Indesit I6GG1(W)/UK User Manual

Displayed below is the user manual for I6GG1(W)/UK by Indesit which is a product in the Cookers category. This manual has pages.

Related Manuals

GB

COOKER

English,1

Contents

Installation, 2-6

Positioning and levelling

Electrical connection

Gas connection

Adapting to different types of gas

Technical data

Table of burner and nozzle specifications

Description of the appliance, 7

Overall view

Control panel

Start-up and use, 8-10

Using the hob

Using the oven

Oven cooking advice table

Precautions and tips, 11

General safety

Disposal

Respecting and conserving the environment

Care and maintenance, 12

Switching the appliance off

Cleaning the appliance

Replacing the oven light bulb

Gas tap maintenance

Assistance

Operating Instructions

GB

You must read these instructions prior to using

your appliance and retain them for future use.

I6GG1/UKI6GG1/UKI6GG1/UK

Removing and fitting the oven door

2

GB

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

Positioning

! !

! !

! This unit may be installed and used only in

permanently ventilated rooms according to the

British Standards Codes Of Practice: B.S. 6172/B.S.

5440, Par. 2 and B.S. 6891 Current Editions. The

following requirements must be observed:

a)a)

a)a)

a )The cooker should not be installed in a bed sitting

room with a volume of less than 20m3. If it is

installed in a room of volume less than 5m3 an air

vent of effective area of 110cm2 is required, if it is

installed in a room of volume between 5m3 and

10m3 a supplementary airvent area of 50cm2 is

required, if the volume exceeds 11m3 no airvent is

required. However, if the room has a door or a

window which opens directly to the outside no air

vent is required even when the volume is between

5m3 and 11m3.

b)b)

b)b)

b )During prolonged use of the appliance you may

consider it necessary to open a window to the

outside to improve ventilation.

c)c)

c)c)

c )If there are other fuel burning appliances in the

same room, B.S.5440 Part 2 Current Edition,

should, be consulted to determine the requisite air

vent requirements.

Levelling

If it is necessary to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (

see

figure

).

Installation

The legs* fit into the slots on

the underside of the base of

the cooker.

Installation of the cooker

The appliance can be installed next to furniture units

which are no taller than the top of the cooker hob.

The wall in direct contact with the back panel of the

cooker must be made of non-flammable material.

During operation the back panel of the cooker could

reach a temperature of 50°C above room

temperature. For proper installation of the cooker,

the following precautions must be taken:

a)a)

a)a)

a )The appliance can be placed in a kitchen, dining

room or bedsit, but not in a bathroom.

b)b)

b)b)

b )All furniture around the appliance must be placed

at least 200 mm from the top of the cooker,

should the surface of the appliance be higher than

the worktop of this furniture. Curtains should not

be placed behind the cooker or less than 200 mm

away from the sides of the appliance.

c)c)

c)c)

c )Any hoods must be installed according to the

requirements in the installation manual for the

hoods themselves.

d)d)

d)d)

d )If the cooker is installed beneath a wall cabinet,

the latter must be situated at a minimum of 420

mm above the hob. The minimum distance

between the worktop and kitchen units made of

combustible material is 700 mm (Fig. A).

e)e)

e)e)

e )The wall in direct contact with the back panel of

the cooker must be made of non-flammable

materials.

f)f)

f)f)

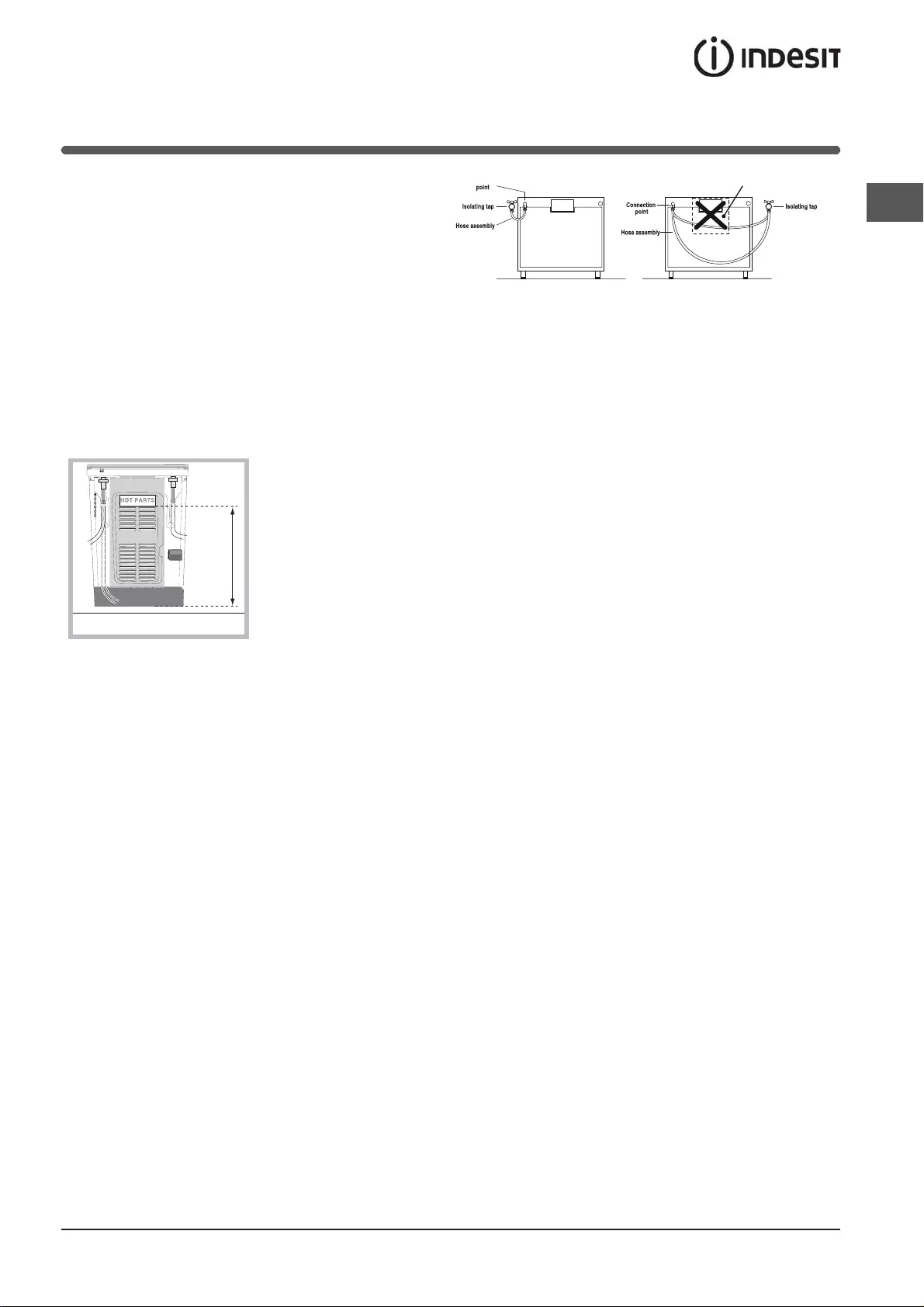

f ) The cooker is fitted with a safety chain that must

be attached to a hook, secured to the wall behind

the appliance.

