Chief Tempo User Manual

Displayed below is the user manual for Tempo by Chief which is a product in the Monitor Mount Accessories category. This manual has pages.

Related Manuals

I N S T A L L A T I O N I N S T R U C T I O N S

Flat Panel Floor Support System

Spanish Product Description

German Product Description

Portuguese Product Description

Italian Product Description

Dutch Product Description

French Product Description

AVSFSS

AVSFSS Installation Instructions

2

DISCLAIMER

Legrand | AV and its affiliated corporations and subsidiaries

(collectively “Legrand | AV”), intend to make this manual

accurate and complete. However, Legrand | AV makes no claim

that the information contained herein covers all details,

conditions or variations, nor does it provide for every possible

contingency in connection with the installation or use of this

product. The information contained in this document is subject

to change without notice or obligation of any kind. Legrand | AV

makes no representation of warranty, expressed or implied,

regarding the information contained herein. Legrand | AV

assumes no responsibility for accuracy, completeness or

sufficiency of the information contained in this document.

Chief® is a registered trademark of Legrand AV Inc.

DEFINITIONS

MOUNTING SYSTEM: A MOUNTING SYSTEM is the

primary Chief product to which an accessory and/or component

and/or another mounting system is attached.

ACCESSORY: AN ACCESSORY is the secondary Chief

product which is attached to a primary Chief product, and may

have a component attached or setting on it.

COMPONENT: A COMPONENT is an audiovisual item

designed to be attached or resting on an accessory or mounting

system such as a video camera, CPU, screen, display,

projector, etc.

WARNING: A WARNING alerts you to the possibility of

serious injury or death if you do not follow the instructions.

CAUTION: A CAUTION alerts you to the possibility of

damage or destruction of equipment if you do not follow the

corresponding instructions.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Failure to read, thoroughly understand, and

follow all instructions can result in serious personal injury,

damage to equipment, or voiding of factory warranty! It is the

installer’s responsibility to make sure all mounting systems

are properly assembled and installed using the instructions

provided.

WARNING: Failure to provide adequate structural strength

for this mounting system can result in serious personal injury

or damage to equipment! It is the installer’s responsibility to

make sure the structure to which this mounting system is

attached or resting on can support five times the combined

weight of all equipment. Reinforce the structure as required

before installing the mounting system. Do not install drywall

anchors into the seam between drywall pieces.

WARNING: Use this mounting system only for its intended

use as described in these instructions. Do not use

attachments not recommended by the manufacturer.

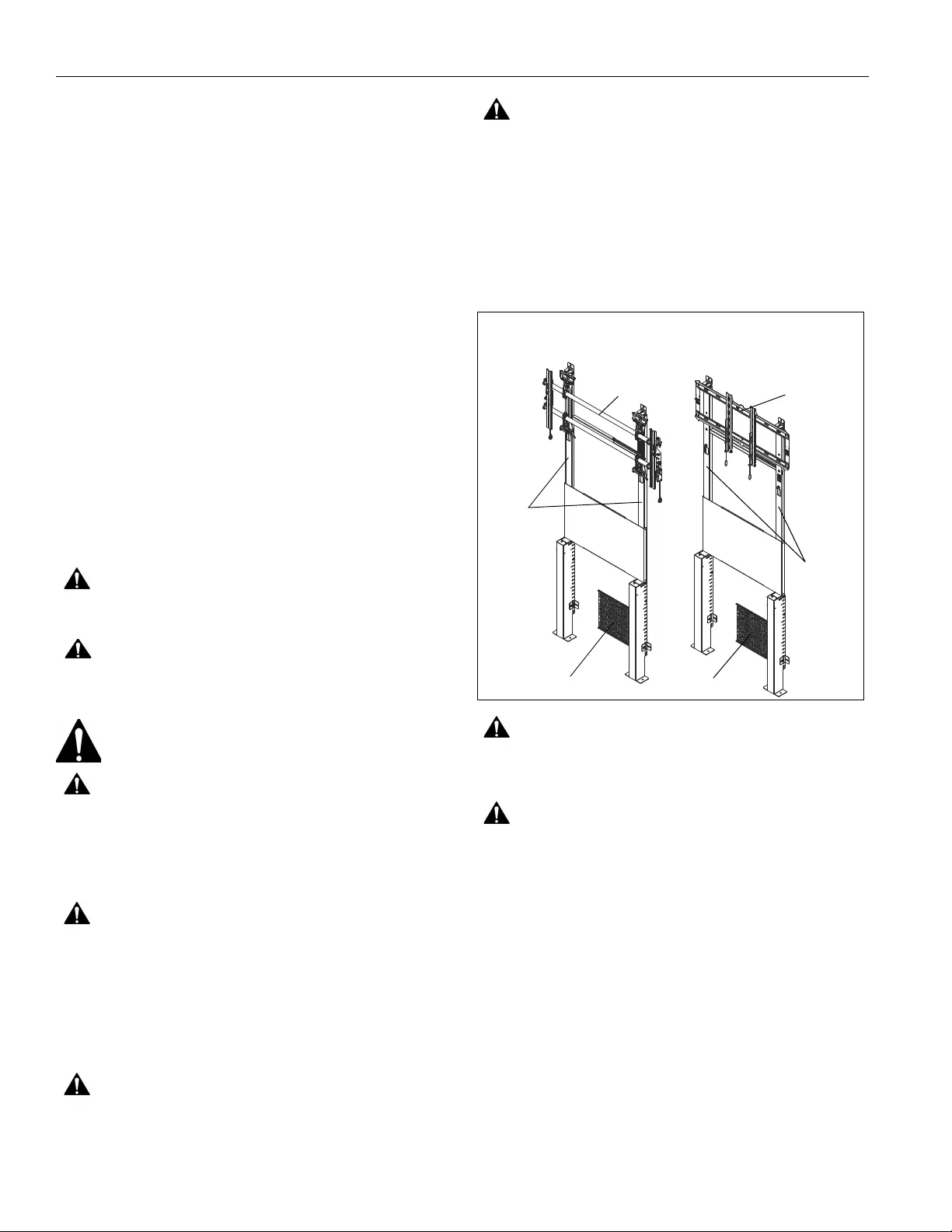

WARNING: Exceeding the weight capacity can result in

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the combined weight of

all components and mounting systems attached to the top

uprights of the AVSFSS does not exceed 217 lbs (98.4 kg).

The combined weight of all components attached to the

mounting system being attached to the AVSFSS cannot

exceed the specific weight limit for that mounting system. The

combined weight of all components attached to the

component storage panel cannot exceed 20 lbs (9.07 kg).

See Figure below.

WARNING: Never operate this mounting system if it is

damaged. Return the mounting system to a service center for

examination and repair.

WARNING: Do not use this mounting system outdoors.

IMPORTANT ! : The AVSFSS mounting system is

compatible with the following Chief® mounting systems:

LTM1U, LSM1U, RXF2, RLF2, RMF2, MTM1U, MSM1U.

