Table of Contents

- Legal information

- Safety information

- Table of Contents

- 1 Information on the product

- 2 For your safety

- 3 Fitting and electrical connection

- 4 Commissioning

- 5 Application programs

- 6 Operation

- 7 Scope of functions

- 8 Notes on software

- 9 Description of channel-independent functions

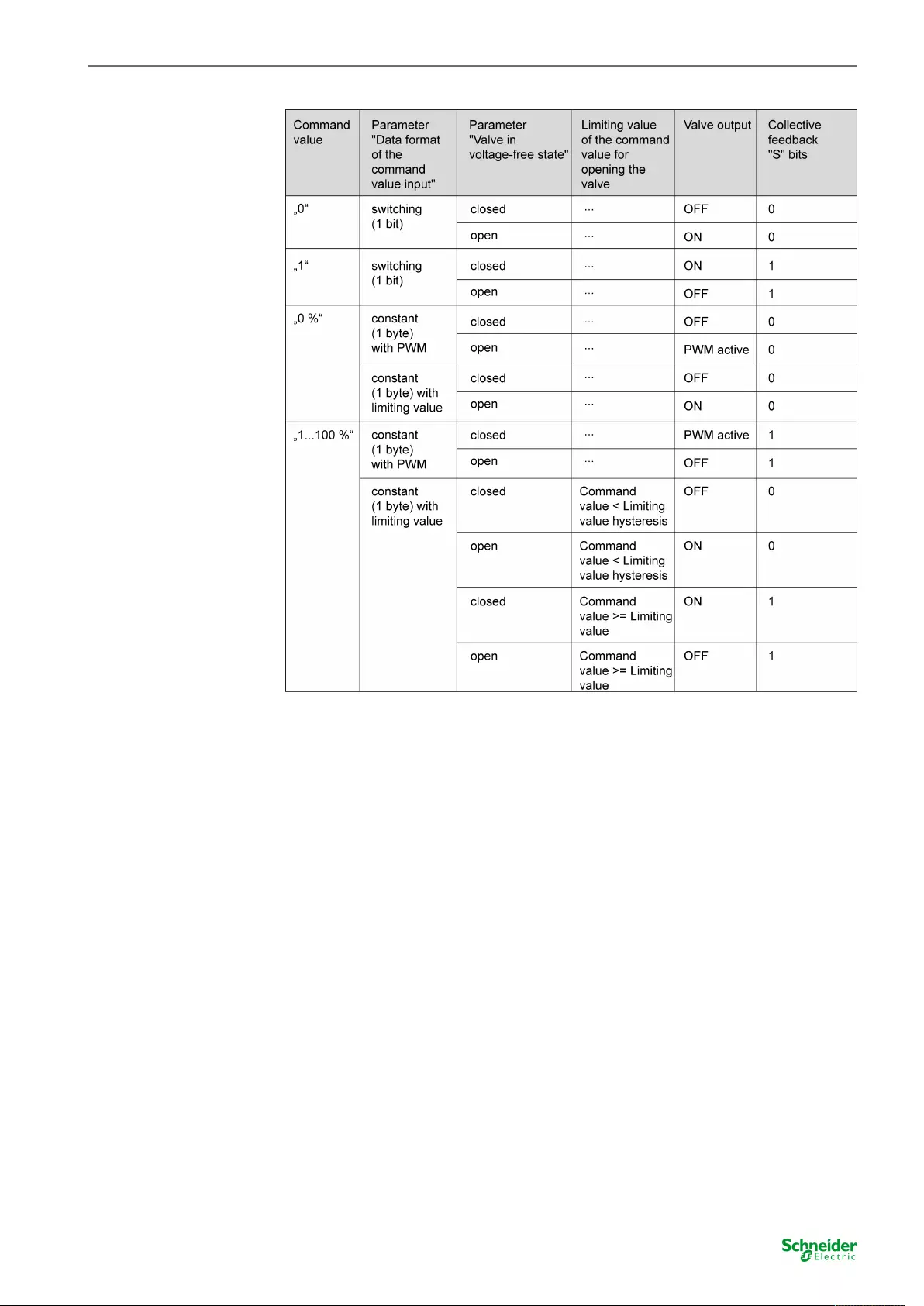

- 9.1 Parameter configuration for valve outputs

- 9.2 Priorities for valve outputs

- 9.3 Manual control for valve outputs

- 9.4 Service mode for valve outputs

- 9.5 Collective feedback for valve outputs

- 9.6 Summer/winter switch-over for valve outputs

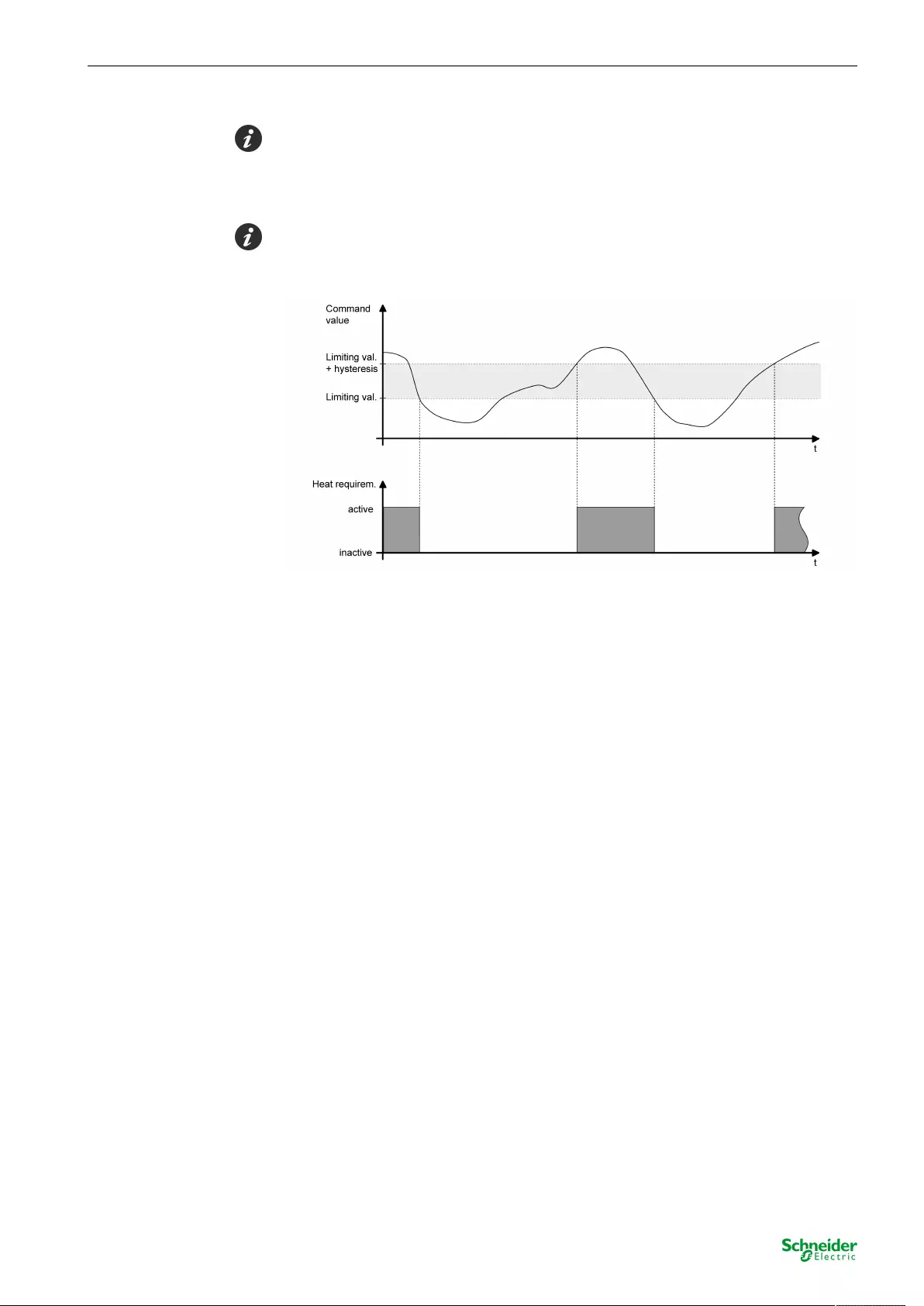

- 9.7 Heat requirement and largest command value for valve outputs

- 9.8 Pump control for valve outputs

- 9.9 Failure of the valve operating voltage

- 9.10 Internal group communication

- 9.11 Channel-independent parameters

- 9.12 Objects for device functions

- 10 Channel-orientated functional description for valve outputs

- 10.1 Valve direction of action

- 10.2 Reset behaviour

- 10.3 Data formats for command values

- 10.4 Cycle time

- 10.5 forced position

- 10.6 Cyclical command value monitoring / emergency operation

- 10.7 Command value limit

- 10.8 Status functions

- 10.9 Short-circuit and overload detection

- 10.10 Valve rinsing

- 10.11 Operating hours counter

- 10.12 Parameter for valve outputs

- 10.13 Objects for valve outputs

- 11 Channel-orientated functional description for controllers

- 11.1 Operating modes and operating mode change-over

- 11.2 Control algorithms and calculation of command values

- 11.3 Adapting the control algorithms

- 11.4 Operating mode switchover

- 11.5 Room temperature measurement

- 11.6 Temperature setpoints

- 11.7 Command value and status output

- 11.8 Disabling functions

- 11.9 Underfloor heating temperature limit

- 11.10 Response after a device reset

- 11.11 Parameters for room temperature controllers

- 11.12 Objects for room temperature controllers

Schneider Electric MTN6730-0002 User Manual

Displayed below is the user manual for MTN6730-0002 by Schneider Electric which is a product in the Electrical Actuators category. This manual has pages.

Related Manuals

SpaceLogic KNX Valve Drive

Controller

Application description

This document describes the ETS software application used to program the device.

MTN6730-0002

11.08.2020

www.se.com

SpaceLogic KNX

SpaceLogic KNX Valve Drive Controller

2 | MTN6730-0002 11.08.2020

Legal information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and fur-

nished for informational use only. No part of this guide may be reproduced or trans-

mitted in any form or by any means (electronic, mechanical, photocopying, record-

ing, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the

guide or its content, except for a non-exclusive and personal license to consult it on

an “as is” basis. Schneider Electric products and equipment should be installed,

operated, serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed

by Schneider Electric and its subsidiaries for any errors or omissions in the inform-

ational content of this material or consequences arising out of or resulting from the

use of the information contained herein.

SpaceLogic KNX Valve Drive Controller

3 | MTN6730-0002 11.08.2020

Safety information

Read these instructions carefully and look at the equipment to become familiar with

the device before trying to install, operate, service, or maintain it. The following

special messages may appear throughout this manual or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that accompany this symbol to

avoid possible injury or death.

DANGER!

DANGER

indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING!

WARNING

indicates a hazardous situation which, if not avoided, could result in death or seri-

ous injury.

CAUTION!

CAUTION

indicates a hazardous situation which, if not avoided, could result in minor or mod-

erate injury

Additonal notes

You will find additional information here to make your work easier.

Table of Contents

SpaceLogic KNX Valve Drive Controller

4 | MTN6730-0002 11.08.2020

Table of Contents

1Information on the product....................................................................................6

1.1 Product catalogue ................................................................................... 6

1.2 Function................................................................................................... 6

1.3 Device components................................................................................. 9

1.4 Delivery state........................................................................................... 9

1.5 Technical data ....................................................................................... 10

2For your safety....................................................................................................12

2.1 Safety instructions ................................................................................. 12

3Fitting and electrical connection .........................................................................13

4Commissioning ...................................................................................................17

5Application programs..........................................................................................18

6Operation............................................................................................................19

6.1 Operating elements ............................................................................... 19

6.2 Status displays and output behaviour ................................................... 19

6.3 Operating modes................................................................................... 22

7Scope of functions ..............................................................................................27

8Notes on software...............................................................................................30

9Description of channel-independent functions....................................................31

9.1 Parameter configuration for valve outputs............................................. 31

9.2 Priorities for valve outputs ..................................................................... 31

9.3 Manual control for valve outputs ........................................................... 32

9.4 Service mode for valve outputs ............................................................. 37

9.5 Collective feedback for valve outputs.................................................... 39

9.6 Summer/winter switch-over for valve outputs........................................ 43

9.7 Heat requirement and largest command value for valve outputs .......... 44

9.8 Pump control for valve outputs.............................................................. 48

9.9 Failure of the valve operating voltage ................................................... 51

9.10 Internal group communication ............................................................... 52

9.11 Channel-independent parameters......................................................... 54

9.12 Objects for device functions .................................................................. 65

10 Channel-orientated functional description for valve outputs...............................69

10.1 Valve direction of action ........................................................................ 69

10.2 Reset behaviour .................................................................................... 69

10.3 Data formats for command values ........................................................ 73

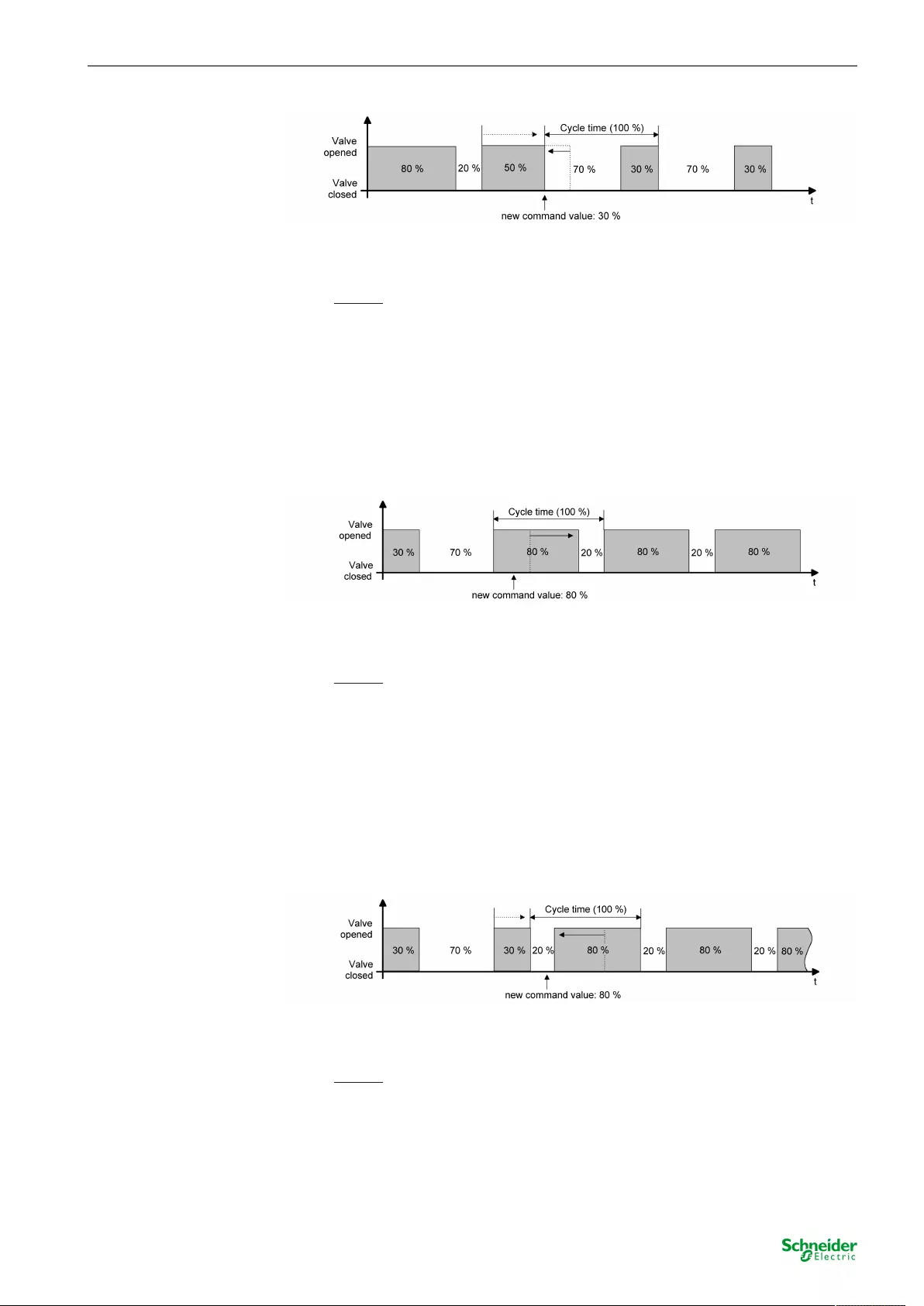

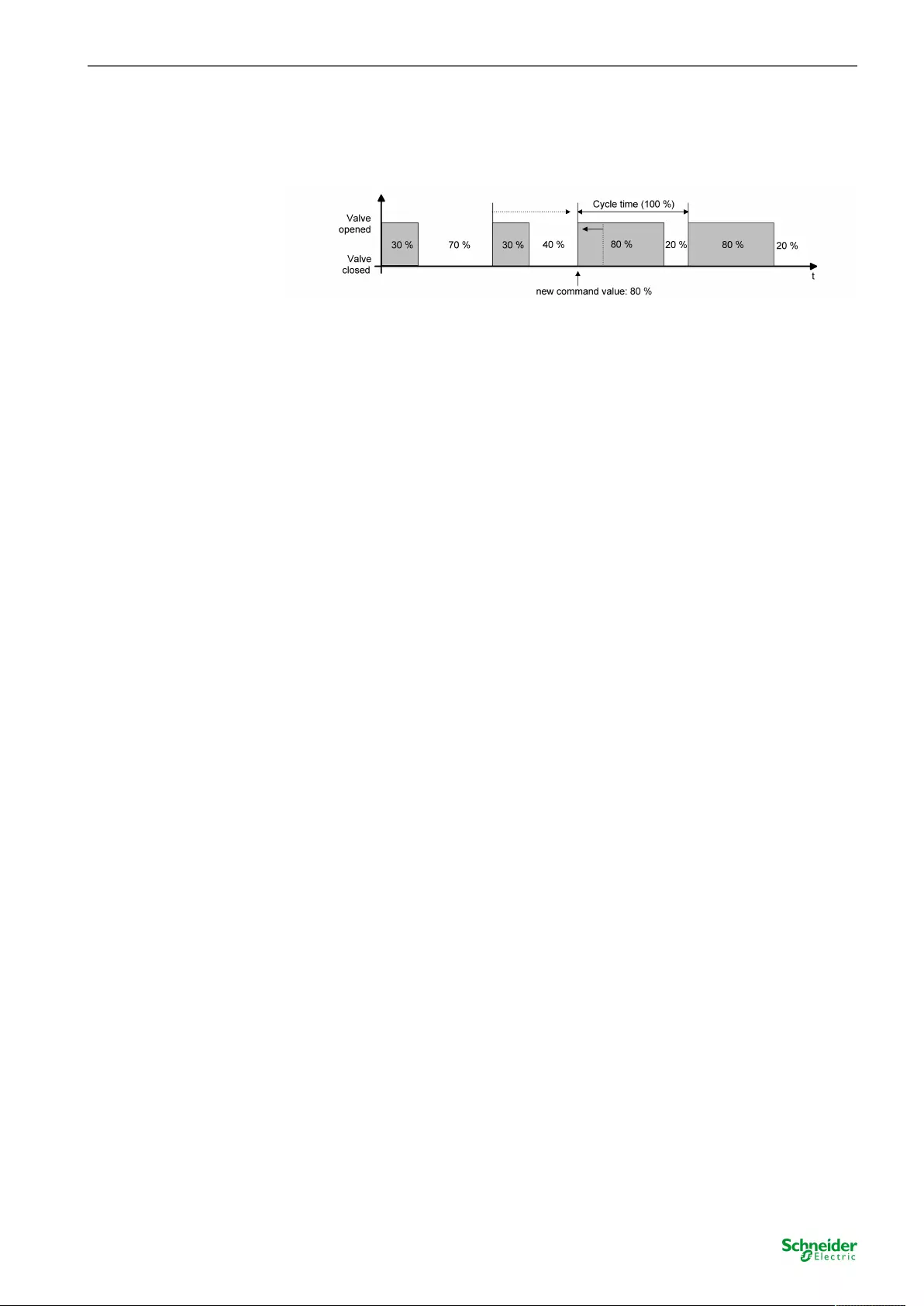

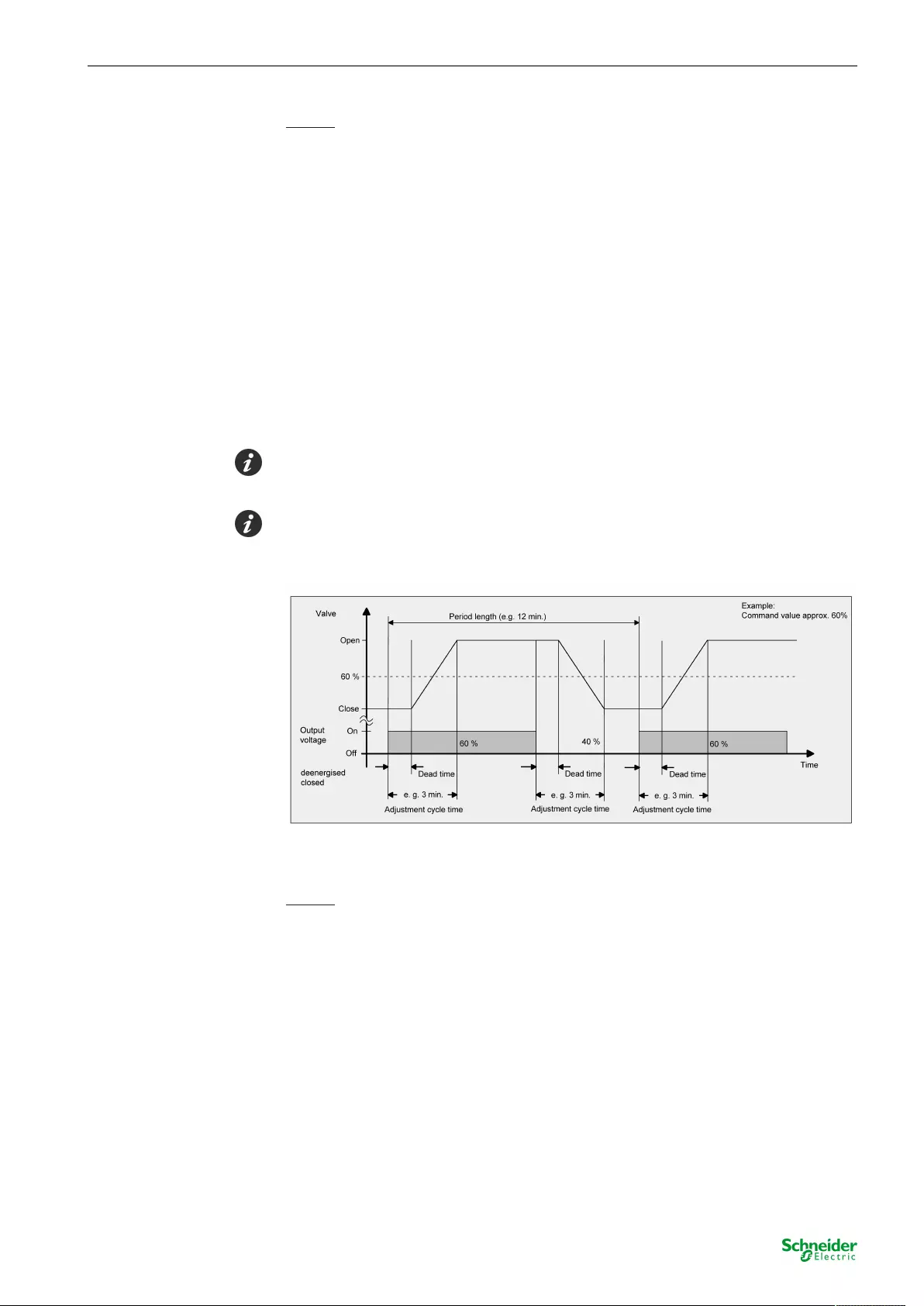

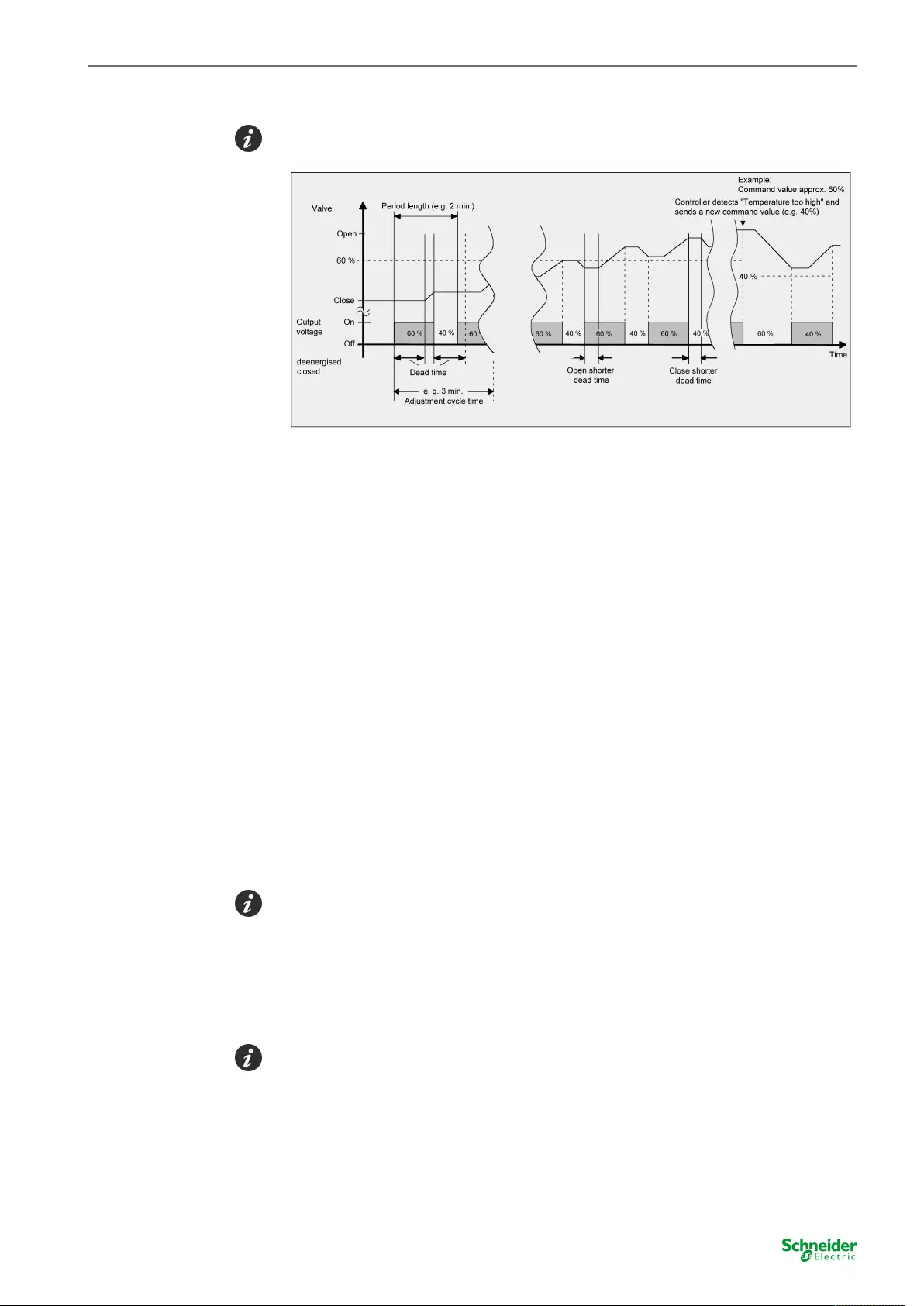

10.4 Cycle time.............................................................................................. 78

10.5 forced position ....................................................................................... 80

10.6 Cyclical command value monitoring / emergency operation ................. 82

10.7 Command value limit............................................................................. 84

10.8 Status functions..................................................................................... 86

10.9 Short-circuit and overload detection...................................................... 92

Table of Contents

SpaceLogic KNX Valve Drive Controller

5 | MTN6730-0002 11.08.2020

10.10 Valve rinsing.......................................................................................... 98

10.11 Operating hours counter...................................................................... 102

10.12 Parameter for valve outputs ................................................................ 106

10.13 Objects for valve outputs..................................................................... 123

11 Channel-orientated functional description for controllers .................................129

11.1 Operating modes and operating mode change-over........................... 129

11.2 Control algorithms and calculation of command values ...................... 131

11.3 Adapting the control algorithms........................................................... 138

11.4 Operating mode switchover................................................................. 140

11.5 Room temperature measurement ....................................................... 147

11.6 Temperature setpoints ........................................................................ 150

11.7 Command value and status output...................................................... 157

11.8 Disabling functions .............................................................................. 163

11.9 Underfloor heating temperature limit ................................................... 163

11.10 Response after a device reset............................................................. 164

11.11 Parameters for room temperature controllers ..................................... 164

11.12 Objects for room temperature controllers............................................ 180

SpaceLogic KNX Valve Drive Controller Product catalogue

6 | MTN6730-0002 11.08.2020

1 Information on the product

1.1 Product catalogue

Product name: SpaceLogic KNX Valve Drive Controller

Use: Actuator

Design: RMD (rail-mounted device)

Art.-no. MTN6730-0002

1.2 Function

General

The heating actuator is used for the activation of electrothermal actuators (ETA) for

heating or cooling systems. It possesses 6 electronic outputs, each of which can si-

lently activate up to 4 (AC 230 V) or 2 (AC 24 V) actuators. Both deenergised

closed and deenergised opened actuators can be connected.

In addition, the actuator contains up to 6 room temperature controllers (RTC),

which are integrated in the device software and which work independently of the

process. The command value outputs of these controllers can be internally linked

to the electronic valve outputs of the actuator, meaning that temperature control

and valve activation can take place using just one bus device, if required. The use

of external room temperature controllers (e.g. push-button sensors with RTC) is

thus not absolutely essential, but is possible as the valve outputs can also be activ-

ated individually via the KNX. The integrated controllers can also transmit com-

mand value telegrams to the KNX and thus activate other heating actuators or fan

coil actuators.

The room temperature is made available to the integrated controllers via separate

communication objects. All the controller functions (e.g. setpoint temperature spe-

cification, operating mode switchover, switchover of the operating mode) are con-

trolled via KNX communication objects (object controller without its own operating

elements), meaning that controller operation is possible via controller extensions or

visualisations.

Functions of the electronic valve outputs

The heating actuator receives 1-bit or 1-byte command value telegrams, transmit-

ted, for example, by external KNX room temperature controllers or by one of the in-

ternal controllers. The actuator controls its valve outputs either in switching form or

with a PWM signal, according to the data format of the command values and the

configuration in the ETS. The cycle time for constant PWM output signals can be

configured separately for each valve output of the heating actuator. This allows in-

dividual adaptation to different actuator types.

On activation with constant command values, an optional command value limit can

be designed, which allows the limitation of received command values at the "Min-

imum" and "Maximum" limits. A minimum command value can be used, for ex-

ample, for the implementation of basic heating or cooling. A maximum command

value allows the limitation of the effective command value range, which usually has

a positive influence on the lifespan of actuators.

The heating actuator possesses a heat requirement and pump controller. This pro-

duces a positive impact on the energy consumption of a housing or commercial

building through the transmission and evaluation of the largest command value in

the heating or cooling system. The information on the largest active command

value can be made available to suitable calorific furnaces with integrated KNX con-

SpaceLogic KNX Valve Drive Controller Function

7 | MTN6730-0002 11.08.2020

troller directly via a KNX telegram (1-byte), for example, to determine the optimum

flow temperature. Alternatively or additionally, the heating actuator can even evalu-

ate the command values of its outputs and make general heat requirement inform-

ation available in the form of limiting value monitoring with hysteresis (1-bit, switch-

ing). Using a KNX switch actuator, this allows the energy-efficient activation of

burner and boiler controllers with suitable control inputs (e.g. requirement-orient-

ated switch-over between the reduction and comfort setpoint in a central combi

boiler).

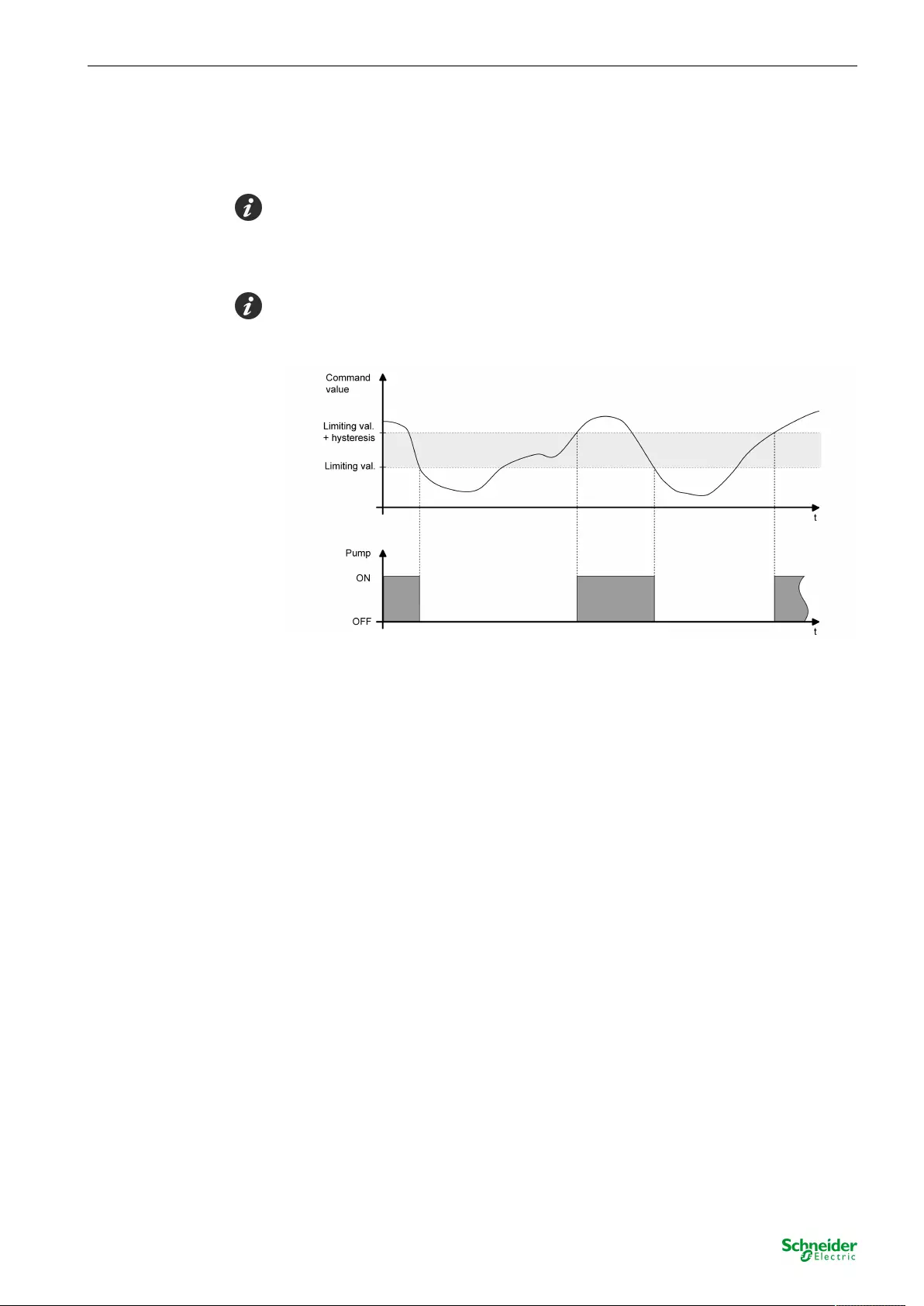

The heating actuator also allows switching activation of the circulation pump of the

heating or cooling circuit via a 1-bit KNX telegram. When using pump control, the

pump is only switched on by the actuator when at least one command value of the

outputs exceeds a limiting value with hysteresis defined in the ETS. The pump is

switched off when the limiting value is reached or undershot again. This saves

electrical energy, as the pump is only activated by sufficiently large, and thus ef-

fective, command values. Optional cyclical anti-sticking protection prevents the

sticking of the pump, if it has not been switched on by the command value evalu-

ation for a longer period of time.

To prevent calcification or sticking of a valve which has not been activated for

some time, the actuator has an automatic valve rinsing function. Valve rinsing can

be executed cyclically or using a bus command, causing the activated valves to run

through the full valve stroke for a preset period of time. If necessary, the intelligent

valve rinsing can be enabled. In so doing, cyclical rinsing using the full stroke is

only executed when a defined minimum command value limiting value was not ex-

ceeded during actuator operation.

Cyclical monitoring of the command values can be performed as an option. If, dur-

ing active cyclical monitoring, there are no command value telegrams during a pre-

set time, then emergency operation is activated for the affected valve output, for

which a configurable constant PWM command value can be preset. In addition, it is

possible to activate a forced position separately for each output using a 1-bit KNX

object. A defined PWM command value is set at the appropriate output.

Emergency operation and forced position can also be activated automatically in

case of bus voltage failure, after bus / mains voltage return or after an ETS pro-

gramming operation. If necessary, the command values for emergency operation

and the forced position can be influenced by the summer and winter mode of the

actuator, allowing the activation of different heating or cooling levels according to

the season. The actuator permits switchover between summer and winter mode at

any time using a 1-bit object.

The heating actuator possesses comprehensive feedback and status functions.

The active command value can be made available as status information, transmit-

ting either passively or actively, separately for each value output. A combined valve

status allows the collective feedback of various functions of an output in a single 1-

byte bus telegram.

The actuator is able to detect an overload or a short-circuit at the valve outputs

and, in consequence, to protect them against destruction. Outputs which have ex-

perienced a short-circuit or a constant load are deactivated after an identification

period. In this case, a short-circuit or overload signal can be transmitted via a KNX

communication object. The actuator can also signal a failure of the valve voltage

on the KNX.

