Fujitsu ASYG14KMTA User Manual

Displayed below is the user manual for ASYG14KMTA by Fujitsu which is a product in the Split-System Air Conditioners category. This manual has pages.

Related Manuals

En-1

CAUTION

• Read carefully all safety information written in this manual before you install or use the

air conditioner.

• Install the product by following local codes and regulations in force at the place of

installation, and the instructions provided by the manufacturer.

• This product is part of a set constituting an air conditioner. The product must not be

installed alone or be installed with a device not authorized by the manufacturer.

• Always use a separate power supply line protected by a circuit breaker operating on

all wires with a distance between contact of 3 mm for this product.

• To protect the persons, earth (ground) the product correctly, and use the power cable

combined with an Earth Leakage Circuit Breaker (ELCB).

• This product is not explosion proof, and therefore should not be installed in an explo-

sive atmosphere.

• To avoid getting an electric shock, never touch the electrical components soon after

the power supply has been turned off. After turning off the power, always wait 5 min-

utes or more before you touch the electrical components.

• This product contains no user-serviceable parts. Always consult experienced service

technicians for repairing.

• When moving or relocating the air conditioner, consult experienced service technicians

for disconnection and reinstallation of the product.

• Do not touch the aluminum ns of heat exchanger built-in the indoor or outdoor unit to

avoid personal injury when you install or maintain the unit.

• Do not place any other electrical products or household belongings under the product.

Condensation dripping from the product might get them wet, and may cause damage

or malfunction to the property.

• Be careful not to scratch the air conditioner when handling it.

Precautions for using R32 refrigerant

The basic installation work procedures are the same as conventional refrigerant (R410A,

R22) models.

However, pay careful attention to the following points:

Since the working pressure is 1.6 times higher than that of refrigerant R22 models,

some of the piping and installation and service tools are special. (See “2.1. Special

tools for R32 (R410A)”.)

Especially, when replacing a refrigerant R22 model with a new refrigerant R32 model,

always replace the conventional piping and flare nuts with the R32 and R410A piping and

are nuts on the outdoor unit side.

For R32 and R410A, the same are nut on the outdoor unit side and pipe can be used.

Models that use refrigerant R32 and R410A have a different charging port thread diam-

eter to prevent erroneous charging with refrigerant R22 and for safety. Therefore, check

beforehand. [The charging port thread diameter for R32 and R410A is 1/2-20 UNF.]

Be more careful than R22 so that foreign matter (oil, water, etc.) does not enter the

piping. Also, when storing the piping, securely seal the opening by pinching, taping, etc.

(Handling of R32 is similar to R410A.)

CAUTION

1-Installation (Space)

• That the installation of pipe-work shall be kept to a minimum.

• That pipe-work shall be protected from physical damage.

• That compliance with national gas regulations shall be observed.

• That mechanical connections shall be accessible for maintenance purposes.

• In cases that require mechanical ventilation, ventilation openings shall be kept clear

of obstruction.

• When disposing of the product is used, be based on national regulations, properly

processed.

AIR CONDITIONER

Wall Mounted Type INSTALLATION MANUAL

Contents

1. SAFETY PRECAUTIONS .................................................................. 1

2. ABOUT THIS PRODUCT................................................................... 3

3. GENERAL SPECIFICATION ............................................................. 4

4. ELECTRICAL REQUIREMENT ......................................................... 4

5. SELECTING THE MOUNTING POSITION ....................................... 4

6. INSTALLATION WORK ..................................................................... 5

7. ELECTRICAL WIRING ..................................................................... 7

8. FINISHING ........................................................................................ 7

9. REMOVING AND REPLACING PARTS ............................................ 8

10. TEST RUN ......................................................................................... 8

11. REMOTE CONTROLLER INSTALLATION ........................................ 8

12. FUNCTION SETTING........................................................................ 9

13. OPTIONAL KIT INSTALLATION .......................................................11

14. SPECIAL INSTALLATION METHODS ............................................. 12

15. CUSTOMER GUIDANCE ................................................................ 12

16. ERROR CODES .............................................................................. 12

PART No. 9387848007

1. SAFETY PRECAUTIONS

• Be sure to read this manual thoroughly before installation.

• The warnings and precautions indicated in this manual contain important information

pertaining to your safety. Be sure to observe them.

• Hand this manual, together with the operating manual, to the customer. Request the

customer to keep them on hand for future use, such as for relocating or repairing the

unit.

WARNING Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation that may result in

minor or moderate injury or damage to property.

WARNING

• Installation of this product must be done by experienced service technicians or profes-

sional installers only in accordance with this manual. Installation by non-professional

or improper installation of the product might cause serious accidents such as injury,

water leakage, electric shock, or re. If the product is installed in disregard of the

instructions in this manual, it will void the manufacturer’s warranty.

• Do not turn on the power until all work has been completed. Turning on the power be-

fore the work is completed can cause serious accidents such as electric shock or re.

• If refrigerant leaks when you are working, ventilate the area. If the leaking refrigerant

is exposed to a direct ame, it may produce a toxic gas.

• Installation must be performed in accordance with regulations, codes, or standards for

electrical wiring and equipment in each country, region, or the installation place.

• Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety. Children should be supervised to ensure that they

do not play with the appliance.

• To avoid danger of suffocation, keep the plastic bag or thin lm used as the packaging

material away from young children.

• The appliance shall be stored in a room without continuously operating ignition

sources (for example: open ames, an operating gas appliance or an operating

electric heater).

• Do not pierce or burn.

• Be aware that refrigerants may not contain an odour.

[Original instructions] For authorized service personnel only.

EnglishDeutschFrançaisEspañolItalianoEλληvIkάPortuguêsРусский

Türkçe

Türkçe

9387848007_IM.indb 1 1/26/2018 16:44:40

En-2

CAUTION

2-Servicing

2-1 Service personnel

• Any person who is involved with working on or breaking into a refrigerant circuit

should hold a current valid certicate from an industry-accredited assessment

authority, which authorises their competence to handle refrigerants safely in accor-

dance with an industry recognised assessment specication.

• Servicing shall only be performed as recommended by the equipment manufacturer.

Maintenance and repair requiring the assistance of other skilled personnel shall be

carried out under the supervision of the person competent in the use of ammable

refrigerants.

• Servicing shall be performed only as recommended by the manufacturer.

2-2 Work

• Prior to beginning work on systems containing ammable refrigerants, safety checks

are necessary to ensure that the risk of ignition is minimized. For repair to the refrig-

erating system, the precautions in 2-2 to 2-8 shall be complied with prior to conduct-

ing work on the system.

• Work shall be undertaken under a controlled procedure so as to minimize the risk of

a ammable gas or vapour being present while the work is being performed.

• All maintenance staff and others working in the local area shall be instructed on the

nature of work being carried out.

• Work in conned spaces shall be avoided.

• The area around the workspace shall be sectioned off.

• Ensure that the conditions within the area have been made safe by control of am-

mable material.

2-3 Checking for presence of refrigerant

• The area shall be checked with an appropriate refrigerant detector prior to and during

work, to ensure the technician is aware of potentially ammable atmospheres.

• Ensure that the leak detection equipment being used is suitable for use with am-

mable refrigerants, i.e. nonsparking, adequately sealed or intrinsically safe.

2-4 Presence of re extinguisher

• If any hot work is to be conducted on the refrigeration equipment or any associated

parts, appropriate re extinguishing equipment shall be available at hand.

• Have a dry powder or CO2 re extinguisher adjacent to the charging area.

2-5 No ignition sources

• No person carrying out work in relation to a refrigeration system which involves

exposing any pipe work that contains or has contained ammable refrigerant shall

use any sources of ignition in such a manner that it may lead to the risk of re or

explosion.

• All possible ignition sources, including cigarette smoking, should be kept sufciently

far away from the site of installation, repairing, removing and disposal, during which

ammable refrigerant can possibly be released to the surrounding space.

• Prior to work taking place, the area around the equipment is to be surveyed to make

sure that there are no ammable hazards or ignition risks. “No Smoking” signs shall

be displayed.

2-6 Ventilated area

• Ensure that the area is in the open or that it is adequately ventilated before breaking

into the system or conducting any hot work.

• A degree of ventilation shall continue during the period that the work is carried out.

• The ventilation should safely disperse any released refrigerant and preferably expel

it externally into the atmosphere.

2-7 Checks to the refrigeration equipment

• Where electrical components are being changed, they shall be t for the purpose

and to the correct specication.

• At all times the manufacturer’s maintenance and service guidelines shall be followed.

• If in doubt consult the manufacturer’s technical department for assistance.

• The following checks shall be applied to installations using ammable refrigerants.

- The charge size is in accordance with the room size within which the refrigerant

containing parts are installed.

- The ventilation machinery and outlets are operating adequately and are not

obstructed.

- If an indirect refrigerating circuit is being used, the secondary circuit shall be

checked for the presence of refrigerant.

- Marking to the equipment continues to be visible and legible. Markings and signs

that are illegible shall be corrected.

- Refrigeration pipe or components are installed in a position where they are unlikely

to be exposed to any substance which may corrode refrigerant containing compo-

nents, unless the components are constructed of materials which are inherently

resistant to being corroded or are suitably protected against being so corroded.

