Vertiv CRV CCD101 User Manual

Displayed below is the user manual for CRV CCD101 by Vertiv which is a product in the Rack Cooling Equipment category. This manual has 126 pages.

Related Manuals

Vertiv | Liebert CRD10 | User Manual 1

Liebert® CRV Row Based Cooling

CRD10 User Manual

Original Instructions

Vertiv | Liebert CRD10 | User Manual i

Copyright

The content in this document is subject to change without notice. All rights, including rights of translation,

reproduced by printing, copying or similar methods, and even of parts, are reserved. Violators will be liable for

damages. All rights, including rights deriving from patent license or registration of a utility model or design, are

reserved. No part of this document may be reproduced or transmitted in any form or by any means without the

prior written consent of Vertiv.

Notice

The purchased products, services, and features are stipulated by the contract made between Vertiv and the

customer. All or part of the products, services, and features described in this document may not be within the

purchasing scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and

recommendations in this document are provided “AS IS” without warranties, guarantees or representations of

any kind, either express or implied. The information in this document is subject to change without notice. Every

effort has been made in the preparation of this document to ensure the accuracy of the contents, but all

statements, information, and recommendations in this document do not constitute a warranty of any kind,

express or implied.

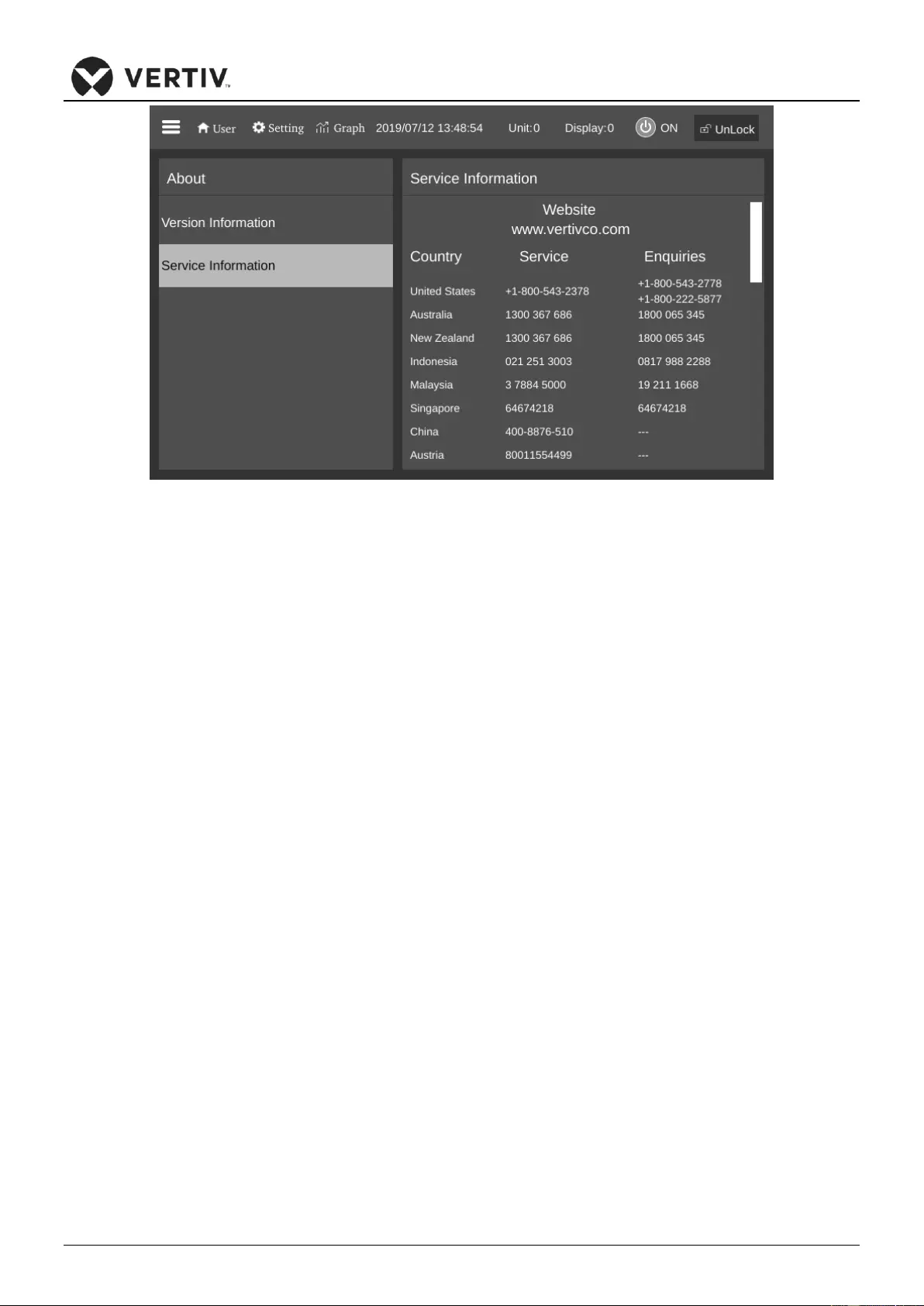

Vertiv

United States

Service Calls;

+1-800-543-2378

General Inquiries;

+1-800-543-2778

+1-800-222-5877

Australia & New

Zealand

Service Calls;

1300 367 686

General Inquiries;

1800 065 345

Indonesia

Service Calls;

0817 988 2288

General Inquiries;

021 251 3003

Malaysia

Service Calls;

19 211 1668

General Inquiries;

3 7884 5000

Singapore

Service Calls;

64674218

General

Inquiries;

64674218

Romania:

800477000

Croatia:

800989019

Qatar:

800100439

Ghana:

242426263

Nigeria:

7080601125

Turkey:

800448826888

Egypt, Bahrain:

390499717744

Greece:

80044146622

UAE:

800035702985

Saudi Arabia:

8008446628

Non-listed Countries:

49872327750

(Austria,

Benelux

, Czech Republic, France, Germany, Hungary, Ireland, Italy, Poland, Russia, Spain,

Sweden

, Switzerland, UK, South Africa):

80011554499

Website: www.vertiv.com;

For Technical Support, users may contact the nearest Vertiv local sales office or service center.

Vertiv | Liebert CRD10 | User Manual ii

Suppliers Declaration of Conformity

Unique Identifier: CRD100-0D00A, CRD101-0D00A, CCD100S-00A.

FCC Compliance Statement (for products subject to Part 15)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Vertiv | Liebert CRD10 | User Manual iii

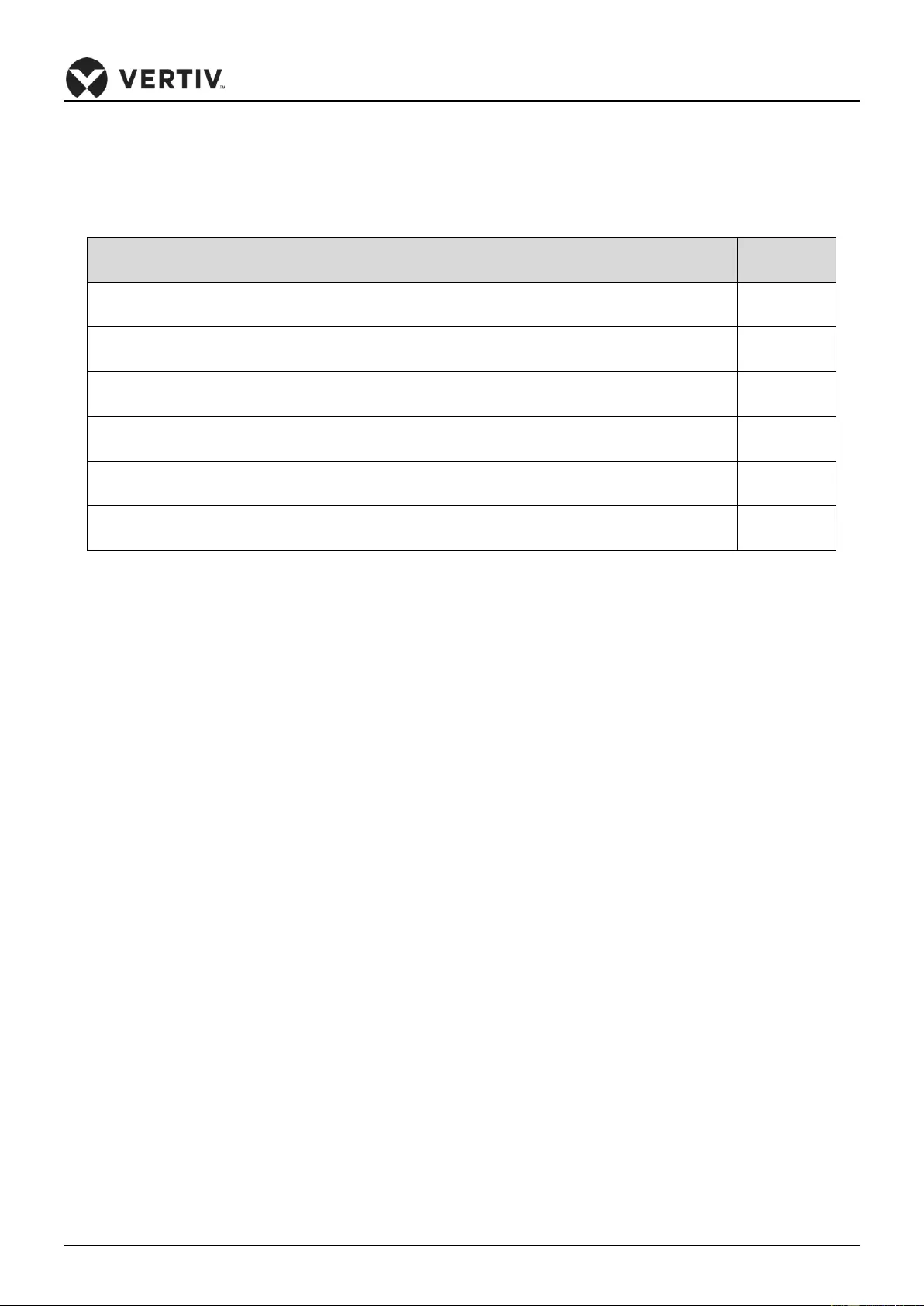

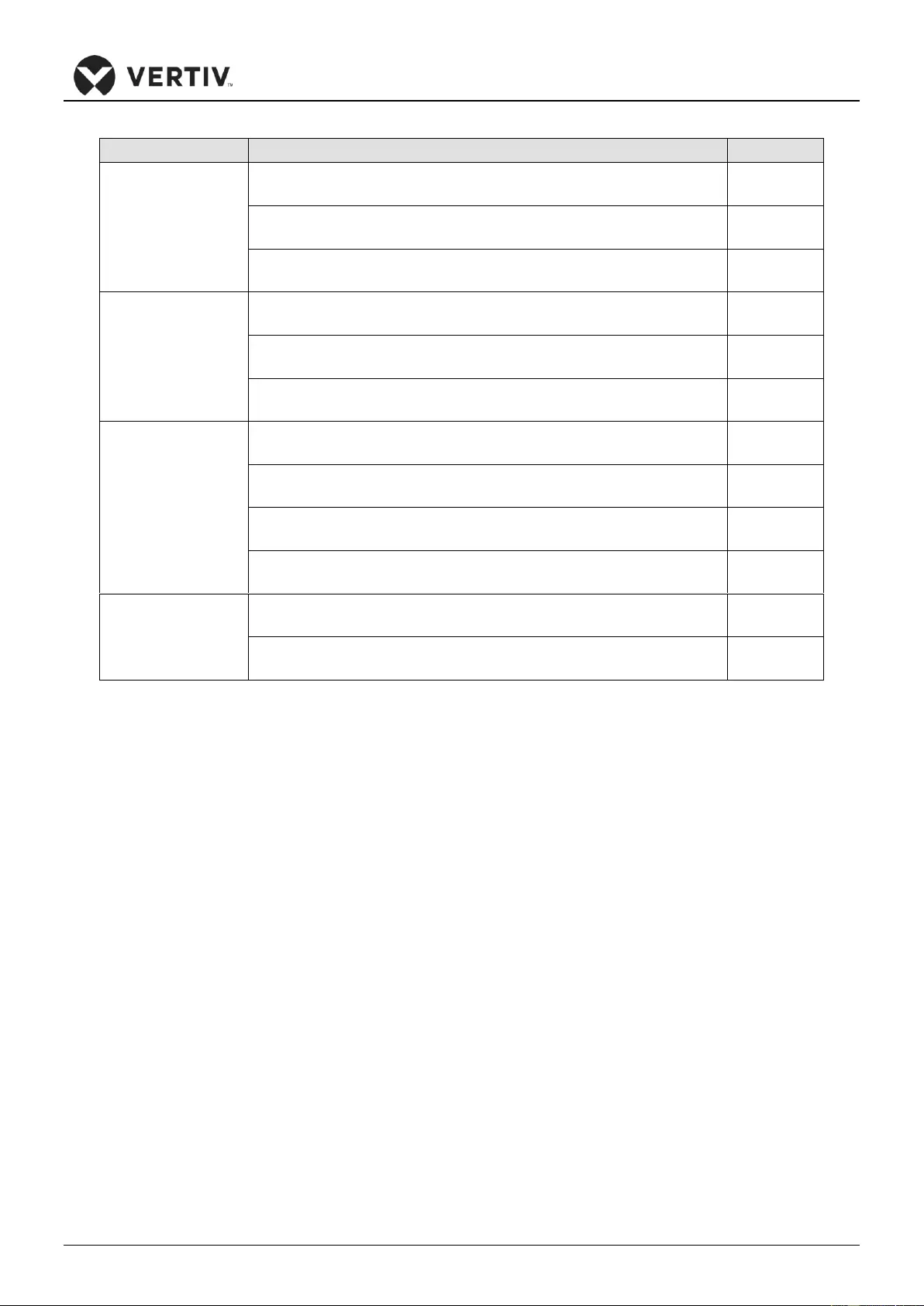

Version History

Revision Date

Code

Version Number

16-06-2019

31014025

1.0

29-07-2019

31014025

1.1

30-10-2019

31014025

1.2

16-03-2020

31014025

1.3

25-05-2020

31014025

1.4

05-11-2020

31014025

1.5

Vertiv | Liebert CRD10 | User Manual iv

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert CRV. Read this manual thoroughly before attempting to install or operate

this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all installation, operation and maintenance instructions and all applicable

national and local building, electrical and plumbing codes.

Any operation that requires opening doors or equipment panels must be carried out only by properly

trained and qualified personnel.

To identify the unit model and serial number for assistance or spare parts, locate the identification

label on the unit.

A warning label on the front and back panels reminds users that:

• the Liebert® CRV restarts automatically

• the main switch must be opened before opening the internal compartments for any operation.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved

personal protective equipment (PPE) per NFPA 70E before working within the electric control

enclosure. Failure to comply can cause serious injury or death. Customer must provide earth ground

to unit, per NEC, CEC and local codes, as applicable. Before proceeding with installation, read all

instructions, verify that all the parts are included and check the nameplate to be sure the voltage

matches available utility power. The Liebert® controller does not isolate power from the unit, even in

the “Unit Off” mode. Some internal components require and receive power even during the “Unit Off”

mode of the controller. The only way to ensure that there is NO voltage inside the unit is to install and

open a remote disconnect switch. Refer to unit electrical schematic. Follow all local codes.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive discharge of

high-pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury, or

death. This unit contains fluids and gases under high pressure. Use extreme caution when charging

the refrigerant system. Do not pressurize the system higher than the design pressure marked on the

unit's nameplate.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or death.

Open all local and remote electric power-supply disconnect switches, verify with a voltmeter that

power is off, and verify that all fan blades have stopped rotating before working in the unit cabinet or

on the fan assembly. If control voltage is applied, the fan motor can restart without warning after a

power failure.

Vertiv | Liebert CRD10 | User Manual v

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury

or death. Read all of the following instructions and verify that all lifting and moving equipment is

rated for the weight of the unit before attempting to move, lift, remove packaging from or prepare

the unit for installation.

WARNING! Risk of unsecured unit rolling off pallet. Can cause equipment damage, injury or death.

The unit is on casters. Ensure that the unit/pallet is located on a flat surface before loosening the

hardware securing the to its shipping pallet.

WARNING! Risk of hair, clothing and jewelry entanglement with high speed rotating fan blades. Can

cause equipment damage, serious injury or death. Keep hair, jewelry and loose clothing secured and

away from rotating fan blades during unit operation.

WARNING! Risk of contact with extremely hot and/or cold surfaces. Can cause injury. Verify that all

components have reached a temperature that is safe for human contact or wear appropriate, OSHA-

approved PPE before working within the electric connection enclosures or unit cabinet. Perform

maintenance only when the system is de-energized and component temperatures have become safe

for human contact.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only by

qualified personnel who have been specially-trained in the installation of air-conditioning equipment

and who are wearing appropriate, OSHA-approved PPE.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated

wire and electrical connection terminals resulting in smoke, fire, equipment and building damage,

injury or death. Use correctly sized copper wire only and verify that all electrical connections are tight

before turning power On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and

remote electric power supply disconnect switches and verify with a voltmeter that power is off before

working within any electric connection enclosures. Service and maintenance work must be performed

only by properly trained and qualified personnel and in accordance with applicable regulations and

manufacturers’ specifications. Opening or removing the covers to any equipment may expose

personnel to lethal voltages within the unit even when it is apparently not operating and the input

wiring is disconnected from the electrical source.

WARNING! Risk of electric shock. Can cause injury or death. Open all local and remote electric power-

supply disconnect switches and verify that power is Off with a voltmeter before working within the

condensate pump electrical connection enclosure. The Liebert® controller does not isolate power

from the unit, even in the “Unit Off” mode. Some internal components require and receive power

even during the “Unit Off” mode of the Liebert® controller.

Vertiv | Liebert CRD10 | User Manual vi

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to

move, lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of exposure to harmful noise levels. Can cause hearing injury or loss. Depending on the

installation and operating conditions, a sound pressure level greater than 70 dB(A) may arise. Take

appropriate technical safety measures. Operating personnel must wear appropriate, OSHA-approved

PPE and observe all appropriate hearing-protection safety requirements.

CAUTION: Risk of excessive refrigerant line pressure. Can cause tubing and component rupture

resulting in equipment damage and personal injury. Do not close off the refrigerant-line isolation

valve for repairs unless a pressure-relief valve is field- installed in the line between the isolation valve

and the check valve. The pressure-relief valve must be rated 5% to 10% higher than the system-design

pressure. An increase in ambient temperature can cause the pressure of the isolated refrigerant to

rise and exceed the system-design pressure rating (marked on the unit nameplate).

NOTICE!

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty

coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up

generator systems) for start-up, commissioning, testing, or normal operation, ensure that these

sources are correctly adjusted to the nameplate voltage and frequency of all equipment to be

connected. In general, power-source voltages should be stabilized and regulated to within ±10% of the

load nameplate nominal voltage. Also, ensure that no three-phase sources are single-phased at any

time.

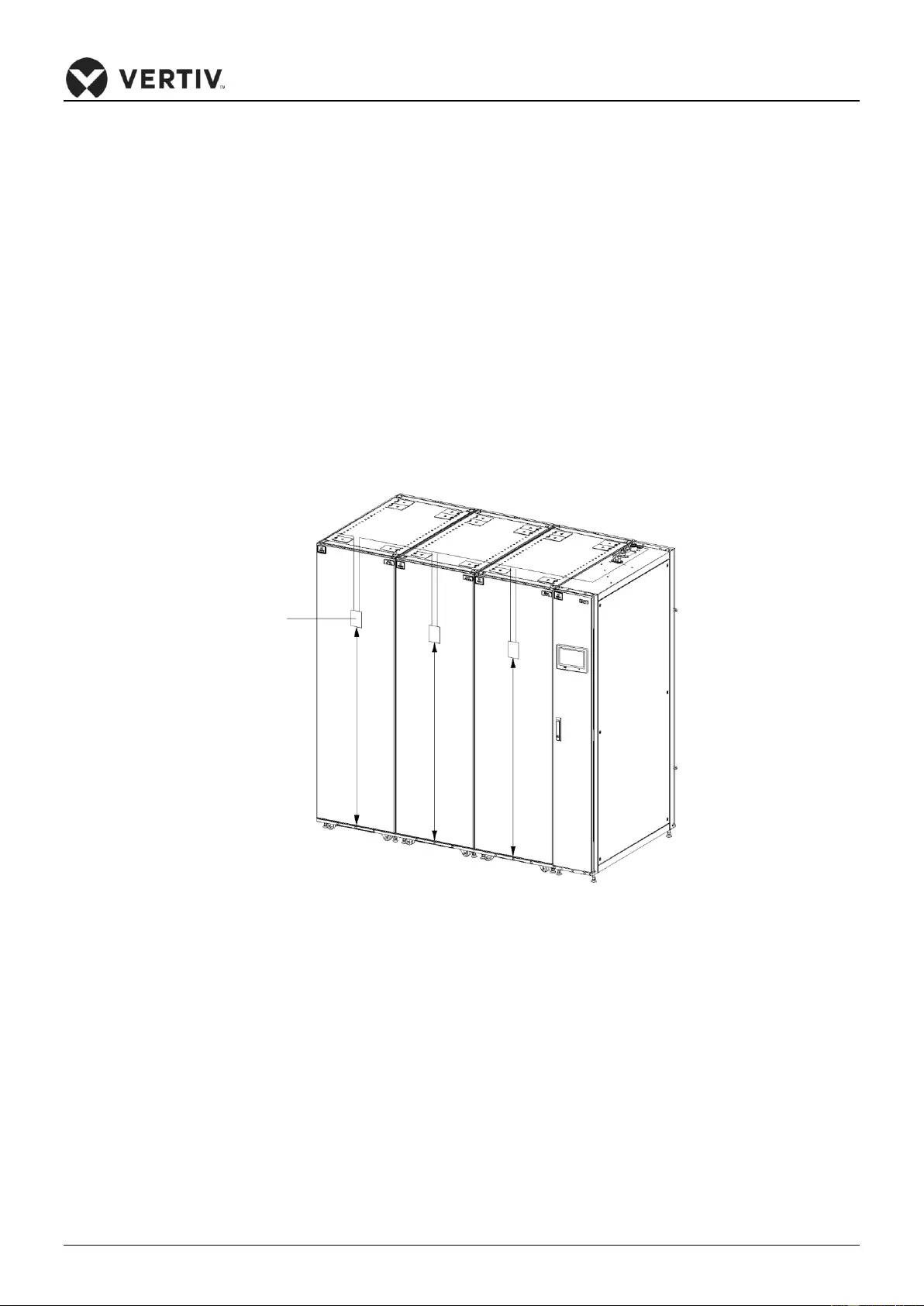

NOTICE!

CRD10 unit 96VA transformer default wiring is orange cable (230V to 24V). If the unit rated voltage is

208V, a properly trained and qualified electrician must change the transformer wiring from orange to

red cable (208V to 24V). See section 4.3.3 Transformer Connection Cable for details.

NOTICE!

Risk of oil contamination with water. Can cause equipment damage.

Liebert® CRV systems require the use of PVE (FV50S) oil. PVE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration

system, extreme care must be used when opening systems during installation or service. If water is

absorbed into the PVE oil, it will not be easily removed and will not be removed through the normal

evacuation process. If the oil is too wet, it may require an oil change. PVE oils also have a property

that makes them act as a solvent in a refrigeration system. Maintaining system cleanliness is

extremely important because the oil will tend to bring any foreign matter back to the compressor.

Vertiv | Liebert CRD10 | User Manual vii

NOTICE!

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air-cooled compressorized systems before they are started.

Starting compressors without proper refrigerant charging can cause the compressors to operate at

less than 5°F (–15°C) evaporator temperature and at less than 20 psig (138 kPa). Operation for

extended periods at less than 20 psig (138 kPa) can cause premature compressor failure.

NOTICE!

Risk of clogged or leaking drain lines and leaking water-supply lines. Can cause equipment and

building damage.

This unit requires a water drain connection. Drain lines must be inspected at start-up and periodically,

and maintenance must be performed to ensure that drain water runs freely through the drain system

and that lines are clear and free of obstructions and in good condition with no visible sign of damage

or leaks. This unit may also require an external water supply to operate.

Improper installation, application and service practices can result in water leakage from the unit.

Water leakage can result in catastrophic and expensive building and equipment damage and loss of

critical data center equipment.

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid-detection system to immediately discover and report

coolant-fluid system and condensate drain-line leaks.

NOTICE!

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too

large to fit through a doorway or hallway while on the skid. Measure the unit and passageway

dimensions, and refer to the installation plans prior to moving the unit to verify clearances.

NOTICE!

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height

suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE!

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and contact

damage.

NOTICE!

Risk of improper maintenance. Can cause equipment damage.

Installation and service of this equipment should be done only by qualified personnel who have been

specially-trained in the installation of air-conditioning equipment and who are wearing appropriate,

OSHA-approved PPE."

Vertiv | Liebert CRD10 | User Manual viii

Ignoring safety instructions is dangerous. Soiled parts cause a loss of performance and, for switch or

control devices, can lead to the breakdown of the unit performance and operation.

NOTICE!

Risk of release of hazardous substances into the environment. Can cause environmental pollution and

violation of environmental regulations.

The Liebert® CRV contains substances and components hazardous for the environment (electronic

components, refrigerating gases and oils). At the end of its useful life, the Liebert® CRV must be

dismantled by specialized refrigerating technicians. The unit must be delivered to suitable centers

specializing in the collection and disposal of equipment containing hazardous substances.

Agency Listed Standard 60-Hz units are UL Certified to the harmonized U.S. and Canadian product safety

standard CSA C22.2 No 236/UL 1995 for “Heating and Cooling Equipment” and are marked with the UL

logo.

Vertiv | Liebert CRD10 | User Manual ix

Table of Contents

Chapter 1: Product Overview .......................................................................................................... 1

1.1 Product Introduction ....................................................................................................................... 1

1.2 Product Description ......................................................................................................................... 3

1.3 Model Nomenclature ....................................................................................................................... 5

1.4 Basic Performance Parameters ....................................................................................................... 7

1.5 Sound parameters ........................................................................................................................... 8

1.6 Main Components of Indoor Unit.................................................................................................... 8

1.7 Technical Specification .................................................................................................................. 14

Chapter 2: Installation ................................................................................................................... 15

2.1 Pre-Installation .............................................................................................................................. 15

2.2 Installation Tools ............................................................................................................................ 16

2.3 Prerequisite Arrangements ........................................................................................................... 17

2.4 Transportation & Movement ......................................................................................................... 18

2.5 Unpacking ...................................................................................................................................... 20

2.6 Installation Preparation (Site Preparation) ................................................................................... 22

2.7 Operating and Storage Environment Conditions .......................................................................... 24

2.8 Weight Bearing Capacity................................................................................................................ 24

2.9 Refrigerant Charging Requirement ................................................................................................ 25

2.10 Inspection ...................................................................................................................................... 25

Chapter 3: Mechanical Installation ................................................................................................ 26

3.1 Installation Notes ........................................................................................................................... 26

3.2 System Arrangement during Installation ....................................................................................... 26

3.3 Product Dimensions ....................................................................................................................... 28

3.4 Top frame and front frame ............................................................................................................ 32

3.5 System Installation Layout ............................................................................................................. 34

3.6 Installation Procedures .................................................................................................................. 35

3.7 Cabinet Connection ....................................................................................................................... 37

3.8 Installing Liquid Line Solenoid Valve Kit and Low Ambient Kit ...................................................... 43

3.9 Recommended Refrigerant and Oil Charging Amount of the System........................................... 46

3.10 Adjusting the Supply Air Baffle and Sealing the Holes .................................................................. 48

3.11 Checklist for Completed Mechanical Installation .......................................................................... 50

Chapter 4: Electrical Installation .................................................................................................... 51

Vertiv | Liebert CRD10 | User Manual x

4.1 Installation Notes ........................................................................................................................... 51

4.2 CRD10 Wiring Connections ............................................................................................................ 52

4.3 Connection of the Control Cables .................................................................................................. 55

4.4 Checklist for the Completed Electrical Installation ....................................................................... 62

Chapter 5: Commissioning Overview ............................................................................................. 63

5.1 Self Check ....................................................................................................................................... 63

5.2 Preparations for Start-up ............................................................................................................... 64

5.3 Refrigerant Charge ......................................................................................................................... 66

5.4 Start-up Procedure ........................................................................................................................ 68

Chapter 6: Micro-Controller .......................................................................................................... 70

6.1 Features ......................................................................................................................................... 70

6.2 Appearance .................................................................................................................................... 71

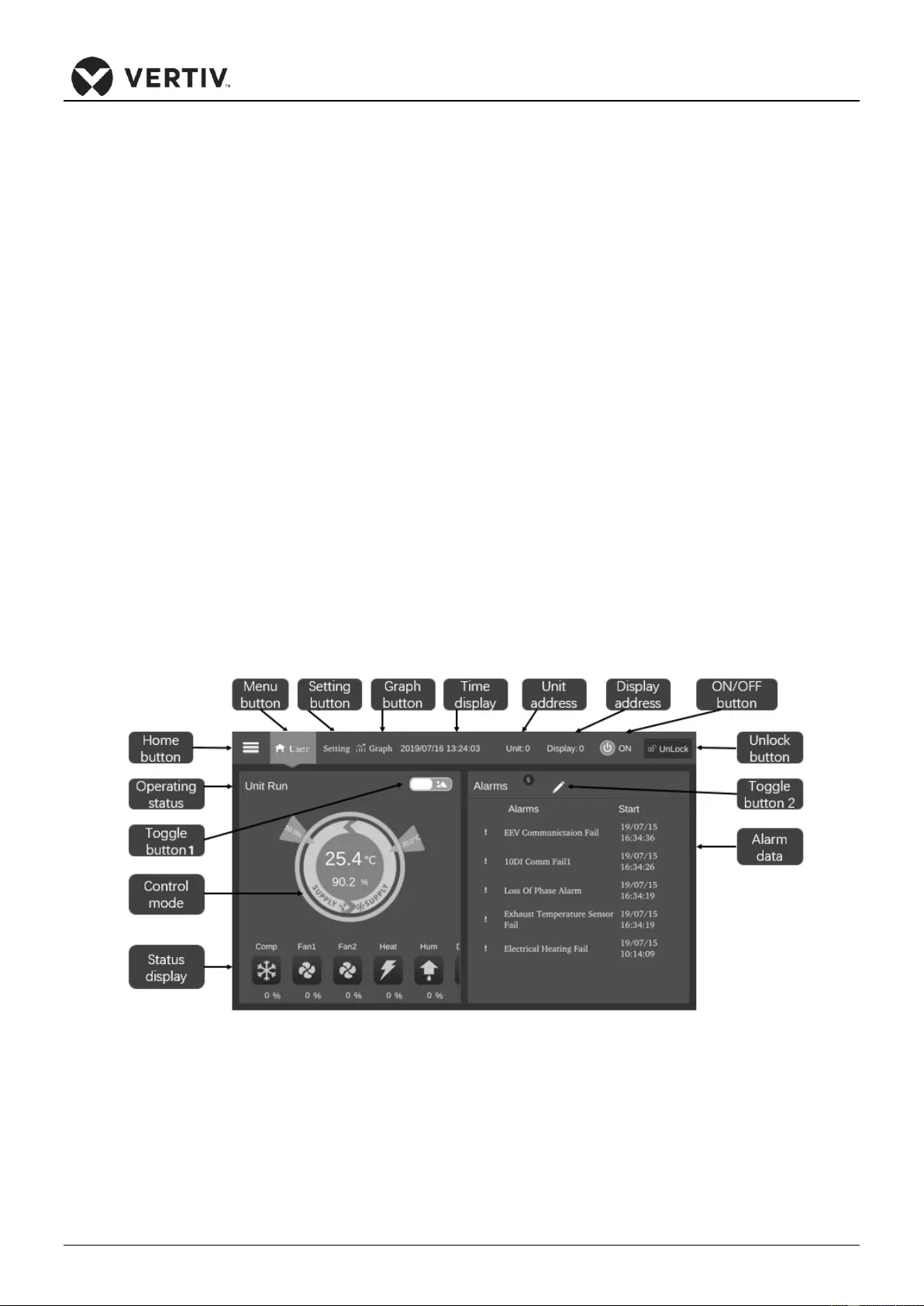

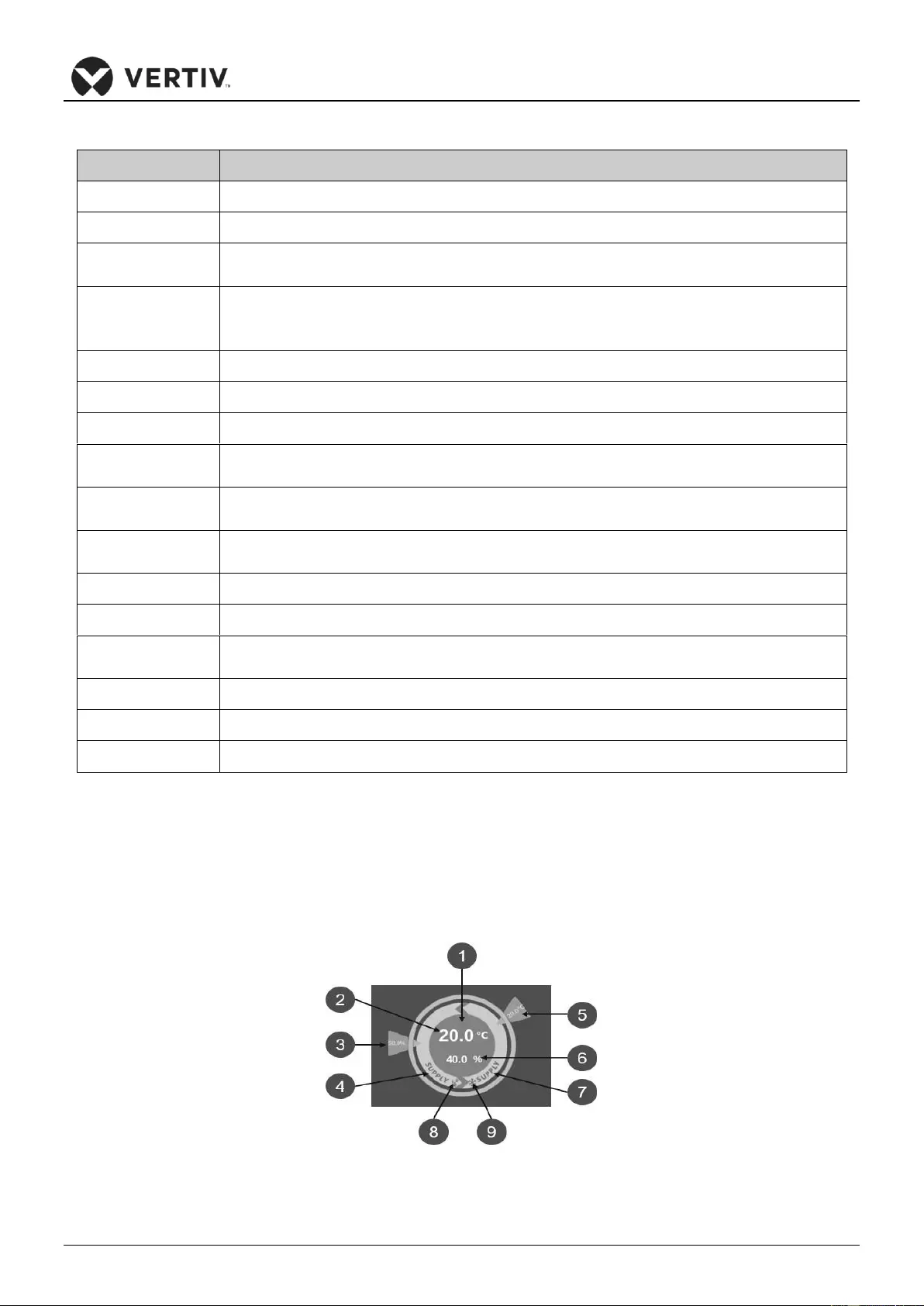

6.3 Control Screen ............................................................................................................................... 72

6.4 Menu Structure .............................................................................................................................. 76

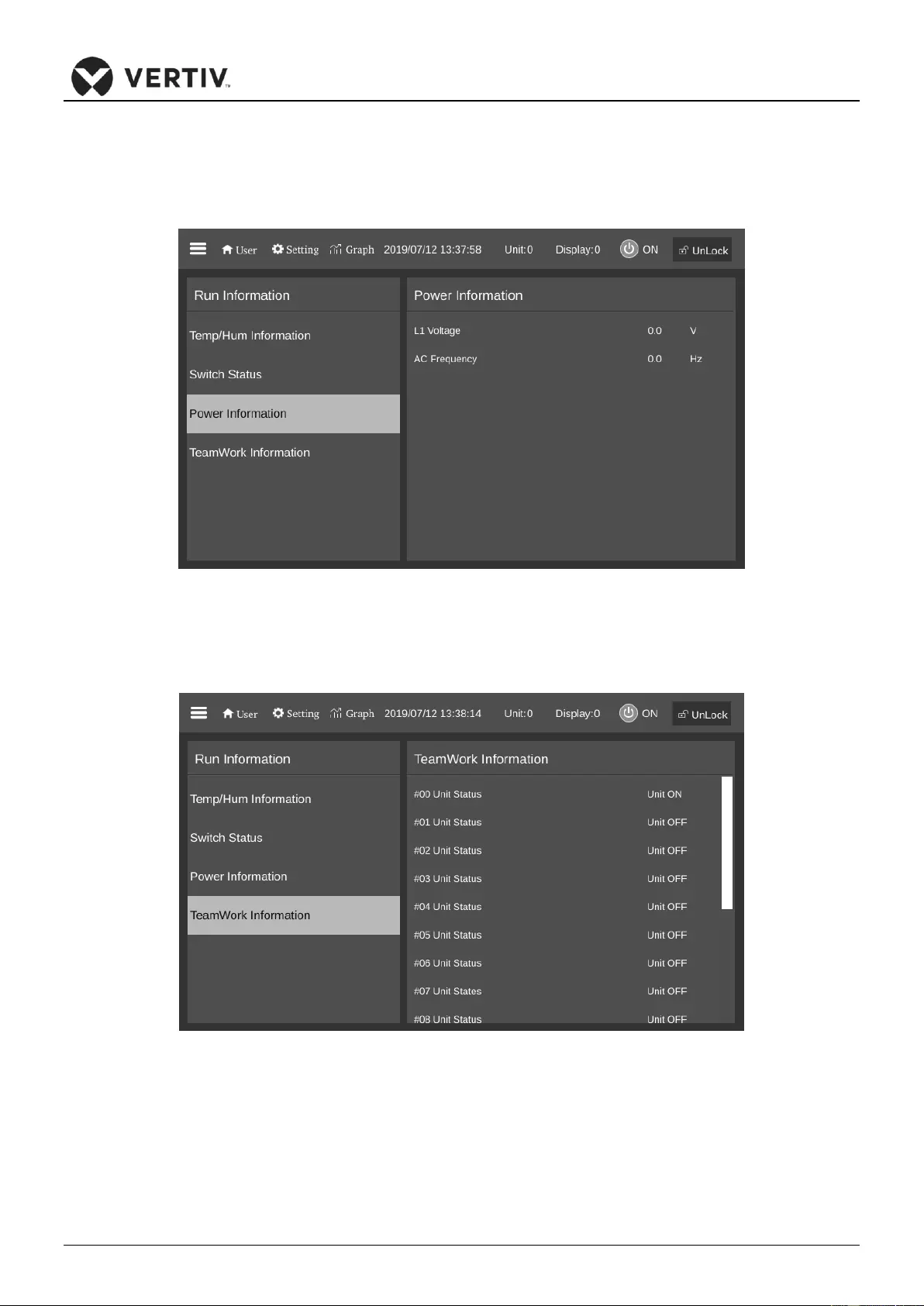

6.5 Run Information ............................................................................................................................. 77

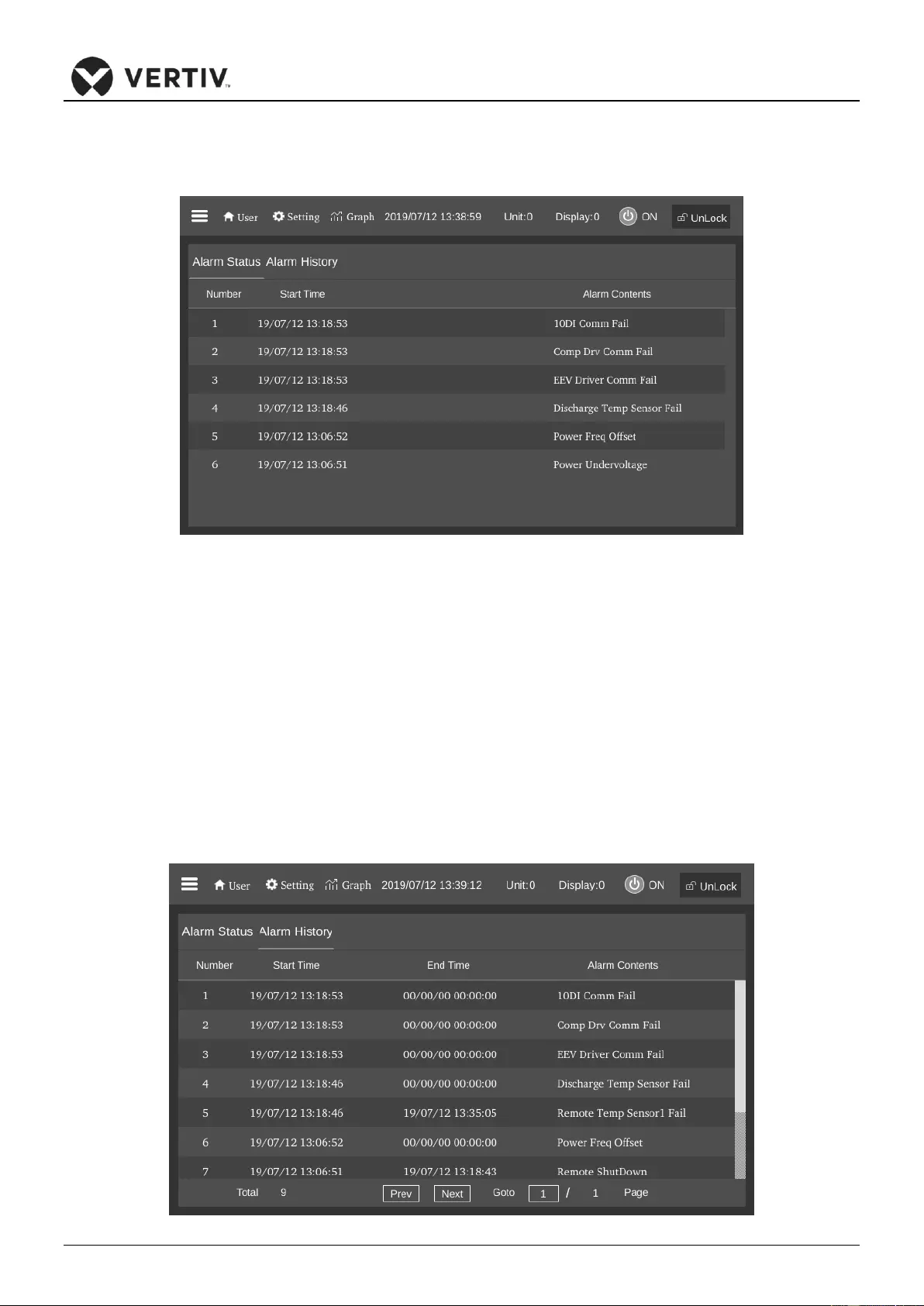

6.6 Alarm Information ......................................................................................................................... 78

