Vertiv WSCK-120 User Manual

Displayed below is the user manual for WSCK-120 by Vertiv which is a product in the Water Detectors category. This manual has 4 pages.

Related Manuals

GEIST™ LEAK DETECTION KIT

Quick Installation Guide

VM1236/590-2262-501A 1

Part Number:

WSCK

Description

Water-sensing cable kits feature

detection cables that recognize the

presence of water along the entire

cable length.

Kit includes:

• LD310 control box

• +5 V power supply

• 15 ft (3 m) leader cable

• 50 ft (16.7 m) 4-conductor

alarm wire

• Orange Leak Detection

Cable(s)

• Accessory hardware - Hex key,

wall mounting hardware and

self-adhesive J-clips

• Terminator plug

(NOTE: Some kits contain a

permanently terminated,

orange Leak Detection Cable

and do not require a separate

terminator plug)

Mounting the LD310

Control Box

Determine the location where the

control box is to be mounted. Take

into consideration power

accessibility and the wire route to

your environmental monitoring unit.

With the provided hex key, loosen

the two set screws on the bottom

end of the control box and remove

the cover. Then locate the two

mounting screw holes on the base.

Hold the bottom of the control box

in place and mark the holes. After

drilling the mounting holes, fasten

the control box in place with the

appropriate hardware.

Before replacing the cover, attach

the Leader Cable, 4-conductor

alarm wires and 5 V power supply

into the terminal block near the

bottom of the control box circuit

board. You may also want to

activate the audible alarm before

replacing the LD310’s cover. When

you are ready to replace the cover,

assemble it to the base and use the

hex key to tighten the screws to

secure it.

See the Geist LD310 Control Box

Wiring Diagram on the following

page for details.

Connecting the Leader Cable

The Leader Cable is a 15-ft (4.57 m)

white cable with a twist-lock

connector on one end and four

bare, stripped and tinned wires on

the other end.

