Table of Contents

Samsung WD12T504DWW User Manual

Displayed below is the user manual for WD12T504DWW by Samsung which is a product in the Washer Dryers category. This manual has pages.

Related Manuals

WASHING MACHINE

DRUM TYPE

WASHING MACHINE (DRUM) CONTENTS

SERVICE

Manual

REPAIR GUIDE

The model code is on the next page.

1. Safety Instructions

2. FeaturesandSpecications

3. Disassembly and Reassembly

4. Troubleshooting

5. Wiring Diagram

6. Reference

WD10T734DBH

WD80T534DBN

WD90T654DBH

WD90T984DSH WD70T4046EW

MODEL CODE

WD1*T****** WD7*T****** WD8*T****** WD9*T******

WD10T534ABW WD70T4046CH WD80T4046CE WD85T4046CH WD90T4046EH

WD10T534DBN WD70T4046EE WD80T4046CW WD85T534DBE WD90T534ABE

WD10T534DBT WD70T4046EW WD80T4046CX WD85T554DBW WD90T534ABW

WD10T534DBW WD70T4047CE WD80T4046EE WD85T654DBH WD90T534DBN

WD10T554DBN WD70T4049CE WD80T4046EW WD85T984DSH WD90T534DBW

WD10T634DBH WD70T554DBE WD80T4047CH WD8ET4049CE WD90T534DBX

WD10T634DBN WD70T654DBN WD80T4047EE WD8ET554ABW WD90T554DBN

WD10T654ABH WD70TA046BE WD80T4049CE WD8ETA049BX WD90T554DBT

WD10T654CBH WD70TA046BH WD80T534ABE WD8FT4049EE WD90T554DBW

WD10T654CBX WD70TA046BN WD80T534DBN WD8TT534ABE WD90T634ABH

WD10T654DBE WD70TA049BE WD80T534DBT WD8XT554ABE WD90T634CBN

WD10T654DBH WD71TA049BE WD80T534DBW WD8XT754AWH WD90T634DBE

WD10T654DBN WD75T4046CE WD80T554ABE WD90T634DBH

WD10T704DBX WD75T534DBE WD80T554ABT WD90T634DBN

WD10T734DBH WD75T554DBE WD80T554CBT WD90T654ABE

WD10T734DBX WD7ETA049BE WD80T554CBX WD90T654ABH

WD10T754ABT WD80T554DBE WD90T654DBE

WD10T754CBH WD80T554DBT WD90T654DBH

WD10T754CBX WD80T554DBW WD90T654DBN

WD10T754DBH WD80T554DBX WD90T654DBX

WD10T754DBN WD80T604DBX WD90T734ABH

WD10T754DBX WD80T634ABH WD90T734DBH

WD10TA046BE WD80T634DBE WD90T734DBX

WD10TA046BX WD80T634DBH WD90T754ABH

WD10TP34DSH WD80T634DBN WD90T754ABT

WD10TP34DSX WD80T654ABH WD90T754DBH

WD10TP54DSX WD80T654AWH WD90T754DBN

WD11T4046CH WD80T654CBE WD90T754DBX

WD11T554AWW WD80T654DBE WD90T954ASH

WD11T554DWW WD80T654DBH WD90T954ASX

WD11T604DBE WD80T654DBN WD90T954DSH

WD11T604DBN WD80T754ABH WD90T984ASE

WD11T704DBX WD80T754ABN WD90T984ASH

WD11T734DBN WD80T754DWH WD90T984DSH

WD11T734DWT WD80T954DSH WD90T984DSX

WD11T754AWH WD80TA046BE WD90TA046BE

WD11T754DBX WD80TA046BH WD90TA046BX

WD11TA046BE WD80TA046BN WD91T984ASH

WD11TA046BN WD80TA046BX WD91TA049BE

WD11TA046BX WD80TA047BT WD92T654CBE

WD12T654DBH WD80TA049BE WD92T734CBT

WD12T654DBN WD81T4049CE WD94T754CBT

WD12T754DBN WD81T534ABW WD95T4046CE

WD13T604DBN WD81T554ABW WD95T534CBE

WD13T704DBH WD81T754ABH WD95T634CBH

WD13T704DBX WD81TA049BE WD95T634DBH

WD13T734DBN WD82T4047CE WD95T754DBH

WD13T754DBN WD83T734CBH WD95T754DBN

WD13T784DBX WD83TA047BH WD95T954ASE

WD13T784DSX WD84T634CBE WD95T984DSX

WD15T634CBH WD85T4046CE WD95TA047BE

CONTENTS

1. Safety instructions .........................................................................1

1-1. Safety instructions ...........................................................................1

2. FeaturesandSpecications ................................................................4

2-1. Specications ................................................................................4

2-2. Comparingspecicationswithexistingmodels ................................................5

2-3. Optionsspecications ........................................................................6

3. Disassembly and Reassembly ...............................................................7

3-1. Toolsfordisassemblyandreassembly .........................................................7

3-2. Standarddisassemblydrawings ...............................................................8

4. Troubleshooting ..........................................................................30

4-1. InformationCode ...........................................................................30

4-2. Problemcheckpoint ........................................................................34

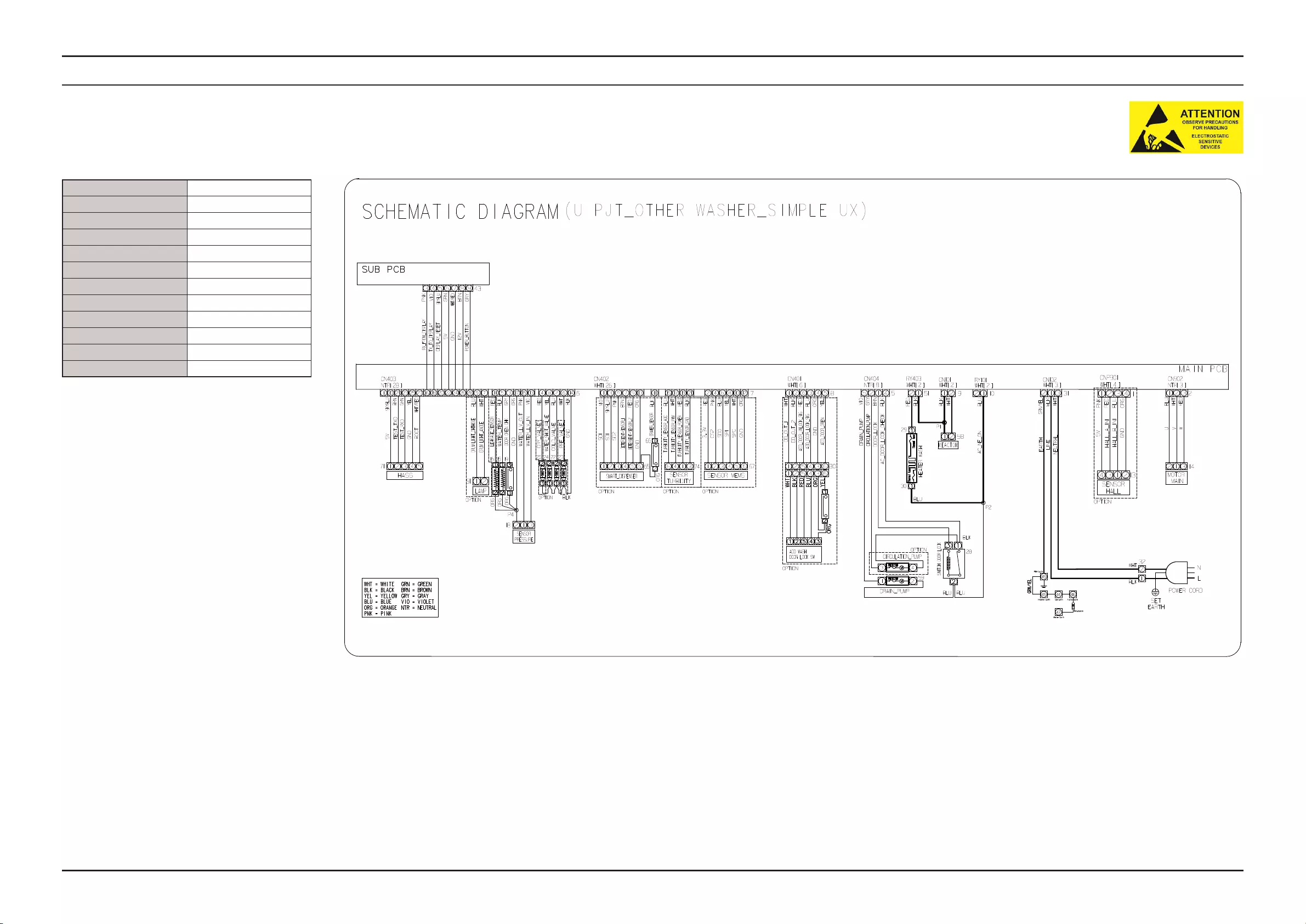

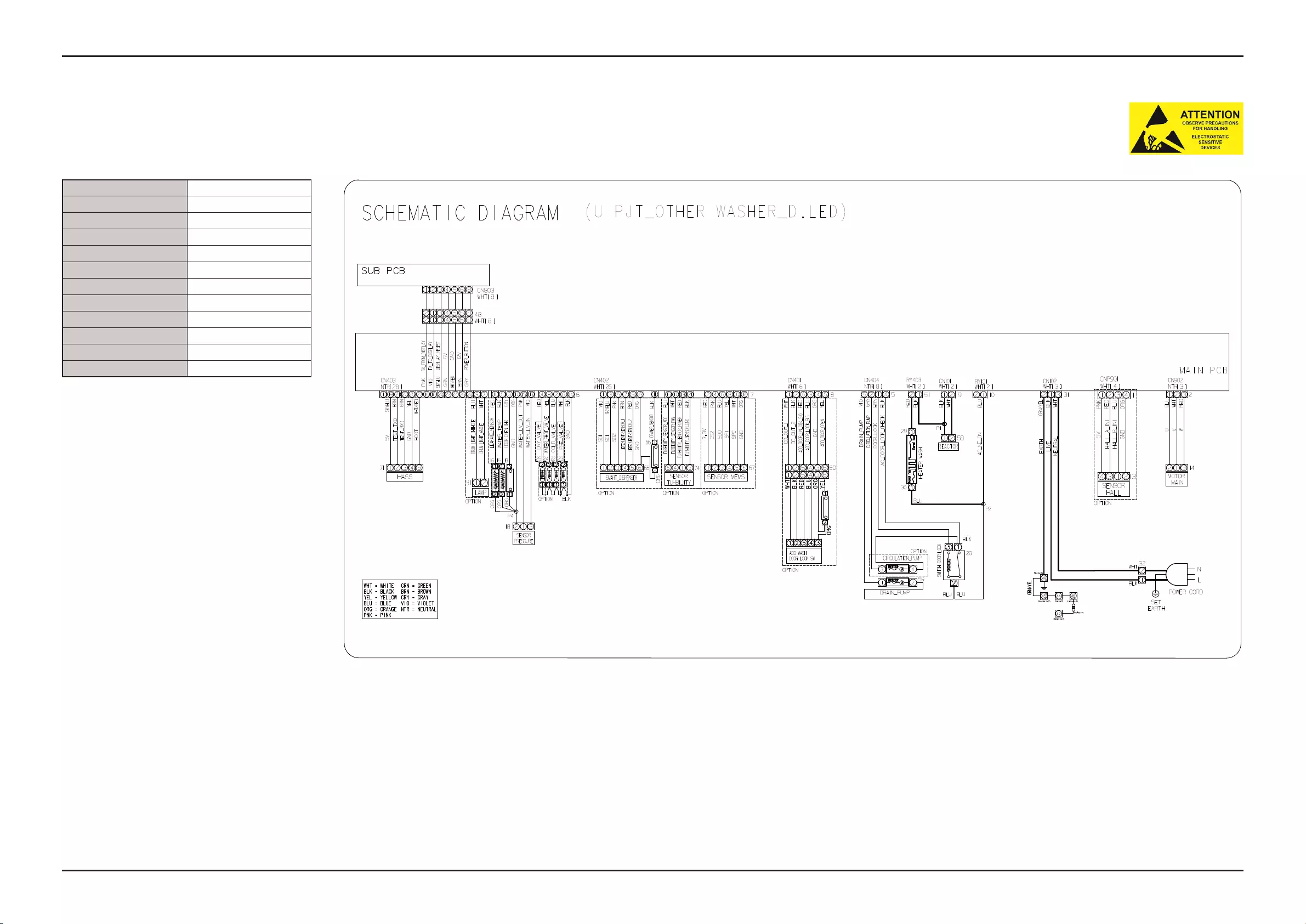

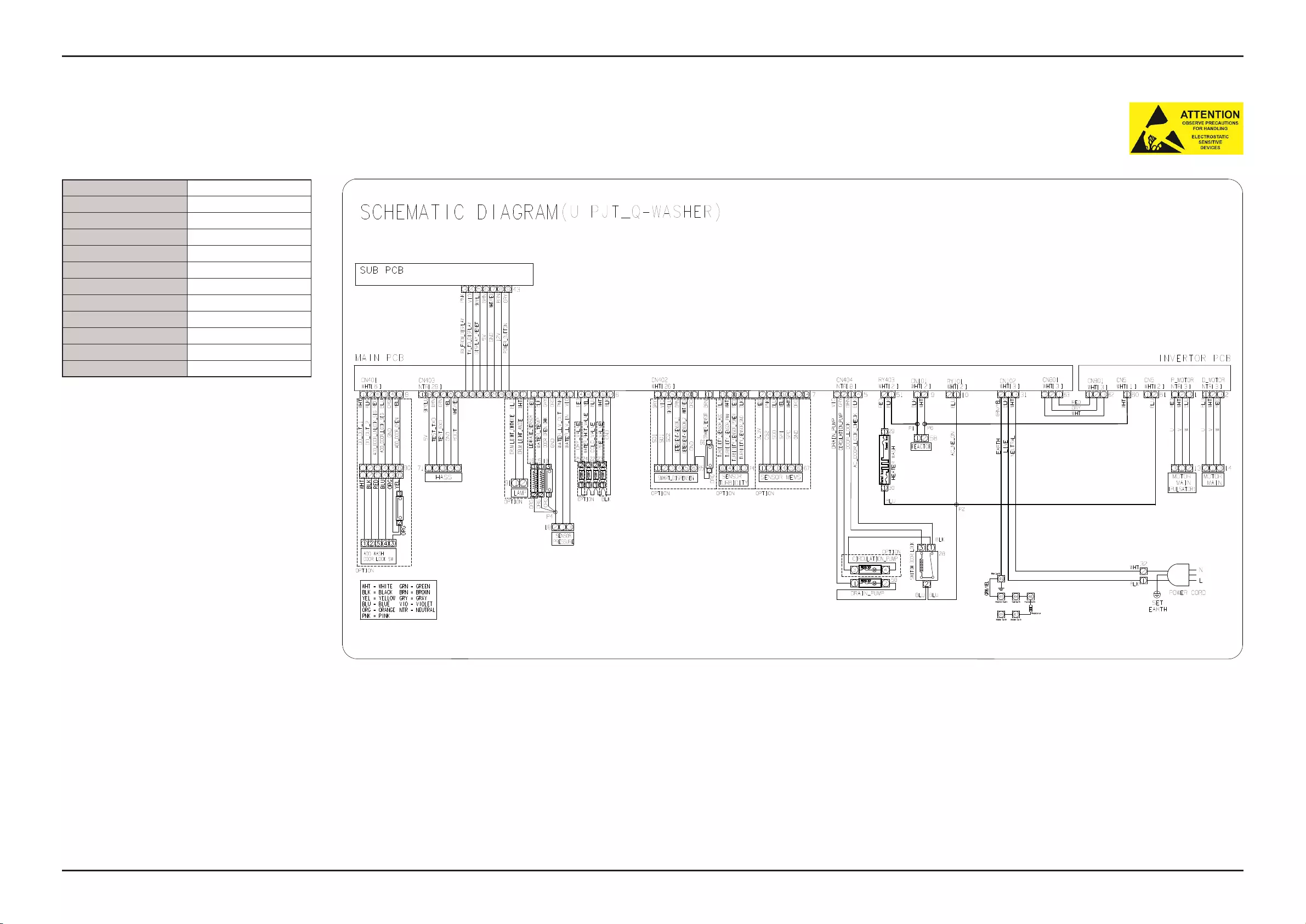

5. Wiring diagram ...........................................................................35

5-1. WiringDiagram(Simple) ....................................................................35

5-2. WiringDiagram(LED) .......................................................................36

5-3. WiringDiagram(Q-Drive) ....................................................................37

6. Reference .................................................................................38

6-1. WD6000T Project name .....................................................................38

6-2. Terminology ................................................................................39

Safety Instructions _ 1

1. SAFETY INSTRUCTIONS

1-1. SAFETY INSTRUCTIONS

► Makesuretoobservethefollowinginstructionstooperatetheproductcorrectlyandsafelyandpreventpossibleaccidentsand

hazardswhileservicing.