Do NOT use with any other mounting system!

IMPORTANT ! :

The AVSFSS

mounting system

is designed

to be mounted to one of the following surfaces:

• a sheetrock drywall with a thickness of 1/2" to

5/8" supported by 16" or 24" wood or steel studs;

or

• a bare concrete wall with a minimum thickness of

8" (203mm); or

• a bare 8" x 8" x 16" (203mm x 203mm x 406mm)

concrete block wall;

IMPORTANT ! : The AVSFSS mounting system needs to

be attached to a sheetrock drywall which is supported by

16" or 24" wood or steel studs, however it does NOT

need to be attached to these studs directly.

--SAVE THESE INSTRUCTIONS--

200 lbs (90.7 kg)

20 lbs (9.07 kg) 20 lbs (9.07 kg)

125 lbs (56.7 kg)

LTM1U RLF2

(example) (example)

*217 lbs (98.4 kg) combined for all components and

mounting systems attached to top uprights of AVSFSS

217 lbs*

(98.4 kg)

217 lbs*

(98.4 kg)

top uprights

top uprights

Installation Instructions AVSFSS

3

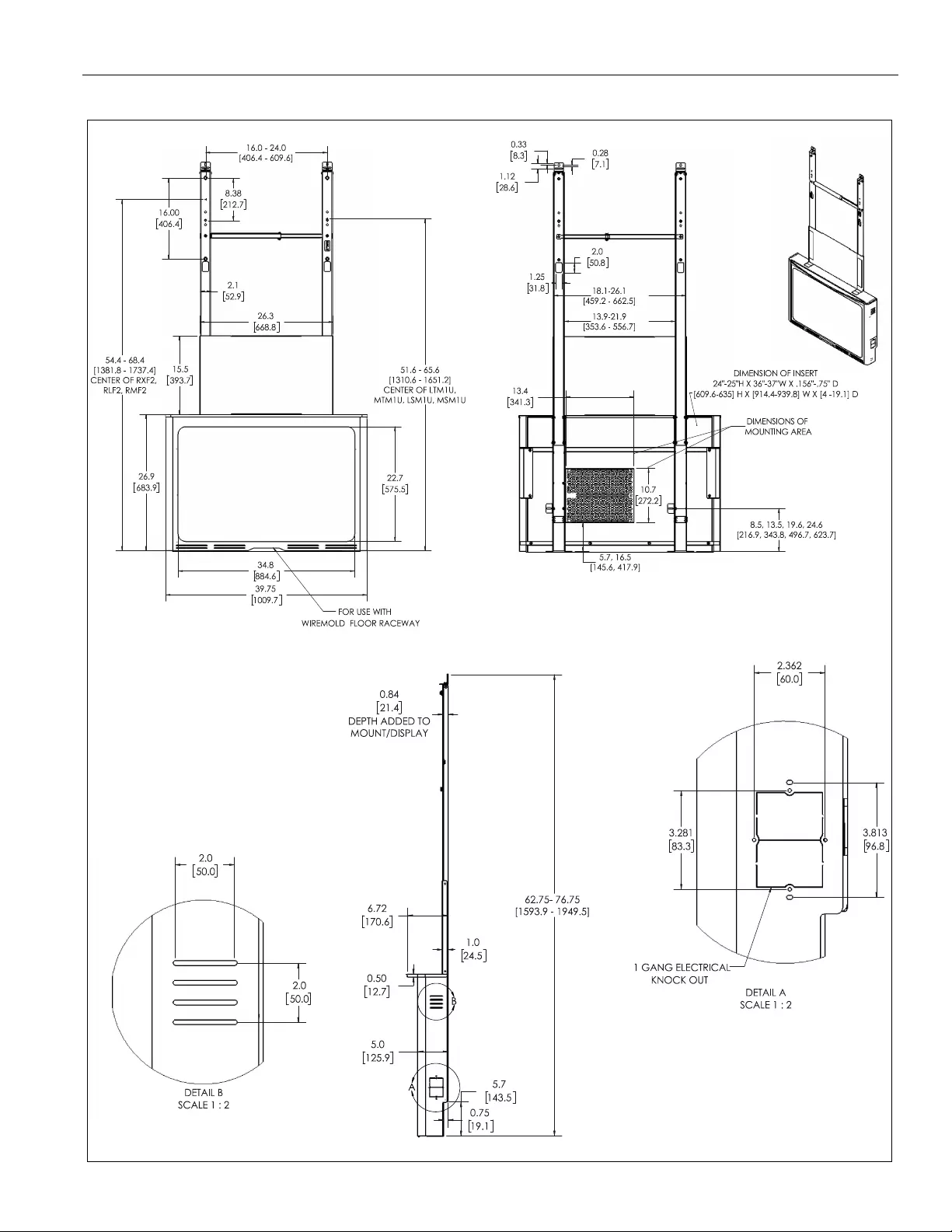

DIMENSIONS

AVSFSS Installation Instructions

4

