DELL E2222H User Manual

Displayed below is the user manual for E2222H by DELL which is a product in the Computer Monitors category. This manual has pages.

Related Manuals

Version: 01

Date: 2021/10/30

Service Manual - E2222H

Product Announcement:

This product is certificated to meet RoHS

Directive and Lead-Free produced definition.

Using approved critical components only is

recommended when the situation to replace

defective parts. Vender assumes no liability

express or implied, arising out of any unauthorized

modification of design or replacing non-RoHS

parts. Service providers assume all liability.

Qualified Repairability:

Proper service and repair is important to the safe,

reliable operation of all series products. The

service providers recommended by vender should

be aware of notices listed in this service manual in

order to minimize the risk of personal injury when

perform service procedures. Furthermore, the

possible existed improper repairing method may

damage equipment or products. It is recommended

that service engineers should have repairing

knowledge, experience, as well as appropriate

product training per new model before performing

the service procedures.

NOTICE:

! To avoid electrical shocks, the products should be

connected to an authorized power cord, and turn

off the master power switch each time before

removing the AC power cord.

! To prevent the product away from water or

expose in extremely high humility environment.

! To ensure the continued reliability of this

product, use only original manufacturer’s

specified parts.

! To ensure following safety repairing behavior, put

the replaced part on the components side of

PWBA, not solder side.

! To ensure using a proper screwdriver, follow the

torque and force listed in assembly and

disassembly procedures to unscrew screws.

! Using Lead-Free solder to well mounted the

parts.

! The fusion point of Lead-Free solder requested in

the degree of 220°C.

1. Important Safety Notice

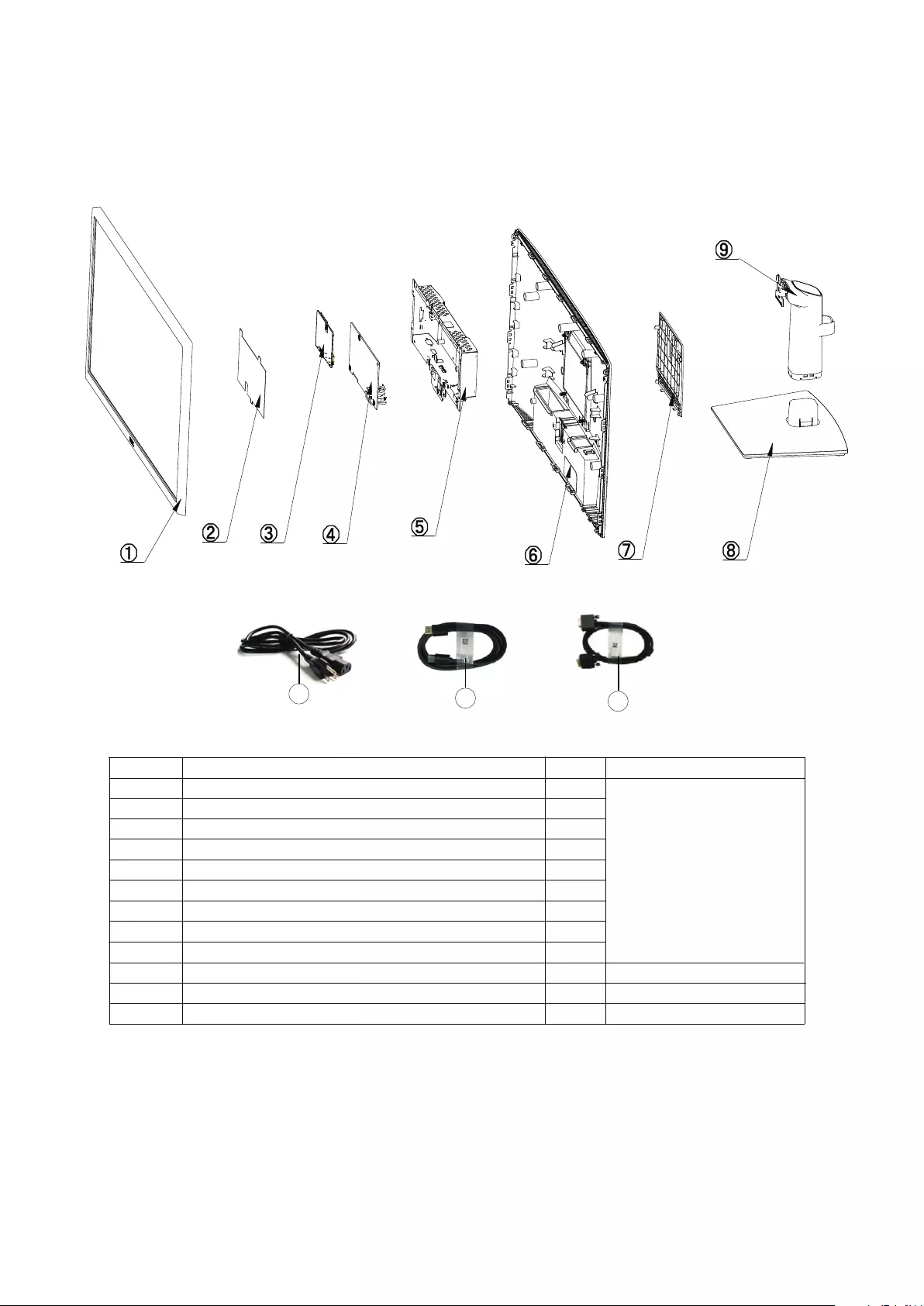

2. Exploded view diagram with list of items

NOTE:

For replacement of power cord, connectivity cable and external power supply (if applicable), contact Dell:

1. Go to https://www.dell.com/support.

2. Verify your country or region in the Choose A Country/Region drop-down menu at the bottom-right corner of the page.

3. Click Contact Us next to the country dropdown.

4. Select the appropriate service or support link based on your need.

5. Choose the method of contacting Dell that is convenient for you.

12

11

10

Item Description Q'ty Remark

1 1

For EMEA Only, not for

other regions

2 1

13

4 3

15

6 1

1

7

8 2

9

10

11

Rear Cover ASSY

12

Interface board

LCM ASSY

Power board

1

1

Main chassis

See “NOTE”

Base

See “NOTE”

Power cable

DisplayPort cable

Stand

Safety Mylar

1

See “NOTE”

VGA cable 1

VESA Cover

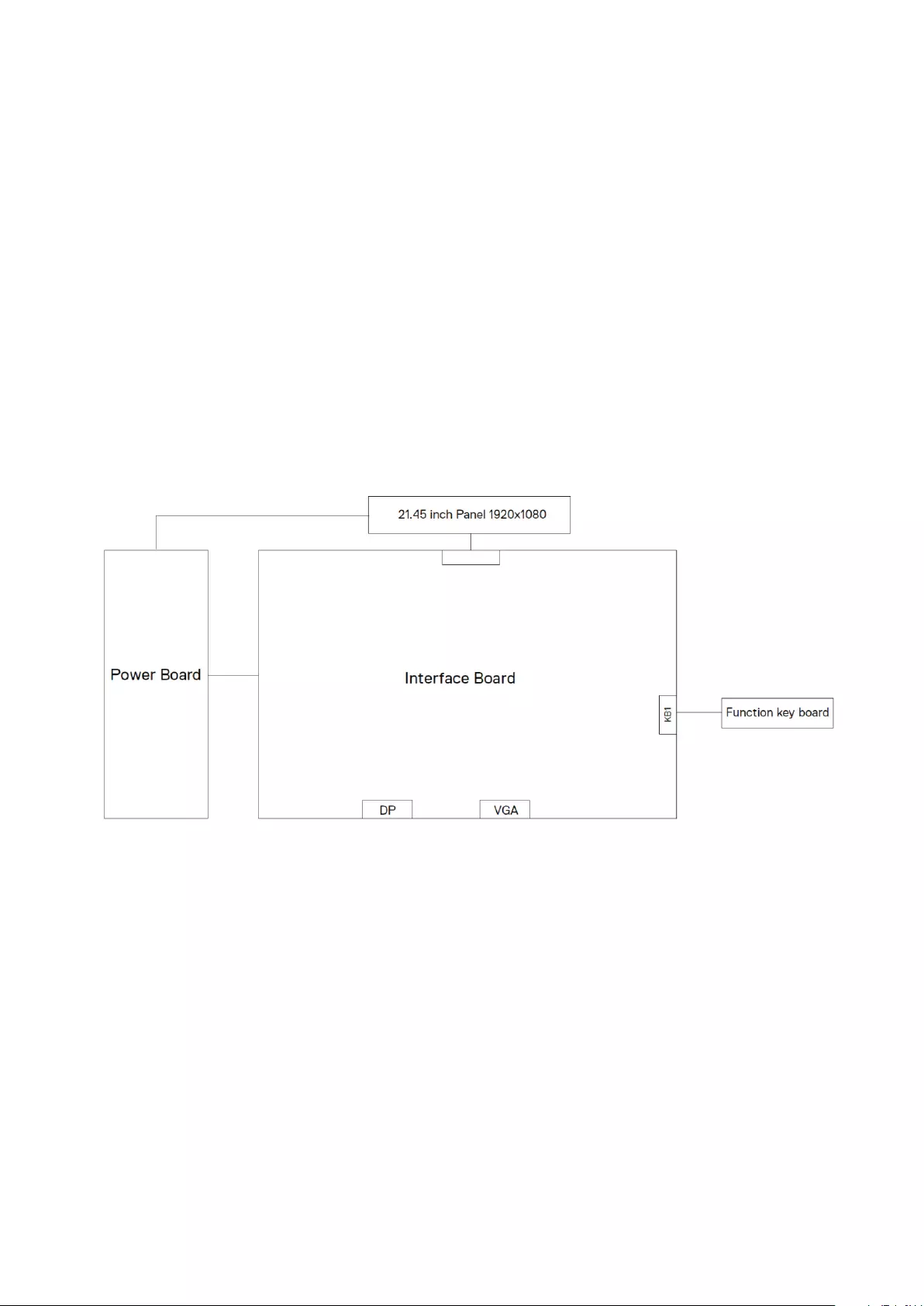

3. Wiring Connectivity Diagram

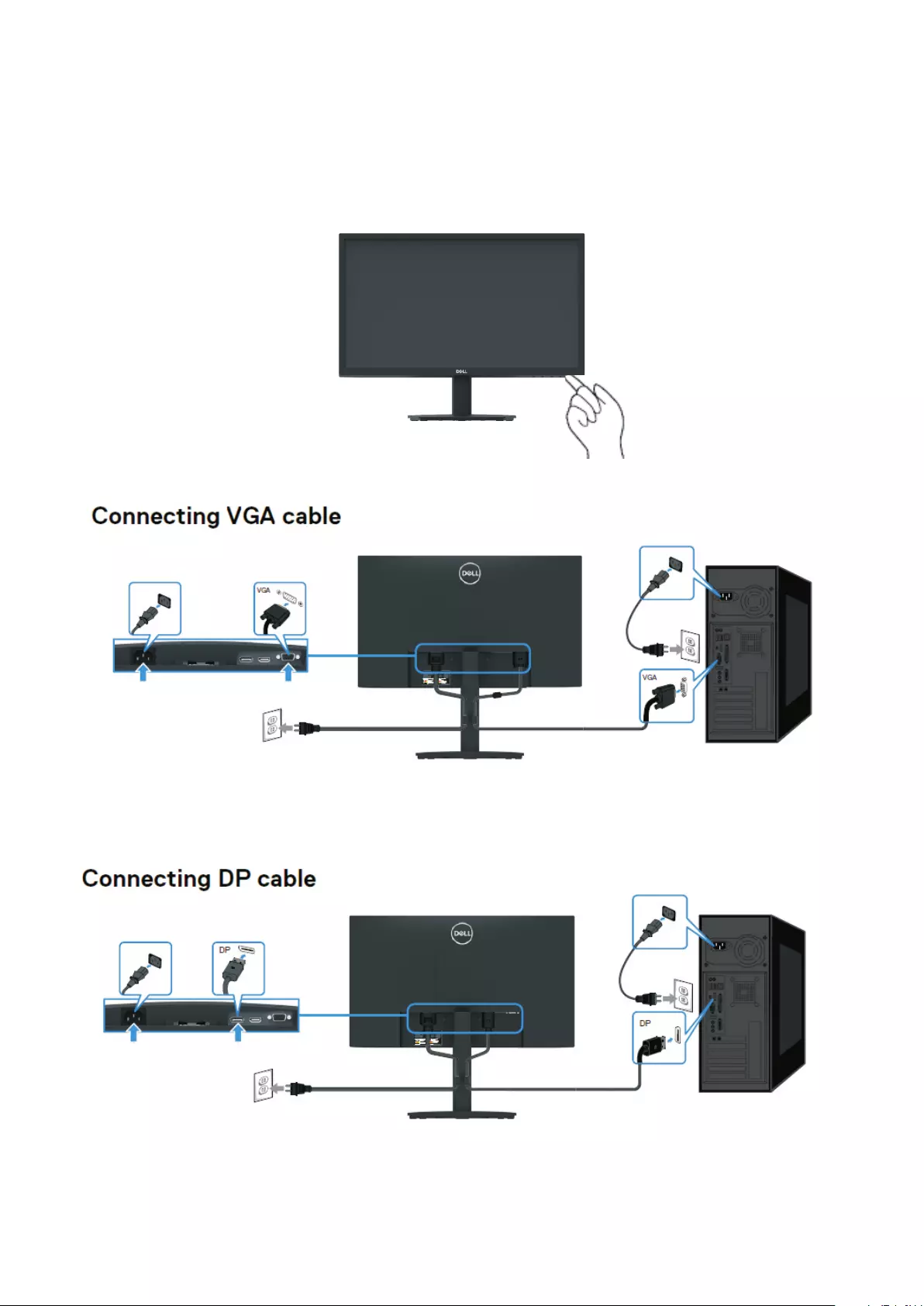

4. How to connect and disconnect power cable/ connectivity cable

WARNING: To change power cable/ connectivity cable, switch off power before unplugging the cable and replugging in required

cable.

