Middle Atlantic Products VWM-2-2-36K-PW User Manual

Displayed below is the user manual for VWM-2-2-36K-PW by Middle Atlantic Products which is a product in the Rack Cabinets category. This manual has pages.

Related Manuals

I-00796 Rev B

VWM SERIES

Vertical Wall Mount Rack

Instruction Sheet

Thank you for purchasing the VWM Series.

Please read these instructions thoroughly before installing or assembling this product.

• Flexible and configurable vertical wall mount solution to accommodate a wide variety of applications.

• Two backpan sizes with multiple rail mounting locations, and rail bracket options allow customers to

choose their mounting depth and rail type (10-32 or cagenut).

• Deeper overall depth helps future-proof your equipment space needs while leaving room for cabling.

• Full and split door options available.

• The enclosure also facilitates cable management and device mounting utilizing the patented Lever

Lock™ system.

THANK YOU

PRODUCT FEATURES

Page 2

Important Safety Instructions...............................................................................................................3 - 4

Weight Ratings..........................................................................................................................................4

Specifications............................................................................................................................................4

Backpan Supplied Components and Hardware........................................................................................5

Required Tools..........................................................................................................................................5

Introduction...............................................................................................................................................6

Removing the Full Door and Top From a Full Door Configuration.....................................................7 - 10

Removing the Split and Front Door From a Split Door Configuration..............................................11 - 13

Reversing the Door (If Applicable)..........................................................................................................14

Removing Extenders From the Backpan (If Applicable)..................................................................14 - 16

Mounting the Backpan............................................................................................................................17

Grounding and Bonding..........................................................................................................................18

Connecting 4” AC Fan Options to Bonding Points..................................................................................18

Relocating Rackrails on the Fixed Position Mounting Rail Brackets.......................................................19

Rotating Pivot Bracket Rackrails From 10-32 to Cagenut (If Desired)....................................................19

Relocating Fixed Position Mounting Rail or Pivot Brackets on the Backpan..........................................20

Using the Pivot Mounting Rail Brackets..................................................................................................21

Relocating the Lever Lock™ Backpan.............................................................................................22 - 24

Venting the Enclosure Passively With a Full Door Configuration............................................................25

Venting the Enclosure Actively With a Full Door Configuration...............................................................26

Venting the Enclosure Passively With a Split Door Configuration...........................................................27

Venting the Enclosure Actively With a Split Door Configuration..............................................................28

Installing the Power Mounting Bracket.............................................................................................29 - 30

Cable Management..........................................................................................................................31 - 32

Warranty..................................................................................................................................................32

TABLE OF CONTENTS

Page 3

IMPORTANT SAFETY INSTRUCTIONS

DANGER HAZARDOUS VOLTAGE: The lightning flash with the arrowhead symbol, within an equilateral triangle is intended to alert the user to the

presence of uninsulated dangerous voltage within the product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

WARNING: A warning alerts you to a situation that could result in serious personal injury or death.

CAUTION: A caution alerts you to a situation that may result in minor personal injury or damage to the product and/or property.

NOTE: A note is used to highlight procedures pertaining to the installation, operation, or maintenance of the product.

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Clean only with dry cloth.

• Only use attachments/accessories specified by the manufacturer.

WARNING: Failure to read, understand and follow the following information can result in serious personal injury, damage to the

equipment or voiding of the warranty.

CAUTION: Ensure that the wall has a structural load capacity that will support the weight of the cabinet fully loaded with

equipment.

CAUTION: All installation and assembly steps must be performed by qualified personnel.

CAUTION: Individual components mounted inside of the wall mount rack must have their own fire enclosure.

CAUTION: Power cord, for fans or other accessories, need to be secured to ensure that they are routed away from pinch points

and moving parts.

CAUTION

:

The following parts are not effectively bonded to the protective earth terminal: Rack rails, lace bars, Lever Lock™, shelves,

baffle, blanking panels, fans, and cable management. If any part needs to be bonded to the protective earth terminal it shall be done in

accordance with Article 250 of the National Electrical Code.

CAUTION: Do not attempt to unload or move the enclosures alone. Make sure to have sufficient amount of personnel and equip-

ment to safely move this product.

CAUTION: To reduce the risk of personal injury, these mounting instructions must be followed and proper weight capacities

must be observed.

CAUTION

:

To reduce the risk of personal injury and conform to the UL listing, the system must be grounded and bonded in accor-

dance with Article 250 of the National Electrical Code.

CAUTION

:

Individual components mounted inside of the wall mount rack must have their own fire enclosure.

Page 4

WEIGHT RATINGS

Model Weight Rating

VWM 150 lbs. Maximum Total Rated Load

Pivoting Mounting Rail Bracket Option 20 lbs. Maximum Total Rated Load

Full Door Option 30 lbs. Maximum Total Rated Load

Heights: 36” and 42”

Widths: 25”

Depths: 10” and 16“ (2, 4, 6, 8, RU with Fixed Position Mounting Rail Bracket; 2 and 4 RU with Pivot

Mounting Rail Bracket)

• Enclosure is intended for use in ambient temperatures of 32°F (0°C) to 140°F (60°C).

SPECIFICATIONS

ATTENTION: Les composants individuels montés à l'intérieur du rack doivent avoir leur propre.

AVERTISSEMENT: Ne pas lire, comprendre et suivre les informations suivantes peut entraîner des blessures graves, des

dommages à l'équipement ou de la nullité de la garantie.

DANGER TENSION DANGEREUSE: Le symbole de la pointe de flèche, dans un triangle équilatéral, est destiné à alerter l'utilisateur sur la

présence de tension dangereuse non isolée dans l'enceinte du produit qui peut être d'une ampleur suffisante pour constituer un risque

d'électrocution.

AVERTISSEMENT: Un avertissement vous avertit d'une situation pouvant entraîner des blessures graves ou la mort.

ATTENTION: Une attention vous avertit d'une situation pouvant entraîner des blessures mineures ou des dommages au produit et/ou à la

REMARQUE: Une remarque est utilisée pour mettre en évidence les procédures relatives à l'installation, au fonctionnement ou à l'entretien du

produit.

INSTRUCTIONS IMPORTANTES SUR LA SÉCURITÉ

• Lire ces instructions.

• Conservez ces instructions.

• Respectez tous les avertissements.

• Suivez toutes les instructions.

• Nettoyer uniquement avec un chiffon sec.

• N'utilisez que des accessoires spécifiés par le fabricant.

ATTENTION: Veiller à ce que le mur a une capacité de charge structurelle qui supporter le poids de le cabinet entièrement

chargé avec l'équipement.

ATTENTION: Toutes installation et de montage étapes doivent être effectuées par du personnel qualifié.

ATTENTION: Le cordon d'alimentation, pour les fans ou autres accessoires, doivent être fixé à veiller à ce que ils sont achemi-

nés loin des points de pincement et des pièces mobiles.

ATTENTION

:

Les pièces suivantes ne sont pas correctement liés à la borne de terre de protection: rails de rack, des bars de dentelle,

Lever Lock™, des étagères, des chicanes, des panneaux d'obturation, des fans, et la gestion des câbles. Si une partie doit être lié à la

borne de terre de protection, il doit être fait conformément à l'article 250 du Code national de l'électricité.

ATTENTION: Ne essayez pas de décharger ou déplacer les enceintes seul. Assurez-vous d'avoir quantité suffisante de personnel

et de matériel pour déplacer ce produit en toute sécurité.

ATTENTION: Pour réduire le risque de blessures, ces instructions de montage doivent être respectées et les capacités de

poids appropriées doivent être respectées.

ATTENTION: Pour réduire le risque de blessure et se conformer à la liste UL, le système doit être mis à la terre et collé

conformément à l'article 250 du Code national de l'électricité.

ATTENTION

:

Les composants individuels montés à l'intérieur de montage mural doivent avoir leur propre armoire à incendie.

Page 5

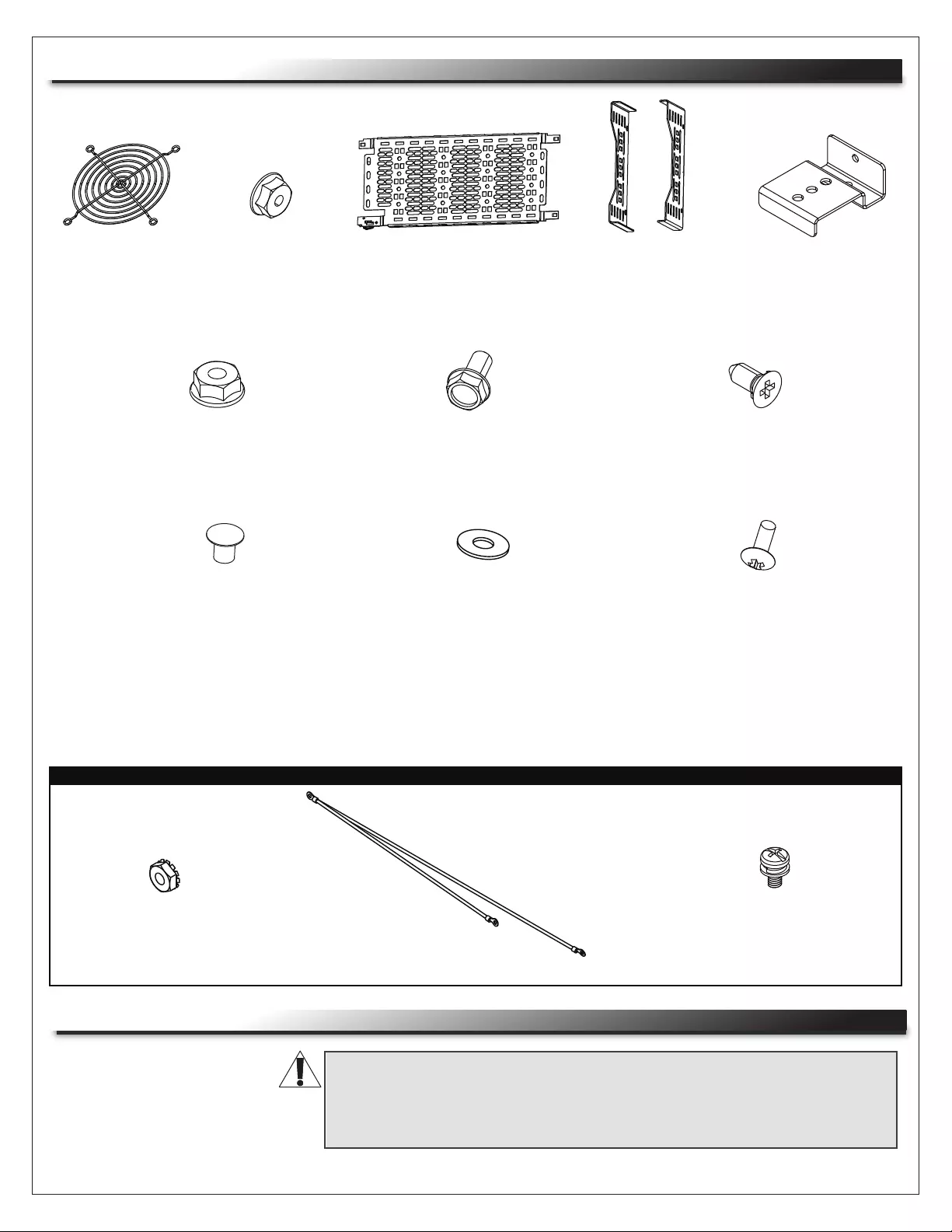

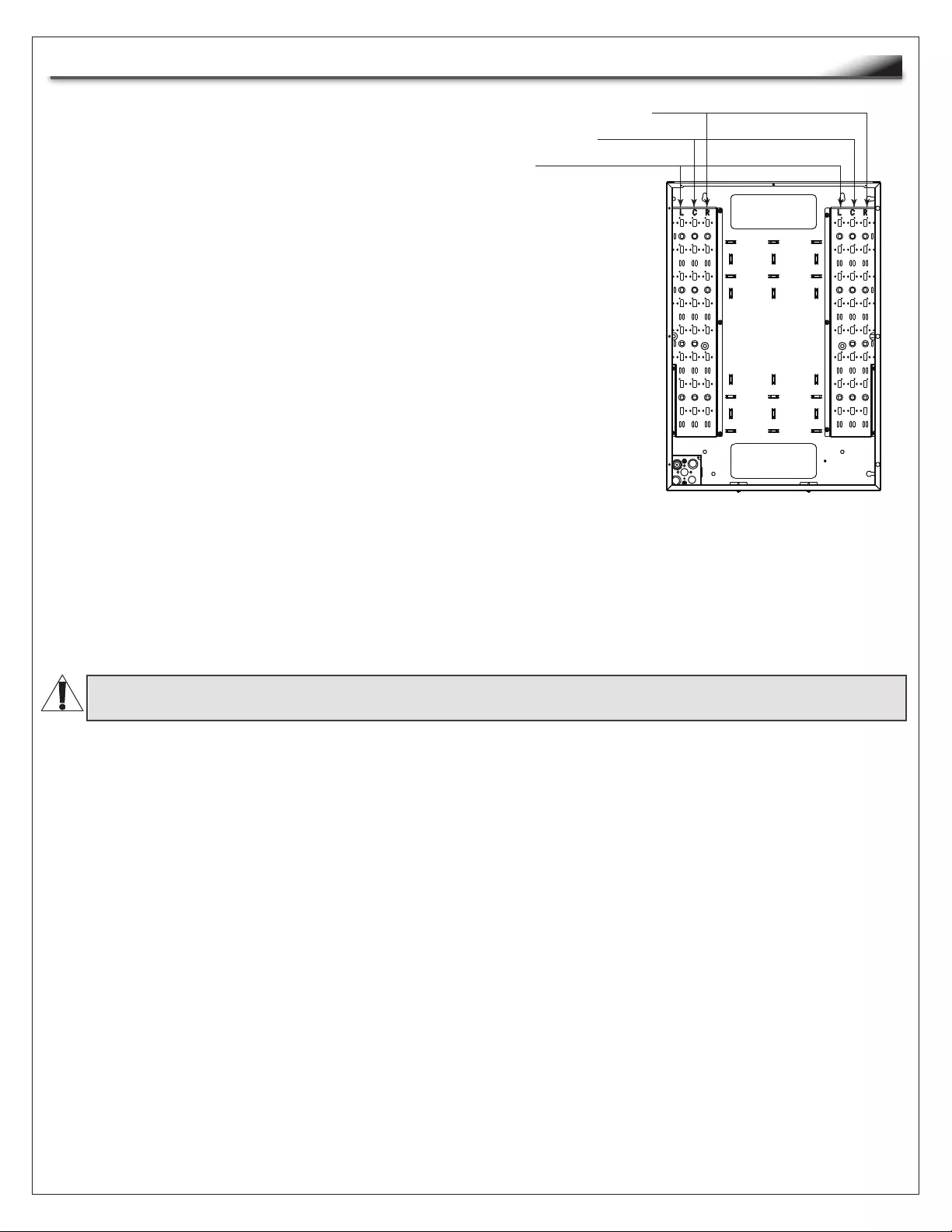

BACKPAN SUPPLIED COMPONENTS AND HARDWARE

(4x) Vent Guard

A

Backpan

Lever Lock

Brackets*

D

(2x) Power

Mounting

Bracket

E

(5x) 6-32 x 5/16”

