Chief TIL1X3IFJ User Manual

Displayed below is the user manual for TIL1X3IFJ by Chief which is a product in the Signage Display Mounts category. This manual has pages.

Related Manuals

INSTALLATION INSTRUCTIONS

TILVAB1 Accessory

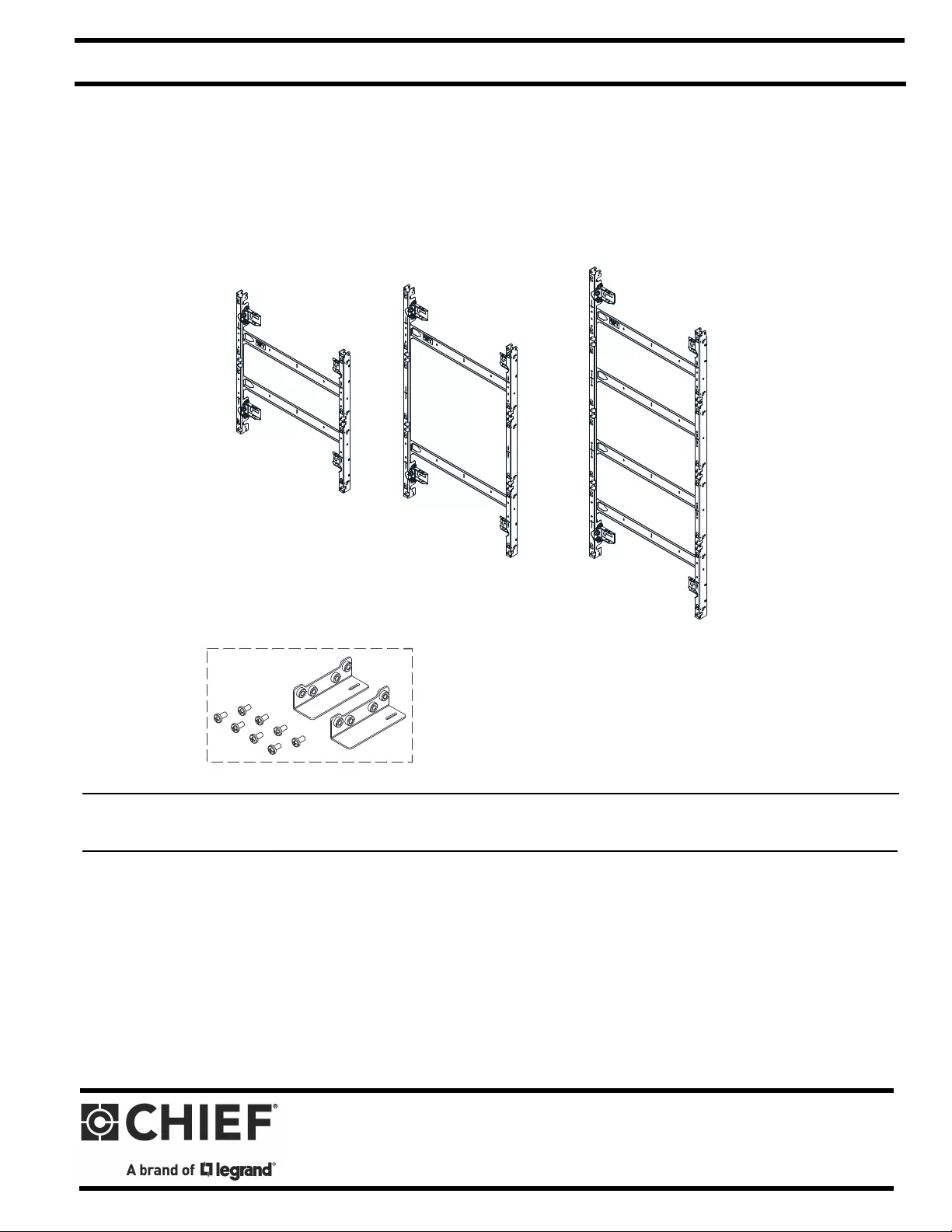

TIL1X2IFJ

TIL1X3IFJ

TIL1X4IFJ

IFJ Series LED Wall Mounts / Accessory

Spanish Product Description

German Product Description

Portuguese Product Description

Italian Product Description

Dutch Product Description

French Product Description

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/

TILVAB1

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

2

DISCLAIMER

Legrand | AV and its affiliated corporations and subsidiaries

(collectively “Legrand | AV”), intend to make this manual

accurate and complete. However, Legrand | AV makes no claim

that the information contained herein covers all details,

conditions or variations, nor does it provide for every possible

contingency in connection with the installation or use of this

product. The information contained in this document is subject

to change without notice or obligation of any kind. Legrand | AV

makes no representation of warranty, expressed or implied,

regarding the information contained herein. Legrand | AV

assumes no responsibility for accuracy, completeness or

sufficiency of the information contained in this document.

Chief® is a registered trademark of Legrand AV Inc.

DEFINITIONS

MOUNTING SYSTEM: A MOUNTING SYSTEM is the

primary Chief product to which an accessory and/or component

is attached.

ACCESSORY: AN ACCESSORY is the secondary Chief

product which is attached to a primary Chief product, and may

have a component attached or setting on it.

COMPONENT: A COMPONENT is an audiovisual item

designed to be attached or resting on an accessory or mounting

system such as a video camera, CPU, screen, display,

projector, etc.

WARNING: A WARNING alerts you to the possibility of

serious injury or death if you do not follow the instructions.

CAUTION: A CAUTION alerts you to the possibility of

damage or destruction of equipment if you do not follow the

corresponding instructions.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Failure to read, thoroughly understand, and

follow all instructions can result in serious personal injury,

damage to equipment, or voiding of factory warranty! It is the

installer’s responsibility to make sure all mounting systems

are properly assembled and installed using the instructions

provided.

WARNING: Failure to provide adequate structural strength

for this mounting system can result in serious personal injury

or damage to equipment! It is the installer’s responsibility to

make sure the structure to which this mounting system is

attached can support five times the combined weight of all

equipment. Reinforce the structure as required before

installing the mounting system. The wall to which the

mounting system is being attached may have a maximum

drywall thickness of 5/8” (1.6cm).

WARNING:

The TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ LED

wall mounts are designed for use with LED panels only.

Exceeding the weight capacity (listed) can result in serious

personal injury or damage to equipment!

• TIL1X2IFJ: 60 lbs (27.2 kg) - 30 lbs (13.6 kg) per

screen;

• TIL1X3IFJ: 90 lbs (40.8 kg) - 30 lbs (13.6 kg) per

screen;

• TIL1X4IFJ: 120 lbs (54.4 kg) - 30 lbs (13.6 kg) per

screen.

WARNING: Use this mounting system only for its intended

use as described in these instructions. Do not use

attachments not recommended by the manufacturer.

WARNING: Never operate this mounting system if it is

damaged. Return the mounting system to a service center for

examination and repair.

WARNING: Do not use this mounting system outdoors.

IMPORTANT ! : The TIL1X2IFJ / TIL1X3IFJ /TIL1X4IFJ LED

wall mounts are designed to be mounted to:

• a bare 8" concrete or 8"x8"x16" concrete block wall; or

• a 3/4" thickness plywood-backed, 2" x 4" wood studs

(16" on center minimum) wall with a maximum drywall

thickness of 5/8"; or

• a 3/4" thickness plywood-backed, steel stud wall

covered with drywall having a maximum thickness of

5/8".

NOTE:

Go to

https://www.legrandav.com/resources/

product_videos?v=Chief_TiLED_LED_Video_Wall

_Mounting_System_Installation

toviewan

introductiontoinstallingChiefTiLEDMounting

Systems.

