Revell P-40B Tiger Shark User Manual

Displayed below is the user manual for P-40B Tiger Shark by Revell which is a product in the Scale Models category. This manual has pages.

Related Manuals

* REPEAT SEVERAL TIMES

* A REPETER PLUSIEURS FOIS

* CEMENT TOGETHER

* A COLLER

* REMOVE AND THROW AWAY

* A RETIRER ET JETER

* DO NOT CEMENT

* NE PAS COLLER

* DECAL

* DECAL COMANIE

* ASSEMBLY CAUTION

*ATTENTION D ASSEMBLEE

* OPTIONAL PARTS

* PIECES EN OPTION

* REPEAT PROCEDURE

* REPETEZ LE PROCEDE

`` ` ` ` `

TIGER SHARK P - 40B

Although lacking somewhat

in maneuverability and rate of

climb, the P-40's top speed of 352

m.p.h. coupled with its rugged

construction, armor plating and fast

diving speed, enabled it to hold

its own against most of the fighter

planes in existence at that time.

Names for the P-40B ranged

from the Curtiss "Hawk", in the

United States, "Tomahawk" in

Great Britain, to the "Tiger Shark"

of the "Flying Tigers" in China.

The "Flying Tigers" of China were

formed into three squadrons, the

1rst (Adam and Eve), the 2nd (Panda

Bears) and the 3rd (Hell's Angels).

They fought their first action on Dec.

20, 1941 and in the following six and a

half months compiled a record of 299

victories with a loss of only 50 planes,

eight pilots killed and four missing.

KIT 5209 85520920200

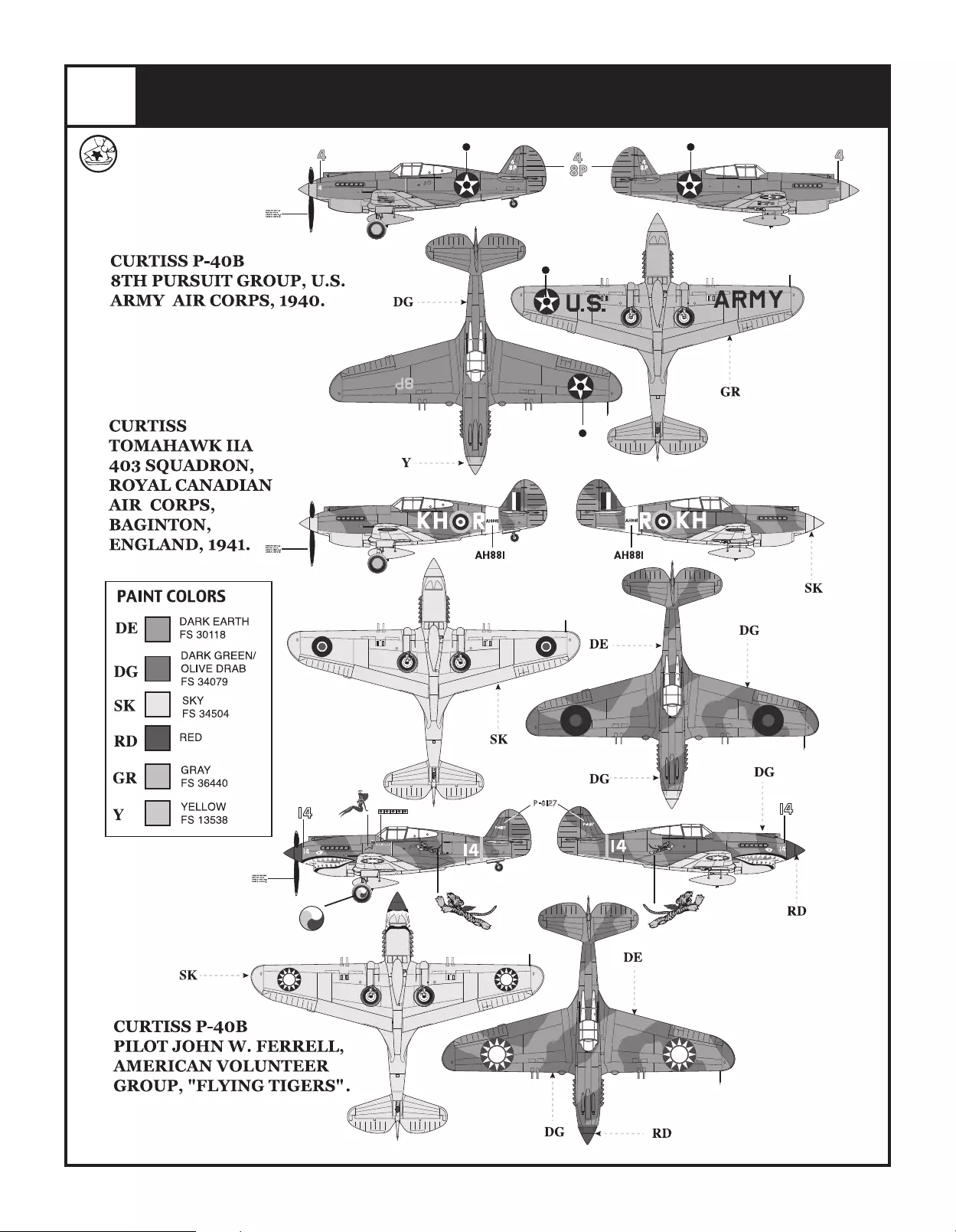

This paint guide is provided to complete this kit

as shown on the box.

