Middle Atlantic Products DWR-18-26 User Manual

Displayed below is the user manual for DWR-18-26 by Middle Atlantic Products which is a product in the Rack Cabinets category. This manual has pages.

Related Manuals

I-00065 Rev R

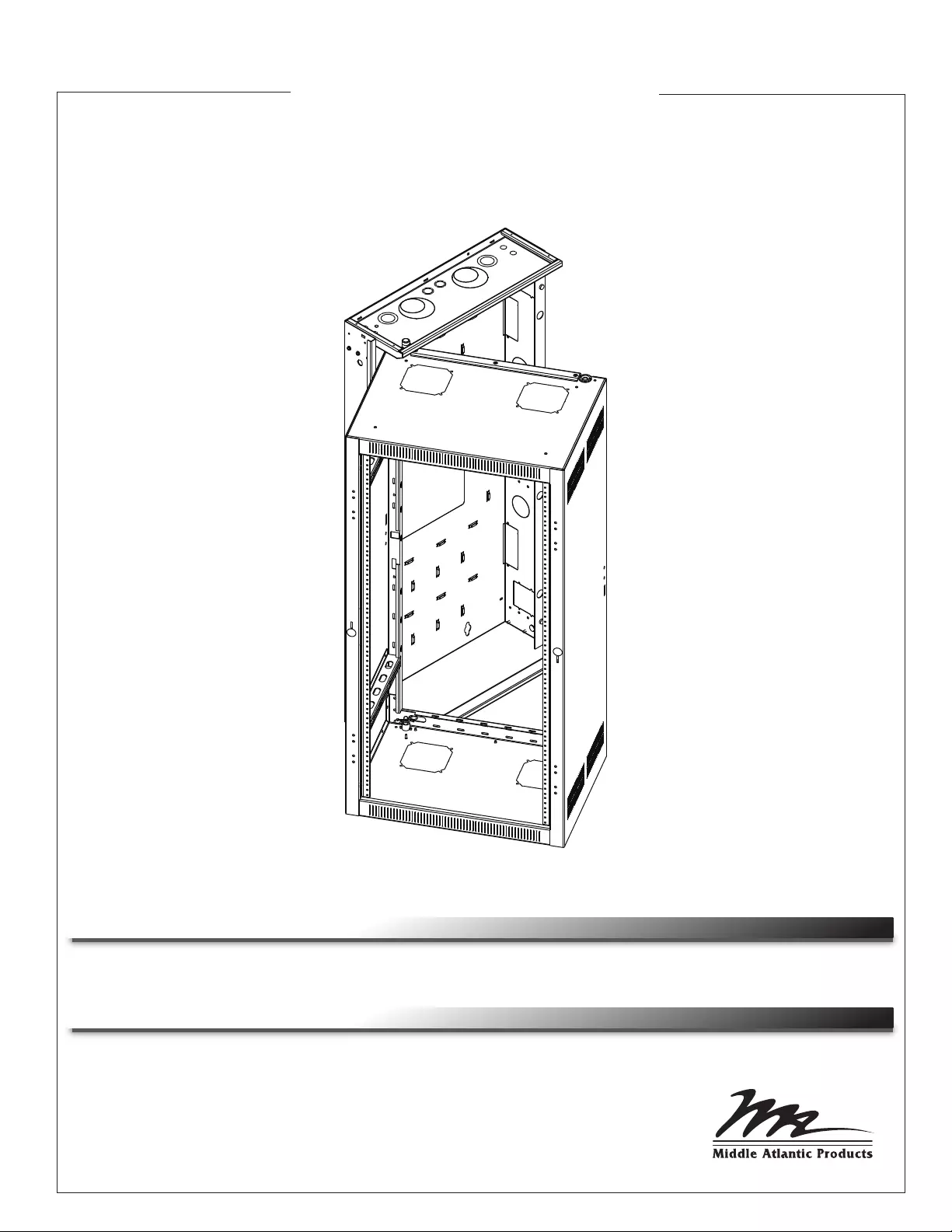

DWR SERIES

SECTIONAL WALL MOUNT RACK

Instruction Sheet

Thank you for purchasing the DWR Series Sectional Wall Rack. Please read these instructions

thoroughly before installing and assembling this product.

• Tool-Free Quick-MountTM system allows easy, one person mounting of center

section to backpan

• Zero Clearance Latch (Optional) allows side-by-side or interior corner

mounting

• Wall mount sectional cabinet provides superior cable management

THANK YOU

PRODUCT FEATURES

SEISMIC COMPLIANCE: An engineered system is vital to achieve seismic rating requirements. A licensed professional engineer

must approve the type of fasteners for the wall where the rack will be mounted. Braced according to specifications set forth by licensed

architects and engineers, the Middle Atlantic Products rack/enclosure you purchased is capable of sustaining a phenomenal lateral

load of high importance equipment with the front rails filled to a maximum capacity of 140 lbs.

!

Page 2

IMPORTANT SAFETY INSTRUCTIONS

DANGER HAZARDOUS VOLTAGE: The lightning flash with the arrowhead symbol, within an equilateral triangle is intended to alert the user to the

presence of uninsulated dangerous voltage within the product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

WARNING: A warning alerts you to a situation that could result in serious personal injury or death.

CAUTION: A caution alerts you to a situation that may result in minor personal injury or damage to the product and/or property.

NOTE: A note is used to highlight procedures pertaining to the installation, operation, or maintenance of the product.

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Clean only with dry cloth.

• Only use attachments/accessories specified by the manufacturer.

WARNING: Failure to read, understand and follow the following information can result in serious personal injury, damage to the

equipment or voiding of the warranty.

CAUTION

:

To avoid an unstable condition, place heavier components at the bottom of the enclosure. When more than one component

is placed in the enclosure, begin at the bottom of the enclosure and place equipment at the lowest available point, evenly distribute

weight (horizontally) within the enclosure.

Component weight should be distributed as follows:

• 1/2 of the total component weight (at a minimum) placed in the bottom third of the cabinet.

