/IFR-F Series : Using Gold Wire LEDs High Luminance Models

For different types and Curved installations

Made in 1⁄4 size of IER/IFR.

Recommended mix installation with IER/IFR.

1. Product Information and Installation Precautions

◆Model Line-up

-This Manual is an Installation Manual for IER/IFR(Appendix. IER-F/IFR-F), which contains information of

models below (Installation process is same for each pitch model)

LED R&D Lab(VD)

11

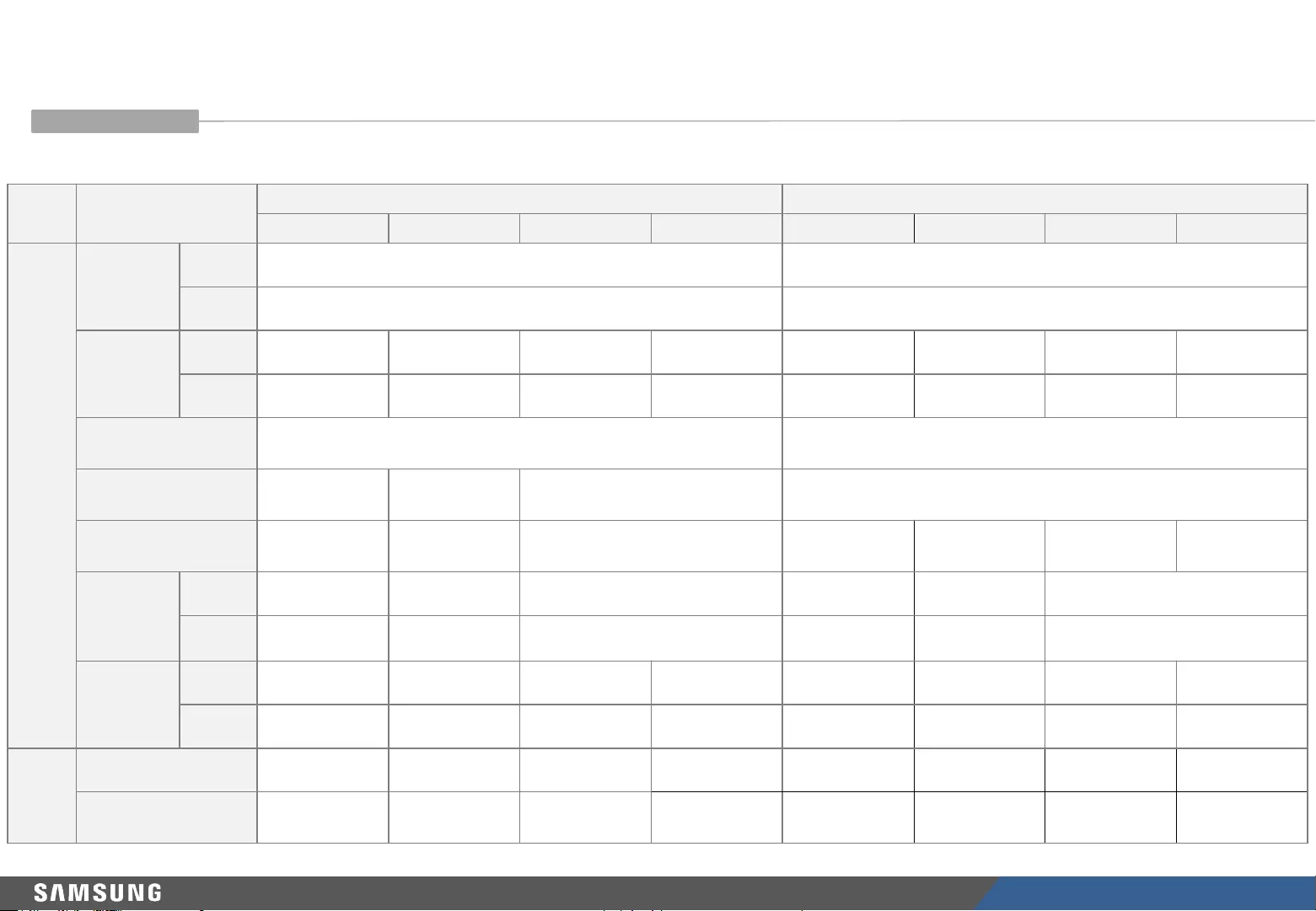

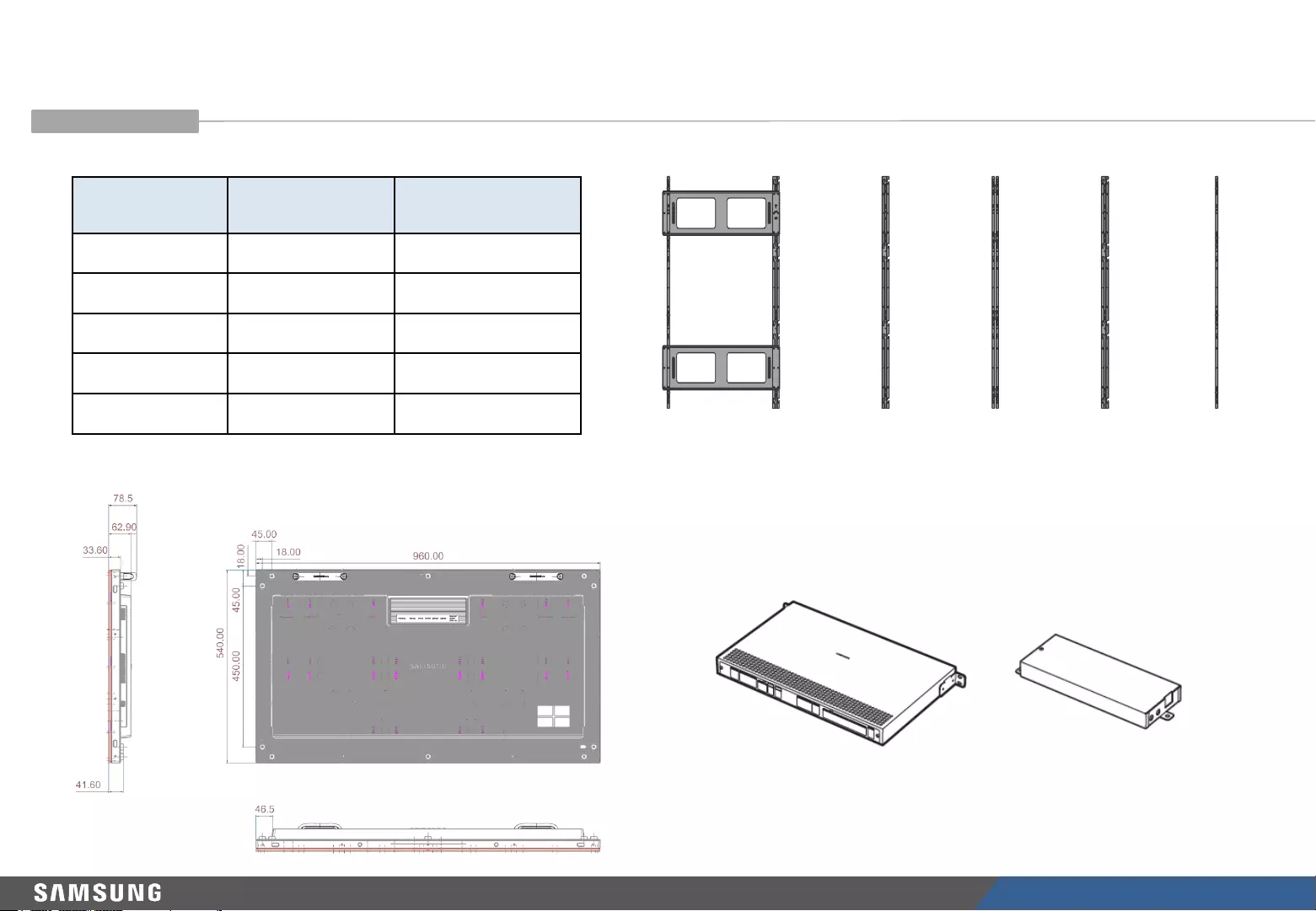

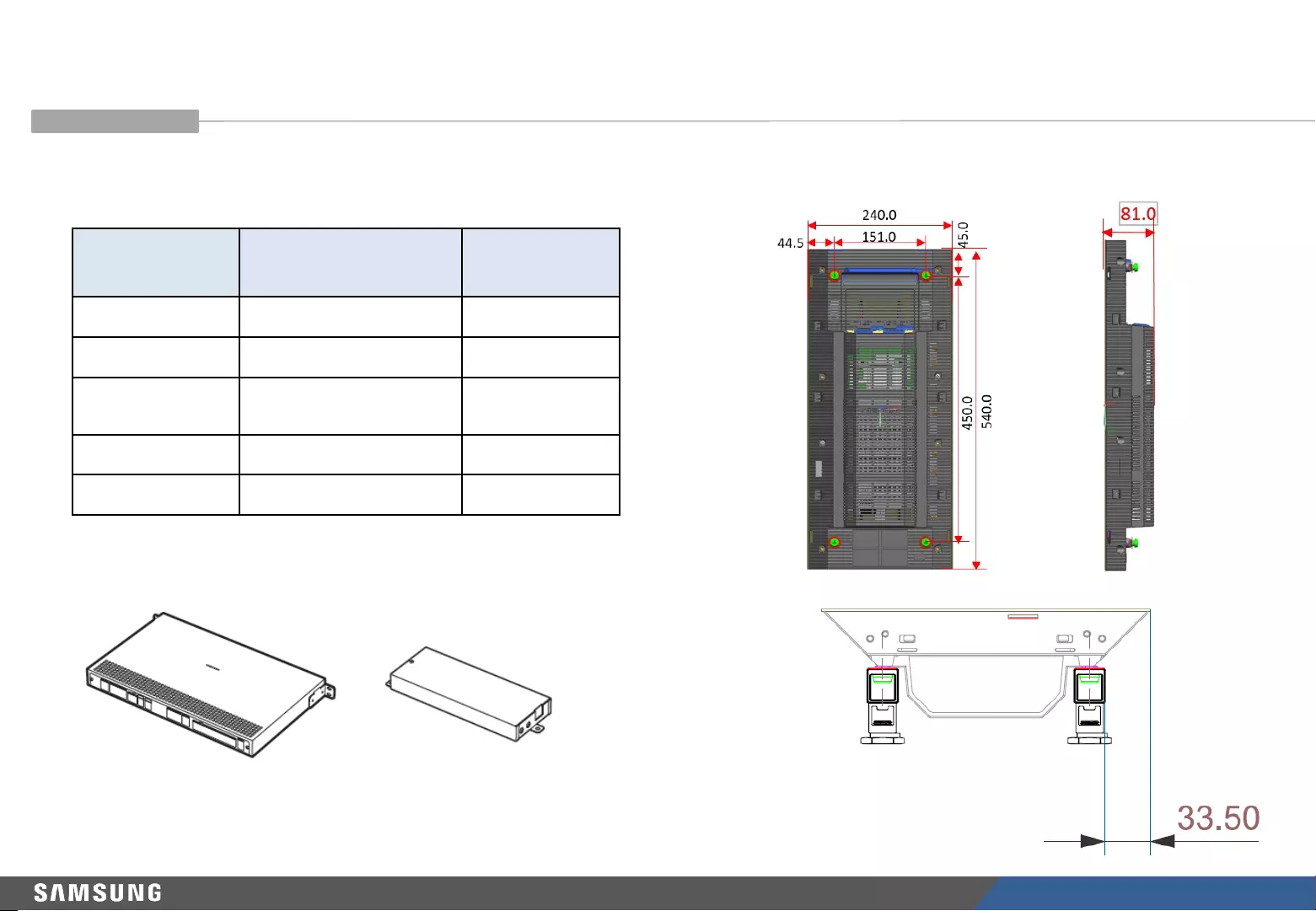

1. Product Information and Installation Precautions

◆Model specification

※ Installation with IER/IFR of same pitch is recommended.

Spec. IER / IFR IER-F / IFR-F

P1.5 P2.0 P2.5 P4.0 P1.5 P2.0 P2.5 P4.0

Cabinet

Size

(mm)

Width 960 240

height 540 540

Resolution

Ver. 640 480 384 240 160 120 96 60

Hor. 360 270 216 135 360 270 216 135

Number of

Module 4 x 3, 12ea 1 x 3, 3ea

Weight

(Cabinet) 11.8kg 12.4kg IER : 10.8kg

IFR : 12.4kg 3.2kg

Power

consumption(W) 260 / 360W 180 / 260W 150 / 260W 80 / 90 W 60 /80 W 50 / 80W 50 / 80W

Max

number

of

connection

(Set)

110V 2 / 1 set 3 / 2 set 4 / 2 set 10 / 7 set 10 / 7 set 10 / 7 set

220V 4 / 3 set 6 / 4 set 7 / 4 set 20 / 15 set 20 / 15 set 20 / 15 set

Brightness

(nit)

Peak 1000 / 1600 1200 / 1600 1200 / 2400 1200 / 1500 1000 / 1600 1200 / 1600 1200 / 2400 1200 / 1500

Max 500 / 800 600 / 1000 600 / 1000 600 / 900 500 / 800 600 / 1000 600 / 1000 600 / 900

FHD

Screen

FHD 3x3, 9set 4x4, 16set 5x5, 25set 8x8, 64set - -

UHD 6x6, 36set 8x8, 64set 10x10,

100set

16x16,

256set

LED R&D Lab(VD)

12

1. Product Information and Installation Precautions

◆Frame Kits configuration (See page 22.)

Frame kit Configuration

for installation

Remarks

VG-LFR84FWL 8*4 (32 sets)

VG-LFR53FWL 5*3 (15 sets)

VG-LFR52SWL 5*2 (10 sets)

VG-LFR51PWL 5*1 P (15 sets) PIVOT installation

VG-LFR11SWL 1*1 (1 set) Narrow <5*3 Frame>

◆Cabinet information

※ Please refer to Appendix for information of IER-F / IFR-F Frame Kit

<S-Box> <I/G>

(Interface Gender)

◆SBB-SNOWJAU, SBB-SNOWJMU, SBB-SNOWRAF

(S-Box, I/G)

LED R&D Lab(VD)

13

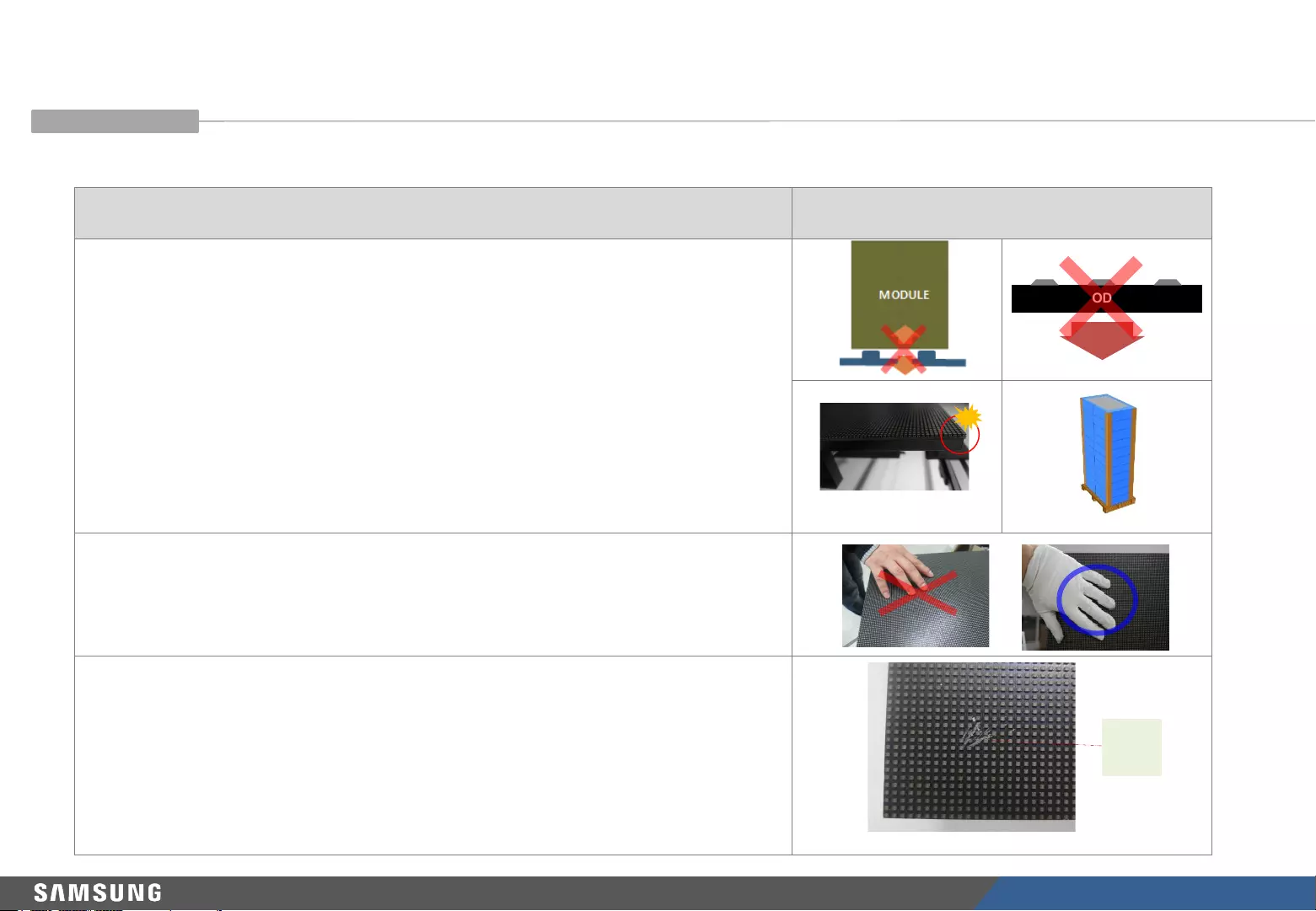

1. Product Information and Installation Precautions

◆Installation precautions (LED damage)

Precautions Images

[Be careful of external impact or dropping]

①After removing the Cover-Corner from the product prior to installation,

exercise caution to ensure that the LED surface is not exposed to physical

impact and the product is not dropped onto the floor.

②Do not place the product on a vibrating object. Make sure the LED surface

does not face down onto the floor.

③Exercise caution to ensure that the corners of the LED module are not

damaged due to contact with external factors.

④Make sure the number of loaded rows does not exceed 12.

① ②

③ ④

[Be careful of LED damage due to static electricity]

▶Do not touch the LED surface with bare hands without anti-static gloves.

[Be careful of LED damage due to metallic foreign material]

▶Exercise caution to ensure that metallic foreign material is not attached to

the LED front.

▶If metallic foreign material is attached, remove the module and use a

magnet to remove the foreign material.

MODULE

Front

Metallic

foreign

material

LED R&D Lab(VD)

14

1. Product Information and Installation Precautions

◆Heat protection guide

Requirements for indoor installation

-Applicable to use of SAMSUNG wall mount (compliant with ADA)

∙Gap between the product front and the wall: 99.5 mm

∙Gap between the product rear and the wall: 35.5 mm

-Entry of sunlight

∙If sunlight enters through glass windows or outer walls of the building,

contact Company HQ for assistance.

-Cold/warm air from HVAC system

∙Make sure cold or warm air (especially warm air) from an HVAC system

does not reach the product.

-Outdoor temperature measurement position

∙Center of the product or the inlet area

※ADA: Americans with Disabilities Act

99.5 mm

35.5 mm

wall

Outdoor temperature

measurement position

Outdoor temperature

measurement position

※This page is written based on the Full white,

650 nit (back light 7) version

LED R&D Lab(VD)

15

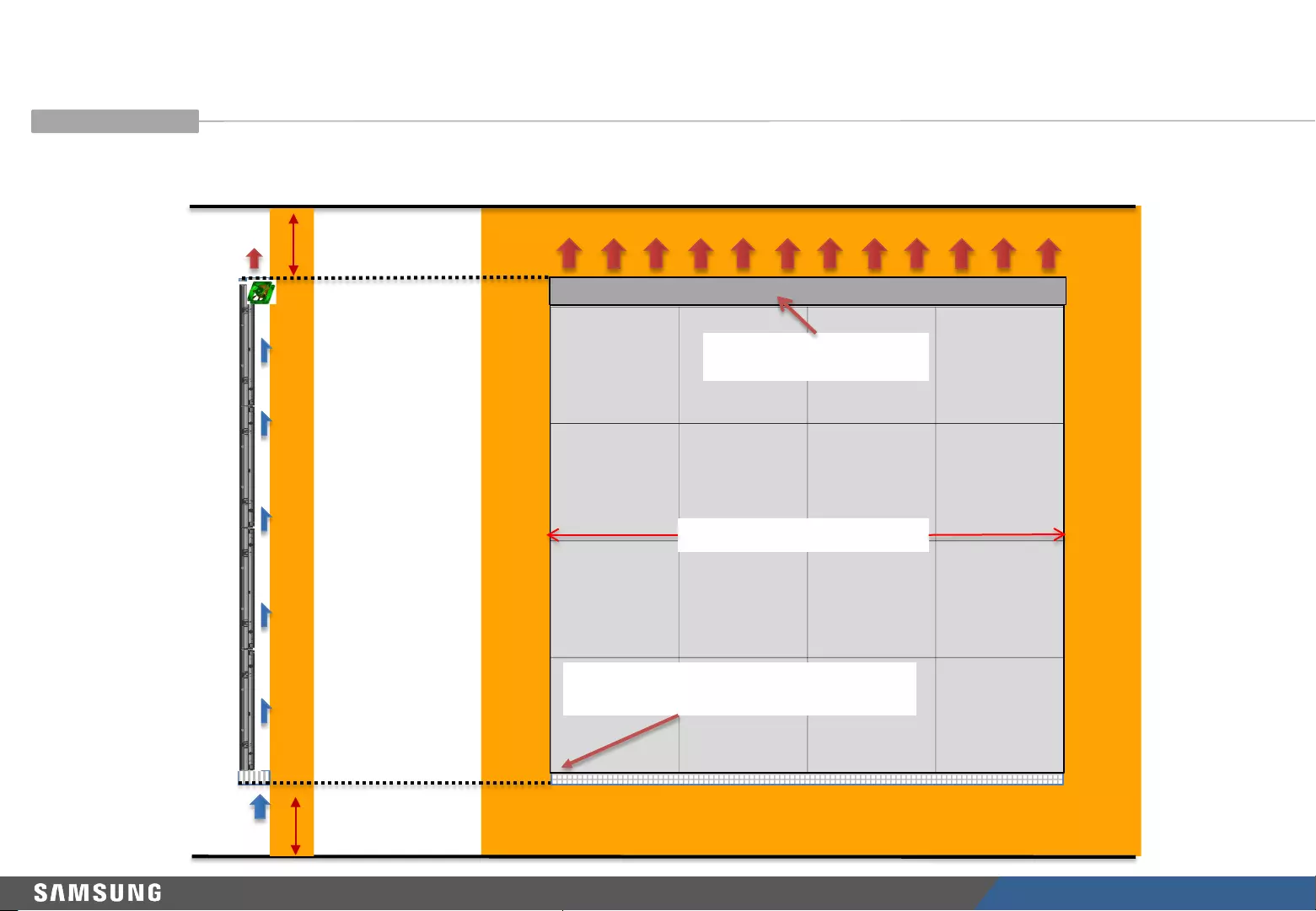

1. Product Information and Installation Precautions

Fan flow rate depending on the number of installed cabinet rows

No. of rows

Outdoor

air temp.

1 to 3

Rows 4 Rows 5 Rows 6 Rows 7 Rows 8 Rows 9 Rows 10 Rows

Below 25℃

Fan is not

necessary

Fan is not necessary 70 80 90 100

25℃to 30℃70 80 100 110 130 145 160

※CFM = cubic feet per minute

※Example) If outdoor air temperature is 30℃and cabinets are

arranged in a 5x4 (horizontal x vertical) configuration,

what is the total CFM ?

→ 70 [CFM/column] x 5 [column]=350 [CFM]

5 Columns

4 Rows

Total minimum flow rate 350 CFM

70 CFM 70 CFM 70 CFM 70 CFM70 CFM

※For installation under other conditions not covered in this guide, contact the Development Team. Air vent area

FAN

※Measurement based on one column

Outdoor air

temperature is

30℃

LED R&D Lab(VD)

16

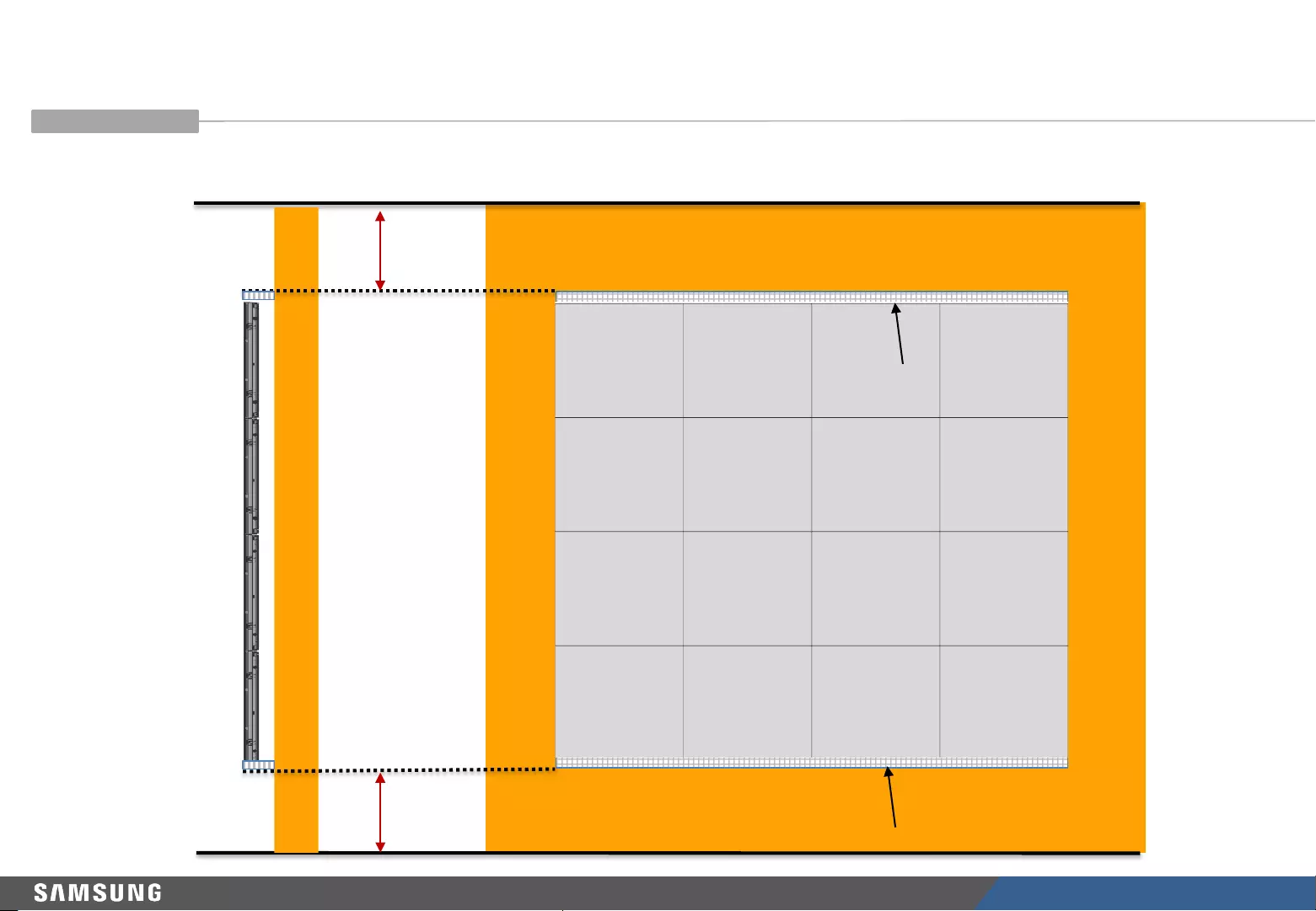

1. Product Information and Installation Precautions

•Requirements for using FAN

–Air vent: Should only be installed on the bottom

–Upper portion: Seal the entirety, except the fan outlets

Shape of FAN unit

WALL

Location of FAN

Air vent area

Seal the left and

right sides

A

B

d

c

Vent requirements

-Use vents with an opening rate of at least 70%

-Opening rate (%) = . ℎ

Seal the left and right sides

LED R&D Lab(VD)

17

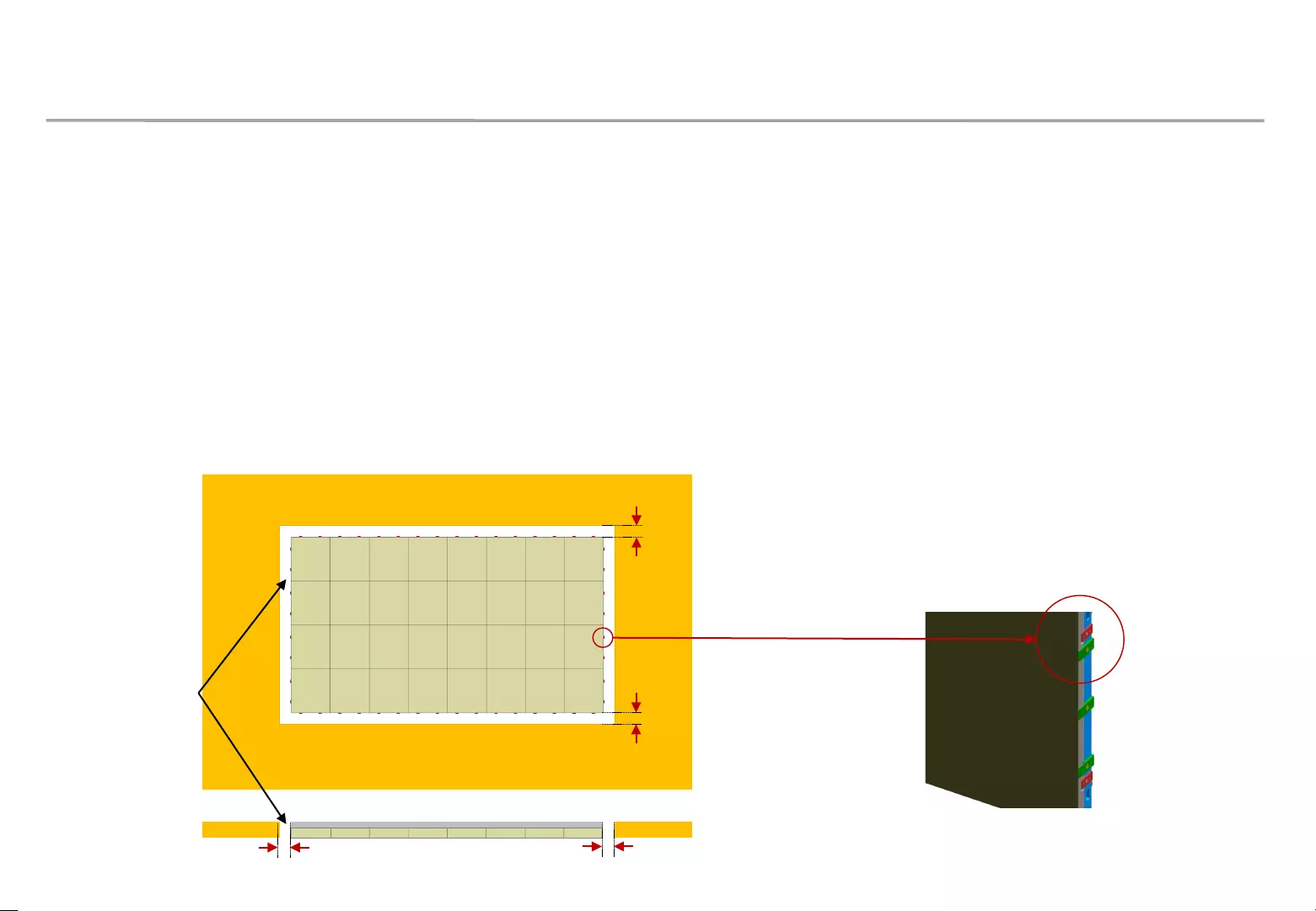

1. Product Information and Installation Precautions

Minimum spacing for wall mounting installation

Air vent area

WALL

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

Air vent area

(more than 60%

of opening rate)

Air vent area

(more than 60%

of opening rate)

LED R&D Lab(VD)

18

1. Product Information and Installation Precautions

Minimum spacing for processed installation

WALL

Min condition: 0mm (set ~ floor)

Recommended condition : more than 500mm

Min condition : 0mm (set ~ ceiling)

Recommended condition : more than 500mm

Essential cond. : more than 30mm of 100% opening rate Air vent area

Air vent area

Essential cond. : more than 30mm of 100% opening rate

LED R&D Lab(VD)

19

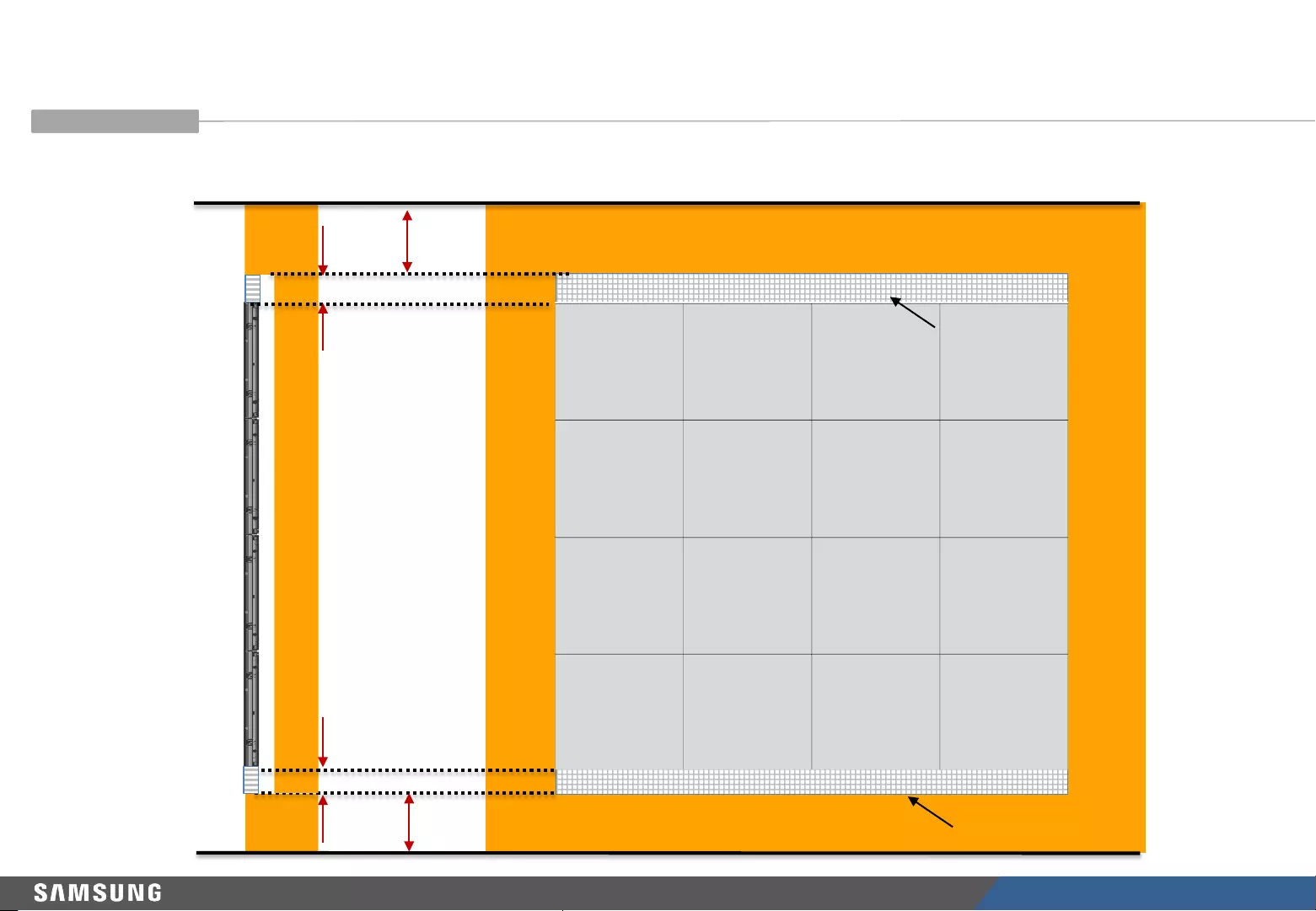

1. Product Information and Installation Precautions

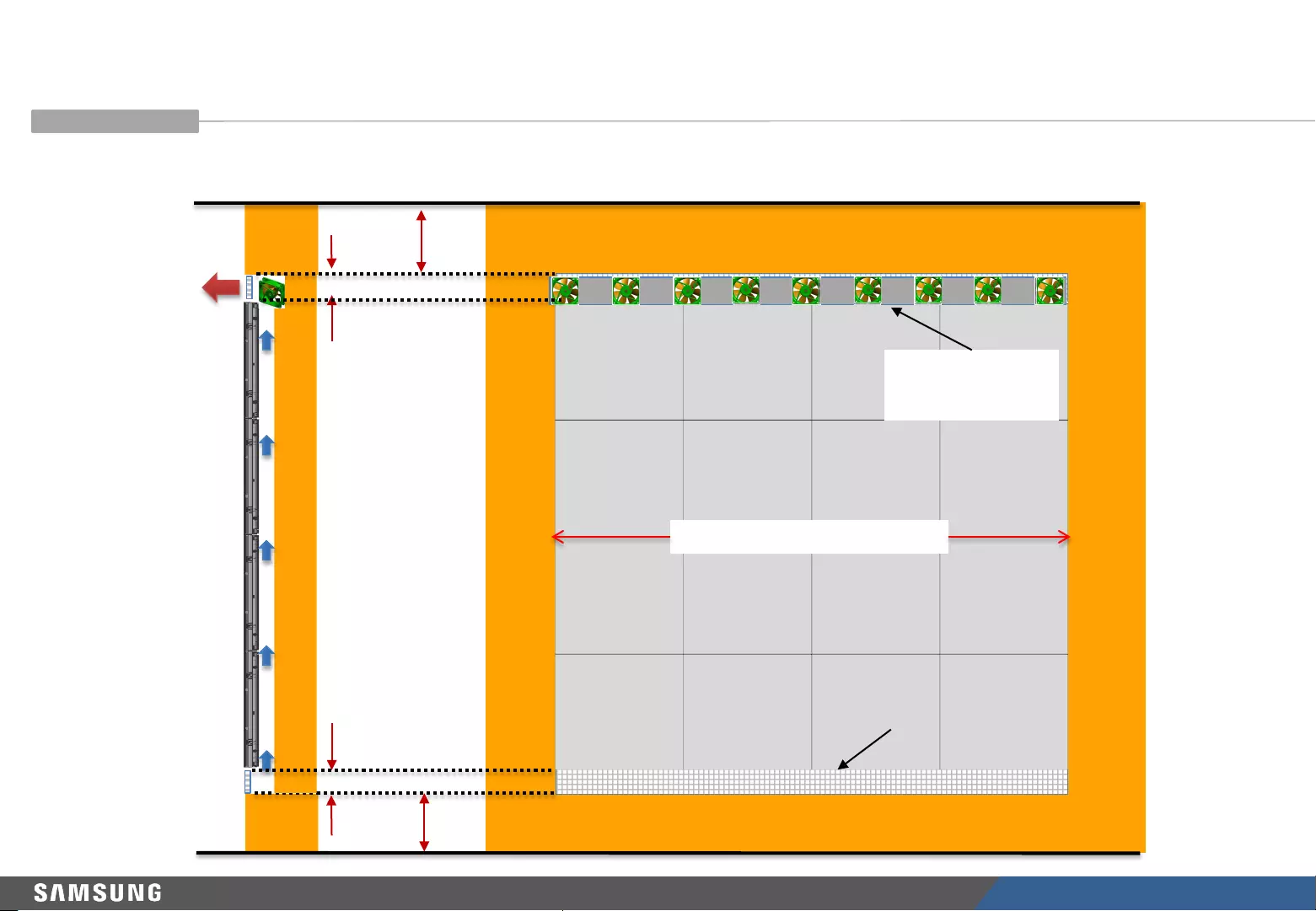

Example of minimum spacing and FAN allocation for wall mounting installation

WALL

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

left and right sealing

Other parts except for FAN

area should be sealed

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

left and right should be sealed

Air vent area should be mesh type with

an opening rate of more than 60%.

