Table of Contents

- 1 Important Safety Instructions

- 2 Introduction

- 3 Equipment Inspection and Handling

- 4 Installation

- 4.1 Prepare the Rack to Receive the Rack Cooling Unit (Vertiv™ VRC-S Self-Contained)

- 4.2 Install the Vertiv™ VRC (Vertiv™ VRC-S with Vertiv VRC Self-Contained)

- 4.3 Attach Air Baffles (Vertiv VRC-S with VRC self-contained)

- 4.4 Prepare the Rack to Receive the Rack Cooling Unit (Vertiv VRC-S with VCR Split)

- 4.5 Install the Vertiv (Vertiv VRC-S with Vertiv VRC Split)

- 4.6 Connect Power to the Backup Fan

- 4.7 Connect Power to the Condensate Pump

- 4.8 Attach the Local Display

- 4.9 Connect the Vertiv™ VRC to the Geist™ rPDU

- 4.10 Attach Ductwork and Ceiling Tile (Vertiv™ VRC Self-Contained)

- 4.11 Install IT Equipment and Final Preparation

- 5 Operation

- 6 Troubleshooting

- 7 Faults, Warnings and Events

- 8 Specifications

- 8.1 Vertiv™ VRC-S with VRC self-contained 120V NAM

- 8.2 Vertiv™ VRC-S with VRC self-contained 208V NAM

- 8.3 Vertiv™ VRC-S with VRC split lee temp 120 V NAM

- 8.4 Vertiv™ VRC-S with VRC split lee temp 208V NAM

- 8.5 Vertiv™ VRC-S with VRC self-contained 230V EMEA

- 8.6 Vertiv™ VRC-S with VRC split and VRC-S with VRC split lee temp 230V EMEA

- 8.7 Vertiv™ VRC-S with VRC self-contained 230V EMEA and Liebert® GXT5

- 8.8 Vertiv™ VRC-S with VRC split and VRC-S with VRC split lee temp 230V EMEA and Liebert® GXT5

- 9 Appendices

Vertiv VRCS3300-230VSL User Manual

Displayed below is the user manual for VRCS3300-230VSL by Vertiv which is a product in the Rack Cooling Equipment category. This manual has pages.

Related Manuals

VRC-S

User Manual

Vertiv™ Vertiv™ VRC-S

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.vertiv.com/en-us/support/ for additional assistance.

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Vertiv™ VRC-S User Manual

TABLE OF CONTENTS

1 Important Safety Instructions 1

2 Introduction 7

2.1 Environmental Conditions 7

2.2 Integrated Rack Characteristics 7

2.3 Vertiv VRC Characteristics 8

2.4 Liebert® GXT5 characteristics 9

2.5 Vertiv™ VRC-S System Connections 10

3 Equipment Inspection and Handling 17

3.1 Storing for Delayed Installation 17

3.2 Handling the Packaged Shipment 18

3.3 Uncrating the Components 19

3.4 What's in the Box 19

4 Installation 21

4.1 Prepare the Rack to Receive the Rack Cooling Unit (Vertiv™ VRC-S Self-Contained) 21

4.2 Install the Vertiv™ VRC (Vertiv™ VRC-S with Vertiv VRC Self-Contained) 22

4.3 Attach Air Baffles (Vertiv VRC-S with VRC self-contained) 22

4.4 Prepare the Rack to Receive the Rack Cooling Unit (Vertiv VRC-S with VCR Split) 24

4.5 Install the Vertiv (Vertiv VRC-S with Vertiv VRC Split) 24

4.6 Connect Power to the Backup Fan 24

4.7 Connect Power to the Condensate Pump 25

4.8 Attach the Local Display 26

4.8.1 Route Display, Fan Cables 27

4.9 Connect the Vertiv™ VRC to the Geist™ rPDU 28

4.10 Attach Ductwork and Ceiling Tile (Vertiv™ VRC Self-Contained) 29

4.11 Install IT Equipment and Final Preparation 30

5 Operation 31

5.1 Initial Startup—Vertiv™ Services 31

5.2 Initial Startup—User 31

5.2.1 Recommended Startup Sequence 31

5.3 Operational Settings 31

5.3.1 Changing Settings with the Geist rPDU 31

5.3.2 Set up Connection between Geist™ rPDU and Liebert® GXT5 33

6 Troubleshooting 35

6.1 Troubleshooting the Vertiv™ VRC 35

6.2 Troubleshooting the Liebert® GXT5 37

6.2.1 Symptoms that Require Troubleshooting 37

6.2.2 Audible Alarm (Buzzer) 37

iii

Vertiv™| VRC-S User Manual

6.2.3 Faults 37

6.2.4 Troubleshooting UPS Issues 38

7 Faults, Warnings and Events 39

8 Specifications 41

8.1 Vertiv™ VRC-S with VRC self-contained 120V NAM 41

8.2 Vertiv™ VRC-S with VRC self-contained 208V NAM 42

8.3 Vertiv™ VRC-S with VRC split lee temp 120 V NAM 44

8.4 Vertiv™ VRC-S with VRC split lee temp 208V NAM 46

8.5 Vertiv™ VRC-S with VRC self-contained 230V EMEA 48

8.6 Vertiv™ VRC-S with VRC split and VRC-S with VRC split lee temp 230V EMEA 49

8.7 Vertiv™ VRC-S with VRC self-contained 230V EMEA and Liebert® GXT5 52

8.8 Vertiv™ VRC-S with VRC split and VRC-S with VRC split lee temp 230V EMEA and Liebert® GXT5 55

9 Appendices 59

Appendix A: Startup Checklist Vertiv™ VRC-S 59

iv

Vertiv™ VRC-S User Manual

1 Important Safety Instructions

Save These Instructions

Vertiv™ VR Rack Safety Guidelines

This manual contains important instructions that must be closely followed during installation of this unit to maintain

compliance with agency listings. Read this manual thoroughly and the safety and regulatory information, available at

https://www.vertiv.com/en-us/support/technical-documents/it-management/it-management-compliance-regulatory-

information/, before attempting to install, service, or operate this unit.

Retain this manual for the entire service life of the unit.

WARNING! Risk of handling heavy unit. Can cause equipment damage, injury or death. Read all

instructions before beginning.

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Only properly trained and qualified personnel wearing appropriate

OSHA-approved personal protection equipment (PPE) should attempt to move, lift, remove

packaging from or prepare this unit for installation. Read all instructions before attempting to

move, lift, remove packaging from or prepare the unit for installation.

Vertiv recommends installing equipment in the Vertiv VR from bottom to top, beginning with

the Vertiv™ VRC in the bottom of the rack. Heavier rack equipment should be installed in the

positions just above the Vertiv VRC, then installing lighter equipment in the upper positions.

WARNING! Risk of shock loading. Can cause equipment damage.

The Vertiv VR rack is equipped with casters that are designed for moving the rack short

distances. Care must be taken to avoid sharp dropoffs that could cause shock loading. Vertiv

recommends using the casters to move only empty racks.

This product is designed for commercial/industrial use only. This product is not intended for use with life support or other

U.S. FDA designated “critical” devices. Maximum loads must not exceed those specified in this manual. The maximum load

rating for the standard Vertiv™VR is 1360 kg (3000 lb.); static load rating is 1022 kg (2250 lb.); dynamic load rating is, 907

kg (2000 lb.). Do not exceed the static load rating. Additional information may be found in the user manual, SL-11425, which

shipped with the Vertiv™ VRC-S and is available at Vertiv's web site www.Vertiv.com.

Install and operate this unit in a clean environment, free from moisture, flammable liquids, gases and corrosive substances.

The Vertiv VRC-S must be installed on a flat, level surface for proper assembly and operation.

Ensure that the rack has proper ventilation. Never block or insert objects into the ventilation holes or other openings.

Maintain minimum clearances as specified in this manual.

1 Important Safety Instructions 1

Vertiv™| VRC-S User Manual

Provide at least the minimum space between the accessories /components and the housing. This spacing must be

maintained for safe operation of the equipment when installed in accordance with the National Electric Code, ANSI/NFPA

70. As appropriate, all wiring and equipment should be installed in accordance with NFPA 70, “National Electrical Code,”

and the applicable sections of ANSI C2, “National Electrical Safety Code."

Vertiv™ VRC Safety Guidelines

WARNING! Risk of handling heavy unit and component parts. Can cause injury and equipment

damage. Use OSHA-recommended safe lifting techniques and/or lifting equipment rated for the

weight of the unit. Unit weights are specified in Specifications on page41 .

WARNING! Risk of improper moving. Can cause equipment damage, injury or death. Use only

lifting equipment that is rated for the unit weight by an OSHA-certified rating organization. The

center of gravity varies depending on the unit size.

CAUTION: Risk of contact with sharp edges, splinters and exposed fasteners. Can cause injury.

Only properly trained and qualified personnel wearing appropriate, OSHA-approved personal

protection equipment should attempt to move, lift, remove packaging from or prepare the unit

for installation.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep the forklift's tines level and at a height suitable to fit

below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness, freezing temperatures

and contact damage.

Vertiv™ Geist™ rPDU Safety Guidelines

•The rack PDU is designed for information technology equipment in a Restricted Access Location. Only service

personnel should install and access the PDU. The rack PDU is not intended for use with life support or other

designated critical devices. If uncertain about its intended application, consult your local dealer or Vertiv

representative.

•Follow nameplate ratings when connecting equipment to the branch circuit. Maximum load must not exceed

the rating shown on the rack PDU nameplate. Take into consideration the effect that overloading of the circuits

might have on overcurrent protection and supplied wiring.

•The rated line voltage must not exceed the specifications on the rPDU's accompanying documentation..

•Operate the rack PDU in an indoor environment only in the appropriate ambient temperature range:

•Install the rack PDU in a clean environment, free of conductive contaminants, moisture, flammable liquids,

gases and corrosive substances.

•The rack PDU must be installed in a restricted-access location. A restricted-access location is an area where

access is possible only through the use of a tool or lock and key or other means of security, and is controlled by

the authority responsible for the location.

1 Important Safety Instructions

2

Vertiv™ VRC-S User Manual

•The rack PDU has no user-serviceable parts, other than the field replaceable plastic carrier (not installed on all

models) that is designed to be field replaceable by qualified service personnel only. Under no circumstances

attempt to gain internal access due to the risk of electric shock or burn.

•Refer any unexpected behavior or unusual fault conditions to your local dealer or Vertiv representative.

•Vertiv recommends powering only devices with safety agency approval from the rack PDU.

•For permanently connected rack PDU’s (hard-wired versions), a readily accessible disconnect device must be

incorporated external to the equipment.

•For rack PDU’s with integral plugs, the socket/outlet or appliance coupler must be installed near the equipment

and must be easily accessible to disconnect for service.

To contact Vertiv technical support: visit Vertiv.com

For more information on this product, visit www.Vertiv.com to download the user manual.

Safety Precautions

WARNING! Observe all cautions and warnings. Failure to do so may result in serious injury or

death. Rack PDU units contain no user-serviceable parts, other than the field replaceable

plastic carrier (not installed on all models) that is designed to be field replaceable by qualified

service personnel only. For service or technical support, contact your local Vertiv

representative. Do not attempt to service this product yourself.

CAUTION: Connecting a rack PDU to a power supply with an incorrect rating in voltage or

amperes may damage the connected equipment and your rack PDU. For questions about the

power supply connections, contact your Vertiv representative.

CAUTION: Ensure that the ratings of the electric circuit of each connected device meet the

specified rating at each branch and receptacle.

NOTE: For power management purposes, record the receptacle where each piece of equipment is

connected. Receptacles on the rack PDU have a numeric designation. The rack PDU identifies the

receptacles with numbers and are grouped by branch with a letter referring to the proper circuit

breaker.

CAUTION: All configuration steps must be completed before attempting to start equipment

connected to the PDU.

1 Important Safety Instructions 3

Vertiv™| VRC-S User Manual

WARNING! Each rack must have its own protective-earth conductor. Do not daisy-chain the

protective-earth circuit using the multiple protective-earthing connection points. Protective-

earthing connections shall be such that disconnection of a protective earth at one point in a

unit or a system does not break the protective-earthing connection to other parts or units in a

system, unless the relevant hazard is removed at the same time.

Vertiv™ Liebert® GXT5 Safety Guidelines

UPS SAFETY NOTES

The UPS contains no user-serviceable parts except the battery pack. Do not remove the cover. Removing the cover may

result in electric shock and will invalidate any implied warranty. The UPS has an internal battery, so the output receptacles

of the UPS may carry live voltage even if the UPS is not connected to mains input power.

Before moving or rewiring the UPS, disconnect mains input power and the battery and make sure that the UPS is

completely shut down. Otherwise, the output terminal may carry live voltage, presenting an electric shock hazard. To ensure

human safety and normal UPS operation, the UPS must be properly grounded before use. When the UPS is connected to an

IT power distribution system, the short-circuit protection device must be installed on the neutral line. Install and use the

UPS in the following environments:

•Temperature: 32°F - 122°F (0°C - 50°C); relative humidity: 0% to 95%

•Out of direct sunlight

•Away from heat source

•Stable surface, not subject to vibrations or shocks

•Away from dust and other particulates

•Away from corrosive substances, salts and flammable gases

Keep the air inlet and outlet of the UPS unobstructed. Poor ventilation will increase the UPS internal temperature and can

shorten the life of the UPS and its batteries. Keep liquid and other foreign objects away from the UPS. In case of fire, use a

dry chemical fire extinguisher to put out the fire. Using a fluid fire extinguisher may cause electric shock. This UPS is not

intended for use with life support and other designated critical devices. Maximum load must not exceed that shown on the

UPS rating label. This UPS is designed for data processing equipment. If uncertain, consult your local dealer or company

representative.

NOTE: Proper ventilation needs to be ensured.

Electromagnetic Compatibility

This UPS complies with the limits for a Class A digital device. Operating this device in a residential area is likely to cause

harmful interference that users must correct at their own expense. This UPS complies with the requirements of EMC

Directive 2014/30/ EU and the published technical standards. Continued compliance requires installation in accordance

with these instructions anduse of accessories approved by Vertiv™.

1 Important Safety Instructions

4

Vertiv™ VRC-S User Manual

BATTERY SAFETY

CAUTION: Do not dispose of the battery in a fire. The battery may explode. Do not open or

damage the battery. Released electrolyte is harmful to skin and eyes. If electrolyte comes into

contact with the skin, wash the affected area immediately with plenty of clean water and get

medical attention.

CAUTION: A battery can present a risk of electrical shock and high short-circuit current. The

following precautions should be observed when working on batteries:

• Remove watches, rings and other metal objects.

• Use tools with insulated handles.

• Wear rubber gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect charging source prior to connecting or disconnecting battery terminals.

• Determine if the battery is inadvertently grounded. If it is inadvertently grounded, remove the source of the

ground. Contact with any part of a grounded battery can result in electrical shock. The likelihood of such shock

will be reduced if grounds are removed during installation and maintenance (applicable to a UPS and a remote

battery supply not having a grounded supply circuit).

1 Important Safety Instructions 5

Vertiv™| VRC-S User Manual

1 Important Safety Instructions

6

This page intentionally left blank

Vertiv™ VRC-S User Manual

2 Introduction

The Vertiv™ VRC-S product line is an IT rack-cooling solution equipped with a network-enabled rPDU and is designed for

critical equipment in small server rooms, network closets and edge computing spaces.

The Vertiv VRC-S is available in these series with either 120 V, 208 V, or 230 V:

•VRCS3350: 42U 800 x 1200

•VRCS3300: 42U 600 x 1200

•VRCS3307: 48U 600 x 1200

•VRCS3357: 48U 800 x 1200

The Vertiv VRC-S is based on the Vertiv™ VR rack. The cabinet is equipped with a Vertiv™ VRC 3.5 kW cooling unit, a

Vertiv™ Geist™ rPDU, optional with Liebert® GXT5™ UPS and sensors, as well as venting to convey heat from the cabinet

into an adjacent space or out of the area. SNMP and Modbus-RTU connectivity permit connection to a building

management system for remote monitoring. See Specifications on page41 for more information.

A backup fan on the rear door is actuated when the temperature at the top front of the cabinet exceeds 32°C (86°F). The fan

shuts off when the temperature sensor, installed at the top front of the cabinet, senses that the temperature has dropped

below 32°C (86°F).

2.1 Environmental Conditions

The Vertiv VRC-S must be installed and operated indoors, within a temperature range of 18°C-30°C (64.4°F-86°F),

condensing and less than 80% relative humidity (non-condensing).

Operating the Vertiv VRC-S in extreme environments may cause condensation inside the cabinet. The VRC-S is not

environmental neutral. The user is encouraged to try to correct this condition by these measures:

•Increasing the supply air operating temperature of the Vertiv™ VRC module. Refer to Operation on page31 for

details.

•Reducing the relative humidity in the operating environment. This can be accomplished through passive

means by adding louvers to doors or walls for more ventilation; or by cooling the room through the building's

cooling system.

2.2 Integrated Rack Characteristics

The cabinet is a Vertiv™ VR rack designed to promote separation of cool supply air from the heat rejected by the IT loads

within the rack.

•solid, sheet-metal sides

•solid top and bottom panels

•air baffles to promote cooling air circulation

For the Vertiv™ VRC-S, the rack also has a factory-installed backup fan on the rear door. The backup fan is connected to the

Geist™ rPDU for backup power and network connectivity. A sensor at the front of the cabinet automatically senses any rise

in cabinet temperature and, in emergency situations, signals the fan to exhaust the warmer air from the rack. The backup fan

is actuated when the temperature at the top front of the rack exceeds 32°C (86°F). It switches Off when the temperature

drops below that threshold.

2 Introduction 7

Vertiv™| VRC-S User Manual

The Vertiv VRC-S, painted RAL 7021 as are its main components, may be controlled through the Geist rPDU, which is

network-enabled and permits remote monitoring and management over a network. A display that may be installed on the

rack's back door, provides local monitoring and control of the Vertiv™ VRC.

The Vertiv™ VRC-S easily accepts either the Vertiv™ Liebert® PSI5 or Vertiv™ Liebert® GXT5 UPS and the Geist rPDU

family of products to provide conditioned and backup power to the rack equipment.

IMPORTANT! If a UPSis installed, it should be installed immediately above the Vertiv VRC. Installing

the UPShigher in the rack could result in a tipping hazard.

2.3 Vertiv VRC Characteristics

The Vertiv VRC cooling unit may be either 120 V, 208 V or 230 V. Each unit will deliver up to 3.5 kW of cooling/heat removal

to the rack-mounted equipment.

The Vertiv™ VRC-S must be installed indoors in an environment with a temperature range of 18°C-30°C (64.4°F-86°F) and

less than 80% relative humidity (non-condensing).

For VRC-S with VRC split the outdoor temperature range is -15°C (5°F) to 45°C (113°F).

For VRC-S with VRC split lee temp the outdoor temperature range is -34°C (-29.2°F) to 45°C (113°F).

2 Introduction

8

Vertiv™ VRC-S User Manual

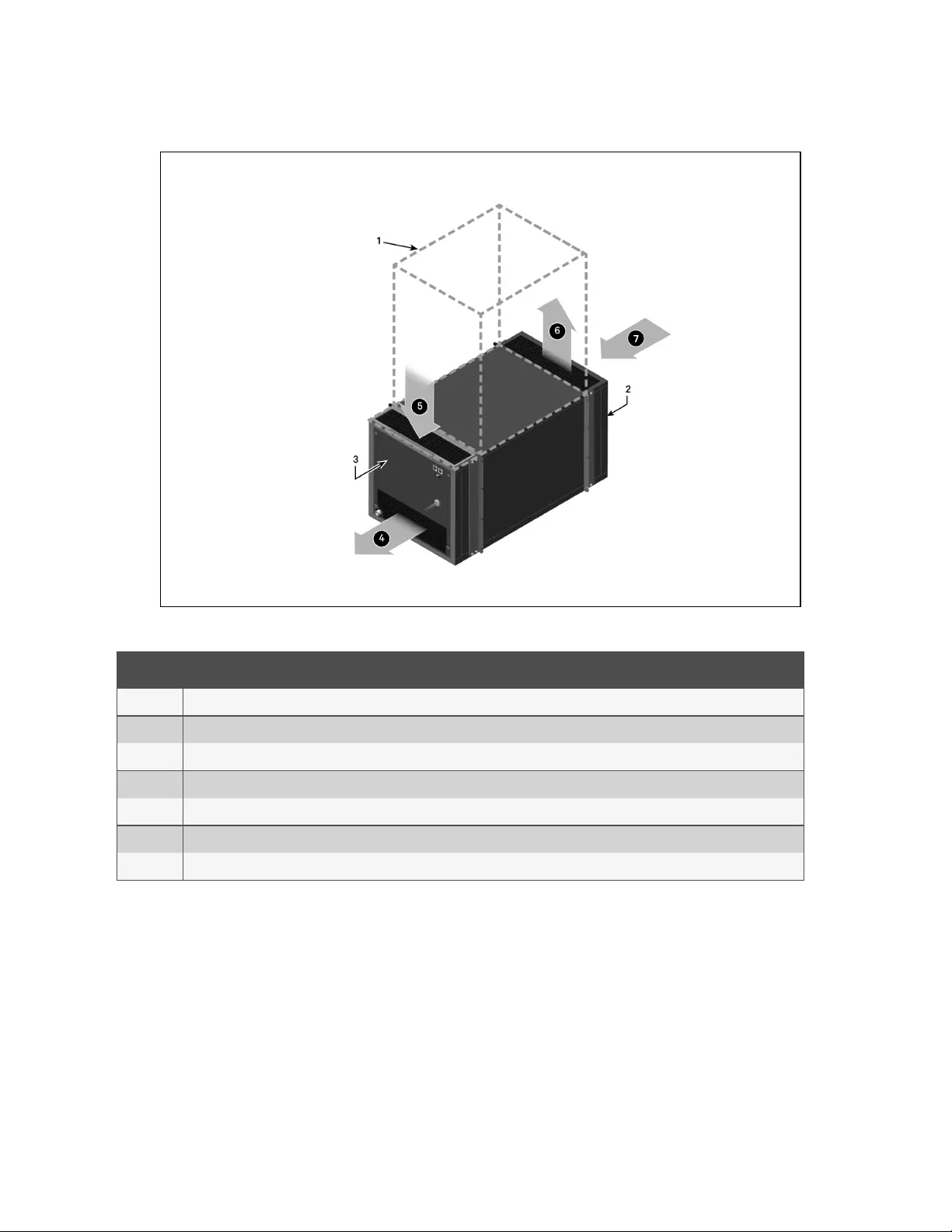

Figure 2.1 Vertiv™ VRC Self-Contained Cooling Airflow

Item Description

1 Rack-equipment area in rack

2 Front of Vertiv VRC

3 Rear of Vertiv VRC

4 Hot air exhaust (Transition piece and duct not shown)

5 Vertiv VRC return air intake, hot air from inside cabinet

6 Cool air supply into rack

7 Cool air for VRC

Table 2.1 Cooling Air Flow Description

2.4 Liebert® GXT5 characteristics

The Liebert GXT5 is a compact, online uninterruptible power system (UPS) that continuously conditions and regulates its

output voltage. The Liebert GXT5 supplies microcomputers and other sensitive equipment with clean sine-wave input

power.

Upon generation, AC power is clean and stable. However, during transmission and distribution it is subject to voltage sags,

spikes, and complete failure that may interrupt computer operations, cause data loss, and damage equipment.

The Liebert GXT5 protects equipment from these disturbances. The Liebert GXT5 continuously charges its batteries from

the mains, enabling it to supply power to connected loads, even when the mains fail.

