Table of Contents

ATEN VK2200 User Manual

Displayed below is the user manual for VK2200 by ATEN which is a product in the Control Processors category. This manual has pages.

Related Manuals

ATEN Control System

User Manual

www.aten.com

VK1100A / VK1200 /

VK2100A / VK2200

Control Box Gen. 2

Setup Guide

Control Box Gen. 2 Setup Guide

ii

Compliance Statements

FEDERAL COMMUNICATIONS COMMISSION INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

The device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC Caution

Any changes or modifications not expressly approved by the party responsible

for compliance could void the user's authority to operate this equipment.

Warning

Operation of this equipment in a residential environment could cause radio

interference.

Achtung

Der Gebrauch dieses Geräts in Wohnumgebung kann Funkstörungen

verursachen.

KCC Statement:

Industry Canada Statement

This Class A digital apparatus complies with Canadian ICES-003.

Control Box Gen. 2 Setup Guide

iii

RoHS

This product is RoHS compliant.

Conventions

Contents

1. Introduction

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Package Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

VK1100A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

VK1200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

VK2100A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

VK2200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VK1200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VK2200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Getting Started

Overall Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rack Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VK2100A / VK2200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VK1100A / VK1200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Powering the Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminology Description

Control Box, Control Box

Gen. 2

Control Box or Control Box Gen. 2 refers to ATEN Control

Box Gen. 2 models, including VK1100A, VK1200, VK2100A,

and VK2200.

controller Controller refers to all models of ATEN Control Box and

Control Pad.

Control Box Gen. 2 Setup Guide

iv

3. Initialization

ID, Network & License Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting Control Box ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Determining the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changing Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

IP Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Upgrading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Adding Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Wiring

Wiring and Connecting to Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12 V DC Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Independent Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using Self-Supplied Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

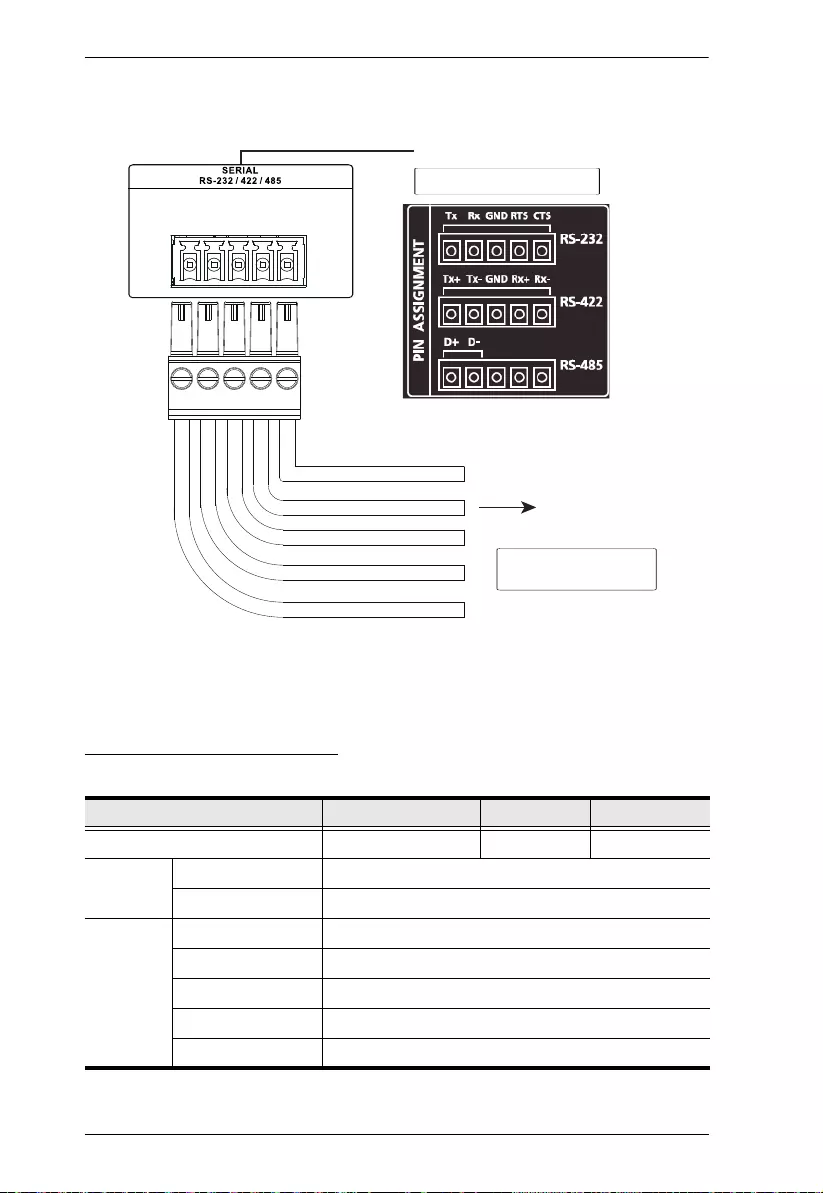

Bidirectional Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

RS-232 (3-Pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

RS-232/422/485 (5-Pin). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

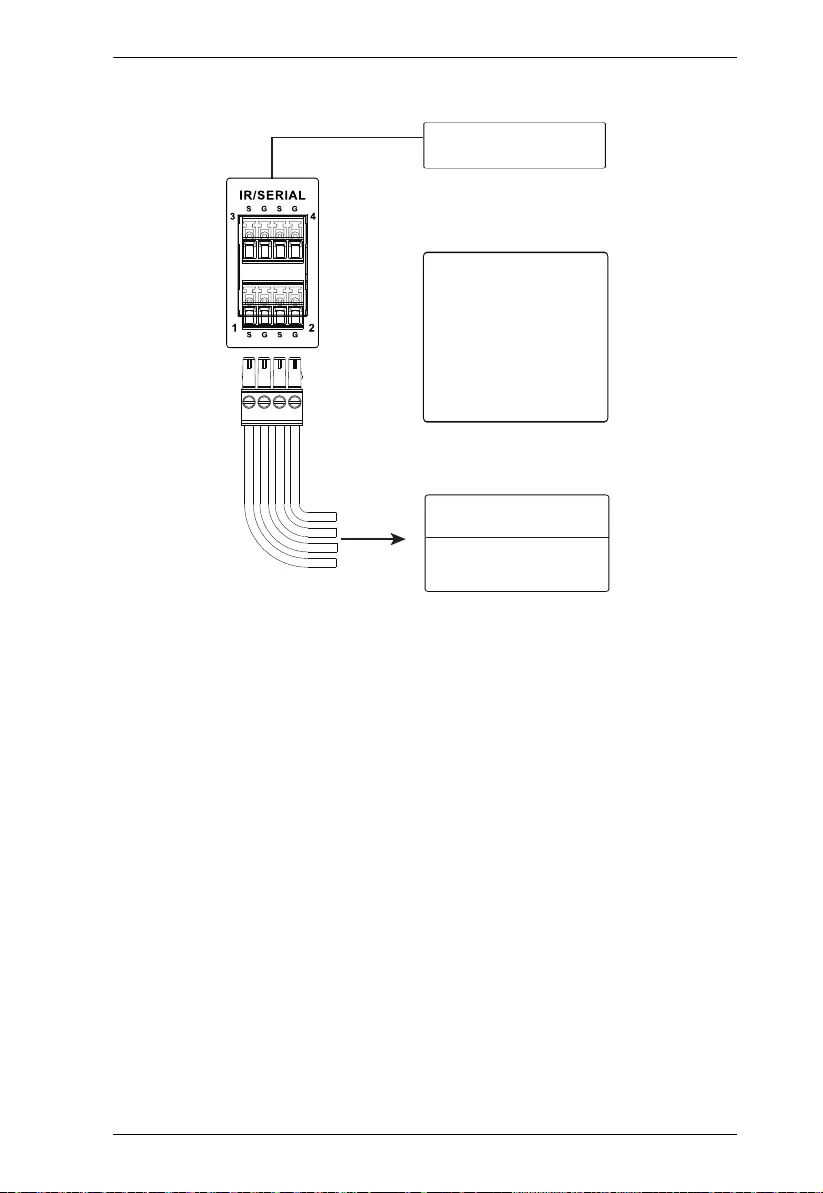

Unidirectional IR / Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IR Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Serial Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

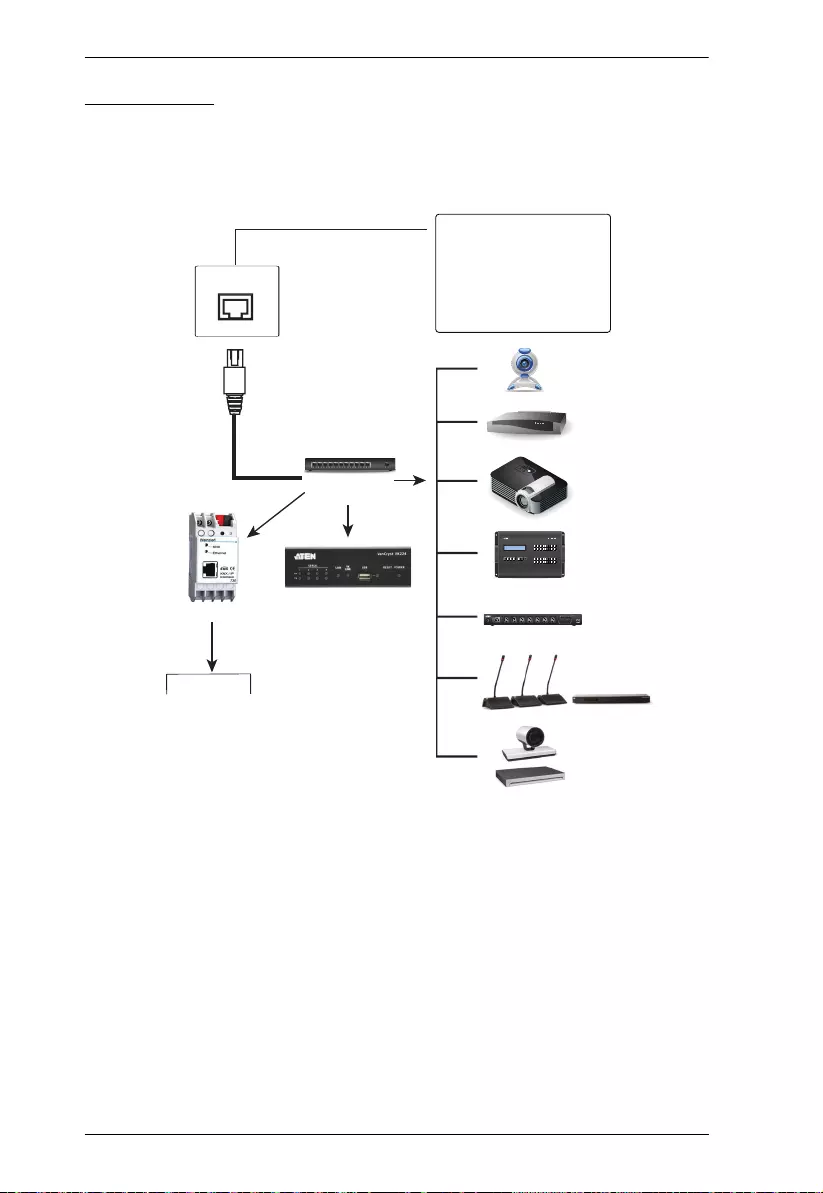

Control LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

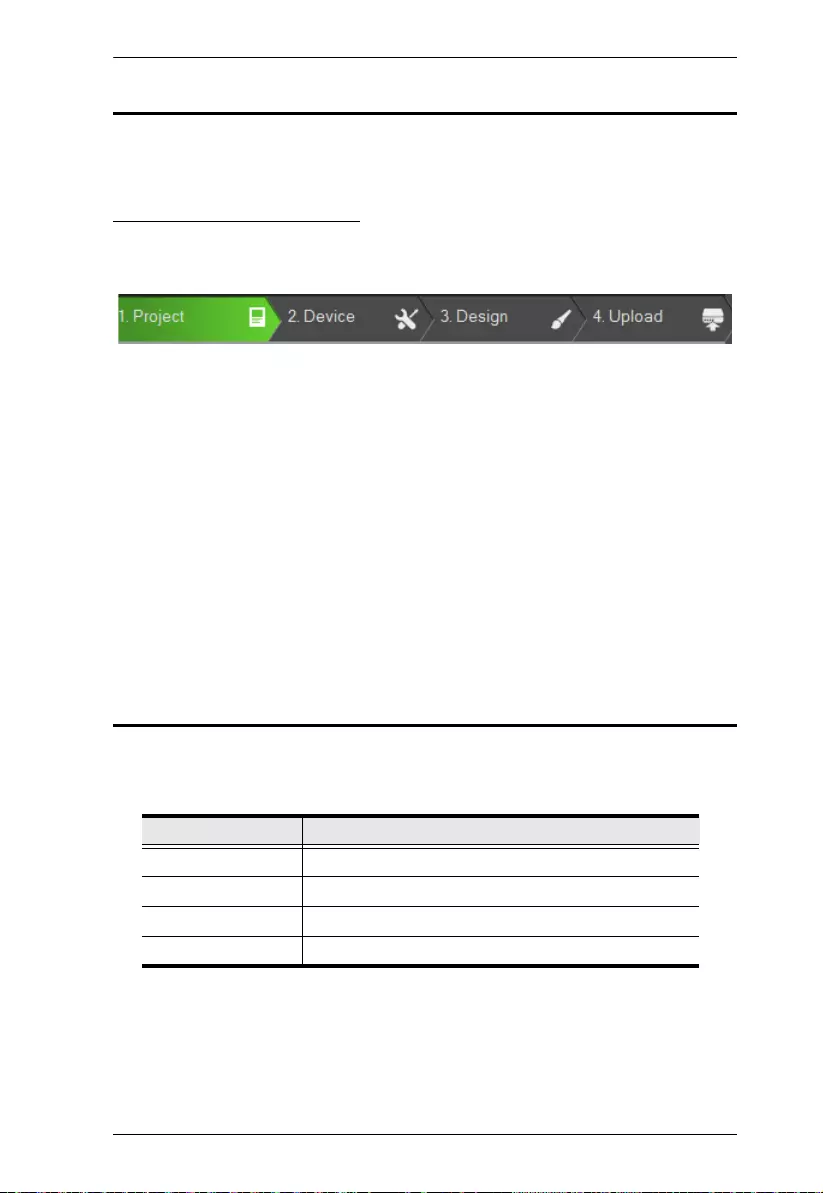

5. ATEN Configurator

ATEN Configurator — VK6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ATEN Expansion Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Control Box Gen. 2 Setup Guide

1

Overview

The Control Box Gen. 2 is an Ethernet-based controller device that connects

and integrates a spate of devices to provide single-access configuration and

convenient remote control for a room setting, such as boardrooms and lecture

halls.

