Salicru SPS ADVANCE RT User Manual

Displayed below is the user manual for SPS ADVANCE RT by Salicru which is a product in the Uninterruptible Power Supplies (UPSs) category. This manual has pages.

Related Manuals

SPS.ADVANCE RT

UNINTERRUPTIBLE POWER SUPPLY

USER'S MANUAL

3

SALICRU

General index

1. Introduction.

1.1. Acknowledgement letter.

2. Information for safety.

2.1. Using this manual.

2.1.1. Conventions and used symbols.

3. Quality and standard guarantee.

3.1. Declaration of the management.

3.2. Standard.

3.3. Environment.

4. Presentation.

4.1. Views.

4.1.1. Equipment views.

4.1.2. Legend corresponding to the equipment views.

4.2. Definition of the product.

4.2.1. Nomenclature.

4.3. Description and operating principle.

4.3.1. Main features.

4.4. Options.

4.4.1. Isolation transformer.

4.4.2. External maintenance manual bypass.

4.4.3. Integration in IT networks by means of the SNMP adaptor.

4.4.4. AS400 card.

4.4.5. MODBUS protocol.

4.4.6. Extensible rail kit for rack cabinet assembling.

5. Installation.

5.1. To be considered in the installation.

5.2. Reception of the equipment.

5.2.1. Unpacking, content checking and inspection.

5.2.2. Storage.

5.2.3. Unpacking.

5.2.4. Vertical assembling -tower type- or rack.

5.2.4.1. Removing or fitting the beauty cover.

5.2.4.2. Rotation of control panel with LCD panel.

5.2.4.3. Vertical assembling -tower type-.

5.2.4.4. Vertical assembling -tower type- , with extended back up time

(battery module).

5.2.4.5. 19" rack cabinet assembling.

5.2.4.6. 19" rack cabinet assembling, with extended back up time (battery

module).

5.3. Connection.

5.3.1. Connection of input.

5.3.2. Connection of the IEC outlets.

5.3.3. Connection of the external batteries (extended back up time).

5.3.4. Connection of main input earth terminal ( ) and the earth bonding

terminal ( ).

5.3.5. EPO terminals in UPSs > 1kVA (Emergency Power Off).

5.3.6. Communication port.

5.3.6.1. RS232 and USB interface.

5.3.6.2. Smart slot.

5.3.6.3. AS400 Interface with DB9 output (option).

5.3.6.4. Protection against transient voltages for modem / ADSL / Fax / ...

lines.

5. 3.7. So f t wa re.

5.3.8. Considerations before commissioning with load connected.

6. Operating.

6.1. Start up.

6.1.1. Controls before commissioning.

6.2. UPS start up and shutdown.

6.2.1. Initial UPS start up.

6.2.2. UPS start up, with mains present.

6.2.3. Start up of the UPS, with no mains present.

6.2.4. UPS shutdown, with mains present.

6.2.5. UPS shutdown, with no mains present.

7. Control panel.

7.1. Functionalities.

7.1.1. Button functions.

7.1.2. Acoustic alarms.

7.1.3. UPS status and colour of the LCD panel, depending on the condition.

7.1.4. Graphics displayed in the LCD panel.

7.1.5. User settings.

7.1.6. Explanations about the user settings and other ones.

7.1.6.1. Operating modes.

7.1.6.2. IEC outlet groups.

7.1.6.3. Setting the UPS to connect it with "n" battery modules.

7.1.6.4. Setting the "Green" function.

8. Maintenance, warranty and service.

8.1. Maintenance of the battery.

8.1.1. Notes for installing and replacing the batteries.

8.2. UPS Trouble Shooting guide.

8.2.1. FAQ. Acoustic alarms.

8.2.2. FAQ. General indications.

8.3. WARRANTY CONDITIONS.

8.3.1. Warranty terms.

8.3.2. Out of scope of supply.

8.4. Technical service network.

9. Annexes.

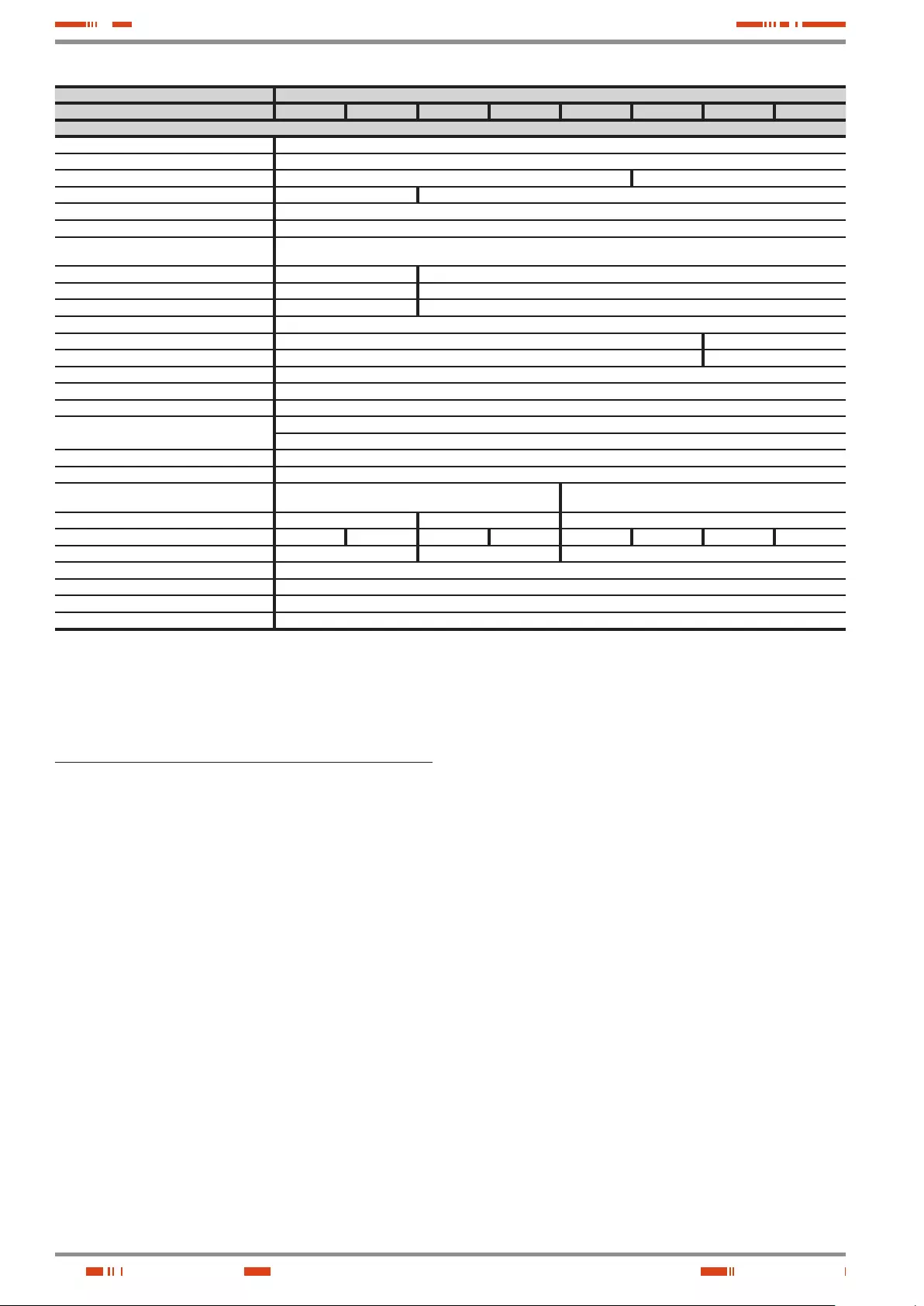

9.1. Main general specifications.

9.2. Glossary.

4

SALICRU

1. Introduction.

1.1. Acknowledgement letter.

We would like to thank you in advance for the trust you have

placed in us by purchasing this product. Read this instruc-

tion manual carefully in order to be familiarized with its con-

tents, because, as much as you know and understand the

equipment the highest will be your satisfaction and safety

levels and their features will be optimized too.

We remain at you entire disposal for any further information or

any query you should wish to make.

Yours sincerely.

• The equipment here described can cause important phys-

ical damages due to wrong handling. This is why, the in-

stallation, maintenance and/or fixing of itself must be done by

our staff or qualified personnel exclusively.

• Although we have made every effort to guarantee a com-

plete and accurate information in this user's manual, we are

not responsible for any errors or omissions that may exist.

The images included in this document are mere illustrations

and they could not represent the part of the equipment ex-

actly, therefore they are not contractual. Nevertheless, dif-

ferences that could exist will be alleviated or solved with the

correct labelling of the equipment.

• According to our policy of constant evolution, we reserve

the right to modify the specifications, operating or de-

scribed actions in this document without forewarning.

• Any reproduction, copy or third party concession, mod-

ification or partial or in whole translations of this manual

or document, in any format or media, is prohibited without

the previous written authorization of our firm, being re-

served the full and exclusive ownership right over it.

USER MANUAL

5

SALICRU

2. Information for safety.

2.1. Using this manual.

The generic information of the equipment is supplied in digital

format in a CD-ROM, and it includes among other documents

the own user's manual of the system and the EK266*08 docu-

ment concerning to «Safety instructions». Before doing any ac-

tion over the equipment regarding installation or commissioning,

change of location, setting or handling, read them carefully.

This user's manual is intended to provide information regarding

the safety and to give explanations about the procedures for the

installation and operating of the equipment. Read them carefully

and follow the stated steps in the established order.

Compliance as regards to “Safety instructions“ is

mandatory, being the user the legal responsible re-

garding to its observance and application.

The equipments are delivered duly labelled for the correct iden-

tification of any their parts, which combined with the instructions

described in this user's manual, allows the end-user to make any

operating of both installation and commissioning, in an easy and

ordered way without doubt.

Finally, once the equipment is installed and operative, for future

requests or doubts that could arise, it is recommended to keep

the CD-ROM documentation in a safe place with easy access.

The following terms are used in the document indistinctly to be

referred to:

• «ADVANCE, ADVANCE RT, RT, equipment, unit o UPS».-

Uninterruptible Power Supply.

Depending on the context of the sentence, it can be referred

either to the own equipment or to the equipment with bat-

teries, although all is assembled in one cabinet or metallic

enclosure.

• «batteries or accumulators».- Group or set of elements

that store the electron flow through electrochemical means.

• «T.S.S.».- Technical Service & Support.

• «client, fitter, operator or end-user».- are used indistinctly

and by extension, to be referred to the fitter and/or operator

which will make the corresponding actions, being respon-

sible the same person about the actions to take on behalf

of himself.

2.1.1. Conventions and used symbols.

Some symbols can be used and shown in the equipment and/or

in the description of this user's manual.

For more information, see section 1.1.1 of EK266*08 document

as regards to «Safety instructions».

6

3. Quality and standard

guarantee.

3.1. Declaration of the management.

Our target is the client’s satisfaction, therefore this Management

has decided to establish a Quality and Environmental policy, by

means of installation a Quality and Environmental Management

System that becomes us capable to comply the requirements

demanded by the standard ISO 9001 and ISO 14001 and by our

Clients and concerned parts too.

Likewise, the enterprise Management is committed with the de-

velopment and improvement of the Quality and Environmental

Management System, through:

• The communication to all the company about the impor-

tance of satisfaction both in the client’s requirements and in

the legal and regulations.

• The Quality and Environmental Policy diffusion and the fixa-

tion of the Quality and Environment targets.

• To carry out revisions by the Management.

• To provide the needed resources.

3.2. Standard.

The SPS.ADVANCE RT product is designed, manufactured and

commercialized in accordance with the standard EN ISO 9001

of Quality Management Systems. The marking shows the

conformity to the EEC Directive by means of the application of

the following standards:

• 2014/35/EU. - Low Voltage Directive (LVD).

• 2014/30/EU. - Electromagnetic Compatibility (EMC).

• 2011/65/EU. - Restriction of Hazardous Substances in

electrical and electronic equipment (RoHS).

In accordance with the specifications of the harmonized stand-

ards. Standards as reference:

• EN-IEC 62040-1. Uninterruptible power supply (UPS). Part

1-1: General and safety requirements for UPS’s used in ac-

cessible areas by end users..

• EN-IEC 60950-1. IT equipments. Safety. Part 1: General re-

quirements.

• EN-IEC 62040-2. Uninterruptible power supply (UPS). Part

2: EMC requirements.

The manufacturers responsibility is excluded in the event

of any modification or intervention in the product by the

customer’s side.

WARNING!:

SPS.ADVANCE RT 0,75.. 3 kVA. This is a category C1 UPS

product.

Declaration of conformity CE of the product is at the client

disposal under previous request to our headquarters offices.

3.3. Environment.

This product has been designed to respect the environment

and has been manufactured in accordance with the standard

ISO 14001.

Equipment recycling at the end of its useful life:

Our company commits to use the services of authorised socie-

ties and according to the regulations, in order to treat the recov-

ered product at the end of its useful life (contact your distributor).

Packaging:

To recycle the packaging, follow the legal regulations in force,

depending on the particular standard of the country where the

equipment is installed.

Batteries:

The batteries mean a serious danger for health and environ-

ment. The disposal of them must be done in accordance with

the standards in force.

