Chief 44U ROTR-HD User Manual

Displayed below is the user manual for 44U ROTR-HD by Chief which is a product in the Rack Cabinets category. This manual has pages.

Related Manuals

Instruction

Sheet

Raxxess

ROTR-HD

Heavy

Duty

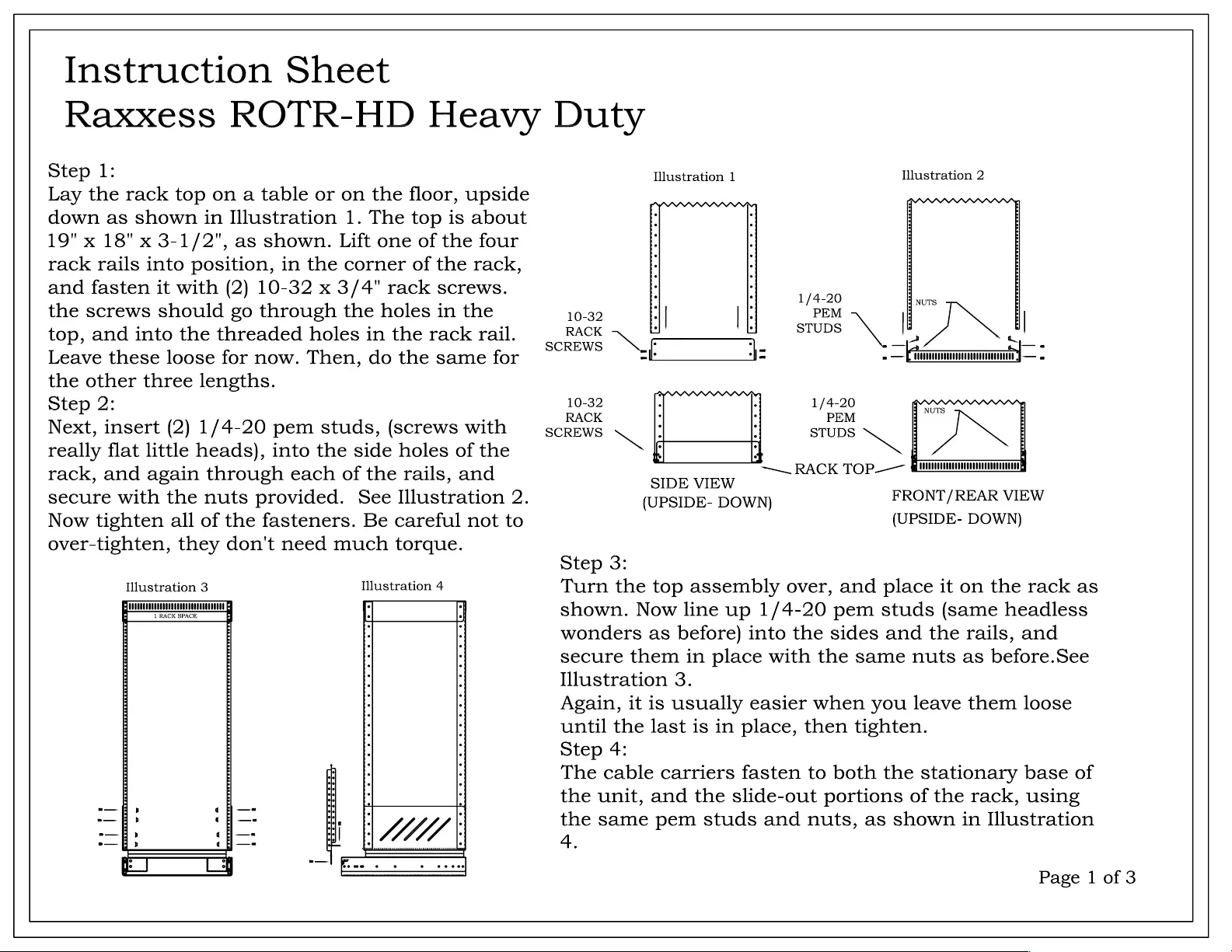

Step

1:

Lay

the

rack

top

on

a

table

or

on

the

floor,

upside

down

as

shown

in

Illustration

1.

The

top

is

about

19"

x

18"

x

3-1/2",

as

shown.

Lift

one

of

the

four

rack

rails

into

position,

in

the

corner

of

the

rack,

and

fasten

it

with

(2)

10-32

x

3/4"

rack

screws.

the

screws

should

go

through

the

holes

in

the

top,

and

into

the

threaded

holes

in

the

rack

rail.