--SAVE THESE INSTRUCTIONS--

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

3

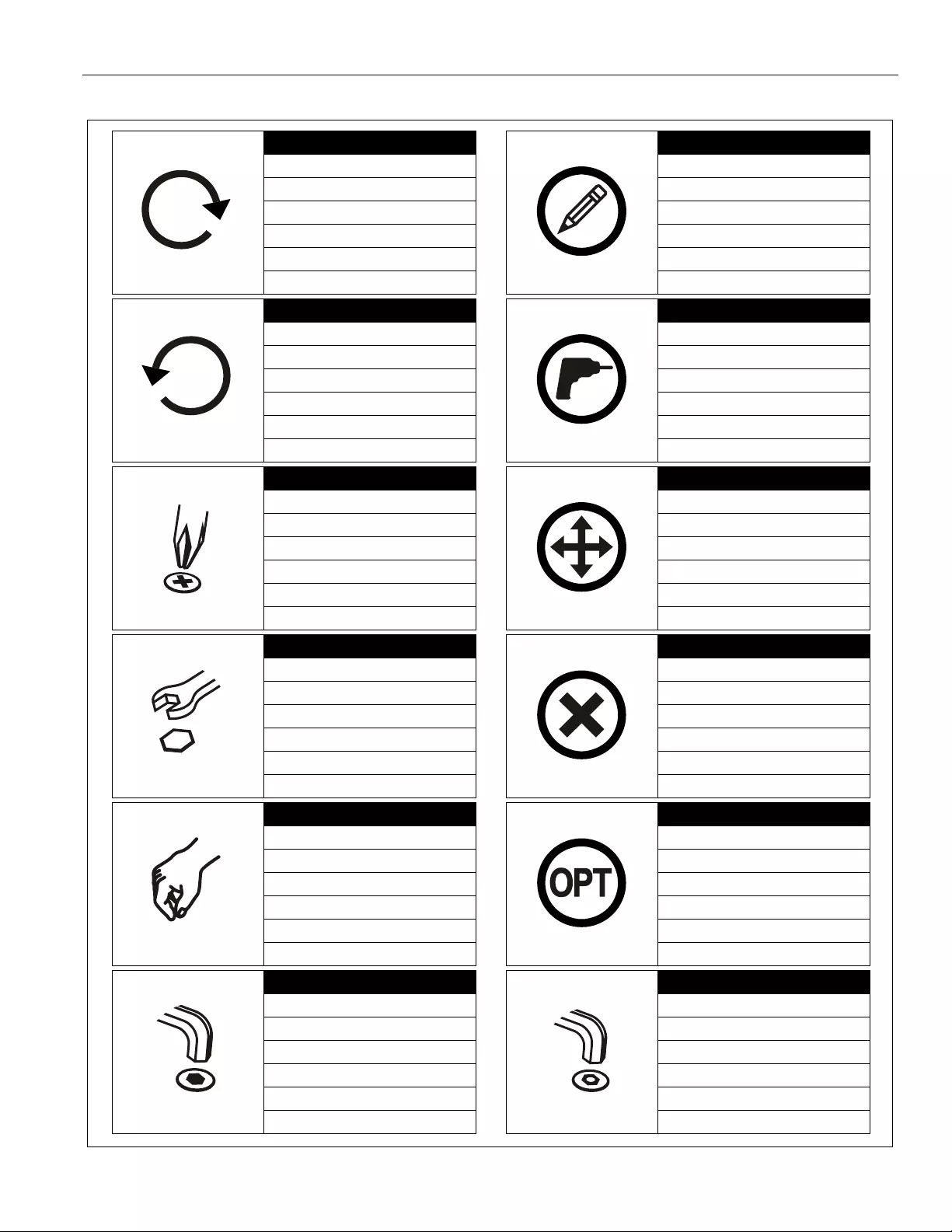

LEGEND

Tighten Fastener

Apretar elemento de fijación

Befestigungsteil festziehen

Apertar fixador

Serrare il fissaggio

Bevestiging vastdraaien

Serrez les fixations

Loosen Fastener

Aflojar elemento de fijación

Befestigungsteil lösen

Desapertar fixador

Allentare il fissaggio

Bevestiging losdraaien

Desserrez les fixations

Phillips Screwdriver

Destornillador Phillips

Kreuzschlitzschraubendreher

Chave de fendas Phillips

Cacciavite a stella

Kruiskopschroevendraaier

Tournevis à pointe cruciforme

Open-Ended Wrench

Llave de boca

Gabelschlüssel

Chave de bocas

Chiave a punte aperte

Steeksleutel

Clé à fourche

By Hand

A mano

Von Hand

Com a mão

A mano

Met de hand

À la main

Hex-Head Wrench

Llave de cabeza hexagonal

Sechskantschlüssel

Chave de cabeça sextavada

Chiave esagonale

Zeskantsleutel

Clé à tête hexagonale

Pencil Mark

Marcar con lápiz

Stiftmarkierung

Marcar com lápis

Segno a matita

Potloodmerkteken

Marquage au crayon

Drill Hole

Perforar

Bohrloch

Fazer furo

Praticare un foro

Gat boren

Percez un trou

Adjust

Ajustar

Einstellen

Ajustar

Regolare

Afstellen

Ajuster

Remove

Quitar

Entfernen

Remover

Rimuovere

Verwijderen

Retirez

Optional

Opcional

Optional

Opcional

Opzionale

Optie

En option

Security Wrench

Llave de seguridad

Sicherheitsschlüssel

Chave de segurança

Chiave di sicurezza

Veiligheidssleutel

Clé de sécurité

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

4

TABLE OF CONTENTS

DISCLAIMER .........................................................................................2

DEFINITIONS ........................................................................................2

IMPORTANT SAFETY INSTRUCTIONS ..............................................2

LEGEND ................................................................................................3

TABLE OF CONTENTS .........................................................................4

TOOLS REQUIRED FOR INSTALLATION ............................................5

PARTS ...................................................................................................5

PRE-INSTALLATION .............................................................................6

Site Assessment ........................................................6

INSTALLATION .....................................................................................7

Adding Vertical Connector Kit ....................................7

If Starting LED Wall Installation With the Top Row.....7

If Starting LED Wall Installation With the Bottom Row7

Preparing LED Cabinet ..............................................8

Assessing the Installation Site ...................................8

Installing First Mount ..................................................8

Adding Additional Mounts ..........................................11

Checking Placement and Alignment ...........................13

Connecting Mounts Above or Below First Row .........15

APPENDIX .............................................................................................16

Fastener Installation Methods ...................................16

Wood Stud ...........................................................16

Concrete or Concrete Block .................................16

Steel Stud .............................................................16

Site Requirements for Wood/Steel Stud Installation....18

DIMENSIONS .........................................................................................19

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

5

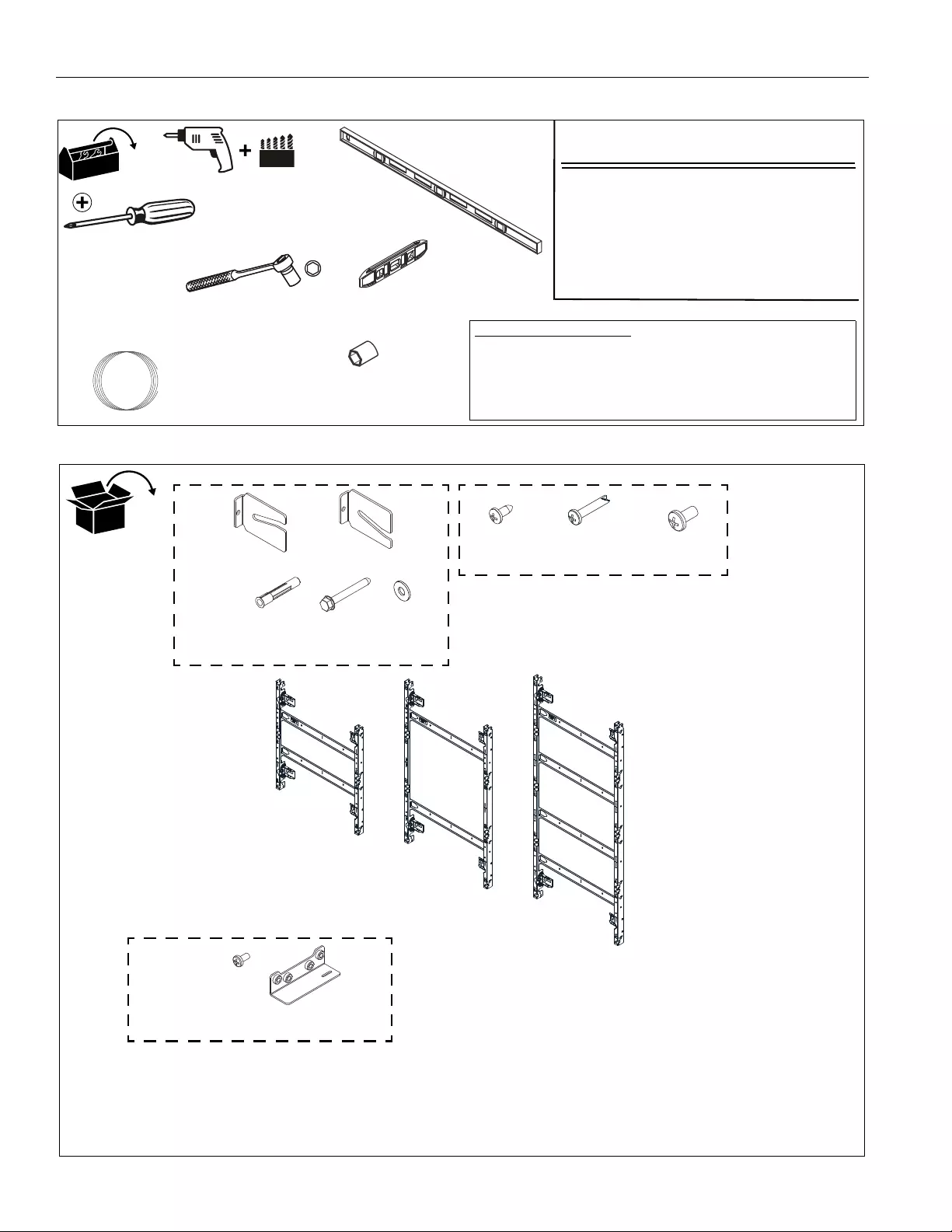

TOOLS REQUIRED FOR INSTALLATION

PARTS

Hardware Required - not included

(for installation into steel stud walls)

1. Chief brand FCAT1 Toggler Kit; OR

2. Hardware for installation to steel stud wall:

• 1/4-20 Toggler Snaptoggle BB (Qty 4)

•1/4-20 x 2-1/2" hex head bolt (Qty 4)

• 1/4" washer (Qty 4)

7/32"

#2, #3

Level

[2 ft. long]

[Small level]

3/8"

1/2"

square drive

[4+ ft. long]

[6+ ft. long]

Bright colored

string

Additional Suggestions

1. Dead blow hammer

2. Masking tape

3. Offset screwdrivers

4. Ratcheting wrenches

5. Laser level

6. Tools required for LED

panels installation.

Most likely metric.

3/4" (19mm)

ratcheting wrench

deep well socket

A (1)

[Adjustment

washer-RIGHT]

C (4)

[UX10x60R D (4)

5/16 x 2-1/2"

E (4)

5/16"

anchor]

B (1)

[Adjustment

washer-LEFT]

Mounting Hardware Kit

F (4)

#10 x 1/2" G (8)

10-24 x 1" H (8)

1/4-20 x 1/2"

OR OR

J (1)

TIL1X4IFJ

J (1)

TIL1X2IFJ

J (1)

TIL1X3IFJ

L (2)

TILVAB1 Vertical Connector Kit

K (8)

1/4-20 x 1/2"

[Vertical connector]

[Sold separately]

TIL1XXIFJ Series Hardware Kit

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

6

PRE-INSTALLATION

IMPORTANT ! : Reference the LED screen installation

manual for specific instructions regarding care, handling,

cabling and installation of the LED screens.

CAUTION: Handle the LED screens with care, being

careful to not impact or drop the LED screen.

CAUTION: There is a magnetic surface on the front of the

LED screen. To prevent damage ensure that no metallic

object is pulled onto the LED screen.

NOTE: When planning the installation, remember the

requirement to run power and signal to the video wall.

Ensure there is also adequate clearance for the plug

head. Recessed outlets or angled plugs may be

required.

Site Assessment

Before beginning any installation the site should be assessed in

several areas to help avoid any issues during the actual

installation.

•Wall Structure - It is recommended that a 3/4"

furniture-grade plywood-backed wall be used in most

LED video walls. The use of a wood stud wall is not

appropriate since the studs won’t be in the proper

location for an LED video wall.

•Wall High/Low Points - Locate any high or low points

on the wall that may cause problems, and try to set up

install so that these points can be avoided, if possible.

•Flatness/Plumb of Wall - Learn how much depth

adjustment will be needed across the LED video wall

mounting area.

•Power/Cable - Locate all power outlets and cable

access holes that need to be cleared by the installation.

Plan appropriately for those holes.

•Installing in a Recess - Verify the level and

squareness of the recessed area. Since these areas

are rarely perfect you may need to decide what to use

as a reference point.

•The recess top or bottom may not be level so the

video wall may need to be installed to align with

the recess, rather than being level with the wall.

• If the recess is not square the sides may make the

recess look crooked. If possible, the recess

should be fixed. If repairing the recess isn’t an

option it may be best to "split the difference"

between the recess sides to make the video wall

appear level.

•Where to Begin the Video Wall - The installer should

make the decision whether the video wall will be started

at the top, bottom, left, right or center.

• If a lower bottom reference is given in the

specifications, it may make sense to start at the

bottom of the video wall to ensure that this

specification is met from the start of installation.

• If building inside of a recess, it may be easier to

start in the center of the space since the video

wall will most likely need to be centered within the

recess.

• Vertical Connector Brackets - If creating a video wall

with more than a single row you will be using the

TILVAB1 vertical connectors which are sold

separately.

•

Vertical Connector Brackets [sold separately]

If the video wall requires multiple rows, decide on

whether the installation will start with the top or

bottom row. This determines to which end (top or

bottom) the vertical connector brackets are

attached.