LED R&D Lab(VD)

20

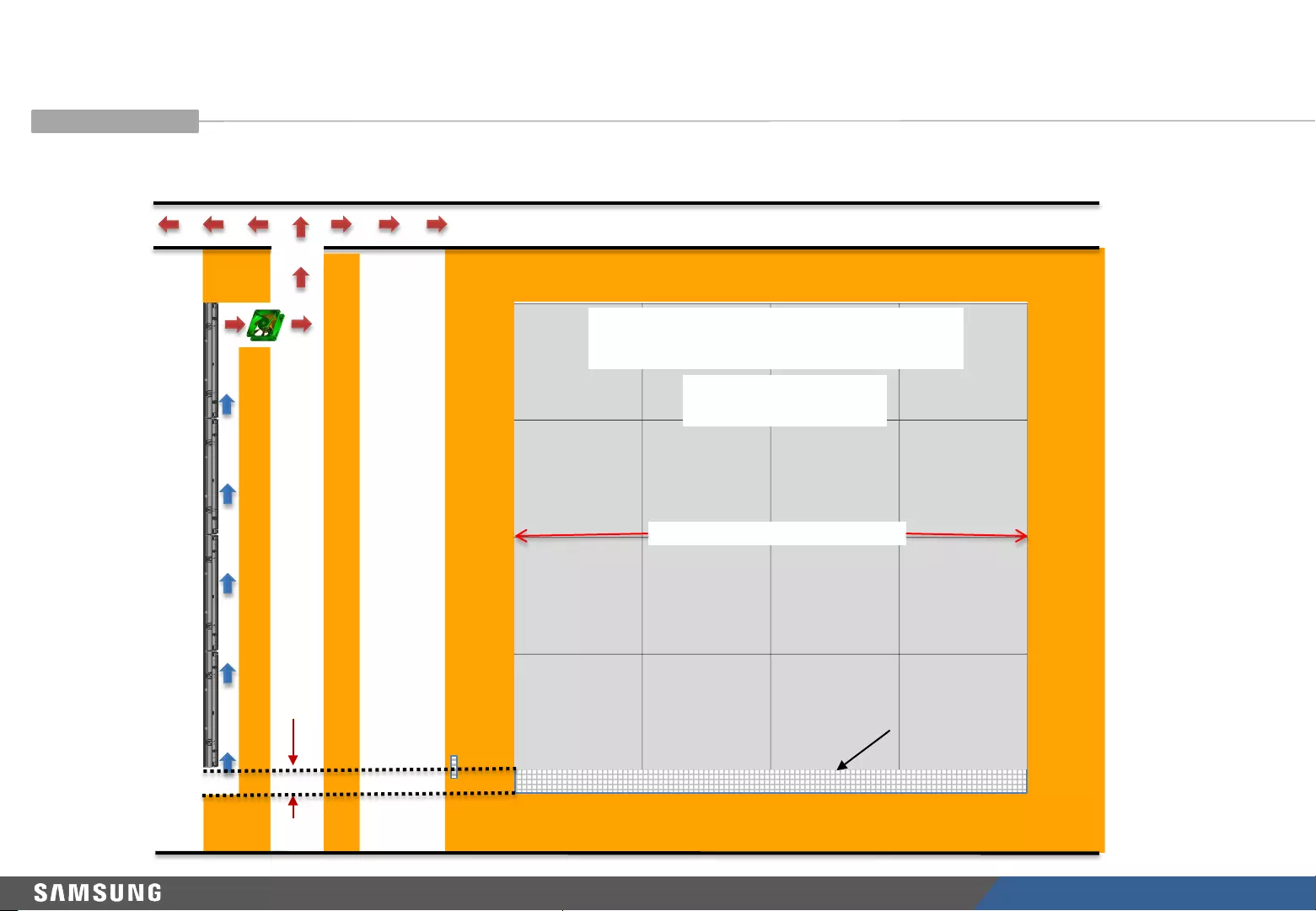

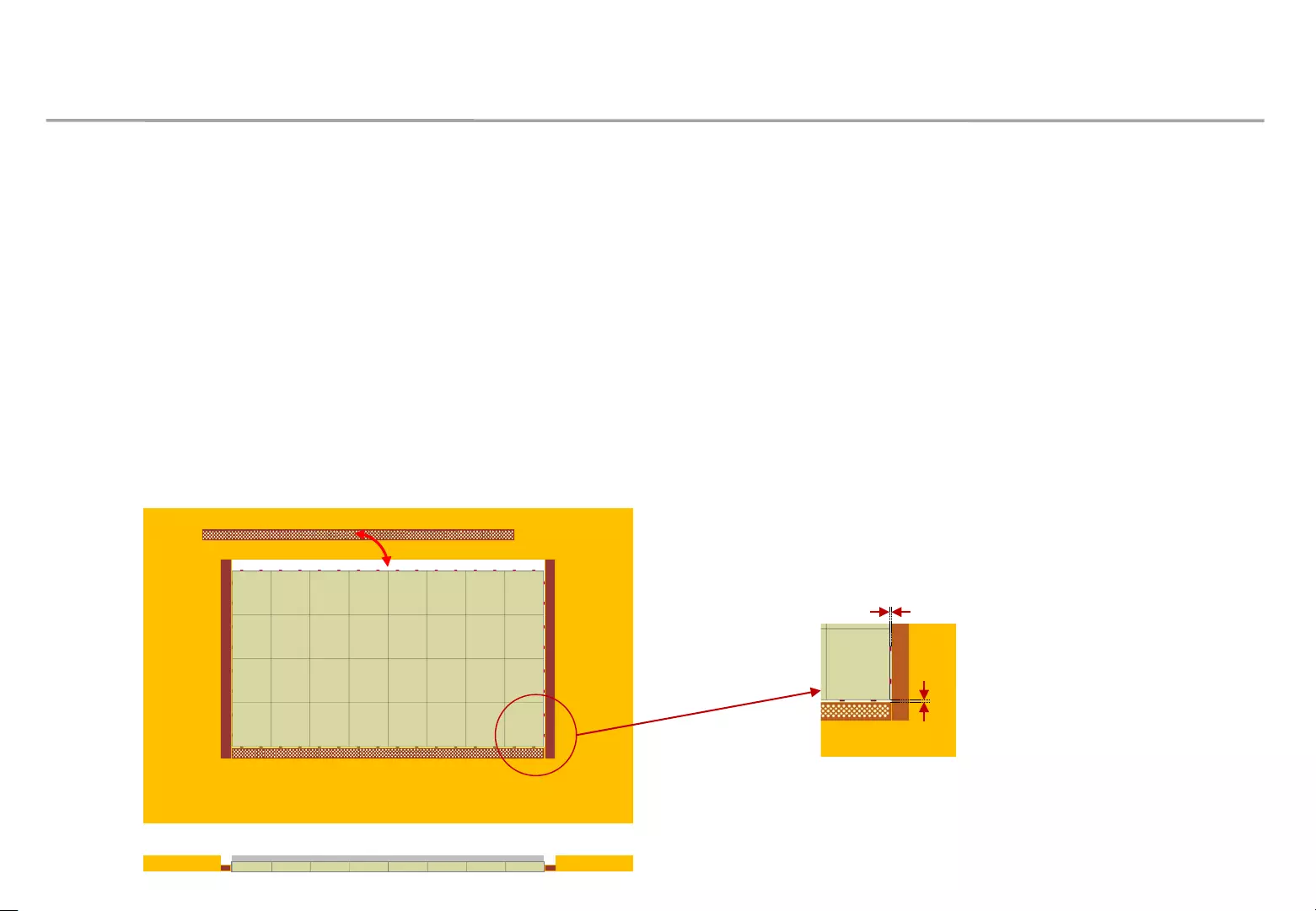

1. Product Information and Installation Precautions

Example of minimum spacing and fan allocation for recessed installation

WALL

left and right should be sealed.

Min condition: 0mm (set ~ floor)

Recommended condition : 500mm

Other parts except

for FAN area should

be sealed

Air vent area

Essential cond. : more than 30mm of 100% opening rate

※ Vent and interior finishing work will proceed after screen installation.

Min condition: 0mm (set ~ ceiling)

Recommended condition : 500mm

Essential cond. : more than 30mm of 100% opening rate

LED R&D Lab(VD)

21

1. Product Information and Installation Precautions

Example of minimum spacing and placement during rear exhaust

left and right should be sealed.

Other parts except for

FAN should be sealed.

Ambient temperature on the back of

the wall should be less than 30 ℃.

WALL

Essential cond. : more than 30mm of 100% opening rate. Air vent area

LED R&D Lab(VD)

22

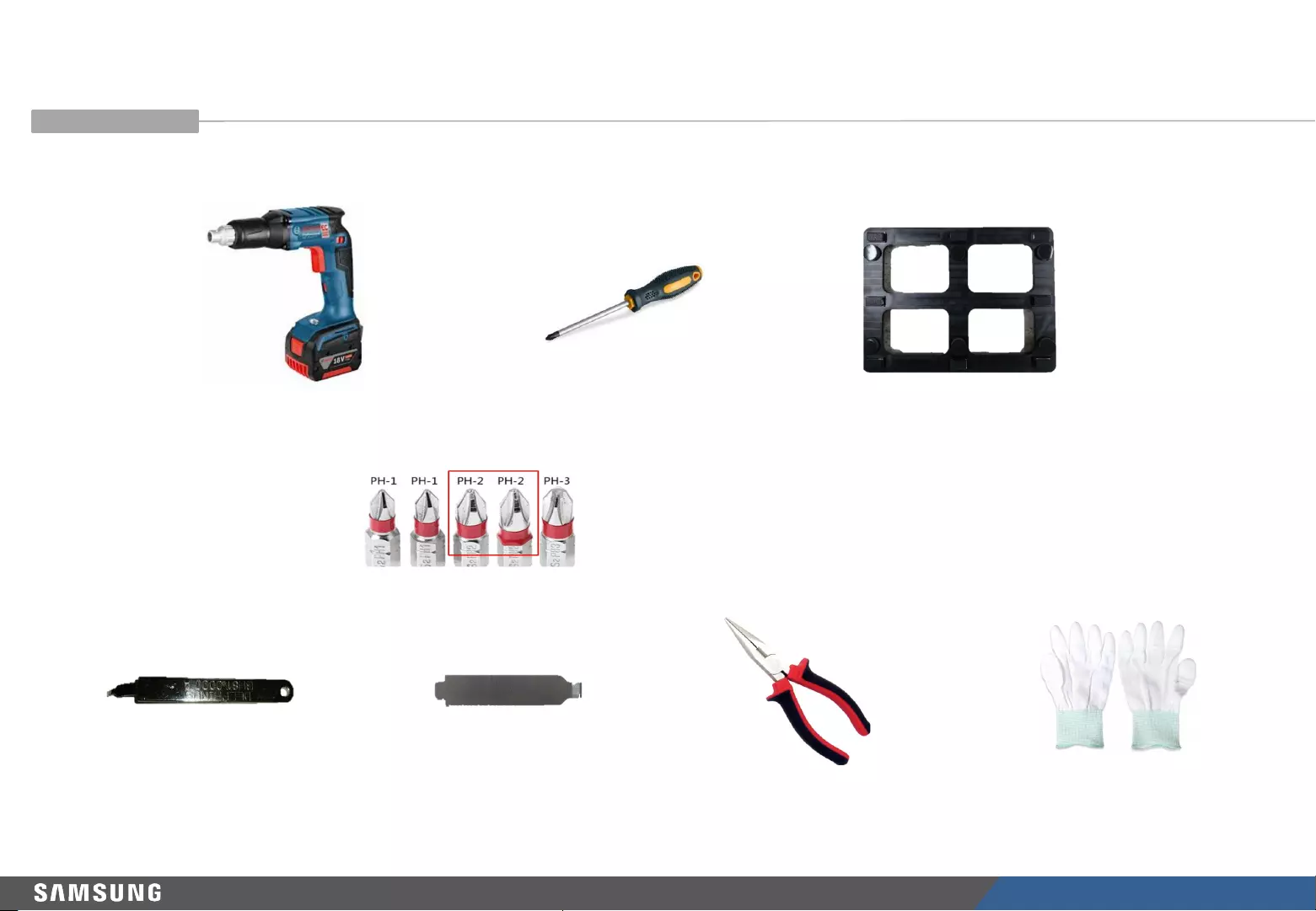

1. Product Information and Installation Precautions

◆Preparation for installation

LED MODULE JIG

(model name: CY-LJRNLS)

Electric screwdriver Phillips (+)

screwdriver

Pliers

Service JIG

(BH81-00001A)

Holder Magnet Tool

(Included in LED MODULE JIG) Anti-static

gloves

※Recommended sizes

LED R&D Lab(VD)

23

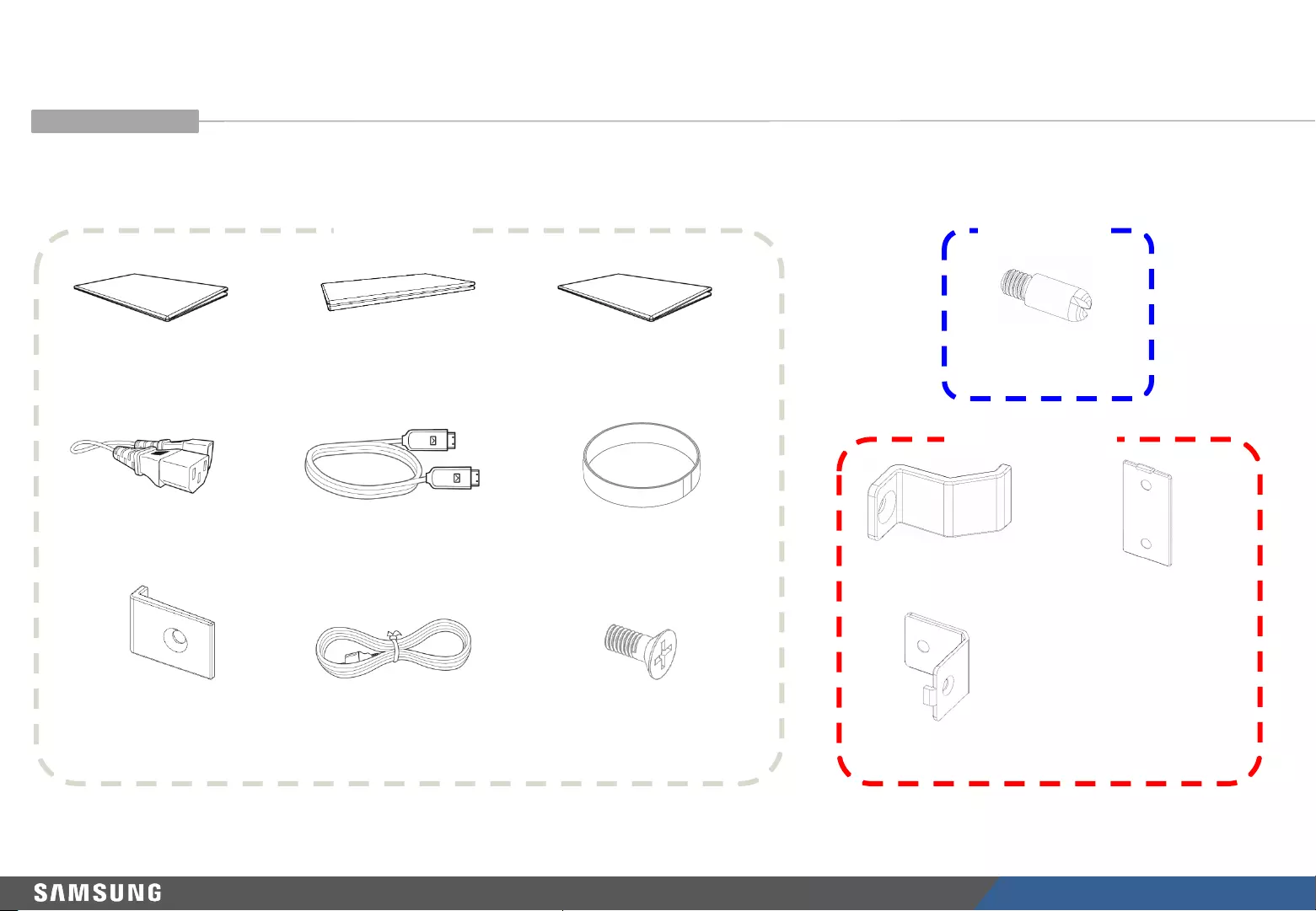

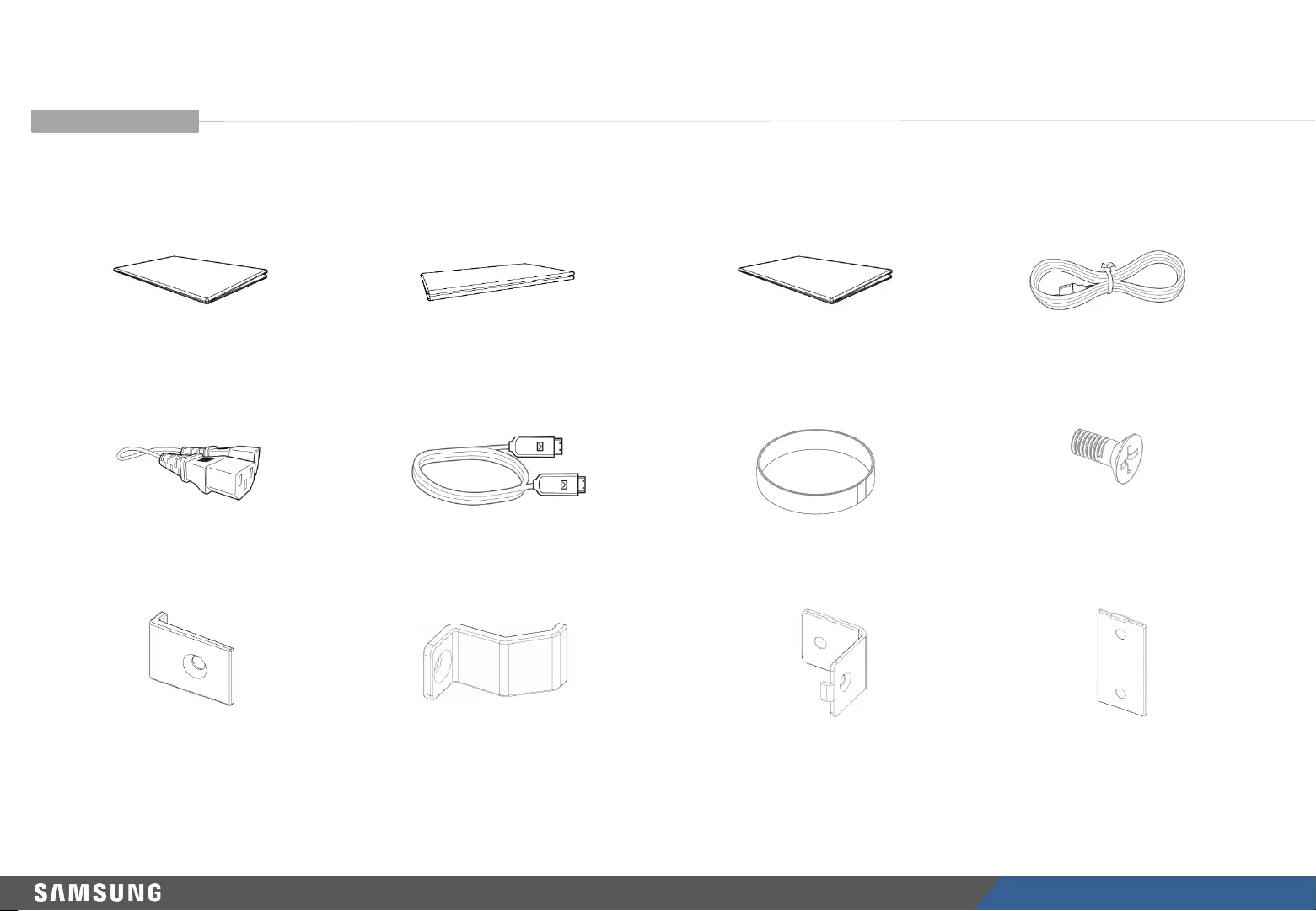

◆IER (IFR) Accessory configuration

1. Product Information and Installation Precautions

Quick Setup Guide Product Warranty Card

(Not provided in some regions) regulation guide

Power Cord

Extension Power Cable OCM Cable

COVER PCB

(IER : 7ea / IER-F : 4ea) Machine Screws

(IER : 7ea / IER-F : 13ea)

PET Tape (W10*L540,1 EA)

STUD PEM

(guide pin,2ea)

COVER PCB (6ea)

BRACKET LINK (2ea)

BRACKET ALIGN (1ea)

Common IER / IFR

IER-F / IFR-F

LED R&D Lab(VD)

24

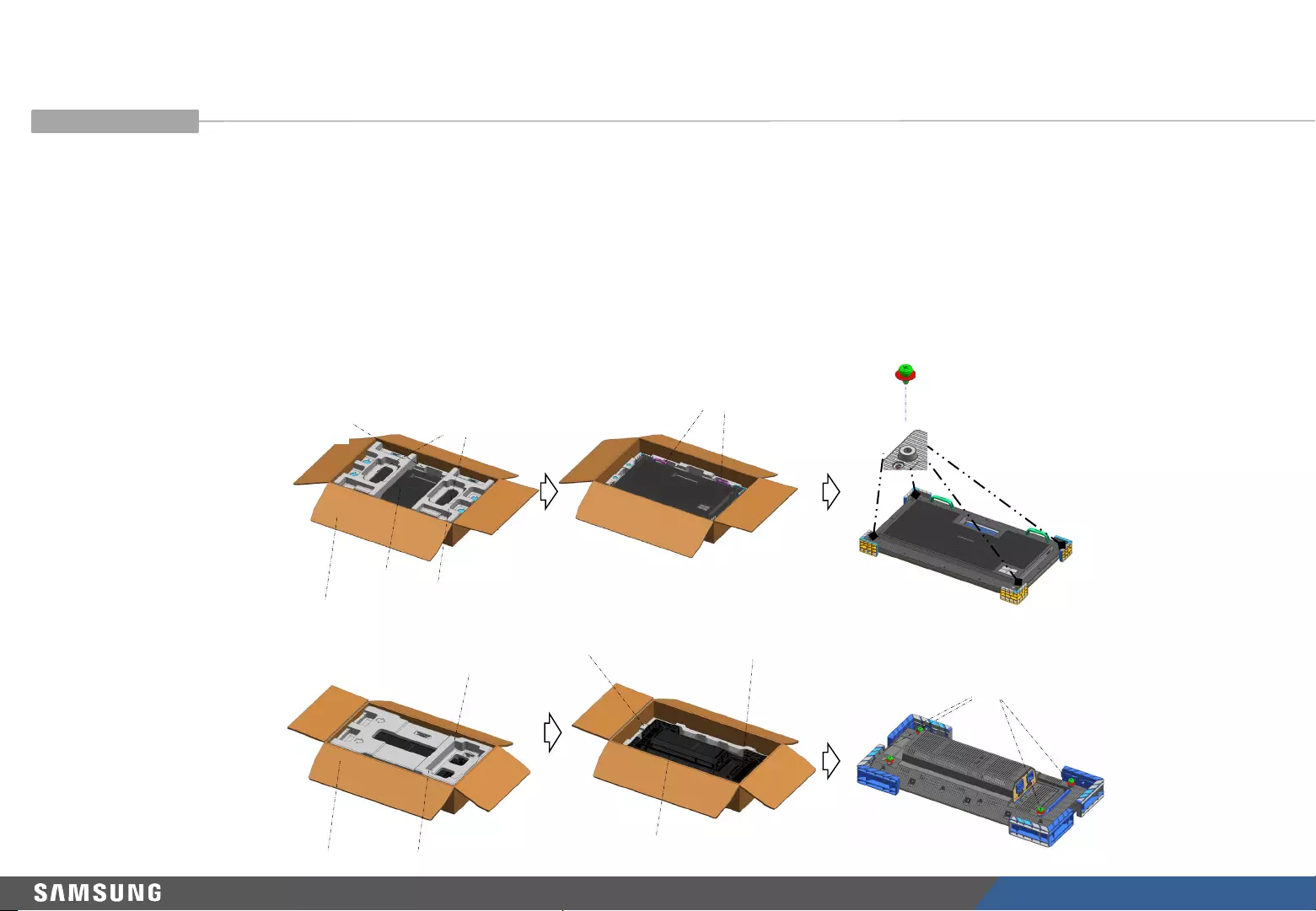

2. Preparation for Cabinet Installation

①Remove the tape on top of the package box and open the box. (See Fig.1.)

②Remove the Top–Cushion and open the shielding bag.

Hold the handles inside, take out the set, and then remove the PE bag. (See Fig.2.)

③Check that the sliding bolts are properly fastened. (See Fig.3.)

Fig.1 Contents of the

package

Fig. 2 Opening the

package

Fig.3 Checking the bolts

handl

e

Top-

Cushio

n

IB &

cable

Bottom-

Cushion

LED

set

Box

SLIDING BOLT

Handle Shape

Top-Cushion

IB & cable

Bottom-Cushion

LED set

Box

SLIDING

BOLT

■IER

■IER- F

◆Preparation for installation

LED R&D Lab(VD)

25

2. Preparation for Cabinet Installation

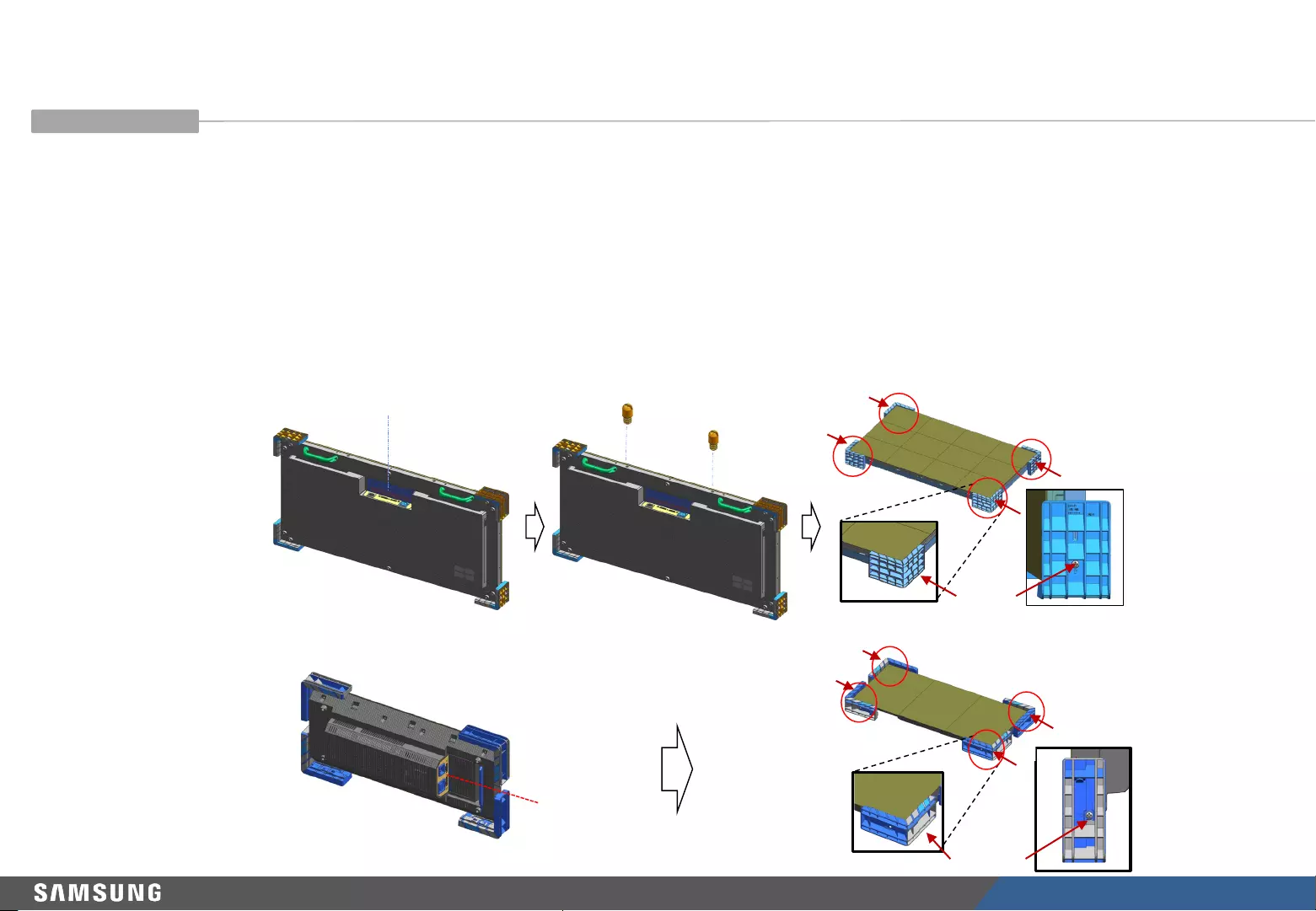

④Connect the power and check for a problem with the screen. (See Fig.4.)

※See page 12 for details on how to check for a screen problem.

⑤Guide Pin (Accessory Enclosed) 2EA is assembled on top of the cabinet. (Excluding the capinet on the top row)

⑥Unfasten the screws (four screws in total) and remove the corner covers. (See Fig.5.)

Fig.4 Checking the screen Fig.6 Removing the corner covers

Switch Button

SCREW

Guide

Pin

Switch Button

SCREW

◆Preparation for installation

Fig.5 Guide Pin Assembly

※IER / IFR

※IER- F / IFR-F

LED R&D Lab(VD)

26

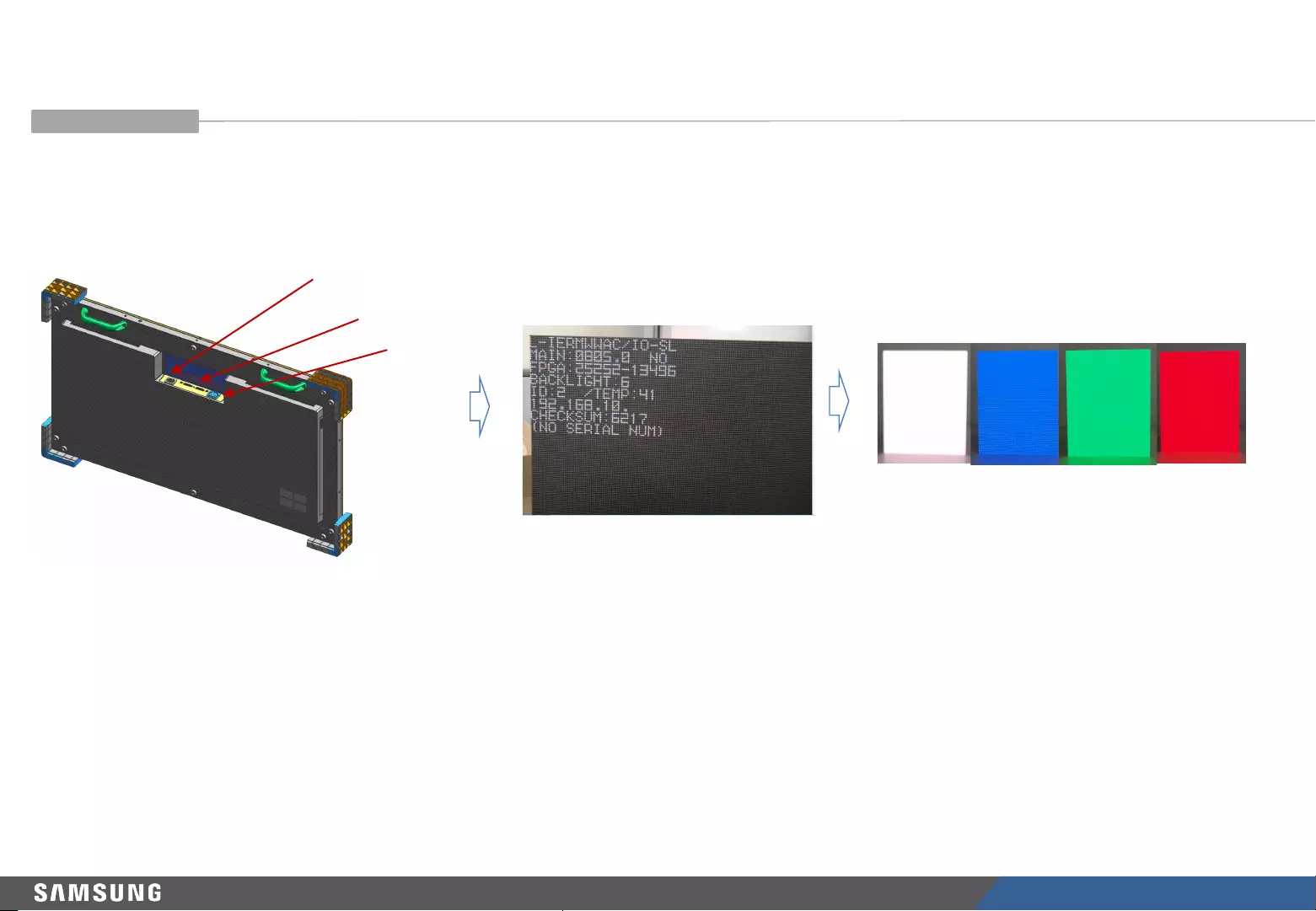

⑥Connect the power cord that came with the product and turn on the product.

Check that there is no LED damage and no problem is found on the screen.

※Steps to perform in the event of White Pattern

-Apply power and press and hold the Switch for 5 seconds.

-When the factory info window appears, press the Switch once again.

-When the color screen appears, press the Switch repeatedly to check for malfunctioning LEDs.

(Each time the Switch is pressed, the LED color is switched in the following order:

white →blue →red →green.)

-To turn off the mode, press and hold the Switch for 5 seconds again.

2. Preparation for Cabinet Installation

◆Note: Checking for a screen problem

Switch (Toggle)

Power In

Power out

LED R&D Lab(VD)

27

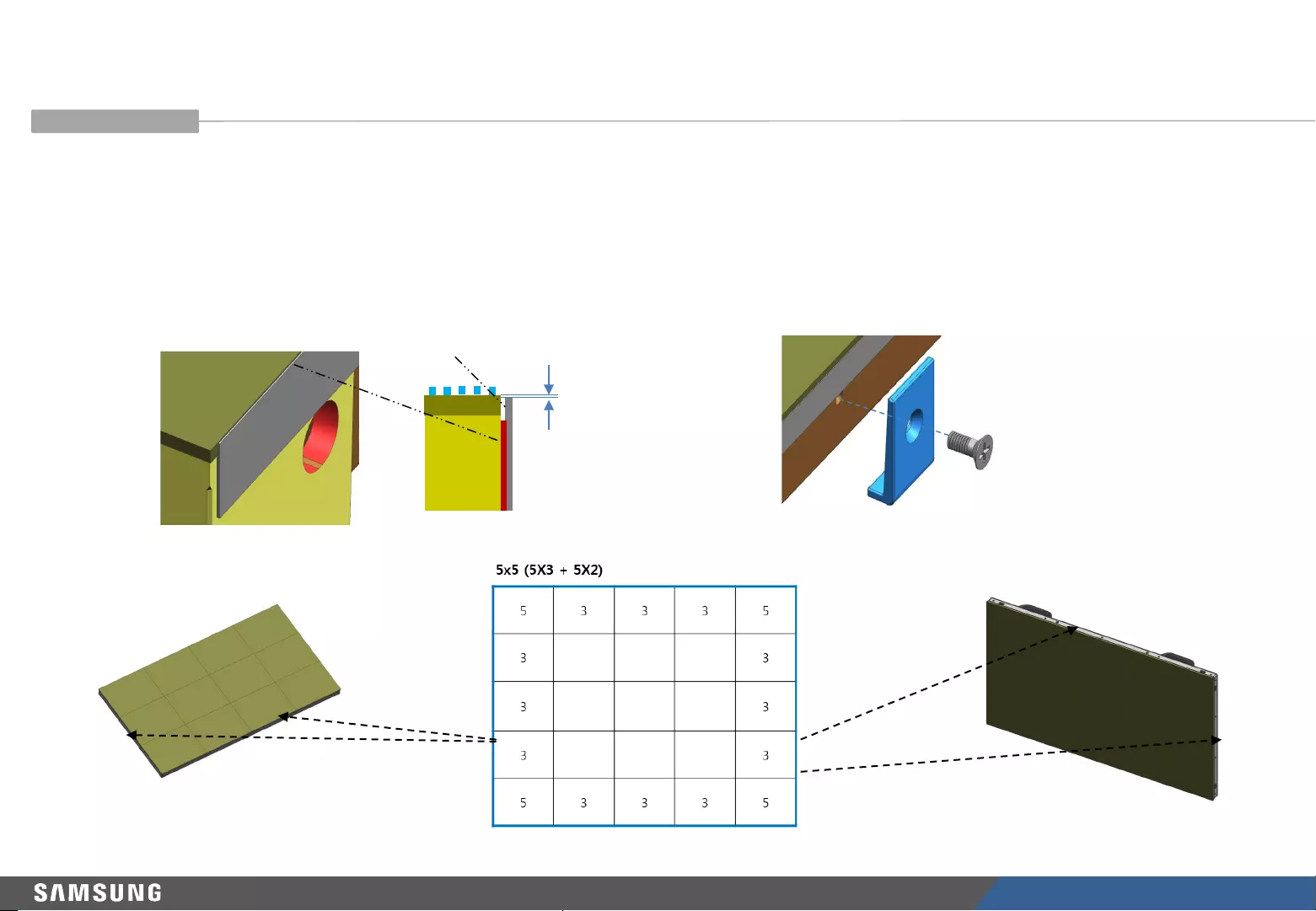

2. Preparation for Cabinet Installation

⑧For cabinets placed on the edge, attach PET sheet before attaching PCB covers.

※Attach PET sheet to all borders of the LED module (Fig.1), and attach PCB covers to the same outer sides where the

PET sheet has been attached (horizontally 5 points and vertically 4 points, as shown by the blue borders in Fig.2).

※Attach PET sheet as shown in Fig.3. Make sure the area with no tape guides the LED module.

※Attach PCB covers as shown in Fig.4.

Fig.2 Borders requiring PET sheet and PCB covers

* Numeric figure: Quantity of PCB covers to attach

Fig.3 Fig.4

PET sheet

No tape

0 to 0.5 mm

Fig.1 Attach PET sheet here

Fig.1 Attach PET sheet here

LED R&D Lab(VD)

28

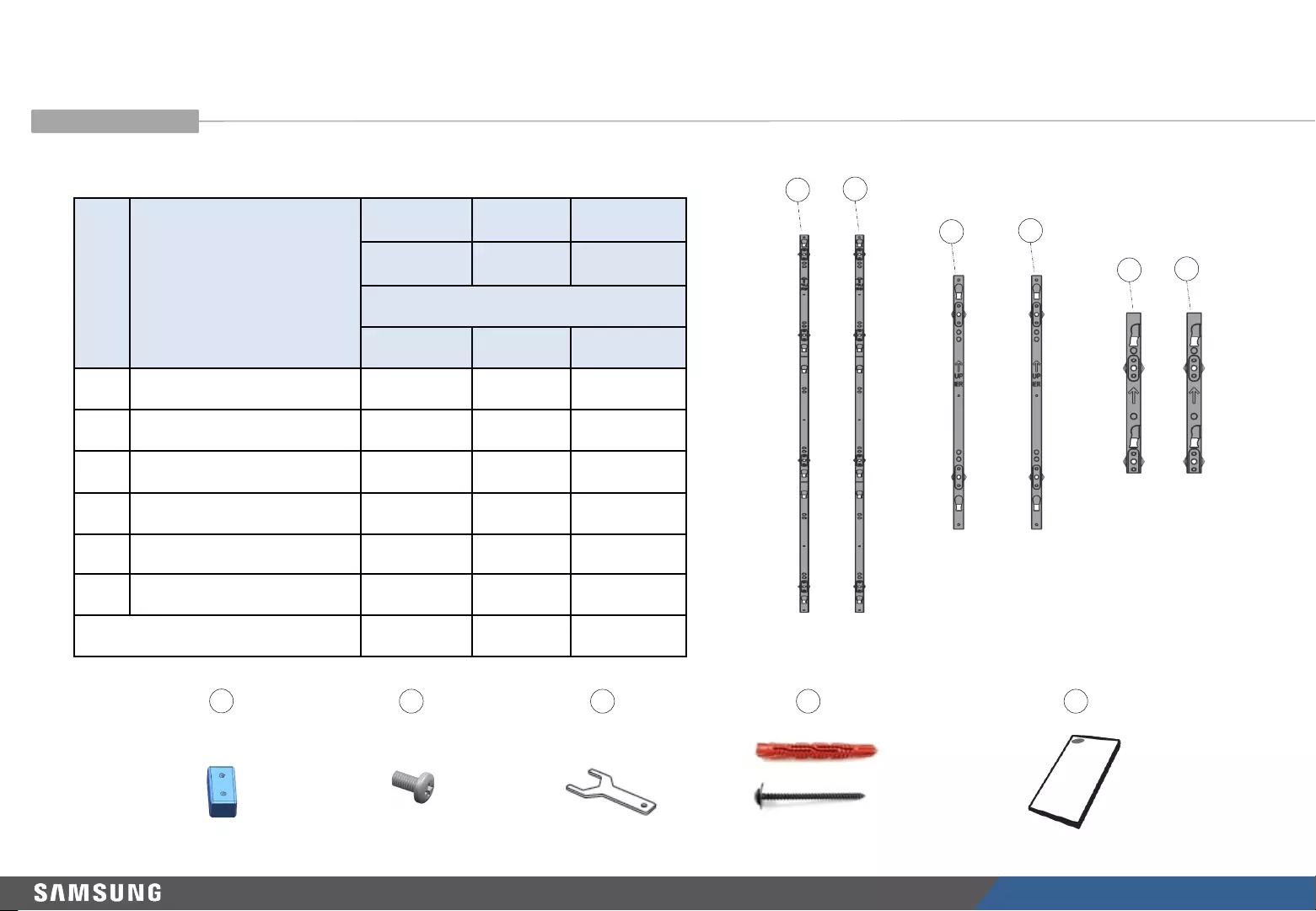

3. Frame kit Components

①Check the configuration below in the frame kit.