2-8 Checks to electrical devices

• Repair and maintenance to electrical components shall include initial safety checks

and component inspection procedures.

• If a fault exists that could compromise safety, then no electrical supply shall be con-

nected to the circuit until it is satisfactorily dealt with.

• If the fault cannot be corrected immediately but it is necessary to continue operation,

an adequate temporary solution shall be used.

• This shall be reported to the owner of the equipment so all parties are advised.

• Initial safety checks shall include.

- That capacitors are discharged: this shall be done in a safe manner to avoid pos-

sibility of sparking.

- That there no live electrical components and wiring are exposed while charging,

recovering or purging the system.

- That there is continuity of earth bonding.

CAUTION

3-Repairs to sealed components

• During repairs to sealed components, all electrical supplies shall be disconnected

from the equipment being worked upon prior to any removal of sealed covers, etc.

• If it is absolutely necessary to have an electrical supply to equipment during servic-

ing, then a permanently operating form of leak detection shall be located at the most

critical point to warn of a potentially hazardous situation.

• Particular attention shall be paid to the following to ensure that by working on electri-

cal components, the casing is not altered in such a way that the level of protection is

affected.

• This shall include damage to cables, excessive number of connections, terminals not

made to original specication, damage to seals, incorrect tting of glands, etc.

• Ensure that apparatus is mounted securely.

• Ensure that seals or sealing materials have not degraded such that they no longer

serve the purpose of preventing the ingress of ammable atmospheres.

• Replacement parts shall be in accordance with the manufacturer’s specications.

NOTE: The use of silicon sealant may inhibit the effectiveness of some types of leak

detection equipment.

Intrinsically safe components do not have to be isolated prior to working on

them.

4-Repair to intrinsically safe components

• Do not apply any permanent inductive or capacitance loads to the circuit without

ensuring that this will not exceed the permissible voltage and current permitted for

the equipment in use.

• Intrinsically safe components are the only types that can be worked on while live in

the presence of a ammable atmosphere.

• The test apparatus shall be at the correct rating.

• Replace components only with parts specied by the manufacturer.

• Other parts may result in the ignition of refrigerant in the atmosphere from a leak.

5-Cabling

• Check that cabling will not be subject to wear, corrosion, excessive pressure, vibra-

tion, sharp edges or any other adverse environmental effects.

• The check shall also take into account the effects of aging or continual vibration from

sources such as compressors or fans.

6-Detection of ammable refrigerants

• Under no circumstances shall potential sources of ignition be used in the searching

for or detection of refrigerant leaks.

• A halide torch (or any other detector using a naked ame) shall not be used.

7-Leak detection methods

• Electronic leak detectors shall be used to detect ammable refrigerants, but the

sensitivity may not be adequate, or may need re-calibration. (Detection equipment

shall be calibrated in a refrigerant-free area.)

• Ensure that the detector is not a potential source of ignition and is suitable for the

refrigerant used.

• Leak detection equipment shall be set at a percentage of the LFL of the refrigerant

and shall be calibrated to the refrigerant employed and the appropriate percentage of

gas (25 % maximum) is conrmed.

• Leak detection uids are suitable for use with most refrigerants but the use of

detergents containing chlorine shall be avoided as the chlorine may react with the

refrigerant and corrode the copper pipe-work.

• If a leak is suspected, all naked ames shall be removed/extinguished.

• If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall

be recovered from the system, or isolated (by means of shut off valves) in a part of

the system remote from the leak.

Oxygen free nitrogen (OFN) shall then be purged through the system both before

and during the brazing process.

8-Removal and evacuation

• When breaking into the refrigerant circuit to make repairs – or for any other

purpose –conventional procedures shall be used.

However, it is important that best practice is followed since ammability is a consid-

eration.

The following procedure shall be adhered to:

• remove refrigerant

• purge the circuit with inert gas

• evacuate

• purge again with inert gas

• open the circuit by cutting or brazing

• The refrigerant charge shall be recovered into the correct recovery cylinders.

• The system shall be “ushed” with OFN to render the unit safe.

• This process may need to be repeated several times.

• Compressed air or oxygen shall not be used for this task.

• Flushing shall be achieved by breaking the vacuum in the system with OFN and

continuing to ll until the working pressure is achieved, then venting to atmosphere,

and nally pulling down to a vacuum.

• This process shall be repeated until no refrigerant is within the system.

• When the nal OFN charge is used, the system shall be vented down to atmospheric

pressure to enable work to take place.

• This operation is absolutely vital if brazing operations on the pipe work are to take

place.

• Ensure that the outlet for the vacuum pump is not close to any ignition sources and

there is ventilation available.

9387848007_IM.indb 2 1/26/2018 16:44:41

En-3

CAUTION

9-Charging procedures

• In addition to conventional charging procedures, the following requirements shall be

followed.

- Ensure that contamination of different refrigerants does not occur when using

charging equipment.

Hoses or lines shall be as short as possible to minimize the amount of refrigerant

contained in them.

- Cylinders shall be kept upright.

- Ensure that the refrigeration system is earthed prior to charging the system with

refrigerant.

- Label the system when charging is complete (if not already).

- Extreme care shall be taken not to overll the refrigeration system.

• Prior to recharging the system it shall be pressure tested with OFN.

• The system shall be leak tested on completion of charging but prior to commission-

ing.

• A follow up leak test shall be carried out prior to leaving the site.

10-Decommissioning

• Before carrying out this procedure, it is essential that the technician is completely

familiar with the equipment and all its details.

• It is recommended good practice that all refrigerants are recovered safely.

• Prior to the task being carried out, an oil and refrigerant sample shall be taken in

case analysis is required prior to re-use of reclaimed refrigerant.

• It is essential that electrical power is available before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure ensure that:

• mechanical handling equipment is available, if required, for handling refriger-

ant cylinders;

• all personal protective equipment is available and being used correctly;

• the recovery process is supervised at all times by a competent person;

• recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed

from various parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with manufacturer’s

instructions.

h) Do not overll cylinders. (No more than 80 % volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been lled correctly and the process completed, make

sure that the cylinders and the equipment are removed from site promptly and all

isolation valves on the equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system un-

less it has been cleaned and checked.

11-Labelling

• Equipment shall be labelled stating that it has been de-commissioned and emptied

of refrigerant.

• The label shall be dated and signed.

• Ensure that there are labels on the equipment stating the equipment contains am-

mable refrigerant.

12-Recovery

• When removing refrigerant from a system, either for servicing or decommissioning, it

is recommended good practice that all refrigerants are removed safely.

• When transferring refrigerant into cylinders, ensure that only appropriate refrigerant

recovery cylinders are employed.

• Ensure that the correct number of cylinders for holding the total system charge are

available.

• All cylinders to be used are designated for the recovered refrigerant and labelled for

that refrigerant (i.e. special cylinders for the recovery of refrigerant).

• Cylinders shall be complete with pressure relief valve and associated shut-off valves

in good working order.

• Empty recovery cylinders are evacuated and, if possible, cooled before recovery

occurs.

• The recovery equipment shall be in good working order with a set of instructions

concerning the equipment that is at hand and shall be suitable for the recovery of

ammable refrigerants.

• In addition, a set of calibrated weighing scales shall be available and in good working

order.

• Hoses shall be complete with leak-free disconnect couplings and in good condition.

• Before using the recovery machine, check that it is in satisfactory working order, has

been properly maintained and that any associated electrical components are sealed

to prevent ignition in the event of a refrigerant release.

Consult manufacturer if in doubt.

• The recovered refrigerant shall be returned to the refrigerant supplier in the correct

recovery cylinder, and the relevant Waste Transfer Note arranged.

• Do not mix refrigerants in recovery units and especially not in cylinders.

• If compressors or compressor oils are to be removed, ensure that they have been

evacuated to an acceptable level to make certain that ammable refrigerant does not

remain within the lubricant.

• The evacuation process shall be carried out prior to returning the compressor to the

suppliers.

• Only electric heating to the compressor body shall be employed to accelerate this

process.

• When oil is drained from a system, it shall be carried out safely.

Explanation of symbols displayed on the indoor unit or outdoor unit.

WARNING

This symbol shows that this appliance uses a ammable

refrigerant.

If the refrigerant is leaked and exposed to an external igni-

tion source, there is a risk of re.

CAUTION This symbol shows that the operation manual should be

read carefully.

CAUTION This symbol shows that a service personnel should be

handling this equipment with reference to the installation

manual.

CAUTION This symbol shows that information is available such as

the operating manual or installation manual.

2. ABOUT THIS PRODUCT

2.1. Special tools for R32 (R410A)

Tool name Change from R22 to R32 (R410A)

Gauge manifold

Pressure is high and cannot be measured with a R22

gauge. To prevent erroneous mixing of other refrigerants,

the diameter of each port has been changed.

It is recommended to use gauge with seals -0.1 to 5.3 MPa

(-1 to 53 bar) for high pressure.

-0.1 to 3.8 MPa (-1 to 38 bar) for low pressure.

Charge hose To increase pressure resistance, the hose material and base

size were changed. (R32/R410A)

Vacuum pump

A conventional vacuum pump can be used by installing a

vacuum pump adapter.

(Use of a vacuum pump with a series motor is prohibited.)

