CDA HNE8FR User Manual

Displayed below is the user manual for HNE8FR by CDA which is a product in the Hobs category. This manual has pages.

Related Manuals

www.cda.eu

HNE8FR

Induction hob with

built in extractor

Installation, use and maintenance

2

Contents:

4 Important information

5 Important safety warnings/notes

6 Important notes for safety, use and care

6 Pacemaker and active implants information

7 Important safety warnings

7 Saving energy

8 Cooking on induction (and pan compatibility)

9 Hob layout

10 Using your hob(s)

11 Booster function

12 Operating time limiter

13 Timer/minute minder

14 Setting the timer on multiple zones

15 Setting the minute minder

16 Pause function

17 Keep warm function

18 Bridge function

19 Control lock

19 Safety key lock

20 Residual heat indicators

21 Auto-heat function

22 Using your extractor

23 Ecient use of your hob

23 Placing your pans correctly

24 Care and maintenance

25 Cleaning guide

25 Customer Care Department contact details

26 Troubleshooting - hob

3

Contents:

28 Troubleshooting - extractor

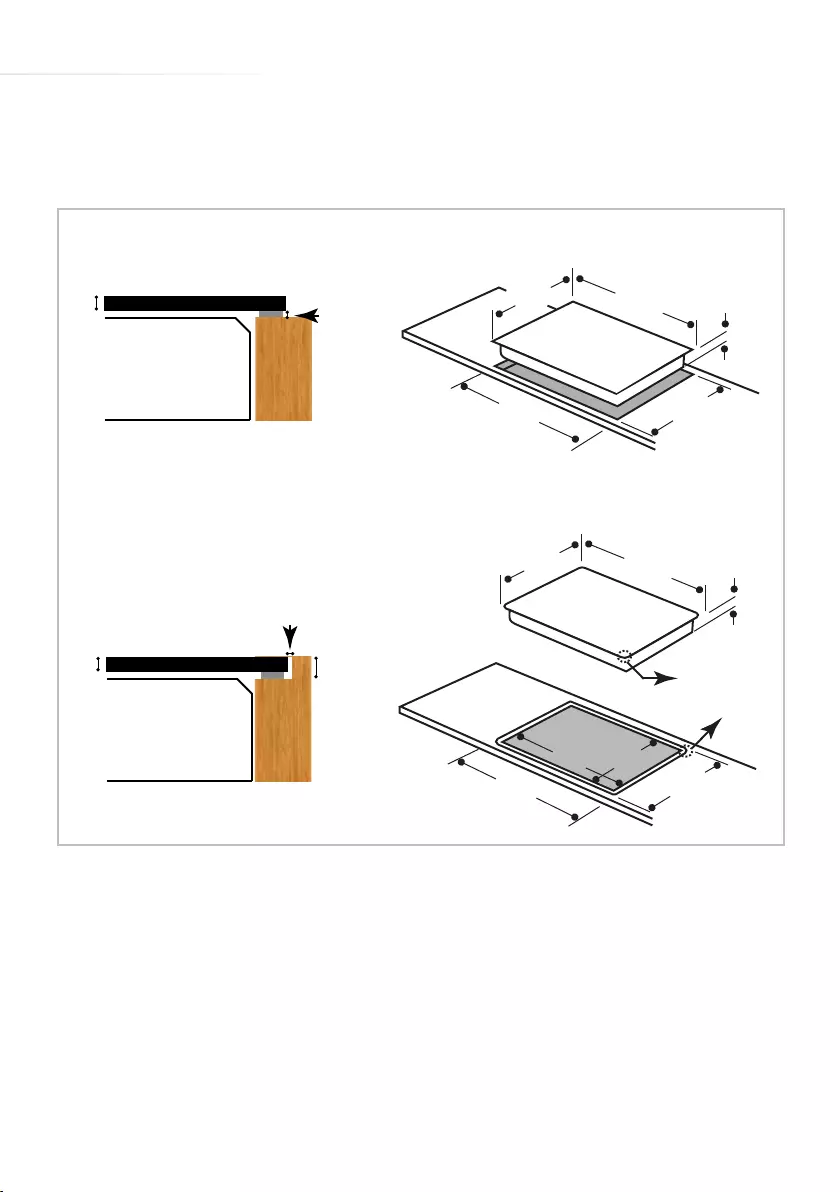

30 Installation - preparation

32 Installation diagrams

33 Flush or inset installation of the hob

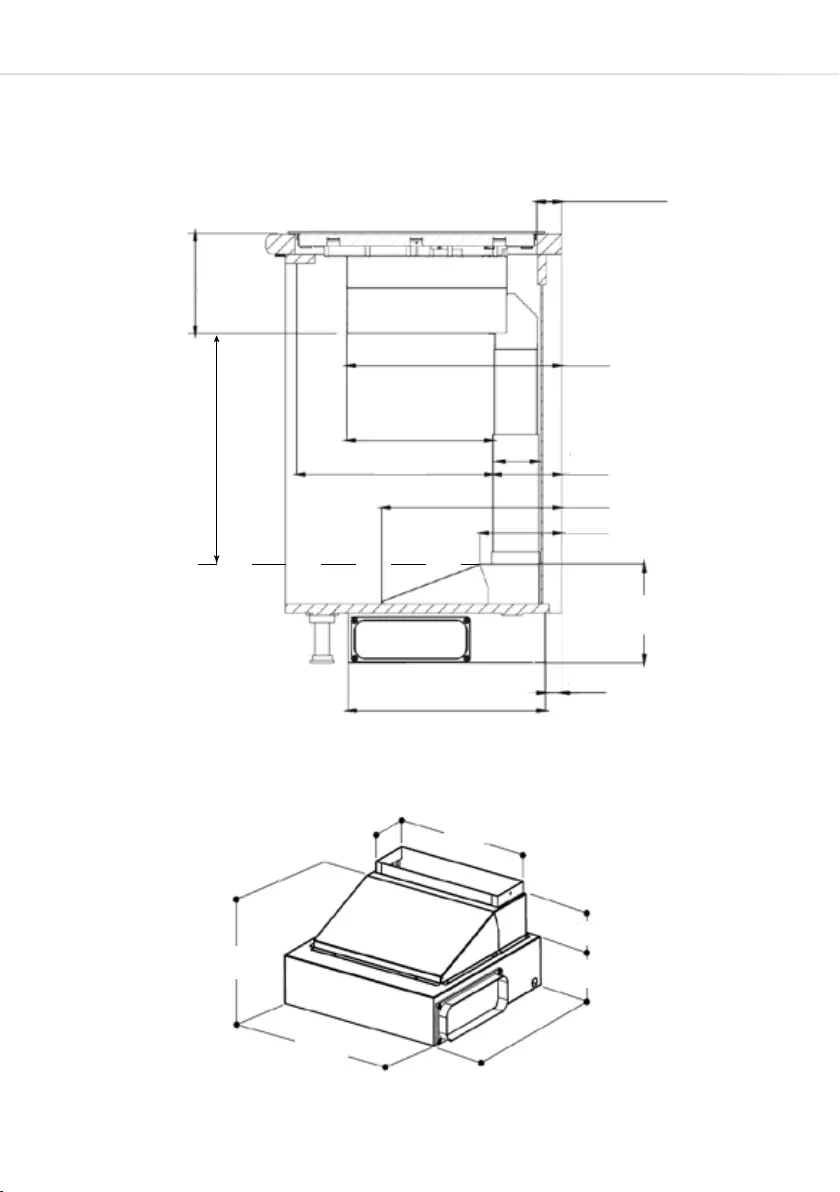

34 Extractor system dimensions

35 Installation - assembly

39 Ducting

40 Connecting the ducting

41 Mains electricity connection

42 Wiring box connections

43 Extractor plug information

46 Energy eciency information

IMPORTANT: IF YOUR EXTRACTOR DOES NOT APPEAR TO BE

WORKING AT ANY TIME, PLEASE ENSURE THAT THE RED POWER

SWITCH ON THE WIRING BOX HAS NOT BEEN SWITCHED OFF

4

Important

The CDA Group Ltd cannot be held responsible for injuries or losses

caused by incorrect use or installation of this product. Please note

that CDA reserve the right to invalidate the guarantee supplied with

this product following incorrect installation or misuse of the appliance

or use in a commercial environment.

This appliance is not designed to be used by people (including

children) with reduced physical, sensorial or mental capacity, or

who lack experience or knowledge about it, unless they have had

supervision or instructions on how to use the appliance by someone

who is responsible for their safety.

Under no circumstances should any external covers be removed for

servicing or maintenance except by suitably qualified personnel.

Appliance information:

Please enter the details on the appliance rating plate below for

reference, to assist CDA Customer Care in the event of a fault with

your appliance and to register your appliance for guarantee purposes.

Appliance Model

Serial Number

EU Declarations of Conformity

This appliance has been manufactured to the strictest standards and

complies with all applicable legislation, including Electrical safety

(LVD) 2014/35/EU and Electromagnetic interference compatibility

5

(EMC) 2014/30/EU. Parts intended to come into contact with food

conform to 1935/2004/EC.

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2012/19/EU.

At the end of its working life, the product must be taken to a special

local authority waste collection centre or to a dealer providing

appliance recycling services.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health. It also

enables the constituent materials to be recovered, saving both energy

and resources. As a reminder of the need to dispose of household

appliances separately, the product is marked with a crossed-out

wheeled dustbin.

Please note:

• Induction hobs become hot and remain hot during and immediately

after use. Do not touch the hob until it has been allowed to cool.

• Keep children away from the appliance when in use.

• Never use the hob top for storage.

• Pan handles should never stand out beyond the edge of the

worktop. This will help to avoid children reaching them.

• Do not lean over the hob when it is in use.

• Follow the cleaning instructions carefully.

• Ensure the base of the saucepan is clean and dry before placing it

on the hob.

• Avoid hard shocks from cookware – the vitroceramic glass surface

is highly resistant but not unbreakable.

6

• Do not place hot lids flat on the hob top. A “suction” eect could

cause damage to the hob.

• Do not drag cookware across the hob top: in the long term, this

could cause damage to the hob.

• Do not store cleaning or flammable products in the unit below the

hob.

• Always use appropriate cookware.

• Do not cook unopened tins of food directly on the hob.

• Never put cooking foil or plastic materials on the ceramic surface

when the hob is hot. These materials could melt and cause

damage to the hob.

• This hob (Class 3) has been designed for use only as a cooking

appliance. Any other use should be considered incorrect and

therefore dangerous.

FOR THOSE WITH HEART PACEMAKERS OR ACTIVE IMPLANTS:

The function of this hob conforms to current electromagnetic

interference standards and thus is in total compliance with legal

requirements (2004/108/CE directives).

To avoid interference between your hob and a pacemaker, your

pacemaker must be designed and programmed in compliance with

the regulations that apply to it. As such, CDA guarantee only that our

product is compliant.

With regard to the compliance of the pacemaker or any potential

incompatibility, you should obtain information from the manufacturer

or your attending physician.

7

Important

• Do not use the hob if the glass surface is cracked or damaged

to prevent the risk of electric shock. Disconnect it from the

power supply.

• Ensure that the power cable of a connected electrical appliance

near the hob is not in contact with the cooking zones.

• NEVER run an empty pan on an induction hob (nor any hob).

• Do not switch on the hob until a pan has been placed on it.

• Keep the control panel(s) clean and free from grease, grime or

debris as these can hamper activity or cause unwanted activation.

• Do not lean over pans when they are warming up or cooking.

• Do not pour any liquids down the extractor area. If any spillages

do occur, follow the care and maintenance section on page 24.

Saving energy

Using energy in a responsible way not only saves money but also

helps the environment. The following will help you to save energy:

• Use proper pans for cooking. A saucepan should never be smaller

than a zone. Always remember to cover any pans.