No. Item

VG-

LFR84FWL

VG-

LFR53FWL

VG-

LFR52SWL

VG-

LFR11SWL

VG-

LFR51PWL

Qty (+spares)

8X4 5X3 5X2 1X1 PIVOT

ⓐASSY BRACKET SIDE 22222

ⓑASSY BRACKET MIDDLE 6 3 3 - 3

ⓒASSY BRACKET CENTER 1 (+1) 1 (+1) 1 (+1) -1 (+1)

ⓓASSY BRACKET JIG 2 2 2 - 1

ⓔJOINT V 10 7727

ⓕASSY ANCHOR SCREW 50 28 21 414

ⓖQUICK INSTALL GUIDE 11111

ⓗService JIG 1 1 1 - -

ⓘWrench 11111

ⓙWASHER (SLIDING BOLT) 10 5 5 - -

ⓚBOLT –ETC ----12

ⓛSCREW (M4) 20 14 14 414

Screen size for installation (mm) 7680 X

2160

4800 X

1620

4800 X

1080

960 X

540

2700 X

2880

※Refer to the attached specifications for the IER-F/IFR-F installation. aa

bbcb

d

g

f

M5,L65, Anchor screw

h

SERVICE JIG

e

JOINT V

j

WASHER

k

BOLT-ETC

QSG

l

SCREW (M4)

i

WRENCH

LED R&D Lab(VD)

29

aa

bbcb

d

4. Frame Installation

②On the left end, place the ⓐBracket Side and fasten the screws to install the Bracket (Fig.3).

※Fasten one screw first, and use a clinometer to vertically align the right edges and fasten screws into the other holes.

(See the next page for precautions when fastening screws.)

Fasten the screws in the order of screw 1 → screw 2 → screw 3. Fig.1

ⓐFix the Bracket Side, following the measurements shown in Fig.4.

Fig.1 Order of fastening the screws

Fig.3 Positions of

components to attach

Fig.4 Screw fastening position

based on screen

12 mm or above

25 mm or above

12 mm or above

a

Fig.2 Screwing hole

Screwing

hole

①

③

③

②

LED R&D Lab(VD)

30

4. Frame Installation

※Precautions when tightening screws

•Make sure you check the location of the wood stud

inside the wall before screwing screws into the wall.

•Minimum wood stud size: 51 x 102 mm (2 x 4 inches)

Drill holes (3 mm) before screwing screws into the wall.

•Make sure you drill screw holes in the middle of the

wood stud.

•If you screw a screw directly into the wood stud without

drilling a hole, the wood may crack.

•Standard wood stud interval of 16” is supported. (24” is

not supported.)

Samsung Electronics is not responsible for

problems caused as a result of failure to follow the

requirements specified in the installation guide.

Installation requirements

①Sufficiently thick concrete or design wall

②Wood stud inside a plaster board, or MDF wall

Frames can be installed on a sufficiently thick concrete or

interior wall. Refer to the following figures.

If installing frames on a wall that is

not flat, irregular openings may

develop and affect the exterior

appearance.

Standard installation requirements by wall type

Check the wall type before installation. First check the wall

specifications (e.g. type,

thickness, floor plan).

Wall

Equipped with stiffeners,

e.g.

MDF or PW (plywood)

MDF, PW

(plywood)

MDF, PW (plywood)

MDF, PW (plywood)

At least 10 mm

At least 50 mm

At least 30 mm

At least 10 mm

At least 30 mm

At least 10 mm

MDF, PW (plywood)

At least

25 mm

At least

25 mm

MDF, PW

(plywood)

(except the

plaster board

thickness)

Concrete

composite wall

(except the

plaster board

thickness)

At least

50 mm

Art Wall Concrete

LED R&D Lab(VD)

31

4. Frame Installation

③Install the ⓑBracket Middle.

※First, check the holes into which to fix the ⓓJIGs. (See Fig.1.)

※Next, align the ⓓJIG with the bracket holes and fasten the four screws. (See Fig.2.)

※Lastly, fasten the screws to fix the ⓑBracket Middle to the wall. (See Fig.3.)

※Caution: The surface ⓓshould be attached to ⓐand ⓑ. The three surfaces (the wall,

ⓐand ⓑ, and ⓓ) should be in parallel. (See Fig.4)

④Use the same steps above to install all ⓑBracket Middle,

in the left-to-right order.

※ Install the bracket center in the center of the frame kit.

※ When installing the Frame Kit, use a laser horizontal meter, thread, etc.

Install the horizontal/longitudinal vertical and horizontal planes while checking them.

※ Since the IER/IFR is far from the FRAME, more vertical horizontal

checks are needed.

Fig.1 Checking the holes Fig.2 Fixing the Jigs

(with screws)

Fig.4 Keeping frames parallel

Fig.3 Fastening the screws Fig.5 Positions of components to attach

ⓐ,ⓑ,ⓒ

Wall

Incorrect

installation

Correct

installation

ⓓ

aa

bbcb

d

LED R&D Lab(VD)

32

4. Frame Installation

Height differenc e

greater than 0.5 mm

Fig.7 Checking height difference Fig.8 Adjusting height difference

Fig.6 Installing cabinets

Height differenc e

smaller than 0.0 mm

Height

dif f erence

Height

dif f erence

Cabinet

⑤After installing the Bracket Center, install the lowest row cabinets. (See Fig.6.)

⑥After installing the cabinets, push the LED modules toward the middle and check the height

difference between the cabinets on both ends and the LED modules. (See Fig.7.)

⑦Roughly adjust the height difference between the left and right sides, and make fine adjustment as

shown below. (See Fig.8.) ★Very important

• If the height difference is greater than 0.5 mm, move the frame outwardly.

• If the height difference is smaller than 0.0 mm, move the frame inwardly.

• Adjust height difference each time an additional cabinet is installed. (Use the Bracket Center for each model in the appropriate

column.)

It is not necessary to adjust a height difference in the 0.0 to 0.5 mm range.

※ Failure to comply with the above may result in poor cabinet installation, difficulty in maintenance due to difficulty in removing

the module, or module breakaway due to excessive assembly.

⑧After adjustment is completed, install the ⓑBracket Middle. (See step ②for details on how to install.)

⑨Lastly, install the ⓐBracket Side.

◆Bracket Center’s usable section,

VG-LFR53FWL: Every 3 rows

VG-LFR52SWL: Every 3 rows

VG-LFR84FWL: Every 4 rows

LED R&D Lab(VD)

33

Fig.7 (check the gap) Fig.8 (adjust the gap)

•Install the Frame Center after a Frame Side and two Frame Middles are installed based on the VG-LFR53FWL.

•Before installing Frame Middle next to the Frame Center, be sure to hang the IER Cabinet on the bottom line.

•Push the modules to the center and check the Frame Center so that there is no gap between cabinets and

between modules.

•When the module’s end is protruded more than 0.5 mm to the right based on the Frame Center, adjust the right

side of Frame Center outward.

•When the module’s end is protruded within 0.0 mm to the right based on the Frame Center, adjust the right side

of Frame Center inward.

•When installed long left to right, repeat the above procedure whenever a Frame Center is installed.

※Otherwise, it may cause maintenance issues due to difficulty in attachment and detachment of a module.

Excessive attachment may cause the module’s dislocation. (see page 27)

◆Bracket Center’s usable section,

VG-LFR53FWL: Every 3 rows

VG-LFR52SWL: Every 3 rows

VG-LFR84FWL: Every 4 rows

LED Module

Gap is within 0.0 mm Gap is over 0.5 mm

Cabinet

Gap

Gap

4. Frame Installation–Adjusting the Frame Center (Important)

LED R&D Lab(VD)

34

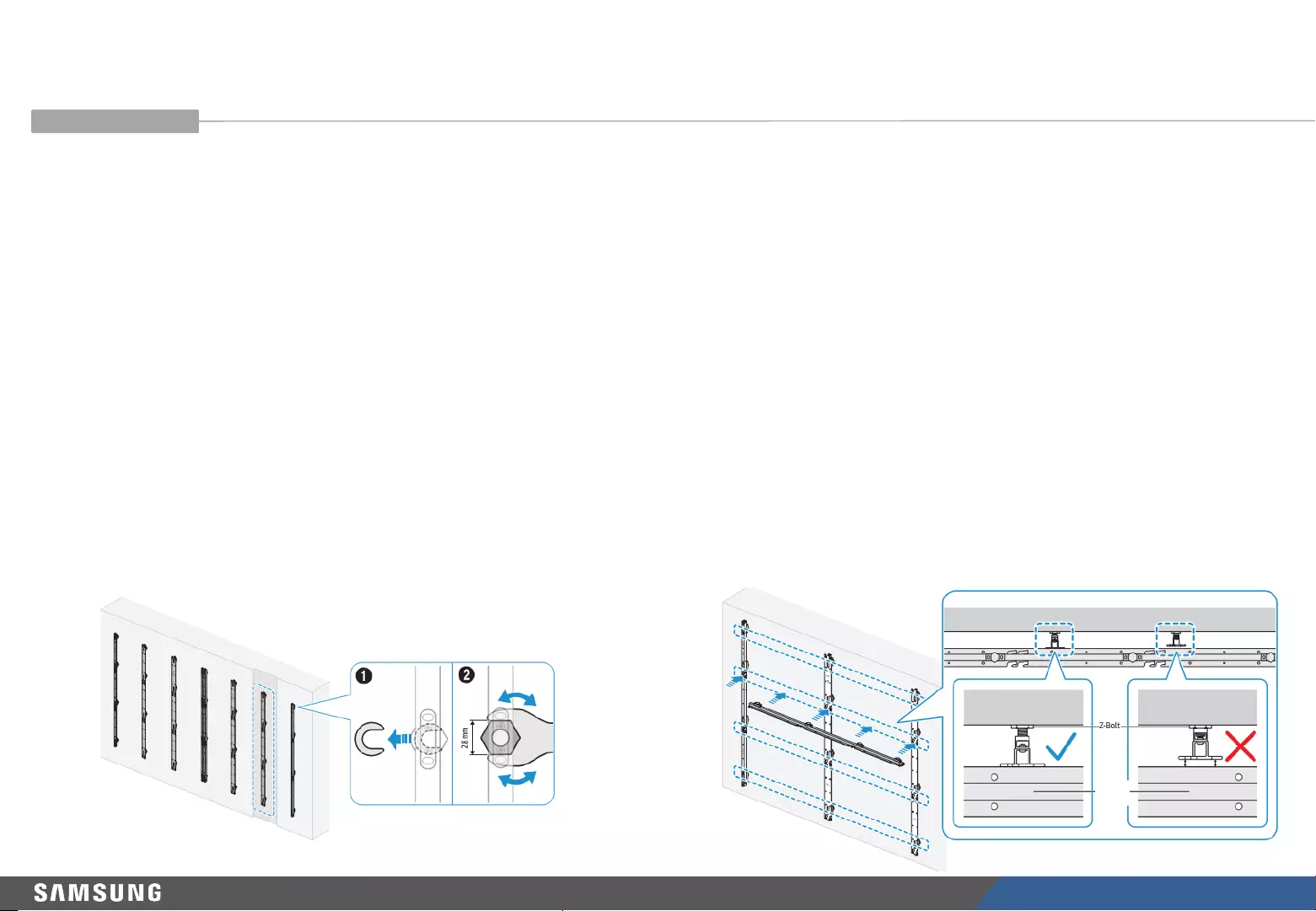

4. Frame Installation

※If installing three or more ASSY BRACKETs, adjust the flatness, because the wall or a

structure may cause warping.

–After installing three or more ASSY BRACKETs, put a spare ASSY

BRACKET horizontally and measure the height difference.

If a height difference is found, adjust the Z-Bolts of the ASSY

BRACKETs to adjust the flatness.

–How to adjust height

1. To adjust the height of a Z-Bolt of a frame, first remove the washer.

2. Use a 28 mm wrench to adjust the Z-Bolt height. Flatness measurement positions:

Around areas where screws are fastened

Wall

Spare

frame

Wall

Wall

LED R&D Lab(VD)

35

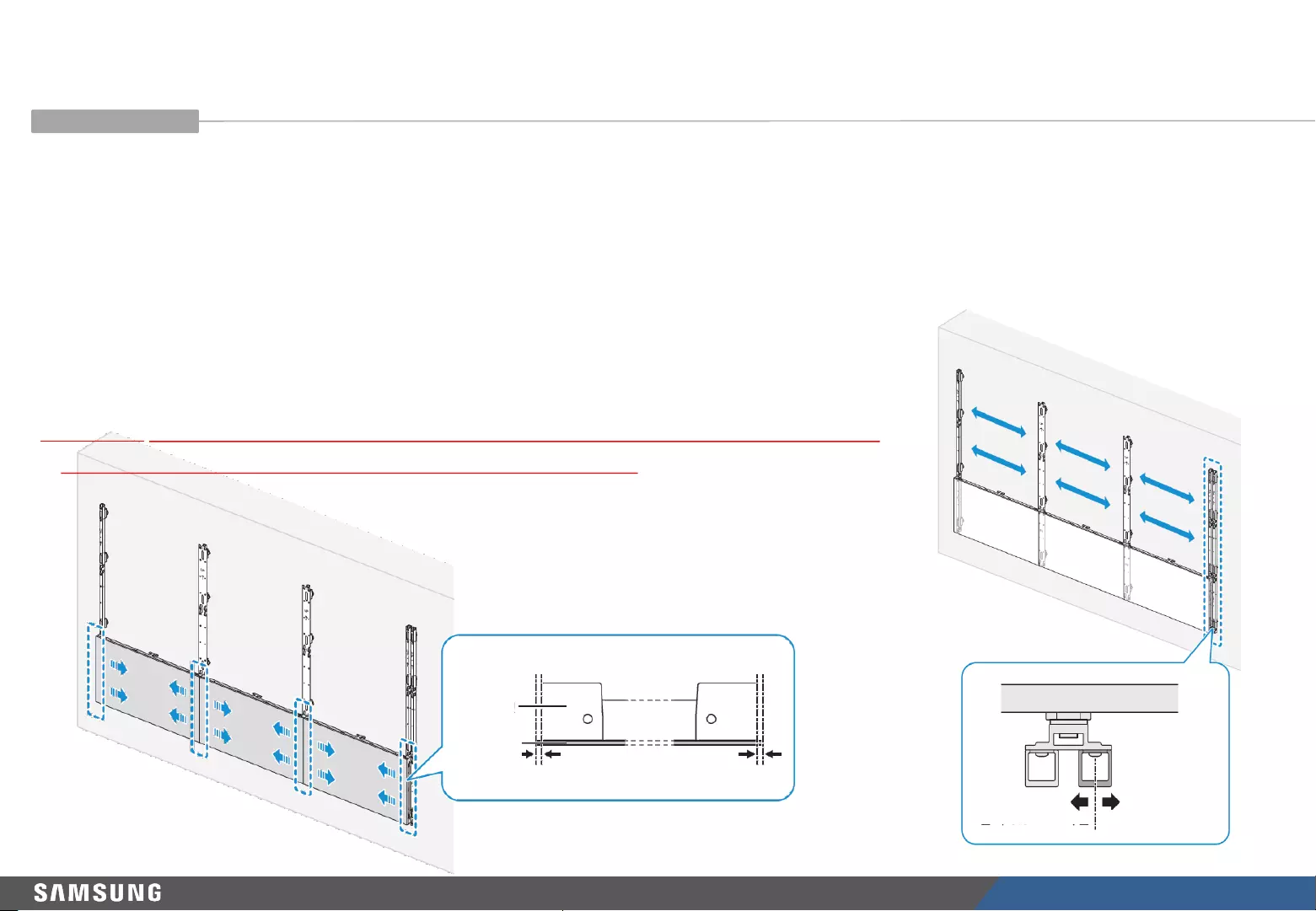

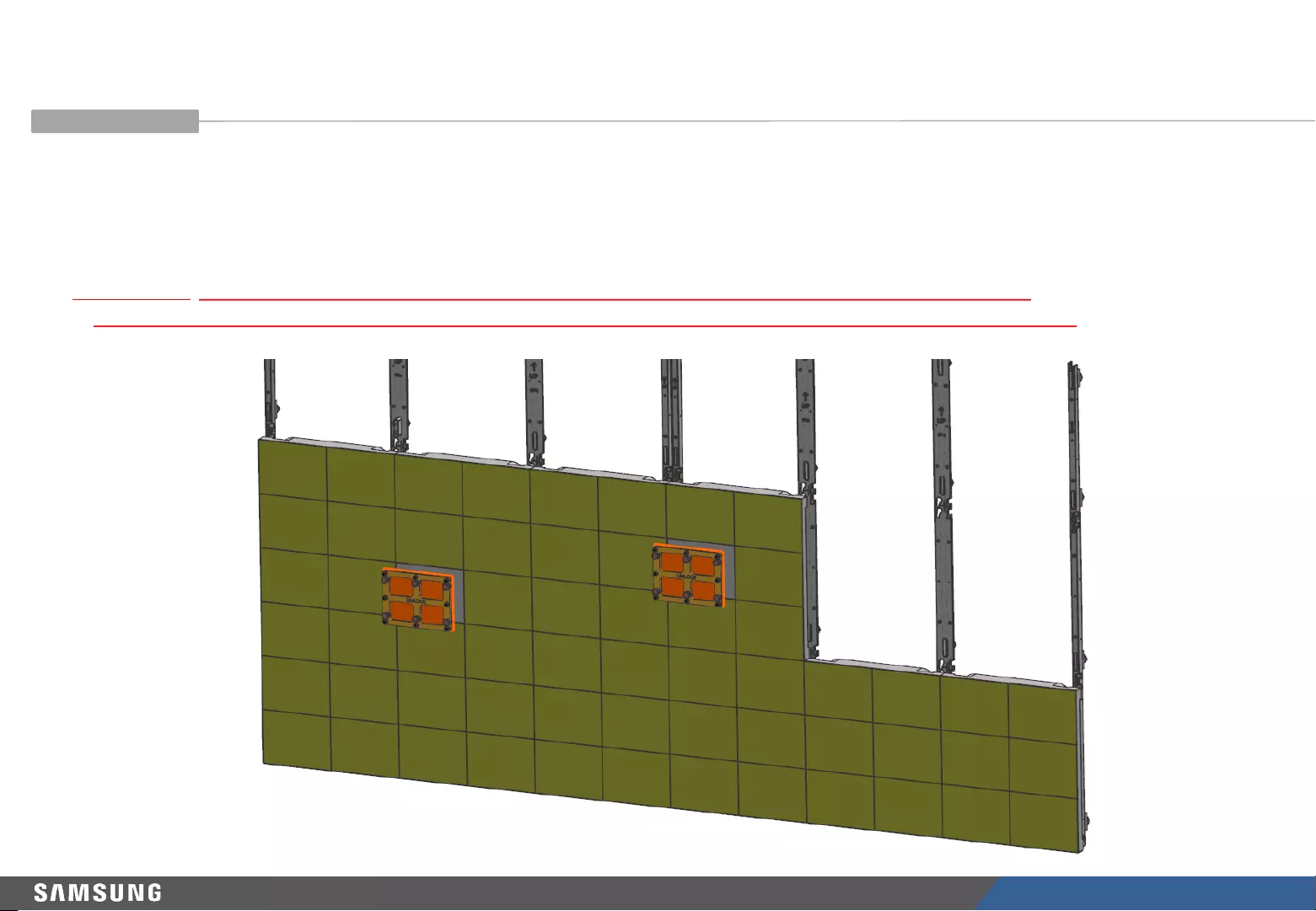

※ The Frame Kit product can be installed by extending the size as required.

-Components can be extended horizontally or vertically for installation.

-When installing ASSY BRACKET JIGs for fixing the joints between ASSY BRACKETs, make sure two persons

work together so that the ASSY BRACKET JIGs can be fixed properly.

(While one person holds an ASSY BRACKET JIG on the position to fix the JIG, the other person can fasten screws

on the ASSY BRACKET JIG.)

-When performing extended installation, an ASSY BRACKET CENTER should be installed between the ASSY

BRACKET MIDDLEs.

(It is recommended that one ASSY BRACKET CENTER be installed for three to four ASSY BRACKET MIDDLEs.)

4. Frame Installation

LED R&D Lab(VD)

36

4. Frame Installation

※Vertical frame extension

-Attach the Joint V (vertical) to the target frame for extension

Fasten M4

<Vertical extension>

M4 screw

-Insert the joints of the additional frame into the existing frame. Insert jigs

to place the frames into position.

-After attaching the jigs, fasten screws between the frames.

-Distance between connected frames for extension is 1 mm.

1 mm

•When extending FRAME, it is easy to turn vertical and horizontal. Horizontal vertical CHECK must be extended.

•(Laser Horizontal System/Sill etc.)

LED R&D Lab(VD)

37

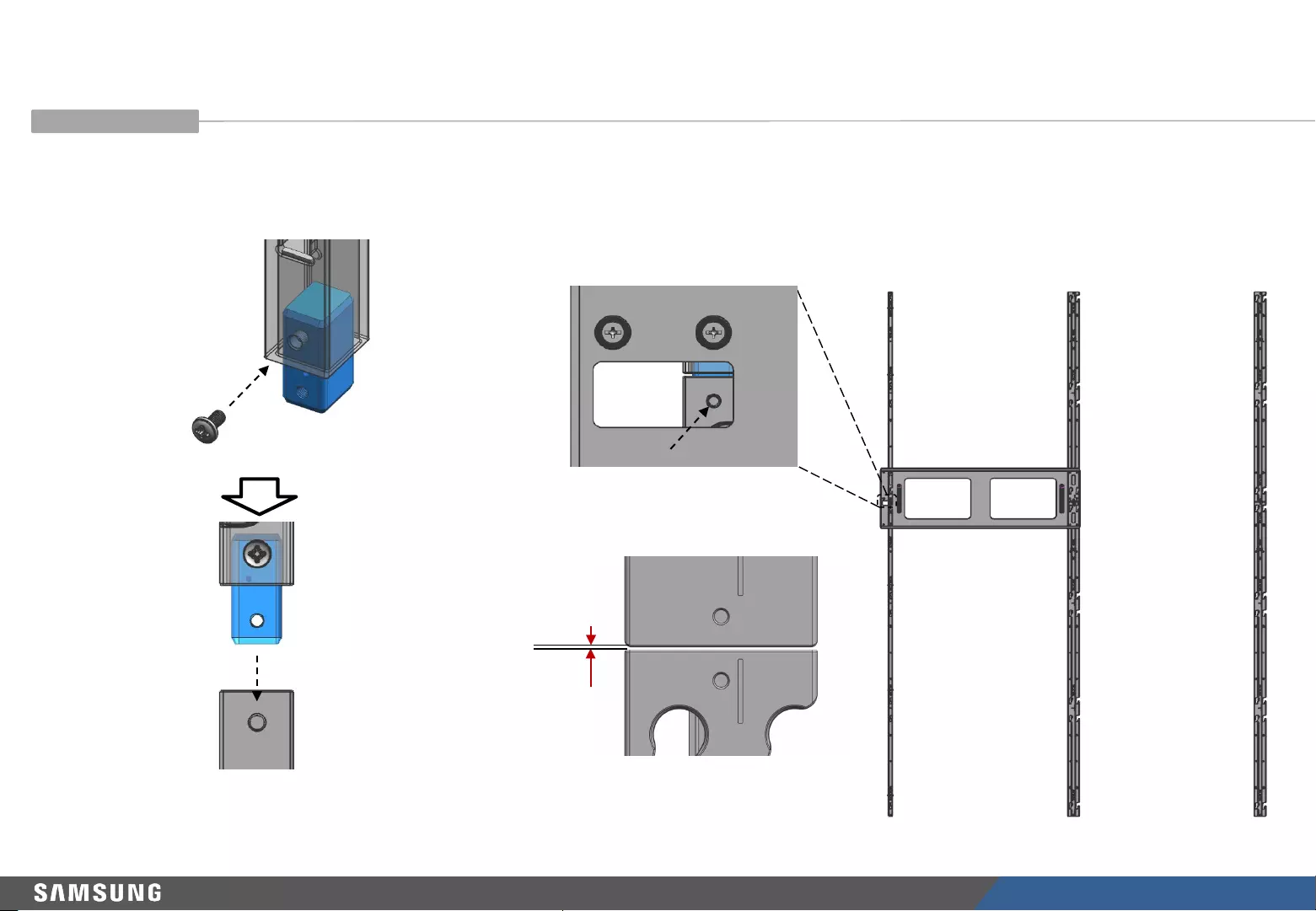

◆Fixing of I/G position

①Attach the I/G on the rear of each cabinet by type, first. (See Fig.1.)

※Installation position: Place the I/G at a spot 35–40 mm below the engraving on the right-side frame, and fasten the screws (Fig.2).

35–40 mm

I/G

Fig1. I/G attachment position / order of installing cabinets

Fig2. I/G attachment position

70–80 mm

5. Cabinet + Frame Installation

LED R&D Lab(VD)

38

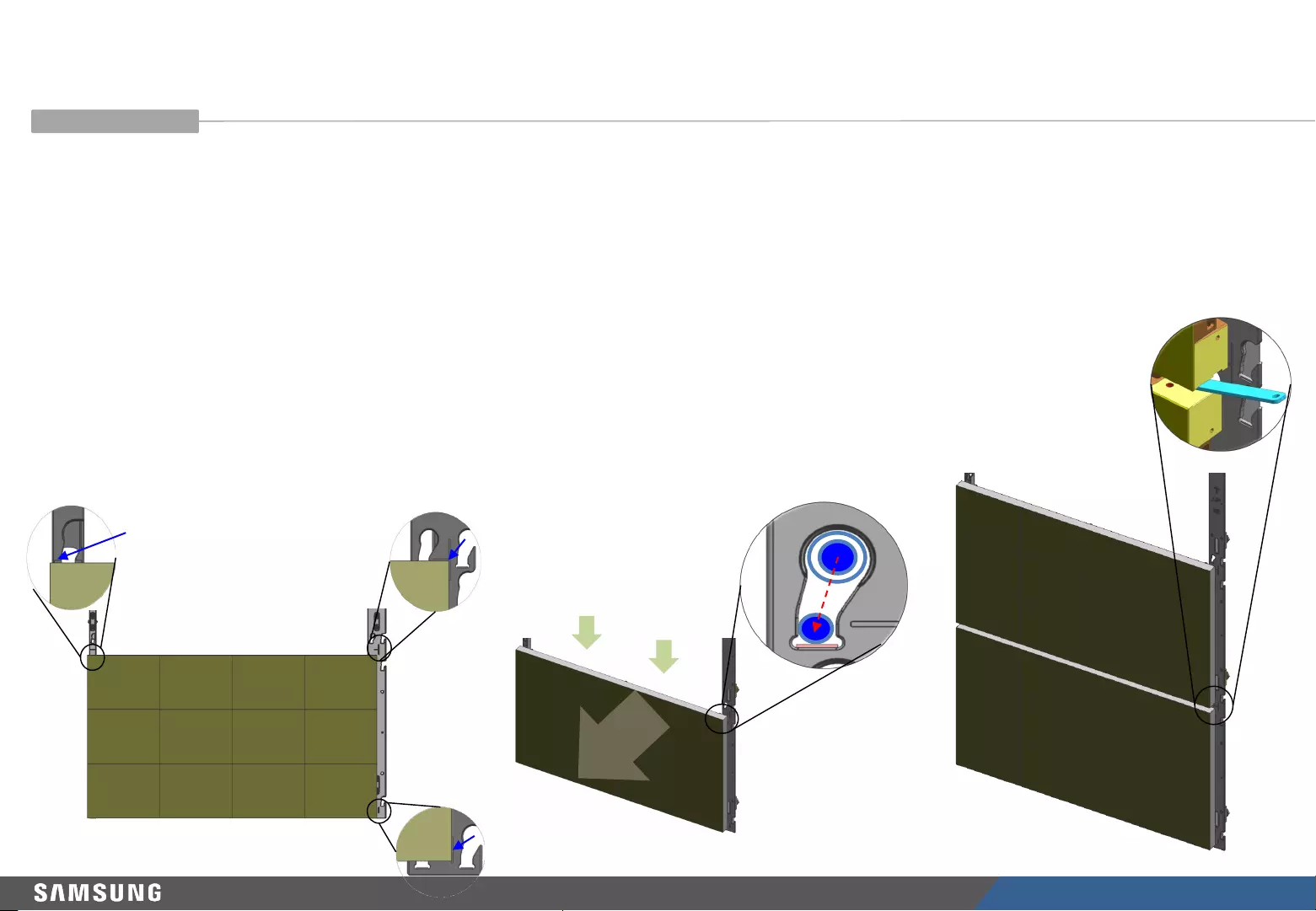

5. Cabinet + Frame Installation

②Draw the cabinet right up against the frames by aligning the cabinet corners with the engravings on the

frames.

※For the order of installing cabinets, see Fig. 1 on page 18 .

※Check that the four bolts are all inserted into the frames. (See Fig.1.)

③Push the top surface of the cabinet corners down so that the cabinet slides down diagonally. (See Fig.2.)

④From the second row and above, insert the Service Jig between the cabinets and attach

the cabinets. Next, remove the Service Jig and slowly lower the cabinets. (See Fig.3.)

※Exercise caution to ensure that the Service Jig does not touch an LED module.

※Each time a cabinet is installed, check that there is no inter-module gap or pitch interval warning found.

engraved

position engraved

position

engraved

position

Fig.1 Fig.2 Fig.3

Sliding Screw

◆Fixing of I/G position

LED R&D Lab(VD)

39

5. Cabinet + Frame Installation

⑤When modules are tightly coupled, it becomes difficult in detaching a module.

Accordingly, sample some modules during installation to check whether module

detachment is possible. ★Important

※Otherwise, it may cause maintenance issues due to difficulty in attachment and detachment of a module.

Excessive action may cause damage to the module. Sampling is recommended for every 2-to 3-row cabinets.

◆Fixing of I/G position

LED R&D Lab(VD)

40

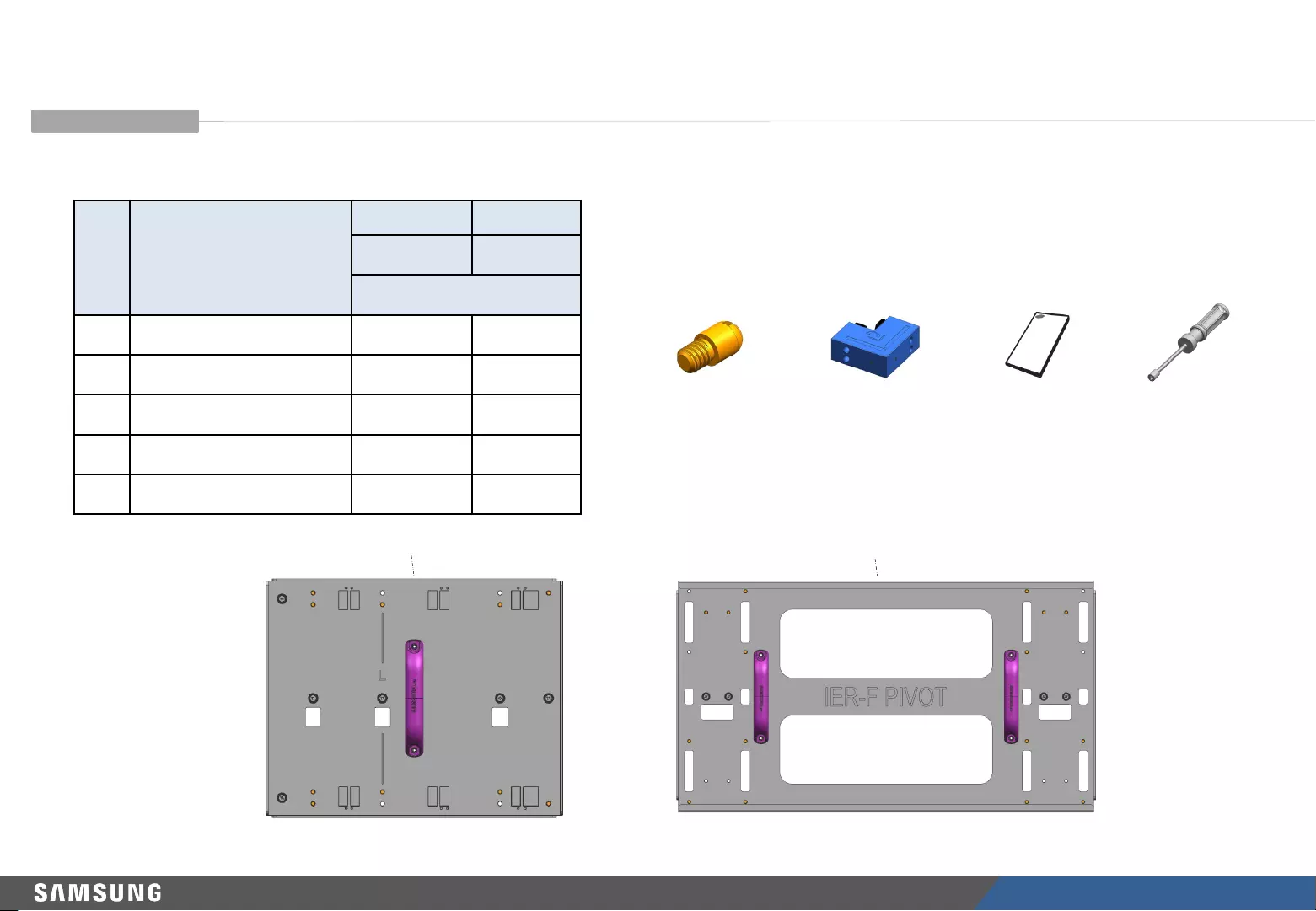

5. Cabinet + Frame Installation

◆PIVOT installation

Fig1. Positions of BOLT ETCs fastened in delivered product Fig2. Positions to fasten BOLT ETCs when installing the PIVOT

When installing the PIVOT, use the PIVOT-specific Frame Kit.

(VG-LFR51PWL / the same installation steps apply)

①Check that the BOLT ETCs are fastened. (Fig.1)

②Fasten the BOLT ETCs again appropriately for PIVOT installation. Fasten

two additional bolts and remove the COVER HANDLEs. (Fig.2)

③Install with the arrow pointing up, by referring to the engraving indicating

the direction.

Engraving indicating

the PIVOT direction

Remove the COVER HANDLEs

5. Cabinet + Frame Installation

◇Installation Guide of recessed screen

When installing recessed screen, minimal work space is needed from the edge of the

screen.

–In order to finish seam adjustment, fixation parts should be installed on the screen edge. If the parts

are not installed, seam between modules could be made.

–The parts can be fixed on the screen by tools and space for tools are needed on the edge. Though

it may be dependent on your tools, more than 50mm is required in general.

Top View

Front View

Left work space

[Fixation parts]

-The Wall : Holder PCB, Cover PCB

-IFH/IFJ/IER/IFR : Cover PCB

More than 50mm

Cabinet

Screen

5. Cabinet + Frame Installation

◇Installation Guide of recessed screen

Work space should be finished with detachable material for service.

–Work space more than 1mm should be secured for safety of the screen.

Be cautious of safety of the screen while detaching and attaching finishing material.

–Top and bottom materials should have enough ventilation hole.

If there is enough heat dissipation space behind the screen, it can be omitted.

–Finishing materials is recommended to have same pattern and material as the wall.

–If metal parts of the screen is shown from the side of it, finish it with black tape.

※ Because wall is not flat perfectly, difference from wall

finishing material and the screen could be made.

In order to prevent it, each part should be designed,

manufactured and constructed.

Top View

Front View

Screen

More than 1mm

Detachable

LED R&D Lab(VD)

43

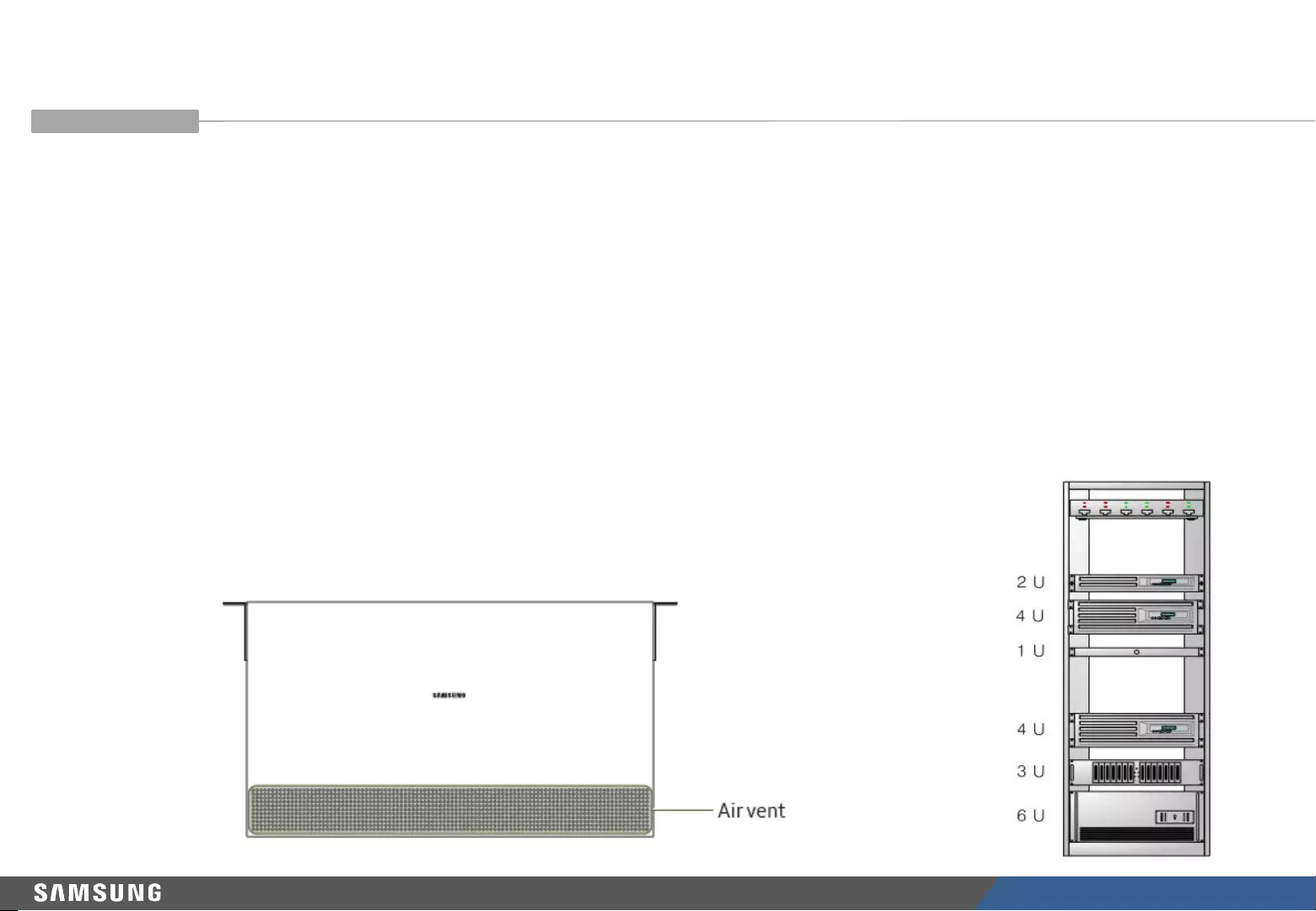

6. S-Box Installation and Connection

①Installing it in a 19-inch server rack is recommended.

※When connecting two or more times for the purpose of using multi-link HDR, install it on the ground shielded rack and use it. (SBB-

SNOWJMU model)

②Make sure the air vent is open and not overturned or turned sideways.

③Exercise caution to ensure that the air vent is not covered by an object. Covered air vent may cause overheating of the product.

④If installing multiple S-Boxes, make sure there is a gap of at least 1U (44.45 mm) from the product at the top.

⑤If installing an S-Box onto a wall, make sure there is a gap of at least 10 mm between the wall and the top, bottom and sides of the

product. Make sure there is a gap of at least 50 mm between the cable ports and the wall to ensure proper cable connection.

⑥Maintain the residual heat inside the rack at a temperature below 35°C.

⑦Exercise caution to ensure that no liquid enters the air vent of the product.