! Some models can have their gas connection

inverted. It is important to make sure the safety

chain is always situated on the side which

corresponds to the hose holder (Fig. B).

Fig. A Fig. B

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

GB

3

Gas connection

T he cooker should be connected to the gas-supply

by a corgi registered installer. During installation of

this product it is essential to fit an approved gas tap

to isolate the supply from the appliance for the

convenience of any subsequent removal or

servicing. Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed “Adaptation to different gas

types”. On some models the gas supply can be

connected on the left or on the right, as necessary;

to change the

connection, reverse the

position of the hose

holder with that of the

cap and replace the

gasket (supplied with

the appliance). In the

case of connection to

liquid gas, by tank, use

pressure regulators that

conform to the

regulation in force. The gas supply must be

connected to the left of the appliance. Be sure that

the hose does not pass through the rear of the

cooker touching hot parts.

! Make sure the supply pressure conforms with the

values shown in the table entitled “Caracteristics of

the burners and nozzles”. When the cooker isWhen the cooker is

When the cooker isWhen the cooker is

When the cooker is

installed between cabinets (recessed), theinstalled between cabinets (recessed), the

installed between cabinets (recessed), theinstalled between cabinets (recessed), the

installed between cabinets (recessed), the

gas connection must be effected by angas connection must be effected by an

gas connection must be effected by angas connection must be effected by an

gas connection must be effected by an

approved flexible hose with bayonet fittingapproved flexible hose with bayonet fitting

approved flexible hose with bayonet fittingapproved flexible hose with bayonet fitting

approved flexible hose with bayonet fitting

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas female

fitting.fitting.

fitting.fitting.

fitting.

Connecting the gas supply

To make the connection, a flexible hose should be

used corresponding to the current gas regulations

which are:

• the hose must never be at any point in its lenght

in contact with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or

torsional stress and it must not have any

excessively narrow curves or bottlenecks;

• the hose must be easy to inspect along its entire

length to check its condition;

• the hose must always be in good condition, never

attempt to repair.

! The installation must comply with gas safety

(installation and use) regulations 1984. In all cases

for the above, by low, a qualified, corgi approved

engineer must be called for installation.

Electrial connection

Power supply voltage and frequency: 230-240V a.c.

50/60 Hz.

!!

!!

! The supply cable must be positioned so that it

never reaches at any point a temperature 50°C

higher than the room temperature. The cable must

be routed away from the rear vents. Should you

require it, you may use a longer cable, however, you

must ensure that the cable supplied with the

appliance is replaced by one of the same

specifications in accordance with current standards

and legislation.

Your appliance is supplied with a 13 amp fused plug

that can be plugged into a 13 amp socket for

immediate use. Before using the appliance please

read the instructions below.

WARNING - THIS APPLIANCE MUST BE

EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE

CARRIED OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA

approved fuse to BS 1362 should always be used,

and the fuse cover re-fitted. If the fuse cover is lost,

the plug must not be used until a replacement is

obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of

the correct colour as indicated by the coloured

marking or the colour that is embossed in words on

the base of the plug. Replacements can be obtained

directly from your nearest Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded plug

and you should wish to remove it to add a cable

extension or to re-route the mains cable through

partitions, units etc., please ensure that either:

• the plug is replaced by a fused 13 amp re-

wireable plug bearing the BSI mark of approval.

700 mm

HOT PARTS

4

GB

or:

• the mains cable is wired directly into a 13 amp

cable outlet, controlled by a switch, (in

compliance with BS 5733) which is accessible

without moving the appliance.

!!

!!

! For appliances with a rating greater than 13 amp

(eg: electric hob, double ovens and freestanding

electric cookers etc.) the mains cable must be wired

into a cooker output point with a rating of 45 amp. In

this case the cable is not supplied.

Disposing of the plug:

Ensure that before disposing of the plug itself, you

make the pins unusable so that it cannot be

accidentally inserted into a socket. Instructions for

connecting cable to an alternative plug:

!!

!!

! The wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

If the colours of the wires in the mains lead do not

correspond with the coloured markings identifying

the terminals in your plug, proceed as follows:

Connect Green & Yellow wire to terminal marked “EE

EE

E”

or or coloured Green or Green & Yellow.

Connect Brown wire to terminal marked “LL

LL

L” or

coloured Red.

Connect Blue wire to terminal marked “NN

NN

N” or

coloured Black.

If a 13 amp plug (BS 1363) is used it must be fitted

with a 13 amp fuse. A 15 amp plug must be

protected by a 15 amp fuse, either in the plug or

adaptor or at the distribution board. If you are in any

doubt about the electrical supply to your machine,

consult a qualified electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in

accordance with the following code:

BLUEBLUE

BLUEBLUE

BLUE “NEUTRALNEUTRAL

NEUTRALNEUTRAL

NEUTRAL” (“NN

NN

N”)

BROWNBROWN

BROWNBROWN

BROWN “LIVELIVE

LIVELIVE

LIVE” (“LL

LL

L”)

GREEN AND YELLOWGREEN AND YELLOW

GREEN AND YELLOWGREEN AND YELLOW

GREEN AND YELLOW “EARTHEARTH

EARTHEARTH

EARTH” (“E

E

EE

E”)

Disposing of the appliance

When disposing of the appliance please remove the

plug by cutting the mains cable as close as

possible to the plug body and dispose of it as

described above.

Checking the connection for leaks

When the installation process is complete, check

the hose fittings for leaks using a soapy solution.

