Chief XFD1U User Manual

Displayed below is the user manual for XFD1U by Chief which is a product in the Signage Display Mounts category. This manual has pages.

Related Manuals

I N S T A L L A T I O N I N S T R U C T I O N S

Instrucciones de instalación

Installationsanleitung

Instruções de Instalação

Istruzioni di installazione

Installatie-instructies

Instructions d´installation

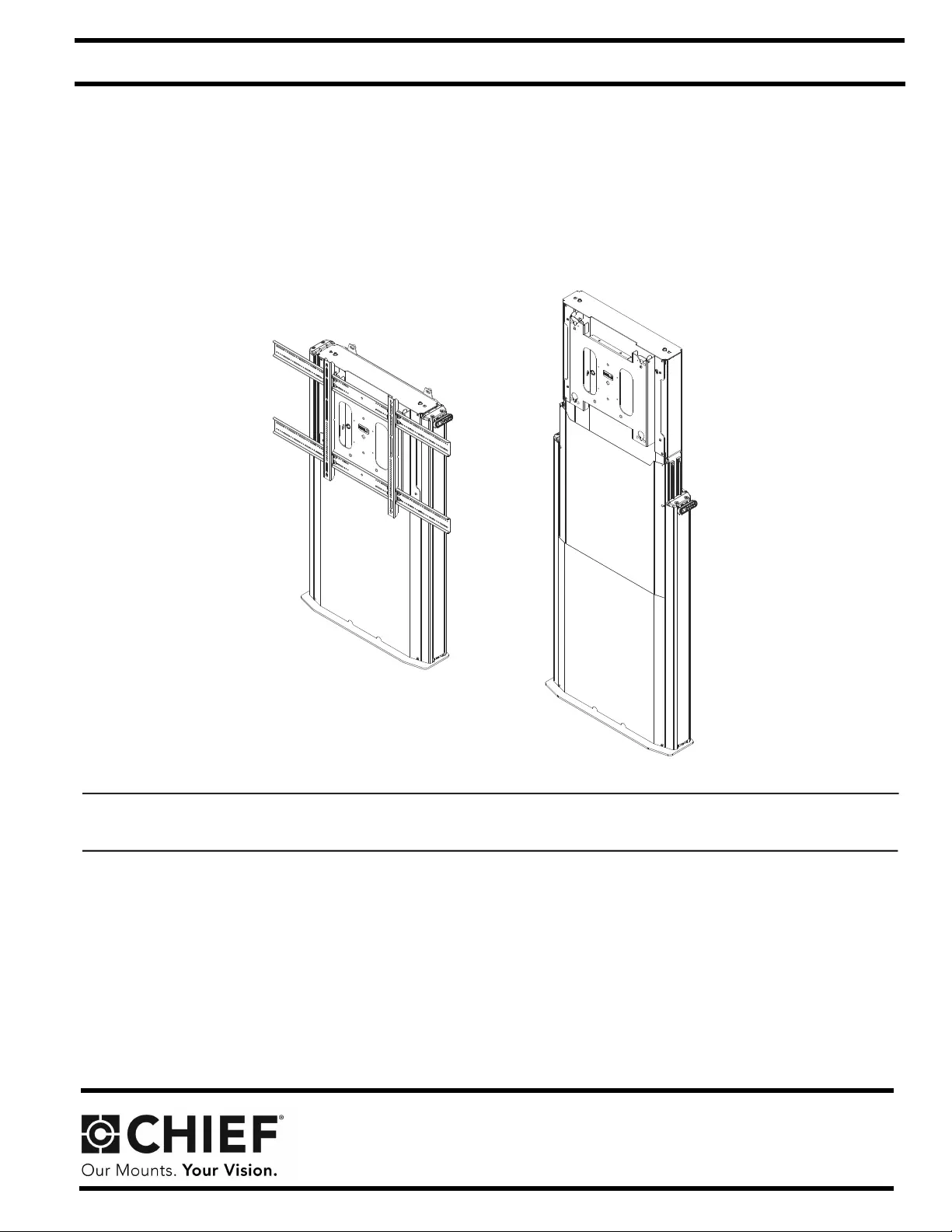

Electrical XL Height Adjustable Floor Stand

Spanish Product Description

German Product Description

Portuguese Product Description

Italian Product Description

Dutch Product Description

French Product Description

XFD1U

XFD1U Installation Instructions

2

DISCLAIMER

Milestone AV Technologies and its affiliated corporations and

subsidiaries (collectively “Milestone”), intend to make this

manual accurate and complete. However, Milestone makes no

claim that the information contained herein covers all details,

conditions or variations, nor does it provide for every possible

contingency in connection with the installation or use of this

product. The information contained in this document is subject

to change without notice or obligation of any kind. Milestone

makes no representation of warranty, expressed or implied,

regarding the information contained herein. Milestone assumes

no responsibility for accuracy, completeness or sufficiency of

the information contained in this document.

Chief® is a registered trademark of Milestone AV Technologies.

All rights reserved.

DEFINITIONS

WARNING alerts you to the possibility of

serious injury or death if you do not follow the instructions.

CAUTION alerts you to the possibility of

damage or destruction of equipment if you do not follow the

corresponding instructions.

DANGER alerts you to an imminently

hazardous situation which, if not avoided, will result in death or

serious injury.

MOUNTING SYSTEM: A MOUNTING SYSTEM is the

primary Chief product to which an accessory and/or component

is attached.

ACCESSORY: AN ACCESSORY is the secondary Chief

product which is attached to a primary Chief product, and may

have a component attached or setting on it.

COMPONENT: A COMPONENT is an audiovisual item

designed to be attached or resting on an accessory or mounting

system such as a video camera, CPU, screen, display,

projector, etc.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: FAILURE TO READ AND FOLLOW

THE FOLLOWING INSTRUCTIONS CAN RESULT IN

SERIOUS PERSONAL INJURY, DAMAGE TO EQUIPMENT

OR VOIDING OF FACTORY WARRANTY. It is the installer’s

responsibility to make sure all components are properly

assembled and installed using the instructions provided.

When using an electrical mounting system, basic precautions

should always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS

PRODUCT!!!!

DANGER: TO REDUCE THE RISK OF

ELECTRIC SHOCK:

1. Always turn off power at source before cleaning.

WARNING: TO REDUCE THE RISK OF

BURNS, FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS:

1. Unplug from outlet before putting on or taking off parts.

2. Close supervision is necessary when this furnishing is used

by, or near children, invalids, or disabled persons.

3. Use this furnishing only for its intended use as described in

these instructions. Do not use attachments not

recommended by the manufacturer.

4. Never operate this mounting system if it has a damaged

cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the

mounting system to a service center for examination and

repair.

5. Keep the cord away from heated surfaces.

6. Never operate the furnishing with the air openings blocked.

Keep the air openings free of lint, hair, and the like.

7. Never drop or insert any object into any opening.

8. Do not use outdoors.

9. Do not operate where aerosol (spray) products are being

used or where oxygen is being administered.

10. To disconnect, turn all controls to the off position, then

remove plug from outlet.

WARNING: Failure to provide adequate

structural strength for this mounting system can result in serious

personal injury or damage to equipment! It is the installer’s

responsibility to make sure the structure to which this mounting

system is attached can support five times the combined weight

of all equipment. Reinforce the structure as required before

installing the mounting system.

WARNING: Exceeding the weight capacity

can result in serious personal injury or damage to equipment! It

is the installer’s responsibility to make sure the weight of all

components attached to the XFD1U does not exceed 310 lbs

(140.6 kg).

WARNING: Use this mounting system only

for its intended use as described in these instructions. Do not

use attachments not recommended by the manufacturer.

WARNING: Never operate this mounting

system if it is damaged. Return the mounting system to a

service center for examination and repair.

Installation Instructions XFD1U

3

IMPORTANT ! : The XFD1U is designed to be mounted

to:

• a bare concrete wall with a minimum thickness of

8" (203mm):

• a bare 8" x 8" x 16" (203mm x 203mm x 406mm)

concrete block wall; or

• wood studs spaced 16" on center with a

maximum drywall covering of 5/8”.

• a 2" x 4"-25ga minimum steel stud wall.

• a bare drywall wall with a minimum thickness of

1/2" (12.7mm).

NOTE: The XFD1U stand has no user serviceable parts.

NOTE: The XFD1U stand can support screen sizes up to a

maximum of 100" wide.

NOTE: The XFD1U stand is intended for Institutional Use.

NOTE: To reduce the risk of electric shock, this furnishing has

a polarized plug (one blade is wider than the other).

This plug will fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install

the proper outlet. Do not change the plug in any way.

