APC Magnum VS 50 w/SNMP User Manual

Displayed below is the user manual for Magnum VS 50 w/SNMP by APC which is a product in the Network Switch Components category. This manual has pages.

Related Manuals

990-1479E 05/2007

Magnum VS 50

Magnum VS 100

-48 Vdc Power Systems

User Manual

Magnum VS –48 Vdc User Manual Page ii

Table of Contents

1 Introduction ............................................................................................................................................................6

1.1. GENERAL INFORMATION ....................................................................................................................................6

2 Installation..............................................................................................................................................................9

2.1. UNPACKING EQUIPMENT ...................................................................................................................................9

2.2. MECHANICAL INSTALLATION...............................................................................................................................9

Room / Location.....................................................................................................................................................9

Mounting ................................................................................................................................................................9

Ventilation ..............................................................................................................................................................9

2.3. AC POWER CONNECTIONS..............................................................................................................................10

AC Connections...................................................................................................................................................10

AC Power Cord Sets............................................................................................................................................11

2.4. BATTERY CONNECTIONS .................................................................................................................................12

Planning the Battery installation ..........................................................................................................................12

Connecting the Cables ........................................................................................................................................12

Battery Temperature Probe Installation...............................................................................................................13

2.5. COUNTER ELECTRO-MOTIVE FORCE (CEMF) CELL CONNECTIONS...................................................................13

2.6. DC SYSTEM GROUNDING ................................................................................................................................14

2.7. LOAD PROTECTION INSTALLATION....................................................................................................................15

Circuit Breaker Installation...................................................................................................................................15

GMT Fuse Installation..........................................................................................................................................15

2.8. LOAD CONNECTIONS.......................................................................................................................................15

Cable Size Considerations ..................................................................................................................................15

Circuit Breaker Protected Load Connections (30 or 60 A) ..................................................................................16

GMT Fuse-protected Load Connections .............................................................................................................16

2.9. MONITORING AND RELAY OUTPUT CONNECTIONS.............................................................................................17

Front Panel DB9 Connection...............................................................................................................................17

RJ45 Ethernet Connector ....................................................................................................................................17

Major, Minor and Relay 1 Output Connections....................................................................................................17

Output Relay 2-6 Connections ............................................................................................................................18

External Alarm Input Connections .......................................................................................................................19

2.10. RECTIFIER MODULE INSTALLATION ...............................................................................................................20

2.11. CONTROLLER MODULE INSTALLATION ..........................................................................................................20

3 Commissioning ....................................................................................................................................................21

3.1. PRE-COMMISSIONING INSPECTION...................................................................................................................21

Environment.........................................................................................................................................................21

Electrical Installation ............................................................................................................................................21

Battery Visual and Safety Inspection...................................................................................................................21

3.2. COMMISSIONING .............................................................................................................................................22

Initial Set-up.........................................................................................................................................................22

AC Power Up .......................................................................................................................................................22

DC Power Up:......................................................................................................................................................22

Rectifier Test:.......................................................................................................................................................23

Battery Power Up.................................................................................................................................................23

LVD Test..............................................................................................................................................................23

Circuit Breaker/ Fuse Test: ..................................................................................................................................23

User Inputs ..........................................................................................................................................................23

Output Relay 1:....................................................................................................................................................24

Battery Temperature Compensation ...................................................................................................................24

3.3. FINAL INSPECTION: .........................................................................................................................................24

4 Technical Description ..........................................................................................................................................25

4.1. RECTIFIER MANAGEMENT................................................................................................................................25

AC Input Power....................................................................................................................................................25

DC Output Power.................................................................................................................................................25

Rectifier alarms reporting.....................................................................................................................................25

4.2. SYSTEM MANAGEMENT ...................................................................................................................................25

System Voltage Monitor and Control...................................................................................................................25

Magnum VS –48 Vdc User Manual Page iii

System Current Monitor.......................................................................................................................................26

System Status and Alarm Reporting ...................................................................................................................26

4.3. LOAD MANAGEMENT .......................................................................................................................................26

Circuit Breakers ...................................................................................................................................................26

GMT Fuses ..........................................................................................................................................................27

4.4. BATTERY MANAGEMENT..................................................................................................................................27

Battery Charging..................................................................................................................................................27

Battery Protection ................................................................................................................................................28

Battery Temperature Monitoring..........................................................................................................................28

Battery Temperature Compensation ...................................................................................................................28

Battery Low Voltage Disconnect..........................................................................................................................28

Counter Electro-Motive Force Module Connections............................................................................................28

4.5. CONTROLS AND INDICATORS ...........................................................................................................................29

Controller Module ................................................................................................................................................29

4.6. ALARM OUTPUTS (OUTPUT RELAYS)................................................................................................................29

4.7. EXTERNAL ALARM INPUTS (USER INPUT)..........................................................................................................29

4.8. NETWORK MANAGEMENT CARD - LOCAL & REMOTE MONITORING.....................................................................29

5 Operation .............................................................................................................................................................30

5.1. DESCRIPTION .................................................................................................................................................30

5.2. CONTROLLER MODULE JUMPERS.....................................................................................................................30

System Voltage J5...............................................................................................................................................30

Remote Lockout J8..............................................................................................................................................30

Firmware Programming Enable J9 ......................................................................................................................30

Vtrim Trip Select J13 ...........................................................................................................................................30

CONTROLLER MODULE ..............................................................................................................................................31

5.3. OPERATION USING THE RS-232 COMM PORT ..................................................................................................32

5.4. OPERATION USING THE 10/100 BASET ETHERNET PORT..................................................................................33

5.5. OPERATION USING NETWORK MANAGEMENT CARD WEB BROWSER INTERFACE ................................................33

5.6. LVD OPERATION ............................................................................................................................................41

5.7. PROGRAMMING OUTPUT RELAYS.....................................................................................................................41

6 Preventive Maintenance ......................................................................................................................................42

6.1. EQUIPMENT ....................................................................................................................................................42

6.2. INSPECTION ....................................................................................................................................................42

Environmental Inspection ....................................................................................................................................42

System Visual and Safety Inspection ..................................................................................................................42

Battery Visual and Safety Inspection...................................................................................................................43

6.3. TEST ..............................................................................................................................................................43

System Voltage Test............................................................................................................................................43

Rectifier Current Share Test................................................................................................................................43

System Current Test............................................................................................................................................43

Rectifier Alarm Test .............................................................................................................................................43

System Temperature Test ...................................................................................................................................43

Battery Current Test ............................................................................................................................................44

Battery Temperature Test....................................................................................................................................44

LVD Test..............................................................................................................................................................44

Battery Preventive Maintenance Procedure ........................................................................................................44

6.4. FINAL INSPECTION: .........................................................................................................................................45

7 Alarm Summary ...................................................................................................................................................46

8 Specifications.......................................................................................................................................................48

8.1. AC INPUT .......................................................................................................................................................48

TWF0500H54B Rectifier......................................................................................................................................48

Magnum VS 50 Power System............................................................................................................................48

Magnum VS 100 Power System..........................................................................................................................48

8.2. DC OUTPUT ...................................................................................................................................................49

TWF0500H54B Rectifier......................................................................................................................................49

Magnum VS 50 Power System............................................................................................................................49

Magnum VS 100 Power System..........................................................................................................................50

8.3. CONTROLS AND INDICATORS ...........................................................................................................................50

TWF0500H54B Rectifier......................................................................................................................................50

Magnum VS –48 Vdc User Manual Page iv

MAGNUM VS CONTROLLER ........................................................................................................................................50

8.4. MECHANICAL ..................................................................................................................................................51

TWF0500H54B Rectifier......................................................................................................................................51

Magnum VS 50 Power System............................................................................................................................51

Magnum VS 100 Power System..........................................................................................................................51

8.5. ENVIRONMENTAL ............................................................................................................................................51

8.6. COMPLIANCE ..................................................................................................................................................52

8.7. COMPLIANCE ..................................................................................................................................................52

8.8. COMPLIANCE ..................................................................................................................................................52

9 APC Worldwide Customer Support .....................................................................................................................53

10 Limited Product Warranty ................................................................................................................................54

TWO YEAR FACTORY WARRANTY ...............................................................................................................................54

10.1..........................................................................................................................................................................54

Table of Figures

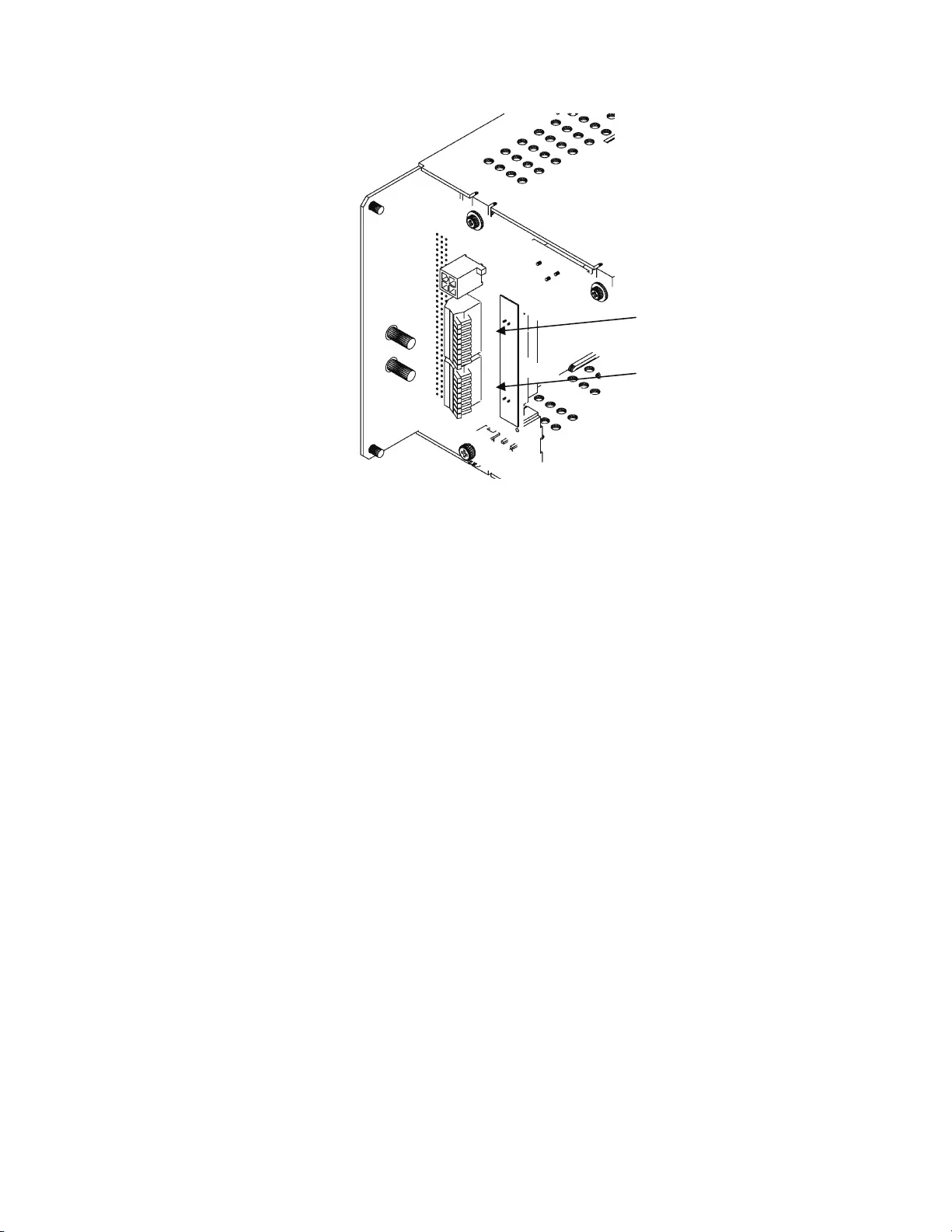

FIGURE 1.1-1 MAGNUM VS 50 –48 VDC POWER PLANT .................................................................................................... 6

FIGURE 1.1-2 MAGNUM VS BLOCK DIAGRAM.................................................................................................................... 8

FIGURE 2.3-1 MAGNUM VS 50 BACKPLANE....................................................................................................................... 10

FIGURE 2.3-2 AC INPUT WIRING........................................................................................................................................... 10

FIGURE 2.4-1 BATTERY CABLE CONNECTION LOCATIONS .......................................................................................... 13

FIGURE 2.4-2 BATTERY TEMPERATURE PROBE INSTALLATION ................................................................................. 13

FIGURE 2.5-1 CEMF CONNECTION LOCATIONS................................................................................................................ 14

FIGURE 2.7-1 GMT FUSE TEMPERATURE DE-RATING CHART....................................................................................... 15

FIGURE 2.8-1 CONNECTIONS TO CIRCUIT BREAKERS .................................................................................................... 16

FIGURE 2.8-2 TOP SHELF GMT FUSE CONNECTIONS....................................................................................................... 16

FIGURE 2.8-3 BOTTOM SHELF GMT FUSE CONNECTIONS.............................................................................................. 17

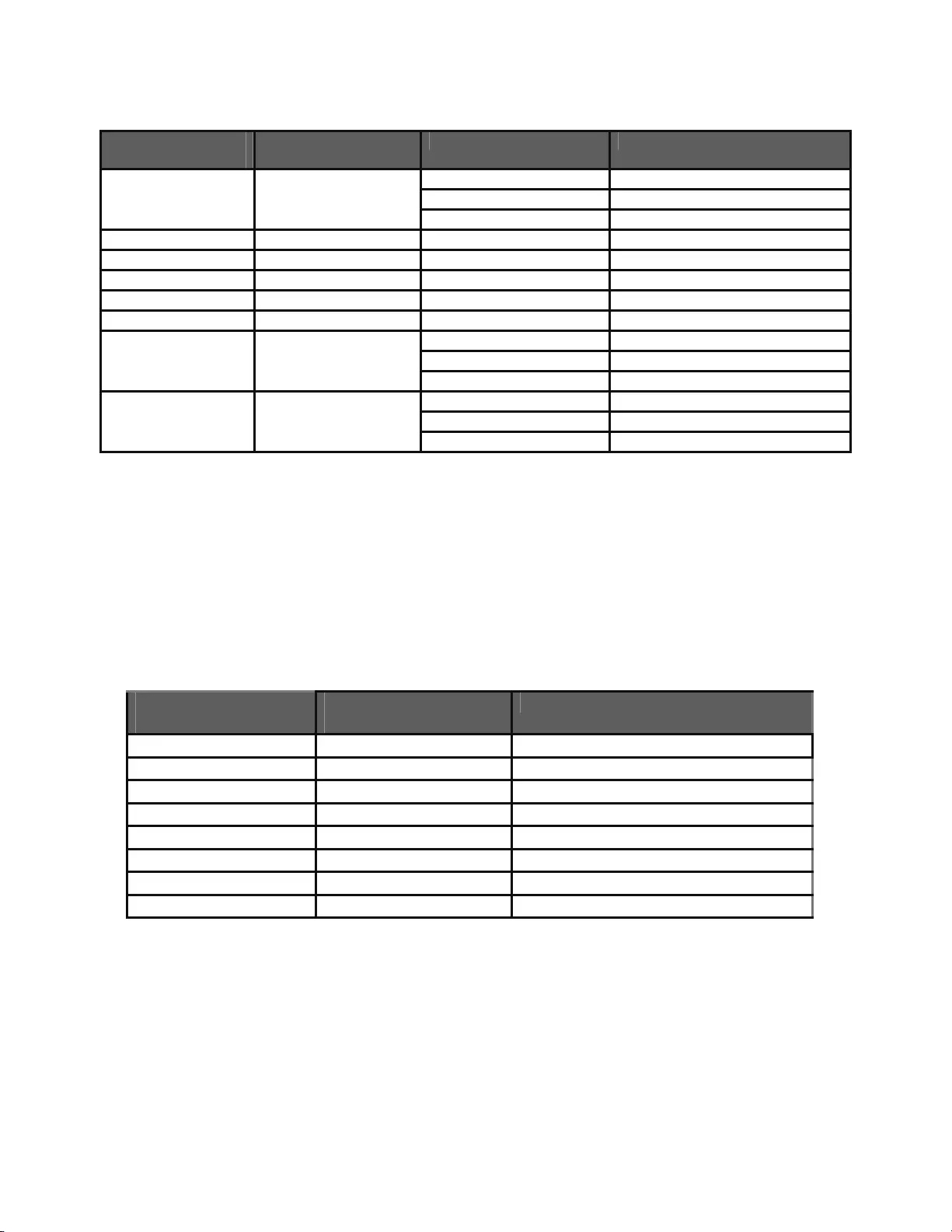

FIGURE 2.9-1 INTERFACE CONNECTIONS .......................................................................................................................... 18

FIGURE 2.9-2 OUTPUT RELAY CONNECTIONS .................................................................................................................. 19

FIGURE 2.9-3 EXTERNAL USER INPUT CONNECTIONS ................................................................................................... 19

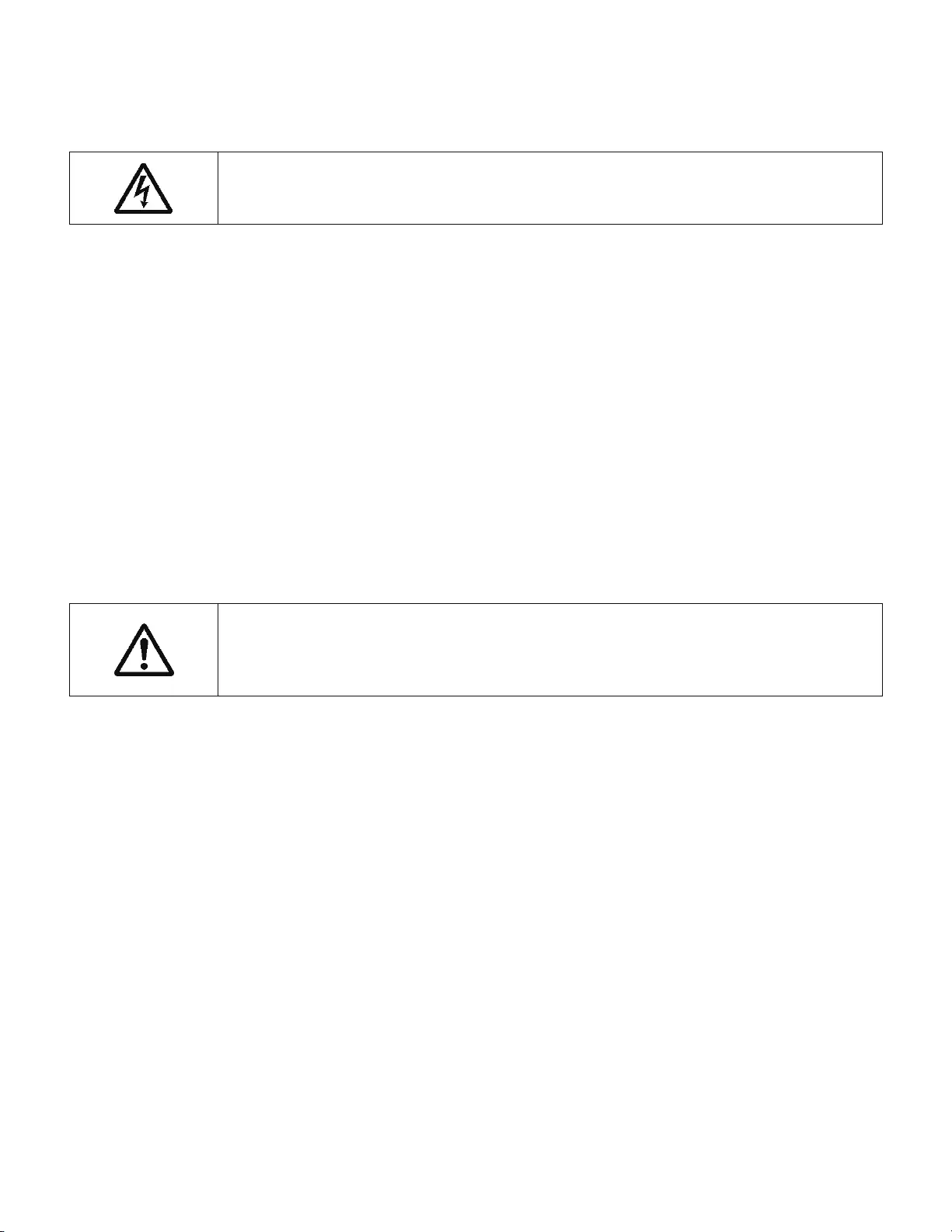

FIGURE 5.2-1 CONTROLLER CARD JUMPER LOCATIONS............................................................................................... 31

FIGURE 0-1 MAGNUM VS CONTROLLER ............................................................................................................................ 32

FIGURE 5.5-1 PARAMETER LOCATIONS, DESCRIPTIONS, AND SETTINGS ................................................................. 34

Entire contents copyright 2007 American Power Conversion. All rights reserved. Reproduction in whole or in part

without permission is prohibited.

APC and the APC logo are trademarks of American Power Conversion Corporation. All other trademarks, product

names, and corporate names are the property of their respective owners and are used for informational purposes

only.

