Table of Contents

Samsung WW80T301MWW User Manual

Displayed below is the user manual for WW80T301MWW by Samsung which is a product in the Washing Machines category. This manual has pages.

Related Manuals

WASHING MACHINE

DRUM TYPE

WASHING MACHINE (DRUM) CONTENTS

SERVICE

Manual

REPAIR GUIDE

1. Safety Instructions

2. FeaturesandSpecications

3. Disassembly and Reassembly

4. Troubleshooting

5. Wiring Diagram

6. Reference

The model code is on the next page.

MODEL CODE

WW7*T****** WW8*T****** WW9*T******

WW70T301MBW WW80T301MBS WW90T304MBW

WW70T301MWW WW80T301MBW WW90T304MWW

WW70T302MBS WW80T301MWW WW90T304PWW

WW70T302MBW WW80T304MBS WW91T304MBW

WW70T302MWW WW80T304MBW WW9FT304PWW

WW70T303MBS WW80T304MWW

WW70T303MBW WW80T304PWW

WW70T303MWW WW81T301MWW

WW70T304MBW WW81T304MWW

WW70T304MWW WW81T304PWW

WW70T304PWW WW8ET304PWW

WW71T301MWW

CONTENTS

1. Safety instructions .........................................................................1

1-1. Safety instructions ...........................................................................1

2. FeaturesandSpecications ................................................................4

2-1. Specications ................................................................................4

2-2. ComparingSpecicationswithExistingModels ................................................5

2-3. Accessories ..................................................................................6

3. Disassembly and Reassembly ...............................................................7

3-1. Toolsfordisassemblyandreassembly .........................................................7

3-2. Standarddisassemblydrawings ...............................................................8

4. Troubleshooting ..........................................................................26

4-1. InformationCode ...........................................................................26

4-2. ProblemCheckPoint ........................................................................28

5. Wiring diagram ...........................................................................29

5-1. Wiringdiagram .............................................................................29

6. Reference .................................................................................30

6-1. WW3000TM Project Name ..................................................................30

6-2. Terminology ................................................................................31

Safety Instructions _ 1

1. SAFETY INSTRUCTIONS

1-1. SAFETY INSTRUCTIONS

► Makesuretoobservethefollowinginstructionstooperatetheproductcorrectlyandsafelyandpreventpossibleaccidentsand

hazardswhileservicing.

► Twotypesofsafetysymbols,WarningandCaution,areusedinthesafetyinstructions.

WARNING

Hazardsorunsafepracticesthatmayresultinseverepersonalinjuryordeath.

CAUTION

Hazardsorunsafepracticesthatmayresultinminorpersonalinjuryorpropertydamage.

► Followingtherepairbyanon-authorisedserviceprovider,self-repairornon-professionalrepairoftheproduct,Samsungisnot

liableforanydamagetotheproduct,anyinjuryoranyotherproductsafetyissuecausedbyanyattempttorepairtheproduct

whichdoesnotcarefullyfollowtheserepairandmaintenanceinstructions.Anydamagetotheproductcausedbyanattemptto

repairtheproductbyanypersonotherthanaSamsungcertiedserviceproviderwillnotbecoveredbythewarranty.

WARNING BEFORE SERVICING

• (Whenservicingelectricalpartsorharnesses)Makesuretodisconnectthepowerplugbeforeservicing.

4 Failingtodosomayresultinariskofelectricshock.

• Adviseconsumersnottoconnectseveralappliancestoasinglepoweroutletatthesametime.

4 Thereisariskofreduetooverheating.

• Whenremovingthepowercord,makesuretoholdthepowerplugwhenpullingtheplugfrom

theoutlet.

4 Failingtodosomaydamagetheplugorpoweroutletandresultinreorelectricshock.

• Whenthewashingmachineisnotbeingused,makesuretodisconnectthepowerplugfromthe

poweroutlet.

4 Failingtodosomayresultinresultinaccidentaloperationofthewashingmachine.

• Donotplaceorusegasoline,thinners,alcohol,orotherammableorexplosivesubstancesnearthewashingmachine.

4 Thereisariskofexplosionandrecausedfromelectricsparks.

2 _ Safety Instructions

WARNING WHILE SERVICING

• Checkifthepowerplugandoutletaredamaged,attened,cutorotherwisedegraded.

4 Iffaulty,replaceitimmediately.

Failingtodosomayresultinelectricshockorre.

• Completelyremoveanydustorforeignmaterialfromthehousing,wiringandconnectionparts.

4 Thiswillpreventariskofreduetotrackingandshortsinadvance.

• Whenconnectingwires,makesuretoconnectthemusingtherelevantconnectorsandcheckthattheyareproperlyconnected.

4 Donotusetapeinsteadoftheconnectors,itmaycausereduetotracking.

• MakesuretodischargethePBApowerterminalsbeforestartingtheservice.

4 Failingtodosomayresultinahighvoltageelectricshock.

• Whenreplacingtheheater,makesuretofastenthenutafterensuringthatitisinsertedintothebracket-heater.

4 Ifnotinsertedintothebracket-heater,ittouchesthedrumandcausesnoiseandelectricleakage.

• Donotrepairthewashingmachinewithoutsafetygloves.

4 It can cause injury.

WARNING AFTER SERVICING

• Checkthewiring.

4 Ensurethatthewiringcannotbedamagedbyanysharpedgesormovingparts.

• Checkforanywaterleakage.

4 Performatestrunforthewashingmachineusingthestandardcourseandcheckwhetherthereisanywaterleakage

throughtheoorsectionorthepipes.

• Adviseconsumersnottorepairorserviceanypartofthewashingmachinethemselves.

4 Thismayresultinpersonalinjuryandshortentheproductlifetime.

Safety Instructions _ 3

CAUTION BEFORE SERVICING

• Donotsprinklewaterontothewashingmachinedirectlywhencleaningit.

4 Thismayresultinelectricshockorre,andmayshortentheproductlifetime.

• Donotplaceanycontainerswithwateroranyotherliquidonthewashingmachine

4 Ifthewaterisspilled,itmayresultinelectricshockorre.Thiswillalsoshortentheproduct

lifetime.

• Donotinstallthewashingmachineinalocationexposedtosnoworrain.

4 Thismayresultinelectricshockorre,andshortentheproductlifetime.

• Donotpressacontrolbuttonusingasharptoolorobject.

4 Thismayresultinelectricshockordamagetotheproduct.

CAUTION WHILE SERVICING

• Whenwiringaharness,makesuretosealitcompletelysonoliquidcanenter.

4 Takecarewhendisconnectingconnectors,donotuseexcessiveforceasthismaydamage

theconnector.

• Checkifthereisanyresiduethatshowsthatliquidenteredtheelectricpartsorharnesses.

4 Ifanyliquidhasenteredintoapart,replaceitorcompletelyremoveanyremainingmoisturefromit.

• Ifyouneedtoplacethewashingmachineonitsbackforservicingpurposes,placeasupport(s)ontheoorandlayitdown

carefullysoitssideisontheoor.

4 Donotlayitdownonitsfront.Thismayresultintheinsidetubdamagingparts.

• Atleasttwopeopleshouldworkwhenworkingwithheavyproducts.