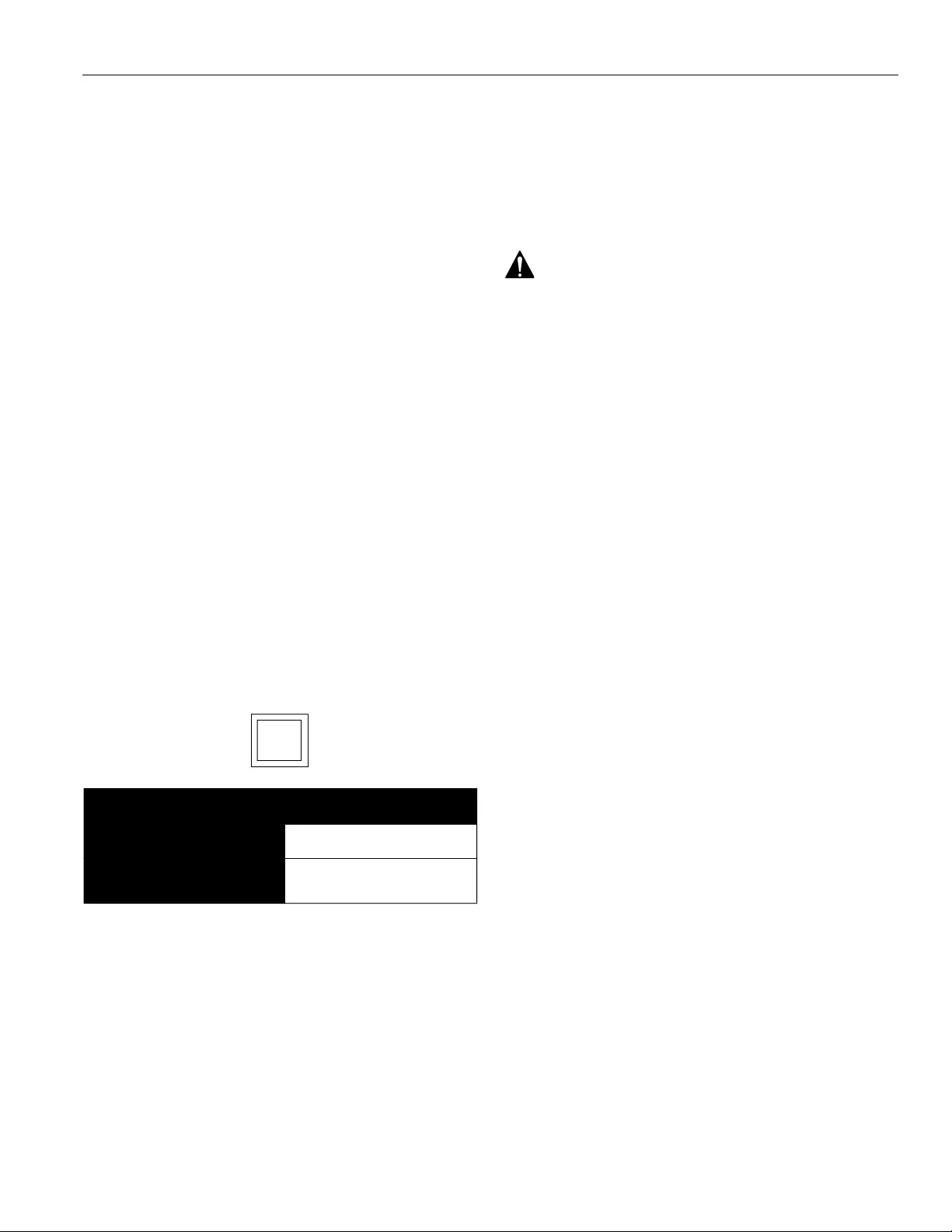

NOTE: This product is a double-insulated, cord-connected

product and must be serviced accordingly. In a double-

insulated product, two systems of insulation are

provided instead of grounding. No grounding means for

grounding to be added to the product Servicing a

double-insulated product requires extreme care and

knowledge of the system, and is to be done only by

qualified service personnel. Replacement parts for a

double-insulated product must be identical to the parts

they replace. A double-insulated product is marked

with the symbol (square within a square)

NOTE: This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to

radio communications. However, there is no guarantee

that interference will not occur in a particular

installation. If this equipment does cause harmful

interference to radio or television reception, which can

be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment

and receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV

technician for help.

CAUTION: Changes or modifications to this

unit not expressly approved by the manufacturer can void the

units FCC compliance rating and make the unit illegal to

operate.

Responsible Party:

Milestone AV Technologies

6436 City West Parkway

Eden Prairie, MN 55344

866-977-3901

info@milestone.com

--SAVE THESE INSTRUCTIONS--

Electrical Specifications

Input voltage, frequency 100-240 V~, 50-60 Hz, 450W

Duty Cycle Intermittent: 10%; max 2

minutes on/18 minutes off

XFD1U Installation Instructions

4

DIMENSIONS

35.96

913.4

MIN 7.94 [201.6]

MAX33.94 [862]

20.37

517.5

MAX

16.00

406.3

61.55

1563.4

26.50

673.1

21.95

557.6

ACCESSORY MOUNTING

PATTERN 3.93 [100mm]

WEIGHT RATING: 310 lbs. (140 kg)

ELECTRICAL RATING:

100-240 VAC, 50-60HZ, 450W

Int. 10 %, Max. 2 min/18min.