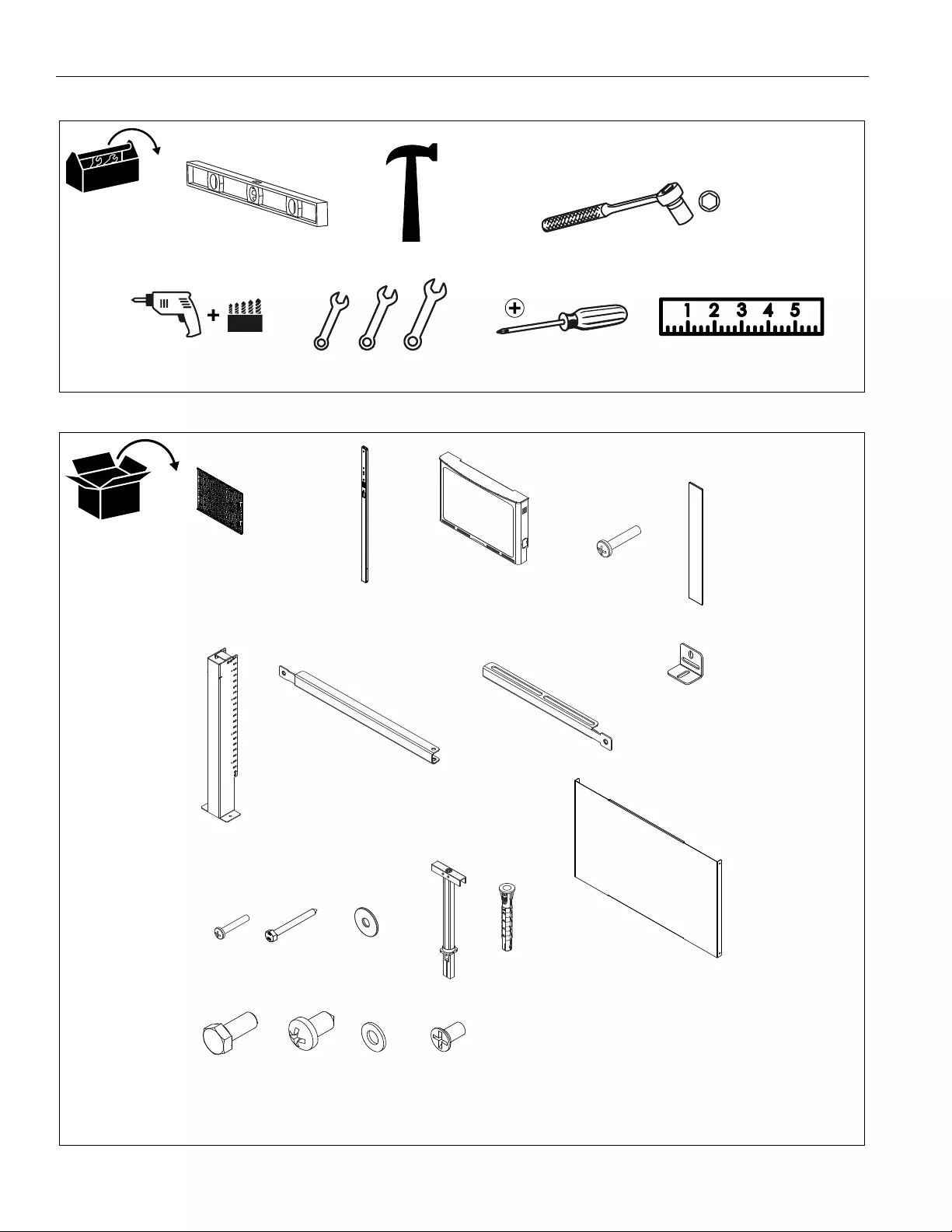

TOOLS REQUIRED FOR INSTALLATION

PARTS

5/16" (7.9mm) - concrete #2

1/2" (12.7mm)

1/2" (12.7mm) - drywall/steel stud

1/8" (3.1mm) - wood stud 7/16" (11.1mm)

(concrete install)

A (1)

[Component storage panel]

B (2)

[Top upright]

C (1)

[Base cover]

F (4)

[Wall bracket]

G (2)

[Bottom upright]

H (1)

[Long spacer bracket]

J (1)

[Short spacer bracket]

K (1)

[Mid cover]

L (4)

1/4-20 x 1 3/4" M (4)

1/4-2 1/2" N (4)

1/4" P (4)

[Toggler anchor]

Q (4)

[Concrete anchor]

R (4)

1/4-20 x 1/2"

S (14)

5/16-18 x 3/4"

T (4)

5/16"

U (2)

1/4-20 x 1/2"

D (1)

1/4-20 x 1 1/4"

E (2)

[Magnetic strip]

Installation Instructions AVSFSS

5

Assembly And Installation

NOTE: For large-scale installations, component storage

panels (A) may be removed from each box and pre-

loaded with components prior to AVSFSS installation.

Stand Assembly

1. Determine distance desired from finished floor to center of

display.

2. Refer to chart below to determine holes to use to assemble

uprights (B and G).