4_FeaturesandSpecications

2. FEATURES AND SPECIFICATIONS

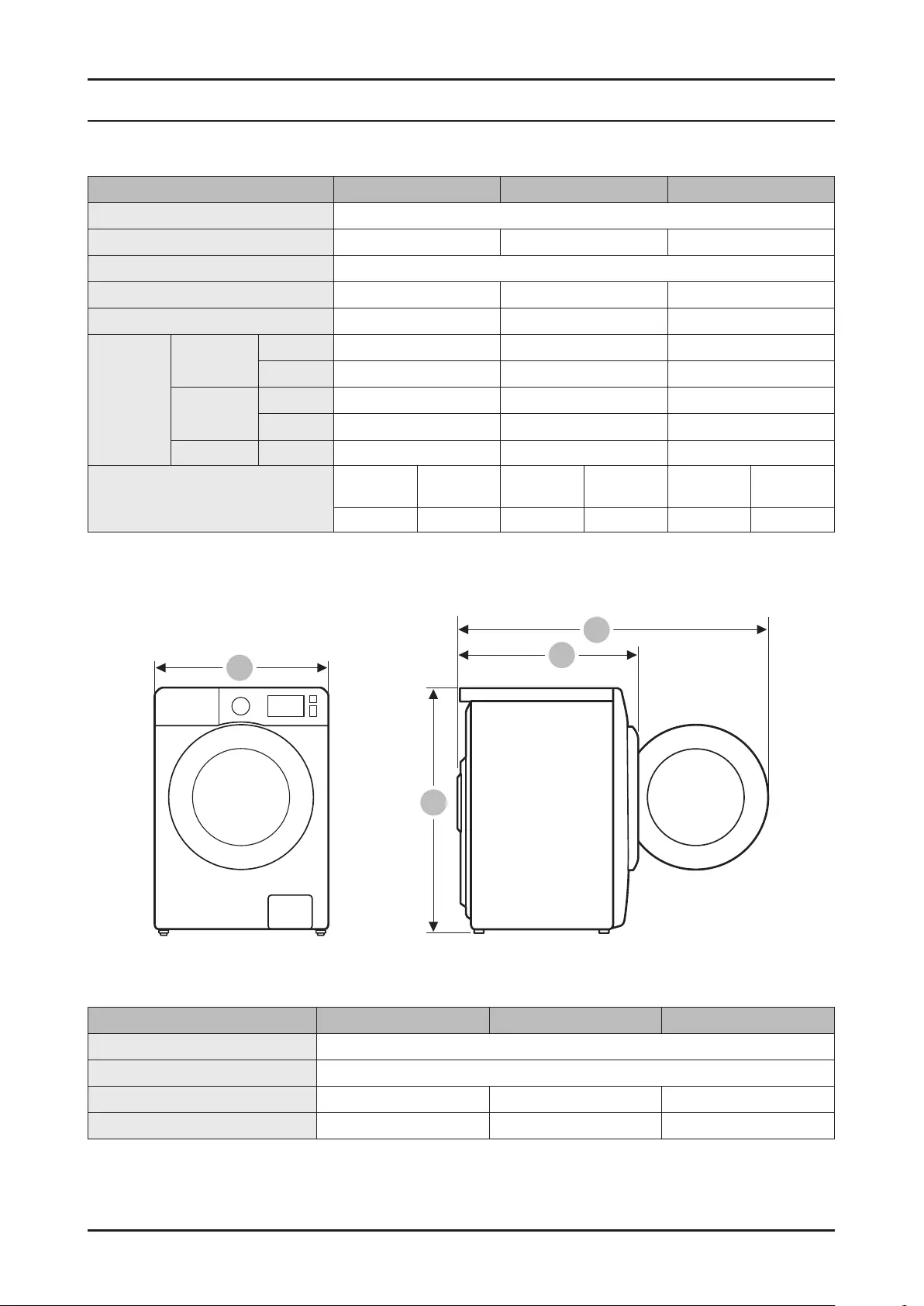

2-1. SPECIFICATIONS

MODEL

WW7*T30*** WW8*T301*** WW9*T304***

Modelname

Frontloadingwashingmachine

Dimensions(mm)

595*495*850 595*520*850 595*560*850

Water pressure

50kPa-800kPa

Netweight(kg) 59

59 64

Washandspincapacity

7kg 8kg 9kg

Power

consumption

Washing 220V

120 W 120 W 120 W

240V

150 W 150 W 150 W

Washingand

heating

220V

1800 W 1800 W 1800 W

240V

2100 W 2100 W 2100 W

Spin+Pump 220V~240

500 W 500 W 500 W

Spinrevolutions

WW9*T304***

WW9*T303***

WW9*T302***

WW9*T301***

WW8*T304***

WW8*T303***

WW8*T302***

WW8*T301***

WW7*T304***

WW7*T303***

WW7*T302***

WW7*T301***

1400rpm 1200 rpm 1400rpm 1200 rpm 1400rpm 1200 rpm

-

PleasevisitSamsungofcialwebsitetoreceivemostup-to-dateinformationaboutsoftwareandproductmaintenance.

Model

WW7*T30*** WW8*T301*** WW9*T304***

Width(A)

595 mm

Height-Overall(B)

850 mm

Depth(C)

495 520 560

Depthwithdooropen90°(D)