Magnum VS –48 Vdc User Manual Page 6

1 Introduction

1.1. General Information

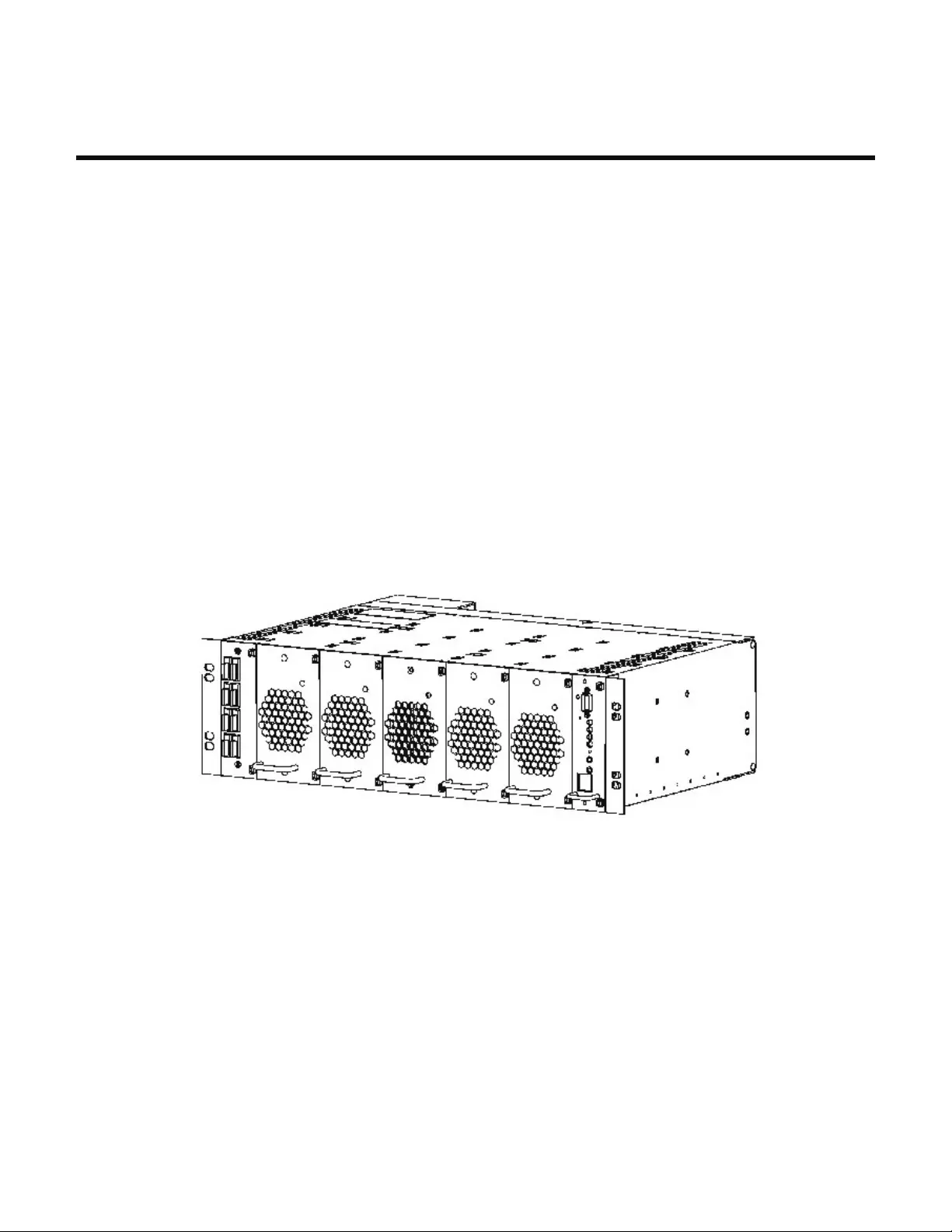

The APC Magnum VS is a modular -48 Vdc power plant. The Magnum VS has unique features that make it

easy to install, maintain, and upgrade. There are two Magnum VS models; Magnum VS 50 and 100. The

Magnum VS 50 is a single shelf system and can support up to 5, 10A rectifiers, for a rated current of 50A.

The Magnum VS 100 is a dual shelf system and can support up to 10, 10A rectifiers, for a rated current of

100A. The rectifier units are modular and “hot-swappable” making it easy to add or remove rectifiers as

dictated by capacity requirements, without having to change the input or output wiring.

There are two basic DC output distribution options, circuit breakers (30A or 60A) or GMT-style fuses. The

DC output distribution module also includes terminals to connect a battery string and a low voltage

disconnect (LVD) device to disconnect the batteries after a deep discharge.

The system controller module provides monitoring and control functions for each component of the

system, and stores alarm events for system diagnosis and maintenance. The system controller module

enables the user to change/update Magnum VS settings, as well as monitor the system via a local

computer directly connected to the Magnum VS system (using the serial cable provided by APC (please

note that a standard serial cable cannot be used; the APC-provided serial cable must be used to connect

directly to the Magnum VS system)), or a remote computer connected to the system over a network using a

10/100 Base-T Ethernet connection.

Figure 1.1-1 Magnum VS 50 –48 Vdc Power Plant

A fully equipped Magnum VS 50 power system is shown in Figure 1.1-1.

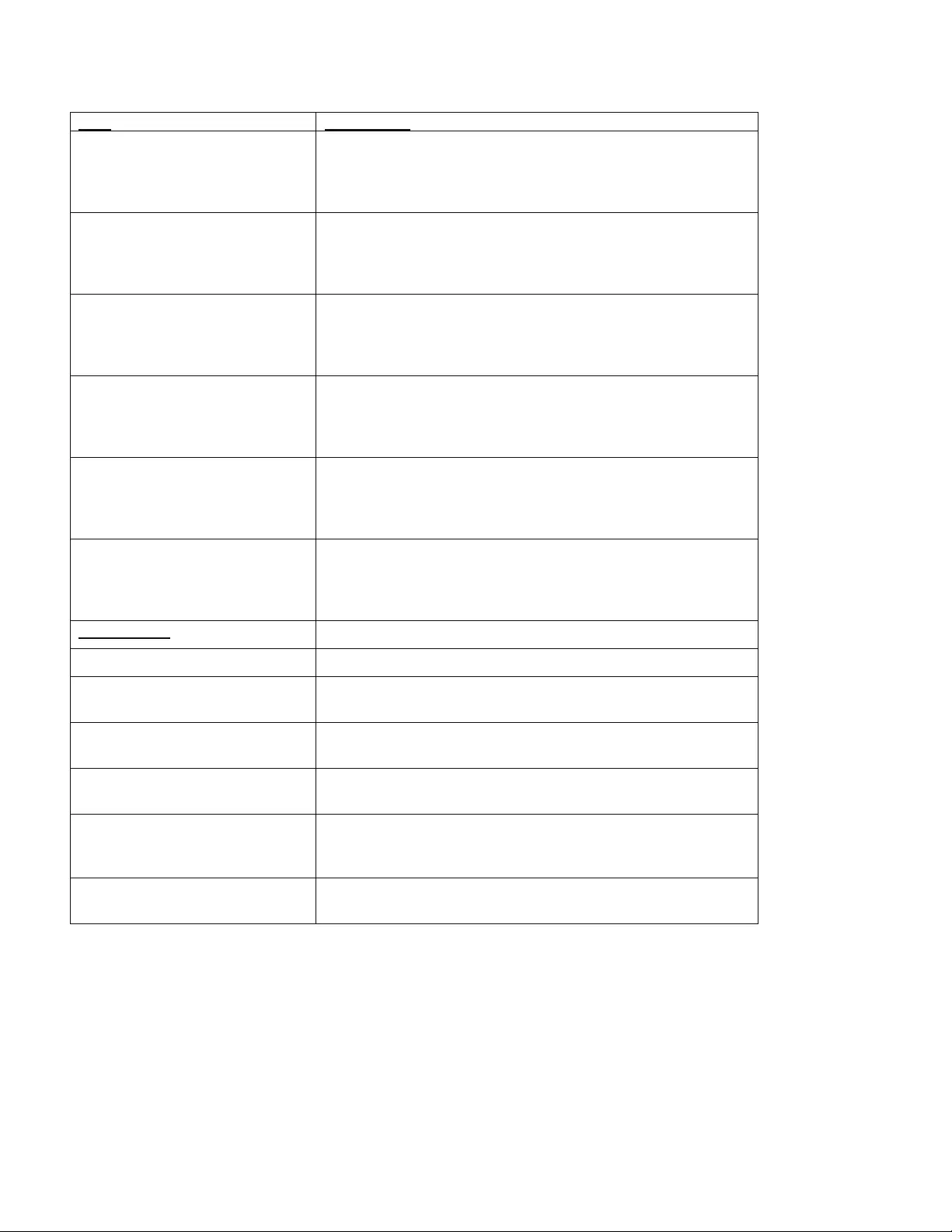

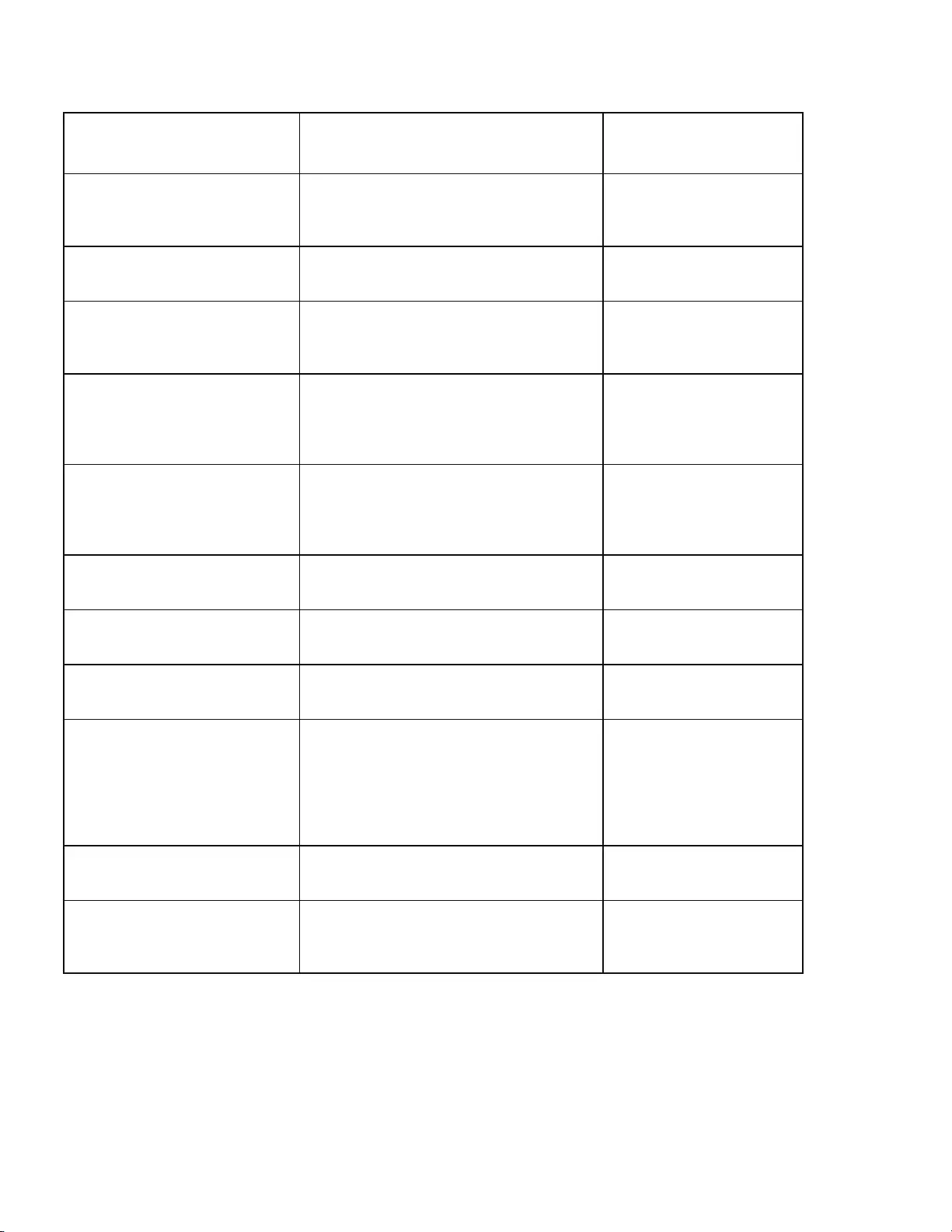

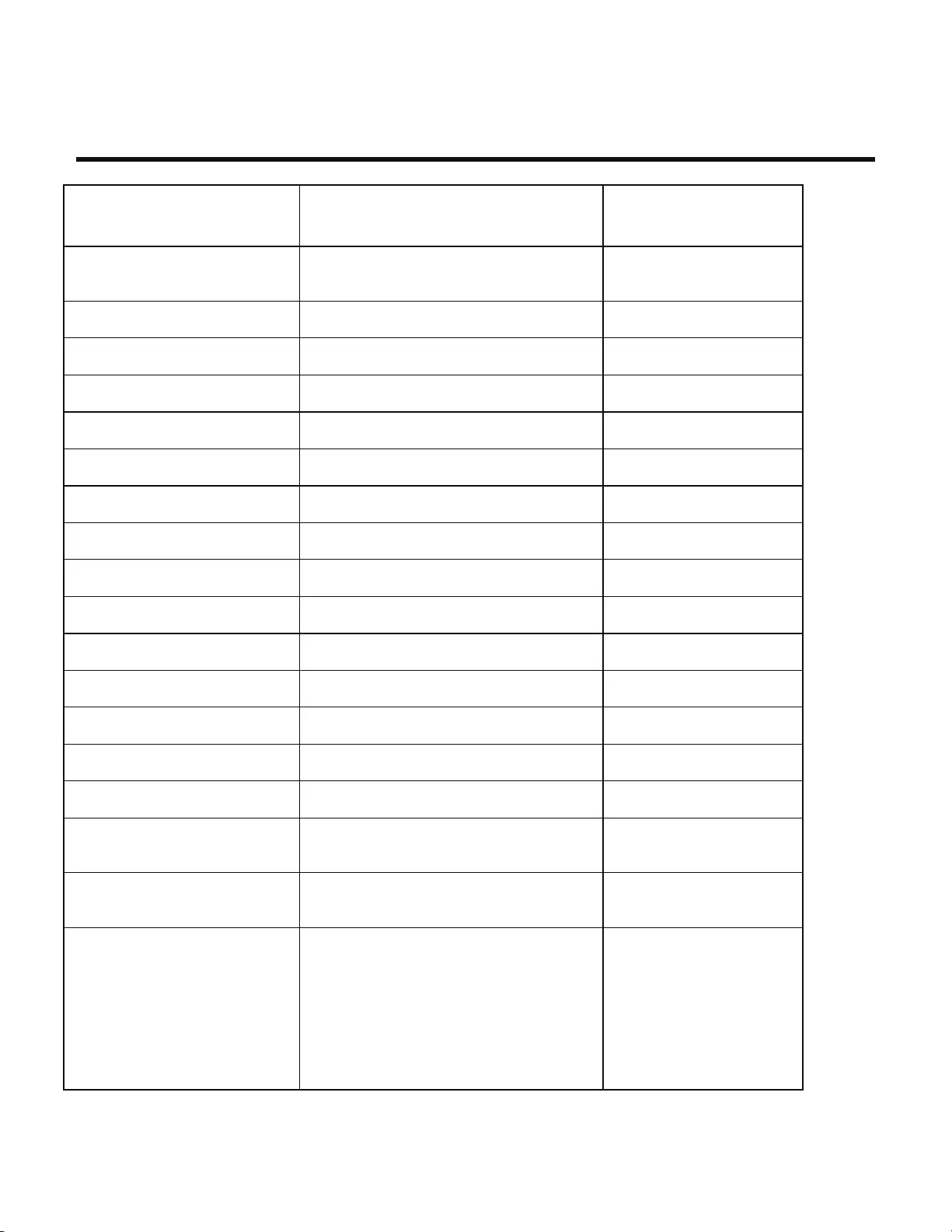

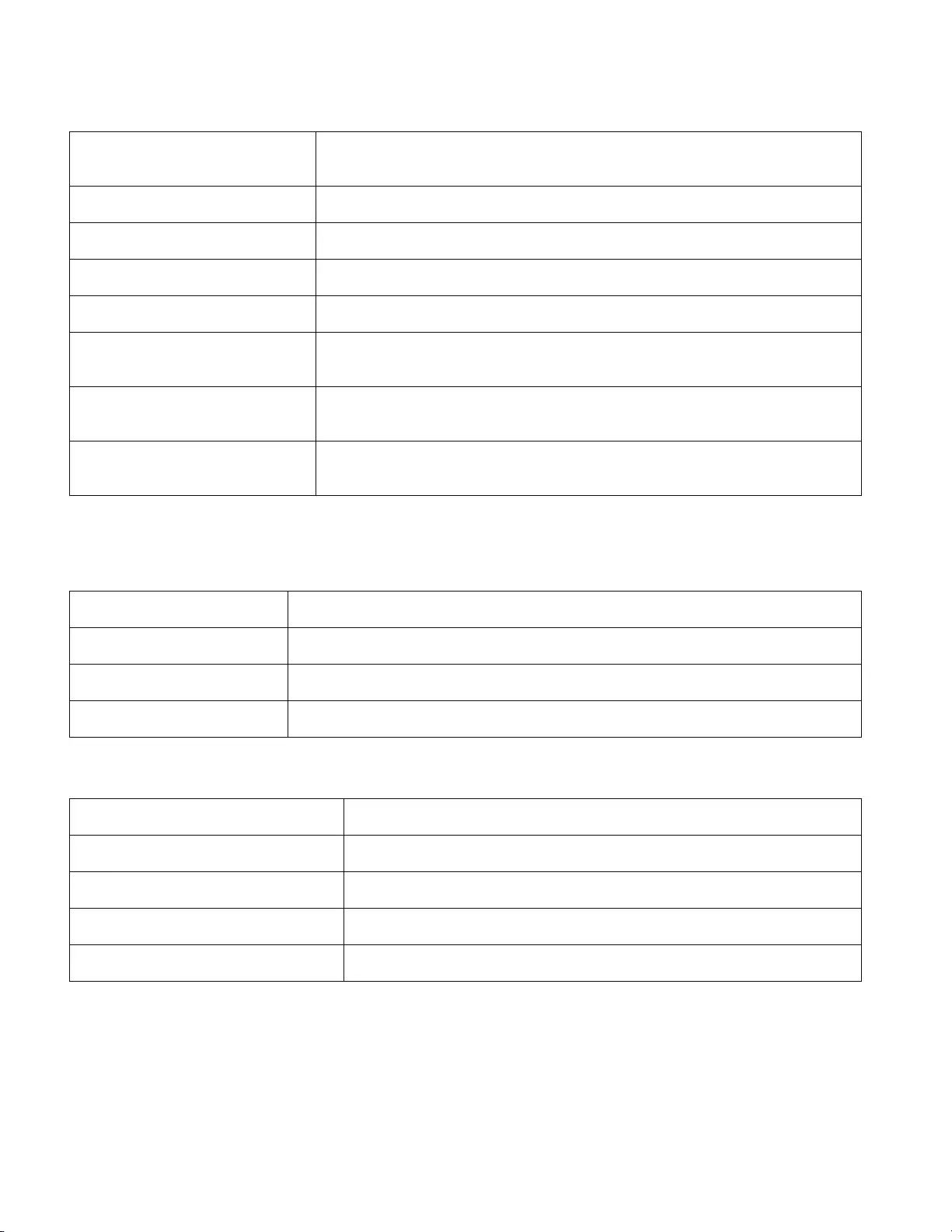

Magnum VS system and accessory SKUs are listed below:

Magnum VS –48 Vdc User Manual Page 7

SKU Description

DCM00K03SGMT Magnum VS 50, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and One (1) GMT Distribution Module (8 Fuse

Positions)

DCM00K03S2X30 Magnum VS 50, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and One (1) Circuit Breaker (CB) Distribution

Module (2–30 A Circuit Breakers)

DCM00K03S1X60 Magnum VS 50, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and One (1) CB Distribution Module (1–60A Circuit

Breaker)

DCM00K06SGMT Magnum VS 100, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and Two (2) GMT Distribution Modules (8 Fuse

Positions (Each))

DCM00K06S4X30 Magnum VS 100, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and Two (2) CB Distribution Modules

(2–30 A Circuit Breakers (Each))

DCM00K03S2X60 Magnum VS 100, Basic Controller and Integrated Network

Management Card (NMC), One (1) 1TWF0500H54B 10 A

Rectifier, and Two (2) CB Distribution Modules

(1–60 A Circuit Breaker (Each))

Accessories

1TWF0500H54B Magnum VS 10A Rectifier

DCMOPTCS1 AC Input Cable Kit; Includes Two (2) 12ft, 10 AWG, L6-30P

Power Cords

DCMOPT23RM Magnum VS 50/100 Mounting Bracket Kit; For 23”

Racks/Frames

DCMOPTBATE EMEA Battery Kit: 2U 19” Battery Disconnect Module with

Four (4) 100 A Disconnect Breakers and Battery Cable Kit

DCMOPTBATN North America Battery Kit: 19”-Frame Battery Tray, Circuit

Breaker Kit, Battery Termination Bus Assembly, and Battery

Cable Kit.

