Vertiv VRC102KIT User Manual

Displayed below is the user manual for VRC102KIT by Vertiv which is a product in the Rack Cooling Equipment category. This manual has pages.

Related Manuals

VRC Self-Contained Rack Cooler

VRC1 Series

User Manual

VRC Self-Contained Rack Cooler

User Manual

Version

V1.4

Revision date

Mar 18, 2020

BOM

31014115

Copyright by Vertiv Group Corp.

The content in this document is subject to change without notice. All rights, including rights of

translation, reproduced by printing, copying or similar methods, and even of parts, are reserved.

Violators will be liable for damages. All rights, including rights deriving from patent license or

registration of a utility model or design, are reserved. No part of this document may be reproduced or

transmitted in any form or by any means without the prior written consent of Vertiv Group Corp.

Notice

The purchased products, services, and features are stipulated by the contract made between Vertiv

Group Corp. and the customer. All or part of the products, services, and features described in this

document may not be within the purchasing scope or the usage scope. Unless otherwise specified in

the contract, all statements, information, and recommendations in this document are provided "AS IS"

without warranties, guarantees or representations of any kind, either express or implied. The

information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure the accuracy of the contents, but all statements, information,

and recommendations in this document do not constitute a warranty of any kind, express or implied.

Vertiv

United States

Australia & New

Indonesia

Malaysia

Singapore

Service Calls;

Zealand

Service Calls;

Service Calls;

Service Calls;

1-800-543-2378

Service Calls;

0817 988 2288

19 211 1668

64674218

General Inquiries;

1300 367 686

General Inquiries;

General

Inquiries;

General Inquiries;

1-800-543-2778

General Inquiries;

021 251 3003

3 7884 5000

64674218

1-800-222-5877

1800 065 345

Romania: 800477000

Egypt, Bahrain: 390499717744

Croatia: 800989019

Greece: 80044146622

Qatar: 800100439

UAE: 800035702985

Ghana: 242426263

Saudi Arabia: 8008446628

Nigeria: 7080601125

Non-listed Countries: 49872327750

Turkey: 800448826888

(Austria, Benelux, Czech Republic, France, Germany, Hungary, Ireland, Italy, Poland, Russia, Spain, Sweden,

Switzerland, UK, South Africa): 80011554499

Website: www.vertiv.com;

For Technical Support, users may contact the nearest Vertiv local sales office or service center.

Purpose of the Document

This document applies to the VRC1 series of cooling solutions which maintain an optimal environmental

control mainly for technological ecosystems at minimal operating costs. This document gives an overview

of the technical specification. The figures used in this document are for reference only. Please read this

manual carefully.

Important Safety Instructions

The important safety instructions that should be followed during the installation and maintenance of the

VRC-Self-contained rack cooler are described in the following sections.

Read the manual prior to installation and operation of the unit. Only qualified personnel should move,

install, or service this equipment.

The user reads all of the precautions, compliance, and safety measures before working on the equipment.

The unit control must be used exclusively for the purpose for which it is intended; the manufacturer takes

no liability for incorrect use or modification to the unit control.

This manual is retained for the entire service life of the machine. The user must read all of the precautions,

danger, warnings, and cautionary measures mentioned in the manual prior to carrying out any operations

on the machine. Before performing any maintenance operation, switch off the machine to eliminate risks

such as electrical shocks, burns, automatic restarting, moving parts, and remote control.

Adhere to all the Warnings and Cautionary measures included in this manual. In the following sections,

look at the various cautionary measures and warnings that need to be read carefully prior to installing or

operating the system.

WARNING! Only trained and qualified personnel must be allowed to install, maintain, and

operate the unit.

WARNING! The sharp edges, sharp angles of the object, and bare buckle can result in severe

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

WARNING: Risk of unit falling over. Improper handling can cause equipment damage, injury or

death. Read all the guidelines pertaining to the system before unpacking, moving, lifting or

installing the components. Read the labels on the unit carefully to understand the safety

measures prior to handling the containment.

WARNING! Risk of electric shock. Can cause injury or death. Open all local and remote electric

power-supply disconnect switches and verify that power is Off with a voltmeter before working

within the condensate pump electrical connection enclosure. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the Liebert® controller.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components

require and receive power even during the “Unit Off” mode of the controller. The only way to

ensure that there is NO voltage inside the unit is to install and open a remote disconnect switch.

Refer to unit electrical schematic. Follow all local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local

and remote electric power supply disconnect switches and verify with a voltmeter that power is

off before working within any electric connection enclosures. Service and maintenance work

must be performed only by properly trained and qualified personnel and in accordance with

applicable regulations and manufacturers’ specifications. Opening or removing the covers to any

equipment may expose personnel to lethal voltages within the unit even when it is apparently

not operating and the input wiring is disconnected from the electrical source.

WARNING! Do not power on the unit until authorized technical personnel have confirmed that

the unit connections are correct.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause

overheated wire and electrical connection terminals resulting in smoke, fire, equipment and

building damage, injury or death. Use correctly sized copper wire only and verify that all

electrical connections are tight before turning power On. Check all electrical connections

periodically and tighten as necessary.

WARNING! During the operation of the precision air conditioner, very high voltage may be

present in the equipment. Adhere to all of the notes and warnings marked on the equipment or

contained in this manual, which may otherwise lead to an injury or fatality.

WARNING! Only qualified maintenance personnel can operate and handle the equipment. All

maintenance and operation must follow the local laws, especially the regulations about the

electric power, refrigeration, and production.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan blades have stopped rotating before working

in the unit cabinet or on the fan assembly.

WARNING! Risk of hair, clothing and jewelry entanglement with high speed rotating fan blades.

Can cause equipment damage, serious injury or death. Keep hair, jewelry and loose clothing

secured and away from rotating fan blades during unit operation.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel who have been specially-trained in the installation of air-conditioning

equipment and who are wearing appropriate, OSHA-approved PPE.

WARNING! Risk of contact with extremely hot and/or cold surfaces. Can cause injury. Verify that

all components have reached a temperature that is safe for human contact or wear appropriate,

OSHA-approved PPE before working within the electric connection enclosures or unit cabinet.

Perform maintenance only when the system is de-energized and component temperatures have

become safe for human contact.

WARNING! Certain circuits carry lethal voltages. Only professional technicians are allowed to

maintain the unit. Extra precautions should be taken when troubleshooting a live unit. Be

particularly careful troubleshooting with the unit’s power switched on.

WARNING! If jumpers are used for troubleshooting, make sure to remove the jumpers after

troubleshooting. If the connected jumpers are not removed, they may bypass certain control

functions causing damage to the equipment.

CAUTION: The center of gravity of the unit is inclined, therefore, when moving the unit adjust

the bearing position of the forklift or hand pallet truck.

CAUTION: Comply with the manufacturer’s instructions before and during maintenance. Failure

to observe this will result in the warranty becoming void. Adherence to the safety instructions is

mandatory to ensure personnel safety and prevent any environmental impact apart from

equipment damage. Unsuitable components will impede equipment performance and may

cause equipment shutdown. Therefore, Vertiv recommends the use of Vertiv OEM or

Vertiv-approved components.

CAUTION: Switch off the VRC1 unit and then switch off the power input during equipment

maintenance. Switch off the equipment power unless the testing devices need power.

CAUTION: Avoid touching or having skin contact with the residual gas and oils in the

compressor. Wear long rubber gloves to handle contaminated parts. The air conditioning system

contains refrigerant. The release of refrigerant is harmful to the environment.

Preface

The Vertiv VRC1 series is a compact, integrated, rack mounted precision cooling unit that has the

evaporator and the condenser unit installed in one enclosure. It is designed specifically to be installed

inside a 19” EIA server rack and is developed based on the Global R&D Platform of Vertiv Group Corp.

This manual focuses on the user instructions, including overview, instructions for installation preparations,

mechanical installation, electrical installation, system startup and commissioning, controller operation,

system operation and maintenance, and troubleshooting, etc.

Please read this manual carefully before installing, maintaining and troubleshooting, especially the warning

information in the manual.

TABLE OF CONTENTS

Table of Contents

1 Product Overview .............................................................................................................................................. 1

1.1 Product Introduction ............................................................................................................................. 1

1.2 Model Description ................................................................................................................................. 1

1.3 Model Nomenclature ............................................................................................................................ 2

1.4 Components .......................................................................................................................................... 2

1.5 Technical Specifications ......................................................................................................................... 5

2 Pre-Installation ................................................................................................................................................... 8

2.1 Fittings ................................................................................................................................................... 9

2.2 Self-Prepared Material .......................................................................................................................... 9

2.3 Transportation and Movement ............................................................................................................. 9

2.4 Unpacking ............................................................................................................................................ 11

2.5 Equipment Installation Room Requirements ...................................................................................... 13

2.6 Environment ........................................................................................................................................ 13

2.7 Installation Space Requirements ......................................................................................................... 14

2.8 Condenser Airflow Clearance Requirement ........................................................................................ 14

2.9 Weight Bearing Capacity ..................................................................................................................... 15

2.10 Inspection ............................................................................................................................................ 15

3 Mechanical Installation (Site Preparation)....................................................................................................... 16

3.1 Installation Notes ................................................................................................................................ 16

3.2 System Installation Layout ................................................................................................................... 16

3.3 Installing the VRC Unit into the Rack ................................................................................................... 17

3.4 Connecting the Accessories................................................................................................................. 20

4 Electrical Installation ........................................................................................................................................ 27

4.1 Installation Notes ................................................................................................................................ 27

4.2 Cable from the Power Supply Connection .......................................................................................... 28

4.3 Installation Inspection ......................................................................................................................... 30

5 Controller Operation Instructions .................................................................................................................... 31

5.1 LCD Screen ........................................................................................................................................... 31

5.2 Control Buttons ................................................................................................................................... 31

5.3 ON Screen ............................................................................................................................................ 32

5.4 Normal Screen ..................................................................................................................................... 32

5.5 Password Interface .............................................................................................................................. 32

5.6 Unit Working Icons .............................................................................................................................. 33

5.7 Menu ................................................................................................................................................... 33

6 Startup Commissioning .................................................................................................................................... 37

6.1 Preparations Before Commissioning ................................................................................................... 37

6.2 Start-up Inspection Checklist ............................................................................................................... 37

6.3 System Commissioning ........................................................................................................................ 37

6.4 Commissioning Complete Inspection .................................................................................................. 38

7 System Operation and Maintenance ............................................................................................................... 39

7.1 Safety Instructions ............................................................................................................................... 39

7.2 Electrical Inspection ............................................................................................................................ 40

7.3 Main Components Maintenance ......................................................................................................... 40

7.4 Maintenance Inspection Checklist ...................................................................................................... 42

7.5 Monthly Routine Inspection Items ...................................................................................................... 42

7.6 Routine Inspection Items (Semi-annually) .......................................................................................... 43

7.7 System Diagnosis Testing ..................................................................................................................... 43

7.8 Electrical Maintenance ........................................................................................................................ 44

7.9 Controller Connections Maintenance ................................................................................................. 44

7.10 Filters Maintenance Guidance ............................................................................................................. 45

7.11 Maintenance Guidance for Fan Kit ...................................................................................................... 47

7.12 Cooling System Maintenance .............................................................................................................. 48

8 Troubleshooting ............................................................................................................................................... 49

8.1 Troubleshooting................................................................................................................................... 49

8.2 Fan Troubleshooting ............................................................................................................................ 50

8.3 Fault Diagnosis and Handling of Electronic Expansion Valve .............................................................. 50

8.4 Fault Diagnosis and Handling of the Air Conditioning System ............................................................ 50

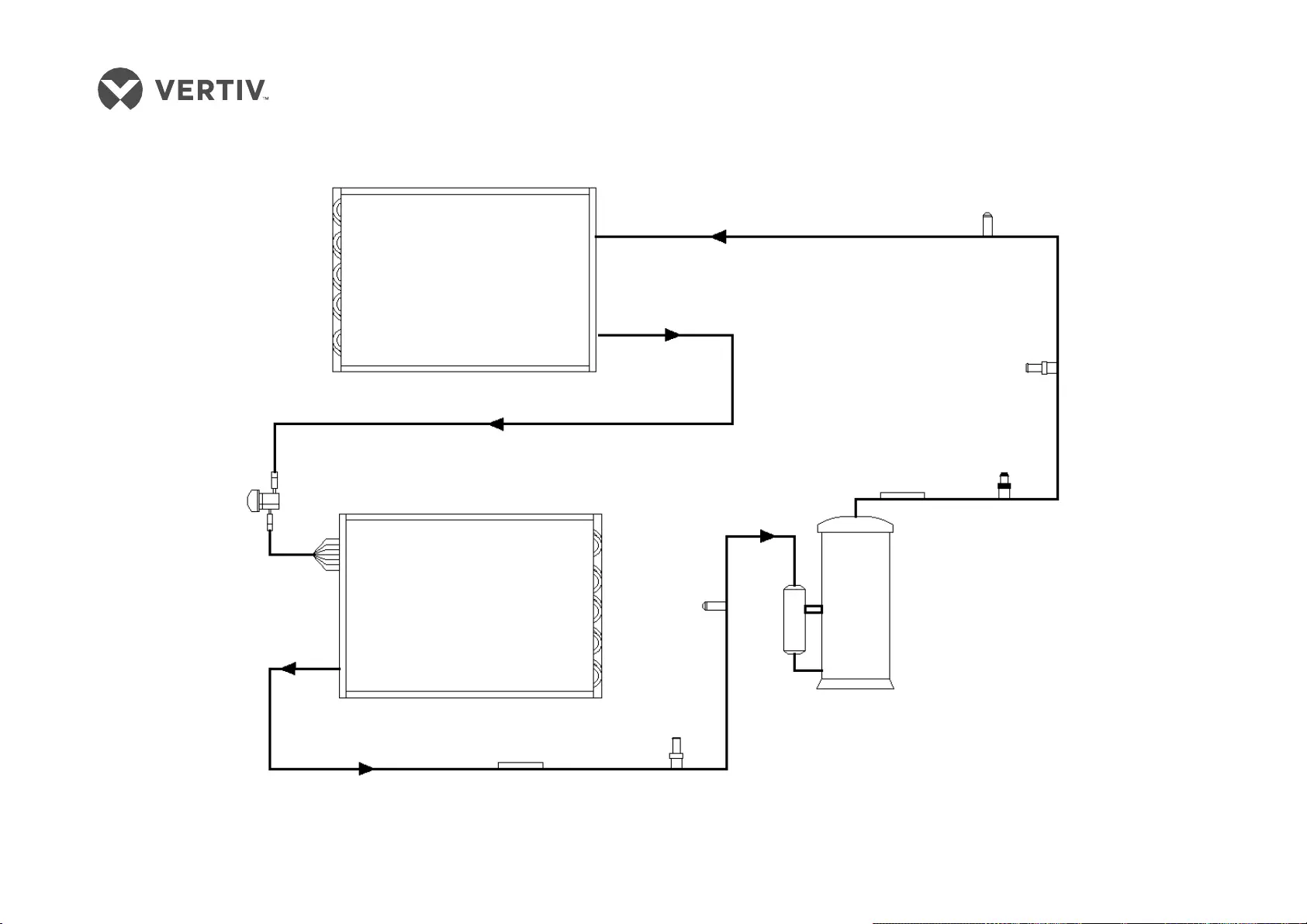

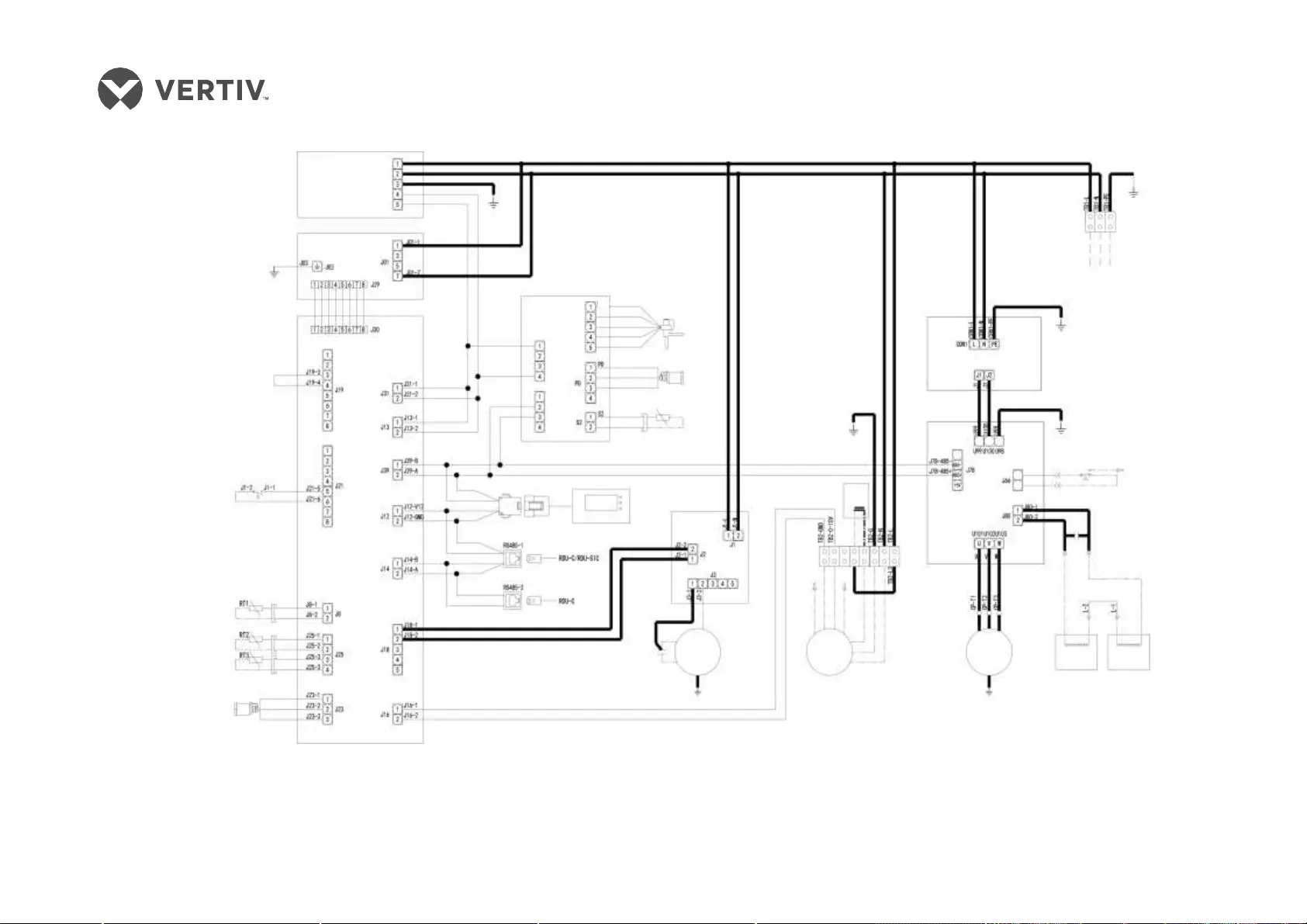

Appendix I: System Diagram.................................................................................................................................... 52