USER MANUAL

7

SALICRU

4. Presentation.

4.1. Views.

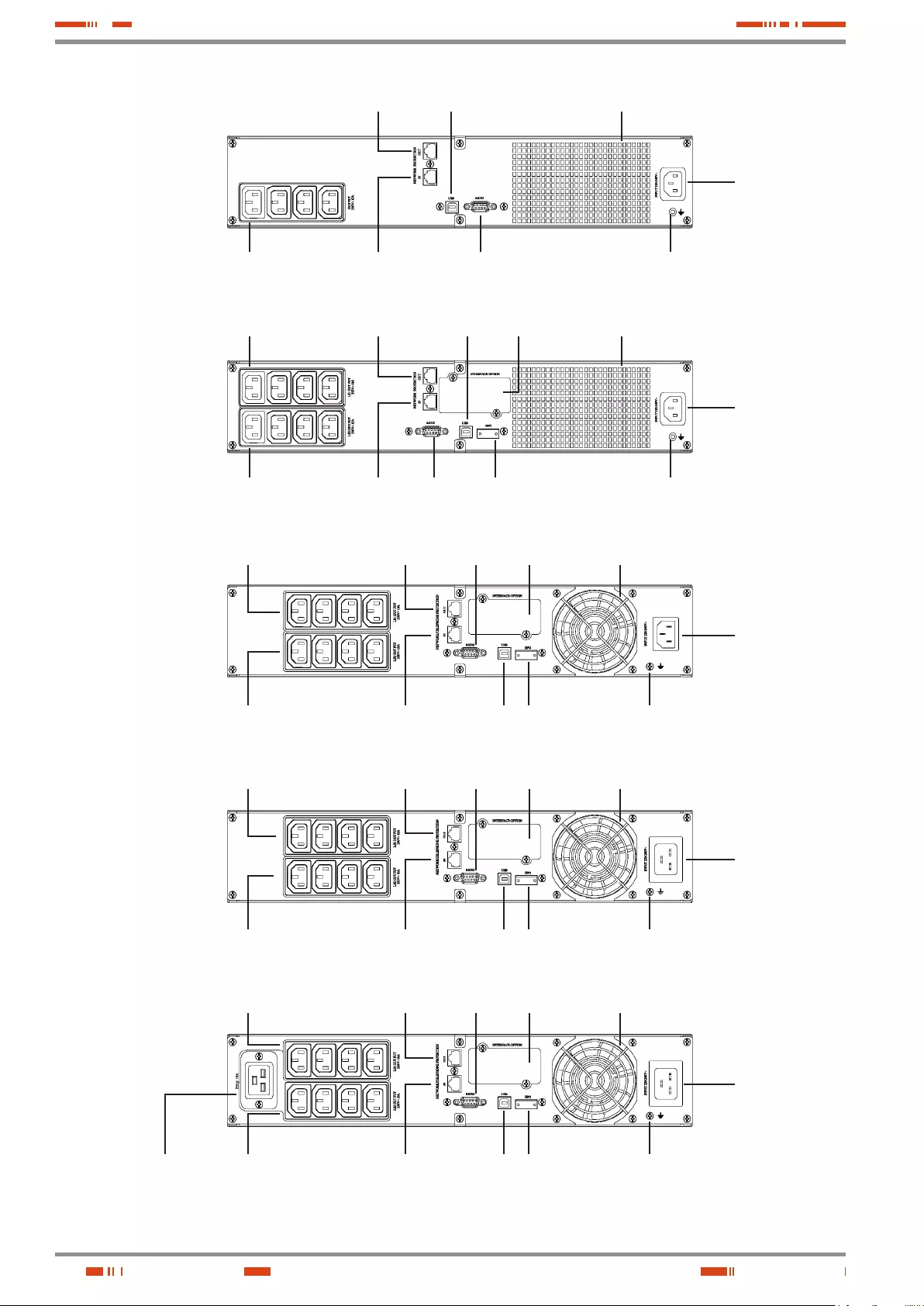

4.1.1. Equipment views.

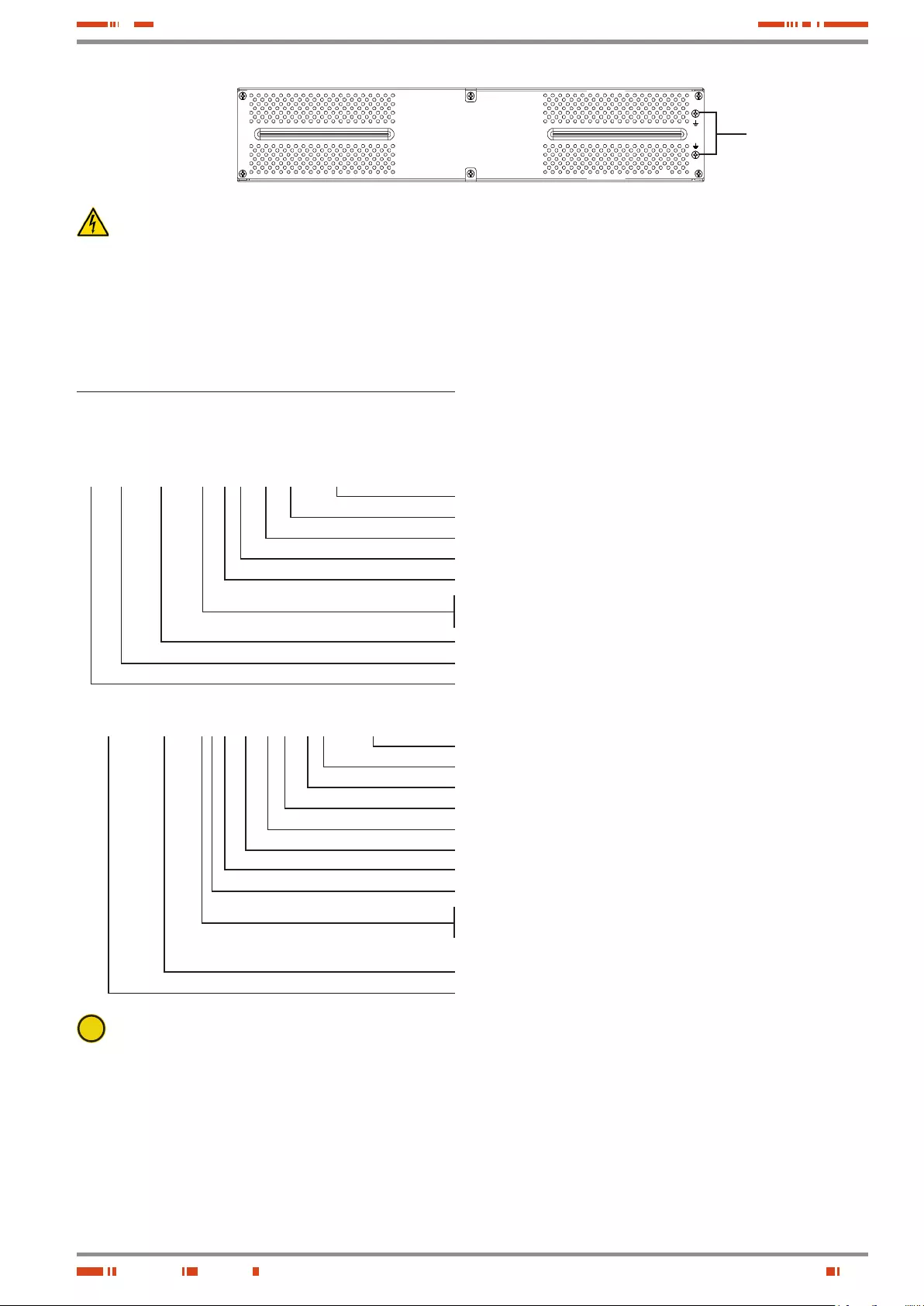

Figures 1 to 3 shows the illustrations of the equipment according

to the format of the enclosure and related to the power of the

model. Nevertheless and due to the constant evolution of the

product, several discrepancies or small contradictions can arise.

If you have any doubt, the labelling on the equipment will always

prevail.

i

In the nameplate sticked in the equipment, all the data re-

ferred to the main features of the equipment can be

checked. Act in accordance with the installation.

Front virew ADVANCE RT

Fixing screws,

Plastic beauty

front

Fixing screws,

Plastic beauty

front

Control panel

with LCD

Plastic beauty

front

Front view battery module for ADVANCE RT

Fig. 1. Front view models from 0,7 to 1 kVA and battery

modules for extended back up times.

4.1.2. Legend corresponding to the

equipment views.

Symbol and their meaning

Symbol Meaning Symbol Meaning

Warning Earth

Electrical shock Alarm silenced

UPS ON /

Battery test Overload

UPS OFF Battery

UPS on Standby

or shutdown Recycling

Alternating (AC)

Keep the UPS i

a well ventilated

place

Direct (DC)

Tabla 1. Used symbology in the equipment and/or this manual..

8

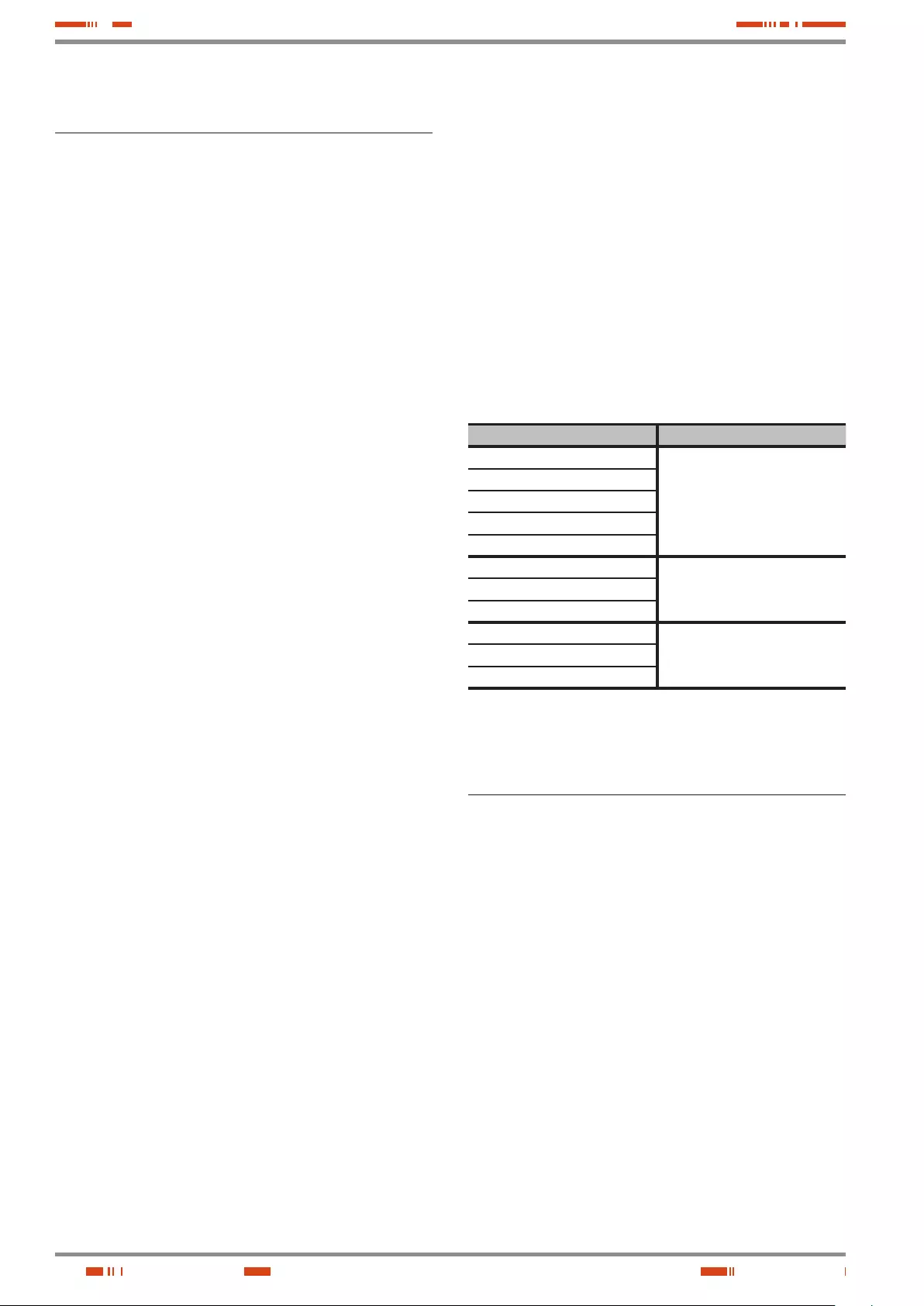

Standard 1500 VA and

(B1)models

IEC outlets

"LS1"

RS232 COM

port

IEC inlet for AC

power supply

Earth connection

for battery module

Output connector, with Módem

/ ADSL / Fax / ... protection

Connector for

external EPO

Smart slot

protection cover Fan

IEC outlets

"LS2"

Input connector, for modem

/ ADSL / Fax / ... line

USB COM

port

IEC outlets

"LS1"

USB COM

port

IEC inlet for AC

power supply

Earth connection

for battery module

Output connector, with Módem

/ ADSL / Fax / ... protection

Connector for

external EPO

Smart slot

protection cover Fan

IEC outlets

"LS2"

Input connector, for modem /

ADSL / Fax / ... line

RS232 COM

port

2000 VA (B1) model

Standard 2000 VA

model

IEC outlets

"LS1"

USB COM

port

IEC inlet for AC

power supply

Earth connection

for battery module

Output connector, with Módem

/ ADSL / Fax / ... protection

Connector for

external EPO

Smart slot

protection cover Fan

IEC outlets

"LS2"

Input connector, for modem /

ADSL / Fax / ... line

RS232 COM

port

Standard 3000 VA and

(B1)model

IEC outlets

"LS1"

USB COM

port

IEC inlet for AC

power supply

Earth connection

for battery module

Output connector, with Módem

/ ADSL / Fax / ... protection

Connector for

external EPO

Smart slot

protection cover Fan

IEC outlets

"LS2"

Input connector, for modem /

ADSL / Fax / ... line

RS232 COM

port

16A IEC outlets

Standard 750 and

1000 VA models

RS232 COM

port

IEC inlet for AC

power supply

Earth connection

for battery module

Output connector, with Módem

/ ADSL / Fax / ... protection Fan

IEC outlets Input connector, for modem

/ ADSL / Fax / ... line

USB COM

port

Fig. 2. Rear view according to the model and power rate of

the equipments.