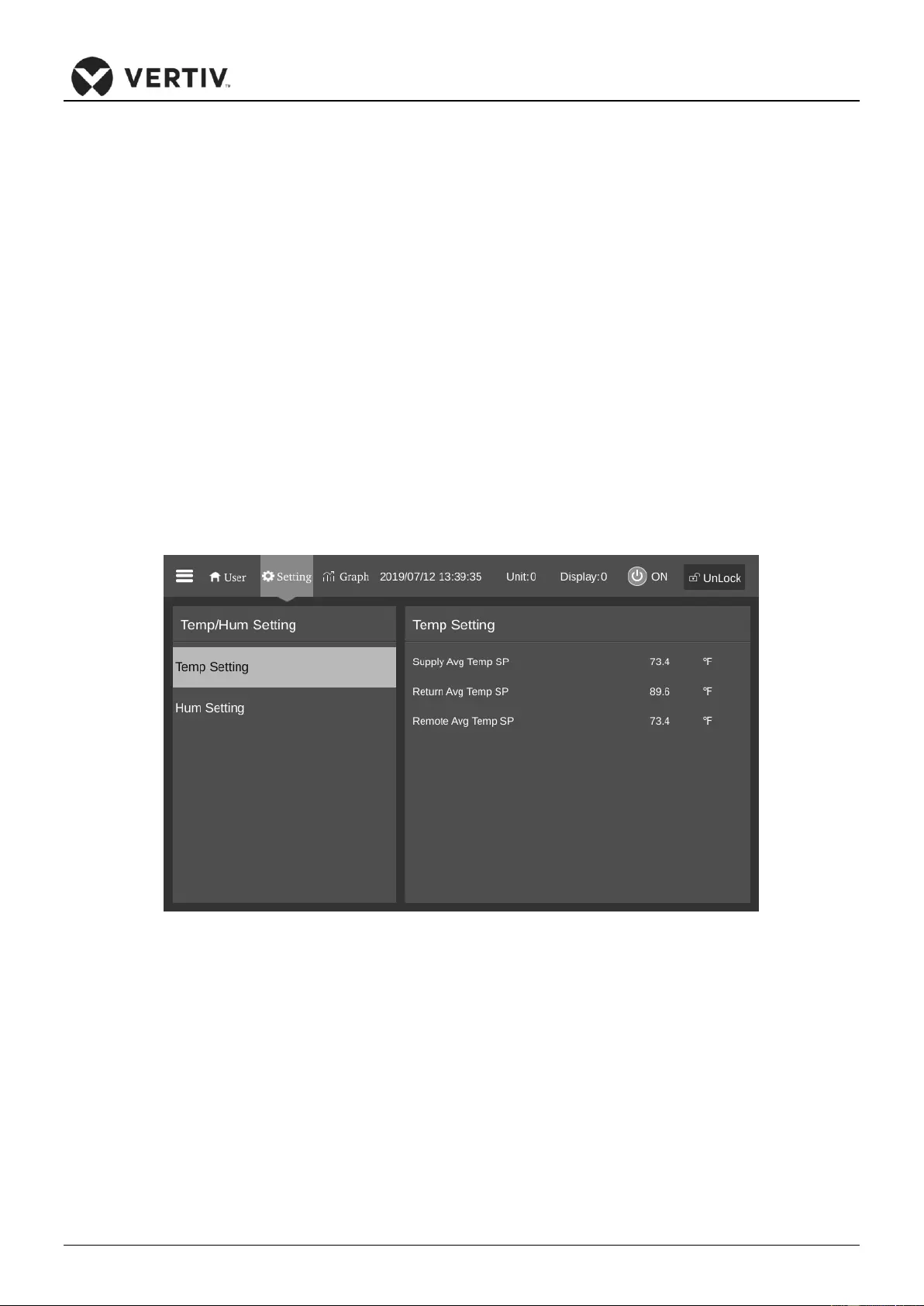

6.7 Temp/Hum Setting ........................................................................................................................ 80

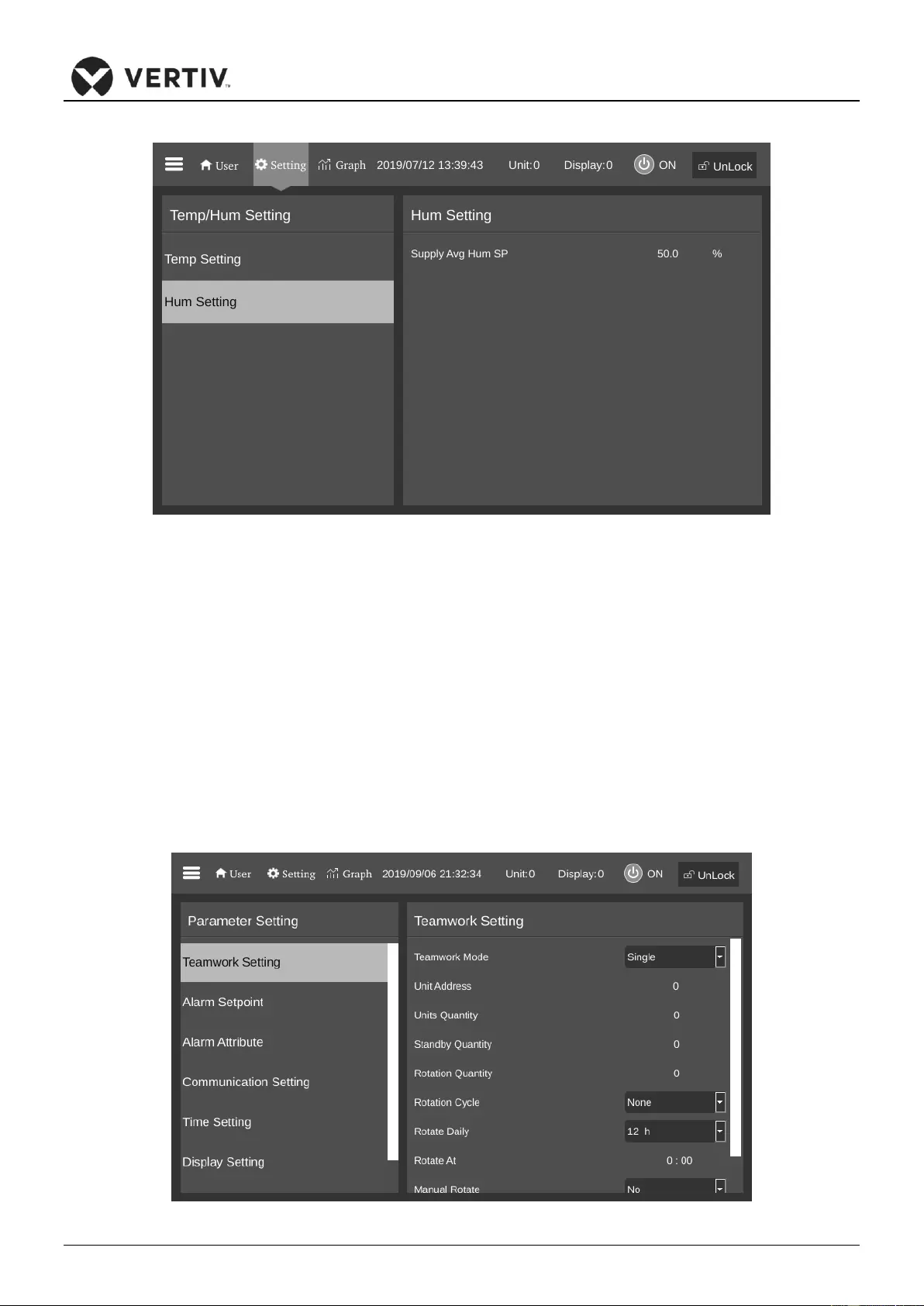

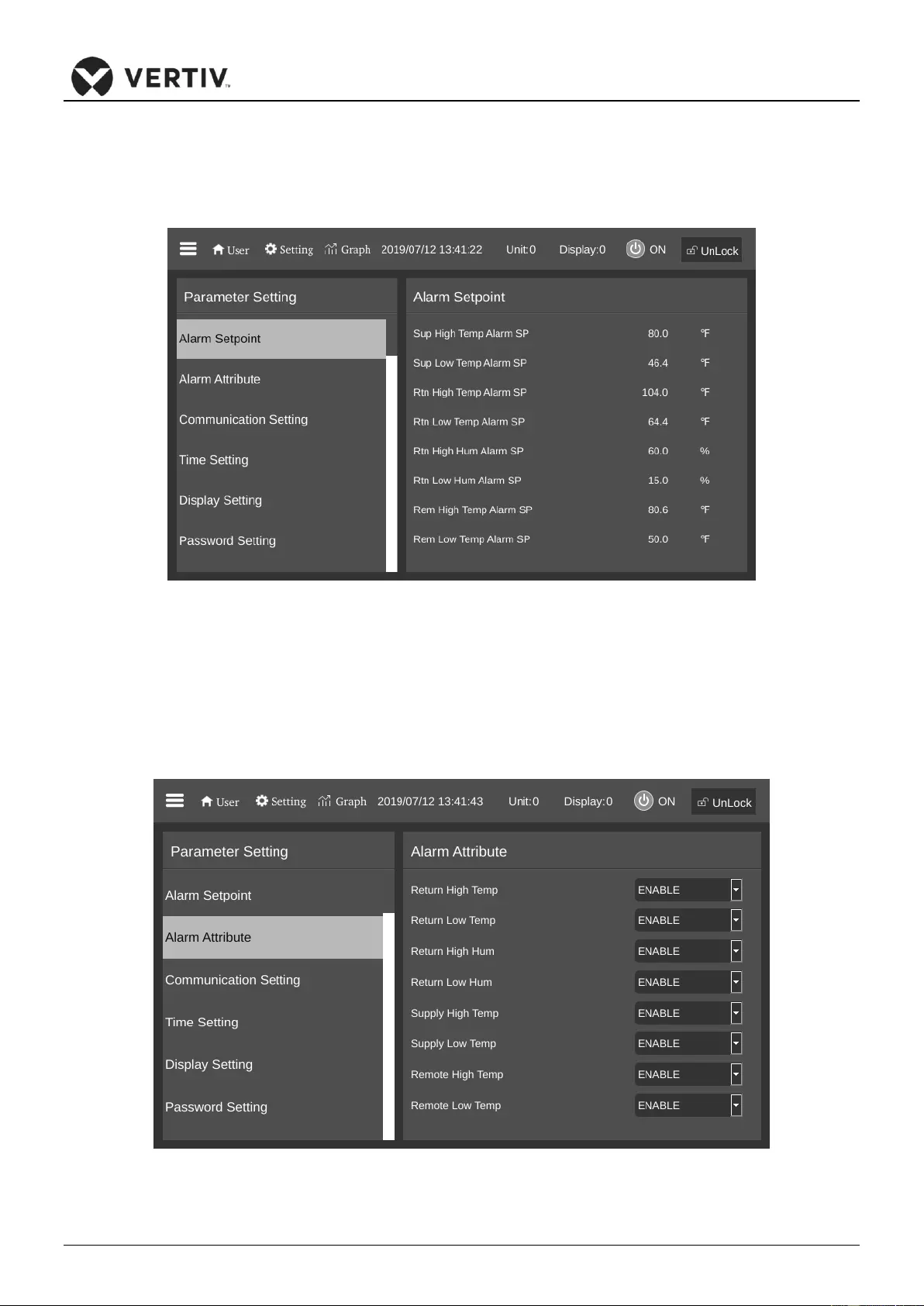

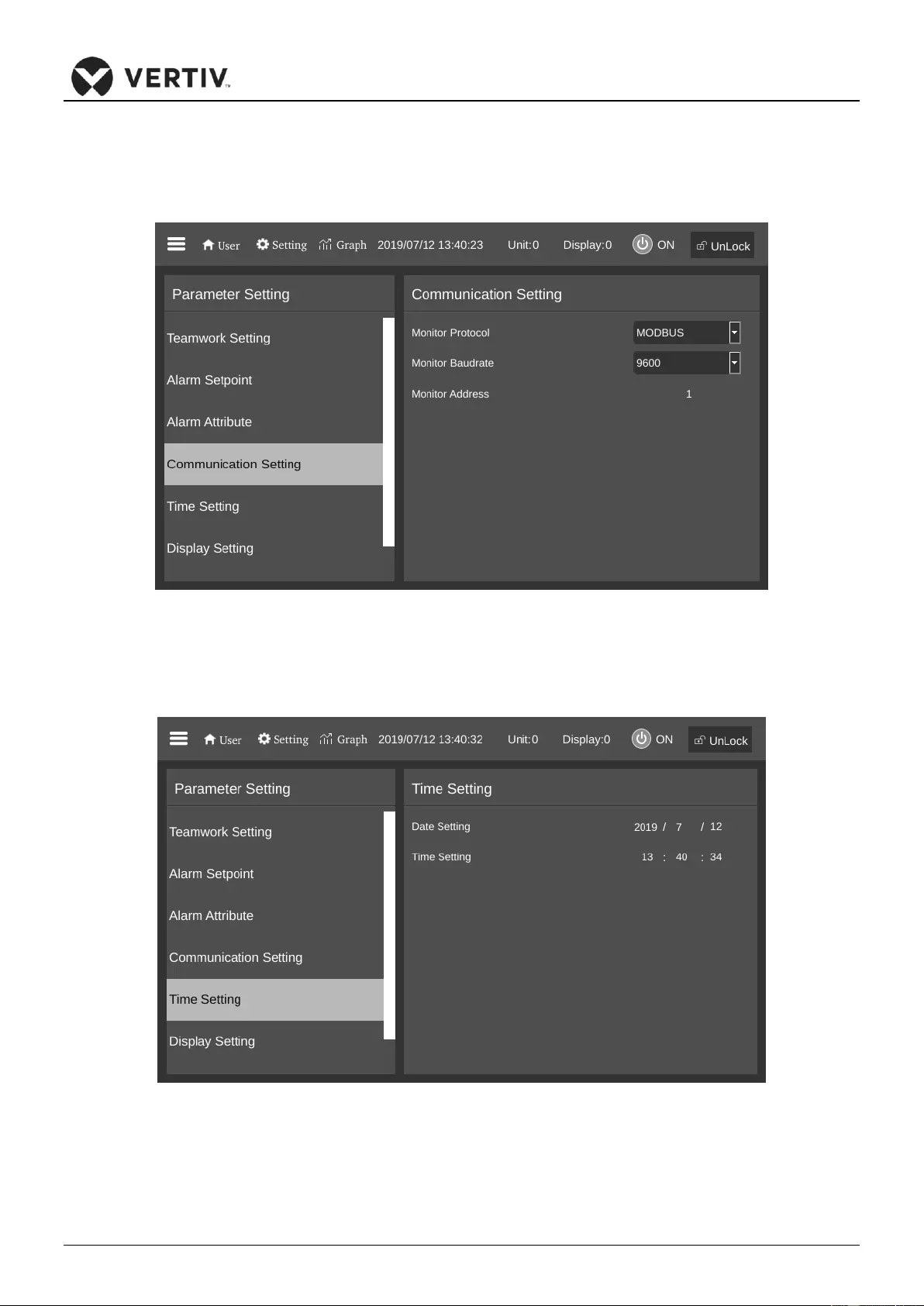

6.8 Parameter Setting .......................................................................................................................... 81

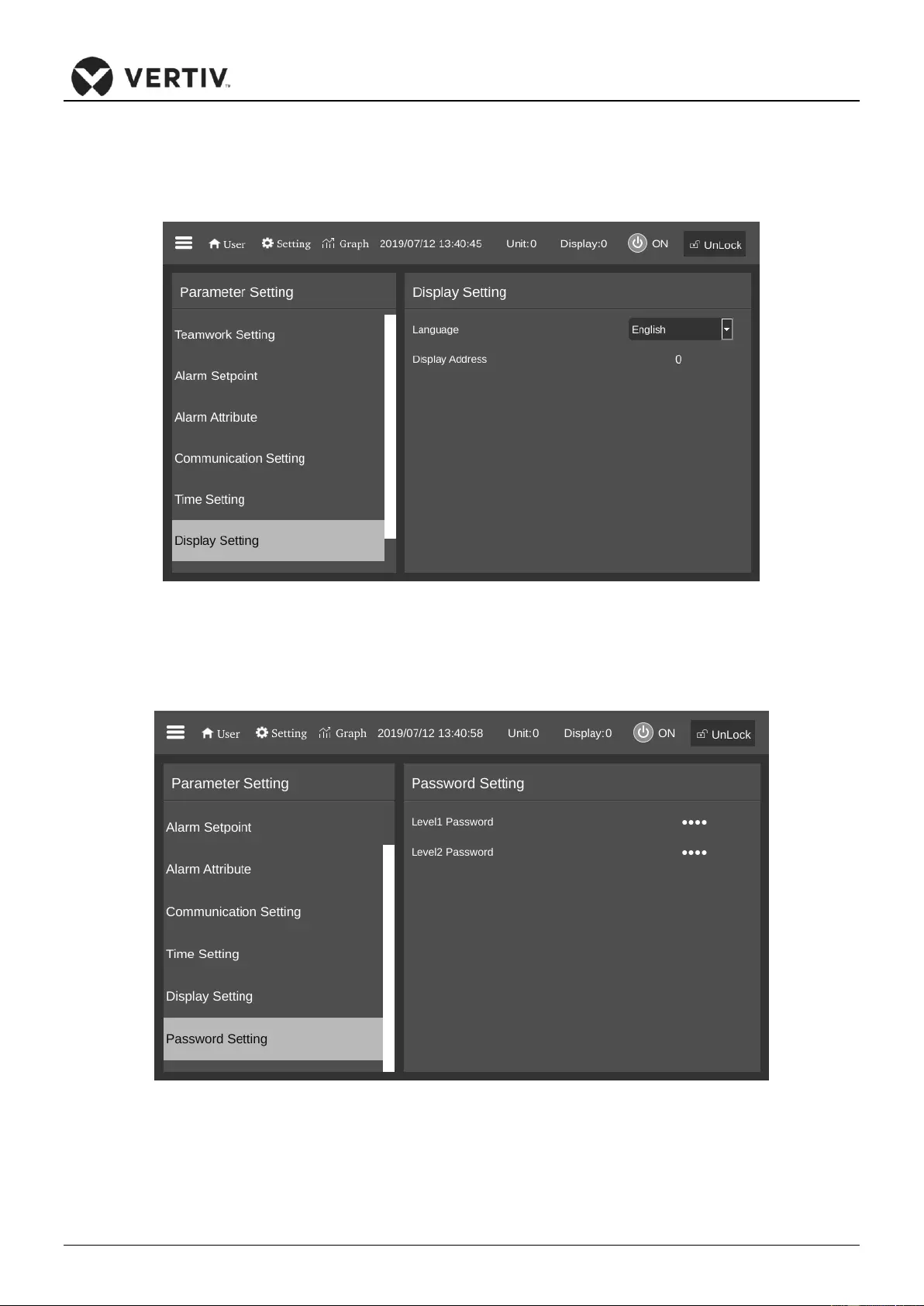

6.9 Graph ............................................................................................................................................. 85

6.10 About ............................................................................................................................................. 85

Chapter 7: Maintenance & Troubleshooting .................................................................................. 87

7.1 Routine Maintenance & Inspection (Monthly) .............................................................................. 88

7.2 Routine Maintenance and Inspection (Semi- annually) ................................................................ 90

7.3 Self-Diagnosing Functions .............................................................................................................. 91

7.4 Maintenance of Electrical Control Utilities .................................................................................... 91

7.5 Air Filter Maintenance ................................................................................................................... 94

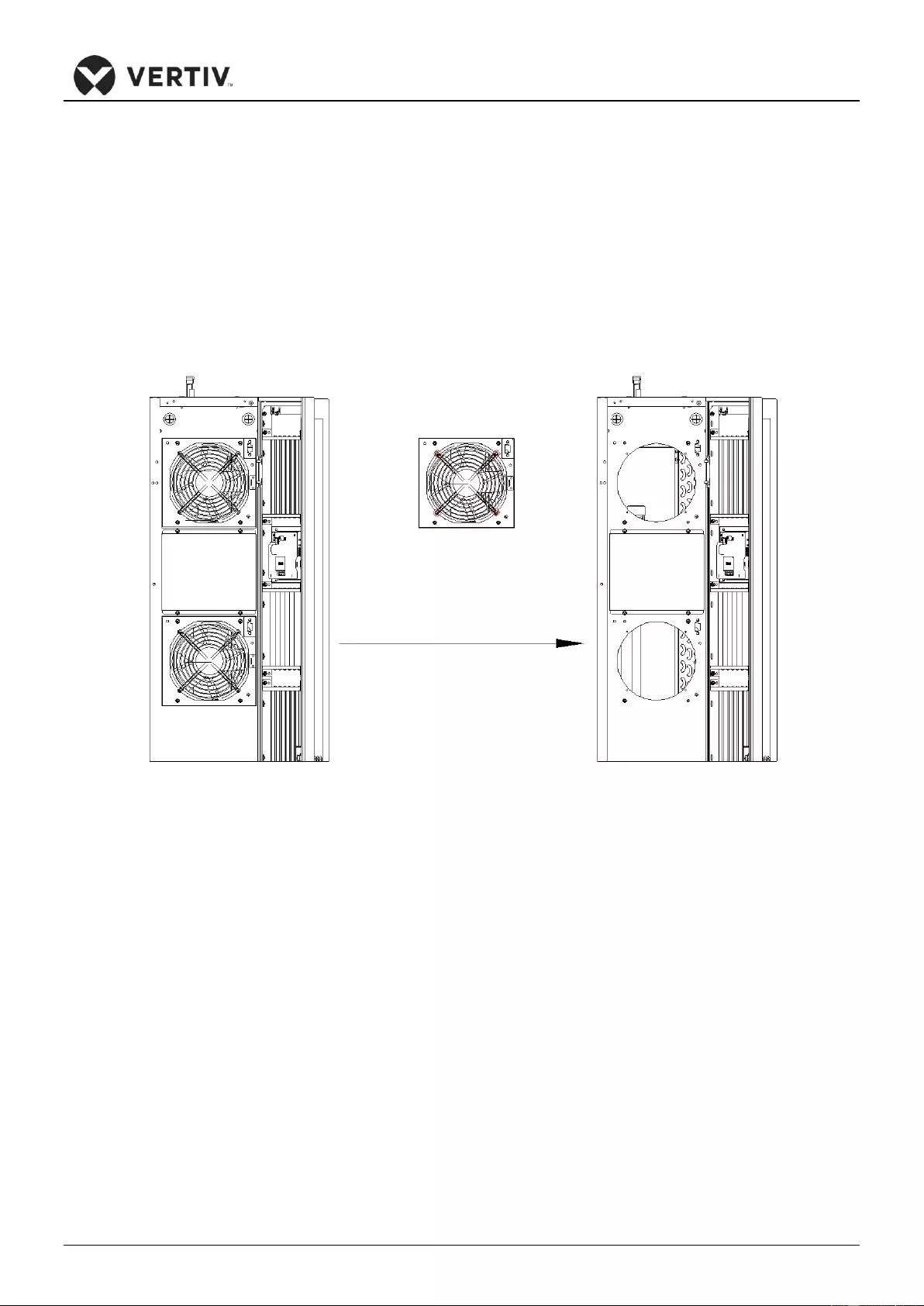

7.6 Fan Kit Maintenance ...................................................................................................................... 94

7.7 Electrical Heater Maintenance (Only CE Model) ........................................................................... 96

7.8 Condensate pump maintenance ................................................................................................... 98

7.9 Refrigerating System Maintenance ............................................................................................... 99

7.10 Drainage System Maintenance ....................................................................................................100

7.11 Dismantling the Unit ....................................................................................................................100

7.12 Troubleshooting ...........................................................................................................................100

Vertiv | Liebert CRD10 | User Manual xi

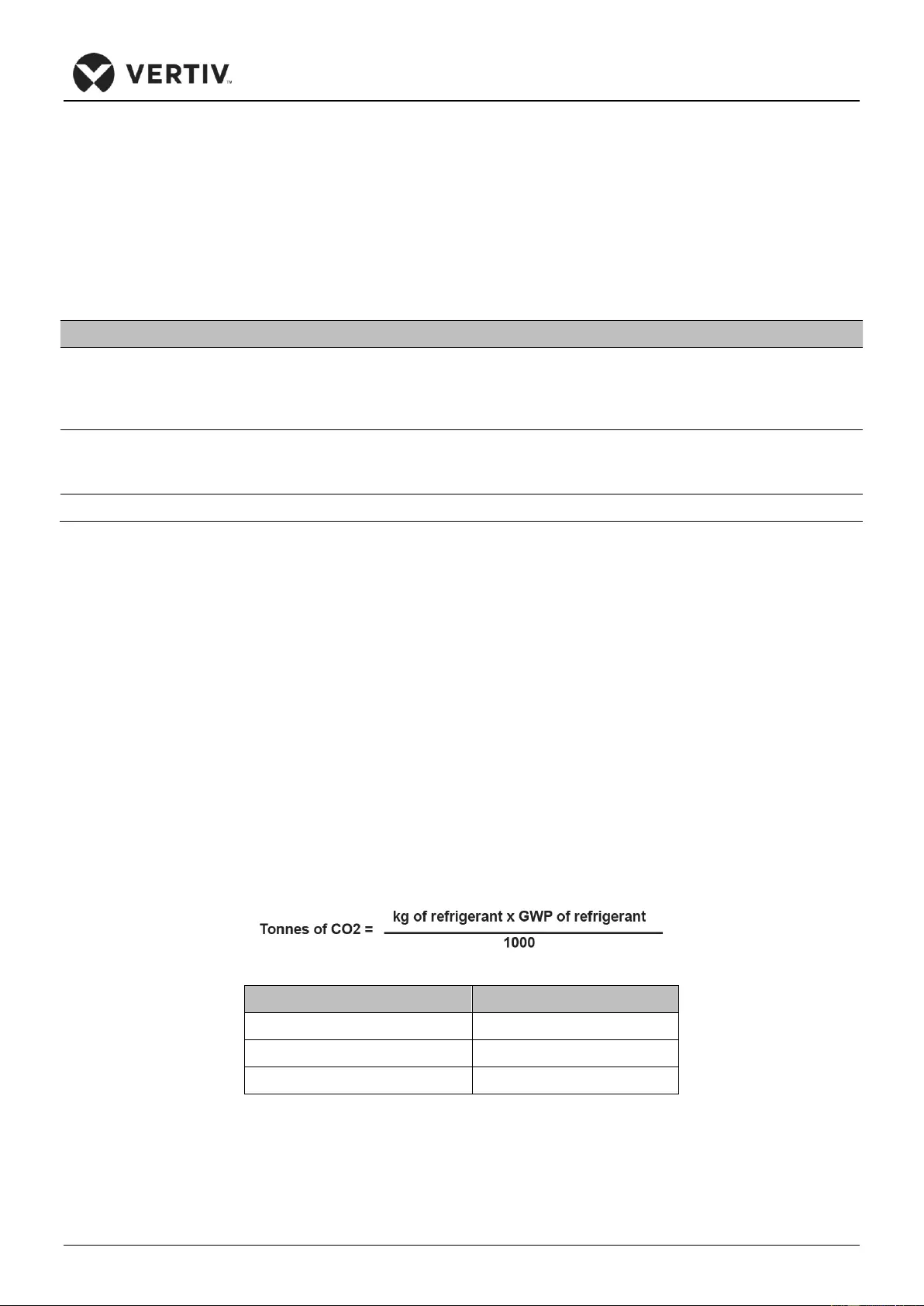

Chapter 8: Regulation (EU) no. 517/2014 (F-gas) .......................................................................... 104

8.1 Introduction .................................................................................................................................104

8.2 Normative References .................................................................................................................104

8.3 Fluorinated Greenhouse Gases ...................................................................................................104

8.4 Operators .....................................................................................................................................105

8.5 Leakage Detection .......................................................................................................................106

8.6 Labelling .......................................................................................................................................106

8.7 Record Keeping ............................................................................................................................107

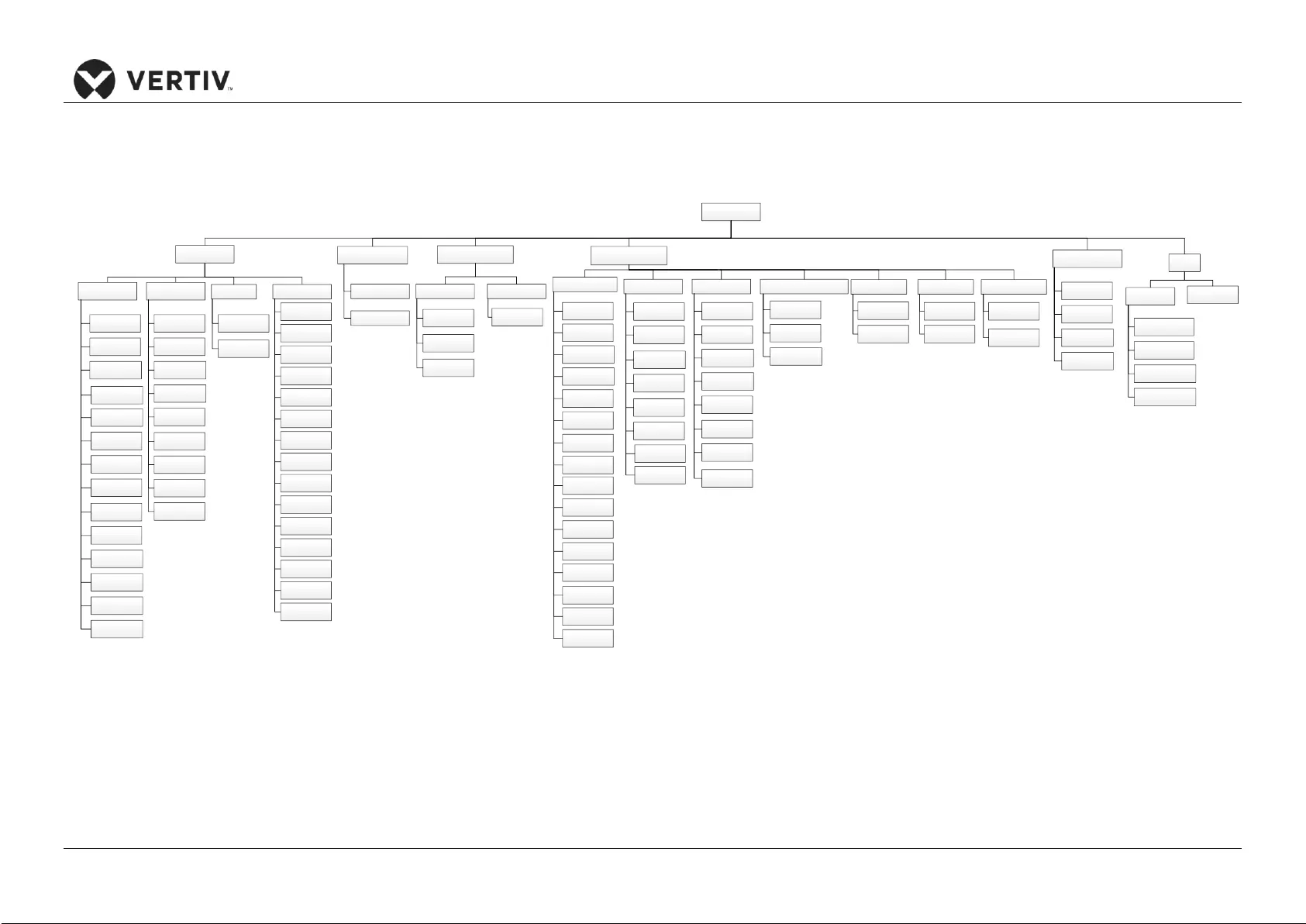

Appendix I: Display menu structure ............................................................................................. 108

Appendix II: Display parameter list .............................................................................................. 109

Appendix III: Alarms Table ........................................................................................................... 112

Product Overview

Vertiv | Liebert CRD10 | User Manual 1

Chapter 1: Product Overview

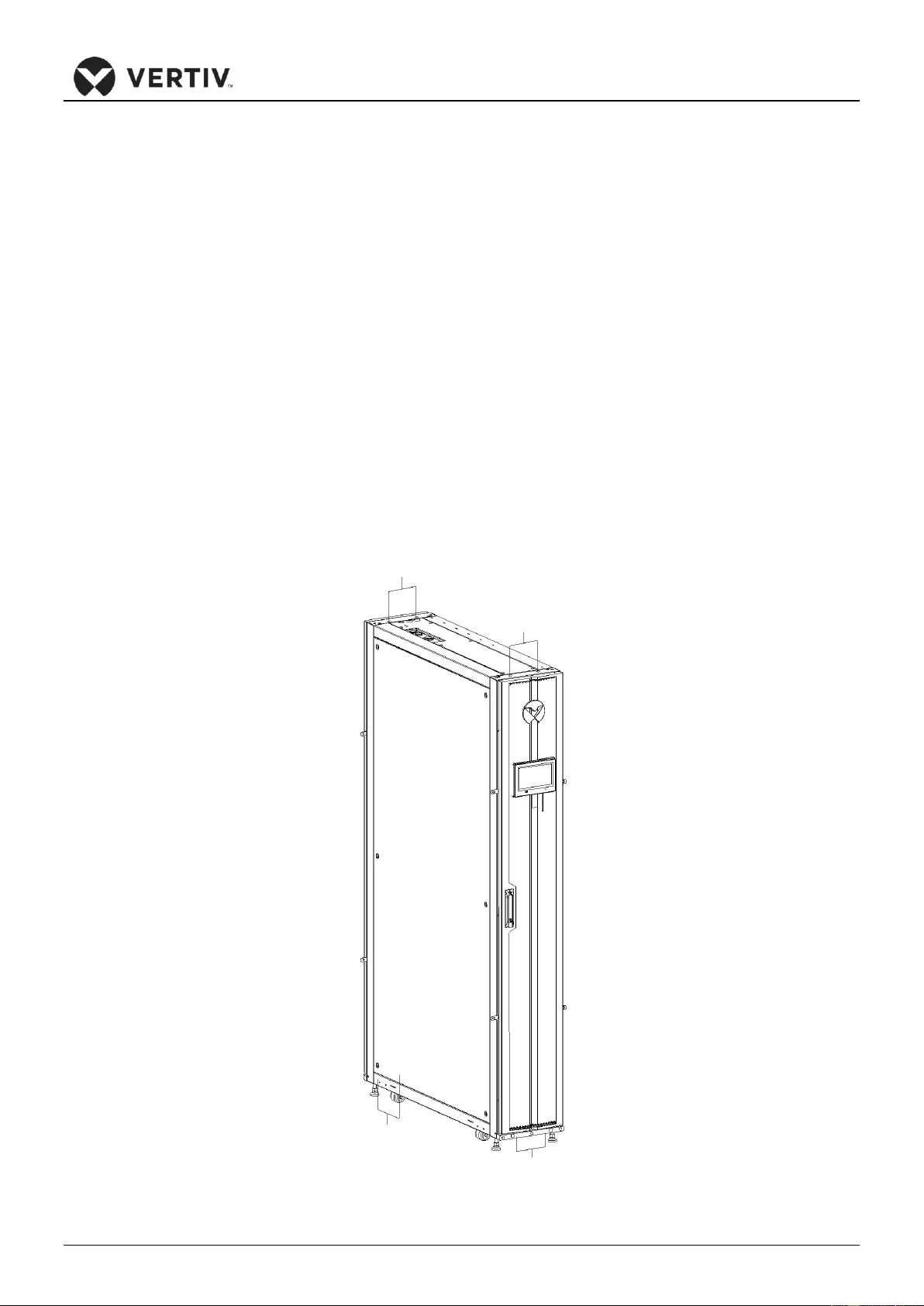

The Liebert CRV, CRD10 is the next generation of air conditioner that provide precise environmental

control. The Liebert CRV, CRD10 models are the latest in the long chain of modern enterprise-grade

products from the Liebert family. Incorporating the high standards associated with the Liebert name, the

CRD10 utilizes the latest technology, system components, and streamlined manufacturing process.

1.1 Product Introduction

CRD10 air conditioners are products specifically created and designed for small to medium data centers,

computer rooms, equipment room, modularized machine room and similar high heat density systems

requiring a high degree of accuracy and precision. It addresses the needs and challenges associated with

such applications and setups. It caters to sensitive applications which need a suitable environment for

optimal performance. Therefore, care should be taken when testing the product to maintain favorable

conditions for mission-critical equipment. Thermal management units must not only keep the room

conditions within a specific range but also be able to react quickly to drastic changes in the heat load and

prevent wide temperature fluctuations.

CRD10 air-cooled AC unit is packed with features like high reliability, high sensible heat ratio, and large

airflow. The Liebert CRD10 is an advanced row-based cooling unit. It provides the 10kW cooling capacity

under designed condition. It can adjust the cooling capacity by changing the output of inverter

compressor and EC fans, depending on the change in the heat load.

CRD10 air-cooled unit requires a condenser. The condenser is powered and controlled by indoor unit.

