Table of Contents

- 15E900 SAS Product Manual

- Seagate® Technology Support Services

- 1.0 Scope

- 2.0 Applicable standards and reference documentation

- 3.0 General description

- 4.0 Performance characteristics

- 5.0 Reliability specifications

- 6.0 Physical/electrical specifications

- 7.0 About FIPS

- 8.0 About self-encrypting drives

- 9.0 Defect and error management

- 10.0 Installation

- 11.0 Interface requirements

Seagate ST600MP0006 User Manual

Displayed below is the user manual for ST600MP0006 by Seagate which is a product in the Internal Hard Drives category. This manual has pages.

Related Manuals

* Default configuration is 512E for 512E / 4KN drives.

See Section 4.2.2 to Fast Format to 4KN in seconds

100827313 - Rev. B

October 2017

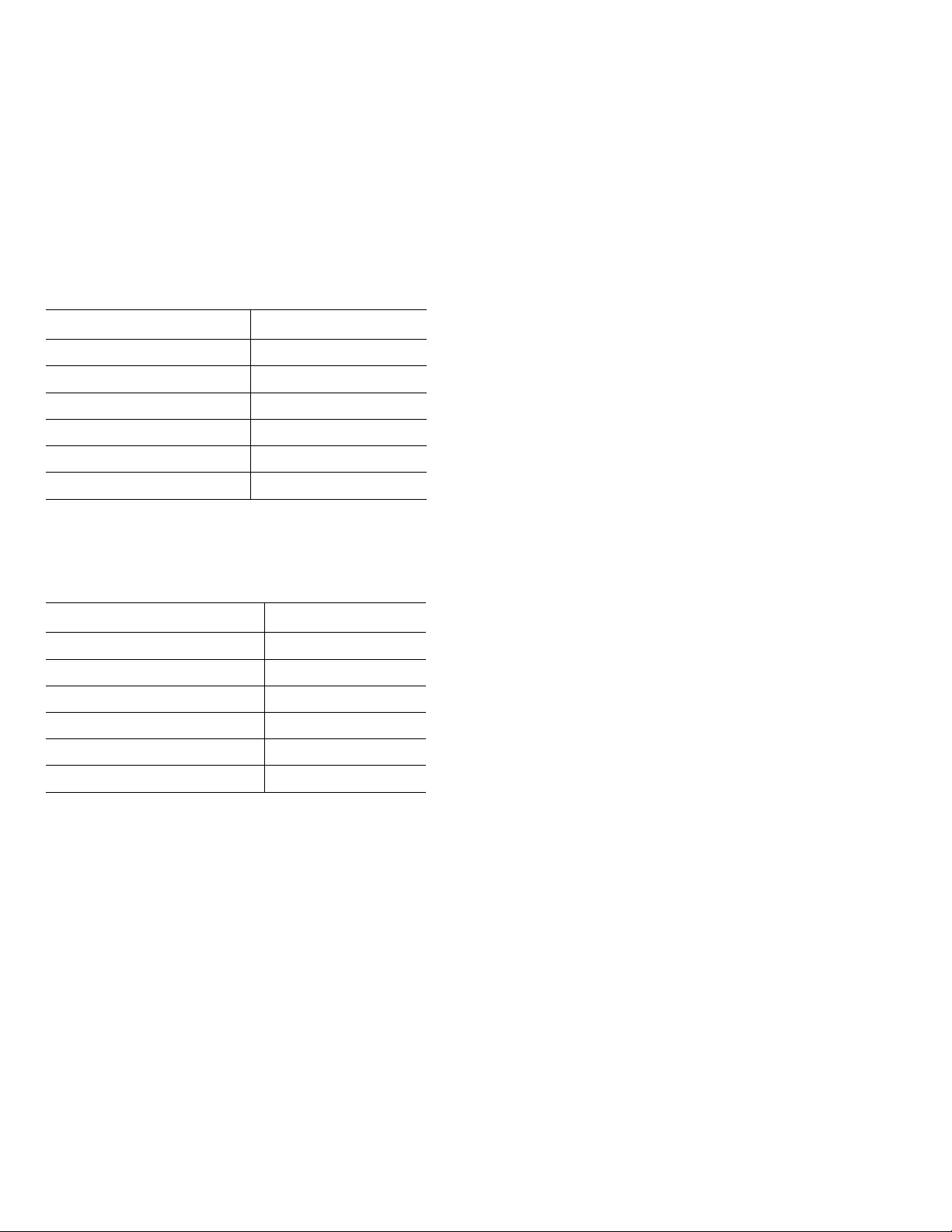

512N sectors

Standard models

ST900MP0006

ST600MP0006

ST300MP0006

Self-Encryption models

ST900MP0016

ST600MP0016

ST300MP0016

Instant Secure Erase models

ST900MP0026

ST600MP0036

ST300MP0026

SED FIPS (140-2) models

ST900MP0126

ST600MP0026

512E* / 4KN sectors

Standard models

ST900MP0146

ST600MP0136

ST300MP0106

Self-Encryption models

ST900MP0156

ST600MP0146

ST300MP0116

Instant Secure Erase models

ST900MP0136

ST600MP0126

ST300MP0096

SED FIPS (140-2) models

ST900MP0166

ST600MP0156

15E900 SAS Product Manual

© 2017 Seagate Technology LLC. All rights reserved.

Publication number: 100827313, Rev. B October 2017

Seagate, Seagate Technology and the Spiral logo are registered trademarks of Seagate Technology LLC in the United States and/or other countries. Power Choice, Raid Rebuild and

SeaTools are either trademarks or registered trademarks of Seagate Technology LLC or one of its affiliated companies in the United States and/or other countries. The FIPS logo is a certi-

fication mark of NIST, which does not imply product endorsement by NIST, the U.S., or Canadian governments. All other trademarks or registered trademarks are the property of their

respective owners.

No part of this publication may be reproduced in any form without written permission of Seagate Technology LLC.

Call 877-PUB-TEK1 (877-782-8351) to request permission.

When referring to drive capacity, one gigabyte, or GB, equals one billion bytes and one terabyte, or TB, equals one trillion bytes. Your computer’s operating system may use a different

standard of measurement and report a lower capacity. In addition, some of the listed capacity is used for formatting and other functions, and thus will not be available for data storage.

Actual quantities will vary based on various factors, including file size, file format, features and application software. Actual data rates may vary depending on operating environment

and other factors. The export or re-export of hardware or software containing encryption may be regulated by the U.S. Department of Commerce, Bureau of Industry and Security (for

more information, visit www.bis.doc.gov), and controlled for import and use outside of the U.S. Seagate reserves the right to change, without notice, product offerings or specifications.

Document Revision History

Revision Date Pages affected and Description of changes

Rev. A 10/05/2017 Initial release.

Rev. B 10/27/2017 Updated (Note:) formatting throughout manual.

36: Remover Figure 10.

Seagate Exos 15E900 SAS Product Manual, Rev. B 2

Contents

Seagate® Technology Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.0 Applicable standards and reference documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Agency and Safety Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.1 Safety certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2 Regulatory Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.4 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.4.1 European Union (EU) CE Marking Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.2 Australian RCM Compliance Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.3 Canada ICES-003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.4 South Korean KC Certification Mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.5 Morocco Commodity Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.6 Taiwanese BSMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.7 FCC verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5 Environmental protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.1 European Union Restriction of Hazardous Substance Law . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.2 China Requirements —China RoHS 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.3 Taiwan Requirements — Taiwan RoHS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.6 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.0 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.5 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.6 Programmable drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.7 Factory installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Internal drive characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.2 Seek performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.2.1 Format command execution time for 512-byte sectors (minutes) . . . . . . . . . . . . . . . . . . . .17

4.2.2 Fast Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.2.3 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.5.3 Hybrid caching operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Seagate Exos 15E900 SAS Product Manual, Rev. B 3

Contents

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Error rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.1.1 Recoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.1.2 Unrecoverable Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.1.3 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.1.4 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.2.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF). . . . . . . . . . . . . . .21

5.2.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.2.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.2.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.2.5 Thermal monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.2.6 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.2.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 PowerChoiceTM power management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.1.1 PowerChoice reporting methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.2 Power Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.4.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.4.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