► Twotypesofsafetysymbols,WarningandCaution,areusedinthesafetyinstructions.

WARNING

Hazardsorunsafepracticesthatmayresultinseverepersonalinjuryordeath.

CAUTION

Hazardsorunsafepracticesthatmayresultinminorpersonalinjuryorpropertydamage.

► Followingtherepairbyanon-authorisedserviceprovider,self-repairornon-professionalrepairoftheproduct,Samsungisnot

liableforanydamagetotheproduct,anyinjuryoranyotherproductsafetyissuecausedbyanyattempttorepairtheproduct

whichdoesnotcarefullyfollowtheserepairandmaintenanceinstructions.Anydamagetotheproductcausedbyanattemptto

repairtheproductbyanypersonotherthanaSamsungcertiedserviceproviderwillnotbecoveredbythewarranty.

WARNING BEFORE SERVICING

• (Whenservicingelectricalpartsorharnesses)Makesuretodisconnectthepowerplugbeforeservicing.

4 Failingtodosomayresultinariskofelectricshock.

• Adviseconsumersnottoconnectseveralappliancestoasinglepoweroutletatthesametime.

4 Thereisariskofreduetooverheating.

• Whenremovingthepowercord,makesuretoholdthepowerplugwhenpullingtheplugfrom

theoutlet.

4 Failingtodosomaydamagetheplugorpoweroutletandresultinreorelectricshock.

• Whenthewashingmachineisnotbeingused,makesuretodisconnectthepowerplugfromthe

poweroutlet.

4 Failingtodosomayresultinresultinaccidentaloperationofthewashingmachine.

• Donotplaceorusegasoline,thinners,alcohol,orotherammableorexplosivesubstancesnearthewashingmachine.

4 Thereisariskofexplosionandrecausedfromelectricsparks.

2 _ Safety Instructions

WARNING WHILE SERVICING

• Checkifthepowerplugandoutletaredamaged,attened,cutorotherwisedegraded.

4 Iffaulty,replaceitimmediately.

Failingtodosomayresultinelectricshockorre.

• Completelyremoveanydustorforeignmaterialfromthehousing,wiringandconnectionparts.

4 Thiswillpreventariskofreduetotrackingandshortsinadvance.

• Whenconnectingwires,makesuretoconnectthemusingtherelevantconnectorsandcheckthattheyareproperlyconnected.

4 Donotusetapeinsteadoftheconnectors,itmaycausereduetotracking.

• MakesuretodischargethePBApowerterminalsbeforestartingtheservice.

4 Failingtodosomayresultinahighvoltageelectricshock.

• Whenreplacingtheheater,makesuretofastenthenutafterensuringthatitisinsertedintothebracket-heater.

4 Ifnotinsertedintothebracket-heater,ittouchesthedrumandcausesnoiseandelectricleakage.

• Donotrepairthewashingmachinewithoutsafetygloves.

4 It can cause injury.

WARNING AFTER SERVICING

• Checkthewiring.

4 Ensurethatthewiringcannotbedamagedbyanysharpedgesormovingparts.

• Checkforanywaterleakage.

4 Performatestrunforthewashingmachineusingthestandardcourseandcheckwhetherthereisanywaterleakage

throughtheoorsectionorthepipes.

• Adviseconsumersnottorepairorserviceanypartofthewashingmachinethemselves.

4 Thismayresultinpersonalinjuryandshortentheproductlifetime.

Safety Instructions _ 3

CAUTION BEFORE SERVICING

• Donotsprinklewaterontothewashingmachinedirectlywhencleaningit.

4 Thismayresultinelectricshockorre,andmayshortentheproductlifetime.

• Donotplaceanycontainerswithwateroranyotherliquidonthewashingmachine

4 Ifthewaterisspilled,itmayresultinelectricshockorre.Thiswillalsoshortentheproduct

lifetime.

• Donotinstallthewashingmachineinalocationexposedtosnoworrain.

4 Thismayresultinelectricshockorre,andshortentheproductlifetime.

• Donotpressacontrolbuttonusingasharptoolorobject.

4 Thismayresultinelectricshockordamagetotheproduct.

CAUTION WHILE SERVICING

• Whenwiringaharness,makesuretosealitcompletelysonoliquidcanenter.

4 Takecarewhendisconnectingconnectors,donotuseexcessiveforceasthismaydamage

theconnector.

• Checkifthereisanyresiduethatshowsthatliquidenteredtheelectricpartsorharnesses.

4 Ifanyliquidhasenteredintoapart,replaceitorcompletelyremoveanyremainingmoisturefromit.

• Ifyouneedtoplacethewashingmachineonitsbackforservicingpurposes,placeasupport(s)ontheoorandlayitdown

carefullysoitssideisontheoor.

4 Donotlayitdownonitsfront.Thismayresultintheinsidetubdamagingparts.

• Atleasttwopeopleshouldworkwhenworkingwithheavyproducts.

FeaturesandSpecications_4

2. FEATURES AND SPECIFICATIONS

2-1. SPECIFICATIONS

MODEL

WD90T654DBH WD10T734DBH WD90T984DSH WD80T534DBN WD70T4046EW

ModelName

Frontloadingwashingmachine

Water Pressure

50kPa-800kPa

NETweight(kg)

68 80 86 68 63

Wash&SpinCapacity

910.5 9 8 7

Dry Capacity

6 6 6 5 4

Power

Consumption

Washing 220V

150W

240V

150W

Washingandheating 220V

2000W

240V

2400W

Drying 220V

1600W

240V

1600W

Spin

220~240V

550W 600W 600W 550W 550W

Pumping

30W

Spinrevolutions

1400 1400 1400 1400 1400

-

PleasevisitSamsungofcialwebsitetoreceivemostup-to-dateinformationaboutsoftwareandproductmaintenance.

Model

WD90T654DBH WD10T734DBH WD90T984DSH WD80T534DBN WD70T4046EW

Width(A)

600mm

Height-Overall(B)

850mm

Depth(C)

650mm 600mm 600mm 600mm 550mm

Depthwithdooropen90°(D)

1160mm 1110mm 1110mm 1110mm 1060mm

A

B

C

D

5_FeaturesandSpecications

2-2. COMPARING SPECIFICATIONS WITH EXISTING MODELS

Model name

WD90T654DBH

WD10T734DBH WD90T984DSH WD80T534DBN WD70T4046EW WD10K64****

Image

Capacity

910.5 9 8 7 10.2

Dry Capacity

6 6 6 5 4 6

Main Spec

DrumVolume

63 70.5 65.9 58 60.1 63

MaxRPM 1400 1400 1400 1400 1400 1400

Motor DD DIT DIT DD DD DD

WaterSupply Coldonly Coldonly Coldonly Coldonly Coldonly Coldonly

Drainage Pump Pump Pump Pump Pump Pump

USP

ECO BUBBLE

●●●●●●

AddWash ● ● ● ● X●

Steam ●●●●● X

AOW/AD X/X X/● ●/● X/● X/X X

BubbleSoak ●●●●●●

SuperSpeed ● ● ● X X ●

Wi ● ● ● ● X●

Q-Drive ● ● XXXX

Design

DOOR Good

TintDoor(Better)

TintDoor(Best)

Basic Basic CrystalGloss

Drum 2ndDiamond Swirl+ Swirl+ 2ndDiamond 2ndDiamond Diamond

DISPLAY Simple Simple Simple Simple LED LED

Dimension

600x850x650 600x850x600 600x850x600 600x850x600 600x850x550 600x850x650

FeaturesandSpecications_6

2-3. OPTIONS SPECIFICATIONS

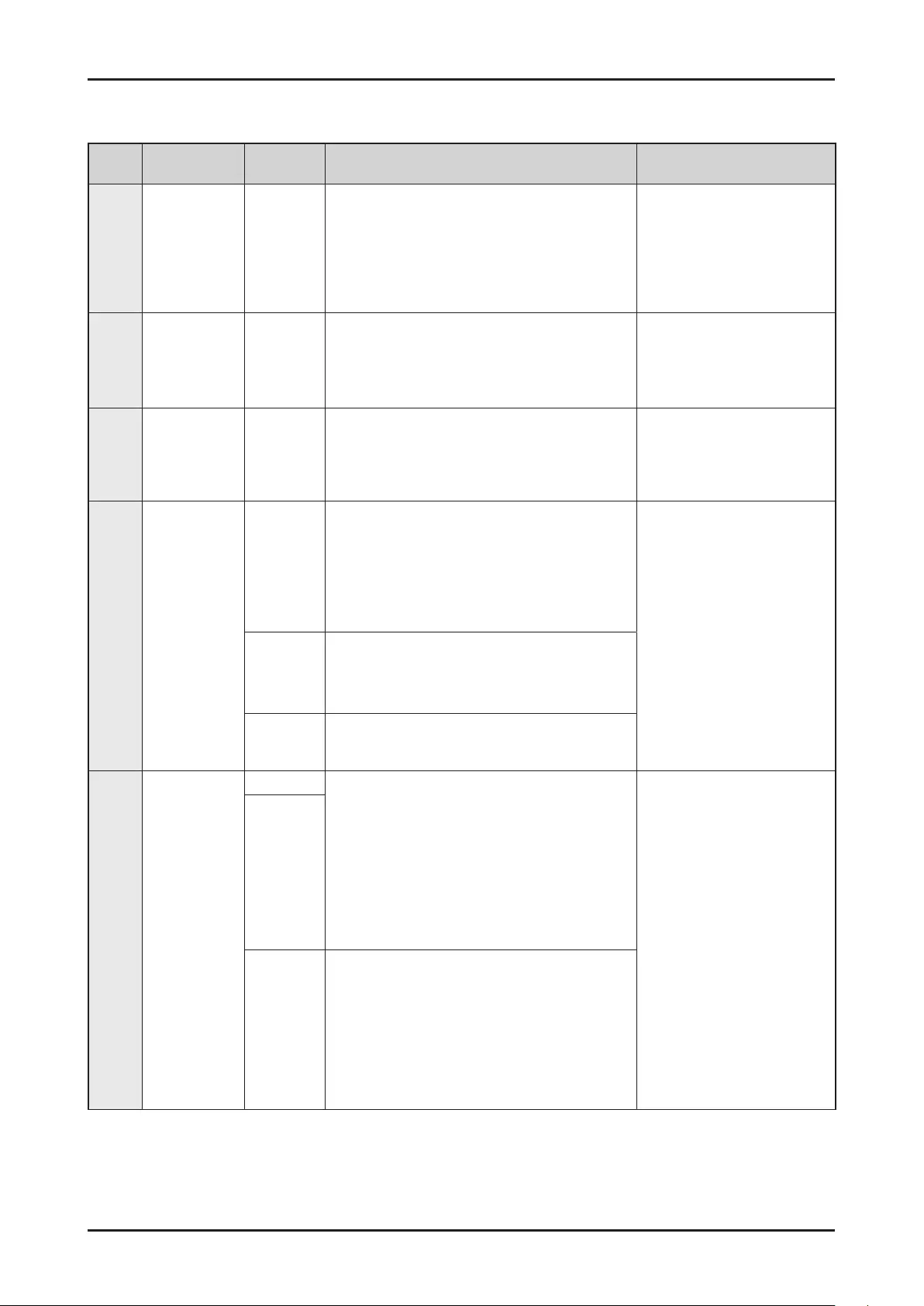

NO Item Code QTY Remarks

1FASTENER-BOLT DC60-00104A 1Default

2CAP-FIXER DC67-00307A 4(8kgmodel)

5(9kgmodel)

Forspecic

modelsonly

3CAP-FIXER DC67-00208B 1Forspecic

modelsonly

4

ASSY HOSE WATER

DC97-16921A ★Forspecic

modelsonly

5HOSE-WATER

(AQUA-STOP) DC62-00079A ★Forspecic

modelsonly

6HOSE-HANGER DC62-10278A 1Default

7GUIDE LIQUID DC61-03510A 1Default

8MANUAL USERS DC68-03745* series 1Default

Note

• (H)issuppliedforspecicmodelsonlyamongthosewithoutwatersupplyhoses.

• Customercanpurchaseadditionalwatersupplyanddrainhosesfromaservicecenter.

• Forbuilt-inmodels,thespanner,watersupplyanddrainhosesarenotsupplied.Boththewatersupplyanddrainhosesare

suppliedduringtheinstallation.

Disassembly and Reassembly _ 7

3. DISASSEMBLY AND REASSEMBLY

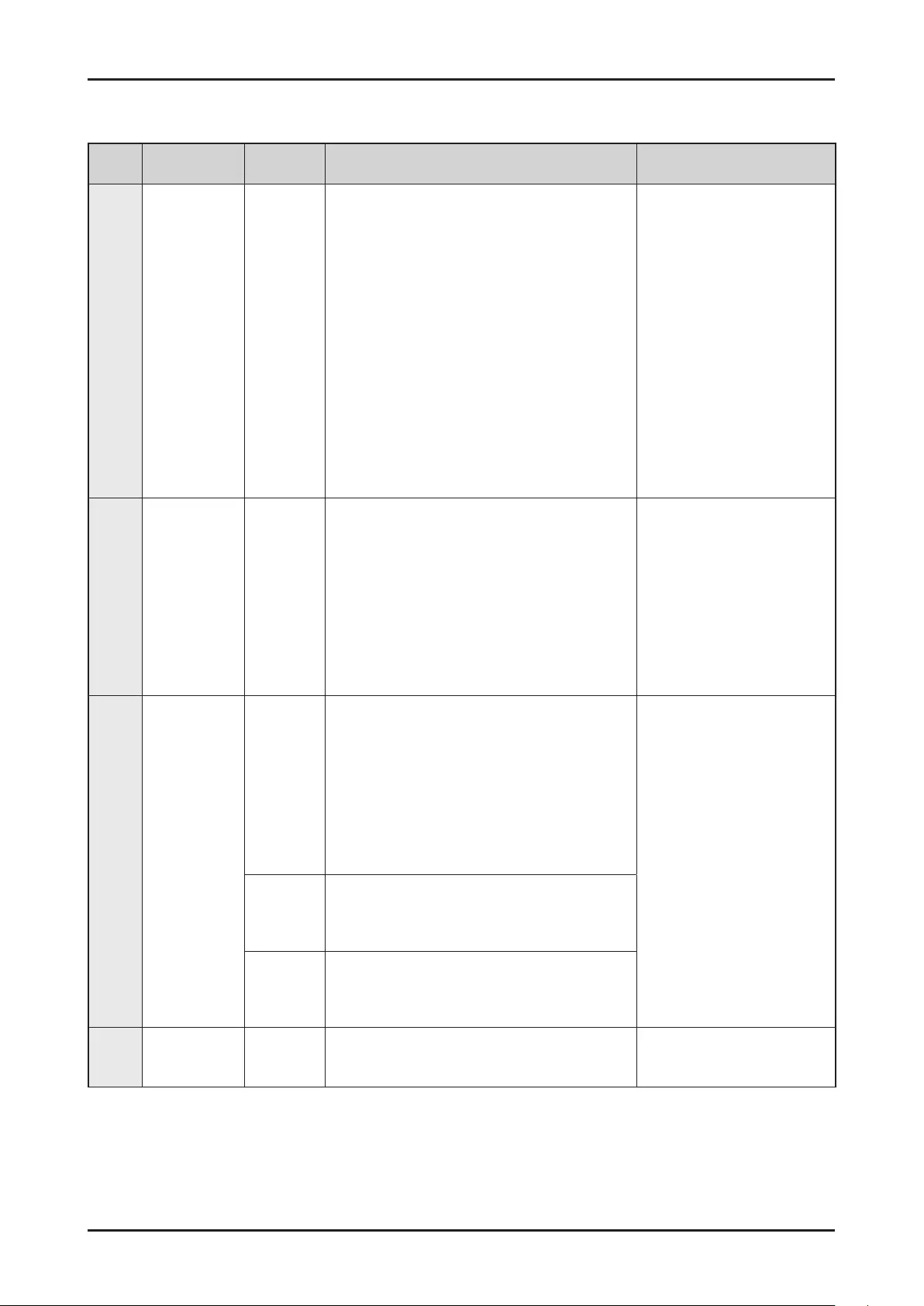

3-1. TOOLS FOR DISASSEMBLY AND REASSEMBLY

Tool Type Remarks

Boxdriver

10mm Heater(1),Tub(12),Fixerscrew(5),Motor(2),

Balance(9)

13mm ShockAbsorber(2holeseachinleft/right),

Damper(2),Damper(friction2)

19mm Pulley(1)

Double-ended

spanner

10mm

13mm

19mm

Replacedbyboxdriver

Leg

Vicepliers

AToolforprotectingemptyturningofboltor

abrasionfromusingboxdriver

FordisassemblyofSpindrum

Others

(screwdriver,nipper,long

nosepliers)

Commontoolsforservicing

Torquewrench TheToolforassemblyofheaterandTub

-Forinformationaboutpurchasingpartsandtool,pleasevisit

http://www.samsung.com/support

-Forthepartcodeinformation,pleaserefertheattachedle'ExplodedView'.

