Eaton 9E 10000I User Manual

Displayed below is the user manual for 9E 10000I by Eaton which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

powerquality.eaton.com

Eaton 9E

6-20kVA

CONTENT:

1. Introduction ............................................................................... 1

1.1 Safety instruction ............................................................... 1

1.2 Certification Standards ....................................................... 3

1.3 Special Symbols ................................................................ 4

2.Presentation ................................................................................ 5

2.1 Model List .......................................................................... 5

2.2 Electrical structure ............................................................. 5

2.3 UPS views ......................................................................... 7

3.Installation ................................................................................ 12

3.1 Unpacking ........................................................................ 12

3.2 Package content .............................................................. 13

3.3 Connection ...................................................................... 13

4.OPERATION .............................................................................. 24

4.1 Display and Buttons ......................................................... 24

4.2 Operating UPS ................................................................. 28

4.3 Configuration ................................................................... 30

4.4 Trouble shooting .............................................................. 32

4.5 Alarm codes ..................................................................... 34

5.Technical data .......................................................................... 35

1

1. Introduction

1.1 Safety instruction

The UPS must be installed and maintained exclusively by quailified

staff. See installation and operation instructions before connecting to

the supply.

The UPS must be installed with an earth connection. It has a high

leakage current. The first wire to be connected is the earth wire, which

must be connected to the terminal marked PE (yellow/green).

The UPS generates a leakage current of over 3.5 mA. The leakage

current of the load should be added to that of the UPS on the

protective earth wire.

The UPS needs a neutral connection to work properly. Operation

without Neutral may damage the unit.

A readily accessible disconnect device shall be incorporated in the

building installation wiring for permanently connected equipment.

The UPS generates hazardous electric voltages inside it even when

the input and/or battery switches are open. The inside of the UPS is

protected by safety guards that are not to be removed by non-qualified

staff. All installation and maintenance or other operations that entail

gaining access to the inside of the UPS require the use of tools and

are to be performed exclusively by qualified staff.

The UPS contains an energy source: the batteries. All terminals and

sockets may be powered even when the UPS is not connected to the

mains.

The total battery voltage is potentially hazardous: it may cause an

electric shock. The compartment containing the batteries is protected

by safety guards, which are not to be removed by non-qualified staff.

2

All battery installation and maintenance operations entail gaining

access to the inside of the UPS and require the use of tools: these

operations are to be performed exclusively by qualified staff.

The batteries replaced are to be considered as toxic waste and treated

accordingly. Dispose of used batteries according to the instructions.

Do not throw the batteries into fire: they could explode. Do not attempt

to open the battery casing: no maintenance work can be done on

them. In addition, the electrolyte is hazardous for the skin and eyes

and may be toxic.

Risk of explosion if battery is replaced by an incorrect type.

Do not turn on the UPS if you see any leaks of liquid or a white

powder residue.

Make sure that no water, liquid in general and/or other foreign matter

gets inside the UPS.

Under hazardous conditions, turn off the UPS at the “1/0” main power

switch and open all the isolators present (see the user manual to

locate the “1/0” main power switch and the isolators).

Do not open the battery fuse holders while the UPS is powering the

load from the batteries. An interruption of the battery DC voltage may

cause an electric arc and result in breakage of the equipment and/or

fire.

The energy required to power the load is provided by the batteries in

the event of a power failure. if the battery protection were open, the

load would be powered off.

Fuses have to be replaced with the same type if necessary.

To connect external battery cabinets, use the expansion cable

suggested by the manufacturer in this manual.

3

1.2 Certification Standards

Safety

IEC 62040-1:2008

IEC 60950-1:2005 (Modified)

EMC

Conducted Emission: IEC 62040-2. Category C3

Radiated Emission: IEC 62040-2. Category C3

ESD:IEC 61000-4-2. Contact: Level 2, Air discharge: Level 3

RS:IEC 61000-4-3. Level 3

EFT:IEC/EN 61000-4-4. Level 4

Surge:IEC/EN 61000-4-5. Level 4

CS:IEC/EN 61000-4-6. Level 3

MS:IEC/EN 61000-4-8. Level 3

Voltage Dips, short interruptions and voltage variations:IEC/EN 61000-4-11

Warning: This is a product for commercial and industrial application, in other

environment installation restrictions or additional measures may be needed to

prevent disturbances. Additional curbs may be needed while output wiring

length is more than 10m or communication wiring length is more than 3m.

4

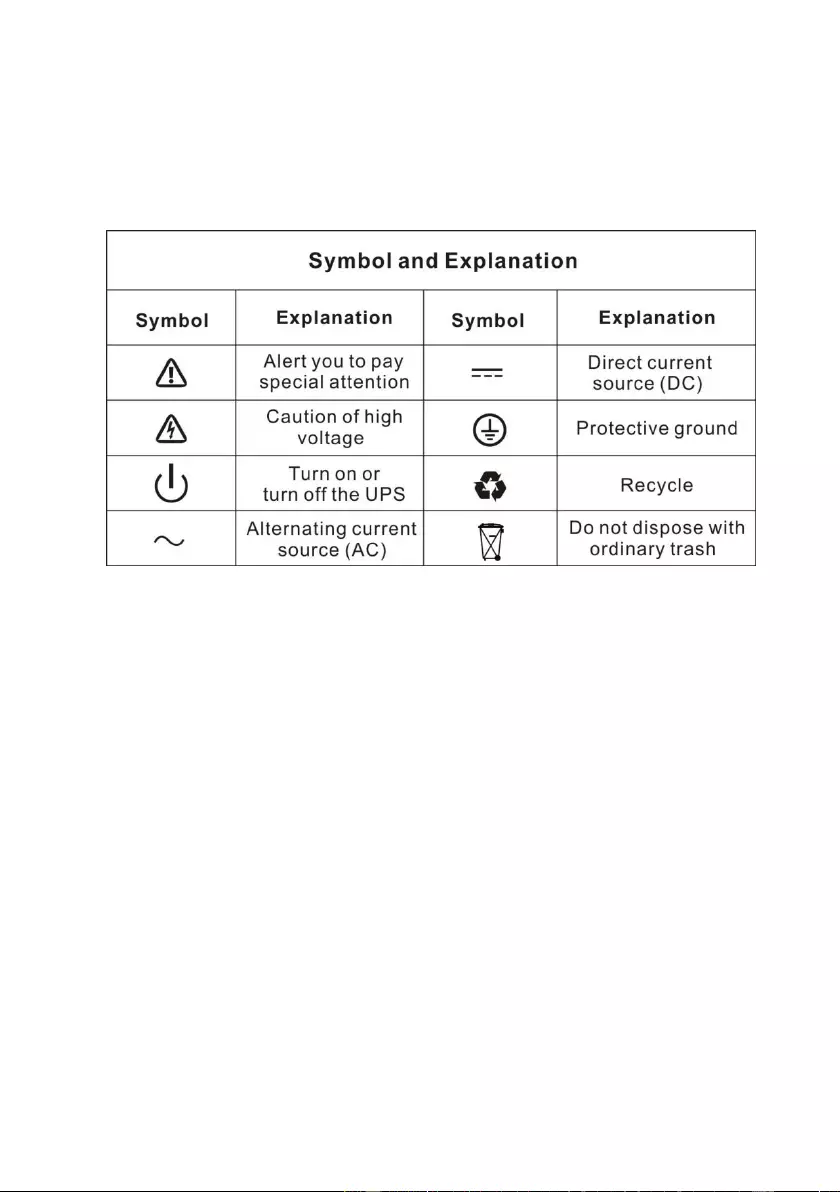

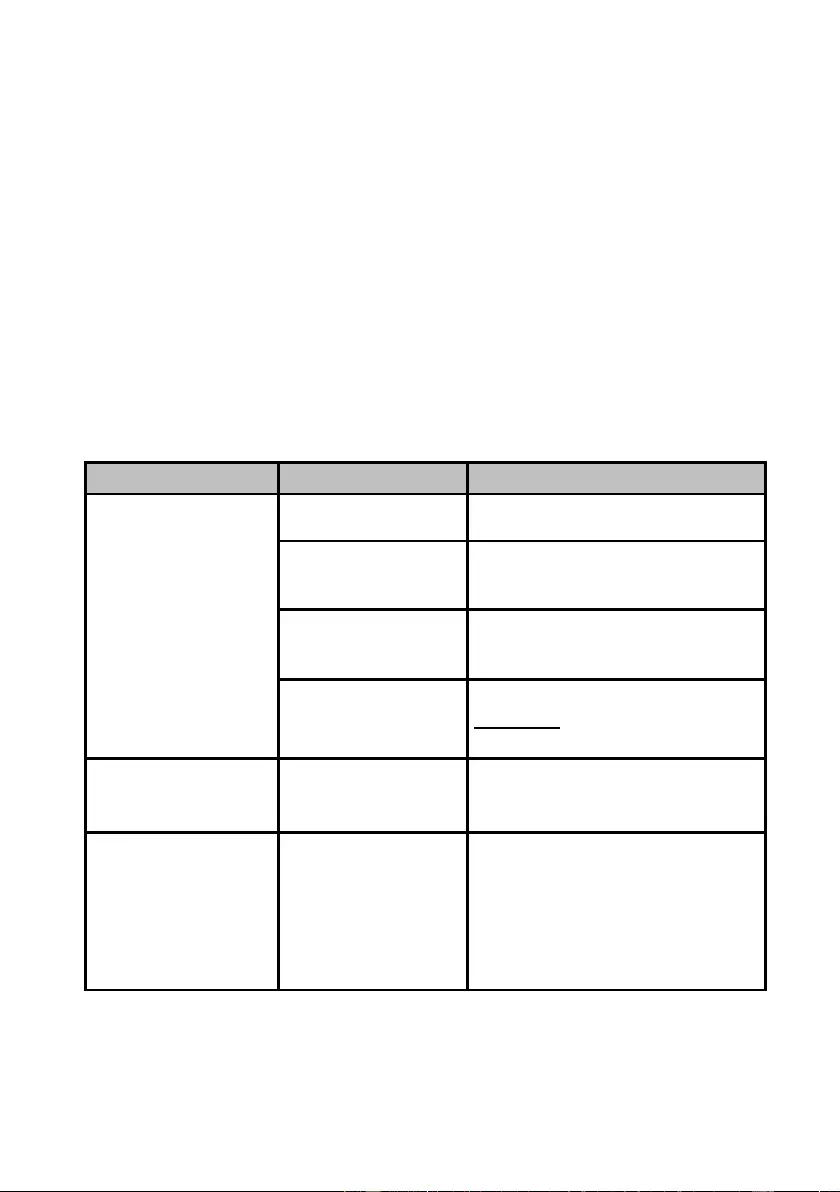

1.3 Special Symbols

The following are examples of symbols used on the UPS or accessories to

show you the important information:

5

2.Presentation

9E series UPS uses ON-LINE double conversion technology, resulting in

the highest levels of reliability and maximum protection for critical loads.

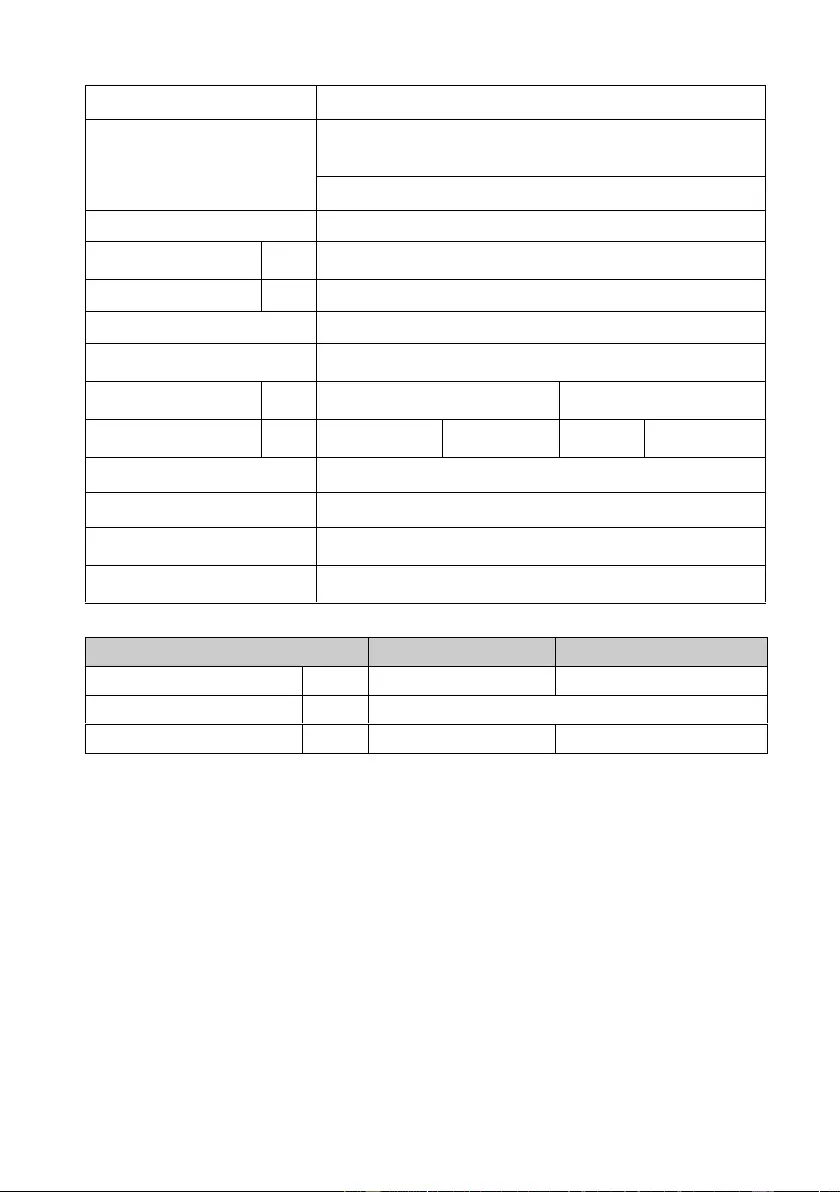

2.1 Model List

Model

Power Ratings

PF

Voltage (Output)

9E6Ki

6kVA/4.8kW

0.8

230V (220/240)

9E10Ki

10kVA/8kW Combo

0.8

230V (220/240)

9E10KiXL

10kVA/8kW Combo

0.8

230V (220/240)

9E15Ki

15kVA/12kW Combo

0.8

230V (220/240)

9E20Ki

20kVA/16kW Combo

0.8

230V (220/240)

9E20KiXL

20kVA/16kW Combo

0.8

230V (220/240)