The switch-on times of the valve outputs can be detected and evaluated separately

by operating hours counters. In addition, service operation is available, which, dur-

ing maintenance or installation, can move all assigned valve drives to a defined po-

sition (completely opened or completely closed) and can lock them against activa-

tion by command value telegrams. Both service mode and the locking status are

preset by a 2-bit forced operation telegram.

SpaceLogic KNX Valve Drive Controller Function

8 | MTN6730-0002 11.08.2020

Function of the room temperature controller

Six controllers are integrated in the device software, which can be used for single-

room temperature control. This allows the temperature to be set in up to 6 rooms or

room areas to specified setpoints through independent control processes. Depend-

ing on the operating mode, current setpoint temperature and room temperature,

using a controller means that a variable for heating or cooling control can be trans-

mitted to the KNX for the control circuit or be forwarded internally to a valve output.

The controller distinguishes between different operating modes (comfort, standby,

night, frost/heat protection) each with their own temperature setpoints for heating

or cooling. For heating and cooling functions, you can select continuous or switch-

ing PI or switching 2-point feedback control algorithms.

In addition to the heating or cooling basic level, activating an additional heater and/

or cooling unit means that an additional heating or cooling unit can be used. In this

connection, you can set the temperature setpoint difference between the basic and

the additional level by a parameter in the ETS. For major deviations between the

temperature setpoint and the actual temperature, you can activate this additional

level to heat up or cool down a room faster. You can assign different control al-

gorithms to the basic and additional stages.

For each controller, the room temperatures are then detected by one or possibly

two external KNX temperature sensors (e.g. push-button sensors with temperature

measurement).

Operation, mounting and electrical connection

The operating elements (4 push-buttons) on the front panel of the device permit in-

fluencing of the electronic outputs of the actuator through manual operation, even

without KNX bus voltage or in a non-programmed state (switch on and off / PWM).

This feature permits a fast function check of the connected actuators. Moreover,

the statuses of the outputs in case of bus voltage failure or bus or mains voltage

return and after ETS programming can be set separately.

The device has a mains voltage connection that is independent of the valve out-

puts for supplying the device electronics of the manual operation and integrated

bus coupling unit. The device electronics and bus coupling unit are also supplied

from the bus coupling unit so that an ETS programming operation or manual oper-

ation is also possible even if the mains voltage is not connected or is switched off.

As long as the bus voltage is connected and ready for operation, no power is

drawn from the device's internal power supply unit. This saves electrical energy.

The valve outputs possess a separate connection for the supply of the connected

actuators (AC 24 V or AC 230 V).

The device is designed for mounting on DIN rails in closed compact boxes or in

distributors in fixed installations in dry interior rooms.

SpaceLogic KNX Valve Drive Controller Device components

9 | MTN6730-0002 11.08.2020

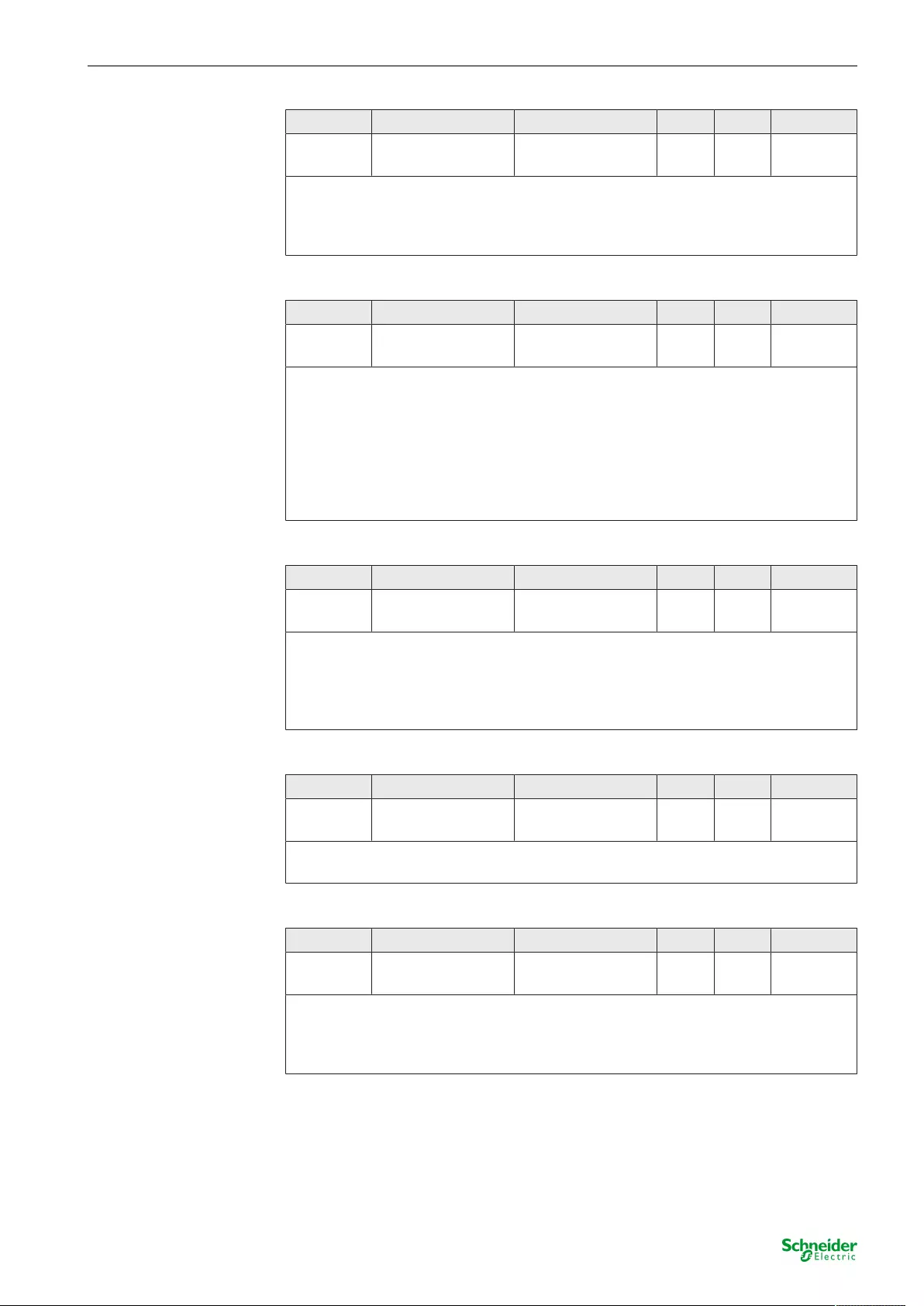

1.3 Device components

Image1: Device components

(1) Connection for the supply of electrothermal actuators (AC 230 V or AC 24

V)

(2) Button field for manual operation

(3) Programming button and LEDs

(4) KNX connection

(5) Connection for mains voltage supply (AC 230 V)

(6) Status LEDs for outputs

(7) Connections for electrothermal actuators

1.4 Delivery state

In the as-delivered state, the actuator is passive, i.e. no telegrams are transmitted

to the bus. The outputs can, however, be activated by manual operation on the

device, if the bus or mains voltage and the valve voltage supply are on. In the

manual control mode, no feedback telegrams are sent to the bus. Other functions

of the actuator, such as the room temperature controllers, are deactivated.

The device can be programmed and put into operation via the ETS. The physical

address is preset to 15.15.255

Furthermore, the device has been configured at the factory with the following char-

acteristics (all valve outputs)...

– Valve direction of action: deenergised closed

– Pulse width modulation on "Open valve": 50 %

– Cycle time: 20 minutes

– Behaviour on bus failure: Activate command value for emergency operation

(30 %), if mains and valve voltage supply available. If the bus and mains

voltage fail, all the valve outputs switch OFF.

– Behaviour after bus voltage return: All the valves close (valve outputs switch

OFF).

The as-delivered state cannot be restored by unloading the application program

with the aid of the ETS. When the application program is removed, all the valve out-

puts remain permanently switched off. The manual operation remains without func-

tion in this case.

SpaceLogic KNX Valve Drive Controller Technical data

10 | MTN6730-0002 11.08.2020

1.5 Technical data

General

Ambient temperature -5 ... +55 °C

Storage/transport temperature -25 ... +70 °C

Fitting width 72 mm / 4 module

Test mark KNX/EIB

Standby power max. 0.4 W

Power loss max. 1 W

KNX supply

KNX medium TP

Commissioning mode S-mode

Rated voltage KNX DC 21 ... 32 V SELV

Power consumption KNX max. 250 mW

Device power supply AC 230 V (L, N)

Rated voltage AC 110 ... 230 V ~

Mains frequency 50 / 60 Hz

Power supply of valve outputs AC 230 V

Rated voltage AC 230 V~

Power supply of valve outputs AC 24 V

Rated voltage AC 24 V ~

Valve outputs

Contact type Semi-conductor (Triac), ε

Switching voltage AC 24 / 230 V ~

Switching current 5 ... 160 mA

Switch-on current AC 230 V max. 1.5 A (2 s)

Switch-on current AC 24 V max. 0.3 A (2 min)

Number of drives per output

230 V drives max. 4

24 V drives max. 2

Connections

Connection mode Screw terminal

Connection type for bus device connection terminal

single stranded 0.5 ... 4 mm²

Finely stranded without conductor sleeve 0.5 ... 4 mm²

SpaceLogic KNX Valve Drive Controller Technical data

11 | MTN6730-0002 11.08.2020

Finely stranded with conductor sleeve 0.5 ... 2.5 mm²

SpaceLogic KNX Valve Drive Controller Safety instructions

12 | MTN6730-0002 11.08.2020

2 For your safety

DANGER!

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Safe electrical installation must be carried out only by skilled professionals. Skilled

professionals must prove profound knowledge in the following areas:

■ Connecting to installation networks

■ Connecting several electrical devices

■ Laying electric cables

■ Connecting and establishing KNX networks

■ Safety standards, local wiring rules and regulations

Failure to follow these instructions will result in death or serious injury.

2.1 Safety instructions

Electrical devices may only be mounted and connected by electrically

skilled persons.

Serious injuries, fire or property damage possible. Please read and follow manual

fully.

Danger of electric shock. Always disconnect before carrying out work on the device

or load. In so doing, take all the circuit breakers into account, which support dan-

gerous voltages to the device and or load.

Danger of electric shock. Device is not suitable for disconnection from supply

voltage. The load is not electrically isolated from the mains even when the device

is switched off.

These instructions are an integral part of the product, and must remain with the

end customer.

SpaceLogic KNX Valve Drive Controller

13 | MTN6730-0002 11.08.2020

3 Fitting and electrical

connection

DANGER!

Electrical shock on contact with live parts in the installation environment.

Electrical shocks can be fatal.

■ Before working on the device, disconnect the power supply and cover up

live parts in the working environment.

Fitting the device

■ Snap onto a suitable DIN rail. The screw terminals of the valve outputs

should be at the top.

A KNX data rail is not required.

Observe the temperature range (see Technical Data) and ensure sufficient cooling,

if necessary.

