Teka HF LUX 60 4G AL User Manual

Displayed below is the user manual for HF LUX 60 4G AL by Teka which is a product in the Hobs category. This manual has pages.

Related Manuals

P20208R07

P20208R08

4

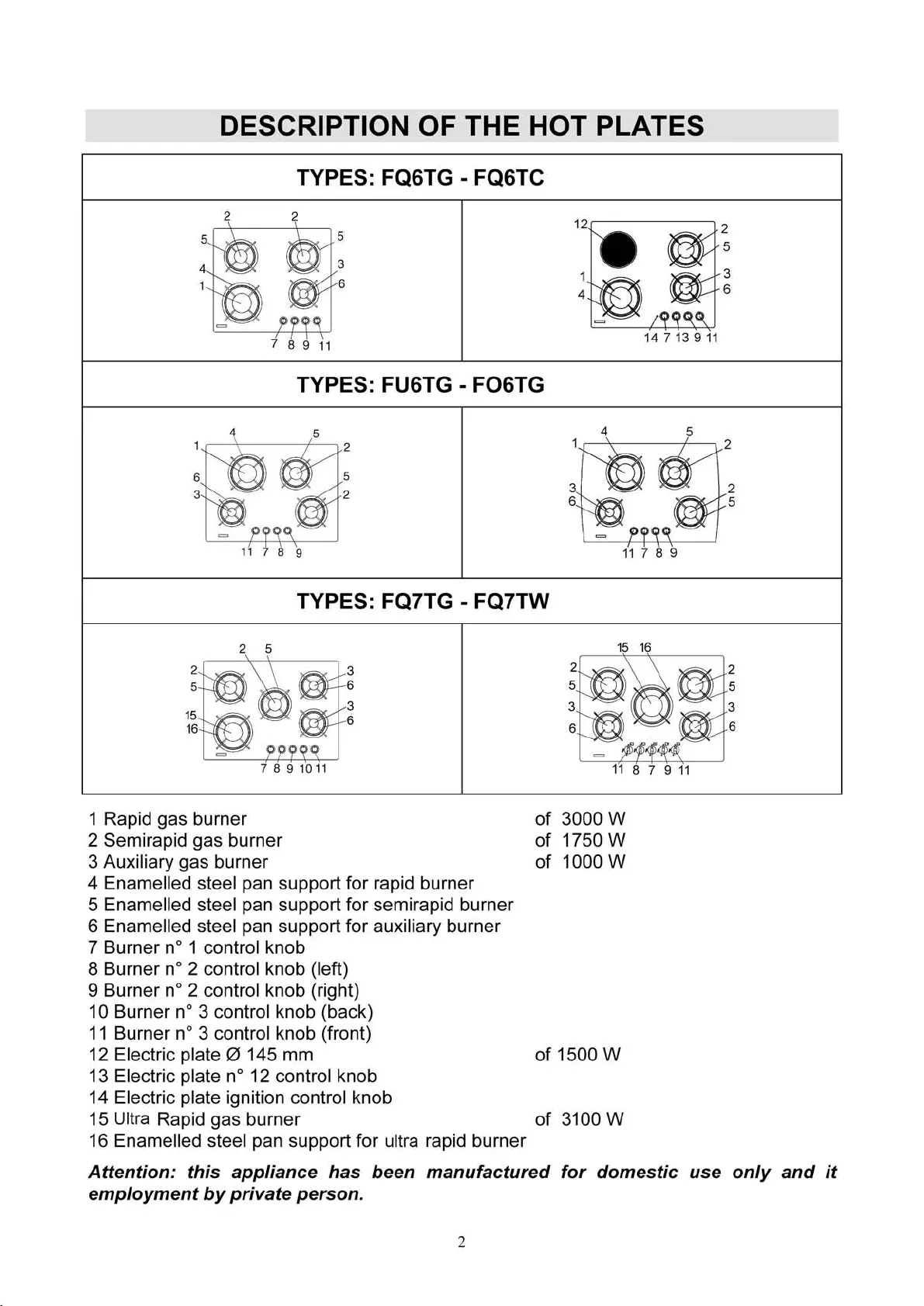

USE

Notes:

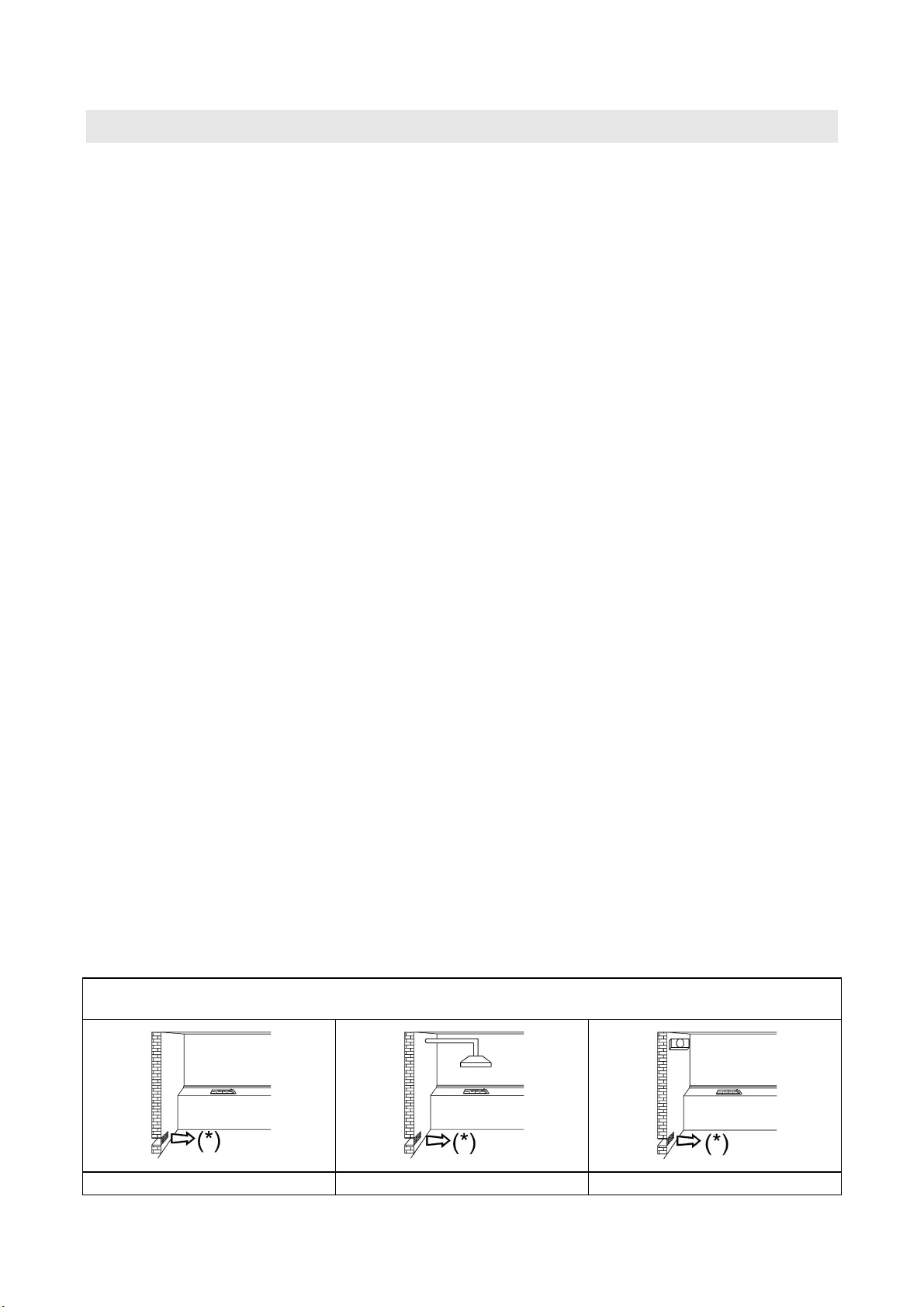

Use of a gas cooking appliance produces heat and moisture in the room in which it

is installed. The room must therefore be well ventilated by keeping the natural air

vents clear (fig. 3) and by activating the mechanical aeration device (suction hood

or electric fan fig. 4 and fig. 5).

Intensive and lengthy use of the appliance may require additional ventilation. This

can be achieved by opening a window or by increasing the power of the mechanical

exhausting system if installed.

(*) AIR INLET: SEE INSTALLATION CHAPTER (PARAGRAPHS 6 AND 7)

