Interline 59692020 User Manual

Displayed below is the user manual for 59692020 by Interline which is a product in the Heat Pumps category. This manual has pages.

Related Manuals

BP-30WS-B

BP-35WS-B

BP-50WS-B

BP-50HS-A

BP-85HS-A

BP-100HS-A

BP-160HS-A

User manual - Heat Pump

E N G L I S H

Page 2-di/of 28

Contents.

1. General warnings and information for the addressee. ............................................................................ 4

Warranty. ................................................................................................................................................ 4

1.1.

General conditions. ......................................................................................................................... 4

1.1.1.

Special conditions. .......................................................................................................................... 4

1.1.2.

Restrictions. .................................................................................................................................... 4

1.1.3.

Symbol key. ............................................................................................................................................ 4

1.2.

Safety regulations for heated pools. ....................................................................................................... 4

1.3.

Energy savings. ...................................................................................................................................... 5

1.4.

General information. ............................................................................................................................... 5

1.5.

Definitions. .............................................................................................................................................. 5

1.6.

2. Product presentation................................................................................................................................... 6

Product scope. ....................................................................................................................................... 6

2.1.

Composition. .......................................................................................................................................... 7

2.2.

3. Technical specifications. ............................................................................................................................ 8

4. Installation. ................................................................................................................................................... 9

Inspection. .............................................................................................................................................. 9

4.1.

Handling. ................................................................................................................................................ 9

4.2.

Positioning. ............................................................................................................................................. 9

4.3.

Support and its location. ................................................................................................................. 9

4.3.1.

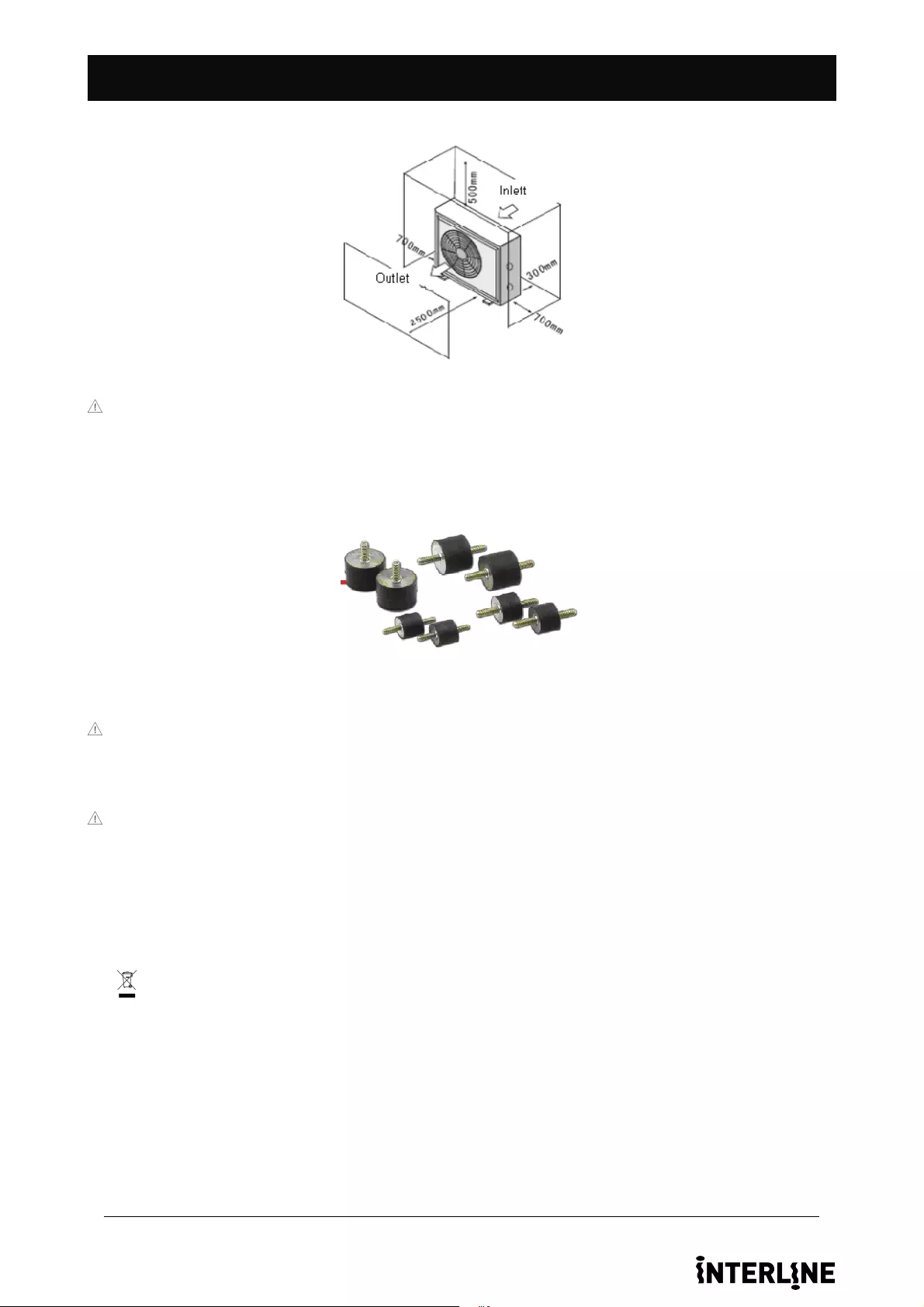

Necessary clearance. ................................................................................................................... 10

4.3.2.

Noise wave echo. .......................................................................................................................... 10

4.3.3.

Disposal. ............................................................................................................................................... 10

4.4.

General instructions. ..................................................................................................................... 10

4.4.1.

Heat pump decommissioning. ...................................................................................................... 10

4.4.2.

Electric/electronic waste disposal. ................................................................................................ 10

4.4.3.

Hydraulic connections. ......................................................................................................................... 11

4.5.

Warnings. ...................................................................................................................................... 11

4.5.1.

Installation hydraulic layout. .......................................................................................................... 11

4.5.2.

Electrical connections. .......................................................................................................................... 12

4.6.

Commissioning, preliminary checks. .................................................................................................... 12

4.7.

Commissioning, precautions. ........................................................................................................ 12

4.7.1.

First start-up, preliminary checks. ................................................................................................. 12

4.7.2.

5. Operations and use. .................................................................................................................................. 12

Introduction. .......................................................................................................................................... 12

5.1.

Control panel use. ................................................................................................................................ 13

5.2.

Turning on the heat pump. ............................................................................................................ 13

5.2.1.

Standby. ........................................................................................................................................ 13

5.2.2.

Turning off the heat pump. ............................................................................................................ 13

5.2.3.

Starting the heat pump.................................................................................................................. 13

5.2.4.

Operating mode selection. ............................................................................................................ 14

5.2.5.

Set temperature regulation. .......................................................................................................... 14

5.2.6.

Minimum working temperature and restart temperature. .............................................................. 14

5.2.7.

Automatic start settings................................................................................................................. 14

5.2.8.

Automatic standby settings. .......................................................................................................... 15

5.2.9.

Manual defrost. ........................................................................................................................... 15

5.2.10.

Key lock. ..................................................................................................................................... 15

5.2.11.

Sensor temperature display. ....................................................................................................... 15

5.2.12.

Manometer use. ................................................................................................................................... 16

5.3.

6. Control and safety devices. ...................................................................................................................... 16

Control devices ..................................................................................................................................... 16

6.1.

Ambient and pool temperature sensors. ....................................................................................... 16

6.1.1.

Flow sensor. .................................................................................................................................. 17

6.1.2.

Safety devices. ..................................................................................................................................... 17

6.2.

Compressor and plate heat exchanger temperature sensors. ..................................................... 17

6.2.1.

High pressure sensor. ................................................................................................................... 17

6.2.2.

Low pressure sensor. .................................................................................................................... 17

6.2.3.

7. Routine, scheduled and extraordinary maintenance. ............................................................................ 18

User controls. ....................................................................................................................................... 18

7.1.

Specialised technician controls. ........................................................................................................... 18

7.2.

E N G L I S H

Page 3-di/of 28

Winter protection. ................................................................................................................................. 18

7.3.

Spring commissioning. ......................................................................................................................... 18

7.4.

Troubleshooting. ................................................................................................................................... 19

7.5.

8. Spare parts. ................................................................................................................................................ 21

E N G L I S H

Page 4-di/of 28

1. General warnings and information for the addressee.

Warranty.

1.1.

1.1.1. General conditions.

i. In accordance with these provisions, the dealer guarantees that the Product under this warranty (“the

Product”) does not have any conformity defect upon delivery.

ii. The Product Warranty Period is two (2) years, effective upon delivery to the purchaser.

iii. In the event of Product conformity defects and the purchaser informs the dealer during the Warranty

period, the dealer must repair or replace the Product at his/her own expense and at the site deemed

most suitable, unless this is impossible or out of proportion.

iv. Should the Product be irreparable or irreplaceable, the purchase may request a proportionate price

reduction or, if the conformity defect is sufficiently important, the termination of the sales contract.

v. Parts replaced or repaired under this warranty do not extend the length of the original Product warranty

but are covered by their own warranty.

vi. To validate this warranty, the purchaser must provide proof of Product purchase and purchase date.

vii. Should the purchaser find conformity defects six months after delivery, the purchaser must prove the

origin and existence of the defect found.

viii. The Warranty Certificate does not restrict or compromise consumer rights provided by mandatory

national regulations.

1.1.2. Special conditions.

i. This warranty covers the products referred to in this manual.

ii. This Warranty Certificate in only applicable in EU member countries.

iii. To validate this warranty, the purchaser must strictly follow the instructions provided by the

Manufacturer in the documents that accompany the Product when applicable according to Product

range and model.

iv. Should a schedule be specified for the replacement, maintenance or cleaning of some Product parts or

components, the warranty is only considered valid if this schedule is correctly observed.

1.1.3. Restrictions.

i. This warranty is only applicable to consumer sales where a "consumer" is the person who purchases

the Product for purposes not pertinent to his/her profession.

ii. The warranty does not cover normal wear due to Product use. As for parts, components and/or

replaceable or consumable materials such as batteries, light bulbs, etc., that instructed in the

documentation that accompanies the Product shall be observed.

iii. The warranty does not cover the cases in which the Product:

a. was subject to incorrect treatment;

b. was subject to repairs, maintenance or tampering by unauthorised personnel;

c. was repaired and equipped with unoriginal parts.

Should the Product conformity defect be consequent to incorrect installation or commissioning

procedure, this warranty shall only be applicable when this installation or commissioning procedure is

included in the Product sales contract and performed by the dealer or under his/her authority.

Symbol key.

1.2.

Indicates hazardous situations and warnings. The manual parts marked by this symbol must be read with

the utmost care.

Indicates that work must not be performed on live electrical equipment. This work can begin after taking

safety measures.

Safety regulations for heated pools1.

1.3.

During normal swimming activities, 26÷30 [°C] water temperature is recommended. 38 [°C] water

temperature is only considered safe for adults in good health conditions. The utmost caution is

recommended for use by children.

Pool temperature must never exceed 40 [°C].

Do not drink alcoholic beverages before, after and while swimming. Alcohol consumption may cause

drowsiness, loss of consciousness and consequent drowning.

Swimming in pools with temperatures over 38 [°C] is not recommended for pregnant women. Excessively hot

water could damage the foetus, especially during the first trimester, causing deformities or brain damage.

Before entering the pool, always check water temperature with a precision thermometer. Temperature

regulated by the heat pump guarantees approximately ±2 [°C] precision.

People who suffer from diabetes, heart disease, circulatory or blood pressure problems should consult a

physician before entering heated pools.

If taking drugs that induce drowsiness (i.e.: tranquillizers, antihistamines or anticoagulants), avoid swimming

in heated pools.

1 Guidelines for safe recreational water environments - VOLUME 2 - SWIMMING POOLS AND SIMILAR

ENVIRONMENTS - WORLD HEALTH ORGANIZATION 2006.

E N G L I S H

Page 5-di/of 28

Prolonged immersion in hot water may cause hyperthermia2, while immersion in cold water may cause

hypothermia3, with symptoms such as: Dizziness, fainting, drowsiness, lethargy4. Consequences of

hyperthermia and hypothermia may be: unawareness of imminent danger, lack of heat or cold perception,

failure to recognise the need to exit the pool, physical inability to exit the pool, damages to foetus for

pregnant women, unconsciousness with consequent drowning risks.

Energy savings.

1.4.

The heat pump slowly heats pool water. For weekend use, keeping pool temperature at the desired value

even when not in use is recommended. If temperature is allowed to drastically reduce, several days may be

required to restore the desired temperature. In the event of prolonged pool disuse (more than one week),

turning off the heat pump or reducing the set temperature by several degrees is recommended to save

energy.

The difference between the ambient temperature and water temperature should never be over 15 [°C]. For

this reason, do not use the heat pump when the ambient temperature is under 15 [°C]. Please see

Paragraph 5.2.7.

For improved energy savings, using the automatic start and stop functions is recommended. Please see

Paragraph 5.2.8 and Paragraph 5.2.9.