• Ensure pans and the hob are kept clean. Soils can prevent heat

transfer and repeatedly burnt-on spillages can often only be

removed by products which cause damage to the environment.

• Do not uncover the pan too often (a watched pot never boils!).

Be sure to recycle all of the packaging. All packaging materials

used are 100% recyclable.

8

Cooking on Induction

The principle of induction cooking is based on magnetic eect.

When you put your cookware on an induction zone and switch it on,

the electronic boards in the hob produce induced currents in the base

of the cookware and instantly raise its temperature. This heat is then

transferred to the food inside the cookware.

The best cookware to use with induction cooking has thick flat bases,

as the heat will be better distributed meaning cooking is more even.

Most cookware is compatible with induction cooking.

There are three ways to check the suitability of your cookware:

1. Using a magnet to see if the base of the pan is magnetic: if the

magnet sticks, then the cookware is compatible.

2. Place the pan on one of the cooking zones and switch the

zone on. If the display continues to show the selected power

level then the cookware is compatible. If the display shows “ ”,

the cookware cannot be used on an induction hob.

3. Check the instructions, base or packaging of the pans for the

symbols indicating suitability for use with induction:

9

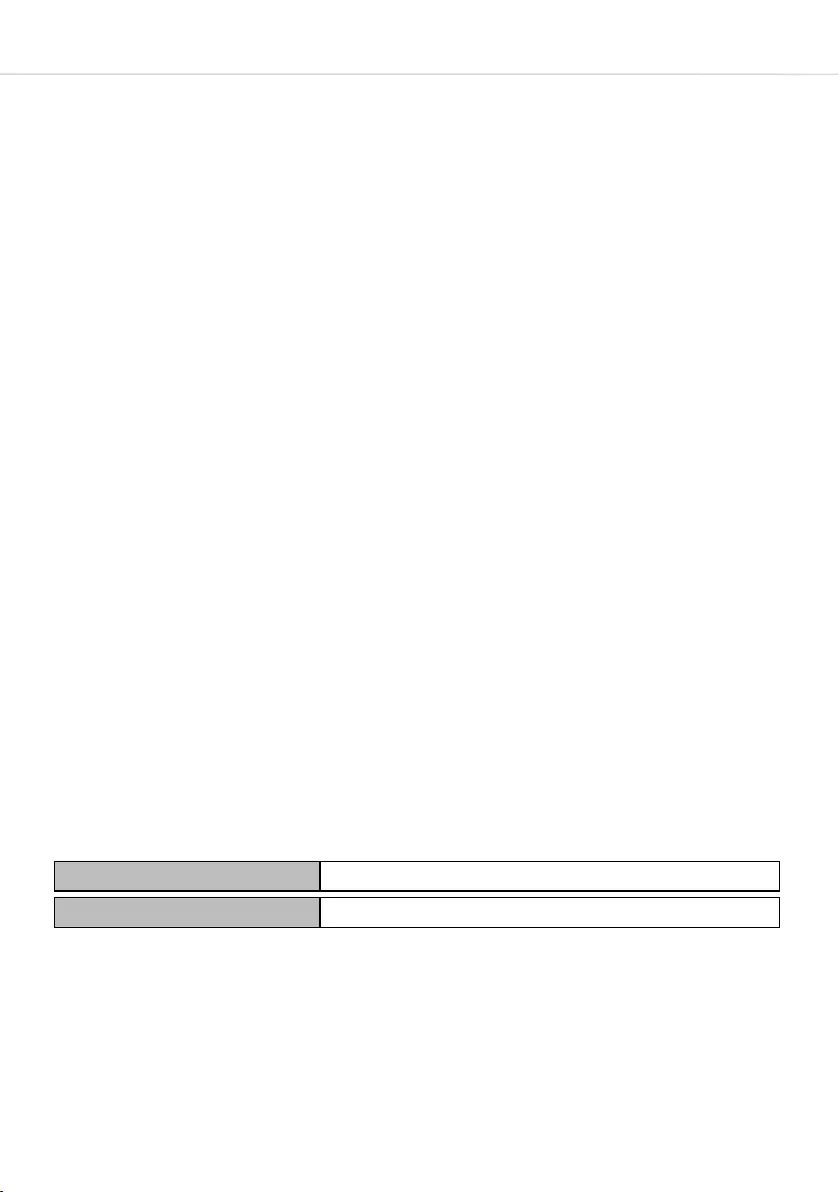

Hob layout

Zones:

1. Rear left 2.1 - 3.7kW 2. Front left 2.1 - 3.7kW

3. Rear right 2.1 - 3.7kW 4. Front right 2.1 - 3.7kW

Please note: The octagonal zone coils and dotted line markings in Fig.

1 are visible for informational purposes.

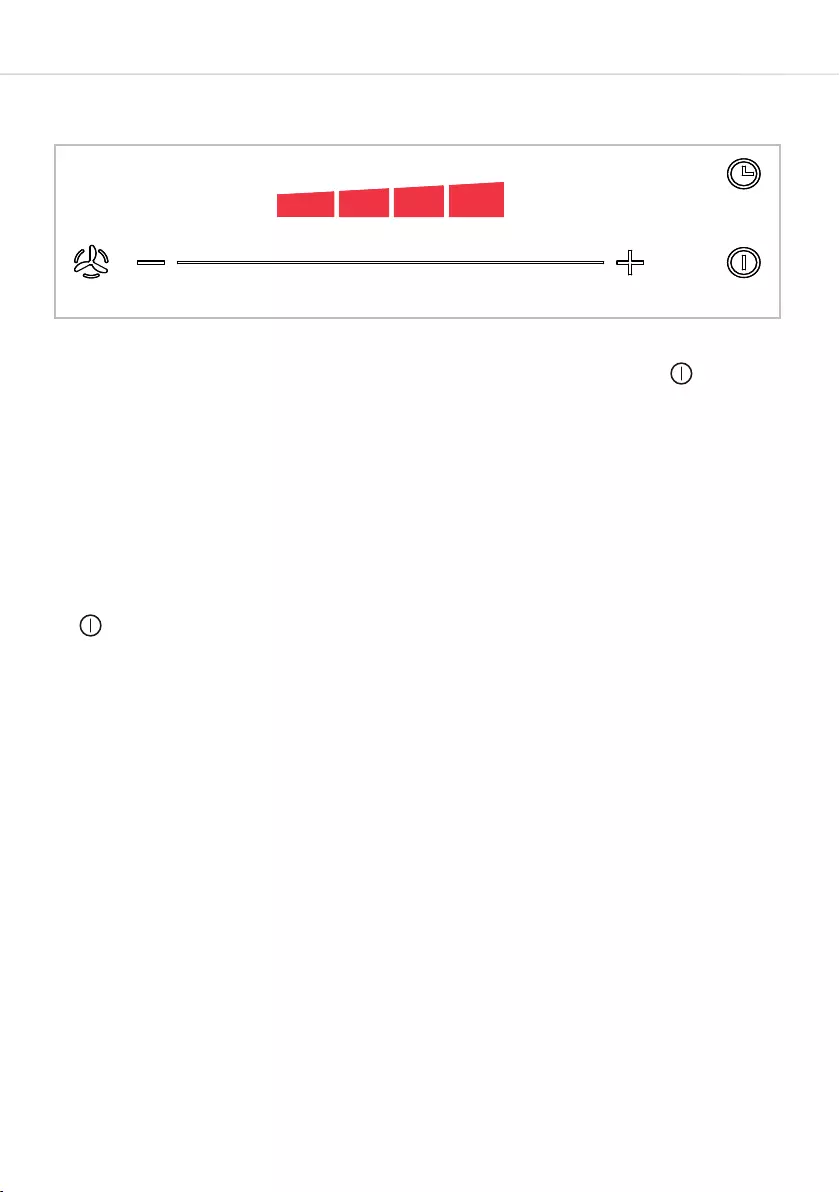

Hob control panel (this is the same for both hobs):

1. Keep warm setting indicators 7. Timer plus setting sensor

2. Cooking zone indicators 8. Pause function sensor with LED

3. Timer activity indicators 9. On/o sensor

4. Bridge function indicator 10. Lock sensor with LED

5. Timer minus setting sensor 11. Heat setting slider sensor

6. Timer display 12. Keep warm function sensor

Fig. 1

min

1

2

3

4

Fig. 2

11

2 3 4 2 3 4

5 7

6

89101111 1212

10

Using your hob(s)

To switch a hob on

• To switch the power on, touch and hold the on/o sensor (9) for

approximately one second. The hob will beep and all cooking zone

indicators will show ‘0’. The inductor modules will click faintly when

turning the hob on (and o).

Please note: If a power level is not set within ten seconds, the hob

will switch o automatically.

To activate a zone and set a power level

• Simply set the desired power level using the heat setting slider

sensor (11). The standard power levels range from 1 (minimum) to

9 (maximum). The hob will then begin heating providing that the

correct cookware is being used.

To deactivate a zone

• Simply use the heat setting slider sensor (11) to return the heat

setting to '0' for that zone.

• If switching o multiple zones, the above step needs to be taken

for each zone. When all the zones are at '0', the hob will switch o

automatically after approximately ten seconds.

• Alternatively, to switch o the hob immediately, touch and hold the

on/o sensor (9) for approximately two seconds.

Please note: Any zones that are still hot to the touch will display the

symbol ' ' provided the mains power supply is not interrupted.

11

Booster function

The hob is equipped with a booster function on all zones, allowing a

higher power level than the maximum for approximately ten minutes.

To activate the booster on a zone

• Regardless of whether a power level is already set, simply touch

the '+' symbol at the end of the slider for the relevant zone. 'P'

will be displayed on the cooking zone indicator to show that the

booster is on.

• The booster function automatically deactivates after 10 minutes of

usage. The cooking zone will continue to operate at its nominal

power at this point. The booster can be reactivated after this time

provided the hob's internal components have not overheated.

To deactivate the booster on a zone

• To cancel the booster at any time, use the heat setting slider sensor

(11) to return the heat setting to '0' or an alternative level.

Please note: The booster function can not be used on all zones at

once. If two zones in a vertically aligned module are placed on boost,

then the first zone to have been placed on boost will be reduced

to power level 5. Additionally, a bridged pair of zones can not be

boosted. This is to help protect the hob's internal components.

If the appliance's electronic circuits or induction coils overheat

whilst the booster function is in operation then the function will be

automatically deactivated and the zone will continue to operate at its

nominal power. The booster function will be available again once the

internal components have been cooled suciently.

12

It is normal for a high pitched whirring noise to begin whilst the

booster function is in use. This is the cooling fan inside the hob

keeping the internal components as cool as possible.

If a pot is removed from the cooking zone whilst the booster function

is in use, the ten minute countdown should continue.

Operating time limiter

In addition to the booster deactivation timer, each zone has an

operating time limiter to increase overall eciency and to prevent

the hob from being left on indefinitely. If a zone's heat setting is

not changed for a specific duration then the associated zone is

automatically switched o and residual heat indicator activated.

Zones can still be used as normal in accordance with the operating

instructions. The operating time limiter is set according to the last

selected heat setting. The maximum operating times for each setting

can be found below.