Phil. Bonding Screw*

H

Backpan

Lever Lock™ Plate*

(LL-VP176-SWP)

C

(2x) Lever Lock

Securing Rivet*

K

(16x) 6-32

Flange Nut

B

(2x) 10-32

Flange Nut

F

• No. 2 Phillips Driver

• 5/16” Socket Wrench

• 3/8” Socket Wrench

• 10mm Socket Wrench

• Hammer

REQUIRED TOOLS

(2x) 10-32 x 3/8”

Thread Forming Screw

G

(16x) 6-32 x 3/8”

Phil. Screw

M

(20x) Lever Lock

Plate Washer*

L

* Not included in pre-configured models.

OPTIONAL PROTECTIVE EARTH TERMINAL COMPONENTS (FOR USE WITH 4” AC FAN OPTIONS, MODEL NO. PET-K-VWM-FAN)

10-32 Locking Nut

N

(2x) M4 x 8MM Phil.

Head Combo Screw

R

Split Bonding Wire

P

NOTE: Additional hardware is included that may not be required for your installation.

WARNING: Use tools with caution and follow all necessary safety

protocols.

AVERTISSEMENT: Utiliser des outils avec prudence et suivre

tous les protocoles de sécurité nécessaires.

INTRODUCTION

Page 6

NOTE: The pre-configured enclosures shown in this instruction sheet includes several components,

such as doors and brackets, which may or may not be a part of your configuration. Topics show how

to remove or reposition many of these items and separate instruction sheets provide even more detail.

BACKPANS FOR DIFFERENT DOORS

There are 2 VWM series backpans that differ based on your selection of a full door or split door as

follows:

NOTE: Images in this guide not specifically illustrating the full or split door may show either backpan.

VWM With Full Door

Backpan: VWM-BP-XXXX-XX

Full (Solid) Door: VWM-SD-XX-XX-U

VWM With Split Door

Backpan: VWM-BPSD-XXXX-XX

Split Plexi Door: VWM-SPD-XXXXXX-U

Solid Split Door: VWM-SSD-XXXXXX-U

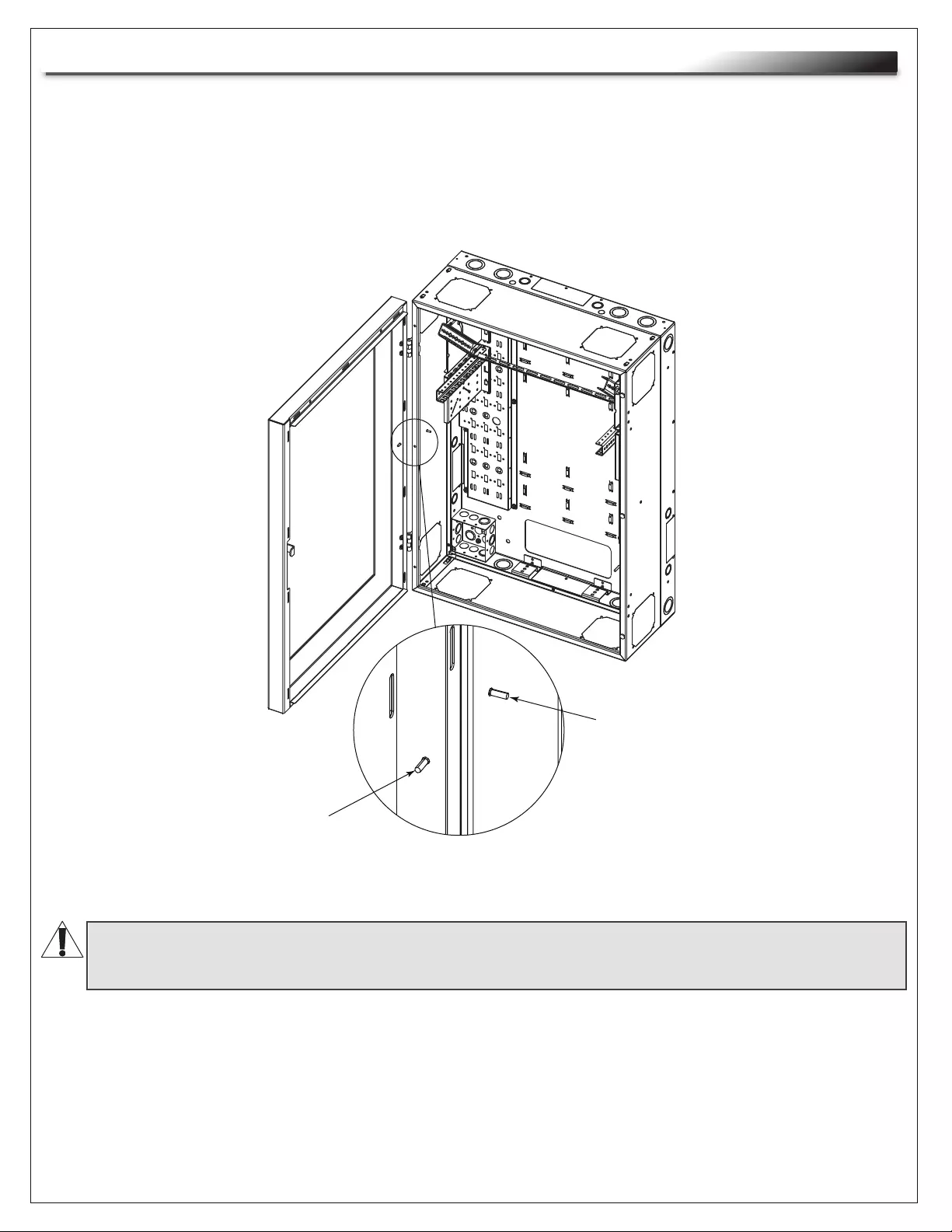

REMOVING THE FULL DOOR AND TOP FROM A FULL DOOR CONFIGURATION

Page 7

NOTE:

• The full door (VWM-SD-XX-XX-U) may be factory installed in pre-configured designs.

• If your pre-configured enclosure includes a full door, it may be helpful to remove either the full door

and/or the top before mounting the backpan and installing any equipment.

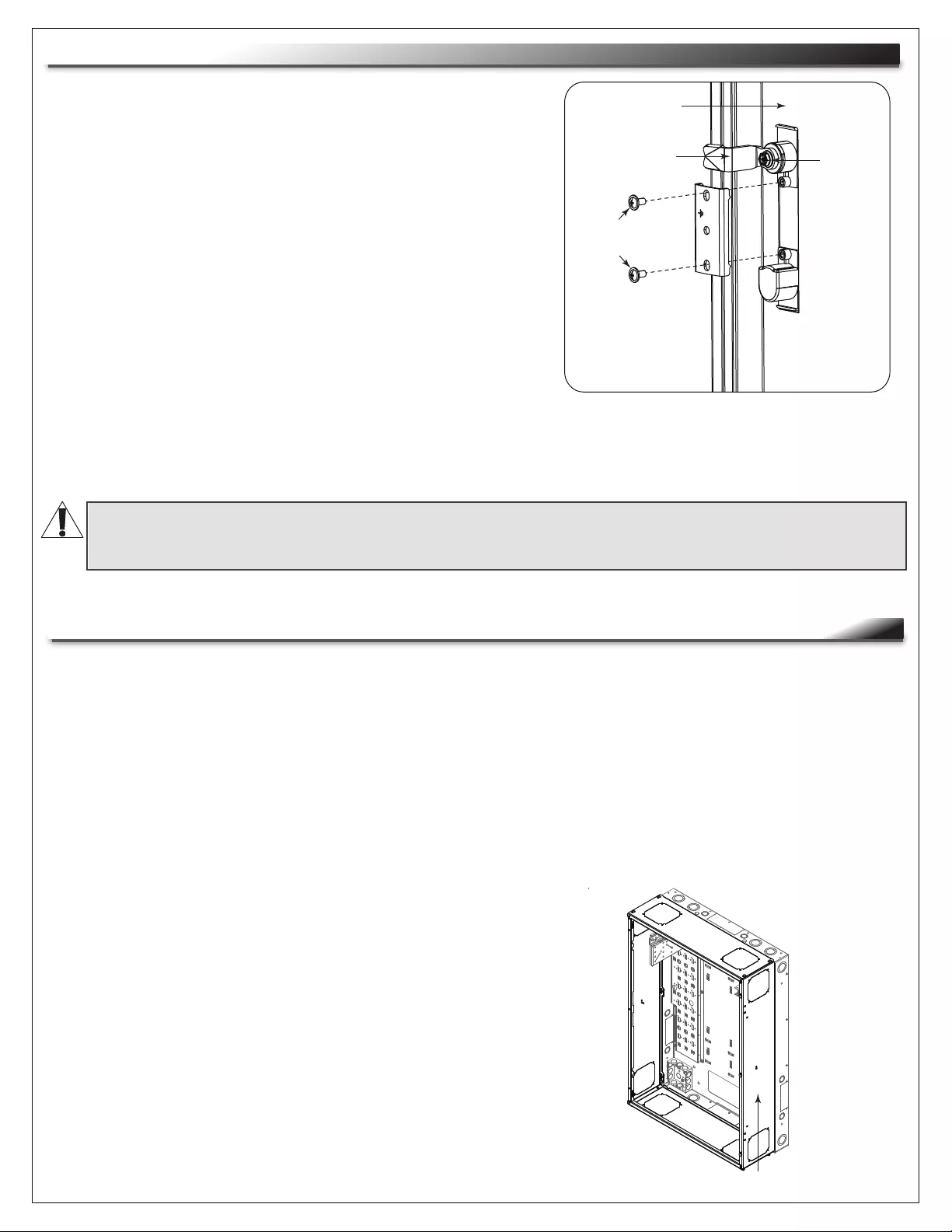

1. Use the quick disconnect on the door bonding wire to free the connection between the full door bonding

stud and the extender bonding stud. (FIGURE A)

Extender

Bonding

Stud

(10-32)

Full Door

Bonding

Stud

(10-32) FIGURE A

CAUTION: The bonding wire must be used when reattaching the door to ensure proper bonding.

ATTENTION: Le fil de liaison doit être utilisé lorsque la porte est remis pour assurer une connexion

électrique appropriée.