Once the ideal water temperature is set, use the key lock function to prevent changes to the set temperature

and/or prevent other adjustments. Please see Paragraph 5.2.11.

Protect the pool from wind.

When the pool is not in use, cover it with a tarp to limit heat dispersion.

General information.

1.5.

SERIES BP heat pumps are devices accessible to the public and were designed to heat and cool water

intended for home pools.

SERIES BP heat pumps must not be used with other heating systems such as electric heaters.

This manual provides instructions for the installation and use of SERIES BP heat pumps. Carefully read

this manual before installation. Failure to observe the manual instructions may cause personal or property

damages or damage the heat pump.

Failure to observe the instructions in this manual immediately null and voids the warranty.

INTERHIVA is not liable for any damages due to improper heat pump use.

The manual must be kept integral and in good conditions. It must accompany the heat pump until it is

decommissioned.

In the event of malfunctions, consult the instruction manual and, if necessary, contact specialised

technicians.

Installation and maintenance must be performed by qualified technicians unless otherwise indicated in the

manual.

Initial system commissioning must only be performed by specialised technicians.

Working on the heat pump when connected to the electrical mains is strictly prohibited. Only begin work

after taking the safety measures.

The heat pump is not suited for people (even children) who suffer from physical, sensorial or mental

handicaps or people who do not have sufficient experience or training unless instructed on heat pump use

and assisted by a person in charge of their safety. Supervise children to ensure they do not play with the

device.

INTERHIVA continually strives to improve all types and models. We trust the user will understand

the technical modifications INTERHIVA reserves the right to make on the shape and fittings on SERIES

BP heat pumps.

Definitions5.

1.6.

Power cord: flexible cord, for power supply, attached to the device.

Tool: Screwdriver, coin or any other object that can be used to move a screw or similar fastening device.

Protection device: Device whose operations prevent hazardous situations in abnormal operating conditions.

Contact switch disconnection: Disconnection of both power conductors with a single contact opening

action.

Heat pump: device that absorbs heat at a given temperature and releases it at a higher temperature.

Heat exchanger: device specifically designed to transfer heat between two physically separate fluids.

Compressor: device specifically designed to increase fluid pressure.

Plate heat exchanger: heat exchanger where coolant is vaporised by heat absorption.

Pressure limiter device: mechanism that automatically responds to a set pressure, interrupting the

operations of the element that controls pressure.

2 Increase in body temperature over physiological limits, maximum limit 37 [°C].

3 Decrease in body temperature over physiological limits, minimum limit 35 [°C].

4 State of inactivity or lack of reactivity that nears unconsciousness.

5 Definitions in accordance with regulation CEI EN 60335.

E N G L I S H

Page 6-di/of 28

Device accessible to the public: device intended to be installed in homes or commercial buildings.

Installation manual: document intended for specialised technicians that illustrates how to commission and

maintain the heat pump.

User manual: document intended for the end user that illustrates how to use the heat pump.

Necessary clearance: minimum heat pump installation area.

2. Product presentation.

Product scope.

2.1.

SERIES BP heat pumps were designed to heat and cool water intended for home pools.

