Table of Contents

- Dell EMC PowerVault ME4 Series Storage System Owner’s Manual

- Storage system hardware

- Troubleshooting and problem solving

- Module removal and replacement

- ESD precautions

- Dealing with hardware faults

- Firmware updates

- Continuous operation during replacement

- Shutting down attached hosts

- Shutting down a controller module

- Verifying component failure

- Customer-replaceable units (CRUs)

- Attach or remove the front bezel of a 2U enclosure

- Replacing a drive carrier module in a 2U enclosure

- Replacing a DDIC in a 5U enclosure

- Replacing a controller module or IOM in a 2U or 5U enclosure

- Replacing a power supply unit (PSU) in a 5U enclosure

- Replacing a fan cooling module (FCM) in a 5U enclosure

- Replacing a power cooling module (PCM) in a 2U enclosure

- Completing the component installation process

- Verifying component operation

- Performing updates in PowerVault Manager after replacing an FC or SAS HBA

- Events and event messages

- Connecting to the CLI port using a serial cable

- Technical specifications

- Standards and regulations

DELL ME4012 User Manual

Displayed below is the user manual for ME4012 by DELL which is a product in the Disk Arrays category. This manual has pages.

Related Manuals

Dell EMC PowerVault ME4 Series Storage

System

Owner’s Manual

July 2020

Rev. A06

Notes, cautions, and warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

© 2018 – 2020 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other

trademarks may be trademarks of their respective owners.

Chapter 1: Storage system hardware................................................................................................ 5

Locate the service tag.......................................................................................................................................................... 5

Enclosure configurations...................................................................................................................................................... 5

Upgrading to dual-controller configuration.................................................................................................................. 6

Removing the second controller....................................................................................................................................6

Enclosure management........................................................................................................................................................ 6

Operation................................................................................................................................................................................ 7

Attach or remove the front bezel of a 2U enclosure.................................................................................................. 9

Enclosure variants................................................................................................................................................................. 9

2U enclosure core product................................................................................................................................................. 10

2U enclosure front panel................................................................................................................................................11

2U enclosure rear panel..................................................................................................................................................11

5U84 enclosure core product.............................................................................................................................................14

5U84 enclosure front panel...........................................................................................................................................14

5U84 enclosure rear panel............................................................................................................................................ 15

5U84 enclosure chassis.......................................................................................................................................................18

5U84 enclosure drawers................................................................................................................................................18

Operator's (Ops) panel LEDs............................................................................................................................................. 19

2U enclosure Ops panel.................................................................................................................................................19

5U enclosure Ops panel................................................................................................................................................20

Controller modules......................................................................................................................................................... 21

CompactFlash...................................................................................................................................................................... 26

Supercapacitor pack......................................................................................................................................................27

Controller failure when a single-controller is operational................................................................................................27

Transporting cache........................................................................................................................................................27

Chapter 2: Troubleshooting and problem solving............................................................................. 28

Overview.............................................................................................................................................................................. 28

Fault isolation methodology................................................................................................................................................28

Fault isolation methodology basic steps..................................................................................................................... 28

Options available for performing basic steps............................................................................................................. 28

Performing basic steps................................................................................................................................................. 29

LEDs......................................................................................................................................................................................30

2U enclosure LEDs......................................................................................................................................................... 31

5U84 enclosure LEDs....................................................................................................................................................33

Troubleshooting 2U enclosures......................................................................................................................................... 36

PCM faults......................................................................................................................................................................36

Thermal monitoring and control...................................................................................................................................37

Thermal alarm.................................................................................................................................................................37

Troubleshooting 5U enclosures......................................................................................................................................... 37

Thermal considerations.................................................................................................................................................38

CLI port connections.....................................................................................................................................................38

Temperature sensors.......................................................................................................................................................... 38

Host I/O................................................................................................................................................................................38

Contents

Contents 3

Chapter 3: Module removal and replacement................................................................................... 39

ESD precautions.................................................................................................................................................................. 39

Dealing with hardware faults............................................................................................................................................. 40

Firmware updates................................................................................................................................................................40

Configuring partner firmware update......................................................................................................................... 40

Continuous operation during replacement....................................................................................................................... 40

Shutting down attached hosts.......................................................................................................................................... 40

Shutting down a controller module....................................................................................................................................41

Using the PowerVault Manager................................................................................................................................... 41

Using the CLI...................................................................................................................................................................41

Verifying component failure................................................................................................................................................41

Customer-replaceable units (CRUs).................................................................................................................................42

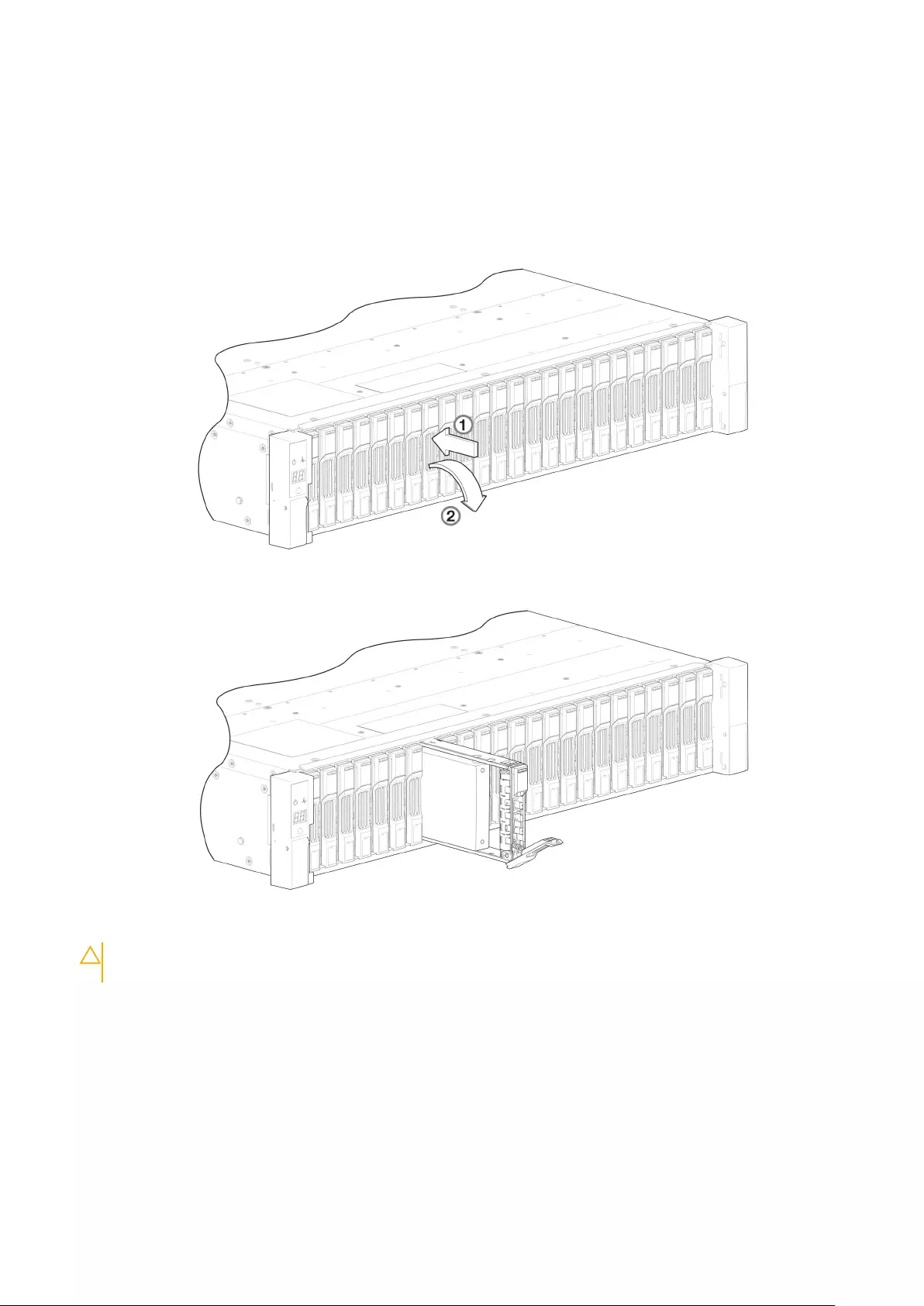

Attach or remove the front bezel of a 2U enclosure................................................................................................ 43

Replacing a drive carrier module in a 2U enclosure...................................................................................................43

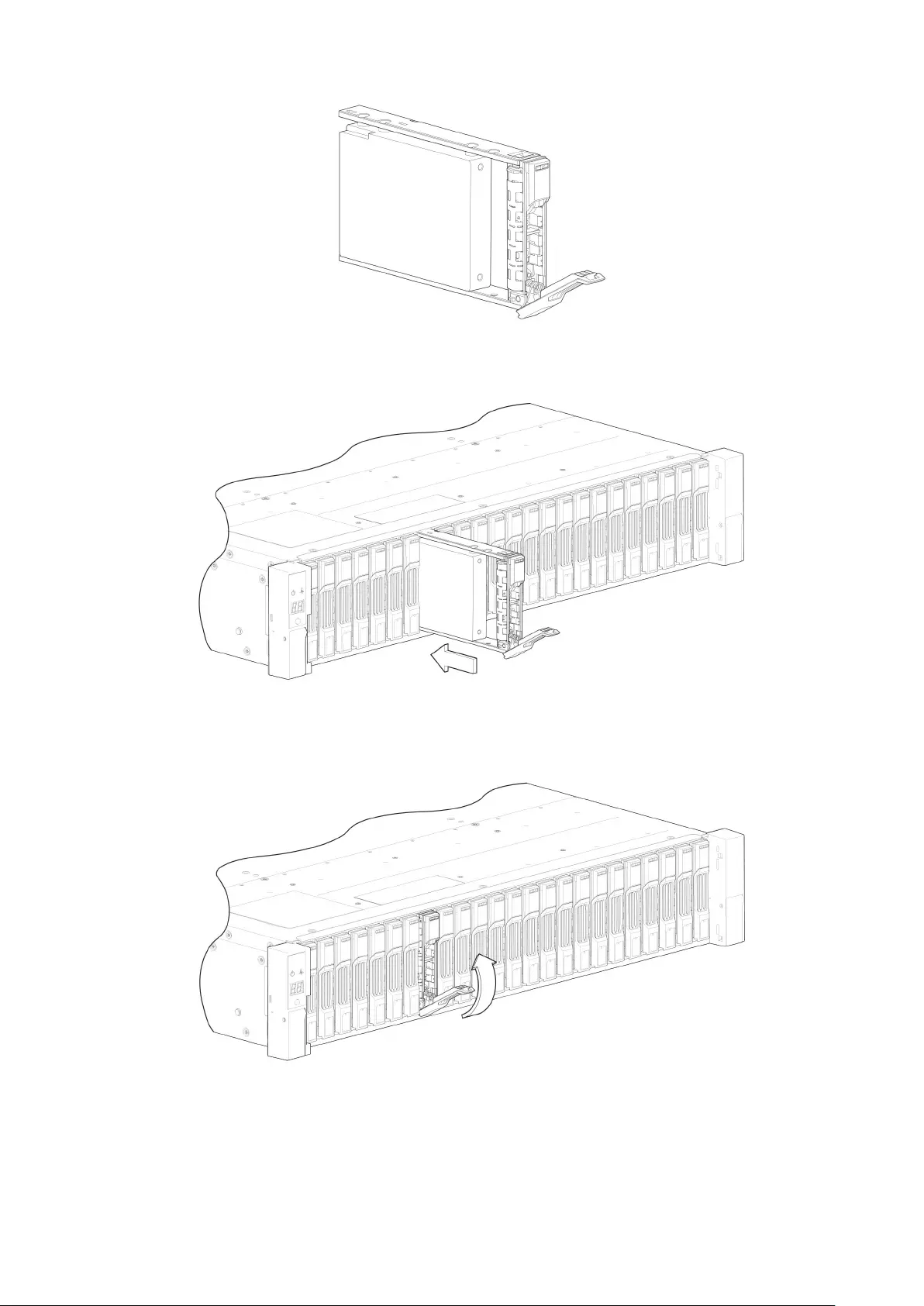

Replacing a DDIC in a 5U enclosure............................................................................................................................ 48

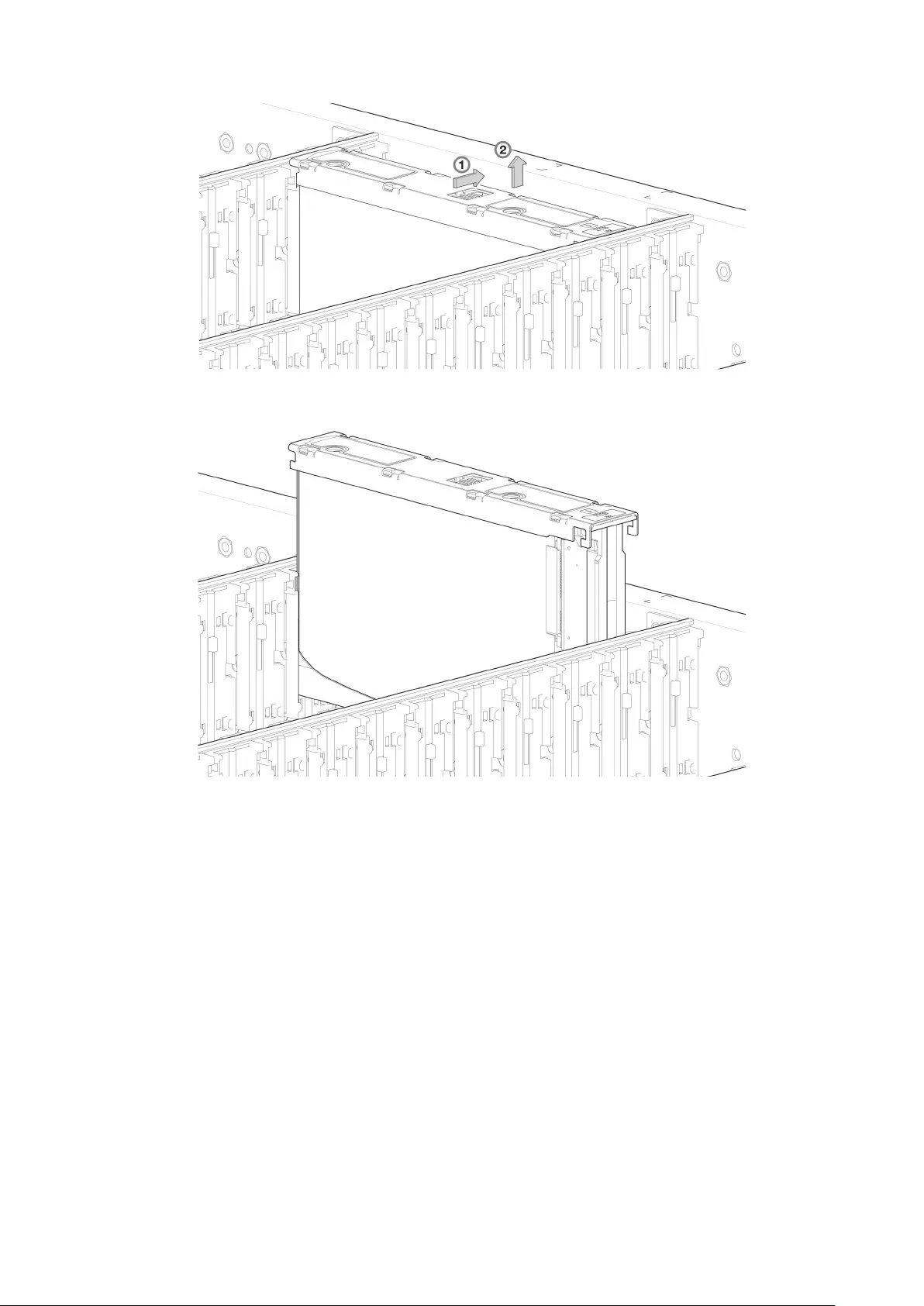

Replacing a controller module or IOM in a 2U or 5U enclosure...............................................................................57

Replacing a power supply unit (PSU) in a 5U enclosure.......................................................................................... 63

Replacing a fan cooling module (FCM) in a 5U enclosure....................................................................................... 65

Replacing a power cooling module (PCM) in a 2U enclosure..................................................................................66

Completing the component installation process....................................................................................................... 68

Verifying component operation......................................................................................................................................... 68

Using LEDs..................................................................................................................................................................... 68

Using management interfaces..................................................................................................................................... 69

Performing updates in PowerVault Manager after replacing an FC or SAS HBA...................................................... 69

Chapter 4: Events and event messages........................................................................................... 70

Event descriptions...............................................................................................................................................................70

Events.................................................................................................................................................................................... 71

Events (continued)............................................................................................................................................................105

Events (continued)............................................................................................................................................................ 124

Removed events................................................................................................................................................................. 141

Events sent as indications to SMI-S clients................................................................................................................... 142

Using the trust command................................................................................................................................................. 142

Appendix A: Connecting to the CLI port using a serial cable............................................................. 143

Mini-USB Device Connection...........................................................................................................................................144

Microsoft Windows drivers.........................................................................................................................................145

Linux drivers..................................................................................................................................................................145

Appendix B: Technical specifications............................................................................................. 146

Appendix C: Standards and regulations......................................................................................... 150

4Contents

Storage system hardware

This chapter describes the front-end and back-end components of ME4 Series enclosures.