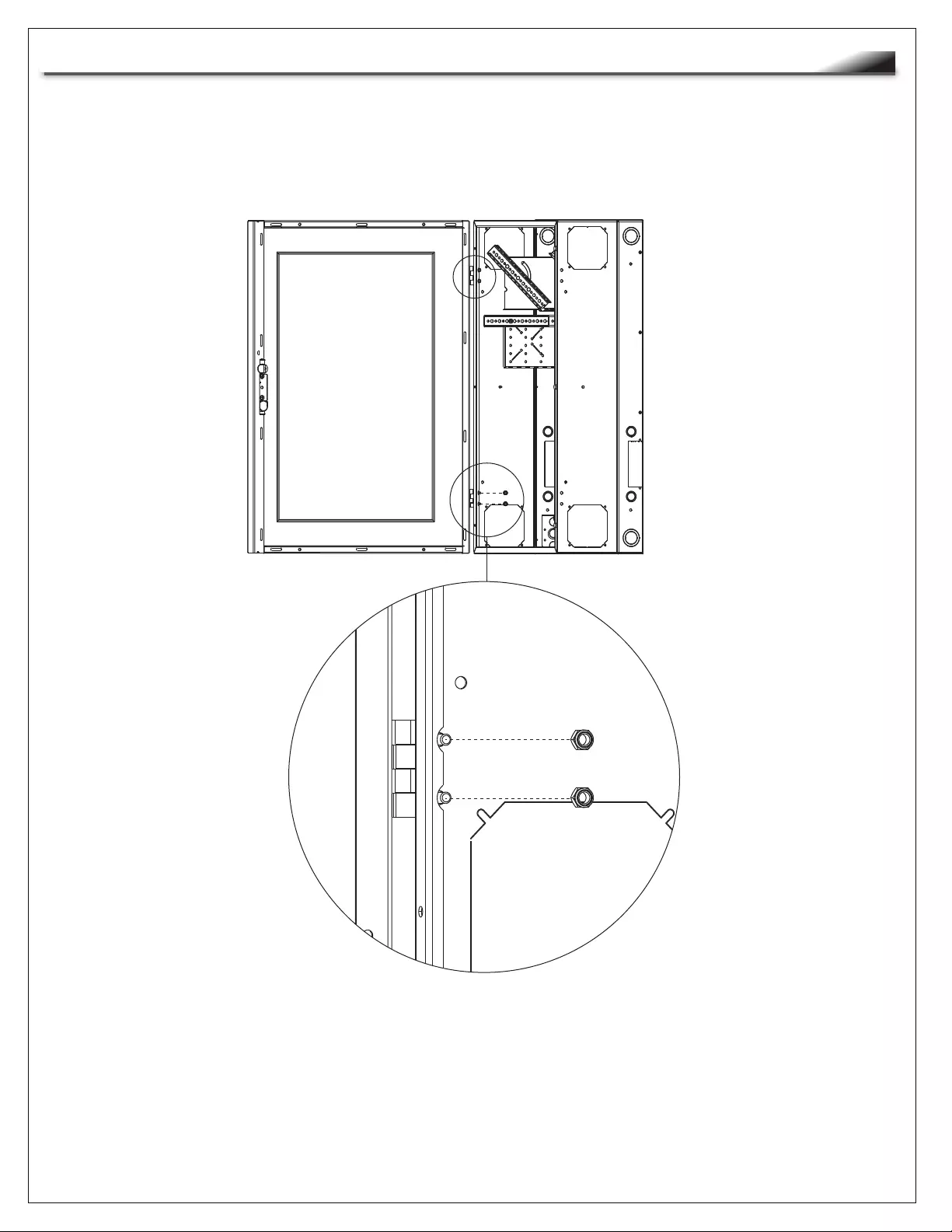

REMOVING THE FULL DOOR AND TOP FROM A FULL DOOR CONFIGURATION (CONTINUED)

2. Open the full door to 90º.

3. Remove the (2x) M6 nuts from each hinge (remove nuts from the bottom hinge first). (FIGURE B)

Carefully set the full door and hardware aside for reinstallation.

Page 8

FIGURE B

REMOVING THE FULL DOOR AND TOP FROM A FULL DOOR CONFIGURATION (CONTINUED)

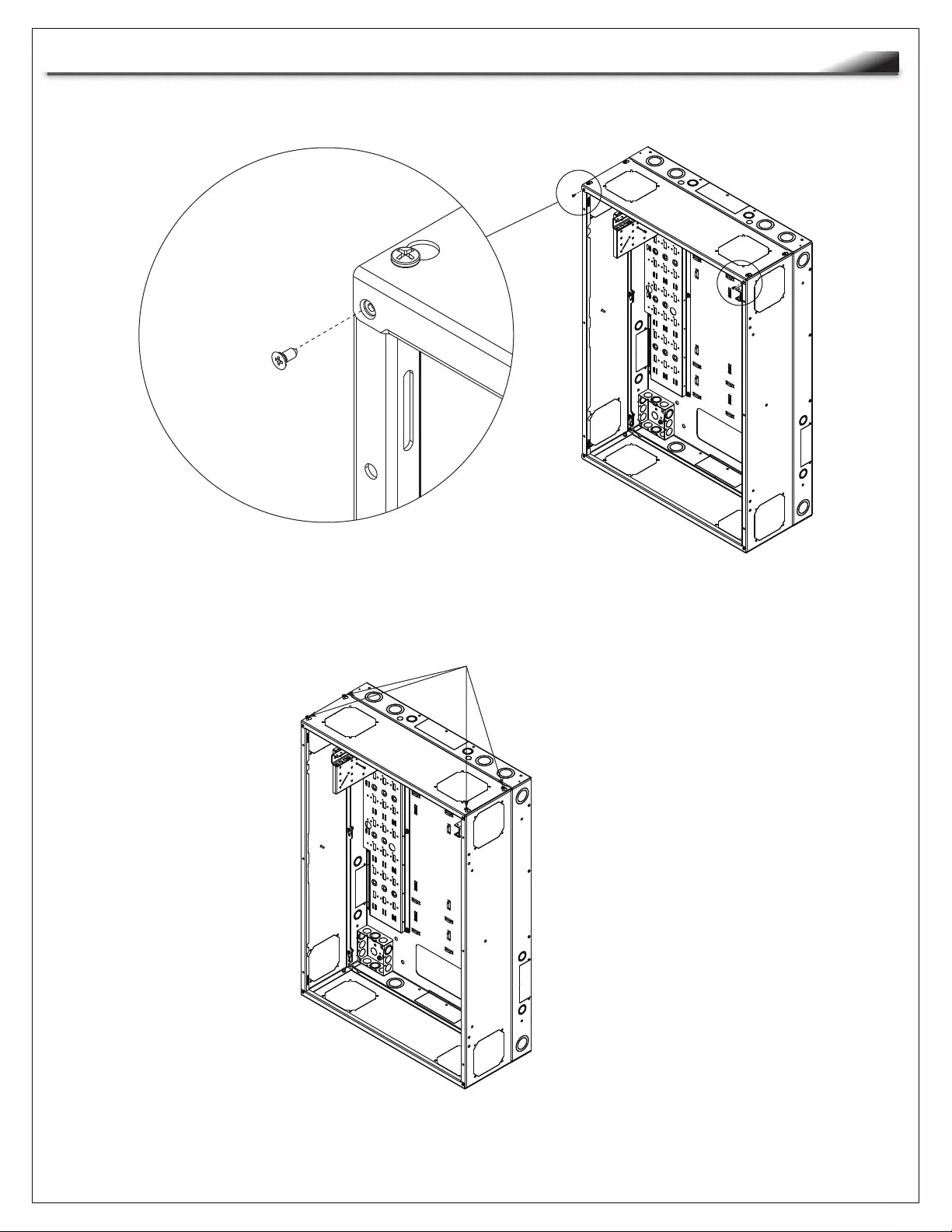

4. Remove (2x)

6-32 x 5/16” bonding

screws from the front corners of the top as shown. (FIGURE C)

5. Loosen (approximately 2 turns) the (4x) 10-32 x 1/2” screws from the top as shown. (FIGURE D)

Page 9

FIGURE C

FIGURE D

(4x) 10-32 x 1/2” screws

REMOVING THE FULL DOOR AND TOP FROM A FULL DOOR CONFIGURATION (CONTINUED)

6. Remove the top by pulling the top towards you, and then lifting the keyholes off the loosened

(4x) 10-32 x 1/2” screws

as shown. (FIGURE E)

Page 10

FIGURE E

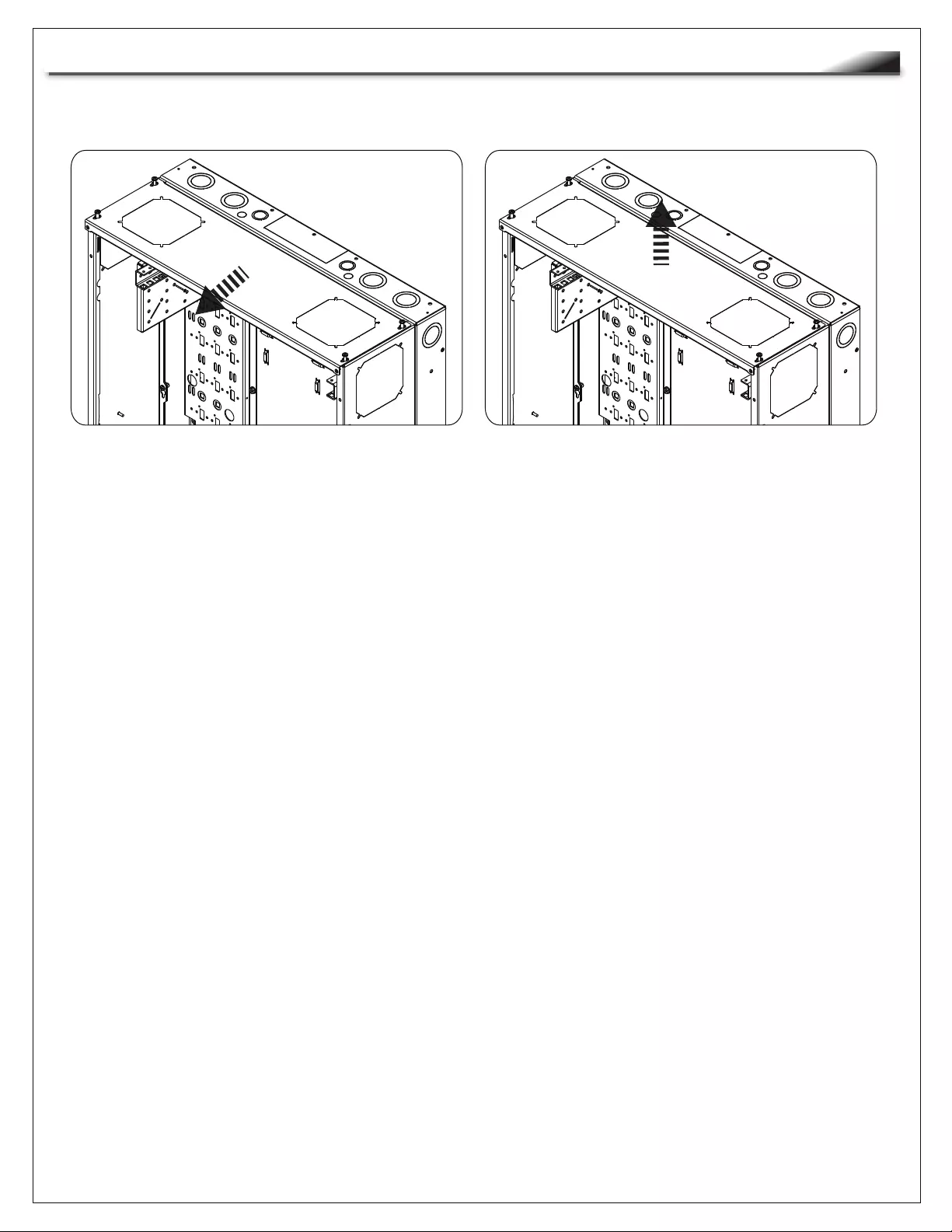

REMOVING THE SPLIT AND FRONT DOOR FROM A SPLIT DOOR CONFIGURATION

1. Remove (3x) 6-32 x 5/16” bonding screws from each side of the split door as shown. (FIGURE F)

2. Carefully remove the split door and set it aside for reinstallation. (FIGURE G)

NOTE: If your pre-configured enclosure includes a split door (VWM-SPD-XXXXXX-U or

VWM-SSD-XXXXXX-U), it may be helpful to remove either the split and/or the front door before

mounting the backpan and installing any equipment.

Page 11

FIGURE G

FIGURE F

(3x) bonding screws on

each side of the split

door.

Page 12

REMOVING THE SPLIT AND FRONT DOOR FROM A SPLIT DOOR CONFIGURATION (CONT’D.)

3. Open the front door to 90º.

4. Use the quick disconnnect on the door bonding wire to free the connection between the front door

bonding stud and the extender bonding stud. (FIGURE H)

Extender

Bonding

Stud

(10-32)

Front Door

Bonding

Stud

(10-32) FIGURE H

CAUTION: The bonding wire must be used when reattaching the door to ensure proper bonding.

ATTENTION: Le fil de liaison doit être utilisé lorsque la porte est remis pour assurer une connexion

électrique appropriée.

5. Remove the (2x) M6 nuts from each hinge (remove nuts from the bottom hinge first). (FIGURE J)

Carefully set the full door and hardware aside for reinstallation.

FIGURE J

Page 13

REMOVING THE SPLIT AND FRONT DOOR FROM A SPLIT DOOR CONFIGURATION (CONT’D.)

REVERSING THE DOOR (IF APPLICABLE)

FIGURE K

FIGURE L

1. Use the quick disconnect on the door bonding wire to free

the connection between the door bonding stud and

the backpan bonding stud.

2. Remove the (4x) M6 nuts from the hinges (lower hinge

first).

3. Carefully set aside front door.

4. Remove and attach the rubber bumpers to the holes on the

opposite side of the hinges.

5. Rotate door and reattach hinges to the opposite side of the

backpan (top hinge first).

6. Remove cam screw and cam. (FIGURE K)

7. Remove the (2x) handle screws as shown. (FIGURE K)

7. Rotate and reattach the handle to the door.

8. Rotate cam 180°, and reattach cam with screw (cam facing

the outside of enclosure). (FIGURE K)

9. Reattach the door bonding wire to the front door to

ensure proper bonding to the backpan.