Installation Instructions XFD1U

5

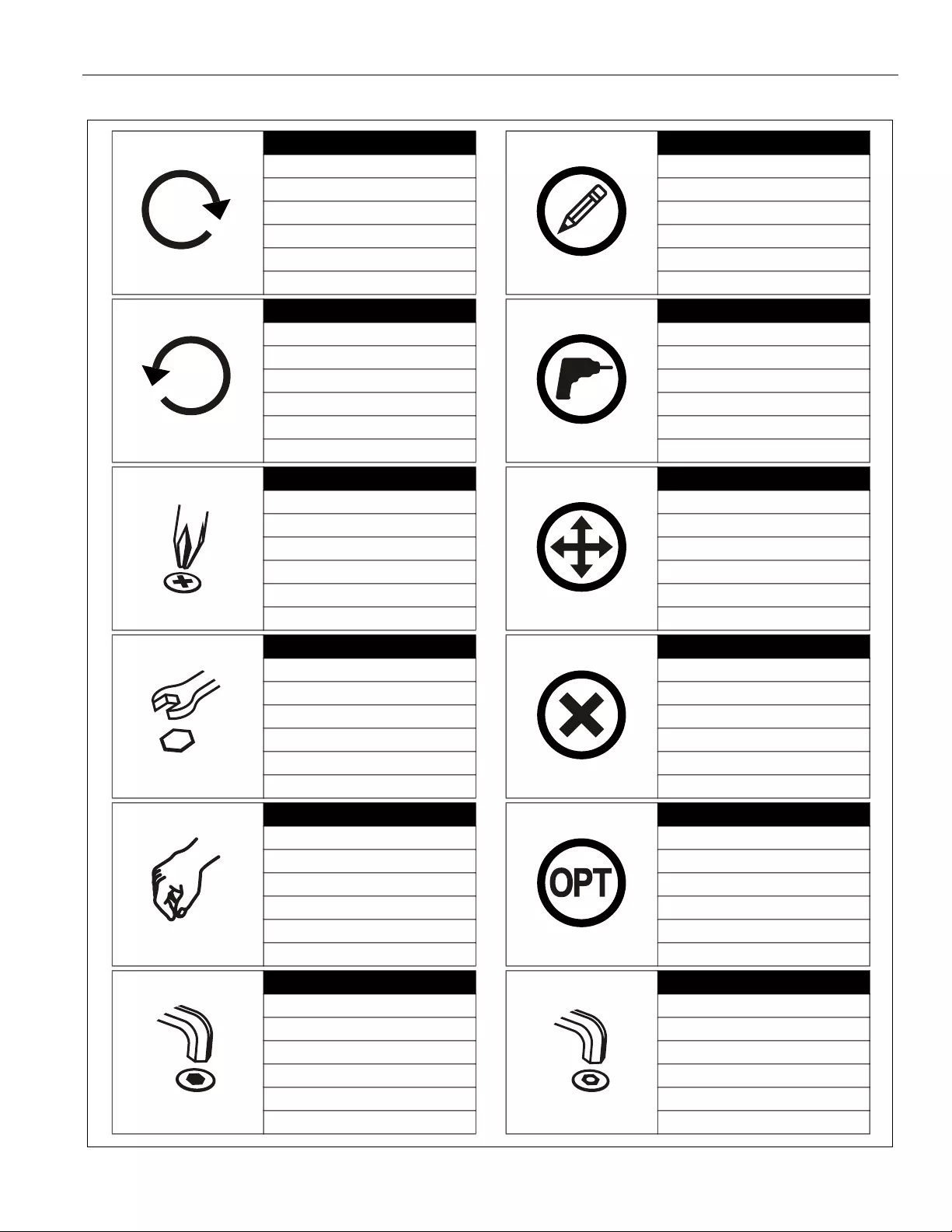

LEGEND

Tighten Fastener

Apretar elemento de fijación

Befestigungsteil festziehen

Apertar fixador

Serrare il fissaggio

Bevestiging vastdraaien

Serrez les fixations

Loosen Fastener

Aflojar elemento de fijación

Befestigungsteil lösen

Desapertar fixador

Allentare il fissaggio

Bevestiging losdraaien

Desserrez les fixations

Phillips Screwdriver

Destornillador Phillips

Kreuzschlitzschraubendreher

Chave de fendas Phillips

Cacciavite a stella

Kruiskopschroevendraaier

Tournevis à pointe cruciforme

Open-Ended Wrench

Llave de boca

Gabelschlüssel

Chave de bocas

Chiave a punte aperte

Steeksleutel

Clé à fourche

By Hand

A mano

Von Hand

Com a mão

A mano

Met de hand

À la main

Hex-Head Wrench

Llave de cabeza hexagonal

Sechskantschlüssel

Chave de cabeça sextavada

Chiave esagonale

Zeskantsleutel

Clé à tête hexagonale

Pencil Mark

Marcar con lápiz

Stiftmarkierung

Marcar com lápis

Segno a matita

Potloodmerkteken

Marquage au crayon

Drill Hole

Perforar

Bohrloch

Fazer furo

Praticare un foro

Gat boren

Percez un trou

Adjust

Ajustar

Einstellen

Ajustar

Regolare

Afstellen

Ajuster

Remove

Quitar

Entfernen

Remover

Rimuovere

Verwijderen

Retirez

Optional

Opcional

Optional

Opcional

Opzionale

Optie

En option

Security Wrench

Llave de seguridad

Sicherheitsschlüssel

Chave de segurança

Chiave di sicurezza

Veiligheidssleutel

Clé de sécurité

XFD1U Installation Instructions

6

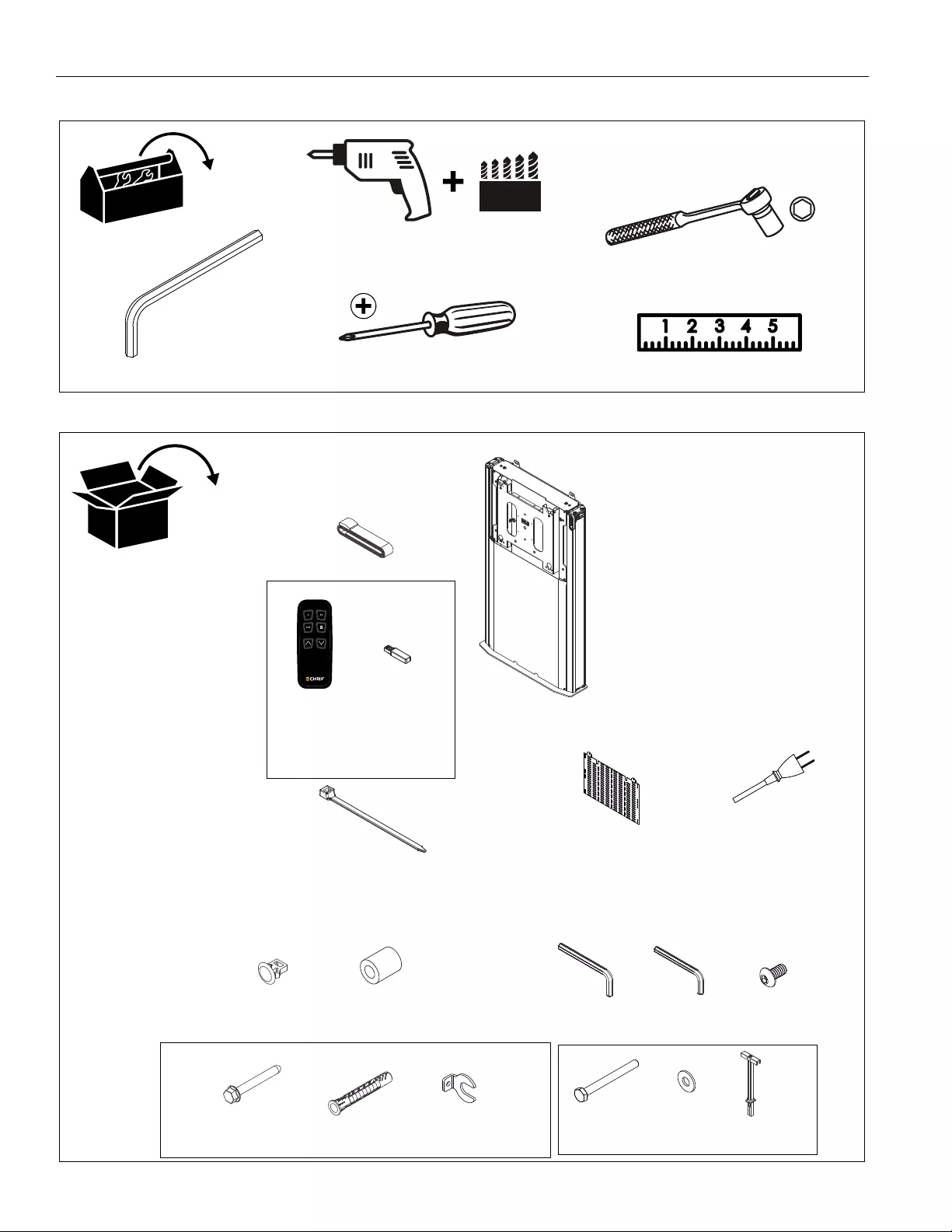

TOOLS REQUIRED FOR INSTALLATION

PARTS

#2

3/16” (included)

1/8” (included)

7/32" (5.3mm) - wood studs

3/8" (10mm) - concrete/drywall

1/2" (12.7mm) - steel studs

1/2" (deep)

D (1)

[Column assembly]

Q (1) - PSBU interface + hardware

K (1)

3/16”

E (8)

[Cable tie]

J (2) L (1)

1/8”

A (1)

[Strap with buckle]

B (1)

#10-24

C (1)

#10

[Large spacer]

G (1)

[Power cable]

H (4)

[Cable clip]

F (1)

[Component bracket]

M (2)

#10-24 x 3/8"

N3 (4)

[5/16" slotted washer]

N (1)

[Hardware bag]

N1 (4)

5/16 x 2 1/2" N2 (4)

Ux10x60mm (not used)

P (1)

[Steel stud hardware bag]

P1 (4)

1/4-20 x 2 1/2"

P2 (4)

1/4" P3 (4)

[1/4-20 toggle anchor]

+ installation instructions

(See PSBU parts list on page 7)

Installation Instructions XFD1U

7

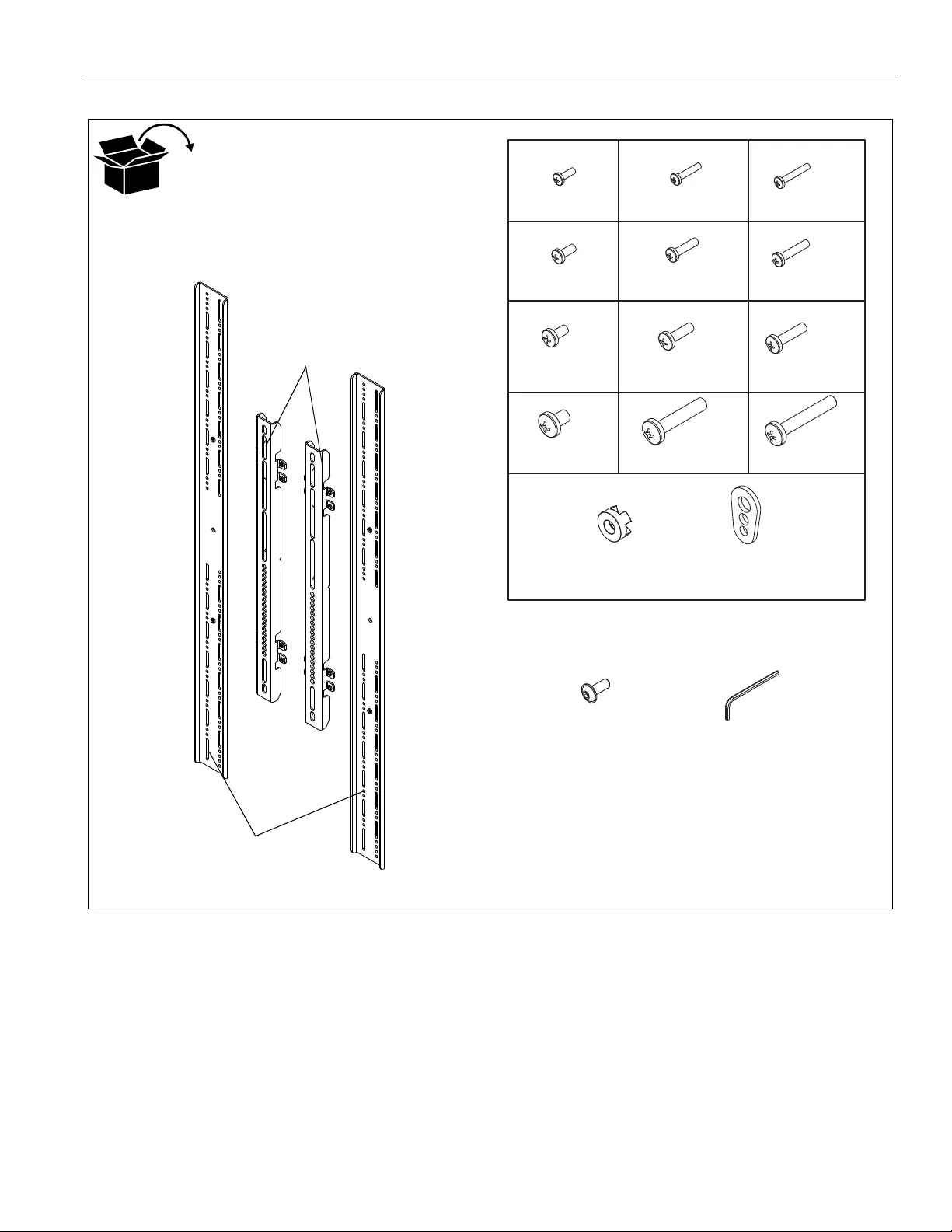

PARTS - PSBU INTERFACE

QR (2)

QJ (4)

QI (4)

QC (4)

QG (4)

QF (4)

QE (4)

QD (4)

QA (4)

QQ (2)

QK (4)

QH (4)

QL (4)

QP (1)

1/8”

Hardware Kit

Bag A Bag B Bag C

Bag D Bag E Bag F

Bag G Bag H Bag I

Bag J Bag K Bag L

Bag M

QB (4)

