Neomounts by Newstar MED-M200 User Manual

Displayed below is the user manual for MED-M200 by Neomounts by Newstar which is a product in the Multimedia Carts & Stands category. This manual has pages.

Related Manuals

MED-M200

EN

NL

DE

FR

IT

ES

PT

DK

NO

SE

FI

PL

CS

SK

RO

Medical mount

Medische steun

Medizinische Halterung

Support médical

Supporto medico

Soporte médico

Suporte medico

Medicinsk beslag

Medisinsk feste

Medicinskt fäste

Medical teline

Uchwyt medyczny

Držák pro lékařské účely

Držiak na lekárske vybavenie

Suport medical

INSTRUCTION MANUAL

WWW.NEOMOUNTS.COM

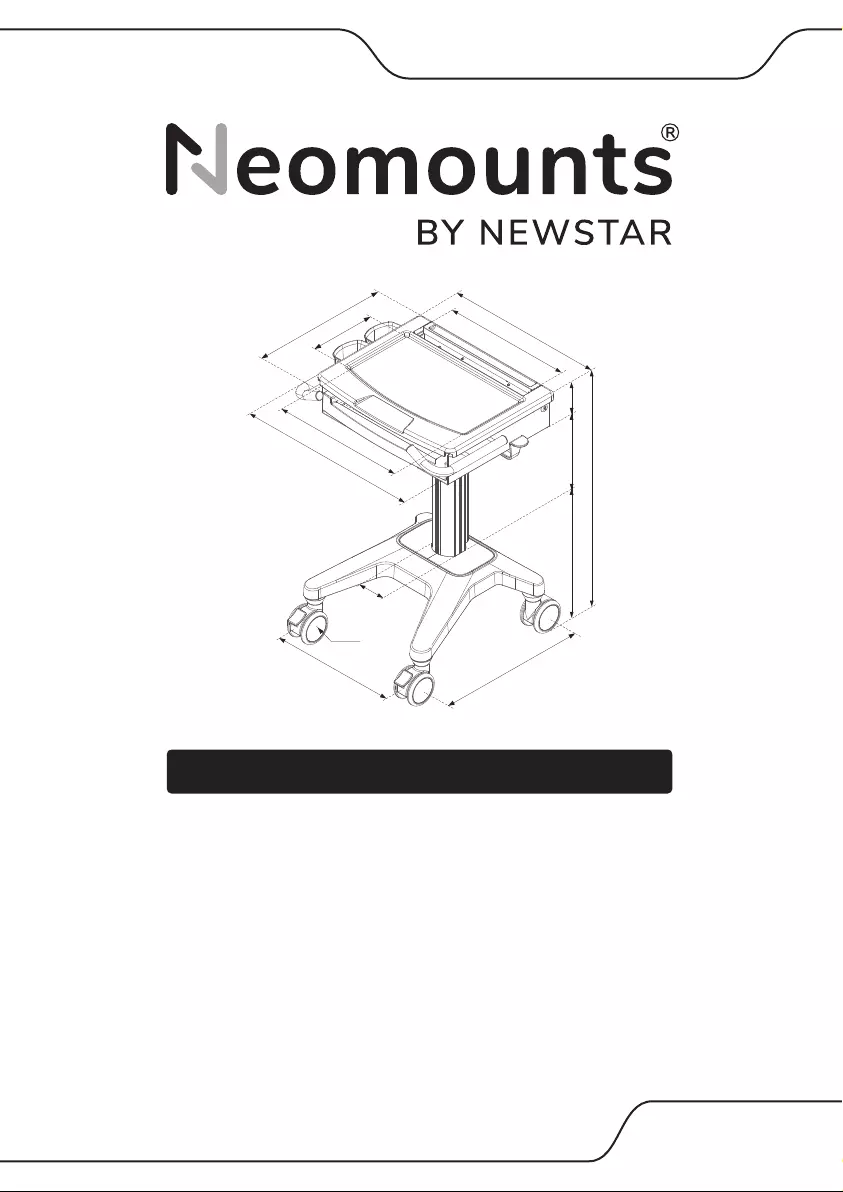

830~1080

247 126460~710

498

221

435

420

537

430

597

89

444

Ø 100

410 198

187

95

120

70

487

(x2)

(x2)

4 mm (x1)

(x1)

PARTS

(x1)