It offers multiple bidirectional serial ports, relays, IR/serial ports, digital I/O,

and 12 V DC power output ports, as well as a dedicated control LAN port,

separate from the corporate LAN, for IP device management within a secure

subnetwork. In addition, it also supports a range of ATEN Expansion Boxes in

providing versatile scalability.

Once successfully connected, users will be able to configure all in-room

devices using the ATEN Configurator software — VK6000, and allow remote

control using ATEN Touch Panel, ATEN Keypads, and Android / iOS /

Windows mobile devices via the ATEN Control System app.

For a centralized management, the VK1200 / VK2200 can be connected to

ATEN Unizon, a global AV management platform software, allowing users to

control and monitor multiple ATEN Ethernet-based solutions across different

locations, including but not limited to ATEN Control Boxes, at the same time.

Package Contents

Make sure the following are present and in working condition:

1 Control Box Gen. 2

1 power cord

1 foot pad set (4 pcs)

1 rack mount kit (VK2100A / VK2200 only)

1 user instructions

1 terminal block kit

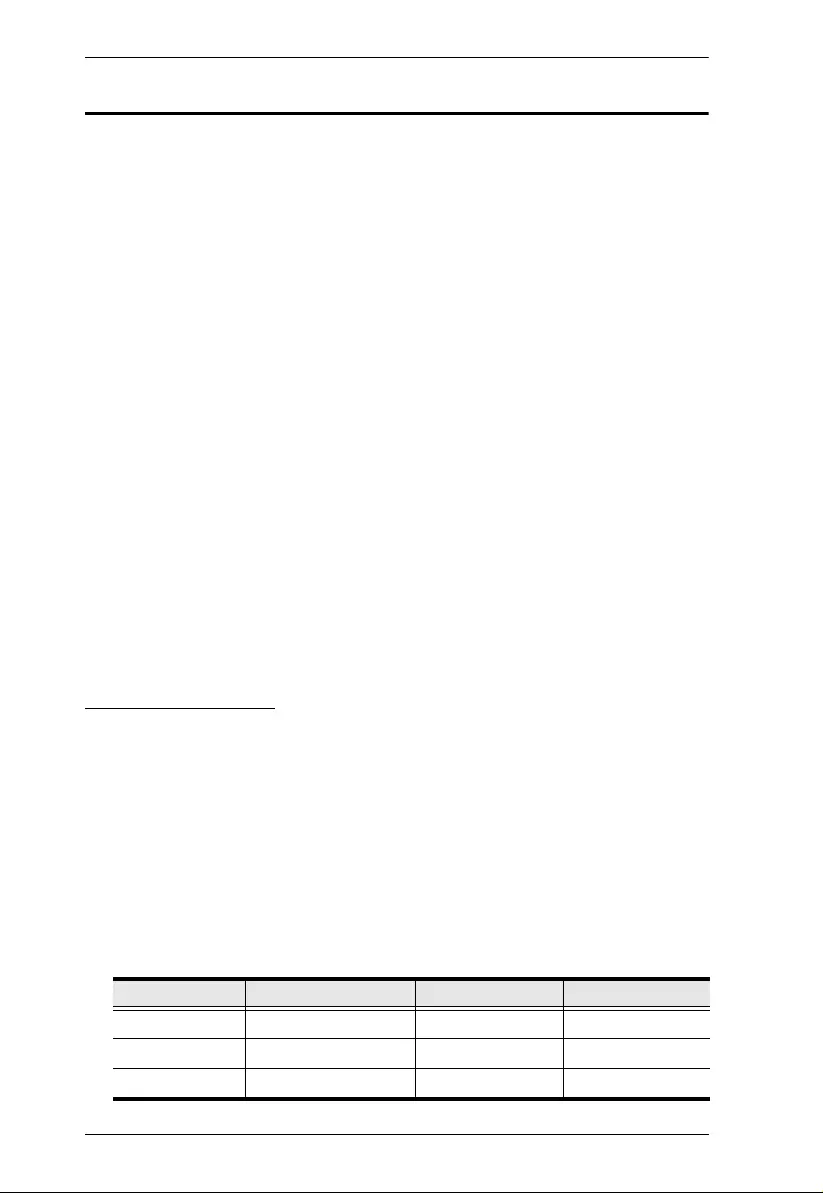

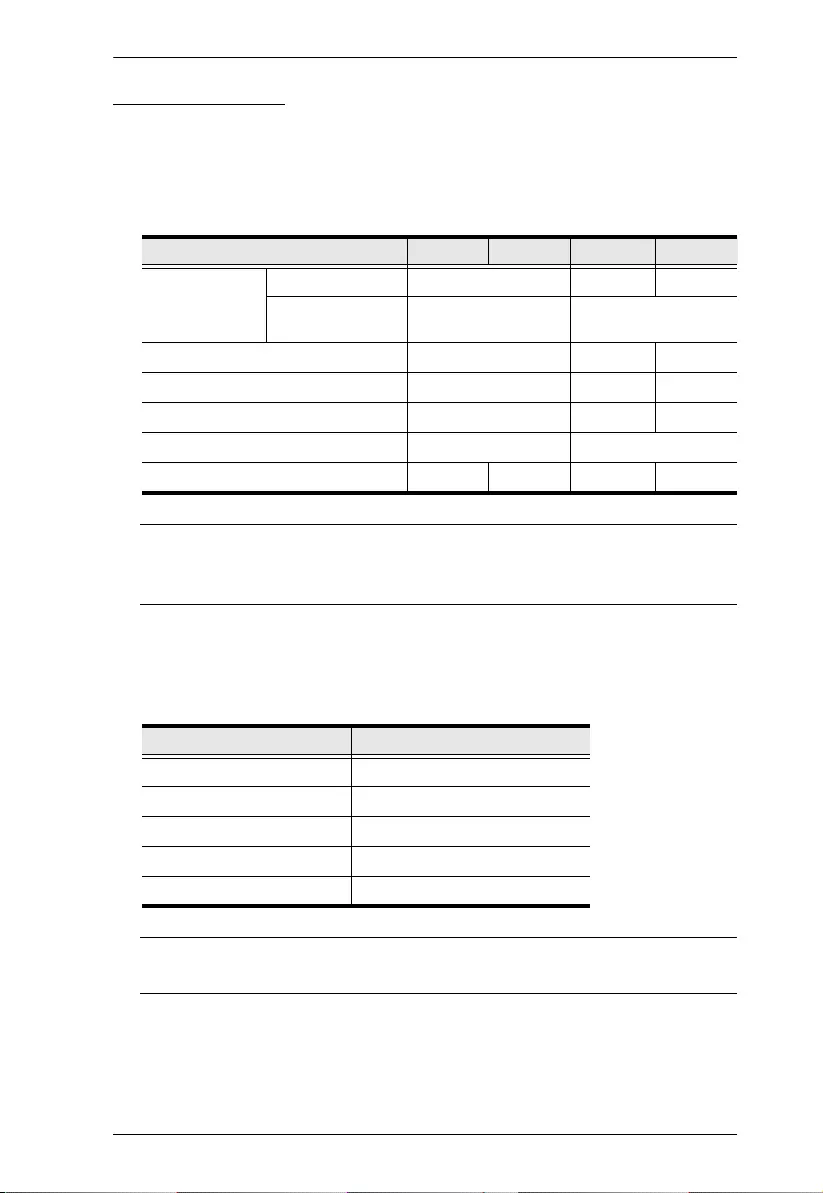

Terminal Block VK1100A / VK1200 VK2100A VK2200

2-Pin 7 12 20

3-Pin 2 4 6

5-Pin 1 3 4

Overview

2

Before You Start

The following is a checklist of the items to prepare / consider before you start:

Go through the numbers and types of ports available, and see if it satisfies

all of the devices you want to be controlled within your room setting.

Note: For more control port interfaces, up to 8 ATEN Expansion boxes per

expander model can be connected to the Control Box. See Compatible

Products on the product web page for details.

Consider the recommended maximum length of each interface cable, as

listed below, and choose an appropriate installation location for the

Control Box.

Note: The maximum allowed length of each interface cable may vary de-

pending on the cable quality.

Interface VK1100A VK1200 VK2100A VK2200

Bidirectional

RS232/422/485

Serial

3-Pin RS-232 1 4 6

5-Pin

RS-232/422/485 12

Unidirectional IR/Serial 2 4 8

Relay 4 4 8

Digital I/O 2 4 8

12 V DC Output 1 4

Ethernet 1 2 1 2

Interface Length (m)

RS-232 15

RS-422/485 350

Relay 30

I/O 30

IR 30

Control Box Gen. 2 Setup Guide

3

Prepare a PC with the following specifications, which may be used to set

the system settings of Control Box Gen. 2 and run VK6000.

Windows 7 / 8 / 8.1 / 10

Installed with .Net Framework V4.5 or later

Take note of the network information and login credentials of each IP

device that will be connecting to and managed by the Control Box, if any.