To connect the Leader Cable,

make sure the four colored wires

Power Failure Sensor

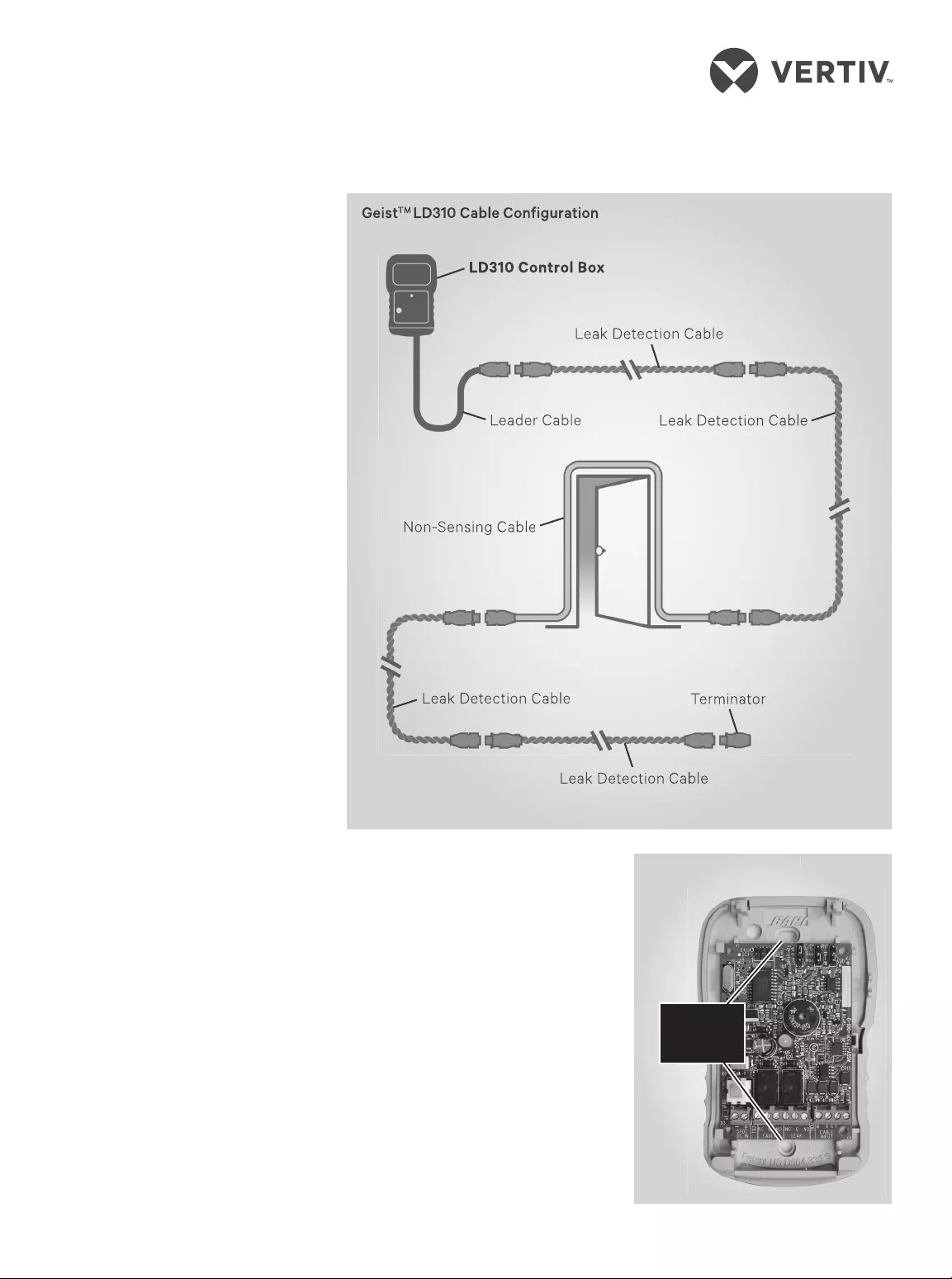

GeistTM LD310 Cable Configuration

Mounting

screw

hole

LD310 Mounting Hole Locations

Leader Cable

LD310 Control Box

Leak Detection Cable

Leak Detection Cable

Non-Sensing Cable

Terminator

Leak Detection Cable

Leak Detection Cable

Geist

TM

LD310 Cable Configuration

Leader Cable

LD310 Control Box

Leak Detection Cable

Leak Detection Cable

Non-Sensing Cable

Terminator

Leak Detection Cable

Leak Detection Cable

Power Failure Sensor

Geist

Power Failure Sensor

Geist

TM

Power Failure Sensor

TM

LD310 Cable Configuration

Power Failure Sensor

LD310 Cable Configuration

GEIST™ LEAK DETECTION KIT

Quick Installation Guide

2 VM1236/590-2262-501A

Power Failure Sensor

are stripped so that approximately

¼ inch (7 mm) of bare wire is

showing. Then insert the wires into

the appropriate terminals of the

CABLE INPUT terminal block and

tighten the screws to lock the

wires into place.

Connecting the relays to a

monitoring unit

Using the 4-conductor alarm wire

supplied with the kit (or any

suitable 4-conductor wire), with the

relay mode jumper in “supervised”

mode, connect the signals between

the LD310 Control Box and the

monitoring unit’s analog-input

terminal block.

Note that the use of inputs #1 and

#2 here is merely an example. Any

of the numbered analog inputs can

be used. That is, as long as the red

and green wires are connected to

di erent inputs, and those inputs

don’t already have other sensors

connected to them. You cannot,

however, connect both the red and

green wires to a single analog

input. The “fault” and “leak” signals

must be connected to separate

inputs for the unit to work properly.

Connecting the 5 V power

supply

The LD310 Control Box is powered

by a standard 5 VDC wall

transformer-style power supply.

Make sure both wires are stripped

so that approximately ¼ inch (7 mm)

of bare wire is showing and then

insert the wires into the appropriate

terminals of the 5 VDC DC IN

terminal block and tighten the

screws to lock the wires in place.

Connecting the Leak-

Detection Cable(s)

Your leak-detection kit includes

one or more lengths of orange

Leak-Detection Cable. The cables

are designed to be daisy-chained

together, so each cable has a 4-pin,

male, twist-lock plug on one end,

and a 4-pin, female, twist-lock

socket on the other end.

The first length of Leak Detection

Cable connects to the Leader

Cable from the LD310 Control Box,

and additional lengths (if any) are

chained together as necessary.