Some of the modules within the enclosure are replaceable as described in Module removal and replacement on page 39. The types of

modules and other components that can be replaced are defined below:

• CRU: Customer-replaceable Unit

• FRU: Field-replaceable Unit (requires service expertise)

The terms CRU and FRU are used throughout this document.

Topics:

•Locate the service tag

•Enclosure configurations

•Enclosure management

•Operation

•Enclosure variants

•2U enclosure core product

•5U84 enclosure core product

•5U84 enclosure chassis

•Operator's (Ops) panel LEDs

•CompactFlash

•Controller failure when a single-controller is operational

Locate the service tag

Your ME4 Series storage system is identified by a unique Service Tag and Express Service Code.

The Service Tag and Express Service Code are found on the front of the system by pulling out the information tag. Alternatively, the

information might be on a sticker on the back of the storage system chassis. This information is used to route support calls to appropriate

personnel.

NOTE: Quick Resource Locator (QRL):

• The QRL code contains information unique to your system. It can be found on the information tag and the

Setting Up

Your Dell EMC PowerVault ME4 Series Storage System

hard copy document provided with your ME4 Series

enclosure.

• Scan the QRL to get immediate access to your system information, using your smart phone or tablet.

Enclosure configurations

The storage system supports three controller enclosure configurations.

• 2U (rack space) controller enclosure (2U12)– see Figure 1. 2U12 enclosure system—front orientation on page 7 and Figure 2. 2U12

enclosure system—rear orientation on page 7: holds up to 12 low profile (1-inch high) 3.5" form factor disk drives in a horizontal

orientation.

• 2U (rack space) controller enclosure (2U24)– see Figure 3. 2U24 enclosure system—front orientation on page 8 and Figure 4.

2U24 enclosure system—rear orientation on page 8: holds up to 24 low profile (5/8 inch high) 2.5" form factor disk drives in a

vertical orientation.

• 5U (rack space) controller enclosure (5U84)– see Figure 5. 5U84 enclosure system—front orientation on page 8 and Figure 6.

5U84 enclosure system—rear orientation on page 9: holds up to 84 low profile (1-inch high) 3.5" form factor disk drives in a vertical

orientation within the disk drawer. Two vertically-stacked drawers each hold 42 disks. If used, 2.5" disks require 3.5" adapters.

These same chassis form factors are used for the supported expansion enclosures; but with I/O modules instead of controller modules.

1

Storage system hardware 5

The 2U12 and 2U24 enclosures support single or dual-controller module configurations, but the 5U84 enclosure only supports a dual-

controller module configuration. If a partner controller module fails, the storage system will fail over and run on a single controller module

until the redundancy is restored. For 2U enclosures, an controller module must be installed in slot A, and a controller module or a module

blank must be installed in slot B to ensure sufficient airflow through the enclosure during operation. For 5U84 enclosures, an controller

module must be installed in both slot A and slot B.

Upgrading to dual-controller configuration

You can upgrade a 2U single-controller module configuration by adding a second controller module in slot B.

Controller module B can be added while controller module A continues to process host I/O requirements. However, we recommend

scheduling configuration changes during a maintenance window with low or no I/O activity.

Data is not impacted when a controller module B is inserted into the enclosure, but we recommended doing a complete data backup

before proceeding.

NOTE:

• When a controller module B is inserted, the redundancy setting is automatically changed from Single Controller

to Active-Active ULP (Unified LUN Presentation). No manual changes are necessary.

• If PFU (partner firmware upgrade) is enabled, when you add controller module B, the system automatically updates

the firmware on second controller module to match the firmware version on the first controller module.

1. Type the following CLI command to confirm that redundancy is configured as Single Controller Mode:

show advanced-settings

This step confirms that controller module A does not report controller module B as missing.

2. Remove the controller blank from slot B.

3. Grasp the controller module with both hands, and with the latch in the open position, orient the module and align it for insertion into

slot B.

4. Ensuring that the controller module is level, slide it into the enclosure as far as it will go.

A controller module that is only partially seated will prevent optimal performance of the controller enclosure. Verify that the controller

module is fully seated before continuing.

5. Set the module in position by manually closing the latch.

You should hear a click as the latch handle engages and secures the controller module to its connector on the back of the midplane.

6. Connect the cables.

7. Map the host ports on controller module B.

Removing the second controller

To remove controller module B and revert back to a single-controller configuration:

1. Shut down controller module B.

2. Remove the controller module from the enclosure.

3. Type the following CLI command to change the redundancy settings to Single Controller Mode:

#set advanced-settings single-controller

4. Install a controller blank in slot B.

Enclosure management

The enclosure is mechanically and electrically compliant with the Storage Bridge Bay (SBB) v 2.1 specification.

SBB modules actively manage the enclosure. Each module has a SAS expander with its own storage enclosure processor (SEP) that

provides a SES target for a host to interface to, through the ANSI SES (SCSI Enclosure Services) standard. If one of these modules fails,

the other module continues to operate.

6Storage system hardware

Management interfaces

When the hardware installation is complete, access the controller module web-based management interface—PowerVault Manager—to

configure, monitor, and manage the storage system. The controller module also provides a command-line interface (CLI) to support

command line entry and scripting. For details, see the Dell EMC PowerVault ME4 Series Storage System CLI Guide for your system.

Operation

CAUTION: Operation of the enclosure with any CRU modules missing will disrupt the airflow, and the enclosure will not

receive sufficient cooling. It is essential that all slots hold modules before the enclosure system is used. Empty drive

slots (bays) in 2U enclosures must hold blank drive carrier modules.

• Read the module bay caution label affixed to the module being replaced.

• Replace a defective power cooling module (PCM) with a fully operational PCM within 24 hours. Do not remove a defective PCM

unless you have a replacement model of the correct type ready for insertion.

• Before removal/replacement of a PCM or power supply unit (PSU), disconnect power supply from the module to be replaced.

• Read the hazardous voltage warning label affixed to power cooling modules.

CAUTION: 5U84 enclosures only

• To prevent overturning, drawer interlocks stop users from opening both drawers at the same time. Do not attempt to force open a

drawer when the other drawer in the enclosure is already open. In a rack containing more than one 5U84 enclosure, do not open more

than one drawer per rack at a time.

• Read the hot surface label affixed to the drawer. Operating temperatures inside enclosure drawers can reach 60ºC. Take care when

opening drawers and removing DDICs.

• Due to product acoustics, ear protection should be worn during prolonged exposure to the product in operation.

• Open drawers must not be used to support any other objects or equipment.

NOTE: See Enclosure variants on page 9 for details about various enclosure options.

Figure 1. 2U12 enclosure system—front orientation

Figure 2. 2U12 enclosure system—rear orientation

The 2U12 controller enclosure in 2U12 enclosure system—rear orientation is equipped with 2 controllers (4–port FC/ISCSI model shown).

Storage system hardware 7

Figure 3. 2U24 enclosure system—front orientation

Figure 4. 2U24 enclosure system—rear orientation

The 2U24 controller enclosure is equipped with dual-controllers (4-port SAS model shown).

Figure 5. 5U84 enclosure system—front orientation

8Storage system hardware

Figure 6. 5U84 enclosure system—rear orientation

The 5U84 controller enclosure is equipped with dual-controllers (4-port FC/iSCSI model shown).

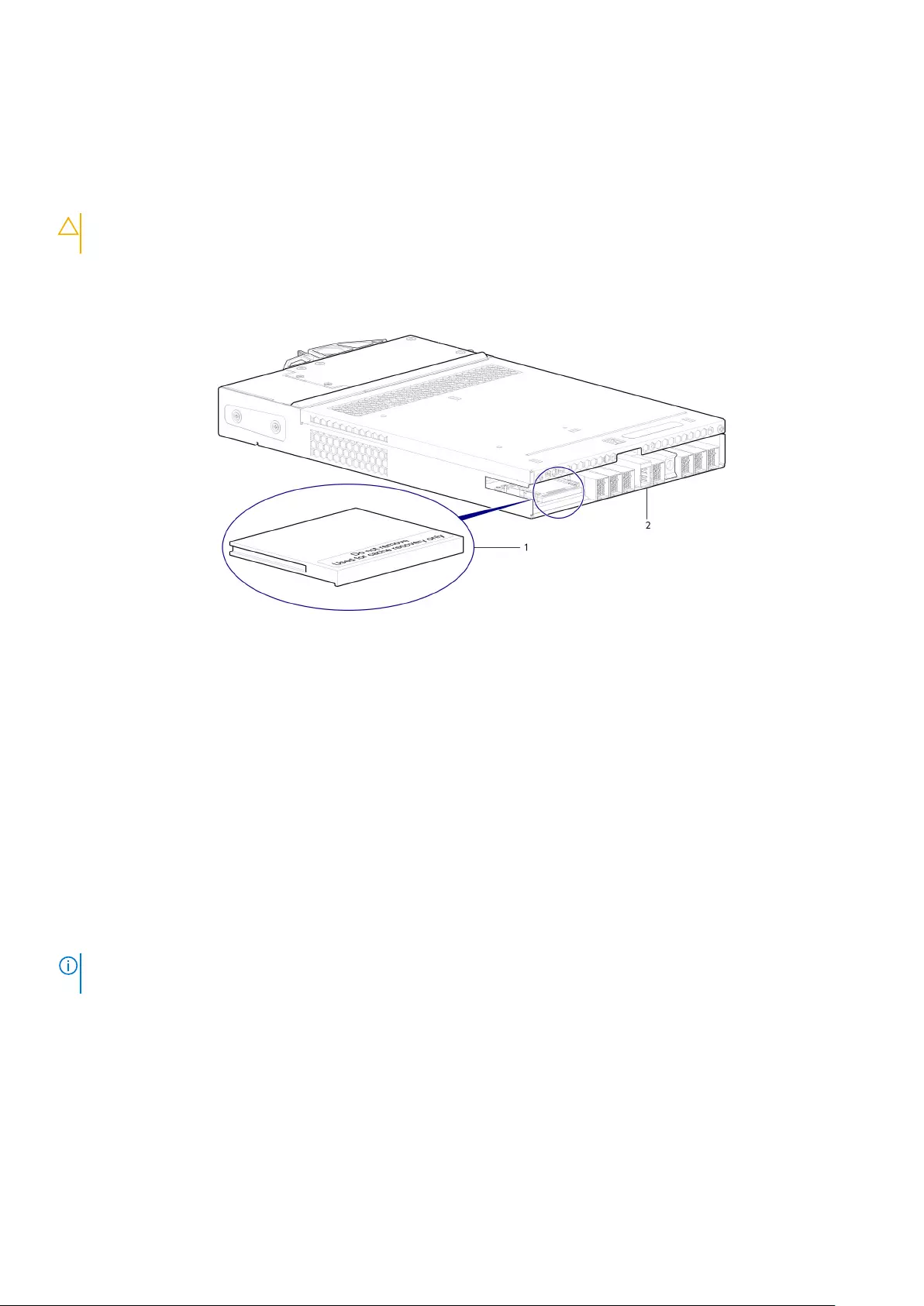

Attach or remove the front bezel of a 2U enclosure

The following figure shows a partial view of a 2U12 enclosure:

Figure 7. Attaching or removing the 2U enclosure front bezel

To attach the front bezel to the 2U enclosure:

1. Locate the bezel, and while grasping it with your hands, face the front panel of the 2U12 or 2U24 enclosure.

2. Hook the right end of the bezel onto the right ear cover of the storage system.

3. Insert the left end of the bezel into the securing slot until the release latch snaps in place.

4. Secure the bezel with the keylock as shown in Attaching or removing the 2U enclosure front bezel.

To remove the bezel from the 2U enclosure, reverse the order of the preceding steps.

NOTE: See Enclosure variants for details about various enclosure options.

Enclosure variants

The 2U chassis can be configured as a controller enclosure ME4012/ME4024, or an expansion enclosure ME412/ME424 as shown in 2U12

enclosure variants and 2U24 enclosure variants. The 5U chassis can be configured as a controller enclosure ME4084 or an expansion

enclosure ME484 as shown in 5U84 enclosure variants.

NOTE:

The 2U and 5U core products—including key components and CRUs–are described in the following sections. Although

many CRUs differ between the form factors, the controller modules and IOMs are common to 2U12, 2U24, and 5U84

chassis. The controller modules and IOMs are introduced in 2U enclosure core product and cross-referenced from 5U84

enclosure core product.

Storage system hardware 9

2U12

2U12 enclosures consist of 12 x LFF (Large Form Factor) disk drives and 12 x HFF (Hybrid Form Factor) disk drives.