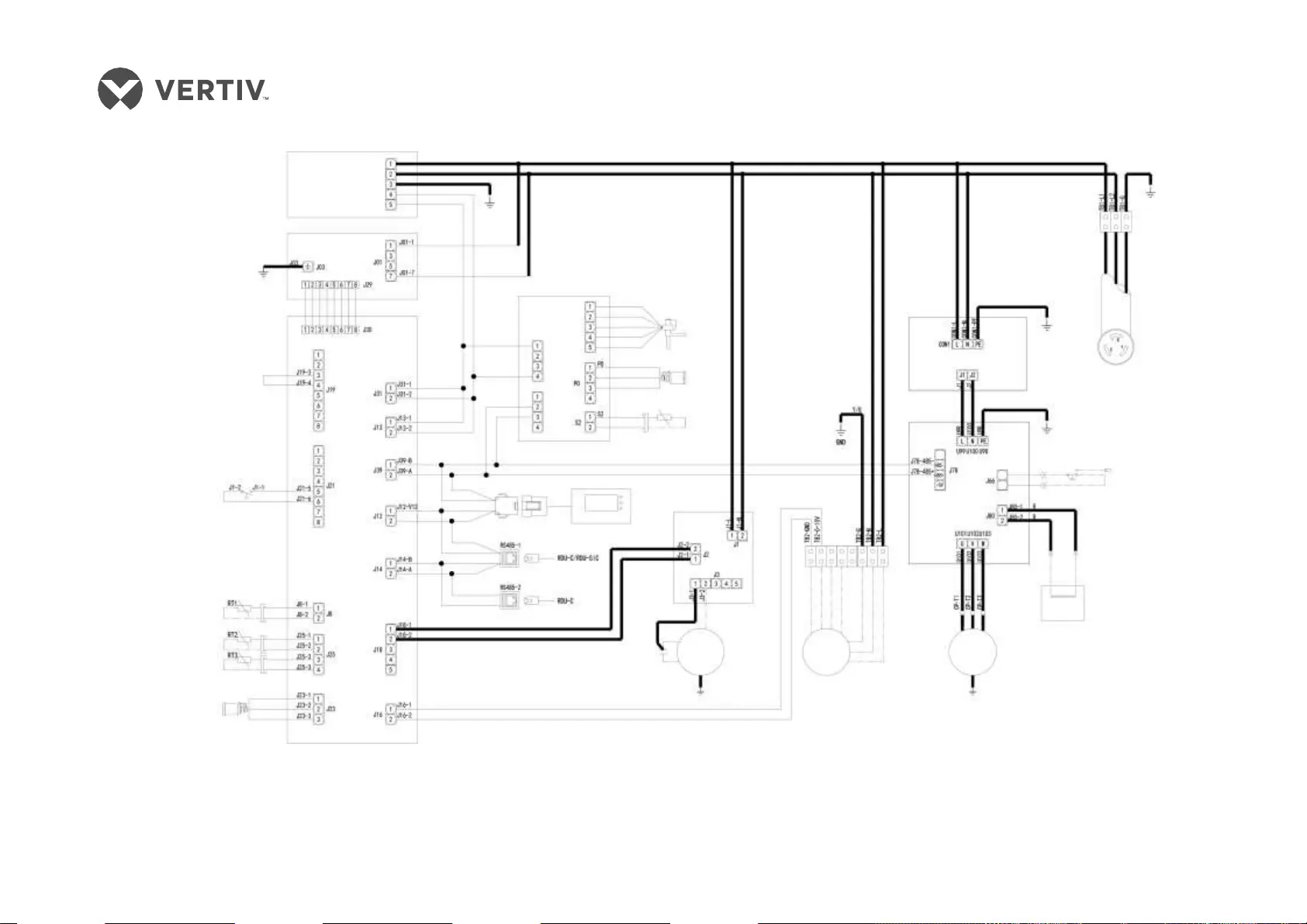

Appendix II: Wiring Diagram(VRC100 Unit) ............................................................................................................. 53

Appendix III:Wiring Diagram(VRC101 Unit)............................................................................................................. 54

Appendix IV:Wiring Diagram(VRC102 Unit) ............................................................................................................ 55

Suppliers Declaration of Conformity ....................................................................................................................... 56

PART-I

GENERAL INFORMATION

1

Vertiv I VRC Self-Contained System I User Manual

1 Product Overview

The VertivTM VRC - VRC100, VRC101 or VRC102 is a compact, integrated, rack mounted cooling unit

(hereinafter referred to as “VRC1 Series”) is engineered for utilization in a 19” EIA server rack. The unit

should be used after reading the manual or consulting Vertiv. This chapter introduces the product

description, model description, product appearance, and main components of the cooling unit.

1.1 Product Introduction

The cooling unit is an integrated precision cooling unit that is a pre-engineered and pre-fabricated cooling

solution for server racks. It is specifically designed for the cooling demands of the equipment mounted

inside the rack, is precisely controlled and has a conducive and safe operating environment. The precision

air conditioner features high reliability, high sensible heat ratio and high airflow. The unit has the following

attributes:

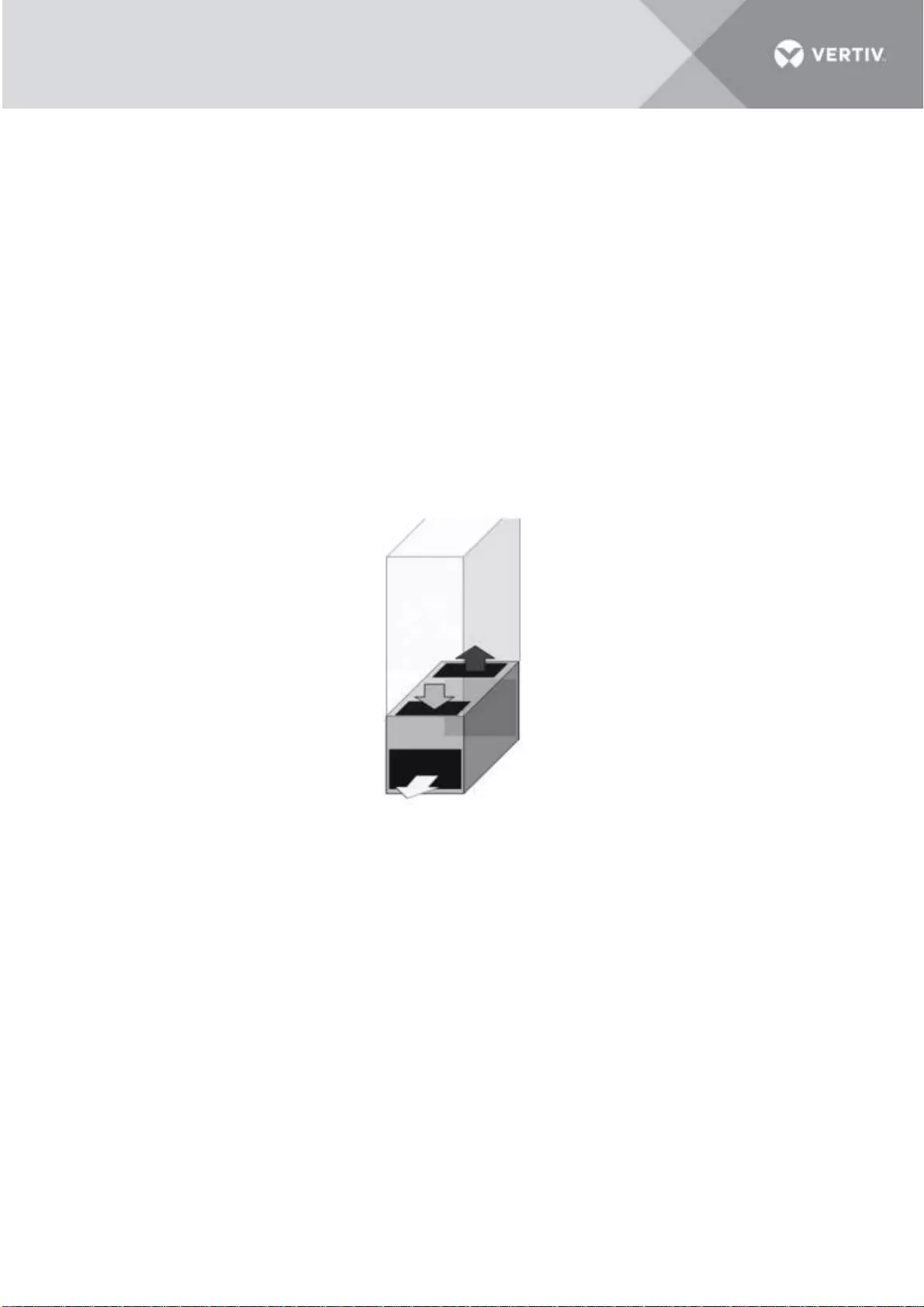

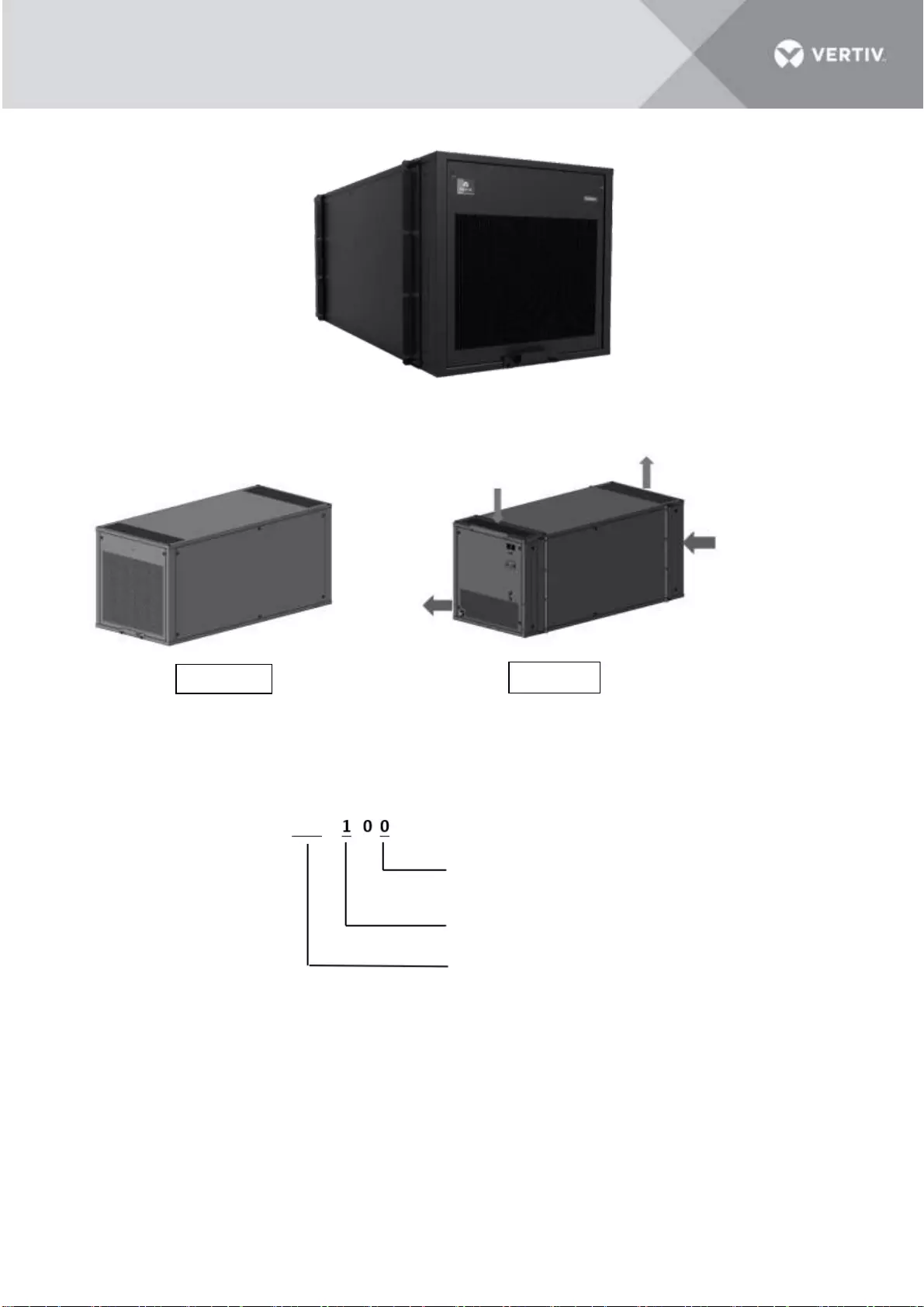

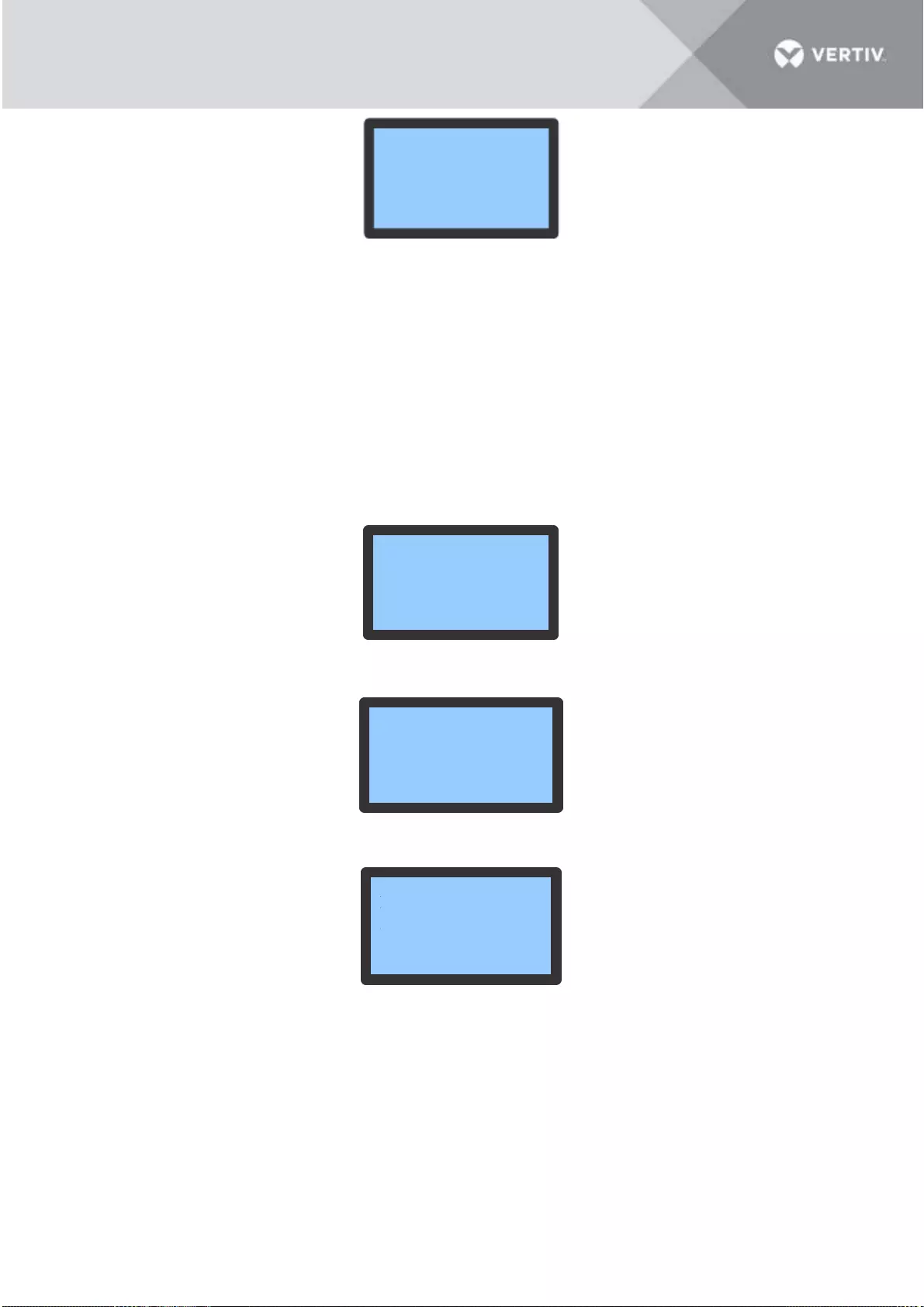

• The cooling unit is installed at the bottom of the cabinet. The airflow path is depicted in Figure 1-1.

The hot return air enters the unit from the rear side of the cabinet and the conditioned cold air is

supplied from the front of the unit directly in front of the servers.

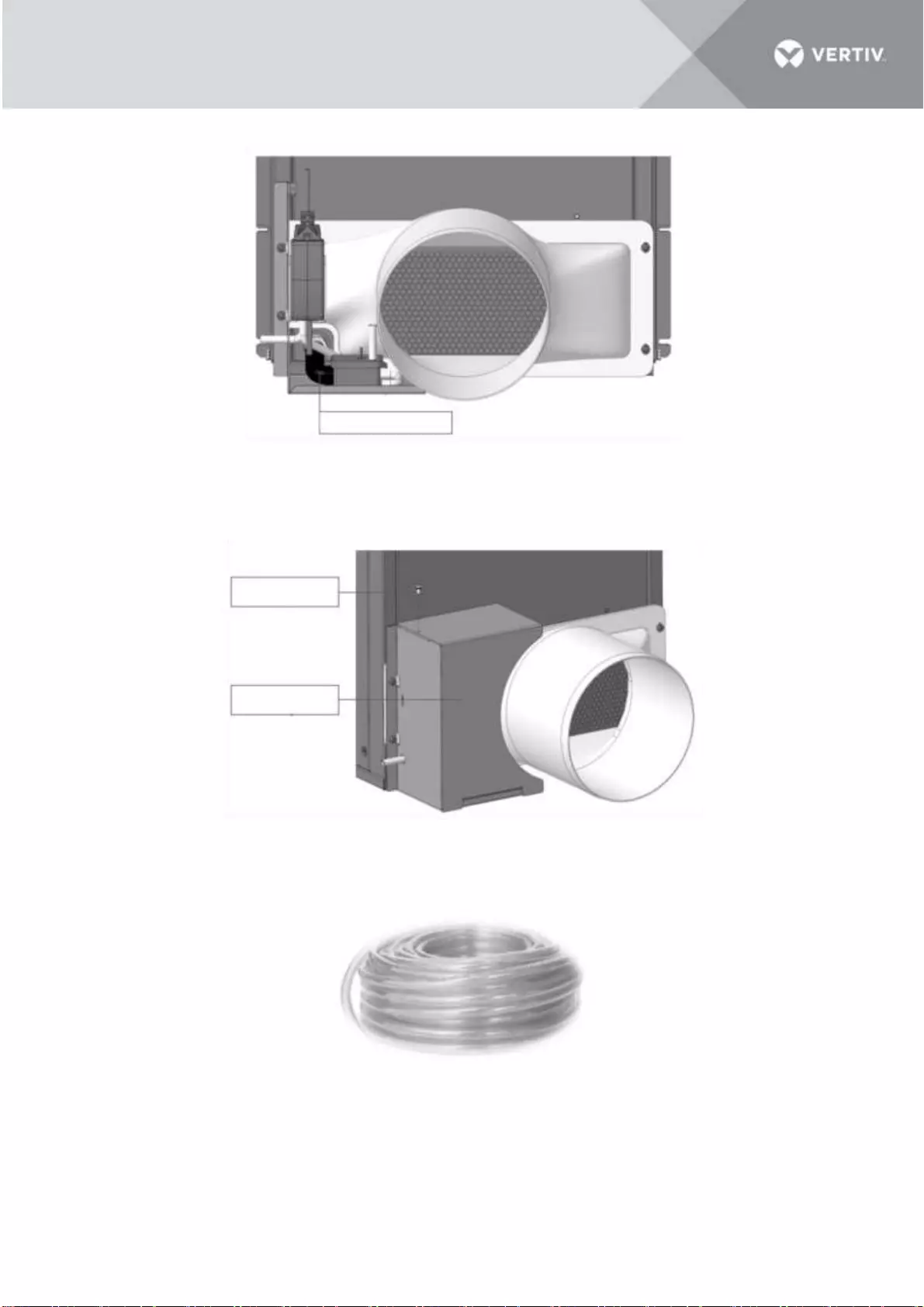

Figure 1-1 VRC unit in cabinet

• The evaporator and heat rejection unit are placed in one enclosure. It’s easy to install being a

plug-and-play unit, eliminating the installation work such as electrical wiring, vacuuming and

refrigerant charge on-site and refrigerant piping.

• The cooling capacity varies from 25% to 100%, approximately 0.9 kW to 3.6 kW. It’s designed to

efficiently cater to part-load or variable cooling loads.

• The unit is designed by Vertiv for high efficiency and reliability, and includes the variable capacity

inverter compressor, electronic expansion valve, variable speed EC-fan, and controller.

• The evaporator EC fan provides energy savings by smoothly varying the fan speed to deliver the

airflow required to match the cooling load.

• The condenser fan speed ranges from 30% to 100% in sync with the variation in the compressor

cooling capacity.