Never use a flame.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

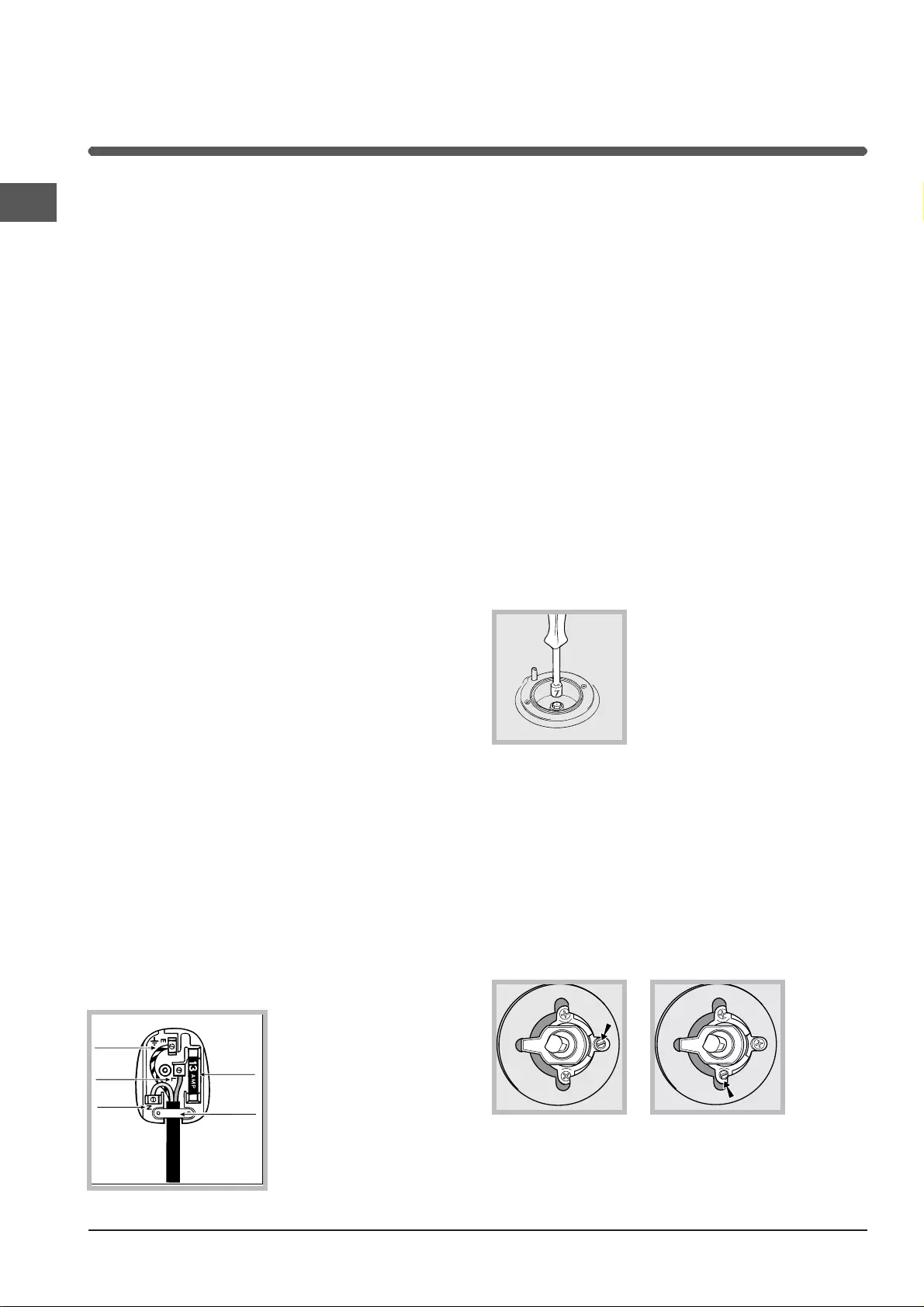

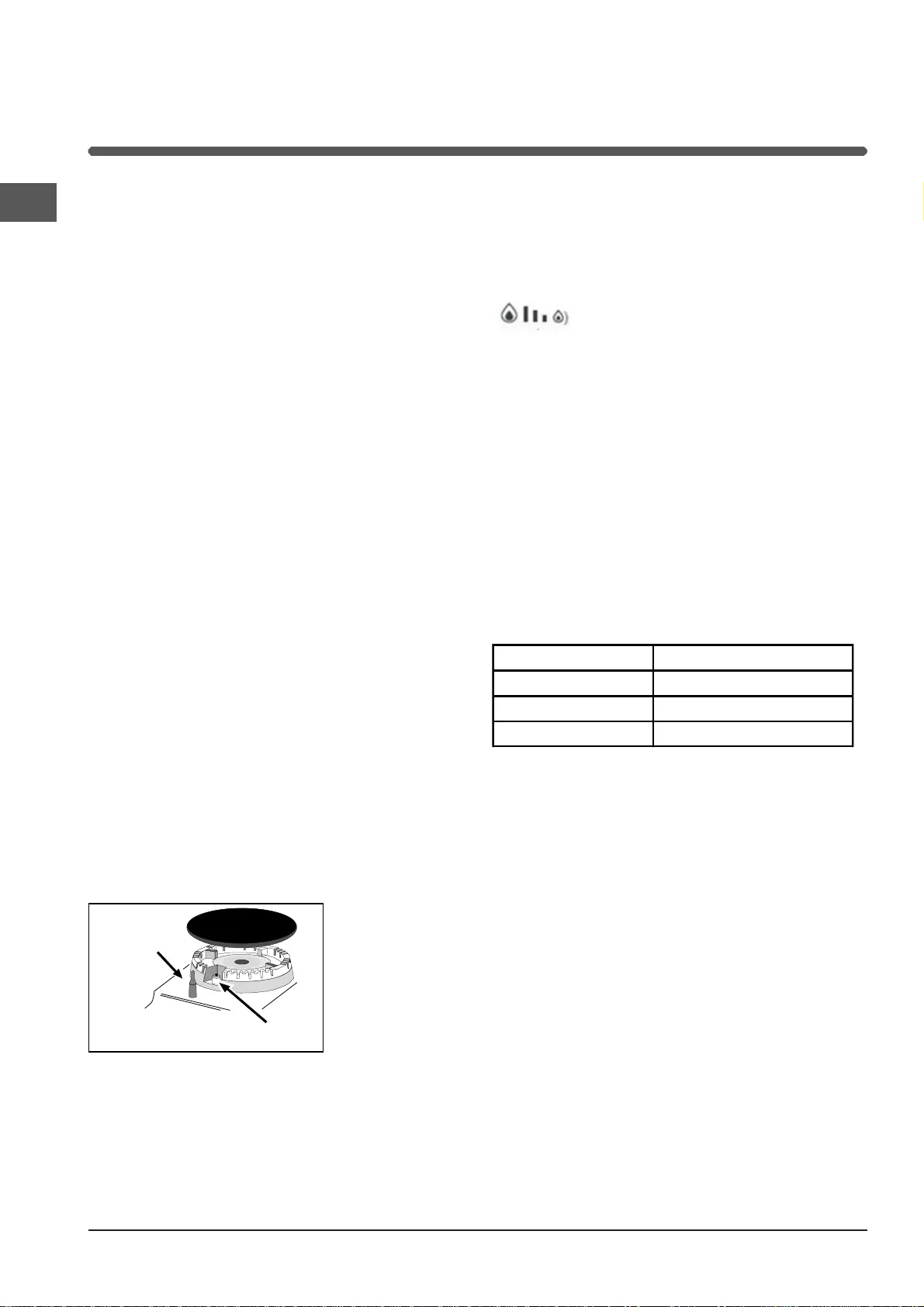

Adapting the hob

Replacing the nozzles for the hob burners:

1. Remove the hob grids and

slide the burners off their

seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (

see

figure

), and replace them with

nozzles suited to the new type

of gas (

see Burner and nozzle

specifications table

).