USER MANUAL

9

SALICRU

Toma tierra para

conexión con equipo

y con otro módulo de

baterías

Battery module

The connection of the battery module with the equipment

and/or with other module is done through the front. To do it,

it will be needed to remove the front plastic trim of all the racks, to

have access to the connection connectors ready for this purpose.

Fig. 3. Rear view of the battery modules for extended back

up times.

4.2. Definition of the product.

4.2.1. Nomenclature.

SPS.1000.ADV RT (B1) WCO 220/220 “EE29503”

MOD BAT ADV RT 2x6AB003 3x40A WCO “EE29503”

EE* Special specifications of the customer.

220 Output voltage. Omitted for 230 V.

220 Input voltage. Omitted for 230 V.

CO “Made in Spain” marking in the UPS and packaging (custom issues).

W Neutral brand.

(B0) No batteries and no space to fit them in.

(B1) Equipment with extra charger and batteries out from UPS.

ADV RT Series of the equipment.

1000 Power in VA.

SPS Acronym for interactive UPS (Standby Power Systems).

EE* Special specifications of the customer.

CO “Made in Spain” marking in the UPS and packaging (custom issues).

W Neutral brand.

40A Protection size.

3x Quantity of protections in parallel. Omitted for one.

003 Last three characters of the battery code.

AB Initials of the battery family.

6 Battery quantity in one string.

2x Quantity of strings in parallel. Omitted for one.

0/ Battery module without them, but the needed accessories

to install them.

ADV RT Series of the battery module.

MOD BAT Battery module.

i Note relative to the batteries. B0 and B1 acronyms

stated the nomenclature related to batteries:

(B0) The equipment is supplied without batteries and without ac-

cessories for them (screws and electrical cables).

Batteries are property of the client, and they will be fitted out

of the UPS case or cabinet.

Under request, it is possible to supply the accessories

(screws and electrical cables), needed to install and con-

nect the external batteries.

(B1) Equipment with extra battery charger. The equipment is

supplied without batteries and without accessories for them

(screws and electrical cables), corresponding to the stated

batteries in the model.

Under request, it is possible to supply the accessories

(screws and electrical cables), needed to install and con-

nect the batteries.

For those equipments requested without batteries, the acquisi-

tion, installation and connection of themselves will always be

done by client and under his responsibility.

Regarding the battery data of quantity, capacity and voltage are stated

in the battery label sticked beside the nameplate of the equipment, re-

spect this data and the polarity of the battery connection strictly.

10

4.3. Description and operating

principle.

This user's manual describes the installation and operating of

the Uninterruptible Power Supply (UPS) from SPS.ADVANCE

RT series, for power ranges between 750 and 3000VA.

These Line-interactive equipments with pure sinewave output,

are designed to protect the most critical electronic devices

against problems of the power supply like undervoltages, peaks,

brownouts, noise in the line and electrical mains fault.

Among other applications, we can quote, PCs, servers, worksta-

tions, and other IT networks devices.

The design allows both the rack-mounting assembling with 2U

height to be fitted in 19" cabinet, previous installation of the side

metallic support with L shape and tower format by using the

plastic supports as a plinth.

The UPS has a front panel with LCD and four buttons (Start up

switch , Silent/UPS test, Setting and Enter) allow an easy moni-

toring: Configuration and control, AC input line, inform about the

wiring fault and the load status. It also includes two LCD bar graphs,

one indicates the battery charge level and the other one the level of

the load connected at its output. Each bar is divided into five parts,

which each one is equivalent to 20% of the total value.

The equipment has four acoustic alarms (Back up time mode

-discharge of the battery-, low battery - end of back up time-,

overload and UPS fault). By means of the Silent/UPS test button

located at the front panel, the acoustic alarm can be deactivated

or to initiated the autotest procedure.

The SPS.ADVANCE RT equipments are fed from AC commer-

cial mains and supply AC energy at their output through the IEC

outlets installed at the rear side of the equipment. In case the

power supply is correct, the load/s are fed through the stabilizer

with «Boost» and «Buck» technology.

In case of mains fault or voltage and/or frequency out of the ac-

ceptable range, load/s will be fed from the batteries through the

inverter for a determined time, depending on the model, battery

charge level and the own load connected at the output.

For models higher than 1000 VA, it is possible to increase the

standard back up time of the equipments, by connecting additional

modules and/or to optimise the recharging time of the accumula-

tors, by fitting chargers with better quality performances (B1).

All the power range has serial and USB communication ports for

communication and equipment control. The serial port supports

the direct communications with a server and the protocol is ac-

cording to a RS-232 interface.

Also, all models have RJ-45 connectors for modem / ADSL / Fax

line protection.

Likewise, the models over 1000 VA have:

• EPO connector, to install the option and external by the own

user, of an emergency power off button.

• Smart slot to install one of the following communication cards:

AS-400 relay interface, with DB9 connection.

SNMP for controlling the equipment via Web.

Card for Internet or Intranet management.

This manual is applicable to the standardized and stated models

in table 2.

4.3.1. Main features.

• Control by microprocessor with high reliability.

• Design of high frequency.

• Stabilizer with «Boost» and «Buck» technology.

• Selectable output range and line sensitivity.

• Cold start.

• Standard communication ports: RS-232 and USB.

• Possible communication extend through the slot.

• Extended back up time by means of the battery modules for

models higher than 1000 VA.

• As an option, more powerful battery chargers, for models

higher than 1000 VA.

• Protection against overload, short-circuit and overtempera-

ture.

• Design 2 in 1, as 19" rack with 2 U height or Tower.

Model Type

SPS.750.ADV RT

Standard

SPS.1000.ADV RT

SPS.1500.ADV RT

SPS.2000.ADV RT

SPS.3000.ADV RT

SPS.1500.ADV RT (B0)

No batteriesSPS.2000.ADV RT (B0)

SPS.3000.ADV RT (B0)

SPS.1500.ADV RT (B1)

Large back up time with additional

charger

SPS.2000.ADV RT (B1)

SPS.3000.ADV RT (B1)

Tabla 2. Standardised models.

4.4. Options.

Depending on the selected configuration, the equipment can in-

clude any of the following options:

USER MANUAL

11

SALICRU

4.4.1. Isolation transformer.

The isolation transformer, provides a galvanic isolation that al-

lows isolating the output from the input completely.

The installation of an electrostatic shield between the primary

and secondary windings of the transformer provides a high level

of attenuation of the electrical noises.

The isolation transformer can be installed at the input or output

of the UPS from SPS.ADVANCE RT series and it will always be

located out from the equipment enclosure.

4.4.2. External maintenance manual

bypass.

The purpose of this option is to isolate electrically the equipment

from mains and critical loads, without breaking the power supply

to the loads. Therefore, in this way the maintenance or fixing

tasks can be done in the equipment with no interruption on the

power supply energy to the protected system, at the same time

that unnecessary risks are avoided to the technical staff.

4.4.3. Integration in IT networks by

means of the SNMP adaptor.

The big IT systems based on LANs and WANs that integrate

servers with different platforms, they have to include an easy

way of controlling and management at the manager system dis-

posal. This facility is got through the SNMP adaptor, which is

well-known by the main software and hardware manufacturers

The available SNMP option for SPS.ADVANCE RT series is a

card to be inserted into the slot that the UPS has in its rear side.

The connection of the UPS with the SNMP is internal meanwhile

the connection between the SNMP and the IT network is done

through a RJ45 connector 10 base.

4.4.4. AS400 card.

See section 5.3.6.3.

4.4.5. MODBUS protocol.

The big IT systems based on LANs and WANs, many times they

require that the communication with any device has to be inte-

grated in the IT network and it has to be done by means of an

industrial standard protocol.

One of the most used industrial standard protocols in the market

is the MODBUS protocol. SPS.ADVANCE RT series is also

ready to be integrated in this type of environments through the

external “SNMP TH card” device with MODBUS protocol.

4.4.6. Extensible rail kit for rack cabinet

assembling.

There is available only one model of telescopic guide kit for all

models, suitable for any type of rack cabinet.

These guides allow installing any unit of the SPS.ADVANCE RT

equipment and their possible battery modules, in case of ex-

tended back up times, as it was a rack with its respective cabinet.

12

5. Installation.

• Check the Safety instructions (see chapter 2).

• Check that the data in the nameplate are the required by the

installation.

• A wrong connection or manoeuvring, can make faults in the

UPS and/or loads connected to itself. Read carefully the in-

structions of this manual and follow the stated steps in the

established order.

• The equipments can be installed and used by per-

sonnel with no specific training just with the help of this

«Manual».

• All connections of the equipment including the control

(interface, remote panel, ...), will be done with the

switches at rest and no voltage present (UPS power supply

switch to «Off»).

• Never forget that the UPS is an electrical energy gen-

erator, so the user has to take the needed cautions

against direct and indirect contacts.

• Under request, we are able to supply a manual bypass panel.

• Battery circuit is not isolated from input voltage. Haz-

ardous voltages can be found out between the battery

terminals and earth. Check that there is not input voltage be-

fore doing any intervention on them.

5.1. To be considered in the

installation.

• All the range has a power cord with plug for input and IEC

outlets for output, as connection parts for power. The rest of

connections are done through the connectors, including the

connection of the equipment with the battery module (it is not

available on equipments below 1000VA).

• Cross cable section of the bypass, input and output lines,

will be calculated from the currents stated in the nameplate

of each equipment, and respecting the Local and/or Na-

tional Low Voltage Electrotechnical Regulations.

• Protections of the switchgear panel, will have the following

features:

For input line, type B for RCD devices and C character-

istic for circuit breakers.

For the output (load feeding), C characteristic for circuit

breaker.

Regarding the size, they will be as minimum to the currents

stated in the nameplate of each UPS.

• In the nameplate of the equipment there are only printed the

nominal currents as it is stated in the safety standard EN-IEC

62040-1. To calculate the input current, the power factor and

the efficiency of the equipment have been considered.

Overload conditions are considered as nonpermanent and

exceptional operating mode.

• If it is added peripherals to the input and/or output like trans-

formers or autotransformers to the UPS, the currents stated in

the own nameplates of those elements has to be considered

in order to use the suitable cross sections, by respecting the

Local and/or National Low Voltage Regulation.

• When an equipment incorporates a galvanic isolation

transformer, as standard, as an option or either in-

stalled by yourself, either at the UPS input or output or at all

of them, protections against indirect contact has to be fitted in

(residual current device) at the output of each transformer,

because due to its specification of isolation it will prevent the

triggering of the protections fitted in the primary of the trans-

former in case of electrical shock in the secondary (output of

the isolation transformer).

• Remind you that all external isolation transformers already

installed or supplied from factory, has the neutral of the sec-

ondary connected to earth by means of a cable bridge be-

tween both terminals. If it were required an isolated output

neutral, remove this cable bridge, keeping the precautions

stated in the respective local and/or national low voltage reg-

ulations.

• All the UPSs have batteries inside the same rack enclosure

of the equipment. Battery protection is by means of fuse and

internal, so it is no accessible by the end-user.

Battery modules have internal protections by fuse, and they

are not accessible by the end-user too.

5.2. Reception of the equipment.

5. 2.1. Unpacking, content checking and

inspection.

• To unpack, see section 5.2.3.

• On receiving the device, make sure that it has not suffered

any damage in transport (impact, drop, ...) and its features

correspond with the ones in the order, so it is recommended

to unpack the UPS and make a first visual inspection.

• In case of observing damages, make all pertinent claims to

the transport agency or in their lack to our company.

Never start up an equipment when external damages

can be observed.

• Also check that the data in the nameplate sticked in the pack-

aging and in the equipment, correspond to the ones stated

in the order, so it is required to unpack it (see section 5.2.3).

Otherwise, make a nonconformity as soon as possible, by

quoting the serial number of the equipment and references

in the delivery note.

• Check the contents of the packaging. Depending, if we are

checking an equipment or battery module, the contents will

vary.

Equipment:

–The own equipment.

–Quick guide in paper.

–1 power cord for input connection -schuko plug and

IEC connector-.

–2 cables for output connection with IEC connectors.

–1 communication cable USB.

–4 plastic pieces to be joint two by two to fit the UPS

in vertical position.

–Two metallic pieces with L shape to adapt the equip-

ment to rack format.

Battery module:

–The own equipment.

–1 connection cable for protection earth, to link the

equipment and module.

–2 plastic pieces to adapt the supports of vertical in-

stallation of the UPS and batteries (battery modules

for equipments up to 3 kVA only).

–1 metallic piece and bolt to joint the battery module

with the equipment on tower format.