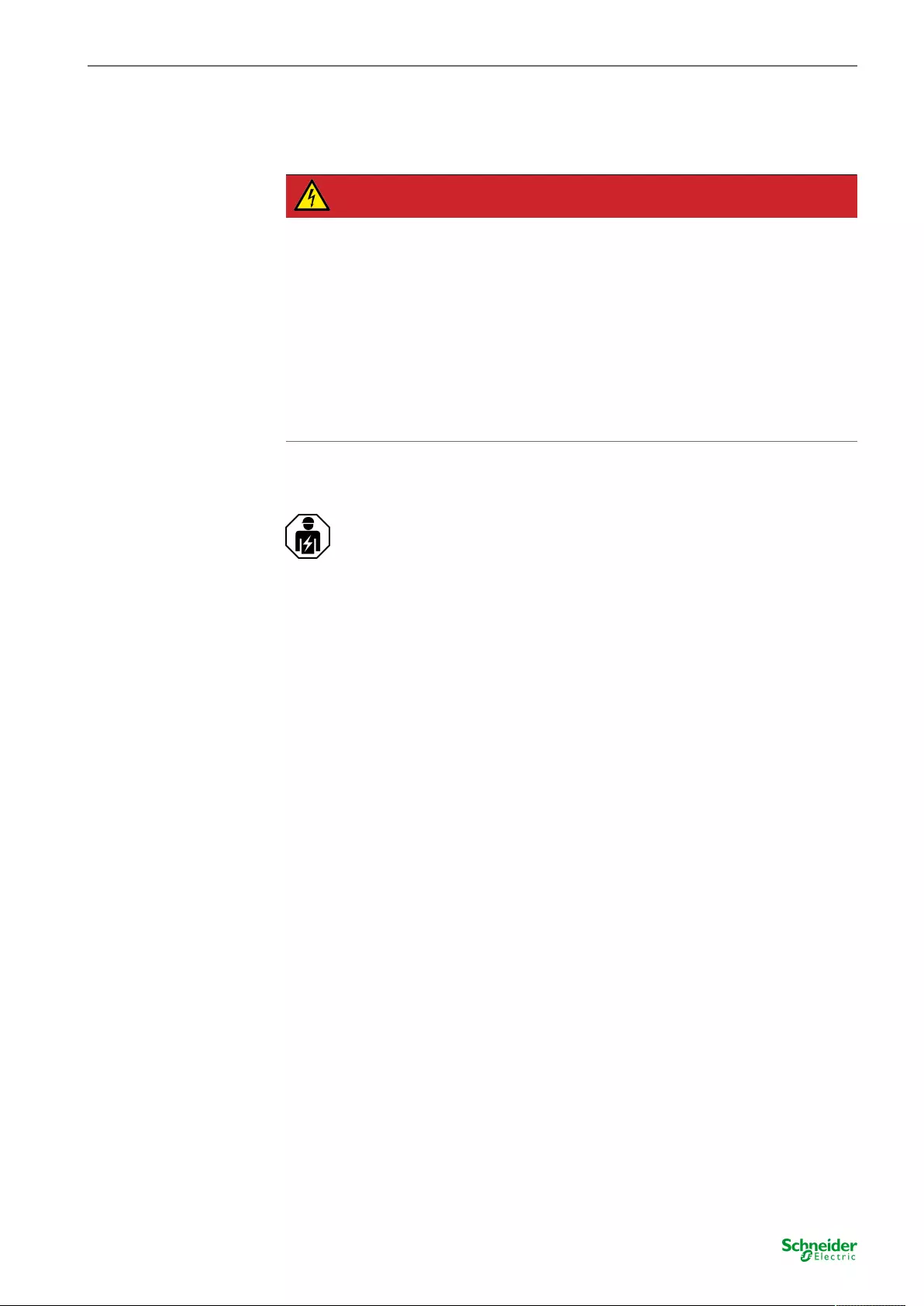

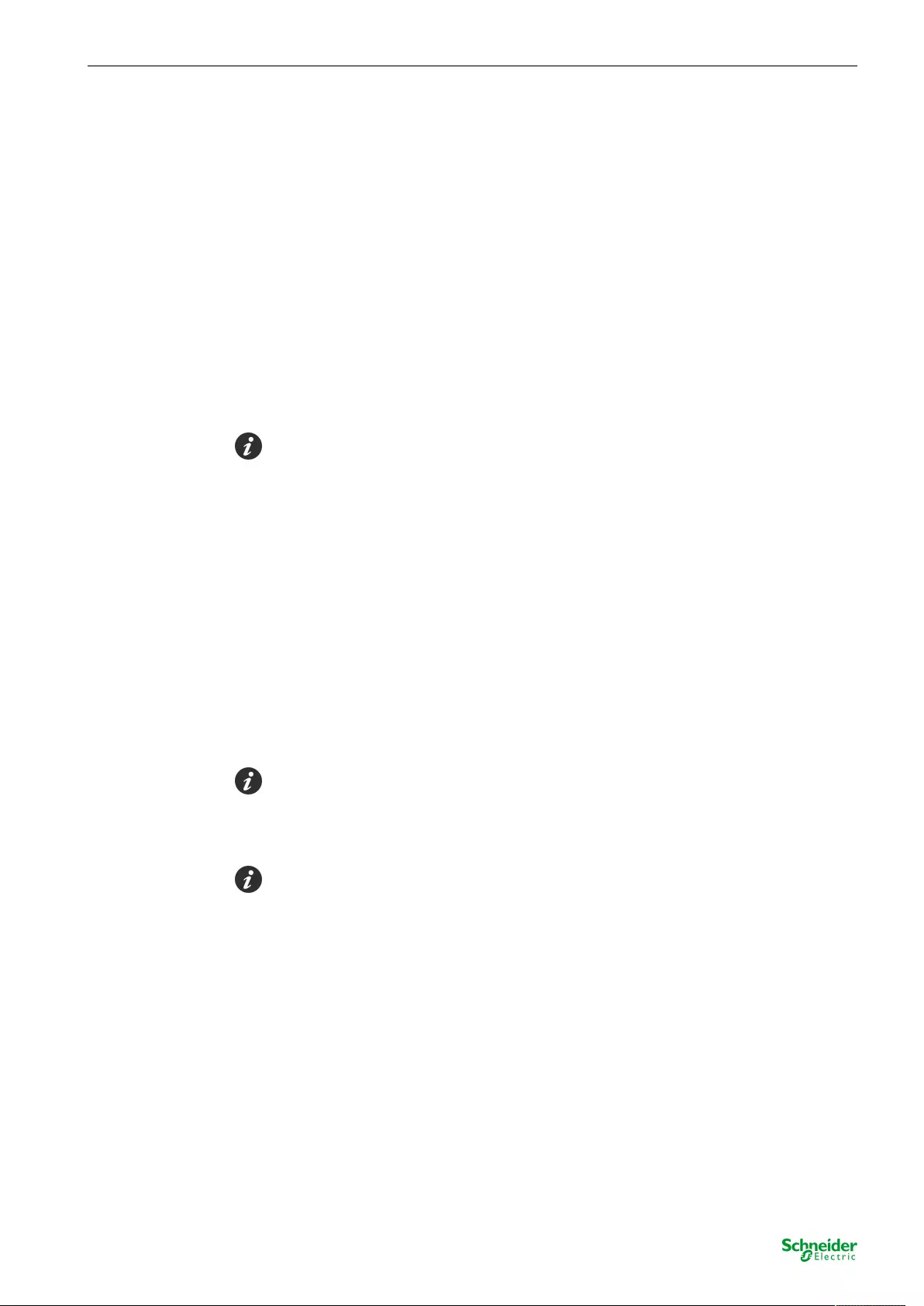

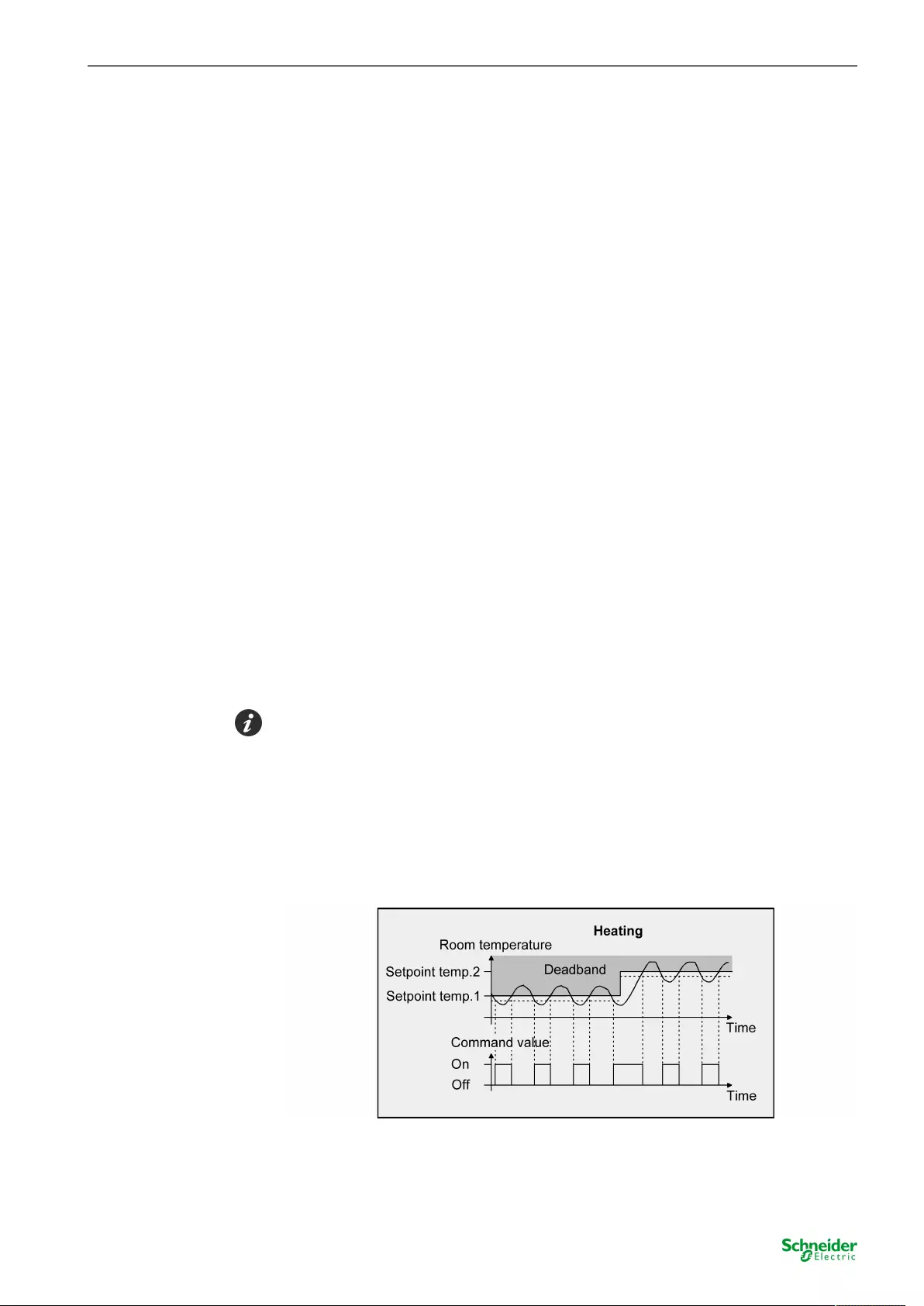

Connect the device for AC 230 V actuators

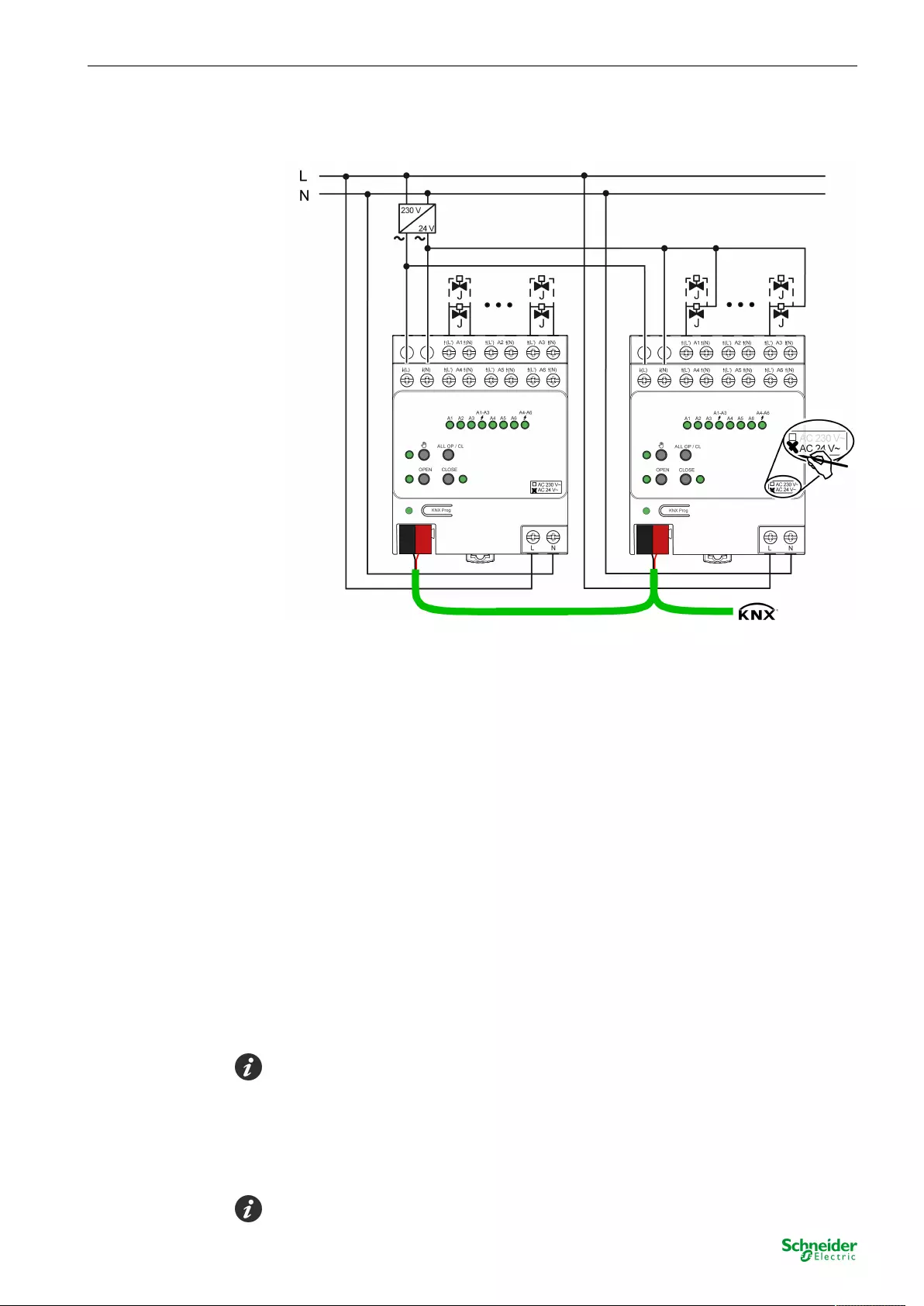

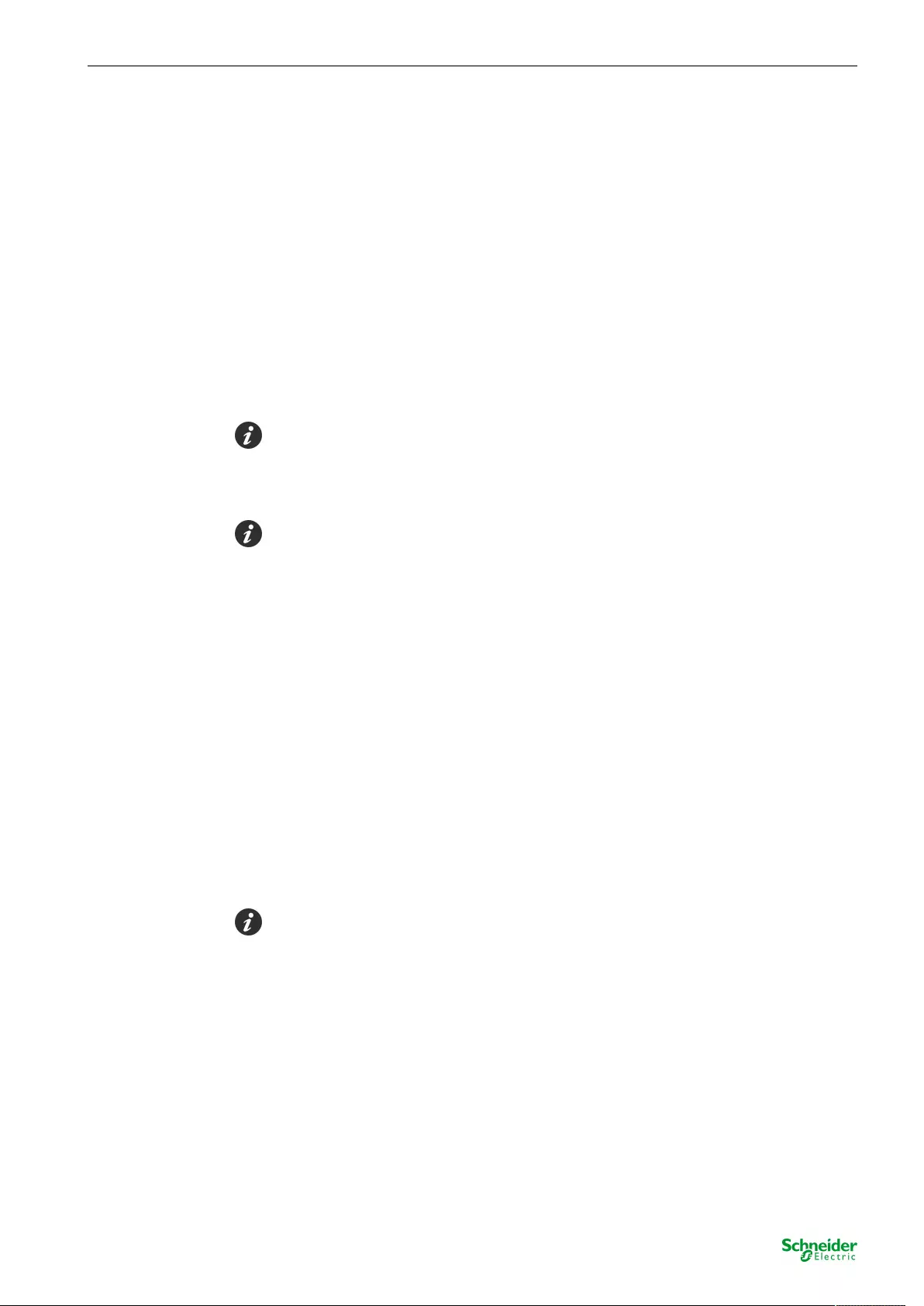

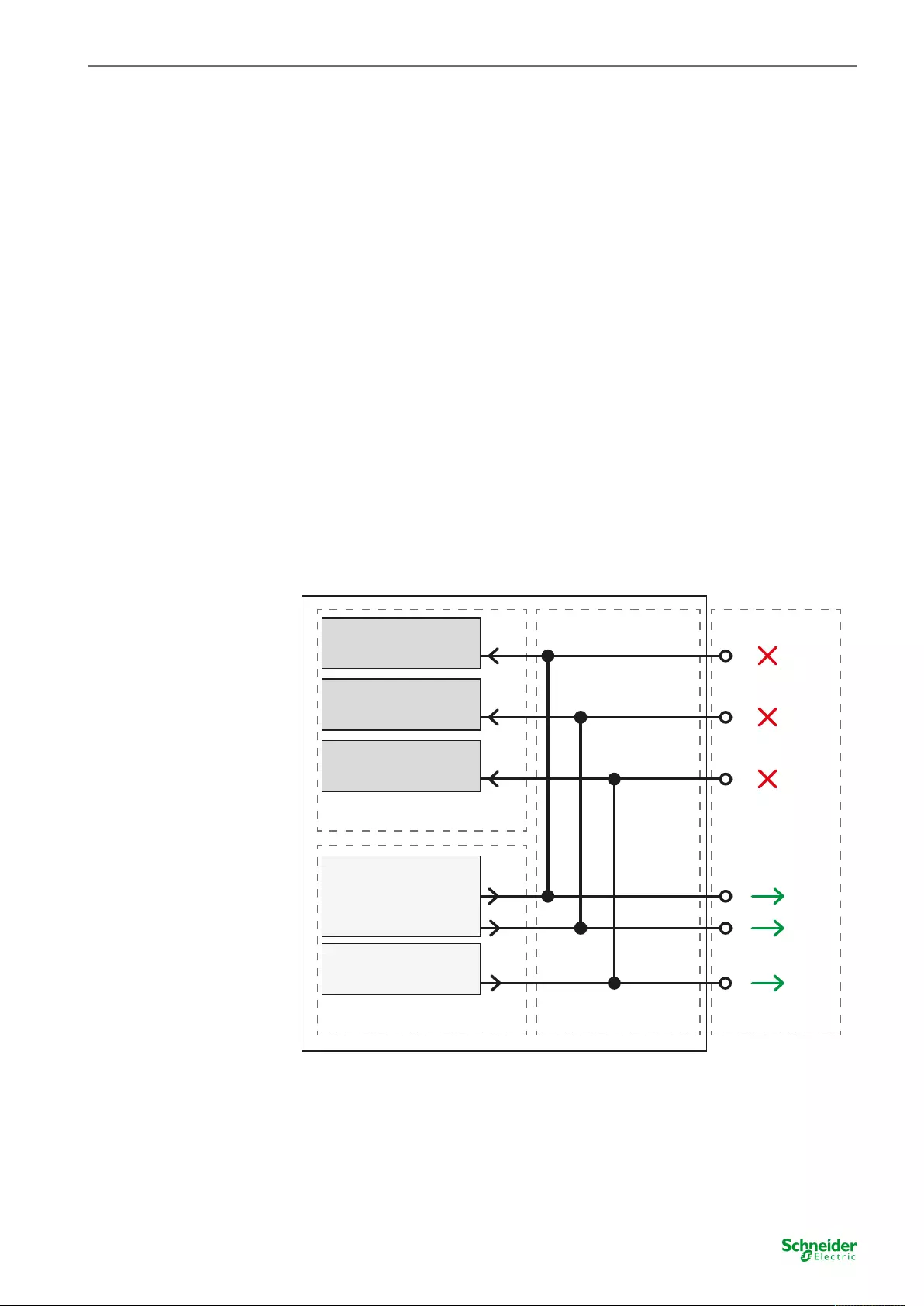

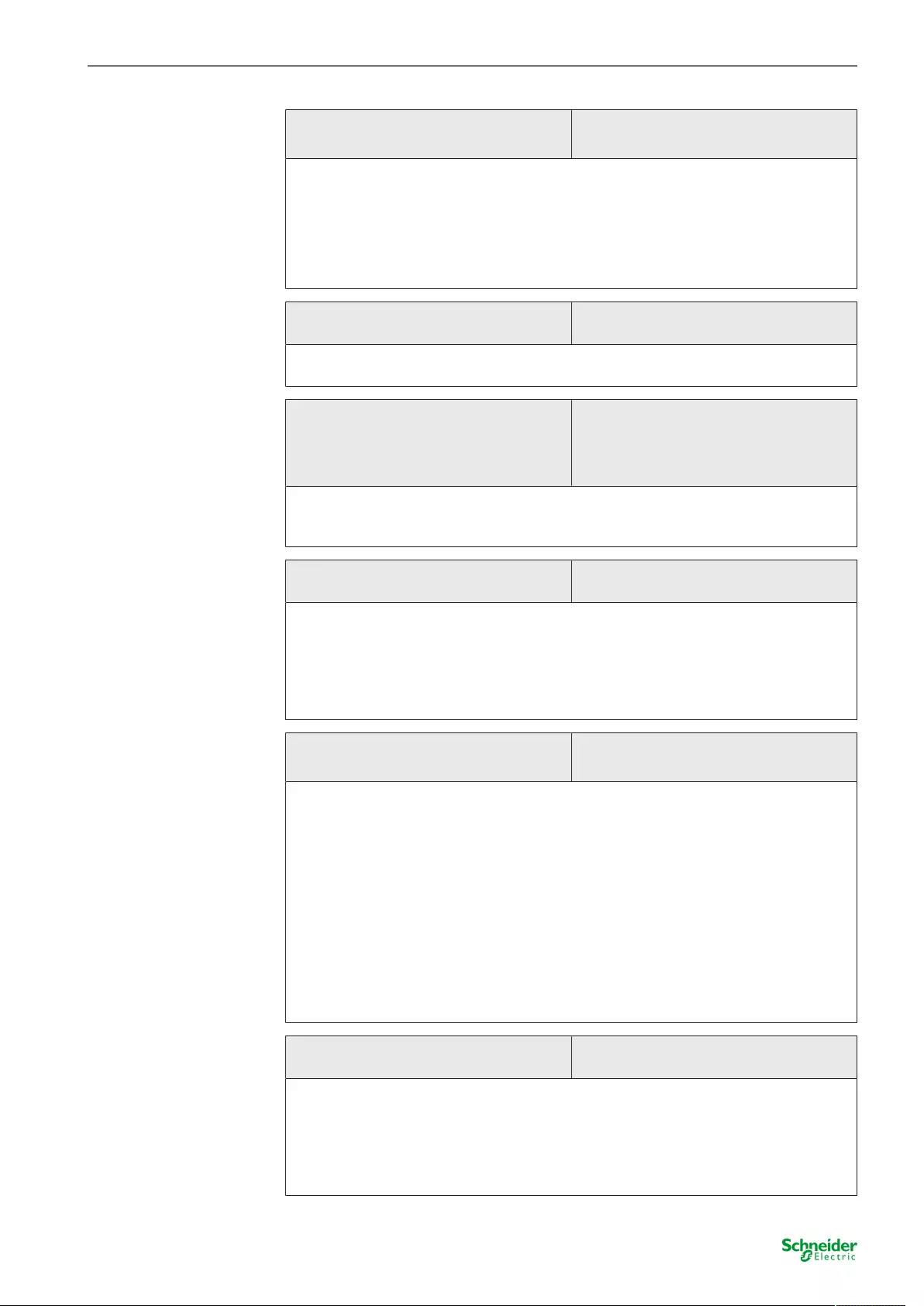

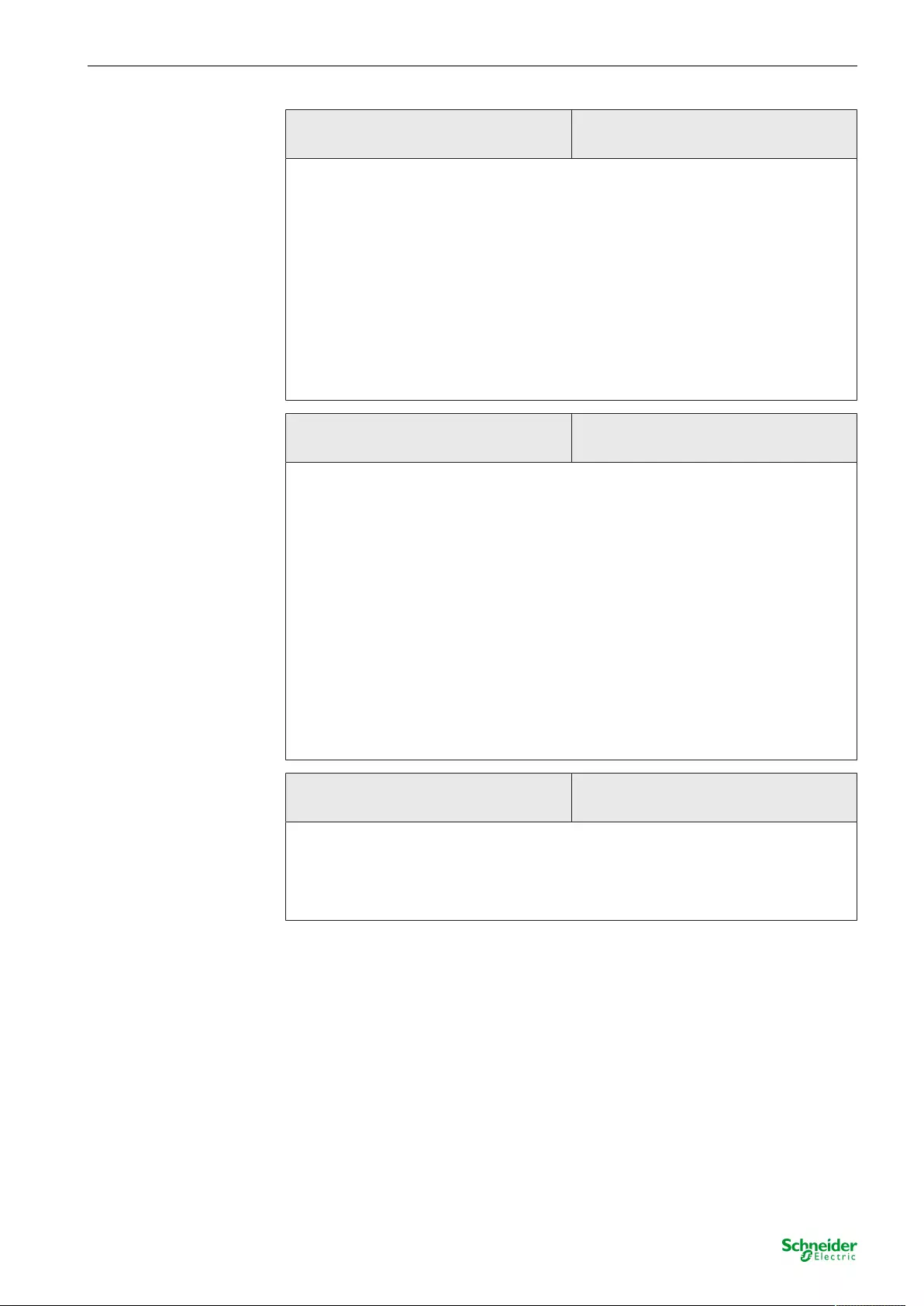

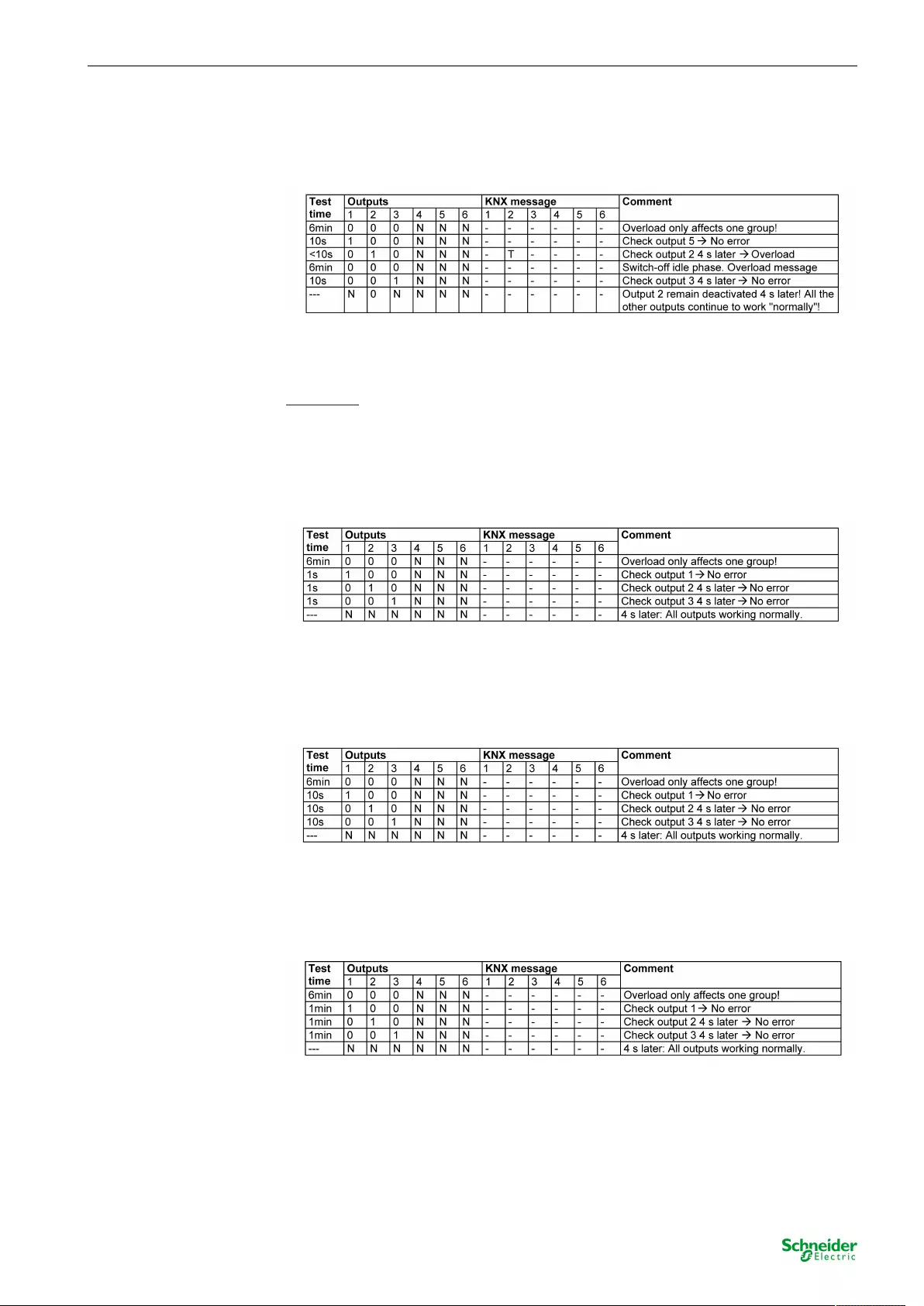

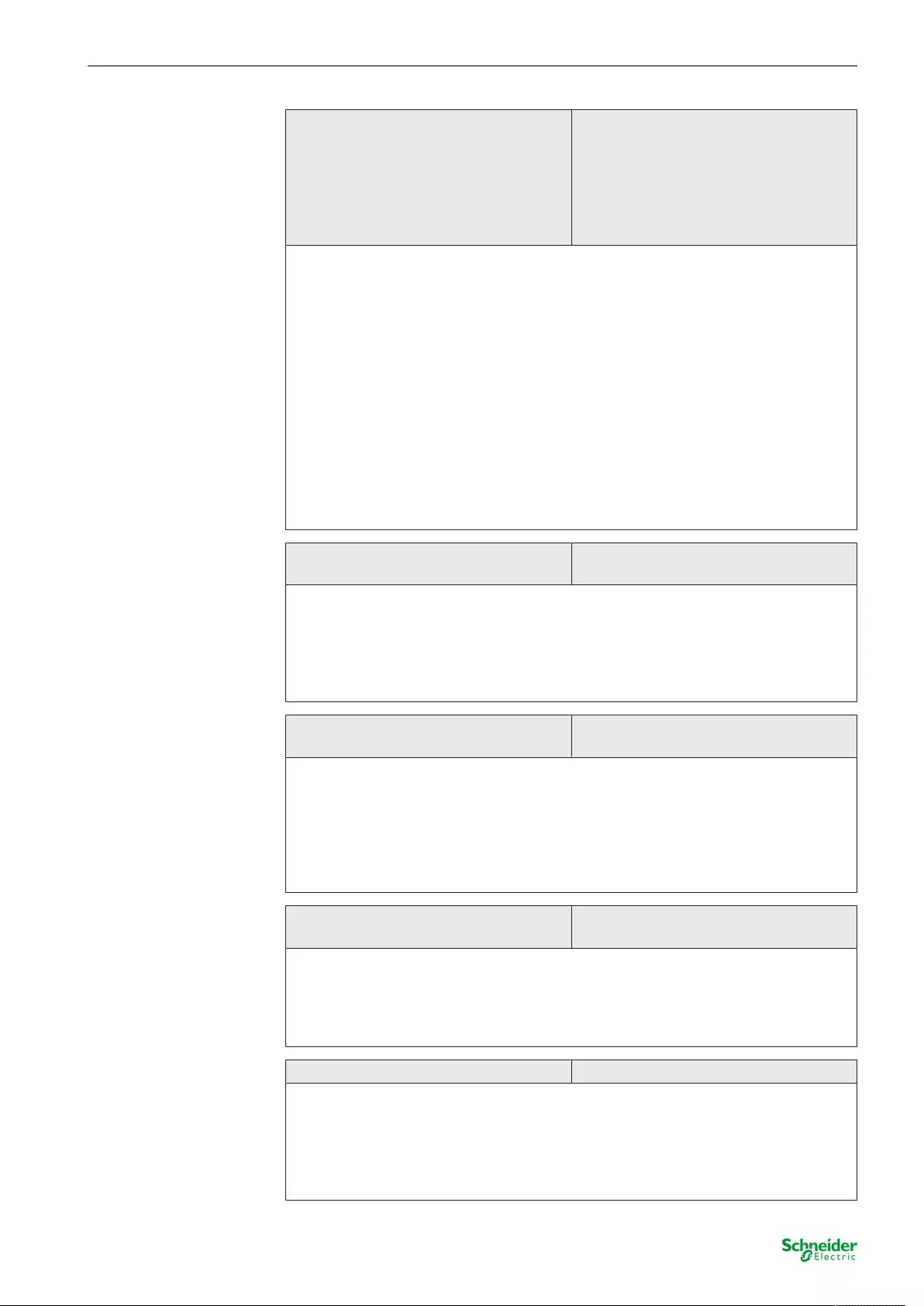

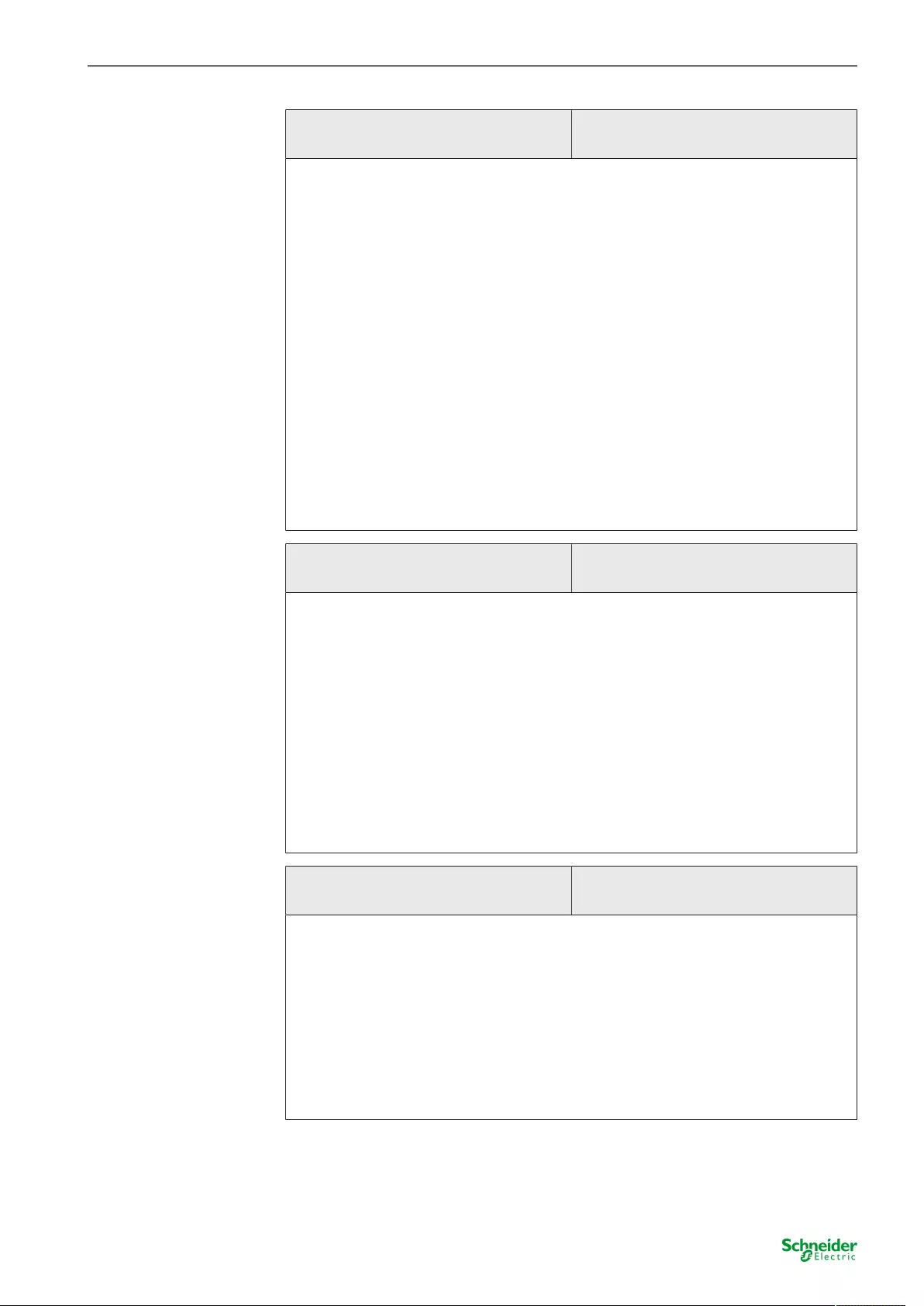

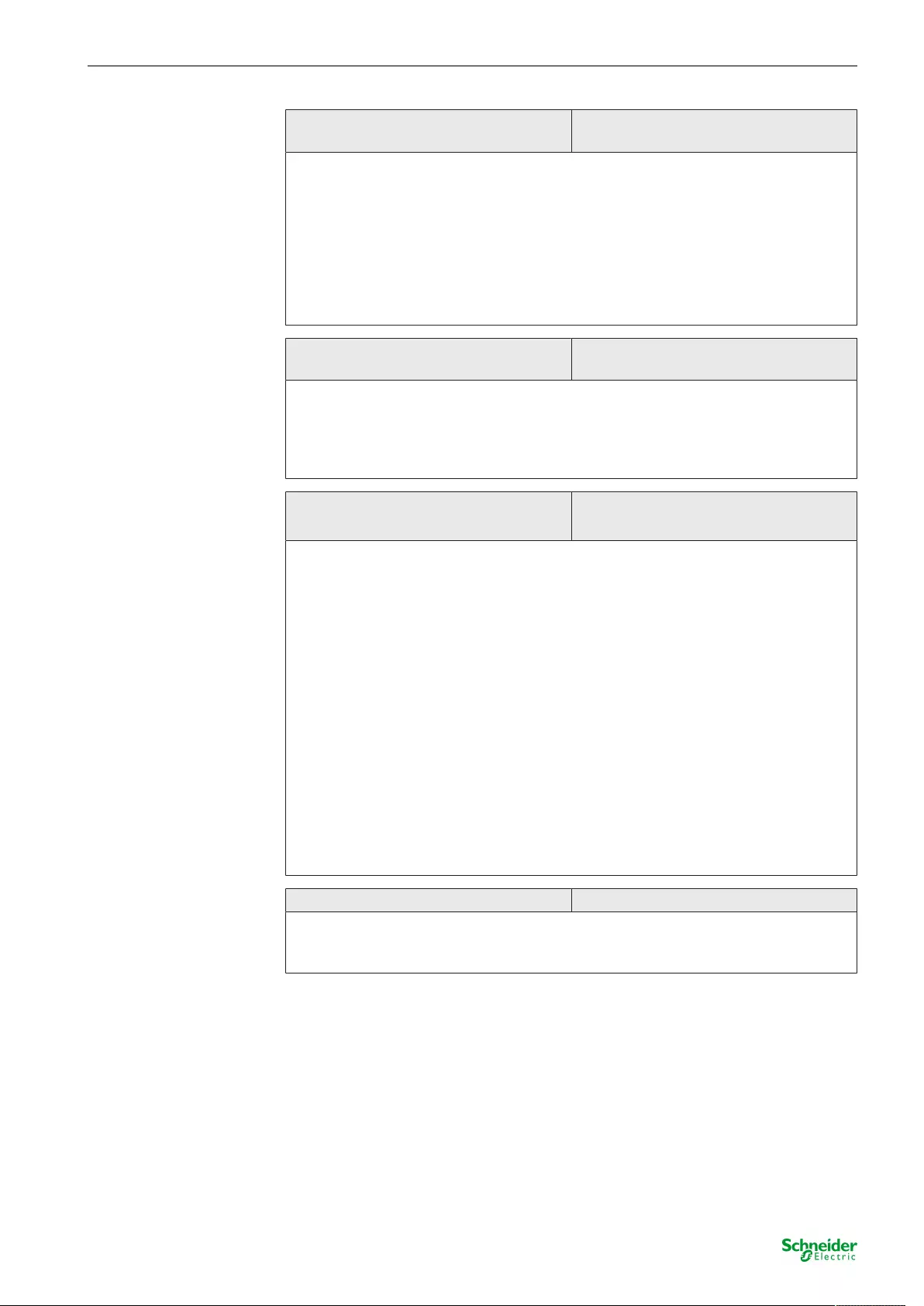

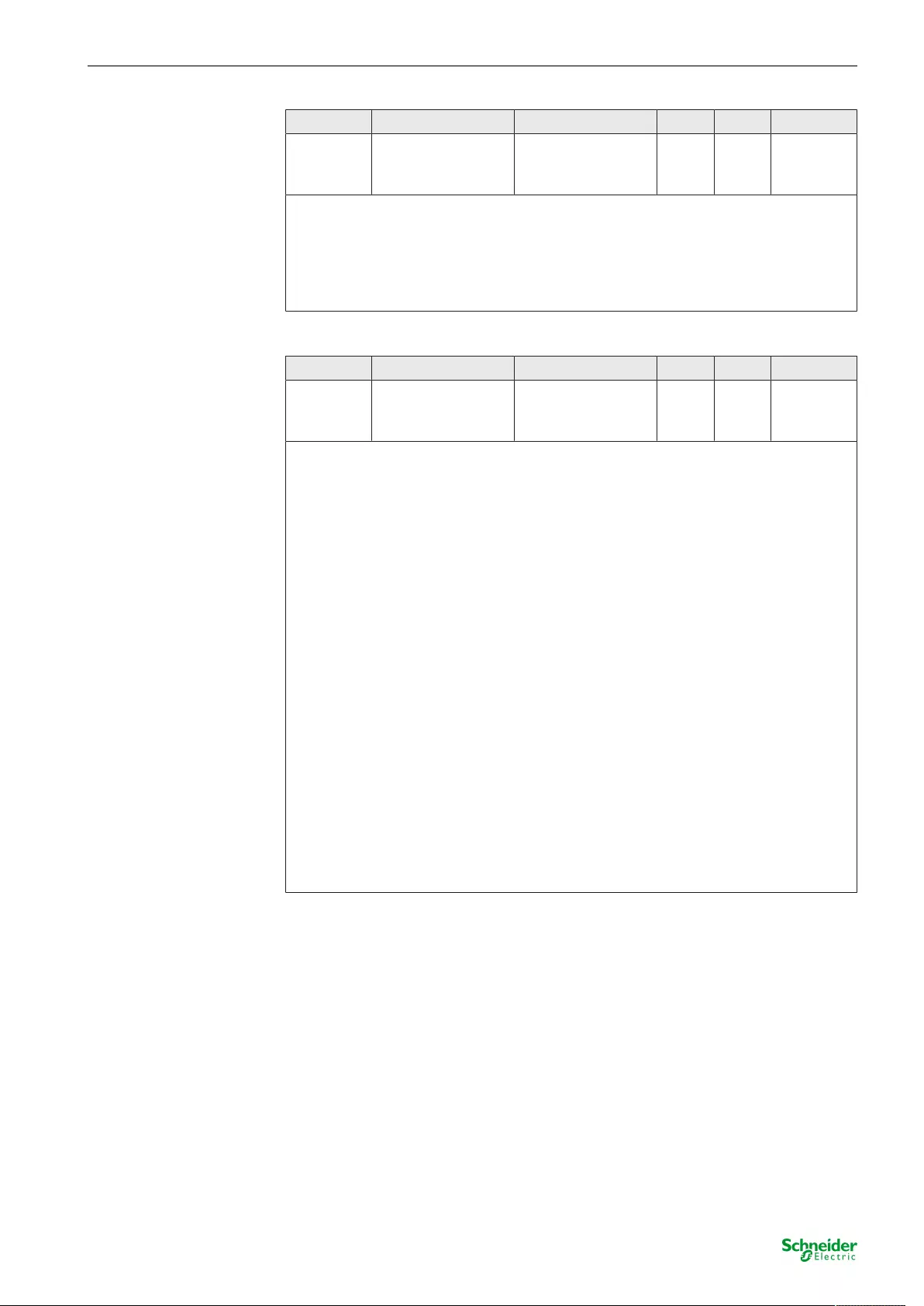

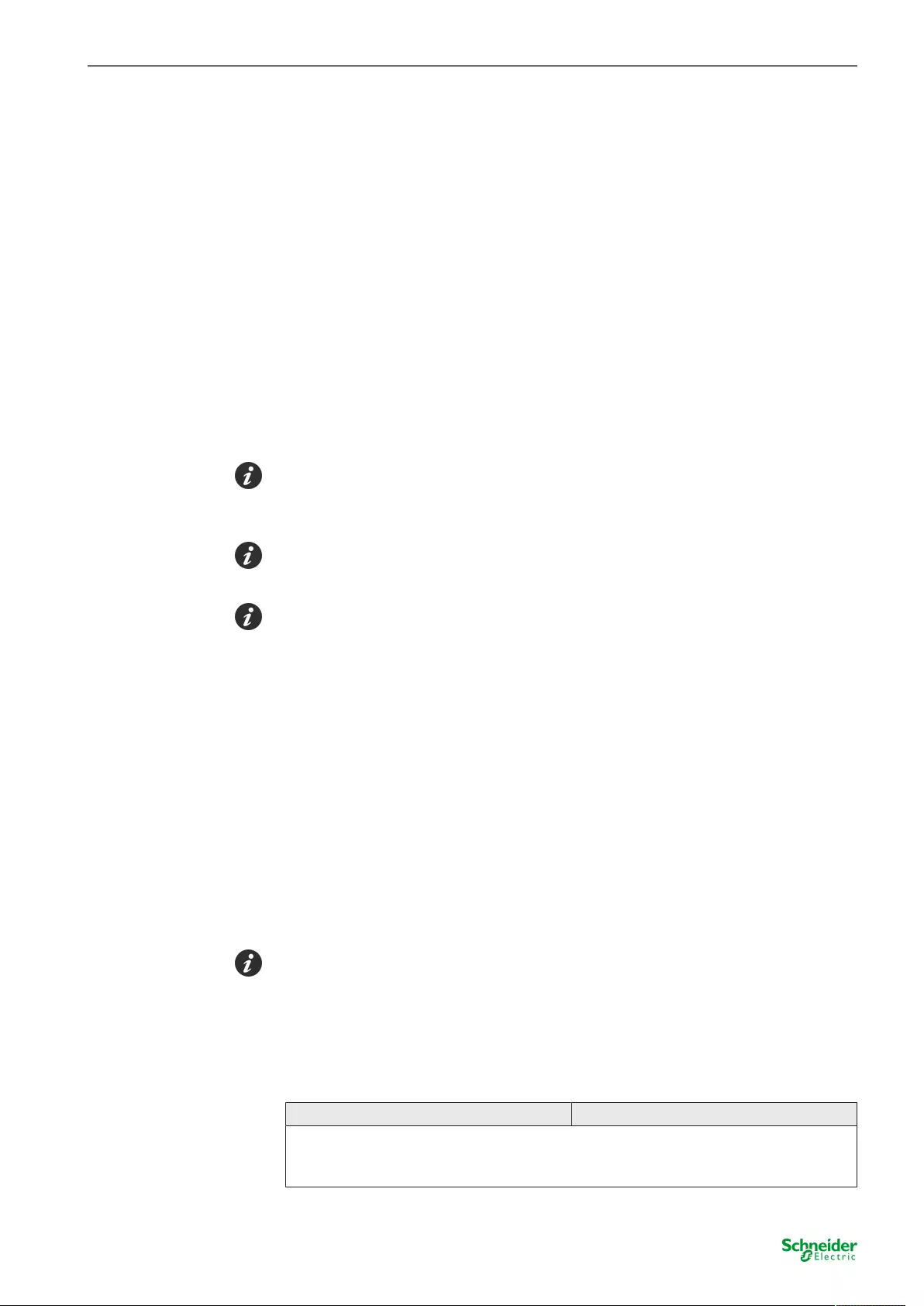

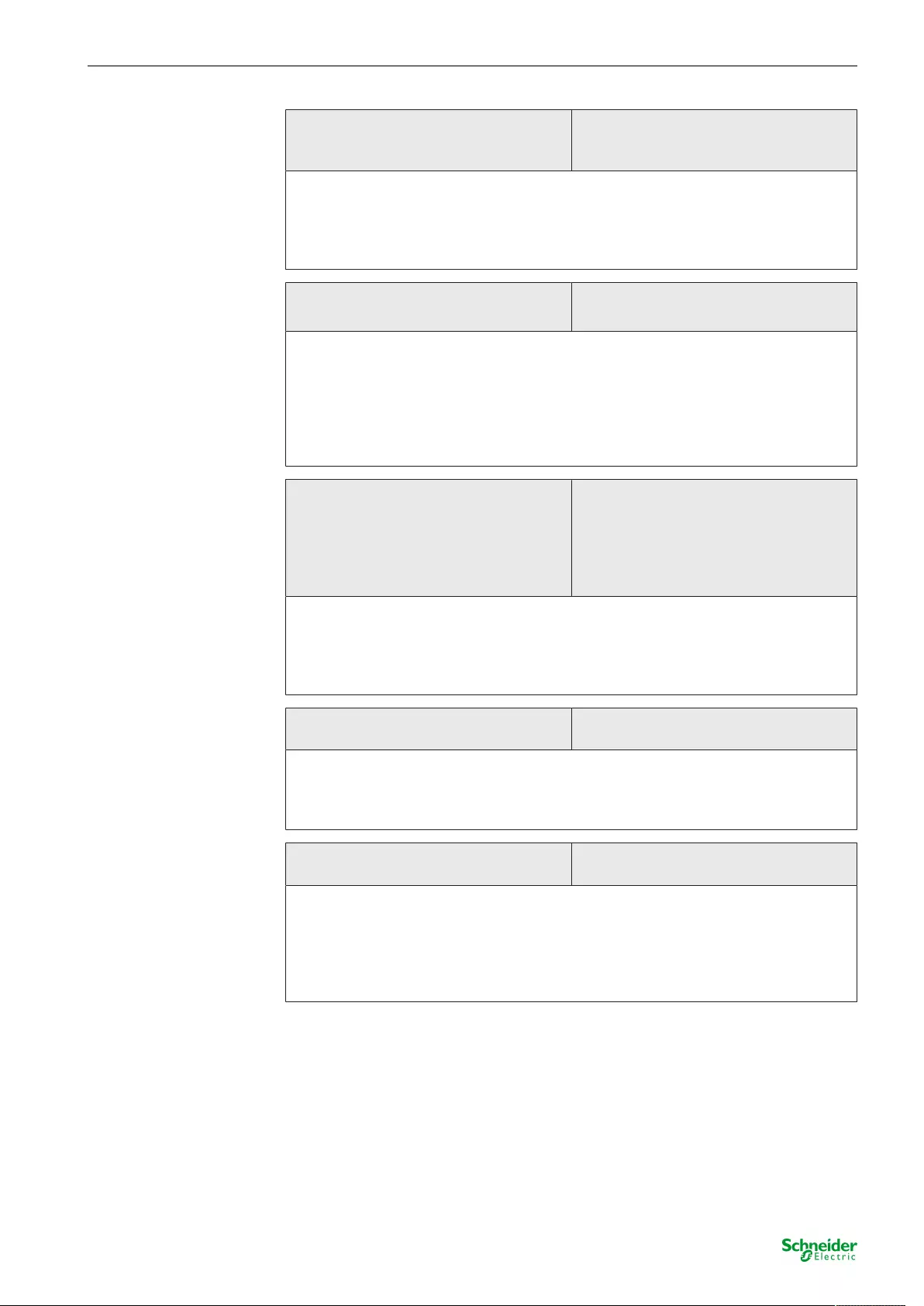

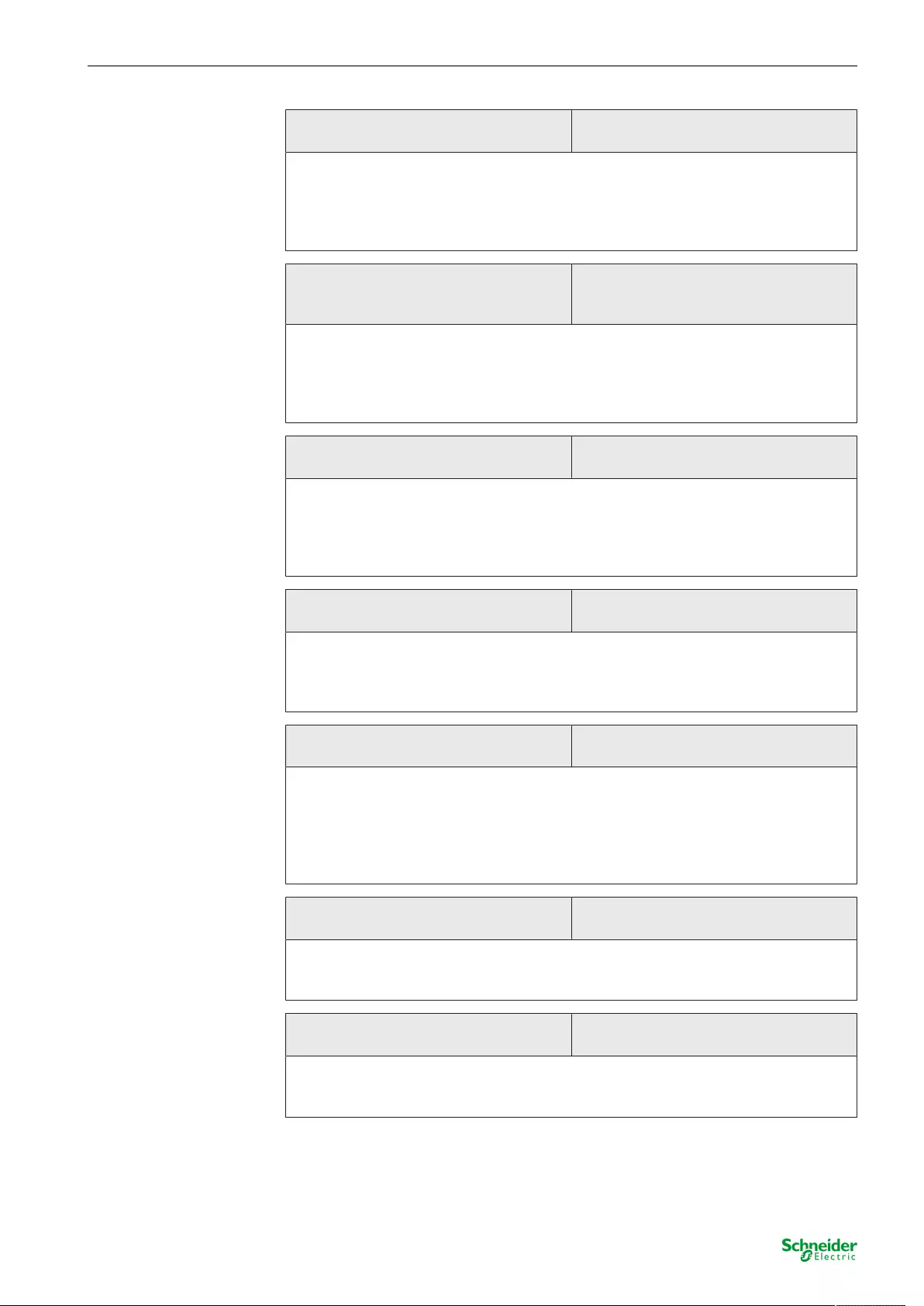

Image2: Connection for AC 230 V actuators (connection examples)

Left: Neutral conductor of the actuators run separately to the actuator /

Right: Shared neutral conductor for actuators

Only connect AC 230 V actuators to all the outputs.

SpaceLogic KNX Valve Drive Controller

14 | MTN6730-0002 11.08.2020

Only connect actuators with the same characteristics to each output (deenergised

closed/opened).

Do not connect unsuitable loads (incandescent lamps, motorised actuators, signal

devices, etc.).

If possible, connect actuators for environments with increased fail-safety require-

ments to the outputs A1 and A4. During overload detection, these are switched off

last.

Do not exceed the maximum number of "4" actuators per output.

Observe the technical data of the valve drives used.

■ Connect the AC 230 V valve drives according to the connection diagram

(see figure 2). The neutral conductors of the actuators can either be con-

nected directly to the N terminals of the outputs of the heating actuator (left-

hand connection example) or, alternatively, jointly with a suitable N potential

(e.g. N conductor terminal in the distributor) (right-hand connection ex-

ample). It is not absolutely necessary to connect the neutral conductor of

the actuators directly to the actuator.

The neutral conductor terminals of the valve outputs are bridged internally in the

device. Do not connect the neutral conductor from the output terminals through to

additional devices in the distribution board or to other consumers. Only use the

neutral conductor terminals of the outputs for the connections of the actuators of an

actuator.

■ Connect the supply (mains voltage AC 230 V) for the actuators to the ter-

minals 8(L) and 8(N) (1).

Do not connect direct current.

■ On the device label, note the type of supply "AC 230 V" with a permanent

marker.

■ Connecting the mains voltage to the terminals L N (5).

The neutral conductor connection of the mains connection terminal is independent

of the N terminals of the valve outputs.

■ Connect bus line with device connection terminal.