Front Panel

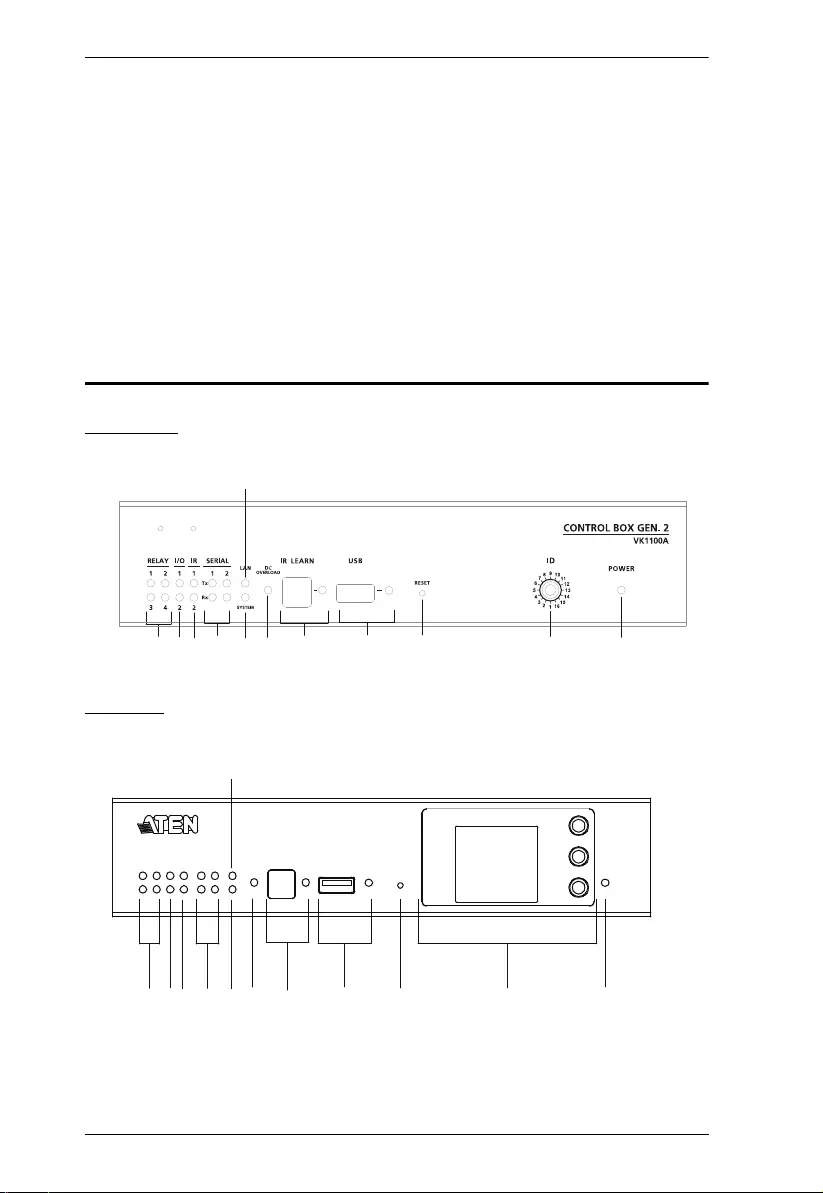

VK1100A

VK1200

12 3 46

5

8 9 10 11 12 14

1

2

35

7

89

4

10 141311

Overview

4

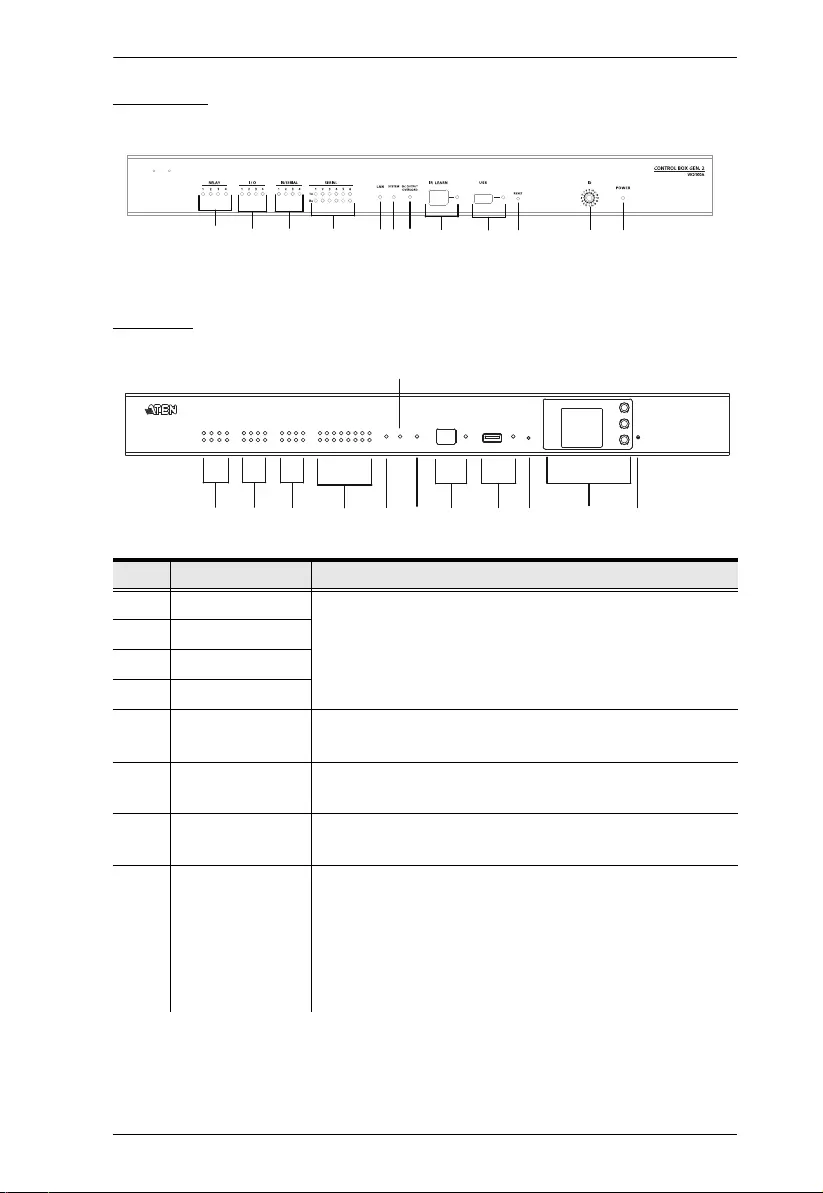

VK2100A

VK2200

No. Component Description

1 relay LEDs

Lights green to indicate an active device connection or

signals being transmitted.

Blinks green once to indicate system startup, with the

buzzer beeping once

2I/O LEDs

3 IR / serial LEDs

4 serial LEDs

5LAN LED Lights green to indicate successful connection to the

network.

6System LED Blinks green to indicate that the system is running without

issues.

7 Control LAN LED Lights green to indicate successful connection to the

network.

8DC output

overload LED

Lights orange to indicate DC output exceeding the

maximum output threshold, with the buzzer beeping for 3

seconds.

Note: Please unplug any of the connected devices to keep

its total output under 12 V DC, 1 A / 2A and restart the

unit.

1234 5

689 10 11 12 14

114

5

24

37910

811 13

Control Box Gen. 2 Setup Guide

5

9 IR receiver / LED Passes the functions of a remote control to the Control Box

in learning mode. The distance between the IR remote and

the receiver window should be kept under 10 cm with a

direct line of sight.

The LED blinks green to indicate the unit is receiving

signals from an IR remote control

The LED lights green to indicate entering learning mode,

or IR learning success with the buzzer beeping once.

10 USB port / LED Note: Control Box Gen 2. is compatible with USB drivers

in NTFS format only.

Plugs in a USB device to upload Viewers (configured by

the VK6000) to the Control Box.

The LED blinks green to indicate that Viewers are being

uploaded, and lights green to indicate a successful

upload, with the buzzer beeping once upon USB plug-in

and once upon upload success.

The LED lights orange to indicate upload failure, with the

buzzer beeping 3 times for no available file found or

upload failure.

11 reset button

Clear all settings but network: Press and hold until

the front panel LEDs blink once, with the buzzer

beeping once (about 8 seconds). The LEDs and

buzzer will trigger once more when the reset is

complete.

Reset network settings: Short press once.

Note: For more reset functions, please refer to the user

manual.

12 Control Box ID

Switch Use the switch to set an ID for the Control Box.

13 LCD panel and

buttons

Use the Up, Down, and Enter buttons to display the unit’s

system information, and set its ID.

14 power LED Lights green when the unit is turned on.

No. Component Description

Overview

6

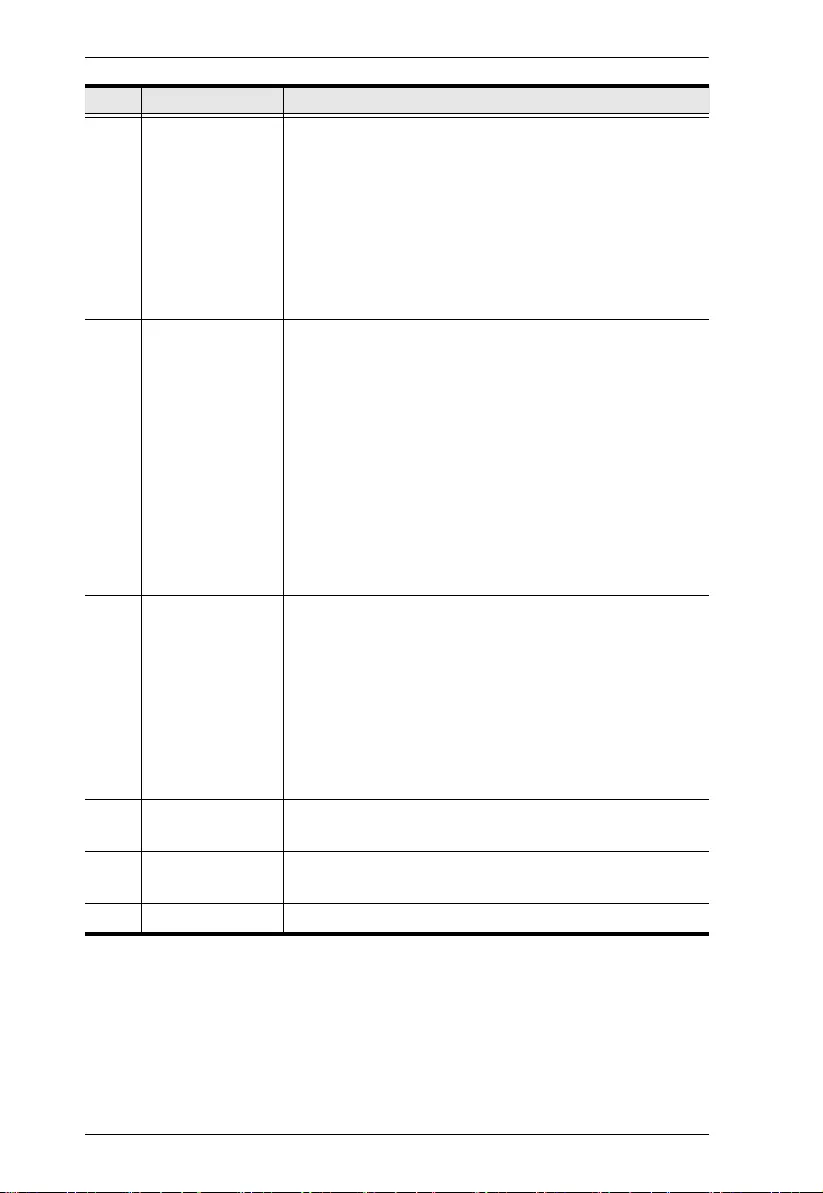

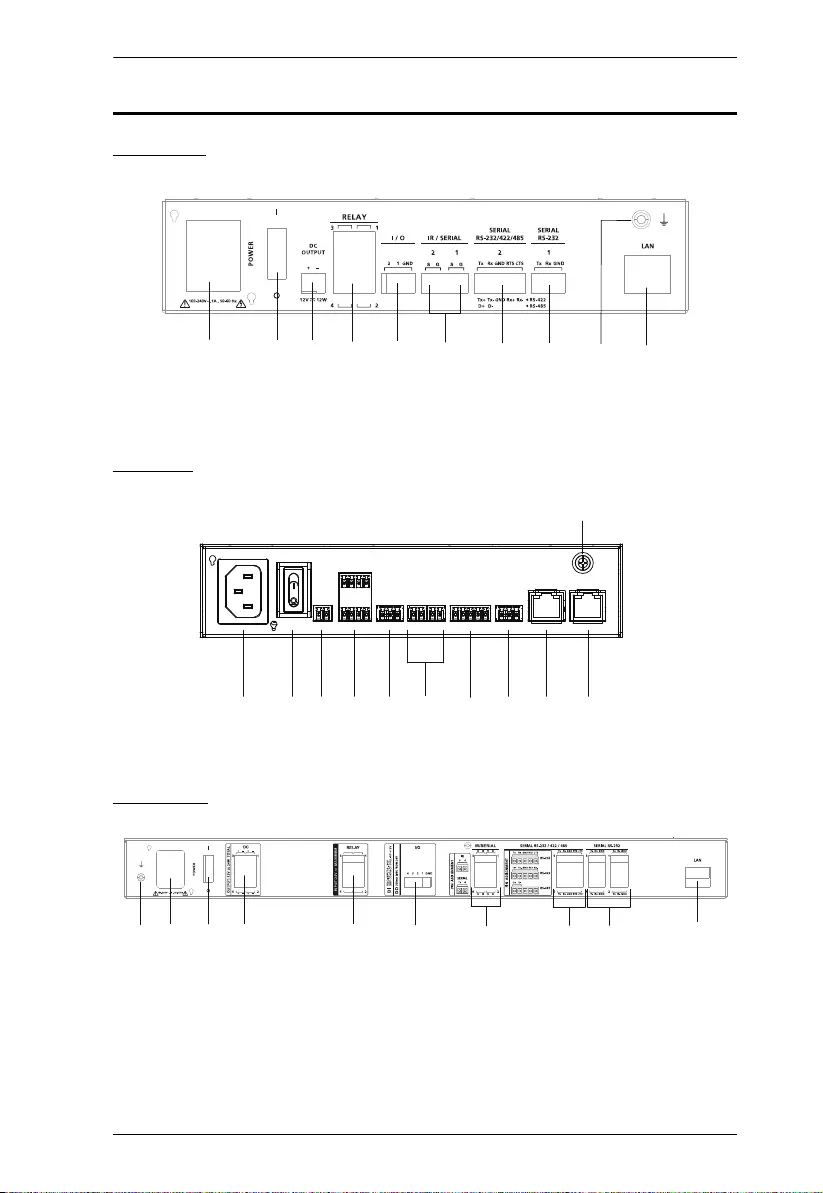

Rear Panel

VK1100A

VK1200

VK2100A

12 3 4510

6789

1 2 3 4 5 106

9

7811

13 4

5

67810

92

Control Box Gen. 2 Setup Guide

7

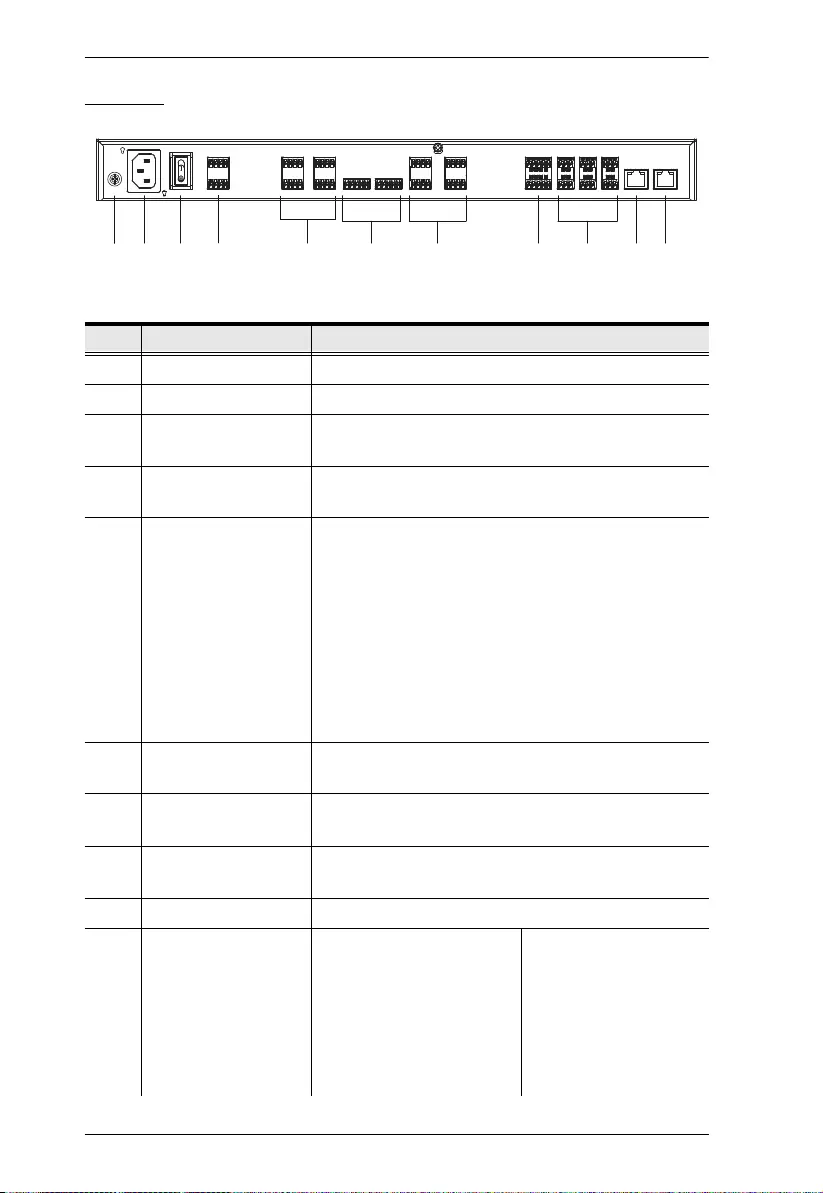

VK2200

No. Component Description

1 power socket Plugs in the power cord from an AC power source.