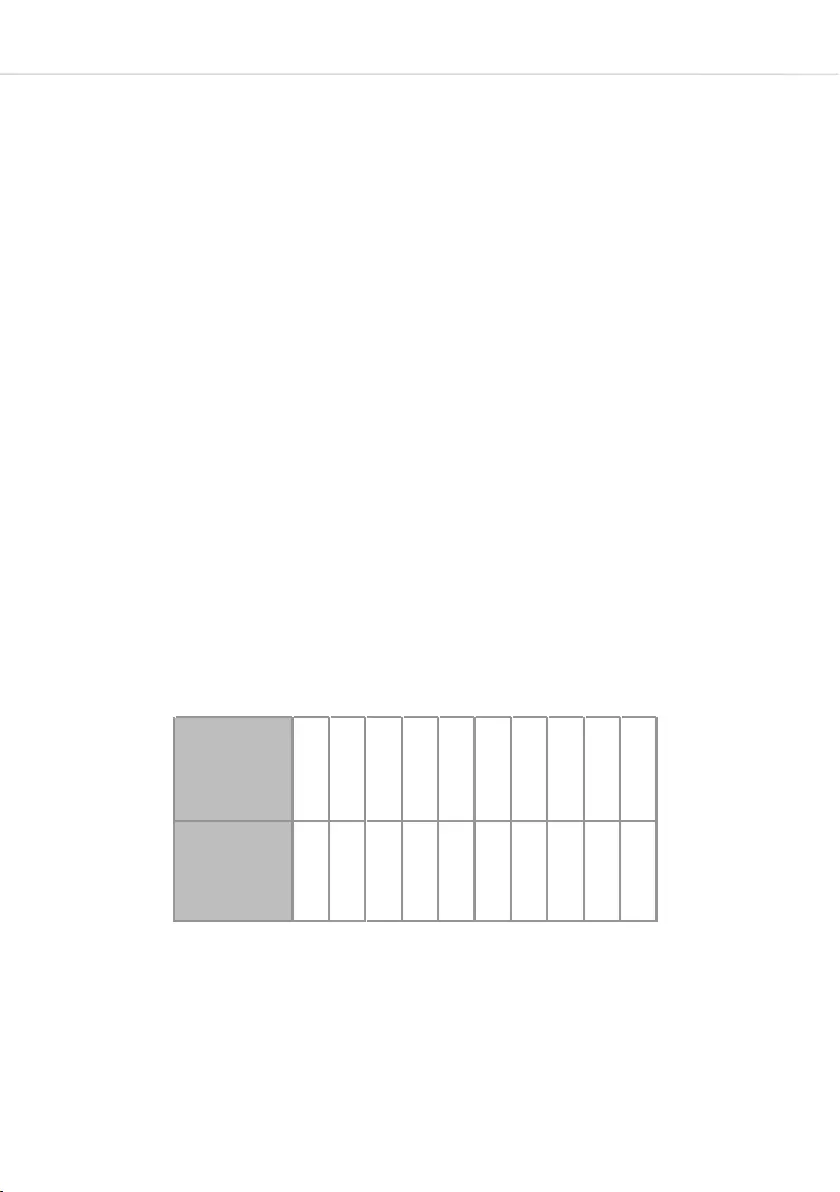

360

1

Zone Heat Setting

Maximum

Operating Time

(minutes)

234 5 6 7 8 9 P

360 300 300 200 90 90 90 90 9.6

13

Timer/Minute minder

The hob is equipped with a timer that allows a finish time to be set for

the end of cooking on any zone, between a minimum of 1 minute and

a maximum of 119 minutes. This timer can be used separately for

each zone, and the timer activity indicator (3) will illuminate faintly

on each zone for which it is set and remain brightest on the first

zone to end. Once the timers are set, the timer display will show the

time remaining on the first zone to finish cooking. In normal use, the

timer ending prompts the zone heating to end as well. However the

timer can also be used as a minute minder to count down time without

halting heating.

Please note: At the end of the timer, the selected zone will switch o

and the timer indicators will flash. The hob will beep for approximately

two minutes. To switch o the beep, touch the timer minus and plus

setting sensors (5 & 7) simultaneously. This beeping also occurs after

the minute minder time has elapsed and the same process to switch

o the beep applies.

If no time is set within 5 seconds of activating the timer, then it will

deactivate automatically.

To set the timer

• First switch on the hob if necessary and set the desired zone to the

power level required.

• Touch the timer minus setting sensor (5) and the timer plus setting

sensor (7) simultaneously. The timer display (6) will illuminate.

• A clock symbol (the timer activity indicator) will appear next to the

power level of the leftmost active zone. This clock indicates which

14

zone the subsequent timer adjustment will aect.

• Next, use the timer plus setting sensor (7) and the timer minus

setting sensor (5) to set the desired timer duration. The timer is

increased in 1 minute increments per each press of the + or -

sensors. If you hold your finger down on either sensor, after

a few seconds, the time will increase by 5 minute increments.

Continuing to hold your finger down will increase the time by 10

minute increments.

To set the timer on multiple zones

• To time each zone when multiple zones are running, set the time for

one zone, as per the section ‘To set the timer’. Wait for

approximately 4 seconds for the time to engage and begin

counting down before switching zones. The timer display (6) will

revert to the soonest time to end.

• Touch the timer minus and plus setting sensors (5 & 7) repeatedly

to cycle through the zones until the timer activity indicator for the

desired zone is lit. Each press will cycle the zone timer one zone to

the right. The zone for which timer adjustment is active will display

a bright clock symbol. Any zones which already have a timer set will

display a dimly lit clock symbol.

• Next, use the timer plus setting sensor (7) and the timer minus

setting sensor (5) to set the desired timer duration. Wait for

approximately 4 seconds for the time to engage and begin

counting down before switching zones. The timer display (6) will

revert to the soonest time to end.

To cancel the timer

• If multiple zones are in use then you will need to touch the timer

15

minus and plus setting sensors (5 & 7) repeatedly to cycle through

the zones until the timer activity indicator for the desired zone is

illuminated brightly.

• Reduce the time on the timer display (6) to 0.00 using the timer

minus setting selector (5). Wait for approximately 4 seconds for the

timer to confirm cancellation before moving on to another zone.

To set the minute minder

• Switch the hob on using the on/o sensor (9) if necessary.

• With no heat level set, touch the timer minus setting sensor (5) and

the timer plus setting sensor (7) simultaneously. The timer display

(6), and the clock symbol beneath it, will illuminate. If a heat level

is set, press the minus and plus setting sensors simultaneously

as many times as necessary until the clock symbol between the

timer sensors is lit.

• Next, use the timer plus setting sensor (7) and the timer minus

setting sensor (5) to set the desired minute minder duration. The

entry will confirm after approximately 4 seconds and begin counting

down.

• Once the set time has elapsed, an acoustic signal will begin to

sound for approximately two minutes. To cancel this signal, press

the timer minus setting sensor (5) and timer plus setting sensor (7)

simultaneously.

To cancel the minute minder

• Press the timer minus and plus setting sensors (5 & 7)

simultaneously to activate timer adjustment (signified by solidly lit

decimal point) and then reduce the time on the timer display (6) to

0.00 using the timer minus setting selector (5).

16

Pause function

The hob is equipped with a pause function that allows the user to

suspend the hob's operation for a brief period of time and to easily

continue cooking when convenient from the previously assigned

settings. This is particularly useful when your attention is drawn from

the hob, i.e. answering the door.

To activate the pause function

• At least one hob zone must be active. Press the ‘pause function

sensor’ (8). All cooking zone indicators will show a pause symbol (II)

and the pause function sensor LED will illuminate.

To deactivate the pause function and resume cooking

• Press the pause function sensor (8) so that the Pause function

LED goes out. A heat setting slider will then illuminate indicating

a swiping motion. Run the ball of your finger from left to right

to deactivate the pause, as the light indicates. The hob should then

resume cooking as it was before the pause function was activated.

Please note: The pause function can only be used for a maximum of

10 minutes. If the hob is not reactivated within this time then the hob

switches itself o.

The pause sensor can be used to restore the last-set cooking

settings if the on/o sensor (9) is accidentally activated and the hob

switched o during use. Simply switch the hob back on using the on/

o sensor (9) and press the pause function sensor (8). This feature

is only available for approximately 7 seconds after the hob has been

switched o.

17

Once power has been restored the pause function LED will flash to

indicate that the previous settings can still be restored.

Keep warm function

Each zone is equipped with a keep warm function that is designed to

keep food at a stable temperature. This allows for the serving of food

to be delayed and also for the melting of butter or chocolate.

• A flat-bottomed pan must be used so that the temperature can be

accurately measured by the detector within the heating zone.

• Due to the potential for the spread of bacteria it is not advisable to

keep food warm for more than two hours.

• There are three temperature levels that can be set: 42°C, 70°C and

94°C.

To activate the keep warm function

• Touch the desired zone’s keep warm function sensor (12) either

once, twice or three times.

• Touching the keep warm function sensor (12) once will activate the

42°C heating level.

• Touching the keep warm function sensor (12) twice will activate the

70°C heating level.

• Touching the keep warm function sensor (12) three times will

activate the 94°C heating level.

Please note: The keep warm setting indicators will display the ( )

symbol when the 42°C heating level is active, the ( ) symbol will be

displayed when the 70°C heating level is active and the ( ) symbol

18

will be displayed when the 94°C heating level is active. The cooking

zone indicator will display a .

To deactivate the keep warm function

• Touch the relevant zone’s keep warm function sensor (12) the

required number of times until the display reads ‘0’ again.

Please note: Any zones that are still hot to the touch will display an

' ' provided the mains power supply is not interrupted.

Bridge function

The hobs are equipped with a bridge function which allows you to

use two heating zones with just one zone's controls. This function is

intended for use with pans such as fish kettles and is available for all

zones. However, only vertically aligned zones can be bridged.

To bridge zones

Touch both heat setting slider sensors (11) of the zones that you want

to bridge. A successful zone bridge will be signified by the bridge

function indicator (4) of both zones illuminating. Only one cooking

zone indicator (2) will be lit however, and it is this zone’s controls that

should be used to control the bridge.

To cancel the bridge

Simply touch the same two sliders that were used to activate the

bridge function. If the bridge has been successfully cancelled then

the two zone indicators that were bridged will each display a ‘0’. The

zones will now be individually operational.

19

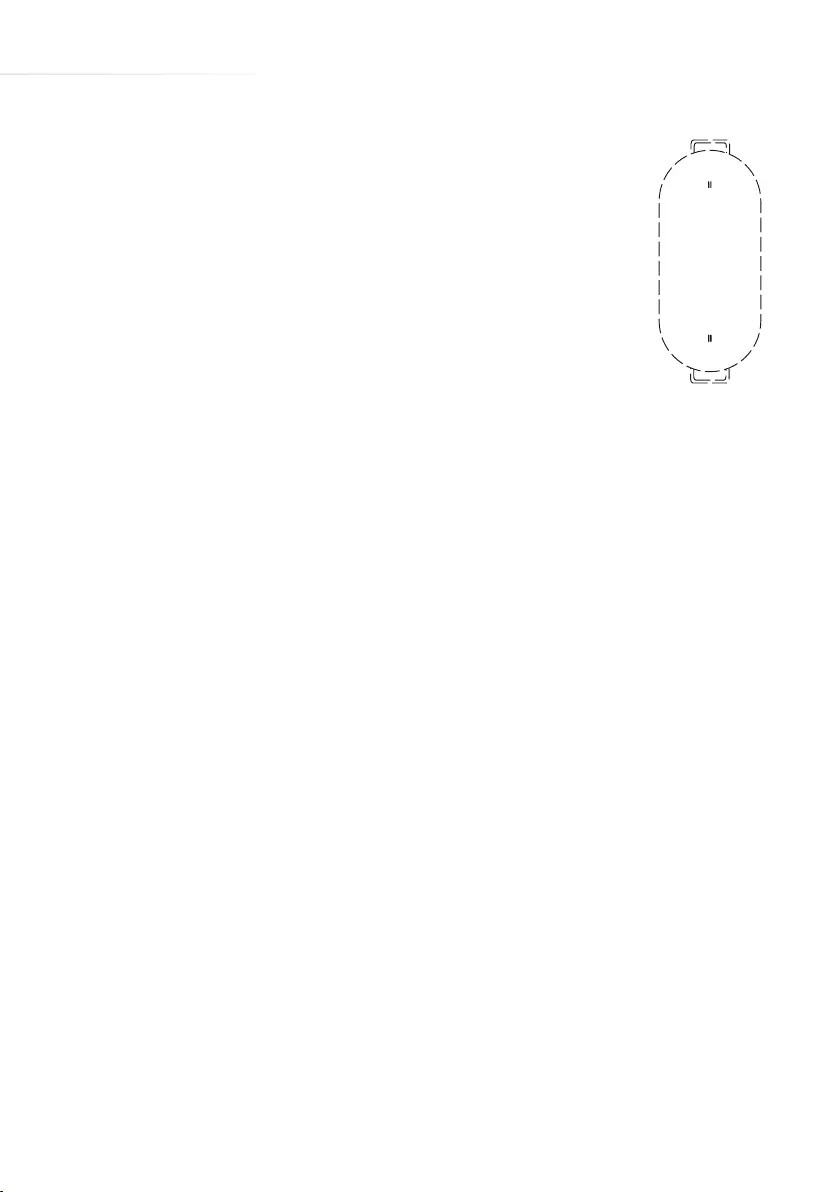

Please note: Pans placed on bridged zones must always cover the

vertical markings (II) on the zones;

Control lock

To prevent accidental use or inadvertent setting

changes, the hob has a control lock which disables

controls. Disconnecting the appliance from the mains will

deactivate the control lock.