2 Introduction 9

Vertiv™| VRC-S User Manual

2.5 Vertiv™ VRC-S System Connections

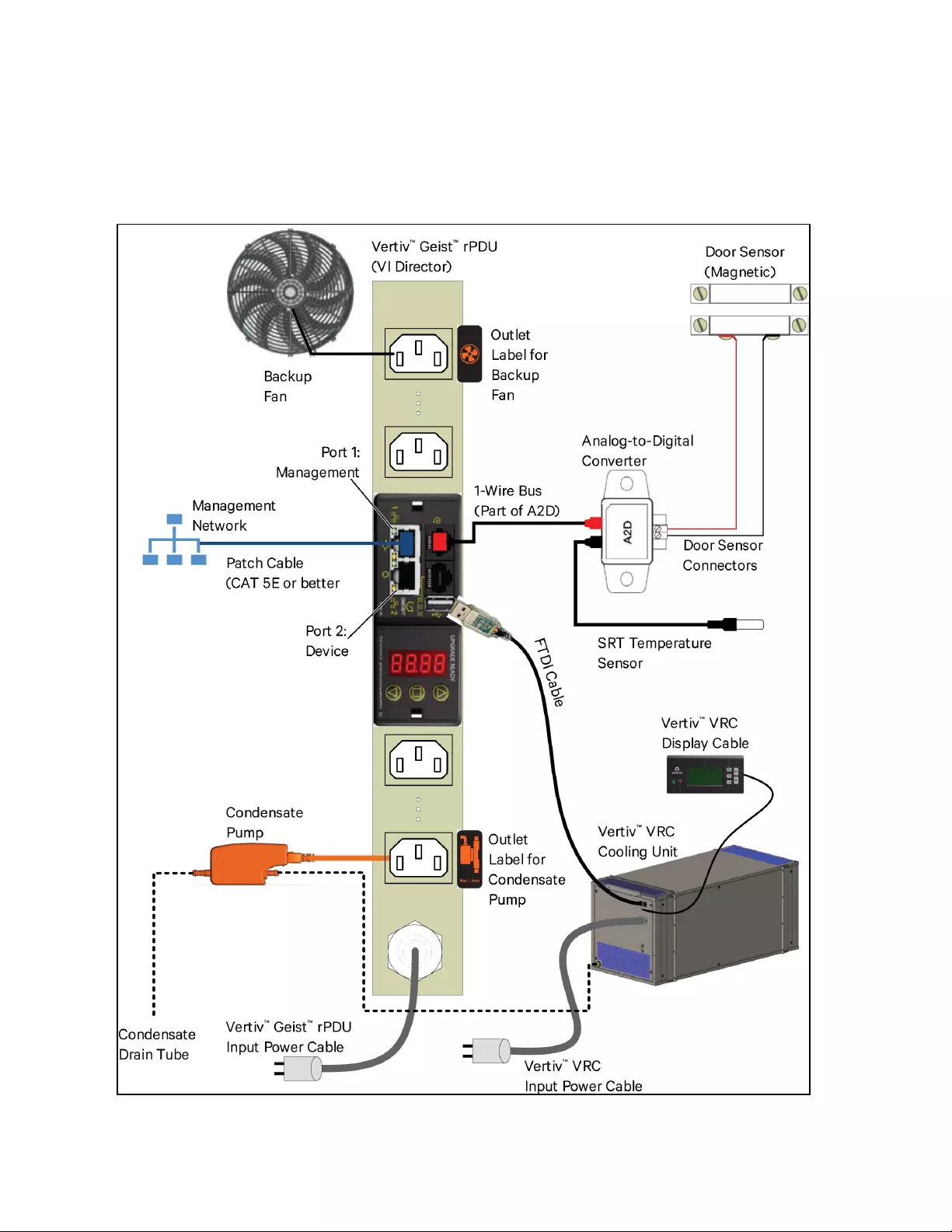

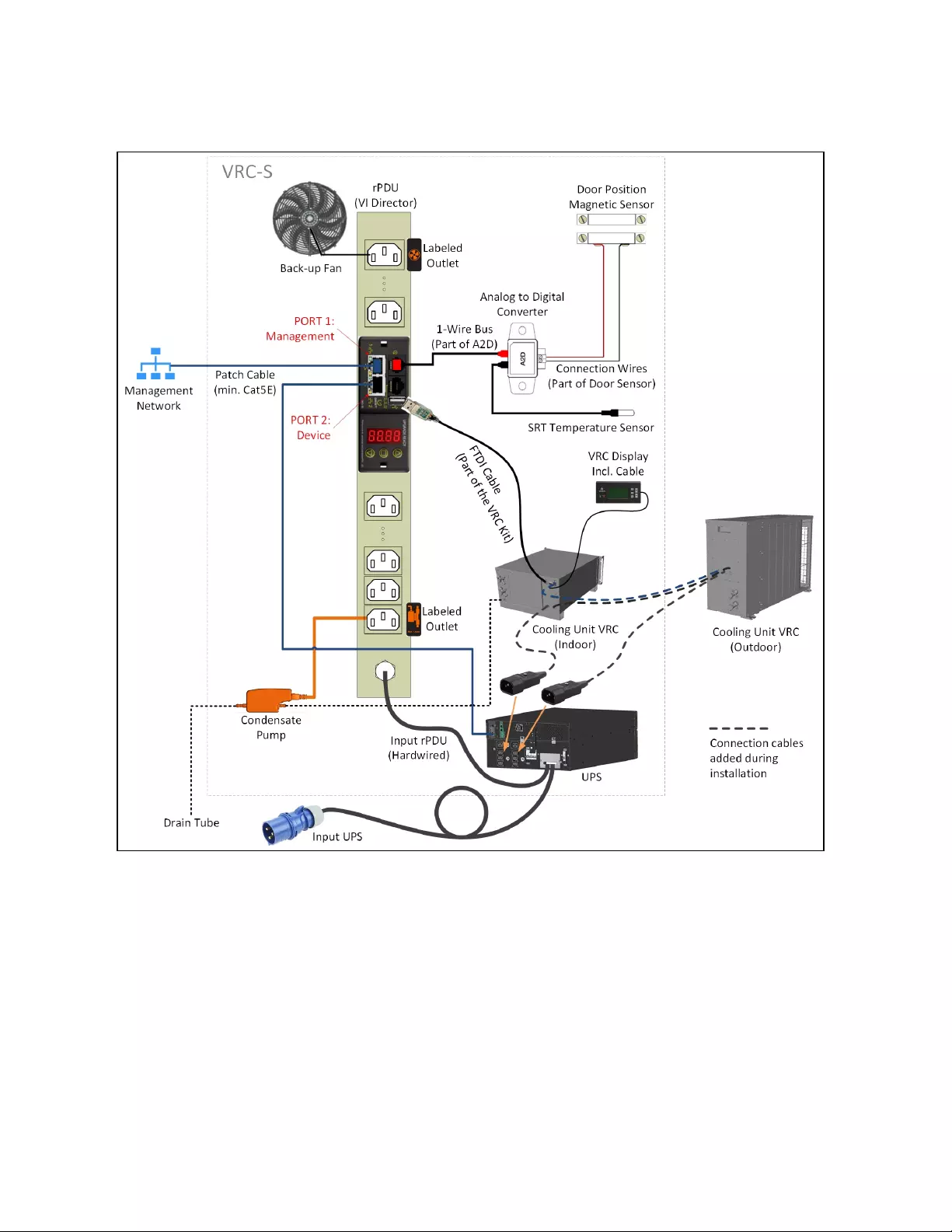

Figure 2.2 One-Line Diagram of Vertiv VRC-S self-contained Connection - NAM (without Liebert®

GXT5)

2 Introduction

10

Vertiv™ VRC-S User Manual

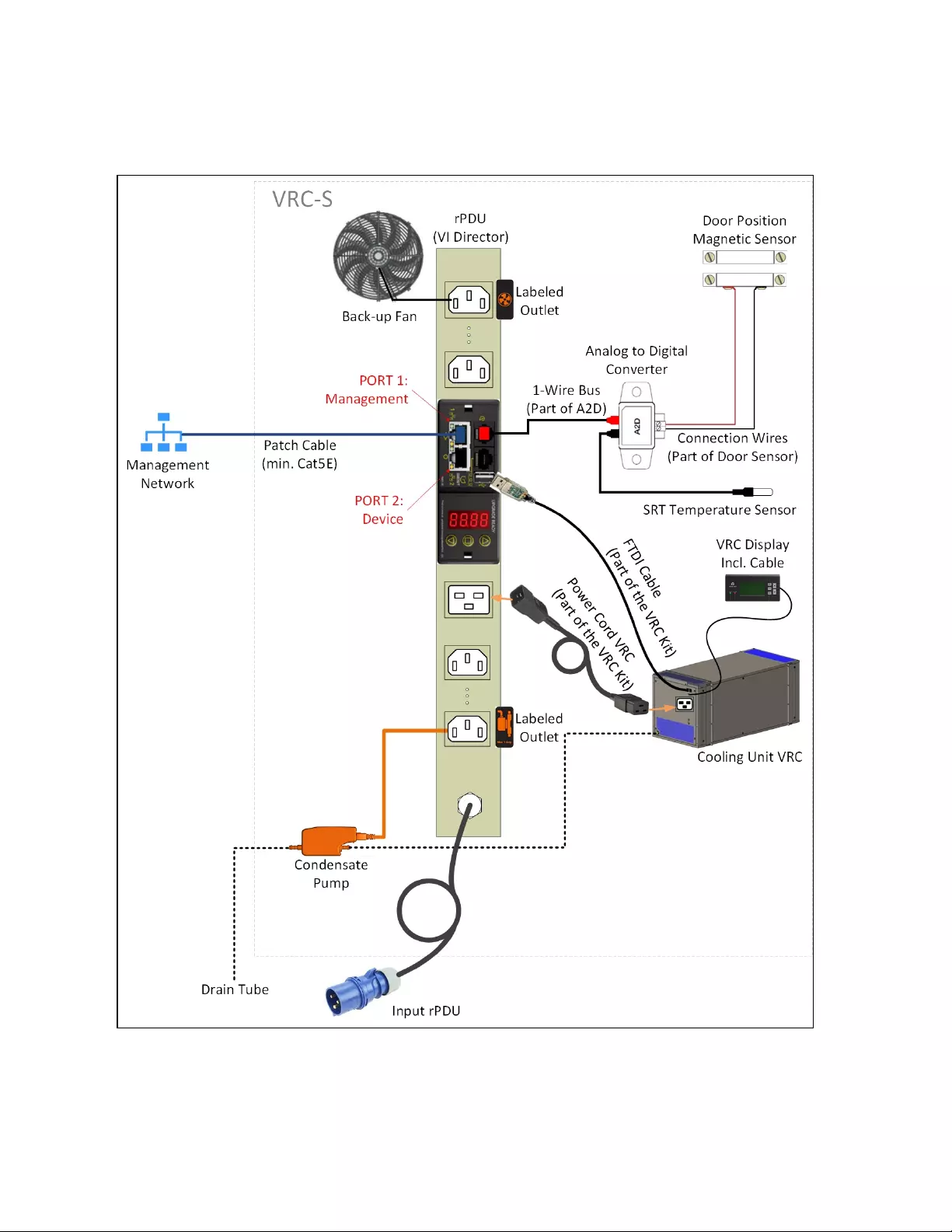

Figure 2.3 One-Line Diagram of Vertiv™ VRC-S self-contained Connection - EMEA (without Liebert®

GXT5)

2 Introduction 11

Vertiv™| VRC-S User Manual

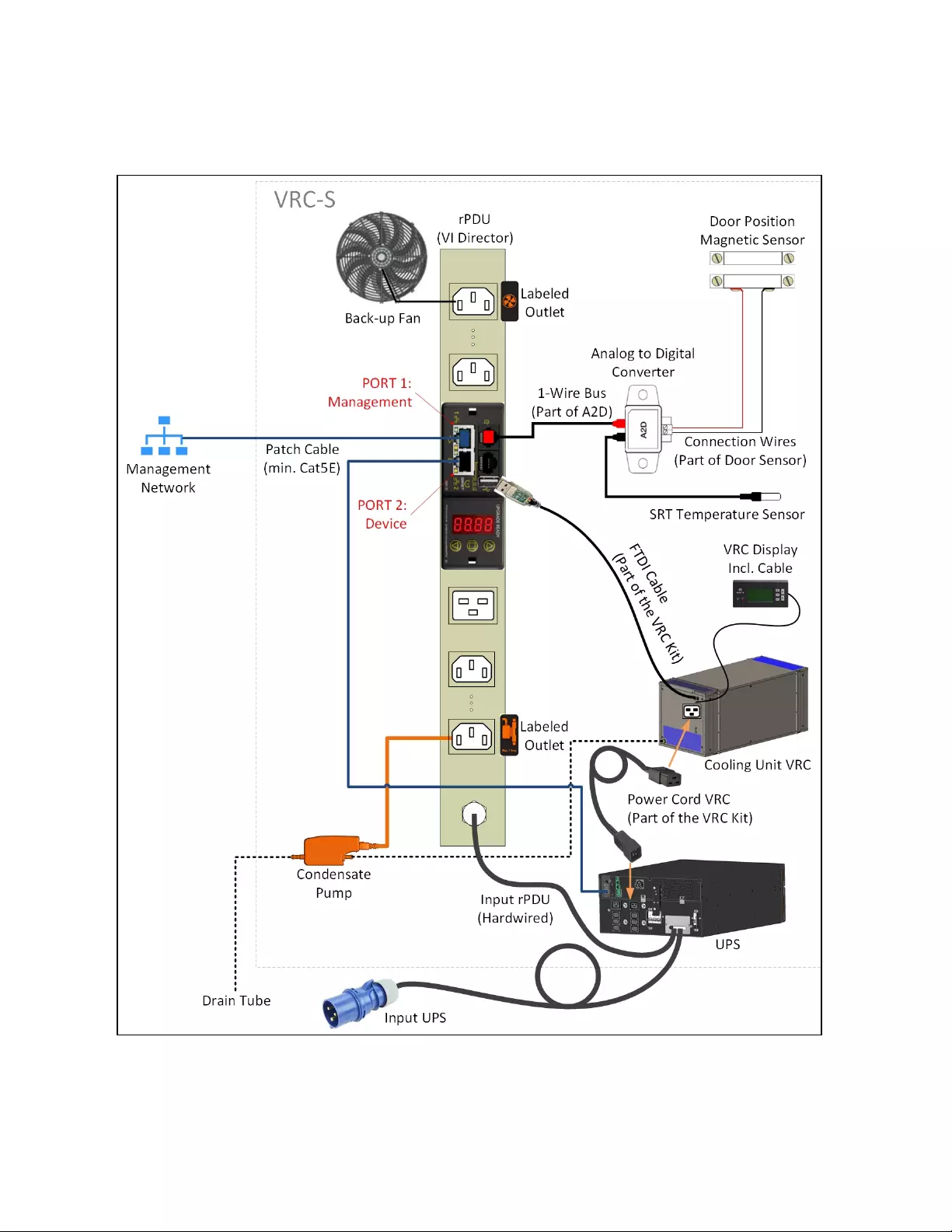

Figure 2.4 One-Line Diagram of Vertiv™ VRC-S self-contained Connection - EMEA (with Liebert®

GXT5)

2 Introduction

12

Vertiv™ VRC-S User Manual

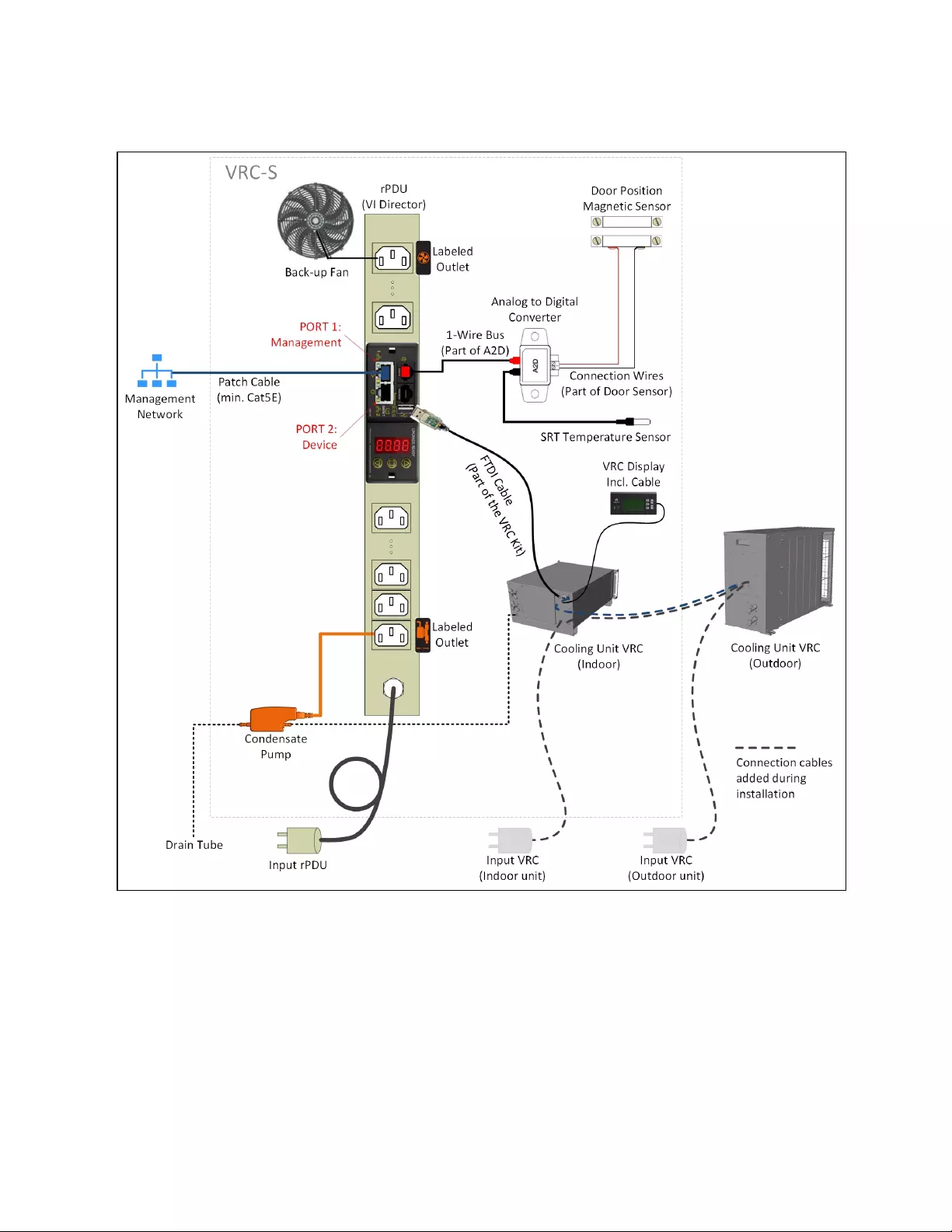

Figure 2.5 One-Line Diagram of Vertiv™ VRC-S split Connection - EMEA (without Liebert® GXT5)

2 Introduction 13

Vertiv™| VRC-S User Manual

Figure 2.6 One-Line Diagram of Vertiv™ VRC-S Split Connection - EMEA (with Liebert® GXT5)

2 Introduction

14

Vertiv™ VRC-S User Manual

Figure 2.7 One-Line Diagram of Vertiv™ VRC-S Split Connection - NAM (without Liebert® GXT5)

2 Introduction 15

Vertiv™| VRC-S User Manual

2 Introduction

16

This page intentionally left blank

Vertiv™ VRC-S User Manual

3 Equipment Inspection and Handling

Upon arrival of the Vertiv™ VRC-S and before beginning to unpack it:

•Verify that the labeled equipment matches the bill of lading.

•Inspect all items for visible or concealed damage.

•Report any damage immediately to the carrier and file a damage claim with a copy sent to Vertiv™ or to your

sales representative.

3.1 Storing for Delayed Installation

The Vertiv VRC-S should be installed promptly after delivery. If installation will be delayed, the shipment must be stored

indoors in a clean, dry, and cool location and protected against impact damage.

Store the unit in the original packaging indoors in an area protected from excessive dirt, debris, and contact damage until

final installation. Observe the following requirements and the conditions listed in Storage Conditions below .

•Do not store the unit outdoors.

•Make sure that the unit is kept upright.

IMPORTANT! If the combined time for shipment and storage exceeds 6 months, the Vertiv™ VRC

requires recalibration for proper performance. If the shipment includes a UPS, refer to that UPS's

manual for battery recharging information.

Condition Requirement

Ambient temperature –20°C to 65°C (–4°F to 149°F)

Ambient humidity less than 95% relative humidity, 39°C (103°F)

Table 3.1 Storage Conditions

3 Equipment Inspection and Handling 17

Vertiv™| VRC-S User Manual

3.2 Handling the Packaged Shipment

Transport the packaged equipment and components as described in each unit's documentation.

The manuals shipped with the Vertiv™ VRC-S. They can be found attached to the interior of the Vertiv™ VR rack. Cut the

plastic wrapping from the rack, using a knife along the corrugated padding to prevent damaging the rack's paint.

Figure 3.1 Manuals and hardware shipped in Vertiv VR

3 Equipment Inspection and Handling

18

Vertiv™ VRC-S User Manual

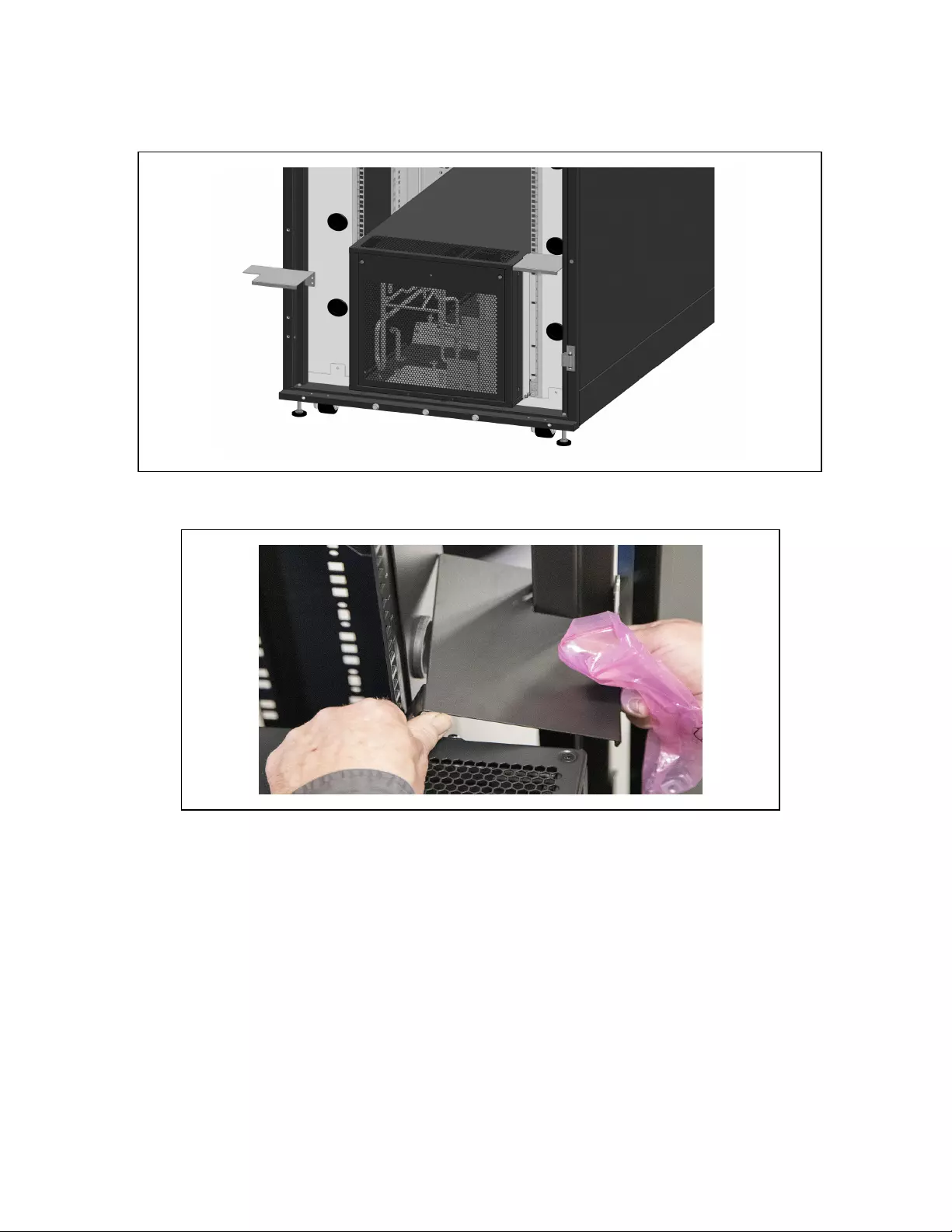

3.3 Uncrating the Components

Once the pallets have been moved as close as possible to the installation location, remove the Vertiv™ VRC-S components

from the shipping pallets. Remove the Vertiv™ VR rack from its pallet first, retrieve the documentation from inside the

cabinet, then uncrate the Vertiv VRC-S kit.

IMPORTANT! Uncrate the components according to the instructions in the documents that were

shipped inside the Vertiv VR rack.

3.4 What's in the Box

The Vertiv VRC-S self-contained is shipped on one pallet with the Vertiv™ VRC installed inside of the specially prepared

VRRack. The Vertiv VRC-S split will be sent on two pallets (the VRC split indoor unit inside the VR Rack and the VRC split

outdoor unit are on separate pallets).

The Vertiv VR, a 19-in. EIA server rack, will have these components factory-installed:

•Thermal separation

•Rack closing kit

•Sensors for temperature and door contact

•Backup fan

•Geist™ rPDU (factory-programmed)

•Liebert® GXT5 (in some EMEA versions)

The VRC10XKIT will have these components:

•Vertiv™ VRC Cooling Unit

•Condensate Pump

•Condensate Pump Bracket

•Condensate Pump Outlet Fitting, L-Shaped

•Plastic Drain Tubes, 2: 1 m (3 ft.) and 7.6 m (25 ft.)

•Rack-Mount Hardware for Vertiv VRC-S Components

•Display monitor in magnetic mounting box

•Display Cables, 2: 50 cm (19.5 in.) and 10 m (32.8 ft.)

•FTDI Cable to connect the Vertiv VRC to the rPDU

•Ceiling Duct Kit

•Hose Clamp

•Ceiling Grille

•Transition Piece (for heat rejection to ducting)

•Filters, 2; Vertiv VRC and Ceiling Grille

•Manuals for the Vertiv VRC and the condensate pump and manual for Liebert GXT5 (for some EMEA versions)

•Screws: 20 M6x12; 10 M5x12; 10 M3x8

3 Equipment Inspection and Handling 19

Vertiv™| VRC-S User Manual

The VRC20XKIT will have these components:

•Vertiv™ VRC Cooling Unit (indoor and outdoor unit)

•Condensate Pump and Pump Bracket

•Condensate Water Pipe (7.5 m/24.6 ft.)

•Drain fitting

•Display and Display Magnetic Box

•10 m Cable of Display

•L-shape Mounting Rail Kit

•Cage Nuts (M6)

•Pan-Head Screws M6x12 (Torx T30)

•Center Screws M5x12 (Torx T20)

•USB Converter Cable

•Side Panel

•Front Panel

•Manuals for the Vertiv VRC and the condensate pump and manual for Liebert®GXT5 (for some EMEA versions)

•Screws (M4x10)

3 Equipment Inspection and Handling

20

Vertiv™ VRC-S User Manual

4 Installation

NOTE: EMEA version: all parts are factory installed.

Assemble the Vertiv™ VRC-S as detailed in documentation for the Vertiv™ VR solution and Vertiv™ VRC. This

documentation shipped inside the rack. However, assembly will be eased by performing these steps before sliding the

cooling unit into the rack:

•Attach the condensate pump and the transition piece to the Vertiv VRC (perform Section 4.3 in the Vertiv VRC

manual before Section 4.1). The pump installation includes attaching the 25-foot (7.5 m) drain tubing if the

shorter, factory-attached piece is not adequate. The drain tube used should be checked for kinks before

attachment. After attaching the tubing, push about half an inch through the outlet hole in the pump shroud.

IMPORTANT! When installing the brass condensate fitting, do not use a wrench. Using a wrench may

cause overtightening and damage internal components. Hand-tighten the fitting only. The tube is a

gravity drain only and is not pressurized.

•For Vertiv VRC Self-Containted, attach the transition piece to the cooling unit (perform Section 4.2 in the Vertiv

VRC manual before Section 4.1). The transition piece is attached to the rear of the cooling unit with six screws.

The lower screws will be easier to manipulate before the cooling unit is inside the rack.

•Attach the condensate pump and bracket (perform Section 4.3 in the Vertiv VRC manual before Section 4.1).

•Install the filter in the Vertiv VRC. The cooling unit has a filter on the top rear that collects particulates from the

return air going back into the Vertiv VRC. The brackets holding the filter in place may need to be loosened

before the filter can be inserted. This is done more easily before the Vertiv VRC is inserted into the cabinet.

Note that the filter has an arrow to indicate the airflow direction.