USER MANUAL

13

SALICRU

• Once the reception is finished, it is advisable to pack the UPS

and the battery module/s again till its commissioning in order

to protect it against mechanical shocks, dust, dirt, etc...

5.2.2. Storage.

• Storage of the equipment will be done in a dry place, safe-

guard from rain, protected from dust, water jets or chemical

agents. It is advisable to keep the equipment and the battery

pack/s, into their original packages, which have been de-

signed to assure the maximum protection during the trans-

port and storage.

• In equipments that include Pb-Ca batteries, the figures,

stated in table 2 of the EK266*08 document, of charge

period time depending on the temperature that they are ex-

posed, must be respected, otherwise the warranty will be in-

validated.

• Do not store the devices where the ambient temperature ex-

ceeds above 50ºC or below -15ºC, otherwise it may degrade

the electrical characteristics of the batteries.

5.2.3. Unpacking.

• The packaging of the equipment consists of a cardboard

enclosure, expanded polystyrene corner pieces (EPS) or

polyethylene foam (EPE), polyethylene sleeve and band,

all of them are recyclable materials; therefore they should

be disposed according to current regulations. We recom-

mend to keep the packaging in case its use is necessary

in the future.

• Proceed as follows:

Cut the strips of cardboard enclosure.

Remove the accessories (cables, supports, ... )

Remove the equipment or battery module from the pack-

aging, keeping in mind that the it is needed the help of a

second person depending on the weight of the model.

Remove the protection corners from the packaging and

the plastic bag.

Do not leave the plastic bag at the children hand,

due to the risk that it means.

Check the equipment before proceeding and in case

damages where confirmed, contact with the supplier or

in lack of it with our firm.

5.2.4. Vertical assembling -tower type- or

rack.

• All the UPSs from SPS.ADVANCE RT series are designed

to assemble the equipment as tower format -vertical position

of the equipment- or rack -horizontal position- for its installa-

tion in 19" cabinets.

Follow the instructions stated in the sections related to any

of both possibilities, attending the particular configuration of

your equipment.

• Figures from 4 to 9 show as an example the graphics of an

equipment. These illustrations are only for help and orien-

tation in the steps to follow and they are not particular for

any model, although in practice, the actions to make are the

same for all models.

Nevertheless when the generic illustrations differ, there will

be new illustrations to show it.

• All the instructions relating to connections will detailed later

on, less those ones regarding the battery connection. There-

fore, this section will only describe the works linked with the

assembling.

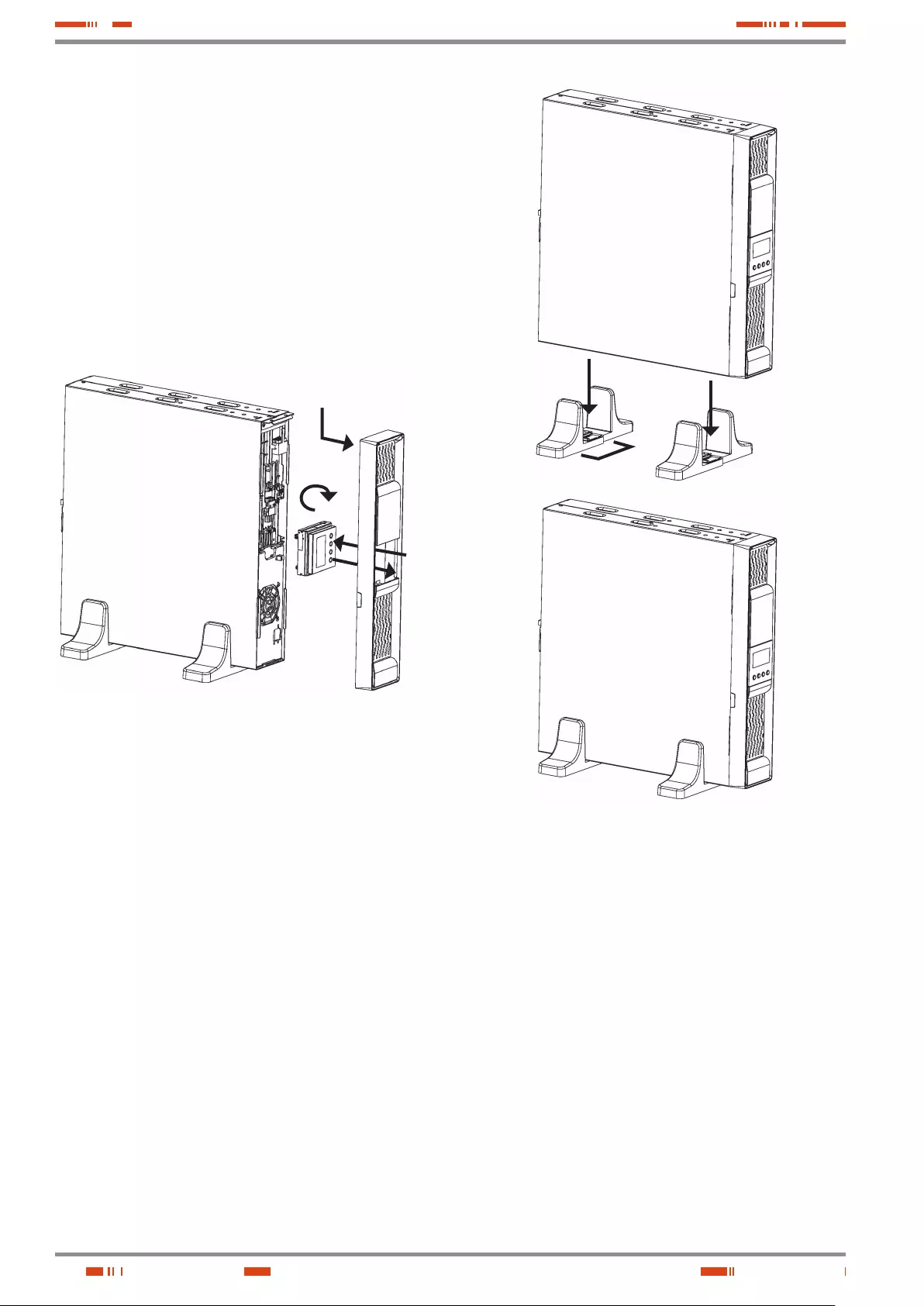

5.2.4.1. Removing or fitting the beauty cover.

"C"

"D"

"D"

Fig. 4. Taking out the beautiful front cover.

14

• To take out the beautiful front cover, proceed as follows (see

figure 4):

Remove the two fixing screws "C" from beautiful plastic

front cover.

Move the front cover to "D" direction, by applying a hard

and moderated knock on its side (side without screws), to

free the trim entered into the metallic frame.

The front is free, but still joint to the equipment through

the connection bus of the control panel.

• To put the beautiful front cover back, proceed in the reverse

way to its removing.

5.2.4.2. Rotation of control panel with LCD

panel.

90º

"A"

"B"

"C"

Take out the beautiful front

cover according to section

5.2.4.1

Fig. 5. Rotation of the control panel with LCD over the beau-

tiful plastic front cover.

• To make easier the message reading when the equipment is

vertically installed, it is advisable to rotate 90º clockwise the

control panel with LCD (see figure 5).

• Also, it is advised to rotate the control panel, if any tower type

equipment requires to be assembled as rack. Consider that the

rotation of the control panel will be counter clockwise.

• Proceed as follows:

Remove the beautiful front cover as it is stated in section

5.2.4.1

Slightly open the nails of the four trims that hold the con-

trol panel with LCD to the beautiful front cover to free it

and push inward "A" to separate both parts.

Rotate it 90º on clockwise "B" and insert it again into

the beautiful front cover till click it "C". Check the correct

closing of the fixing nails.

Put the beautiful front cover back, in the reverse way as

its removing (see section 5.2.4.1).

5.2.4.3. Vertical assembling -tower type-.

• Rotate the control panel according to section 5.2.4.2.

• Take the 4 plastic pieces "A" with angle shape supplied with

the equipment and joint them two by two till obtain two sup-

ports or stabilizers "B".

• Put the UPS vertical between the two stabilizers supports "B"

(see figure 6).

"A"

"A"

"B"

Fig. 6. Vertical -tower type- assembling.