3. Replace all the components by following the

above instructions in reverse.

Adjusting the hob burners’ minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

! If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible.

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

GREEN &

YELLOW

BROWN

BLUE

13 amp fuse

CROSS-BAR

CORD GRIP

GB

5

V

! The hob burners do not require primary air adjustment.

! After adjusting the appliance so it may be used

with a different type of gas, replace the old rating

label with a new one that corresponds to the new

type of gas (these labels are available from

Authorised Technical Assistance Centres).

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

Adapting the oven

Replacing the oven burner nozzle

1. open the oven door fully

2. pull out the sliding oven

bottom

3. unscrew the burner

fastening screws

4. remove screw “VV

VV

V” and then

the oven burner;

5. Unscrew the oven burner

nozzle using the special

socket spanner for the

nozzles, or a 7 mm socket

spanner, and replace it with a

nozzle suited to the new type

of gas (see Table 1).

Take particular careTake particular care

Take particular careTake particular care

Take particular care

handling the spark plug wires and thehandling the spark plug wires and the

handling the spark plug wires and thehandling the spark plug wires and the

handling the spark plug wires and the

thermocouple pipes.thermocouple pipes.

thermocouple pipes.thermocouple pipes.

thermocouple pipes.

6. Replace all the parts, following the steps

described above in the reverse order..

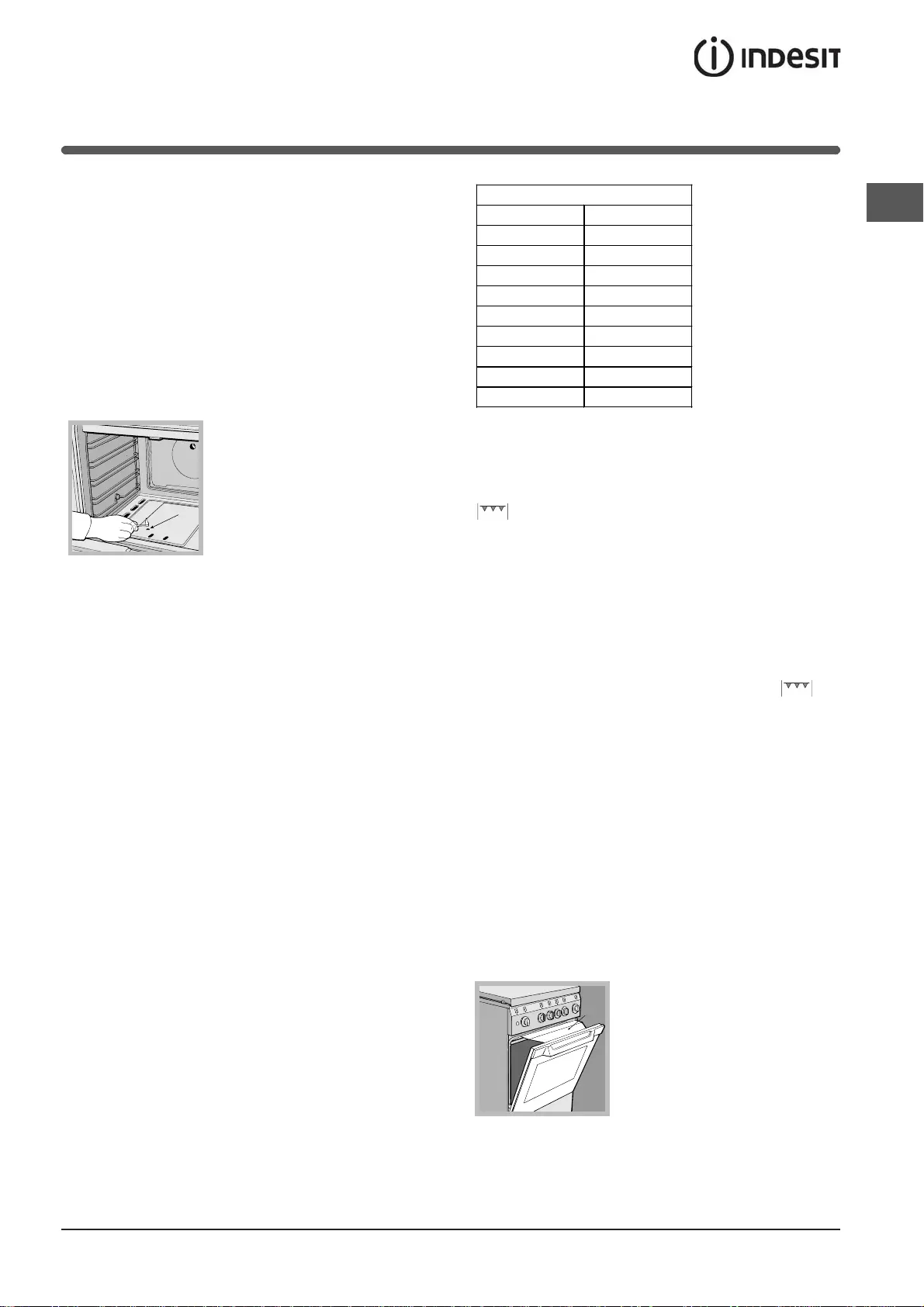

Adjusting the gas oven burner’s minimum setting:

1. Light the burner (

see Start-up and Use

).

2. Turn the knob to the minimum position (MIN) after

it has been in the maximum position (MAX) for

approximately 10 minutes.

3. Remove the knob.

4. Tighten or loosen the adjustment screws on the

outside of the thermostat pin (

see figure

) until the

flame is small but steady.

! If the appliance is connected to liquid gas, the

adjustment screw must be fastened as tightly as

possible.

5. Turn the knob from the MAX position to the MIN

position quickly or open and shut the oven door,

making sure that the burner is not extinguished.

Adapting the grill

Replacing the grill burner nozzle:

1. Remove the oven burner

after loosening screw V (

see

figure

).

2. Unscrew the grill burner

nozzle using a special nozzle

socket spanner (

see figure

) or

preferably with a 7 mm socket

spanner, and replace it with a

new nozzle that is suited to the

new type of gas (

see Burner

and nozzle specifications table

).

! Be careful of the spark plug wires and the

thermocouple tubes.

! The oven and grill burners do not require primary

air adjustment.

! After adjusting the appliance so it may be used

with a different type of gas, replace the old rating

label with a new one that corresponds to the new

type of gas (these labels are available from

Authorised Technical Assistance Centres).

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

V

I

6

GB

TECHNICAL DATA

Oven Dimensions

HxWxD 31x43,5x43,5 cm

Volume 58 l

Useful

measurements

relating to the

oven compartment

width 46 cm

depth 42 cm

height 8,5 cm

Voltage and

frequency see data plate

Burners

may be adapted for use with any

type of gas shown on the data

plate.