Some kits are supplied with a cable

that is permanently terminated on

one end. If your kit is one of these,

the terminated cable must be the

last cable in the chain.

If your kit does not include a

pre-terminated cable, the

Terminator Plug must be attached

to the last cable in the chain.

“Non-Sensing Cable”

(optional)

The Non-Sensing Cable, available

as an optional accessory, is an

economical way to route around or

over non-monitored spaces, such

as doorways. It also provides

greater flexibility in where to mount

the control box without wasting

Leak Detection Cables across

areas where there is no need to

actually sense liquids.

NOTE: The Non-Sensing Cable can

be connected anywhere within the

chain.

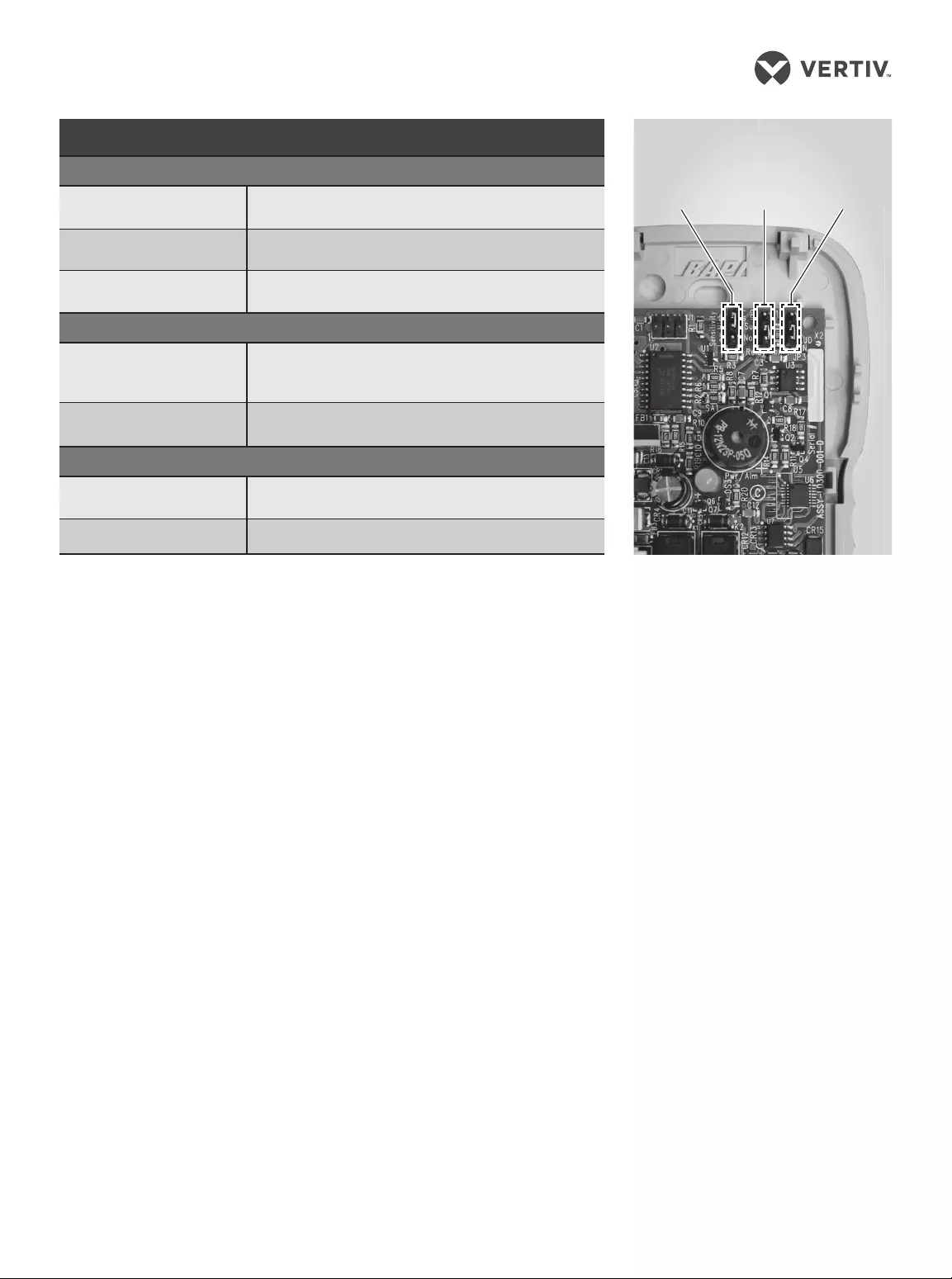

Program Jumpers

The LD310 has three sets of 3-pin

jumpers. JP1 is used to configure

the sensitivity of the leak setting.