• 1/4 of the total component weight (at a maximum) placed in the middle third of the cabinet.

• 1/4 of the total component weight (at a maximum) placed in the top third of the cabinet.

CAUTION: Do not attempt to unload or move the enclosures alone. Make sure to have sufficient amount of personnel and equip-

ment to safely move this product.

CAUTION: Ensure that the floor has a structural load capacity that will support the weight of the cabinet fully loaded with

equipment.

CAUTION: All installation and assembly steps must be performed by qualified personnel.

CAUTION: Power cord, for fans or other accessories, need to be secured to ensure that they are routed away from pinch points

and moving parts.

CAUTION

:

The following parts are not effectively bonded to the protective earth terminal: Rack rails, lace bars, Lever Lock™, shelves,

baffle, blanking panels, and cable management. If any part needs to be bonded to the protective earth terminal it shall be done in

accordance with Article 250 of the National Electrical Code.

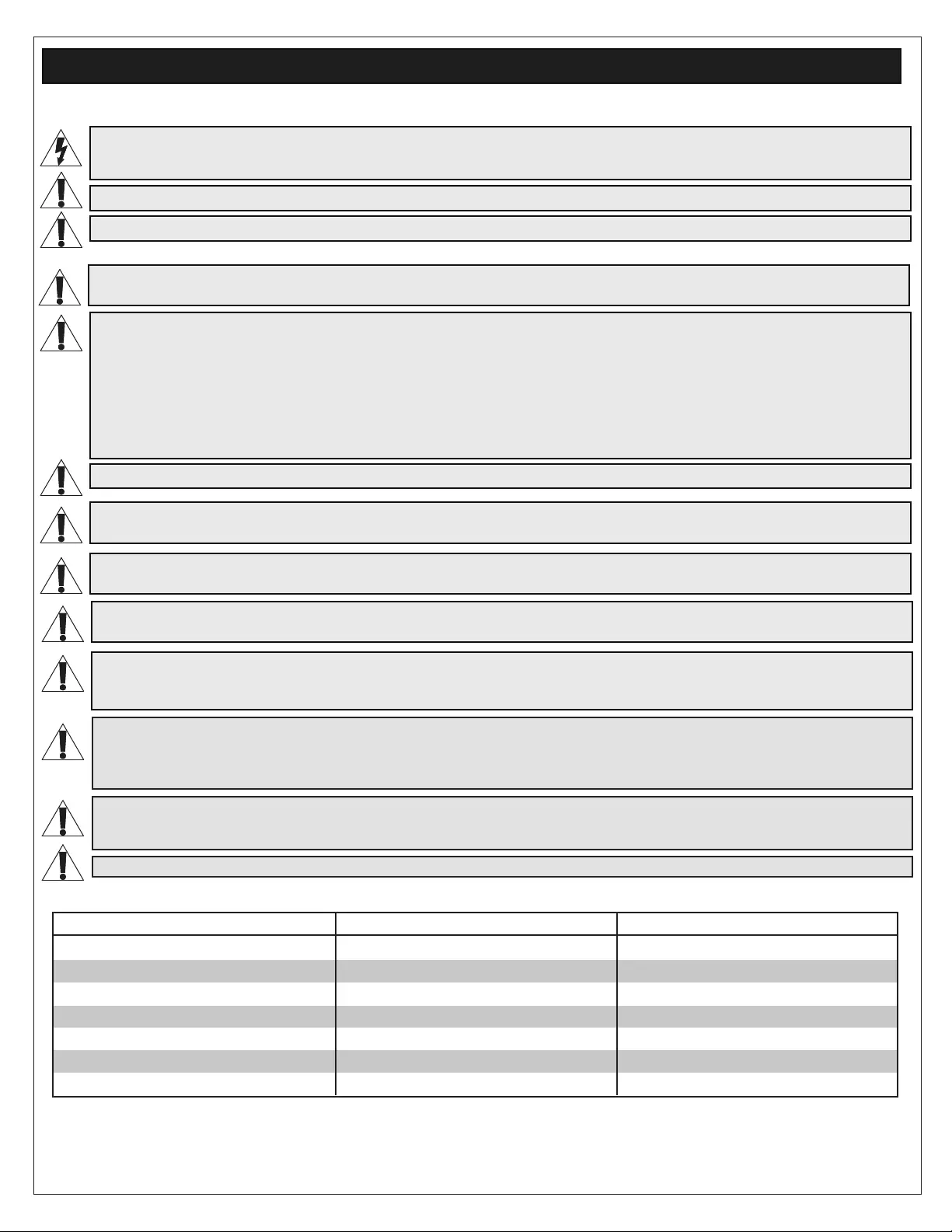

CAUTION

:

To reduce the risk of personal injury and conform to the ul listing these mounting instructions must be followed and proper

weight capacity must be observed (see table below). As a general rule, heavier equipment should be placed towards the bottom of the

rack.

CAUTION

:

Individual components mounted inside of the wall mount rack must have their own fire enclosure.

DWR-10-17/22

DWR-12-17/22/26/32

DWR-16-17/22

DWR-18-17/22/26/32

DWR-21-17/22

DWR-24-17/22/26/32

DWR-35-17/22/26

Part Number

4

4

4

4

5

5

6

Number of Mounting Holes

200 lbs.

200 lbs.

200 lbs.

250 lbs.

250 lbs.

300 lbs.

300 lbs.

Maximum Weight Capacity

RESPECT SISMIQUE: Un système conçu est indispensable pour atteindre exigences de notation sismiques. Un ingénieur agréé

doit approuver le type d'attaches pour le mur où la grille sera monté. Haubanée selon les spécifications énoncées par architectes

agréés et des ingénieurs, la Middle Atlantic Products rack/enceinte vous avez acheté est capable de soutenir une charge latérale

phénoménale de équipement de haute importance avec les rails de front remplis à une capacité maximale de 63.5 kg (140 lbs).

AVERTISSEMENT: Ne pas lire, comprendre et suivre les informations suivantes peut entraîner des blessures graves, des

dommages à l'équipement ou de la nullité de la garantie.