Gas leakage detector Special gas leakage detector for HFC refrigerant R410A or

R32.

Copper pipes

It is necessary to use seamless copper pipes and it is desirable that the amount of residual

oil is less than 40 mg/10 m. Do not use copper pipes having a collapsed, deformed or

discolored portion (especially on the interior surface). Otherwise, the expansion value or

capillary tube may become blocked with contaminants.

As an air conditioner using R32 (R410A) incurs pressure higher than when using R22, it is

necessary to choose adequate materials.

WARNING

• Do not use the existing (for R22) piping and are nuts.

If the existing materials are used, the pressure inside the refrigerant cycle will rise and

cause failure, injury, etc. (Use the special R32/R410A materials.)

• Use (rell or replace with) specied refrigerant (R32) only. Use of unspecied refriger-

ant can cause product malfunction, burst, or injury.

• Do not mix any gas or impurities except specied refrigerant (R32). Inow of air or ap-

plication of unspecied material makes the internal pressure of the refrigerant cycle too

high, and may cause product malfunction, burst of piping, or injury.

• For installation purposes, be sure to use the parts supplied by the manufacturer or

other prescribed parts. The use of non-prescribed parts can cause serious accidents

such as the unit falling, water leakage, electric shock, or re.

• Do not turn on the power until all work has been completed.

CAUTION

This manual describes how to install the indoor unit only. To install the outdoor unit or

branch box, (if any), refer to the installation manual included in each product.

9387848007_IM.indb 3 1/26/2018 16:44:43

En-4

2.2. Accessories

The following installation accessories are supplied. Use them as required.

Name and Shape

Q’ty

Name and Shape

Q’ty

Operating Manual

1

Cloth tape

1

Operating Manual

(CD-ROM)

1

Tapping screws (large)

5

Installation Manual

(This manual)

1

Tapping screws (small)

2

Remote controller

1

Battery

2

Remote controller holder

1

Wall hook bracket

1

The following items are necessary to install this air conditioner. (The items are not includ-

ed with the air conditioner and must be purchased separately.)

Additional materials

Connection pipe assembly Wall cap

Connection cable (4-conductor)

Saddle

Wall pipe Drain hose

Decorative tape Tapping screws

Vinyl tape Putty

2.3. Optional parts

Refer to each installation manual for the method of installing optional parts.

KG series

Parts name Model No. Application

Wired remote controller (*1) UTY-RNRZFor air conditioner operation

(2-wired type)

UTY-RLR

External input and output PCB UTY-XCSXZ2 For control input/output port

External connect kit UTY-XWZX For control input/output port

Communication kit UTY-TWRXZ2 For the installation of optional parts

WLAN adapter UTY-TFSXW1 For wireless LAN control

*1: Optional Communication kit (UTY-TWRXZ2) is necessary for installation.

KM series

Parts name Model No. Application

Wired remote controller (*2) UTY-RVNMFor air conditioner operation

(3-wired type)

UTY-RNNM

Simple remote controller (*2) UTY-RSNMFor air conditioner operation

(3-wired type)

External connect kit (*2) UTY-XWZXZ5 For control input/output port

Communication kit UTY-TWBXF2 For the installation of optional parts

WLAN adapter UTY-TFSXW1 For wireless LAN control

*2: Optional Communication kit (UTY-TWBXF2) is necessary for installation.

3. GENERAL SPECIFICATION

This installation manual briefly outlines where and how to install the air conditioning

system. Please read over the entire set of instructions for the indoor and outdoor units and

make sure all accessory parts listed are with the system before beginning.

3.1. Type of copper pipe and insulation material

CAUTION

Refer to the installation manual for the outdoor unit for description of allowable pipe

length and height difference.

Gas pipe size (thickness) [mm] Liquid pipe size (thickness) [mm]

Ø

9.52 (3/8 in.)

Ø

6.35 (1/4 in.)

CAUTION

• Wrap heat insulation around both gas pipe and liquid pipe.

No heat-insulation work or incorrect heat-insulation work may cause water leaks.

• In a reverse cycle model, use heat insulation with heat resistance above 120 °C.

• If expected humidity of the installation location of refrigerant pipes is higher than 70

%, wrap the heat insulation around the refrigerant pipes.

If the expected humidity is between 70 % and 80 %, use heat insulation that has

a thickness of 15 mm or more.

If the expected humidity is higher than 80 %, use heat insulation that has a thickness

of 20 mm or more.

• The use of thinner heat insulation than specied above, may cause a condensation

on the surface of the insulation.

• Use heat insulation with thermal conductivity of 0.045 W/(

m•K

) or less, at 20

°C

.

4. ELECTRICAL REQUIREMENT

The indoor unit is powered from the outdoor unit. Do not power indoor unit from separate

power source.

WARNING

Standard for electrical wiring and equipment differs in each country or region. Before you

start electrical working, conrm related regulations, codes, or standards.

Cable

Conductor size [

mm2

]Type

Remarks

Connection cable

1.5 Type 60245 IEC 57 3 cable + Earth (Ground),

1 Ø 230 V

Cable Length: Limit voltage drop to less than 2%. Increase cable gauge if voltage drop is

2% or more.

5. SELECTING THE MOUNTING POSITION

Decide the mounting position with the customer as follows:

(1) Install the indoor unit level on a strong wall which is not subject to vibration.

(2) The inlet and outlet ports should not be obstructed: the air should be able to blow all

over the room.

(3) Install the unit a dedicated electrical branch circuit.

(4) Do not install the unit where it will be exposed to direct sunlight.

(5) Install the unit where connection to the outdoor unit is easy.

(6) Install the unit where the drain pipe can be easily installed.

(7) Take servicing, etc. into consideration and leave the spaces shown in “6.1. Installation

dimensions”. Also install the unit where the lter can be removed.

Correct initial installation location is important because it is difcult to move the unit after it

is installed.

WARNING

Install the indoor unit where is capable to support the weight of the unit. Secure the

unit rmly so that the unit does not topple or fall.

CAUTION

Do not install the unit in the following areas:

• Area with high salt content, such as at the seaside. It will deteriorate metal parts, caus-

ing the parts to fail or the unit to leak water.

• Area lled with mineral oil or containing a large amount of splashed oil or steam, such

as a kitchen. It will deteriorate plastic parts, causing the parts to fail or the unit to leak

water.

• Area where is close to heat sources.

• Area that generates substances that adversely affect the equipment, such as sulfuric

gas, chlorine gas, acid, or alkali. It will cause the copper pipes and brazed joints to cor-

rode, which can cause refrigerant leakage.

• Area that can cause combustible gas to leak, contains suspended carbon bers or

ammable dust, or volatile in ammables such as paint thinner or gasoline.

• If gas leaks and settles around the unit, it can cause a re.

• Area where animals may urinate on the unit or ammonia may be generated.

• Do not use the unit for special purposes, such as storing food, raising animals, grow-

ing plants, or preserving precision devices or art objects. It can degrade the quality of

the preserved or stored objects.

• Install the unit where drainage does not cause any trouble.

• Install the indoor unit, outdoor unit, power supply cable, transmission cable, and re-

mote control cable at least 1 m away from a television or radio receivers. The purpose

of this is to prevent TV reception interference or radio noise.

(Even if they are installed more than 1 m apart, you could still receive noise under

some signal conditions.)

• If children under 10 years old may approach the unit, take preventive measures so that

they cannot reach the unit.

• Install the indoor unit on the wall where the height from the oor is more than 1.8 m.

9387848007_IM.indb 4 1/26/2018 16:44:45

En-5

6. INSTALLATION WORK

WARNING

During transportation or relocation of the indoor unit, pipes shall be covered with the

wall hook bracket for protection. Do not move the appliance by holding the indoor unit

pipes.

(The stress applied to the pipe joints may cause the ammable gas to leak during

operation.)

CAUTION

• Do not hit or push the human sensor. This may lead to damage or malfunction.

• Do not touch the human sensor. Any scratches or dirt may lead to incorrect detection.

• Do not place large objects near the

human

sensor. Also keep heating units outside the

sensor’s detection area.

Detection range of the

human

sensor is as follows (KG series only).

Vertical angle 90° (Side view)

90° 50°50°

6 m

6 m

Horizontal angle 100° (Top view)

6.1. Installation dimensions

Keep the distance between the wall hook bracket or indoor unit to the surrounding walls

as indicated in the following gure.

Wall hook bracket

Outline of the indoor unit

(50 or

more)

67 or

more

The are connection

part should be installed

outdoors.

(40 or

more)

(70 or

more)

107 or

more

1,500

or more

1,800 or more

Unit: mm

183 or

more

6.2. Indoor unit piping direction

The piping can be connected in 2 directions. When the piping is connected in direction (B),

cut out a hole in the under cover along the piping groove with a hacksaw.

(B) Right

outlet

(A) Rear

outlet

(Rear)

Under cover

Under cover (inside view)

Piping groove

6.3.

Cutting the hole in the wall for connecting the pipes

(1) Cut a 65 mm diameter hole in the wall at the position shown in the following.

(2) Cut the hole so that the outside end is lower (5 to 10 mm) than the inside end.

(3) Always align the center of the wall hole. If misaligned, water leakage will occur.

(4)

Cut the wall pipe to match the wall thickness, stick it into the wall cap, fasten the cap with

vinyl tape, and stick the pipe through the hole.