JP2 configures the relay outputs.

JP3 configures the audible alarm.

If you change the jumpers, you

must cycle power to the LD310 in

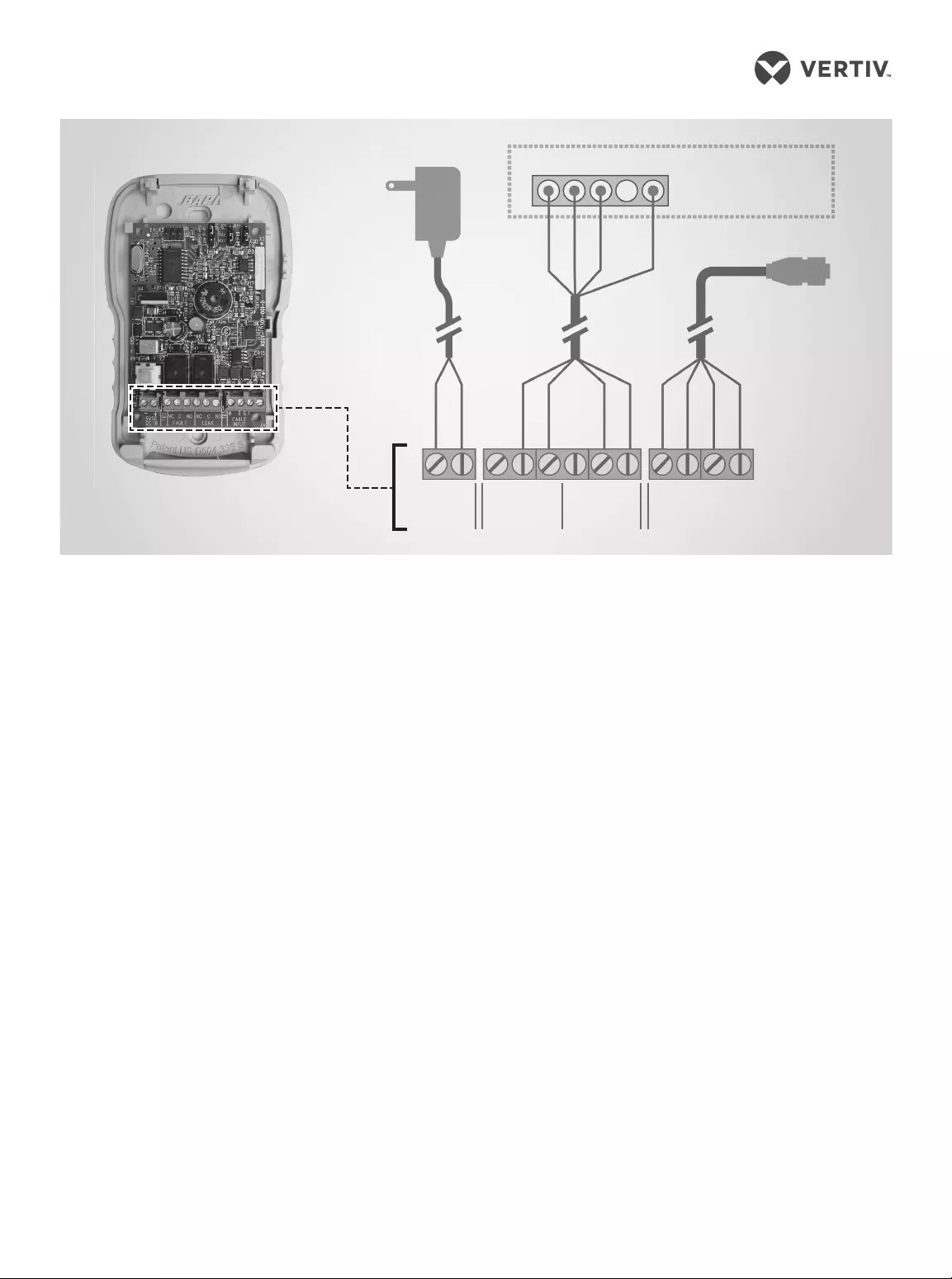

W B G R

CABLE

INPUT

Red

Green

Black

White

NC C NO

LEAK

NC C NO

FAU LT

– +

5VDC

DC IN

Striped

Unstriped

White

Green

Black

Red

C 1 2 3 C Monitoring

unit

Leader

Cable

5V power

supply

LD310 Control Box

GeistTM LD310 Control Box Wiring Diagram

Red

Green

Black

White

GEIST™ LEAK DETECTION KIT

Quick Installation Guide

VM1236/590-2262-501A 3

order for it to recognize the

change.

See the table above for jumper

configuration settings.

LED

The LD310 has one LED, which is

used to report a variety of

conditions.

• Power On / Normal - The LED is

on and displays a solid green

color during normal operation

with no alarm present.

• Cable Break - The LED flashes

orange while the audible alarm

sounds. Once the alarm silence

button is pushed, the LED will

continue to flash orange slowly

until the cable break is resolved.

• Leak - The LED flashes red

while the audible alarm sounds.

Once the alarm silence button

is pushed, the LED will continue

to display a solid red color until

the leak is resolved and the

cable is dry.

Audible Alarm and Silence/

Test/Reset Button

By default, the audible alarm on the

LD310 is disabled. To activate the

audible alarm, first loosen the

screws on the bottom of the

enclosure and remove the unit’s

cover. Remove the warning sticker

from the top of the audible alarm,

move the jumper on J3 to cover the

bottom two pins and cycle power

to the unit. Replace the LD310’s

cover and tighten the screws to

secure it.

The LD310 has one push-button

switch, which is used to silence the

audible alarm and to test and reset

the system.

The audible alarm sounds when a

cable break or leak is detected.

When the audible alarm is

activated, push the button once to

silence the alarm.

Test mode allows the LD310 to test

its internal components. To initiate