ATTENTION

:

Pour éviter un état instable, placez composants les plus lourds au fond de l'enceinte. Lorsque plus d'un composant est

placé dans la enceinte, commencer par le bas de l'enceinte et placer l'équipement à la point le plus bas disponible, de distribuer

uniformément le poids (horizontalement) dans le enceinte.

Le poids des composants devrait être réparti comme suit:

• 1/2 du poids total de la composante (au minimum) placé dans le tiers inférieur de l'armoire.

• 1/4 du poids total de la composante (au maximum) placé dans le tiers médian de l'armoire.

• 1/4 du poids total de la composante (au maximum) placé dans le tiers supérieur de l'armoire.

ATTENTION: Ne essayez pas de décharger ou déplacer les enceintes seul. Assurez-vous d'avoir quantité suffisante de personnel

et de matériel pour déplacer ce produit en toute sécurité.

ATTENTION: Veiller à ce que le sol a une capacité de charge structurelle qui supporter le poids de le cabinet entièrement

chargé avec l'équipement.

ATTENTION: Toutes installation et de montage étapes doivent être effectuées par du personnel qualifié.

ATTENTION: Le cordon d'alimentation, pour les fans ou autres accessoires, doivent être fixé à veiller à ce que ils sont achemi-

nés loin des points de pincement et des pièces mobiles.

ATTENTION

:

Les pièces suivantes ne sont pas correctement liés à la borne de terre de protection: rails de rack, des bars de dentelle,

Lever Lock™, des étagères, des chicanes, des panneaux d'obturation, et la gestion des câbles. Si une partie doit être lié à la borne de

terre de protection, il doit être fait conformément à l'article 250 du Code national de l'électricité.

ATTENTION

:

Pour réduire le risque de blessures et conforme au ul inscription de ces instructions de montage doivent suivre et bonne

poids capacité doit être observée (voir tableau ci-dessous). En regle generale, équipement placer les plus lourds vers le bas de la

grille.

ATTENTION

:

Les composants individuels montés à l'intérieur de montage mural doivent avoir leur propre armoire à incendie.

DWR-10-17/22

DWR-12-17/22/26/32

DWR-16-17/22

DWR-18-17/22/26/32

DWR-21-17/22

DWR-24-17/22/26/32

DWR-35-17/22/26

Numéro de Partie

4

4

4

4

5

5

6

Nombre de Trous de Montage

90.7 kg (200 lbs.)

90.7 kg (200 lbs.)

90.7 kg (200 lbs.)

113.3 kg (250 lbs.)

113.3 kg (250 lbs.)

136 kg (300 lbs.)

136 kg (300 lbs.)

Capacité de Charge Maximale

Page 3

DANGER TENSION DANGEREUSE: Le symbole de la pointe de flèche, dans un triangle équilatéral, est destiné à alerter l'utilisateur sur la

présence de tension dangereuse non isolée dans l'enceinte du produit qui peut être d'une ampleur suffisante pour constituer un risque

d'électrocution.

AVERTISSEMENT: Un avertissement vous avertit d'une situation pouvant entraîner des blessures graves ou la mort.

ATTENTION: Une attention vous avertit d'une situation pouvant entraîner des blessures mineures ou des dommages au produit et/ou à la

REMARQUE: Une remarque est utilisée pour mettre en évidence les procédures relatives à l'installation, au fonctionnement ou à l'entretien du

produit.

INSTRUCTIONS IMPORTANTES SUR LA SÉCURITÉ

• Lire ces instructions.

• Conservez ces instructions.

• Respectez tous les avertissements.

• Suivez toutes les instructions.

• Nettoyer uniquement avec un chiffon sec.

• N'utilisez que des accessoires spécifiés par le fabricant.

