Saeco RI9745/01 User Manual

Displayed below is the user manual for RI9745/01 by Saeco which is a product in the Coffee Makers category. This manual has pages.

Related Manuals

Type HD8743 / HD8745 / HD8747 - Cod.15002552 Rev.00 del 15-03-10

Th e ma nu fa ct u re r re s erve s th e r i ght t o c ha ng e t he f ea tu re s of t h e pr od uc t w it h ou t pr i o r no ti c e.

www.philips.com/saeco

EN

SAECO INTERNATIONAL GROUP S.P.A

Via Torretta, 240 - 40041 Gaggio Montano (Bo) - Italy

declare under our responsibility that the product :

AUTOMATIC COFFEE MAKER

SUP 033R

to which this declaration relates is in conformity with the following standards

or other normative documents :

• Safety of household and electrical appliances - General requirements

EN 60335-1(2002) + A1(2004) + A2(2006) + A11(2004) + A12(2006)+

A13(2008)

• Safety of household and electrical appliances - Part 2-15

Particular requirements for appliances for heating liquids

EN 60335-2-15(2002) + A1(2005) + A2 (2008).

• Household and similar electrical appliances - Electromagnetic elds - methods

for evaluation and measurement - EN 62233 (2008).

• Household and similar electrical appliances - safety - Part 2-14

Particular requirements for kitchen machines

EN 60335-2-14 (2006) + A1 (2008).

• Electromagnetic compatibility (EMC) - Requirements for household appliances

, electric tools and similar apparatus - Part 1 - Emission EN 55014-1 (2006).

• Electromagnetic compatibility (EMC) - Part. 3^ Limits - Section 2 : Limits for

harmonic current emissions (equipment input current ≤ 16A for phase)

EN 61000-3-2 (2006)

• Electromagnetic compatibility (EMC) - Part 3^ : Limits - Section 3 : Limitation

of voltage changes , voltage uctuations and icker in public low - voltage sup-

ply systems , for equipment with rated current ≤ 16 A for phase and not subject

to conditional connection

EN 61000-3-3 (1995)+ corr.(1997) +A1 (2001) + A2 (2005).

• Electromagnetic compatibility - Requirements for household appliances , elec-

tric tools and similar apparatus - Part 2. Immunity - Product family standard

EN 55014-2 (1997) + A1 (2001)

following the provisions of the Directives: EC 2006/95 , EC 2004/108.

EC DECLARATION OF CONFORMITY

YEAR 09

EC 2006/95, EC 2004/108,

R & D Manager

Mr . Andrea Castellani

Gaggio Montano

li, 28/04/2009

OPERATING INSTRUCTIONS

READ THESE OPERATING INSTRUCTIONS CAREFULLY BEFORE USING THE MACHINE.

Register your product and get support at

www.philips.com/welcome

EN

English

Type HD8743 / HD8745 / HD8747

SUP 033R

• 2 •

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be

followed, including the following:

1. Read all instructions.

2. Do not touch hot surfaces. Use handles or knobs.

3. To protect against fire, electric shock and injury to persons do not immerse

cord, plugs, or appliance in water or other liquid.

4. Close supervision is necessary when the appliance is used by or near

children.

5. Unplug from outlet when not in use and before cleaning. Allow to cool

before putting on or taking off parts, and before cleaning the appliance.

6. Do not operate any appliance with a damaged cord or plug or after the

appliance malfunctions, or has been damaged in any manner. Return

appliance to the nearest authorized service facility for examination, repair

or adjustment.

7. The use of accessory attachments not recommended by the appliance

manufacturer may result in fire, electric shock or injury to persons.

8. Do not use outdoors.

9. Do not let cord hang over edge of table or counter, or touch hot

surfaces.

10. Do not place on or near a hot gas or electric burner, or in a heated

oven.

11. Always attach plug to appliance first, then plug cord into wall outlet. To

disconnect, turn any control to “off”, then remove plug from wall outlet.

12. Do not use appliance other than for intended use.

13. Save these instructions.

SAVE THESE INSTRUCTIONS

• 3 •

English

CAUTION

This appliance is for household use only. Any servicing, other than cleaning

and user maintenance, should be performed by an authorized service center.

Do not immerse machine in water. To reduce the risk of fire or electric shock,

do not disassemble the machine. There are no parts inside the machine

serviceable by the user. Repair should be done by authorized service personnel

only.

1 Check voltage to be sure that the voltage indicated on the nameplate

corresponds with your voltage.

2 Never use warm or hot water to fill the water tank. Use cold water only.

3 Keep your hands and the cord away from hot parts of the appliance during

operation.

4 Never clean with scrubbing powders or harsh cleaners. Simply use a soft

cloth dampened with water.

5 For optimal taste of your coffee, use purified or bottled water. Periodic

descaling is still recommended every 2-3 months.

6 Do not use caramelized or flavored coffee beans.

INSTRUCTIONS FOR THE POWER

SUPPLY CORD

A. A short power-supply cord (or detachable power-supply cord) is to be

provided to reduce risks resulting from becoming entangled in or tripping

over a longer cord.

B. Longer detachable power-supply cords or extension cords are available

and may used if care is exercised in their use.

C. If a long detachable power-supply cord or extension cord is used,

1. The marked electrical rating of the detachable power-supply cord or extension

cord should be at least as great as the electrical rating of the appliance

2. If the appliance is of the grounded type, the extension cord should be a

grounding-type 3-wire cord, and

3. The longer cord should be arranged so that it will not drape over the counter top

or table top where it can be pulled on by children or tripped over.

• 4 •

GENERAL INFORMATION

The co ee machine is suitable for preparing espresso co ees using whole co ee beans and is

equipped with a device to dispense steam and hot water.

The machine is designed for domestic use and is not suitable for heavy or professional use.

Keep these operating instructions in a safe place and make them available to anyone

who may use the co ee machine.

For further information or in case of problems that are not included or not completely explai-

ned in these instructions, please contact the Saeco customer service or an authorized service

center.

Warning. No liability is assumed for damage caused by:

• Incorrect use not in accordance with the intended uses;

• Repairs not carried out by authorized service centers;

• Tampering with the power cord;

• Tampering with any part of the machine;

• Storage or use of the machine at a temperature outside the operating temperature

range (+15°C / +45°C);

• Use of non-original spare parts and accessories.

In these cases, the warranty shall be deemed null and void.

SAFETY REGULATIONS

Never allow water to come into contact with any of the electrical parts of the

machine: Danger of short circuit! Steam and hot water may cause scalding! Do

not direct the steam or hot water jet towards body parts. Carefully handle the steam/

hot water spout by means of the special handle: Danger of scalding!

Intended Use

The co ee machine is intended for domestic use only. Do not make any technical changes or use

the machine for unauthorized purposes since this would create serious hazards! The appliance is

not to be used by persons (including children) with reduced physical, mental or sensory abilities

or with limited experience and/or expertise, unless they are supervised by a person responsible

for their safety, or they are instructed by this person on how to properly use the machine.

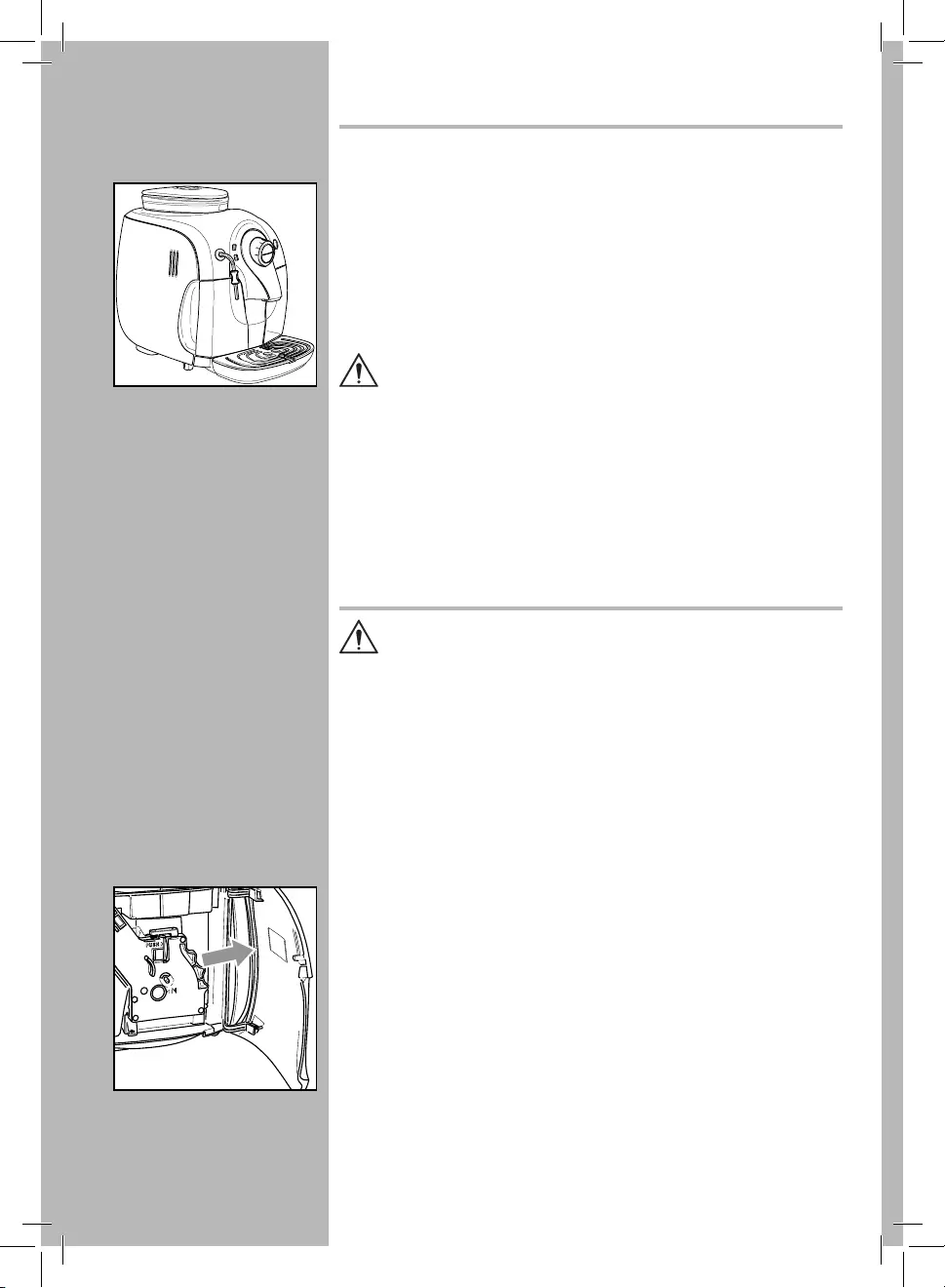

Power Supply - Power Cord

Only connect the co ee machine to a suitable power socket.

The voltage must correspond to the indication on the machine label located on the inside of

service door.

Never use the co ee machine if the power cord is defective or damaged.