9EEBM180

For 9E6Ki

180V

9EEBM240

For 9E10Ki, 9E10KiXL

240V

“XL” Model: Model with internal supercharger, and without internal

batteries. Other models with internal batteries

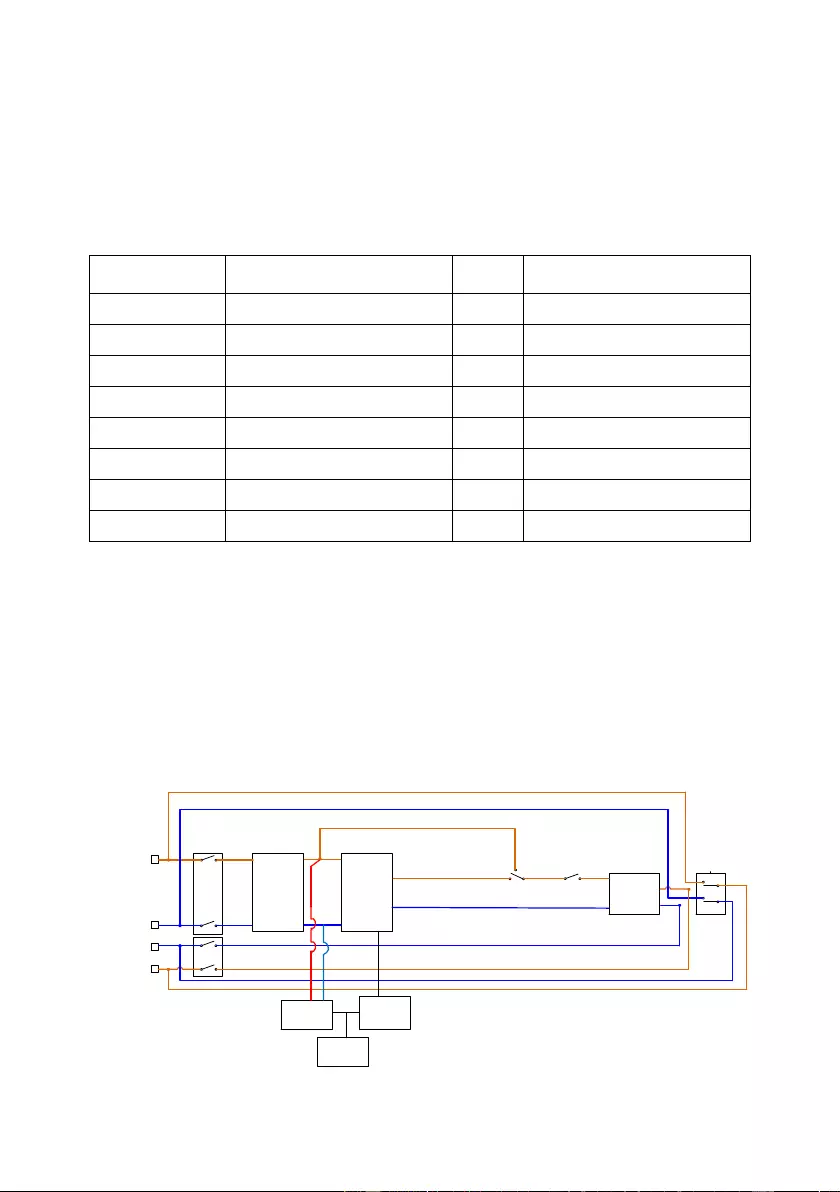

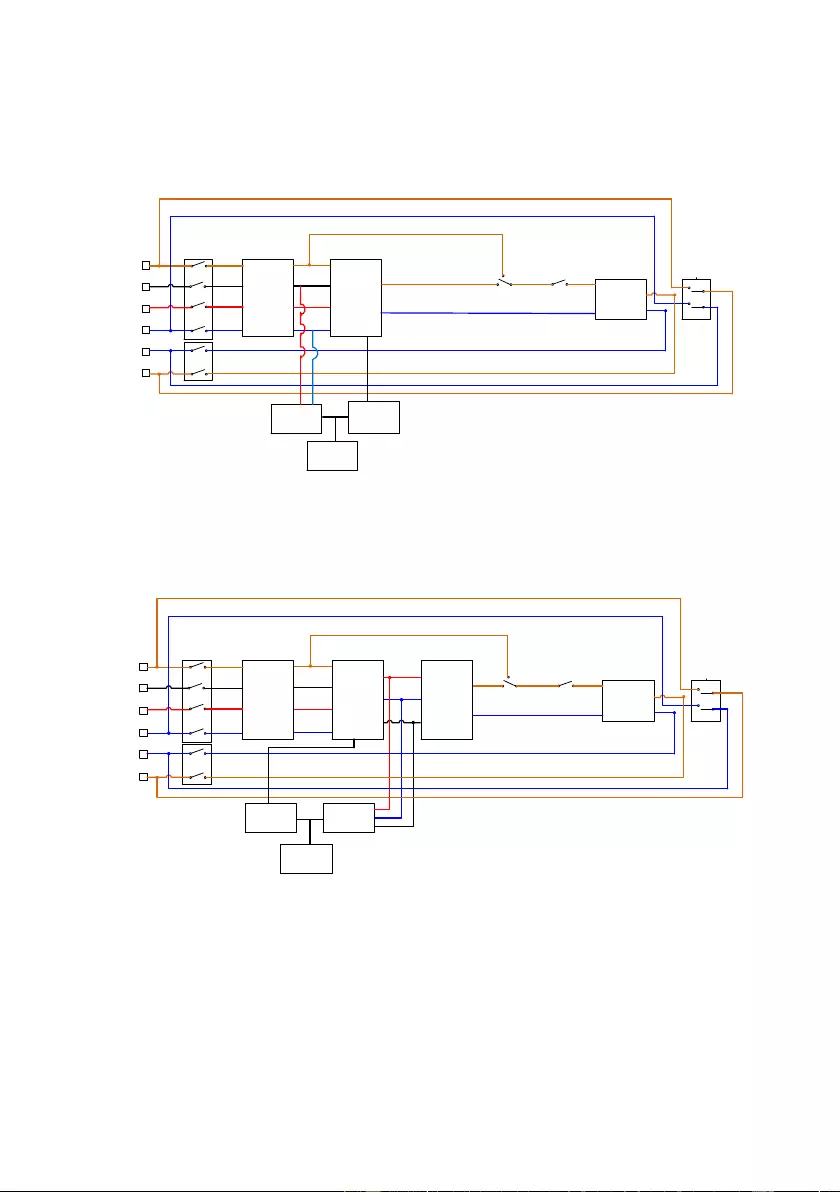

2.2 Electrical structure

9E6Ki

INPUT

OUTPUT

N

L

N

L1

Input

filter AC/DC—DC/AC Output

filter

Internal

power

Charger

Battery

Input

Switch

Bypass

Maintain Switch

`

Output

Switch

Main power wiring

6

9E10Ki, 9E10KiXL

INPUT

OUTPUT

N

L

N

L2

L1

L3

Input

filter AC/DC—DC/AC Output

filter

Internal

power

Charger

Battery

Input

Switch

Bypass

Maintain Switch

`

Output

Switch

Main power wiring

9E15Ki, 9E20Ki, 9E20KiXL

INPUT

OUTPUT

N

L

N

L2

L1

L3

Input

filter AC-DC DC-AC Output

filter

Internal

power Charger

Battery

Input

Switch

Bypass

Maintain Switch

`

Output

Switch

Main power wiring

7

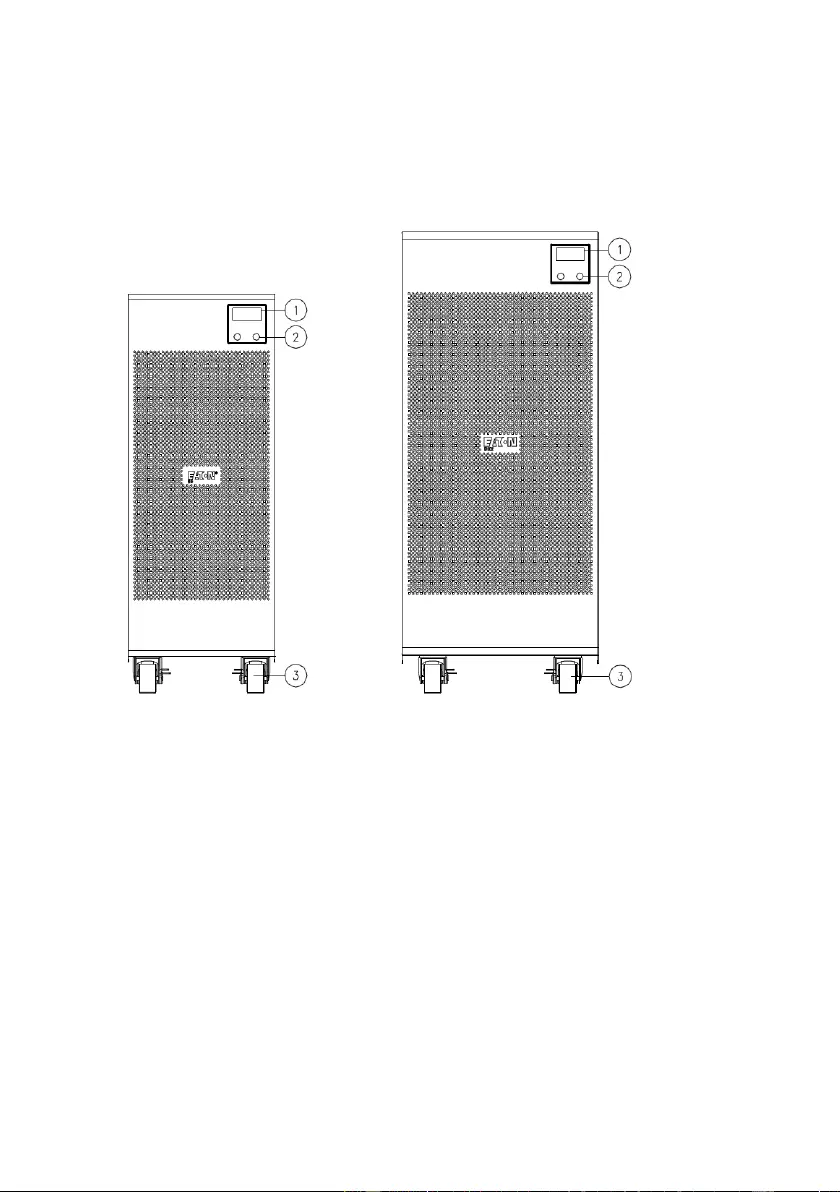

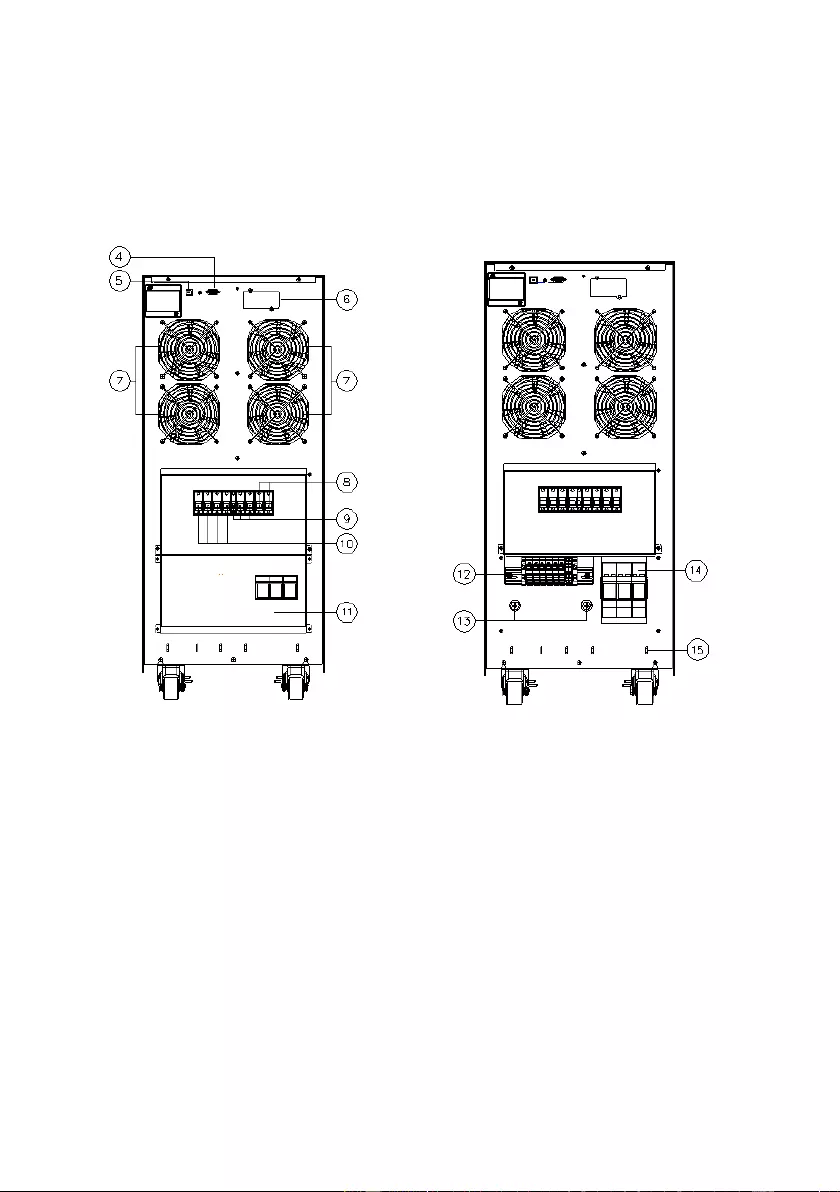

2.3 UPS views

2.3.1 UPS Front view

①

Display

②

Multipurpose buttons

③

Wheels (front wheels swivel and can be locked, fixed rear wheels)

8

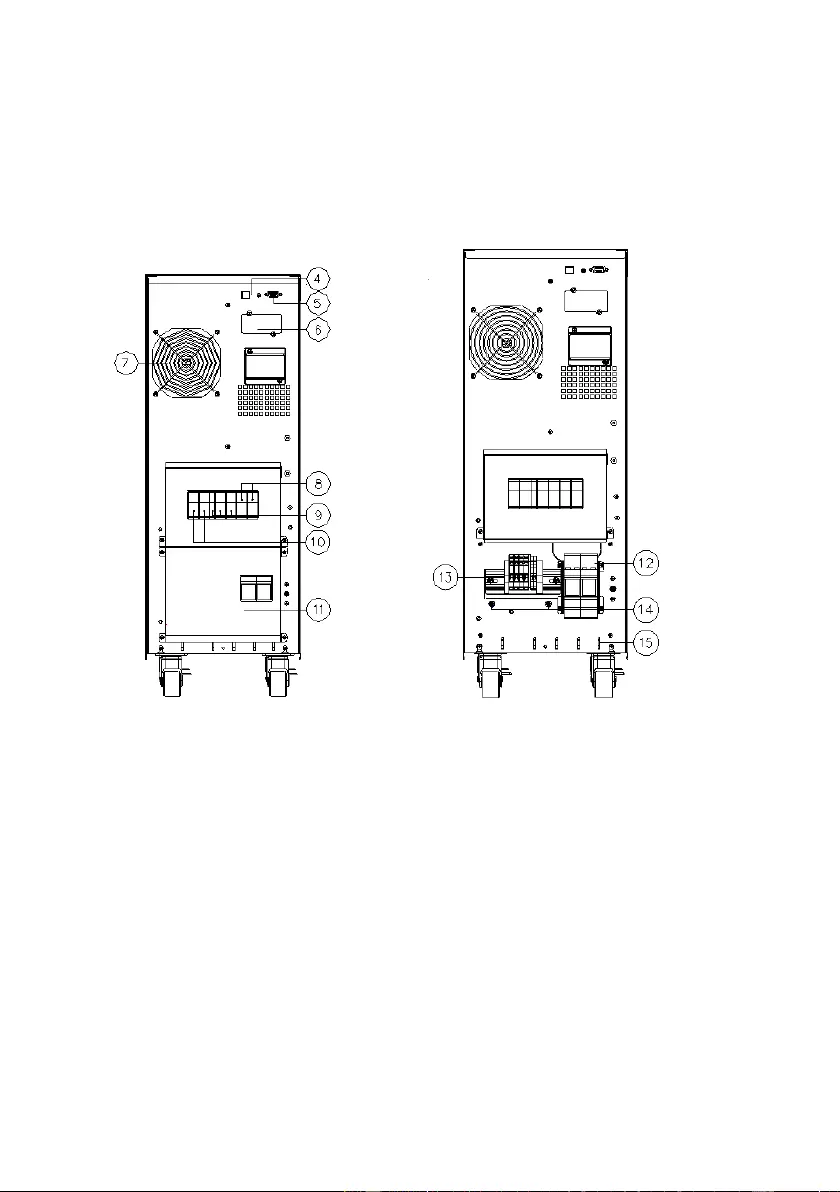

2.3.2 UPS Rear view

9E6Ki

With backpanel cover

9E6Ki

Without backpanel cover

④

USB communication port

⑩

Input switch

⑤

RS232 communication

port

⑪

Cover for terminals

⑥

Slot for optional

communication card

⑫

Fuse

⑦

Cooling fan(s)