SpaceLogic KNX Valve Drive Controller

15 | MTN6730-0002 11.08.2020

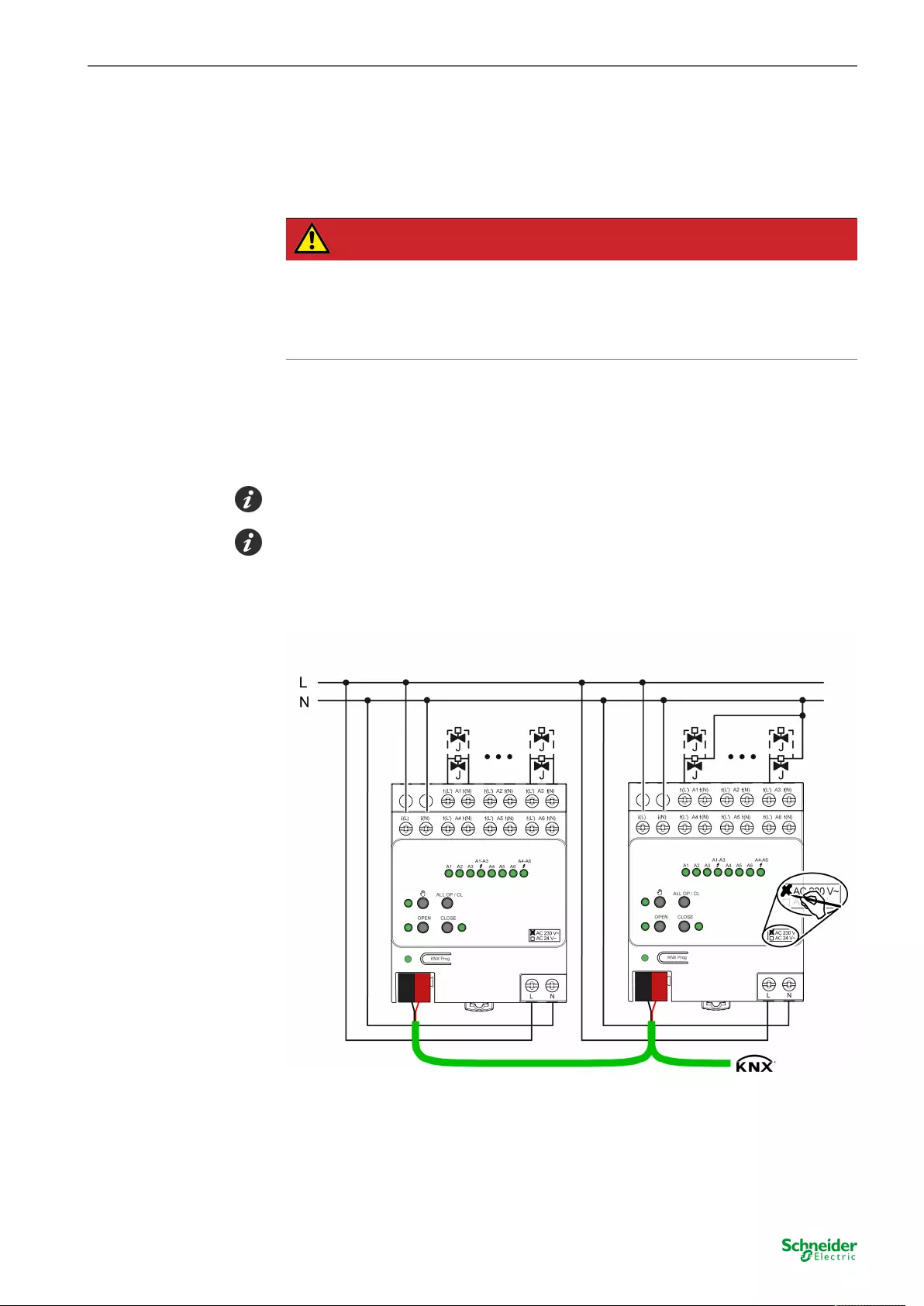

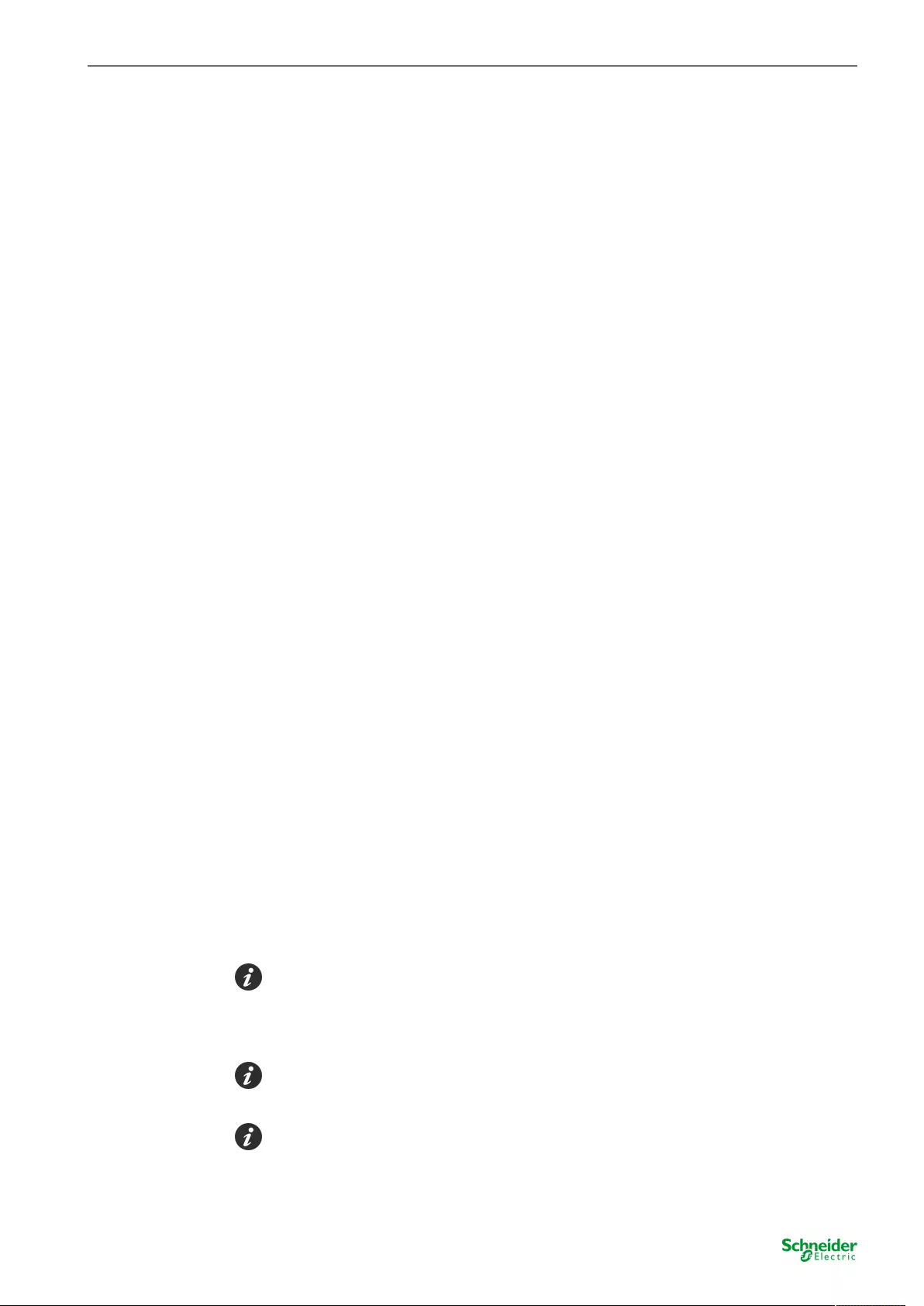

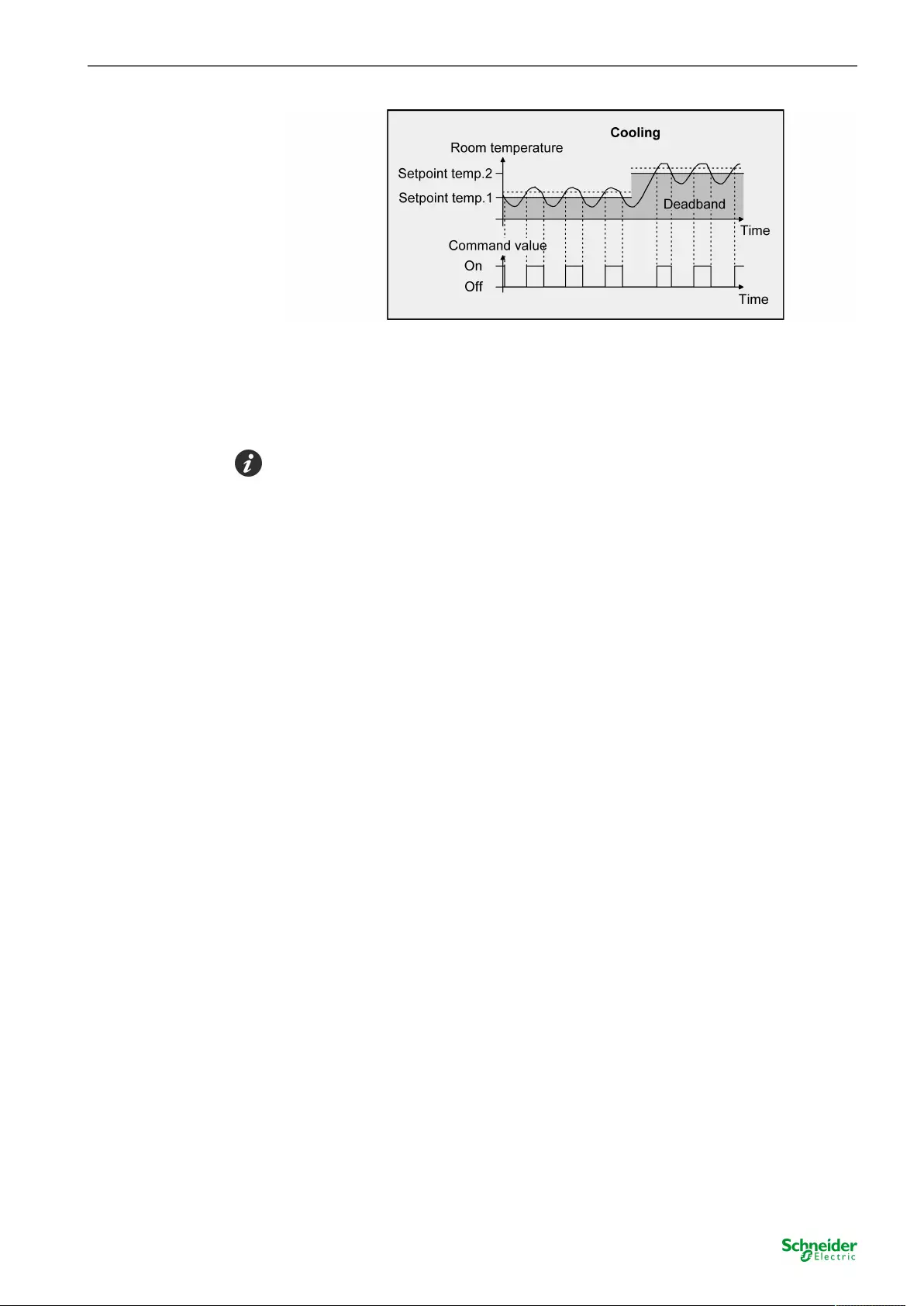

Connect the device for AC 24 V actuators

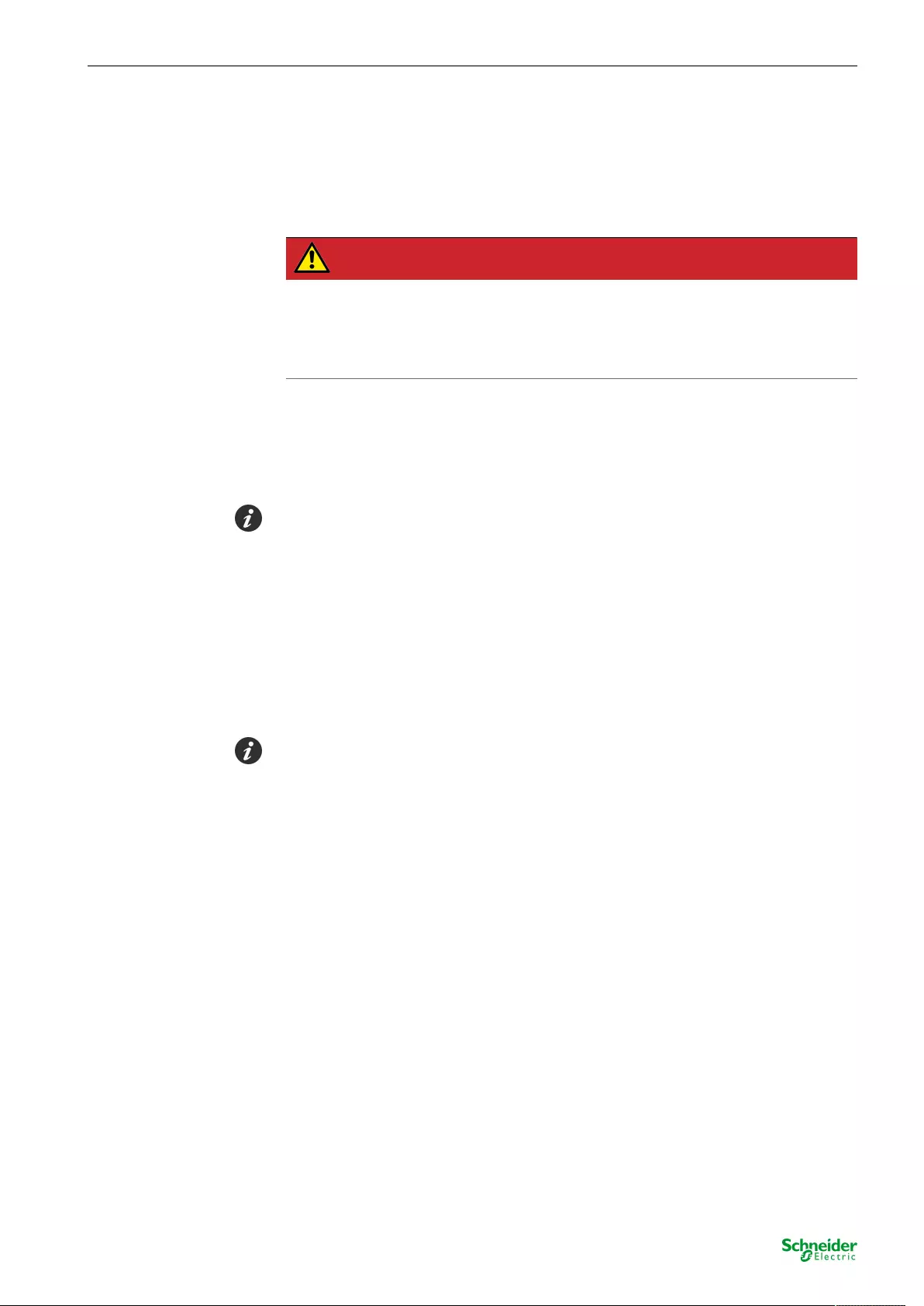

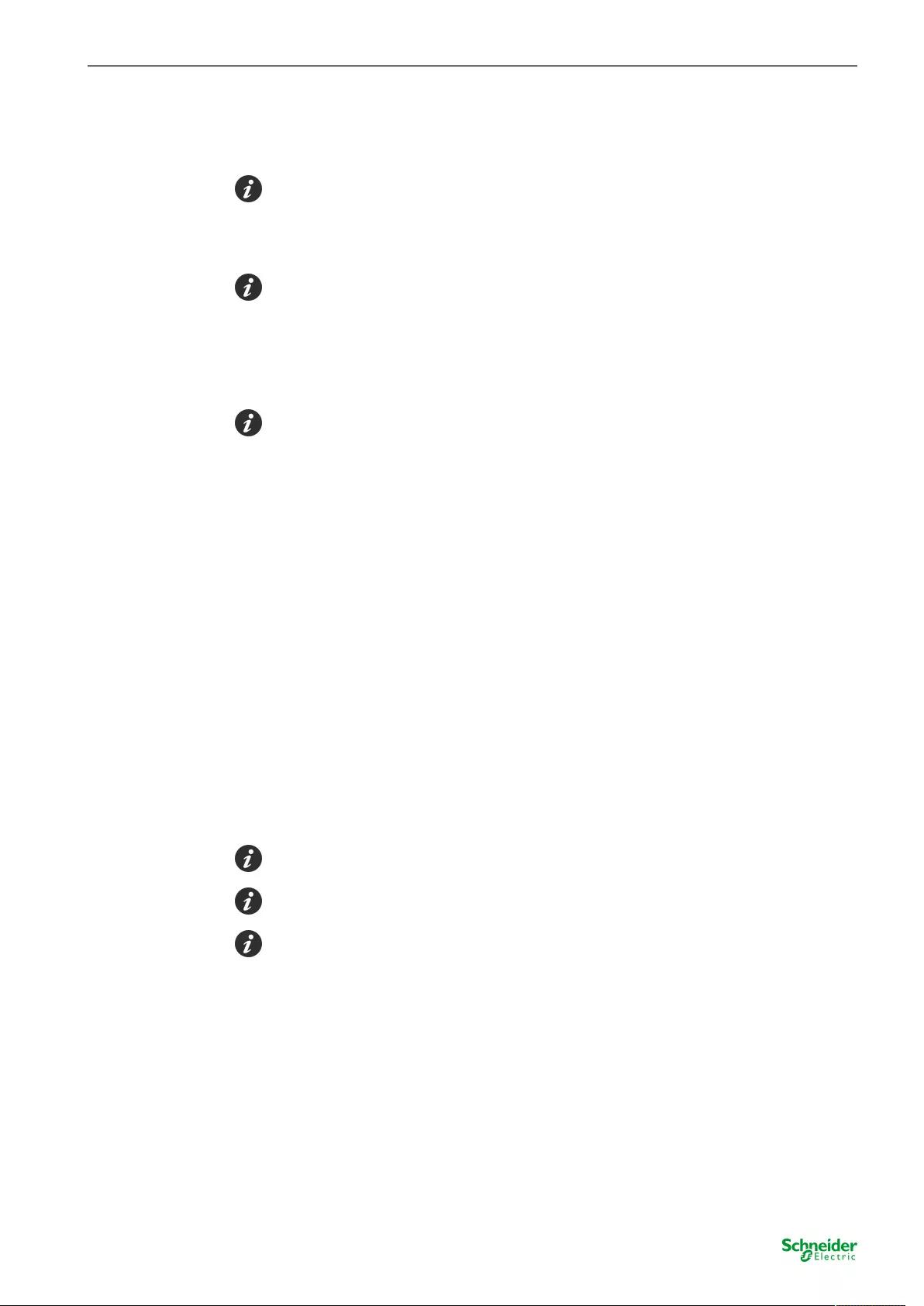

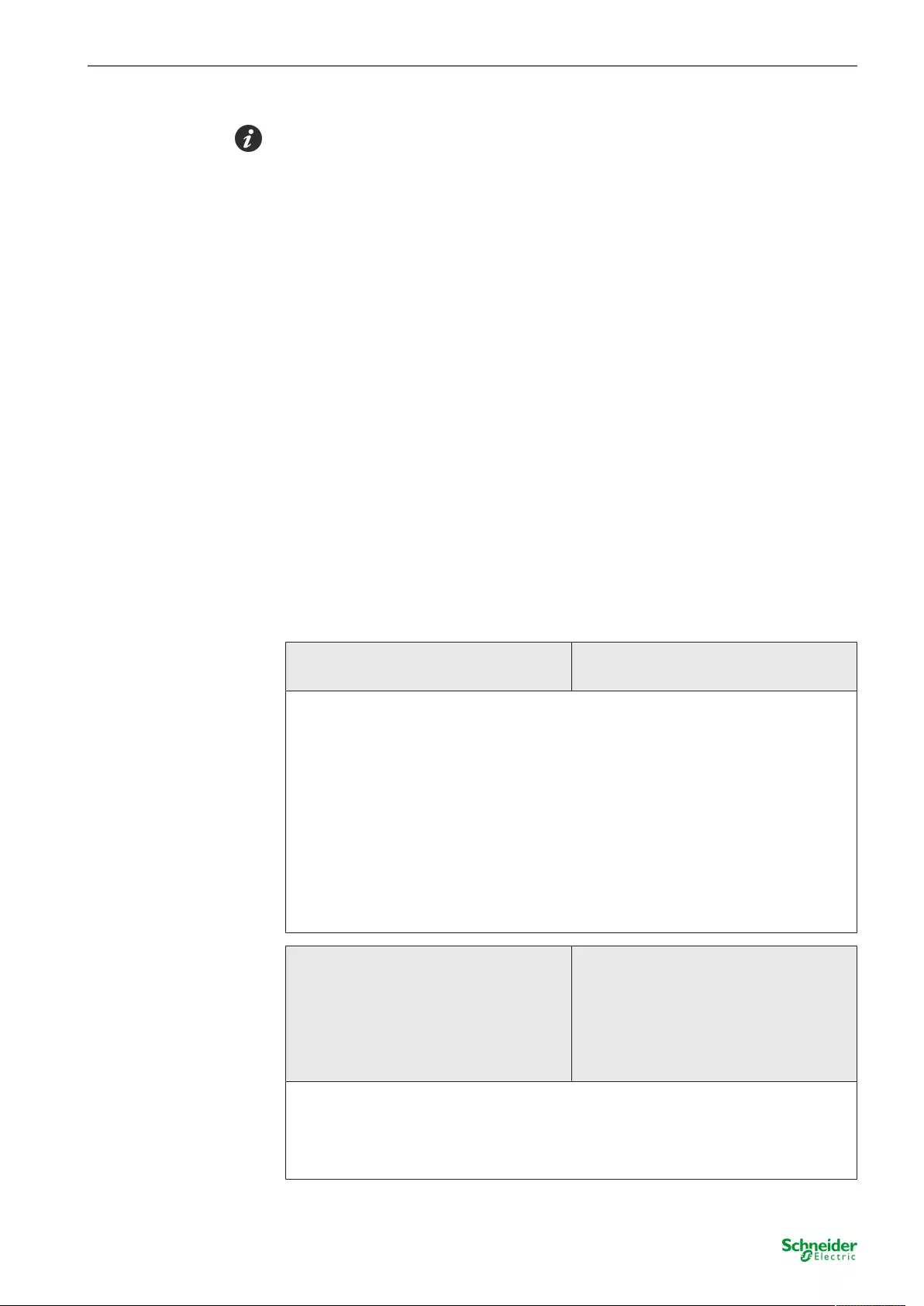

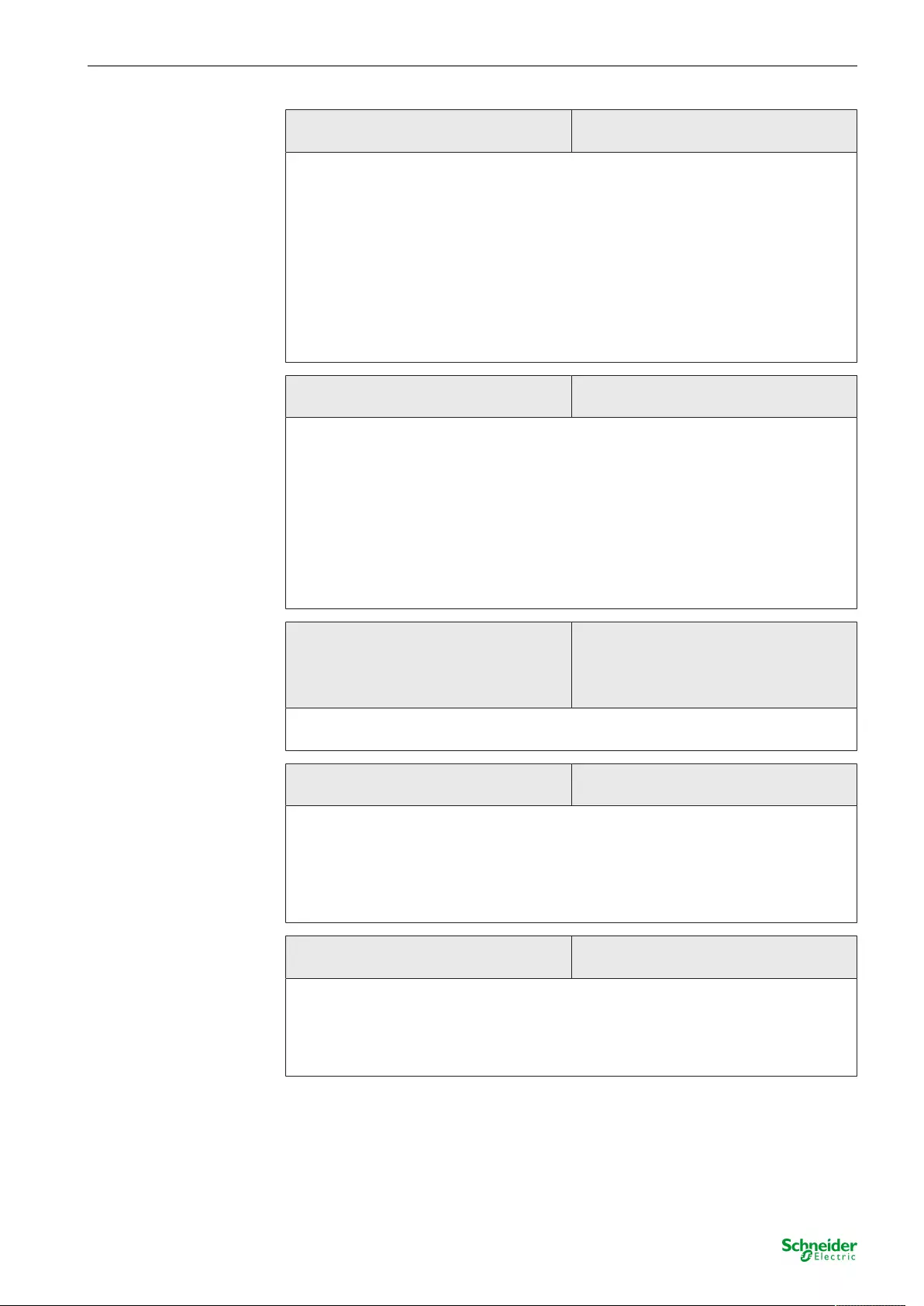

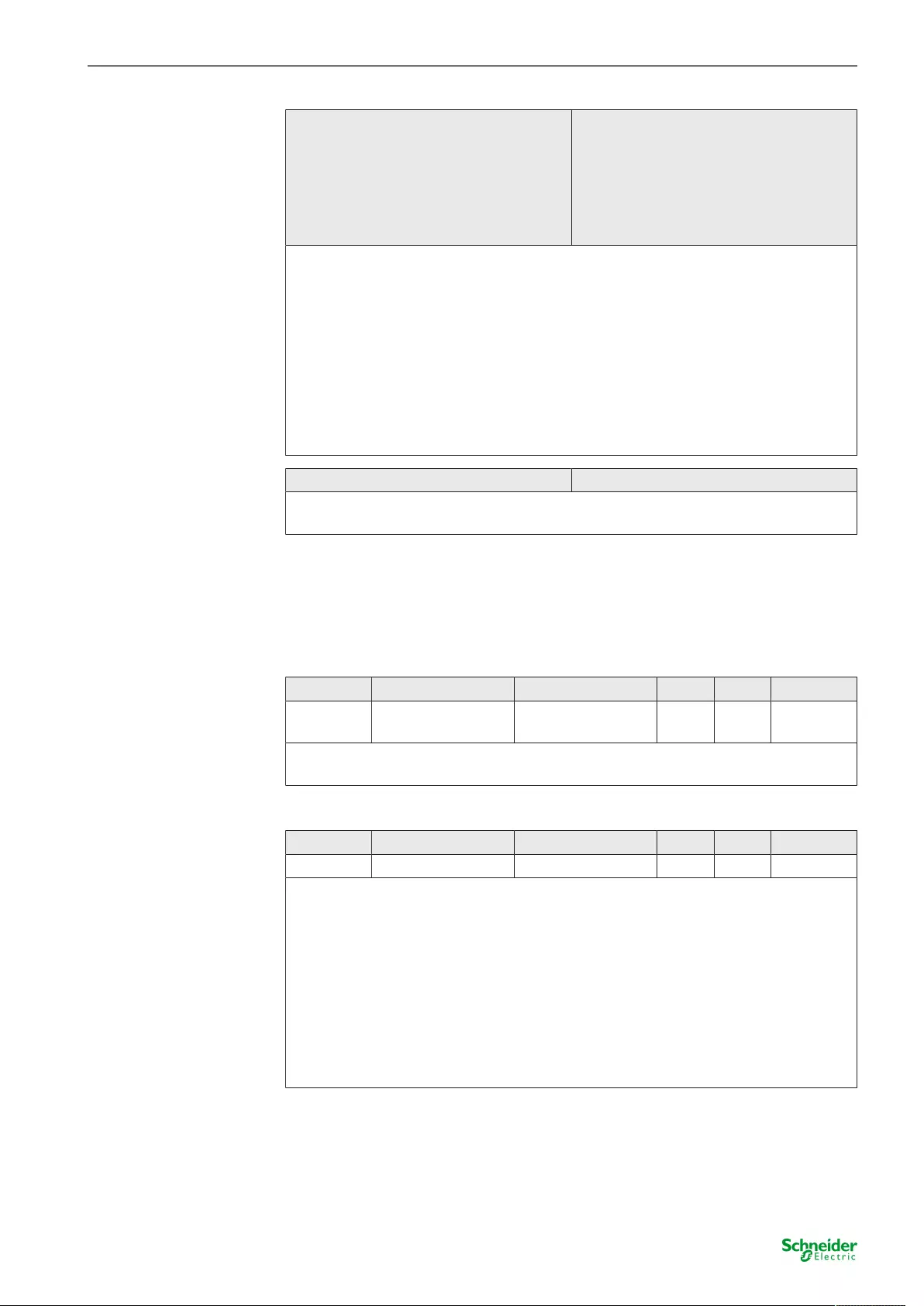

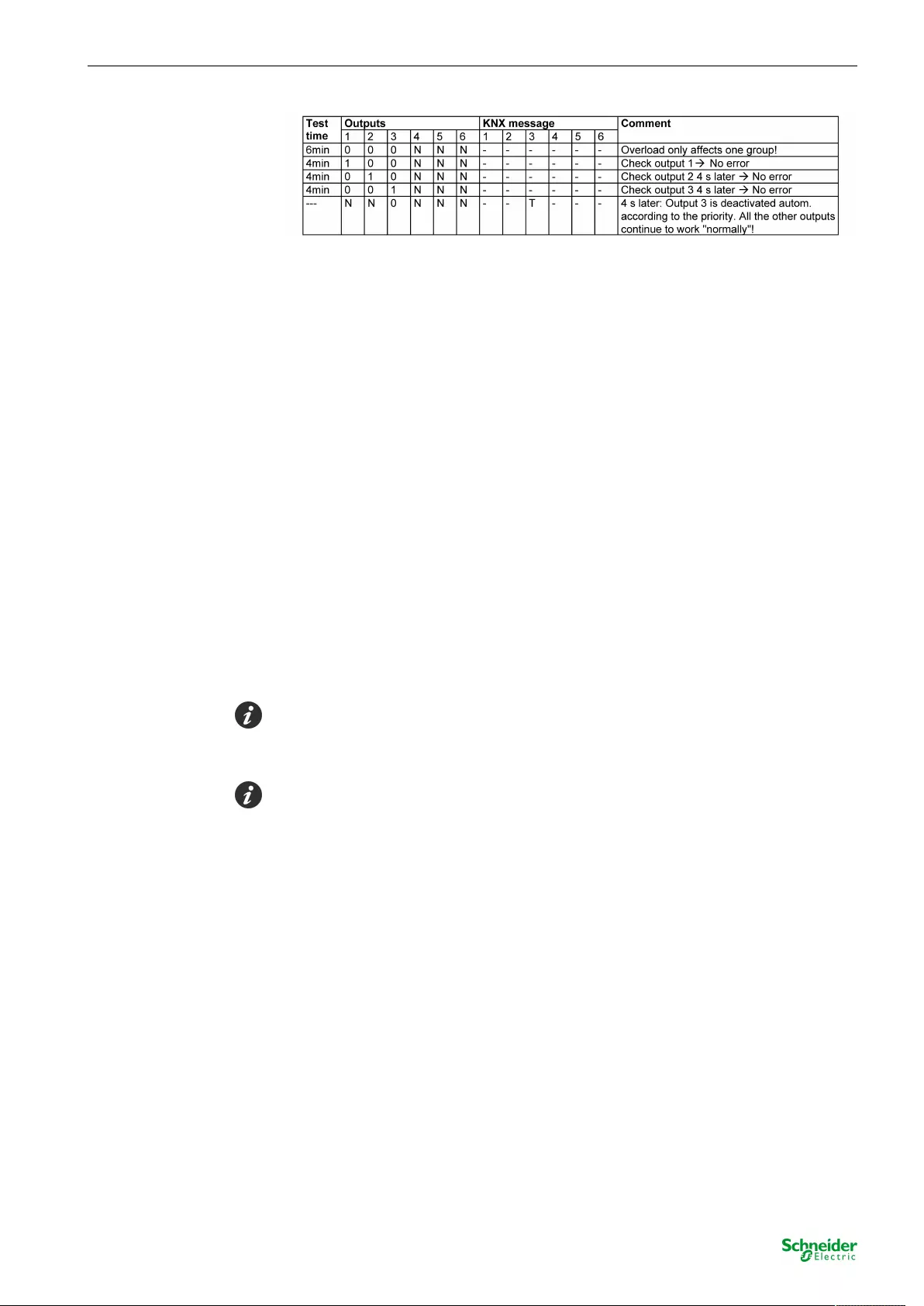

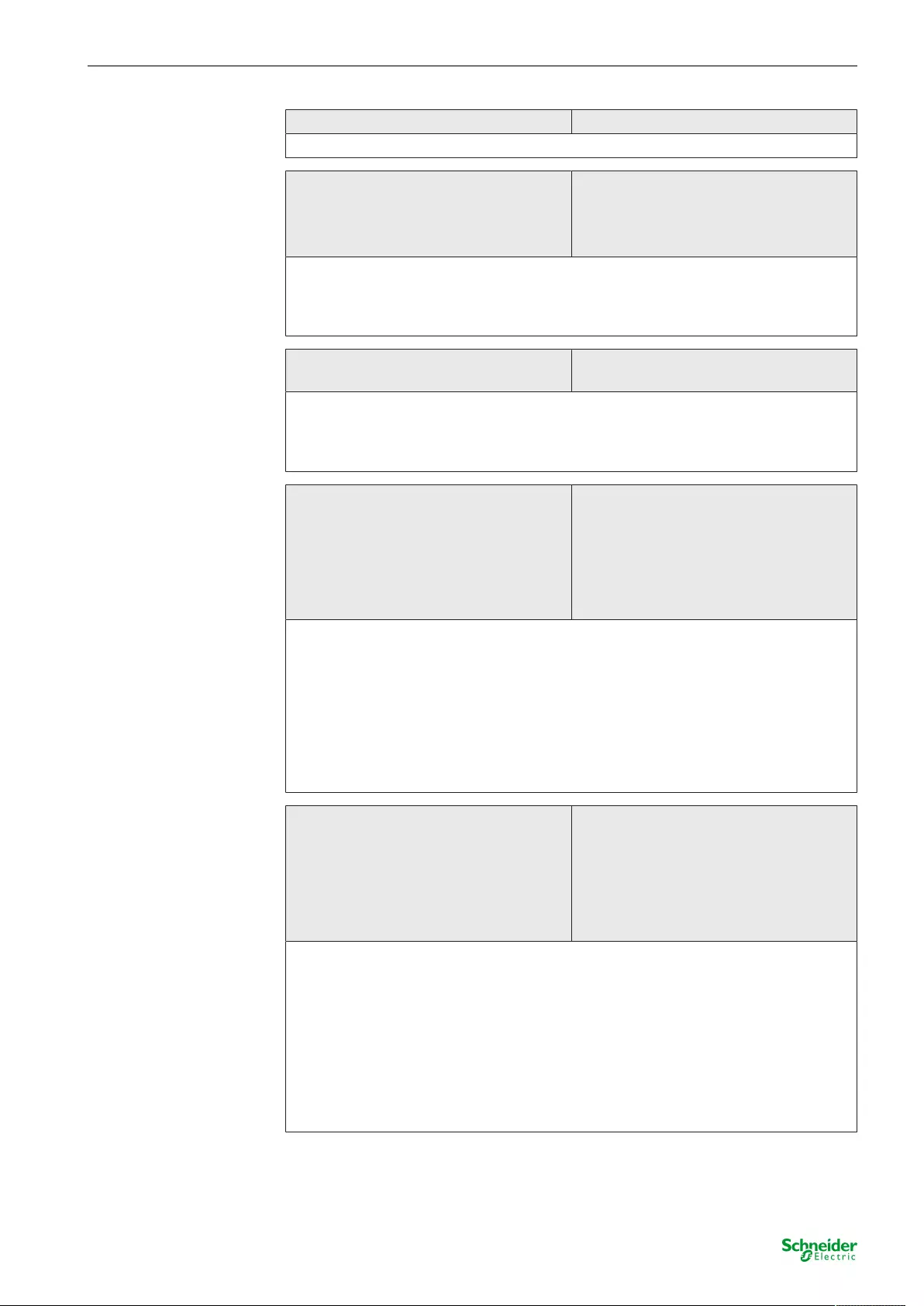

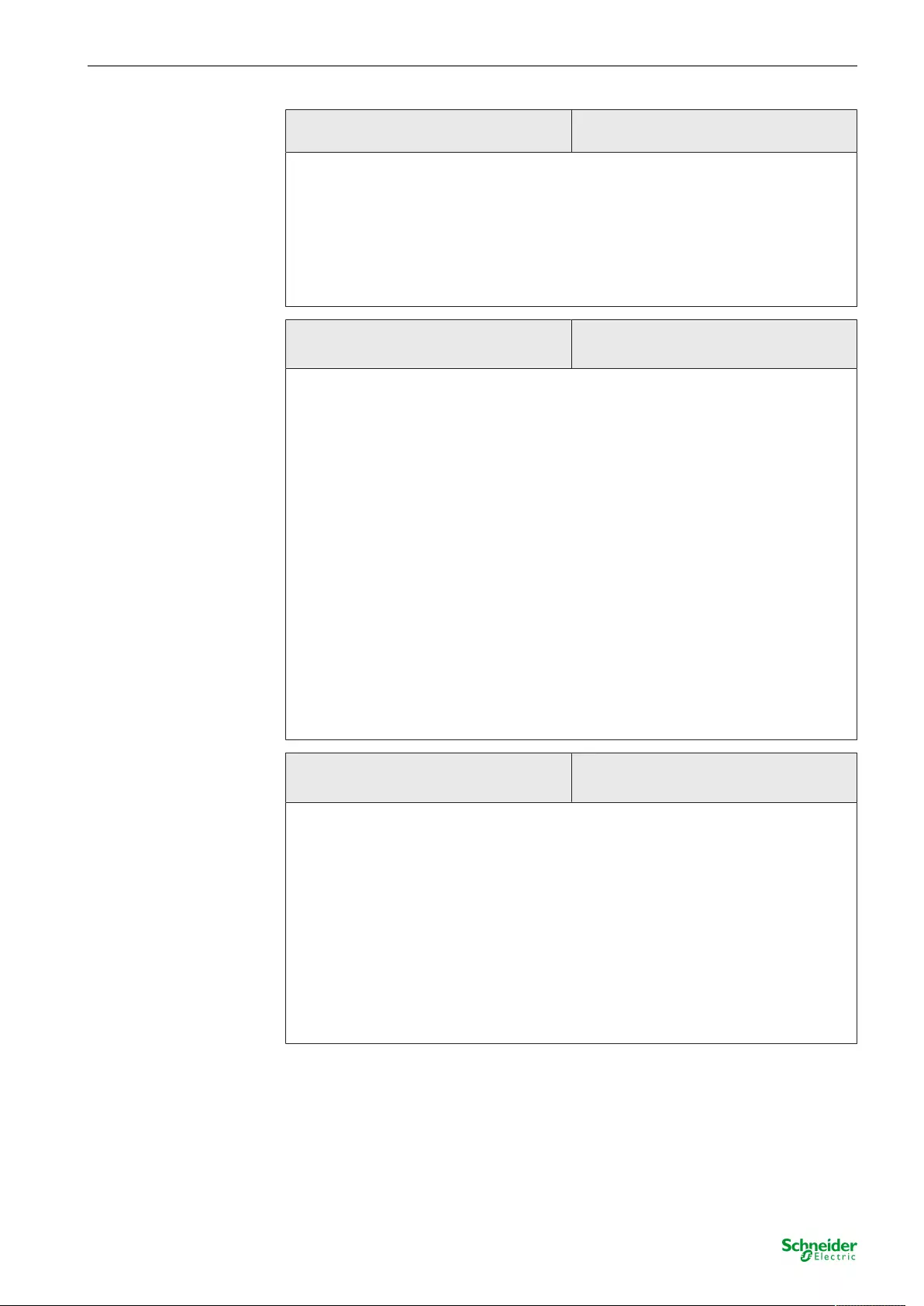

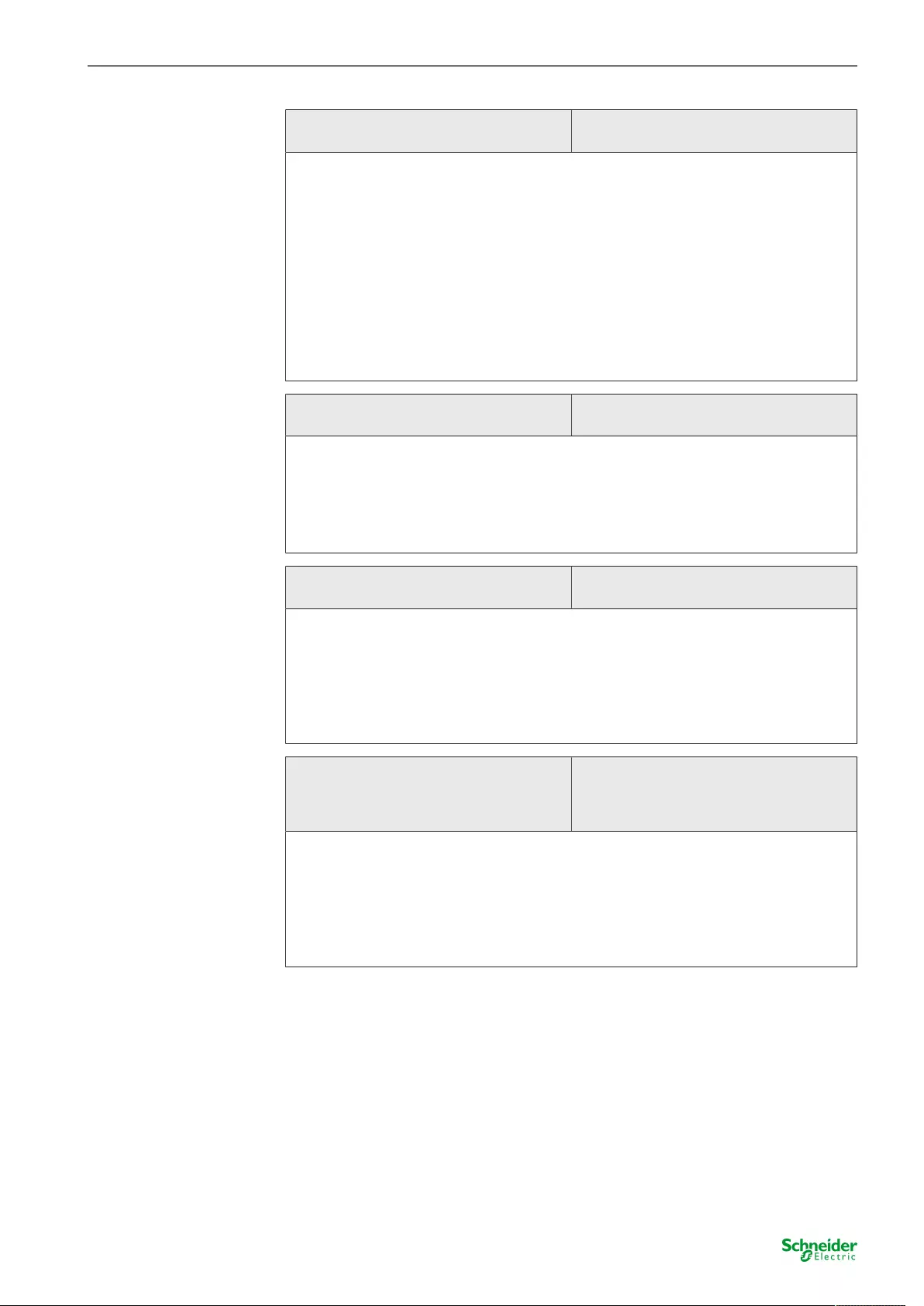

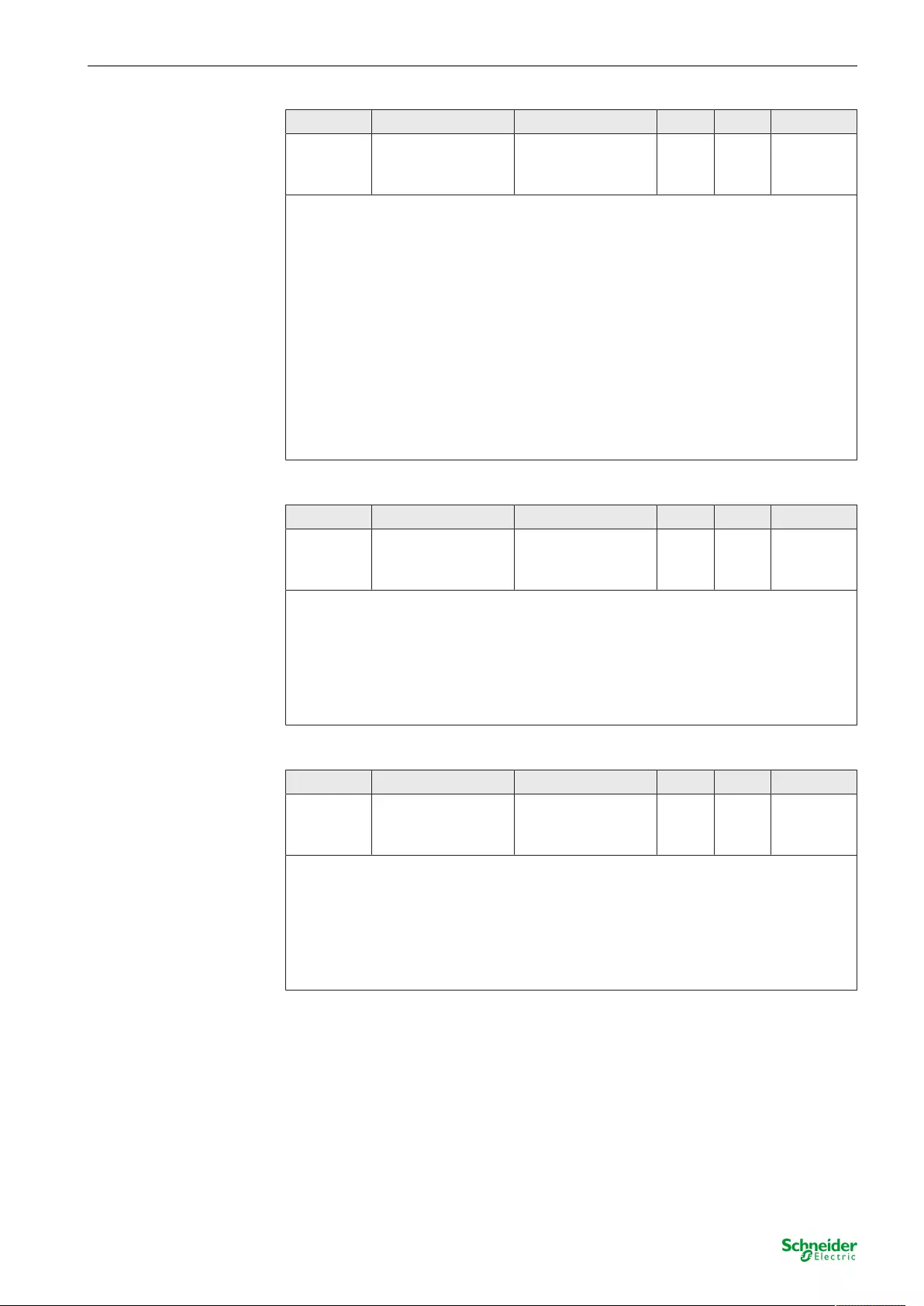

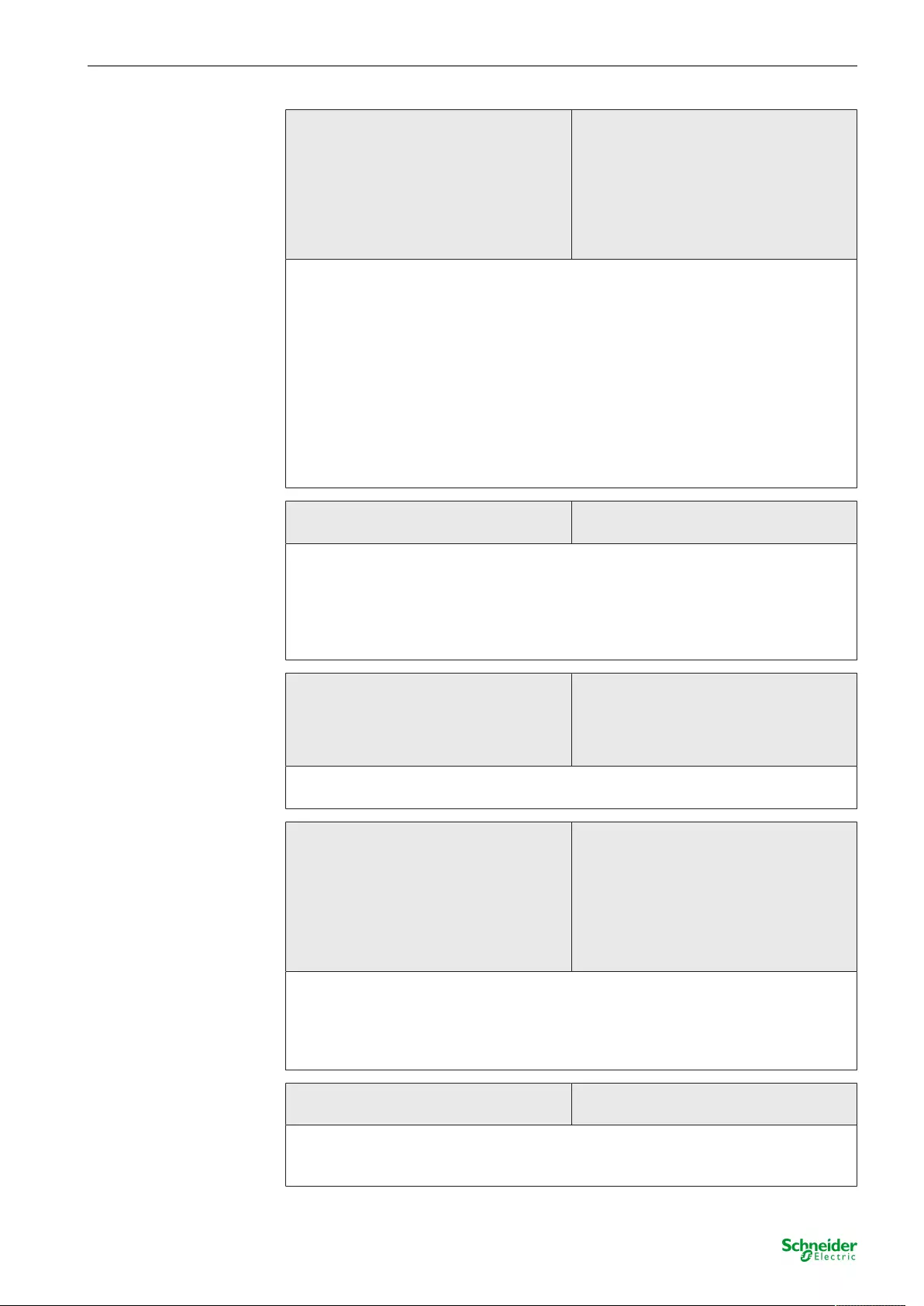

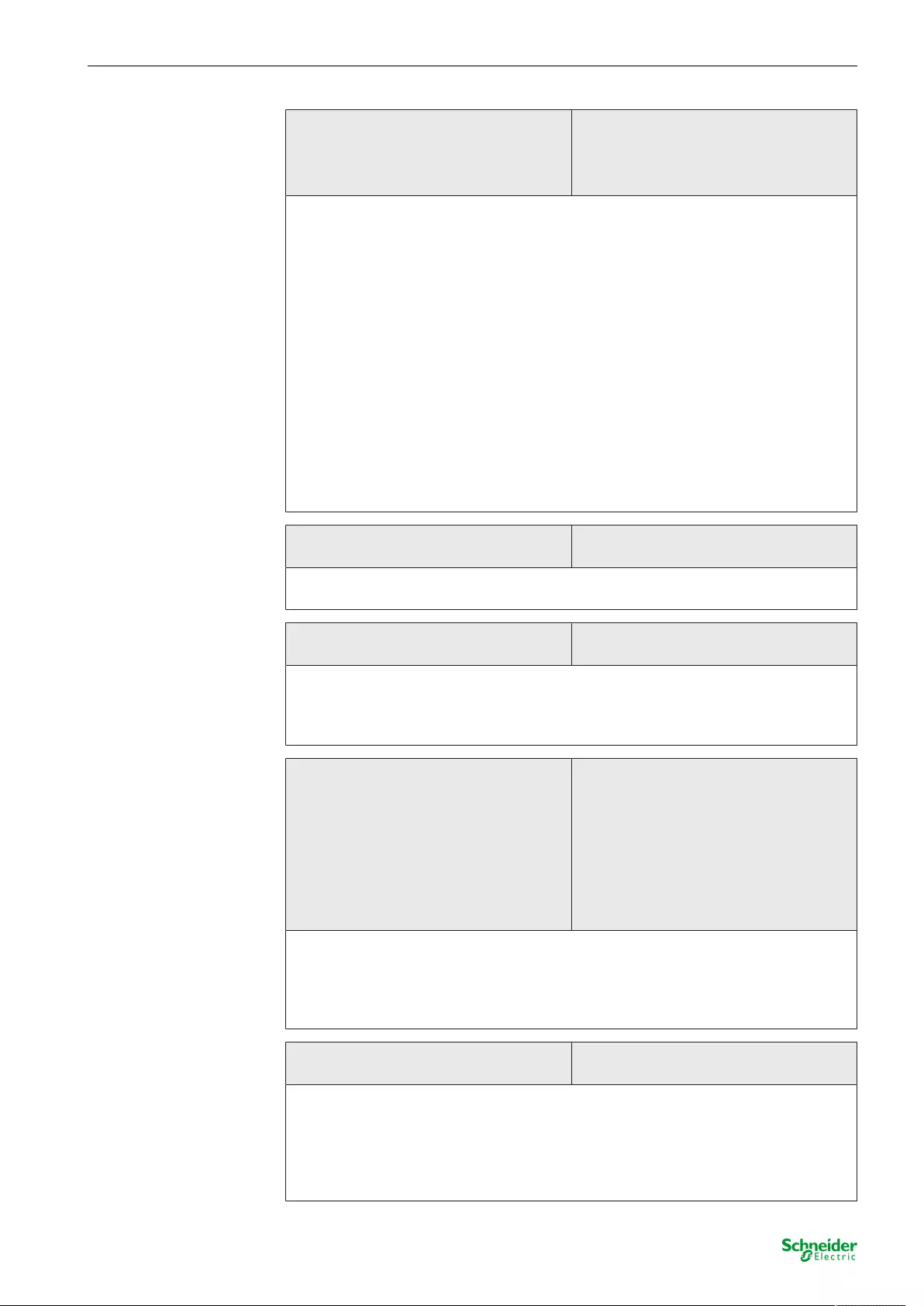

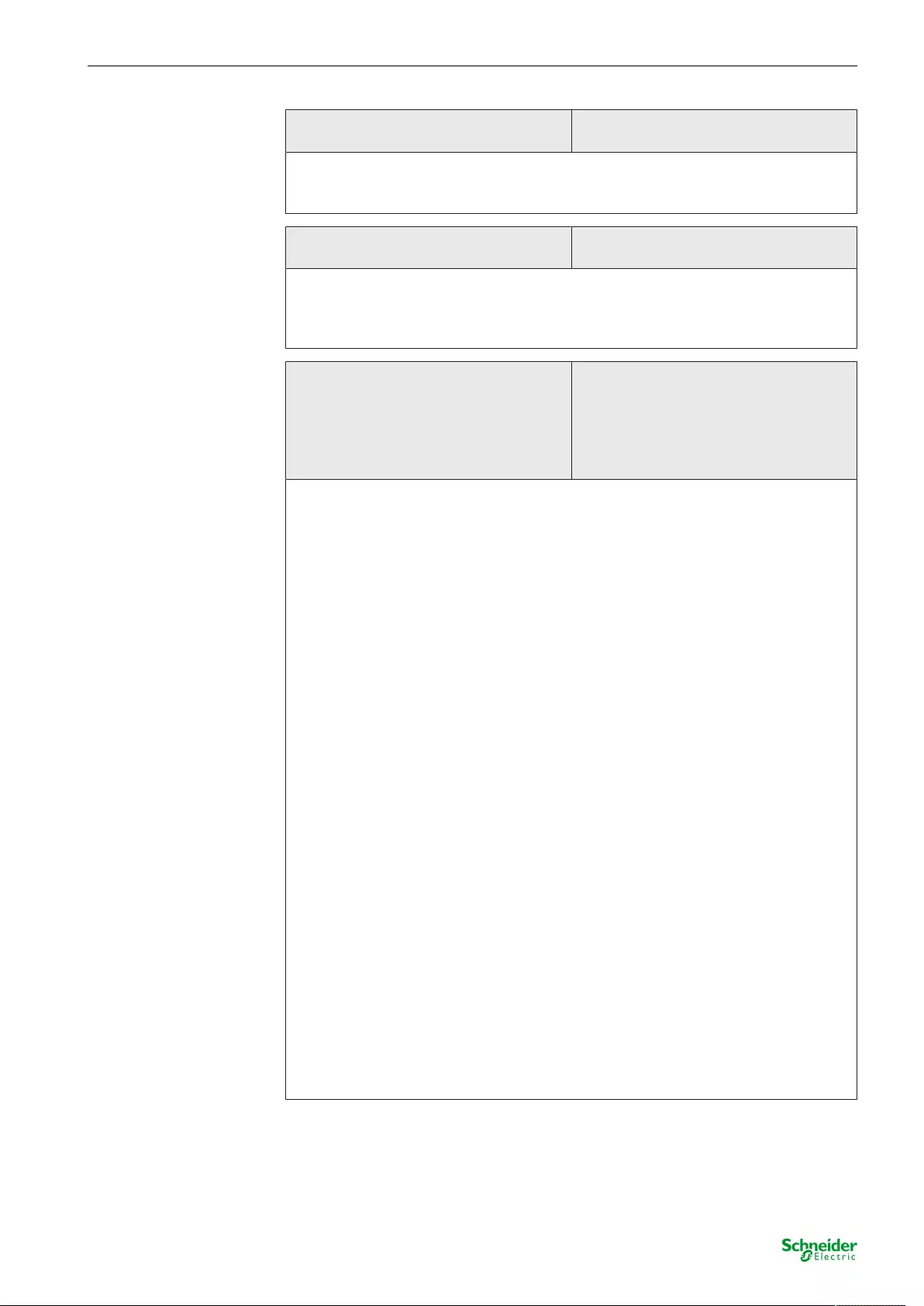

Image3: Connection for actuators AC 24 V

Left: Isolated connection of the actuators, separately on the actuator /

Right: Shared conductor for actuators

Only connect AC 24 V actuators to all the outputs.

Only connect actuators with the same characteristics to each output (deenergised

closed/opened).

Do not connect unsuitable loads (incandescent lamps, motorised actuators, signal

devices, etc.).

If possible, connect actuators for environments with increased fail-safety require-

ments to the outputs A1 and A4. During overload detection, these are switched off

last.

Do not exceed the maximum number of "2" actuators per output.

Observe the technical data of the valve drives used.

■ Connect the AC 24 V valve drives according to the connection diagram

(see figure 3). It is possible to connect the actuators individually and directly

with the terminals of the outputs of the heating actuator (left-hand connec-

tion example) or, alternatively, using a shared conductor (right-hand con-

nection example).

The terminals of the valve outputs indicated with "(N)" are bridged internally in the

device. The terminals may only be used for the connection of the actuators of an

actuator. Never connect N potential (mains voltage)!

■ Connect the supply for the actuators (AC 24 V) to the terminals 8(L) and

8(N) (1). In so doing, use a low voltage AC 24 V from a suitable power sup-

ply (transformer, mains power supply).

Do not connect direct current.

SpaceLogic KNX Valve Drive Controller

16 | MTN6730-0002 11.08.2020

■ On the device label, note the type of supply "AC 24 V" with a permanent

marker.

■ Connect mains voltage AC 230 V to the terminals L N (5).

The neutral conductor connection of the mains connection terminal is independent

of the N terminals of the valve outputs.