If damaged, the power cord must be replaced by the manufacturer or an authorized service

center. Do not pass the power cord around corners, over sharp edges or over hot objects and

keep it away from oil. Do not use the power cord to carry or pull the co ee machine.

Do not pull out the plug by the power cord or touch it with wet hands. Do not let the power cord

hang freely from tables or shelves.

For the Safety of Others

Keep children under control to prevent them from playing with the product. Children are not

aware of the risks related to electric household appliances. Do not leave the machine packaging

materials within the reach of children.

• 5 •

English

Danger of Burns

Never direct the jet of hot steam and/or hot water towards yourself or others: Danger of scal-

ding! Always use the handles or knobs provided.

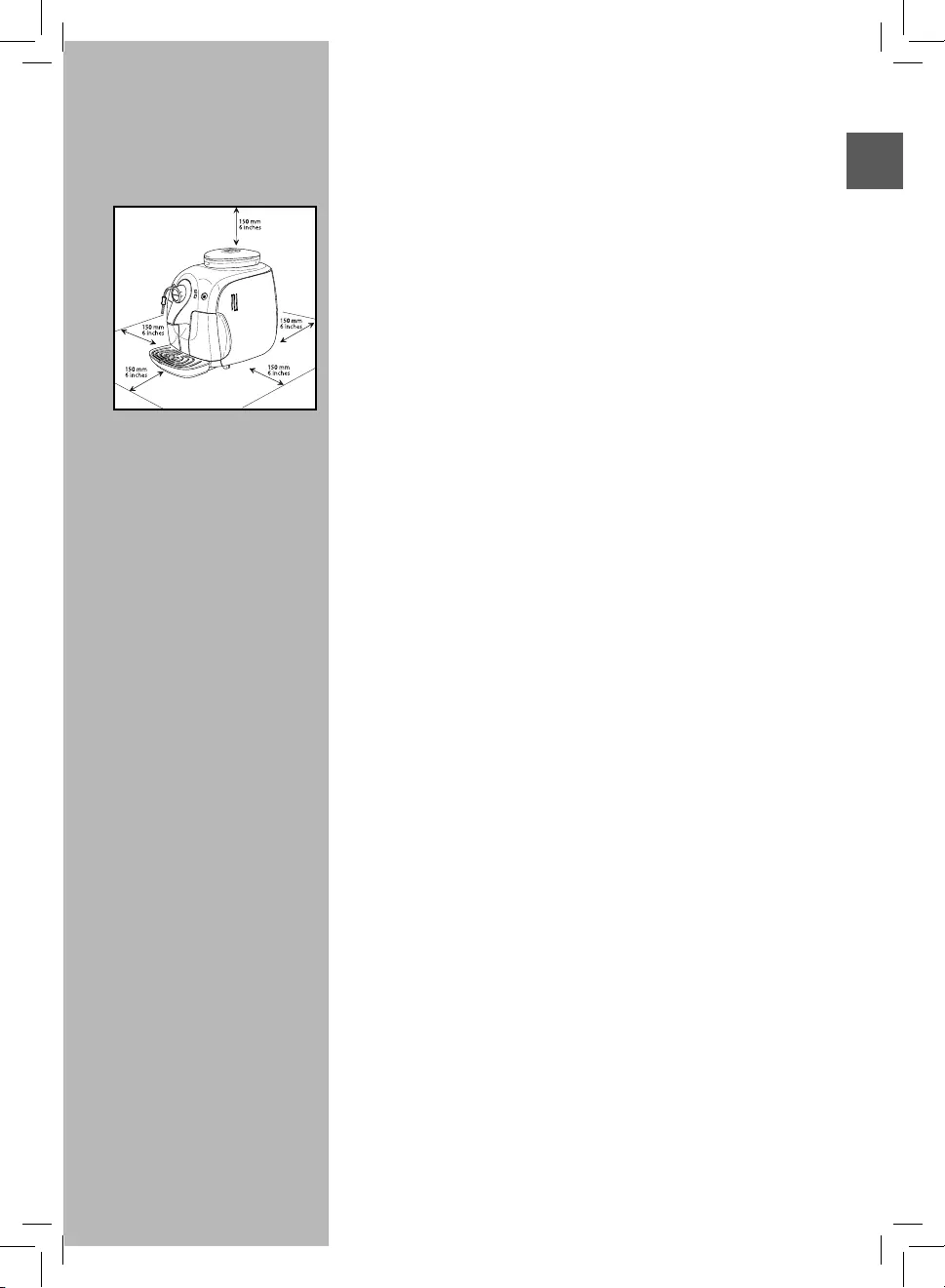

Machine Location - Suitable Location for Operation and Maintenance

For best use, it is recommended to:

• Choose a safe, level surface, where there will be no danger of overturning it or being inju-

red.

• Choose a location that is su ciently well-lit, clean and near an easily reachable socket.

• Allow for a minimum distance from the sides of the machine as shown in the illustration;

• During machine turning on/o , it is recommended to place an empty glass under the di-

spensing spout.

Do not keep the machine at a temperature below 0°C (32°F). Frost may damage the machine.

Do not use the co ee machine outdoors. In order to prevent its housing from melting or being

damaged, do not place the machine on very hot surfaces or close to open ames.

Storing the Machine - Cleaning

Before cleaning the machine, turn it o by pressing the ON/OFF button, then remove the plug

from the socket.

Wait for the machine to cool down.

Never immerse the machine in water!

It is strictly forbidden to tamper with the internal parts of the machine.

Water left in the tank for several days should not be consumed. Wash the tank and ll it with

fresh drinking water.

If the machine is to remain inactive for a long time, dispense water from the steam wand, and

carefully clean the Pannarello (if supplied), then turn it o and unplug it. Store it in a dry place,

out of the reach of children. Keep it protected from dust and dirt.

Repairs / Maintenance

In case of failure, problems or a suspected fault resulting from the falling of the machine, im-

mediately remove the plug from the socket. Never attempt to operate a faulty machine.

Servicing and repairs may only be carried out by authorized service centers. All liability for

damages resulting from work not carried out by professionals is declined.

Fire Safety Precautions

In case of re, use carbon dioxide (CO2) extinguishers. Do not use water or dry powder extin-

guishers.

• 6 •

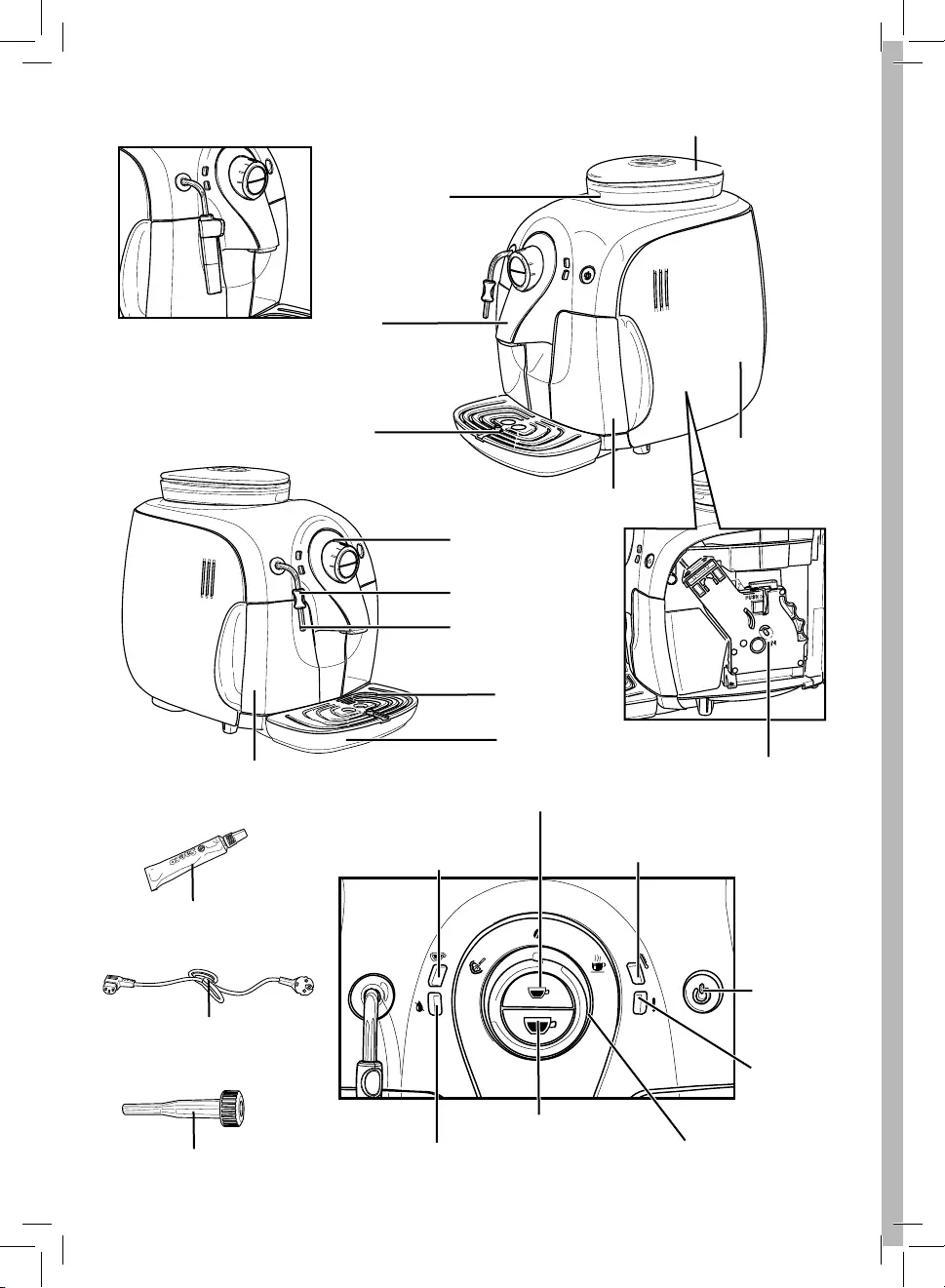

Co ee bean hopper lid

Grinder adjustment key

Power cord

Brew group lubricant

Double co ee light and brewed

co ee length setting Temperature light

Water tank level

light

Warning light

Small co ee button

Large co ee button

Control dial

ON/OFF button

Pannarello (optional - only available

for certain models)

Brew group

Dregdrawer

Service door

Co ee bean hopper

Dispensing spout

Grill

Full drip tray indicator

Drip tray

Water tank

Hot water/steam wand

Protective handle

Control panel

• 7 •

English

INSTALLATION

For your safety and the safety of

others, carefully follow the instruc-

tions provided in the “Safety Regula-

tions” section.

Machine Packaging

The original packaging has been designed

and constructed to protect the machine

during transport. We recommend keeping

the packaging material for possible future

transport.