(5) For the right piping, cut the hole a little lower so that drain water will ow freely.

Wall hook bracket Centering marks

65 mm hole

94 mm

* Locally purchased

Fasten with vinyl tape *

5~10 mm

Wall pipe *Wall cap *

(Inside) (Outside)

Wall

WARNING

Always use the wall pipe. If the wall pipe is not used, the cable that is connected between

the indoor unit and the outdoor unit may touch metal, and cause an electric discharge.

6.4. Installing the wall hook bracket

(1) Install the wall hook bracket so that it is correctly positioned horizontally and vertically.

If the wall hook bracket is titled, water will drip to the oor.

(2)

Install the wall hook bracket so that it is strong enough to support the weight of the unit.

• Fasten the wall hook bracket to the wall with 5 or more screws through the holes near

the outer edge of the bracket.

• Check that there is no rattle at the wall hook bracket.

Wall hook bracket

Screws (large, accessories)

CAUTION

Install the wall-hook bracket both horizontally and vertically aligned.

Misaligned installation may cause water leakage.

6.5.

Forming the drain hose and pipe

CAUTION

• Insert drain hose and drain cap securely. Drain should slope down to avoid water leakage.

• When inserting the drain hose, no other material than water should be applied.

Application of other material than water will cause deterioration of the hose, and may

cause water leakage.

• After you remove a drain hose, be sure to attach the drain cap.

• When you secure the piping and drain hose with tape, arrange the drain hose so that

it is at the bottom of the piping.

• For drain hose piping in low temperature environment, you need to apply freeze

protection to prevent a frozen drain hose.

After cooling operation is performed in low temperature environment (when outdoor

temperature under 0 °C), water in the drain hose could be frozen. Frozen drain water

will block the water ow in the hose, and may cause water leakage at the indoor unit.

9387848007_IM.indb 5 1/26/2018 16:44:48

En-6

[Rear piping, Right piping]

• Install the indoor unit piping in the direction of the wall hole and bind the drain hose

and pipe together with vinyl tape.

• Install the piping so that the drain hose is at the bottom.

• Wrap the pipes of the indoor unit that are visible from the outside with decorative tape.

Right piping

Bind with vinyl tape

(locally purchased)

Indoor unit drain hose (bottom)

Pipe (top)

CAUTION

Insert the drain hose and drain cap into the drain port, making sure that it comes

in contact with the back of the drain port, and then mount it. If the drain hose is not

connected properly, leaking will occur.

[Installing the indoor unit]

• Hang the indoor unit from the hooks at the top of the wall hook bracket.

• Insert the spacer, etc. between the indoor unit and the wall hook bracket and separate

the bottom of the indoor unit from the wall.

Top hooksCenter of upper rail

(Fittings) Bottom hooks

Indoor unit

Wall hook bracket

(Spacer)

• After hooking the indoor unit to the top hook, hook the ttings of the indoor unit to the

bottom hooks while lowering the unit and pushing it against the wall.

6.6. Pipe connection

CAUTION

Tighten the flare nuts with a torque wrench using the specified tightening method.

Otherwise, the are nuts could break after a prolonged period, causing refrigerant to leak

and generate hazardous gas if the refrigerant comes into contact with a ame.

6.6.1. Flaring

Use special pipe cutter and are tool designed for R410A or R32 pipework.

(1) Cut the connection pipe to the necessary length with a pipe cutter.

(2) Hold the pipe downward so that cuttings will not enter the pipe and remove any burrs.

(3) Insert the are nut (always use the are nut attached to the indoor unit(s) and outdoor

unit or branch box respectively) onto the pipe and perform the are processing with a

are tool. Use the special R410A or R32 are tool, or the conventional are tool. Leak-

age of refrigerant may result if other are nuts are used.

(4) Protect the pipes by pinching them or with tape to prevent dust, dirt, or water from

entering the pipes.

Die

A

Pipe

B

L

Check if [L] is flared uniformly

and is not cracked or scratched.

Pipe outside diameter

[mm (in.)]

Dimension A [mm]

Dimension B [mm]

Flare tool for R32,

clutch type

6.35 (1/4)

0 to 0.5

9.1

9.52 (3/8) 13.2

12.70 (1/2) 16.6

15.88 (5/8) 19.7

19.05 (3/4) 24.0

When using conventional are tools to are R32 pipes, the dimension A should be approx-

imately 0.5 mm more than indicated in the table (for aring with R32 are tools) to achieve

the specied aring. Use a thickness gauge to measure the dimension A.

Width across

flats Pipe outside diameter [mm (in.)] Width across flats

of Flare nut [mm]

6.35 (1/4) 17

9.52 (3/8) 22

12.70 (1/2) 26

15.88 (5/8) 29

19.05 (3/4) 36

6.6.2. Bending pipes

CAUTION

• To prevent breaking of the pipe, avoid sharp bends.

• If the pipe is bent repeatedly at the same place, it will break.

• The pipes are shaped by your hands. Be careful not to collapse them.

• Bend R70 mm or more with a pipe bender.

• Do not bend the pipes in an angle more than 90°.

• When pipes are repeatedly bend or stretched, the material will harden, making it difcult

to bend or stretch them anymore.

• Do not bend or stretch the pipes more than 3 times.

• When bending the pipe, do not bend it as

is. The pipe will be collapsed. In this case,

cut the insulating pipe with a sharp cutter

as shown on the right, and bend it after

exposing the pipe. After bending the pipe

as you want, be sure to put the heat insu-

lating pipe back on the pipe, and secure it

with tape.

Pipe

Insulating

Pipe

Cutter

Cut line

6.6.3. Flare connection

WARNING

The are connection shall not be performed indoors.

CAUTION

• Be sure to install the pipe against the port on the indoor unit correctly. If the center-

ing is improper, the are nut cannot be tightened smoothly. If the are nut is forced

to turn, the threads will be damaged.

• Do not remove the are nut from the indoor unit pipe until immediately before con-

necting the connection pipe.

• Hold the torque wrench at its grip, keeping it in the right angle with the pipe, in order

to tighten the are nut correctly.

• Tighten the are nuts with a torque wrench using the specied tightening method.

Otherwise, the are nuts could break after a prolonged period, causing refrigerant to

leak and generate hazardous gas if the refrigerant comes into contact with a ame.

• Connect the piping so that the control box cover can easily be removed for servic-

ing when necessary.

• In order to prevent water from leaking into the control box, make sure that the pip-

ing is well insulated.

When the flare nut is tightened properly by your hand, hold the body side coupling with a

wrench, then tighten with a torque wrench. (See the following table for the flare nut tighten-

ing torques.)

Tighten with 2 wrenches.

Holding wrench

Flare nut

Connection pipe

Torque wrench

Indoor unit pipe

(Body side)

Flare nut [mm (in.)] Tightening torque [N·m (kgf·cm)]

6.35 (1/4) dia. 16 to 18 (160 to 180)

9.52 (3/8) dia. 32 to 42 (320 to 420)

12.70 (1/2) dia. 49 to 61 (490 to 610)

15.88 (5/8) dia. 63 to 75 (630 to 750)

19.05 (3/4) dia. 90 to 110 (900 to 1,100)

Do not remove the cap from the connection pipe before connecting the pipe.

9387848007_IM.indb 6 1/26/2018 16:44:49

En-7

(3) Connect specied wires securely, and fasten them so that there is no stress applied on

the terminals.

(4) Use a screwdriver with an appropriate bit size to tighten the terminal screws. Using of

screwdriver with inappropriate bit size will damage the screw heads, and the screws

will not be tightened properly.

(5) Do not overtighten the terminal screws. Otherwise, the screws may break.

Screw with special washer

Wire Ring terminal

Terminal blocks Wire

Screw with special washer

Ring terminal

(6) See the table for the terminal screw tightening torques.

Tightening torque [N·m (kgf·cm)]

M4 screw 1.2 to 1.8 (12 to 18)

CAUTION

• Match the terminal block numbers and connection cable colors with those of the

outdoor unit. Incorrect wiring may cause a re.

• Connect the connection cables rmly to the terminal block. Imperfect installation may

cause a re.

• When xing the connection cable with the cable clamp, always fasten the cable at the

plastic jacket portion, but not at the insulator portion. If the insulator is chafed, electric

leakage may occur.

• Always connect the earth (ground) wire. Improper earthing (grounding) work can

cause electric shocks.

• Do not use the earth (ground) screw for the indoor unit to the outdoor unit unless it is

specied.

8. FINISHING

(1) Insulate between pipes.

• Insulate suction and discharge pipes separately.

• For rear, right, and bottom piping, overlap the connection pipe heat insulation and

indoor unit pipe heat insulation and bind them with vinyl tape so that there is no gap.

(2) Temporarily fasten the connection cable along the connection pipe with vinyl tape.

(Wrap to about 1/3 the width of the tape from the bottom of the pipe so that water

does not enter.)

(3) Fasten the connection pipe to the outside wall with a saddle, etc.

(4) Fill the gap between the outside wall pipe hole and the pipe with sealer so that rain

water and wind cannot blow in.

(5) Fasten the drain hose to the outside wall, etc.

(6) Check the drainage.