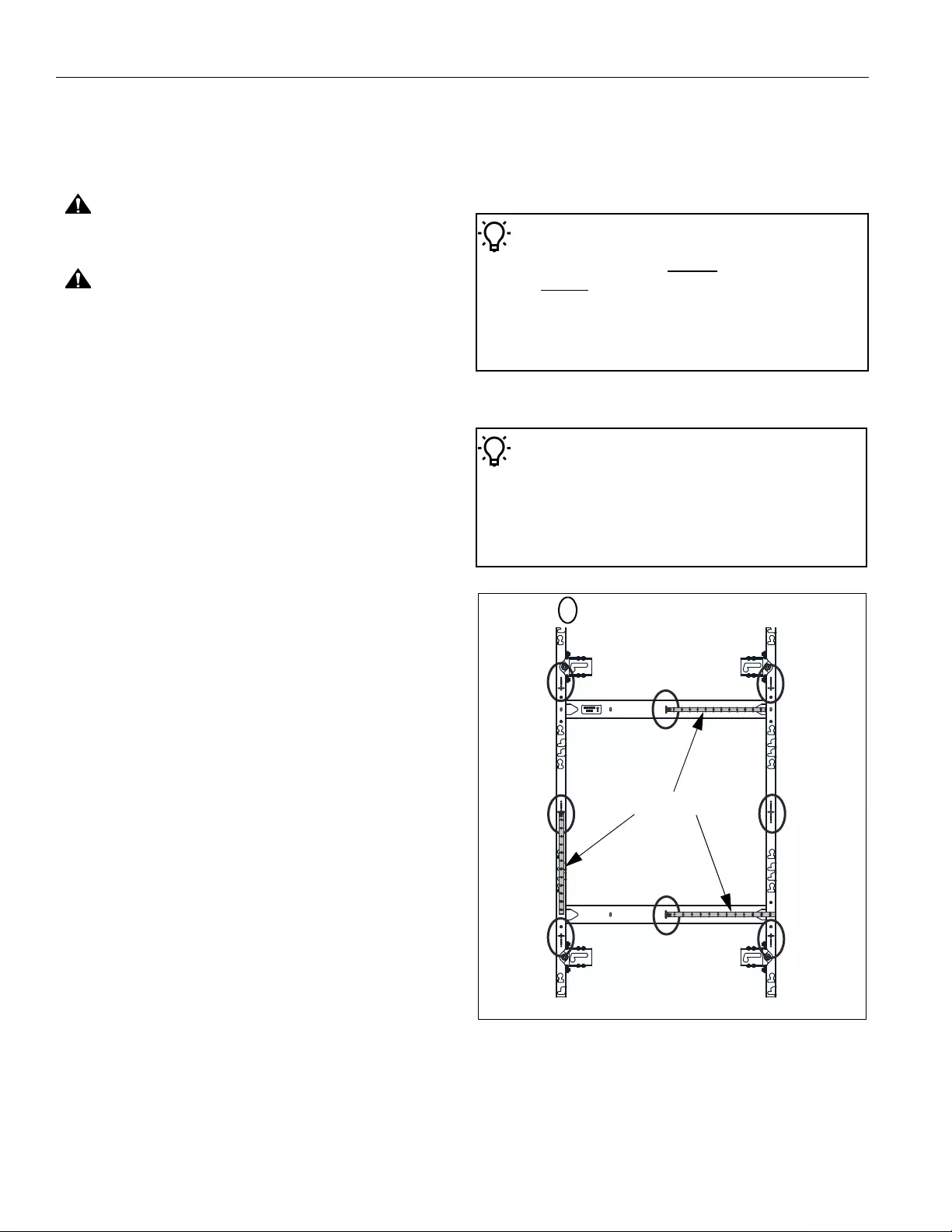

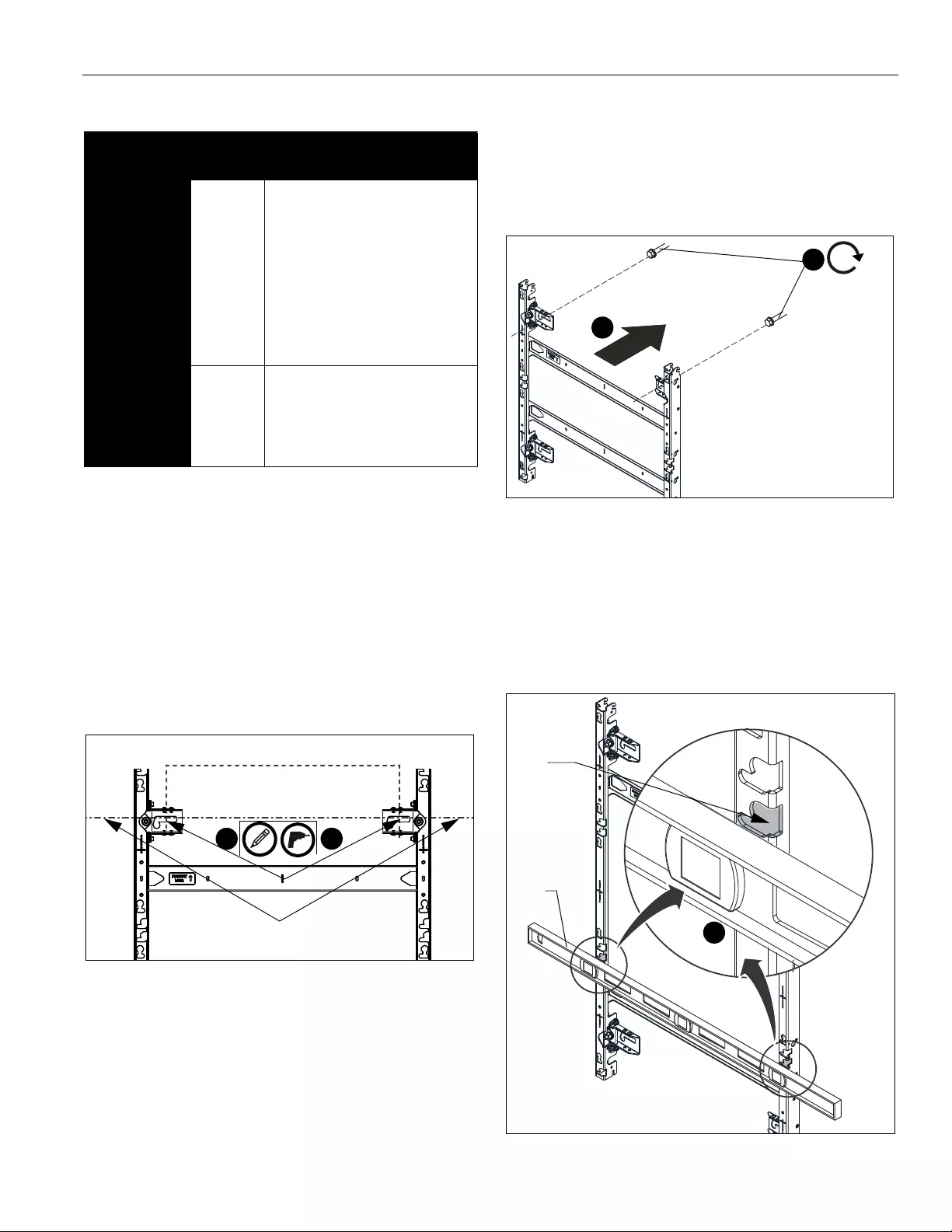

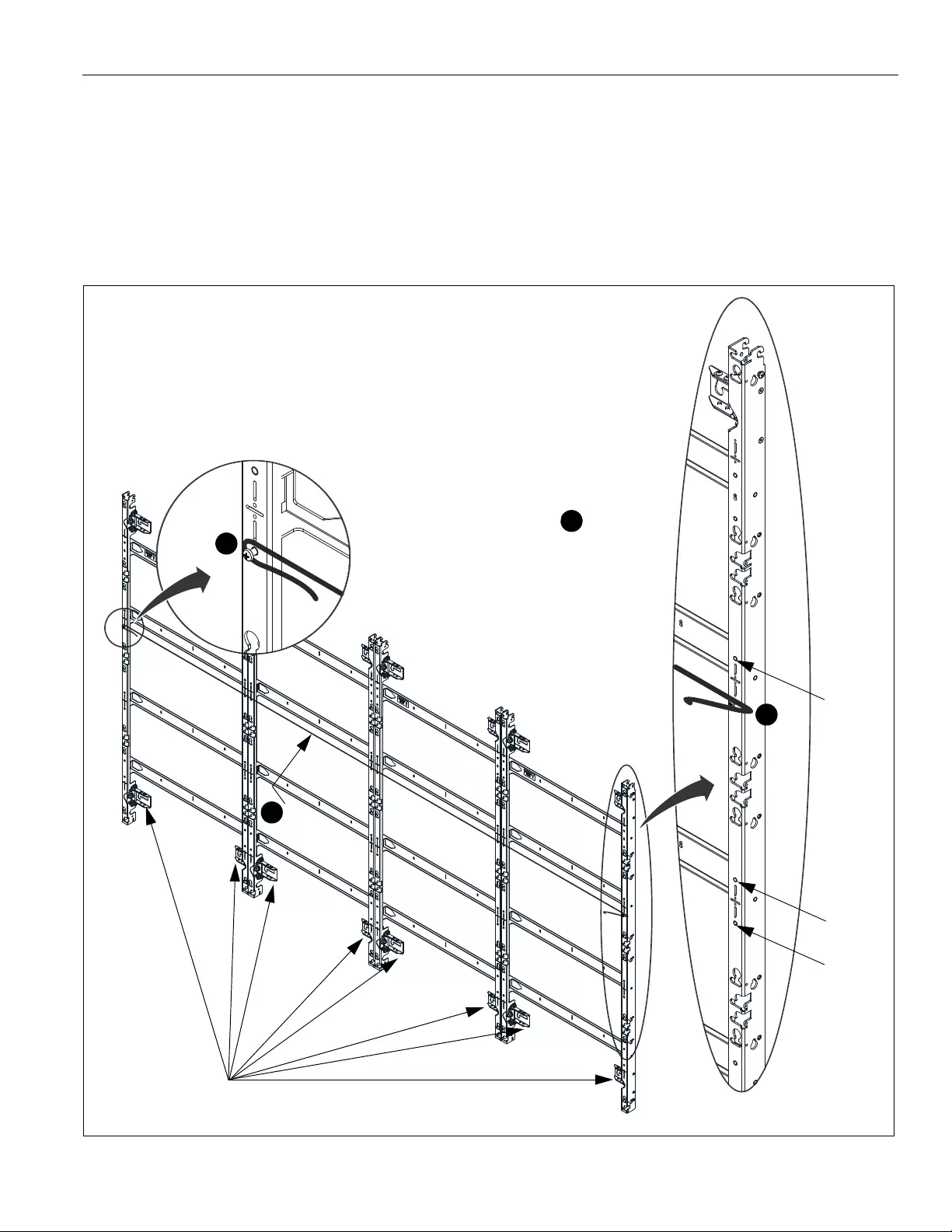

Figure 1

Just a tip - For larger LED walls it is helpful to

check placement and alignment of the mounts by

putting a few cabinets without the LED’s in place in

the bottom row of the installed mounts (referencing

the LED screen installation manual for specific

instructions) during the mount installation, verifying

that everything is staying aligned and level, and

then continuing the mount installation.

Just a tip - The horizontal slots located along

the vertical mount pieces (and vertical slots

located along the horizontal mount pieces) are the

center-of-screen indicators to illustrate where the

center of each LED screen will be located, and can

be used to hold a tape measure tab while

measuring. (See Figure 1)

= Center-of-screen indicators

Tape

Measure

[TIL1X3IFJ shown as example]

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

7

INSTALLATION

Adding Vertical Connector Kit

NOTE: If more LED screens will need to be added to the top or

bottom of the screen configuration, add TILVAB1

vertical connector kit to top or bottom of wall mount

using the following instructions. If you are NOT adding

the TILVAB1 connector kit, proceed to Installing First

Mount section.

IMPORTANT ! : Install the vertical connector kit

BEFORE the mounts are attached to the wall.

If Starting LED Wall Installation With the Top Row

NOTE: If you’re starting the installation at the top of the LED

video wall, the vertical connector brackets should be

attached to the BOTTOM of the mounts to create the

top row and each successive lower row.

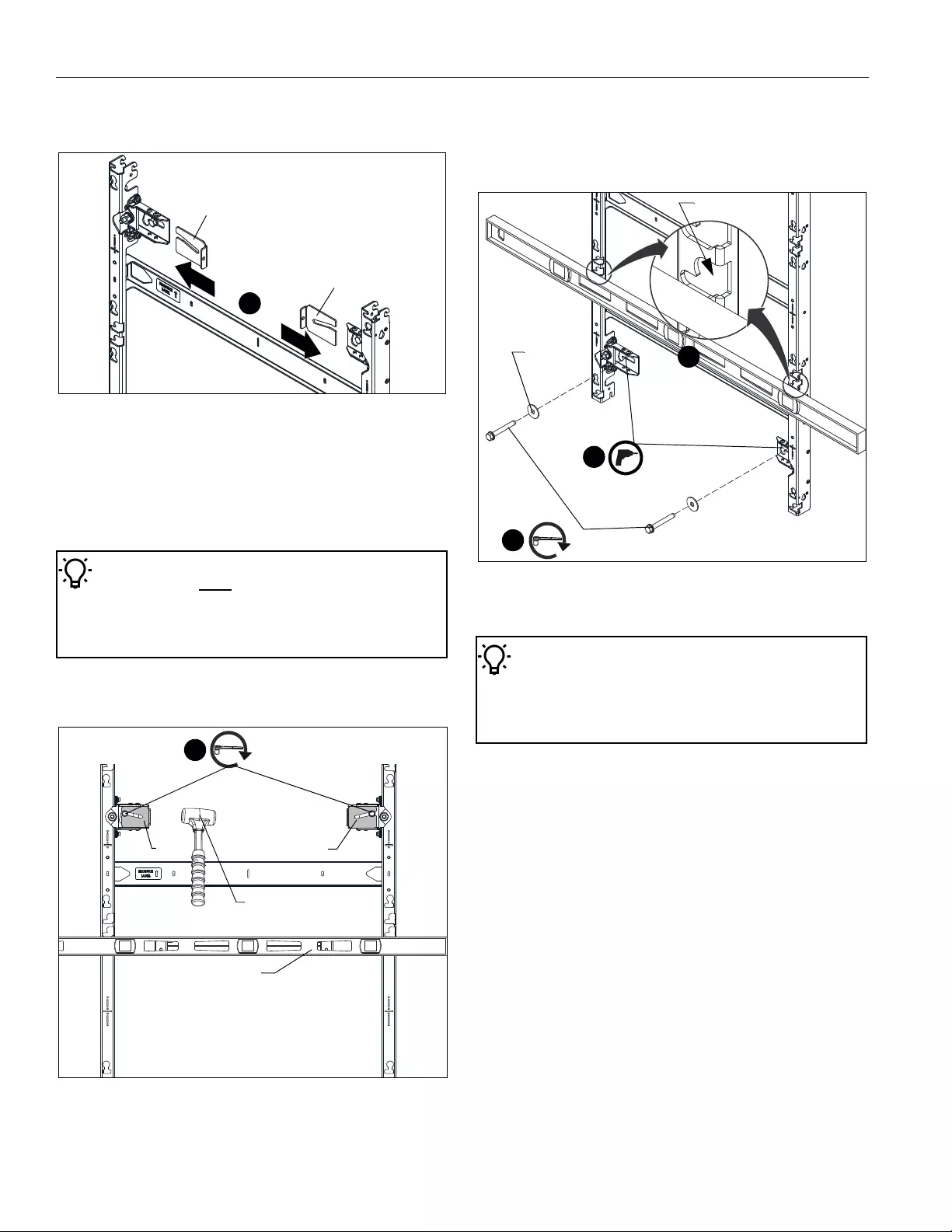

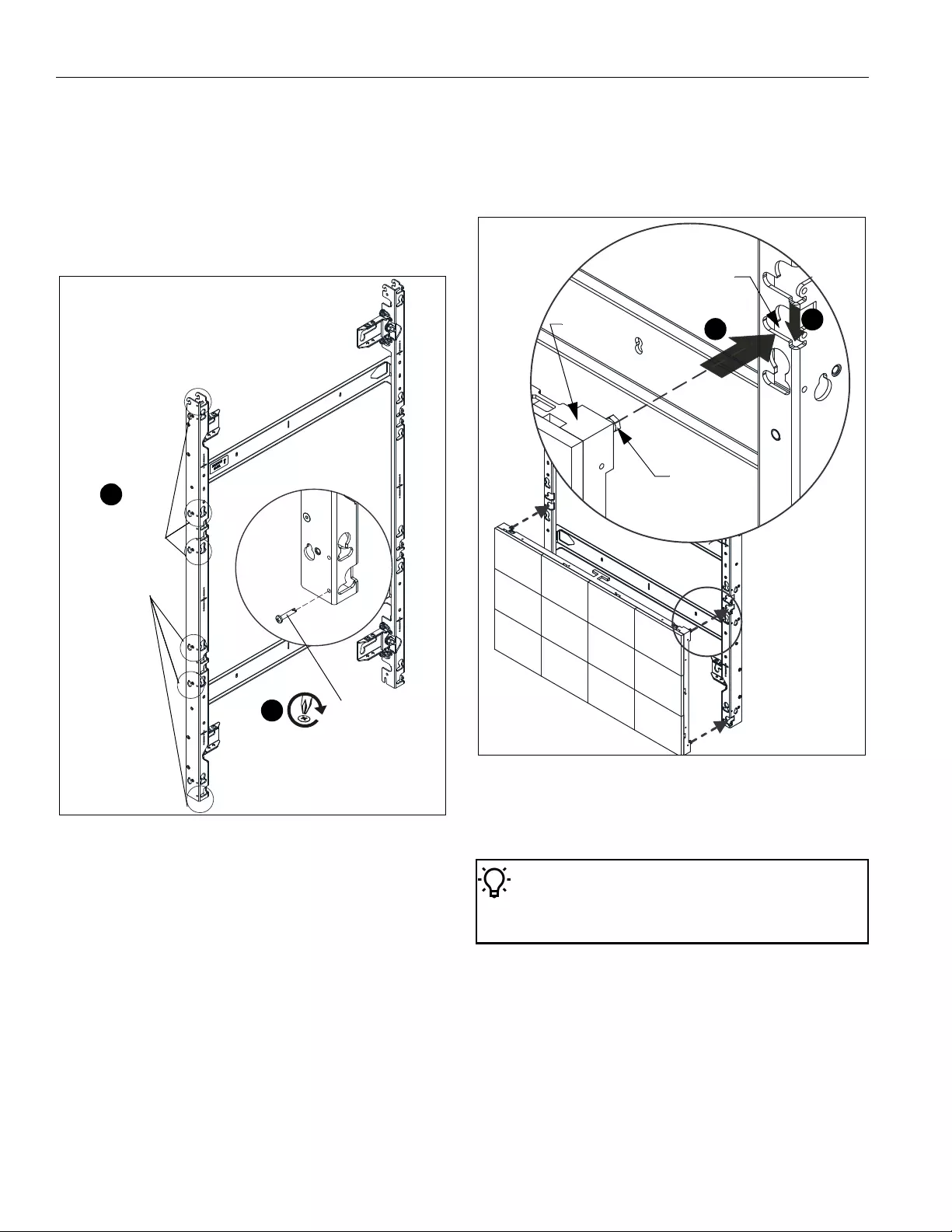

1. Slide the vertical connector (L) up from the bottom of the

mount, and attach with two 1/4-20 x 1/2" Phillips pan head

screws (K) per vertical connector. (See Figure 2)

2. Partially install one 1/4-20 x 1/2" Phillips pan head screw (K)

in the upper screw hole at the bottom of each vertical

connector (L). (See Figure 2)

Figure 2

If Starting LED Wall Installation With the Bottom Row

NOTE: If you’re starting the installation at the bottom of the

LED video wall, the vertical connector brackets should

be attached to the TOP of the mounts to create the

bottom row and each successive upper row.