■ Connect bus line with device connection terminal.

SpaceLogic KNX Valve Drive Controller

17 | MTN6730-0002 11.08.2020

4 Commissioning

After mounting of the actuator and connection of the bus line, the mains power

supply, the power supply of the actuators and of all electrical loads, the device can

be put into operation. The following procedure is generally recommended...

DANGER!

Electrical shock on contact with live parts in the installation environment.

Electrical shocks can be fatal.

■ Before working on the device, disconnect the power supply and cover up

live parts in the working environment.

Commissioning with the ETS

■ Switch on the bus voltage. Make sure that the bus voltage is available inter-

ruption free during the commissioning.

The device has a mains voltage connection that is independent of the valve outputs

for supplying the device electronics of the manual operation and integrated bus

coupling unit. The device electronics and bus coupling unit are also supplied from

the bus coupling unit so that an ETS programming operation or manual operation is

also possible even if the mains voltage is not connected or is switched off. As long

as the bus voltage is connected and ready for operation, no power is drawn from

the device's internal power supply unit. This saves electrical energy.

■ Configure and program the physical address with the help of the ETS.

■ Download the application data with the ETS.

The device is ready for operation.

When the mains supply is on, the valve outputs of the actuator can be switched via

manual operation, even if there is no bus voltage or if the actuator is not yet pro-

grammed. Due to this feature, the actuators connected to the individual outputs can

be checked for proper functioning already during construction site operation.

Number of communication objects: 308

(max. object number 738 - gaps in

between)

Number of addresses (max.): 760

Number of assignments (max.): 760

SpaceLogic KNX Valve Drive Controller

18 | MTN6730-0002 11.08.2020

5 Application programs

ETS search paths: 7.1 Heating/Single Room Thermostat / 7.1.2 Heating/Switch

actuator / SpaceLogic KNX Ventilantriebsregler

Application:

Name Valve Drive Controller 2073/1.0

Version: 1.1 for ETS4 Version 4.2 onwards and ETS5

from mask version SystemB (07B0)

Summarized de-

scription

Multifunctional heating actuator application:

Activation of up to 6 valve outputs for electrothermal actuat-

ors. Optionally with room temperature control through 6 integ-

rated room temperature controllers. With manual control.