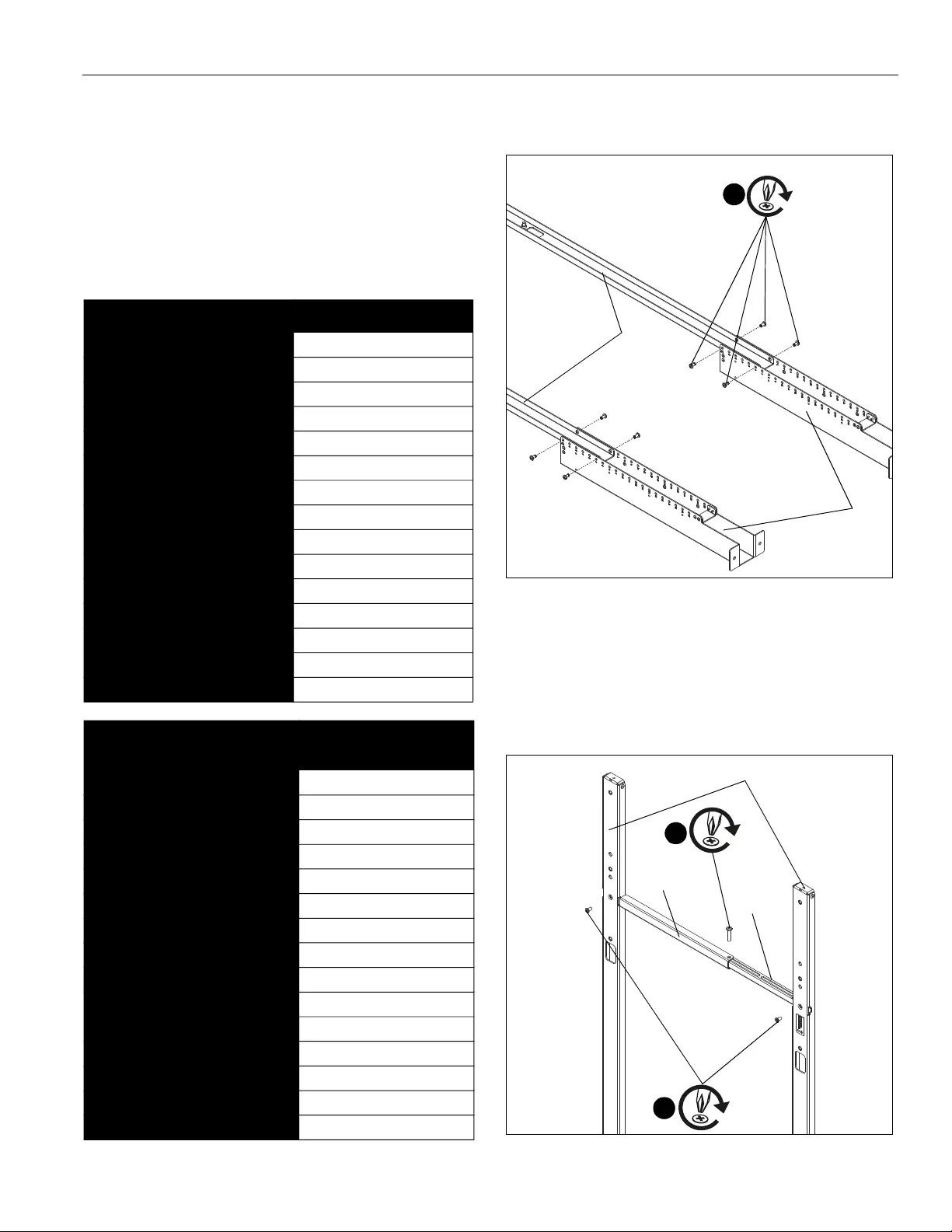

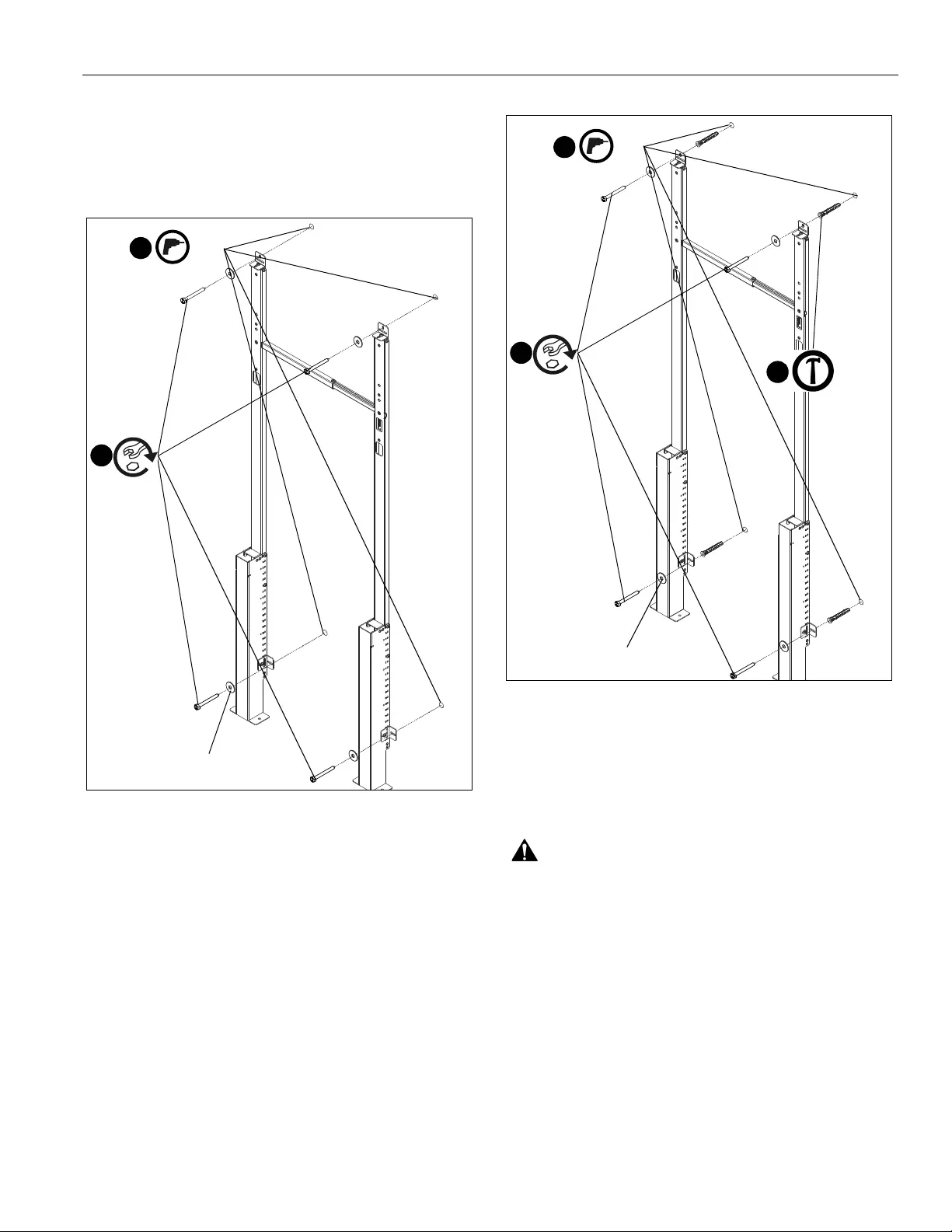

3. Use four 1/4-20 x 1/2" Phillips tapping screws (S) to secure

top uprights (B) to buttom uprights (G). (See Figure 1)

Figure 1

4. Use two 1/4-20 x 1/2" Phillips flathead screws (U) to secure

long spacer bracket (H) and short spacer bracket (J) to top

uprights (B). (See Figure 2)

5. Use 1/4-20 x 1" Phillips pan machine screw (D) to secure

long spacer bracket (H) and short spacer bracket (J)

together. (See Figure 2)

Figure 2

WITH RXF2/RLF2/RMF2 HOLE NUMBERS

68.4" (173.7cm) from floor 1, 6

67.4" (171.2cm) from floor 2, 7

66.4" (168.6cm) from floor 3, 8

65.4" (166.1cm) from floor 4, 9

64.4" (163.5cm) from floor 5, 10

63.4" (161cm) from floor 6, 11

62.4" (158.5cm) from floor 7, 12

61.4" (156cm) from floor 8, 13

60.4" (153.4cm) from floor 9, 14

59.4" (150.9cm) from floor 10, 15

58.4" (148.3cm) from floor 11, 16

57.4" (145.8cm) from floor 12, 17

56.4" (143.2cm) from floor 13, 18

55.4" (140.7cm) from floor 14, 19

54.4" (138.1cm) from floor 15, 20

WITH LTM1U/MTM1U/LSM1U/

MSM1U

HOLE NUMBERS

65.6" (166.6cm) from floor 1 and 6

64.6" (164cm) from floor 2 and 7

63.6" (161.5cm) from floor 3 and 8

62.6" (159cm) from floor 4 and 9

61.6" (156.5cm) from floor 5 and 10

60.6" (153.9cm) from floor 6 and 11

59.6" (151.4cm) from floor 7 and 12

58.6" (148.8cm) from floor 8 and 13

57.6" (146.3cm) from floor 9 and 14

56.6" (143.7cm) from floor 10 and 15

55.6" (141.2cm) from floor 11 and 16

54.6" (138.7cm) from floor 12 and 17

53.6" (136.1cm) from floor 13 and 18

52.6" (133.6cm) from floor 14 and 19

51.6" (131.1cm) from floor 15 and 20

3

(S) x 4

(G) x 2

(B) x 2

(U) x 2

4

(D)

5

(H)

(J)