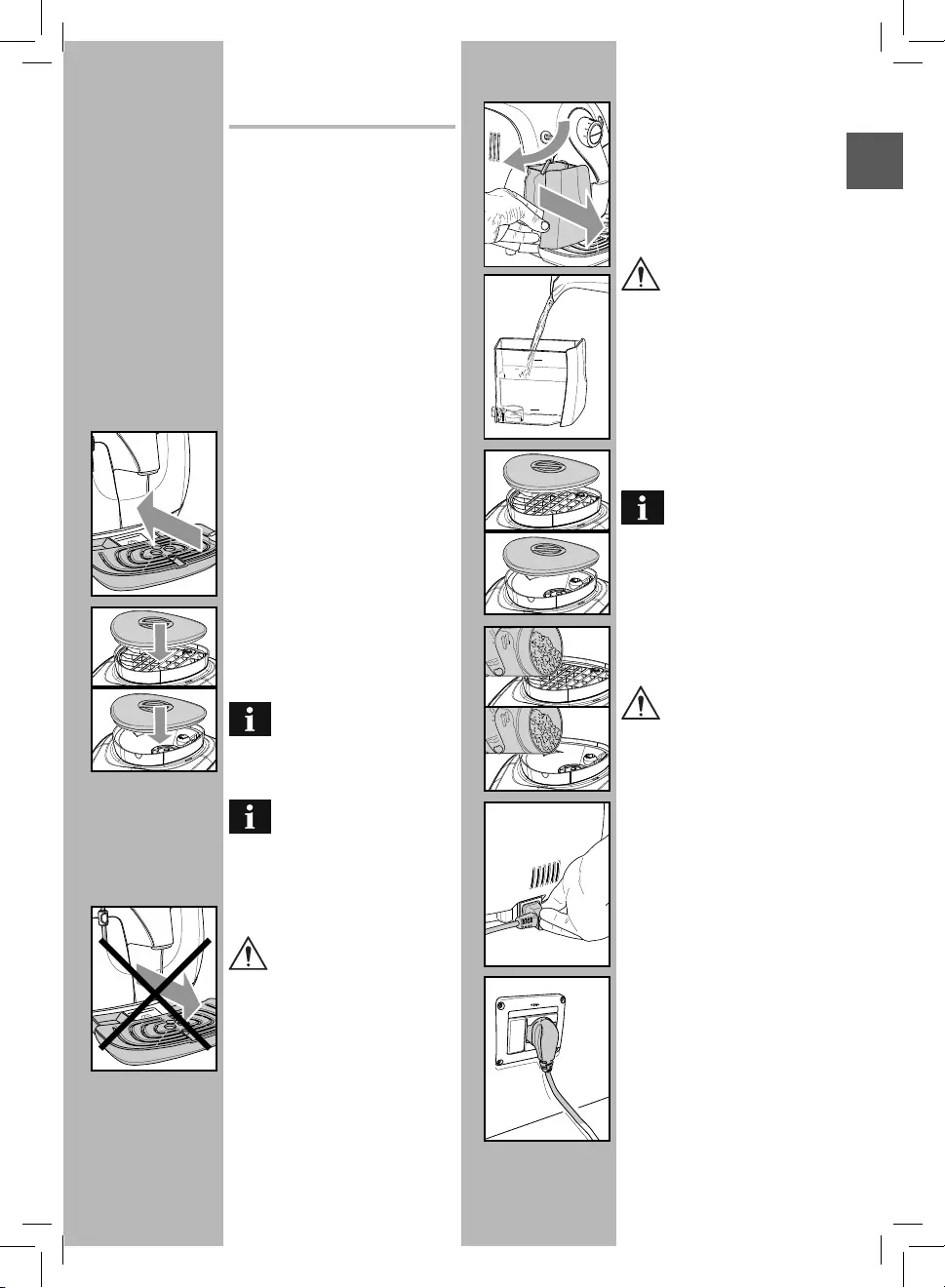

Preliminary Operations

• Remove the co ee bean hopper lid and

the drip tray with grill from the packa-

ging.

• Remove the co ee machine from the

packaging and position it in a place that

meets the requirements described in the

“Safety Regulations”.

• Place the drip tray with grill into its

appropriate seat on the machine. Make

sure it is fully inserted to its limit stop.

• Replace the co ee bean hopper lid.

Note: Insert the plug into the

socket only when indicated

and check that the ON/OFF button is

not pressed.

Important Note: Carefully read

the explanations of all the

warnings displayed by the machine

to the user by means of the lights on

the control panel (see section “Control

Panel Lights”).

NEVER remove the drip tray

when the machine is turned on.

Wait a couple of minutes after turning

on/o , since the machine will carry out

a rinse/self-cleaning cycle (see section

“Rinse/Self-Cleaning Cycle”).

MAX

MIN

• Remove the water tank.

• Rinse and ll it with fresh water ma-

king sure that it is not lled exceeding

the MAX level indicated in the water

tank. Put the water tank back in its

seat to its limit stop.

Use only fresh, non-sparkling

water to fill the tank. Hot

water or any other liquid may damage

the tank and/or the machine. Do not

turn on the machine when the tank

is empty: Make sure there is enough

water in the tank.

• Remove the co ee bean hopper lid.

Note: The hopper may be

fitted with different safety

features according to the regula-

tions of the country of use of the

machine.

• Slowly pour the co ee beans into the

hopper.

Only co ee beans must be put

into the co ee bean hopper.

Ground coffee, instant coffee or

any other object may damage the

machine.

• Replace the lid on the co ee bean hop-

per.

• Insert the plug into the socket located

on the back of the machine.

• Insert the plug of the other end of the

power cord into a wall socket with

suitable power voltage.

• 8 •

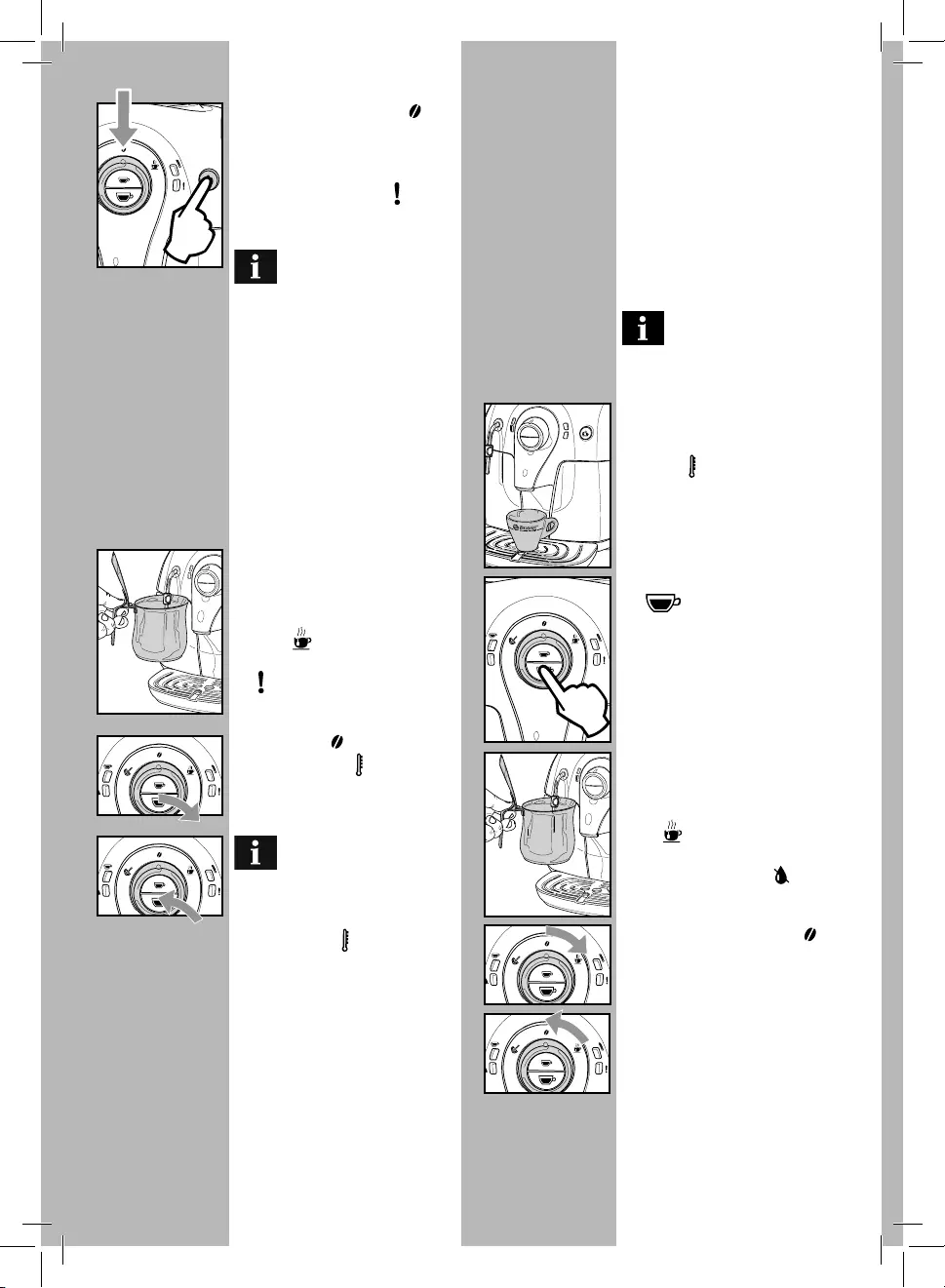

• Make sure control dial is on “ ” posi-

tion; if this is not the case, set it to that

position.

• Simply press the ON/OFF button to

turn the machine on; the “ “ light will

begin to blink rapidly indicating that

the water circuit must be primed.

Note: Before starting the

machine for the first time,

prime the water circuit.

Using the machine for the

first time or after a long

period of inactivity.

These simple operations will make it pos-

sible to always brew excellent co ee.

They have to be performed:

A) At rst start-up.

B) When the machine remains inactive

for a long time (more than 2 weeks).

Dispensed water must be em-

ptied into an adequate drain.

It is not suitable for food use.

1 Place a container under the dispensing

spout.

2 Before starting the procedure, check

that the “ “ light is steady on.

Priming the Water Circuit

• To prime the water circuit, place a

container under the hot water / steam

wand.

• Turn the control dial clockwise to set it

to the “ ” position and wait.

When water steadily comes out and the

““ light will blink slowly - indicating

that the knob can be turned o - rotate

the control dial counter-clockwise to set

it back to the “ ” position.

• At this point the “ “ light begins to

blink slowly, indicating that the ma-

chine is in warm-up mode.

When warm-up is complete,

the machine performs a rinse

cycle of the internal circuits.

• When the above steps are complete,

check that the “ “ light is on steady.

The machine is now ready for use.

• To brew co ee, dispense hot water or

steam, and for a proper use of the ma-

chine, carefully follow the instructions

provided.

3 Brew one co ee. Press and release the

““ button. The machine starts

brewing co ee.

4 Wait until brewing is complete and

remove the container.

5 Place a container under the steam wand

(Pannarello, if supplied).

6 Turn the selector switch clockwise to

the “ ” position.

7 Dispense water until the no water

signal is displayed. The “ ” light re-

mains steady on.