2 power switch Powers the unit on or off.

3 12 V DC output ports 1 / 4 DC output port(s) providing a total output of 12 V

DC, 1 / 2 A from the Control Box.

4 relay channels 4 / 8 channels; normally open, isolated relays with a

contact rating of 24 V DC, 2 A max.

5 I/O channels 2 / 4 / 8 channels that can be configured as digital

inputs or outputs, with the first pin being ground and

the rest being number pins.

Digital Input:

VDC Mode: 0 - 24 V DC; programmable range

of 1 - 24 V DC

Dry Contact Mode: Pull-up 2k Ω to +12 V DC

Digital Output: 300 mA sink from 24 V DC

6 IR / serial ports 2 / 4 / 8 IR ports that can also be configured as RS-232

TX ports. pin 1: Signal / pin 2: Ground.

7 RS-232/422/485

serial ports

1 / 2 5-pin RS-232/422/485 serial ports by pin

assignment.

8 RS-232 serial ports 1 / 4 / 6 3-pin RS-232 serial ports with Tx, Rx and

GND.

9 grounding terminal Connects to the grounding wire.

10 LAN

Connects the unit to the

corporate LAN for remote

access and centralized

management by ATEN

Unizon.

Default network settings

when no dynamic IP

address is assigned, by

a DHCP server, after 30

seconds:

IP: 192.168.1.60 / mask:

255.255.255.0

91 2 3456 10

811

7

Overview

8

11 Control LAN Connects the unit to a

secure subnetwork,

separate from the corporate

LAN, for managing IP

devices and configuration

by the ATEN Configurator

VK6000, as well as for

remote control by ATEN

Keypads, Touch Panel or

the ATEN Control System

app on mobile devices.

Default network settings

when no dynamic IP

address is assigned, by

a DHCP server, after 30

seconds:

IP: 192.168.0.60 / mask:

255.255.255.0

No. Component Description

Control Box Gen. 2 Setup Guide

9

Overall Installation Procedure

The installation of the Control Box Gen. 2 shall be done in the following order:

Step 1 — Mounting the Control Box

see Placement, page 10.

Step 2 — Powering the Control Box

see Powering the Control Box, page 13.

Step 3 — ID Setting and Initialization

see ID, Network & License Configuration, page 14.

Step 4 — Wiring and Connecting Devices

see Wiring and Connecting to Devices, page 19.

Step 5 — Adding the Control Box on VK6000

see ATEN Configurator — VK6000, page 30.

Getting Started

10

Placement

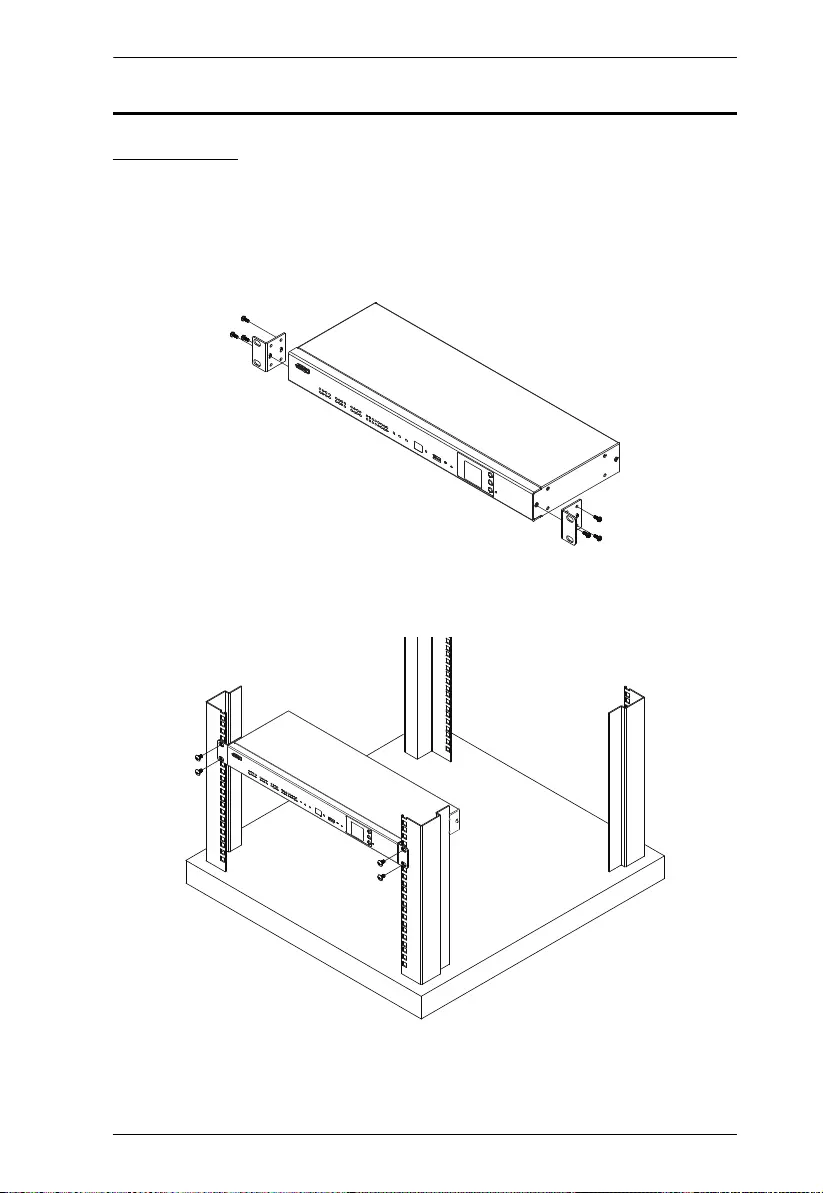

Rack Mount

The Control Box can be mounted onto a 19” (1U) system rack.

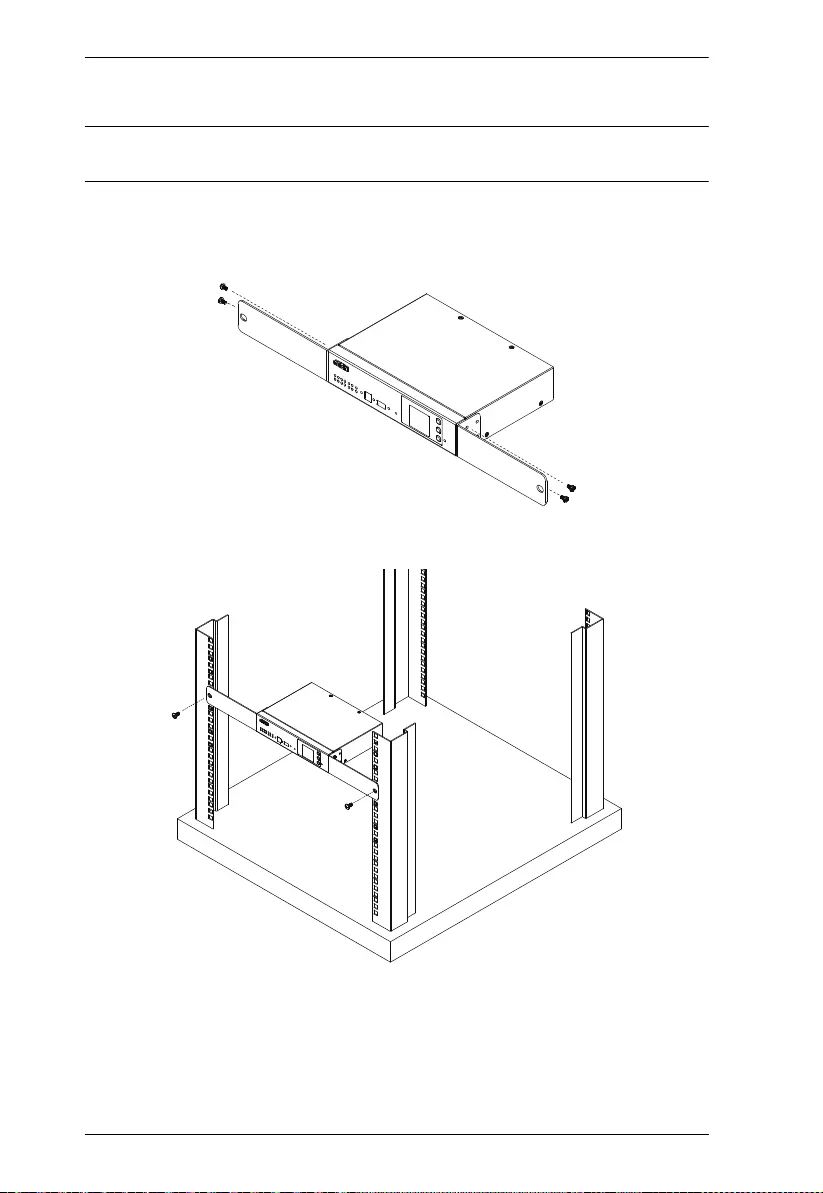

VK2100A / VK2200

1. Using the rack mount kit, attach the 2 mounting brackets onto the sides of

the unit with the 6 screws (M3x6) included.

2. Align the mounting brackets’ screw holes with that of the front of the rack,

and secure the unit onto the rack using 4 self-supplied screws.

Control Box Gen. 2 Setup Guide

11

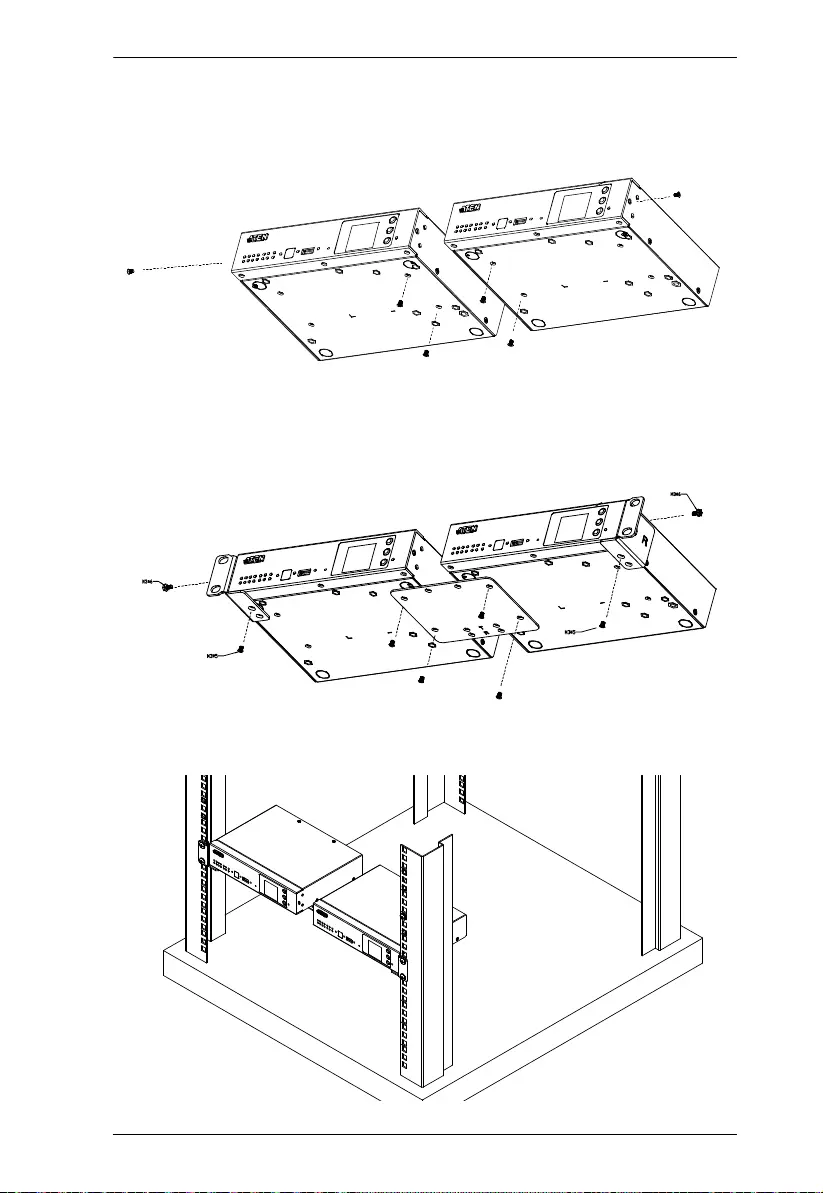

VK1100A / VK1200

Note: For VK1100A / VK1200, the rack mount kit (2X-021G / 2X-049G)

must be purchased separately.

2X-049G (single rack mount)

1. Using the rack mount kit, attach the 2 mounting brackets onto the sides of

the unit with the 4 screws (M3x6) included.

2. Align the mounting brackets’ screw holes with that of the front of the rack,

and secure the unit onto the rack using 2 self-supplied screws.

Getting Started

12

2X-021G (dual rack mount)

1. Remove 2 screws at the bottom and 1 screw at the side from each of the

two VK1100A / VK1200 units, as shown below.

2. Use 4 of the screws from step 2 to secure the two VK1100A / VK1200

units together with the link bracket. Then install the left and right

mounting brackets onto the sides of the units using 2 of the M3x5 and

M3x6 screws included.

3. Align the mounting brackets’ screw holes with that of the front of the rack,

and secure the units onto the rack using 4 self-supplied screw.

Control Box Gen. 2 Setup Guide

13

Desktop

To place the Control Box on a flat surface, such as a desk, simply attach the

foot pad set provided onto its 4 corners and place it on the surface.