M4 x 20mm

#10-24 x 1/2"

M4 x 25mm

M5 x 12mm M5 x 20mm M5 x 25mm

M6 x 12mm M6 x 20mm M6 x 25mm

M8 x 12mm M8 x 20mm M8 x 30mm

[Vertical bracket]

[Horizontal bracket]

M4 x 12mm

QMA (8)

[Nesting spacer]

QMB (4)

[Universal spacer]

QN (8)

XFD1U Installation Instructions

8

Assembly And Installation

Stand Assembly/Setup

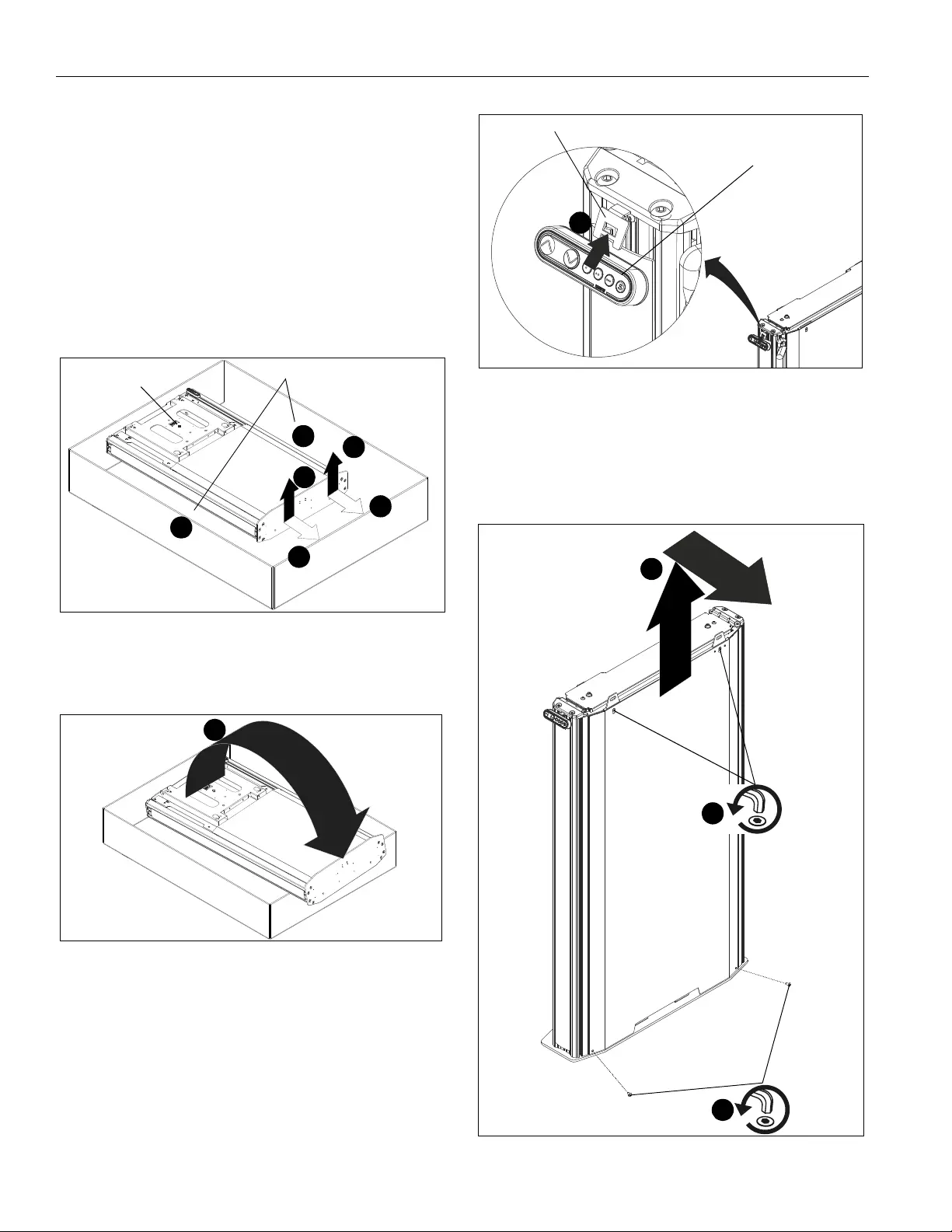

IMPORTANT ! : The XFD1U packaging was designed to

help make the installation and setup easier. Do NOT

remove assembly prior to reading installation

instructions!

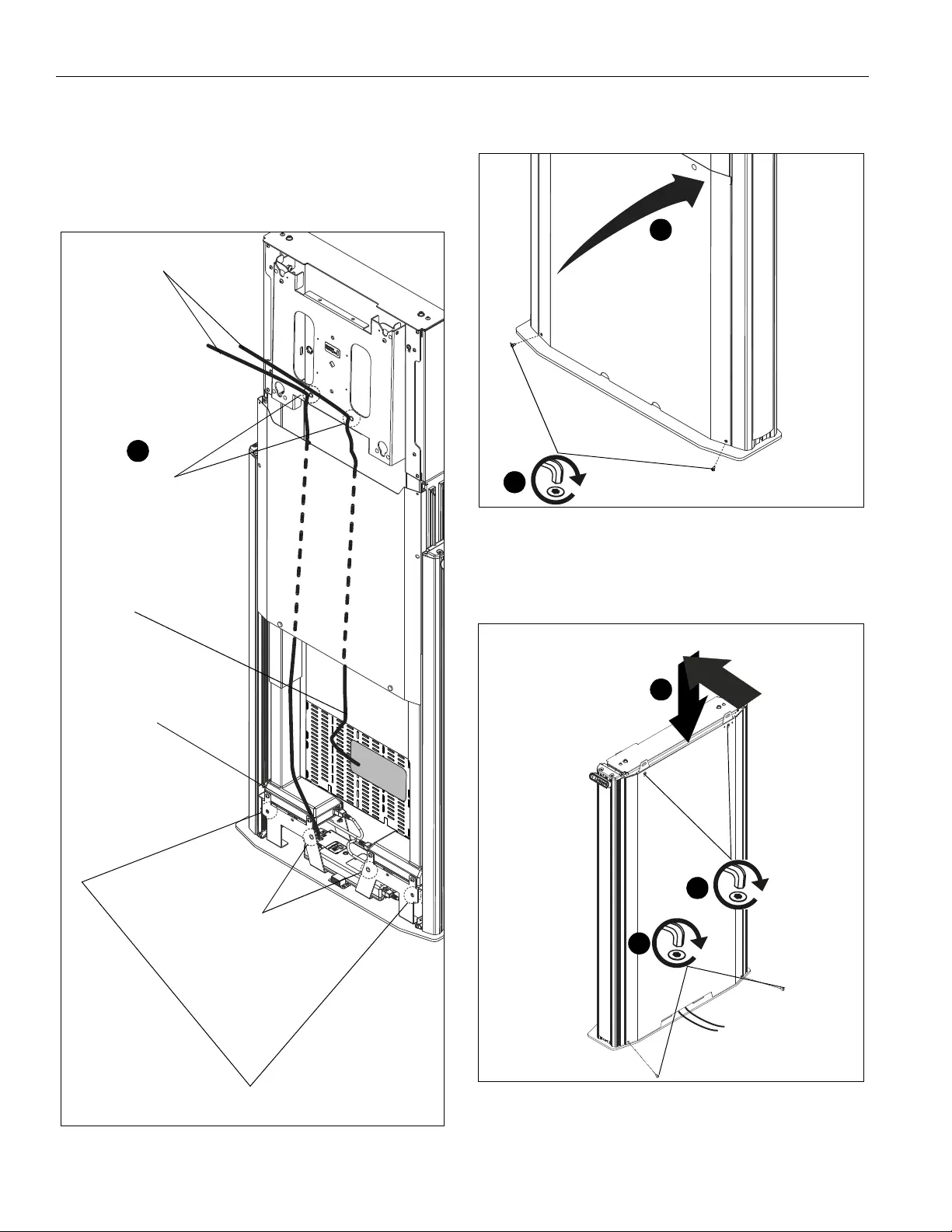

1. Remove all parts and extra packaging from sides of box

leaving only the column assembly (D) in the box. (See

Figure 1)

2. Lift column assembly (D) up using the two finger tabs at the

bottom of the assembly. (See Figure 1)

3. Carefully set column assembly (D) base on the edge of box.

(See Figure 1) and (See Figure 2)

Figure 1

4. Remove stand from box by tipping it from the top onto its

base. (See Figure 2)

Figure 2

5. Secure control pad into control pad bracket. (See Figure 3)

Figure 3

6. Remove bottom two screws from back cover. (See Figure 4)

7. Loosen top two screws from back cover. (See Figure 4)

8. Remove back cover by lifting cover up and out. (See Figure

4)

Figure 4

1

1

remove parts and packaging

2

2

3

3

(D)