Leave

these

loose

for

now.

Then,

do

the

same

for

the

other

three

lengths.

step

2:

Next,

insert

(2)

1/4-20

pem

studs,

(screws

with

really

flat

little

heads),

into

the

side

holes

of

the

rack,

and

again

through

each

of

the

rails,

and

secure

with

the

nuts

provided.

See

Illustration

2.

Now

tighten

all

of

the

fasteners.

Be

careful

not

to

over-tighten,

they

don't

need

much

torque.

Illustration

3

Illustration

4

WONNUANOOOAONANONOOOONORANOOOONENO

1

RACK

SPACE

|

Li

Illustration

1

Illustration

2

1/4-20

we

BL

IG

sat!

\

NS

screws

Nfs

=

Gi

|

—IALAAAAAAAA

10-32

. °

1/4-20

RACK

:

PEM

SCREWS

\

STUDS

NN

4

RACK

TOP_—

fmm

SIDE

VIEW

(UPSIDE-

DOWN)

FRONT/REAR

VIEW

(UPSIDE-

DOWN)

step

3:

Turn

the

top

assembly

over,

and

place

it

on

the

rack

as

shown.

Now

line

up

1/4-20

pem

studs

(same

headless

wonders

as

before)

into

the

sides

and

the

rails,

and

secure

them

in

place

with

the

same

nuts

as

before.See

Illustration

3.

Again,

it

is

usually

easier

when

you

leave

them

loose

until

the

last

is

in

place,

then

tighten.

step

4:

The

cable

carriers

fasten

to

both

the

stationary

base

of

the

unit,

and

the

slide-out

portions

of

the

rack,

using

the

same

pem

studs

and

nuts,

as

shown

in

Illustration

4.

Page

1

of

3

Instruction

Sheet

Raxxess

ROTR-HD

Heavy

Duty

"Flats"

Xen

5

Turn

Counter-

Clockwise

aC CL

Cr

Cy CY Cy

Illustration

6

O°

°o

fe)

r°

Turn

]