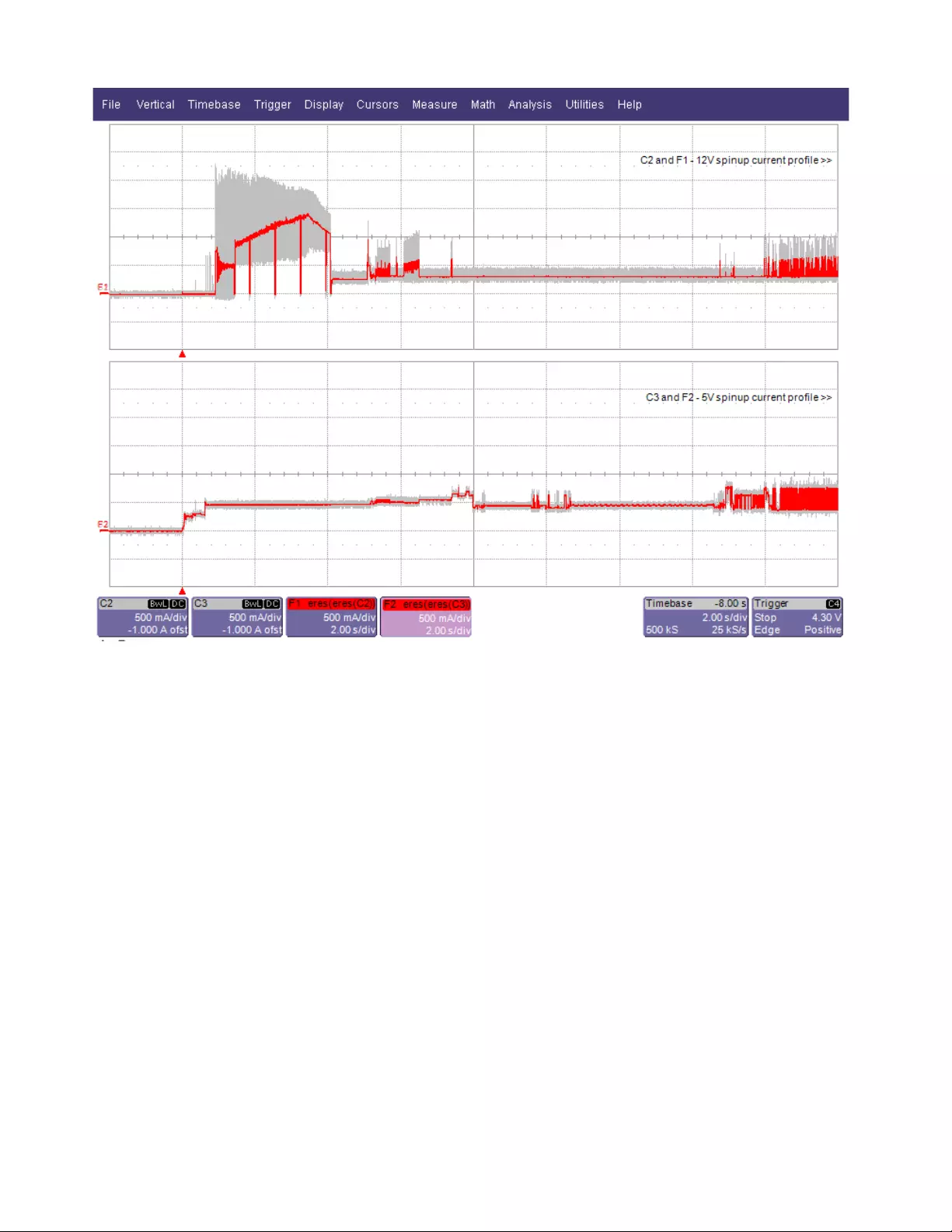

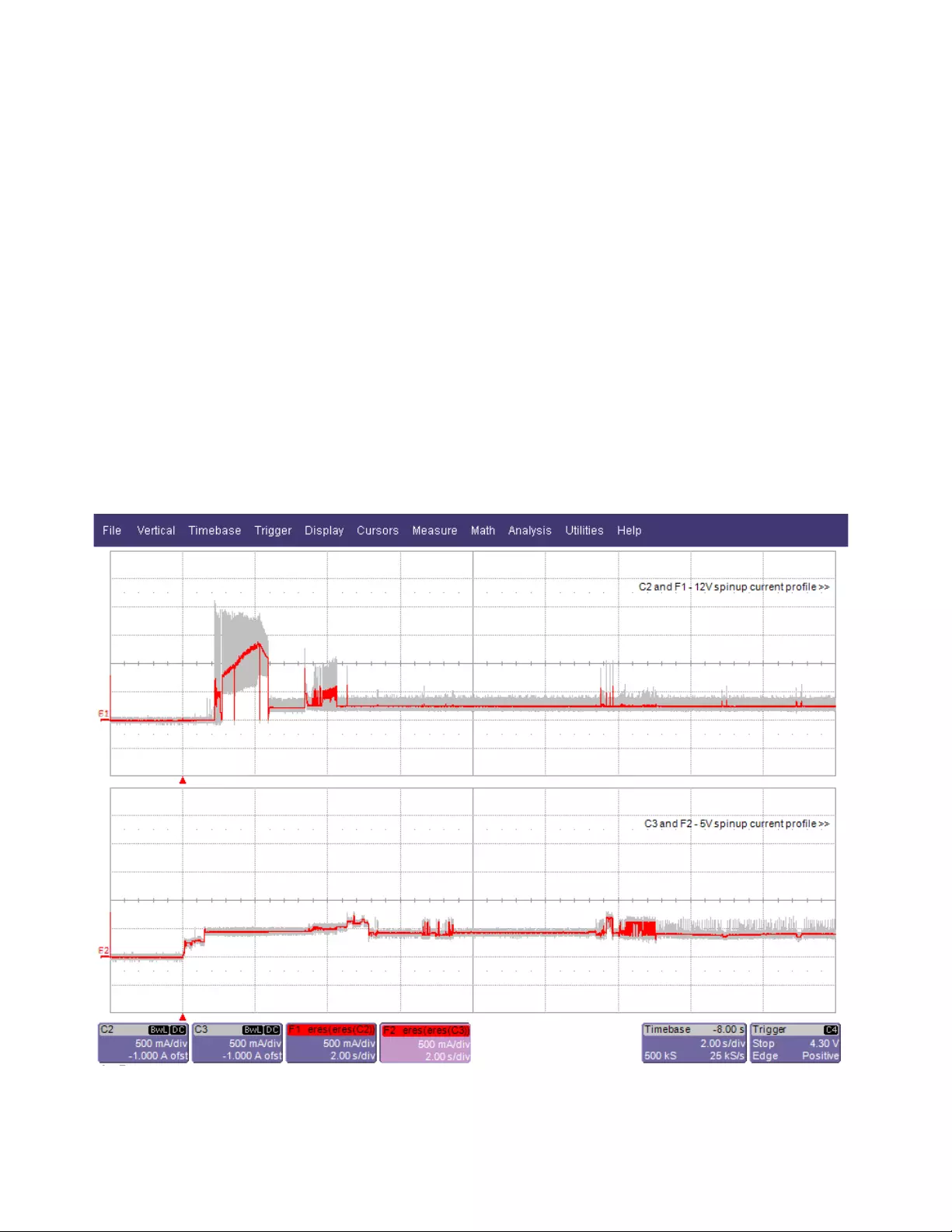

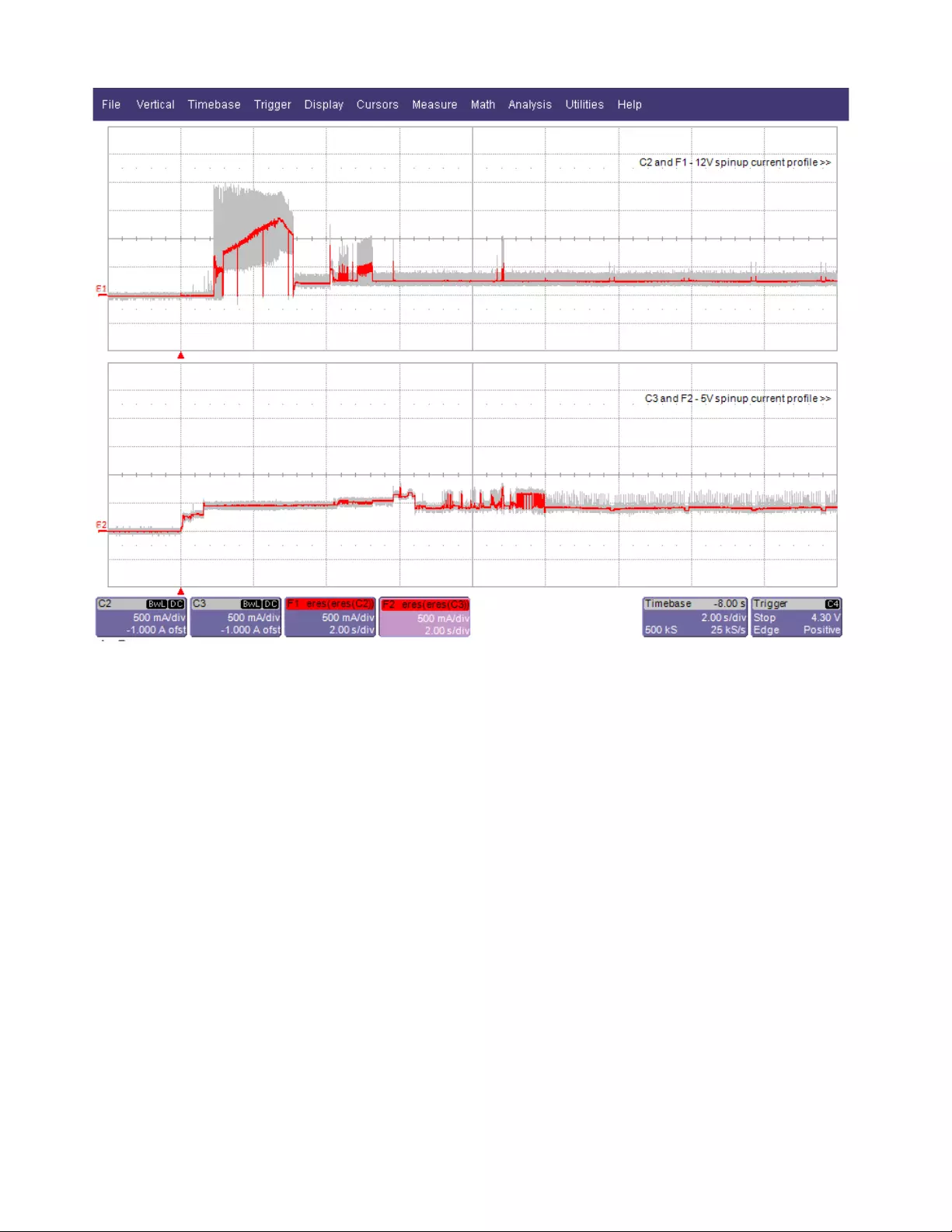

6.4.3 Current profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

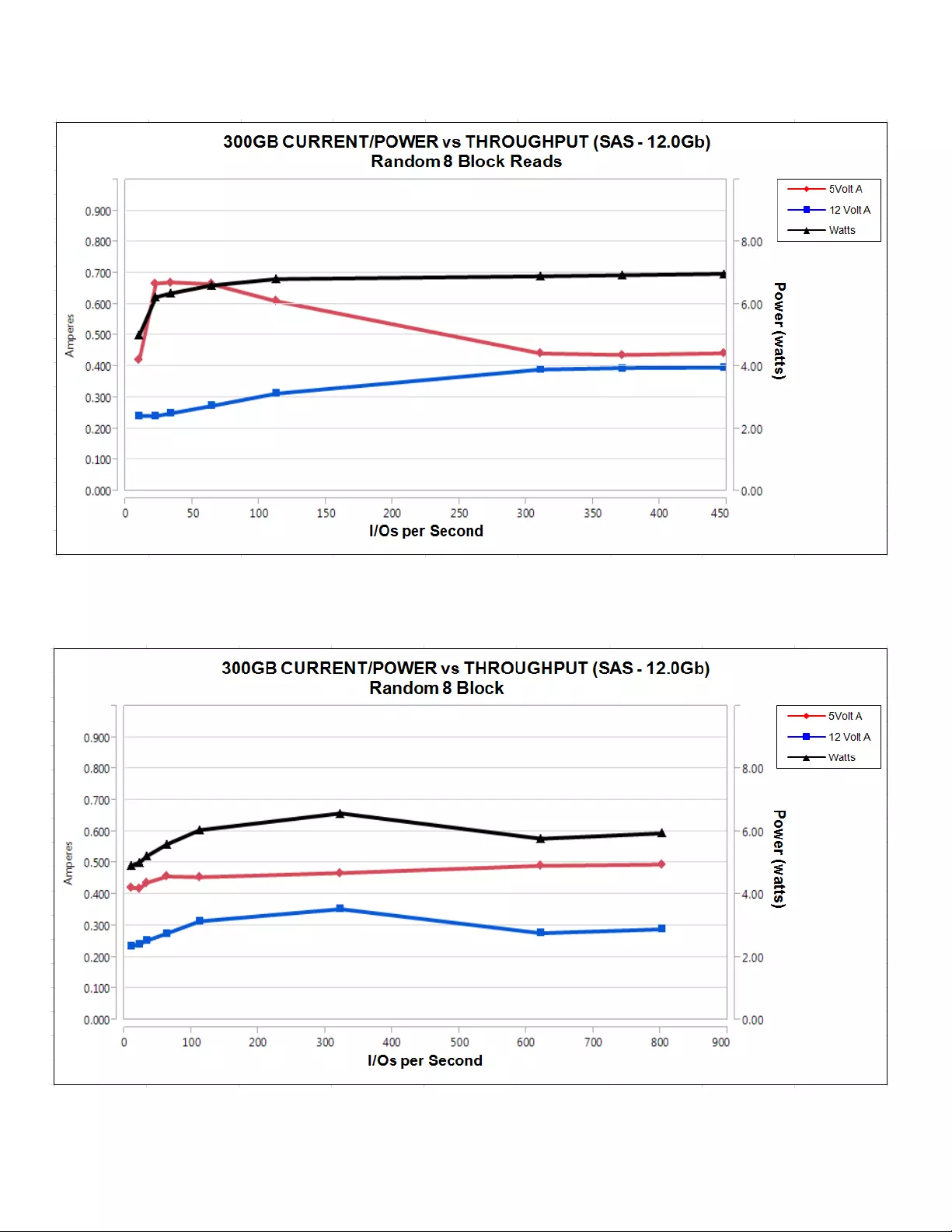

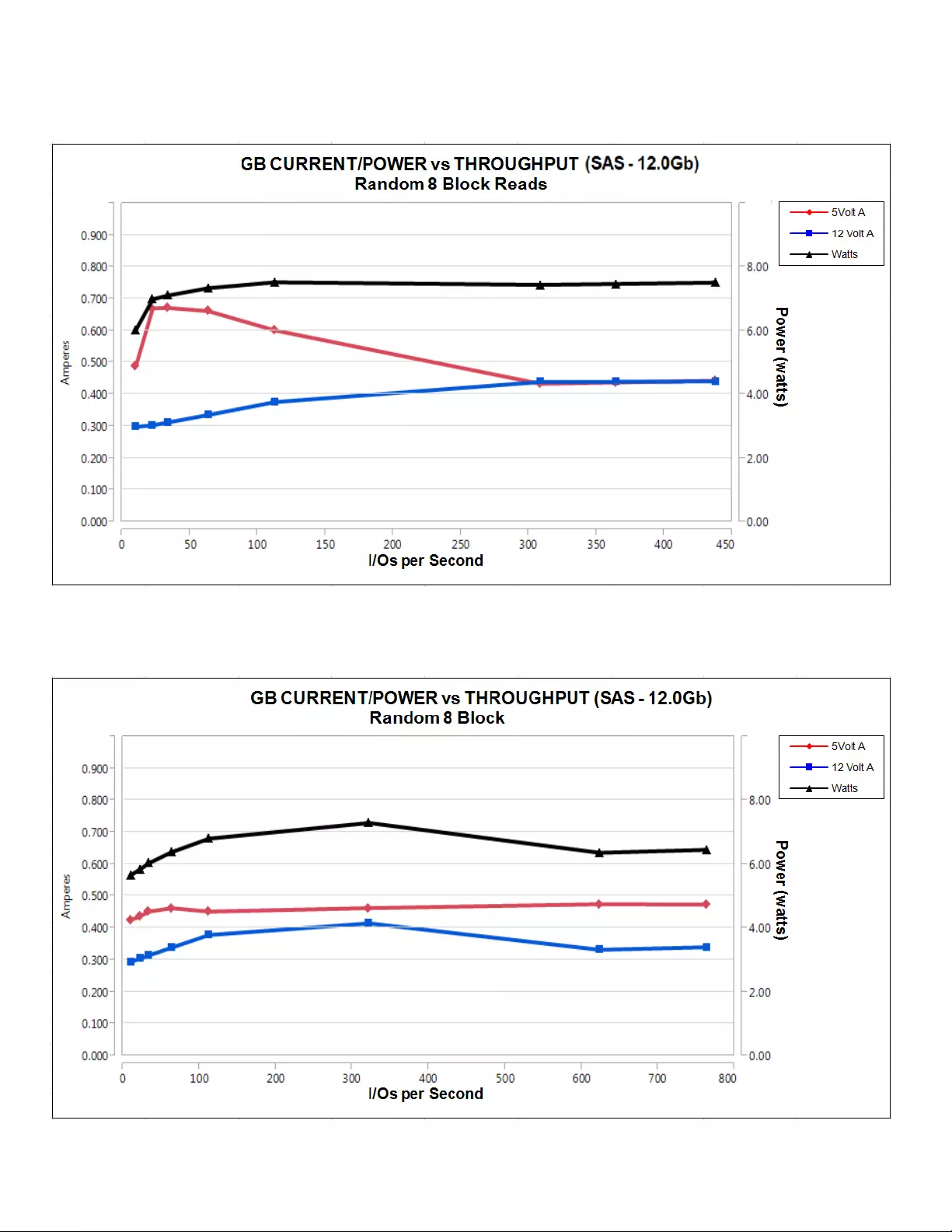

6.5 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.6 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.6.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.6.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.6.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.6.4 Shock and vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.6.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.6 Corrosive environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.7 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.8 Electromagnetic susceptibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

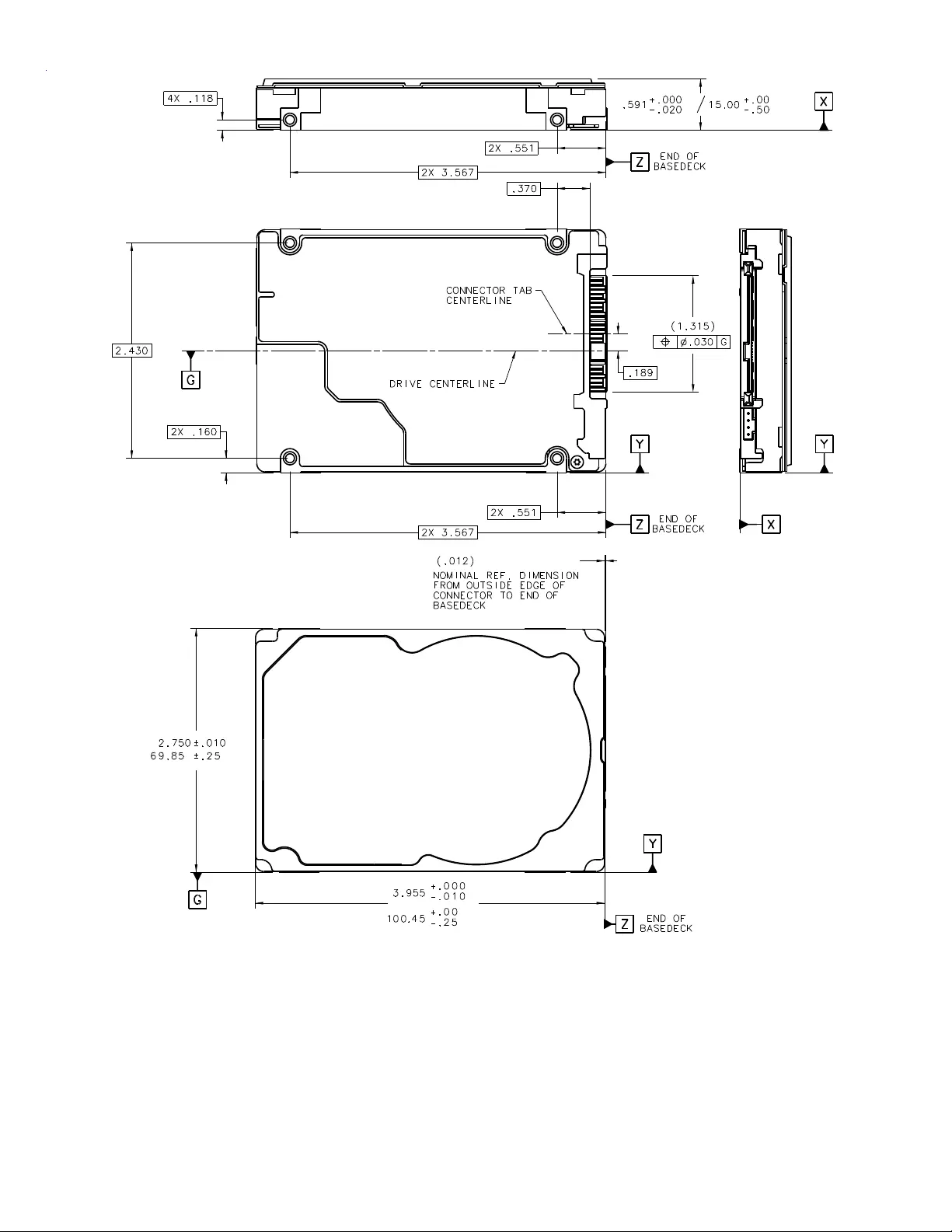

6.7 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Seagate Exos 15E900 SAS Product Manual, Rev. B 4

Contents

7.0 About FIPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.0 About self-encrypting drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Data encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2 Controlled access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2.1 Admin SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2.2 Locking SP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2.3 Default password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.3 Random number generator (RNG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.4 Drive locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.5 Data bands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.6 Cryptographic erase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.7 Authenticated firmware download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.8 Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.9 Supported commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.10 RevertSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1 Drive internal defects/errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.3 SAS system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.4 Deferred Auto-Reallocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.5 Protection Information (PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.5.1 Levels of PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.5.2 Setting and determining the current Type Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.5.3 Identifying a Protection Information drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.6 Seagate RAID Rebuild ™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