4

control pad

control pad bracket

5

x 2

6

8

7

loosen x 2

Installation Instructions XFD1U

9

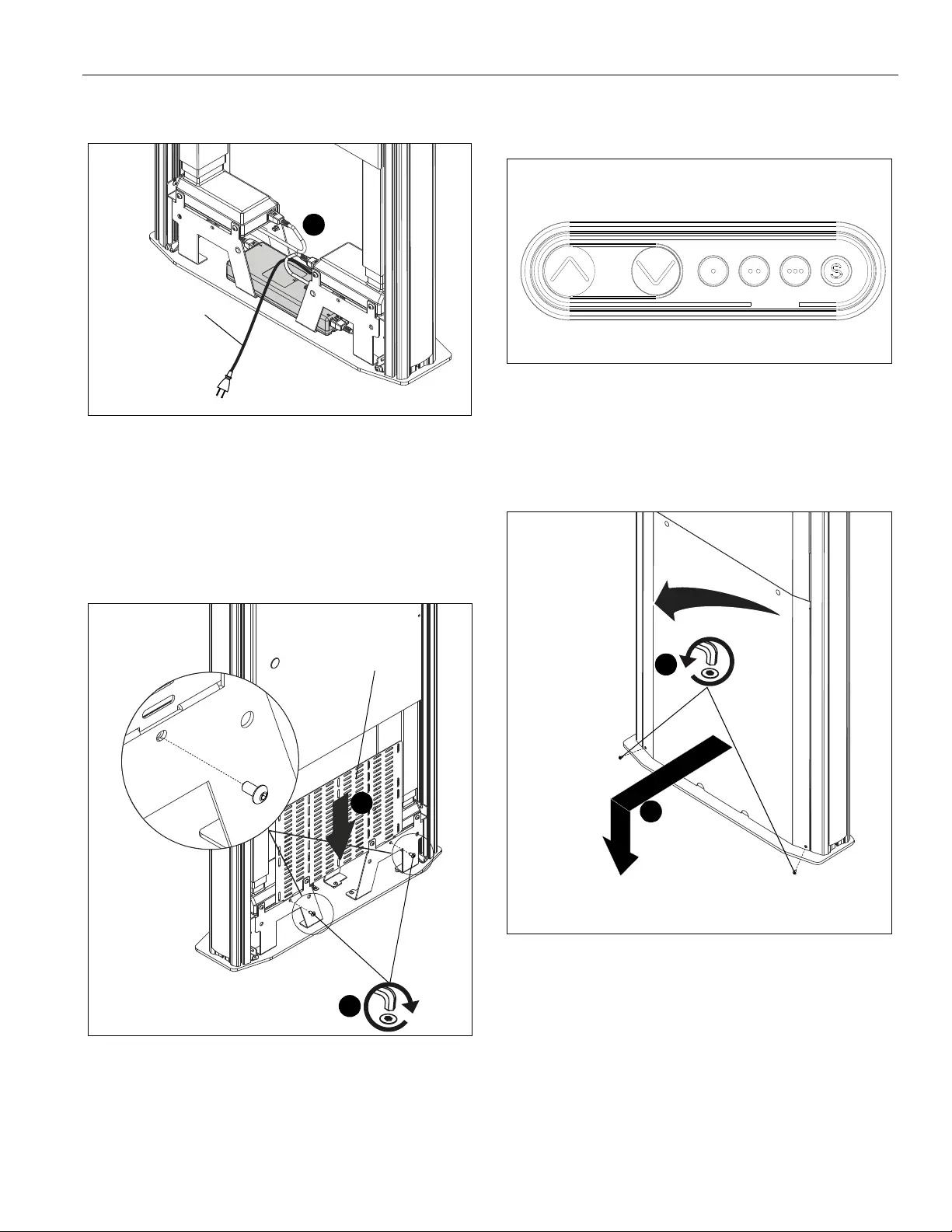

9. Plug in power cable (G) to power supply. Provide strain

relief using the cable tie (E) on nearest cable clip. (See

Figure 5)

Figure 5

10. (Optional) Place component bracket (F) in mounting

position. (See Figure 6)

11. (Optional) Use two #10-24 x 3/8" button head cap screws

(M) to secure component bracket. (See Figure 6)

NOTE: Strap with buckle (A) and/or cable ties (E) may be used

to secure components to component bracket (F).

Figure 6

12. Press and hold "DOWN" button for three seconds to

initialize lift mechanism. (See Figure 7)

13. Press and hold "UP" button until mount reaches it’s

maximum height. (See Figure 7)

NOTE: If lifting mechanism does not function properly refer to

"Troubleshooting" Section.

Figure 7

14. Remove bottom two screws from front cover. (See Figure 8)

15. Use finger tabs to pull front cover out and slide down. Cover

must be flexed to remove pins from uprights in order to

remove. (See Figure 8)

Figure 8

9

(G)

(M) x 2

11

10

(F)

"UP" "DOWN" "PRESETS" "SAVE"

x 2

14

15

XFD1U Installation Instructions

10

16. Attach display and signal cables to power source. Use cable

clips (H) and cable ties (E) to route as necessary. (See

Figure 9)

IMPORTANT ! : Make sure to install cables when lift is at

the highest position and so that there is enough length to

reach input locations for display and signal.

Figure 9

17. Reinstall front cover by using two screws removed in Step

13. (See Figure 10)

Figure 10

18. Reinstall rear cover and secure by installing screws

removed in Step 6. (See Figure 11)

19. Tighten screws that were loosened in Step 7. (See Figure

11)

Figure 11

20. Lower mount to its lowest position and move it to desired

mounting location.

enough distance to

reach inputs

16

power cable

signal cable

to signal box

(example)

(example)

recommended strain relief

locations

(pre-installed cable clips)

recommended strain relief

locations

(pre-installed cable clips)

additional cable tie locations

if extra cable clips (H) are used

x 2

17

17

x 2

18

18

19

tighten x 2

Installation Instructions XFD1U

11

Attachment to Wall

The XFD1U is designed to be mounted to:

• a bare concrete wall with a minimum thickness of

8" (203mm):

• a bare 8" x 8" x 16" (203mm x 203mm x 406mm)

concrete block wall; or

• wood studs spaced 16" on center with a

maximum drywall covering of 5/8”.

• a 2" x 4"-25ga minimum steel stud wall.

• a bare drywall wall with a minimum thickness of

1/2" (12.7mm).

NOTE: Space can be created behind the mount (on any

substrate) by using large spacers (J) or nesting

spacers included with PSBU behind installation tabs

during installation. Large spacers (J) will provide 0.75"

while two nesting spacers will provide 0.375".

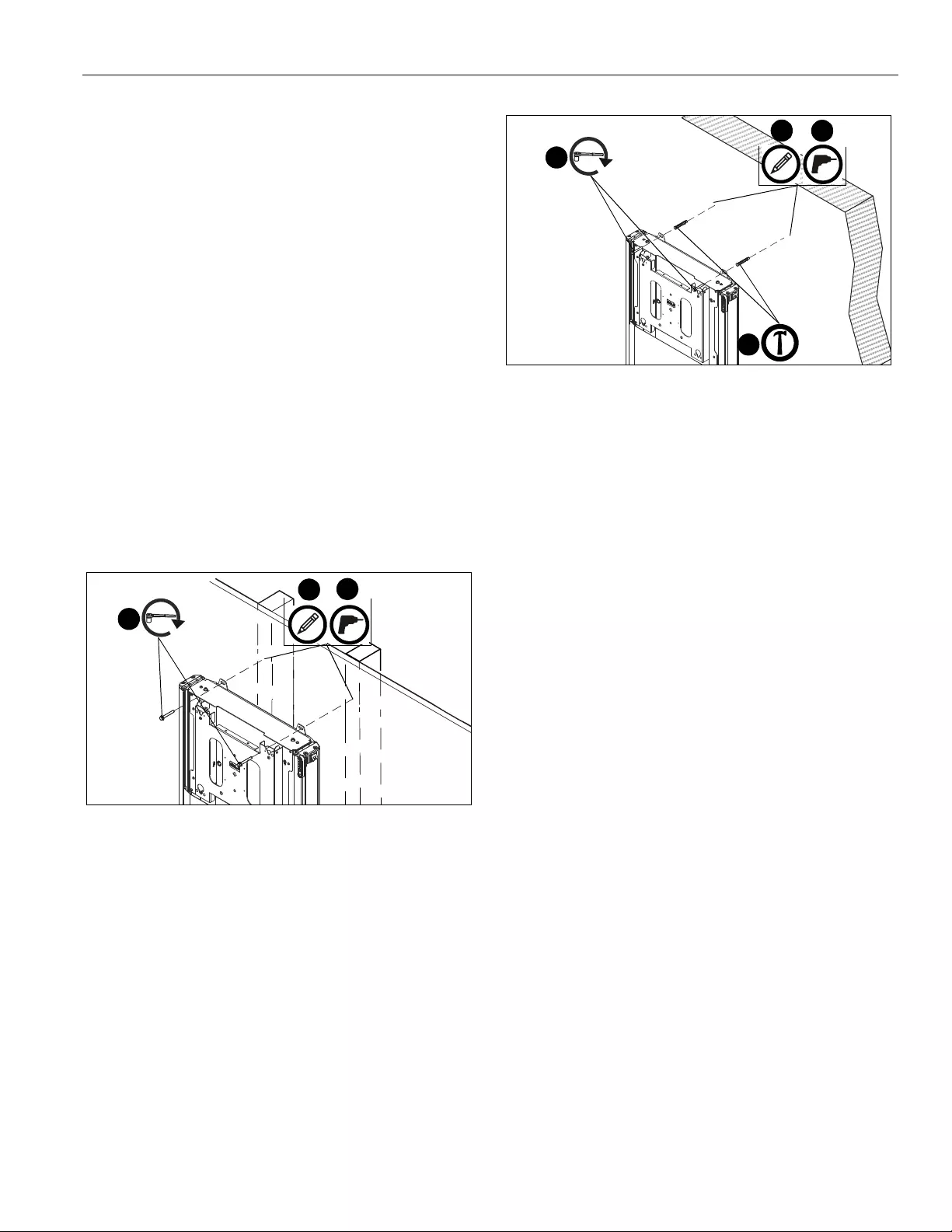

Installing to Wood Stud Wall

1. Use a stud-finder to locate 16" studs.

2. Place column assembly against wall making sure to line up

attachment brackets with studs. (See Figure 12)

3. Mark hole locations at each mounting location. (See Figure

12)

4. Drill two 7/32” holes at marked hole locations. (See Figure

12)

Figure 12

5. Install two 5/16 x 2 1/2” hex head cap screws (N1) through

holes on attachment brackets and into drilled holes on wall.