Ce guide de peintures est fourni pour reproduire le modèle

réduit qui apparaît sur la boîte.

Aluminum

Noir mat

Terre foncé

Gris

Brun clair

Gris vert

Rouge

Bleu ciel

Havane

Jaune

Chromate de zinc

Aluminum

Flat Black

Dark Earth

Gray

Light Brown

Olive Drab

Red

Sky Blue

Tan

Yellow

Zinc Chromate (Interior Green)

DECAL PLACEMENT

8

If you have any questions or comments, call our hotline at: (800) 833-3570

or, please write to:

Revell Inc Consumer Service Department, 1850 Howard Street Unit A, Elk Grove Village, Illinois 60007

Be sure to include the plan number (85520920200), part number, description, your return address and phone number.

Visit our website: www.revell.com

Revell Inc Elk Grove Village, IL. Copyright © 2010. All rights reserved.

* Study the assembly drawings.

* Each plastic part is identified by a number.

* In the assembly drawings, some parts will be

marked by a star (H) to indicate chrome

plated plastic.

* For better paint and decal adhesion, wash

the plastic parts in a mild detergent solution.

Rinse and let air dry.

* Check the fit of each piece before cementing

in place.

* Use only cement for polystyrene plastic.

* Scrape plating and paint from areas

to be cemented.

* Allow paint to dry thoroughly before

handling parts.

* Any unused parts may be discarded.

DECAL APPLICATION INSTRUCTIONS

1. Cut desired decal from sheet.

2. Dip decal in water for a few seconds.

3. Place wet decal on paper towel.

4. Wait until decal is movable on paper backing.

5. Place decal in position on model, face up and

slide backing away.

6. Press out air bubbles with a soft damp cloth.

7. Milkiness that may appear is for better decal

adhesion and will dry clear. Wipe away any

excess adhesive.

8. Do not touch decal until fully dry.

9. Allow the decals 48 hours to dry before

applying clear coat.

NOTE: Decals are compatible with setting

solutions or solvents.

READ THIS BEFORE YOU BEGIN LIRE CE QUI SUIT AVANT DE COMMENCER

* Etudier les schémas de montage.

* Chaque pièce en plastique est identifiée par un numéro.

* Sur les schémas de montage, certaines pièces sont

marquées d'une étoile (H) pour indiquer qu'elles sont en

plastique chromé.

* Pour une meilleure prise de la peinture et des autocollants,

laver les pièces en plastique avec une solution détergente

peu concentrée. Les rincer et les laisser sécher à l'air.

* Vérifier que chaque pièce s'ajuste bien avant

de la coller en place.

* N'utiliser que de la colle pour polystyrène.

* Gratter les parties à coller pour enlever le chrome et la peinture.

* Laisser la peinture bien sécher avant de manipuler les pièces.

* Toute pièce inutilisée peut être jetée.

DIRECTIVES D'APPLICATION DES AUTOCOLLANTS

1. Découper l'autocollant désiré de la feuille.

2. Tremper l'autocollant dans de l'eau pendant quelques secondes.

3. Placer l'autocollant mouillé sur une serviette en papier.

4. Attendez que l'autocollant puisse être déplacé sur son support

en papier.

5. Mettre l'autocollant en position sur le modèle face sur

le dessus et faire glisser le support pour l'enlever.

6. Appuyer avec un chiffon doux humide pour éliminer les bulles d'air.

7. La substance laiteuse qui peut apparaître est destinée à

améliorer l'adhésion de l'autocollant et devient incolore au

séchage. Essuyer pour enlever tout excédent d'adhésif.

8. Ne pas toucher l'autocollant tant qu'il n'est pas bien sec.

9. Laisser l'autocollant sécher pendant 48 heures avant

d'appliquer une couche transparente.

REMARQUE: Les autocollants sont compatibles avec les

solutions de fixage ou les solvants.