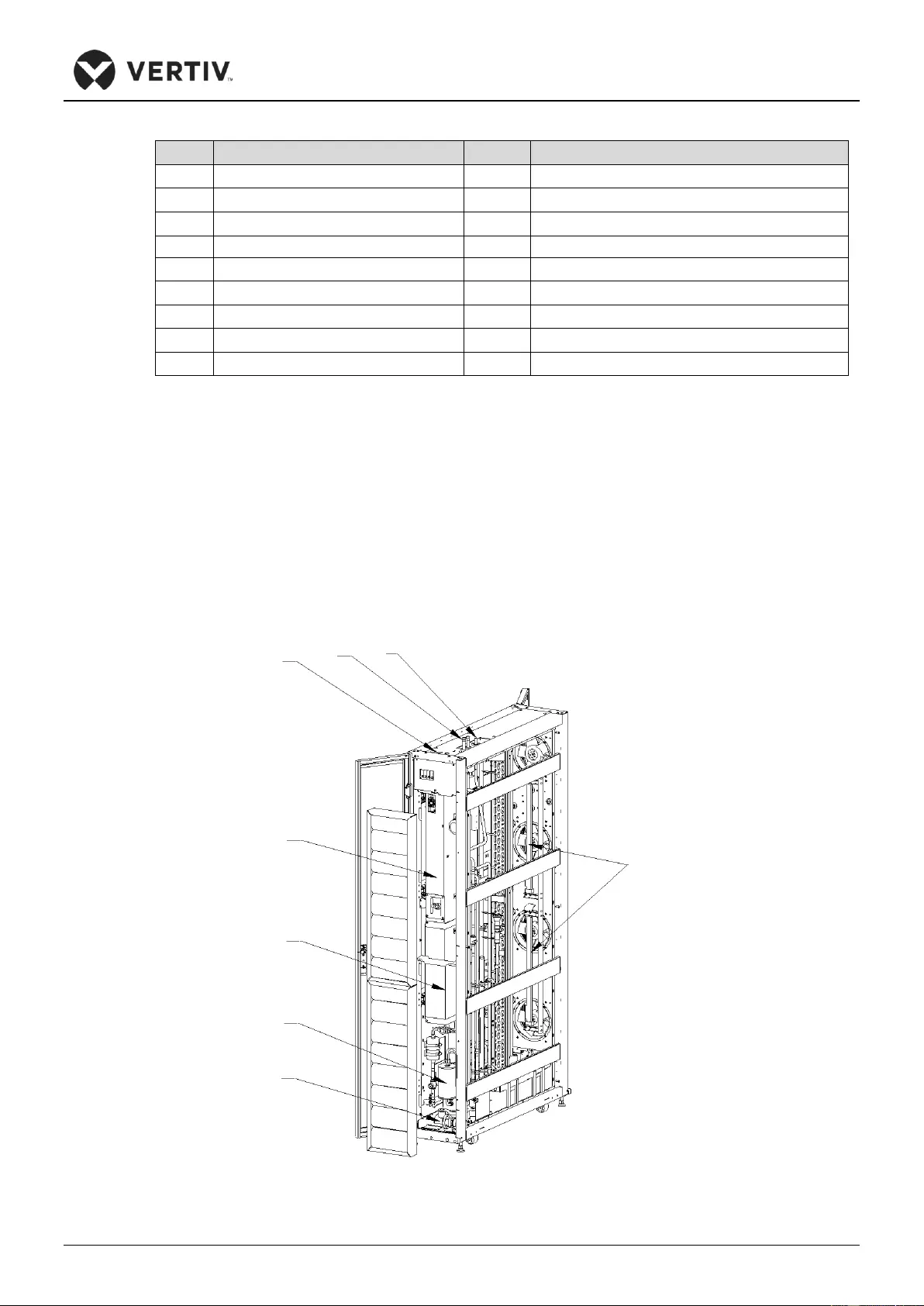

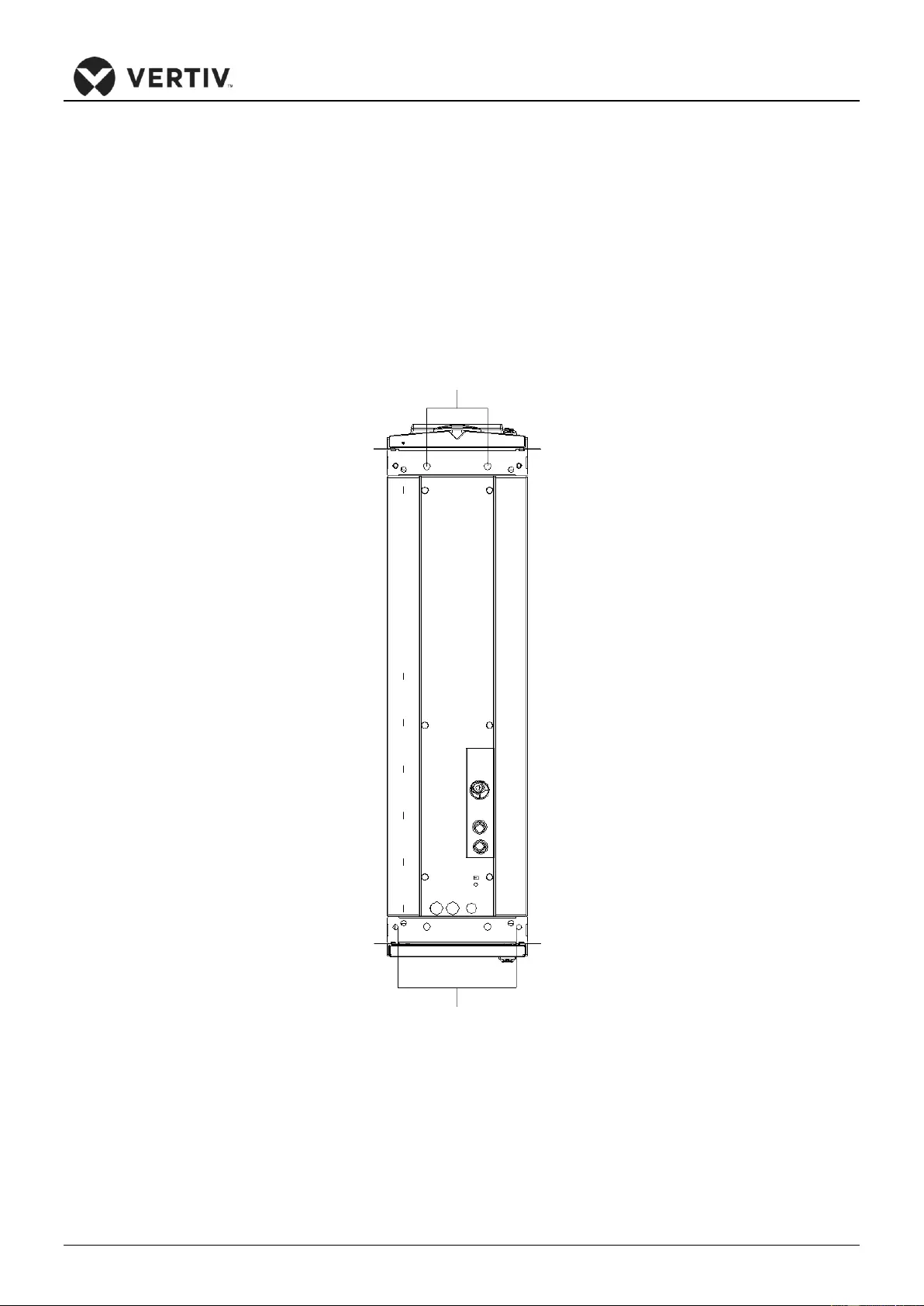

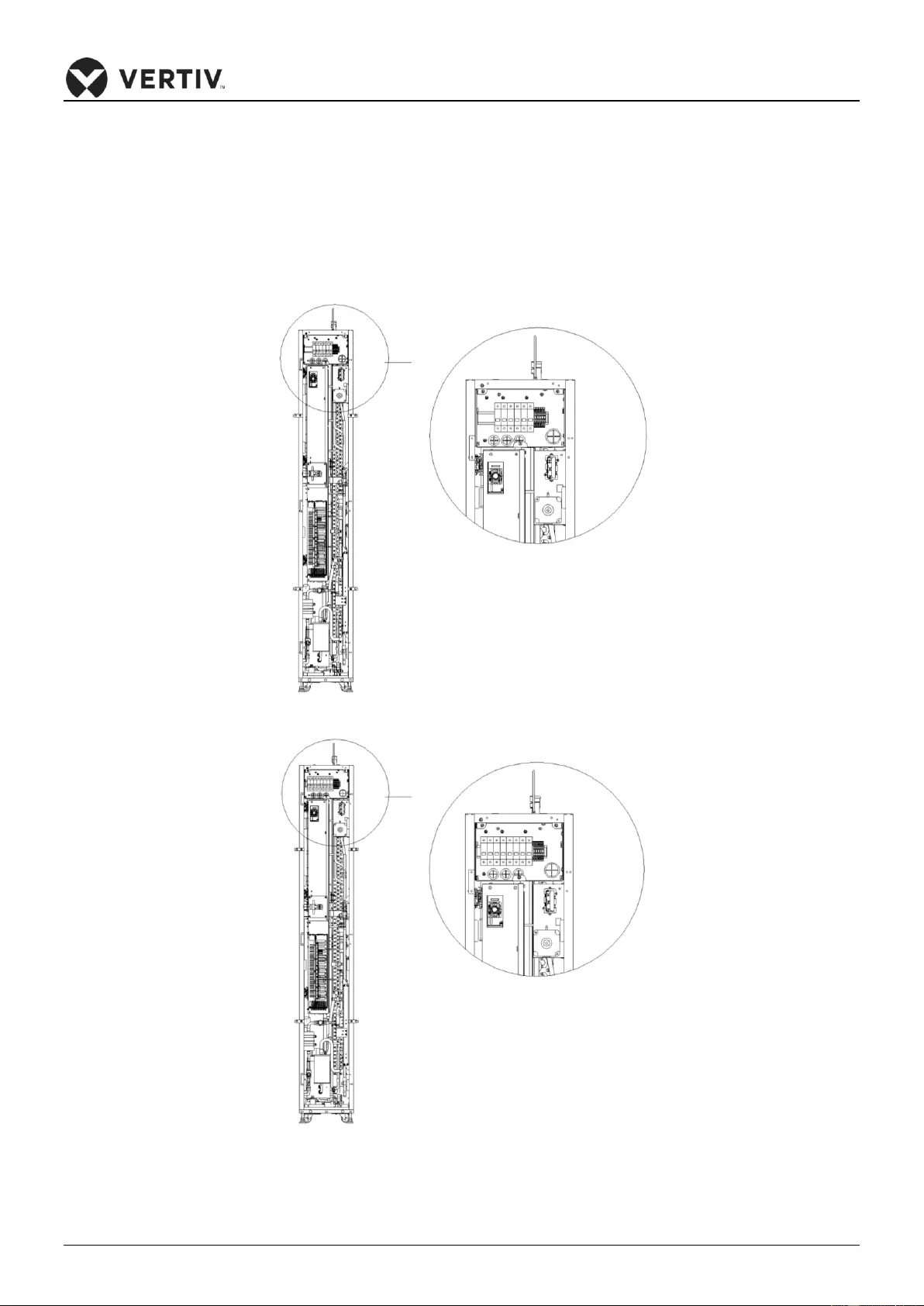

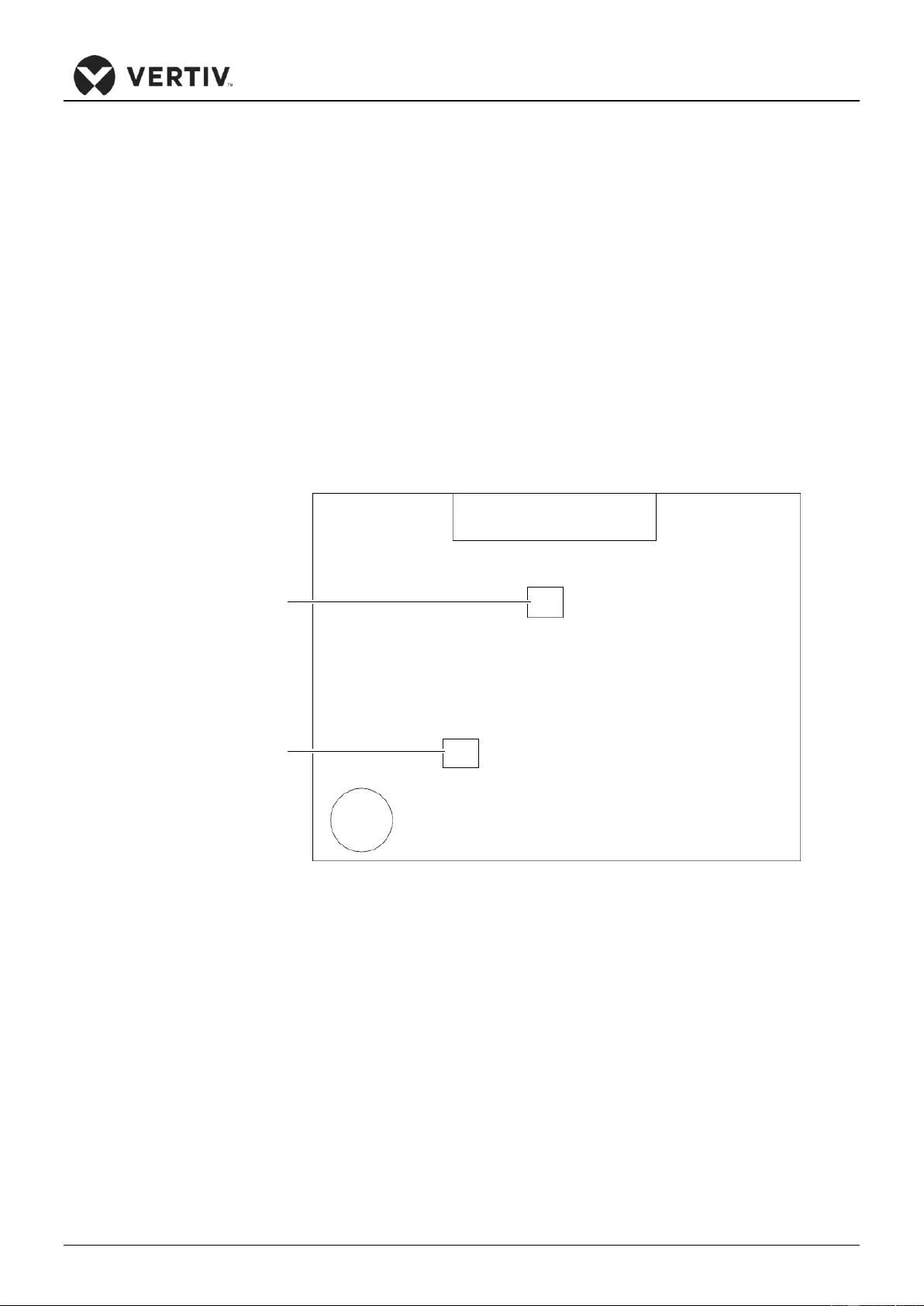

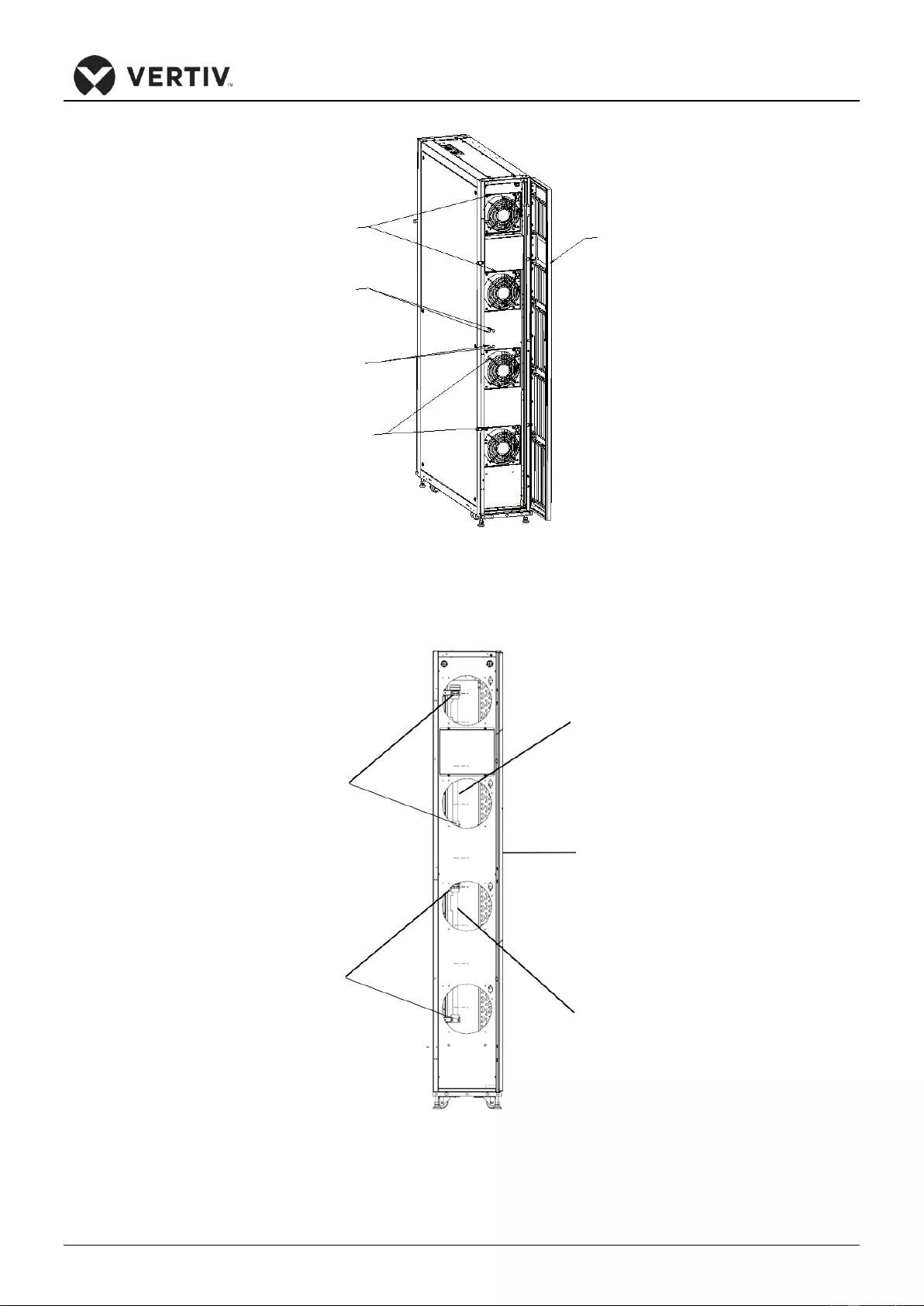

Figure 1-1 Appearance of the Air Conditioner

Front Rear

Product Overview

Vertiv | Liebert CRD10 | User Manual 2

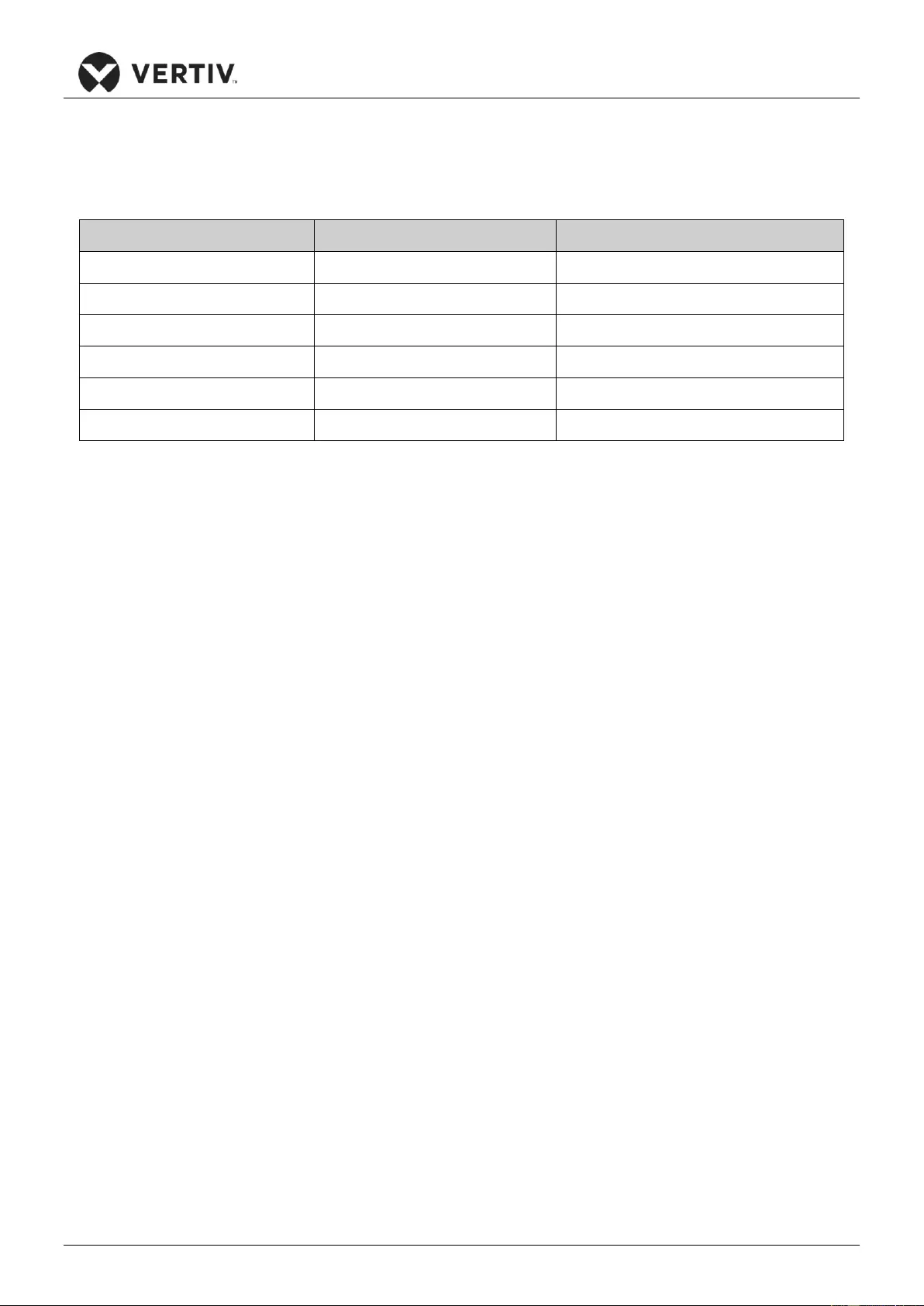

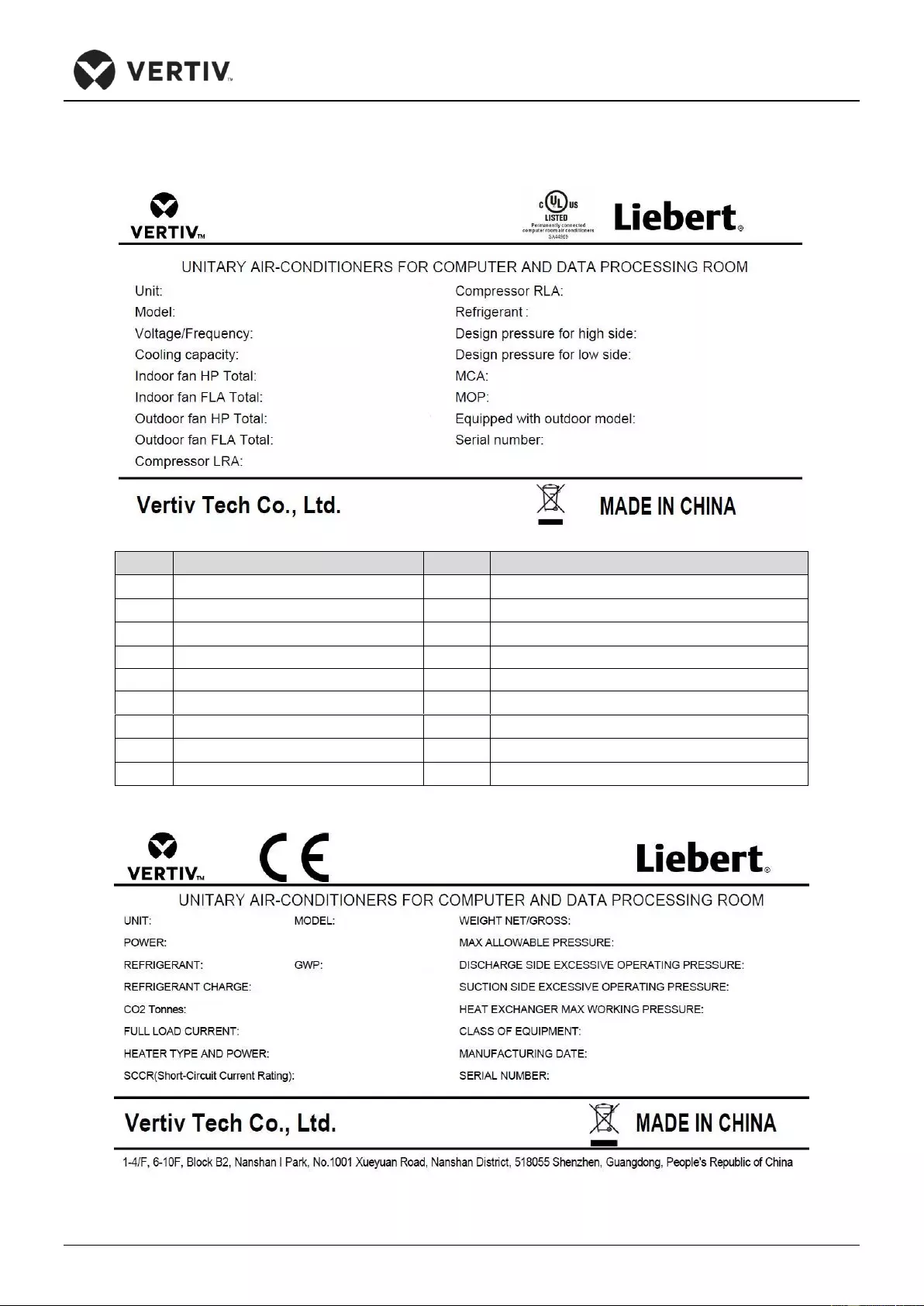

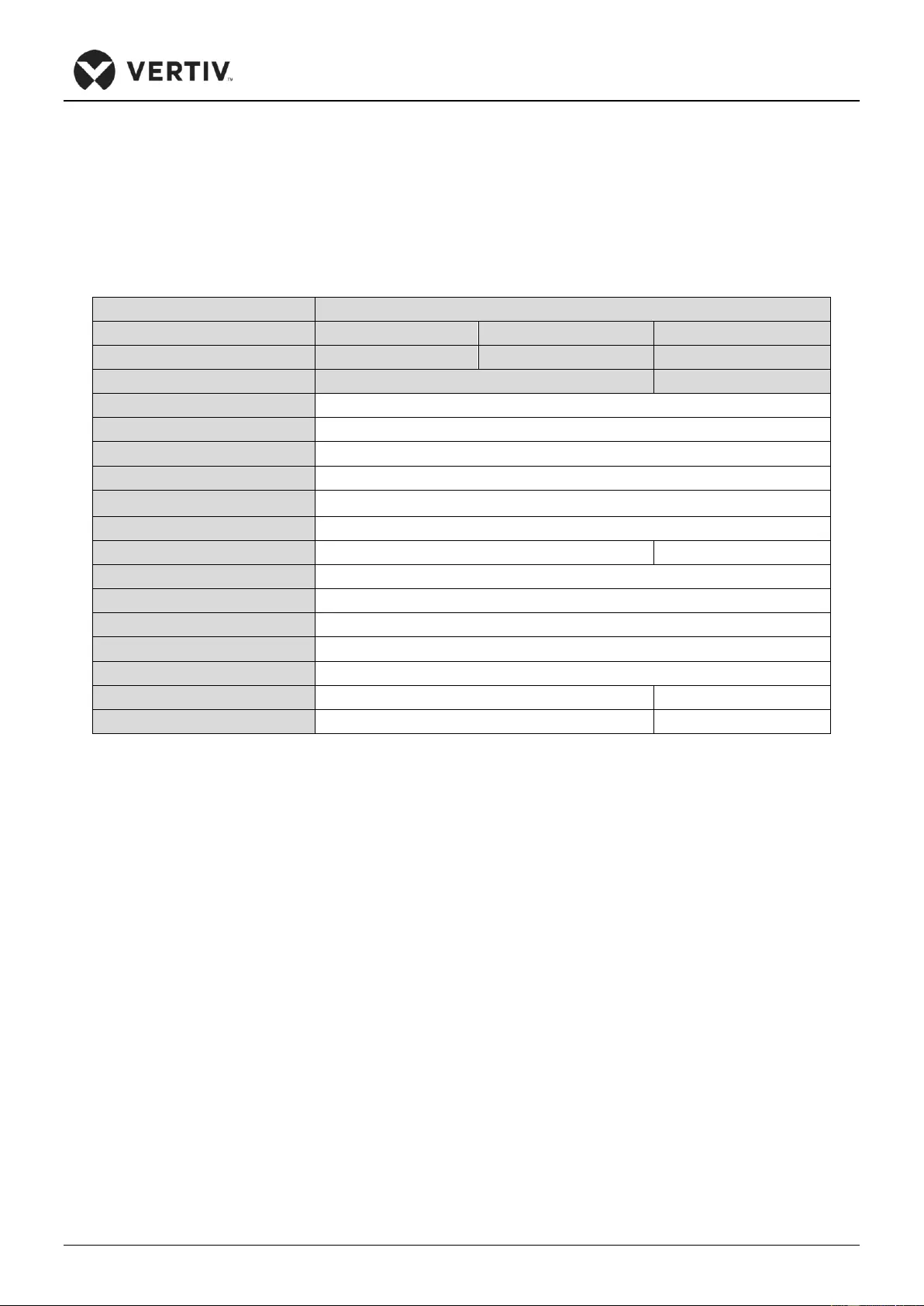

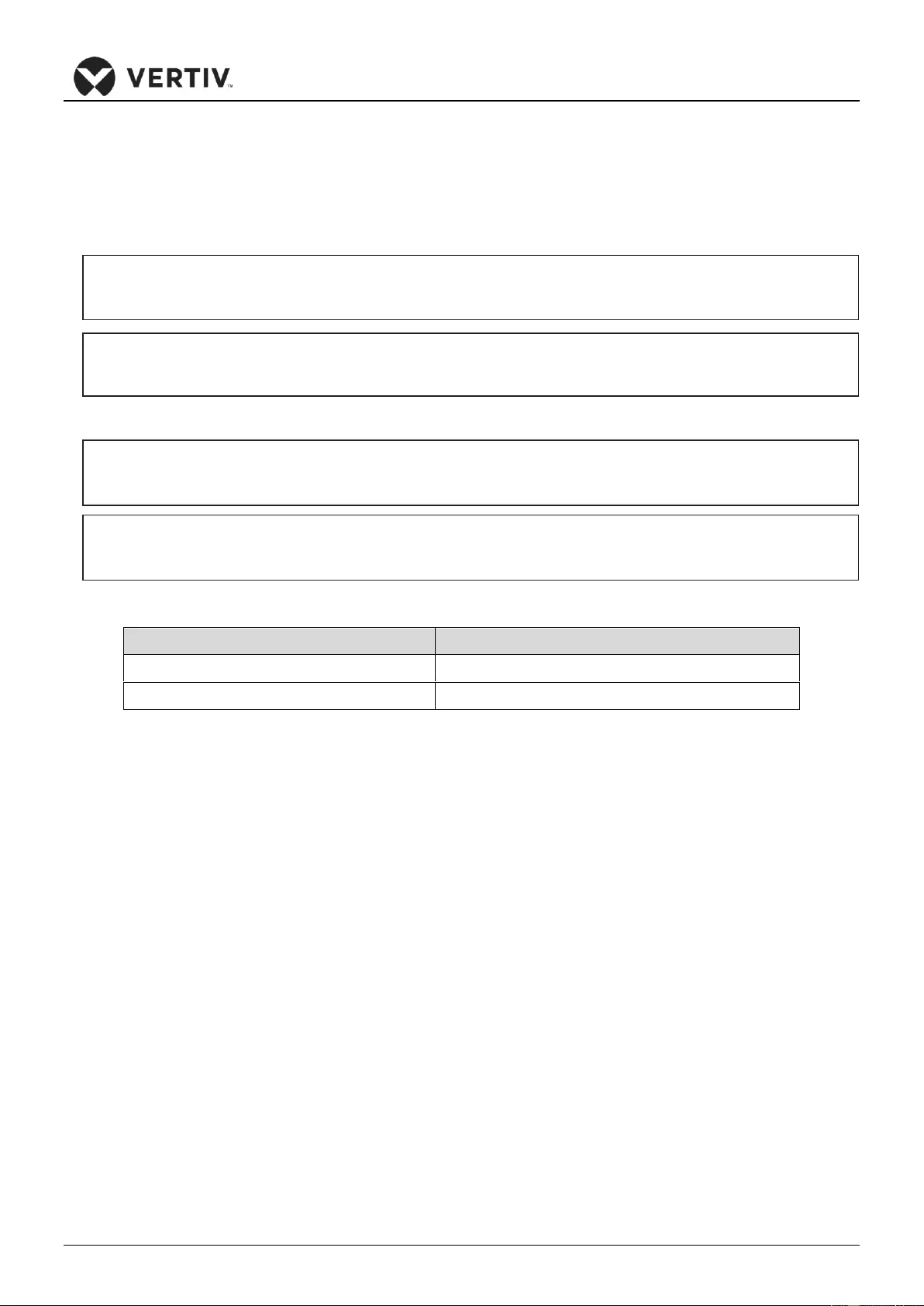

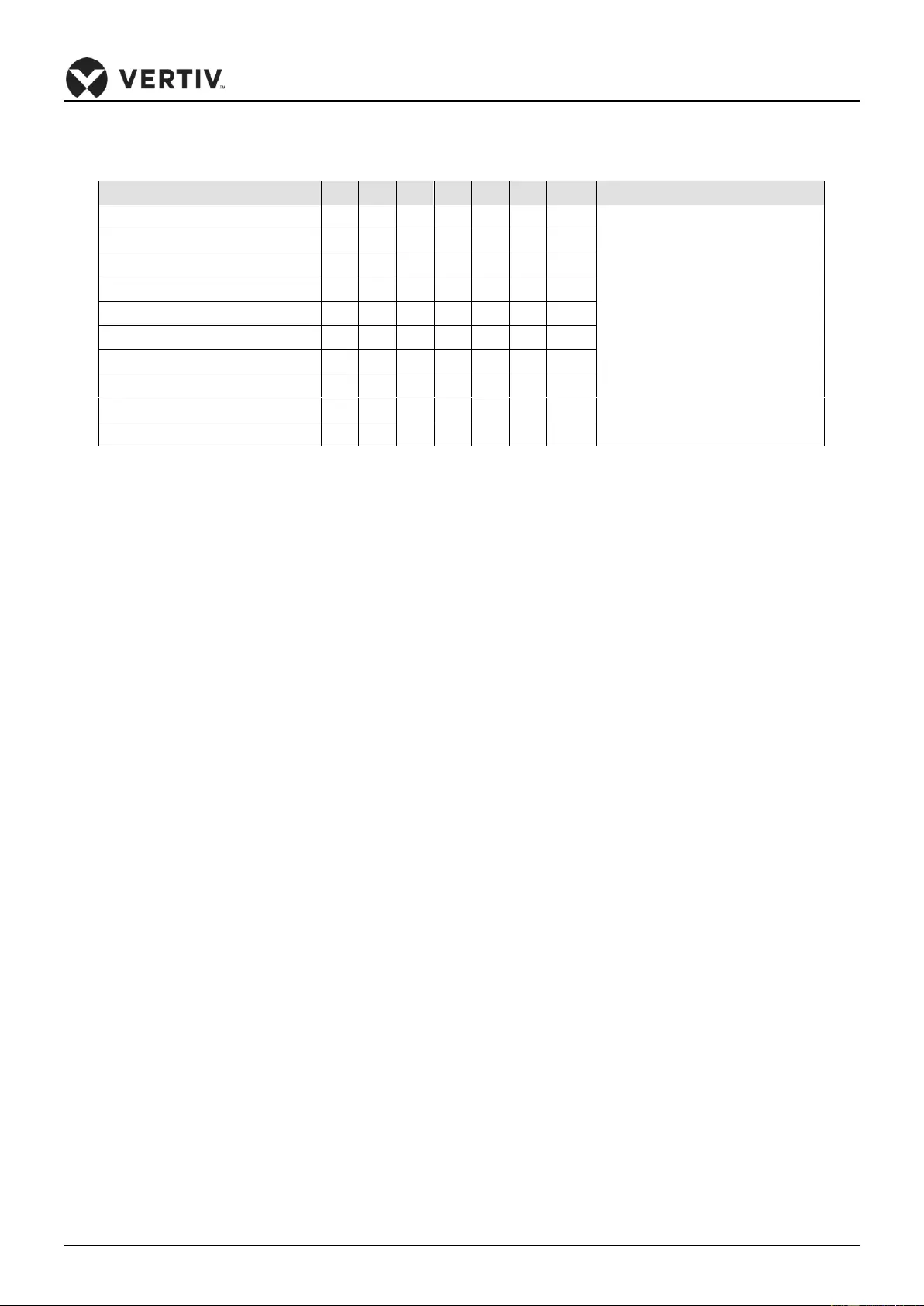

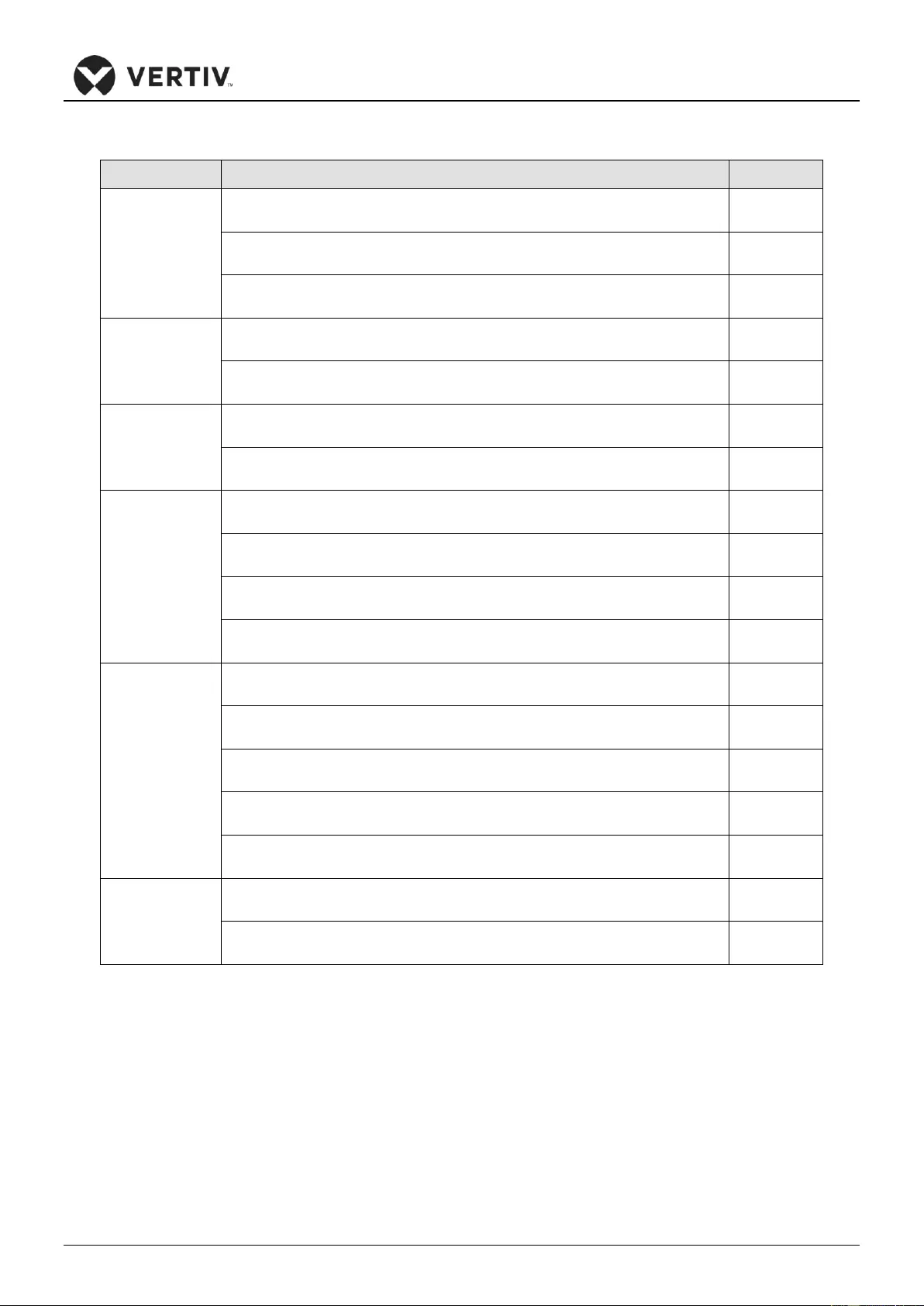

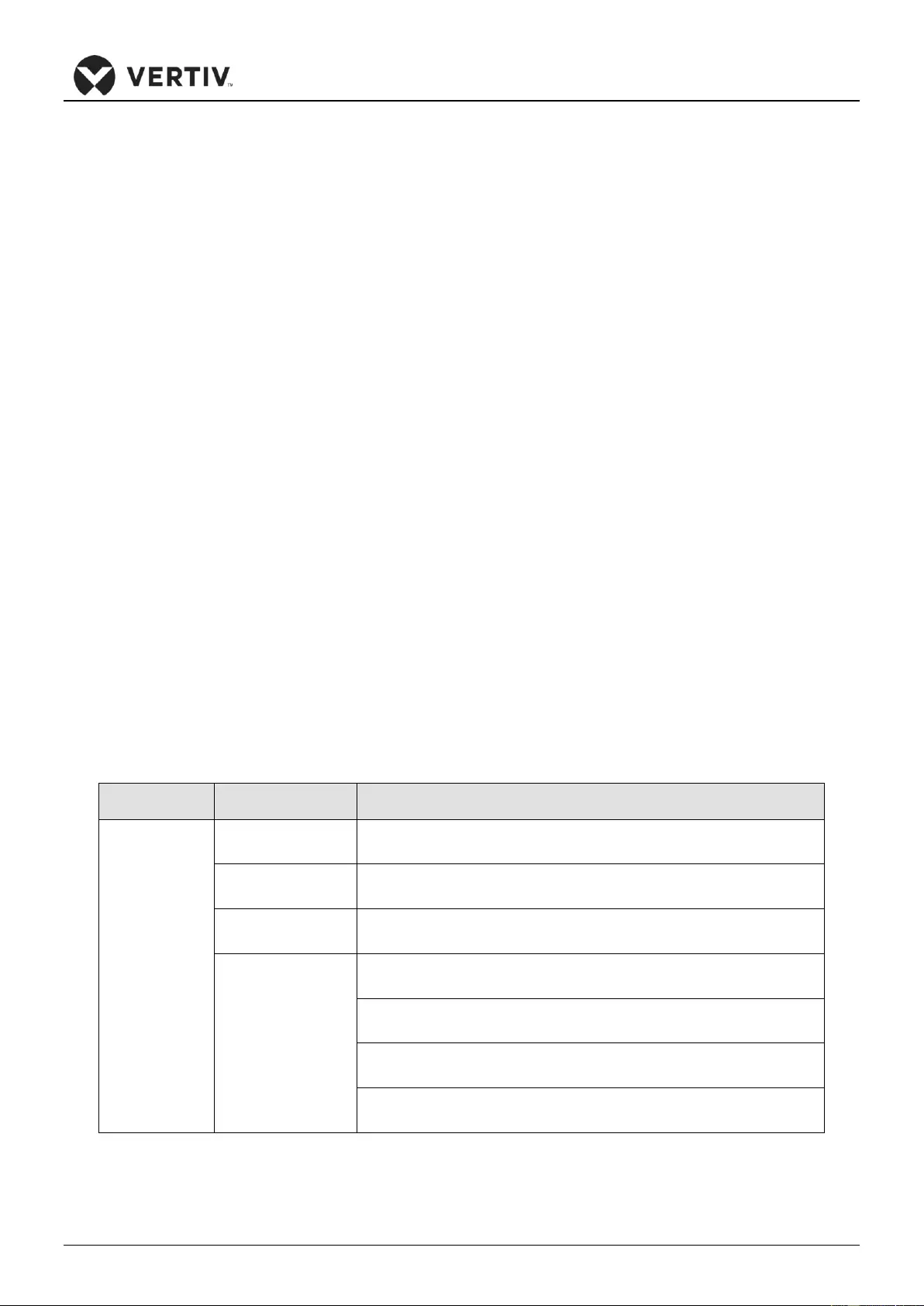

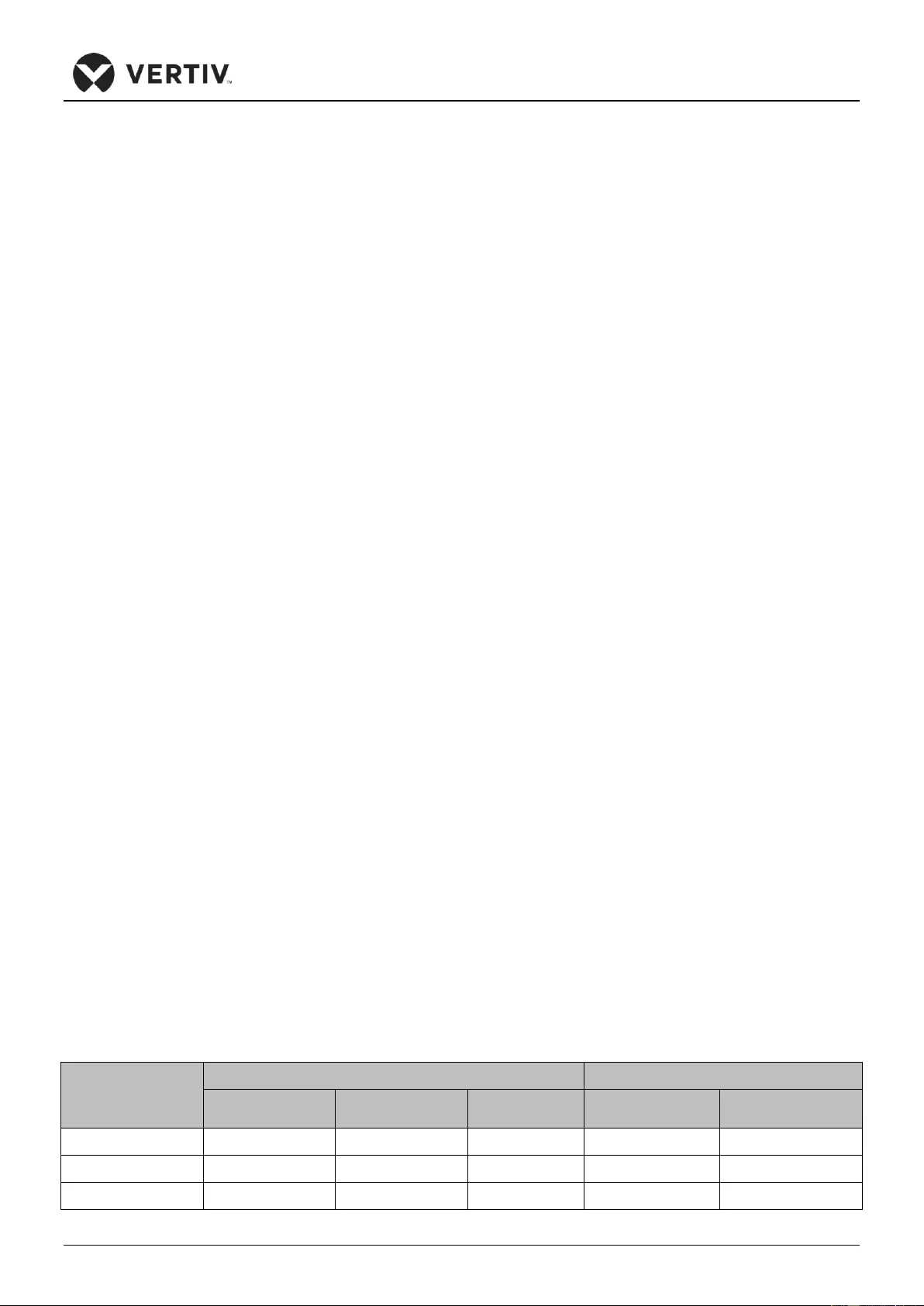

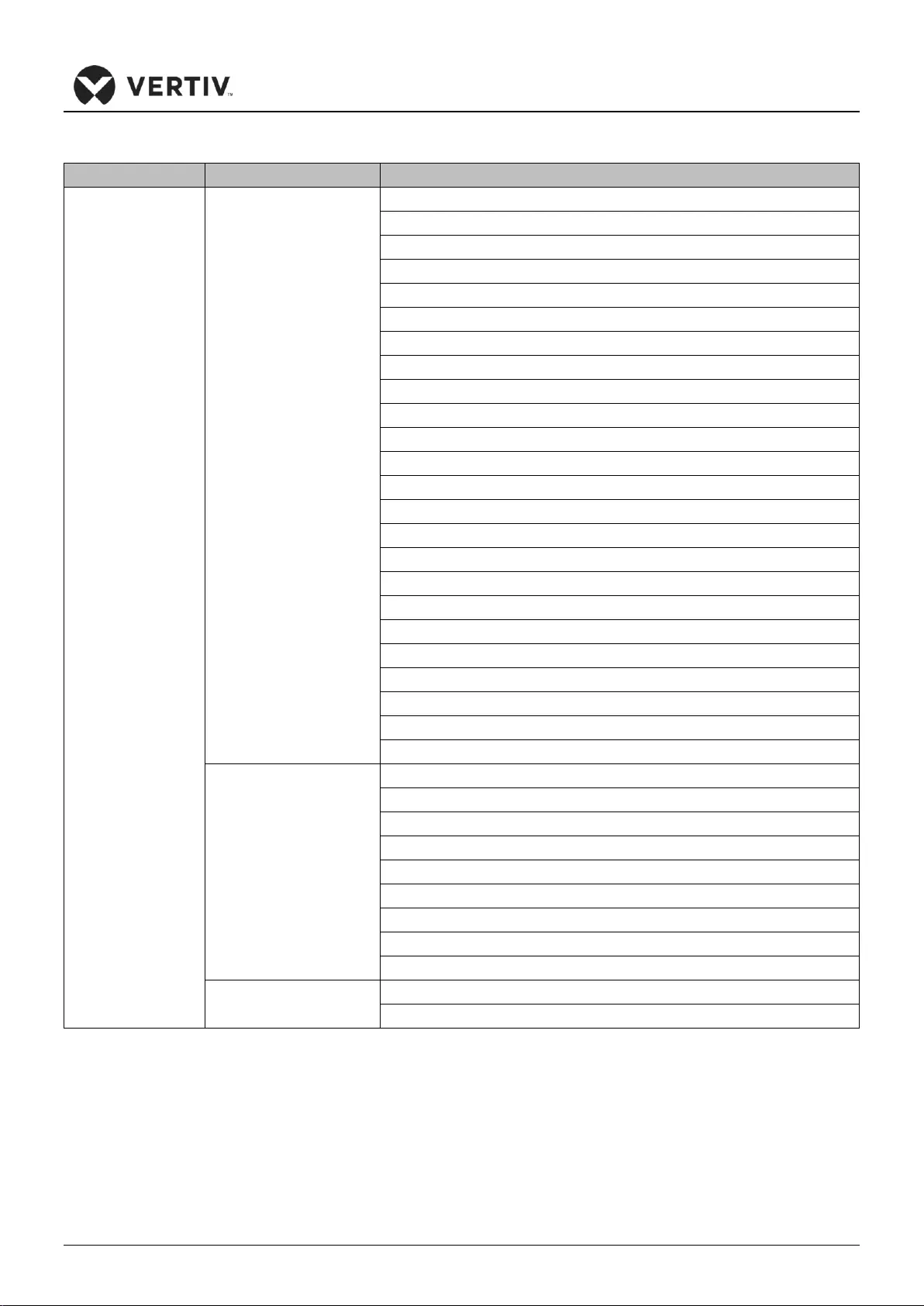

Refer Figure 1-2 for the nameplate description of the CRD10 model:

UL Model:

POS.

DESCRIPTION

POS.