To activate the control lock

Turn on the hob, set a power level if required, and then touch and

hold the lock sensor (10) for approximately 1 second. The hob should

beep and the LED above the sensor should illuminate. The hob will

now be significantly more protected from inadvertent use. The on/o

sensor (9) can still be used to switch the hob o but when it is turned

back on the lock will still be active.

To deactivate the control lock

To switch o the lock, switch on the hob if necessary and then touch

and hold the lock sensor (10) for approximately 1 second. The hob

should beep and the LED above the sensor should extinguish. The

hob should now be usable as normal.

Safety key lock

To further protect the hob from accidental use or to help prevent

children from activating the hob, it also features a more intricate safety

key lock.

20

To activate the safety key lock

Turn on the hob but do not set a power level on any zone. Touch the

lock sensor and the pause sensor simultaneously, release them and

touch the lock sensor again. This must be done within 10 seconds

of switching the hob on. An ‘L’ symbol will appear on all displays to

confirm that the safety key lock is active. You can switch the appliance

o when the lock is active, but it will remain active when you switch

the appliance back on.

To deactivate the safety key lock

• To switch o the safety key lock completely, switch on the hob

if necessary and touch the lock sensor and the pause sensor

simultaneously, release them and touch the pause sensor again.

• To switch o the safety key lock temporarily, switch on the hob

if necessary and touch the lock sensor and the pause sensor

simultaneously. This will mean that the safety key lock will be active

again the next time you switch on the hob and is useful if you want

the controls to be locked all of the time.

Residual heat indicators

The hob is equipped with residual heat indicators to warn when zones

are still hot to the touch after use. The symbol ‘ ’ will show in a zone’s

indicator for a preset period of time after the hob has been used.

IMPORTANT: You should avoid touching any zone whilst the hob is in

use or whilst residual heat indicators are displayed. In the event of a

power cut or failure the residual heat indicators will not illuminate after

the power supply is restored, nor when there is no power supply to

21

the hob, yet the hob zone(s) may still be hot so extra care must be

taken.

Auto-heat function

Every zone is equipped with an auto-heat function, which reduces the

warming up time for the zone.

To activate the auto-heat function on a zone

• Simply set the desired power level using the heat setting slider

sensor (11). Hold your finger in the same position on the slider

sensor for approximately three seconds, until the letter 'A' appears.

• The display will alternate between the set power level and ‘A’ for a

preset period of time, before reducing the power to the originally

selected heat setting. The duration of each auto-heat setting's

limiter is shown in the table below.

To deactivate the auto-heat function

• Simply set the desired power level using the heat setting slider

sensor (11).

Please note: The auto-heat function is not compatible with the keep

warm function or P (Boost).

48

1

Zone Heat Setting

Maximum

Operating Time

(seconds)

234 5 6 7 8 9 P

144 228 372 408 120 168 216 - -12

22

Using your extractor

To switch the extractor on and adjust the speed

• To switch the power on, touch and hold the on/o sensor for

approximately one second. The extractor should turn on at the

default speed of 2 (represented by 2 solid red bars).

• Use the setting slider to adjust the speed between levels 1 and 4.

To switch the extractor o

• To switch the power o, touch and hold the extractor on/o sensor

for approximately one second.

To set a 10 minute shut o timer

• Touch the timer sensor when any speed is active. This will activate a

10 minute timer, after which the extractor will switch o.

Grease filter saturation

• After approximately 30 hours of total operation, the speed indicators

will all flash simultaneously. This is a sign that the grease filters are

due to be cleaned. Remove the metal grid and the grease filters,

clean the filters using warm, soapy water, dry them and place them

back into the appliance. Press and hold the extractor timer sensor

for approximately 3 seconds when the appliance is on standby to

reset the function.

Fig.4

23

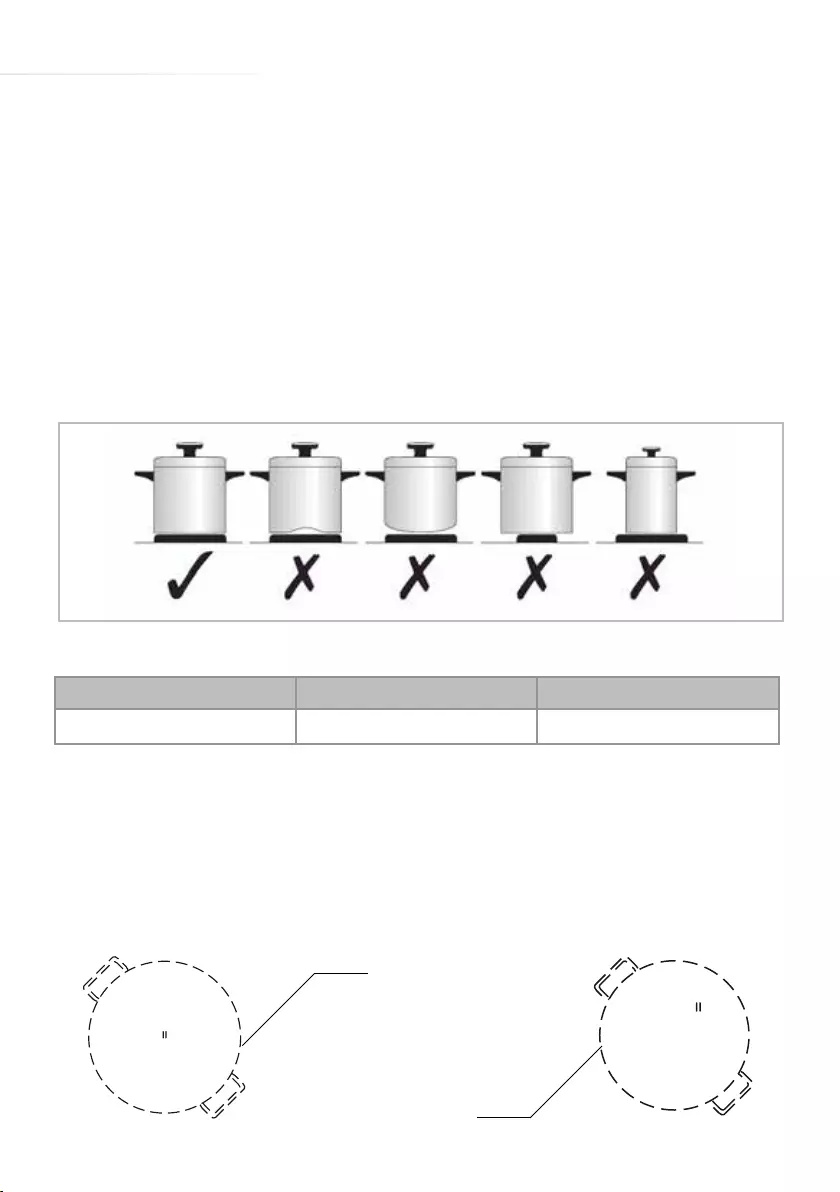

Ecient use of your hob

The hob is equipped with zones designed to accommodate most

shapes and sizes of pan. For best results, only use pans with flat

bottoms. The most ecient use of the hob is shown below, where the

pan and zone are correctly chosen.

Use pan lids where possible to minimize the energy usage of your

appliance.

Pans placed on the zones must always cover the vertical markings

(II) on a zone. When bridged, the pan(s) must cover both zone’s

markings. Locating the centre of a pan on the zone markings will

ensure optimum eciency.

Fig.5

Zone Size Minimum Pan Size (mm) Maximum Pan Size (mm)

220 x 184mm 110 220

Best position

Satisfactory position

24

It is very important that the pans used on the hob are made of a suitable

material and have the correct type of base. The base of the pan and

the hob top must be clean before use to prevent any scratches on the

hob top.

Please note: Extra care should be taken if cast iron pans are used as

these have coarse bases which may damage the hob top.

Care and maintenance

Always disconnect the appliance from the power supply before

undertaking any cleaning or maintenance.

Important:

• Steam cleaners must not be used when cleaning this appliance.

• You should use a non-abrasive cleaner to clean the hob top. Any

abrasive cleaner (including Cif) will scratch the surface and could

erase the control panel markings.

• Sugar and starch can cause permanent damage to the surface of

the hob. Wipe away any spillages immediately but be careful given

that the hob top will be hot during and after usage.

• Avoid letting pans boil over where possible to ensure that the need

for cleaning is minimal.

• Always use a soft sponge or cloth where possible. Utensils such as

scouring sponges and some brushes could cause scratches to the

hob top.

• Do not pour any liquids down the extractor area. If any spillages

do occur, switch power o to both the hob and extractor. Allow the

hob to cool and remove the metal grid, grease filters (and charcoal

filters if present), magnetic centre bar and dry up the spillage.

25

Type of residue Clean with Cleaning advice

Light Cleaning sponge

and soft cloth

Wipe over the zone to be cleaned with

a sponge and hot water, and then wipe

o with a soft dry cloth.

Accumulated baked-

on stains/dirt, sugar

spills or melted

plastics

Cleaning sponge

or glass scraper

and soft cloth

Wipe over the zone to be cleaned

with a sponge and hot water, using a

ceramic scraper to remove any large

marks or stains and then wipe o with

a soft dry cloth.

Rings and hard water

residues

White vinegar and

soft cloth

Pour a small amount of warm white

vinegar onto the stain, leave it to stand,

and then wipe o with a soft dry cloth.

Shiny metallic streaks

Cleaning agent for

vitroceramic glass

etc.).

Use specialist vitroceramic glass

cleaner (preferably one with silicone

for its protective properties)

9 fast frying steaks

Ceramic glass cleaning guide

If your hob is not working:

1. Check that the zone is switched on.

2. Check that the mains supply has not been switched o.

3. Check that the fuse in the spur has not blown.

In the event of a fault with the hob please advise CDA Customer Care.

Contact CDA Customer Care

A: Customer Care Department, The CDA Group Ltd, Harby Road,

Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003

E: customer.care@cda.eu W: www.cda.eu

26

Troubleshooting - hob

On switching on

You observe that Possible Causes What should you do?

The hob does not work and

the lights on the control panel

do not switch on

The hob is not

connected to the

power supply or the

power supply is faulty

Check the electrical

circuit breaker and fuses

The hob is not working and the

display shows a non-standard

graphic

The electronics

are not functioning

correctly

Call CDA Customer Care

The hob is not working and the

display shows

The safety key lock

is on

Switch o the safety key

lock (see page 7)

fast frying steaks

Problem Possible Causes Possible Remedy

The appliance does not

work and no indicators are

lit.

The appliance has no

power.

Check the fuse and

replace if blown.

Sensor fields do not

respond when touched.

Appliance is not turned on.

A sensor field has been

touched too briefly (less

than a second).

Multiple sensors have been

touched/covered at the

same time.