913 938 978

A

B

C

D

FeaturesandSpecications_5

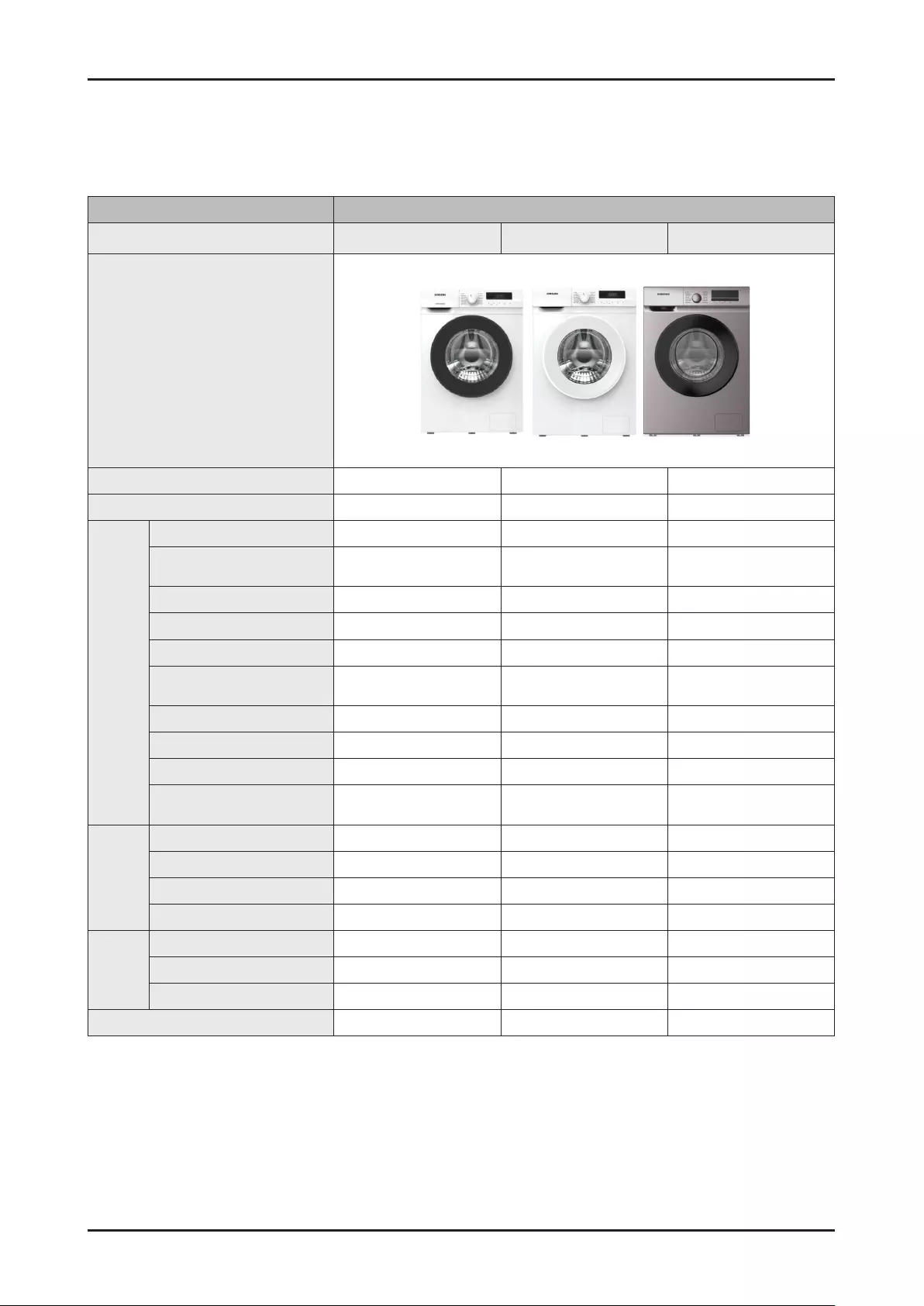

2-2. COMPARING SPECIFICATIONS WITH EXISTING MODELS

Project WW3000TM

Model Name WW9*T304*** WW8*T30**** WW7*T30****

Image

Feature ---

Capacity 9.0kg 8.0kg 7.0kg

Main

Spec

DrumVolume 60 L 53 L 49 L

MaxRpm 1400 rpm 1400 / 1200 rpm 1200,1400/1200,1400rpm

Motor DIT DIT/Universal DIT/Universal

ControlSys General General General

WeightDetection Yes Yes Yes

WashHeaterCapacity 1800-2100W /

220-240V 1800-2100W / 220-240V 1800-2100W / 220-240V

WaterSupply ColdOnly ColdOnly ColdOnly

Drainage Pump Pump Pump

Power-OutageCompensation No No No

ZeroStanbyPower Yes

(0.5WorLess)

Yes

(0.5WorLess)

Yes

(0.5WorLess)

USP

EcoBubble

TM

No No No

DelayEnd Yes Yes Yes

ChildLock Yes Yes Yes

DiamondDrum No No No

Design

Door 450mm 450mm 450mm

CenterJogDial No No No

Display LED LED LED

Dimension(WxDxH) 595x560x850(mm) 595x520x850(mm) 595x495x850(mm)

(★) : Special models only

6_FeaturesandSpecications

2-3. ACCESSORIES

Figure Unit Code QTY Description

BoltSpanner - 1

Toremovetheshippingbolts

Toadjustthelevelingleg

Assy Hose Water -Coldonly1(★)Tosetupwatersupply.

Hose Water

(Aqua-Stop) -1(★)Tosetupwatersupply.

CapFixer - 4 Tocovertheholes.

Hose Hanger - 1 Tosecurethedrainhose.

Note

• (H)issuppliedforspecicmodelsonlyamongthosewithoutwatersupplyhoses.

• Customercanpurchaseadditionalwatersupplyanddrainhosesfromaservicecenter.

• Forbuilt-inmodels,thespanner,watersupplyanddrainhosesarenotsupplied.Boththewatersupplyanddrainhosesare

suppliedduringtheinstallatio.

Disassembly and Reassembly _ 7

3. DISASSEMBLY AND REASSEMBLY

3-1. TOOLS FOR DISASSEMBLY AND REASSEMBLY

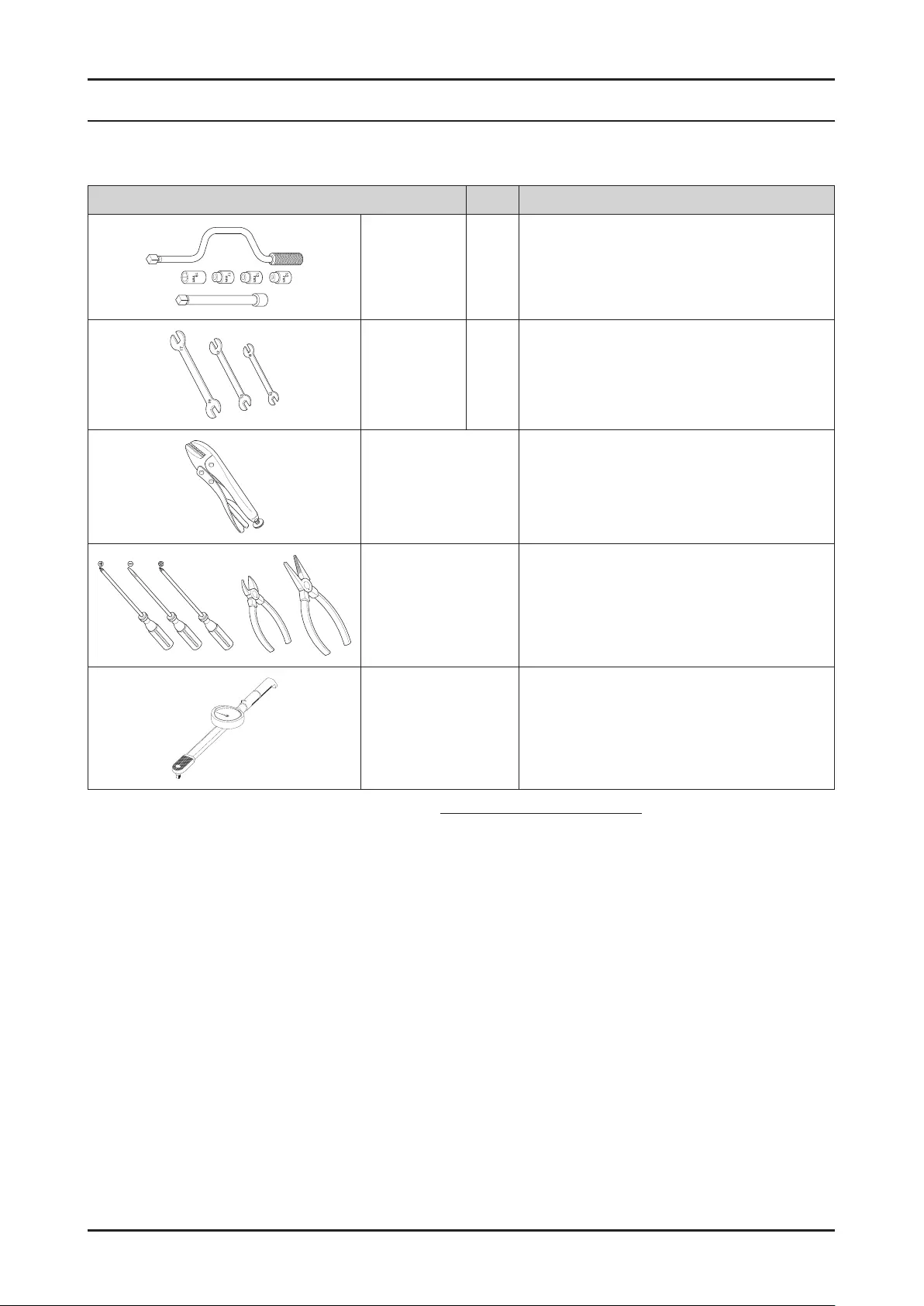

Tool Type Remarks

Boxdriver

10mm Heater(1),Tub(12),Fixerscrew(4),Motor(2),

13mm ShockAbsorber(3holeseachinleft/right),

Damper(3),Damper(friction2),Balance(6)

17mm Pulley(1)

Double-ended

spanner

10mm

13mm

17mm

Replacedbyboxdriver

Leg

Vicepliers

AToolforprotectingemptyturningofboltor

abrasionfromusingboxdriver

FordisassemblyofSpindrum

Others

(screwdriver,nipper,long

nosepliers)

Commontoolsforservicing

Torquewrench TheToolforassemblyofheaterandTub

-Forinformationaboutpurchasingpartsandtool,pleasevisithttp://www.samsung.com/support

-Forthepartcodeinformation,pleaserefertheattachedle'ExplodedView'.