DESCRIPTION

1

Unit defined by 6 digits

10

Rated load current of compressor

2

Model defined by 12 digits

11

Refrigerant Amount Charged on site

3

Supply Power

12

Discharge Side Excessive Operating Pressure

4

Cooling capacity

13

Suction Side Excessive Operating Pressure

5

Indoor fan power in total

14

Minimum Circuit Amps

6

Indoor fan full load current in total

15

Maximum Overcurrent Protection

7

Outdoor fan power in total

16

Equipped with outdoor model

8

Outdoor fan full load current in total

17

Serial Number

9

Locked rotor current of compressor

CE Model:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

3

4

6

7

8

9

10

2

5

11

12

13

14

15

16

17

18

Product Overview

Vertiv | Liebert CRD10 | User Manual 3

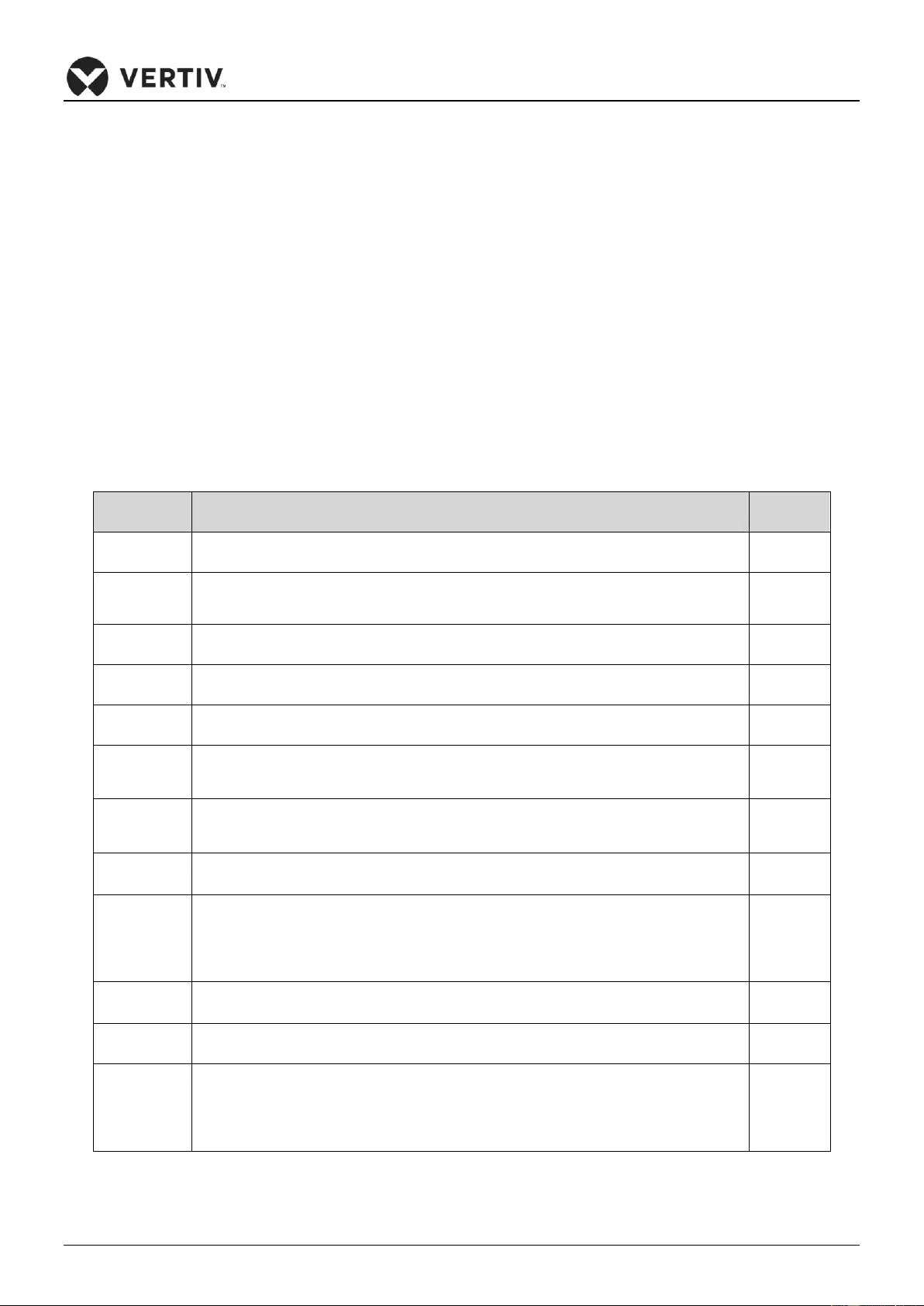

POS.

DESCRIPTION

POS.

DESCRIPTION

1

Unit defined by 6 digits

10

Short-circuit current rating

2

Model defined by 12 digits

11

Net weight and Gross weight

3

Supply Power

12

Max Allowable Pressure of the Unit

4

Refrigerant Category

13

Discharge Side Excessive Operating Pressure

5

Global Warming Potential

14

Suction Side Excessive Operating Pressure

6

Refrigerant Amount Charged on site

15

Heat Exchange Max Working Pressure

7

CO2 Tonnes

16

Class of Equipment

8

Full load Current

17

Manufacturing Date

9

Heater type and power

18

Serial Number

Figure 1-2 Product Nameplate and Model Description

1.2 Product Description

The CRD10 cooling unit is a comprehensive system that includes all the main functions fundamental to

precision cooling units such as cooling, dehumidification, reheating(CE certified model only), air filtration,

condensation management, temperature control, alarm functions and compatibility with data

communications. CRD10 is designed to comply with mission-critical requirements and ensure that servers

are maintained at the correct temperature and humidity levels. Figure 1-3 & 1-4 shows the various

components and their respective locations.

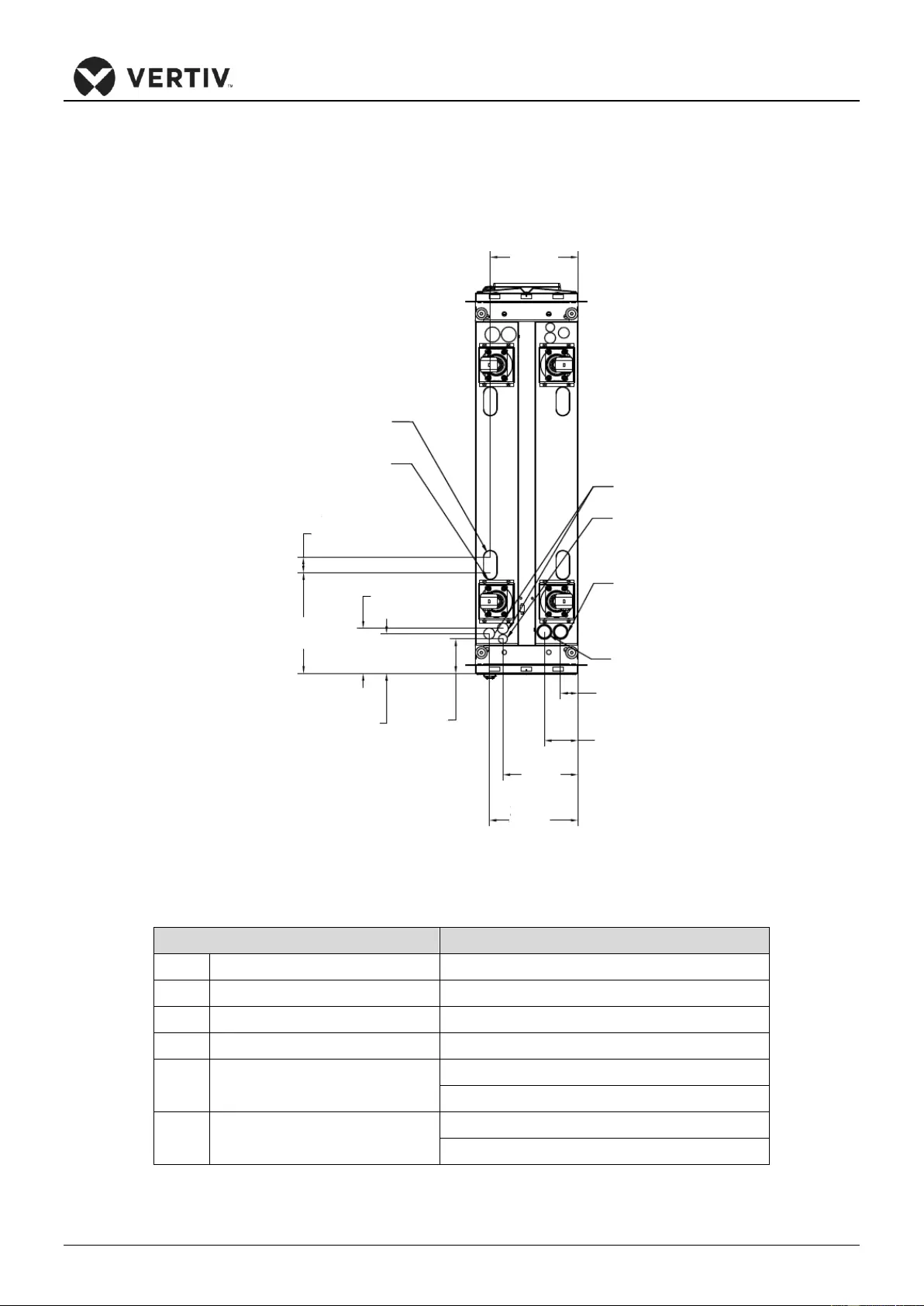

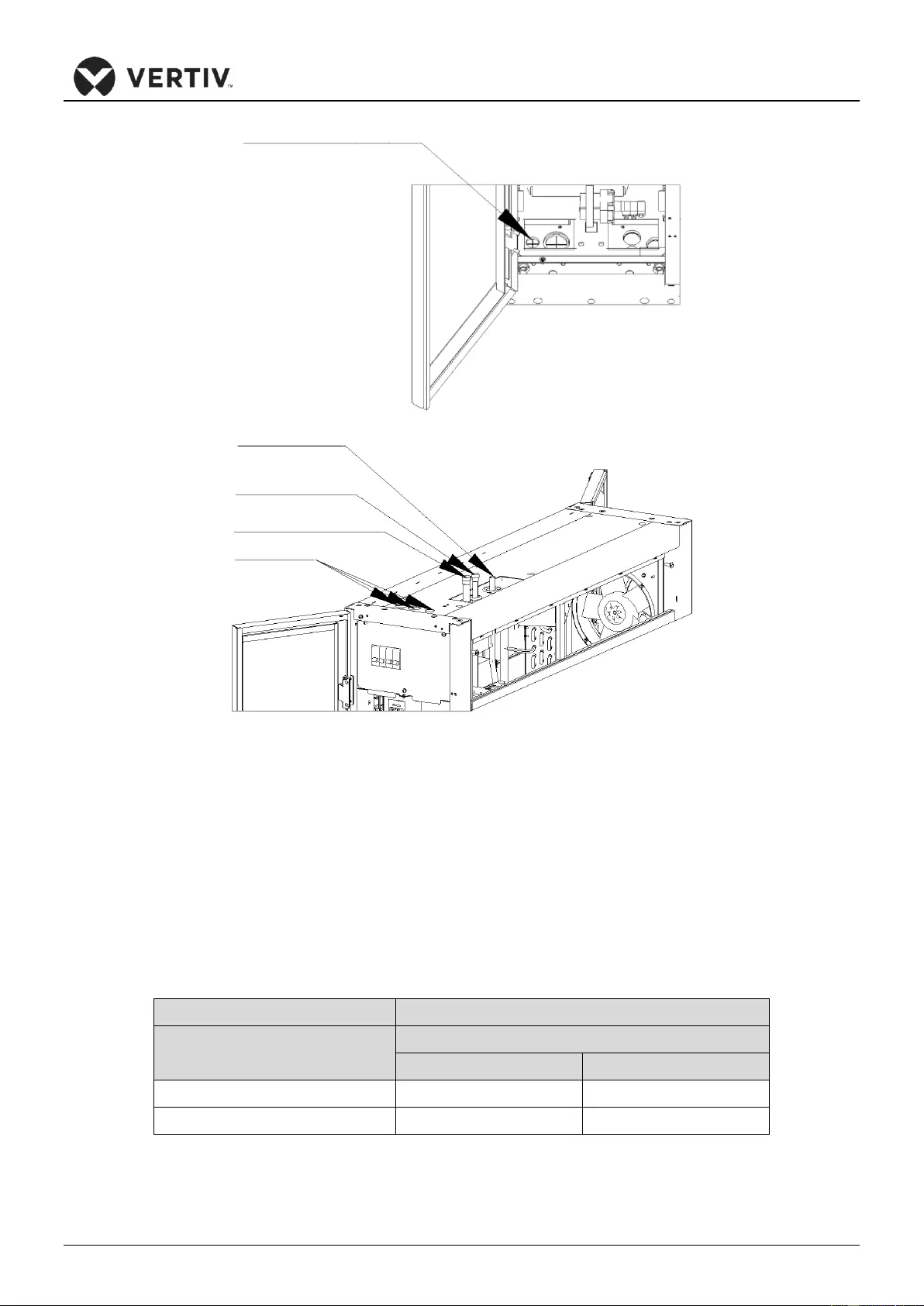

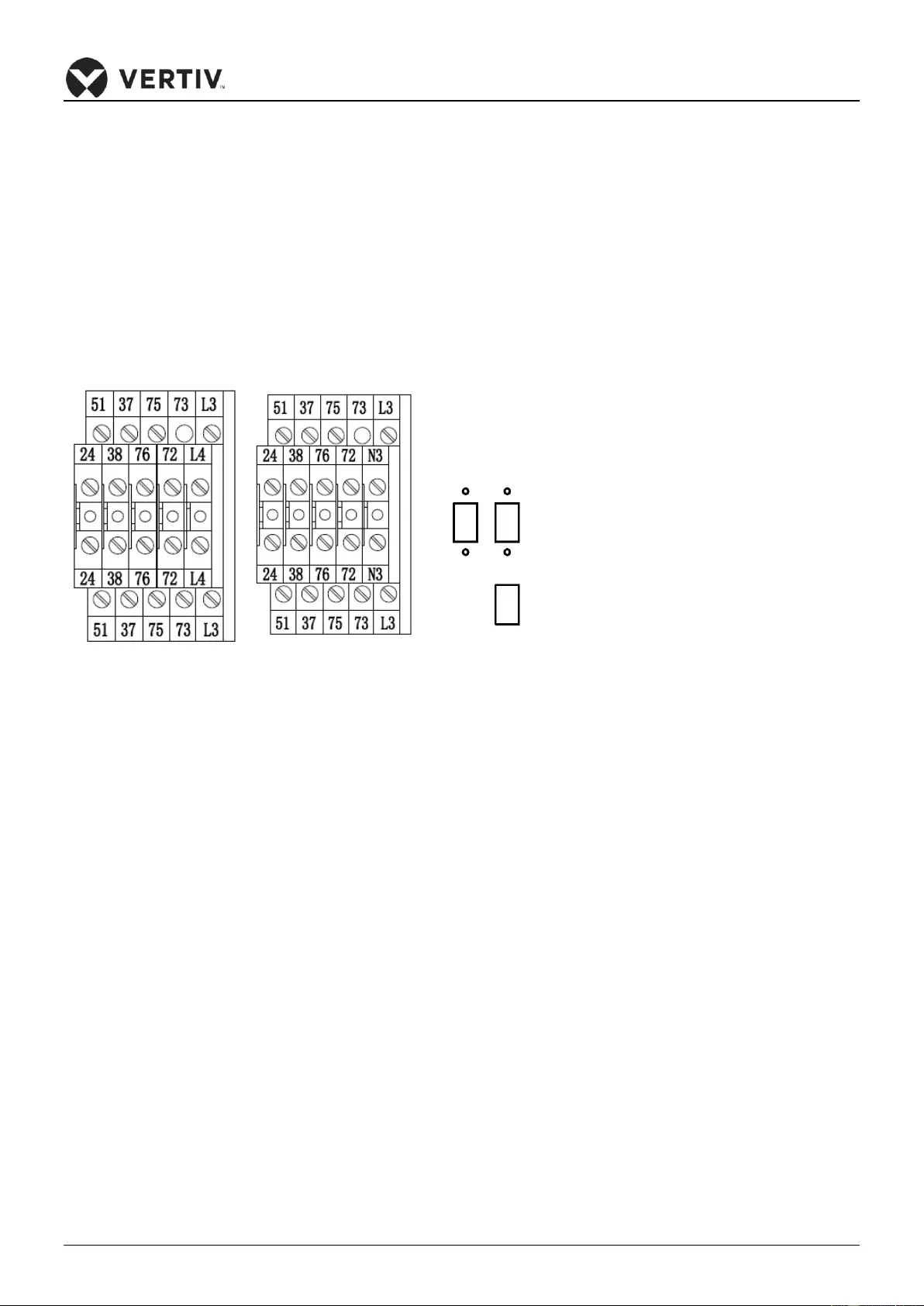

Figure 1-3 Components and their Locations at Rear

1

2

3

4

5

6

7

8

Product Overview

Vertiv | Liebert CRD10 | User Manual 4

Figure 1-4 Components and their Locations at Front

Item

Description

Item

Description

1

Drainage pipe of pump

7

Condensate pump

2

Supply and Return refrigerant pipe

8

Electric heaters (optional)

3

Top electrical entrance

9

Evaporative Coil

4

Electric box

10

EC plug fans

5

Compressor Driver

11

Baffles

6

Compressor

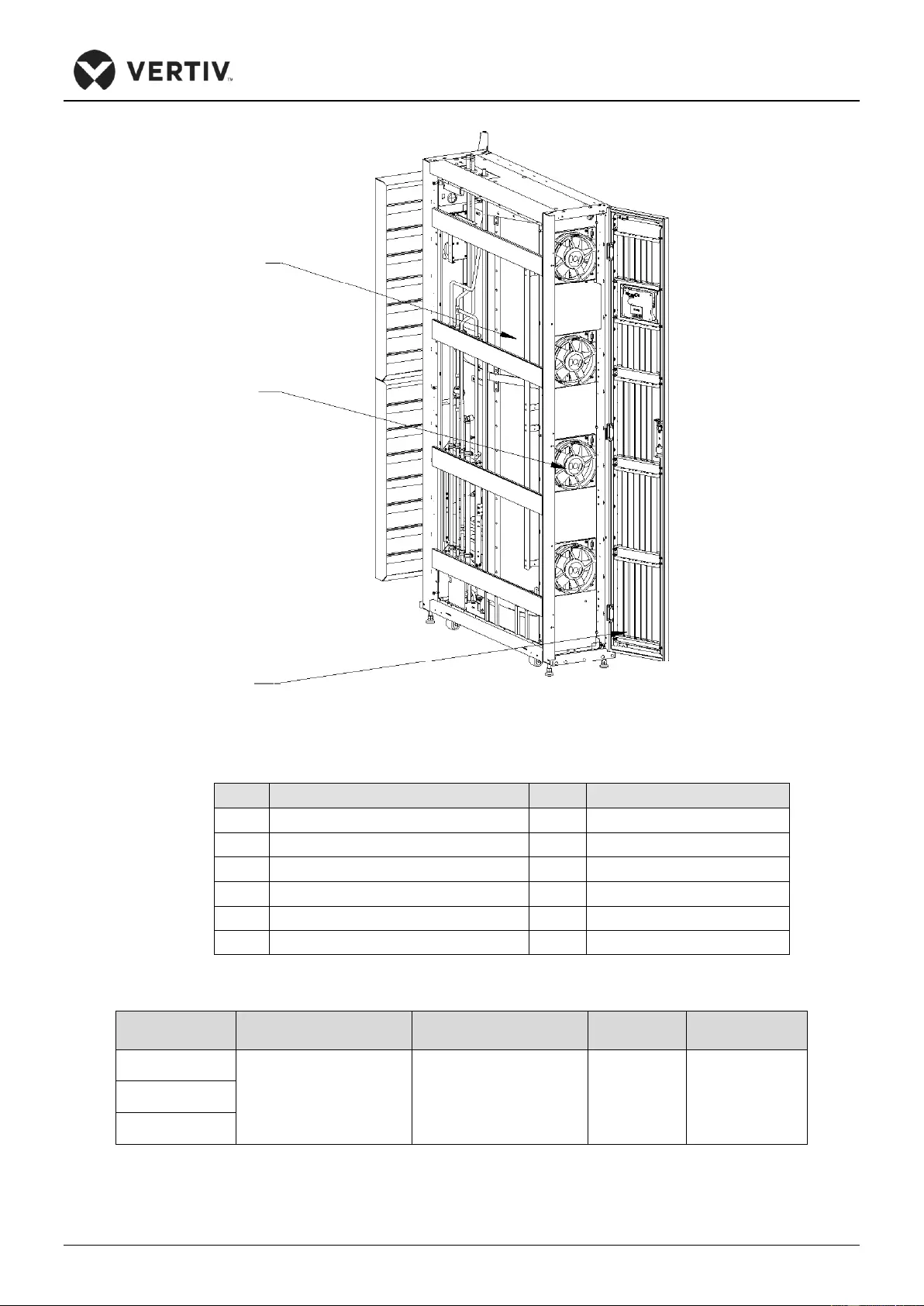

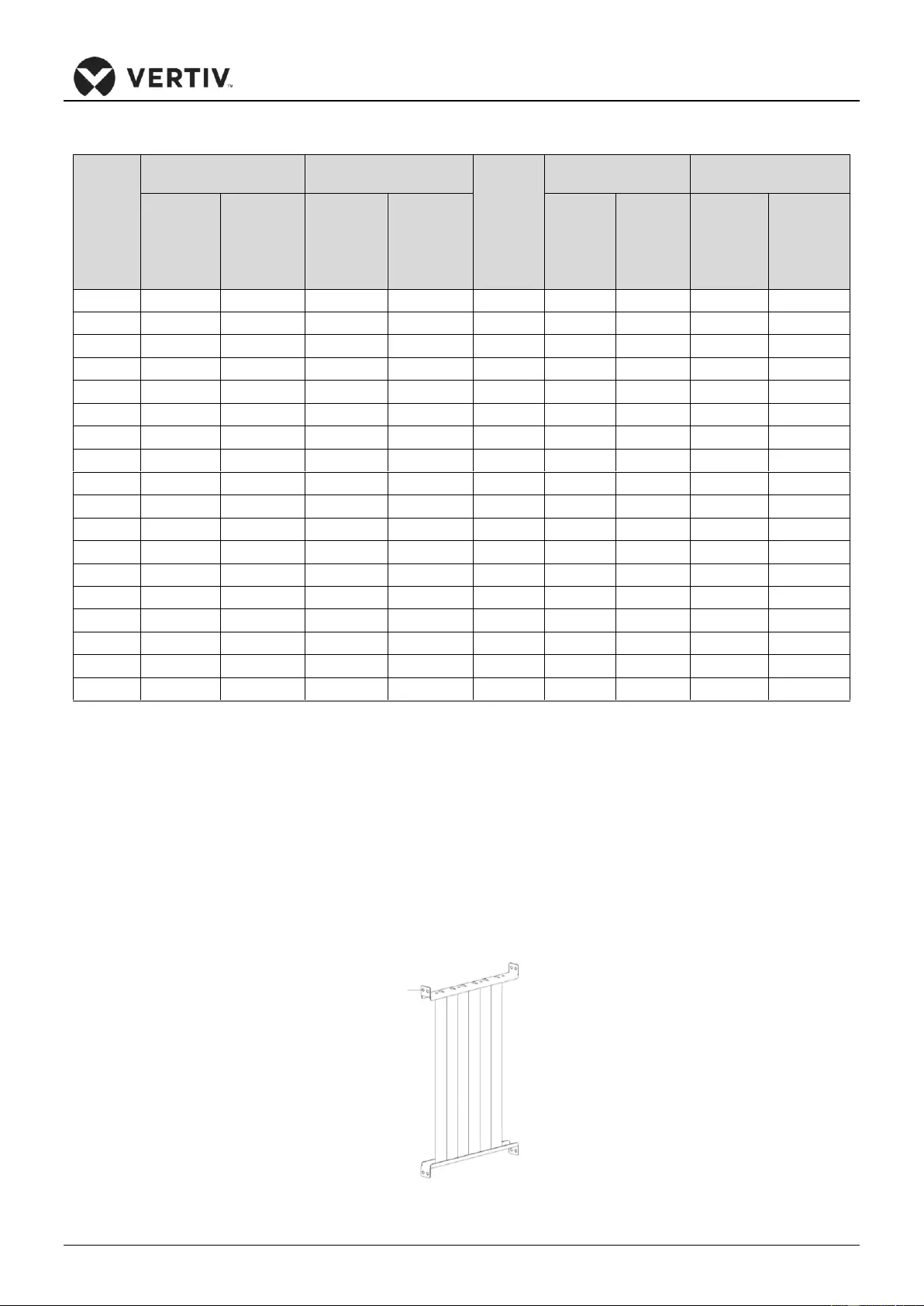

Table 1-1 CRD10 Dimensions

Model

Unit Dimensions

(W x D x H) mm(inch)

Package Dimensions

(W x D x H) mm(inch)

Net weight

(kg/lb)

Gross weight

(kg/lb)

CRD100-0D00A

300x1132x2000

(11.8x44.6x78.7)

776x1276x2228

(30.6x50.2x87.7)

231/509

313/690

CRD101-0D00A

CRD102-1D00A

9

10

11

Product Overview

Vertiv | Liebert CRD10 | User Manual 5

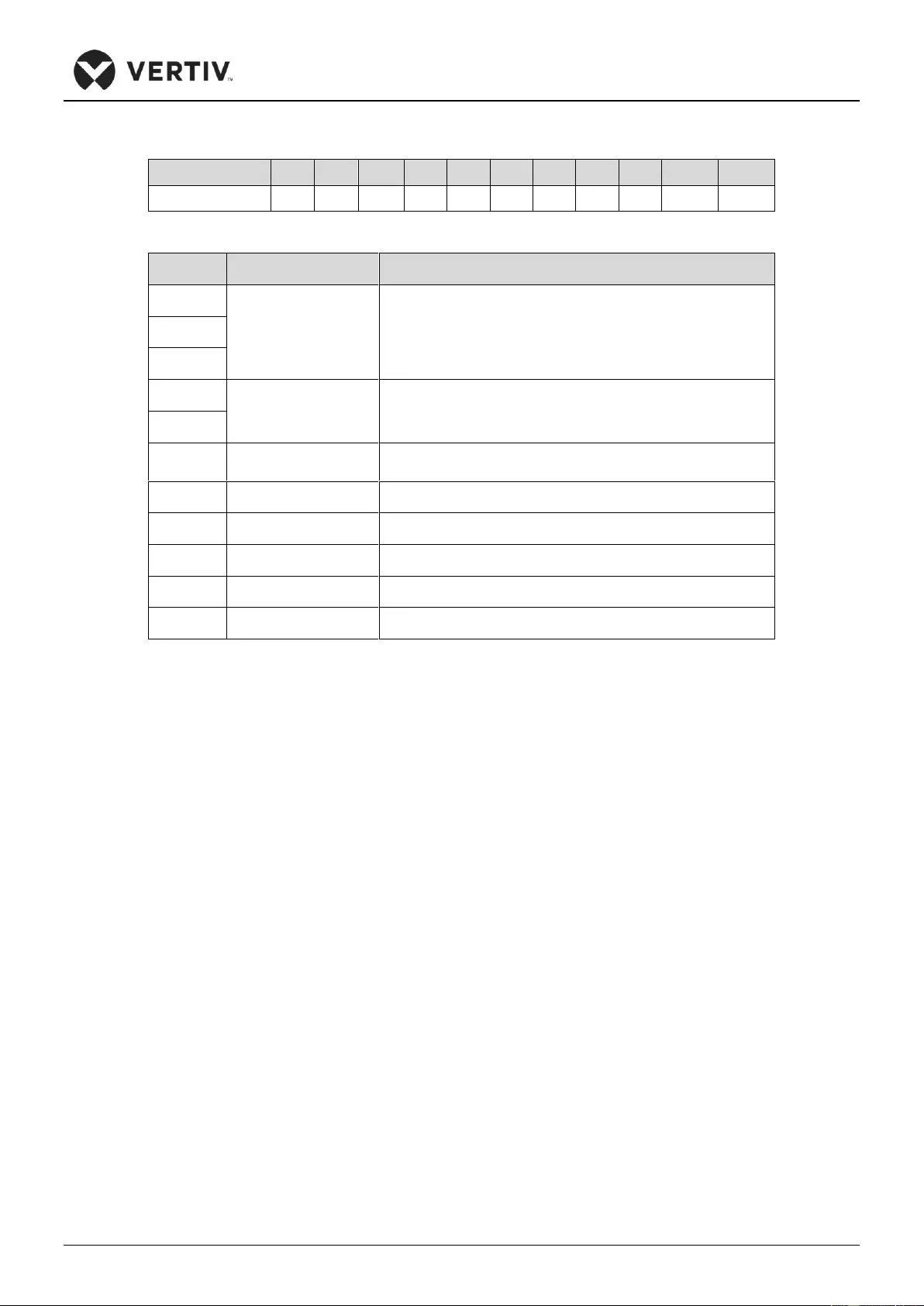

1.3 Model Nomenclature

The model of the CRD10 air conditioner is fully-defined by 12 digits as shown in Table 1-2, and details of the

condenser is given in Table 1-3.

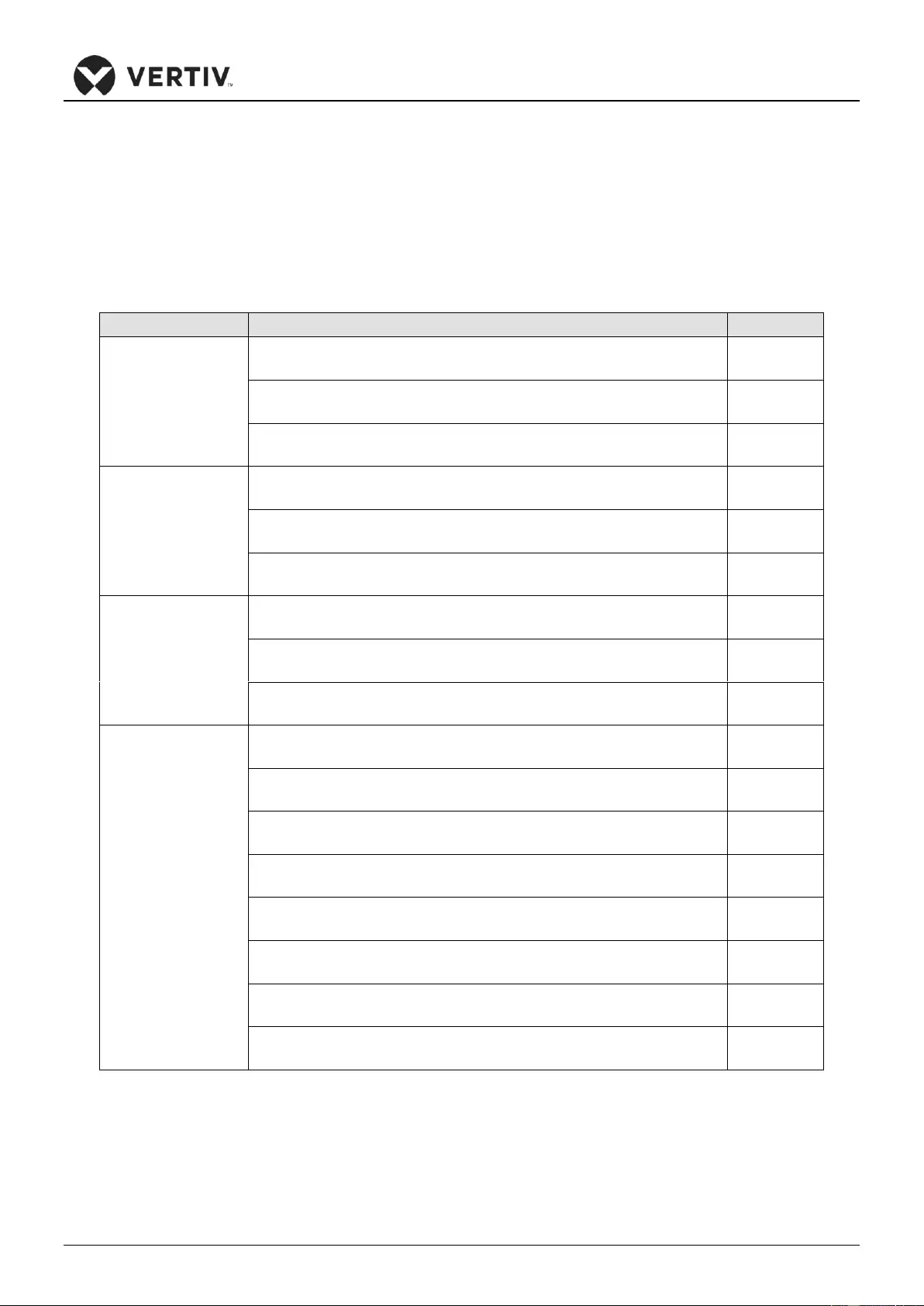

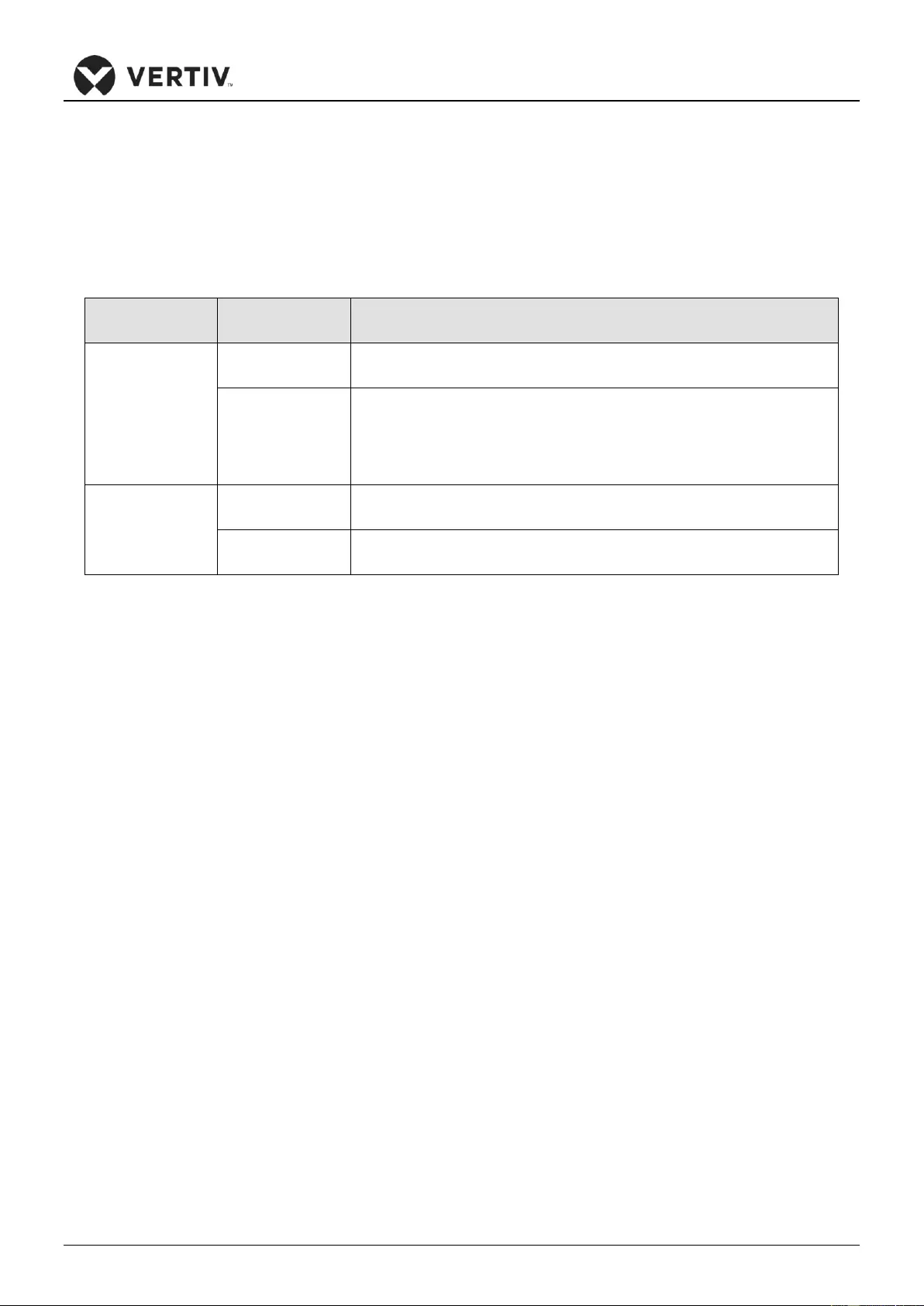

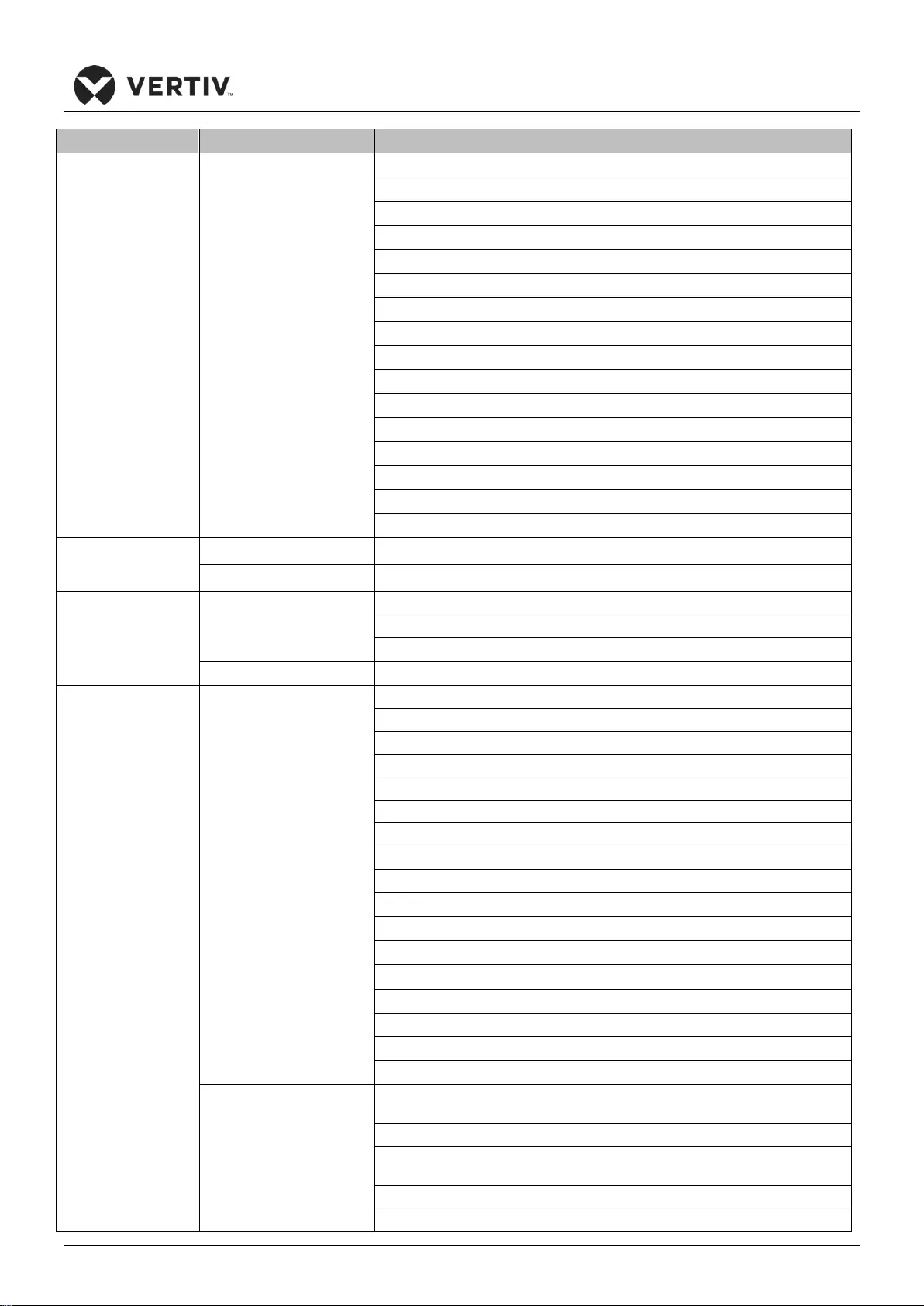

Table 1-2 Model Nomenclature Indoor Unit

Digit

1

2

3

4

5

6

7

8

9

10

11

12

Example

C

R

D

1

0

0

-

0

D

0

0

A

Digit

Variable

Description of Variable

1

CR

Liebert CRV

2

3

D

D- DX (Air cooled)

W- (Water cooled)

C- (Chilled water)

4

10

Model Number: 10

5

6

0,1,2

0- 208/230V/1Ph/60Hz, UL

1- 208/230V/3Ph/60Hz, UL

2- 230V/1Ph/50/60Hz, CE

7

-

Separator

8

0,1

0- Cooling only

1- Reheat only

9

D

D- Dual Power Supply

10

0

0- R410A refrigerant

11

0

Free digit (future)

12

A~Z

Revision

Product Overview

Vertiv | Liebert CRD10 | User Manual 6

Table 1-3 Model Nomenclature of Condenser Unit

Digit

1

2

3

4

5

6

7

8

9

10

11

Example

C

C

D

1

0

0

S

-

0

0

A

Digit

Variable

Description of Variable

1

CCD

Liebert CRV Condenser

2

3

4

10

Model Number: 10

5

6

0,1

0- 208/230V/1Ph/60Hz, UL

1- 230V/1Ph/50/60Hz, CE

7

S

S- Standard Temp (-15°C to 45°C [5°F to 113°F])

8

-

Separator

9

0

0- R410A refrigerant

10

0

Free digit (future)

11

A~Z

Revision

Product Overview

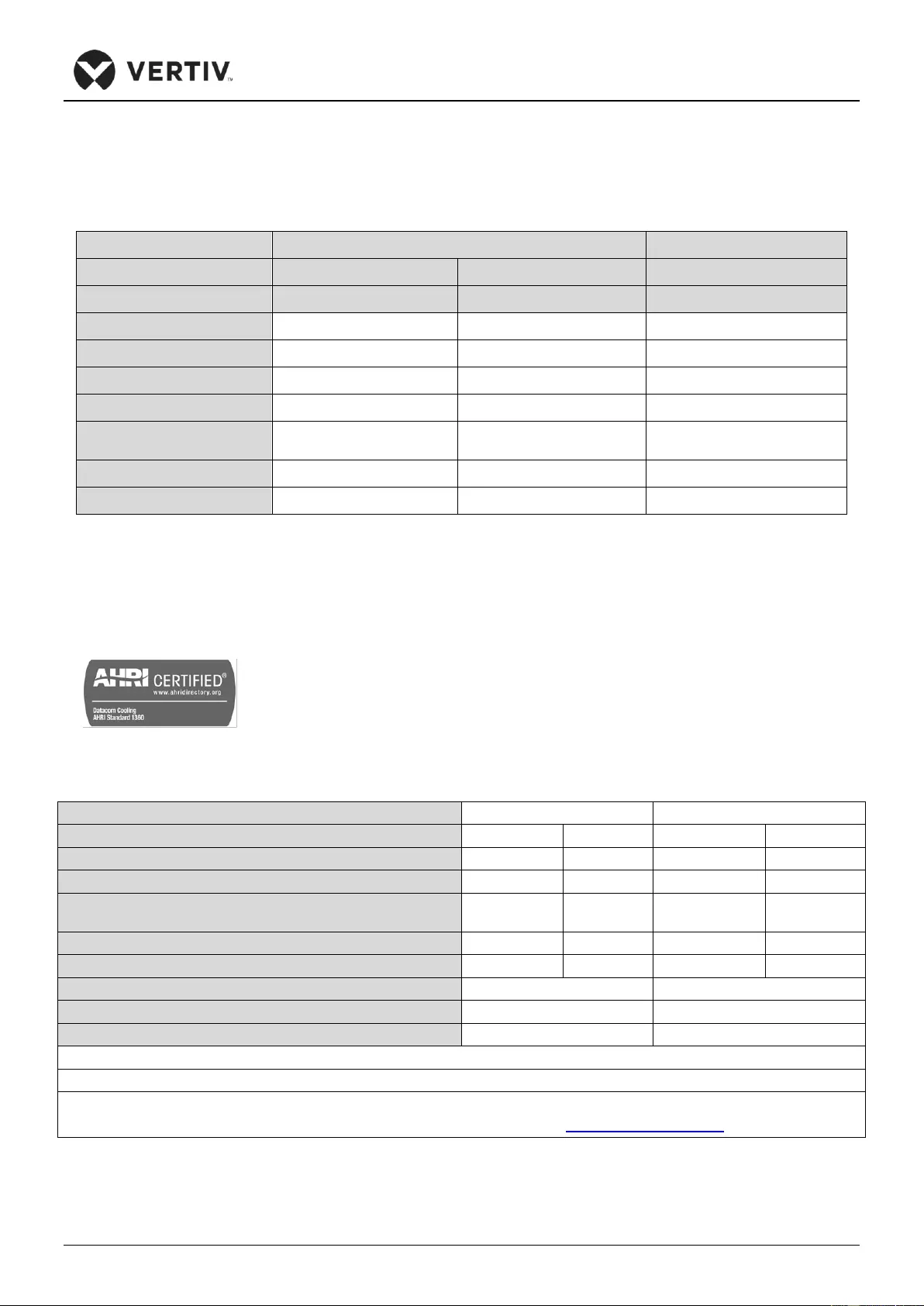

Vertiv | Liebert CRD10 | User Manual 7

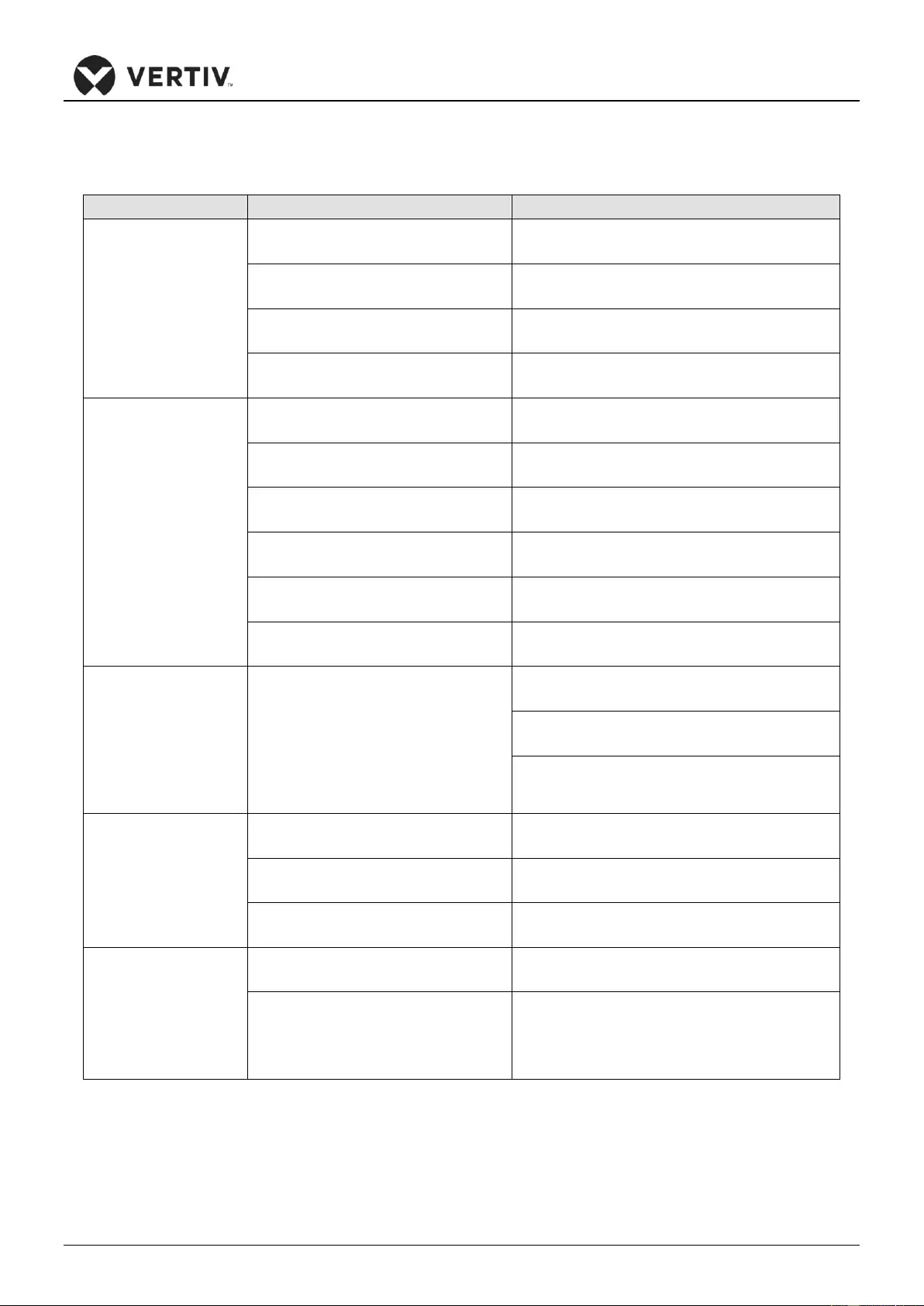

1.4 Basic Performance Parameters

The basic performance parameters of the Liebert CRD10 are given in Table 1-4.