1. Slide the vertical connector (L) down from the top of the

mount, and attach with two 1/4-20 x 1/2" Phillips pan head

screws (K) per vertical connector. (See Figure 3)

2. Partially install one 1/4-20 x 1/2" Phillips pan head screw (K)

in the lower screw hole at the top of each vertical connector

(L). (See Figure 3)

Figure 3

(L)

(K) x 2

1

2

(K)

1

(L)

Mount

(K) x 2

1

1

2

(K)

(L)

Mount

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

8

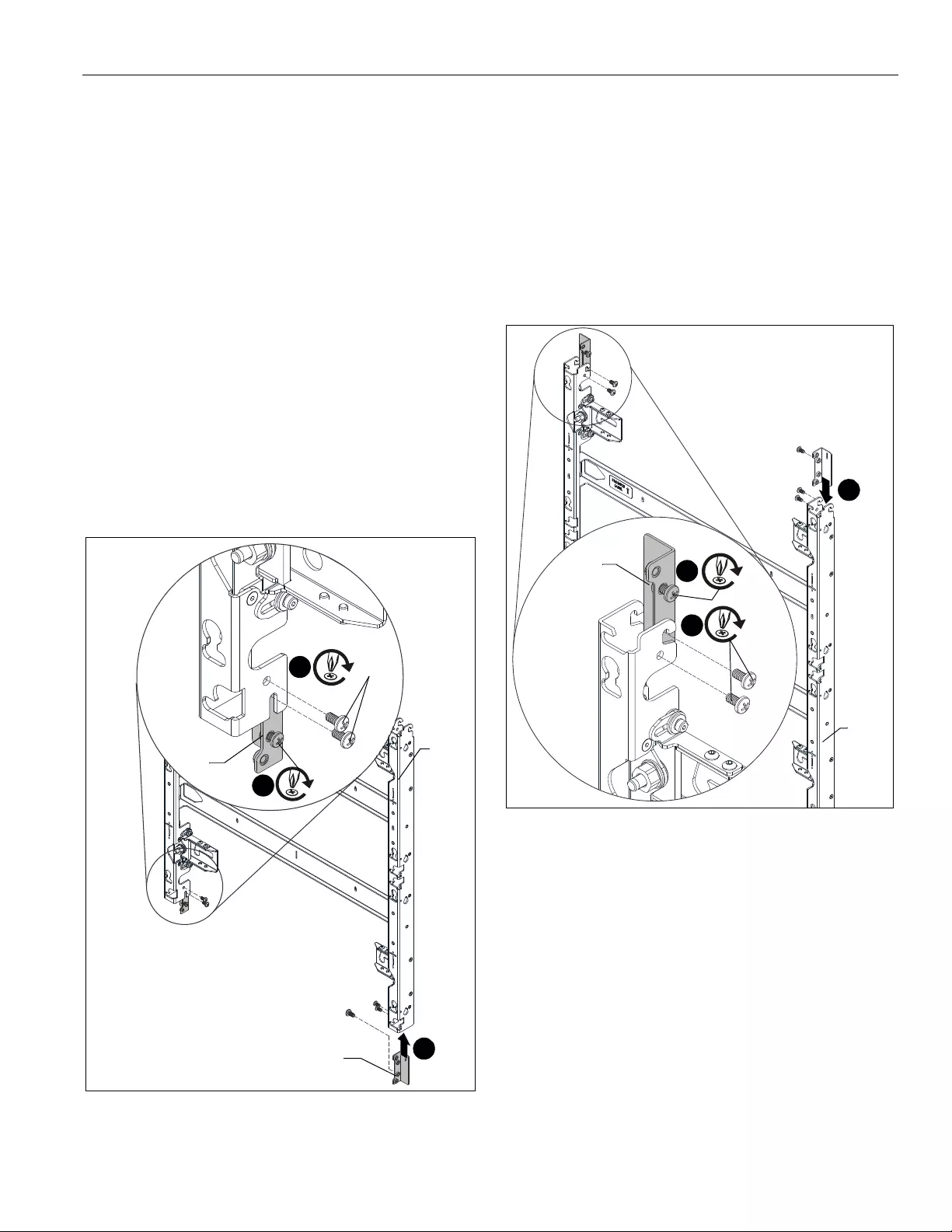

Preparing LED Cabinet

NOTE: If mounting buttons are already installed to your LED

cabinet, proceed to Assessing the Installation Site

section.

1. Attach four mounting buttons (supplied by Samsung) using

the hardware and following the instructions included with

the LED cabinets.

Assessing the Installation Site

IMPORTANT ! :

The top of the LED panel is 5.5" above

the top of the

UPPER

mounting slots, and the bottom of

the LED panel is 6.25" below the top of the

LOWER

mounting slots. (See Figure 4)

NOTE: If desired, the mount installation may be started in the

middle of the video wall, attaching mounts out from the

center to the left and right ends. (Review Site

Assessment section for further information.)

Installation on smaller walls may be easier if started at

the left or right side of the video wall using the following

instructions.

1. Determine top or bottom panel height location and

horizontal placement of mounts. (See Figure 4)

2. Make a mark 5.5"

below

the planned top edge (or 6.25"

above

the planned lower edge of the LED wall. (See Figure 4)

3. Using a level, mark a horizontal line across width of LED

wall from the mark made in Step 2.

NOTE:

This line will be located at the top of the mounting slots

across the width of the LED video wall. The oversize

mounting slots will allow some upward adjustment as

needed. (See Figure 4)

Figure 4

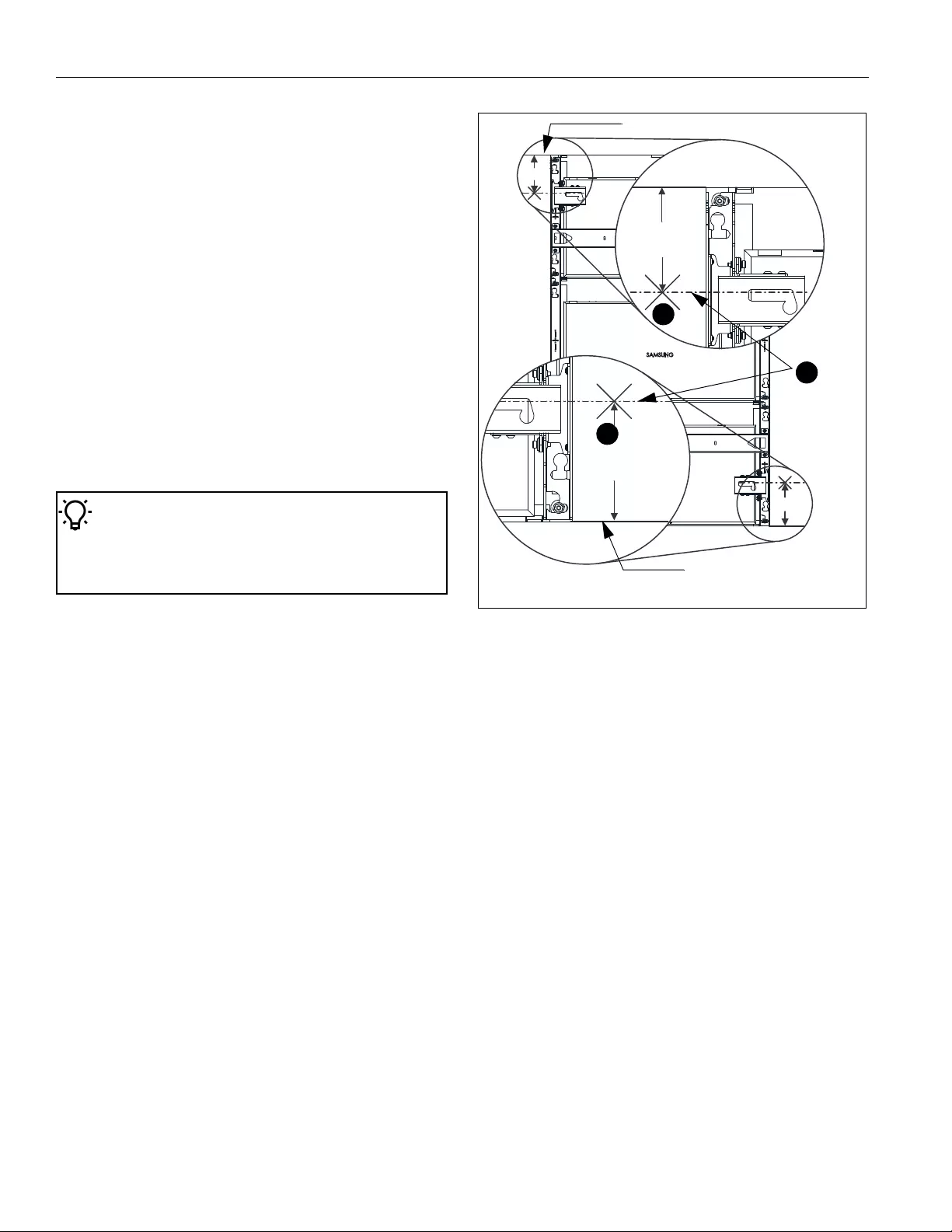

Installing First Mount

The TIL1X2IFJ / TIL1X3IFJ /TIL1X4IFJ LED wall mounts are

designed to be mounted to:

• a bare 8" concrete wall or 8"x8"x16" concrete block

wall; or

• a 3/4" thickness plywood-backed, 2" x 4" wood studs

(16" on center minimum) wall with a maximum drywall

thickness of 5/8"; or

• a 3/4" thickness plywood-backed, steel stud wall

covered with drywall having a maximum

thickness of 5/8".

Just a tip - It is often a good idea to review

installation instructions and dimensional drawings

(at end of instructions), and then utilize masking

tape to lay out the entire LED video wall to lessen

the chance of any surprises later in the installation.

5.5”

6.25”

5.5”

6.25”

Top of LED cabinet

[TIL1X3IFJ mount shown - Wall side - Rear View]

2

2

3

Horizontal

mark through

top of mount

slots

Bottom of LED cabinet

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

9

Table 1: Fastener Information

1. Make final decision on where to begin the LED video wall

installation (left, right or center; and top or bottom).

2. Make sure the vertical connectors are attached to top or

bottom depending on installation decision.

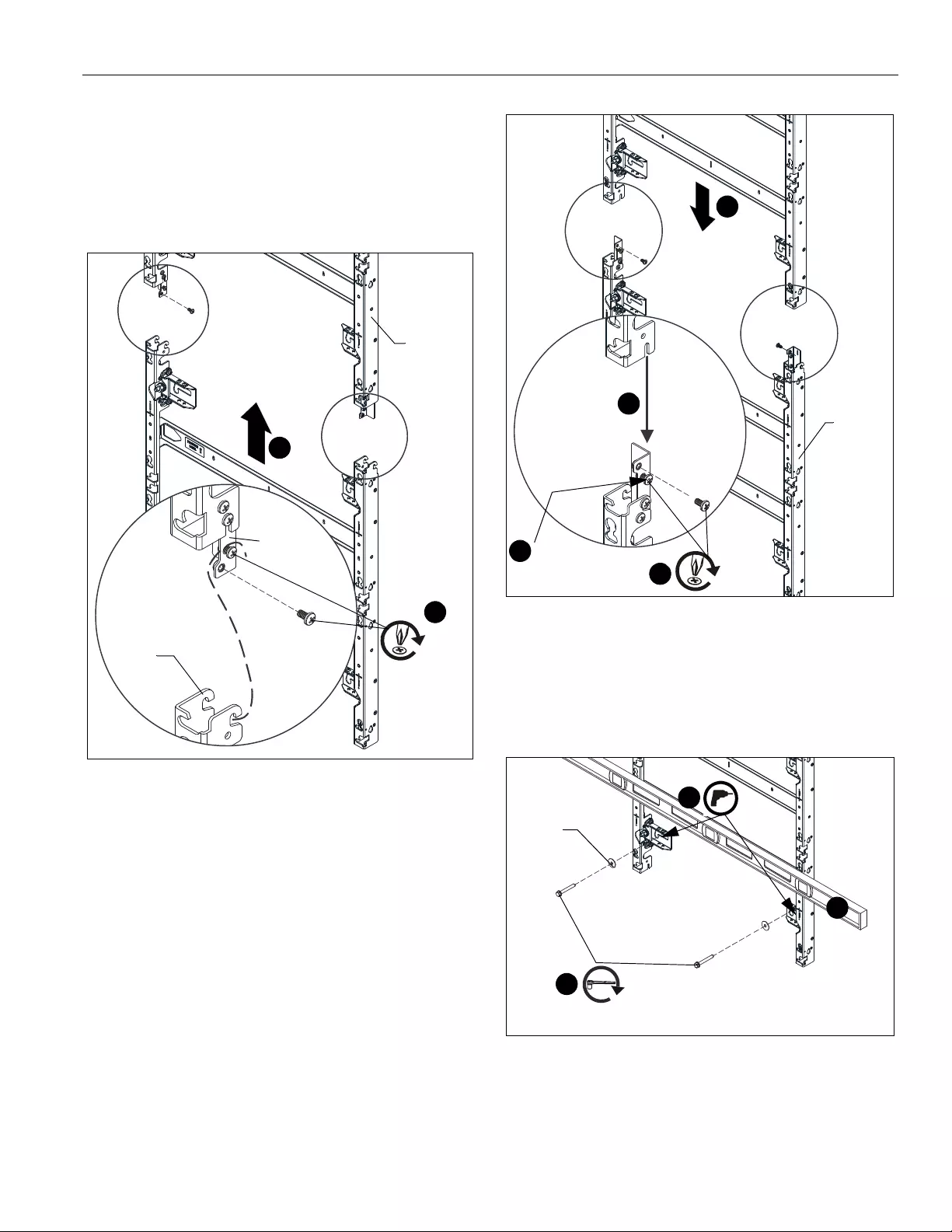

3. Place mount against wall matching the top of the mounting

slots with the horizontal line previously drawn.