⑬

Terminals for I/O cable connection

(refer to related section)

⑧

Output switch

⑭

Earthing screws

⑨

Manual bypass for

maintenance

⑮

Tie wrap hold-down

9E10Ki/9E10KiXL

With backpanel cover

9E10Ki/9E10KiXL

Without backpanel cover

9

④

USB communication port

⑩

Input switch

⑤

RS232 communication

port

⑪

Cover for terminals

⑥

Slot for optional

communication card

⑫

Fuse

⑦

Cooling fan(s)

⑬

Terminals for I/O cable connection

(refer to related section)

⑧

Output switch

⑭

Earthing screws

⑨

Manual bypass for

maintenance

⑮

Tie wrap hold-down

10

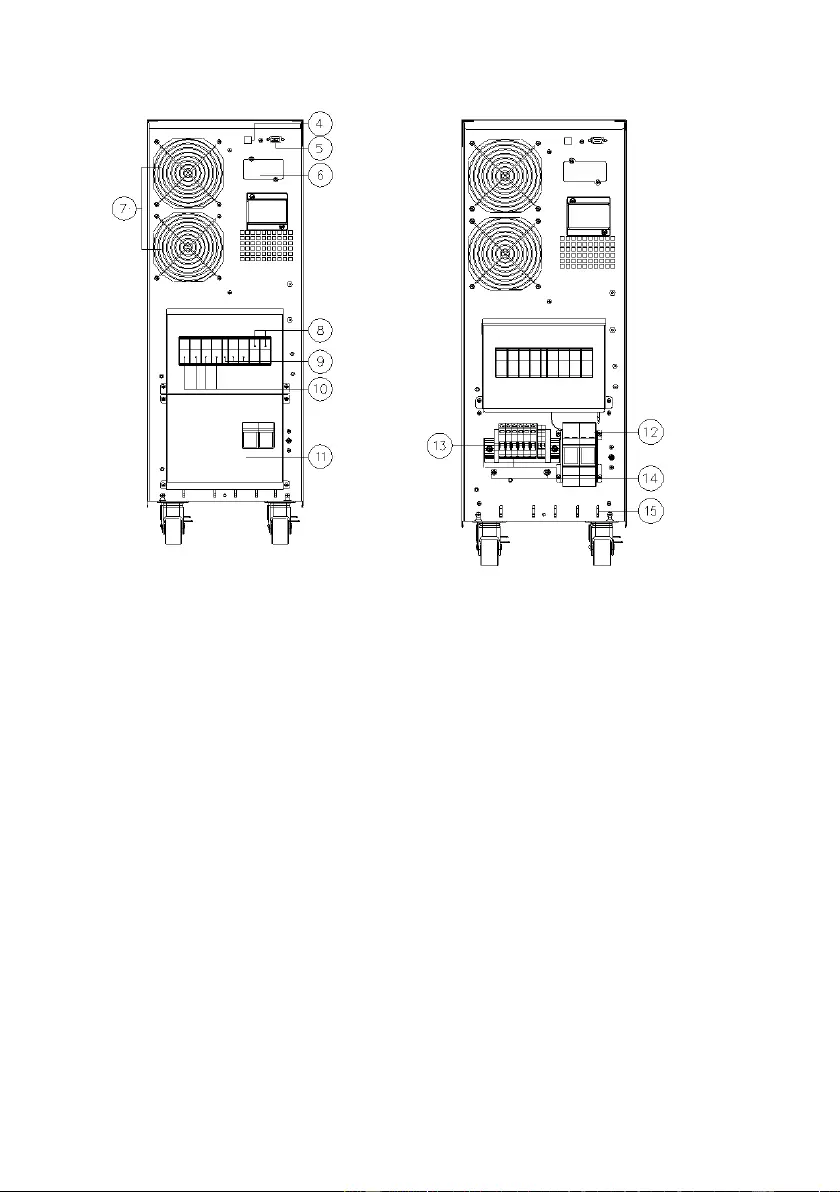

UPS Rear view

9E15Ki/9E15KiXL/9E20Ki/9E20KiXL

With backpanel cover

9E15Ki/9E15KiXL/9E20Ki/9E20KiXL

Without backpanel cover

④

RS232 communication port

⑩

Input switch

⑤

USB communication port

⑪

Cover for terminals

⑥

Slot for optional

communication card

⑫

Terminals for I/O cable connection

(refer to related section)

⑦

Cooling fans

⑬

Earthing screws

⑧

Output switch

⑭

Fuse

⑨

Manual bypass for

maintenance

⑮

Tie wrap hold-down

11

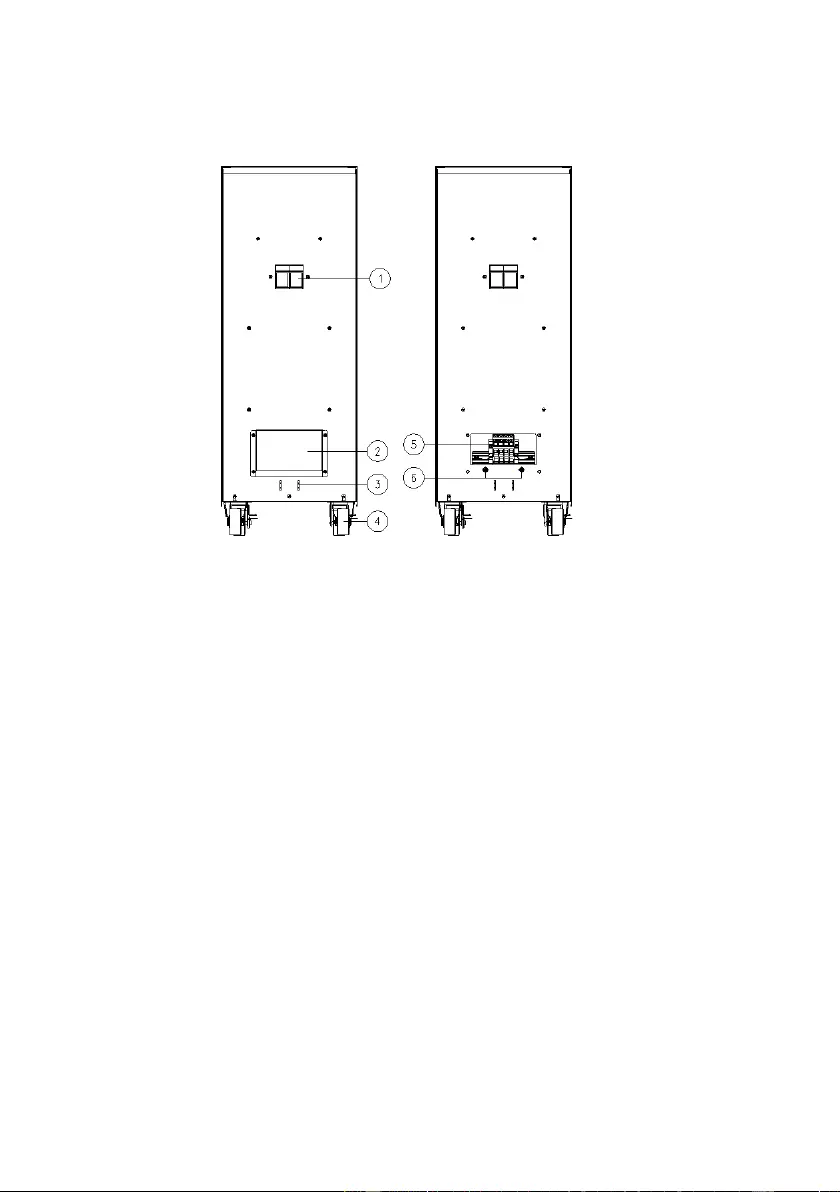

2.3.3 EBM Rear view

①

Fuse

②

Cover for terminals

③

Tie wrap hold-down

④

Wheels (front wheels swivel and can be locked, fixed rear wheels)

⑤

Terminals for I/O cable connection (refer to related section)

⑥

Earthing screws

12

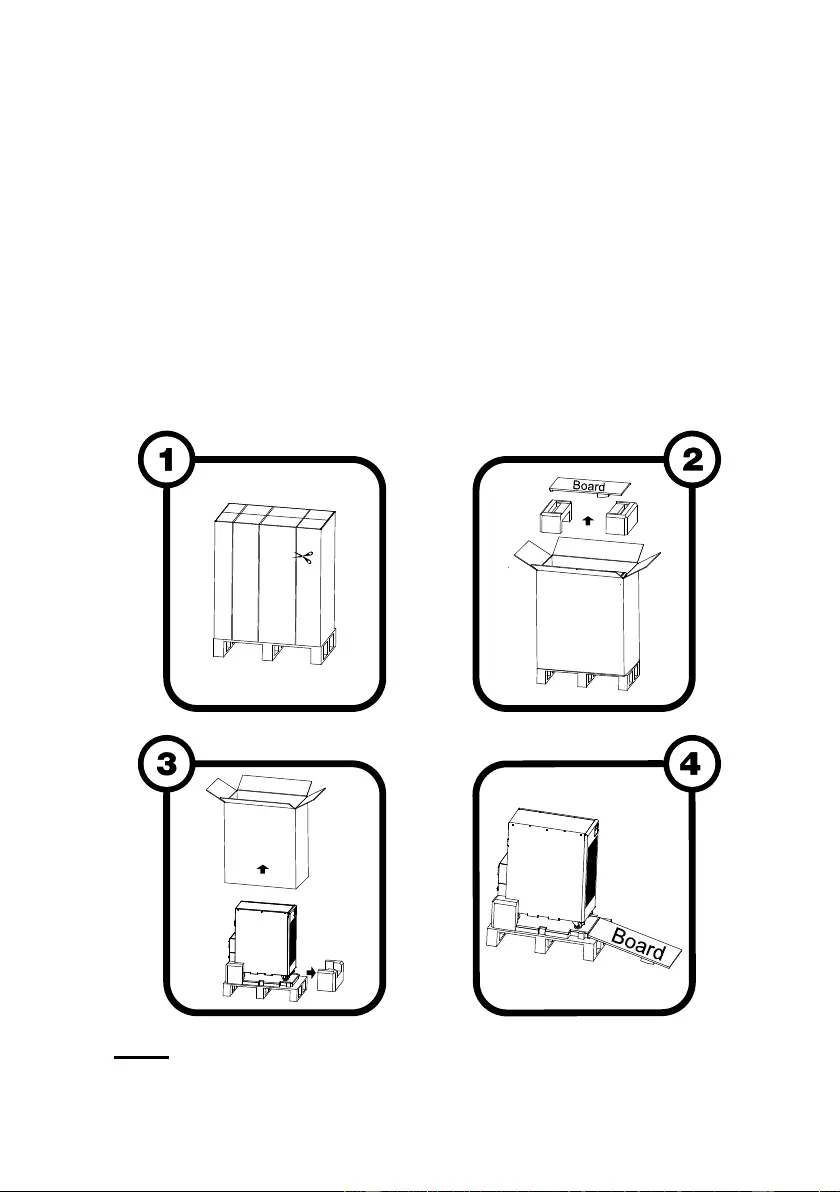

3.Installation

3.1 Unpacking

1. Cut the straps

2. Open the carton, take off wood board, accessory pack and PE form.

3. Remove carton upward and take out front PE form.

4. Put the wood board (removed at step2) as figure showed. Make sure

that the slide rests firmly against the pallet so it remains in place during

unloading operations. Pull the UPS from the front with caution when

sliding it off the pallet.

NOTE: All parts of the packaging should be kept for future use.