SpaceLogic KNX Valve Drive Controller Operating elements

19 | MTN6730-0002 11.08.2020

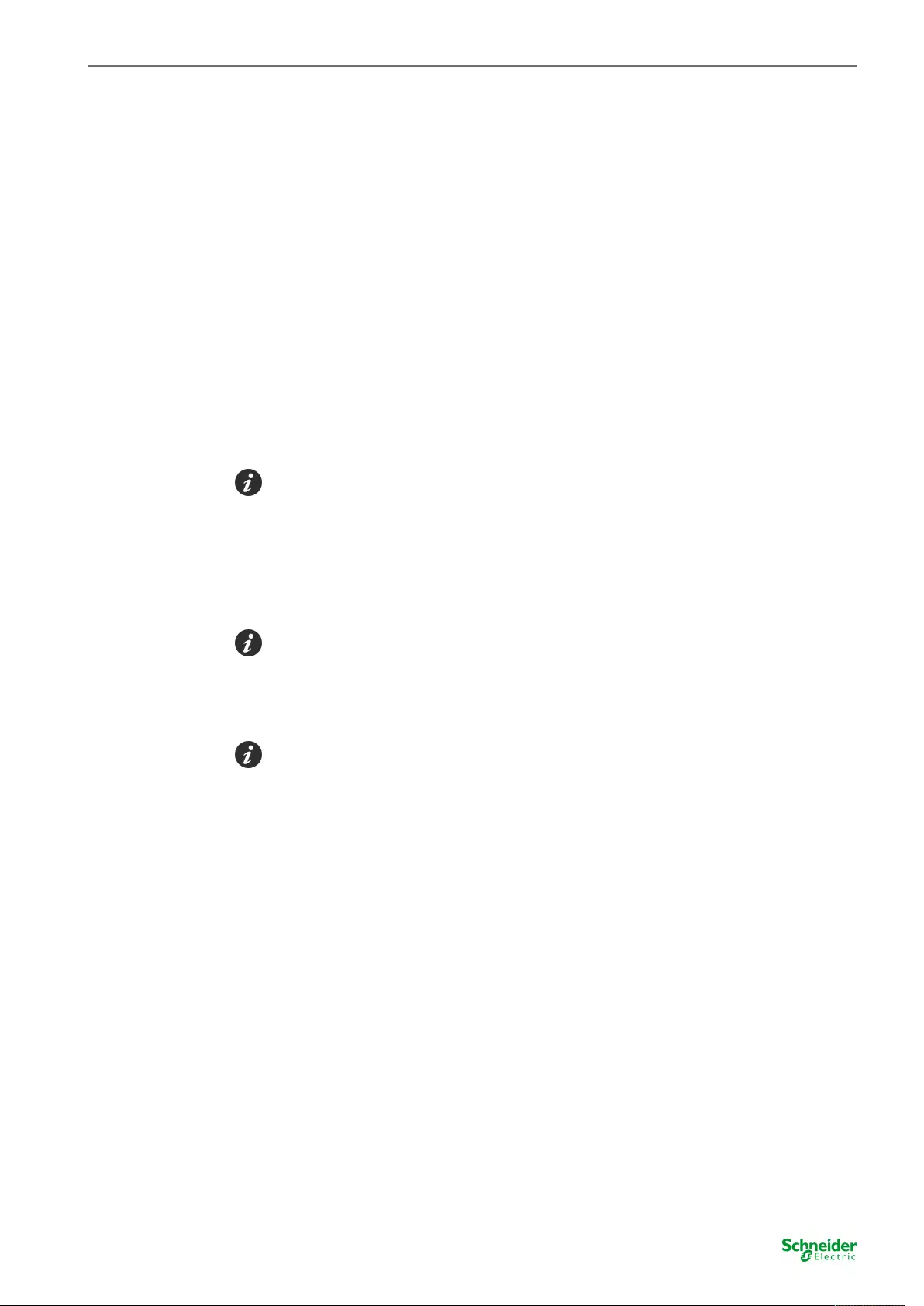

6 Operation

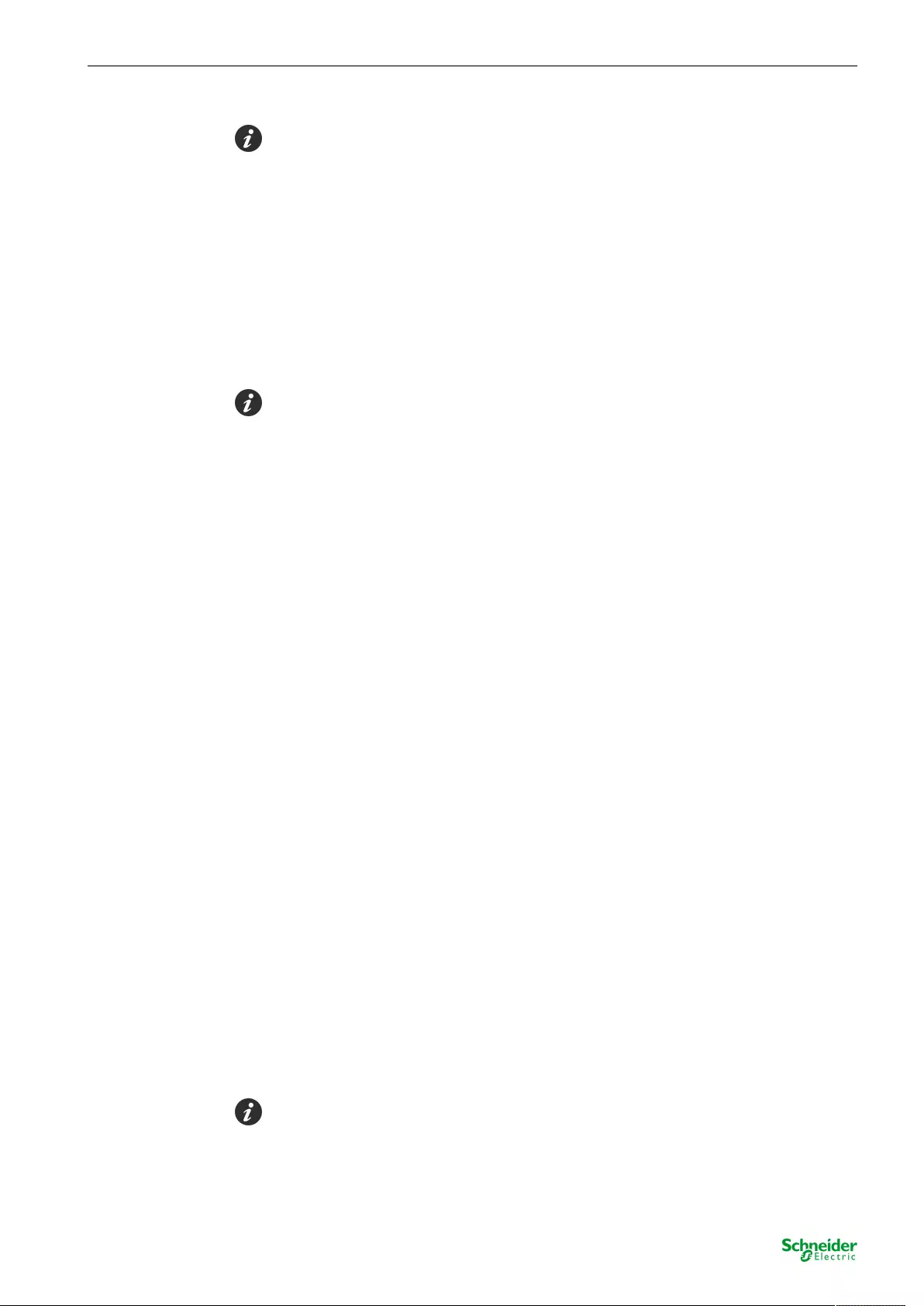

6.1 Operating elements

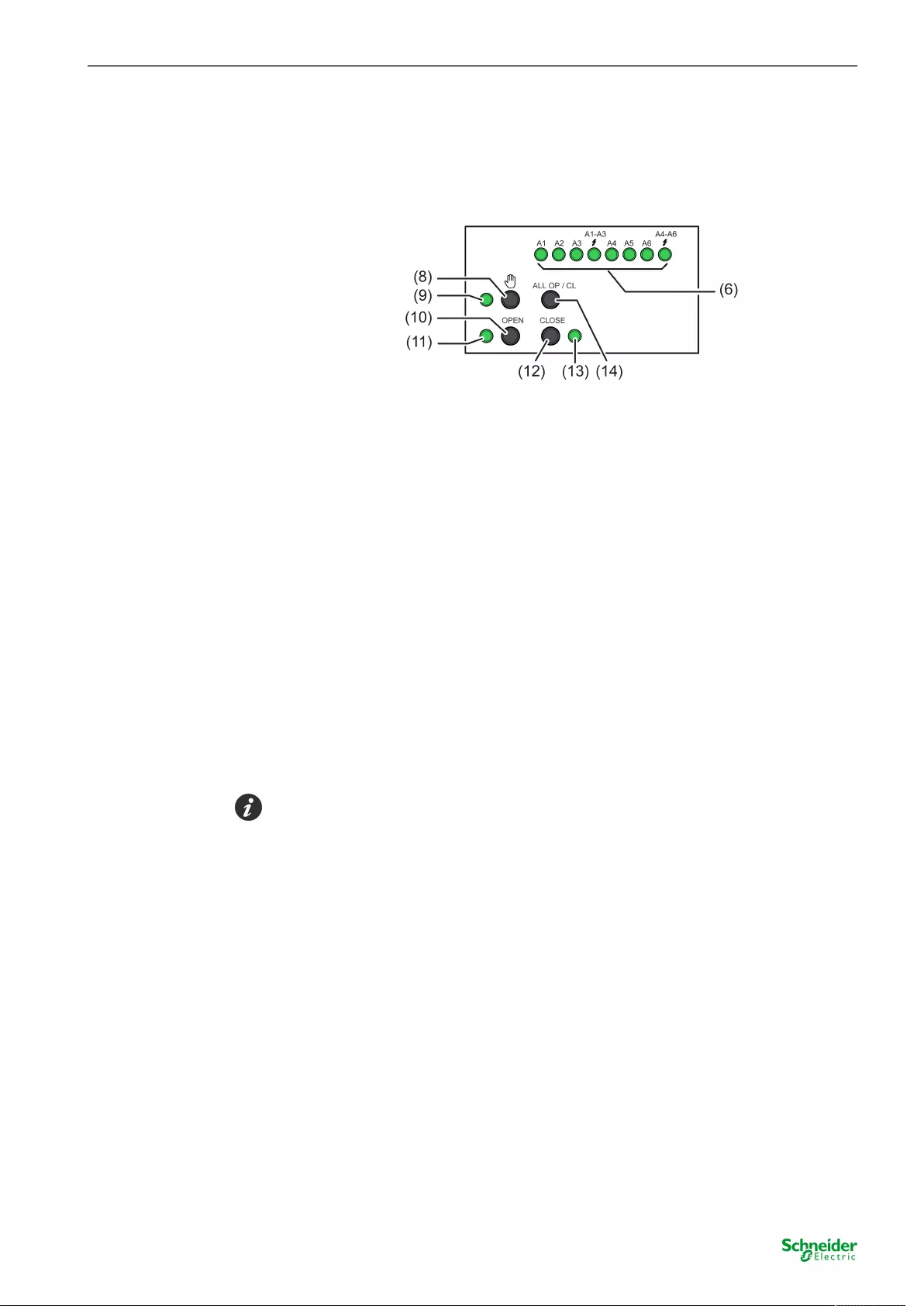

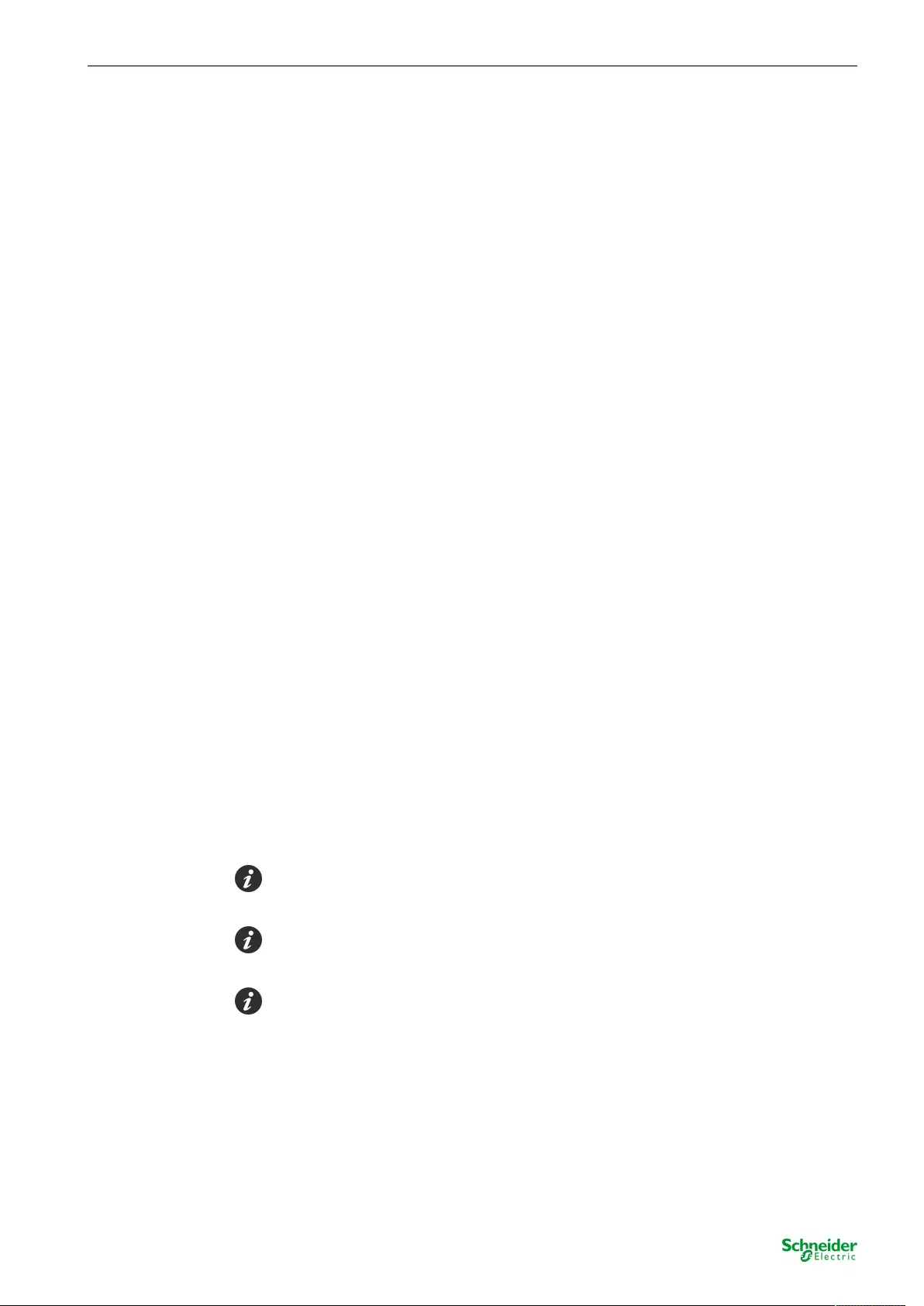

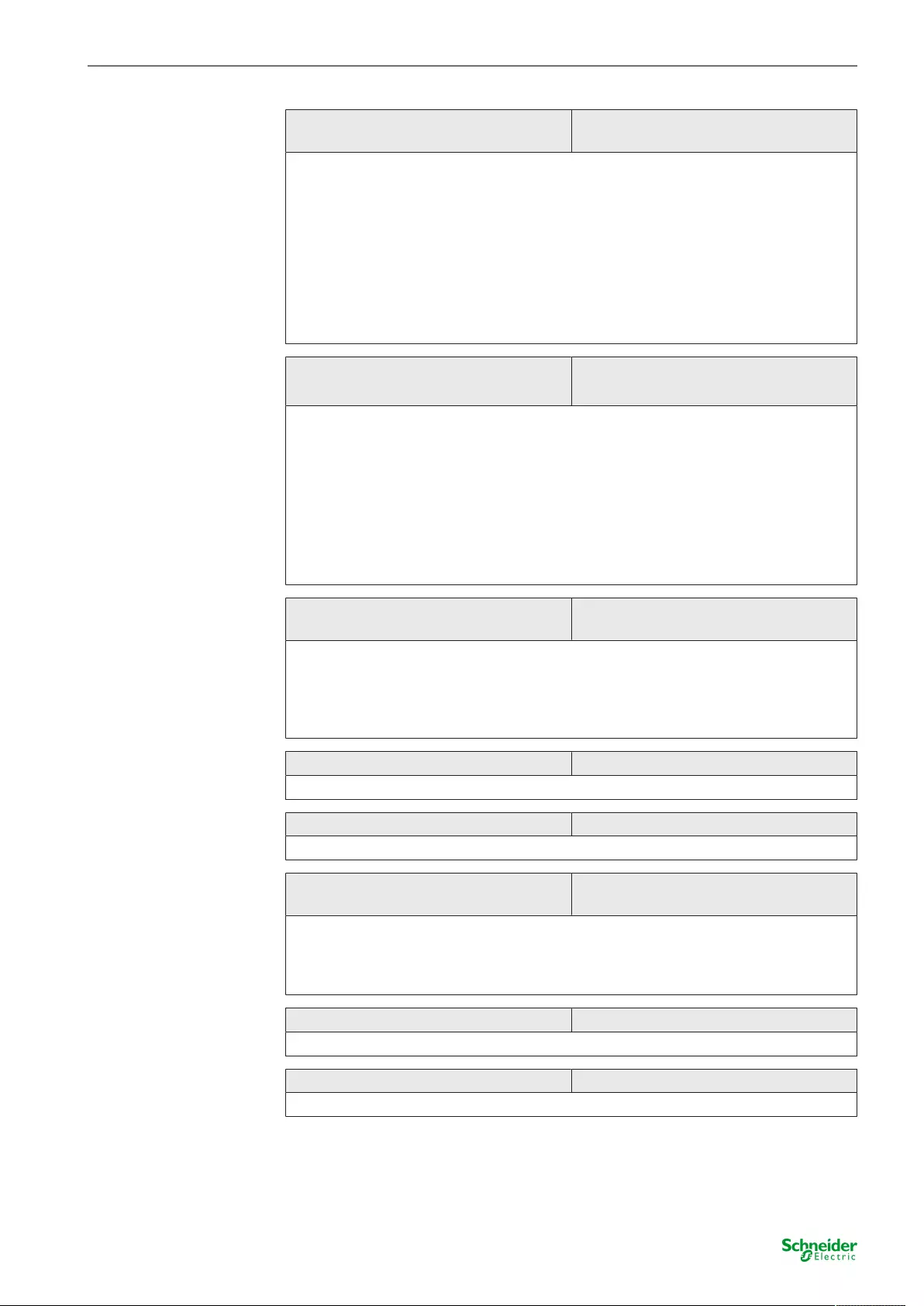

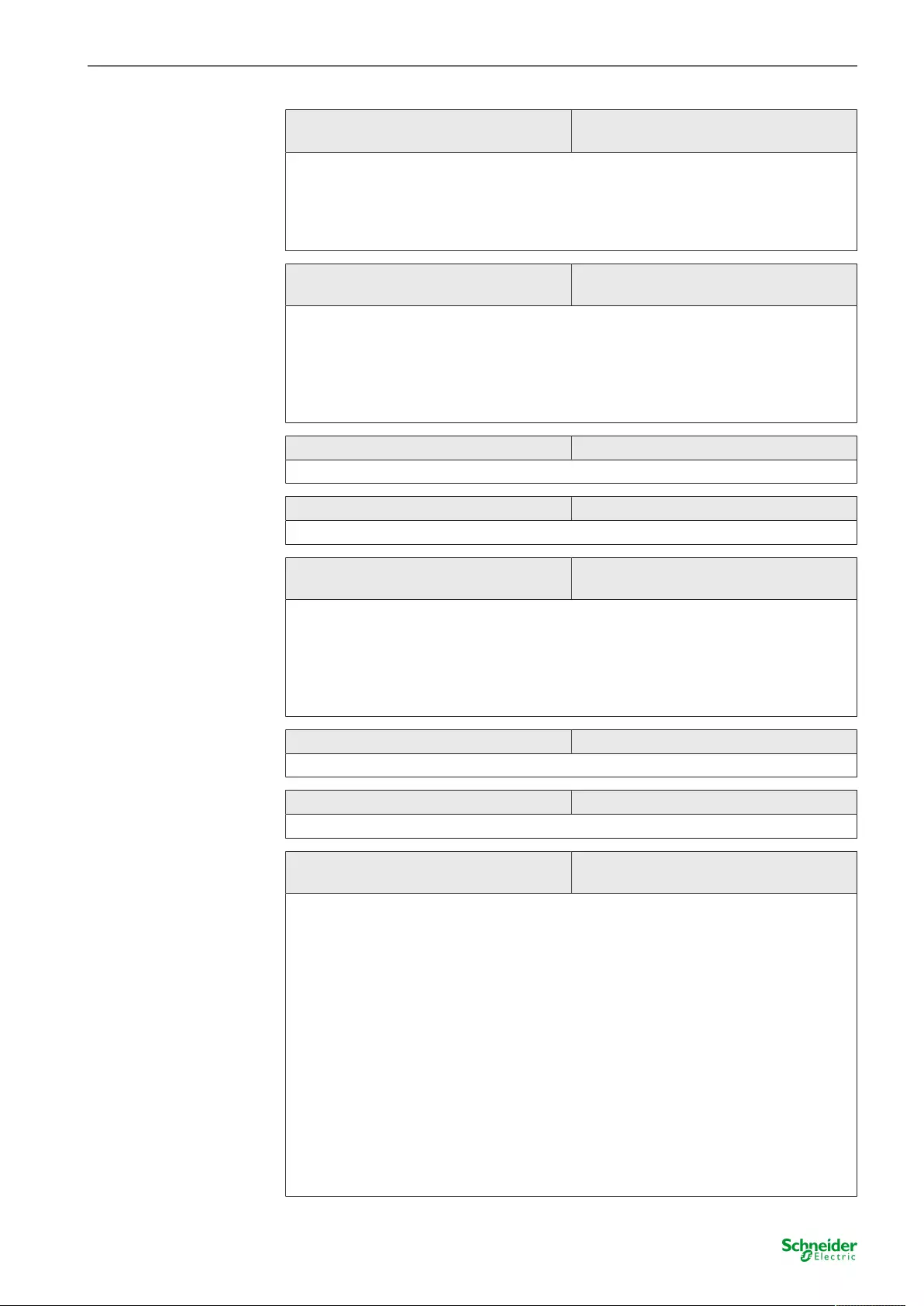

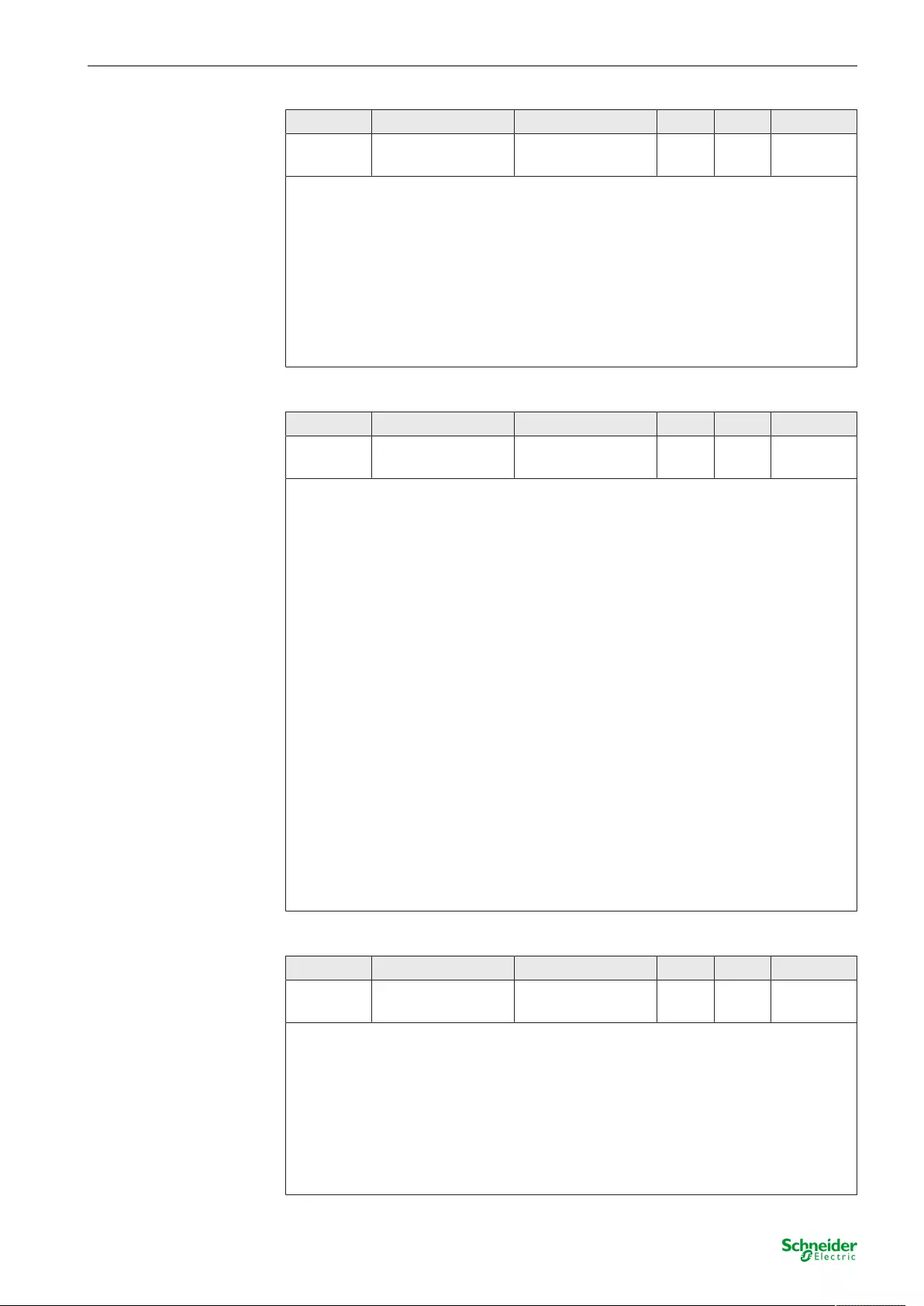

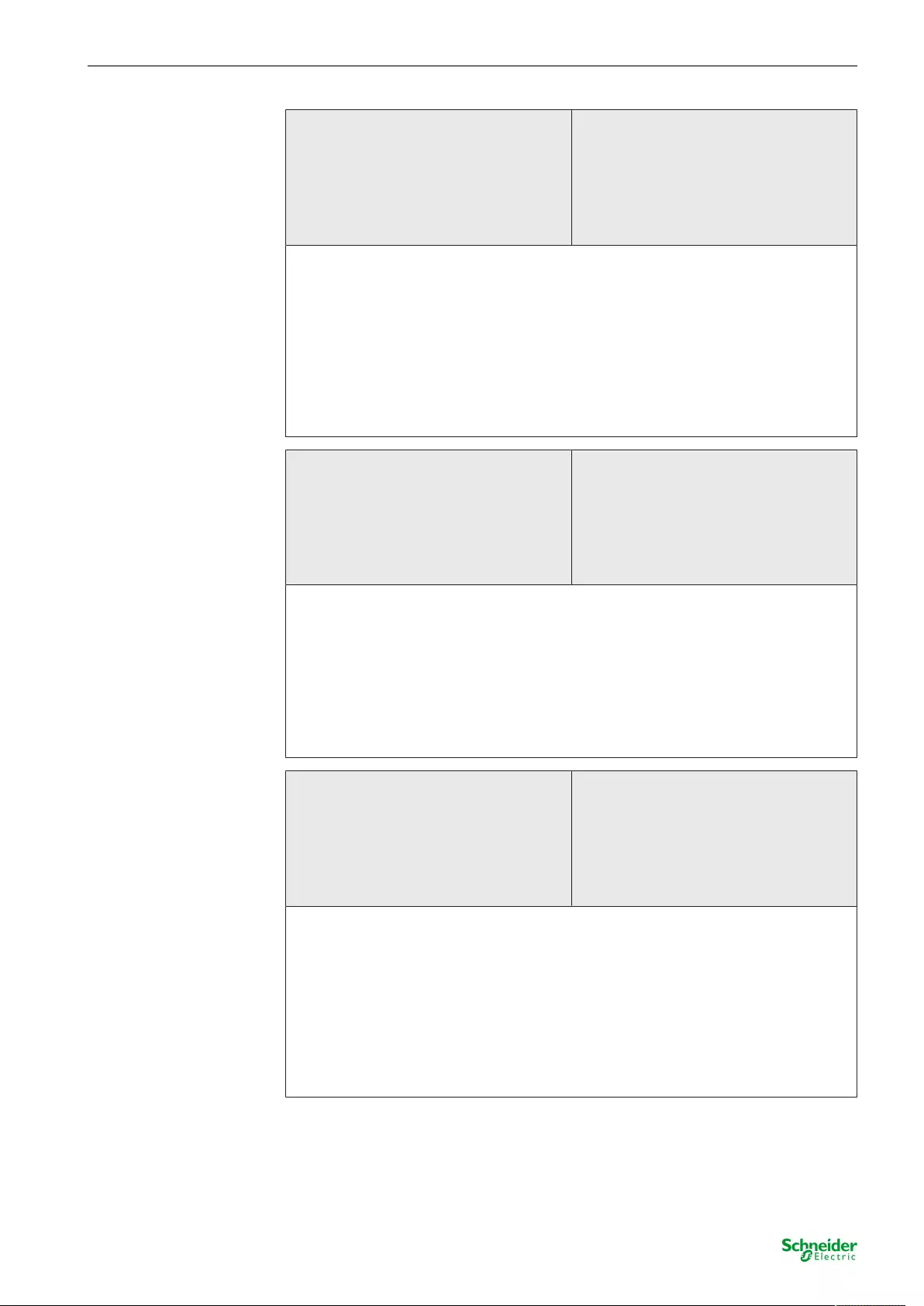

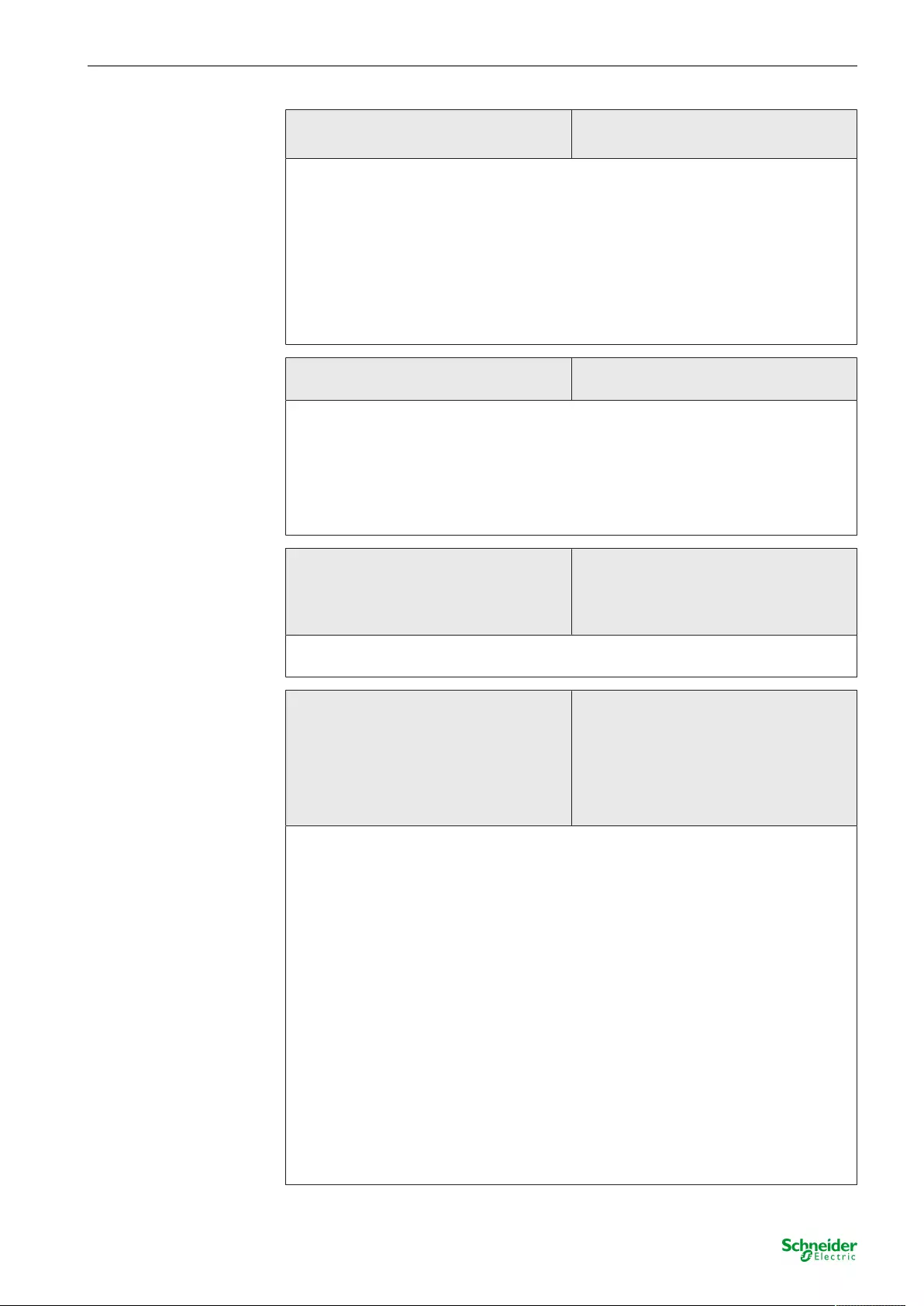

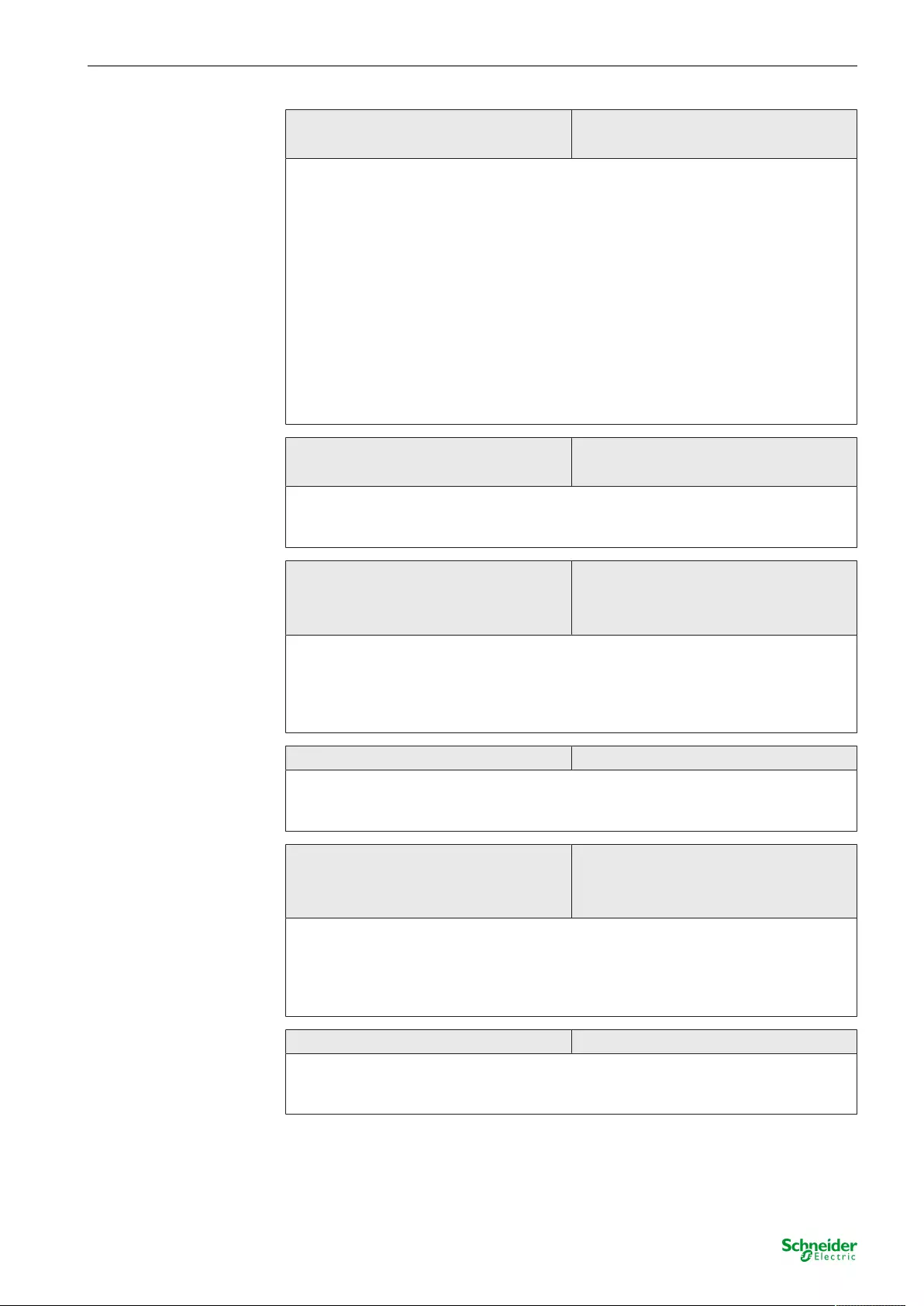

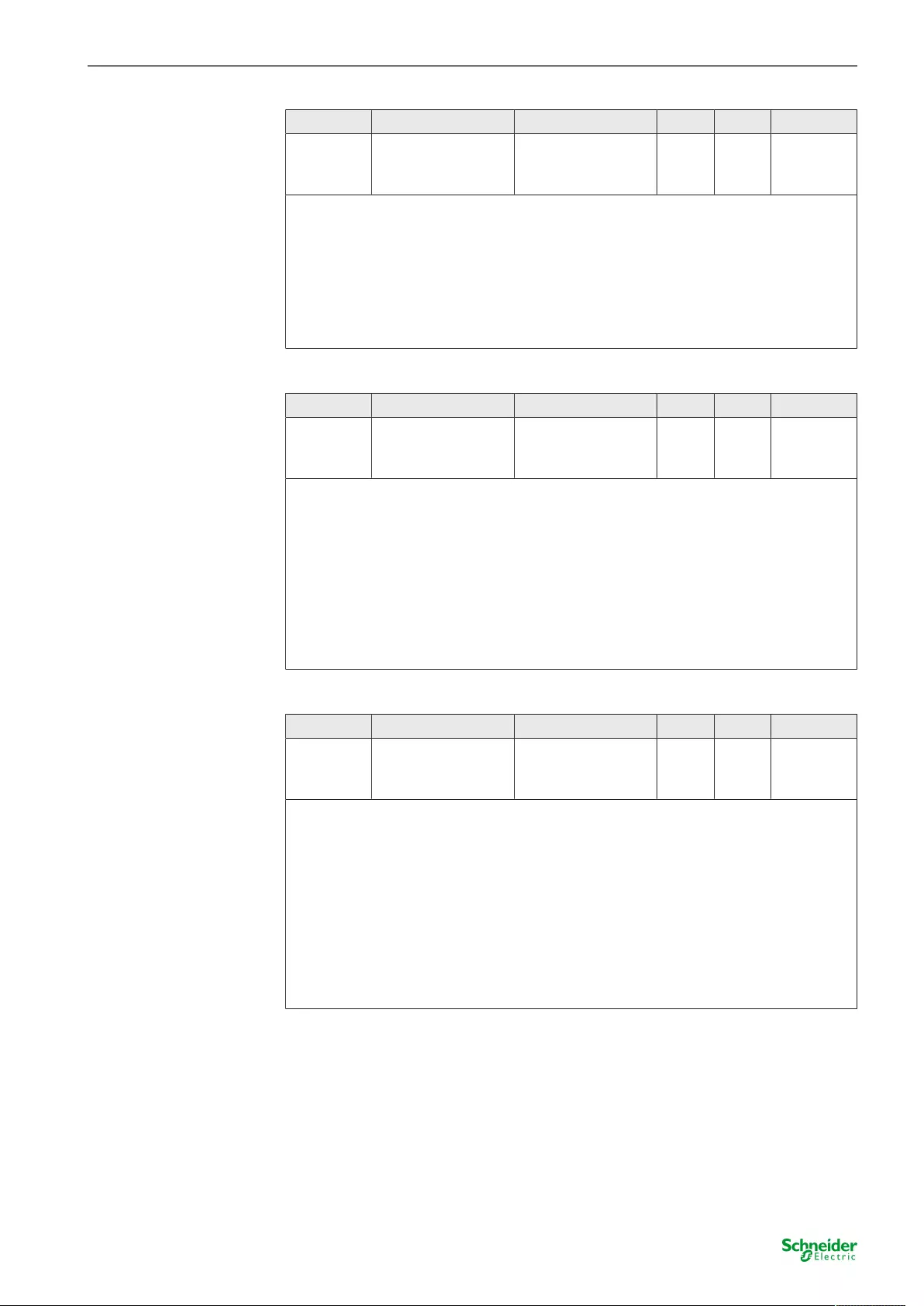

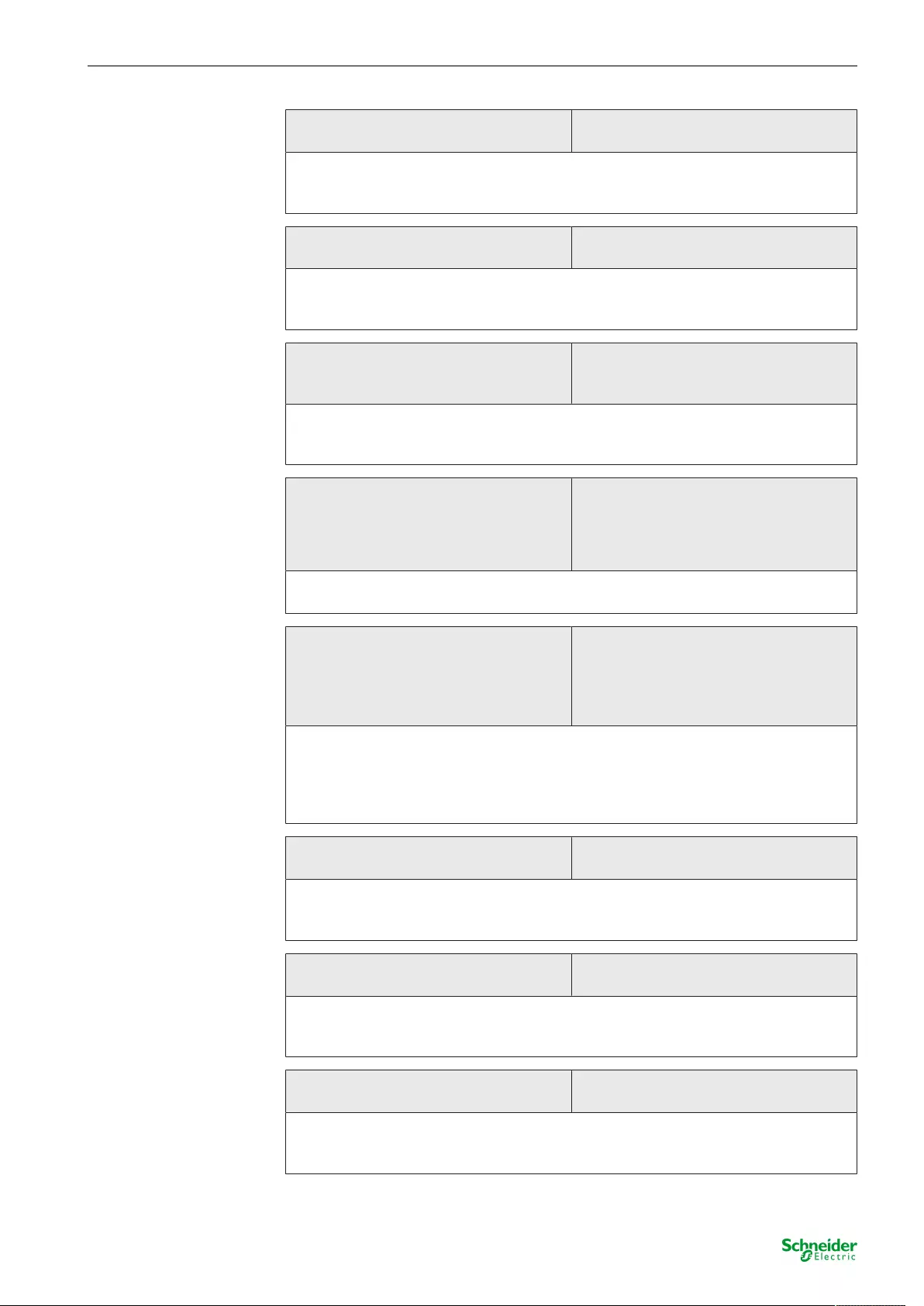

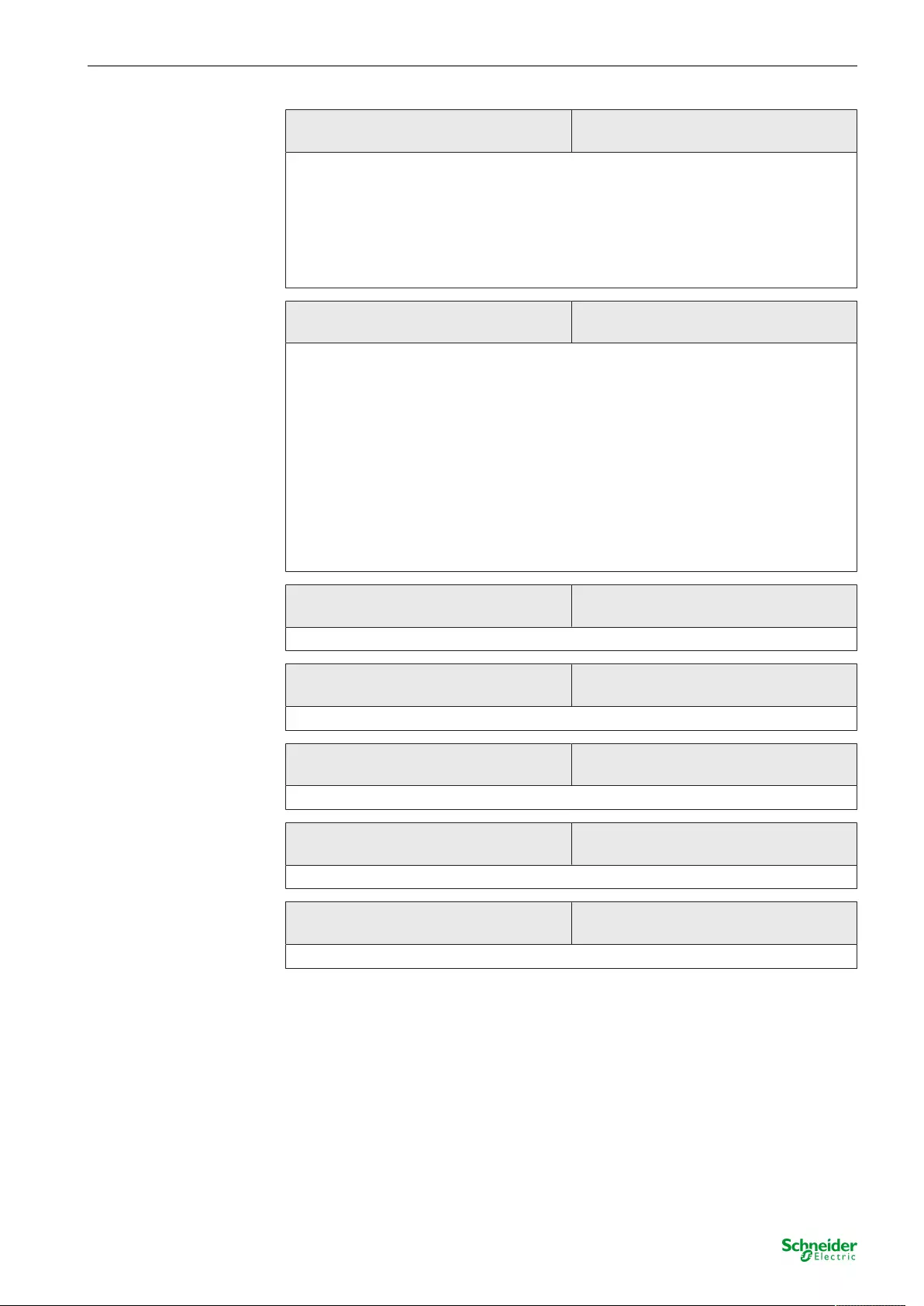

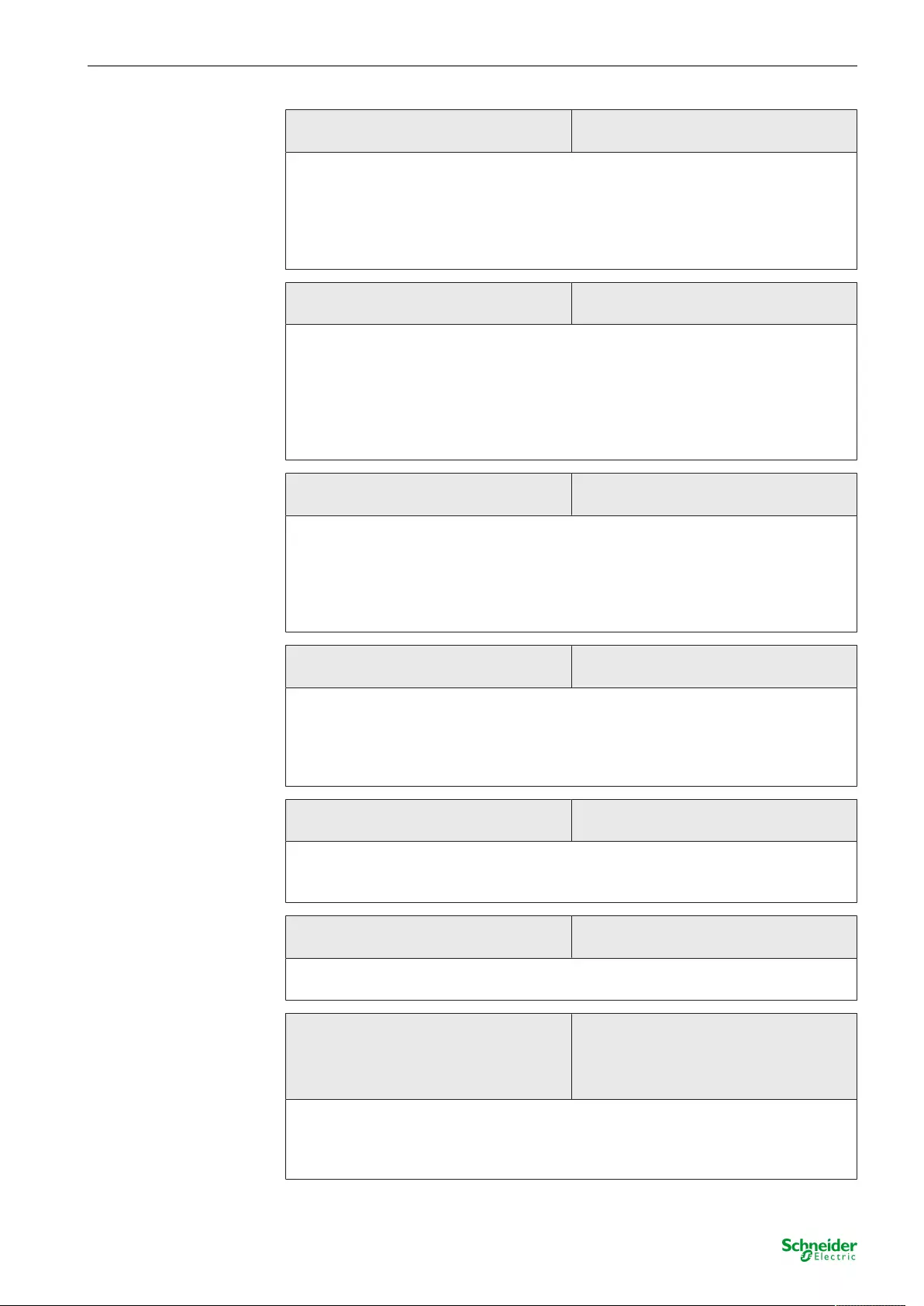

Image4: Controls and indicators on the front panel of the device

(6) A1...A6: Status LEDs of the valve outputs (LEDs light up when outputs are

energised)

ŋA1-A3, ŋA4-A6: Display "Overload/short-circuit" for appropriate output

group

(8) Buttonc:Activation / deactivation of manual control

(9) LED c: Indicates permanent manual operation when ON.