Inside of

Front Door

Cam Cam

Screw

Handle

Screws

Page 14

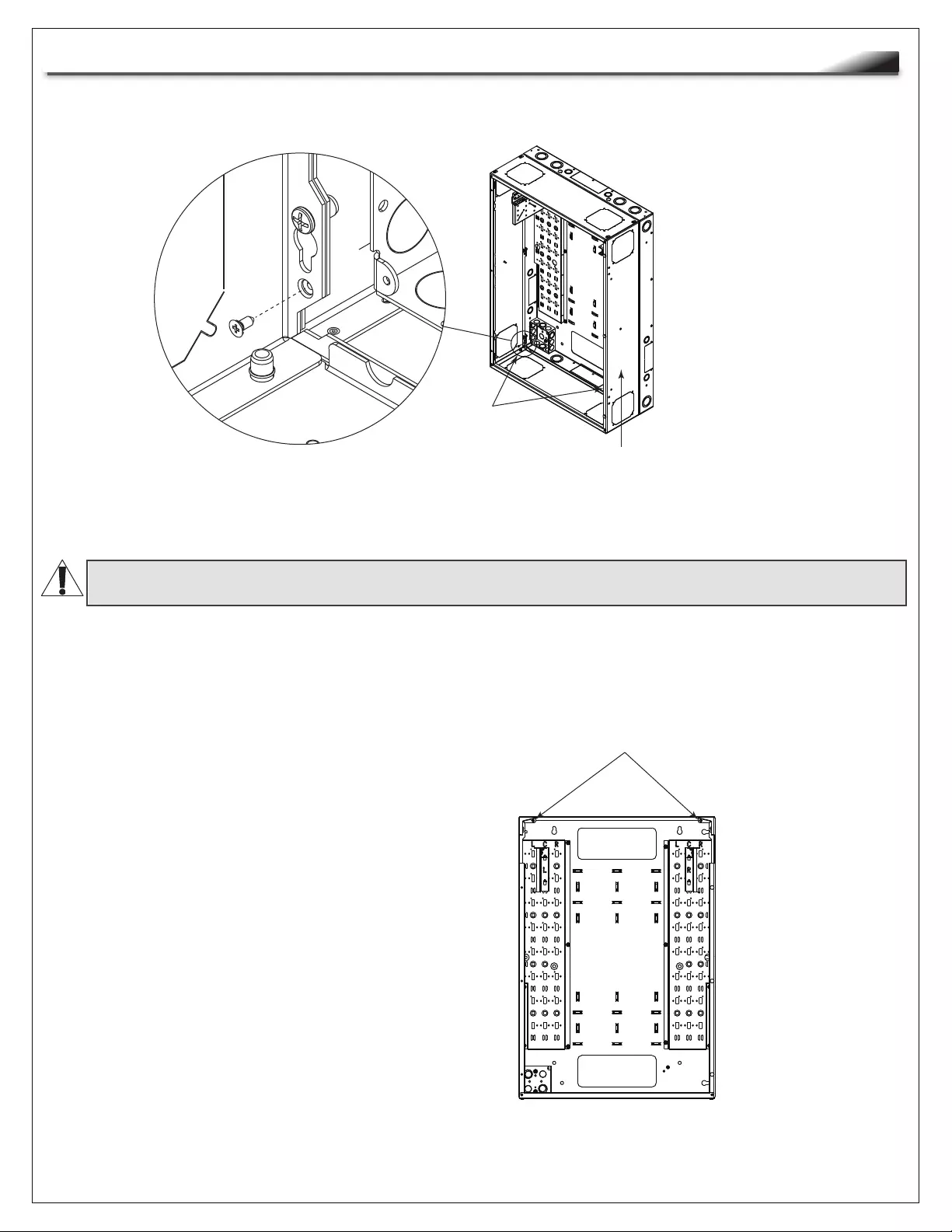

REMOVING EXTENDERS FROM THE BACKPAN (IF APPLICABLE)

NOTE:

• It may be helpful to remove extenders for some mounting and equipment installations.

(FIGURE L)

• Mounting equpment in the center of the backpan is recommended when removing and reinstalling

extenders. For more information, see “Relocating Fixed Position Mounting Rail or Pivot Brackets

on the Backpan” on page 20.

• A longer drill bit may be required when reinstalling extenders to the backpan after mounting equiment

in the center of the enclosure.

1. If you have a pre-installed door, use the previous topics to remove the door before proceeding.

NOTE: When removing extenders,

do not remove the top on the full

door configuration.

Extender

CAUTION: The bonding wire must be used when reattaching the door to ensure proper bonding.

ATTENTION: Le fil de liaison doit être utilisé lorsque la porte est remis pour assurer une connexion

électrique appropriée.

FIGURE M

FIGURE N

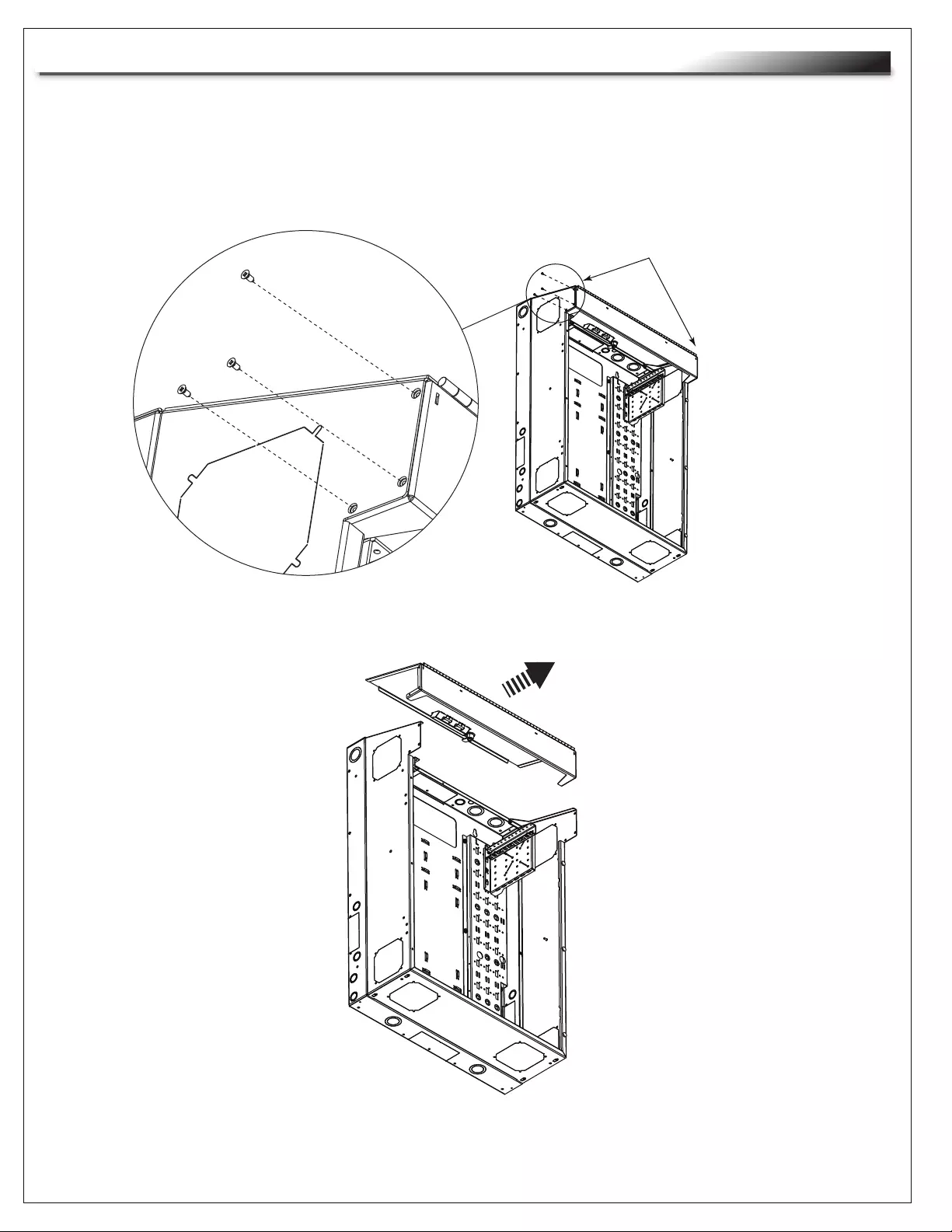

REMOVING EXTENDERS FROM THE BACKPAN (IF APPLICABLE, CONTINUED)

Page 15

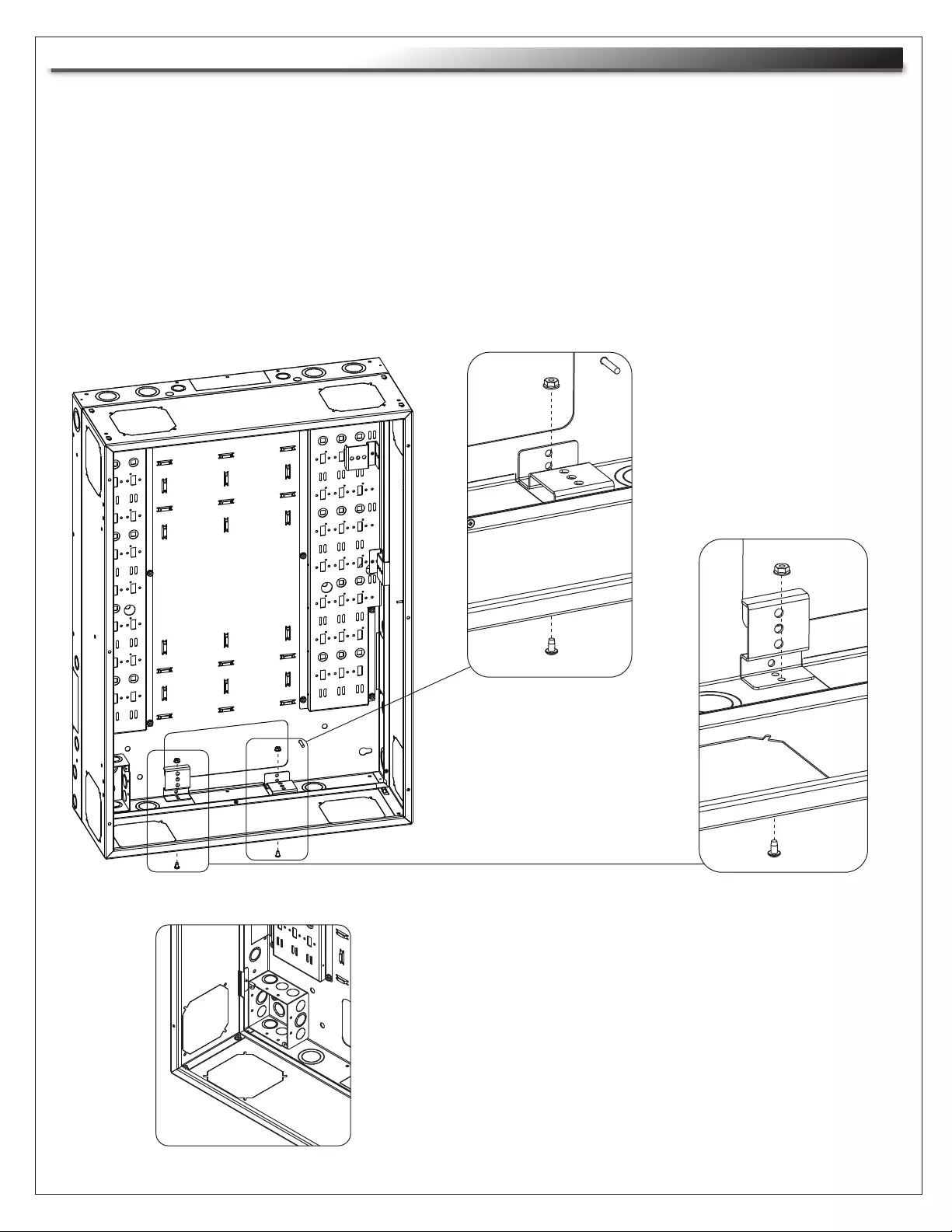

2. Remove the (2x) 6-32 x 5/16” bonding screws connecting the lower-back corners of the extender to

the backpan as shown. (FIGURE M)

3. Split door configuration only:

Remove the (2x) 10-32 x 1/2” screws

connecting the top of the

extender to the backpan as shown.

(FIGURE N)

NOTE:

• Split door configurations have 2

extra 10-32 x 1/2” screws.

• Split door removed for clarity.

A bonding

screw is in each

lower back

corner. Extender

CAUTION: The bonding screws must be used as explained to ensure proper bonding.

ATTENTION: Les vis doivent être utilisées comme expliqué pour assurer approprié électrique de liaison.

FIGURE P

FIGURE R

REMOVING EXTENDERS FROM THE BACKPAN (IF APPLICABLE, CONTINUED)

Page 16

4. Loosen (approximately 2 turns) the (6x) 10-32 x 1/2” screws connecting the extender to the backpan

as shown. (FIGURE P)

5. Lift and remove the extender keyholes from the loosened screws on the backpan as shown.

(FIGURE R)

10-32 x 1/2”

screw

Extender Backpan

(6x) 10-32 x 1/2”

screw locations

NOTE: Extender

removed for clarity.