*Locally purchased

Pipe

Saddle*

Outside wall cap*

Sealer putty*

(Outdoors)

Wall

Overlap the insulation

Vinyl tape*

Wrap with cloth tape.

Cloth tape (accessory)

Drain hose

Pipe

Connection pipe

(heat insulation) Indoor unit pipe

(heat insulation)

Bind the pipes together

so that there is no gap.

GOOD

Drain hose

Saddle

Lifted up Wave End in water

PROHIBITED

7. ELECTRICAL WIRING

WARNING

• Before connecting the wires, make sure the power supply is OFF.

• Every wire must be connected rmly.

• No wire should be allowed to touch refrigerant tubing, the compressor, or any mov-

ing part.

• Loose wiring may cause the terminal to overheat or result in unit malfunction. A re

hazard may also exist. Therefore, be sure all wiring is tightly connected.

• Connect wires to the matching numbers of terminals.

CAUTION

Be careful not to generate a spark as follows for using a ammable refrigerant.

• Do not remove the fuse while the power is on.

• Do not disconnect the wiring while the power is on.

• It is recommended to position the outlet connection in a high position. Place the

cords so that they do not get tangled.

7.1.

Wiring system diagram

Type 60245 IEC57

Cable size 1.5 mm2

(Inter-unit)

Earth (Ground) line

OUTDOOR UNIT

Please connect to the

specied terminal.

INDOOR UNIT

TERMINAL

Power line

Control line

7.2.

Indoor unit wiring

(1) Remove the intake grille. (Refer to “9.1. Intake grille removal and installation”.)

(2) Remove the tapping screw for the wire cover and the wire cover. (Wire covers A and B

come off together.)

Screw

Wire cover

(3) Remove the tapping screw and while minding the cable clamp hook, remove the cable

clamp.

Screw

Cable clamp

7.3. How to connect wiring to the terminals

Caution when wiring cable

To strip off the insulation of a lead wire, always use a special tool such as a wire stripper.

If there is no special tool, carefully strip off the insulation by using a knife or other utensil.

(1) Use ring terminals with insulating sleeves as shown in the gure to connect to the

terminal block.

(2) Securely clamp the ring terminals to the wires by using an appropriate tool so that the

wires do not come loose.

Strip : 10 mm Ring terminal

Sleeve

9387848007_IM.indb 7 1/26/2018 16:44:51

En-8

9. REMOVING AND REPLACING PARTS

9.1. Intake grille removal and installation

Intake grille removal

(1) Hold the intake grille with both hands at the side, then pull to the front until it becomes

hooked.

(2) Keeping the intake grille in a horizontal position, pull the mounting shaft on the left and

right to release.

Intake grille

Mounting

shaft

Mounting

shaft

Intake grille installation

(1) Attach the left and right mounting shaft in the direction of the arrow to the panel top

bearing while supporting the intake grille horizontally. Press this until it clicks so that

each shaft snaps into place.

Mounting shaft

Mounting

shaft

Bearing

Bearing

(2) Press and close the intake grille.

Press here

9.2. Front panel / control cover removal and installation

* In this description, the intake grille and wire cover already has been removed.

9.2.1. Front panel / control cover / under cover removal

(1) Remove the under covers. (Press down on the markings on the side, then slide down.)

(2) Remove the screw covers (2 places) on the bottom of the front panel, and then remove

the screws (4 places).

(3) Push down on the markings (2 places) on top of the front panel to release the hooks

(3 places), then pull the front panel towards you.

(4) Pinch the tab on the control cover to release the hook, then open.

Control cover

Screws (4 places)

Hook (3 places)

Markings

(triangle)

Markings (triangle)

Markings (triangle)

Markings (triangle)

Screw covers

Tab

Under covers

9.2.2. Front panel / control cover / under cover installation

Reverse the procedures in “9.2.1. Front panel / control cover / under cover removal”.

* Be sure to replace the screws (4 places) and screw cover (2 places).

CAUTION

Please take caution when removing or installing the front panel. If the front panel falls,

there is a risk of injury.

9.3. Uninstalling the indoor unit

Remove the indoor unit from the wall hook bracket as follows.

(1) Remove the under covers. (See “9.2.1. Front panel / control cover / under cover

removal”.)

(2) Insert your ngers in the opening shown in the gure.

While pushing down on the lower part of the opening, release the hooks (2 places).

(3) Pull the indoor unit towards you.

Markings (triangle)

Hooks (rear side)

10. TEST RUN

Check items

(1) Is operation of each button on the remote controller normal?

(2) Does each lamp light normally?

(3) Do airow direction louvers operate normally?

(4) Is the drain normal?

(5) Do not have an abnormal noise and vibration during operation?

Do not operate the air conditioner in test run for a long time.

[Operation method]

Depending on your installation, choose from the following:

By the wireless remote controller (with [TEST RUN] button)

• To start test run, press [START/STOP] and [TEST RUN] on the remote controller.

• To end test run, press [START/STOP] on the remote controller.

By the indoor unit or IR receiver unit

• To start test run, press [MANUAL AUTO] of the unit for more than 10 seconds (forced

cooling).

•

To end test run, press [MANUAL AUTO] for more than 3 seconds or press [START/STOP]

on the remote controller.

By the wired remote controller

• For the operation method, refer to the installation manual and the operating manual of

the wired remote controller.

The Operation indicator lamp and Timer indicator lamp will simultaneously ash during the

test run mode.

Heating test run will begin in a few minutes when HEAT is selected by the remote control-

ler [reverse cycle model only].

11. REMOTE CONTROLLER INSTALLATION

Check that the indoor unit correctly receives the signal from the remote controller, then

install the remote controller holder.

CAUTION

Do not install the remote controller holder in the following conditions:

• Any places exposed in direct sunlight

• Positions affected by the heat from a stove or heater

9387848007_IM.indb 8 1/26/2018 16:44:53

En-9

11.1. Remote controller holder installation

• Install the remote controller a maximum distance of 7 m from the remote control signal

receiver. After installing the remote controller, check that it operates correctly.

• I

nstall the remote controller holder to a wall, pillar, etc. with the tapping screw.

Remote controller

holder

Tapping

screw

(small)

(1) Set

Remote

controller

(2) Down

11.2. Remote controller custom setting

Use the following steps to select the custom code of the remote controller. (Note that

the air conditioner cannot receive a signal if the air conditioner has not been set for the

matching custom code.)

(1) Press [ ] until only the clock is displayed on the

remote controller display.

(2) Press [MODE] for at least 5 seconds to display the

current custom code (initially set to A).

(3) Press [TEMP. ( / )] to change the custom code

between A↔B↔C↔D .

Match the code on the display to the air conditioner

custom code.

(4) Press [MODE] again to return to the clock display. The

custom code will be changed.

• If no buttons are pressed within 30 seconds after the custom code is displayed, the

system returns to the original clock display. In this case, start again from step 1.

• The air conditioner custom code is set to A prior to shipment.

12. FUNCTION SETTING

Perform the Function Setting according to the installation conditions using the remote

controller.

CAUTION

• Conrm whether the wiring work for outdoor unit has been nished.

• Conrm that the cover for the electrical enclosure on the outdoor unit is in place.

• This procedure changes to the Function Settings used to control the indoor unit

according to the installation conditions. Incorrect settings can cause the indoor unit to

malfunction.

• After the power is turned on, perform the Function Setting according to the installation

conditions using the remote controller.

• The settings may be selected between the following two: Function Number or Setting

Value.

• Settings will not be changed if invalid numbers or setting values are selected.

Entering the Function Setting Mode

While pressing [POWERFUL] and [TEMP. ( )] simultaneously, press [RESET] to enter

the function setting mode.

STEP 1 (KM series only)

Selecting the Remote Controller Custom Code

Use the following steps to select the custom code of the remote con-

troller.

(Note that the air conditioner cannot receive a signal if

the air conditioner has not been set for the matching custom

code.)

The custom codes that are set through this process are applicable

only to the signals in the function setting. For details on how to set

the custom codes through the normal process, refer to “11.2 Remote

controller custom setting”.

(1) Press [TEMP. ( / )] to change the custom code between . Match

the code on the display to the air conditioner custom code. (initially set to ) (If

the custom code does not need to be selected, press [10°C HEAT] and proceed to

STEP 2.)

(2)

Press [MODE] and check that the indoor unit can receive signals at the displayed

custom code.

(3) Press [10°C HEAT] to accept the custom code, and proceed to STEP 2.

STEP 2 (KM series, KG series)

Selecting the Function Number and Setting Value

(1) Press [TEMP. ( / )] to select the function

number. (Press [10°C HEAT] to switch between

the left and right digits.)

(2) Press [POWERFUL] to proceed to setting value.

(Press [POWERFUL] again to return to the func-

tion number selection.)

Function

Number

Setting

Value

(3) Press [TEMP. ( / )] to select the setting value. (Press [10°C HEAT] to switch be-

tween the left and right digits.)

(4) Press

[MODE]

once. Please conrm the beeping sound.

(5) Next, please press [ ] once to x the Function Setting. Please conrm the beeping

sound.

(6) Press [RESET] to cancel the Function Setting mode.

(7) After completing the Function Setting, be sure to disconnect the power supply and

then reconnect it.

CAUTION

After disconnecting the power supply, wait 30 seconds or more before reconnecting it.