A

Clockwise

JF}

OF

EF

LI

BOLTS

Nh

|i

Adjustable

Support

Cylinders

Roller

Assembly

Support

Mounting

Brackets

Illustration

7

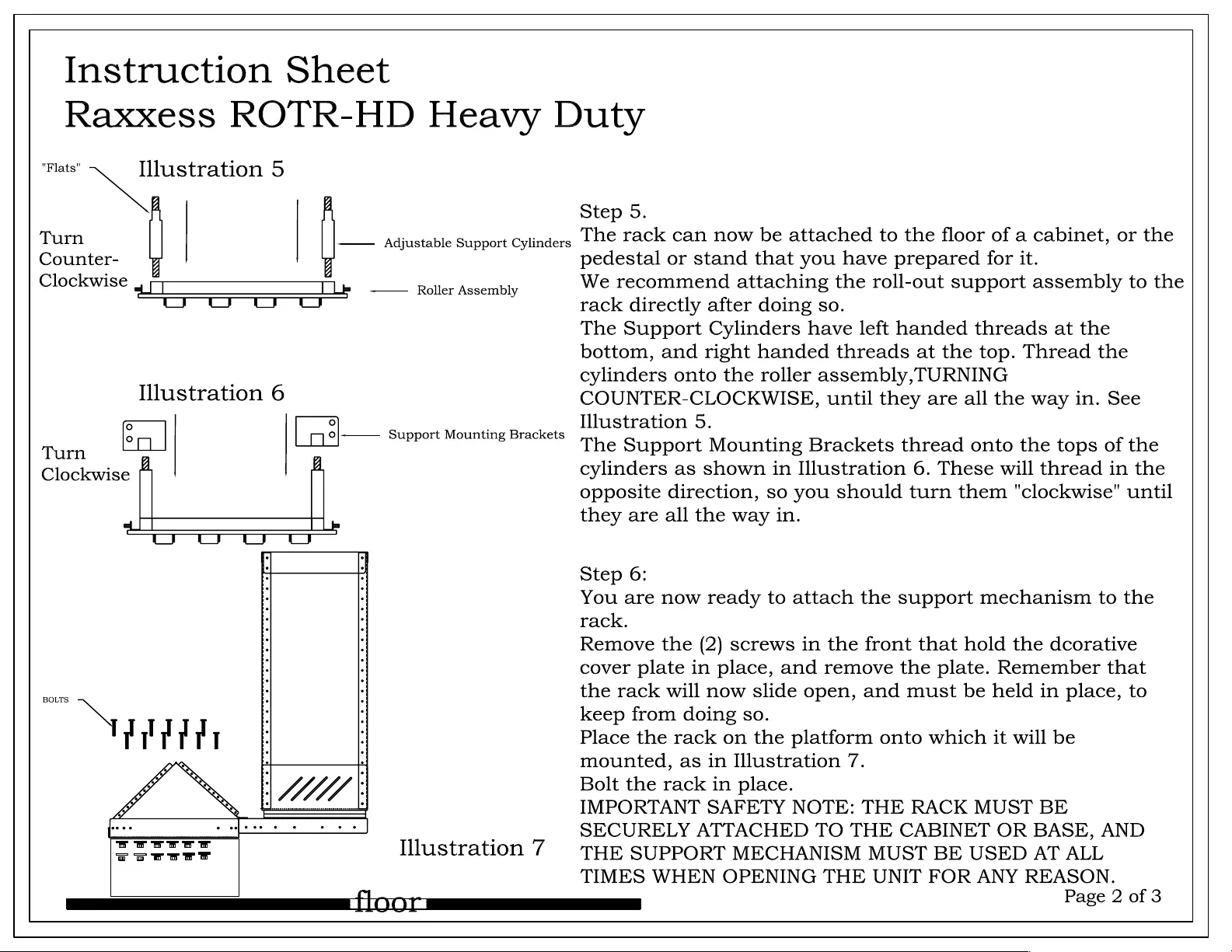

Step

5.

The

rack

can

now

be

attached

to

the

floor

of

a

cabinet,

or

the

pedestal

or

stand

that

you

have

prepared

for

it.

We

recommend

attaching

the

roll-out

support

assembly

to

the

rack

directly

after

doing

so.

The

Support

Cylinders

have

left

handed

threads

at

the

bottom,

and

right

handed

threads

at

the

top.

Thread

the

cylinders

onto

the

roller

assembly,

TURNING

COUNTER-CLOCKWISE,

until

they

are

all

the

way

in.

See

Mlustration

5.

The

Support

Mounting

Brackets

thread

onto

the

tops

of

the

cylinders

as

shown

in

Illustration

6.

These

will

thread

in

the

opposite

direction,

so

you

should

turn

them

"clockwise"

until

they

are

all

the

way

in.

step

6:

You

are

now

ready

to

attach

the

support

mechanism

to

the

rack.

Remove

the

(2)

screws

in

the

front

that

hold

the

dcorative

cover

plate

in

place,

and

remove

the

plate.

Remember

that

the

rack

will

now

slide

open,

and

must

be

held

in

place,

to

keep

from

doing

so.

Place

the

rack

on

the

platform

onto

which

it

will

be

mounted,

as

in

Illustration

7.

Bolt

the

rack

in

place.

IMPORTANT

SAFETY

NOTE:

THE

RACK

MUST

BE

SECURELY

ATTACHED

TO

THE

CABINET

OR

BASE,

AND

THE

SUPPORT

MECHANISM

MUST

BE

USED

AT

ALL

TIMES

WHEN

OPENING

THE

UNIT

FOR

ANY

REASON.

rf)

) |

Page

2

of

3

Instruction

Sheet

Raxxess

ROTR-HD

Heavy

Duty

Illustration

8

Support

Mounting

Brackets

Adjustable

Support

Cylinders

Roller

Assembly

AF)

RS

LI

LS

Turn

cylinders

and

watch

the

assembly

rise

up

to

meet

the

rack!

Illustration

9

Protective

Floor

Mat

e

e

oe

°

ie

eo eo

e °

oe

S

e

0

@

©

jo

¢ © © © ©

»