FIG. 3 FIG. 4 FIG. 5

5

USE

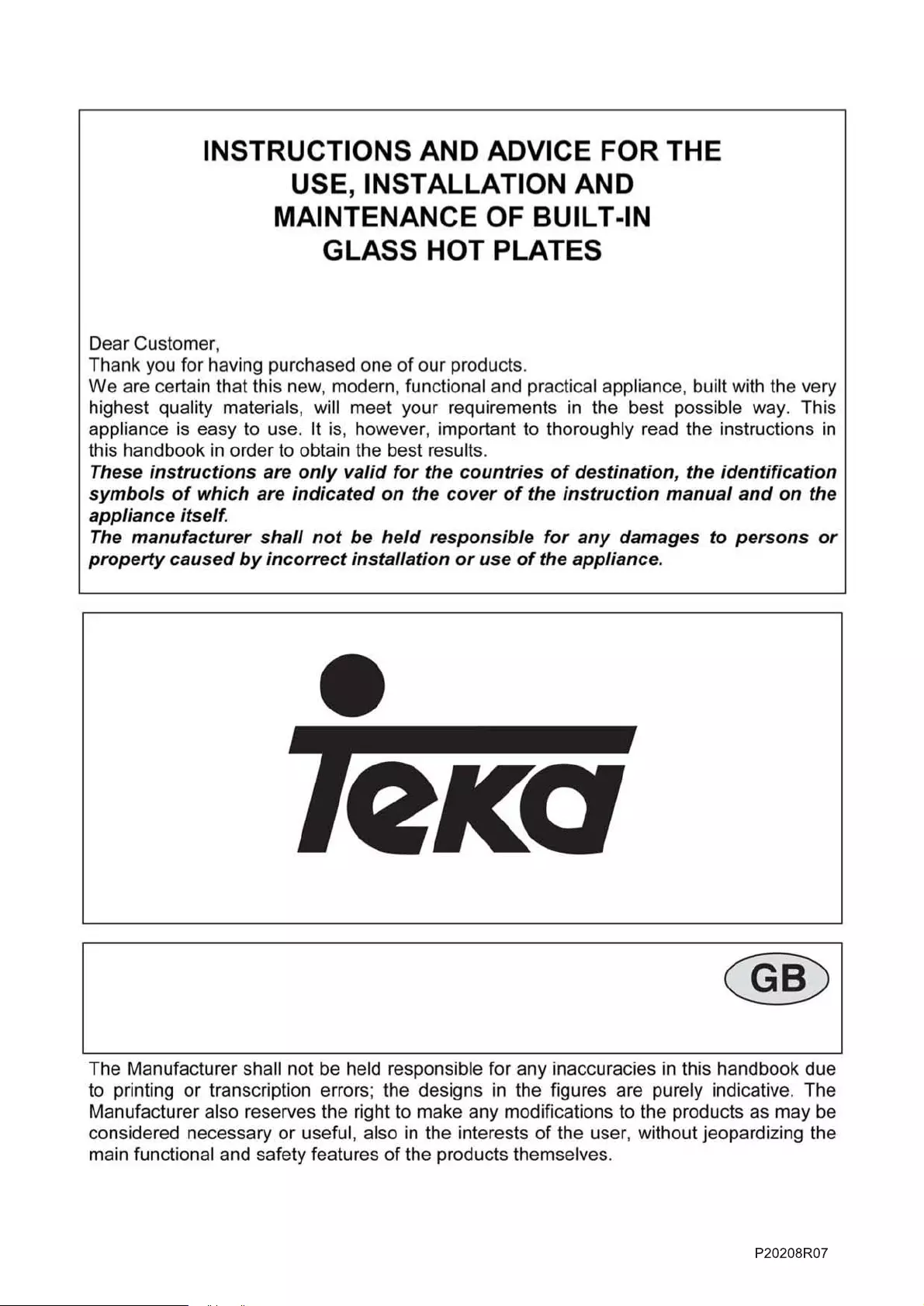

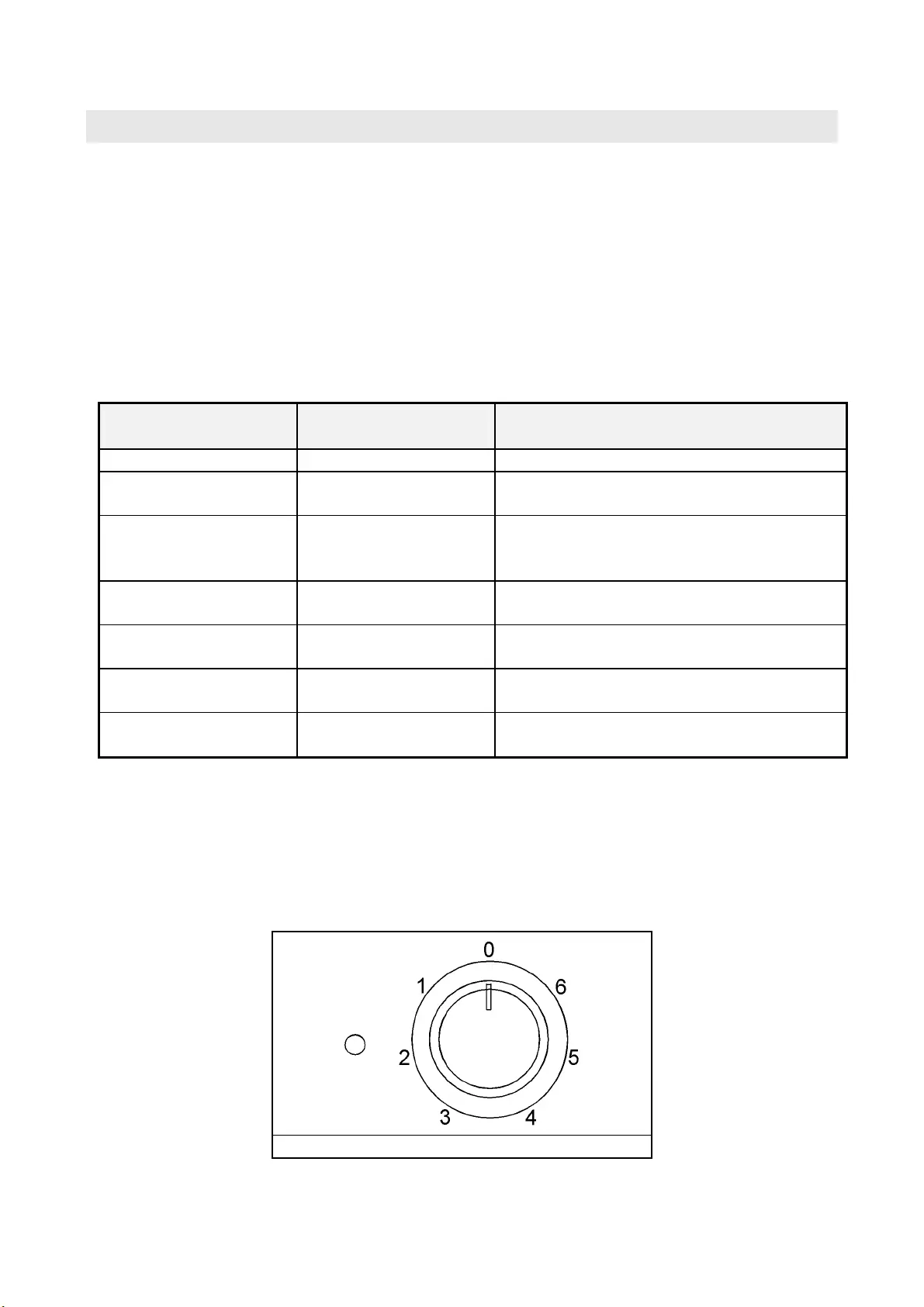

2) HOW TO USE THE ELECTRIC PLATES

Mixed hot pl ates may be eq uipped with a nor mal or rapid electric plates. There are

controlled by switches with various positions (see fig. 6) and is switched on by turning the

knob to the required setting. A diagram is screen-printed above each knob on the f ront

panel. This diagram indicates to w hich electric plates the knob i n question corresponds

(see fig. 6). A red warning light will come on to indicate that the plate is operating.