NOTE: Do not discard the handles removed from the Vertiv VRC cooling unit after sliding it into the

Vertiv VR. Retain the handles and the bolts for use in handling the cooling unit should it need to be

removed from the cabinet.

4.1 Prepare the Rack to Receive the Rack Cooling Unit

(Vertiv™ VRC-S Self-Contained)

Inserting cage nuts into the proper slots in the rack's rails before sliding the Vertiv VRC into the rack will also ease

assembly. The cage nuts may be inserted after the cooling unit is in the rack, but tighter quarters with the cooling unit

inside the rack means there will be less room to manipulate the cage nuts.

The cage nuts are used to attach the rack cooling unit to the rack's rails and to attach air baffles in the front of the rack even

with the top of the Vertiv VRC. Cage nuts are supplied with the rack. They may be found in the bag attached with the

manuals inside the rack.

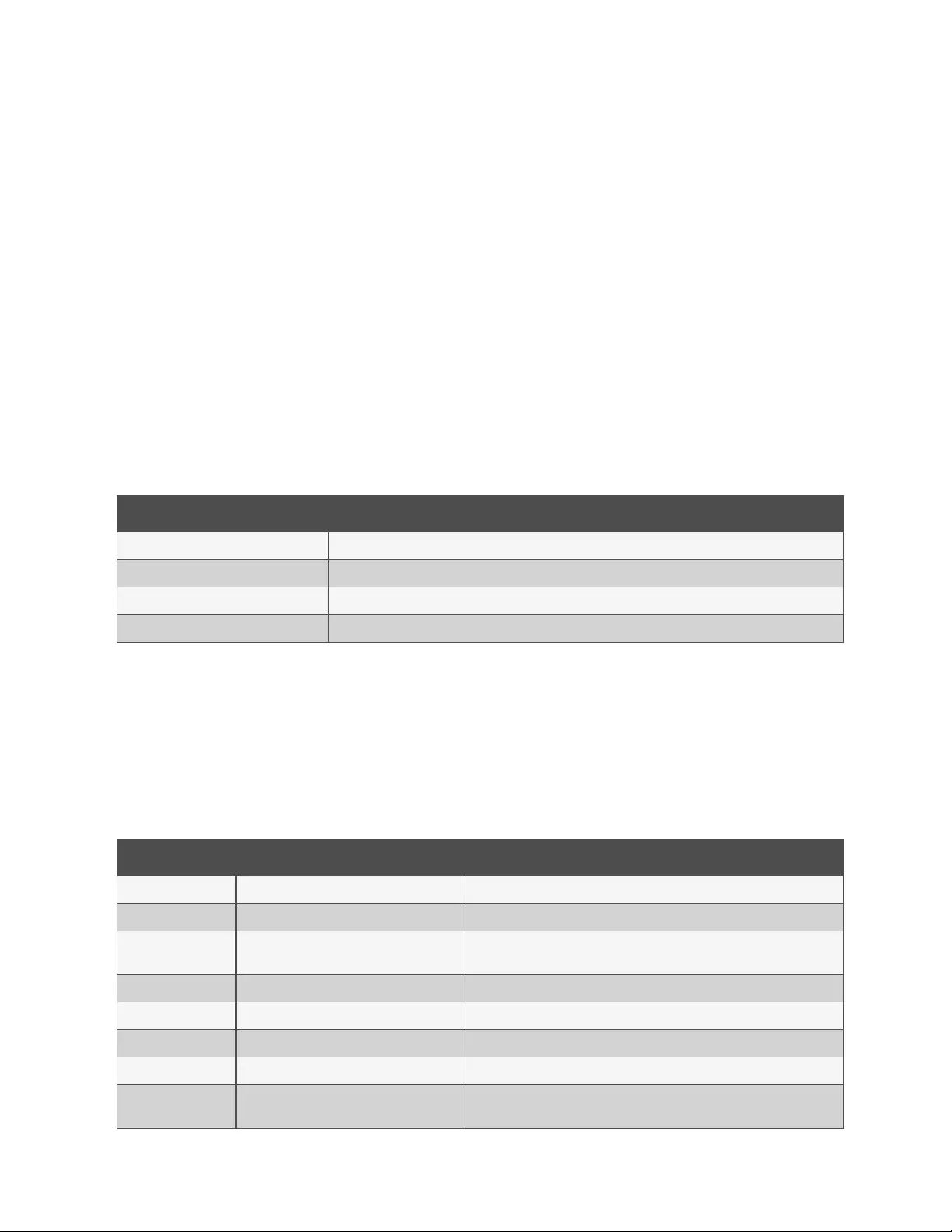

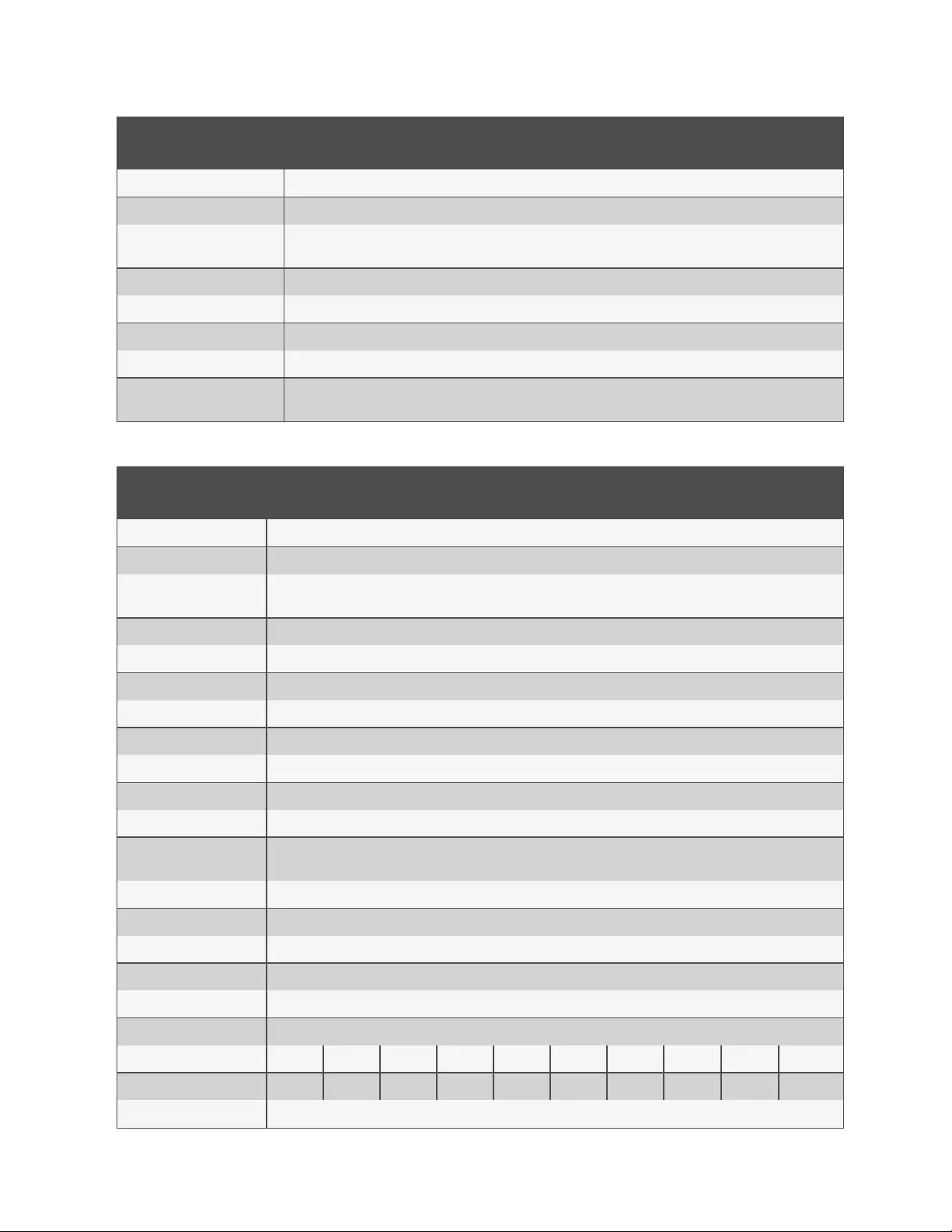

Install cage nuts at these positions, except the 10U positions, on each of the cabinet's four rails. Insert cage nuts at the 10U

positions, 6U for split in the front rails only.

4 Installation 21

Vertiv™| VRC-S User Manual

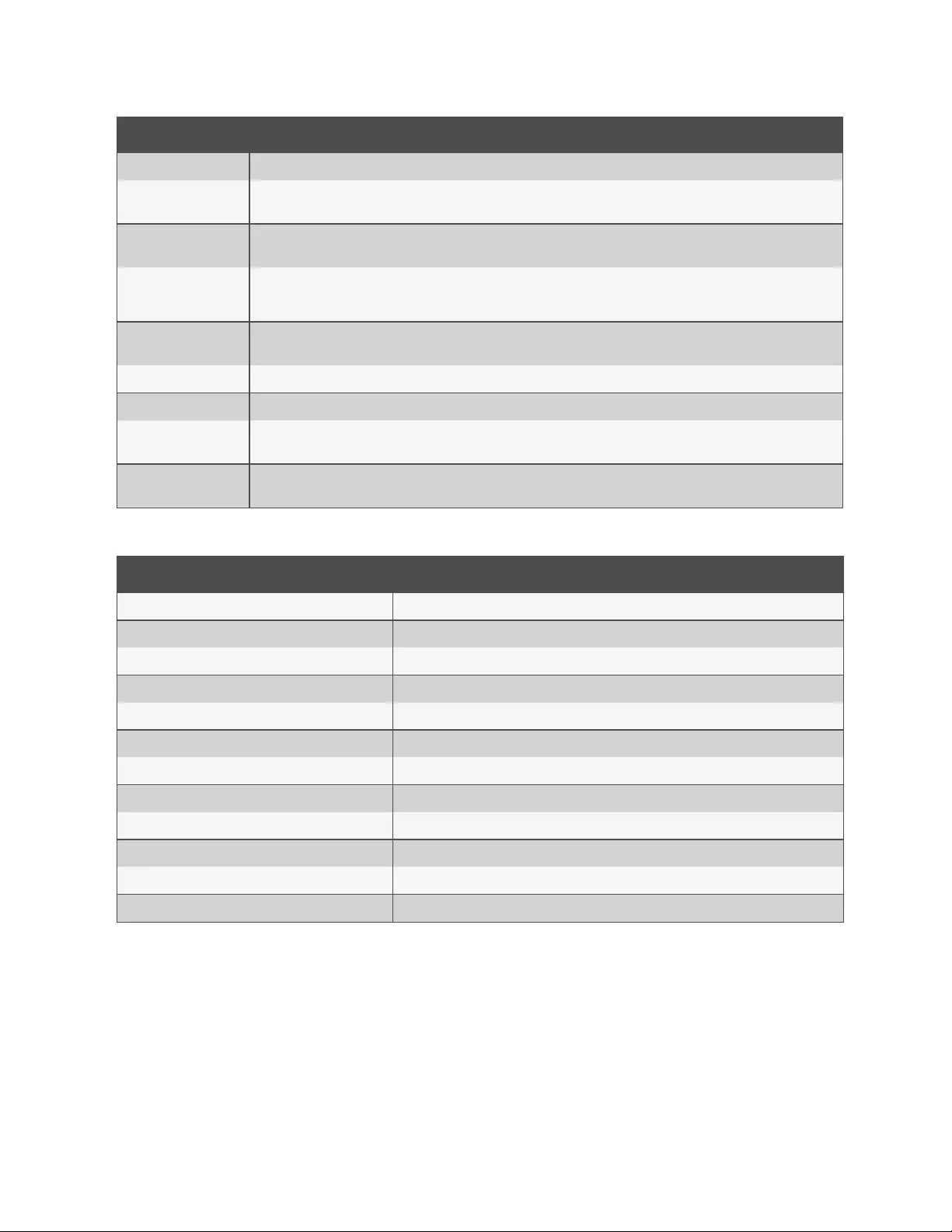

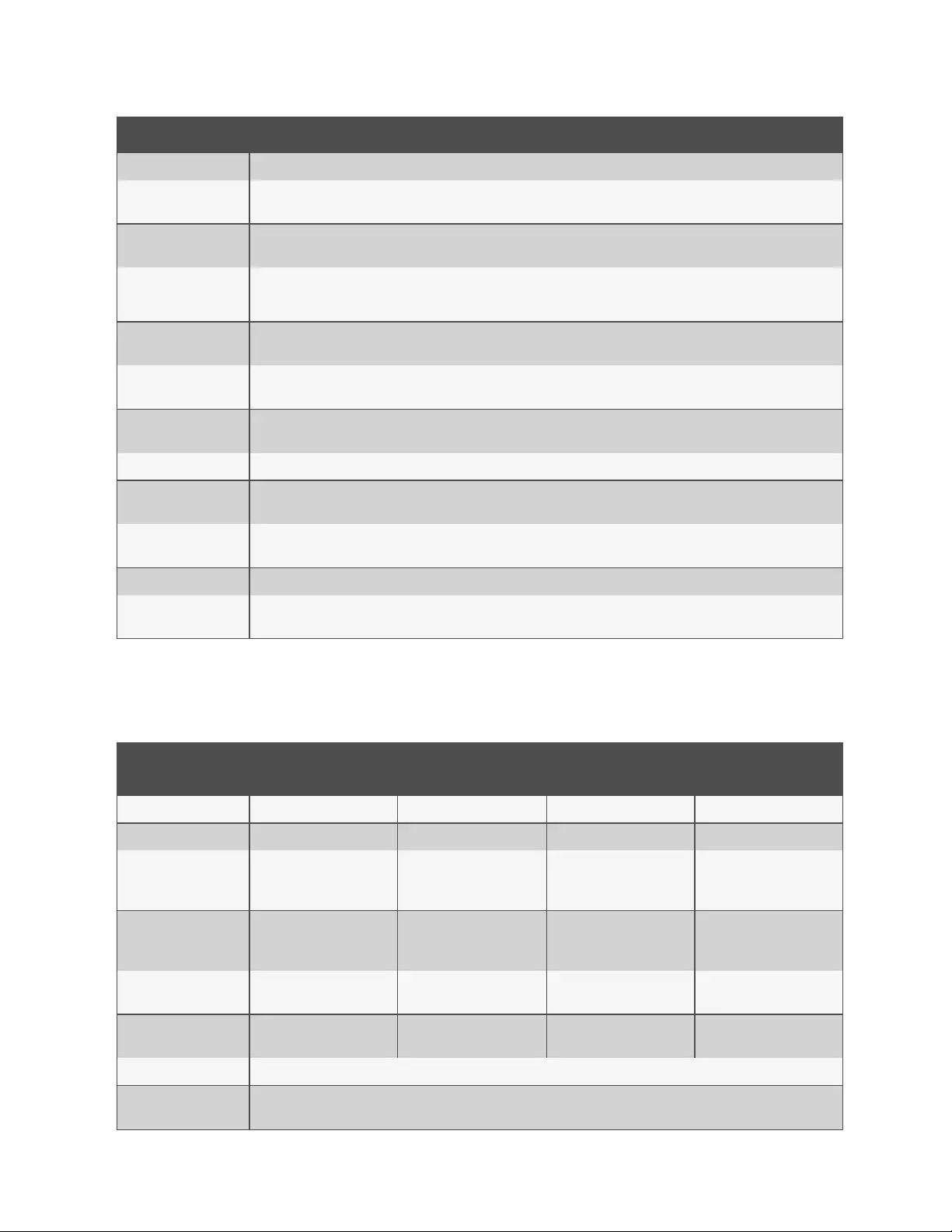

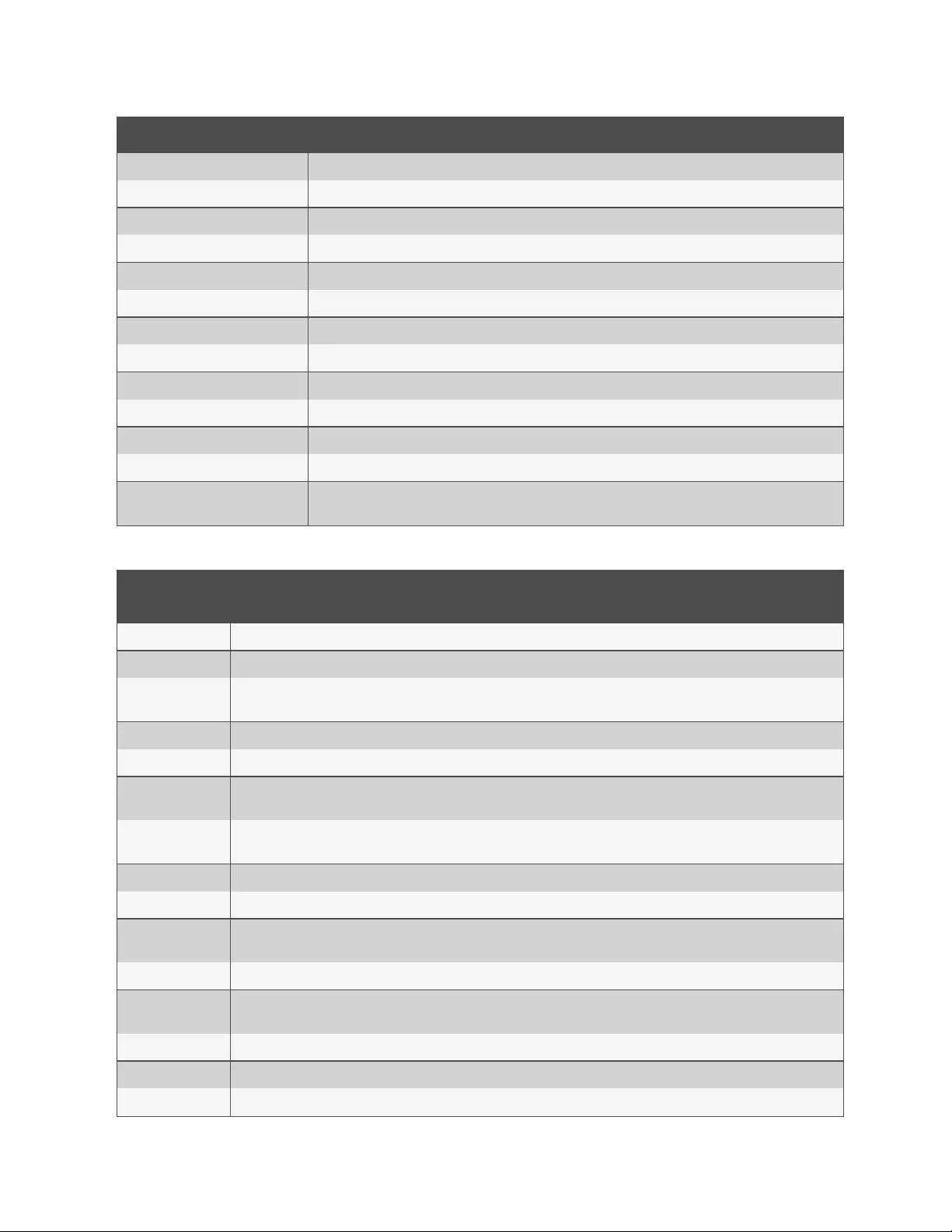

Cage Nut

Location Cage Nut Purpose Install On

2U Middle Position Vertiv VRC Bracket All Four Rails

4U Middle Position Vertiv VRC Bracket All Four Rails

7U Middle Position Vertiv VRC Bracket All Four Rails

9U Middle Position Vertiv VRC Bracket All Four Rails

10U Middle Position for Air Baffle Front Rails Only

10U Top Position for Air Baffle Front Rails Only

4.2 Install the Vertiv™ VRC (Vertiv™ VRC-S with Vertiv VRC

Self-Contained)

Prepare the rack to receive the Rack Cooling Unit (self contained) and install the Vertiv VRC in the rack as described in the

unit's manual, which shipped with the Vertiv™ VRC-S. For the M6x12 T30 screws, used to secure the Vertiv VRC to the EIA-

rails, use 5.6 Nm (4.13 ft-lb.) tightening torque.

4.3 Attach Air Baffles (Vertiv VRC-S with VRC self-

contained)

Two air baffles are supplied to help cooling air circulate efficiently inside the rack equipment section of Vertiv VRC-S. Cage

nuts should have been attached to the rails before the Vertiv VRC was inserted into the cabinet.

Air barrier placement on the Vertiv VRC-S uprights varies according to the size of your rack. Depending on the cabinet

model, there is a tab on the air barrier that is bent up (600 mm (23.62 in.) cabinet) or bent down (800 mm (31.5 in.) cabinet).

• 600 mm (23.62 in.): The air barriers should be mounted so the top of the air barrier tab is even with the top of

the Vertiv VRC.

• 800 mm (31.5 in.): The air barriers should be mounted so that the flat part of the air barrier (not the tab) is even

with the top of the Vertiv VRC.

To install the air baffles:

1. Refer to the 800 mm (31.5 in.) air barriers image, below, and identify the left air barrier; hold it in position and

fasten it to the upright using one M6x12 T30 screw and M6 cage nut (4.13 ft-lb /5.6 Nm torque).

2. Repeat for the right air barrier.

4 Installation

22

Vertiv™ VRC-S User Manual

Figure 4.1 Air Barriers—800 mm (31.5 in.)

Figure 4.2 Attach Air Baffles—800 mm (31.5 in.) Rack

4 Installation 23

Vertiv™| VRC-S User Manual

Figure 4.3 Air Baffle Installed—800 mm (31.5 in.) Rack

4.4 Prepare the Rack to Receive the Rack Cooling Unit

(Vertiv VRC-S with VCR Split)

Cage nuts are also necessary but only on the front rail and in different position, see SL-07002.

4.5 Install the Vertiv (Vertiv VRC-S with Vertiv VRC Split)

Prepare the rack to receive the Rack Cooling Unit (split) and install the Vertiv VRC in the rack as described in the unit's

manual, which shipped with the Vertiv VRC-S. For the M6x12 T30 screws, used to secure the Vertiv VRC to the EIA-rails, use

5.6 Nm (4.13 ft-lb.) tightening torque.

For VRC split there is need to interconnect the indoor and outdoor unit, for more details see VRC manual.

NOTE: Piping between the indoor and outdoor units must be routed so that it does not block the IT

space above and does not extend into the space between the EIA rails.

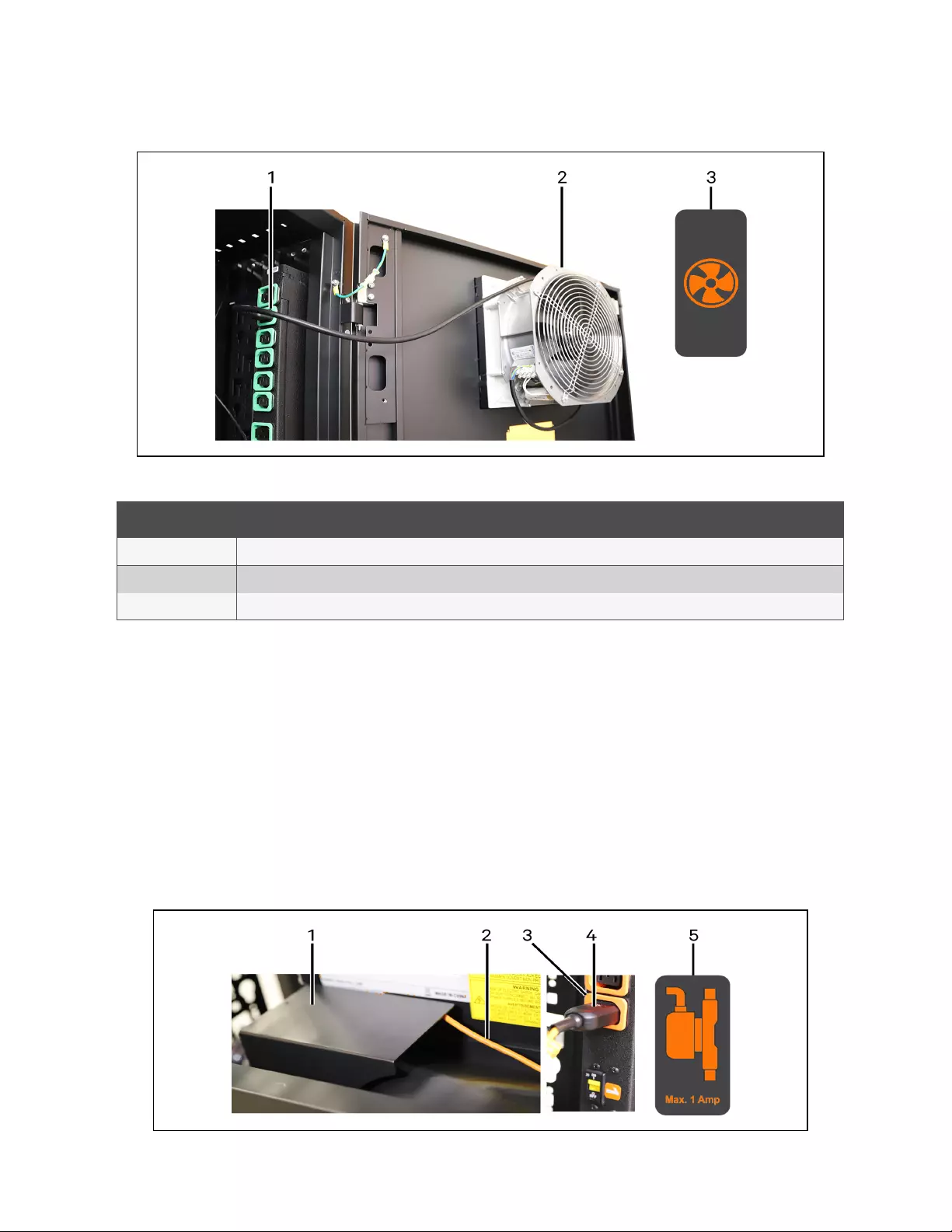

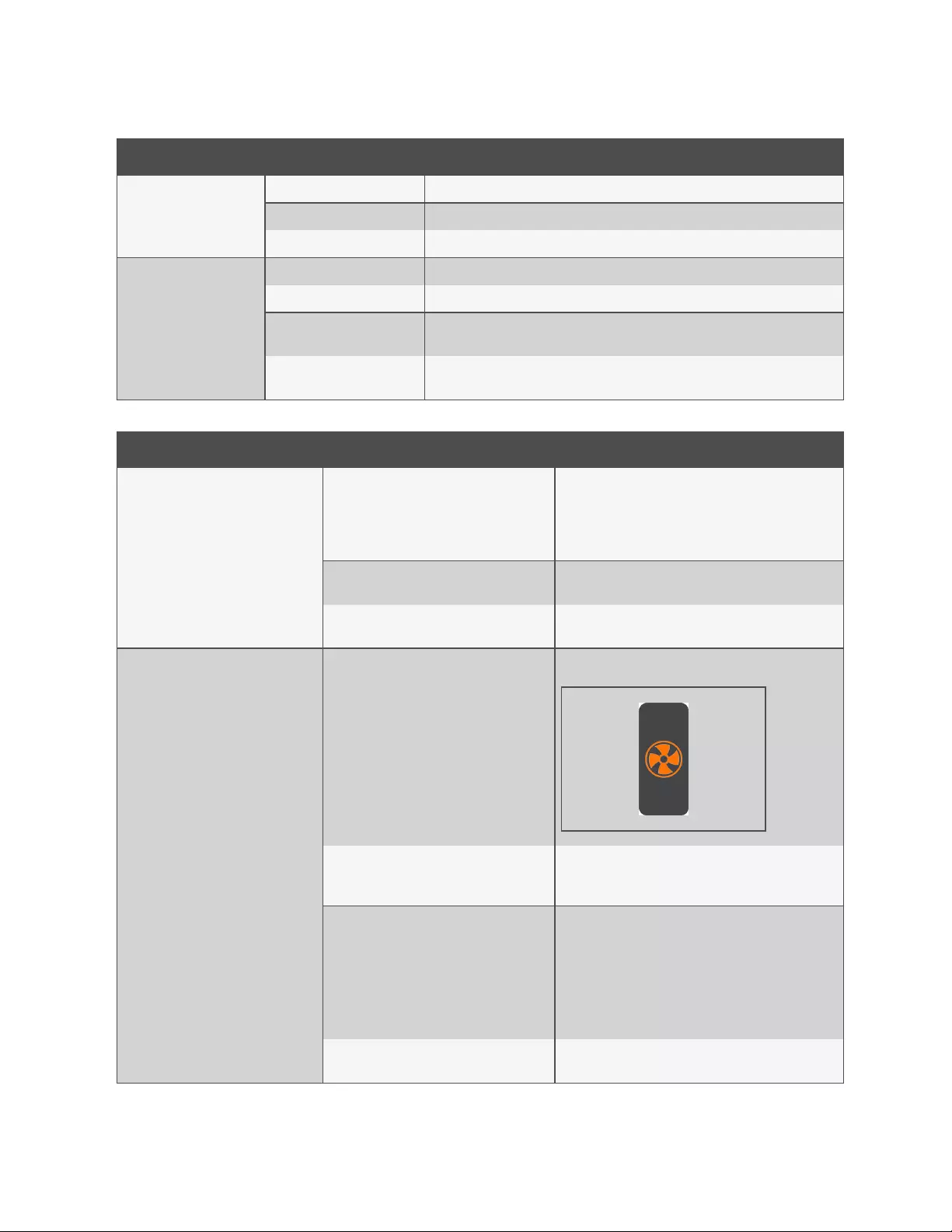

4.6 Connect Power to the Backup Fan

The backup fan requires connection to the correct, dedicated receptacle on the factory-installed Geist™ rPDU for proper

operation. The Geist rPDU is marked to facilitate proper connection.