• Precautions for installing S-Box

SBB-SNOWJAU / SBB-SNOWJMU

LED R&D Lab(VD)

44

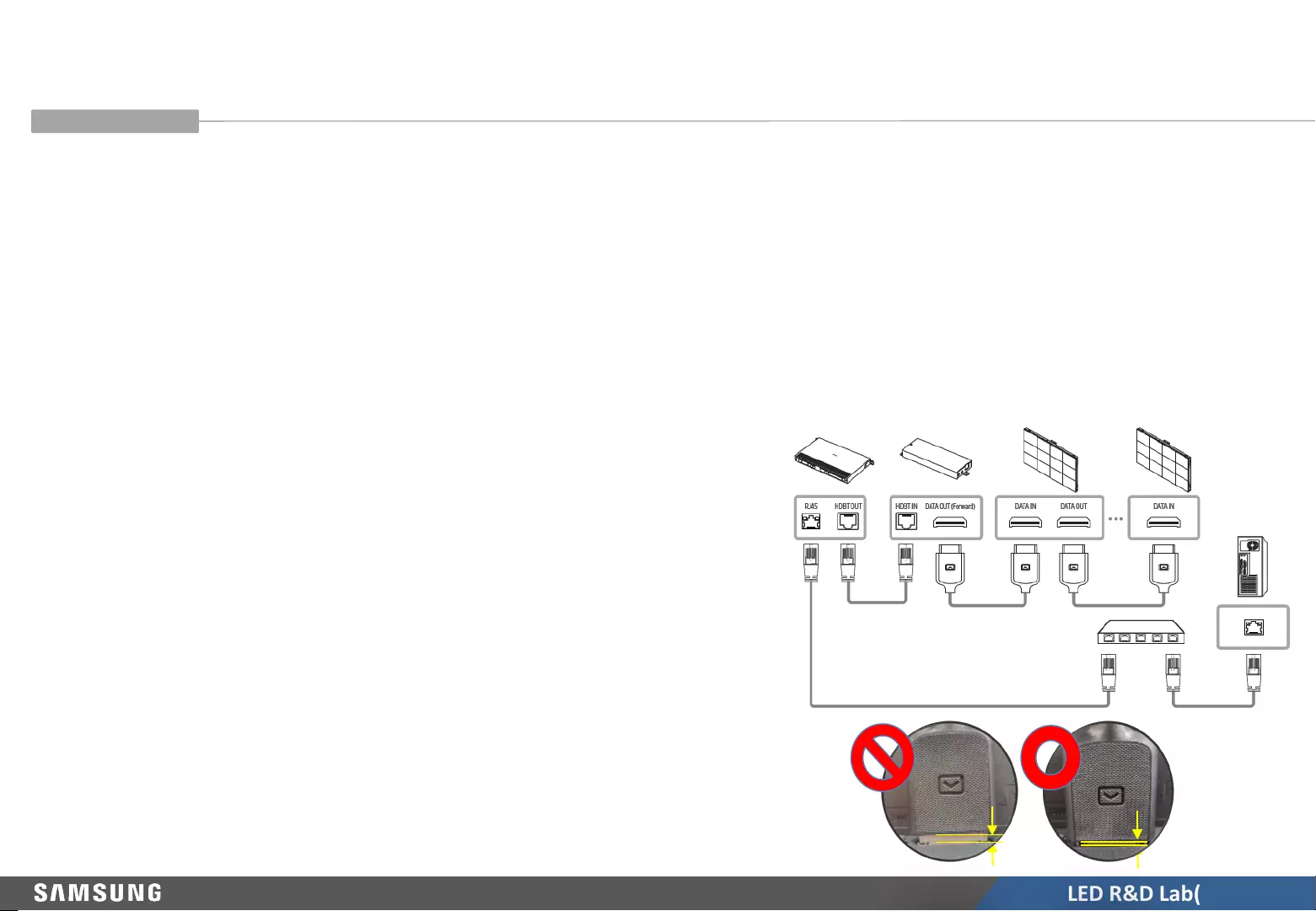

6. S-Box Installation and Connection

• S-Box connection

①Send visual signal input into the S-Box (input ports: HDMI, DP).

②Use the SOURCE STATUS to check the signal input (Red: HDMI1, Green: HDMI2, Blue: DISPLAY PORT).

③Use the LAN cable to connect the HDBT OUT port on the S-Box to the HDBT IN port on the Interface Gender.

④Use the OCM cable to connect the DATA OUT port on the Interface Gender to the DATA IN port on the first cabinet.

⑤Please add input signal with “Input signal Plus” menu for UHD resolution

※Menu – Picture – Advanced Settings –Input signal plus : add input signal

(The default setting is OFF. If this setting is changed, the S-Box is rebooted.)

⑥The screen is displayed based on the cabinet in the top left.

To view the screen, connect to the HDBT OUT1 port on the S-Box.

⑦For each S-Box, the same type pitch cabinet can only be supported

simultaneously. When installing the product, only connect

compatible cabinets to the product.

LED R&D Lab(VD)

45

6. S-Box Installation and Connection

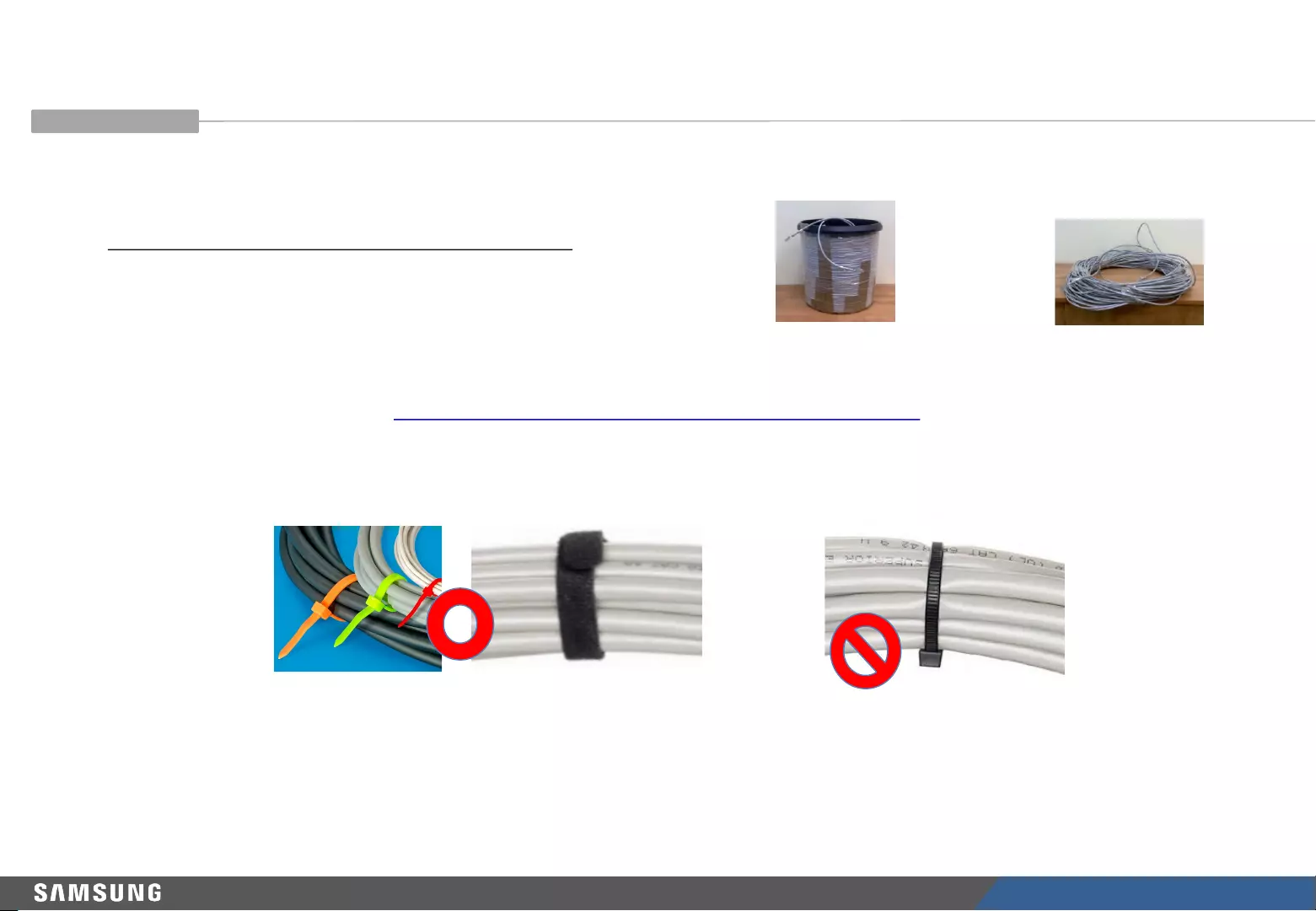

⑧Cable recommendations for HDBaseT

Do not use “comb” or “pinstripe” type cables.

Use HDBaseT cables that are 15 m to 100 m long.

Use HDBaseT Cables recommended at the following Alliance website.

HDBaseT Alliance website: https://hdbaset.org/hdbaset-recommended-cables/

Do not bend HDBaseT cables to ensure signal consistency.

When organizing HDBaseT cables, make sure the cables are not tied too tight.

Do not bind HDBaseT cables and AC power cables together.

EMI sources: Ensure that the product is placed away from the electromagnetic environment (e.g. high-voltage

wires, electric motor-based equipment such as an elevator or refrigerator, fluorescent lights, lighting fixture).

Keep a distance of at least 12” (=30.48cm) between HDBaseT cables and AC power cables.

A maximum of four cables connected to a single S-Box can be bounded together.

★Orderly Rolled (Recommend) ★Random Rolled

(Not Recommend)

• S-Box connection

LED R&D Lab(VD)

46

6. S-Box Installation and Connection

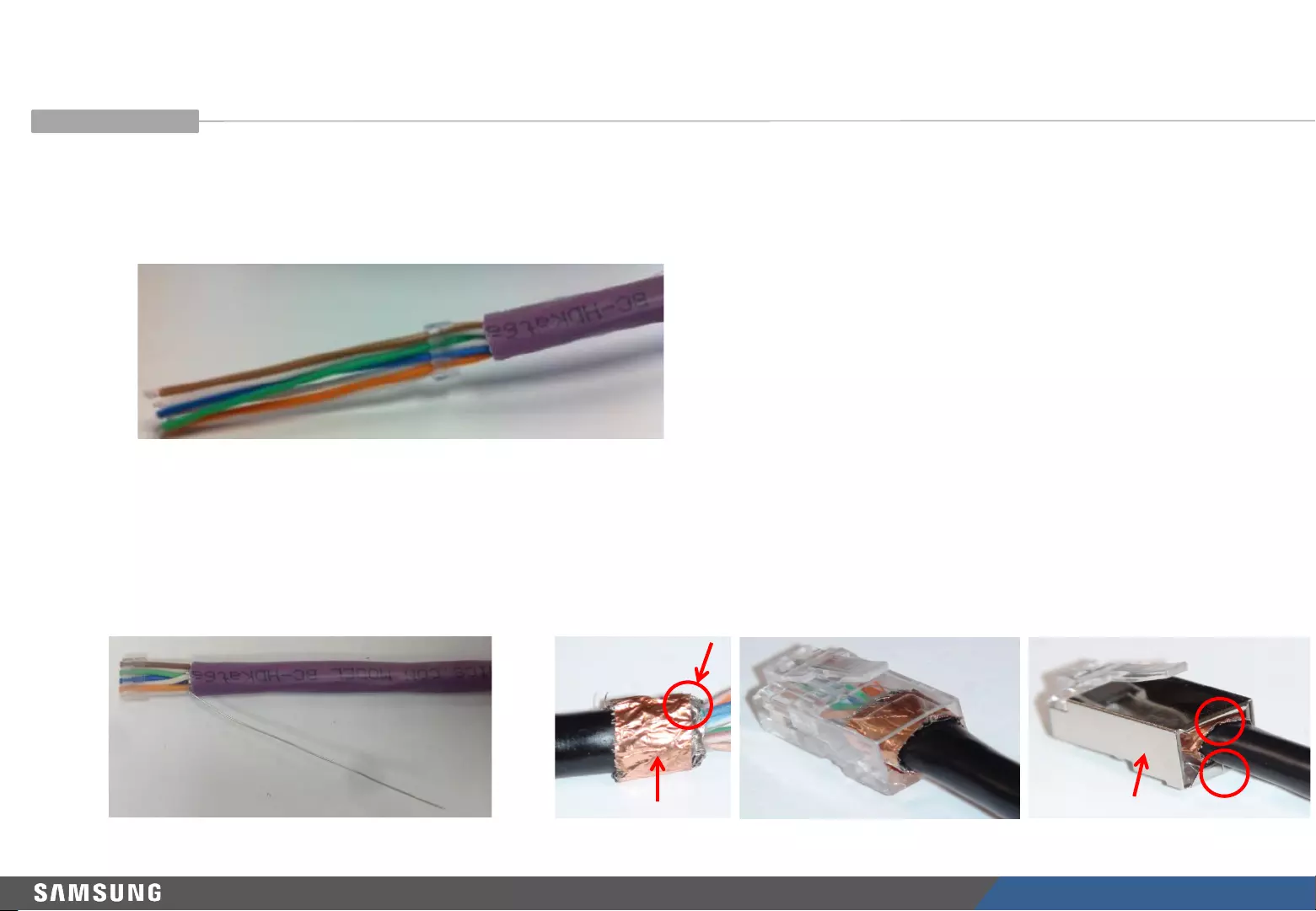

Using shielded STP RJ45: Use a shielded RJ45 connector, and a CAT 6 or CAT 7 connector using a plastic load bar.

Insertion of conductors (conducting wires) into plastic loader: Insert conducting wires into the RJ45 connector, as shown by

the conducting wire structure (T-568B) in the following figure. Plastic load bar is required. (The reason is that the thickness of a

CAT 6 cable prevents the cable from being placed flatly in an RJ-45 connector, unlike general CAT 5 cables.)

⑨Finishing the HDBaseT cable after installation

Load bar

Wires aligned with load bar

Load bar and drain wires

• S-Box connection

LED R&D Lab(VD)

47

6. S-Box Installation and Connection

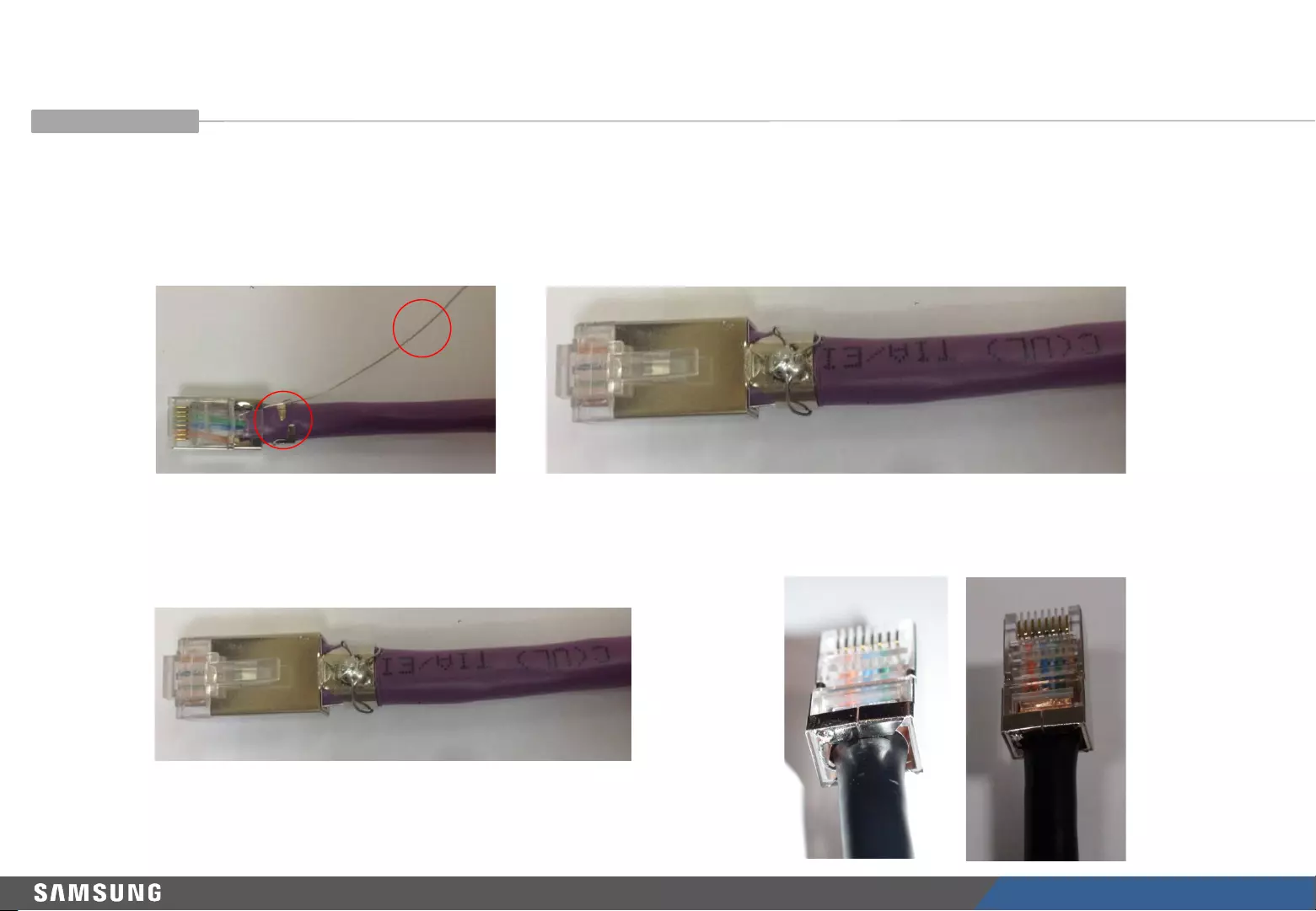

•Pushing in of plastic loader to fullest extent: Push the plastic load bar as close as possible to the cable.

•Use a wire stripper to cut all conductors (conducting wires) down to a length of about 0.5 inches.

•With drain wire: Refer to the next page.

※Without drain wire: Use copper foil to contact the connector shell part, as shown below.

Copper foil

Fold aluminum foil or braid back and wrap it with copper foil.

Connector shell

• S-Box connection

⑩Finishing the HDBaseT cable after installation

LED R&D Lab(VD)

48

•Fold and raise the drain wire above the RJ-45 connector. Use pliers to attach the deformation prevention parts together, as

shown below.

•Soldering of drain wire to metallic part of RJ45 connector: Solder the drain wire to the metallic part of the RJ45 connector

and cut unnecessary parts out. Use a cable tester to the conductors and shield status (continuity).

6. S-Box Installation and Connection

⑩Finishing the HDBaseT cable after installation

Recommendation) Drain wire soldering + copper foil

• S-Box connection

LED R&D Lab(VD)

49

6. S-Box Installation and Connection

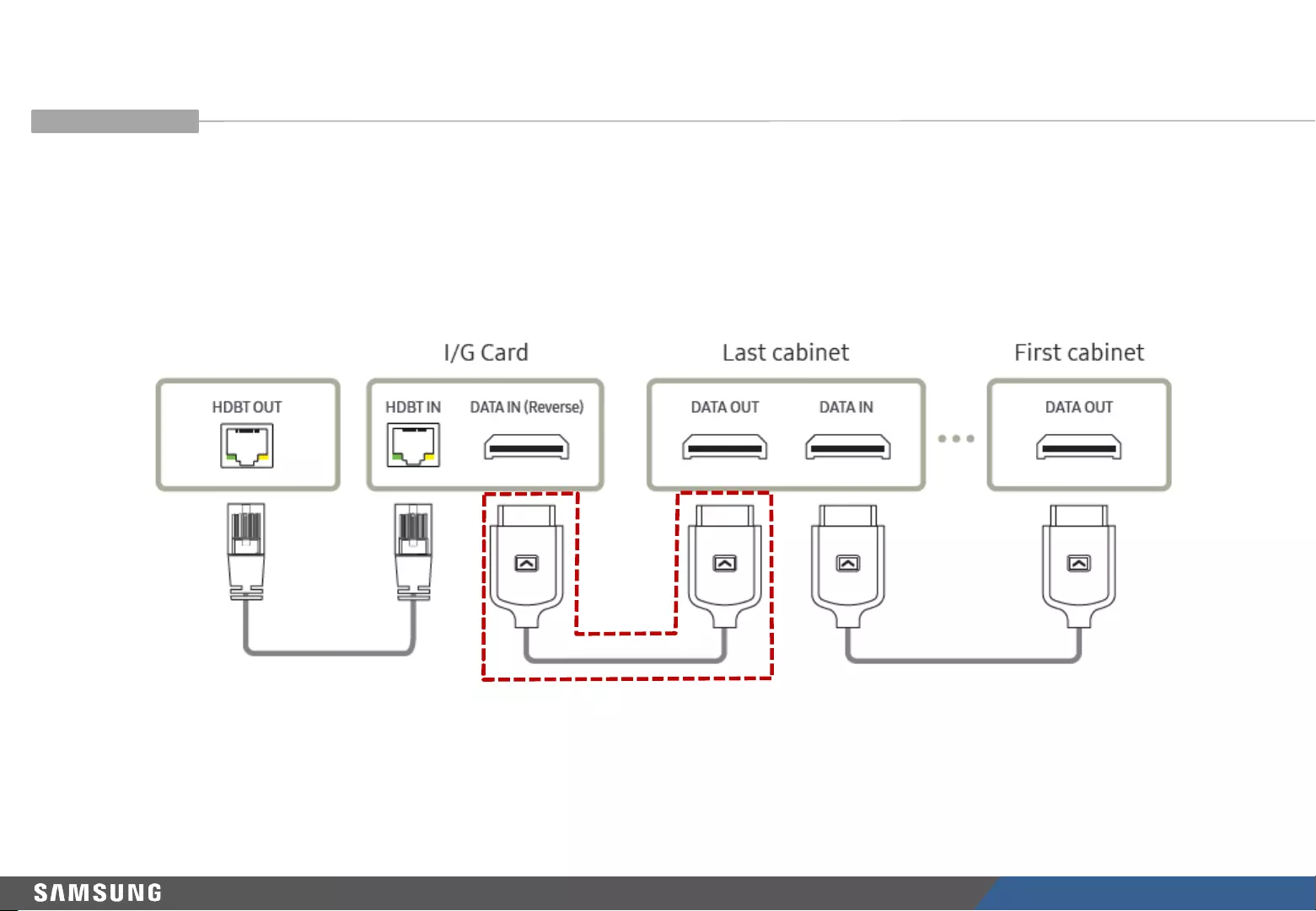

• S-Box connection (Redundancy)

①If a redundancy feature is required

Use the OCM cable to connect the DATA IN port on the Interface Gender to the DATA OUT port on the last cabinet.

•Use 15–100 m long CAT 6 *STP and *FTP level cables

to ensure HDBT signal stability.

•Do not bend cables or bind multiple cables together.

SNOW-1801U

LED R&D Lab(VD)

50

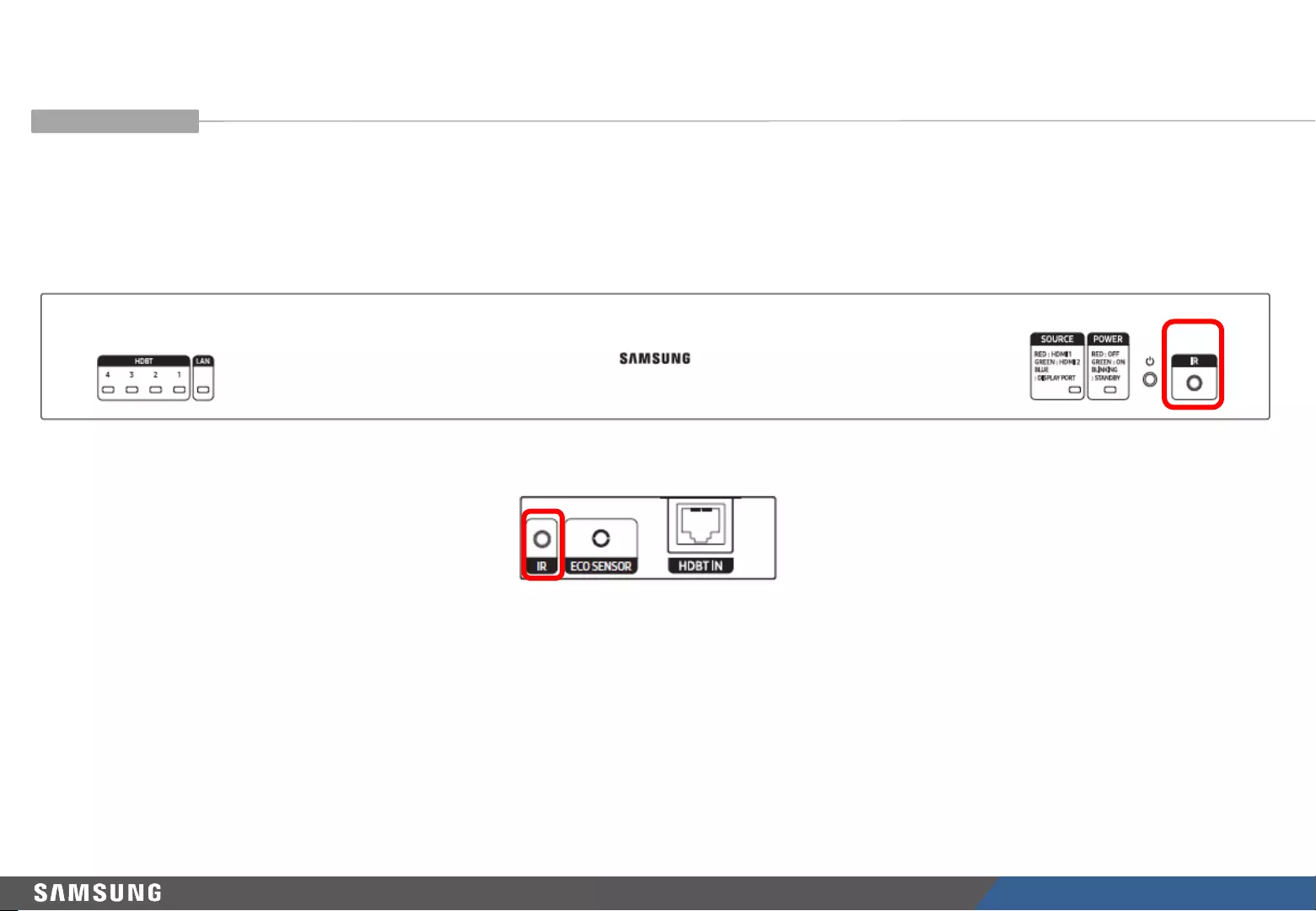

※Only one external IR receiver is provided for a set.

-External IR receiver can be connected to the S-Box body or Interface Gender card (I/G card).

6. S-Box Installation and Connection

• S-Box connection (External IR Receiver)

OR

※When connected to the I/G card, make sure “Network Standby” is set to “On” in System -Power Control.

LED R&D Lab(VD)

51

6. S-Box Installation and Connection

• S-Box connection (Panel configuration)

①Initial S-Box picture quality settings

•S-Box is delivered with default picture quality settings optimized for the IWJ cabinet.

•After an LED display is installed, the picture quality settings become automatically optimized for the installed LED display model.

•To ensure configuration of optimum picture quality settings, make sure you use the LSM SW to connect the S-Box to the LED display.

•Make sure the LED display is connected to HDBT Port 1.

•Picture quality settings are configured based on the master cabinet model connected to HDBT Port 1.

* If the S-Box is not connected to the LED display via LSM, displayed colors may not look natural.

<Connection screen>

Control PC

(LSM)

S-Box

Ethernet

Interface Gender

Vx1

……………

HDBT Vx1+Ethernet

Cabinet 1

(Master) Cabinet N

LED R&D Lab(VD)

52

6. S-Box Installation and Connection

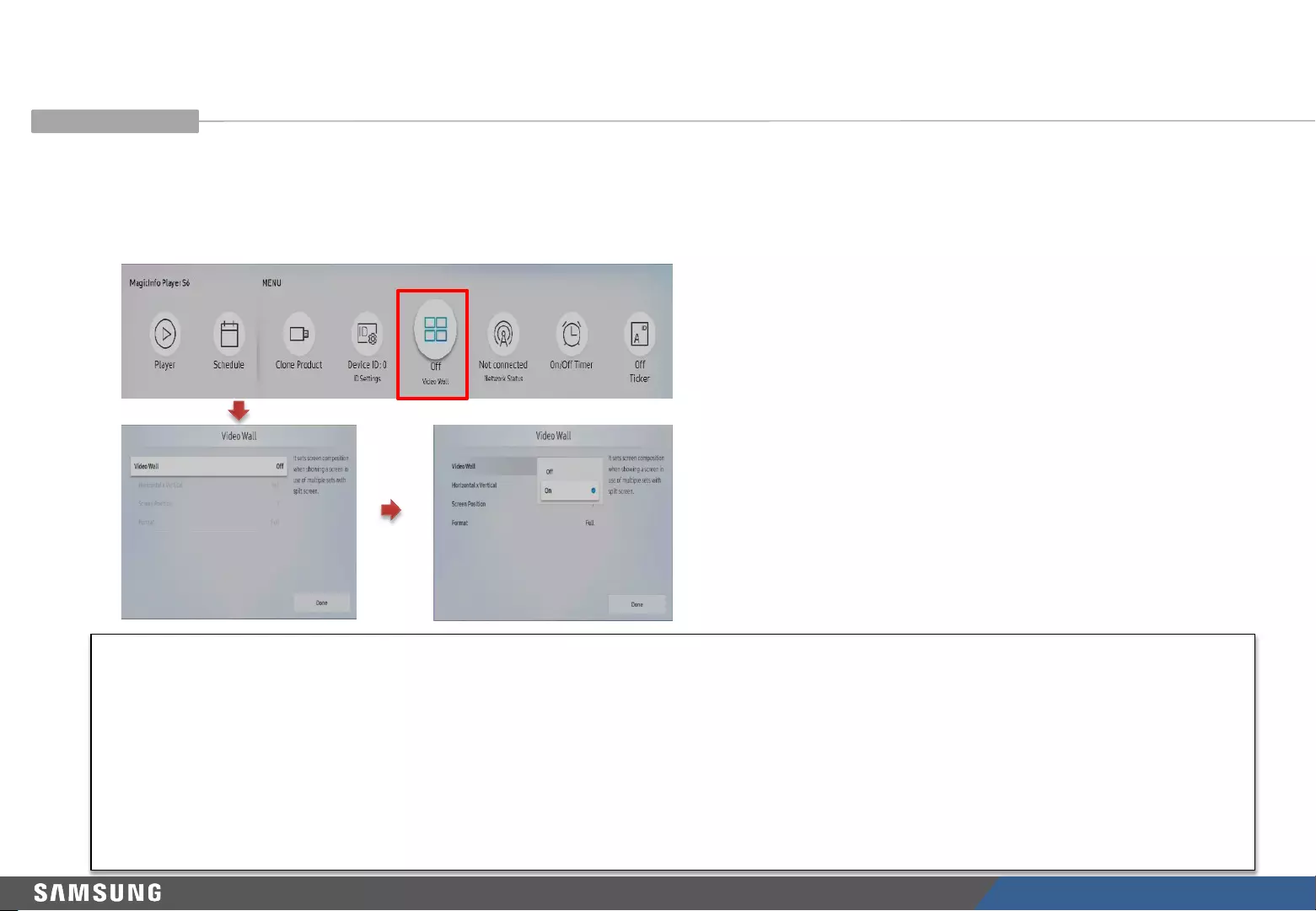

• S-Box connection (Panel configuration)

Press the Home button on the remote control and set Video Wall to “On”

[Precautions]

1) Prior to running S-Box Grouping from LSM (LED Signage Manager), make sure you set the resolution for the input source

device to a resolution compatible with S-Box Grouping.

2) If a resolution not compatible with S-Box Grouping is selected, a blank or static screen may be displayed. If this is the

case, turn off the Video Wall function and change the resolution for the video output source to 50 Hz or 60 Hz.

※Since June 2013, the S-Box Grouping function has been provided through LSM. Check the latest LSM version.

②S-BOX 연결 (Grouping)

LED R&D Lab(VD)

53

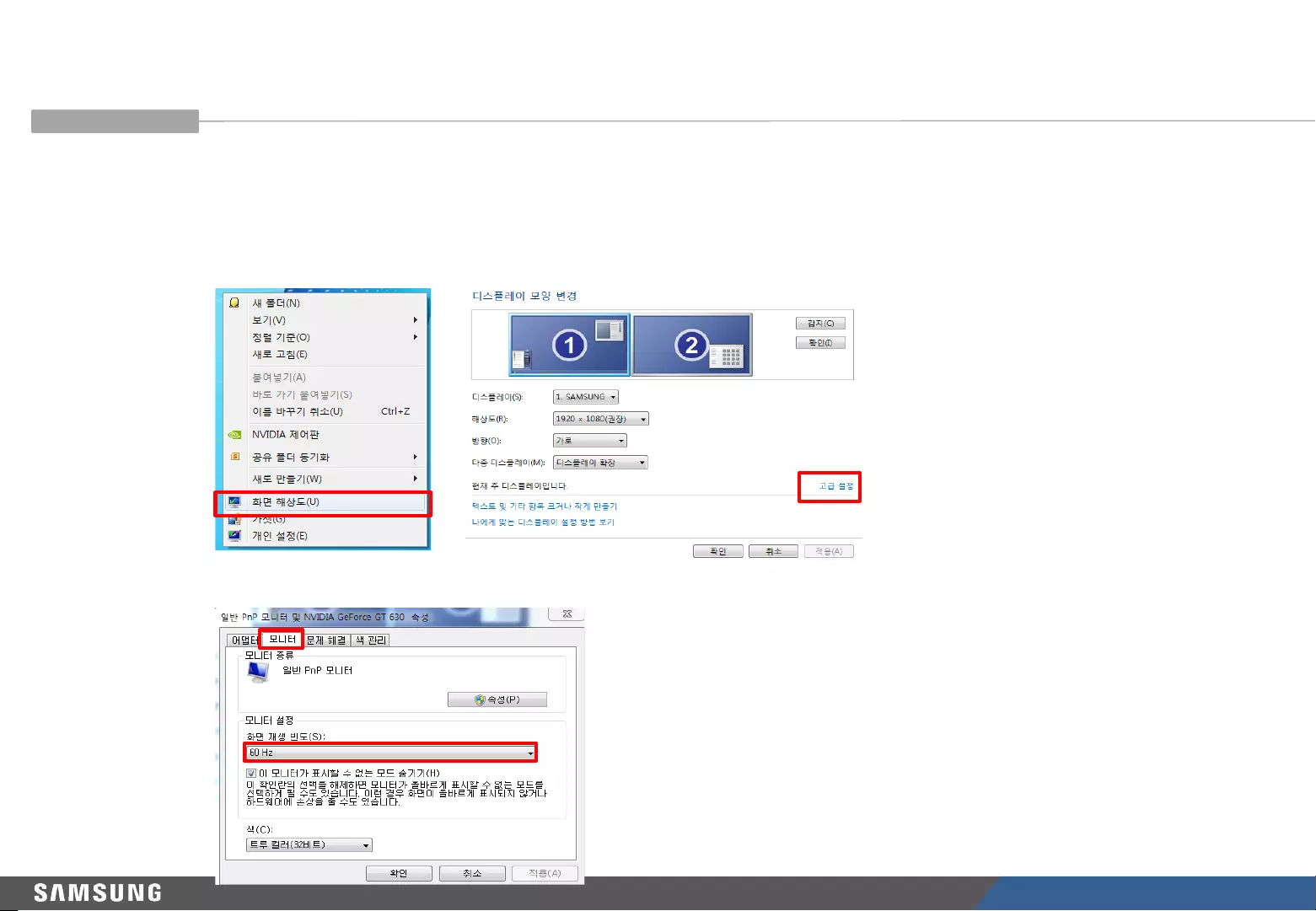

6. S-Box Installation and Connection

•Right-click with the mouse on the computer desktop and click “Screen Resolution” → “Advanced settings.”

•Click the “Monitor” tab and select “60 Hertz” from the “Screen refresh rate” dropdown box under “Monitor Settings.”