EC Directives 2006/95/EC dated

12/12/06 (Low Voltage) and

subsequent amendments -

04/108/EC dated 15/12/04

(Electromagnetic Compatibility)

and subsequent amendments -

2009/142/EC dated 30/11/09 (Gas)

and subsequent amendments -

90/68/EEC dated 22/07/93 and

subsequent amendments. -

2002/96/EC.

1275/2008(Stand-by/Off-mode)

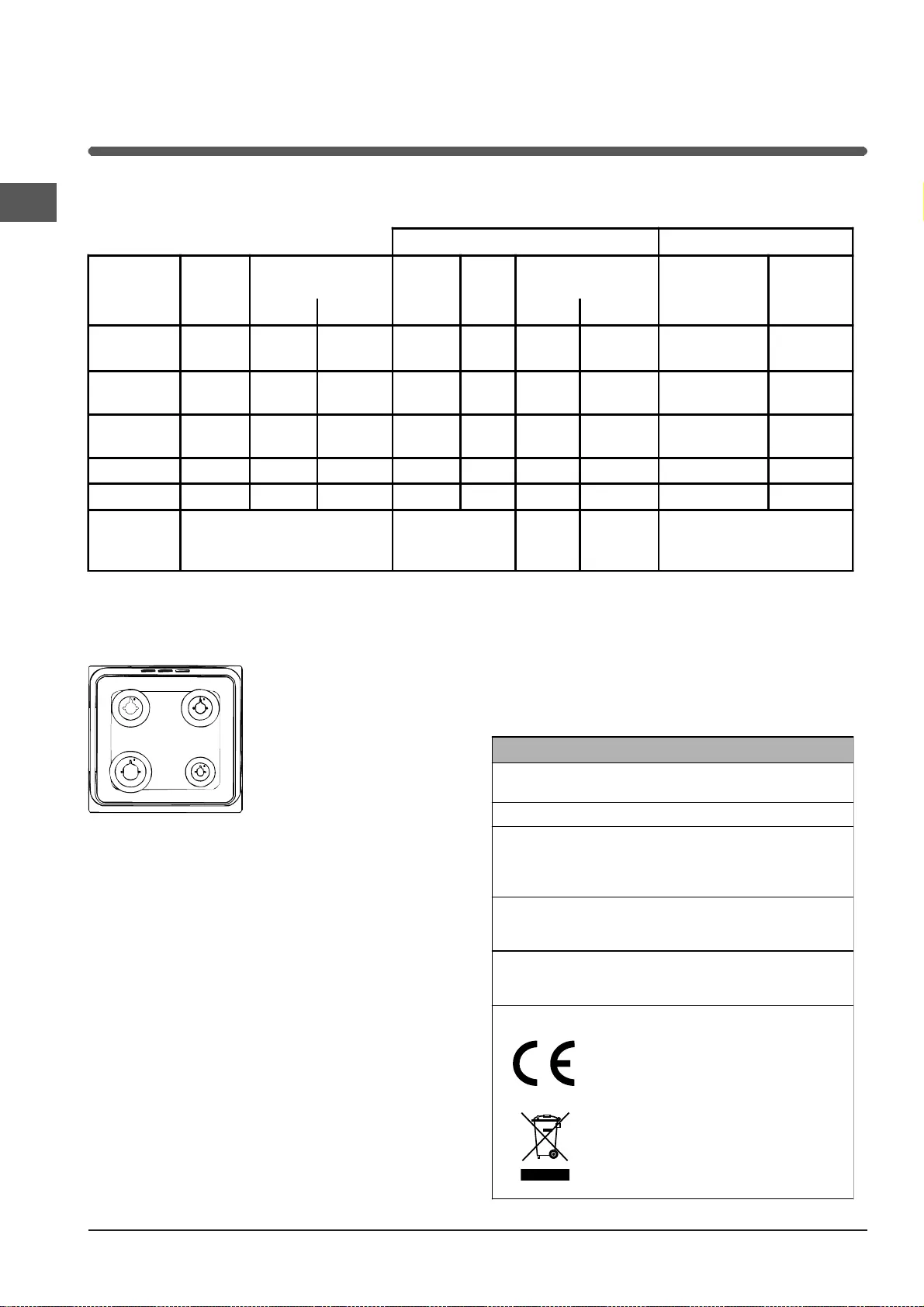

Table of burner and nozzle specifications

Ta ble 1 Li quid G a s Na t ura l G a s

Burner Diameter

(mm) Ther ma l Pow e r

kW (p.c.s.*) By-Pass

1/100 Nozzle

1/100 Flow*

g/h Nozzle

1/100 Flow*

l/h

Nominal Reduced (mm) (mm) *** ** (mm)

Fast

(Large)(R) 100 3,00 0,7 41 87 218 214 128 286

Semi Fast

(Medium)(S) 75 1,90 0,4 30 69 138 136 104 181

Auxiliary

(Small)(A) 51 1,00 0,4 30 50 73 71 78 95

Oven - 2,60 1,0 52 78 189 186 119 248

Grill - 2,30 - - 75 167 164 114 219

Supply

Pressures

Nominal (mbar)

Mini mu m (mbar)

Max i mu m (mbar)

28-30

20

35

37

25

45

20

17

25

* At 15°C and 1013 mbar- dry gas

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m3

SS

RA

I6GG1/UK

GB

7

Description of the

appliance

Control panel

Overall view

Hob grid

Control panel

GRILL rack

DRIPPING PAN

GUIDE RAILS

for the sliding racks

position 3

position 2

position 1

Gas burner Containment

surface for spills

Adjustable foot Adjustable foot

position 5

position 4

Button for Oven Light Electronic Lighting for Hob Burners

Oven and Grill

Control Knob Timer Knob

Control Knobs for Gas

Burners on Hob

On

Off

8

GB Using the hob

Lighting the burners

For each BURNER knob there is a complete ring

showing the strength of the flame for the relevant

burner.

To light one of the burners on the hob:

1. Bring a flame or gas lighter close to the burner.

2. Press the BURNER knob and turn it in an

anticlockwise direction so that it is pointing to the

maximum flame setting E.

3. Adjust the intensity of the flame to the desired

level by turning the BURNER knob in an

anticlockwise direction. This may be the minimum

setting C, the maximum setting E or any position in

between the two.

If the appliance is fitted with an electronic lighting

device* (

see figure

), press the ignition button,

marked with the symbol 11

11

1, then hold the BURNER

knob down and turn it in an anticlockwise direction,

towards the maximum flame setting, until the burner

is lit.The burner may be extinguished when the knob

is released. If this occurs, repeat the operation,

holding the knob down for a longer period of time.

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight it.

If the appliance is equipped with a flame failure

safety device*, press and hold the BURNER knob for

approximately 3-7 seconds to keep the flame alight

and to activate the device.