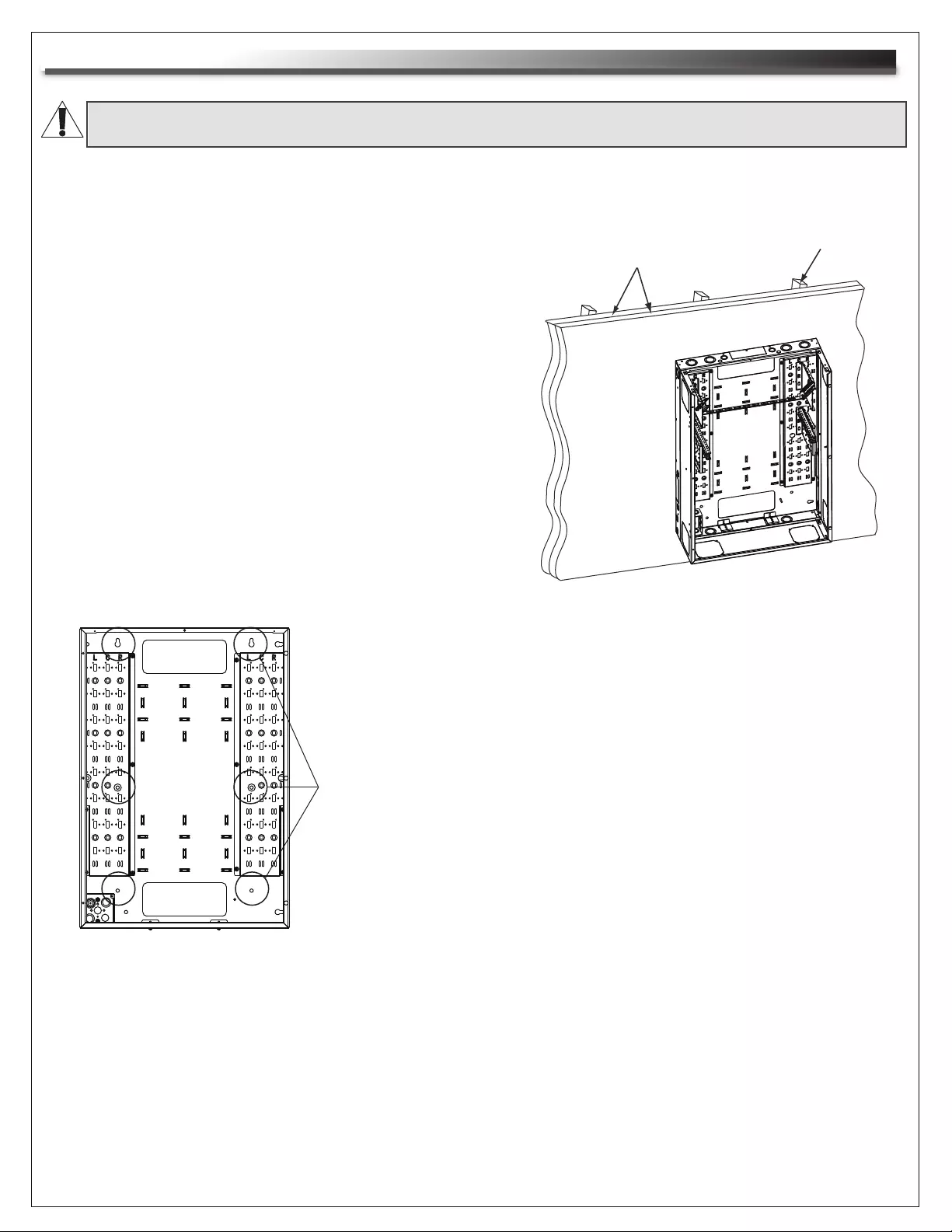

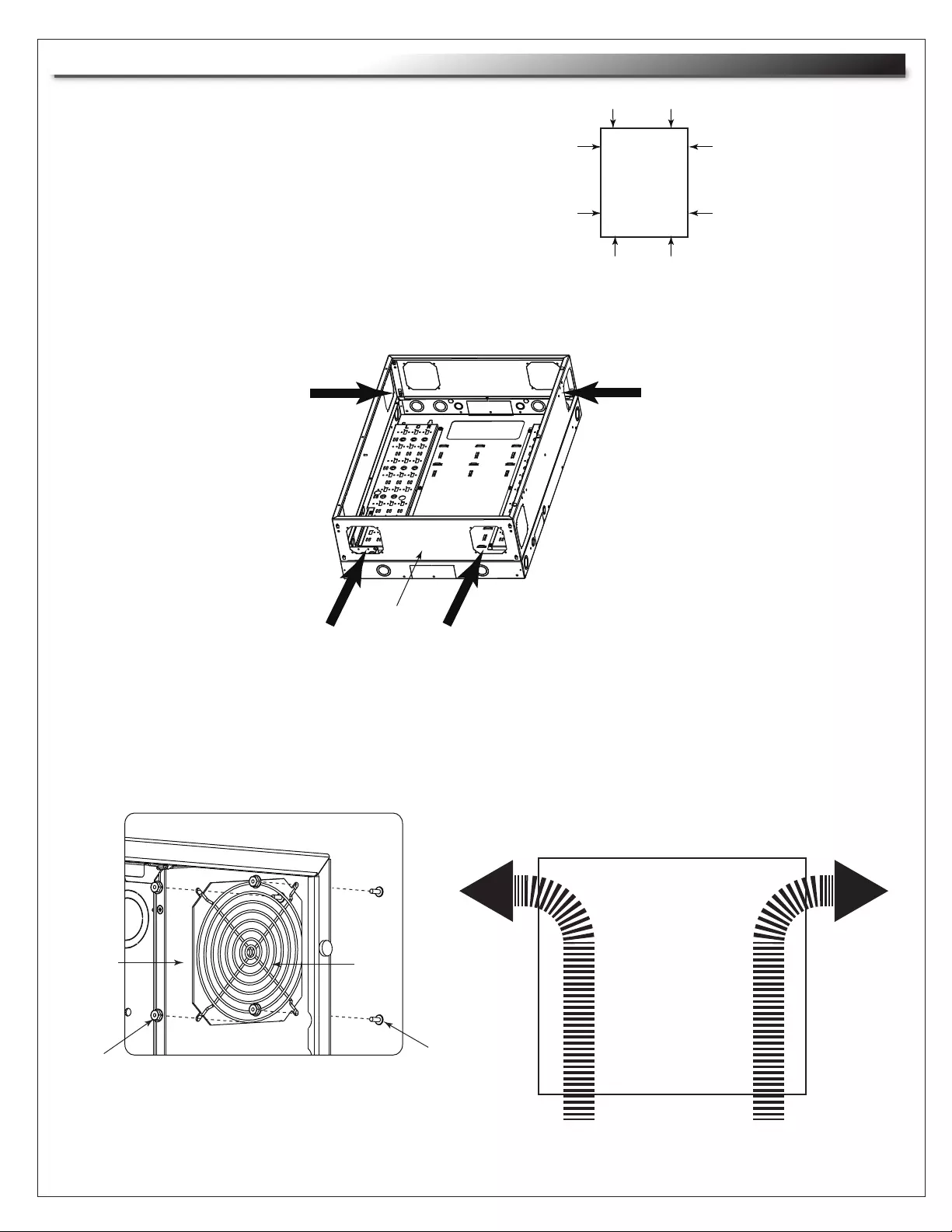

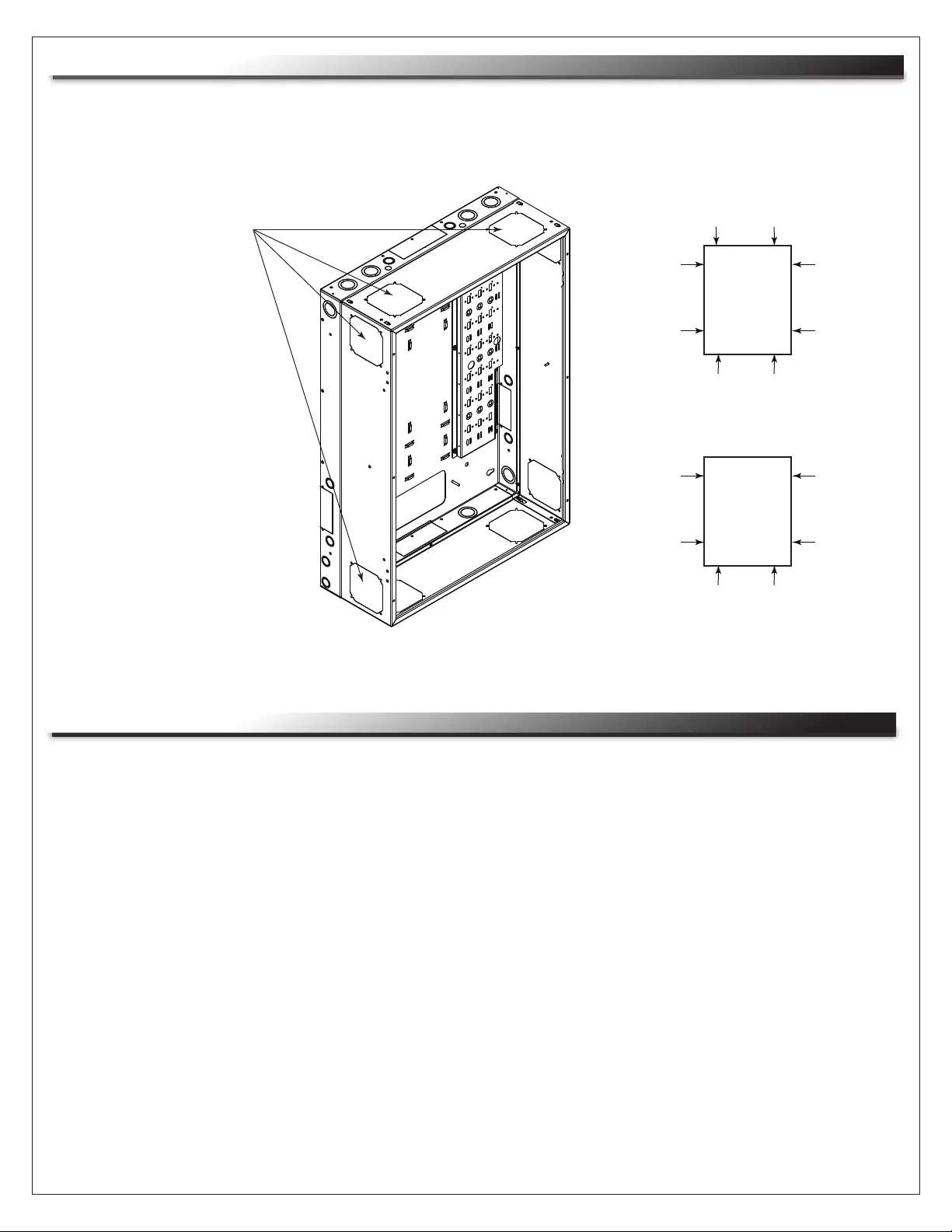

1. Install one of the top mounting bolts. Do not tighten.

(FIGURE S)

2. Check for plumb and level before installing the second

top mounting bolt. Tighten both bolts.

3. Install the remaining mounting bolts.

NOTE: When mounting the backpan:

• Ensure the backpan is screwed to the studs.

(FIGURE S)

• Use 3/8" diameter lag bolts with a minimum length of 2"

and standard flat washers for hardware (not provided).

• The standard flat washers must be installed under

the lag bolt heads.

• The backpan must be mounted using all 6 mounting

points. (FIGURE T)

MOUNTING THE BACKPAN

FIGURE S

FIGURE T

Wall

Mounting

Points

Page 17

STUD

1/2” DRYWALL

CAUTION: The backpan must be installed plumb and level for proper operation.

ATTENTION: La plaque profilée doit etre aplomb et de niveau pour un fonctionnement.

NOTE:

• The backpan PET stud is on the lower-right

(facing) of the backpan on both the full door

and split door options.

• The door bonding stud is on the hinge side

of both the full door and split door options.

• Additional bonding hardware is provided with

optional components.

NOTE:

• Follow installation steps as described in the instructions provided with your 4” AC fan option.

• For more information, see "Venting The Enclosure Actively With A Full Door Configuration" or "Venting

The Enclosure Actively With A Split Door Configuration," on pages 26 and 28, respectively.