Now turn the selector switch counter-

clockwise to set it back to the “ ” po-

sition.

8 At the end, fill the water tank again.

Then the products can be brewed as

described in the following sections

• 9 •

English

+

Blinking

Steady on

Rinse/Self-Cleaning Cycle

This cycle will rinse the internal circuits

with fresh water.

The cycle is carried out:

• At machine start (with cold boiler)

• After priming the water circuit (with

cold boiler)

• During the standby preparation phase

(if a co ee product has been brewed)

• During the turning off phase after

pressing the ON/OFF button (if a co ee

product has been brewed).

Note: Before dispensing,

place a container beneath the

dispensing spout.

A small amount of water will be dispensed

which will rinse and heat all the machine

components; in this phase the indicator

lights ash counter-clockwise.

Wait for the cycle to nish automatically.

You can stop dispensing as well, by pres-

sing either co ee button.

ADJUSTMENTS

The machine that you have bought allows

for certain adjustments that will permit

you to use it to its full potential.

Saeco Adapting System

Coffee is a natural product and its cha-

racteristics may change according to its

origin, blend and roast. The Saeco co ee

machine is equipped with a self-adjusting

system that allows the use of all types of

co ee beans available on the market (non

caramelized).

• The machine automatically adjusts

itself in order to optimize the extrac-

tion of the coffee, ensuring perfect

compression of the beans to obtain a

creamy espresso co ee that will release

all the aromas, regardless of the type of

co ee used.

• The optimization process is a learning

process that requires the brewing of a

certain number of co ees to allow the

machine to adjust the compactness of

the ground co ee.

• Attention should be given to spe-

cial blends, which require grinder

adjustments in order to optimize the

extraction of the co ee (see section

“Co ee Grinder Adjustment”).

• 10 •

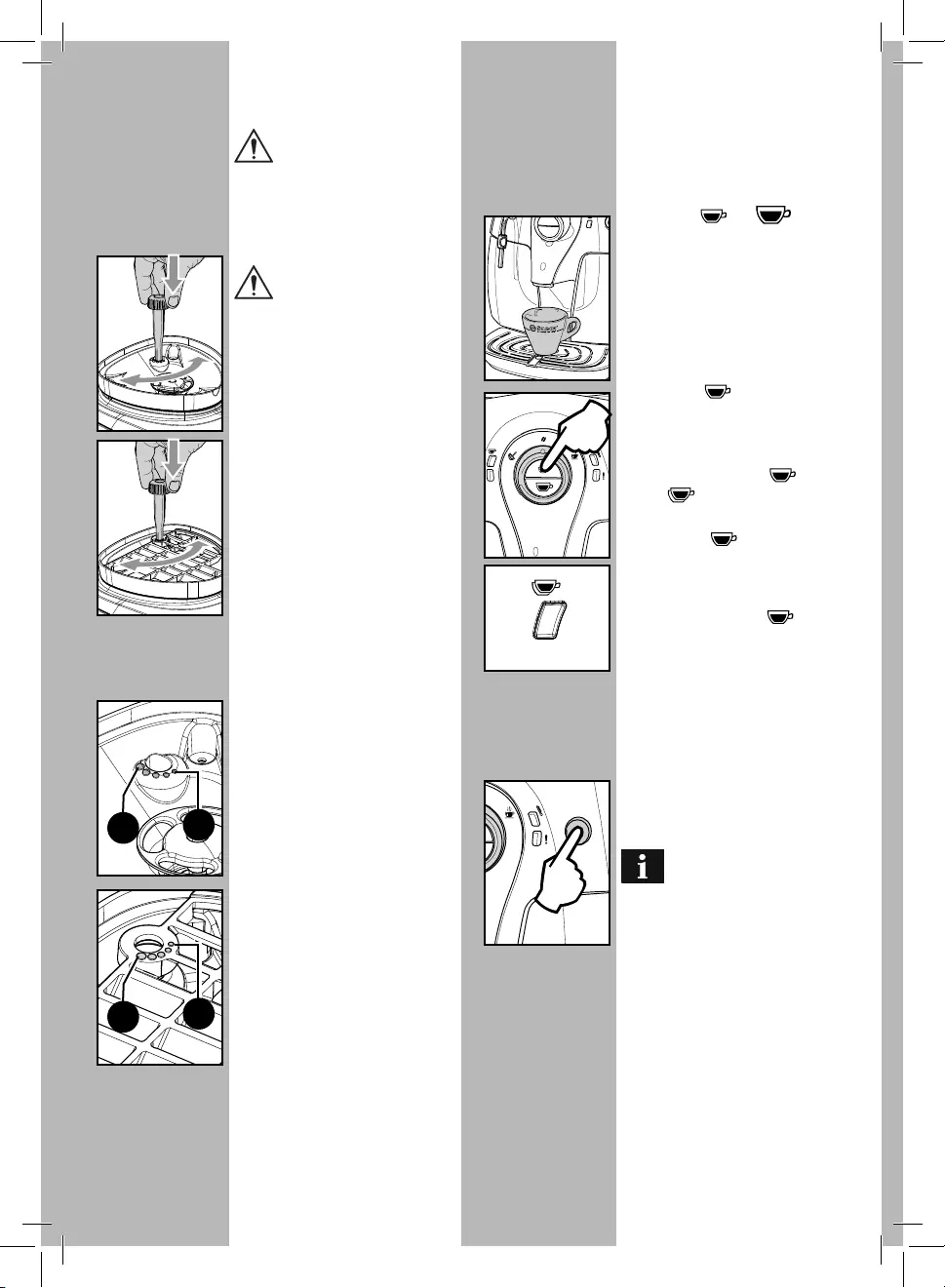

Coff ee Grinder Adjustment

Warning! The grinder

adjustment knob, inside the

co ee bean hopper, must be turned

only when the grinder is working. Do

not pour ground and/or instant co ee

into the co ee bean hopper.

Do not insert any material

other than co ee beans into

the hopper. The grinder contains

moving parts that may be dangerous.

Therefore, do not insert ngers and/

or other objects. Only adjust the

grinder using the grinder adjustment

key. Turn o the machine by pressing

the ON/OFF button and remove the

plug from the socket before carrying

out any type of operation inside the

coffee bean hopper. Do not pour

co ee beans when the co ee grinder

is working.

The machine lets you make slight

adjustments to the coffee grinder to

adapt it to the kind of co ee used.

This adjustment should be carried out

by adjusting the pin on the inside of the

coffee bean hopper; this pin must be

pressed and turned only with the grinder

adjustment key provided with the co ee

machine.

Press and turn the pin one notch at a

time. You must brew 2-3 coffees before

you will taste a di erence.

The reference marks inside the coffee

bean hopper indicate the grind setting.

There are 5 di erent grind settings to cho-

ose from with the following references:

1 - Coarse Grind

2 - Fine Grind

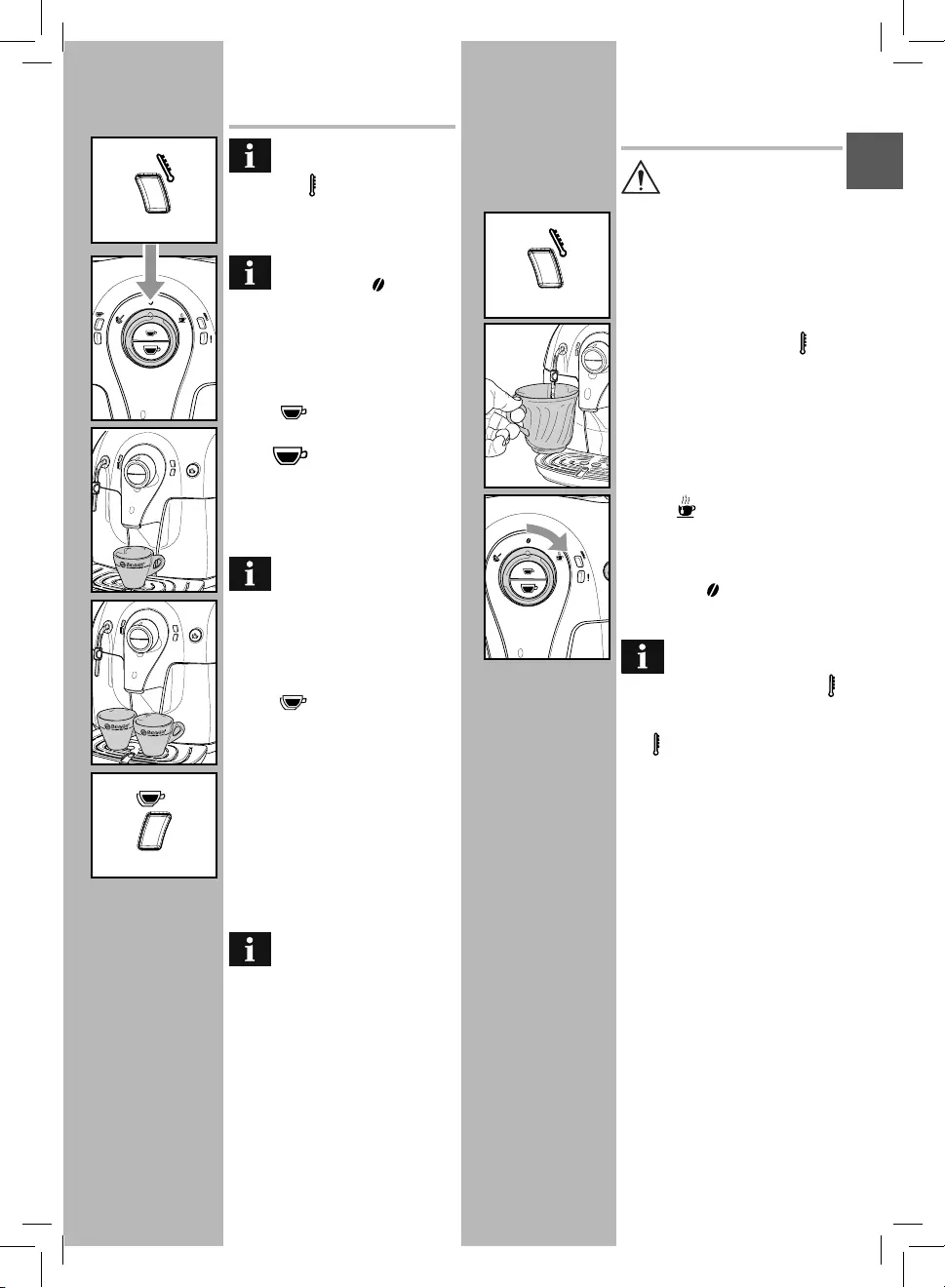

Adjusting the Brewed Coff ee

The machine allows you to adjust the

amount of brewed coffee according to

your taste and/or the size of your cups.

Each time the “ “ or “ “ buttons

are pressed and released, the machine

brews a pre-set amount of coffee. This

amount may be reprogrammed to your

taste. Each button may be individually

programmed for a speci c brew setting.

As an example, the following procedure

describes the programming of the small

coffee button “ “, which is normally

associated with espresso co ee.