③Changing the PC output frequency

• S-Box connection (Panel configuration)

LED R&D Lab(VD)

54

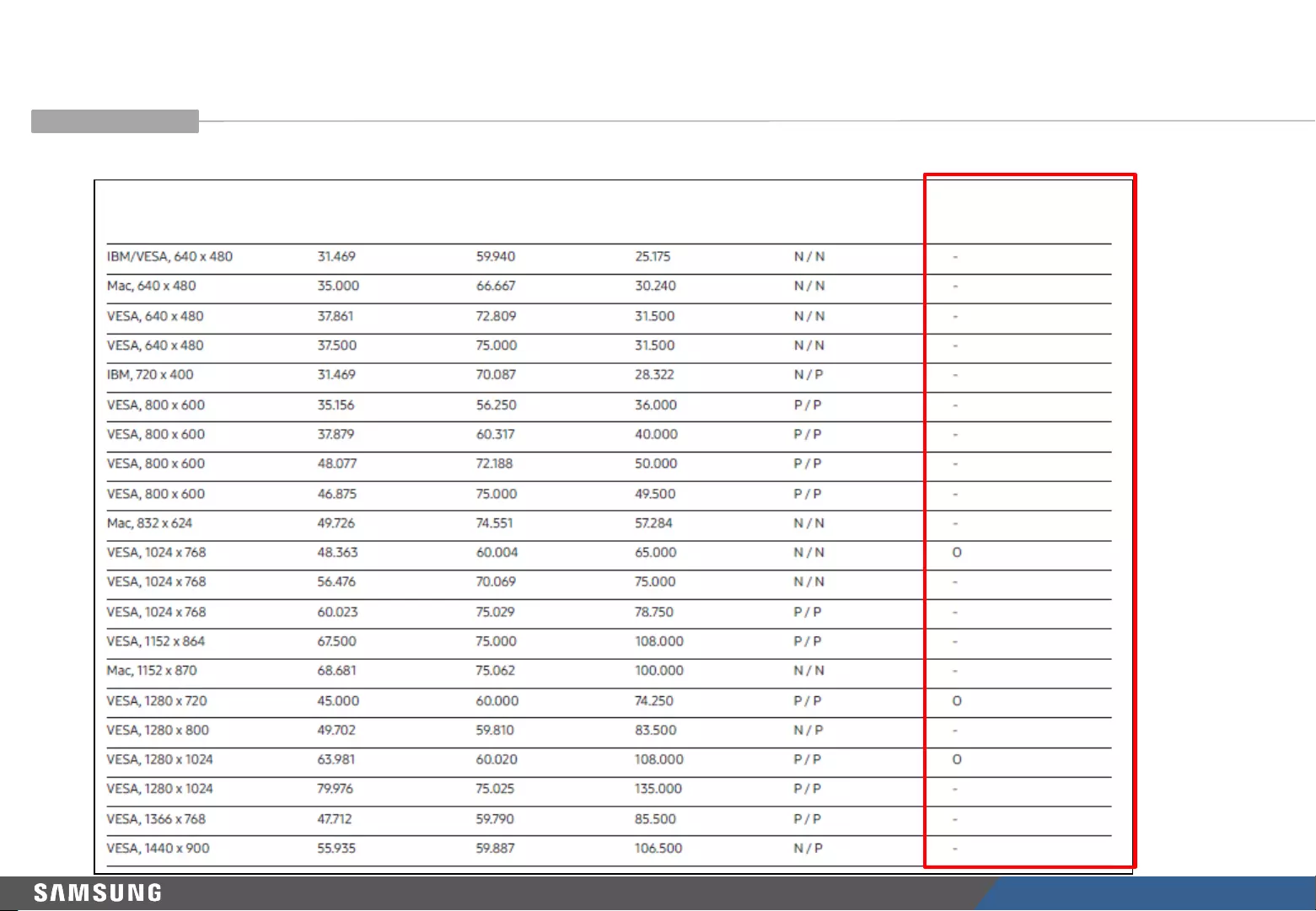

6. S-Box Installation and Connection

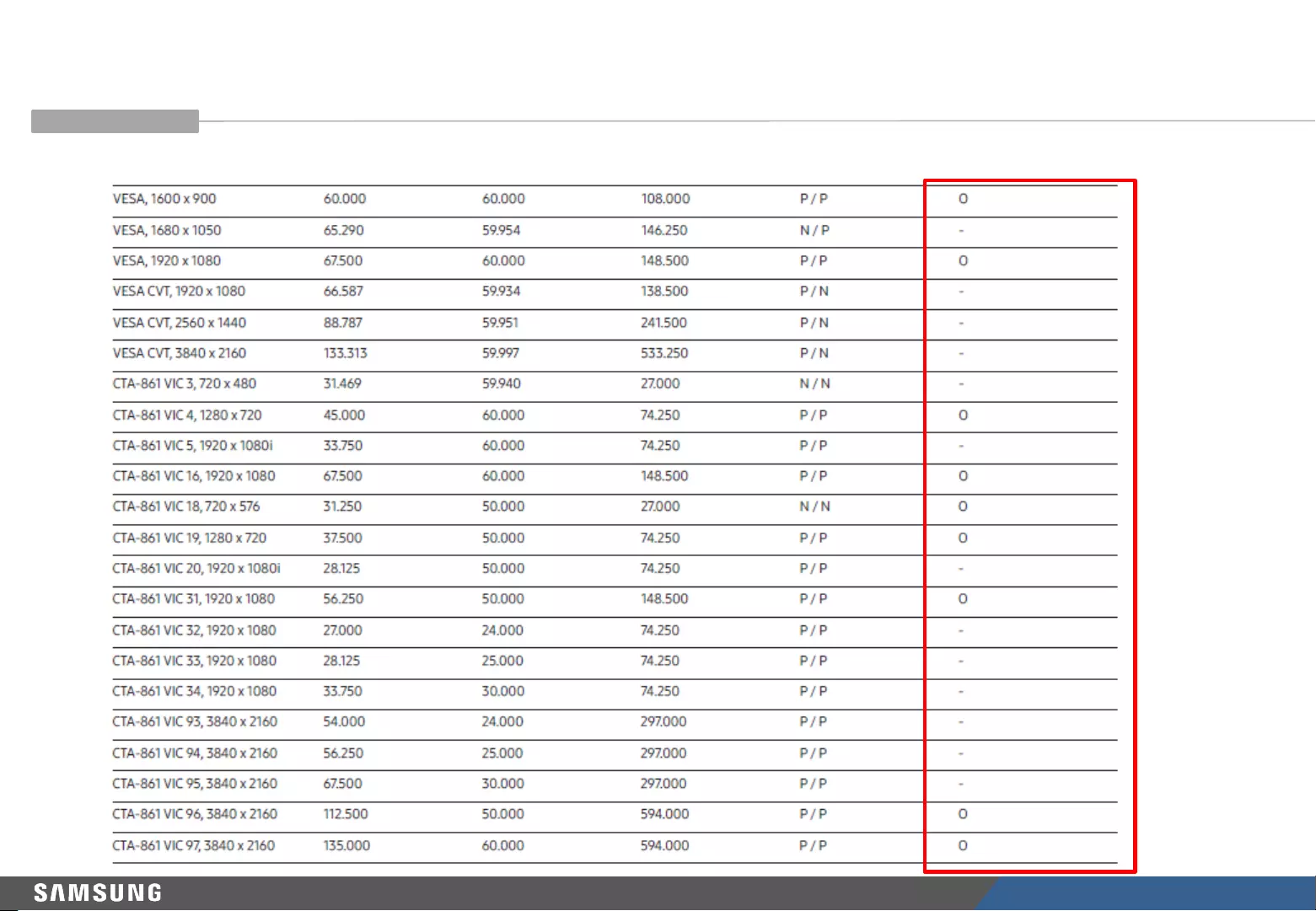

④Frequencies compatible with S-Box Grouping (1/2)

Resolution Horizontal frequency Vertical frequency Clock frequency Polarity

(KHz) (KHz) (MHz) Horizontal / Vertical S-Box Grouping

LED R&D Lab(VD)

55

6. S-Box Installation and Connection

④Frequencies compatible with S-box Grouping (2/2)

LED R&D Lab(VD)

56

6. S-Box Installation and Connection

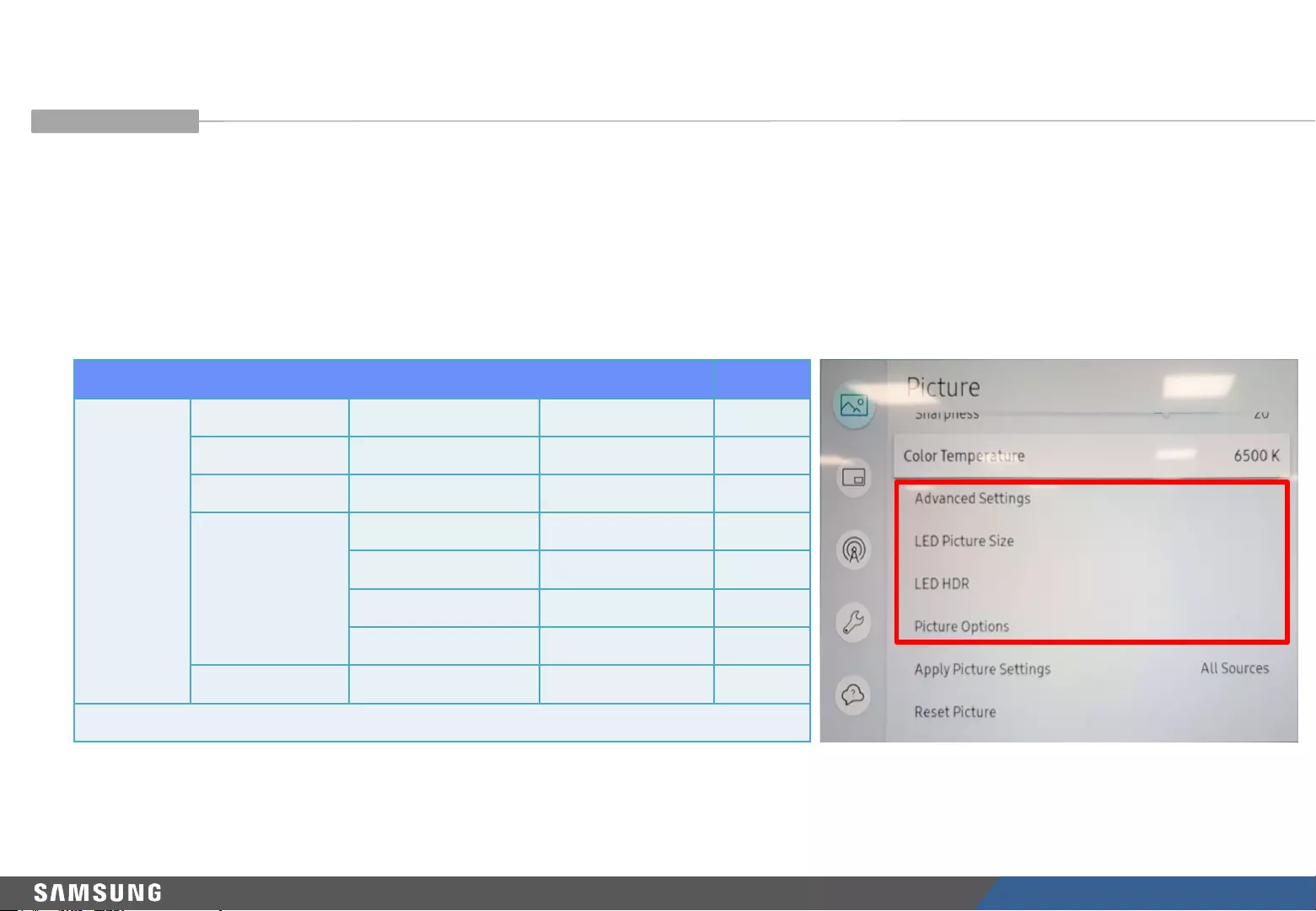

• S-BOX Connection (Panel configuration)

⑤Picture menu setting

•When using S-Box grouping, you must set Picture mode to Calibration. Calibration mode deactivates Contrast Enhancer,

Black Tone, Auto Motion plus function so that there is no screen difference between S-Box.

•In addition, change the option in other picture modes as follows table.

SBB-SNOWJAU / SBB-SNOWJMU

Picture Setting Option

Picture Mode

Picture Mode Calibration

Advanced Settings Picture Enhancer Off

LED Picture Size Output Resolution UHD

LED HDR

Inverse Tone Mapping Off

Dynamic Peaking Off*

Eco Image Enhancer

Off

Color Mapping Off

Picture Option Color Tone Off

*

If Multi link HDR is used, the Dynamic Peaking must turn “On”.

LED R&D Lab(VD)

57

6. S-Box Installation and Connection

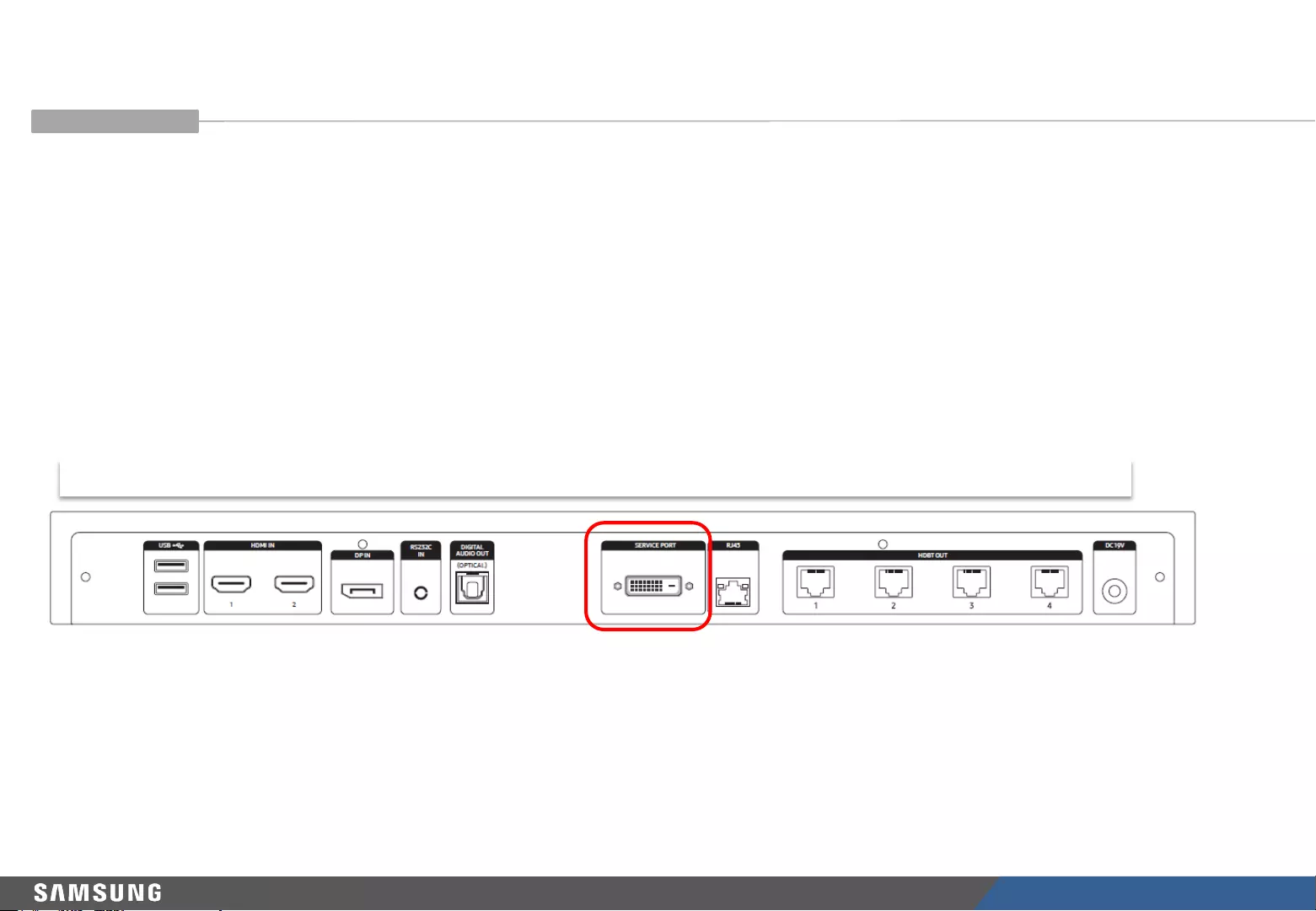

①The Service port is a dedicated monitoring port used to access the OSD menu during initial installation of an S-Box and

check the playback status of a source device.

②The resolution for the Service port is FHD (1920*1080 @ 60 Hz).

③If a source device with a UHD resolution is connected to an S-Box, screen flickering may occur or a corrupted screen

may be displayed. This issue is caused due to 2:1 downscaling of the Service port with no specific scaling algorithm and

has nothing to do with the actual LED cabinet screen display.

[Caution!] This port is for service use only and has no function for the user. Do not connect any cable to this port.

• S-BOX Connection (Service Port)

LED R&D Lab(VD)

58

6. S-Box Installation and Connection

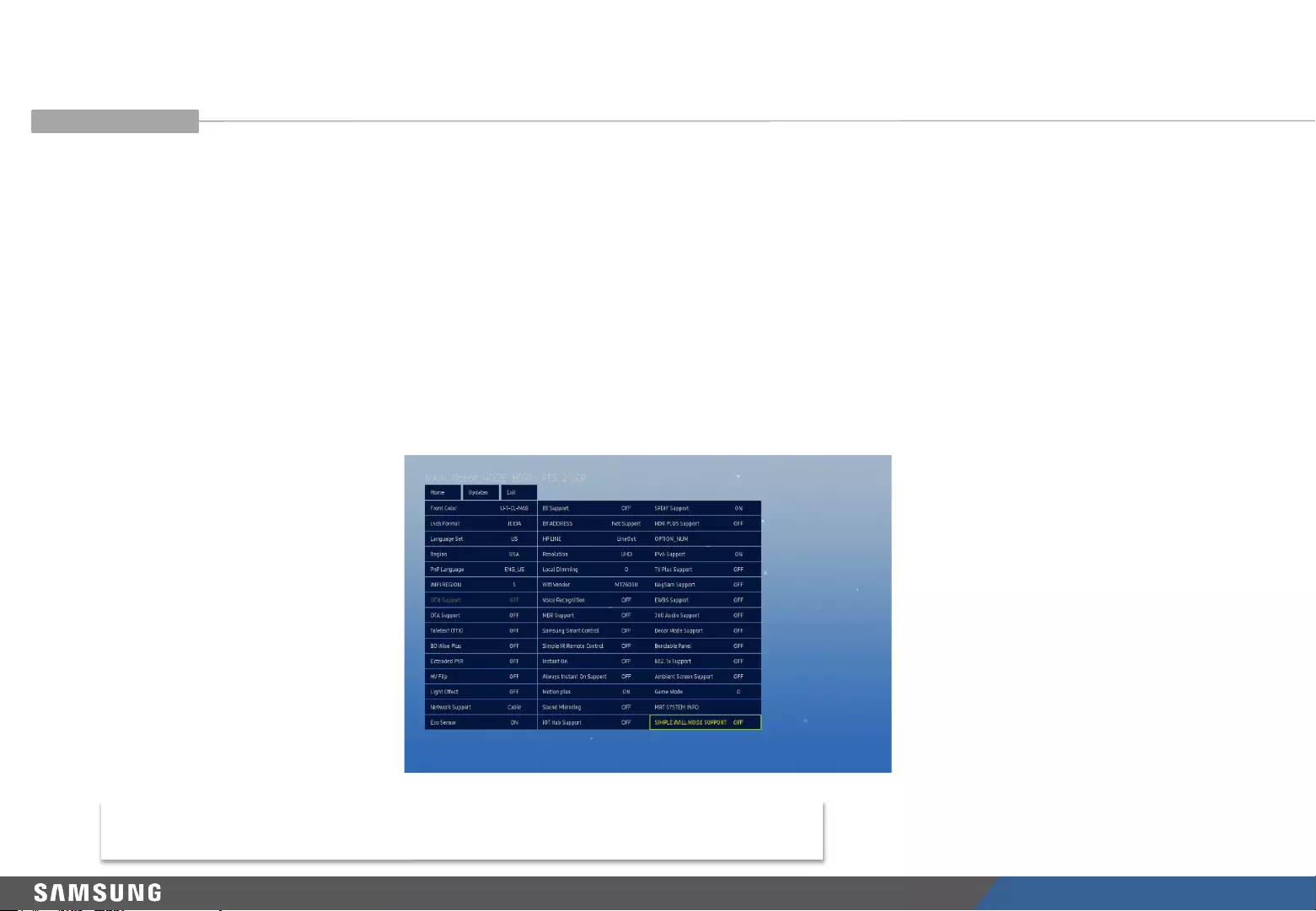

①Follow the steps below to access the Factory Menu.

-Connect the external IR cable to the S-Box.

-Press the power off button on the remote control Wait for 10 seconds Press Mute -1 -8 - 2

Click the “Power on” button

②In the Factory Menu, select Option MRT option SIMPLE WALL MODE SUPPORT ON

[Caution!] Do not run Simple wall mode if multiple S-Boxes are connected.

The S-Boxes may not display wallpaper simultaneously.

• Simple wall mode

This mode is used to easily display a wallpaper when you do not want the product to display a blank

screen while not in use.

If the screen resolution is smaller than the S-Box output resolution, use the Factory Menu to turn on the

Simple wall mode.

LED R&D Lab(VD)

59

6. S-Box Installation and Connection

•Product recommend installing this product in a standard 19-inch server rack, please refer 35 page about basic

installation guide.

• How to install when use Multi Link HDR function

①Please open rubber plug of Multi Link HDR port.

②Connect the connector of the cable of Multi Link HDR to the

Multi Link HDR port of each S-BOX.

(※ Note : Connect the connector’s structure to face up)

③Menu –Picture –LED HDR –Multi Link HDR Settings –ON

④Set the quantity of S-BOX connected each other. (2/3/4)

⑤Set S-BOX ID

(※ ID must not be duplicated between linked S-BOX )

Multi Link HDR Port

Multi Link HDR Port

UP

SIDE

(No support for SBB-SNOWJAU or below models)

LED R&D Lab(VD)

60

•Use the appropriate cable according to the quantity of S-BOX connected.

(Check the number of 2/3/4 connection cables and connectors)

• Multi Link HDR Cable

Multi Link HDR Port

Multi Link HDR Port

6. S-Box Installation and Connection

(No support for SBB-SNOWJAU or below models)

LED R&D Lab(VD)

61

※Note : Before update, disconnect the Multi Link HDR Cable from S-BOX.

• FPGA Update Guide when using Multi Link HDR Cable

Factory update method

①Save a SW program called ‘TB-XCKUSBMWWS.bin’ in

USB root.

②Connect the USB to S-BOX.

③Enter Factory mode.

(Remote control ‘mute +1+8+2+Power ON’ in power off state)

④Select “SVC → UPGRADE” menu.

⑤Move the cursor to “FPGA UPGRADE” menu.

⑥Press ‘Enter’ in the remote control.

⑦Press ‘▶’ button in remote control to start the upgrade.

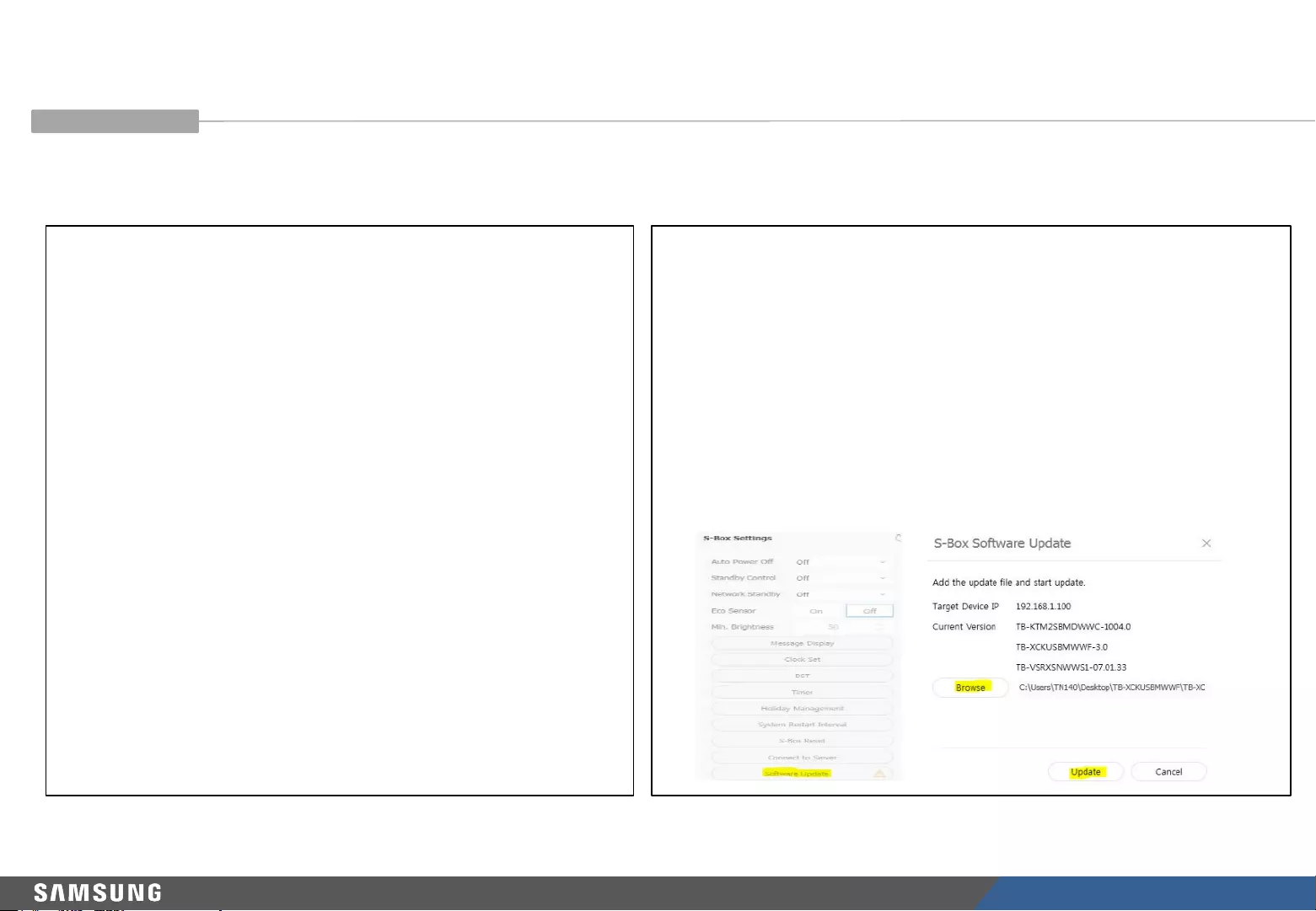

LSM update method

①Select ‘S-BOX Settings –Software Update’ in LSM menu.

②Select ‘Browser’ and move to the folder with the FPGA update file

(TB-XCKUSBMWWF.bin + Info.txt) ※ Version in ‘Info.txt’ file should

be higher than currently installed version

③Select ‘TB-XCKUSBMWWF.bin’ file.

④Select ‘Update’ button to start the upgrade.

※ Note : In case of the sites that are difficult to remove the Multi Link HDR cable, all connected S-BOX should be AC power off/on

after LSM update done. (Must turn off AC power after the update of all S-BOX are completed)

Check the version of FPGA after update.

6. S-Box Installation and Connection

(No support for SBB-SNOWJAU or below models)

Multi Link HDR Port

LED R&D Lab(VD)

62

7. Settings / How to Use

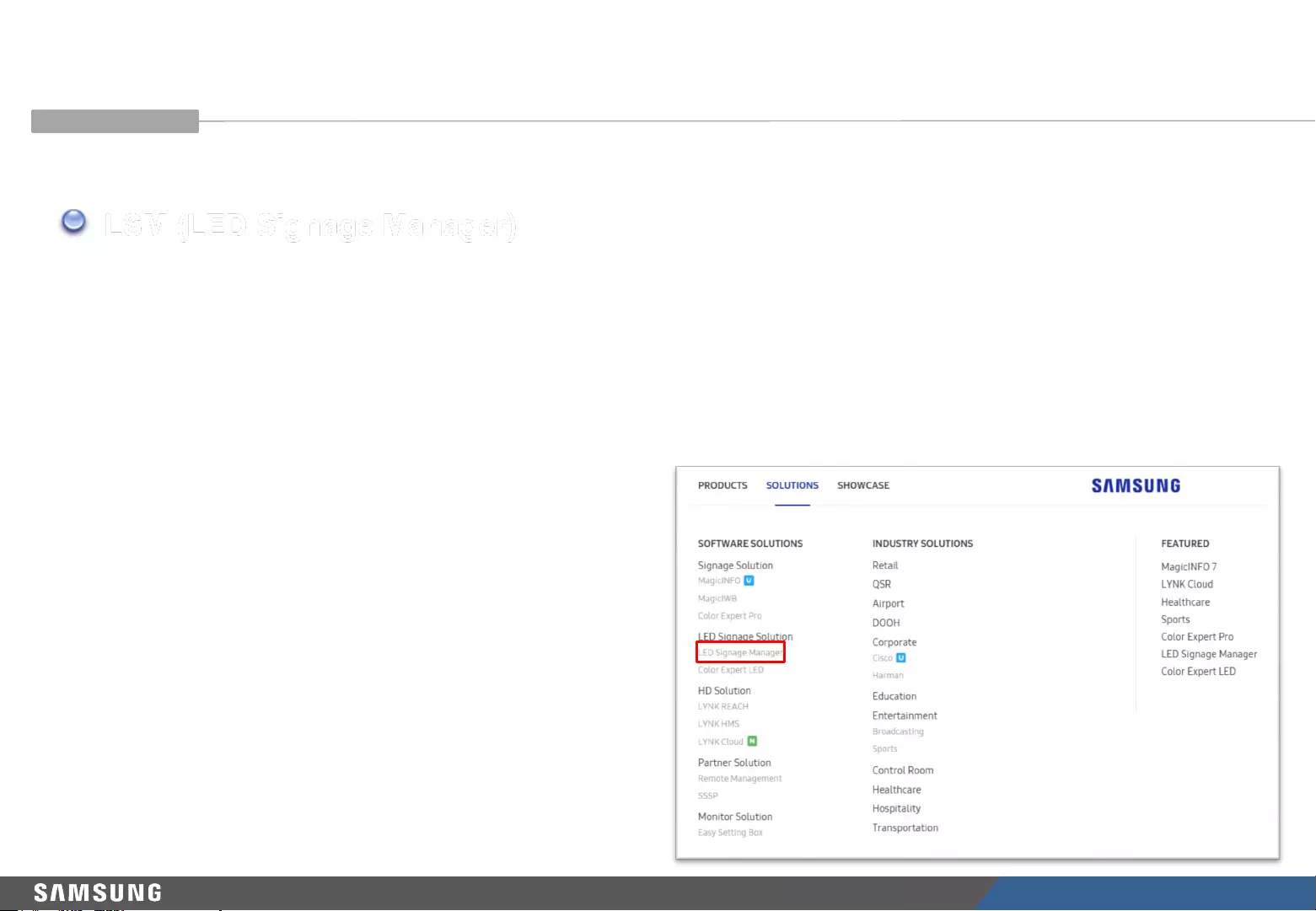

7-1. PC-specific control software

•Software that remotely adjusts the layout of the LED cabinet

•LSM Program Download Location: Samsung Display Solutions (https://displaysolutions.samsung.com)

Samsung Display Solutions > SOLUTIONS > SOFTWARE SOLUTIONS > LED Signage Solution > LED Signage Manager

※ Partner login is required for program download

LSM (LED Signage Manager)

LED R&D Lab(VD)

63

7. Settings / How to Use

7-1. PC-specific control software

Network IP Setting by USB Configuration File

(※ S-Box(SBB-SNOWJAU/SBB-SNOWJMU) support since v1050.0) tizen_netconf.toml

[network]

device_name = "SNOWBOX“

ip_v4 = "192.168.100.10“

gateway = "192.168.100.1“

subnet = "255.255.255.0“

dns = "192.168.100.11“

[magicinfo]

ip_v4 = "127.0.0.1“

port = 7001

ssl = false

[pc_connection]

mode = "LAN" #LAN : RJ-45, Serial : RS232C

#this is a comment

This is how to set the network information of S-Box with USB

configuration file instead of network IP setting tool.

1. Saves the network information to be configured in the file

'tizen _netconf.toml'.

2. Copy the file 'tizen_netconf.toml'to USB memory.

3. When you plug the USB memory into the USB port on the S-Box,

it is automatically set.

4. If the IP settings are successful, the LSM and S-Box are normally

connected and the execution result can be viewed through the

'tizen_netconf_result.log' file that is automatically generated in

the USB memory.

[★Notice!] If you plug the USB memory where the file 'tizen_netconf.toml'

is stored into the S-Box, the IP is automatically set. Please rename or delete

the setting file after the configuration is completed.

LED R&D Lab(VD)

64

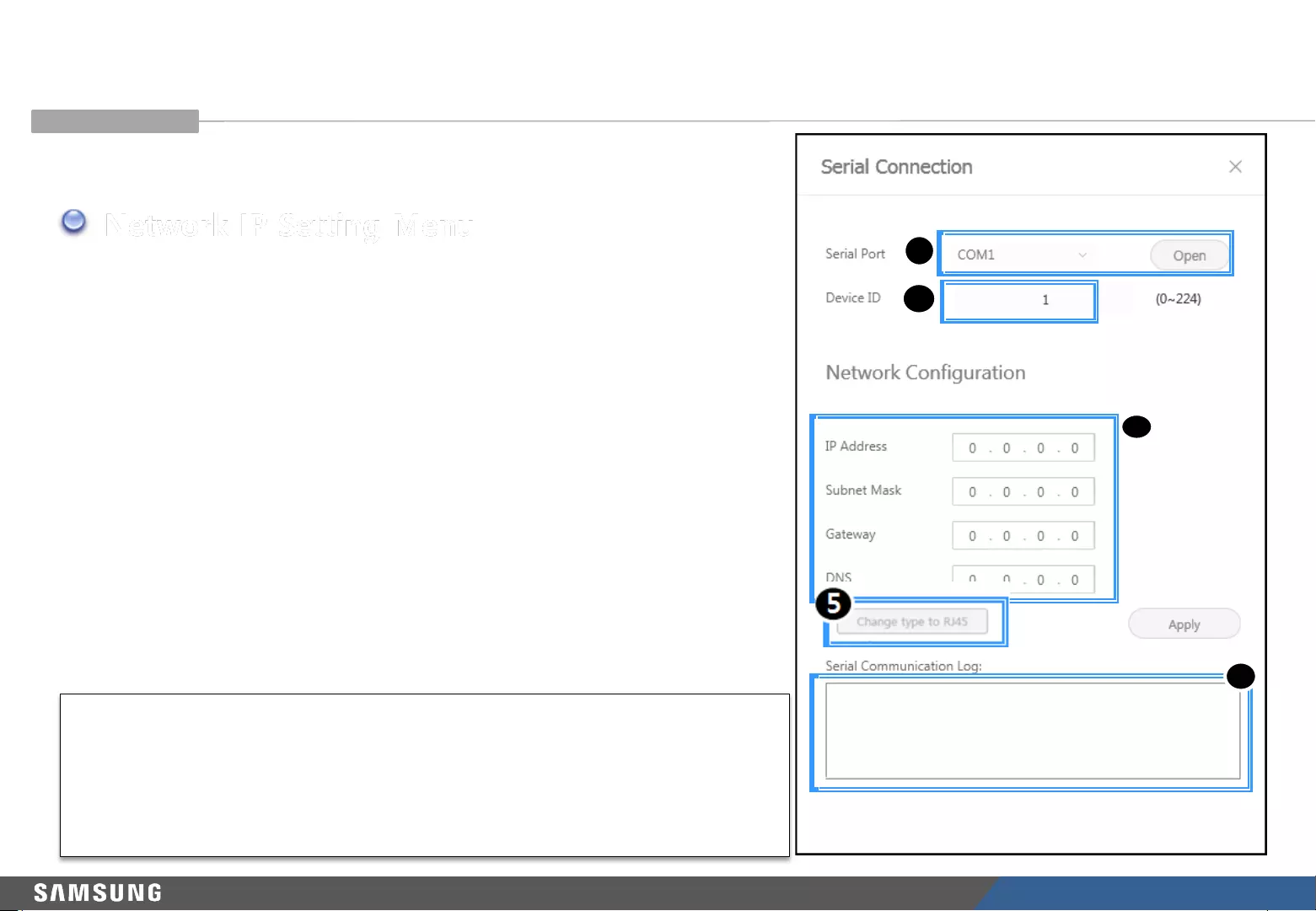

7. Settings / How to Use

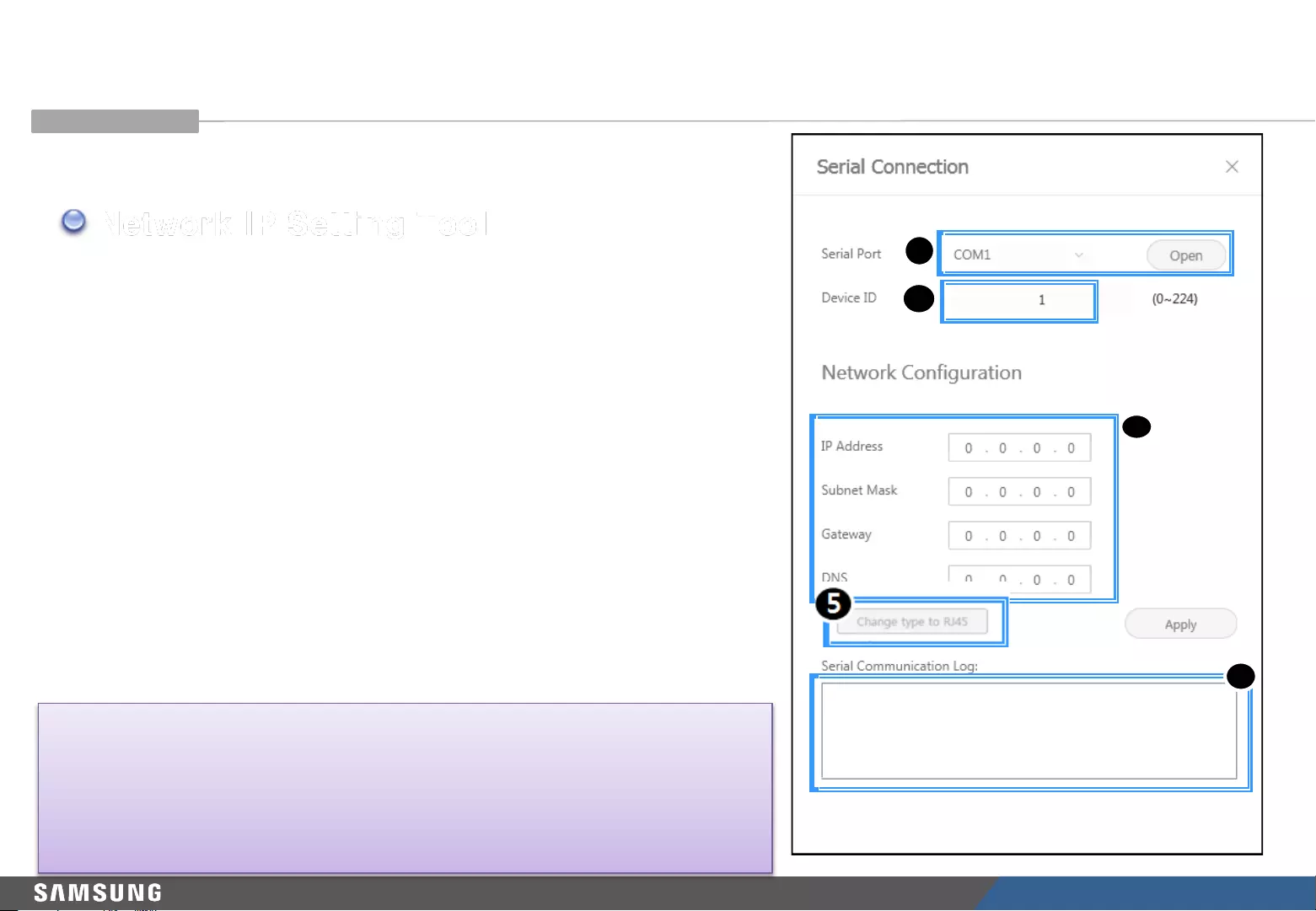

7-1. PC-specific control software

Network IP Setting Tool

Execute : [Start] –Program – Samsung – LED Signage Manager –Network

Configuration

1. Connect PC and Sbox with RS232C Cable, select connected

SerialPort(COM*). And click “open” button.

2. Default ID of SBox is 1.

3. Enter IP, SubnetMask, Gateway, DNS of S-box, and click “Apply”

button.

4. Check the result of connection and status of MDC Protocol.

5. When IP address is normally setup, “Change Type to RJ45” button is

appear.If LSM and SBox is connected successfully, click “Change Type

to RJ45”. Then, PC connection with s-box is changed to RJ45 from

RS232.

[★Cautions!] Recommend to use static IP address for the S-Box.

If DHCP is used, IP address is changed automatically and LSM can be

disconnected.

The 192.168.10.x band is used for internal communication of the LED Cabinet.

Please use IP another IP band (except 192.168.10.x band)

Do not assign the temporary IP, assign the S-Box IP (1 EA) through IT

manager.

3

1

2

4

LED R&D Lab(VD)

65

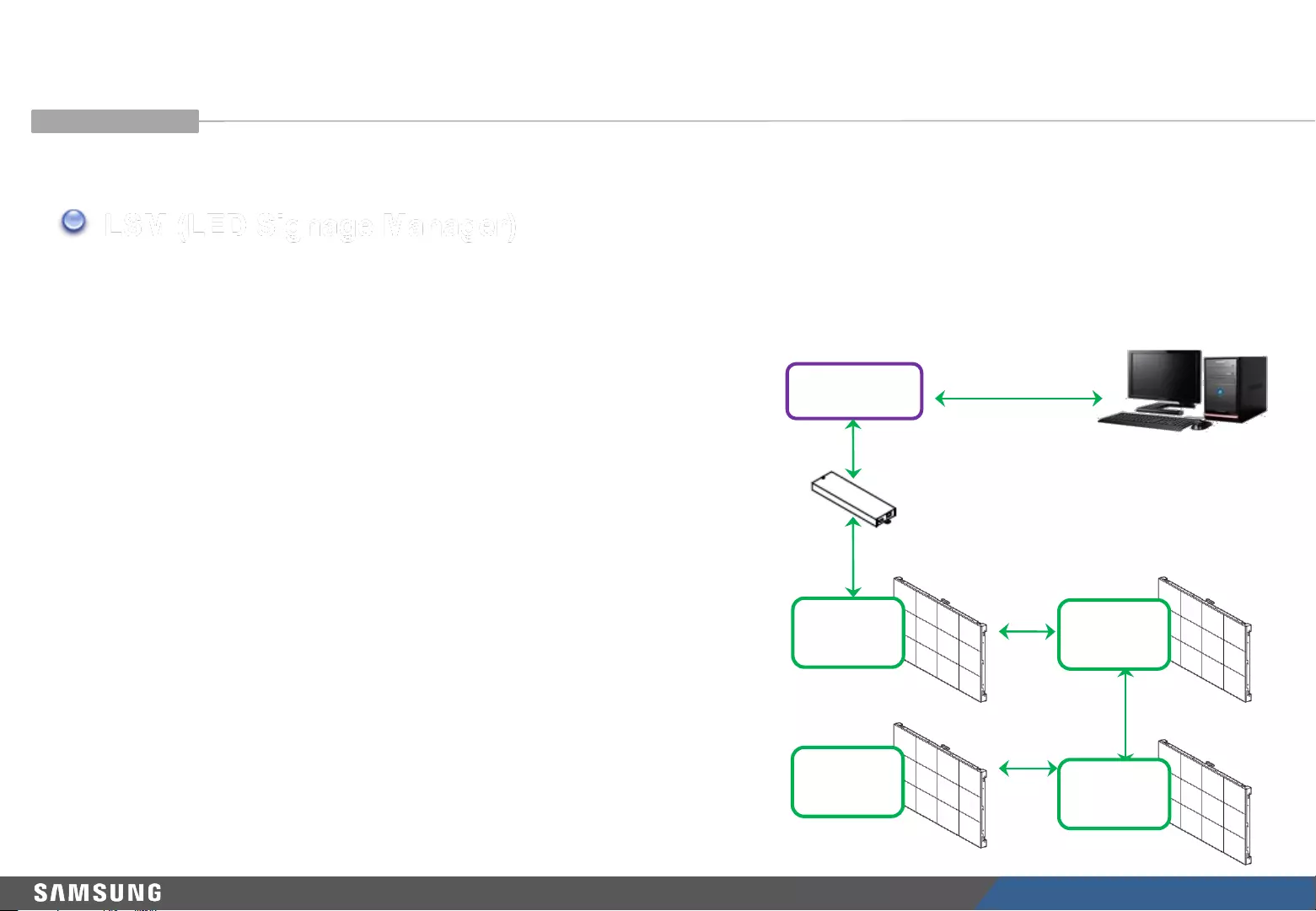

•Software for remote control of LED cabinet layout

LSM (LED Signage Manager)

Control PC

S-Box

Cabinet 1

Ethernet

Interface Gender

Vx1

Vx1

Vx1

HDBT

Vx1+Ethernet

Cabinet 2

Cabinet 3

Cabinet 4

1. Connect the PC to the S-Box via Ethernet.

2. Use aLAN cable to connect the S-Box to the Interface Gender.

3. Use an OCM cable to connect the Interface Gender to the first LED

cabinet.

4. Use OCM cables to connect the LED cabinets to one another in a

daisy-chain configuration.

7-1. PC-specific control software

7. Settings / How to Use

LED R&D Lab(VD)

66

•Start – Login Page

1. When the LSM is launched for the first time, the password setting

page appears.

2. To set a password, enter the same password of your choice twice and

click the Start button.

3. If you do not want to use a password, select the “Don’t use password”

checkbox.

