KitchenAid KEIPP 12020 User Manual

Displayed below is the user manual for KEIPP 12020 by KitchenAid which is a product in the Cooker Hoods category. This manual has pages.

Related Manuals

Instructions for use

Important instructions for safety 4

Installation 6

Safeguarding the environment 6

Troubleshooting guide 7

After-sales Service 7

Cleaning 7

Maintenance 8

Material supplied 9

Installation - preliminary assembly instructions 9

Installation dimensions 10

Installation - assembly instructions 10

Maintenance 12

Description and use of hood 12

These instructions are also available on the website: www.kitchenaid.eu

4

YOUR SAFETY AND THAT OF OTHERS IS

HIGHLY IMPORTANT.

This manual and the appliance itself provide

important safety warnings, to be read and observed

at all times.

This is the attention symbol, pertaining to

safety, which alerts users to potential risks to

themselves and others.

All safety warnings are preceded by the attention

symbol and the following terms:

indicates a hazardous situation which, if not

avoided, will cause serious injury.

indicates a hazardous situation which, if not

avoided, could cause serious injury.

All safety warnings specify the potential

danger/warning to which they refer and indicate

how to reduce the risk of injury, damage and

electrical shock resulting from incorrect use of the

appliance. Comply with the following instructions:

• Installation or maintenance must be carried out by

a specialized technician, in compliance with the

manufacturer’s instructions and local safety

regulations.

Do not repair or replace any part of the appliance

unless specifically requested in the user manual.

• The appliance must be disconnected from the

power supply before carrying out any installation

work.

• Earthing of the appliance is compulsory. (Not

necessary for class II hoods identified by the

symbol on the specifications label).

• The power supply cable must be long enough to

permit connecting the appliance to the mains

socket outlet.

• Do not pull the power supply cable in order to

unplug the appliance.

• The electrical components must no longer be

accessible to the user after installation.

• Do not touch the appliance with any wet part of

the body and do not operate it when barefoot.

• This appliance may be used by children older

than 8 years of age and by persons with reduced

physical, sensory or mental capacities or with

inadequate experience and knowledge only if they

are supervised or if they have been taught how to

use the appliance in conditions of safety and if

they are aware of the dangers involved. Children

must not play with the appliance. Cleaning and

maintenance must not be carried out by children,

unless they are supervised by adults.

• Do not repair or replace any part of the appliance

unless specifically indicated in the manual.

Defective parts must be replaced using genuine

parts. All other maintenance services must be

carried out by a specialized technician.

• Children must be supervised to ensure they do not

play with the appliance.

• When drilling through a wall or the ceiling, pay

attention not to damage electric connections

and/or pipes.

• The ventilation ducts must always discharge to

the outside.

• Exhaust air must not be vented through a flue

used for removal of fumes produced by

appliances burning gas or other fuels, but must

have a separate outlet. All national regulations

governing extraction of fumes must be observed.

• If the hood is used together with other appliances

operating on gas or other fuels, the negative

pressure in the room must not exceed 4 Pa (4 x

10-5 bar).

For this reason, make sure the room is adequately

ventilated.

• The Manufacturer declines any liability for

improper use or incorrect setting of the controls.

• Regular cleaning and maintenance is essential to

correct functioning and good performance of the

appliance. Frequently clean all encrustations from

dirty surfaces to prevent the accumulation of

grease. Regularly clean or replace the filters.

• Failure to observe the instructions for cleaning the

hood and replacing the filters may result in a fire.

• The fume extractor hood must never be opened

without the grease filters installed and it should

be kept under constant supervision.

• Gas appliances must be used under the extractor

hood only with pans resting.

• When using more than three gas cooking points,

the hood should be operating at power level 2 or

greater. This will eliminate heat congestion in the

appliance.

• Before touching the bulbs, first ensure that they

are cold.

• Do not use or leave the hood without its lamps

correctly installed - risk of electric shock.

• Wear work gloves for all installation and

maintenance operations.

• The product is not suitable for outdoor use.

• When the hob is in use, accessible parts of the

hood may become hot.

• Never flame cook food (flambé) under the

appliance. Using free flames might cause fire.

• Do not leave frying pans unattended when frying,

as the frying oil may catch fire.

WARNING:

DANGER:

Important instructions for safety

5

Scrapping of household appliances

• This appliance is manufactured with recyclable or

reusable materials. Dispose of it in accordance

with local waste disposal regulations. Before

disposing of it, make it unusable by cutting off its

power supply cable.

• For further information on the treatment, recovery

and recycling of household appliances, contact

your competent local authority, the collection

service for household waste or the shop where

you purchased the appliance.

KEEP THESE INSTRUCTIONS

Declaration of conformity

• This appliance has been designed, manufactured

and marketed in compliance with:

- safety objectives of the “Low Voltage” Directive

2006/95/EC (which replaces 73/23/EEC and

subsequent amendments);

- the ecodesign requirements of european

regulations n. 65/2014, and n. 66/2014 in

conformity to the european standard EN 61591

- the protection requirements of Directive “EMC”

2004/108/EC.

Electrical safety of the appliance can only be

guaranteed if it is correctly connected to an

approved earthing system.

Energy saving tips

• Switch ON the hood at minimum speed when you

start cooking and kept it running for few minutes

after cooking is finished.

• Increase the speed only in case of large amount of

smoke and vapour and use boost speed(s) only in

extreme situations.

• Replace the charcoal filter(s) when necessary to

maintain a good odour reduction efficiency.

• Clean the grease filter(s) when necessary to

maintain a good grease filter efficiency.

• Use the maximum diameter of the ducting system

indicated in this manual to optimize efficiency and

minimize noise.

6

Disposal of packing

The packing material is 100% recyclable and is

marked with the recycle symbol . The various

parts of the packing must be disposed of responsibly

and in full compliance with local authority

regulations governing waste disposal.

Disposal of the appliance

- This appliance is marked in compliance with

European Directive 2012/19/EU on Waste

Electrical and Electronic Equipment (WEEE).

- By ensuring that this appliance is disposed of

correctly, you can help prevent potentially

damaging consequences for the environment and

health.

- The symbol on the product or on the

accompanying documentation indicates that it

should not be treated as domestic waste but must

be taken to an appropriate collection centre for the

recycling of electrical and electronic equipment.