Table 1-4 Performance Parameters

Certification

UL

CE

Unit

CRD100

CRD101

CRD102

Model

CRD100-0D00A

CRD101-0D00A

CRD102-1D00A

Voltage/Frequency

208/230V 1PH 60Hz

208/230V 3PH 60Hz

230V 1PH 50/60Hz

Cooling Capacity (kW)

10.0

10.0

10.0

Heating Capacity (kW)

-

-

2.0

Power Input(kW)

3.2

3.2

3.2(Without the heater)

Full Load Current (A)

-

-

38 (With the heater)

28 (Without the heater)

MCA (A)

29

21

-

MOP (A)

40

30

-

Test Condition: Return air 29.4°C (85°F), 32% RH & 35°C (95°F) Outdoor temperature.

Note: The allowed thermal load shall not be lower than 20% of nominal air conditioner cooling capacity.

Lower thermal load will drive to imprecise temperature and humidity control and frequent compressor(s)

switch on/off.

The performance data of CRD100 and CRD101 rated with the AHRI stand 1360 are given in Table 1-5.

Table 1-5 Performance data of AHRI

Model Number

CRD100-0D00A

CRD101-0D00A

Voltage (Volts/Phase/Hz)

208/1/60

230/1/60

208/3/60

230/3/60

Net Total Cooling Capacity, kW (kBtuh)

10.0(34.1)

9.98(34.0)

10.32(35.2)

10.41(35.5)

Net Sensible Cooling Capacity, kW (kBtuh)

9.92(33.8)

9.96(33.9)

10.08(34.4)

10.12(34.5)

Net Sensible Coefficient of Performance (NSenCOP),

kW/kW

3.57

3.62

3.69

3.71

Unit Airflow, ACFM

1960

1961

1897

1898

Unit Airflow, SCFM

1896

1887

1835

1836

Ext. Static Pressure, Pa

0.0

0.0

Humidification

None

None

Refrigerant

R-410A

R-410A

Return Air Conditions 95°F DB, 52°F DP (35°C DB, 11.1°C DP) 32% RH

Outdoor Ambient Temperature 95°F (35°C)

Certified in accordance with the AHRI Datacom Cooling Certification Program at AHRI Standard 1360 Standard

Rating Conditions. Certified units may be found in the AHRI Directory at www.ahridirectory.org.

Product Overview

Vertiv | Liebert CRD10 | User Manual 8

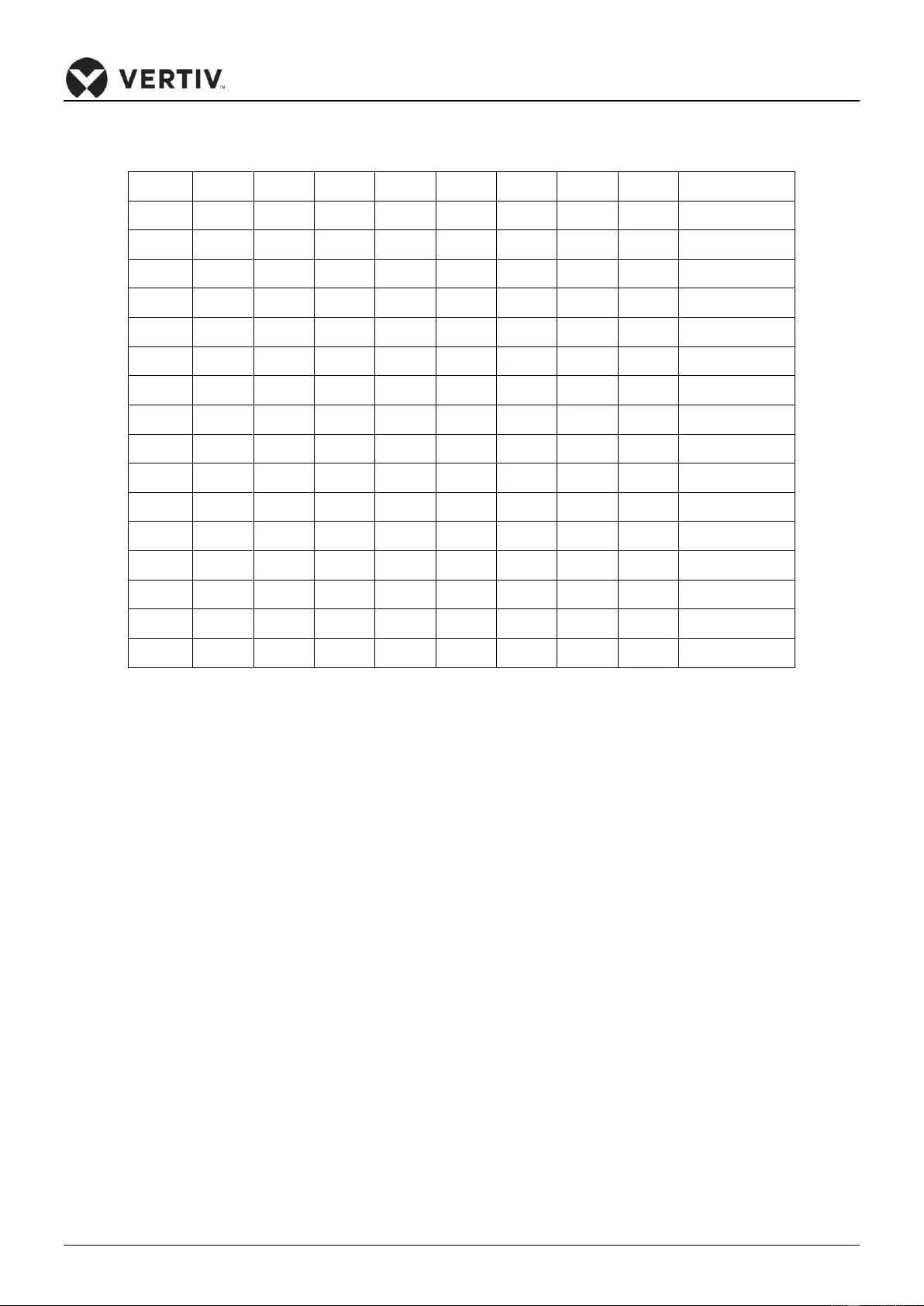

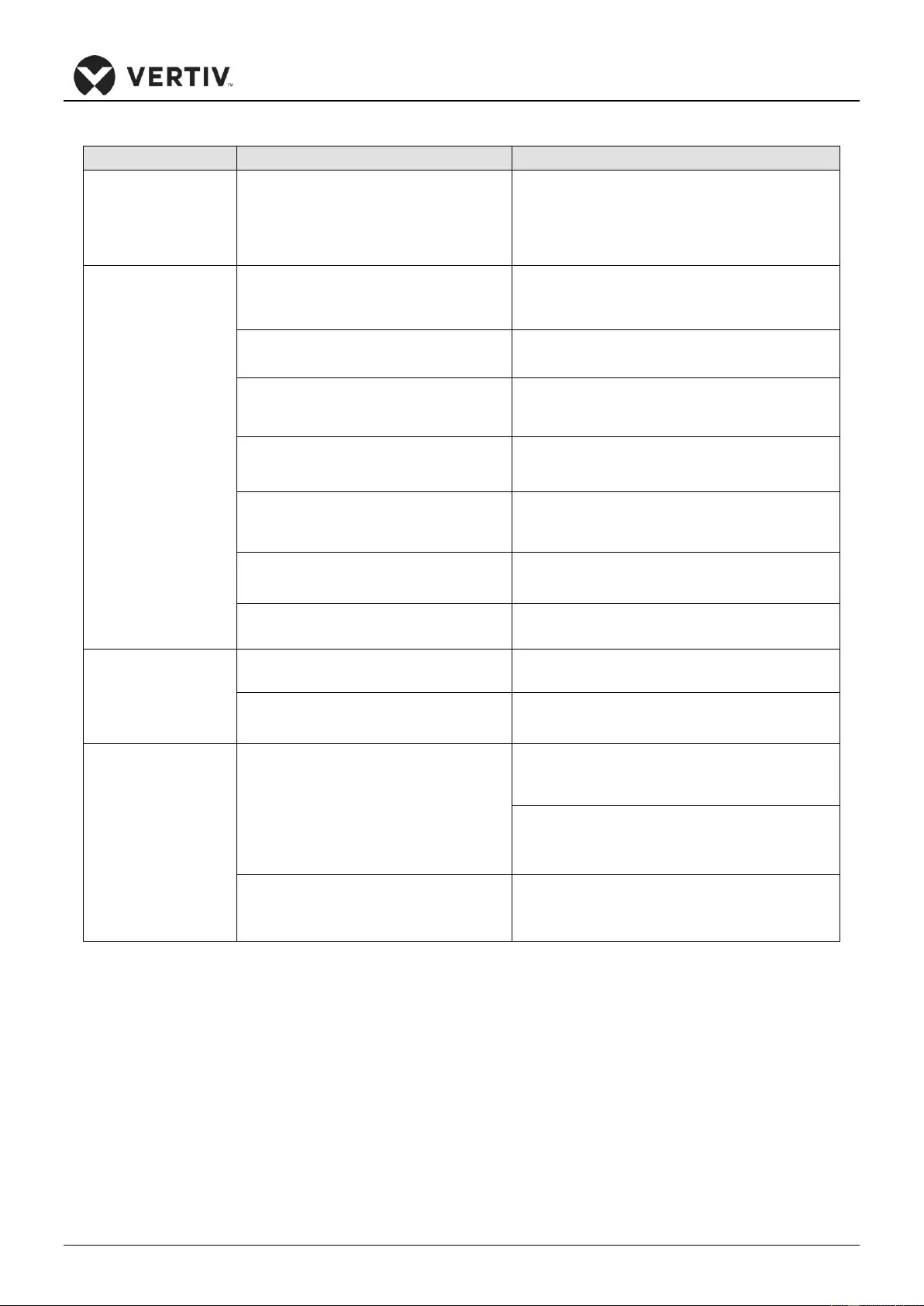

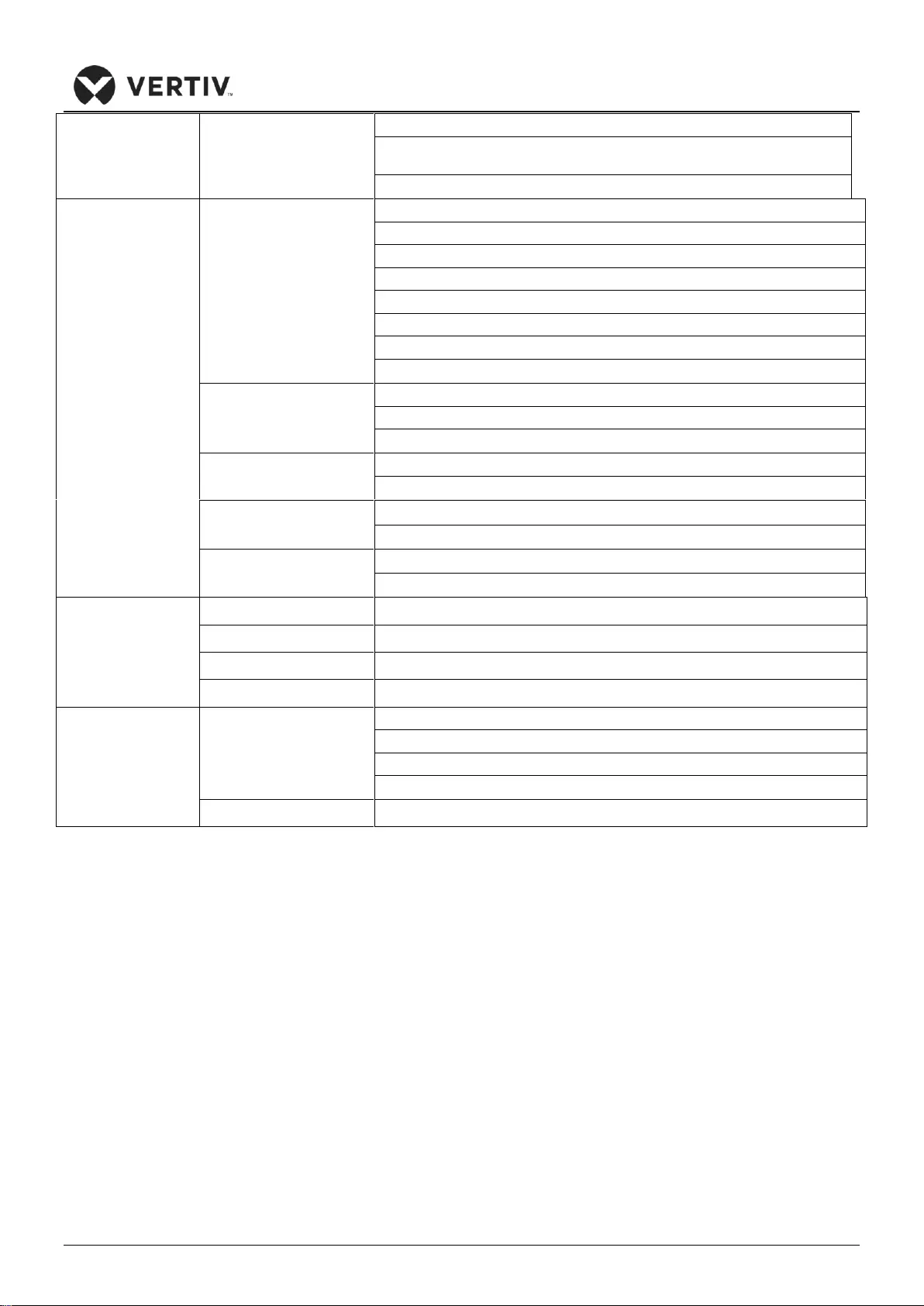

1.5 Sound parameters

The sound parameters of the Liebert CRD10 are given in Table 1-6.

Table 1-6 Sound Parameters

1/3 Octave

Band Center

Freq [Hz]

Air volume

50

dB

63

dB

80

dB

100

dB

125

dB

160

dB

200

dB

250

dB

315

dB

400

dB

500

dB

630

dB

m3/h

SCFM

IDFAN 75%

3250

1913

28.6

25.4

33.8

33.7

32.3

40.2

42.7

46.4

52.9

68.3

67.3

58.0

IDFAN 70%

3000

1766

29.1

24.5

34.7

31.2

30.9

38.2

40.5

45.2

53.6

64.4

58.9

56.2

IDFAN 60%

2500

1471

24.8

26.8

28.9

28.9

30.9

33.9

39.3

45

59.3

59.5

53.2

59.4

1/3 Octave

Band Center

Freq [Hz]

800

dB

1000

dB

1250

dB

1600

dB

2000

dB

2500

dB

3150

dB

4000

dB

5000

dB

6300

dB

8000

dB

10000

dB

db(A

)

IDFAN 75%

63

63.1

67.8

65.7

65.4

66.4

63.7

61.8

59.8

57.4

55.2

49.4

76.3

IDFAN 70%

62.1

58.7

64.4

64.4

63.6

64.1

61.5

60.1

57.8

55.2

52.6

47.2

73.1

IDFAN 60%

60

59.2

59.7

60.4

59

59.7

57.4

55.4

53.1

50.1

47.1

42.3

70.1

Test Conditions:

• Semi-anechoic chamber environmental test.

• The test point is 2m(6.6ft.) away from the unit and 1m(3.3ft.) away from the ground.

1.6 Main Components of Indoor Unit

The following section expounds the list of components used in the CRD10 Precision Air conditioning models.

1.6.1

DC Brushless Compressor

The CRD10 Air conditioning models comprise of a DC Brushless compressor which has a host of promising

features as mentioned in the following list:

• Low operational noise

• Rapid Cooling

• Less Vibration

Figure 1-5 DC Brushless Compressor

Product Overview

Vertiv | Liebert CRD10 | User Manual 9

1.6.2

Fan

The EC Fan used in the CRD10 models are energy-efficient and innovative with integrated electronics and a

maintenance-free design.

• Ability to regulate the airflow and reduce the fan input power leading to high energy-efficiency.

• Hot swappable, easy-to-connect facility with minimal wiring resulting in to high performance with a wide

range of possible air flow rates. Figure 1-6 shows the EC Fan used in CRD10 model.

Figure 1-6 EC Fan

1.6.3

Evaporator

The sophisticated design of the distributor ensures that the refrigerant is evenly distributed in each loop,

thereby improving the effectiveness of the heat exchanger.

• Streamlined heat exchanger design and air distribution for optimum performance.

• Fin-tube heat exchanger for higher efficiency Figure 1-7 shows the image of an evaporator.

Figure 1-7 Evaporator

Product Overview

Vertiv | Liebert CRD10 | User Manual 10

1.6.4

Electronic Expansion Valve (EEV)

The EEV is designed for modulating control of the refrigerant mass flow with precision. The EEV simultaneously

collects temperature and pressure signals regulate the refrigerant flow accurately. The EEV’s wide operating

envelope also lowers down the condensing pressure, thereby resulting in significant energy savings.

• Designed for modulating control of the refrigerant mass flow with precision

• Ensures effective control on super-heating at the end of the evaporator

• Better low load capacity

• Designed for easy Installation-and-Service. Figure 1-8 shows the image for the EEV used in the CRD10

models.

Figure 1-8 Electronic Expansion Valve

1.6.5

Electric Heater

In the CRD10 models, the PTC (Positive Temperature Coefficient) heater is used on models equipped with

reheat, as they have lower running temperatures, thereby ensuring operational safety.

• Less susceptible to overheating and long lasting due to less wear

• Lower Maintenance and smooth operation, Figure 1-9 shows an image of the electric heater.

Figure 1-9 PTC Heater

1.6.6

Sight Glass

The sight glass is a utility for observing the refrigerant state; specifically, the moisture content of the system. If

the moisture content exceeds the defined standards, the color changes, thereby, indicating irregularity in the

moisture content.

Product Overview

Vertiv | Liebert CRD10 | User Manual 11

1.6.7

Filter Drier

Moisture in the refrigeration lifecycle can adversely affect the operations and service life of a system. In order

to rectify that condition, filter driers are used to filter out particles, remove, and hold moisture to prevent it

from circulating through the system.

1.6.8

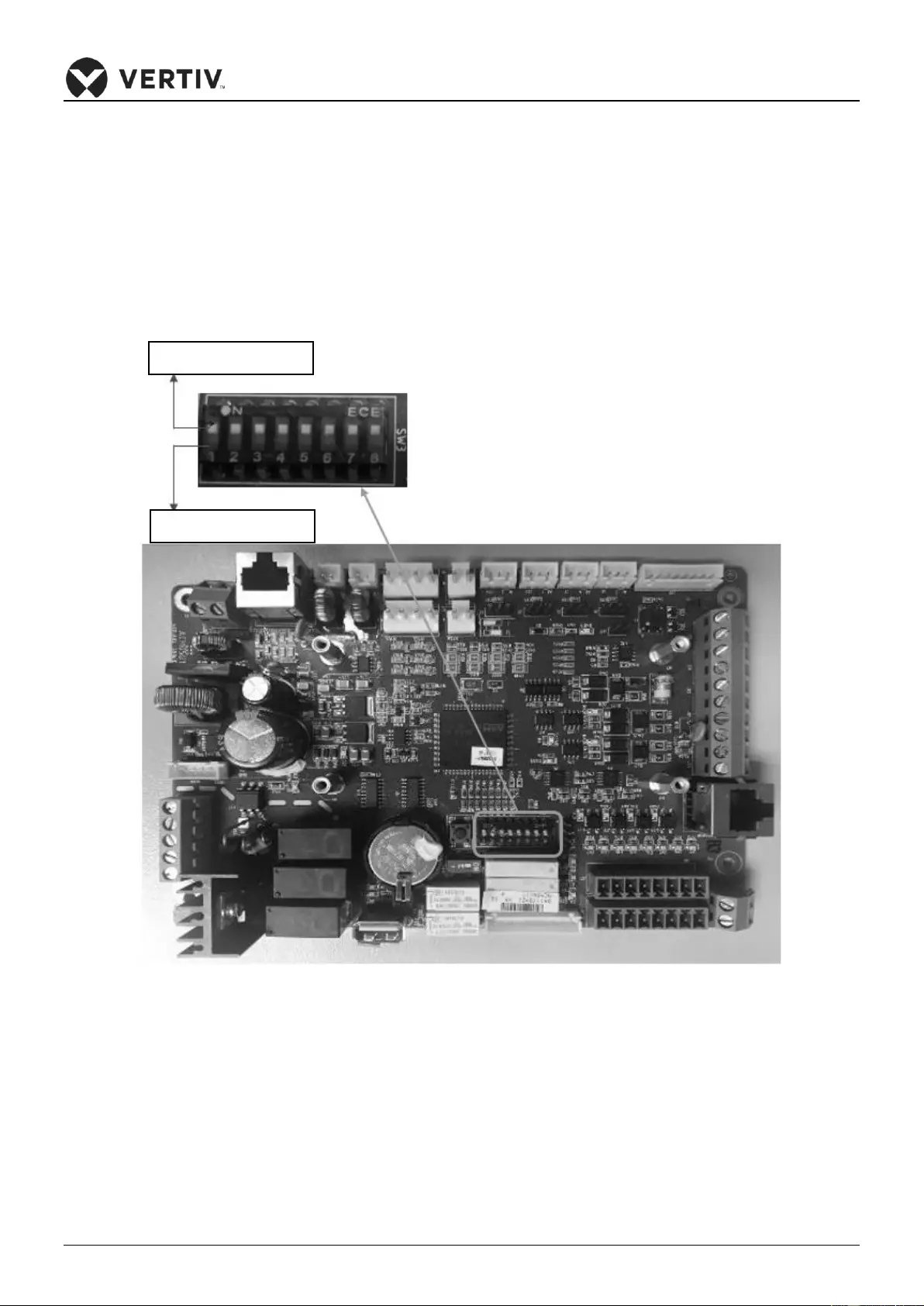

Micro-Controller

The micro-controller used in CRD10 provides a simple operational user-interface and is developed using the

latest and highly advanced PID (Proportional–Integral–Derivative) regulation technology.

• Multilevel Password protection

• Self-recovery upon power failure, high-voltage & low-voltage protection & Phase loss protection

• Automatic phase-sequence switching upon the antiphase and rotate speed control of the outdoor fan

• High-end Fault diagnostic system to facilitate easy equipment maintenance Figure 1-10 shows the image of

the micro-controller

Figure 1-10 Display Panel of the Controller

1.6.9

Unity Card

The CRD10 unit is equipped with a Unity card. Unity card employs the Modbus Protocol to monitor and manage

a wide range of operating parameters, alarms, and notifications from the Micro-controller. The card

communicates with Building Management Systems and Network Management Systems via BACnet, Modbus,

SNMPv1/v2c/v3, LIFE/Remote Services, and YDN23 protocols.

The Unity card monitors up to 10 Liebert SN modular and integrated sensors. Available sensor types include

Product Overview

Vertiv | Liebert CRD10 | User Manual 12

temperature, humidity, door closure, contact closure and leak detection. Sensor tab menus permit configuring

sensors and putting them in user-configured order for easier checking of high-priority conditions. Sensor data is

available via SNMP and the Web user interface.

1.6.10

Remote Temperature Sensor

The Liebert CRD10 models are compatible with multiple temperature sensors based on the requirement. Each

unit can be connected with up to maximum 10 temperature sensors.

1.6.11

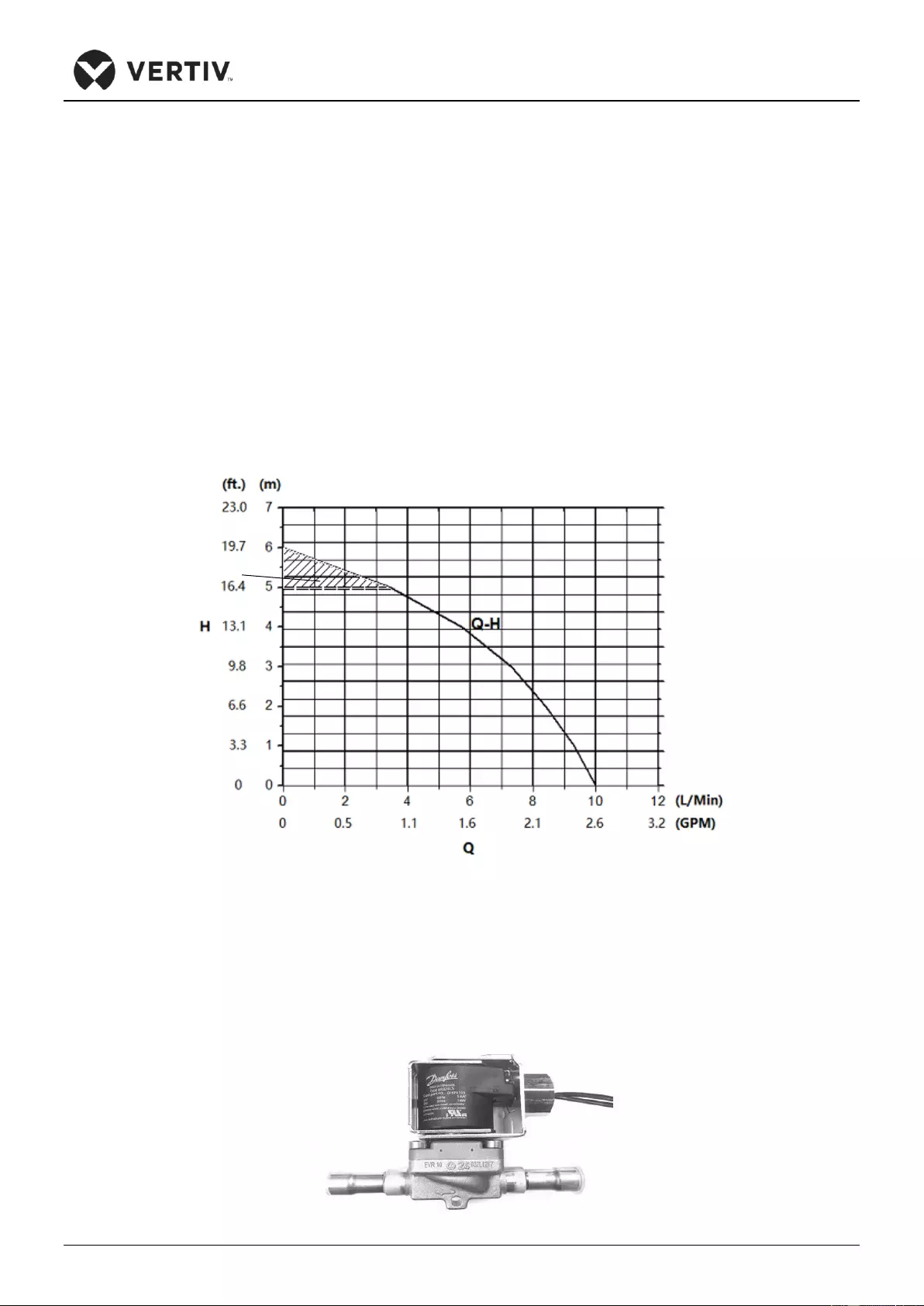

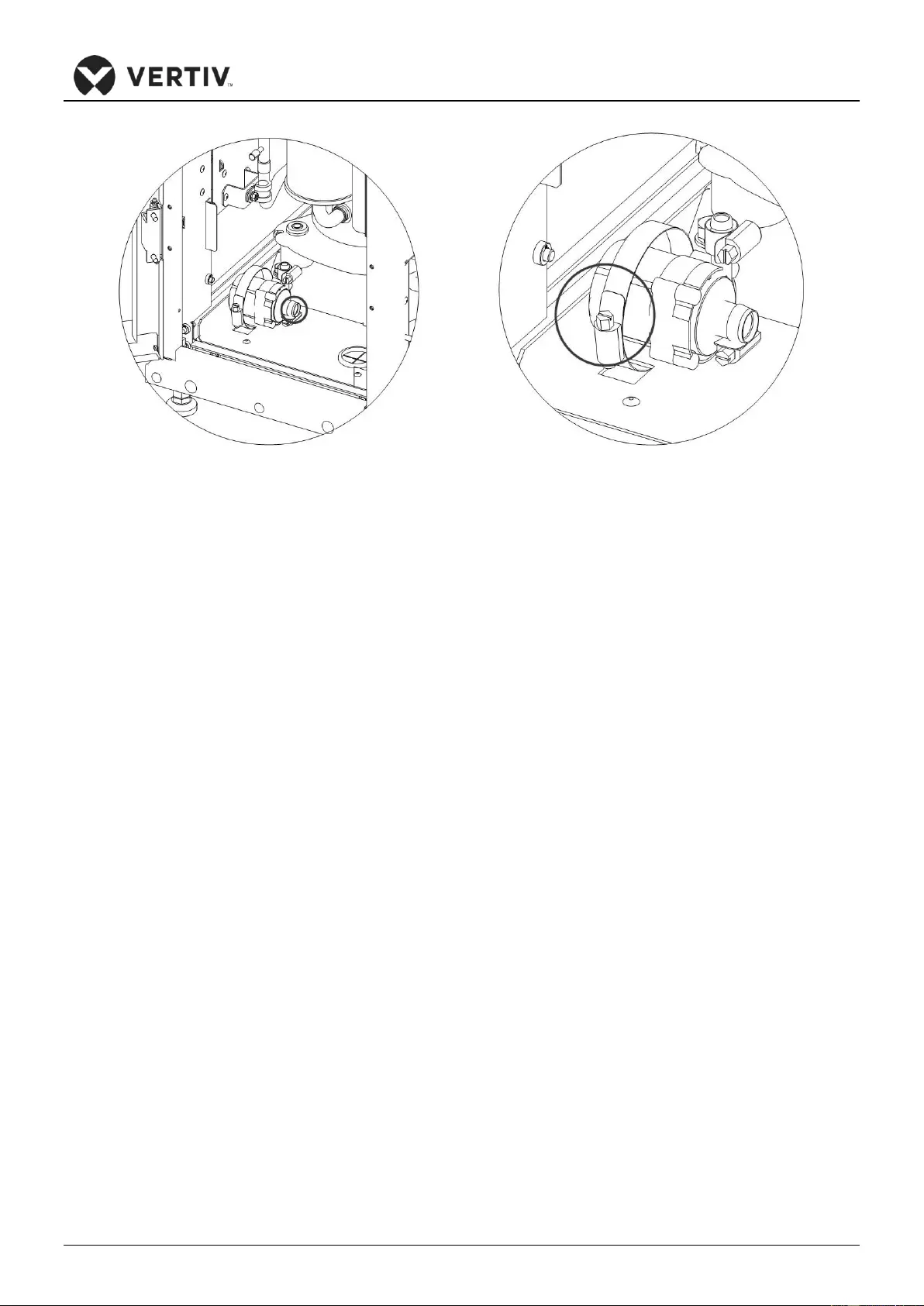

Condensate pump

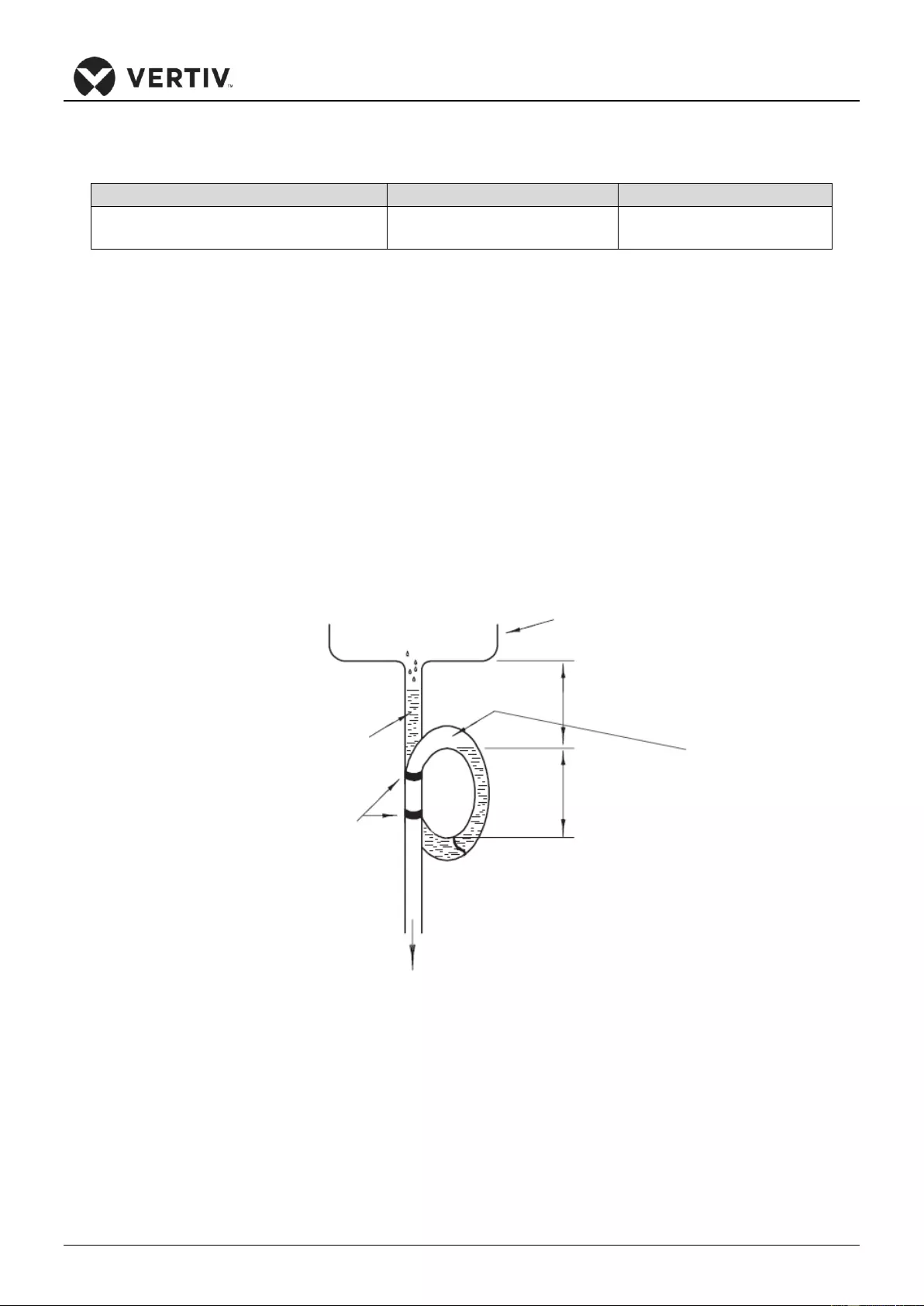

The Liebert CRD10 models include a condensate pump which is used for drainage. The performance curve is

shown in Figure 1-11.

Note: Maximum recommended vertical rise is 5m(16.4ft.).

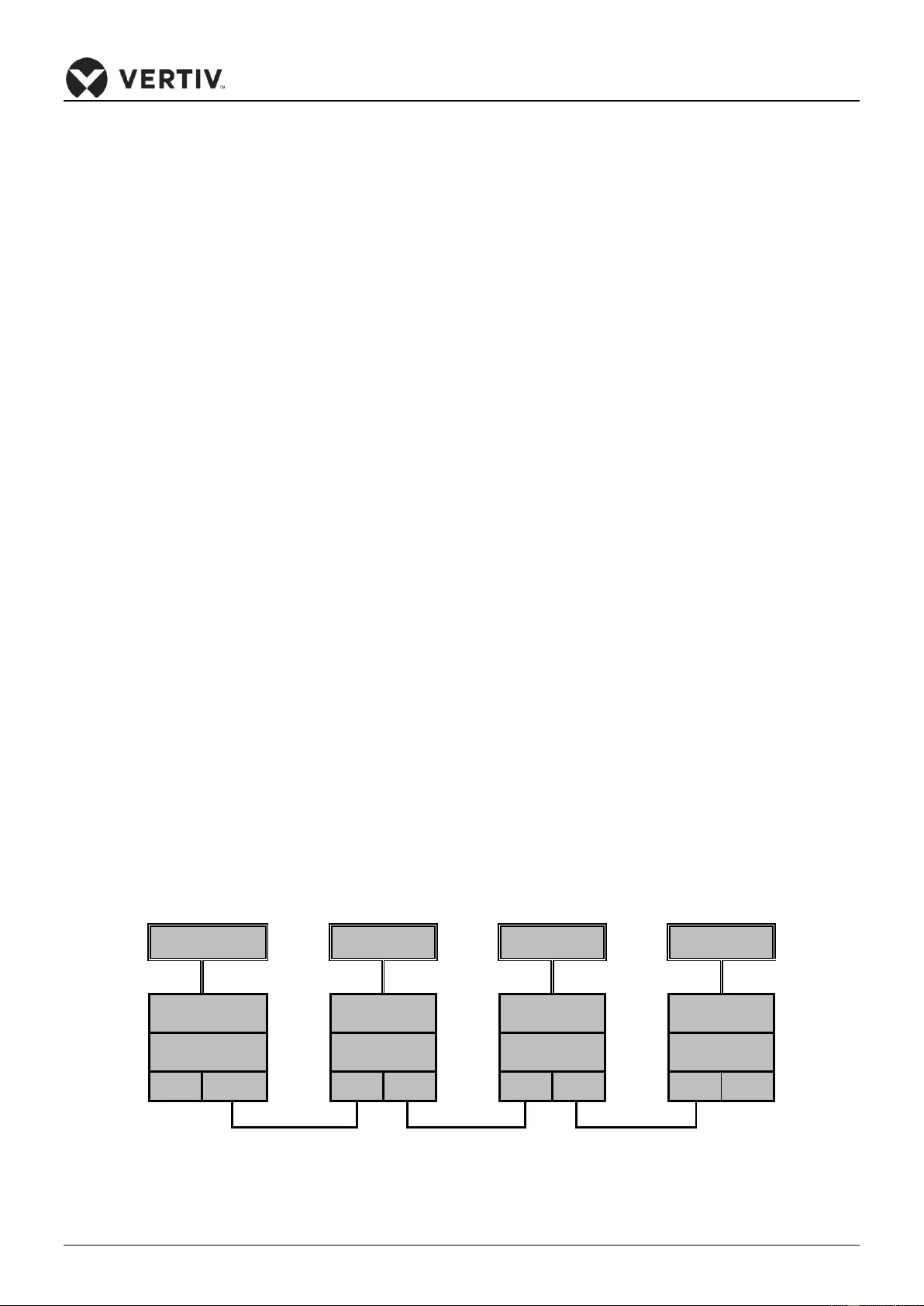

Figure 1-11 Performance curve of condensate pump

1.6.12

Liquid Line Solenoid Kit

The liquid line solenoid kit is a solenoid valve used to prevent refrigerant from condensing into liquid line in

condenser and pipe of outdoor when the unit is turned off at the condition of low ambient temperature.

Figure 3-1 shows the install location of solenoid valve in the system. Figure 1-12 shows the solenoid valve.