DCBT005 DC System Battery Module: -48V Battery String (Power

Battery CSL-12100) with Hardware Kit

Magnum VS –48 Vdc User Manual Page 8

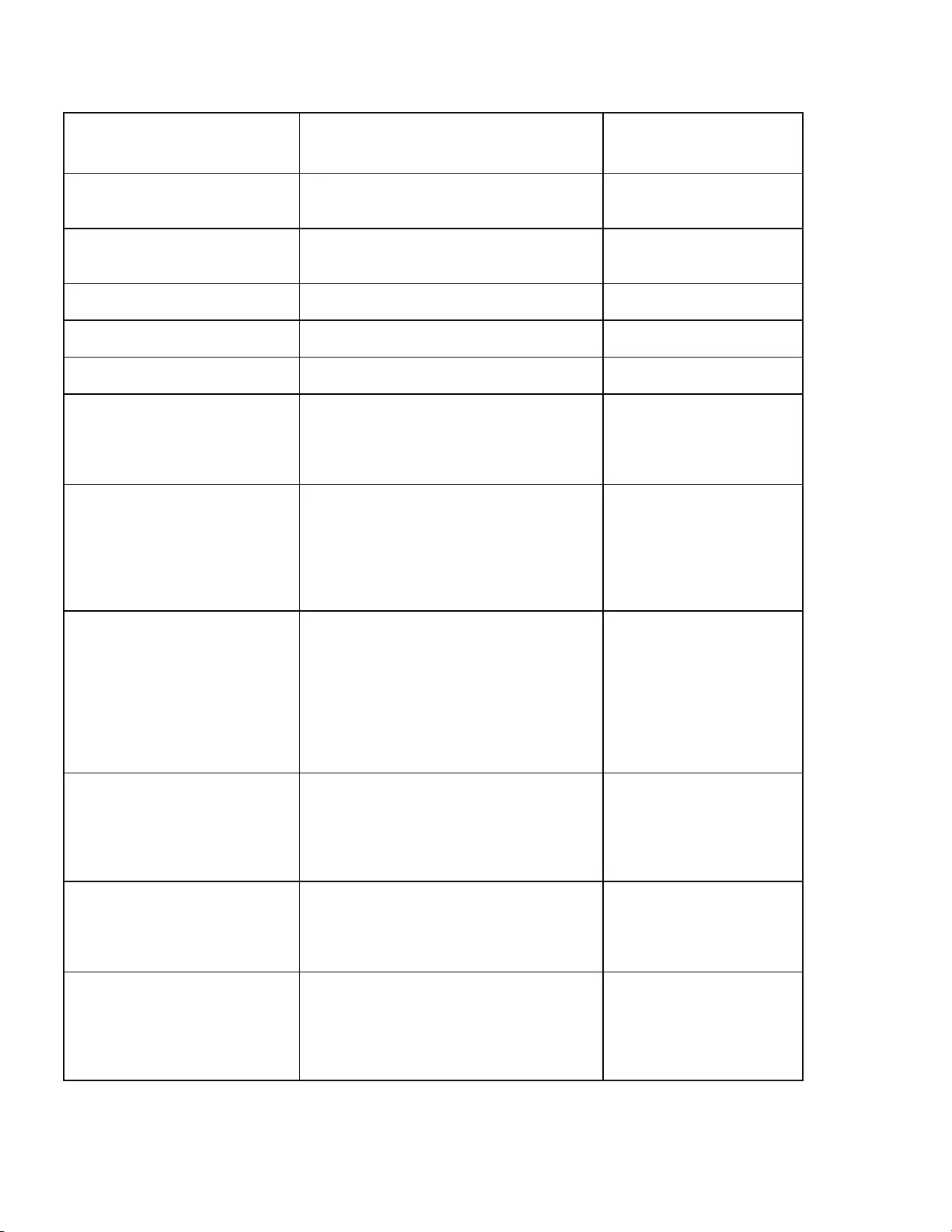

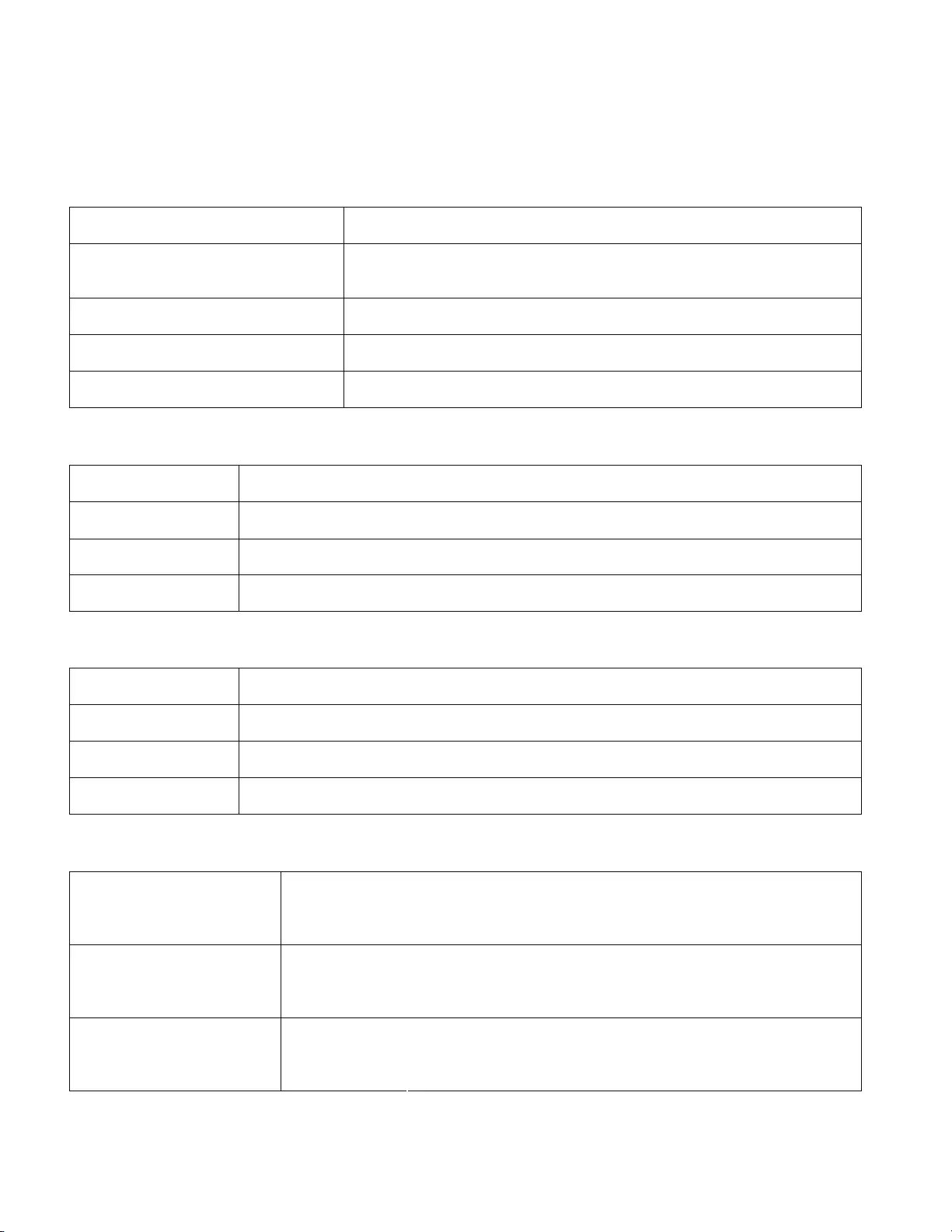

AC

DC

Control

AC

DC

Control

AC

DC

Control

AC

DC

Control

AC

DC

Control

GND

L1 L2/N

GND

L1 L2/N

GND

L1 L2/N

GND

TRM15

1

2

3

4

5

6

7

8

ALM RTN

ALM RTN

ALM RTN

ALM RTN

1

2

3

4

5

6

7

8

9

1

2

3

4

MAJ NC

MAJ NO

MIN NC

MIN NO

USER NC

USER C

MIN C

MAJ C

USER NO

TMP

-BAT

+12 PWR

-PWR

+PWR

CONTROL BUS

Power Distribution Backplane

RESET

CONTROL BUS

CONTROL BUS

Energized

TX2 Relay

BATTERY

LVD

AC

DC

Control

AC

DC

Control

AC

DC

Control

AC

DC

Control

AC

DC

Control

GND

L1 L2/N

GND

L1 L2/N

GND

L1 L2/N

GND

TRM15

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

1

2

3

4

-PWR

+PWR

CONTROL BUS

Power Distribution Backplane

CONTROL BUS

Energized

TX2 Relay

BATTERY

LVD

Visual Alarm

Stud outputs:

Rear

Blank Panel

COVERED

COVERED

COVERED

MINOR

ALM IN_1

ALM IN_2

ALM IN_3

ALM IN_4

COMM

PORT

DB-9

PORT

2 Visual Alarms

(1 per group of 4)

DC OK

MAJOR

OUT RLY

USER

ALARM

INPUTS

ALARM

RELAY

OUTPUTS

BATTERY

TEMPERATURE

PROBE

Signals Cable

TOP SHELF

BOTTOM SHELF

8 outputs: Rear

GMT Load Distribution Module

( 0P1849 )

BATTERY

SHUNT

BATTERY

SHUNT

2 CB Load Distribution Module ( 0P1852 )

Microprocessor

Control Board

( 0P1838 )

WEB

SNMP Card

( AP9617 )

( 0P1839 )

( 0P1839 )

BATTERY (–)

BATTERY (+)

BATTERY (–)

BATTERY (+)

Visual Alarm

100 Amp System Only

Bus Bars

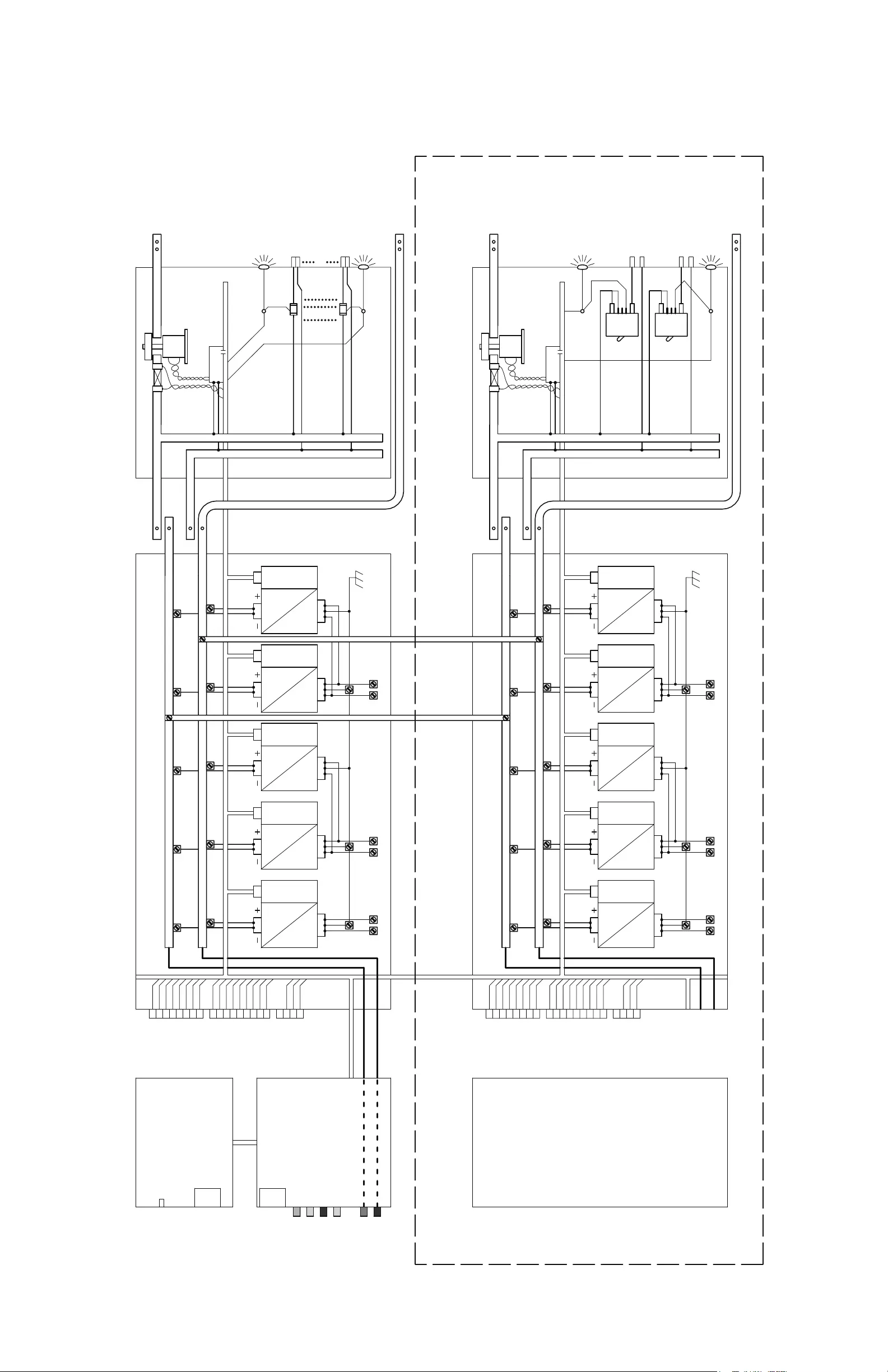

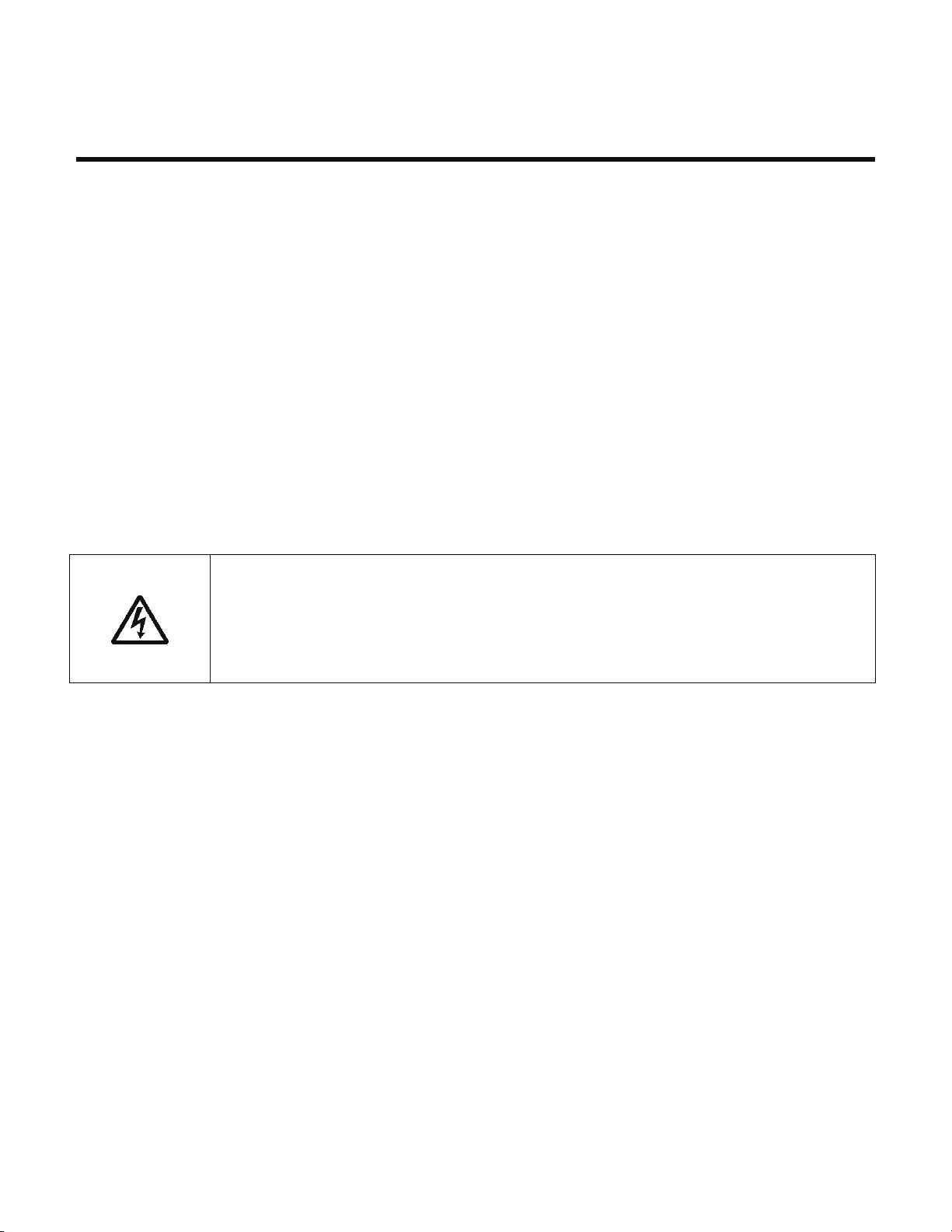

Figure 1.1-2 Magnum VS BLOCK DIAGRAM

Magnum VS –48 Vdc User Manual Page 9

2 Installation

2.1. Unpacking Equipment

Remove equipment from packing material and inspect for shipping damage or missing items. It is important to

report damage or material shortages to the shipping carrier while a representative is on site.

If concealed damage or material shortages are found at a later time, contact the shipper to make arrangements for

inspection and claim filing. Refer to Section Error! Reference source not found. in the event it is necessary to

return equipment to APC.

CAUTION: Appropriate lifting techniques and safety equipment should be used to remove

equipment from packing.

RECYCLE: The shipping materials can be recycled. Save them for later use or dispose

properly.

2.2. Mechanical Installation

Room / Location

NOTE: The APC dc power plant is to be installed in a room, vault, or similar enclosure accessible only to qualified

persons in accordance with the national and local electrical codes.

Prior to installation, drawings, floor loading requirements, external alarm points, ac service entrance, and grounding

schemes should all be checked and confirmed. If batteries are to be mounted in a room separate from the power

plant, careful attention should be paid to battery cable voltage drop effects. Environmental operating temperatures

and ventilation/cooling considerations should also be noted, not just for the power system but also for all other

equipment that may reside in the power room area.

Mounting

The Magnum VS 50 and 100 include brackets to mount the system in a standard EIA 19” rack. Install the

power system using hardware designed for the rack. To install a Magnum VS 50 or 100 in a 23-inch rack

use the 23” Mounting Bracket Kit (DCMOPT23RM).

Ventilation

The rectifier modules for this system have fans that provide front-to-rear airflow for internal cooling. The power

system housing should be mounted such that there is free airflow to the front and back of the unit. [Refer to

Section 8.5 for environmental characteristics.] Free airflow should be ensured so that the power system can

provide full power without de-rating.

Magnum VS –48 Vdc User Manual Page 10

2.3. AC Power Connections

WARNING: Ensure that all of the external dc and ac circuit breakers are in the OFF position

prior to connecting service to the power plant. Confirm that all voltages have been removed

including any battery sources before proceeding.