The safety key lock is

engaged.

Turn on the appliance.

Touch the sensor field

again and for longer.

Only touch one sensor

field at a time unless

instructed otherwise.

Disengage the safety

key lock as per page 20.

The appliance does not

respond and emits an

extended beep

Improper use (wrong

sensor fields touched or

touched too briefly).

Switch the appliance o

via the on/o sensor and

at the mains and then

switch the power and

appliance on again.

The appliance switches

itself o

No heat level has been

set within 10 seconds of

activating the appliance.

Sensor fields covered or

dirty.

Switch on the appliance

and set zone and heat

setting without delay.

Uncover or clean the

sensor fields.

A cooking zone switches

itself o and a residual heat

indicator is shown.

Operating time limiter has

activated.

Sensor fields covered or

dirty.

Electronic components

have overheated.

Nothing (see page 12).

Uncover or clean the

sensor fields.

Nothing. Allow appliance

to cool.

27

Should any error code show on the zone displays, or the above

steps not resolve an issue, please contact CDA Customer Care for

assistance. Contact details are on page 25.

IMPORTANT - PLEASE NOTE: In the event of any breakage, crack

or cracking – even minimal – of the vitroceramic glass, immediately

disconnect your appliance to prevent a risk of electric shock and

contact CDA Customer Care.

You observe that Possible Causes What should you do?

The hob has stopped

operating. The hob beeps

and ER03 is displayed on

the zone display

There was an overflow or

an object is in contact with

the control panel

Clean the hob or

remove the object, and

begin cooking again

The hob has stopped

operating and the display

shows E2, ER21 or ER40

The electronics have

overheated

Allow the hob to cool

down.

See the Installation

section to check the

ventilation requirements

have been met

After turning on a zone, the

zone display shows

The cookware used is not

suitable for induction or

is less than 11cm on the

160mm zones, or 145mm

on the 200mm zones

See the section on

cookware for induction

The saucepans make noise

during cooking or your hob

makes a clicking sound

during cooking

This is normal with some

types of cookware. This is

caused by the transfer of

energy from the hob to the

cookware

Nothing. There is no

risk, neither to your hob

nor to your cookware

The fan continues to

function for a few minutes

after the hob is turned o

Cooling of the electronic

components.

Working normally

Nothing.

Problem Possible Causes Possible Remedy

Residual heat indicator

has extinguished despite

zone(s) still being hot.

The appliance has no

power.

Check the fuse and

replace if blown.

Hob top is broken, cracked

and/or chipped.

Stop using the appliance immediately and switch the

appliance o at the mains. Contact CDA Customer

Care to arrange a repair.

The appliance makes a

buzzing noise.

Buzzing noises are normal whilst the hob is in use

(inductor modules functioning) and after the hob has

been used (cooling fan in operation).

The appliance makes

noises similar to whistles,

hisses and pops.

These noises are normal. If several cooking zones

are used at once then the hob can make hissing

or whistling noises due to the frequencies used to

power the inductor modules. Popping noises can

often be heard when pans are being heated.

Cooking zone or multiple

zones do not work.

One or more zones display

a “ ” symbol

The internal electronics

may be faulty and in need

of a reset.

The selected pan is not

suitable for use with this

hob.

Reset the appliance by

disconnecting it from the

mains for a few minutes

before reconnecting it.

See page 8 for more

information on selecting

a correct pan.

28

Troubleshooting - extractor

If your extractor is not working:

1. Check that the mains supply has not been switched o.

2. Check that the fuse in the spur has not blown.

3. Check that the red power switch on the wiring box has not

been turned o (page 3).

4. Check that the connection lead from the wiring box to the

extractor/hob has not popped out and is fastened properly.

If the performance is not matching the demands of cooking:

Increase the speed if possible. Check that the grease filters are clean,

seated properly and are clear from obstructions. Also, remove the

grease filters (and charcoal filters if present) and check, visually, that

nothing is obstructing the air passages. Switch o the power to

the hob/extractor before doing this. If none of these steps help, try

opening a window or similar means of ventilation provided it is safe to

do so.

If you notice speed 4 reverting to speed 2 or 3 after approximately

6 minutes:

This is not a fault. Regulations issued by the European Commission in

January 2015 dictate that internal motor extractors with a maximum air

capacity higher than 650m/h must be equipped with a timer device

that automatically switches the speed from ‘4th’, or intensive, after 6

minutes of operation.

29

If the keys are (temporarily) responding incorrectly or not at all:

If the power supply to the extractor is cut and then restored, the

appliance will run an approximately 15 second diagnostic programme.

During this time the controls may not function properly. There may

also be debris, grease or similar stopping the controls from working

properly. Clean this o if so.

If the speed indicators are flashing:

This is not a fault. After 30 hours of usage all speed indicators will

flash to signal that the grease filter needs to be cleaned. Press the

timer key to reset after cleaning.

If the extractor switches itself o:

The extractor features an automatic switch-o that activates after

approximately 4 hours of continued use if no settings have been

changed.

If any of the potential resolutions in this guide do not resolve your

issue, please contact CDA Customer Care using the contact details

below.

Contact CDA Customer Care

A: Customer Care Department, The CDA Group Ltd, Harby Road,

Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003

E: customer.care@cda.eu W: www.cda.eu

30

Installation - preparation

The installation of this product must be carried out by suitably

qualified personnel. Always wear adequate PPE (Personal

Protective Equipment) for the tasks at hand. This product may

have sharp edges. This is a 2 person minimum install.

Unpacking the appliance:

Take care not to drop any parts. Check any parts for visible signs of

damage. If any components are damaged, contact your retailer and do

not proceed with installation.

Fitting position of the hob:

This appliance must be, when installed, a minimum of 50mm from any

back wall and a minimum of 55mm away from any adjacent vertical

surfaces, e.g. a tall cupboard end panel. The 55 may be reduced

to 50mm if the adjacent surface is resistant to fire (tiles or steel for

example). The dimensions for this are shown in Fig.7 on page 32.

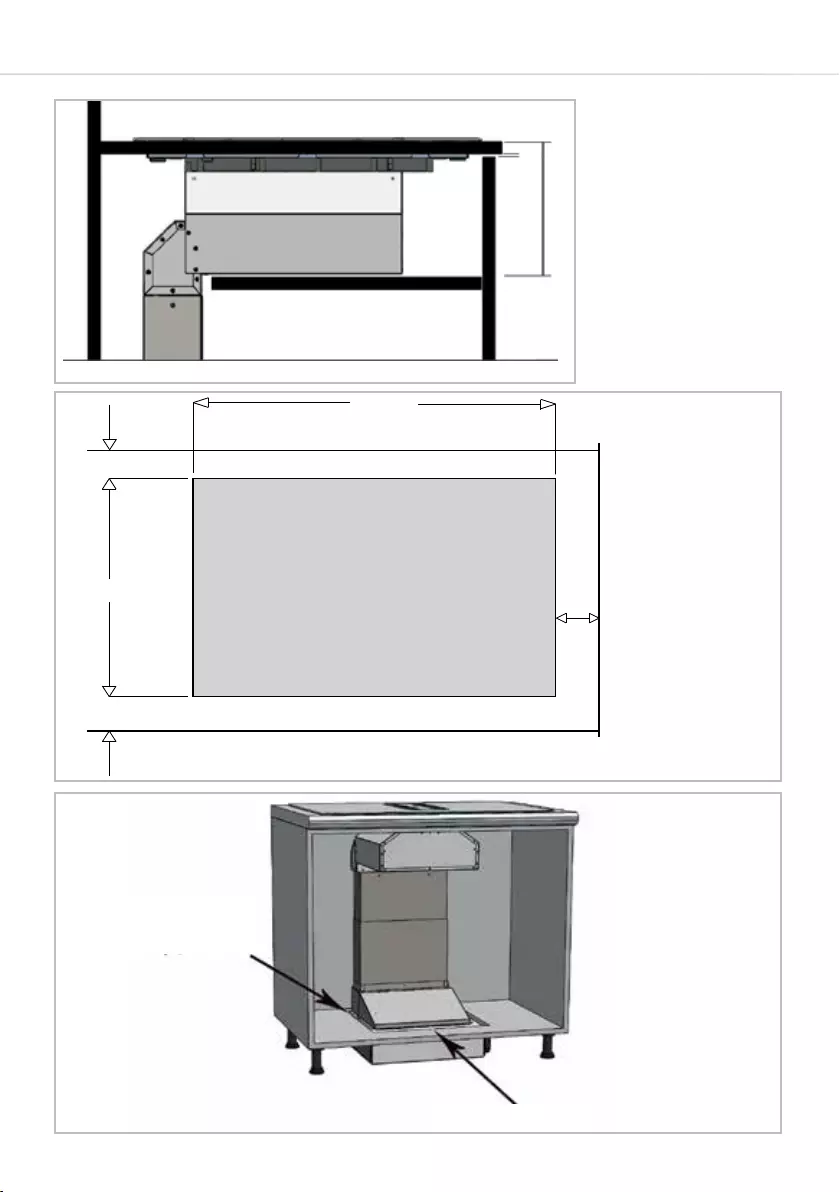

Ventilation requirements:

This appliance must be installed to allow air to flow freely to the air

intakes and from the air outlet. An air gap of 205mm is recommended

immediately below the hob (this takes into account the depth of the air

box), and a 5mm minimum gap in the worktop, as per Fig. 6.

Failure to allow sucient ventilation could cause problems with

operation or damage to the hob and constitutes incorrect installation,

which is not covered by the product’s warranty.

Wall furniture requirements:

The minimum height of any cabinet immediately above the hob is

31

900mm. The minimum height of any adjacent units (including light

pelmets) is 400mm, unless they are manufactured from a material

resistant to fire (steel, for example).

Furniture requirements:

We recommend fitting this appliance within a 900mm or 1000mm

base unit. Ensure that the unit you fit the appliance within does not

hamper or foul the ventilation fans on the underside of the hob(s). A

minimum gap of 50mm all around the underside/edges of the hob

(with the exception of the air box area, Fig. 6) applies. Normally, your

unit will need a 410mm x 410mm hole for the motor box (Fig. 8).

If the appliance’s extracted air is to be re-circulated through

charcoal filters, a 5mm ventilation gap in the plinth all around the

entire perimeter of the island, or front of the unit run, will need to

be included. It is also possible to fit a ventilation grill in the plinth

line where the motor has been installed to allow air to circulate.

Important notes:

• Do not position this appliance above a refrigeration unit. The heat

generated may cause the refrigeration unit to fail.

• This appliance is designed to be installed into cabinet units capable

of withstanding temperatures of 100°C +.

• Never place perishable foods, cleaning products or flammable items

in any cupboard below the appliance.

• Ensure that the top rail is removed prior to installation, and that

no unit cross member is blocking the hob air outlets.

• If the appliance is to be located above an accessible unit or

working drawer(s), a partition panel must be fitted first, as per

Fig. 6 on page 32.

32

min. 50 mm

20 mm

3

min. 50 mm

20 mm

3

5mm

205mm

Fig.6

Rear Wall

Front edge of worktop

Adjacent vertical surface

(cupboard etc. -

Measurement applicable

to both sides.)

750

490 Min.

Cut-out

65

Min.

65

Min.

55

Fig.7

410mm

410mm

Fig.8

33

Flush or inset installation of the hob:

Depending on whether you would like the hob to be inset or flush fit

into the worktop, the cutout requirements are slightly dierent:

IMPORTANT: When fitting the hob into the worktop, you should never

seal it in place with silicone sealant or similar means. The appliance

may need to be removed at a later date for servicing.

The appliance should be installed with sucient ventilation so

ambient temperatures (e.g. if an oven is installed nearby) do

not exceed 60°C. Such temperatures will cause issues with the

controls.