Powering the Control Box

1. Use a grounding wire to ground the unit by connecting one end to the

grounding terminal (No. 9, Rear Panel, page 6) and the other end to a

suitable grounded object.

Note: Do not omit this step. Proper grounding helps prevent damage to the

unit from power surges and static electricity.

2. Plug the power cord into the unit’s power socket (No. 1, Rear Panel,

page 6), and connect it to an AC power source.

3. Using a self-supplied Cat 5e/6 cable, connect the unit to a secured

subnetwork via:

Control LAN port for VK1200 / VK2200 (No. 11, Rear Panel, page 6)

LAN port for VK1100A / VK2100A (No. 10, Rear Panel, page 6)

4. (Optional) For VK1200 / 2200, use another Cat 5e/6 cable to connect the

unit to the corporate LAN, via its LAN port (No. 10, Rear Panel, page 6),

for remote access and/or centralized management by ATEN Unizon.

5. Start the unit by switching on its power switch (No. 2, Rear Panel,

page 6). Upon startup, all of the Control Box’s interface LEDs will blink

once, with the buzzer beeping once.

14

ID, Network & License Configuration

Setting Control Box ID

For VK1200 / VK2200, use the LCD panel on the front panel to set its ID.

For VK1100A / VK2100A, use the Control Box ID switch to set its ID.

Note: Take note of the control box ID, which should be unique and unrepeated

if there are other controllers within the same subnet.

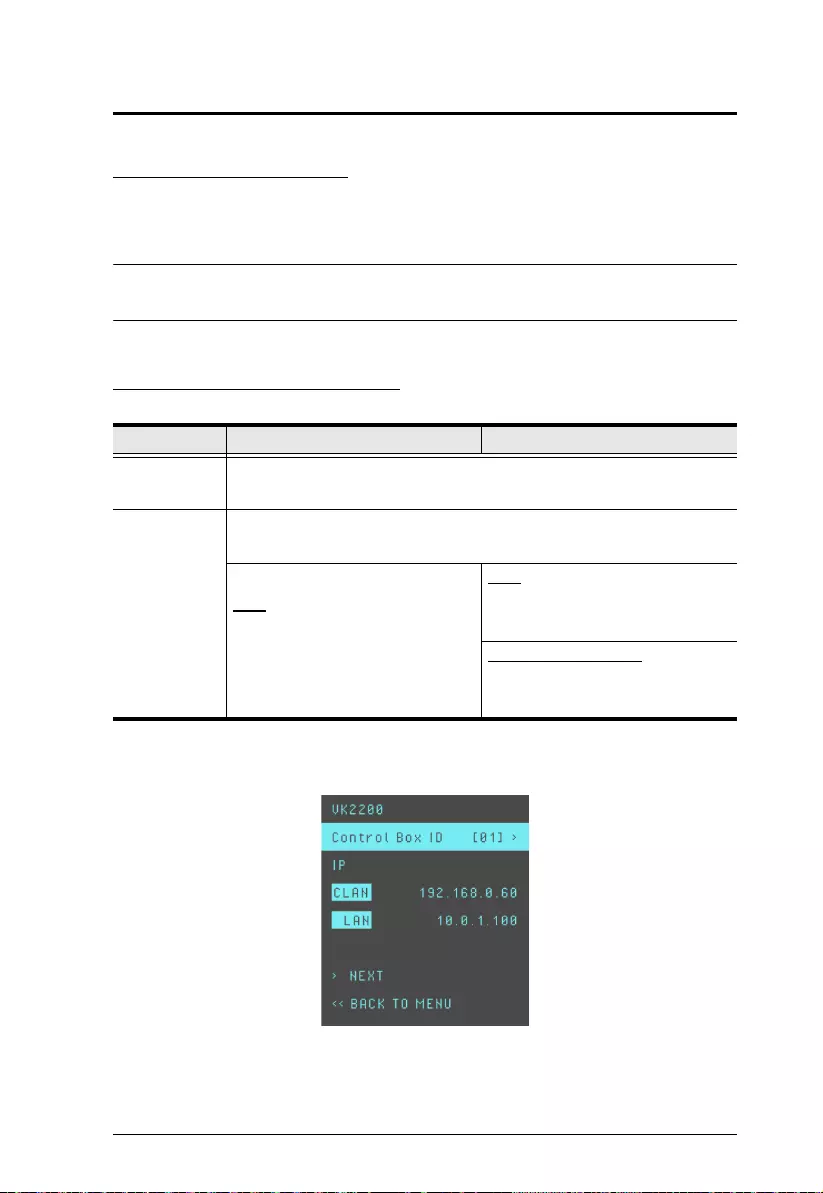

Determining the IP Address

The network information of the VK1200 / VK2200 can be found on its LCD

panel, via Information, as illustrated below.

VK1100A / VK2100A VK1200 / VK2200

DHCP When connected to a DHCP network, the control box is assigned with

an IP address automatically upon startup.

Non-DHCP

When no dynamic IP address is assigned to it within 30 seconds after

startup, the control box’s default network settings are applied:

LAN

Default IP Address: 192.168.0.60

Subnet Mask: 255.255.255.0

LAN

Default IP Address: 192.168.1.60

Subnet Mask: 255.255.255.0

Control LAN (CLAN)

Default IP Address: 192.168.0.60

Subnet Mask: 255.255.255.0

Control Box Gen. 2 Setup Guide

15

The network information of the VK1100A / VK2100A can be determined

using the IP Installer. Follow the steps below to install IP Installer.

1. Using a Windows PC, download the IP Installer zip file in Support and

Downloads from the ATEN controller’s product web page.

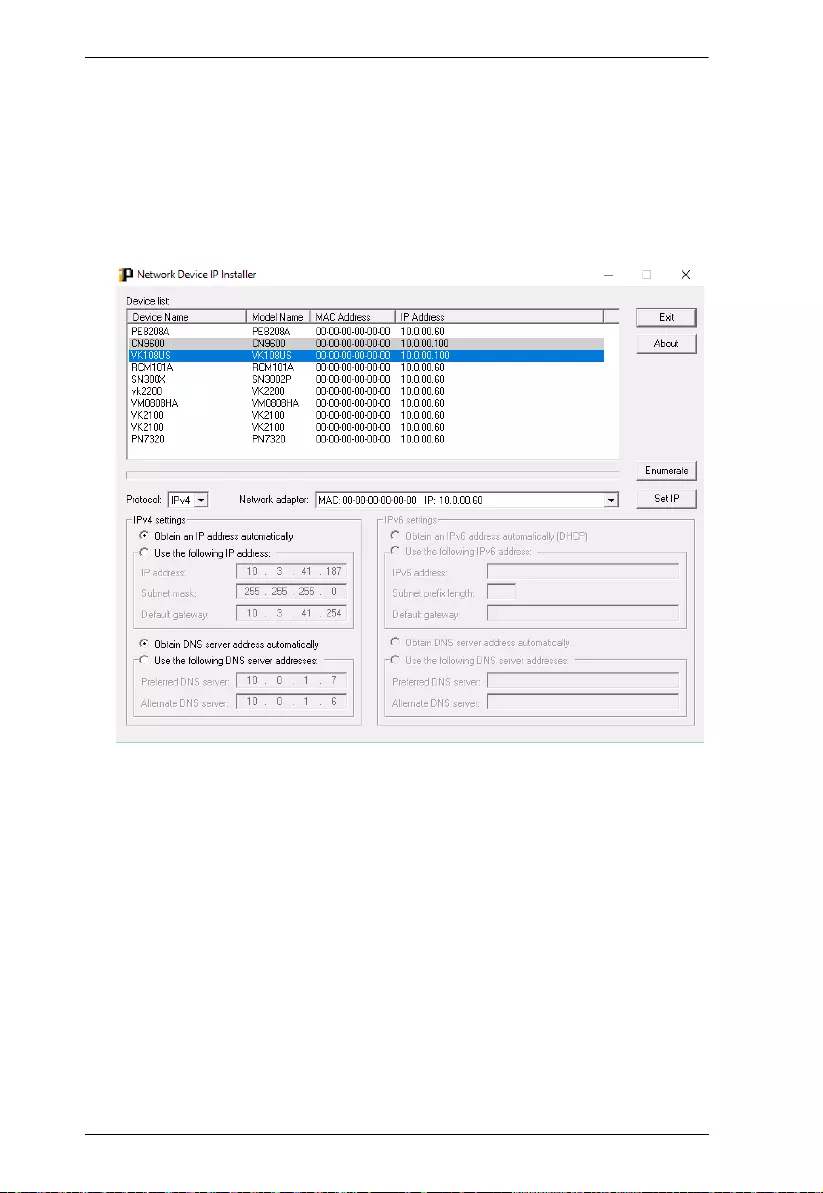

2. Extract and execute IPInstaller.exe. A window similar to the one below

appears.

3. Make sure the proper network adapter is selected and click Enumerate to

search for and display your ATEN controllers within the Device List.

Initialization

16

Changing Network Settings

There are two methods of changing the network settings of the Control Box —

via IP Installer or web interface — on a PC within the same subnet.

IP Installer

1. Using a Windows PC, download IP Installer zip file under Support and

Downloads from the Control Box’s product web page. Then extract and

execute IPInstaller.exe.

2. Select the Control Box model from the Device List, and select Use the

following IP address under IPv4 settings to change its IP address, subnet

mask, and default gateway.

Web Interface

Accessing the Web Interface

1. Open a web browser, enter the Control Box’s IP address, and log into its

web interface using the default access key — password. Upon login, the

user will be prompted and required to set a new password for the unit.

2. Click Settings

> Network, select Manually (DHCP off) from the

Get IP Address drop-down list, and change its network settings, namely

IP address, subnet mask, and default gateway.

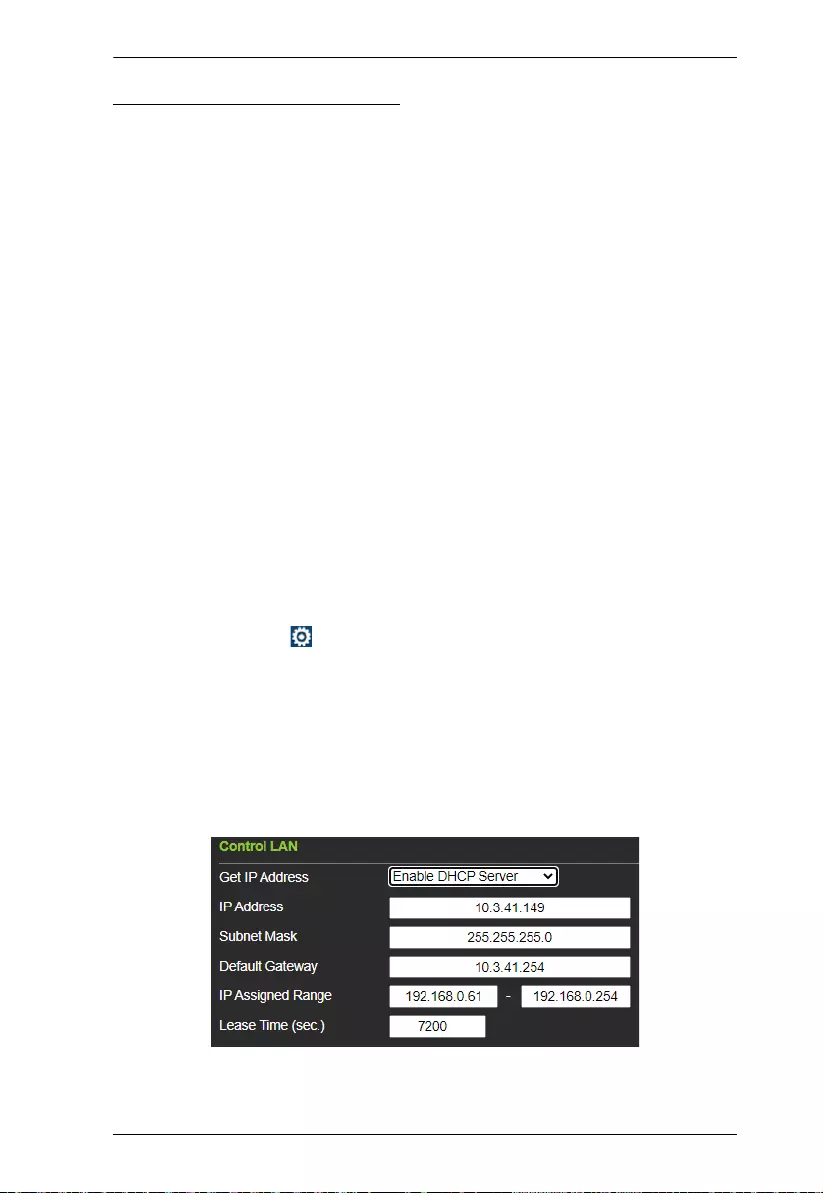

Working as a DHCP Server

To set the VK1200 / VK2200 as a DHCP server for automatically

assigning dynamic IP addresses to the IP devices managed via its Control

LAN, do the following:

Control Box Gen. 2 Setup Guide

17

1. From the Get IP Address drop-down list, select Enable DHCP Server,

and optionally change the network settings of the VK1200 / VK2200,

namely IP address, subnet mask, and default gateway.

2. Next to IP Assigned Range, define the desired range of IP that can be

used for assigning IP addresses to the connecting IP devices.

3. Next to Lease Time, define the amount of time an assigned IP address

becomes available for use after the IP device it is previously assigned

to has been inactive for.