(B) x 2

AVSFSS Installation Instructions

6

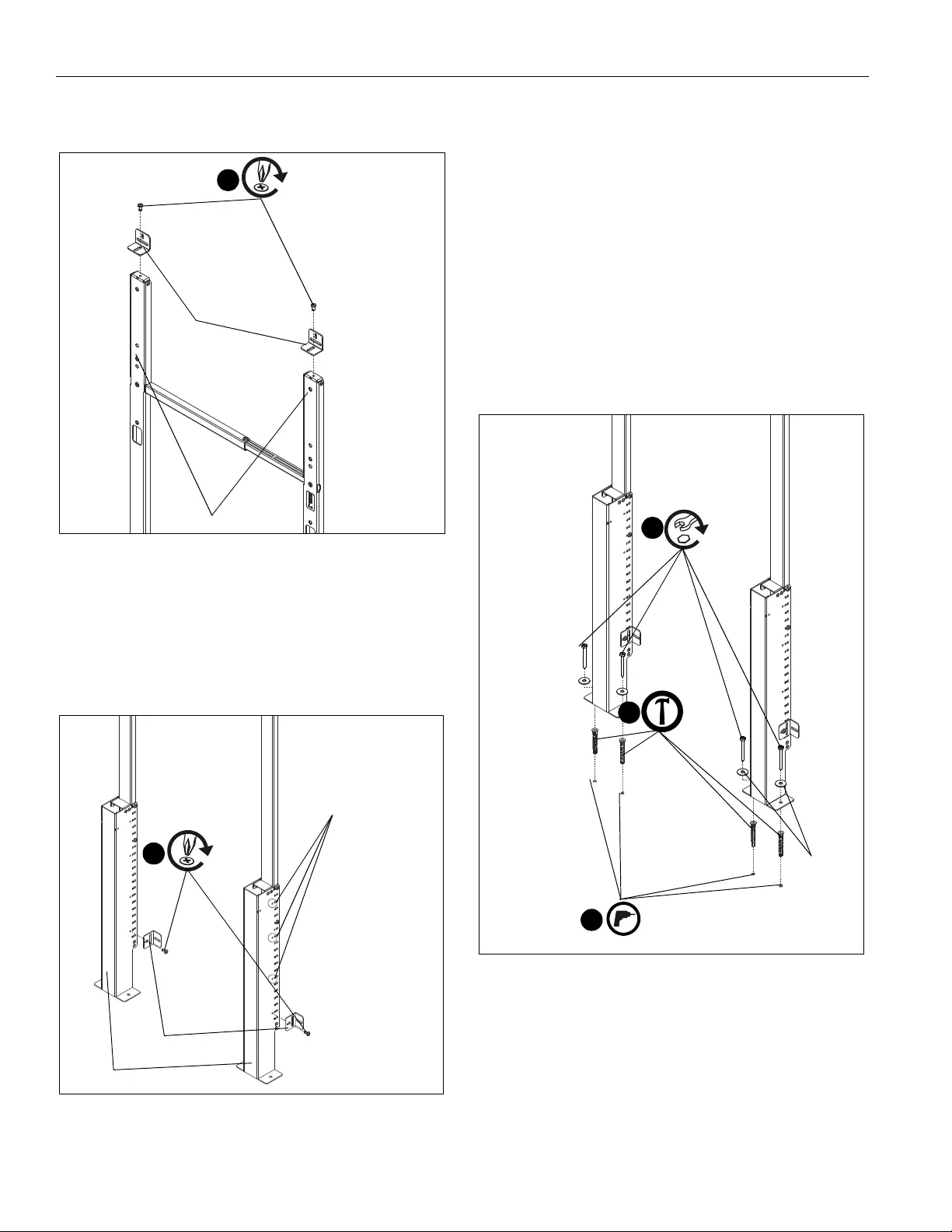

6. Use two 1/4-20 x 1/2" button head cap screws (S) to secure

two wall brackets (F) to top uprights (B). (See Figure 3)

Figure 3

7. Use two 1/4-20 x 1/2" button head cap screws (S) to secure

two wall brackets (F) to bottom uprights (G). (See Figure 4)

NOTE: Any of the four holes on each upright (G) can be used

on either side depending on where uprights were

attached to each other and/or component storage

panel location. (See Figure 4)

Figure 4

Attach to Concrete Floor (Optional)

IMPORTANT ! : AVSFSS may be bolted down to floor for

additional security and support. It may NOT be installed

to the floor ONLY without being also attached to the wall!

NOTE: If installing to floor, it is recommended to install to floor

BEFORE installing to wall or it will need to be

uninstalled from wall prior to floor installation.

1. Position assembled stand against wall at desired mounting

location and mark hole locations at each mounting location.

(See Figure 5)

2. Remove stand from location and drill 5/16" holes with a

depth of 2 3/8" (60mm) on marked hole locations. (See

Figure 5)

3. Use hammer to install four concrete anchors (Q) into drilled

holes. (See Figure 5)

Figure 5

4. Use four 1/4-20 x 2 1/2" hex head lag screws (M) and four

1/4" washers to secure wall brackets (F) to floor. (See

Figure 5)

6

(S) x 2

(F) x 2

(B) x 2

7

(S) x 2

(F) x 2

(G) x 2

other mounting holes

3/8"

2

(M) x 4

4

(Q) x 4

3

(N) x 4

Installation Instructions AVSFSS

7

Attach to Wall

Sheetrock Installations

IMPORTANT ! : The AVSFSS mounting system needs to

be attached to a sheetrock drywall which is supported by

16" or 24" wood or steel studs, however it does NOT

need to be attached to these studs directly.

Drywall Installation (Not attached to Studs)