1.2 Model Description

I.T. Space inside cabinet

Evaporator air

outlet

Evaporator

air inlet

Front

Rear

Condenser air outlet

2

Vertiv I VRC Self-Contained System I User Manual

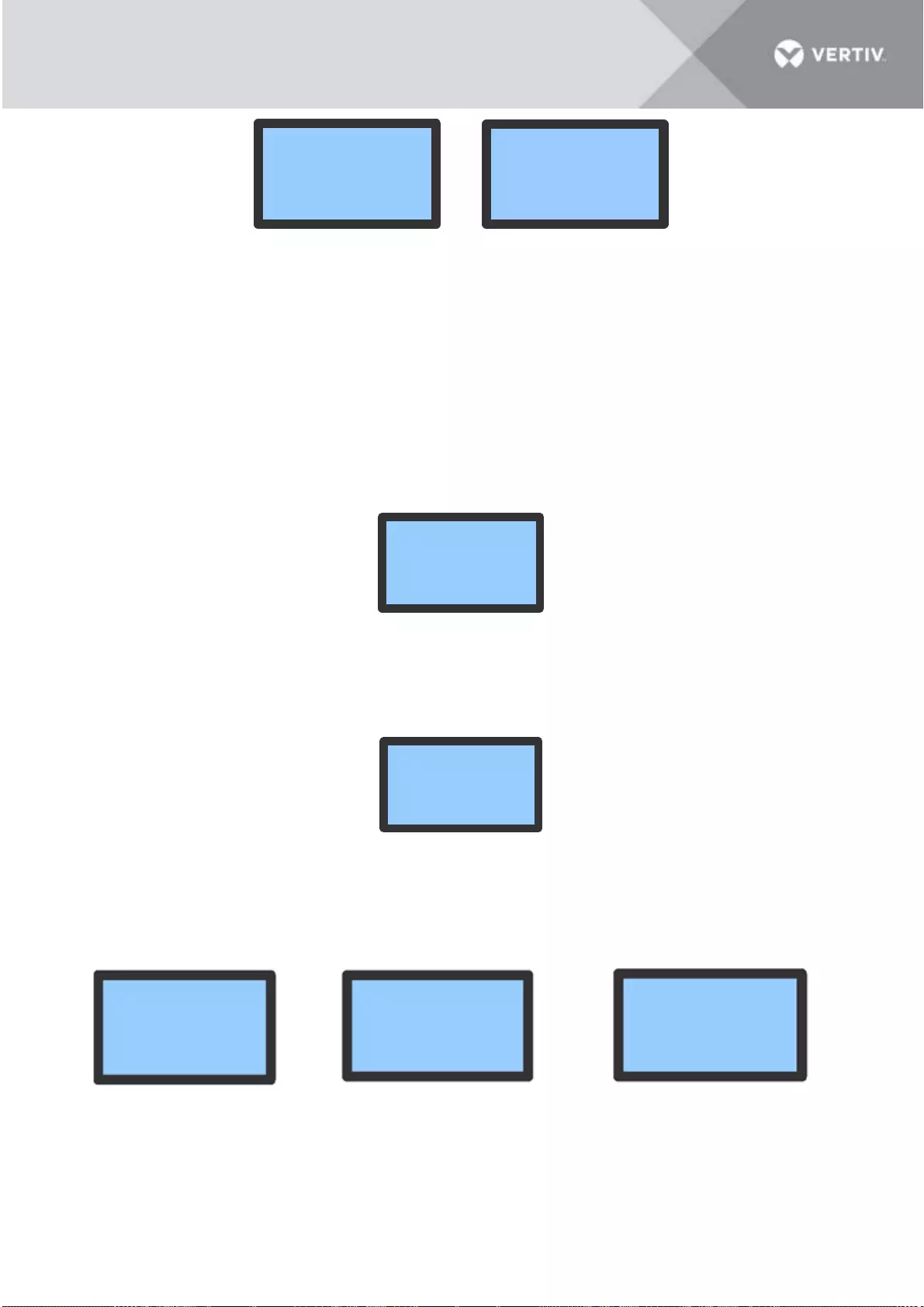

The physical appearance of the cooling module is shown in Figure 1-2.

Figure 1-2 Appearance of the VRC precision air conditioner

The rear view and front view of cooling module are shown in Figure 1-3.

Figure 1-3 Front view and rear view of the cooling unit

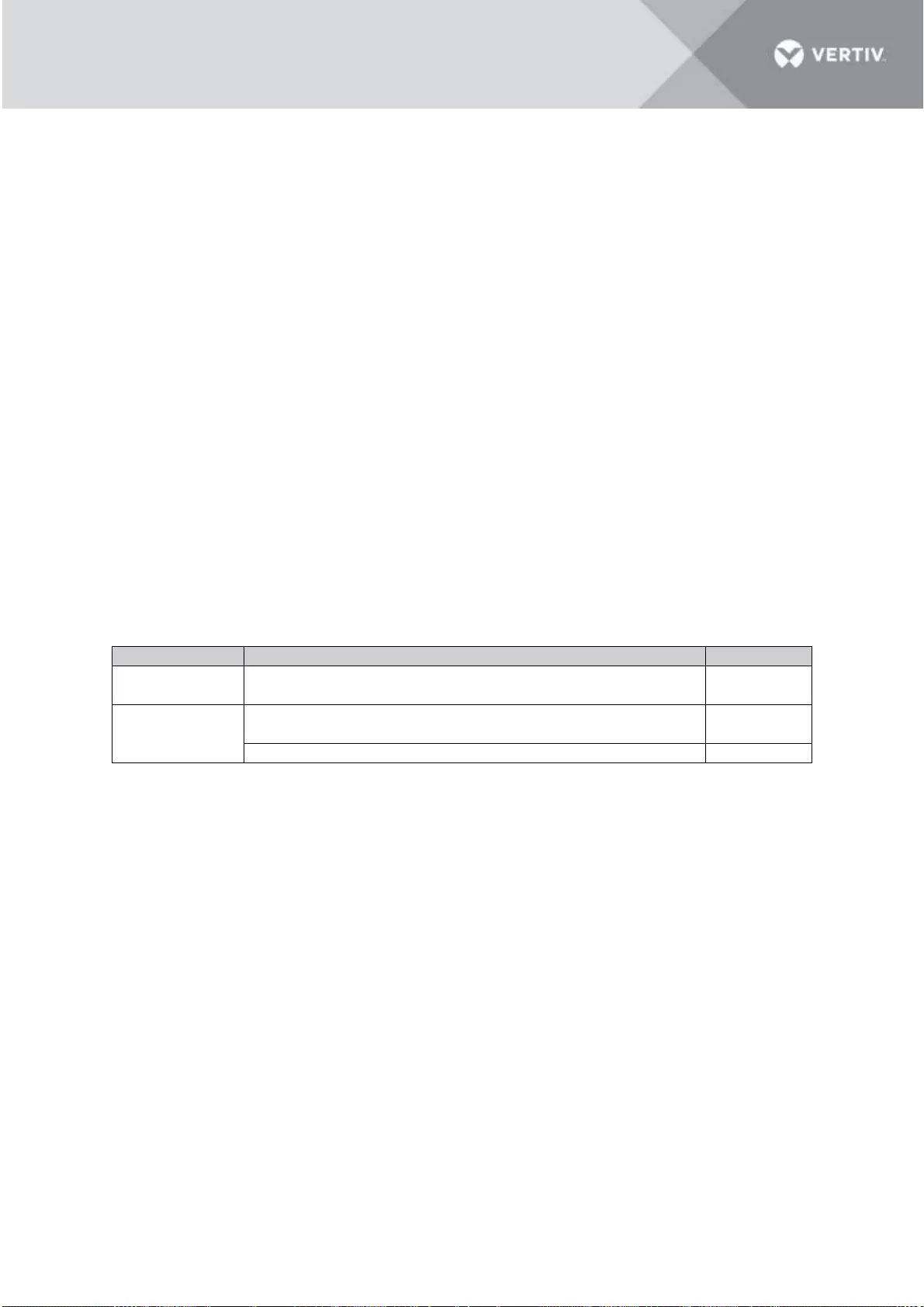

1.3 Model Nomenclature

The nomenclature of the VRC units is shown in Figure 1-4.

Figure 1-4 Nomenclature

1.4 Components

The major components of the cooling module include the evaporator coil, evaporator EC fan, electronic

expansion valve, compressor, condenser coil, and condenser AC fan which are placed in the VRC unit as

shown below.

Rear View

Front View

Supply air

Return air

Condenser in

Evaporator Side

Condenser out

0 = 120 V, 1 Ph, 60 Hz

1 = 208/230 V, 1 Ph, 60 Hz

2 = 230 V,1 Ph, 50/60 Hz

1 = Self Contained Cooling Module

VRC=Vertiv Rack Cooler

VRC

3

Vertiv I VRC Self-Contained System I User Manual

Figure 1-5 Schematic diagram of internal parts of cooling section

• Evaporator Coil

The design of the V shaped evaporator coil provides maximum surface area for heat transfer which

provides a high sensible heat ratio (SHR) of > 0.9. The coil is constructed from copper tubes with aluminum

fins. Low air pressure difference across the coil reduces fan energy even at higher air flow rates, and the

coil section is light and compact.

• Condensate Drain Tray

With a metal condensate drain tray placed under the coil assembly, condensation drains to a

condensate outlet connection.

• Variable Speed Evaporator EC Fan

The cooling module is equipped with a high-efficiency EC fan made of aluminum

that delivers high airflow rates to meet the airflow demands during the entire

time of operational. The EC fan has a smooth speed variation across its operating

speeds that work in synchronization with the entire system components to deliver

precise output capacity.

• Electronic Expansion Valve

The system is incorporated with an electronic expansion valve that monitors

temperature and pressure signals simultaneously to maintain precise adjustment

of the refrigerant flow. The electronic expansion valve ensures even flow

distribution from each end.

Evaporator

EC fan

Condenser

AC fan

Condenser

Compressor

Evaporator

4

Vertiv I VRC Self-Contained System I User Manual

• Compressor

The cooling module is equipped with a variable speed inverter rotary compressor that

works on R410A refrigerant and which varies its cooling output capacity as per the

cooling demands.

• Condenser Coil

The L-shaped condenser coil is designed for a maximum contact area. It is made of copper tubes with an

aluminum fin configuration.

• Condenser Fan

The condenser unit is equipped with an AC fan which varies the operating speed

with the cooling variations of the compressor to maintain a suitable condensing

pressure. The condenser fans are made of metallic material for prolonged life and

durability..

5

Vertiv I VRC Self-Contained System I User Manual

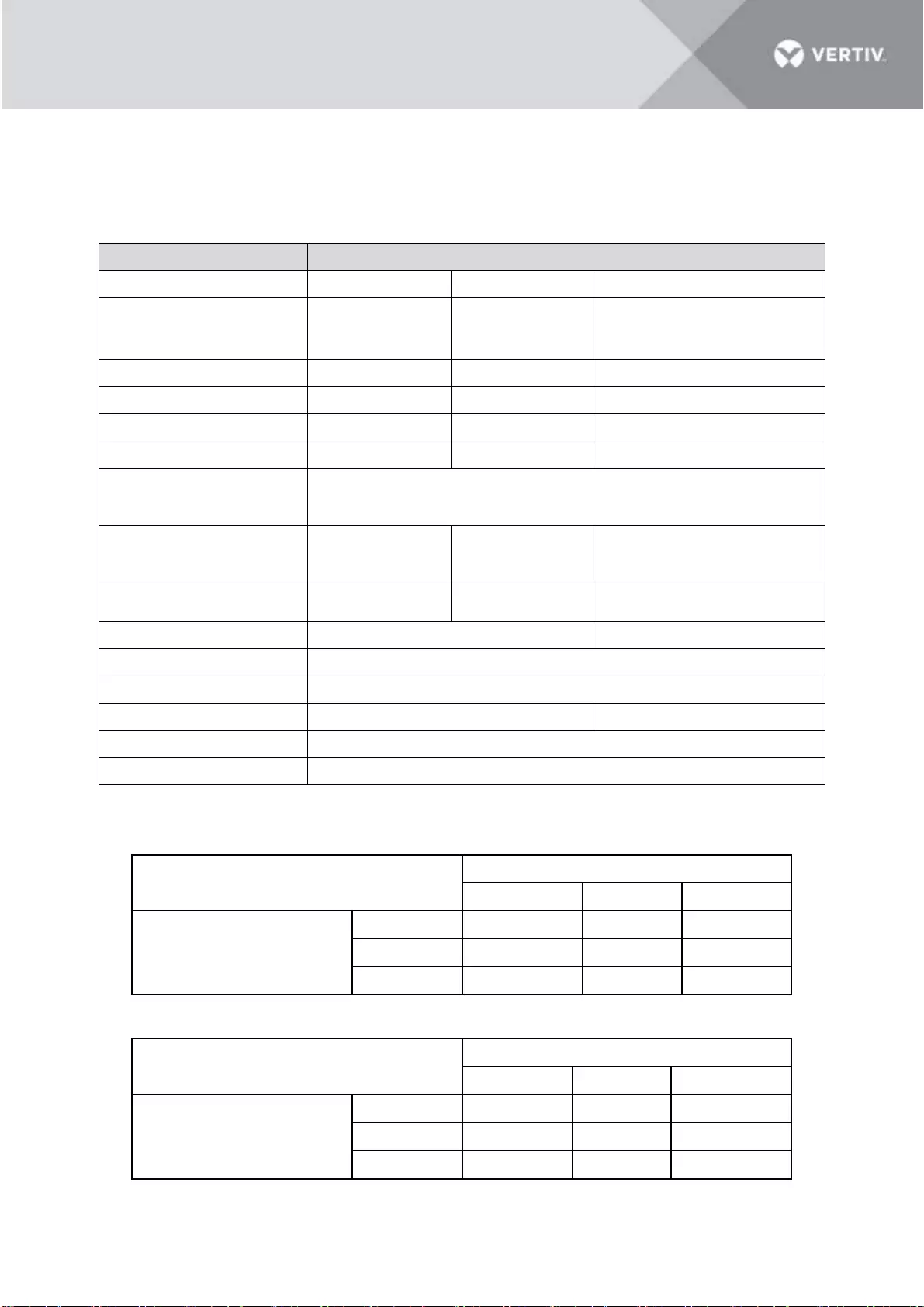

1.5 Technical Specifications

The detailed technical specifications which include the mechanical and the electrical details are mentioned

in the below table:

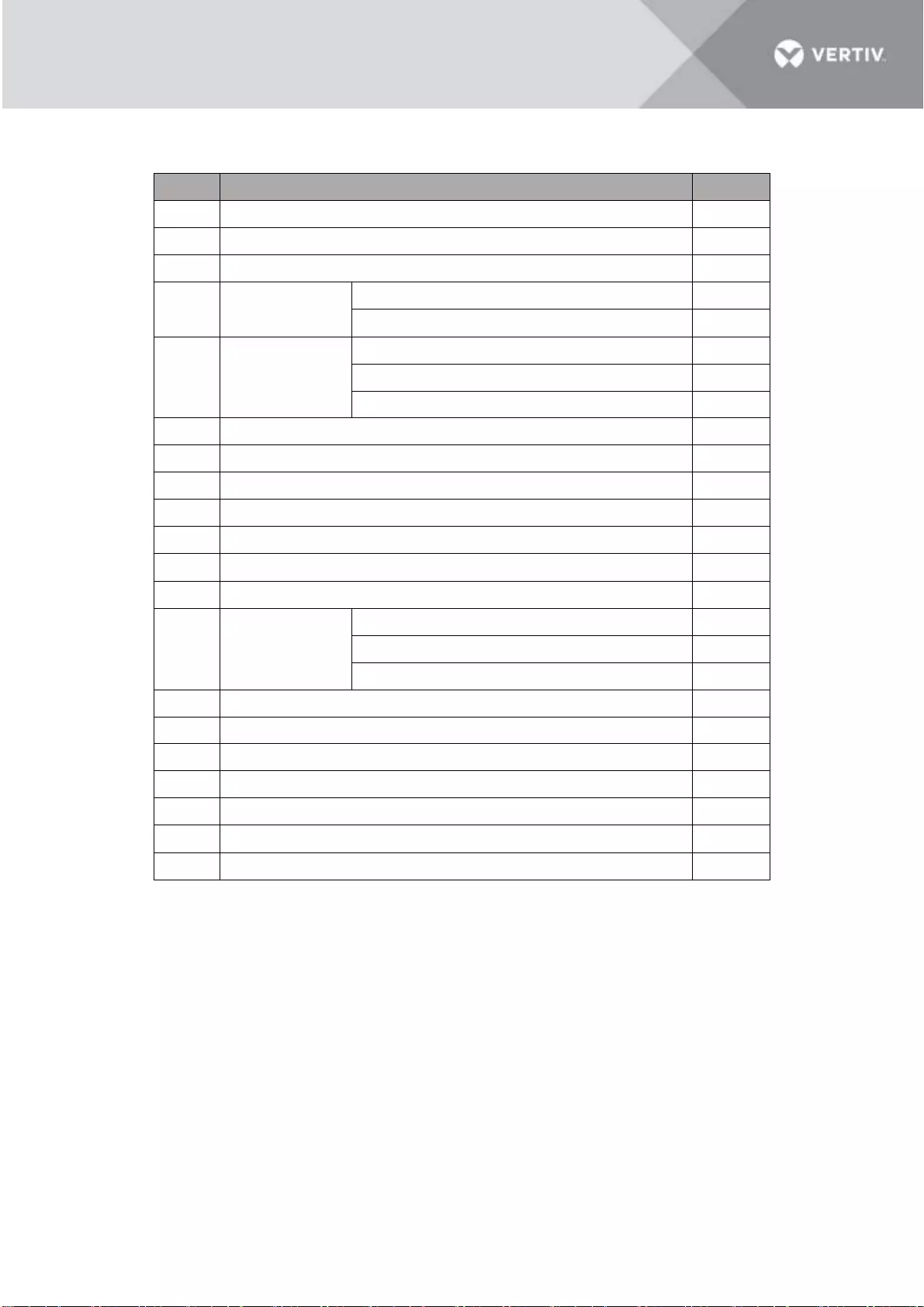

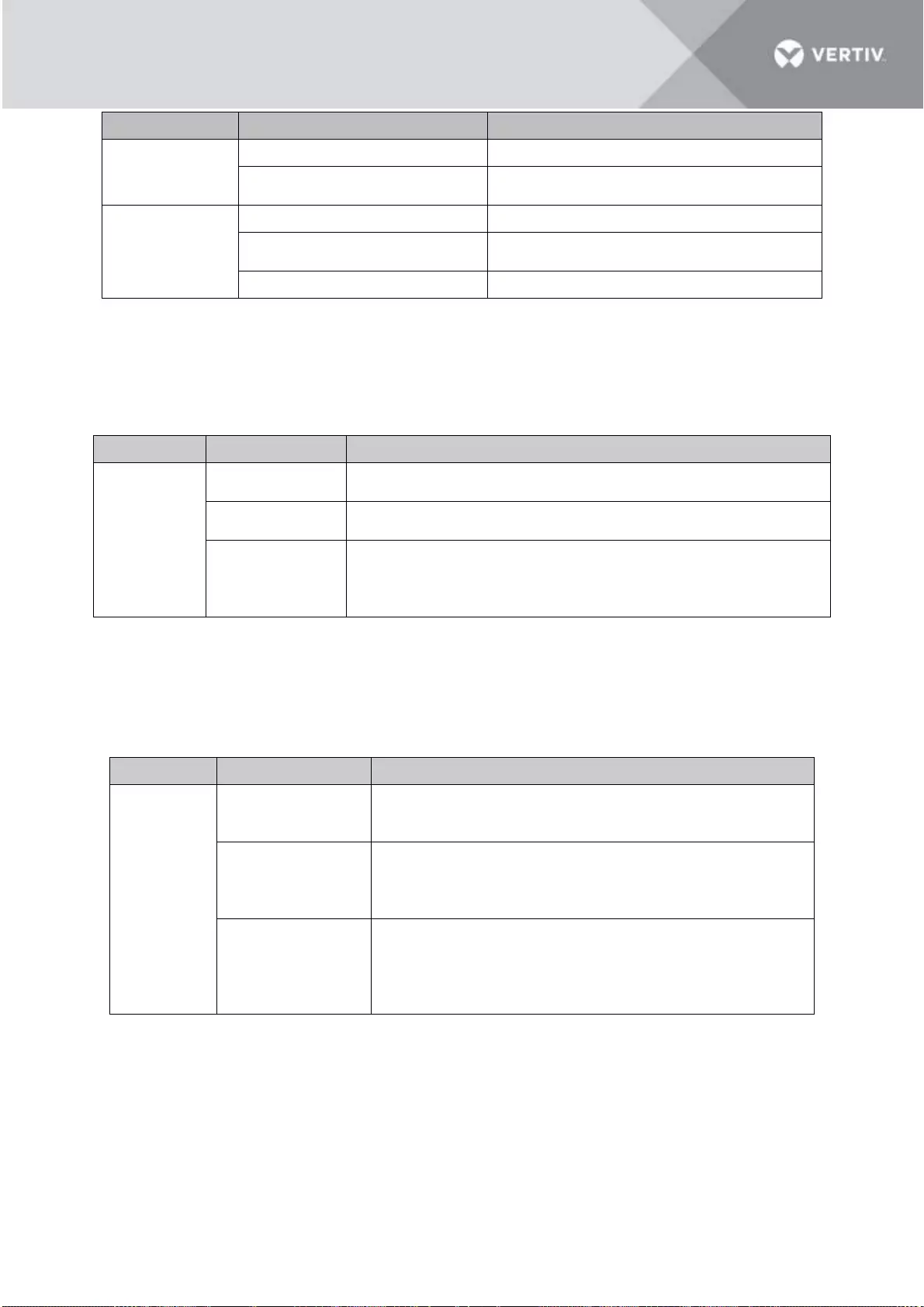

Table 1-1 Technical specifications

Parameters

Specification

Model

VRC100

VRC101

VRC102

Certification

UL484

UL484

CE

(EN 60335-1; EN 60335-2-40;