8 _ Disassembly and Reassembly

3-2. STANDARD DISASSEMBLY DRAWINGS

► Thisisastandarddisassemblydiagramandmaydifferfromtheactualproduct.

Usethismaterialasareferencewhendisassemblingandreassemblingtheproduct.

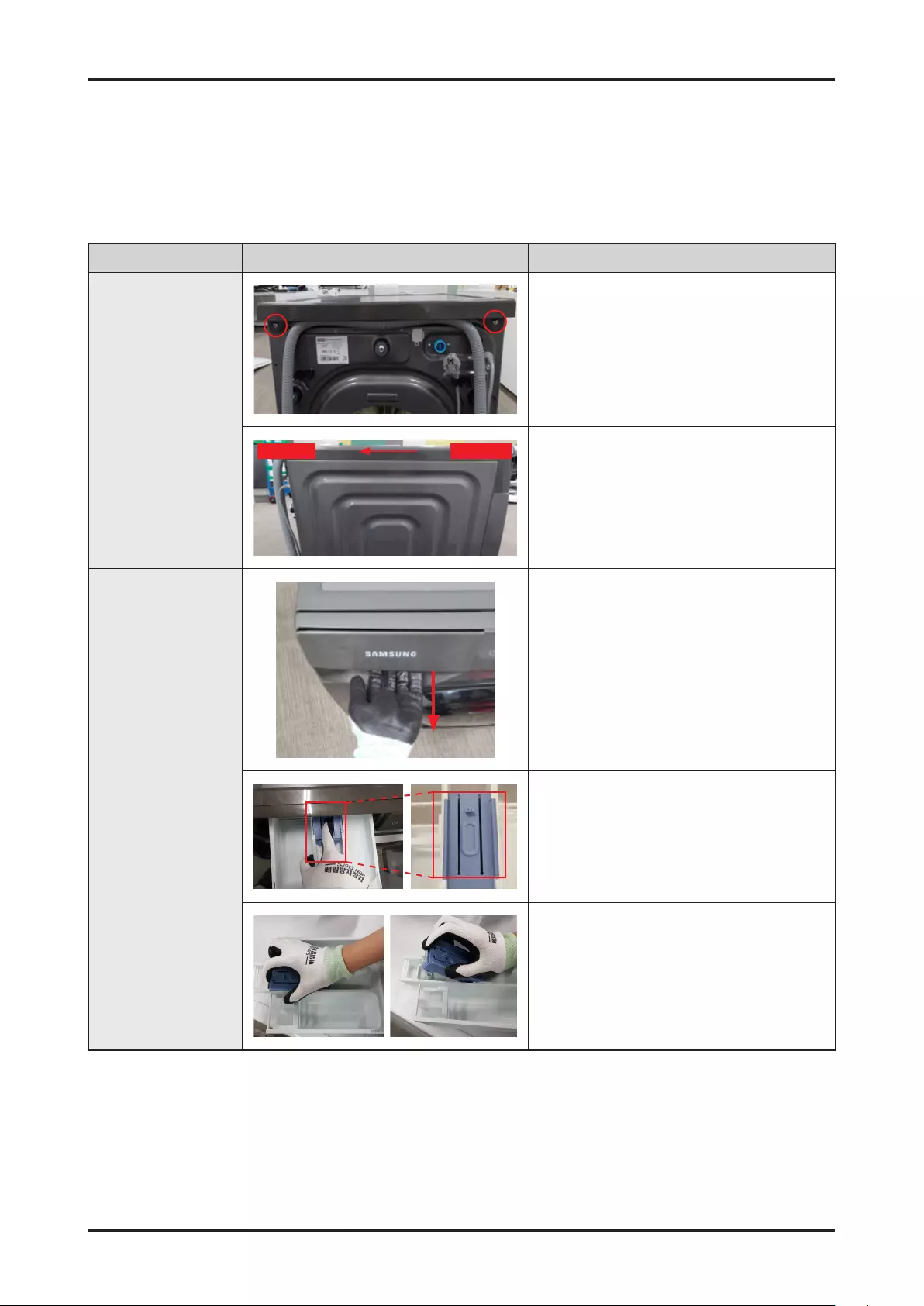

Disassembly

Part Figure Description

Assy Cover Top

1. Remove2screwsholdingtheCoverTopatthe

backoftheunitusing(+)screwdriver.

BACK FRONT

2. RemovetheCoverTopbyliftingitupafter

pullingitbackabout15mm.

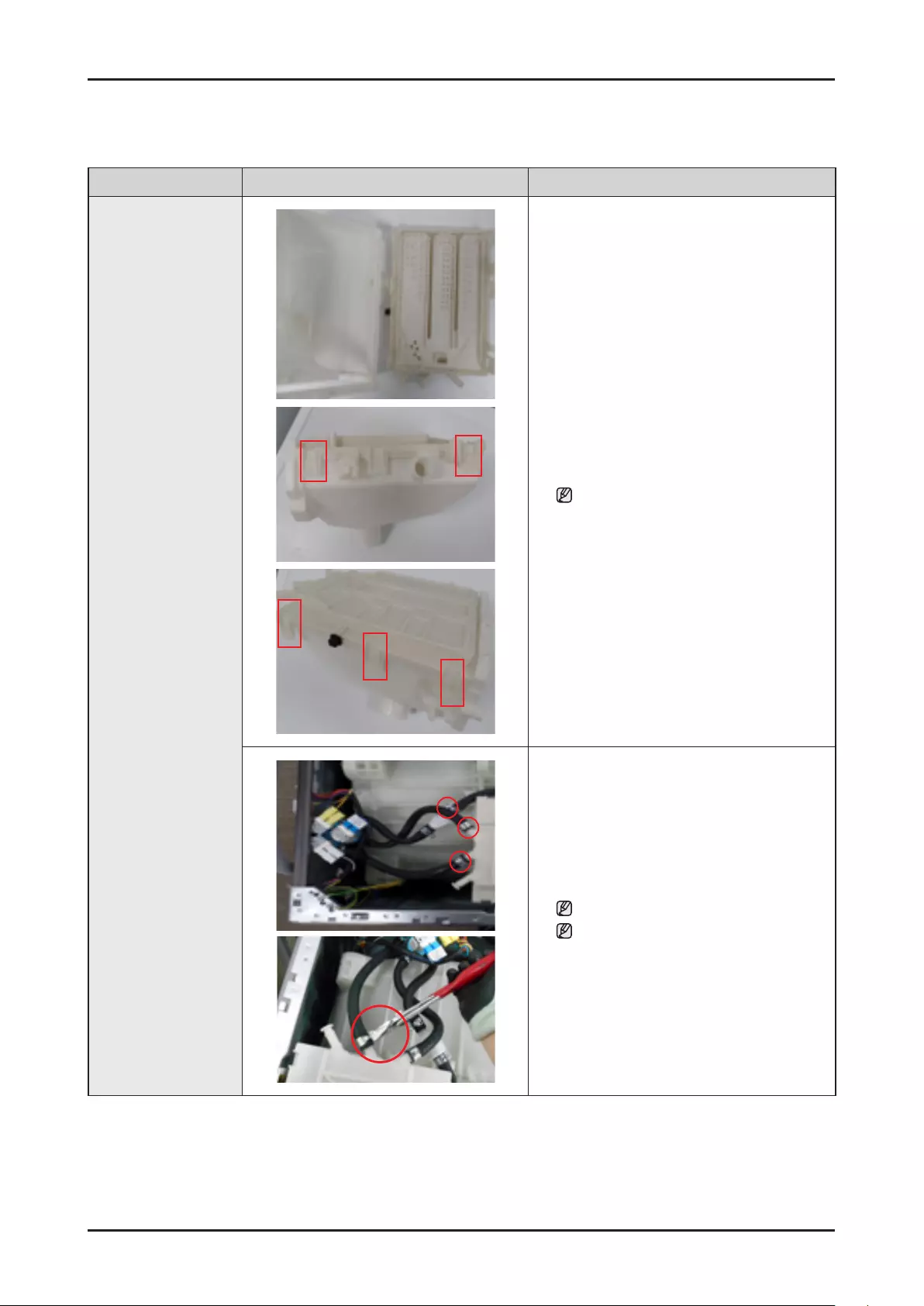

Assy Drawer

1. OpentheDrawerbyhand

2. Whileholdingdownthereleaseleverinsidethe

drawer(redbox),slideopenthedrawer.

3. PulluptheCapRinsetoremoveit.

Disassembly and Reassembly _ 9

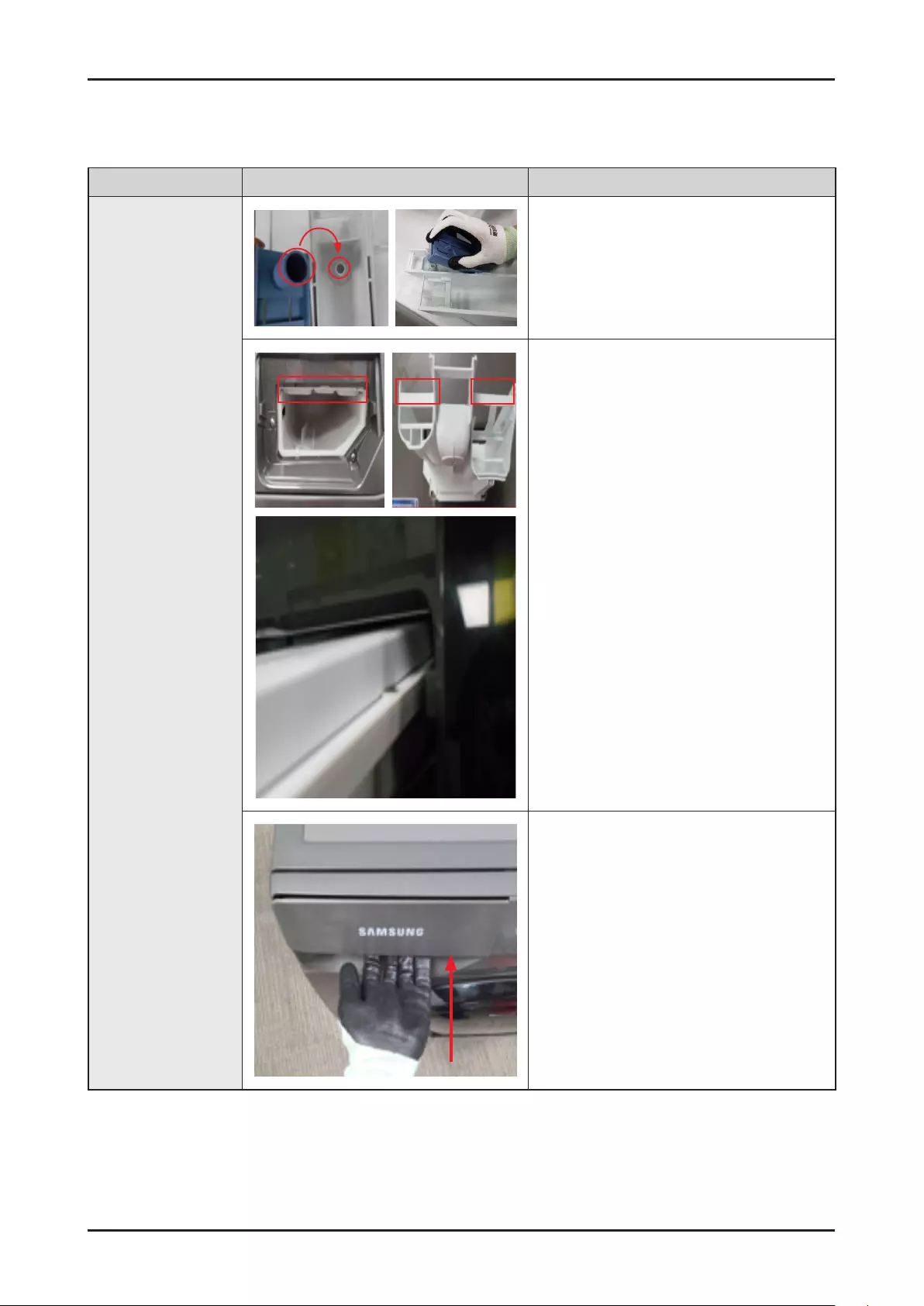

Reassembly

Part Figure Description

Assy Drawer

1. FittheholeandpresstheCapRinsesothatit

canbeassembled.

2. Makesuretottherailwhenreassemblingthe

Assydrawer.