The Function Setting will not become active unless the power supply is disconnected

and then reconnected.

12.1. Function Details

Filter sign

Select appropriate intervals for displaying the lter sign on the indoor unit according to the

estimated amount of dust in the air of the room.

If the indication is not required, select “No indication” (03).

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

11

00 Standard (400 hours)

01 Long interval (1000 hours)

02 Short interval (200 hours)

03 No indication ♦

Room temperature control for indoor unit sensor

Depending on the installed environment, correction of the room temperature sensor may

be required.

Select the appropriate control setting according to the installed environment.

The temperature correction values show the difference from the “Standard setting” (00)

(manufacturer’s recommended value).

(♦... Factory setting)

Function Number Setting

Value Setting Description

30

(For cooling)

31

(For heating)

00 Standard setting ♦

01 No correction 0.0 °C (0 °F)

02 -0.5 °C (-1 °F)

More

Cooling

Less

Heating

03 -1.0 °C (-2 °F)

04 -1.5 °C (-3 °F)

05 -2.0 °C (-4 °F)

06 -2.5 °C (-5 °F)

07 -3.0 °C (-6 °F)

08 -3.5 °C (-7 °F)

09 -4.0 °C (-8 °F)

10 +0.5 °C (+1 °F)

Less

Cooling

More

Heating

11 +1.0 °C (+2 °F)

12 +1.5 °C (+3 °F)

13 +2.0 °C (+4 °F)

14 +2.5 °C (+5 °F)

15 +3.0 °C (+6 °F)

16 +3.5 °C (+7 °F)

17 +4.0 °C (+8 °F)

9387848007_IM.indb 9 1/26/2018 16:44:54

En-10

Room temperature control for wired remote controller sensor

Depending on the installed environment, correction of the wire remote temperature sensor

may be required.

Select the appropriate control setting according to the installed environment.

To change this setting, set Function 42 to “Both” (01).

Ensure that the Thermo Sensor icon is displayed on the remote controller screen.

(♦... Factory setting)

Function Number Setting

Value Setting Description

35

(For cooling)

36

(For heating)

00 No correction ♦

01 No correction 0.0 °C (0 °F)

02 -0.5 °C (-1 °F)

More

Cooling

Less

Heating

03 -1.0 °C (-2 °F)

04 -1.5 °C (-3 °F)

05 -2.0 °C (-4 °F)

06 -2.5 °C (-5 °F)

07 -3.0 °C (-6 °F)

08 -3.5 °C (-7 °F)

09 -4.0 °C (-8 °F)

10 +0.5 °C (+1 °F)

Less

Cooling

More

Heating

11 +1.0 °C (+2 °F)

12 +1.5 °C (+3 °F)

13 +2.0 °C (+4 °F)

14 +2.5 °C (+5 °F)

15 +3.0 °C (+6 °F)

16 +3.5 °C (+7 °F)

17 +4.0 °C (+8 °F)

Auto restart

Enable or disable automatic restart after a power interruption.

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

40 00 Enable ♦

01 Disable

* Auto restart is an emergency function such as for power outage etc. Do not attempt to

use this function in normal operation. Be sure to operate the unit by remote controller or

external device.

Room temperature sensor switching

(Only for wireless remote controller)

When using the Wired remote controller temperature sensor, change the setting to “Both” (01).

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

42 00 Indoor unit ♦

01 Both

00: Sensor on the indoor unit is active.

01: Sensors on both indoor unit and wired remote controller are active.

*

Remote controller sensor must be turned on by using the remote controller

Remote controller custom code

(Only for wireless remote controller)

The indoor unit custom code can be changed. Select the appropriate custom code.

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

44

00 A ♦

01 B

02 C

03 D

External input control

“Operation/Stop” mode or “Forced stop” mode can be selected.

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

46

00 Operation/Stop mode 1 ♦

01 (Setting prohibited)

02 Forced stop mode

03 Operation/Stop mode 2

Room temperature sensor switching (Aux.)

To use the temperature sensor on the wired remote controller only, change the setting to “Wired

remote controller” (01). This function will only work if the function setting 42 is set at “Both” (01)

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

48 00 Both ♦

01 Wired remote controller

Indoor unit fan control for energy saving for cooling

Enables or disables the power-saving function by controlling the indoor unit fan rotation when

the outdoor unit is stopped during cooling operation. (♦... Factory setting)

Function

Number

Setting

Value Setting description

49

00 Disable

01 Enable

02 Remote controller ♦

00: When the outdoor unit is stopped, the indoor unit fan operates continuously following

the setting on the remote controller.

01: When the outdoor unit is stopped, the indoor unit fan operates intermittently at a very

low speed.

02: Enable or disable this function by remote controller setting.

*When using a wired remote controller without Indoor unit fan control for energy saving for

cooling function, or when connecting a single split converter, the setting cannot be made

by using the remote controller. Set to (00) or (01).

To conrm if the remote controller has this function, refer to the operating manual of each

remote controller.

Switching functions for external output terminal (KG series only)

Functions of the external output terminal can be switched.

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

60

00 Operation status ♦

01 to 08 (Setting prohibited)

09 Error status

10 Indoor unit fan operation status

11 (Setting prohibited)

Setting record

Record any changes to the settings in the following table.

Setting Description Setting Value

Filter sign

Room temperature control for indoor

unit sensor

Cooling

Heating

Room temperature control for

wired remote controller sensor

Cooling

Heating

Auto restart

Room temperature sensor switching

Remote controller custom code

External input control

Room temperature sensor switching (Aux.)

Indoor unit fan control for energy saving for cooling

Switching functions for external output terminal

After completing the Function Setting, be sure to disconnect the power supply and then recon-

nect it.

9387848007_IM.indb 10 1/26/2018 16:44:55

En-11

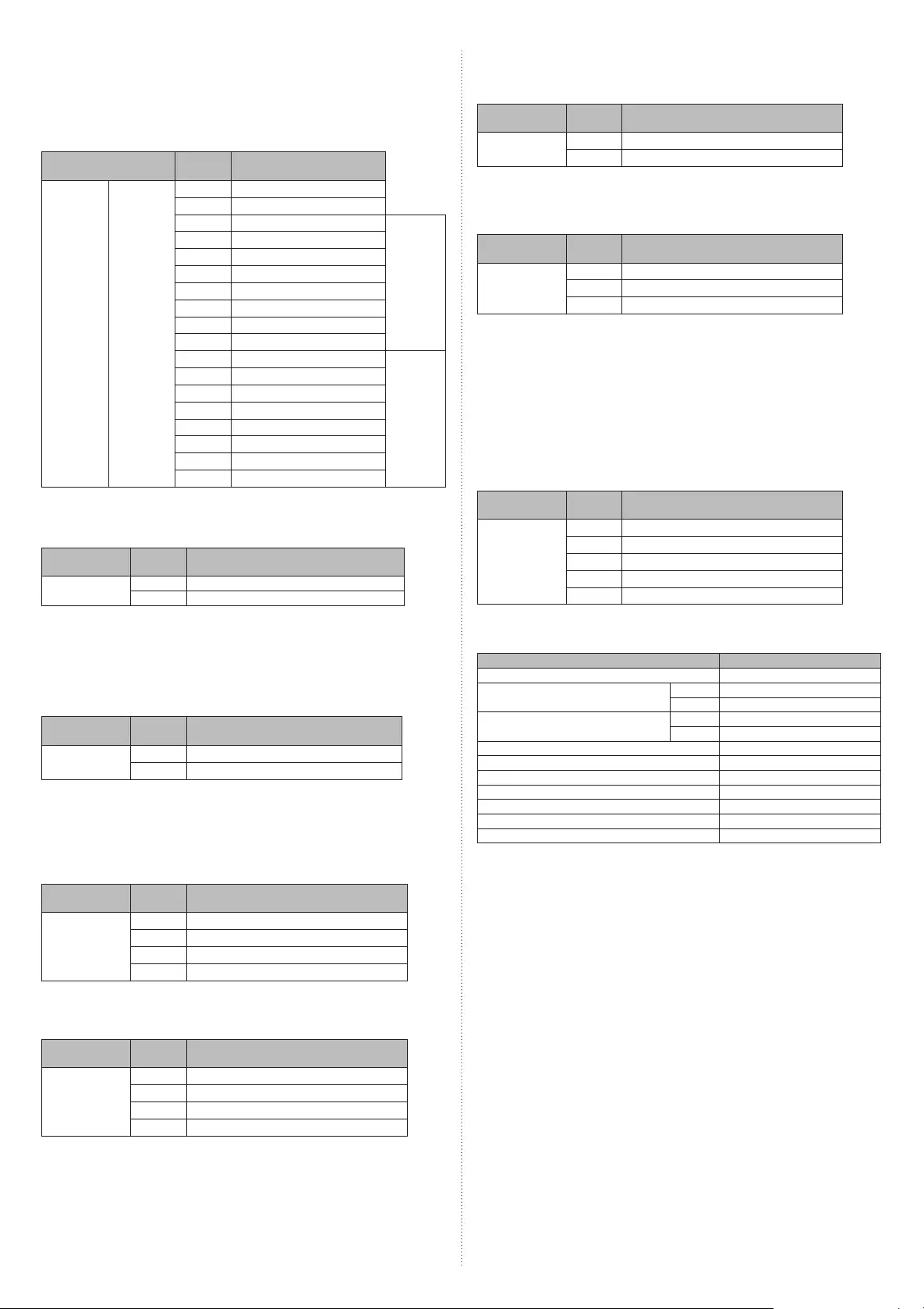

13. OPTIONAL KIT INSTALLATION

13.1. Installing the WLAN adapter

NOTES:

Be sure to keep the wireless LAN label attached to the WLAN adapter by writing the details

down or pasting it on the setting manual of the WLAN adapter.