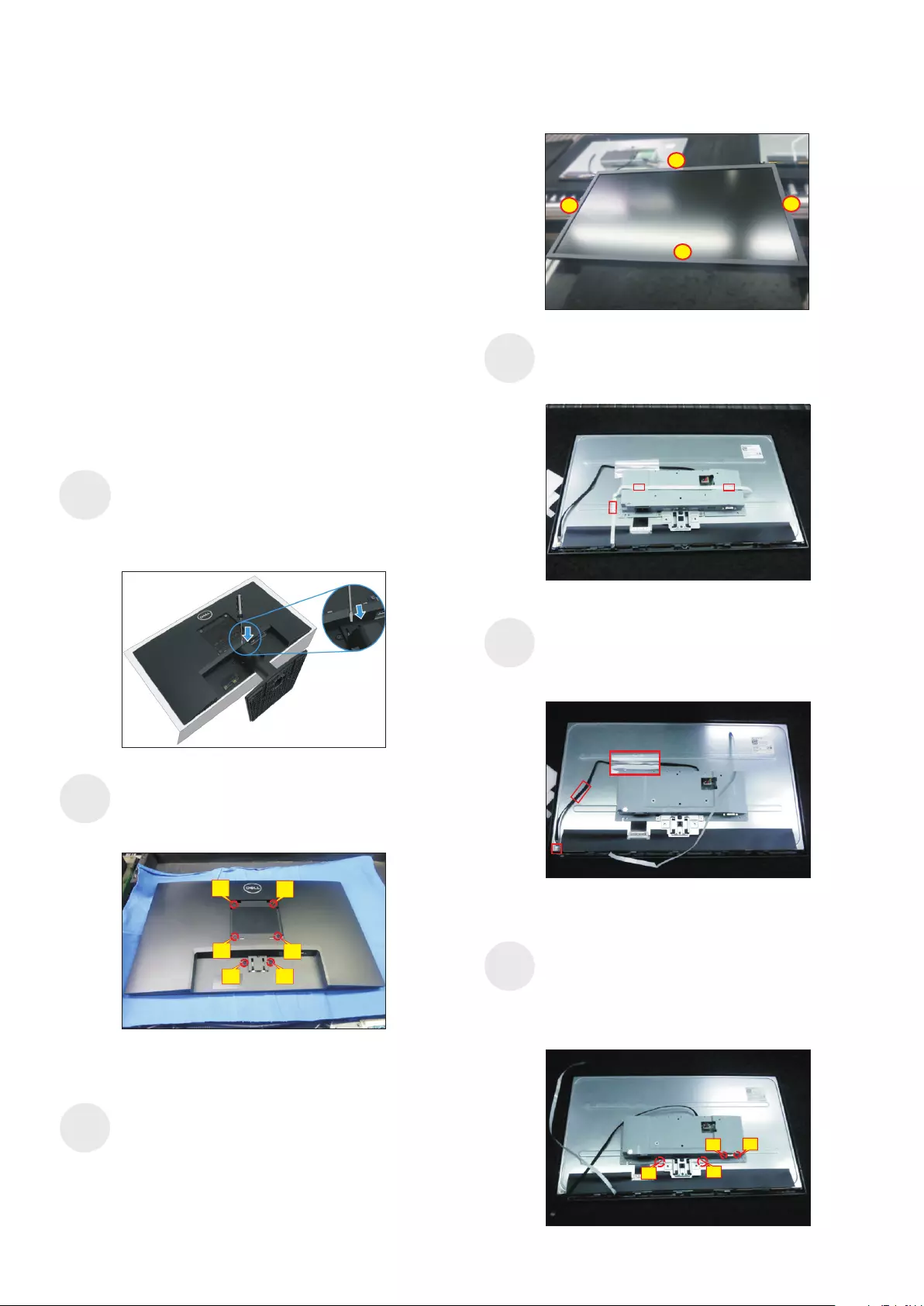

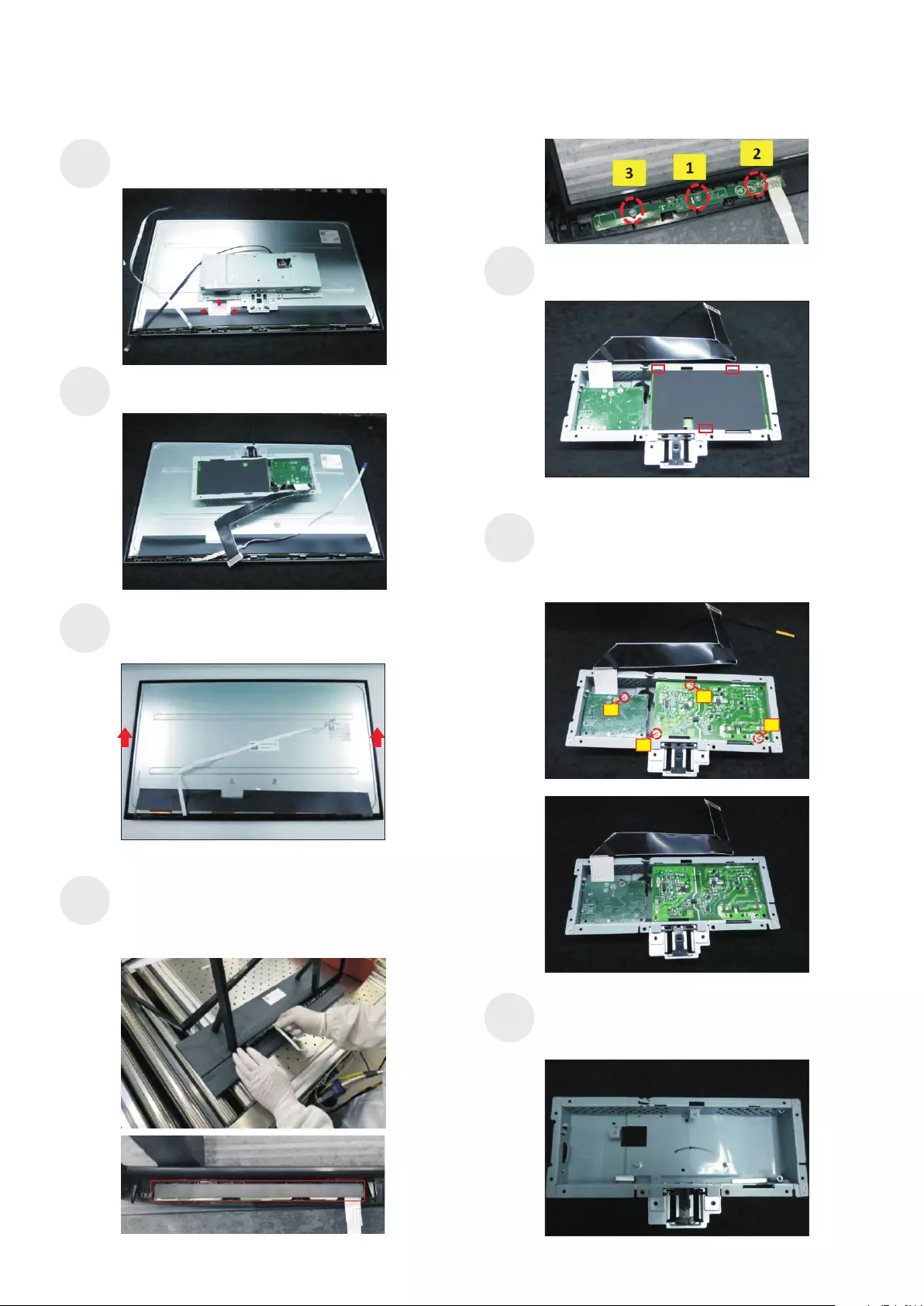

5. Disassembly and Assembly Procedures

5.1 Disassembly Procedures:

Tool Required:

List the type and size of the tools that would typically can be

used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Description:

- Screwdriver(Phillip head) #1

- Screwdriver(Phillip head) #2

- Penknife

- Soldering iron and absorber

NOTE:

This “Disassembly and Assembly Procedures” is for EMEA only,

not for other regions. Please note that Dell will deem warranty void

if any disassembly is done on the monitors.

S2

S1S1

Use a Philips-head screwdriver to remove 6pcs

screws for unlocking mechanisms.

(No.1~4 screw size=M4x11; Torque=11 1kgfxcm;

No.5~6 screw size=M4x6; Torque=11 1kgfxcm)

±

±

23

41

5

6

Remove the monitor stand base:

1. Place the monitor on a soft cloth or cushion.

2. Remove VESA cover to access the release button.

3. Use a long and thin screwdriver to push the release

latch located in a hole just above the stand.

4. Once the latch is released, remove the base away

from the monitor.