Firmware

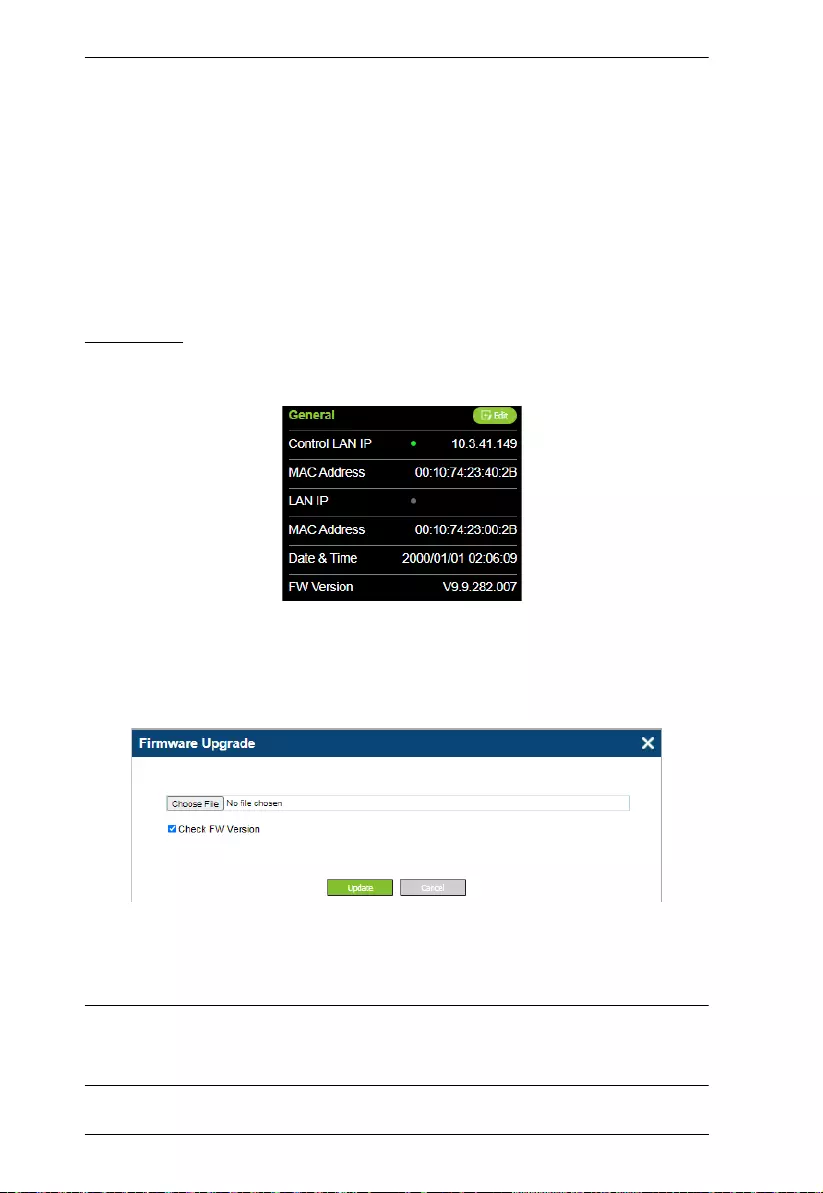

The current firmware version of the Control Box is displayed on its web

interface main page, as shown below.

Upgrading Firmware

To upgrade the Control Box’s firmware, download the latest firmware file from

its product web page, and save it on the PC.

On the Control Box’s web interface main page, click Edit next to General, and

click Update under Firmware. Then browse for the downloaded firmware file

to upgrade.

Note: When Check FW Version is checked, the unit will compare its current

firmware version with that of the firmware file selected, and only allow

upgrading to a later version.

Initialization

18

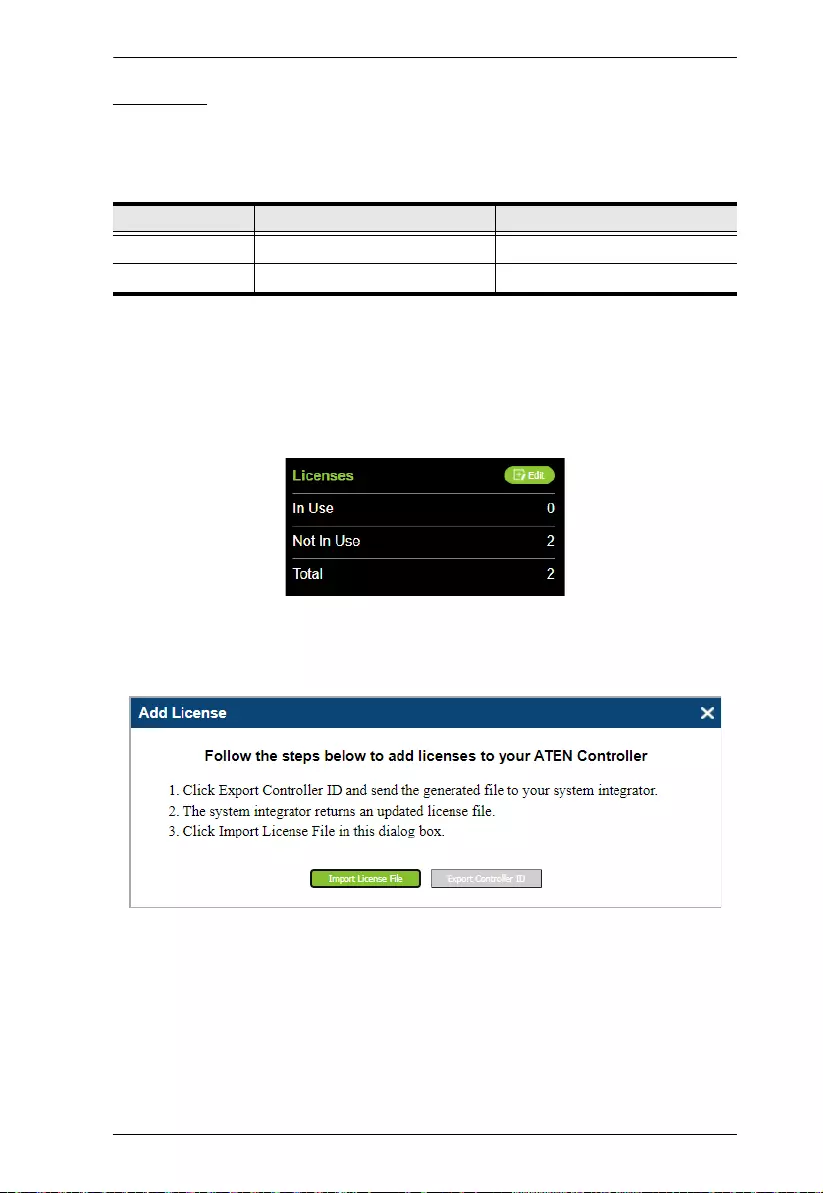

Licenses

A license is a software permit that a Control Box grants to a mobile device for

remote control. The Control Box’s numbers of free and maximum licenses are

described below:

Adding Licenses

By default, the Control Box is supplied with 2 free licenses for granting remote

control to 2 mobile devices.

To add additional licenses, click Edit next to Licenses on its web interface main

page, and click Add License. Then follow the on-screen instructions to export

a license file, apply for a license upgrade, and import the upgraded license file.

License VK1100A / VK2100A VK1200 / VK2200

Free Licenses 22

Max. Licenses 16 32

19

Wiring and Connecting to Devices

To connect the Control Box to various devices, for integration and control,

refer to the corresponding interface for the wiring information of each.

12 V DC Power Outputs — see 12 V DC Power Output, page 19.

Relay — see Relay, page 21.

Digital I/O — see Digital I/O, page 23.

Bidirectional Serial — see Bidirectional Serial, page 26.

Unidirectional IR / Serial — see Unidirectional IR / Serial, page 27.

Control LAN — see Control LAN, page 29.

Note: All diagrams herein are exemplified using VK2200.

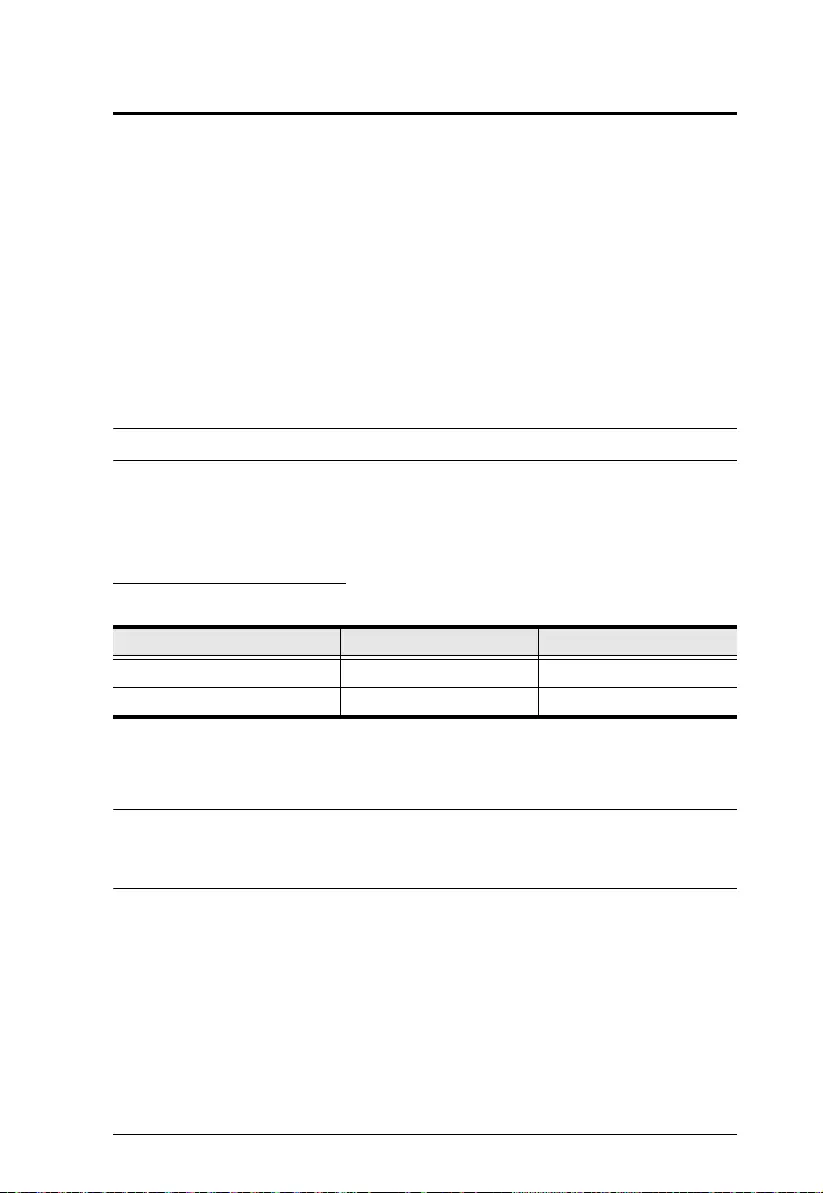

12 V DC Power Output

The Control Box Gen. 2 provides the following 12 V DC output(s):

It can power one or four independent hardware device(s), as illustrated below,

as well as relay or digital output devices.

Note: For powering relay or digital output devices connected, please refer to

Powered by 12 V DC Power Output, page 22, and Powered by 12 V DC

Power Output, page 24, respectively.

VK1100A / VK1200 VK2100A / VK2200

Number of Channels 14

Max. Power Supply DC 12 V, 1 A DC 12 V, 2 A

Wiring

20

Independent Power Supply

When the total current exceeds the maximum threshold, the DC power

overload LED lights orange, and the alarm beeps for 3 seconds, while turning

the channel(s) off.

To correct power overload:

1. Turn off the Control Box.

2. Disconnect all devices connected to the 12 V DC outputs.

3. Turn the Control Box back on.

4. Reconnect the devices one at a time, to ensure the maximum current

threshold is not exceeded.

Power Supply: 12 V DC, 1 A /

2 A Max

Provides 12 V DC power to

independent hardware devices.

Connects to

12 V DC Output Ports

Control Box Gen. 2 Setup Guide

21

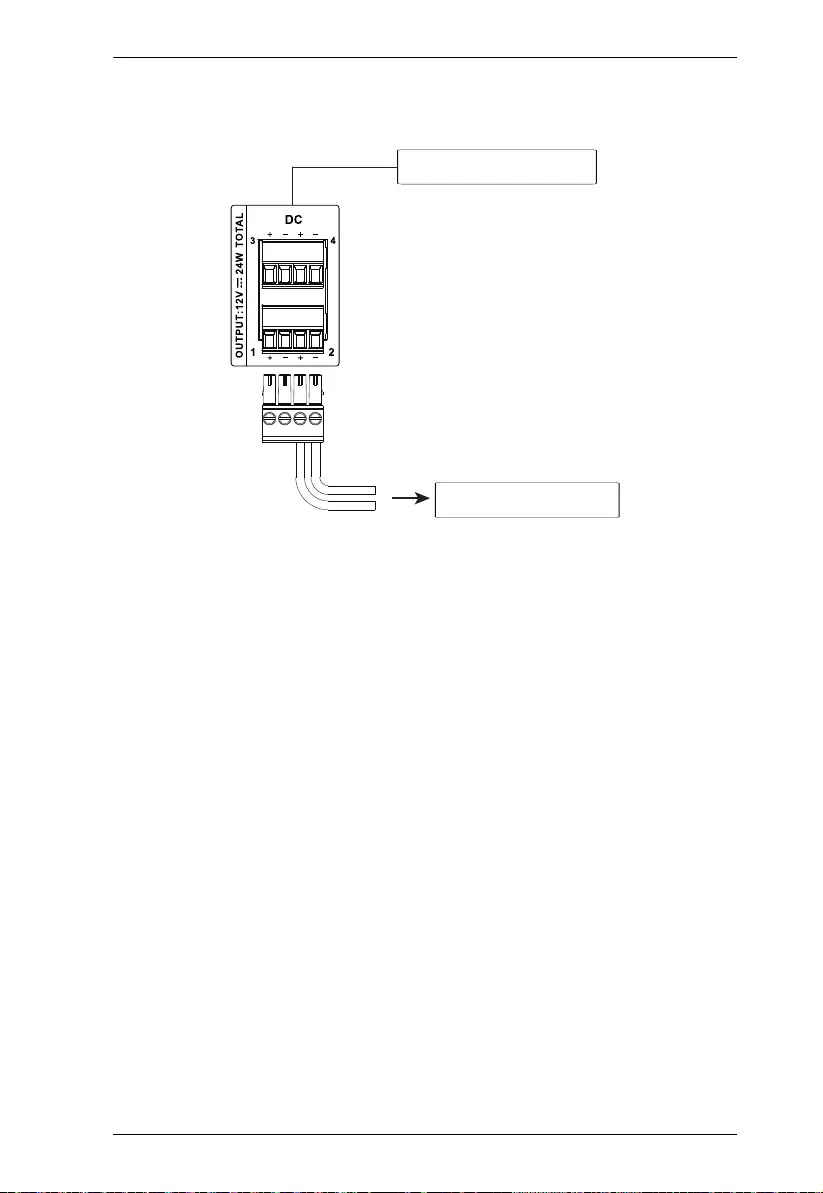

Relay

The VK1200 / VK2200 provides the following isolated relays:

Using Self-Supplied Power

VK1100A / VK1200 / VK2100A VK2200

Number of Channels 48

Contact Rating 24 V DC, 2 A

Default Status Normally Open

Normally

Open Closed

Normally Open, Isolated Relays

Contact Rating: 24 V DC 2 A Max

Switch, Screen, Projector Lift,

Lighting, Motorized Equipment,

Motion Device, etc.