KIT 5209 - Page 8

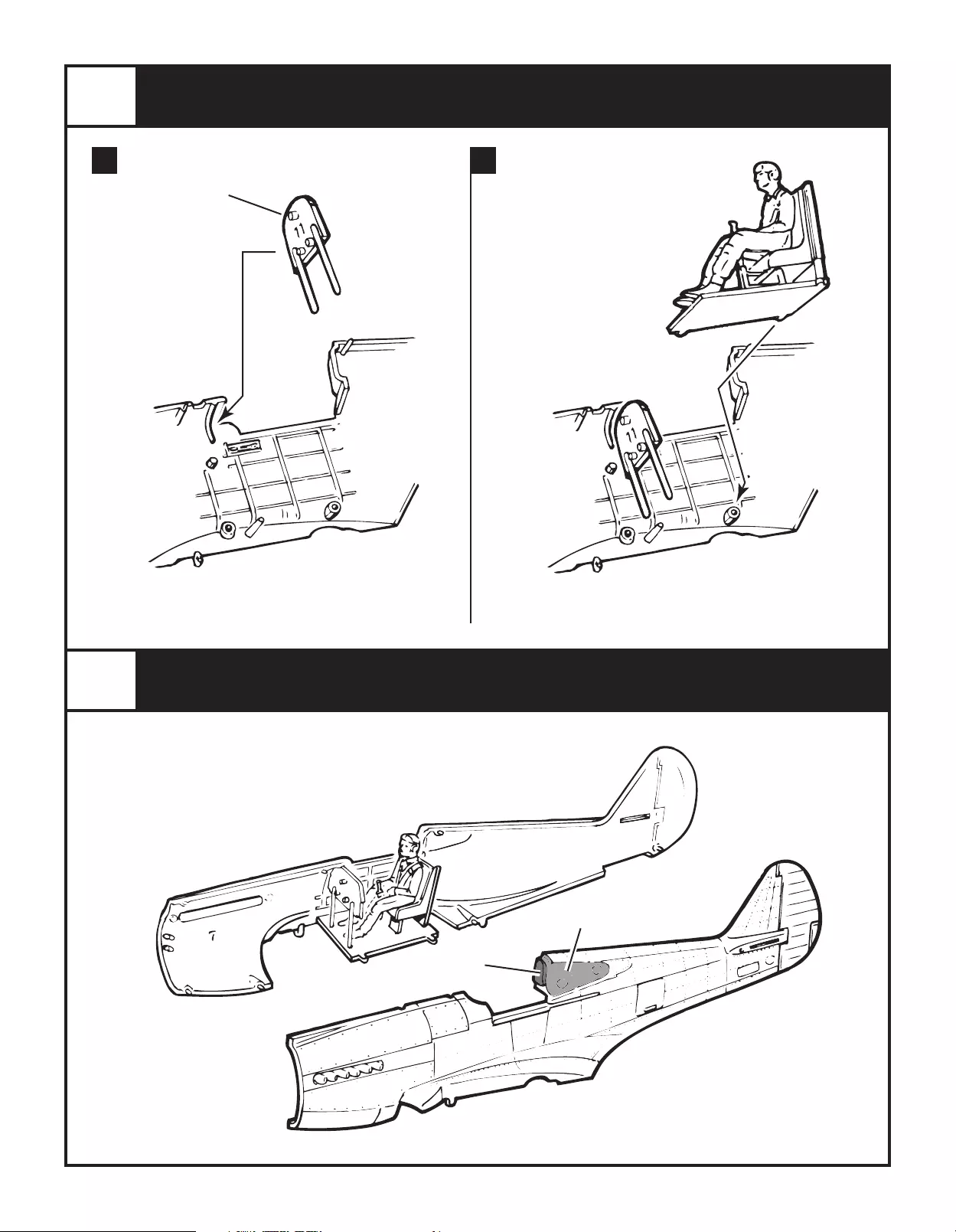

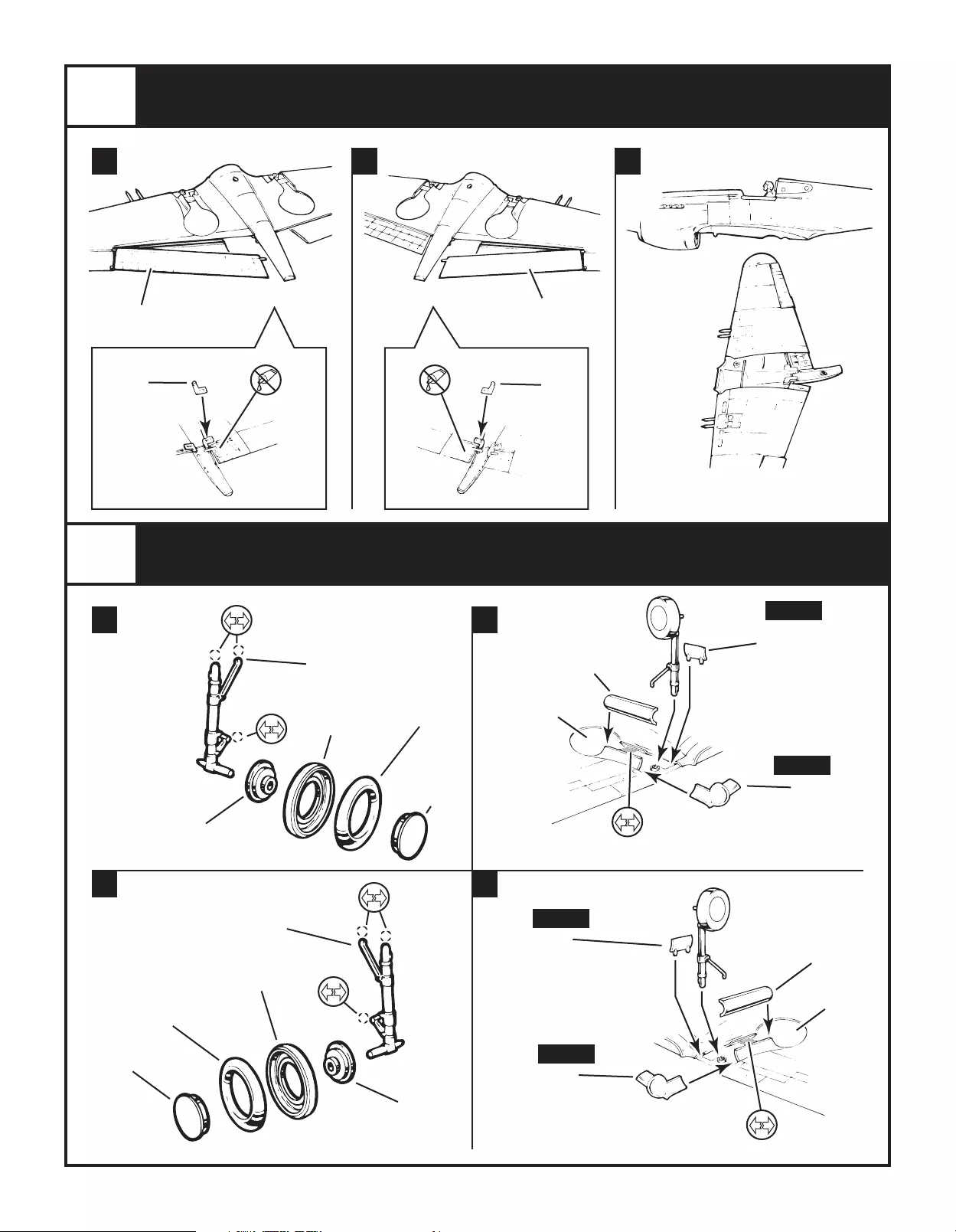

COCKPIT ASSEMBLY

1

REPEAT FOR OTHER SIDE

USING (8) FUSELAGE HALF

2

CONTROL STICK

ZINC CHROMATE

5

FLAP LEVER

ZINC CHROMATE

4

FLOORBOARD

ZINC CHROMATE

9

PANEL

FLAT BLACK

10

PANEL

FLAT BLACK

53

PROPELLER

FLAT BLACK

(PAINT TIPS YELLOW)