Safeguarding the environment

After unpacking the appliance, check for any

damage caused during transport. In case of

problems, contact the dealer or the After-Sales

Service. To avoid any damage, it is advisable to

only remove the appliance from the polystyrene

base just before installation.

PREPARATION FOR INSTALLATION

this appliance is heavy; the hood should only be

lifted and installed by two or more people.

The minimum distance between the cooking pan

support on top of the cooker and the bottom of the

hood must not be less than 50 cm for electric

cookers and 65 cm for gas or mixed cookers.

Before installation also check the minimum

distances stated in the manual of the cooker.

If the installation instructions for the cooker specify

a greater distance between cooker and hood, this

distance must be observed.

ELECTRICAL CONNECTIONS

Make sure the power voltage specified on the

appliance rating plate is the same as the mains

voltage.

This information may be found on the inside of the

hood, under the grease filter.

Power cable replacement (type H05 VV-F 3 x 0.75

mm²) must be carried out by a qualified electrician.

Contact an authorized service centre.

If the hood is fitted with an electric plug, connect

the plug to a socket complying with current

regulations, located in an accessible place. If no

plug is fitted

(direct wiring to the mains), or if the socket is not

located in an accessible place, install a standardized

double pole power switch that will enable complete

isolation from the mains in case of category III

overvoltage conditions, in accordance with wiring

rules.

GENERAL RECOMMENDATIONS

Before use

Remove cardboard protection pieces, transparent

film and adhesive labels from accessories.

Make sure the appliance has not been damaged

during transport.

During use

Do not place weights on the appliance, as they

could damage it.

Do not expose the appliance to atmospheric agents.

WARNING:

Installation

7

The appliance does not work:

• Check the domestic power supply and ensure the

appliance is connected to the mains properly.

• Switch the hood off and then on again to see if

the problem has been resolved.

The hood is not extracting satisfactorily:

• Check the extraction speed is set to the desired

level;

• Check the filters are clean;

• Check the air vents are not blocked;

The light does not work:

• Check to see if the lamp needs replacing;

• Check to see if the lamp has been fitted properly;

Troubleshooting guide

Before calling the After-sales Service:

1. See if you can solve the problem yourself with

the help of the “Troubleshooting guide”.

2. Switch the hood off and then on again to see if

the problem has been resolved.

If, after the above checks, the problem persists,

contact your nearest After-sales Service.

Always provide:

• a brief description of the problem;

• the type and specific model of the appliance;

• the Service number (this is the number which

follows the word SERVICE on the dataplate),

inside the appliance. The Service number is also

printed on the warranty booklet;

• your full address;

• your telephone number;

If any repairs are needed, contact an authorized

Service Centre (to ensure that only original spare

parts are used and that repairs are made correctly).

After-sales Service

- Do not use steam cleaners.

- Disconnect the appliance from the power

supply.

IMPORTANT: Do not use corrosive or abrasive

detergents. If any of these products accidentally

comes into contact with the appliance, clean it

immediately with a damp cloth.

• Clean the surfaces with a damp cloth. If very

dirty, add a few drops of washing up detergent to

the water. Dry with a dry cloth.

IMPORTANT: Do not use abrasive sponges or

metallic scrapers or scouring pads. Their use

could eventually ruin the enamelled surfaces.

• Use specific detergents to clean the appliance and

follow the manufacturer’s instructions

IMPORTANT: Clean the filters at least once a

month to remove built-up oil and grease.

WARNING:

Cleaning

8

Maintenance

- use safety gloves.

- disconnect the appliance from the mains power supply.