780

520

750 490

51

2 mm

5.5 mm

5.5 mm

2 mm

780

520

784 524

51

750 490

R.6

R.4

Inset installation

Flush installation

6 mm

Fig.9

34

Installation - extractor system dimensions

570

Max.

205

min. 50

435

400 93

296

140

365

165

200

33

400

200

400 400

110

90

342

99

35

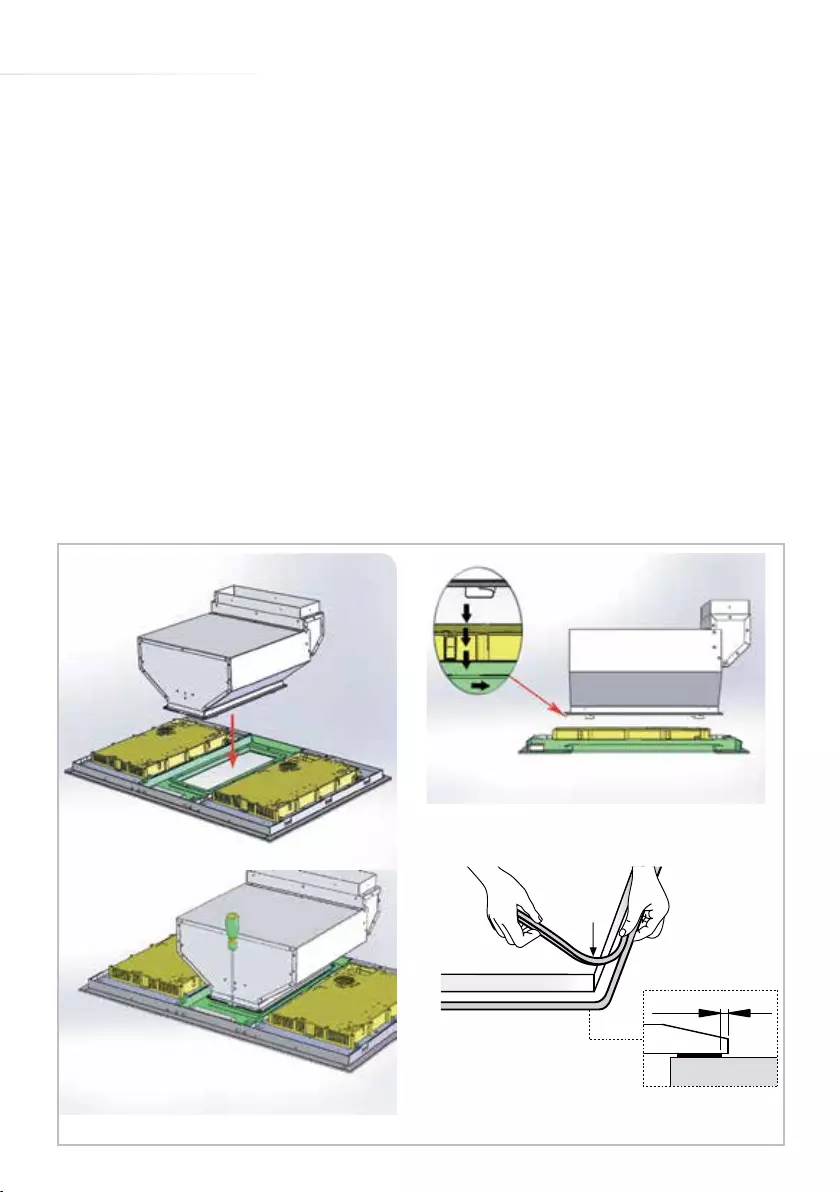

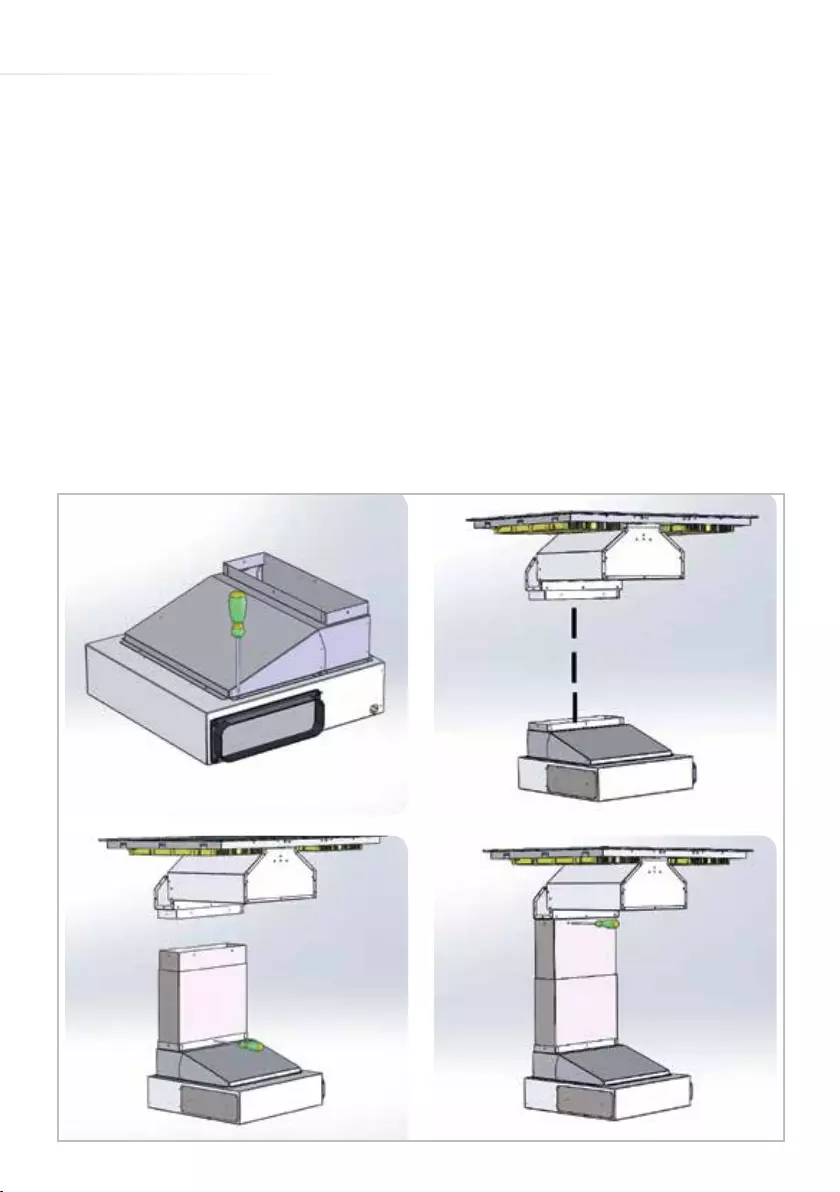

Installation - assembly

Always wear adequate PPE (Personal Protective Equipment) for

the tasks at hand. This product may have sharp edges.

Lay a clean, soft towel (or similar) somewhere smooth and flat. This will

protect the hob and the surface below. Remove the hob, turn it upside

down and place it on the towel. Place the airbox onto the extractor

opening as per Fig. 10. There are hooks and slots on the airbox and

hob respectively; slot the airbox in and push in the direction that the

hooks dictate, as per Fig. 11. Fasten the airbox to the hob using the

metric screw provided and the screw hole near the extractor opening

(Fig. 12).