Connects to

Relay Channels

Wiring

22

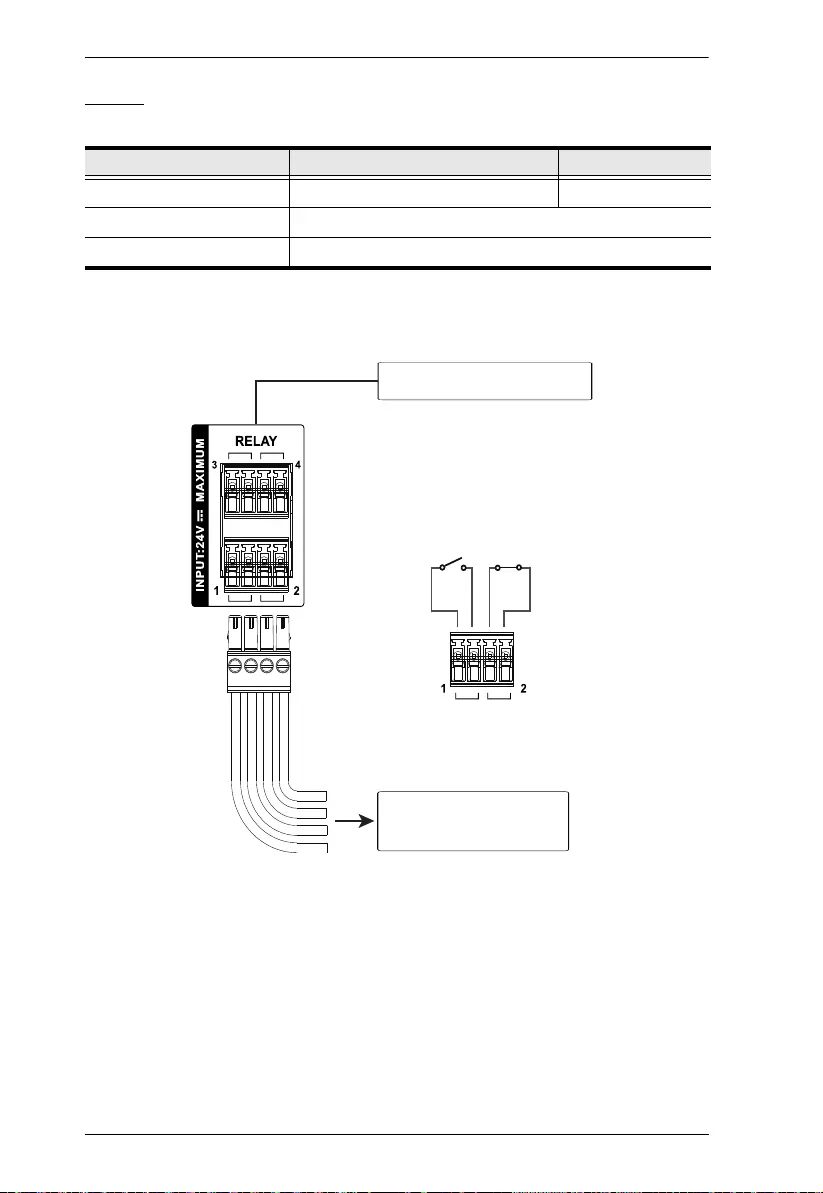

Powered by 12 V DC Power Output

Connects to

Provides 12 V DC power

for the relay loop.

Power Supply: 12 V DC, 1 A /

2 A Max

12 V DC Output Ports

Switch, Screen, Projector Lift,

Lighting, Motorized Equipment,

Motion Device, etc.

Control Box Gen. 2 Setup Guide

23

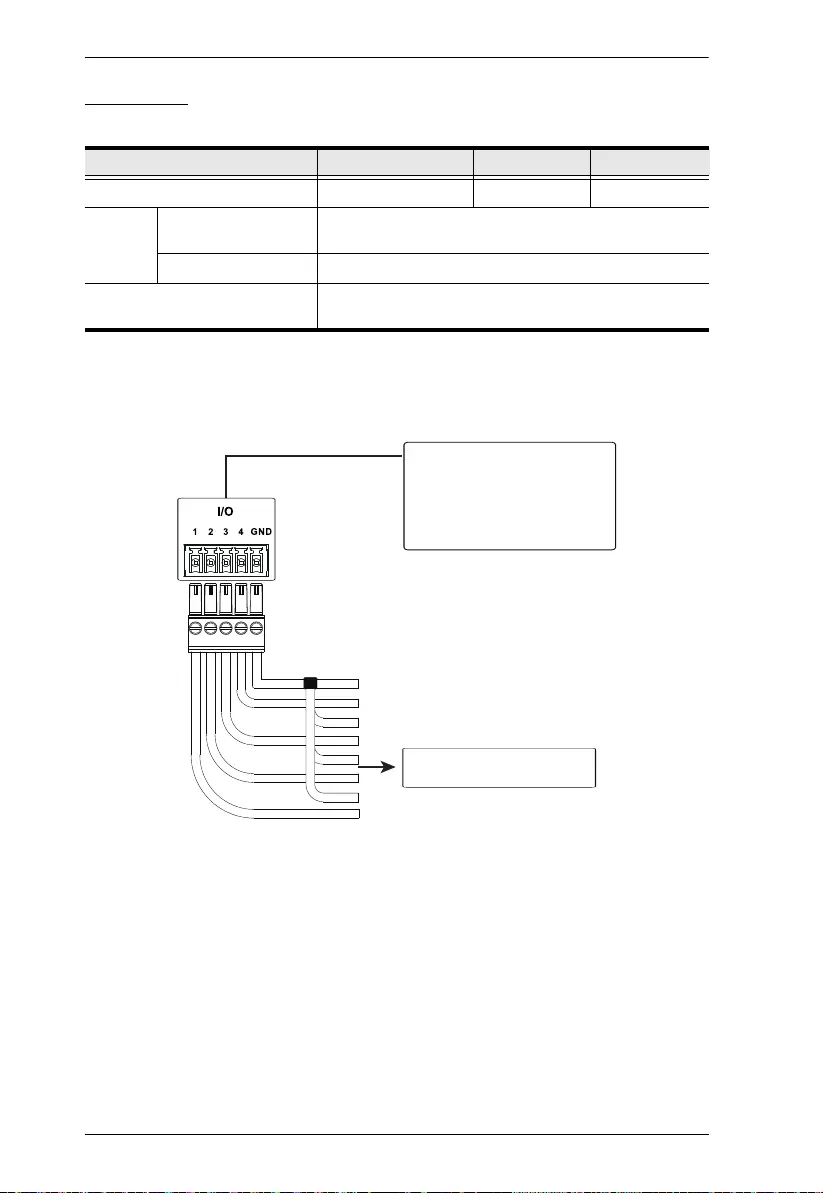

Digital I/O

The Control Box Gen. 2 provides the following digital input/output channels:

Digital Input

Dry Contact

Connects to digital I/O devices with a input loop — open or closed — for

providing indicators from sensors or switches of an event, which can be

used by the Control Box to trigger certain events and/or functions.

VDC Mode

Connects to DC devices for providing voltage signals (1 ~ 24 V) to the

Control Box, to trigger certain events and/or functions when the voltage

signals are above or below the defined threshold.

VK1100A / VK1200 VK2100A VK2200

Number of Channels 248

Digital

Input

VDC Mode Voltage range: 0 ~ 24 V DC

Programmable range: 1 ~ 24 V DC

Dry Contact Mode Pull-up: 2 kΩ to +12 V DC

Digital Output Normally Open

300 mA sink from 24 V DC

Connects to

Programmable Digital

Input Channels

Digital Input

VDC Mode:

- Input Range: 0 ~ 24 V DC

- Programmable Range: 1 ~ 24 V DC

Dry Contact Mode:

- Pull-up 2kΩ to + 12 V DC

Digital Input: Switches, Sensors

Monitors and Button Triggers.

Wiring

24

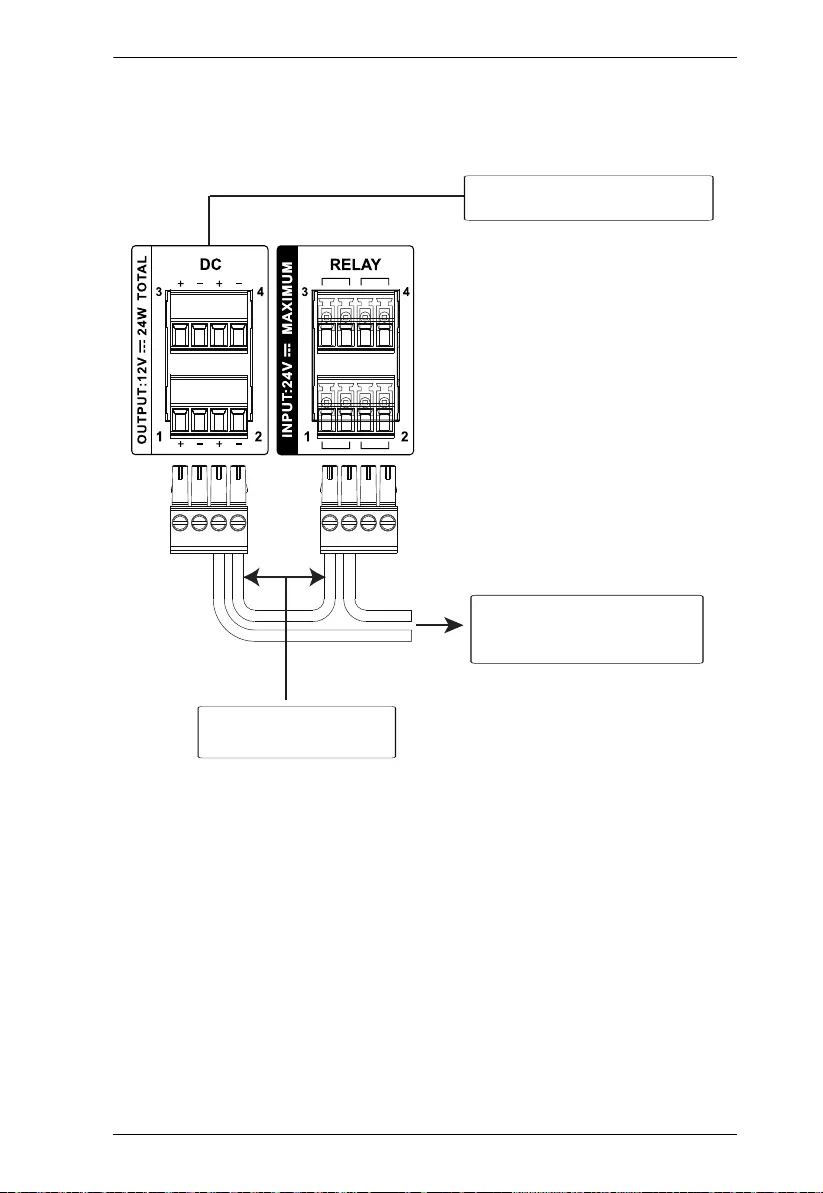

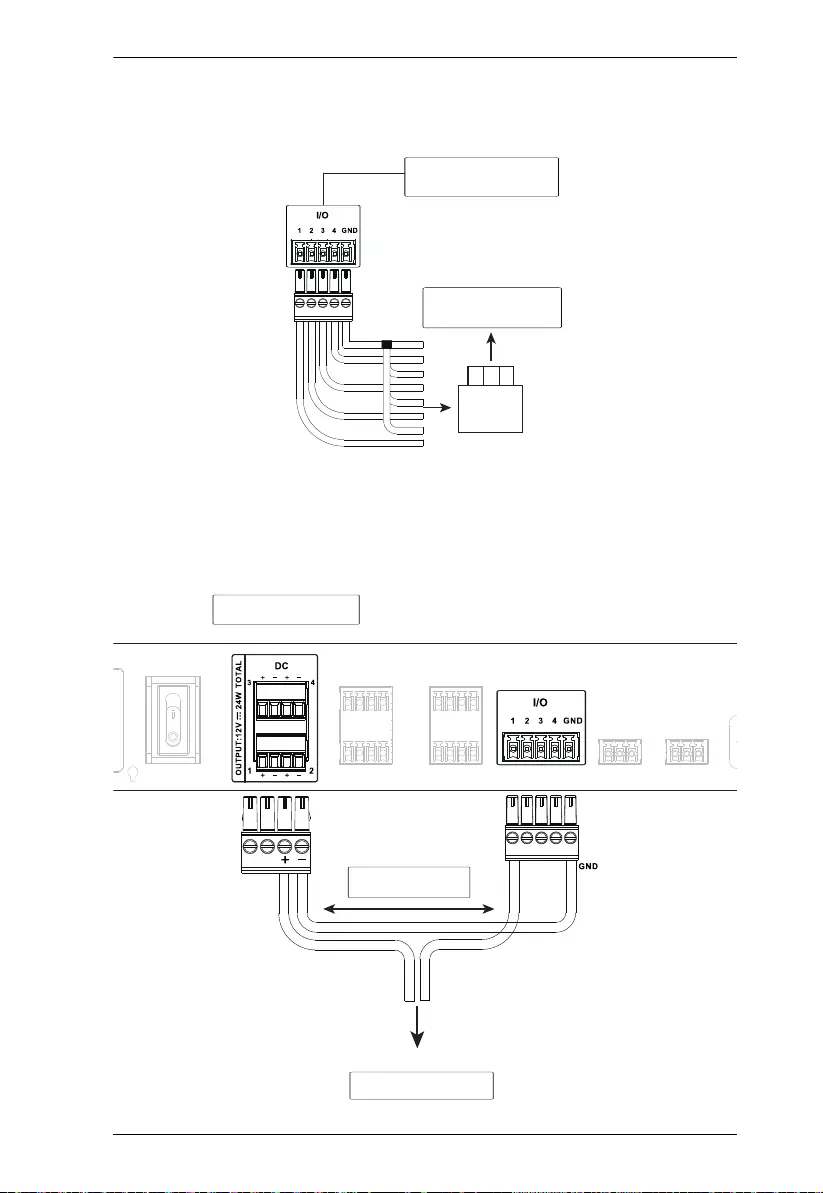

Digital Output

Digital outputs provide non-powered dry contact (open and closed) circuit

control of devices, which must be connected using a relay module.