test mode, push and hold the

button for approximately five

seconds. When the LED flashes red

and green, the audible alarm

sounds and the relays activate

(change state), the test is complete

and you can release the button.

After the test cycle, the entire unit

resets and the LED returns to

green. If there was a leak or cable

break present before you ran the

test and that leak or break is still

present, the unit will alarm for this

condition again after a few seconds.

Test the System

Once the LD310 is set up, you

should test the system. If the

LD310 is connected to a BMS or

NMS, notify monitoring personnel

before you test.

To verify the LD310’s functionality,

test three points within the length

of the sensing cable - one at the

beginning, one in the middle of the

length, and another near the end of

the length of cable.

There are a variety of ways to

simulate a leak.

• Pour a small puddle of water on

the cable while it rests on the

floor.

• Dunk the cable in a cup of

water.

• Wet a paper towel or rag and

wrap it loosely around the

cable. This is popular if the

cable is used in pipe

applications. Be careful to wrap

JUMPER SETTINGS

JP1 SET THE LEAK SENSITIVITY

Jumper spans top two pins High sensitivity - most sensitive - system alarms with

.5-inch (13 mm) wetted cable.

Jumper is not installed Medium sensitivity - system alarms with 2-inch (51 mm)

wetted cable.

Jumper spans bottom two

pins

Low sensitivity - least sensitive - system alarms with

6-inch (152 mm) wetted cable.

JP2 CONFIGURE THE RELAY OUTPUTS

Jumper spans top two pins Relays are supervised; relays remain ON until either power

is disabled or an alarm is detected, at which time the relays

turn OFF.

Jumper spans bottom two

pins

Relays are non-supervised; relays remain OFF until an

alarm is detected, at which time the relays turn ON.

JP3 CONFIGURE THE AUDIBLE ALARM

Jumper is not installed Audible alarm is disabled. This is the LD310’s default

setting.

Jumper spans bottom two pins Audible alarm is enabled.