Figure 1-12 Solenoid Valve

Not Recommended

Performance curve

Product Overview

Vertiv | Liebert CRD10 | User Manual 13

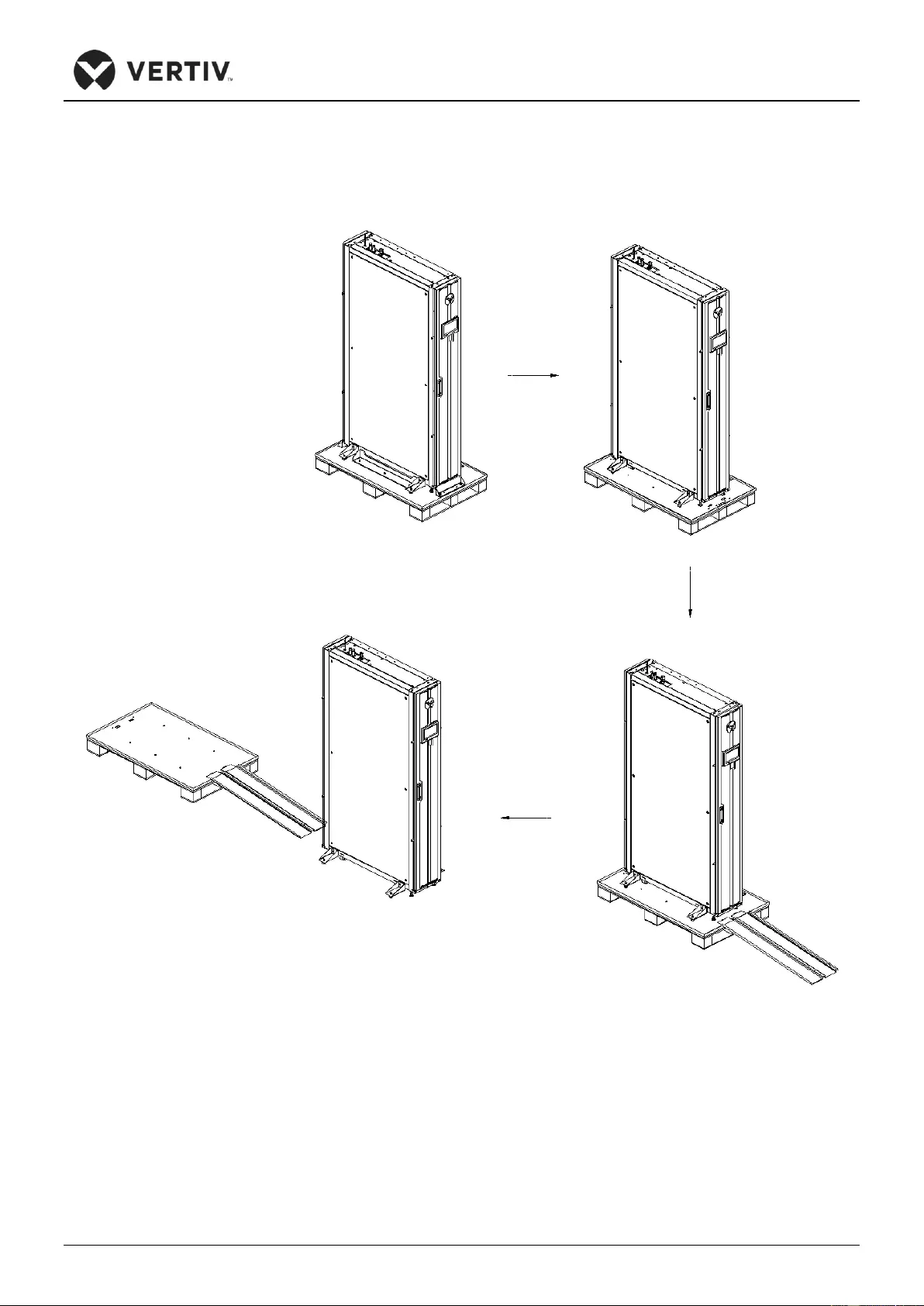

1.6.13

Ramp

Ramp is used to easily remove the unit from the pallet, the operation process illustration is shown in Figure

1-13.

Figure 1-13 Ramp Unloading

Remove the

fixing screws and

sheet metal

Place a slope

and connect it

with the pallet

Push the cabinet

slowly from the pallet

down to the ground

along the slope

Product Overview

Vertiv | Liebert CRD10 | User Manual 14

1.7 Technical Specification

The detailed technical specifications which include the mechanical and the electrical details are mentioned

in Table 1-7.

Table 1-7 Technical Specifications of the Unit

Parameters

Specifications

Unit

CRD100

CRD101

CRD102

Model

CRD100-0D00A

CRD101-0D00A

CRD102-1D00A

Certification

UL

CE

Cooling Type

Air Cooled

Cold Source Type

DX

Refrigerant

R410A

Compressor Type

Double rotor DC Inverter Compressor

Flow Control

Electronic Expansion Valve

Fan Type

EC Fan

Air Filter

MERV8

G4

Air Discharge Baffles

Standard

Drain Pump

Standard

Air Pressure Switch

Standard

Unity Card

Standard

Remote Sensors

Standard

Reheat

No

Standard

Matched with outdoor model

CCD100S-00A

CCD101S-00A

Installation

Vertiv | Liebert CRD10 | User Manual 15

Chapter 2: Installation

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only by

qualified personnel who have been specially-trained in the installation of air-conditioning equipment

and who are wearing appropriate, OSHA-approved PPE.

NOTICE:

Before installing unit, determine whether any building alterations are required to run piping, wiring

and duct work. Follow all unit dimensional drawings and refer to the submittal engineering

dimensional drawings of individual units for proper clearances.

The Installation process consists of the following procedures, namely-

• Pre-installation

• Installation Preparation

• Mechanical Installation

• Electrical Installation

2.1 Pre-Installation

CRD10 precision air conditioner is an engineered equipment and requires installation works for which the

preliminary preparation is very important. This chapter describes the pre-installation, including how to prepare

the installation environment, space and reserve the maintenance space; the air conditioner running and

storage environment requirement, and how to unpack and inspect.

NOTE: Please read this chapter carefully before installation.

Pre-installation contains the following 3 sub sections, namely-

• Transportation & Movement

• Unpacking

• Inspection

Installation

Vertiv | Liebert CRD10 | User Manual 16

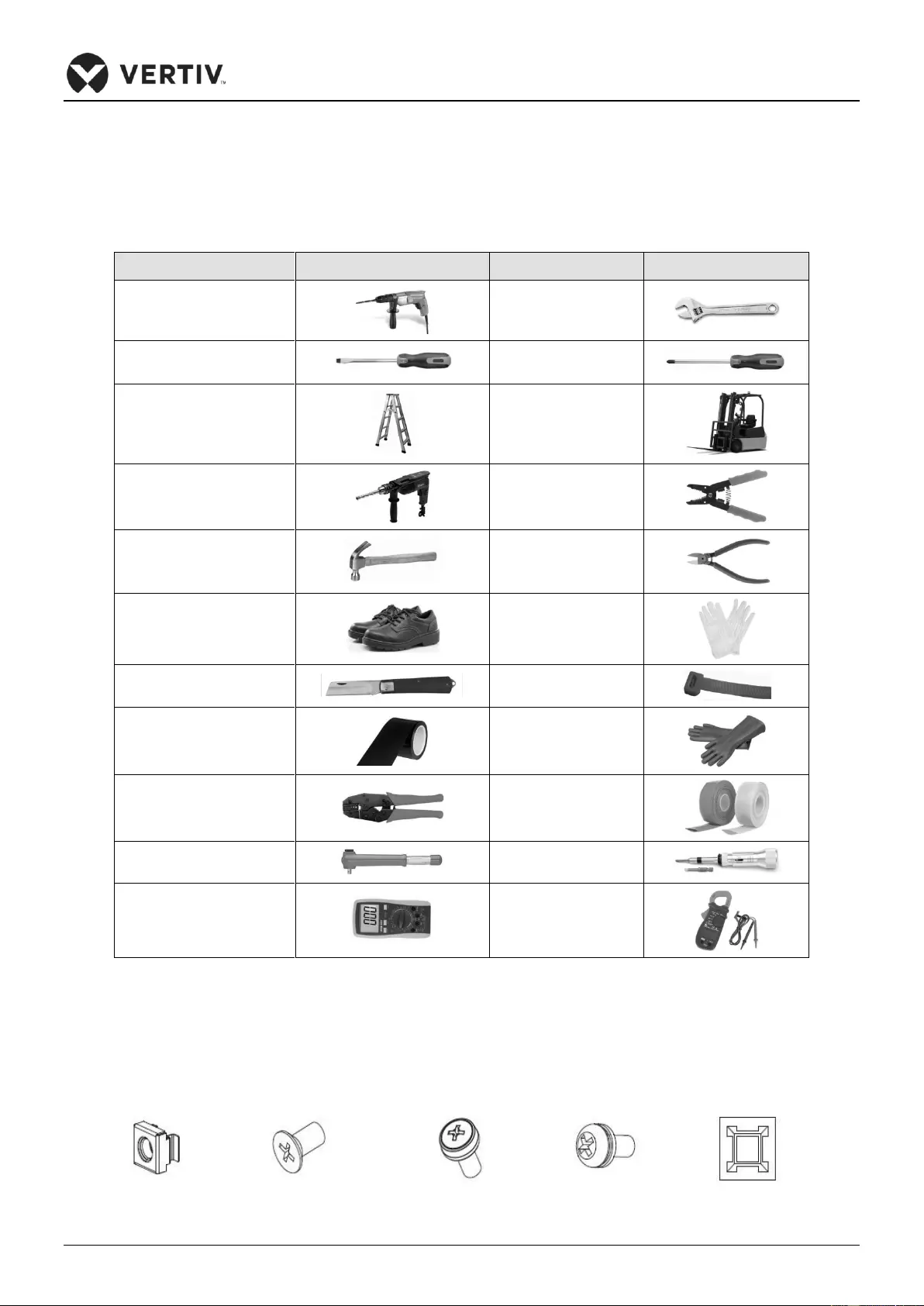

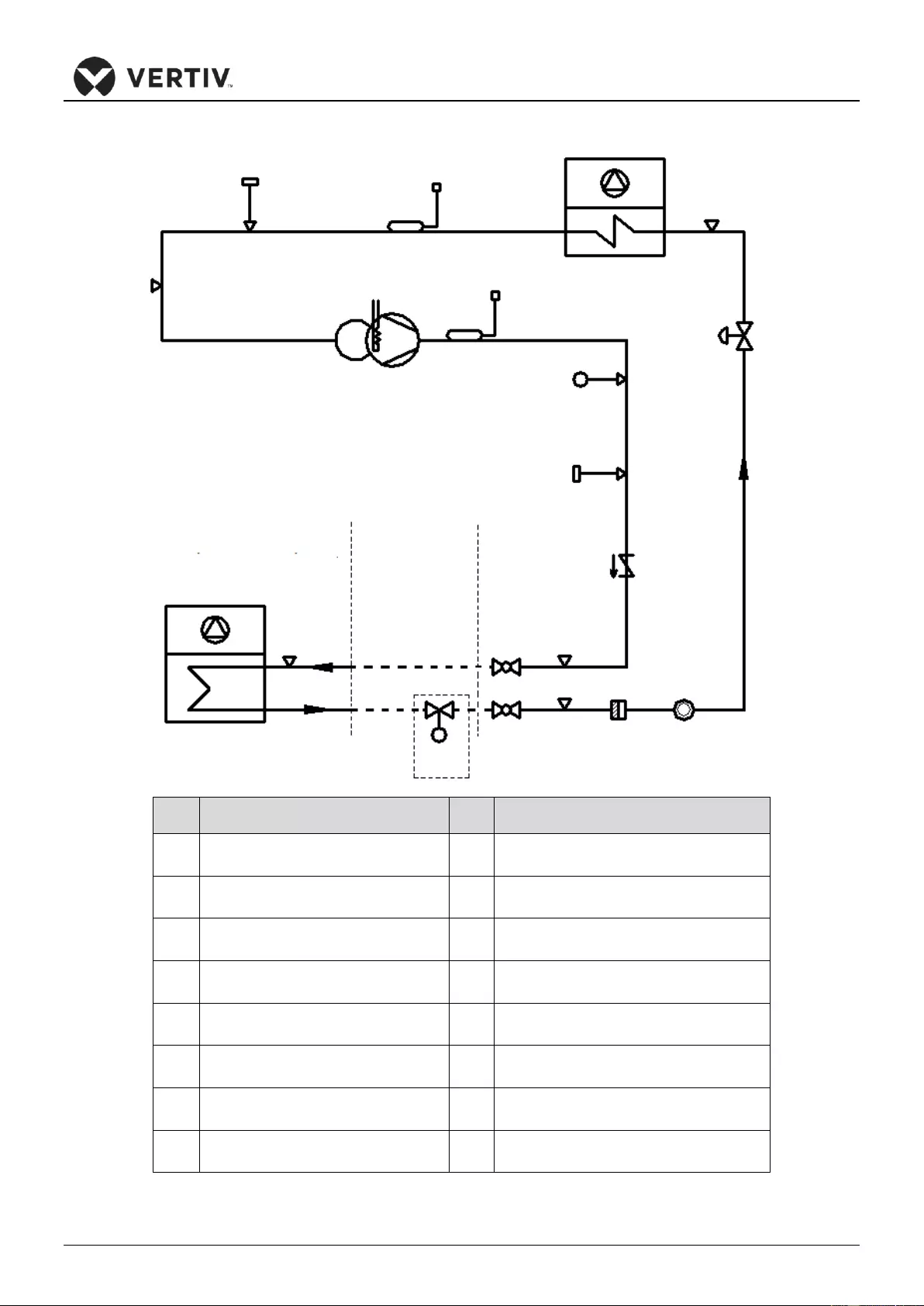

2.2 Installation Tools

Table 2-1 shows the standard tool sets and utilities used in the installation and maintenance process:

Table 2-1 Standard Tool Sets

Name

Drawing

Name

Drawing

Electric hand drill

Adjustable wrench

Slotted screwdriver

Cross head screwdriver

Stepladder

Forklift

Drill

Wire cutting pliers

Claw hammer

Diagonal cutting

pliers

Insulating shoes

Antistatic gloves

Electrician knife

Cable ties

Insulating tape

Insulating gloves

Crimping pliers

Heat shrinkable tube

Insulated torque wrench

Torque screwdriver

Multimeter

Clip-on ammeter

The tools mentioned in Table 2-1 are standard and commonplace; however, depending on various factors such

as site environment, cables, installation equipment, and on-site electrical connections these tools may vary in a

real-time scenario.

• Fasteners

The fasteners are shown in the Figure 2-1.

Figure 2-1 Fasteners

Floating nut

M5 countersunk head screw

M6 panel screw

M6 panel head screw

Cable tie fixture kit

Installation

Vertiv | Liebert CRD10 | User Manual 17

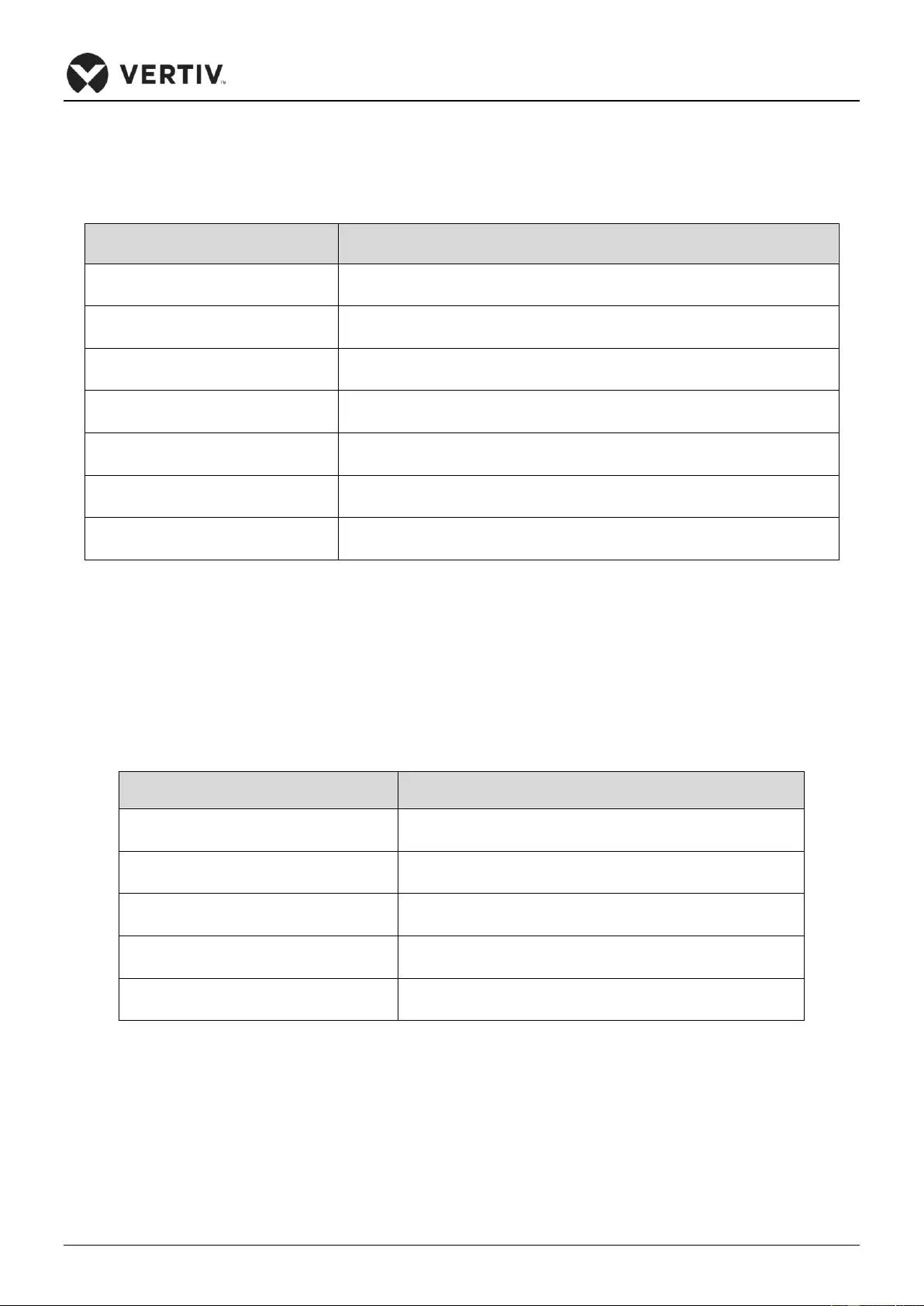

The fastener nuts and their usage are shown in Table 2-2.

Table 2-2 Fitting Utilities

Fasteners

Usage

Floating Nut

Used together with the M6 screw, used to install the parts in the cabinet

M5 Countersunk Head Screw

Used to install the cabinet connector

M6 Panel Screw

Used to install the power distribution unit, monitoring system, & User

equipment

M6 Pan Head Screw

Used to connect and fix the frame

M6 Flange Nut

Used together with the M6 Pan head screw, used to install the L Fastener

Adhesive Tape

Used to seal the gap between the connected frames

Cable Tie Fixture Kit

Used to fix & bind the cables

2.3 Prerequisite Arrangements

The cables routed from the room to the CRD10 unit and the circuit breakers must be prepared at the

customer’s site or obtained by the customer; the specifications for the site preparation are given in the Table 2-

3.

Table 2-3 Prerequisite Materials Requirements

Parts

Specifications

Input power supply cables

Please refer to FLA (MCA) of the Unit

System Grounding cables

Please prepare the yellow/Green cable

Liquid copper pipes

Please refer to pipe connection of Unit

Gas copper pipes

Please refer to pipe connection of Unit

External drainage pipe

External drainage pipe with screws, please refer to drainage

pipe connection.

Installation

Vertiv | Liebert CRD10 | User Manual 18

2.4 Transportation & Movement

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury

or death. Read all of the following instructions and verify that all lifting and moving equipment is

rated for the weight of the unit before attempting to move, lift, remove packaging from or prepare

the unit for installation.

WARNING! Risk of unsecured unit rolling off pallet. Can cause equipment damage, injury or death.

The unit is on casters. Ensure that the unit/pallet is located on a flat surface before loosening the

hardware securing the to its shipping pallet.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to

move, lift, remove packaging from or prepare the unit for installation.

NOTICE!

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too

large to fit through a doorway or hallway while on the skid. Measure the unit and passageway

dimensions, and refer to the installation plans prior to moving the unit to verify clearances.

NOTICE!

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height

suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE!

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and contact

damage.

Transportation by rail or by ship are the preferred options for the units. If transport by rail or by ship is

unavailable, transport by road is recommended. When selecting road transport, roads without too many

bumps are highly recommended.

• Liebert CRD10 unit is heavy, it is recommended to use the mechanical equipment like electrical forklift to

move the unit.

• Move the equipment to the location near the installation site.

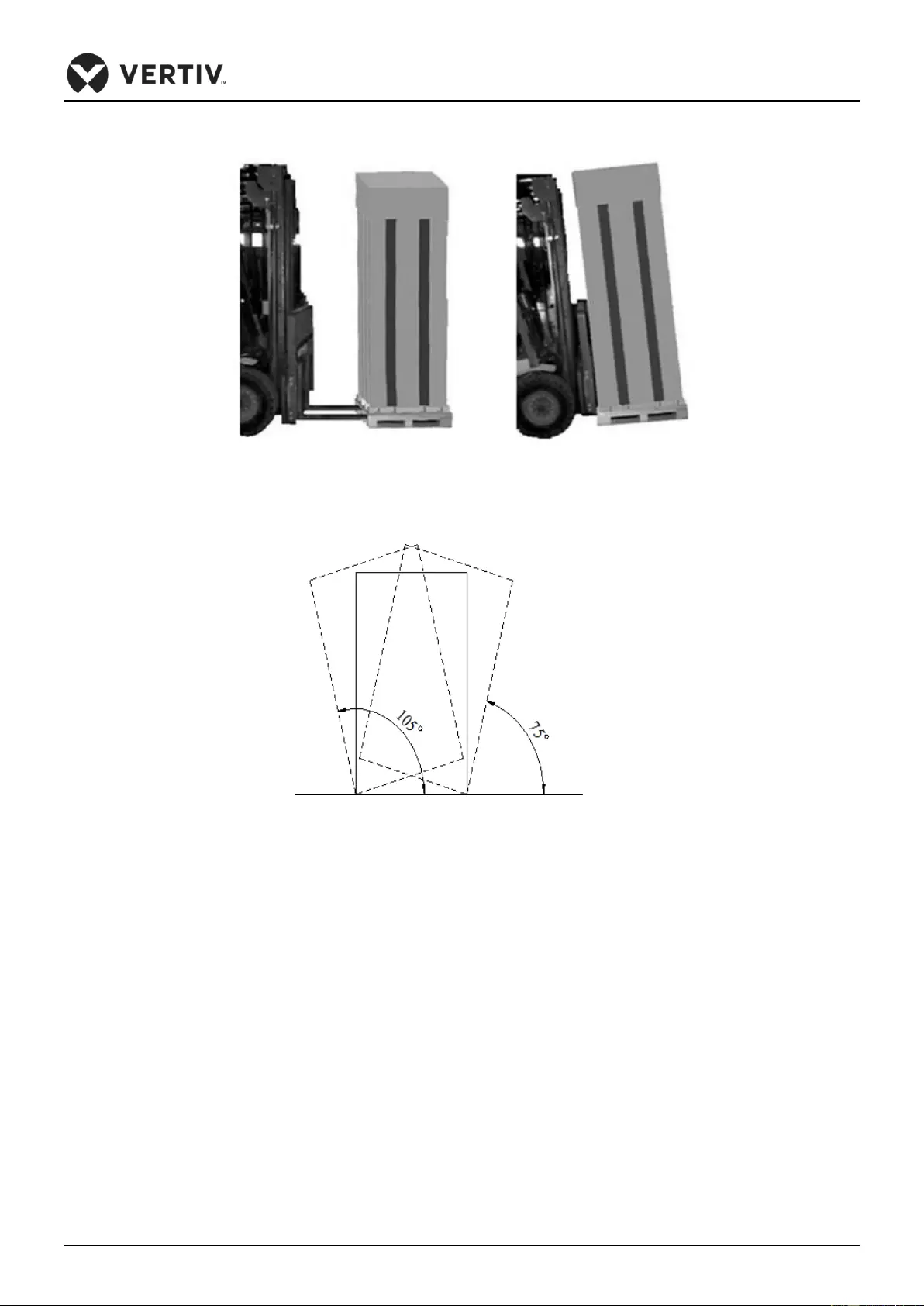

• If an electric forklift is used, insert the tines of the forklift below the pallet as displayed in Figure 2-2.

• Figure 2-2 shows how the forklift tines are inserted underneath the pallet and shows in the same picture

below the illustration to the right that the lines should be aligned with the center of gravity to prevent the

Installation

Vertiv | Liebert CRD10 | User Manual 19

equipment from falling over.

Figure 2-2 Moving the Equipment using a Forklift Truck

While moving the indoor unit, keep the obliquity within the range of 75° to 105°, as shown in Figure 2-3.

Figure 2-3 Obliquity of the System

Installation

Vertiv | Liebert CRD10 | User Manual 20

2.5 Unpacking

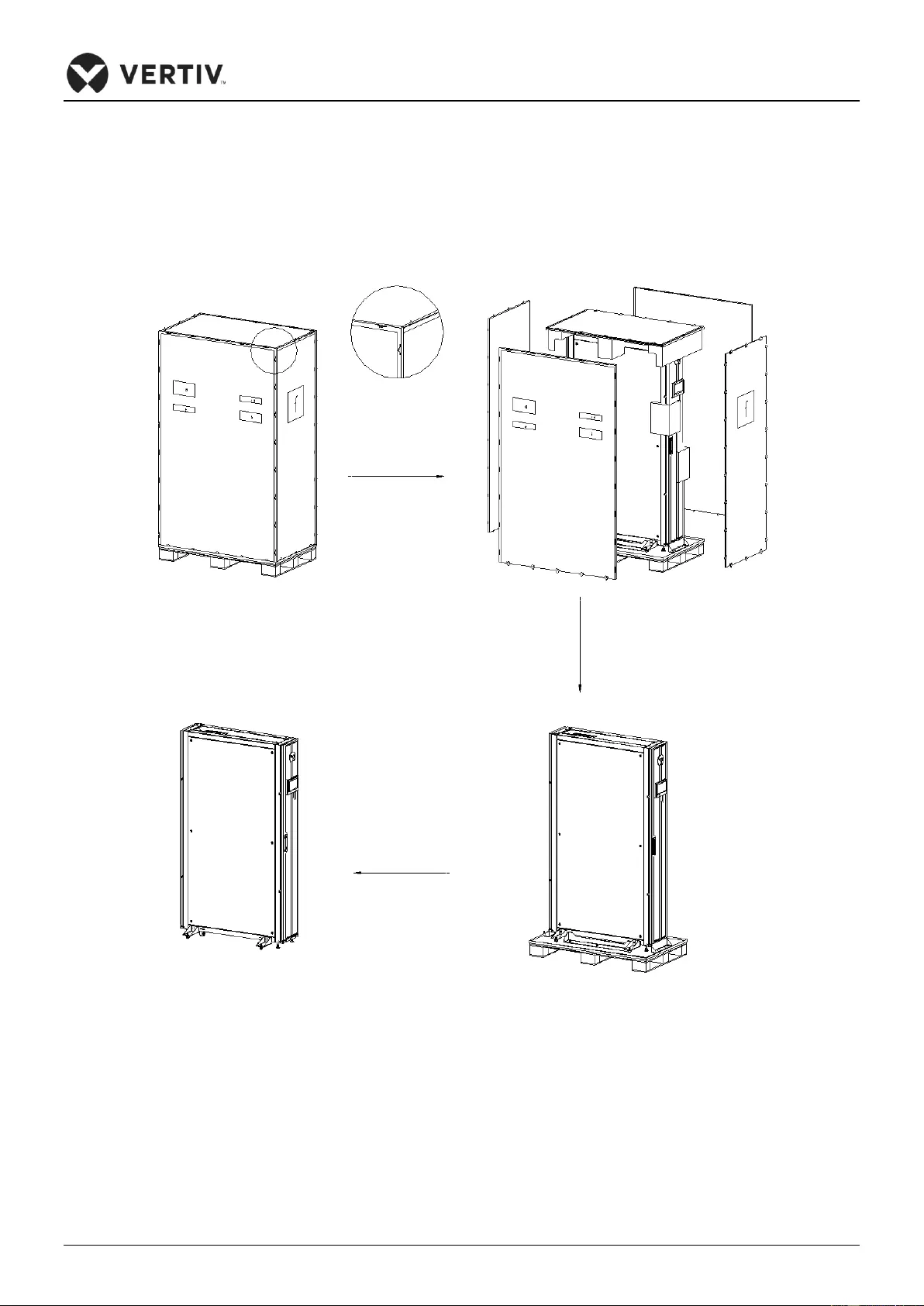

Shift the product to a location closer to the final installation site prior to unpacking the unit. Open all the

latches on the shipping crate, then remove top and later wooden panels of shipping crate as depicted in Figure

2-4.

Figure 2-4 Unpacking the Outer Package

Remove the side

wooden panel

Remove the top

wooden panel

Remove attaching screws

Installation

Vertiv | Liebert CRD10 | User Manual 21

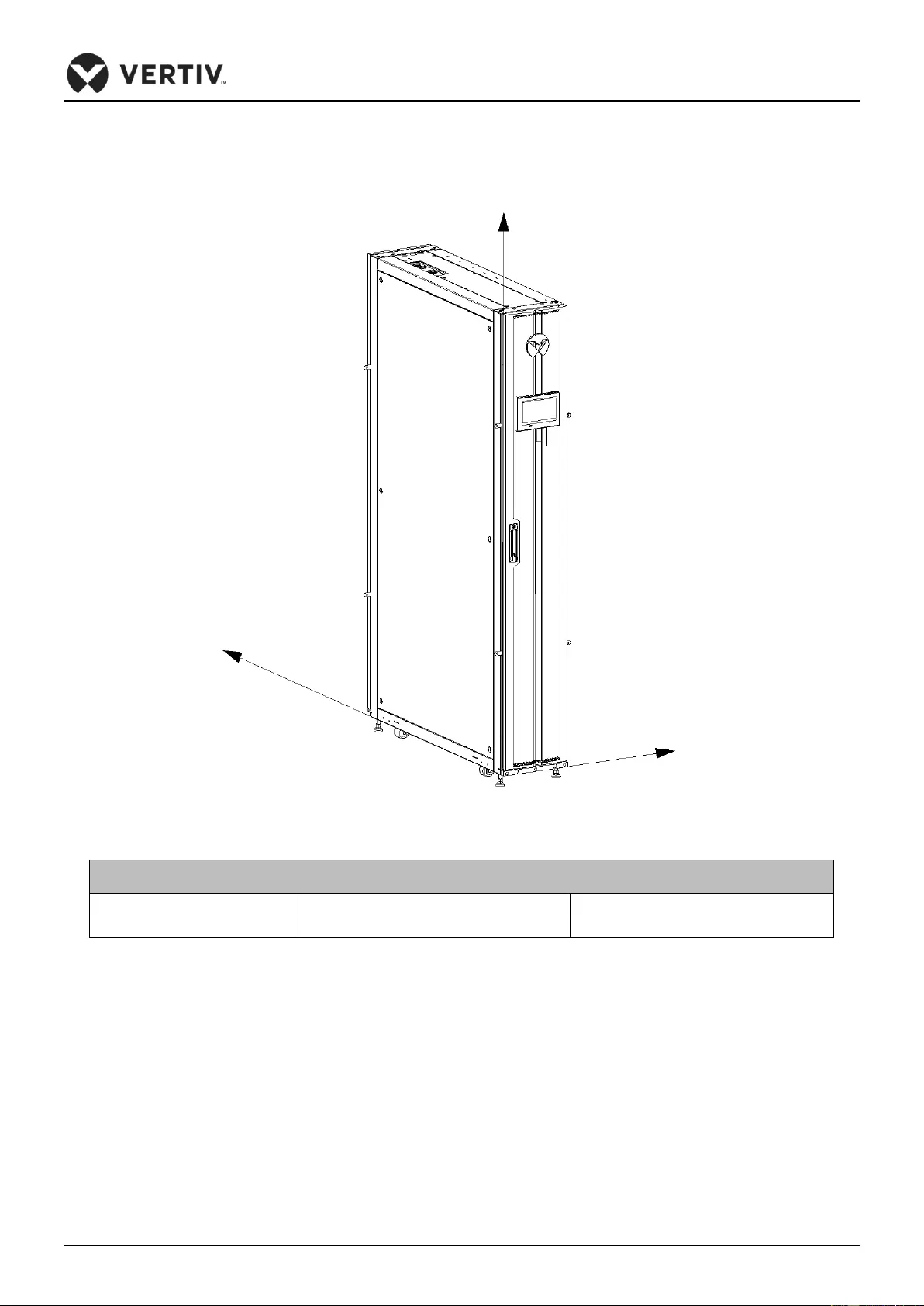

Take care of the center of the gravity.

Figure 2-5 Axis of Coordinates

•

Inspection

Moving forward, check the system fittings and its components against the packing list to ensure that

everything is in place and the assembly is intact. If any parts or components are missing or damaged,

immediately report the issue to the carrier and the local office of Vertiv at the earliest.

CENTER OF GRAVITY

±10mm (0.4in.)

X

Y

Z

150mm (5.9in.)

550mm (21.7in.)

970mm (38.2in.)

X

Y

Z

Installation

Vertiv | Liebert CRD10 | User Manual 22

2.6 Installation Preparation (Site Preparation)

The CRD10 models of air conditioners are streamlined for maintaining a favorable environment for data

centers, computer rooms, and similar systems. Strict adherence to the installation procedures is mandatory

to ascertain proper installation of the air conditioner.

2.6.1

Equipment Room Requirement

The equipment room must be prepared to ensure smooth operation and obtain accurate results. The

equipment room must meet the standards for appropriate ventilation and heating. The design specifications

for the air conditioners must be ideal and should be-in-line with energy-efficient design standards. Following

are the requirements for maintaining a favorable room environment prior to installation:

1. The equipment room should be well insulated and have a sealed damp-proof layer.

2. The outdoor air entering in should be kept at a minimum. The outside air will add the loads of heating,

cooling, humidifying, and dehumidifying of the system. It is recommended that the inhalation of outside

air be kept below 5% of the total indoor airflow.

3. All the doors and windows should be properly sealed to minimize the leakage. The seams should be as

narrow as possible.

NOTES:

• Vertiv recommends defining the site preparation as per the requirements. However, if these

requirements are not met, the site must be rectified to meet the specified requirements and

conditions.

• If the recommended rectifications or modifications are not implemented, then Vertiv does not

guarantee the accuracy and precision of the temperature and humidity provided by the Liebert CRD10

models.

• An important aspect to be considered is that the indoor unit must not be used for the outdoor

environment.

2.6.2

Installation Space Requirements

The Liebert CRD10 models are advanced precision air cooling units and therefore, air conditioners must be

installed, preferably in a row of cabinets with high heat density and in a hot aisle and cold aisle arrangement.

Allocate space to make it accessible to qualified service staff for repair, maintenance and service.

A minimum space of 600mm[23.6in.] must be assigned for maintenance at the front of the system and at

the rear of the system. The allocated space is to facilitate regular maintenance tasks such as removing filters

for cleaning, fans or compressor. Figure 2-6 shows the space allocation for servicing and maintenance.

Installation

Vertiv | Liebert CRD10 | User Manual 23

Figure 2-6 CRD10 Maintenance Space

1944mm

[76.5in.]

600mm

[23.6in.]

600mm

[23.6in.]

Installation

Vertiv | Liebert CRD10 | User Manual 24

2.7 Operating and Storage Environment Conditions

In this section, take a look at the environmental conditions including the Operating and Storage environment.

2.7.1

Operating Condition

Table 2-4 defines the operating condition parameters including the ambient temperature, protection level,

altitude and voltage range.

Table 2-4 Operating Parameters

Item

Requirement

Ambient temperature

Indoor: Temperature 18°C (64.4F) to 40°C (104F), Relative humidity 17% to 60%

Outdoor: Temperature -15°C (5°F ) to 45°C (113°F) without Low Ambient Kit

Temperature -34°C (-29.2°F ) to 45°C (113°F) with Low Ambient Kit

Protection level

Indoor Unit: IP20, Outdoor Unit: IPX4

Altitude

< 2000m(6561.6ft.). Above that, please contact Vertiv

Operation voltage range

CRD100-0D00A

CRD101-0D00A

CRD102-1D00A

208/230V/1PH/60Hz

208/230V/3PH/60Hz

230V/1PH/50/60Hz

2.7.2

Storage Condition

Table 2-5 defines the Storage condition parameters including the ambient humidity, ambient temperature, and

storage time conditions.

Table 2-5 Storage Parameters

Item

Requirement

Storage environment

Indoor, clean (without dust)

Ambient humidity

< 95%RH @ 30°C (86F)

Ambient temperature

-40°C (-40F) to 70°C(158F)

Storage time

Total transportation and storage time should not exceed six months. Otherwise, the

performance needs to be re-calibrated

2.8 Weight Bearing Capacity

The CRD10 unit is installed on the floor of the computer room, Therefore, the weight bearing capacity of the

floor of the computer room must be taken into consideration.

If the weight bearing capacity cannot be estimated, consult Vertiv or the customer service/support center.

Installation

Vertiv | Liebert CRD10 | User Manual 25

2.9 Refrigerant Charging Requirement

The CRD10 unit has a specifically designed air conditioning system that requires a desired pre-specified

quality of refrigerant (R410A) to perform continuously at the most optimum efficiency. For the details on the

quantity of refrigerant to be charged inside the system please refer to the installation section.

NOTE: Do not use refrigerant of inferior quality, Vertiv does not assume responsibility for warranty or any

consequences resulting from using inferior quality refrigerant.

2.10 Inspection

NOTES:

• To ensure that everything is in its designated position and that the entire product assembly is intact,

check the system fittings and their components against the packing list.

• Check that the fittings are complete and the components are intact against the packing list. Please

report immediately to the carrier’s local offices and Vertiv if any parts are missing or damage is found.

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 26

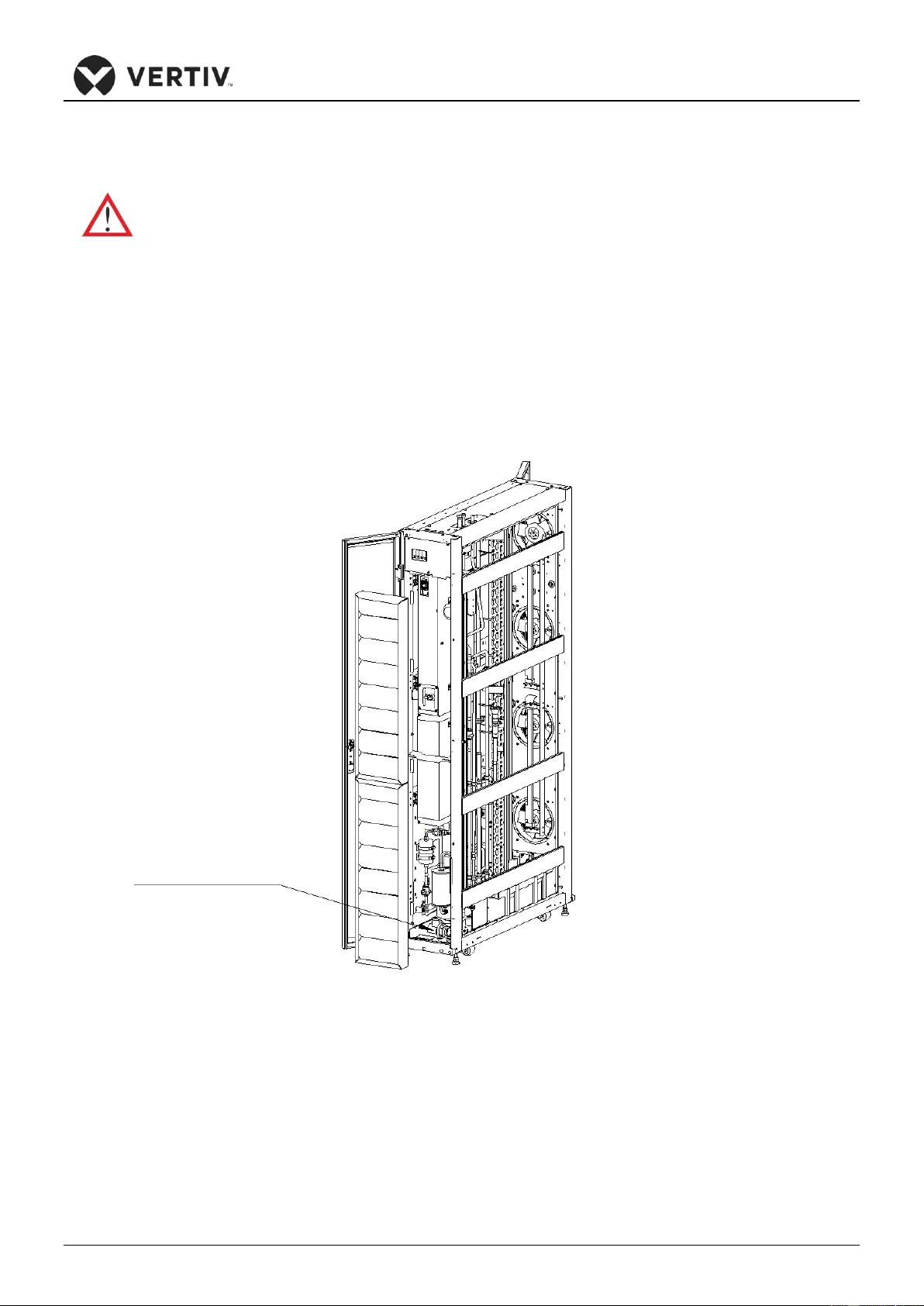

Chapter 3: Mechanical Installation

To achieve optimum performance and prolong product life, proper installation is important. In this section, the

mechanical installation will be discussed in detail to help the personnel with the installation process. Before

proceeding with the mechanical installation, the following 3.1 installation notes need to be considered.

3.1 Installation Notes

1. Prior to installation, ensure that the installation preparations have been carefully read and implemented

as per the requirement (refer to section 2.6 on ‘Installation Preparation’ for the details). Check if any

modifications are made to the plumbing, wiring, or ventilation facility before mounting the equipment.

After considering the installation preparations, proceed to the next step in the installation process and

finally set up the system.

2. The CRD10 is designed as a split system. The indoor unit must be installed on the floor of the equipment

room or computer room. The outdoor unit must be installed outdoors or on the floor of the other rooms

as per the building architecture.

3. Industry-wide standards are followed for the selection, layout, and fixing of pipes.

4. During the design and installation process, various factors such as pressure drop, compressor oil return,

noise reduction, and vibration must be considered.

5. When installing the equipment, follow the design drawings strictly. Reserve space as per the

maintenance and serviceability instructions in the Chapter 2, section ‘Installation Preparation’. The

manufacturing engineering dimension drawings must be taken as a reference while installing the

equipment.