INDEX

Parts p. 2

Features p. 3

Step 1-2-3 p. 4

Step 4-5-6 p. 5

Step 7-8 p. 6

Adjustment and operation p. 7

Safety notes p. 8

Maintainance p. 10

MED-M200

Screen size

VESA

Weight capacity

Tilt

Swivel

Rotate

Height

Depth

Gas spring

Curved screen compatible

Quick-release VESA

Top-x clamp

180° lock system

Handlebar

Crossbar

Cable management

Screen size

VESA

Weight capacity

Tilt

Swivel

Rotate

Height

Depth

Gas spring

Curved screen compatible

Quick-release VESA

Top-x clamp

180° lock system

Handlebar

Crossbar

Cable management

0-5 kg |

0-11 lbs

Screen size

VESA

Weight capacity

Tilt

Swivel

Rotate

Height

Depth

Gas spring

Curved screen compatible

Quick-release VESA

Top-x clamp

180° lock system

Handlebar

Crossbar

Cable management

Screen size

VESA

Weight capacity

Tilt

Swivel

Rotate

Height

Depth

Gas spring

Curved screen compatible

Quick-release VESA

Top-x clamp

180° lock system

Handlebar

Crossbar

Cable management

83-108 cm

(x1)

(x1)

5 mm (x1) (x3) (x1)

(x1)

(x2)

(x2)

(x2)

(x2)

(x4)

(x4)

(x4)

3 mm (x1)