49

WINDSHIELD

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

52

OPEN CANOPY

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

48

CLOSED CANOPY

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

51

RIGHT WINDOW

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

50

LEFT WINDOW

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

55

BEAD SIGHT

FLAT BLACK

54

RING SIGHT

FLAT BLACK

1

SEAT

ZINC CHROMATE

3

PILOT

TAN

6

EXHAUST PIPES

LIGHT BROWN

7

RIGHT FUSELAGE

39

TANK TOP

FUSELAGE BOTTOM

COLOR

40

TANK BOTTOM

FUSELAGE BOTTOM COLOR

8

LEFT FUSELAGE

7

RIGHT FUSELAGE

ALUMINIUM LIGHT BROWN

OLIVE DRAB

LIGHT BROWN

FLAT BLACK

ZINC CHROMATE

ZINC CHROMATE

A

C

E

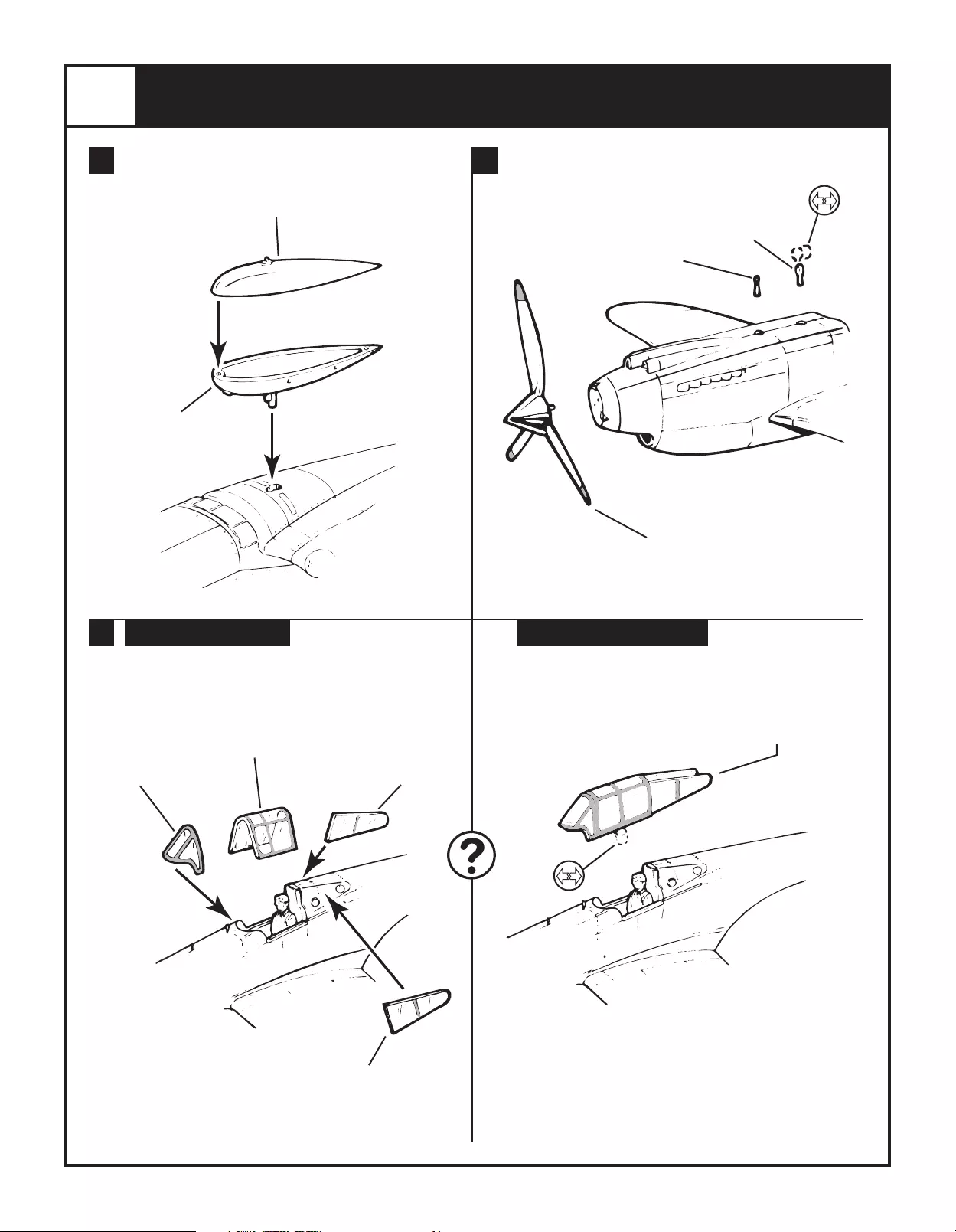

FINAL ASSEMBLY

7

B

D

F

A B

COPEN CANOPY CLOSED CANOPY

KIT 5209 - Page 7

KIT 5209 - Page 2

COCKPIT ASSEMBLY CONTINUED

1

FUSELAGE ASSEMBLY

2

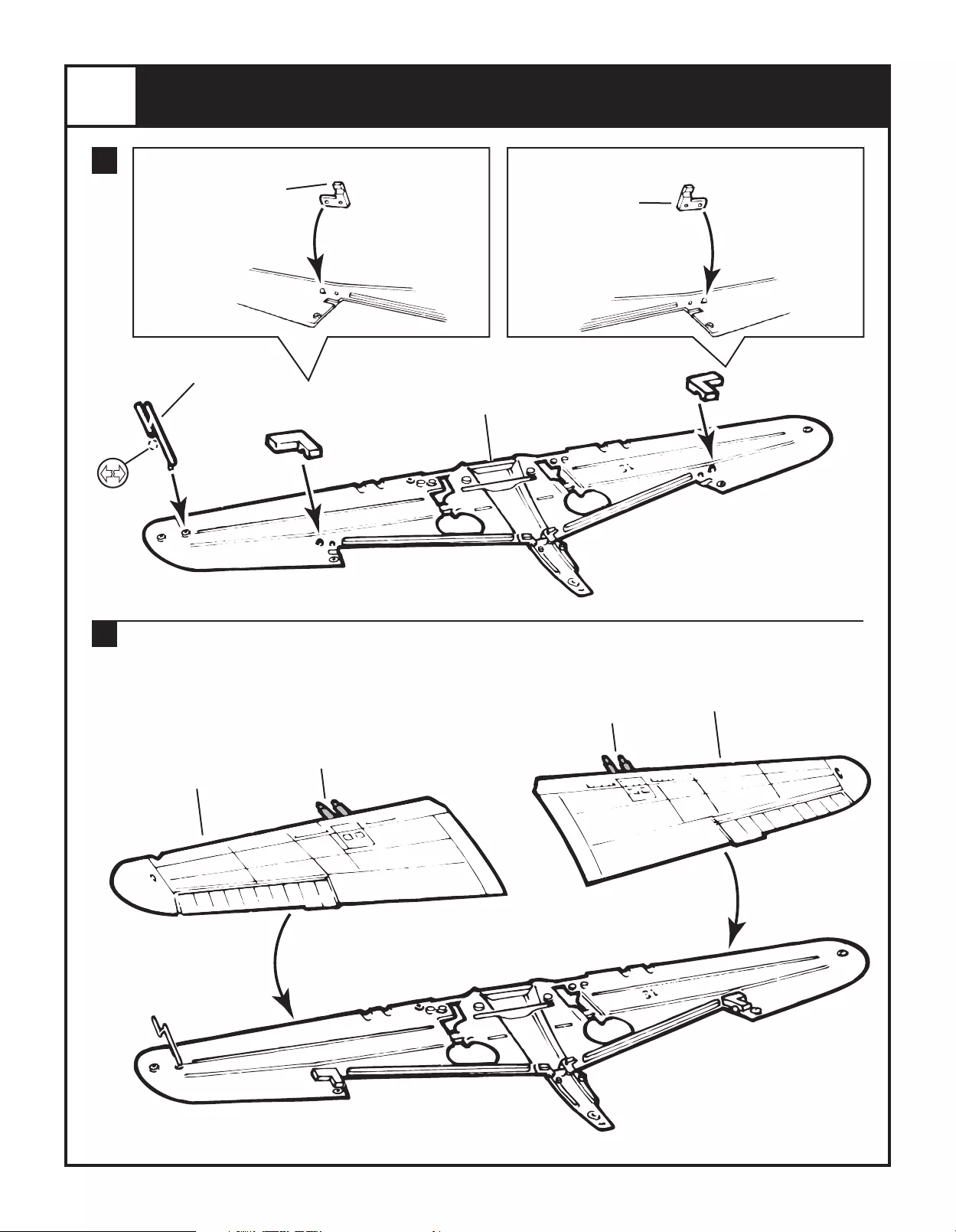

WING FLAP ASSEMBLY

5

LANDING GEAR ASSEMBLY

6

11

INSTRUMENT PANEL

FLAT BLACK

WITH SILVER DETAILS

24

RIGHT LANDING GEAR

ALUMINUM

28

LEFT LANDING GEAR

ALUMINUM

43

INNER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

41

RIGHT GEAR

HOUSING

(PAINT ZINC

CHROMATE INTERIOR)