3. Putthedrawerintherightdirection.

10 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Assy Drawer

(Auto Dispense)

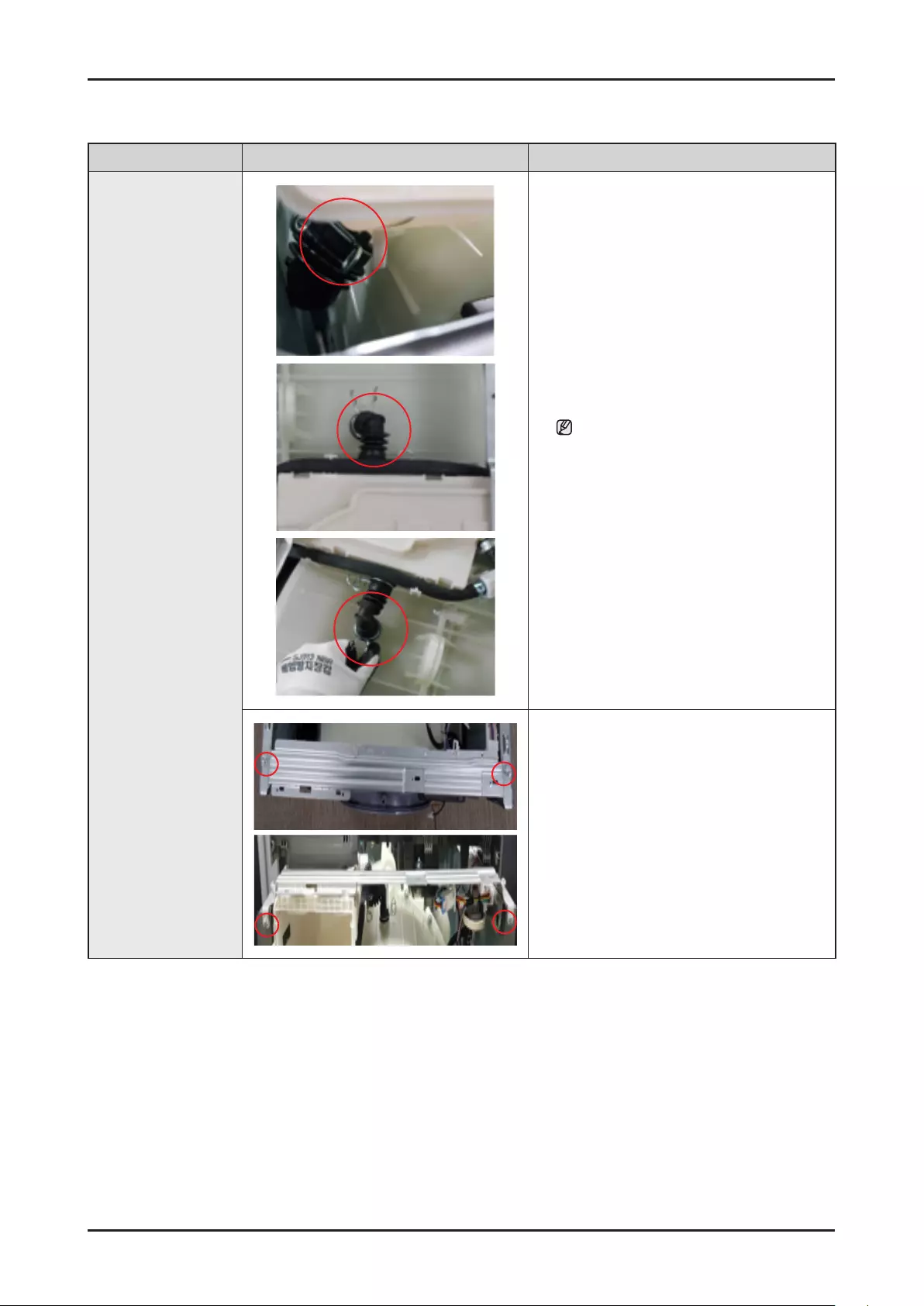

1. PulltoopentheDrawerbyhand.

2. Whileholdingdownthereleaseleverinsidethe

drawer(redbox),slideopenthedrawer.

3. DisassembletheCoverDrawerbyhand.

4. PulluptheCapRinsetoremoveit.

Disassembly and Reassembly _ 11

Reassembly

Part Figure Description

Assy Drawer

(Auto Dispense)

1. FittheholeandpresstheCapRinsesothatit

canbeassembled.

2. AssembletheCoverDrawerbyhand.

3. Makesuretottherailwhenreassemblingthe

Assydrawer.

4. Placethedrawerintherightdirection.

12 _ Disassembly and Reassembly

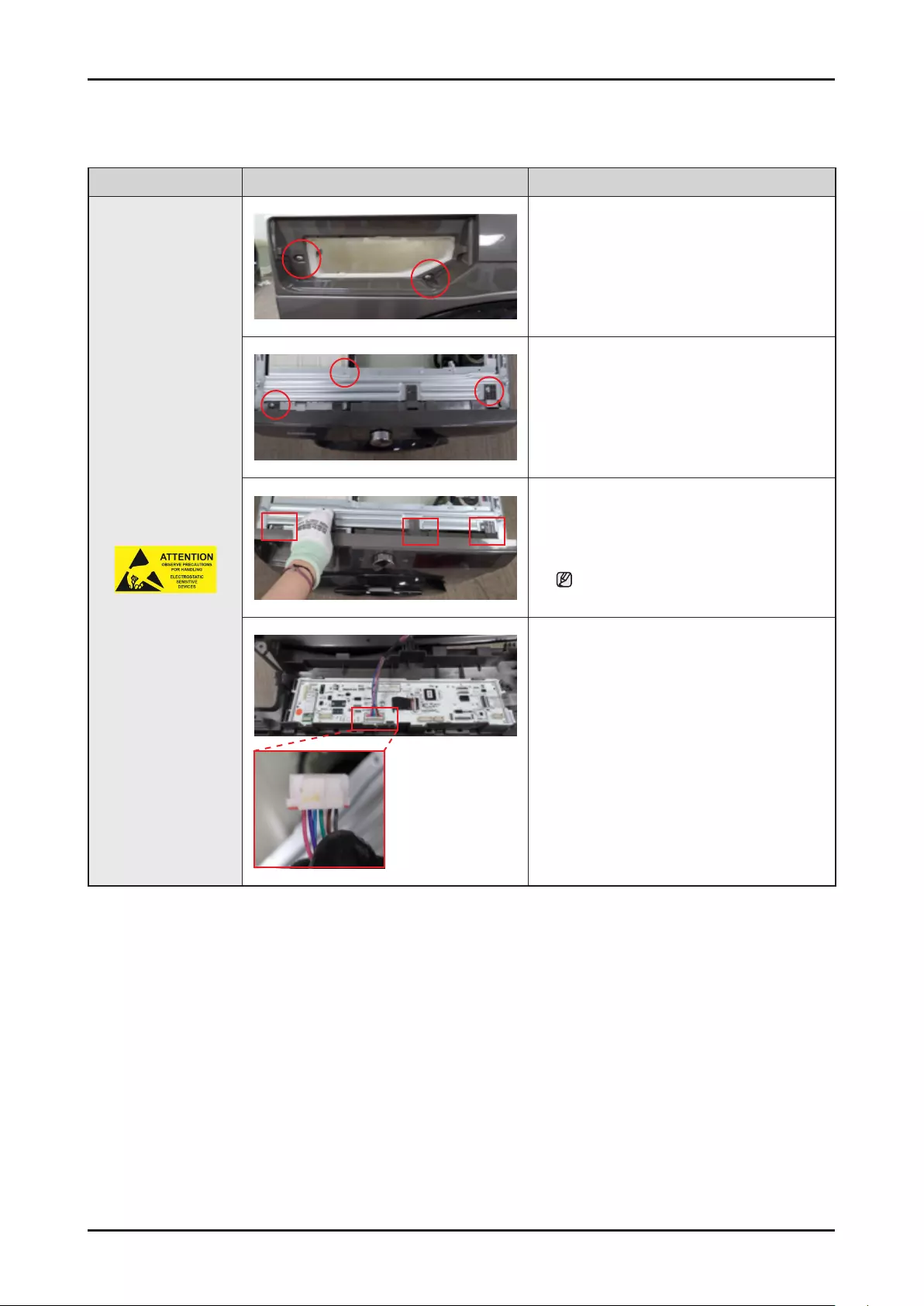

Disassembly

Part Figure Description

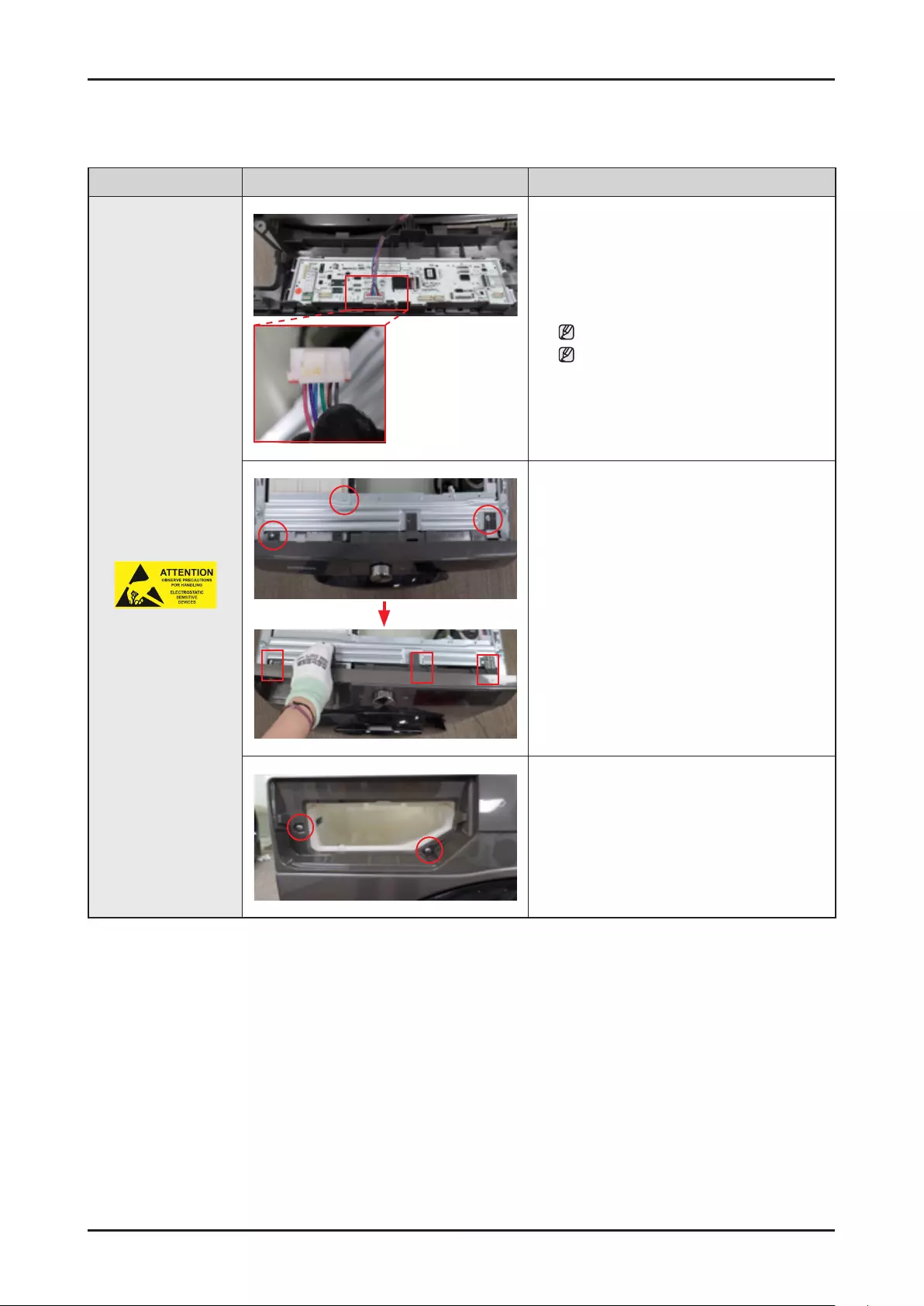

Assy Panel Control

(Simple)

-Beforeyoustart,disassembleAssyCoverTop,Assy

Drawer.

1. Remove2screwsholdingthedrawerandpanel

using(+)screwdriver.

2. RemovethescrewsatthetopoftheASSY-

PANELCONTROLusing(+)screwdriver.(3ea)

3. Grabthepanelandslightlypushthehousing

drawertoremovethehookandpullthepanel

upwardstodisassemblewithbody

Becarefulnottobreakthehook.

4. HoldtheASSY-PANELCONTROLwhilepulling

itupwardsanddisassembletheterminalto

removeit.Pressthehookwhileremovingthe

terminal.

Disassembly and Reassembly _ 13

Reassembly

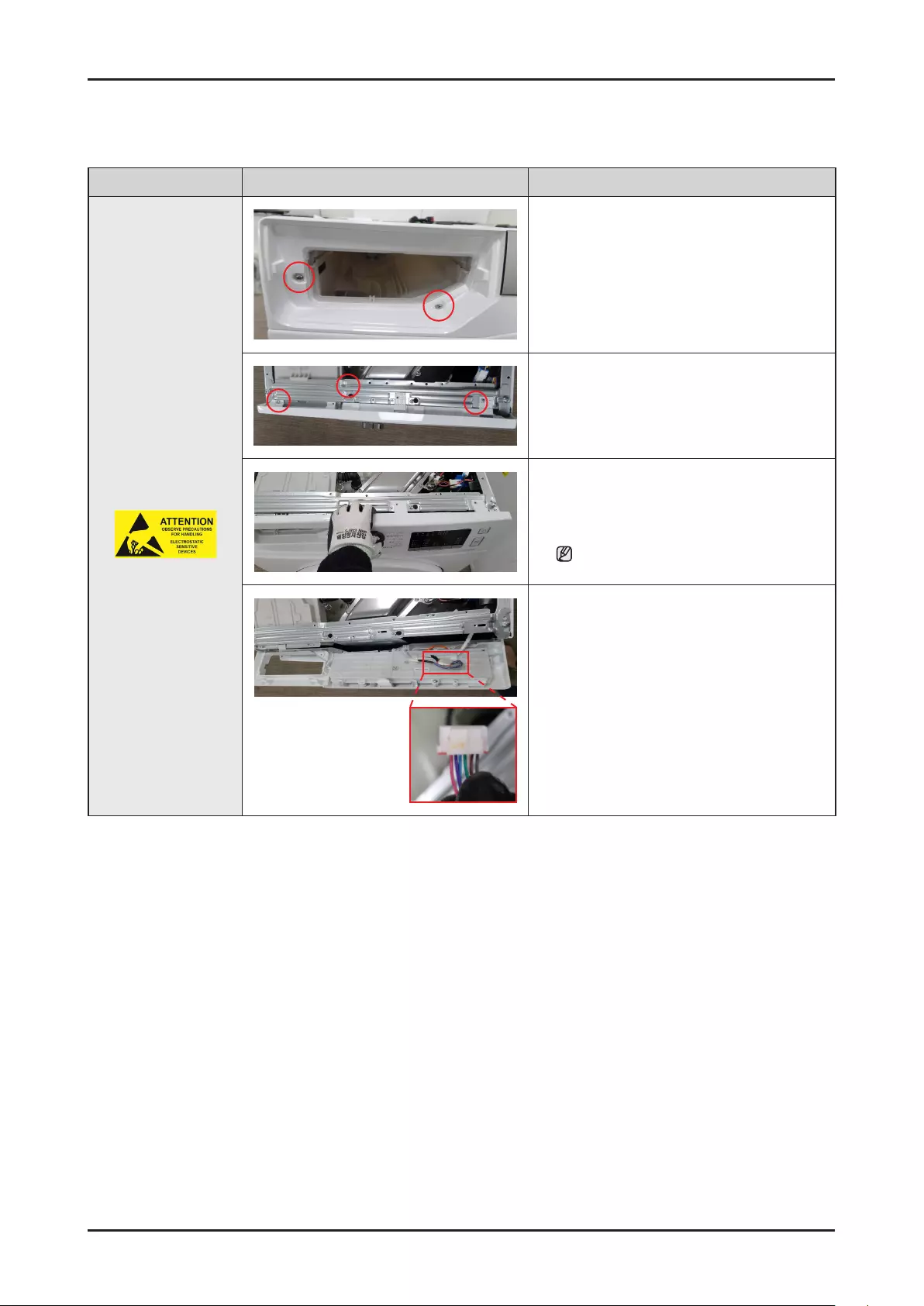

Part Figure Description

Assy Panel Control

(Simple)

1. Connecttheterminalbyhand.Takealookat

thehookandputitintherightplace.

Becarefulnottobreakthehook.

MakesuretheWireharnessarenotgetting

stuckinotherparts.

2. Assemblethehookofhousingdrawerand

aseemblescrewsatthetopoftheASSY-PANEL

CONTROLwith(+)screwdriver.

3. Assemble2screwsholdingthedrawerand

panelwith(+)screwdriver.

14 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Assy Panel Control

(LED)

-Beforeyoustart,disassembleAssyCoverTop,Assy

Drawer.

1. Remove2screwsholdingthedrawerandpanel

using(+)screwdriver.

2. RemovethescrewsatthetopoftheASSY-

PANELCONTROLusing(+)screwdriver.(3ea)

3. Grabthepanelandslightlypushthehousing

drawertoremovethehookandpullthepanel

upwardstodisassemblewithbody.

Becarefulnottobreakthehook.

4. HoldtheASSY-PANELCONTROLwhilepulling

itupwardsanddisassembletheterminalto

removeit.Pressthehookwhileremovingthe

terminal.