Page 4

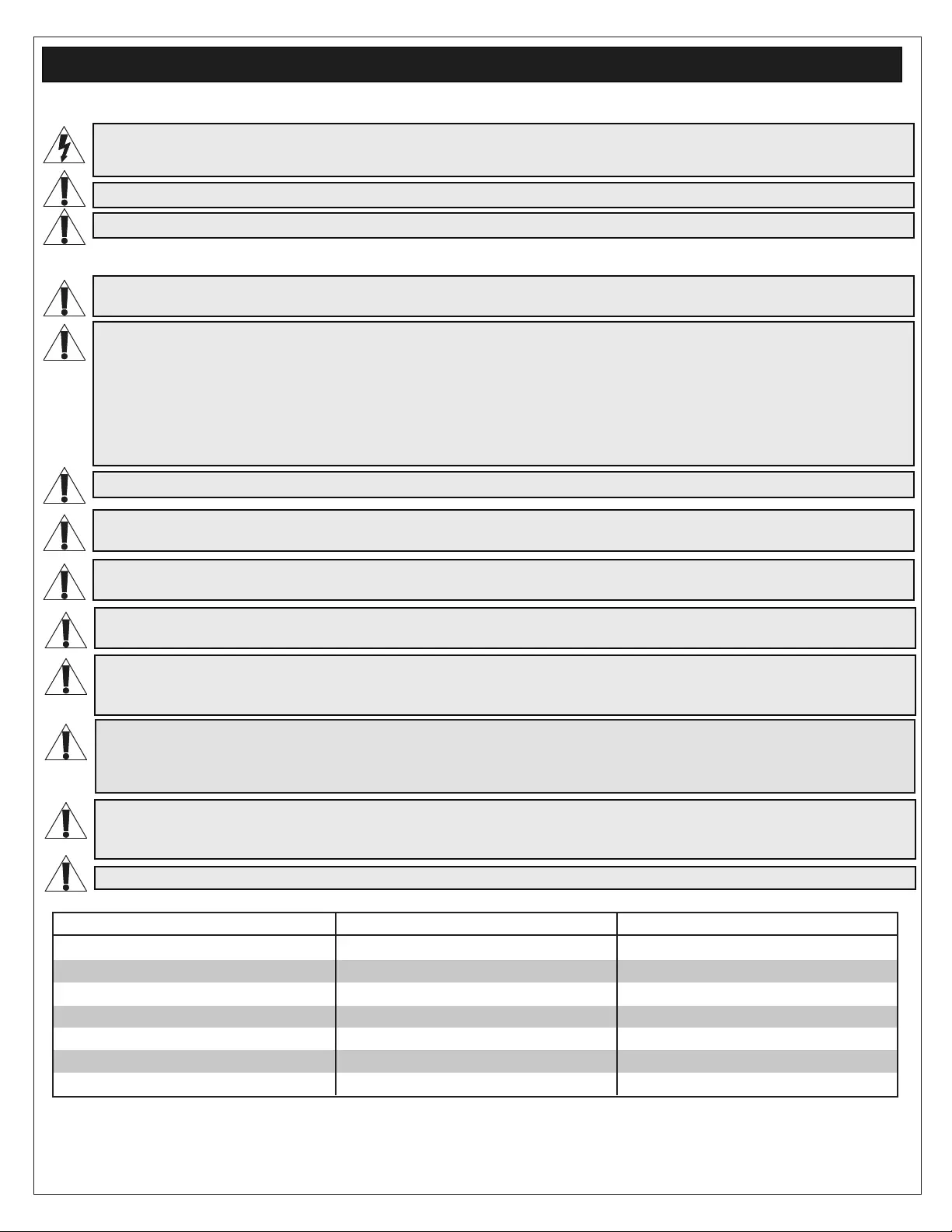

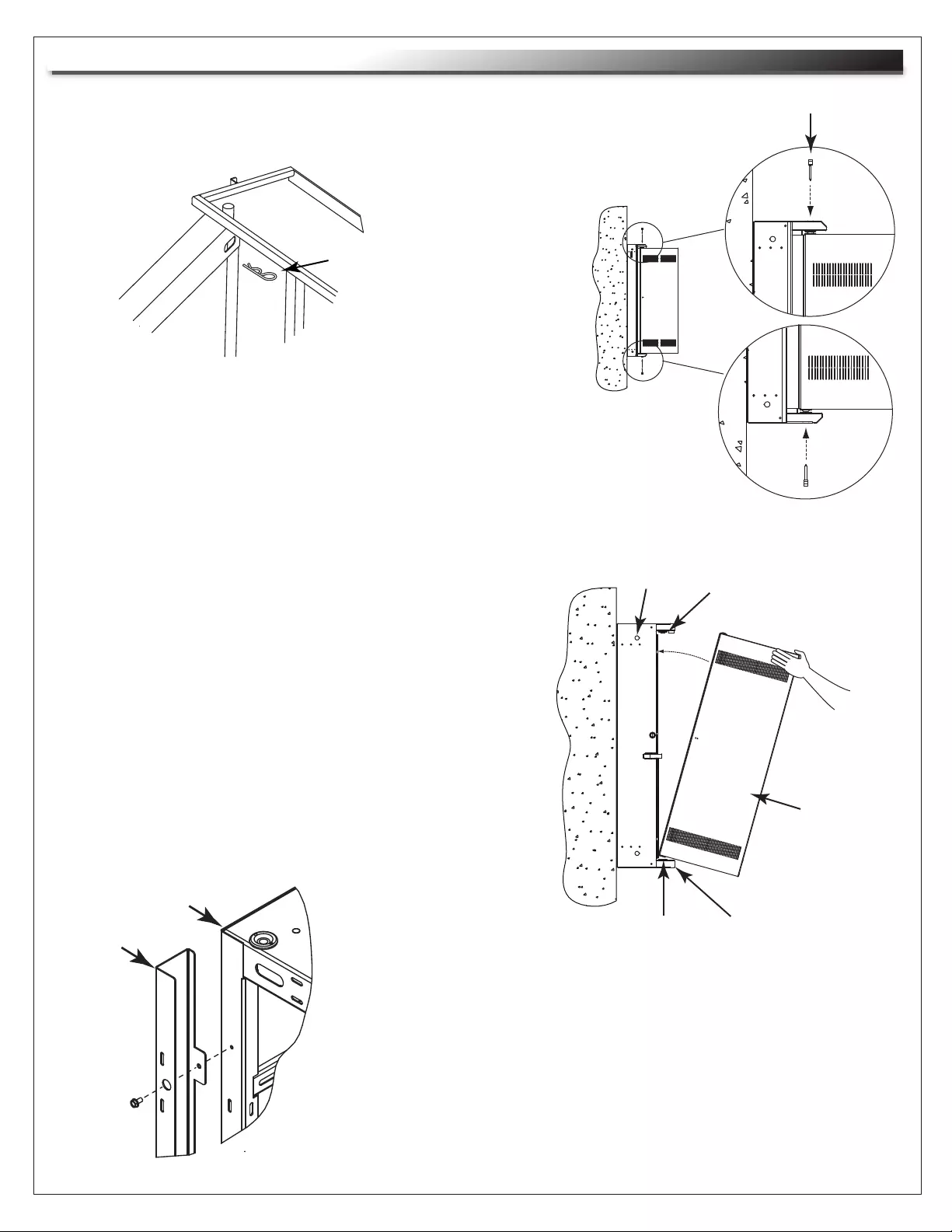

1. Separate backpan from center section and determine hinge side.

NOTE: Ensure the backpan is screwed to the studs. All DWRs may be mounted using the method

outlined in step 2, and DWRs up to 26” overall depth may also be mounted on concrete walls. You

can install 32” overall depth DWRs as outlined in step 2 only.

2. Mount backpan to wall (a minimum of 4" clearance

top and bottom is required) using 3/8" dia. lag bolts with

a minimum length of 2" and standard flat washers.

(FIGURE A)

NOTE:

• The standard flat washers must be installed under

the lag bolt heads. Refer to the chart on the previous

page for the number of mounting holes required. All

mounting holes must be used.

• Feet are included with the 24 and 35 rackspace

DWRs only. These feet are to be used when

mounting in close proximity to the floor (4”). The

feet help reduce the shear weight off of the mounting

hardware that is used to hold the rack to the wall

when a significant amount of weight is loaded in the

rack.