E N G L I S H

Page 7-di/of 28

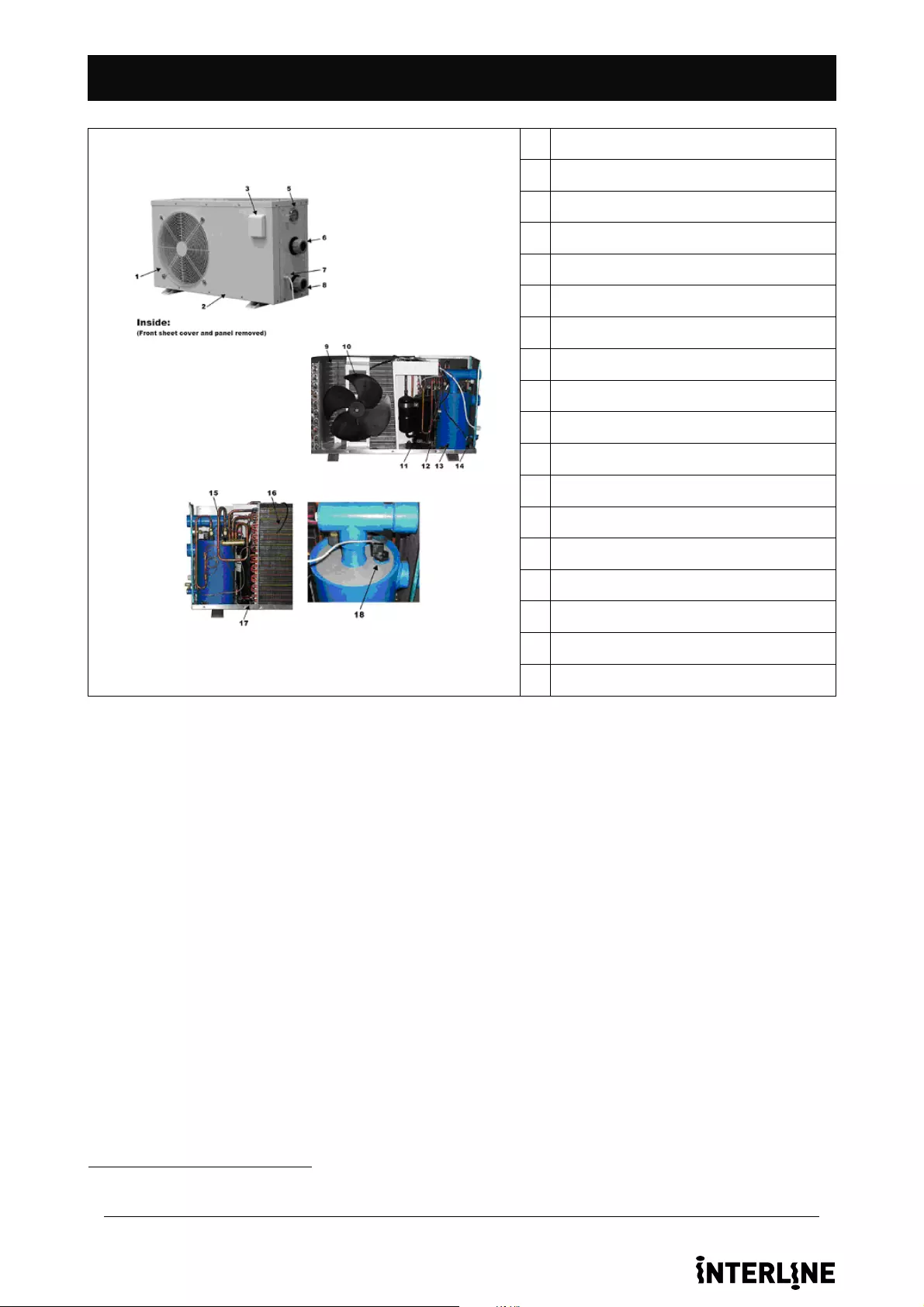

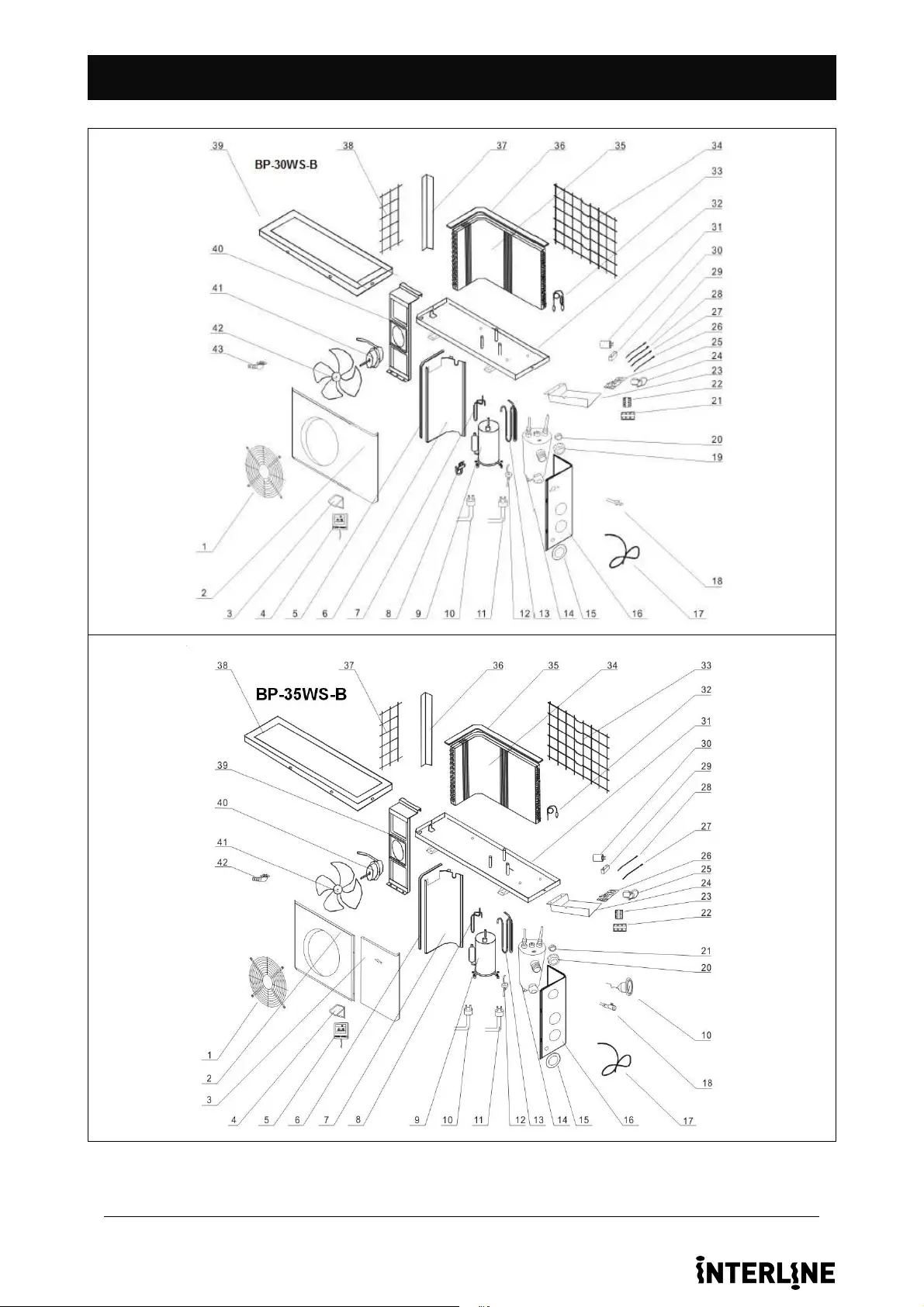

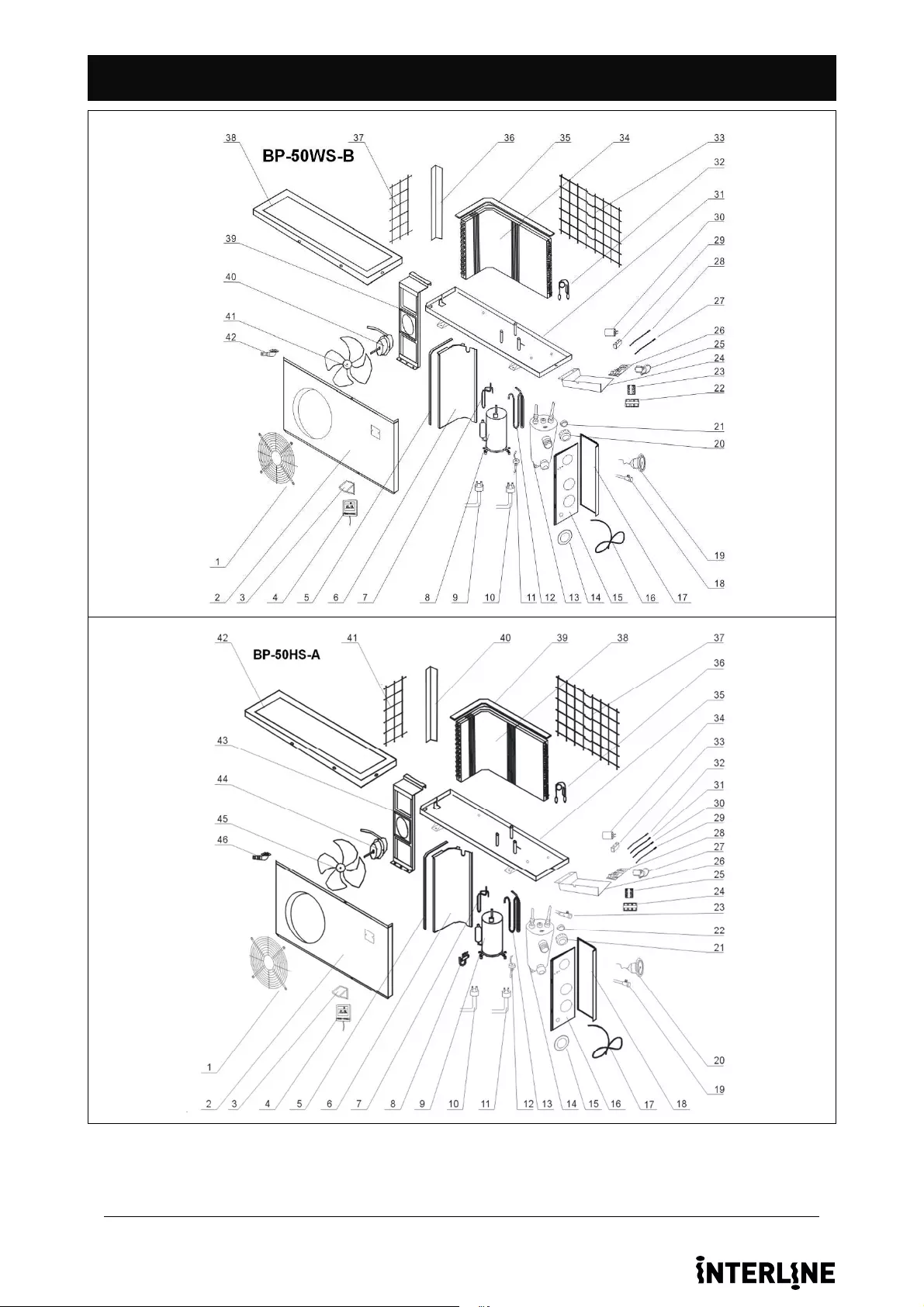

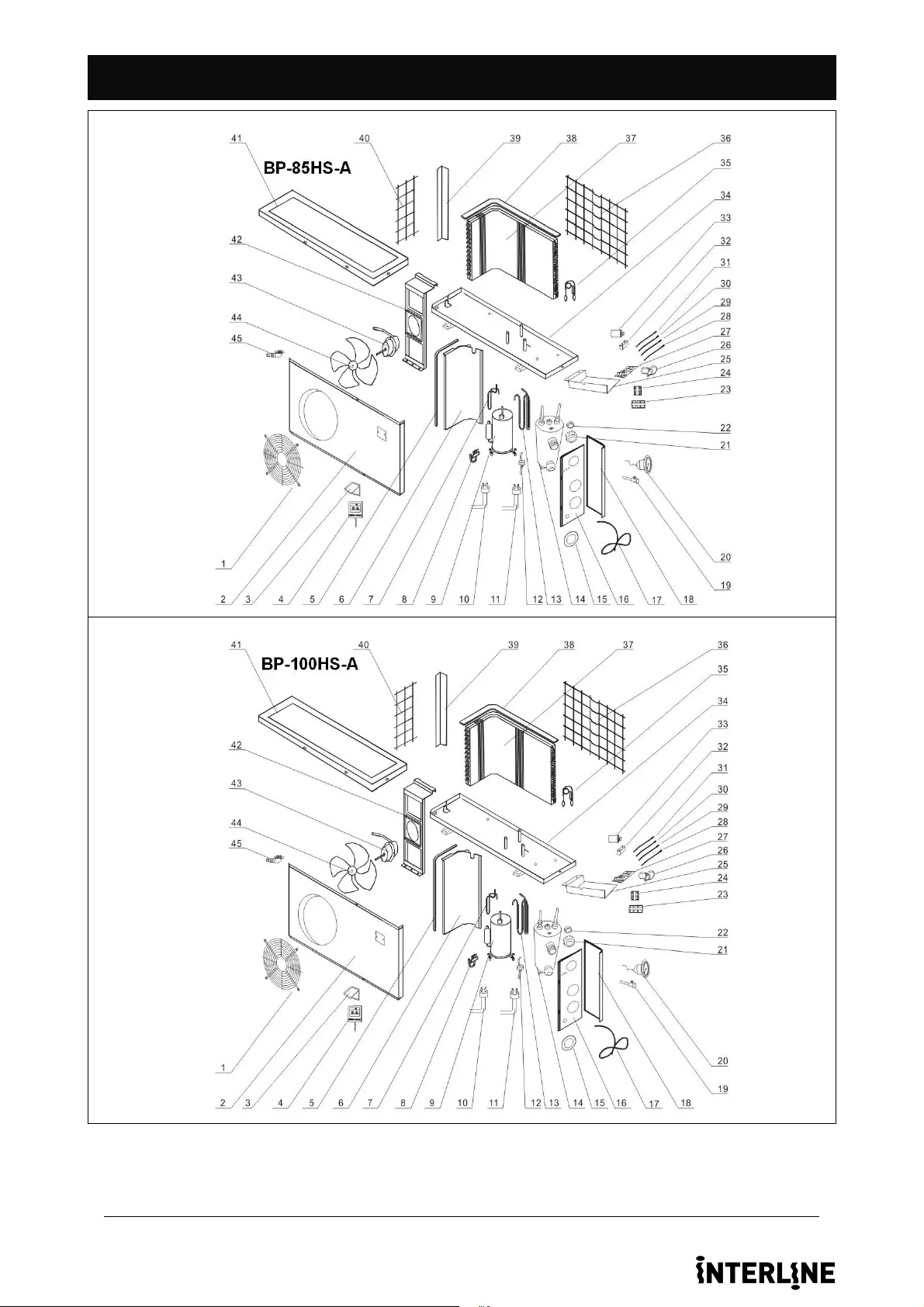

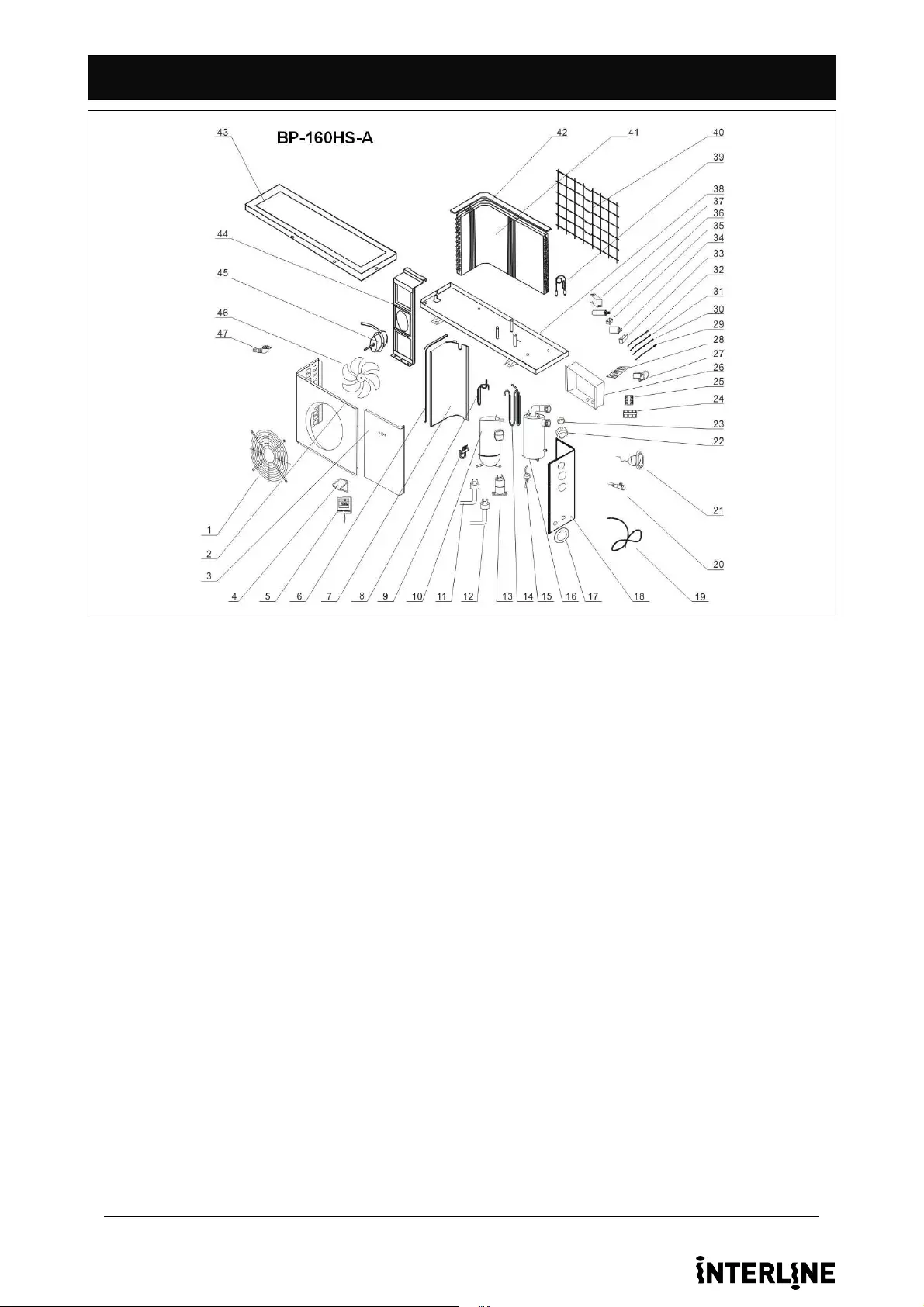

Composition.

2.2.

Figure 1: main heat pump parts.

1 Fan protection net

2 Body

3 Display

4 Refrigerant charge valve (inside for BP-35WS-B)

5 Pressure manometer

6 Water outlet

7 Power cord

8 Water inlet

9 Plate heat exchanger

10 Fan

11 Compressor

12 Pressure sensor

13 Heat exchanger

14 Water sensor

15 Four way valve6

16 Ambient sensor7

17 Plate heat exchanger temperature sensor8

18 Flow sensor

6 Not included in model BP-xxWS-B (xx=30, 35, 50).

7 Not included in model BP-xxWS-B (xx=30, 35, 50).

8 Not included in model BP-xxWS-B (xx=30, 35, 50).

E N G L I S H

Page 8-di/of 28

9 Variable according to ambient conditions.

10 Operating mode not included.

11 Variable according to ambient conditions.

12 Variable according to ambient conditions.

13 Single phase alternating current.

14 Operating mode not included.

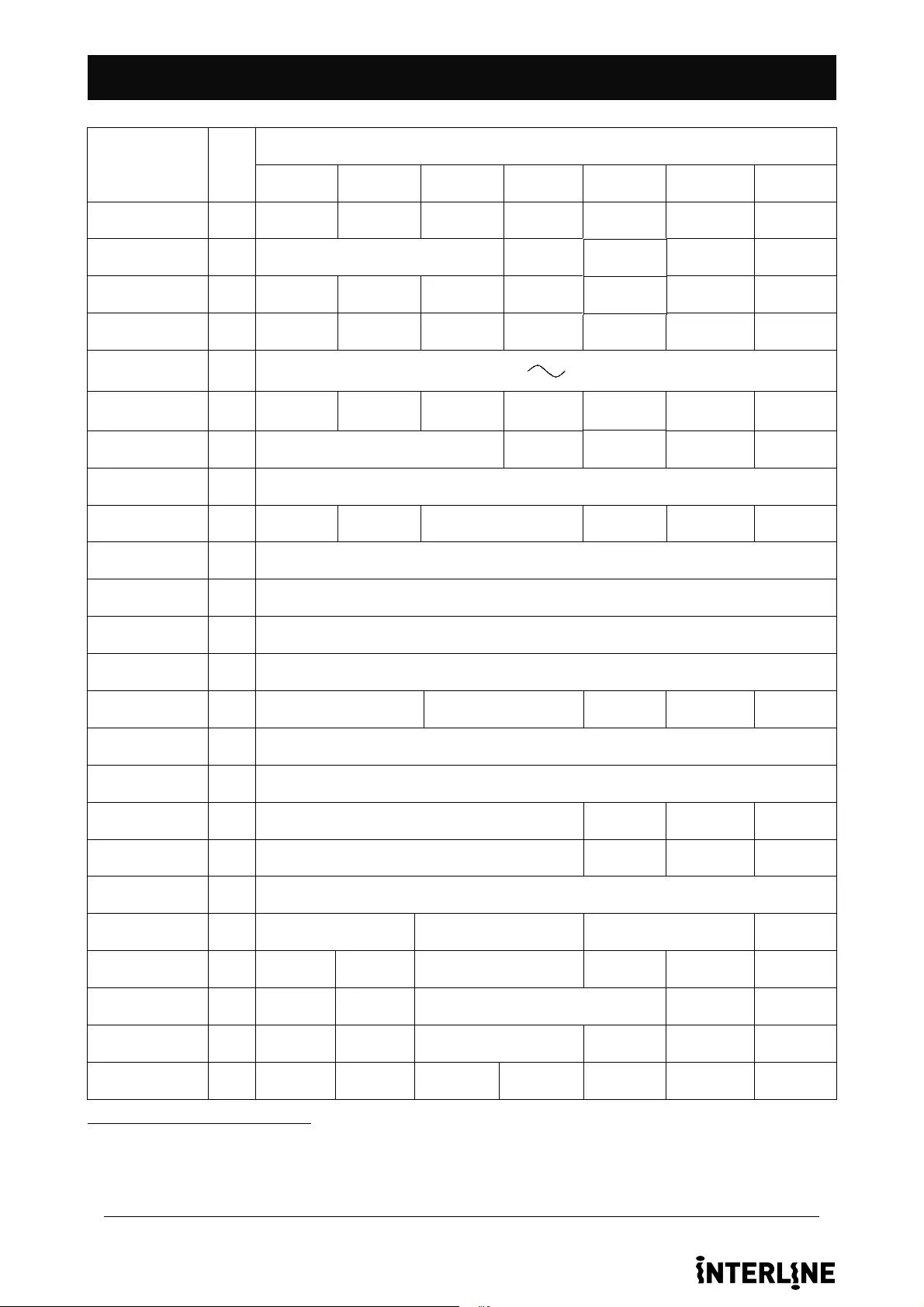

3. Technical specifications.

Unit of

measure

Model

BP-30WS-EB BP-35WS-EB BP-50WS-EB

BP-50HS-A BP-85HS-A BP-100HS-A BP-160HS-A

Thermal power

(heating)9 [kW]