EN 55014-1; EN 55014-2; EN 61000-3-2;

EN 61000-3-3; EN 50581)

Cooling Capacity, kW

0.9 - 3.6

0.9 - 3.6

0.9 - 3.6

Air Volume, m3/h (CFM)

750 (441)

750 (441)

750 (441)

Max Power Input, kW

1.63

1.86

1.86

Full Load Amperage, A

16.5

13

11.5

Dimensions (Without

Package)

W x D x H mm (Inches)

442x978x439 (17.4” x 38.5” x 17.28”)

Input Type

Power Cord (3.2m)

with NEMA 5-20P

Power Cord (3.2m)

with NEMA L6-20P

IEC 60320 C20 Inlet

+ Interconnection Cable (3.0m)

IEC 60320 C19 to C20

Voltage (Vac)

L+N+G, 120 Vac

L1+L2+G, 208

Vac/230 Vac

L+N+PE, 230 Vac

Frequency, Hz

60

50/60

Color

EG7021 (Black)

System Protection Grade

IP20 (IEC 60529)

Net Weight, kg (lbs)

72 (158.7)

74 (163.1)

Gross Weight, kg (lbs)

134 (295.4)

Noise Level, dB(A)

<66

In the case that VRC is installed on the bottom of the rack, the maximum capacities at various evaporator

and condenser air inlet temperatures are mentioned below:

Maximum Capacity, kW

Condenser Air Temperature

29.4 °C (85 °F)

35 °C (95 °F)

40 °C (104 °F)

Evaporator Air Temperature to

Cooling Module

(Return Control)

29.4 °C (85 °F)

3.1

2.6

2.2

35 °C (95 °F)

3.4

3.3

2.8

40 °C (104 °F)

3.6

3.5

3.1

Maximum Capacity, kW

Condenser Air Temperature

25 °C (77 °F)

30 °C (86 °F)

35 °C (95 °F)

Evaporator Air Temperature to

IT Devices

(Supply Control)

19 °C (66 °F)

3.3

3.2

3.1

21 °C (70 °F)

3.5

3.4

3.3

23 °C (73 °F)

3.6

3.5

3.4

6

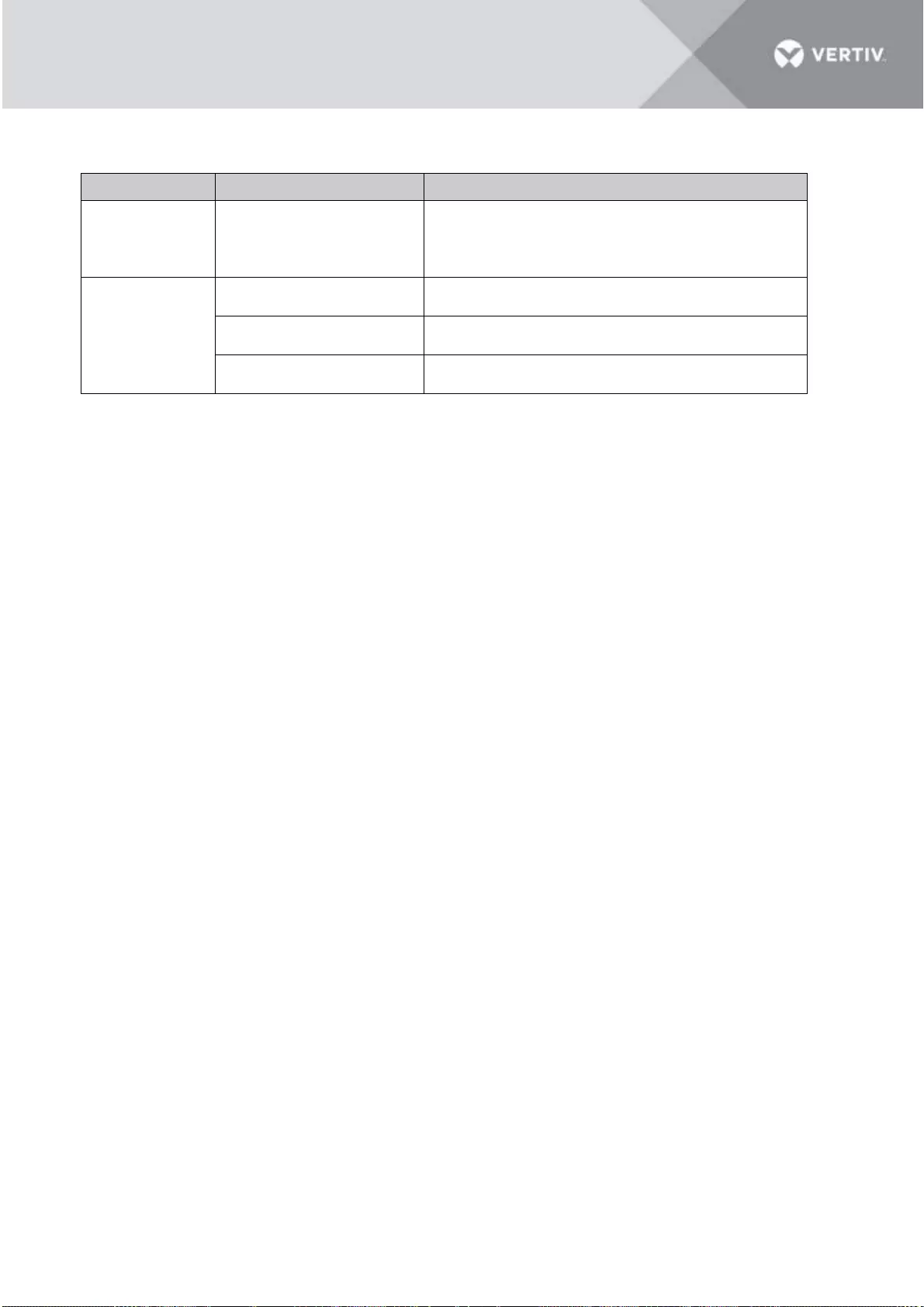

Vertiv I VRC Self-Contained System I User Manual

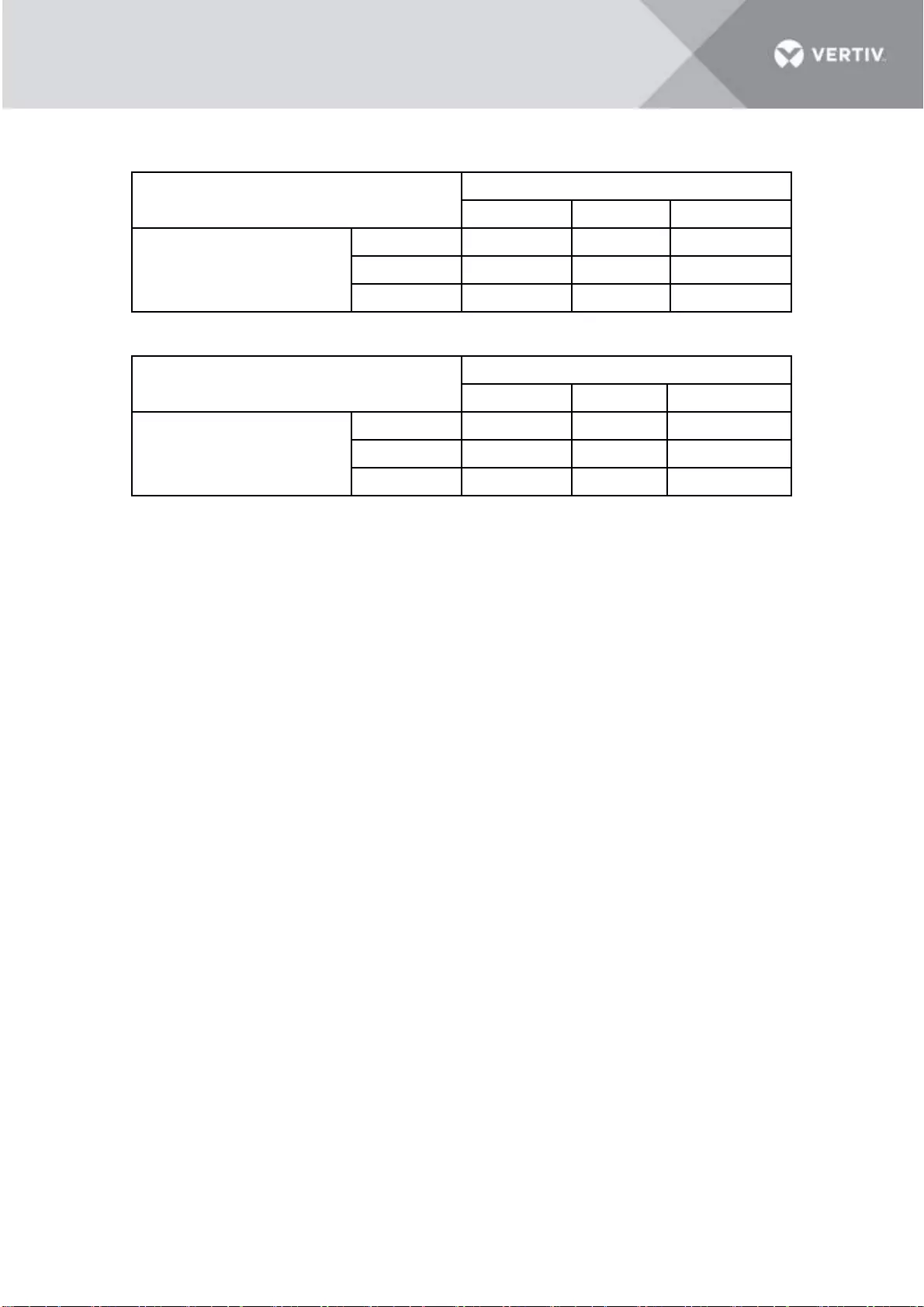

In the case that VRC is installed on the bottom of the rack, the minimal cooling capacity are mentioned

below:

Minimum Capacity, kW

Condenser Air Temperature

29.4 °C (85 °F)

35 °C (95 °F)

40 °C (104 °F)

Evaporator Air Temperature to

Cooling Module

(Return Control)

29.4 °C (85 °F)

0.90

0.88

0.86

35 °C (95 °F)

0.92

0.90

0.88

40 °C (104 °F)

0.94

0.92

0.90

Minimum Capacity, kW

Condenser Air Temperature

25 °C (77 °F)

30 °C (86 °F)

35 °C (95 °F)

Evaporator Air Temperature to

IT Devices

(Supply Control)

19 °C (66 °F)

0.89

0.88

0.87

21 °C (70 °F)

0.90

0.89

0.88

23 °C (73 °F)

0.91

0.90

0.89

NOTES:

• Capacity may be reduced with addition of heat rejection ductwork.

• There are two control methods which are supply control and return control. The return control

mode is applied to an open environment, while the supply control mode is applied to an enclosed

cabinet, such as Vertiv’s VRC-S.

• Supply air temperature set point variable between 18 °C (64.4 °F) – 23 °C (73.4 °F). The

recommended supply air temperature set point is 21 °C (69.8 °F).

• When the VRC unit is used in an enclosed cabinet, the heat load should be evenly placed in the

cabinet. And unused rack position should be covered with blanking plates.

7

Vertiv I VRC Self-Contained System I User Manual

PART II

INSTALLATION

8

Vertiv I VRC Self-Contained System I User Manual

2 Pre-Installation

The air conditioner is engineered equipment and requires precise installation procedures for which the

preliminary preparation is very important. This chapter details the installation preparation, including how

to prepare the installation environment and space and reserve the maintenance space, the air conditioner

running and storage environment requirement, and how to unpack and inspect. Please read this chapter

carefully before installation.

WARNING! Only trained and qualified personnel must be allowed to install, maintain, and

operate the unit.

WARNING! The sharp edges, sharp angles of the object, and bare buckle can result in severe

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

WARNING: Risk of unit falling over. Improper handling can cause equipment damage, injury or

death. Read all the guidelines pertaining to the system before unpacking, moving, lifting or

installing the components. Read the labels on the unit carefully to understand the safety

measures prior to handling the containment.

CAUTION: The center of gravity of the unit is inclined, therefore, when moving the unit adjust

the bearing position of the forklift or hand pallet truck.

9

Vertiv I VRC Self-Contained System I User Manual

2.1 Fittings

The hardware used for fittings are shown in Figure 2-1.

Figure 2-1 Fittings

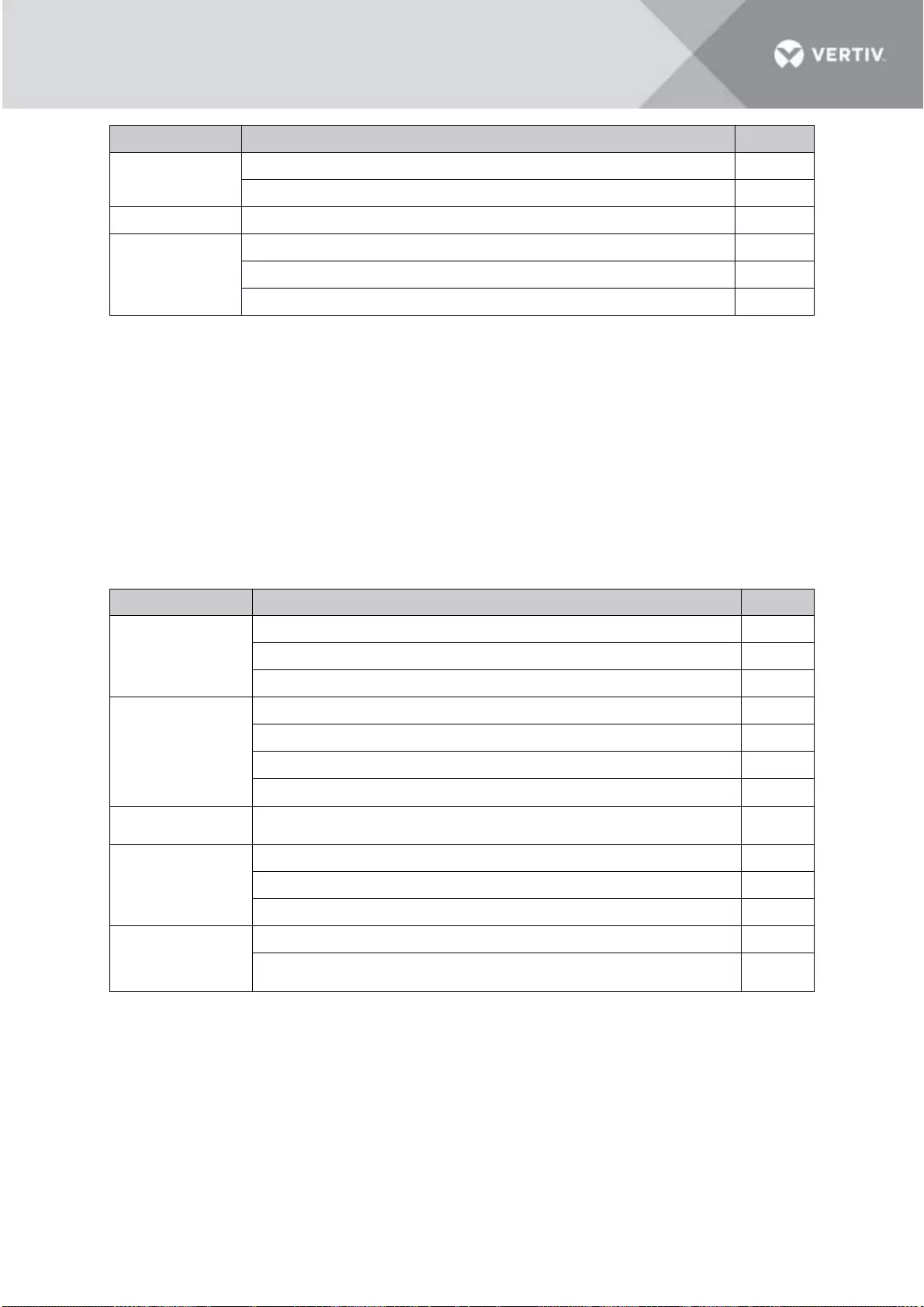

The fitting nuts and their usage are shown in Table 2-1.

Table 2-1 Fitting utilities

2.2 Self-Prepared Material

The circuit breakers must be prepared at the customer site or are to be obtained by the customer; the

specifications for the same are given in Table 2-2.

Table 2-2 Self-prepared materials

Parts

Specifications

External circuit breaker

Please refer to FLA of Unit

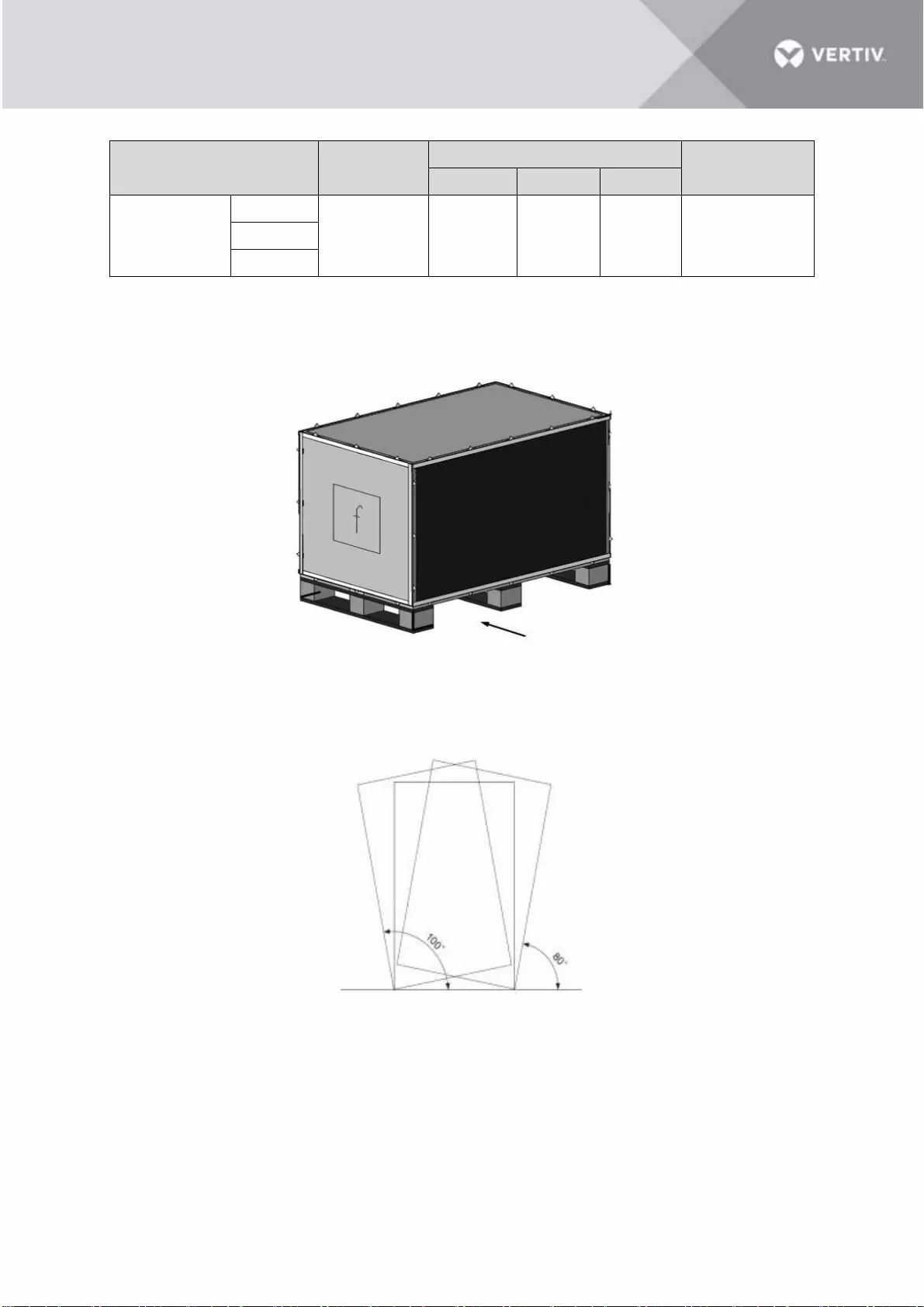

2.3 Transportation and Movement

The VRC1 need to be moved to the vicinity of the installation site. The cooling unit with heavy components,

needs to be transported using equipment such as a hand pallet truck or electric forklift. Table 2-3 and

Figure 2-2 show the dimensions of the unit with packaging.