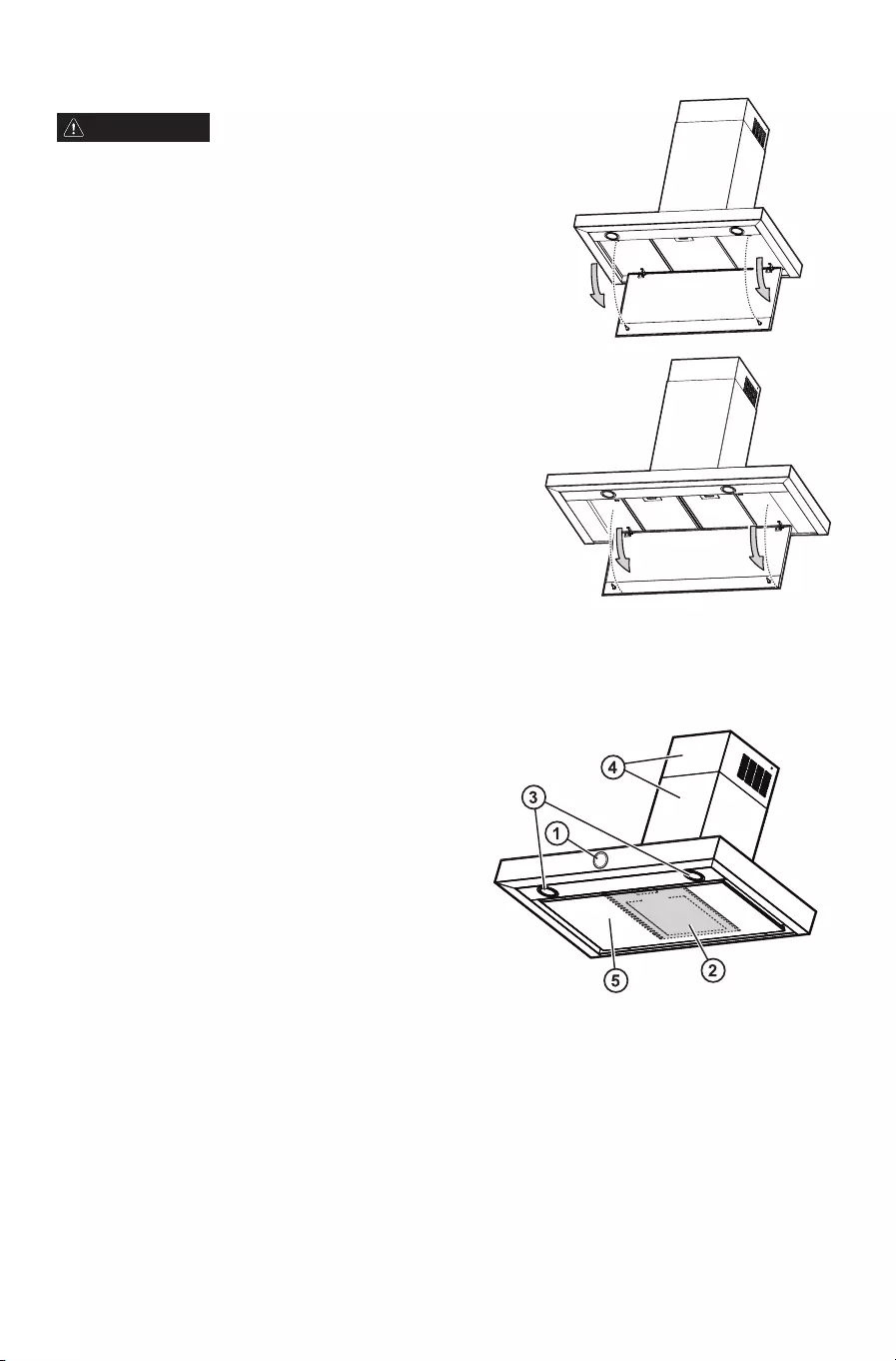

GREASE FILTERS

The metal grease filter has an unlimited life and should be cleaned

once a month by hand or in a dishwasher at low temperature and

with a short cycle. Cleaning in a dishwasher may cause discoloring

of the grease filter, but its filtering efficiency is unaffected.

Pull out the handle to remove the filter.

Wash the filter and leave it to dry, proceeding in reverse order to

refit.

REPLACING LAMPS

The hood lighting system is based on LED technology.

The LEDs provide optimal illumination, with a lifetime up to ten times longer than traditional lamps but

with 90% less energy consumption.

Contact the technical support service for replacements.

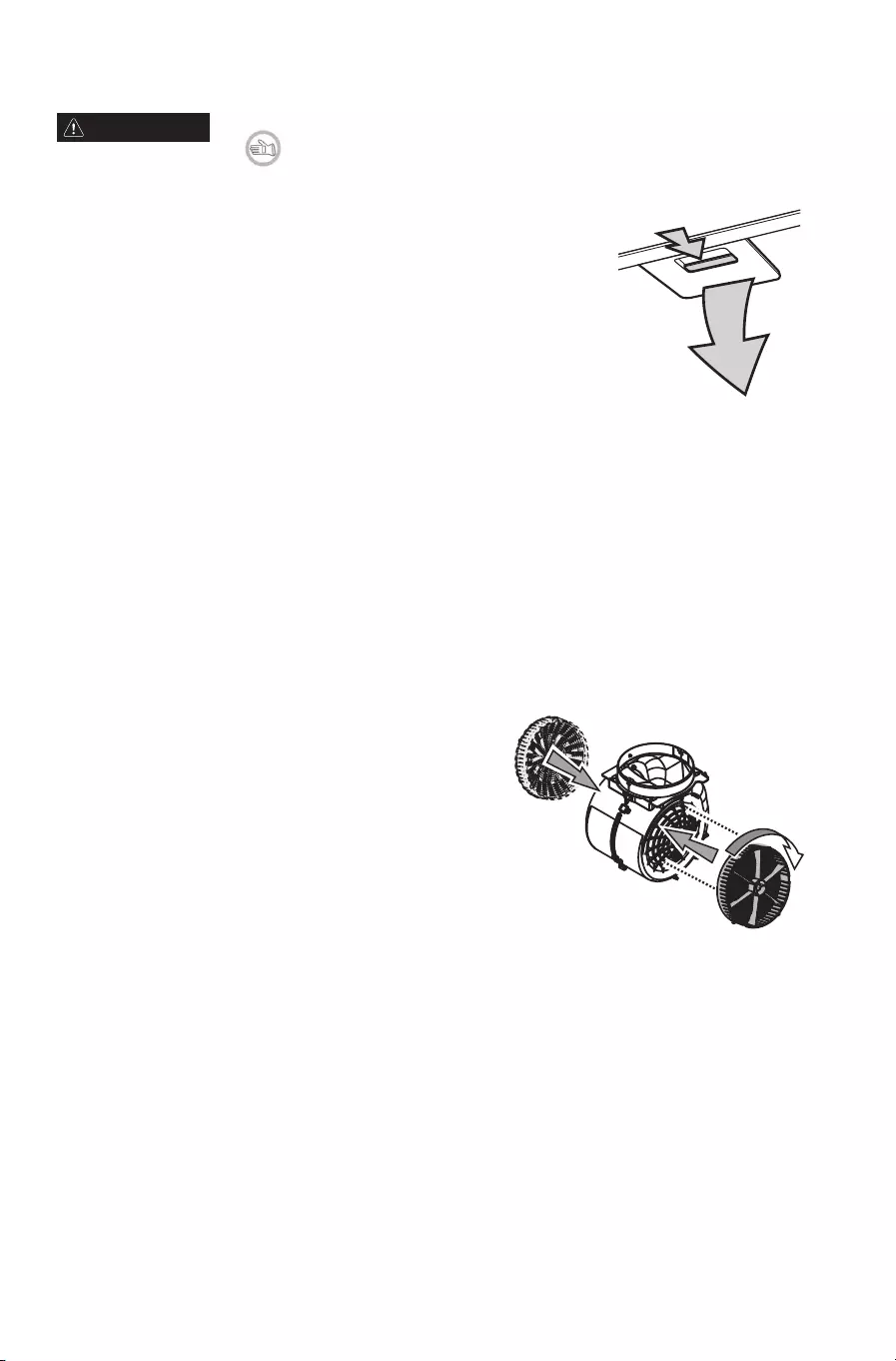

CARBON FILTER

(filter hoods only):

It captures and neutralizes unwanted cooking odors.

Change the carbon filter every 4 months.

Fitting or changing the carbon filter

1. Disconnect the hood from the power supply.

2. Open the extraction panel and remove it.

3. Remove the grease filters.

4. Fit one carbon filter each side, covering both

protection grilles of the motor impeller. Turn the filters

clockwise to secure them to the middle pins.

Proceed in reverse order to remove.

Re-fit the grease filters and extraction panel.

WARNING:

9

Material supplied

Remove all the components from the packets. Check that all the components are included.

• Hood assembled with motor, lamps and grease filters installed.