INSTALLATION

3. To install feet, remove screws on bottom of backpan

(both sides) and reattach with feet in position. (FIGURE B)

Backpan

Screws

FIGURE A

Foot

FIGURE B

CAUTION: The backpan must be installed plumb and level for proper operation.

ATTENTION: La plaque profilée doit etre aplomb et de niveau pour un fonctionnement.

Min. 4” Clearance Required Stud

1/2” Drywall

Min. 4” Clearance Required

NOTE: DWR center section can be opened from left-to-right or vice versa depending on how backpan

is installed.

OVERALL DIMENSIONS

Width: 23.4"

Height: 10 RU - 35 RU

Depths: 17", 22", 26"* and 32"*

* Available for certain heights only

Page 5

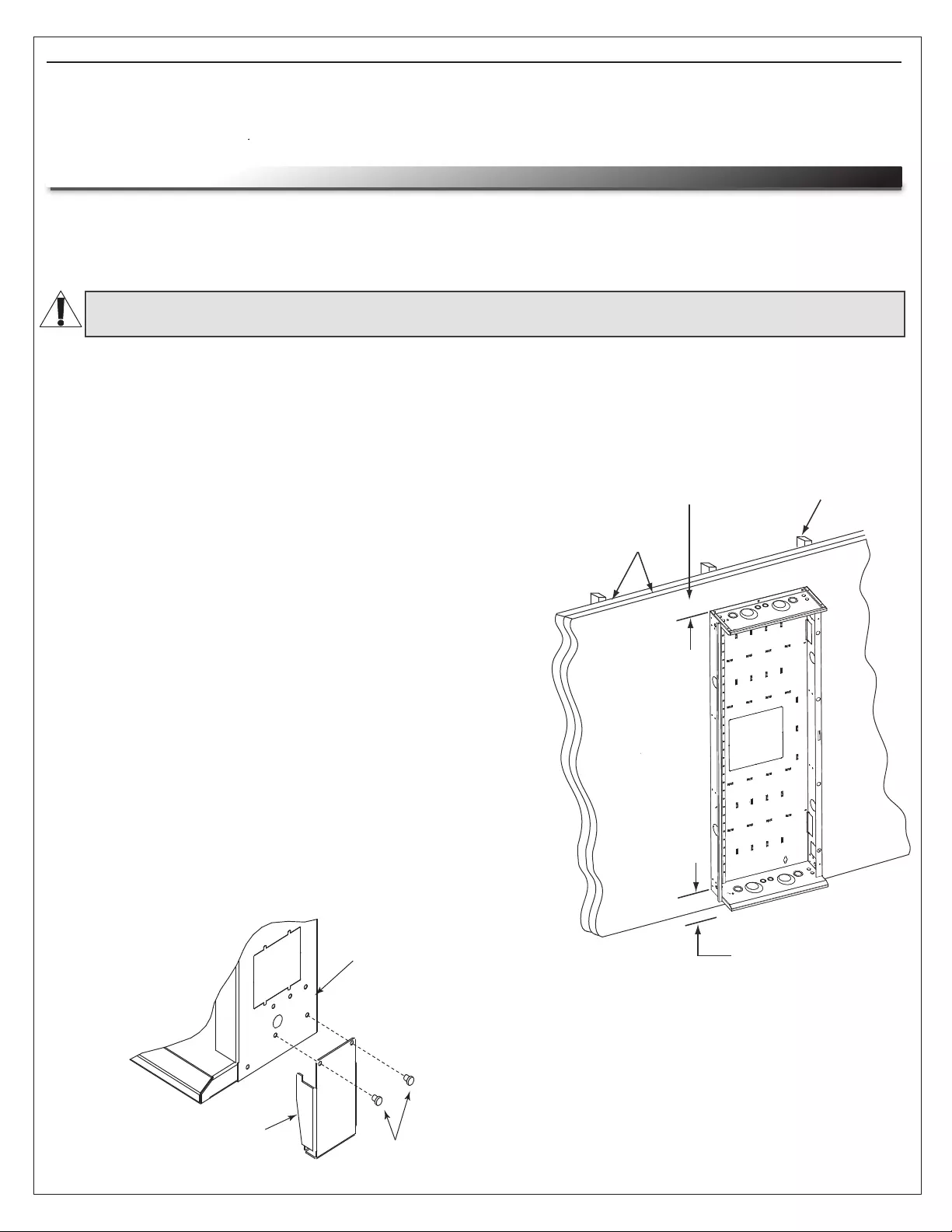

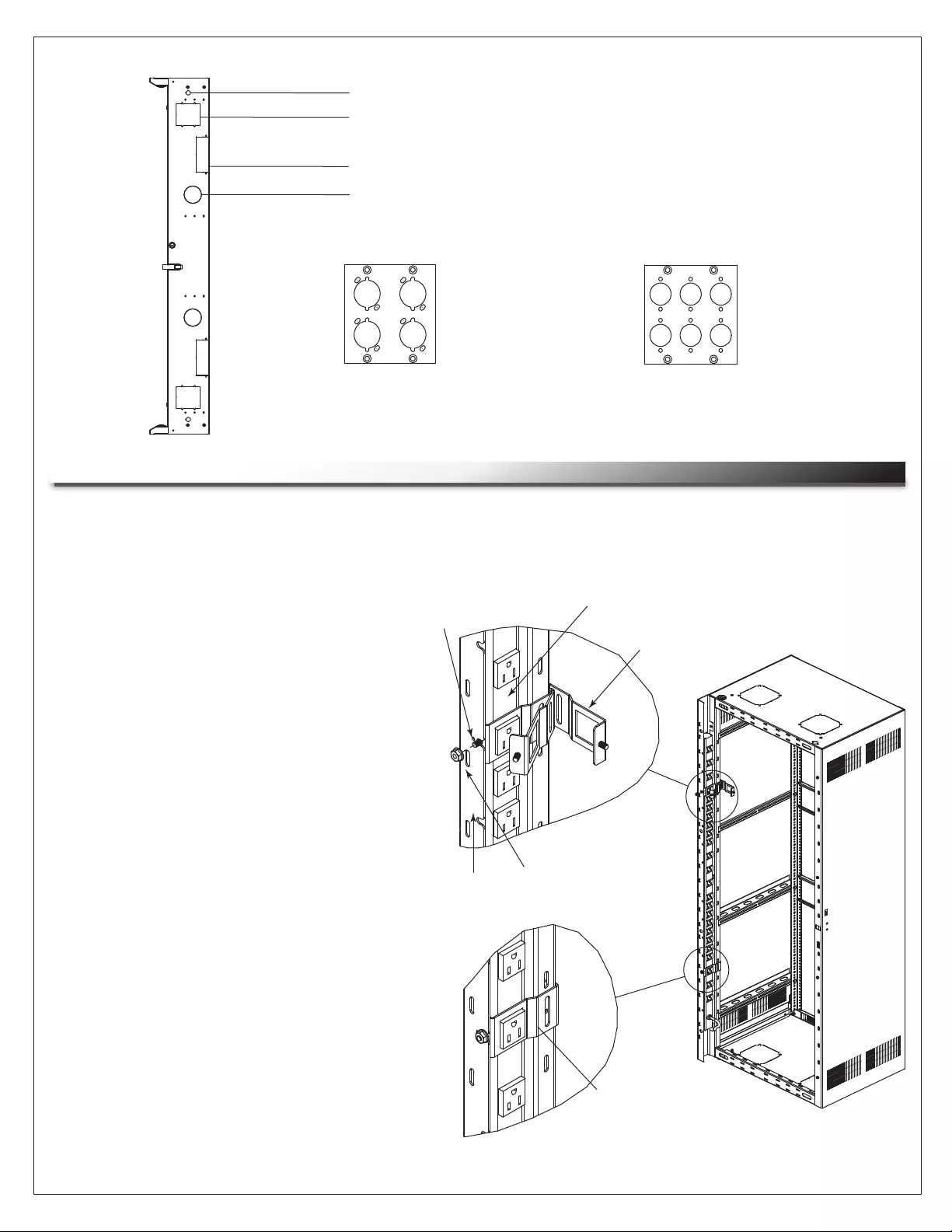

4. Remove security clips located at top and bottom of unit. (FIGURE C)

5. Remove pivot pins located at the top and bottom of backpan. (FIGURE D)

6. Lift the center section and place the bottom glide strip on the

edge of the backpan. Position the center section so as to

engage the lower pivot bushing on the backpan. (FIGURE E)

10. Install trim on the pivot side of the center section with a

5/16” socket/nut driver using screws preinstalled on the

back of the center section. (FIGURE F)

NOTE: Thread cutting screws supplied on both sides for your

convenience. Leave unused thread cutting screws in place on

opposite side.

FIGURE E

Place hand here

to pivot into place.

Backpan Upper

Pivot

Bushing

Upper

Pivot Bushing

Glide Strip

7. Pivot top of center section into backpan and align with upper pivot bushing.