13

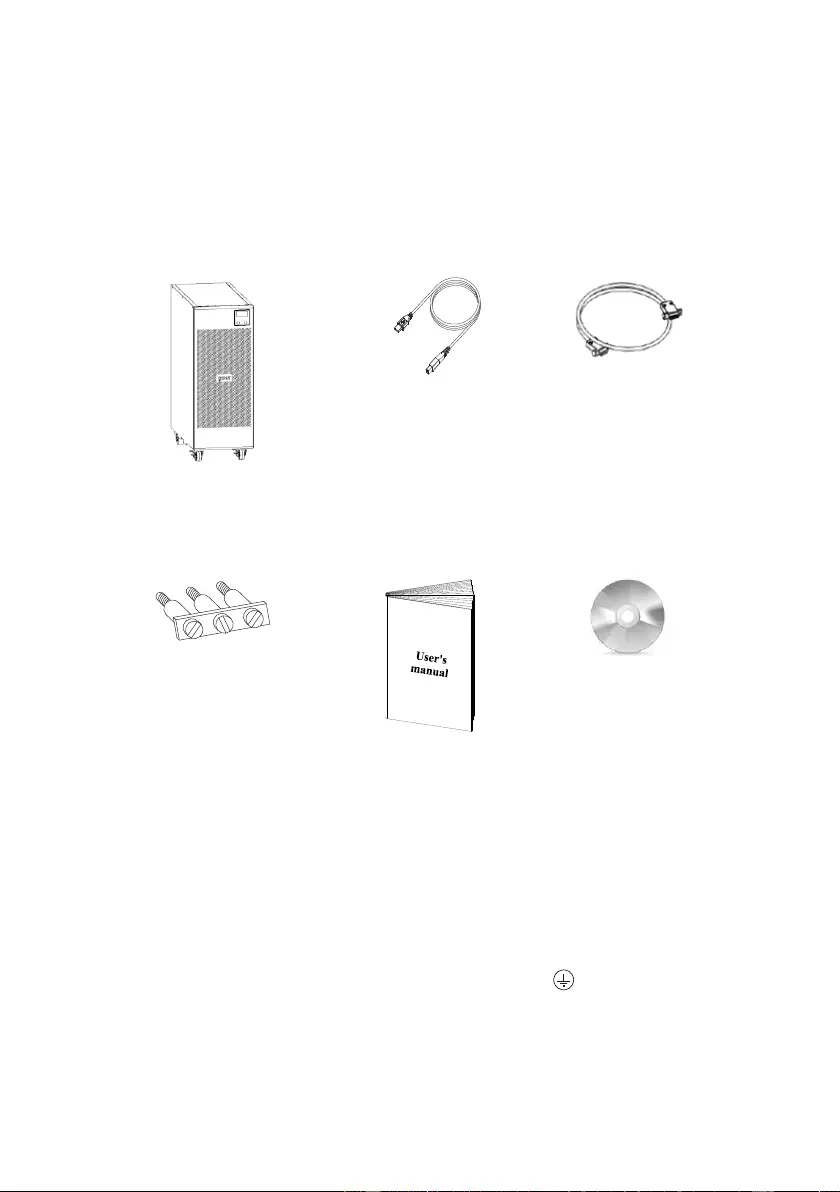

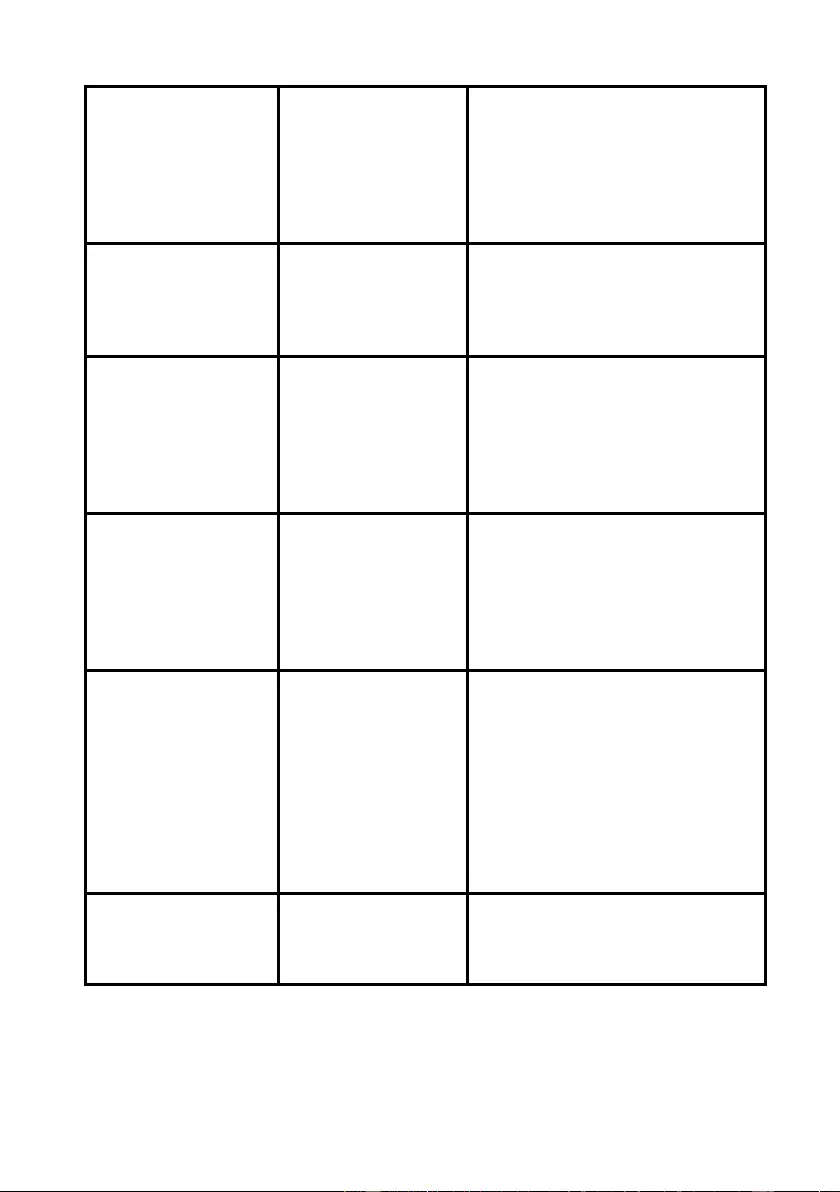

3.2 Package content

After opening the packaging, it is first necessary to check the contents.

The package must contain:

3.3 Connection

3.3.1 Installation requirements

Warning:

Installation must be performed by qualified personnel. The first

connection to perform is the protective conductor (earth cable),

which must be connected to the screw marketed .

The UPS, when inserted in an installation, does not alter the existing

neutral (system earthing) arrangements.

UPS

USB cable

RS232 cable

Jumper

(15/20kVA models only)

User manual

Software CD

14

A differential switch upstream will also be triggered for a fault occurring

downstream of the UPS. In calculating reactivity of this switch, account

must be taken of the leakage current of the UPS (approx. 8 mA) plus that

of the load which come together on the UPS’s earth conductor.

UPS input

Differential switch

Single-phase

Type B or Type A

Three-phase

Type B

The neutral arrangements are altered only if there is an isolating

transformer or when the UPS operates with a neutral that is disconnected

upstream.

In any case avoid connecting the output neutral with the input neutral

or to the earth as this could damage the UPS.

Reminder : The UPS needs a neutral connection to work properly.

Operation without Neutral may damage the unit.

For installation with change in system earthing arrangement or

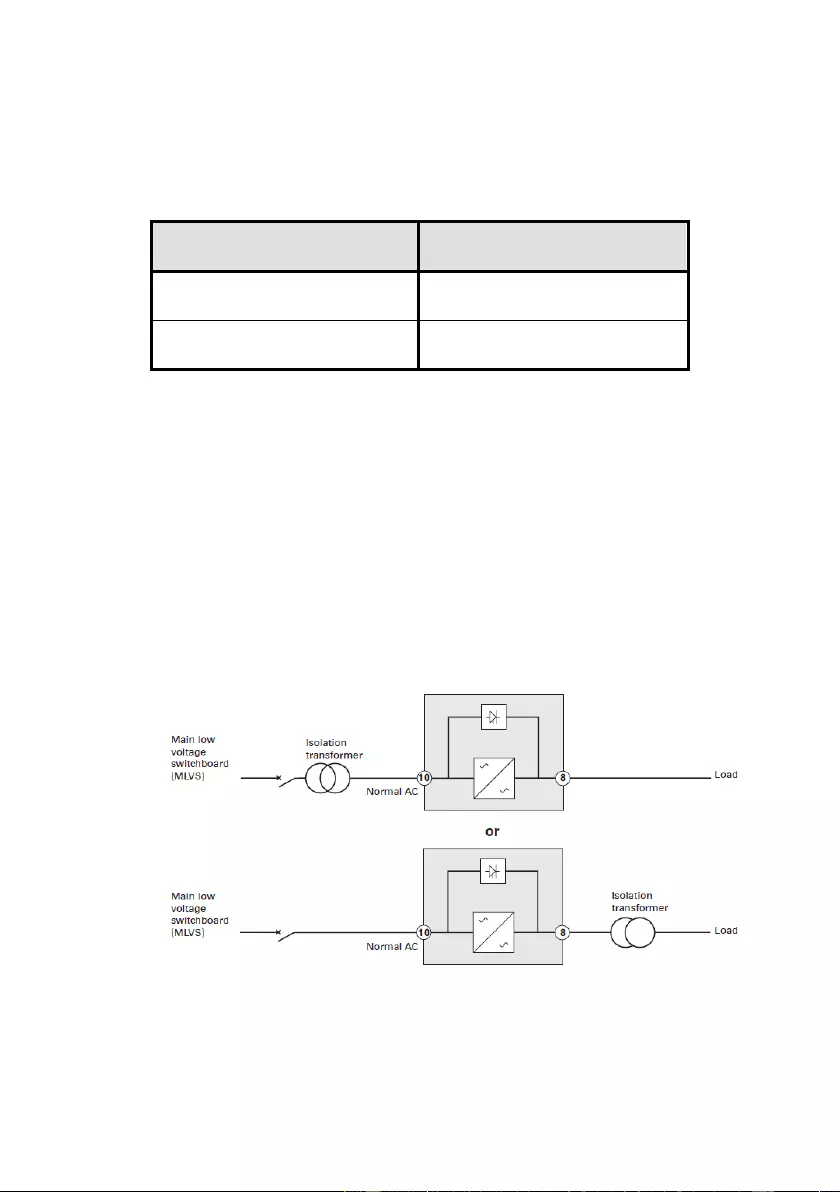

galvanic isolation see below schematic

Fig.3-1 Change in SEA or Galvanic isolation

15

Notice: It is required to install an external isolating device against current

backfeed between Mains input and UPS. After the device is installed, it

must add a warning label with the following wording or the equivalent on

the external AC contactor: RISK OF VOLTAGE BACKFEED. Isolate the

UPS before operating on this circuit, then check for hazardous voltage

between all terminals. The current rating of T - AC contactor should be

more than 1.3 times of UPS capacity

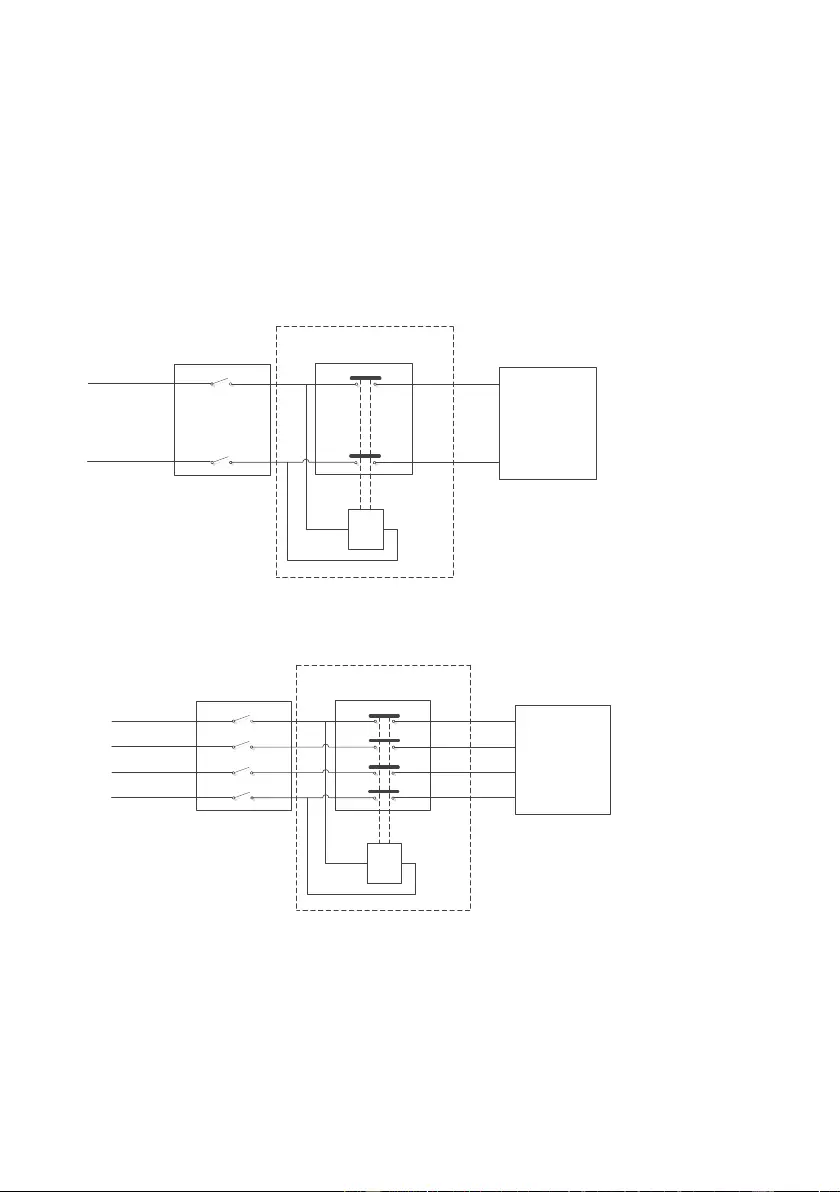

MAIN INPUT

UPS

B

Q T

L

N

B coil remote switch

Q input main switch

T AC contactor

L line input

N neutral

MAIN INPUT

UPS

B

Q T

L1

L2

L3

N

B coil remote switch

Q input main switch

T AC contactor

L1 L2 L3 line input

N neutral

Fig.3-2 Typical external isolating device installation

3.3.2 UPS Wiring Connection

To make the mains power and load connections, follow the instructions

below:

Single phase input

Three phase input

16

1. Install a magneto-thermal switch (63A for 6 & 10kVA versions, 125A

for 15 and 20kVA versions) with intervention curve D upstream of the

machine (4 poles for three-phase versions, 2 poles for single-phase

versions).

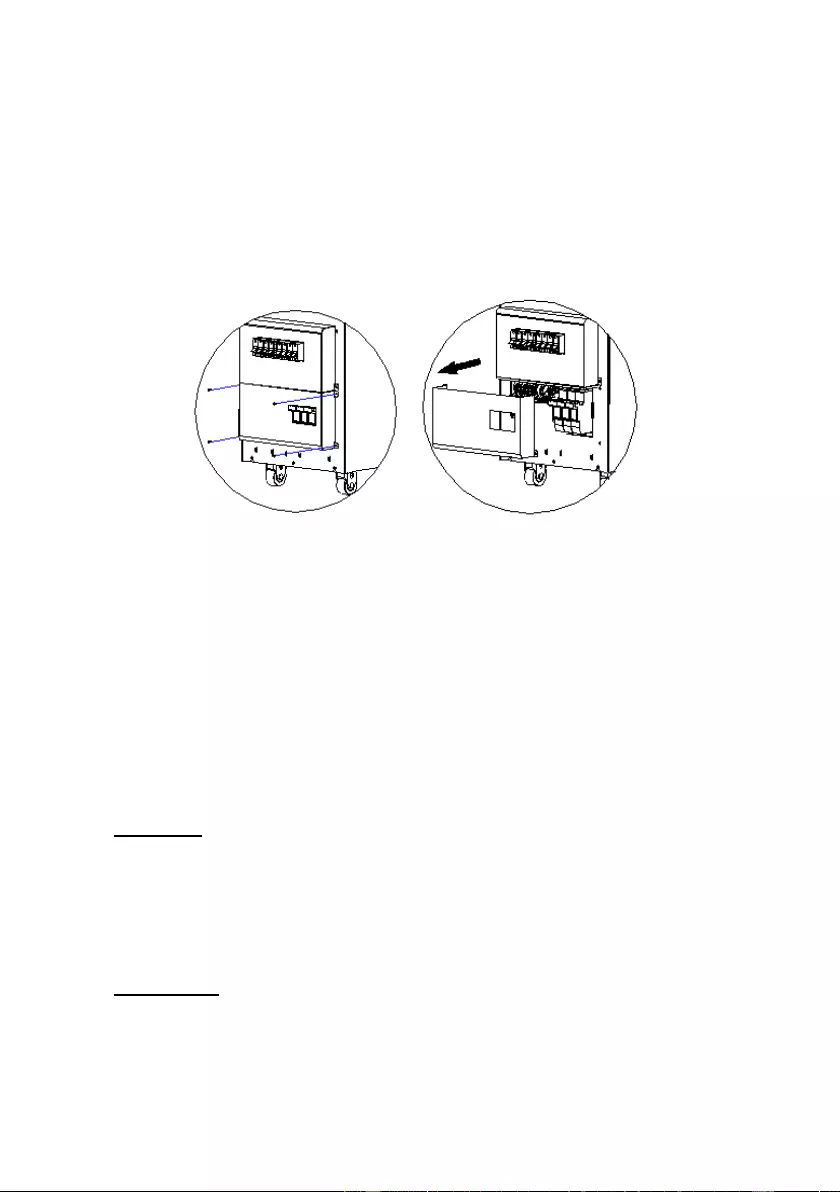

2. The connection terminals to use for the input and output lines are

located on the backpanel. Unscrew the 4 screws located on the sides

of the cover (one on each side, see figure).