A purely indicative regulation table for the normal electric plates is given below.

TABLE

NORMAL OR

RAPID PLATE HEAT

INTENSITY POSSIBLE COOKING

PROCESSES

0 Off

1 Weak To dissolve butter, chocolate, etc.. T o

heat small amounts of liquid.

2 Low To heat l arger amounts of liquid. To

prepare cremes and suces requiring long

slow cooking times.

3 Slow To thaw frozen foods and prepare stews,

heat to boiling point or simmer.

4 Medium To heat foods to boiling point. To brown

delicate meats and fish.

5 Strong For escalopes and steaks. T o simmer

large amounts of food.

6 High To bring large amounts of liquid to the

boil. For frying.

FIG. 6

7

CLEANING

IMPORTANT:

Always disconnect the appliance from the gas and electricity mains before carrying

out any cleaning operation.

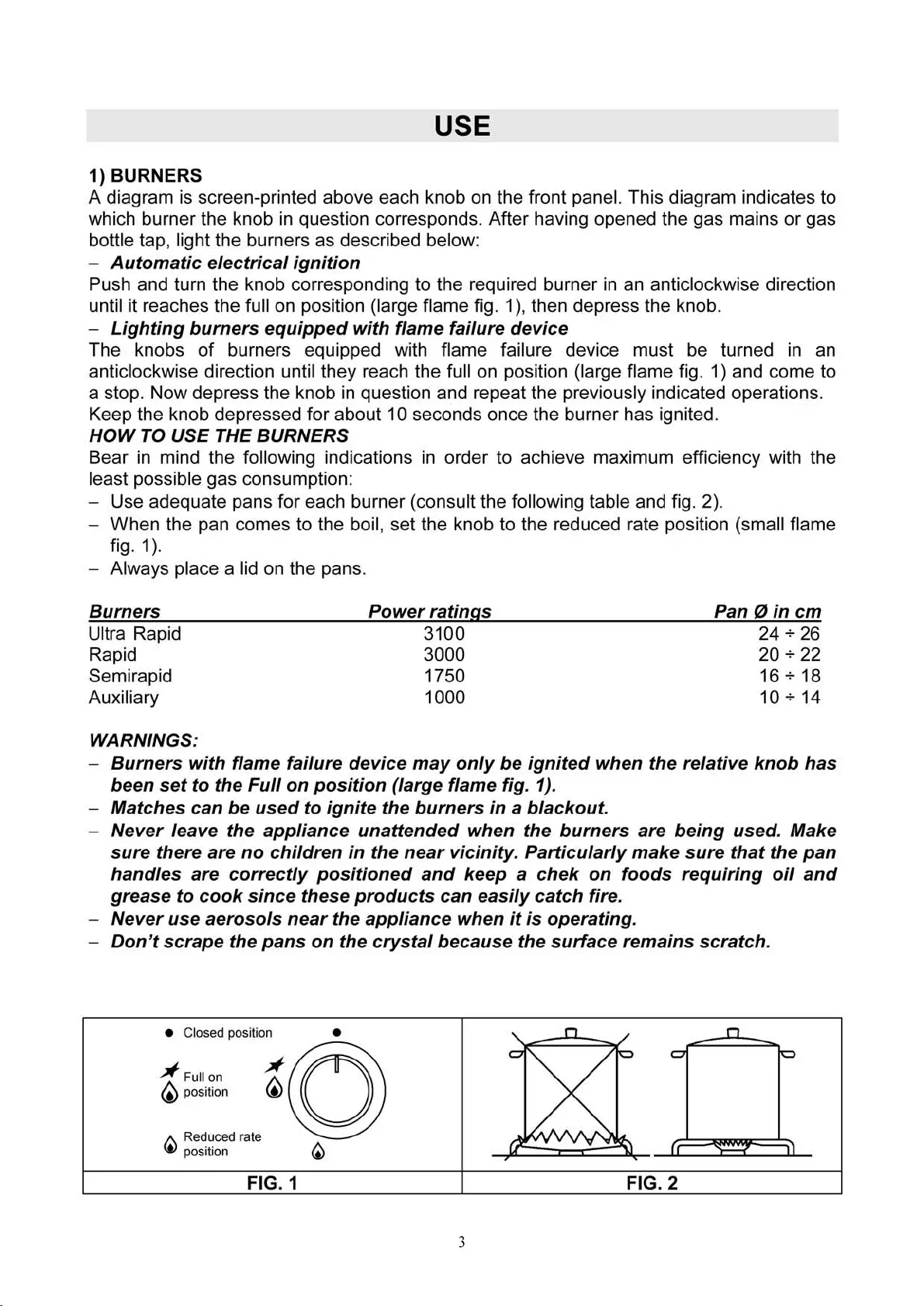

3) HOT PLATE

Periodically wash the hot pl ate, the enamel led stell pan suppor t, the enamel led burner

caps “C” and the burner heads “M” (see fig. 8) with lukewarm soapy water.

Following this, all parts should be thoroughly rinsed and dried.

Never wash them while they are still warm and never use abrasive powders.

Do not allow vinegar, coffee, milk, salted water, lemon or tomato juice from remaining in

contact with the enamelled surfaces for long periods of time.

WARNINGS:

Comply with the following instructions, before remounting the parts:

− Check that burner head slots “M” (fig. 8)have not become clogged by foreign

bodies.