43

INNER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

44

RIGHT OUTER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

45

LEFT OUTER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

42

LEFT GEAR HOUSING

(PAINT ZINC CHROMATE

IN INTERIOR)

23

INNER

WHEEL

ALUMINUM

23

INNER

WHEEL

ALUMINUM

26

INNER TIRE HALF

FLAT BLACK

26

INNER TIRE HALF

FLAT BLACK

25

OUTER

TIRE HALF

FLAT BLACK

25

OUTER TIRE HALF

FLAT BLACK

ZINC CHROMATE

ZINC CHROMATE

27

WHEEL

COVER

FUSELAGE

BOTTOM

COLOR

27

WHEEL

COVER

FUSELAGE

BOTTOM

COLOR

ZINC CHROMATE

LIGHT BROWN

35

RIGHT WING FLAP

37

LEFT WING FLAP

36

RIGHT

PIVOT

RETAINER

38

LEFT

PIVOT

RETAINER

G H

A

A

CB

B

DC

LAST

FIRST

FIRST

LAST

KIT 5209 - Page 3KIT 5209 - Page 6

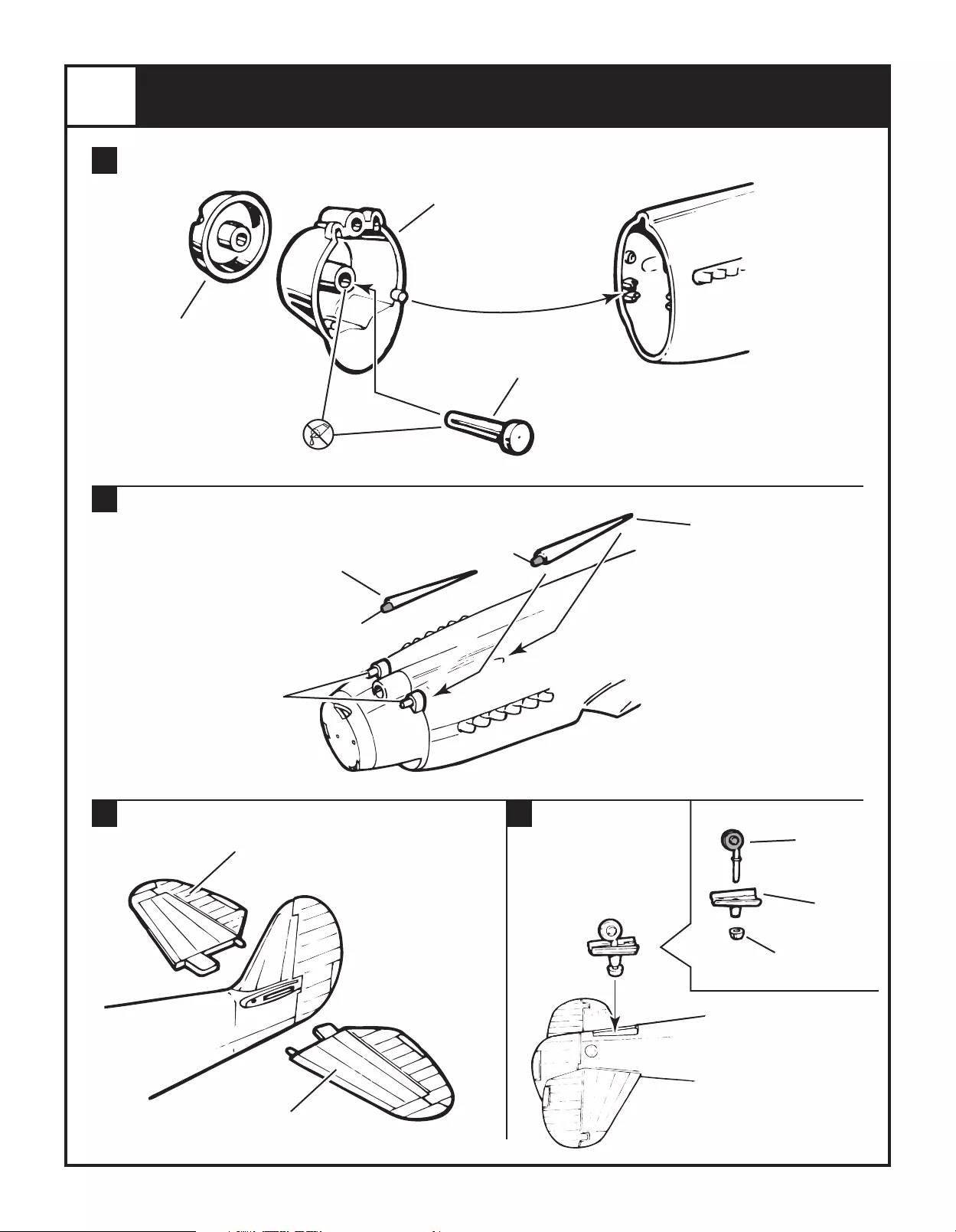

NOSE/TAIL ASSEMBLY

3WING ASSEMBLY

4

14

SPINNER BACK

13

NOSE SECTION

12

PROPELLER SHAFT

15

RIGHT MACHINE

GUN HOUSING

FUSELAGE COLOR

16

LEFT MACHINE

GUN HOUSING

FUSELAGE COLOR

17

RIGHT HORIZONTAL STABILIZER

FUSELAGE COLOR

18

LEFT HORIZONTAL STABILIZER

FUSELAGE COLOR

19

TAIL WHEEL

ALUMINIUM

(PAINT SHADED AREA

FLAT BLACK)