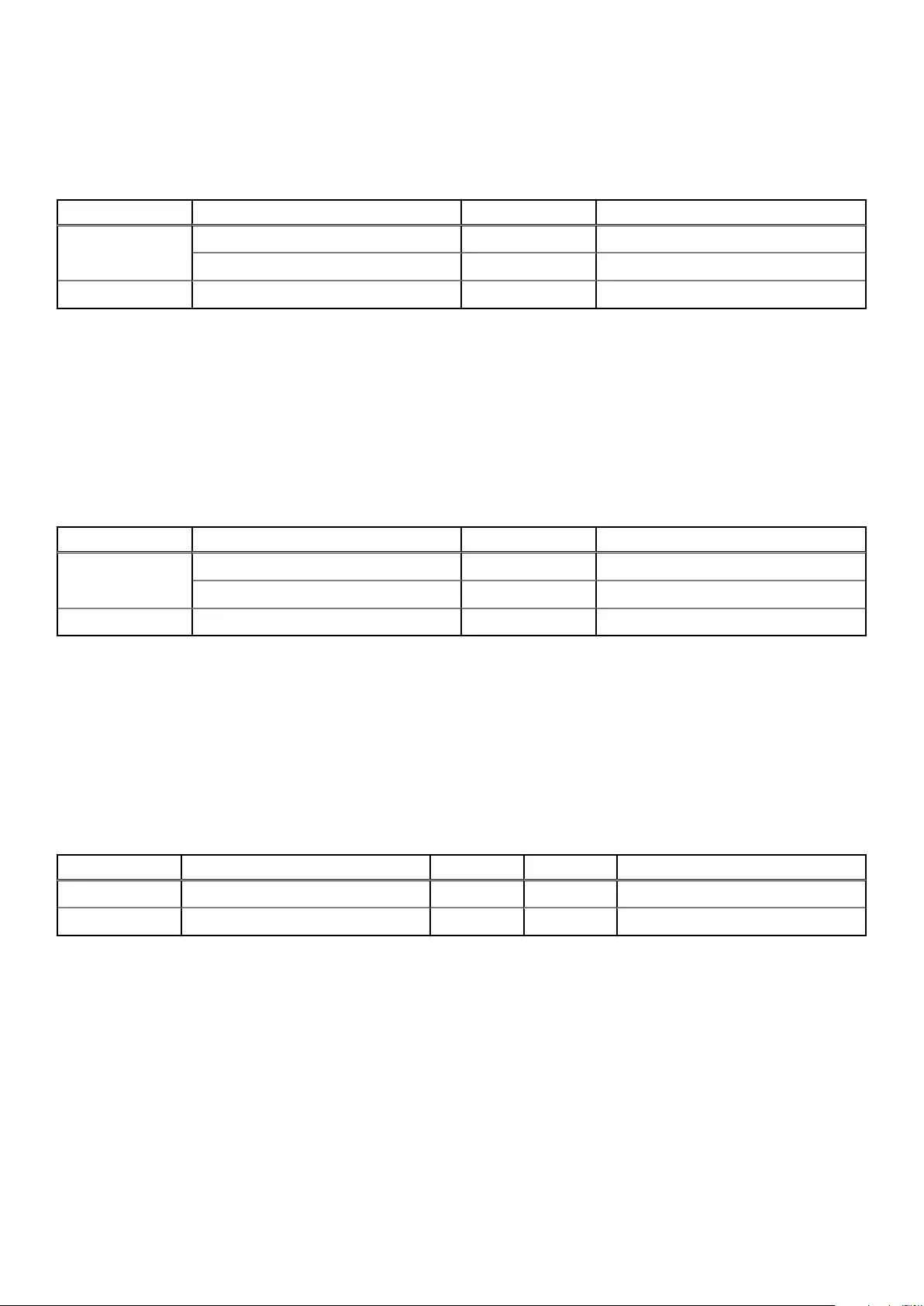

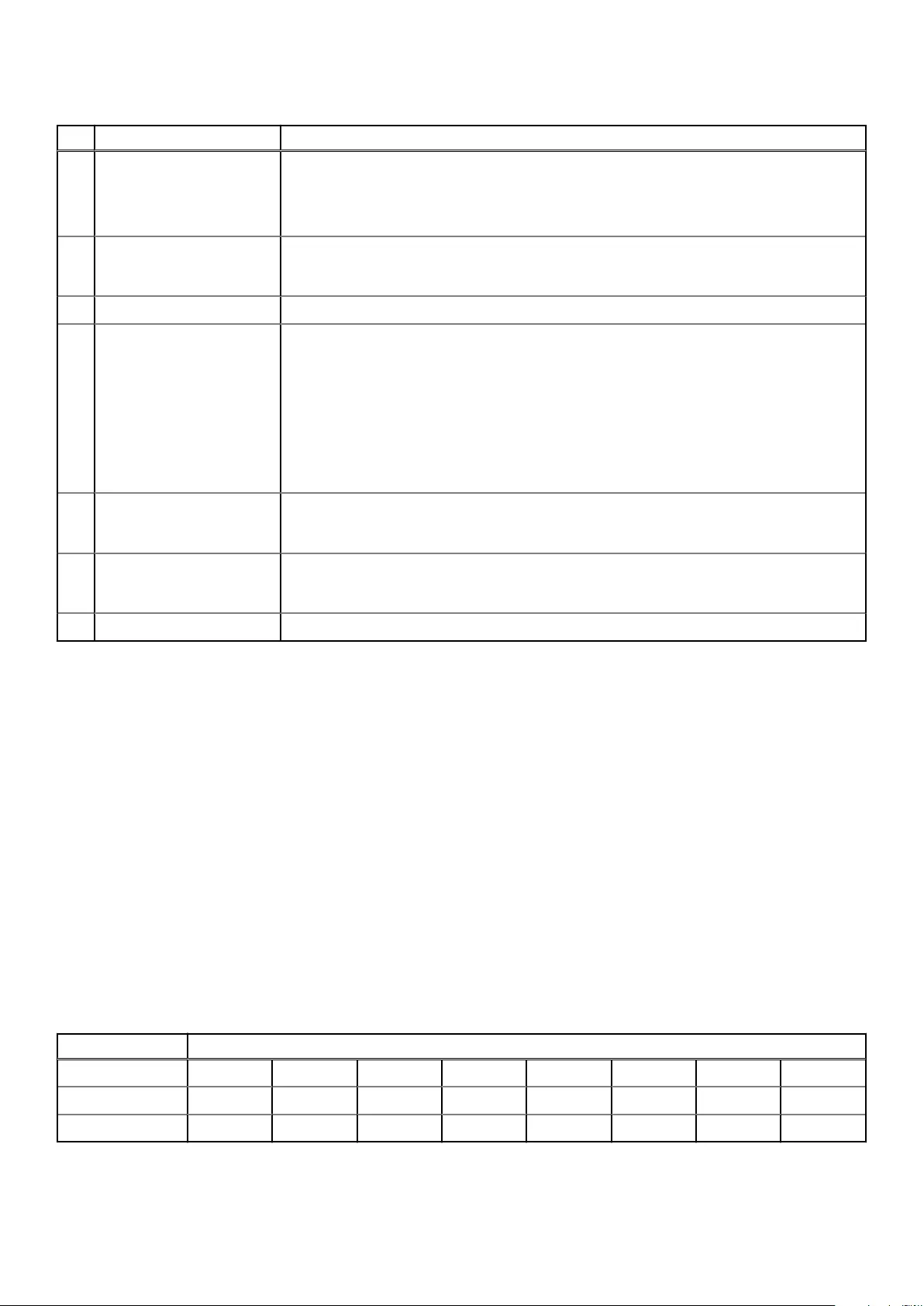

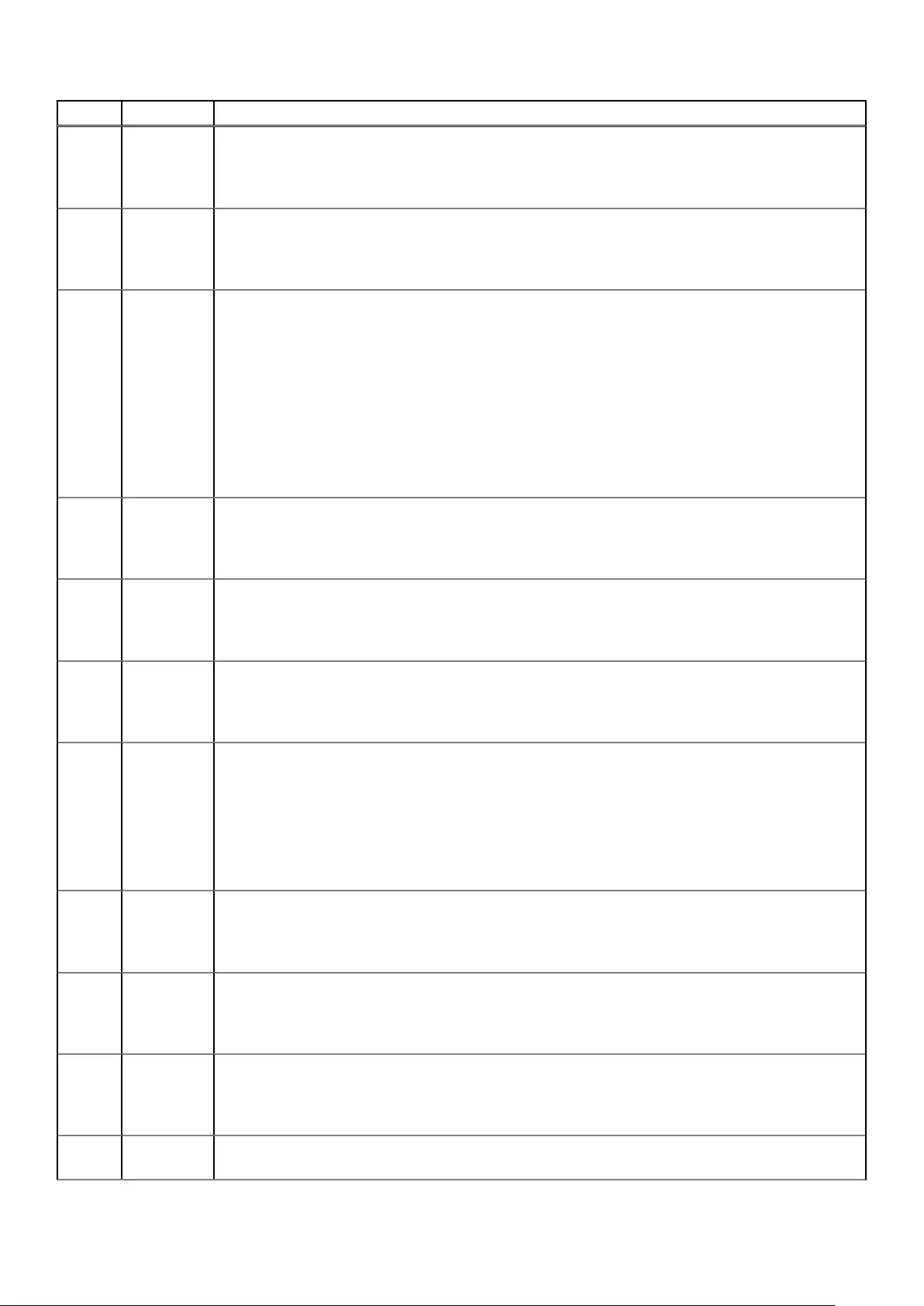

Table 1. 2U12 enclosure variants

Product Configuration PCMs1Controller modules and IOMs2,3

ME4012 12 Gb/s direct dock LFF SAS 2 2

12 Gb/s direct dock LFF SAS 2 1

ME412 12 Gb/s direct dock LFF SAS 2 2

1Redundant PCMs must be compatible modules of the same type (both AC).

2Supported controller modules include 4-port FC/iSCSI, 4-port HD mini-SAS, and 4-port iSCSI 10Gbase-T. Supported IOMs are used in

expansion enclosures for adding storage.

3In single-controller module configurations, the controller module is installed into slot A, and a controller blank is installed in slot B.

2U24

2U24 enclosures consist of 24 x SFF (Small Form Factor) disk drives.

Table 2. 2U24 enclosure variants

Product Configuration PCMs1Controller modules and IOMs2,3

ME4024 12 Gb/s direct dock SFF SAS 2 2

12 Gb/s direct dock SFF SAS 2 1

ME424 12 Gb/s direct dock SFF SAS 2 2

1-Redundant PCMs must be compatible modules of the same type (both AC).

2-Supported controller modules include 4-port FC/iSCSI, 4-port HD mini-SAS, and 4-port iSCSI 10Gbase-T. Supported IOMs are used in

expansion enclosures for adding storage.

3-In single-controller module configurations, the controller module is installed in slot A, and a controller blank is installed in slot B.

5U84

5U84 enclosures consist of 84 x LFF or SFF disk drives held in two 42-slot vertically-stacked drawers.

Table 3. 5U84 enclosure variants

Product Configuration PSUs1FCMs2Controller modules and IOMs3

ME4084 12 Gb/s direct dock SFF SAS 2 5 2

ME484 12 Gb/s direct dock SFF SAS 2 5 2

1-Redundant PCMs must be compatible modules of the same type (both AC).

2-The fan control module (FCM) is a separate CRU (not integrated into a PCM).

3-Supported controller modules include 4-port FC/iSCSI, 4-port HD mini-SAS, and 4-port iSCSI 10Gbase-T. Supported IOMs are used in

expansion enclosures for adding storage.

2U enclosure core product

The design concept is based on an enclosure subsystem together with a set of plug-in modules.

The following figures show component locations—together with CRU slot indexing—relative to 2U enclosure front and rear panels.

10 Storage system hardware

2U enclosure front panel

Integers on disks indicate drive slot numbering sequence.

Figure 8. 2U12 enclosure system—front panel components

Figure 9. 2U24 enclosure system—front panel components

NOTE:

• For information about enclosure front panel LEDs, see 2U enclosure Ops panel on page 19.

• For information about disk LEDs for LFF and SFF disk modules, see Verify front panel LEDs.

• For information about the optional 2U enclosure front bezel, see Figure 7. Attaching or removing the 2U enclosure

front bezel on page 9.

2U enclosure rear panel

Alphabetic designators on controller modules or IOMs and numeric designators on PCMs indicate slot sequencing for the modules used in

2U enclosures. Controller modules, IOMs, and PCMs are available as CRUs. The ME4 Series RBODs use 4-port controller modules. These

RBODs support the ME412/ME424/ME484 EBODs for optionally adding storage.

Figure 10. 2U controller enclosure—rear panel components (4-port FC/iSCSI)

1. Power cooling module slot 0 2. Power cooling module slot 1

3. Controller module slot A 4. Controller module slot B

Figure 11. 2U controller enclosure—rear panel components (4-port iSCSI 10Gbase-T)

1. Power cooling module slot 0 2. Power cooling module slot 1

3. Controller module slot A 4. Controller module slot B

Storage system hardware 11

Figure 12. 2U controller enclosure—rear panel components (4-port SAS)

1. Power cooling module slot 0 2. Power cooling module slot 1

3. Controller module slot A 4. Controller module slot B

NOTE: The preceding figures show dual controller module configurations. Alternatively, you can configure the 2U

controller enclosure with a single controller module. In single controller module configurations, the controller module is

installed in slot A, and a blank plate is installed in slot B.

Figure 13. 2U expansion enclosure—rear panel components

1. Power cooling module slot 0 2. Power cooling module slot 1

3. IOM slot A 4. IOM slot B

2U rear panel components

This section describes the controller module, expansion enclosure IOM, and power cooling module components.

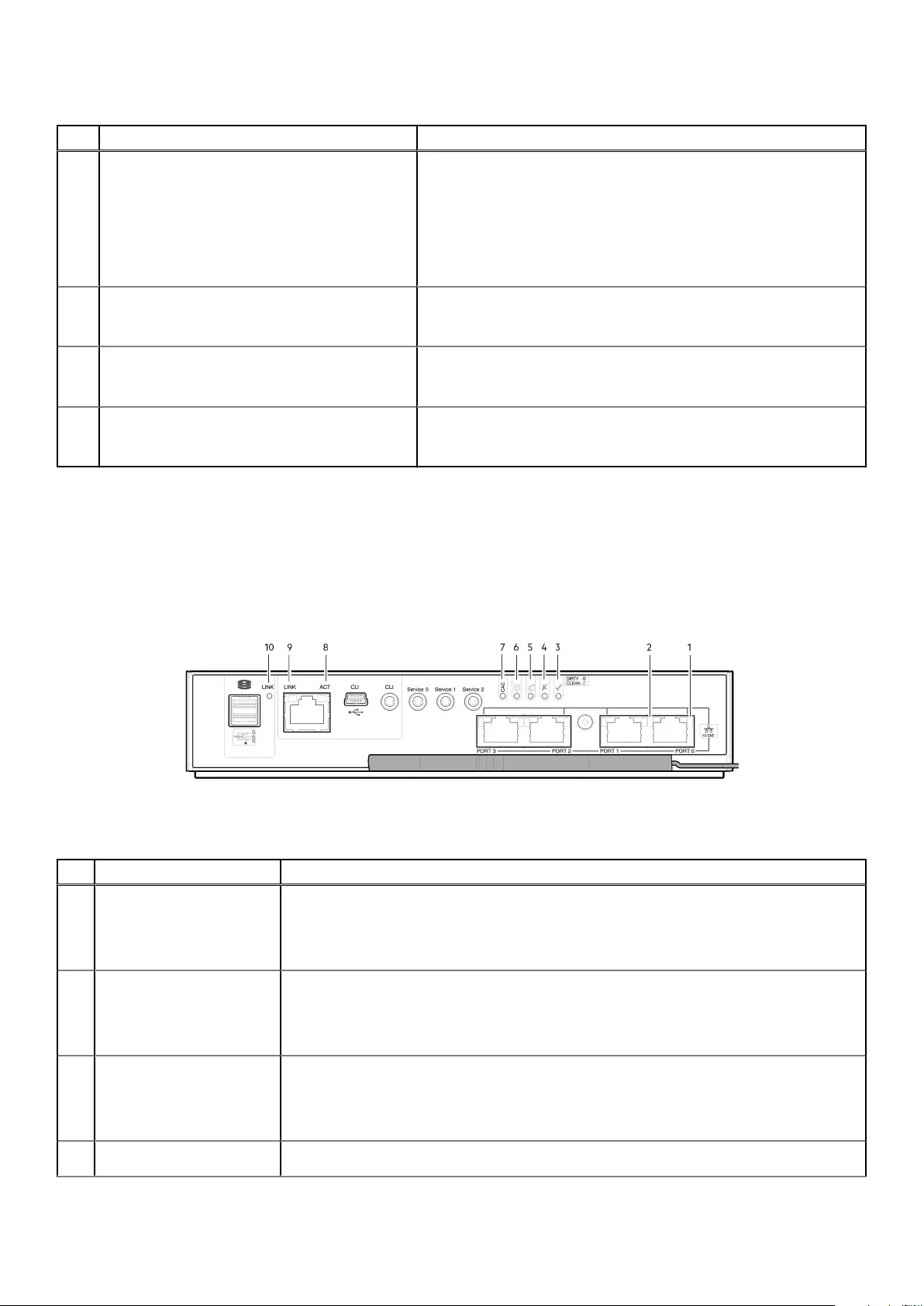

Controller module

The top slot for holding controller modules is designated slot A and the bottom slot is designated slot B. The face plate details of the

controller modules show the modules aligned for use in slot A. In this orientation, the controller module latch shown at the bottom of the

module and it is in a closed/locked position. The following figures identify the ports on the controller modules. See 12 Gb/s controller

module LEDs on page 22 for LED identification.