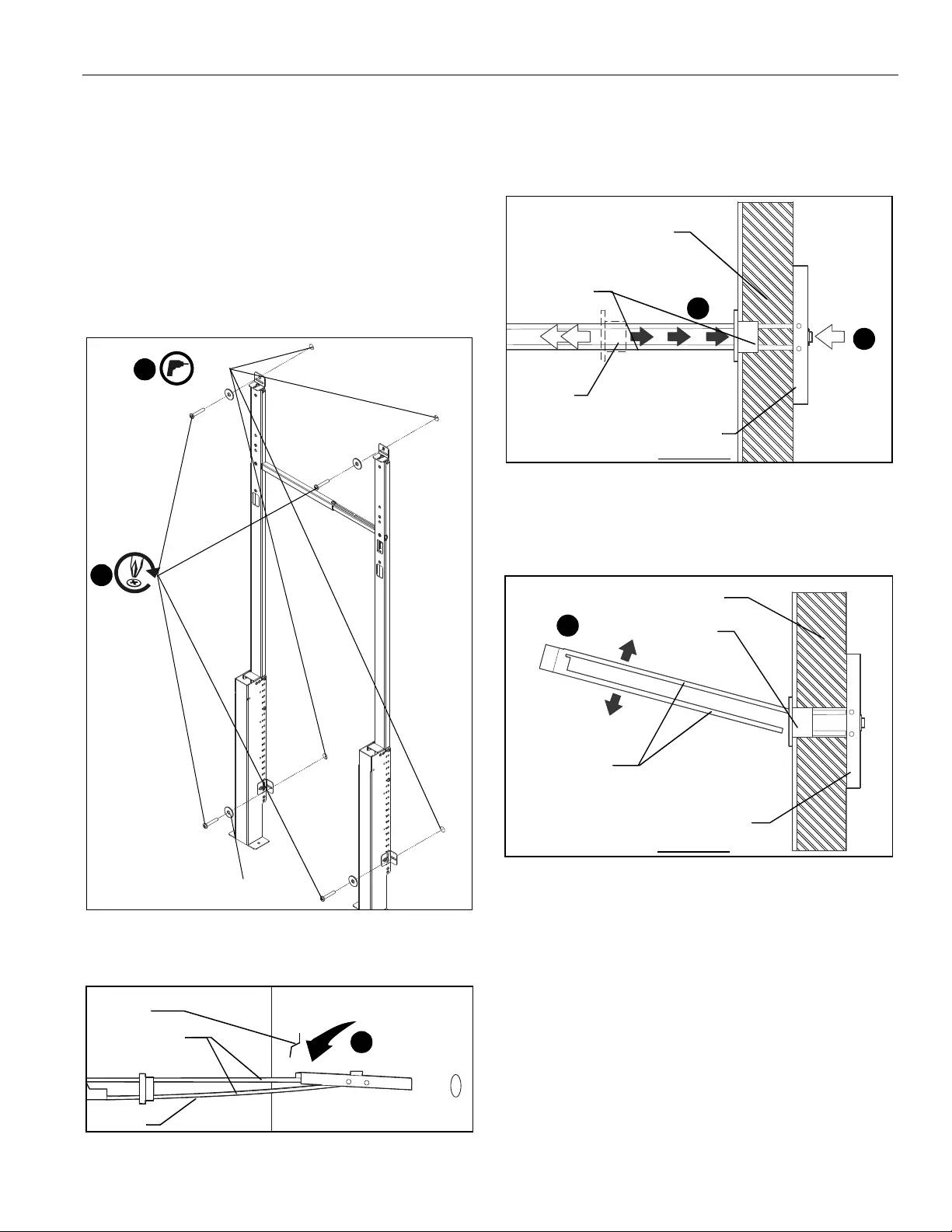

1. Mark hole locations at each mounting location based on

locations of wall brackets (F). Use a level to ensure of an

even mount. (See Figure 6)

2. Drill 1/2" holes on marked hole locations. (See Figure 6)

Figure 6

3. Hold metal channel on anchor (P) flat alongside plastic

straps and slide channel through hole. (See Figure 7)

Figure 7

4. Holding plastic straps on anchor (P), pull anchor away from

wall until channel rests flush behind wall making sure

anchor channel is positioned vertically on drywall. (See

Figure 8)

5. Slide plastic cap on anchor (P) towards wall until flange of

cap is flush with wall. (See Figure 8)

Figure 8

6. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 9)

Figure 9

7. Repeat Steps 3 through 6 for the other mounting holes.

8. Use four 1/4-20 x 1 3/4" Phillips pan machine screws (L)

and four 1/4" washers (N) to secure wall brackets (F) to wall.

(See Figure 6)

1/2"

2

(L) x 4

8

(N) x 4

(P)

Drywall

Plastic Straps

3

(L)

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

4

5

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

6

AVSFSS Installation Instructions

8

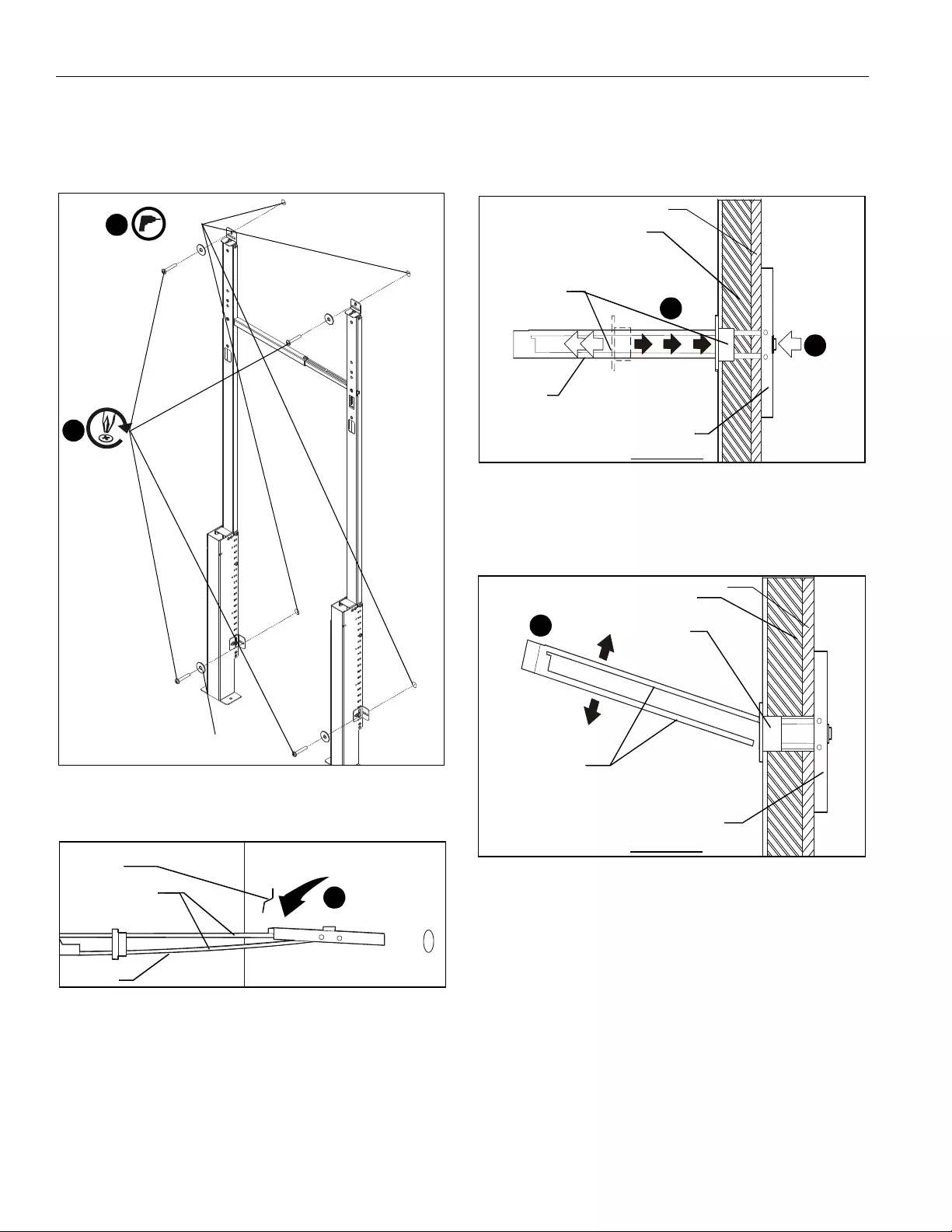

Drywall (Into Steel Studs)

1. Mark hole locations at each mounting location based on

locations of wall brackets (F) and steel studs. Use a level to

ensure of an even mount. (See Figure 10)

2. Drill 1/2" holes on marked hole locations. (See Figure 10)

Figure 10

3. Hold metal channel on anchor (P) flat alongside plastic

straps and slide channel through hole. (See Figure 11)

Figure 11

4. Holding plastic straps on anchor (P), pull anchor away from

wall until channel rests flush behind wall making sure

anchor channel is positioned vertically on stud. (See Figure

12)

5. Slide plastic cap on anchor (P) towards wall until flange of

cap is flush with wall. (See Figure 12)

Figure 12

6. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 13)

Figure 13

7. Repeat Steps 3 through 6 for the other mounting holes.

8. Use four 1/4-20 x 1 3/4" Phillips pan machine screws (L)

and four 1/4" washers (N) to secure wall brackets (F) to wall.