10.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

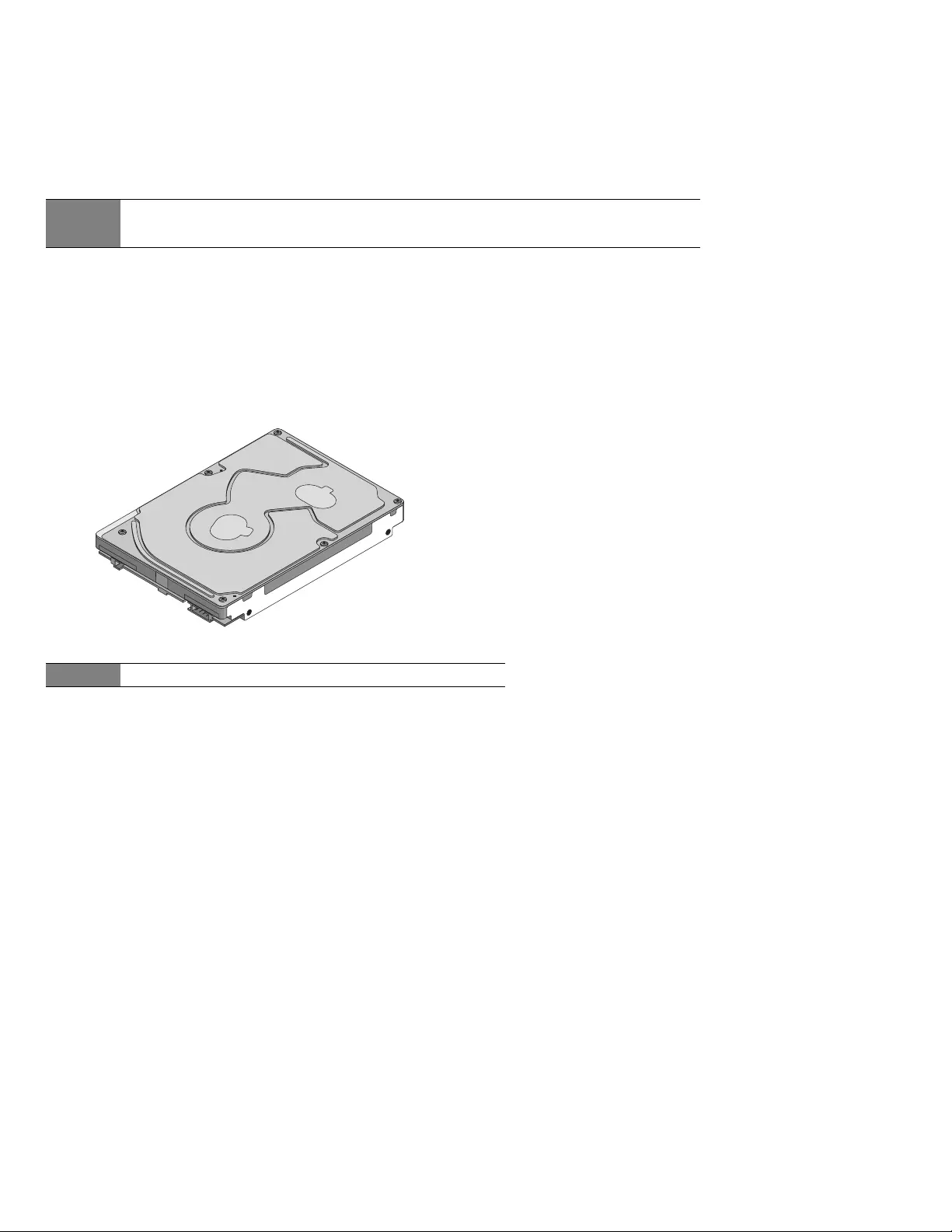

10.1 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

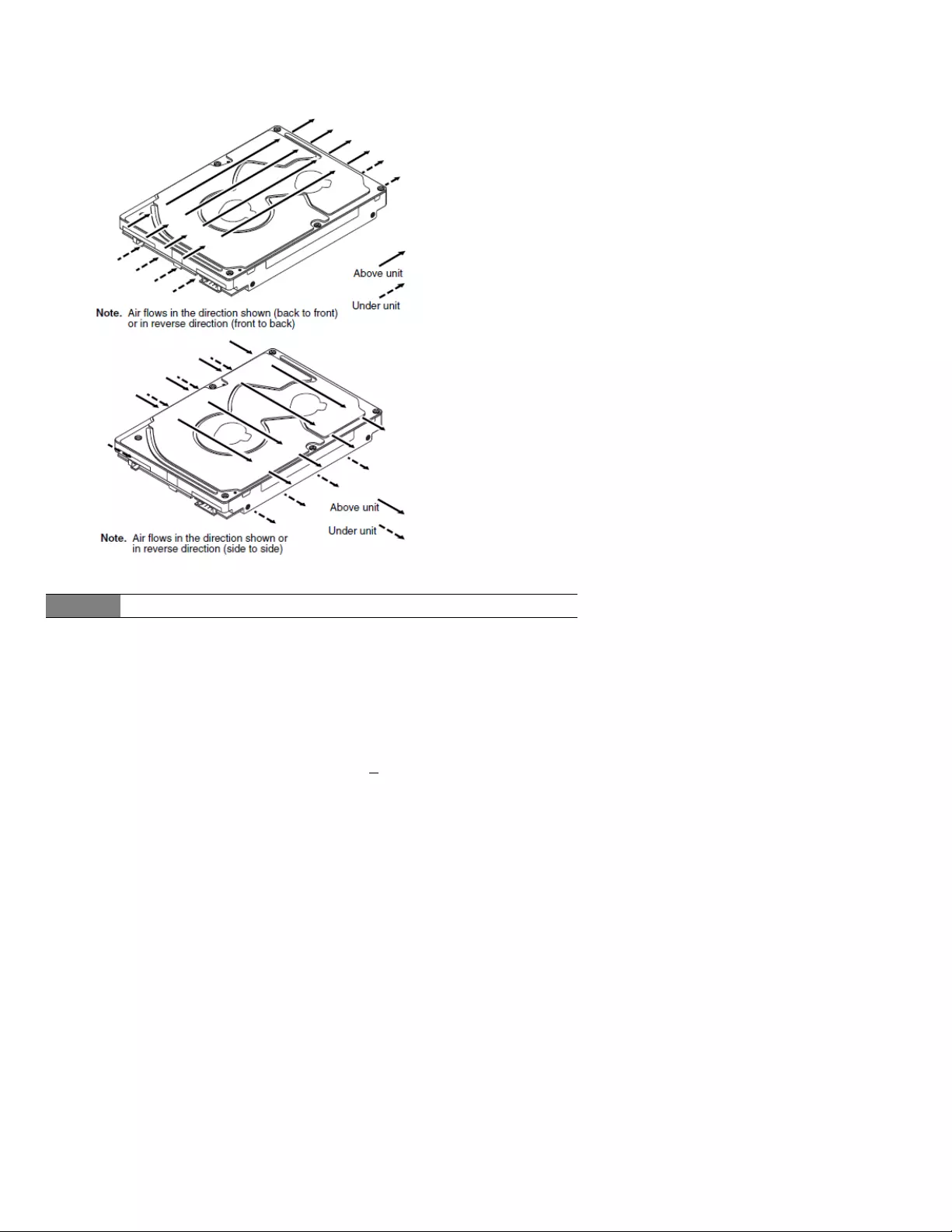

10.2 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

10.3 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

10.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Seagate Exos 15E900 SAS Product Manual, Rev. B 5

Contents

11.0 Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.1 SAS features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

11.1.1 Task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

11.1.2 Task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

11.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

11.3 SCSI commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

11.3.1 Inquiry data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

11.3.2 Mode Sense data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

11.4 Miscellaneous operating features and conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

11.4.1 SAS physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

11.4.2 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

11.4.3 Connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

11.4.4 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

11.4.5 Pin descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

11.4.6 SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

11.4.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

11.5 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

11.5.1 Ready LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

11.5.2 Differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

11.6 SAS-3 Specification compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

11.7 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Seagate Exos 15E900 SAS Product Manual, Rev. B 6

Figures

Figure 1. Current profile for 300GB models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2. Current profile for 600GB models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 3. Current profile for 900GB models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4. 300GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 33

Figure 5. 300GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 33

Figure 6. 600GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 34

Figure 7. 600GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 34

Figure 8. 900GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 35

Figure 9. 900GB models (12Gb) DC current and power vs. input/output operations per second . . . . . . . . . . . . . 35

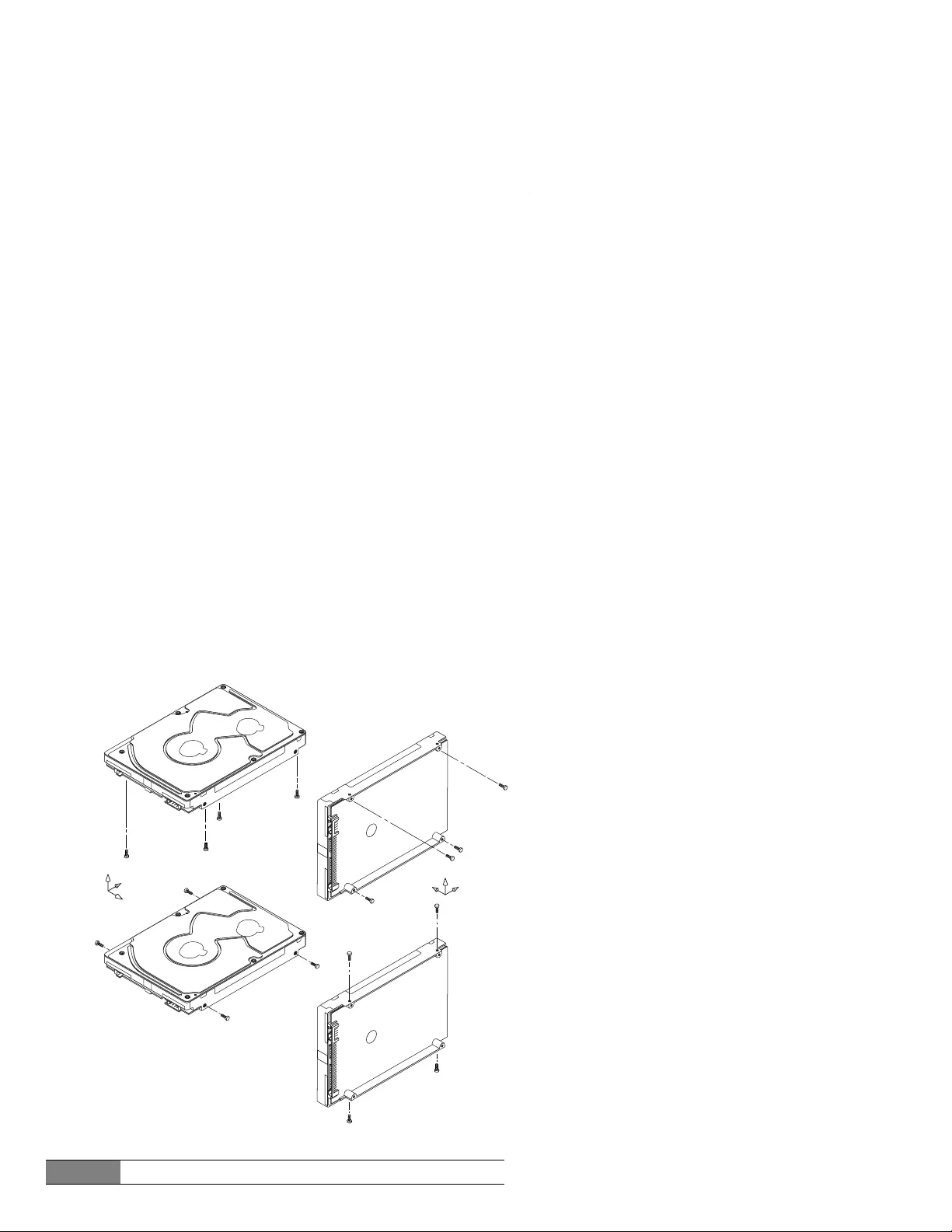

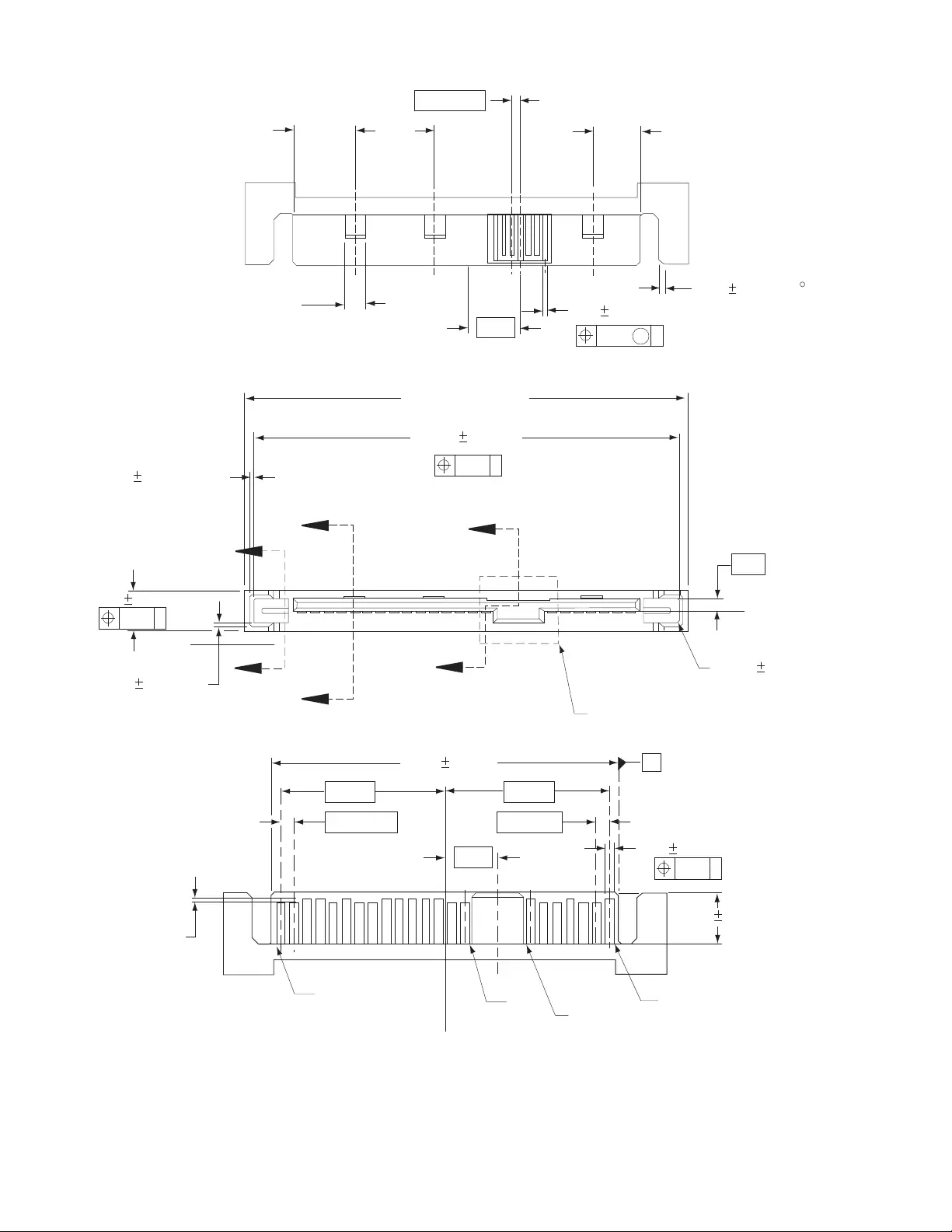

Figure 10. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 11. Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 12. Example of FIPS tamper evidence labels/seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 13. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 14. Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 15. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