To switch the burner off, turn the knob until it reaches

the stop position •.

Start-up and use

Practical advice on using the burners

For the burners to work in the most efficient way

possible and to save on the amount of gas consumed,

it is recommended that only pans that have a lid and a

flat base are used. They should also be suited to the

size of the burner.

Burner ø Cookware diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

To identify the type of burner, please refer to the

diagrams contained in the “Burner and nozzle

specifications”.

! On the models supplied with a reducer shelf,

remember that this should be used only for the

auxiliary burner when you use casserole dishes with

a diameter under 12 cm.

HOB GAS BURNER

SAFETY DEVICE

ELECTRONIC

LIGHTING DEVICE

Flame adjustment according to levels

the burner flame intensity can be adjusted with the

knob according to 6 power levels, from maximum

to minimum with 4 intermediate positions:

a click will indicate the change from one level to

another when turning the knob. The system

guarantees a more precise adjustment, allows

to replicate the flame intensity and to identify

easily the preferred level for different cooking

operations.

Flame adjustment according to levelsFlame adjustment according to levels

GB

9

turn it in an anticlockwise direction, towards the MAX

position, until the burner is lit. If, after 15 seconds,

the burner is still not alight, release the knob, open

the oven door and wait for at least 1 minute before

trying to light it again. If there is no electricity the

burner may be lit using a flame or a lighter, as

described above.

! The oven is fitted with a safety device and it is

therefore necessary to hold the OVEN control knob

down for approximately 6 seconds.

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight the oven.

Adjusting the temperature

To set the desired cooking temperature, turn the

OVEN control knob in an anticlockwise direction.

Temperatures are displayed on the control panel and

may vary between MIN (150°C) and MAX (250°C).

Once the set temperature has been reached, the oven

will keep it constant by using its thermostat.

Conventional Oven

Gas mark °C

MIN MIN

1 155

2 160

3 170

4 180

5 200

6 220

7 230

MAX 250

Grill

To light the grill, bring a flame or gas lighter close to

the burner and press the OVEN control knob while

turning it in a clockwise direction until it reaches the

position. The grill enables the surface of food to

be browned evenly and is particularly suitable for

roast dishes, schnitzel and sausages. Place the

rack in position 4 or 5 and the dripping pan in

position 1 to collect fat and prevent the formation of

smoke.

If the appliance is fitted with an electronic lighting

device*, press the ignition button, marked with the

symbol 11

11

1, then hold the OVEN control knob and

turn it in an clockwise direction, towards the

position. If, after 15 seconds, the burner is still not

alight, release the knob, open the oven door and

wait for at least 1 minute before trying to light it

again. If there is no electricity the burner may be lit

using a flame or a lighter, as described above.

! The grill is fitted with a safety device and it is

therefore necessary to hold the OVEN control knob

down for approximately 6 seconds.

Using the oven

! The first time you use your appliance, heat the

empty oven with its door closed at its maximum

temperature for at least half an hour. Ensure that the

room is well ventilated before switching the oven off

and opening the oven door. The appliance may emit

a slightly unpleasant odour caused by protective

substances used during the manufacturing process

burning away.

! Before operating the product, remove all plastic

film from the sides of the appliance.

! Never put objects directly on

the bottom of the oven; this

will avoid the enamel coating

being damaged. Only use

position 1 in the oven when

cooking with the rotisserie

spit.

Lighting the oven

To light the oven burner, bring a flame or gas lighter

close to opening F (

see figure

) and press the OVEN

control knob while turning it in an anticlockwise

direction until it reaches the MAX position.

If the appliance is fitted with an electronic lighting

device*, press the ignition button, marked with the

symbol 11

11

1, then hold the OVEN control knob and

F

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight the grill.

! When using the grill, leave the oven door ajar,

positioning the deflector D between the door and the

control panel (

see figure

) in

order to prevent the knobs

from overheating.

D

10

GB

Oven cooking advice table

Foods Weight (in

kg) Rack

position Preheating time (min) Recommended

Temperature (°C) Cooking t ime

(minutes)

Pasta

Lasagne

Cannelloni

Gratin dishes

2.5

2.5

2.5

3

3

3

10

10

10

210

200

200

60-75

40-50

40-50

Meat

Veal

Chicke n

Duck

Rabbit

Pork

Lamb

1.7

1.5

1.8

2

2.1

1.8

3

3

3

3

3

3

10

10

10

10

10

10

200

220

200

200

200

200

85-90

90-100

100-110

70-80

70-80

90-95

Fish

Mackerel

Dentex

Trout baked in foil

1.1

1.5

1

3

3

3

10

10

10

180-200

180-200

180-200

35-40

40-50

40-45

Pizza

Neapolitan-style

1

3

15

220

15-20

Pies

Biscuits

Tart

Savoury pies

Leavened cakes

0.5

1.1

1

1

3

3

3

3

15

15

15

15

180

180

180

180

30-35

30-35

45-50

35-40

Gr illed foods

Veal steak

Cutlets

Hamburgers

Mackerel

Toast

1

1.5

1

1

4 pcs

4

4

3

4

4

5

5

5

5

5

15-20

20-30

20-30

15-20

2-4

Using the grill pan kit

The grill pan handle is detachable from the pan to

facilitate cleaning and storage. Fix the pan handle

securely before use:

1. Fit the handle to the grill pan so the external

‘hooks’ embrace the that edge of the pan (fig. 1)

2. Make sure that the middle part of the handle fits

exactly the protruding support of the pan (fig .2)

and holds the pan from the bottom.

The food must be placed on the rack in the grill pan.

Position the grill pan on top of the oven rack. The

best results are achieved by placing the oven rack

on the uppermost shelves. Pouring a little water into

the grill pan will make the collection of grease

particles more efficient and prevent the formation of

smoke.

12

Oven light

The light may be switched on at any moment by

pressing the OVEN LIGHT button.

Timer

To activate the Timer proceed as follows:

1. Turn the TIMER knob in a clockwise direction 4

for almost one complete revolution to set the buzzer.

2. Turn the TIMER knob in an anticlockwise direction

5 to set the desired length of time.

GB

11

Precautions and tips

! This appliance has been designed and manufactured in

compliance with international safety standards.

The following warnings are provided for safety reasons and must

be read carefully.

General safety

• The appliance was designed for domestic use inside the home

and is not intended for commercial or industrial use.

• The appliance must not be installed outdoors, even in covered

areas. It is extremely dangerous to leave the appliance exposed

to rain and storms.

• Do not touch the appliance with bare feet or with wet or damp

hands and feet.

•

The appliance must be used by adults only for

the preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous.

The manufacturer may not be held liable for

any damage resulting from improper, incorrect

and unreasonable use of the appliance

• The instruction booklet accompanies a class 1 (insulated) or

class 2 - subclass 1 (recessed between 2 cupboards)

appliance.