• 1 Pre-assembled truss

• 1 Filter connector with extensions

• Instructions for assembly and use

• 1 electrical cable

• 1 cable clamp

• 1 Assembly template

• 6 screws Ø 6x70

• 6 wall plugs Ø 10x60

• 14 screws Ø 4x7

• 42 screws Ø 3.5x9.5

• 2 adapter inserts

Installation - preliminary assembly instructions

The hood is designed for installation and use in “Extractor version” or in “Filter version”.

Note: the model with electric valve can only be used in “Extractor version” and the exhaust pipe must be

connected to a peripheral extraction unit.

Extractor Version

Fumes are extracted and expelled to the outside through an exhaust pipe (not supplied) fixed to the hood

exhaust pipe connector.

Depending on the exhaust pipe purchased, provide for suitable fixing to the exhaust pipe connector.

IMPORTANT: If already installed, remove the carbon filter/s.

Filter Version

Air is filtered through the carbon filter/s and recycled into the surrounding environment.

IMPORTANT: Check that air recirculation is ensured.

If the hood does not have the carbon filter/s, order one/them and fit before use.

Install the hood away from very dirty areas, windows, doors and heat sources.

The hood comes with all the materials necessary for installation on the majority of walls/ceilings. However,

a qualified technician must ensure that the materials are suitable according to the type of wall/ceiling.