Disassembly and Reassembly _ 15

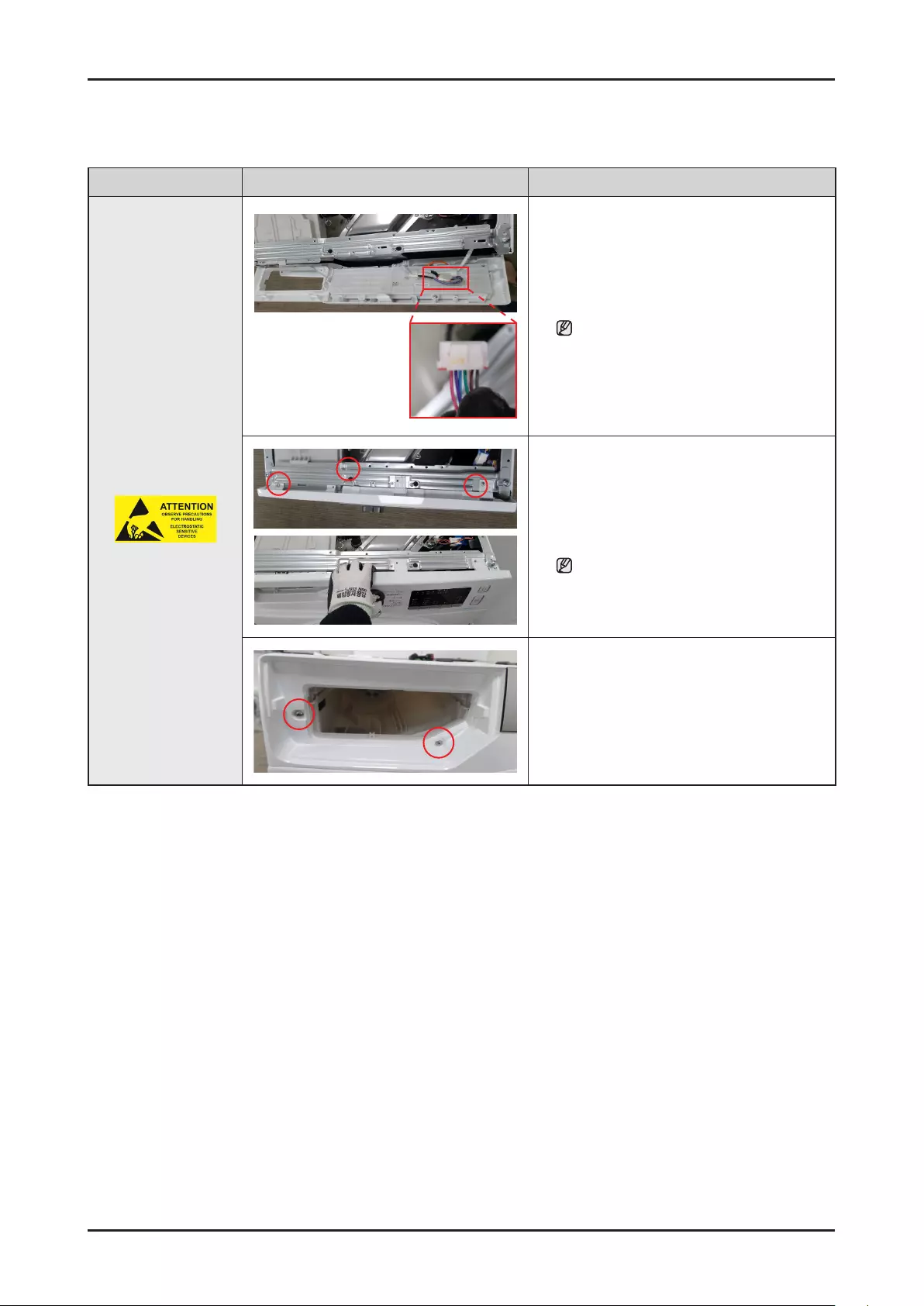

Reassembly

Part Figure Description

Assy Panel Control

(LED)

1. Connecttheterminalbyhand.Takealookat

thehookandputitintherightplace.

MakesuretheWireharnessarenotgetting

stuckinotherparts.

2. Assemblethehookofhousingdrawerand

aseemblescrewsatthetopoftheASSY-PANEL

CONTROLwith(+)screwdriver.

Becarefulnottobreakthehook.

3. Assemble2screwsholdingthedrawerand

panelwith(+)screwdriver.

16 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Assy Housing-Drawer

Beforeyoustart,disassembleAssyCoverTop,Assy

PanelControl.

1. Remove4screwstodisassembleframeplate-

upusing(+)screwdriver.

2. RemovetheBand-ring.(2ea)

Becarefulnottobreakthehose.

Disassembly and Reassembly _ 17

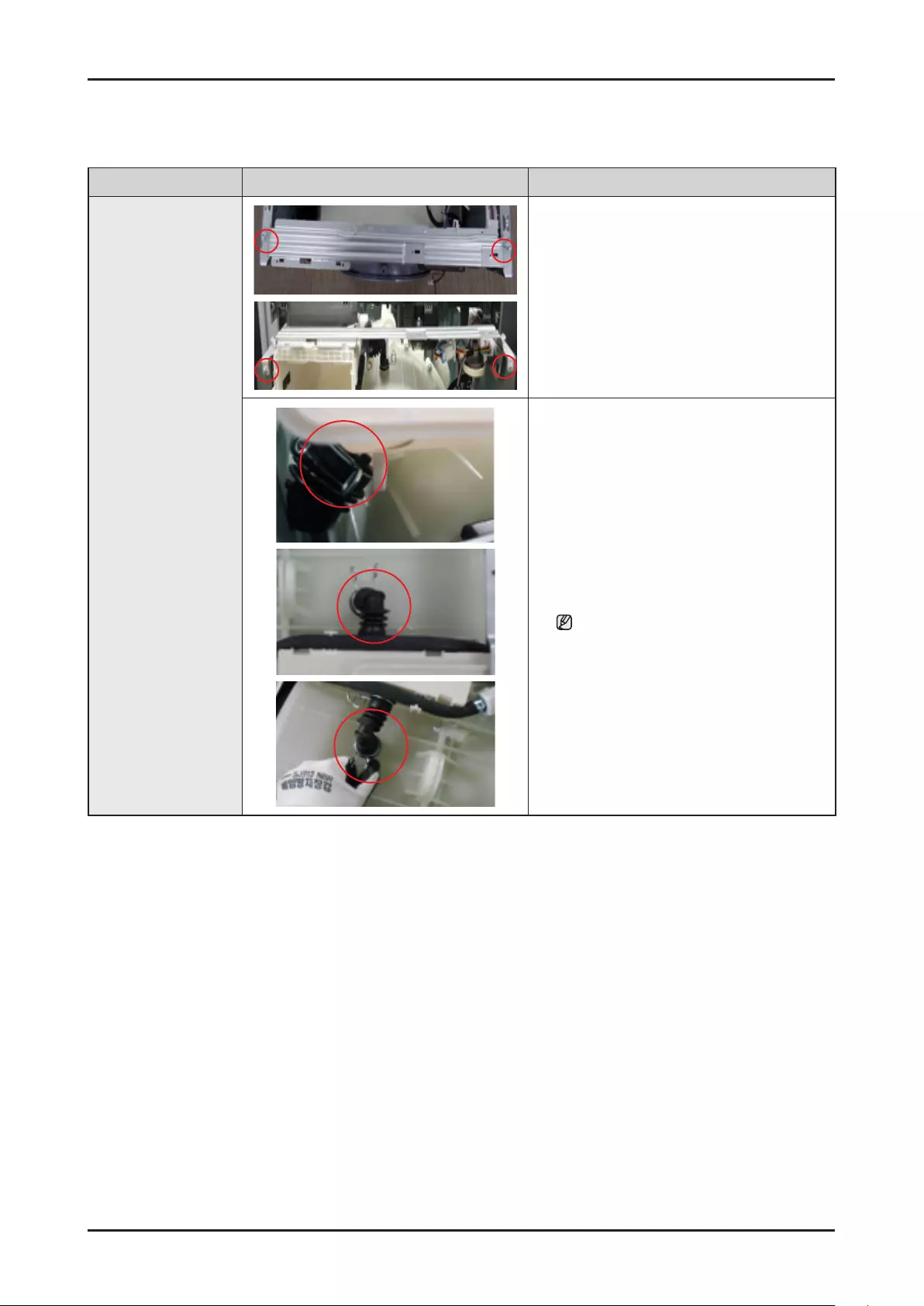

Part Figure Description

Assy Housing-Drawer

3. Separatethewatervalvehosewithlongnose

plier.

4. SeparateHousingDrawerlowbypressingthe

hooksonbothsidesbyhand.Tofullyseparate,

disassembleWaterValve.

Becarefulnottobreakthehook.

18 _ Disassembly and Reassembly

Part Figure Description

Assy Housing Drawer

(Auto Dispense)

1. Disassemblethe6screwsholdingthepump

with(+)screwdriver.

Tofullyseparate,disassembleWaterValve.

2. SeparateHousingDrawerlowbypressingthe

hooksonbothsidesbyhand.

Tofullyseparate,disassembleWaterValve.

Disassembly and Reassembly _ 19

Part Figure Description

Assy Housing Drawer

(Auto Dispense)

1. AssembletheHousingDrawerlowbypressing

thehooksonbothsidesbyhand.

2. Assemblethe6screwsholdingthepumpwith

(+)screwdriver.

20 _ Disassembly and Reassembly

Reassembly

Part Figure Description

Assy Housing-Drawer

1. AssembletheHousingDrawerlowbypressing

thehooksonbothsidesbyhand.

Becarefulnottobreakthehose.

2. Assemblethewatervalvehosewithlongnose

plier.

Becarefulnottobreakthehook.

Makesuretoinsertthehosesandassemble

theclamp,bandringscorrectly.There’re

risksofleakageorpoorperformancewhen

it’smisassembled.

Disassembly and Reassembly _ 21

Part Figure Description

Assy Housing-Drawer

3. AssembletheBandrings.(2ea)

Makesuretoinsertthehosesandassemble

theclamp,bandringscorrectly.There’re

risksofleakageorpoorperformancewhen

it’smisassembled.

4. Remove4screwstodisassembleframeplate-

upusing(+)screwdriver.

22 _ Disassembly and Reassembly

Disassembly

Part Figure Description

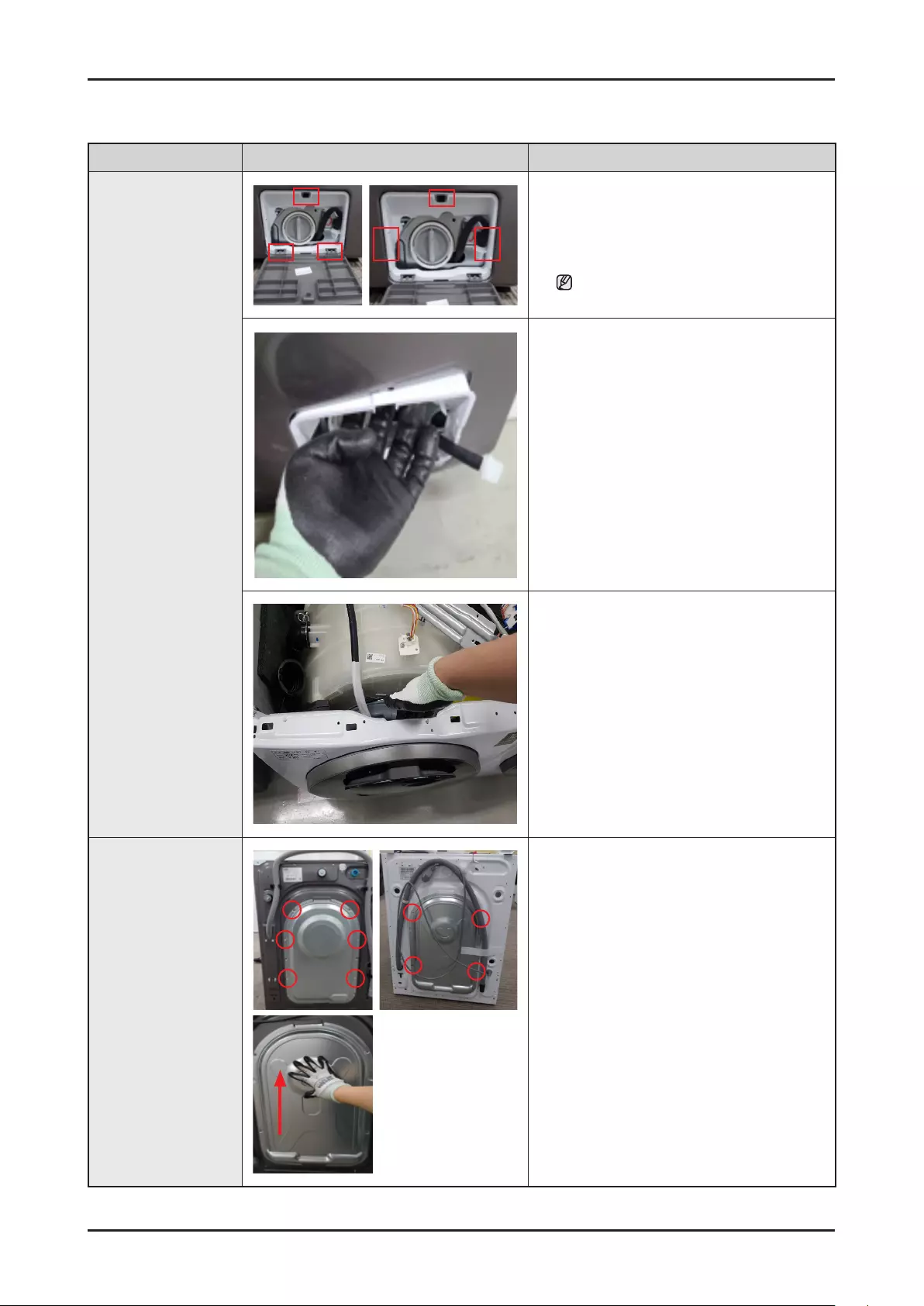

Frame Front

Beforeyoustart,disassembleAssyCoverTop,Assy

PanelControl.

Becarefulnottotearupthediaphragm.

1. Usinglongnosepliers,pickuponeofthe

ringsonWire-Diaphragmwhichconnectthe

springandthewireends.Then,separatethe

Wire-DiaphragmfromtheFRAME-FRONTand

DisconnecttheDiaphragm.

2. Remove2screwsholdingtheDOOR-LOCK

switchwith(+)screwdriver.

3. Disassembletheterminal(theblueboxis

terminallocation)bypressingthebluecircle

partandremove2screwsholdingtheFrame

Frontwith(+)screwdriver.

4. Pressthecircledplacetoopenupthecover

lter.

5. Remove3screwsholdingthebottomofthe

FRAME-FRONTwith(+)screwdriver.

Disassembly and Reassembly _ 23

Part Figure Description

Frame Front

6. Removecoverlterbyhand.

7. PressthehooktoremoveGuidecoverlter

using(-)screwdriver.

Becarefulnottobreakthehook.

8. PulltheGuideltertowardsyou.

9. LiftFramefrontuptodisassemble.

Cover-Back

Unfasten6(Dependingonthemodel,therecanbe

4screws)screwsthatholdthecoverbackinplace

with(+)screwdriver.

Removethebackcoverbyslidingitup.

(Whenassembling,slidethebackcoverdown.)