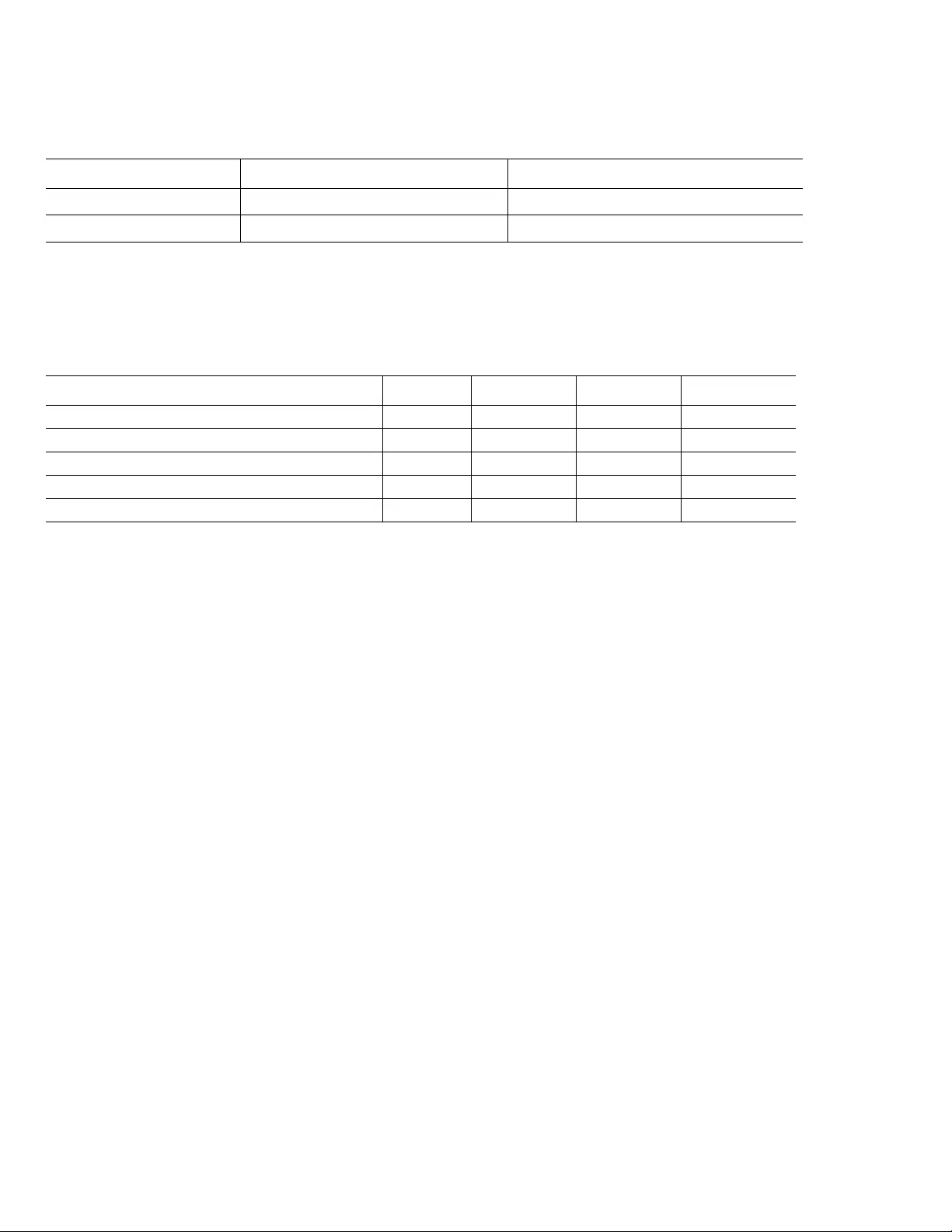

Figure 16. SAS device plug dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 17. SAS device plug dimensions (detail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

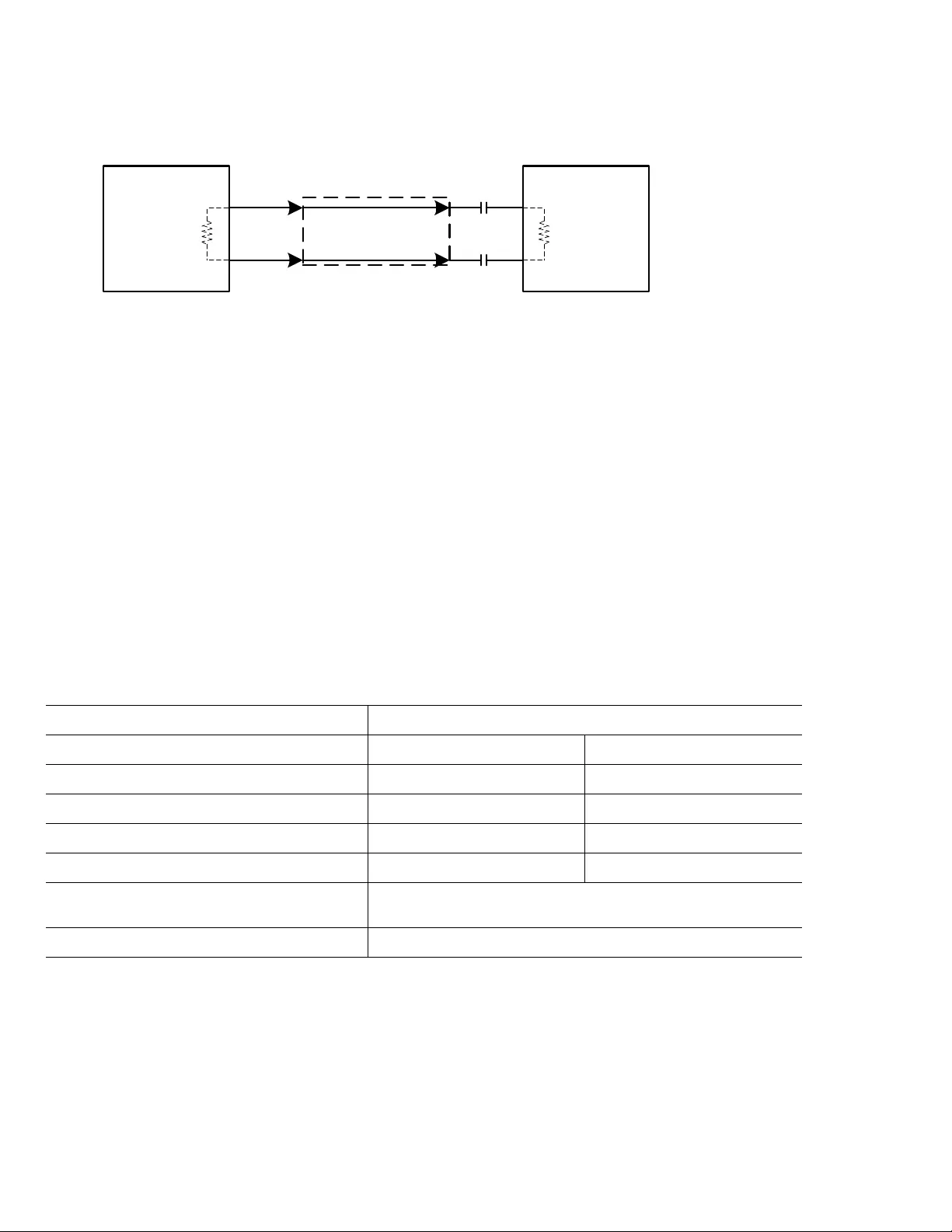

Figure 18. SAS transmitters and receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Seagate Exos 15E900 SAS Product Manual, Rev. B 7

For information regarding online support and services, visit: http://www.seagate.com/contacts/

For information regarding Warranty Support, visit: http://www.seagate.com/support/warranty-and-replacements/

For information regarding data recovery services, visit: http://www.seagate.com/services-software/recover/

For Seagate OEM, Distribution partner and reseller portals, visit: http://www.seagate.com/partners/

Seagate® Technology Support Services

Seagate Exos 15E900 SAS Product Manual, Rev. B 8

1.0 Scope

This manual describes the Seagate® Exos™ 15E900 SAS SAS (Serial Attached SCSI) disk drives.

These drives support the SAS Protocol specifications to the extent described in this manual. The SAS Interface Manual (part number

100293071) describes the general SAS characteristics of this and other Seagate SAS drives. The Self-Encrypting Drive Reference

Manual, part number 100515636, describes the interface, general operation, and security features available on Self-Encrypting Drive

models.

Product data communicated in this manual is specific only to the model numbers listed in this manual. The data listed in this manual

may not be predictive of future generation specifications or requirements. If designing a system which will use one of the models

listed or future generation products and need further assistance, please contact the Field Applications Engineer (FAE) or our global

support services group as shown in “Seagate® Technology Support Services” on page 7.

Unless otherwise stated, the information in this manual applies to standard and Self-Encrypting Drive models.

For more information on FIPS 140-2 Level 2 certification see Section 7.0 on page 40.