10

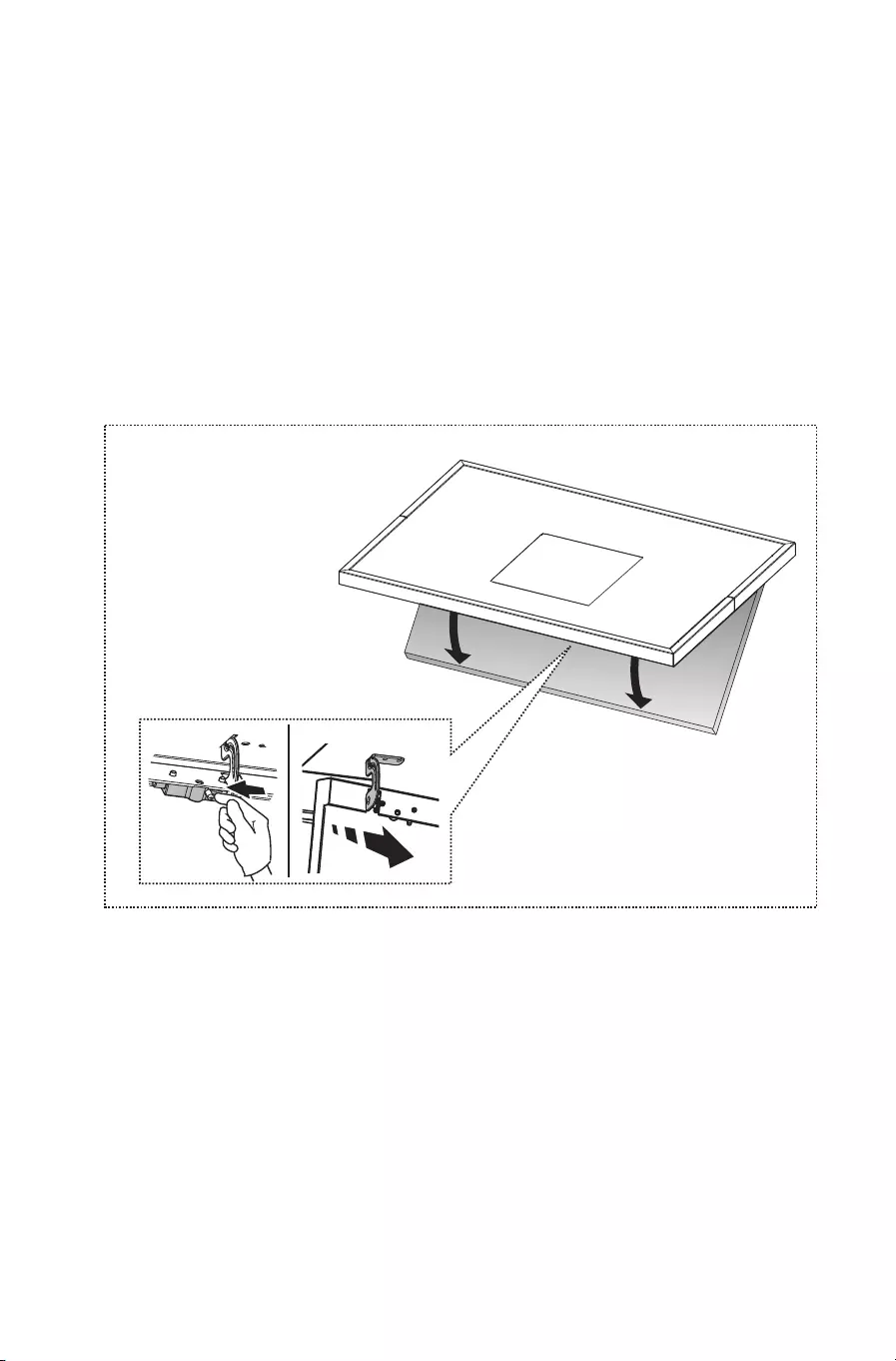

Installation dimensions

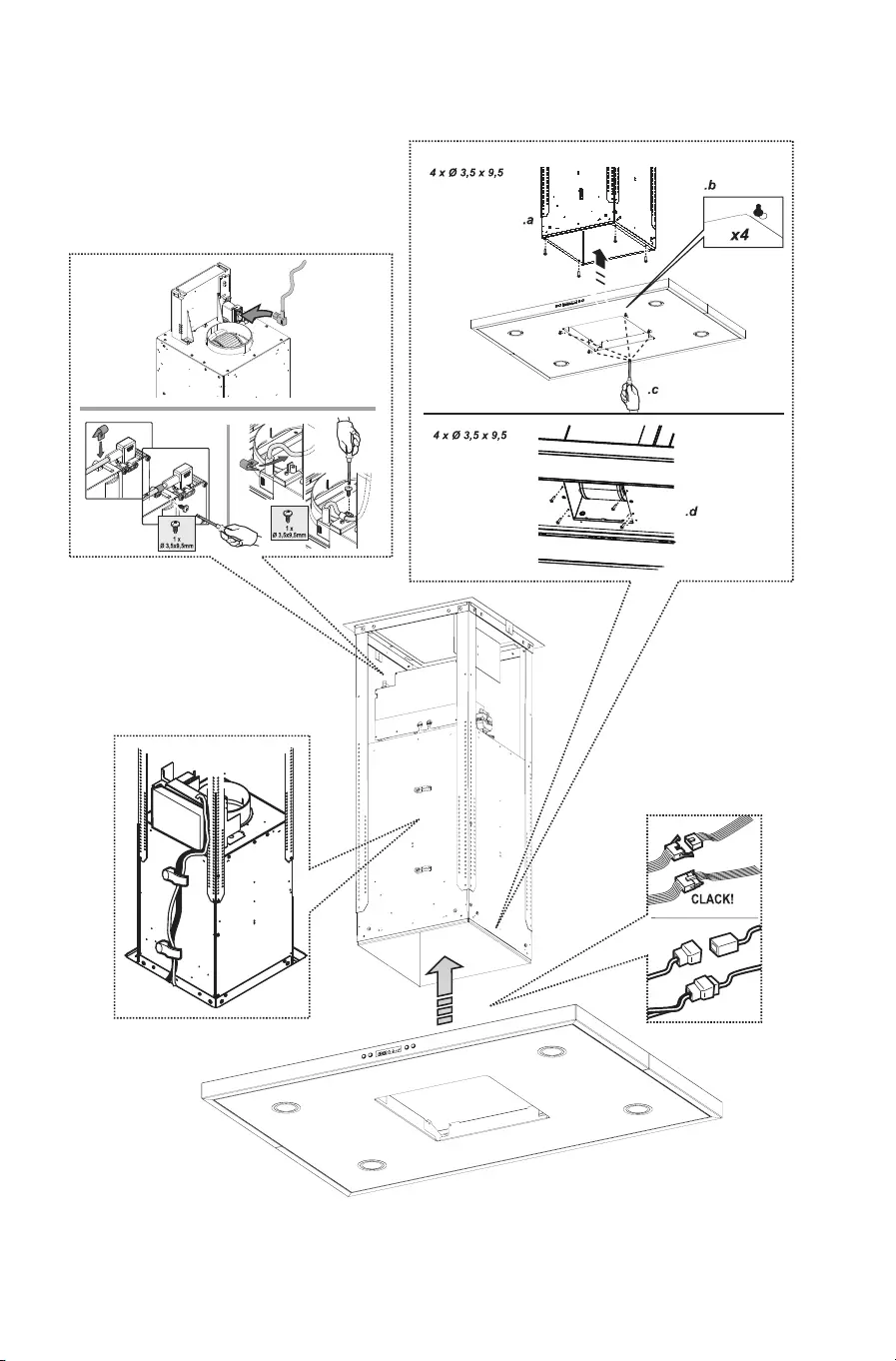

The instructions below, to be carried out in the order in which they are numbered, refer to the figures (with

the same step numbers) given on the last pages of this manual.

Before starting the installation steps:

- remove the extraction panel “P”

- push the lever (located at the bottom of the panel) to the left

- release the supports panel

- remove the grease filters

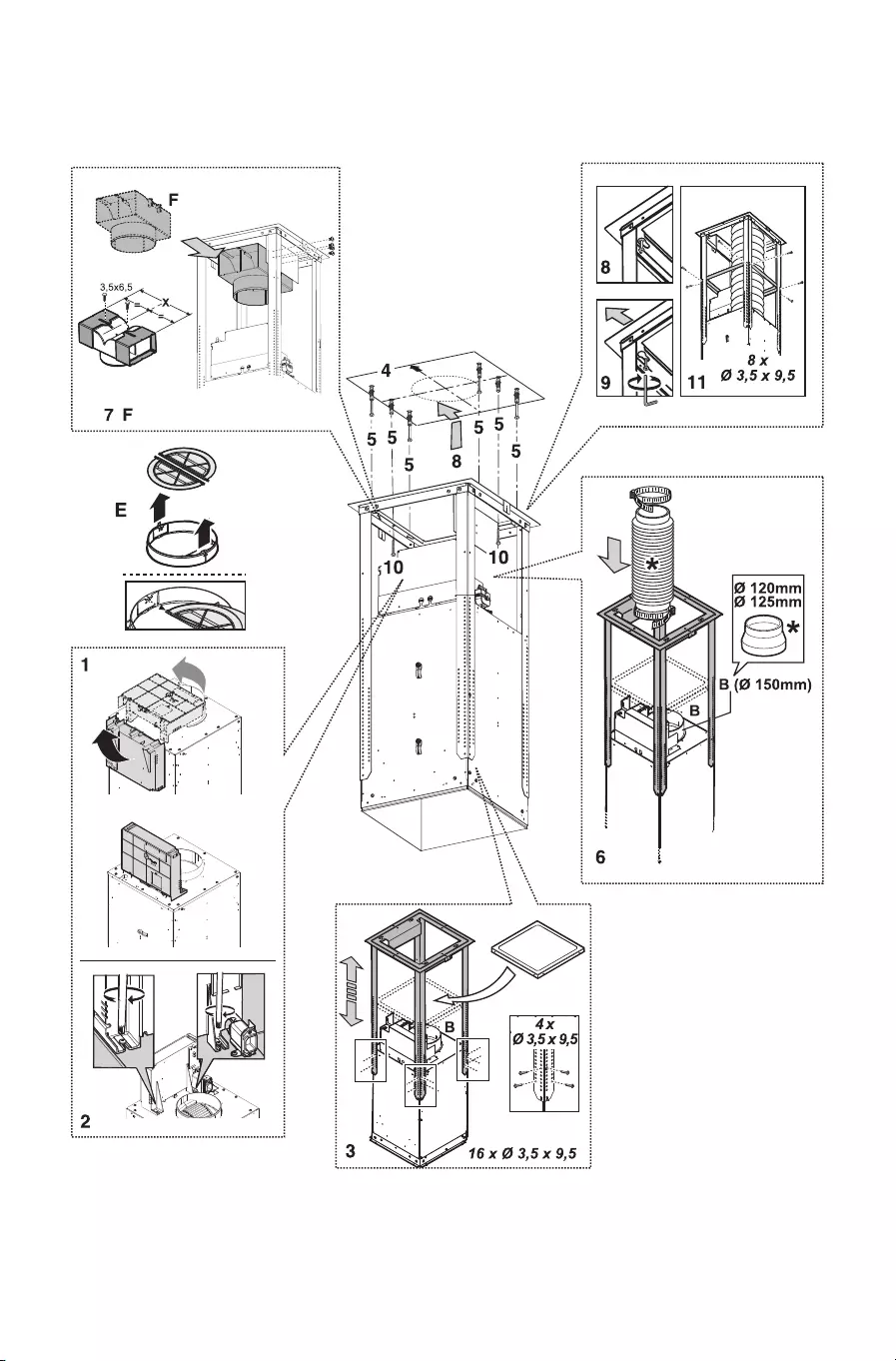

1. Remove the tape fixing the control electronics box to the motor body.

Note: The drawing is only a guide, and the box may be temporarily fixed to other sides of the motor

body.