The Converged Network Controller (CNC) ports on the 4-port FC/iSCSI controller module can be configured with 16Gb/s FC SFPs or 10

GbE iSCSI SFPs.

Figure 14. 4-port FC/iSCSI controller module detail

1. Back-end expansion SAS port 2. Ethernet port used by management interfaces

3. USB serial port (CLI) 4. 3.5 mm serial port (CLI)

5. 3.5 mm serial ports (service only) 6. Reset

7. CNC ports (ports 3, 2, 1, 0)

The following figure shows iSCSI 10Gbase-T host interface ports that ship configured with pre-installed external connectors.

12 Storage system hardware

Figure 15. 4-port iSCSI 10Gbase-T controller module detail

1. Back-end expansion SAS port 2. Ethernet port used by management interfaces

3. USB serial port (CLI) 4. 3.5 mm serial port (CLI)

5. 3.5 mm serial ports (service only) 6. 10Gbase-T ports (ports 3, 2, 1, 0)

The following figure shows SAS host interface ports that ship configured with 12 Gb/s mini-SAS HD (SFF-8644) external connectors.

Figure 16. 4-port mini-SAS HD controller module detail

1. Back-end expansion SAS port 2. Ethernet port used by management interfaces

3. USB serial port (CLI) 4. 3.5 mm serial port (CLI)

5. 3.5 mm serial ports (service only) 6. Reset button

7. SAS ports (ports 3, 2, 1, 0)

Expansion enclosure IOM

The following figure shows the IOM used in supported expansion enclosures for adding storage. Ports A/B/C ship configured with 12

Gb/s mini-SAS HD (SFF-8644) external connectors.

Figure 17. IOM detail – ME412/ME424/ME484

1. 3.5 mm serial port (service only) 2. SAS expansion ports

3. SAS expansion port B (disabled) 4. Ethernet port (disabled)

NOTE: For RBOD/EBOD configurations:

• When the IOM shown in Figure 17. IOM detail – ME412/ME424/ME484 on page 13 is used with ME4 Series controller

modules for adding storage, the middle HD mini-SAS expansion labeled port B is disabled by the firmware.

• The Ethernet port on the IOM is not used in controller/expansion enclosure configurations, and is disabled.

Power cooling module

The following figure shows the power cooling module (PCM) used in controller enclosures and optional expansion enclosures. The PCM

includes integrated cooling fans. The example shows a PCM oriented for use in the left PCM slot of the enclosure rear panel.

Storage system hardware 13

Figure 18. Power cooling module (PCM)

1. PCM OK LED (Green) 2. AC Fail LED (Amber/blinking amber)

3. Fan Fail LED (Amber/blinking amber) 4. DC Fail LED (Amber/blinking amber)

5. On/Off switch 6. Power connector

7. Release latch

LED behavior:

• If any of the PCM LEDs are illuminated amber, a module fault condition or failure has occurred.

• For a detailed description of PCM LED behavior, see 2U enclosure LEDs on page 31.

5U84 enclosure core product

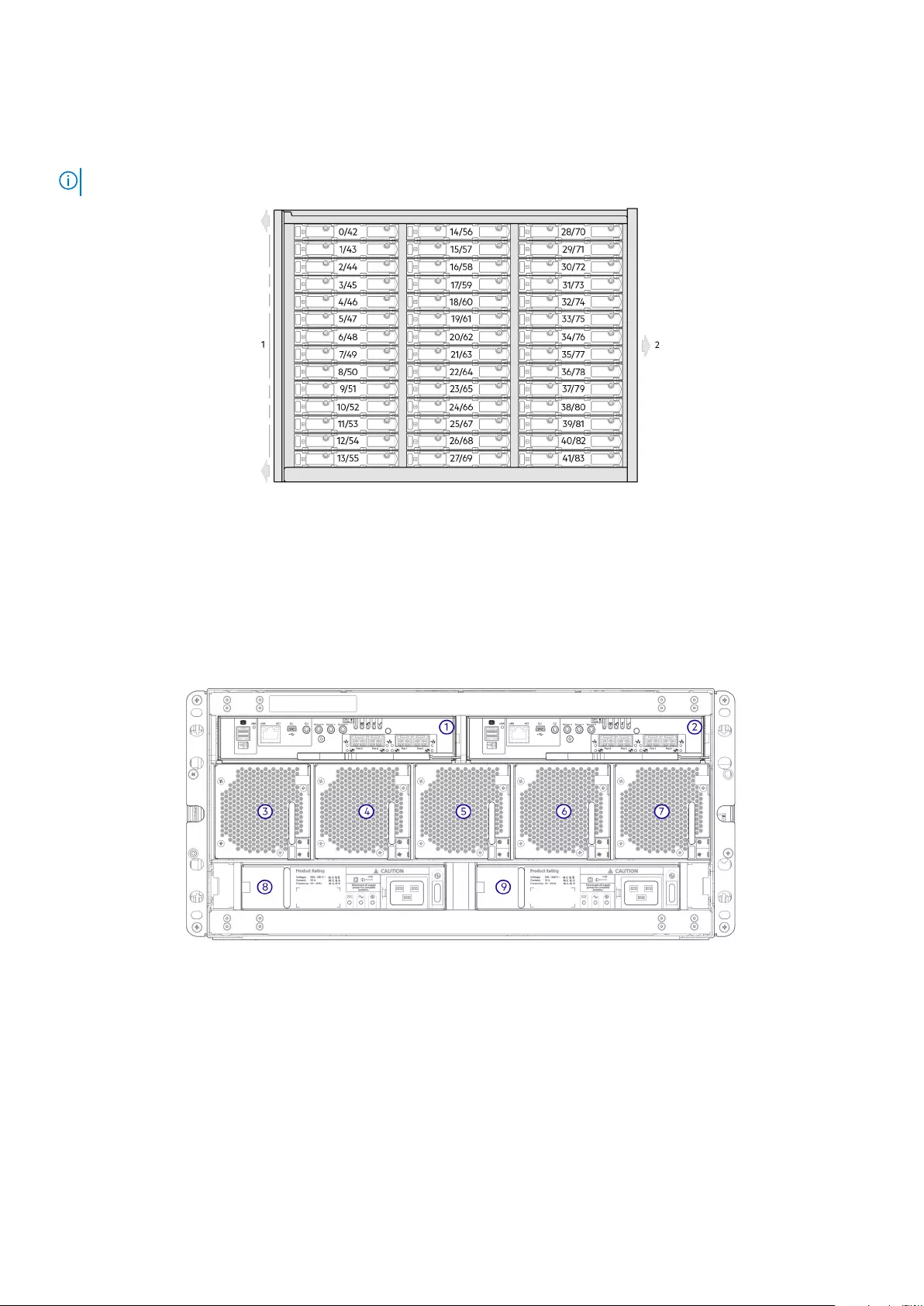

Figure 19. 5U84 enclosure—front panel components on page 14 and Figure 20. 5U84 enclosure system - plan view of drawer accessed

from front panel on page 15 show component locations—together with CRU slot indexing—relative to the 5U84 enclosure front panel

with drawers, and the rear panel.

The 5U84 supports up to 84 DDIC modules populated within two drawers (42 DDICs per drawer; 14 DDICs per row).

NOTE:

• The 5U84 does not ship with DDICs installed. DDICs ship in a separate container, and must be installed into the

enclosure drawers during product installation and setup.

• To ensure sufficient circulation and cooling throughout the enclosure, all PSU slots, cooling module slots, and IOM

slots must contain a functioning CRU. Do not replace a faulty CRU until the replacement is available and in hand.

5U84 enclosure front panel

Figure 19. 5U84 enclosure—front panel components

1. 5U84 enclosure drawer (slot 0 = top drawer)

14 Storage system hardware

2. 5U84 enclosure drawer (slot 1 = bottom drawer)

This figure shows a plan view of an enclosure drawer that is accessed from the enclosure front panel. The conceptual graphics are

simplified for clarity.

NOTE: See DDIC LEDs on page 35 for 5U84 (LFF disks) DDIC LED behavior.

Figure 20. 5U84 enclosure system - plan view of drawer accessed from front panel

1. Drawer front panel (shown as an edge in plan view)

2. Direction into the enclosure drawer slot (slot 0 or 1)

5U84 enclosure rear panel

Alphabetic designators on controller modules and IOMs, and numeric designators on PSUs (Power Supply Units) and FCMs (Fan Control

Modules) indicate slot sequencing for modules used in 5U84 enclosures. Controller modules, IOMs, PSUs, and FCMs are available as

CRUs.

Figure 21. 5U84 controller enclosure—rear panel components (4-port FC/iSCSI)

1. Controller module slot A 2. Controller module slot B

3. FCM slot 0 4. FCM slot 1

5. FCM slot 2 6. FCM slot 3

7. FCM slot 4 8. PSU slot 0

9. PSU slot 1

Storage system hardware 15

Figure 22. 5U84 controller enclosure—rear panel components (4-port SAS)

1. Controller module slot A 2. Controller module slot B

3. FCM slot 0 4. FCM slot 1

5. FCM slot 2 6. FCM slot 3

7. FCM slot 4 8. PSU slot 0

9. PSU slot 1

Figure 23. 5U84 controller enclosure—rear panel components (4-port iSCSI 10Gbase-T)

1. Controller module slot A 2. Controller module slot B

3. FCM slot 0 4. FCM slot 1

5. FCM slot 2 6. FCM slot 3

7. FCM slot 4 8. PSU slot 0

9. PSU slot 1

16 Storage system hardware

Figure 24. 5U84 expansion enclosure—rear panel components

1. IOM slot A 2. IOM slot B

3. FCM slot 0 4. FCM slot 1

5. FCM slot 2 6. FCM slot 3

7. FCM slot 4 8. PSU slot 0

9. PSU slot 1

NOTE: 5U84 controller enclosures support dual-controller module configuration only. If a partner controller module

fails, the controller will fail over and run on a single controller module until the redundancy is restored. Both controller

module slots must be occupied to ensure sufficient airflow through the controller during operation.

5U84 rear panel components

This section describes the rear-panel controller modules, expansion module, power supply module, and fan cooling module.

Controller modules

The 5U84 controller enclosure uses the same controller modules that are used by 2U12 and 2U24 enclosures.

Expansion module

The 5U84 expansion enclosure uses the same IOMs that are used by 2U12 and 2U24 enclosures.