S3

Turn over the LCD monitor to let the screen faced

up, place a cloth on the panel where you are working

on to protect the panel. Continually, wedge your

fingers between the front bezel and the panel in

order of arrow preference for unlocking

mechanisms. Turn over the LCD monitor to let the

screen faced down and then remove the rear cover.

3

1

22

S4

S5

S6

Use a Philips-head screwdriver to remove 2pcs

screws for unlocking the bracket with panel module.

Use a Hex-head screwdriver to remove 2pcs screws

for unlocking the VGA connector.

(No.1~2 screw size=M3x2.6, Torque=4 0.5kgfxcm;

No.3~4 screw size=M3x8, Torque=6±0.5kgfxcm)

±

Disconnect the function key cable away from the

connector of the board, then tear off 3pcs adhesive

tape for releasing the function key board.

Tear off 1pcs aluminum foil on the back of the panel

lamp cable for unlocking panel lamp cable, and then

disconnect the panel lamp cable away from the

connector of panel module.

2

34

1

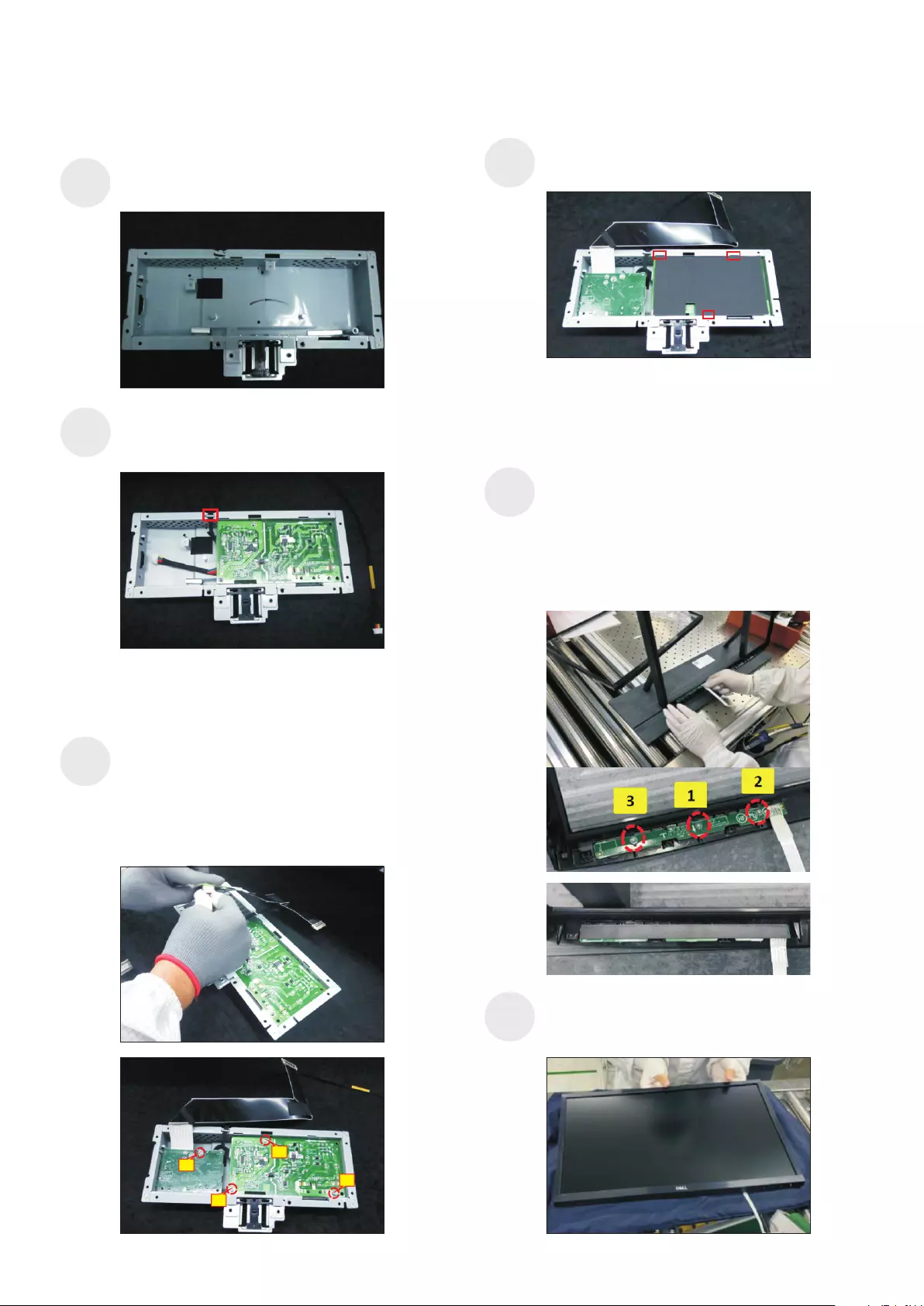

5. Disassembly and Assembly Procedures

S10

S7

S9

S11

S13

S12

Tear off the mylar tape, then ut the front bezel into a

fixture, then u

p

se a Philips-head screwdriver to

remove 3pcs screws for unlocking the function key

board with the front bezel.

(No.1~3 screw size=M2x2.4, Torque=0.8±0.2kgfxcm

Release the panel module away from the hooks of

the front bezel, then l

.

ift up the panel module and

take away the front bezel with key board

L

.

ift up the bracket chassis and put it on a protective

cushion

S8

Use a Philips-head screwdriver to remove 4pcs

screws for unlocking the circuit board, release all the

cables from the hooks.

(No.1 screw size=M4x8, Torque=6±0.5kgfxcm;

No. 2~4 screw size=M3x7.5, Torque=6±0.5kgfxcm)

Remove the Mylar from the hooks of the bracket

chassis module.

Remove the interface board and power board from

the bracket chassis module carefully, and disconnect

all the cables.