20

TAIL WHEEL DOORS

ZINC CHROMATE

(INSIDE)

21

RETAINER

32

PITOT TUBE

ALUMINIUM

FLAT BLACK

FLAT BLACK

29

LEFT PIVOT

RETAINER 30

RIGHT PIVOT

RETAINER

31

WING BOTTOM

33

LEFT WING TOP

34

RIGHT WING TOP

A

B

C D

FLAT BLACK

FLAT BLACK

FLAT BLACK

A

B

KIT 5209 - Page 5

KIT 5209 - Page 4

NOSE/TAIL ASSEMBLY

3WING ASSEMBLY

4

14

SPINNER BACK

13

NOSE SECTION

12

PROPELLER SHAFT

15

RIGHT MACHINE

GUN HOUSING

FUSELAGE COLOR

16

LEFT MACHINE

GUN HOUSING

FUSELAGE COLOR

17

RIGHT HORIZONTAL STABILIZER

FUSELAGE COLOR

18

LEFT HORIZONTAL STABILIZER

FUSELAGE COLOR

19

TAIL WHEEL

ALUMINIUM

(PAINT SHADED AREA

FLAT BLACK)

20

TAIL WHEEL DOORS

ZINC CHROMATE

(INSIDE)

21

RETAINER

32

PITOT TUBE

ALUMINIUM

FLAT BLACK

FLAT BLACK

29

LEFT PIVOT

RETAINER 30

RIGHT PIVOT

RETAINER

31

WING BOTTOM

33

LEFT WING TOP

34

RIGHT WING TOP

A

B

C D

FLAT BLACK

FLAT BLACK

FLAT BLACK

A

B

KIT 5209 - Page 5

KIT 5209 - Page 4

COCKPIT ASSEMBLY CONTINUED

1

FUSELAGE ASSEMBLY

2

WING FLAP ASSEMBLY

5

LANDING GEAR ASSEMBLY

6

11

INSTRUMENT PANEL

FLAT BLACK

WITH SILVER DETAILS

24

RIGHT LANDING GEAR

ALUMINUM

28

LEFT LANDING GEAR

ALUMINUM

43

INNER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

41

RIGHT GEAR

HOUSING

(PAINT ZINC

CHROMATE INTERIOR)

43

INNER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

44

RIGHT OUTER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

45

LEFT OUTER DOOR

(PAINT ZINC CHROMATE

IN INTERIOR OF DOOR)

42

LEFT GEAR HOUSING

(PAINT ZINC CHROMATE

IN INTERIOR)

23

INNER

WHEEL

ALUMINUM

23

INNER

WHEEL

ALUMINUM

26

INNER TIRE HALF

FLAT BLACK

26

INNER TIRE HALF

FLAT BLACK

25

OUTER

TIRE HALF

FLAT BLACK

25

OUTER TIRE HALF

FLAT BLACK

ZINC CHROMATE

ZINC CHROMATE

27

WHEEL

COVER

FUSELAGE

BOTTOM

COLOR

27

WHEEL

COVER

FUSELAGE

BOTTOM

COLOR

ZINC CHROMATE

LIGHT BROWN

35

RIGHT WING FLAP

37

LEFT WING FLAP

36

RIGHT

PIVOT

RETAINER

38

LEFT

PIVOT

RETAINER

G H

A

A

CB

B

DC

LAST

FIRST

FIRST

LAST

KIT 5209 - Page 3KIT 5209 - Page 6

COCKPIT ASSEMBLY

1

REPEAT FOR OTHER SIDE

USING (8) FUSELAGE HALF

2

CONTROL STICK

ZINC CHROMATE

5

FLAP LEVER

ZINC CHROMATE

4

FLOORBOARD

ZINC CHROMATE

9

PANEL

FLAT BLACK

10

PANEL

FLAT BLACK

53

PROPELLER

FLAT BLACK

(PAINT TIPS YELLOW)

49

WINDSHIELD

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

52

OPEN CANOPY

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

48

CLOSED CANOPY

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

51

RIGHT WINDOW

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

50

LEFT WINDOW

CLEAR

(PAINT SHADED AREA

FUSELAGE COLOR)