8 _ Disassembly and Reassembly

3-2. STANDARD DISASSEMBLY DRAWINGS

► Thisisastandarddisassemblydiagramandmaydifferfromtheactualproduct.

Usethismaterialasareferencewhendisassemblingandreassemblingtheproduct.

Disassembly

Part Figure Description

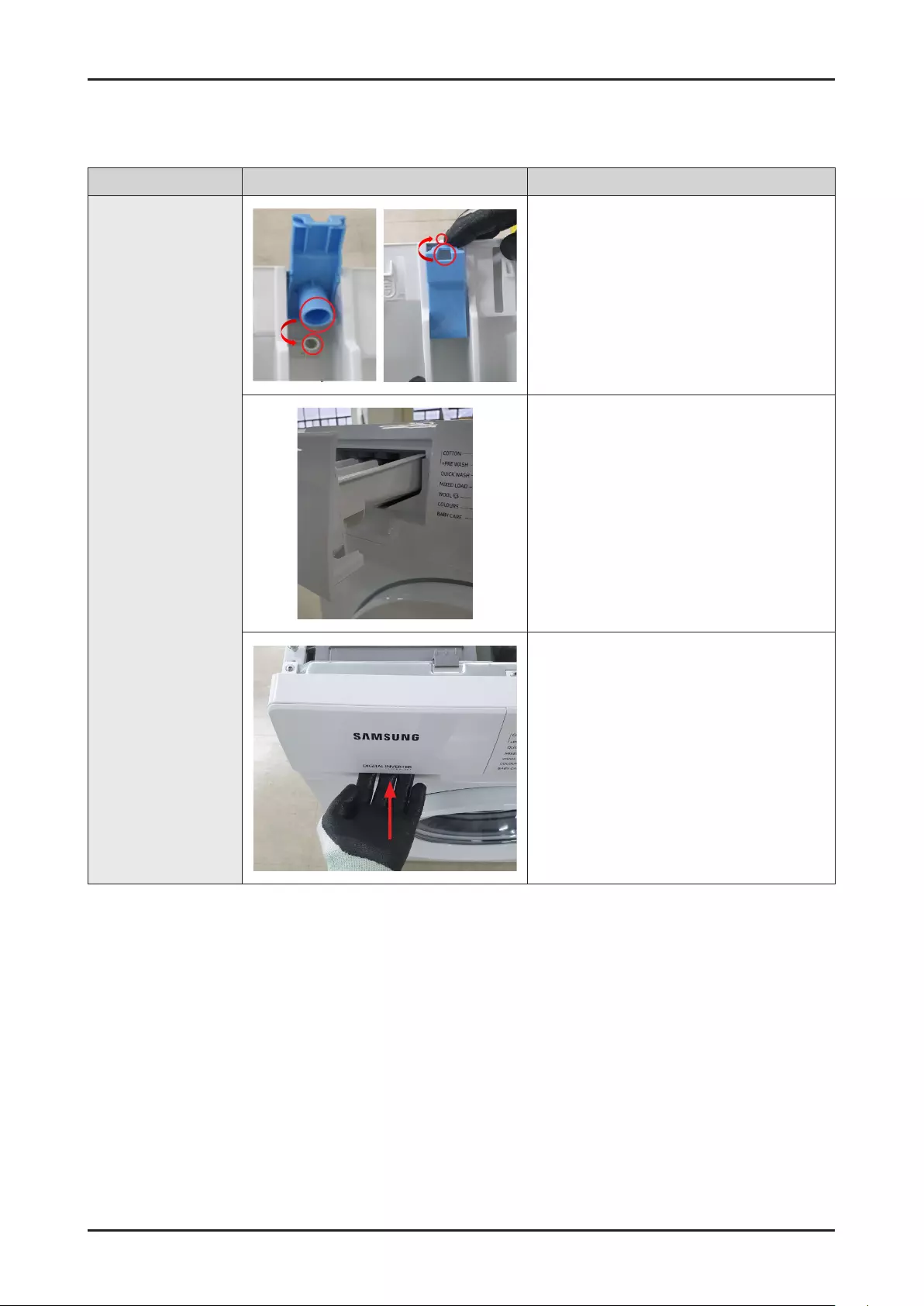

Assy Cover Top

1. Remove2screwsholdingtheCoverTopatthe

backoftheunitusing(+)screwdriver.

Back Front

2. RemovetheCoverTopbyliftingitupafter

pullingitbackabout15mm.

Assy Drawer

1. OpentheDrawerbyhand.

2. Whileholdingdownthereleaseleverinsidethe

Drawer(redbox),slideopentheDrawer.

3. PulluptheCapRinsetoremoveit.

Disassembly and Reassembly _ 9

Reassembly

Part Figure Description

Assy Drawer

1. FittheholeandpresstheCapRinsesothatit

canbeassembled.

2. Makesuretottherailwhenreassemblingthe

AssyDrawer.

3. InserttheDrawerasshowninthepicture.

10 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Assy Panel Control

1. Remove2screwsholdingtheDrawerandPanel

using(+)screwdriver.

2. Removethe2screwsatthetopoftheAssy

PanelControlusing(+)screwdriver.

3. IfyouholdthePanelandpullitforward,the

HookwillcomeoffandthePanelwillbe

separated.

BecarefulnottobreaktheHook.

4. RemovetheConnectorwhilepressingtheHook

onthe7ConnectorsinsertedinthePBAofthe

AssyPanel.

5. RemovetheCableTiethatisxedintwoplaces

asshowninthepicture.

Disassembly and Reassembly _ 11

Reassembly

Part Figure Description

Assy Panel Control

1. Insertthe7WireConnectorsintoPBAandx

the2CableTies.

MakesuretheHookislockedproperly.

2. AssembletheAssyPanelControltotheproduct.

3. Assemblethe2screwsonbothsidesofthe

AssyPanelControl.

4. Assemble2screwsholdingtheDrawerand

Panelwith(+)screwdriver.