• Place a cup under the dispensing

spout.

• Press and hold down the “ “ button;

the “ “ light blinks during this

phase.

• Release the “ “ button when the

amount of coffee in the cup reaches

the desired level.

At this point the button “ “ is pro-

grammed; each time it is pressed and

released, the machine will brew the same

amount of co ee that was just program-

med.

Standby

The machine is designed for energy sa-

ving.

After 60 minutes of inactivity, the machi-

nes turns o automatically.

Note: During the turning o

phase, the machine performs

a rinse cycle, if a co ee product has

been brewed.

To turn the machine on again, simply

press the ON/OFF button; in this case the

machine will go through the rinse cycle

only if the boiler is cold.

1

1

2

2

Blinking

• 11 •

English

COFFEE BREWING

Before brewing co ee, make

sure that the green tempe-

rature light “ “ is steady on and that

the water tank and the co ee hopper

are full.

Leave the control dial on the

co ee position “” during the

dispensing phase.

• Place 1 or 2 cups under the dispensing

spout.

• To brew co ee, press and release:

the “ “ button for an espresso

co ee;

the “ “ button for a long co ee.

• To dispense 1 cup of co ee, press the

button once. To dispense 2 cups of co ee,

press the button twice.

In this operating mode, the

machine automatically grin-

ds and doses the correct amount of

co ee. Brewing two co ees requires

two grinding cycles and two brewing

cycles, automatically carried out by

the machine; this option is indicated

by the ““ light being constantly

on.

• After the prebrewing cycle, co ee be-

gins to dispense out of the dispensing

spout.

• Coffee brewing stops automatically

when the pre-programmed level is rea-

ched; however, it is possible to interrupt

co ee brewing by pressing the button

initially pressed.

The machine is adjusted to

brew a true Italian espresso

coffee. This feature may slightly

lengthen the brewing time, allowing

the intense flavor of the coffee to

develop fully.

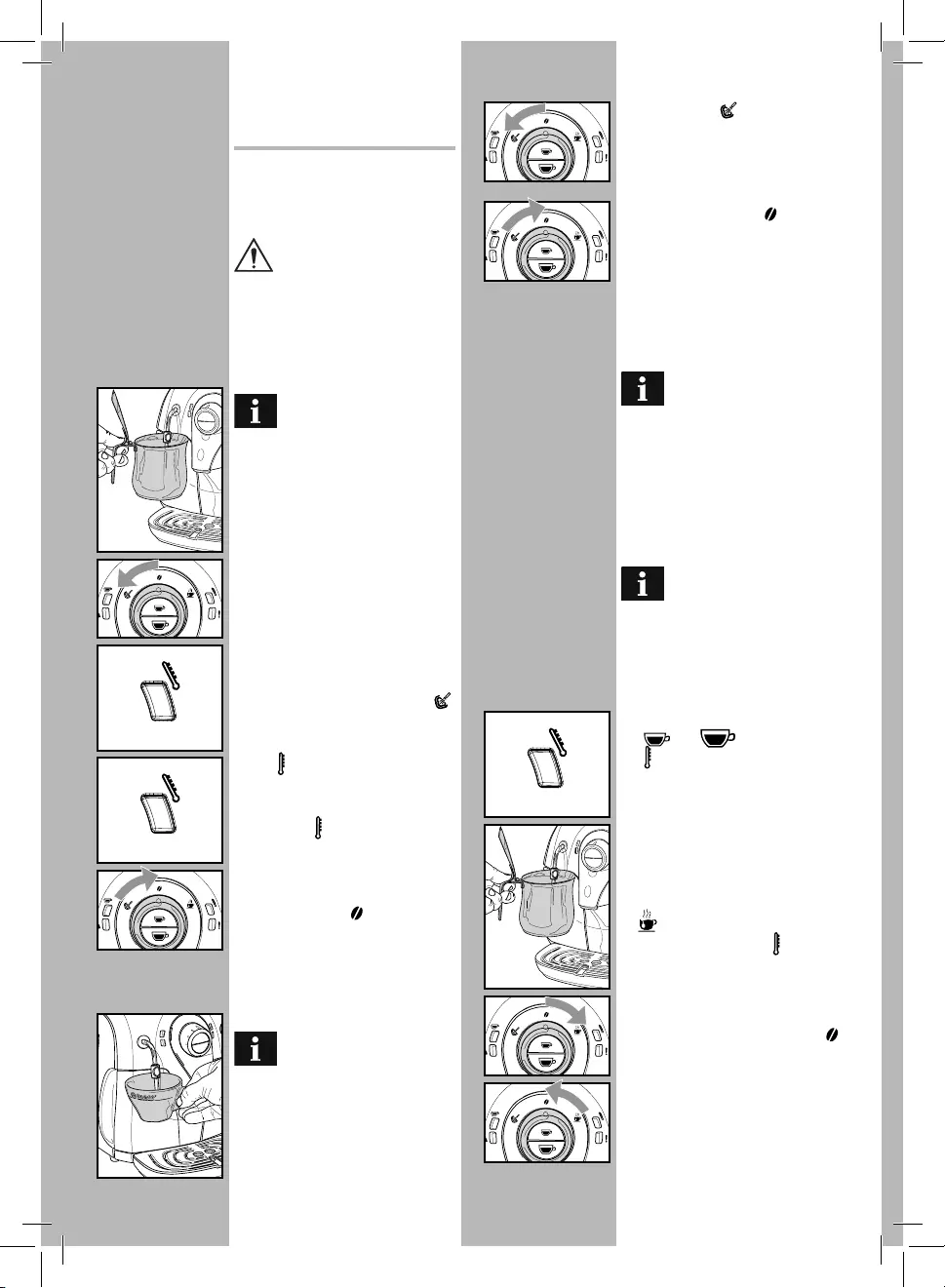

DISPENSING HOT

WATER

Warning: Dispensing may be

preceded by short sprays of

hot water, and scalding is possible.

The hot water/steam wand may reach

high temperatures. Do not touch it

with bare hands; use the appropriate

handle only.

• Before dispensing hot water, check

that the green temperature “ “ light

is steady on.

When the machine is ready, proceed as

follows:

• Place a container under the hot water /

steam wand (Pannarello, if supplied);

• Turn the control dial clockwise to set it

to the “ ” position.

• Fill the cup with hot water to the desi-

red level; to stop hot water dispensing,

turn control dial counter-clockwise

back to the “ ” position. The machine

returns to the normal operating mode.

Occasionally, after turning

the control dial, hot water

may not be dispensed and the “ “

light may blink slowly. To obtain a

ow of hot water, simply wait until

the “ “ light stops blinking and re-

mains steady.

Steady on

Steady on

Steady on

• 12 •

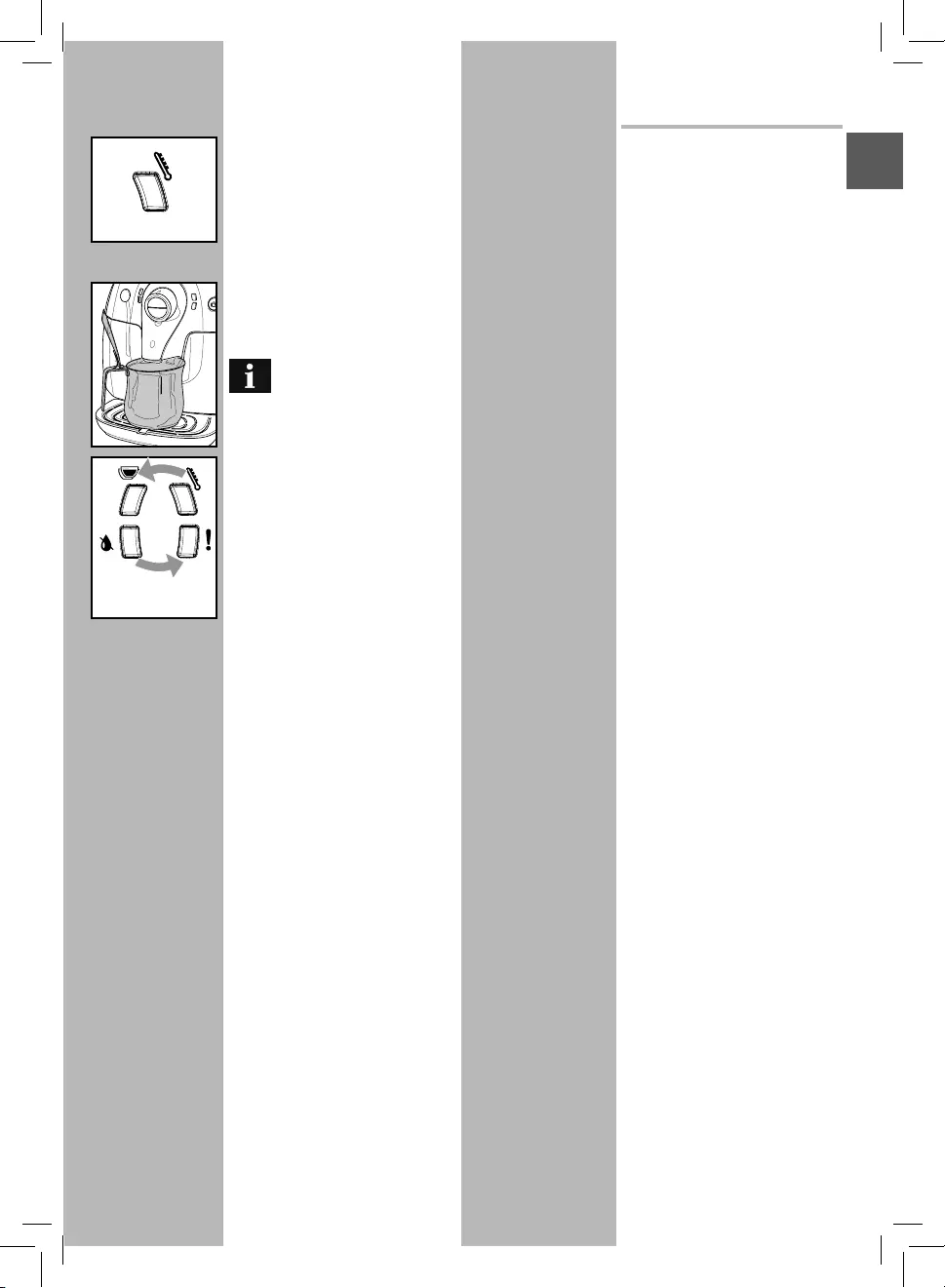

STEAM DISPENSING /

CAPPUCCINO BREWING

Steam may be used to froth milk for a

cappuccino, as well as to reheat other

beverages.

Warning: Dispensing may be

preceded by short sprays of

hot water, and scalding is possible.

The hot water/steam wand may reach

high temperatures. Do not touch it

with bare hands; use the appropriate

handle only.