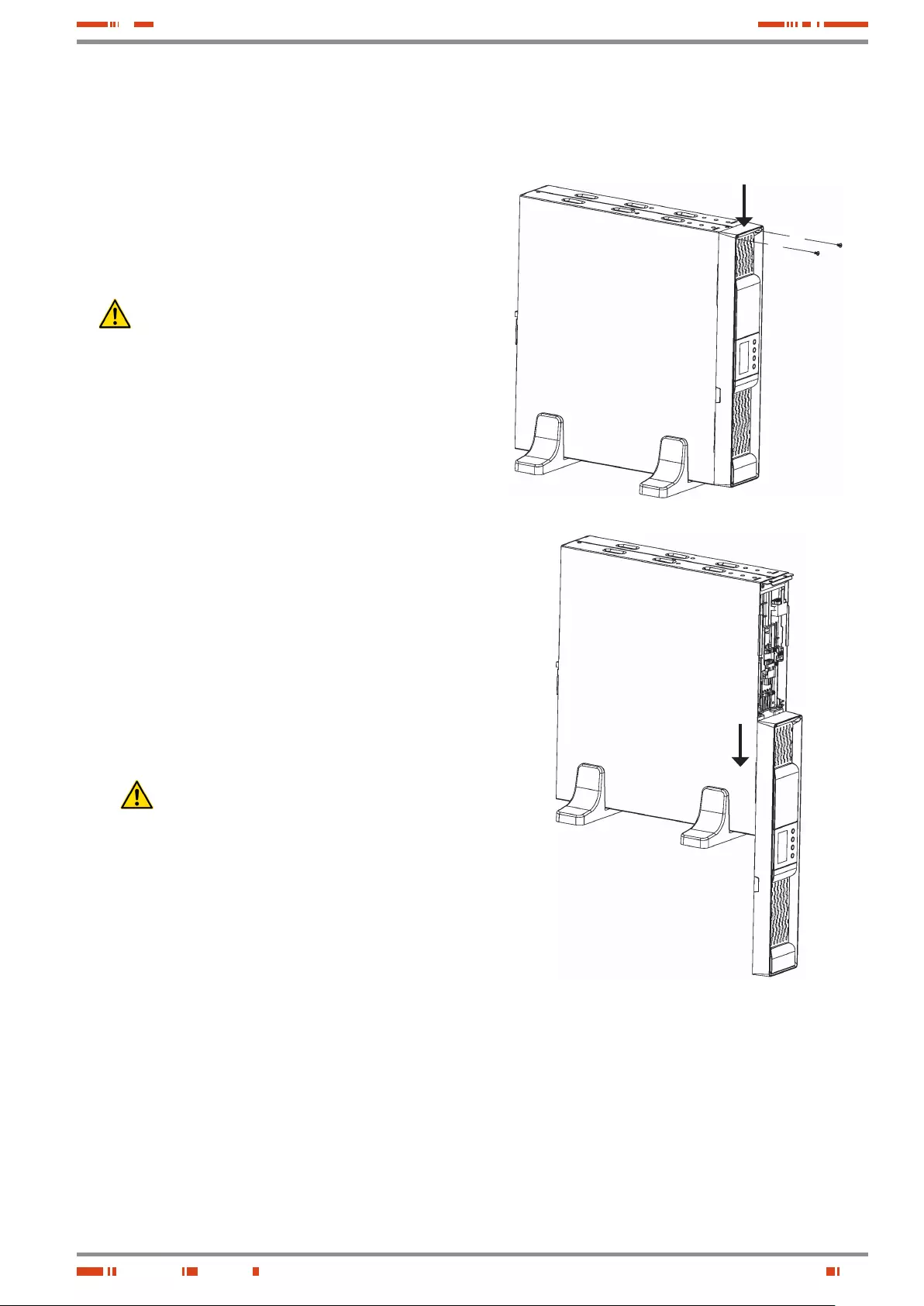

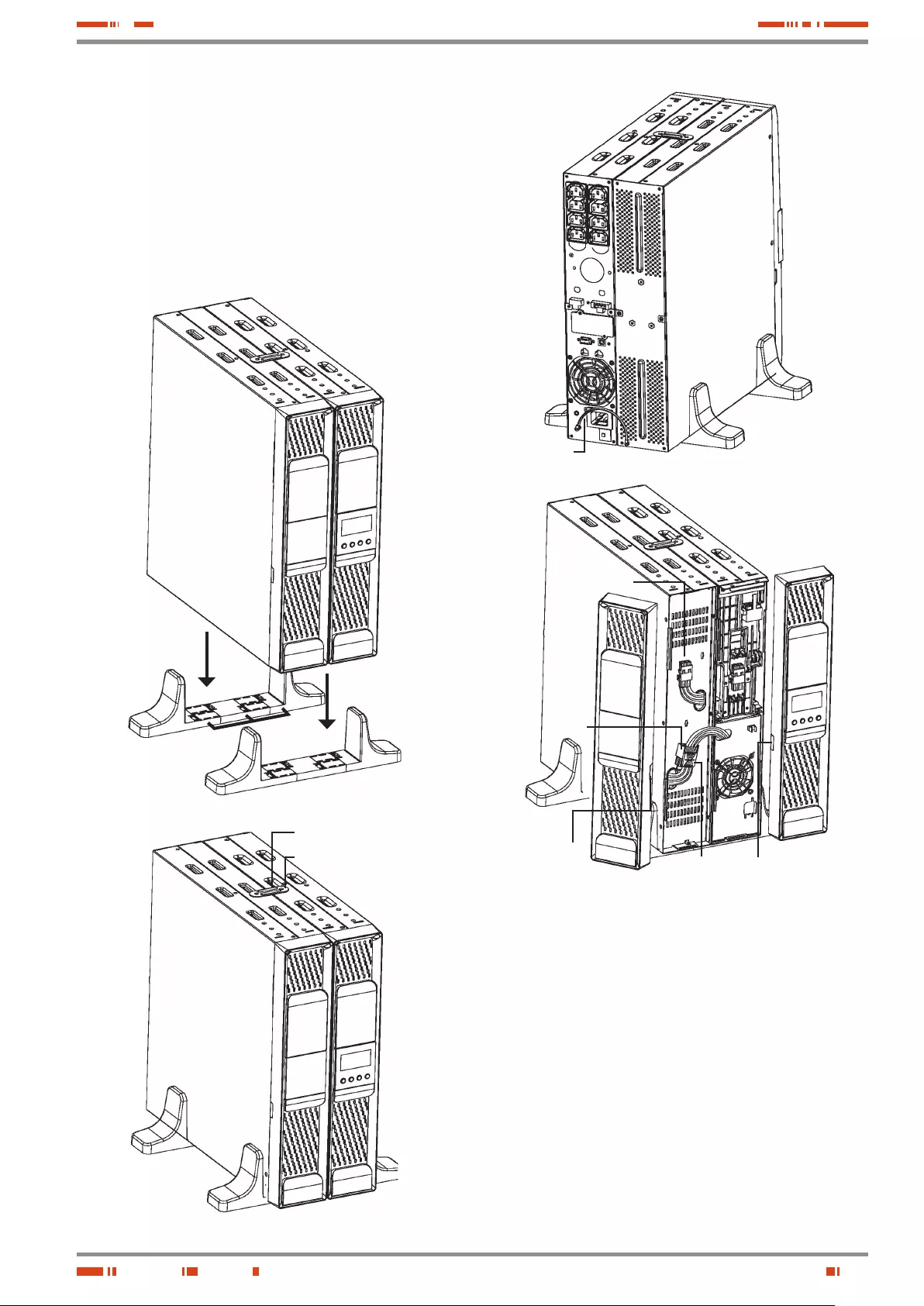

5.2.4.4. Vertical assembling -tower type- , with

extended back up time (battery module).

• The description of this section is based on an equipment

with only one battery module (see figure 7). For a higher

quantity of modules proceed to the connection among them.

• Rotate the control panel of the equipment according to sec-

tion 5.2.4.2.

• Take the 4 plastic pieces "A" with angle shape and supplied

with the UPS and the two supplied with the battery module

"B", and joint them till obtain two supports or stabilizers "C" to

hold the equipment and battery module.

• Put the UPS and battery module on vertical position between

the stabilizers supports "C".

• Fix the "D" metallic piece that joint UPS and battery module

by means of the supplied screws "E".

• Regarding the connections of the UPS with the battery module,

make the following steps, but reading section 5.3.3 previously:

Connect the supplied earth joint cable "F", between the

UPS and battery module.

USER MANUAL

15

SALICRU

Remove the beautiful front cover of the equipment and

battery module, as it is described in section 5.2.4.1.

Take the extensible cable with connector "H" of the bat-

tery module and connect it with the "G" connector of the

equipment.

To connect it with other battery modules, there is the "J"

connector. Take the extensible cable with "H" connector

of the beside battery module and connect it to the "J" con-

nector of the previous one. Repeat the same steps for a

high quantity of modules.

"A"

"A" "B"

"C"

"D"

"E"

"F"

"H"

"J"

"G"

"K"

"K"

Fig. 7. Model in vertical -tower type- assembling with ex-

tended back up time (battery module).

In the side of each front cover, there are the "K" trims as a

notch to go the cables through it with the battery modules.

Break the needed trims to pass the connection bus.

Put the beautiful front cover back of the equipment and

battery module, as it is stated in section 5.2.4.1.

5.2.4.5. 19" rack cabinet assembling.

• All models can be installed in a 19" rack cabinet, attending

the height of each one of them is 2 units.

• Proceed as follows (see figure 8):

Fix both adaptor angles "A" of the equipment as rack, to

its side by means of the supplied screws.

Put a UPS in a rack cabinet, it is needed to have the side

internal rail as support mode "C". In lack of them and

under request, a rails can be supplied as a guide, to be

16

installed by the end user. Make the assembling at the

required height, assuring the correct torque of the fixing

screws.

Face the equipment over the rails and enter it to the bottom.

Depending on the model of the equipment and as a result

of the weight, it is recommended to make the installation

works by two persons, and even more when they are

done on the top and bottom of the cabinet.

Fix the equipment to the frame of the cabinet by means

of the screws "B".

"A""C"

"B"

Fig. 8. 19" rack cabinet assembling.

5.2.4.6. 19" rack cabinet assembling, with

extended back up time (battery module).

• This section describes a single equipment with only one bat-

tery module (see figure 9). For higher quantity of modules

reproduce the connection procedure among them.

• All models can be installed in a 19" rack cabinet, attending

the height of each one of them is 2 units.

• Proceed as follows:

Fix both adaptor angles "A" to the equipment and to the

battery module as rack, on their side, by means of the

supplied screws.

"C" "B"

"F"

"G"

"J"

"K"

"K"

"H"

Fig. 9. Model in rack-mounting format in 19" cabinet, with

extended back up time (battery module).

Put a UPS in a rack cabinet, it is needed to have the side

internal rails as support mode "C". In lack of them and

under request, a universal rails can be supplied as a

guide, to be installed by the end user. Make the assem-

bling at the required height, assuring the correct torque of

the fixing screws.

Face the equipment over the rails and enter it to the bottom.

Proceed in the same way for the battery module.

USER MANUAL

17

SALICRU

Depending on the weight of model of the equipment and

battery module, it is recommended to make the installa-

tion works by two persons.

Fix the equipment to the frame of the cabinet by means

of the screws "B".

• Regarding the connections of the UPS with the battery

module, make the following steps, but reading section 5.3.3

previously:

Connect the supplied earth joint cable "F", between the

UPS and battery module.

Remove the beautiful front cover of the equipment and

battery module, as it is described in section 5.2.4.1.

Take the extensible cable with connector "H" of the bat-

tery module and connect it with the "G" connector of the

equipment.

To connect it with other battery modules, there is the "J"

connector. Take the extensible cable with "H" connector

of the beside battery module and connect it to the "J" con-

nector of the previous one. Repeat the same steps for a

high quantity of modules.

In the side of each front cover, there are the "K" trims as a

notch to go the cables through it with the battery modules.

Break the needed trims to pass the connection bus.

Put the beautiful front cover back of the equipment and

battery module, as it is stated in section 5.2.4.1.

5.3. Connection.

• Cross cable section used in the power supply of the

equipment and loads to feed, will be sized according

to the nominal current stated in the nameplate sticked on the

equipment, by respecting the Low Voltage Electrotechnical

Regulations or norms of the corresponding country.

• Installation will have the suitable input protections sized to

the current of the equipment and stated in the nameplate of

the equipment (residual current devices type B and circuit

breaker with C characteristic or any other equivalent one).

Overload conditions are considered as a nonpermanent an

exceptional operating mode, so these currents will not be

kept in mind when sizing the protections.

• Output protection will be done with a circuit breaker of C

characteristic or any other equivalent one.

The equipments can be installed and used by per-

sonnel with not specific training, just with only help of

this «Manual».

• To insert the option cards, it is needed to remove the fixing

screws of the smart slot and the own cover.

When finalising the corresponding tasks, the cover will be

installed and its fixing screws again.

5.3.1. Connection of input.

• As this is a device with class I protection against elec-

tric shocks, it is essential to install a protective earth

conductor (connect earth( )). Connect the conductor be-

fore connecting the power supply to the input power block.

• Take the power cord with schuko plug and IEC connector

and connect the IEC connector to the UPS inlet. Next insert

the schuko plug to the AC mains outlet.

5.3.2. Connection of the IEC outlets.

• As this is a device with class I protection against elec-

tric shocks, it is essential to install a protective earth

conductor (connect earth( )). Connect the conductor to

the terminal, before connecting the power supply to the input

power block.

• All the equipments have female IEC outlets, in greater or lesser

numbers depending on the power rate of the equipment:

Models up to 1 kVA: 1 group of 4 IEC outlets of 10A.

Models of 1,5 and 2 kVA: 2 groups of 4 IEC outlets of 10A la-

belled as LS1 and LS2, which can be set through the control

panel and/or Win Power.

Models of 3 kVA: 2 groups of 4 IEC outlets of 10A labelled

as LS1 and LS2, which can be set through the control panel

and/or Win Power, plus a IEC connector of 16A.

Loads can be connected to the IEC outlets, mean-

while the features of the equipment and IEC out-

lets limitations are not exceeded, otherwise there will be

sudden blackouts in the power supply of the connected

loads at the output.

• If besides of the critical loads, it is required to connect lag-

ging loads of high consumption, like laser printers or CRT

monitors, the inrush currents of these peripherals will be kept

in mind in order to avoid blocking the equipment under the

worst conditions.

It is better to not connect the loads of this kind, due to the high

quantity of energy resources that take from the UPS.

5.3.3. Connection of the external

batteries (extended back up time).

• As this is a device with class I protection against elec-

tric shocks, it is essential to install a protective earth

conductor (connect earth( )). Connect the conductor to

the terminal, before connecting the power supply to the input

power block.

• To not respect the stated indications in this section

and the safety instructions (see chapter 2), means a

high risk of electrical discharge and even the death.

• To connect the batteries with the equipment, follow the de-

scribed steps in sections 5.2.4.4 and 5.2.4.6.

• All the standard UPSs have batteries in the same enclosure,

less the B0 and B1 (not available for models equal or below

1kVA). Battery protection is done by internal fuses and not ac-

cessible for the end-user.

Battery modules have internal protections for the batteries

too and they are not accessible for the end-user.

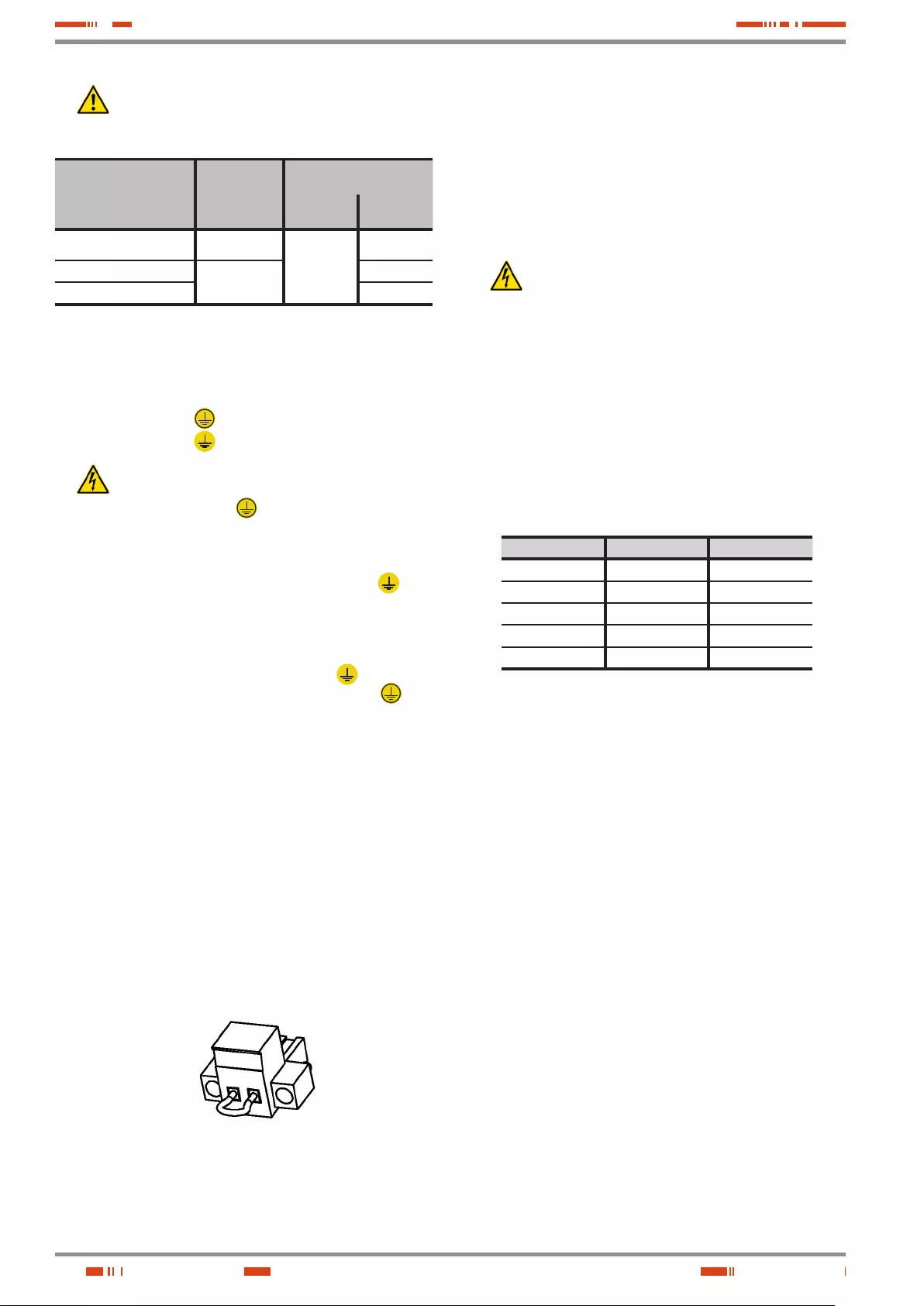

• IMPORTANT FOR SAFETY: In case of installing the

batteries by yourself, the accumulators has to be pro-

vided with a two pole circuit breaker protection sized to the

features stated in table 3.