Figure 2-2 Package dimensions

Fitting Utility

Usage

Quantity

M6 cage nut

Used with M6 pan-head screws for tightening pillars

20

M5 center screw

Used to fasten the L-shape rails

10

M5 pan-head screw

Used to fasten the transition part

10

M6 Pan-head screw

Used to install the VRC 10X unit

20

Contact washer

Used together with the M5 pan-head screw

10

M6 Cage Nut

M5 Center Screw

M5 Pan-head Screw

M6 Pan-head Screw

Contact Washer

W

D

H

10

Vertiv I VRC Self-Contained System I User Manual

Table 2-3 Overall dimensions and weight of the unit with packaging

Component

Packaging

Material

Dimensions

Weight with

Packaging

H

W

D

The VRC1 (With

Packaging)

VRC100

Wood case

900 mm

(35.4”)

730 mm

(28.7”)

1170 mm

(46.1”)

134 kg

(295.4 lbs)

VRC101

VRC102

If a hand pallet truck or an electric forklift truck is used, the tines of the hand pallet or electric forklift must

be aligned with the center of gravity to prevent the package from toppling or falling over as depicted in

Figure 2-3.

Figure 2-3 Forklift direction

While moving the package, the obliquity has to be maintained at an angle of 90 ± 10 °. Figure 2-4 depicts

the 90 ± 10 ° obliquity that is suitable to move the unit to the vicinity of the desired location.

Figure 2-4 Carrying obliquity

NOTES:

• Ensure that the equipment stands upright. Do not place the equipment outdoors.

• While using the forklift or the hand pallet truck, ensure that the fork arms (if adjustable and

flexible) open to the greatest extent. This is done so that the fork arms can be placed under the

pallet of the equipment in a precise manner.

• Ensure that the length of the fork arms match with that of the equipment.

Forklift direction

11

Vertiv I VRC Self-Contained System I User Manual

2.4 Unpacking

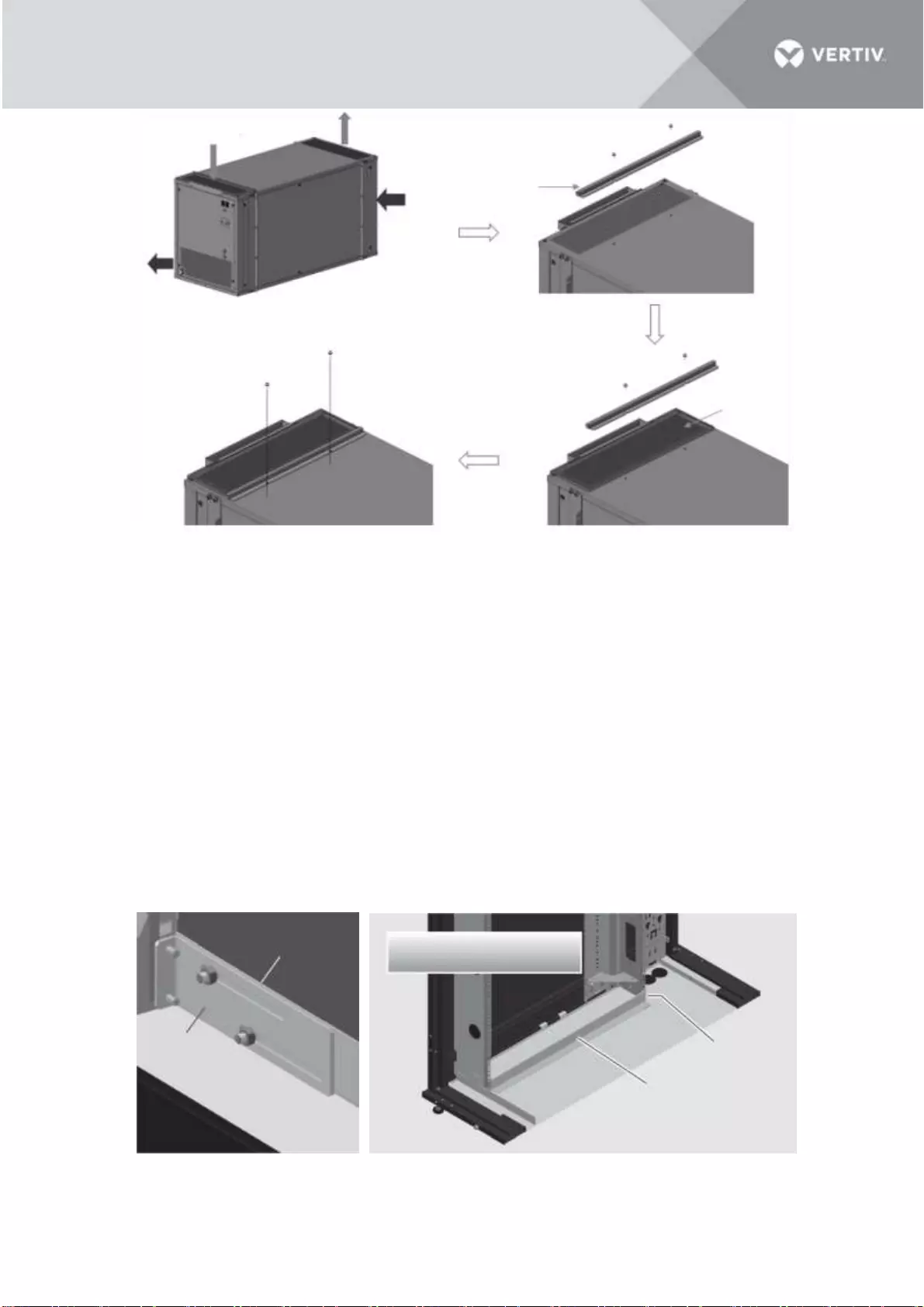

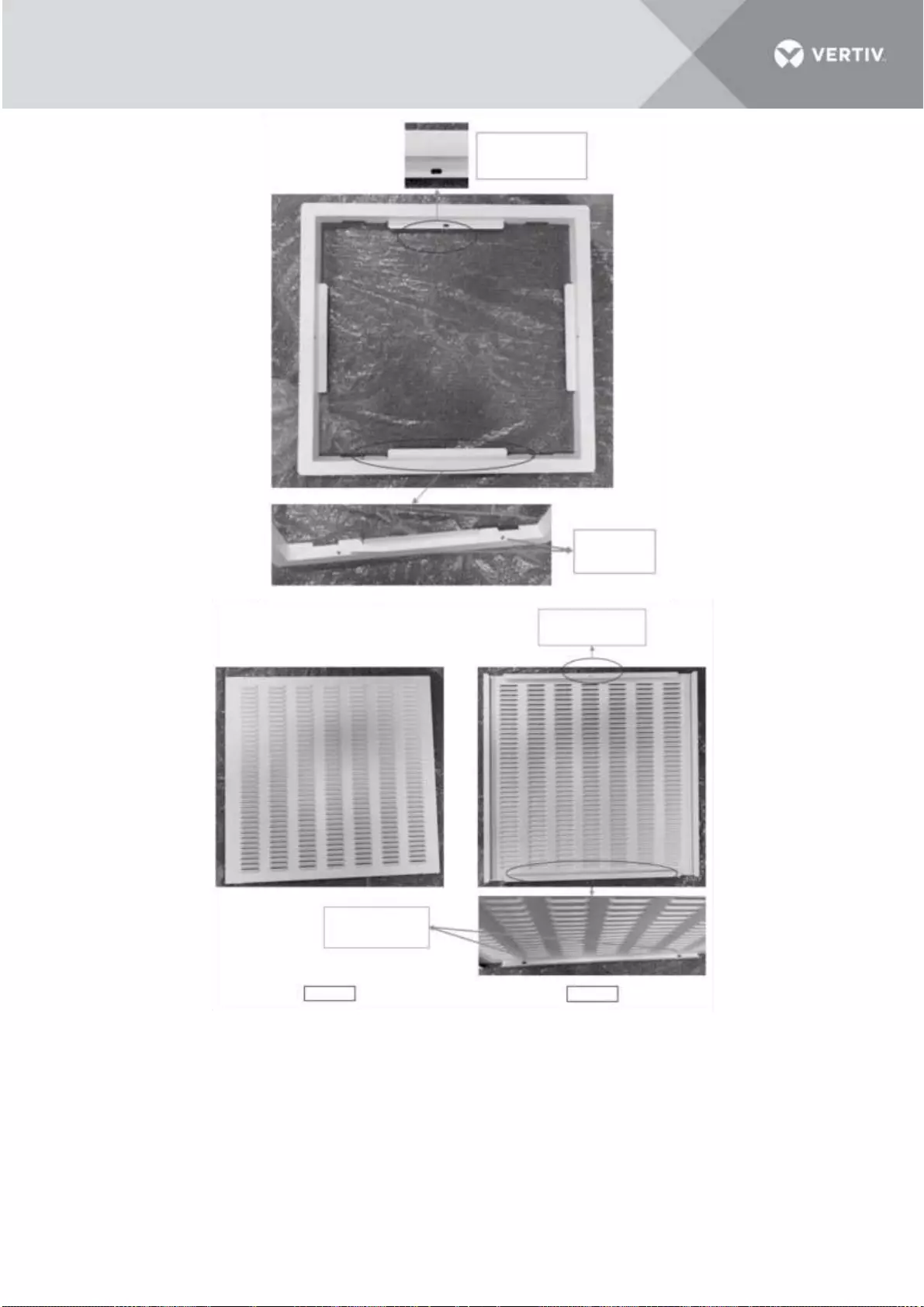

Unpacking the unit is show in Figure 2-5 below.

Figure 2-5 Unpacking

NOTES:

• Packing materials of the unit are recyclable. Retain the packing materials for further use or dispose

them appropriately as per the protocols and local regulations.

Wooden case

EPE

Wooden pallet

EPE

Ceiling tile kit

(4)

Cooling unit

(19)

Transition Part (1)

Duct (2)

Pump Bracket (Pump is

preinstalled) (5)

EPE

SIC Card (8)

L-shape Mounting Rail

(7)

12

Vertiv I VRC Self-Contained System I User Manual

The accessory list is shown in the table below.

Table2-4 Accessory list

Sr No.

Item

Quantity

1

Transition Part

1

2

Flex Duct (3.8 m / 12.5 ft.)

1

3

Duct Clamp

2

4

Ceiling Tile Kit

Ceiling Tile for Air Outtake

1

Ceiling Tile for Filter Pad

1

5

Drainage Kit

Condensate Pump Kit

1

Condensate Pump Brackets

1

Condensate Water Pipe (7.5 m / 24.6 ft.)

1

6

L-shape Mounting Rail Kit

2

7

SIC Card Kit

1

8

Pan-Head Screws M6x12 (Torx T30)

20

9

Cage Nuts (M6)

20

10

Pan-Head Screws M5x12 (Torx T25)

10

11

Contact Washers for Pan-Head Screw M5x12

10

12

Center Screws M5x12 (Torx T20)

10

13

Display kit

Display

1

10 m (32.8 ft.) Cable of Display

1

0.5 m (1.6 ft.) Cable of Display

1

14

Evaporator Filter

1

15

User Manual

1

16

Cable Ties 100x2.5

5

17

USB Converter Cable

1

18

Lifting Straps

2

19

VRC Cooling Unit

1

20

VRC102 Power Cable (Only for VRC102)

1

Following the steps below during the unpacking process. For installation, please refer to chapter 3.

• Move the equipment to level ground.

• Unlock the wooden case from the wooden pallet.

• Pull up the wooden case.

• Put the EPE and the ceiling tile kit aside.

• Remove the VRC 10X unit from the wooden pallet that is beneath the VRC 10X unit.

13

Vertiv I VRC Self-Contained System I User Manual

2.5 Equipment Installation Room Requirements

For best performance install the unit in thermally separated racks and install blanking panels in unoccupied

U spaces to avoid hot air recirculation. Hot Air recirculation could de-stabilize the temperature gradient in

front of the IT equipment.

NOTES:

• Avoid locating the indoor unit in concave or narrow areas which can affect the airflow. It is

prohibited to use the cooling system in an outdoor environment.

2.6 Environment

Following are the requirements that need to be observed from the environment point of view for site

preparation of the unit:

• Keep the unit in a place far away from flame or any heat source.

• Direct sunshine is detrimental to the system and therefore, the system needs to be placed at a

location where it is not directly affected by sunlight.

• Emission of erosive gases and organic solvents should not be near the unit.

2.6.1 Operating Environment

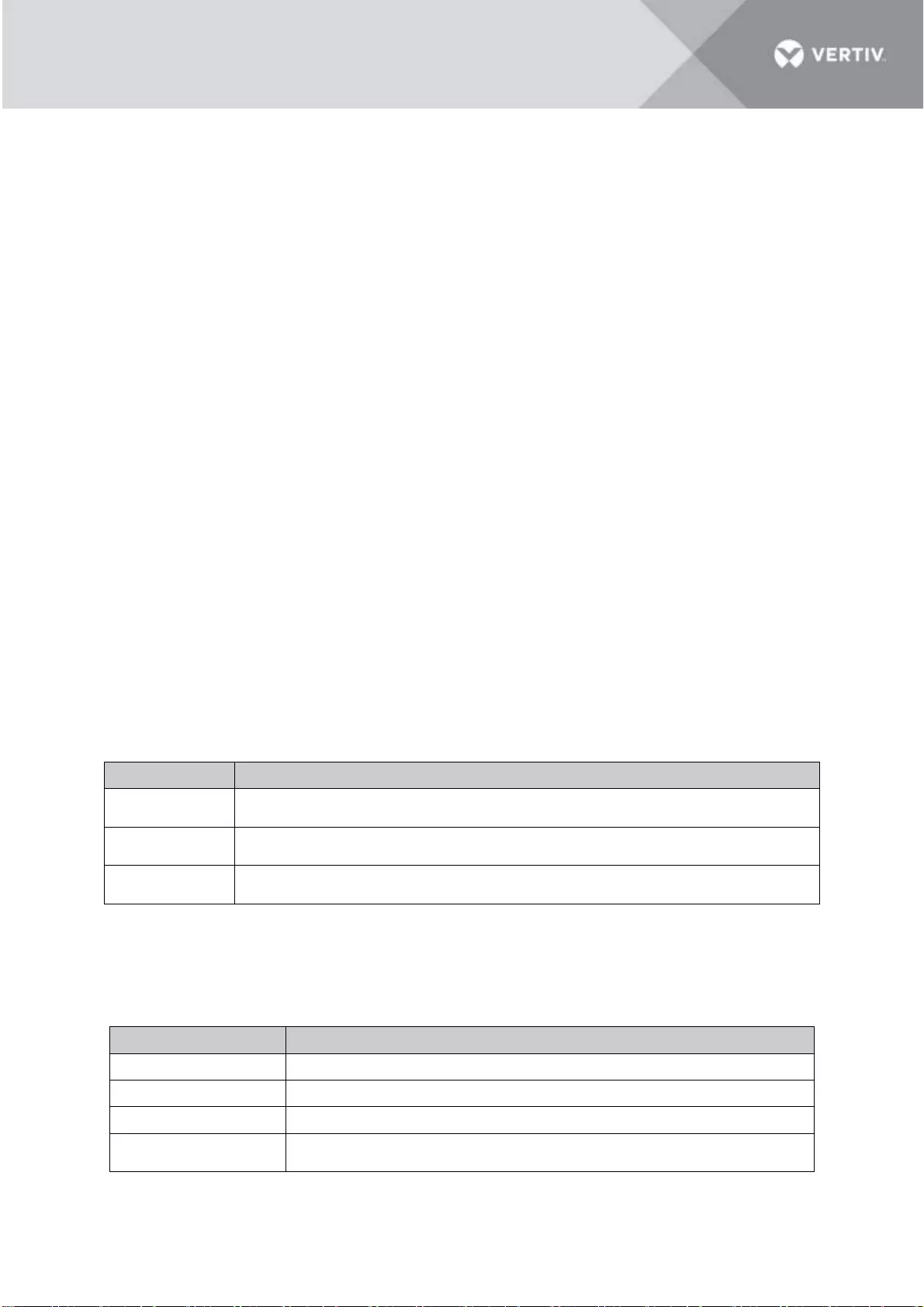

The operating environment requirements for the unit are specified in Table 2-5:

Table 2-5 Operating environment

Item

Requirements

Ambient

temperature

Indoor: +18 °C - +40 °C (64.4 °F – 104 °F)

Heat rejection Air: 0 °C - +40°C (32 °F – 104 °F)

Ambient

humidity

<90% RH (30 °C / 86 °F)

Altitude

<1000 m (3,280 ft.). For every 1000 m (3,280 ft.) increase in elevation, the evaporation

temperature drops by 0.5 °C (0.9 °F), and the net cooling capacity drops by 7%.

2.6.2 Storage Environment

The storage environment requirements for the unit are specified in Table 2-6.

Table 2-6 Storage environment

Item

Requirements

Storage environment

Clean (without dust)

Ambient humidity

< 95% RH (40 °C / 104 °F)

Ambient temperature

-40 °C - +70 °C (-40 °F – 158 °F)

Storage time

The total shipment and storage time should not exceed 6 months. Otherwise,

the performance needs to be re-calibrated

14

Vertiv I VRC Self-Contained System I User Manual

2.7 Installation Space Requirements

The cooling unit is a specifically engineered air conditioning unit. It is recommended to install the unit

inside the cabinet at the lowest section, as shown in the installation section 3.3.

• To facilitate ease of installation and maintenance, sufficient space needs to be provisioned as per

Figure 2-6 below.

• The distance from the front door to the wall or other obstacles must be greater than 1050 mm, which

to ensure the pull-out of the unit entirely for maintenance.

Figure 2-6 Minimum distance to pull-out the unit for maintenance

2.8 Condenser Airflow Clearance Requirement

To have sufficient space for condenser air inlet or outlet, the clearance in front and behind the VRC1XX unit

should not be less than 600 mm (23.6’’).

NOTES:

• In the case that the air conditioner is installed in a rack, please refer to the rack instruction to check

the clearance in front and behind the rack for installation or maintenance.

Figure 2-7 The required airflow clearance

1050 mm (41.3”)

Server

Flexible duct

Hot Air from

Servers

Cold Air

Outlet to Servers

Heat Rejection

Air Outlet

Heat Rejection

Air Inlet

Transition

parts

VRC UNIT

Wall

≥ 23.6"

[≥ 600mm]

≥ 23.6"

[≥ 600mm]

Rack

15

Vertiv I VRC Self-Contained System I User Manual

2.9 Weight Bearing Capacity

The unit will be installed inside the cabinet which will increase the cabinet concentrated floor loading.

Therefore, the weight bearing capacity of the floor of the room must be taken into consideration.

2.10 Inspection

• The unit is pre-charged. Check that there are no refrigerant or oil leaks.

• Check the system fittings and its components against the packing list to ensure that everything is in its

designated position and the entire product assembly is intact.

• Immediately report any missing or damaged parts or components to the carrier. If hidden damages

are observed, then contact the local service offices as soon as possible.

16

Vertiv I VRC Self-Contained System I User Manual

3 Mechanical Installation (Site Preparation)

Proper installation is essential to achieve the intended design performance of the equipment and to

maximize its service life. This chapter describes the mechanical installation of the precision air conditioner,

including installation notes, system installation layout, end installation, unit piping installation, installation

finishing work and installation inspection. This section should be used in conjunction with current

mechanical and electrical installation regulations.

3.1 Installation Notes

NOTES:

• The air conditioner needs to be installed inside the cabinet with the mounting rails as per the

procedure mentioned in Section 3.3.

• Before installation, make sure that the installation environment meets the requirements (Table 2-5

Operating Environment) and there must be sufficient provision for connecting the condensate drain

line to the drain point.

• Follow the design drawings strictly while installing the equipment and reserving the space for

maintenance.

• It needs 2 persons during installation.

• Torx bits T20, T25 and T30 are needed during installation.