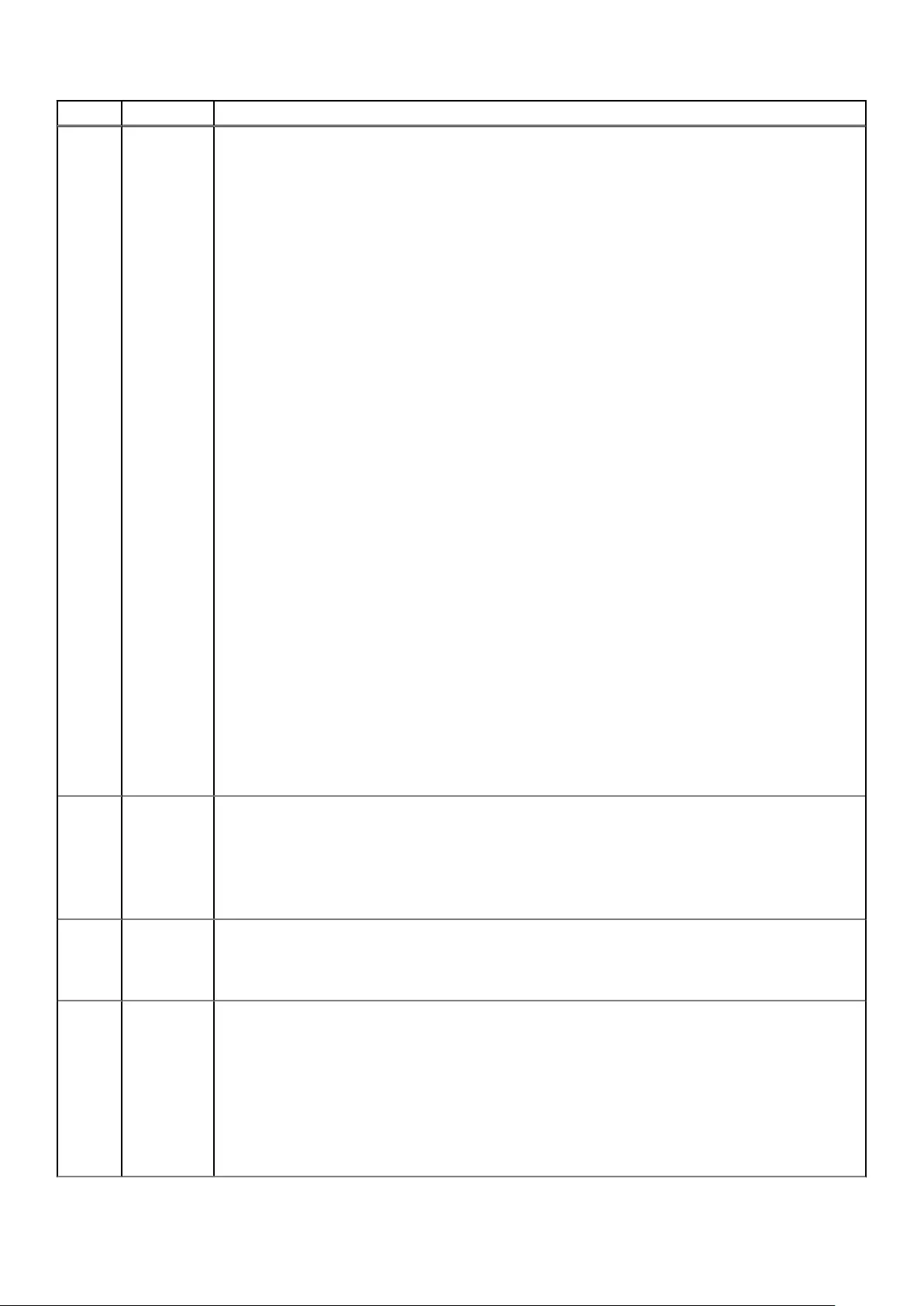

Power supply module

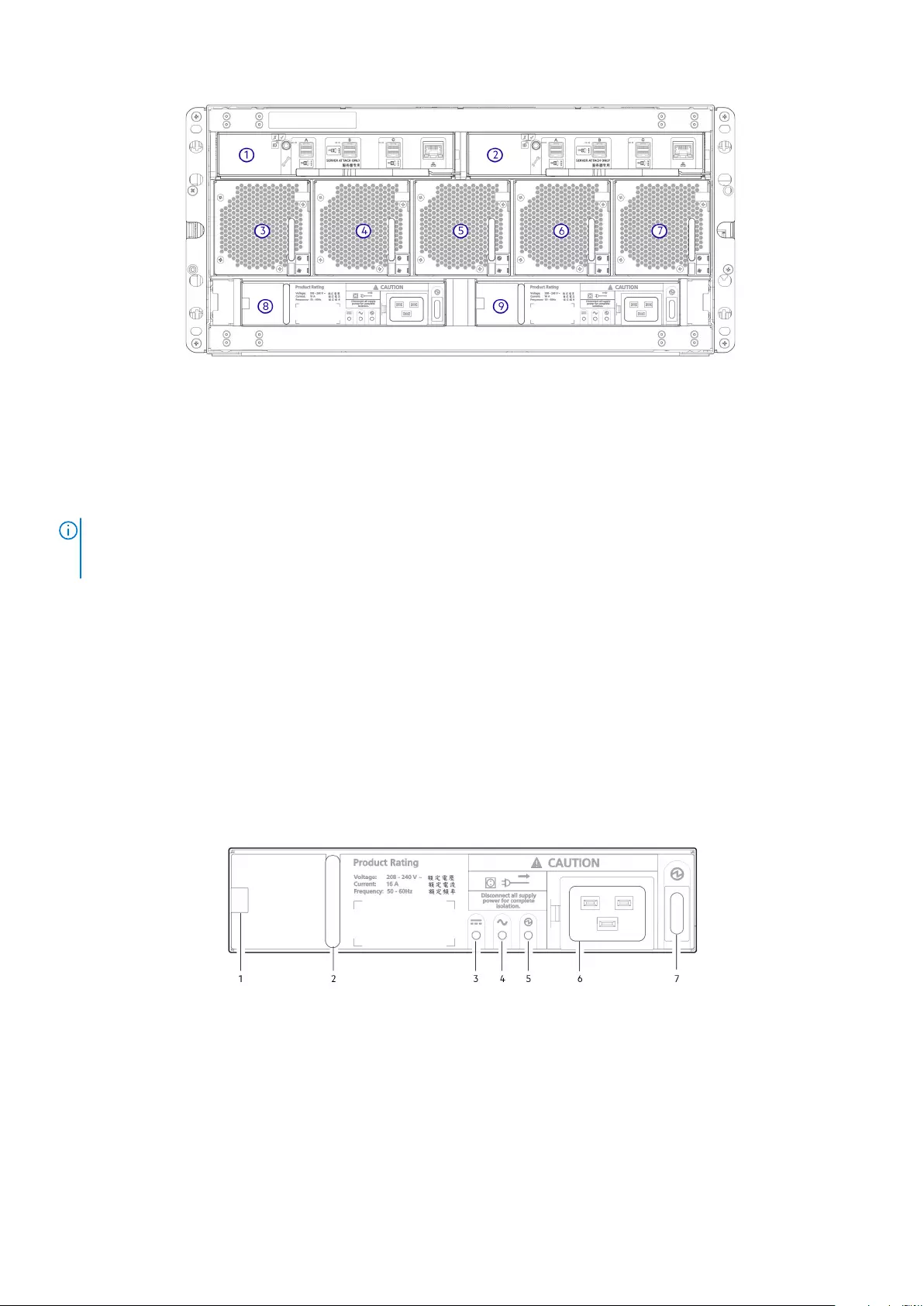

This figure shows the power supply unit that is used in 5U controller enclosures and optional 5U84 expansion enclosures.

Figure 25. Power supply unit (PSU)

1. Module release latch 2. Handle

3. PSU Fault LED (Amber/blinking amber) 4. AC Fail LED (Amber/blinking amber)

5. Power OK LED (Green) 6. Power connect

7. Power switch

LED behavior:

• If any of the PSU LEDs are illuminated amber, a module fault condition or failure has occurred.

• For a detailed description of PSU LEDs, see Table 16. FCM LED descriptions on page 34.

Storage system hardware 17

The 5U84 enclosures use separate CRU modules for power supply and cooling/circulation, respectively. Power supply unit (PSU) shows

the power supply module, which provides the enclosure with power connection and a power switch. Fan cooling module (FCM) shows the

fan cooling module that is used in 5U84 enclosures. The FCM is smaller than the PCM, and five of them are used within the 5U enclosure

to provide sufficient airflow throughout the enclosure.

Fan cooling module

The following figure shows the fan cooling module (FCM) used in 5U controller enclosures and optional 5U expansion enclosures.

Figure 26. Fan cooling module (FCM)

1. Module release latch 2. Handle

3. Module OK LED (Green) 4. Fan Fault LED (Amber/blinking amber)

LED behavior:

• If any of the FCM LEDs are illuminated amber, a module fault condition or failure has occurred..

• For a detailed description of FCM LEDs, see Fan cooling module LEDs on page 34.

5U84 enclosure chassis

The 5U84 enclosure includes the following features:

• 5U84 chassis configured with up to 84 LFF disks in DDICs. See Figure 20. 5U84 enclosure system - plan view of drawer accessed

from front panel on page 15.

• 5U84 chassis configured with SFF disks in 2.5" to 3.5" hybrid driver carrier adapter.

• 5U84 empty chassis with midplane, module runner system, and drawers.

The chassis has a 19-inch rack mounting that enables it to be installed onto standard 19-inch racks and uses five EIA units of rack space

(8.75").

At the front of the enclosure, two drawers can be opened and closed. Each drawer provides access to 42 slots for Disk Drive in Carrier

(DDIC) modules. DDICs are top mounted into the drawers as shown in Figure 20. 5U84 enclosure system - plan view of drawer accessed

from front panel on page 15. The front of the enclosure also provides enclosure status LEDs and drawer status/activity LEDs.

The rear of the enclosure provides access to rear panel CRUs:

• Two controller modules or IOMs

• Two PSUs

• Five FCMs

5U84 enclosure drawers

Each enclosure drawer contains 42 slots, each of which can accept a single DDIC containing a 3.5" LFF disk drive or a 2.5" SFF disk drive

with an adapter.

Opening a drawer does not interrupt the functioning of the storage system, and DDICs can be hot-swapped while the enclosure is in

operation. However, drawers must not be left open for longer than two minutes, or airflow and cooling will be compromised.

NOTE: During normal operation, drawers should be closed to ensure proper airflow and cooling within the enclosure.

A drawer is designed to support its own weight, plus the weight of installed DDICs, when fully opened.

18 Storage system hardware

CAUTION: The sideplanes on the enclosure drawers are not hot swappable or customer serviceable.

Safety features

• To prevent the rack from tipping, slide only one enclosure out of the rack at a time.

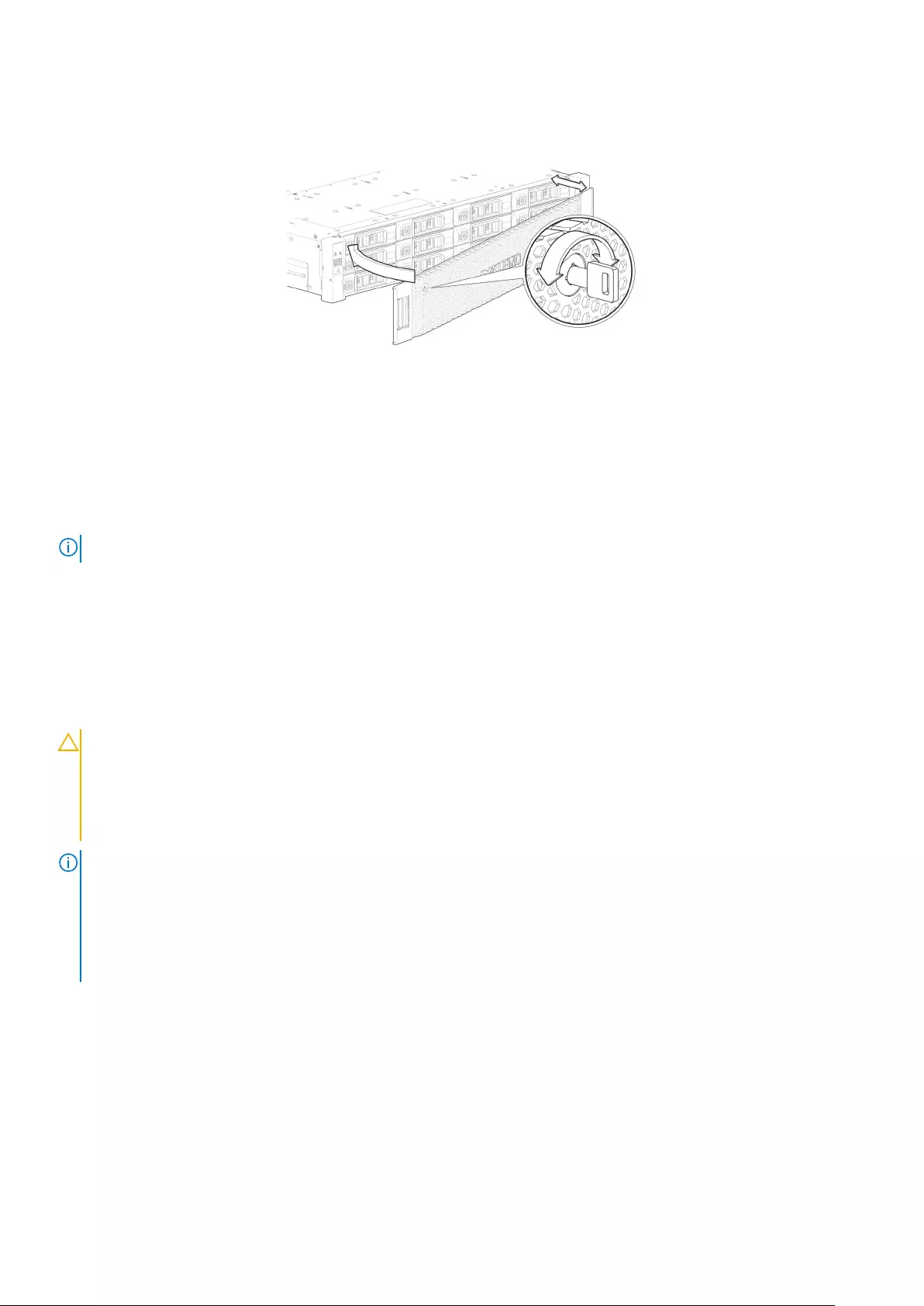

• The drawer locks into place when fully opened and extended. To reduce finger pinching hazards, two latches must be released before

the drawer can be pushed back into the drawer slot within the enclosure.

Each drawer can be locked shut by turning both anti-tamper locks clockwise using a screwdriver with a Torx T20 bit (included in your

shipment). The anti-tamper locks are symmetrically placed on the left and right sides of the drawer bezel. Drawer status and activity LEDs

can be monitored by two drawer LEDs panels located next to the two drawer-pull pockets located on the left and right side of each

drawer.

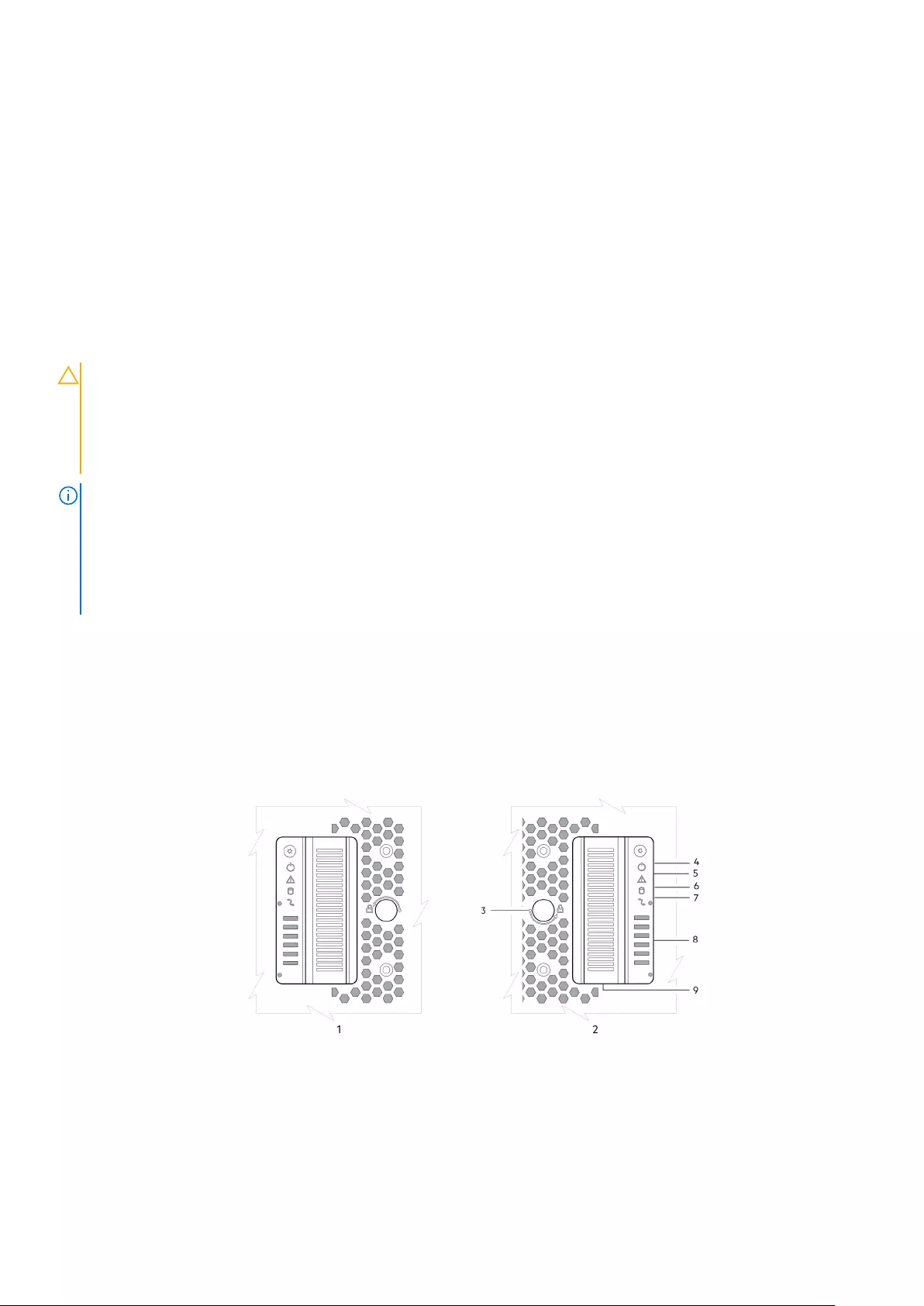

Figure 27. Drawer bezel details

1. Left side 2. Right side

3. Anti-tamper lock 4. Sideplane OK/Power Good

5. Drawer fault 6. Logical fault

7. Cable fault 8. Drawer activity

9. Drawer pull handle

NOTE: For descriptions of drawer LED behavior, see Table 18. Drawer LED descriptions on page 34.

Operator's (Ops) panel LEDs

Each ME4 Series enclosure features an Ops panel located on the chassis left ear flange. This section describes the Ops panel for 2U and

5U enclosures.

2U enclosure Ops panel

The front of the enclosure has an Ops panel located on the left ear flange of the 2U chassis. The Ops panel is an integral part of the

enclosure chassis, but is not replaceable on site.