4. Mark mounting holes in two top mounting slots along the

horizontal line marked in Step 3 of Assessing the

Installation Site section. (See Figure 5)

NOTE: The mounting holes are 25.0" apart on-center. (See

Figure 5)

Figure 5

5. Drill two pilot holes (see Table 1 for size) at each location

marked in Step 4 (See Figure 5) and follow fastener

information (appropriate for wall type) located in Table 1.

IMPORTANT ! : Refer to Fastener Installation Methods

(located in Appendix at end of Installation Instructions)

for details on installing product into various wall types.

6. Partially install two lag screws into wall, but do NOT

completely tighten to wall. (See Figure 6)

NOTE: Utilizing the two adjustment washers (A, B) allows the

installer to pre-install the top mounting fasteners and

hang the mount from them utilizing the mounting slots.

This allows the weight of the mount to be held by the

mounting bolts during installation, and not the installer.

Figure 6

7. Hang wall mount, aligning upper mounting slots over

fasteners, and adjust side-to-side for proper location. (See

Figure 6)

8. Place a level across front of the mount at bottom of teardrop

slots. (See Figure 7)

9. Check the level of the mount at the teardrop slots. (See

Figure 7)

Figure 7

WALL

TYPE PILOT

HOLE FASTENERS (see PARTS

drawing)

Drywall

attached to

plywood-

backed walls

/Steel studs

Drywall

attached to

plywood-

backed walls

/Wood studs

1/2"

7/32" x 3"

- 1/4-20 x 2-1/2" hex head lag (not

included)

- 1/4" washer (not included)

- 1/4-20 Toggler Snaptoggle BB

(not included)

- 5/16 x 2-1/2" flanged hex head

lag (D)

- 5/16" washer (E)

- Adjustment washers (A, B)

Concrete or

concrete

block

3/8" x 3" - 5/16 x 2-1/2" flanged hex head

lag (D)

- 5/16" washer (E)

- Adjustment washers (A, B)

- Fischer Anchor UX10x60R (C)

4

25.0 inches

5

Line showing top

of mounting slots

7

x 2

[TIL1X2IFJ shown as example]

6

8

Mount

teardrop

Level

slots

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

10

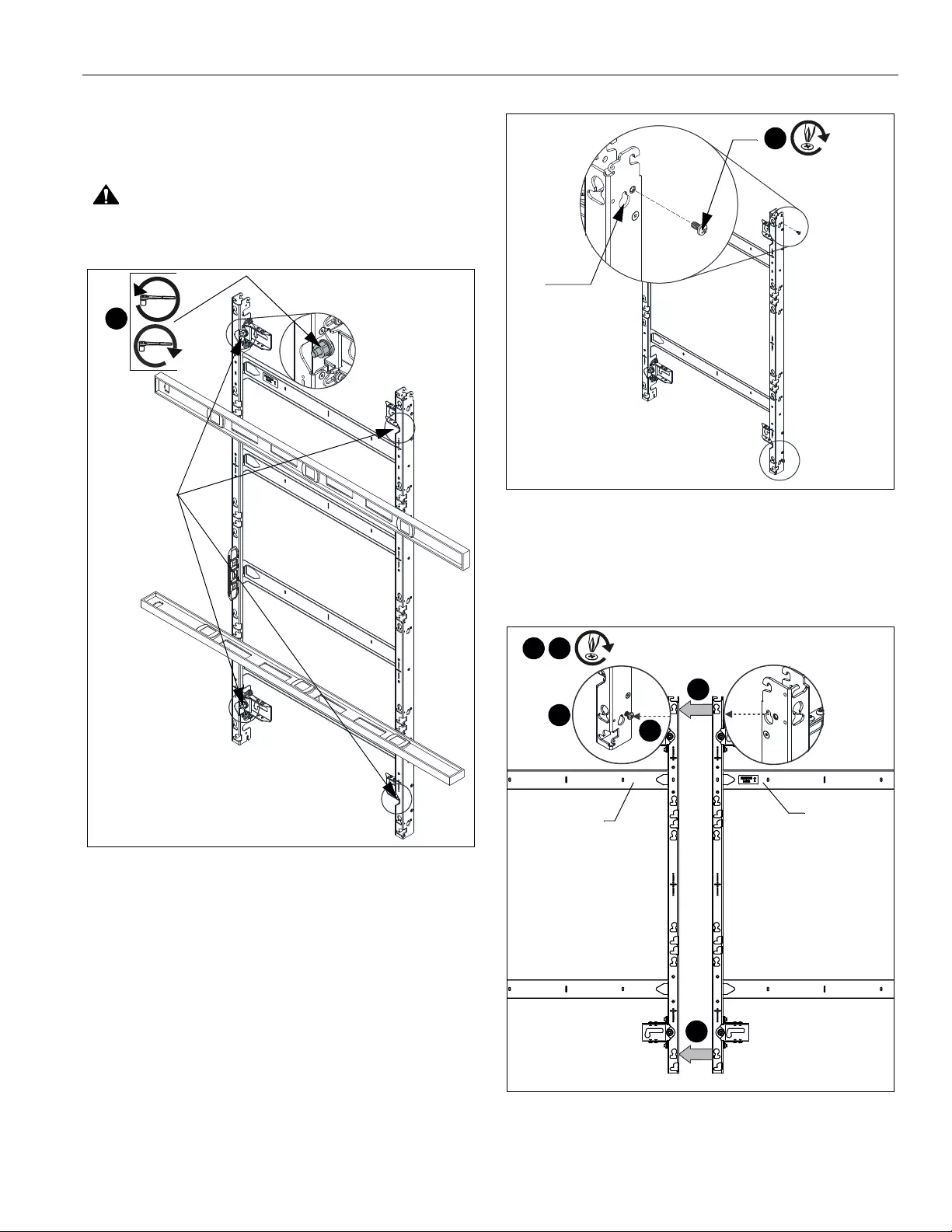

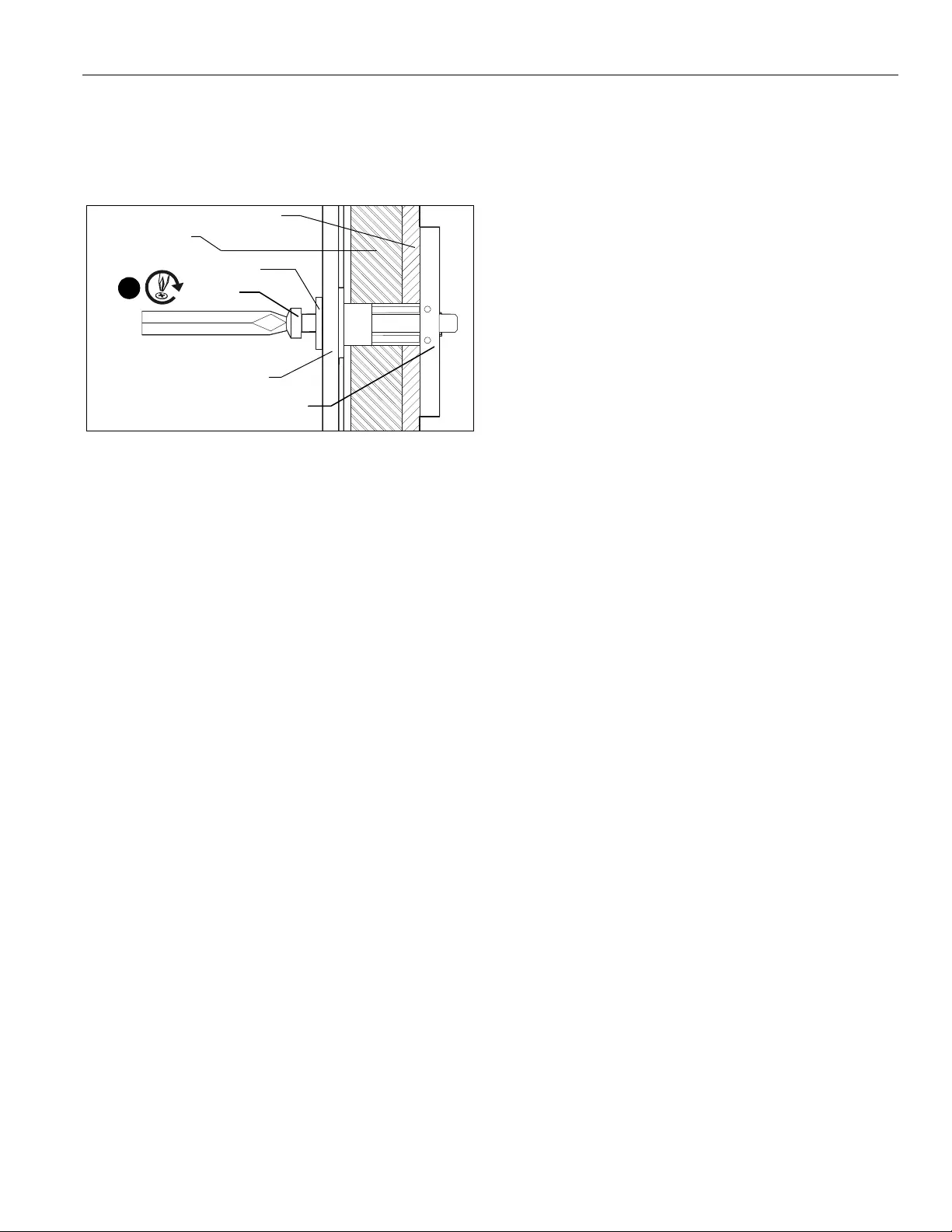

10. Slide the left (B) and right adjustment washers (A) into place

behind the partially installed lag screws. (See Figure 8)

Figure 8

11. Check the level of the mount at the bottom of the teardrop

slots. (See Figure 9)

12. If the mount is not level, slide or use a dead blow hammer

to lightly tap the spacer into place. This will lift the mount up

as the lag screw rides in the washer’s angled slot. (See

Figure 9)

13. When the mount is leveled, tighten the lag screws (D). (See

Figure 9)

Figure 9

14. Drill pilot holes in centerline of lower slots (see Table 1 for

size) and follow fastener information (appropriate for wall

type) located in Table 1. (See Figure 10)

15. Double check the level of the mount at the bottom of the

teardrop slots. (See Figure 10)

16. Fully tighten the 5/16 x 2-1/2" lag screws (D) through the 5/16"

fender washers (E). (See Figure 10)

Figure 10

(B)

(A)

10

Just a tip - Tighten down the lag screw on the

side that does NOT need to be raised. This

creates a pivot point for when the opposite

adjustment washer is tapped into place, and

allows that correct side of the mount to move up.

Level

Dead blow

hammer

(B) (A)

13

(D) x 2

16

(E) x 2

15

(D) x 2

4

x 2

Teardrop slots

Just a tip - After the first mount is installed, it

may be easier to adjust the plumb at this time. If a

lot of adjustment is going to be necessary it’s best

to adjust it right away to avoid any twist or tension

on the mount.

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

11

17. Using a level on the front of the mount in various places, use

a 3/4" or 19mm deep-well socket and square drive

ratcheting wrench to adjust the leveling feet on the mount

until the mount is plumb or even with something that is being

used as a reference point. (See Figure 11)

CAUTION: Over-torquing may cause damage. Do NOT

use a drill to make the depth adjustment.

Figure 11

Adding Additional Mounts

1. Partially install two 1/4-20 x 1/2" Phillips head screws (H)

into the fastener holes (next to the teardrop holes) at the top

and bottom of the mount, and on the side of the mount you

want to attach another mount. (See Figure 12)

Figure 12

2. Hang the second mount (using teardrop slots at top and

bottom on the left side) onto the fasteners installed in Step 1.

(See Figure 13)

3.

Fully tighten fasteners installed in Step 1.