12 _ Disassembly and Reassembly

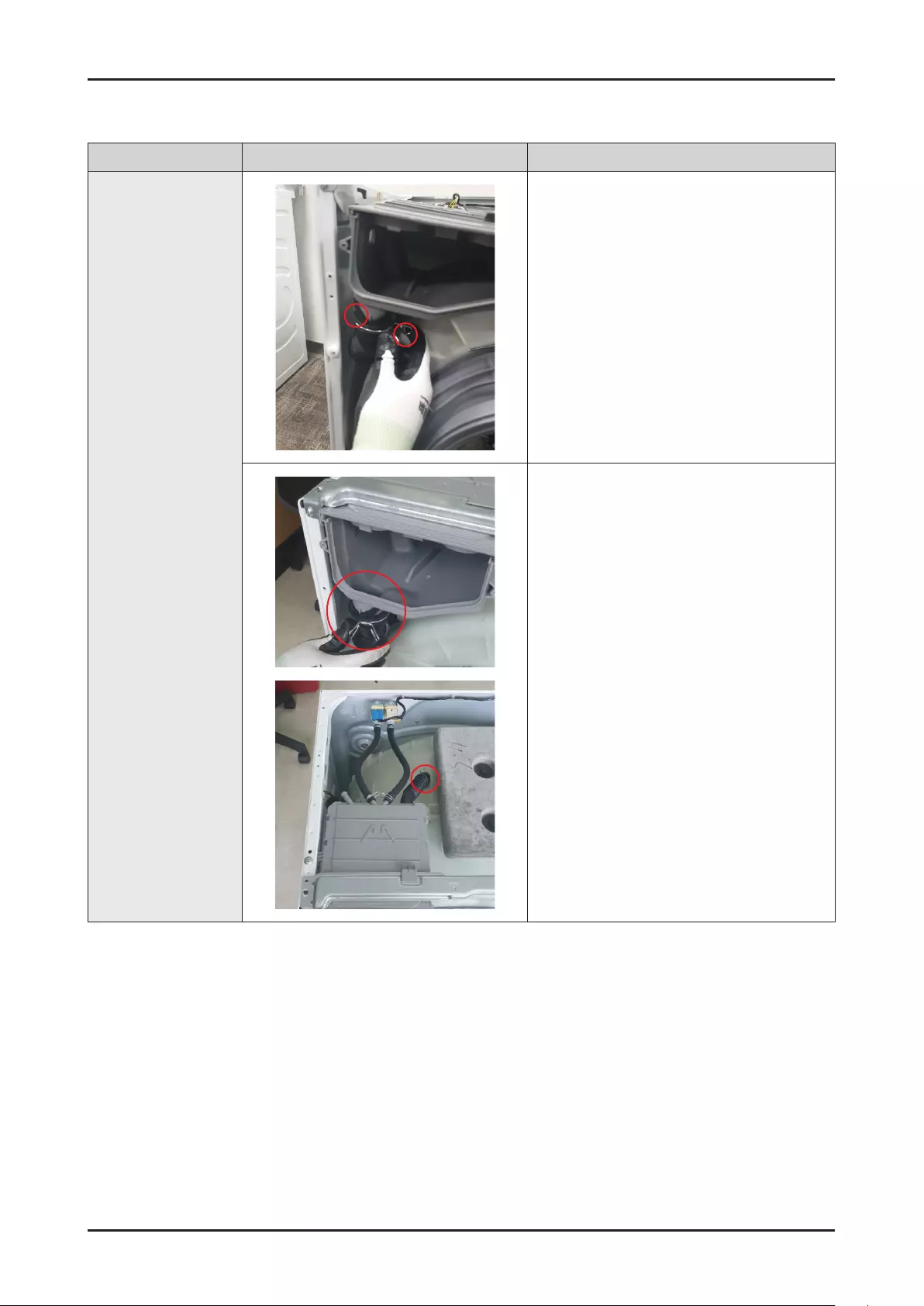

Disassembly

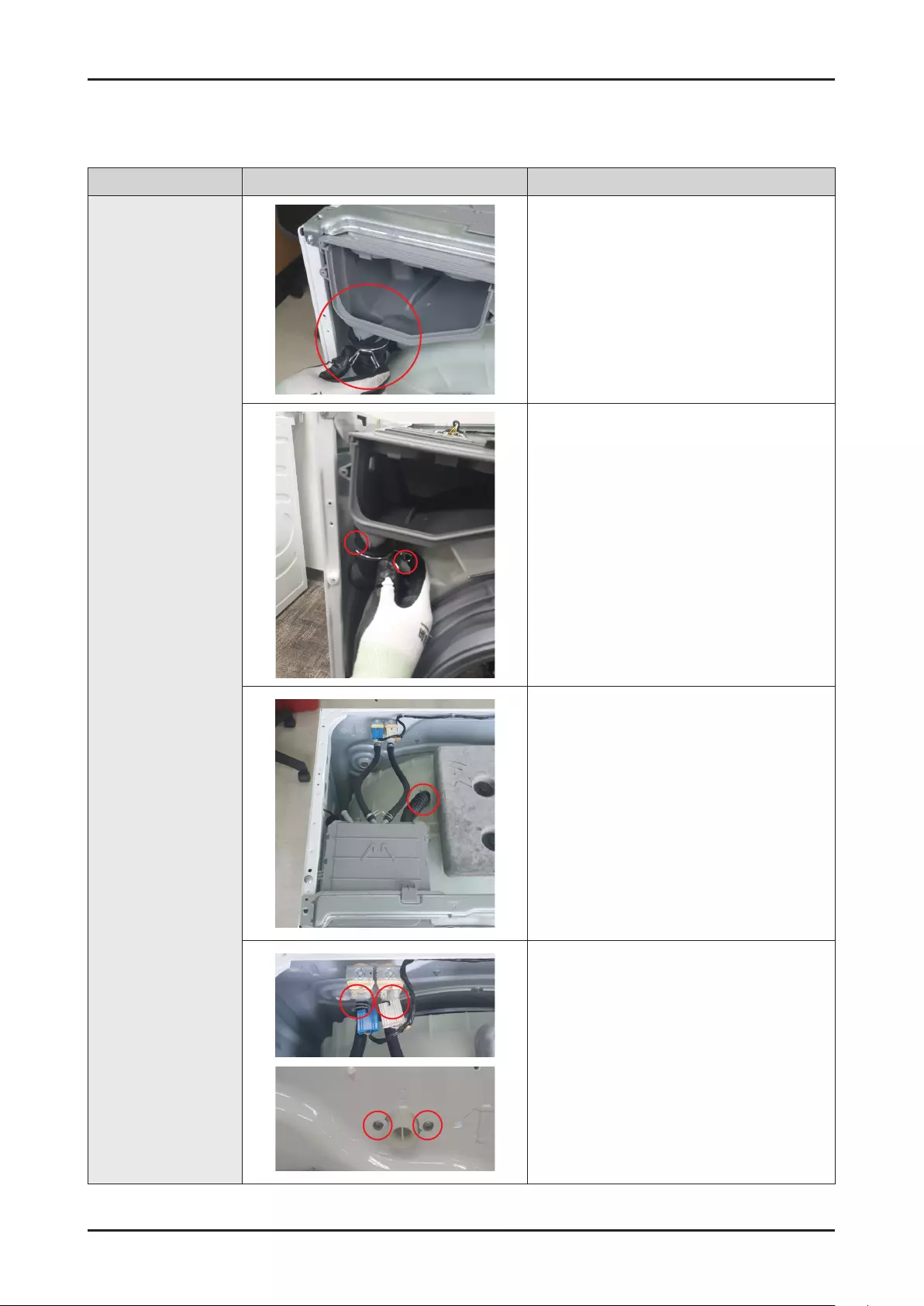

Part Figure Description

Assy Housing-Drawer

1. SeparatetheClamp.

2. RemovetheHoseDrawerTubxedtotheAssy

Housing-Drawer.

3. SeparatetheClampxedtotheTub.

4. Removethe2Connectorsand2screwsxedto

theWaterValve.