(10) OPEN button: Open valve (configured valve direction of action is taken

into account)

(11) OPEN LED: When ON in manual operation, signals an opened or opening

valve

(12) CLOSE button: Close valve (configured valve direction of action is taken

into account)

(13) CLOSE LED: When ON in manual operation, signals a closed or closing

valve

(14) ALL OP / CL button: Central operating function for all valve outputs. Open

and close all the valves alternately.

OPEN (10) and CLOSE (13) LEDs: The LEDs light up statically during manual op-

eration, showing the valve status set or to be set (valve is closed or closing / valve

is opened or opening). Even on valve outputs working with an 8-bit command value

(PWM), the LEDs display the logical valve state statically in the same way. The

LEDs do not signal the dynamic switch-on and switch-off phases of the pulse width

modulation.

If no valve voltage is connected or switched on at the terminals 8(L) and 8(N), then

the LEDs are also always switched off, even if bus voltage or mains voltage is

available (terminals L N), as the valve outputs cannot be energised.

6.2 Status displays and output behaviour

Status indication

The Status LEDs A1...A6 show whether the current flow is switched on or switched

off at the appropriate output. The connected heating or cooling valves open and

close according to their characteristics.

SpaceLogic KNX Valve Drive Controller Status displays and output behaviour

20 | MTN6730-0002 11.08.2020

Pilot valve LED ON LED OFF

Deenergised closed Output energised

Valve opened / Opening

phase

Active heating or cooling

Output not energised

Valve closed / Closing

phase

Deenergised opened Output energised

Valve closed / Closing

phase

Output not energised

Valve opened / Opening

phase

Active heating or cooling

Status display according to the energisation state of the valve outputs

In the case of valve outputs working with an 8-bit command value (PWM), the LEDs

dynamically display the switch-on and switch-off phases of the pulse width modula-

tion.

If no valve voltage is connected or switched on at the device connection terminals

8(L) and 8(N), then all the status LEDs are also always switched off, even if bus

voltage or mains voltage is available (terminals L N), as the valve outputs cannot

be energised.

On the LED status display, the valve direction of action configured for each output

in the ETS is not taken into account. As a result, the LEDs do not immediately dis-

play the valve state (opened / closed). Inversion of the status display according to

the valve direction of action thus does not take place.

Short-circuit / overload display

In order to protect the device and connected actuators, in case of overload the

device determines which output is involved and switches it off. Non-overloaded

outputs continue to work, which means that the corresponding rooms are still

heated or cooled.

– In the case of short-circuits or overloads, the actuator first switches off the

affected output groups A1...A3 or A4...A6.

– The actuator determines the overloaded or short-circuited output in up to 4

testing cycles.

– If, in the event of only a minor overload, it is not possible to unambiguously

identify any output as overloaded, then the actuator switches individual out-

puts of the overloaded group off one after the other.

– A detected overload or a detected short-circuit can be sent separately to the

KNX using a 1-bit signal telegram for each valve output.

The status LEDs ŋA1-A3 or ŋA4-A6 on the front panel of the device flash slowly

during the time of an overload or short-circuit identification (1 Hz) to signalise that

the output groups are temporarily deactivated. The LEDs flash quickly when the

actuator has safely identified all or individual valve outputs of the affected group as

overloaded or having short-circuited.

In the testing phase of a short-circuit/overload detection, the outputs of the affected

group(s) cannot be selected during manual operation.

The testing cycle is explained in detail in the "Software description" chapter of this

documentation.

SpaceLogic KNX Valve Drive Controller Status displays and output behaviour

21 | MTN6730-0002 11.08.2020

Activation of the outputs in manual mode

During manual operation, all the valve outputs are activated with a pulse-width

modulation (PWM) using the OPEN button, irrespective of the configured com-

mand value data format (1-bit or 1-byte). The cycle time of the PWM signal for a

valve output activated by manual operation is configured centrally on the para-

meter page "Manual operation" in the ETS. In consequence, a manual operation

locally on the device can allow the use of a different cycle time than in normal oper-

ation of the actuator (activation via KNX telegrams). The CLOSE command always

closes the valves completely (0 %).

An exception is the central operating function of all valve outputs with the ALL OP /

CL button. Here, the actuator always activates the valve outputs with a constant

signal (0 % or 100 %).

In manual operation, the configured valve direction of action (deenergised closed /

deenergised opened) is taken into account during valve activation. With deener-

gised closed valves, the switch-on time is derived directly from the configured

PWM and the cycle time. Example: PWM = 30 %, cycle time = 10 minutes ->

Switch-on time = 3 minutes, switch-off time = 7 minutes.

In the case of deenergised opened valves, the switch-on time is inverted. Example:

PWM = 30 %, cycle time = 10 minutes -> Switch-on time = 7 minutes, switch-off

time = 3 minutes.

Pressing the OPEN button when valves are already opened produces no reaction.

The cycle time of a PWM signal is not restarted. On previously closed valves,

pressing the CLOSE button also does not produce a reaction.

After permanent manual operation has been switched on, the states of the outputs

last set initially remain active. However, for opened valve outputs, the pulse width

modulation is automatically adjusted to the preset value of manual operation.

After temporary manual operation is switched on, the states of the outputs last set

also initially remain active. However, for opened valve outputs, the pulse width

modulation is not adjusted to the preset value of manual operation. This only takes

place when the valves are first closed and then reopened, in the course of brief

manual operation.

In the state as supplied, the valve direction of action for all the valve outputs is set

to "Deenergised closed". The actuator then works with a PWM of 50 % and a cycle

time of 20 minutes.

First Open function

In most cases, deenergised closed actuators possess the "First Open function".

Such an valve drive must, before it can be used normally in combination with the

heating actuator, be energised for a specific period during the first electrical com-

missioning, in order to deactivate an internal mechanical block.

Normally, an intact block in the as-delivered state of the drives means that the

valve drive does not close fully. This means that the flow rate of the actuators and

the hydraulic system can be checked as part of installation and commissioning,

even without electrical actuation of the drives. An additional advantage is that the

small opening of the valve in the as-delivered state means that systems can heat

or cool in a restricted area (frost/heat protection), without the existence of a func-

tioning room temperature control.

Deenergised closed actuators with the First Open function are not usually com-

pletely closed in the as-delivered state. Such drives must be unlocked using the

First Open function, thus activating them for use by the heating actuator.

SpaceLogic KNX Valve Drive Controller Operating modes

22 | MTN6730-0002 11.08.2020

The activation of the actuators for the execution of the First Open function is easily

possible using manual operation of the heating actuator (in construction site mode,

only through an applied mains and valve power supply). In the as-delivered state,

the actuator works with a PWM of 50 % and a cycle time of 20 minutes. This pro-

duces a switch-on time of 10 minutes, when the command "Open valve" is ex-

ecuted in manual operation. This time is sufficiently long to execute the First Open

function properly. In the ETS, both the cycle time and the PWM of manual opera-

tion can be configured and thus adjusted to a desired value.

Alternatively, the central operating function can be used with the ALL OP / CL but-

ton to execute the First Open function. In so doing, all the valve outputs execute

the open or close command simultaneously (depending on the most recent preset-

ting).

6.3 Operating modes

The manual operation of the actuator distinguishes between the following operating

modes:

– Bus operation: Operation via room temperature controllers, push-button

sensors, or other bus devices,

– Temporary manual control: manual control locally with keypad, automatic

return to bus control,

– Permanent manual operation: Exclusively manual operation on the device

(e.g. construction site mode, commissioning phase).

When manual control is active, the outputs cannot be controlled via the bus.

In cases of bus voltage failure, manual operation is possible, provided that the

mains voltage supply of the actuator (terminals L N) is switched on. On bus voltage

return, manual operation can be terminated (central reset function) or continued

without interruption, depending on the configuration.

In manual mode, bus operation can be disabled via a telegram. Manual operation is

terminated on activation of the disabling function.

No manual operation of the device is possible if the actuator is programmed by the

ETS with an incorrect application program or if the application program was un-

loaded. In the state of the actuator as supplied, manual operation can be used even

before commissioning via the ETS (building site operation).

Further details concerning manual control, especially with respect to the possible

parameter settings and the interaction with other functions of the actuator can be

found in chapter 4, "Software description" of the present documentation.

Switching on the temporary manual control

Manual operation is enabled in the ETS and not blocked.

■ Press the c button briefly.

Temporary manual control is active.

The status LED A1 flashes. The LED c remains off.

SpaceLogic KNX Valve Drive Controller Operating modes

23 | MTN6730-0002 11.08.2020

After the temporary manual operation is switched on, the most recently set states of

the outputs initially remain active. For opened valve outputs, the pulse width modu-

lation is not adjusted to the preset value of manual operation. This only takes place

when the valves are first closed and then reopened, in the course of brief manual

operation.

After 5 seconds without a button actuation, the actuator returns automatically to bus

operation.

Switching off temporary manual operation

The device is in short-term manual mode.

■ No button-press for 5 seconds.

- or -

■ Select all outputs one after another by a brief press of the c button. There-

after, press the button again,

- or -

■ Switch off the mains voltage and the bus voltage.

- or -

■ On bus voltage return when mains voltage is available, although only when

the parameter "Response of the manual operation to bus voltage return" is

configured as "Exit manual operation".

Bus operation is active. LEDs A1...A6 no longer flash, but rather indicate the

output status, provided that the valve power supply and the bus or mains

voltage is switched on.

Manual operation is always exited after an ETS programming operation.

The state of all outputs set via manual control is not changed when temporary

manual control is switched off. If, however, a function with a priority higher than that

of normal operation (e.g. forced position, safety operation) was activated for the

valve outputs via the bus before or during manual operation, the actuator executes

the function with the higher priority for the outputs concerned.

Switching on permanent manual control

Manual operation is enabled in the ETS and not blocked.

Bus operation or temporary manual control is active.

■ Press the c button for at least 5 seconds.

Permanent manual operation is active and the LED c is illuminated. The

status LED A1 flashes. The two status LEDs OPEN and CLOSE show the

current status of A1.

After permanent manual operation has been switched on, the states of the outputs

last set initially remain active. However, for opened valve outputs, the pulse width

modulation is automatically adjusted to the preset value of manual operation.

Switching off permanent manual control

The device is in continuous manual mode.

■ Press the c button for at least 5 seconds.

SpaceLogic KNX Valve Drive Controller Operating modes

24 | MTN6730-0002 11.08.2020

- or -

■ Switch off the mains voltage and the bus voltage.

- or -

■ Block manual operation via the corresponding disabling object,

- or -

■ On bus voltage return when mains voltage is available, although only when

the parameter "Response of the manual operation to bus voltage return" is

configured as "Exit manual operation".

Bus operation is active. LEDs A1...A6 no longer flash, but rather indicate the

output status, provided that the valve power supply and the bus or mains

voltage is switched on.

Manual operation is always exited after an ETS programming operation.

Depending on the configuration of the actuator in the ETS, the outputs will be set to

the state last adjusted in the manual operation or to the state internally tracked (e.g.

forced position, service operation) when permanent manual operation is switched

off.

Operating the outputs

In manual operation the outputs can be operated instantly. The outputs are always

activated with pulse width modulation by manual operation with the OPEN com-

mand. The cycle time of the PWM signal for a valve output activated by manual op-

eration is configured centrally on the parameter page "Manual operation" in the

ETS. The CLOSE command closes the valves completely (0 %).

The device is in continuous or short-term manual mode.

■ Press c button briefly, < 1 s, as many times as necessary until the desired

output is selected.

The LED of the selected output A1...A6 flashes. Additionally, the status of

the selected output is indicated by the LED OPEN or CLOSE.

■ Press the OPEN button.

The valve opens (configured valve direction of action is taken into account).

■ Press the CLOSE button.

The valve closes (configured valve direction of action is taken into account).

The LEDs OPEN and CLOSE display the valve status.

Short-term manual operation: After running through all of the outputs, the device

exits manual operation after another brief press of the c button.

Executing the OPEN command when valves are already opened causes no reac-

tion. The cycle time of a PWM signal is not restarted. On previously closed valves,

pressing the CLOSE button also does not produce a reaction.

Depending on the parameter configuration in the ETS, feedback telegrams are

transmitted to the bus via the status objects of an output during operation, as ne-

cessary.

SpaceLogic KNX Valve Drive Controller Operating modes

25 | MTN6730-0002 11.08.2020

Operate all outputs simultaneously

All the valve outputs of the actuator can be activated at the same time. In contrast

to the operating function using the OPEN or CLOSE buttons, the actuator always

activates the valve outputs with a constant signal (0 % or 100 %), when they are

activated simultaneously. Thus, the valves close or open completely. No pulse

width modulation is executed.

This operating function is particularly practical for performing the First Open func-

tion of deenergised closed valves during first commissioning.

The device is in continuous manual mode.

■ Press the ALL OP / CL button.

Each time the button is pressed, the valves open and close alternately (all

open -> all close -> all open...). The configured valve direction of action is

taken into account.

Executing the OPEN central command when valves are already opened causes

PWM to be terminated. The command value switches to 100 %. The cycle time of a

PWM signal is not restarted. On previously closed valves, executing the CLOSE

central command does not produce a reaction.

The ALL OP / CL button has no function in temporary manual operation. In this

case pressing this button produces no reaction.

Disabling bus control of individual outputs manually

It is possible to use manual operation to disable selected valve outputs in such a

way that they can no longer be activated via the bus.

The device is in continuous manual mode.

Disabling of the bus control mode must have been enabled in the ETS.

■ Press the c button briefly as many times as necessary until the desired out-

put is selected.

The status LED of the selected output A1...A6 flashes. The two status LEDs

OPEN and CLOSE show the current status of the selected output.

■ Press the OPEN and CLOSE buttons simultaneously for at least 5 seconds.

The selected valve output is disabled (activation via the bus no longer pos-

sible). The status LED of the disabled output flashes quickly and constantly

(even with manual operation deactivated).

An output that has been disabled in manual control can thereafter only be operated

in permanent manual control.

Cancelling the disabling of bus control of individual

outputs via manual control.

The device is in continuous manual mode.

Bus control of a valve output has been disabled previously in permanent manual

operation.

■ Press the c button briefly as many times as necessary until the desired out-

put is selected.

The status LED of the selected output A1...A6 flashes quickly. The two

status LEDs OPEN and CLOSE show the current status of the selected out-

put.

SpaceLogic KNX Valve Drive Controller Operating modes

26 | MTN6730-0002 11.08.2020

■ Press the OPEN and CLOSE buttons simultaneously for at least 5 seconds.

Selected output is enabled.

The selected valve output is re-enabled (activation via the bus is possible

again after manual operation has been deactivated).

The status LED of the enabled output flashes slowly.

SpaceLogic KNX Valve Drive Controller

27 | MTN6730-0002 11.08.2020

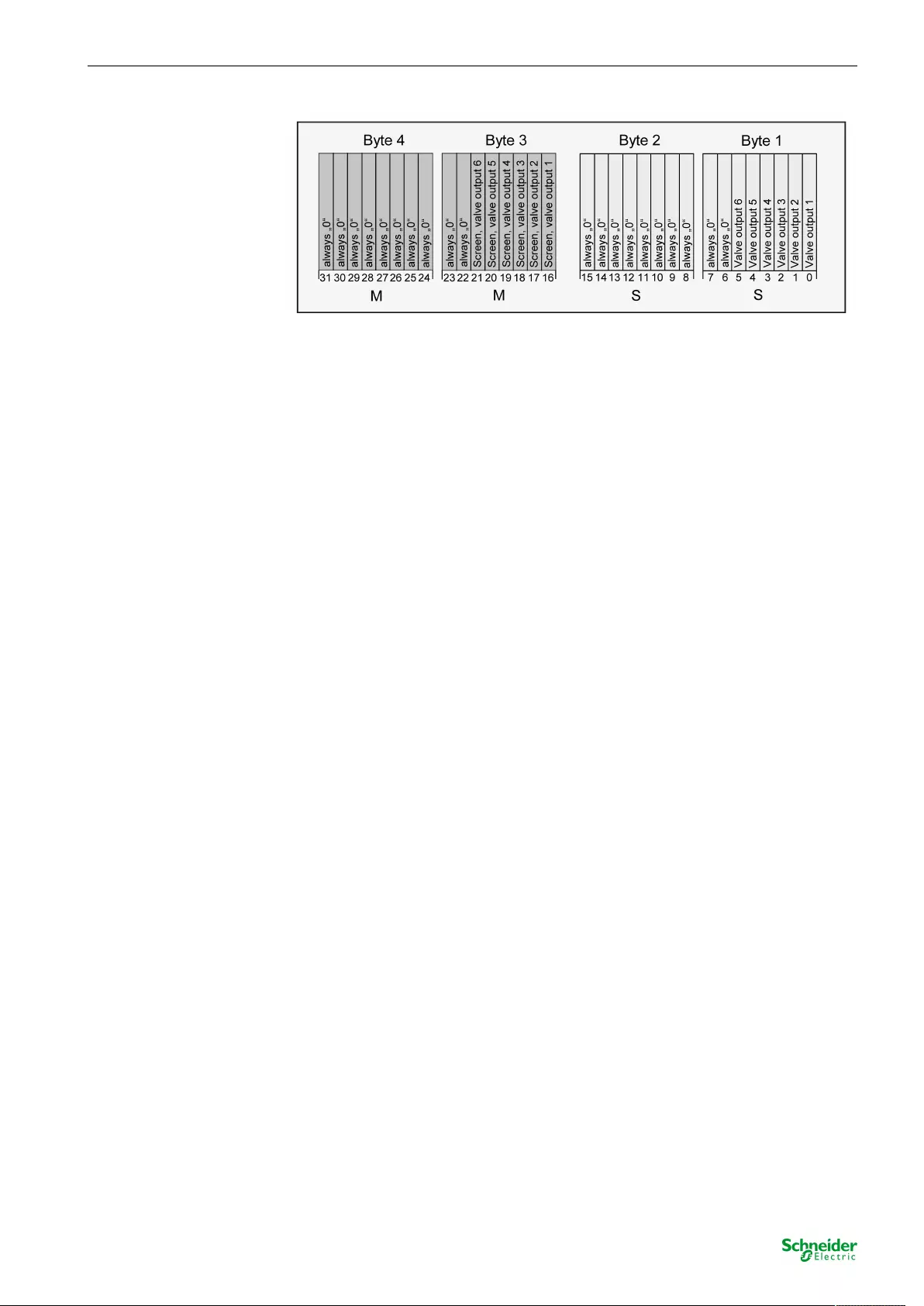

7 Scope of functions

Valve outputs

– 6 independent electronic valve outputs.

– Valve activation (deenergised opened / closed) can be configured for each

output.

– Actuator evaluation as "Switching, 1-bit", "Constant, 1-byte" or "Constant 1-

byte with actuator limiting value and hysteresis".

– With a 1-byte command value, the outputs are activated by pulse width

modulation (PWM). The cycle time can be configured for each valve output.

– Status feedback (1 bit or 1 byte) of each output possible automatically or on

read request.

– Collective feedback of all valve states possible via 4-byte telegram.

– A combined valve status allows the collective feedback of various functions

of an output in a single 1-byte bus telegram.

– Failure signal of the valve operating voltage can be configured (1-bit).

– Overload and short-circuit signal can be set separately via a 1-bit object for

each valve output (polarity can be configured). Global reset of all short-cir-

cuit / overload signals possible.

– Heat requirement and pump control, for positive influencing of the energy

consumption of a housing or commercial building. Provision of the largest

active command value directly via KNX telegram (1-byte constant). Alternat-

ively or additionally, evaluation of the actuator command values for provi-

sion of the general heat requirement information in the form of limiting value

monitoring with hysteresis (1-bit switching). Activation of a circulation pump

of the heating or cooling circuit via a 1-bit KNX telegram with limiting value

evaluation. Optional cyclical anti-sticking protection prevents the sticking of

the pump.

– Summer or winter mode can be selected via an object (polarity configur-

able).

– Each valve output can be locked in a forced position with bus control. Differ-

ent command values can be configured for summer and winter mode.

– Cyclical monitoring of the command value of each output can be set, taking

into account a configurable monitoring time. If no telegram is received within

the preset monitoring time, the valve output concerned switches to emer-

gency operation. Different command values can be configured for summer

and winter mode. The fault telegram is configurable.

– On activation with constant command values, an optional command value

limit can be designed, which allows the limitation of received command val-

ues at the "Minimum" and "Maximum" limits.

– Automatic valve rinsing to prevent calcification or sticking of a valve which

has not been activated for some time.

– Operating hours counter to record the switch-on times of the valve outputs.

– Service mode for the maintenance or installation of valve drives (locking of

the valve outputs in a defined state). Both service mode and the locking

status are preset by a 2-bit forced operation telegram.

SpaceLogic KNX Valve Drive Controller

28 | MTN6730-0002 11.08.2020

– Manual operation of outputs independent of the KNX (for instance, con-

struction site mode) with LED status indicators. Separate status feedback to

the KNX for manual operation. Manual operation can also be disabled via

the KNX. Own cycle time and PWM setting for manually-operated valve out-

puts. Central activation of all valve outputs (0 % / 100 %).

– Behaviour in case of bus voltage failure and bus voltage return as well as

after ETS programming settable for each valve output.

– Various actively transmitting feedback or status signals can be delayed

globally after bus voltage return or after an ETS programming operation.

– The parameters of the outputs can be set individually (each valve output

possesses its own parameters) or globally (all the valve outputs are con-

figured in the same way with a single configuration).

Room temperature controller

– Up to 6 independent room temperature controllers.

– Individual control of a controller using communication objects.

– Various operating modes can be activated: Comfort, Standby, Night and

Frost/heat protection

– Each operating mode can be assigned its own temperature-setpoints (for

heating and/or cooling).

– Configuring the temperature setpoints as relative (derived from basic set-

point) or absolute (independent setpoint temperatures for each operating

mode).

– Comfort extension possible using presence button in Night or Frost/heat

protection mode. Configurable duration of the comfort extension.

– Operating mode switchover via 1-byte objects according to the KNX spe-

cification or using up to four individual 1-bit objects.

– Status feedback telegrams (also KNX compliant) can be configured.

– Frost/heat protection switchover via window status or by automatic frost pro-

tection.

– Operating modes "Heating", "Cooling", "Heating and cooling" each with or

without additional level. The temperature setpoints for the additional level

are derived via a configurable level offset from the values of the basic level.

– Various control types can be configured for each heating or cooling level: PI

control (permanent or switching PWM) or 2-point feedback control (switch-

ing).

– Control parameter for PI controller (if desired: proportional range, reset

time) and 2-point controller (hysteresis) adjustable.

– Automatic or object oriented switch-over between "heating" and "cooling".

– A temporary or permanent setpoint shift for a relative setpoint specification

through communication objects is possible (e.g. via a controller extension).

– Configurable step width of the setpoint shift (0.1 K / 0.5 K).

– Deactivating the feedback control or the additional level possible using sep-

arate 1-bit objects.

– Room temperature measurement via up to two external KNX temperature

sensors. Calibration of the temperature values possible and measured

value formation of the external sensors can be configured. Settable polling

time of the externally received temperature values.

– The actual and setpoint temperatures can be output on the bus if a configur-

able deviation is detected (also periodically).

SpaceLogic KNX Valve Drive Controller

29 | MTN6730-0002 11.08.2020

– Separate or shared command value output in heating and cooling mode.

This produces one or two command value objects for each level.

– Normal or inverted command value output configurable

– Automatic transmission and cycle-time for actuating output configurable

– Command value limit possible.

– Floor temperature limit possible in heating mode. Thus temperature-con-

trolled switch-off of a floor heater as protective function.

– Setpoint temperature limit possible in cooling mode. If necessary, the con-

troller limits the setpoint temperature to specific values and prevents an ad-

justment beyond statutory limits.

SpaceLogic KNX Valve Drive Controller

30 | MTN6730-0002 11.08.2020

8 Notes on software

ETS project design and commissioning

For project design and commissioning of the device, ETS4 from Version 4.2 on-

wards or ETS5 is required.

Safe-state mode

If the device does not work properly - for instance as a result of errors in the project

design or during commissioning - the execution of the loaded application program

can be halted by activating the safe-state mode. In safe-state mode, activation of

the MSA outputs via the KNX or manual operation is not possible. The room tem-

perature controllers also have no function. The actuator remains passive in safe-

state mode, since the application program is not being executed (state of execu-

tion: Terminated). Only the system software is still functional so that the ETS dia-

gnosis functions and also programming of the device continue to be possible.

Activating the safe-state mode

■ Shut off the bus and the mains voltage supply. Wait a bit.

■ Press and hold down the programming button.

■ Switch on the bus or mains voltage. Release the programming button only

after the programming LED starts flashing slowly.

The safe-state mode is activated. With a new brief press of the program-

ming button, the programming mode can be switched on and off as usual

also in the safe-state mode. The programming LED stops flashing. How-

ever, safe-state mode remains active.

The safe-state mode can be terminated by switching off the supply voltage

(bus and mains) or by programming with the ETS.

Unloading the application program

The application program can be unloaded with the ETS. In this case the device is

without function. Manual operation is no longer possible.

SpaceLogic KNX Valve Drive Controller Parameter configuration for valve outputs

31 | MTN6730-0002 11.08.2020

9 Description of channel-

independent functions

9.1 Parameter configuration for valve outputs

To simplify the configuration, all the valve outputs can be assigned to the same

parameters in the ETS and thus configured identically. The parameter "Setting of

the output parameters" on the parameter page "General" specifies whether every

valve output of the device can be configured individually or whether all the outputs

should be configured by the same parameters.

In the "All outputs equal" setting, the number of parameters in the ETS is reduced.

The visible parameters are then used on all the valve outputs automatically. Only

the communication objects can then be configured separately for the outputs. This

setting should be selected, for example, if all the actuators behave identically and

should only be activated by different group addresses (e.g. in office blocks or in

hotel rooms).

In the parameter setting "Each output individually", each valve output possesses its

own parameter pages in the ETS.

9.2 Priorities for valve outputs

The heating actuator distinguishes between various functions and events, which

either affect all of some of the assigned valve drives globally, or only specifically af-

fect individual outputs. Because these functions and events cannot be executed

simultaneously, there must be priority control. Each global or output-orientated

function and each incoming event possesses a priority. The function or the event

with the higher priority overrides the lower-priority functions and events.

The following priorities are defined...

– Overload / short-circuit (highest priority)

– Manual operation

– Behaviour after ETS programming

– Behaviour in case of mains or bus voltage return / bus voltage failure

– Service mode

– Valve rinsing

– forced position

– Command value limit

– Emergency operation (through cyclical monitoring of the command value)

– Normal operation (activation using command value telegrams)

The behaviour after an ETS programming operation is only executed if there have

been changes in the configuration of the device. If just an application download is

executed with a project design already located in the actuator, then the actuator will

executed the behaviour after bus voltage return.

In manual operation and in service mode, a parameter separately defines the be-

haviour of each of the valve outputs at the end of these functions. The heating ac-

tuator only then executes the configured behaviour if, at the time of enabling, no

function with a lower priority is active. Should a lower-level function be active (e.g.

forced position), then the actuator will execute the behaviour of this function again.

SpaceLogic KNX Valve Drive Controller Manual control for valve outputs

32 | MTN6730-0002 11.08.2020

Special case: A function with a higher priority (e.g. manual operation) is active. Be-

fore this, a function with a lower priority (e.g. service mode) was active. This func-

tion is deactivated whilst the higher-level function remains active. At the end of the

higher-priority function, the state of the outputs should be tracked. The actuator

then evaluates the command value of the lower-level function and checks how the

behaviour is preset or configured here. The actuator then executes the command

value presetting of the lower-level function. If tracking is also preset or configured

for this function, the actuator will still go one layer lower and evaluate the behaviour

configured there.

Example 1: Service mode is active (valve completely opened / 100 % command

value). A value of 10 % was most recently preset via a command value telegram

(normal operation). No other functions are active. Service mode is configured in

such a way that the starting state should be tracked at the end of this function.

Permanent manual operation is now activated. The actuator assumes the com-

mand value of manual operation (e.g. 50 %). Whilst manual operation is active, ser-

vice mode is deactivated via the KNX. The actuator remains in manual operation

until this is exited via the button field. As no more lower-level functions are active,

the heating actuator evaluates the parameter "Behaviour at the end of permanent

manual operation during bus operation". As this parameter is set to "Track outputs",

the actuator now evaluates the command value to be tracked. For this, it checks

how the behaviour at the end of service mode is preset. Here too, the state should

be tracked. Thus, the actuator evaluates the other lower-level functions. As no

other functions were and are activated, the actuator sets the last command value

presetting at the valve output using the KNX telegram (here 10 %).

Example 2: Service mode is active (valve completely opened / 100 % command

value). A value of 10 % was most recently preset via a command value telegram

(normal operation). No other functions are active. Service mode is configured in

such a way that no change should be executed at the end of this function.

Permanent manual operation is now activated. The actuator assumes the com-

mand value of manual operation (e.g. 50 %). Whilst manual operation is active, ser-

vice mode is deactivated via the KNX. The actuator remains in manual operation

until this is exited via the button field. As no more lower-level functions are active,

the heating actuator evaluates the parameter "Behaviour at the end of permanent

manual operation during bus operation". As this parameter is set to "Track outputs",

the actuator now evaluates the command value to be tracked. For this, it checks

how the behaviour at the end of service mode is preset. There, the configuration

states that there should be no change. Thus, the heating actuator for the affected

valve output assumes the command value of service mode (here 100 %) and sets

this at the output. In this case, the actuator no longer evaluates other lower-level

functions.

9.3 Manual control for valve outputs

All the valve outputs of the device have electronic manual operation. The button

field with 4 function keys and 3 status LEDs on the front panel of the device can be

used for setting the following modes of operation...

– Bus operation: Operation via room temperature controllers, push-button

sensors, or other bus devices,

– Temporary manual control: manual control locally with keypad, automatic

return to bus control,

– Permanent manual operation: Exclusively manual operation on the device

(e.g. construction site mode, commissioning phase).

SpaceLogic KNX Valve Drive Controller Manual control for valve outputs

33 | MTN6730-0002 11.08.2020

The operation of the function keys, the activation of the valve outputs and the

status display are described in detail in chapter "Operation" (siehe Kapitel "Opera-

tion" } Page 19). The configuration, status feedback, disabling via bus operation,

and interaction with other functions of the device when manual operation is activ-

ated and deactivated are described in greater detail below.

Manual control is possible while the device is supplied with power from the mains

or bus. In the state as supplied the manual control mode is fully enabled. In this un-

programmed state, all the outputs can be controlled by manual operation, so that

fast function checking of the connected valve drives (e.g. on the construction site)

is possible.

After initial commissioning of the actuator via the ETS, manual control can be en-

abled or disabled separately for various states of operation. Manual control can, for

instance, be disabled during bus operation (bus voltage applied). Another option

consists in the complete disabling of the manual control only in case of bus voltage

failure. Therefore manual control can be disabled completely, if the bus disable and

bus failure disable are active.

Enabling the manual control mode

Manual control for the different states of operation is enabled or disabled by means

of the parameters "Manual control in case of bus voltage failure" and "Manual con-

trol during bus operation".

■ Set the parameter "Manual control in case of bus voltage failure" to "en-

abled".

Manual control is then basically enabled when the bus voltage is off. This

setting corresponds to the setting of the actuator as delivered.

■ Set the parameter "Manual control in case of bus voltage failure" to "dis-

abled".

Manual control is completely disabled when the bus voltage is off. In this

case, bus operation is not possible either so that the outputs of the actuator

can no longer be activated.

■ Set the parameter "Manual control during bus operation" to "enabled".

Manual control is then basically enabled when the bus voltage is on. The

outputs of the actuator can be activated via the bus or manually. This set-

ting corresponds to the setting of the actuator as delivered.

■ Set the parameter "Manual control during bus operation" to "disabled".

Manual control is completely disabled when the bus voltage is on. In this

configuration, the actuator outputs can only be operated via the bus.

Presetting a manual control disable

The manual control mode can be separately disabled via the bus, even if it is

already active. If the disabling function is enabled, then as soon as a disabling tele-

gram is received via the disabling object of the manual control, the actuator imme-

diately terminates an activated manual control and locks the function keys on the

front panel of the device. The telegram polarity of the disabling object is paramet-

erisable.

The manual control mode during bus operation must be enabled.

■ Set the parameter "Disabling function ?" on parameter page "Manual con-

trol" to "yes".

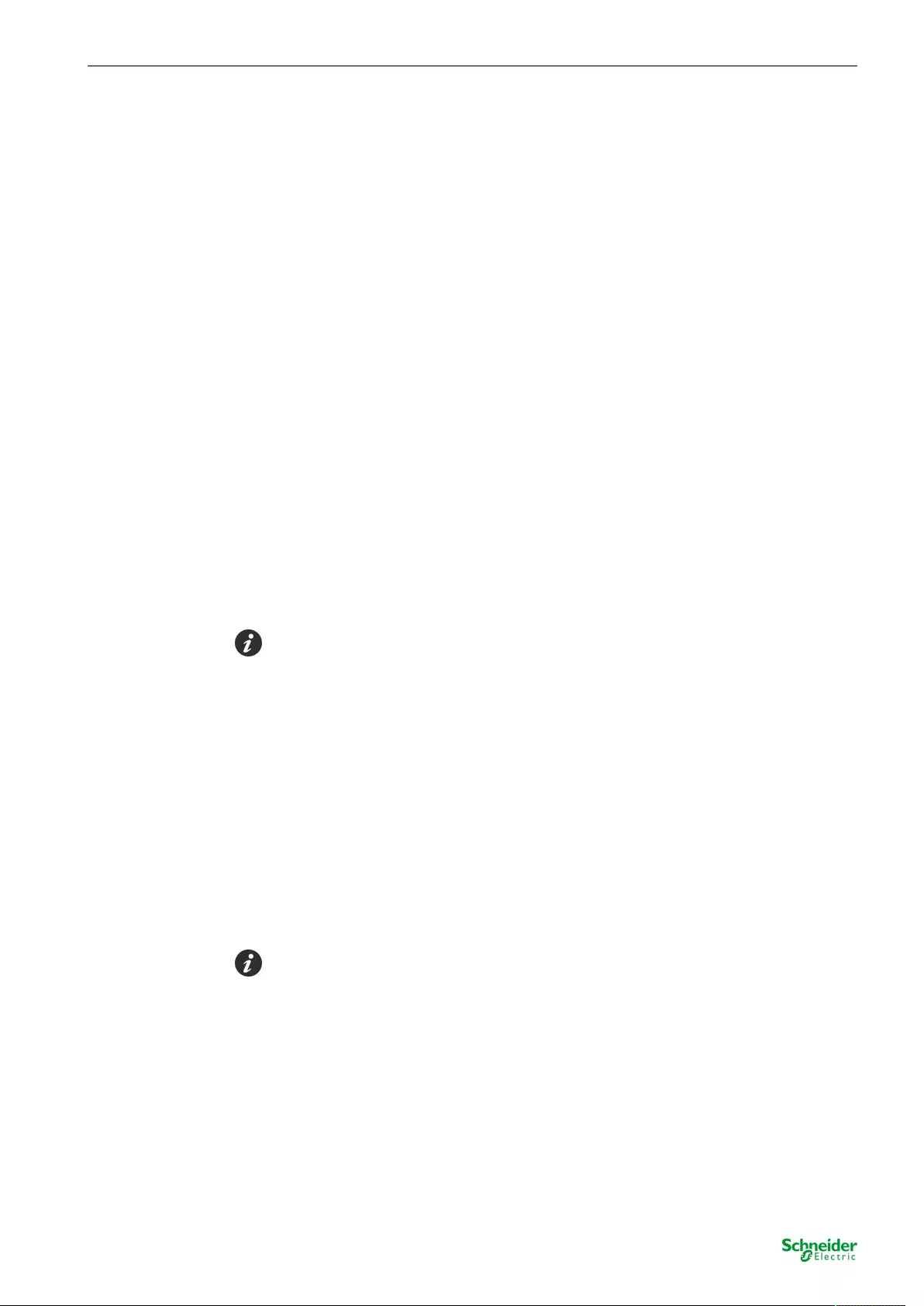

The disabling function of the manual control mode is enabled and the dis-

abling object is visible.

SpaceLogic KNX Valve Drive Controller Manual control for valve outputs

34 | MTN6730-0002 11.08.2020

■ Select the desired telegram polarity in the "Disabling object polarity" para-

meter.