(FIGURE E)

8. Insert pivot pin into upper bushing, hand tighten fully and

then back out one turn. Repeat for lower bushing. (FIGURE D)

9. Install the security clips to prevent removal of pivot

pins from exterior of enclosure. (FIGURE C)

FIGURE D

Pivot Pin

INSTALLATION (CONTINUED)

NOTE: When installing front door, the factory rackrail

setback will be 1-1/2" to the inside of the door. The

lock and handle located at the center of the door will

have an additional setback of 1/2". Please adjust

rackrail accordingly before installing equipment.

FIGURE C

Security Clip

Center Section

Center Section

Trim

FIGURE F

Page 6

GROUNDING AND BONDING

Protective Earth Terminals (PET) are located in backpan of the wall rack. These terminals are marked with the symbol

Wall rack parts, center section and door, contain or are provided with bonding points for connection to the backpan / PET.

Protective earth and bonding connections shall be in accordance with Article 250 of the National Electric Code.

PARTS LIST

• Backpan bonding wire [12 Gauge Wire

(#10 ring terminal to 1/4” ring terminal)] 14”]

• Flange Nut 1/4-20

• Locking Nut 10-32

QTY

(1)

(1)

(1)

(1) (1)

(1)

(1)(1)

OPTIONAL PROTECTIVE EARTH TERMINAL KIT: #PET-K-D/EWR

OPTIONAL PROTECTIVE EARTH TERMINAL KIT: #PET-K-D/EWRD

PARTS LIST

• Door bonding wire [12 Gauge Wire

(#10 ring terminal to male disconnect) 6”]

• Door bonding wire [12 Gauge Wire

(#10 ring terminal to female disconnect) 4”]

• Thread forming screw M4 x .7

• Locking Nut 10-32

QTY

(1)

(1)

(1)

(1) (1) (1)