(See Figure 12)

Installing to a Concrete Wall

1. Place column assembly against wall at desired mounting

location. (See Figure 13)

2. Mark hole locations at each mounting location. (See Figure

13)

3. Drill two 3/8” holes at marked hole locations. (See Figure

13)

4. Install an anchor (N2) into each pilot hole using a hammer,

making sure that the anchor is flush with the wall. (See

Figure 13)

Figure 13

5. Install two 5/16 x 2 1/2” hex head cap screws (N1) through

holes on attachment brackets and into anchors (N2) on wall.

(See Figure 13)

Installing to Steel Studs/Drywall

NOTE: The installation procedure is the same for installing to

steel studs and drywall only except that a pilot hole

does not need to be drilled if installing to drywall only.

34

(N1) x 2

5

7/32” (5.3mm)

23

(N1) x 2

5

(N2) x 2

4

3/8"

XFD1U Installation Instructions

12

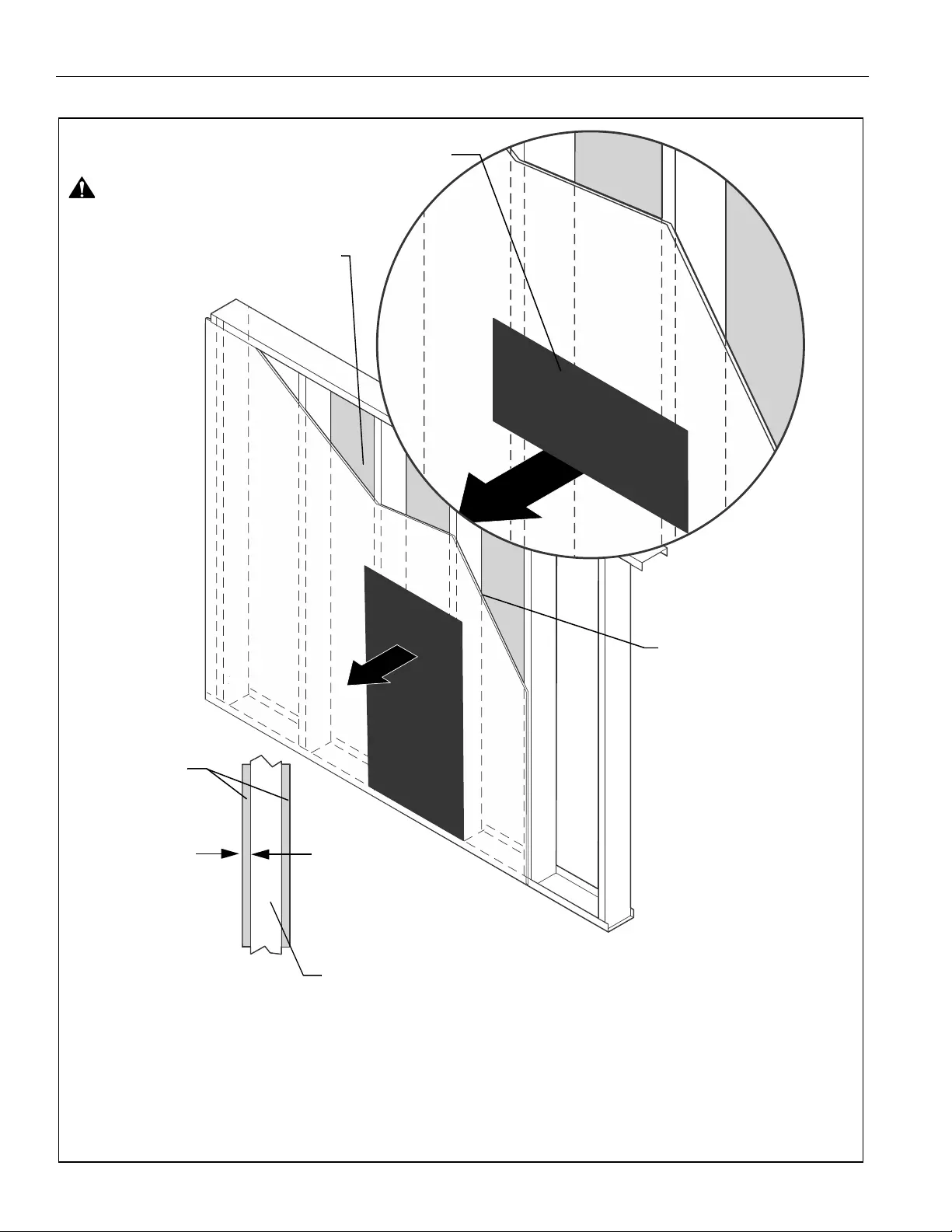

Site Requirements (Steel Studs)

(Must be centered over two studs)

Drywall

**1/2" minimum

Drywall Thickness

XFD1U Installation Location

FRONT

(Both Sides of Stud)

There must be a minimum of

1-7/8" (48mm) clearance

inside wall

16" (on center) Studs

If back side of wall is unfinished, drywall must be installed

to a minimum of one stud left and right of the studs

being used to install the mount. Drywall must be

secured to studs with screws 12" on center

Steel Stud (2 x 4 / 25ga minimum)

Stud type and structural strength must conform to the North American

Specification for the Design of Cold-Formed Steel Structural Members.

**See hazard statement

on page 2!

[362, 125 18, C-Shape, S - Stud Section]

Installation Instructions XFD1U

13

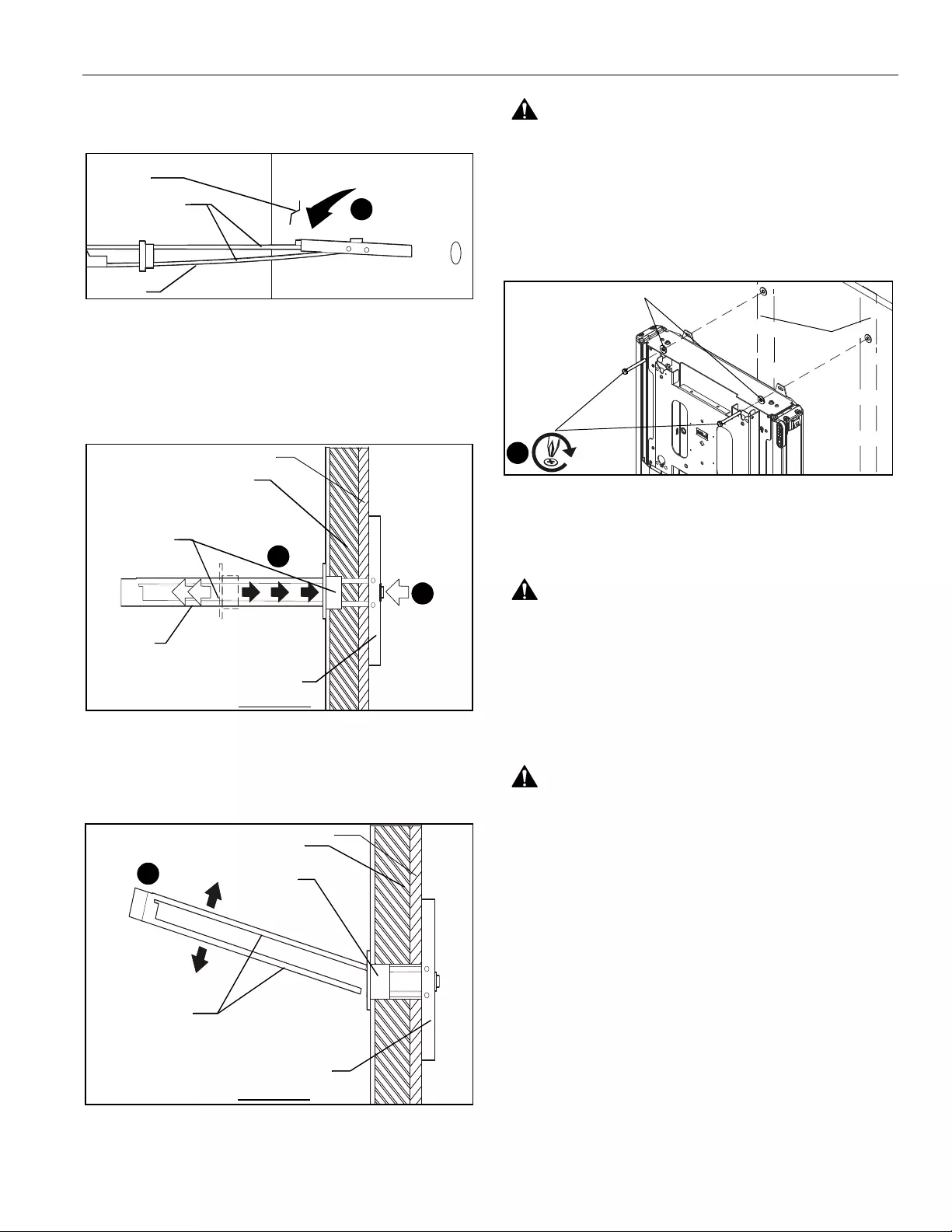

1. Drill a 1/2" hole at the desired mounting locations.

2. Hold metal channel on anchor (P3) flat alongside plastic

straps and slide channel through hole. (See Figure 14)

Figure 14

3. Holding plastic straps on anchor (P3), pull anchor away

from wall until channel rests flush behind wall making sure

anchor channel is positioned vertically on stud. (See Figure

15)

4. Slide plastic cap on anchor (P3) towards wall until flange of

cap is flush with wall. (See Figure 15)

Figure 15

5. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 16)

6. Repeat Steps 1 through 5 for the other mounting hole.

Figure 16

7. Place mount over anchors and align mounting holes on

mount with holes in anchors. (See Figure 17)

WARNING: IMPROPER INSTALLATION CAN LEAD TO

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Overtightening of

mounting hardware can damage the steel studs. DO NOT

overtighten mounting hardware!