(See Figure 10)

1/2"

2

(L) x 4

8

(N) x 4

(P)

Drywall

Plastic Straps

3

(L)

Plastic Cap

Drywall

Anchor Metal Channel

SIDE VIEW

4

Steel Stud

5

Plastic Straps

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

6

Steel Stud

Installation Instructions AVSFSS

9

Drywall Installation (Into Wood Studs)

1. Mark hole locations at each mounting location based on

locations of wall brackets (F) and wood studs. Use a level to

ensure of an even mount. (See Figure 14)

2. Drill 1/8" holes on marked hole locations. (See Figure 14)

Figure 14

3. Use four 1/4-20 x 2 1/2" hex head lag screws (M) and four

1/4" washers (N) to secure wall brackets (F) to wall. (See

Figure 14)

Concrete Installation

1. Mark hole locations at each mounting location based on

locations of wall brackets (F). Use a level to ensure of an

even mount. (See Figure 15)

2. Drill 7/32" holes with a depth of 2 3/8" on marked hole

locations. (See Figure 15)

3. Use hammer to install four concrete anchors (Q) into drilled

holes. (See Figure 15)

Figure 15

4. Use four 1/4-20 x 2 1/2" hex head lag screws (M) and four

1/4" washers (N) to secure wall brackets (F) to wall. (See

Figure 15)

Display Installation

WARNING: Exceeding the weight capacity can result in

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the combined weight of

all components and mounting systems attached to the top

uprights of the AVSFSS does not exceed 217 lbs (98.4 kg).

The combined weight of all components attached to the

mounting system being attached to the AVSFSS cannot

exceed the specific weight limit for that mounting system.

1/8"

2

(M) x 4

3

(N) x 4

7/16"

3/8"

2

(M) x 4

4

(Q) x 4

3

(N) x 4

7/16"

AVSFSS Installation Instructions

10

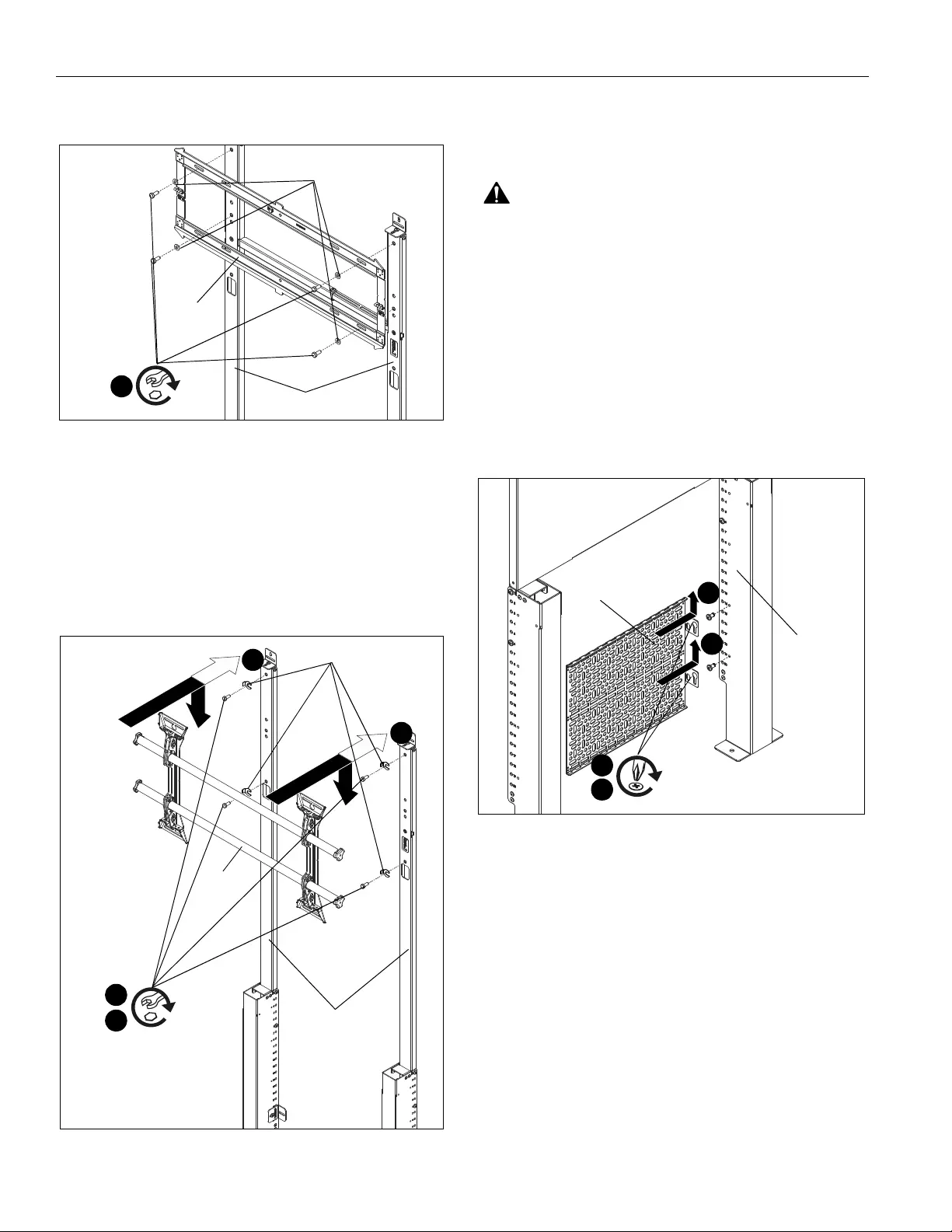

1. (For RMF2/RLF2/RXF2) Use four 1/4-20 x 1/2" hex head

cap screws (R) and four 5/16 washers (T) to secure main

assembly of RLF2 onto top uprights (B). (See Figure 16)

Figure 16

2. (For LTM1U/LSM1U/MTM1U/MSM1U) Loosely install

four 1/4-20 x 1/2" hex head cap screws (R) and four slotted

washers (included with LTM1U) into top holes of top

uprights (B). (See Figure 17)

3. (For LTM1U/LSM1U/MTM1U/MSM1U) Use teardrop

holes to place LTM1U main assembly onto screws (R). (See

Figure 17)

4. (For LTM1U/LSM1U/MTM1U/MSM1U) Tighten four

screws (R) to secure LTM1U to top uprights (B). (See Figure

17)

Figure 17

5. Install display to mount following installation instructions

included with RMF2/RLF2/RXF2/LTM1U/LSM1U/MTM1U/

MSM1U mounting system.