3.1 4.3 6.1 18.1

Refrigerant power

(cooling) [kW] -10

11.4

Absorbed power11 [kW]

0.45 0.65 0.9 3.3

Absorbed current12 [A] 3.0

3.3 4.6 5.5

Power voltage13 [V]

[Hz]

220-240

50

COP

(Coefficient Of

Performance) [ ]

6.1 6.0 6.1 6.1

ERR (Energy Efficient

Ratio) [ ] -14

3.5

Refrigerant -

R32

Refrigerant gas quantity [kg]

0.28 0.3 1.15

Protection grade at

water input - IPX4

Number of compressors - 1

Compressor type - Rotativo

Heat exchanger - Titanio

Minimum water flow [m3/h]

3.5

Hydraulic connections [mm] 50

Number of fans - 1

Absorbed power by fan [W] 70 85 100 220

Fan RPM [RPM] 830 900 850 800

Fan air flow direction Orizzontale

Fan air flow [m3/h] 1200 1600 2000 3400

Noise [dB(A)]

<47 49 5052

54

57

Dimensions (L/D/H) [mm]

640x265x495 660x265x495

Net/gross weight [kg]

27/3030/34 38/42 46/5054/58 86/96

t CO2 [t]

0.19 0.21 0.29 0.29 0.44 0.51 0.78

6.18.9 11

45.9 7.2

1.1 1.71.95

4.8 7.4 8.8

6.1 6.0 6.0

3.6

3.5 3.7

0.42 0.65 0.75

5 6 6.5 8

845x285x540 900x305x615 1030x400x790

E N G L I S H

Page 9-di/of 28

4. Installation.

The heat pump must be installed and commissioned by specialised technicians and in keeping with

current national system regulations.

Installation must be conducted evaluating all the specific site factors: vicinity and height of walls, public

accessibility, etc.

Inspection.

4.1.

Upon receiving the heat pump, check packaging integrity. The machine should come with complete

manuals, for the user and for installation.

Handling.

4.2.

The unit is equipped with suitable protections to protect the heat pump for any damages during handling.

Avoid exerting pressure on the sides of the packaging.

Once the heat pump is unpacked, avoid exerting pressure on the body, plate heat exchanger and fan

protection net. See Figure 1.

Positioning.

4.3.

The heat pump must be positioned by specialised technicians and in keeping with current national system

regulations.

The heat pump must be carefully positioned considering the following aspects:

•Dimensions and origin of hydraulic tubes.

•Location of the power supply.

•Support and its location.

•Necessary clearance.

•Noise wave and vibration echo.

•Condensation discharge.

4.3.1. Support and its location.

The heat pump must be installed outdoors. It cannot be installed indoors and must be at least 3.5 [m]

from the pool surface (zone 215).

During normal operations, the heat pump plate heat exchanger produces condensation. The amount of

condensation produced varies according to ambient conditions. The higher the air humidity, the higher the

amount of condensation produced. The heat pump comes with a condensation drain. Make sure there are no

obstacles to condensation draining.

The heat pump must be positioned to avoid damages attributable to any water or condensation leaks. If

necessary, install suitable discharge outlets or collection containers.

The heat pump must be installed on a solid and level support (cement slab or prefabricated platform).

Avoid positioning the heat pump on instable ground. In this case, installing a suitably dimensioned support

slab or platform is recommended. The support surface must be slightly tilted to promote collected rain water

and condensation draining from the device base.

Support surface inclination must be a maximum of 2%.

Make sure the pump is not subject to rain water flows from nearby building roofs. Protruding roofs without

gutters could pour significant amounts of water and/or debris on the heat pump which could damage it. If

necessary, install gutters or discharge outlets to protect the heat pump.

If the heat pump is installed under the pool level, any water leaks could cause significant water leaks or

floods. INTERHIVA is not liable for any of said leaks, floods or consequent damages.

Make sure the heat pump is not within the range of action of any irrigation systems. If necessary, install

suitable protections.

15 See CEI 64-8/7 for pool zone classifications.

E N G L I S H

Page 10-di/of 28

4.3.2. Necessary clearance.

Minimum clearance required for heat pump installation is illustrated in the following figure.

Figure 2: Clearance required for correct installation.

Clearance guarantees accessibility during SERIES BP heat pump maintenance and operations.

Avoid hot air from circulating between machine distribution and suction. See Figure 2. For this purpose,

avoid all situations in which there could be an obstacle to the free flow of air produced by the fan.

Specifically, pay careful attention to the direction of strong winds in the heat pump installation area. Strictly

avoid installing the heat pump where the direction of strong wind is contrary to heat pump flow.

4.3.3. Noise wave echo.

SERIES BP heat pumps were designed with special attention to noise and vibrations. Retail or accessory

shock absorbers can be used to diminish vibrations and noise.

Figure 3: Shock absorber supports.

To diminish noise wave echoes, avoid positioning the pump in the immediate vicinity of vertical walls.

Disposal.

4.4.

4.4.4. General instructions.

Collecting recyclable material, both those used for packaging (cardboard, nylon, etc.) and those replaced

during routine and extraordinary maintenance is recommended.

Suitable collection of waste material for recycling, processing and environmentally compatible disposal

contributes in avoiding possible negative effects on the environment and health and promote the reuse

and/or recycling of device materials.

Illicit product disposal by the user may be punishable by current national laws.

4.4.5. Heat pump decommissioning.

When the unit reaches the end of its working life and must be removed and/or replaced, follow the

instructions below:

•Refrigerant gas must be collected by specialised technicians and sent to collection centres.

•Compressor lubricant oil must be collected by specialised technicians and sent to collection centres.

•The body and various parts, if unusable, should be dismantled and divided according to their material

type (for example, copper, aluminium, plastic, etc.) and must be sent to collection centres.

4.4.6. Electric/electronic waste disposal.

In keeping “Implementation of Directives 2002/95/CE, 2002/96/CE and 2003/108/CE” on the

reduction of the use of hazardous substances in electric and electronic material as well as waste

disposal. The barred bin symbol on the equipment or packaging indicates that the product must be

separated from other waste at the end of its working life. Therefore, the user must take equipment to

electronic and electro-technical waste collection centres at the end of its working life or return it to

the dealer when purchasing similar new equipment, on a one to one basis. Suitable collection of

decommissioned equipment for recycling, processing and environmentally compatible disposal

contributes in avoiding possible negative effects on the environment and health and promote the

reuse and/or recycling of device materials. Illicit product disposal by the user may be punishable by

current national laws.

E N G L I S H

Page 11-di/of 28

Hydraulic connections.

4.5.

4.5.7. Warnings.

The heat pump hydraulic connections must be performed by specialised technicians and in keeping with

current national system regulations.

During hydraulic connections, avoid using free flames near or within the heat pump.

The following retail components are recommended for hydraulic connections:

•Cut-off valves upstream and downstream from the heat pump to facilitate maintenance and/or heat pump

bypass from the pool hydraulic system.

•Hydraulic circuit charge and drain valve for the heat pump.

•Hydraulic circuit bypass valve, see Figure 6.

•Mechanical filter upstream from the heat pump, usually a sand filter.

•Non-return valve, installed between the pool and the heat pump output fitting, to prevent water reflux.

Tubes that have the same diameter of the heat pump inlet and outlet are recommended for upstream and

downstream heat pump connections.

During periods of heat pump disuse, for example, during the winter, drain water from the heat pump

circuit and heat pump.

Chemical dosing devices, when applicable, must be installed downstream from the heat pump and non-

return valve. This prevent chemically saturated water reflux which could damage the heat pump.

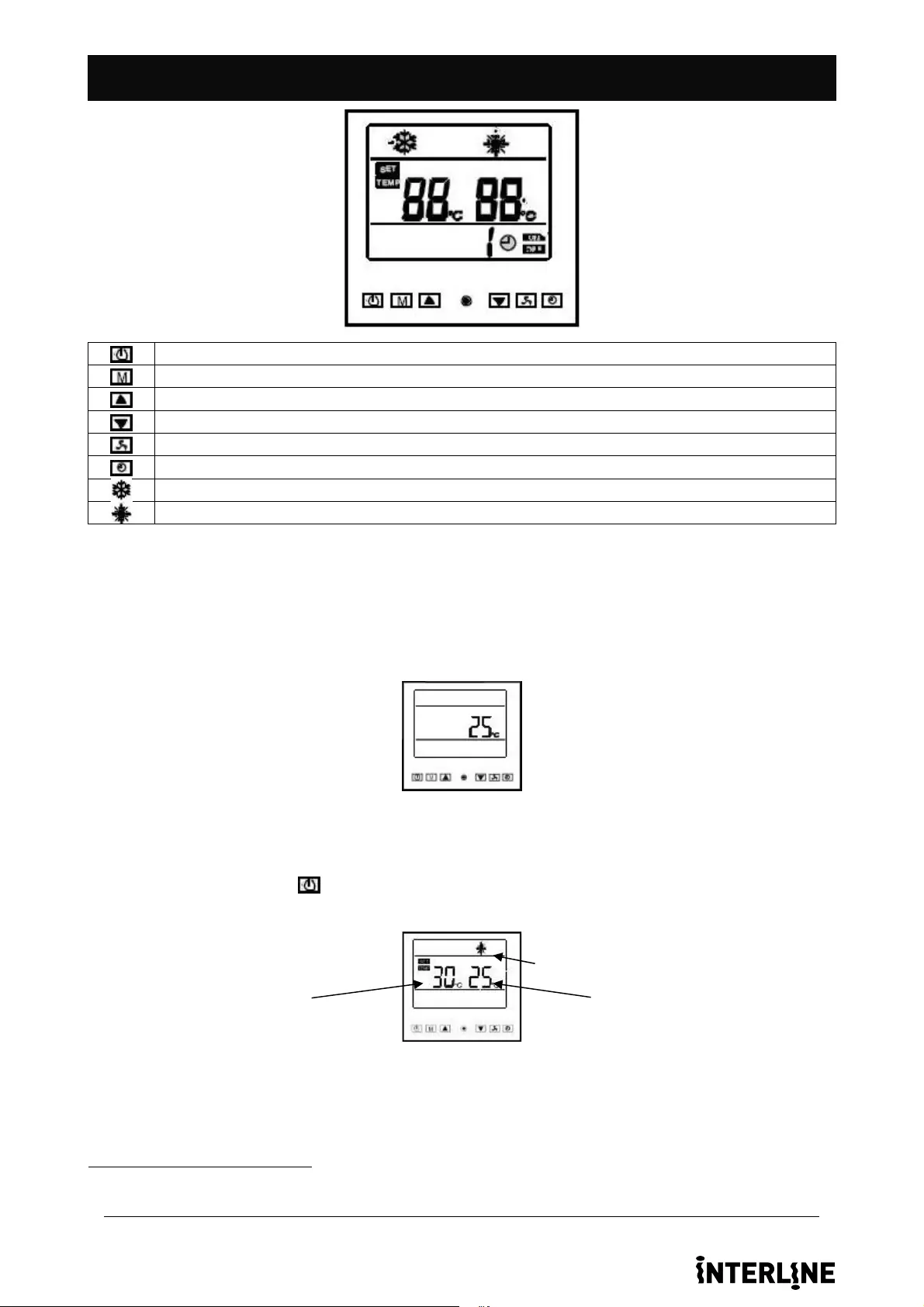

4.5.8. Installation hydraulic layout.

The hydraulic circuit where the heat pump is installed must be created observing the following general

layout.

Figure 4: General hydraulic circuit layout.

The pump must be hydraulically connected with PVC tubes with 50 [mm] external diameters. Tubes must be

inserted in the fittings for about 1÷2 [cm] and secured with the supplied fast connections.

Figure 5: Hydraulic connections

The hydraulic circuit is usually created as illustrated in the following figure.

Swimming

pool

Pump

Filter

Heat pump

Non return

valve

Chemical

regulator

Output fitting

Input fitting

E N G L I S H

Page 12-di/of 28

Figure 6: Typical hydraulic circuit part layout.

Minimum heat pump water input flow must not be under the value required for the model in question. See

Paragraph 3. For system layouts such as that in Figure 6, water flow can be regulated using the bypass

valve. Electrical connections.

4.6.

The heat pump electrical connections must be performed by specialised technicians and in keeping with

current national system regulations.

Working on live electrical equipment is prohibited. Before starting work, make sure the heat pump is

disconnected from the electrical mains.

Modifying electrical connections inside the heat pump without INTERHIVA authorisation is strictly

prohibited.