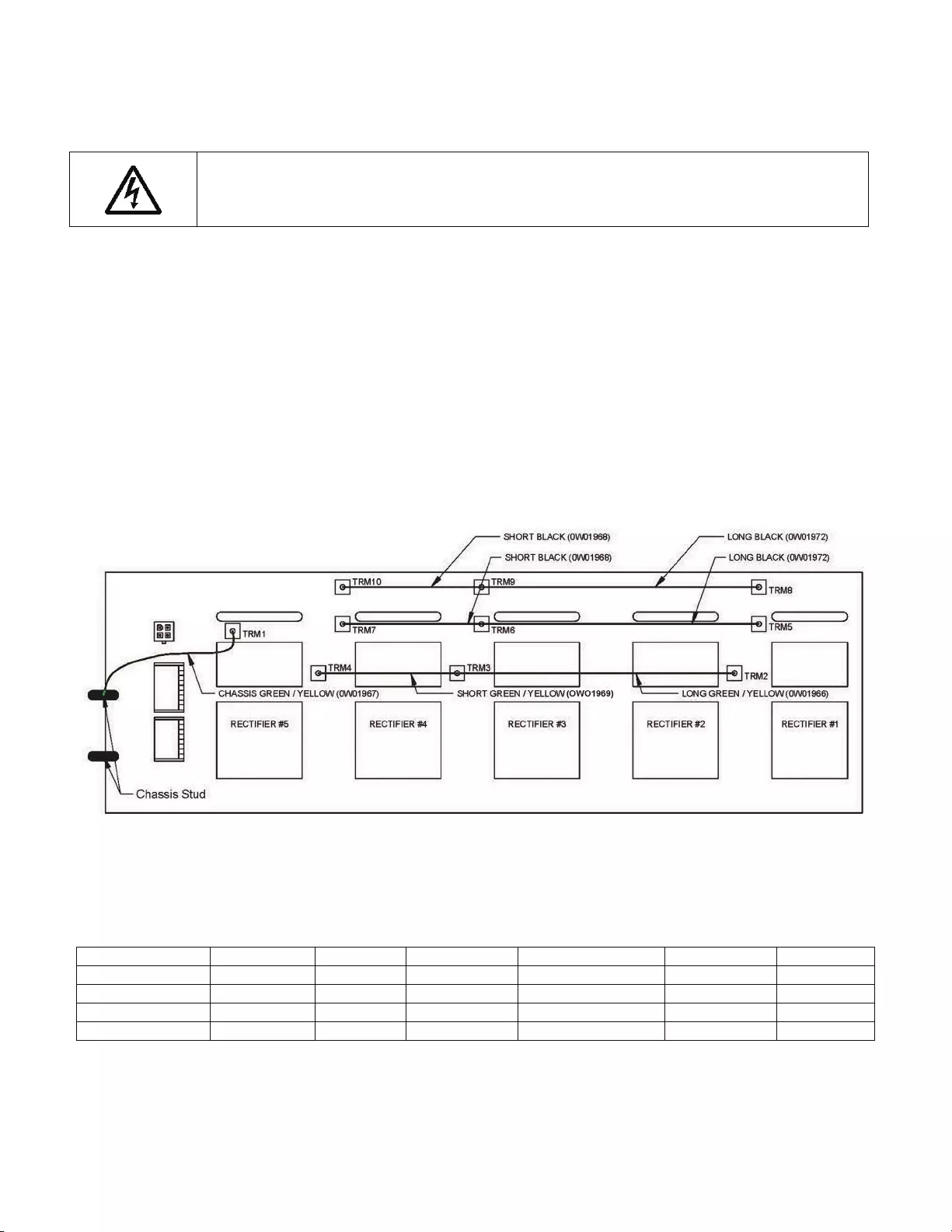

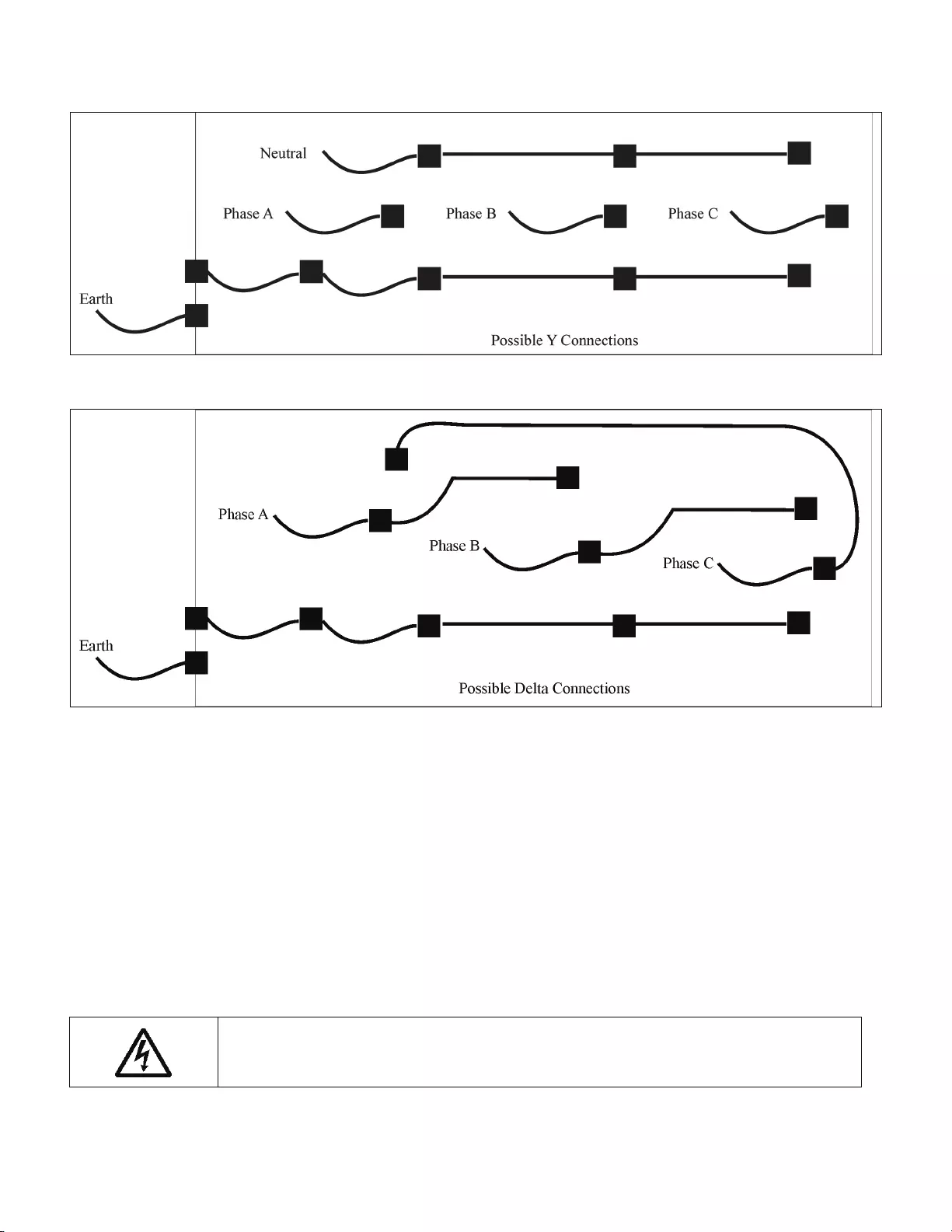

AC Connections

The Magnum VS DC power system, specifically each rectifier, requires a single phase input AC supply

(Range: 85–264 VAC, 47–63 Hz) to operate. Each Magnum VS shelf has three (3) sets of input terminals

(TRM 2, 5, 8; TRM 3, 6, 9; and TRM 4, 7, 10). As a result, each Magnum VS shelf can be wired such that

three (3) different AC sources (e.g., three phase, delta or star, connections) provide power to the rectifiers

(see Figure 3.3-2), or, a single AC source is used to provide power to the rectifiers, and jumper cables are

used to interconnect the different input terminals (as appropriate, and provided the input wiring is not

overloaded; see Figure 3.3-1).

The Magnum VS 50 SKUs are shipped configured (including the appropriate jumper cables) for operation

from a single AC source.

The Magnum VS 100 SKUs are shipped configured (including the appropriate jumper cables) for operation

from two AC sources (one for each shelf).

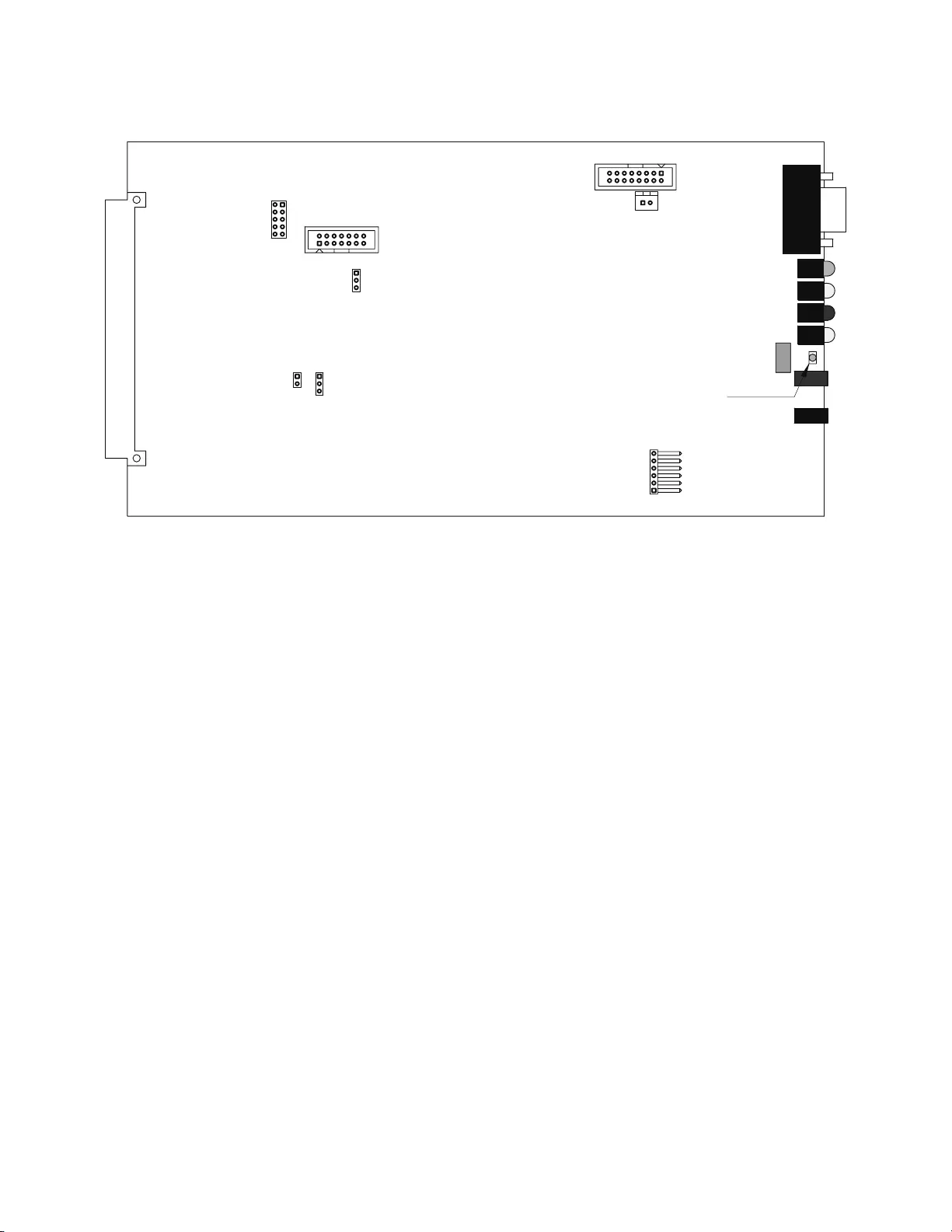

Figure 2.3-1 Magnum VS 50 Backplane

If a single AC source is used it is typically connected to TRM 10 (Line), 7 (Neutral) and 4 (Ground).

Rectifier Terminal # Function Terminal # Function Terminal # Function

Rectifier 1 TRM2 Ground TRM5 Line or Neutral TRM8 Line

Rectifier 2 & 3 TRM3 Ground TRM6 Line or Neutral TRM9 Line

Rectifier 4 & 5 TRM4 Ground TRM7 Line or Neutral TRM10 Line

Chassis TRM1 Ground

Figure 2.3-2 AC Input Wiring

Magnum VS –48 Vdc User Manual Page 11

Each phase should be wired for a minimum of 15 A.

The rear cover of each Magnum VS shelf in the power system has two 1.125-inch (2.858 cm) diameter holes

for electrical conduit. Conduit can be run to each Magnum VS shelf, or, alternatively, strain relief is

provided for the direct installation of AC power cables. Please note that the ambient temperature and the

number of wires in a conduit must be considered in accordance with national and local wiring code

requirements (e.g., NEC).

AC Power Cord Sets

The AC power cord sets are not included with the Magnum VS DC System, and must be purchased

separately, or provided by the Licensed Electrician installing the system.

APC offers a standard AC input cable kit that includes two (2), 12 foot, 10 AWG, L6-30P power cords (SKU:

DCMOPTCS1).

WARNING: Hazardous ac voltage levels are present inside the power system. Keep the

rear cover in place when the system is operational or energized.

Magnum VS –48 Vdc User Manual Page 12

2.4. Battery Connections

WARNING: Hazardous energy levels are present on bare conductors in the DC distribution

connection area of the plant. Accidental shorting of distribution conductors can cause

arcing and high currents that can cause serious burns or other physical harm. It is

recommended to:

Remove any jewelry, rings, or watches while working on this equipment.

• Use insulated wrenches, screwdrivers, cutters, pliers and other tools.

WARNING: Rectifier output DC circuits will be damaged if the batteries are installed

incorrectly. Ensure proper battery polarity and that the battery is isolated from the rest

of the system.

Planning the Battery installation

The battery cable(s) should be sized to limit the voltage drop from the dc power plant to the battery during charging

per system design requirements. The cable(s) must also carry the full load current during battery operation. If

assistance is required to determine the necessary cables for the application, contact your sales representative or

APC (Refer to Section Error! Reference source not found. for APC Customer Support information). A fuse or

circuit breaker (various options are available from APC) is recommended in the negative line to protect the cables

from the battery to the DC power plant. If a circuit breaker is used, the power plant can monitor auxiliary contacts

from this breaker.

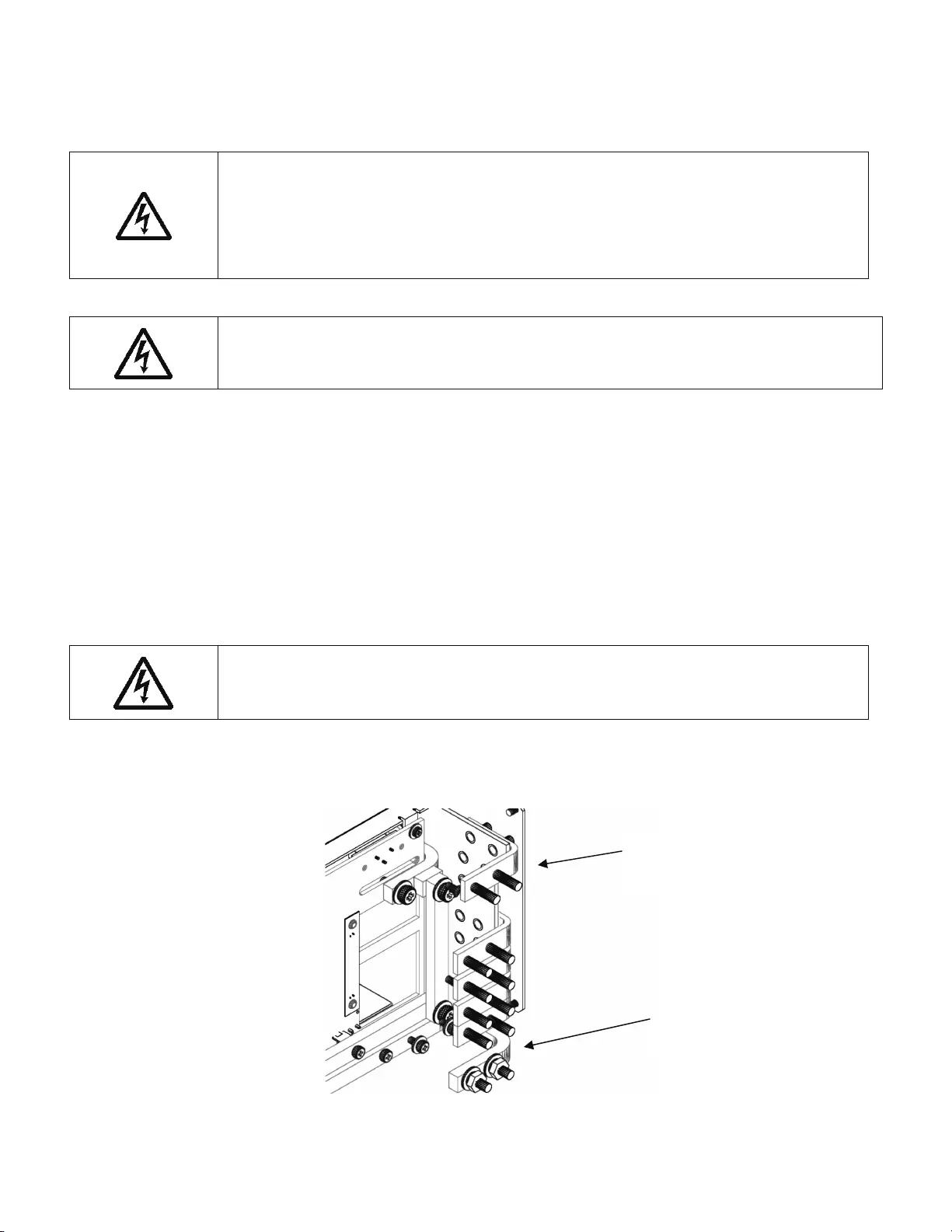

Connecting the Cables

WARNING: Make certain that the battery polarity is correct when making connections

to the DC power plant. Incorrect connections can cause severe equipment damage.

The battery cable connections are located at the rear of the unit as shown in Figure 2.4-1. The battery positive and

battery negative buses each provide a pair of #10-32 studs on 5/8” centers for connecting two-hole battery cable

lugs. A ring size of 6 mm may also be used. Connect the battery cables as applicable using #10-32 nuts. Cover

connections with heat shrink after assembly.

Battery Negative

Connection

Battery Return

Connection

Magnum VS –48 Vdc User Manual Page 13

Figure 2.4-1 Battery Cable Connection Locations

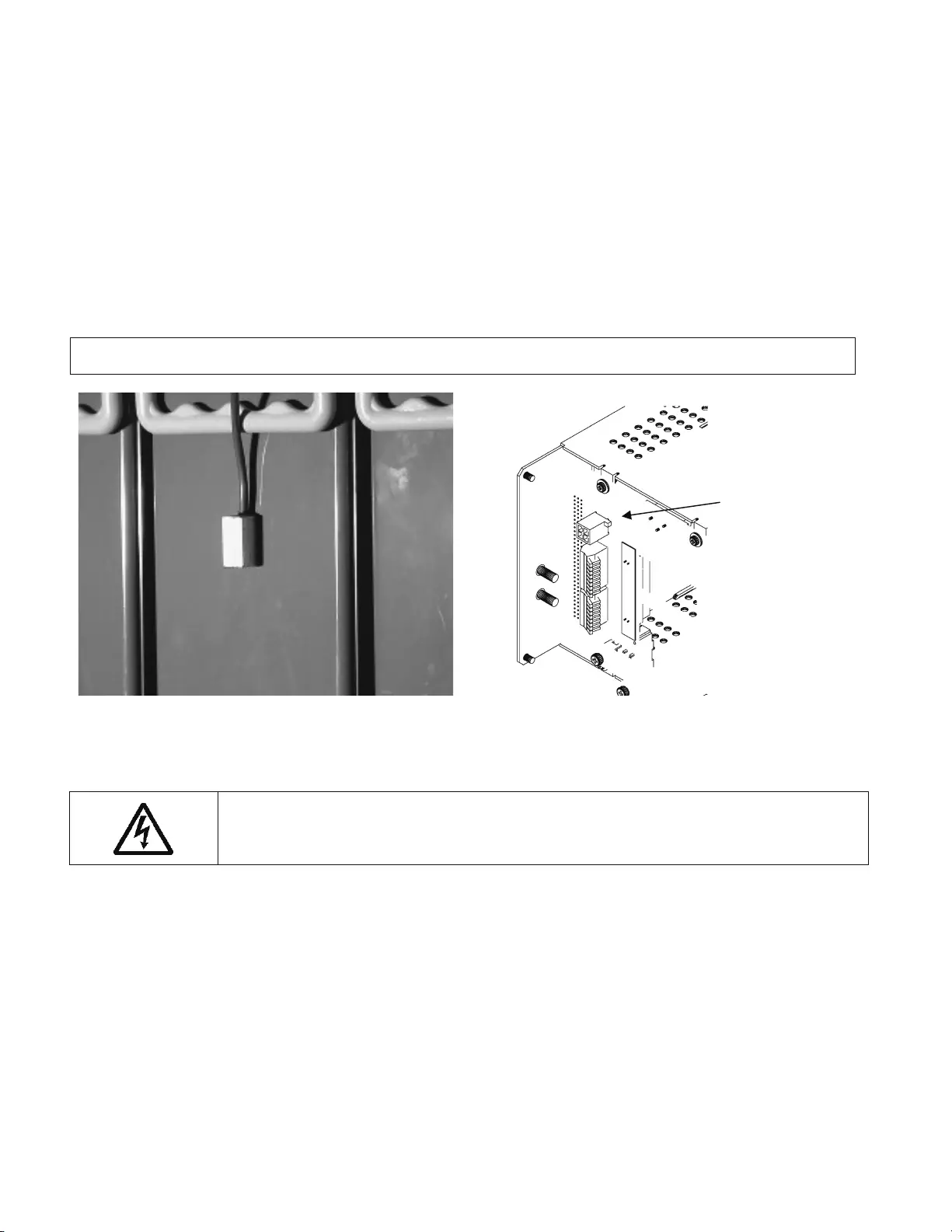

Battery Temperature Probe Installation

The temperature probe is used to monitor the battery string temperature. To get the most representative

temperature measurement, the probe should be placed in contact with a battery cell that is centrally located. The

probe should be placed directly in contact with the cell (not the frame surrounding the cell). Generally, the cell

cover can be used; be careful not to allow the probe body to touch the terminals. Plug the connector end of the

temperature probe into J410 of the backplane card. Route the cable as required positioning the probe on the

selected battery cell. Remove the adhesive protection strip from the probe body and press the adhesive side of the

probe on the battery cell cover. Refer to Figure 2.4-2 for details.

Note: Program Hardware Battery Temperature Alarm to “Ignore” if no battery temperature probe is

connected to J410.