If this checkbox is selected, you not prompted for a password when

the LSM is launched subsequently.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

LED R&D Lab(VD)

67

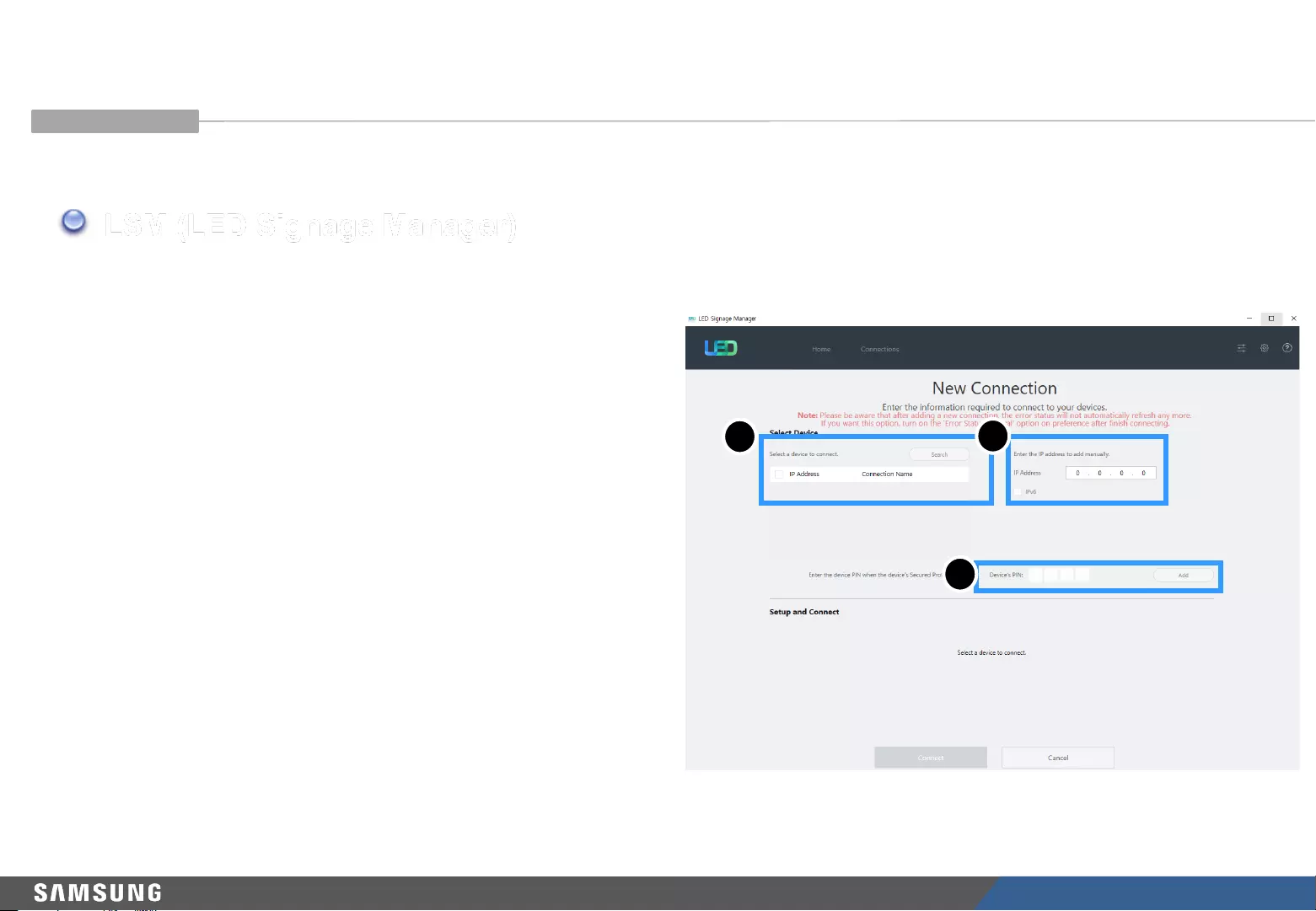

•New Connection

1. To add connection information, use the Search button to

search for an IP address or manually enter an IP address.

If you click the Search button, the IP address for LSBs

available for connection on the same network appear.

Alternatively, manually enter the IP address if you know

the IP address for the target LSB for connection.

2. Click the Add button. Entered connection information is

added to the Setup and Connect settings. When S-Box’s

Secured Protocol option is On, Enter Device’s PIN and

click Add button.

3. The user can select an S-Box model type. Three model

types are available for selection:

Without Cabinet IP / With Cabinet IP(FHD) / With Cabinet IP(UHD).

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

11

2

LED R&D Lab(VD)

68

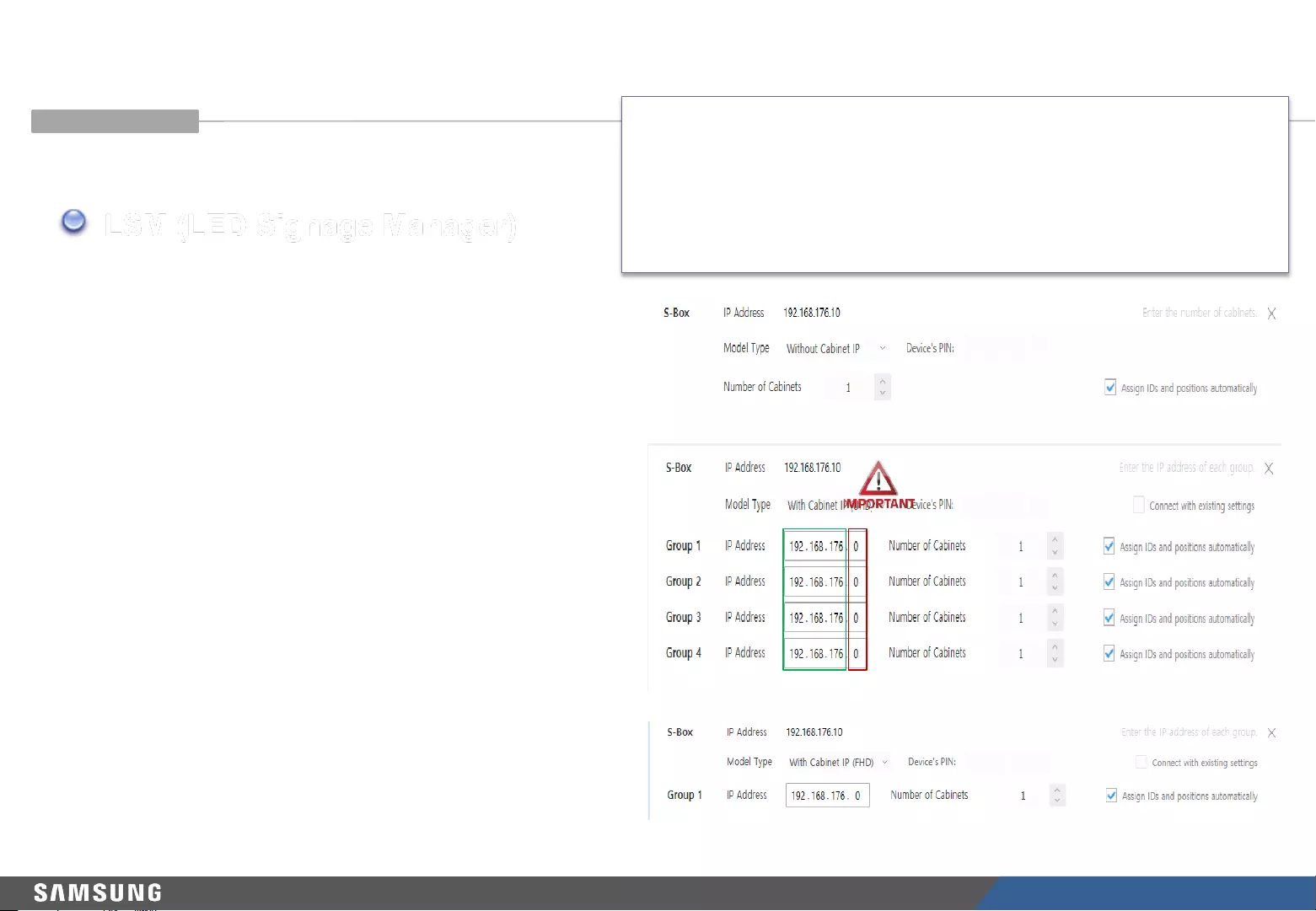

•New Connection-Connect

1. If using an old version LSB, select “Without Cabinet IP.”

2. If using a UHD LSB, select “With Cabinet IP (UHD).” Make

sure assigning a different IP address for each port connected

LED cabinets. Set the number of connected cabinets and click

“Connect.”

3. If using an FHD LSB, select “With Cabinet IP (FHD).” Set the

IP addresses for the LED cabinets, and the number of

connected cabinets, and then click “Connect.”

※If IP addresses are already set for the cabinets, select the

“Connect with existing settings” checkbox.

※If using UHD and some of the four ports will only be used, only

enter the IP addresses for the corresponding groups.

[★Caution!] When configuring LED cabinet network settings, it is recommended

that a static IP address be used.

If DHCP is used and the IP address is changed, the connection with LSM may be

disconnected. The 192.168.10.x band is used for internal communication with LED

cabinets.

Use an IP address that does not belong to this band.

Use the IP address for LED (x4) assigned by your IT administrator. Do not assign

an IP address arbitrarily.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

※ Should be same as S-Box

※ Should be different than S-Box / Should be different for each groups

LED R&D Lab(VD)

69

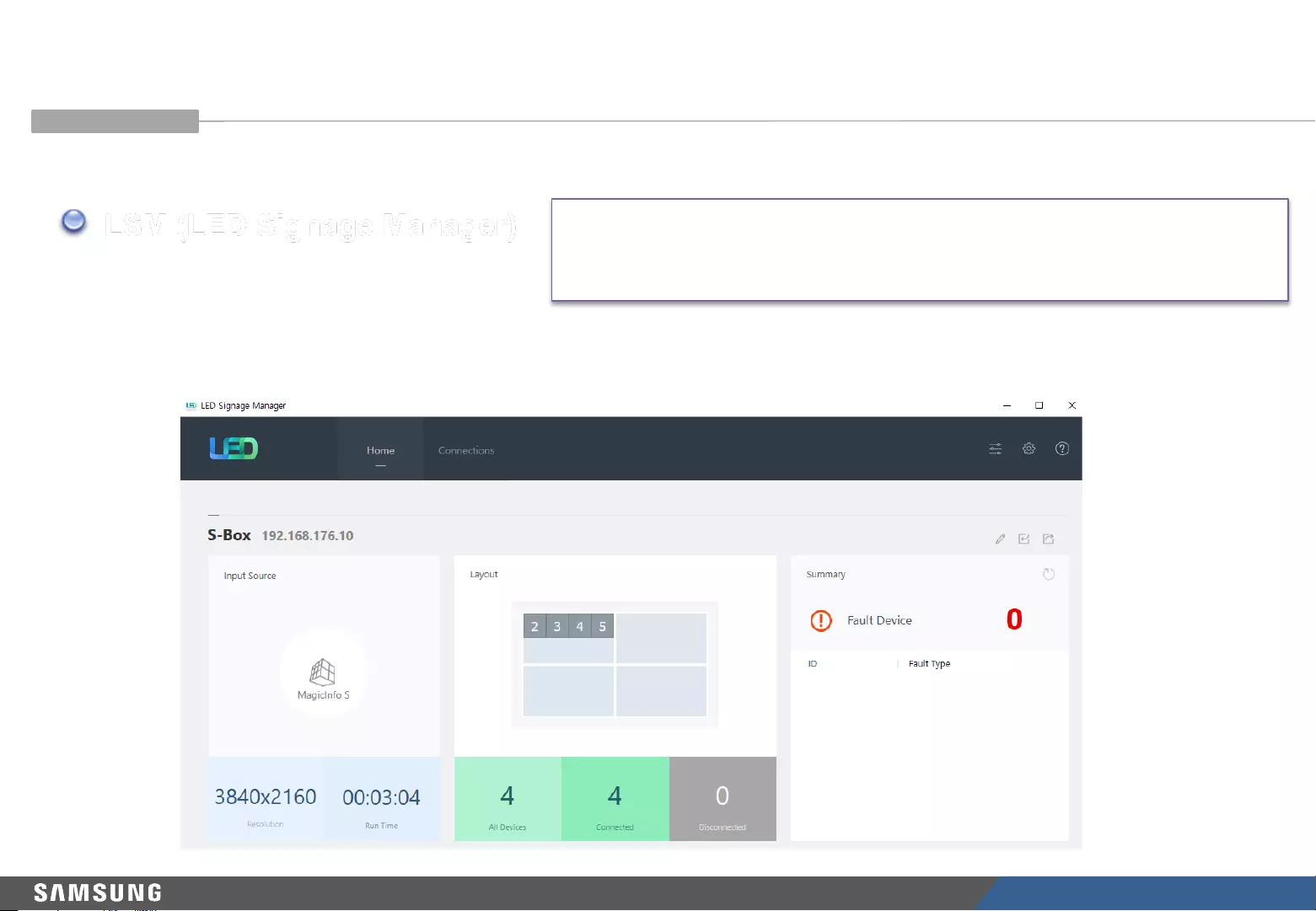

•Main Window-Home Window

1. Home screen:Shows information about connected devices, the input source, the cabinet configuration, and devices with errors.

[★Caution!] For internal communication between the S-Box and LED cabinets, use

ports 1515, 48484, 48485 and 58585.

When firewalls / security network are in use, make sure the corresponding port bet

ween the S-Box and LED cabinets is enabled.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

LED R&D Lab(VD)

70

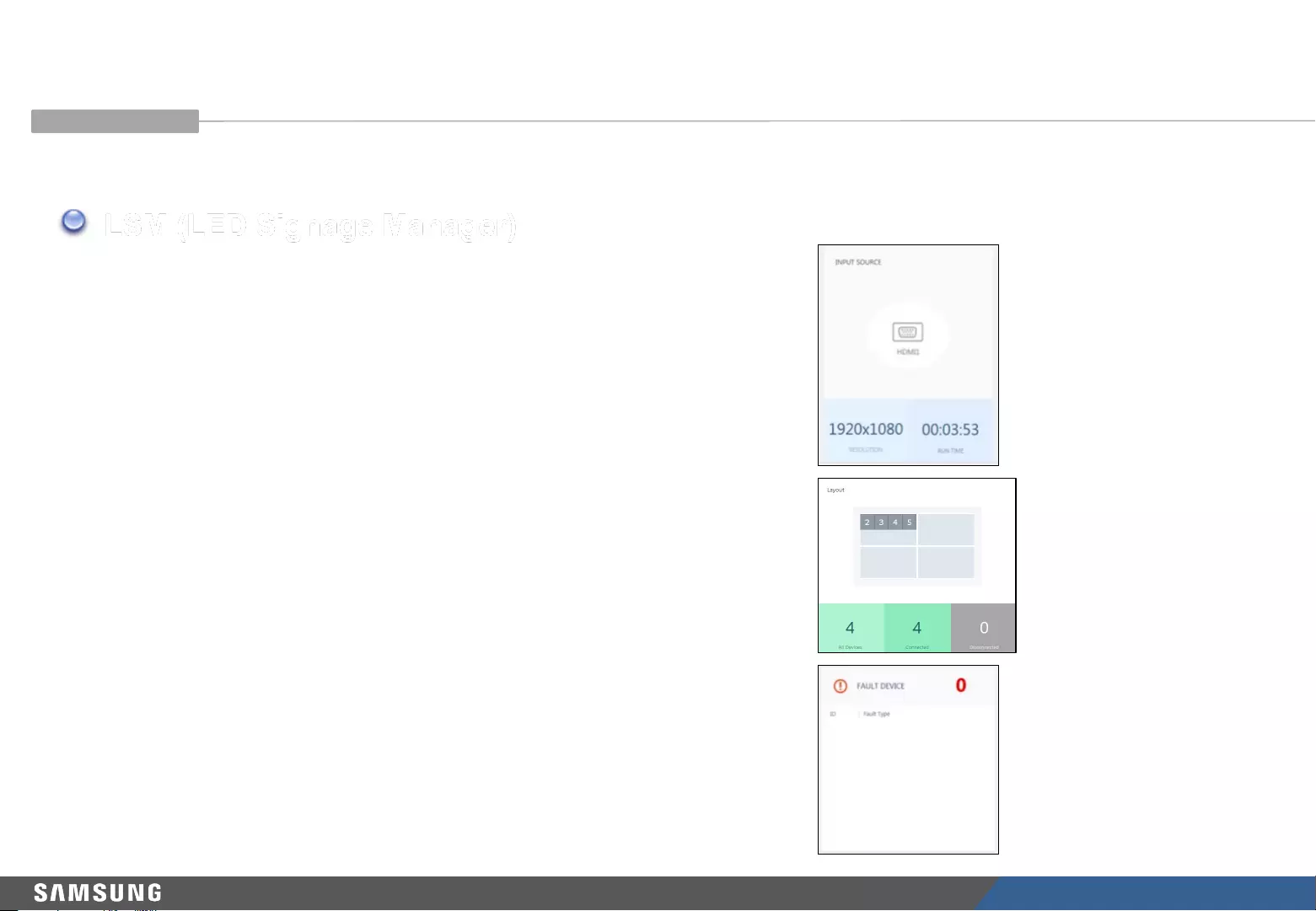

1. INPUT SOURCE:Shows the LSB input source, resolution

and connection duration.

2. LAYOUT:Shows the layout and quantity of all LED cabinets

and the quantities of connected and disconnected cabinets.

3. FAULT DEVICE:Shows the IDs of faulty LED cabinets and

the fault details.

7-1. PC-specific control software

LSM (LED Signage Manager)

•Main Window-Home Window

7. Settings / How to Use

LED R&D Lab(VD)

71

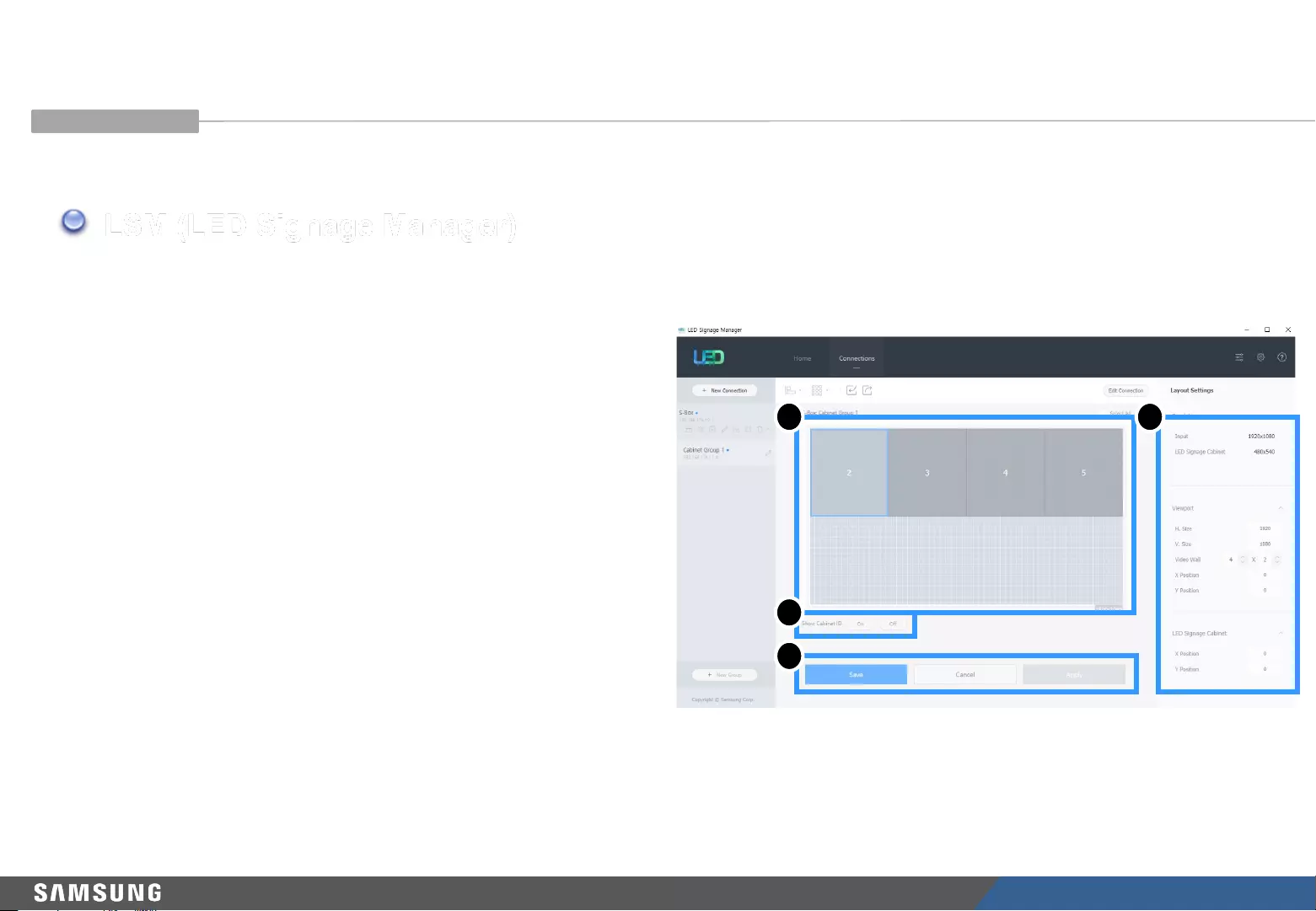

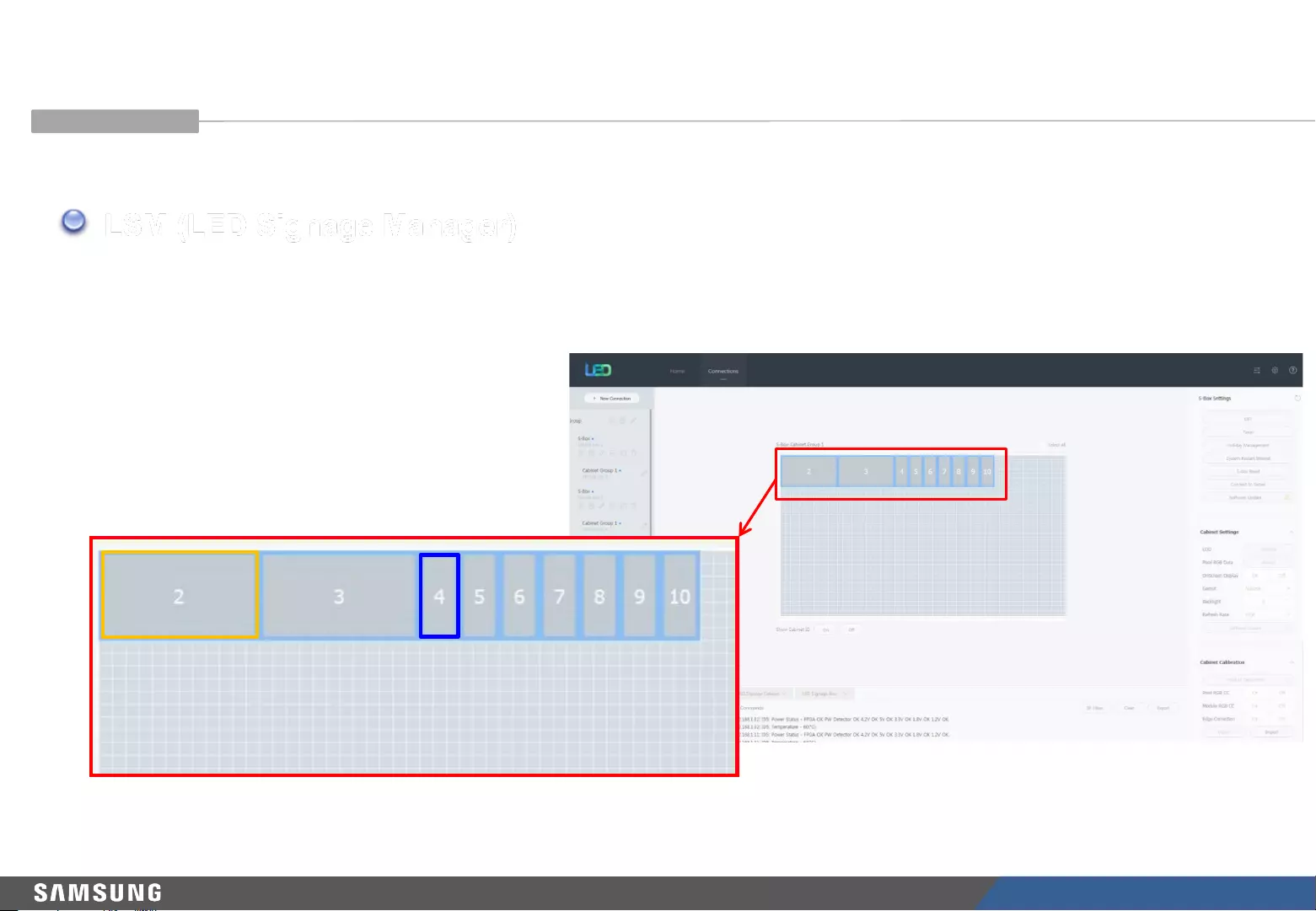

1. Connection layout: Use the LSB output source section to adjust the

LED cabinet layout by rearranging cabinets.

2. Feature View: Provides the Edit button used to edit connection

information and the automatic LED cabinet alignment function.

3. Device Information/Setting View:

Shows LED cabinet information based on the following categories.

(i) Resolution: Resolution of the input source

(ii) Viewport: Width/height, video wall matrix, x/y coordinate settings

(iii) LED Signage Cabinet: X, Y positions of LED cabinets

4. Show ID: Select to cause each of all connected LED cabinets to

display their ID.

5. Save/apply or cancel settings

7-1. PC-specific control software

LSM (LED Signage Manager)

•Main Window-Edit Connection Layout Window

7. Settings / How to Use

12

4

3

LED R&D Lab(VD)

72

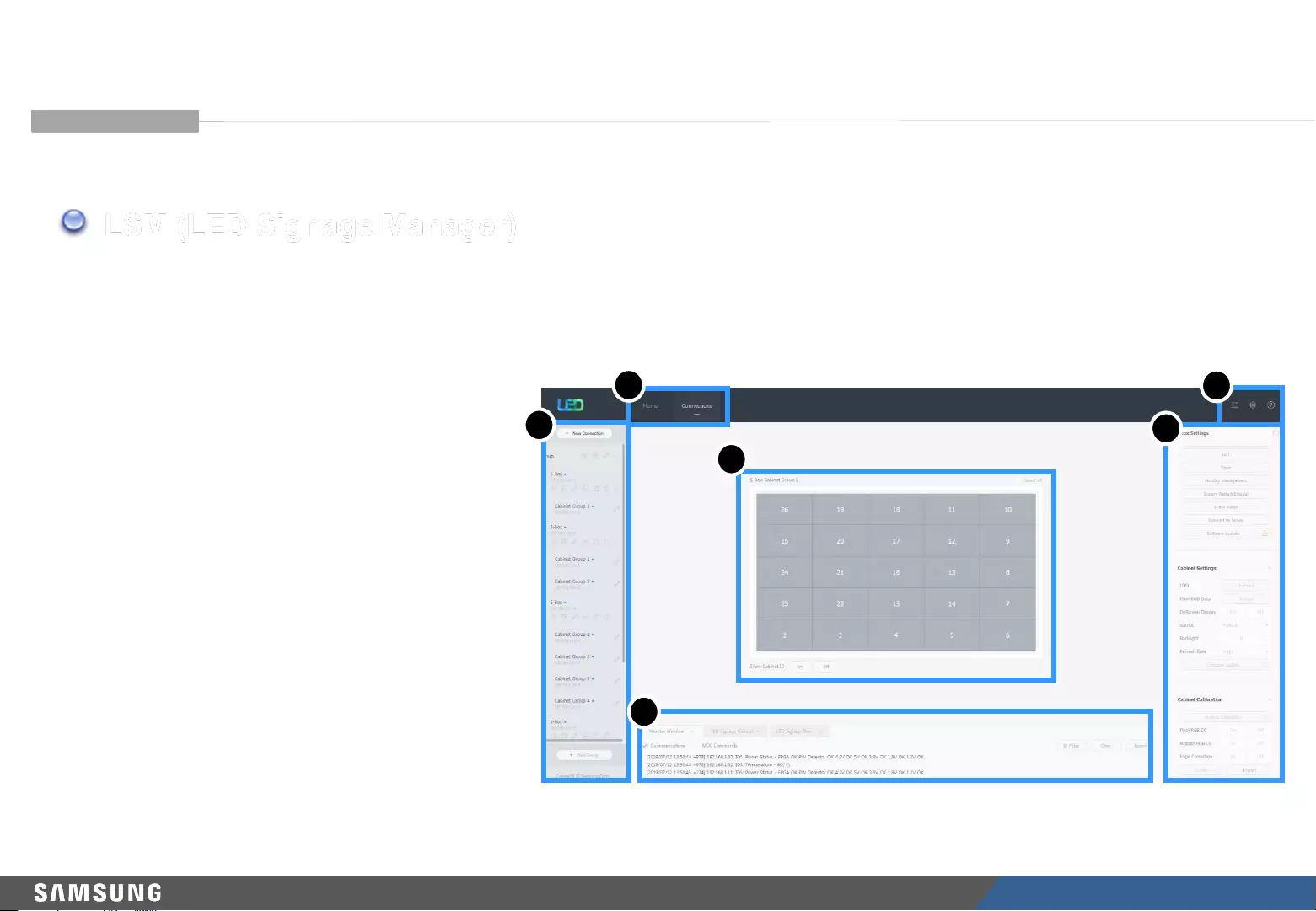

•Main Window-Connection Window

1. Device connection list view:

View LSB configuration information. Edit or delete

LSB connections. View LED cabinets by group.

2. Connection layout (View Port):

View the LED cabinet layout and the position of each

LED cabinet

3. Category View:

Use the Home and Connections tabs to configure

system settings.

4. Device Information/Setting View:

Change LSB settings (e.g. screen settings).

5. Sub Information View: Displays

monitoring logs, and LSB and LED cabinet

information.

6. Link of LED Configurator, Preference, Help files

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

1

2

4

5

36

LED R&D Lab(VD)

73

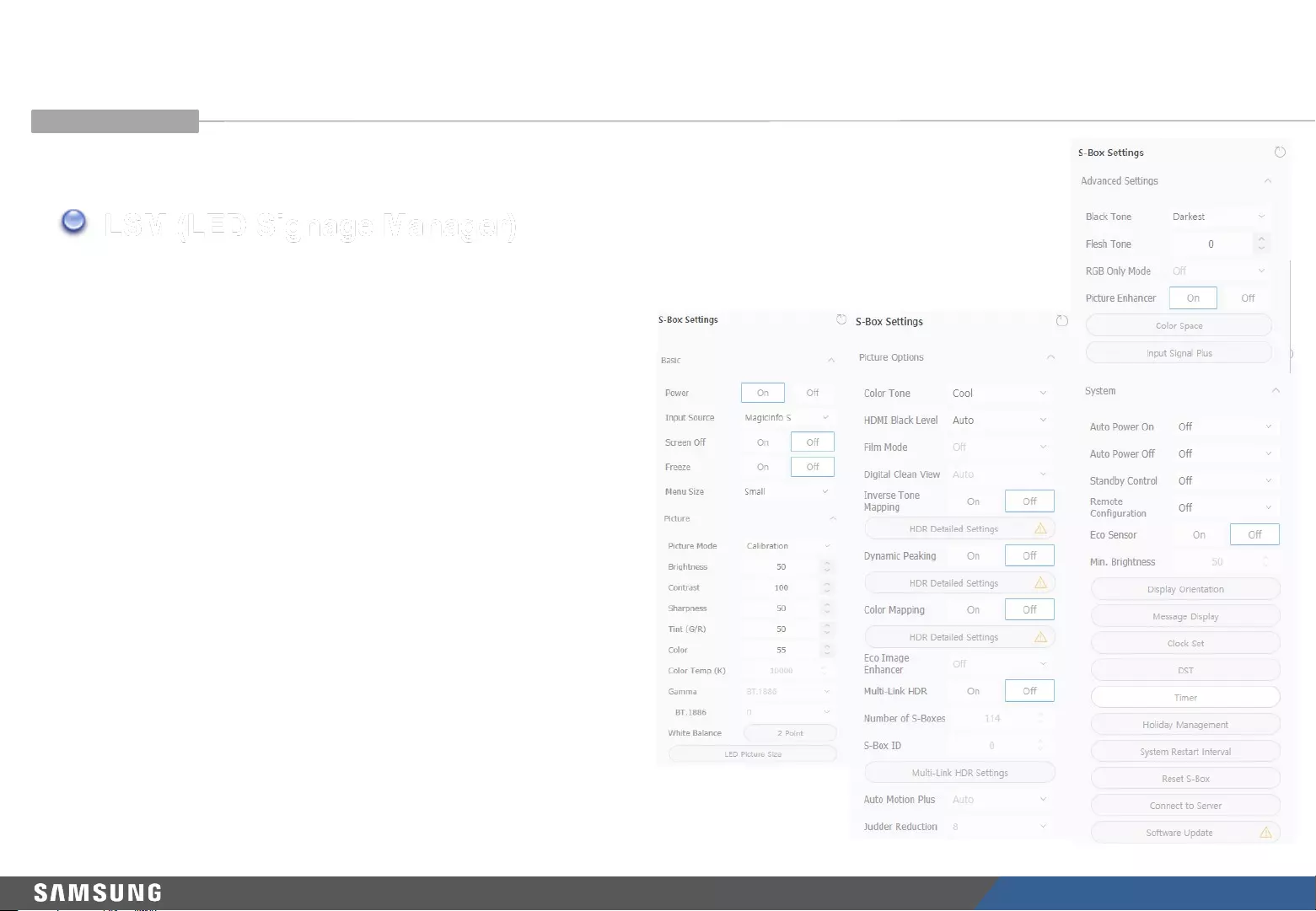

•Main Window-Connection Window -Device Information/Setting View

1. Basic :

. Turn on/off the S-Box. Change the input source. Mute or free

the screen.

2. Picture

. Change the screen mode. Adjust brightness, contrast,

sharpness, color, tint (G/R), color temperature (K), gamma or

white balance.

3. Picture Options

. Adjust color tone, HDMI black level, film mode and other

settings.

4. Advanced Settings

. Adjust black tone, facial color tone, color space and other

settings.

5. System

. Turn on/off Auto Power On or Off. Turn on/off Standby Control.

Set the clock, timer and/or system restart interval. Use the

software update function.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

LED R&D Lab(VD)

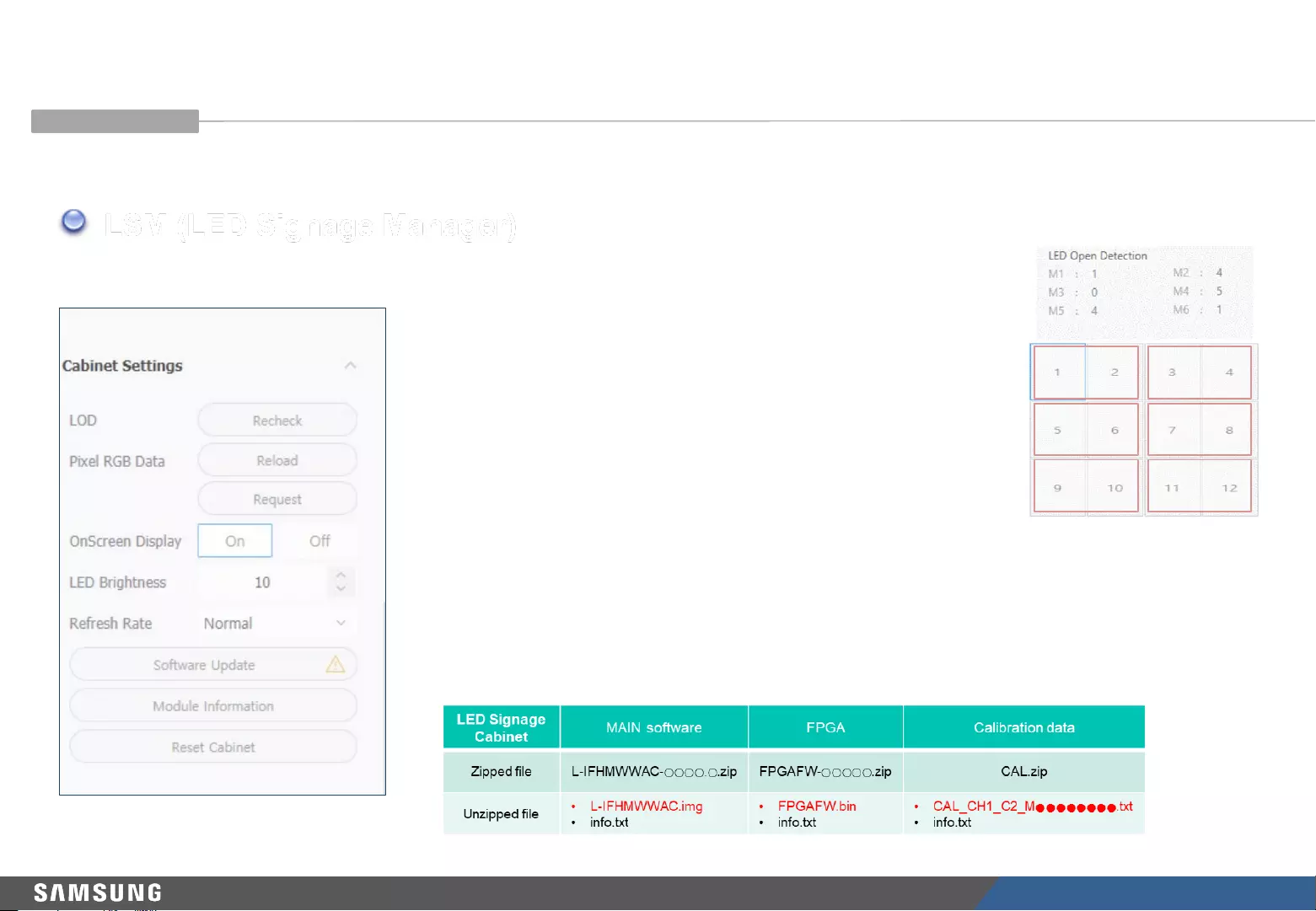

74

•Main Window-Connection Window -Device Information/Setting View

6. Cabinet Settings (※Each menu can be supported for some specific models)

. LOD (LED Open Detection) : Check the number of LED Off

(Screen can be blinking when Recheck)

. Pixel RGB Data Reload : Load the Pixel Calibration data to the screen

. Pixel RGB Data Request : Download the calibration data via Cal Reader.

. OnScreen Display : On or Off for “No Video” OSD display on cabinet.

. LED Brightness : Adjust the screen brightness (0 ~ 10)

. Refresh Rate : Adjust refresh rate (Normal or High)

(Some models support only High)

. Software update : Update the cabinet software (Main sw, FPGA, Calibration data)

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

※ Refer the module position of

LOD result for IER, IFR and IFJ

M1 M2

M3 M4

M5 M6

LED R&D Lab(VD)

75

7. Settings / How to Use

7-1. PC-specific control software

•Main Window-Connection Window -Device Information/Setting View

LSM (LED Signage Manager)

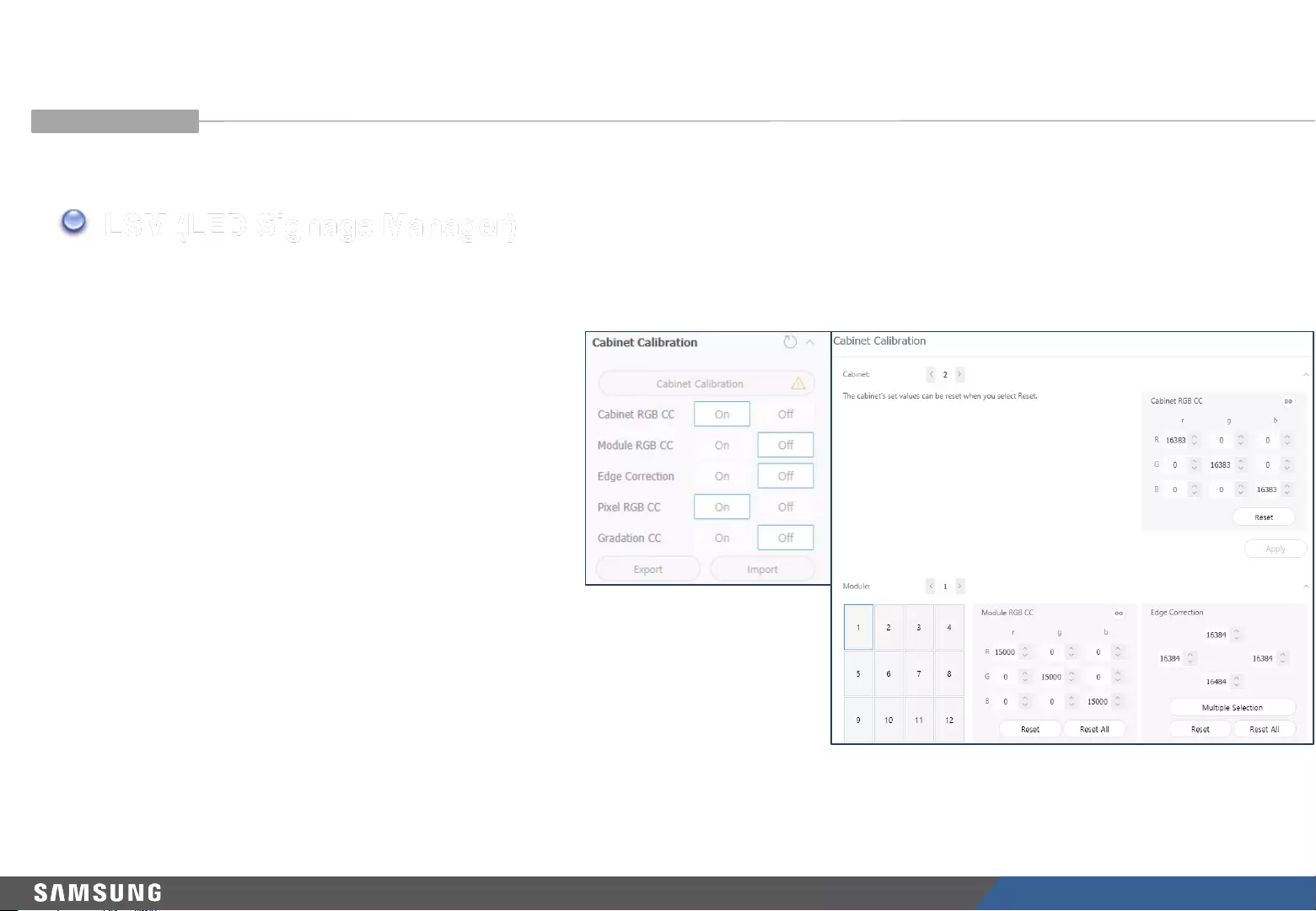

7. Cabinet Calibration

. Perform RGB CC calibration for each module/

Cabinet.