Page 18

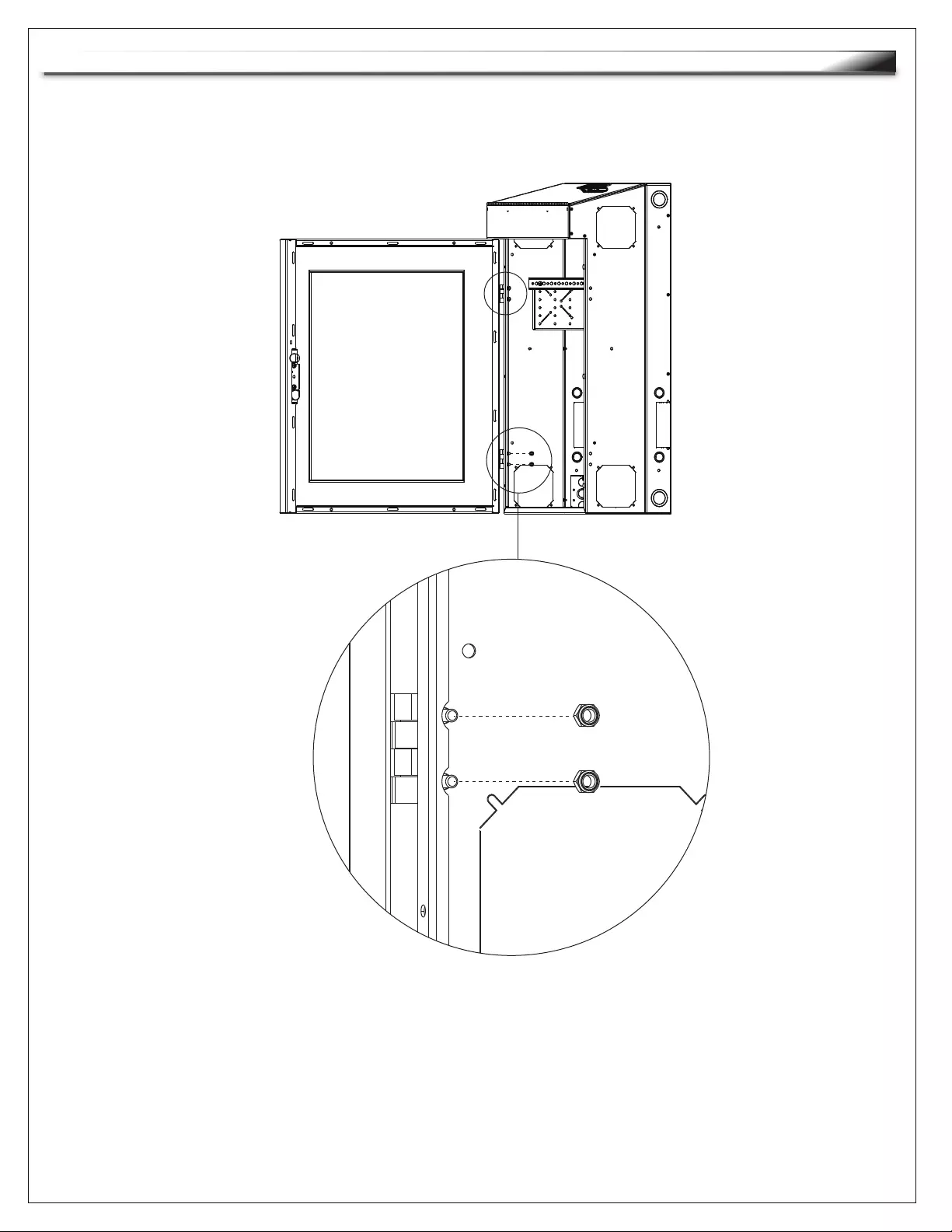

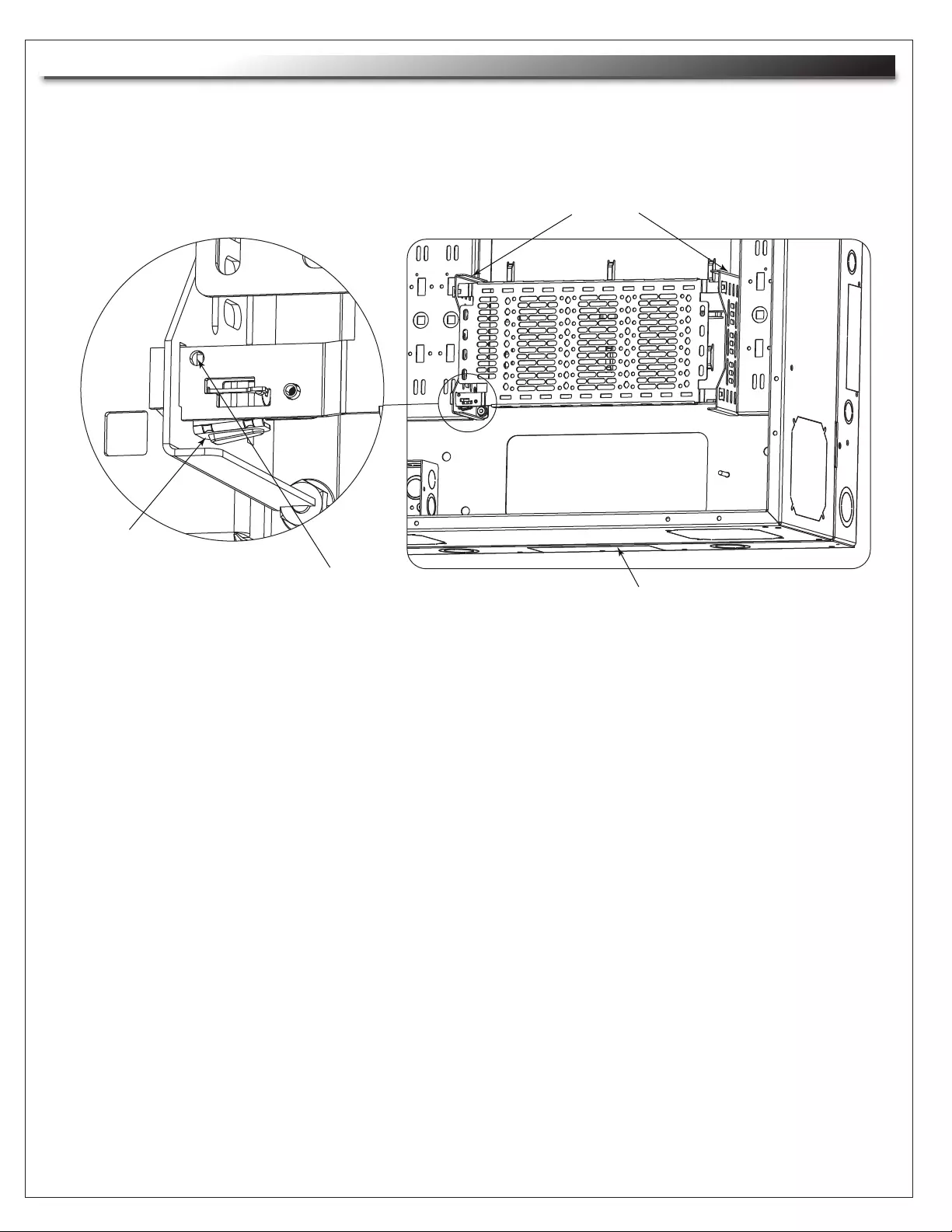

GROUNDING AND BONDING

CONNECTING 4” AC FAN OPTION TO BONDING POINTS

The main protective earth ground needs to be the first terminal placed on the PET and this terminal

needs to be secured on its own with a nut. (FIGURE U)

Backpan

PET

Stud

(1/4”-20)

FIGURE U

Protective Earth Terminals (PET) are located in the backpan of the wall rack. These terminals are marked with the symbol

. Wall rack parts, center section, door, and fans contain or are provided with bonding points for connection to the PET.

Protective earth and bonding connections shall be in accordance with Article 250 of the National Electric Code.

1. Use the locking nut (N) to connect the first eyelet on the bonding wire (P) to a bonding point on either

side of the extender’s interior as shown. (FIGURE V)

2. Use the M4 screws (R) to connect the second and third bonding wire eyelets to the ground points

(GND) on each 4” AC fan option (not provided, sold separately). (FIGURE V)

FIGURE V

4” AC Fan Option

GND

Bonding

Points

CAUTION: The bonding wire must be used when connecting AC fans to ensure proper bonding.

ATTENTION: Le fil de liaison doit être utilisé lors de la connexion des AC ventilateurs pour assurer une

connexion électrique appropriée.

NOTE: The pivoting mounting rail bracket option (VWM-RR-PIV-X) may be factory installed in

pre-configured designs.

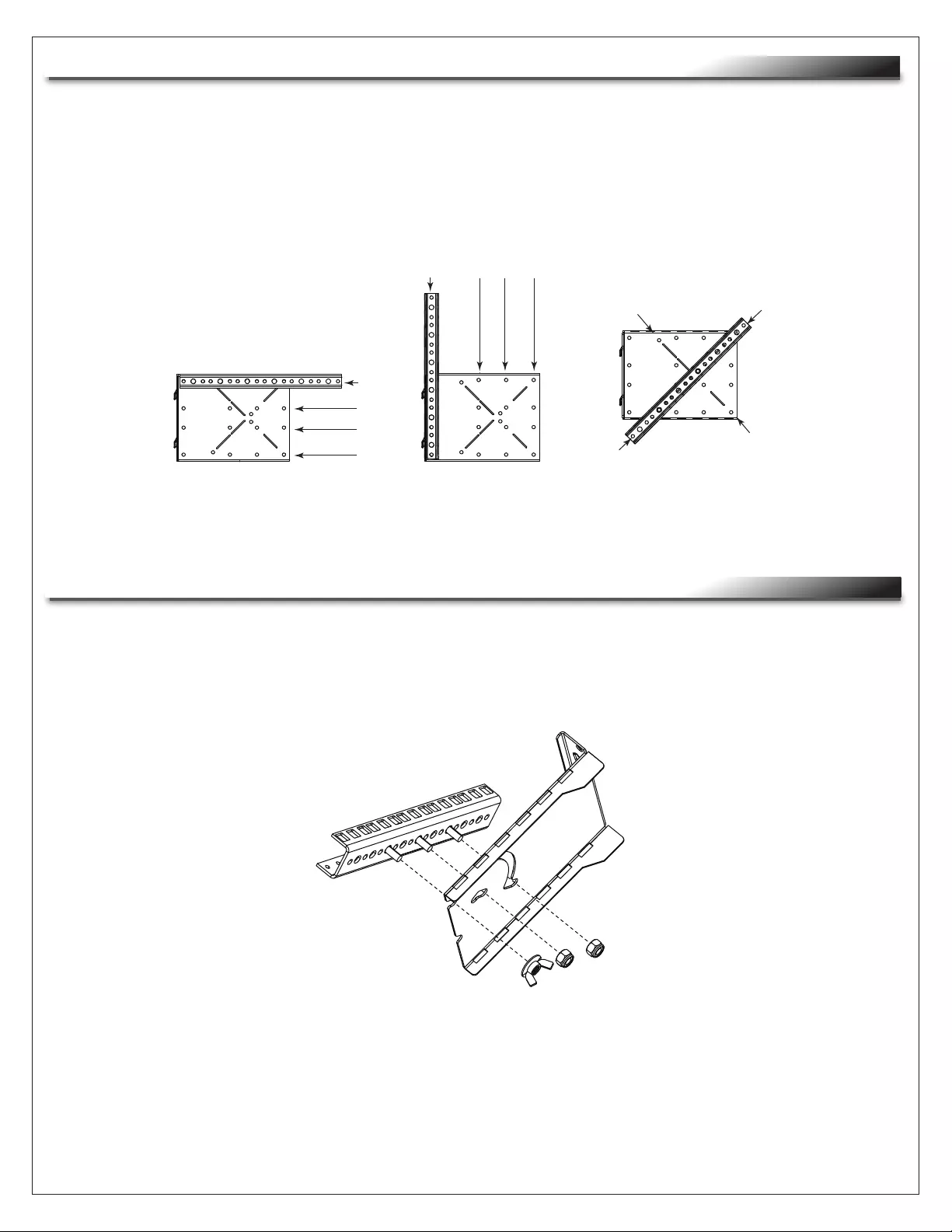

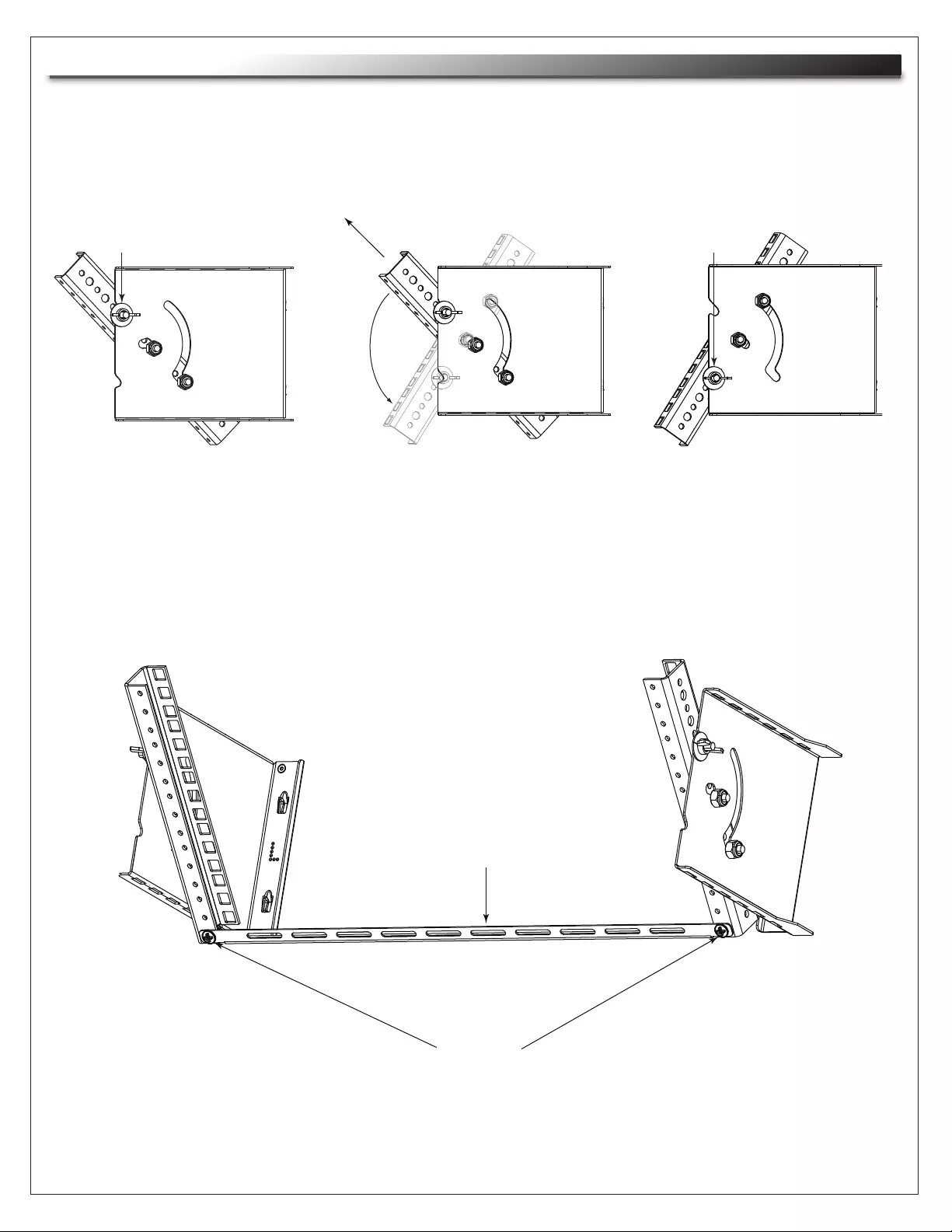

1. Remove the wing nuts and 5/16”-18 nuts from the studs. (FIGURE X)

2. Rotate the rackrails so the cagenut holes are positioned for use.

3. Reattach wing nuts and 5/16”-18 nuts to the studs on both rackrails.

NOTE: Leave the 5/16”-18 nuts loose enough so the rackrails pivot on the brackets.

ROTATING PIVOTING BRACKET RACKRAILS FROM 10-32 TO CAGENUT (IF DESIRED)

FIGURE X

Page 19

NOTE:

• The fixed position mounting rail bracket option (VWM-RR-XX) may be factory installed in pre-configured

designs.