Figure 2.4-2 Battery Temperature Probe Installation

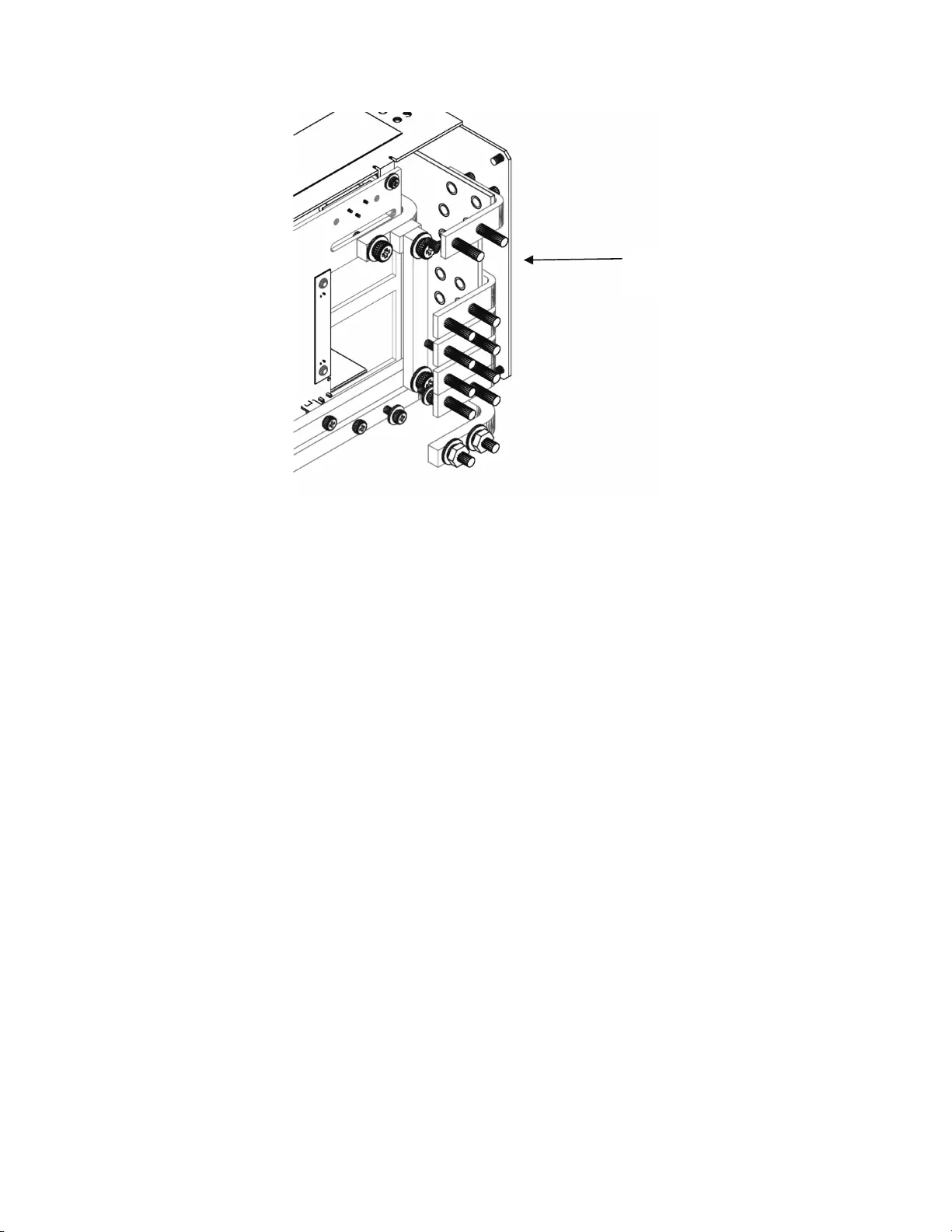

2.5. Counter Electro-Motive Force (CEMF) Cell Connections

WARNING: Hazardous energy levels are present on the CEMF connection area of the

plant. Accidental shorting of conductors can cause arcing and high currents that can cause

serious burns or other physical harm.

In some applications, a CEMF cell is used to lower the dc voltage delivered to the loads. The CEMF cell is

mounted externally to the Magnum VS. The CEMF connections are located at the rear of the unit as shown in

Figure 2.5-1. Two bus-plates, installed at the factory, bypass the CEMF connection. If a CEMF cell will be used,

remove the bus plate connecting the two CEMF connection points and install two connection buses before installing

the CEMF. The CEMF connection buses each provide a pair of #10-32 studs on 5/8” centers for connecting two-

hole CEMF cable lugs. A ring size of 6 mm may also be used. Connect the CEMF cables as applicable using #10-

32 nuts.

Battery

Temperature

Probe Connector

J410 (Rear Cover

Removed)

Magnum VS –48 Vdc User Manual Page 14

Figure 2.5-1 CEMF Connection Locations

2.6. DC System Grounding

The positive bus for the power plant should be connected to the Central Office Ground. The Battery Return

provides a pair of #10-32 studs on 5/8-inch centers for connection of a two-hole lugged cable to the Central Office

Ground. A ring size of 6 mm may also be used. Cover this connection with heat shrink tubing after assembly.

CEMF Connections

Magnum VS –48 Vdc User Manual Page 15

2.7. Load Protection Installation

Circuit Breaker Installation

Standard circuit breaker output distribution modules are available with two 30-A breakers or one 60-A breaker.

Output distribution modules are installed at the factory and are typically not field replaceable units. Contact APC if

the output configuration is not suitable for your needs. Other breaker sizes are not readily available.

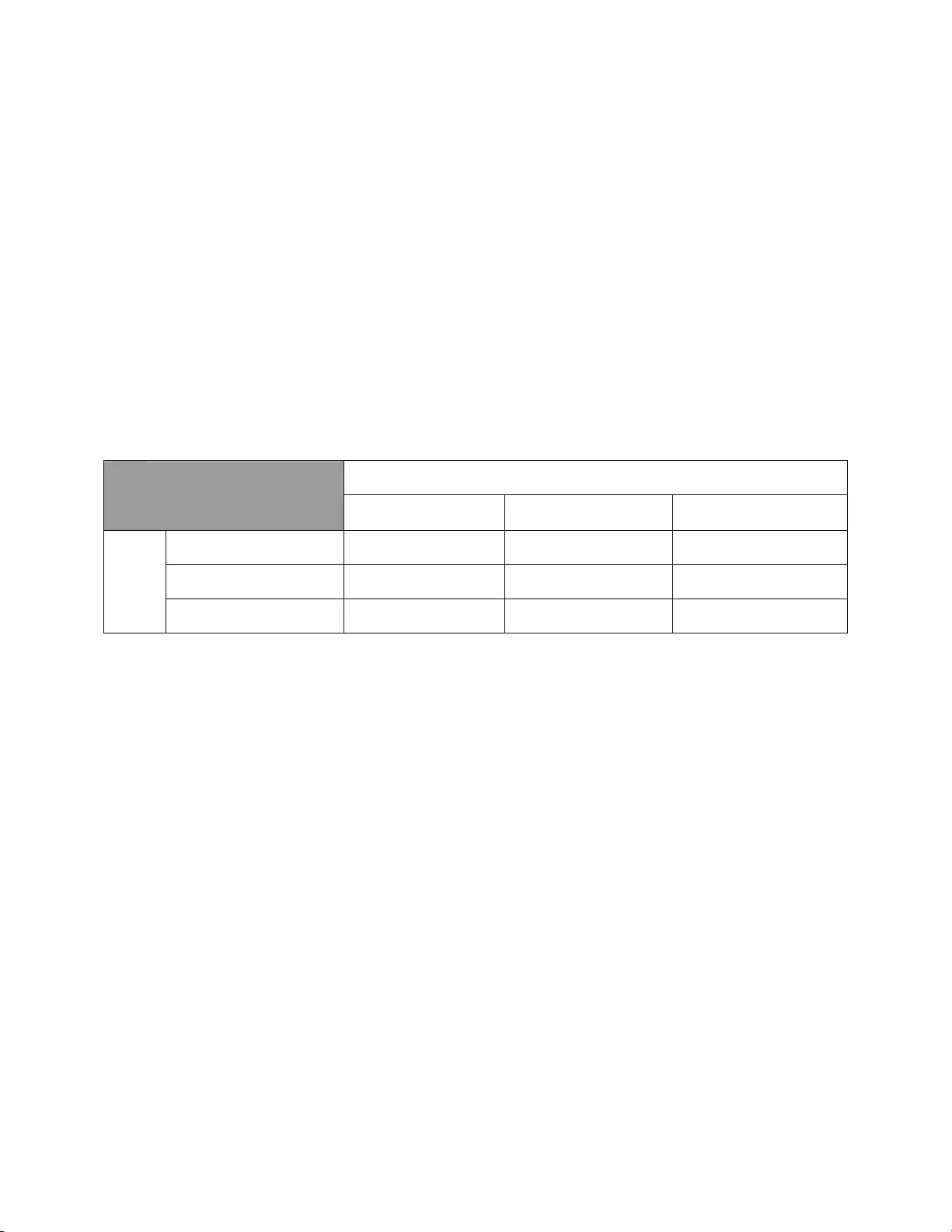

GMT Fuse Installation

The standard GMT output distribution module includes eight (8) fuse positions and is installed on the left side of the

Magnum VS shelf. The GMT fuse holders are located on the front panel of the unit. Insert the fuses into the

holder; observing the tripped indicator is correctly oriented. Use the chart shown in Figure 2.7-1 to help determine

what size fuses will carry the desired current. When using several of the larger GMT fuses in one shelf, better heat

dissipation will be achieved if the fuses are spaced out evenly within the output panel. The following GMT-type

fuses are provided by APC with the DCM00K03SGMT or DCM00K06SGMT Magnum VS systems: 1A, 3A, 5A,

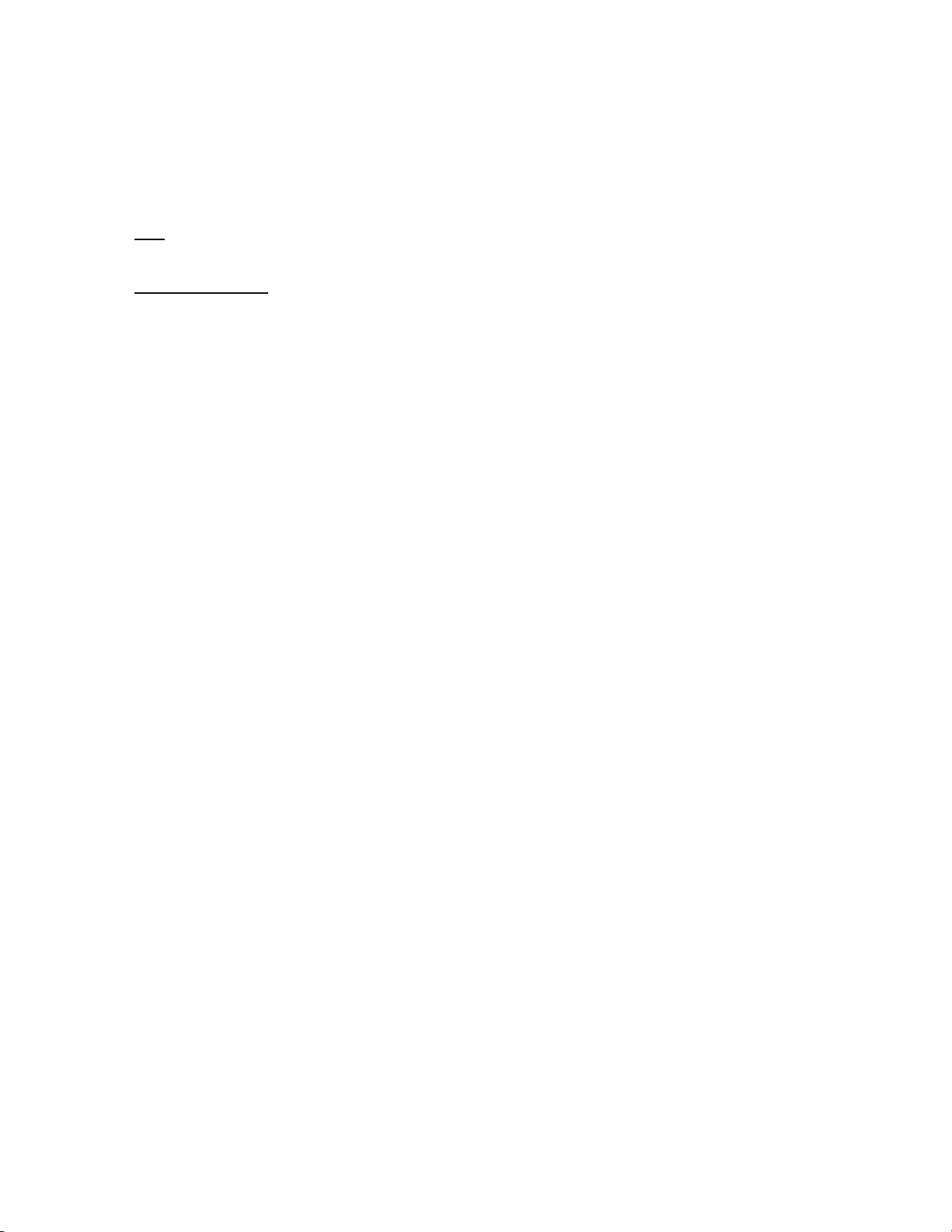

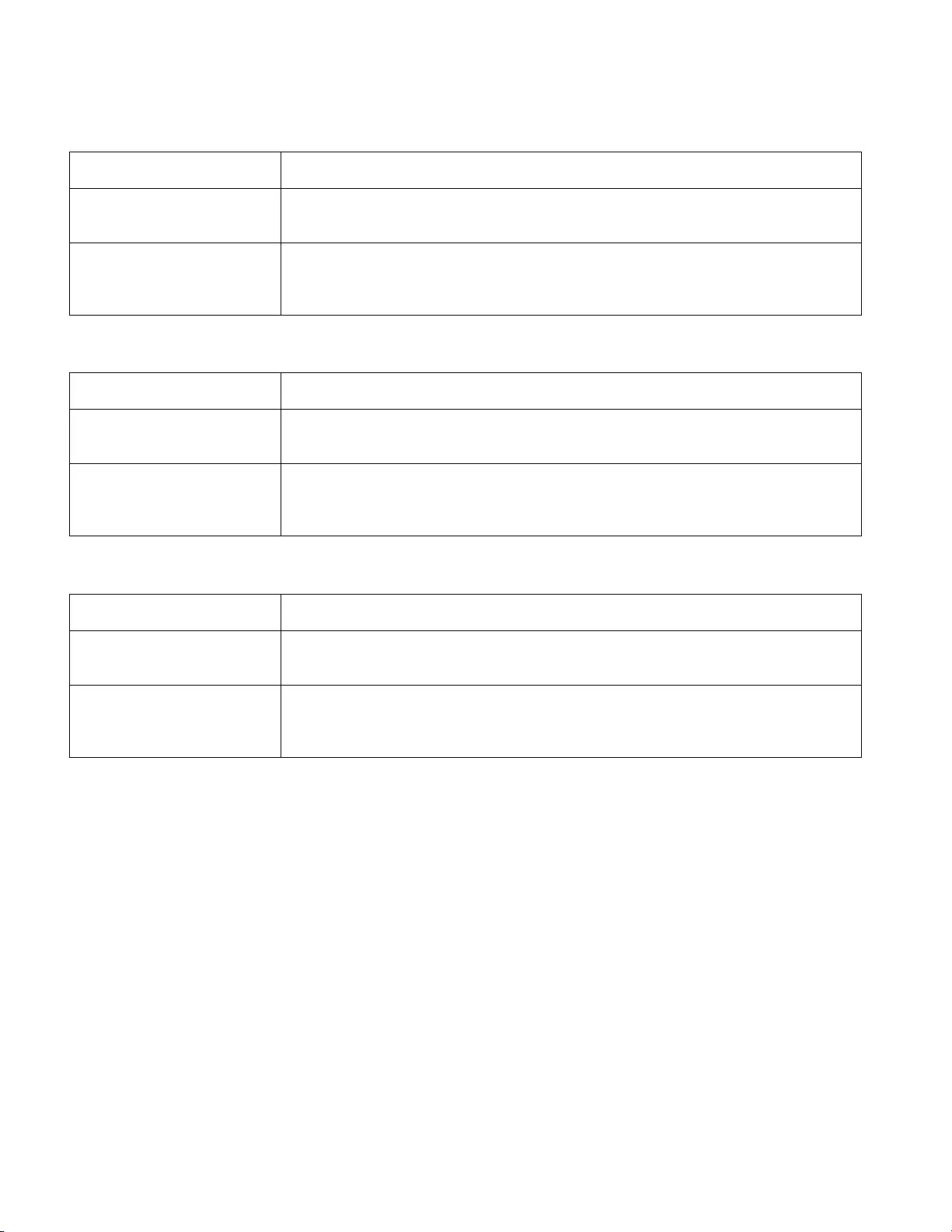

7.5A, and 10A.

AMBIENT TEMPERATURE

20° C 50° C 60° C

7.5 A 5 A 4.5 A 4 A

10 A 7 A 6 A 5 A

FUSE

SIZE

15 A 10 A 9 A 8 A

Figure 2.7-1 GMT Fuse Temperature De-rating Chart

2.8. Load Connections

Cable Size Considerations

The DC load cable(s) should be sized to limit the voltage drop from the dc power plant to the loads per system

design requirements. The cable(s) must also carry the full load current during battery operation. During battery

operation the voltage will be lower and for constant power loads, the current will typically be higher. If assistance is

required to determine the necessary cables for the application, contact your sales representative or APC.

Magnum VS –48 Vdc User Manual Page 16

Circuit Breaker Protected Load Connections (30 or 60 A)

The circuit breaker lug landing connection provides a pair of #10-32 studs on 5/8” centers for mounting two-hole

lugs. A ring size of 6 mm may also be used. A right angle bus bar with two studs is provided to land the lugs.

Load Connections should be made as shown in. Cover connections with heat shrink after assembly.

Figure 2.8-1 Connections to Circuit Breakers

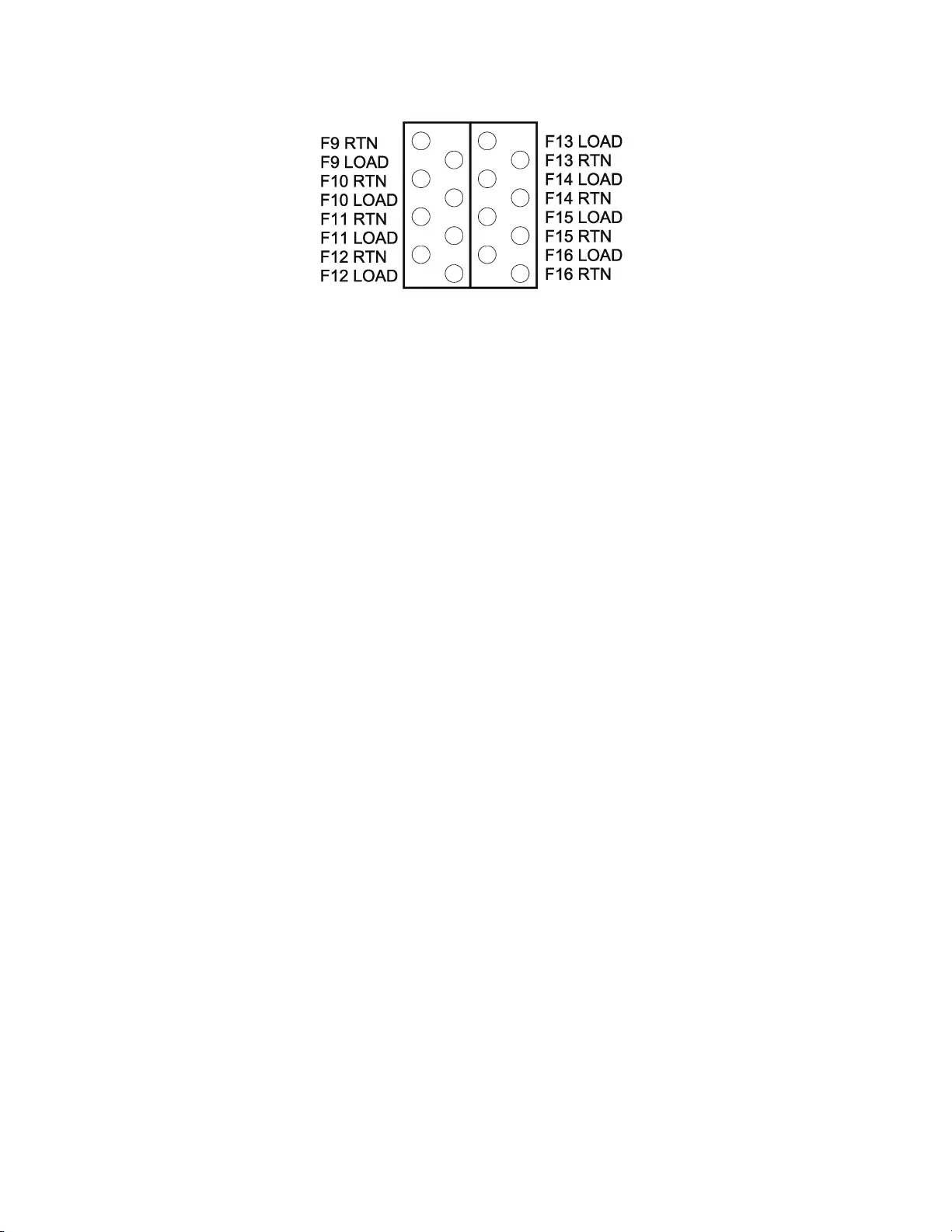

GMT Fuse-protected Load Connections

Connections for 1A to 14A loads require a ring terminal with a 0.170 in (4.3 mm) clearance hole and are located at

the rear of the unit. Load connections should be made as shown in Figure 2.8-2 and Figure 2.8-3.

Figure 2.8-2 Top Shelf GMT Fuse Connections

Load Returns

-54 Volt Load Connections

Magnum VS –48 Vdc User Manual Page 17

Figure 2.8-3 Bottom Shelf GMT Fuse Connections

2.9. Monitoring and Relay Output Connections

Front Panel DB9 Connection

The front panel DB-9 connector is used to hook up a standard RS-232 cable (such as APC part number 0129-XX.

A 0129-6 is included with this manual. ). This will allow local access through a Terminal Emulation program such

as HyperTerminal™ or ProComm. ™

RJ45 Ethernet Connector

The management card has an RJ-45 connector to support a TCP/IP protocol over a 10/100 BaseT Ethernet Local

Area Network (LAN).