Figure 28. LEDs: Ops panel—2U enclosure front panel

Storage system hardware 19

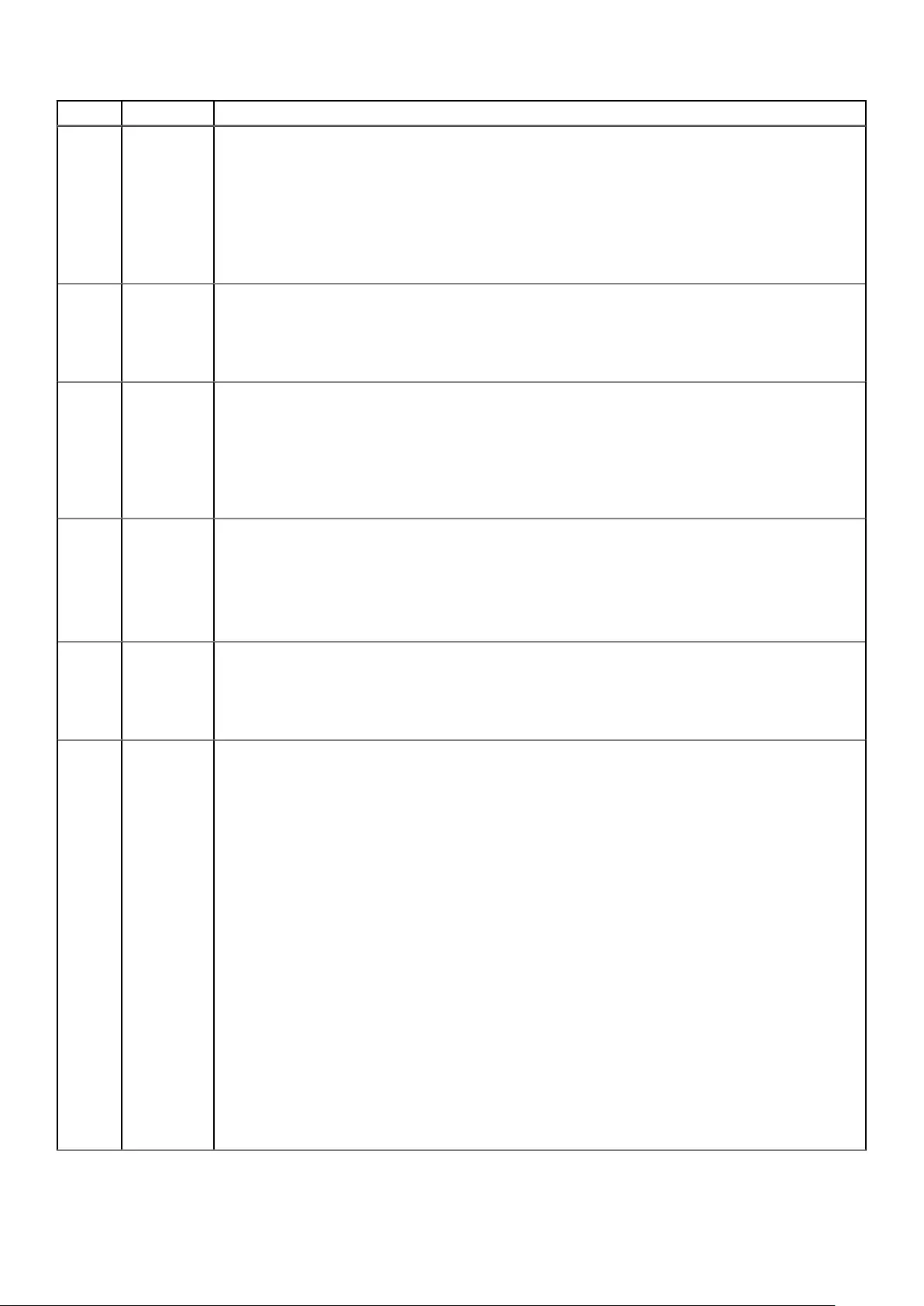

Table 4. Ops panel functions

No. Indicator Status

1 System power Constant green: at least one PCM is supplying power

Off: system not operating regardless of AC present

2 Status/Health Constant blue: system is powered on and controller is ready

Blinking blue (2 Hz): Enclosure management is busy

Constant amber: module fault present

Blinking amber: logical fault (2 seconds on, 1 second off)

3 Unit identification display (UID) Green (seven-segment display: enclosure sequence)

4 Identity Blinking blue (0.25 Hz): system ID locator is activated

Off: Normal state

System power LED (green)

LED displays green when system power is available. LED is off when system is not operating.

Status/Health LED (blue/amber)

LED illuminates constant blue when the system is powered on and functioning normally. LED blinks blue when enclosure management is

busy, for example, when booting or performing a firmware update. LEDs helps you identify which component is causing the fault. LED

illuminates constant amber when experiencing a system hardware fault which could be associated with a Fault LED on a controller module,

IOM, or PCM. LED illuminates blinking amber when experiencing a logical fault.

Unit identification display (green)

The UID is a dual seven-segment display that shows the numerical position of the enclosure in the cabling sequence. This is also called the

enclosure ID. The controller enclosure ID is 0.

Identity LED (blue)

When activated, the Identity LED blinks at a rate of 1 second on, 1 second off to easily locate the chassis within a data center. The locate

function can be enabled or disabled through SES. Pressing the button toggles the state of the LED. Setting the enclosure ID using the

System ID button is not supported by the firmware.

5U enclosure Ops panel

The front of the enclosure has an Ops panel located on the left ear flange of the 5U chassis.

The Ops panel is an integral part of the enclosure chassis, but is not replaceable on site.

Figure 29. LEDs: Ops panel—5U enclosure front panel

20 Storage system hardware

Table 5. Ops panel functions

No. Indicator Status

1 Unit identification display (UID) Green (seven-segment display: enclosure sequence)

2 System power on/Standby Constant green: positive indication

Constant amber: system in standby (not operational)

3 Module fault Constant or blinking amber: fault present

4 Logical status Constant or blinking amber: fault present

5 Top drawer fault Constant or blinking amber: fault present in drive, cable, or sideplane

6 Bottom drawer fault Constant or blinking amber: fault present in drive, cable, or sideplane

Unit identification display

The UID is a dual seven-segment display that shows the numerical position of the enclosure in the cabling sequence. This is also called the

enclosure ID. The controller enclosure ID is 0.

System power on/Standby LED (green/amber)

LED is amber when only the standby power is available (non-operational). LED is green when system power is available (operational).

Module fault LED (amber)

LED turns amber when experiencing a system hardware fault. This LED helps you identify the component causing the fault, which can be

associated with a Fault LED on a controller module, IOM, PSU, FCM, DDIC, or drawer.

Logical status LED (amber)

This LED indicates a change of status or fault from something other than the enclosure management system. This may be initiated from

the controller module or an external HBA. The indication is typically associated with a DDIC and LEDs at each disk position within the

drawer, which help to identify the DDIC affected.

Drawer fault LEDs (amber)

This LED indicates a disk, cable, or sideplane fault in the drawer indicate: Top (Drawer 0) or Bottom (Drawer 1).

CAUTION: The sideplanes on the enclosure drawers are not hot swappable or customer serviceable.

Controller modules

This section describes the controller modules used in 12 Gb/s storage enclosures. They are mechanically and electrically compliant to the

latest SBB v2.1 specification.

The following figure shows a 4-port FC/iSCSI controller module aligned for use in the top slot located on the 2U enclosure rear panel. The

controller module is also properly aligned for use in either slot located on the 5U84 enclosure rear panel.

Figure 30. Controller module – rear orientation

Storage system hardware 21

Each controller module maintains VPD (Vital Product Data) in EEPROM devices. In a dual-controller module system, controller modules

are interconnected by SBB-defined I2C buses on the midplane. In this way, the SBB module can discover the type and capabilities of the

partner SBB module, and vice versa, within the enclosure.

12 Gb/s controller module LEDs

The diagrams with tables that immediately follow provide descriptions for the different controller modules that can be installed into the

rear panel of the controller enclosures. Showing controller modules separately from the enclosure enables improved clarity in identifying

the component items called out in the diagrams and described in the companion tables within the figure/table ensembles.

NOTE: Consider the following when viewing the controller module diagrams on the following pages:

• In each diagram, the controller module is oriented for insertion into the top slot (A) of 2U enclosures. When oriented for use in the

bottom slot (B) of 2U enclosures, the controller module labels appear upside down.

• In each diagram, the controller module is oriented for insertion into either slot of 5U84 enclosures.

• Alternatively, you can configure the 2U controller enclosure with a single controller module. Install the controller module in slot A, and

install a blank plate in slot B.

Figure 31. LEDs: ME4 Series Storage System FC/iSCSI controller modules (FC and 10GbE SFPs)

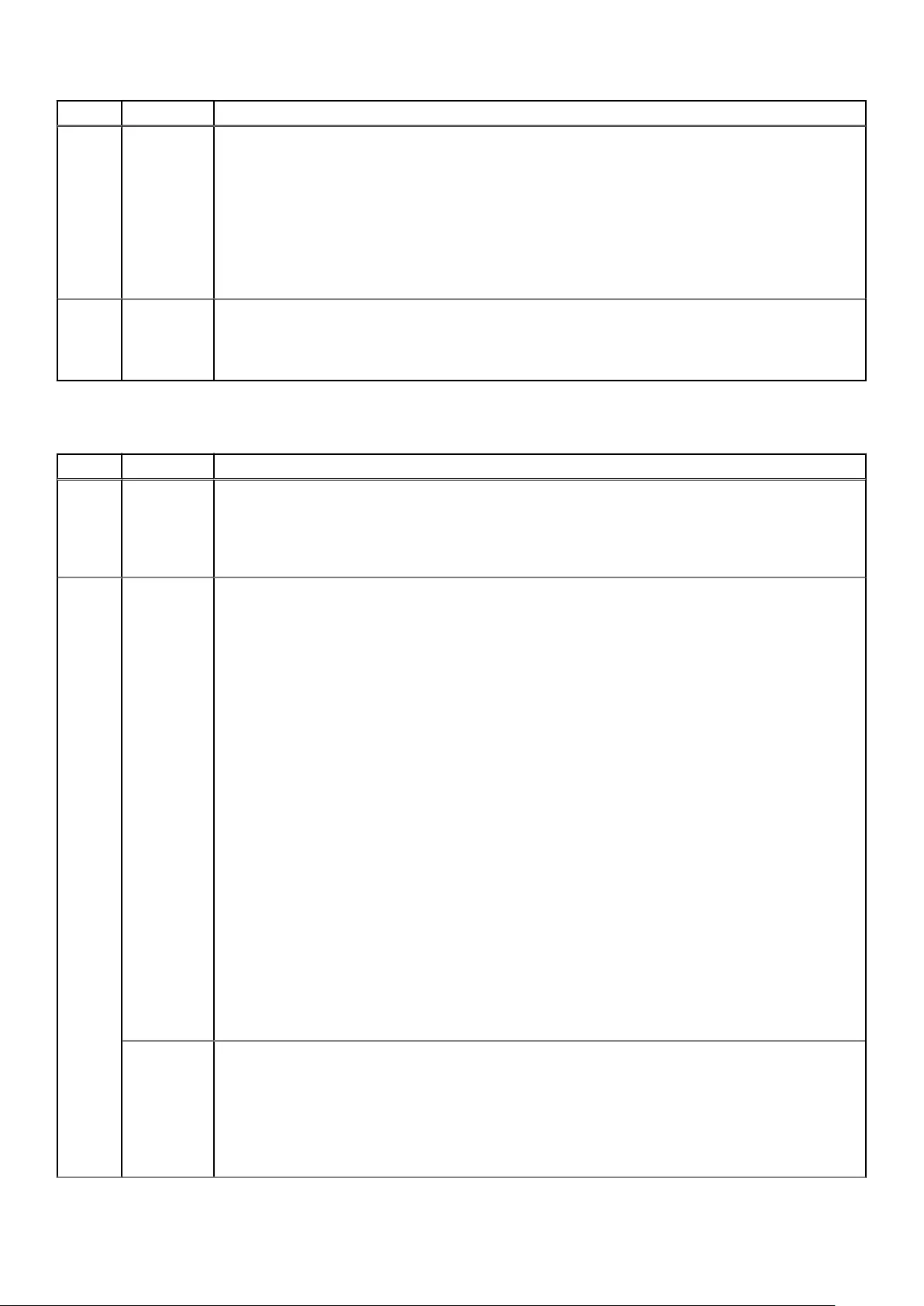

Table 6. LEDs: ME4 Series controller modules (FC and iSCSI SFPs)

LED Description Definition

1Host 4/8/16 Gb FC1

Link Status

Link Activity

Off—No link detected.

Green—The port is connected and the link is up.

Blinking green—The link has I/O activity.

2Host 10 GbE iSCSI2,3

Link Status

Link Activity

Off —No link detected.

Green—The port is connected and the link is up.

Blinking green—The link has I/O or replication activity.

3 OK Green—The controller is operating normally.

Blinking green—System is booting.

Off—The controller module is not OK, or is powered off.

4 Fault Off —The controller is operating normally.

Amber—A fault has been detected or a service action is required.

Blinking amber—Hardware-controlled power-up or a cache flush or

restore error.

5 OK to remove Off—The controller is not prepared for removal.

Blue—The controller module is prepared for removal.

6 Identify White—The controller module is being identified.

7 Cache status4Green—Cache is dirty (contains unwritten data) and operation is normal.

The unwritten information can be log or debug data that remains in the

22 Storage system hardware

Table 6. LEDs: ME4 Series controller modules (FC and iSCSI SFPs) (continued)

LED Description Definition

cache, so a green cache status LED does not, by itself, indicate that any

user data is at risk or that any action is necessary.

Off—In a working controller, cache is clean (contains no unwritten data).

This is an occasional condition that occurs while the system is booting.

Blinking green—A CompactFlash flush or cache self-refresh is in progress,

indicating cache activity.

8 Network Port Link Active Status5Off—The Ethernet link is not established, or the link is down.

Green—The Ethernet link is up (applies to all negotiated link speeds).

9 Network Port Link Speed5Off—Link is up at 10/100 base-T negotiated speeds.

Amber—Link is up and negotiated at 1000 base-T.

10 Expansion Port Status Off—The port is empty or the link is down.

Green—The port is connected and the link is up.

1When in FC mode, the SFPs must be qualified 8Gb or 16Gb fiber optic option. A 16 Gb/s SFP can run at 16 Gb/s, 8 Gb/s, 4 Gb/s, or

auto-negotiate its link speed. An 8 Gb/s SFP can run at 8 Gb/s, 4 Gb/s, or auto-negotiate its link speed.

2When in 10 GbE iSCSI mode, the SFPs must be a qualified 10 GbE iSCSI optic option.

3When powering up and booting, iSCSI LEDs are on/blinking momentarily, then they switch to the mode of operation.

4Cache Status LED supports power on behavior and operational (cache status) behavior. See also Table 9. Cache Status LED – power on

behavior on page 25.

5When port is down, both LEDs are off.

Figure 32. LEDs: ME4 Series 10Gbase-T controller module

Table 7. LEDs: ME4 Series 10Gbase-T controller module

LED Description Definition

1Host 10Gbase-T iSCSI

Link Status/ Link Activity

Off — No link detected.

Green — The port is connected and the link is up.

Blinking green — The link has I/O activity.

2Host 10Gbase-T iSCSI

Link Speed

Off — The link is not established, or the link is down.

Green — The link is up at 10 G negotiated speed.

Amber — The link is up at 1 G negotiated speed.

3 OK Green — The controller is operating normally.

Blinking green — System is booting.

Off — The controller module is not OK, or is powered off.

4 Fault Off — The controller is operating normally.

Storage system hardware 23

Table 7. LEDs: ME4 Series 10Gbase-T controller module (continued)

LED Description Definition

Amber — A fault has been detected or a service action is required.

Blinking amber — Hardware-controlled power-up or a cache flush or restore error.

5 OK to remove Off — The controller is not prepared for removal.

Blue — The controller module is prepared for removal.

6 Identify White — The controller module is being identified.

7 Cache status3Green — Cache is dirty (contains unwritten data) and operation is normal. The unwritten

information can be log or debug data that remains in the cache, so a green cache status LED does

not, by itself, indicate that any user data is at risk or that any action is necessary.

Off — In a working controller, cache is clean (contains no unwritten data). This is an occasional

condition that occurs while the system is booting.

Blinking green — A CompactFlash flush or cache self-refresh is in progress, indicating cache

activity.

8 Network Port Activity Status4Off — The Ethernet link is not established, or the link is down.

Green — The Ethernet link is up (applies to all negotiated link speeds).

9 Network Port Link Speed4Off — Link is up at 10/100base-T negotiated speeds.

Amber — Link is up and negotiated at 1000base-T.

10 Expansion Port Status Off — The port is empty or the link is down.

Green — The port is connected and the link is up.

110Gbase-T connectors must use qualified cabling options.

2When powering up and booting, iSCSI LEDs will be on/blinking momentarily, then they will switch to the mode of operation.

3Cache Status LED supports power on behavior and operational (cache status) behavior.

4When port is down, both LEDs are off. See also Table 9. Cache Status LED – power on behavior on page 25.