. Calibrate the boundary surface of each module.

. Multiple Selection : Check next page.

. Turn on/off CC. Turn on/off Edge Correction.

. Gradation Calibration : For expert user only.

. Download module calibration data through Batch

Upload/Import/Export.

LED R&D Lab(VD)

76

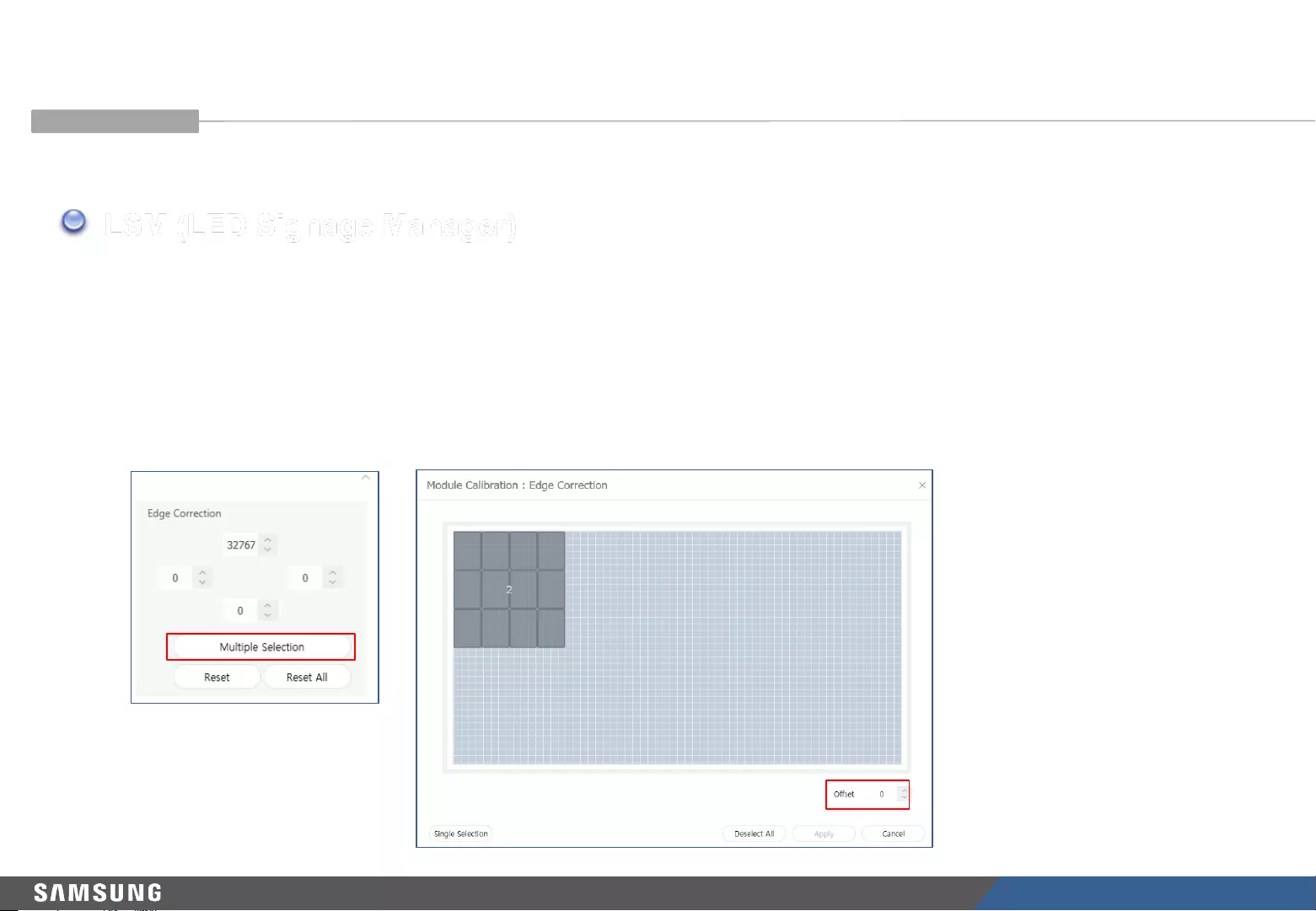

7. Settings / How to Use

7-1. PC-specific control software

•Main Window-Connection Window -Device Information/Setting View

LSM (LED Signage Manager)

. Cabinet Calibration

└ Multiple Selection

: Calibrate the boundary surface of selected multiple modules. Change offset then brightness is adjusted for edge.

Use Apply button for applying.

LED R&D Lab(VD)

77

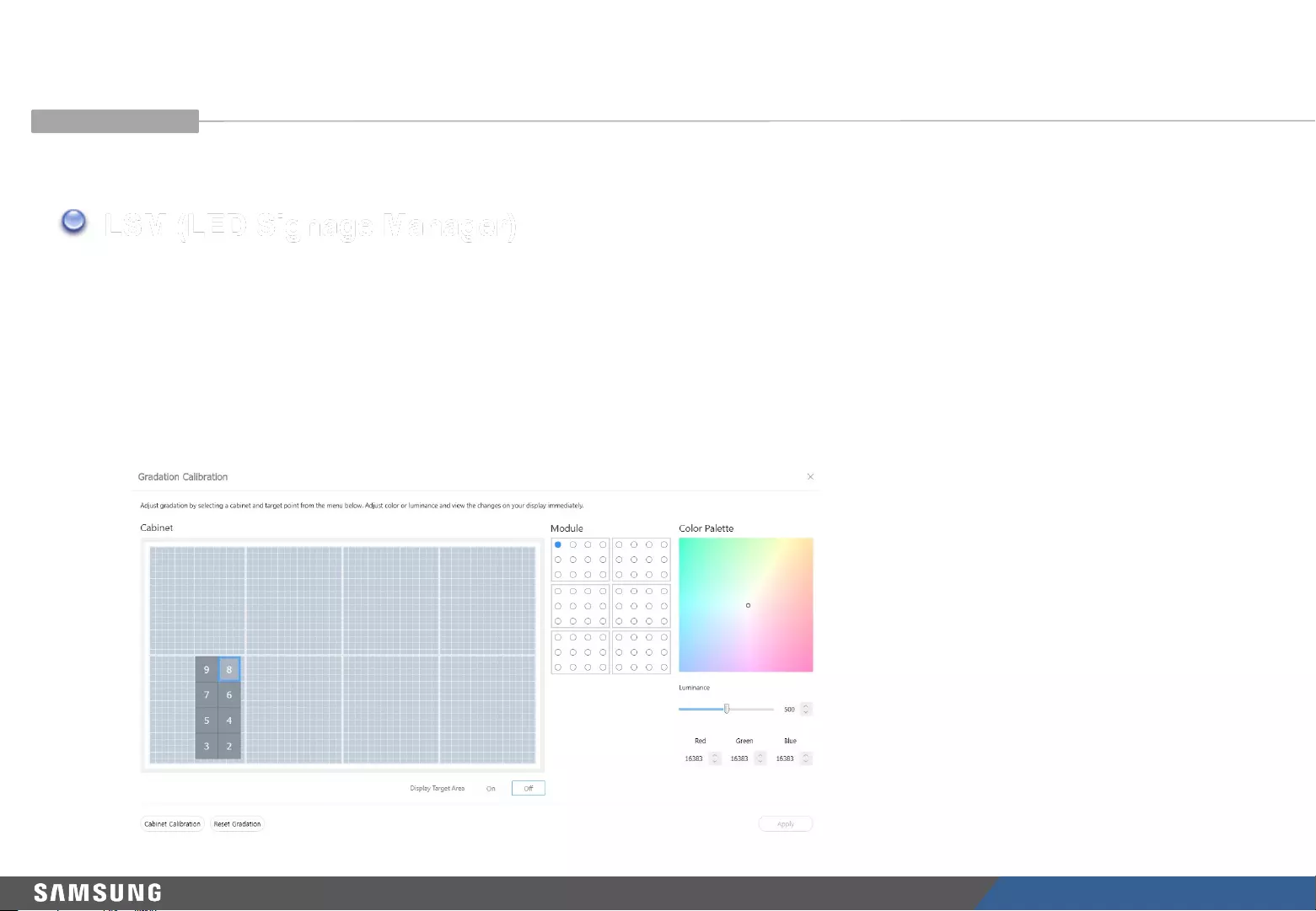

7. Settings / How to Use

7-1. PC-specific control software

•Main Window-Connection Window -Device Information/Setting View

LSM (LED Signage Manager)

. Cabinet Calibration

└ Gradation Calibration

: For expert user only. It can be supported for some models only (IWJ, IWR, …)

Color Gradation can be adjusted for module block unit by RGB gain and Luminance value

Adjusted value can be reverted by Reset Gradation.

LED R&D Lab(VD)

78

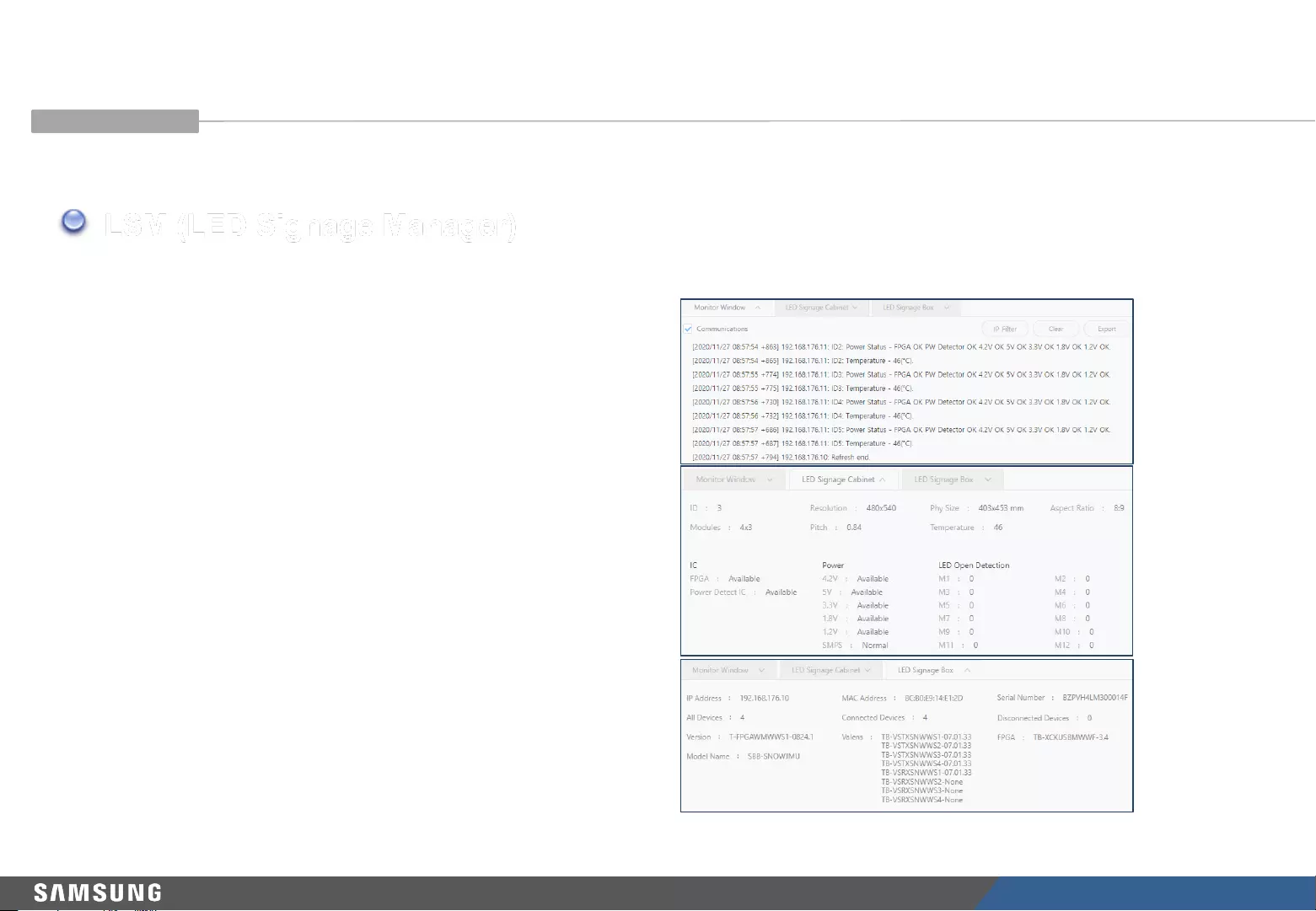

1. Monitor Window:

View MDC communication logs and information about

connected devices. Extract data by using files.

2. LED Signage Cabinet: Shows chip information and

cabinet power information.

3. LED Signage Box:

Shows the IP address, MAC address, LED cabinet ID

range, numbers of all, connected and disconnected,

serial number, and version information.

7-1. PC-specific control software

LSM (LED Signage Manager)

•Main Window-Connection Window -Sub Information View

7. Settings / How to Use

LED R&D Lab(VD)

79

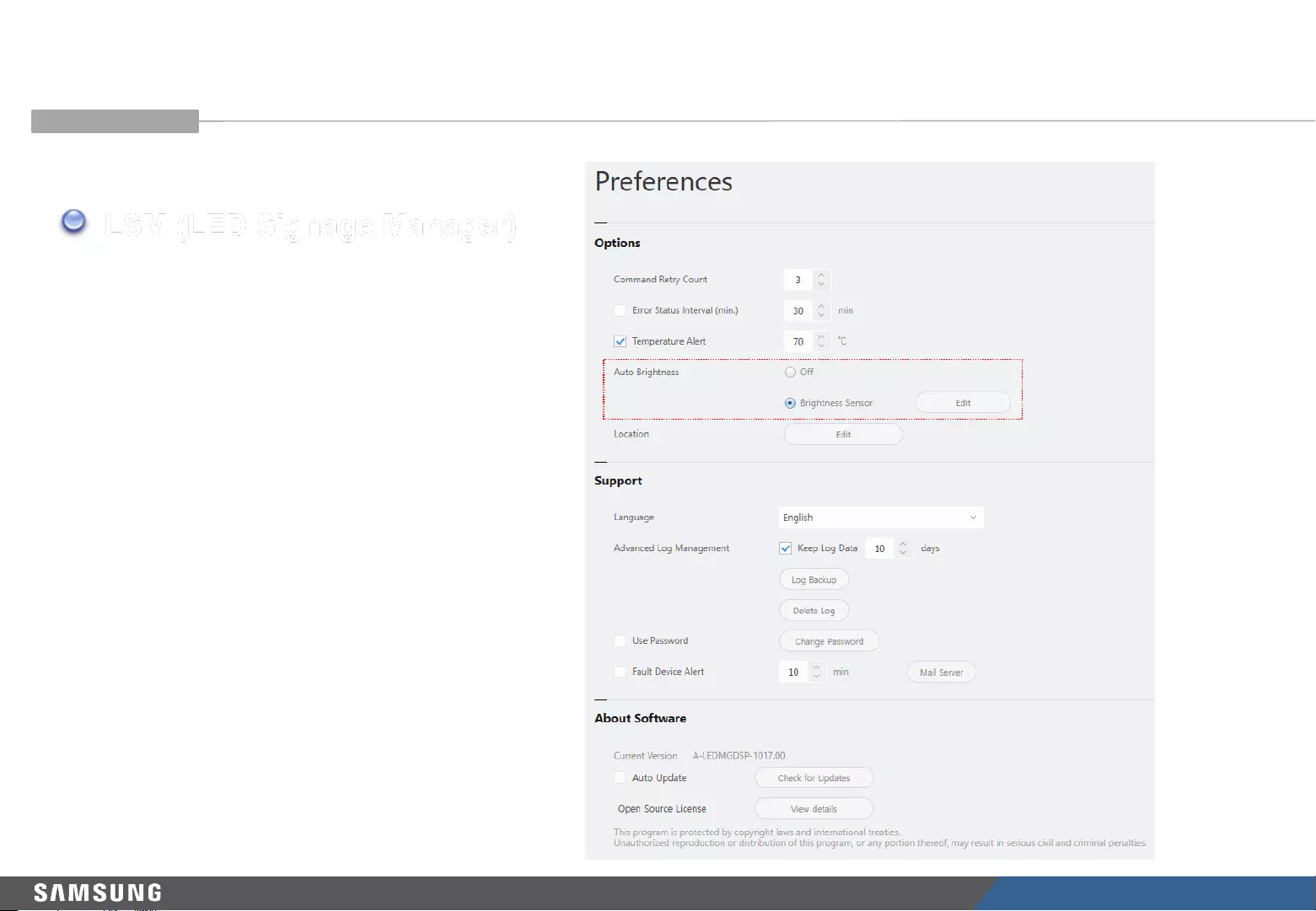

•Main Window -Preference

1. Options

Set the command retry count.

Set the error status checking interval.

Set the temperature alert threshold.

2. Support

Select a language.

Configure log data management settings.

3. Set the interval to email a device error alert.

Change the password.

4. About Software

Shows the LSM version and provides the update

function.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

※ For some models only (IS, IL)

LED R&D Lab(VD)

80

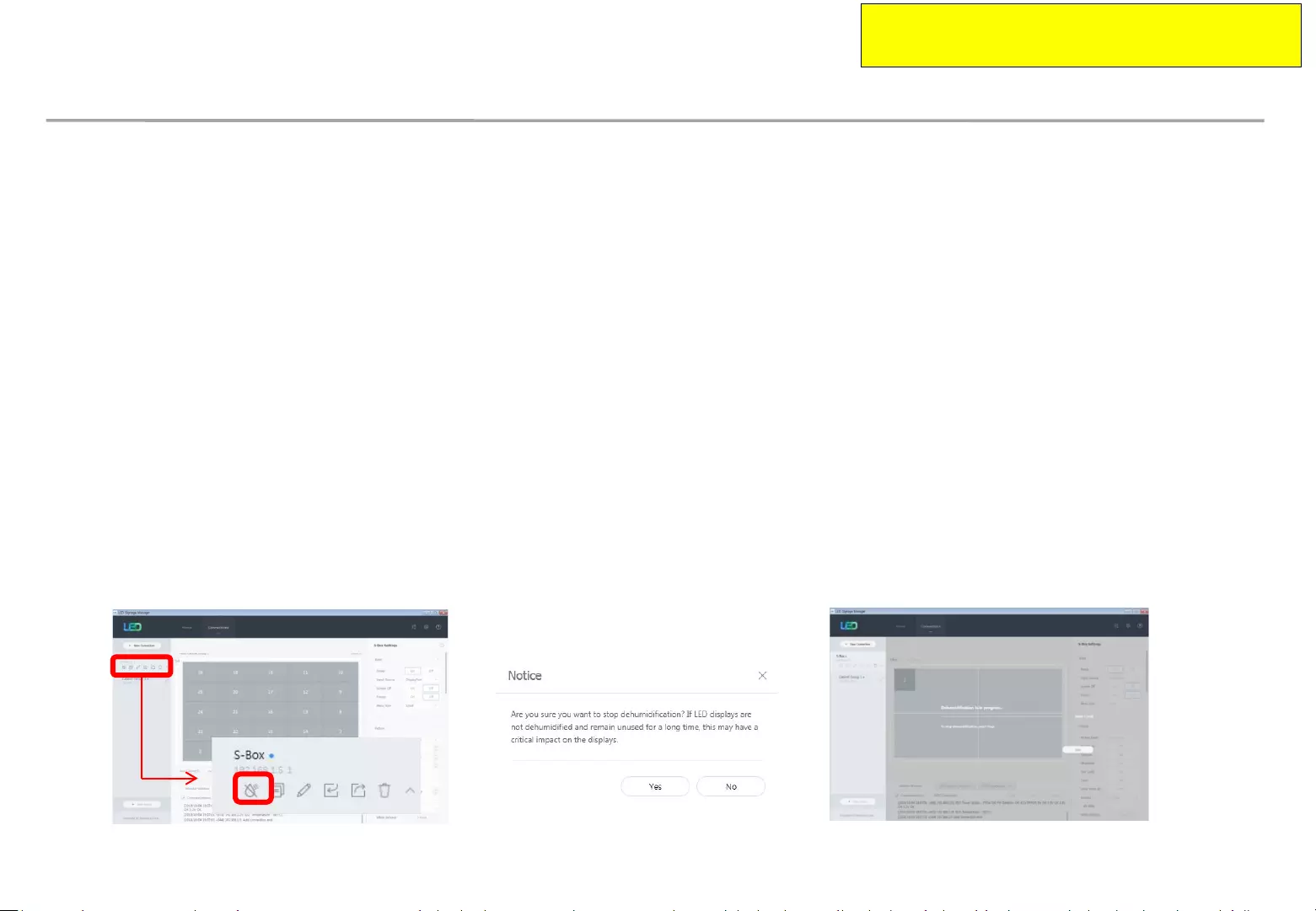

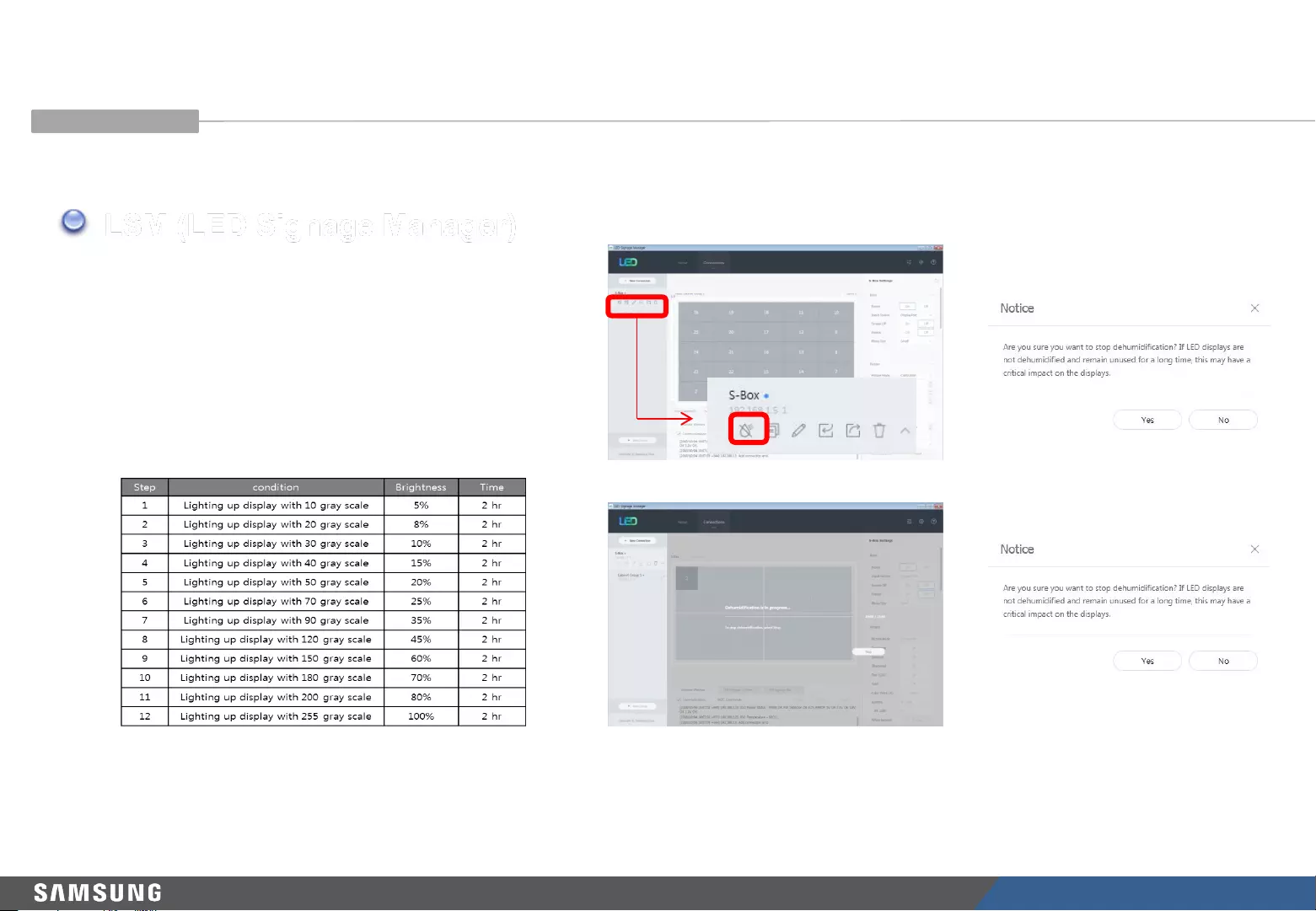

•Dehumidification Mode using LSM

1. The dehumidification mode icon is provided

under the S-Box menu.

2. To turn on dehumidification mode, click the icon.

(Proceed : 24 hours)

3. It is possible to view how long the

dehumidification has been on.

4. To turn off the mode, click the “Stop” button.

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

LED R&D Lab(VD)

81

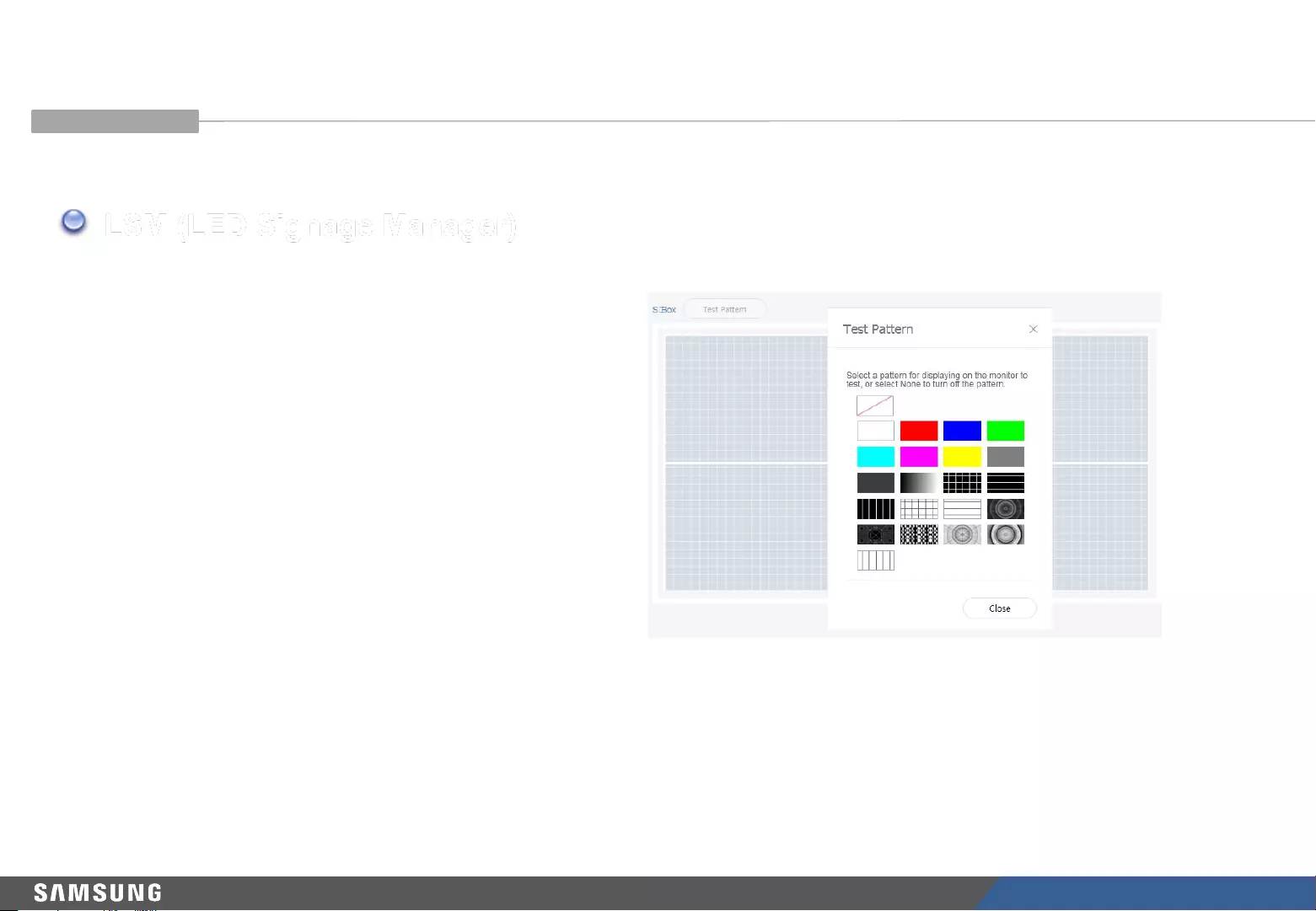

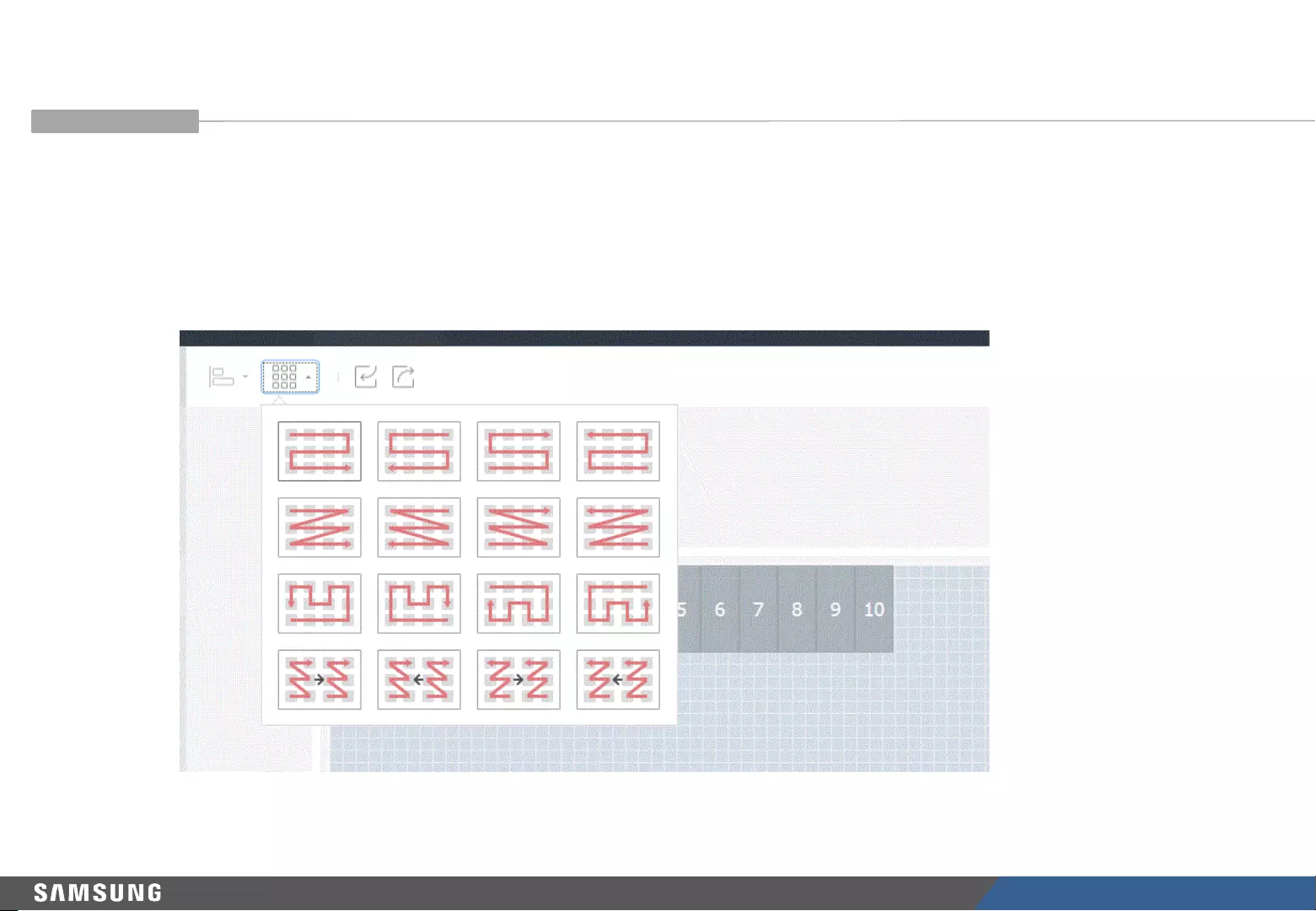

7-1. PC-specific control software

LSM (LED Signage Manager)

7. Settings / How to Use

•test pattern using LSM

1. S-Box Test Pattern

-Utilize when installing cabinets (only for test)

* When the test pattern is turned on / off or the pattern

is changed, background screen may be visible for a

while by overlay layer switching.

LED R&D Lab(VD)

82

•Supports mixed two-model installation

1. ※IER and IER-F can be connected to the same port.

2. There is no connection order for IER and IER-F.

3. Combination is possible within an FHD screen

(the same I/G port).

4. Use the same firmware for both IER and IER-F.

5. Use the same firmware for both IFR and IFR-F.

IER IER-F

7-1. PC-specific control software

LSM (LED Signage Manager)

※ For IER (IFR)/IER-F (IFR-F) mixed connections, the luminance is lower than the single specification when using the

Dynamic peaking function and Multi link HDR function

7. Settings / How to Use

LED R&D Lab(VD)

83

Info.txt

L-IERMWWAC-1001.0

FPGAFW.bin

Info.txt

L-IERMWWAC-1001.0

FPGAFW-2525218466

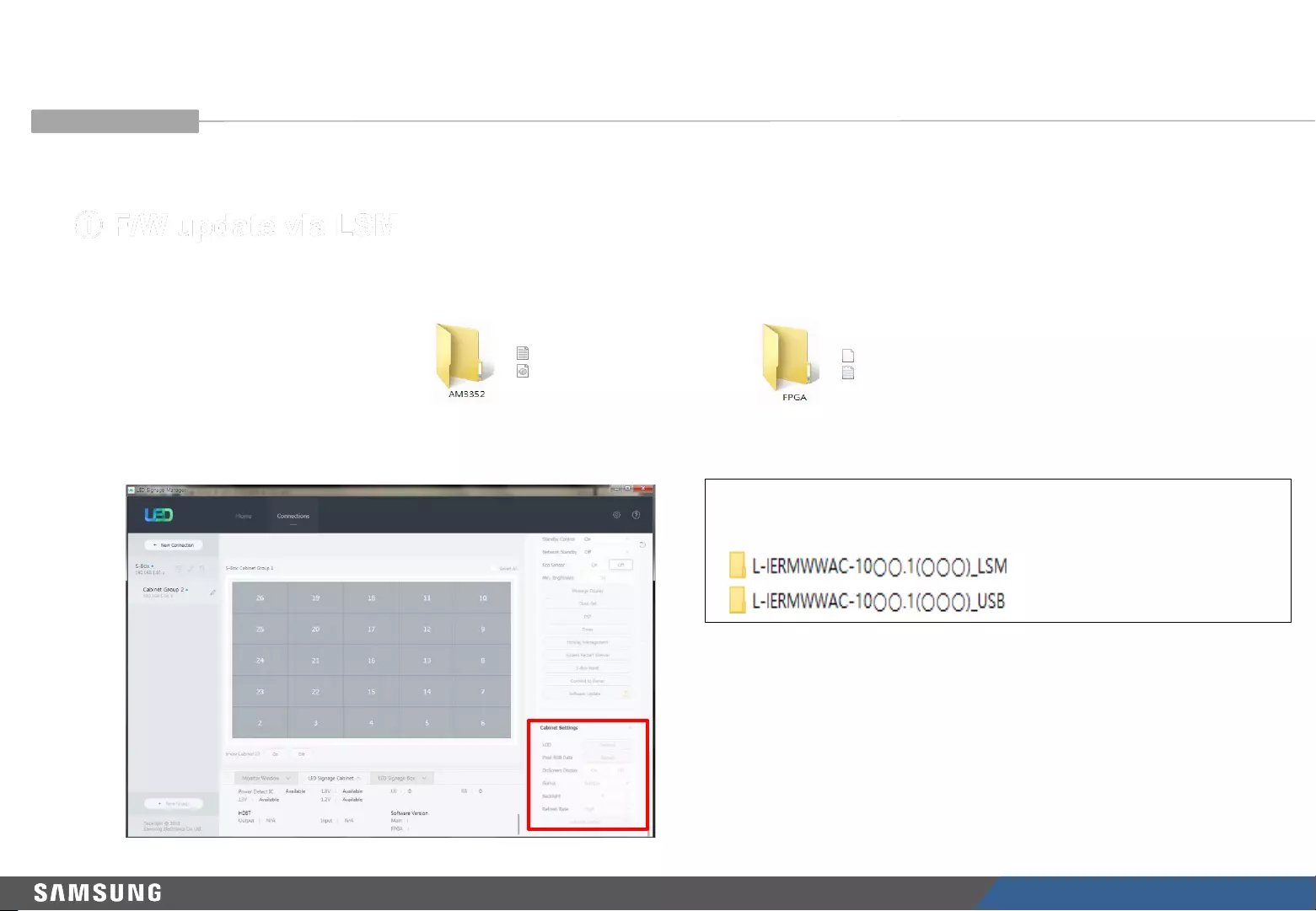

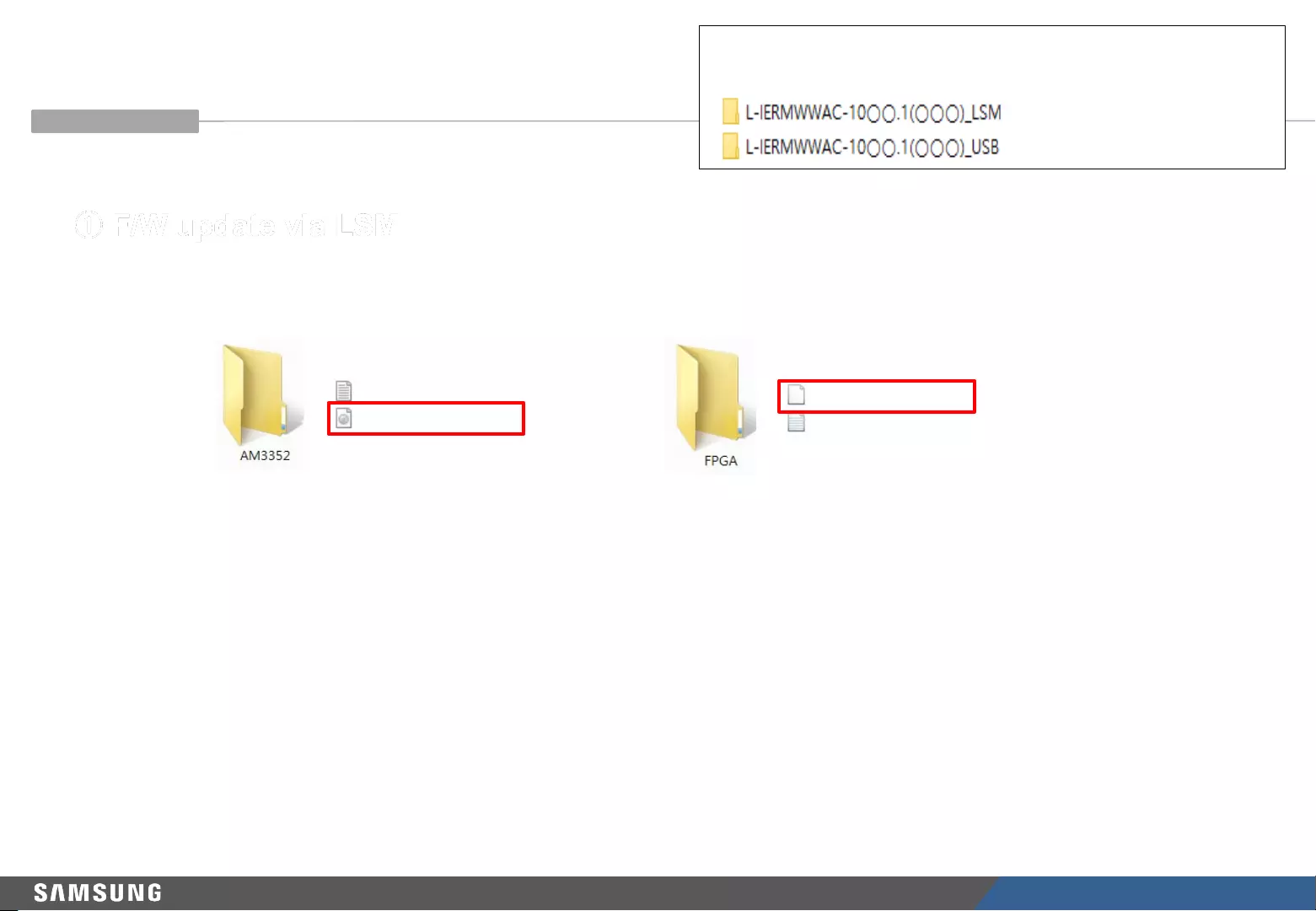

7-2. SW Update

①F/W update via LSM

1. Prepare the update SW File

2. Click on the "Software Update" button in "Cabinet Settings" on the LSM menu.

※ For AM3352, update files for LSM and USB are different.