2. Fully tighten the screws, already partially tightened, that fix the electronics box to the motor body.

3. Adjust the extension of the hood support structure, as the final height of the hood depends on this.

Note: in some cases the support structure is fixed to the motor group with 1 or more screws. Check for

and temporarily remove any screws to enable adjustment of the support structure. Fix the two sections

of the structure using 16 screws (4 each corner).

Note: if required; fit the reinforcement bracket into the truss and place it on the motor unit.

After installing the truss to the ceiling, fix the bracket in its position.

4. Place the ceiling hole diagram directly above the cooktop (the center of the diagram must match the

center of the cooktop and the edges must be parallel to the sides of the cooktop, the side of the diagram

with the wording FRONT (or with the arrows) corresponds to the control panel side).

Prearrange the electrical connection.

5. Drill as shown (6 holes for 6 wall plugs) and insert the 6 plugs in the 6 drilled holes, tighten 4 screws on

the outer holes shown on the drawing, leaving a space of about 1 cm between the screw head and the

ceiling.

6. Fit an exhaust pipe inside the truss and connect it to the collar of the motor compartment (* exhaust pipe

and clamps are not provided).

7. For filter operation (7F), remove the fumes non-return valve “E”, fit the deflector Fon the truss and fix

it with 4 screws to the special bracket. Adjust the deflector according to the flue width. Finally, connect

the exhaust pipe to the collar located on the deflector.

Installation - assembly instructions

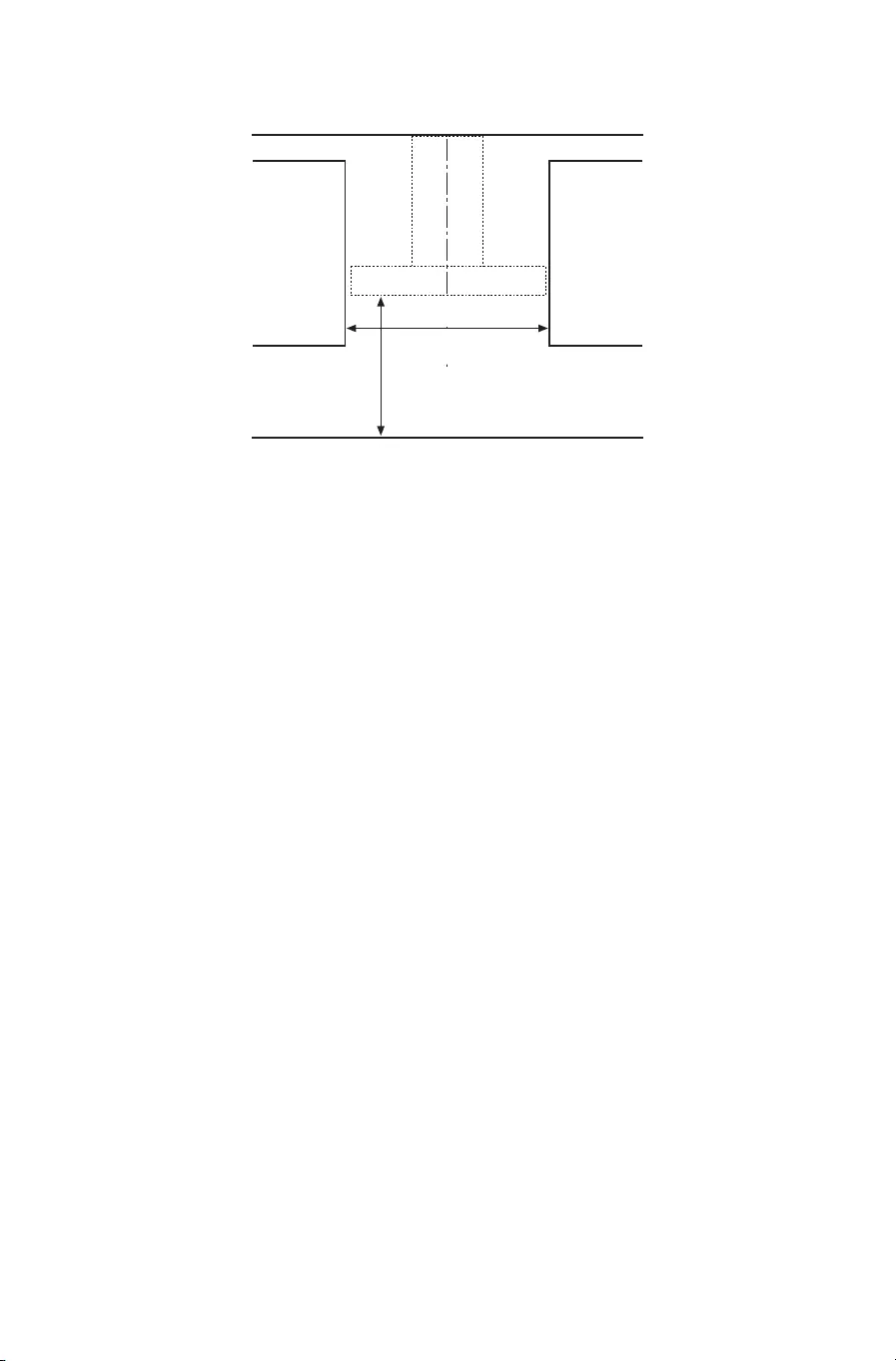

Adjacent wall units Adjacent wall units

central line65 cm (gas or combi cookers)

50 cm (electric cookers)

hob surface

1200 mm min (120 cm wide model)

900 mm min (90 cm wide model)

700 mm min (70 cm wide model)

600 mm min (60 cm wide model)

11

8. Hook the truss on the 4 screws (see step 8).

WARNING: the side of the truss with electrical connection box corresponds to the side of the

control panel with hood assembled.