To connect power and sensor control to the backup fan:

1. Take the power cord attached to the backup fan and cut the zip tie.

2. Connect the power cord to the Geist rPDU as shown in Figure 4.4 on the facing page .

3. Route the power cord to the Geist rPDU.

4. Locate the proper receptacle on the Geist rPDU and plug the power cord into it. The receptacle is marked with

a sticker showing a small fan (see Figure 4.4 on the facing page ).

4 Installation

24

Vertiv™ VRC-S User Manual

Figure 4.4 Backup Fan Power Cord Routing, Connection

Item Description

1 Backup fan power cord plugged into Geist rPDU

2 Backup fan

3 Backup fan symbol on GeistrPDU to indicate proper power connection

Table 4.1 Backup Fan Power Cord Routing, Connection Description

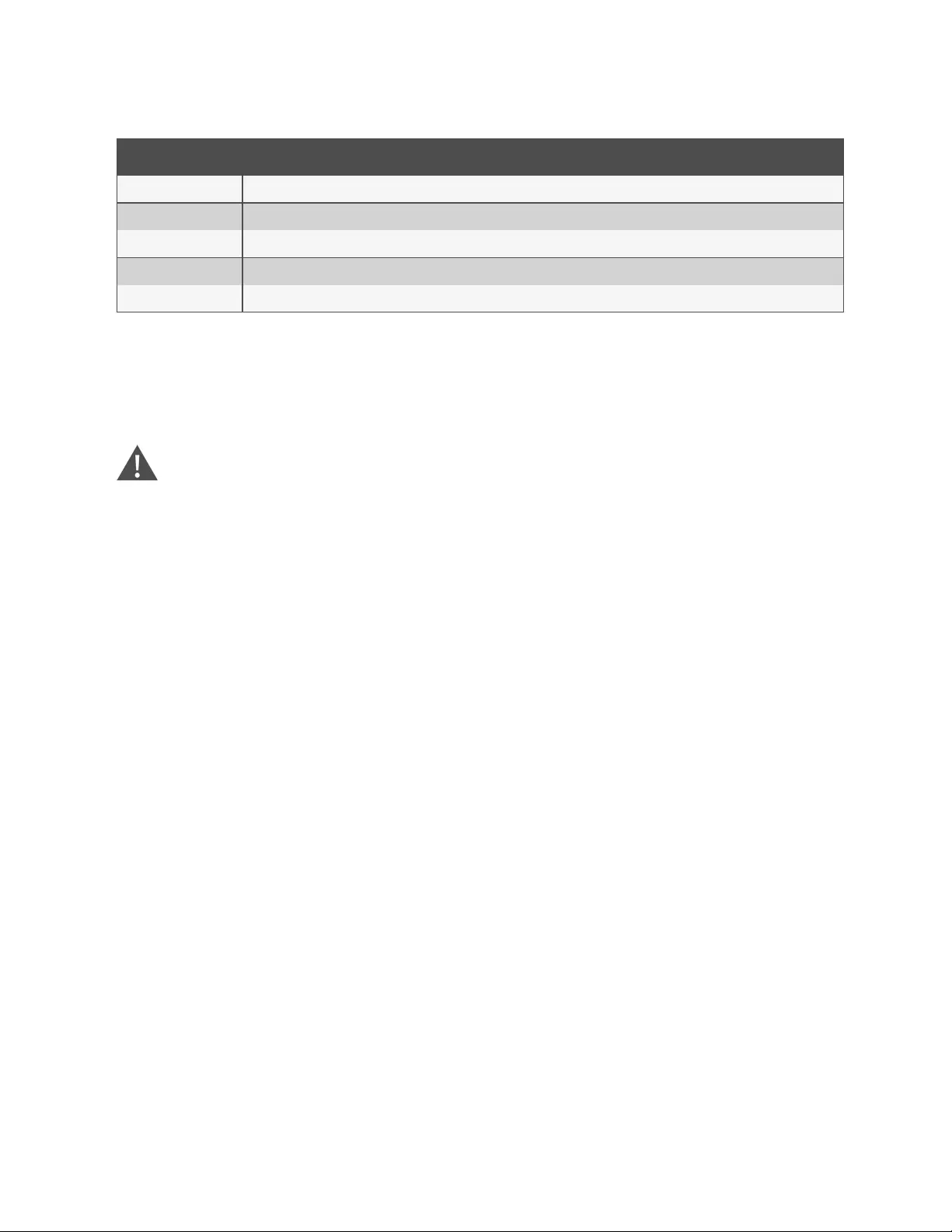

4.7 Connect Power to the Condensate Pump

The condensate pump requires connection to the correct, dedicated receptacle on the factory-installed Geist™ rPDU for

proper operation. The Geist rPDU is marked to facilitate proper connection.

To connect power to the condensate pump:

1. Connect the power cord to the condensate pump as shown in Figure 4.5 below .

2. Route the power cord over top of the transition piece to the Geist rPDU.

3. Locate the proper receptacle and plug the power cord into the Geist rPDU receptacle. The receptacle is

marked with a sticker to indicate where the condensate plug should go.

Figure 4.5 Condensate Pump Power Cord Routing, Connection

4 Installation 25

Vertiv™| VRC-S User Manual

Item Description

1 Condensate pump shroud

2 Condensate pump power cord

3 Geist rPDU locking receptacle

4 Condensate pump power cord plugged in

5 Condensate pump symbol on Geist rPDU to indicate proper power connection

Table 4.2 Condensate Pump Power Cord Routing, Connection Descriptions

4.8 Attach the Local Display

A local display and two communication cables are included in the Vertiv™ VRC kit. The display permits checking

conditions in the rack without opening a door or using a network computer. (The Geist™ rPDU is network-enabled and

permits monitoring and managing the Vertiv VRC's operation over your network.)

The local display may be installed on either the door or laid on the Vertiv VRC. If the display is to be placed on the cooling

unit, simply attach the 20in. (50cm) communication cable to the rack and to the rear of the cooling unit as shown Figure 4.6

below .

IMPORTANT! Vertiv recommends installing the display in the opening fabricated in the rear door.

To install the local display on the door:

1. Remove the magnetic case from the display by extracting the four screws holding the assembly together.

2. Insert the display into the cutout on the rear door of the Vertiv™ VR and secure it with the four screws removed

in Step 1 .

3. Connect the 32 ft. (10m) display cable to the display and route it around the top of the exhaust fan and to the

Vertiv VRC.

4. Plug the cable into the Vertiv VRC as shown in Figure 4.6 below .

Figure 4.6 Display Cable Attachment and Connections

4 Installation

26

Vertiv™ VRC-S User Manual

Item Description

1 Local Display

2 Communication Port on Local Display

3 One of Four Screws Securing Local Display to the Vertiv™ VR Door

4 Local Display Cable Connected to Rear of Vertiv VRC

5 RJ-45-to-USB Cable between Geist™ rPDU and Vertiv™ VRC

Table 4.3 Display Cable Attachment and Connections Descriptions

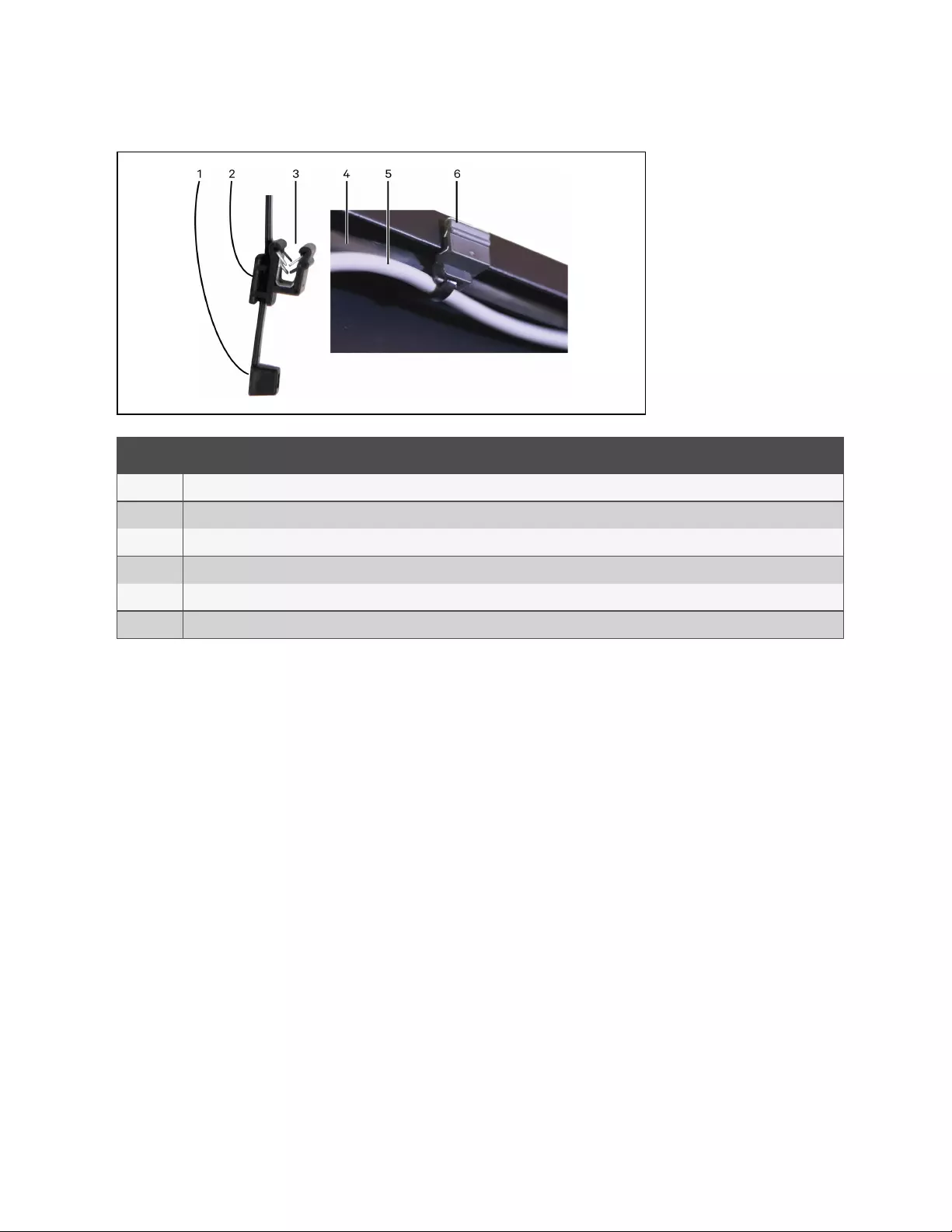

4.8.1 Route Display, Fan Cables

The cables for the local display and fan must be routed along the upper edge of the door and down the rack rail to protect

them from damage and strain when the rear door is opened and closed. Cable ties with a special clip are factory-supplied

to attach the cables to the door lip and the rack rail.

WARNING! Risk of electric shock. Can cause property damage, injury and death. The backup

fan input power cable is a live wire when connected. Pulling it loose from the connector or

abrading it on the rack may expose personnel to hazardous voltage. When routing the cable, be

sure to leave enough slack in the cables to permit the door to open fully without straining the

cables' connections.

To route the cables for the local display and the fan:

1. Open the rear door of the Vertiv™ VRC-S.

2. Route the local display and fan cables around the outside edge of the fan housing and up to the top of the door.

3. Use a factory-supplied cable tie to bundle the two cables as shown in Figure 4.7 on the next page and as

detailed below.

a. Place the cables against the pad on the cable tie.

IMPORTANT! The cables must be properly placed in the cable tie so they can be positioned under the

lip of the door for protection against pinching.

b. Slip the longer end around the cables and through the ratcheted end of the cable tie.

c. Pull the cable tie until it is snug around the cables.

d. Snip off the excess cable to ease attachment to the door.

4. Leaving adequate slack in the cables, press the clip onto the top inner edge of the rear door as shown in Figure

4.7 on the next page . The cables should be under the door's lip to prevent pinching.

5. Repeat 3 to attach at least one more cable tied bundle near the hinged edge of the door.

6. Leaving adequate slack in the cables for the door to open, secure the cables to the rack rail near the Geist™

rPDU.

7. Secure the cables to the rack rail as needed for good cable management.

4 Installation 27

Vertiv™| VRC-S User Manual

Figure 4.7 Secure the Local Display and Fan Cables

Item Description

1 Ratcheted end of cable tie

2 Location of local display and fan cables

3 Toothed clip to secure the bundle to the lip of the door

4 Fan cable

5 Local display cable

6 Cable tie clipped to the door

4.9 Connect the Vertiv™ VRC to the Geist™ rPDU

The factory-installed Geist rPDU is network-enabled, permitting monitoring and managing the Vertiv VRC over a network.

Use the supplied cable to set up the connection. the cable has an RJ-45 connector on one end and a USBconnector on the

other.

To connect the Vertiv VRC to the Geist rPDU:

1. Take the communication cable out of the packaging and straighten the coils, removing any kinks.

2. Plug the RJ-45 connector into either of the two ports on the rear of the Vertiv VRC.

3. Route the cable to the Geist rPDU and connect it as shown in Figure 4.8 on the facing page .

4 Installation

28

Vertiv™ VRC-S User Manual

Figure 4.8 Vertiv VRC Monitoring Connections

Item Description

1 RJ-45 port on the rear of the Vertiv VRC (either port may be used)

2 Monitoring cable connected to an RJ-45 port on the rear of the Vertiv VRC (either port may be used)

3 Monitoring cable connected to the Geist rPDU

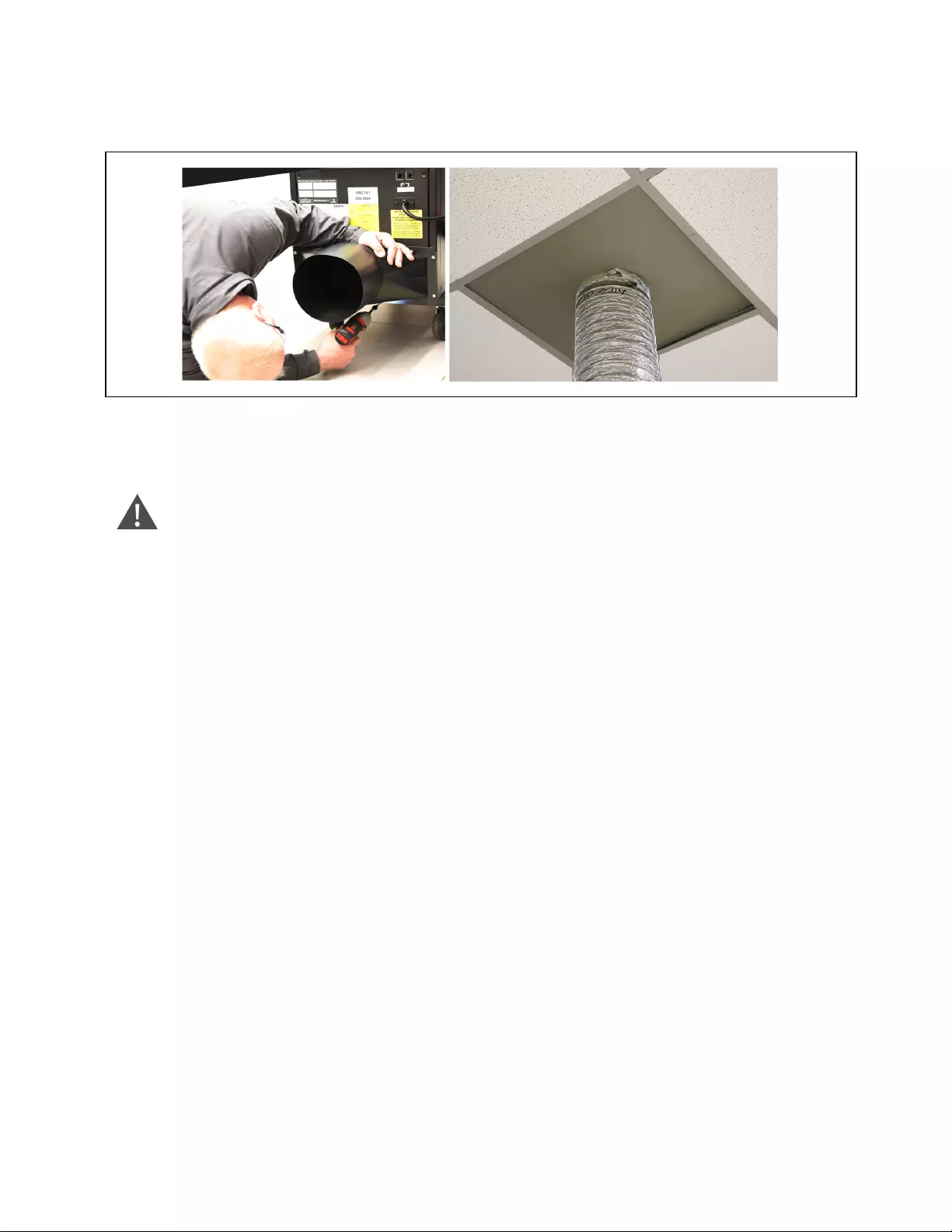

4.10 Attach Ductwork and Ceiling Tile (Vertiv™ VRC Self-

Contained)

Depending on the site's cooling requirements, warm air from the Vertiv™ VRC-S may be exhausted into the room. There it

may be handled by room cooling units or absorbed by the ambient air.

The Vertiv VRC-S includes a flexible duct and two ceiling tiles, one to move warm air from the Vertiv VRC-C into the ceiling

or and adjacent area through the duct. The second tile is for make-up air to deliver enough fresh air to the room.

WARNING! The two air traces (warm air and make-up air) must be separated.

The factory-supplied ducting attaches to the transition piece on the rear of the Vertiv VRC with a large hose clamp (factory-

supplied) that tightens around the two pieces. The ceiling grille may be used where a conventional dropped ceiling with

frames is used. The flexible ducting connects to the ceiling tile with the second hose clamp supplied by the factory.

4 Installation 29

Vertiv™| VRC-S User Manual

Figure 4.9 Attaching Transition Piece, Ducting to Ceiling Tile

4.11 Install IT Equipment and Final Preparation

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Only properly trained and qualified personnel wearing appropriate

OSHA-approved personal protection equipment (PPE) should attempt to move, lift, remove

packaging from or prepare this unit for installation. Read all instructions before attempting to

move, lift, remove packaging from or prepare the unit for installation.

Vertiv recommends installing equipment in the Vertiv VR from bottom to top, to promote a

lower center of gravity.

All equipment must be installed using the rails or a support shelf. No equipment should be

installed directly on the Vertiv VRC or Liebert®GXT5. This arrangement is necessary to permit

replacing the Vertiv VRC's filter and to permit the unit's removal for service.

IMPORTANT! As a best practice, all unused rack space should be covered with the optional blanking

panels to promote the most effective airflow patterns and prevent short cycling of cooling airflow.

4 Installation

30

Vertiv™ VRC-S User Manual

5 Operation

5.1 Initial Startup—Vertiv™ Services

Startup services are available from Vertiv Services Services. If startup services are included with your unit, Vertiv personnel

will start the Vertiv™ VRC-S and make all settings required for proper operation.

5.2 Initial Startup—User

Once installation is complete, including all cabling and power connections and installation of the rack equipment, the Vertiv

VRC-S is ready for startup.

NOTE: Vertiv recommends installing and preparing rack equipment before starting the Vertiv VRC-S so

that the cooling unit will have a heat load to operate with. Starting up the Vertiv™ VRC with the

maximum heat load can cause erratic operation and may damage the cooling unit.

Refer to the Vertiv VRC user manual, which shipped with the Vertiv VRC-S, for instructions on starting the unit.

5.2.1 Recommended Startup Sequence

Vertiv recommends starting the Vertiv VRC then starting the equipment in the rack. Starting the ITequipment first may

lead to heat spikes in the enclosure before the system cooling stabilizes.

5.3 Operational Settings

The Vertiv VRC-S may be monitored and managed either remotely, over your network through the Geist™ rPDU, or locally

through the attached LCD or with a computer connected to the Geist rPDU or to the Vertiv VRC. Connection through the

Geist rPDUwill be made using Vertiv™ Intelligence Director, which is embedded in the Geist rPDU.

5.3.1 Changing Settings with the Geist rPDU

Using the Geist rPDU to monitor and manage the Vertiv VRC-S requires connecting the rPDU to the cooling unit with the

FTDIcable, shipped in the Vertiv VRC kit. See Connect the Vertiv™ VRC to the Geist™ rPDU on page28 for more

information on connecting the rPDU to the cooling unit. The Geist rPDU must also be connected to your Ethernet network.

Refer to the Geist rPDU user manual, which shipped with your unit, for details on connecting to your network.

After connecting the rPDU to your network, log in as detailed in the rPDU user manual. You must create an account and

password. Open the Sensors page and scroll to the Vertiv VRC panel at the bottom of the page.

NOTE: Low temperature alarm is shown under standard conditions.

Check the settings for the cooling unit and adjust as required. The Vertiv VRC must be operated as specified in

Specifications on page41 .