Power Failure Sensor

JP3

Audible

Alarm

JP2

Relay Output

Configuration

JP1

Leak

Sensitivity

Jumper Locations

To contact Vertiv Technical Support: visit www.VertivCo.com

© 2019 Vertiv Co. All rights reserved. Vertiv and the Vertiv logo are trademarks or registered trademarks of Vertiv Co. All other names and logos referred to are trade names,

trademarks or registered trademarks of their respective owners. While every precaution has been taken to ensure accuracy and completeness herein, Vertiv Co. assumes no

responsibility, and disclaims all liability, for damages resulting from use of this information or for any errors or omissions. Specifications are subject to change without notice.

GEIST™ LEAK DETECTION KIT

Quick Installation Guide

4 VM1236/590-2262-501A

the wet cloth loosely around the

cable. Do not put pressure on the

cable.

Remove the simulated leak sources

and return the system to its normal

operating state.

To test the cable fault alarm,

remove the end-of-line terminator

(EOL) from the end of the sensing

cable. This will cause a cable break,

which should be reported

appropriately by the LD310. Once

the cable break alarm is verified,

reapply the EOL and ensure the

system returns to its normal

operating state.

CONFIGURING THE

SYSTEM’S SETTINGS

The first step is to re-name the

analog inputs to something more

descriptive, to help identify the

“cable fault” and “leak” signals

when looking at the unit’s logged

data or e-mailed alert messages.

These names can be changed from

the Sensor tab of the monitoring

unit’s application.

If you connected the signals

according to the Control Box

Wiring Diagram on page 2, Analog 1

will be the “Cable Fault” signal, and

Analog 2 will be the “Leak

Detection” signal.

CLEANING THE LEAK

DETECTION CABLES

If the orange Leak Detection

Cables become contaminated by

oils, solvents or conductive

residues, it may continue to give a

“wet” signal, even though the cable

and surrounding area appears dry.

If this happens, the cable can be

cleaned as follows:

Clean the cable with

isopropyl alcohol

Cleaning the cable with alcohol

allows you to clean the sensing

cable without completely

disconnecting and removing it from

its installed location. Instead, you’ll

remove each section of cable you

wish to clean from its J-clips, wipe

it down, and reinstall the cable.

This method will clean most

contaminants from the cable, and is

generally su icient in most cases.

1. Obtain a dye-free heavy cloth

rag and a bottle of isopropyl

alcohol.

2. Remove the first section of

cable to be cleaned from its

J-clips.

3. Soak the rag with alcohol.

4. Wrap the rag around the cable

and squeeze firmly while pulling

the rag down the length of the

cable.

5. Flip the rag over every several

feet. Re-saturate the rag with

alcohol as required.

6. Once you’ve reached the end of

the first section of cable, place

it back in the J-clips and

proceed to the next section.

7. Replace the rag if it becomes

too dirty.

Clean the cable with warm,

soapy water

If the cable still gives a false “wet’

signal, even after you’ve cleaned it

with isopropyl alcohol as above, or

if the cable appears so dirty that it

requires a more intense scrubbing,

the cables may be cleaned with

warm, soapy water instead. This

process requires you to completely

remove the cable from its installed

location, submerge it in a soap-and-

water solution, scrub it with a brush,

and hang it to dry for several hours,

so it is highly recommended to try

the alcohol-cleaning method first.

1. Remove the sensing cable from

its installed location. Labeling

the sections of cable to note

their location for later

re-installation is highly

recommended.

2. Add dish soap (such as Dawn™)

to a bucket of warm water,

using about 1 cup (250 ml) of

detergent per gallon (4 L) of

water.

3. Submerge a section of the

cable in the water and, using a

scrub brush or rag, scrub along

the surface of the cable with

firm pressure. Be sure to scrub

all sides of the cable.

4. Remove the section of the

cable from the soapy solution

and rinse it in a bucket of clean,

fresh water.

5. Ensure there are no oily

deposits along the length of the

cable. If the cable does not

appear clean, repeat steps 3

and 4.

6. Hang up the cable to dry. Try to

point the connectors down, so

water cannot pool inside the

connectors. The drying process

may take 6 - 48 hours,

depending on the room

conditions.

7. Once the cable is completely

dry, reinstall it in its original

location.