9. Tighten firmly the 4 screws.

10. Insert and tighten firmly another 2 screws in the remaining free holes for secure fixing.

Note - only for Extraction version: connect the upper end of the exhaust duct to the outdoor

exhaust device (e.g.: hole on the ceiling).

11. Fix the reinforcement bracket (see step 3) to the truss in a position as intermediate as possible. Carry

out the electrical connection to the mains power supply, only turn on the power supply with

assembly completed.

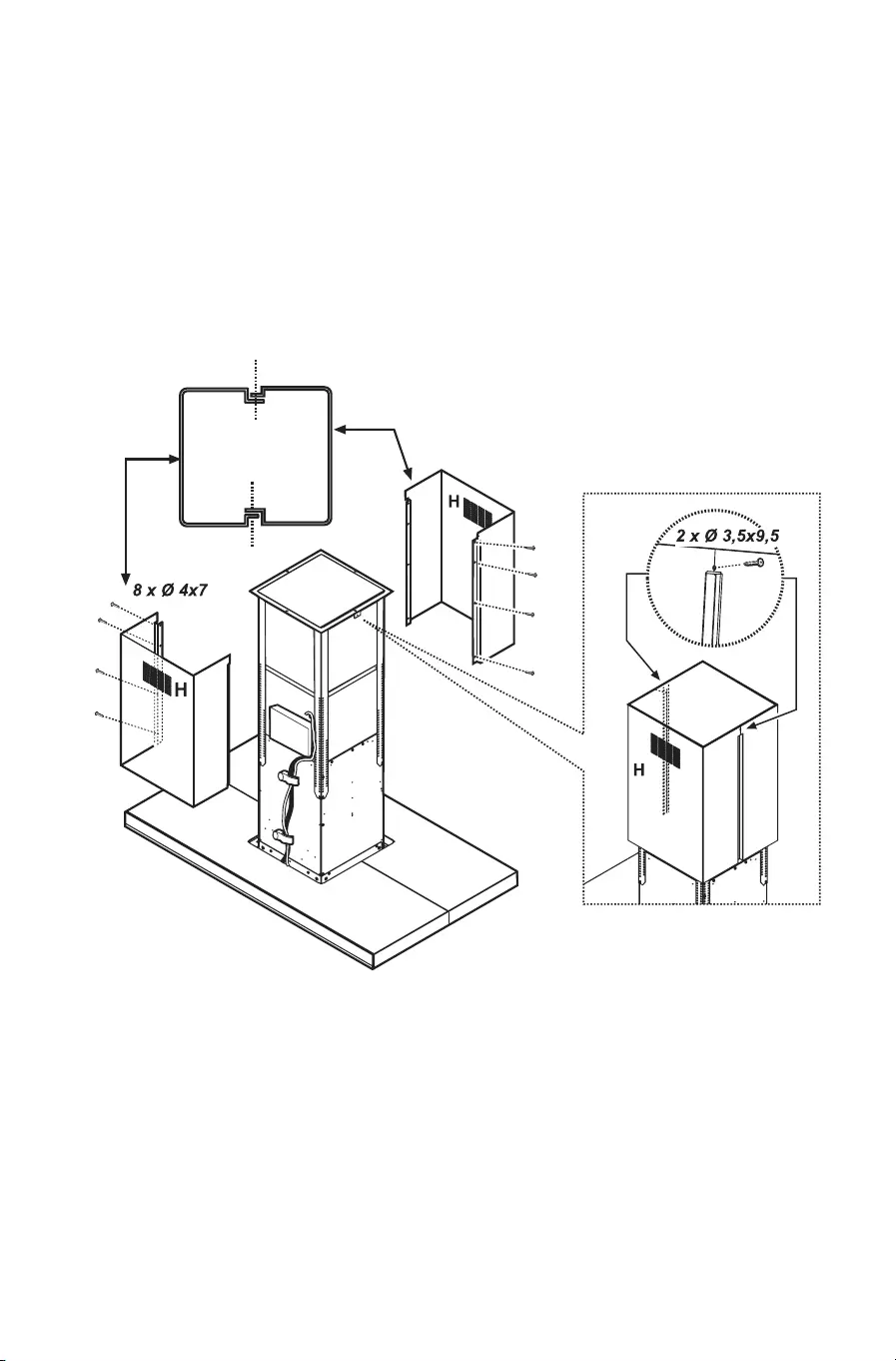

12. Fix the hood to the truss with 8 screws.

WARNING: the side of the truss with electrical connection box corresponds to the side of the

control panel with hood assembled.

13. Carry out the electrical connection of control panel and the lamps.

Position the power cable in its housing and secure the cable to the cable clamp (13a).

Note: hook the excess cable to the appropriate cable glands (fitted with screw for tightening).