Cabinet

toor

or

base

am

oH

ea

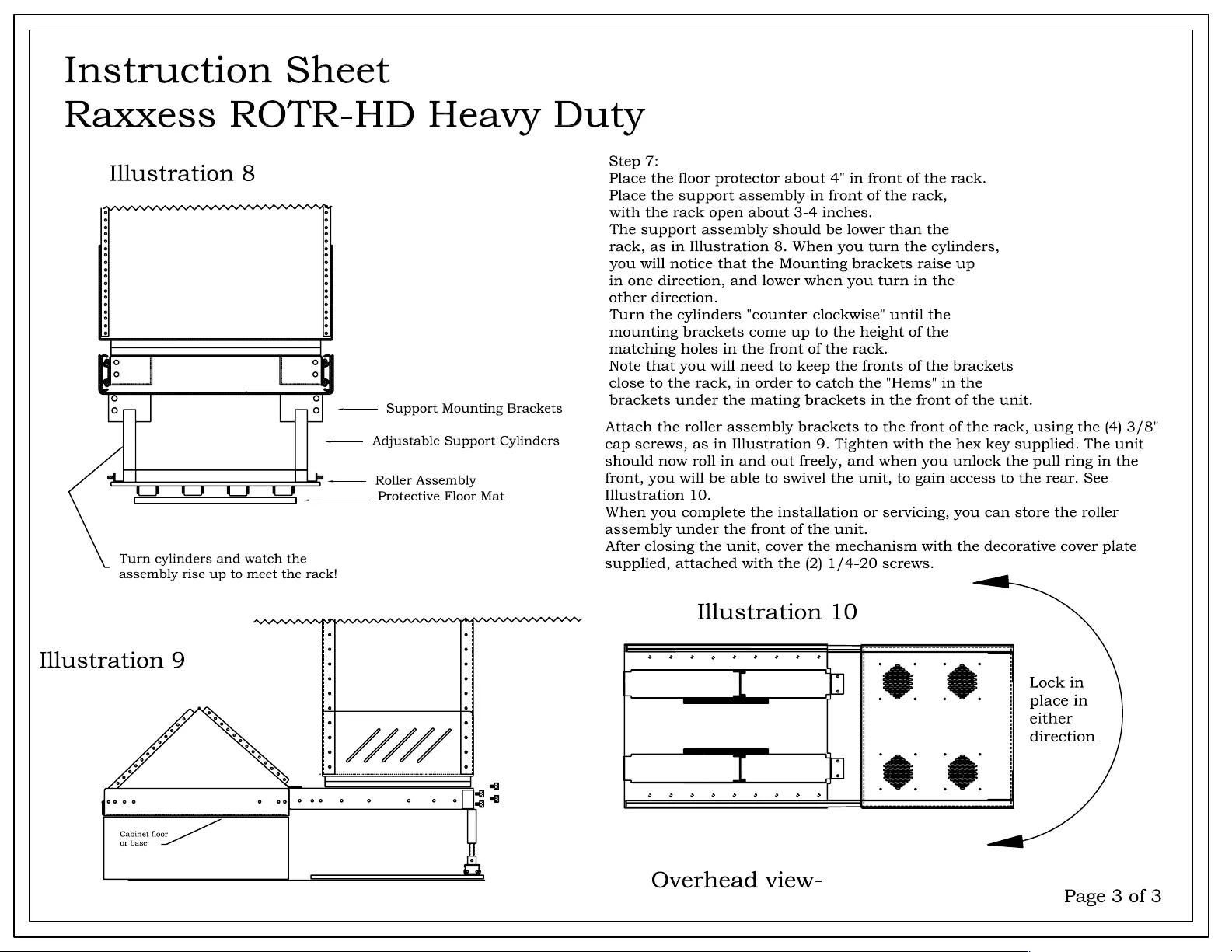

Step

7:

Place

the

floor

protector

about

4" in

front

of

the

rack.

Place

the

support

assembly

in

front

of

the

rack,

with

the

rack

open

about

3-4

inches.

The

support

assembly

should

be

lower

than

the

rack,

as

in

Illustration

8.

When

you

turn

the

cylinders,

you

will

notice

that

the

Mounting

brackets

raise

up

in

one

direction,

and

lower

when

you

turn

in

the

other

direction.

Turn

the

cylinders

"counter-clockwise"

until

the

mounting

brackets

come

up

to

the

height

of

the

matching

holes

in

the

front

of

the

rack.

Note

that

you

will

need

to

keep

the

fronts

of

the

brackets

close

to

the

rack,

in

order

to

catch

the

"Hems"

in

the

brackets

under

the

mating

brackets

in

the

front

of

the

unit.

Attach

the

roller

assembly

brackets

to

the

front

of

the

rack,

using

the

(4)

3/8"

cap

screws,

as

in

Illustration

9.

Tighten

with

the

hex

key

supplied.

The

unit

should

now

roll

in

and

out

freely,

and

when

you

unlock

the

pull

ring

in

the

front,

you

will

be

able

to

swivel

the

unit,

to

gain

access

to

the

rear.

See

Illustration

10.

When

you

complete

the

installation

or

servicing,

you

can

store

the

roller

assembly

under

the

front

of

the

unit.

After

closing

the

unit,

cover

the

mechanism

with

the

decorative

cover

plate

supplied,

attached

with

the

(2)

1/4-20

screws.

Illustration

10

Lock

in

place

in

either

direction

Overhead

view-

Page

3

of

3