2

FEATURES

1. Laptop compartment

2. Storage basket

3. Work surface

4. Lift brake release (release brake to raise or lower the cart)

5. Cable management

6. Sliding keyboard tray with mouse holder and sliding mouse tray (to accomodate both right and left hand users)

7. Casters (2 rear non-locking and 2 front locking)

8. Latch

9. Key and lock hole

10. Hanger for accessories

11. Track for accessories mounted

FEATURES

1

2

3

4

5

6

7

8

10

11

9

250mm 350mm

ADJUSTMENT DIRECTION

3

54

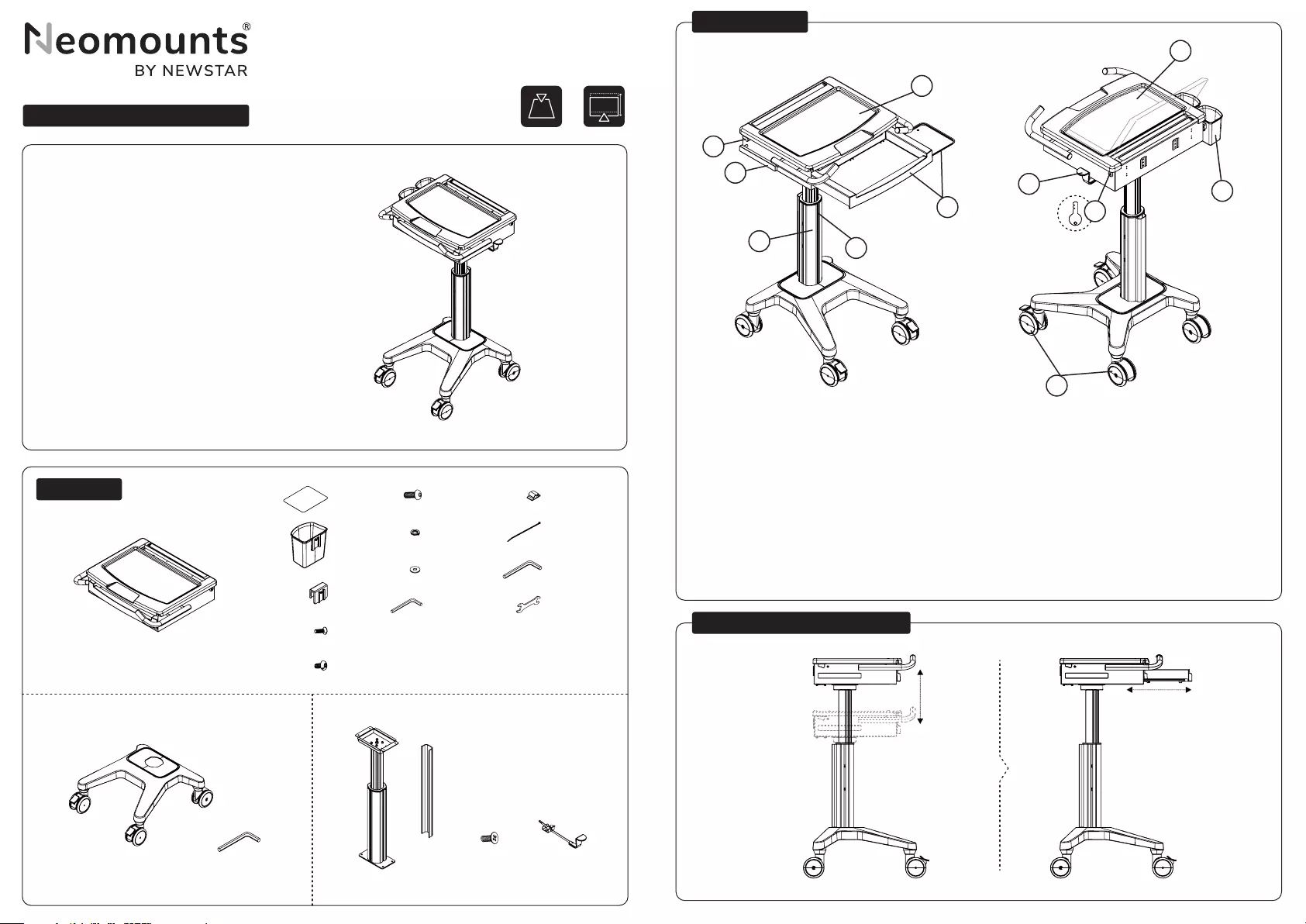

STEP 1

STEP 2

5mm

STEP 3

Latch

Lock

Open

Unlock the work surface

by turning the key

counterclockwise.

Push the latch backward

to lift the work surface.

Disamble the lid.

STEP 4 STEP 5

STEP 6

4mm

4mm

3mm

Use the screws to combine the top plate and the middle pilar.

or

Place the storage baskets on the side of the cart. Place the storage baskets at the back of the cart.