55

BEAD SIGHT

FLAT BLACK

54

RING SIGHT

FLAT BLACK

1

SEAT

ZINC CHROMATE

3

PILOT

TAN

6

EXHAUST PIPES

LIGHT BROWN

7

RIGHT FUSELAGE

39

TANK TOP

FUSELAGE BOTTOM

COLOR

40

TANK BOTTOM

FUSELAGE BOTTOM COLOR

8

LEFT FUSELAGE

7

RIGHT FUSELAGE

ALUMINIUM LIGHT BROWN

OLIVE DRAB

LIGHT BROWN

FLAT BLACK

ZINC CHROMATE

ZINC CHROMATE

A

C

E

FINAL ASSEMBLY

7

B

D

F

A B

COPEN CANOPY CLOSED CANOPY

KIT 5209 - Page 7

KIT 5209 - Page 2

* REPEAT SEVERAL TIMES

* A REPETER PLUSIEURS FOIS

* CEMENT TOGETHER

* A COLLER

* REMOVE AND THROW AWAY

* A RETIRER ET JETER

* DO NOT CEMENT

* NE PAS COLLER

* DECAL

* DECAL COMANIE

* ASSEMBLY CAUTION

*ATTENTION D ASSEMBLEE

* OPTIONAL PARTS

* PIECES EN OPTION

* REPEAT PROCEDURE

* REPETEZ LE PROCEDE

`` ` ` ` `

TIGER SHARK P - 40B

Although lacking somewhat

in maneuverability and rate of

climb, the P-40's top speed of 352

m.p.h. coupled with its rugged

construction, armor plating and fast

diving speed, enabled it to hold

its own against most of the fighter

planes in existence at that time.

Names for the P-40B ranged

from the Curtiss "Hawk", in the

United States, "Tomahawk" in

Great Britain, to the "Tiger Shark"

of the "Flying Tigers" in China.

The "Flying Tigers" of China were

formed into three squadrons, the

1rst (Adam and Eve), the 2nd (Panda

Bears) and the 3rd (Hell's Angels).

They fought their first action on Dec.

20, 1941 and in the following six and a

half months compiled a record of 299

victories with a loss of only 50 planes,

eight pilots killed and four missing.

KIT 5209 85520920200

This paint guide is provided to complete this kit

as shown on the box.

Ce guide de peintures est fourni pour reproduire le modèle

réduit qui apparaît sur la boîte.

Aluminum

Noir mat

Terre foncé

Gris

Brun clair

Gris vert

Rouge

Bleu ciel

Havane

Jaune

Chromate de zinc

Aluminum

Flat Black

Dark Earth

Gray

Light Brown

Olive Drab

Red

Sky Blue

Tan

Yellow

Zinc Chromate (Interior Green)

DECAL PLACEMENT

8

If you have any questions or comments, call our hotline at: (800) 833-3570

or, please write to:

Revell Inc Consumer Service Department, 1850 Howard Street Unit A, Elk Grove Village, Illinois 60007

Be sure to include the plan number (85520920200), part number, description, your return address and phone number.

Visit our website: www.revell.com

Revell Inc Elk Grove Village, IL. Copyright © 2010. All rights reserved.

* Study the assembly drawings.

* Each plastic part is identified by a number.

* In the assembly drawings, some parts will be

marked by a star (H) to indicate chrome

plated plastic.

* For better paint and decal adhesion, wash

the plastic parts in a mild detergent solution.

Rinse and let air dry.

* Check the fit of each piece before cementing

in place.

* Use only cement for polystyrene plastic.

* Scrape plating and paint from areas

to be cemented.

* Allow paint to dry thoroughly before

handling parts.

* Any unused parts may be discarded.

DECAL APPLICATION INSTRUCTIONS

1. Cut desired decal from sheet.

2. Dip decal in water for a few seconds.

3. Place wet decal on paper towel.

4. Wait until decal is movable on paper backing.

5. Place decal in position on model, face up and

slide backing away.

6. Press out air bubbles with a soft damp cloth.

7. Milkiness that may appear is for better decal

adhesion and will dry clear. Wipe away any

excess adhesive.

8. Do not touch decal until fully dry.

9. Allow the decals 48 hours to dry before

applying clear coat.

NOTE: Decals are compatible with setting

solutions or solvents.

READ THIS BEFORE YOU BEGIN LIRE CE QUI SUIT AVANT DE COMMENCER

* Etudier les schémas de montage.

* Chaque pièce en plastique est identifiée par un numéro.

* Sur les schémas de montage, certaines pièces sont

marquées d'une étoile (H) pour indiquer qu'elles sont en

plastique chromé.

* Pour une meilleure prise de la peinture et des autocollants,

laver les pièces en plastique avec une solution détergente

peu concentrée. Les rincer et les laisser sécher à l'air.

* Vérifier que chaque pièce s'ajuste bien avant

de la coller en place.

* N'utiliser que de la colle pour polystyrène.

* Gratter les parties à coller pour enlever le chrome et la peinture.

* Laisser la peinture bien sécher avant de manipuler les pièces.

* Toute pièce inutilisée peut être jetée.

DIRECTIVES D'APPLICATION DES AUTOCOLLANTS

1. Découper l'autocollant désiré de la feuille.

2. Tremper l'autocollant dans de l'eau pendant quelques secondes.

3. Placer l'autocollant mouillé sur une serviette en papier.

4. Attendez que l'autocollant puisse être déplacé sur son support

en papier.

5. Mettre l'autocollant en position sur le modèle face sur

le dessus et faire glisser le support pour l'enlever.

6. Appuyer avec un chiffon doux humide pour éliminer les bulles d'air.

7. La substance laiteuse qui peut apparaître est destinée à

améliorer l'adhésion de l'autocollant et devient incolore au

séchage. Essuyer pour enlever tout excédent d'adhésif.

8. Ne pas toucher l'autocollant tant qu'il n'est pas bien sec.

9. Laisser l'autocollant sécher pendant 48 heures avant

d'appliquer une couche transparente.

REMARQUE: Les autocollants sont compatibles avec les

solutions de fixage ou les solvants.

KIT 5209 - Page 8