Disassembly and Reassembly _ 13

Part Figure Description

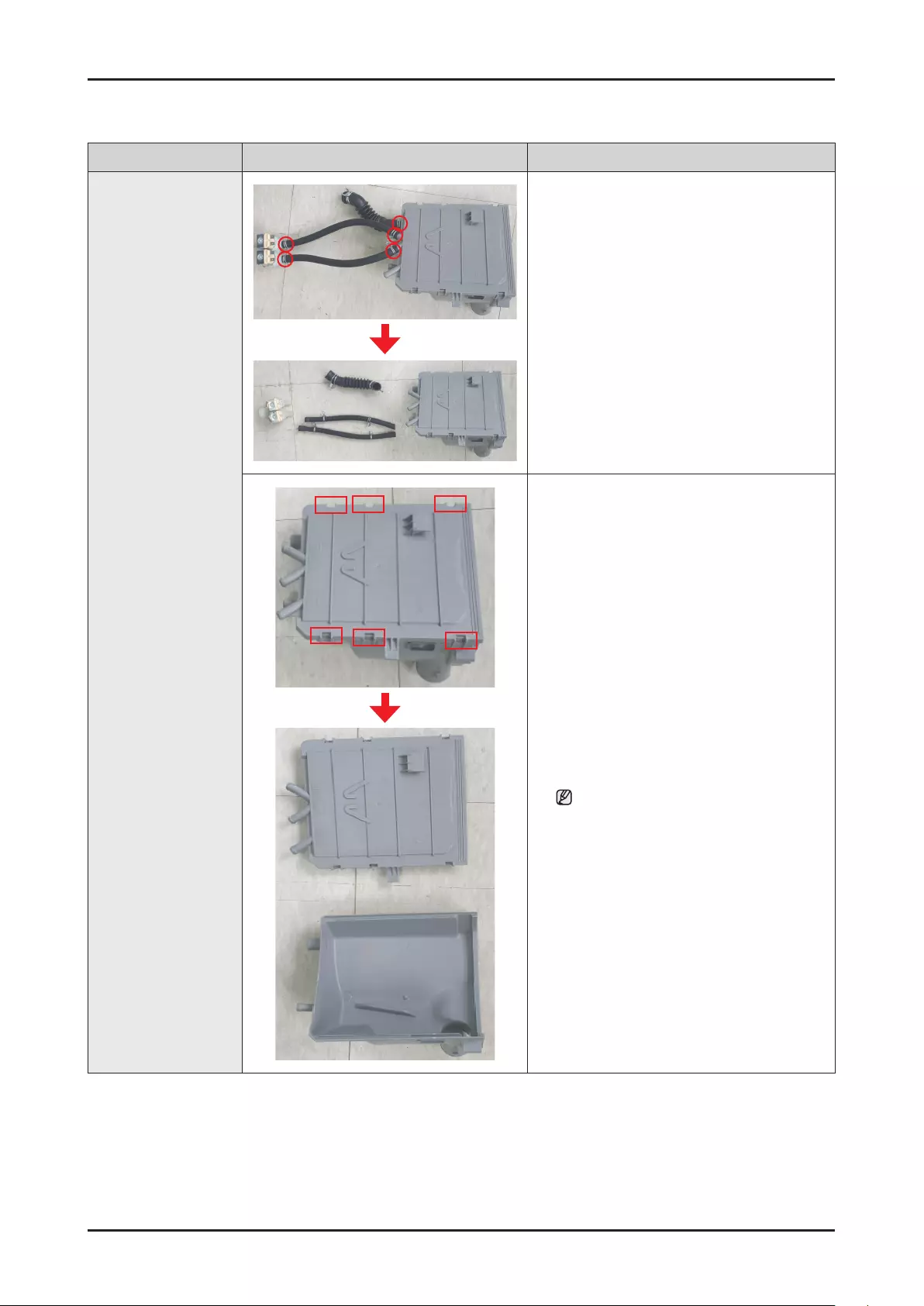

Assy Housing-Drawer

1. SeparatetheallClamps.

2. Separatethe6Hooksfrombothsidesof

Housing-Drawer.

BecarefulnottobreaktheHook.

14 _ Disassembly and Reassembly

Reassembly

Part Figure Description

Assy Housing-Drawer

1. Assemblethe6Hooksonbothsidesof

Housing-Drawer.

2. First,assembletheHosetotheWaterValveand

Housing-DrawerandthenxtheClamps.

3. AftermountingtheAssyHousing-Draweron

theproduct,assemblethe2Connectorsand2

screwsontheWaterValve.

Disassembly and Reassembly _ 15

Part Figure Description

Assy Housing-Drawer

4. AssembletheHoseDrawerTubtoAssy

Housing-Drawer.

5. AssembletheClamp.

16 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Water Valve

1. SeparatetheAssyCoverTop.

2. Separatethe2ConnectorsandClampsbyhand

andremove2Hoseswithlongnosepliers.

3. Removethe2screwsholdingtheWaterValve

using(+)screwdriver.

Reassembly

Part Figure Description

Water Valve

1. Assemblethe2screwsholdingtheWaterValve

using(+)screwdriver.

2. Assemblethe2hosestothewatervalveusing

longnosepliers.

3. Assemblethe2Clampsand2WireConnectors

asshowninthepicture.

MakesuretheHookislockedproperly.