3. Remove the backpanel cover (see figure to the side).

Fig.3-3 Wiring connection

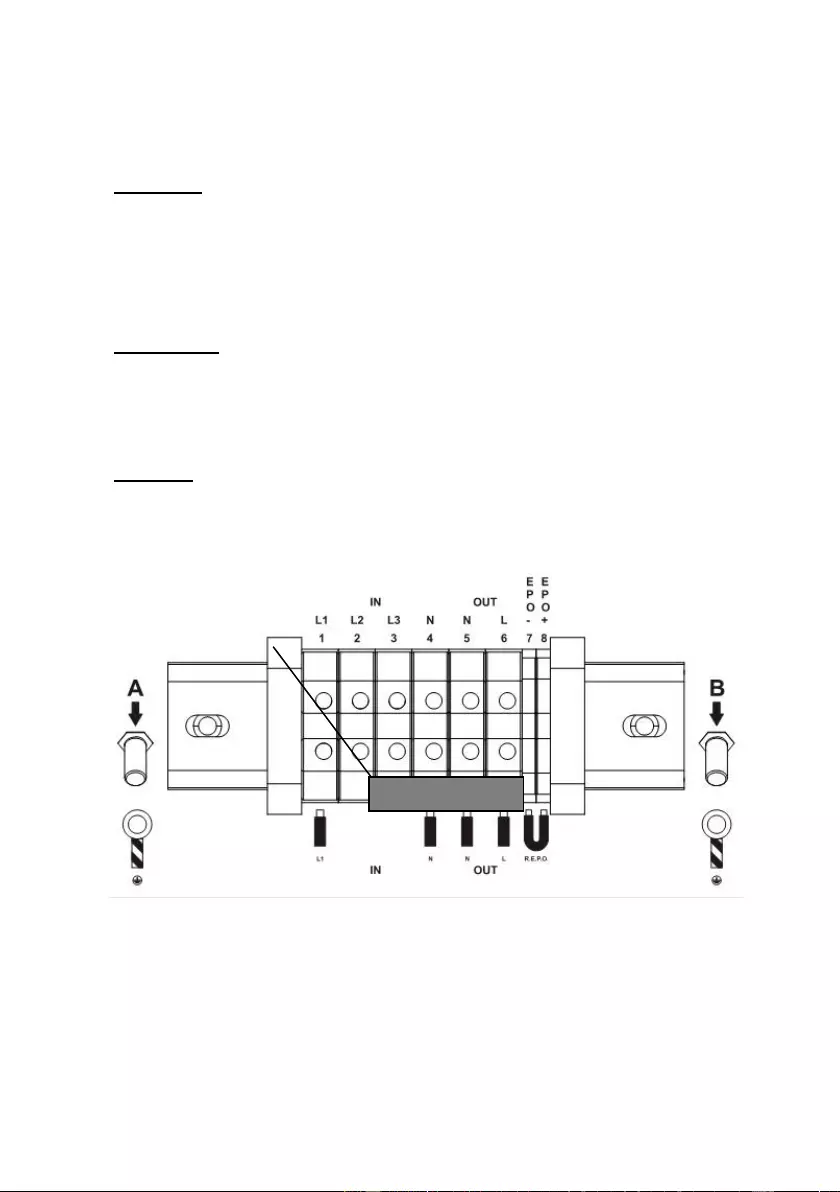

Single-phase version (9E6Ki only)

4. (SINGLE-PHASE CONNECTION 9E6KI): use 3 cables with cross-

section 6 mm2 (EARTH, N and L) for the input, and 3 cables with

cross-section 6 mm2 for the output (EARTH, N and L).

5. Connect the wires to the relative terminals, following exactly the

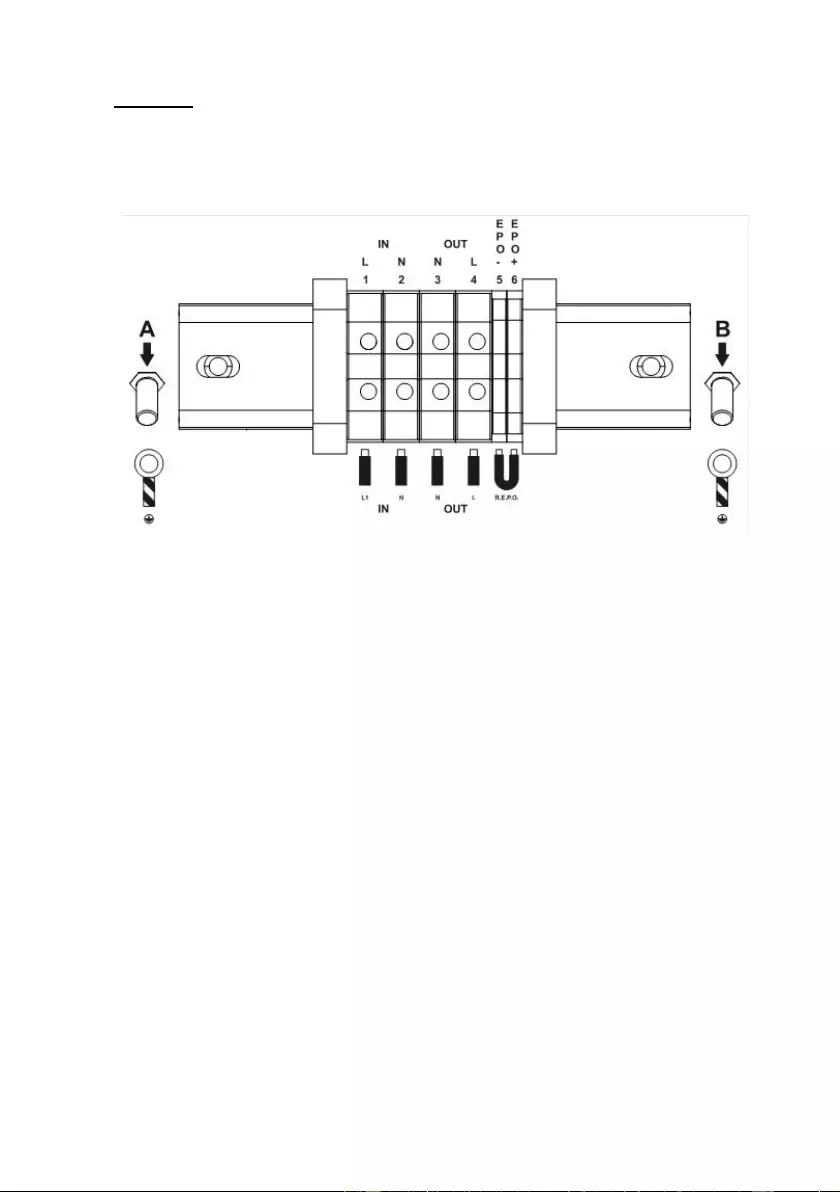

instructions given below:

Input line

a - Make sure that the magneto-thermal switch upstream is open.

b - Connect the earth wire to screw A.

c - Connect the neutral wire to terminal 2.

d - Connect the live wire to terminal 1.

Output line

a - Connect the earth wire to screw B.

b - Connect the neutral wire to terminal 3.

c - Connect the live wire to terminal 4.

17

R.E.P.O.

a - The REPO connection (between terminal 5 and 6) is normally open.

For more information please refer to the REPO section of this

manual

Fig.3-4 6K terminal view

6. Tighten the terminals well, close the backpanel cover and secure it with

the screws taken out earlier.

The suggested tighten force is 1.2~1.6Nm.

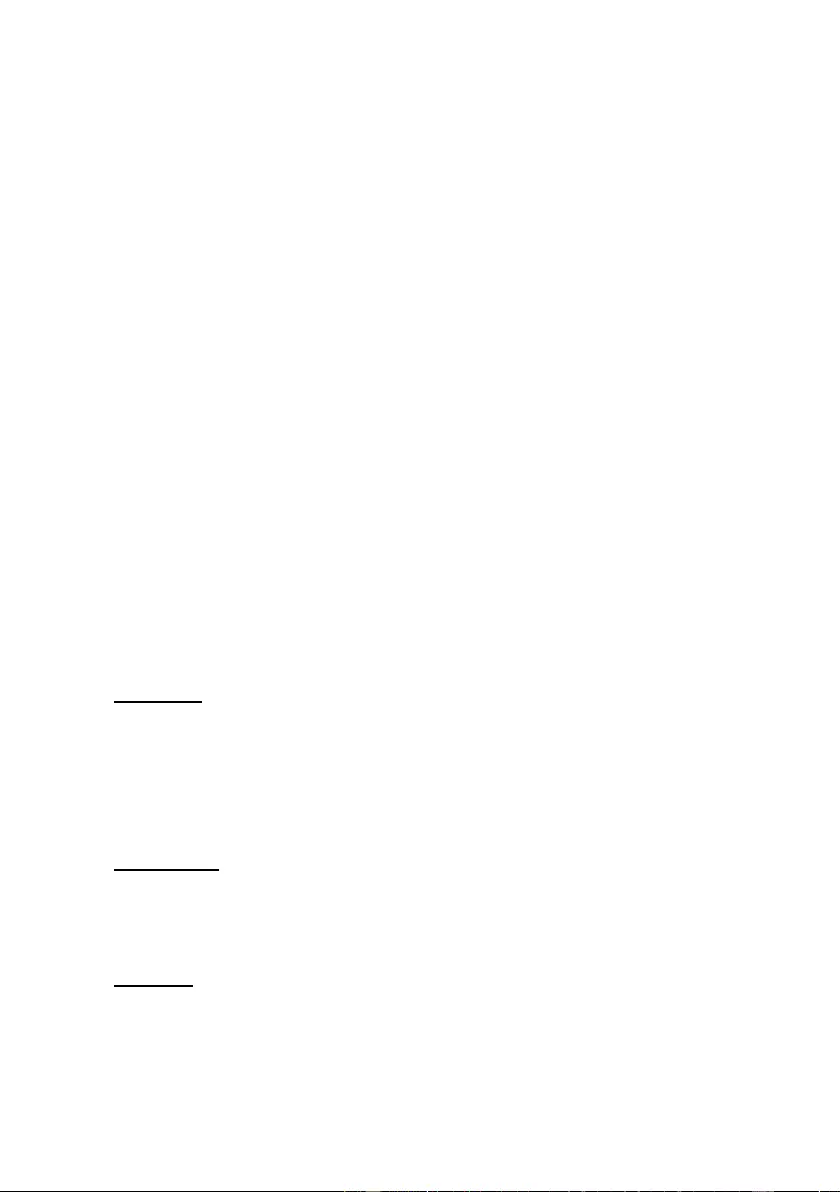

Combo version

Single-phase connection

4. (SINGLE-PHASE CONNECTION 9E10KI, 9E10KIXL): use 3 cables of

cross-section 10 mm2 (EARTH, N and L) for the input, and 3 cables

of cross-section 10 mm2 for the output(EARTH, N and L).

(SINGLE-PHASE CONNECTION 9E15KI, 9E15KIXL): use 3 cables of

cross-section 16 mm2 (EARTH, N and L) for the input, and 3 cables

of cross-section 16 mm2 for the output(EARTH, N and L).

(SINGLE-PHASE CONNECTION 9E20KI, 9E20KIXL): use 3 cables of

cross-section 25 mm2 (EARTH, N and L) for the input, and 3 cables

of cross-section 25 mm2 for the output(EARTH, N and L).

18

5. Short-circuit the input terminals (1, 2 and 3) with the jumper provided in

the accessories kit. Connect the wires to the respective terminals,

following exactly the instructions below:

Input line

a - Ensure that the upstream magneto-thermal switch is open.

b - Connect the earth wire to screw A.

c - Connect the neutral wire to terminal 4.

d - Connect the live wire to terminal 1.

Output line

a - Connect the earth wire to screw B.

b - Connect the neutral wire to terminal 5.

c - Connect the live wire to terminal 6.

R.E.P.O.

a - The REPO connection (between terminal 5 and 6) is normally open.

For more information please refer to the REPO section of this

manual

Fig.3-5 10~20K single phase input terminal view

6. Tighten the terminals well, close the backpanel cover and secure it with

the screws taken out earlier.

For 10 to 15kVA the suggested tighten force is 1.2~1.6Nm. For 20kVA,

the suggested tighten force is 2.5~3 Nm.

JUMPER

19

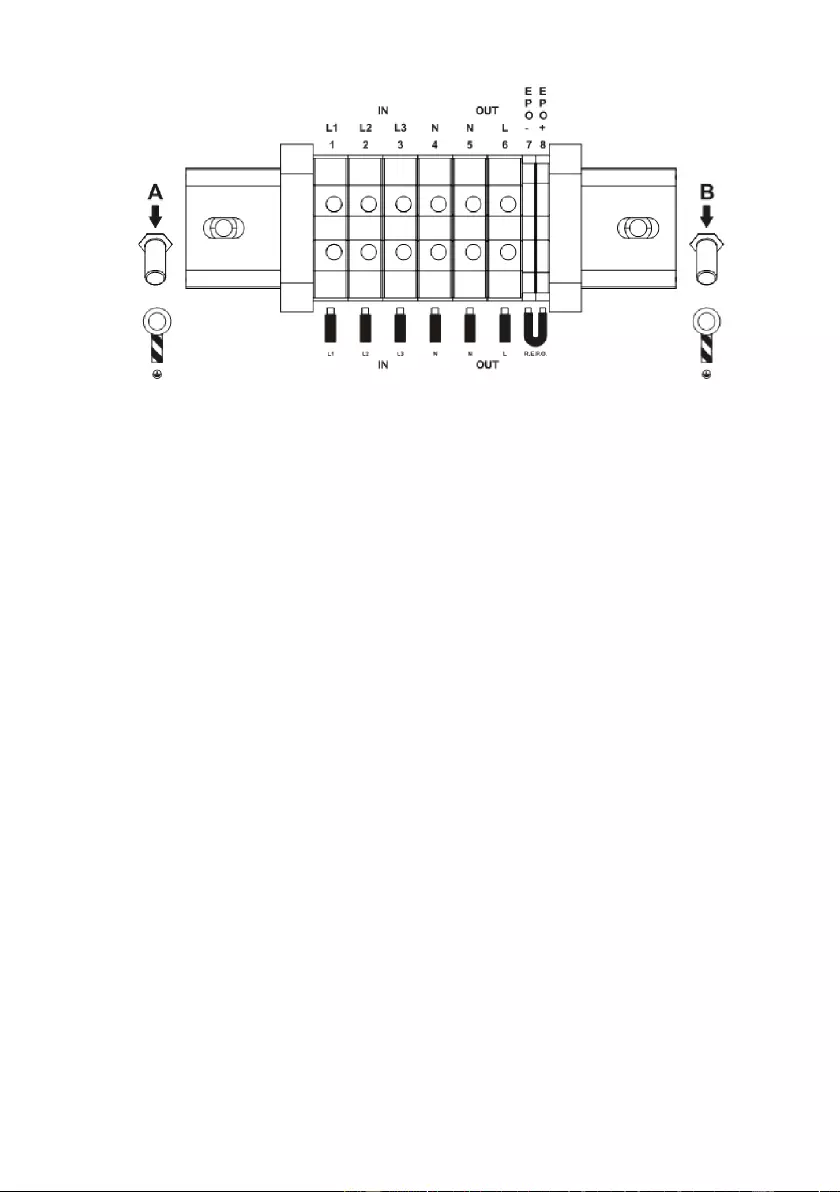

Three-phase connection

1. (THREE-PHASE CONNECTION 9E10KI, 9E10KIXL): Use 2 cables of

cross-section 4 mm2 (L2 and L3) and 3 with cross-section 10 mm2

(EARTH, N, L1) for the input (N.B.: L1 and N are of greater cross-

section because in bypass operation they have to carry all of the

input current). For the output use 3 cables of cross-section 10 mm2

(EARTH, N and L).