• The rackrails have 10-32 and cagenut sides for convenience.

1. Use (2x) 10-32 screws and (2x) 10-32 nuts in the outermost holes to remove and reattach rackrails

to the inside of mounting rail brackets. There are 4 horizontal, vertical, and diagonal (45º) positions

available. (FIGURE W)

2. Repeat the process with a second rackrail and the other fixed position mounting rail bracket.

RELOCATING RACKRAILS ON THE FIXED POSITION MOUNTING RAIL BRACKETS

(4x) Horizontal Positions (4x) Vertical Positions (4x) Diagonal (45º) Positions

1

1

2

2

3

3

4

4

1

2

3

4

FIGURE W

NOTE:

• The fixed position mounting rail

bracket option (VWM-RR-XX) and the

pivoting mounting rail bracket option

(VWM-RR-PIV-X) may be factory installed

in pre-configured designs.

• Consider your equipment’s power and

cabling requirements to determine a

left, center, or right bracket alignment.

Pre-installed brackets are in the center

position.

• Fixed position mounting rail and pivoting

bracket pairs are labeled left (L) and right

(R).

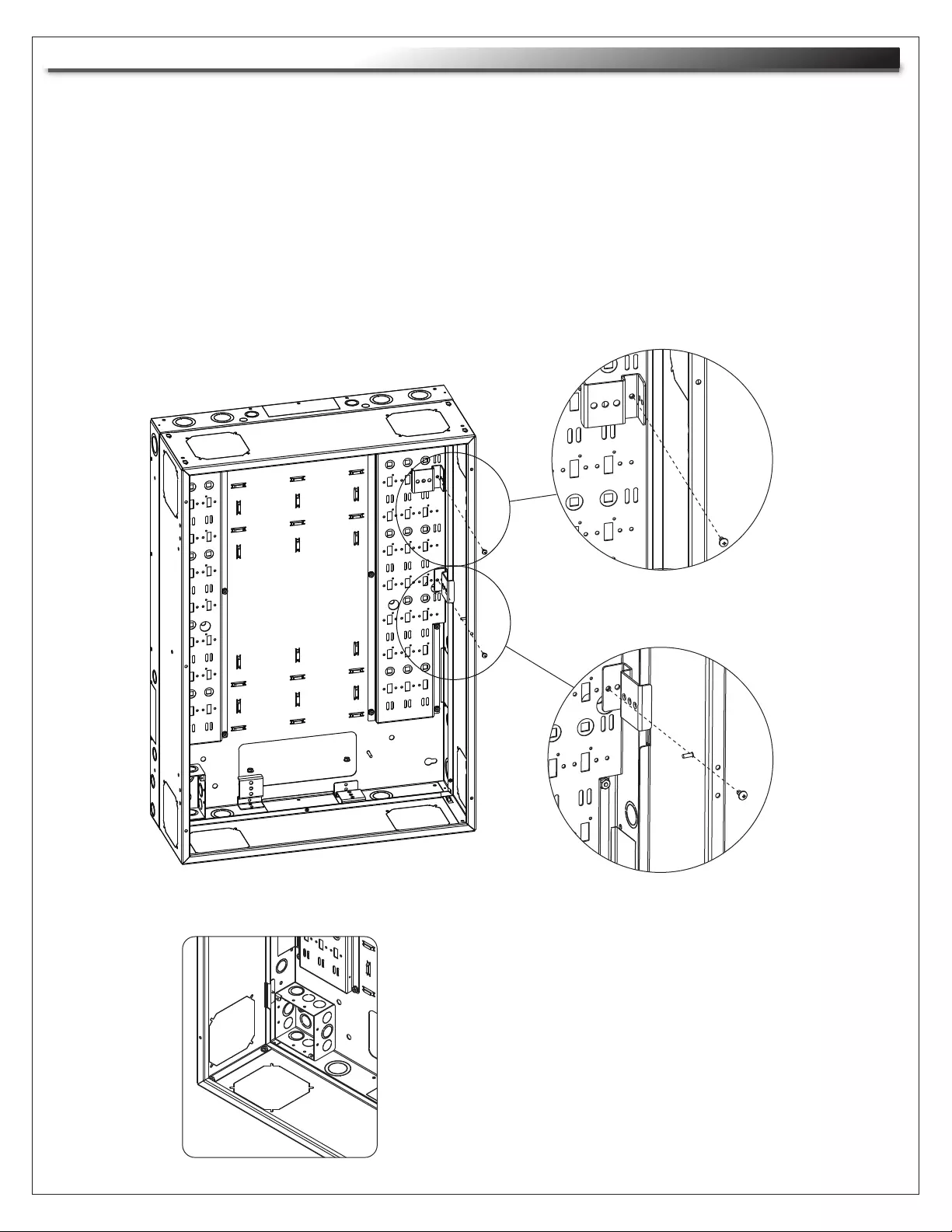

RELOCATING FIXED POSITION MOUNTING RAIL OR PIVOT BRACKETS ON THE BACKPAN

FIGURE Y

Left Alignment

Center Alignment

Right Alignment

1. Remove the (2x)

6-32 x 5/16” bonding

screws from each bracket (1x

per bracket).

2. Remove and reattach fixed position mounting rail or pivot bracket

pairs to labeled columns on the backpan for left (column L), center

(column C), and right (column R) alignment of your equipment.

(FIGURE Y)

3. Reattach the

bonding

screws (1x per bracket) to ensure proper

bonding.

Page 20

CAUTION: The bonding screws must be used as explained to ensure proper bonding.

ATTENTION: Les vis doivent être utilisées comme expliqué pour assurer approprié électrique de liaison.

NOTE: The pivoting mounting rail bracket option (VWM-RR-PIV-X) may be factory installed in

pre-configured designs.

1. Loosen the wing nuts on both sides of the rackrail, lift, and rotate the assembly from the in-use to

punch down and service position. Tighten the wing nuts. Do not overtighten. (FIGURE Z)

USING THE PIVOTING MOUNTING RAIL BRACKETS

FIGURE Z

2. When rotating, the bottom of the mounted component(s) swing forward for easier access to the

connection points.

3. Use (2) 10-32 x 3/4” screws to attach the lacer bar. (FIGURE AA)

In-Use Position

Punch Down and

Service Position

Lift

Loosen Tighten

Top Top

Rotate

FIGURE AA

10-32 x 3/4”

Screws

Page 21

Lacer Bar

NOTE: The Lever Lock™ backpan option (LL-VWM-BPK) may be factory installed in pre-configured

designs.

1. Press the clip on one corner to remove the Lever Lock backpan plate from the brackets. (FIGURE AB)

RELOCATING THE LEVER LOCK™ BACKPAN

Page 22

FIGURE AB Bottom

Clip

NOTE: Install plastic securing

rivet (K) into hole to secure the

clip more permanently, if

desired.

Brackets

NOTE: (20x) Lever Lock plate washers (L) are provided for equipment mounting convenience.

2. Remove (4x)

6-32 x 5/16” bonding

screws (2x per side) to relocate brackets into any of the following

backpan locations. (FIGURE AC)

RELOCATING THE LEVER LOCK BACKPAN (CONTINUED)

FIGURE AC

Page 23

Bonding

Screw

LOCATION 1

LOCATION 2

LOCATION 3

Bracket

Bonding Screw

Holes on

Backpan

(4x holes per

location)

CAUTION: The bonding screws must be

used as explained to ensure proper bonding.

ATTENTION: Les vis doivent être utilisées

comme expliqué pour assurer approprié

électrique de liaison.

RELOCATING THE LEVER LOCK BACKPAN (CONTINUED)

Page 24

FIGURE AE

• The Lever Lock backpan plate may be installed on the brackets at different depths. All 4 corners of

the Lever Lock backpan plate must be inserted into the brackets at the same depth in order to function

correctly.

• Reattach the Lever Lock backpan plate by installing the side without the clip into the brackets

first. Then install the side with the clip until it clicks into place. (FIGURE AE)

Side with

clip

Side without

clip

NOTE:

• The bracket bonding screw holes are located on the inside edges of the backpan. Each bracket is

assembled as shown. (FIGURE AD)

FIGURE AD

Bracket Bonding

Screw Holes

Page 25

(8x) Knockout Locations

Inside of

Enclosure

FIGURE AH

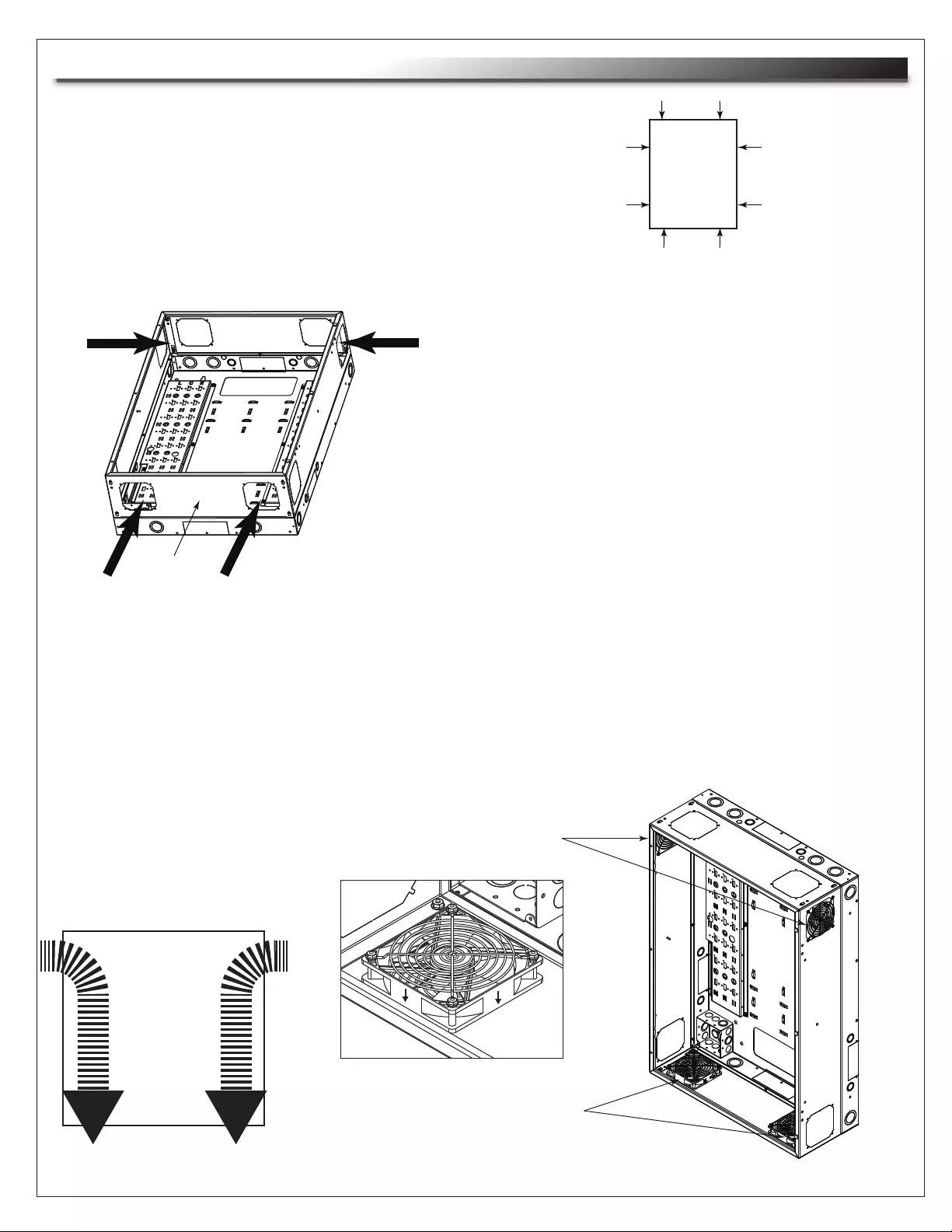

VENTING THE ENCLOSURE PASSIVELY WITH A FULL DOOR CONFIGURATION

1. Use a hammer to knock out the 4 plates as shown. (FIGURE AG)

2. Install a vent guard into each of the 4 openings (from the outside into the enclosure) using a guard (A),

(4x) 6-32 x 3/8” screws (M), and (4x) 6-32 flange nuts (B) in each location. (FIGURE AH)

FIGURE AG

NOTE: There are 8 knockout locations

available on your full door enclosure for a

variety of ventilation configurations.

(FIGURE AF)

The configuration used in this topic provides an

example.

VWM

Rack

Front FIGURE AF

Bottom

NOTE: With

knockouts

cleared and vent

guards installed,

passive ventilation

then

produces the

following

upward airflow

pattern

through the

enclosure.

BM

A

NOTE: With

knockouts

cleared, vent

guards, and fans

installed,

active ventilation

then

produces the

following

downward airflow

pattern

through the

enclosure.