8. Insert two 1/4-20 x 2 1/4" hex head tapping bolts (P1)

through two 1/4" washers (P2), corresponding mounting

holes on mount and into anchors (P3) and tighten until flush

against mount. DO NOT overtighten! (See Figure 17)

Figure 17

Display Installation

WARNING: Exceeding the weight capacity can result in

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the combined weight of

all accessories and components attached to the XFD1U head

assembly up to (and including) the display does not exceed

310 lbs (140.6 kg).

1. Make sure height is at the lowest possible position.

2. Make sure latching flags are in "open" position.

WARNING: IMPROPER INSTALLATION CAN LEAD TO

MOUNT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! DO NOT substitute

hardware. Only use hardware provided or specified by

manufacturer.

(P3)

Drywall

Plastic Straps

2

(P3)

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

3

Steel Stud

4

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

5

Steel Stud

8

Steel Studs

(P1) x 2

(P2) x 2

XFD1U Installation Instructions

14

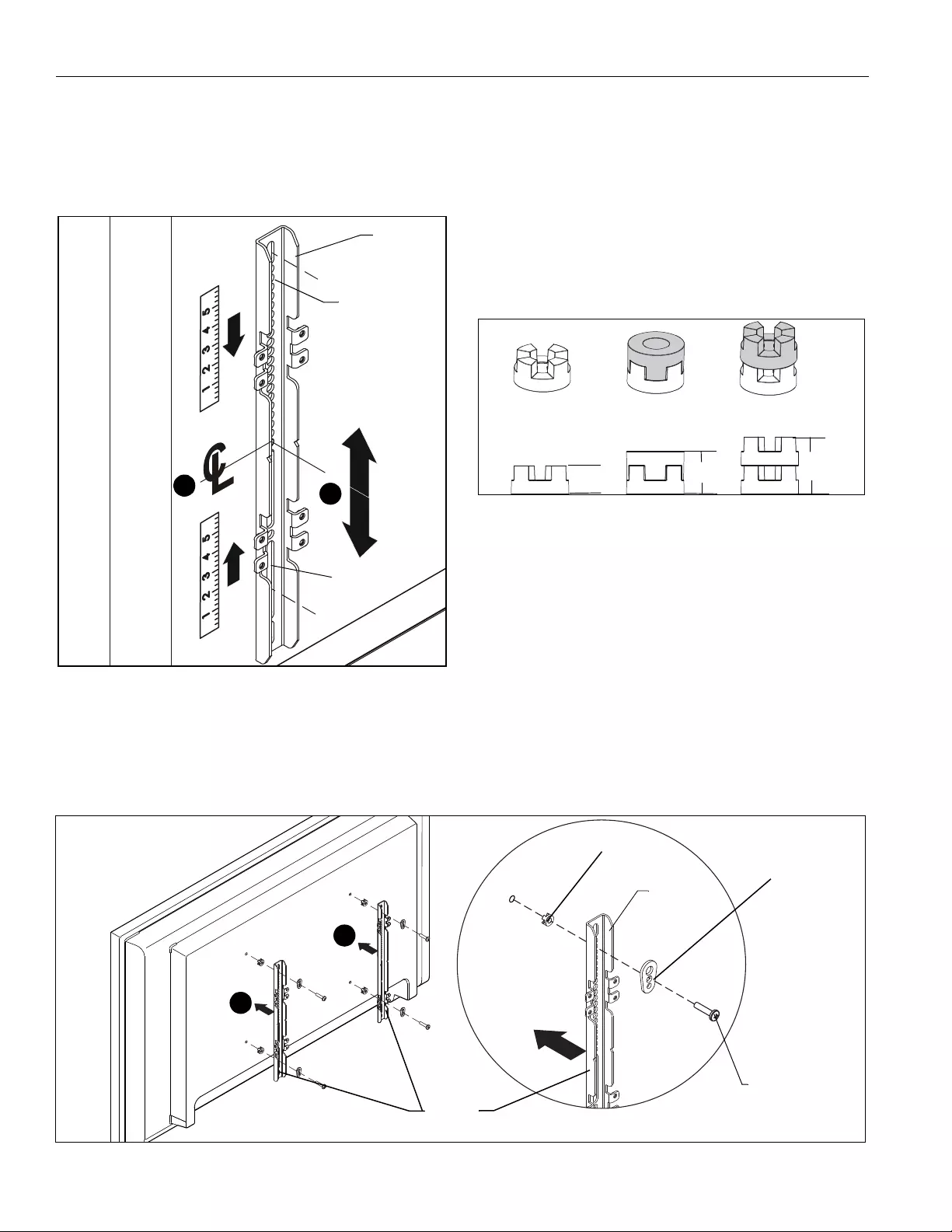

3. Determine and mark the vertical center position between

the Left side Upper and Lower mounting holes in display.

(See Figure 18)

4. Determine and mark the vertical center position between

the Right side Upper and Lower mounting holes in display.

(See Figure 18)

Figure 18

5. Orient vertical mounting bracket (QR) so that mounting

holes are on top and mounting slots are on bottom. (See

Figure 18)

6. Align mounting holes in vertical mounting bracket (QR) with

upper and lower mounting holes in display.

7. Adjust vertical mounting bracket (QR) position until mark

made in Step 1 aligns with center mark in vertical mounting

bracket (QR).

8. Select correct screws, nesting spacers (if necessary) and

universal washers (if required) from the hardware bag (QA-

QM) and attach brackets to back of screen. (See Figure 20)

IMPORTANT ! : The M8 screws do NOT require a

washer. Use the universal washer (QMB) only with M4,

M5 and M6 screws.

NOTE: The nesting spacers (QMA) may be used separately,

or put two together in different configurations to create

different size spacers. (See Figure 19)

Figure 19

9. If the display has a recessed mounting surface, protrusions

or a power box, a spacer and longer mounting hardware

must be placed between the display and vertical mounting

bracket (QR). (See Figure 20)

10. Repeat Steps 5 through 8 for Right side vertical mounting

bracket using the same hole locations to align brackets

horizontally.

6

3

(QR) x 2

Mounting holes

Mounting Slots

(Single) (Nested) (Stacked)

0.375

[9.5]

0.563

[14.3]

0.750

[19.1]

Figure 20

10

8

(QR) x 2

(QMA) x 4

(QA through QL)

x 4

(QMB) x 4

(QR)