Figure 33. LEDs: ME4 Series SAS controller module

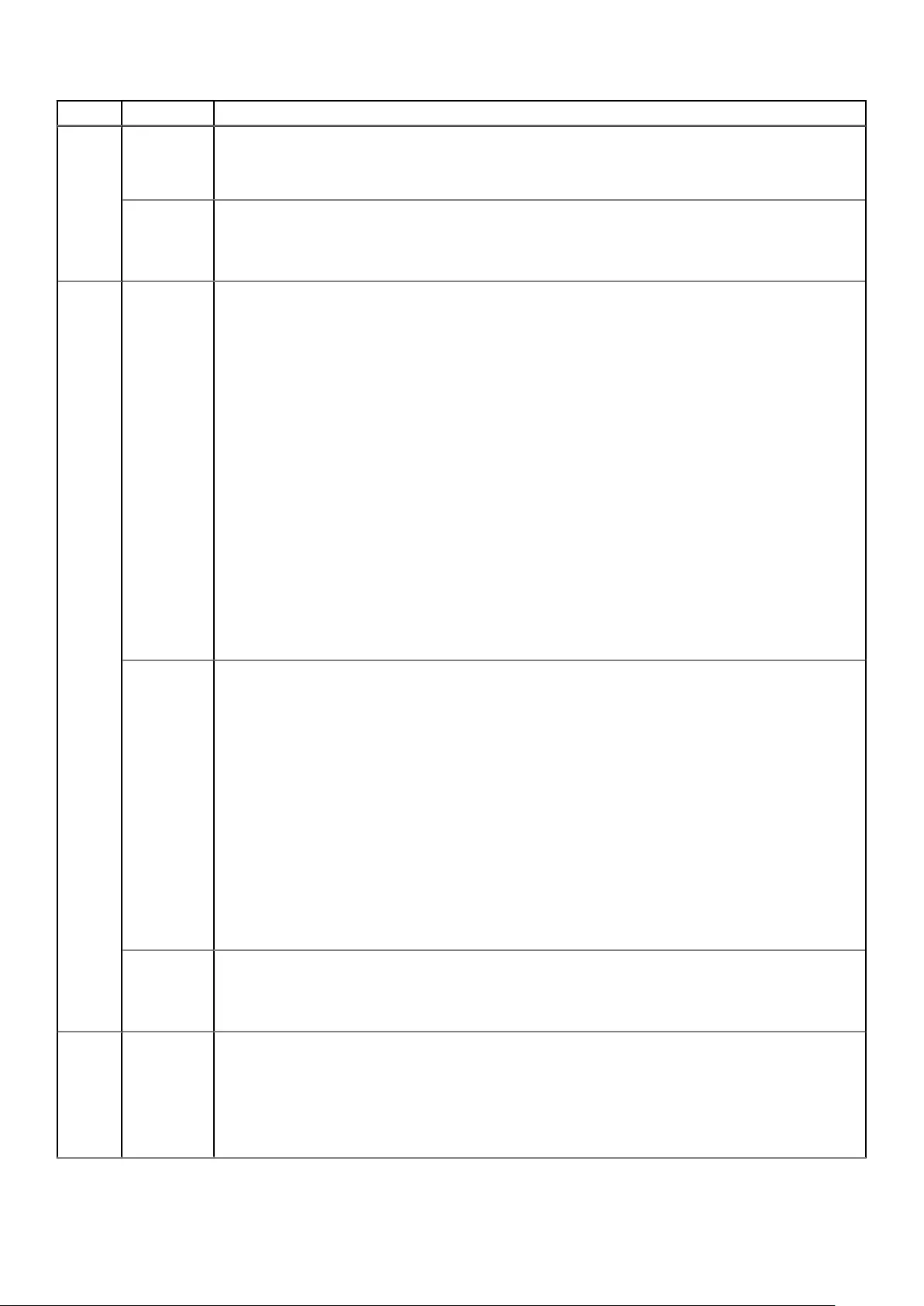

Table 8. LEDs: ME4 Series SAS controller module

LED Description Definition

1Host 12 Gb SAS1-2

Link Status

Link Activity

Green — The port is connected and the link is up.

Amber — Partial link exists (one or more lanes down).

Blinking green or amber — Host link activity is detected.

2 OK Green — The controller is operating normally.

Blinking green — System is booting.

Off — The controller module is not OK, or is powered off.

24 Storage system hardware

Table 8. LEDs: ME4 Series SAS controller module (continued)

LED Description Definition

3 Fault Off — The controller is operating normally.

Amber — A fault has been detected or a service action is required.

Blinking amber — Hardware-controlled power-up or a cache flush or restore error.

4 OK to remove Off — The controller is not prepared for removal.

Blue — The controller module is prepared for removal.

5 Identify White — The controller module is being identified.

6 Cache status3Green — Cache is dirty (contains unwritten data) and operation is normal.

The unwritten information can be log or debug data that remains in the cache, so a green cache

status LED does not, by itself, indicate that any user data is at risk or that any action is necessary.

Off — In a working controller, cache is clean (contains no unwritten data).

This is an occasional condition that occurs while the system is booting.

Blinking green — A CompactFlash flush or cache self-refresh is in progress, indicating cache

activity.

7 Network Port Activity Status4Off — The Ethernet link is not established, or the link is down.

Green — The Ethernet link is up (applies to all negotiated link speeds).

8 Network Port Link Speed4Off — Link is up at 10/100base-T negotiated speeds.

Amber — Link is up and negotiated at 1000base-T.

9 Expansion Port Status Green — The port is connected and the link is up.

1Cables must be qualified HD mini-SAS cable options.

2Use a qualified SFF-8644 to SFF-8644 cable option when connecting the controller to a 12Gb SAS HBA.

3Cache Status LED supports power on behavior and operational (cache status) behavior. See also Table 9. Cache Status LED – power on

behavior on page 25.

4When port is down, both LEDs are off. See also Power on/off behavior on page 25.

5Once a Link Status LED is lit, it remains so, even if the controller is shut down using the PowerVault Manager or the CLI.

When a controller is shut down or otherwise rendered inactive—its Link Status LED remains illuminated— falsely indicating that the

controller can communicate with the host. Though a link exists between the host and the chip on the controller, the controller is not

communicating with the chip. To reset the LED, the controller must be power-cycled.

Cache status LED details

This section describes the behavior of the LEDs during powering on and off and cache status behavior.

Power on/off behavior

During power on, discrete sequencing for power on display states of internal components is reflected by blinking patterns displayed by the

Cache Status LED.

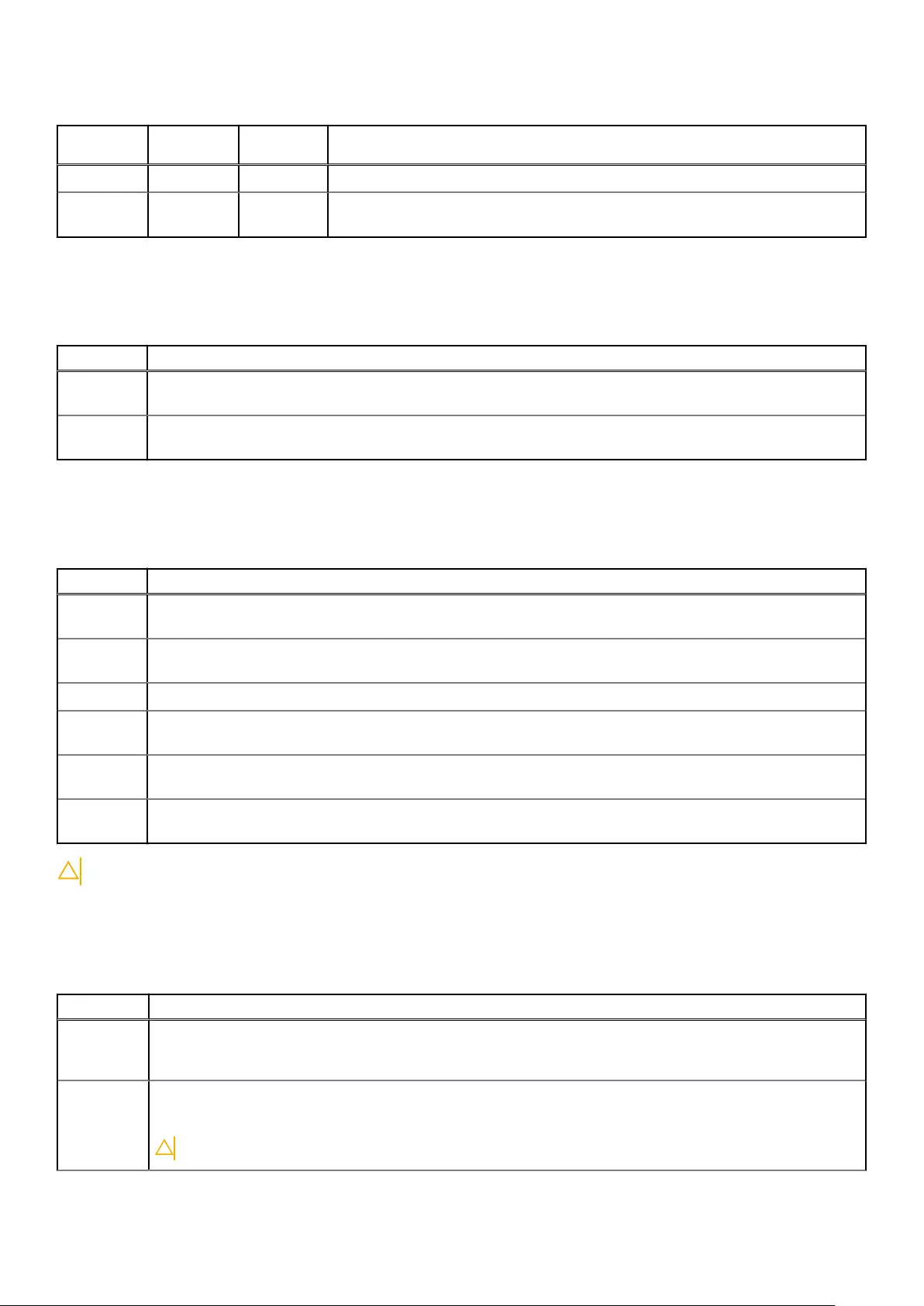

Table 9. Cache Status LED – power on behavior

Item Display states reported by Cache Status LED during power on sequence

Display state 0 1 2 3 4 5 6 7

Component VP SC SAS BE ASIC Host Boot Normal Reset

Blink pattern On 1/Off 7 On 2/Off 6 On 3/Off 5 On 4/Off 4 On 5/Off 3 On 6/Off 2 Solid/On Steady

Once the enclosure has completed the power on sequence, the Cache Status LED displays Solid/On (Normal), before assuming the

operating state for cache purposes.

Storage system hardware 25

Cache status behavior

If the LED is blinking evenly, a cache flush is in progress. When a controller module loses power and write cache is dirty (contains data that

has not been written to disk), the supercapacitor pack provides backup power to flush (copy) data from write cache to CompactFlash

memory. When cache flush is complete, the cache transitions into self-refresh mode.

If the LED is blinking momentarily slowly, the cache is in a self-refresh mode. In self-refresh mode, if primary power is restored before the

backup power is depleted (3–30 minutes, depending on various factors), the system boots, finds data preserved in cache, and writes it to

disk. This means the system can be operational within 30 seconds, and before the typical host I/O time-out of 60 seconds, at which point

system failure would cause host-application failure. If primary power is restored after the backup power is depleted, the system boots and

restores data to cache from CompactFlash, which can take about 90 seconds. The cache flush and self-refresh mechanism is an

important data protection feature; essentially four copies of user data are preserved: one in controller cache and one in CompactFlash of

each controller. The Cache Status LED illuminates solid green during the boot-up process. This behavior indicates the cache is logging all

Power On Self Tests (POSTs), which will be flushed to the CompactFlash the next time the controller shuts down.

NOTE:

If the Cache Status LED illuminates solid green—and you wish to shut down the controller—do so from the user

interface, so unwritten data can be flushed to CompactFlash.