(See Figure 13)

Figure 13

Leveling feet

locations

17

1

(H) x 2

[TIL1X3IFJ shown as example]

Teardrop

hole

2

3

(H) x 2

Second

wall mount

2

1

Installed

mount

2

1

wall

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

12

4.

Drill pilot hole towards top and in centerline of upper

mounting slot of second mount closest to installed mount

(see Table 1 for size) and follow fastener information

(appropriate for wall type) located in Table 1. (See Figure 14)

Figure 14

5. Loosen the side connector screws (installed in Step 1)

about 1/4 turn.

6.

Slide the adjustment washer into place behind the partially

installed lag screw until the bottom of the teardrop slots are

aligned.

(See Figure 15)

7. Tighten first lag screw.

Figure 15

NOTE: The second mount will most likely need to be raised

slightly to align with installed mount.

8. After the first lag screw is installed, hold the second mount

at approximately parallel with the installed mount, and drill a

pilot hole in the center of the remaining upper mounting slot.

9. Install adjustment washer and push in until the mounting

slots are level and aligned.

10. Tighten second lag screw.

11. Re-tighten connector screws, upper and lower. (See

Figure 13)

12. Drill lower pilot holes on second mount at the center both

vertically and horizontally within lower mounting slots and

use same fasteners used at top of mount.

13. Continue installation of mounts in this manner until the row

is complete.

Just a tip - The plumb on these mounts at this

point doesn’t have to be perfect. Final adjustments

can be done once all the mounts are installed.

Checking and adjusting plumb at this point

ensures the mounts are closely aligned on the

same plane to prevent the mount from twisting or

bending when the lag screws are installed.

4

x 2

Second mount

Just a tip - The lag screws need to be at the

top of the mounting slot to allow the mount to be

raised slightly, if needed, to align it with the

previously installed mount.

Slide adjustment

washer into place

6

Installed wall mount

Second wall mount

Align bottom of

6

teardrop slots

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

13

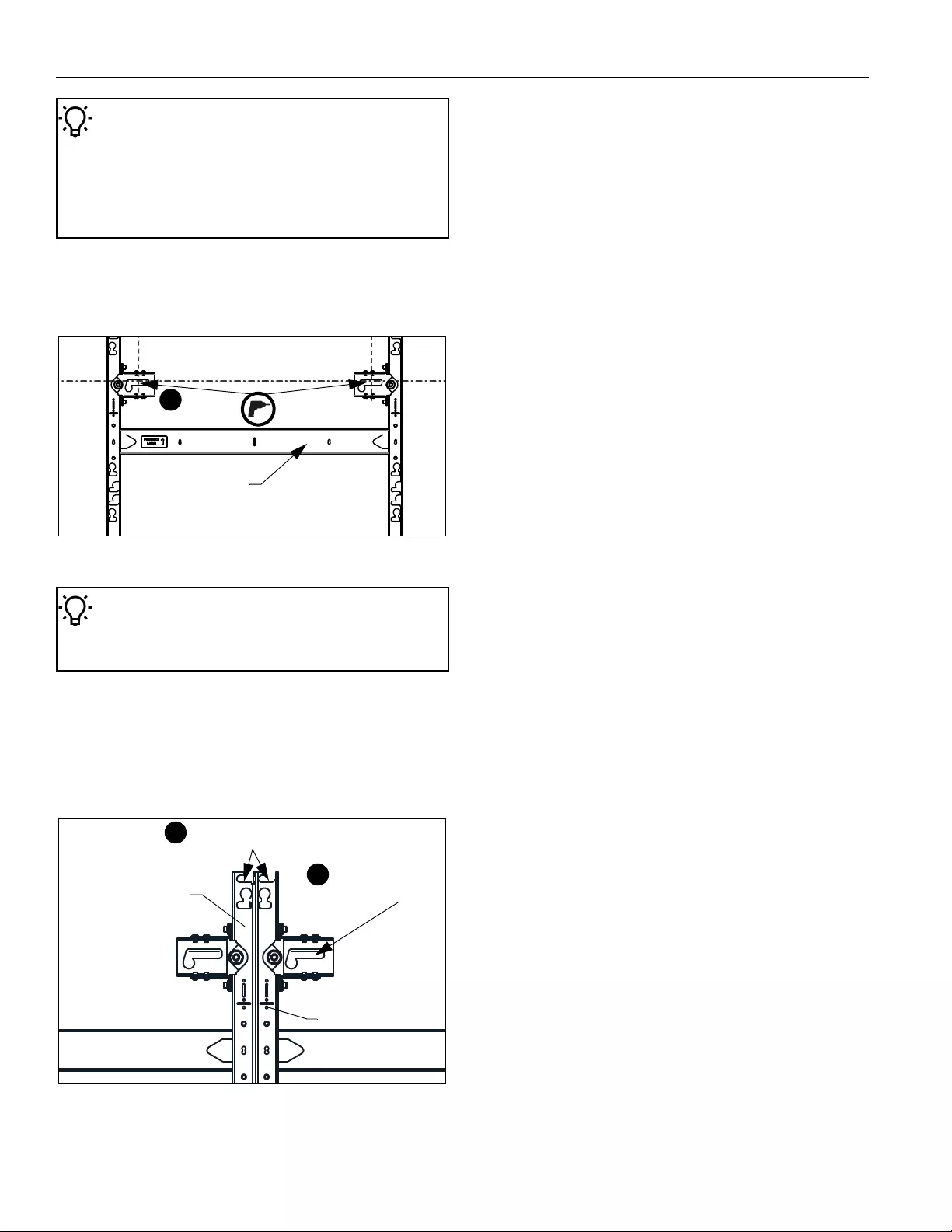

Checking Placement and Alignment

1. The holes around slots on the mounts can be used for the

included #10 x 1/2" self-tapping screws (F) to help attach a

string to help in aligning and plumbing the mounts.

NOTE: There are multiple points on each mount where the

screws can be installed for the plumb line. At a

minimum, the plumb strings should be strung next to

each adjustment point (at every leveling foot). (See

Figure 16)

2. Loosely install the self-tapping screws then wrap the string

around the screw and tighten. (See Figure 16)

3. Run the string tightly between the same hole at each end of

the row of mounts. (See Figure 16)

Figure 16

1

Arrows indicate tapping

screw hole locations for

attaching string to assist

with alignment of mounts

String to

assist with

alignment

2

3

Leveling feet

(top and bottom,

of each mount)

left and right

2

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

14

4. If the cabinets need to be moved slightly to either the left or

right, insert two 10-24 x 1" self-tapping screws (G) per

cabinet into the left or right side of the mount. (See

Figure 17)

NOTE: There are two places on each cabinet for the side stop

screws to be installed. These screws will act as an

adjustable left or right stop. Turn the screw IN to adjust

the stop to the right, and back the screw OUT to move

the stop to the left.

Figure 17

5. When installing a cabinet to the mounting system, line up

mounting buttons with mounting holes at each corner.

6. Guide cabinet mounting buttons into mounting holes.

7. Lower cabinet ensuring that mounting buttons are securely

seated in the four mounting holes. (See Figure 18)

Figure 18

8. After the bottom row of cabinets are installed, it is a good

idea to install the far left or right column of cabinets to check

that everything is square and straight.

NOTE: There

are 2 places on

each cabinet for

left or right side

4

4

to be installed

stop screws

(G)

[TIL1X3IFJ shown as example]

Mounting

button

6

Mounting hole

7

Cabinet

Just a tip - When installing in a recess it may

also be helpful to install the far right column. This

allows you to check for squareness and level

inside of the recess.

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

15

Connecting Mounts Above or Below First Row

• Hanging Mounts from an Upper Row

1.

Hang the lower mount on the partially installed

Phillips head screws (K) in the vertical connectors

(L). (See Figure 19)

2. Tighten both lower screws (K) on both vertical

connectors (L). (See Figure 19)

Figure 19

• Installing Mounts onto a Lower Row

3. Make sure the 1/4-20 x 1/2" Phillips head screw

(K) is already loosely installed in the vertical

connector (L) on both sides of the mount. (See

Figure 20)

4. Slide mount down onto the screws so that upper

mount sets on lower mount.

5. Install two 1/4-20 x 1/2" Phillips head screws (K)

into upper hole on both vertical connectors, and

tighten all screws. (See Figure 20)

6. Place a long level against front of the mounts and

adjust the depth of the newly attached mount to

align it with the first, installed mount.

7. Adjust the leveling feet on the newly installed

mount so that they are touching the wall.

8. Drill pilot holes in centerline of each mounting slot

on each leveling foot of the added mount (see

Table 1 for size) and follow fastener information

(appropriate for wall type) located in Table 1. (See

Figure 20)

Figure 20

9. Double check the level of the mount at the bottom of the

teardrop slots, and make sure the new mount stays

perfectly aligned with the upper or lower mount to which it

was attached. (See Figure 21)

10. Fully tighten the fasteners. (See Figure 21)

Figure 21

11. Continue on until the entire LED wall is assembled.

Installed

mount

1

(L)

Lower

mount

(K) x 2

2

(K) x 2

5

Set mount

3

4

Installed

mount

4

on loosely

installed screw

(E) x 4

8

x 4

9

10

(D) x 4

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

16

APPENDIX

Fastener Installation Methods

IMPORTANT ! : See Table 1 for appropriate hardware

and pilot hole sizes for various wall types.

IMPORTANT ! : The expanse of the LED wall will most

likely mean that attachment of the wall mounts will not all

be in studs. The attachment method will most likely vary

throughout the installation, and more than one of the

various methods outlined here will most likely be used.

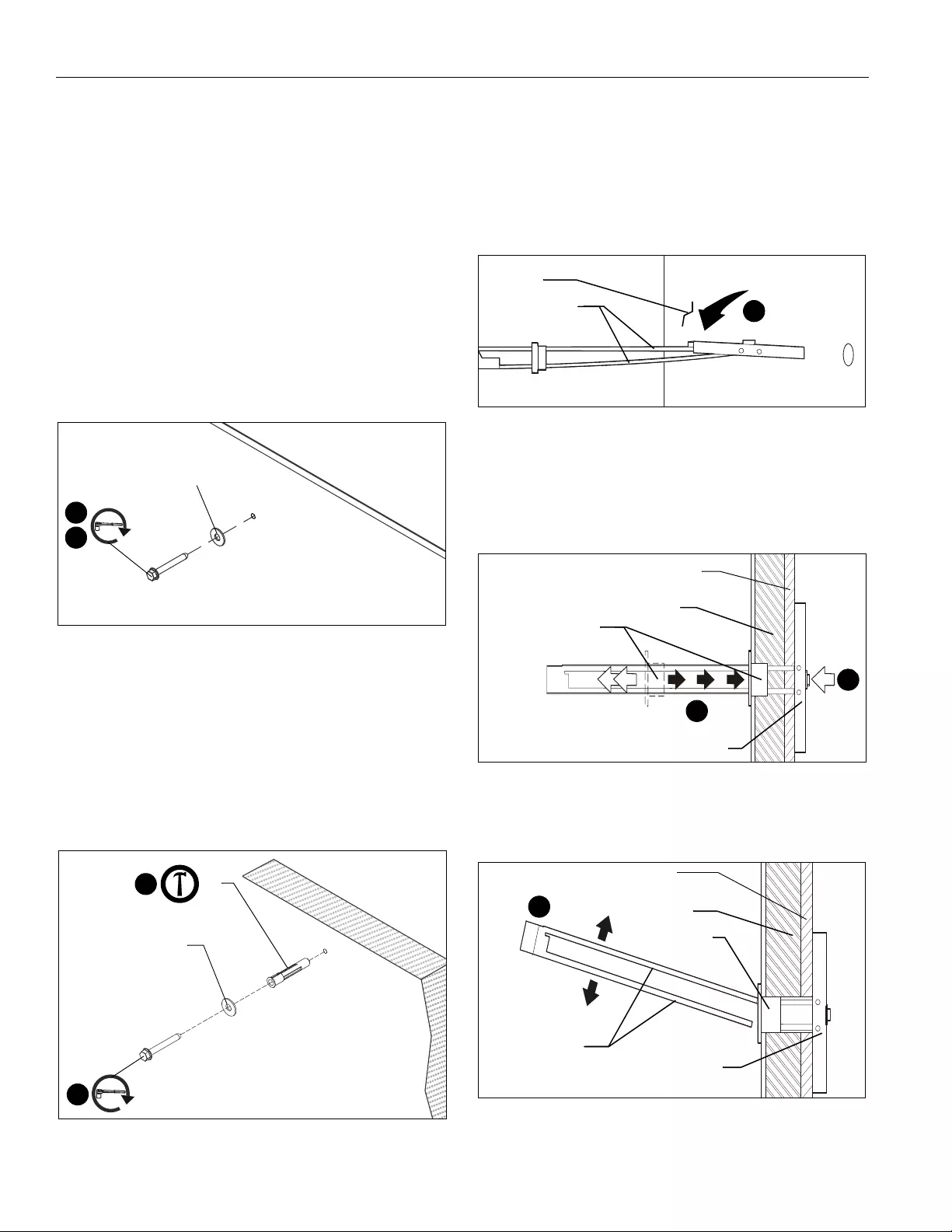

Wood Stud

1. Use one 5/16" x 2-1/2" hex flange head lag bolt (D) and one

5/16" washer (E) through product and into pilot hole. (See

Figure 22)

2. Repeat for remaining pilot holes.

Figure 22

Concrete or Concrete Block

1. Install one UX10X60R anchor (C) into each pilot hole using

a hammer, making sure that the anchor is flush with the wall.