• Before starting the connection between the bat-

tery module/s and the equipment, check that the

equipment and loads are in "Off" position.

Likewise when batteries are installed by the own user,

the fuse or switch has to be turned off.

• Connection terminals of external batteries with the equip-

ment are done with a polarised Anderson connector. This

connector is not available in models up to 1kVA.

• For battery connection with the equipment, follow the stated

steps in sections 5.2.4.4 and 5.2.4.6, keeping in mind the model.

18

• Each battery module is independent for each equip-

ment. It is completely forbidden to connect to equip-

ments to the same battery module.

Model

Batteries

(U elemento x Nº) =

U nominal / U floating

Minimum features of fast

fuse type

Voltage

DC (V) Current (A)

SPS.1500.ADV RT (12 V x 3 ) =

36 V / 41.4 V

250

50

SPS.2000.ADV RT (12 V x 6 ) =

72 V / 82.8 V

60

SPS.3000.ADV RT 60

Tabla 3. Specifications of the protection between the equipment and

battery module.

5.3.4. Connection of main input earth

terminal ( ) and the earth bonding

terminal ( ).

• As this is a device with class I protection against elec-

tric shocks, it is essential to install a protective earth

conductor (connect earth( )). Connect the conductor to

the terminal, before connecting the power supply to the input

power block.

• Make sure that all the loads connected to the UPS are only

connected to the protective earth bonding terminal ( ). The

fact of not restricting the earthing of the load or loads and/or

the batteries case/s or cabinet/s to this single point will create

a return loops to earth which will affect the quality of the sup-

plied power.

• All terminals identified as earth bonding ( ), are joined

together, to the main protective earthing terminal ( ) and

to the frame of the device.

5.3.5. EPO terminals in UPSs > 1kVA

(Emergency Power Off).

• All UPSs have two terminal to install an external button, for

Emergency Power Off (EPO).

• As an illustration mode, figure A, it is shown a connector of

two pins.

• By default, the equipment is supplied from factory with the

EPO circuit as open (NO). So, the UPS will break the output

power supply, emergency power off, when opening the cir-

cuit:

Either by removing the female connector inserted in the

plinth. This connector has a cable bridge to close the cir-

cuit (Fig. A).

Fig. A

Or by turning on the external button installed and be-

longing to the end-user. The connection in the button has

to be in normally closed because it will open the circuit

when turning it on.

• To restore the normal operating mode of the UPS, the con-

nector with the cable bridge has to be fitted back in the terminal

strip or to deactivate the EPO button and later on to cancel the

EPO status in the control panel . The equipment will be opera-

tive.

5.3.6. Communication port.

5.3.6.1. RS232 and USB interface.

• Communication line (COM) is a very low voltage circuit

of safety. To preserve the quality, it has to be installed

separate from other lines that have dangerous voltages (energy

distribution line).

• RS232 and USB interfaces are used by the monitoring soft-

ware and firmware updating.

• It is not possible to use both ports at the same time.

• Signal pin-out of the DB9 connector are shown in table

4. In the connector, the RS-232 signal and dry contacts

through optocouplers can be found, not available on models

SPS.750.ADV RT and SPS.1000.ADV RT.

RS232 port consists in a serial data transmission, so an im-

portant quantity of information can be sent through a com-

munication cable of 3 wires.

Pin # Description Input / Output

1 (*) Low battery Output

2RXD Input

3TXD Output

5 (**) GND / common -

8 (*) Mains fault Output

(*) Normally open dry contacts (NO), maximum applicable voltage

and current is 30V DC and 1A.

Not available on models SPS.750.ADV RT and SPS.1000.ADV RT.

(**) GND for RS232 and common for dry contacts.

Tabla 4. Pin-out of the RS232 and optocouplers dry contact in the

DB9 connector.

• USB communication port is compatible with the USB 1.1 pro-

tocol for communication software.

5.3.6.2. Smart slot.

• UPSs have a unique slot, hidden rear the cover stated in the

views of the equipment as "Smart slot", and allows inserting

any of the following options cards:

SNMP for control via Web.

Remote UPS management through Internet or Intranet.

AS400 (for more details see the next section).

• For more information, contact with our S.T.S or our nearest

distributor.

USER MANUAL

19

SALICRU

5.3.6.3. AS400 Interface with DB9 output

(option).

• Communication line (COM) is a very low voltage circuit

of safety. To preserve the quality, it has to be installed

separate from other lines that have dangerous voltages (energy

distribution line).

• UPS has a dry contact card for the AS400 communication

protocol, it provides digital signals in a free potential way, with

a maximum applicable voltage and current of 240 V ac or

30 V dc and 1A. Pin-out of the DB9 connector are stated in

figure 10 and detailed in table 5.

• The most common use of this type of ports is to provide the

needed information for the closing file software.

• For more information, contact with our S.T.S or our nearest

distributor.

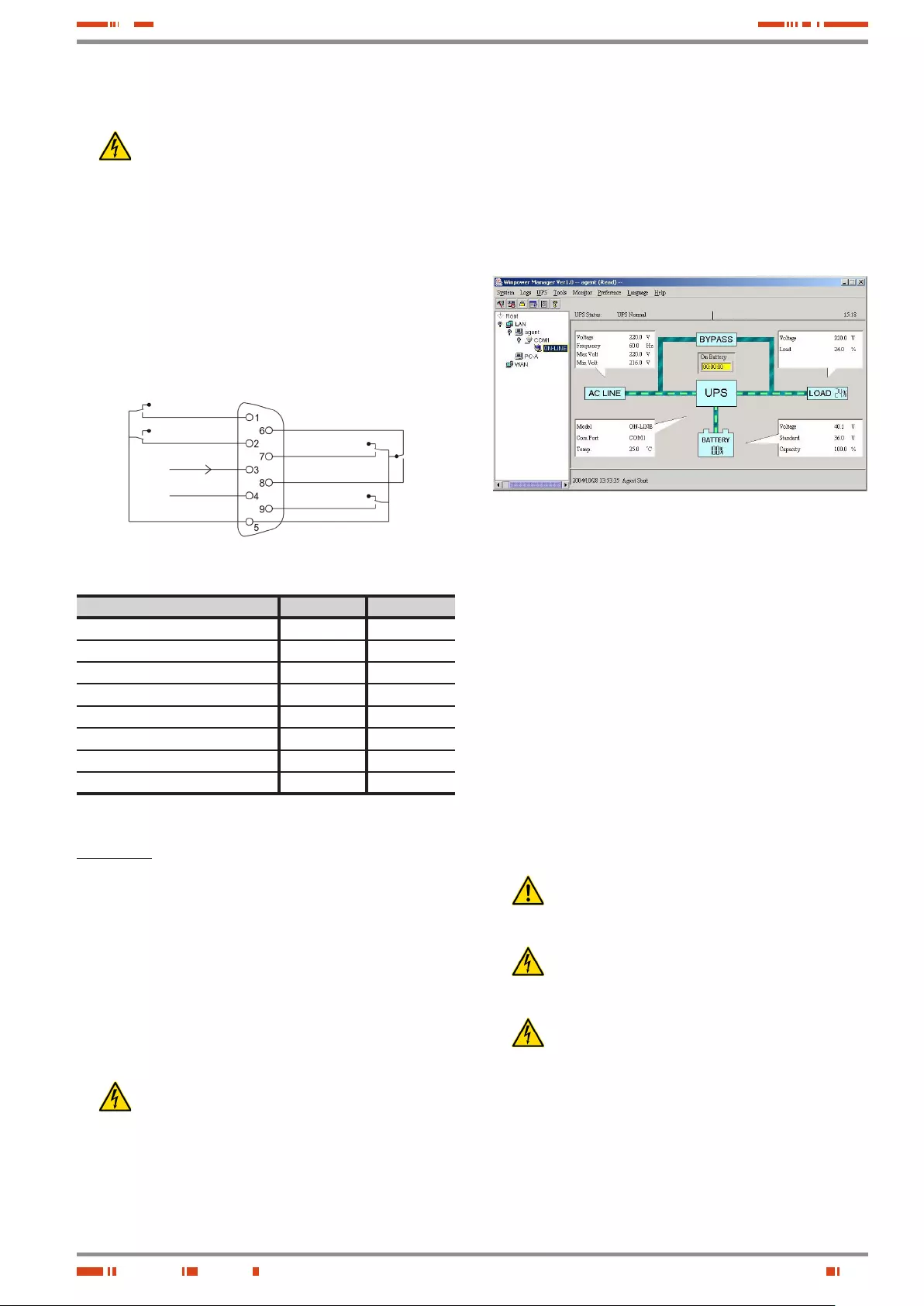

UPS fault

General alarm

Ground (GND)

Common

Bypass

Low battery

UPS on

AC mains fault

Fig. 10. AS400 dry contact pin-out.

Description Pin-out Input/output

UPS fault 1Output

General alarm 2Output

Ground (GND) 3Input

Common 5Input

Bypass 6Output

Low battery 7Output

UPS "On" 8Output

AC mains fault 9Output

Tabla 5. AS400 dry contacts alarms.

Installation.

• Remove the screws that fix the protection cover of the slot of

the equipment and the own cover.

• Take the AS400 card and insert it into the smart slot. Make

sure that it is well connected, so the resistance that the own

connector inside the slot makes has to be overcome.

• Fix the card with the previous removed screws.

• Connect the DB9 connector from AS400 with the peripheral

to be communicated.

5.3.6.4. Protection against transient voltages for

modem / ADSL / Fax / ... lines.

• Communication line (COM) is a very low voltage circuit

of safety. To preserve the quality, it has to be installed

separate from other lines that have dangerous voltages (energy

distribution line).

• Connect the main line for the modem / ADSL / Fax /... to the

RJ45 connector of the equipment, labelled as "Input".

• Connect the own modem / ADSL / Fax /... to RJ45 connector

of the equipment, labelled as "Output".

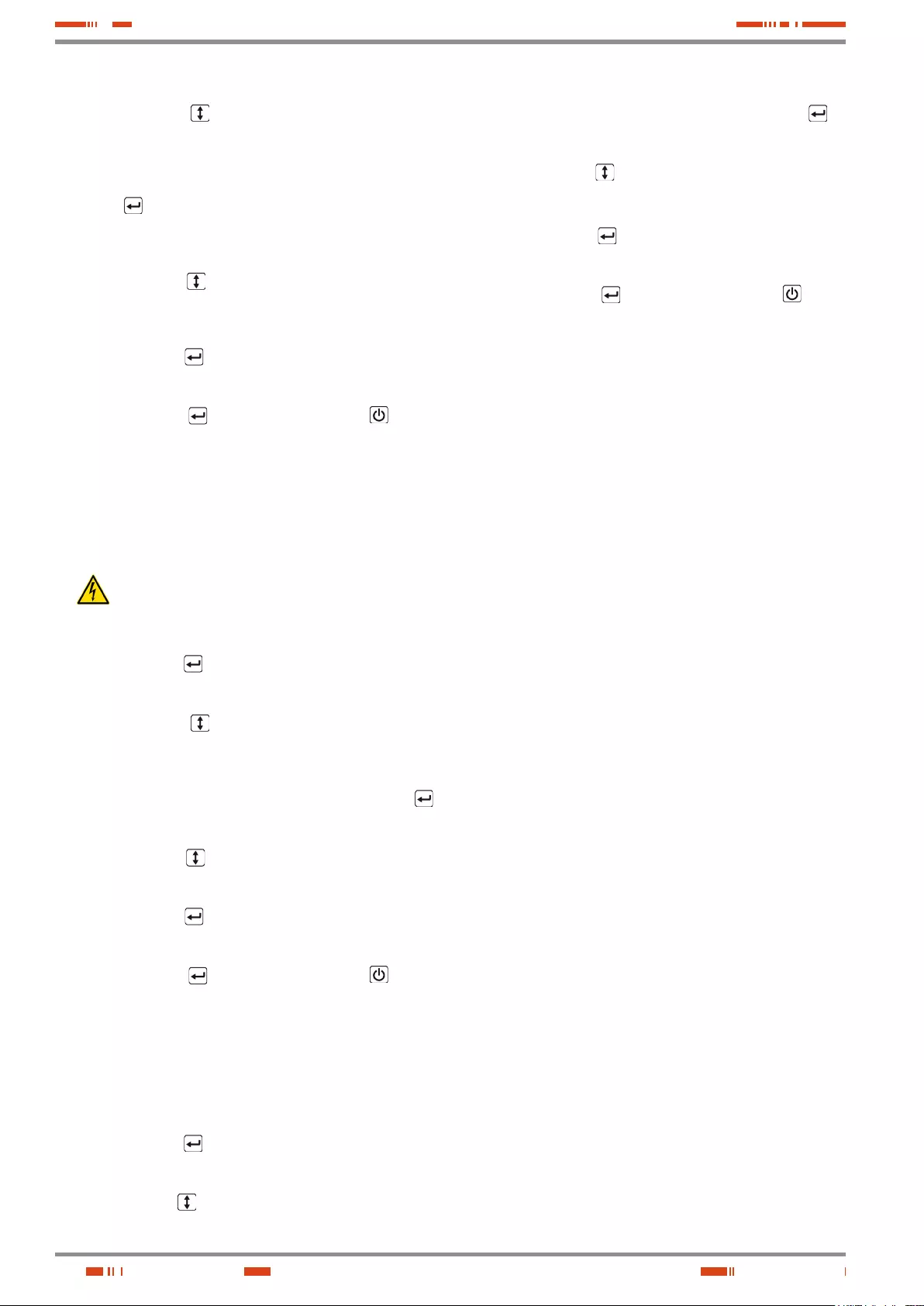

5.3.7. Software.

• Free software download - WinPower.