Disassembly and Reassembly _ 17

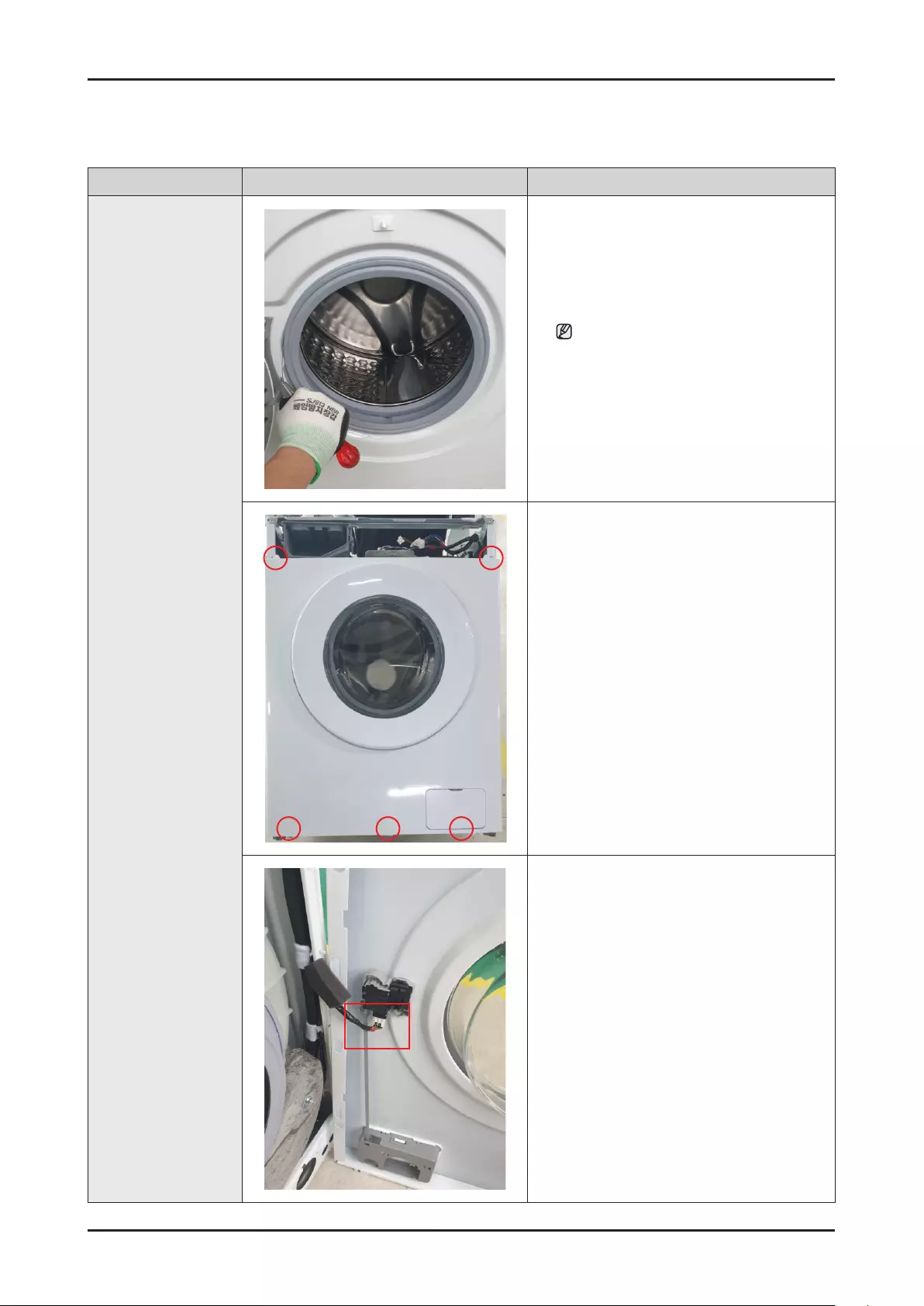

Disassembly

Part Figure Description

Frame Front

Beforeyoustart,disassembleAssyCoverTop,

AssyPanelControl.

BecarefulnottotearuptheDiaphragm.

1. Usinglongnosepliers,pickuponeoftherings

onWire-Diaphragmwhichconnectthespring

andthewireends.Then,separatetheWire-

DiaphragmfromtheFrameFront.

2. Removethe2screwsfromthetopand3screws

fromthebottom.

3. SeparatetheConnectorofDoorS/Wxedinside

theFrameFront.

18 _ Disassembly and Reassembly

Part Figure Description

Frame Front

4. Removethe2screwsandseparatetheAssyDoor.

5. SeparatetheDoorS/Wbypressingthemolded

objectaboveandbelowDoorS/W.

6. OpentheHookontheupperpartoftheFilter

Coverbypressingitdownwitha(-)screwdriver

orapointedtool.

7. Separatethe8hooksxedtotheFrameFront.

Disassembly and Reassembly _ 19

Reassembly

Part Figure Description

Frame Front

1. Assemblethe8Hooksbycheckingthedirection

oftheGuideFilter.

2. AfterxingtheCoverFiltertothelower2places

oftheGuideFilter,presstheupperpartto

assemble.

3. AssemblebypressingDoorS/Winlinewith

FrameFrontgroove.

4. Assemblebyfastening2screwstoAssyDoor.

20 _ Disassembly and Reassembly

Part Figure Description

Frame Front

5. Fastenthe5screwsintheupper2placesand

thelower3places.

6. AssembletheDoorDiaphragmonFrameFront.

7. FixtheClamp.

Disassembly and Reassembly _ 21

Disassembly

Part Figure Description

Assy Door

OpentheDoor.

Removethe2screwsxedtotheFrameFrontand

Doorusinga(+)screwdriver.

Remove10screwsusinga(+)screwdriver,and

removebyinsertinganawlintotheHolder.

22 _ Disassembly and Reassembly

Part Figure Description

Assy Door

Remove4screwswith(+)screwdriverand

disassembletheDoorHingeandDoorLever

assembledinHolderandthenseparatetheDoor

GlassfromHolderGlassHook.

Disassembly and Reassembly _ 23

Reassembly

Part Figure Description

Assy Door

InserttheDoorGlassintotheHolderGlasstotthe

grooveandfastenthedoorleverwithtwoscrews

andthenassembletheHingeDoortoHolderand

fastenwith2screws.

AssembletheCoverDoortoHolderGlassandfasten

the10screws.

AssyDoorisassembledtoFrameFrontbyfastening

2screws.

24 _ Disassembly and Reassembly

Disassembly

Part Figure Description

Door-Lock S/W

Beforeyoustart,disassembleAssyCoverTop,Assy

PanelControl.

BecarefulnottotearuptheDiaphragm.

1. Usinglongnosepliers,pickuponeoftherings

onWire-Diaphragmwhichconnectthespring

andthewireends.Then,separatetheWire-

DiaphragmfromtheFrameFront.

Removethe2screwsfromthetopand3screws

fromthebottom.

SeparatetheDoorS/Wbypressingthemolded

objectaboveandbelowDoorS/W.

SeparatetheConnectorofDoorS/Wxedinsidethe

Frame Front.

Disassembly and Reassembly _ 25

Reassembly

Part Figure Description

Door-Lock S/W

InserttheConnectorofDoorLockS/W.

Insertthe2HoldersofDoorLockS/WintotheHole

of Frame Front.

Fastenthe5screwsintheupper2placesandthe

lower3places.

26 _ Troubleshooting

4. TROUBLESHOOTING

4-1. INFORMATION CODE

► When an abnormal condition occurs, melody sounds and displays Info. code indications as shown in the following Info. codes

are shown until the status has cleared.

No. Information Type Information

Code Causes Corrective Actions

1WaterLevel 0C/1C

-Inletvalvefailure

-Thecomputerboardisfaulty(theSCRofthewaterinletvalve

isshort-circuited)

-Waterlevelsensorfailure(lessthan20KHzormorethan

50KHzbeyondthenormalrange)

-Theterminalofthewaterlevelsensorisnotpluggedinorthe

wiringharnessisfaulty.

•Replacethewaterinletvalve

•Replacecomputerboard

•Replacethewaterlevelsensor

•Checkwhetherthewiringharness

terminalisrmlyconnectedor

replacethewiringharness

2 Motor 3C

-Themotorwiringharnessterminalislooseorthewiring

harnessisfaulty

-Motortemperaturerisetoohighthermalprotectionaction

(lockedrotorfailure,checkthemotorspeedis0for5

consecutivetimes,every5secondsinterval)

-Themotoritselfisfaulty

-Computerboardfailure

-UVWshortcircuit;motorcoilinsulationisdamaged(variable

frequencyvariant)

-UVWwiringisoff(variablefrequencyvariant)

-Poorheatdissipation(variablefrequencyvariant)

•Checkwhetherthewiringharness

terminalsarermlyconnectedor

replacethewiringharness

•Checkiftheclothesaretoomuchor

stuck.Afterpoweroffandcooling

foraperiodoftime,youcanpower

on again

•Replacethemotor

•Replacecomputerboard

•Checkifthewiringharnessterminal

isshortedorreplacethemotor

(variablefrequencyvariant)

•Checkwhetherthewiringharness

terminalisrmlyconnectedor

replacethewiringharness(variable

frequencyvariant)

•Waitingtocooldown(variable

frequencyvariant)

3WaterSupply 4C

-Thefaucetisnotturnedonorthewaterowistooslow

-Thedrainagepipeisnotsuspended

-Airlevelsensororaircollectiontubeleaks

-Theinletvalveisdamaged

-Thecomputerboardisfaulty(theSCRofthewaterinletvalve

isopenortheSCRofthepumpisbrokendown)

-waterlevelsensorfailure

(alwaysmaintainacertainwaterlevelvalue)

•Checkwhetherthefaucetisturned

onandthesizeofthewaterow

•Hangthedrainpipe

•Checkthewaterlevelsensorandgas

manifoldassembly,orreplace

•Replacethewaterinletvalve

•Replacethecomputerboard

•Replacethewaterlevelsensor

4Drain 5C

-Drainpumplterisdirty

-Thedrainagepipeisblocked

-Drainpumpfailure

-Thedrainpumpwiringharnessplugisloose,notconnected,

orthewiringharnessisfaulty

-Computerboardfailure(waterlevelsensorterminalshort

circuit)

-Waterlevelsensorfailure(alwayskeephigherthanthe

emptywaterlevelvalue)

•Clearpumplter

•Dredgingthedirtydrainpipe

•Replacethedrainagepump

•Checkwhetherthewiringharness

terminalisrmlyconnectedor

replacethewiringharness

•Replacethecomputerboard

•Replacethewaterlevelsensor

5Communication

AC -Theterminalisnotpluggedinorthewiringharnessisfaulty

-Powercomputerboardordisplayboardfailure

•Checkwhetherthewiringharness

terminalsarermlyconnectedor

replacethewiringharness

•Replacecomputerboard

AC6 -Theterminalisnotpluggedinorthewiringharnessisfaulty.