Unplug the LVDS cable from the connector of the

panel module by pushing the earing-locks.

3

2

4

1

5. Disassembly and Assembly Procedures

Take a mylar to insert the hooks of the bracket to

cover the power board.

S4

Turn over a power board and put the power board

into the bracket chassis, locate the panel power

cable into the hook of the bracket chassis.

Place a bracket chassis base on a protective

cushion.

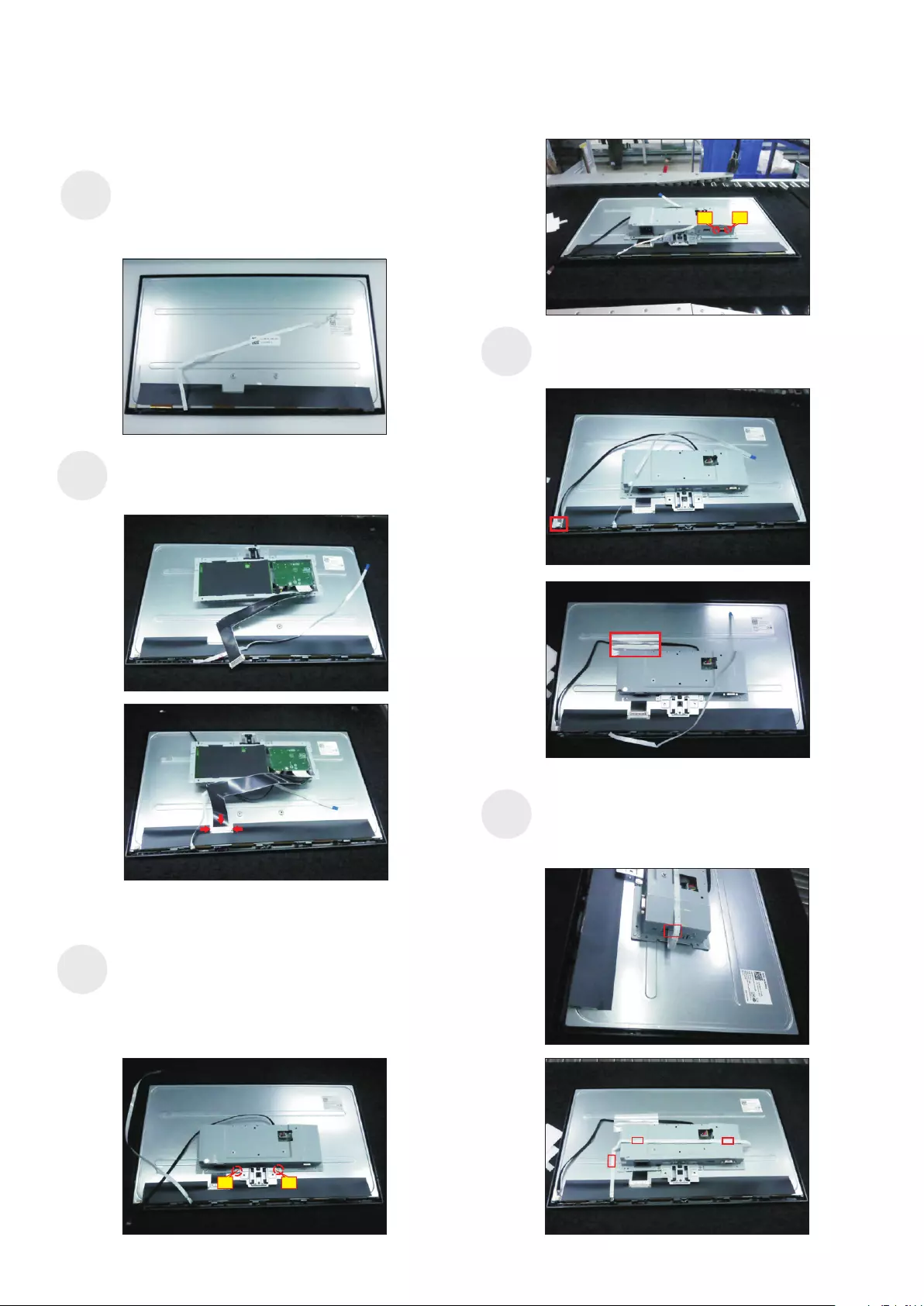

5.2 Assembly Procedures:

S2

S1

Take a interface board, connect a LVDS cable to the

connector of the interface board, then connect the

cable of the power board to the connector of the

interface board. Turn over the interface board and

locate it into the bracket. Use a Philips-head

screwdriver to tighten 4pcs screws for locking the

power board and interface board.

(No.1 screw size=M4x8, Torque=5±0.5kgfxcm;

No.2~4 screw size=M3x7.5, Torque=5±0.5kgfxcm)

S3

3

2

4

1

Take 1pcs panel module, then put the panel into the

front bezel and locate the panel into the hooks of the

front bezel for the two parts firmly attached.

S6

The following two steps (S6 and S7) is processed in

LCM assemble line. Take 1pcs function key board

and 1pcs front bezel from the carton, then put the

middle bezel into a fixture, and locate the function

keyboard into the hooks of the front bezel Use a

Philips-head screwdriver to tighten 3pcs screws for

locking the function key board with the front bezel,

then paste 1pcs black mylar tape to cover the

function key board.

.

(No.1~3 screw size=M2x2.4, Torque=0.8±0.2kgfxcm

S5

5. Disassembly and Assembly Procedures

Adjust the bracket chassis to the correct position,

then use a Philips-head screwdriver to tighten 2pcs

screws for locking the bracket with panel module.

Use a Hex-head screwdriver to lock 2pcs screws for

locking the VGA connector.