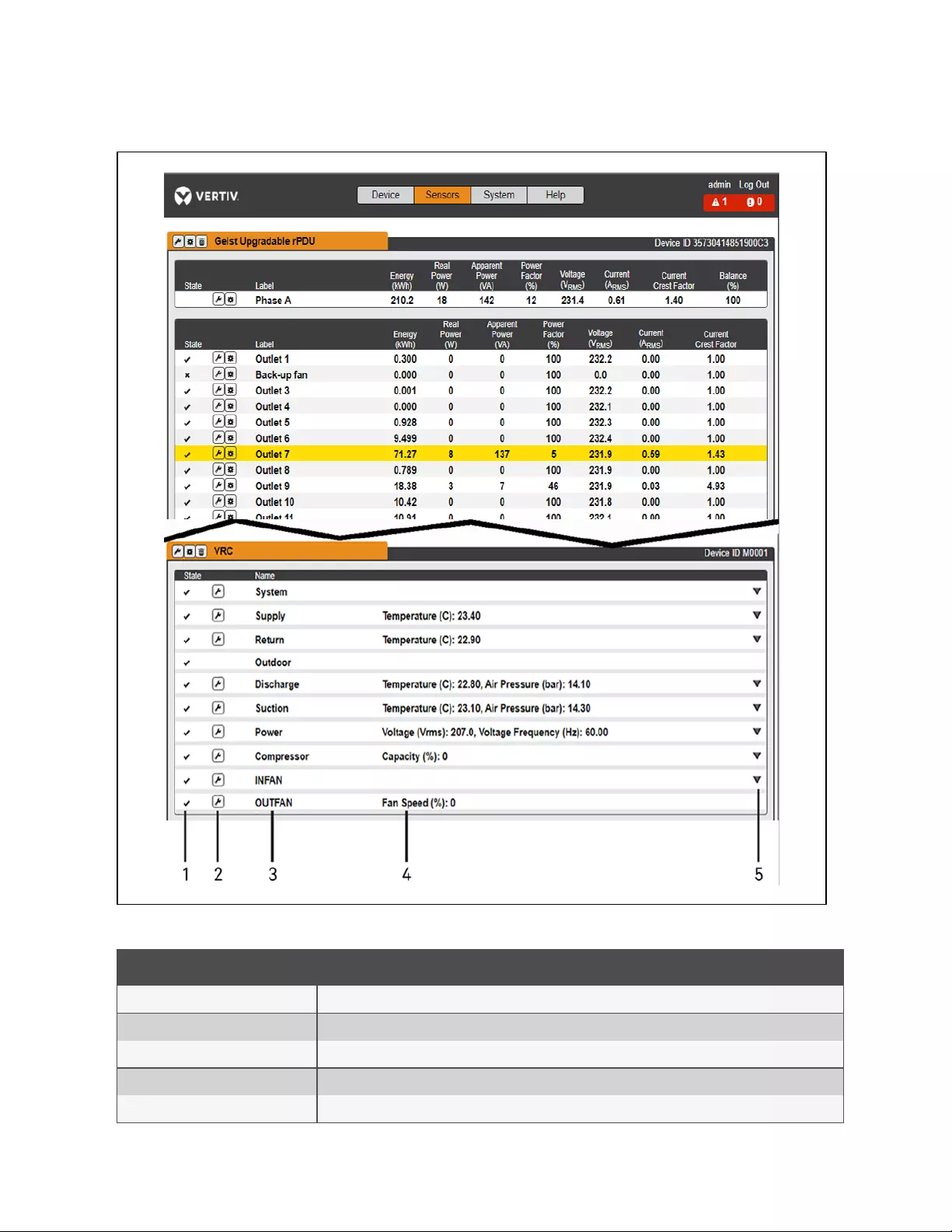

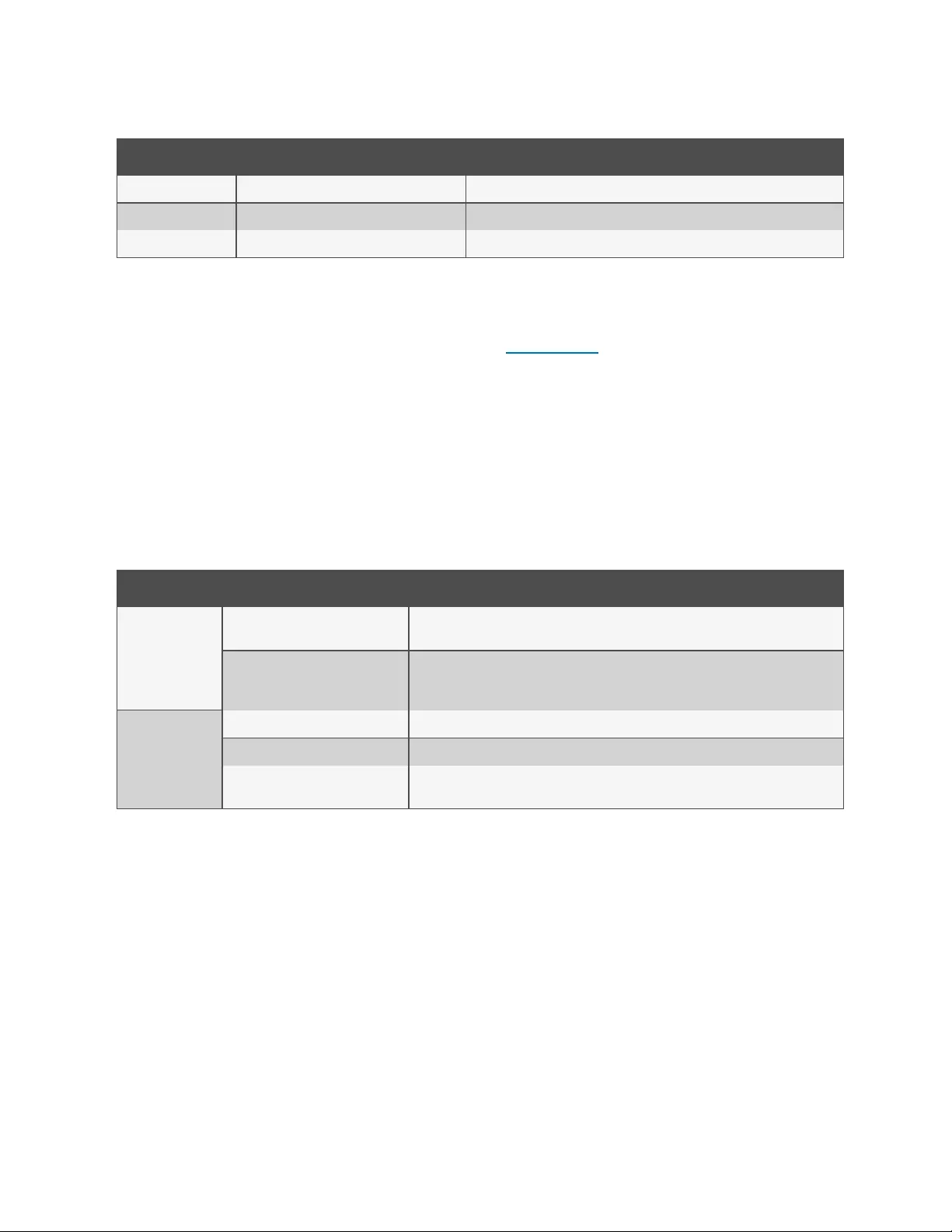

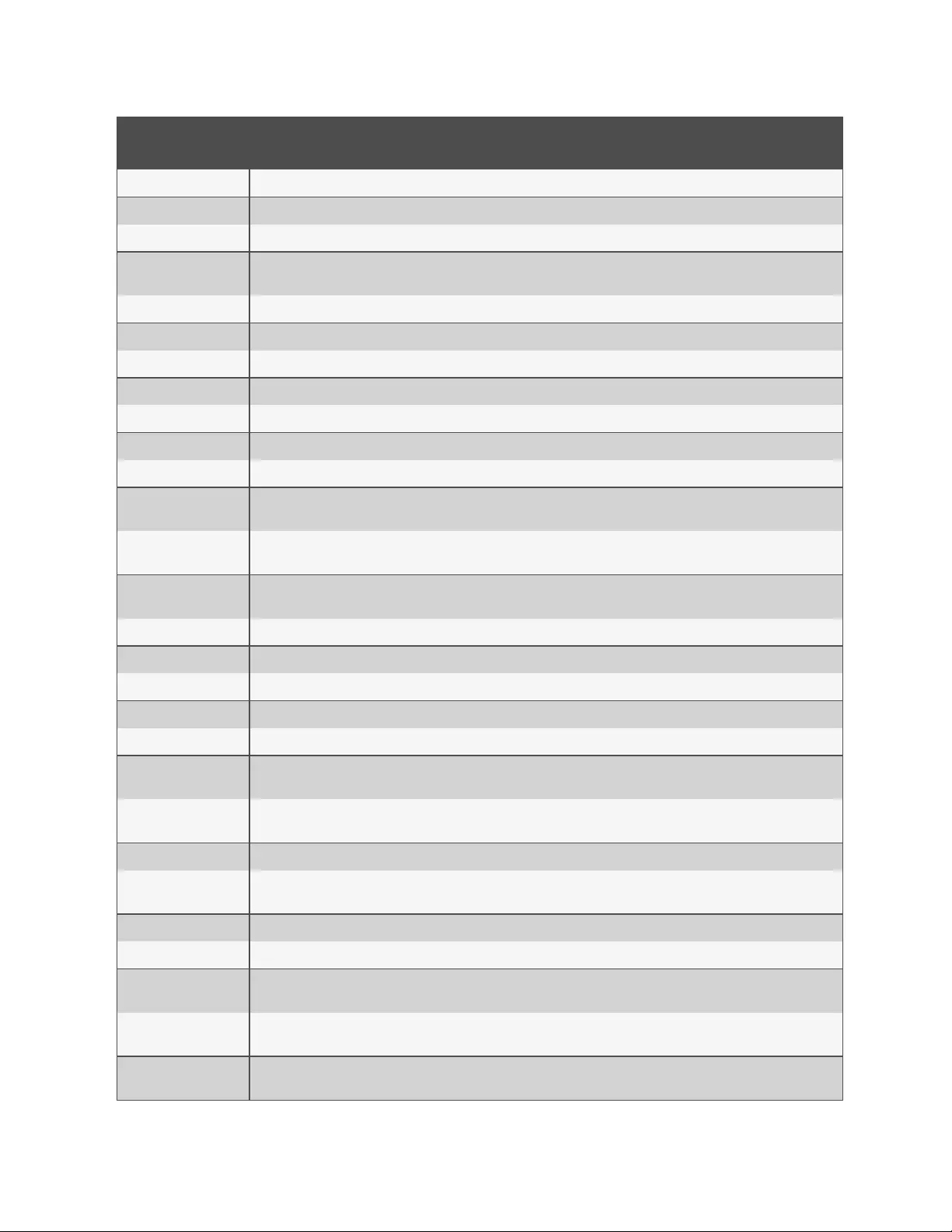

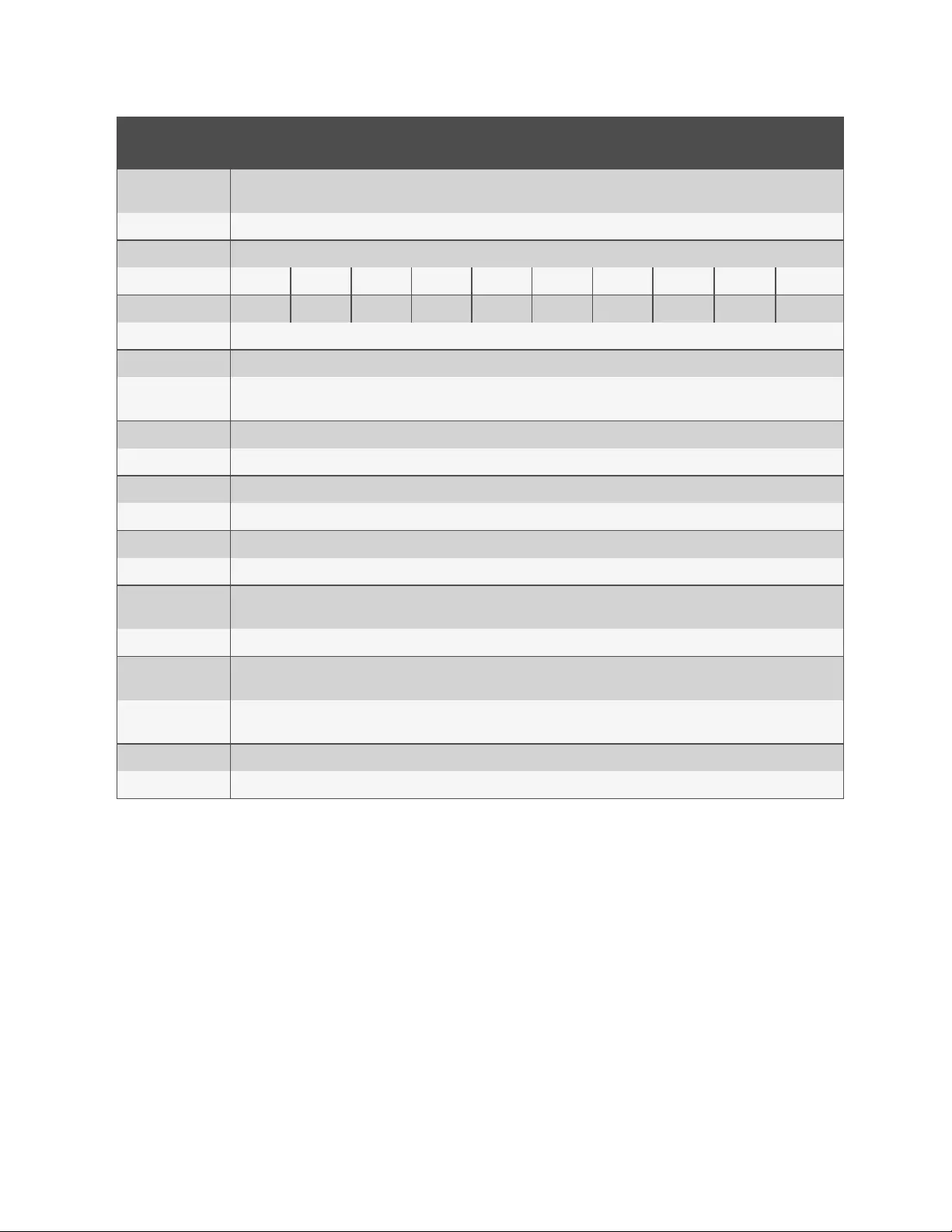

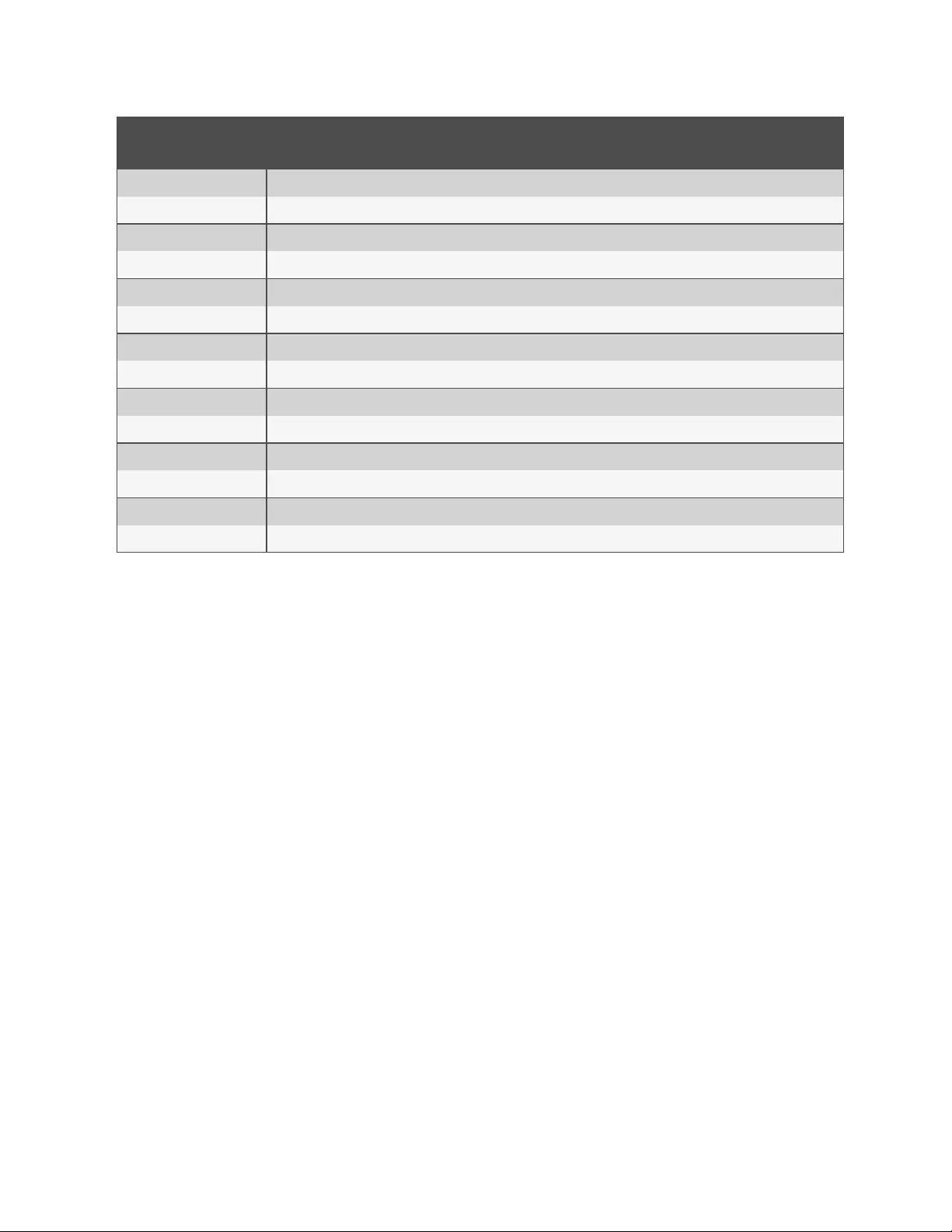

The Geist rPDU interface, shown in Figure 5.1 on the next page , permits monitoring and managing the Vertiv VRC-S. The

interface recognizes the Vertiv VRC as a sensor. The Sensors page shows the status of the component or function, a wrench

symbol permits changing the configuration if logged in with proper access, the name of the component or function, current

readings and an arrow reveals additional information in a drop-down menu.

For details on changing the settings, refer to the Geist rPDU manual that shipped with the unit.

5 Operation 31

Vertiv™| VRC-S User Manual

Figure 5.1 Geist rPDU Sensor Page > Vertiv VRC Settings

Item Description

1 Component Status Column

2 Change Configuration Settings Icon

3 Component Name

4 Current Readings

5 Additional Information

Table 5.1 Geist rPDU Sensor Page > Vertiv VRC Settings Descriptions

5 Operation

32

Vertiv™ VRC-S User Manual

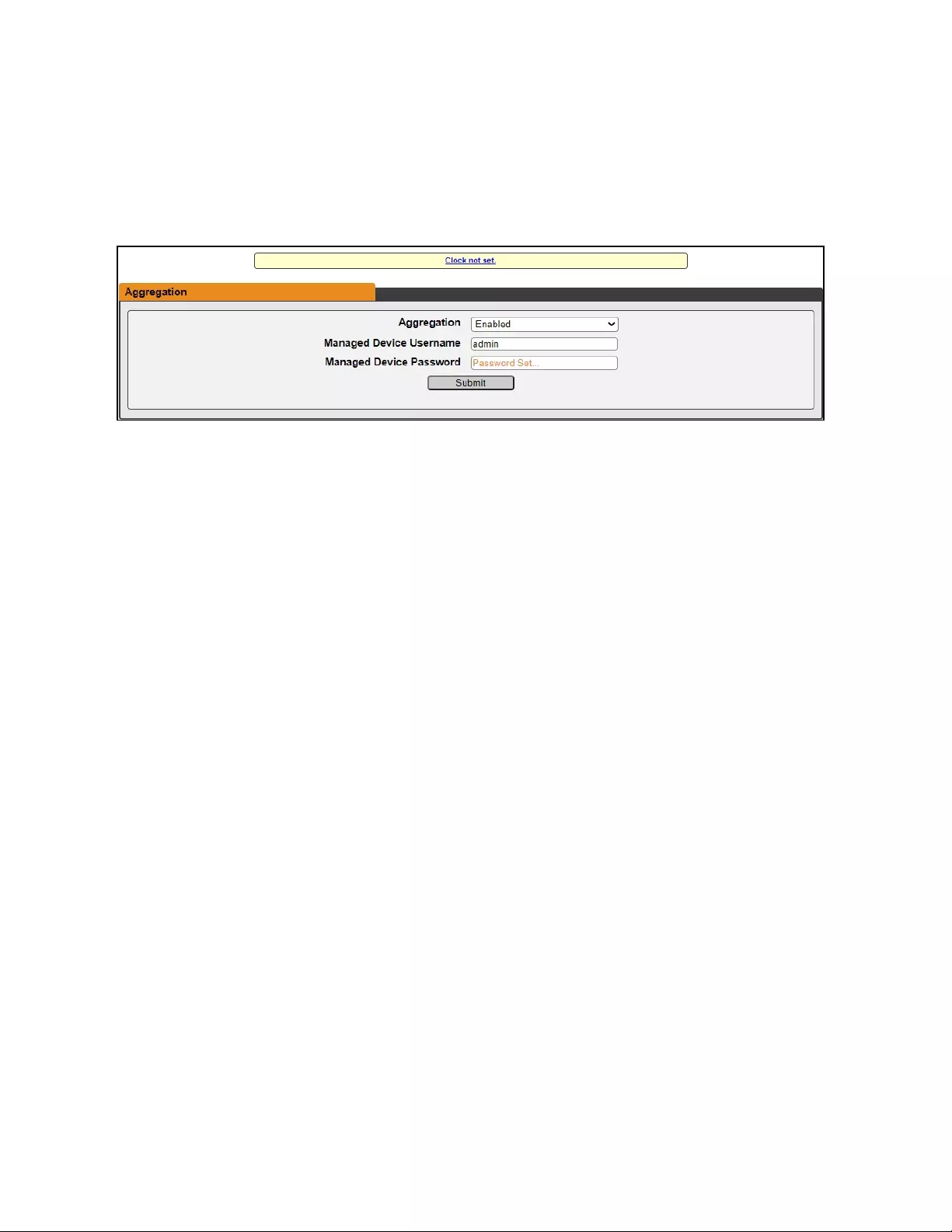

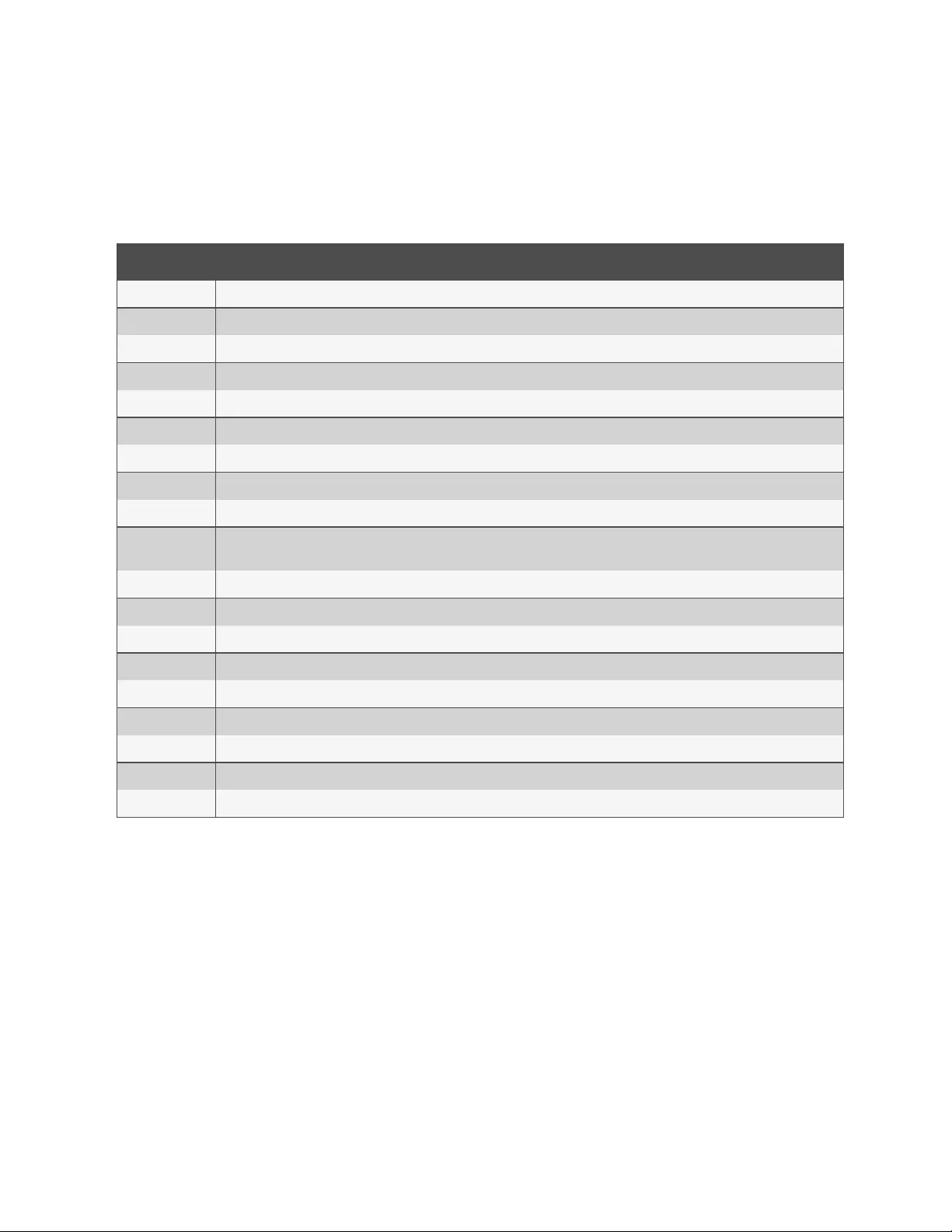

5.3.2 Set up Connection between Geist™ rPDU and Liebert® GXT5

In case of versions with integrated Liebert GXT5 the aggregation function in the GeistrPDU web UI needs to be enabled,

Geist rPDU Manual for more information.