-Computerboardorinverterboardisfaulty

•Checkwhetherthewiringharness

terminalsarermlyconnectedor

replacethewiringharness

•Replacecomputerboardorinverter

board

- -Motherboardvariantandinvertermodeldonotmatch •Resetvariants

•Replacetheinverter

Troubleshooting _ 27

No. Information Type Information

Code Causes Corrective Actions

6DOOR

DC

-Thedoorisnotclosed

-Microswitchfailure

-Theterminalisnotpluggedinorthewiringharnessisfaulty

-Computerboardfailure

•Checkifthedoorisclosedproperly

•Replacethedoordetectionswitch

•Checkifthewiringharnessterminals

arermlyconnectedorreplace

•Replacecomputerboard

DC1

-Thedoorisnotclosed

-Doorlockfailure

-Theterminalisnotpluggedinorthewiringharnessisfaulty

-Computerboardfailure(triacfailure)

•Checkifthedoorisclosedproperly

•Replacethedoorlock

•Checkifthewiringharnessterminals

arermlyconnectedorreplace

•Replacecomputerboard

7HEATER HC

-Theterminaloftheheatingpipelineislooseorthewiring

harnessisfaulty.

-Heatingtubefailure

-Computerboardfailure(ordryingcomputerboardfailure)

•Checkwhetherthewiringharness

terminalsarermlyconnectedor

replacethewiringharness

•Replacetheheatingtube

•Replacethecomputerboard

(ordrythecomputerboard)

8WaterLeakage LC

-Heaterengagementfault.(outofplace)

-Theairhoseisoutofplaceandwaterleakageoccursduring

thespincycle.

-Thetubbackatthesafetyboltsxingpartisbroken.

-Waterleakageoccursatthefrontwithfoamingbecauseof

toomuchdetergent.

-Waterleakageoccursbecausetheconnectinghosetothe

detergentdrawerisconnectedincorrectly.

-Thedrainpumpltercoverisengagedincorrectly.

-Waterleakageoccursatthedrainhose.

-Theductcondensingholdingscrewsareworn.

-Thenozzle-diaphragmisengagedintheoppositedirection

ortherubberpackagingisomitted.

-Waterleakageoccursbecausethescrewsthatholdthetub

backandfrontinplacearefastenedincorrectly.

-Theleakagesensorisfaulty.

•CheckWaterLeakage

•DVCASEforeignmaterialoccurs

•Leakageoftheproductinsidethe

hoseandpartsmoldedproblem

9Temperature

Sensor TC1

-Theterminalofthewaterheatingtemperaturesensorwiring

harnessislooseorthewiringharnessisfaulty.

-Temperaturesensorfailure

-Computerboardfailure

•Checkwhetherthewiringharness

terminalsarermlyconnectedor

replacethewiringharness

•Replacetemperaturesensor

•Replacethecomputerboard

10 Variant settings

abnormal

AllDisplay

Blink

-Thevariantsettingsdonotmatchthecurrentsoftware

-Variantinformationstorageabnormality(FlashorEeprom

failure)

•Loginvariantsettingmodeandreset

thevariant

• MCU or Eeprom

28 _ Troubleshooting

PROBLEM SOLUTION

Thewashingmachinewon’tstart.

•Makesurethewashingmachineispluggedin.

•Makesurethedoorisproperlyclosed.

•Makesurethewatertapisopen.

• Tap Start or Press Start/Pausebuttonagain.

Watersupplyisinsufcient,ornowater

issupplied.

•Openthewatertapfully.

•Makesurethewatersupplyhoseisnotfrozen.

•Makesurethewatersupplyhoseisnotkinkedorclogged.

•Cleanthelteronthewatersupplyhose.

Thewashingmachinevibratesbadly,or

makesnoise.

•Makesurethewashingmachineisinstalledonaleveloor.Iftheoorisnotlevel,

usethelevelingfeettoadjustthelevel.

•Makesurethattheshippingboltsareremoved.

•Makesurethewashingmachineisnottouchinganyotherobject.

•Makesurethelaundryloadisbalanced.

Thewashingmachinedoesnotdrain

and/orspin.

•Makesurethedrainhoseisstraightenedallthewaytothedrainsystem.

•Makesurethedebrislterisnotclogged.

Thedoorwon’topen.

•PresstheStart/Pausebuttontostopthewashingmachine.

•Thedoorstayslockedaslongasthewashingmachineisstillhotinsideaftera

heatingoperation.

•Itmaytakeseveralsecondstodisengagethedoorlockmechanism.

ButtonCheck •bCoccurs.ReferthebCtroubleshooting.

4-2. PROBLEM CHECK POINT

Wiring Diagram _ 29

5. WIRING DIAGRAM

5-1. WIRING DIAGRAM

► ThisDocumentcannotbeusedwithoutSamsung’sauthorization.

n REFERENCE INFORMATION

BLK BLACK

BLU BLUE

GRN GREEN

GRY GRAY

NTR NATURAL

ORG ORANGE

PNK PINK

RED RED

SKYBLU SKYBLUE

VIO VIOLET

WHT WHITE

YEL YELLOW

30 _ Reference

6. REFERENCE

6-1. WW3000TM PROJECT NAME

WW 90 T 3 0 4 M W W EP

Type Capa PJT Product

name Feature1 Feature2 Door Body Buyer

Code Content Code Content Code Year Code Panel Code MOTOR RPM Code Feature Code Door Code Body Code

WW Washer

90

9E

9F

9kg T2020 3Basic 1UNI 1200 0Non-functional WWHITE WWHITE SA NewZealand

WD Combo 85 8.5kg 2021 2DIT 1200 2AquaHose BBLACK SSILVER SV Vietnam

80 8kg 3UNI 1400 MCirculationPump EU U.K

70 7kg 4DIM 1400 PCirculationPump+

AquaHose EC Spain

60 6kg EO Poland

EP Portugal

EG Germany

EF France

: :

Reference _ 31

6-2. TERMINOLOGY

1. Drain Pump Thepumpthatdrainsthewaterfromthewashingmachinegeneratedwhilethewashing

machineisrunning.

2. Heater Theheaterislocatedonthetubinsidethewashingmachine.

Itheatsthewatertoincreasewashefciency.

3.DoorLockSwitch Detectswhetherthedoorofthewashingmachineisopenorclosedifthedoorisopenwhile

thewashingmachineisrunningthecycleistemporarystopped.

ThisServiceManualisapropertyofSamsungElectronicsCo.,Ltd.

AnyunauthorizeduseofManualcanbepunishedunderapplicable

Internationaland/ordomesticlaw.

© 2021 Samsung Electronics Co.,Ltd. All rights

reserved.

Printed in Korea

GSPN (GLOBAL SERVICE PARTNER NETWORK)

Area Web Site

Europe,CIS,Mideast&Africa gspn1.samsungcsportal.com

Asia gspn2.samsungcsportal.com

North&LatinAmerica gspn3.samsungcsportal.com

China china.samsungportal.com