Component Storage Panel Installation

WARNING: Exceeding the weight capacity can result in

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the combined weight of

all components attached to the component storage panel

cannot exceed 20 lbs (9.07 kg).

1. Install components to component storage panel (A) using

appropriate hardware (not included) for each component.

(See Figure 18)

2. Loosely install two 1/4-20 x 1/2" Phillips pan machine

screws (S) to either bottom upright (G) at desired mounting

location. (See Figure 18)

3. Use teardrop mounting holes to install component storage

panel (A) onto installed screws (S). (See Figure 18)

4. Tighten screws (S) to secure panel (A) to upright (G). (See

Figure 18)

Figure 18

(R) x 4

1

(T) x 4

RLF2

(B) x 2

(RLF2 shown)

1/2"

(R) x 4

2

(slotted washers) x 4

(B) x 2

LTM1U

(LTM1U shown)

1/2"

3

3

4

(A)

(S) x 2

4

(G)

2

3

3

Installation Instructions AVSFSS

11

Covers Installation

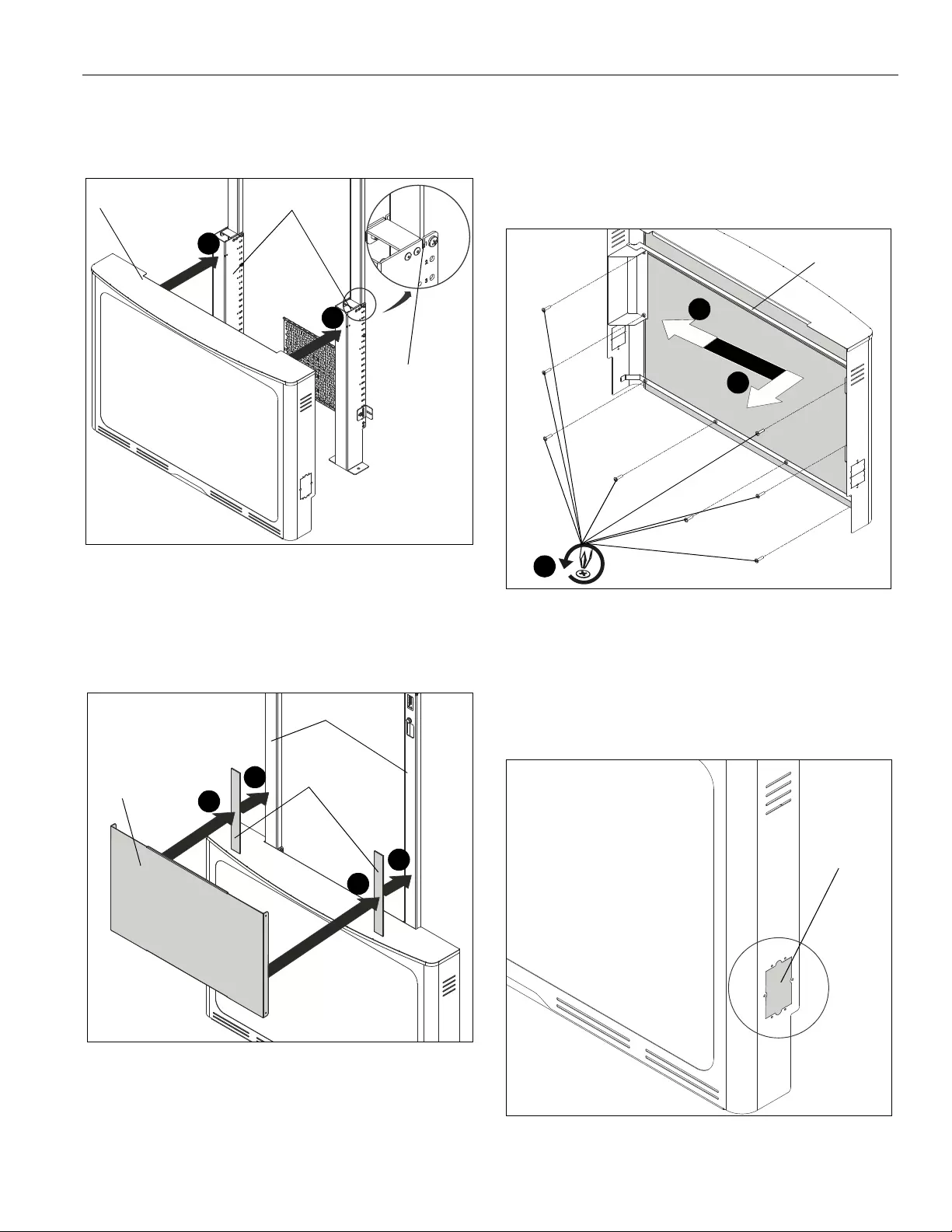

1. Place base cover (C) onto bottom uprights (G) and slide into

slots on top of uprights. (See Figure 19)

Figure 19

2. Install two magnetic tape strips (E) onto top uprights (B) by

removing adhesive cover to permanently secure them to

uprights. Strips (E) should be located approximately 1"

above base cover (C). (See Figure 20)

3. Place mid cover (K) onto two magnetic strips (E). (See

Figure 20)

Figure 20

Aesthetic Cover Removal/Replacement/

Adjustment

1. Remove eight Phillips screws holding aesthetic cover inside

base cover (C) and spanning bracket. (See Figure 21)

2. Remove aesthetic cover from base cover by sliding it first to

one side and then out. (See Figure 21)

3. (Optional) Replace with alternative cover (not included) and

secure with removed screws.

NOTE: If cover becomes wrinkled or loose, loosen bottom four

screws as needed, tighten the fabric and the re-tighten

screws.

Figure 21

Cover Knockout Usage (Optional)

1. Remove knockouts on base cover (C) as desired for cable

management or to install control boxes. (See Figure 22)

NOTE: Holes around knockout box may be used to secure

boxes or accessories to base cover using appropriate

hardware.

Figure 22

(C)

1

1

(G) x 2

slot

2

2

3

3

(E) x 2

(K)

(B) x 2

x 8

1

2

2

spanning

bracket

knockout

AVSFSS Installation Instructions

USA/International A 6436 City West Parkway, Eden Prairie, MN 55344

P800.582.6480 / 952.225.6000

F877.894.6918 / 952.894.6918

Europe A Franklinstraat 14, 6003 DK Weert, Netherlands

P+31 (0) 495 580 852

F+31 (0) 495 580 845

Asia Pacific A Office No. 918 on 9/F, Shatin Galleria

18-24 Shan Mei Street

Fotan, Shatin, Hong Kong

P852 2145 4099

F852 2145 4477

8800-003158 Rev03

2019 Legrand | AV

www.legrandav.com

11/19