Major, Minor and Relay 1 Output Connections

There are three output relays available that provide outputs via Form “C” contacts. The output relays are named

Minor, Major and Out Relay 1. Various system alarm conditions can be assigned to any of these three output

relays. Most alarm conditions are shipped programmed to Minor or Major Relay. Wago connectors are located on

the backplane card mounted in the left rear of the unit. Refer to the board layout in Figure 2.9-1 for Output Relay

connections. The Wago connectors accept wires 26 AWG to 20 AWG (0.129 mm2 to 0.518 mm2). To connect the

relay output, remove ¼ in (6 mm) of insulation from the end of the wire. Push down the white tab on the Wago

connector, insert the stripped wire and release the tab to make the connection. The relay contacts should only be

used to switch resistive loads of 0.5 A or less at 60 V or less. Figure 2.9-2 shows the alarm output connection

designations. Whenever possible use the common and normally closed contacts. If the alarm wiring gets pulled

loose, or the controller is removed, you will get an alarm. The Major relay is energized (C-NO contacts closed)

during normal (non-alarm) operating conditions; the other relays energize when an alarm condition occurs. If your

Major relay wiring uses the C-NO contacts, then a major relay output will be seen whenever the controller is

removed from the shelf.

Magnum VS –48 Vdc User Manual Page 18

Figure 2.9-1 Interface Connections

Output Relay 2-6 Connections

Output Relays 2 through 6 are virtual relays and are not available for physical connection by the user. The small

size of this unit limits the number of relays that can be placed in the system. These output relays are supported by

the controller and reported by the network management card. Any alarm condition can be programmed to map to

one of these relays. The alarm will activate the relay, illuminate the front panel Out Relay LED, and send the relay

output message to the network management card.

Output Relays

(J411)

User Inputs

(J412)

Magnum VS –48 Vdc User Manual Page 19

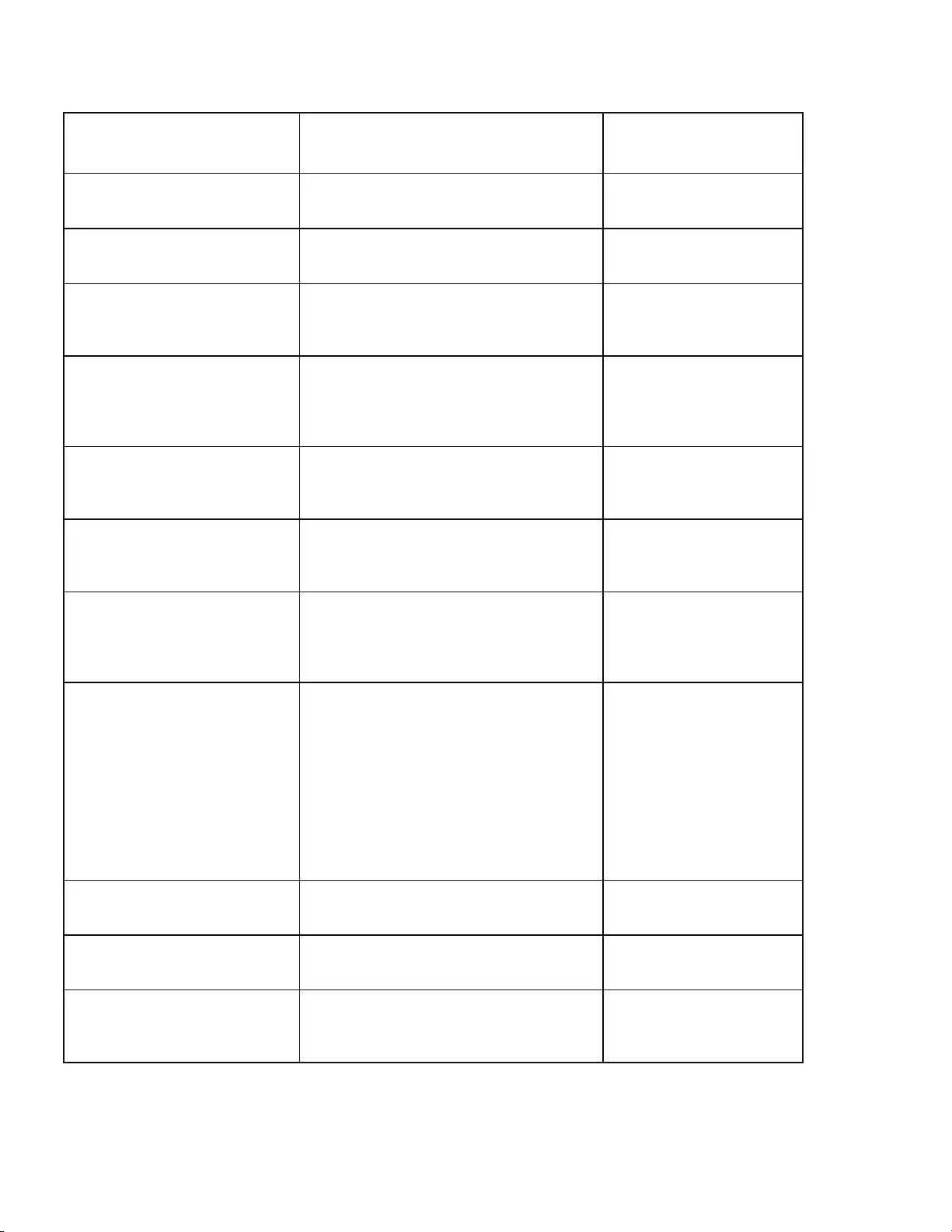

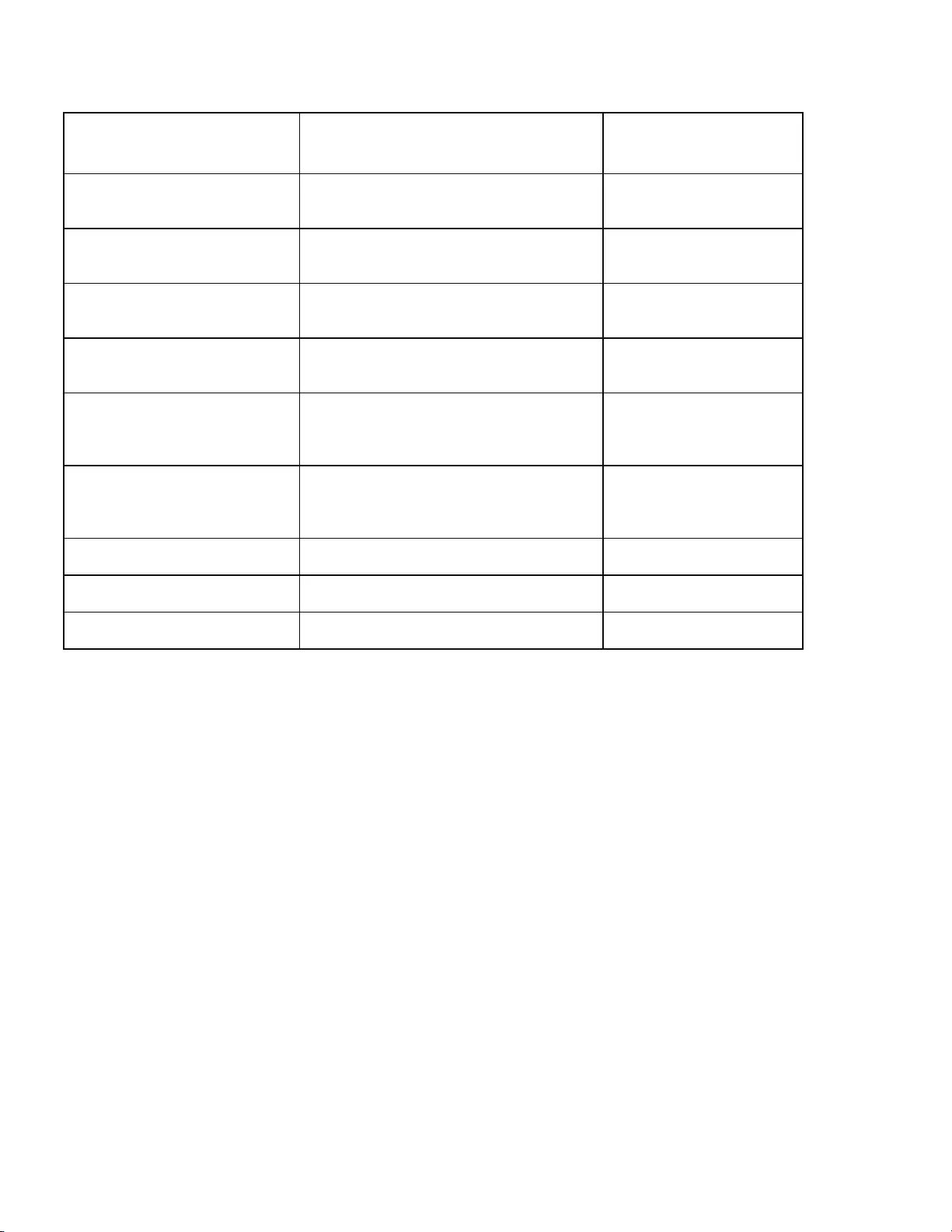

RELAY

OUTPUT

J 411 TERMINAL

DESIGNATIONS

RELAY ALIAS OUTPUT RELAY NOTES

NO

OUT RELAY #1 C

NC

OUT RELAY #2 N/A

OUT RELAY #3 N/A

OUT RELAY #4 N/A

OUT RELAY #5 N/A

OUT RELAY #6 N/A

NO N/A

MINOR C N/A

NC N/A

NO N/A

MAJOR C N/A

NC N/A

Figure 2.9-2 Output Relay Connections

External Alarm Input Connections

Four external alarm inputs with assignable relay outputs are available. User 1 and 2 inputs respond only to

external dry contact closures between normally open (NO) and common (C) and User 3 and 4 respond only to

external dry contact openings between normally closed (NC) and C. A Wago connector is located on the

backplane card mounted in the left rear of the unit. The Wago connectors accept wires 26 AWG to 20 AWG

(0.129 mm2 to 0.518 mm2). To connect the user input, remove ¼ in (6 mm) of insulation from the end of the wire.

Push down the white tab on the Wago connector, insert the stripped wire and release the tab to make the

connection. Refer to Figure 2.9-1 for backplane board connections.

EXTERNAL ALARM

INPUT

J412 TERMINAL

DESIGNATIONS

USER ALARM NOTES

#1 NO USER1NO

#2 NO USER2NO

#3 NC USER3NC

#4 NC USER4NC

#1 C USER1C

#2 C USER2C

#3 C USER3C

#4 C USER4C

Figure 2.9-3 External User Input Connections

Magnum VS –48 Vdc User Manual Page 20

2.10. Rectifier Module Installation

WARNING: Rectifier output DC circuits will be damaged if the batteries are installed

incorrectly. Before installing additional rectifiers, ensure proper battery polarity, and

that the battery is isolated from the rest of the system.

The Magnum VS system includes one (1), 10A, rectifier module. To install additional rectifier modules

(shipped separately), follow the procedure outlined below. Rectifiers are “hot-swappable”, and, hence,

may be installed when the DC system is turned on and in service.

1) Remove the rectifier from its shipping container.

2) Slide the rectifier module into the shelf between the guides until it is fully seated.

3) Secure the rectifier in place with the captive rectifier retaining screws.

Since all system settings are made from the system controller, no physical rectifier settings or adjustments

are necessary.

2.11. Controller Module Installation

The Magnum VS Controller Module is installed at the factory. In the Magnum VS 50, the Controller Module is

installed in the right-most slot of the power system. In the Magnum VS 100, the Controller Module is installed in the

upper right-hand slot of the power system.

CAUTION: The controller and the network management card have lithium batteries. These

batteries are not field serviceable.

• Danger of explosion if battery is replaced by an incorrect type.

• Dispose of used batteries according to the manufacturer’s instructions.

Magnum VS –48 Vdc User Manual Page 21

3 Commissioning

This section is intended as a guide when powering up a system for the first time. It may not be desirable to perform

some steps depending on the particular installation. Refer to the appropriate section for information relating to how

these steps should be performed.

3.1. Pre-Commissioning Inspection

Environment

1. Ensure the dc system environment is suitable for operation.

2. Ensure that there is sufficient clearance around the system for service.

3. Ensure that there is no sign of damage to the dc system.

4. Disable installed alarms before servicing the unit. This will allow the unit to be serviced without creating

false alarms.

Electrical Installation

1. Ensure that the dc wiring is properly installed, sized, terminated and identified.

2. Ensure that the ac wiring is properly installed, sized, terminated and identified.

3. Ensure that the battery wiring is properly installed.

4. Ensure that the dc output over-current protection devices are adequate for the size of wiring installed.

5. Ensure that the dc positive is bonded to central office ground.

6. Note the resistance of the ground bond.

7. Note any currents flowing in the ground.

8. Record ambient temperature.

9. Verify that the battery polarity is correct.

10. If a battery disconnect device(s) is/are present, note the following for each device:

a. DC voltage Rating.

b. DC Current Rating

c. Interrupting Current Rating

Battery Visual and Safety Inspection

1. Check the mechanical integrity of the battery framing, racking, or cabinet.

2. Check that the battery framing, racking or cabinet is adequately secured to the floor.

3. Check compliance with seismic zone requirements.

4. Check the general appearance and cleanliness of the battery.

5. Record the manufacturer, model number, and capacity of the battery string(s).

6. Record the batch number, date code, and serial number of each cell or mono-block, and any other

pertinent information that is available on the battery cells.

7. Check that the cell or mono-block numbering starts at the positive battery string terminal and is correct.

8. Check that anti-oxidation compound is properly applied.

9. Visually inspect each cell for:

a. Cracks.

b. Case leaks.

c. Post-seal leaks.

d. Pressure relief valve leaks (VRLA only).

e. Case swelling (VRLA only).

10. Check the torque of all battery inter- cell connector in accordance with the battery manufacturer’s

specifications.

Magnum VS –48 Vdc User Manual Page 22

3.2. Commissioning

Initial Set-up

1. Remove all rectifiers.

2. Disconnect battery by removing a link in each string or opening the battery disconnects.

3. Check that battery voltage does not appear on the system bus.

4. Disconnect all loads.

AC Power Up

WARNING: The dc power plant is supplied from a nominal high voltage ac voltage source.

Keep the ac input enclosure cover in place when the system is operational or energized

1. Verify that all of the circuit breaker positions are labeled to the corresponding rectifier correctly.

2. Insert all rectifiers.

3. Turn all rectifier circuit breakers on.

4. Each rectifier should have green Input Healthy and Output Healthy LEDs illuminated.

NOTE: When ac power is initially applied, there is a 60-second period during which no alarms are reported.

DC Power Up:

1. Verify, with a voltmeter, that the DC voltage is within 0.1 Vdc of the System Voltage

2. Using the Controller interface (direct serial or network-based connection), adjust battery float voltage to

negative 49 Vdc.

3. Verify System Low Voltage Alarm.

4. Using the Controller interface (direct serial or network-based connection), adjust battery float voltage to

negative 57 Vdc.

5. Verify System High Voltage Alarm.

6. Restore the battery float voltage to negative 54.00 Vdc or desired voltage.

Magnum VS –48 Vdc User Manual Page 23

Rectifier Test:

1. To verify that all rectifiers are reporting correctly to the controller, navigate through the menu and verify that

the status for every rectifier in the system is correct.

2. Remove any rectifier and verify that you get a Minor Relay Output for rectifier 1 of n failure.

3. Remove a second rectifier and verify that you get a Major Relay Output for rectifier 2 of n failure.

Battery Power Up

1. Monitor battery current and verify that it is +/- 0.1 A.

2. Set battery maximum recharge value in the Max Batt Rech screen.

3. Monitor the battery current while closing the battery disconnects or installing open battery links. Arcing can

occur during this connection.

4. The voltage may drop if the maximum battery recharge current is exceeded.

5. The current should gradually decrease when the battery is nearing full charge.

LVD Test

1. Enable LVD 1.

2. Set the LVD trip for LVD 1 to negative 56 Vdc.

3. The LVD should have dropped out (opened). Verify by monitoring the voltage at the battery connection.

Also, the minor alarm should be on.

4. Set LVD Trip back to negative 42 Vdc.

5. The LVD should have closed. Verify visually or by monitoring the voltage at the battery connection. The

minor alarm should be off.

6. Ensure that the LVD parameters are set to desired value.

Circuit Breaker/ Fuse Test:

1. Monitor alarm screen for fuse alarm while installing blown GMT fuses in each position.

2. Verify proper voltage at fuse and circuit breaker output connections.

3. Turn on fuses and circuit breakers as desired.

User Inputs

1. Change the user input to desired output relay via the controller for any input that will be used.

2. Exercise the output relay by causing the user input to change state.

3. Verify the desired relay output LED on the controller module.

Magnum VS –48 Vdc User Manual Page 24

Output Relay 1:

1. Minor and Major output relays were tested in the rectifier test section.

2. Change the alarm to desired relay output via the controller for any relay output that will be used. All alarm

parameters are shipped as either major or minor, but may be changed to output relay 1.

3. Program output relay 1 to desired major or minor alarm to complete programming.

4. Exercise the output relay by causing the alarm to change state.

Battery Temperature Compensation

1. Enable battery temperature compensation if desired.

2. Ensure that battery temperature probe is connected to the system and attached to the battery.

3. Verify that the system voltage is above the float voltage setting if the battery temperature is below 25

degrees C and below the float voltage setting if the battery temperature is above 25 degrees C.

3.3. Final Inspection:

1. Verify that the interior and exterior of the system is clean and free from debris.

2. Ensure all wires connected and bolts are properly tightened.

3. Ensure the following the User, Service, and Calibration parameters are set properly on the controller:

LVD

LVD1 Trip

LVD1 Reset

Battery Parameters

Discharge Threshold

Float Voltage

Maximum Recharge

Compensation Method

4. Verify that the system is functioning correctly with no alarms.

Be sure to leave the site as orderly and neat as possible.

Magnum VS –48 Vdc User Manual Page 25

4 Technical Description

The Power System is designed to supply safe –54 Vdc primary power through the use of up to 10 rectifier modules.

The controller will monitor all functions and provides battery management including controlled battery recharge with

temperature compensation and low voltage disconnect. Integrated dc output distribution supports loads ranging

from ¼ A all the way to 60 A. The controller can monitor up to 4 discrete external events with voltage free (“dry

contact”) user inputs.

4.1. Rectifier Management

AC Input Power

The basic component of the power system is the rectifier module, which rectifies utility ac into nominal 48 Vdc.

Each rectifier module requires 85 – 264 Vac, 47 – 63 Hz single phase power. Available cord sets include a variety

of blade and twist lock plugs. Dedicated wiring inside conduit can also be used.

DC Output Power

The dc outputs of all the rectifiers in the system are connected to a common bus that is rated to carry the current of

the entire system. The rectifier modules will equally share the entire load, independent of the controller. The

rectifiers will continue to provide dc power (-54.5 Vdc) if the controller is removed or fails.

Rectifier alarms reporting

The rectifier has numerous sensors inside the unit that monitor fan fail, high temperature, high/low voltage, etc.

These rectifier sensors trigger outputs that are monitored by the controller. In addition rectifier current is measured

inside each rectifier. The controller can trigger output relays in the event of a rectifier alarm. Refer to Section 4.5

for controller functions.

4.2. System Management

System Voltage Monitor and Control

The controller monitors and adjusts the system voltage. It uses a voltage trim input to the rectifier to precisely

control the dc output voltage. In the event of controller removal or failure, individual rectifiers will default to the

analog voltage level (-54.5 Vdc) preset at the factory. System high and low voltage alarms are reported by the

controller.

Magnum VS –48 Vdc User Manual Page 26

System Current Monitor

The controller monitors individual rectifier currents and displays total system current as a sum of rectifier currents.

Load current can be found by adding battery current to system current. Battery Current is positive when the battery

is discharging.

Sys Current + Batt current = Load Current

For example, if the battery is charging the Batt Current reading could be (–) 10 A, Sys Current reading could be 50

A. Load Current would be:

Sys Current + Batt current = Load Current

50 A + (-) 10 A = 40 A.

If the battery is discharging the Batt Current reading could be 10 A, Sys Current reading could be 30 A. Load

current would be:

Sys Current + Batt current = Load Current

30 A + 10 A = 40 A.

System Status and Alarm Reporting

The controller will monitor system, temperature. The controller reports system high and low temperature alarms.

4.3. Load Management

Circuit Breakers

The Magnum VS Distribution Module includes two (2) 30A or one (1) 60A circuit breaker, or eight (8) GMT fuses.

When a circuit breaker trips, a normally open switch closes and the Controller reports a CB alarm. Alarms are

reported only when a breaker is tripped. When a breaker is turned off, no alarm is generated. Circuit Breaker

Alarms 1 or 2 are reported when a circuit breaker in the top shelf trips. Circuit Breaker Alarms 3 or 4 are reported

when a circuit breaker in the bottom shelf trips. Please note that if a Magnum VS 100 system has one (1) circuit

breaker in the top shelf and one (1) circuit breaker in the bottom shelf, the circuit breakers in the bottom shelf will be

labeled CB2 on the front panel, but Circuit Breaker Alarm 3 will be reported. To disconnect a load attached to a

circuit breaker, move the lever down to the “OFF” position.

Magnum VS –48 Vdc User Manual Page 27

GMT Fuses

When a GMT fuse trips, a fuse element burns out allowing the indicator to connect DC power to the alarm contact.

This turns on the fuse alarm LED on the fuse panel indicating the affected group and the Controller reports a fuse

alarm. Each Controller fuse alarm combines alarms from 4 individual fuses:

Fuse F1 to F4: Controller Fuse Alarm 1

Fuse F5 to F8: Controller Fuse Alarm 2

Fuse F9 to F12: Controller Fuse Alarm 3

Fuse F13 to F16: Controller Fuse Alarm 4.