•When the appliance is in use, the heating

elements and some parts of the oven door

become extremely hot. Make sure you don't

touch them and keep children well away.

• Make sure that the power supply cables of other electrical

appliances do not come into contact with the hot parts of the

oven.

• The openings used for the ventilation and dispersion of heat

must never be covered.

• Always use oven gloves when placing cookware in the oven or

when removing it.

• Do not use flammable liquids (alcohol, petrol, etc...) near the

appliance while it is in use.

• Do not place flammable material in the lower storage

compartment or in the oven itself. If the appliance is switched

on accidentally, it could catch fire.

• The internal surfaces of the compartment (where present) may

become hot.

• Always make sure the knobs are in the • position and that the

gas tap is closed when the appliance is not in use.

• When unplugging the appliance, always pull the plug from the mains

socket; do not pull on the cable.

• Never perform any cleaning or maintenance work without

having disconnected the appliance from the electricity mains.

• If the appliance breaks down, under no circumstances should you

attempt to repair the appliance yourself. Repairs carried out by

inexperienced persons may cause injury or further malfunctioning of

the appliance. Contact Assistance.

• Do not rest heavy objects on the open oven door.

• The appliance should not be operated by people (including

children) with reduced physical, sensory or mental capacities,

by inexperienced individuals or by anyone who is not familiar

with the product. These individuals should, at the very least,

be supervised by someone who assumes responsibility for their

safety or receive preliminary instructions relating to the

operation of the appliance.

• Do not let children play with the appliance.

Disposal

• When disposing of packaging material: observe local legislation so

that the packaging may be reused.

• The European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE), requires that old household

electrical appliances must not be disposed of in the normal

unsorted municipal waste stream. Old appliances must be

collected separately in order to optimise the recovery and

recycling of the materials they contain and reduce the impact

on human health and the environment. The crossed out

“wheeled bin” symbol on the product reminds you of your

obligation, that when you dispose of the appliance it must be

separately collected.

Consumers should contact their local authority or retailer for

information concerning the correct disposal of their old

appliance.

Respecting and conserving the

environment

• You can help to reduce the peak load of the electricity supply

network companies by using the oven in the hours between

late afternoon and the early hours of the morning.

• Check the door seals regularly and wipe them clean to ensure

they are free of debris so that they adhere properly to the door,

thus avoiding heat dispersion.

If the cooker is placed on a pedestal, take the neces-

sary precautions to prevent the cooker from sliding

off the pedestal itself.

•

12

GB Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Never use steam cleaners or pressure cleaners on

the appliance.

• The stainless steel or enamel-coated external parts

and the rubber seals may be cleaned using a

sponge that has been soaked in lukewarm water

and neutral soap. Use specialised products for the

removal of stubborn stains. After cleaning, rinse

well and dry thoroughly. Do not use abrasive

powders or corrosive substances.

• The hob grids, burner caps, flame spreader rings

and burners may be removed to make cleaning

easier; wash them in hot water and non-abrasive

detergent, making sure all burnt-on residue is

removed before drying them thoroughly.

• Clean the terminal part of the flame failure safety

devices* frequently.

• The inside of the oven should ideally be cleaned

after each use, while it is still lukewarm. Use hot

water and detergent, then rinse well and dry with a

soft cloth. Do not use abrasive products.

•Clean the glass part of the oven door using a

sponge and a non-abrasive cleaning product, then

dry thoroughly with a soft cloth. Do not use rough

abrasive material or sharp metal scrapers as these

could scratch the surface and cause the glass to

crack.

• The accessories can be washed like everyday

crockery, and are even dishwasher safe.

• Do not close the cover when the burners are alight

or when they are still hot.

Inspecting the oven seals

Check the door seals around the oven regularly. If the

seals are damaged, please contact your nearest

Authorised After-sales Service Centre. We recommend

that the oven is not used until the seals have been

replaced.

Replacing the oven light bulb

1. After disconnecting the oven

from the electricity mains,

remove the glass lid covering

the lamp socket (

see figure

).

2. Remove the light bulb and

replace it with a similar one:

voltage 230 V, wattage 25 W,

cap E 14.

3. Replace the lid and reconnect the oven to the

electricity supply.

Gas tap maintenance

Over time, the taps may become jammed or difficult to

turn. If this happens, the tap must be replaced.

! This procedure must be performed by a qualified

technician authorised by the manufacturer.

Assistance

! Never use the services of an unauthorised

technician.

Please have the following information to hand:

• The type of problem encountered.

• The appliance model (Mod.).

• The serial number (S/N).

The latter two pieces of information can be found on

the data plate located on the appliance.