Figure 5.2 Aggregation

5 Operation 33

Vertiv™| VRC-S User Manual

5 Operation

34

This page intentionally left blank

Vertiv™ VRC-S User Manual

6 Troubleshooting

6.1 Troubleshooting the Vertiv™ VRC

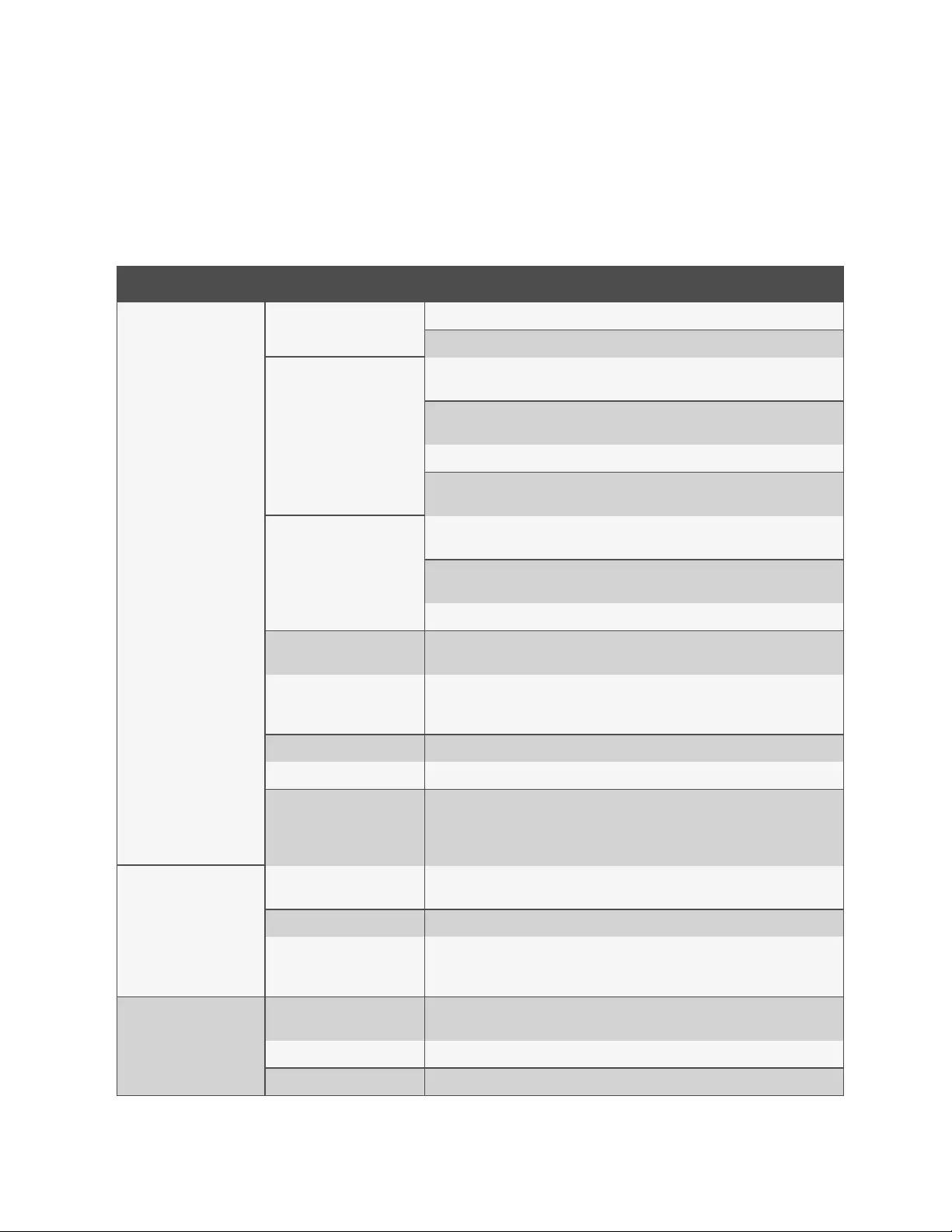

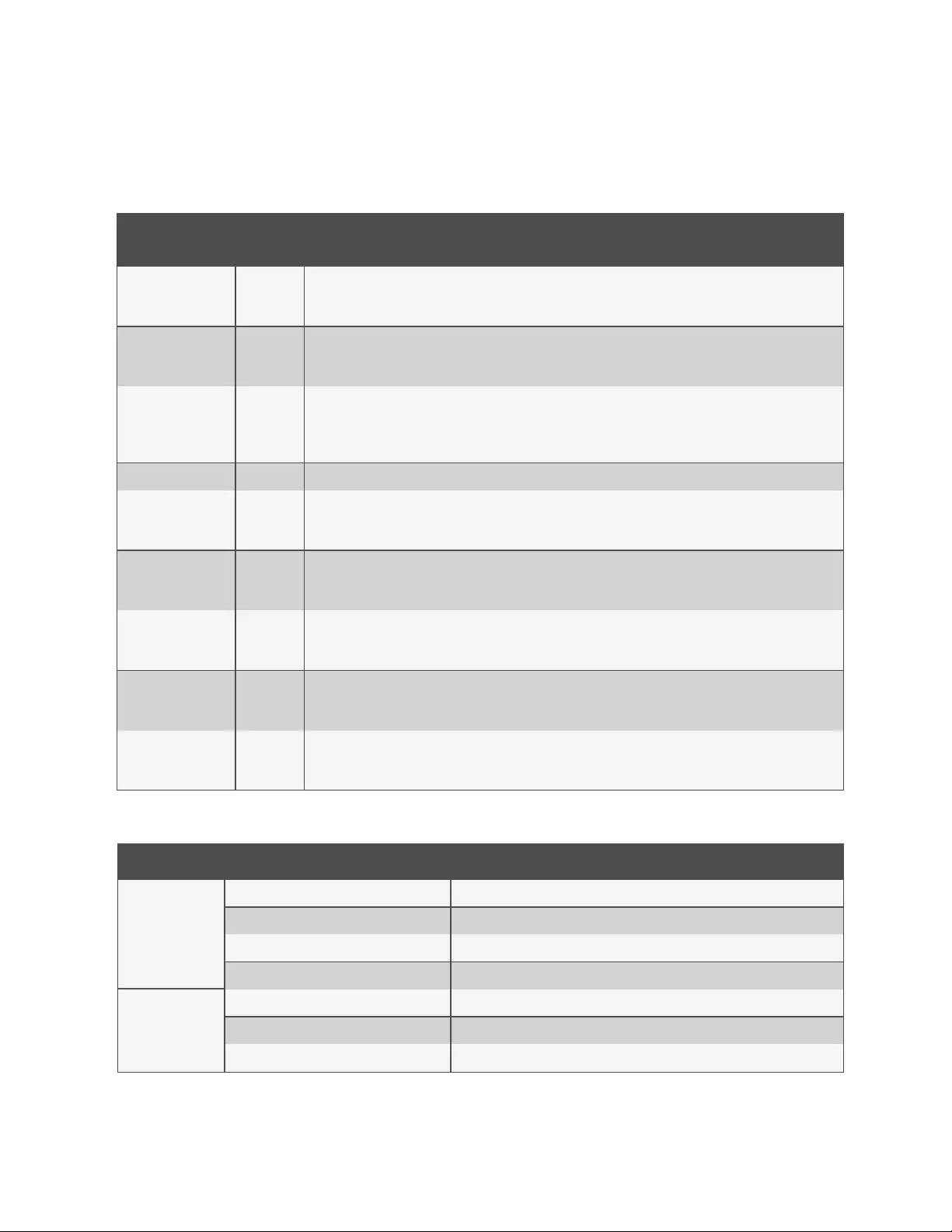

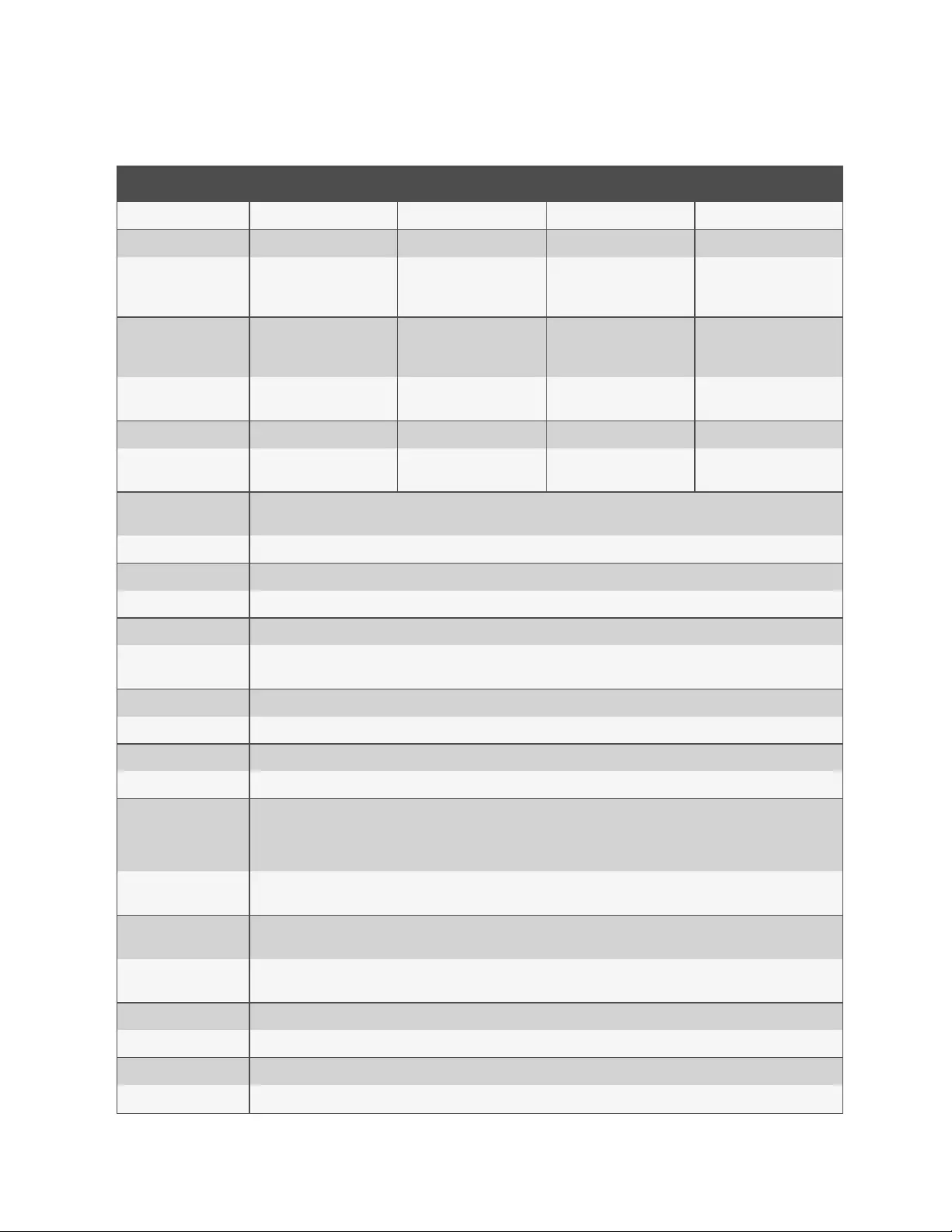

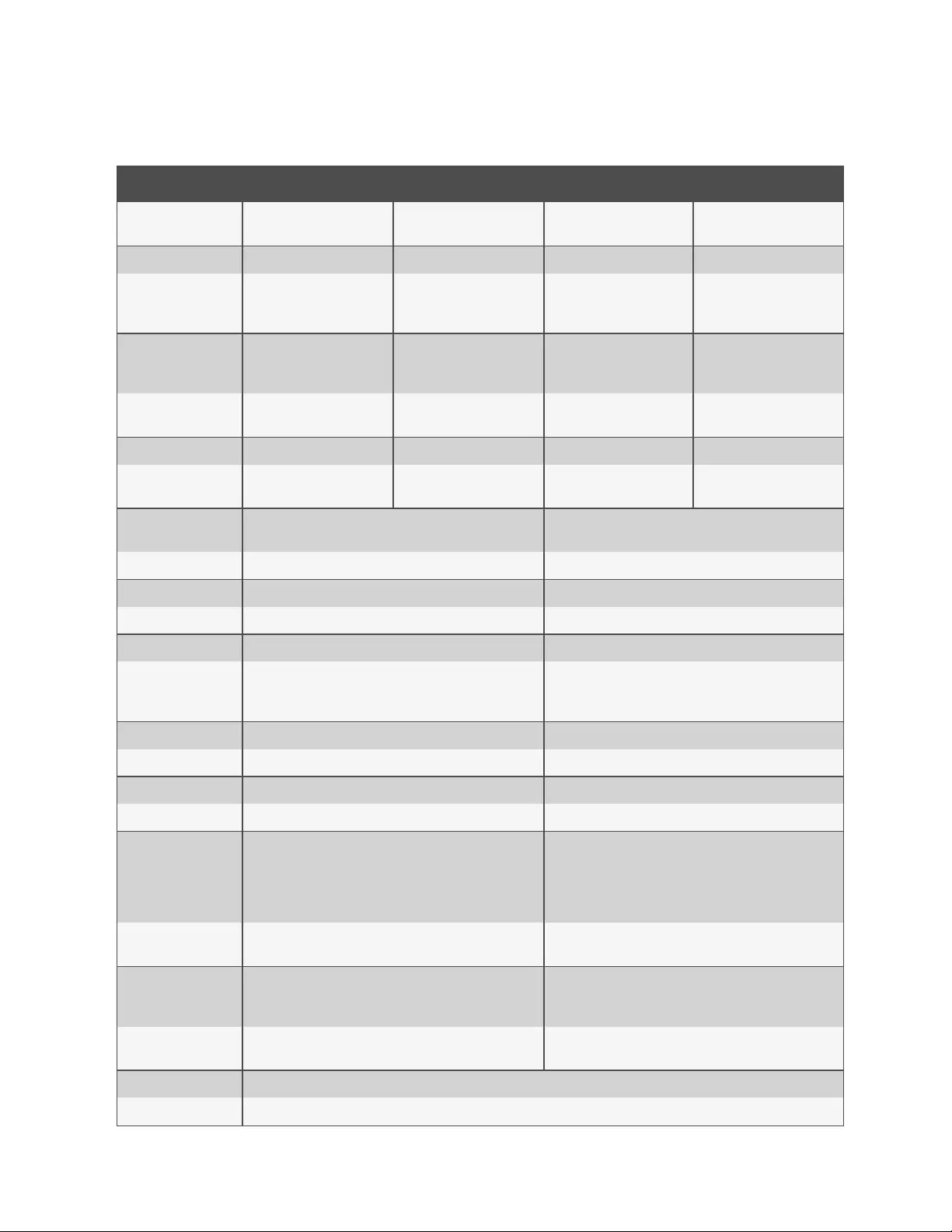

Message or Problem Possible Cause Suggested Action

High

Temperature

Loss of

power

Check the input cord and ensure that it is connected to the specified power source.

Reset building input circuit breaker.

Poor

Internal

Airflow

Confirm that blanking panels are installed in any unused rack space to prevent short-

cycling of Vertiv VRC airflow.

Confirm there are no obstructions such as cable bundles or equipment chassis blocking

the internal supply and return airflow paths.

Review and follow Preventive Maintenance procedures in the Vertiv VRC user manual.

Check the front and rear filters. Replace them if they are dirty as described in the Vertiv

VRC user manual.

Poor External Airflow

Confirm that the rack has unobstructed front and rear clearances of at least 12 in. (305

mm).

Verify that the heat rejection duct at the rear of the rack is free of debris and airflow

obstructions.

The warm ambient air influences the indoor temp because the system is not sealed.

Alarm temperature setpoint is

too low.

Adjust the setpoint temperature that triggers the alarm. Refer to the Vertiv VRC user

manual.

Thermal overload

Make sure that the actual heat load is not above the maximum rated value. The Vertiv

VRC's maximum load at 30°C (86°F) is 3,3 kW; the Vertiv VRC's cooling module is rated

to remove 3.5 kW worth of heat.

Fan malfunction. Contact Vertiv Technical Support.

Compressor malfunction. Contact Vertiv Technical Support.

Air mixing in the rack due to

gaps between front and rear of

rack.

Equipment or blanking panels should be added to prevent this. The equipment should

cover the whole width of 19 in. profile, with adapters. Add additional blanking panels or

equipment. Airflow should not be able to mix from front to rear; this will inhibit the cool

airflow up the front of the rack.

Water Leaking from or into

the Cabinet

Internal drain line clogged or

kinked

Check the condensate drain line for obstructions and verify it is not kinked and runs

freely.

Cabinet not level Confirm that the leveling feet are adjusted to the make the cabinet level.

Drain line is not connected to

condensate pump.

Confirm that the condensate drain line is properly connected to the condensate pump

outlet. Loosen the O-ring clamp if necessary and press the line onto the outlet nozzle,

tighten clamp.

Low Temperature

Alarm temperature setpoint too

high. Adjust the setpoint temperature that triggers the alarm.

Fan malfunction. Contact Vertiv Technical Support.

Compressor malfunction Contact Vertiv Technical Support.

Table 6.1 Troubleshooting the Vertiv VRC

6 Troubleshooting 35

Vertiv™| VRC-S User Manual

Message or Problem Possible Cause Suggested Action

High Pressure

Insufficient air flow Remove obstruction or debris from air inlets.

Vertiv VRC Fan malfunction Contact Vertiv Technical Support.

Pressure-sensor malfunction Contact Vertiv Technical Support.

Low Pressure

Insufficient air flow Remove obstruction or debris from air inlets.

Vertiv VRC Fan malfunction Contact Vertiv Technical Support.

Electronic Expansion Valve

(EEV) malfunction Contact Vertiv Technical Support.

Condenser malfunction or

refrigerant leak Contact Vertiv Technical Support.

Table 6.1 Troubleshooting the Vertiv VRC (continued)

Message or Problem Possible Cause Suggested Action

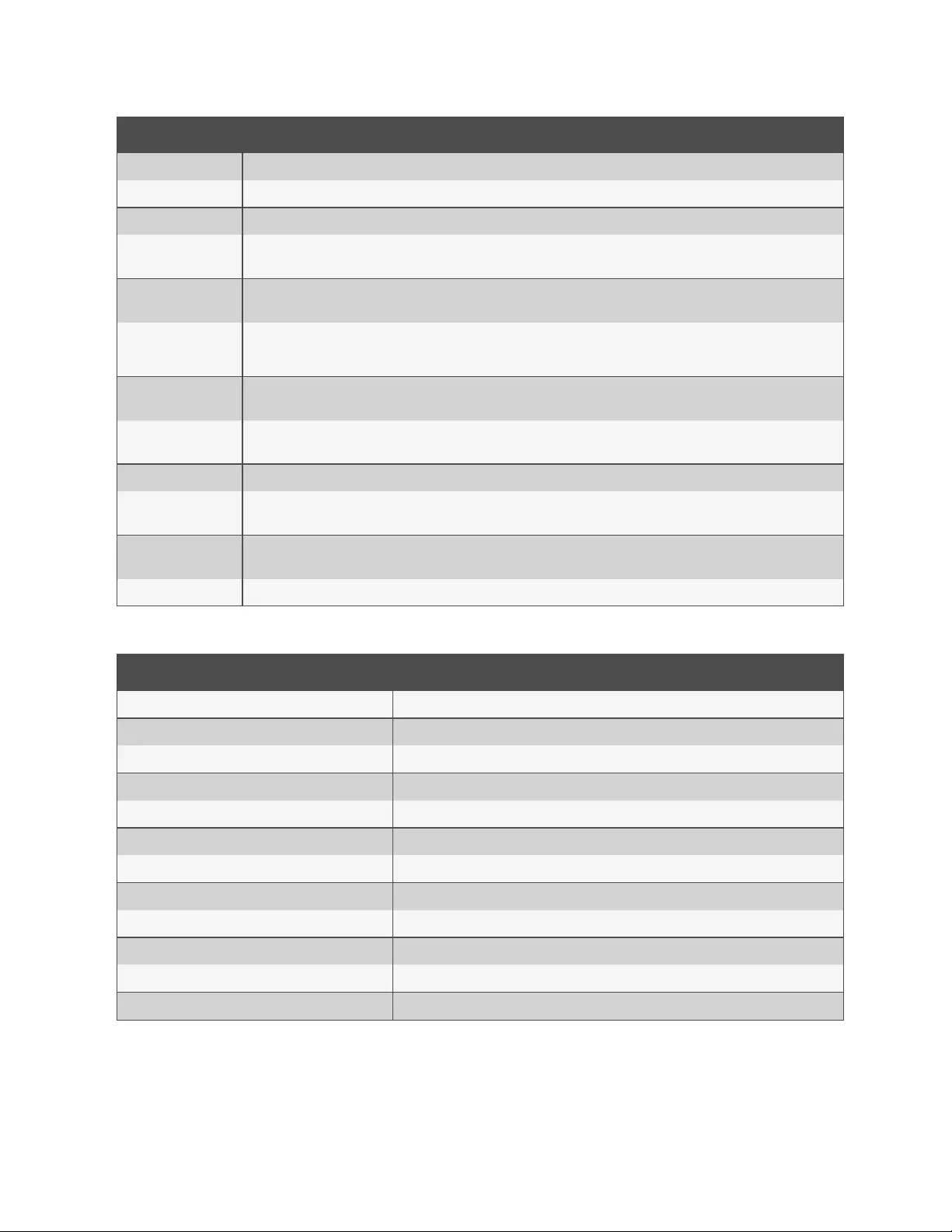

Backup Fan Operates Continuously

IT equipment or other heat source is blowing

directly on the sensor.

Reposition heat source away from the sensor at the top

front of the Vertiv™ VRC or relocate sensor away from heat

source. If rearranging equipment proves insufficient,

contact your Vertiv representative about obtaining a

Vertiv™ Geist™ SwitchAir™.

Heat sensor is incorrectly programmed. Reprogram the high temperature setpoint via the rack PDU

network card or contact Vertiv Technical Support.

High temperature in cabinet Refer to Troubleshooting the Vertiv VRC on the previous

page .

Backup Fan Fails to Operate as Expected

Fan input power cord plugged into the incorrect

outlet on the Geist™ rPDU.

Confirm the power plug from the fan is plugged into outlet

marked with the symbol for the fan.

Lack of input power.

Verify that the backup fan is connected to the Geist™ rPDU

outlet with the fan symbol.

Reset the building's input circuit breaker.

Programming of the Geist rPDU is incorrect or

an alarm keeping the outlet Off has not been

cleared.

Contact Vertiv™ support to ensure programming is correct.

•United States:1-800-543-2378

•Australia and New Zealand:1300 367 686

•Indonesia:0817 988 2288

•Mayasia:19 211 1668

•Singapore:64674218

Contamination of filter-pads (front and back

door mounted) Clean the filter according to filter and filter fan manual

Table 6.2 Troubleshooting the Backup Fan

6 Troubleshooting

36

Vertiv™ VRC-S User Manual

6.2 Troubleshooting the Liebert® GXT5

This section indicates various UPS symptoms you may encounter and provides a troubleshooting guide in the event the

UPS develops a problem. Use the following information to determine whether external factors caused the problem and how

to remedy the situation.

6.2.1 Symptoms that Require Troubleshooting

The following symptoms indicate the UPS is malfunctioning:

•The alarm indicator illuminates, indicating the UPS has detected a problem.

•An alarm buzzer sounds, alerting the user that the UPS requires attention.

6.2.2 Audible Alarm (Buzzer)

An audible alarm accompanies various events during UPS operations. Table 6.3 below , describes the sounds and their

meaning.

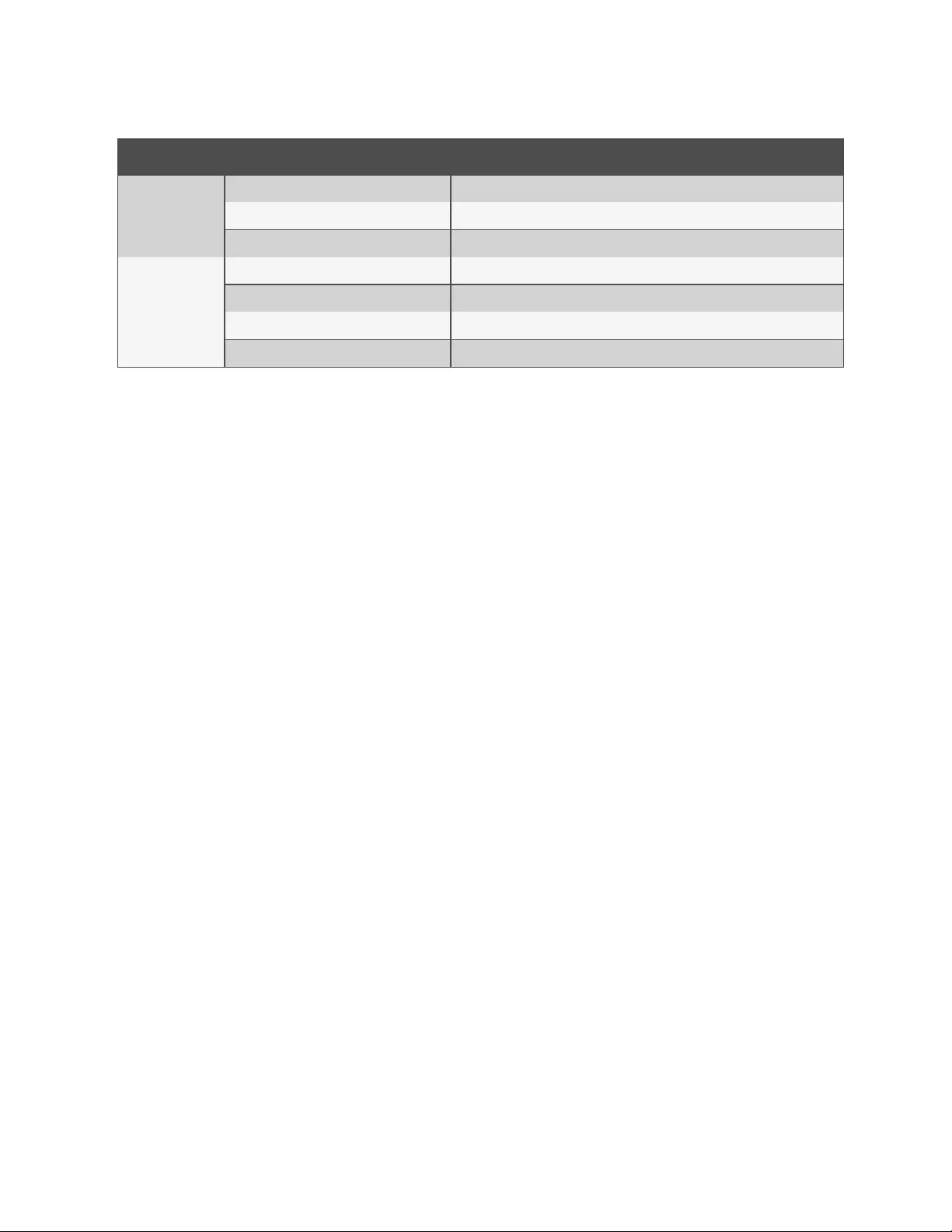

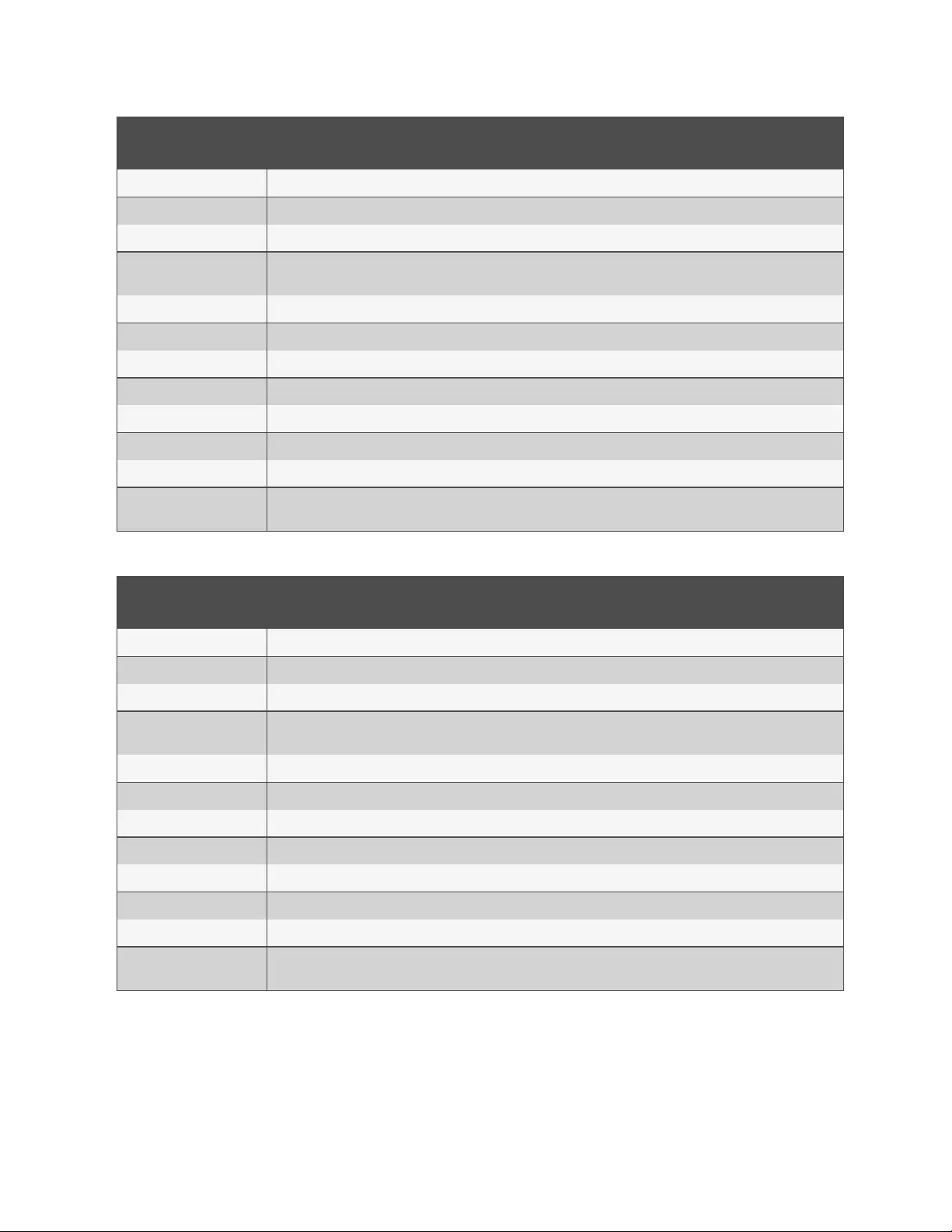

SOUND INDICATES

Continuous beep Generated when a UPS fault appears, such as a fuse or hardware failure.