Power voltage must not vary more than 10 % from the nominal value. It must be within the 207÷253 [V]

interval. If power voltage is subject to frequent variations, contact specialised technicians for suitable

protection devices.

Install a protection device, circuit breaker with delayed type 16 [A] fuse, upstream from the heat pump. This

protection device must only service the heat pump. Furthermore, install a contact switch protection device,

circuit breaker, that has nominal operating differential current not over 30 [mA].

Figure 7: Protection device and/or contact switch.

The electrical mains connected to the heat pump must be grounded.

If a socket is installed for electrical mains connections, the latter must have a protection grade no lower than

IPX4 and must have a grounding terminal. The same applies for the mains which must be grounded.

Commissioning, preliminary checks.

4.7.

4.7.9. Commissioning, precautions.

Before starting the pump, make sure there is water in the pool, that the skimmer and suction fittings, when

installed, are submerged, that the cut-off valves do not prevent water flow from the pool to the heat pump

and vice versa and that the circulation pump is on.

4.7.10. First start-up, preliminary checks.

At first heat pump start-up, make sure that:

•the electrical mains were connected in keeping with current national system regulations, see Paragraph

4.6.

•there are no refrigerant fluid leaks checking the pressure on the manometer, see Paragraph 5.3, using

leak detection devices.

•Make sure hydraulic connections were correctly performed, see Paragraph 4.5.

•Make sure all body panels are in place and locked with screws.

•Make sure there are no impediments to free water flow from the pool to the heat pump and vice versa.

5. Operations and use.

Introduction.

5.1.

Please read the paragraph on energy savings, see Paragraph 1.5.

SERIES BP heat pumps are equipped with control boards which, thanks to a simple but functional interface,

allow heat pump programming to guarantee efficient service.

E N G L I S H

Page 13-di/of 28

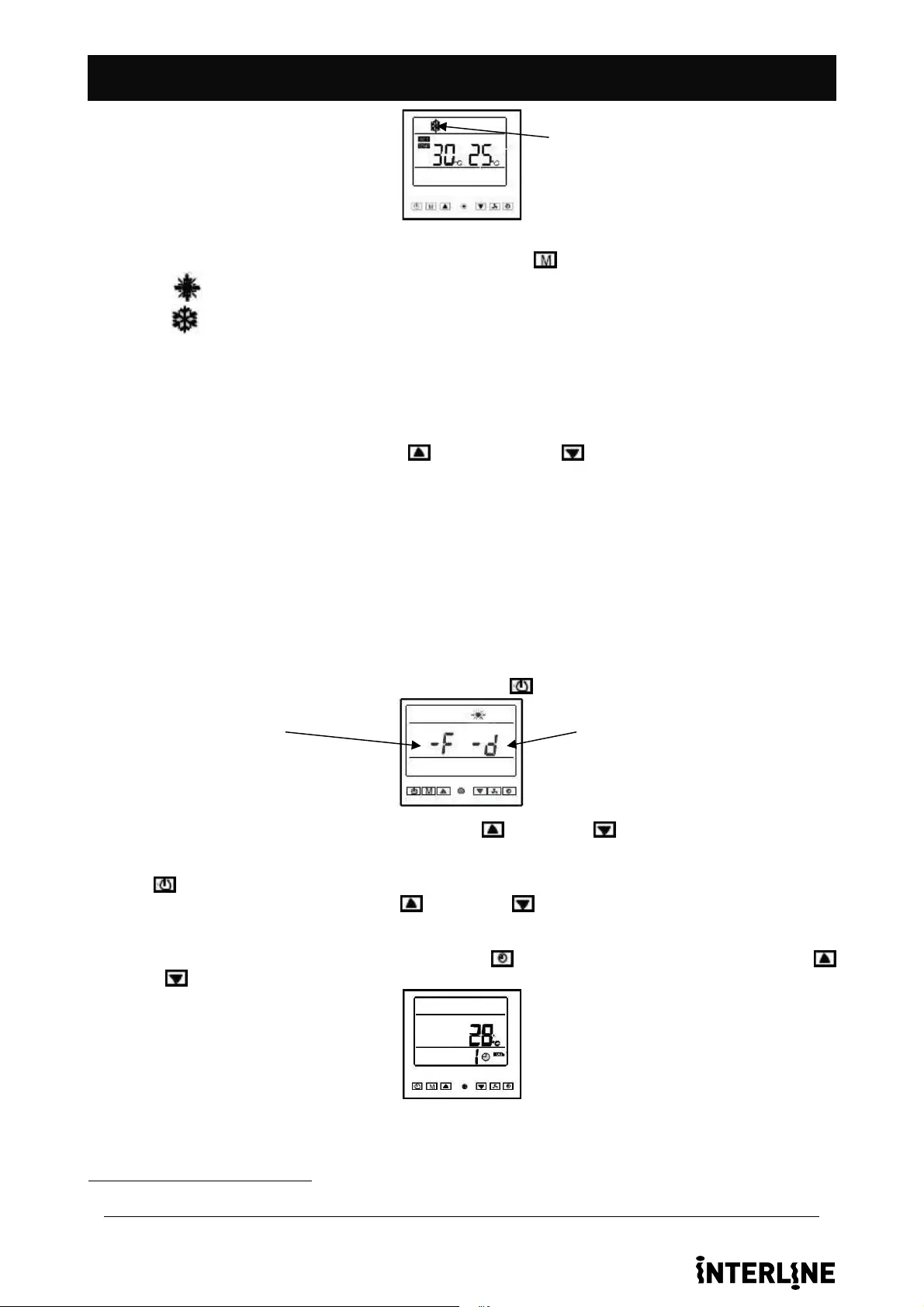

Figure 8: Heat pump panel.

Heat pump on/off button.

Operating mode selection button (heating/cooling

16

) or operating parameter programming access.

Up button.

Down button.

Multi-function button.

Timer or temperature control on/off button.

Heat pump operating mode indication: cooling

17

.

Heat pump operating mode indication: heating.

Table 2: control panel display symbol key.

Control panel use.

5.2.

The control panel displays all information required for the user, data and/or error messages. Please see

Paragraph 7.5.

5.2.1. Turning on the heat pump.

Use the protection device and/or contact switch to turn on the heat pump. Please see Paragraph 4.6.

5.2.2. Standby.

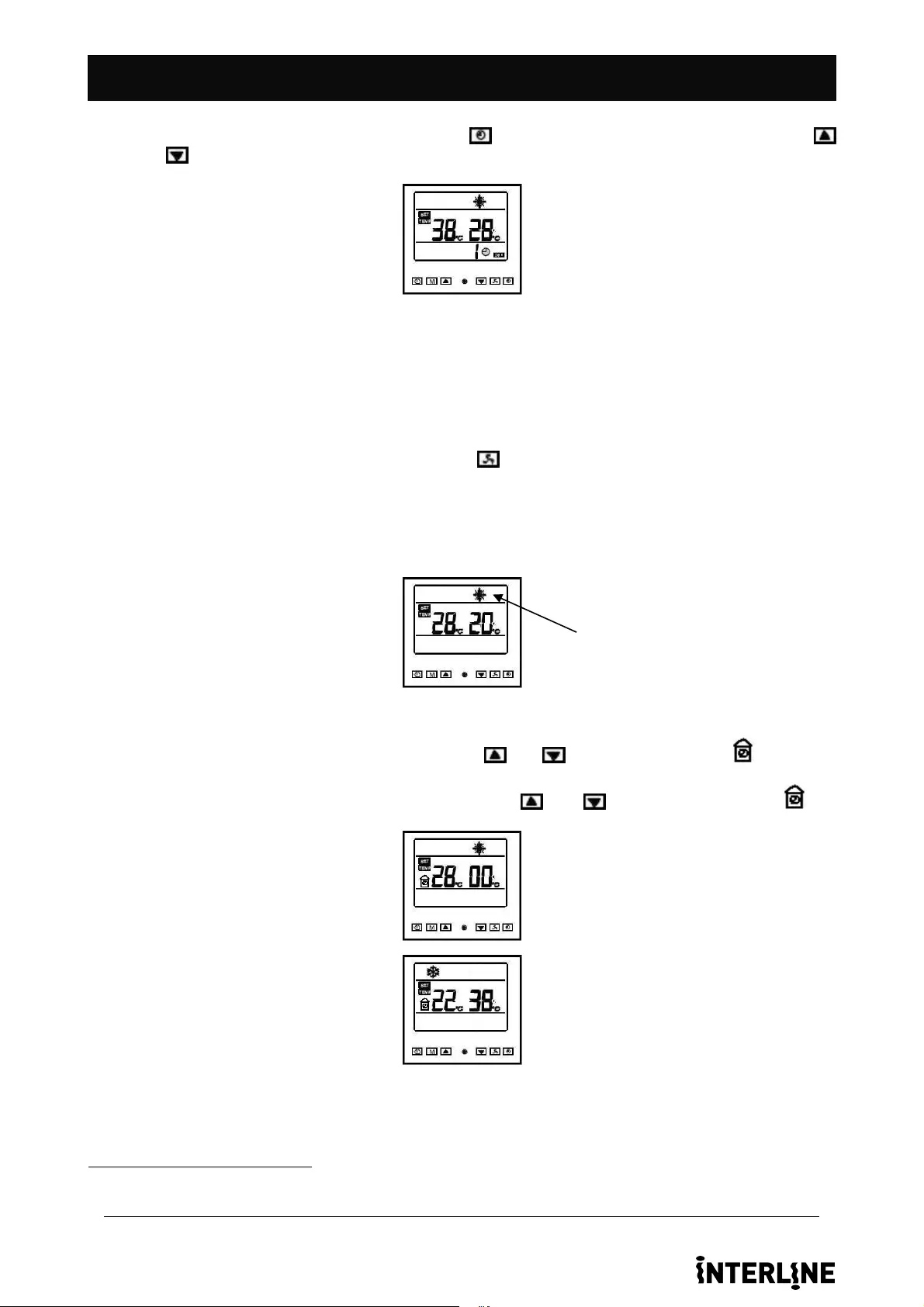

Water temperature is displayed when the heat pump is turned on. Please see Figure 9. The heat pump is in

standby conditions. It does not heat or cool pool water.

Figure 9: Heat pump display in standby conditions.

5.2.3. Turning off the heat pump.

Use the protection device and/or contact switch to turn off the heat pump. Please see Paragraph 4.6.

Make sure the heat pump is in standby before turning it off.

5.2.4. Starting the heat pump.

To start the heat pump, press . The heat pump starts within 3 minutes. The last selected operating mode

(heating or cooling18), see Figure 10, Figure 11, the last temperature set and the current pool water

temperature (heating or cooling) is immediately displayed.

Figure 10: Heat pump display when turned on, heating mode.

16 The BP-xxWS-B (xx=30, 35, 50) model has only one operating mode: heating.

17 Operating mode not included in model BP-xxWS-B (xx=30, 35, 50).

18 Operating mode not included in model BP-xxWS-B (xx=30, 35, 50).

Heating mode

Current pool water temperature

Set temperature

E N G L I S H

Page 14-di/of 28

Figure 11: Heat pump display when turned on, cooling mode.

5.2.5. Operating mode selection19.

Start the heat pump, see Paragraph 5.2.4, press to select the operating mode:

•Heating, is displayed, see Figure 10.

•Cooling, is displayed, see Figure 11.

Whenever the operating mode changes, the set temperature is switched to the following default values:

•Heating mode, 25 [°C].

•Cooling mode, 30 [°C].

Thus, the set temperature must be regulated, see Paragraph 5.2.6, whenever the operating mode changes.

5.2.6. Set temperature regulation.

Before regulating the set temperature, carefully read the instructions in Paragraph 1.4.

Set temperature can be regulated by pressing , to increase it and , to decrease it. Set temperature can

be selected in the interval 5÷45 [°C].

Parameter programming, upon heat pump assembly, guarantees that the difference between pool water

temperature and set temperature is never over 2 [°C] as illustrated by the following examples:

•Heating mode, set temperature 30 [°C], pool water temperature is never under 28 [°C].

•Cooling mode, set temperature 15 [°C], pool water temperature is never over 18 [°C].

5.2.7. Minimum working temperature and restart temperature20.

Once the pump is started, see Paragraph 5.2.4. if the ambient temperature is lower than the minimum

working temperature, the heat pump stops, displaying error message “EE C”, and only restarts if the ambient

temperature exceeds the restart temperature. When the pump is constructed, the minimum working

temperature and restart temperature are a –15 [°C] and –13 [°C] respectively, minimum admissible values.

The minimum working temperature must be at least 2 [°C] lower than the restart temperature.

Proceed as follows to set minimum working temperature:

•When the pump is in standby, see Paragraph 5.2.2, press and hold down for 3 seconds.

Figure 12: Minimum working temperature and restart temperature.

•Regulate minimum working temperature with keys (increase), (decrease). Minimum working

temperature cannot be under –15 [°C] (-F), the regulation interval for minimum working temperature is -

15÷97 [°C].

•Press , to regulate the restart temperature.

•Regulate restart temperature with keys (increase), (decrease). Minimum restart temperature

cannot be under -13 [°C] (-d), the regulation interval for restart temperature is -13÷99 [°C].