If the polarity is "0=disabled; 1=enabled", the disabling function is immediately

active on return of bus/mains voltage or after an ETS programming operation (ob-

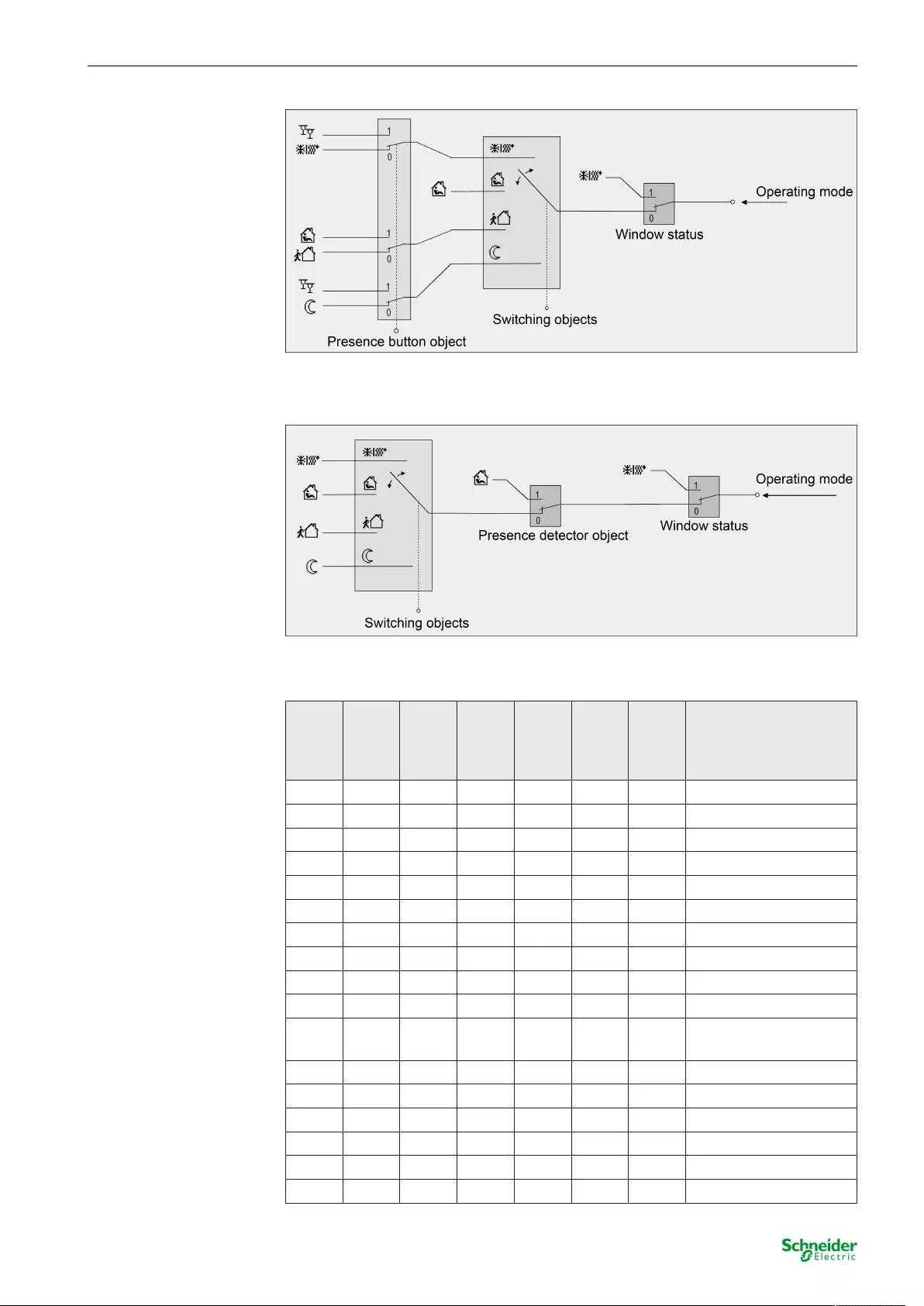

ject value"0"). To activate the manual control in this case, an enable telegram "1"

must first be sent to the disabling object.

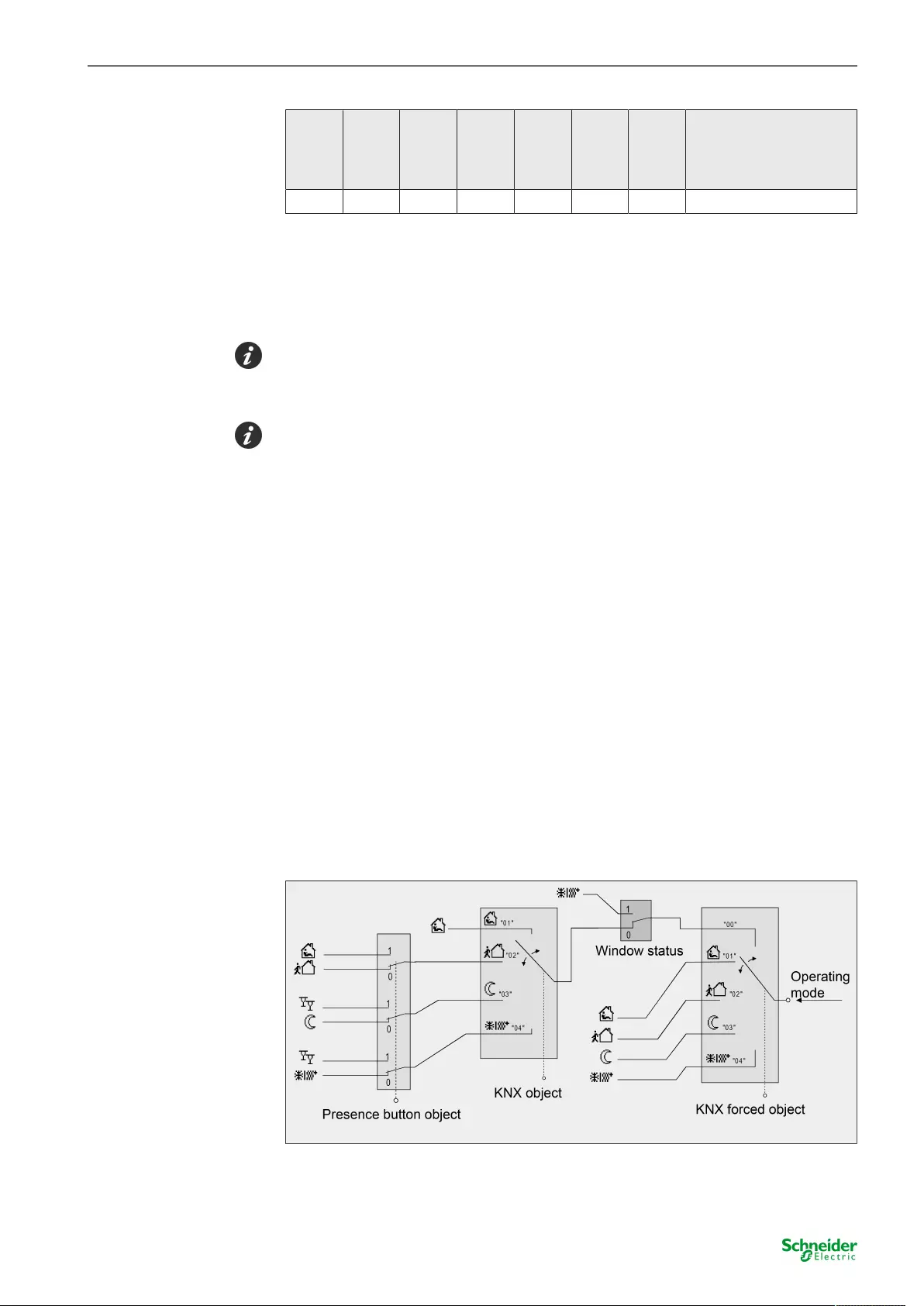

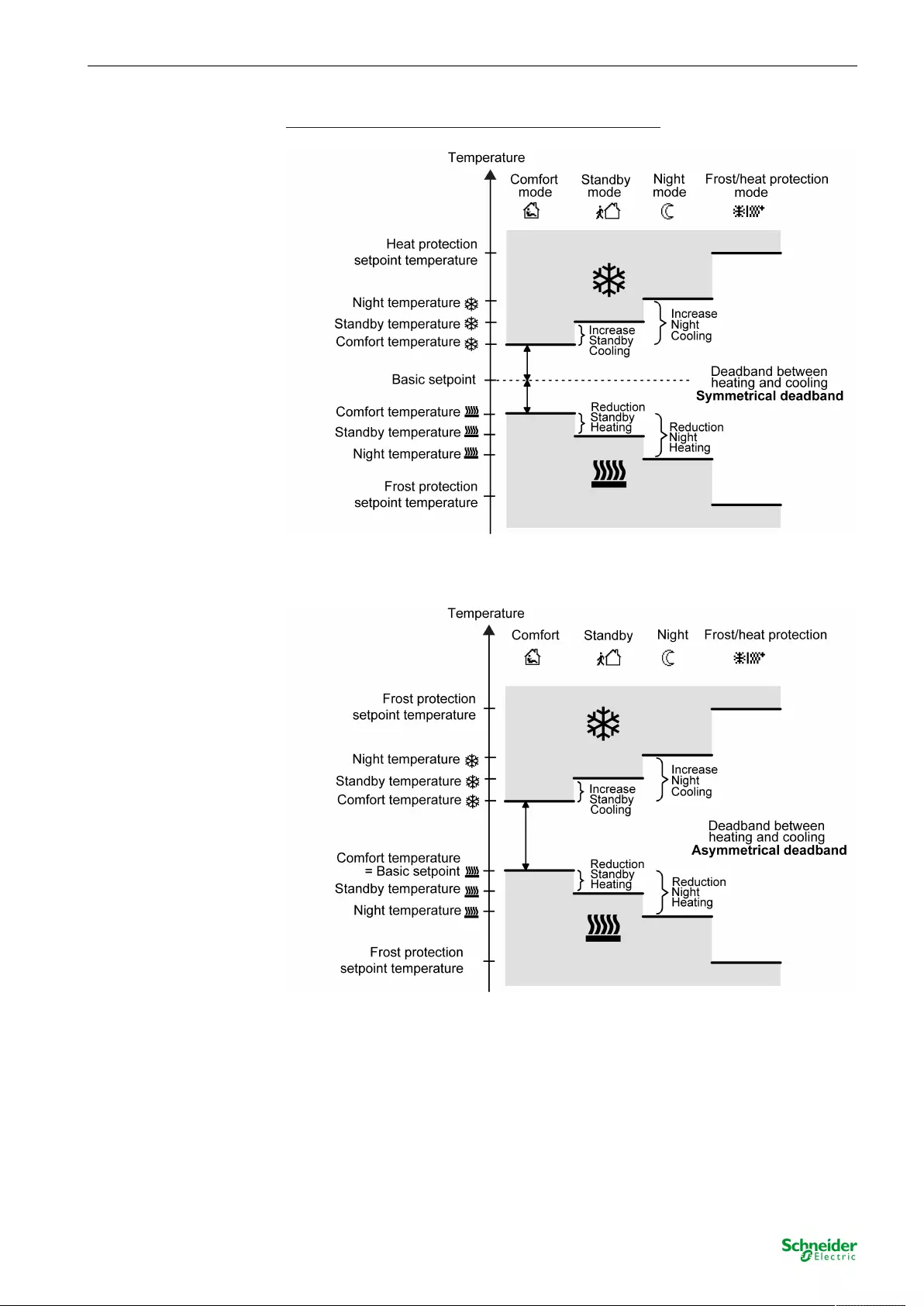

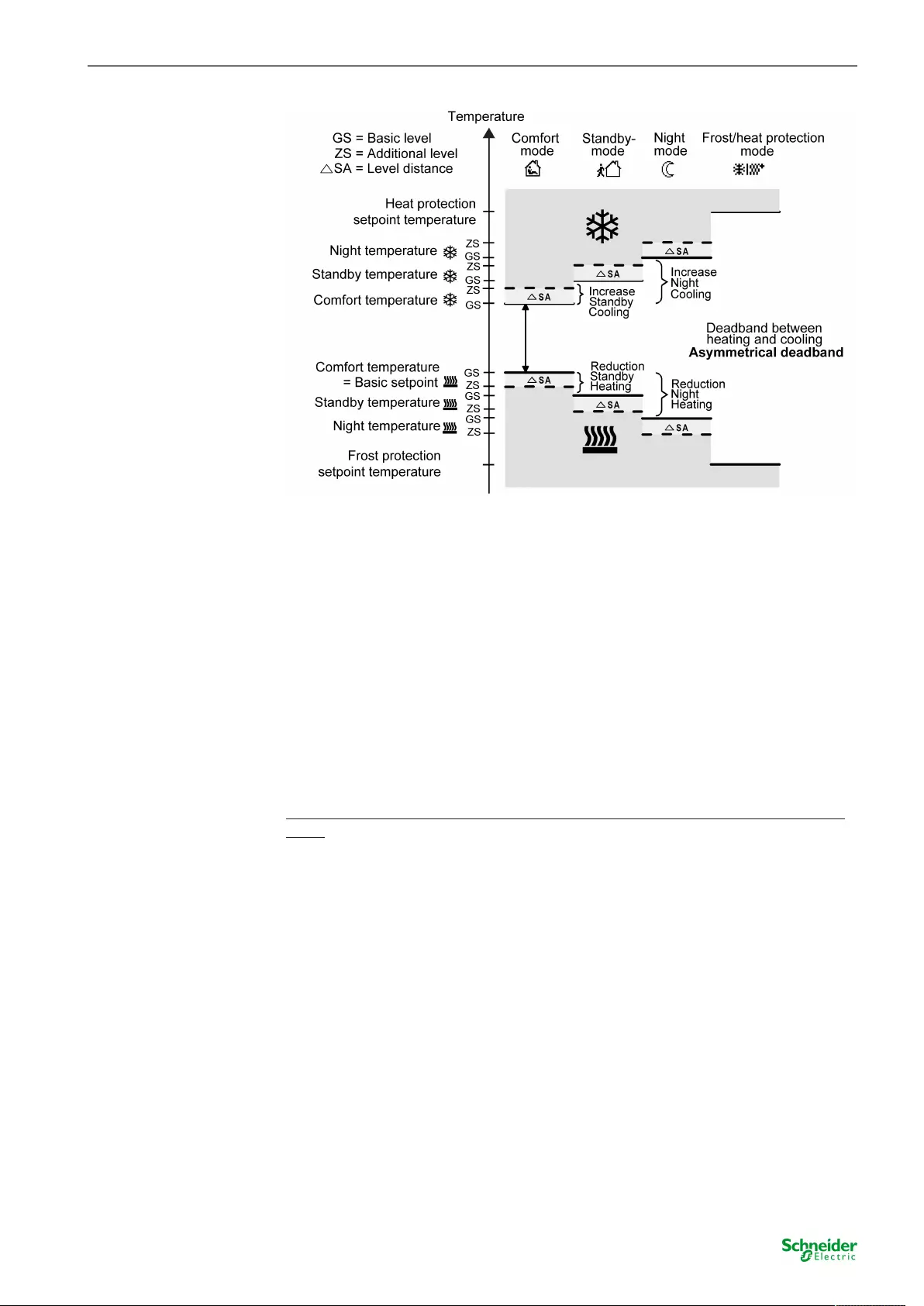

In case of bus voltage failure, disabling via the disabling object is always inactive

(depending on parameterization, the manual control is then either enabled or com-

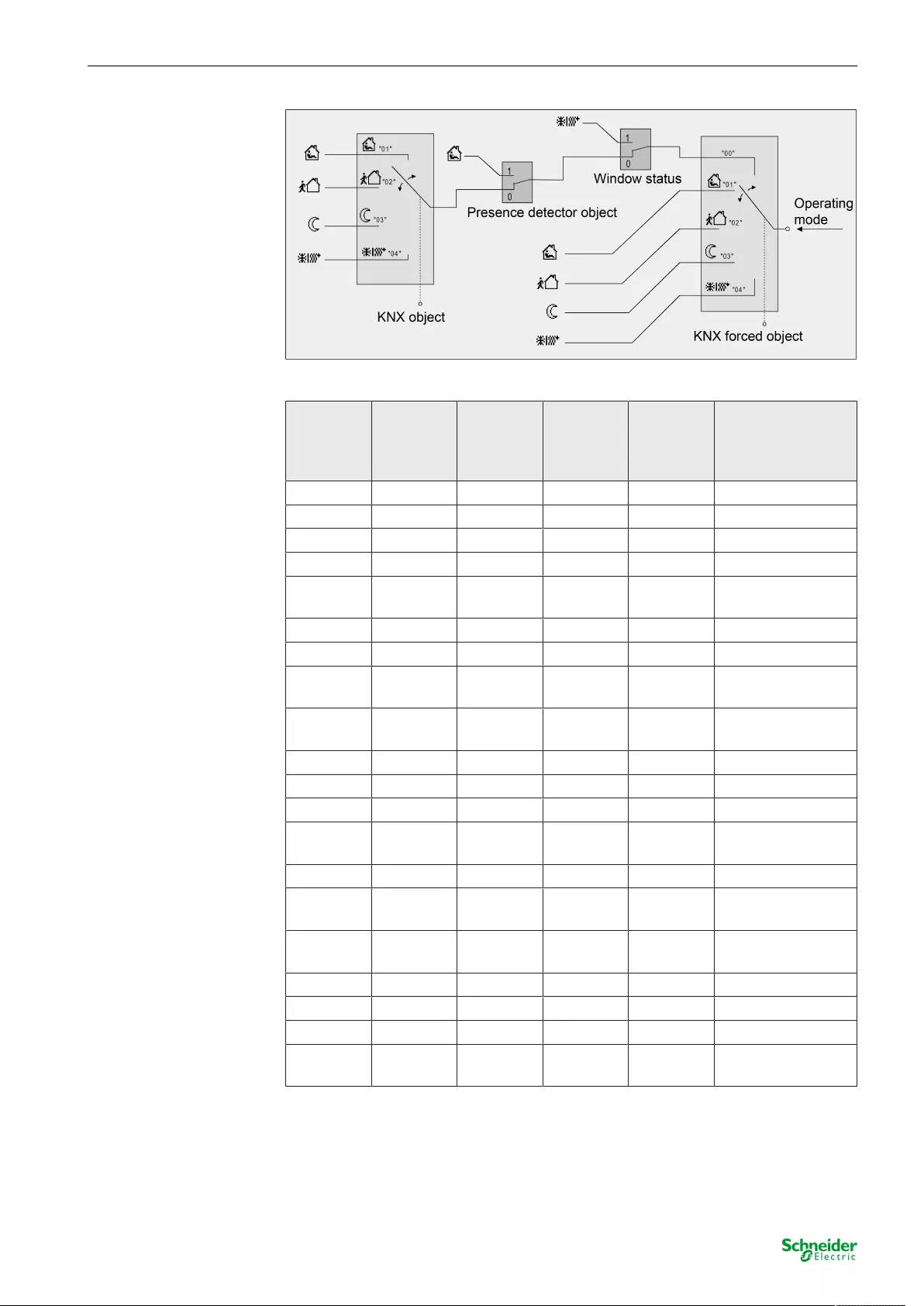

pletely disabled). After bus and mains voltage return, a disabled state that was act-

ive beforehand is always inactive when the polarity of the disabling object is non-in-

verted. If only the bus voltage has failed and been switched on again (mains

voltage is available without interruption), then an activated disable remains intact.

When an active manual control is terminated by a disable, the actuator will also

transmit a "Manual control inactive" status telegram to the bus, if the status mes-

saging function is enabled.

Presetting the status message function for the manual

control mode

An actuator can transmit a status telegram to the bus via a separate object when

the manual operation is activated or deactivated. The status telegram can only be

transmitted when the bus voltage is switched on. The polarity of the status tele-

gram can be parameterised.

The manual control mode during bus operation must be enabled.

■ Set the parameter "Transmit status ?" on parameter page "Manual control"

to "yes".

The status messaging function of manual control is enabled and the status

object is visible.

■ Specify in the parameter "Status object function and polarity" whether the

status telegram is generally a "1" telegram whenever the manual control

mode is activated or only in those cases where the permanent manual

mode is activated.

The status object is always "0" when the manual control mode is deactivated.

The status is not transmitted automatically after bus/mains voltage return.

When active manual control is terminated by a disable, the actuator will also trans-

mit a "Manual control inactive" status telegram to the bus.

Presetting the behaviour at the beginning and at the

end of manual control

The manual control distinguishes the temporary and permanent manual control.

The behaviour is different depending on these modes of operation, especially at

the end of manual control. It should always be noted that bus operation is always

disabled while manual operation is active, as manual operation has a higher prior-

ity (siehe Kapitel "Priorities for valve outputs" } Page 31).

Behaviour at the beginning of manual control:

The behaviour at the beginning of manual operation differs for temporary and per-

manent manual operation. On activation of short-time manual operation, the most

SpaceLogic KNX Valve Drive Controller Manual control for valve outputs

35 | MTN6730-0002 11.08.2020

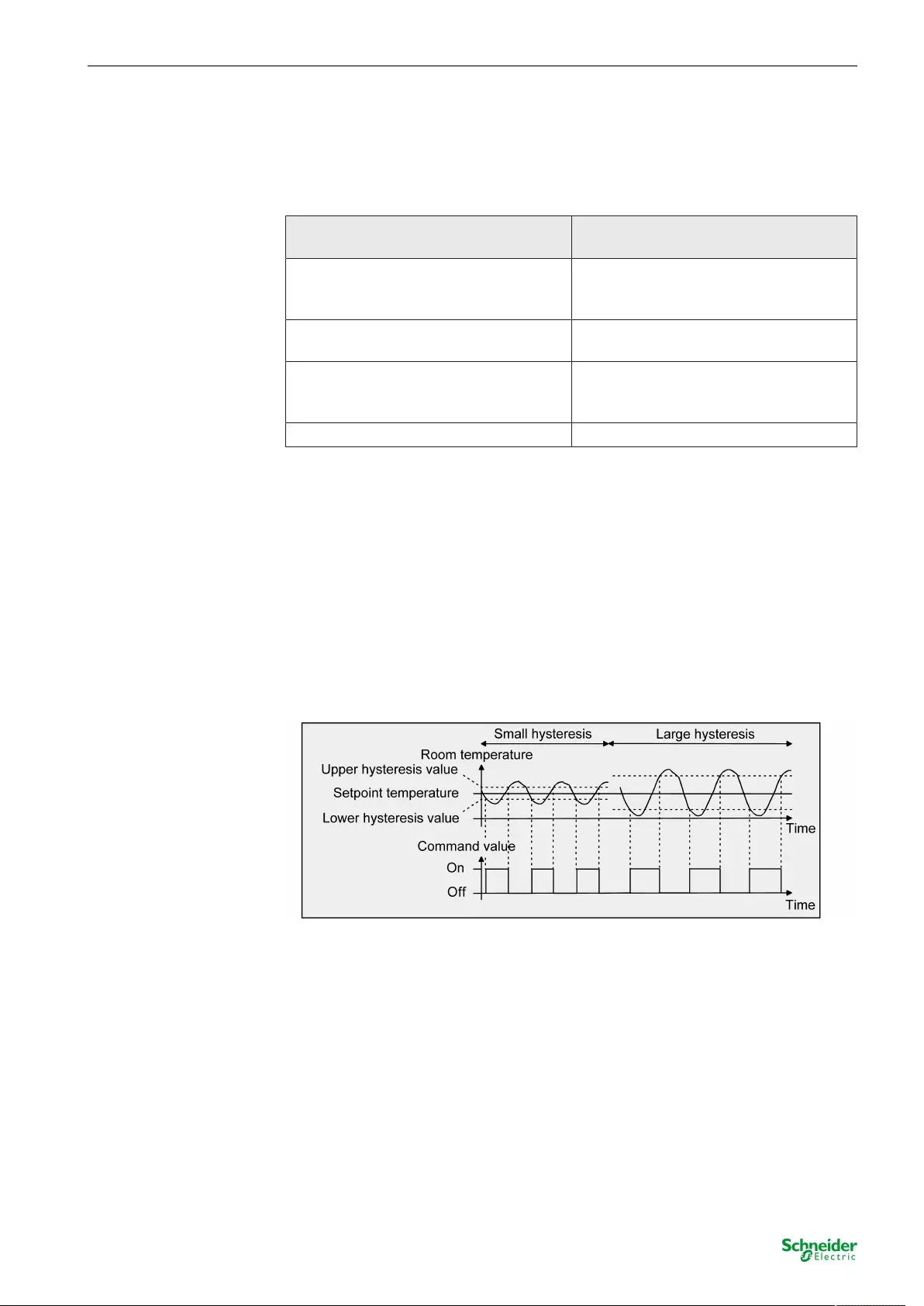

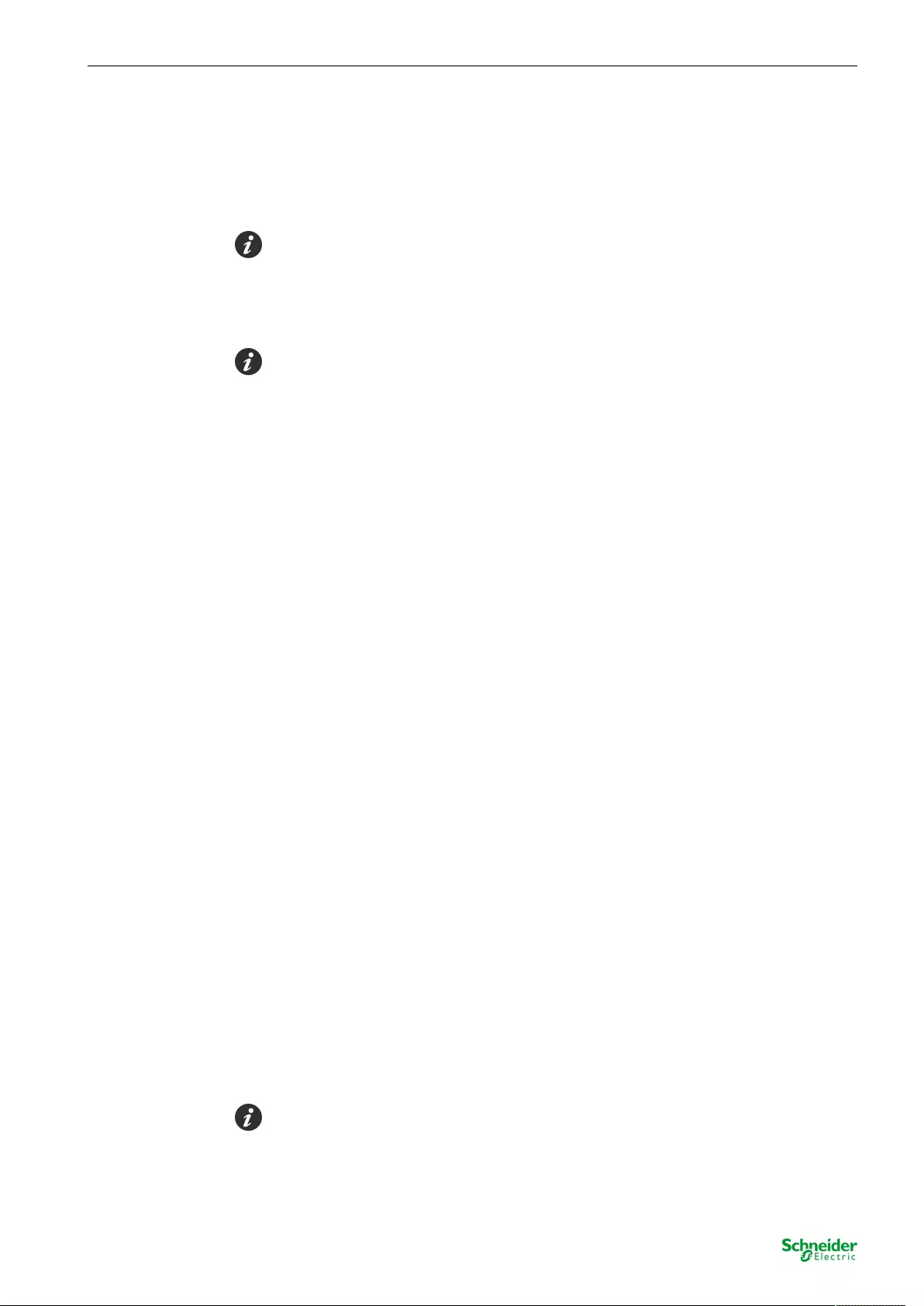

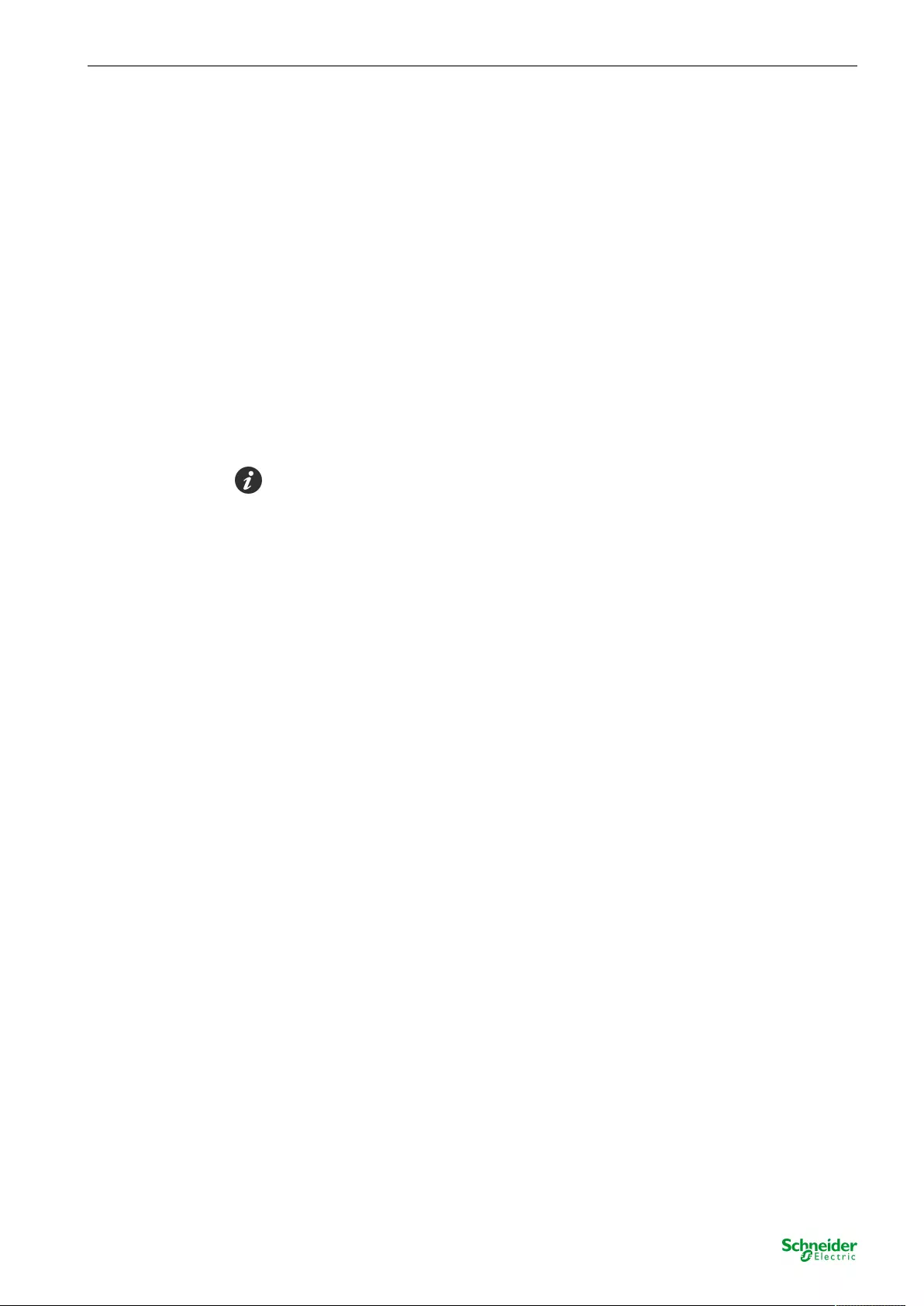

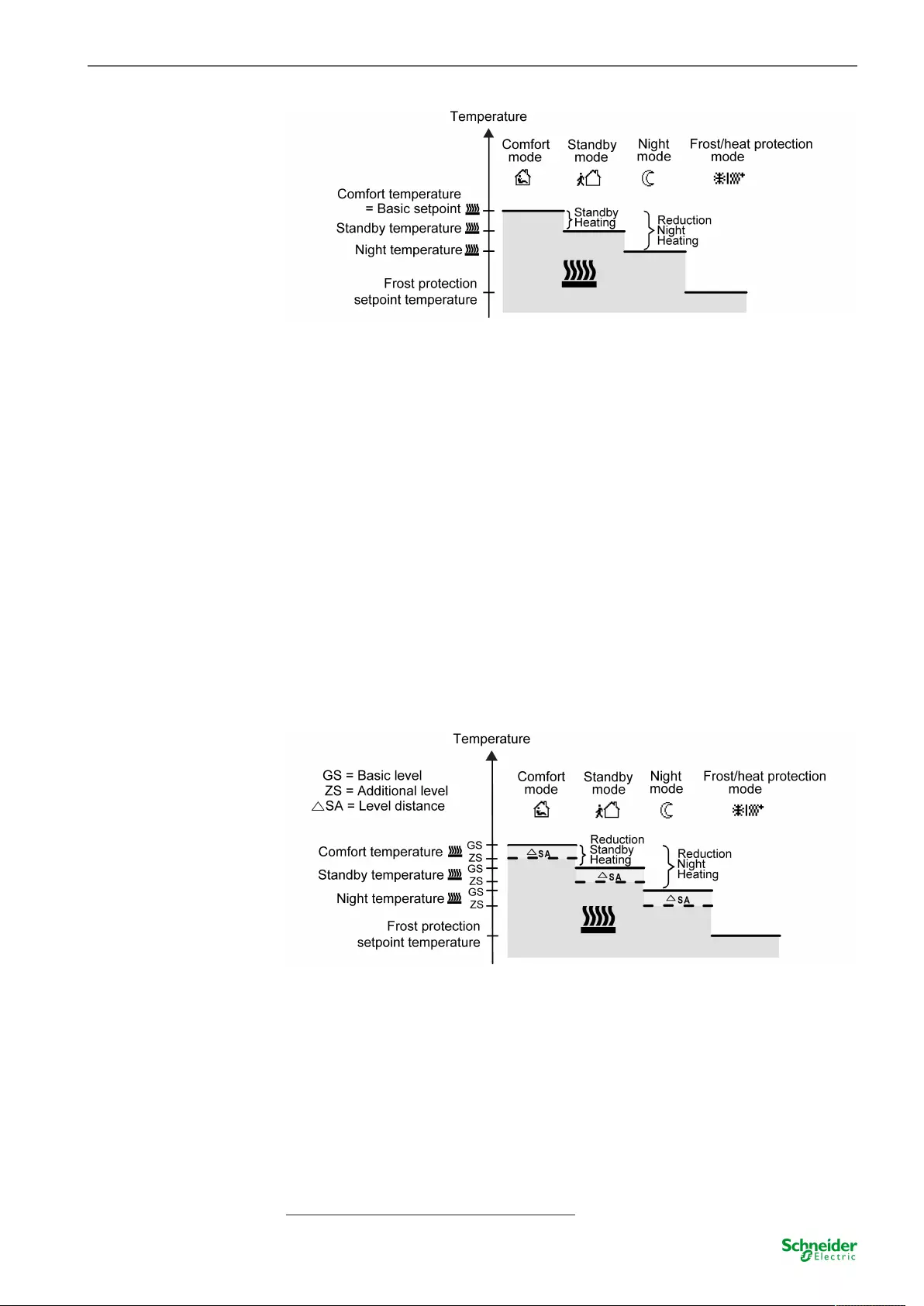

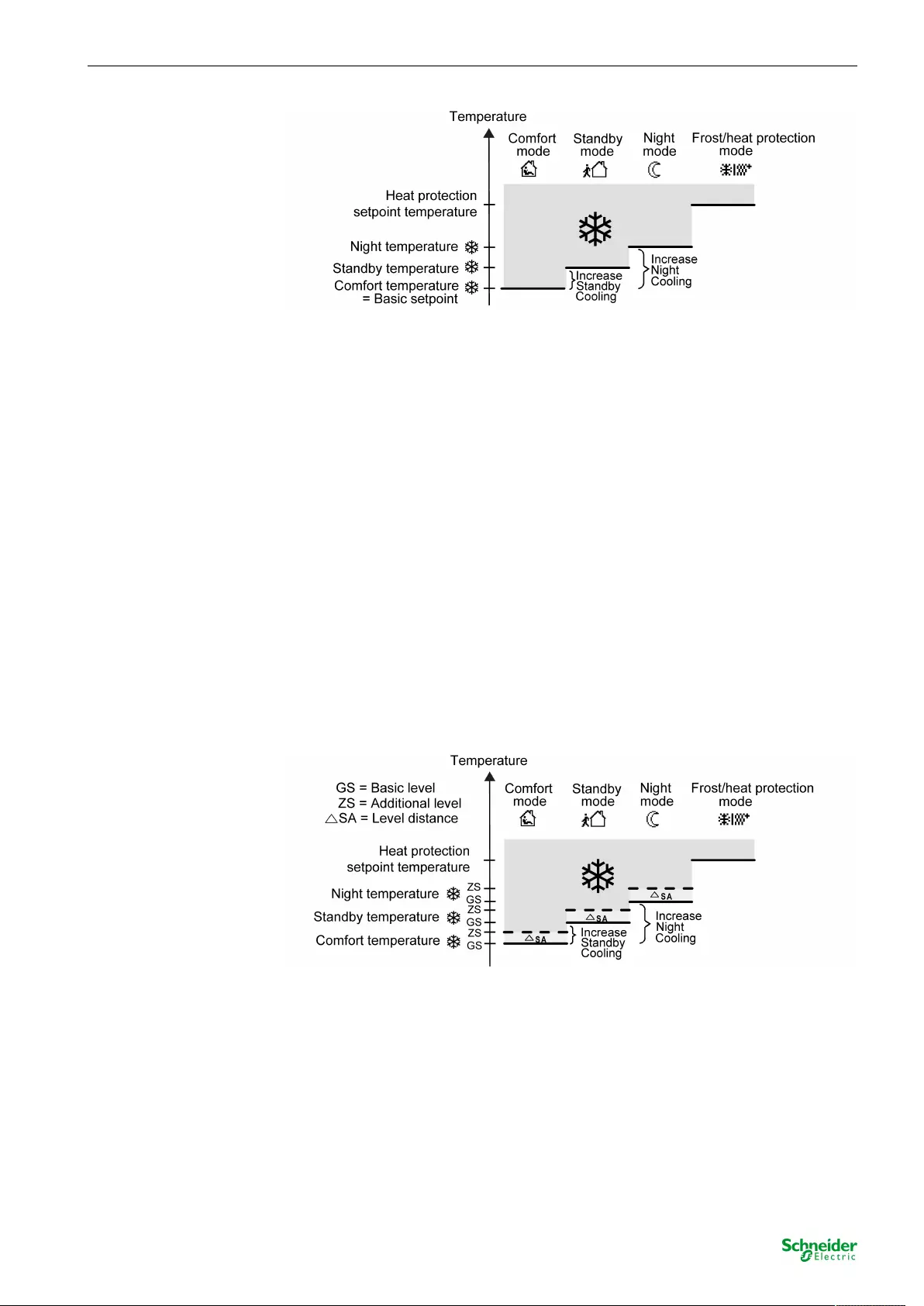

recently set states of the outputs initially remain active. For opened valve outputs,