Page 7

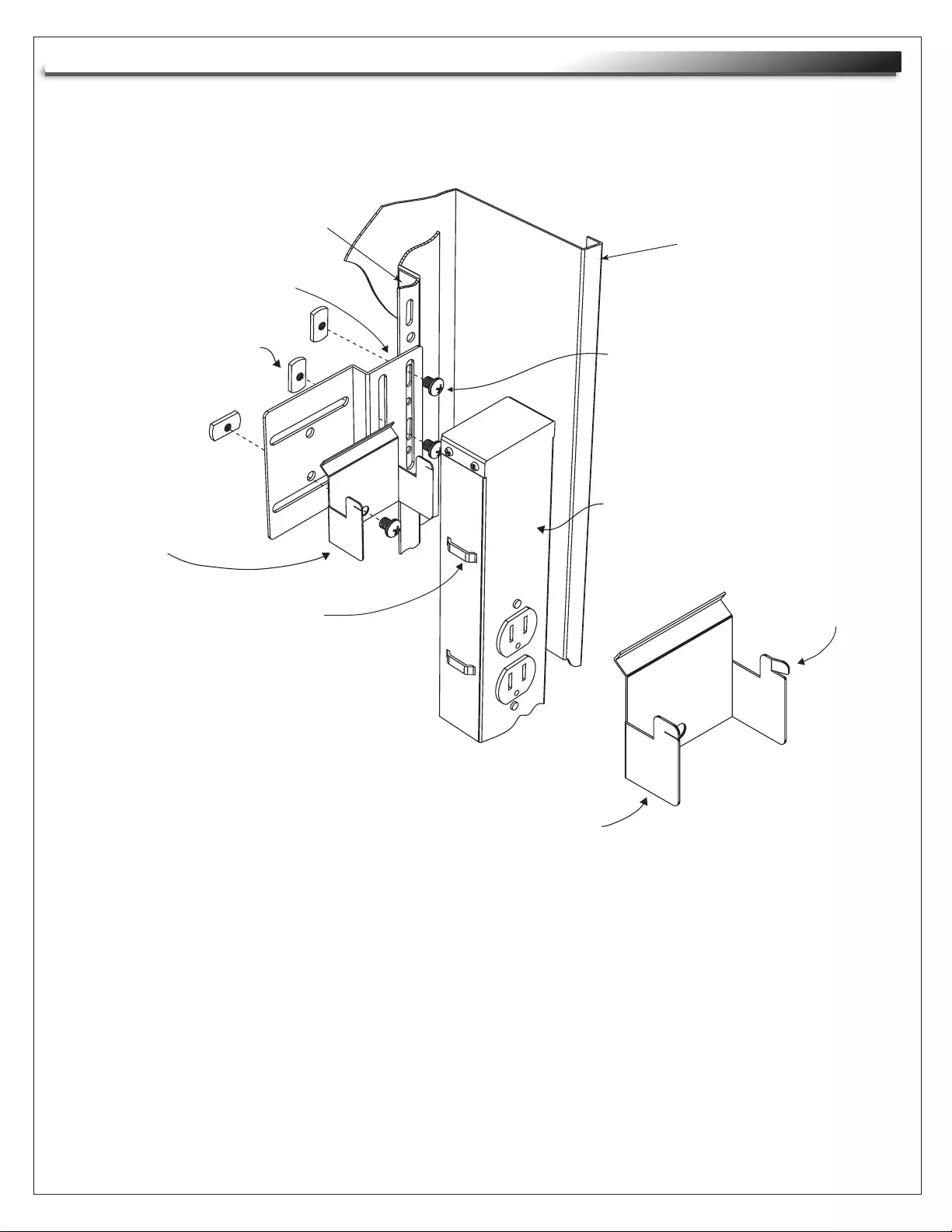

GROUNDING AND BONDING (CONTINUED)

Center

Section

Backpan

Door

Center Section Bonding Studs

10-32 (4 Upper and 4 Lower)

Backpan PET Stud

Door Bonding Points

(1 Upper and 1 Lower)

1. Attach backpan bonding wire from 1/4”-20 backpan protective earth terminal (PET) to nearest

center section bonding stud (10-32) using hardware provided. (FIGURE G)

NOTE: The main protective earth ground needs to be the first terminal placed on the PET and this

terminal needs to be secured on its own with a nut. The bonding wire for the center section can

be added to the PET after securing the nut for the main ground. (FIGURE G)

2. FOR OPTIONAL DOOR: Attach door bonding wire (with male or female disconnect end) to door

bonding point with thread forming screw (included). (FIGURE G)

3. Attach remaining door bonding wire to nearest center section bonding stud (10-32) using hardware

provided. (FIGURE G)

4. Connect male and female ends of door bonding wire set.

FIGURE G

OVERHEAD VIEW FRONT VIEW

Door

CENTER SECTION

• Use Hook and loop slots and/or cable ties

provided on top, bottom, and sides of center

section for cable management.

• Use hook and loop slots and/or cable ties in

Z-bracket or cable management.

• Use hook and loop slots and/or cable ties in

bridge lances on backpan for cable

management.

MOUNTING WALL

BACKPAN Dress wires

as shown

on pivot side.

Pinch

Point

Do not

dress wires

on this side.

TOP VIEW

UHF/VHF

Antenna KO 5/8”

1” and 1-1/2” EKO

2” and 3” EKO

1/2” and 3/4” EKO

• Laser knockouts are located in

the center of the backpan for large

electrical boxes.

• Knockouts provided in top/bottom

for electrical fittings, UHF/VHF

antenna, and cable entry.

NOTE: Optional grommets, Middle

Atlantic Products model number GR-30,

are available to protect wiring when

using knockouts.

Page 8

CABLE MANAGEMENT

SIDE VIEW KNOCKOUTS PROVIDED ON SIDE INCLUDE:

UHF/VHF antenna

Middle Atlantic Products UCP modules (used to mount

commonly used input and output connectors)

4" cable duct (accommodates Wiremold™ 4000 series)

2" LKO (NOTE: 2" LKO on 21 space rack and up only)

EXAMPLE OF MIDDLE ATLANTIC PRODUCTS UCP MODULES

XLR

UNIV4

(Fits Neutrik MPL, LNEMP

and other connectors)

(Fits Neutrik FP, MP, MDL

and other connectors)

Middle Atlantic Products power strips (PD-815SC, PD-815SC-NS, PD-2415SC,PD-2415SC-NS and

PD-2420SC-NS only) can be mounted inside the center section trim with the included hardware. This

simplifies cable management by requiring no additional accessories.

Page 9

NOTE:

• PD-2415SC, PD-2415SC-NS, and

PD-2420SC-NS power strips only fit in the 35

space wall rack and require the use of (2x)

clips. Install clips only to trim notches with a

h ole. (Only 1x power strip can be mounted

to the trim.)

• Power strips PD-815SC and PD-815SC-NS

fit in all DWR Series racks and require only

(1x) clip. The clip can be installed on any trim

notch. (Only 1x power strip can be mounted

to trim for 10-18 space wall racks; either 1x

or 2x power strips can be mounted to trim

for 21 and 24 space wall racks.)