~ 2 mm

Fig. 10 Fig. 11

Fig. 12 Fig. 13

36

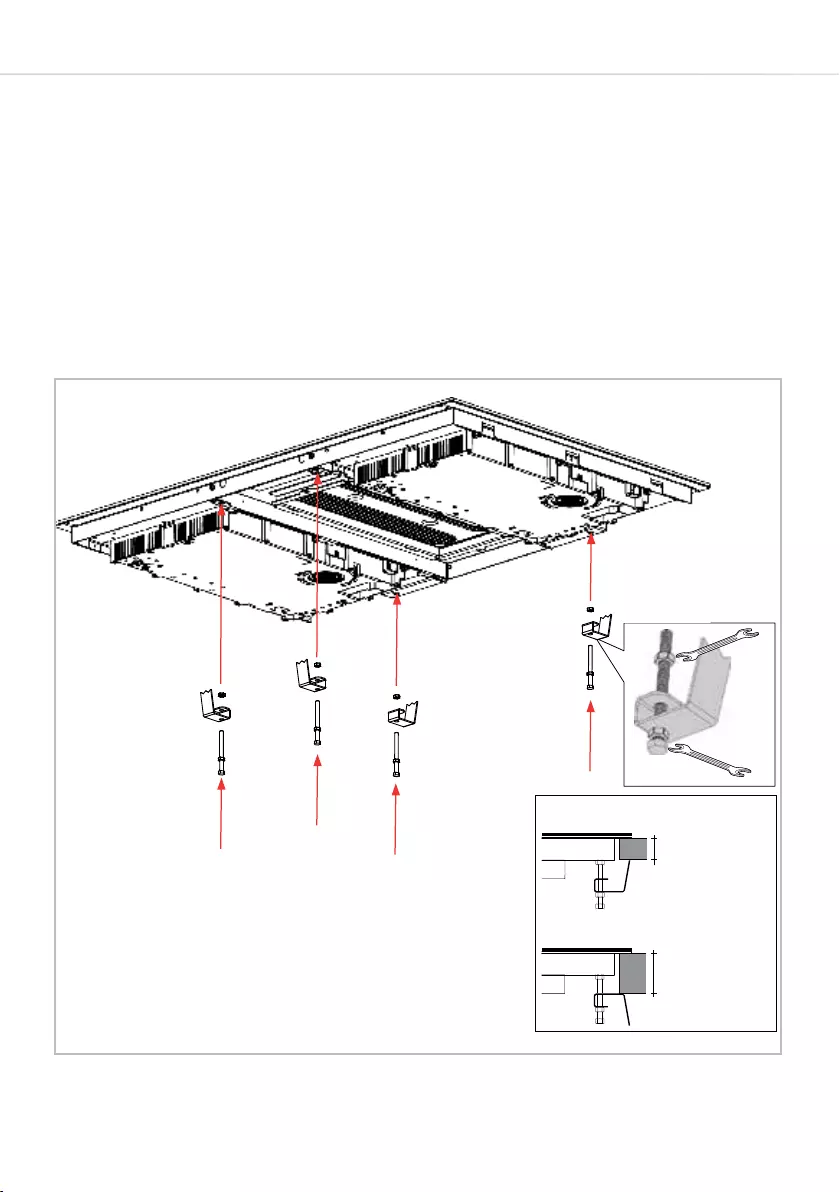

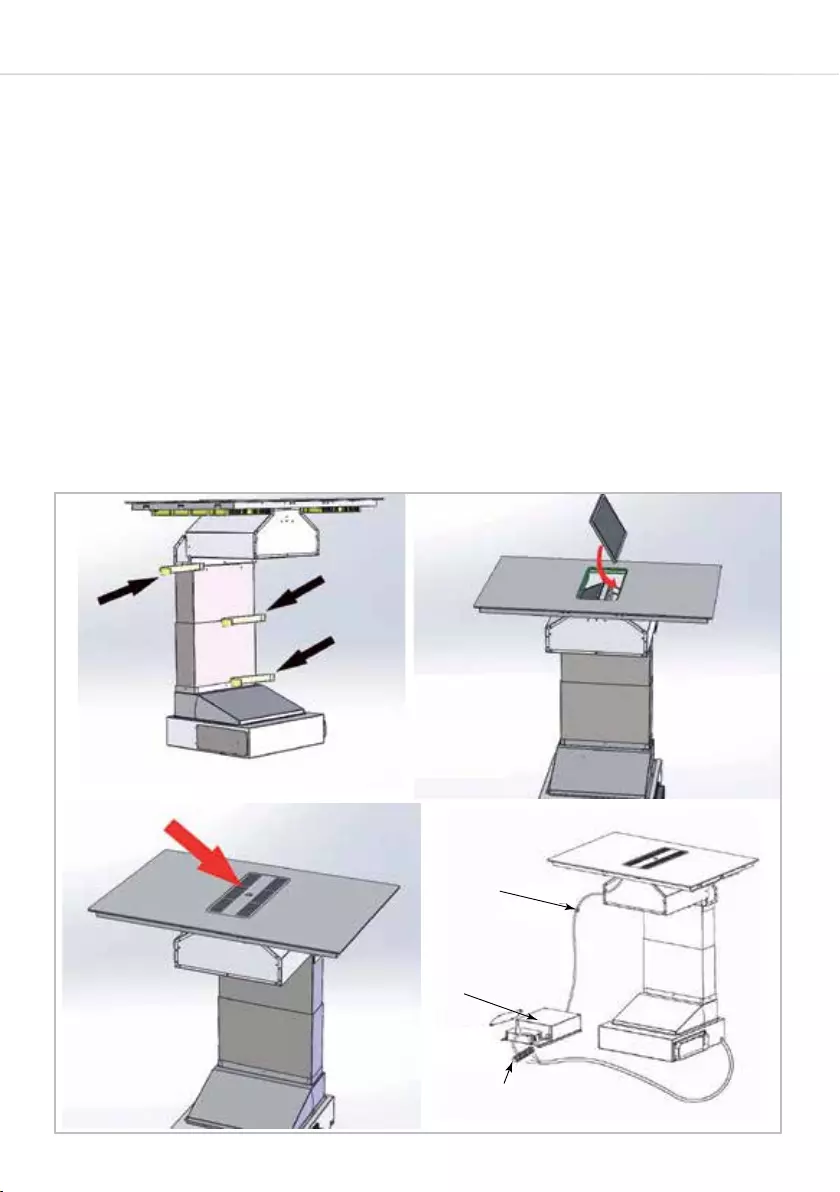

Apply the supplied hob seal to the whole of the underside of the

hob as per Fig. 13. Do not leave gaps in the seal. Fit the hob into the

worktop opening, taking care not to damage the appliance or the

units/worktop. Fit the fixing clips to the underside of the hob, in the

pre-threaded metal holes, as per Fig. 14. The orientation of the clips

depends upon the thickness of the worktop, as per parts A and B.

Ensure the clips are fastened tightly to the worktop but do not use

power tools to do this.

Please note: If space is limited, you may need to remove the airbox to

fit the fixing clips. If you do, replace the box as per page 35.

A

B

min 10 max 30 mm

min 30 max 50 mm

A

B

min 10 max 30mm

min 30 max 50mm

Fig.14

37

Locate the motor box and attach the conduit chamber to it using the

screws provided, as per Fig. 15. Loosely attach the chimney conduits

to the base section, raise them up to the hob extractor outlet and

fit them as though you were completing the conduit section install.

Whilst another person supports the sections, ensure that everything is

aligned and nothing is being strained or twisted. Then, if you haven’t

already prepared the area and provided you are running the ducting

under the unit(s), draw a 410 x 410mm square around the motor box,

remove the box and conduits and cut the hole in the base of the

unit. Replace all of the components in the same order as above and

secure the lower conduit to the motor box as per Fig. 17.

Fig.15

Fig.17

Fig.16

Fig.18

38

Raise the upper conduit section and secure it to the airbox as per Fig.

18 on page 37. Secure all of the connection areas with the supplied

tape as per Fig. 19. Fit the grease filters into the extractor aperture

as per Fig. 20. Leave the handles on the filters accessible (if you are

using charcoal filters, fit these before the grease filters). Place the

metal grate onto the extractor aperture, as per Fig. 21.

Make the connections as per Fig. 22. The connections between the

motor box and the wiring box are shown on a label on the wiring box

itself. In case this label is missing or damaged, it is shown in Fig. 24 on

page 42.

Connection

Connections

Wiring box

Fig.19

Fig.21

Fig.20

Fig.22

39

IMPORTANT: Secure the metal wiring box (indicated in Fig.

22) at least 10cm above floor level and at least 65cm from gas

appliances, heat sources and the hob/extractor surface of the

appliance itself. Do not place near water inlets or outlets.

Ducting

The ducting used should be rigid pipe of a constant diameter and

must be manufactured from fire retardant material, produced to BS

476 or DIN 4102-B1.

Wherever possible utilise rigid circular pipe which has a smooth

interior, rather than the expanding concertina type ducting. The

lengths of ducting with minimal eect on performance are as follows:

• 4 metres with 1 x 90° bend.

• 3 metres with 2 x 90° bends.

• 2 metres with 3 x 90° bends.

Please note: Ducting components and ducting kits are optional

accessories and have to be ordered, they are not automatically

supplied with the hood. Use of ducting of a lesser diameter than

the flanges supplied will aect performance and increase the noise

produced by the extractor. Longer ducting can be used but the

performance of the extractor will likely be reduced.

Note that the ducting should be secured and sealed to the vent outlet

pipe / valve using appropriate jubilee clips or securing means.

40

Connecting the ducting

You can use either the air outlet on the right of the motor box or the air

outlet on the left, depending upon the install requirements. If you need

to change the position of the outlet flange, cover the exposed side

with the blanking plate provided and four screws. The outlet which is

not to be used must always be covered with the metal blanking plate.

There are four flanges supplied to suit your install;

230 x 80mm to 150mm circular

230 x 80mm (this can be used for rigid rectangular ducting)

220 x 90mm (this can be used for rigid rectangular ducting)

218 x 55mm

If you are re-circulating through charcoal filters and not ducting

it outside, we recommend fitting the supplied flange that has a

measurement of 218 x 55 mm.

All flanges should be attached to the motor box and secured with a

suitable means and then sealed with the tape provided.

41

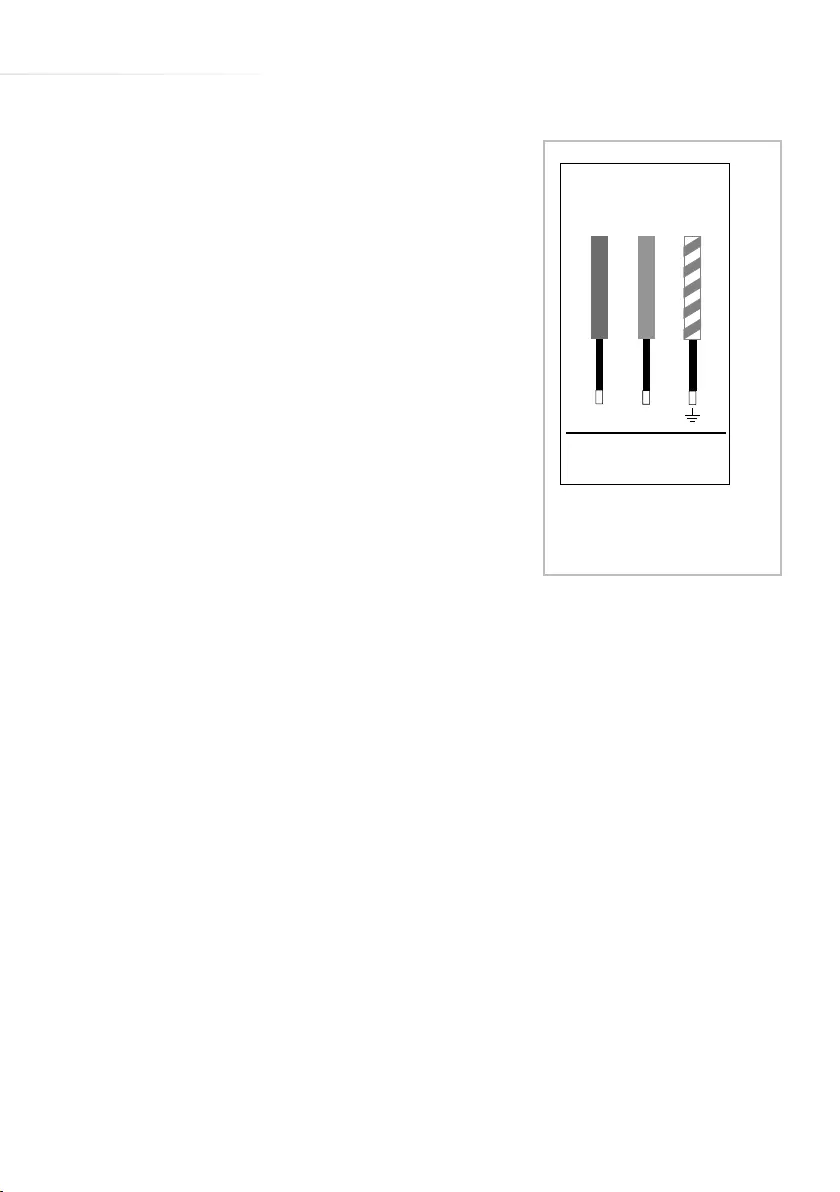

EYNG

N

UB

NB

L

Live L: BN - brown

Neutral N: BU - blue

Earth PE: GNYE -green/yellow

2 x 220 - 240V ~ 50 Hz

3 x 1.5mm²

Fig. 23

Mains electricity connection

Warning! This appliance must be earthed.

• The appliance must be connected by a

qualified electrician, who is a member of

the N.I.C.E.I.C. and who will comply with the

I.E.T. and local regulations.

• When installing this product we

recommend you seek the help of

another individual.

• The hobs are intended to be connected

to fixed wiring and are NOT suitable for

connection to a 13A plug or 13A supply.

• The hobs are intended to be connected

to fixed wiring by a double pole switch,

having a contact separation of at least 3mm in all poles.

The switch must be positioned no further than 2m from the

appliance and the switch must be accessible at all times.

• The extractor comes fitted with a 3A plug but can be connected

to fixed wiring by a double pole switch, having a contact

separation of at least 3mm in all poles.

Please note:

• The mains cable(s) must only be replaced by a qualified electrician

or service engineer and must be of equivalent or better rating (i.e.

3G 1.5mm, S1HF for the hobs and 3G 0.75mm HO5VV-F for the

extractor).

• Each hob is intended to be connected to the mains supply with a

cable of cross sectional area 1.5mm.

• The extractor is intended to be connected to the mains supply

42

with a cable of cross sectional area 0.75mm.

• The current rating of the fuse or circuit breakers protecting this

appliance should be marked on the socket outlets.

• Should the mains cables be damaged or need to be replaced,

contact CDA Customer Care to arrange a service visit. Contact

details are on the rear cover of this manual.