(No.1~2 screw size=M3x4, Torque=5 0.5kgfxcm;

No.3~4 screw size=M3x8, Torque=6±0.5kgfxcm)

±

Connect the function key cable to the connector of

board, then tear off the 3pcs double-faced tape on

the back of the back and fix the cable on the bracket

as the picture below shown.

Take out 1pcs panel assembled module with front

bezel and function key board from the carton, and

then examine the panel surface according to

inspection criteria. Turn over the panel, and then

place screen faced down for later assembling.

S7

Move the bracket close to the panel, then use a

proper tool to connect LVDS cable to the connector

of the panel.

S8

2

S11

1

Connect the panel lamp cable to the connector of

the panel module, then fix the panel lamp cable with

1pcs aluminum foil as the picture below shown.

34

S10

S9

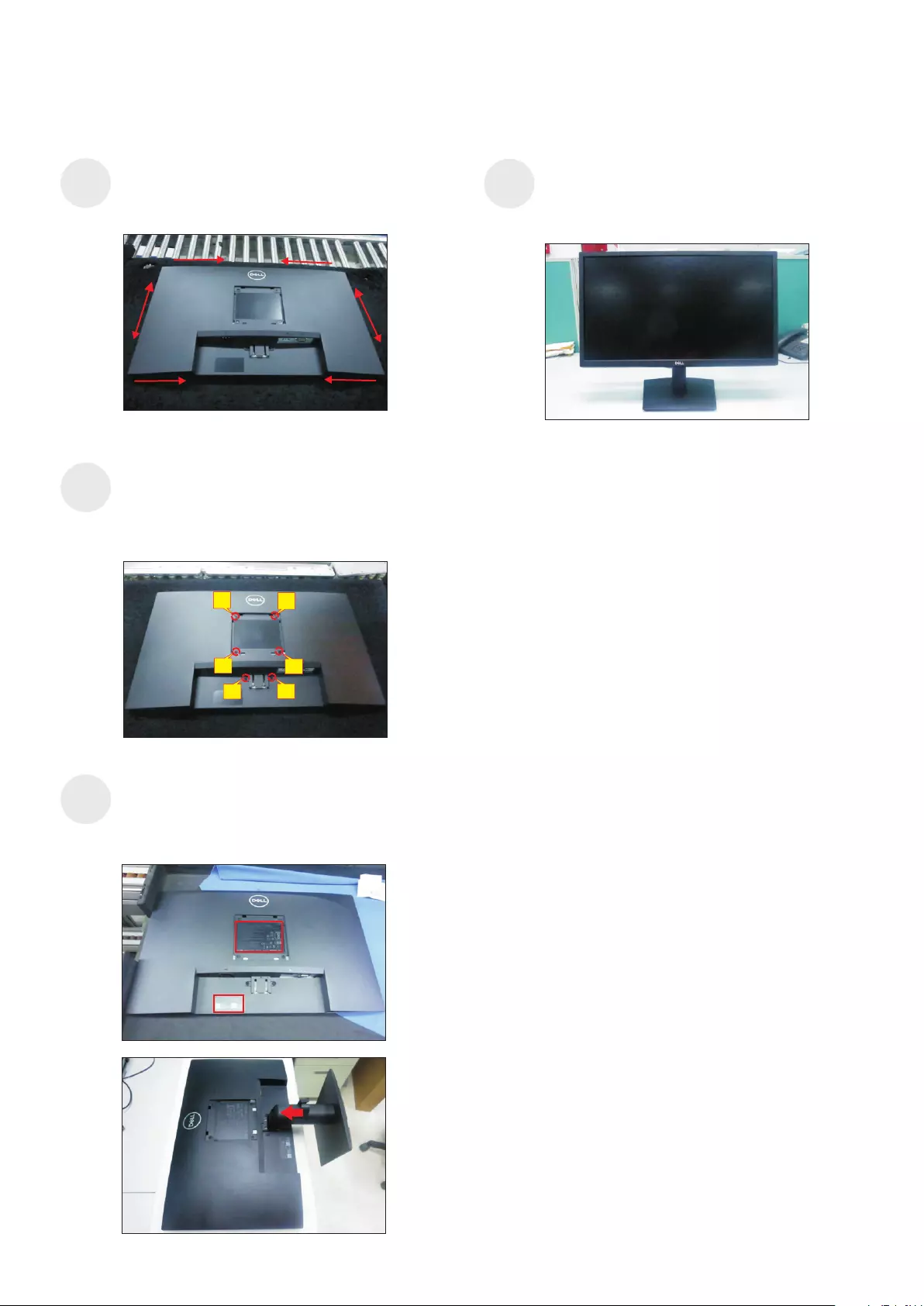

5. Disassembly and Assembly Procedures

Use a Philips-head screwdriver to tighten 4pcs

screws for locking rear cover with the assembled

unit, to tighten 2pcs screws for locking the rear cover

with bracket chassis module.

(No.1~4 screw size=M4x11; Torque=10 12kgfxcm;

No.5~6 screw size=M4x6; Torque=10 12kgfxcm)

~

~

Take 1pcs rear cover, put down the rear cover

and push the rear cover on the positions marked

as the picture below shown for mechanisms

engagement.

S13

S12

L

front bezel with panel module , then provide power

supply and a video signal to the monitor, then turn

on the monitor for functionality check.

ift up the monitor to checking the gap between the

S15

Stick 2pcs labels on the specific positions as the

picture below shown. Take 1pcs stand riser and

1pcs stand base, assemble the stand base with

stand riser. Insert the stand-riser into monitor groove

until it snaps into its place.

S14

23

41

5

6

6. Trouble Shooting Instructions

Self-test

Your monitor provides a self-test feature that allows you to check if your monitor is functioning

properly. If your monitor and computer are properly connected but the monitor screen remains

dark, run the monitor self-test by performing the following steps:

1. Turn off both your computer and the monitor.

2. Disconnect all video cables from the monitor. This way, the computer does not have to be

involved.