Page 26

(8x) Knockout Locations

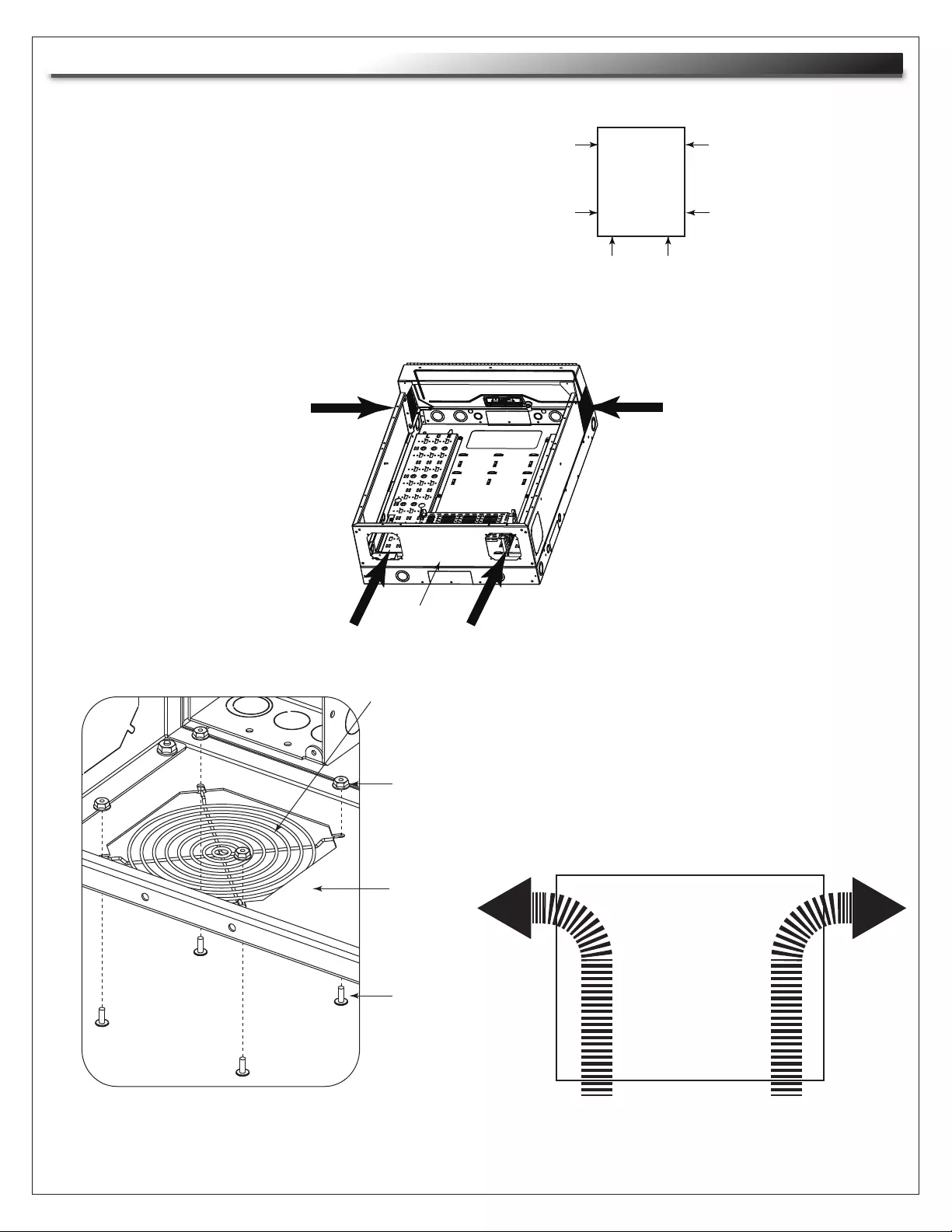

VENTING THE ENCLOSURE ACTIVELY WITH A FULL DOOR CONFIGURATION

FIGURE AJ

FIGURE AL

Vent guards on

the top sides of

the extenders.

Install fans with downward airflow.

NOTE: There are 8 knockout locations available on your full

door enclosure for a variety of ventilation configurations.

(FIGURE AJ)

The configuration used in this topic provides an example.

2. Install any 4” AC fan option (not provided, sold

separately) into each of the 2 openings on the bottom

of the rack using a fan, (4x) screws and (4x) nuts

from the hardware provided with your fan.

(FIGURE AL)

NOTE: If using a 4” AC fan option, be sure to bond it correctly. For

more information, see “Connecting 4” AC Fan Options to Bonding

Points” on page 18.

3. Install a vent guard into each of the 2 openings on the top sides of the rack (from the outside into the

enclosure) using a guard (A), (4x) 6-32 x 3/8” screws (M), and (4x) 6-32 flange nuts (B) in each location.

(FIGURE AH)

1. Use a hammer to knock out the 4 plates as shown.

(FIGURE AK)

VWM

Rack

Front FIGURE AJ

Bottom

4” AC

Fan Option

2. Install a vent guard into each of the 4 openings (from

the outside into the enclosure) using a guard (A), (4x)

6-32 x 3/8” screws (M), and (4x) 6-32 flange nuts (B)

in each location. (FIGURE AP)

Page 27

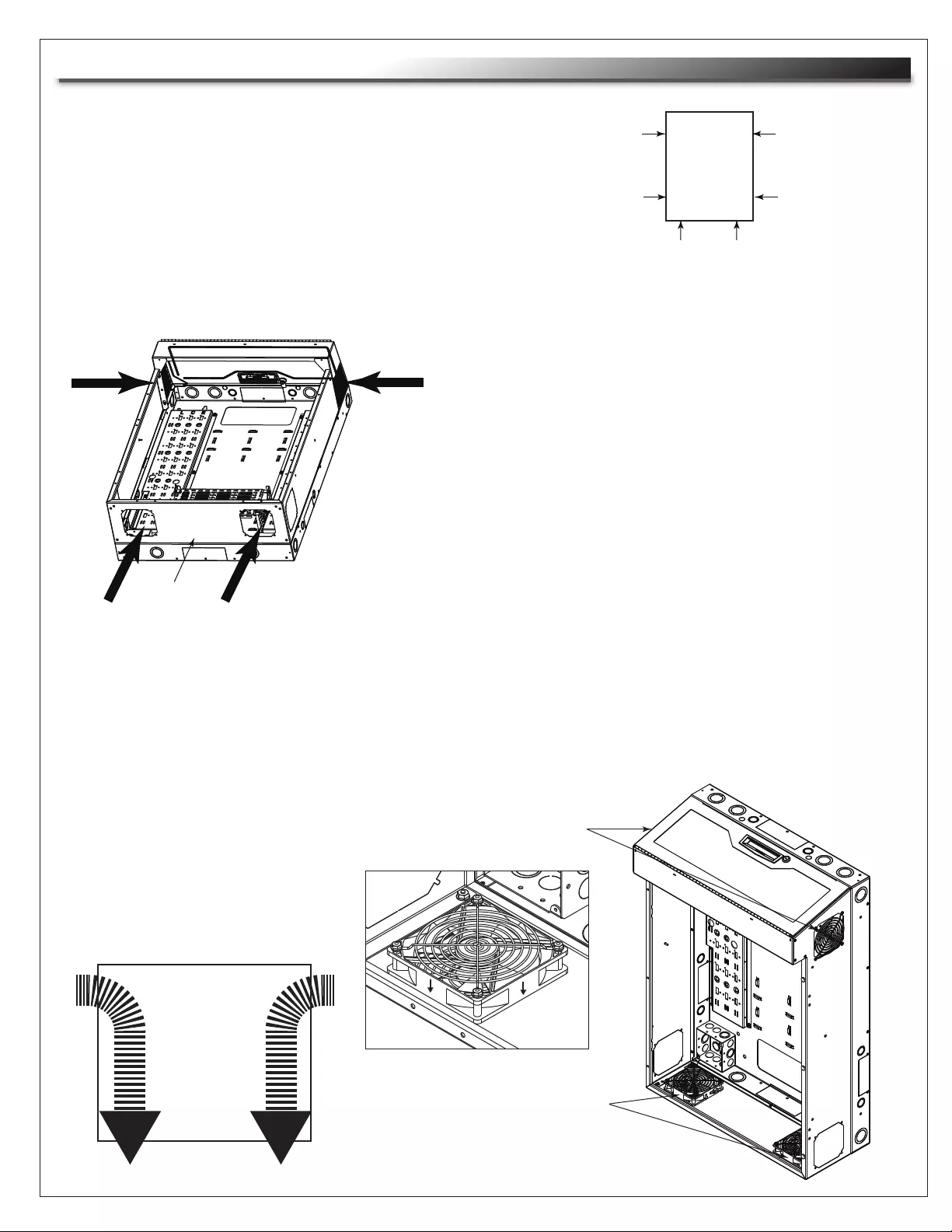

(6x) Knockout Locations

VENTING THE ENCLOSURE PASSIVELY WITH A SPLIT DOOR CONFIGURATION

1. Use a hammer to knock out the 4 plates as shown. (FIGURE AN)

FIGURE AN

FIGURE AP

NOTE: There are 6 knockout locations

available on your split door enclosure for a

variety of ventilation configurations.

(FIGURE AM)

The configuration used in this topic provides an

example.

VWM

Rack

Front FIGURE AM

NOTE: With

knockouts

cleared,

passive ventilation

then

produces the

following upward

airflow pattern

through the

enclosure.

Bottom

Bottom of

Enclosure

B

M

A

Page 28

(6x) Knockout Locations

VENTING THE ENCLOSURE ACTIVELY WITH A SPLIT DOOR CONFIGURATION

FIGURE AT

4” AC

Fan Option

Install fans with downward airflow.

NOTE: There are 6 knockout locations available on your split door

enclosure for a variety of ventilation configurations. (FIGURE AR)

The configuration used in this topic provides an example.

1. Use a hammer to knock out the 4 plates as shown. (FIGURE AS)

2. Install any 4” AC fan option (not provided, sold

separately) into each of the 2 openings on the bottom

of the rack using a fan, (4x) screws and (4x) nuts from

the hardware provided with your fan. (FIGURE AT)

3. Install a vent guard into each of the 2 openings on the top sides of the rack (from the outside into

the enclosure using a guard (A), (4x) 6-32 x 3/8” screws (M), and (4x) 6-32 flange nuts (B) in each

location. (FIGURE AH)

VWM

Rack

Front FIGURE AR

NOTE: With

knockouts

cleared and fans

installed,

active ventilation

then

produces the

following downward

airflow pattern

through the

enclosure.

FIGURE AS

Bottom

Vents on the top

sides of the split

door.

NOTE: If using a 4” AC fan option, be sure to bond it correctly. For

more information, see “Connecting 4” AC Fan Options to Bonding

Points” on page 18.

NOTE:

• Before installing the power mounting bracket to the backpan, install the clip included with your PDU to

the bracket using the 10-32 nut and screw provided with your PDU.

• PDU products are sold separately.

• The power mounting bracket may be installed in a variety of configurations. The following procedures

are meant to provide some examples.

NOTE: A junction box is also

included in the lower-left of the

enclosure.

Installing Vertically to the Backpan

Use a 10-32 x 3/8” screw (G) to install the power mounting bracket vertically to the backpan with outlets

facing forward or inside the enclosure as shown. (FIGURE AU and AV, respectively)

Page 29

INSTALLING THE POWER MOUNTING BRACKET

FIGURE AU

FIGURE AV

Bracket attached vertically,

positioning outlets inside.

Bracket attached vertically,

positioning outlets forward.

NOTE:

• Before installing the power mounting bracket to the backpan, install the clip included with your PDU to

the bracket using the 10-32 nut and screw provided with your PDU.

• PDU products are sold separately.

• The power mounting bracket may be installed in a variety of configurations. The following procedures

are meant to provide some examples.

NOTE: A junction box is also

included in the lower-left of the

enclosure.

Installing Horizontally to the Bottom of the Backpan

Use a 10-32 x 3/8” screw (G) and a 10-32 flange nut (F) to install the power mounting bracket

horizontally to the bottom of the backpan with outlets facing upward or forward as shown.

(FIGURE AW and AX, respectively)

Page 30

INSTALLING THE POWER MOUNTING BRACKET (CONTINUED)

FIGURE AW

FIGURE AX

Bracket attached horizontally,

positioning outlets upward.

Bracket attached horizontally,

positioning outlets forward.

Page 31

CABLE MANAGEMENT

• Route cables using the following knockouts provided on the top, sides, and bottom of the backpan.

(FIGURE AY)

NOTE:

• Cable ties (not provided) may be used with bridge lances on the backpan to secure cabling.

• Optional grommets (GR-30) are available to protect wiring when using circular knockouts.

• Optional VWM Series Cable Entry Brush Grommet (VWM-6BR-BP) is also available. For more

information, refer to the VWM Series Cable Entry Brush Grommet instruction sheet (I-00820).

1” and 1 1/2” EMT Knockouts

1/2” and 3/4” EMT Knockouts

5/8” EMT Knockout

FIGURE AY

1” and 1 1/2” EMT

Knockouts

1” and 1 1/2” EMT

Knockouts

1/2” and 3/4” EMT

Knockouts

Wiremold

4000

1/2” and 3/4” EMT

Knockouts

1” and 1 1/2”

EMT Knockouts

Cable Entry

Brush Grommet

Knockouts

Cable Entry

Brush Grommet

Knockouts

Wiremold

4000

Page 32

CABLE MANAGEMENT (CONTINUED)

NOTE: The vent openings on the upper and lower parts of the enclosure may be used to

accommodate larger cable bundles. Optional grommets (GK4 and GK-4G) may be used to protect

wiring when using the vent openings. (FIGURE AZ)

Some vent openings

on the top and

backpan.

WARRANTY

For warranty information, refer to http://www.middleatlantic.com/company/about-us.aspx#warranty

Corporate Headquarters

Corporate Voice: 973-839-1011 - Fax: 973-839-1976 / International Voice: +1 973-839-8821 -

Fax: +1 973-839-4982

www.middleatlantic.com - info@middleatlantic.com

Middle Atlantic Canada

Voice: 613-836-2501 - Fax: 613-836-2690 / ca.middleatlantic.com -

customerservicecanada@middleatlantic.ca

Factory Distribution

USA: NJ - CA - IL Canada: ON - BC

At Middle Atlantic Products we are always listening. Your comments are welcome.

Middle Atlantic Products is an ISO 9001 and ISO 14001 Registered Company.

FIGURE AZ

(8x) Knockout Locations

(Full Door Configuration)

VWM

Rack

Front

(6x) Knockout Locations

(Split Door Configuration)

VWM

Rack

Front