1. Place the power strip in the trim,

positioned so the clip mounts over an

outlet and clip aligns with the notch

as shown.

2. Install clip and tighten flange nut as shown.

NOTE: Installation using a PD-24XX power

strip with two clips is shown.

Clip Shown Installed

Flange Nut

Trim

Clip

Power Strip

Notch With

Hole

POWER STRIP INSTALLATION

Page 10

NOTE: Requires Middle Atlantic Products part number PB-DWR (sold seperately).

Z Bracket

1. Install PB-DWR power bracket (2x provided) to Z bracket.

Slide Nut

2. Quick clip (2x provided)

for corded model strips.

3. Slide bridge lance onto clip.

NOTE: Four Phillips head screws and (4x)

slide-nuts are provided with PB-DWR,

(2x) Phillips head screws and (2x) slide-nuts

are provided with power strip.

Quick Clip

(2x provided)

for hard wired model

strips as shown.

Power Strip

Phillips Head Screw

Backpan Section

Bend tab

after hanging

power strip.

VERTICAL POWER STRIP INSTALLATION

Page 11

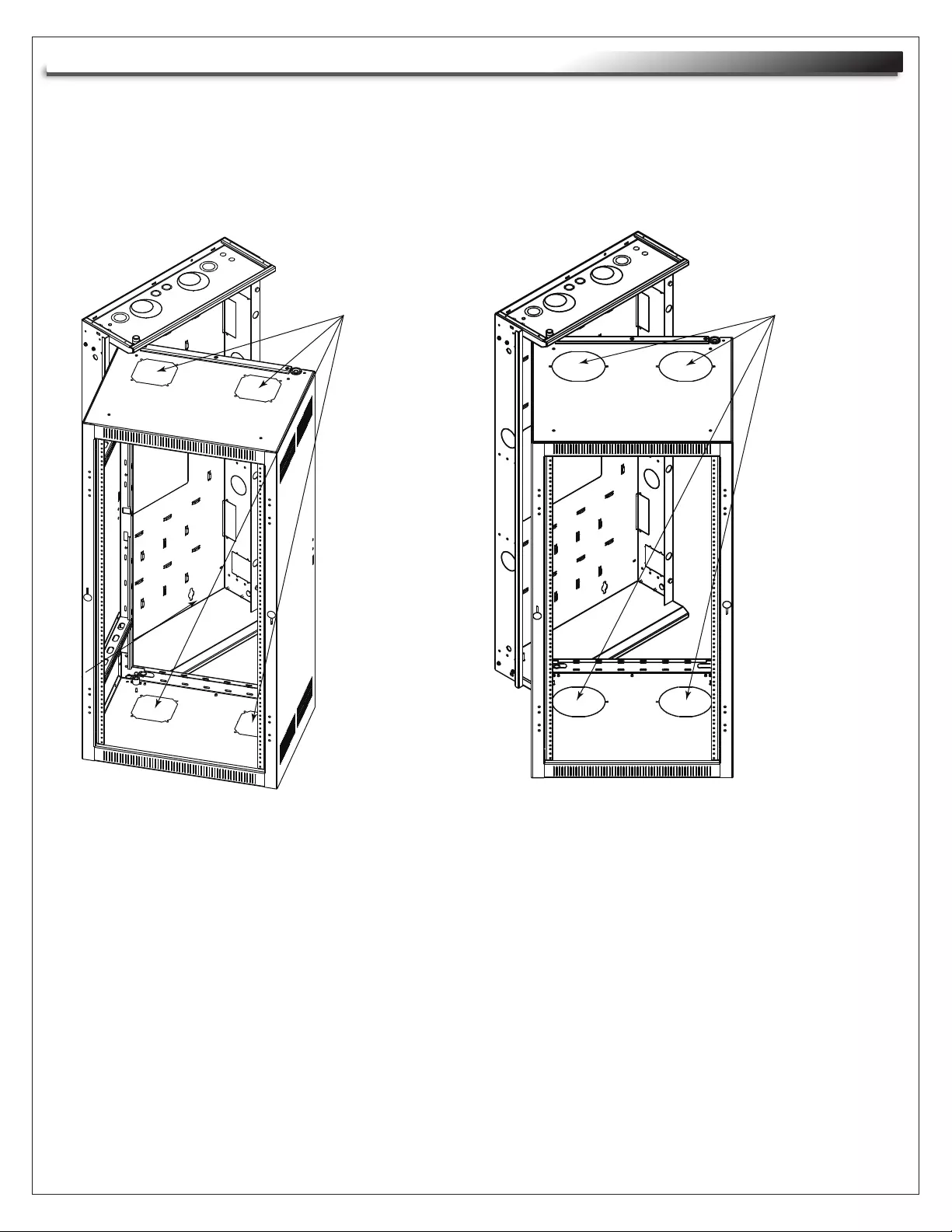

Knockouts

For 6” Fans

Knockouts

For 4” Fans

Thermal knockout sizes vary based on the following enclosure depths:

• Enclosures 17” and 22” deep accept (2x) 4” fans. (FIGURE H)

• Enclosures 26” and 32” deep accept (2x) 6” fans. (FIGURE J)

THERMAL KNOCKOUTS BASED ON ENCLOSURE DEPTHS

FIGURE H FIGURE J

Page 12

WARRANTY

For warranty information, refer to http://www.middleatlantic.com/company/about-us.aspx#warranty

Corporate Headquarters

Corporate Voice: 973-839-1011 - Fax: 973-839-1976 / International Voice: +1 973-839-8821 -

Fax: +1 973-839-4982

www.middleatlantic.com - info@middleatlantic.com

Middle Atlantic Canada

Voice: 613-836-2501 - Fax: 613-836-2690 / ca.middleatlantic.com -

customerservicecanada@middleatlantic.ca

Factory Distribution

USA: NJ - CA - IL Canada: ON - BC

At Middle Atlantic Products we are always listening. Your comments are welcome.

Middle Atlantic Products is an ISO 9001 and ISO 14001 Registered Company.