(See Figure 23)

2. Use one 5/16" x 2-1/2" hex flange head lag bolt (D) and one

5/16" washer (E) through product into each anchor in wall.

(See Figure 23)

3. Repeat for remaining pilot holes.

Figure 23

Steel Stud

IMPORTANT ! : See Site Requirements for Steel Stud

Installation section before proceeding with Steel Studs

installation to ensure installation site meets requirements!

The drywall must have a minimum thickness of 1/2"!

1. Hold metal channel on anchor flat alongside plastic straps

and slide channel through hole. (See Figure 24)

Figure 24

2. Holding plastic straps on anchor, pull anchor away from wall

until channel rests flush behind wall making sure anchor

channel is positioned vertically on drywall, or steel stud (if

present). (See Figure 25)

3. Slide plastic cap on anchor towards wall until flange of cap

is flush with wall. (See Figure 25)

Figure 25

4. Snap off plastic straps on anchor at wall by pushing side to

side, snapping off straps level with flange of plastic cap.

(See Figure 26)

Figure 26

1

2

(D)

(E)

1

2

(D)

(C)

(E)

Drywall

Plastic straps

1

Plastic cap

Drywall

Anchor metal channel

3

Steel stud

(side view)

2

(if present)

Plastic straps

Drywall

Anchor metal channel

Plastic cap

4

Steel stud

(side view)

(if present)

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

17

5. Line up anchor with attachment point.

6. Insert 1/4-20 x 2-1/2" hex head screw through 1/4" washer,

corresponding mounting hole in wall bracket and into

anchor, and tighten until flush against wall bracket. DO NOT

over tighten! (See Figure 27)

Figure 27

Drywall

Anchor metal channel

Hex Head

6

Steel stud

Washer

(side view)

Wall bracket

(if present)

screw

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

18

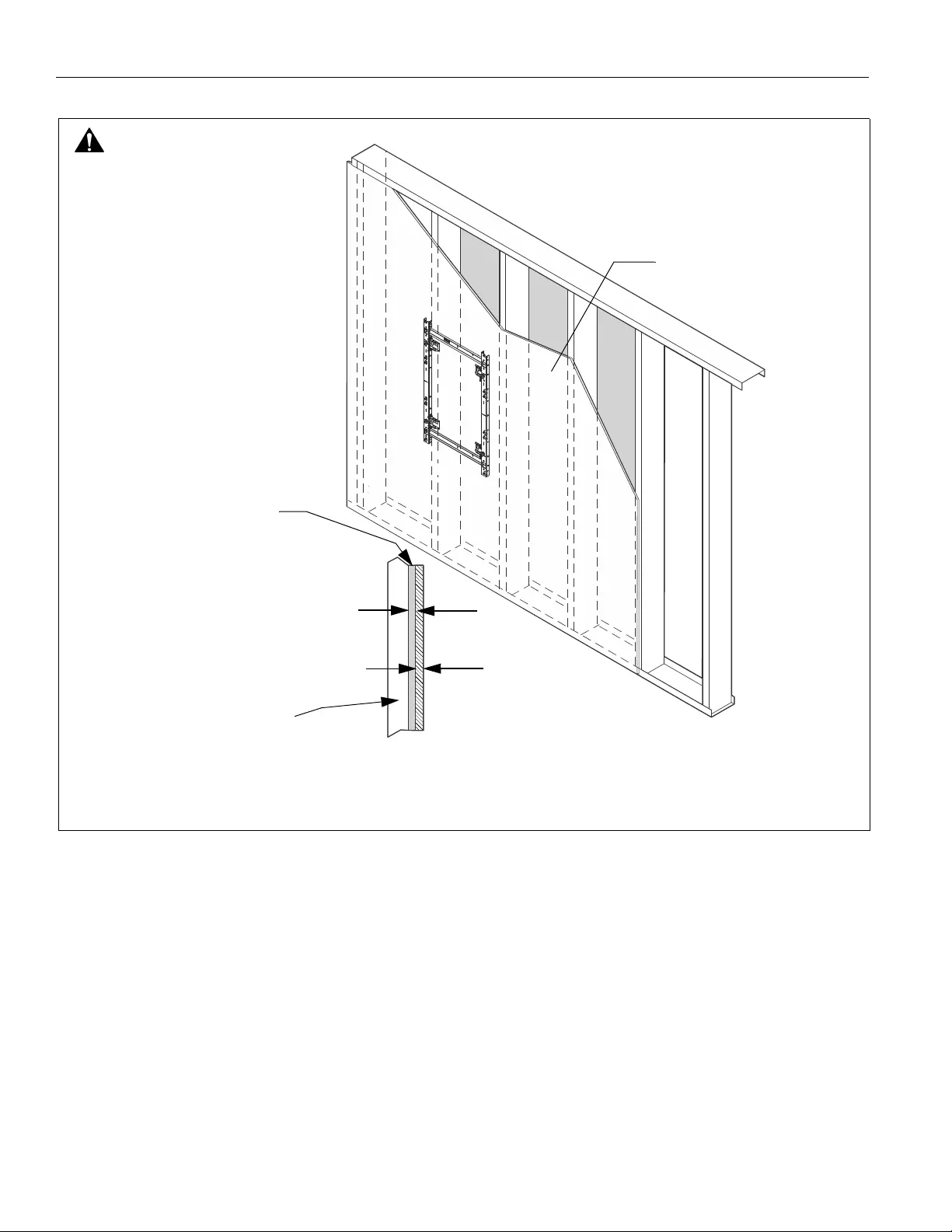

Site Requirements for Wood or Steel Stud Installation

Figure 28

FRONT

There must be a minimum of

1-7/8" (48mm) clearance

inside wall

16" or 24" (on center) Studs

If back side of wall is unfinished,

to a minimum of one stud left

drywall must be installed

and right of the stud(s) being used

to install the mount. Drywall must be

secured to studs with screws a

maximum of 12" (305mm) apart

down center of stud.

Steel Stud (2 x 4 / 25ga minimum)

Stud type and structural strength must conform to the North American

Specification for the Design of Cold-Formed Steel Structural Members.

(Both Sides of Stud)

[362 S 125 18, C-Shaped, S-Stud Section]

Plywood

3/4" minimum thickness

plywood covered

with drywall having

maximum thickness of 5/8"

5/8" maximum

drywall thickness

Stud

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

19

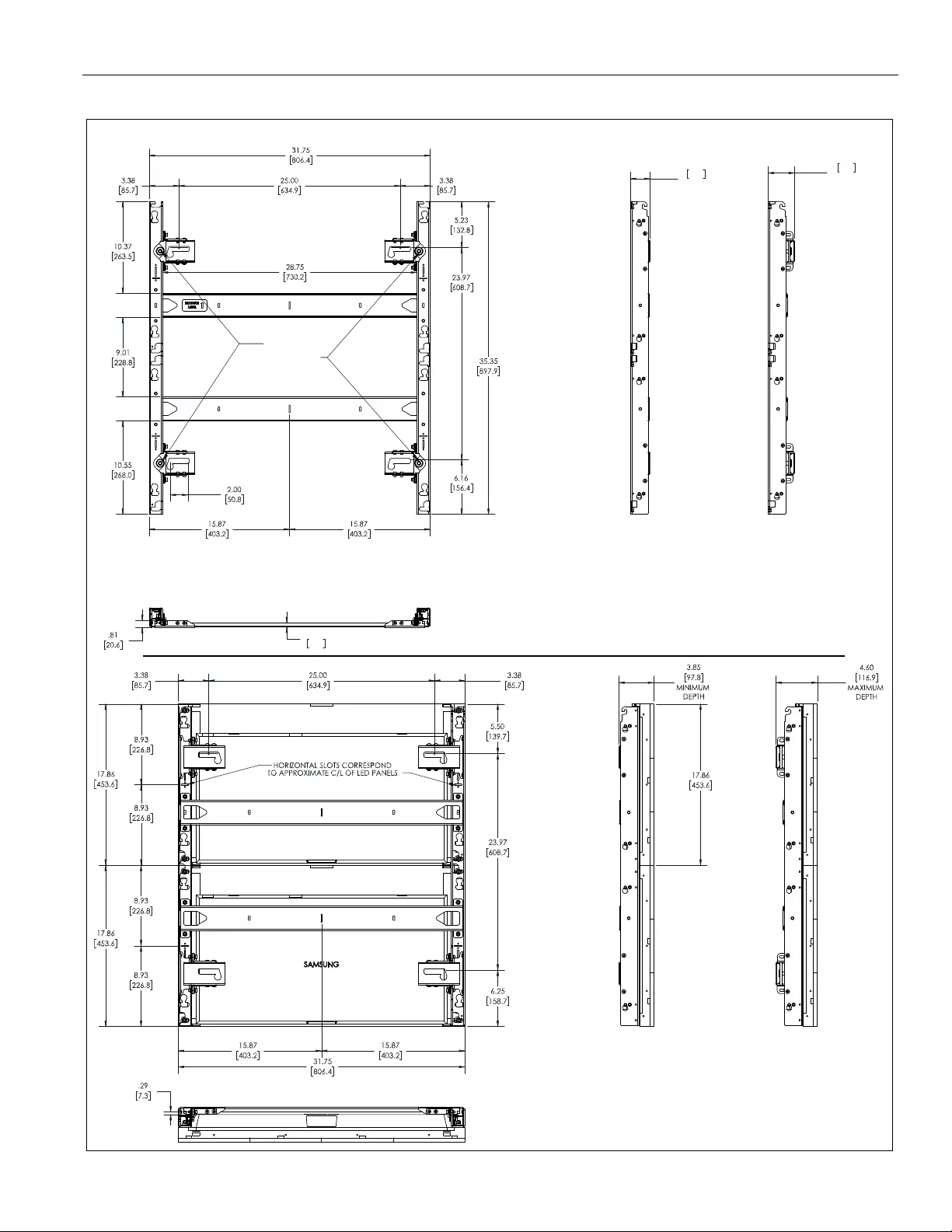

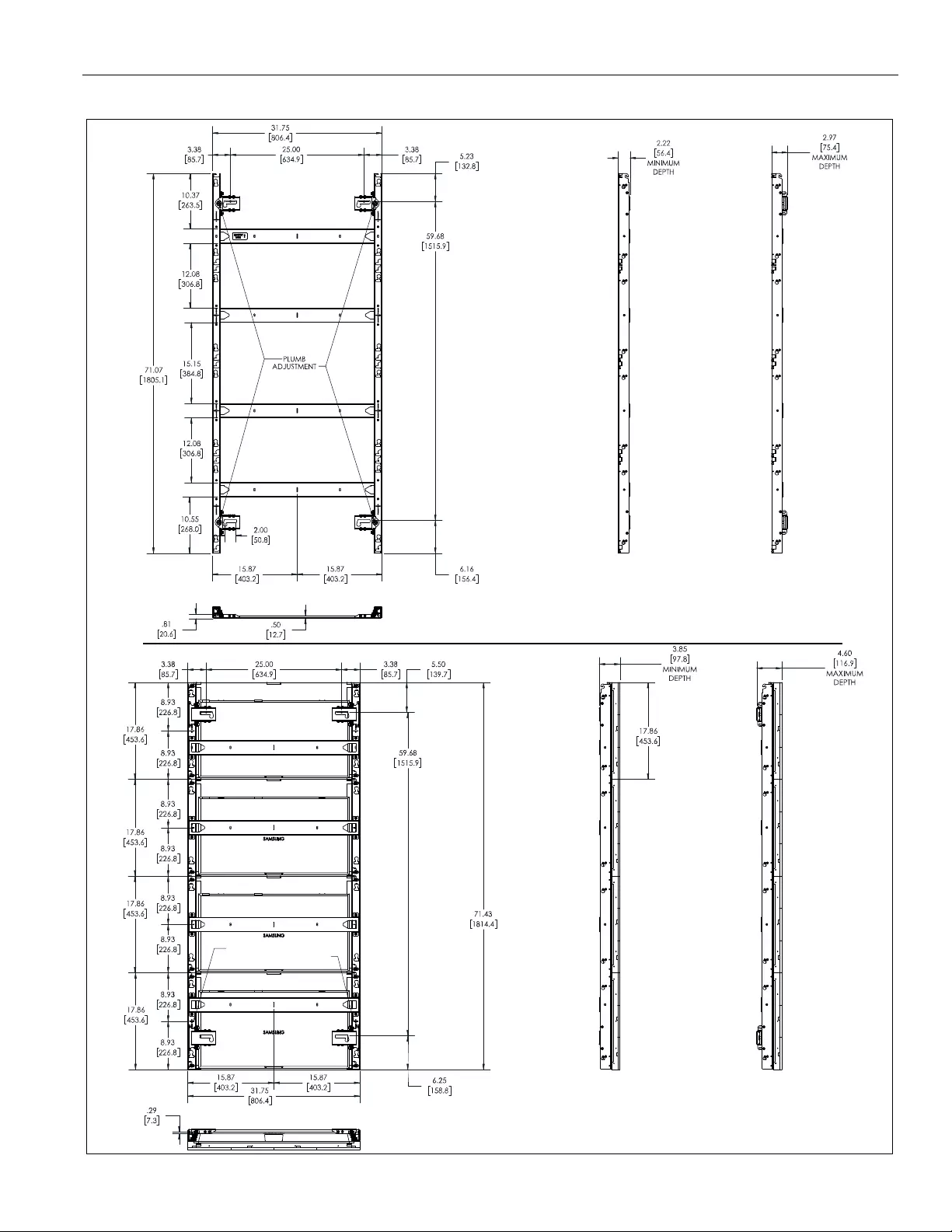

DIMENSIONS

TIL1X2IFJ

PLUMB

ADJUSTMENT

2.22

56.4

MINIMUM

DEPTH

2.97

75.4

MAXIMUM

DEPTH

.50

12.7

SHOWN WITH SAMSUNG IFJ SERIES LED PANELS

DIMENSIONS: INCHES

[MILLIMETERS]