24 _ Disassembly and Reassembly

Disassembly

Part Figure Description

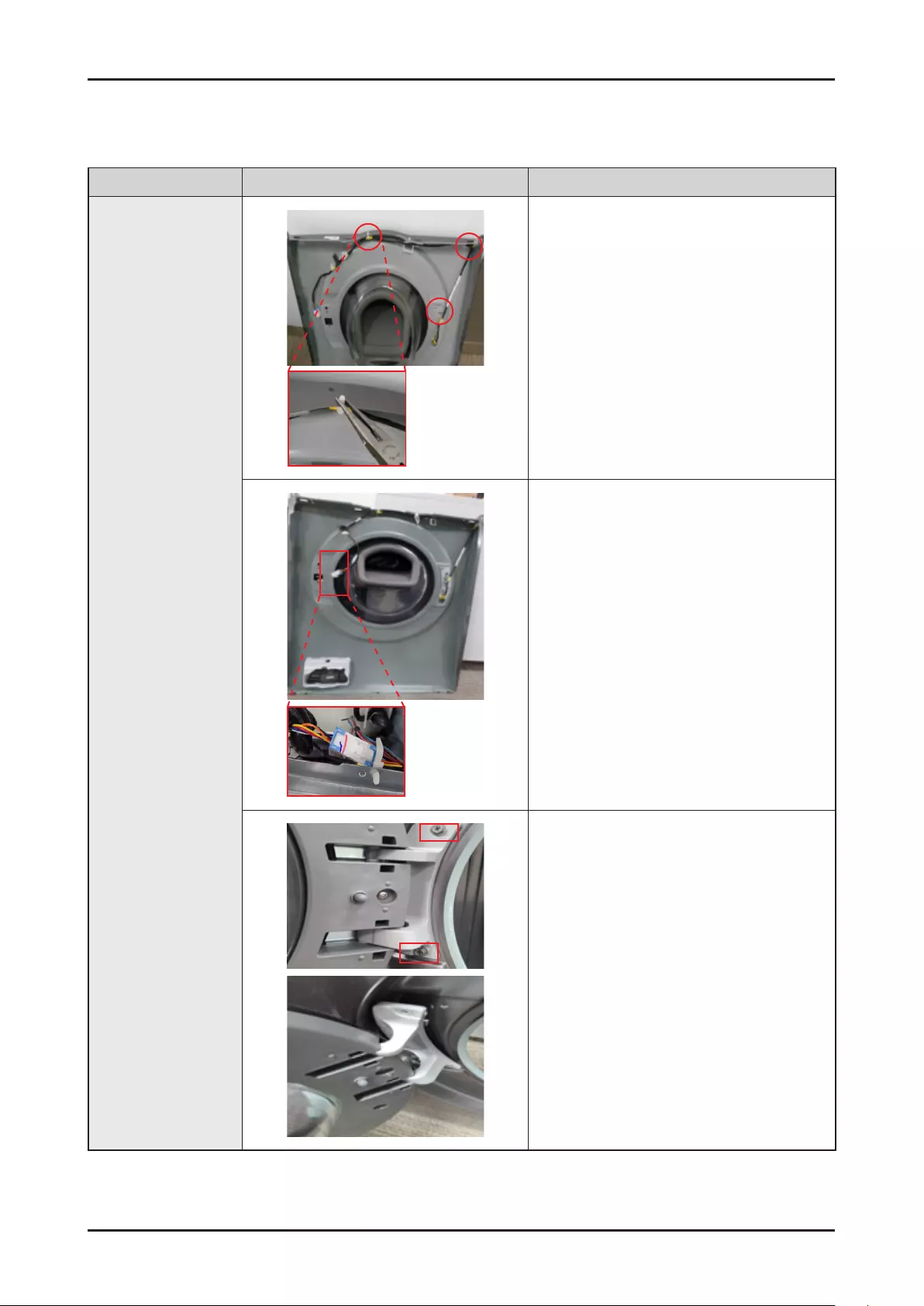

Assy Door

Beforeyoustart,disassembleAssyCoverTop,Assy

PanelControlandFrameFront.

1. Removethewirebydisassemblingthe3hooks

usinglongnoseplier.

2. Disassembletheterminalandremovethe

holdersusinglongnosepliers.

3. Remove2screwsholdingtheAssydoor.

Removethedoorbyslightlyliftingthedoor.

Disassembly and Reassembly _ 25

Reassembly

Part Figure Description

Assy Door

BACK SIDE FRONT SIDE

1. Puttheterminalthroughthebiggestholeand

assemble3hooksasshowninthepictures.

2. AssemblethedoorwithFrameFrontbytting

thetwohooksandassemble2screwsholding

theAssydoorwith(+)screwdriver.

3. Assemble3hooksusinghand.

4. Assembletheterminalandtheholders.

MakesuretheWireharnessarenotgetting

stuckinotherparts.

26 _ Disassembly and Reassembly

Disassembly

Part Figure Description

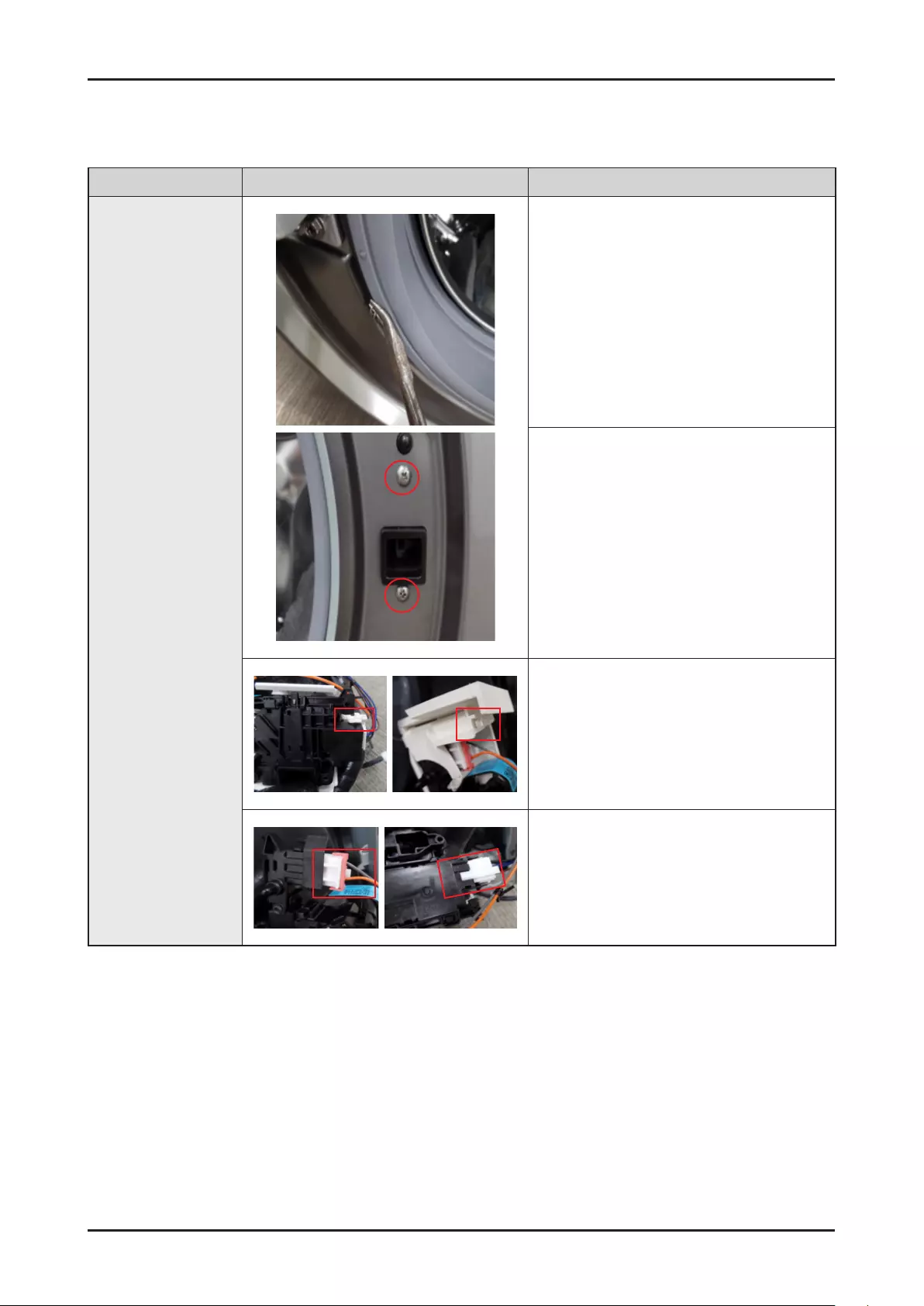

Door-Lock S/W

Beforeyoustart,disassembleAssyCoverTopand

AssyPanelControl.

1. OpentheDoor.RemovetheWireDiaphragm

andremovetheFrameFront.

2. Remove2screwswith(+)screwdriver.

3. RemoveCoverDoorSwitchbygentlypushing

theredboxpartwith(-)screwdriver.

4. Disassembletheterminals.(2ea)

Disassembly and Reassembly _ 27

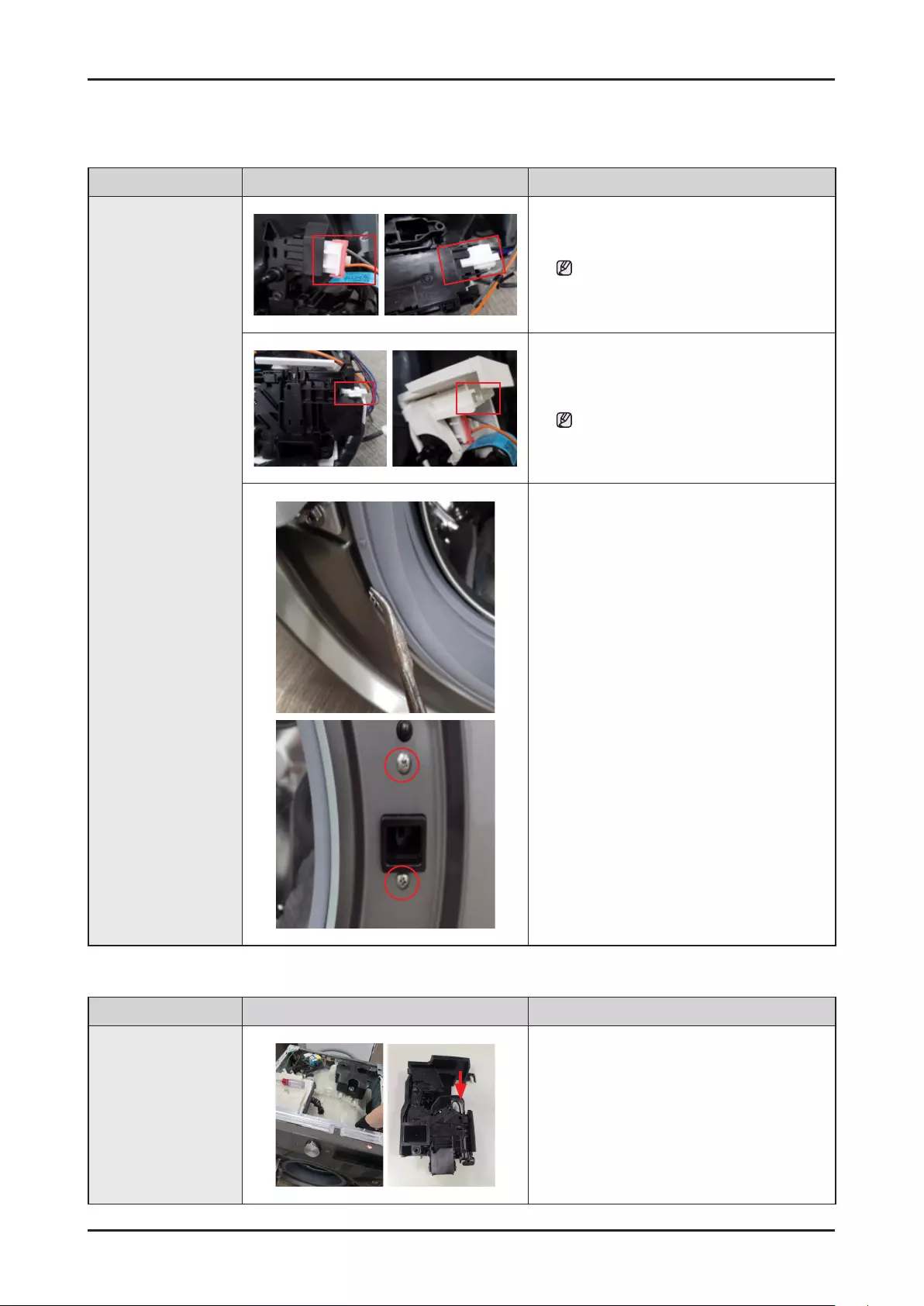

Reassembly

Part Figure Description

Door-Lock S/W

1. Assembletheterminals.(2ea)

MakesuretheWireharnessarenotgetting

stuckinotherparts.

2. AssembletheCoverDoorSwitchbygently

pushingtheredboxpartwithhand.

MakesuretheWireharnessarenotgetting

stuckinotherparts.

3. Assemblethescrewswith(+)screwdriver.(2ea)

4. AssemblethewirediaphragmandFrameFront.

Ifthewirediaphragmislooseafterassembly

orisnotcorrectlyassembledatthecorrect

position(5o'clockor7o'clock),waterleakage

may occur.

How to force open the locked Door

Part Figure Description

Door-Lock S/W

Beforeyoustart,disassembleCoverToprst

1. PutyourhandtopresstheDoor-LockSwitch.

(Thelocationyouneedtopressisshowninthe

picturewitharrow)

28 _ Disassembly and Reassembly

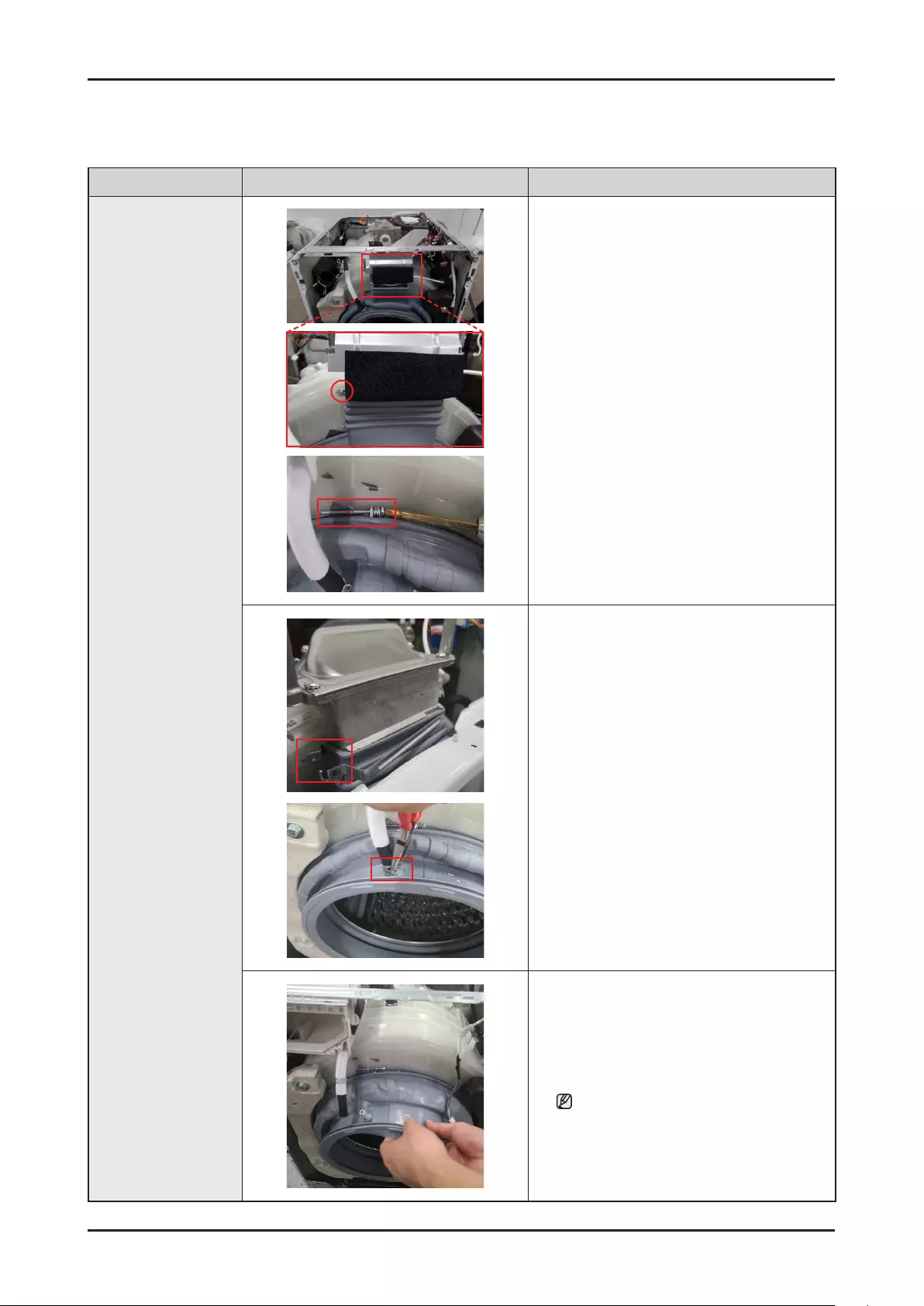

Disassembly

Part Figure Description

Diaphragm

Beforeyoustart,removecovertop,AssyDrawer,

AssyPanelControlandFrameFront.