5.2.8. Automatic start settings.

When the pump is in standby, see Paragraph 5.2.2, press to turn on the automatic start mode. Press

(increase), (decrease) to select when the heat pump should automatically start (1÷24 hours).

Figure 13: Automatic start settings.

Automatic start can only be set when the pump is in standby, see Paragraph 5.2.4.

19 Not included in model BP-xxWS-B (xx=30, 35, 50).

20 Not included in model BP-xxWS-B (xx=30, 35, 50).

Cooling mode

Restart temperature Minimum working

temperature

E N G L I S H

Page 15-di/of 28

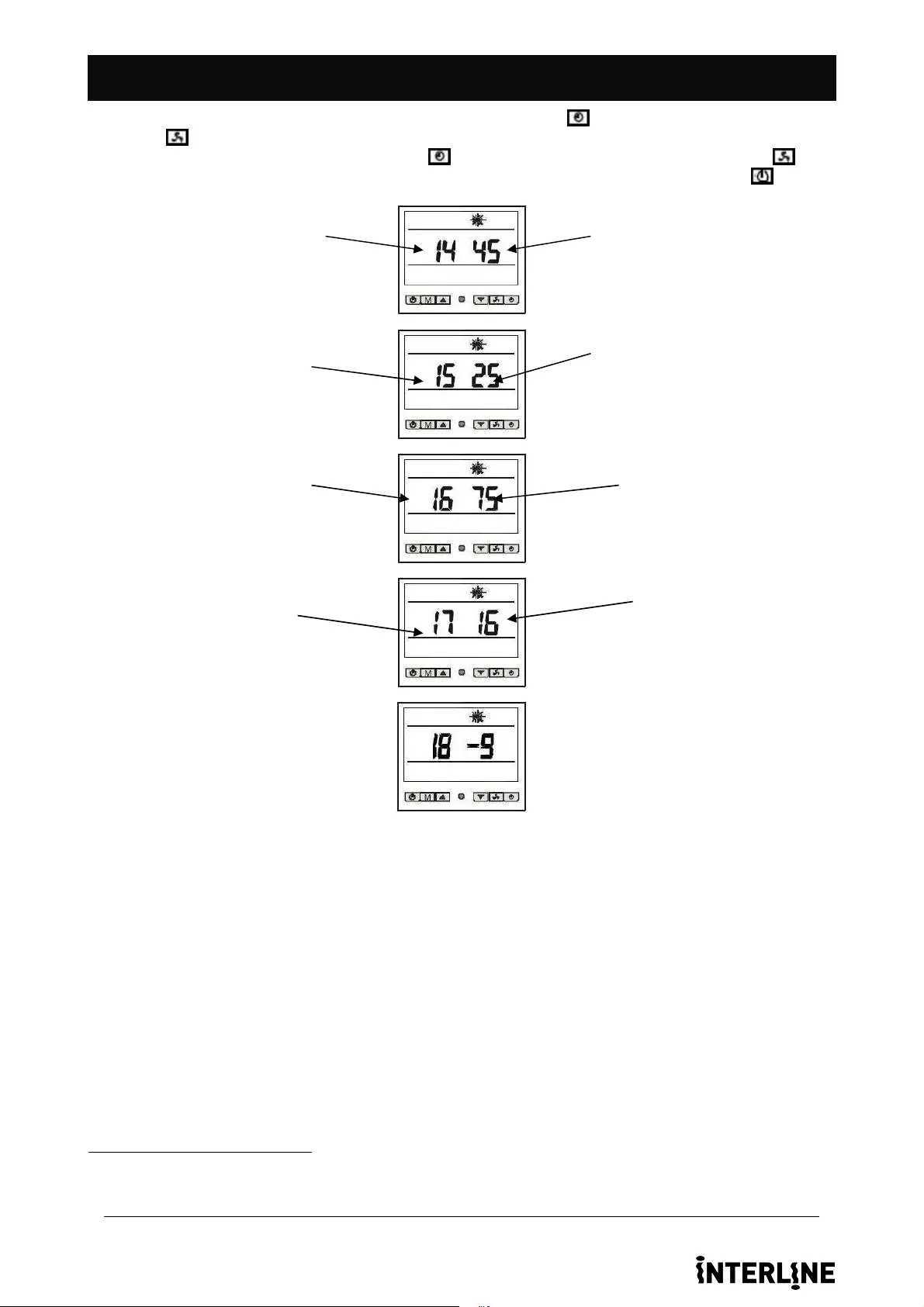

5.2.9. Automatic standby settings.

When the pump is running, see Paragraph 5.2.4, press to turn on the automatic standby mode. Press

(increase), (decrease) to select when the heat pump should automatically return to standby mode (1÷24

hours), see Paragraph 5.2.2.

Figure 14: Automatic standby settings.

Automatic standby can only be set when the pump is running, see Paragraph 5.2.4.

5.2.10. Manual defrost21.

Frost may form on the plate heat exchanger during normal operations in heating mode, see Figure 1. Frost

on the plate heat exchanger reduces heat pump performance. Frost is formed during heating mode because

the heat pump cools surrounding ambient air to heat water. SERIES BP pumps are equipped with a

temperature sensor that detects frost on the plate heat exchanger and starts automatic defrost. However, if

this is insufficient, manual defrost can be started.

Manual defrost can only be started when the heat pump is running in heating mode.

When the pump is running, see Paragraph 5.2.4, press and hold down for 5 seconds to turn on manual

defrost. Manual defrost lasts several minutes. At the end of the manual defrost cycle, the heat pump

automatically starts.

When defrosting, refrigerant fluid pressure is increased to make refrigerant fluid hotter so that it heats the

plate heat exchanger during circulation to defrost.

When defrosting, refrigerant fluid pressure significantly increases. For further information, see Paragraph 5.3.

The heating mode icon blinks during defrost. See Figure 15.

Figure 15: Manual defrost.

5.2.11. Key lock.

Keys can be locked to prevent accidental regulations.

To lock keys, press and simultaneously hold down keys and for 5 seconds. Symbol will appear

on the display. See Figure 16 and Figure 17.

To unlock keys, press and simultaneously hold down keys and for 5 seconds. Symbol will

disappear on the display.

Figure 16: Key lock, heating mode.

Figure 17: Key lock, cooling mode.

5.2.12. Sensor temperature display.

SERIES BP heat pumps are equipped with 4 temperature sensors that continuously read pool water,

ambient22, compressor and plate heat exchanger temperatures23.

21 Operating mode not included in model BP-xxWS-B (xx=30, 35, 50).

22 Not included in model BP-xxWS-B (xx=30, 35, 50) where the sensor is not installed.

23 Not included in model BP-xxWS-B (xx=30, 35, 50) where the sensor is not installed.

blinks

E N G L I S H

Page 16-di/of 28

The temperature read by each sensor can be displayed by pressing (for model BP-xxWS-B (xx=30, 35,

50), press ) and hold down for 3 seconds with the pump is running, see Paragraph 5.2.4. To display

temperatures read by the various sensors, press (for model BP-xxWS-B (xx=30, 35, 50), press ). The

temperature read by the sensor is displayed for 10 seconds, if no other key is pressed, or press to return

usual information to the display, see Figure 10 and Figure 11.

Figure 18: Pool water temperature sensor.

Figure 19: Ambient temperature sensor24.

Figure 20: Compressor temperature sensor.

Figure 21: Condenser temperature sensor.

Figure 22: Sensor not used25.

Manometer use26.

5.3.

SERIES BP heat pumps are equipped with a manometer that displays refrigerant fluid pressure in the high

pressure circuit.

Typical pressure values are the following:

•Heat pump off or in standby, the indicated pressure is between 14÷16 [bar] ([kg/cm2]);

•Heat pump running, the indicated pressure is between 21÷35 [bar] ([kg/cm2]).

When defrosting, refrigerant fluid pressure is increased to make refrigerant fluid hotter so that it heats the

plate heat exchanger during circulation to defrost. Defrosting lasts several minutes.

6. Control and safety devices.

Control devices

6.1.

6.1.1. Ambient27 and pool temperature sensors.

SERIES BP control pumps are equipped with sensors that continuously check ambient and pool water

temperatures. The sensors are located as illustrated in the following figures.

24 For model BP-xxWS-B (xx=30, 35, 50), parameter 15 indicates the compressor temperature sensor.

25 Not used for SERIES BP heat pump control.

26 Not included in model BP-xxWS-B (xx=30).

27 Not included in model BP-xxWS-B (xx=30, 35, 50).

Temperature read

Temperature read

Temperature read

Temperature read

Pool water temperature

sensor number

Condenser temperature

sensor number

Compressor temperature

sensor number

Ambient temperature sensor

number

E N G L I S H

Page 17-di/of 28

Figure 23: Ambient temperature sensor. Figure 24: Pool water temperature sensor.

6.1.2. Flow sensor.

SERIES BP control pumps are equipped with a flow sensor that continuously reads water flow. The sensor is

located as illustrated in the following figure.

Figure 25: Flow sensor position.

Safety devices.

6.2.

6.2.3. Compressor and plate heat exchanger temperature sensors28.

SERIES BP heat pumps are equipped with 2 temperature sensors that continuously read compressor and

plate heat exchanger temperatures. The sensors are located as illustrated in the following figures.

Figure 26: Plate heat exchanger temperature sensor. Figure 27: Compressor temperature sensor.

6.2.4. High pressure sensor.

The high pressure sensor stops the compressor when supply pressure, in the refrigerant circuit high

pressure section, exceeds the calibration value.

The high pressure sensor signal is not considered during either manual or automatic defrost. For further

information see Paragraph 5.2.10 and Paragraph 5.3.

Trigger pressure is 4.2 [bar]. After a high pressure alarm, see Paragraph 7.5, the heat pump must be

manually restarted, see Paragraph 5.2.4.

6.2.5. Low pressure sensor.

The low pressure sensor stops the compressor when suction pressure in the high pressure section is under

the calibration value.

Trigger pressure is 0.05 [bar]. After a low pressure alarm, the heat pump must be manually restarted, see

Paragraph 5.2.4.

Figure 28: High pressure sensor. Figure 29: Low pressure sensor.

28 Not necessary in model BP-xxWS-B (xx=30, 35, 50) since there is no plate heat exchanger defrost process.

E N G L I S H

Page 18-di/of 28

7. Routine, scheduled and extraordinary maintenance.

Periodic controls are required to keep SERIES BP heat pumps in good working order and to guarantee

the foreseen performance and safety levels. Some controls can be performed by the user while specialised

technicians are required for others.

During normal operations, the heat pump plate heat exchanger produces condensation. The amount of

condensation produced varies according to ambient conditions. The higher the air humidity, the higher the

amount of condensation produced. The lower heat pump panel acts as a condensation collection tray. Keep

the drain hole clean.

User controls.

7.1.

SERIES BP heat pump users must periodically make sure that:

•Dirt is not accumulated near the heat pump (leaves, paper, etc.). Performing this control weekly is

recommended. Use caution when nearing the plate heat exchanger blade since rather sharp.

•There are no leaks in the hydraulic circuit. Conduct this control monthly.

•Electrical mains wires and connections are integral, Performing this control monthly is recommended.

•The correct chemical balance in the pool water is guaranteed in order to guarantee hygienic accessibility

conditions and long heat pump life. Conducting this control daily with specific retail kits is recommended.

•The pressure values indicated on the manometer are correct. See Paragraph 5.3.

•Make sure the condensation drain hole is open.

Specialised technician controls.

7.2.

The following controls must be conducted by a specialised technician at least once a year to guarantee safe

and efficient SERIES BP heat pump operations:

•Electrical mains wire and connection integrity.

•Hydraulic system integrity.

•Inspect and clean the plate heat exchanger coil.

•Check correct heat pump operations, start, see Paragraph 5.2.4.

•Check usual pressure values indicated by the manometer, see Paragraph 5.3.

•Make sure there are no oil leaks from the compressor.

Winter protection.

7.3.

The following instructions must be observed to protect SERIES BP heat pumps for the winter:

•Disconnect the electrical mains using the protection device and/or contact switch, see Paragraph 5.2.3.

•Drain the heat pump hydraulic system using the cut-off valve, see Paragraph 4.5.

•Protect the plate heat exchanger and fan from dirt accumulation. Do not wrap the heat pump with plastic

or other material that can hold heat and/or humidity inside the device.

Spring commissioning.

7.4.

The following instructions must be observed for SERIES BP heat pump spring commissioning.

•Remove any protections used for winter protection, see Paragraph 7.3.

•Fill the heat pump hydraulic system using the cut-off valve, see Paragraph 4.5.

•Check the water chemical composition, see Paragraph 7.1, act accordingly if necessary.

•Restore the electrical mains using the protection device and/or contact switch, see Paragraph 4.6.

E N G L I S H

Page 19-di/of 28

Troubleshooting.

7.5.