Figure 3-1 Torx bits

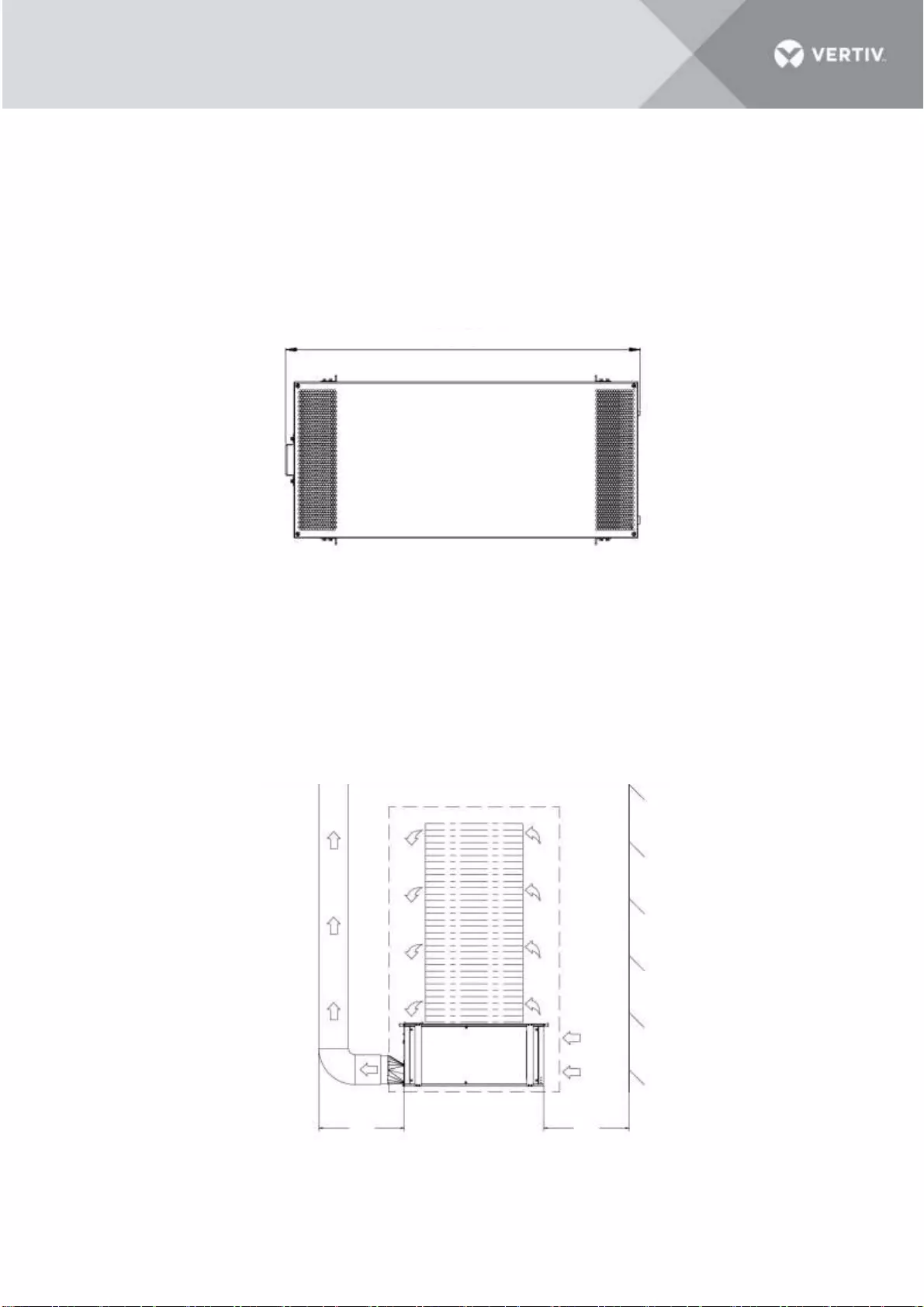

3.2 System Installation Layout

3.2.1 Overall layout of the system

The overall layout of the unit is depicted in the Figure 3-2 below. Hot air generated by the condenser of

VRC 1XX is discharged through transition part and ducted to the ceiling. Condensate water is drained out

by the pump.

17

Vertiv I VRC Self-Contained System I User Manual

Figure3-2 Overall layout of the system

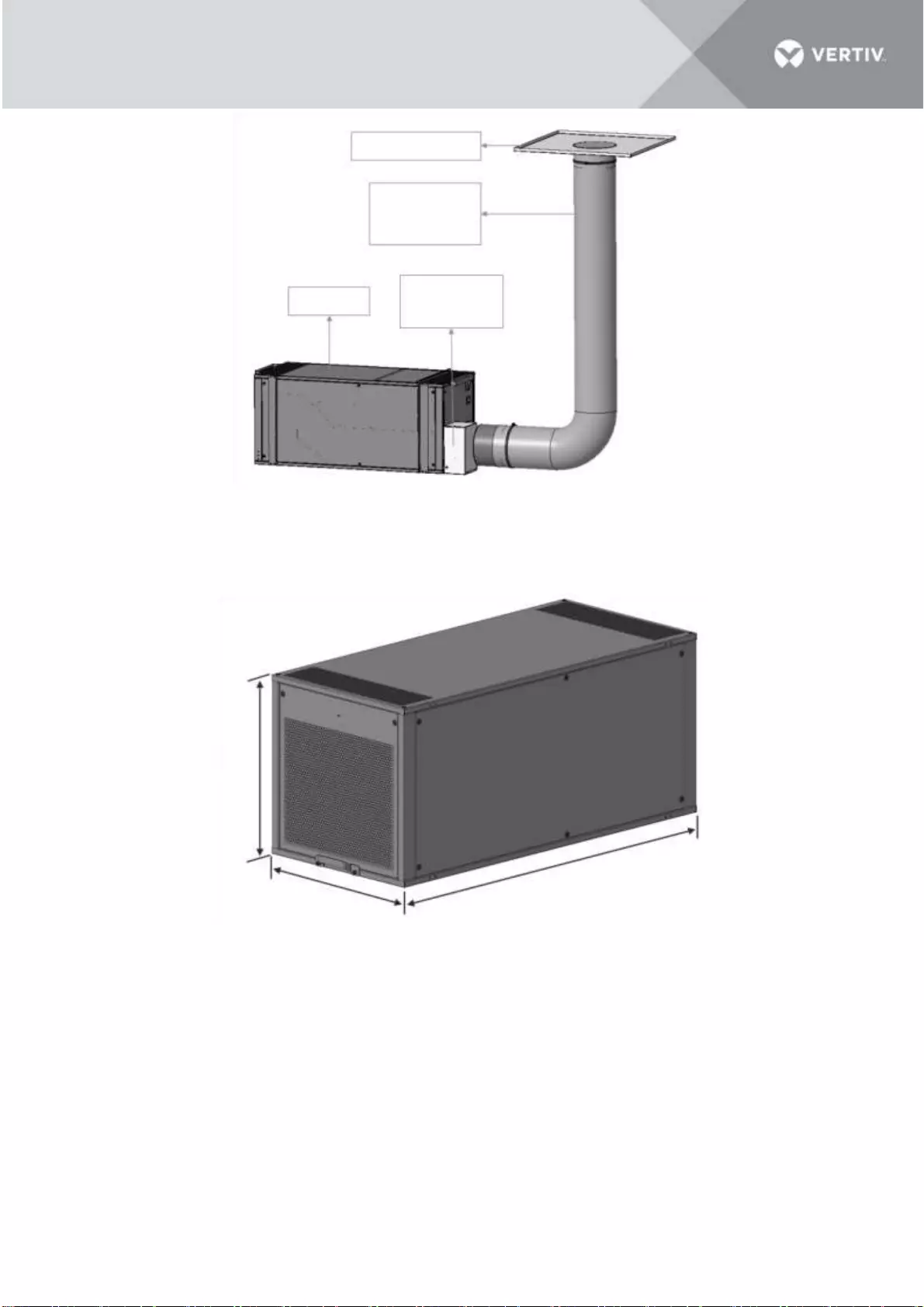

3.2.2 Overall layout of the VRC unit

The overall layout of the unit is depicted in the Figure 3-2 below.

Figure 3-3 Overall layout of the unit

3.3 Installing the VRC Unit into the Rack

The installation process for the cooling unit consists of mounting the unit inside the cabinet, connecting

the condenser duct and the drain piping.

3.3.1 Evaporator filter installation

The filter is installed on the air return side of the evaporation side.

Ceiling Tile Unit

Flex Duct

Max length=3.8

m/12.5 ft

VRC1 Unit

Condensate

Pump Unit

439 mm

(17.3 in)

442 mm

(17.4 in)

978 mm

(38.5 in)

18

Vertiv I VRC Self-Contained System I User Manual

Figure 3-4 Install the evaporator filter

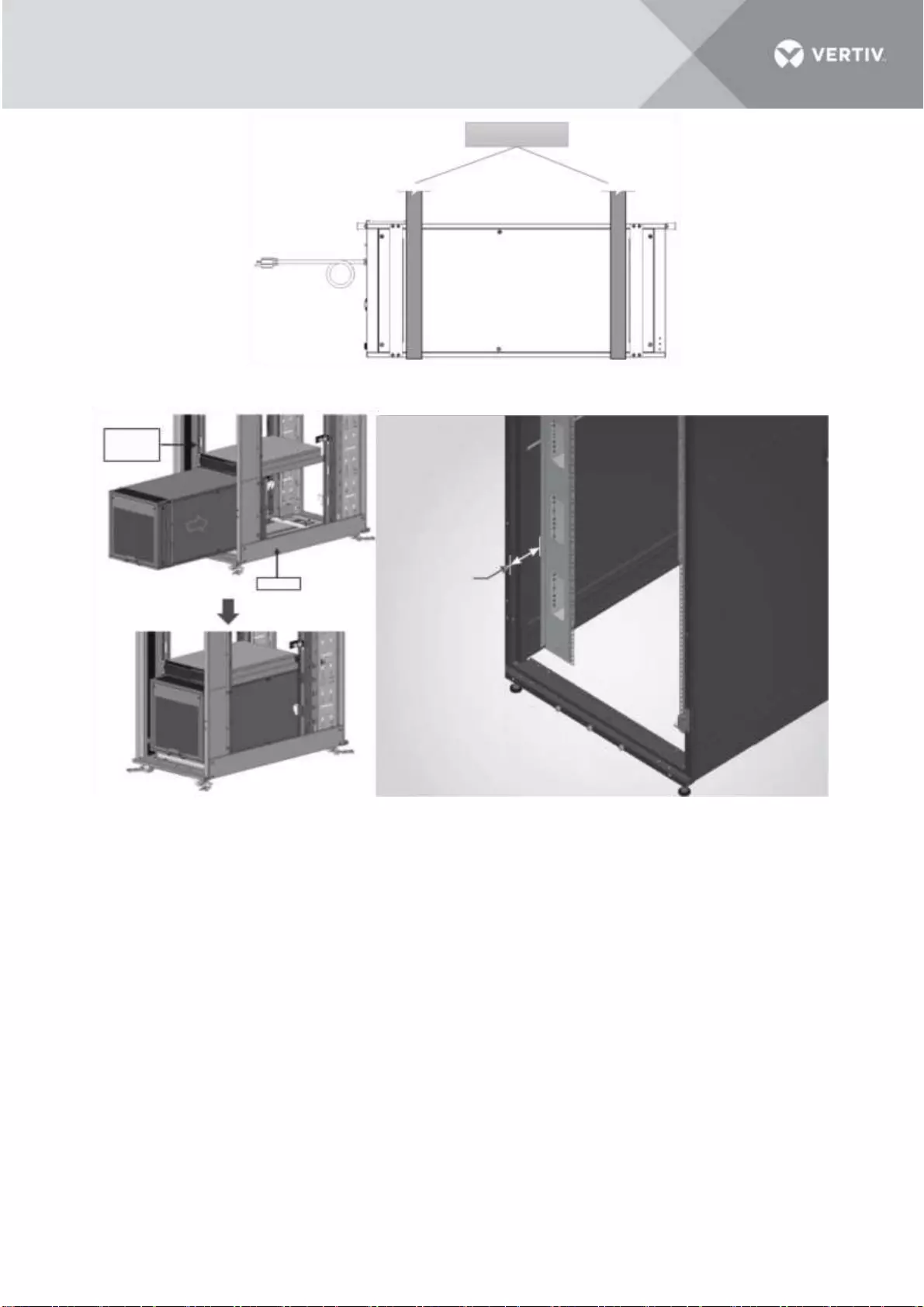

3.3.2 Installing the unit inside the 4-post rack

For installation in a 4-post rack, please refer to the procedure below.

NOTES:

• For installation in a 2-post rack, please purchase accessory 2POSTRMKITVRC. Installation

instructions are included with this rail kit.

1. Mount the L-shaped rails in the rack.

Each of the two L-shape rails are comprised of two parts, a long front rail and a slotted rear bracket. There

are left and right VRC rails. The flanges of each of the front rails should be on the bottom and pointing

toward the center of the rack. Slip the slots in the rear rail bracket over the pressed studs in the front rail

part. Loosely fasten with nuts. Fasten the ends of the front rails and rear brackets to the uprights using

center screws M5x12 T20. Torque=4.0 Nm (2.95 lb-ft). Once in place, tighten the nuts on the front rail part

studs. Torque = 5.6 Nm (4.13 lb-ft).

Figure 3-5 L-shape rails installation

1. Loosen the

screws and

remove this

bracket.

2. Place the filter

on the air return

position

3. Tighten the

screws to secure

the filter

Filter

Supply air

Return air

Condenser in

Evaporator Side

Condenser out

Front rail part

Slotted rear

bracket

Cross section of vRack shown for

illustrative purposes.

VRC rear left

bracket

VRC front left rail

19

Vertiv I VRC Self-Contained System I User Manual

2. Dismantle the C-pillar and D-pillar from the rear side.

NOTES:

• The direction of the pillar is correct as Figure 3-6 depicted.

• The distance between A-pillar and C-pillar (or between B-pillar and D-pillar) is 737 mm (29’’).

• The distance between C-pillar and D-pillar is 460 mm (18.1’’).

Figure 3-6 Right-side view

Figure 3-7 Back view

3. Use 2 lifting straps and VRC handles to slide in the unit inside the cabinet from the front side till the

B-pillar and the A-pillar are completely flushed against the cabinet 19’’ profiles. The distance from

front rails to front door is 121 mm (4.76’’).

B-pillar

I: The direction of the pillar

D-pillar

Back

Front

A-pillar

C-pillar

737 mm / 29.0"

C-pillar

Strain Relief

Bushing

Electrical

Access Panel

3.5"

[88.9mm]

5.2"

[133.3mm]

3.5"

[88.9mm]

14.2"

[360.3mm]

18.1"

[460mm]

4.8"

[121.1mm]

1.0"

[25.4mm]

8Xø0.27"

[8Xø7mm]

20

Vertiv I VRC Self-Contained System I User Manual

Figure 3-8 Lifting straps

Figure 3-9 Mounting the VRC into the rack

4. The distance between A-pillar and C-pillar (or between B-pillar and D-pillar) is 737 mm (29’’). If the

cabinet space is suitable, then install the C-pillar and D-pillar back again onto the unit body casing. If

not, then only installing A-pillar and B-pillar is OK.

5. Firmly secure A-pillar, B-pillar, C-pillar and D-pillar on the cabinet column with 2 M6x12 screws

(fastened with cage nuts) per pillar. Torque = 5.6 Nm (4.13 lb-ft).

NOTES:

• Ensure that the installation direction of pillars is correct. And ensure the VRC unit is installed

horizontally, otherwise high-water level alarms may be triggered incorrectly.

3.4 Connecting the Accessories.

If the unit must be placed in an environment where the hot air from the condenser duct needs to be

extracted from the room and discharged at a suitable pre-determined location, an air duct is provided as a

part of the accessories shipped with the unit and can be connected to the condenser discharge side.

Lifting straps

Other

devices

Rack

Profile Distance

121 mm/4.76”

FRONT VIEW

OF BACK

21

Vertiv I VRC Self-Contained System I User Manual

If a gravity drain is not possible, a condensate pump kit is provided as a part of the accessory shipped with

the unit and can be installed in the field.

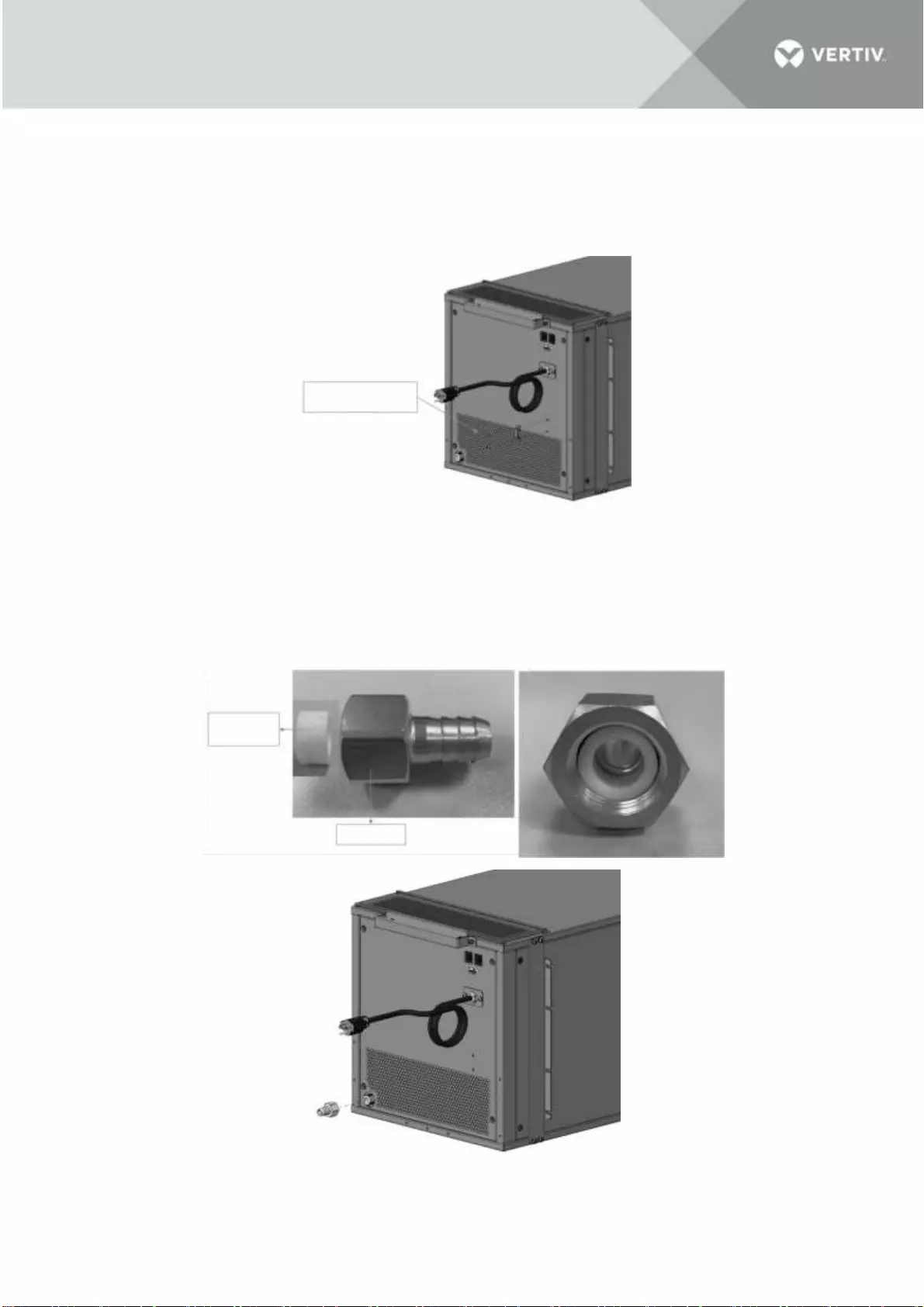

3.4.1 Remove the power cable clamp from the VRC1 unit

The power cable clamp is used to secure the power cable during transportation. Before installing the

accessories, it needs to be removed.

Figure 3-10 Remove the power cable bracket

3.4.2 Installing the drain fitting to the VRC1 unit

Fasten the drain fitting to the drain port of the VRC1 unit. The drain fitting contains a sealing block, which

is used for preventing the water leaking from the drain fitting port. Make sure the sealing block is installed

tightly.