(1) Remove the intake grille. Refer to “9. REMOVING AND REPLACING PARTS”.

(2) Remove 1 screw and take off the upper part of the wire cover.

(Wire cover B)

(3) Attach the connector cable of the WLAN adapter to the wire and connector from the

indoor unit.

(4) Push the cable into the back area. Insert the left side of the WLAN adapter into the

box.

(5) Set the WLAN adapter by pushing the right side until the tab is rmly set.

(6) Close the wire cover B with 1 screw, then replace the intake grille.

(3)

(5)

(4)

Screw

Tab

WLAN connector

WLAN adapter

with cable

Install the WLAN adapter in the direction

as shown in the gure.

Wire cover B

13.2. Installing the External input/output PCB (KG series only)

(1) Remove the Intake grille, front panel, and control cover. Refer to “9. REMOVING AND

REPLACING PARTS”.

(2) Insert the PCB to the clasps (2 places). Push the PCB down until the clasp on the

left is set.

Clasp Clasps

(2 places)

External input/

output PCB

(3) Disconnect the WLAN adapter wire (CN65), then replace it with the wire for External

input/output PCB.

(4) Hook the WLAN adapter wire to the control box. Fix it with a cable tie.

Cable tie

External input/

output PCB wire

CN65 (External input/

output PCB)

(5) Replace the control cover, front panel, and Intake grille.

13.3. Installing the Communication kit

For KG series

(1) Remove the Intake grille, front panel, and control cover. Refer to “9. REMOVING AND

REPLACING PARTS”.

(2) Insert the PCB to the clasps (2 places). Push the PCB down until the clasp on the

bottom is set.

(3) Connect the wire with EMI core to the terminal board.

Clasp Communication

PCB

Clasps

(4) Attach the terminal board to the indoor unit with 1 screw (accessory for option).

(5) Connect the wire with EMI core to the communication PCB, then x it with the cable

tie (accessory for option).

(6) Connect the communication kit and main PCB.

(7) Connect the wired remote controller cable to the terminal board as shown in the gure.

Cable tie

Communication

wire

CN13

(Communi-

cation kit)

Cable clamp

Wired remote

controller cable

Screw (accessory

for option)

Tab

(8) Replace the control cover, front panel, and Intake grille.

For KM series

(1) Remove the Intake grille, front panel, and control cover. Refer to “9. REMOVING AND

REPLACING PARTS”.

(2) Insert the PCB to the clasps (2 places). Push the PCB down until the clasp on the

bottom is set.

Communication

PCB

Clasps

(3) Connect the communication kit and main PCB.

(4) Replace the control cover, front panel, and intake grille.

CNC01 (Wired remote controller)

Cable clamp

CN2

(Communication kit)

Communication wire

CNB02

(Error status)

CNB01 (Ext. out)

CND01

(Communication kit)

CNA01 (Ext. in)

Wired remote

controller cable

9387848007_IM.indb 11 1/26/2018 16:44:59

En-12

14. SPECIAL INSTALLATION METHODS

Group control system

A number of indoor units can be operated at the same time using a single remote controller.

*When connecting different types of indoor units (such as wall mounted, cassette, duct, or

other types), some functions may be restricted.

(1) Connect multiple indoor units in a system.

A

BCDE

I.U. I.U. I.U. I.U.

Remote

controller

A, B, C, D, E : Remote controller cable.

KM series: A+B+C+D+E ≤ 300 m *

KG series: A+B+C+D+E ≤ 500 m

* Crimping terminal (locally purchased) is necessary. (For details, refer to the technical

manual).

The cable size needs to be changed depending on the total wiring length.

Total wiring length of

remote controller cable

(A+B+C+D+E)

Cross section of cable

KM series KG series

100 m or less 0.3-0.8 mm2

0.3-1.25 mm2

100-200 m 0.5-0.8 mm2

200-300 m 0.8 mm2

300-500 m

Example of wiring method (2-wired type)

Y1

Y2

Remote

controller cable

Remote controller

PCB or terminal block

for wired remote controller

Indoor unit 1 Indoor unit 2 Indoor unit 3 Indoor unit 4

(2) Set the R.C. address (Function setting)

(a) 2-wired type

Automatic setting:

• Addresses will be automatically set when initially starting up this unit. In such a

case, do not change the R.C. address of the indoor unit, and keep it at the initial

setting (00).

Manual setting:

•

Only set addresses manually when using different numbers for addresses.

Set the R.C. address of each indoor unit with the wireless remote controller.

Also set the R.C. address of the wired remote controller. For details, please refer

to the remote controller installation manual.

* In manual setting, connect up to 15 indoor units in a system.

* Do not use the R.C. address “00”.

(b) 3-wired type

Manual setting:

• Set the R.C. address of each indoor unit with the wireless remote controller.

• Set each R.C. address in sequence from “00”.

• Connect up to 16 indoor units in a system.

Example of R.C. address setting (3-wired type)

RC AD

00

RC AD

01

RC AD

02

RC AD

03

Remote

controller

Indoor unit 1 Indoor unit 2 Indoor unit 3 Indoor unit 4

Remote controller address setting

(♦... Factory setting)

Function

Number

Setting

Value Setting Description

00

00 2-wired type: Setting prohibited ♦

3-wired type: Unit no. 0

01 Unit no. 1

02 ~ 13 Unit no. 2 ~ Unit no. 13

14 Unit no. 14

15 Unit no. 15

* Do not use the same setting value.

* After completing the Function Setting, be sure to disconnect the power supply and then

reconnect it.

NOTES:

Set the R.C. address by the wireless remote controller.

15. CUSTOMER GUIDANCE

Explain the following to the customer in accordance with the operating manual:

(1) Starting and stopping method, operation switching, temperature adjustment, timer, airow

switching, and other remote control unit operations.

(2) Air lter removal and cleaning, and how to use the air louvers.

(3) Give the operating manual to the customer.

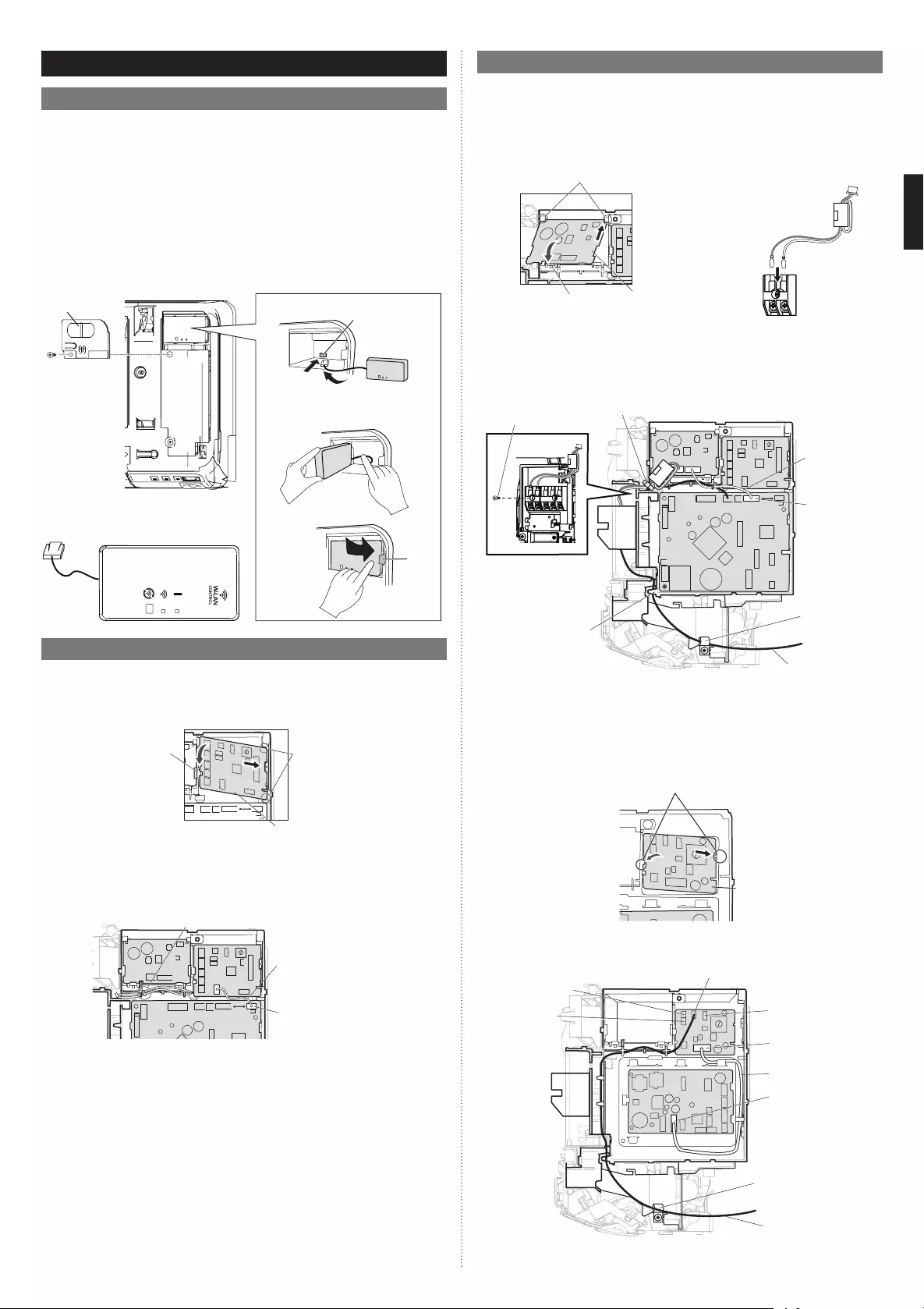

16. ERROR CODES

If you use a wireless remote controller, the lamp on the photo detector unit will output error

codes by way of blinking patterns. If you use a wired remote controller, error codes will ap-

pear on the remote control display. See the lamp blinking patterns and error codes in the

table. An error display is displayed only during operation.