(THREE-PHASE CONNECTION 9E15KI, 9E15KIXL): Use 2 cables of

cross-section 4 mm2 (L2 and L3) and 3 of cross-section 16 mm2

(EARTH, N, L1) for the input (N.B.: L1 and N are of greater cross-

section because in bypass operation they have to carry all of the

input current). For the output use 3 cables of cross-section 16 mm2

(EARTH, N and L).

(THREE-PHASE CONNECTION 9E20KI, 9E20KIXL): Use 2 cables of

cross-section 6 mm2 (L2 and L3) and 3 of cross-section 25 mm2

(EARTH, N, L1) for the input (N.B.: L1 and N are of greater cross-

section because in bypass operation they have to carry all of the

input current). For the output use 3 cables of cross-section 25 mm2

(EARTH, N and L).

2. Connect the wires to the respective terminals, following exactly the

instructions below:

Input line

a - Ensure that the upstream magneto-thermal switch is open.

b - Connect the earth wire to screw A.

c - Connect the neutral wire to terminal 4.

d - Connect the wires of the phases to terminals 1, 2 and 3 (for L1 use

red wire).

Output line

a - Connect the earth wire to screw B.

b - Connect the neutral wire to terminal 5.

c - Connect the live wire to terminal 6.

R.E.P.O.

a - The REPO connection (between terminal 5 and 6) is normally open.

For more information please refer to the REPO section of this

manual

20

Fig.3-6 10~20K three phase input terminal view

3. Tighten the terminals well, close the backpanel cover and secure it with

the screws taken out earlier.

For 10 to 15kVA the suggested tighten force is 1.2~1.6Nm. For 20kVA,

the suggested tighten force is 2.5~3 Nm.

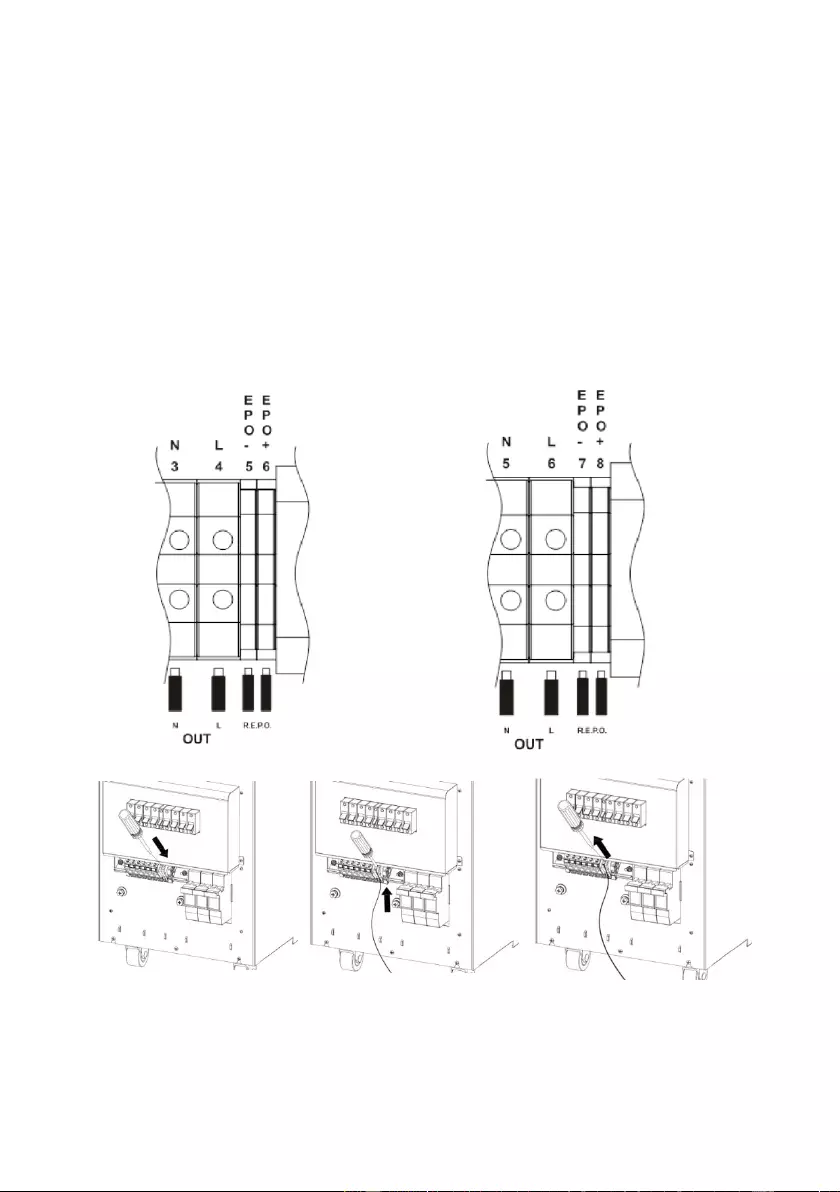

R.E.P.O.

The terminal block on the back of the UPS also implements the R.E.P.O.

(Remote Emergency Power Off) function that can be used to shut off the

UPS remotely in case of an emergency.

For installation, connect to the device's normally open contact .

In case of an emergency, if the stop device is used, the REPO control is

closed and the UPS goes into stand-by mode and the load is completely

disconnected.

Attention: before restarting the UPS, reset the stop device.

The circuitry of the remote control terminal board is self-powered with

SELV circuits. Therefore, an external voltage supply is not required. When

a contact is closed, a maximum current of 15mA circulates.

All connections with the remote control terminal board are made through a

cable which guarantees a double insulation connection.

If you would like to bring the R.E.P.O. control outside, unscrew the two

screws securing the lower part of the backpanel cover and remove it (as

indicated in the section “Connections”). Then, proceed as follows:

21

1. Use a 2x0.75mm2 cable to make the connection with the R.E.P.O.

terminals.

2. Insert the screw driver in the square hole and press down to make the

round hole terminal open. Then insert the wire into the round hole. Then

pull out the screw driver. Connect the two wires of the cable to terminals

5 and 6 (for version 9E6Ki), 7 and 8 (for versions 9E10Ki, 9E10KiXL,

9E15Ki, 9E15KiXL, 9E20Ki, 9E20KiXL) to be able to remotely shut off

the UPS.

9E6Ki

9E10Ki, 9E10KiXL, 9E15Ki,

9E15KiXL, 9E20Ki, 9E20KiXL

Fig.3-7 EPO terminal connection

3. Close the backpanel cover and secure it with the screws taken out

earlier.

22

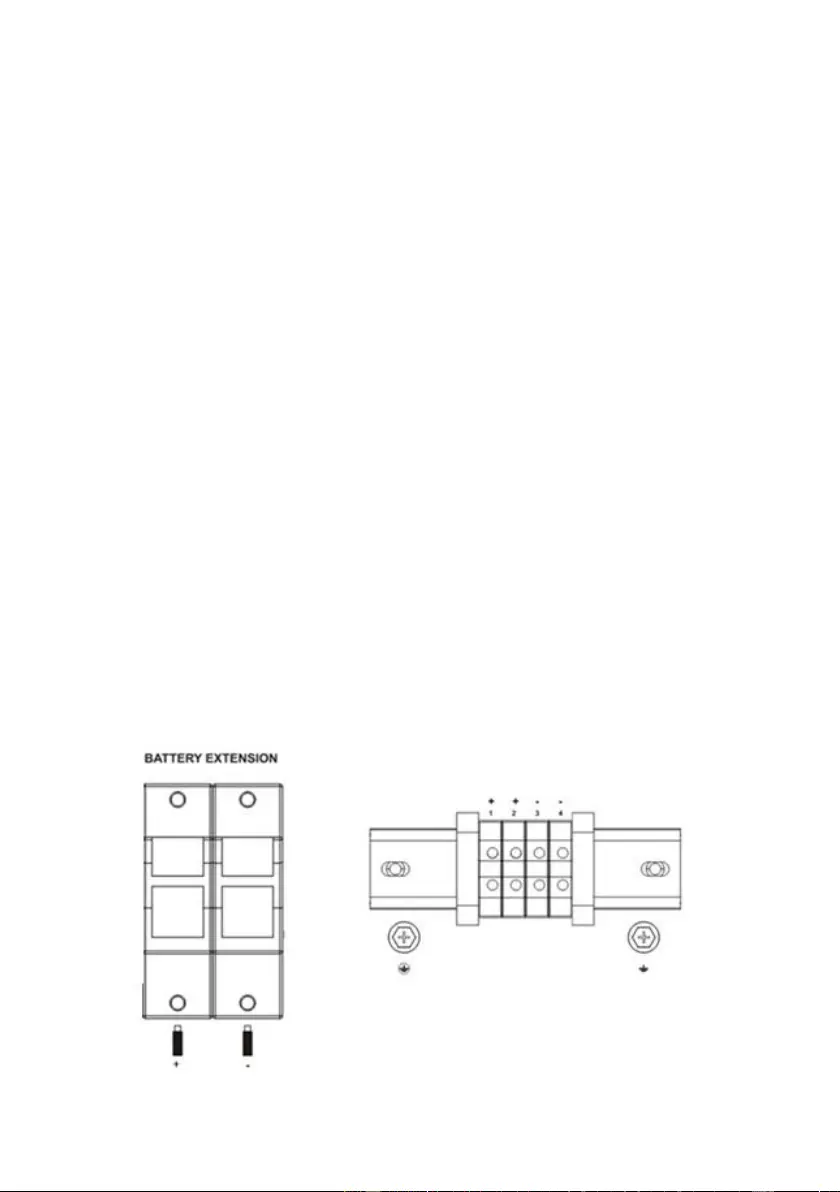

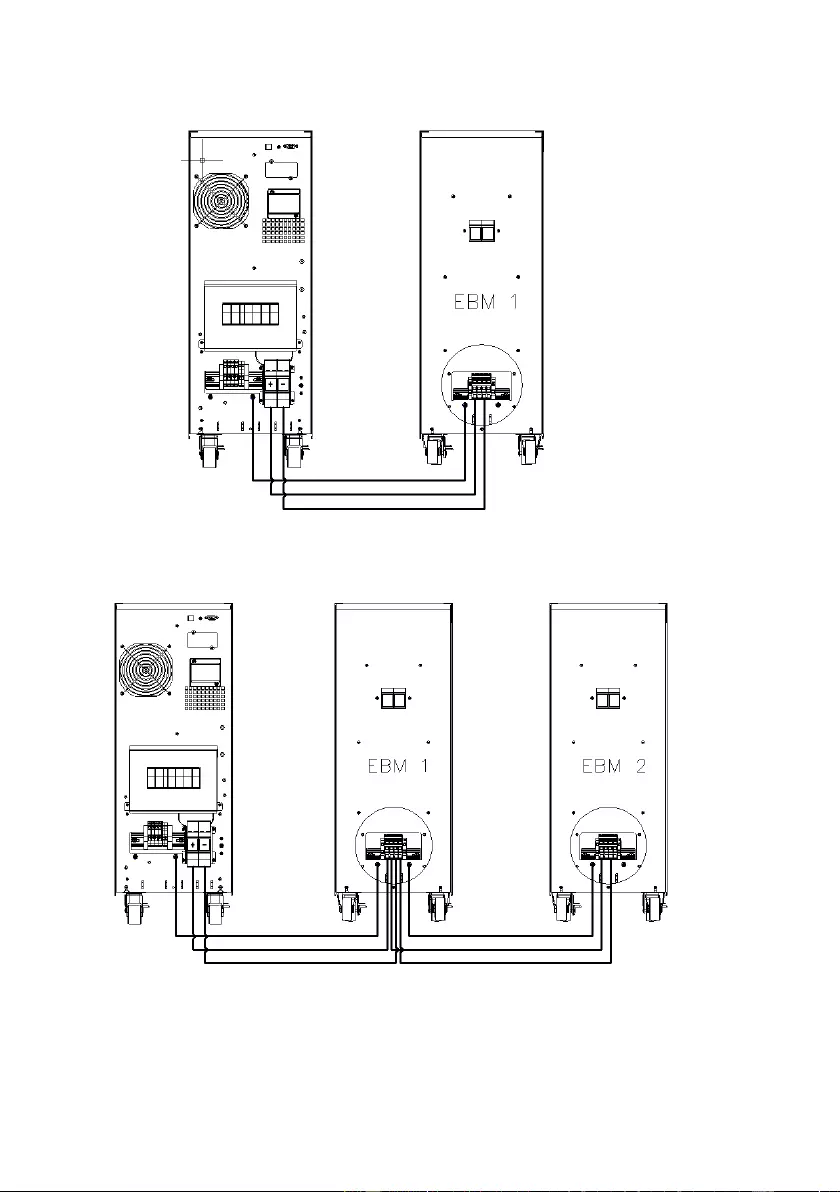

3.3.3 EBM Wiring Connection

It is possible to connect more than one EBM in order to achieve any level

of autonomy without mains power.

In order to ensure the battery runtime displayed is accurate, please set

your battery configuration through UPS Configuration Tool (download

available here: http://pqsoftware.eaton.com).

Connect any Battery Boxes in a cascade as shown in the figure below:

1. CONNECTION: Use 3 cables with 10 mm2 section (Earth, +, N and -

)

2. Connect the wires to the relative terminals, following exactly the

instructions given below:

For 9E6Ki, 9E10Ki, 9E10KiXL

a - Make sure that the fuse holder of the external battery box is open.

b - Connect the earth (PE) wire to EBM’s earth (PE) screw

c - Connect the positive (+) branch wire to EBM’s positive (+) terminal.

d - Connect the negative (-) branch wire to EBM’s negative (-)

terminal.

The suggested tighten force is 1.6Nm. (Detailed wiring diagram see fig

3-9~10)

Fig.3-8 EBM terminal view (Fuse for 9E6Ki,

9E10Ki, 9E10KiXLwithout Neutral)

23

Versions 9E6Ki, 9E10Ki, 9E10KiXL

Note: For 9E15Ki, 9E20Ki, 9E20KiXL EBM wiring connection, you

should check the 9EEBM manual in EBM package.