Installation Instructions XFD1U

15

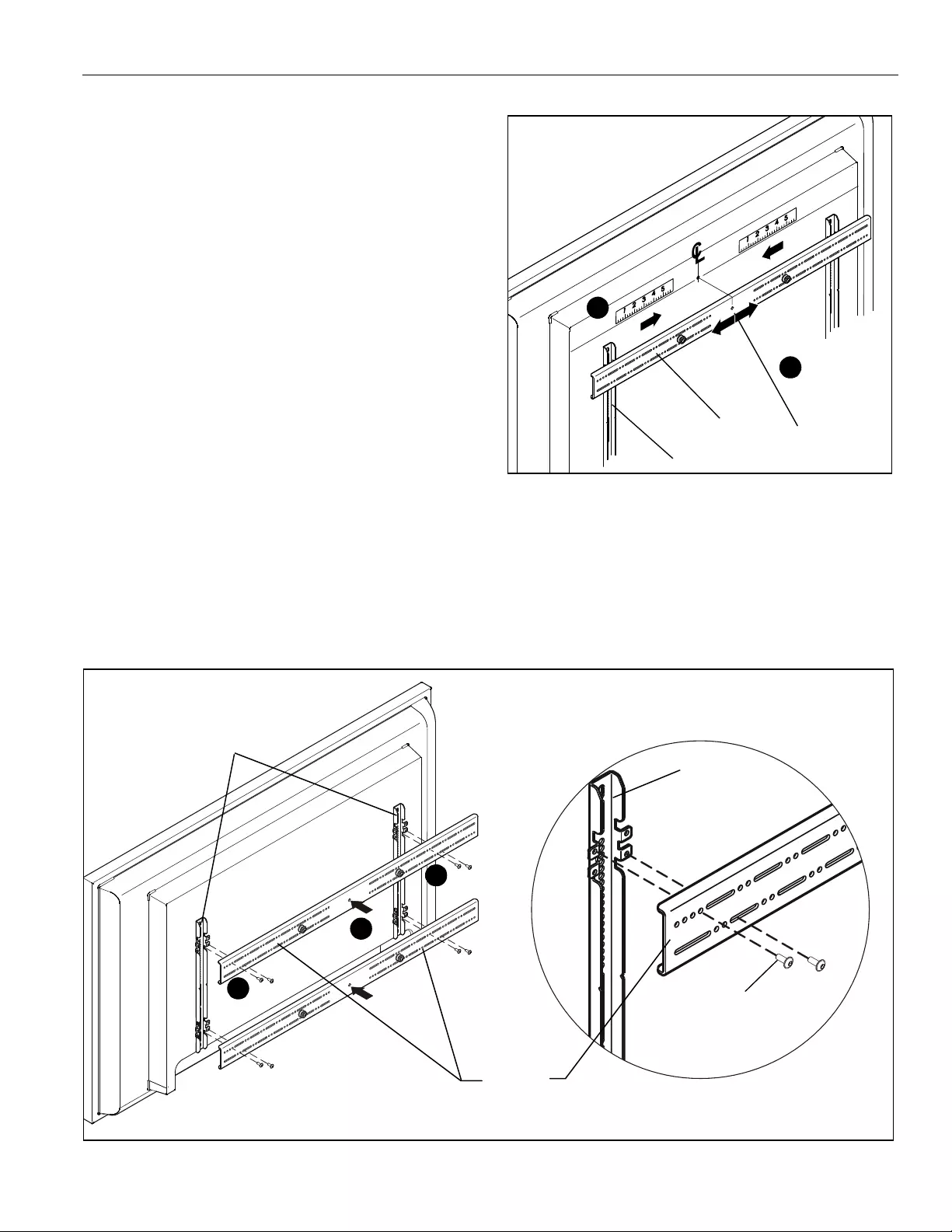

11. Determine and mark the horizontal center position between

the Left and Right TOP mounting holes in display.

(See Figure 21)

12. Determine and mark the horizontal center position between

the Left and Right BOTTOM mounting holes in display. (See

Figure 21)

13. Orient upper horizontal mounting bracket (QQ) so that

flanges are facing towards display and resting in recessed

area of left and right vertical mounting brackets (QR). (See

Figure 21)

14. Adjust Upper horizontal mounting bracket (QQ) position

until center diamond in horizontal mounting bracket (QU)

aligns with mark made in Step 9, and mounting holes and

slots in horizontal mounting bracket (QQ) are aligned with

threaded holes in mounting tabs of left and right vertical

mounting brackets (QR). (See Figure 21) and (See Figure

22)

15. Use 1/8" hex key (QP) to secure upper horizontal mounting

bracket (QQ) to left and right vertical mounting brackets

(QR) using four button head flanged screws (QN). (See

Figure 22)

16. Repeat Steps 12 through 15 for lower horizontal mounting

bracket (QQ).

IMPORTANT ! : The orientation of, and mounting holes used,

when installing the lower horizontal mounting bracket must be

the same as the upper horizontal mounting bracket. Vertically

align upper and lower brackets by aligning holes or end of slots.

(See Figure 22)

IMPORTANT ! : Whenever possible install mounting

screws diagonally as shown in detail in Figure 22 below.

17. Install display with attached universal interface to mount

following the installation instructions provided with the

mount.

Figure 21

12

11

(QR) x 2

Center Mark

(QQ) x 2

Figure 22

15

15

(QQ) x 2

(QR) x 2

(QN) x 8

(QR) x 2

14

XFD1U Installation Instructions

16

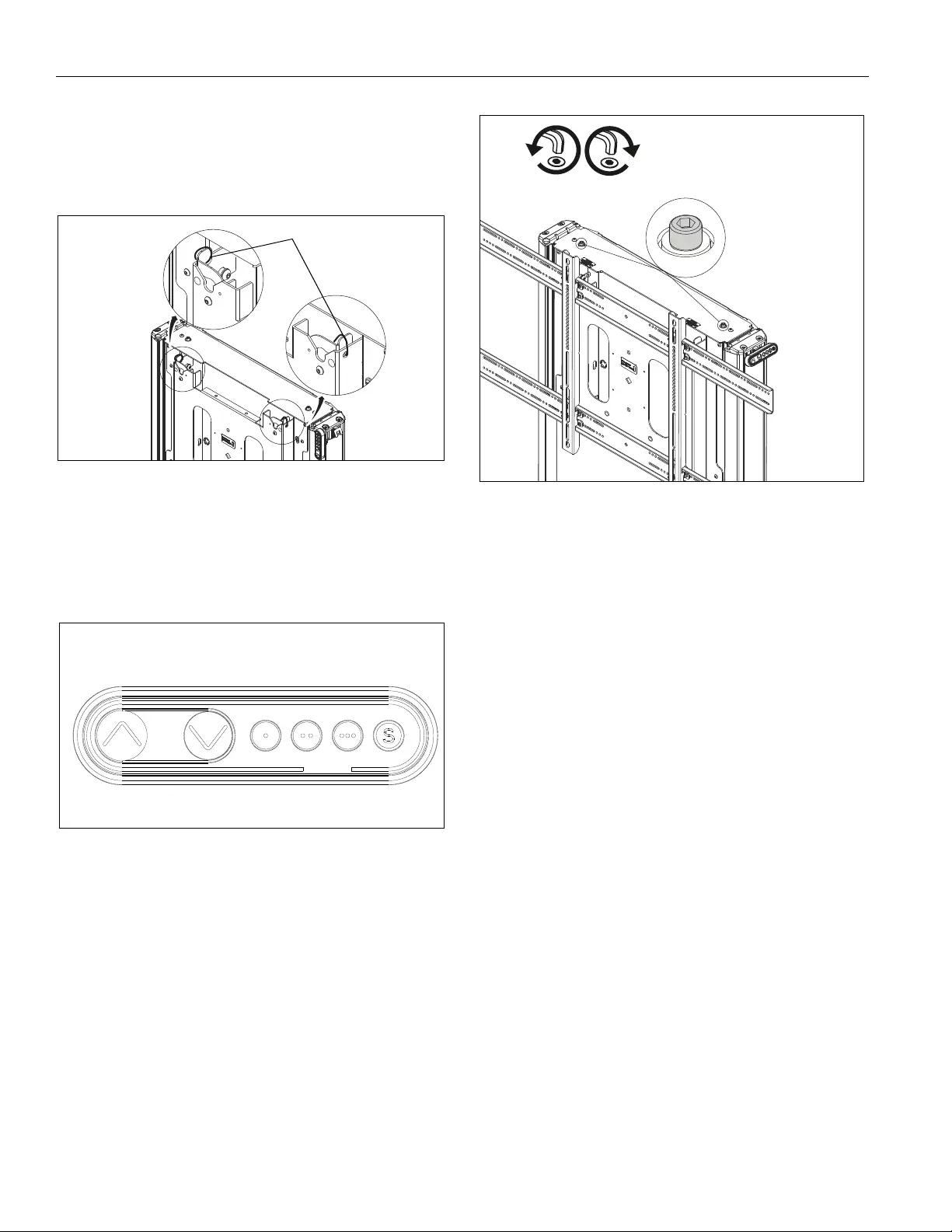

18. Make sure latching flags are in "closed" position prior to

using cart!

IMPORTANT ! : Manufacturer recommends using cable

ties (Z) to secure the latching flags in closed position on

both sides if padlock is not being used. (See Figure 23)

Figure 23

Adjustments

Height Adjustment

1. Press "UP" or "DOWN" buttons to raise or lower height as

desired. (See Figure 24)

Figure 24

Save Height Levels

1. Adjust height until desired preset level is reached using

"UP" and "DOWN" buttons. (See Figure 24)

2. Press "SAVE" button. (See Figure 24)

3. Press one of three preset buttons (., .. or ...) to save preset

position. (See Figure 24)

4. Repeat Steps 1-3 as desired.

Leveling Adjustment

1. Use 3/16" hex key to adjust leveling adjustment screws on

top of stand. (See Figure 25)

• Turn Counterclockwise to lower

• Turn Clockwise to raise

Figure 25

Troubleshooting

If lifting function does not work properly, try to following

troubleshooting steps. If none of these work, contact customer

service.

1. If there is uneven movement, initialize the control box

(reset)

• Hold "Down" button until lift has reached it’s lower

limit.

• Briefly release "Down" button

• Press and hold "Down" for five seconds, wait until

all movement has stopped, then release

2. If there is no movement, check the following

• Check all cable connectors between controllers

and actuators.

• Check power cable connection to control box.

3. If there is slight movement and then reverse travel, check

for any obstructions that may be interfering such as cables

or peripheral devices.

4. Contact customer service if none of the above steps fix the

problem.

Using Remote and Dongle

Refer to installation instructions included with remote (B) and

dongle (C) to set up remote system.

(Z) x 2

"UP" "DOWN" "PRESETS" "SAVE"

lower raise

Installation Instructions XFD1U

17

XFD1U Installation Instructions

18

Installation Instructions XFD1U

19

XFD1U Installation Instructions

USA/International A 6436 City West Parkway, Eden Prairie, MN 55344

P800.582.6480 / 952.225.6000

F877.894.6918 / 952.894.6918

Europe A Franklinstraat 14, 6003 DK Weert, Netherlands

P+31 (0) 495 580 852

F+31 (0) 495 580 845

Asia Pacific A Office No. 918 on 9/F, Shatin Galleria

18-24 Shan Mei Street

Fotan, Shatin, Hong Kong

P852 2145 4099

F852 2145 4477

Chief, a products division of

Milestone AV Technologies

8800-003012 Rev03

2018 Milestone AV Technologies

www.milestone.com

09/18