Important Note: Immediately

after using the steam to froth

the milk, clean the steam wand (or

Pannarello when provided). When

the machine is ready, brew a small

amount of hot water in a glass and

clean the wand (or Pannarello when

provided) externally. In this way, all

parts will be perfectly cleaned and

free of any milk residue.

• Place a container under the hot water /

steam wand (Pannarello, if supplied).

• When the machine is ready to brew

co ee, turn the control dial counter-

clockwise to set it onto the “ ”

position. Residual water may come out

of the wand (Pannarello, if supplied).

• The “ “ light blinks during the prehea-

ting time required by the machine.

• Steam dispensing will begin when the

green light “ “ remains steady on; soon

after only steam will begin to come

out.

• Turn the control dial clockwise and

set it back to the “ ” position to stop

dispensing steam.

• Fill 1/3 of the container you wish to use

to prepare the cappuccino with cold

milk.

Use cold milk for better

results when preparing a

cappuccino.

• Immerse the steam wand (Pannarello,

if supplied) in the milk to be heated and

turn the control dial counter-clockwise

to set it to the “ ” position. Froth the

milk by gently swirling the cup and

moving it up and down.

• After dispensing steam for the desired

time, turn the control dial clockwise

and set it back to the “ ” position to

stop dispensing steam.

• The same procedure can be used to heat

other beverages.

After using the steam wand (Pannarello,

if supplied), wash it as described in the

“Cleaning and Maintenance” section.

After using steam to prepare

a beverage;

To brew a coffee: Follow the procedu-

re described in section “Steam/Coffee

Switchover” to bring the machine back to

the co ee brewing temperature.

To dispense hot water: Follow the pro-

cedure described in section “Dispensing

Hot Water”.

If the control dial is left on the

central position, the machine,

in order to save energy, automatically

reaches the temperature needed to

dispense co ee.

Steam/Coff ee Switchover

• After dispensing steam and pressing

“ “ or “ “ co ee button, the

““ light blinks quickly to show that

the machine is overheated and cannot

brew co ee.

• To brew coffee, first drain a small

amount of water.

Place a container under the steam wand

(Pannarello, if supplied) and turn the

control dial clockwise to set it to the “

” position.

Wait for the temperature “ “ light to be

steady.

Then turn the control dial counter-

clockwise and set it back to the “ ”

position to stop dispensing.

• Now follow the procedure described in

the “Coffee Brewing” section to brew

co ee.

Steady on

Blinking

Blinking fast

• 13 •

English

CLEANING AND

MAINTENANCE

General Cleaning

• Empty and clean the dregdrawer daily,

with the machine turned on.

• Maintenance and cleaning operations

can only be carried out when the ma-

chine is turned o and unplugged.

• Do not immerse the machine in water.

• Do not wash any of its parts in the

dishwasher.

• Do not use alcohol, solvents, and/or

abrasive objects to clean the machine.

• Use a soft, dampened cloth to clean the

machine.

• Do not dry the machine and/or its

components using a microwave and/or

standard oven.

After brewing milk beverages,

dispense hot water from the

hot water / steam wand (Pannarello,

if supplied) to obtain a thorough

cleaning.

• Every day, after heating the milk, remove

the external part of the Pannarello (if

supplied) and wash it with fresh drinking

water.

• Clean the hot water / steam wand we-

ekly. In order to do this, perform the

following operations:

- Remove the external part of the

Pannarello (for standard cleaning);

- Remove the upper part of the Panna-

rello from the wand;

- Wash the upper part of the Pannarello

with fresh drinking water;

- Wash the wand with a wet cloth and

remove any milk residue;

- Replace the upper part in the wand

(make sure it is completely inserted).

Reassemble the external part of the

Pannarello.

• It is recommended to clean the water

tank daily:

- Remove the small white lter from

the water tank and wash it under

running drinking water.

- Reposition the small white lter in

its housing by gently pressing and

turning it at the same time.

- Fill the water tank with fresh drinking

water.

• Empty and clean the drip tray daily.

Perform this operation also when the

oat is raised.

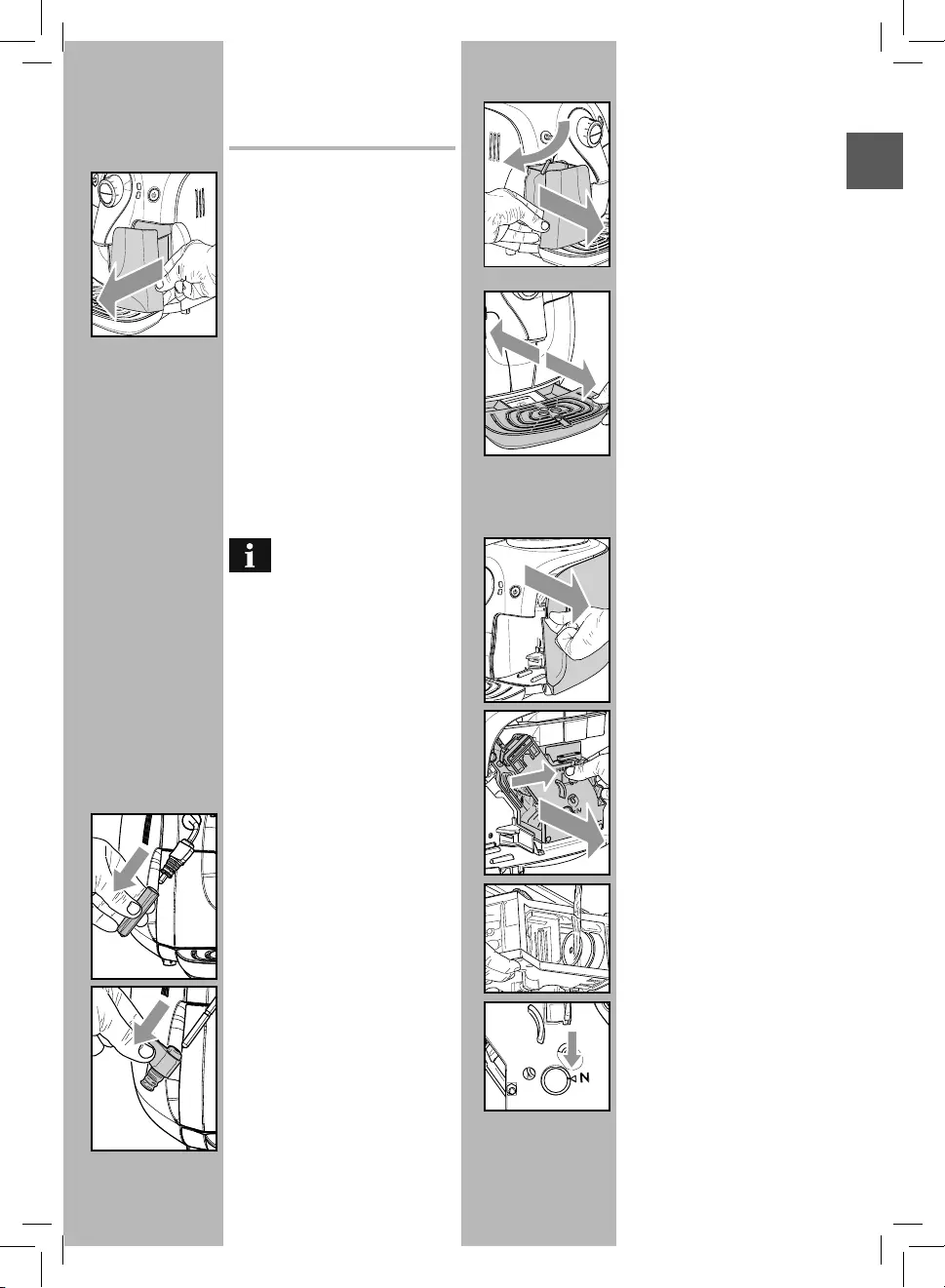

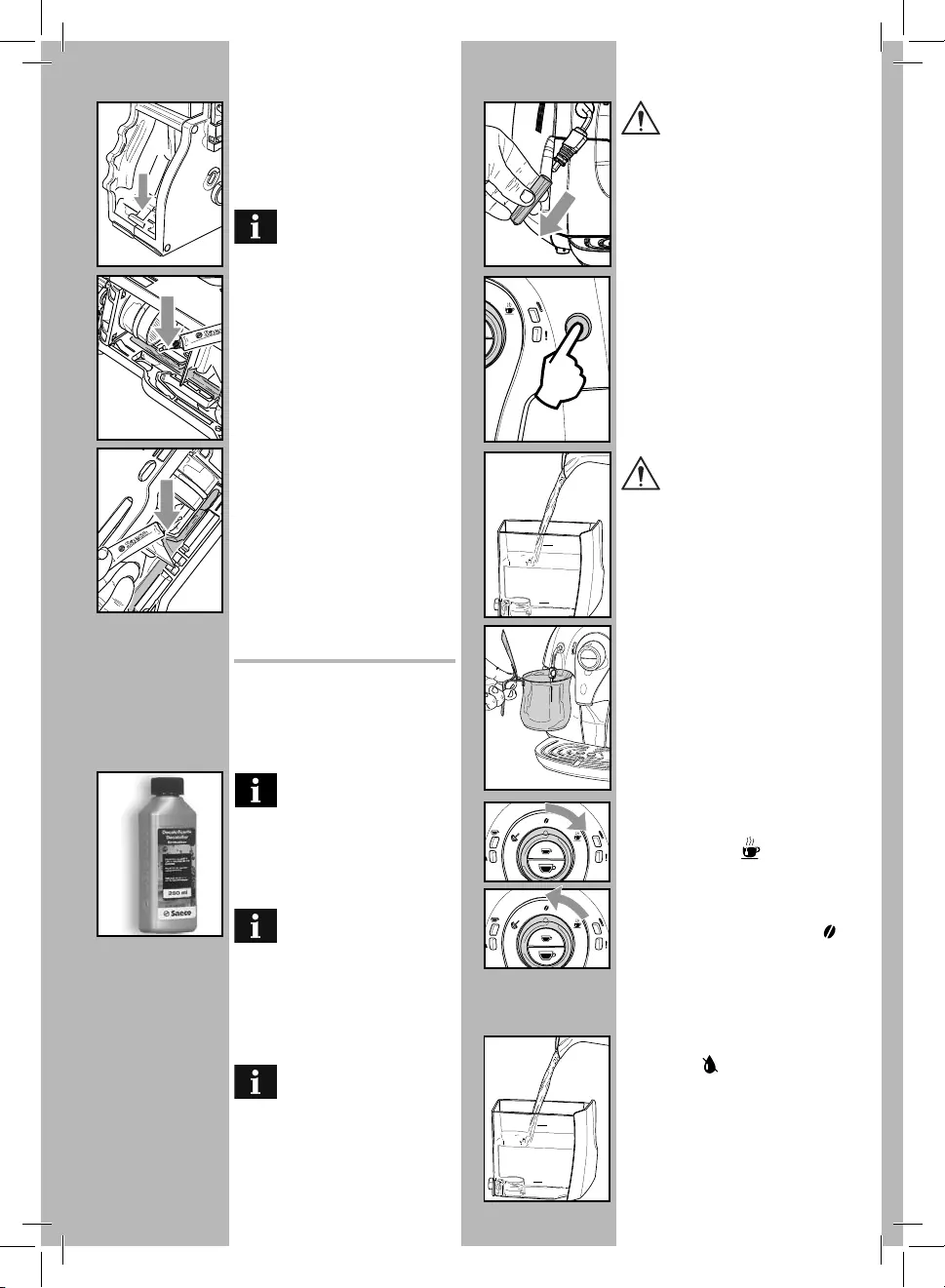

Brew Group

• The brew group should be cleaned

every time the co ee bean hopper is

lled or at least once a week.