Fig.3-10 EBM terminal connection for 9E6Ki,

9E10Ki, 9E10KiXL With Mutliple EBM

Fig.3-9 EBM terminal connection for 9E6Ki,

9E10Ki, 9E10KiXL With Single EBM

24

4.OPERATION

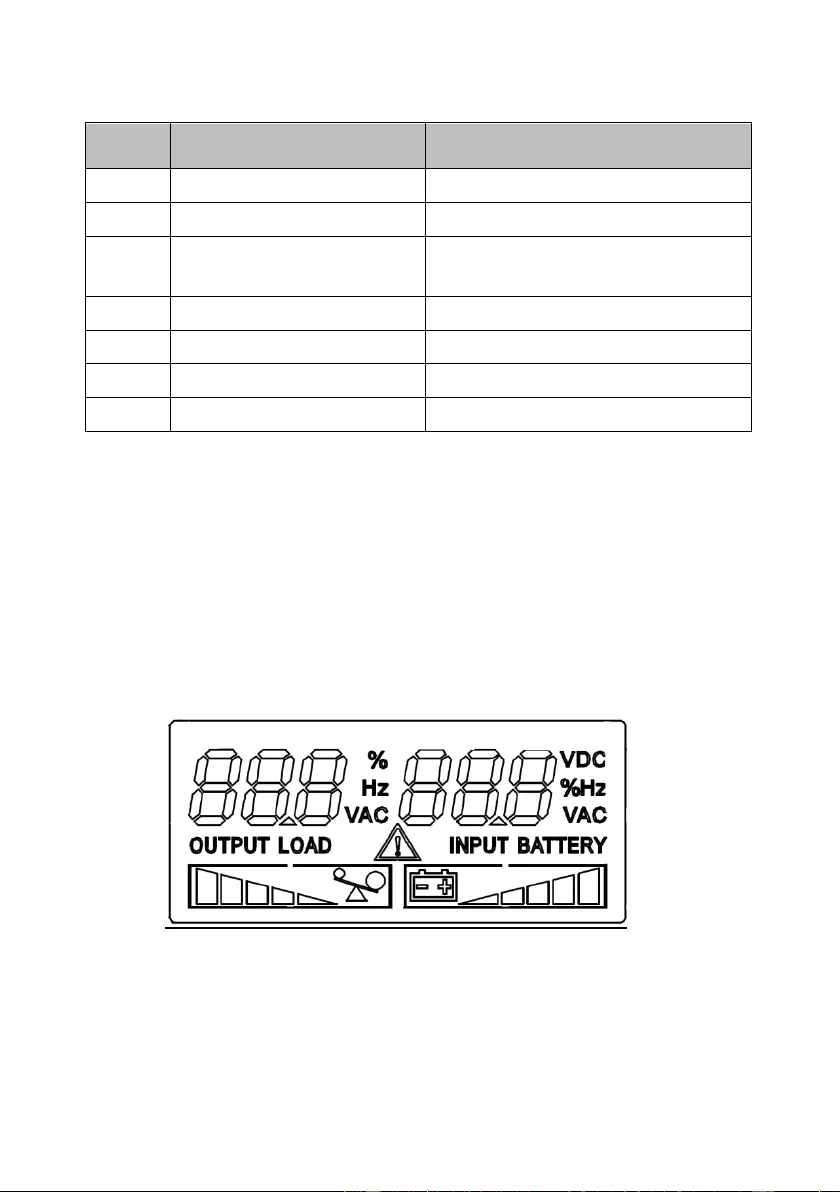

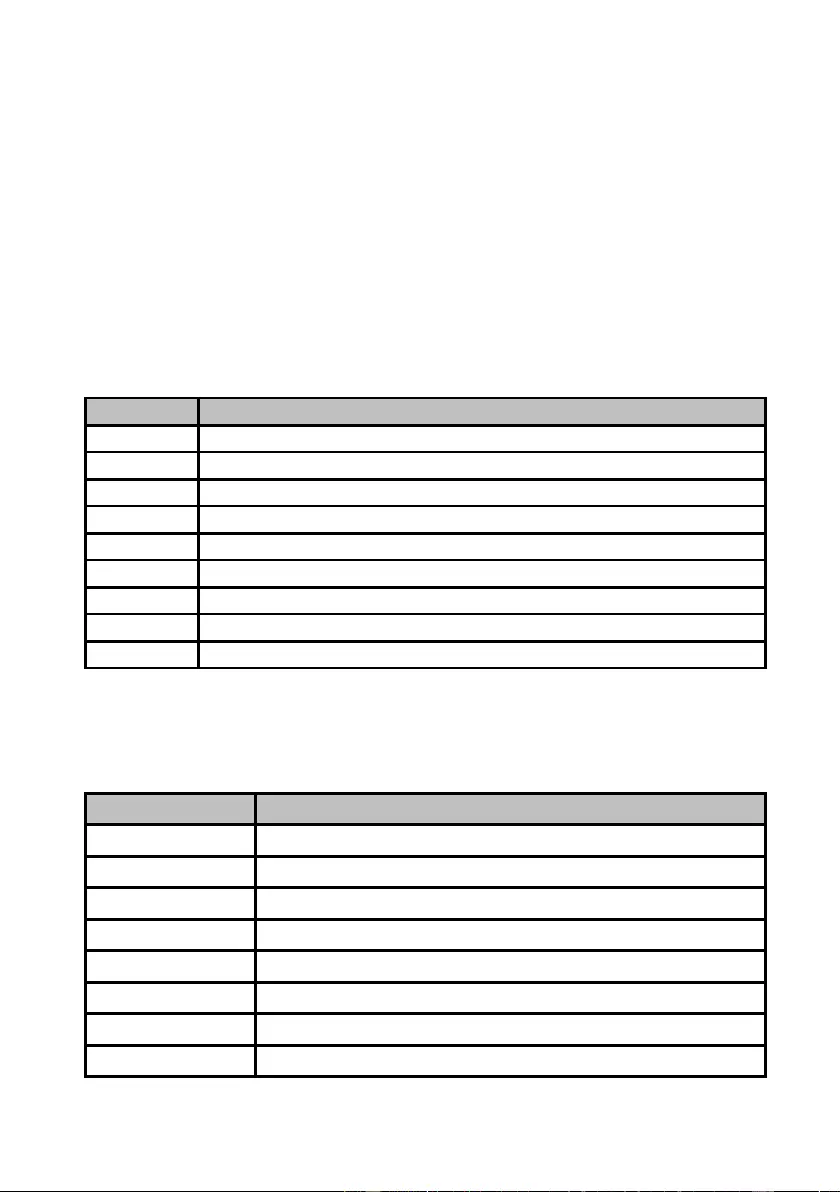

4.1 Display and Buttons

Fig. 4-1 Control Panel

The following tables shows the buttons, LCD indicator and LED indicator

status and description:

Table 4-1 Control Buttons Functions

The Button

Function

Illustration

Turn on

If the UPS is in standby or bypass mode, press >2s,

the buzzer will beep once, then the UPS system will

be turned on.

Turn off

If the UPS is in line, battery, HE or battery test mode,

press >3s, the buzzer will beep once, then the UPS

will be turned off.

Transfer

If the UPS is in fault mode, and the fault cause has

disappeared, press >2s, the buzzer will beep once,

fault will be cleared and UPS will turn to standby

mode.

Function key

Battery test on line mode,Press the button >2s

Mute: Press the button >2s

Down to next page: Press the button<200ms

25

Table 4-2 LED indicator

LED name

Colour

Description

Line

Green

It indicates the utility is normal

Battery

Yellow

It indicates the input is connected with battery, and the

input power is supplied from the battery.

Bypass

Yellow

It indicates the UPS is in bypass mode, the load current

is directly supplied from the utility power

Inverter

Green

It indicates that the inverter is OK and the load is

supplied from the inverter.

Note: After UPS power on, all LEDs will be lightened for 2 seconds, and

then turn to normal status. When UPS is turning on, 4 LEDs will be

lightened one by one until the UPS is turned on successfully.

⊙:Utility is normal

●: Lightened constantly

★: Flashing every 4s

◇: Depended on the fault status

□: Depend on the original display

LED

Line

Battery

Bypass

Inverter

No Output mode

⊙

Bypass mode

●

●

Line mode

●

●

Battery mode

●

●

Battery test mode

★

●

Fault mode

□

◇

Warning

□

□

□

□

26

Table 4-3 Buzzer

Priority

UPS condition

Buzzer

1

UPS fault and failure

Continuous

2

Normal mode

No beep

3

Battery/battery test mode

One beep per 4 sec

(One beep per 1s when battery low)

4

Bypass mode

One beep per 2 minutes

5

Overload

One beep per 500ms

6

Other alarm

One beep per 1s

7

Manual bypass

One beep per 1s

Note: buzzer alarm can be enable/disable by function button, if buzzer

alarm is disabled, all present alarm is muted except that the button press

still has a tick beep. Buzzer alarm will be enabled automatically once new

alarm arises.

Interface

In order to make sure all segments are OK, LCD begins to do self-test after

power on. During self-test, all the segments will be lighted for 2 seconds,

then the LCD will turn to normal display status.

Fig. 4-2 The default LCD display

27

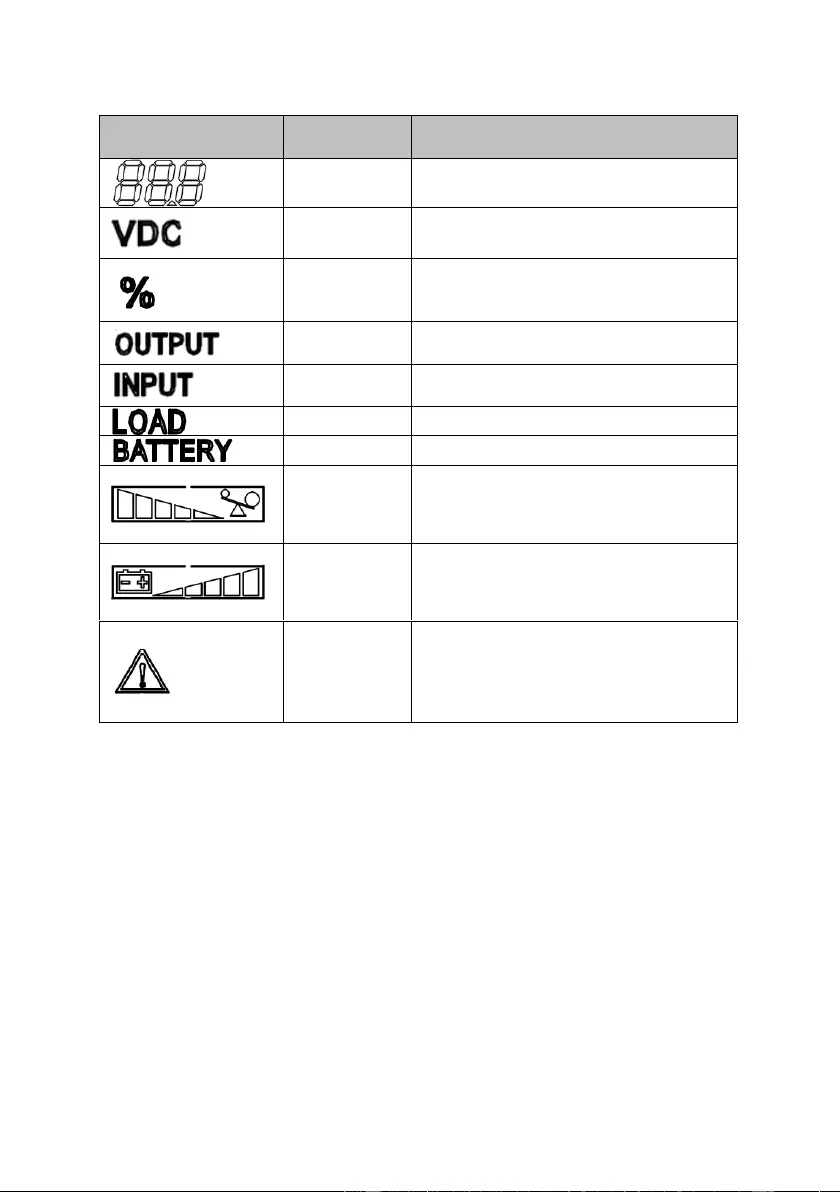

Icon

Icon name

Description

Measureme

nts

Display values, eg: voltage,

frequency, load percentage, etc.

DC Voltage

Battery voltage

Percentage

The percentage, eg: Load

percentage and battery capacity

percentage

Output

It indicates information for output.

Input

It indicates information for input.

Load

It indicates information for load.

Battery

It indicates information for battery.

Load level

It indicates the load level. Load

border will flash if the load is

overload.

Battery level

It indicates the battery capacity.

Battery border will flash if the battery

is low.

Warning/Fau

lt

It indicates warnings or UPS Fault .

If it is a warning, the icon will flash; if

it is a fault, the icon will be lighted

constantly.

28

4.2 Operating UPS

Notice: Please switch off the connected loads first before turning on the

UPS, and switch on the loads one by one after the UPS is turned on.

Switch off all of the connected loads before turning off the UPS.

Notice: Power on for the first time

1. Close the magnetothermic switch located upstream of the UPS.

2. Close the input and output switches and insert the battery fuses (if any)

located on the back of the UPS’s backpack.

4.2.1 Turning on UPS with mains

Check that all connections are correct. Check the breaker of external

battery pack is in “ON” position.

Set input breaker in “ON” position. At this time the fan begins to rotate. By

pressing button continuously for more than 2 second, the buzzer will

beep once, UPS starts to turn on.

A few seconds later, the UPS turns into Line mode. If the mains power is

abnormal, the UPS will transfer to Battery mode without output interruption

of the UPS.

4.2.2 Turning on UPS without mains

Check that all connections are correct. Check the breaker of external

battery pack is in “ON” position.

By pressing button continuously for more than 2s, the buzzer will beep

once, UPS starts to turn on.

A few seconds later, the UPS turns into Battery mode. If the mains power

comes back, the UPS will transfer to Line mode without output interruption

of the UPS.

4.2.3 Turning off UPS with mains

To turn off the inverter of UPS press button continuously for more than

3s and the buzzer beep once.

The UPS will turn into standby mode.

Cut off the mains power supply.

A few seconds later, LCD display shuts down.

29

4.2.4 Turning off UPS without mains

To power off the UPS press button continuously for more than 3s, and

the buzzer beep once. The UPS will cut off the output.

A few seconds later, LCD shuts down and no voltage is available from the

UPS output.

4.2.5 Transfer to Bypass

To transfer the UPS in internal bypass mode, press on/off button and test

button at the same time for more than 4 seconds.

To transfer the UPS back to normal mode, press on/off button and test

button at the same time for more than 4 seconds.

4.2.6 Transfer to maintenance Bypass

To transfer the UPS in maintenance bypass mode, switch on the

maintenance switch. And then the UPS will transfer to maintenance bypass

mode. Switch off the input and output switch before doing maintenance on

the UPS.

To transfer the UPS back to normal mode, switch on the input and output

switch and then switch off the maintenance switch. Then turn on the UPS

following “Turning on UPS” steps.

4.2.7 Transfer to manual Bypass

Press the on/off button and function button continuously for 4s, the UPS

will transfer to manual bypass mode.

If execute manual bypass operation when the UPS is working on ECO

mode, the UPS will transfer to bypass output mode. If press the on/off

button again to clear manual bypass, the UPS will not transfer back to ECO

mode and will stays in bypass output mode.

Only when ups working in line-on mode before executing manual bypass

operation, UPS will auto restart to line mode after clearing the manual

bypass operation.