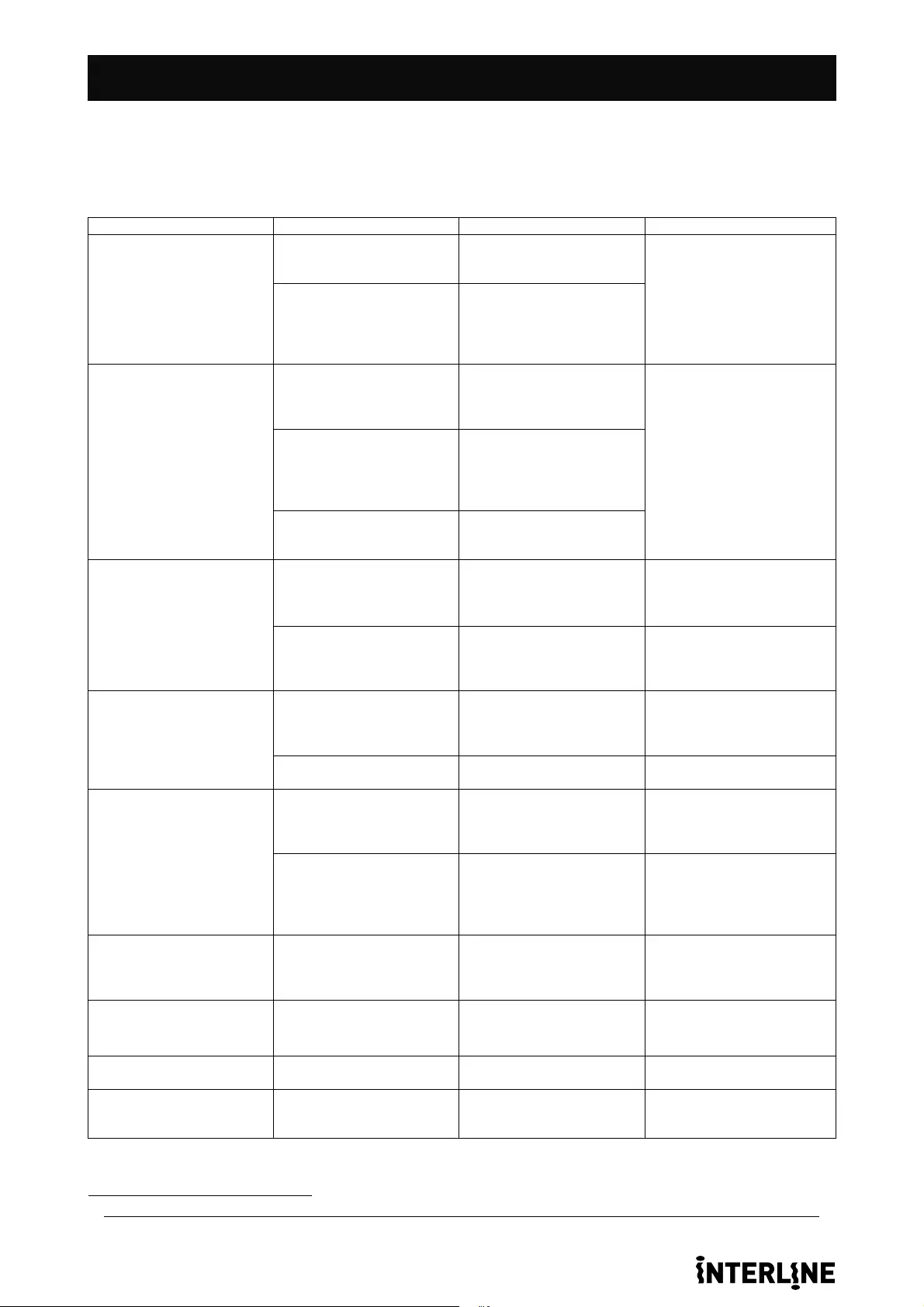

The following table can be used to solve main heat pump problems. When a message error is displayed, the

following is required to restore operations:

•turn off the heat pump, see Paragraph 5.2.3;

•turn on the heat pump, see Paragraph 5.2.1;

•start the heat pump, see Paragraph 5.2.4.

Problem

Possible cause

1

st

solution

2

nd

solution

The heat pump does not

turn on, see Paragraph

5.2.1.

The instructions in

Paragraph 5.2.1 were not

followed.

Follow the instructions in

Paragraph 5.2.1.

The mains connection line

protection device fuse is

burned out or the contact

switch triggered, see

Paragraph 4.6.

Reset the switch and/or

replace the fuse.

The heat pump does not

start, see Paragraph 5.2.6.

The 3 minutes required for

pump start have not

elapsed. See Paragraph

5.2.4.

Wait until the 3 minutes

required for pump start

have elapsed. See

Paragraph 5.2.4.

Pool temperature is greater

than or equal to set

temperature. See

Paragraph 5.2.6.

The pump will start when

the pool temperature is

lower than the set

temperature. See

Paragraph 5.2.6.

The pump operating mode

is not the required mode.

See Paragraph 5.2.5.

Set the required operating

mode. See Paragraph

5.2.5.

The heat pump is running

but the water is not heating.

The heat pump was just

installed.

24÷48 hours may be

required to reach the set

temperature. See

Paragraph 1.5.

Contact specialised

technicians.

Pool water has significantly

cooled since the last heat

pump use.

24÷36 hours may be

required to reach the set

temperature. See

Paragraph 1.5.

Contact specialised

technicians.

There is frost on the plate

heat exchanger.

Too low ambient

temperature and/or a

significant amount of

humidity in the air.

Start manual defrost. See

Paragraph 5.2.10.

Pressure refrigerant drop

down. Contact specialised

technicians.

Water leaks from the heat

pump.

Probable accumulation of

condensation. See

Paragraph 4.3.

Put the heat pump in

standby, see Paragraph

5.2.2, if the leak stops, this

is normal condensation.

Possible water leak from

the water exchanger or from

hydraulic unit connection

devices. See Figure 1

and/or Figure 5.

Tighten the fastening nut,

for an example, see Figure

5.

Error message EE b is

displayed. Insufficient water flow

Increase water flow in the

hydraulic circuit that

supplies the heat pump.

After 2 minutes restart.

Contact specialised

technicians.

Error message EE c is

displayed.

Ambient temperature under

-15 [°C]. See Paragraph

5.2.7.

Wait until ambient

temperature rises to start

the heat pump.

Contact specialised

technicians.

Error message

EE d

is

displayed. Contact specialised

technicians.

The heat pump does not

work 29 and error message

EE 1 is displayed.

Contact specialised

technicians.

29 Compressor and fan off.

E N G L I S H

Page 20-di/of 28

Problem

Possible cause

1

st

solution

2

nd

solution

The heat pump does not

work 30 and error message

EE 2 is displayed.

Contact specialised

technicians.

The heat pump is running

work 31 and error message

EE 3 is displayed.

Contact specialised

technicians.

The heat pump is running

32

and error message EE 4 is

displayed.

Automatic defrost did not

run correctly.

Increase water flow at pump

inlet.

Contact specialised

technicians.

Error message

EE 5

is

displayed.33 Contact specialised

technicians.

The heat pump does not

work 34 and error message

EE 6 is displayed.

Compressor temperature

too high. Wait until compressor

temperature drops. Contact specialised

technicians.

The heat pump does not

work 35 and error message

EE 7 is displayed.

Contact specialised

technicians.

The heat pump does not

work and error message EE

8 is displayed.

Contact specialised

technicians.

Error message EE 9 is

displayed.

Pool temperature too high. Wait until pool temperature

drops. Contact specialised

technicians.

Ambient temperature too

high.

Wait until ambient

temperature drops.

Contact specialised

technicians.

Manual defrost started

without frost on plate heat

exchanger

Turn off, see Paragraph

5.2.3, turn on, see

Paragraph 5.2.1, and start

the pump, see Paragraph

5.2.4.