※ A separate tool is required to update the FPGA SW to USB.

7. Settings / How to Use

LED R&D Lab(VD)

84

4. Press the Update button to update the cabinet.

7-2. SW Update

3. Click the Browse button to select the SW file to update.

※ For AM3352, update files for LSM and USB are different.

※ A separate tool is required to update the FPGA SW to USB.

①F/W update via LSM

※ Never update the "info.txt" file. Causes system failure.

Info.txt

L-IERMWWAC-1001.0

FPGAFW.bin

Info.txt

7. Settings / How to Use

LED R&D Lab(VD)

85

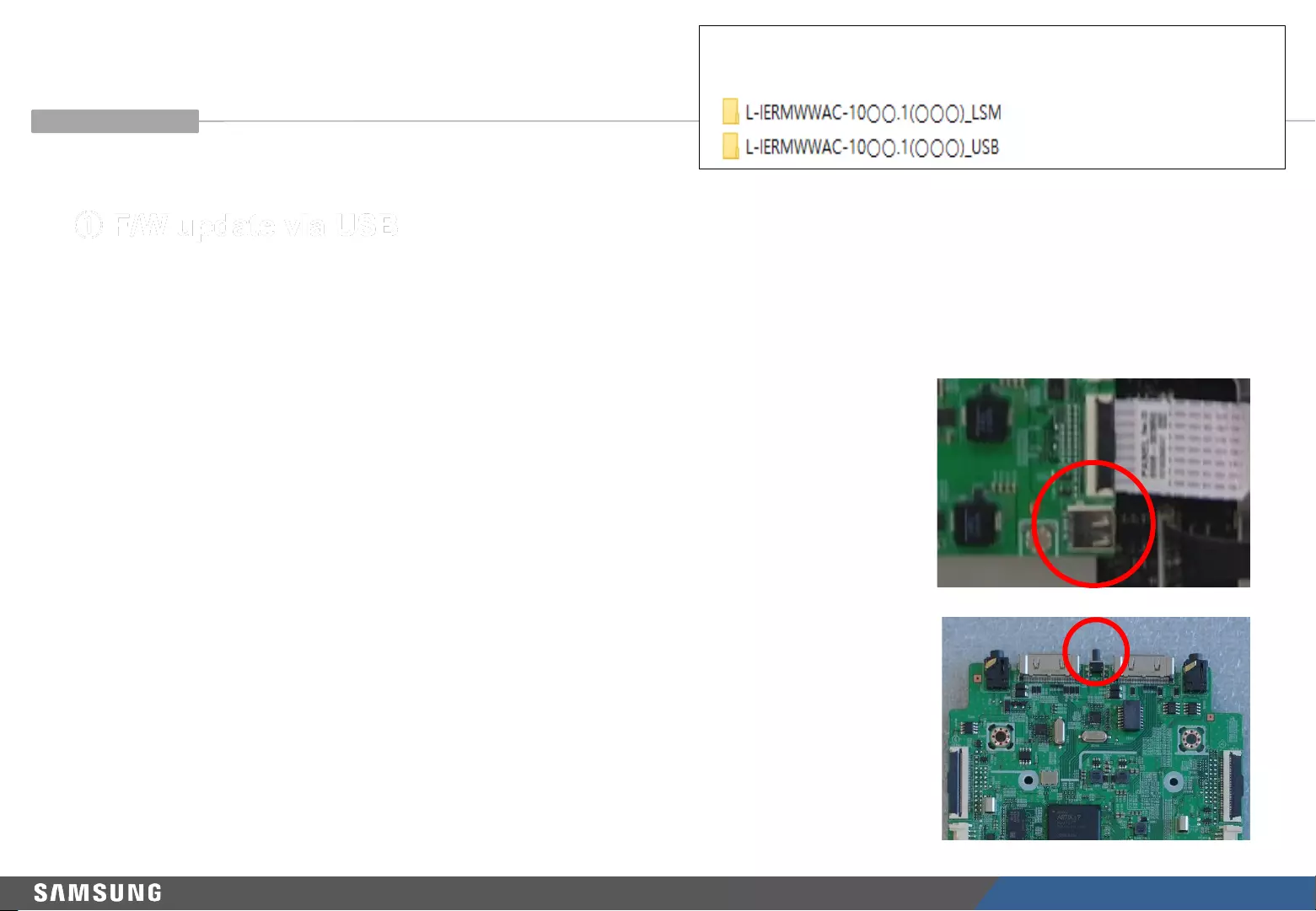

※ For AM3352, update files for LSM and USB are different.

※ A separate tool is required to update the FPGA SW to USB.

①F/W update via USB

1. Prepare the items below.

-USB memory formatted in FAT32 format

-Copy files for updates to the USB root folder

2. Disassemble the back cover of the Cabinet and insert the USB memory into

the TCO Board.

-Located at the bottom right of the T-CON board (USB terminal)

3. Press and hold the toggle switch on the top of the TCO Board and turn it on.

-Press and hold and turn on AC power

-Press the switch for 4 seconds after AC power is turned on to proceed with

the update.

4. Check the Cabinet Info by entering the test pattern after power loss.

-See page 15 on how to enter the test pattern

7-2. SW Update

7. Settings / How to Use

LED R&D Lab(VD)

86

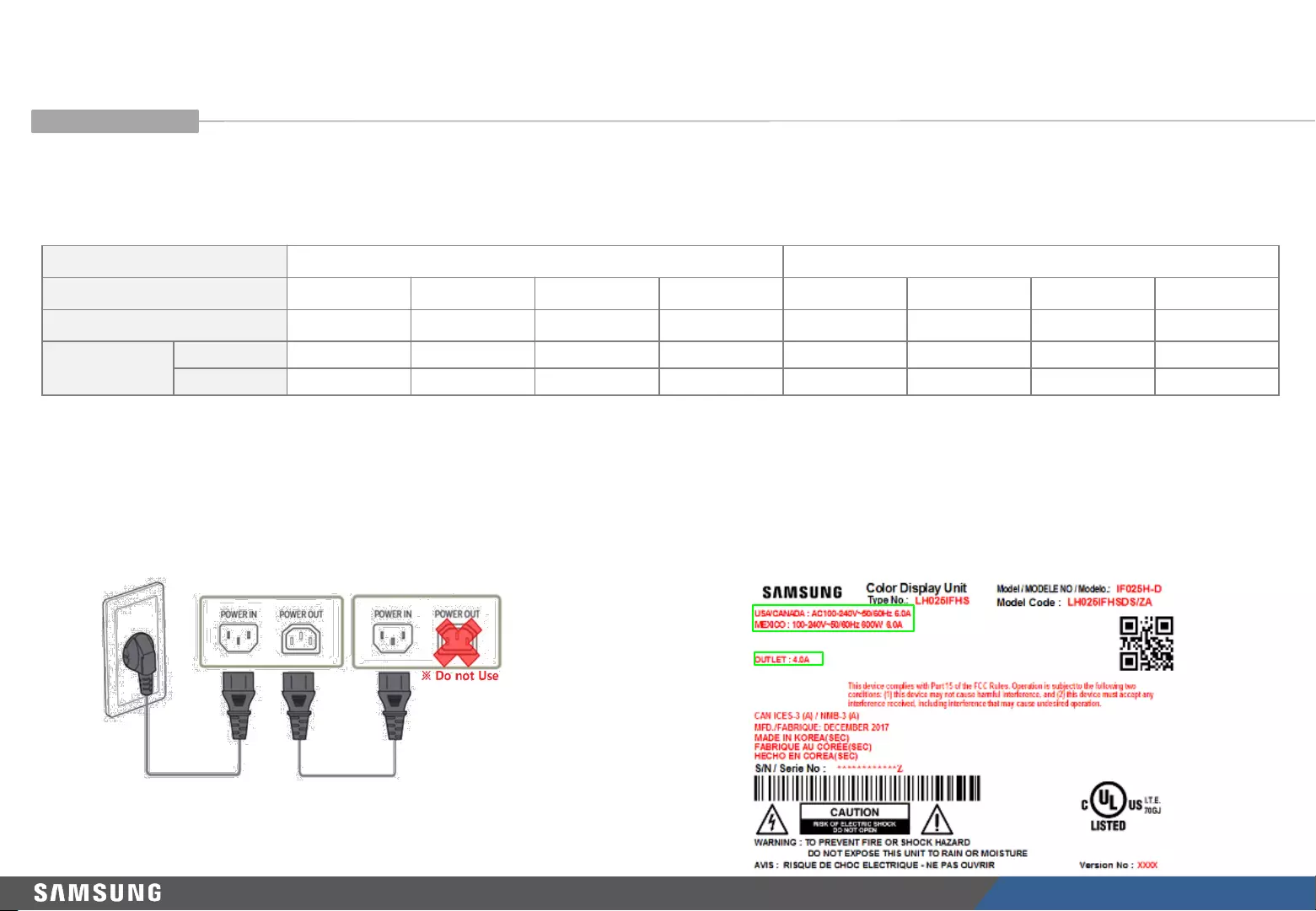

8. Power and Cable Connection

•Transfer power by daisy chain with extension power cable

•Do not use Power out socket of last Cabinet

8-1. Cable connection (IER Series)

•Please check the maximum number of connections in the cabinet when connecting to the Cabinet.

•In case of powering IER and IER-F together, adjust cabinet number so that total Power consumption is under 1000W

•Make sure the quantity of connected cabinets does not exceed the recommended quantity. If the recommended quantity is

exceeded, the breaker may trip or the product may become damaged due to over-current.

※Samsung Electronics is not responsible for problems caused as a result of exceeding the recommended quantity of connections.

•The rated voltage for the product and the rated current for the outlet can be found in the label attached on the rear of the product.

Model IER / IFR IER-F / IFR-F

Pitch P1.5 P2.0 P2.5 P4.0 P1.5 P2.0 P2.5 P4.0

Max Power consumption (W) 260 / 360W 180 / 260W 150 / 260W 150 / 260W 80 / 90 W60 / 80 W50 / 80 W50 / 80 W

Max Num. of

Cabinets

110V 2 / 1 set 3 / 2 set 4 / 2 set 4 / 2 set 7/ 7 set 10 / 7 set 10 / 7 set 10 / 7 set

220V 4/ 3 set 6 / 4 set 7 / 4 set 7 / 4 set 15 / 15 set 20 / 15 set 20 / 15 set 20 / 15 set

LED R&D Lab(VD)

87

1) If cabinets are installed on a dedicated wall mount, the cabinets are fastened toward

the bottom-left direction. Sets can only be installed in the left-to-right direction.

→ The set installation direction may be different from the cable connection direction.

2) After installing all cabinets for one row, connect the signal and power cables and turn

on the sets to check that there is no problem with connection before installing

cabinets for the next row.

3) To connect cables between upper and lower sets, first connect the cables to the lower

sets before assembling the upper sets.

→ If installing upper and lower sets together before connecting cables, it is difficult to

connect cables to the lower cabinets.

3) The two Video Out ports on the Interface Gender should be connected to the first and

last cabinets by using OCM cables so as to ensure proper redundancy operation.

→ The Interface Gender should be installed in the middle on the left end of the LED

wall. (See page 13.)

→ The distance between the first and last cabinets should be within 2 to 4 m to be

connected with OCM cables.

8. Power and Cable Connection

8-2. Precautions during cabinet installation and cable connection (Full Front)

LED R&D Lab(VD)

88

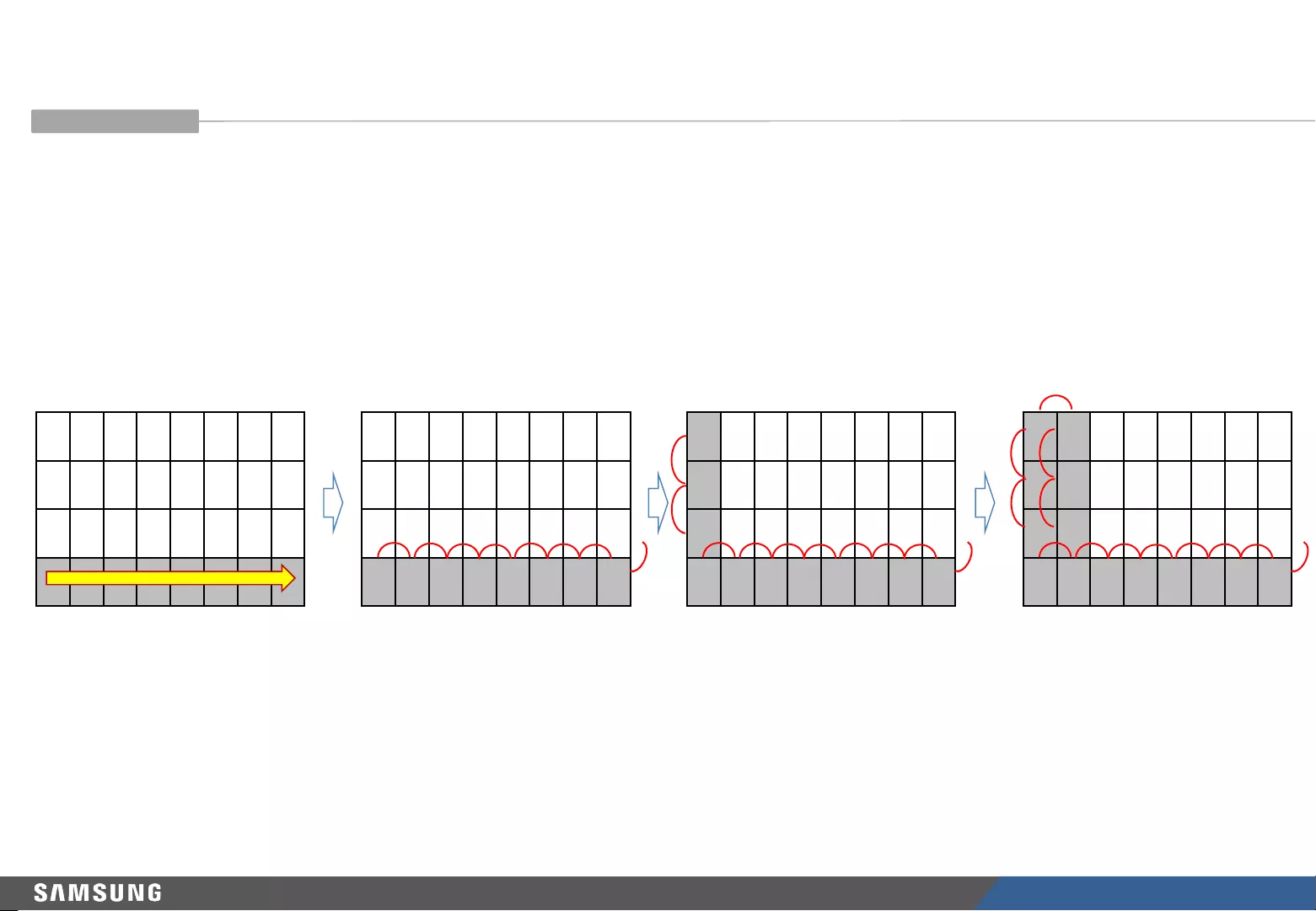

1) For the lowest row, install cabinets in the left-to-right direction.

2) After installing one row of sets is completed, connect signal and power cables between the cabinets.

※After installation of one row of sets and signal connection are completed, turn on the sets to check that the

installation has been done correctly before installing the next row sets.

3) From the second row, install cabinets vertically (left→right).

1) First row: Install in the

left → right direction

Check that there is no

significant height

difference between

modules inside cabinets.

After connecting all signal/power

cables between the sets, make

sure you turn on the sets to

check that the display on one row

works properly before installing

the upper row.

2) Connect signal/power

cables between the sets

Check that there is no

significant front/back height

difference between cabinets

and the LEDs are arranged in

a straight line.

3) From second row: Install

cabinets and connect

cables vertically

4) Use the same method

to install cabinets and

connect cables

vertically.

8. Power and Cable Connection

8-3. Cabinet Installation Direction (Full Front Installation)

LED R&D Lab(VD)

89

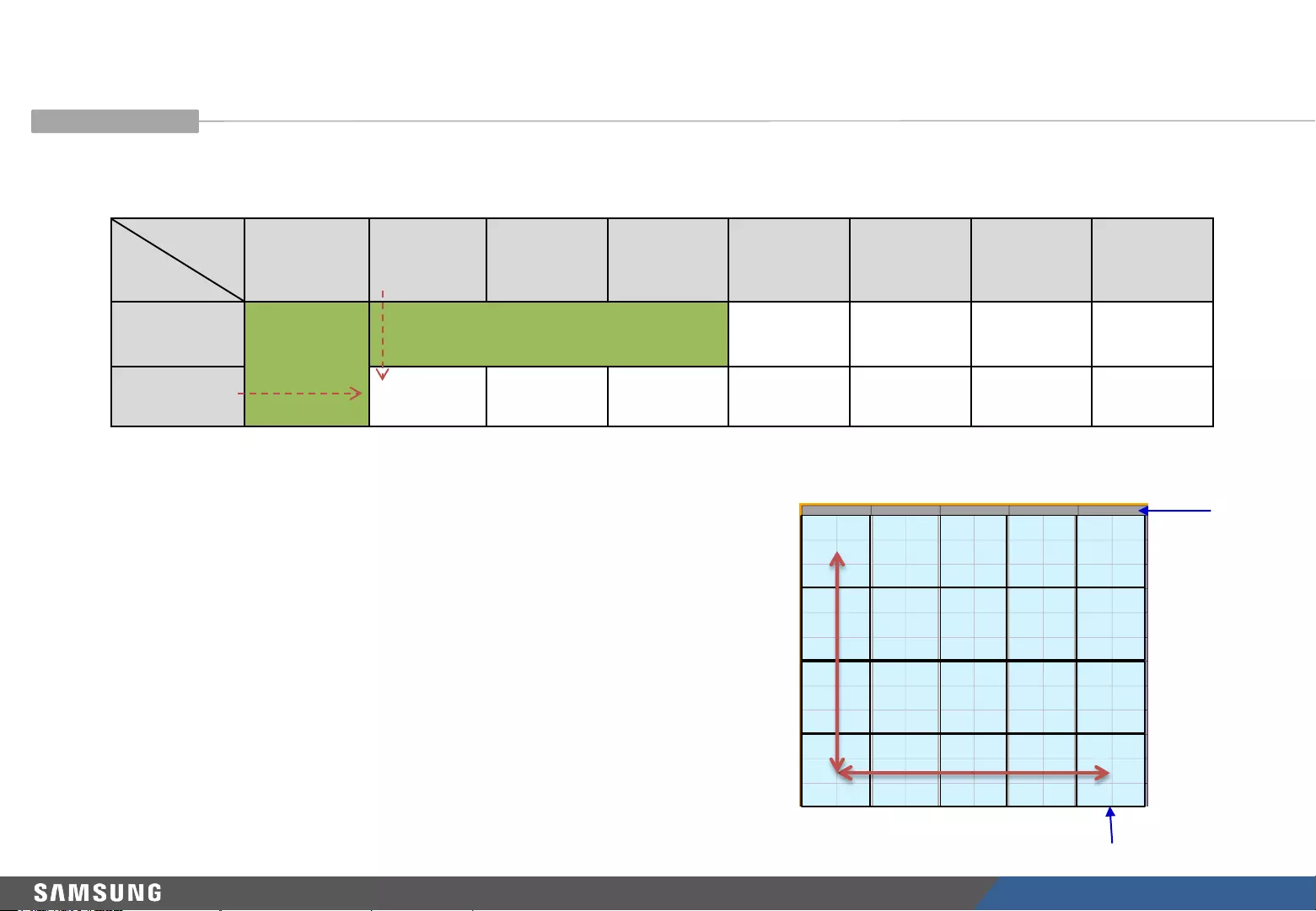

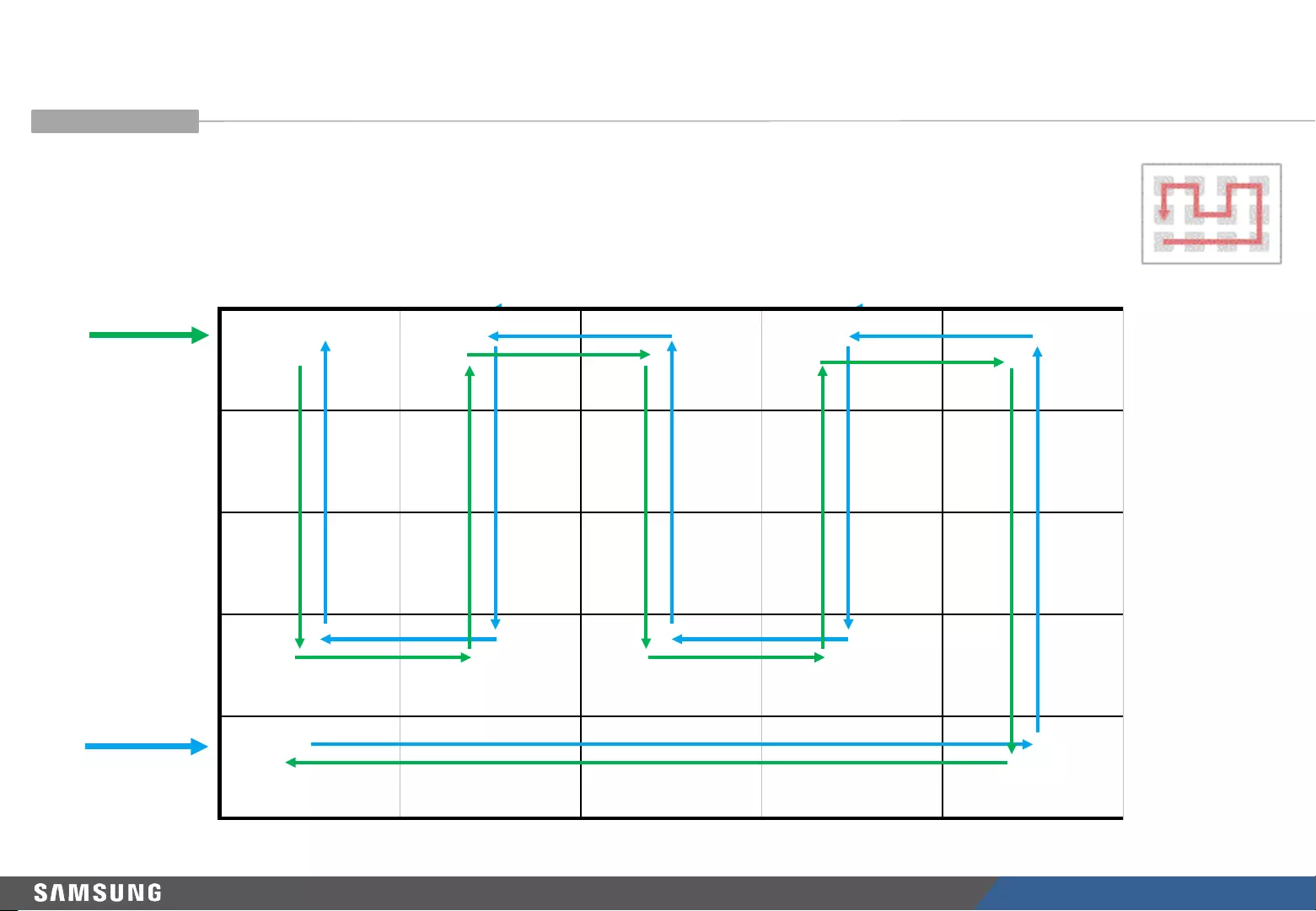

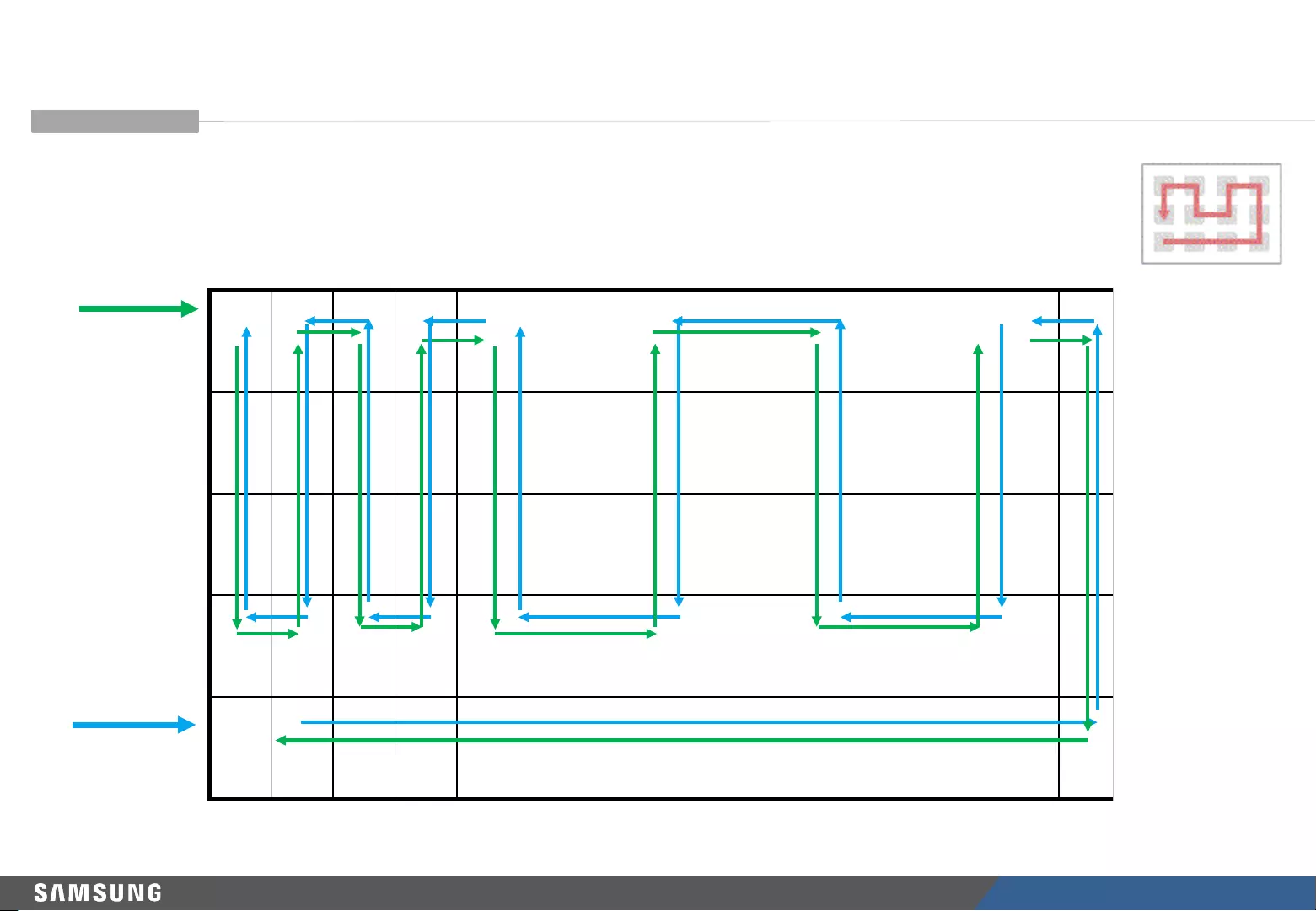

-After installation and connection, automatic sorting can be made on LSM. (automatic sorting for cabinets)

-It is recommended to install the cabinets in automatic sorting order.

8. Power and Cable Connection

8-4. Cable connection

LED R&D Lab(VD)

90

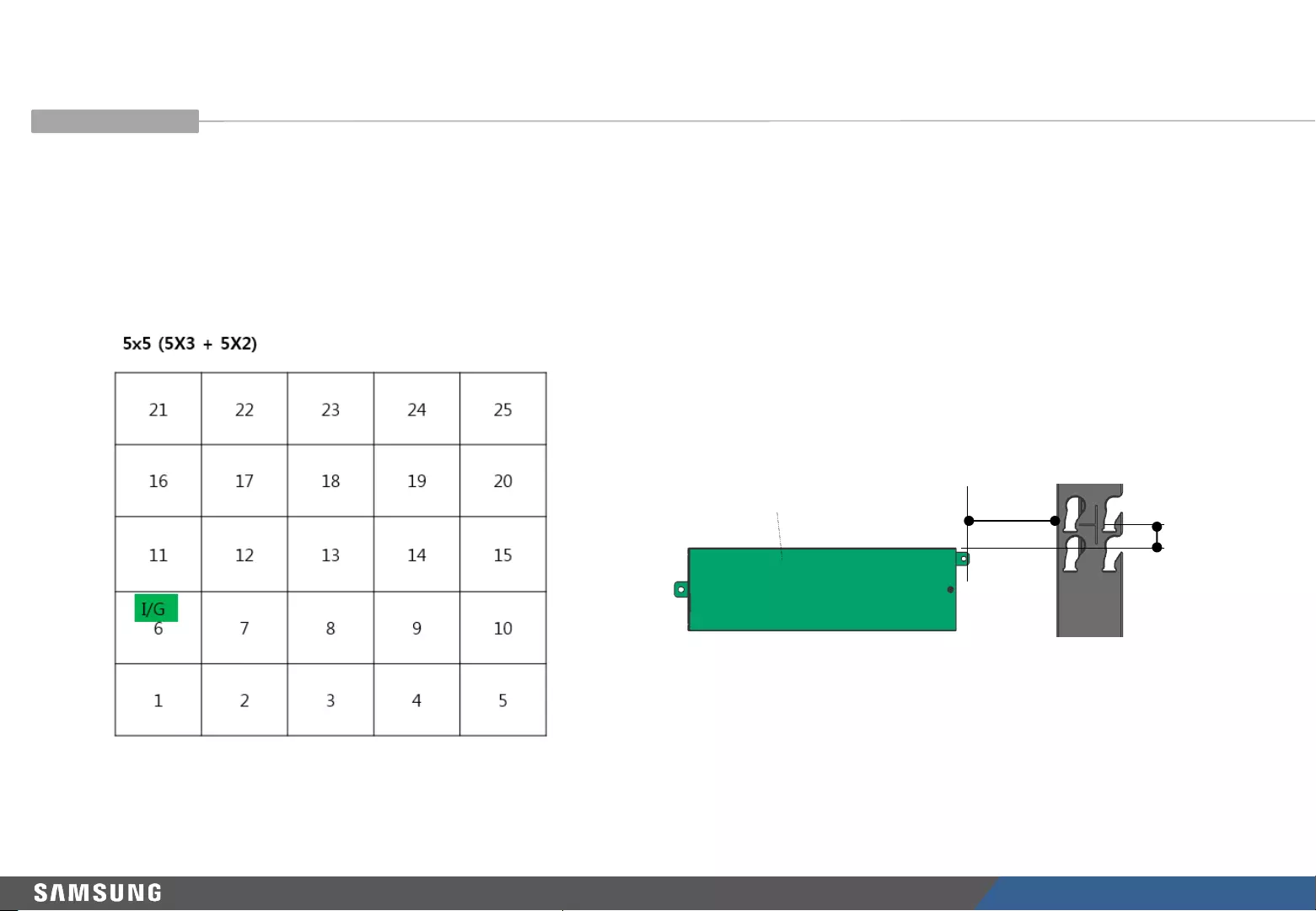

FHD 50/60 Hz screen with IER/IFR would be : 4x4 for P2.0 / 5x5 for P2.5 / 8x8 for P4.0

Forward

Reverse

Case 1:

Ex )

26 19 18 11 10

25 20 17 12 9

24 21 16 13 8

23 22 15 14 7

23456

8. Power and Cable Connection

8-4. Cable connection

LED R&D Lab(VD)

91

FHD 50/60 Hz screen with IER-F/IFR-F would be : 16x4 for P2.0 / 20x5 for P2.5 / 32x8 for P4.0

(recommended to install mixed with IER/IFR)

● ● ●

101 94 93 86 25

100 95 92 87 24

99 96 91 88 23

98 97 90 89 22

2345 21

Forward

Reverse

Case 2:

●●●

8-4. Cable connection Ex )

8. Power and Cable Connection

LED R&D Lab(VD)

92

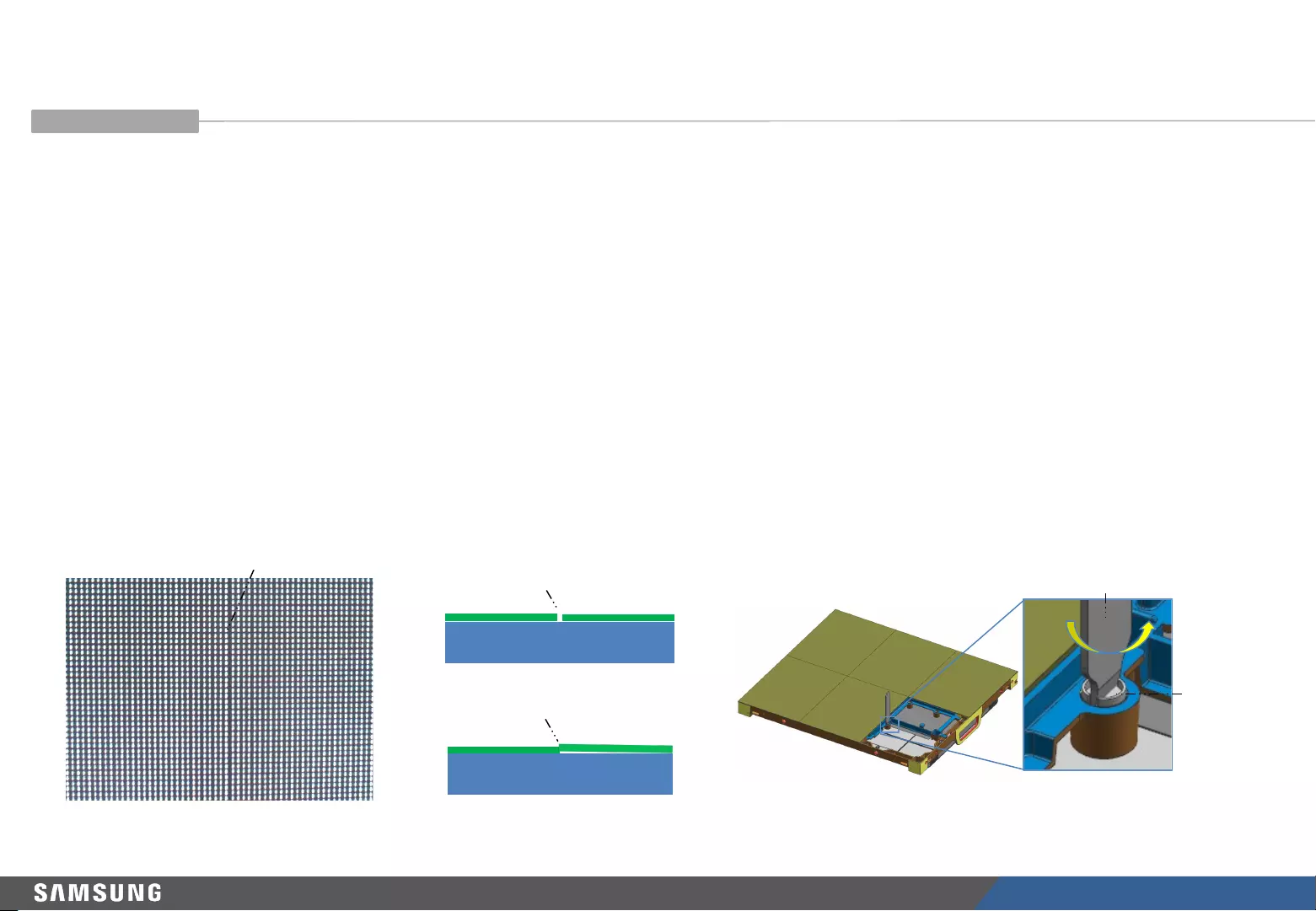

Black line found on white screen

①On the white screen, check that there is no black line found between cabinets. (See Fig.1.)

②Check for a gap or significant height difference between modules. (See Fig.2.)

※If a gap is found: A black line is visible from all directions.

※If a significant height difference is found: A white line is visible when viewed from one direction. When viewed from the opposite

direction, a black line is visible.

③If a gap is found, move the modules with hands, beginning from the outer modules.

④If a significant height difference is found, disassemble the lower LED modules and adjust the height

by turning the Holder-Magnet with an appropriate tool.

※If the Holder-Magnet is turned halfway and then turned 360 degrees with the tool, the module height is moved by 0.1 mm (Fig.3).

CABINET

LED module 1 LED module 2

Height

difference

CABINET

LED module 1 LED module 2

Gap

Fig.1 Black line Fig.2 Gap / height difference

between modules

Fig.3 Adjusting height difference

Tool

Holder Magnet

Moves by 1

mm per full

turn

9. Seam Adjustment

9-1. Checking and adjusting seam

LED R&D Lab(VD)

93

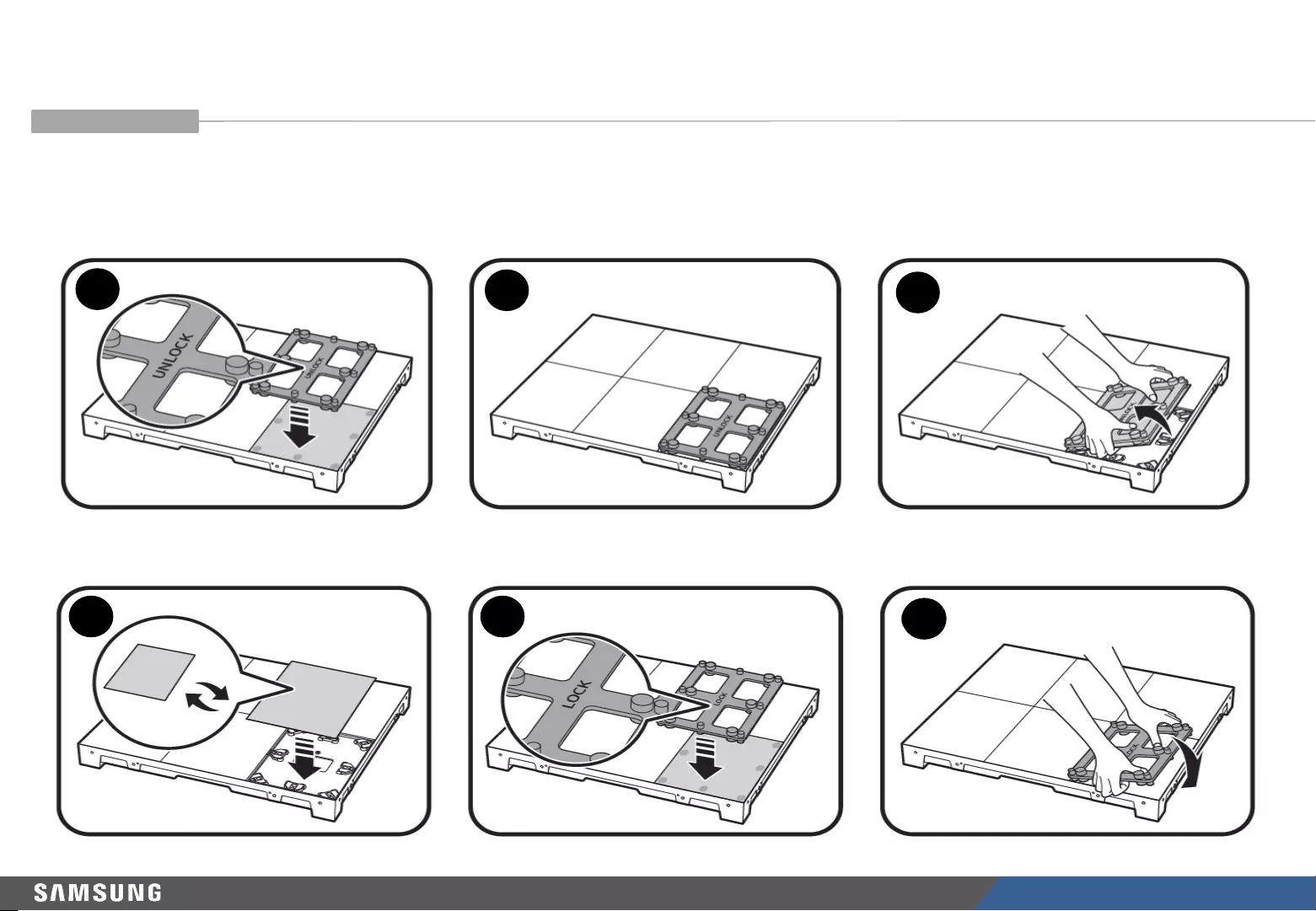

123

6

54

Hold the JIG with the UNLOCK marking facing up. Put the JIG to the LED module. Separate the JIG and the module together.