− Check that enamelled burner cap “C” (fig. 8) have correctly positioned on the

burner head. It must be steady.

− The exact position of the pan support is established by the rounded corners,

which should be set towards the side edge of the hot plate.

− Do not force the taps if they are difficult open or close.

Contact the technical

assistance service for repairs.

− Don’t use steam jets for the equipment cleaning.

FIG. 8

9

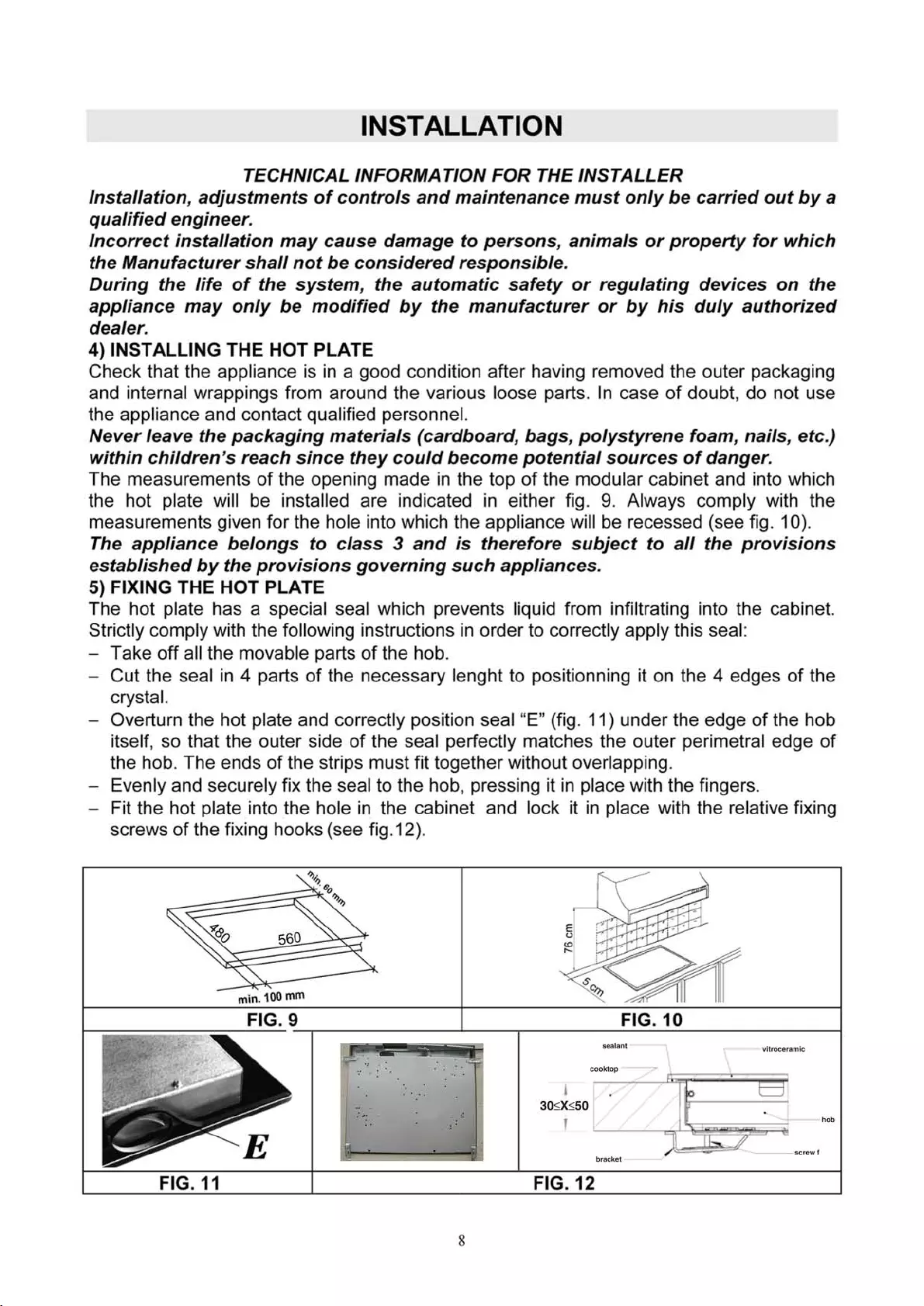

INSTALLATION

IMPORTANT INSTALLATION SPECIFICATIONS

The installer should note that the appliance that side walls should be no higher than

the hot plate itself. Furthermore, the rear wall, the surfaces surrounding and

adjacent to the appliance must be able to withstand an overtemperature of 65 K.

The adhesive used to stick the plastic laminate to the cabinet must be able to

withstand a temperature of not less than 150° C otherwise the laminate could come

unstuck.

The appliance must be installed in compliance with the provisions in force.

This appliance is not connected to a device able to dispose of the combustion

fumes. It must therefore be connected in compliance with the above mentioned

installation standards. Particular care should be paid to the following provisions

governing ventilation and aeration.

6) ROOM VENTILATION

It is essential to ensur e that the r oom in which the appliance is installed is permanently

ventilated in order to allow the appliance itself to operate correctly. the necessary amount

of air is that required for regular gas combustion and ventilation of the relative room, the

volume of which must not be l ess than 20 m3. Air must naturally flow through permanent

openings in the w alls of the r oom in question. These openings must vent the fumes

outdoors and thei r section must be at l east 100 cm 2 (see fig. 3). Construction of the

openings must ensure that the openi ngs themselves may never be bl ocked. Indirect

ventilation by air drawn from an adjacent room is also permitted, in strict compliance with

the provisions in force.