30 Compressor and fan off.

31 Compressor and fan on.

32 Compressor and fan on.

33 This error message is not used and should not be displayed.

34 Compressor and fan off.

35 Compressor and fan off.

E N G L I S H

Page 21-di/of 28

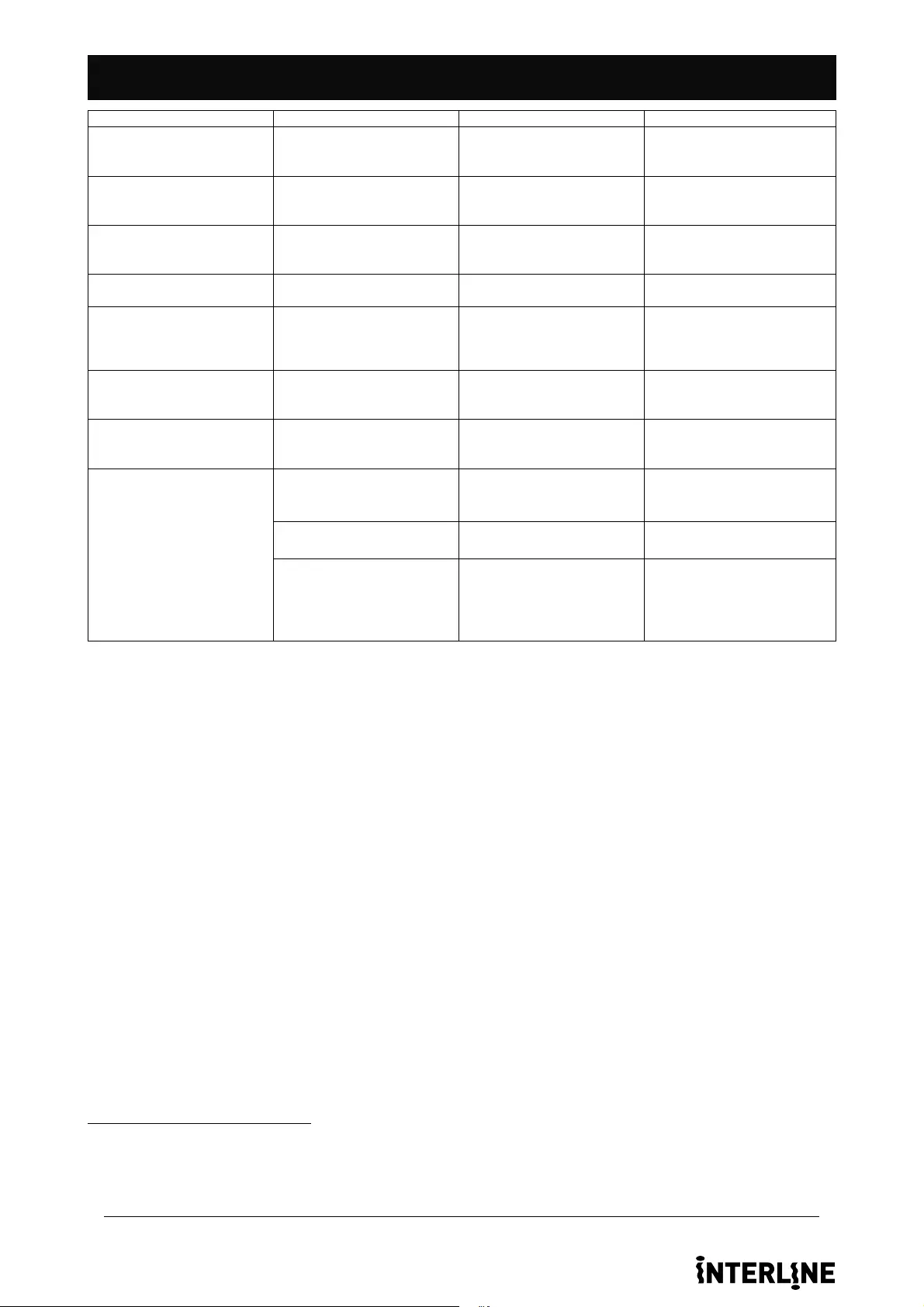

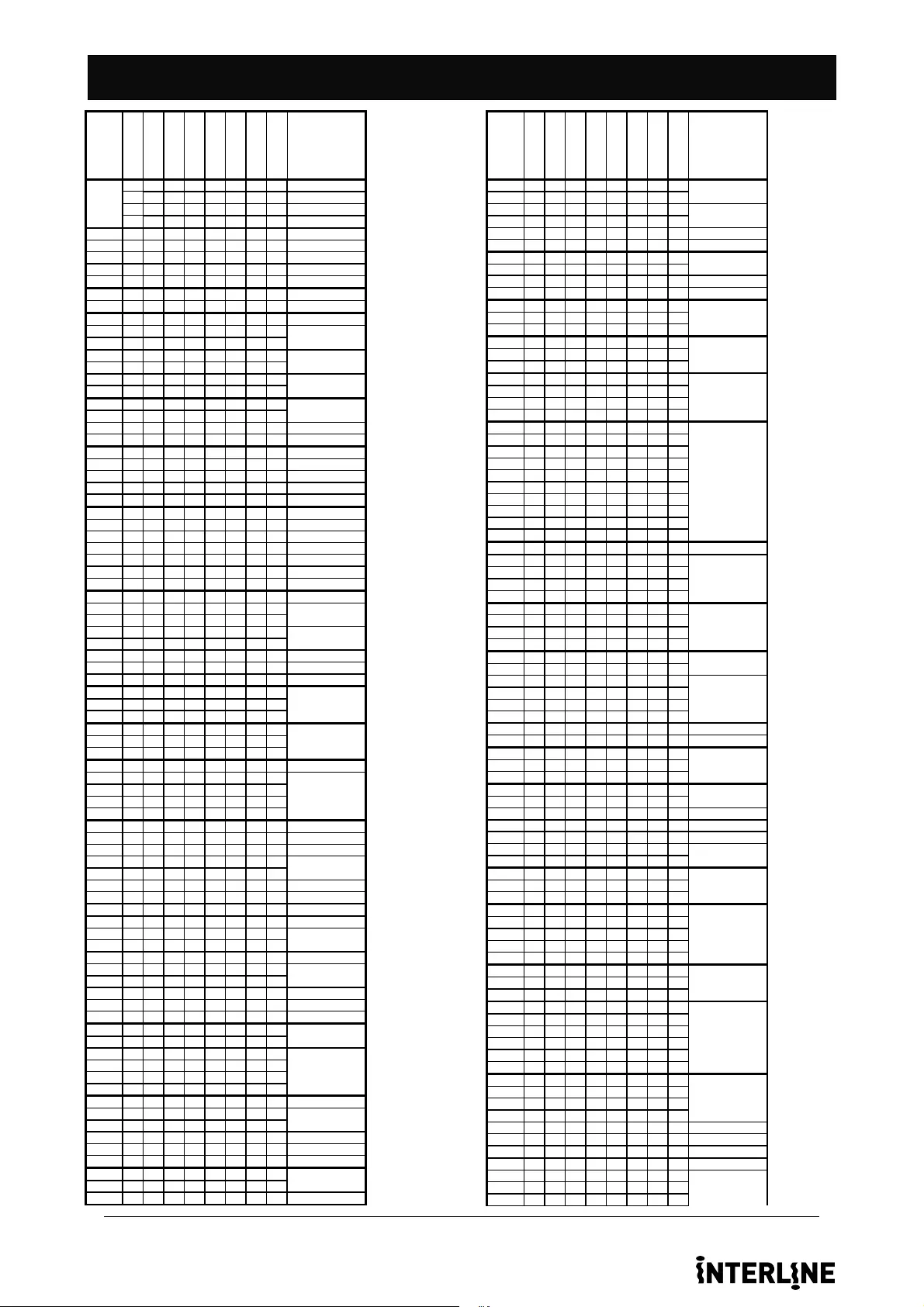

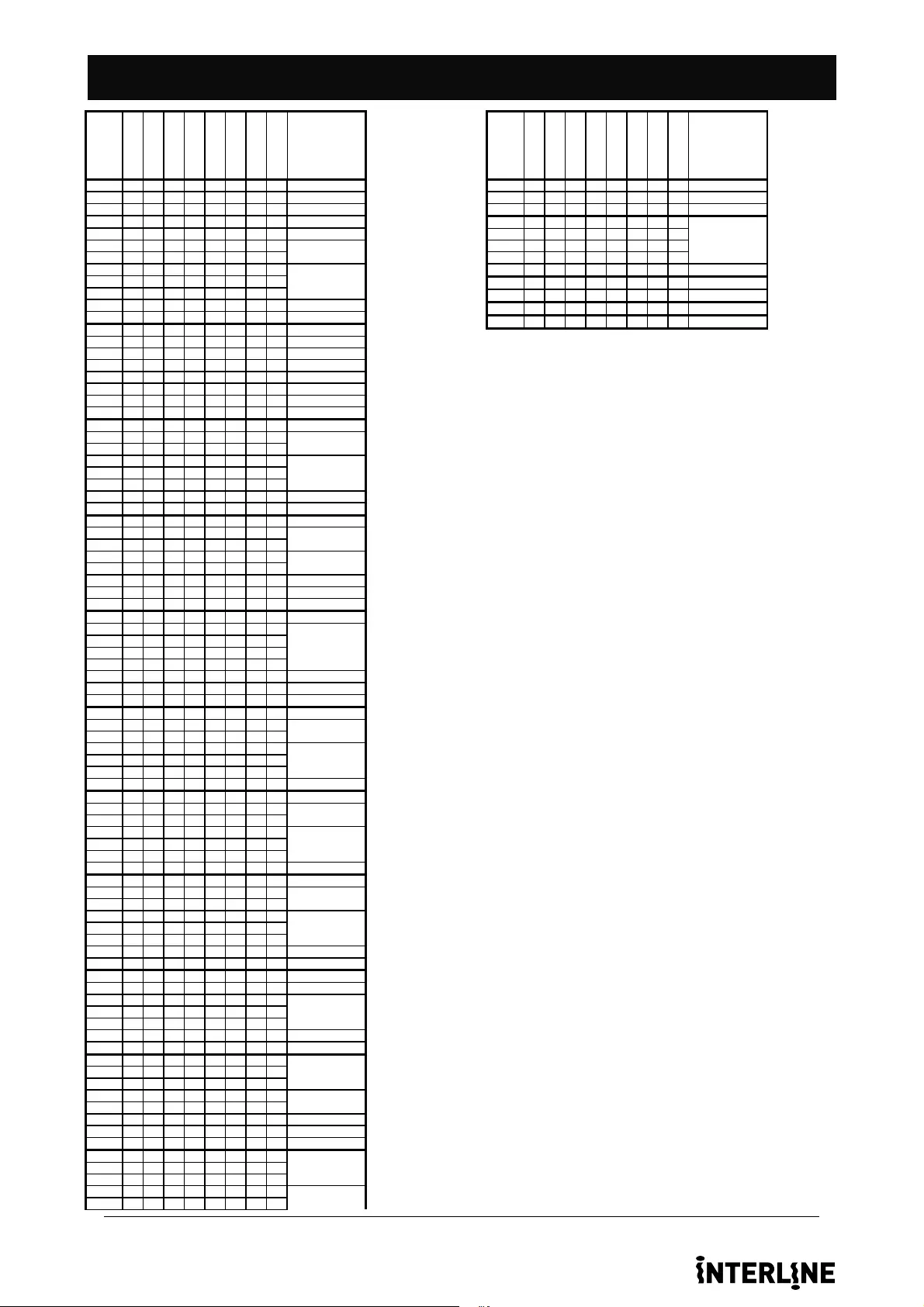

8. Spare parts.

E N G L I S H

Page 22-di/of 28

E N G L I S H

Page 23-di/of 28

E N G L I S H

Page 24-di/of 28

E N G L I S H

Page 25-di/of 28

#

BP-30WS-B

BP-35WS-B

BP-35HS-A

BP-50WS-B

BP-50HS-A

BP-85HS-A

BP-100HS-A

BP-160HS-A

1

X X XW35HSI001A

X X X XW50HSI001A

X XW100HSI001A

X XW160HSI001A

2 X XW30HSI002A

2 X X XW35HSI002A

3 X X XW35HSI002B

2 X X X XW50HSI002A

2 X XW100HSI002A

2 X XW160HSI002A

3 X XW160HSI002B

3 X X XW50HSI003A

3 X X X X XW50HSI003B

4 X X X

4 X XW50WSI004A

5 X X

4 X X X XW50HSI004A

5 X X

6 X X XW50HSI005A

5 X X X X

5 X XW100HSI005A

6 X XW160HSI005A

6 X XW30HSI006A

7 X X XW35HSI006A

6 X X X XW50HSI006A

6 X XW100HSI006A

7 X XW160HSI006A

7 X XW30HSI007A

8 X XW35WSI007A

8 X -

7 X X XW50HSI007A

7 X XW85HSI007A

7 X XW100HSI007A

8 X XW160HSI007A

9 X XW30HSI009A

9 X XW35HSI009A

10 X

8 X XW50HSI009A

9 X

9 X XW85HSI009A

9 X XW100HSI009A

10 X XW160HSI009A

9 X

XW50HSI010A 10 X X X X X

11 X X

10 X

XW50HSI011A 11 X X X X X

12 X X

12 X XW50HSI012A

12 X X X X X

XW50HSI012B

11 X

13 X

15 X

13 X XW30HSI013A

13 X XW35WSI013A

14 X -

12 X XW50HSI013A

13 X

13 X XW85HSI013A

13 X XW100HSI013A

14 X XW160HSI013A

14 X XW30HSI014A

14 X XW35HSI014A

15 X

14 X XW50HSI014A

13 X XW50HSI014B

14 X

14 X XW85HSI014A

14 X XW100HSI014A

16 X XW160HSI014A

15 X -

16 X

14 X

XW50HSI015B

15 X X X X X

16 X

17 X

16 X XW30HSI016A

16 X XW35HSI016A

17 X

16 X X X XW50HSI016A

16 X XW100HSI016A

18 X XW160HSI016A

17 X X XW50HSI018A

18 X X

18 X XW100HSI018A

#

BP-30WS-B

BP-35WS-B

BP-35HS-A

BP-50WS-B

BP-50HS-A

BP-85HS-A

BP-100HS-A

BP-160HS-A

17 X XW35HSI017A

18 X

15 X XW50HSI017A

17 X X

17 X XW100HSI017A

19 X XW160HSI017A

9 X XW50HSI008A

8 X X

8 X X XW85HSI008A

9 X XW160HSI008A

18 X X X

XW50HSI019B 19 X X X X

20 X

19 X X

XW50HSI020A 20 X X X X

21 X

19+20

X

XW50HSI021A

20+21

X X

21+22

X X X

22+23

X X

20 X X

XW50HSI022A

21 X

21 X

22 X

20 X

21 X X X

22 X

21 X X

22 X X X X

23 X

23 X XW50HSI023A

21 X

XW50HSI024A

22 X X

23 X X X

24 X X

22 X

XW50HSI025A

23 X X

24 X X X

25 X X

24 X XW35HSI026A

25 X

23 X

XW50HSI026A

26 X

25 X

24 X

25 X XW100HSI026A

26 X XW160HSI026A

27 X X

XW50HSI026A 26 X X X

25 X X

25 X XW50WSI028A

26 X X

28 X XW50HSI028A

28 X XW50HSI028B

28 X XW50HSI028C

28 X X XW50HSI028D

27 X X X

26

XW50HSI029A

28 X X X

29 X X

27 X X

XW50HSI030A

29 X X X

27 X

30 X X

28

30 X

XW50HSI031A 30 X X

31 X X

29 X

XW50HSI032A

31 X

32 X

28 X X

31 X X

32 X

29 X X

XW50HSI033A

32 X

29 X

33 X

32 X XW85HSI033A

32 X XW100HSI033A

33 X XW160HSI033A

31 X XW30HSI031A

30 X

XW50HSI034A 33 X

34 X

E N G L I S H

Page 26-di/of 28

#

BP-30WS-B

BP-35WS-B

BP-35HS-A

BP-50WS-B

BP-50HS-A

BP-85HS-A

BP-100HS-A

BP-160HS-A

30 X

33 X XW85HSI034A

33 X X XW100HSI034A

34 X XW160HSI034A

32 X XW30HSI032A

31 X XW35HSI035A

34 X

35 X

XW50HSI035A 31 X

34 X

34 X XW100HSI035A

38 X XW160HSI035A

33 X XW30HSI033A

32 X XW35WSI036A

35 X -

32 X XW50WSI036A

36 X XW50HSI036A

35 X XW85HSI036A

35 X XW100HSI036A

39 X XW160HSI036A

34 X XW30HSI034A

33 X XW35HSI037A

36 X

37 X

XW50HSI037A 33 X

36 X

36 X XW100HSI037A

40 X XW160HSI037A

35 X XW30HSI035A

34 X XW35HSI038A

37 X

38 X XW50HSI038A

34 X

37 X XW85HSI038A

37 X XW100HSI038A

41 X XW160HSI038A

35 X XW50WSI039A

36 X

XW50HSI039A

38 X

35 X

39 X

38 X XW85HSI039A

38 X XW100HSI039A

42 X XW160HSI039A

37 X XW30HSI037A

36 X XW35HSI040A

39 X

40 X

XW50HSI040A 38 X

39 X

39 X XW100HSI040A

38 X XW30HSI038A

37 X XW35HSI041A

40 X

41 X

XW50HSI041A 37 X

41 X

40 X XW100HSI041A

39 X XW30HSI039A

41 X XW35HSI042A

38 X

42 X

XW50HSI042A 38 X

41 X

41 X XW100HSI042A

43 X XW160HSI042A

40 X XW30HSI040A

39 X XW35HSI043A

43 X

XW50HSI043A 39 X

42 X

42 X XW100HSI043A

44 X XW160HSI043A

41 X

XW35HSI044A

43 X

40 X

44 X XW50HSI044A

40 X

43 X XW85HSI044A

43 X XW100HSI044A

45 X XW160HSI044A

42 X

XW35HSI045A

41 X

44 X

45 X XW50HSI045A

41 X

#

BP-30WS-B

BP-35WS-B

BP-35HS-A

BP-50WS-B

BP-50HS-A

BP-85HS-A

BP-100HS-A

BP-160HS-A

44 X

44 X XW100HSI045A

46 X XW160HSI045A

43 X

XW50HSI046A

46 X

42 X X

45 X X X

20 X XW160HSI046A

13 X XW160HSI048A

35 X XW160HSI049A

36 X XW160HSI050A

37 X XW160HSI051A

E N G L I S H

Page 27-di/of 28

Page 28-di/of 28

www.interline-products.com