Figure 3-11 Install the drain fitting

Remove the power

cable bracket

Drain Fitting

Sealing Block

Drain Fitting

22

Vertiv I VRC Self-Contained System I User Manual

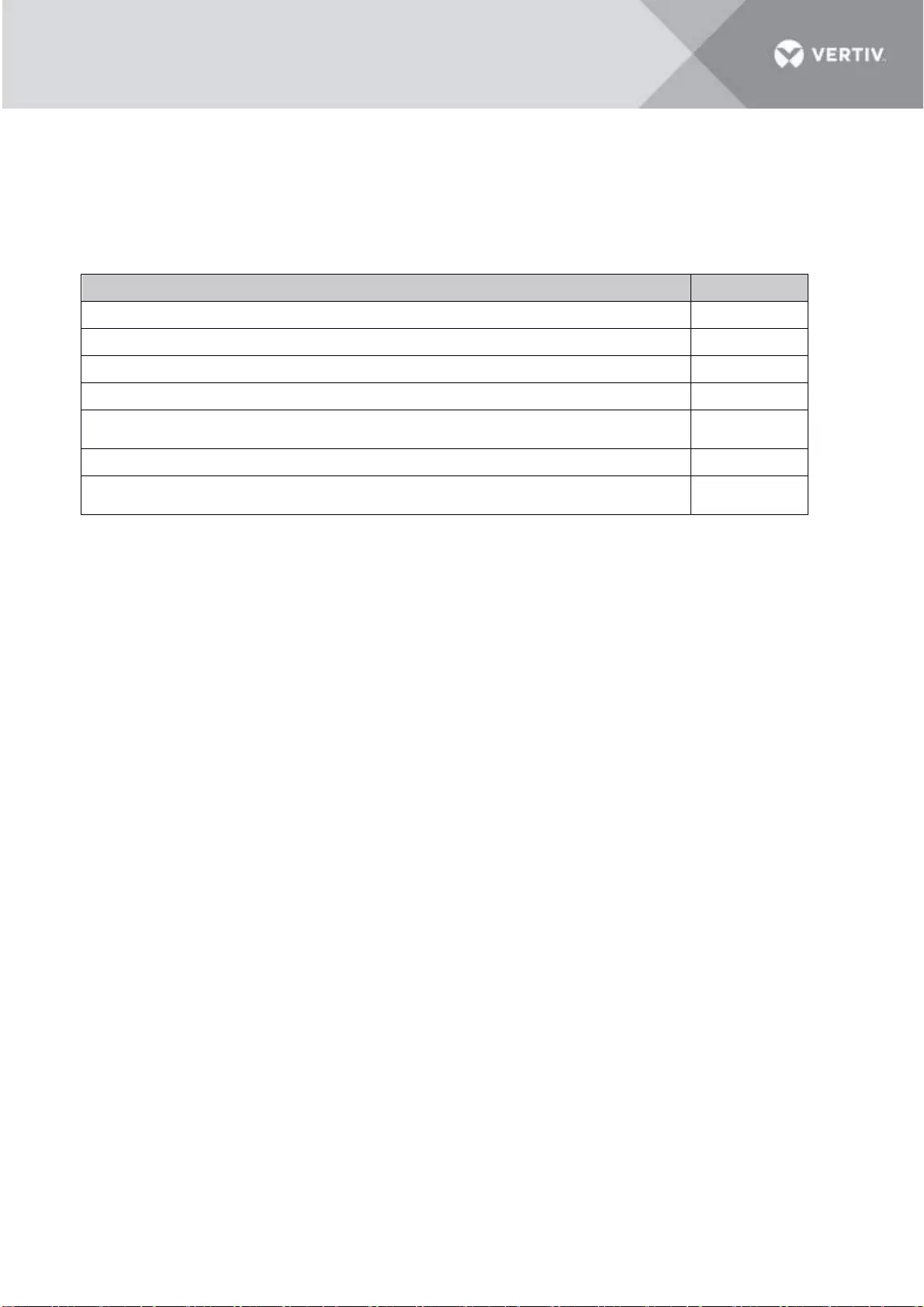

3.4.3 Installing the transition part on VRC1 unit

The transition part is installed on the condensing air discharge side. On this step, it can be installed with 6

M5x12 pan-head screws and 6 M5 contact washers. Torque=4.0 Nm (2.95 lb-ft)

Figure3-12 Transition part installation

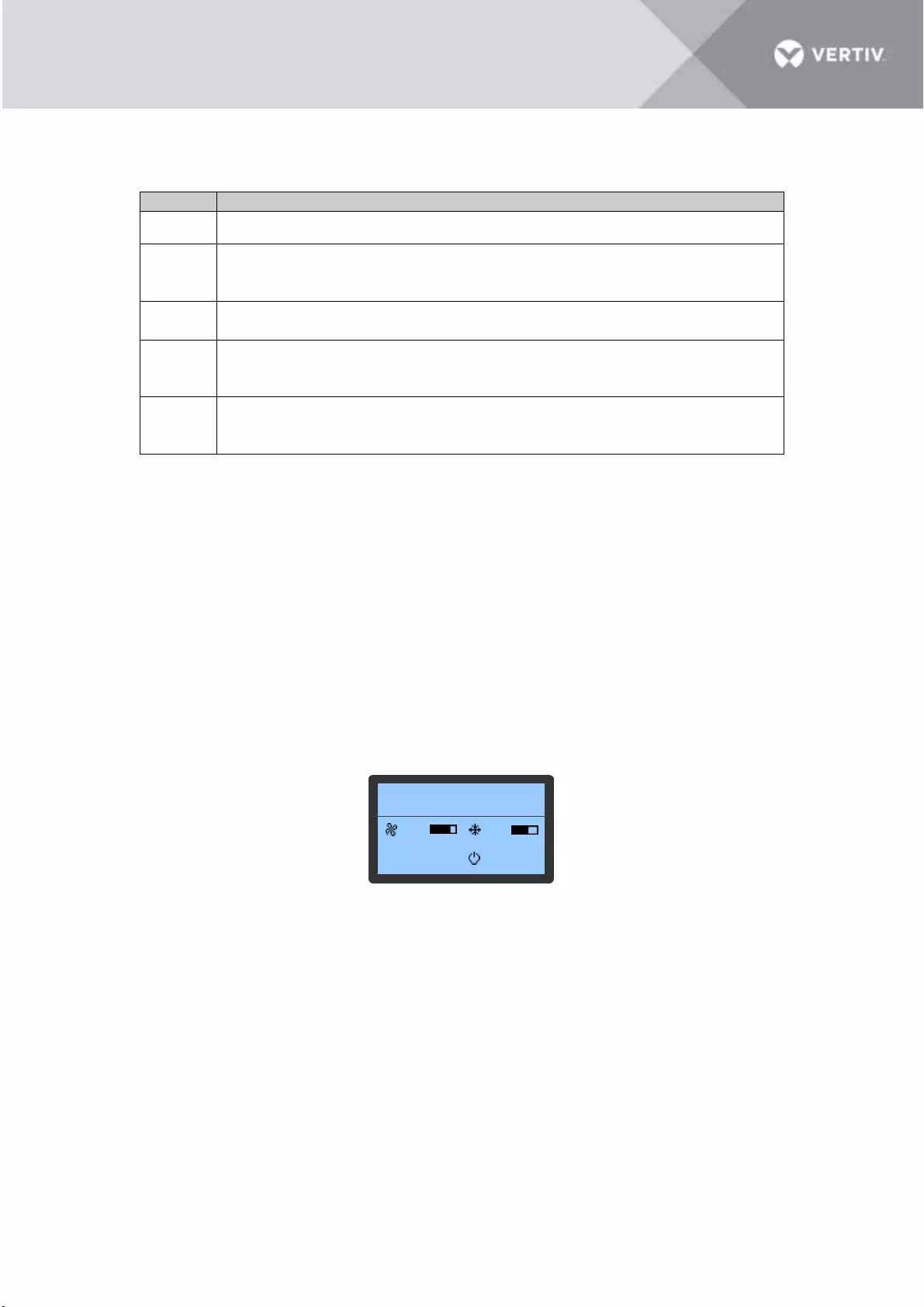

3.4.4 Connect the L-shape pipe to the drain fitting

The L-shape pipe, ID=16 mm (5/8’’) is placed in the pump kit.

Figure 3-13 L-shape pipe

Connect the L-shape pipe to the drain fitting. Use a cable tie to fasten it.

Figure 3-14 Connect the pipe 4 to the drain fitting

Transition part

Contact washer

5(x6)

Pan-head screw

M5x12(x6)

VRC 10X

Connect the L-shape

pipe, ID=16 mm (5/8")

to the drain fitting.

Use a cable tie to

fasten it.

23

Vertiv I VRC Self-Contained System I User Manual

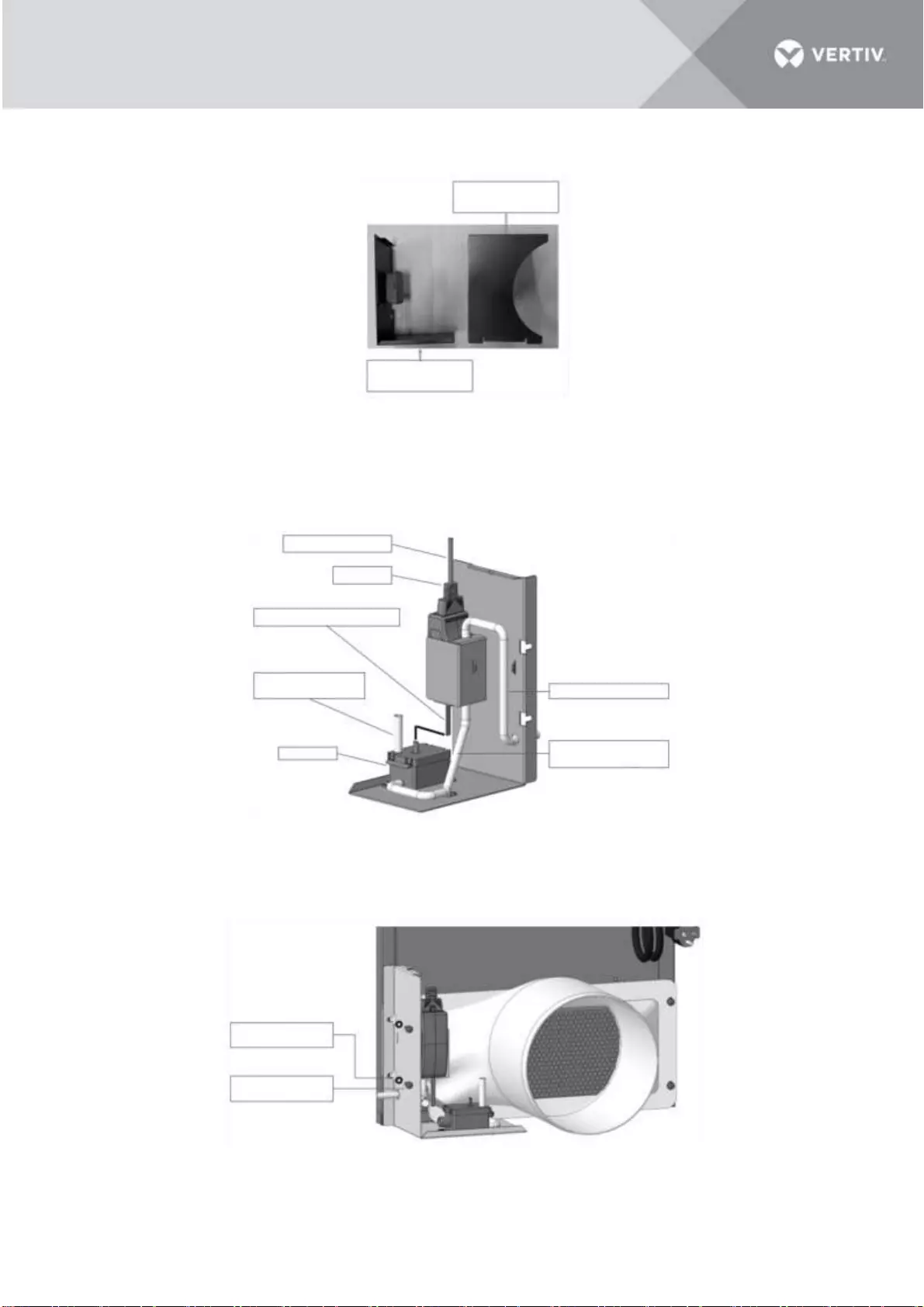

3.4.5 Installing the pump

1. The pump bracket is comprised of two parts, pump bracket 1 and pump bracket 2.

Figure 3-15 Pump bracket

2. Loose the screw and remove the pump bracket part 2 from the pump bracket part 1. The pump is

pre-installed on the pump bracket part 1 in factory.

Figure 3-16 Pump is pre-installed on the bracket 1

3. Install the pump bracket part 1 on the condensing air discharge side of the VRC1, tightened by two

pan-head screws with contact washer (M5 x 12). Torque=4.0 Nm (2.95 lb-ft).

Figure 3-17 Install the pump bracket part 1 on the unit

Condensate pump

bracket part 2

Condensate pump

bracket part 1

Pump power cable

Pump

Pump communication cable

Pipe 1 ID=6mm (1/4")

L=60mm (2.4")

Pipe 3 ID=6mm (1/4")

Pipe 2 ID=6mm (1/4")

L=300mm (11.8")

Reservoir

Contact washer

5(x2)

Pan-head screw

M5x12(x2)

24

Vertiv I VRC Self-Contained System I User Manual

4. Then connect the L-shape pipe and the reservoir. Use a cable tie to fix it.

Figure 3-18 Connect the pipe 4 and the reservoir

5. After that, condensate pump bracket part 2 should be tightened by a M5 screw. Torque=4.0 Nm (2.95

lb-ft).

Figure 3-19 Pump bracket part 2 installation

6. There are a condensate water pipe (7.5 m / 24.6 ft) in the package, which can be used to extend

drainage lines.

Figure 3-20 Anti-Siphoning device and condensate water pipe

The pump power plug can be pulled out from the gap between the pump bracket and the transition part.

In case of powering the condensate pump not through rPDU in vRack, the pump must be protected by a 1

A inline fuse upstream.

Use a cable tie to fix it

Using a screw to

install it

Condensate pump

bracket part 2

25

Vertiv I VRC Self-Contained System I User Manual

Figure 3-21 Pull out the pump power plug

The pump power plug for different versions of VRC1 units is depicted as the table below.

Table3-1 Pump power plug

Unit

Plug

Rating

VRC100

NEMA 5-20

20 A, 125 Vac

VRC101

IEC60320 C14

10 A, 250 Vac

VRC102

IEC60320 C14

10 A, 250 Vac

3.4.6 Connect the duct to the transition part

The total length of the cylindrical part of the transition part is 100 mm (3.94’’). To ensure the connection

reliability, the minimal overlapping of duct and transition part should not be less than 90 mm (3.54’’), and

make sure the clamping force is sufficient.

Figure 3-22 Connect the duct and transition part

NOTES:

• Before connecting the duct, the air duct needs to pass through the rear cabinet plinth firstly.

Rear cabinet door shown removed

for illustrative purposes.

Transition

PN : 21121507

Condensate pump

PN : 02092419

Pipe clamp

PN : 63128710

It is showed in a VRC-S

for illustrative purpose.

The thermal separation

kit and plinth are not

included in the VRC kit.

Plinth

Air duct

PN : 27140303

26

Vertiv I VRC Self-Contained System I User Manual

3.4.7 Connect the duct to the ceiling tile for air outtake

Connect the duct to the ceiling tile for air outtake which will be mounted on the ceiling and secure it with a

clamp. Also, the minimal overlapping of duct and transition part should not be less than 90 mm (3.54’’),

and make sure the clamping force is sufficient to ensure the connection reliability.

Figure 3-23 Connect the duct and ceiling tile for air outtake

NOTES:

• There is a hook on the ceiling tile for air outtake for safety reason when connecting the ceiling tile

to the ceiling construction.

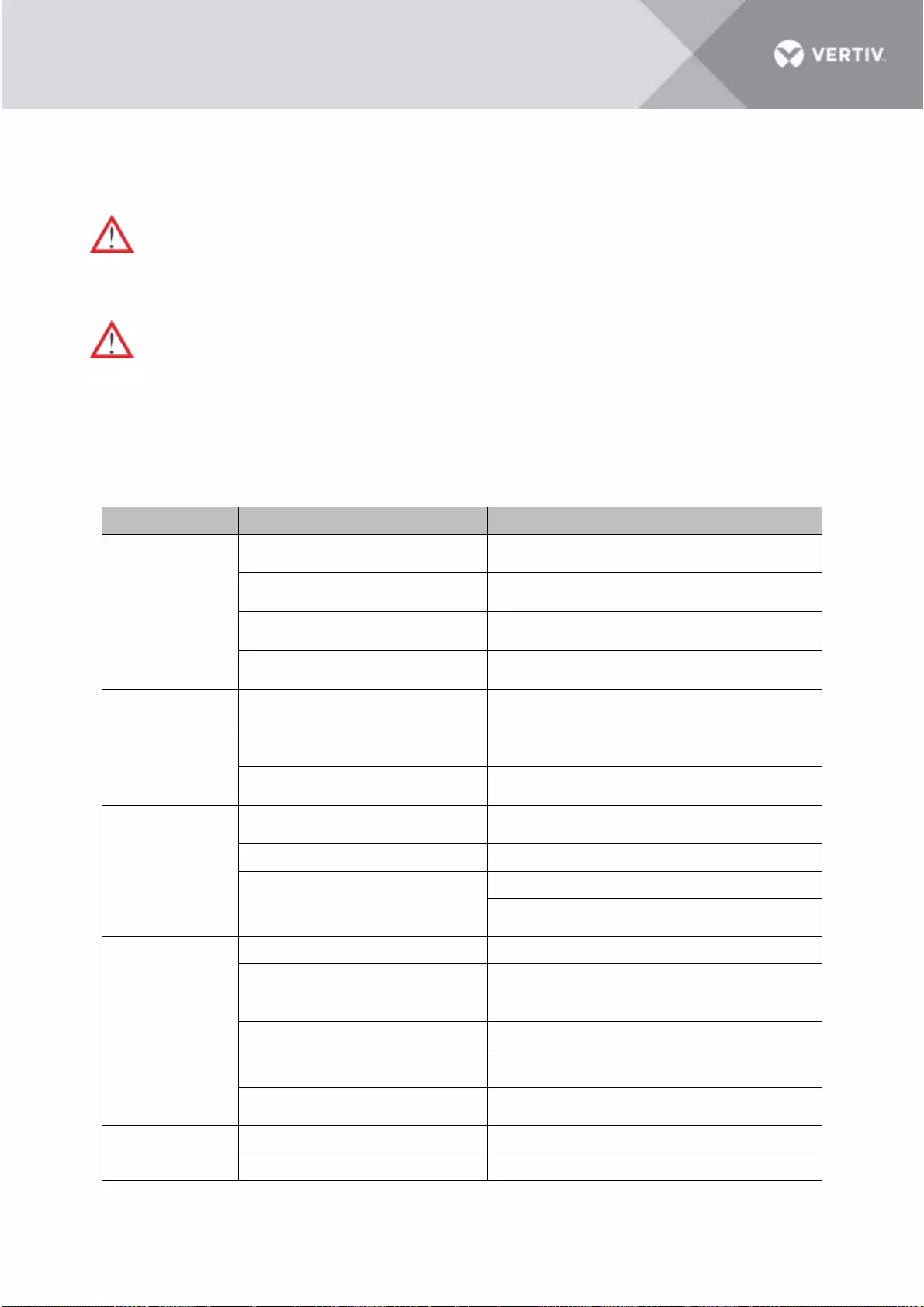

3.4.8 Install the ceiling tile for filter pad

The ceiling tile for filter pad is installed in a 2’x2’ ceiling tile at the air inlet. The fresh air enters the

condenser for heat exchange through the ceiling tile filter. The ceiling tile for filter pad is used to clean the

fresh air.

Figure 3-24 The ceiling tile for filter pad

3.4.9 Installation/Pre- commissioning Check List

After the unit is installed with all of the necessary mechanical connections, check the installation per Table

3-2.

Table 3-2 Mechanical installation checklist

Items

Results

Sufficient space for maintenance activities at site

Ensure all the fittings are tightly connected.

Make sure that the unit is placed correctly. Verify that the supply air is sent to the

cold aisle at the front of the unit and that the hot air is drawn to the return air inlet

in the back of the unit.

Foreign materials in and around the equipment are removed (such as shipping

materials, removed structural materials, tools, and so on)

The condensate drain pipe is connected properly

After all these items are checked and confirmed, continue with the electrical installation procedure for the

unit.

A hook for

construction

Flex Air Duct

PN:27140303

Clamp

PN:63128710

Ceiling tile for air outtake

PN:21243048

27

Vertiv I VRC Self-Contained System I User Manual

4 Electrical Installation

This chapter describes the electrical installation of the air-conditioning unit, including task introduction,

installation precautions, end cable connection and electrical inspection.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components

require and receive power even during the “Unit Off” mode of the controller. The only way to

ensure that there is NO voltage inside the unit is to install and open a remote disconnect switch.