CAUTION: if the burners of the cooking top are without safety thermocouple, the

ventilation outlet must have a minimum 200 cm² section.

7) LOCATION AND AERATION

Gas cooking appliances must always dispose of their combustion fumes through hoods.

These must be connected to f lues, chimneys or straight outside. If it is not possible to

install a hood, an electric fan can be installed on a window or on a wall facing outside (see

fig. 4). This must be acti vated at the same ti me as the appl iance (see fig. 5), so long as

the specifications in the provisions in force are strictly complied with.

10

INSTALLATION

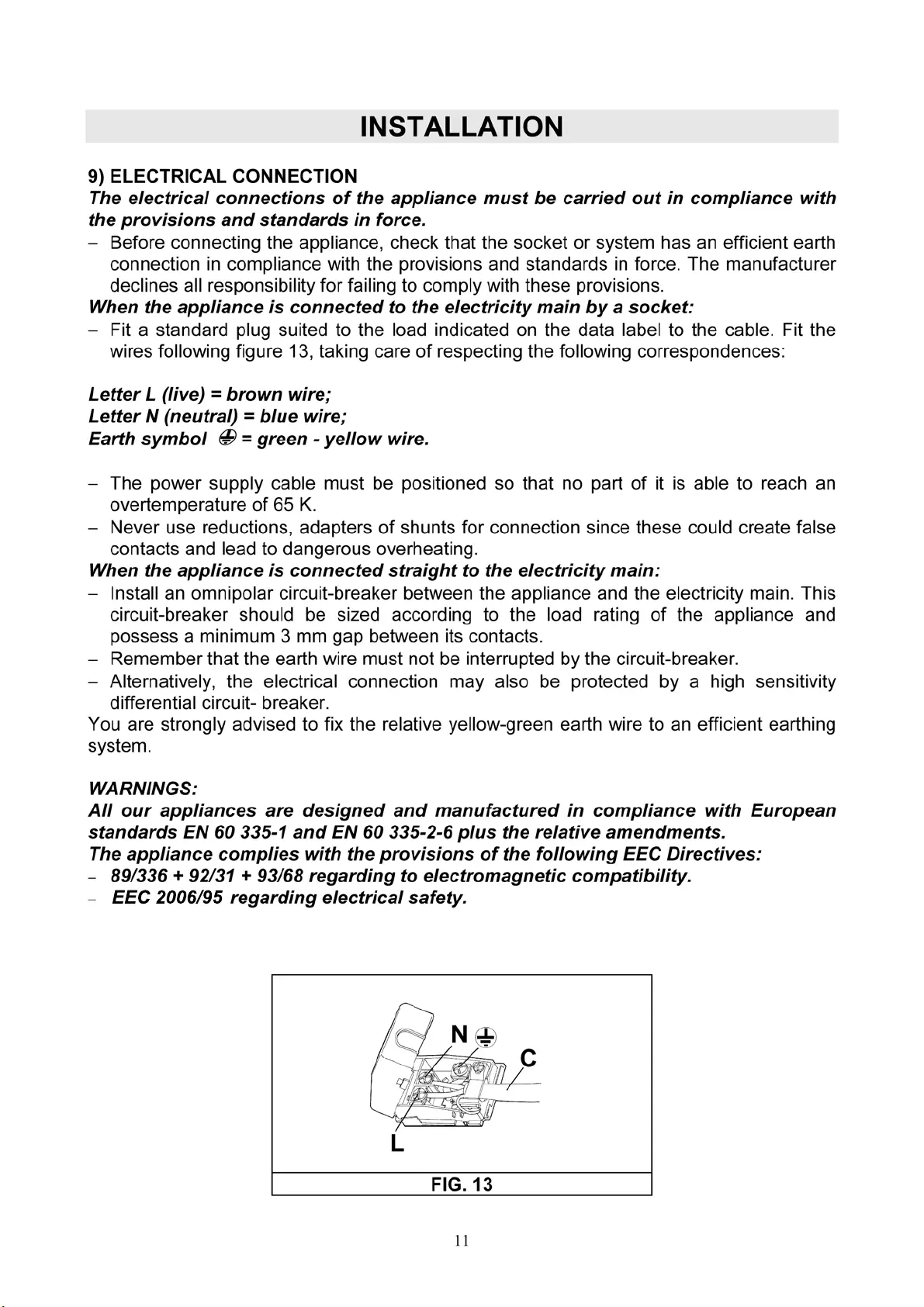

8) GAS CONNECTION

Before connecting the appliance, check that the values on the data label affixed to

the underside of the hot plate correspond to those of the gas and electricity mains

in the home.

A label on the appliance indicates the regulating conditions: type of gas and

working pressure. Gas connection must comply with the pertinent standards and

provisions in force.

When gas is supplied through ducts, the appl iance must be connected to the g as

supply system:

ο with a r igid steel pipe. The joints of this pipe must consist of threaded fittings

conforming to the standards UNI-ISO 7/1.

ο With copper pipe. The joints of this pipe must consist of unions with mechanical seals.

ο With seamless flexible stainless steel pipe. The length of this pipe must be 2 meter s at

most and the seals must comply with the standards.

When the gas is supplied by a bottle, the appliance must be f uelled by a pressure

governor conforming to the provisions in force and must be connected:

ο with a copper pipe. The joints of this pipe must consist of unions with mechanical seals.

ο With seamless flexible stainless steel pipe. The length of this pipe must be 2 meter s at

most and the seals must comply with the standards. It is advisable to apply the special

adapter to the flexible pipe. This is easily available from the shops and f acilitates

connection with the hose nipple of the pressure governor on the bottle.