Care and maintenance

GB

13

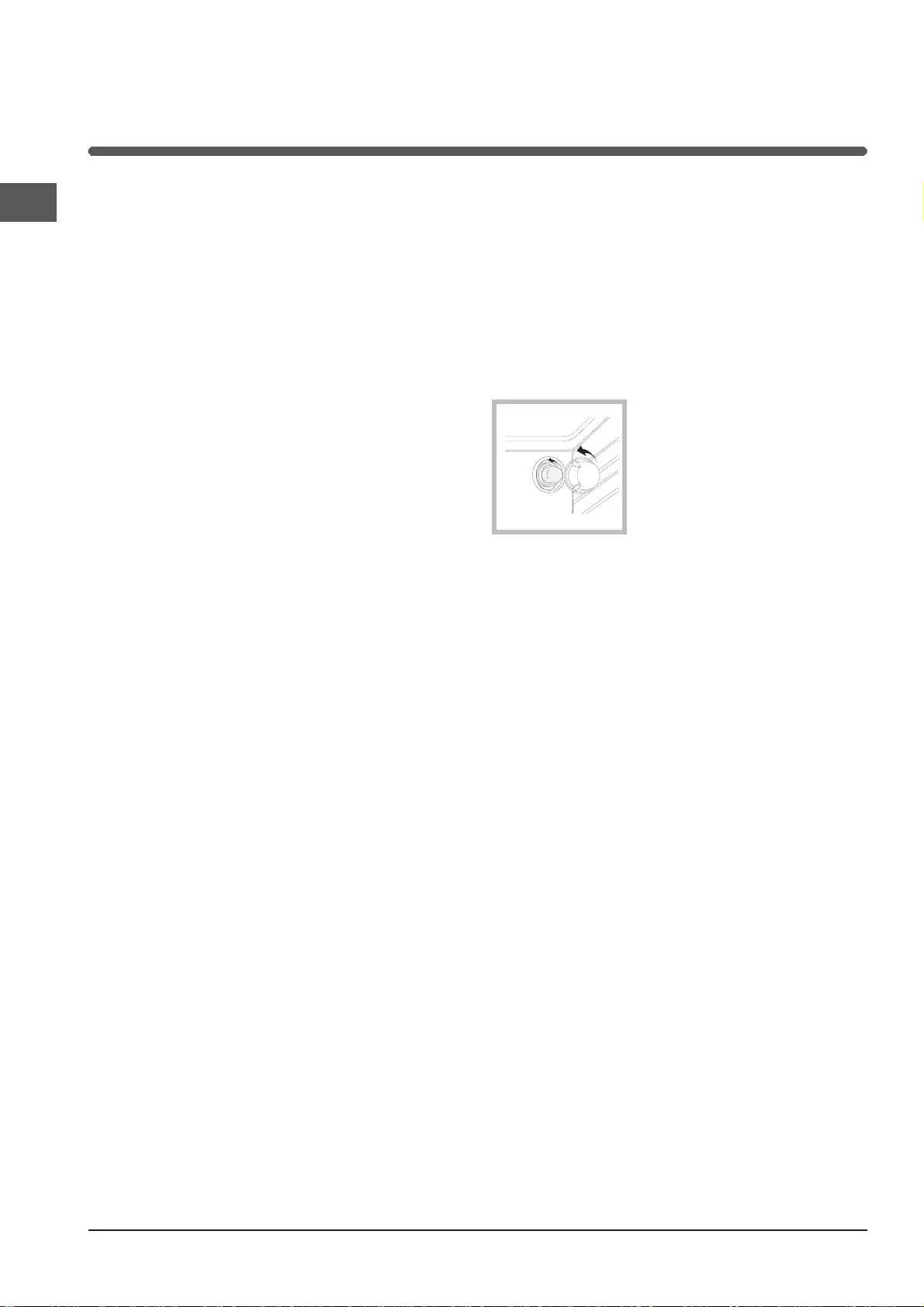

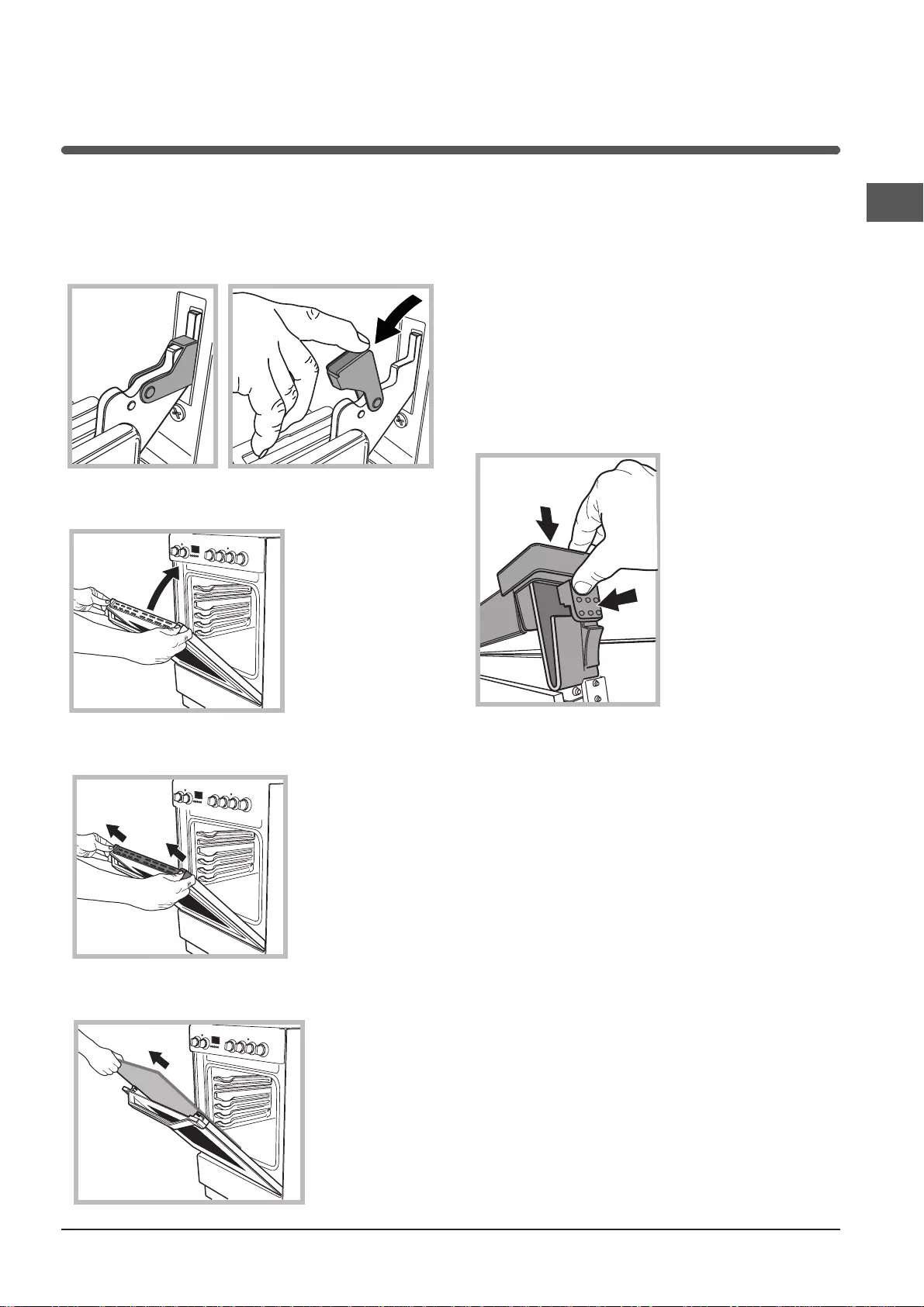

Removing and fitting the oven door:

1.Open the door

2.Make the hinge clamps of the oven door rotate

backwards completely (see photo)

3. Close the door until the clamps stop (the door will

remain open for 40° approx.) (see photo)

4.Press the two buttons on the upper profile and

extract the profile (see photo)

5.Remove the glass sheet and do the cleaning as

indicated in chapter: "Care and maintenance".

6.Replace the glass.

7.Replace the profile, a click will indicate that the

part is positioned correctly.

8.Open the door completely.

9.Close the supports (see photo).

10.Now the door can be completely closed and the

oven can be started for normal use.

Removing and fitting the oven door:

WARNING! Oven must not be operated with inner

door glass removed!

WARNING! When reassembling the inner door

glass insert the glass panel correctly so that the

inscription written on the panel is not reversed and

can be easily legible.

WARNING! Oven must not be operated with inner

door glass removed!

WARNING! When reassembling the inner door

glass insert the glass panel correctly so that the

can be easily legible.

WARNING! Oven must not be operated with inner

door glass removed!

WARNING! When reassembling the inner door

glass insert the glass panel correctly so that the

can be easily legible.

inscription written on the panel is not reversed andinscription written on the panel is not reversed and

°

404040

14

GB

GB

15

16

GB

04/2013- 195109387.00

XEROX FABRIANO