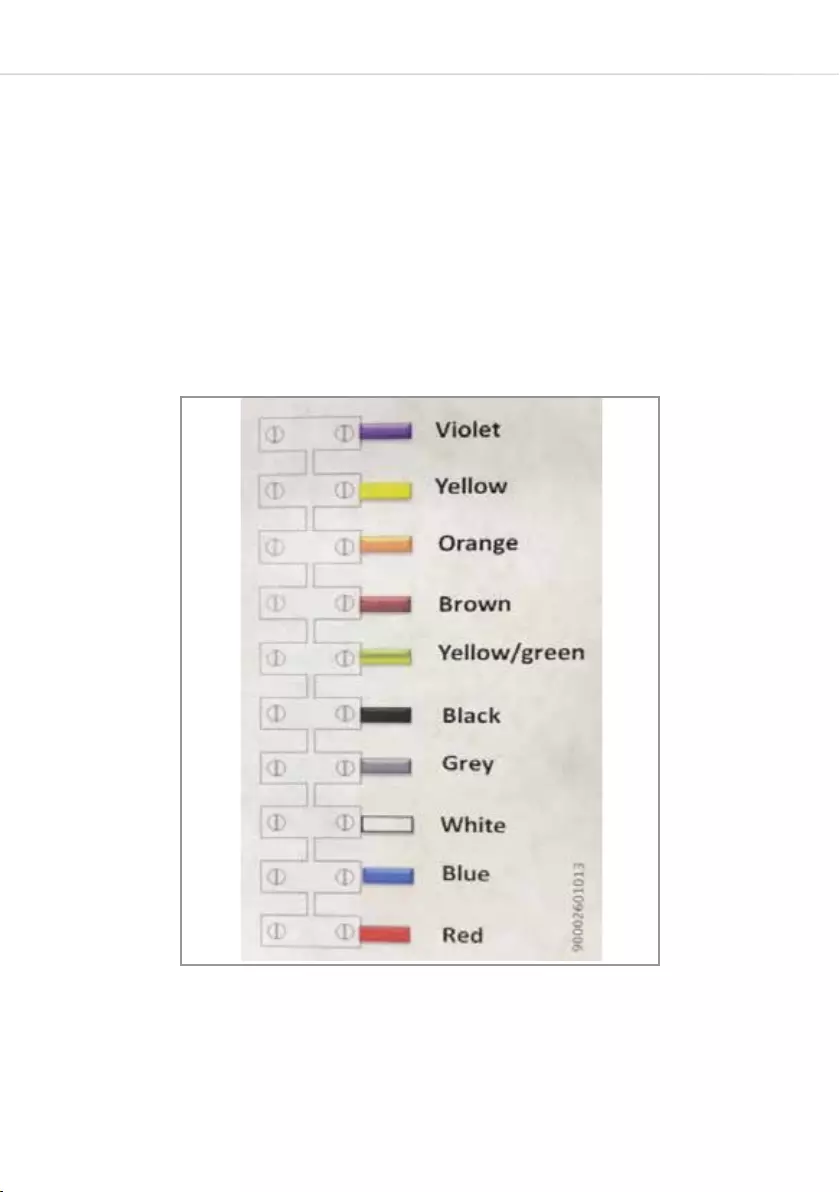

Wiring box connections:

Appliance electrical rating:

Hob(s): 7.4 kW (3.7 kW each)

Extractor: 168W

Fig. 24

43

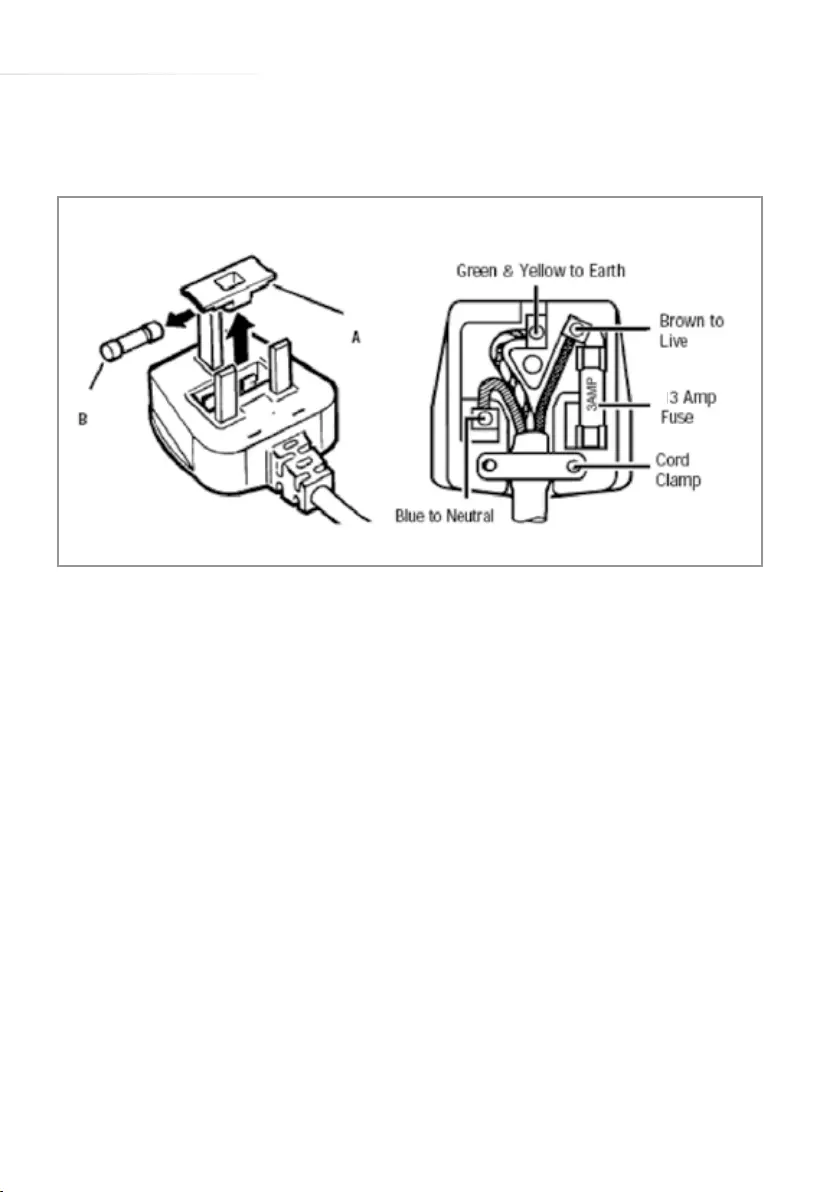

Extractor plug information

Warning! This appliance must be earthed.

The mains lead of this appliance has been fitted with a BS 1363A 3

amp fused plug. To change a fuse in this type of plug, follow the steps

below:

1. Remove the fuse cover (A) and fuse (B).

2. Fit a replacement 3A fuse, ASTA approved to BS 1362 type, into the

fuse cover.

3. Replace fuse cover.

Important: Do not use the appliance without the fuse cover in

position. Do not use the appliance nor plug it in if the plug is

damaged or any internal components are exposed in any way.

44

How to connect an alternative plug

If the fitted plug is not suitable for your socket outlet, then it should

be cut o and disposed of safely to avoid the risk of electric shock.

Ensure there is no power to the appliance if/when you do this! A

suitable alternative plug of at least 3 amp rating to BS 1363 should be

used.

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:-

• The wire which is coloured GREEN and YELLOW must be

connected to the terminal which is marked with the letter (E) or by

the Earth symbol or coloured GREEN and YELLOW.

• The wire which is coloured BLUE must be connected to the terminal

which is marked with the letter (N) or coloured BLACK or BLUE.

• The wire which is coloured BROWN must be connected to the

terminal which is marked with the letter (L) or coloured RED or

BROWN.

Electrical connection of this appliance must be carried out by a

qualified electrician.

Do not shorten the supply cable, the appliance may require removing

for servicing.

N.B. Ensure that the plug socket is situated in an easily accessible

place.

45

NOTES:

46

Attribute Symbol Value Units

CDA model HNE8FR Hobs

Builtin

4

Induction

cooking zones

Ø

cm

L

W

NA cm

EC Electric cooking FL:171/

FR:171/

RL:171/

RR:171

Wh/kg

EC Electric hob 171 Wh/kg

FL:22.0 x 18.4

FR:22.0 x 18.4

RL:22.0 x 18.4

Energy Eciency Information

For circular cooking zones or area:

diameter of useful surface area per

electric heated cooking zone, rounded

to the nearest 5mm

Heating technology (induction cooking

zones and cooking areas, radiant

cooking zones, solid plates)

Number of cooking zones and/or areas

For non-circular cooking zones or

areas: length and width of useful

surface area per electric heated

cooking zone or area, rounded to the

nearest 5mm

Energy consumption per cooking

zone or area calculated per kg

Energy consumption for the hob

calculated per kg

Type of hob

RR:22.0 x 18.4

47

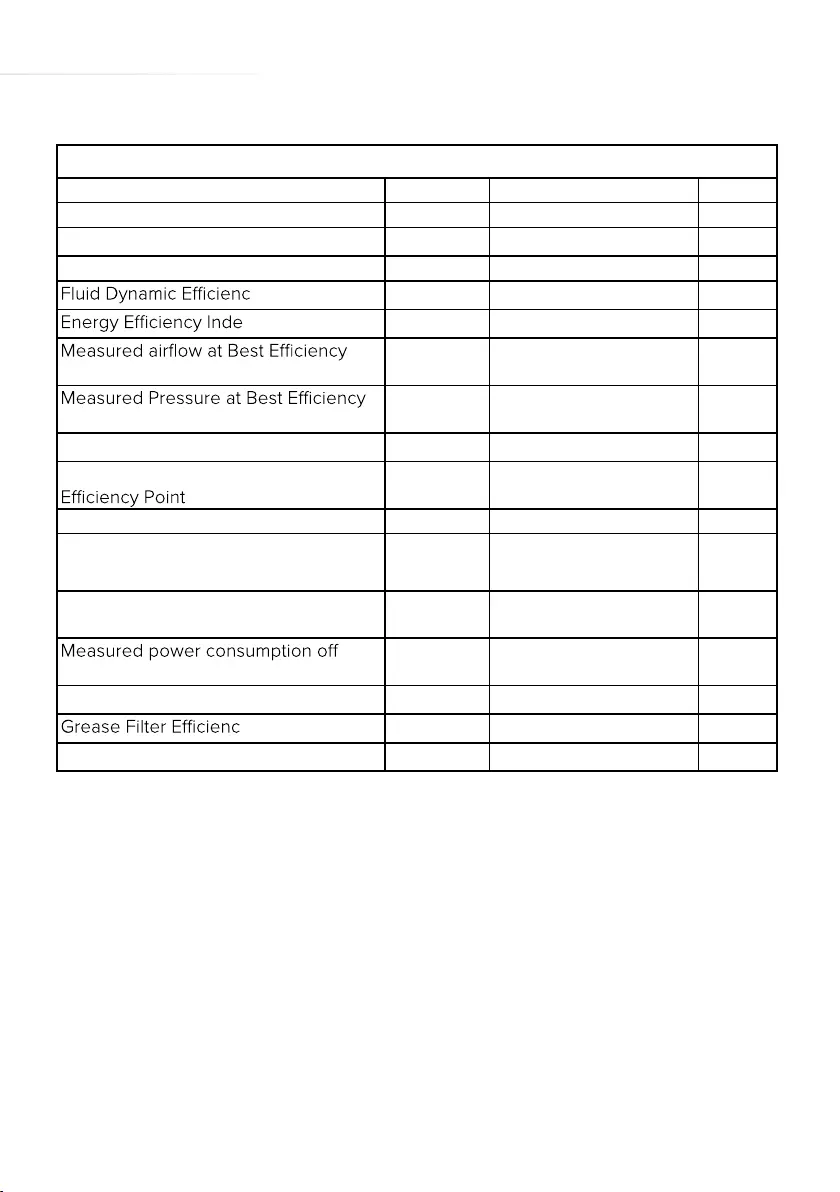

HNE8FR ExtractornoitacifitnedI ledoM

Annual Energy Consumption AECHood

61.6 kWh

Time increase factor f

y FDEHood 27.1 (B)

x EEIHood 56.9 (B)

Point

QBEP 336.2 m3/h

Point

PBEP 490 Pa

Maximum airflow QMAX 662 m3/h

Measured electric power at Best WBEP 168.9

N/A

N/A

W

Nominal lighting power WL W

Average illumination of the lighting

system on the cooking surface

EMiddle Lux

Measured power consumption in

standby

PS0.49 W

mode

PO0 W

Sound power level LWA 72 dBA

y GFEHood 75.6 (C) %

ELycneiciffe pmaL Hood 0.0 %

0.7

Energy Eciency Information

Attribute Symbol Value Units

www.cda.eu

Customer Care Department. The CDA Group Ltd, Harby Road, Langar, Nottinghamshire, NG13 9HY

T: 01949 862 012 F: 01949 862 003 E: customer.care@cda.eu

For service or queries relating to your product please contact:

The Customer Care Department on 01949 862 012 or email customer.care@cda.eu

For more information please contact:

The Sales Department on 01949 862 010 or email sales@cda.eu