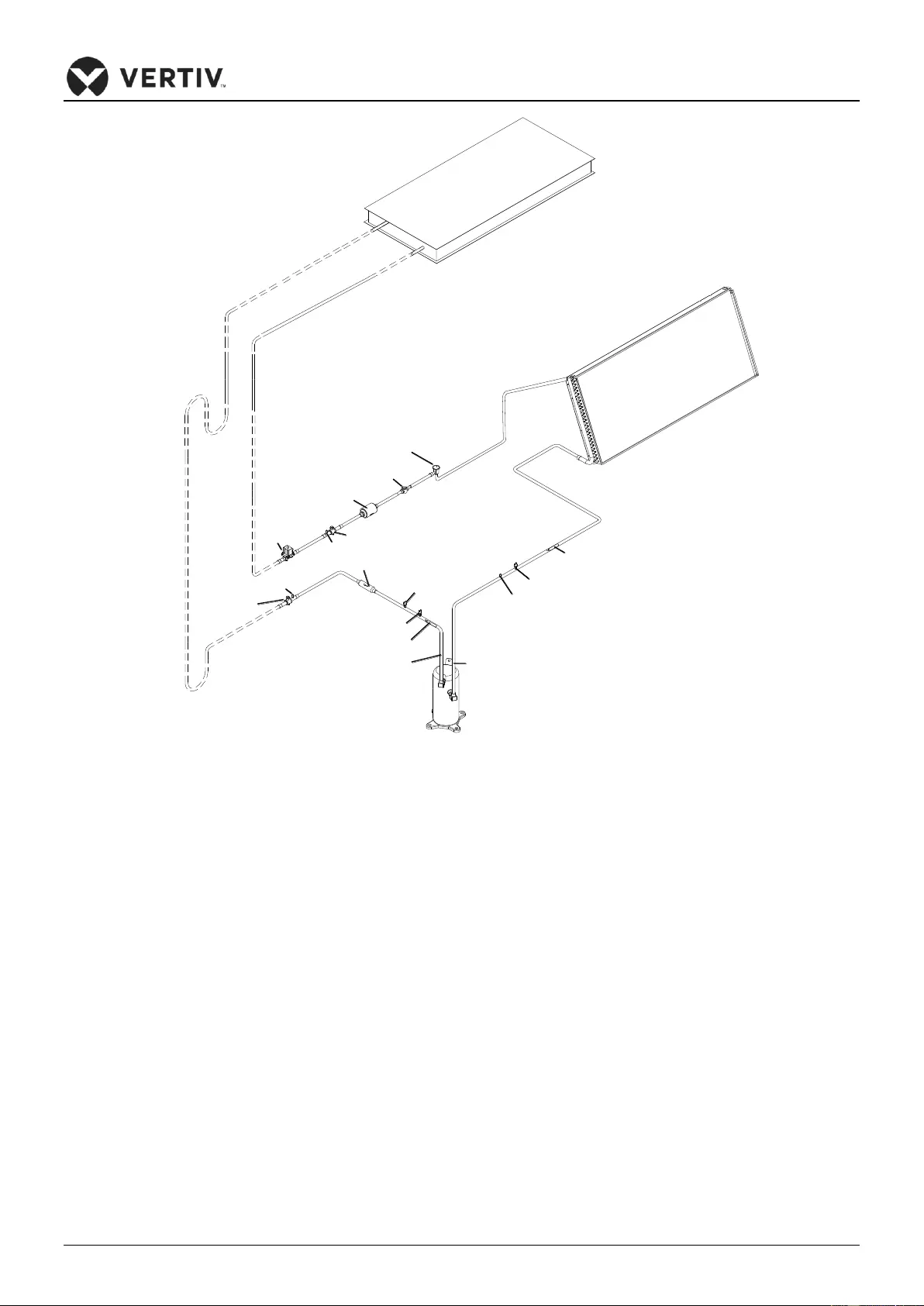

3.2 System Arrangement during Installation

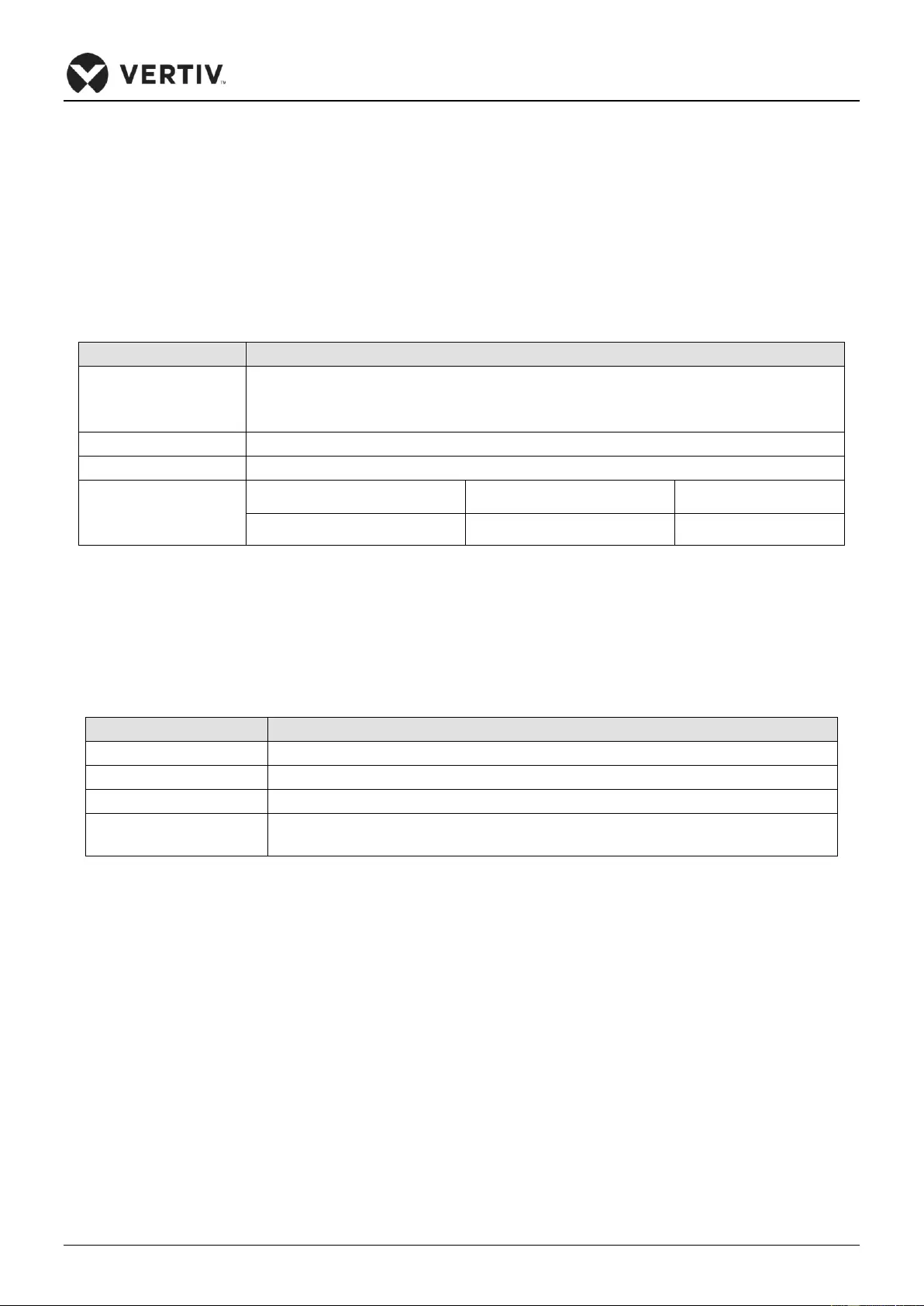

The general arrangement of the CRD10 air cooled AC unit is shown in Figure 3-1, and the Table 3-1 shows the

calibration of safety components.

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 27

Pos.

Description

Pos.

Description

1

Compressor

9

Air Cooled Condenser

2

Crankcase Heater

10

Solenoid Valve (Connection on site)

3

Discharge Temperature Sensor

11

Filter Drier

4

High Pressure Switch

12

Sight Glass

5

High Pressure Transducer

13

Electronic Expansion Valve

6

Schrader Valve

14

Evaporating Coil

7

Ball Valve

15

Suction Temperature Sensor

8

Check Valve

16

Low Pressure Transducer

Figure 3-1 System Arrangement of the Unit System

CRD10 Indoor unit

External to CCD Condenser

Connection pipe

○

16

○

15

○

14

○

6

○

6

○

2

○

1

MC

○

3

○

4

○

5

○

8

○

6

○

7

○

9

○

6

○

10

○

7

○

6

○

11

○

12

○

13

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 28

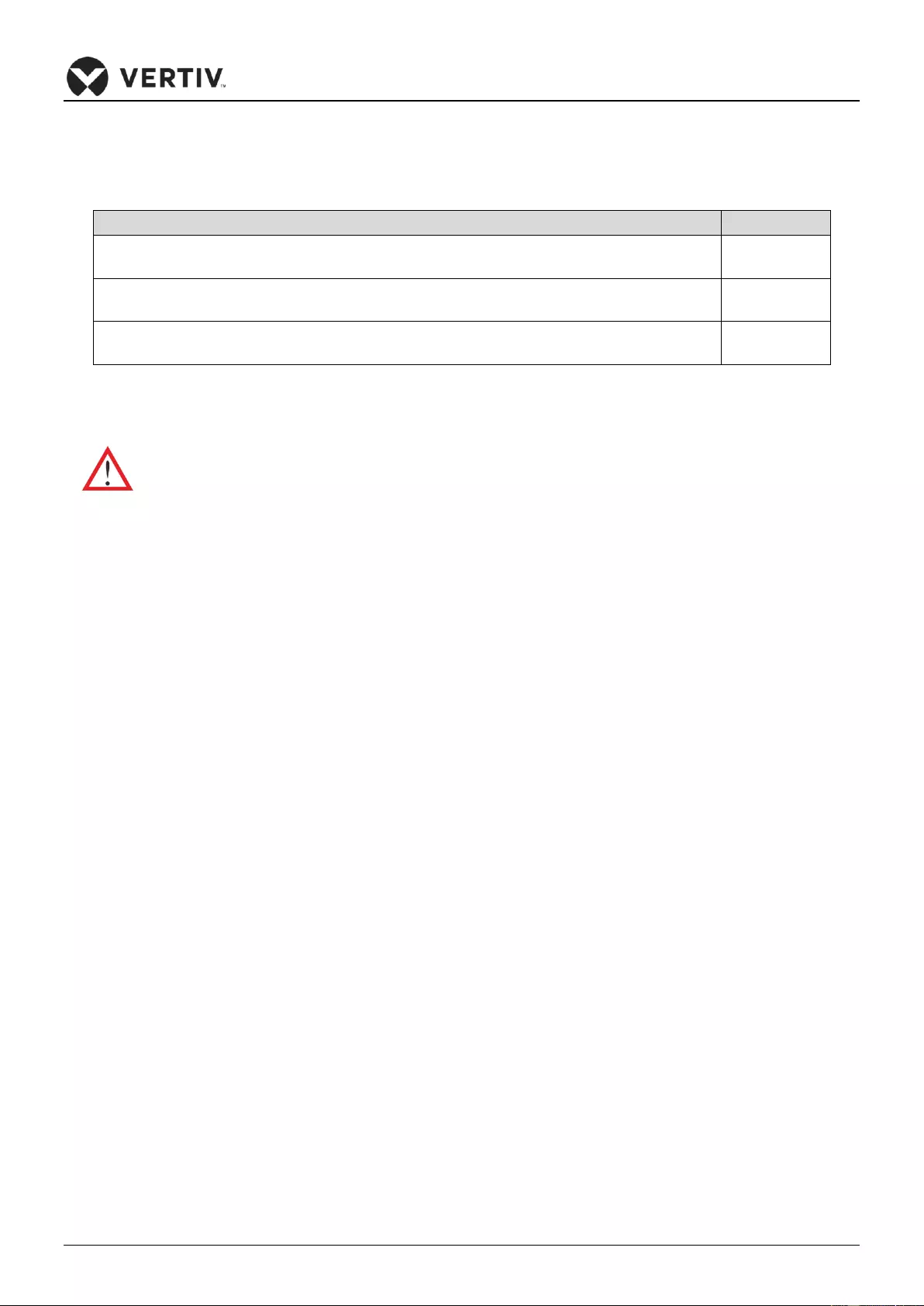

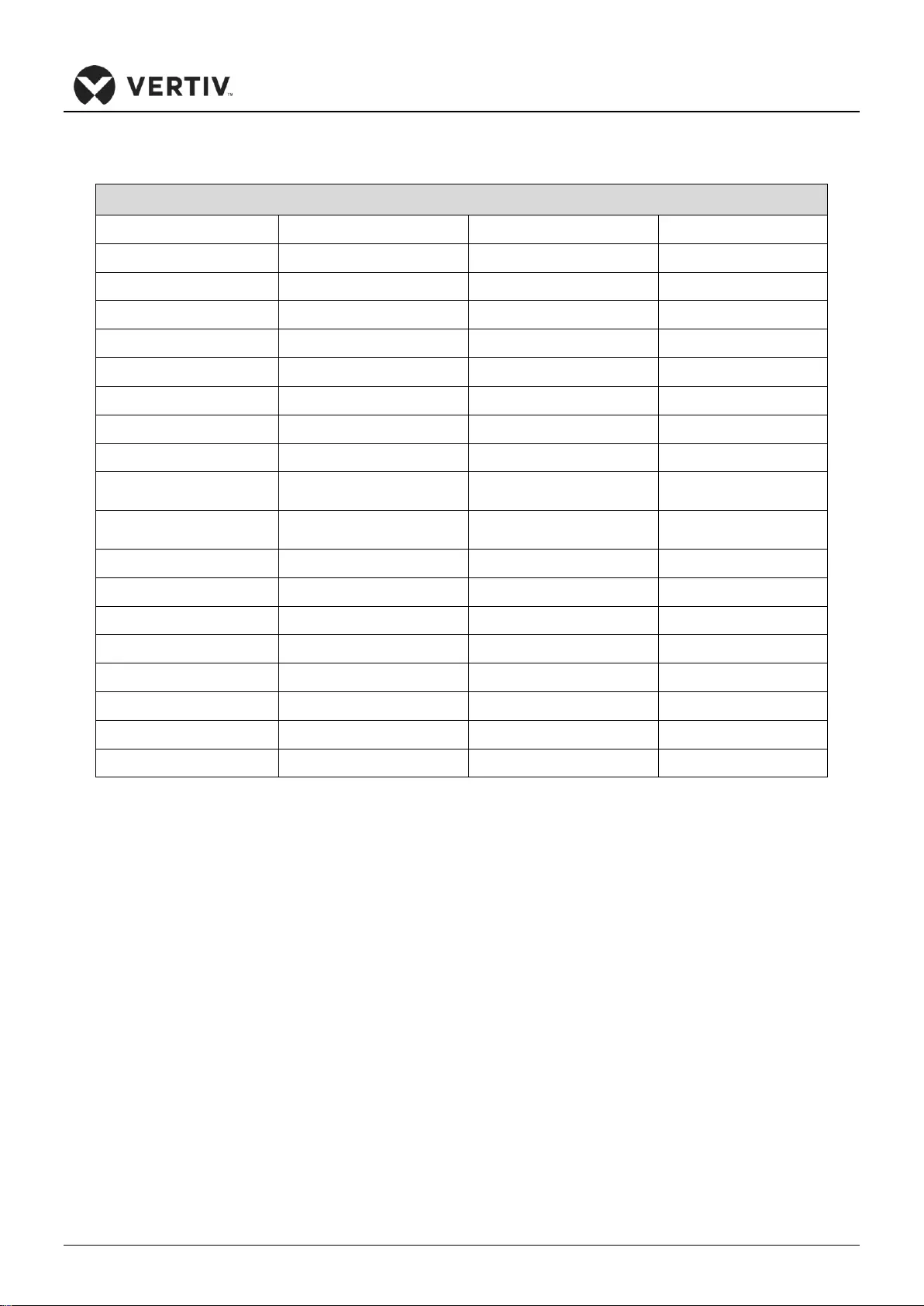

Table 3-1 Calibrations of electrical components

Refrigeration Circuit

Item No

Component

Setting

Notes

Contact

4

High Pressure Switch

Open 4.1±0.1MPa

Close 3.3±0.1MPa

Normally

Closed

5

High Pressure

Transducer

Range 0-4.5MPa

0.5-4.5VDC

-

16

Low Pressure

Transducer

Range 0-1.73MPa

0.5-4.5VDC

-

-

Clogged Filter

Different Pressure

Switch

Set Point Range

50-400Pa

Normally

Closed

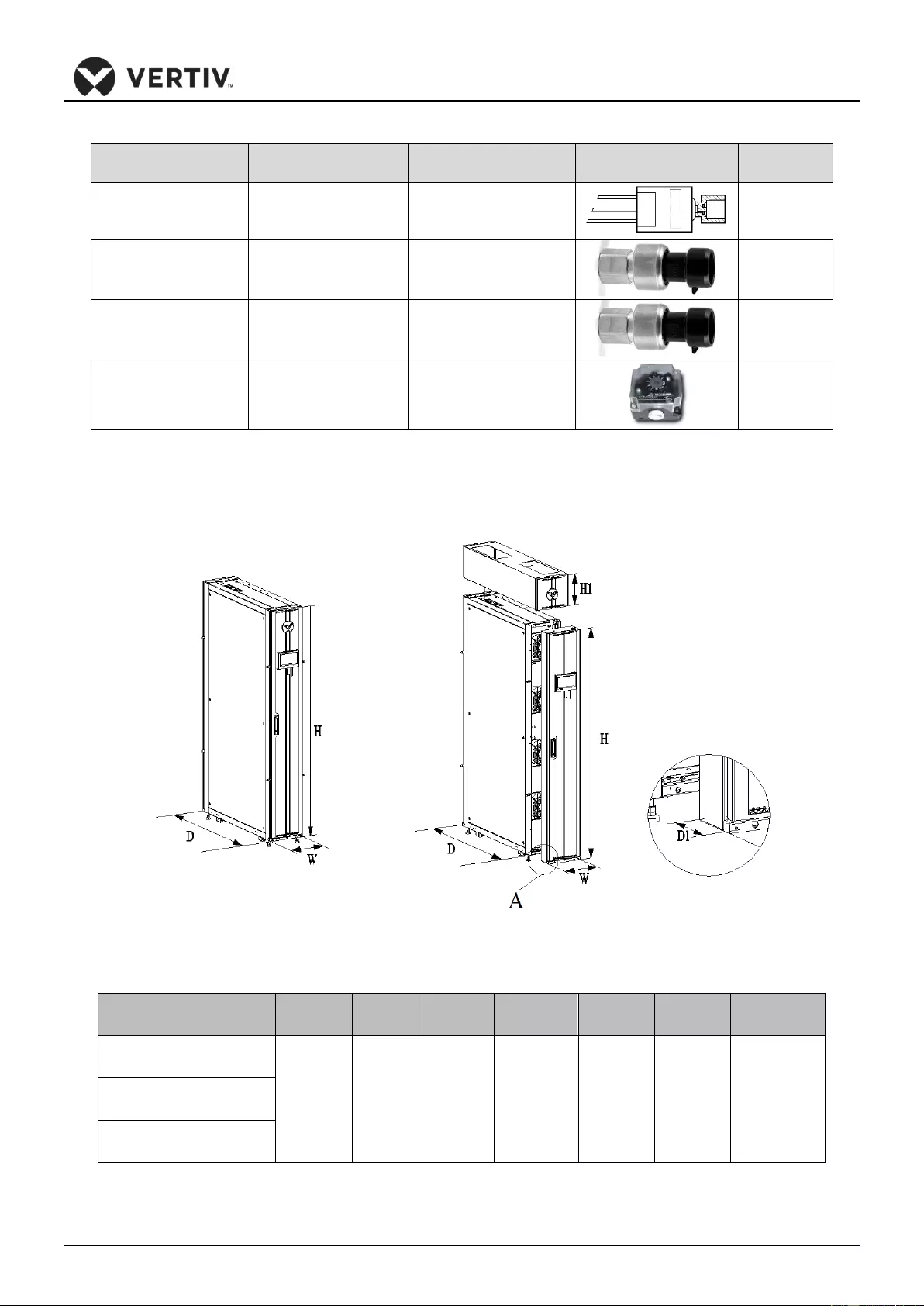

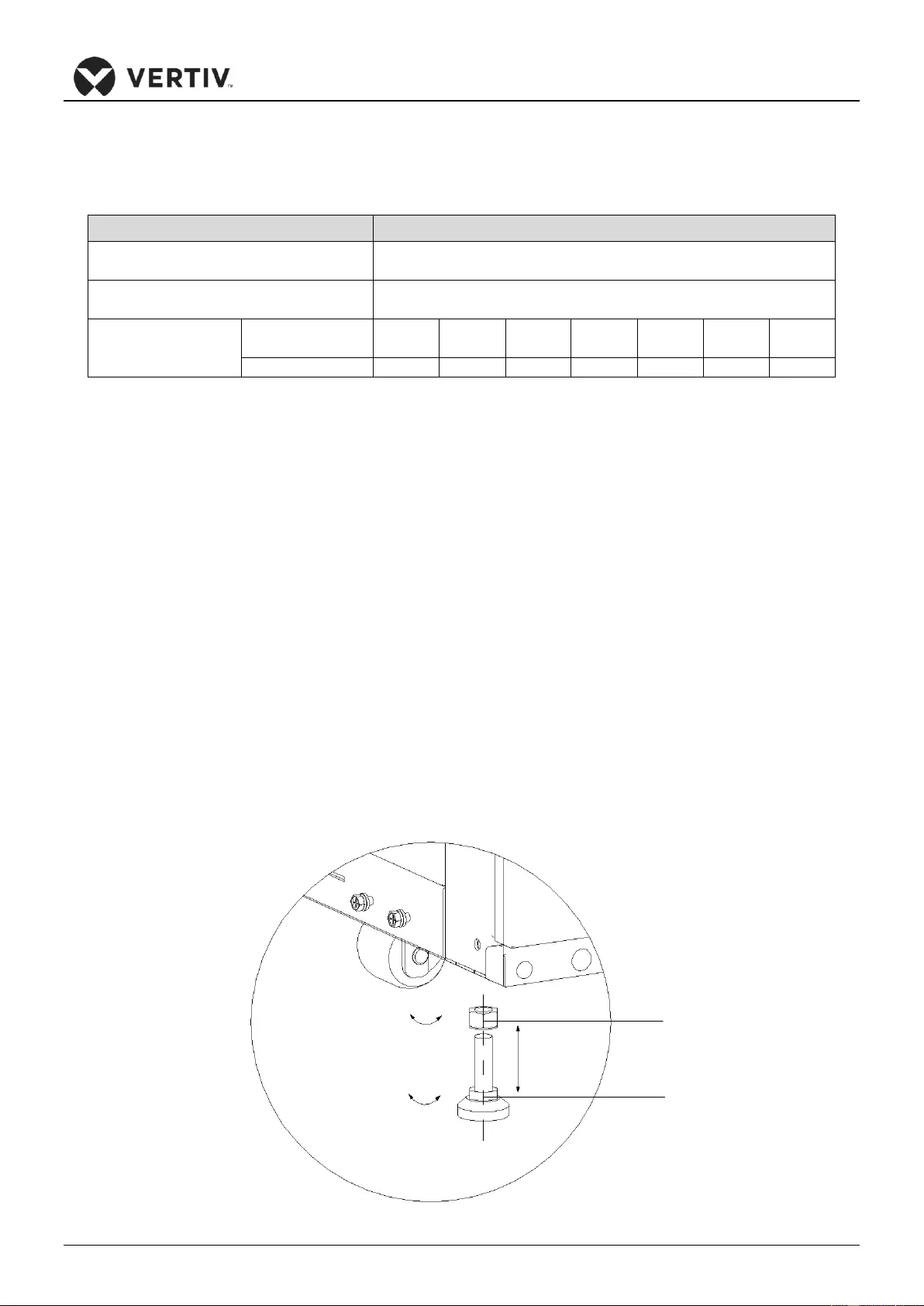

3.3 Product Dimensions

The dimensions and weight of the indoor unit are shown in Figure 3-2 and in Table 3-2.

Figure 3-2 Dimensions of the Indoor Unit

Table 3-2 Dimension of the Indoor Unit

Model

H

(mm/in.)

H1

(mm/in.)

D

(mm/in.)

D1

(mm/in.)

W

(mm/in.)

Net

weight

(kg/lb)

Gross weight

(kg/lb)

CRD100-0D00A

2000/78.7

267/10.5

1132/44.6

100/3.9

300/11.8

231/509

313/690

CRD101-0D00A

CRD102-1D00A

Note: H1 and D1 dimensions are associated with optional frame extension kits allowing CRD10 to match

rack heights or depths.

A amplified

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 29

3.3.1

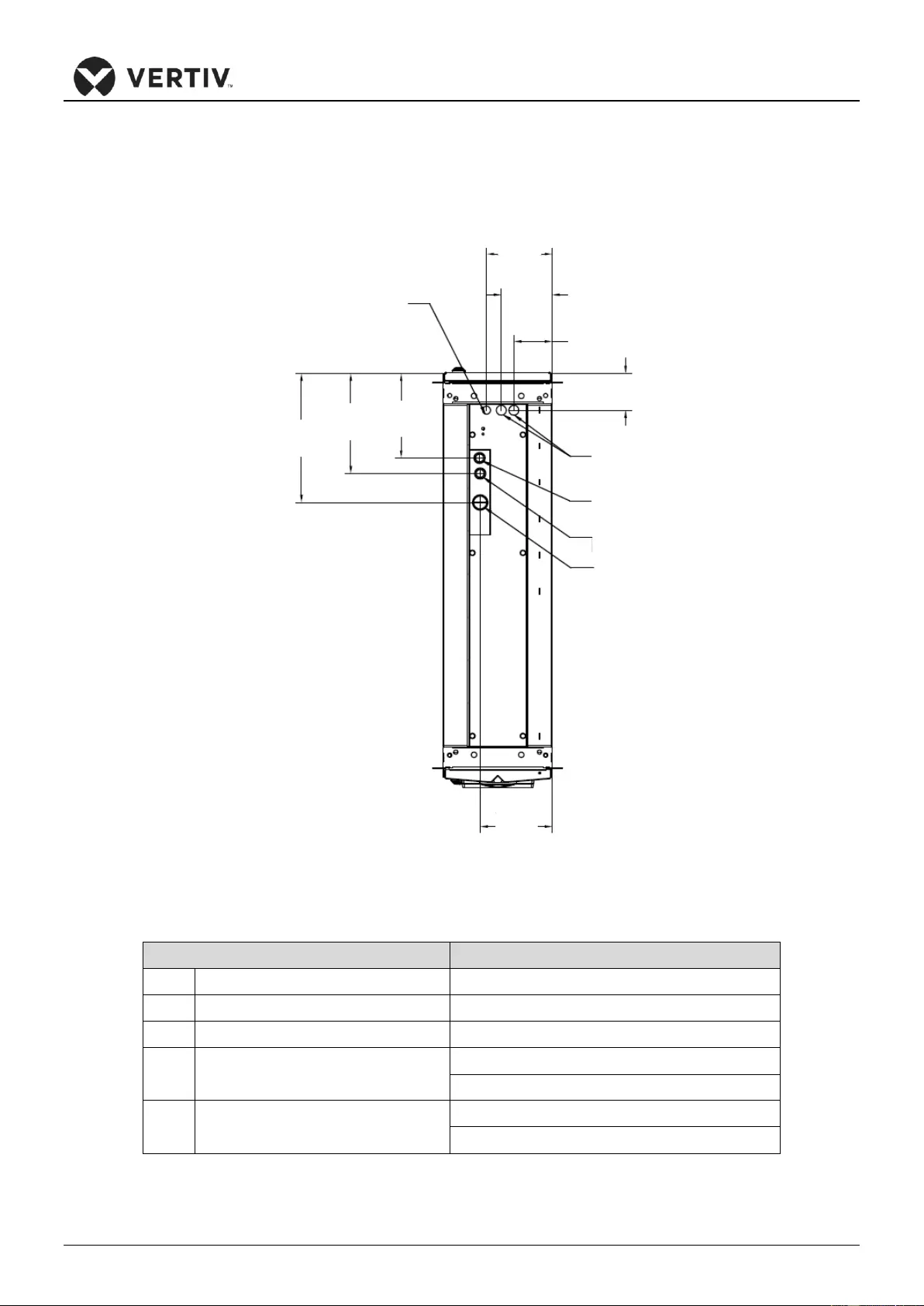

Base Plate Pipe Outlet Location & Dimensions

The locations of the pipe inlets and outlets on the unit base plate are shown in Figure 3-3 and corresponding

dimensions of the base plate pipe outlet are tabulated in Table 3-3.

Figure 3-3 Base Plate Location for Pipe Outlets

Table 3-3 Dimensions of Base Plate Pipe Outlet (mm/inch)

UNIT BOTTOM CONNECTIONS

CRD10

RLT

Refrigerant Liquid Line Inlet

1/2" O.D. Copper

RGT

Refrigerant Gas Line Outlet

5/8" O.D. Copper

CPT

Condensate Pump

NPT 1/2"(Rc1/2”) Female copper threaded joint

CGT

Condensate Gravity

NPT 1/2" (Rc1/2”) Female copper threaded joint

HVT

High Voltage Bottom Connection

Combination Knockout

1-1/8" (29 mm)

LVT

Low Voltage Bottom Connection

Knockout Hole Diameter

7/8" (22 mm)

NOTE: NPT threaded joint is for UL model, Rc threaded joint is for CE model.

256mm

[10 1/16”]

RGT

RLT

HVT

LVT

CGT

CPT

54mm

[2 1/16”]

295mm

[11 9/16”]

132mm

[5 3/16”]

118mm

[4 5/8”]

101mm

[3 15/16”]

219mm

[8 5/8”]

260mm

[10 1/4”]

51mm

[2”]

98mm

[3 3/16”]

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 30

3.3.2

Top plate pipe outlet Locations & Dimensions

The locations of the pipe inlets and outlets on the unit top plate are shown in Figure 3-4 and corresponding

dimensions of the top plate pipe outlet are tabulated in Table 3-4.

Figure 3-4 Top Plate Locations for Pipe Outlets

Table 3-4 Dimension of Top Plate Pipe Outlet (mm/inch)

UNIT TOP CONNECTIONS

CRD10

RLT

Refrigerant Liquid Line Inlet

1/2" O.D. Copper Sweat

RGT

Refrigerant Gas Line Outlet

5/8" O.D. Copper Sweat

CPT

Condensate Pump

NPT 1/2" (Rc1/2”) Female copper threaded joint

HVT

High Voltage Top Connection

Combination Knockout

1-1/8" (29 mm)

LVT

Low Voltage Top Connection

Knockout Hole Diameter

7/8" (22 mm)

NOTE: NPT threaded joint is for UL model, Rc threaded joint is for CE model.

180mm

[7 1/16”]

140mm

[5 1/2”]

105mm

[4 1/8”]

102mm

[4”]

HVT

RGT

RLT

CPT

356mm

[14”]

276mm

[10 7/8”]

233mm

[9 3/16”]

198mm

[7 3/4”]

LVT

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 31

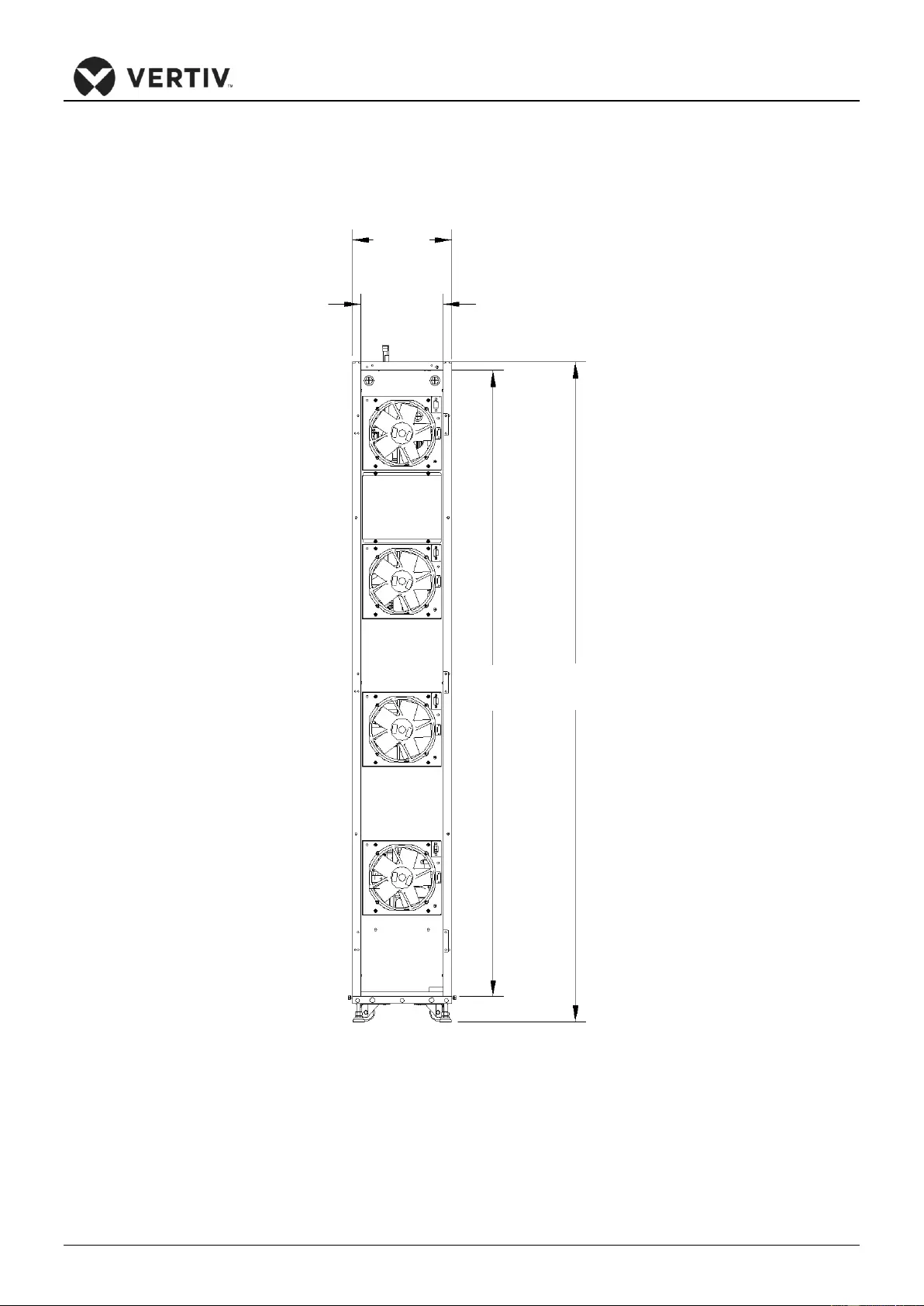

3.3.3

Front Air outlet Locations and Dimensions

The location and dimensions of the air outlet at the front are shown in Figure 3-5.

Figure 3-5 Front Air Outlet Locations & Dimensions

300mm

[11.8in.]

250mm

[9.8in.]

1895mm

[74.6in.]

2000mm

[78.7in.]

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 32

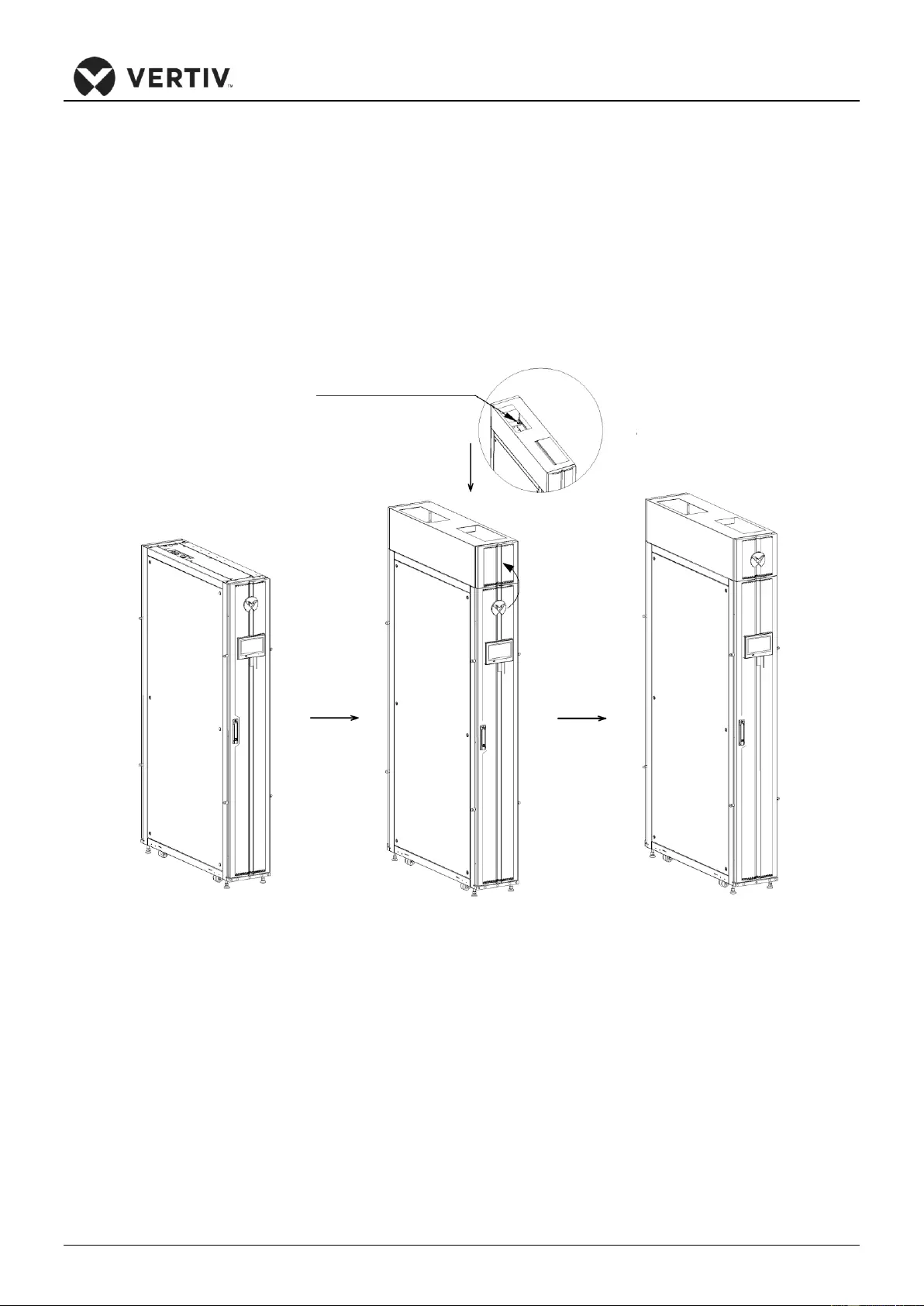

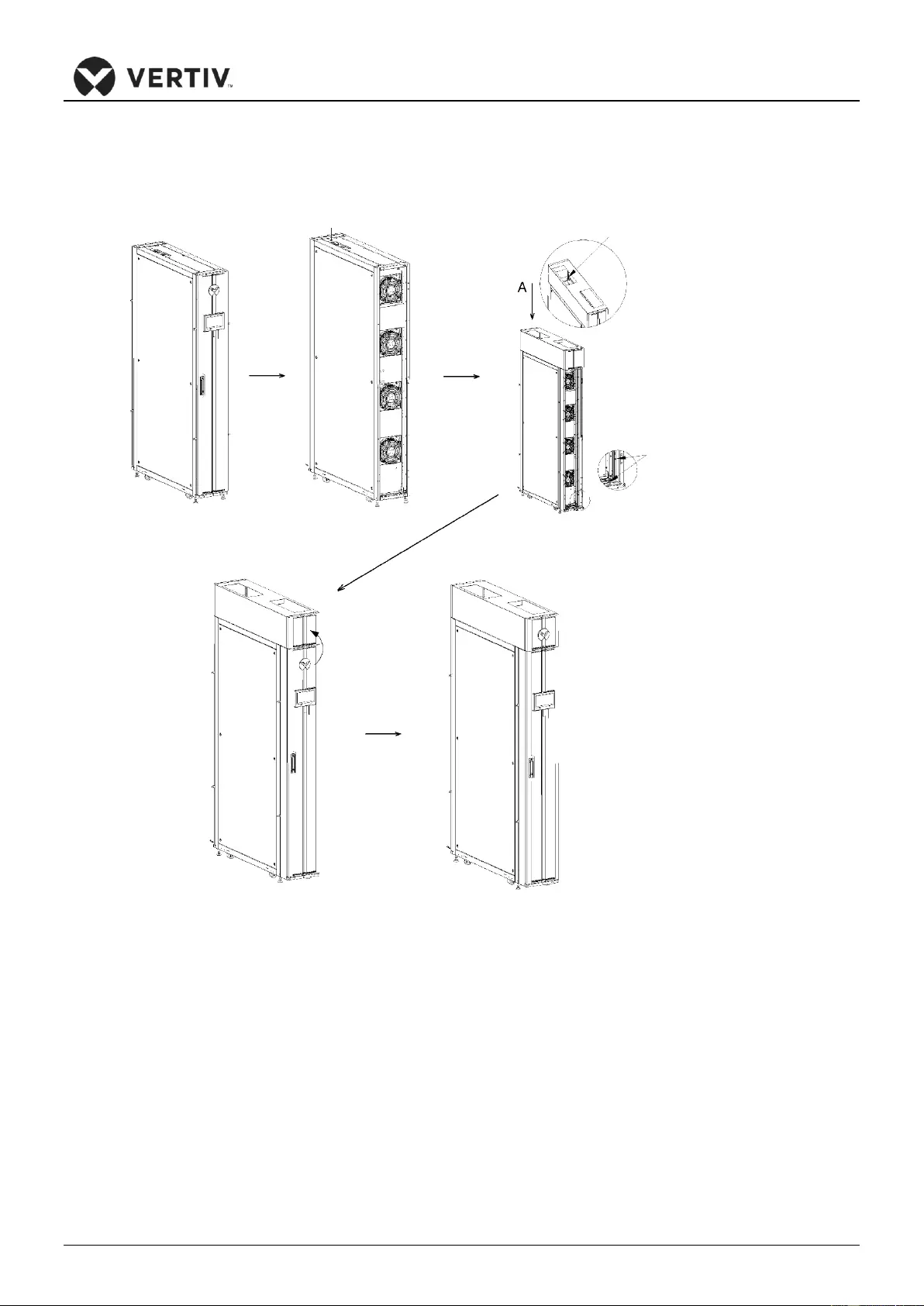

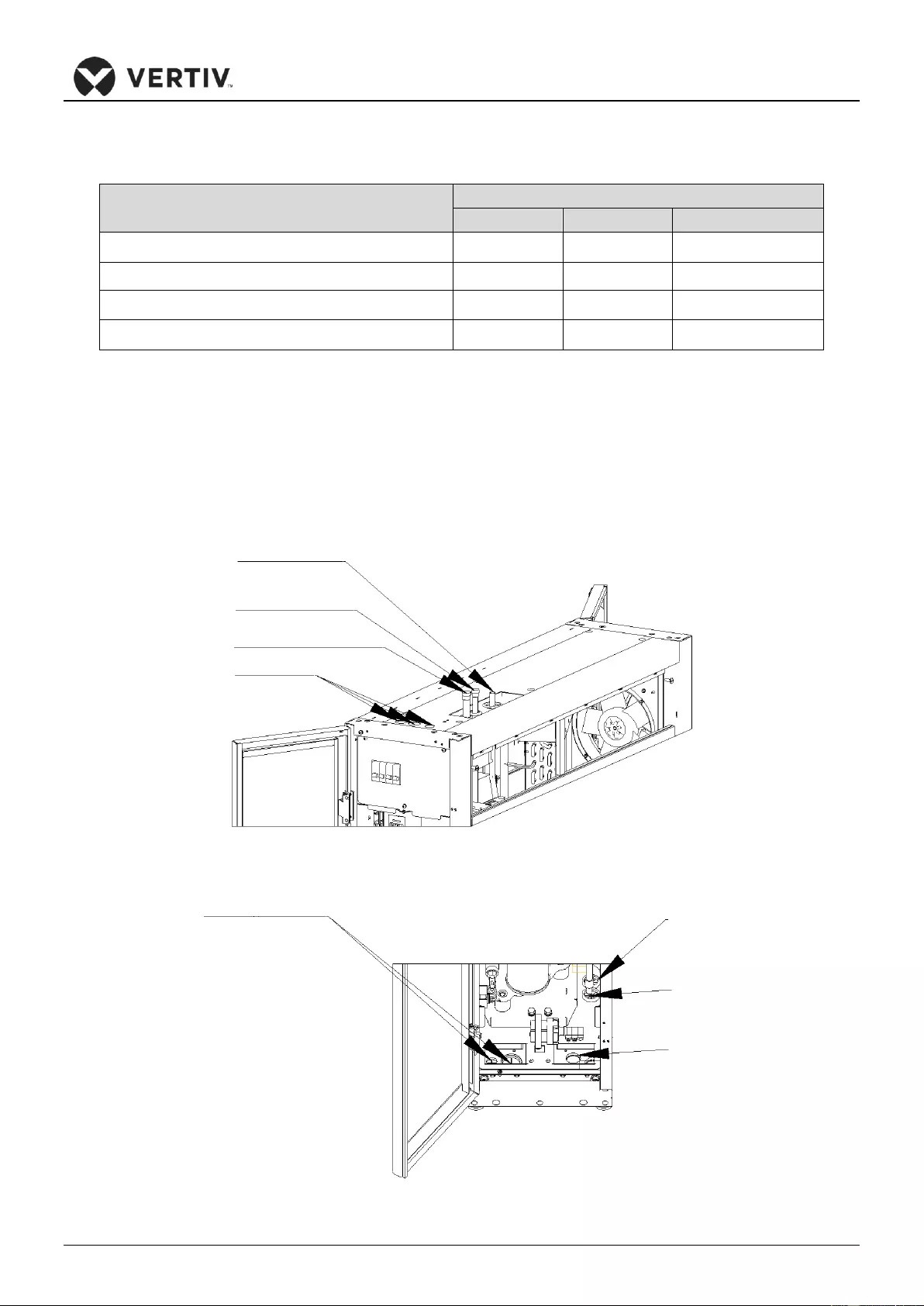

3.4 Top frame and front frame

The CRD10 unit can be optionally field configured with a top frame and a front frame. The top frame and front

frame are installed as follows.