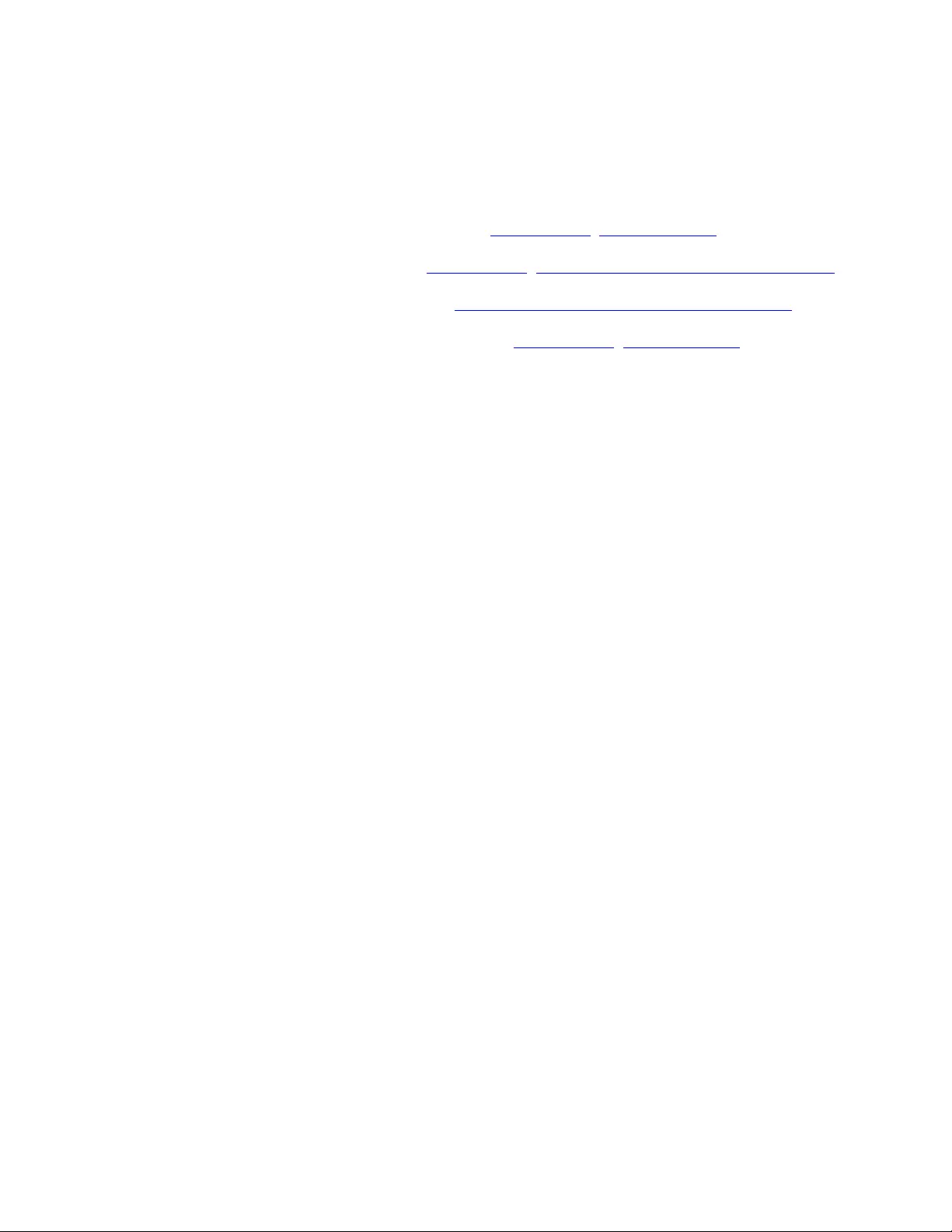

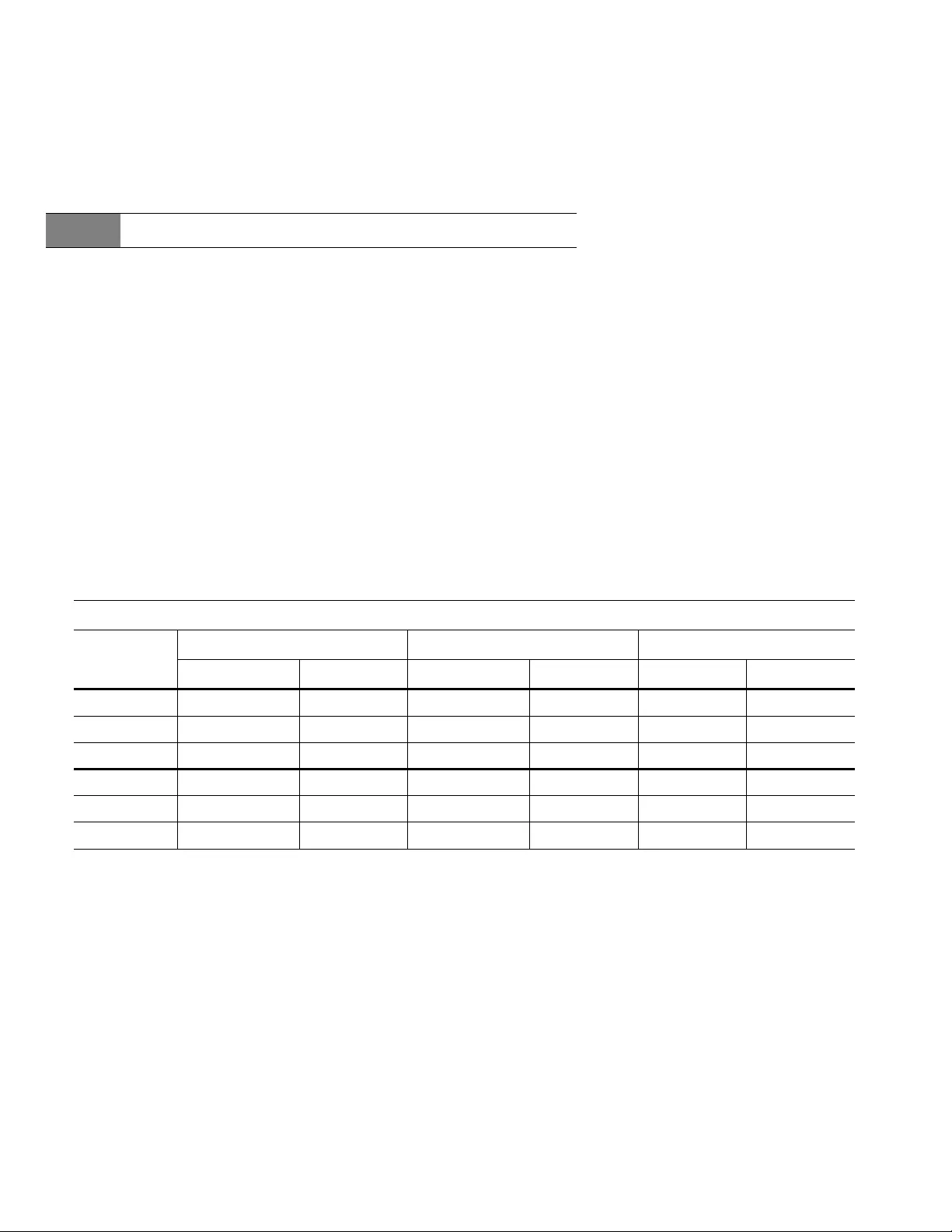

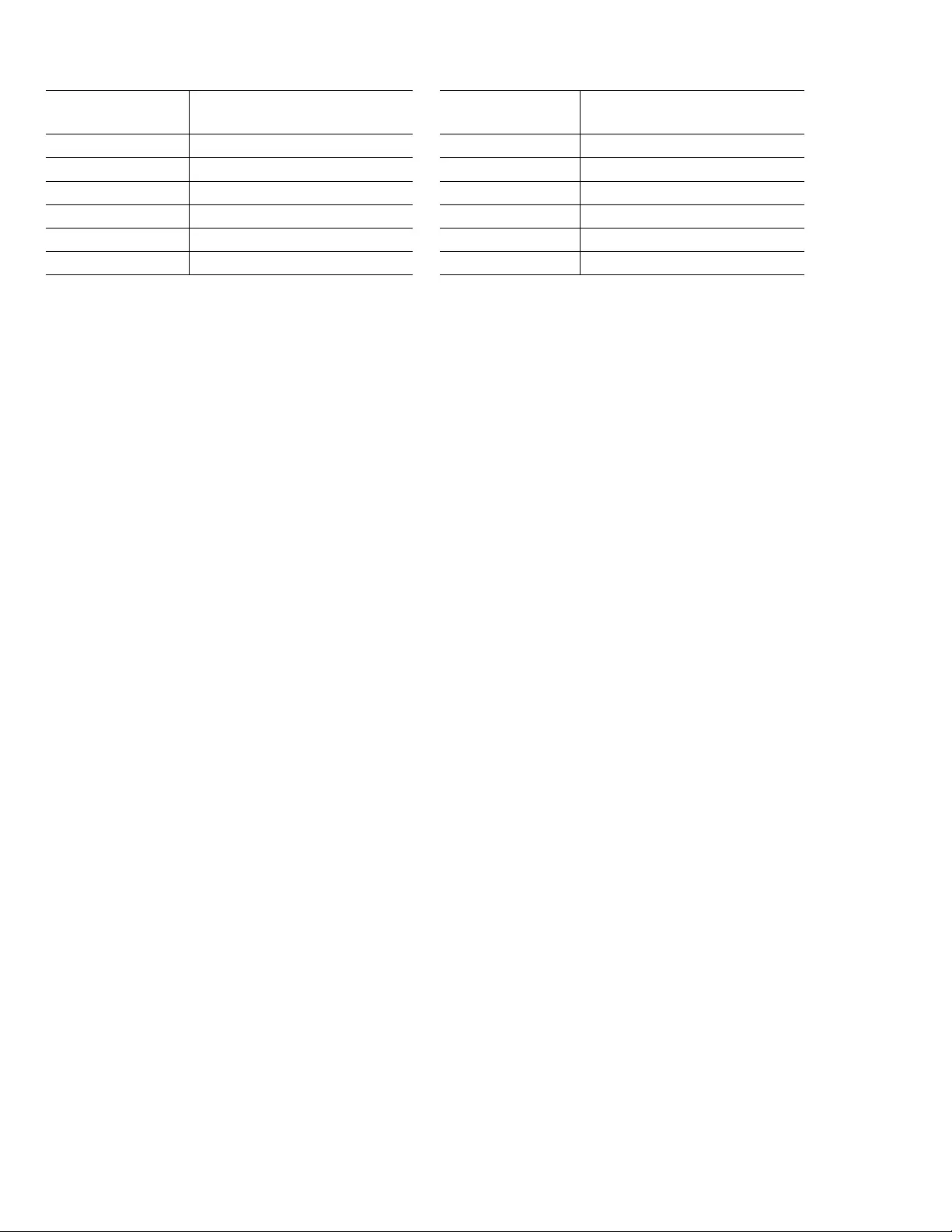

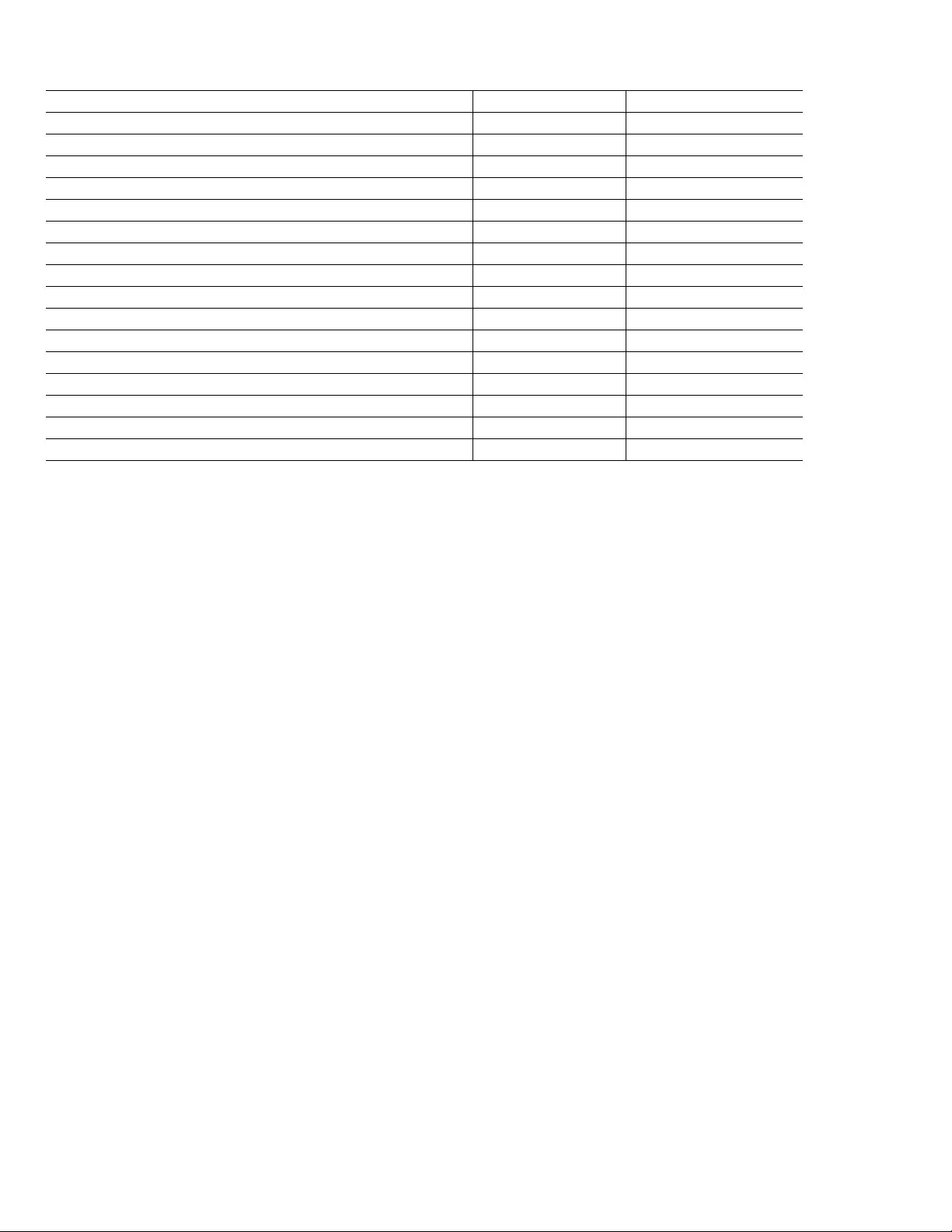

Standard Models Self-Encrypting Drive (SED) Models Instant Secure Erase (ISE) Models FIPS 140-2 Level 2 Models

512 Native

ST900MP0006 ST900MP0016 ST900MP0026 ST900MP0126

ST600MP0006 ST600MP0016 ST600MP0036 ST600MP0026

ST300MP0006 ST300MP0016 ST300MP0026

4096 / 512 Emulation

ST900MP0146 ST900MP0156 ST900MP0136 ST900MP0166

ST600MP0136 ST600MP0146 ST600MP0126 ST600MP0156

ST300MP0106 ST300MP0116 ST300MP0096

Note Previous generations of Seagate Self-Encrypting Drive models were called Full Disk Encryption (FDE) models

before a differentiation between drive-based encryption and other forms of encryption was necessary.

Note The Self-Encrypting Drive models indicated on the cover of this product manual have provisions for “Security of Data

at Rest” based on the standards defined by the Trusted Computing Group (see www.trustedcomputinggroup.org).

Seagate Exos 15E900 SAS Product Manual, Rev. B 9

2.0 Applicable standards and reference documentation

The drives documented in this manual have been developed as system peripherals to the highest standards of design and

construction. The drives depends on host equipment to provide adequate power and environment for optimum performance and

compliance with applicable industry and governmental regulations. Special attention must be given in the areas of safety, power

distribution, shielding, audible noise control, and temperature regulation. In particular, the drive must be securely mounted to

guarantee the specified performance characteristics. Mounting by bottom holes must meet the requirements of Section

10.3.Agency and Safety Certifications

2.1 Agency and Safety Certifications

Each Hard Drive and Solid State Drive ("drives") has a product label that includes certifications that are applicable to that specific

drive. The following information provides an overview of requirements that may be applicable to the drive.

2.1.1 Safety certification

These products are certified to meet the requirements of UL/cUL 60950-1, EN 60950-1, and may also include, IEC 62368, UL 62368

and EN 62368.

The security features of Self-Encrypting Drive models are based on the “TCG Storage Architecture Core Specification” and the “TCG

Storage Workgroup Security Subsystem Class: Enterprise_A” specification with additional vendor-unique features as noted in this

product manual.

2.2 Regulatory Models

The following regulatory model number represent all features and configurations within the series:

Regulatory Model Numbers: STT001

2.3 Electromagnetic susceptibility

The drive as delivered is tested to meet susceptibility requirements in a representative enclosure. It is the responsibility of those

integrating the drive within their systems to perform those tests required and design their system to ensure that equipment

operating in the same system as the drive or external to the system does not adversely affect the performance of the drive. See

Section 6.3, DC power requirements.

2.4 Electromagnetic compliance

Seagate uses an independent laboratory to confirm compliance with the directives/standards for CE Marking and RCM Marking. The

drive was tested in a representative system for typical applications and comply with the Electromagnetic Interference/

Electromagnetic Susceptibility (EMI/EMS) for Class B products. The selected system represents the most popular characteristics for

test platforms. The system configurations include:

• Typical current use microprocessor

•Keyboard

• Monitor/display

•Mouse

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee that all systems will

comply. The computer manufacturer or system integrator shall confirm EMC compliance and provide the appropriate marking for

their product.

Seagate Exos 15E900 SAS Product Manual, Rev. B 10

2.4.1 European Union (EU) CE Marking Requirements

Drives that display the CE mark comply with the European Union (EU) requirements specified in the Electromagnetic Compatibility

Directive (2014/30/EU) put into force on 20 April 2016. Testing is performed to the levels specified by the product standards for

Information Technology Equipment (ITE). Emission levels are defined by EN 55032:2012, Class B and the immunity levels are defined

by EN 55024:2010.

The drives also meet the requirements of The Low Voltage Directive (LVD) 2014/35/EU.

Seagate drives are tested in representative end-user systems. Although CE-marked Seagate drives comply with all relevant

regulatory requirements and standards for the drives, Seagate cannot guarantee that all system-level products into which the drives

are installed comply with all regulatory requirements and standards applicable to the system-level products. The drive is designed

for operation inside a properly designed system (e.g., enclosure designed for the drive), with properly shielded I/O cable (if

necessary) and terminators on all unused I/O ports. Computer manufacturers and system integrators should confirm EMC

compliance and provide CE marking for the system-level products.

For compliance with the RoHS "Recast" Directive 2011/65/EU (RoHS 2), see Section 2.5.1 on page 11.

2.4.2 Australian RCM Compliance Mark

If these models have the RCM marking, they comply with the Australia/New Zealand Standard AS/NZ CISPR32 and meet the

Electromagnetic Compatibility (EMC) Framework requirements of the Australian Communication and Media Authority (ACMA).

2.4.3 Canada ICES-003

If this model has the ICES-003:2016 marking it complies with requirements of ICES tested per ANSI C63.4-2014.

2.4.4 South Korean KC Certification Mark

The South Korean KC Certification Mark means the drives comply with paragraph 1 of Article 11 of the Electromagnetic Compatibility

control Regulation and meet the Electromagnetic Compatibility (EMC) Framework requirements of the Radio Research Agency (RRA)

Communications Commission, Republic of Korea.These drives have been tested and comply with the Electromagnetic Interference/

Electromagnetic Susceptibility (EMI/EMS) for Class B products. Drives are tested in a representative, end-user system by a Korean-

recognized lab.

2.4.5 Morocco Commodity Mark

To satisfy our OEM customers, Seagate has added the Moroccan Commodity Mark to the drives provided to the OEM for the sale of

Customer Kits produced by our OEM customers that are intended to be incorporated into the OEM's finished system-level product by

an end user. The Customer Kits are considered 'devices' under Morocco's Order of the Minister of Industry, Trade, Investment and

Digital Economy No. 2574-14 of 29 Ramadan 1436 (16 July 2015) on electromagnetic compatibility of equipment.

Seagate drives are tested for compliance and complies with the European Union (EU) Electromagnetic Compatibility (EMC) Directive

2014/30/EU and the Low Voltage Directive (LVD) 2014/35/EU. Accordingly, the drives also meets the requirements of Morocco's

Order of the Minister of Industry, Trade, Investment and Digital Economy No. 2574-14 of 29 Ramadan 1436 (16 July 2015) on

electromagnetic compatibility of equipment.

2.4.6 Taiwanese BSMI

Drives with the Taiwanese certification mark comply with Chinese National Standard, CNS13438.

For compliance with the Taiwan Bureau of Standards, Metrology and Inspection’s (BSMI) requirements, see Section 2.5.3 on page 12.

ࣗطیࡈ߇ΰח

%

ɼࢽࡈ؏ܞݦࢢ

ࢇЕɼࢽࡈ% ࢷળࢶଢԻ۰࣯Ի

ɼࢽ߾۰یࡈଜЕʨࡶּࢶࡳԻଜֲ ֻҘ

ࠇ߾۰یࡈଟܹݡТЬ

Seagate Exos 15E900 SAS Product Manual, Rev. B 11

2.4.7 FCC verification

These drives are intended to be contained solely within a personal computer or similar enclosure (not attached as an external

device). As such, each drive is considered to be a subassembly even when it is individually marketed to the customer. As a

subassembly, no Federal Communications Commission verification or certification of the device is required.