Refer to unit electrical schematic. Follow all local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local

and remote electric power supply disconnect switches and verify with a voltmeter that power is

off before working within any electric connection enclosures. Service and maintenance work

must be performed only by properly trained and qualified personnel and in accordance with

applicable regulations and manufacturers’ specifications. Opening or removing the covers to any

equipment may expose personnel to lethal voltages within the unit even when it is apparently

not operating and the input wiring is disconnected from the electrical source.

WARNING! Risk of electric shock. Can cause injury or death. Open all local and remote electric

power-supply disconnect switches and verify that power is Off with a voltmeter before working

within the condensate pump electrical connection enclosure. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the Liebert® controller.

WARNING! Do not power on the unit until authorized technical personnel have confirmed that

the unit connections are correct.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause

overheated wire and electrical connection terminals resulting in smoke, fire, equipment and

building damage, injury or death. Use correctly sized copper wire only and verify that all

electrical connections are tight before turning power On. Check all electrical connections

periodically and tighten as necessary.

4.1 Installation Notes

NOTES:

• All power and control wiring and ground connections must be in accordance with the National

Electrical Code and local codes.

• Refer to the equipment nameplate for full load current and electrical requirements. The wire sizes

should meet the local wiring standards and regulations.

28

Vertiv I VRC Self-Contained System I User Manual

• Requirements for the main power supply 120 Vac ± 10%, 1 Ph, 60 Hz or 208 Vac ± 10%, 1 Ph, 60 Hz

or 230 Vac ± 10%, 1 ph, 50/60 Hz must be consistent with the unit nameplate power supply.

• Power cord is a Y-type connection. If the power cord is damaged, it must be replaced by a

professional maintenance person.

• Before performing any electrical works, use a voltmeter to measure the power supply voltage and

make sure that the power supply has been switched off.

• The equipment needs to be installed with screws, rails and other methods to avoid shaking during

startup or operation process.

• Disconnect the rated circuit breaker from the power supply.

4.2 Cable from the Power Supply Connection

4.2.1 Electrical Box Placement

The electric box is located at the back of the unit as shown in Figure 4-1. For VRC100 and VRC101, the

power cord with plug comes pre-attached from the factory.

VRC100 and VRC101

VRC102

Figure 4-1 Electric box of VRC100, VRC101 and VRC102

For the VRC102, the interconnection cable IEC 320 C19 to C20 is provided in the package. Connecting the

power cables between the VRC102 and the power supply onsite.

4.2.2 Display connection

The display board is connected to the unit with a power cable (Available in two lengths of cables, one is 10

m and the other is 0.5 m) as show in Figure 4-2.

Back Plate

Power Plug

Electric Box

5-20P for VRC100

L6-20P for VRC101

3PIN Terminal

Interconnection Cable (3.0m) IEC 60320 C19 to C20

29

Vertiv I VRC Self-Contained System I User Manual

Figure 4-2 Display, power and monitoring cable connections

4.2.3 Communication

There are two RJ-45 ports present on the unit for communication with third party monitoring systems to

enable remote monitoring of the unit. The RS485-1 (With 12 V power supply) could connect with the SIC

card monitoring kit. For detailed installation, please refer to SIC Field Instructions. The RS485-2 can be used

for communication with Vertiv rPDU. The aforementioned connections are shown in Figure 4-3 and Table

4-1.

NOTES:

• The VRC has only one slave port for master (Modbus RTU slave). It cannot support two Modbus RTU

masters simultaneously.

Figure 4-3 Communication cable connections

Table 4-1 Communication port description

Port Type

RS485-1

RS485-2

1

12 V

NC

2

3

NC

NC

4

GND

GND

5

6

NC

NC

7

D+

D+

8

D-

D-

Display board plug

Power cable (with plug)

Communication

Strain Relief Bushings

Power cable

Display connector

30

Vertiv I VRC Self-Contained System I User Manual

4.3 Installation Inspection

• After the electrical installation is completed, perform the installation inspection listed in Table 4-2.

• After confirming the above items, you can start the commissioning of the VRC unit.

Table 4-2 Installation inspection

Items

Results

The power supply voltage meets the rated voltage on the unit nameplate

The system electric loop has no open circuit or short circuit

There must be no open-circuit or short-circuit in the electrical connections.

The power cable and grounding cable to the air-break switch are connected.

The ratings of the Miniature Circuit Breaker and fuses are correct (Refer to unit nameplate to

select suitable Miniature Circuit Breaker or fuses)

The control cables are tightly connected.

All the cables connections are fastened appropriately, with no loose screws at the

connections

31

Vertiv I VRC Self-Contained System I User Manual

5 Controller Operation Instructions

This chapter gives a detailed description of the features, appearance, LCD screen, control buttons, control

interface and menu structure of the air conditioner.

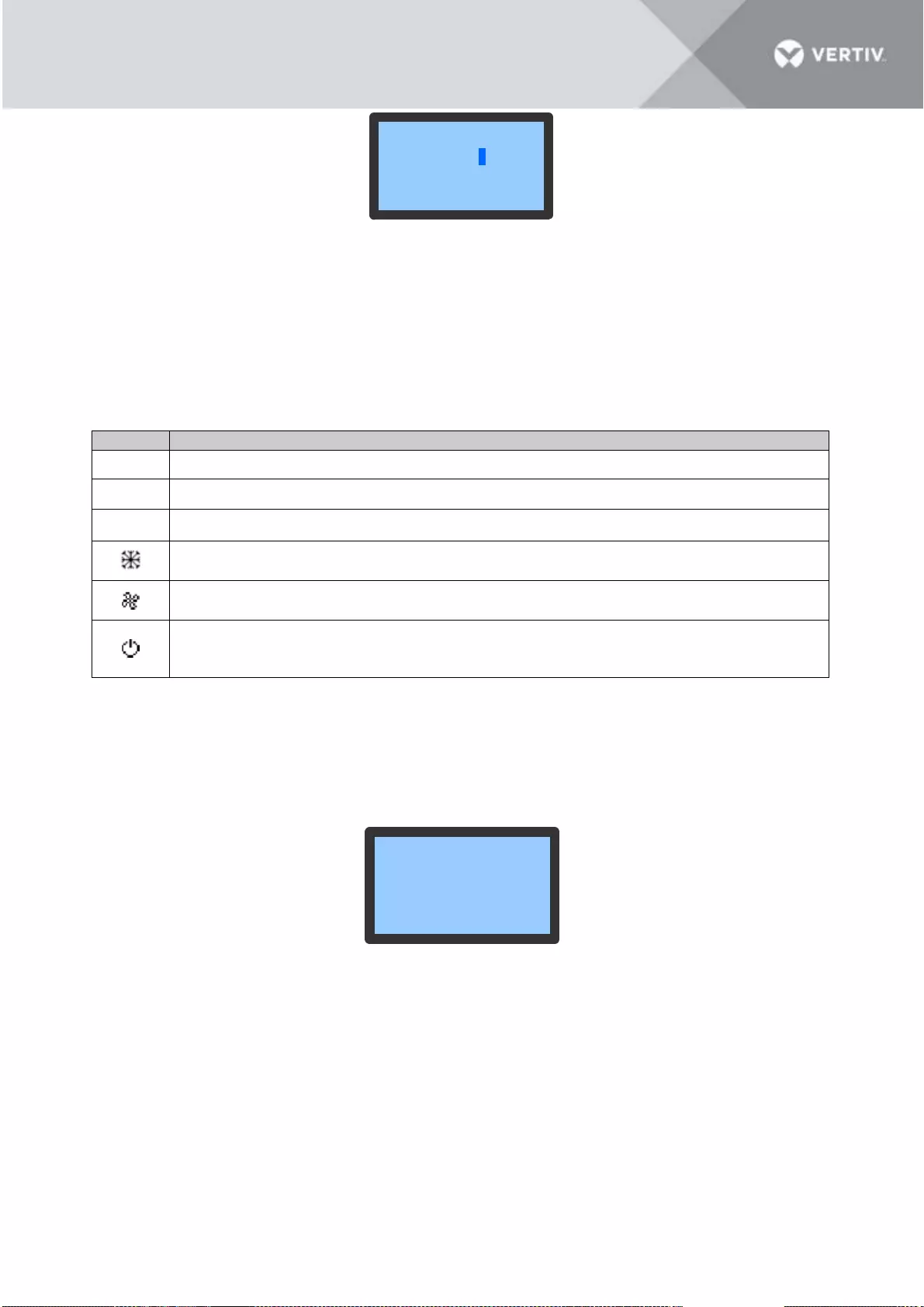

5.1 LCD Screen

The backlit LCD screen displays English menus. Figure 5-1 depicts the image of the controller display.

Figure 5-1 Controller display

5.2 Control Buttons

The micro-processing controller provides five control buttons, as shown in Figure 5-2, below.

Figure 5-2 Control buttons

LCD Screen

ON/ OFF Button

Up Arrow

Enter Button

Down Arrow

Run Indicator

Alarm Indicator

Escape Button

RUN

ALARM

ENT

ESC

ON/ OFF Button

Up Arrow

Down Arrow

Escape Button

ENT

ESC

ENT Button

32

Vertiv I VRC Self-Contained System I User Manual

The functions of the control buttons are described in Table 5-1.

Table 5-1 Functional description of the controller buttons

5.3 ON Screen

After the unit is powered on, the LCD screen will display the ON screen. You can choose the display board

language.

5.4 Normal Screen

After the unit is powered on, the Normal screen will be displayed after 10 seconds, as shown in Figure 5-3.

NOTES:

• The temperature units of VRC100, VRC101 are Fahrenheit. And the temperature units of VRC102 is

Celsius. The VRC100 is used as an example.

Figure 5-3 Normal screen

It displays the settings and actual values in the upper half of the display related to the settings and actual

air supply temperature in the first column, humidity in the second column, and air return temperature in

the third column.

In the lower part of the screen, it displays the unit output status (fan, cooling) and unit operation status

(off, running, standby, and locked).

The icons on the main screen indicate the unit output status, unit property, and unit operating status.

5.5 Password Interface

Press the Enter button on the Normal screen to display the Password screen. See Figure 5-4, below.

SUP 68 SUP - - % RET 90

70 - - % 86

75 %

S / ON

ACT

63%

℉

℉

℉

℉

Key

Function Description

ON/OFF

Switch on/off the controller by pressing for 3 seconds.

ENT

(Enter

button)

Enter the selected menu screen. Validate the parameter setting value.

ESC

Exit the current menu and return to the Normal screen or previous menu screen. Abort

parameter change; make the audible alarm silent.

Up

Arrow

Button

Move the cursor up or increase the parameter value. For a toggle selection: scroll

through the options. For a multi-screen menu: scroll up the screen

Down

Arrow

Button

Move the cursor down or decrease the parameter value. For a toggle selection: scroll

through the options. For a multi-screen menu: scroll down the screen.

SUP

ACT

RET

SUP

S / ON

33

Vertiv I VRC Self-Contained System I User Manual

Figure 5-4 Password interface

The user does not need to enter the password, just press the ENTER key four times to enter the next

interface.

5.6 Unit Working Icons

The icons and their definitions are listed in Table 5-2.

Table 5-2 Description of Icons

Icon

Description

SUP

Supply air temperature setpoint

ACT

Actual air temperature

RET

Specified return temperature

Cooling, the output of compressor. Displays the percentage of actual compressor capacity.

Rotating speed rate of the fan, ranging from 40% to 95%. Displays the percentage of actual fan

rotating speed.

Unit attribute/running state. S: standalone; RUN: running; OFF: shutdown.

Unit property/operation status. S: single; ON: running; R-OFF: remote shutdown; L-OFF: local

shutdown; M-OFF: monitoring shutdown; MANU: manual mode; BKUP: backup; Lock: lock.

5.7 Menu

5.7.1 Alarm menu

Select Alarm Menu on the Main Menu screen to enter the screen shown in Figure 5-5. Press the UP or

Down button to scroll up or down the menu items.

<ALM Set>

<ALM Status>

<HP Abnormal>

Figure 5-5 Alarm menu screen

5.7.2 Alarm status

Alarm status menu is used to monitor the current alarm status of the air conditioner unit. It displays no

alarm or specific alarm information. The specific alarm information includes XX/YY, alarm type, and alarm

generation time, as shown in Figure 5-6. XX indicates the alarm SN, and YY indicates the total number of

reported alarms.

Password:1***

Password:

<ALM Status>

<HP Abnormal>

<ALM Set>

34

Vertiv I VRC Self-Contained System I User Manual

Figure 5-6 Current alarm menu

NOTES:

• The latest alarm SN is the biggest number. Press the Up or Down button to scroll through the alarm

status records if more than one alarm is activated.

• The current alarms are automatically cleared upon system power failure.

5.7.3 Alarm Setup

Enter the alarm setup screen on the Alarm Setup menu. Use the Up or Down key to query menu items. The

alarm setup menu includes Alarm Setpoint, System Alarms, and Alarm Handle, as shown in Figure 5-7,

Figure 5-8 and Figure 5-9. Parameter settings can be saved permanently.

Lo Sup Temp

Hi Sup Temp 80.6

Hi Ret Temp

℉

46.4

86

℉

℉

Figure 5-7 Items of the alarm value setup menu

Lo Sup Temp

Hi Sup Temp ON

ON

ON

ON

Hi Ret Temp

Water HL

Figure 5-8 System alarm setup menu

Clr HP Abnor

Filt Maint Yes

No

Figure 5-9 Alarm handle menu

5.7.4 Temp Set

Select Main Menu -> Temp Set and press Enter as shown in Figure 5-10, and the Temperature Setting

values will be permanently saved.

ALM Status 1/1

Hi Sup Temp

2018/01/01 12:00

Hi Sup Temp 80.6 °F

Lo Sup Temp 46.4 °F

Hi Ret Temp 86 °F

Hi Sup Temp ON

Lo Sup Temp ON

Hi Ret Temp ON

Water HL ON

Filt Maint Yes

Clr HP Abnor No

35

Vertiv I VRC Self-Contained System I User Manual

Ret Stpt

Sup Stpt

Ctrl Mode Sup Air

Temp DB

60.8 ℉

82.4

0.9 ℉

℉

Cool Prop 9℉

Figure 5-10 Temp & Hum set menu

NOTES:

• The specified temperature value is the target temperature to ensure that the system is running

normally. When the control mode is set to return or supply air, the specified temperature is the

temperature of the return air or supply air.

• The default control mode of the unit is supply air control mode.

• If the AC is used in the open rack, use the return air control mode.

5.7.5 System Status

Select Main Menu -> System State to enter the System State menu, as shown in Figure 5-11.

<Run Time >

Figure 5-11 System State

5.7.6 Run Time

You can query the operation time of the device on this menu, as shown in Figure 5-12.

Fan 23 h

Comp 0 h

Figure 5-12 Run time menu

5.7.7 Help Menu

The menu includes Date and Time information. You can view the relevant information, as shown in Figure

5-13.

Figure 5-13 Date and Time menu

<Run Time>

Fan 23 h

Comp 0 h

Time (M) 20

Time (S) 30

Date (Y) 2018

Date (M) 1

Date (D) 1

Time (H) 12

<Date&Time>

Ctrl Mode Sup Air

Sup Stpt 60.8 °F

Ret Stpt 82.4 °F

Temp DB 0.9 °F

Cool Prop 9 °F

36

Vertiv I VRC Self-Contained System I User Manual

PART III

SYSTEM OPERATION AND

GENERAL MAINTENANCE

37

Vertiv I VRC Self-Contained System I User Manual

6 Startup Commissioning

This chapter describes the startup commissioning, including specific operations.

6.1 Preparations Before Commissioning

Mechanical part

• Connect the condensate water drain system piping and inspect for any leakage in the connections.

• Ensure that the unit has at least 30% of the designated head load. If not, use other heating devices

that compensate for the heat load to ensure the necessary amount of heat load for commissioning.

Electronic part

• Ensure that the input voltage of the main power supply is within ± 10% of the rated voltage and that

the power disconnector is closed.

• Ensure that the power cord and the communication cable are segregated from each other.

6.2 Start-up Inspection Checklist

Before powering up the unit, ensure the below mechanical and electrical inspections are properly checked

as per the Table 6-1 below.

Table 6-1 Start-up inspection checklist

Inspection

Items

Remarks

Mechanical

Inspection

Verify that the drainage pipe is tightly connected.

And there are no kinks or blockages in the hose.

Electrical

Inspection

Verify that the AC main voltage and frequency are normal. Make sure

that the main connection is correct and does not short circuit.

Make sure that the electrical and control connections are tight.

6.3 System Commissioning

Start up the unit

• Switch on the circuit breaker and connect to utility power.

• Press and hold the ‘ON’ button on the display board for 3 seconds to power up the unit.

• Pay attention to the controller display to ensure that there are no alarms or warnings displayed.

• There will be short vibration when starting or switching off. After running for more than half an hour,

ensure the operating status of the compressor, evaporator fan and condenser fan is smooth and that

there are no vibrations or any kind of noise from any of these components.

• Observe and monitor whether the system parameters are within the normal range, such as return air

temperature and supply air temperature, etc. as per the set operational functionality.

38

Vertiv I VRC Self-Contained System I User Manual

System Parameters Normal Range

Item

Range

Suction Pressure (Gauge)

800 kPa (116.0 psig) – 1500 kPa (217.6 psig)

Discharge Pressure (Gauge)

2000 kPa (290.1 psig) – 3600 kPa (522.1 psig)

Discharge Temperature

40 oC (104oF) – 115 oC (239 oF)

Tret - Tsup

3 oC(37oF) - 50 oC (122 oF)

• If any abnormal operation is noticed, stop the unit by pressing the ‘ON/OFF’ button on the display

board for 3 seconds, and disconnect all air circuit breakers.

6.4 Commissioning Complete Inspection

Inspect the items in Table 6-2, Checklist after Commissioning.

Table 6-2 Checklist after commissioning

Inspection Items

Inspection Results

Check that all outputs are functional.

Check that the temperature settings are correct and are controlled within range.

Check that there are no abnormal alarms or warnings displayed on the controller.

Make sure all the other functions are set correctly.

39

Vertiv I VRC Self-Contained System I User Manual

7 System Operation and Maintenance

Periodic system maintenance is crucial to ensure product reliability and validity. This chapter describes the

operation and maintenance of the precision air conditioner, including routine maintenance, system

diagnostic testing, and maintenance of filters, fan components, refrigeration systems and drainage

systems.

7.1 Safety Instructions

WARNING! During the operation of the precision air conditioner, very high voltage may be

present in the equipment. Adhere to all of the notes and warnings marked on the equipment or

contained in this manual, which may otherwise lead to an injury or fatality.

WARNING! Only qualified maintenance personnel can operate and handle the equipment. All

maintenance and operation must follow the local laws, especially the regulations about the

electric power, refrigeration, and production.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan blades have stopped rotating before working

in the unit cabinet or on the fan assembly.

WARNING! Risk of hair, clothing and jewelry entanglement with high speed rotating fan blades.

Can cause equipment damage, serious injury or death. Keep hair, jewelry and loose clothing

secured and away from rotating fan blades during unit operation.

WARNING! Risk of contact with extremely hot and/or cold surfaces. Can cause injury. Verify that

all components have reached a temperature that is safe for human contact or wear appropriate,

OSHA-approved PPE before working within the electric connection enclosures or unit cabinet.

Perform maintenance only when the system is de-energized and component temperatures have

become safe for human contact.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment

damage, serious injury or death. Installation and service of this equipment should be done only

by qualified personnel who have been specially-trained in the installation of air-conditioning

equipment and who are wearing appropriate, OSHA-approved PPE.

CAUTION: Comply with the manufacturer’s instructions before and during maintenance. Failure

to observe this will result in the warranty becoming void. Adherence to the safety instructions is

mandatory to ensure personnel safety and prevent any environmental impact apart from

equipment damage. Unsuitable components will impede equipment performance and may

cause equipment shutdown. Therefore, Vertiv recommends the use of Vertiv OEM or

Vertiv-approved components.

CAUTION: Switch off the VRC1 unit and then switch off the power input during equipment

maintenance. Switch off the equipment power unless the testing devices need power.

40

Vertiv I VRC Self-Contained System I User Manual

7.2 Electrical Inspection

Inspect the control board and temperature sensor every 6 months for loose electrical connections and

circuit corrosion.

The steps to inspect the boards are as follows:

• Firmly tighten all the electrical contacts.