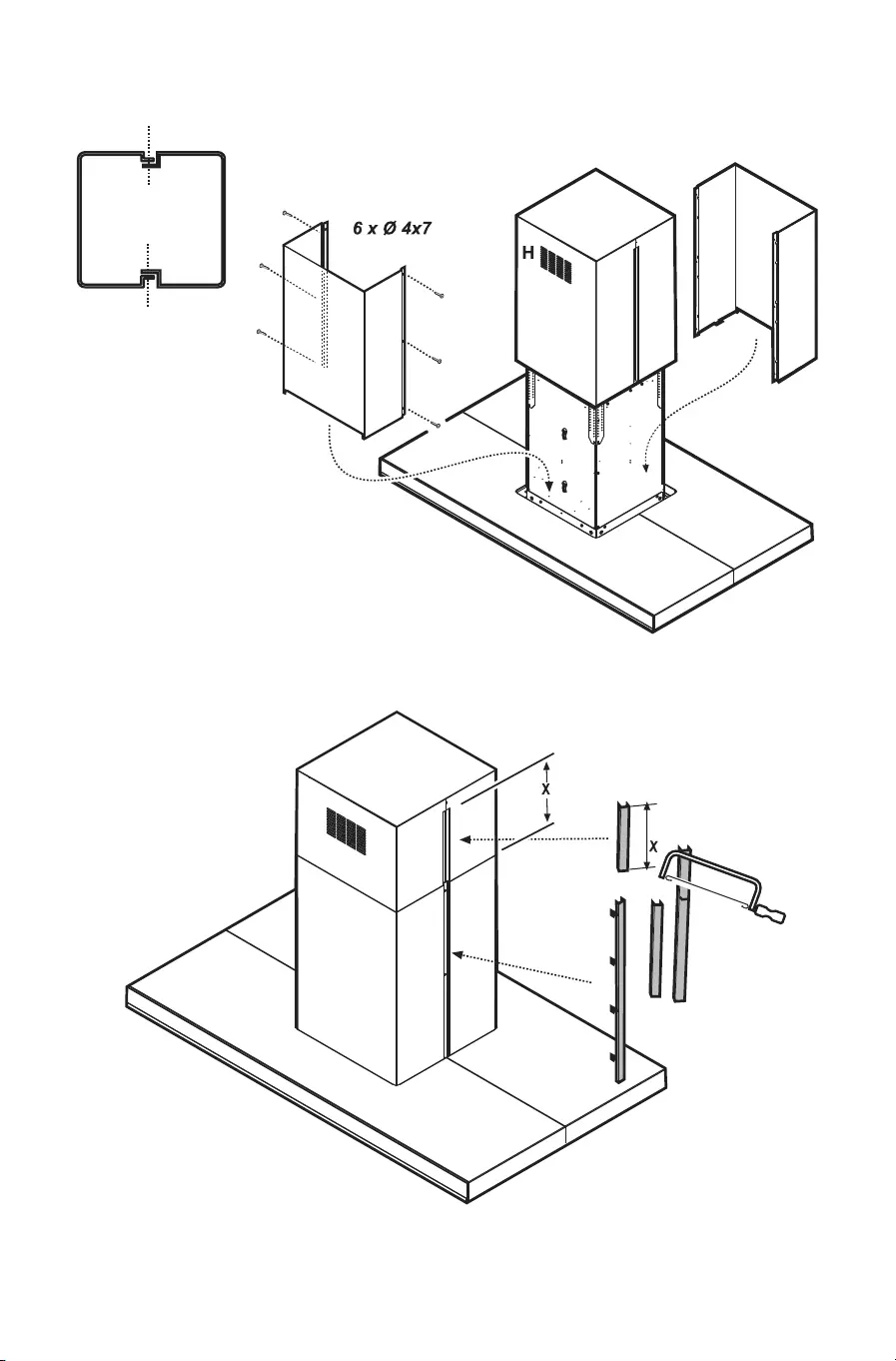

14. Join the two top sections of the flue to cover the truss so that one of the slots on the sections is situated

on the same side of the control panel and the other on the opposite side.

Screw the two sections with 8 screws (4 each side - see the plan diagram for joining the two sections).

15. Fix the top flue assembly to the truss, near the ceiling, with 2 screws (one each side).

16. Join the two bottom sections of the flue covering the truss using 6 screws (3 each side - also see the plan

diagram for joining the two sections).

17. Insert the bottom section of the flue in the special seat to completely cover the motor compartment and

electrical connection box.

18. Apply the 2 tabs (supplied) to cover the fixing points of the bottom flue sections (IMPORTANT! IT IS

EASY TO RECOGNIZE THE LOWER FLUE TRIMS AS THEY ARE NARROWER AND LESS

DEEP).

The wider and deeper trims are those used for the upper flue, and they must be cut to size. Refit the

grease filter and the perimeter extraction panel.

Turn the mains power on again at the central electrical panel and check for correct hood operation.

12

1. Control panel.

2. Grease filters (over the perimeter extraction panel).

3. Halogen lamps.

4. Telescopic flue.

5. Perimeter extraction panel.

Description and use of hood

- Disconnect the appliance from the power supply

Cleaning the perimeter extraction panel

Removal:

pull the handle (FRONT) firmly downwards.

Cleaning:

The extraction panel must be cleaned as often as the grease filter,

using a rag moistened with neutral liquid detergent.

Do not use products containing abrasives.

IMPORTANT: Do not use alcohol.

Fitting:

The panel must be fixed at the front, in the special pins on the

hood surface.

IMPORTANT: Always make sure the panel is firmly fixed in

place.

WARNING:

Maintenance

13

Operation

Use the fastest speed setting for particularly concentrated steam and

fumes. It is advisable to switch the hood on 5 minutes before starting

to cook and leave it running for another 15 minutes at the end of

cooking.

The control panel is composed of a backlit rotary disk

• To switch the lights on and off:

Press the disk (T) to turn the lights on and off

• To select the extraction speed available:

Turn the disk (T) clockwise to turn on and increase the extraction speed and counterclockwise to decrease

it, and turn off the hood.

The crown (L) lights on to indicate the extraction speed selected:

• L1 on

speed 1 (minimum). • L1+L2 on

speed 2 (medium).

• L1+L2+L3 on

speed 3 (maximum).

• L1+L2+ L3+L4 on in flashing mode

speed 4 (intensive): 5 minutes on, after which the hood automatically sets to speed 2

• L off:

Extraction motor off

Filters saturation control device

The hood is equipped with a device that signals when the filters require maintenance. The grease filter

saturation control device is always on. The activated carbon filter control device is usually off.

To turn it on, proceed as follows:

- Turn off the hood.

- Press the disk (T), for more than 5 seconds

The crown (L) lights up completely, flashing, and an acoustic signal is emitted: the activated carbon filter

control device is on.

Note = to turn it off, turn off the hood and press the disk

(T), L1+L2 are backlit and flashing; wait for the acoustic signal that confirms that they are off.

Grease filter saturation indicator

L1 + L2 will flash when maintenance is required on the grease filter

Activated carbon filter saturation indicator

L3 + L4 will flash when maintenance is required on the activated carbon filter

Filter saturation signaling reset

After the filters maintenance turn on the hood and press the disk (T) for more than 5 seconds: a long

acoustic signal (beep) is emitted to indicate that the reset was completed successfully.

Note: in case of simultaneous signaling (grease filter and activated carbon filter saturation), it is necessary

to repeat the reset operation twice.

14

P

15

X2

16

13

12

13

13a

17

14

14

14

15

18

16

16

17

17

18

400010803598

Printed in Italy n

06/15

GB