1. Unfastenthescrewwith(+)screwdriveron

JointDiaphragmandwirediaphragm.

2. RemoveJointDiaphragmbyhand.

3. Removehoseandclampwithlongnoseplier.

4. Pulldiaphragmtowardsyou.

Becarefulnottoripdiaphragm.

Disassembly and Reassembly _ 29

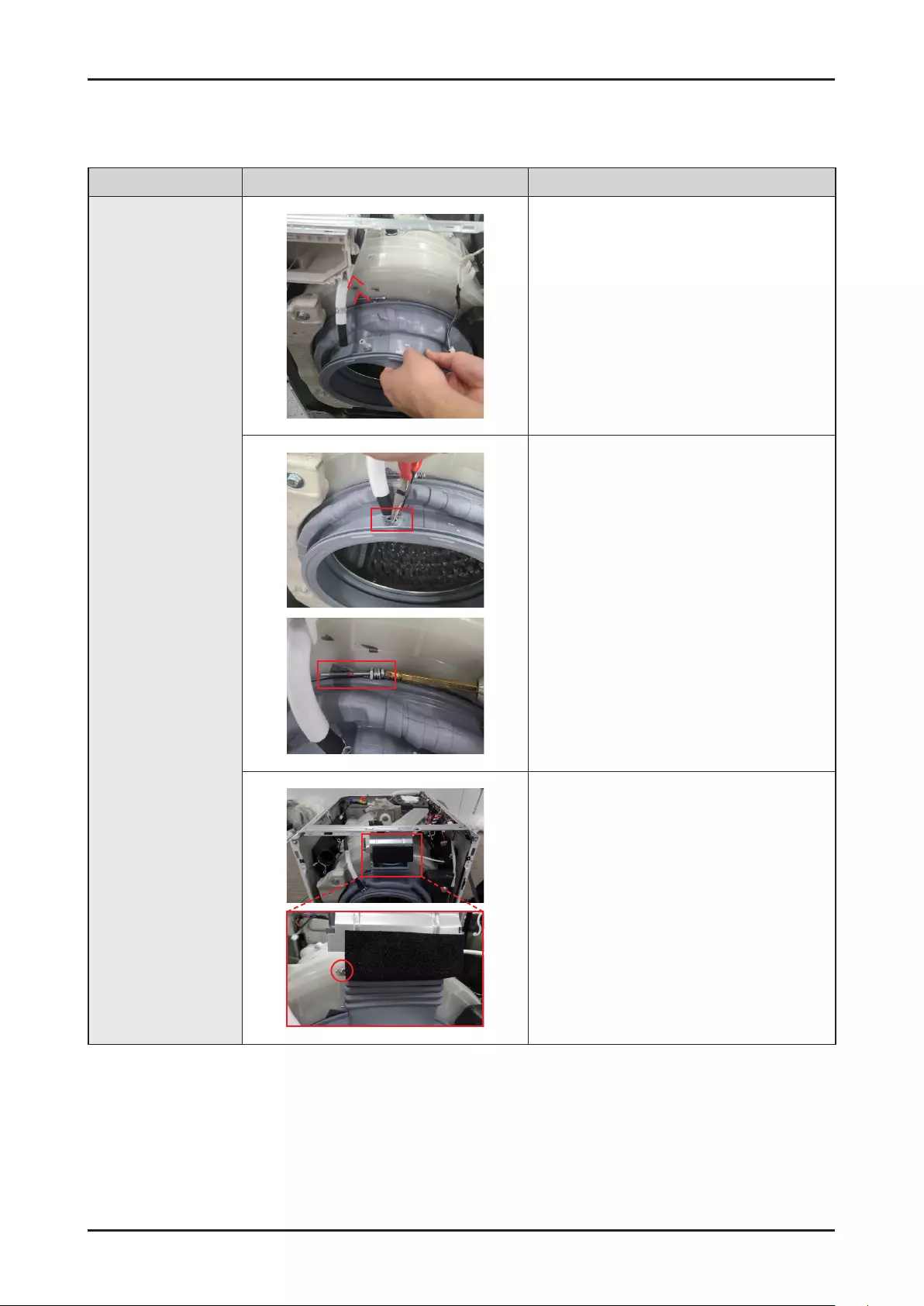

Reassembly

Part Figure Description

Diaphragm

1. AssembletheDiaphragmwithtubbyhand.

Diaphragmandtubhastrianglepartmakesure

totthemcorrectly.

2. Assemblehoseandclampwithlongnoseplier,

andfastenthescrewwith(+)screwdriver.

3. AssembleJointdiaphragmandfastenthescrew

with(+)screwdriver.

30 _ Troubleshooting

4. TROUBLESHOOTING

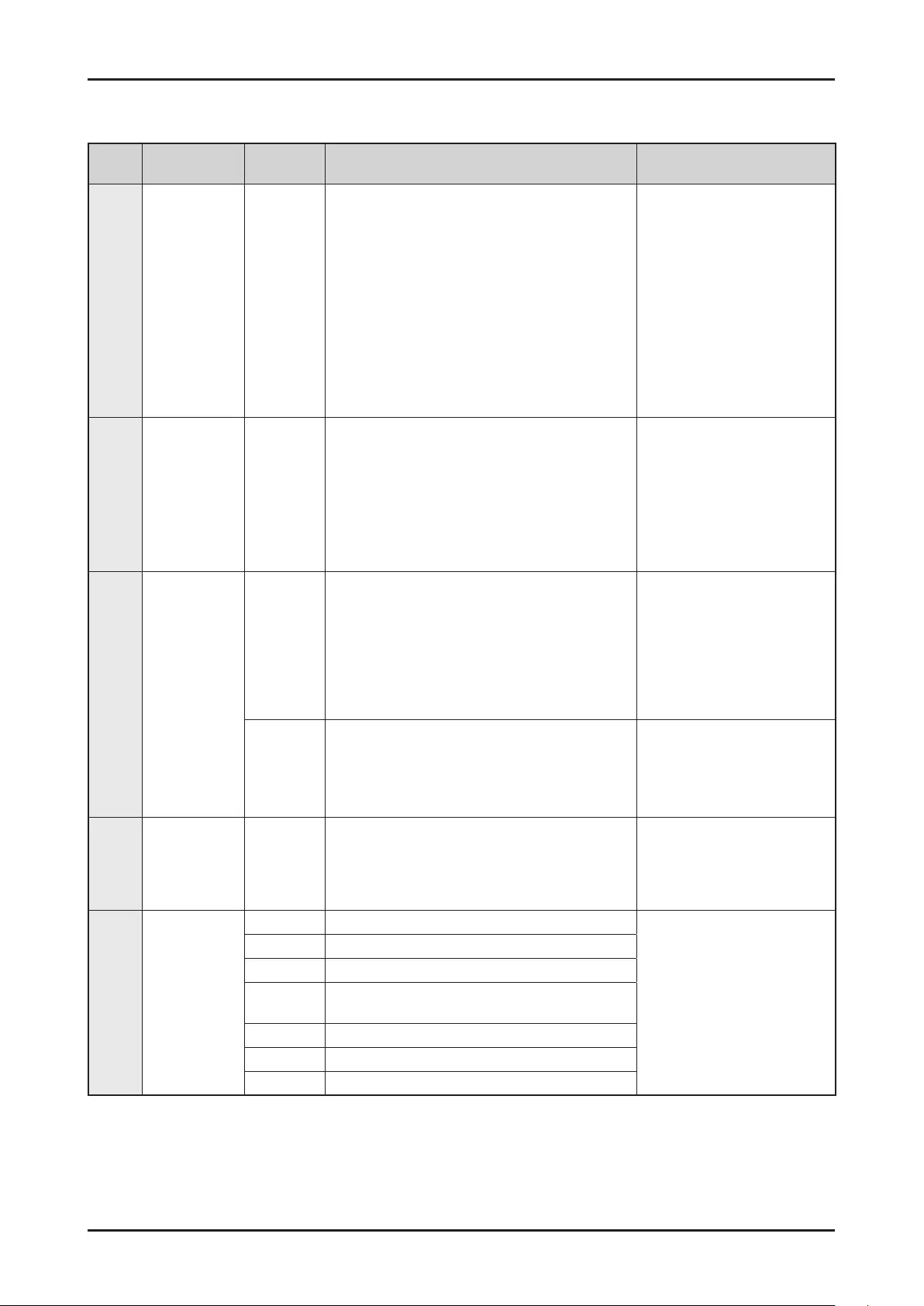

4-1. INFORMATION CODE

► When an abnormal condition occurs, melody sounds and displays Info. code indications as shown in the following Info. codes

are shown until the status has cleared.

No. Information Type Information

Code Causes Corrective Actions

1WaterLevel 1C

- Thepartofthehosewherethewaterlevelsensoris

locatedisdamaged(punctured).

- Thehoseiscloggedwithforeignmaterial.

- Thehoseisfolded.

- Toomuchlubricanthasbeenappliedtotheinsertion

partoftheairhose.

- Hoseengagementerror(disengaged)

- Partfault(Faultyinternalsoldering)

- Thewaterlevelsensorterminalisdisengaged.

- MainPBAfault

•Waterlevelsensorfault.

•Thewaterlevelsensorterminalis

disengaged.

•Thepartofthehosewherethe

waterlevelsensorfolded.

•MainPCBfault.

2Motor

3C

- ThePBAconnectorterminalisnotconnected.

- Themotorspinnetisnotengaged.

- Themotor’sinternalcoilisdamaged(short-circuited

orcut)

- Foreignmaterial(ascrew)hasenteredthemotor.

•Washingmotorfault.

•CheckWashingmotorconnector.

•Washingmotorrotor/statorfault.

•MainPCBfault.

3C1

- Motoroverloadedduetotoomuchlaundry(Non

sensing)

- PBAfault

3C2 - ThemotordrivingerrorfromthePBAisweak:

Unstablerelayoperation,etc.

3C3 - TheIPMterminalofthemainPBAisnotconnected.

- TheDDmotorcoverisoutofplace.

3C4

- ThePCBhousingterminalisnotconnected.

- PBAfault

- DDmotorfault

3WaterSupply

4C

- Foreignmaterialisenteringthewatersupplyvalve.

- Thewatersupplyvalveterminalisnotconnected.

(Wiredisconnected)

- Thewarmwaterandrinseconnectorsarewrongly

connectedtoeachother.

- ThisoccursifthePCBterminalfromthedrainhoseto

thedetergentdrawerisnotconnected.Checkwhether

thetransparenthoseisfoldedortorn.

- ThisoccursWaterpressureisweak,acertaintime

delay.

- ThisoccursWaterValvebyfreezinginwinterseason.

•Watersupplyvalvefault.

•MainPCBfault.

•Freezingbywinterseason.

4C2 - Thewatertemperatureissensedashigherthan50˚C

intheWoolorLingeriecourses -

4Drain 5C

- Thepumpmotorimpellerisdamagedinternally.

- Thewrongvoltage(220V→110V)issuppliedtothe

parts.

- Partfault

- Thisoccursduetofreezinginthewinterseason.

- Thedrainhoseisclogged.(Injectionerror,foreign

material)

- Cloggedwithforeignmaterial.

- Thewaterpumpterminalisnotconnected:rubber

band,bills,cotton,hairpins,coins.

•Drainpumpfault.

•Freezingbywinterseason.

•Checkinsideforeignmaterialof

drainpump.

•MainPCBfault.

Troubleshooting _ 31

No. Information Type Information

Code Causes Corrective Actions

5Communication AC

- ThesignalsbetweenthesubandmainPBAsarenot

sensedbecauseofacommunicationserror.

- Checktheconnectorconnectionsbetweenthesub

andmainPBAscarefully.→Checkforincorrector

looseconnections,etc.

- RemovethesubPBAC/Panelandcheckforanyfaulty

soldering.

•MainPCBandSubPCBSignal

Detectionfault.

•MainPCBandSubPCBwire

connectionfault.

6SWITCH

(Mainrelay) BC2

- AbuttonotherthanthePowerbuttoniscontinually

pressed(formorethan30seconds).

- Deformationofaninternalplasticinjectionpart.

- AscrewforassemblingthesubPBAistightenedtoo

much.

•WhenpressedPowerbutton.

•Whenpressedbuttonexceptfor

powerbutton.

•MainPCBrelayfault.

7COOLING CC

- Whenthetemperatureofthewaterisgreaterthanor

equalto55℃,thiscodeappearswhenthemachine

doesnotdrain.(reason:Itisunsafeforhotwaterto

drainasmayburniftouched).

- Temperaturesensorfault,orincorrectuse.

•Washingtemperaturesensor

check.

•DescriptionPLAccident

prevention.

8DOOR

dC

- Aswitchcontacterrorbecauseofadeformationofthe

doorhook.

- Whenthedoorispulledbyforce.

- Thisoccursinthehotwashesbecausethedooris

pushedduetoapressuredifferencefrominternal

temperaturechanges.

- S/WcontactfaultbecauseofLIDTC“L”transformation. •Doorlockswitchfault.

•Drainpumpfault.

•Dryductfanmotorfault.

•MainPCBfault.

dC1

- Thedoorlockswitchterminalisconnectedincorrectly.

- Thedoorlockswitchterminalisbroken.

- ThisoccursduetoLowinsualtionofthewiringassy

- MainPCBfault

dC2

- ThisoccursifthePowerswitchisturnedon/off

continuallyandtoomuchheatisgenerated(Thiserror

isdifculttobereproduced.)

9HEATER

HC - Thewashingheaterisshort-circuitedorhasawire

disconnected.

- Thewashingheaterinthetubhasanerror.(Contact

error,temperaturesensorfault)

- Ifthewaterlevelsensoroperateswithoutwater

becausewaterisfrozenorforanyotherreasonand

thetemperaturesensorengagedatthebottomto

preventoverheatingforthewashingheaterdetects

atemperatureof100to150˚C,thewashingmachine

turnstheinputpoweroff.

•Heaterfault.

•Redtemperaturesensoratthe

centerofthedryheater.

•Steamfunctionfault.

•Freezingbywinterseason.

HC1

HC2

- Thiserroroccurswhentheredtemperaturesensorat

thecenterofthedryheateroperates(atatemperature

higherthan145˚C)

:Correctiveaction–Pressthebuttonatthecenter

lightly.

Thewashingmachinewilloperatenormally.

Alternatively,replacethetemperaturesensorifthe

temperaturesensingisunstablebecauseoffunctional

degradation.

32 _ Troubleshooting

No. Information Type Information

Code Causes Corrective Actions

10 WaterLeakage LC

LC1

- Heaterengagementfault.(outofplace)

- Theairhoseisoutofplaceandwaterleakageoccurs

duringthespincycle.

- Thetubbackatthesafetyboltsxingpartisbroken.

- Waterleakageoccursatthefrontwithfoaming

becauseoftoomuchdetergent.

- Waterleakageoccursbecausetheconnectinghoseto

thedetergentdrawerisconnectedincorrectly.

- Thedrainpumpltercoverisengagedincorrectly.

- Waterleakageoccursatthedrainhose.

- Theductcondensingholdingscrewsareworn.

- Thenozzle-diaphragmisengagedintheopposite

directionortherubberpackagingisomitted.

- Waterleakageoccursbecausethescrewsthat

holdthetubbackandfrontinplacearefastened

incorrectly.