3. Turn on the monitor.

If the monitor is working correctly, it detects that there is no signal and one of the following

message appears. While in self-test mode, the power LED remains white.

E2222H

Dell 22 Monitor

No DP Cable

www.dell.com/E2222H

The display will go into Standby mode in 4 minutes.

E2222H

?

NOTE: This message also appears during normal operation, when the video

cable is disconnected or damaged.

4. Turn off your monitor and reconnect the video cable; then turn on your computer and the

monitor.

If your monitor remains dark after you reconnect the cables, check your video controller

and computer.

6. Trouble Shooting Instructions

Built-in diagnostics

Your monitor has a built-in diagnostic tool that helps you determine if any screen abnormality

you experience is an inherent problem with your monitor, or with your computer and video card.

1234

Label Description

1Button 1

2Button 2

3Button 3

4Button 4

To run the built-in diagnostics:

1. Ensure that the screen is clean (no dust particles on the surface of the screen).

2. Press and hold Button 4 for about 4 seconds and wait for a pop up menu.

3. Use Button 1 or 2 to select the and press to confirm.

A gray test pattern appears at the beginning of the diagnostic program.

4. Carefully inspect the screen for abnormalities.

5. Press Button 1 to change the test patterns.

6. Repeat steps 4 and 5 to inspect the display in red, green, blue, black, white and text

screens.

7. When in White color test screen, check for white color uniformity and if there white color

appears greenish/reddish, etc.

8. Press Button 1 to end the diagnostic program.

6. Trouble Shooting Instructions

Common problems

The following table provides general information about common monitor problems

you might encounter and the possible solutions:

Common symptoms Possible solutions

No video/Power LED off • Ensure that the video cable connecting the monitor and the computer is

properly connected and secure.

• Verify that the power outlet is functioning properly using any other electrical

equipment.

• Ensure that the power button is pressed.

• Ensure that the correct input source is selected via the Input Source menu.

No video/Power LED on • Increase brightness and contrast controls using the OSD.

• Perform monitor self-test feature check.

• Check for bent or broken pins in the video cable connector.

• Run the built-in diagnostics.

• Ensure that the correct input source is selected via the Input Source menu.

Poor focus • Eliminate video extension cables.

• Reset the monitor to Factory Settings (Factory Reset).

• Change the video resolution to the correct aspect ratio.

Shaky/Jittery video • Reset the monitor to Factory Settings (Factory Reset).

• Check environmental factors.

• Relocate the monitor and test in another room.

Missing pixels • Cycle power On-off.

• Pixel that is permanently off is a natural defect that can occur in LCD

technology.

• For more information about Dell Monitor Quality and Pixel Policy, see Dell

Support site at:

https://www.dell.com/support/monitors.

Stuck-on pixels • Cycle power On-off.

• Pixel that is permanently off is a natural defect that can occur in LCD

technology.

• For more information about Dell Monitor Quality and Pixel Policy, see Dell

Support site at:

https://www.dell.com/support/monitors.

Brightness problems • Reset the monitor to Factory Settings (Factory Reset).

• Adjust brightness and contrast controls using OSD.

Geometric distortion • Reset the monitor to Factory Settings (Factory Reset).

• Adjust horizontal and vertical using OSD.

Horizontal/Vertical lines • Reset the monitor to Factory Settings (Factory Reset).

• Perform monitor self-test feature check and determine if these lines are also

in self-test mode.

• Check for bent or broken pins in the video cable connector.

• Run the built-in diagnostics.

6. Trouble Shooting Instructions

Common symptoms Possible solutions

Synchronization

problems

• Reset the monitor to Factory Settings (Factory Reset).

• Perform monitor self-test feature check to determine if the scrambled

screen appears in self-test mode.

• Check for bent or broken pins in the video cable connector.

• Restart the computer in safe mode.

Safety related issues • Do not perform any troubleshooting step.

• Contact Dell immediately.

Intermittent problems • Try different Preset Modes in Color settings OSD. Adjust R/G/B value in

Custom Color in Color settings OSD.

• Change the Input Color Format to RGB or YPbPr in the Color settings

OSD.

• Run the built-in diagnostics.

Missing color • Perform monitor self-test feature check.

• Ensure that the video cable connecting the monitor to the computer is

connected properly and is secure.

• Check for bent or broken pins in the video cable connector.

Wrong color • Try different Preset Modes in Color settings OSD. Adjust R/G/B value in

Custom Color in Color settings OSD.

• Change the Input Color Format to RGB or YCbCr/YPbPr in the Color

settings OSD.

• Run the built-in diagnostics.

Image retention from a static

image left on the monitor for

a long period of time

• Set the screen to turn off after a few minutes of screen idle time. These can

be adjusted in Windows Power Options or Mac Energy Saver setting.

• Alternatively, use a dynamically changing screensaver.

Video ghosting or

overshooting

• Change the Response Time in the Display OSD to Fast or Normal

depending on your application and usage.

Product-specific problems

Specific symptoms Possible solutions

Screen image is too small • Check the Aspect Ratio setting in the Display settings OSD.

• Reset the monitor to Factory Settings (Factory Reset).

Cannot adjust the monitor

with the buttons on the

bottom of the panel

• Turn off the monitor, unplug the power cord, plug it back, and then turn on

the monitor.

No input signal when user

controls are pressed

• Check the signal source. Ensure that the computer is not in standby or

sleep mode by moving the mouse or pressing any key on the keyboard.

• Check if the video cable is plugged in properly. Disconnect and reconnect

the video cable if necessary.

• Reset the computer or video player.

The picture does not fill the

entire screen

• Due to different video formats (aspect ratio) of DVDs, the monitor may

display in full screen.

• Run the built-in diagnostics.