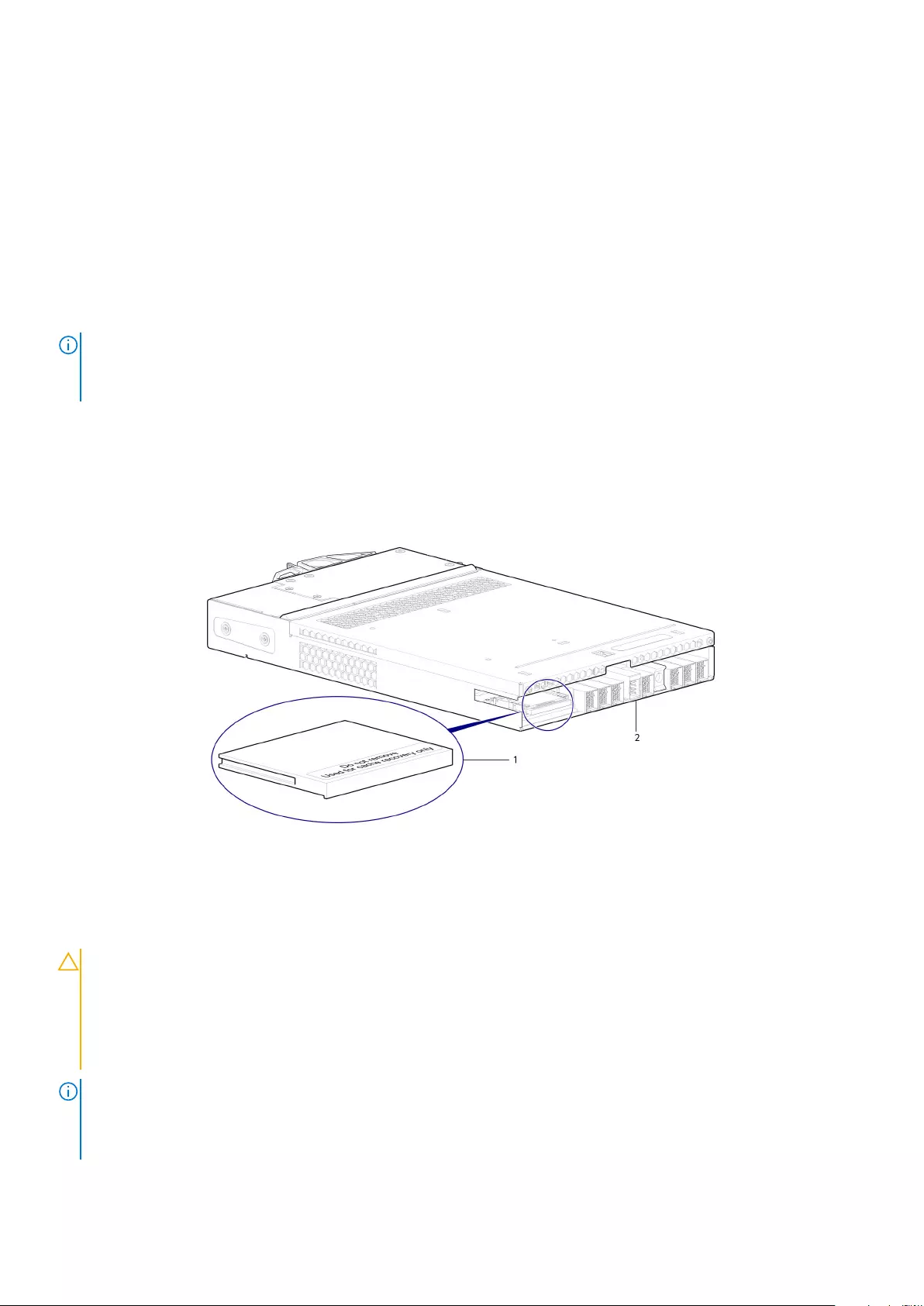

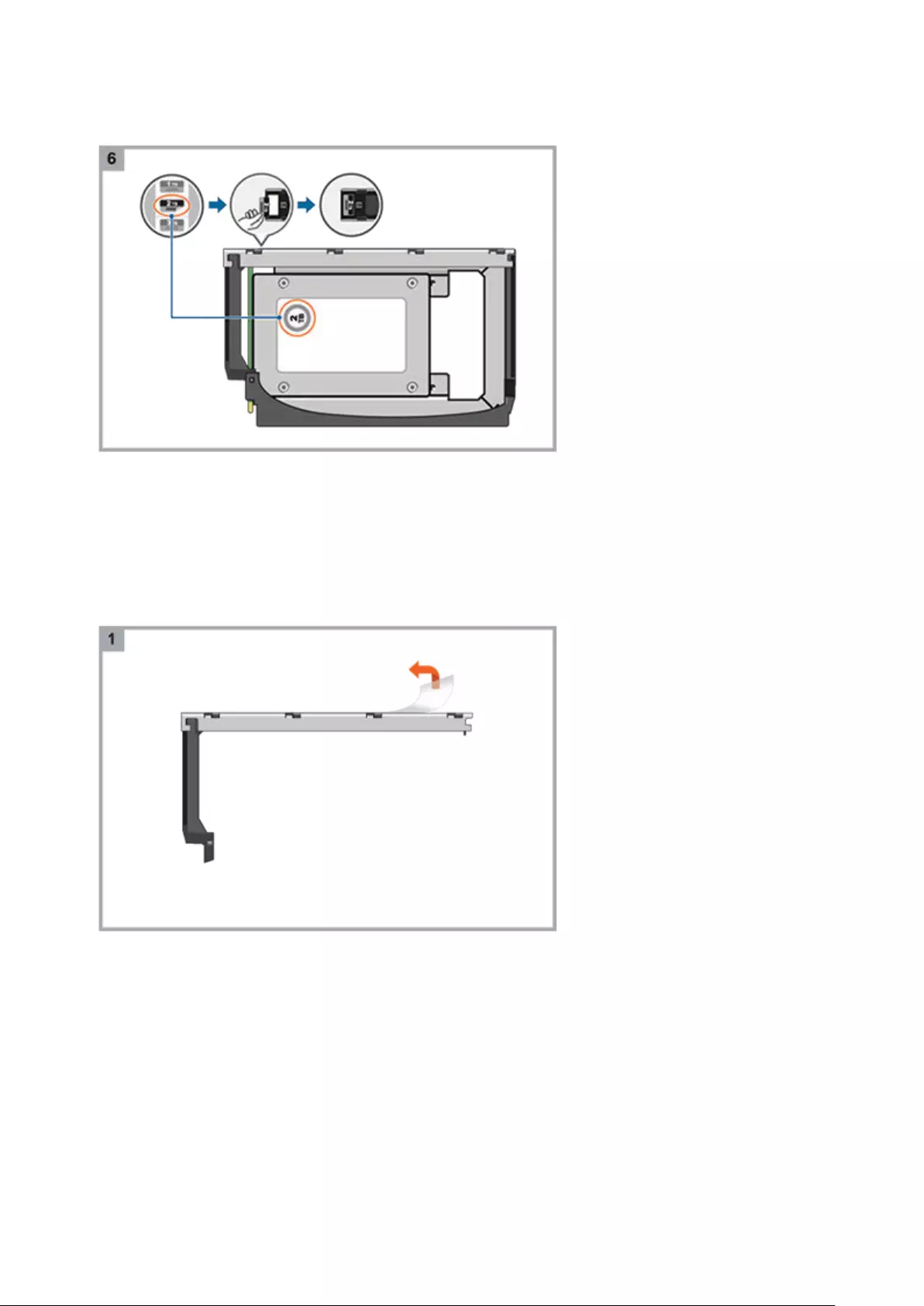

CompactFlash

During a power loss or controller failure, data stored in cache is saved off to non-volatile memory (CompactFlash). The data is restored to

cache, and then written to disk after the issue is corrected. To protect against writing incomplete data to disk, the image stored on the

CompactFlash is verified before committing to disk. The CompactFlash memory card is located at the midplane-facing end of the

controller module. Do not remove the card; it is used for cache recovery only.

Figure 34. CompactFlash memory card

1. CompactFlash memory card

2. Controller module viewed from back

In single-controller module configurations, if the controller module has failed or does not start, and the Cache Status LED is on or blinking,

the CompactFlash needs to be transported to a replacement controller to recover data not flushed to the disk.

CAUTION: For single-controller module configuration only, to preserve the existing data stored in the CompactFlash,

you must transport the CompactFlash from the failed controller module to the replacement controller module. This

procedure is outlined in the

Dell EMC PowerVault ME4 Series Storage System Owner's Manual

within the procedure for

replacing a controller module. Failure to use this procedure will result in the loss of data stored in the cache module. The

CompactFlash must stay with the same enclosure. If the CompactFlash is used/installed in a different enclosure, data

loss/data corruption will occur.

NOTE: In dual-controller module configurations featuring one healthy partner controller module, there is no need to

transport the CompactFlash from the failed controller module to the to the replacement controller module. The cache is

duplicated between the controller modules, provided that volume cache is set to standard on all volumes in the pool

owned by the failed controller module.

26 Storage system hardware

Supercapacitor pack

To protect controller module cache in case of power failure, each controller enclosure model is equipped with supercapacitor technology,

in conjunction with CompactFlash memory, built into each controller module to provide extended cache memory backup time. The

supercapacitor pack provides energy for backing up unwritten data in the write cache to the CompactFlash, in the event of a power

failure. Unwritten data in CompactFlash memory is automatically committed to disk media when power is restored. In the event of power

failure, while cache is maintained by the supercapacitor pack, the Cache Status LED blinks at a rate of 1/10 second on and 9/10 second

off.

Controller failure when a single-controller is

operational

The following information applies to 2U single controller enclosures when the controller fails. The following information also applies or 2U

and 5U dual-controller enclosures when one of the controllers is down and the other controller fails.

Cache memory is flushed to CompactFlash in the case of a controller failure or power loss. During the write to CompactFlash process, only

the components needed to write the cache to the CompactFlash are powered by the supercapacitor. This process typically takes 60

seconds per 1Gbyte of cache. After the cache is copied to CompactFlash, the remaining power left in the supercapacitor is used to refresh

the cache memory. While the cache is being maintained by the supercapacitor, the Cache Status LED blinks at a rate of 1/10 second on

and 9/10 second off.

NOTE: Remove the CompactFlash memory card only if recommended by Dell EMC technical support.

Transportable cache only applies to single-controller configurations. In dual-controller configurations featuring one

healthy partner controller, there is no need to transport failed controller cache to a replacement controller because the

cache is duplicated between the controllers, provided that the volume cache is set to standard on all volumes in the pool

owned by the failed controller.

Cache status LED – corrective action

If the controller has failed or does not start, check if the Cache status LED is on or blinking.

Table 10. LEDs: Rear panel Cache Status

Status Action

Cache status LED status is off, and the controller does

not boot.

If the problem persists, replace the controller module.

Cache status LED is off, and the controller boots. The system has flushed data to disks. If the problem persists, replace the

controller module.

Cache status LED blinks at a 1:10 rate - 1 Hz, and the

controller does not boot.

You may need to replace the controller module.

Cache status LED blinks at a 1:10 rate - 1 Hz, and the

controller boots.

The system is flushing data to CompactFlash. If the problem persists, replace

the controller module.

Cache status LED blinks at a 1:1 rate - 2 Hz, and the

controller does not boot.

You may need to replace the controller module.

Cache status LED blinks at a 1:1 rate - 1 Hz, and the

controller boots.

The system is in self-refresh mode. If the problem persists, replace the

controller module.

Transporting cache

To preserve the existing data stored in the CompactFlash, you must transport the CompactFlash from the failed controller to a

replacement controller. Failure to transport the CompactFlash will result in loss of data stored in the cache module.

CAUTION: Remove the controller module only after the copy process has completed, which is indicated by the Cache

Status LED being off, or blinking on 1:10 rate.

Storage system hardware 27

Troubleshooting and problem solving

These procedures are intended to be used only during initial configuration, for the purpose of verifying that hardware setup is successful.

They are not intended to be used as troubleshooting procedures for configured systems using production data and I/O.

Topics:

•Overview

•Fault isolation methodology

•LEDs

•Troubleshooting 2U enclosures

•Troubleshooting 5U enclosures

•Temperature sensors

•Host I/O

Overview

The enclosure system includes a Storage Enclosure Processor (SEP) and associated monitoring and control logic to enable it to diagnose

problems with the enclosure’s power, cooling, and drive systems. Management interfaces allow for provisioning, monitoring, and managing

the storage system.

NOTE: See Fault isolation methodology on page 28 when conducting system diagnostics.

Fault isolation methodology

Dell EMC PowerVault ME4 Series Storage Systems provide many ways to isolate faults. This section presents the basic methodology used

to locate faults within a storage system, and to identify the pertinent CRUs affected.

Use the PowerVault Manager to configure and provision the system upon completing the hardware installation. As part of this process,

configure and enable event notification so the system will notify you when a problem occurs that is at or above the configured severity

(see the topic about configuring event notification within the Dell EMC PowerVault ME4 Series Storage System Administrator’s Guide).

With event notification configured and enabled, you can follow the recommended actions in the notification message to resolve the

problem, as further discussed in the options presented in the following section.

Fault isolation methodology basic steps

Following is a summary of the basic steps used to perform fault isolation and troubleshooting:

• Gather fault information, including using system LEDs as described in Gather fault information

• Determine where in the system the fault is occurring as described in Determine where the fault is occurring.

• Review event logs as described in Review the event logs.

• If required, isolate the fault to a data path component or configuration as described in Review the event logs .

Options available for performing basic steps

When performing fault isolation and troubleshooting steps, select the option or options that best suit your site environment. Use of any

option (four options are described below) is not mutually exclusive to the use of another option. You can use the PowerVault Manager to

check the health icons/values for the system and its components to ensure that everything is okay, or to drill down to a problem

component. If you discover a problem, either the PowerVault Manager or the CLI provide recommended-action text online. Options for

performing basic steps are listed according to frequency of use:

•Use the PowerVault Manager

•Use the CLI

•Monitor event notification

2

28 Troubleshooting and problem solving

•View the enclosure LEDs

Use the PowerVault Manager

The PowerVault Manager uses health icons to show OK, Degraded, Fault, or Unknown status for the system and its components. The

PowerVault Manager enables you to monitor the health of the system and its components. If any component has a problem, the system

health will be Degraded, Fault, or Unknown. Use the web application’s GUI to drill down to find each component that has a problem, and

follow actions in the Recommendation field for the component to resolve the problem.

Use the CLI

As an alternative to using the PowerVault Manager, you can run the show system CLI command to view the health of the system and

its components. If any component has a problem, the system health will be Degraded, Fault, or Unknown, and those components will be

listed as Unhealthy Components. Follow the recommended actions in the component Health Recommendation field to resolve the

problem.

Monitor event notification

With event notification configured and enabled, you can view event logs to monitor the health of the system and its components. If a

message directs you to check whether an event has been logged, or to view information about an event in the log, you can do so using

the PowerVault Manager or the CLI. Using the PowerVault Manager, you can view the event log and then click the event message to see

detail about that event. Using the CLI, run the show events detail command (with additional parameters to filter the output) to see

the detail for an event.

View the enclosure LEDs

You can view the LEDs on the hardware (while referring to LED descriptions for your enclosure model) to identify component status. If a

problem prevents access to the PowerVault Manager or the CLI, this is the only option available. However, monitoring and management

are often done at a management console using storage management interfaces, rather than relying on line-of-sight to LEDs of racked

hardware components.

Performing basic steps

You can use any of the available options described in performing the basic steps comprising the fault isolation methodology.

Gather fault information

When a fault occurs, it is important to gather as much information as possible. Doing so will help you determine the correct action needed

to remedy the fault.

Begin by reviewing the reported fault:

• Is the fault related to an internal data path or an external data path?

• Is the fault related to a hardware component such as a disk drive module, controller module, or power supply unit?

By isolating the fault to one of the components within the storage system, you will be able to determine the necessary corrective action

more quickly.

Determine where the fault is occurring

When a fault occurs, the Module Fault LED—located on the Ops panel on an enclosure’s left ear—illuminates. Check the LEDs on the

back of the enclosure to narrow the fault to a CRU, connection, or both. The LEDs also help you identify the location of a CRU reporting a

fault.

Use the PowerVault Manager to verify any faults found while viewing the LEDs. The PowerVault Manager is also a good tool to use in

determining where the fault is occurring if the LEDs cannot be viewed due to the location of the system. This web application provides

you with a visual representation of the system and where the fault is occurring. The PowerVault Manager also provides more detailed

information about CRUs, data, and faults.

Review the event logs

The event logs record all system events. Each event has a numeric code that identifies the type of event that occurred, and has one of

the following severities:

Troubleshooting and problem solving 29

• Critical. A failure occurred that may cause a controller to shut down. Correct the problem immediately.

• Error. A failure occurred that may affect data integrity or system stability. Correct the problem as soon as possible.

• Warning. A problem occurred that may affect system stability, but not data integrity. Evaluate the problem and correct it if necessary.

• Informational. A configuration or state change occurred, or a problem occurred that the system corrected. No immediate action is

required.

The event logs record all system events. It is very important to review the logs, not only to identify the fault, but also to search for events

that might have caused the fault to occur. For example, a host could lose connectivity to a disk group if a user changes channel settings

without taking the storage resources assigned to it into consideration. In addition, the type of fault can help you isolate the problem to

either hardware or software.

Isolate the fault

Occasionally, it might become necessary to isolate a fault. This is particularly true with data paths, due to the number of components

comprising the data path. For example, if a host-side data error occurs, it could be caused by any of the components in the data path:

controller module, cable, or data host.

If the enclosure does not initialize

It may take up to two minutes for all enclosures to initialize. If an enclosure does not initialize:

• Perform a rescan

• Power cycle the system

• Make sure the power cable is properly connected, and check the power source to which it is connected

• Check the event log for errors

Correcting enclosure IDs

When installing a system with drive enclosures attached, the enclosure IDs might not agree with the physical cabling order. This is because

the controller might have been previously attached to enclosures in a different configuration, and it attempts to preserve the previous

enclosure IDs, if possible. To correct this condition, make sure that both controllers are up, and perform a rescan using the PowerVault

Manager or the CLI. This will reorder the enclosures, but can take up to two minutes for the enclosure IDs to be corrected.

To perform a rescan using the CLI, type the following command:

rescan

To perform a rescan using the PowerVault Manager:

1. Verify that both controllers are operating normally.

2. Do one of the following:

• Select the System tab and click Rescan Disk Channels.

• In the System topic. select Action > Rescan Disk Channels.

3. Click Rescan.

NOTE: The reordering enclosure IDs action only applies to dual-controller mode. If only one controller is available, due to

either single-controller configuration, or controller failure, a manual rescan will not reorder the drive enclosure IDs.

LEDs

LED colors are used consistently throughout the enclosure and its components for indicating status:

• Green – Good or positive indication

• Blinking green/amber – Non-critical condition

• Amber – Critical fault

• Blue – Controller module or IOM identification

30 Troubleshooting and problem solving

2U enclosure LEDs

PCM LEDs

Under normal conditions, the PCM OK LEDs will be a constant green.

Table 11. PCM LED states

PCM OK

(Green)

Fan Fail

(Amber)

AC Fail

(Amber)

DC Fail

(Amber)

Status

Off Off Off Off No AC power on any PCM

Off Off On On No AC power on this PCM only

On Off Off Off AC present; PCM working correctly

On Off Off On PCM fan speed is outside acceptable limits

Off On Off Off PCM fan has failed

Off On On On PCM fault (above temperature, above voltage, above current)

Off Blinking Blinking Blinking PCM firmware download is in progress

Ops panel LEDs

The Ops panel displays the aggregated status of all the modules. See 2U enclosure Ops panel on page 19. The Ops panel LEDs are defined

in the following table.

Table 12. Ops panel LEDs

System Power

(Green/Amber)

Module Fault

(Amber)

Identity

(Blue)

LED

display

Associated LEDs /

Alarms

Status

On Off Off X 5V standby power present, overall power

failed or switched off

On On On On Ops panel power on (5s) test state

On Off Off X Power on, all functions good

On On X X PCM fault LEDs, fan

fault LEDs

Any PCM fault, fan fault, above or below

temperature

On On X X SBB module LEDs Any SBB module fault

On On X X No module LEDs Enclosure logical fault

On Blink X X Module status LED

on SBB module

Unknown (invalid or mixed) SBB module

type installed, I2C bus failure (inter-SBB

communications). EBOD VPD configuration

error

On Blink X X PCM fault LEDs, fan

fault LEDs

Unknown (invalid or mixed) PCM type

installed or I2C bus failure (PCM

communications)

X Blink Enclosure identification or invalid ID selected

X= Disregard

Actions:

• If the Ops panel Module Fault LED is on, check the module LEDs on the enclosure rear panel to narrow the fault to a CRU, a

connection, or both.