WinPower is a UPS monitoring software, which makes a

user-friendly interface of monitoring and management. This

software supplies an auto Shutdown for a system based on

several PCs in case of an electrical blackout. With this soft-

ware, the end-users can monitor and manage any UPS in the

same IT network, through the RS232 or USB communication

port, never mind the distance between them.

Fig. 11. Main screen of the monitoring software.

• Installation procedure:

Go to website:

http://support.salicru.com

Choose the operating platform that you need and follow

the instructions described in the web site to download the

software.

When downloading the needed files from Internet, enter

the following licence to install the software:

511C1-01220-0100-478DF2A .

When the computer is rebooted, WinPower software will be

shown as an icon with plug shape and green colour in the

system tray, near the clock.

5.3.8. Considerations before

commissioning with load

connected.

• It is recommended to charge the batteries for 12 hours

as minimum before using the UPS for first time. When

supplying voltage to the equipment, the battery charger will

automatically work.

• (B1) equipments with extended back up time has a

battery charger with higher quality performances. It is

recommended to charge the batteries for 12 hours as min-

imum before using the UPS for first time.

• Nevertheless, those equipments with extended back

up time and with no additional battery charger, it s rec-

ommended to charge the batteries of each battery module

for 12 hours.

• Although the equipment can work without charging the bat-

teries during the stated time without any problem, the risk of

a long blackout has to be valued during the first operating

hours and the available autonomy time in the UPS.

• Do not start up the equipment and loads completely till

chapter 6 states it.

20

Nevertheless, when it is done, it will be done gradually to

avoid any problem, as minimum in the first commissioning.

• If inductive loads with big inrush current apart from sensi-

tive ones are required to be connected like laser printers or

CRT monitors, keep in mind the start inrush currents of these

peripherals in order to avoid that the equipment becomes

blocked under the worst conditions.

It is better to not connect the loads of this kind, due to the high

quantity of energy resources that take from the UPS.

USER MANUAL

21

SALICRU

6. Operating.

6.1. Start up.

6.1.1. Controls before commissioning.

• Make sure that all the connections have been made prop-

erly, respecting the labelling of the equipment and the in-

structions of chapter 5.

• Check that the UPS is turned Off (shutdown).

• Be sure that all the loads are turned «Off».

Turn off the connected loads before starting up the

UPS , and start up the loads one by one, when the

UPS is started up only. Before shutdown the UPS, check all

the loads are out of service (Off).

• It is very important to proceed in the established order.

• For UPS view, see figures 1 to 3.

6.2. UPS start up and shutdown.

6.2.1. Initial UPS start up.

• Check that the power supply connection is correct.

• Connect the power cord from UPS input to mains power

supply. The LCD panel lights and shows the UPS status,

"STBY" (Wait mode).

• Press over the start up key for more than 3 seconds. The

UPS will shift to "NORM" mode (Line mode).

• Check that there are not any alarm or warning activated in

the UPS screen and in case of them fix them before pro-

ceeding (consult the troubleshooting guide).

• In case of having battery modules connected to the equip-

ment, it is needed to set the complete system (UPS - quan-

tity of battery modules), see section 7.1.6.3.

• To change or modify other factory preset values, consult sec-

tion 7 of this document.

• In the initial start up, the UPS auto-senses the input fre-

quency and established it as the standard one.

In extreme cases can happen, although is almost not pos-

sible, that the mains frequency is very high or low from the

nominal and takes as a default value the wrong one. Check

the frequency in the control panel and repeat the procedure

if this circumstance would occur.

6.2.2. UPS start up, with mains present.

• For the daily start up of the equipment, press over the start up

key for more than 3 seconds, the acoustic alarm will beep

for 1 sec. and the UPS will start up.

• Fan will be started up and the LCD from control panel will

show the status of the equipment.

• After several seconds, the UPS is established on "NORM"

(Line mode). If the mains voltage is wrong, the UPS will shift

to battery mode "BATT", with no break in the power supply to

the outlets.

• Start up the load/s, without overloading the equipment.

6.2.3. Start up of the UPS, with no mains

present.

• Press over the start up key for more than 3 seconds, the

acoustic alarm will beep for 1 sec. and the UPS will start up.

Fan will be started up and the LCD from control panel will

show the status of the equipment.

• After several seconds, the UPS is established on battery

mode "BAT T". If mains is restored, the UPS will shift to line

mode "NORM", with no break in the power supply to the out-

lets.

• Start up the load/s, without overloading the equipment.

6.2.4. UPS shutdown, with mains

present.

• Shutdown the load/s.

• Press over the start up key for more than 3 seconds to

shutdown the inverter. Several seconds after, the LCD panel

is shutdown and the complete equipment will be out of ser-

vice.

• Outlets will be with no voltage.

6.2.5. UPS shutdown, with no mains

present.

• Shutdown the load/s.

• Press over the start up key for more than 3 seconds to

shutdown the UPS. Several seconds after, the LCD panel is

shutdown and the complete equipment will be out of service.

• Outlets will be with no voltage.

22

• The following critical alarms do not allow deactivating

the own acoustic alarm:

Low battery, Fan fault, internal Over temperature in the equip-

ment and battery fault or damaged.

• The acoustic alarm can be deactivated when beeping,

but it will be activated again as soon as a new alarm

is triggered.

7.1. 2 . Acoustic alarms.

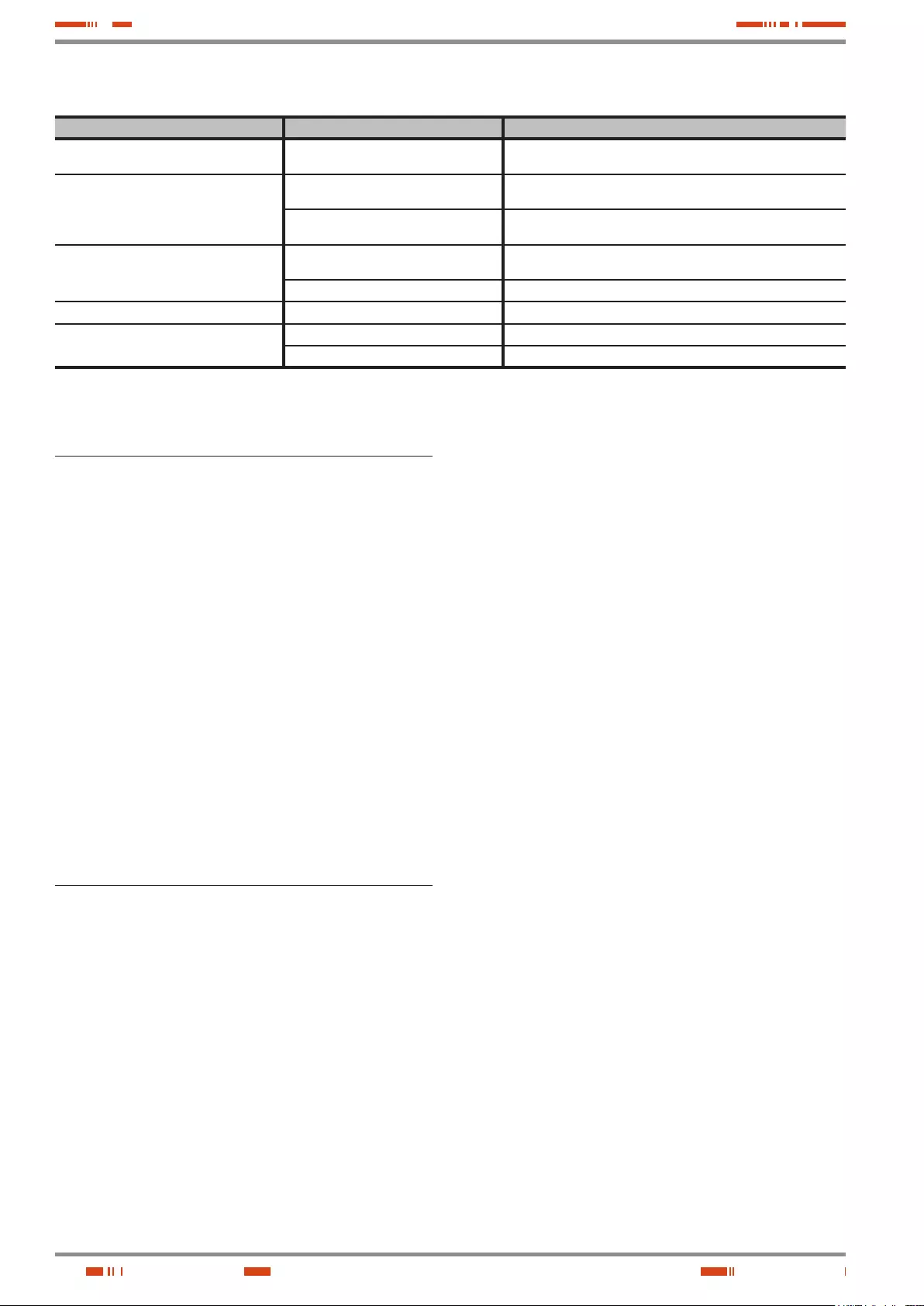

Code Condition Modulation Alarm silent function

BAT T Warning Every 4 sec. It can be silenced

BTOP Warning Every 1 sec. It can be silenced

TEST Warning Every 2 sec. It can be silenced

OPVH Fault Continuous It can be silenced

OPVL Fault Continuous It can be silenced

OPST Fault Continuous It can be silenced

OVLD Warning Every 1 sec. It can be silenced

BATH Warning Continuous It can be silenced

BATL Warning Every 1 sec. It can't be silenced

OVTP Warning Every 1 sec. It can't be silenced

OVTP Fault Continuous It can't be silenced. It is silenced

when temperature decreases.

FNLK Fault Continuous It can't be silenced. It is silences

whtn fan works.

BTWK Warning Continuous It can be silenced

Tabla 7. Acoustic alarms. Condition and modulation.

7.1.3. UPS status and colour of the LCD

panel, depending on the condition.

By means of an abbreviated chain of 3 to 4 characters (code), in

the LCD panel is displayed the status of the equipment.

The following table 8 shows the corresponding description to

each letter sequence or chain.

Code Condition Description LCD colour

STBY Status UPS working on Standby. Blue

IPVL Status Input voltage too low. Blue

IPVH Status Input voltage too high. Blue

IPFL Status Input frequency too low. Blue

IPFH Status Input frequency too high. Blue

NORM Status UPS working on line mode. Blue

AVR Status UPS working on stabilizer mode. Blue

BAT T Warning UPS working on battery mode. Blue

BTOP Warning Battery disconnected. Red

TEST Warning UPS working on battery in life / function

test. Blue

OPVH Fault Battery mode with output voltage too

high. Red

OPVL Fault Output voltage is too low. Red

OPST Fault Short-circuit at the output. Red

OVLD Warning Overload. Red

BATH Warning Battery voltage is too high. Red

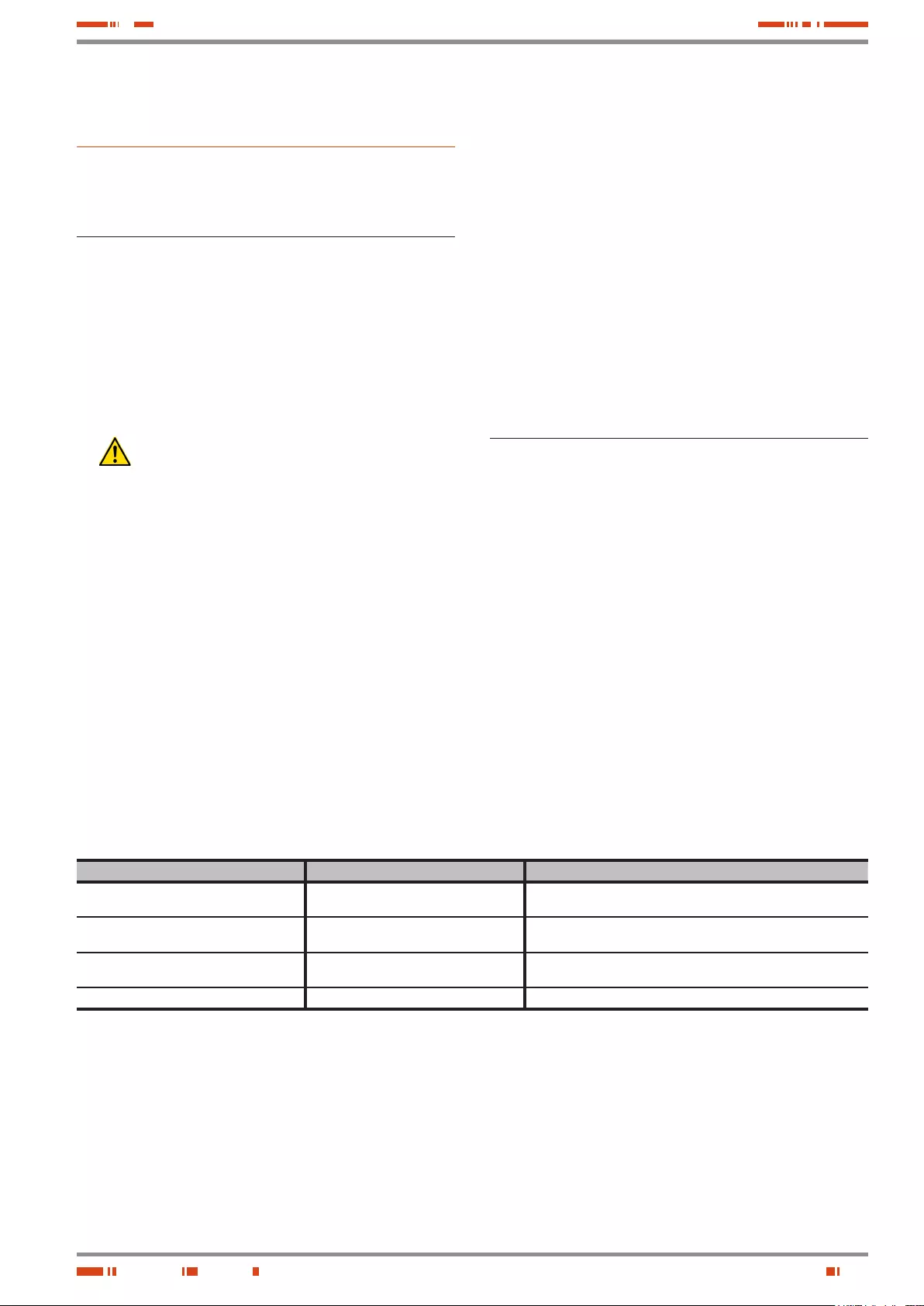

7. Control panel.

7.1. Functionalities.

Fig. 12. Control panel view.