Powered by 12 V DC Power Output

Digital Output: Switch, Screen,

Projector Lift, Lighting and

Equipment Control.

Connects to

Programmable Digital

Output Channels

Digital Output:

300 mA sink from 24 V DC

Relay

Module

Power Supply: 12 V DC, 1 A /

2 A Max

Connects to

Switch, Screen, Projector Lift,

Lighting and Equipment Control.

12 V DC Output Ports

Provides 12 V DC power

for the digital output loop.

Control Box Gen. 2 Setup Guide

25

Digital Output Dual Power Supply

Power Supply: 12 V DC, 1 A /

2 A Max

12 V DC Output Ports

Provides 12 V DC power

for the digital output loop.

Provides connection to

digital output #2.

Provides connection to

digital output #1.

Wiring

26

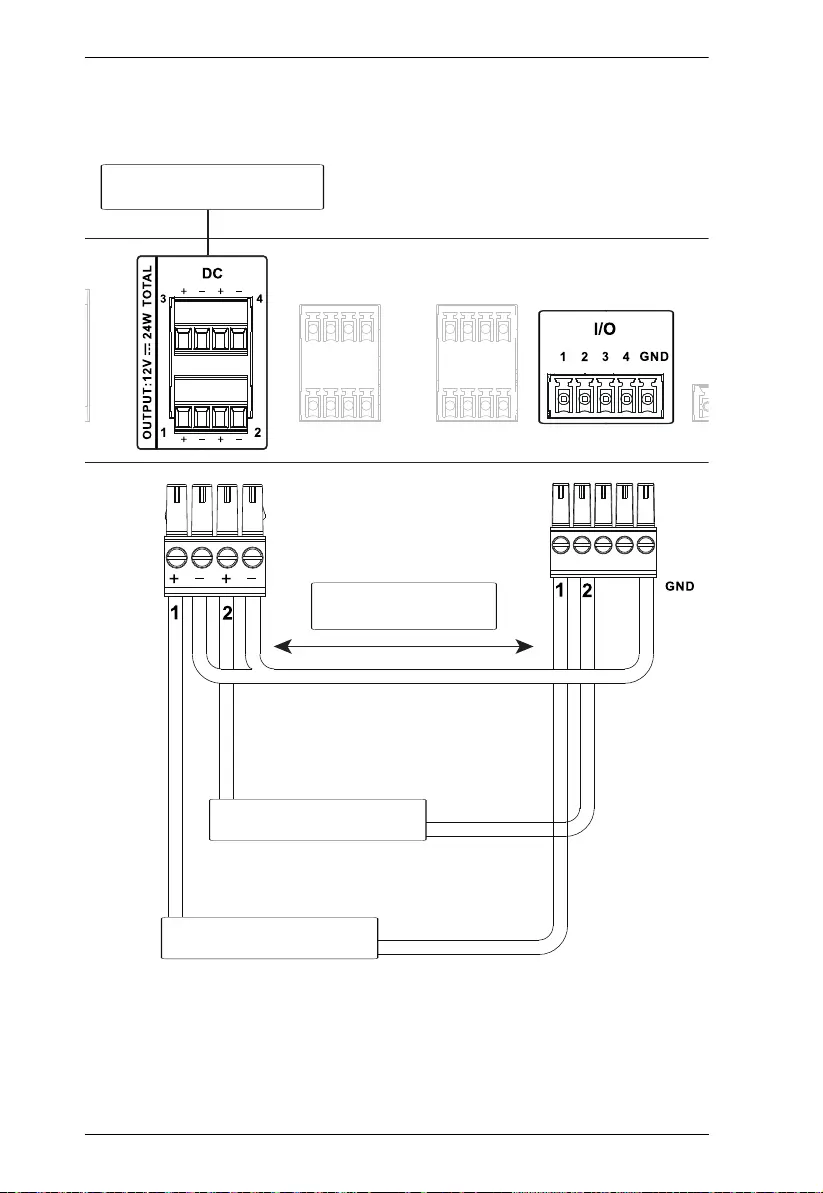

Bidirectional Serial

The Control Box Gen. 2 provides the following RS-232/422/485 ports:

RS-232 (3-Pin)

Connect to devices for controlling and receiving status messages from them.

For bi-directional RS-232 control, the transmit (TX), receive (RX) and ground

(GND) terminals must be wired on both the Control Box and the device

connecting.

VK1100A / VK1200 VK2100A VK2200

Number of

Channels

3-Pin

RS-232 146

5-Pin

RS-232/422/485 122

Baud rate 300 ~ 115200 (default: 9600)

Data bit 7, 8 (default)

Stop bit 1 (default), 2

Parity None (default), Even, Odd

Projector, Matrix Switch,

Camera, etc.

Baud Rate: 300 to 115200

(default: 9600)

Data Bit: 8 (default) or 7

Stop Bit: 1 (default) or 2

Parity: None (default), even or

odd

Connects to

Bidirectional RS-232 Ports

Control Box Gen. 2 Setup Guide

27

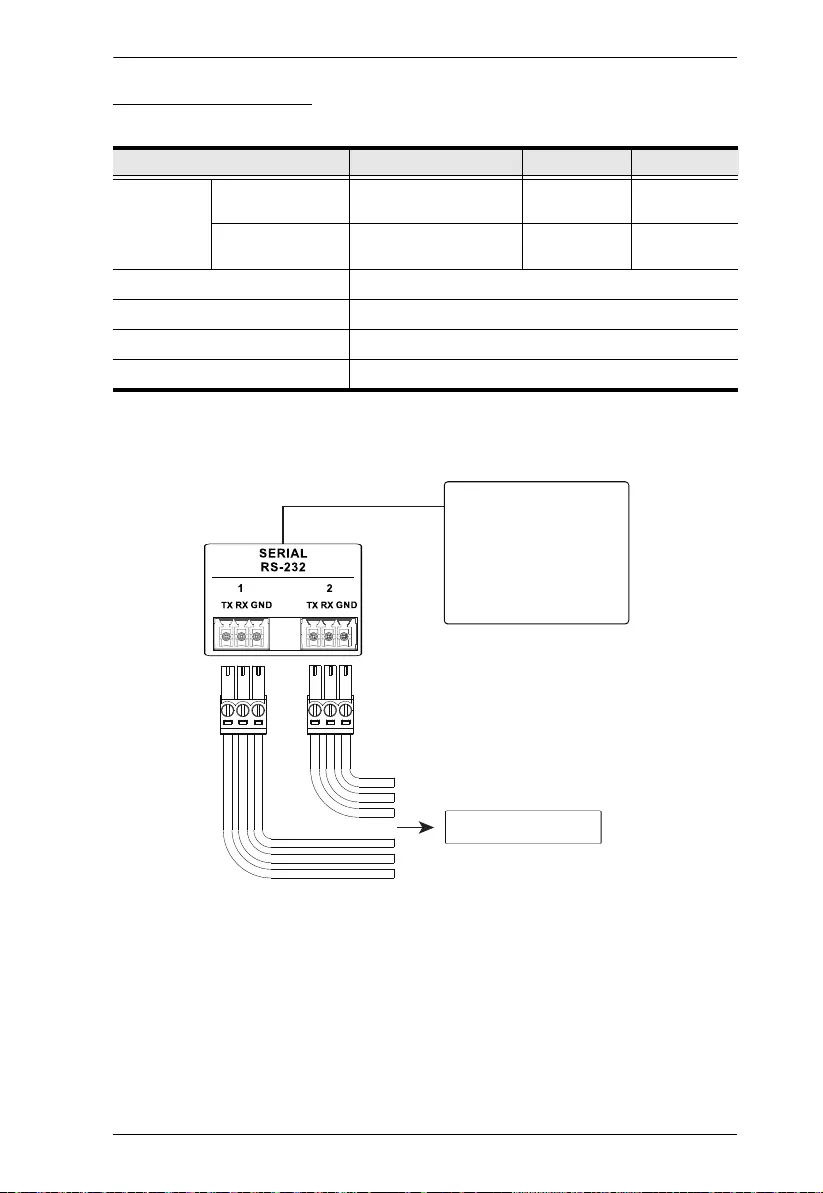

RS-232/422/485 (5-Pin)

Connect to devices, configurable by pin assignments, for controlling and

receiving status messages from them.

Unidirectional IR / Serial

The Control Box Gen. 2 provides the following IR / serial (RS-232) ports:

VK1100A / VK1200 VK2100A VK2200

2-Pin IR/Serial 248

IR

Carrier Frequency 10 ~ 455 kHz

Default Level Low

Serial

(RS-232

Baud rate 300 ~ 115200 (default: 9600)

Data bit 7, 8 (default)

Stop bit 1 (default), 2

Parity None (default), Even, Odd

Signal Level TTL (0 ~ 5 V DC)

Projector, Matrix Switch,

Camera, etc.

Connects to

Configurable by pin assignment

Bidirectional

RS-232 / 422 / 485 Ports

Wiring

28

Connect to IR and/or RS-232 devices. By default, these channels are set to

transmit IR signals.

IR Connection

Connect a transmitter cable to a set of IR and ground terminals of the Control

Box, and set up the IR transmitter on or near the IR receiving port of the IR

device.

Serial Connection

Connect a serial device's receiver (RX) and ground (GND) terminals to a set of

serial (TX) and ground (GND) terminals of the Control Box.

Unidirectional TTL Level

(0 ~ 5 V)

Baud Rate: 300 to 115200

(default: 9600)

Data Bit: 8 (default) or 7

Stop Bit: 1 (default) or 2

Parity: None (default), Even or

Odd

IR: Blu-ray / DVD Player, TV,

Audio Receiver, Projector, etc.

RS-232: Camera, Projector,

Switch, Audio Mixer, Multimedia

Device, etc.

Connects to

RS-232

TTL Level (0 ~ 5 V)

Carrier Frequency:

10 ~ 455 kHz

IR

or

Control Box Gen. 2 Setup Guide

29

Control LAN

The LAN (VK1100A / VK2100A) or Control LAN (VK1200 / VK2200) port

provides an Ethernet connection for controlling up to 25 / 64 IP devices and/or

remote control by ATEN Keypads, Touch Panel, and the ATEN Control

System app on a mobile device within the same subnetwork.

Control LAN

VK224

VK236

VK248

VK258

Expansion Box

SELECT

PDU

CURRENT

OUTLET

CURRENT

IP

ADDRESS

SENSOR

1

SENSOR

2

OUTLET STATUS

ONVIF

TCP

PJLink

Telnet

Telnet

The RJ-45 port is used to connect to

and access TCP, UDP, PJLink,

ONVIF, HTTP, HTTPS, and Telnet

devices.

The VK1200 / 2200 can operate as

an DHCP server for assigning IP

addresses to the devices

eco PDU

Modular Matrix Switch

Ethernet Switch

UDP

Lighting HVAC Systems

KNX IP Interface

HTTP

HTTPS

Video Conferencing System

30

ATEN Configurator — VK6000

Download the ATEN Configurator software — VK6000 — from the product

web page, and install it on a PC.

Adding the Control Box

1. After installing the ATEN Configurator, the main page appears. start by

clicking the Project tab at the top.

2. On the Project tab, provide the information of the Control Box. Then click

Start Project.

3. In the Device tab, add all devices to be managed by the Control Box into

the Device Configuration list.

Once all devices are successfully added and configured by the VK6000, users

can start designing dedicated control interfaces — Viewers — on the VK6000

to be uploaded into the Control Box for easy remote control to all devices via

ATEN Keypads, Touch Panel, or Control System app with mobile devices.

For detailed information on VK6000, as well as Control System mobile app,

please refer to the Control System User Manual.

ATEN Expansion Box

For adding additional ports, users can purchase the ATEN Expansion Boxes to

be connected to the Control Box for flexible scalability, including:

© Copyright 2021 ATEN® International Co., Ltd.

Released: 2022-01-21

ATEN and the ATEN logo are registered trademarks of ATEN International Co., Ltd. All rights reserved.

All other brand names and trademarks are the registered property of their respective owners.

Model Description

VK224 4-Port Bidirectional Serial Expansion

VK236 6-Port Unidirectional IR/Serial Expansion Box

VK248 8-Channel Relay Expansion Box

VK258 8-Channel Digital I/O Expansion Box