- Theleakagesensorisfaulty.

•CheckWaterLeakage.

•DVCASEforeignmaterialoccurs.

•Leakageoftheproductinsidethe

hoseandpartsmoldedproblem.

11 OVER FLOW OC

OF

- Waterissuppliedcontinuallybecausethewaterlevel

detectiondoesnotwork.

- Becausethedrainhoseiscloggedandthereisan

injectionerror(atanarrowsection),thewaterlevel

detectiondoesnotworkandwaterissupplied

continually.

- Waterissuppliedcontinuallybecauseoffreezingor

becausethereisforeignmaterialinthewatersupply

valve.

- Thismayoccurwhenthesensorisfaultyorthe

pressuretubeisblockedordamaged.

•Waterlevelsensorfault.

•Freezingbywinterseason.

12 Temperature

Sensor

TC1

- Thewashingheaterinthetubhasanerror.

(Contacterror,temperaturesensorfault)

- Theconnectorisconnectedincorrectlyoris

disconnected.

- Ifthewaterlevelsensoroperateswithoutwater

becausethewaterisfrozenorforanyotherreason

andthetemperaturesensorengagedatthebottom

topreventoverheatingforthewashingheaterdetects

atemperatureof100to150˚C,thewashingmachine

turnstheinputpoweroff.

•Washingtemperaturesensor

check.

•Drytemperaturesensorcheck

•Drycondensingtemperature

sensorcheck.

•ProblemscausedbythemainPCB

fault.

•Problemscausedbythefreezing

inwinter.

TC2

- Thetemperaturesensorfortheductassyfanhousing

isfaulty.(Asensorfaultsuchasaninternalshort-

circuitorwiredisconnection)

- Theconnectorisoutofplaceorhasacontacterror.

TC3

- Thisoccurswhentheductcondensingtemperature

sensor is open.

- Thisoccurswhentheductcondensingtemperature

sensorhasawiredisconnectedorisshort-circuited.

13 UNBALANCE UB

- Aslaundrycausesthiserror,checkthelaundry.

- Findthereasonfortheunbalanceandsolveitas

directedintheusermanual.

•Thisoccursbylaundry.

Troubleshooting _ 33

No. Information Type Information

Code Causes Corrective Actions

14 Power UC

(9C)

- Powerconditionfault.

- Thisoccurswhenunderorovervoltageissupplied.

- Extensionleadorplugadapterisbeingused.

- MainPBAfault(sometimes)

•Checkthepowersupply,

polarityandvoltage.

•Selectahotwashordrycycle

(wdonly),measurethevoltage

suppliedduringheating.(Aerror

occurswhenundervoltageis

detected.)

*Safetyensuresafeworking

practicesobservedwhentesting

liveappliance.

•Checkifasocketoutletadaptoris

beingused.

•MainPCBfault(sometimes)

15 Mems PBA 8C - ErrordetectedintheMemsPBAordataerror

detected.

•Checkthewireconnections.

Replaceifnecessary.

1.Checkthewireconnections.

2.ReplacetheMemsPBA.

3.MainPBAwireconnection

errororPBA’ssilvernanopart

malfunction.

Replaceifnecessary.

16 AddDoor

DDC

- AswitchcontacterrorbecauseofdamagetotheAdd

Doorswitch.

- Whentheadddoorispulledbyforce.

- Thisoccursinthehotwashbecausetheadddooris

pushedduetoapressuredifferencefrominternal

temperaturechanges.

- S/WcontactfaultbecauseofLIDTC“L”

transformation.

•Adddooropen/closeswitchfault.

•MainPCBfault.

DC3

- TheAddDoorlockswitchterminalisconnected

incorrectly.

- TheAddDoorlockswitchterminalisbroken.

- ThisoccursduetoLowinsualtionofthewiringassy.

- MainPCBfault.

•Adddoorlockswitchfault.

•MainPCBfault.

17 Detergent

DrawerMotor 6C

- Autodetergentdispensemotorconstrain

- Autodetergentdispensemotorwiring

- Autodetergentdispensemotornotoperate

•Checkmotoroperationby

pressingthelaundrywhenyou

enterautodetergentdispenser.

•IfnotoperationchangeASSY

PUMP DRAIN.

18 Auto Dispense

6C1 - Theinputarrestofthedetergentmotorissensed.

Checkthewireandifnecessary

replaceit.

1.CheckWireconnection

2.ReplaceAssyPump

6C2 - Thenon-operationofthedetergentmotorissensed.

6C3 - Theinputarrestofthefabricsoftenermotorissensed.

6C4 - Thenon-operationofthefabricsoftenermotoris

sensed.

6C5 - Themotormotionperceptionsensorfault

6C6 - Thedetergentlevelperceptionsensorfault

6C7 - Thefabricsoftenerlevelperceptionsensorfault

34 _ Troubleshooting

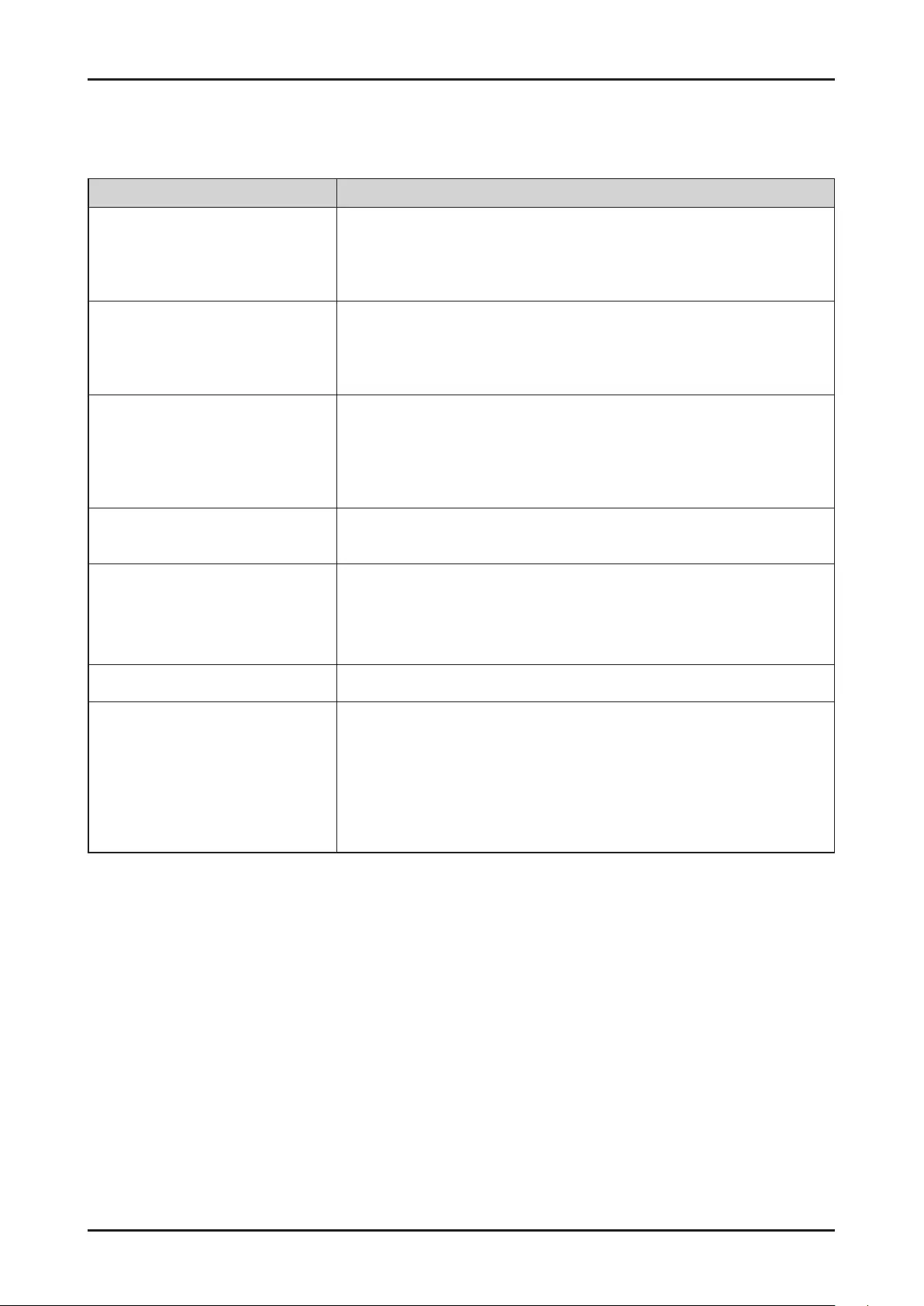

PROBLEM SOLUTION

Thewashingmachinewon’tstart.

•Makesurethewashingmachineispluggedin.

•Makesurethedoorisproperlyclosed.

•Makesurethewatertapisopen.

•TapStartorPressStart/Pausebuttonagain.

Watersupplyisinsufcient,ornowater

issupplied.

•Openthewatertapfully.

•Makesurethewatersupplyhoseisnotfrozen.

•Makesurethewatersupplyhoseisnotkinkedorclogged.

•Cleanthelteronthewatersupplyhose.

Thewashingmachinevibratesbadly,or

makesnoise.

•Makesurethewashingmachineisinstalledonaleveloor.Iftheoorisnot

level,usethelevelingfeettoadjustthelevel.

•Makesurethattheshippingboltsareremoved.

•Makesurethewashingmachineisnottouchinganyotherobject.

•Makesurethelaundryloadisbalanced.

Thewashingmachinedoesnotdrain

and/orspin.

•Makesurethedrainhoseisstraightenedallthewaytothedrainsystem.

•Makesurethedebrislterisnotclogged.

Thedoorwon’topen.

•PresstheStart/Pausebuttontostopthewashingmachine.

•Thedoorstayslockedaslongasthewashingmachineisstillhotinside

afteraheatingoperation.

•Itmaytakeseveralsecondstodisengagethedoorlockmechanism.

ButtonCheck •bCoccurs.ReferthebCtroubleshooting.

CanIopentheAddDoor

at any time?

•TheAddDoorcanbeopenedonlywhentheindicatorappears.

However,itdoesnotopeninthefollowingcases:

-Whenthewatertemperatureisabove55degorthedryingprocessisrunning,

whenthedrumisrotating,atanypointontheECOdrumcleancycle.

-IfyousettheChildLockforsafetyreasons.

-Whenthedrumwashordrumdryingcycleisrunningthatdoesnotinvolve

additionallaundry.

4-2. PROBLEM CHECK POINT

Wiring Diagram _ 35

5. WIRING DIAGRAM

5-1. WIRING DIAGRAM (SIMPLE)

► ThisDocumentcannotbeusedwithoutSamsung’sauthorization.

n REFERENCE INFORMATION

BLK BLACK

BLU BLUE

GRN GREEN

GRY GRAY

NTR NATURAL

ORG ORANGE

PNK PINK

RED RED

SKYBLU SKYBLUE

VIO VIOLET

WHT WHITE

YEL YELLOW

36 _ Wiring Diagram

5-2. WIRING DIAGRAM (LED)

► ThisDocumentcannotbeusedwithoutSamsung’sauthorization.

n REFERENCE INFORMATION

BLK BLACK

BLU BLUE

GRN GREEN

GRY GRAY

NTR NATURAL

ORG ORANGE

PNK PINK

RED RED

SKYBLU SKYBLUE

VIO VIOLET

WHT WHITE

YEL YELLOW

Wiring Diagram _ 37

5-3. WIRING DIAGRAM (Q-DRIVE)

► ThisDocumentcannotbeusedwithoutSamsung’sauthorization.

n REFERENCE INFORMATION

BLK BLACK

BLU BLUE

GRN GREEN

GRY GRAY

NTR NATURAL

ORG ORANGE

PNK PINK

RED RED

SKYBLU SKYBLUE

VIO VIOLET

WHT WHITE

YEL YELLOW

38 _ Reference

6. REFERENCE

6-1. WD6000T PROJECT NAME

► Door

10-Digit DOOR

DESIGN

DOOR

COLOR

DECO

COLOR

SBest Black D.silver

B Better Black Black

W Better Black White

LGood Black D.silver

HGood White D.silver

A Basic Black Black

T Basic White White

COldBasic Black -

EOldBasic White -

► Region

12,13-Digit Country 12,13-Digit Country

S1 UNITEDKINGDOM,

IRELAND EC SPAIN

S2

GERMANY

EE

DENMARK

AUSTRIA FINLAND

NETHERLANDS,

BELGIUM,

LUXEMBOURG

NORWAY

S3

FRANCE,MONACO SWEDEN

ITALIA.\,MALTA,

SAN MARINO EF FRANCE

SPAIN EG GERMANY

PORTUGAL

EN

NETHERLAN

DS

S4

SWEDEN,FINLAND,

DENMARK,

NORWAY,ICELAND

BELGIUM

S5 SWITZERLAND EO POLAND

S6

POLAND EP PORTUGAL

GREECE,CYPRUS ET ITALIA

HUNGARY

LE AD

(SEAD)향

ALBANIA

S7

BULGARIA BULGARIA

ROMANIA CROATIA

CZECH CZECH

SLOVAKIA HUNGARIA

LITHUANIA MACEDONIA

LATNIA ROMANIA

ESTONIA SERBIA

SLOVENIA SLOVAKIA

SERBIA LITHUANIA

MACEDONIA LATNIA

CROATIA ESTONIA

ALBANIA SLOVENIA

GREECE

MODEL NAME

► Product Type

1,2-

Digit

Type

WW Washer

WD Combo

DV Dryer

MODEL CODE

90 BWD

► Capacity

3,4-Digit Capacity

13 13

12 12.5

12 12

11 11.5

11 11

10 10.5

10 10

95 9.5

90 9

85 8.5

80 8

75 7. 5

70 7

6 5

► Feature4

9-Digit SUPER

SPEED L.SENSOR A.HOSE BUBBLE WIFI

A

● ● ● ● ●

B

●X● ● ●

C

● ● X● ●

D

●X X ● ●

A

X● ● ● ●

B

X X ● ● ●

C

X●X● ●

D

X X X ● ●

9

X● ● ● X

8

X X ● ● X

7

X●X●X

6

X X X ●X

3

X● ● X X

2

X X ●X X

1

X●X X X

0

X X X X X

► Feature2

7-Digit ADD WASH STEAM AOW/AD

8● ● ●

5● ● X

3 X ● ●

0 X ●X

► Feature1

6-Digit Q-DRIVE UX GRADE

9●

Simple Best

8●

Simple Better

72nd

Simple Better

6 X

Simple Good

5 X

Simple Basic

A X

LED _5000_UI

4 X

LED _4000_UI

4 D

► Body

11-Digit BODY

D.PANEL

HWhite

Silver

EWhite

Black

TWhite

D.silver

W

White

Silver

XInox Black

NInox D.silver

► Feature3

8-Digit RPM

MOTOR

6 1600 DIT

4 1400 DIT

2 1200 DIT

H

► Project

5-Digit Year

J2015

K2016

M 2017

N 2018

R 2019

T 2020

TEU

Reference _ 39

6-2. TERMINOLOGY

1. Drain Pump Thepumpthatdrainsthewaterfromthewashingmachinegeneratedwhilethewashing

machineisrunning

2. Heater Theheaterislocatedonthetubinsidethewashingmachine.Itheatsthewatertoincrease

washefciency.

3.DoorLockSwitch Detectswhetherthedoorofthewashingmachineisopenorclosedifthedoorisopenwhile

thewashingmachineisrunningthecycleistemporarystopped.

ThisServiceManualisapropertyofSamsungElectronicsCo.,Ltd.

AnyunauthorizeduseofManualcanbepunishedunderapplicable

Internationaland/ordomesticlaw.

© 2020 Samsung Electronics Co.,Ltd. All rights

reserved.

Printed in Korea

GSPN (GLOBAL SERVICE PARTNER NETWORK)

Area Web Site

Europe,CIS,Mideast&Africa gspn1.samsungcsportal.com

Asia gspn2.samsungcsportal.com

North&LatinAmerica gspn3.samsungcsportal.com

China china.samsungportal.com