To disconnect a load attached to a GMT fuse, pull the fuse straight out of the fuse holder base.

4.4. Battery Management

Battery Charging

Battery charging is integrated into the dc power system to support the primary function of providing power to the

load. Accurate measurement of battery parameters such as voltage, current and temperature are used to maintain

and protect the batteries attached to the power plant.

Charging the battery at the correct rate reduces battery heating, increases the charge returned to the battery and

prevents excess hydrogen generation or, in the case of Valve Regulated Lead Acid (VRLA) batteries, possible

thermal runaway. The Magnum VS operates as a current limited constant voltage battery charger. The current

limit value is set by the controller’s Battery Maximum Recharge Current parameter and is normally based on the

size of the battery plant in ampere-hours.

Consult the battery manufacturer for the recommended maximum charging current. This is frequently expressed as

a percentage of the battery's 20-hour ampere-hour capacity rating, commonly abbreviated as "C". For example, the

maximum recharge current in amperes may be expressed as 0.2C, 20% C or C/5, all of which are equivalent. If the

battery used has a capacity of 120 Ah, then the 0.2 C max current is 24 amperes. Manufacturers typically specify

max recharge current between 0.1C to 0.3C (C/10 to C/3). Avoid high recharge rates that may induce elevated

battery temperatures that can lead to thermal runaway. A 0.1C max recharge current is generally a conservative

value that will result in a 90-95% recharge in 12-15 hours, depending on the initial depth of discharge. In this case

charging current will begin to taper (reduce) from the current limited value after 3.5 - 7 hours.

Typically four 12-volt batteries are connected in series to form a battery string. The ampere-hour rating for one 12-

volt battery will equal the Ah rating of the string. For multiple parallel strings, add the Ah rating of each string

together to get the total Ah rating.

Magnum VS –48 Vdc User Manual Page 28

Battery Protection

An external disconnect should be mounted at the battery string to protect the system from the high energy stored in

the battery if a short occurs. The battery LVD will not be energized until a battery string is installed with the proper

polarity and the battery disconnect switch is turned on. The battery connections are to be used for the battery only.

Do not attach loads to the battery connections or erroneous battery current will be reported. The controller reports

Battery high and low voltage alarms and LVD alarms.

Battery Temperature Monitoring

Battery temperature is monitored using a probe attached to the battery casing. The controller reports Battery high

and low temperature alarms.

Battery Temperature Compensation

The Battery Float Voltage is set to the value recommended by the battery manufacturer in order to maintain correct

battery charge at 25ºC. As temperature rises, electrochemical activity in a battery increases. Similarly, as

temperature falls, electrochemical activity in a battery decreases. As temperature rises, charging voltage should be

reduced to prevent overcharge and possible thermal runaway. As battery temperature falls, voltage is increased to

prevent undercharge. The dc power system uses Battery Temperature compensation to change output voltage to

compensate for temperature changes monitored at the battery temperature probe. This temperature compensation

function is programmed into the controller using the compensation parameters settings. Default settings can be

changed to values recommended by the particular battery manufacturer. The controller will not allow the system

voltage to be adjusted beyond the range of –47 Vdc to –56.5 Vdc.

Battery Low Voltage Disconnect

In order to prevent damage to the battery due to deep discharge, the dc power system has hardware and software

support for a battery Low Voltage Disconnect (LVD). When the battery voltage reaches the threshold set by the

LVD 1 Trip Voltage setting during discharge, the dc power system will activate the LVD contactor to disconnect the

battery from the system. The LVD will remain open until ac power is restored to the system and the bus voltage

reaches the level defined by the LVD 1 Reset Voltage variable. The LVD control can be disabled on the LVD

parameters screen in the controller.

NOTE: The LVD is normally energized and must be commanded to open. This assures that the LVD will remain

closed even if the controller fails or is removed.

The LVD will not be energized until a battery string is installed with the correct polarity and the battery disconnect

switch is turned on. This will prevent the battery from being hooked up backwards and damaging the rectifiers

and/or the loads. Once the battery is connected correctly and the LVD is closed, the LVD will open only in low

voltage situations. The battery connections are to be used for the battery only.

Counter Electro-Motive Force Module Connections

A connection is provided to connect a Counter Electro-Motive Force (CEMF) Module. A CEMF is a semiconductor

device connected in series with a battery and used to reduce the voltage to loads that cannot tolerate the “normal”

main cell voltage. The CEMF cells are automatically switched out of the circuit when the discharge voltage drops to

a predetermined level and are automatically switched back into the circuit when the battery approaches its normal

float value.

Magnum VS –48 Vdc User Manual Page 29

4.5. Controls and Indicators

Controller Module

All status monitoring and/or parameter changes are made using a computer connected to the Magnum VS system

over an (10/100 Base-T) Ethernet network or directly connected via a serial cable. Refer to Section 5 for additional

information.

There are five visual indicators (LEDs) on the Controller Module. The Major LED (Red) is on when the Major Relay

is de-energized. The Major Relay is energized when there is no alarm. This will produce a major relay output even

when all power is lost. The Minor LED (Yellow) is on when the Minor Relay is energized. The Out Relay LED

(Yellow) is on when the Out Relay is energized. The DC OK LED (Green) is on when the voltage is between 50

and 57 Vdc. The green LED behind the front panel is slowly flashing when the controller is processing data.

4.6. Alarm Outputs (Output Relays)

There are three alarm output relays designated Out Relay 1, Minor, and Major. Various system parameters may be

programmed to activate any of these output relays when set thresholds are exceeded or specific conditions occur.

Out Relay 1 can also be routed or “mapped” to “Out Relay 1-6,” “Minor Relay,” “Major Relay” or “Ignore.” This

feature makes it possible for a single alarm condition to activate multiple alarm output relays including the Minor or

Major alarm relay. For information on making wiring connections to the alarm output relays refer to Section 2.9

In addition to the output relays described above there are 5 outputs that do not support actual hardware. These are

called Output Relay 2 through 6. While the relay hardware is not available, the programming can still be used to

provide more detailed information through the network management card. Using the actual relay 1 and the 5 virtual

relays 2-6, six different parameters can be alarmed with unique messages through the network management card.

Various system parameters may be programmed to activate any of these output relays when set thresholds are

exceeded or specific conditions occur. Relay 2-6 can also be routed or “mapped” to “Out Relay 1-6,” “Minor Relay,”

“Major Relay” or “Ignore.”

Out Relay 1-6 can be renamed using the Relay Alias setup screen. Each relay name can be up to sixteen

characters in length. This name will appear in the messages generated by the network management card. This

can be used to give specific information on the exact nature of the active alarm.

4.7. External Alarm Inputs (User Input)

The Controller can monitor any external device that uses a voltage free (“dry contact”) switch or relay to output

status information. The four external user inputs can be routed or “mapped” to alarm output relays. Available

assignments are “Ignore”, “Major”, “Minor”, and “Out Relay 1.” For information on wiring connections to these

inputs refer to Section 2.9

4.8. Network Management Card - Local & Remote Monitoring

The Magnum VS controller includes an APC AP9617 Network Management Card which allows both local and

remote access to the power system. The AP9617 is a web-based management product that uses multiple, open

standards such as Telnet, HTTP, and SNMP to provide full management of supported devices. The following is a

list of some of this Management Card’s features:

- Provides a Data Log accessible by FTP or a Web browser.

- Provides an Event Log accessible by Telnet, FTP, or a Web browser

- Detects connection speed of 10/100 MB per second.

- Generates Email notifications for DC Power Plant events and system events.

-Limits SNMP traps and Email notifications based on the severity level of the DC Power Plant or system events

The Management Card has two internal interfaces (control console and Web interface) which provide menus with

options that allow you to manage the DC Power Plant and the Management Card. The Management Card’s SNMP

interface also allows you to use an SNMP browser with the PowerNet® Management Information Base (MIB) to

manage the DC Power Plant.

Magnum VS –48 Vdc User Manual Page 30

5 Operation

5.1. Description

The Magnum VS is designed for years of operation with no user input. The power system is pre-programmed at

the factory with all parameters needed for normal operation. The front panel LEDs and the alarm output relays,

indicate the general health of the unit.

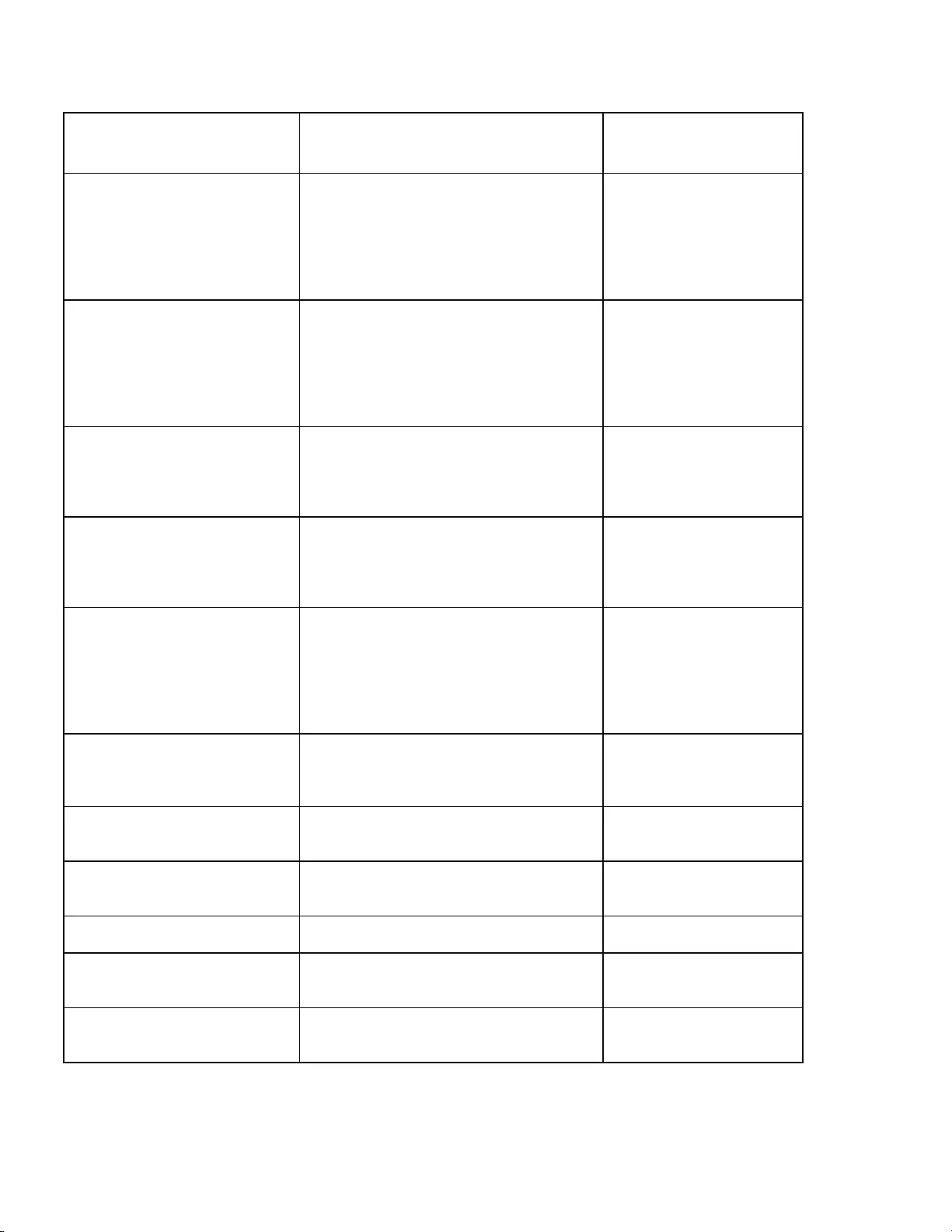

5.2. Controller Module Jumpers

System Voltage J5

The positioning of jumpers on header J5 will determine the operating voltage of the controller card operates.

Options include –48 V, +24 V, +48 V, or –24 V systems. The Magnum VS is only a –48 V system. The only setting

allowed is the –48 V setting, which is J5-1 jumpered to J5-6 and J5-2 jumpered to J5-7.

Remote Lockout J8

It is possible to make parameter changes to the controller card through the RS232 port or through the 10/100 Base

T port of the network management card. The controller card is shipped with a jumper between pins J8-2 and J8-3,

allowing such parameter changes. If the user wishes to disable the remote configuration feature, then the jumper is

moved to pins J8-1 and J8-2.

Firmware Programming Enable J9

When the operating system is initially installed at the factory, J9-1 is jumpered to J9-2. This setting interferes with

normal operation. To ensure normal operation, the controller card is shipped without this jumper. During normal

operation, the only setting allowed is no jumper between J9-1 and J9-2.

Vtrim Trip Select J13

The header J13 is a factory set header that allows this controller to work with different types of rectifiers. The

Magnum VS always uses the Magnum VS rectifier. During normal operation, the only setting allowed is J13-2

jumpered to J13-3.

Magnum VS –48 Vdc User Manual Page 31

J1

1

11

10 1

65

J5 J3

J13

J9 J8

J2

J12

J4

DB9 - RS232 Port

MAJOR

DC GOOD

MINOR

OUT RLY

VR1

J10

J11

System Voltage Select

SNMP Interface

Vtrim Dropout

Parameter Change LockoutFirmware Change

Positive Test Jack

Negative Test Jack

Display Contrast

"HEARTBEAT" LED

Display Interface

Display Backlight Power

1

J6

Keypad Interface

Figure 5.2-1 Controller Card Jumper Locations

Controller Module

All status monitoring and/or parameter changes are made using a computer connected to the Magnum VS system

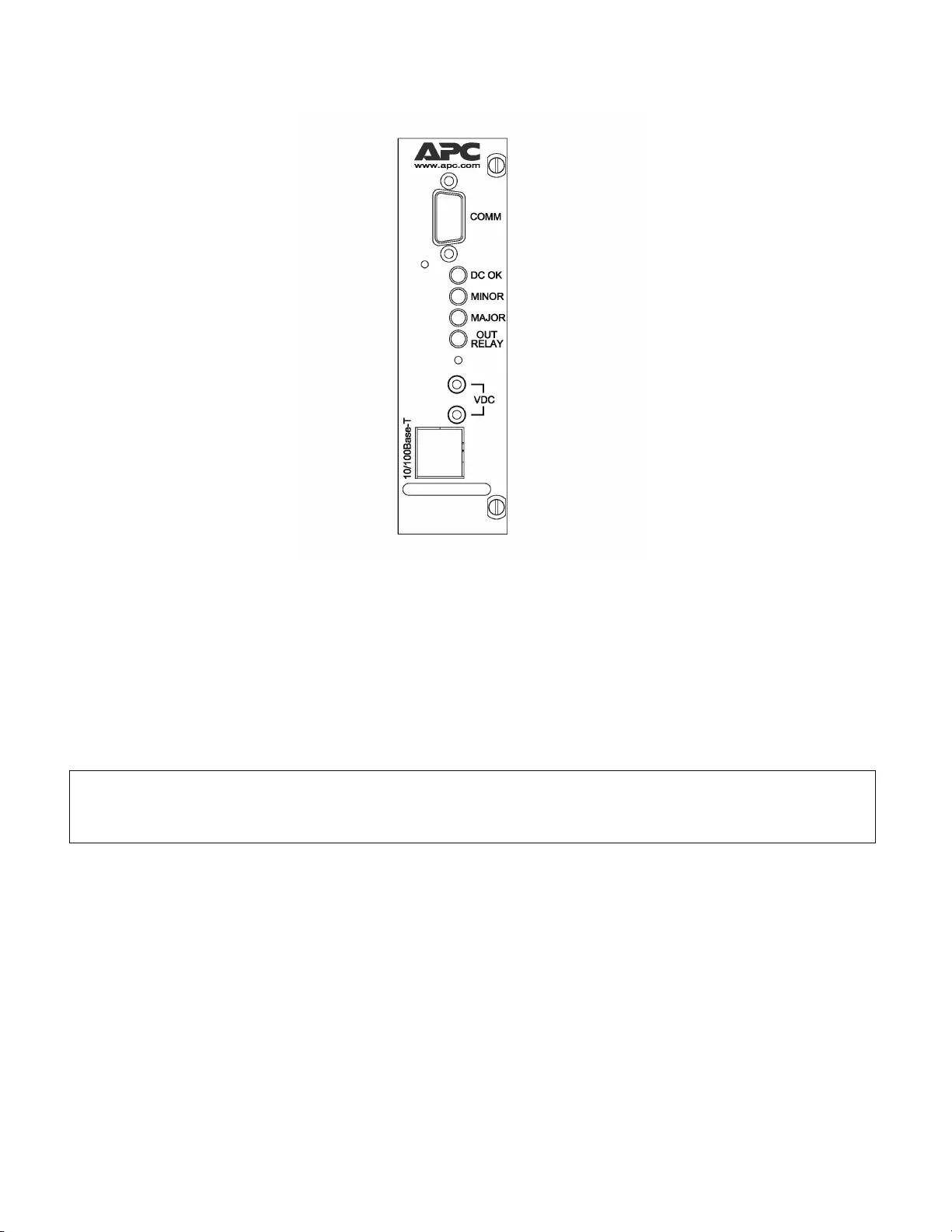

over an (10/100 Base-T) Ethernet network or directly connected via a serial cable. Refer to Figure 0-1 for the front

panel layout.

Magnum VS –48 Vdc User Manual Page 32

Figure 0-1 Magnum VS Controller

5.3. Operation Using the RS-232 Comm Port

The front panel DB-9 connector provides a means to connect a PC to the controller locally to set controller

parameters and to view status. To connect to this port use a straight through cable such as APC part number

0129-XX. A 0129-6 is included with this manual. . Refer to the Network Management Card Quick Start Manual or

the User's Guide supplied on the CD shipped with the system for details on how to communicate to the controller

using a terminal emulation program like HyperTerminal(TM) or ProComm(TM

NOTE: The smart-signaling cable (940-0024 or 940-1524) referenced in the Quick Start Manual and User's Guide

does not apply to the Magnum VS. Use a straight through cable such as APC part number 0129-XX. A 0129-6 is

included with this manual.

Communication to the controller through the local serial port is accomplished via the network management card's

Control Console interface. This is a simple text based menu interface.

Magnum VS –48 Vdc User Manual Page 33

5.4. Operation Using the 10/100 BaseT Ethernet Port

The RJ-45 10/100 Base-T port is primarily intended for connection to an intranet for remote access to the DC power

system. However with the use of a crossover cable or a hub, a direct PC to 10/100 Base-T local connection may

also be made.

After the Management Card is configured and running on your network, you can use several different interfaces to

access the Management Card: Web, Telnet, SNMP and FTP.

-The Web interface uses a web browser such as Microsoft ® Internet Explorer 5.0 (and higher) or Netscape ® 4.0.8

(and higher) to configure Management Card options and to view DC power system status, alarms and events.

-Telnet is used to access a Management Card’s Control Console and is the same user interface available via the

local RS-232 serial port.

-SNMP access is available after you add the PowerNet MIB to a standard SNMP MIB browser.

-FTP access is used to download new firmware to a Management Card, or to access a copy of a Management

Card’s event or data logs.

Complete documentation for the use of the management card accompanies the DC power system in the form of a

Quick Start Guide and a CD. The CD contains electronic copies of User’s Manuals along with the necessary

software utilities to support the management function. Some of the functions supported by the network card are not

supported by this power system.