30

4.3 Configuration

4.3.1 UPS parameters

In order to change UPS parameters (Output Voltage, Number of EBM, ....)

please use UPS Configuration Tool (download available here:

http://pqsoftware.eaton.com).

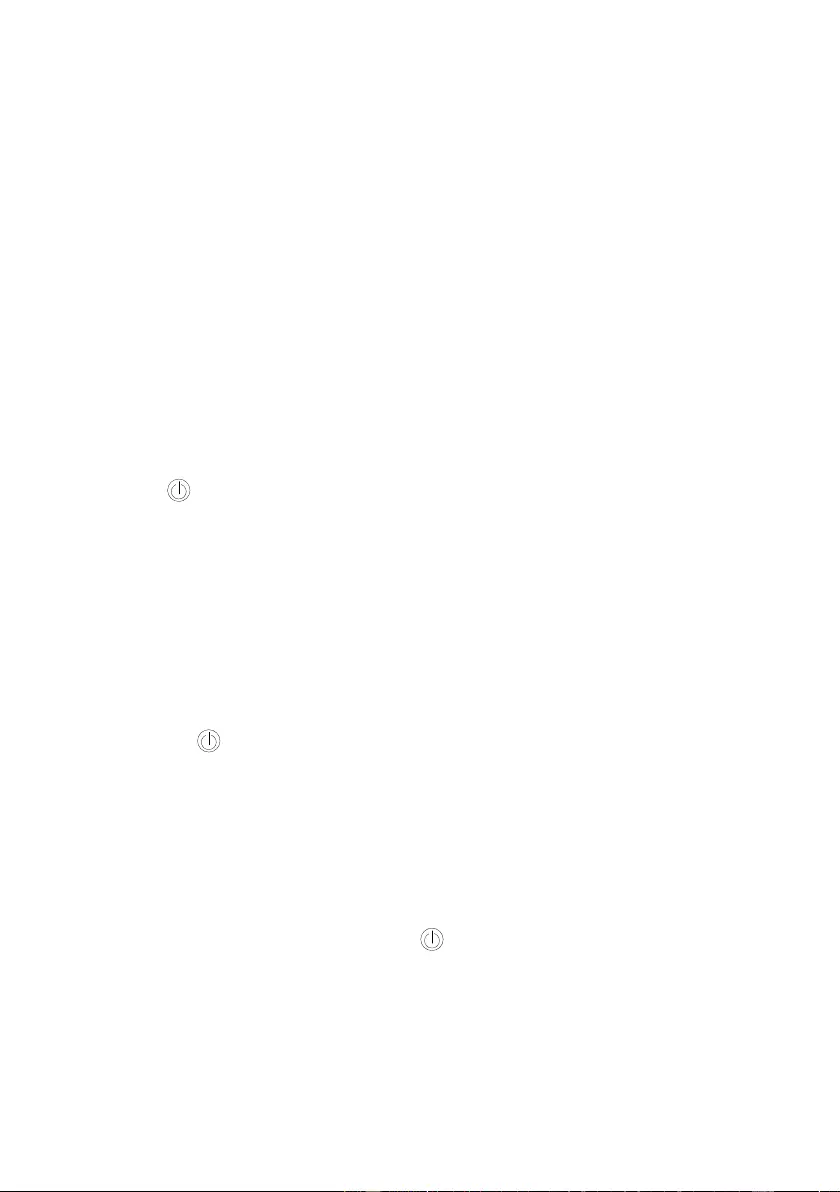

4.3.2 Communication ports

On the back of the UPS (see UPS Views), the following communication

ports are present: RS232 connector, USB connector, Slot for optional

connectivity cards.

RS232 or USB communication ports

The RS232 and USB communication ports cannot operate simultaneously.

1. Connect the RS232 or USB communication cable to the serial or USB

port on the computer.

2. Connect the other end of the communication cable to the RS232 or

USB communication port on the UPS.

The UPS can now communicate with EATON power management software.

31

Connectivity Cards

The UPS is equipped with an expansion slot for optional Connectivity

Cards (see figure on right).

It is not necessary to shutdown the UPS before installing a communication

card.

1. Remove the slot cover secured by screws.

2. Insert the communication card in the slot.

3. Secure the card cover with the 2 screws

Connectivity cards allow the UPS to communicate in a variety of

networking environments and with different types of devices.

• Network-MS card - has SNMP and HTTP capabilities as well as

monitoring through a Web browser interface; connects to Ethernet

network. In addition, a Environmental Monitoring Probe can be atta-

ched to obtain humidity, temperature, smoke alarm, and security

information.

• Modbus-MS card - has connection to Modbus protocol in addition to

network management.

• Relay-MS card - has isolated dry contact (Form-C) relay outputs for

UPS status: Utility failure, Battery low, UPS alarm/OK, or on Bypass.

4.3.3 Eaton Intelligent Power Software suite

32

Each 9E UPS ships with Eaton Intelligent Power Software suite. To begin

installing, see the instructions accompanying the Software suite CD.

Eaton Software suite provides up-to-date graphics of UPS power and

system data and power flow.

It also gives you a complete record of critical power events, and it notifies

you of important UPS or power

information.

If there is a power outage and the 9E UPS battery power becomes low,

Eaton Software suite can automatically shut down your computer system to

protect your data before the UPS shutdown occurs.

4.4 Trouble shooting

PROBLEM

POSSIBLE CAUSE

SOLUTION

THE DISPLAY DOES

NOT LIGHT UP

INPUT SWITCH

OPEN

Close the input switch located on

the back of the UPS.

MAIN

CONNECTION

CABLE MISSING

Check that the power cable is

connected correctly.

NO MAINS

VOLTAGE

(BLACKOUT)

Check that the power reaches the

UPS

UPSTREAM

THERMAL

PROTECTION TRIP

Reset the thermal protection.

CAUTION: Check that there is no

output overload to the UPS.

THE DISPLAY IS ON

BUT THE LOAD IS

NOT POWERED

THE UPS IS IN

Standby mode

Press the “ON” button on the front

panel to power the loads.

THE UPS IS

OPERATING FROM

THE BATTERY

DESPITE THE

PRESENCE OF

MAINS VOLTAGE

THE INPUT

VOLTAGE IS

OUTSIDE THE

PERMITTED

TOLERANCE

RANGE FOR MAINS

OPERATION

Problem with the mains. Wait until

the input mains voltage returns

within the tolerance range. The

UPS will automatically return to

mains operation.

33

THE BUZZER

SOUNDS

CONTINUOUSLY

AND THE DISPLAY

SHOWS ONE OF THE

FOLLOWING CODES:

A80E, A810, F808

THE LOAD

APPLIED TO THE

UPS IS TOO HIGH

Reduce the load to within the

threshold of 100% (or user

threshold in the case of code

A80E).

If the display shows an Fault:

remove the load and switch the

UPS off and back on again.

THE DISPLAY

SHOWS THE

FOLLOW CODE:

A60D

BATTERIES

MISSING OR

BATTERY BOX

MISSING OR NOT

CONNECTED

Check that the Battery Box is

inserted and connected to the UPS

correctly.

THE BUZZER

SOUNDS

CONTINUOUSLY

AND THE DISPLAY

SHOWS ONE OF THE

FOLLOWING CODES:

A004 F004

THE

TEMPERATURE

INSIDE THE UPS IS

TOO HIGH

Check that the temperature of the

environment in which the UPS is

located does not exceed 40°C.

THE BUZZER

SOUNDS

CONTINUOUSLY

AND THE DISPLAY

SHOWS ONE OF THE

FOLLOWING CODES:

F805

THERE IS A FAULT

ON ONE OR MORE

OF THE LOADS

POWERED BY THE

UPS

Disconnect all the utilities, switch

the UPS off and back on again,

reconnect the utilities one at a time

to identify which one is faulty.

THE BUZZER

SOUNDS

CONTINUOUSLY

AND THE DISPLAY

SHOWS ONE OF THE

FOLLOWING CODES:

F704,

F70D,F70C,F302,

F303,F305,F300,F301

,F304, F002

THE UPS IS

MALFUNCTIONING

If possible, disconnect the power

to the load, switch the UPS off and

back on again; if the problem

occurs again, call the support

centre.

THE DISPLAY

SHOWS THE CODE:

A900

THE

MAINTENANCE

BYPASS FUNCTION

IS ACTIVE

To take the UPS out of the

maintenance bypass function,

open the manual bypass switch on

the back of the UPS.

34

4.5 Alarm codes

Using a sophisticated self-diagnosis system, the UPS is able to check its

own status and any anomalies and/or faults which may occur during

normal operation and display them on the display panel. If there is a

problem, the UPS signals the event by showing the code and the type of

active alarm on the display.

Alarms

“Minor” problems which reduce performance or prevent certain functions

from being used.

CODE

DESCRIPTION

A007

Fans blocked

A107

Cable connection error

A10A

Unbalanced input voltages (three-phase input)

A806

E.P.O control active

A80E

Overload: load > 105%

A810

Load percentage greater than the user threshold set

A60D

Batteries missing or Battery Box missing or not connected

A802

Low battery

AC20

UPS work in Manual Bypass operation mode

Faults

Faults are normally preceded by an alarm signal and their scale leads to

the power-off of the inverter and the load being powered by the bypass

line.

CODE

DESCRIPTION

F002

UPS Fault

F004

Dissipator over temperature

F302 F303

Capacitor bank undervoltage

F300 F301

Capacitor bank overvoltage

F304

Unbalanced capacitor bank

F305

Failed capacitor bank soft start

F70D

Inverter overvoltage

F805

Short circuit

35

F704

Failed inverter soft start

F70C

Inverter undervoltage

F808

Output overload fault

F811

Negative output power

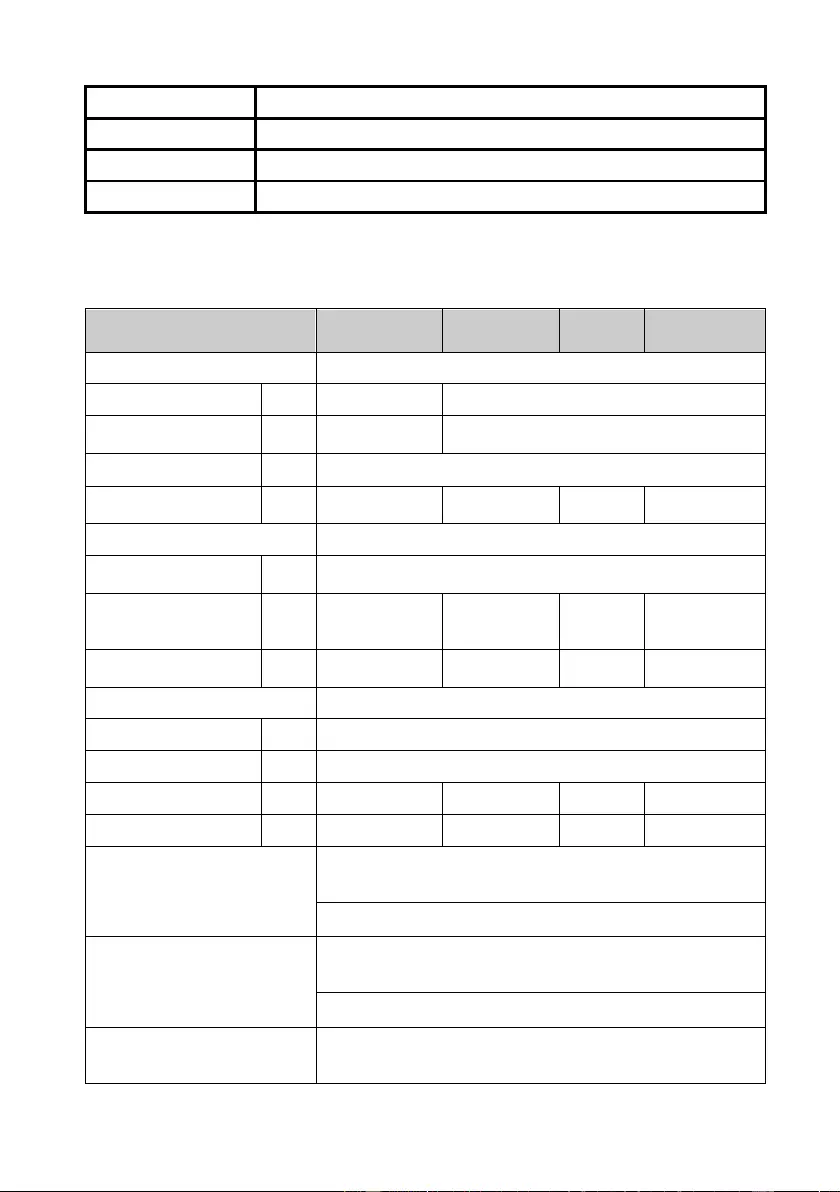

5.Technical data

UPS MODELS

9E6Ki

9E10Ki,

9E10KiXL

9E15Ki

9E20Ki,

9E20KiXL

INPUT

Nominal voltage

[Vac]

220 - 230 - 240

220 - 230 – 240 / 380 – 400 - 415

Maximum operating

voltage

[Vac]

276

276 / 478

Nominal frequency

[Hz]

50 - 60

Nominal current

[A]

26

41 / 16

(42 / 20,5 XL)

62 / 22

82 / 28

(83 / 29,5 XL)

BATTERY

Recharge time

(standard versions)

[h]

< 8h for 90% of the charge

Expandability and

nominal voltage of the

Battery Box

180Vdc

240Vdc

240 +

240Vdc

240 +

240Vdc

Charging current

(for XL versions only)

Not

applicable

4,4A

5A

5A

OUTPUT

Nominal voltage

[Vac]

Selectable: 220/230/240

Frequency

[Hz]

Selectable: 50, 60 or auto sensing

Nominal power

[VA]

6000

10000

15000

20000

Nominal power

[W]

4800

8000

12000

16000

Overload: 105% < load <

110%

Bypass line available: activates the bypass

after 5 min, then

continues to work

Bypass line not available: locks after 5 min

Overload: 110% < load <

130%

Bypass line available: activates the bypass

after 1 min, then

locks after 1 min

Bypass line not available: locks after 1 min

Overload: 130% < load <

150%

Bypass line available: activates the bypass

after 10 s, then

locks after 10 s

36

Bypass line not available: locks after 10 s

Overload load > 150%

Bypass line available: activates the bypass

after 100 ms, then

locks after 1 s

Bypass line not available: locks after 1 s

OTHER

Leakage current to

earth

[mA]

< 8mA

Ambient temperature

[°C]

0 – 40

Humidity

< 95% without condensation

Protection devices

Batteries deep discharge - overcurrent - short circuit -

overvoltage - undervoltage - circuit breaker

Dimensions

W x D x H

[mm]

262 x 613x 709

350 x 706 x 818

Weight

[kg]

68.8

86

(29 XL)

147

160

(48.5 XL)

Operating Temperature

0 oC to 40 oC

Operating humidity

0-95% no condensing

Altitude

Up to 1,000 meters above sea level with 10% derating per

1000m

Storage temperature

-15oC to 60oC without batteries

0~35°C with batteries

EBM

180VDC 9Ah

240VDC 9Ah

Nominal battery voltage

[Vdc]

180Vdc

240Vdc

Dimensions W x D x H

[mm]

262 x 580 x 709

Weight

[kg]

105.5

132.4

37

38

614-06847-03