One beep every 0.5 seconds Generated when a UPS critical alarm appears, such as on inverter overload.

One beep every 1 second. Generated when a UPS critical alarm appears, such as on battery low voltage

One beep every 3.3 seconds Generated when a UPS general alarm appears

Table 6.3 Audible-alarm Descriptions

NOTE: When an alarm is indicated, an alarm message is logged. See Liebert® GTX5 User Manual that

describes the alarm messages. When a fault is indicated, front-panel display list the fault, which are

described in Table 6.4 below .

6.2.3 Faults

When the fault indicator is illuminated, the LCD displays the fault. The faults are described in Table 6.4 below .

FAULT CAUSE CORRECTIVE STEPS

Battery test fail The battery is bad or weak. Contact technical support.

Rectifier fault A rectifier failure occurred. Contact technical support.

Inverter overload,

Bypass overcurrent The UPS is overloaded, Bypass is over current. Reduce the load and contact technical support.

Inverter fault The inverter is faulty. Contact technical support.

Battery aged The battery is bad or weak. Replace the battery.

Output short The output connection is short-circuited. Shut-down the equipment and contact technical support.

DC bus fail The DC bus is faulty. Contact technical support.

System overtemp Over-temperature condition in the UPS. The

UPS will transfer to bypass mode. Reduce the load and contact technical support.

Table 6.4 Description of Displayed Faults

6 Troubleshooting 37

Vertiv™| VRC-S User Manual

FAULT CAUSE CORRECTIVE STEPS

Charger fault The charger is faulty. Contact technical support.

Fan fault At least one fan is faulty. Contact technical support.

DC/DC fault A DC-DC charger failure occurred. Contact technical support.

Table 6.4 Description of Displayed Faults (continued)

6.2.4 Troubleshooting UPS Issues

In the event of an issue with the UPS, refer to Table 6.5 below , to determine the cause and solution. If the fault persists,

contact Vertiv Technical Support. Visit the GXT5 product page at www.vertiv.com for contact information.

When reporting a UPS issue to Vertiv, include the UPS model and serial number. These are located in several places for

your ease of location:

•On the top panel (rack mount orientation)

•The left side (tower orientation)

•The rear panel

•On the front of the unit behind the front plastic bezel

•On the LCD select Main Menu > About

PROBLEM CAUSE SOLUTION

UPS fails to start

UPS is short- circuited or overloaded. Ensure UPS is Off. Disconnect all loads and ensure nothing is lodged in output receptacles.

Ensure loads are not defective or shorted internally.

Batteries are not charge denough or

not connected.

Check to ensure the internal battery is connected. If it is not, fully remove and reinstall the

battery, and try to start the unit. If the battery is connected, leave the UPS connected to

input power for 24 hours to recharge batteries, then try to start the unit.

UPS has reduced

battery backup

time

Batteries are not fully charged. Keep UPS plugged in continuously at least 24 hours to recharge batteries.

UPS is overloaded. Check load level indicator and reduce the load on the UPS.

Batteries may not be able to hold a

full charge due to age.

Replace batteries. Contact your Vertiv representative or Vertiv Technical Support for

replacement battery kit.

Table 6.5 Troubleshooting

6 Troubleshooting

38

Vertiv™ VRC-S User Manual

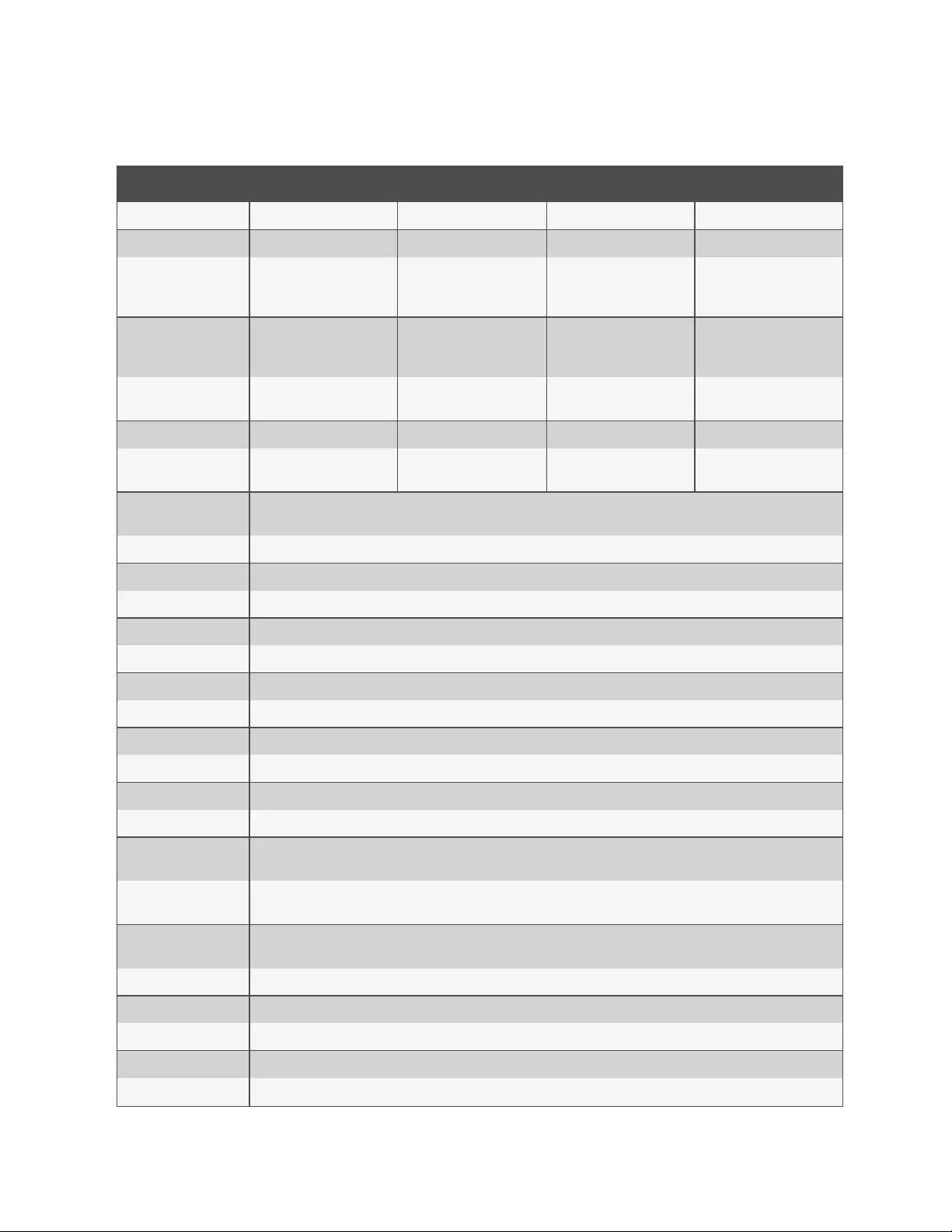

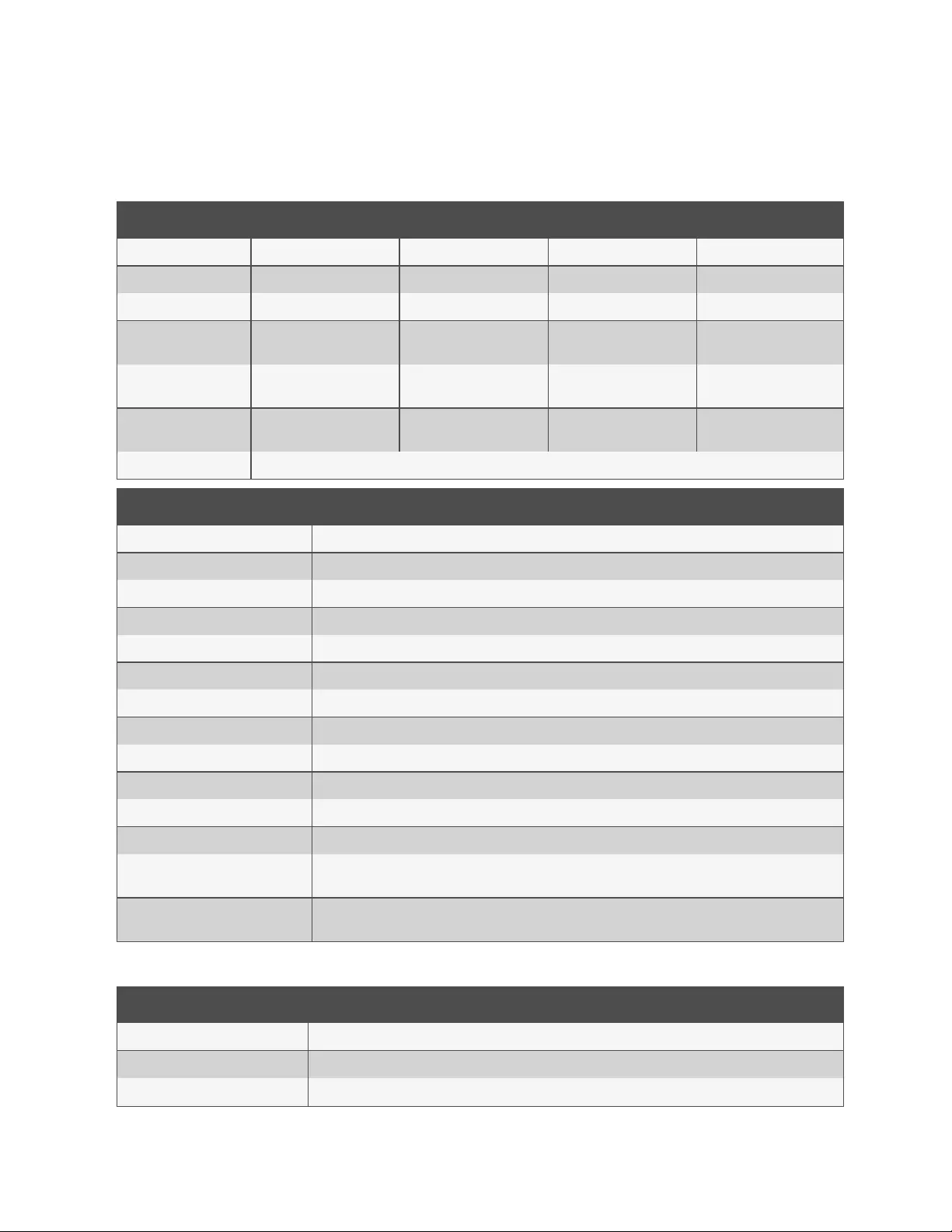

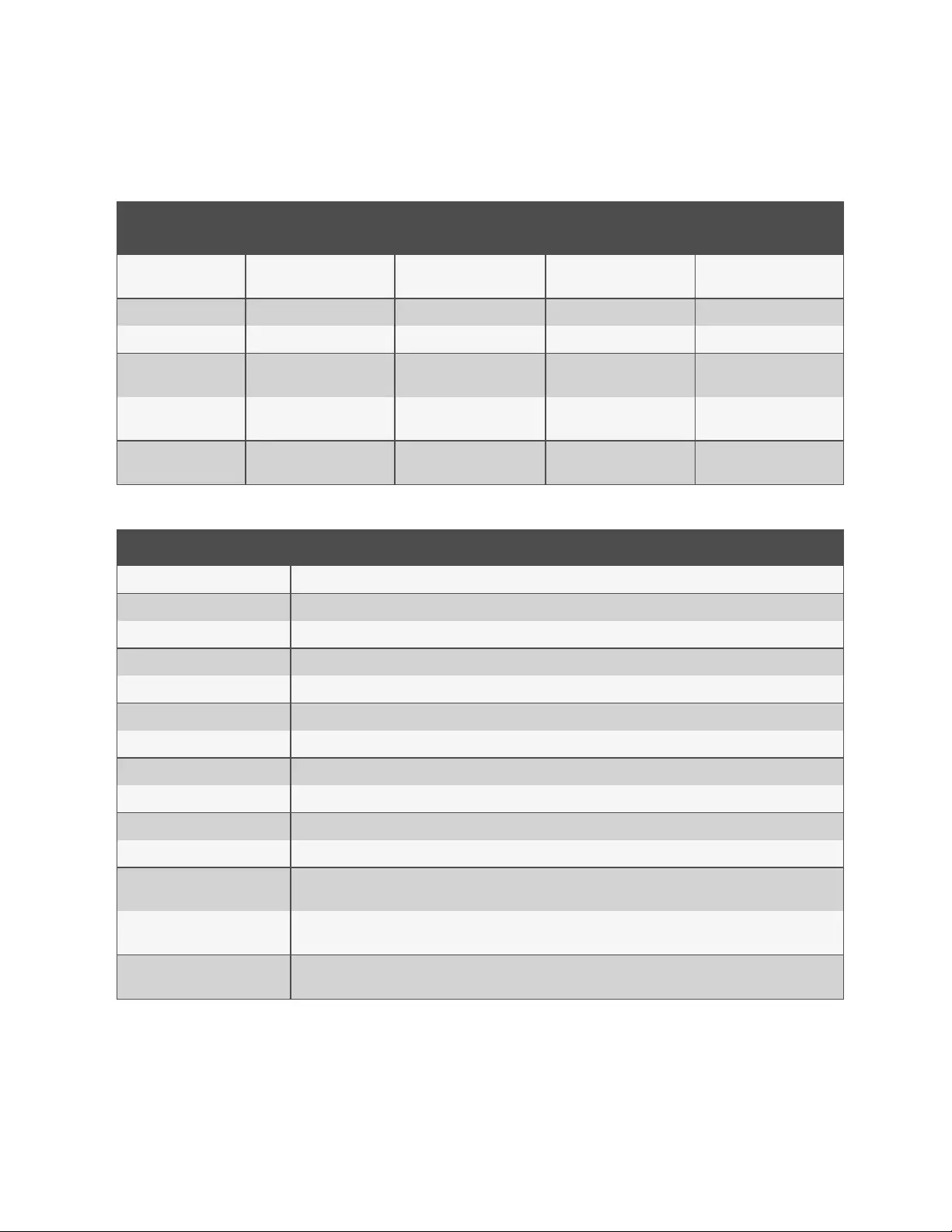

7 Faults, Warnings and Events

Display IMD

Type Explanation

Err1

IMD-01

(Metered

only)

The IMD discovered either none or more than one input boards. This may be caused by internal cabling issues or

an unresponsive input board. This is also displayed if there is a measurement error reported by the input board.

8888

IMD-02,

IMD-03,

IMD-3

IMD is booting and has yet to discover the simple display and shows boot on it.If this is displayed for more than a

few seconds there is a problem with the display board or with internal cabling.

“--”

(Two dashes on the

rightmost display

position)

IMD-02,

IMD-03,

IMD-3

The IMD cannot communicate with the input board. This may also be shown intermittently for individual

measurements. There is a problem with the input board or with internal cabling.

boot IMD-01 IMD is booting and discovering the input board.

boot

IMD-02,

IMD-03,

IMD-3

Firmware is initializing. This will be displayed while firmware is being updated in slave boards.

updt

IMD-02,

IMD-03,

IMD-3

Firmware update in progress.

rset dflt

IMD-02,

IMD-03,

IMD-3

Following user action, rset (Reset) will appear during a parameter reset sequence. During a parameter reset, dflt

(Default) will appear briefly.

bcup

IMD-02,

IMD-03,

IMD-3

bcup (Backup) will appear during a configuration backup.

rest conf

IMD-02,

IMD-03,

IMD-3

rest (Restore) and Conf (Configuration) will appear during a configuration restore.

Table 7.1 IMD Display Codes-Geist™ rPDU

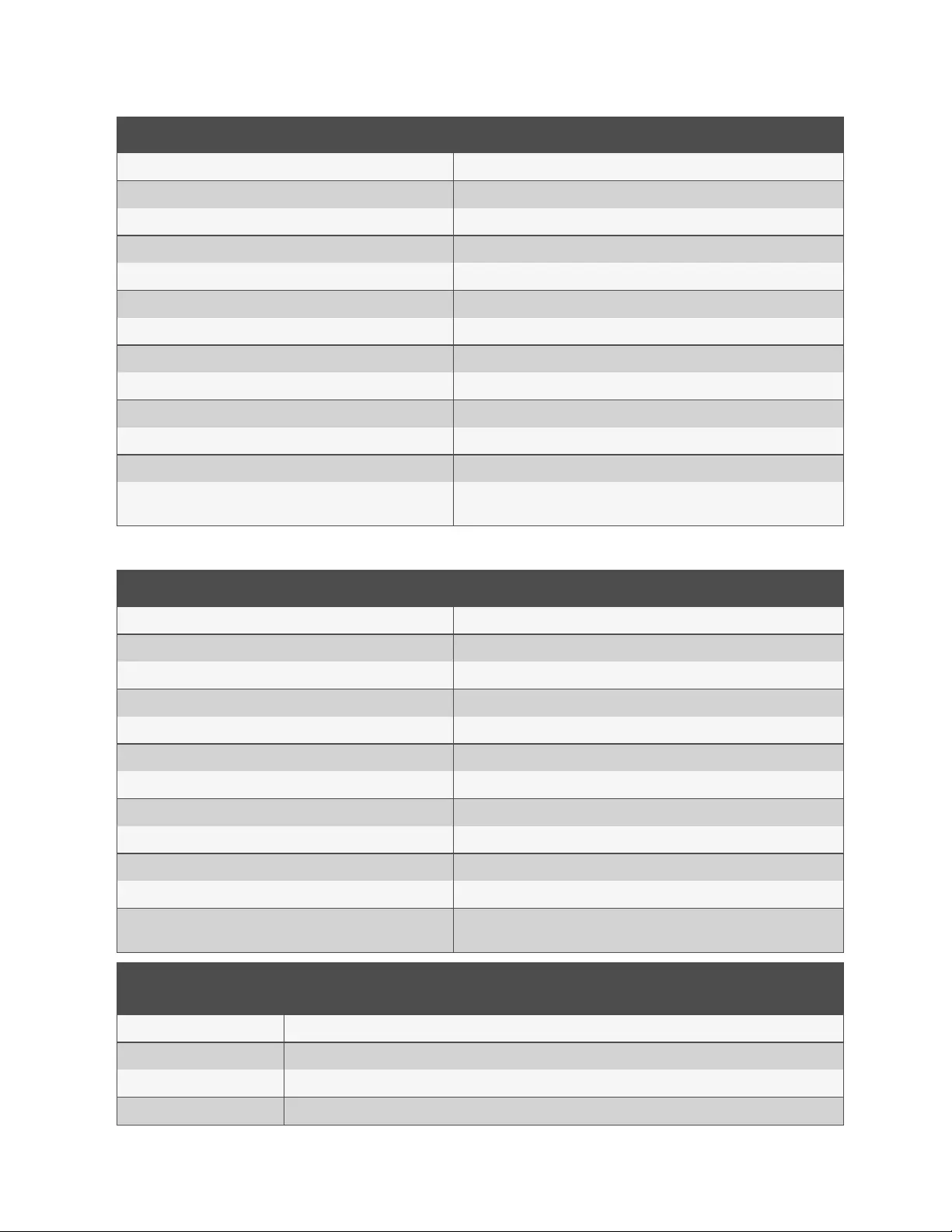

Message Possible cause Check or Remedy

High Temperature

Alarm temperature setpoint too low. Adjust the setpoint temperature that triggers the alarm.

Overload condition. Make sure that the actual head load is not above the maximum rated value.

Fan malfunction. Contact Vertiv Technical Support.

Compressor malfunction. Contact Vertiv Technical Support.

Low Temperature

Alarm temperature setpoint too high. Adjust the setpoint temperature that triggers the alarm.

Fan malfunction. Contact Vertiv Technical Support.

Compressor malfunction. Contact Vertiv Technical Support.

Table 7.2 Alarm Messages—Vertiv™ VRC

7 Faults, Warnings and Events 39

Vertiv™| VRC-S User Manual

Message Possible cause Check or Remedy

High Pressure

Insufficient air flow. Remove obstruction or debris from air inlets.

Fan malfunction. Contact Vertiv Technical Support.

Pressure-sensor malfunction. Contact Vertiv Technical Support.

Low Pressure

Insufficient air flow. Remove obstruction or debris from air inlets.

Fan malfunction. Contact Vertiv Technical Support.

EEV malfunction Contact Vertiv Technical Support.

Condenser malfunction or refrigerant leak. Contact Vertiv Technical Support.

Table 7.2 Alarm Messages—Vertiv™ VRC (continued)

7 Faults, Warnings and Events

40

Vertiv™ VRC-S User Manual

8 Specifications

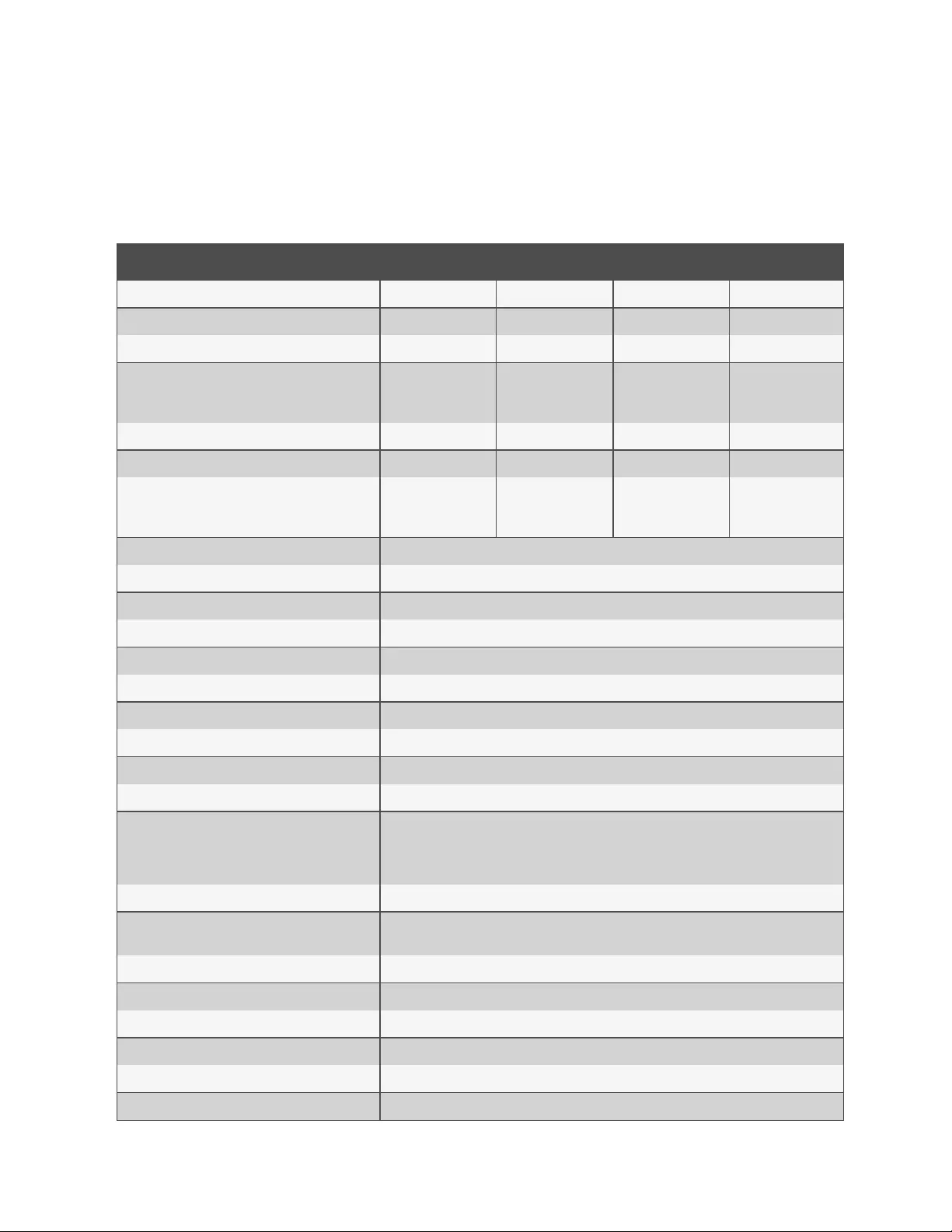

8.1 Vertiv™ VRC-S with VRC self-contained 120V NAM

VRC-S SKUs VRCS3350-120V VRCS3300-120V VRCS3307-120V VRCS3357-120V

Configured system weight 319 kg (704 lb.) 274 kg (605 lb.) 310 kg (684 lb.) 337 kg (743 lb.)