Seagate has tested this device in enclosures as described above to ensure that the total assembly (enclosure, disk drive,

motherboard, power supply, etc.) does comply with the limits for a Class B computing device, pursuant to Subpart J, Part 15 of the

FCC rules. Operation with noncertified assemblies is likely to result in interference to radio and television reception.

Radio and television interference. This equipment generates and uses radio frequency energy and if not installed and used in

strict accordance with the manufacturer’s instructions, may cause interference to radio and television reception.

This equipment is designed to provide reasonable protection against such interference in a residential installation. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or

television, which can be determined by turning the equipment on and off, users are encouraged to try one or more of the following

corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the computer into a different outlet so that the receiver and computer are on different branch outlets.

If necessary, users should consult a dealer or an experienced radio/television technician for additional suggestions. Users may find

helpful the following booklet prepared by the Federal Communications Commission: How to Identify and Resolve Radio-Television

Interference Problems. This booklet is available from the Superintendent of Documents, U.S. Government Printing Office, Washington,

DC 20402. Refer to publication number 004-000-00345-4.

2.5 Environmental protection

Seagate designs its products to meet environmental protection requirements worldwide, including regulations restricting certain

chemical substances.

2.5.1 European Union Restriction of Hazardous Substance Law

2.5.1.1 Restriction of Hazardous Substances in Electrical and Electronic Equipment

Seagate drives are designed to be compliant with the European Union RoHS "Recast" Directive 2011/65/EU (RoHS 2) as amended by

Directive (EU) 2015/863. The RoHS2 restricts the use of certain hazardous substances such as Lead, Cadmium, Mercury, Hexavalent

Chromium, Polybrominated Biphenyls (PBB) and Polybrominated Diphenyl Ether (PBDE), BisBis(2-Ethylhexyl) phthalate (DEHP),

Benzyl butyl phthalate (BBP), Dibutyl phthalate (DBP), and Diisobutyl phthalate (DIBP) in electrical and electronic equipment (EEE).

2.5.1.2 Substances of Very High Concern (SVHC)

The European Union REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) Regulation (EC) 1907/2006

regulates chemicals shipped into and used in Europe. A number of parts and materials in Seagate products are procured from

external suppliers. We rely on the representations of our suppliers regarding the presence of REACH substances in these articles and

materials. Our supplier contracts require compliance with our chemical substance restrictions, and our suppliers document their

compliance with our requirements by providing full-disclosure material content declarations that disclose inclusion of any REACH-

regulated substance in such articles or materials. Product-specific REACH declarations are available upon request through your

Seagate Sales Representative.

Seagate Exos 15E900 SAS Product Manual, Rev. B 12

2.5.2 China Requirements —China RoHS 2

China RoHS 2 refers to the Ministry of Industry and Information Technology Order No. 32, effective July 1, 2016, titled

Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products. To

comply with China RoHS 2, Seagate determines this product's Environmental Protection Use Period (EPUP) to be 20

years in accordance with the Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical Products,

SJT 11364-2014.

2.5.3 Taiwan Requirements — Taiwan RoHS

Taiwan RoHS refers to the Taiwan Bureau of Standards, Metrology and Inspection’s (BSMI) requirements in standard CNS 15663,

Guidance to reduction of the restricted chemical substances in electrical and electronic equipment. Seagate products must comply

with the “Marking of presence” requirements in Section 5 of CNS 15663, effective January 1, 2018. This product is Taiwan RoHS

compliant.

The following table meets the Section 5 “Marking of presence” requirements.

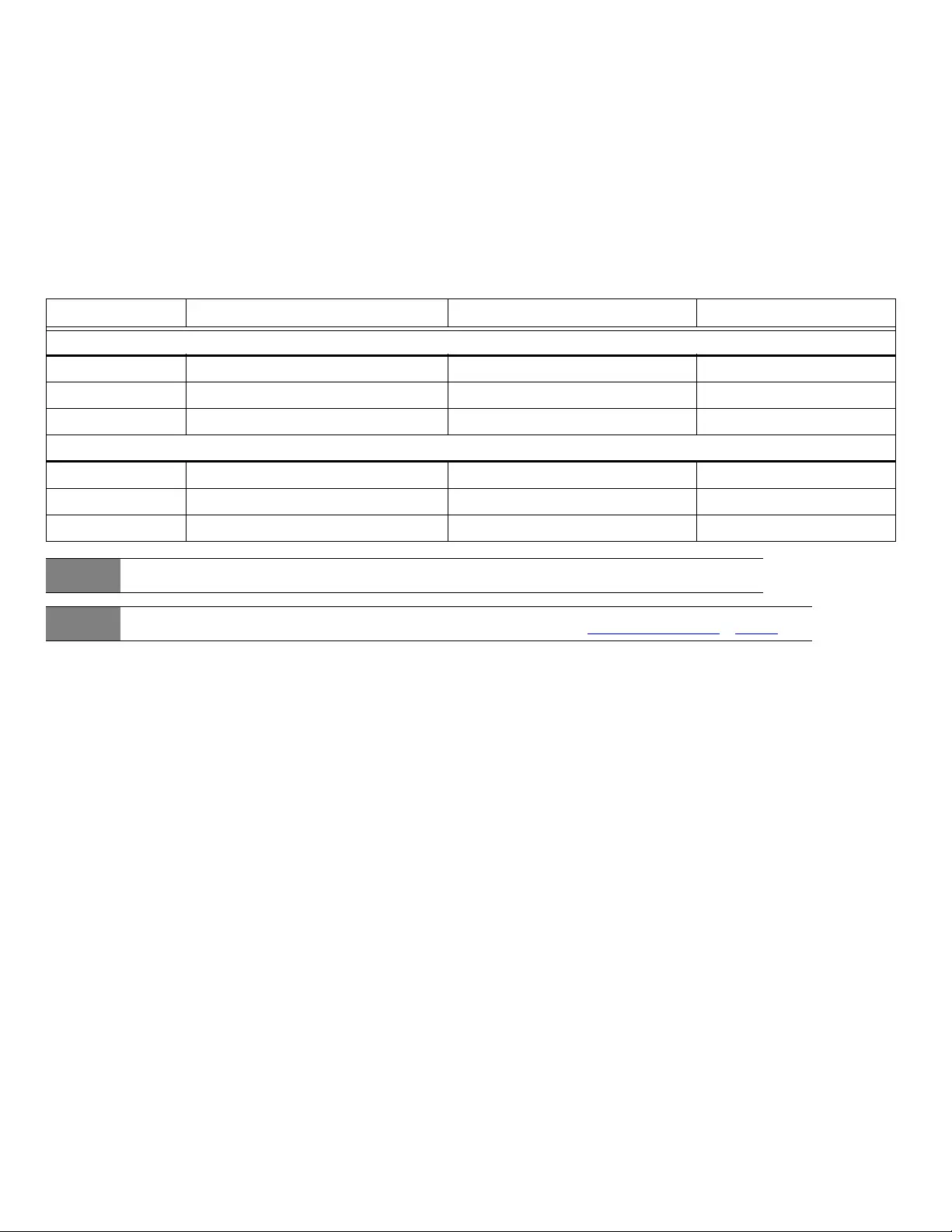

Table 1 China - Hazardous Substances

部件名称

Part Name

有害物质

Hazardous Substances

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr+6)

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

硬盘驱动器

HDD XOO O O O

印刷电路板组装

PCBA XOO O O O

本表格依据 SJ/T 11364 的规定编制。

This table is prepared in accordance with the provisions of SJ/T 11364-2014

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

O:Indicates that the hazardous substance contained in all of the homogeneous materials for this

part is below the limit requirement of GB/T26572.

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

X:Indicates that the hazardous substance contained in at least one of the homogeneous materials

used for this part is above the limit requirement of GB/T26572.

Table 2 Taiwan - Restricted Substances

設備名稱:硬盤設備,型號:僅適用于內部使用

Equipment Name: Hard Disk Device, Type Designation: Internal Use Only

單元

Unit

限用物質及其化學符號

Restricted Substance and its chemical symbol

鉛

(Pb)

汞

(Hg)

鎘

(Cd)

六價鉻

(Cr+6)

多溴聯苯

(PBB)

多溴二苯醚

(PBDE)

硬盤驅動器

HDD —OOOOO

印刷電路板组装

PCBA —OOOOO

備考 1. "O" 係指該项限用物質之百分比含量未超出百分比含量基準值。

Note 1. "O" indicates that the percentage content of the restricted substance

does not exceed the percentage of reference value of presence.

備考 2. "—" 係指該项限用物質為排除項目。

Note 2. "—" indicates that the restricted substance corresponds to the exemption.

20

Seagate Exos 15E900 SAS Product Manual, Rev. B 13

2.6 Reference documents

SAS Interface Manual

Seagate part number: 100293071

SCSI Commands Reference Manual

Seagate part number: 100293068

Self-Encrypting Drives Reference Manual

Seagate part number: 100515636

ANSI SAS Documents

SFF-8223 2.5” Drive Form Factor with Serial Connector

SFF-8460 HSS Backplane Design Guidelines

SFF-8470 Multi Lane Copper Connector

SFF-8482 SAS Plug Connector

INCITS 481-2011 Fibre Channel Protocol for SCSI -4 (FCP-4)

INCITS 502 SCSI Primary Commands-5 (SPC-5) Rev. 10

INCITS 506 SCSI Block Commands-4 (SBC-4) Rev. 10

INCITS 519 Serial Attached SCSI (SAS-3) Rev. 06

INCITS 538 SCSI Protocol Layer-4 (SPL-4) Rev. 08

INCITS 536 Zone Block Commands (ZBC)

ANSI Small Computer System Interface (SCSI) Documents

INCITS 515 SCSI Architecture Model (SAM-5) Rev. 11

Trusted Computing Group (TCG) Documents (apply to Self-Encrypting Drive models only)

TCG Storage Architecture Core Specification, Rev. 1.0

TCG Storage Security Subsystem Class Enterprise Specification, Rev. 1.0

Specification for Acoustic Test Requirement and Procedures

Seagate part number: 30553-001

In case of conflict between this document and any referenced document, this document takes precedence.

Seagate Exos 15E900 SAS Product Manual, Rev. B 14

3.0 General description

These drives provide high performance, high capacity data storage for a variety of systems including engineering workstations,

network servers, mainframes, and supercomputers. The Serial Attached SCSI interface is designed to meet next-generation

computing demands for performance, scalability, flexibility and high-density storage requirements.

The hybrid functionality of the 15K drive provides improved performance over standard HDDs in real-world workloads. This

improvement is due to the addition of a solid state component that caches “hot” data for reads as well as protects write data via non-

volatile cache (NVC).

These drives are random access storage devices designed to support the Serial Attached SCSI Protocol as described in the ANSI

specifications, this document, and the SAS Interface Manual (part number 100293071) which describes the general interface

characteristics of this drive. These drives are classified as intelligent peripherals and provide level 2 conformance (highest level) with

the ANSI SCSI-1 standard. The SAS connectors, cables and electrical interface are compatible with Serial ATA (SATA), giving future

users the choice of populating their systems with either SAS or SATA hard disk drives. This allows integrators to continue to leverage

existing investment in SCSI while gaining a 12.0Gb/s serial data transfer rate.

The Self-Encrypting Drive models indicated on the cover of this product manual have provisions for “Security of Data at Rest” based

on the standards defined by the Trusted Computing Group (see www.trustedcomputinggroup.org).

The head and disk assembly (HDA) is sealed at the factory. Air recirculates within the HDA through a non-replaceable filter to

maintain a contamination-free HDA environment.

The heads automatically go to the ramp load/unload when power is removed from the drive and during the deeper sleep modes.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement during shipping and

handling. The shipping lock disengages and the head load process begins when power is applied to the drive.

These drives decode track 0 location data from the servo data embedded on each surface to eliminate mechanical transducer

adjustments and related reliability concerns.

The drives also use a high-performance actuator assembly with a low-inertia, balanced, patented, straight arm design that provides

excellent performance with minimal power dissipation.

Note Never disassemble the HDA and do not attempt to service items in the sealed enclosure (heads, media, actuator, etc.) as this

requires special facilities. The drive does not contain user-replaceable parts. Opening the HDA for any reason voids the warranty.

Seagate Exos 15E900 SAS Product Manual, Rev. B 15

3.1 Standard features

Exos 15E900 SAS drives have the following standard features:

• 256MB data buffer (see Section 4.5)

• 128-deep task set (queue)

• 3.0 / 6.0 / 12.0 Gb Serial Attached SCSI (SAS) interface

• Automatic shipping lock

•Drive Self Test (DST)

• Dynamic spindle brake

• ECC maximum burst correction length of 520 bits for 512 byte blocks and 3360 bits for 4k byte blocks

• Embedded servo design

• Enhanced Caching - 8MB NVC-backed write cache on 512E/4KN and 3.2MB on 512N

• Firmware downloadable using the SAS interface

• Flawed logical block reallocation at format time

• Idle Read After Write (IRAW)

• Industry standard SFF 2.5-in dimensions

• Integrated dual port SAS controller supporting the SCSI protocol

• Jumperless configuration

• No preventive maintenance or adjustments required

• Perpendicular recording technology

• Power Balance supported (see Section 6.2 on page 26)

•Power Save

• Programmable auto write and read reallocation

• Programmable logical block reallocation scheme

• Reallocation of defects on command (Post Format)

•SAS Power Disable

• Self diagnostics performed when power is applied to the drive

• Support for SAS expanders and fanout adapters

• Supports up to 32 initiators

• T10 Fast Format supported (see <hypertext_blue>Section 4.2.2)

•TurboBoost

TM 16GB read cache 512E / 4KN

• User-selectable logical block size for 4KN (4096, 4160 or 4224 bytes per logical block)

• User-selectable logical block size for 512N/512E (512, 520, or 528 bytes per logical block)

• Vertical, horizontal, or top down mounting

• Zone bit recording (ZBR)

Self-Encrypting Drive models have the following additional features:

• 16 independent data bands

• Authenticated firmware download

• Automatic data encryption/decryption

• Controlled access

• Cryptographic erase of user data for a drive that will be repurposed or scrapped

•Drive locking

•Random number generator

3.2 Media description

The media used on the drive has a glass substrate coated with a thin film magnetic material, overcoated with a proprietary

protective layer for improved durability and environmental protection.

Seagate Exos 15E900 SAS Product Manual, Rev. B 16

3.3 Performance

• 15K RPM spindle. Average latency = 2.0 ms

• 600 MB/s maximum instantaneous data transfers

• Adaptive seek velocity; improved seek performance

• Background processing of queue

• Firmware-controlled multisegmented cache designed to dynamically adjust segments for enhanced system performance

• Supports start and stop commands (spindle stops spinning)

3.4 Reliability

• 5-year warranty

• Annualized Failure Rate (AFR) of 0.44%

• Balanced low mass rotary voice coil actuator

• Incorporates industry-standard Self-Monitoring Analysis and Reporting Technology (S.M.A.R.T.)

• Mean Time Between Failures (MTBF) of 2,000,000 hours

3.5 Formatted capacities

Standard OEM models are formatted to 512 bytes per block. The block size is selectable at format time and must be a multiple of 4

bytes. Users having the necessary equipment may modify the data block size before issuing a format command and obtain different

formatted capacities than those listed.