ο With rubber hose pipe in compliance with standards. The diameter of this hose pi pe

must be 8 mm and i ts length must be no l ess than 400 mm and no mor e than 1500

mm. It must be firmly fixed to the hose nipple by means of the safety clamp specified by

standards.

At the connection end, verify the gasproof using a soap solution, never a flame.

WARNINGS:

−

−−

−

Remember that the gas inlet union on the appliance is a 1/2" gas parallel male

type in compliance with ISO 228-1 standards.

−

−−

−

The appliance complies with the provisions of the following EEC Directives:

90/396 + 93/68 regarding gas safety.

The installer should bear in mind that the mixed appliance is the Y type. The rear

wall, adjacent and surrounding surfaces must therefore be able to withstand an

overtemperature of 65 K.

a/b

a/b

14

SERVICING

Always disconnect the appliance from the electricity and gas mains before

proceeding with any servicing operation.

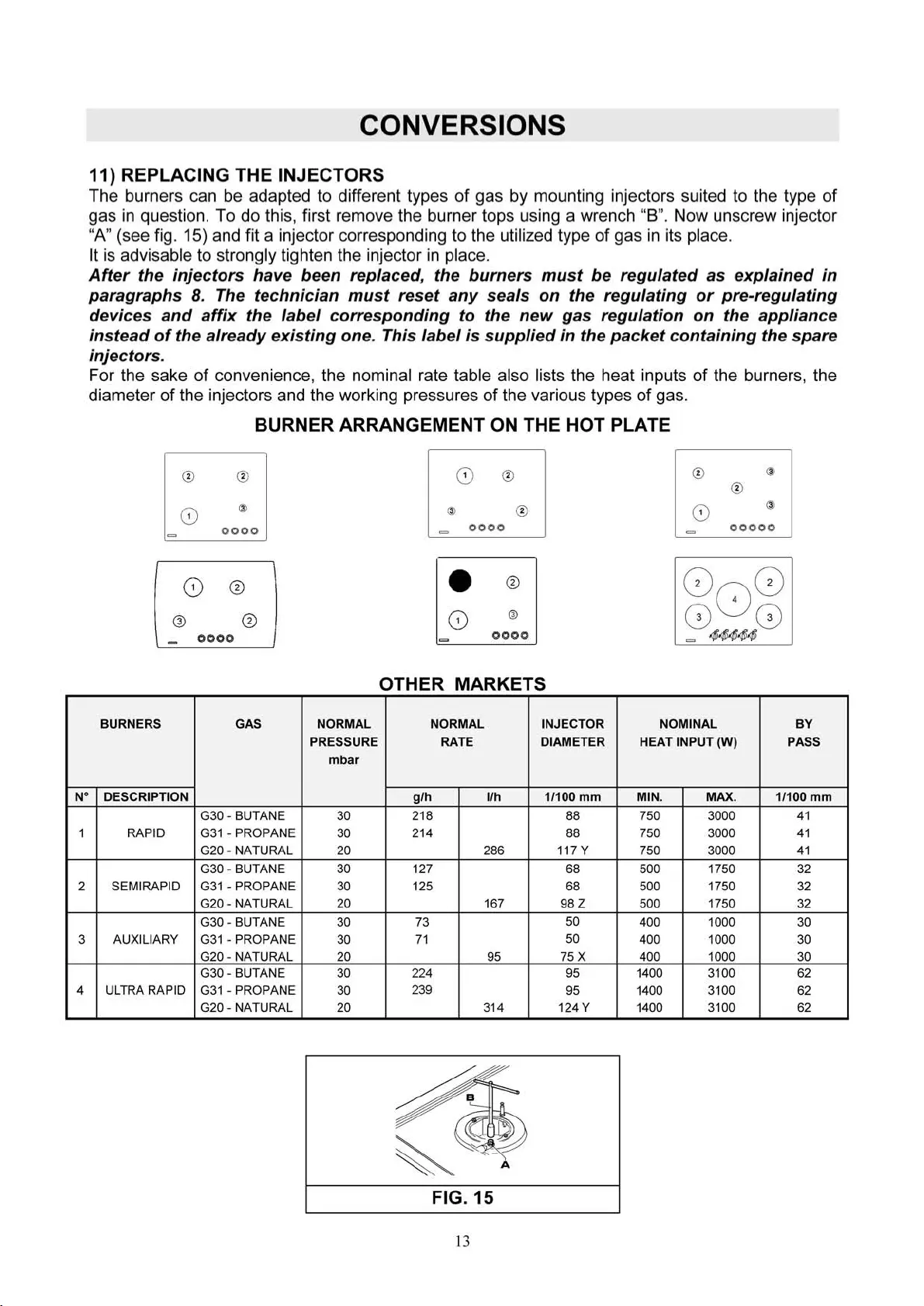

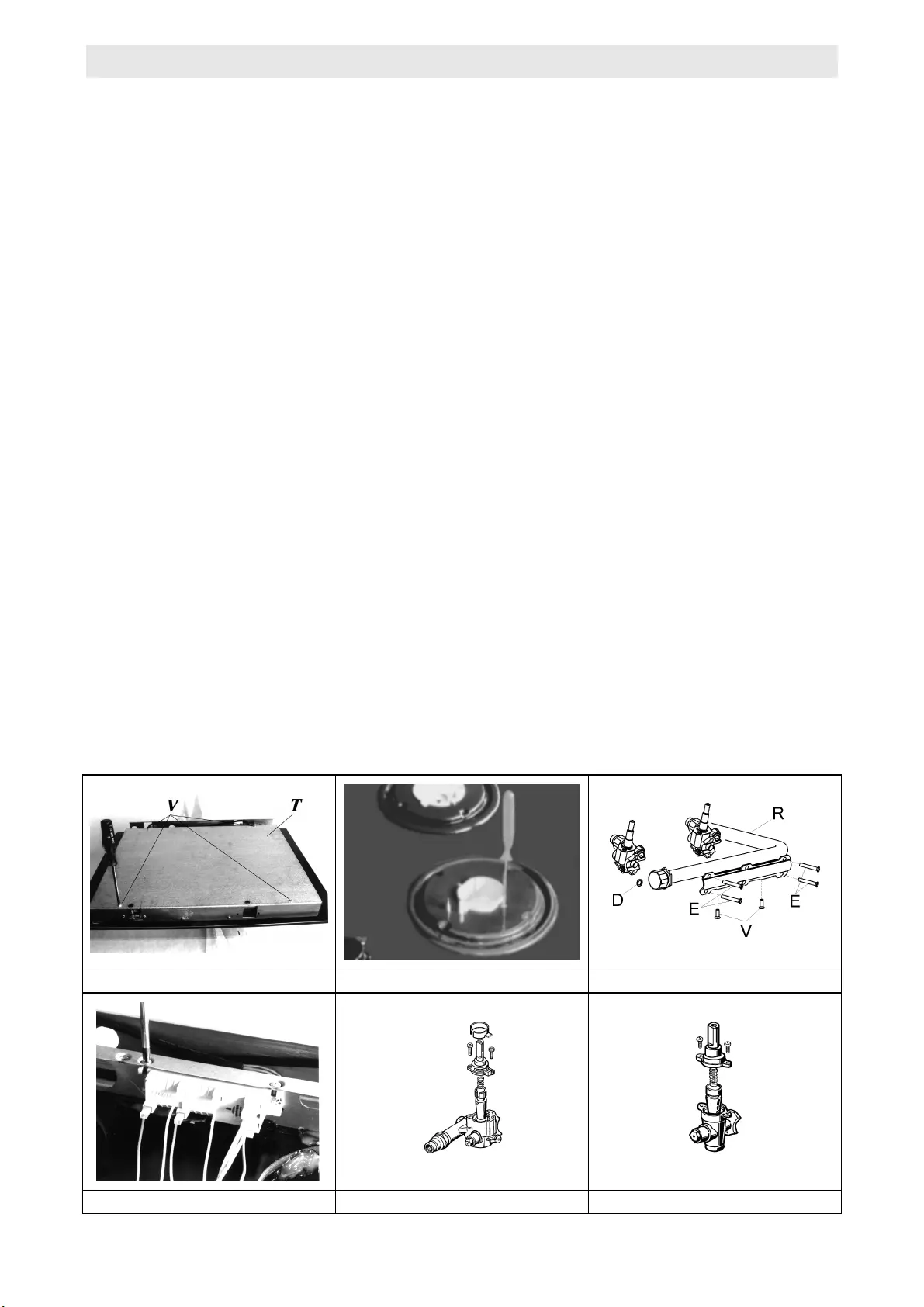

12) REPLACING HOT PLATE PARTS

When parts housed within the hot plate need replacing, it is first necessary to remove the

hot plate itself from the cabinet, to overturn it, unscrew screws “V” and to remove part “T”

(see fig. 16).

After having carried out the above listed operations, the burners (fig. 17), taps (fig. 18) and

electrical components can all be replaced (fig. 19).

It is advisable to change seal “D” whenever a tap is replaced to ensure a perfect tightness.

Greasing the taps (see fig. 20 - 21)

If a tap becomes sti ff to operate, it must be immediately greased in compliance with the

following instructions:

− Remove the tap.

− Clean the cone and its housing using a cloth soaked in diluent.

− Lightly spread the cone with the relative grease.

− Fit the cone back in place, operate it several times and then remove it again. Eliminate