• Turn o the machine by pressing the

ON/OFF button and remove the plug

from the socket.

• Remove the dregdrawer. Open the

service door.

• To remove the brew group, pull it by the

handle and press the «PUSH» button.

The brew group must be washed only

with lukewarm water with no deter-

gent/soap.

• Wash the brew group with lukewarm

water, carefully clean the upper lter

and dry.

• Thoroughly wash and dry all the parts

of the brew group.

• Thoroughly clean the inside of the

machine.

• Make sure that the two reference marks

match up.

• 14 •

• Make sure that the lever is in contact

with the brew group. Press the “PUSH”

button to make sure that the brew

group is in the correct position.

Lubricate the brew group

after approximately 500

brewing cycles. The brew group

lubricant may be purchased through

Saeco or authorized service centers.

• Lubricate the brew group guides using

the supplied lubricant only.

• Apply the lubricant evenly on both side

guides.

• Insert the brew group in its seat until it

locks into place WITHOUT pressing the

“PUSH” button.

• Insert the dregdrawer. Close the service

door.

Warning! Never drink the

descaling solution or any pro-

ducts dispensed until the cycle has

been carried out to the end. Never use

vinegar as a descaling solution.

Before descaling, remove the Pannarello

(if supplied) from the steam wand as de-

scribed in the “Cleaning and Maintenance”

section.

• Turn the machine on by pressing the

ON/OFF button. Wait for the machine

to finish its rinse and warm-up

process.

MAX

MIN

MAX

MIN

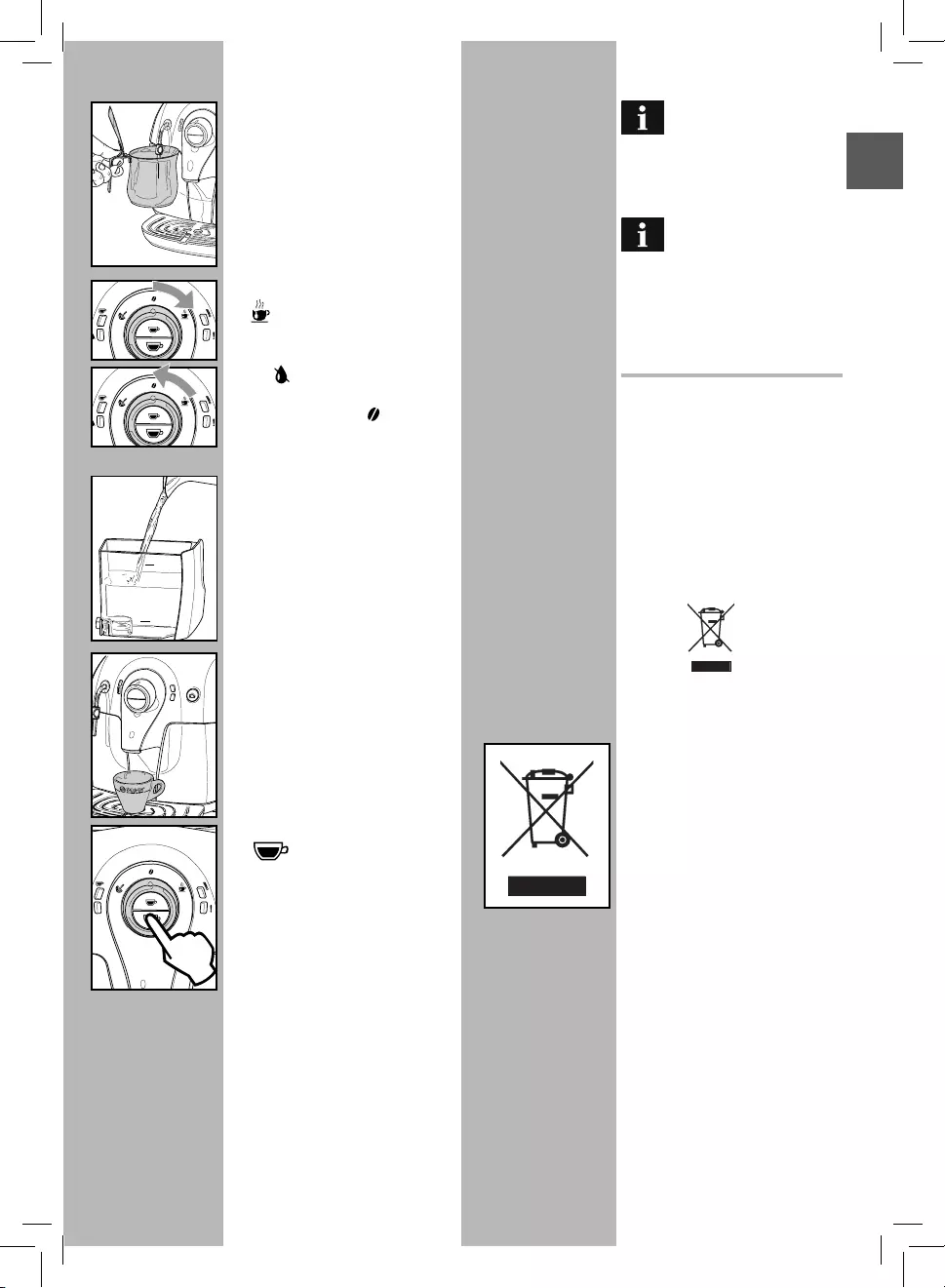

DESCALING

Limescale normally builds up with the

use of the appliance. The machine needs

descaling every 1 - 2 months or whenever

a reduction in water ow is noticed.

In case of conflict, priority

must be given to what is

indicated in the operation and main-

tenance manual over the instructions

provided on separately sold accesso-

ries and materials.

Use the Saeco descaling pro-

duct. Its formula has been

designed to ensure better machine

performance and operation for its

whole operating life. If correctly used,

it also avoids alterations in the brewed

product.

Do not turn the machine o or

put it in stand-by mode during

the descaling process.

Warning! Remove the “Inten-

za” filter before adding the

descaling solution.

• Pour the entire content of the Saeco

concentrated descaling solution into

the water tank, and then ll the tank

with fresh drinking water up to the

MAX level. Place the tank back into the

machine.

1 Place a container under the steam

wand.

2 Only after adding the descaling solution

in the tank, turn the selector switch

clockwise to the “ ” position, and

dispense 2-3 cups of water (approx. 150

ml).

3 Stop dispensing by turning the selector

switch back to its central position “ ”.

4 Let the descaling solution take e ect

for 10 minutes.

5 Repeat steps 2 and 3 at intervals of 3

minutes, until there is no descaling

solution left in the water tank.

6 When the “ ” light remains steady

on, rinse the tank thoroughly and re ll

it with fresh drinking water.

• 15 •

English

MAX

MIN

7 Empty the container used to collect the

liquid dispensed by the machine and

place it under the steam wand.

8 Turn the selector switch clockwise to the

“” position. The machine rinse cycle

starts.

9 When the water in the tank is nished,

the “ ” light remains steady on to

indicate that the selector switch must

be turned back to the “ ” position.

10 Rinse the tank thoroughly and re ll it

with fresh drinking water.

11 Empty the container used to collect the

liquid dispensed by the machine.

12 Place a container under the dispensing

spout.

13 Brew one co ee. Press and release the

““ button. The machine starts

brewing co ee.

14 Wait until brewing is complete and

remove the container.

15 Then repeat operations from step 7 to

step 10 until the second water tank is

empty.

16 At the end, ll the water tank again.

When descaling is complete, insert the

Pannarello (if supplied) onto the steam

wand as described in the “Cleaning and

Maintenance” section.

The descaling cycle is complete. Then, the

products can be brewed.

The descaling solution must

be disposed of according

to the manufacturer’s instructions

and/or regulations in force in the

country of use.

If the machine is switched o

during the descaling cycle,

next time the machine is switched

on the cycle must be repeated from

the beginning.

MACHINE DISPOSAL

- The packing materials can be re-

cycled.

- Appliance: unplug the appliance and

cut the power cord.

- Deliver the appliance and power cord to

a service center or public waste disposal

facility.

This product complies with eu directive

2002/96/ec.

The symbol

on the product or on

its packaging indicates that this product

may not be treated as household waste.

Instead it shall be handed over to the ap-

plicable collection point for the recycling

of electrical and electronic equipment.

By ensuring this product is disposed of

correctly, you will help prevent potential

negative consequences for the environ-

ment and human health, which could

otherwise be caused by inappropriate

waste handling of this product. For more

detailed information about recycling of

this product, please contact your local

city o ce, your household waste disposal

service or the shop where you purchased

the product.