To provide a stable target capacity environment and at the same time provide users with flexibility if they choose, Seagate

recommends product planning in one of two modes:

Seagate designs capacity points at certain block sizes that Seagate guarantees current and future products will meet. We

recommend customers use this capacity in their project planning, as it ensures a stable operating point with backward and forward

compatibility from generation to generation. The current guaranteed operating points for this product are:

3.6 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the Mode Select (6)

parameter list table in the SAS Interface Manual, part number 100293071. A value of zero in the Number of Blocks field indicates that

the drive will not change the capacity it is currently formatted to have. A number other than zero and less than the maximum

number of LBAs in the Number of Blocks field changes the total drive capacity to the value in the Number of Blocks field. A value

greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.7 Factory installed options

Integrators may order the following items which are incorporated at the manufacturing facility during production or packaged

before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protection against transit damage. Units

shipped individually require additional protection as provided by the single unit shipping pack. Users planning single unit distribution should

specify this option.

• The Safety and Regulatory Agency Specifications, part number 75789512, is usually included with each standard OEM drive shipped, but extra

copies may be ordered.

Note There is no significant performance difference between Self-Encrypting

Drive and standard (non-Self-Encrypting Drive) models.

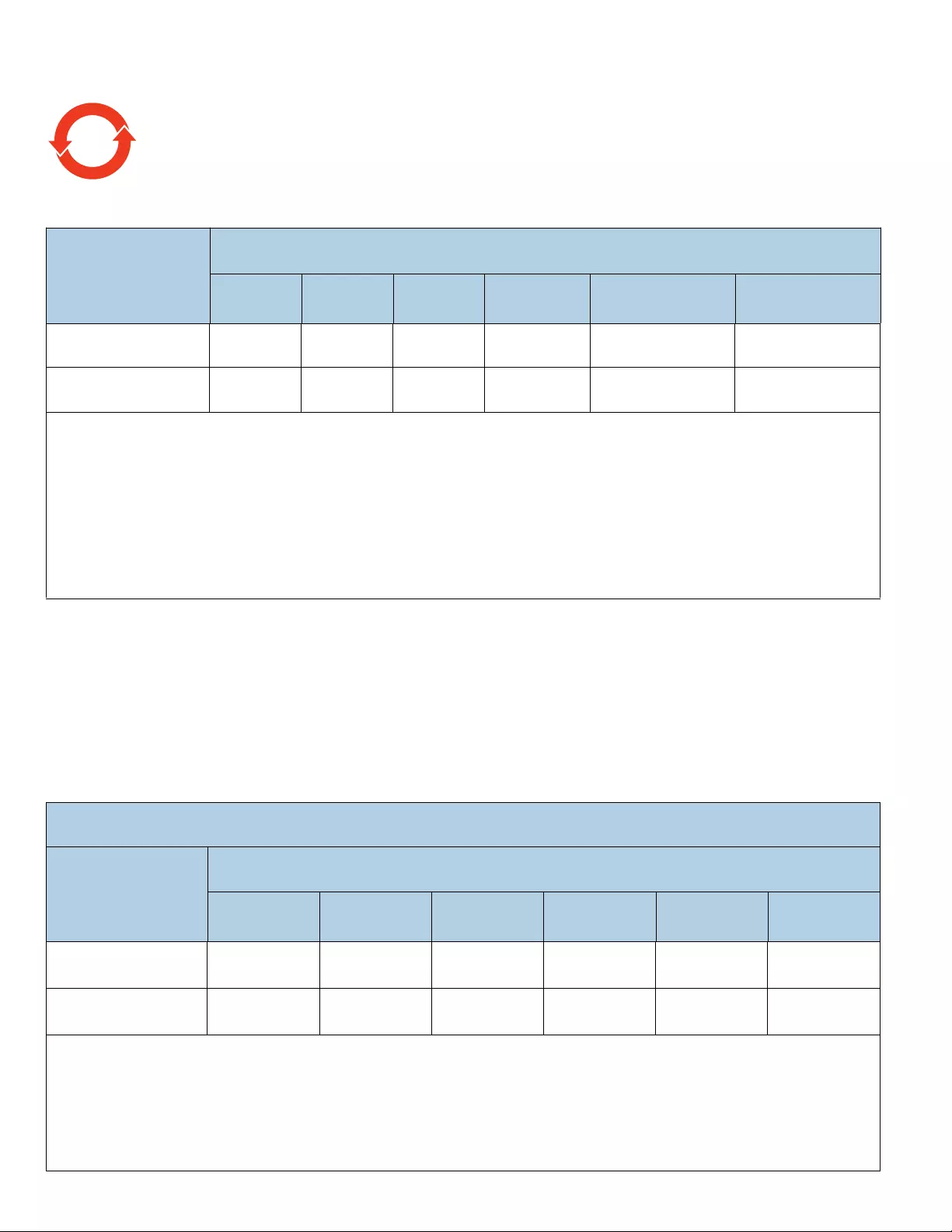

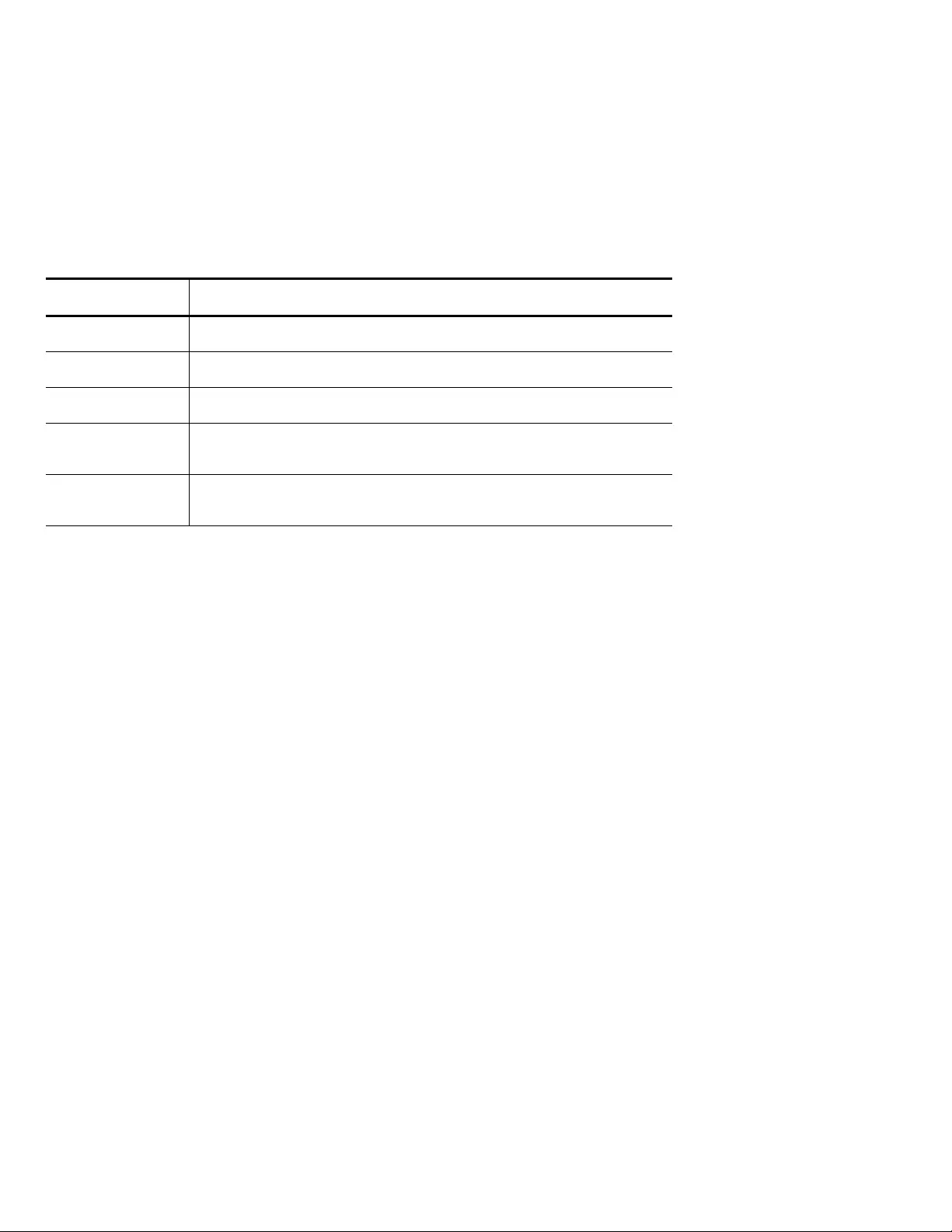

Capacity (Blocks)

Sector Size

900GB Models 600GB Models 300GB Models

Decimal Hex Decimal Hex Decimal Hex

512 1,758,174,768 68CB9E30h 1,172,123,568 45DD2FB0h 585,937,500 22ECB25Ch

520 1,720,961,544 6693CA08h 1,147,307,696 446286B0h 573,653,848 22314358h

528 1,673,624,336 63C17B10h 1,115,749,560 4280FCB8h 557,874,778 21407E5Ah

4096 219,771,846 D1973C6h 146,515,446 8BBA5F6h 73,259,046 45DD826h

4160 215,480,776 CD7F9C8h 143,653,848 88FFBD8h 71,826,928 447FDF0h

4224 211,150,576 C95E6F0h 140,767,048 863EF48h 70,383,528 431F7A8h

Seagate Exos 15E900 SAS Product Manual, Rev. B 17

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of Exos 15E900 SAS drives.

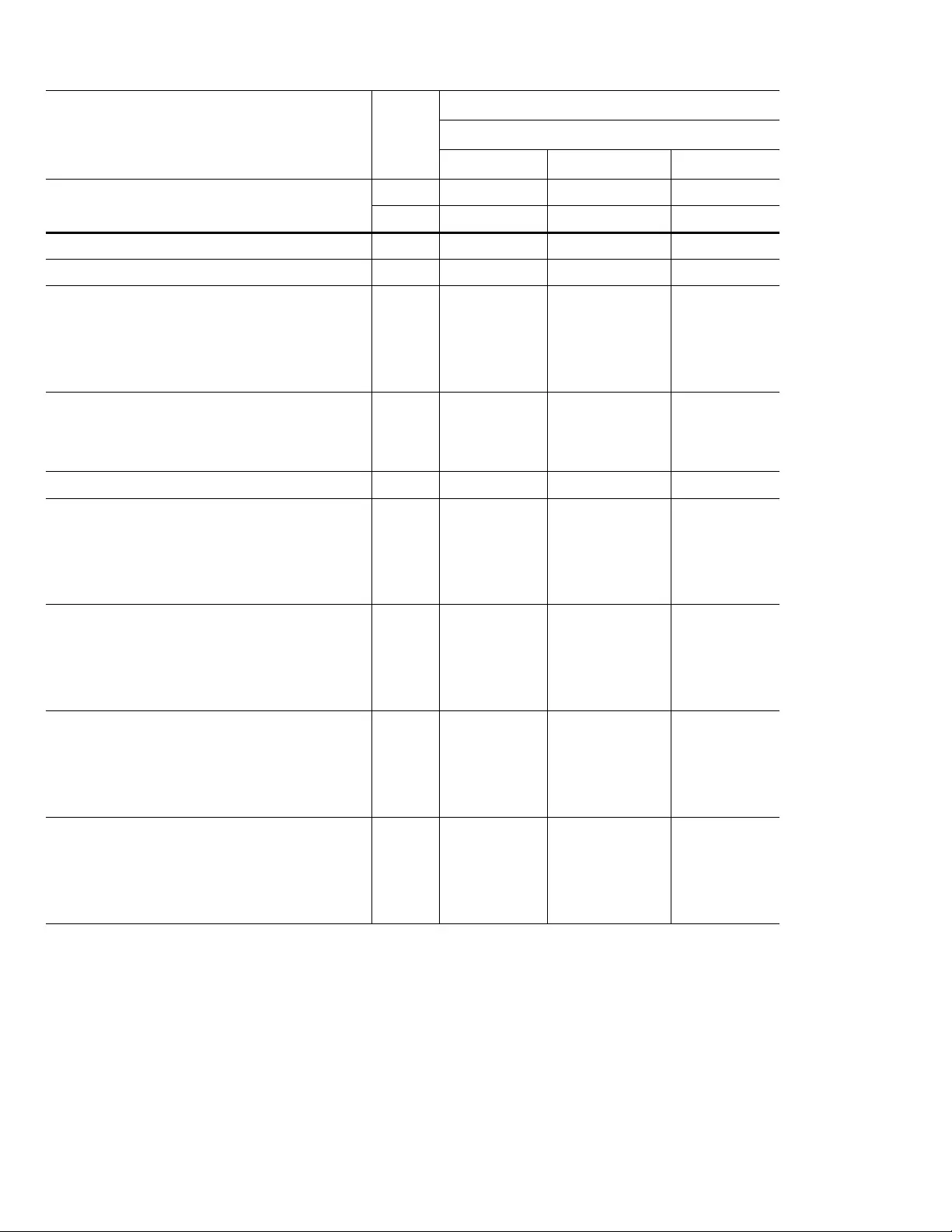

4.1 Internal drive characteristics

900GB Models 600GB Models 300GB Models

Drive capacity 900 600 300 GB (formatted, rounded off value)

Read/write data heads 6 4 2

Bytes per track 1055/1081 1055/1081 1055/1081 KBytes (avg, rounded off values)(4KN or 512E / 512N)

Bytes per surface 150,000 150,000 150,000 MBytes (unformatted, rounded off values

Tracks per surface (total) 138.8 138.8 138.8 KTracks (user accessible) (4KN or 512E / 512N)

Tracks per in 335 335 335 KTPI (average) (4KN or 512E / 512N)

Peak bits per in 2091/2277 2091/2277 2091/2277 Kbits/in

Areal density 684/744 684/744 684/744 Gb/in2 (4KN or 512E / 512N)

Disk rotation speed 15K 15K 15K RPM

Avg rotational latency 2.0 2.0 2.0 ms

4.2 Seek performance characteristics

4.2.1 Format command execution time for 512-byte sectors (minutes)

Execution time measured from receipt of the last byte of the Command Descriptor Block (CDB) to the request for a Status Byte

Transfer to the Initiator (excluding connect/disconnect).

When changing sector sizes, the format times shown above may need to be increased by 30 minutes.

4.2.2 Fast Format

Drive sector size transition

• Single code to support sector sizes from 512E to 4KN

• T10 fast format conversion between 4KNand 512E configurations in the field.

• Possible only if sector sizes are exact multiples of 8 & vice versa

• The selected sector size will take effect only after fast format or full format

• Drive default is 512E from the factory.

• 512E / 4KN features set after Fast Format

T10 Fast Format

• Implements the fast format based on T10 Spec.

• To request Fast Format, the FFMT bits (Byte 4, Bits 1:0) should be set to 01b.

• A setting of 10b or 11b will return a check condition with 05/24 sense code (pointing to FFMT MSB in CDB).

Mode Select - Parameter list header

• Set Write buffer: // Set Block Descriptor Length = 0x08, Number of LBA's = 0xFFFFFFFF

• 00 00 00 00 00 00 00 08 FF FF FF FF 00 00 02 00 // Set block size to 0512 (0x0200)

•10 00 // Set block size to 4096 (0x1000)

• Then Send Mode Select Command

• cdb: 55 01 00 00 00 00 00 00 10 00 // (SP bit = 1, Parameter list = 0x10)

Format Unit - Parameter list header

• Set Write buffer: // Set IMMED = 1

• 00 02 00 00

• Then Send Format Unit Command

• cdb: 04 14 00 00 01 00 // (FMTDAT = 1, DEFECT LIST FORMAT = 010b, FFMT = 01b)

900GB Models 600GB Models 300GB models

Maximum (with verify) 180 120 60

Maximum (without verify) 90 60 30

Seagate Exos 15E900 SAS Product Manual, Rev. B 18

4.2.3 General performance characteristics

4.3 Start/stop time

The drive accepts the commands listed in the SAS Interface Manual less than 3 seconds after DC power has been applied.