The UPS has a graphic screen with LCD panel with four keys

and to colour backlight, blue and red. It is used the blue colour

as backlight with black text. When any critical alarm of the equip-

ment is triggered, the light changes to red (see table 8).

7.1.1. Button functions.

Button Function Description

Start up and

shutdown

ON / OFF

To start up or shutdown the equipment:

Press the key for more than 3 sec..

To escape from fault mode:

Turn off the input protection from mains or

unplug the schucko plug from the wall outlet

and press this key for more than 2 seconds.

UPS test.

acoustoc alarm

silencer

To do a battery test:

Hold this key pressed for more than 3 seconds.

To do the battery lifetime test:

Hold this key pressed for more than 10

seconds.

To deactivate the acoustic alarm:

Press this key for one seconde.

Selection

Press this key to select the setting value, one by

one.

Enter

Enter into the setting mode:

Hold this key pressed for more than 3 seconds.

Introducir la opción de ajuste:

Hold this key pressed for more than 1 second.

The equipment allows setting the blinking

parameters and the characters chain.

Conrm settings:

Hold this key pressed for 1 second.

Escape from setting mode:

Hold this key pressed for 3 seconds or the key

ON/OFF for 0,5 seconds.

Tabla 6. Functionality of the control panel keypad.

• Make sure that batteries are completely charged be-

fore doing any corresponding test.

USER MANUAL

23

SALICRU

Code Condition Description LCD colour

BATL Warning Battery voltage is too low. Red

OVTP Fault Fault due to internal temperature too

high. Red

FNLK Fault Fan is faulty or doesn't work. Red

BTWK Warning Battery faulty or damaged. Red

Tabla 8. UPS status and LCD panel colour depending on the

condition.

7.1.4. Graphics displayed in the LCD

panel.

Icon Description Function

Input voltage

and frequency.

It displays the voltage and frequency values of

the input.

Input plug

indicator.

The icon is displayed in the screen, if the mains

is inside the permissible range of the equipment.

Output voltage

and frequency.

It displays the voltage and frequency values of

the output.

Output plug

indicator.

The UPS has two outlets groups, > 1 kVA

models. the icon is displayed when their

respective outlets have voltage.

UPS status

/ User setting

screen.

Acronym chain of the status mode. They diosplay

the condition of the equipment (see table 8).

Acronym chain of the values. They displayes the

options of the user setting (see table10).

Warning

indicator.

It is activated as warning fault mode or alarm in

the equipment.

Setting or

configuration.

It is activated when the equipment is on setting

or configuration mode .

Battery level

graph.

It displayes the battery charge level in %, which is

equal to the available energy capacity.

The bar is divided into five parts, each part

corresponds to a 20 % of the total capacity of

the battery set.

Load level graph.

It displayes the load level connected at the output

of the equipment in %, equivalent to the power

consumed in real time.

The bar is divided into five parts, each part

corresponds to a 20 % of the load or nomknal

power of the equipment.

Tabla 9. Button or control panel keypad funcionality.

7.1.5. User settings.

By means of an abbreviated chain of 2 to 4 characters (code), the

configurable parameters are displayed in the LCD panel.

Table 10 shows the corresponding description to each one of

these letters sequences or chain, as well as the possible se-

lectable variables or values.

Code Description Values

OPV Output voltage selection.

(220)=220V

(230)=230V

(240)=240V

AVR Input voltage type

(000)=Normal range

(001)=Wide range

(002)=Gen set

EBM External battery module 0 - 9 it is the quantity of

battery modules

TEST Auto test. (000) Deactive

(001) Active

AR Automatic restart. (000) Deactive

(001) Active

GF

Green mode.

(000) Deactive

(001) Active

BZ Acoustic alarm control. (000) Deactive

(001) Active

LS1 IEC outlets group 1

(not available in equipments ≤ 1 kVA)

(000) Deactive

(001) Active

LS2 IEC outlets group 2

(not available in equipments ≤ 1 kVA)

(000) Deactive

(001) Active

Tabla 10. UPS status and character chain description.

7.1.6. Explanations about the user

settings and other ones.

7.1.6.1. Operating modes.

• Normal range: In this mode, the input voltage range are ±20%.

• Wide range: In this mode, the input voltage range are from

+20% to –30%.

• Gen mode: On this mode the load is transferred to battery

mode (inverter output), when frequency is higher than the

upper and lower threshold , of 40 and 70 Hz respectively.

• Battery mode (inverter output): When the UPS is working

out from the range or during a blackout, the acoustic alarm

beeps every four seconds. Also the LCD panel displays the

"BATT" indication, corresponding to the status of the equip-

ment to show the UPS operating mode -Battery mode-.

If on this condition, the battery capacity is low, the alarm

beeps once per second and the LCD panel displays the

"BATL" indication.

• Standby mode.

When the UPS is shutdown and it remains connected to the

wall outlet, it will be on standby mode. In the LCD panel will

display "STBY" to show that the power supply to the loads is

not available. On this mode the battery will be charged, if it

was needed.

7.1.6. 2. IEC outlet groups.

• It is possible to set the status (active or deactive) of the both

available connector groups LS1 and LS2, at any time and

separately.

This function is not available in equipments ≤ 1 kVA,

because there is only one IEC connector group.

• To set the IEC outlet group through the LCD panel of the

equipment, proceed as follows:

1.- Enter into the configuration mode.

Press the key for more than 3 seconds and the UPS

will shift to setting mode.

24

2.- Select the configuration elements.

Press the key to select the configurable elements

stated in table 10 and go forward or backward till reaching

"LS1" or "LS2" as it is required.

3.- Validate the configuration element.

When the LCD panel displays "LS1" or "LS2", press the

key for more than one second to enter into the ele-

ment to set. The values of the variables blink (blinking

mode).

4.- Select the configuration value.

Press the key to select the configuration value. Se-

lect the value (001) or (000) to set the desired IEC outlet

group, as turned on or off respectively.

5.- Confirm the configuration.

Press the key for one second, the UPS will return to

the previous point 2.

6.- Escape from setting mode.

Press the key for 3 seconds or the key for 0,5

seconds, to escape from the setting mode.

7.1.6.3. Setting the UPS to connect it with "n"

battery modules.

• In order to be sure that the LCD panel displays the correct

remaining capacity of the batteries, the available quantity of

battery modules has to be set and updated when facing any

modification, otherwise the displayed data will not be real.

Models ≤ 1 kVA do not have connectors to extend the

back up time.

• Proceed as follows:

1.- Enter into the configuration mode.

Press the key for more than 3 seconds and the UPS

will shift to setting mode.

2.- Select the configuration elements.

Press the key to select the configurable elements

stated in table 10 and go forward or backward till reaching

"EBM".

3.- Validate the configuration element.

When the LCD panel displays "EBM", press the key

for more than one second to enter into the element to set.

4.- Select the configuration value.

Press the key to select the quantity of battery mod-

ules available for the UPS.

5.- Confirm the configuration.

Press the key for one second, the UPS will return to

the previous point 2.

6.- Escape from setting mode.

Press the key for 3 seconds or the key for 0,5

seconds, to escape from the setting mode.

7.1.6.4. Setting the "Green" function.

• If this function is activated, the UPS disable the output when

it is on battery mode when it is not detected a minimum of

consumption. By default, this feature is deactivated, if it is

needed to modify it, proceed as follows:

1.- Enter into the configuration mode.

Press the key for more than 3 seconds and the UPS

will shift to setting mode.

2.- Select the configuration elements.

Press the key to select the configurable elements stated

in table 10 and go forward or backward till reaching "GF".

3.- Validate the configuration element.

When the LCD panel displays "GF", press the key for

more than one second to enter into the element to set.

4.- Select the configuration value.

Press the key to select the configuration value.

Select the value (001) to activate function.

5.- Confirm the configuration.

Press the key for one second, the UPS will return to

the previous point 2.

6.- Escape from setting mode.

Press the key for 3 seconds or the key for 0,5

seconds, to escape from the setting mode.

USER MANUAL

25

SALICRU

8. Maintenance, warranty

and service.

8.1. Maintenance of the battery.

• Pay attention to the safety instructions regarding battery (see

document EK266*08).

• The equipment from SPS.ADVANCE RT series only re-

quires a minimum maintenance. The used battery in the

standard models is Pb-Ca, sealed, VRLA and maintenance

free. These models require a minimum of reparations. The

only requirement is to charge the UPS regularly, in order to

prolong the battery lifetime. Meanwhile, it is connected to the

power supply, never mind if the UPS is ON or OFF, it will keep

the batteries charged.

• In equipments that include Pb-Ca batteries, the figures,

stated in table 2 of the EK266*08 document, of charge

period time depending on the temperature that they are ex-

posed, must be respected, otherwise the warranty will be in-

validated.

• Under normal conditions, the battery lifetime is from 3 to 5

years 25º C. In case that the battery was not in good condi-

tions, it has to be replaced before. This replacement has to

be done by qualified staff.

• Always replace them with the same quantity and type.

• Do not replace one battery only. All batteries have to be re-

placed at the same time and following the instructions of the

manufacturer.

8.1.1. Notes for installing and replacing

the batteries.

• If it is needed to replace the connection of any wire, purchase

original parts through authorised distributors or service cen-

tres in order to avoid overheating or sparks with risk of fire

because the size could not be enough.

• Do not short the + and - poles of the batteries, there is risk of

fire or electrocution.

• Be sure that there is no voltage before touching the batteries.

Battery circuit is not isolated from the input circuit. Hazardous

voltages can be found between the battery and earth termi-

nals.

• Even with the input circuit breaker switch from protection

panel is turned off, the internal parts of the UPS are still con-

nected to the batteries, so there are hazardous voltages in-

side.

Therefore, before doing any reparation or maintenance task,

the internal battery fuses and/or the interlink connections be-

tween them and the UPS, have to be removed.

• Batteries have hazardous voltages. The battery main-

tenance and replacement have to be done by qualified

personnel and familiarised with them. Nobody else can ma-

nipulate them.

8.2. UPS Trouble Shooting guide.

If the UPS doesn't work properly, check the information given

by the LCD of the control panel, according to the models and

power of the equipment. Try to solve the problem by means

of the established steps in the tables 11 and 12. In case the

problem persists, consult with our Service and Technical Sup-

port S.T.S..

When it is needed to contact with our Service and Technical

Support S.T.S. , provide the following information:

• UPS model and serial number.

• Date when the problem occurred.

• Complete description of the problem, including the informa-

tion given by the LCD panel and the status of the alarms.

• Power supply condition, type of load and the level connected

to the UPS, ambient temperature, cooling conditions.

• Information of the batteries (capacity and battery quantity), if

the equipment is (B0) or (B1) -with external batteries-.

• Other informations that you may think that they are important.

8.2.1. FAQ. Acoustic alarms.

Acoustic alarm Possible cause Solution

Beep every 4 seconds. The equipment is on battery mode Check the input voltage and/or the power cord is connected to the AC

wall outlet.

Beep every second with LCD from control

panel with "BATL" indication. Low battery voltage. Save the taks in process and shutdown the load/s and the UPS.

Beep every second with LCD from control

panel with "OVLD" indication. Overload at the output. Check the load level connected at the output and proceed to remove

the exceeded one, keeping in mind the critical loads.

LCD panel is still on red colour UPS fault. Consult with the S.T.S..

Tabla 11. Acoustic alarms.

26

8.2.2. FAQ. General indications.

Problem Possible cause Solution

The equipment doesn't start up when pressing

over the corresponding key. Internal fuse blown. Consult with the S.T.S..

The equipment is ON but the loads do not

have power supply