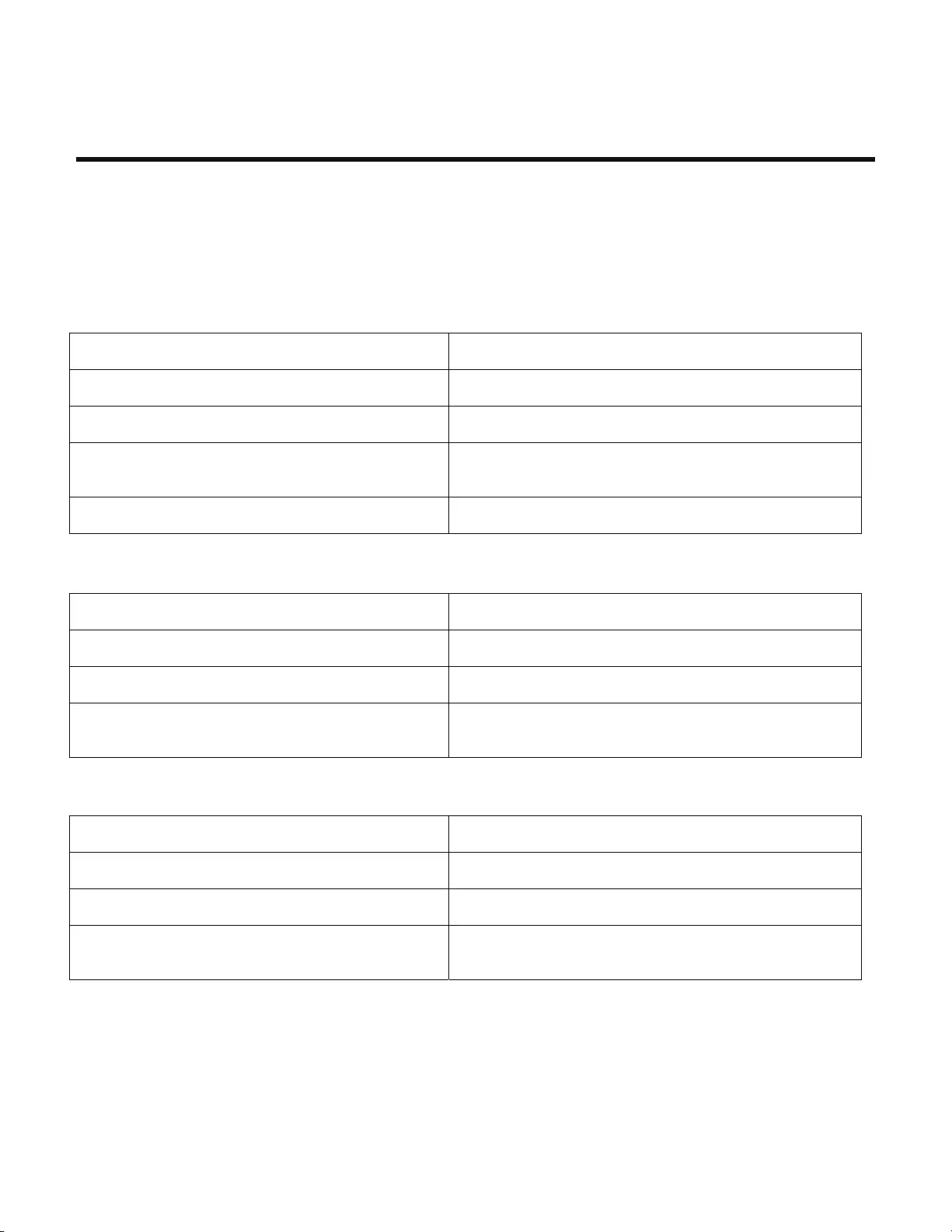

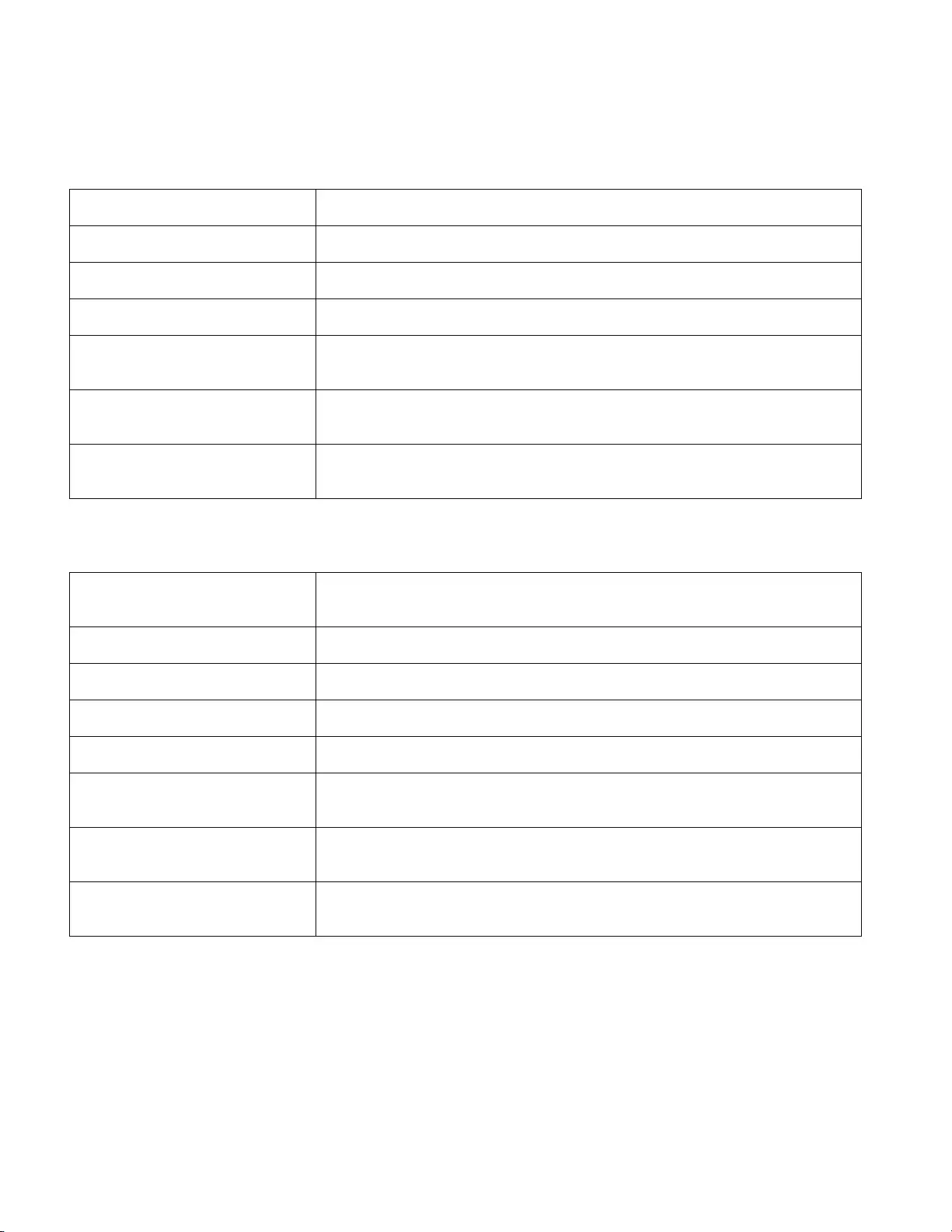

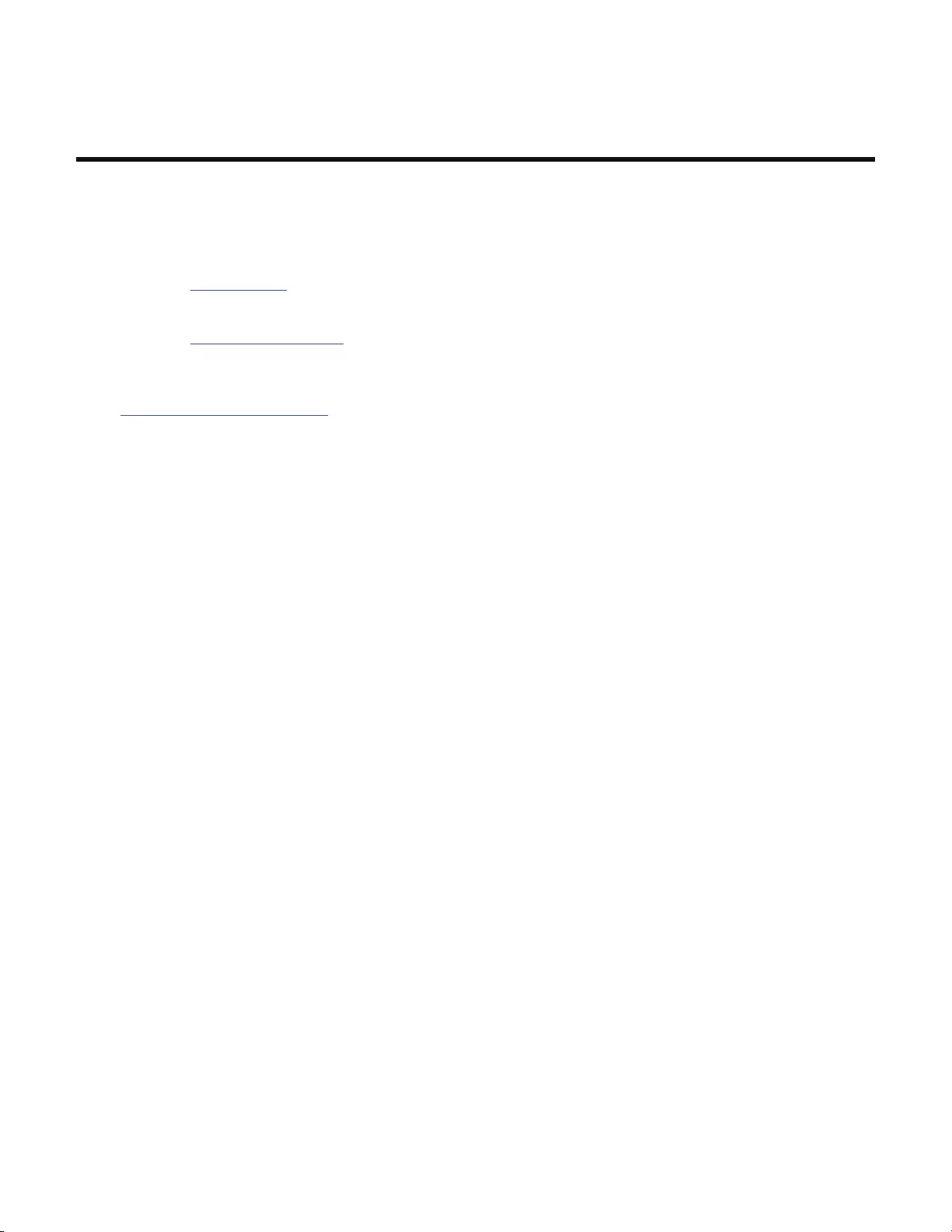

5.5. Operation using Network Management Card Web Browser Interface

The location, description, and factory programmed default value for each of the Magnum VS system parameters

accessible via a Web browser is found in the table below. The table also shows all of the status and information

screens with typical displays. The location of a parameter screen is shown in brackets, for example: [Power

Modules/Rectifiers]. This table is organized alphabetically by parameter name.

Magnum VS –48 Vdc User Manual Page 34

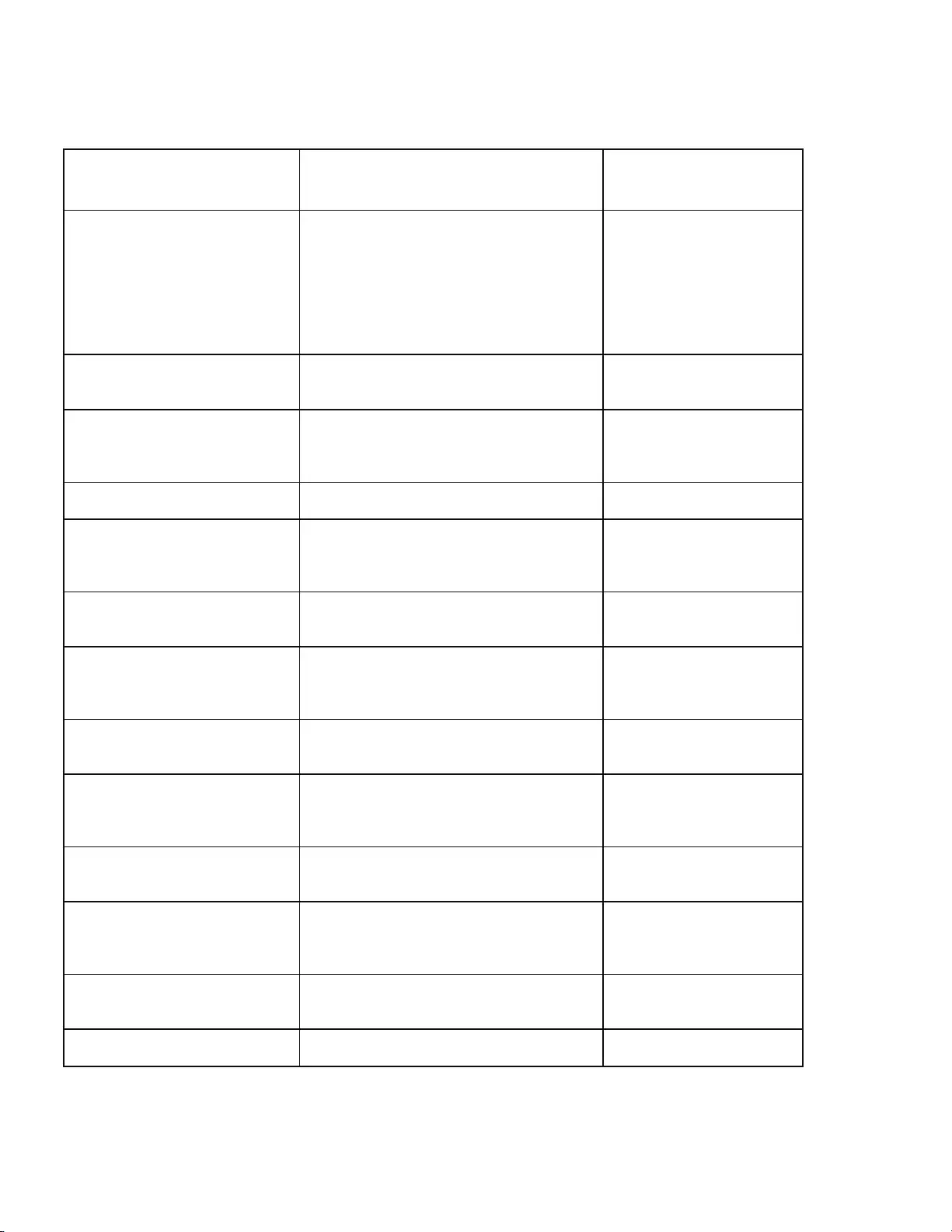

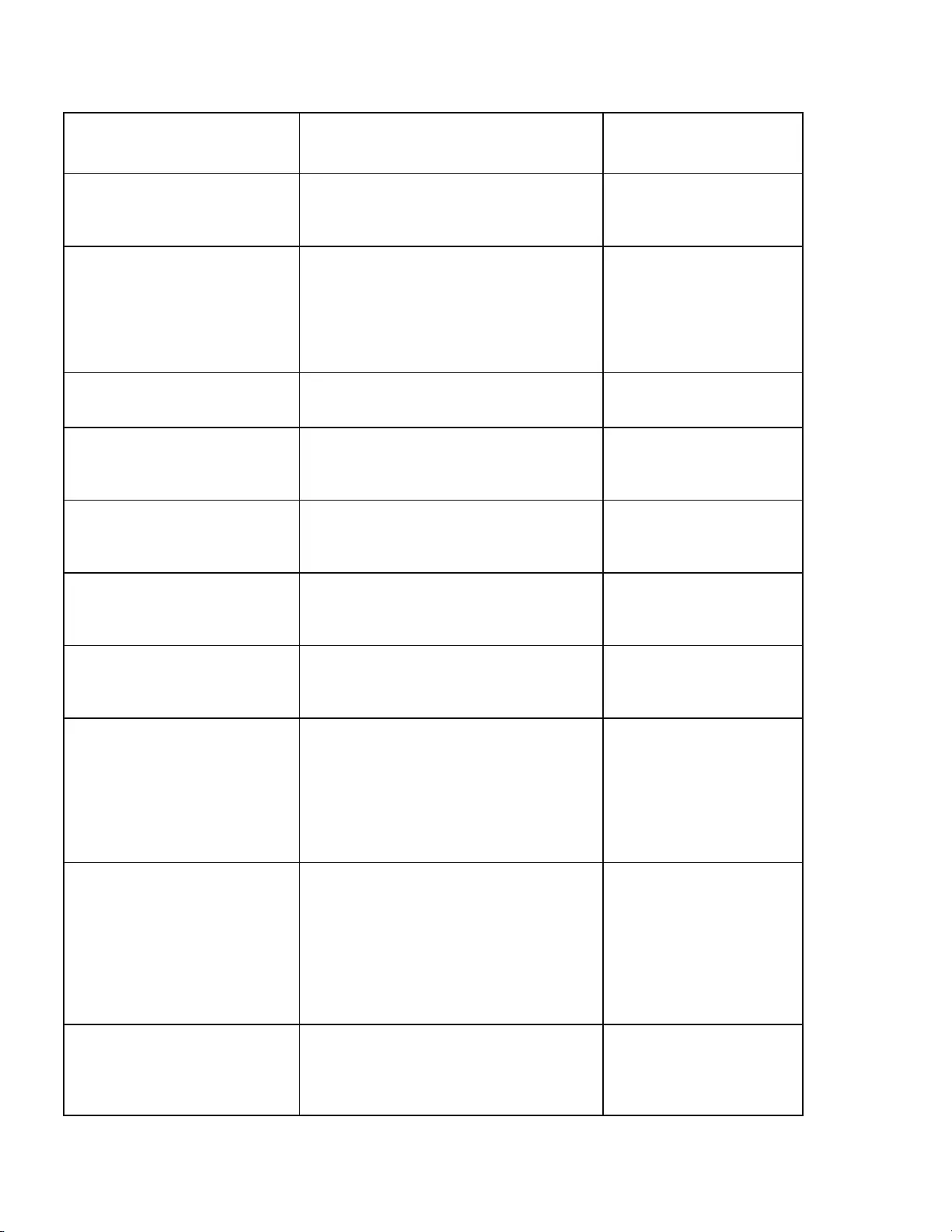

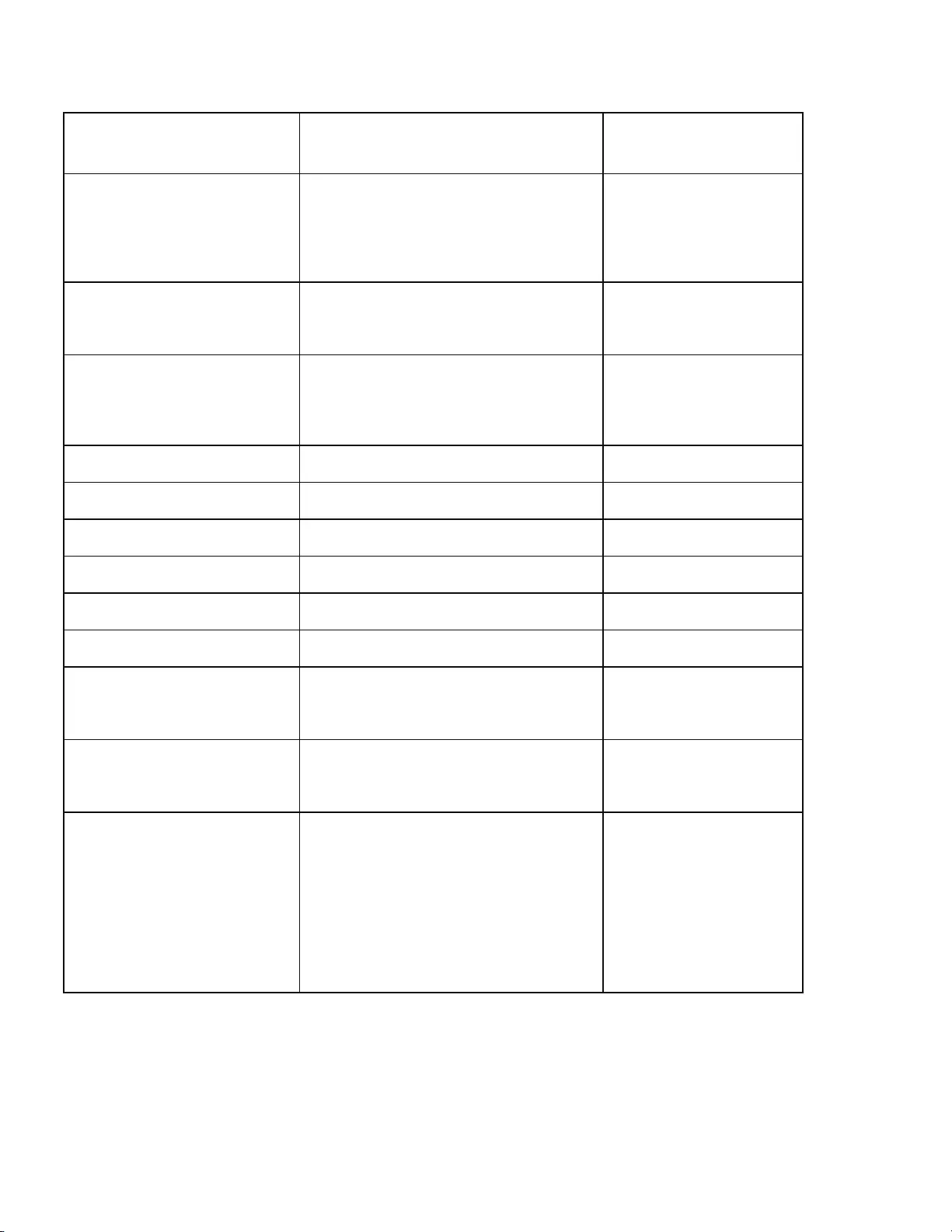

Figure 5.5-1 Parameter Locations, Descriptions, and Settings

PARAMETER NAME/

[MENU LOCATION]

DESCRIPTION SETTINGS (Default

settings in BOLD)

Alarms Item 1

{Status Only}

[System/Active Alarms]

•

•

•

Alarms Item 16

[System/Active Alarms]

Display of up to 16 active alarms (a

typical alarm screen is shown).

•

•

•

Display of up to 16 active alarms (a

typical alarm screen is shown).

No Alarms

•

•

•

No Alarms

Battery Current

{Status Only}

[System/DC Parameters]

Battery current measured by the system

controller at the battery current shunt.

Status Only

Battery Discharge Alarm

[Batteries/Parameters]

Defines the output relay that is energized

if the battery discharge current exceeds

the programmed battery discharge

threshold.

Ignore, Minor, Major

Output Relay 1-6

Battery Discharge Threshold

[Batteries/Parameters]

An alarm is generated if the battery

discharge current exceeds this value.

0 A – 20A, 5 A

Battery Float Voltage

[Batteries/Parameters]

One of three parameters that control the

dc output voltage. Set the Float Voltage

at 25° C battery temperature per the

battery manufacturer recommendations.

-56.5 – -47.0, -54.00 V

Battery High Temperature

Alarm

[Batteries/Parameters]

Defines the output relay that is energized

if the battery temperature exceeds the

Battery High Temperature threshold.