If the drive receives a NOTIFY (ENABLE SPINUP) primitive through either port and has not received a START STOP UNIT command

with the START bit equal to 0, the drive becomes ready for normal operations within 20 seconds (excluding the error recovery

procedure).

If the drive receives a START STOP UNIT command with the START bit equal to 0 before receiving a NOTIFY (ENABLE SPINUP)

primitive, the drive waits for a START STOP UNIT command with the START bit equal to 1. After receiving a START STOP UNIT

command with the START bit equal to 1, the drive waits for a NOTIFY (ENABLE SPINUP) primitive. After receiving a NOTIFY (ENABLE

SPINUP) primitive through either port, the drive becomes ready for normal operations within 20 seconds (excluding the error

recovery procedure).

If the drive receives a START STOP UNIT command with the START bit and IMMED bit equal to 1 and does not receive a NOTIFY

(ENABLE SPINUP) primitive within 5 seconds, the drive fails the START STOP UNIT command.

The START STOP UNIT command may be used to command the drive to stop the spindle. Stop time is 20 seconds (maximum) from

removal of DC power. SCSI stop time is 20 seconds. There is no power control switch on the drive.

4.4 Prefetch/multi-segmented cache control

The drive provides a prefetch (read look-ahead) and multi-segmented cache control algorithms that in many cases can enhance

system performance. Cache refers to the drive buffer storage space when it is used in cache operations. To select this feature, the

host sends the Mode Select command with the proper values in the applicable bytes in page 08h. Prefetch and cache operations are

independent features from the standpoint that each is enabled and disabled independently using the Mode Select command;

however, in actual operation, the prefetch feature overlaps cache operation somewhat as described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode parameter values (Mode Page 08h) for standard OEM versions of this drive family are given in

Table 12 for 300GB, Table 13 for 600GB and Table 14 for 900GB.

4.5 Cache operation

Note. Refer to the SAS Interface Manual for more detail concerning the cache bits.

Of the 256MB physical buffer space in the drive, approximately 66MB for 512E/4KN and 84MB for 512N are available as a data cache.

The remaining buffer space is reserved for internal drive use.

The drive keeps track of the logical block addresses of the data stored in each segment of the buffer. If the cache is enabled (see RCD

bit in the SAS Interface Manual ), data requested by the host with a read command is retrieved from the buffer, if possible, before any

disk access is initiated. If cache operation is not enabled, the buffer is still used, but only as circular buffer segments during disk

medium read operations (disregarding Prefetch operation for the moment). That is, the drive does not check in the buffer segments

for the requested read data, but goes directly to the medium to retrieve it. The retrieved data merely passes through some buffer

segment on the way to the host. All data transfers to the host are in accordance with buffer-full ratio rules. See the explanation

provided with the information about Mode Page 02h (disconnect/reconnect control) in the SAS Interface Manual.

Sustained transfer rate 210 to 315 MB/s 512E / 4KN **

205 to 300 MB/s 512N **

SAS Interface maximum instantaneous transfer rate 1200 MB/s* per port

(dual port = 2,400 MB/s*)

Logical block sizes

512 (default), 520 and 528

4k - 4096 (default), 4160 and 4224

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact

(for flaws reallocated at format time using the spare sectors per sparing zone reallocation scheme.)

Negligible

Average rotational latency 2.0 ms

* Assumes no errors and no relocated logical blocks. Rate measured from the start of the first logical block transfer to or from the host.

** MB/s ÷ 1.048 = MiB/s

Seagate Exos 15E900 SAS Product Manual, Rev. B 19

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and all of the requested logical blocks are already in the cache:

1. Drive transfers the requested logical blocks to the initiator.

Case B—A Read command requests data, and at least one requested logical block is not in any segment of the cache:

1. The drive fetches the requested logical blocks from the disk and transfers them into a segment, and then from there to the host in accordance

with the Mode Select Disconnect/Reconnect parameters, page 02h.

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Each cache segment is actually a self-contained circular buffer whose length is an integer number of logical blocks. The drive

dynamically creates and removes segments based on the workload. The wrap-around capability of the individual segments greatly

enhances the cache’s overall performance..

4.5.1 Caching write data

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the data to be written to the

medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read

cache hits. The same buffer space and segmentation is used as set up for read functions. The buffer segmentation scheme is set up or

changed independently, having nothing to do with the state of RCD. When a write command is issued, if RCD=0, the cache is first

checked to see if any logical blocks that are to be written are already stored in the cache from a previous read or write command. If

there are, the respective cache segments are cleared. The new data is cached for subsequent Read commands.

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the segment is reached,

the data is written into the beginning of the same cache segment, overwriting the data that was written there at the beginning of

the operation; however, the drive does not overwrite data that has not yet been written to the medium.

If write caching is enabled (WCE=1), then the drive may return Good status on a write command after the data has been transferred

into the cache, but before the data has been written to the medium. If an error occurs while writing the data to the medium, and

Good status has already been returned, a deferred error will be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium. Upon completion of

a Synchronize Cache command, all data received from previous write commands will have been written to the medium.

in Table 12 for 300GB, Table 13 for 600GB and Table 14 for 900GB shows the mode default settings.

4.5.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the disk immediately beyond that which was requested by a

Read command are retrieved and stored in the buffer for immediate transfer from the buffer to the host on subsequent Read

commands that request those logical blocks (this is true even if cache operation is disabled). Though the prefetch operation uses the

buffer as a cache, finding the requested data in the buffer is a prefetch hit, not a cache operation hit.

To enable prefetch, use Mode Select page 08h, byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0 enables prefetch.

The drive does not use the Max Prefetch field (bytes 8 and 9) or the Prefetch Ceiling field (bytes 10 and 11).

When prefetch (read look-ahead) is enabled (enabled by DRA = 0), the drive enables prefetch of contiguous blocks from the disk

when it senses that a prefetch hit will likely occur. The drive disables prefetch when it decides that a prefetch hit is not likely to occur.

4.5.3 Hybrid caching operations

Hybrid caching operation Read data that has been promoted into the hybrid read cache does not persist through a power cycle. The

read data can always be retrieved from the rotating media.

When WCE=0, Hybrid 15K provides NVC-protected write caching over the portion of the DRAM used to coalesce writes. Write data

only goes into NVC when there is an unexpected power loss to the drive. The NVC has 90-day data retention.

If WCE=1, then a hybrid drive will operate on writes like a standard HDD–writes in cache are not protected by NVC and may be lost

with power loss.”

Note

The size of each segment is not reported by Mode Sense command page 08h, bytes 14 and 15. The value 0XFFFF is always

reported regardless of the actual size of the segment. Sending a size specification using the Mode Select command (bytes

14 and 15) does not set up a new segment size. If the STRICT bit in Mode page 00h (byte 2, bit 1) is set to one, the drive

responds as it does for any attempt to change an unchangeable parameter.

Note Write caching in this section is the traditional SCSI write caching (WCE=1) where writes are not protected on power loss.

Note Refer to the SAS Interface Manual for more detail concerning the cache bits.

Seagate Exos 15E900 SAS Product Manual, Rev. B 20

5.0 Reliability specifications

The following reliability specifications assume correct host and drive operational interface, including all interface timings, power

supply voltages, environmental requirements and drive mounting constraints.

5.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated in accordance with this manual using DC power as defined in paragraph 6.4, "DC power requirements."

• Errors caused by host system failures are excluded from error rate computations.

•Assume random data.

• Default OEM error recovery settings are applied. This includes AWRE, ARRE, full read retries, full write retries and full retry time.

5.1.1 Recoverable Errors

Recoverable errors are those detected and corrected by the drive, and do not require user intervention.

Recoverable Data errors will use Error Correction when needed.

Recovered Data error rate is determined using read bits transferred for recoverable errors occurring during a read, and using write

bits transferred for recoverable errors occurring during a write.

5.1.2 Unrecoverable Errors

An unrecoverable data error is defined as a failure of the drive to recover data from the media. These errors occur due to head/media

or write problems. Unrecoverable data errors are only detected during read operations, but not caused by the read. If an

unrecoverable data error is detected, a MEDIUM ERROR (03h) in the Sense Key will be reported. Multiple unrecoverable data errors

resulting from the same cause are treated as 1 error.

5.1.3 Seek errors

A seek error is defined as a failure of the drive to position the heads to the addressed track. After detecting an initial seek error, the

drive automatically performs an error recovery process. If the error recovery process fails, a seek positioning error (Error code = 15h

or 02h) will be reported with a Hardware error (04h) in the Sense Key. Recoverable seek errors are specified at Less than 10 errors in

108 seeks. Unrecoverable seek errors (Sense Key = 04h) are classified as drive failures.

5.1.4 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the device port connected to

the receiver. The error may be detected as a running disparity error, illegal code, loss of word sync, or CRC error.

Seek error rate: Less than 10 errors in 108 seeks

Read Error Rates1

1. Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

Recovered Data Less than 10 errors in 1012 bits transferred (OEM default settings)

Unrecovered Data Less than 1 sector in 1016 bits transferred

Miscorrected Data Less than 1 sector in 1021 bits transferred

Interface error rate: Less than 1 error in 1012 bits transferred

Mean Time Between Failure (MTBF): 2,000,000 hours

Annualized Failure Rate (AFR) 0.44%

Preventive maintenance: None required

Seagate Exos 15E900 SAS Product Manual, Rev. B 21

5.2 Reliability and service

Integrators can enhance the reliability of Exos 15E900 SAS disk drives can be enhanced by ensuring that the drive receives adequate

cooling. Section 6.0 provides temperature measurements and other information that may be used to enhance the service life of the

drive. Section 10.2 provides recommended air-flow information.

5.2.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF)

The production disk drive shall achieve an annualized failure-rate of 0.44% (MTBF of 2,000,000 hours) over a 5 year service life when

used in Enterprise Storage field conditions as limited by the following:

• 8760 power-on hours per year.

• HDA temperature as reported by the drive <= 50C

• Ambient wet bulb temp <= 26°C

• The AFR (MTBF) is a population statistic not relevant to individual units.

• ANSI/ISA S71.04-2013 G2 classification levels and dust contamination to ISO 14644-1 Class 8 standards (as measured at the device)

The MTBF specification for the drive assumes the operating environment is designed to maintain nominal drive temperature and

humidity. The rated MTBF is based upon a sustained drive temperature of up to 122°F (50°C) and wet bulb temperature up to 78.8°F

(26°C). Occasional excursions in operating conditions between the rated MTBF conditions and the maximum drive operating

conditions may occur without significant impact to the rated MTBF. However continual or sustained operation beyond the rated

MTBF conditions will degrade the drive MTBF and reduce product reliability.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Hot plugging the drive

When a disk is powered on by switching the power or hot plugged, the drive runs a self test before attempting to communicate on

its’ interfaces. When the self test completes successfully, the drive initiates a Link Reset starting with OOB. An attached device should

respond to the link reset. If the link reset attempt fails, or any time the drive looses sync, the drive initiated link reset. The drive will

initiate link reset once per second but alternates between port A and B. Therefore each port will attempt a link reset once per 2

seconds assuming both ports are out of sync.

If the self-test fails, the drive does not respond to link reset on the failing port.

5.2.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Monitoring Analysis and Reporting Technology. This technology is intended to recognize conditions

that indicate imminent drive failure and is designed to provide sufficient warning of a failure to allow an application to back up the

data before an actual failure occurs.

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating performance of the drive

and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions Control mode page

(1Ch). Use the DEXCPT bit to enable or disable the S.M.A.R.T. feature. Setting the DEXCPT bit disables all S.M.A.R.T. functions. When

enabled, S.M.A.R.T. collects on-line data as the drive performs normal read and write operations. When the PERF bit is set, the drive is

considered to be in “On-line Mode Only” and will not perform off-line functions.

Applications can measure off-line attributes and force the drive to save the data by using the Rezero Unit command. Forcing

S.M.A.R.T. resets the timer so that the next scheduled interrupt is in one hour.

Applications can interrogate the drive through the host to determine the time remaining before the next scheduled measurement

and data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E. This allows applications to

control when S.M.A.R.T. interruptions occur. Forcing S.M.A.R.T. with the RTZ command resets the timer.

Note

It is the responsibility of the systems integrator to assure that no temperature, energy, voltage hazard,

shorting of PCBA to ground, or ESD potential hazard is presented during the hot connect/disconnect

operation. Discharge the static electricity from the drive carrier prior to inserting it into the system.

Caution The drive motor must come to a complete stop prior to changing the

plane of operation. This time is required to insure data integrity.

Note The drive’s firmware monitors specific attributes for degradation

over time but can’t predict instantaneous drive failures.

Seagate Exos 15E900 SAS Product Manual, Rev. B 22

Performance impact

S.M.A.R.T. attribute data is saved to the disk so that the events that caused a predictive failure can be recreated. The drive measures

and saves parameters once every hour subject to an idle period on the drive interfaces. The process of measuring off-line attribute

data and saving data to the disk is interruptable. The maximum on-line only processing delay is summarized below:

Reporting control

Reporting is controlled by the MRIE bits in the Informational Exceptions Control mode page (1Ch). Subject to the reporting method.

For example, if the MRIE is set to one, the firmware will issue to the host an 01-5D00 sense code. The FRU field contains the type of

predictive failure that occurred. The error code is preserved through bus resets and power cycles.

Determining rate

S.M.A.R.T. monitors the rate at which errors occur and signals a predictive failure if the rate of degraded errors increases to an

unacceptable level. To determine rate, error events are logged and compared to the number of total operations for a given attribute.

The interval defines the number of operations over which to measure the rate. The counter that keeps track of the current number of

operations is referred to as the Interval Counter.

S.M.A.R.T. measures error rates. All errors for each monitored attribute are recorded. A counter keeps track of the number of errors for

the current interval. This counter is referred to as the Failure Counter.

Error rate is the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of error is to set thresholds for the

number of errors and their interval. If the number of errors exceeds the threshold before the interval expires, the error rate is

considered to be unacceptable. If the number of errors does not exceed the threshold before the interval expires, the error rate is

considered to be acceptable. In either case, the interval and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is performing unacceptably for a period of time. The firmware keeps a running

count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a counter is incremented each

time the error rate is unacceptable and decremented (not to exceed zero) whenever the error rate is acceptable. If the counter

continually increments such that it reaches the predictive threshold, a predictive failure is signaled. This counter is referred to as the

Failure History Counter. There is a separate Failure History Counter for each attribute.

5.2.5 Thermal monitor

Exos 15E900 SAS drives implement a temperature warning system which:

1. Signals the host if the temperature exceeds a value which would threaten the drive.

2. Saves a S.M.A.R.T. data frame on the drive which exceeds the threatening temperature value.

A temperature sensor monitors the drive temperature and issues a warning over the interface when the temperature exceeds a set

threshold. The temperature is measured at power-up and then at ten-minute intervals after power-up.

The thermal monitor system generates a warning code of 01-0B01 when the temperature exceeds the specified limit in compliance

with the SCSI standard.

This feature is controlled by the Enable Warning (EWasc) bit, and the reporting mechanism is controlled by the Method of Reporting

Informational Exceptions field (MRIE) on the Informational Exceptions Control (IEC) mode page (1Ch).

[a]. Do not reset the log parameter.

[b]. Do not make any requested changes in any field in any log parameter in any log page.

Maximum processing delay

Fully-enabled delay DEXCPT = 0

S.M.A.R.T. delay times 70 milliseconds