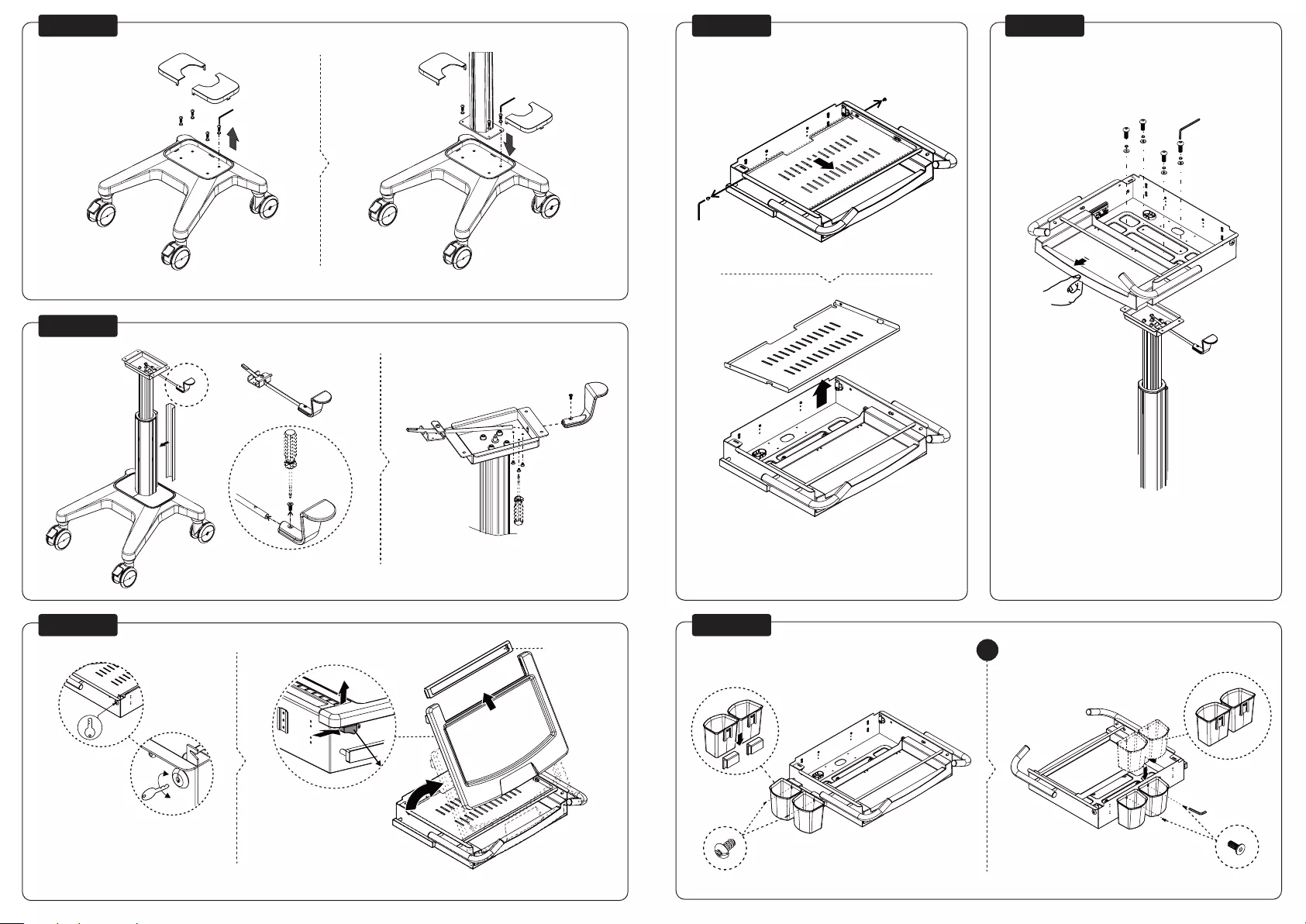

Use a 4mm Allen key to loosen the screws. Push the cooling

pad forward to take it out.

6

STEP 7

To avoid

ngers getting

caught/hurt,

please slide

the mouse tray

by using the

palm.

Direction of cable management and accessory assembly.

Holes for cable

management.

Storage for

cables and

adapters.

STEP 8

4mm

Put back the cooling pad and fasten the screws by using a

4mm Allen key.

Place the laptop in the compartment and place back the work

surface. Please notice the work surface must be locked and

the latch must be pushed forward before moving this cart.

Lock

Open

ADJUSTMENT AND OPERATION

Release brake to

adjust the height.

In case of cart damage, do not adjust the lift mechanism with an empty cart, since this may cause the work surface to

rise too quickly.

Notice:

Make sure to put a hand on both sides of the work surface while releasing the brake to higher or lower the work surface,

as shown in the gure. Do not push the center of the work surface to lower the height. When raising the work surface,

use two hands to slightly lift the surface if it remains motionless.

7

250mm

SAFETY NOTES

WARNING

Please notice that the latch must be pushed forward after placing back the work surface.

WARNING

When moving the cart over irregular surface or thresholds, please lift the cart from the bottom of the keyboard compartment, as shown in

the gure. Do not lift the cart from the handles.

WARNING

When the cart is in its place/not moving, make sure to put the brake on the two front casters.

WARNING

Make sure to put a hand on both sides of the work surface while releasing the brake to higher or lower the work surface, as shown in

the gure. Do not push the center of the work surface to lower the height. When raising the work surface, use two hands to slightly lift

the surface if it remains motionless.

Height adjustment

button

WARNING

Please do not apply pressure to the work surface, especially not in the center area, except when adjusting the height.

8 9

11

MAINTENANCE

All cart maintenance must be carried out at least once a month by a professional technician.

Cleaning warning

Because the cart is in the environment of electrical equipment, the usage of inammable cleansers are strictly forbidden.

1. Before cleaning the cart, please make sure the cart is unplugged from the mains and switched off.

2. Please ensure the cart is entirely dry before plugging the power into the socket.

3. While cleaning the cart, please use a damp cloth to wipe off the supercial cleansers until completely dry.

4. The cart is not to be used in a moist environment and liquids have to be avoided from running into the cart.

5. To avoid the nishing of the surface being damaged, do not use any abrasive materials for cleaning.

6. Before using any cleanser on the cart, please test them on a small part to see whether it affects the surface or not.

Please note that these guidelines give no guarantee whatsoever in terms of infection control. Kindly consult your medical infection

control specialist for cleaning advice.

Cleaning recommendations

1. Please use non-abrasive or diluted products such as soap water and diluted alcohol to clean the plastic components.

2. In case of spots of pen or maker on the cart’s surface, a soft cloth with 91% isopropyl alcohol is suggested for cleaning.

3. In cased of iodine spots on the cart’s surface, a soft cloth with soap water or diluted alcohol is suggested for cleaning.

The following chemicals are strictly forbidden for cleaning the cart: Abrasive cleansers, acetone , mineral spirits, point thinner or any

other harsh or toxic chemicals.

lnspections

All cart inspections must be carried out at least once a month by a professional technician.

In case of faults or damage occurring, stop operating the cart and contact your distributor for further assistance.

Casters

To allow the cart to move as intended, please inspect the casters regularly and keep the cart away from damaged and irregular surfaces.

Fasteners

lf fasteners/ screws become loose and need to be tightened, do not over-tighten them. Over-tightened fasteners/ screws might not only

cause damage to the screws but also to the components.

Troubleshooting

The cart is difcult to move

Ensure the two front locking casters are not locked. Check if any debris is sticking to casters and remove it.

The cart is difcult to adjust in height

Ensure the lift brake is pressed completely and lift the work surface slightly, to prevent the work surface to rise too quickly. lf the lift

mechanism still doesn’t work, please contact your distributor for further assistance. Also contact your distributor for assistance if the lift

mechanism keeps going up automatically.

10