• 16 •

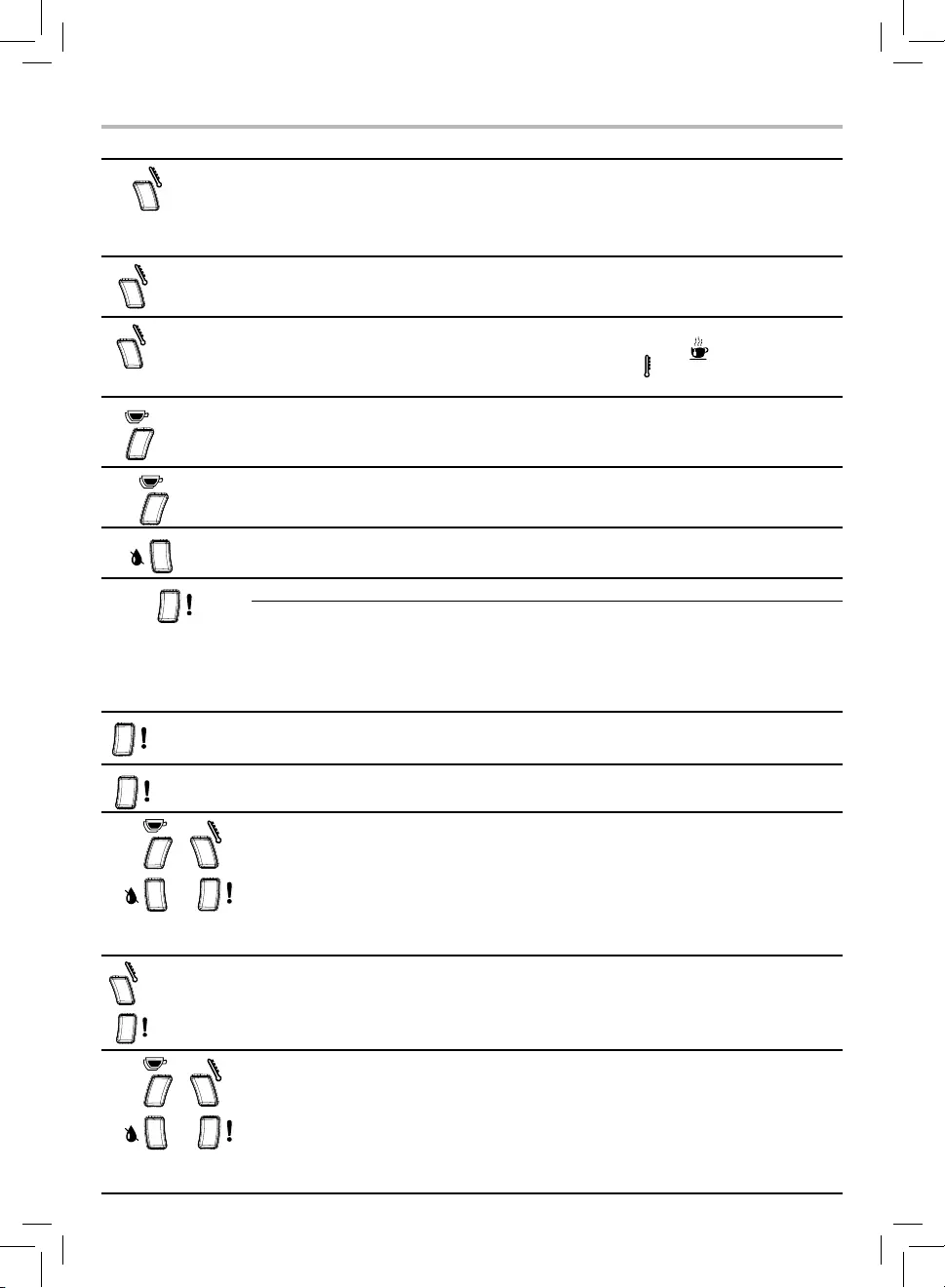

Light Signals Causes Solutions

Steady on

The machine has reached the right temperature and

is now ready:

- For co ee brewing;

- For hot water dispensing;

- For steam dispensing

Slowly ashing The machine is warming up to brew coffee and

dispense hot water or steam.

Quickly ashing Machine is overheating. Co ee may not be brewed. The water must be drained into a container by turning the

selector switch clockwise to the “ ” position until the green

ready temperature light “ “ stays constantly on. After that, stop

dispensing water.

Slowly ashing

Indicates that the machine is programming the

amount of co ee to brew (see section “Adjusting the

Brewed Co ee”).

Steady on

The machine is brewing a double co ee

Steady on

Low water level. Fill the water tank with fresh drinking water. After re lling the water

tank, the indicator light turns o .

Steady on

The co ee bean hopper is empty. Fill the hopper with co ee beans and start the procedure again.

The dregdrawer is full With the machine turned on, empty the dregdrawer. The dregdrawer

must be emptied after every 8 co ee cycles. If the dregdrawer is

emptied with the machine turned o , or when the indicator light

is not illuminated, the count of co ee cycles is not reset. For this

reason, the indicator light to empty the dregdrawer may illuminate

even when it is not full.

Quickly ashing

The water circuit is empty. Fill the tank with fresh drinking water and prime the water circuit as

described in Section “Using the Machine for the First Time”.

Slowly ashing

Brew group not inserted. Dregdrawer not inserted.

Service door open. Control dial is not in correct position.

Make sure that all components have been correctly inserted and

closed. The blinking red light will now turn o .

+

Blinking in counter-

clockwise direction (cyclical)

The machine is performing the rinse/self-cleaning

cycle

The machine ends the cycle automatically.

You can interrupt the cycle by pressing either co ee button.

Flashing

alternately

A fault has occurred in the brew group. Try again to brew another co ee.

+

Flashing

simultaneously

A fault has occurred in the machine and hot water,

steam or co ee cannot be dispensed.

Turn the machine o . After 30-seconds, turn it back on.

Try this 2 or 3 times.

If the machine does NOT start, contact an authorized service center.

CONTROL PANEL LIGHTS

• 17 •

English

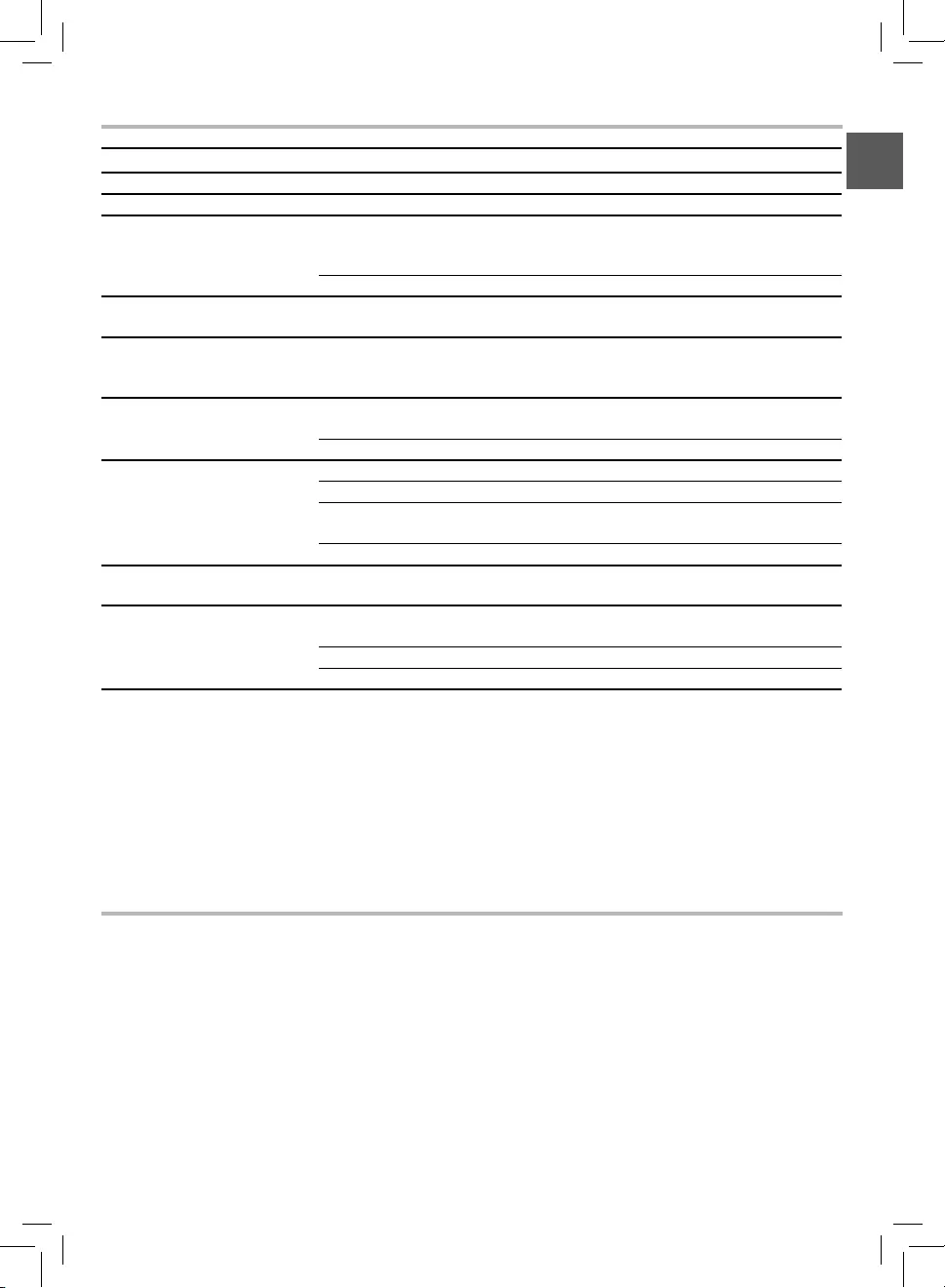

Problems Causes Solutions

The machine does not turn on. The machine is not connected to the power source. Connect the machine to the power source.

The co ee is not hot enough. The cups are cold. Preheat the cups with hot water.

Hot water or steam is not dispensed. The hole of the hot water / steam wand is clogged. Clean the hole of the hot water / steam wand using a pin.

Make sure that the machine is turned o and has cooled

before performing this operation.

Pannarello is dirty (if supplied). Clean the Pannarello.

The co ee is not creamy enough.

(See note)

The co ee blend is unsuitable, the co ee is not freshly

roasted or the grind is too coarse.

Change co ee blend or adjust the grinder as explained in section

“Co ee Grinder Adjustment”.

The machine takes a long time to warm up or

the amount of water dispensed from the wand

is too little.

The machine’s water circuit is obstructed by limescale

build-up

Descale the machine.

The brew group cannot be removed. The brew group is out of place. Turn the machine on. Close the service door. The brew group au-

tomatically returns to the correct position.

The dregdrawer is inserted. Remove the dregdrawer rst, then the brew group.

The machine grinds the co ee beans but no cof-

fee comes out.

(See note)

The brew group is dirty. Clean the brew group (section “Brew Group”).

The circuit is not primed. Prime the circuit (section “Using the Machine for the First Time”).

Rare event that occurs when the machine is automati-

cally adjusting the dose.

Brew a few co ees as described in section “Saeco Adapting Sys-

tem”.

The dispensing spout is dirty. Clean the dispensing spout.

The co ee is too weak.

(See note)

Rare event that occurs when the machine is automati-

cally adjusting the dose.

Brew a few co ees as described in section “Saeco Adapting Sys-

tem”.

Co ee is brewed slowly.

(See note)

The co ee grind is too ne. Change co ee blend or adjust the grind as explained in section

“Co ee Grinder Adjustment”.

The water circuit is not primed. Prime the circuit (section “Using the Machine for the First Time”).

The brew group is dirty. Clean the brew group (section “Brew Group”).

Note: These problems can be considered normal if the co ee blend has been changed or if the machine has just been installed. In this case

wait until the machine performs a self-adjusting operation as described in section “Saeco Adapting System”.

Please contact customer service for any problems not covered in the above table or when the suggested solutions do not solve the pro-

blem.

TROUBLESHOOTING

TECHNICAL SPECIFICATIONS

The manufacturer reserves the right to make changes to the technical speci cations of the product.

Nominal Voltage - Power Rating - Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See label on the inside of the service door

Housing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ABS - Thermoplastic

Size (w x h x d) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295 x 325 x 420 mm - 11.5” x 13” x 16.5”

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.9 kg - 15 lbs.

Power Cord Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 m - 47”

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front

Pannarello (only available for certain models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Special for cappuccinos

Water Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 litres – 33 oz. / Removable

Co ee Bean Hopper Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170 - 6.5 oz.

Dregdrawer Drawer Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pump pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 bar

Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless steel

Safety mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermal fuse

• 18 •

• 19 •

English