any excess grease and check that the gas ducts have not become clogged.

− Fit all parts back in place, complying with the demounting order in reverse.

− Ceck the tightness by using soapy water. The use of the flame is prohibited.

To facilitate the servicing technician’s task, here is a chart w ith the types and sections of

the powering cables and the ratings of the electrical components.

Remove the screws and buttons shown with V that connect the burners to the glass. After

removing the lower cover screws shown with Y, you can replace the electric components.

Pool cups are bonded to the glass with silicone, do not remove them.

FIG. 16 FIG. 17 FIG. 18

FIG. 19 FIG. 20 FIG. 21

16

TECHNICAL DATA FOR THE APPLIANCE GAS REGULATION

TECHNICAL ASSISTANCE AND SPARE PARTS

Before leaving the f actory, this appliance w ill have been tested and regulated by expert

and specialized personnel in order to guarantee the best performances.

Any repairs or adjustments which may be subsequently required may only be carried out

by qualified personnel with the utmost care and attention.

For this reason, always contact your Dealer or our nearest After Sales Service Center

whenever repairs or adjustments are required, specifying the type of fault and the model

of the appliance in your possession.

Please also note that genuine spare parts are only available from our After Sales Service

Centers and authorized retail outlets.

The above data are printed on the data label put on the i nferior part of the appliance and

on the packing label.

The above informations give to the technical assistant the possibility to get fit spare parts

and a heaven-sent intervention. We suggest to fill the table below.

MARK: ........................................................

MODEL: .....................................................

SERIES: .....................................................