Shipping weight 419 kg (924 lb.) 361 kg (796 lb.) 397 kg (876 lb.) 437 kg (964 lb.)

Sound (at 60% fan speed and 40% compressor speed) 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m

Rack dimensions U; H, W, D

42U; 2000 mm, 800

mm, 1200 mm (78.6

in., 31.5 in., 47.8 in.)

42U; 2000 mm, 600

mm, 1200 mm (78.6

in., 23.6 in., 47.8 in.)

48U; 2200 mm, 600

mm, 1200 mm (86.6

in., 23.6 in., 47.8 in.)

48U; 2200 mm, 800

mm, 1200 mm (86.6

in., 31.5 in., 47.8 in.)

Usable space available for IT equipment 32U 32U 38U 38U

Shipping weight of rack N /A N /A N /A N /A

Shipping dimensions of rack H, W, D

2134 mm, 826 mm,

1385 mm(84 in., 32.5

in., 54.5 in.)

2134 mm, 626 mm,

1385 mm(84 in., 24.6

in., 54.5 in.)

2396 mm, 626 mm,

1385 mm (94.3 in.,

24.6 in., 54.5 in.)

2396 mm, 826 mm,

1385 mm (94.3 in.,

32.5 in., 54.5 in.)

rPDU (Pre-installed in rack) NU30021

rPDU sub-type Switched

rPDU type Outlet Level Monitoring

Voltage 120 V

Input current 30 A

Regulatory derated input current (North America) 24 A

rPDU rated maximum 2.8 kW

Horizontal/Vertical Vertical

rPDU input plug NEMA L5-30P

Cord length 3 m

Outlets

(24) NEMA 5-20R

NOTE: (2) NEMA 5-20R outlets will be required and preprogrammed for the

backup fan and condensate pump.

Vertiv Intelligence Director enabled YES

Geist Upgradable 2.0 protocols supported ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP, RSTP, STP, DNS, HTTP, HTTPS (TLSv1.2),

SMTP, SMTPS, DHCP, SNMP (v1/v2c/v3), LDAP, NTP, SSH, and Syslog

Certifications/Agency approvals UL & c-UL Listed 60950, RoHS Compliant, FCC Part 15 Class A Conformance

Cooling Kit Type VRC100KIT

Cooling capacity 0.9 - 3.5 kW

Air Volume 750 m³/h

VRC Input plug NEMA 5-20P

Cord length 3.2 m (10ft)

8 Specifications 41

Vertiv™| VRC-S User Manual

VRC-S SKUs VRCS3350-120V VRCS3300-120V VRCS3307-120V VRCS3357-120V

Voltage/Frequency 120 Vac, 60 Hz

Full Load Amperage (FLA) 16 A

Refrigerant type (pre-charged) R410A, 720 g (1.58 lb.)

VRC form factor

10U

NOTE: Do not block any U spaces with equipment past the rear EIA mounting

rails

Shipping dimensions H, D, W 1194 mm, 737 mm, 889 mm (47 in., 29 in., 35 in.)

VRC-S operating temperature 18°C-30°C (65°F-86°F)

VRC-S operating humidity 8%-80% (non-condensing)

LCD screen included Yes

Condensate Pump integrated Yes, powered via rPDU

Condensate pump tube length 7.5 m (24 ft.)

Duct length 3.8 m (12.4 ft.)

Certifications UL 484

8.2 Vertiv™ VRC-S with VRC self-contained 208V NAM

VRC-S SKUs VRCS3350-208V VRCS3300-208V VRCS3307-208V VRCS3357-208V

Configured system weight 319 kg (704 lb.) 274 kg (605 lb.) 310 kg (684 lb.) 337 kg (743 lb.)

Shipping weight 419 kg (924 lb.) 361 kg (796 lb.) 397 kg (876 lb.) 437 kg (964 lb.)

Sound (At 60% fan speed and 40%

compressor speed) 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m

Rack dimensions U; H, W, D

42U; 2000 mm, 800

mm, 1200 mm (78.6 in.,

31.5 in., 47.8 in.)

42U; 2000 mm, 600

mm, 1200 mm (78.6 in.,

23.6 in., 47.8 in.)

48U; 2200 mm, 600

mm, 1200 mm (86.6 in.,

23.6 in., 47.8 in.)

48U; 2200 mm, 800

mm, 1200 mm (86.6 in.

31.5 in., 47.8 in.)

Usable space available for IT equipment 32U 32U 38U 38U

Shipping weight of rack: N / A N / A N / A N / A

Shipping dimensions of rack H, W, D

2134 mm, 826 mm, 1385

mm (84 in., 32.5 in., 54.5

in.)

2134 mm, 626 mm, 1385

mm (84 in., 24.6 in., 54.5

in.)

2396 mm, 626 mm,

1385 mm (94.3 in., 24.6

in., 54.5 in.)

2396 mm, 826 mm,

1385 mm (94.3 in., 32.5

in., 54.5 in.)

rPDU (Pre-installed in rack) VP8641 VP5870V

rPDU sub-type Switched Switched

rPDU type Outlet Level Monitoring Outlet Level Monitoring

Voltage 208 V 208 V

Input current 30 A 30 A

Regulatory derated input current (North

America) 24 A 24 A

rPDU rated maximum 4.9 kW 4.9 kW

8 Specifications

42

Vertiv™ VRC-S User Manual

VRC-S SKUs VRCS3350-208V VRCS3300-208V VRCS3307-208V VRCS3357-208V

Horizontal/Vertical Vertical Vertical

rPDU input plug NEMA L6-30P NEMA L6-30P

Cord length 3 m 3 m

Outlets

(20) U-Lock IEC C13 (4) U-Lock IEC C19

NOTE: (2) U-Lock IEC C13 outlets will be

required and preprogrammed for the

backup fan and condensate pump

(30) U-Lock IEC C13 (6) U-Lock IEC C19

NOTE: (2) U-Lock IEC C13 outlets will be

required and preprogrammed for the

backup fan and condensate pump

Vertiv Intelligence Director enabled Yes Yes

Geist Upgradable 2.0 protocols supported

ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP,

RSTP, STP, DNS, HTTP, HTTPS (TLSv1.2), SMTP,

SMTPS, DHCP, SNMP (v1/v2c/v3), LDAP, NTP,

SSH, and Syslog

ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP,

RSTP, STP, DNS, HTTP, HTTPS (TLSv1.2), SMTP,

SMTPS, DHCP, SNMP (v1/v2c/v3), LDAP, NTP,

SSH, and Syslog

Certifications/Agency approvals UL & c-UL Listed 60950, RoHS Compliant, FCC Part

15 Class A Conformance

UL & c-UL Listed 60950, RoHS Compliant, FCC

Part 15 Class A Conformance

Cooling kit type VRC101KIT

Cooling capacity 0.9 - 3.5 kW

Air volume 750 m³/h

VRC Input plug NEMA L6-20P

Cord length 3.2 m (10ft)

Voltage/Frequency 208 Vac, 60 Hz

Full Load Amperage (FLA) 13.0 A

Refrigerant type (pre-charged) R410A, 720 g (1.58 lb.)

VRC form factor

10U

NOTE: Do not block any U spaces with equipment past the rear EIA mounting rails

Shipping dimensions H, D, W 1194 mm, 737 mm, 889 mm (47 in., 29 in., 35 in.)

VRC-S operating temperature 18 °C - 30 °C (65 °F - 86 °F)

VRC-S operating humidity 8%-80 % (non-condensing)

LCD screen included Yes

Condensate pump integrated Yes, powered via Geist™ rPDU

Condensate pump tube length 7.5 m (24 ft.)

Duct length 3.8 m (12.4 ft.)

Certifications UL 484

8 Specifications 43

Vertiv™| VRC-S User Manual

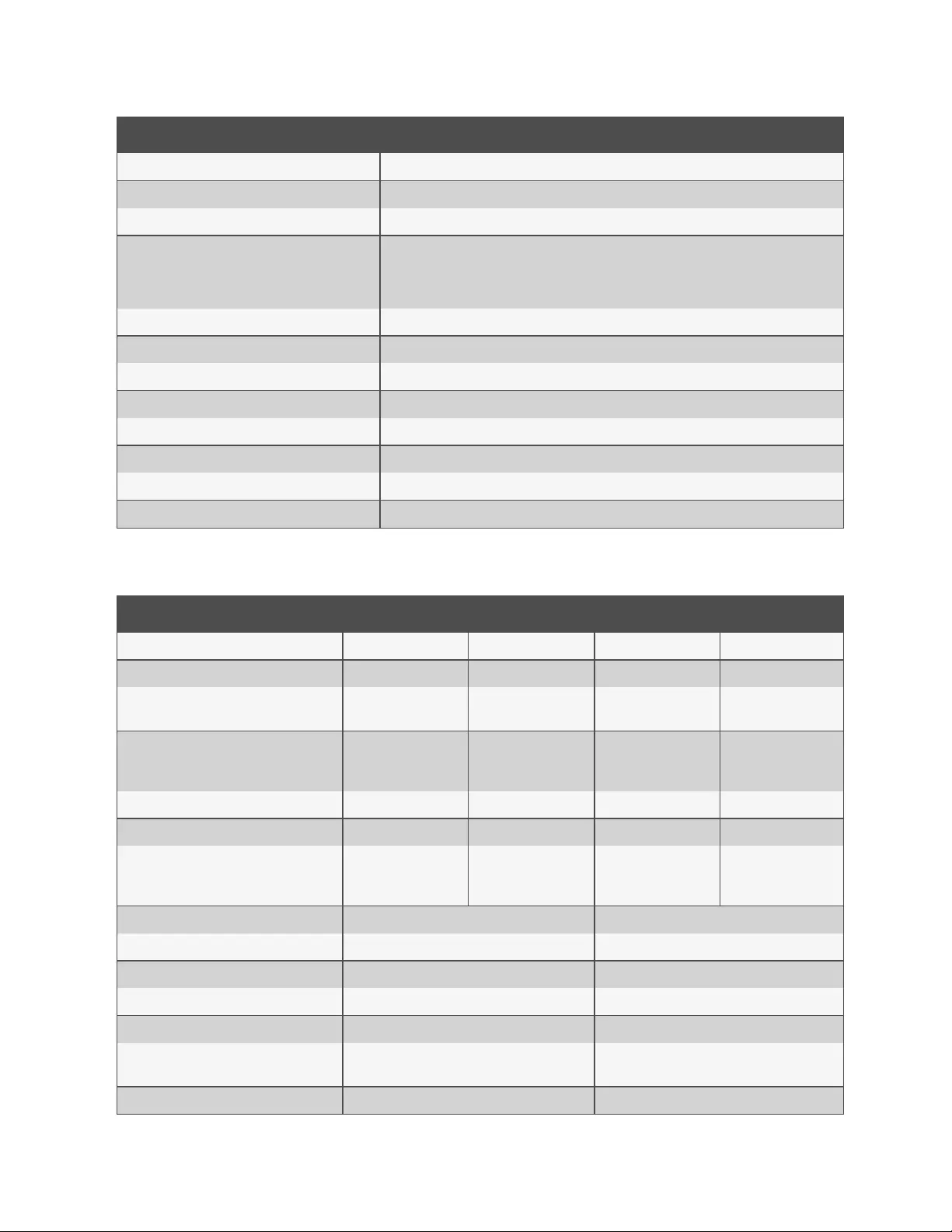

8.3 Vertiv™ VRC-S with VRC split lee temp 120 V NAM

VRC-S SKUs VRCS3350-120VSL VRCS3300-120VSL VRCS3307-120VSL VRCS3357-120VSL

Configured system weight 270 kg (595 lb.) 225 kg (496 lb.) 261 kg (575 lb.) 288 kg (635 lb.)

Shipping weight 336 kg (741 lb.) 278 kg (613 lb.) 314 kg (692 lb.) 354 kg (781 lb.)

Sound (At 60% fan speed

and 40% compressor

speed)

52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m

Rack dimensions U; H, W,

D

42U; 2000 mm, 800 mm,

1200 mm (78.6 in., 31.5 in.,

47.8 in.)

42U; 2000 mm, 600 mm,

1200 mm (78.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 600 mm,

1200 mm (86.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 800 mm,

1200 mm (86.6 in., 31.5 in.,

47.8 in.)

Usable space available

for IT equipment 36U 36U 42U 42U

Shipping weight of rack: N /A N /A N /A N /A

Shipping dimensions of

rack H, W, D

2134 mm, 826 mm, 1385 mm

(84 in., 32.5 in., 54.5 in.)

2134 mm, 626 mm, 1385 mm

(84 in., 24.6 in., 54.5 in.)

2396 mm, 626 mm, 1385 mm

(94.3 in., 24.6 in., 54.5 in.)

2396 mm, 826 mm, 1385 mm

(94.3 in., 32.5 in., 54.5 in.)

rPDU (Pre-installed in

rack) NU30021

rPDU sub-type Switched

rPDU type Outlet Level Monitoring

Voltage 120 V

Input current 30 A

Regulatory derated input

current (North America) 24 A

rPDU rated maximum 2.8 kW

Horizontal/Vertical Vertical

rPDU input plug NEMA L5-30P

Cord length 3 m

Outlets

(24) NEMA 5-20R

NOTE: (2) NEMA 5-20R outlets will be required and preprogrammed for the backup fan and

condensate pump

Vertive Intelligence

Director enabled YES

Geist Upgradable 2.0

protocols supported

ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP, RSTP, STP, DNS, HTTP, HTTPS (TLSv1.2), SMTP, SMTPS, DHCP, SNMP

(v1/v2c/v3), LDAP, NTP, SSH, and Syslog

Certifications/Agency

approvals UL & c-UL Listed 60950, RoHS Compliant, FCC Part 15 Class A Conformance

Cooling kit type VRC200KIT

Cooling capacity 0.9 - 3.5 kW

Air Volume 750 m³/h

VRC Input hardwired L1+L2+G

8 Specifications

44

Vertiv™ VRC-S User Manual

VRC-S SKUs VRCS3350-120VSL VRCS3300-120VSL VRCS3307-120VSL VRCS3357-120VSL

Voltage, Frequency 120 Vac , 60 Hz

Full Load Amperage

(FLA) 2,1 A

Refrigerant type (pre-

charged) R410A, indoor unit 400 g (0.88 lb.)

VRC Form Factor

6U

NOTE: Do not block any U spaces with equipment past the rear EIA mounting rails.

VRC-S operating

temperature 18°C-30°C (65°F-86°F)

VRC-S operating humidity 8%-80% (non-condensing)

LCD screen included Yes

Condensate pump

integrated Yes, powered via rPDU

Condensate pump tube

length 7.5 m (24 ft.)

NOTE: Condenser will be shipped separate to customer.

Split System Condensing Unit VRC351KIT

Input power hardwired L1+L2+L3+G

Voltage, Frequency 208/230 Vac , 60 Hz

Full Load Amperage (FLA) 7,2 A

Refrigerant type (pre-charged) R410A, outdoor unit 900 g (1.98 lb.)

Dimensions H, W, D 527 mm, 282 mm, 1158 mm ( 20.75 in., 11.10 in., 45.60 in.)

Net weight 68 kg (150 lb.)

Shipping dimensions H, W, D 755 mm, 480 mm, 1350 mm (29.72 in., 18.90 in., 53.20 in.)

Shipping weight 85 kg (187 lb.)

IP Code IPX4 (IEC 60529)

Outdoor temperature range -15°C (5°F) to 45°C (113°F)

Noise level <55 dB(A)

Certifications UL 1995 (CSA C22.2 NO2236-11)

8 Specifications 45

Vertiv™| VRC-S User Manual

8.4 Vertiv™ VRC-S with VRC split lee temp 208V NAM

VRC-S SKUs VRCS3350-208VSL VRCS3300-208VSL VRCS3307-208VSL VRCS3357-208VSL

Configured system

weight 270 kg (595 lb.) 225 kg (496 lb.) 261 kg (575 lb.) 288 kg (635 lb.)

Shipping weight 336 kg (741 lb.) 278 kg (613 lb.) 314 kg (692 lb.) 354 kg (781 lb.)

Sound (At 60% fan

speed and 40%

compressor speed)

52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m

Rack dimensions U; H,

W, D

42U; 2000 mm, 800 mm,

1200 mm (78.6 in., 31.5 in.,

47.8 in.)

42U; 2000 mm, 600 mm,

1200 mm (78.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 600 mm,

1200 mm (86.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 800 mm,

1200 mm (86.6 in., 31.5 in.,

47.8 in.)

Usable space available

for IT equipment 36U 36U 42U 42U

Shipping weight of rack N / A N / A N / A N / A

Shipping dimensions of

rack H, W, D

2134 mm, 826 mm, 1385 mm

(84 in., 32.5 in., 54.5 in.)

2134 mm, 626 mm, 1385 mm

(84 in., 24.6 in., 54.5 in.)

2396 mm, 626 mm, 1385 mm

(94.3 in., 24.6 in. 54.5 in.)

2396 mm, 826 mm, 1385 mm

(94.3 in., 32.5 in., 54.5 in.)

rPDU (Pre-installed in

rack) VP8641 VP5870V

rPDU sub-type Switched Switched

rPDU type Outlet Level Monitoring Outlet Level Monitoring

Voltage 208 V 208 V

Input current 30 A 30 A

Regularoty derated

input current (North

America)

24 A 24 A

rPDU rated maximum 4.9 kW 4.9 kW

Horizontal/Vertical Vertical Vertical

rPDU input plug NEMA L6-30P NEMA L6-30P

Cord length 3 m 3 m

Outlets

(20) U-Lock IEC C13 (4) U-Lock IEC C19

NOTE: (2) U-Lock IEC C13 outlets will be required

and preprogrammed for the backup fan and

condensate pump

(30) U-Lock IEC C13 (6) U-Lock IEC C19

NOTE: (2) U-Lock IEC C13 outlets will be required

and preprogrammed for the backup fan and

condensate pump

Vertive Intelligence

Director enabled YES YES

Geist Upgradable 2.0

protocols supported

ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP, RSTP, STP,

DNS, HTTP, HTTPS (TLSv1.2), SMTP, SMTPS, DHCP, SNMP

(v1/v2c/v3), LDAP, NTP, SSH, and Syslog

ARP, IPv4, IPv6, ICMP, ICMPv6, NDP, TCP, UDP, RSTP, STP,

DNS, HTTP, HTTPS (TLSv1.2), SMTP, SMTPS, DHCP, SNMP

(v1/v2c/v3), LDAP, NTP, SSH, and Syslog

Certifications/Agency

approvals

UL & c-UL Listed 60950, RoHS Compliant, FCC Part 15 Class A

Conformance

UL & c-UL Listed 60950, RoHS Compliant, FCC Part 15 Class

A Conformance

Cooling Kit Type VRC201KIT

Cooling capacity 0.9 kw-3.5 kW

8 Specifications

46

Vertiv™ VRC-S User Manual

VRC-S SKUs VRCS3350-208VSL VRCS3300-208VSL VRCS3307-208VSL VRCS3357-208VSL

Air volume 750 m³/h

VRC input hardwired L1+L2+G

Voltage, Frequency 208/230 Vac , 60 Hz

Full Load Amperage

(FLA) 1,7 A

Refrigerant type (pre-

charged) R410A, indoor unit 400 g (0.88 lb.)

VRC form factor

6U

NOTE: Do not block any U spaces with equipment past the rear EIA mounting rails

VRC-S operating

temperature 18°C-30°C (65°F-86°F)

VRC-S operating

humidity 8%-80% (non-condensing)

LCD screen included Yes

Condensate pump

integrated Yes, powered via rPDU

Condensate pump tube

length 7.5 m (24 ft.)

Certifications UL 1995 (CSA 22.2 NO.236-11)

NOTE: Condenser will be shipped separate to customer.

Split System Condensing Unit VRC351KIT

Input Power hardwired L1+L2+L3+G

Voltage, Frequency 208 Vac , 60 Hz

Full Load Amperage (FLA) 7,2 A

Refrigerant type (pre-charged) R410A, outdoor unit 900 g (1.98 lb.)

Dimensions H, W, D 527 mm, 282 mm, 1158 mm ( 20.75 in., 11.10 in., 45.60 in.)

Net Weight 68 kg (150 lb.)

Shipping dimensions H, W, D 755 mm, 480 mm, 1350 mm (29.72 in., 18.90 in., 53.20 in.)

Shipping weight 85 kg (187 lb.)

IP code IPX4 (IEC 60529)

Outdoor temperature range -15°C (5°F) to 45°C (113°F)

Noise level <55 dB(A)

Certifications UL 1995 (CSA 22.2 NO.236-11)

8 Specifications 47

Vertiv™| VRC-S User Manual

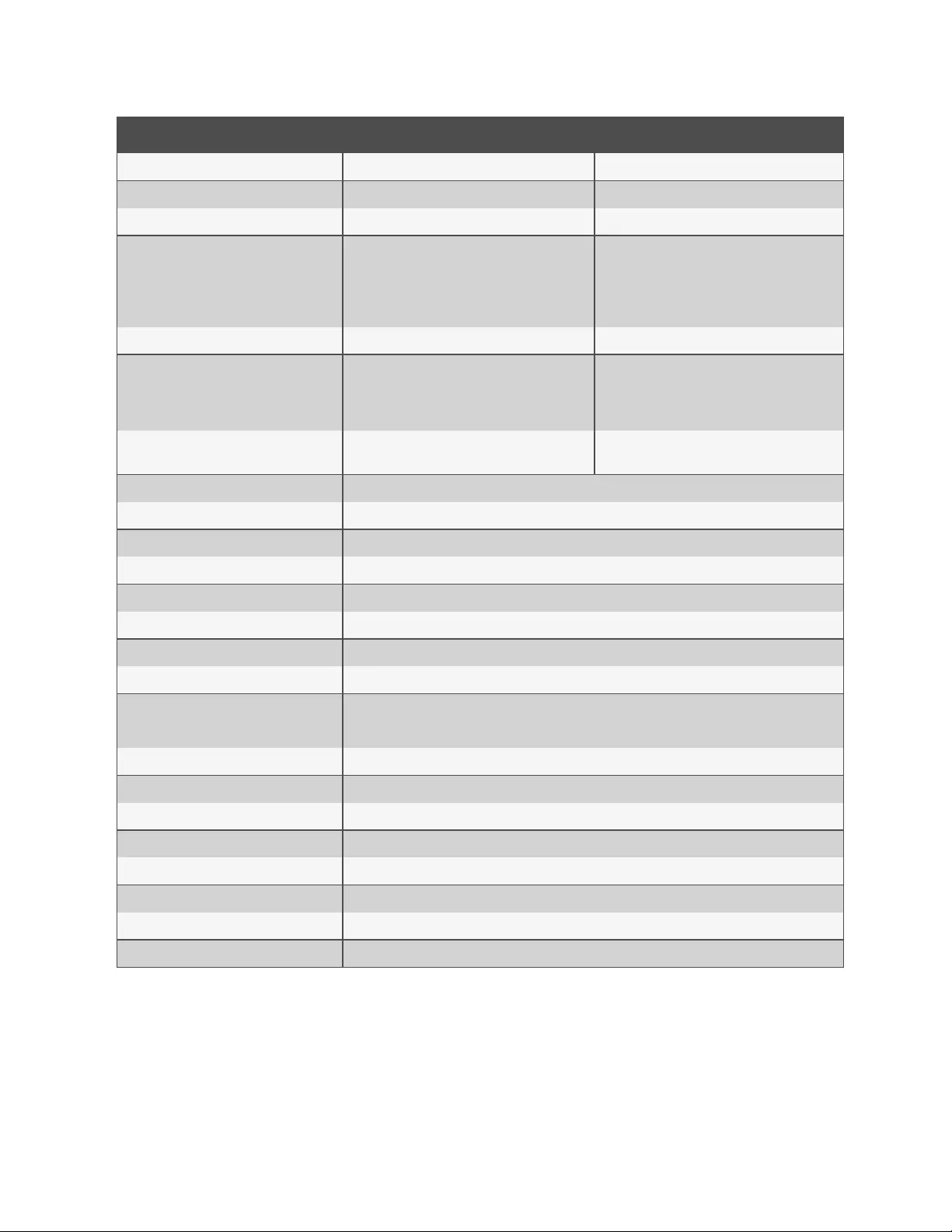

8.5 Vertiv™ VRC-S with VRC self-contained 230V EMEA

VRC-S SKUs VRCS3350-230V VRCS3300-230V VRCS3307-230V VRCS3357-230V

Configured system weight 321 kg (708 lb.) 276 kg (609 lb.) 312 kg (688 lb.) 339 kg (747 lb.)

Shipping weight 421 kg (928 lb.) 363 kg (800 lb.) 399 kg (880 lb.) 439 kg (968 lb.)

Sound (At 60% fan speed

and 40% compressor

speed)

52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m 52.5 dBA @ 1 m

Rack dimensions U; H, W,

D

42U; 2000 mm, 800 mm,

1200 mm (78.6 in., 31.5 in.,

47.8 in.)

42U; 2000 mm, 600 mm,

1200 mm (78.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 600 mm,

1200 mm (86.6 in., 23.6 in.,

47.8 in.)

48U; 2200 mm, 800 mm,

1200 mm (86.6 in., 31.5 in.,

47.8 in.)

Usable space available

for IT equipment 32U 32U 38U 38U

Shipping weight of rack: N/A N/A N/A N/A

Shipping dimensions of

rack H, W, D

2134 mm, 826 mm, 1385 mm

(84 in., 32.5 in., 54.5 in.)

2134 mm, 626 mm, 1385 mm

(84 in., 24.6 in., 54.5 in.)

2396 mm, 626 mm, 1385 mm

(94.3 in., 24.6 in., 54.5 in.)

2396 mm, 826 mm, 1385 mm

(94.3 in., 32.5 in., 54.5 in.)

rPDU (Pre-installed in

rack) GU30017L

Category Switched

Sub Category Outlet Level Monitoring EC