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

20

DIMENSIONS -- cont’d

PLUMB

ADJUSTMENT

TIL1X3IFJ

SHOWN WITH SAMSUNG IFJ SERIES LED PANELS

DIMENSIONS: INCHES

[MILLIMETERS]

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

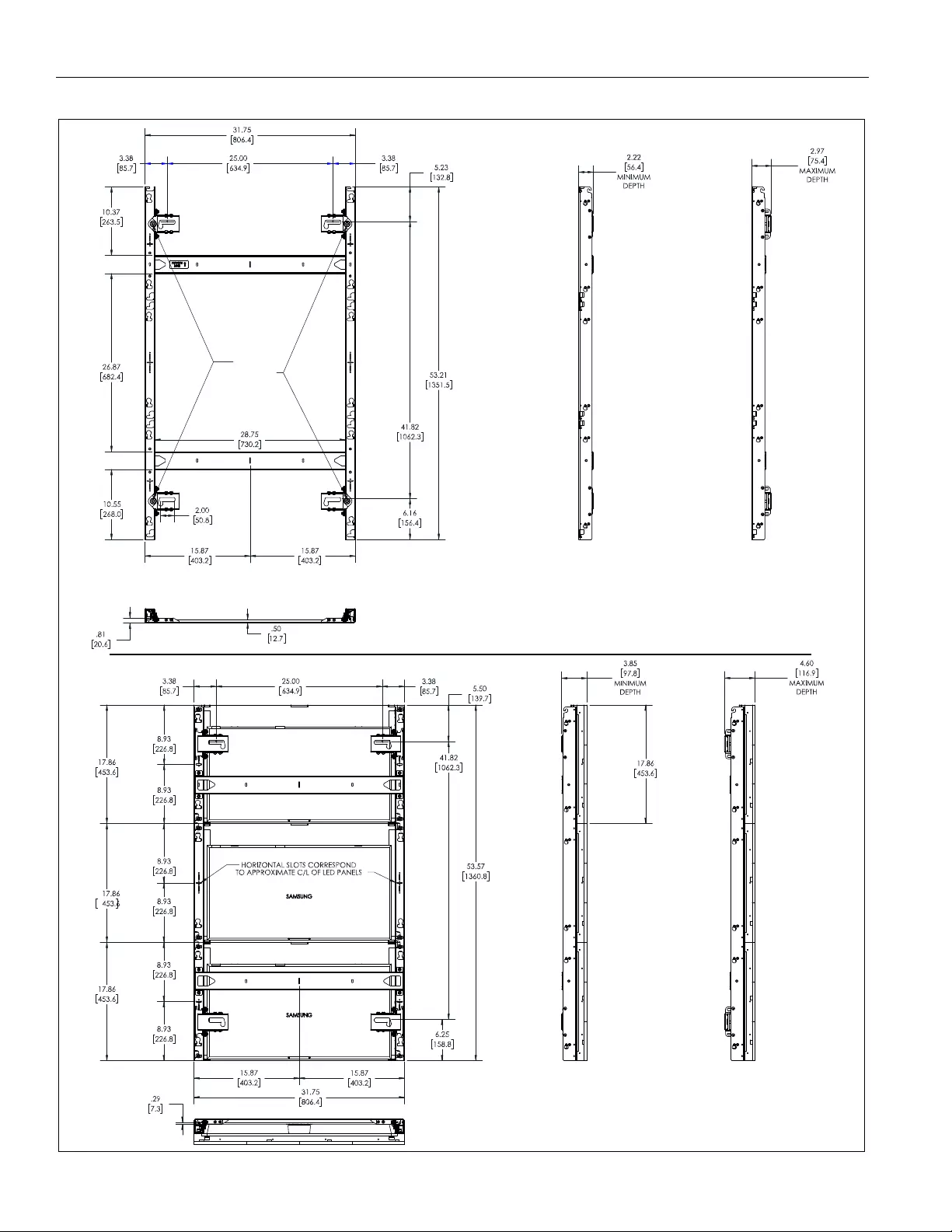

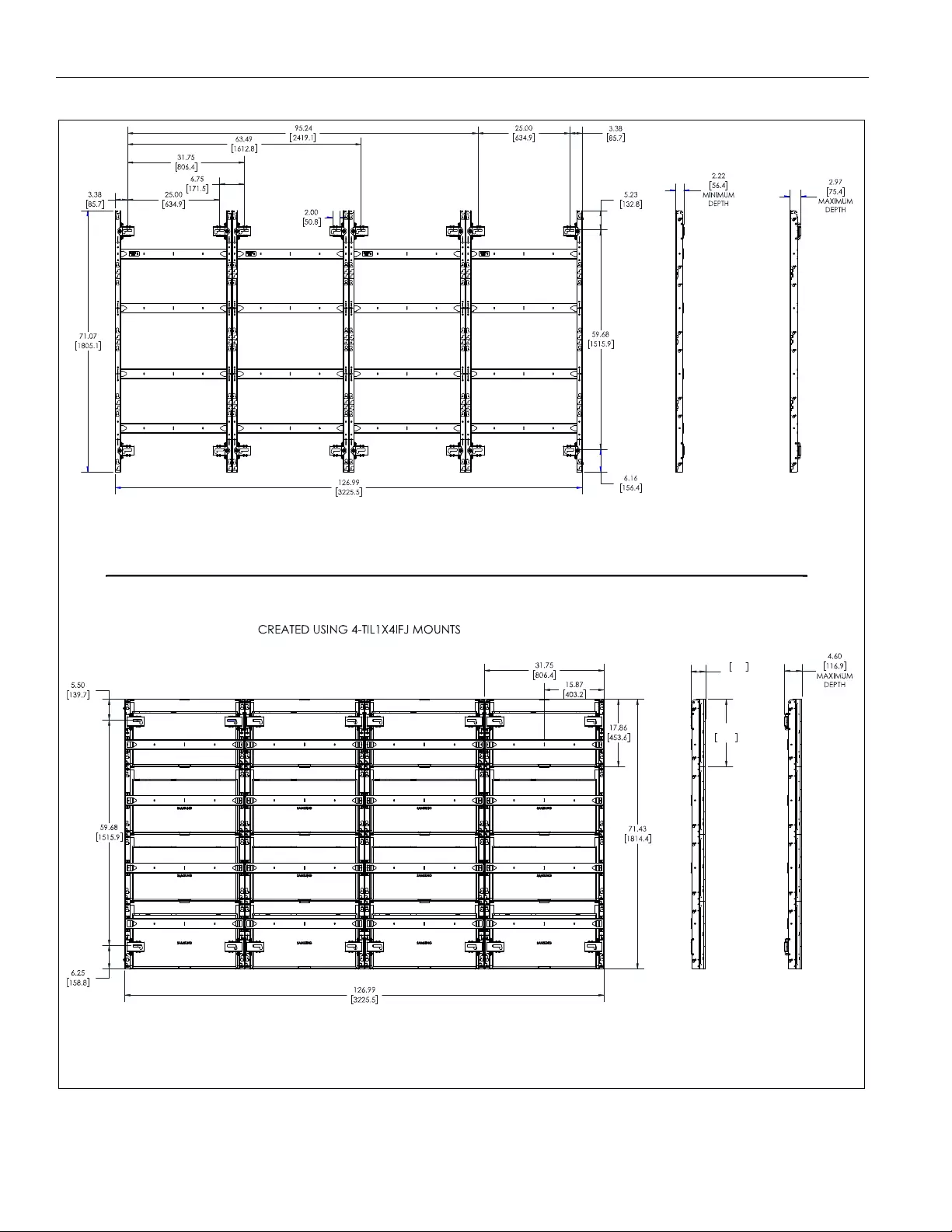

21

DIMENSIONS -- cont’d

HORIZONTAL SLOTS CORRESPOND

TO APPROXIMATE C/L OF LED PANELS

SHOWN WITH SAMSUNG IFJ SERIES LED PANELS

TIL1X4IFJ

DIMENSIONS: INCHES

[MILLIMETERS]

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

22

DIMENSIONS -- cont’d

CREATED USING 4 TIL1X4IFJ MOUNTS

4X4 WALL

SHOWN WITH SAMSUNG IFJ PANELS

3.85

97.8

MINIMUM

DEPTH

17.86

453.6

CREATED USING 4 TIL1X4IFJ MOUNTS

DIMENSIONS: INCHES

[MILLIMETERS]

Installation Instructions TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1

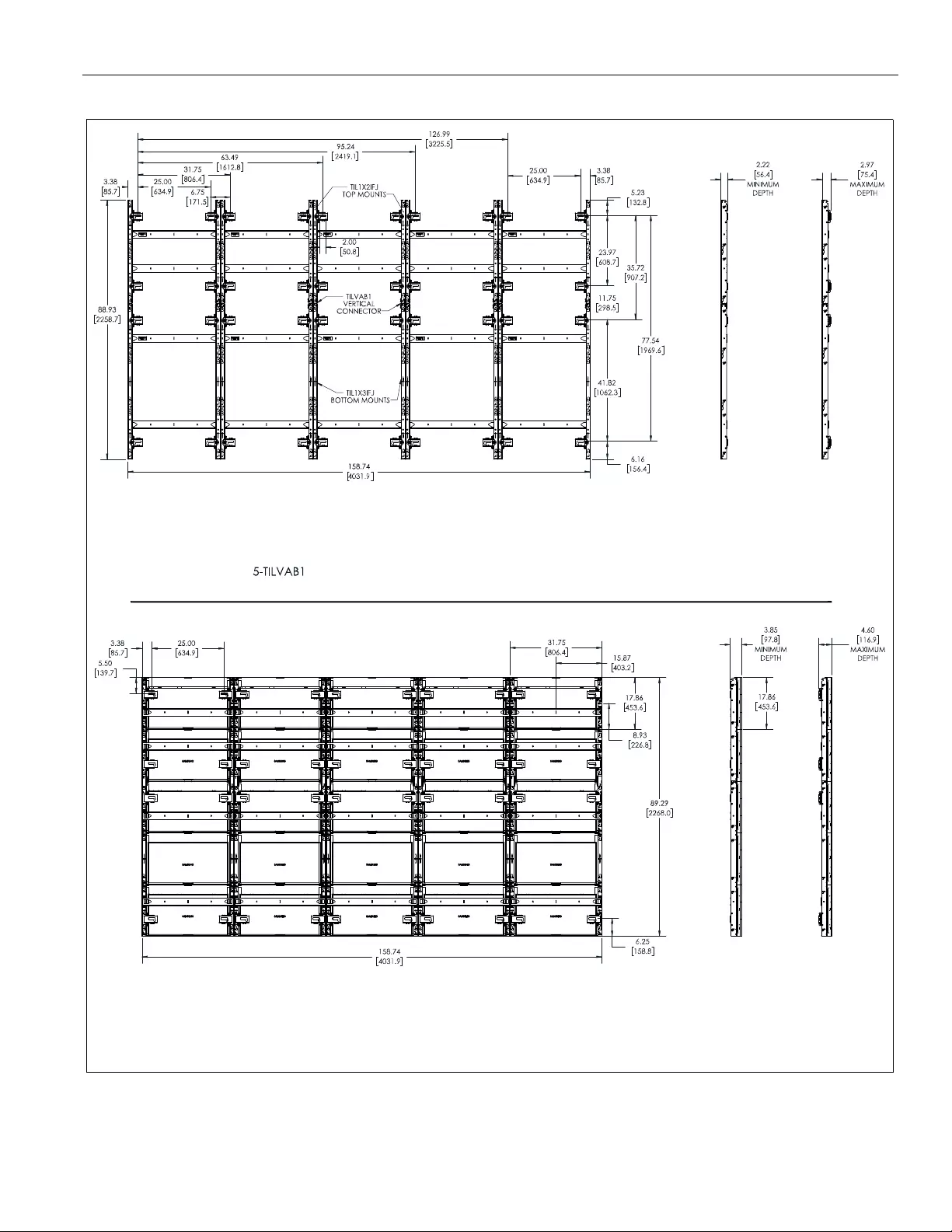

23

DIMENSIONS -- cont’d

5 X 5 CONFIGURATION CREATED UTILIZING

5-TIL1X3IFJ

5-TIL1X2IFJ

5X5 WALL

SHOWN WITH SAMSUNG IFJ PANELS

5 X 5 CONFIGURATION CREATED UTILIZING

5-TIL1X3IFJ

5-TIL1X2IFJ

5-TILVAB1

DIMENSIONS: INCHES

[MILLIMETERS]

TIL1X2IFJ / TIL1X3IFJ / TIL1X4IFJ/ TILVAB1 Installation Instructions

USA/International A 6436 City West Parkway, Eden Prairie, MN 55344

P800.582.6480 / 952.225.6000

F877.894.6918 / 952.894.6918

Europe A Franklinstraat 14, 6003 DK Weert, Netherlands

P+31 (0) 495 580 852

F+31 (0) 495 580 845

Asia Pacific A Office No. 918 on 9/F, Shatin Galleria

18-24 Shan Mei Street

Fotan, Shatin, Hong Kong

P852 2145 4099

F852 2145 4477

8800-00003231 Rev00

2020 Legrand | AV

www.legrandav.com

12/2020