3.4.1

Top frame installation without front frame

The 267×1132mm (10.5×44.6in.) specification top frame installation does not require the front frame to be

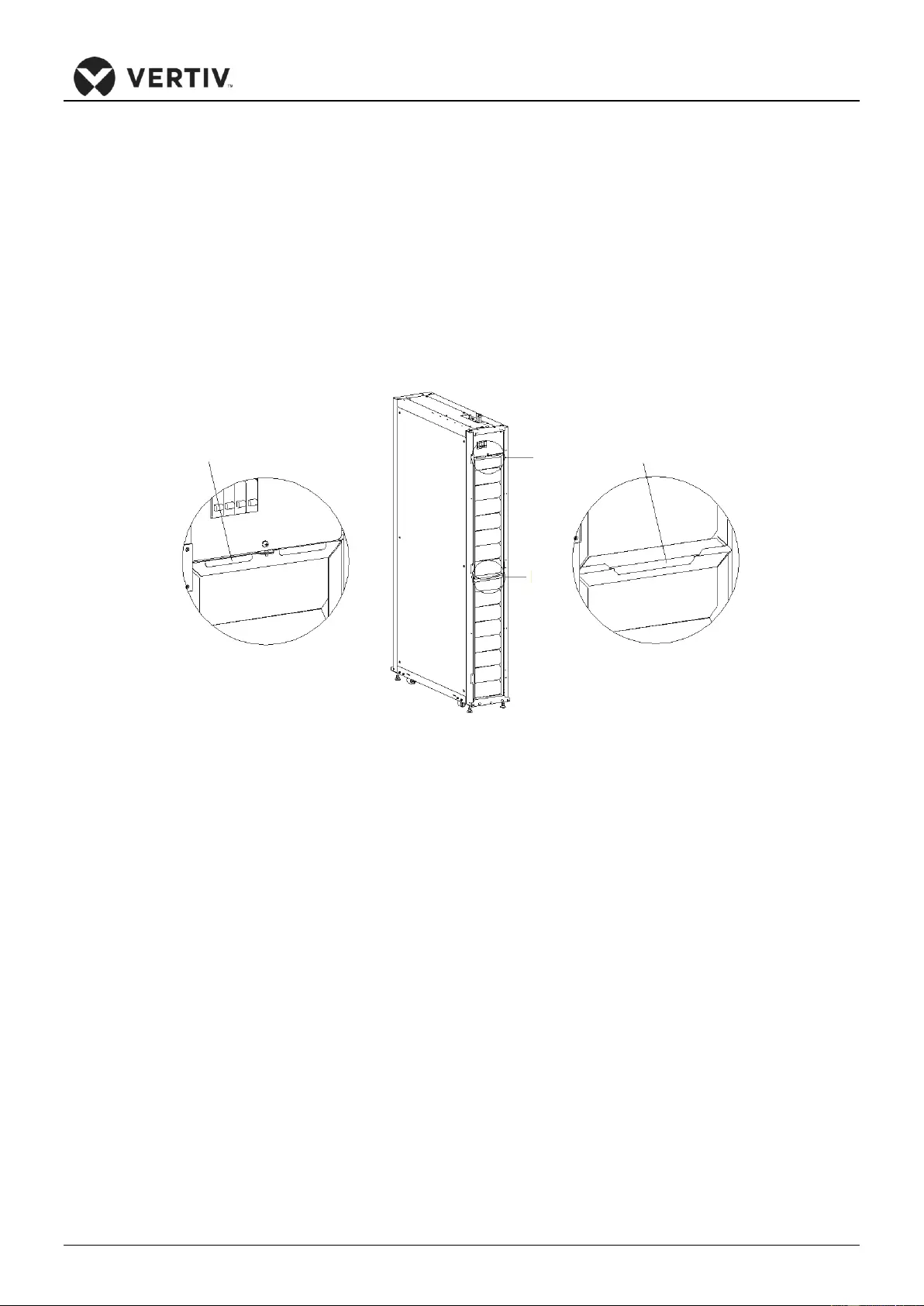

installed, and the top frame can be directly installed. The installation method is as follows in figure 3-6.

Figure 3-6 Top frame installation without front frame

3.4.2

Top frame installation with front frame

When installing the 267×1232mm (10.5×48.5in.) specification top frame, the front frame needs to be

installed at the same time. The installation method is as shown in figure 3-7. The door is linked to the cabinet

by hinges, and the display and foot rail is fixed with screws. To remove them, pull out the hinges and loosen the

screw.

Screw (M12×30) ×4

Step1: Install the top frame

and fixed it with M12×30

screws(4PCS).

Step2: Move the V logo to

the top frame.

A

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 33

Figure 3-7 Top frame installation with front frame

Step1: Remove front door, display and

foot rail from the unit.

Step2: Fix front frame with M5×12 screws(10PCS). And

fix the top frame with M12×30(4PCS) as well. Then

install back the front door, display and foot rail.

Screw(M12×30) ×4

Screw(M5×12) ×10

Step3: Move the V logo to the

top frame.

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 34

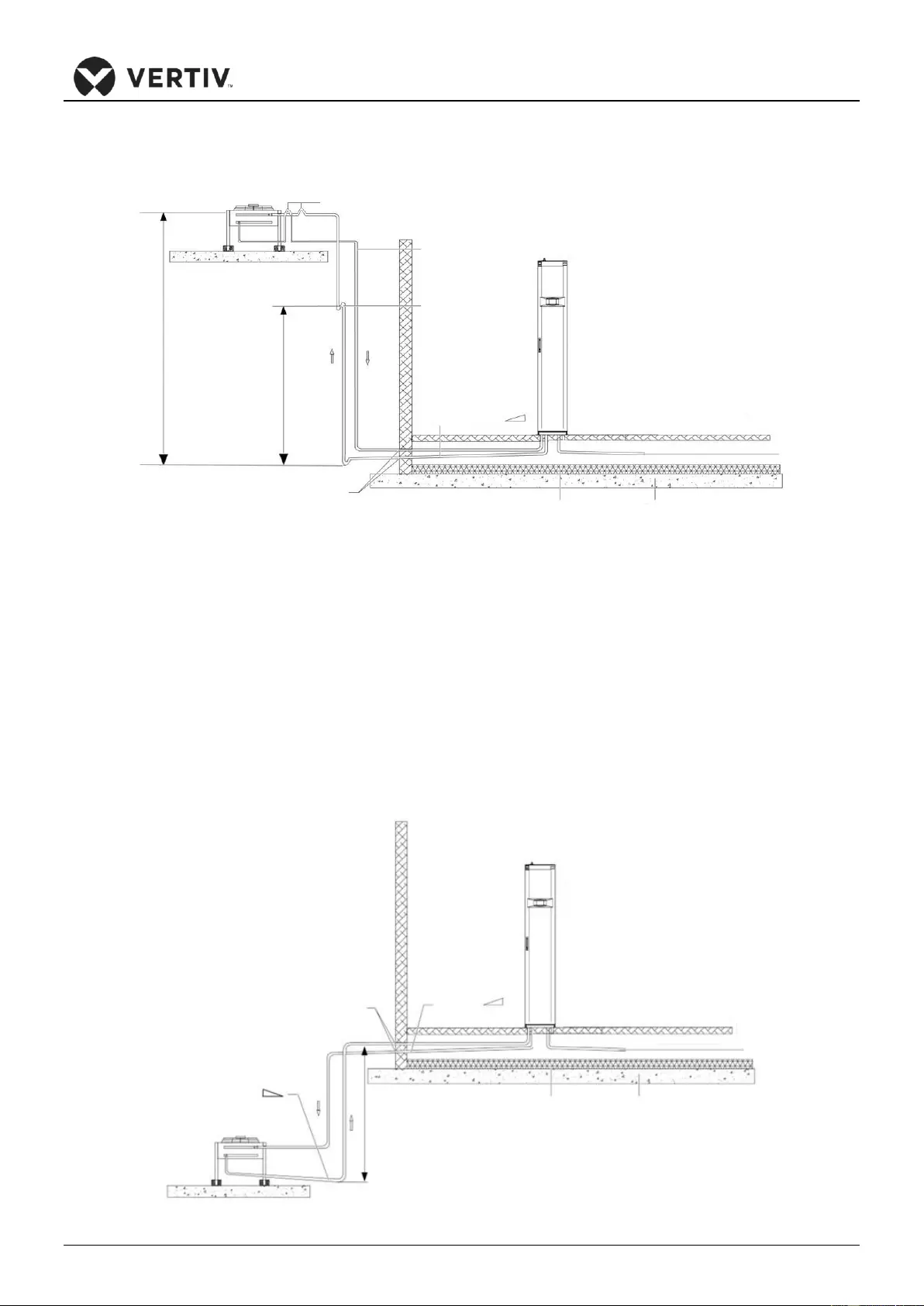

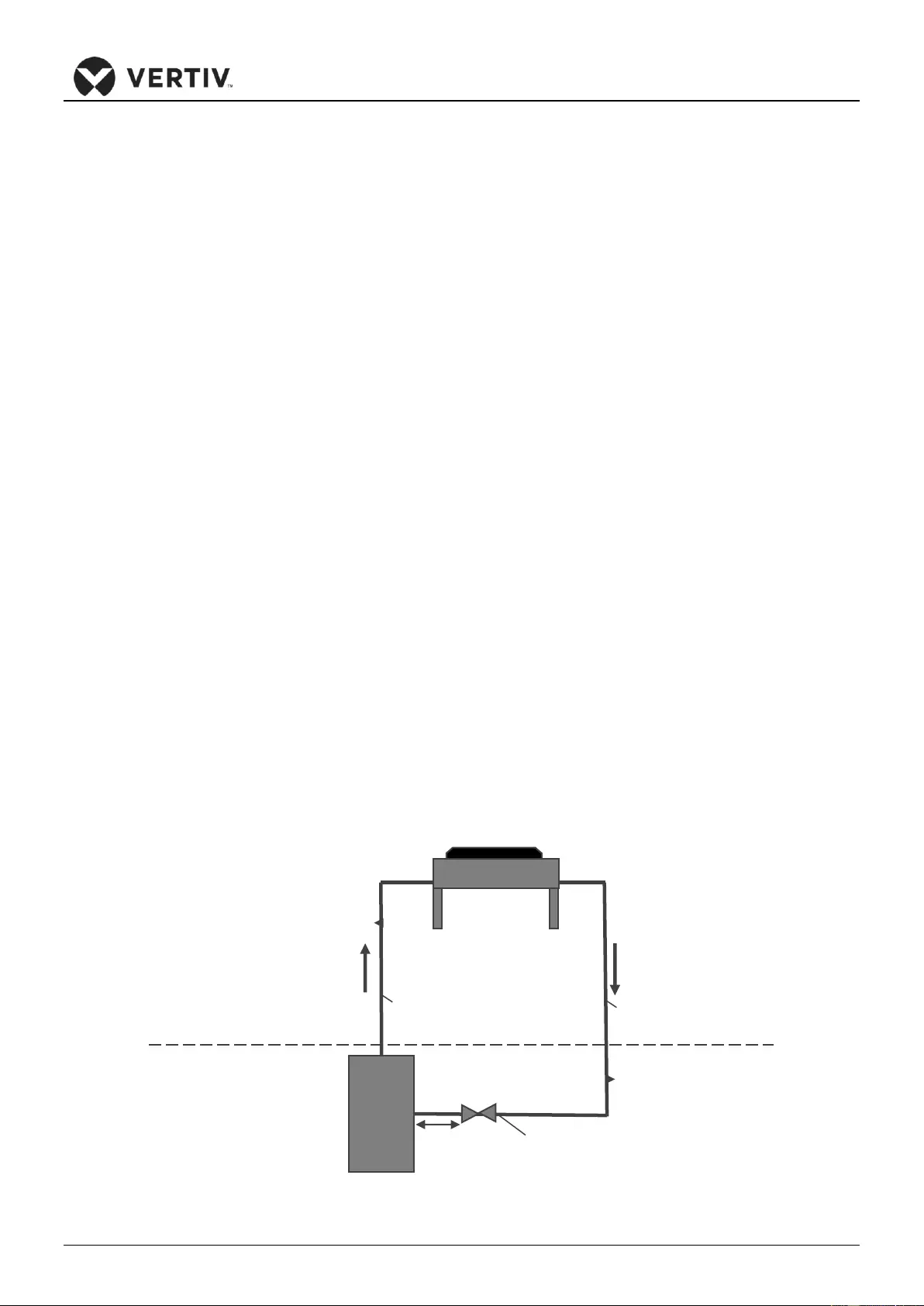

3.5 System Installation Layout

The installation modes of the CRD10 unit are shown in Figure 3-8 and 3-9.

Figure 3-8 Condenser is Placed Higher than the Compressors during Installation

In Figure 3-8, the condenser is installed higher than the compressor. Therefore, an inverted trap is fitted to the

discharge line and the liquid line of the condenser. The inverted trap is essential as it helps prevent the liquid

refrigerant from flowing back once the condenser stops. The top end of the inverted trap must be installed

higher than the ultimate level of the copper pipe of the condenser. Recommended the minimum height

difference is 150mm (5.9in.). A trap must be installed every 7.5m(24.6ft.) of the vertical discharge line.

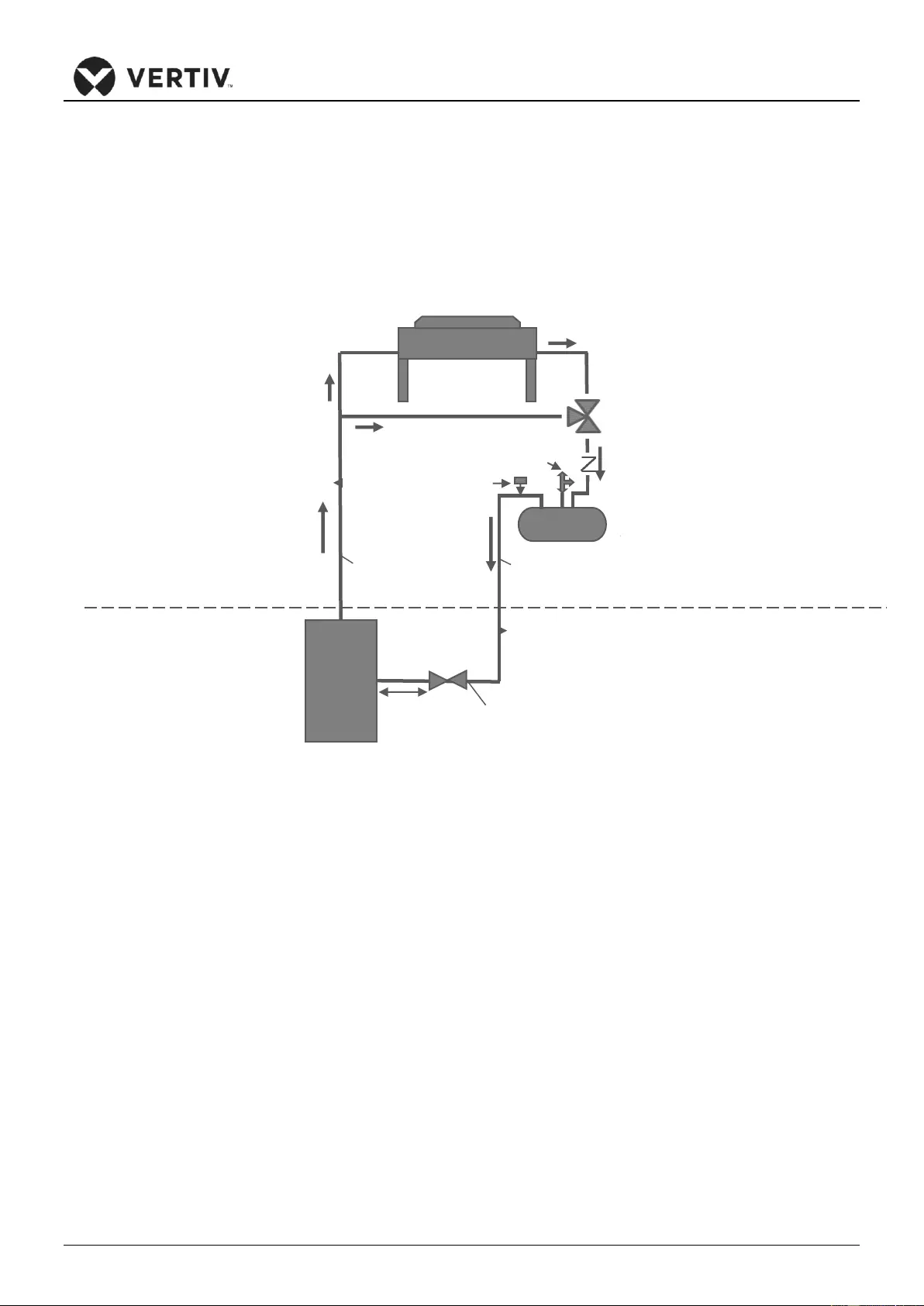

However, if the condenser is installed lower than the compressor, then no modification is required. Figure 3-9

shows the schematic diagram of system installation when the condenser is installed at a lower level than the

compressor. If using low ambient kit when mounting condenser below level of the indoor unit, the allowable

height refers to Table 3-5.

Figure 3-9 The Condenser is Lower than the Compressor during Installation

Max.30m(98.4ft.)

Outdoor unit

Inverted trap (must higher than the highest copper pipe of the condenser)

Liquid line (avoid exposure to direct sunlight)

Trap

Slope discharge

Indoor unit

Raised floor

Condensed

water

Heat insulation floor

Floor

Sealed

Max.7.5m(24.6ft.)

Slope

discharge

Sealed

Slope liquid

Outdoor unit

Max.8m(26.2ft.)

Heat insulation floor

Floor

Condensed

water

Raised floor

Indoor unit

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 35

Table 3-5 shows the allowable vertical distance between condenser and indoor unit.

Table 3-5 Vertical Distance between Condenser and Indoor Unit

Positioning of the Outdoor Unit

Height

Outdoor unit is higher than the

Indoor unit

Maximum: +30m (98.4ft.)

Outdoor unit is lower than the

indoor unit

Maximum: -8m (-26.2ft.)

Outdoor unit with Low

Ambient Kit is lower

than the indoor unit

Piping Equivalent

Length m(ft.)

10(33)

15(49)

30(99)

45(147)

60(197)

75(246)

91(300)

Max. Height m(ft.)

-5(-16)

-4.7(-15)

-3.7(-12)

-2.8(-9)

-1.9(-6)

-1(-3)

0(0)

3.6 Installation Procedures

The CRD10 models of air conditioners are used between racks and one side of it is adjacent to the server

cabinet. The CRD10 models of air conditioners are targeted for small-and-medium data centers,

computer rooms, and similar systems.

3.6.1

Leveling the Cabinet

Once all the components of the cabinet have been installed, level the cabinet. The following section is a

step-by- step illustration of the process of leveling the cabinet.

1. Place the cabinet at the desired location (preferably an open ground). Use a movable wrench to

loosen the fixing nuts on the four foot bolts in a clockwise direction.

2. Rotate the hexagonal bolts at the bottom of the feet in the clockwise or counterclockwise direction

until the feet rise or fall to a suitable position. Use a gradient measuring tool to ensure that the cabinet

is in a uniform level state. Refer to the Figure 3-10 to understand the process better.

Figure 3-10 Leveling the Cabinet

Clockwise

Counter clockwise

or clockwise

The feet rise

or drop

Fixing nut

Hexagonal nut

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 36

3. Screw down the fixing nuts on the feet bolts counter-clockwise and the leveling gets completed. If the

machine room has a mounting bracket, and its width does not exceed 30mm, remove the feet and fix

the cabinet onto the mounting bracket.

3.6.2

Removing the Feet and Fixing the Cabinet

NOTE: Before removing the feet and eventually fixing the cabinet, it is vital that 2 Technicians will be

required for this operation to avoid personal injury and cabinet damage.

Follow the instructions to remove the feet and fixing the cabinet;

•

Removing the feet: Use a movable wrench to loosen the fixing nuts on the four feet bolts in a

clockwise direction. Rotate the hexagon bolts at the bottom of the feet clockwise until the feet drops

from the cabinet frames.

•

Fixing the cabinet: As shown in Figure 3-11, the cabinet provides two holes (diameter: 13.5 mm) on top,

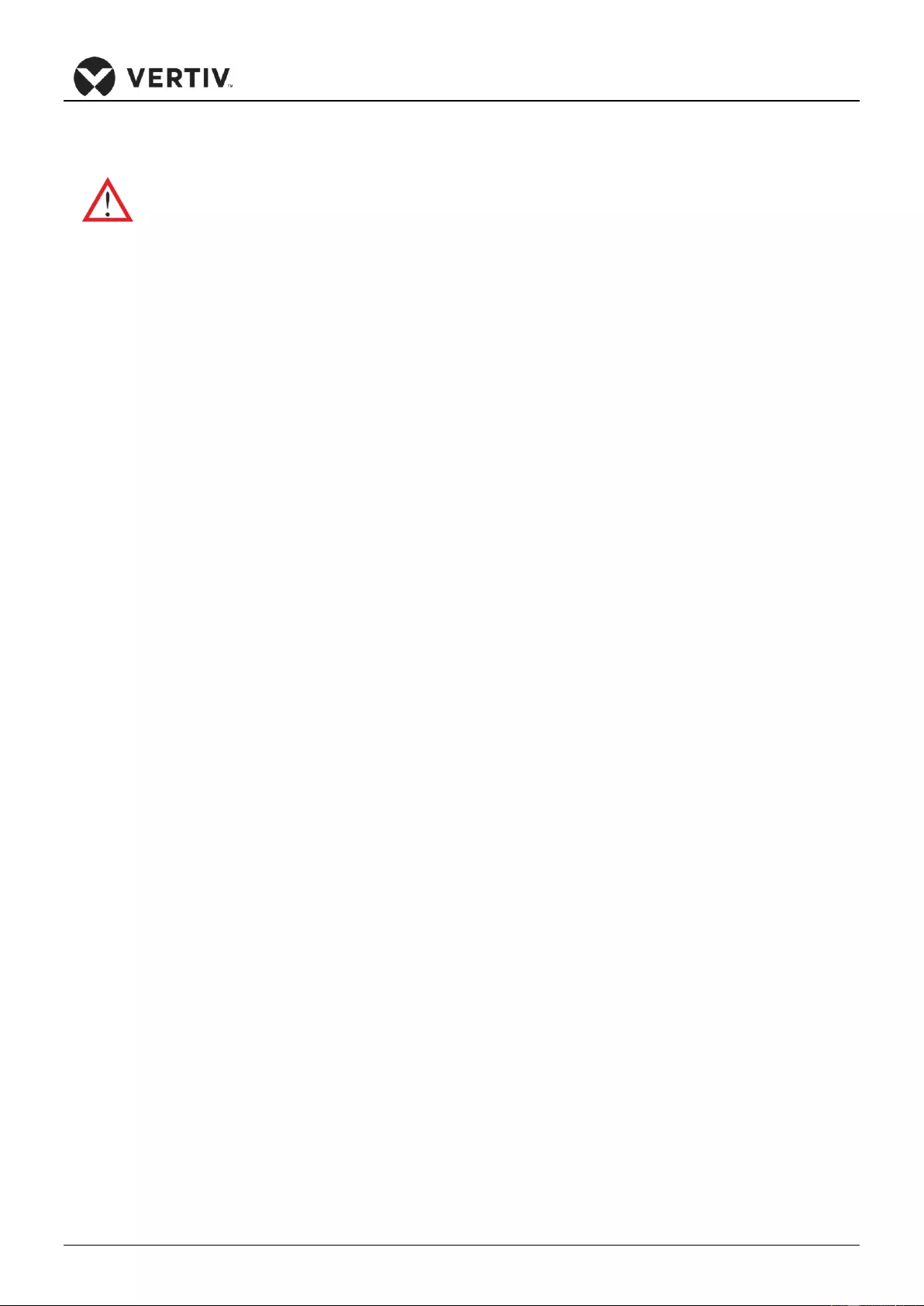

bottom, front and rear respectively.

Figure 3-11 Fixing Holes of the Cabinet

Top fixing hole

Top fixing hole

Bottom fixing hole

Bottom fixing hole

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 37

Install bolts in the four holes at the bottom to fix the cabinet onto the floor bracket of the equipment

room. Install bolts in the four holes at the top to fix the cabinet to connect the cabinet with the top

bracket of the machine room.

3.7 Cabinet Connection

The cabinet connectors come along with the accessories. Connect the unit with adjacent cabinets using

the cabinet connectors. Refer the following procedures for connecting the cabinet.

NOTE: Before connecting the cabinet, level the cabinet as mentioned in the earlier section (for more

details, refer to section 3.6.1 “Leveling the Cabinet”).

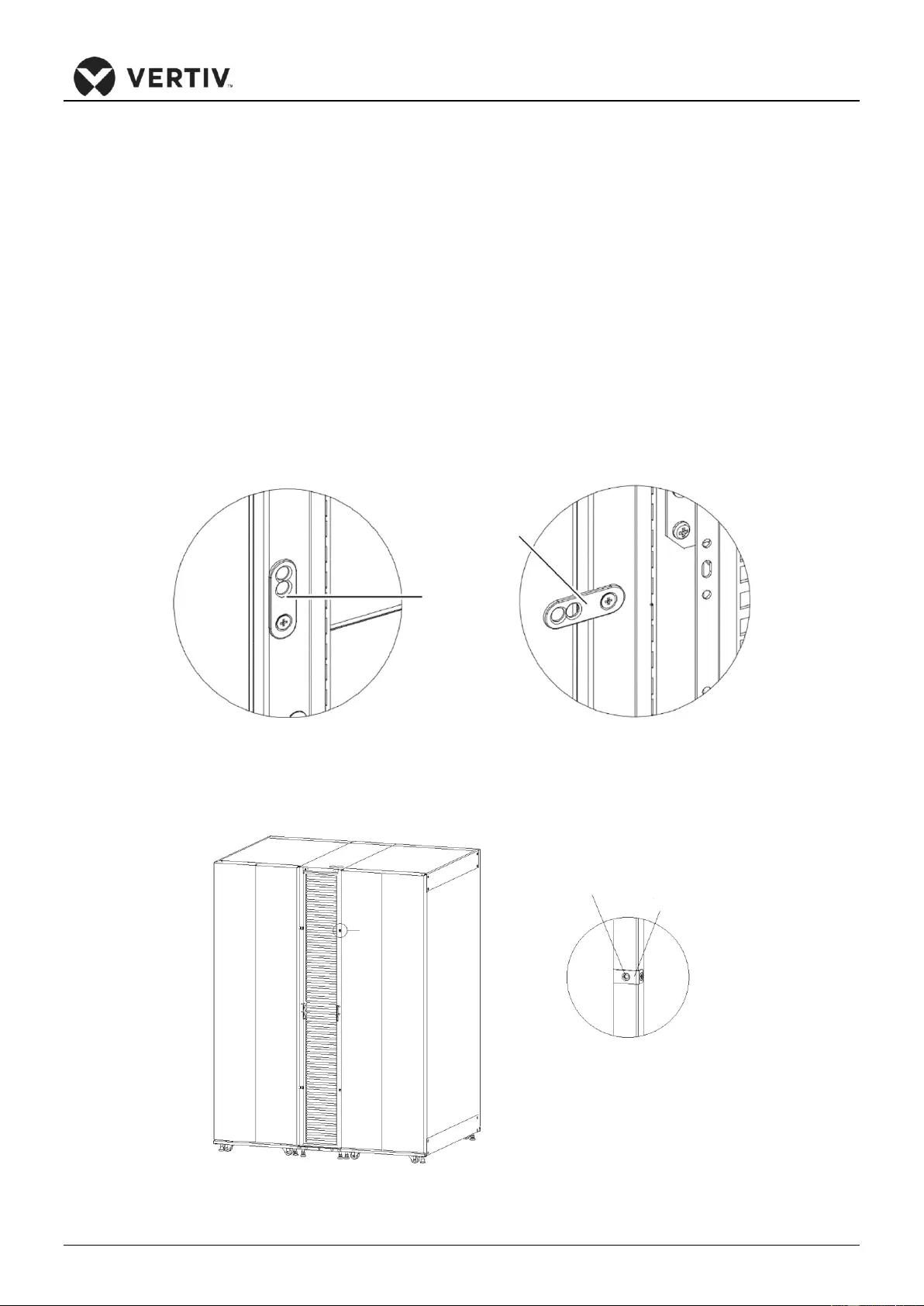

1. Loosen the fixing screw of the cabinet connector on the frame of the cabinet. Rotate the cabinet

connector to 90° horizontally. Use M5 countersunk head screws to fix it on the cabinet frame (side of

the door lock) as shown in Figure 3-12.

Figure 3-12 Rotating the Cabinet Connector

2. Use the M5 countersunk head screws to fix the cabinet connector (L-shaped) in the installation holes

of the cabinet frame (side of the hinge) and rack frame adjacent to the cabinet as shown in Figure 3-13.

Figure 3-13 Schematic Diagram for Connecting the Cabinet

3. Repeat step 1 and 2 to Install the other 6 cabinet connectors based on the same method.

Cabinet connector

Cabinet

connector

A

Mounting screw M5×12

Cabinet connector

A amplified

Mechanical Installation

Vertiv | Liebert CRD10 | User Manual 38

3.7.1

Piping Connections

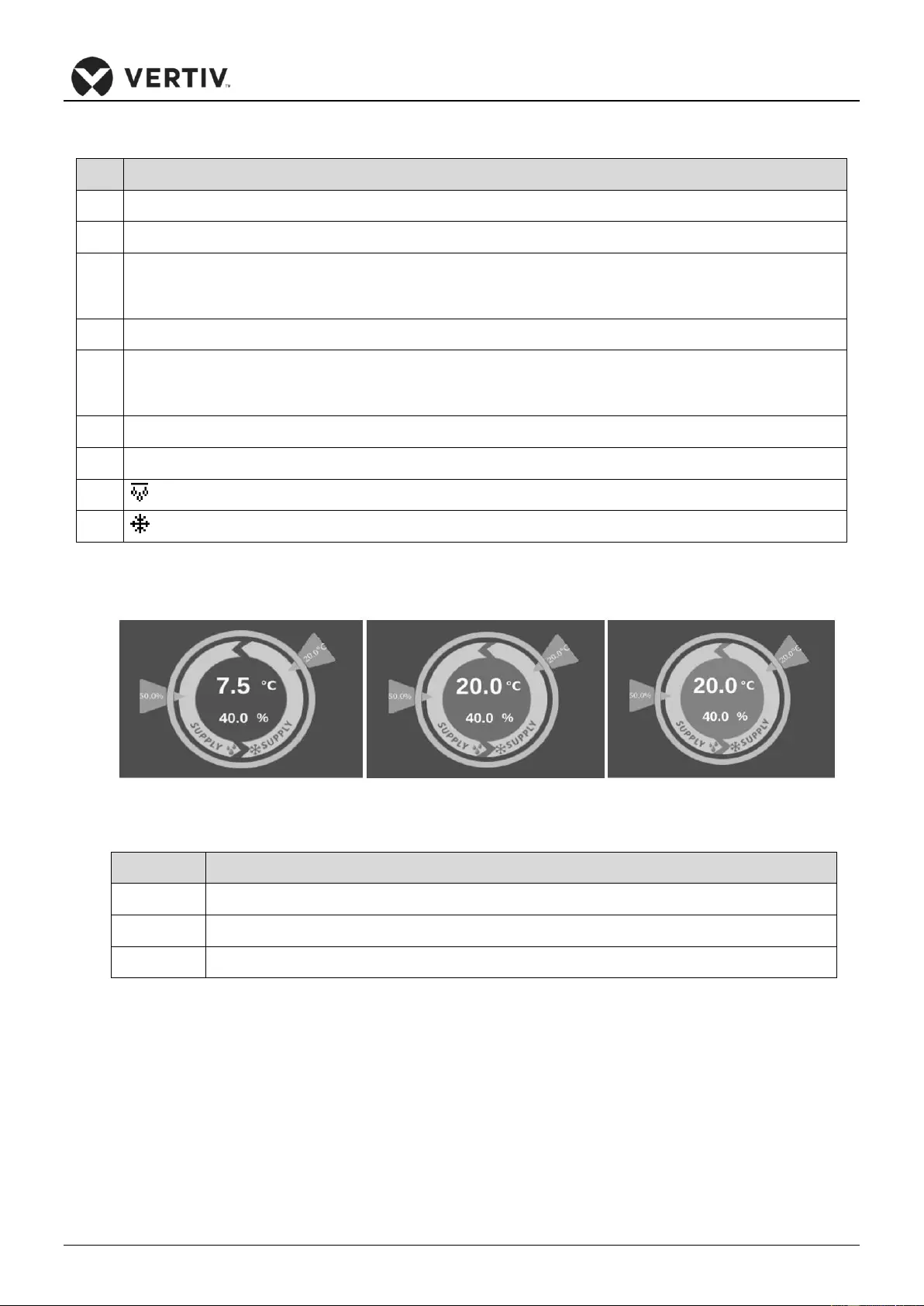

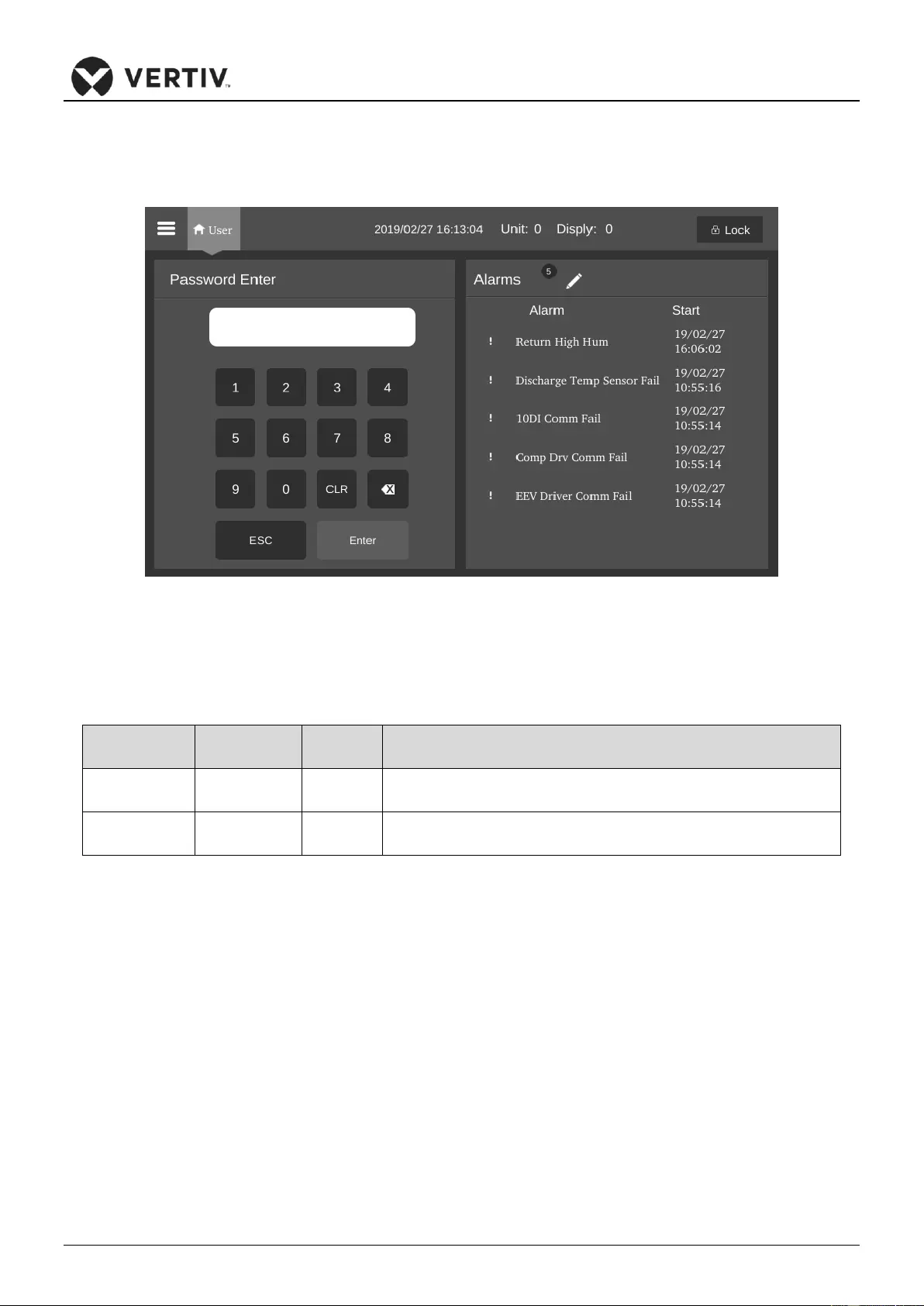

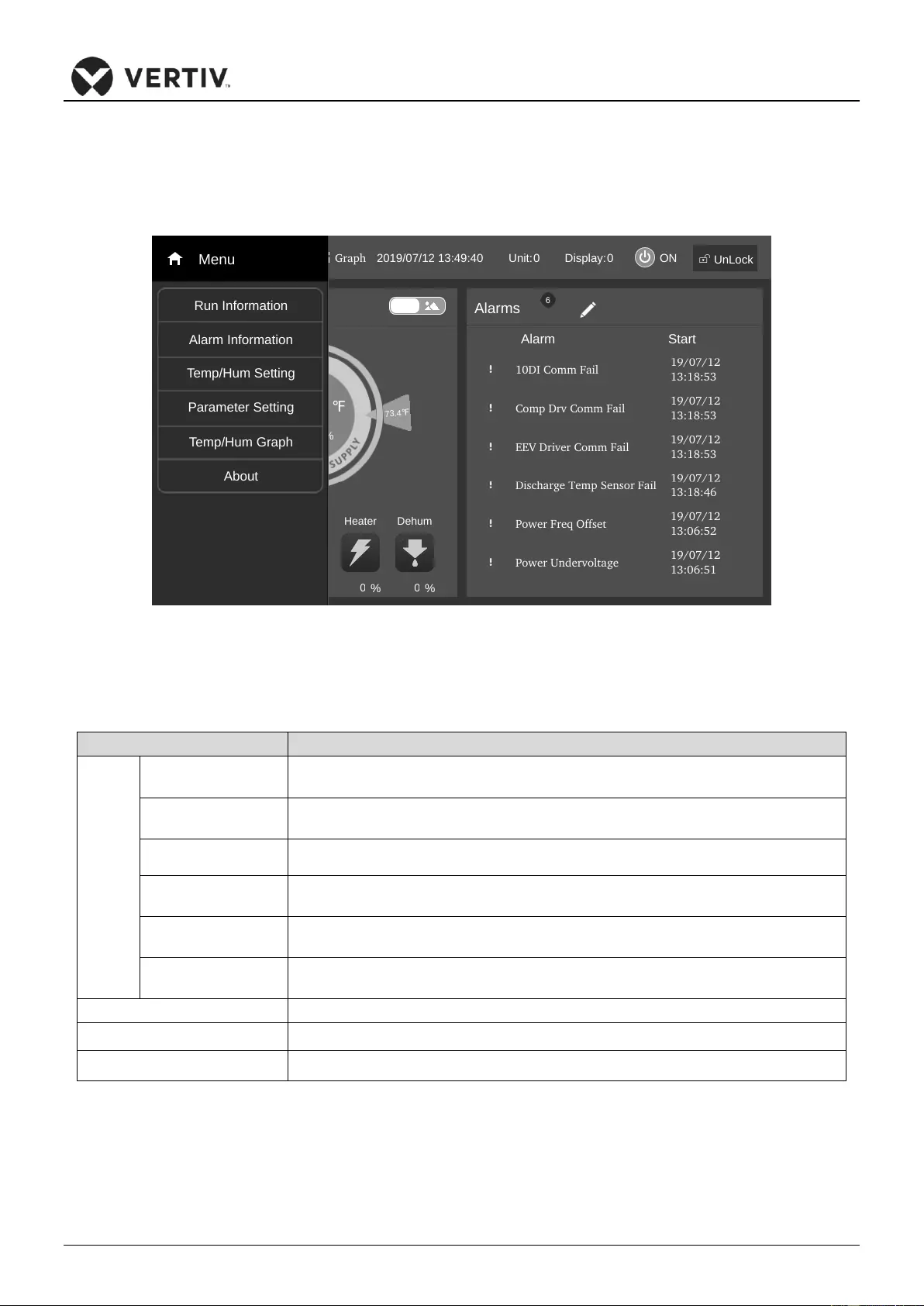

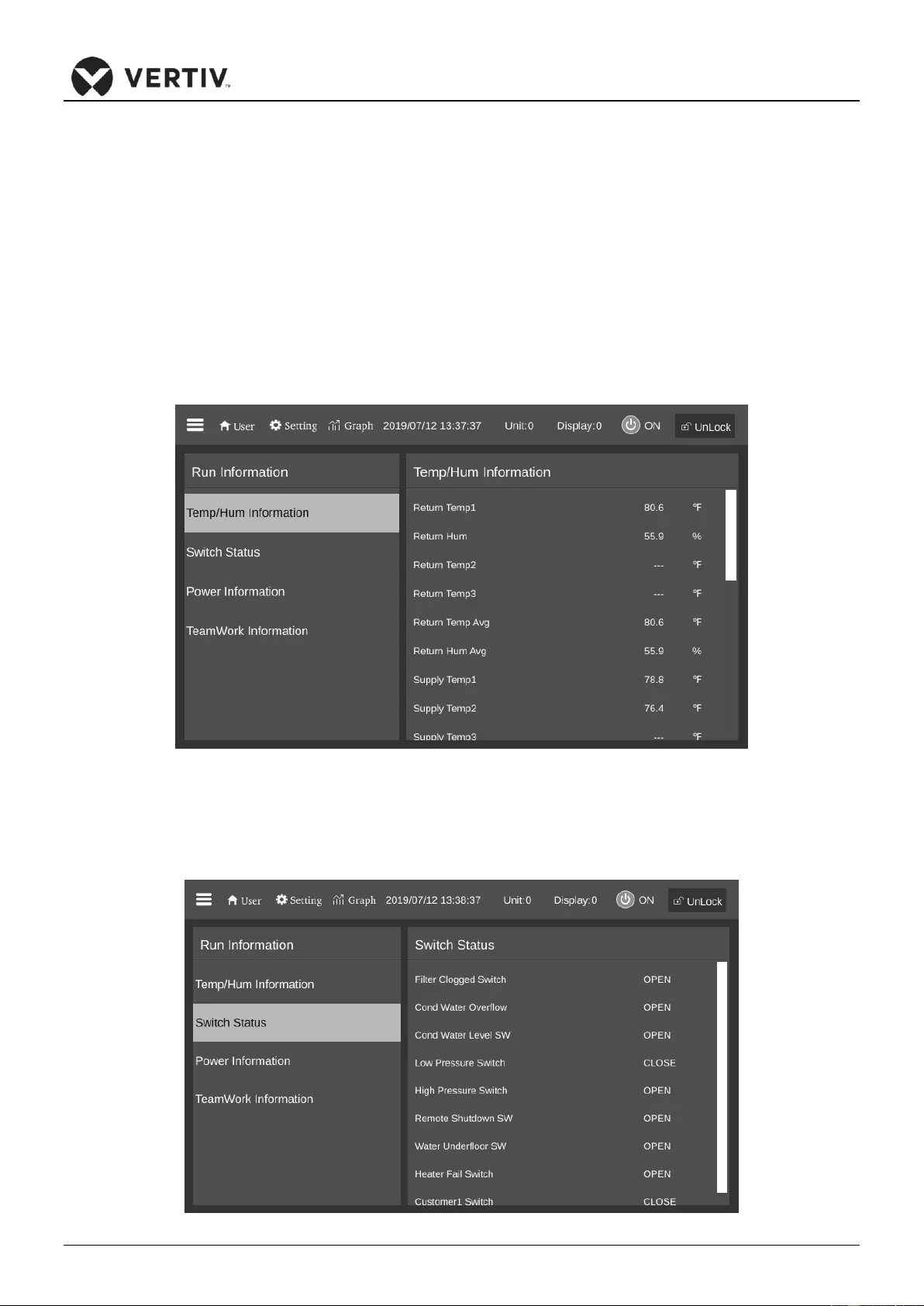

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive discharge of