Error display

Error code Description

OPERATION

lamp

(green)

TIMER

lamp

(orange)

ECONOMY

lamp

(green)

(1) (1) Serial communication error

(1) (2)

• Wired remote controller

communication error

• Server room control

communication error

(1) (5) Check run unfinished

Automatic airflow adjustment error

(1) (6) Peripheral unit transmission PCB

connection error

(1) (8) External communication error

(2) (1)

Unit number or Refrigerant circuit

address setting error

[Simultaneous Multi]

(2) (2) Indoor unit capacity error

(2) (3) Combination error

(2) (4)

• Connection unit number

error (indoor secondary unit)

[Simultaneous Multi]

• Connection unit number error

(indoor unit or branch unit)

[Flexible Multi]

(2) (6) Indoor unit address setting error

(2) (7) Primary unit, secondary unit setup

error [Simultaneous Multi]

(2) (9) Connection unit number error in

wired remote controller system

(3) (1) Power supply interruption error

(3) (2) Indoor unit PCB model

information error

(3) (3) Indoor unit motor electricity

consumption detection error

(3) (5) Manual auto switch error

(3) (9) Indoor unit power supply error for

fan motor

(3) (10) Indoor unit communication circuit

(wired remote controller) error

9387848007_IM.indb 12 1/26/2018 16:45:03

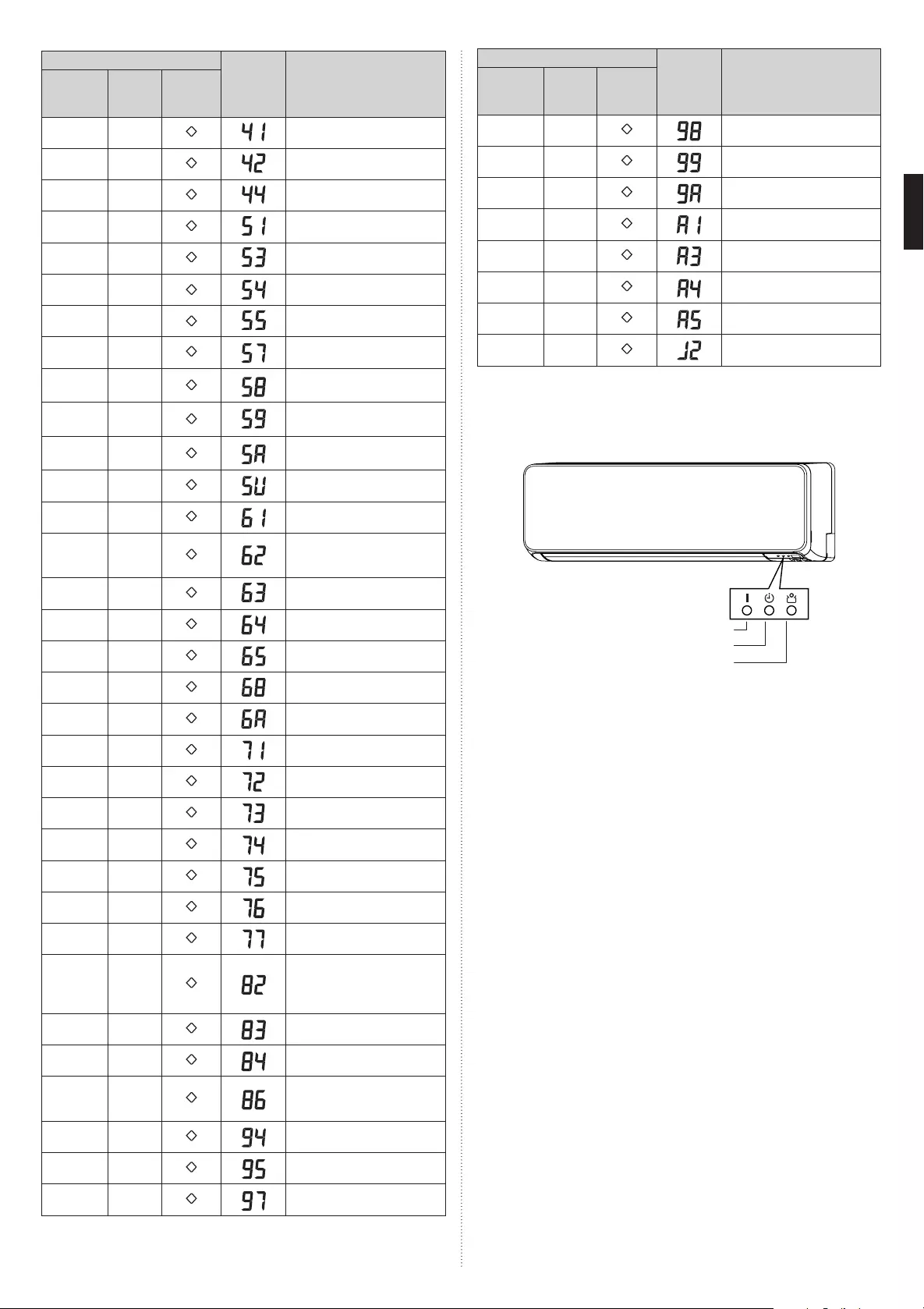

En-13

Error display

Error code Description

OPERATION

lamp

(green)

TIMER

lamp

(orange)

ECONOMY

lamp

(green)

(4) (1) Room temp. sensor error

(4) (2)

Indoor unit heat ex. middle temp.

sensor error

(4) (4)

Human sensor error

(5) (1) Indoor unit fan motor error

(5) (3) Drain pump error

●(5) ●(4) Electric air cleaner reverse VDD

error

●(5) ●(5) Filter set error

(5) (7) Damper error

●(5) ●(8) Intake grille error

●(5) ●(9) Indoor unit fan motor 2 error

(Left side fan)

●(5) ●(10) Indoor unit fan motor 3 error

(Right side fan)

(5) (15) Indoor unit error

(6) (1) Outdoor unit reverse/missing

phase and wiring error

(6) (2)

Outdoor unit main PCB

model information error or

communication error

(6) (3) Inverter error

(6) (4) Active filter error, PFC circuit error

(6) (5) Trip terminal L error

(6) (8) Outdoor unit rush current limiting

resister temp. rise error

(6) (10) Display PCB microcomputers

communication error

(7) (1) Discharge temp. sensor error

(7) (2) Compressor temp. sensor error

(7) (3) Outdoor unit Heat Ex. liquid temp.

sensor error

(7) (4) Outdoor temp. sensor error

(7) (5) Suction Gas temp. sensor error

(7) (6) • 2-way valve temp. sensor error

• 3-way valve temp. sensor error

(7) (7) Heat sink temp. sensor error

(8) (2)

• Sub-cool Heat Ex. gas inlet

temp. sensor error

• Sub-cool Heat Ex. gas outlet

temp. sensor error

(8) (3) Liquid pipe temp. sensor error

(8) (4) Current sensor error

(8) (6)

• Discharge pressure sensor error

• Suction pressure sensor error

• High pressure switch error

(9) (4) Trip detection

(9) (5) Compressor rotor position

detection error (permanent stop)

(9) (7) Outdoor unit fan motor 1 error

Error display

Error code Description

OPERATION

lamp

(green)

TIMER

lamp

(orange)

ECONOMY

lamp

(green)

(9) (8) Outdoor unit fan motor 2 error

(9) (9) 4-way valve error

(9) (10) Coil (expansion valve) error

(10) (1) Discharge temp. error

(10) (3) Compressor temp. error

(10) (4) High pressure error

(10) (5) Low pressure error

(13) (2) Branch boxes error

[Flexible Multi]

Display mode ● : 0.5s ON / 0.5s OFF

◊

: 0.1s ON / 0.1s OFF

( ) : Number of flashing

[Troubleshooting with the indoor unit display]

OPERATION indicator lamp (green)

TIMER indicator lamp (orange)

ECONOMY indicator lamp (green)

9387848007_IM.indb 13 1/26/2018 16:45:10